Patents

Literature

5036results about How to "Lower sintering temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Tricalcium phosphates, their composites, implants incorporating them, and method for their production

InactiveUS20050031704A1Easily controlEnhance packing and densificationBiocideHeavy metal active ingredientsChemistryProsthetic implants

Methods for the synthesis of tricalcium phosphates are presented, as well as a series of specific reaction parameters that can be adjusted to tailor, in specific ways, properties in the tricalcium phosphate precursor precipitate. Particulate tricalcium phosphate compositions having an average crystal size of about 250 nm or less are provided. Compositions of the invention can be used as prosthetic implants and coatings for prosthetic implants.

Owner:PIONEER SURGICAL TECH INC

Tunable dielectric compositions including low loss glass

InactiveUS6905989B2Lower sintering temperatureIncrease varietyFixed capacitor dielectricCeramic layered productsBreakdown strengthStrontium titanate

Tunable dielectric materials including an electronically tunable dielectric ceramic and a low loss glass additive are disclosed. The tunable dielectric may comprise a ferroelectric perskovite material such as barium strontium titanate. The glass additive may comprise boron, barium, calcium, lithium, manganese, silicon, zinc and / or aluminum-containing glasses having dielectric losses of less than 0.003 at 2 GHz. The materials may further include other additives such as non-tunable metal oxides and silicates. The low loss glass additive enables the materials to be sintered at relatively low temperatures while providing improved properties such as low microwave losses and high breakdown strengths.

Owner:NXP USA INC

Gravel attapulgite flower ceramsite

ActiveCN102503372BHigh strengthLower sintering temperatureCeramic materials productionCeramicwarePhysical chemistryMaterials science

The invention discloses gravel attapulgite flower ceramsite. The key point of the technical scheme is that the gravel attapulgite flower ceramsite consists of high-viscosity attapulgite clay powder, attapulgite clay tailing powder, red bentonite powder, sludge, kieselguhr tailing powder and rice husk powder.t. The gravel attapulgite flower ceramsite is produced by the following steps of mixing the ingredients, pelleting, baking, cooling, smashing, sieving and packaging. The gravel attapulgite flower ceramsite is an irregularly-shaped granule, and has a rough and porous surface, light weight, high strength and high water absorption. The gravel attapulgite flower ceramsite can be soaked in water without being cracked and release nutrition required by flowers continuously and slowly. The gravel attapulgite flower ceramsite is produced by utilizing the sludge and tailings comprehensively, so that the utilization rate of resources is improved, waste materials are changed into wealth, and environment is protected. Besides, the gravel attapulgite flower ceramsite is suitable for planting the flowers and vegetables.

Owner:江苏世澳非金属应用科技有限公司

Spherical attapulgite flower ceramsite

ActiveCN102503539AReduce manufacturing costHigh strengthCeramic materials productionCeramicwareMetallurgyBentonite powder

The invention discloses spherical attapulgite flower ceramsite. The key points of the technical scheme are that the spherical attapulgite flower ceramsite consists of high-adhesion attapulgite clay powder, attapulgite clay tailing powder, red bentonite powder, sludge, diatomite tailing powder and rice husk powder. The spherical attapulgite flower ceramsite is produced by the following steps of mixing the ingredients, pelleting, roasting, cooling, screening and packaging. The spherical attapulgite flower ceramsite has a rough and porous surface, is light in weight, high in strength and water absorption rate, can be immersed in water throughout the year without cracking and can continuously and slowly release nutrition required by flowers. Moreover, the spherical attapulgite flower ceramsite is produced by comprehensively utilizing the sludge and tailings, so that the resource utilization rate is improved, waste is turned into wealth, and environment is protected. Besides, the cylindrical attapulgite flower ceramsite is applicable to cultivation of various flowers and vegetables.

Owner:江苏世澳非金属应用科技有限公司

Process for producing shrinkage-matched ceramic composites

InactiveUS6576182B1Large particle sizeHigh sintering activitySemi-permeable membranesOther chemical processesCeramic matrix compositeMetallurgy

A process for producing a composite, containing at least one shrinkage-matched ceramic layer, wherein a starting material for the ceramic layer(s) has shrinkage behavior on sintering which is matched to remaining layer(s), and which is selected such that the ceramic-forming constituent of the same contains at least one ceramic powder of a specific size, and which process entails joining the layers of the composite by sintering.

Owner:NASS RUEDIGER

Low-density ceramic proppant and preparation method thereof

The invention relates to a low-density ceramic proppant and a preparation method thereof, which belong to the field of exploring petroleum and natural gas. The preparation method of the low-density ceramic proppant comprises the steps of forming an inner core made of bauxite and coal gangue and a shell made of bauxite and trimanganese tetroxide into a ball and sintering to obtain low-density ceramic. The ceramic has higher strength and low density and is applicable to a ceramic proppant for fracturing a deep-level oil-gas well with high closed pressure and low permeability; the sintering temperature is relatively reduced in the range of 1,300-1,380DEG C, so that thus the energy consumption is effectively reduced and the energy can be saved by 20 percent; and meanwhile, the effect with low crushing rate can be achieved.

Owner:阳泉市长青石油压裂支撑剂有限公司

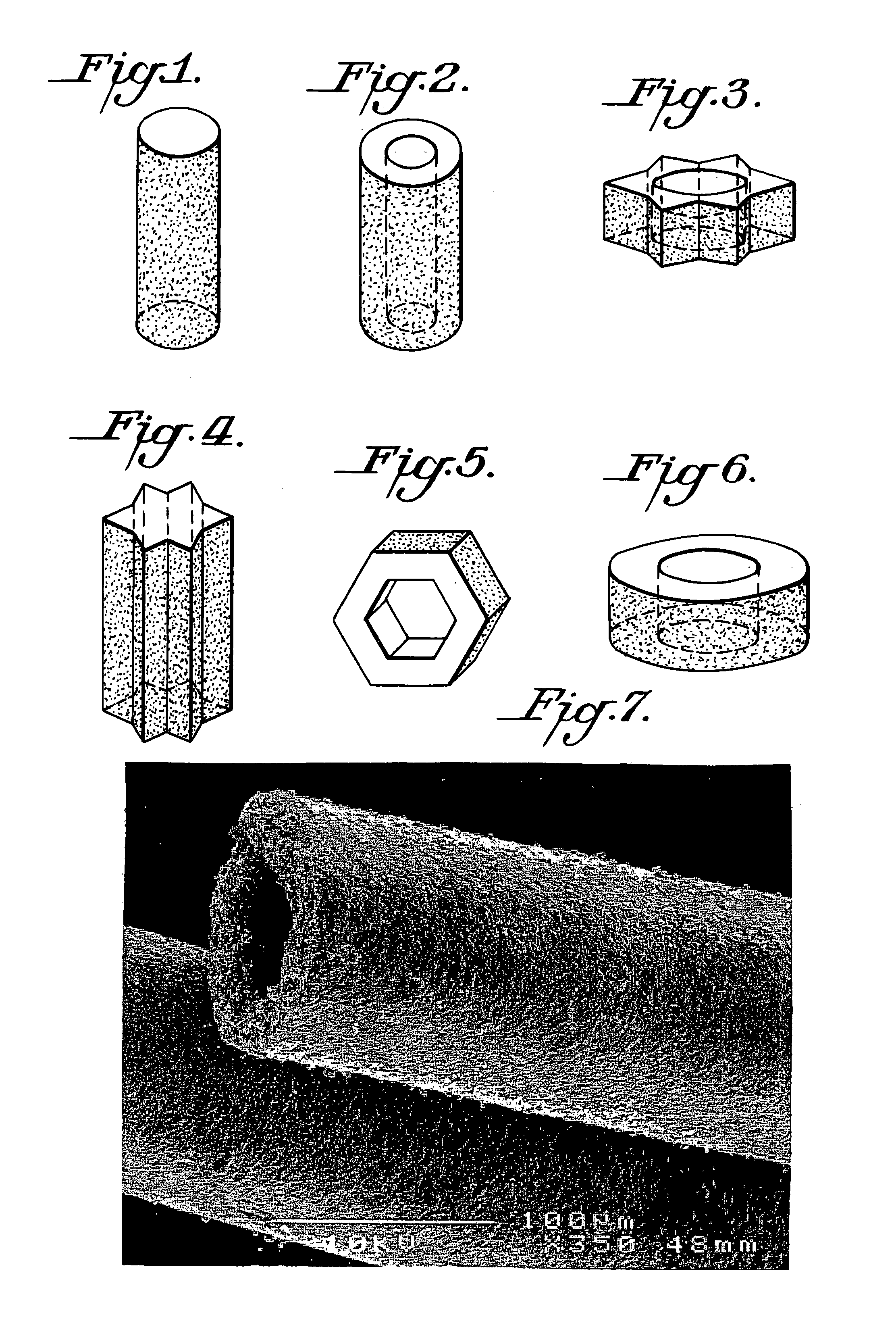

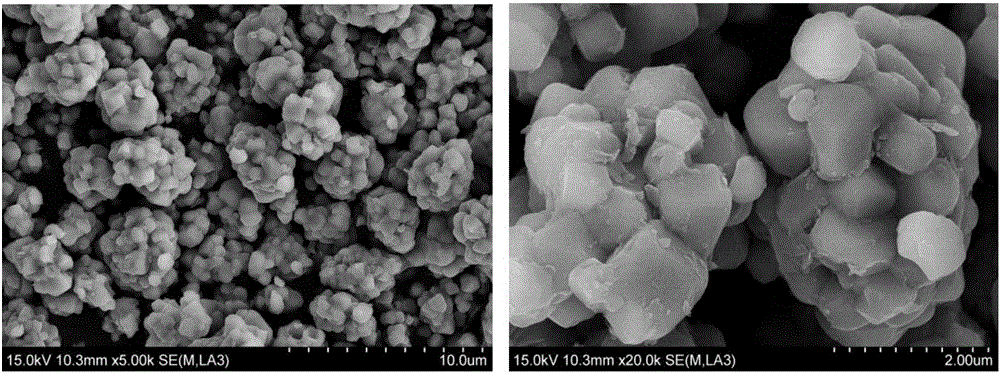

Microcrystalline alpha-Al2O3 shaped body, method for the production and use thereof

InactiveUS7169198B2Lower sintering temperatureHigh densityPigmenting treatmentOther chemical processesMetallurgySolvent

The invention relates to a method for the production of a sintered, microcrystalline α-Al2O3-based shaped body, which are used, for example, as abrasive bodies, wherein an α-Al2O3 powder is used as starting material, said powder having an average particle diameter of <2 μm, and processed with at least one binder and a solvent with the purpose of obtaining an extrudable material that is subsequently extruded. The extrudate is then further processed into a shaped body that is sintered at a temperature range of between 1300° C. and 1750° C.

Owner:IMERTECH SAS

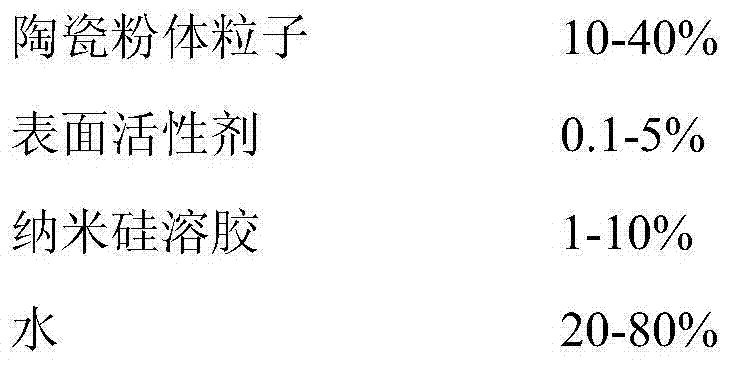

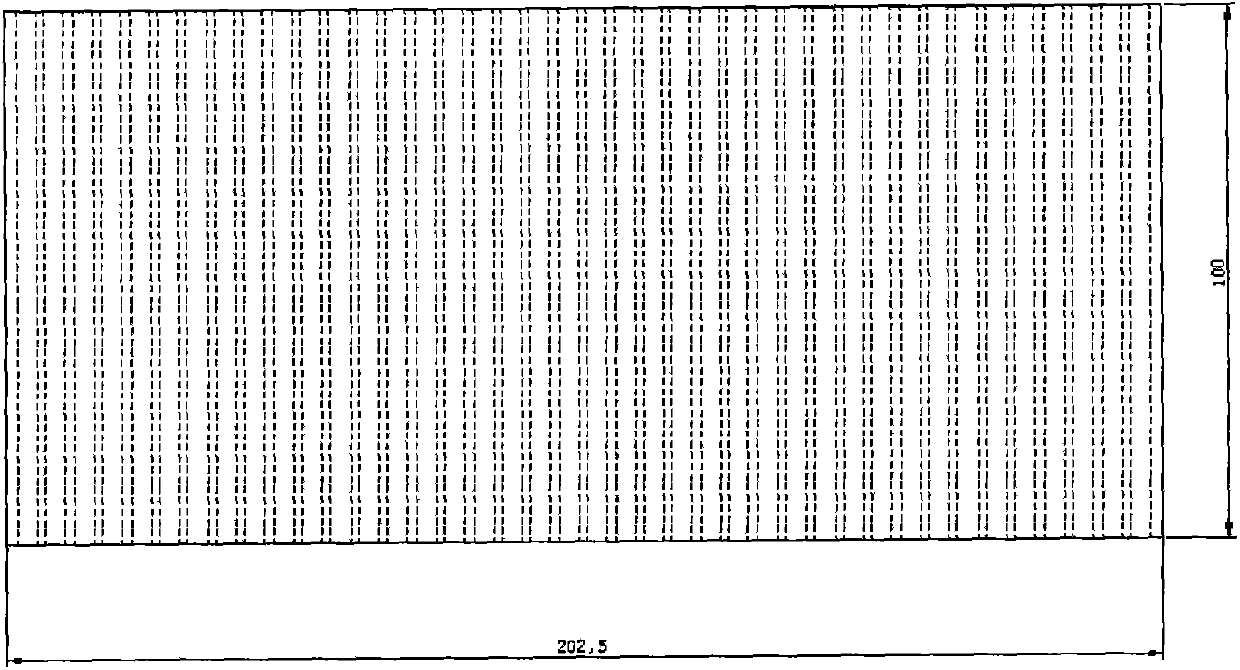

Preparation method of large-size thin-wall hollow flat-plate ceramic film

ActiveCN104258737ALower sintering temperatureReduce production energy consumptionSemi-permeable membranesLarge sizeEnergy consumption

The invention belongs to the technical field of ceramic films, and in particular relates to a preparation method of a large-size thin-wall hollow flat-plate ceramic film. The preparation method comprises preparation of a flat-plate ceramic supporting body and preparation of a separation film layer. According to the preparation method, an alpha-Al2O3 powder body is coated by nano silicon dioxide dispersing liquid, so that the sintering temperature of the flat-plate film supporting body is greatly lowered, and the production energy consumption of a product is reduced; furthermore, chemical components of the supporting body are relatively high in purity, and the acid-alkali corrosion resistance is high; in a process of preparing a large-size thin-wall flat-plate film, deformation of a flat-plate film blank in extrusion, drying and sintering processes can be greatly reduced, and the yield of the flat-plate film is increased; the separation film layer adopts ceramic powder body particles modified by nano-silica sol; the surfaces of the particles are rounded and spheroidized; a duct of the prepared separation film layer is smooth and is low in filtering resistance; the water flux can be increased by over 30 percent.

Owner:SHANDONG RES & DESIGN ACADEMY OF IND CERAMICS

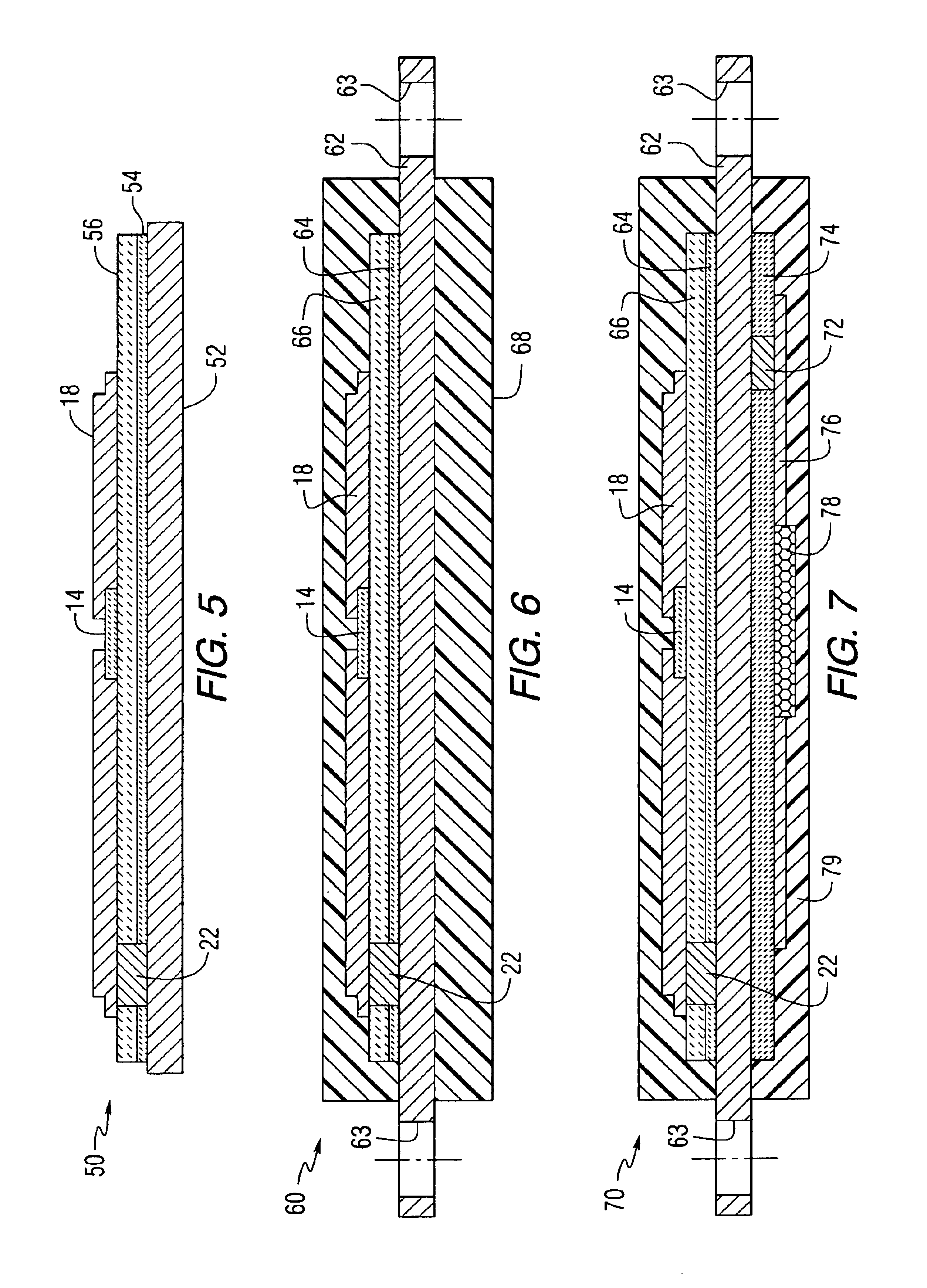

Garnet-type ion conducting oxide, complex, lithium secondary battery, manufacturing method of garnet-type ion conducting oxide and manufacturing method of complex

ActiveUS20150056519A1Reduce the temperatureAccelerates dissolution and diffusionElectrode thermal treatmentFinal product manufactureElectrolyteLithium borate

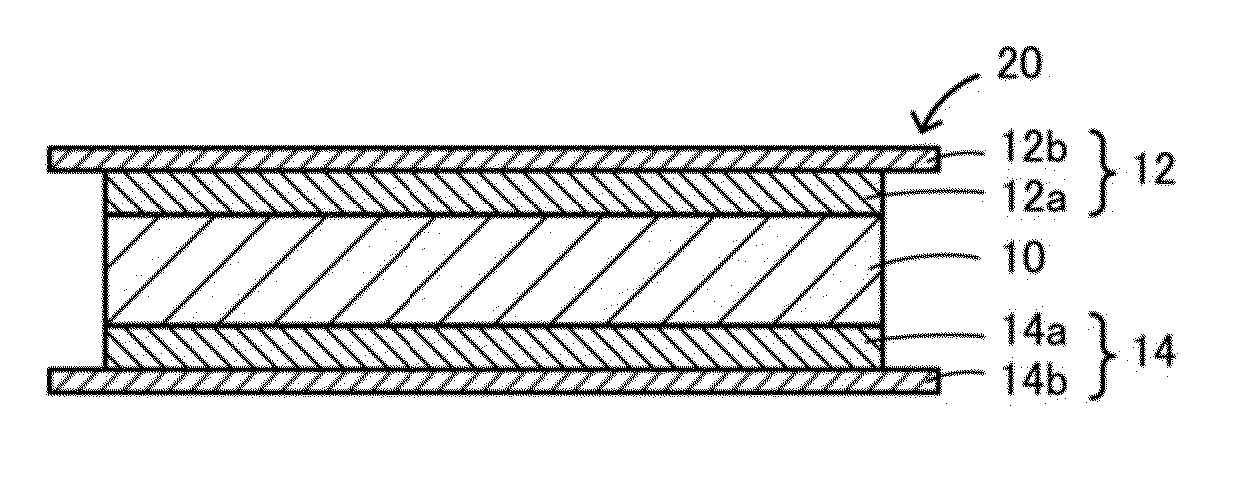

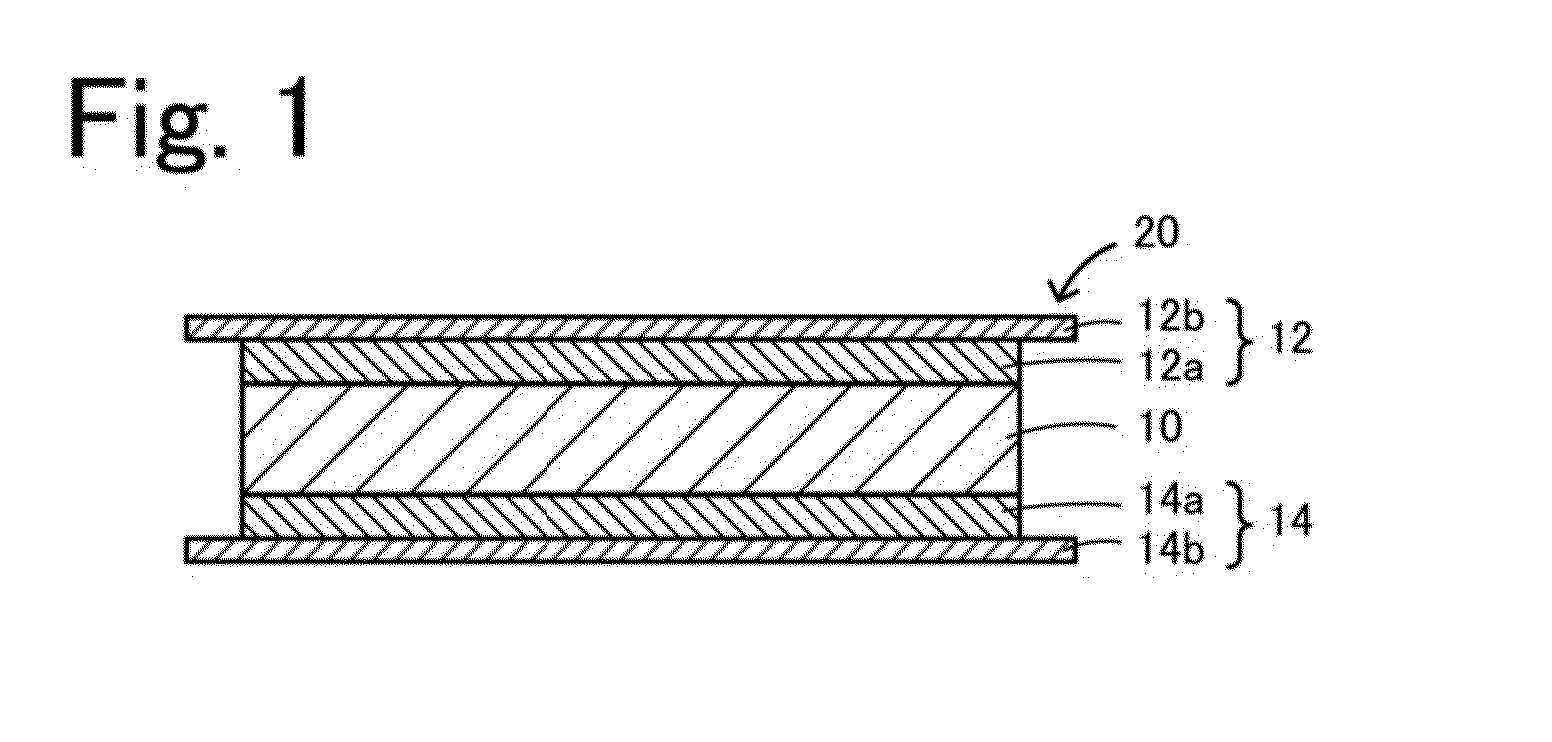

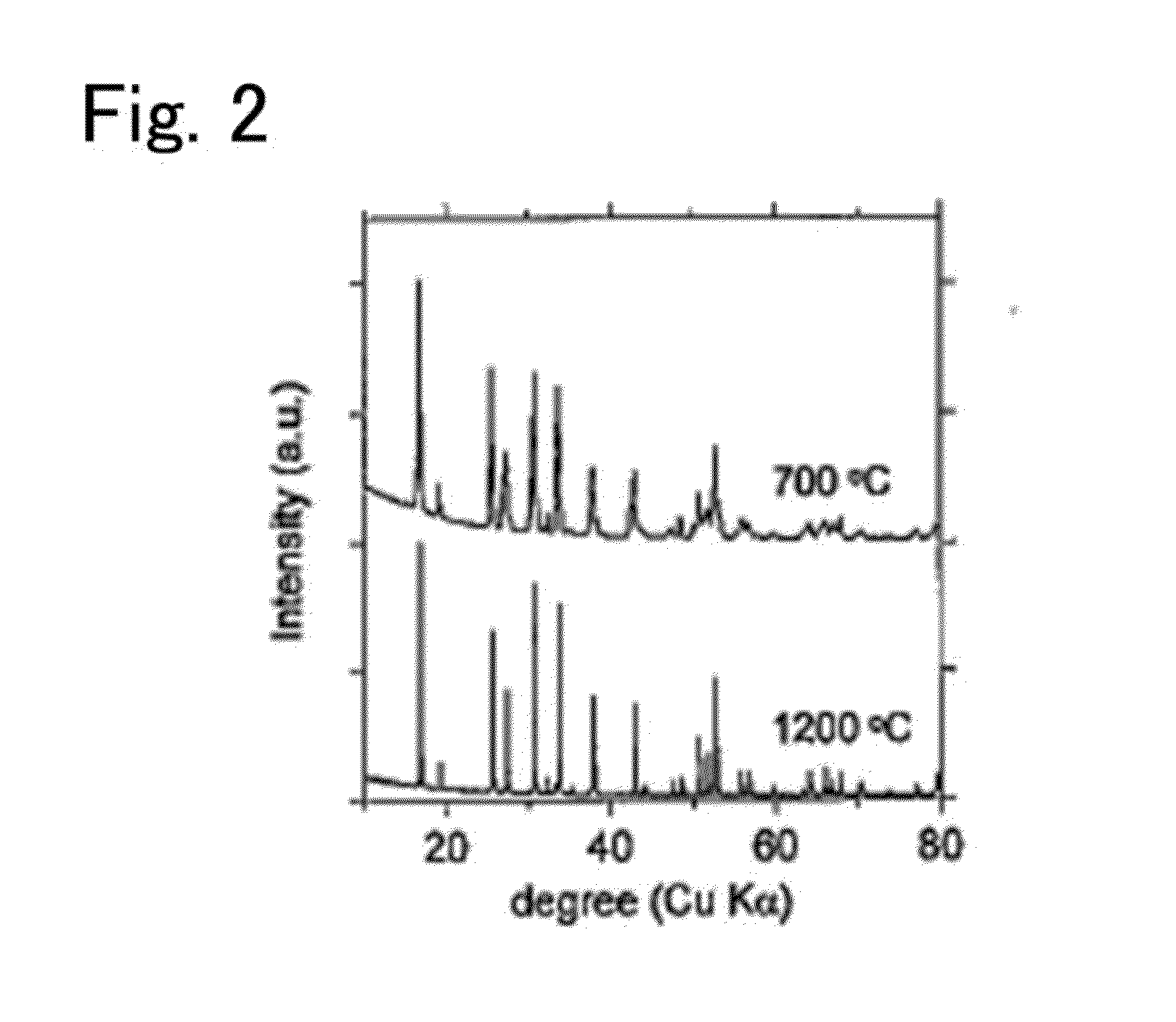

An all-solid lithium secondary battery 20 includes a solid electrolyte layer 10 composed of a garnet-type oxide, a positive electrode 12 formed on one surface of the solid electrolyte layer 10 and a negative electrode 14 formed on the other surface of the solid electrolyte layer 10. This all-solid lithium secondary battery 20 includes an integrally sintered complex of the solid electrolyte layer 10 and the positive electrode active material layer 12a. This complex is obtained by integrally sintering a stacked structure of an active material layer and a solid electrolyte layer. The solid electrolyte layer includes: abase material mainly including a fundamental composition of Li7+X−Y(La3−x,Ax) (Zr2−Y,TY)O12, wherein A is one or more of Sr and Ca, T is one or more of Nb and Ta, and 0≦X≦1.0 and 0≦Y<0.75 are satisfied, as a main component; and an additive component including lithium borate and aluminum oxide.

Owner:TOYOTA CENT RES & DEV LAB INC

Magnesium aluminate spinel foamed ceramic filter as well as preparation method thereof

ActiveCN103553686APrevent plastic crackingImprove high temperature stabilityCeramicwareMg alloysSlurry

The invention relates to a magnesium aluminate spinel foamed ceramic filter which is excellent in high-temperature chemical stability and thermal shock resistance. A preparation method of the magnesium aluminate spinel foamed ceramic filter comprises the following steps: firstly, using water-base resin, a dispersing agent and water as a solvent, forming ceramic powder by using magnesium aluminate spinel powder, aluminum oxide powder and magnesium hydroxide powder, and mechanically stirring to prepare slurry; soaking polyurethane porous sponge serving as a carrier in slurry, pressing to remove excessive slurry to prepare a preform body, drying and sintering to obtain the magnesium aluminate spinel foamed ceramic filter. The foamed ceramic filter disclosed by the invention can satisfy rigorous requirements of filtering of molten magnesium alloy, has good high-temperature stability, does not pollute the alloy, has good filtering and adsorbing effect on inorganic impurities in the molten magnesium alloy, and is good in filtering and purifying effect, small in fluid resistance, and large in filtration yield; and good using effect is obtained through trial in casting production of metal magnesium and magnesium alloy.

Owner:SINOSTEEL LUOYANG INST OF REFRACTORIES RES

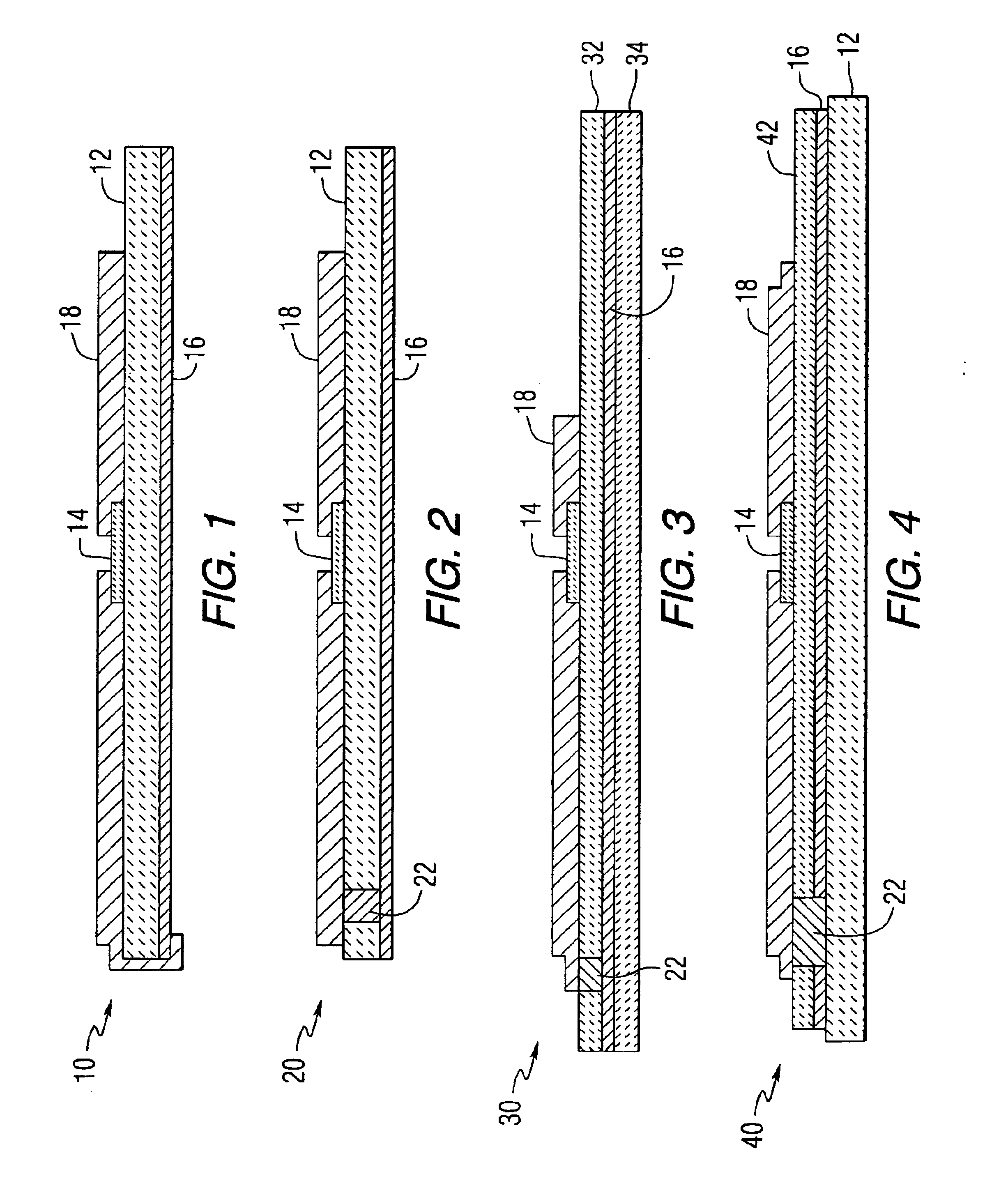

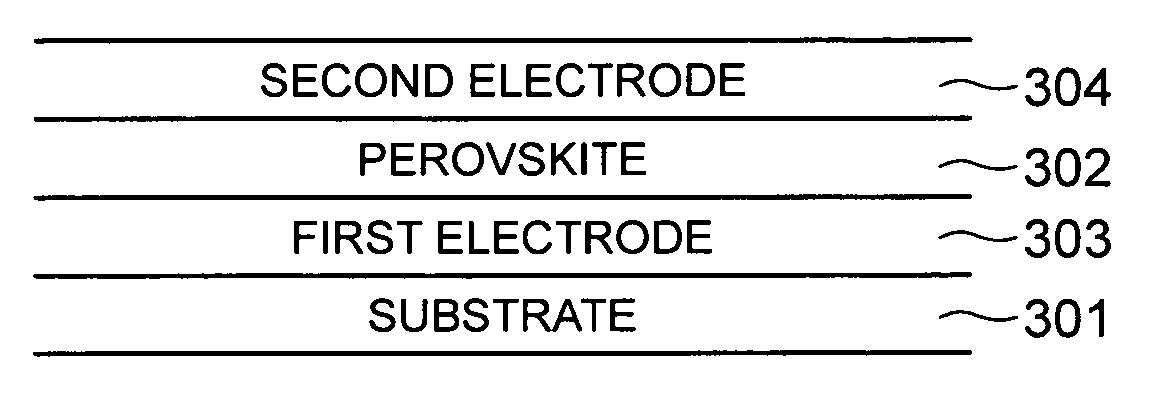

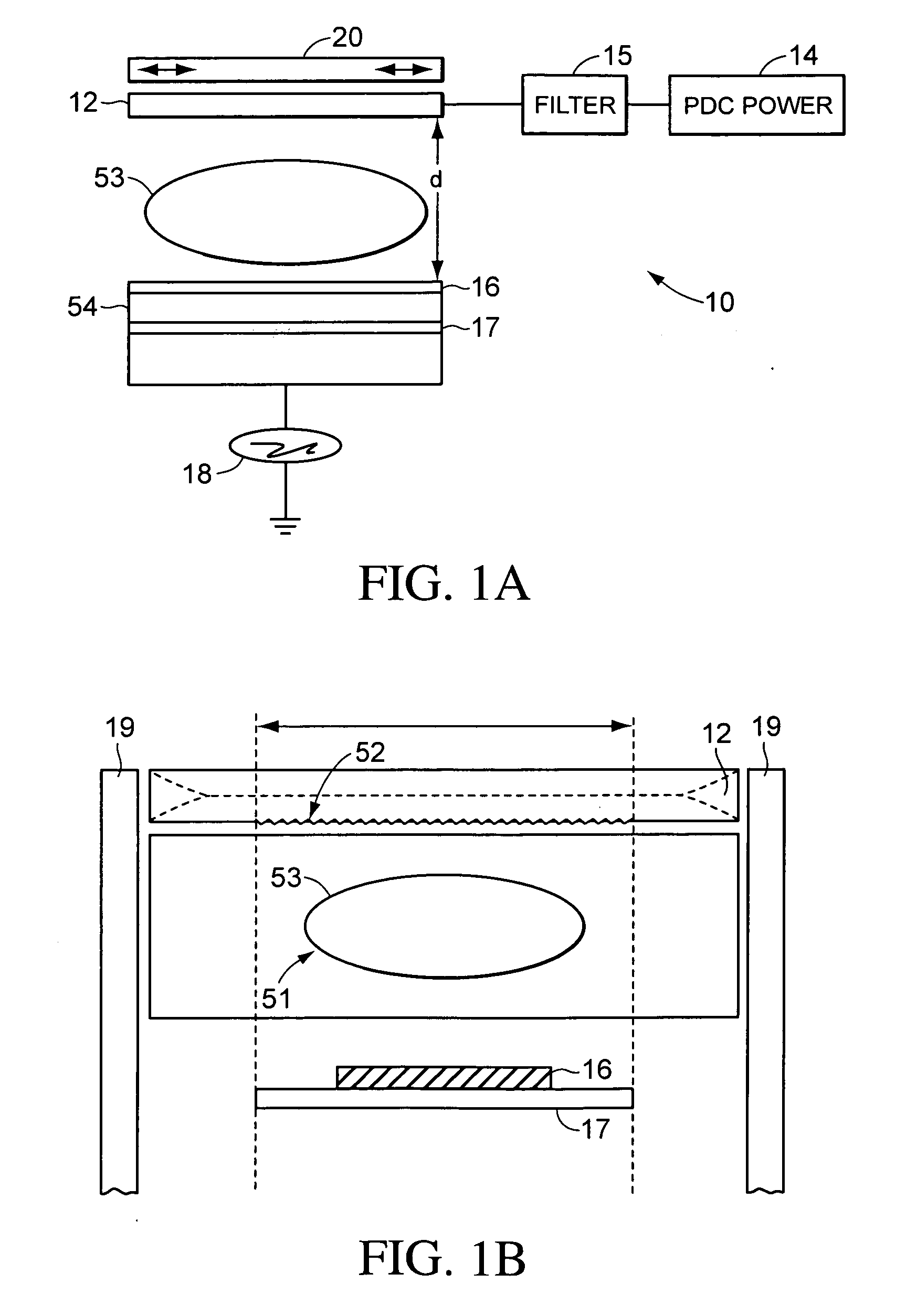

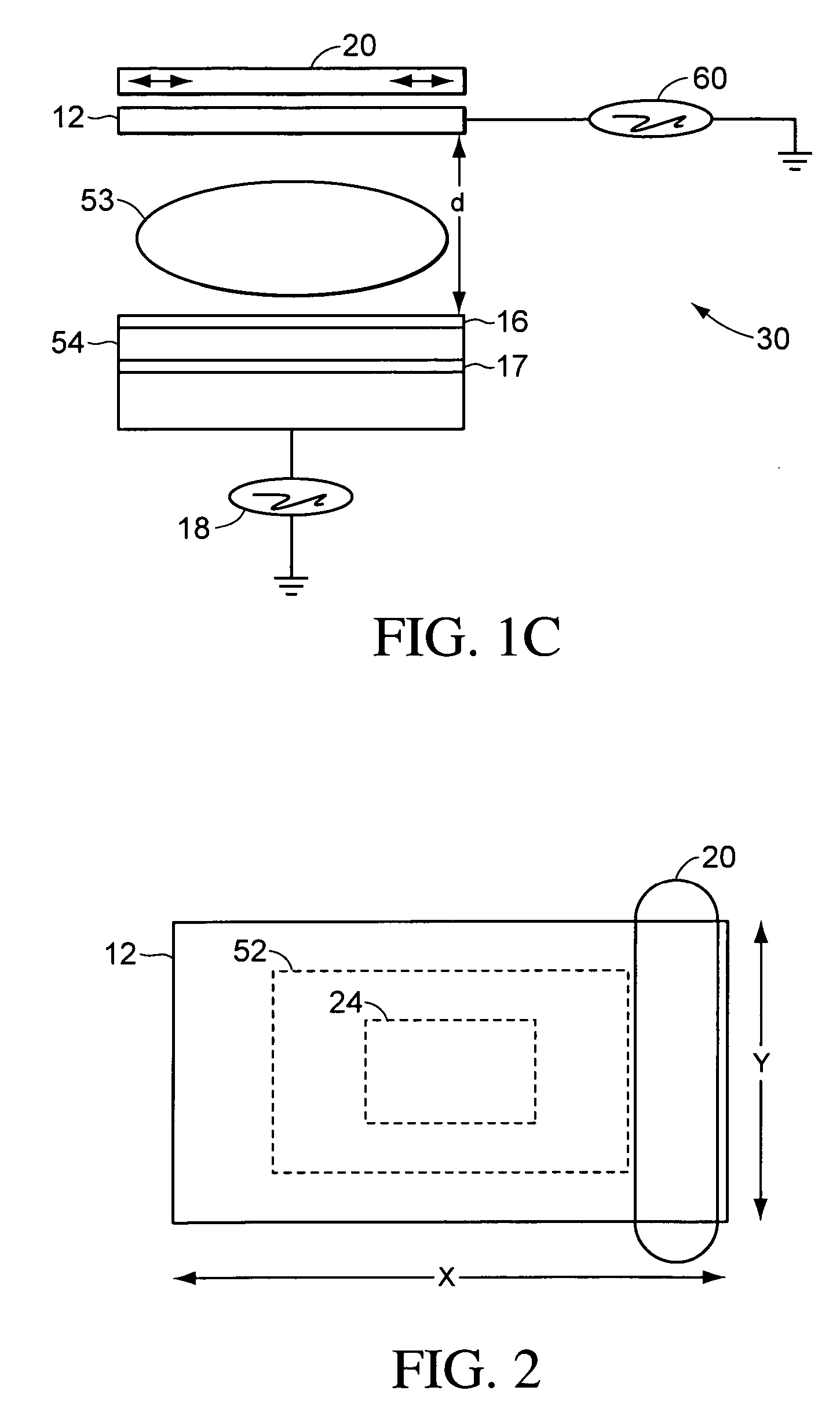

Deposition of perovskite and other compound ceramic films for dielectric applications

InactiveUS20070053139A1Increase capacitanceReduce the temperatureThin/thick film capacitorFixed capacitor dielectricHigh ratePulsed DC

In accordance with the present invention, deposition of perovskite material, for example barium strontium titanite (BST) film, by a pulsed-dc physical vapor deposition process or by an RF sputtering process is presented. Such a deposition can provide a high deposition rate deposition of a layer of perovskite. Some embodiments of the deposition address the need for high rate deposition of perovskite films, which can be utilized as a dielectric layer in capacitors, other energy storing devices and micro-electronic applications. Embodiments of the process according to the present invention can eliminate the high temperature (>700° C.) anneal step that is conventionally needed to crystallize the BST layer.

Owner:DEMARAY

Gravel-shaped attapulgite fireproof ceramsite

The invention discloses a gravel-shaped attapulgite fireproof ceramsite. The key points of the technical scheme are as follows: the gravel-shaped attapulgite fireproof ceramsite is composed of high-viscosity attapulgite clay powder, attapulgite clay tailing powder, granulated blast furnace slag powder, iron tailing powder, coal gangue powder, bauxite tailing powder and diatomite tailing powder. After ingredients of the gravel-shaped attapulgite fireproof ceramsite are mixed, granulated, baked, cooled, crushed and screened, the obtained product is packaged to obtain the gravel-shaped attapulgite fireproof ceramsite. The gravel-shaped attapulgite fireproof ceramsite is a grain with an irregular shape and the grain is internally provided with a plurality of small air holes; and the gravel-shaped attapulgite fireproof ceramsite is the fireproof ceramsite which has the advantages of light weight, strong compressive strength, low coefficient of heat conductivity, high refractoriness, stablechemical performance, and good corrosion resistance and heat-preservation and sound-proof effects. The gravel-shaped attapulgite fireproof ceramsite can be produced by comprehensively utilizing a plurality of types of the tailings, so that the gravel-shaped attapulgite fireproof ceramsite is good for improving the resource utilization rate, changing wastes to valuable things, and protecting the environment; and the gravel-shaped attapulgite fireproof ceramsite is applicable to producing fireproof ceramsite concrete and heat-preservation and sound-proof materials.

Owner:NANGTONG HAODI ANTICORROSION EQUIP

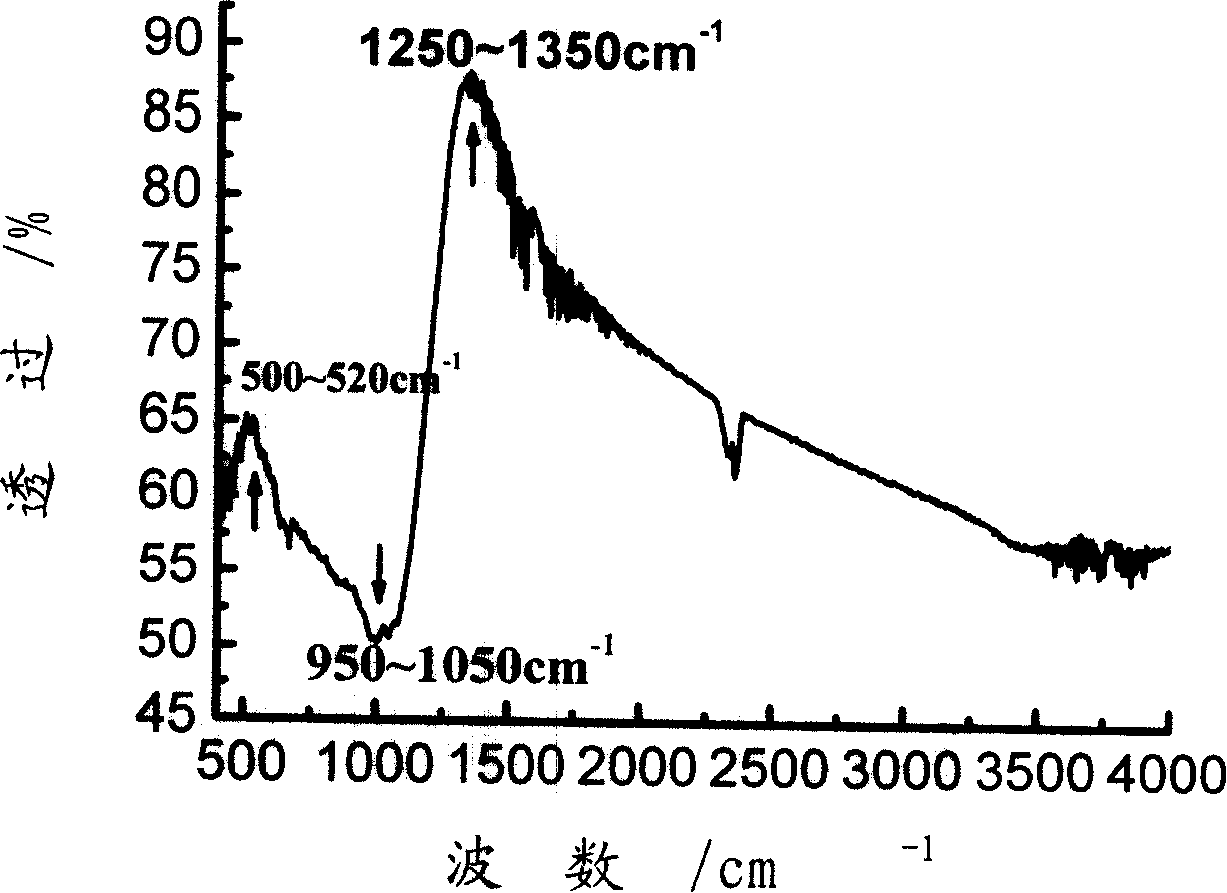

Leadless tellurate low melting sealing glass

The leadless tellurate low melting glass is used for seal-glass and functional paste-composition binder for sintering. It is characterized by that components (mass percentages): TeO2 10-90%, V205 2-40%, SiO2 0-5%, B203 0-5%, ZnO 0-10%, Bi203 0-20%, Sb203 0-8%, Al203 0-4%, SnO2 0-6%, Ag20 0-10%, BaO 0-5%, MgO+CaO+SrO 0-5% Na20+Li20+K20 0-5%. The infrared absorption spectrum has strong absorption band at 950 to 1050cm-1, and two transmission peaks at 500 to 520cm-1 and 1250 to 1350cm-1 respectively, its sealing temperation is between 350 and 580deg.C.

Owner:BEIJING INSTITUTE OF GRAPHIC COMMUNICATION

Porcelainized polyolefin composite material and preparation method thereof

InactiveCN104497404AImprove integritySimple processPlastic/resin/waxes insulatorsPolyolefinAntioxidant

The invention discloses a porcelainized polyolefin composite material, comprising the following raw materials in parts by weight: 50-100 parts of polyolefin resin, 10-200 parts of porcelainized powder, 0.1-50 parts of an accelerant, 0-100 parts of a fire retardant, 0.3-15 parts of a compatilizer, 0.2-10 parts of a coupling agent, 0.1-5 parts of a lubricant and 0.1-8 parts of an antioxidant. The porcelainized polyolefin composite material disclosed by the invention is simple in technological process, easy to operate, free of three wastes, and excellent in mechanical property and electric property, and can be sintered into ceramic at a temperature over 600 DEG C or in a flame within 5-10 minutes; and the formed shell is good in integrity, free of cracking or drippage, has excellent fireproof performance and heat-insulating property, and has high application value in the fields of fire-resistant wires and cables and indoor fire-resistant decoration.

Owner:常州市沃科科技有限公司

Preparation method of hollow flat plate structure type ceramic filter membrane element

ActiveCN103623711ALower sintering temperatureSmall filter resistanceSemi-permeable membranesAluminium hydroxideChemical separation

The invention provides a preparation method of a hollow flat plate structure type ceramic filter membrane element. The method comprises the following steps: (1) preparing a hollow structure type ceramic membrane supporting body by using an extrusion molding method, namely sintering aluminum hydroxide obtained by calcination at 600 DEG C as a main raw material to prepare the ceramic membrane supporting body; (2) preparing the ceramic filter membrane by using a plasma spray method. When the ceramic membrane supporting body is prepared, the selected and used raw material is calcined aluminum hydroxide, so that the sintering temperature of the ceramic membrane supporting body can be greatly reduced, and the sufficient strength of the supporting body can be guaranteed; when the ceramic filter membrane layer is prepared, the thickness of the filter membrane can be excellently controlled by using the plasma spray process, and the filter resistance is reduced; the membrane layer has the uniform pore size distribution and the high separation accuracy; the membrane layer is closely combined with the supporting body. The ceramic filter membrane is prepared by using plasma spraying without sintering, so that the process is simple, the production cost of the ceramic filter membrane can be effectively reduced, the production efficiency is improved, and the process can be widely applied to the fields of sewage treatment and filtration, solid-liquid chemical separation, and the like.

Owner:雅安沃克林环保科技有限公司

Ultralight-weight proppant and preparation method thereof

The invention relates to an utralight-weight proppant and a preparation method thereof, belonging to the field of fracturing extraction of oil and gas wells. The preparation method of the utralight-weight proppant comprises the following steps: sintering 1-50 parts by weight of fly ash, 0.5-20 parts by weight of coal gangue, 20-50 parts by weight of clay and 10-30 parts by weight of bauxite whichare used as aggregate, and balling, thereby obtaining the utralight-weight haydite. The utralight-weight proppant provided by the invention utilizes industrial waste, and the production can be easilycontrolled; the sintering temperature is greatly lowered, ranging 1100-12500 DEG C; and the energy consumption is effectively lowered, and the energy can be saved by 20%. The percentage of damage of the utralight-weight proppant under 69 MPa is lower than 5%, the volume density is lower than 1.25g / cm<3>, and the apparent density is lower than 2.0g / cm<3>, so the utralight-weight proppant can completely substitute medium-density haydite.

Owner:BEIJING QISINTAL SCI & TECH

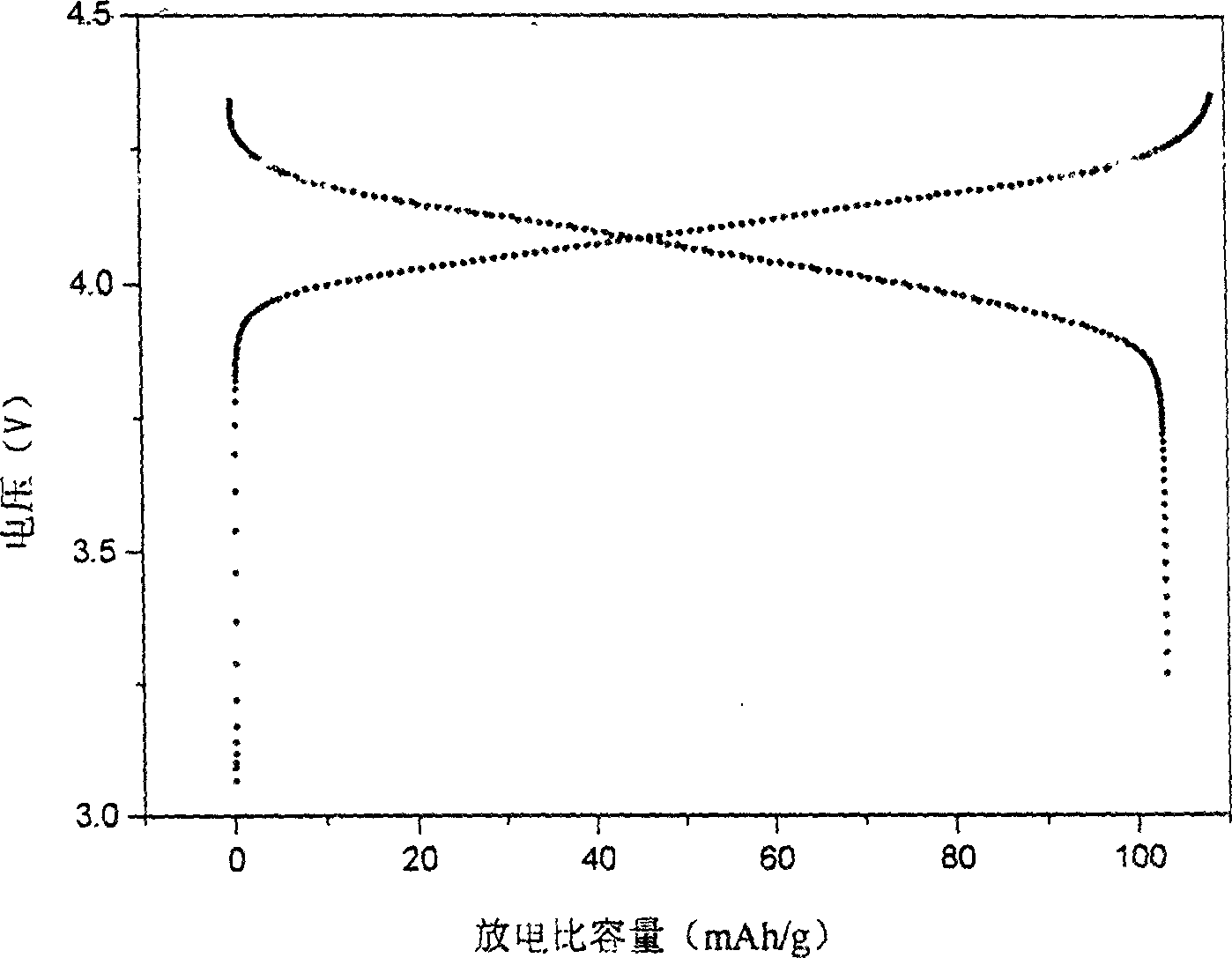

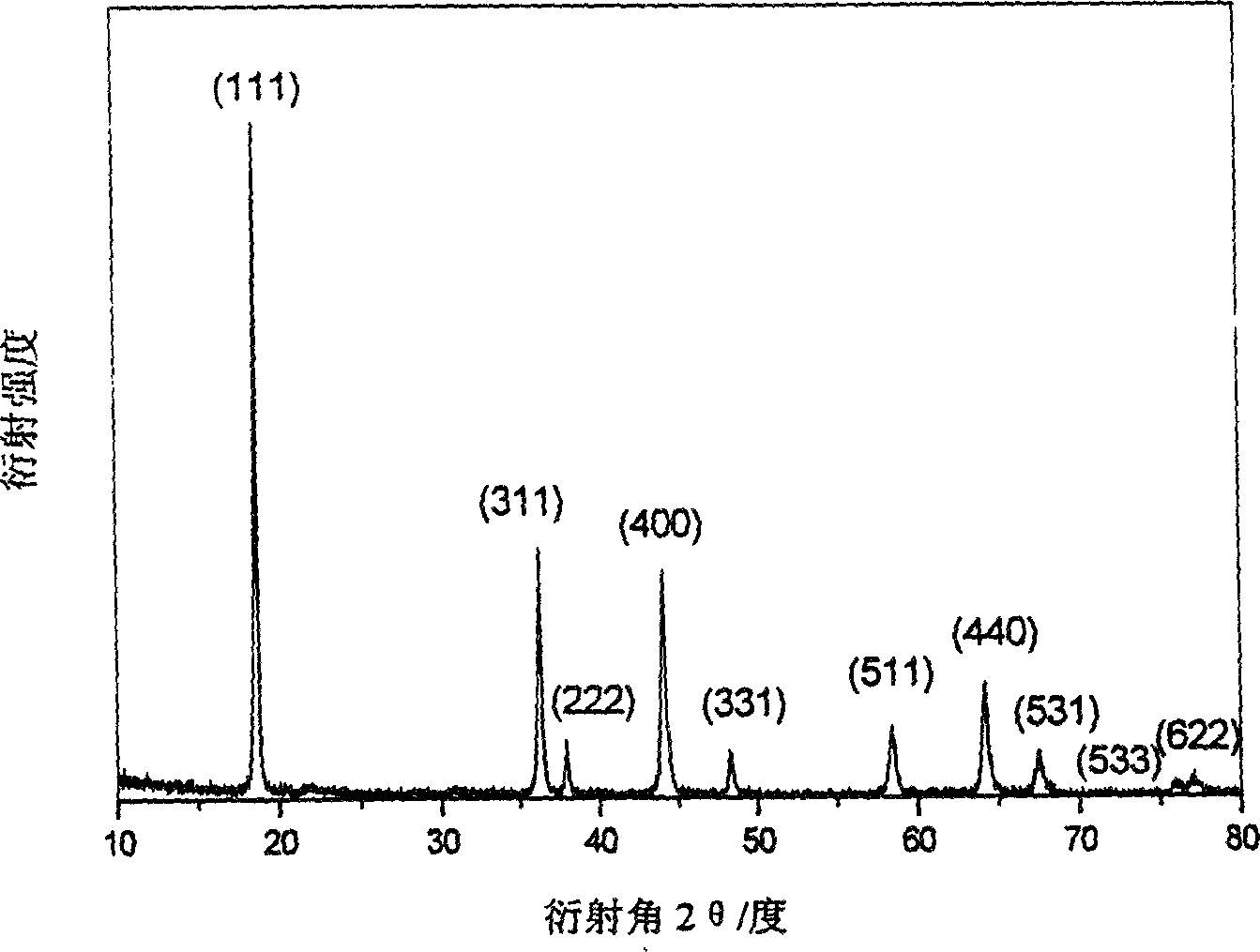

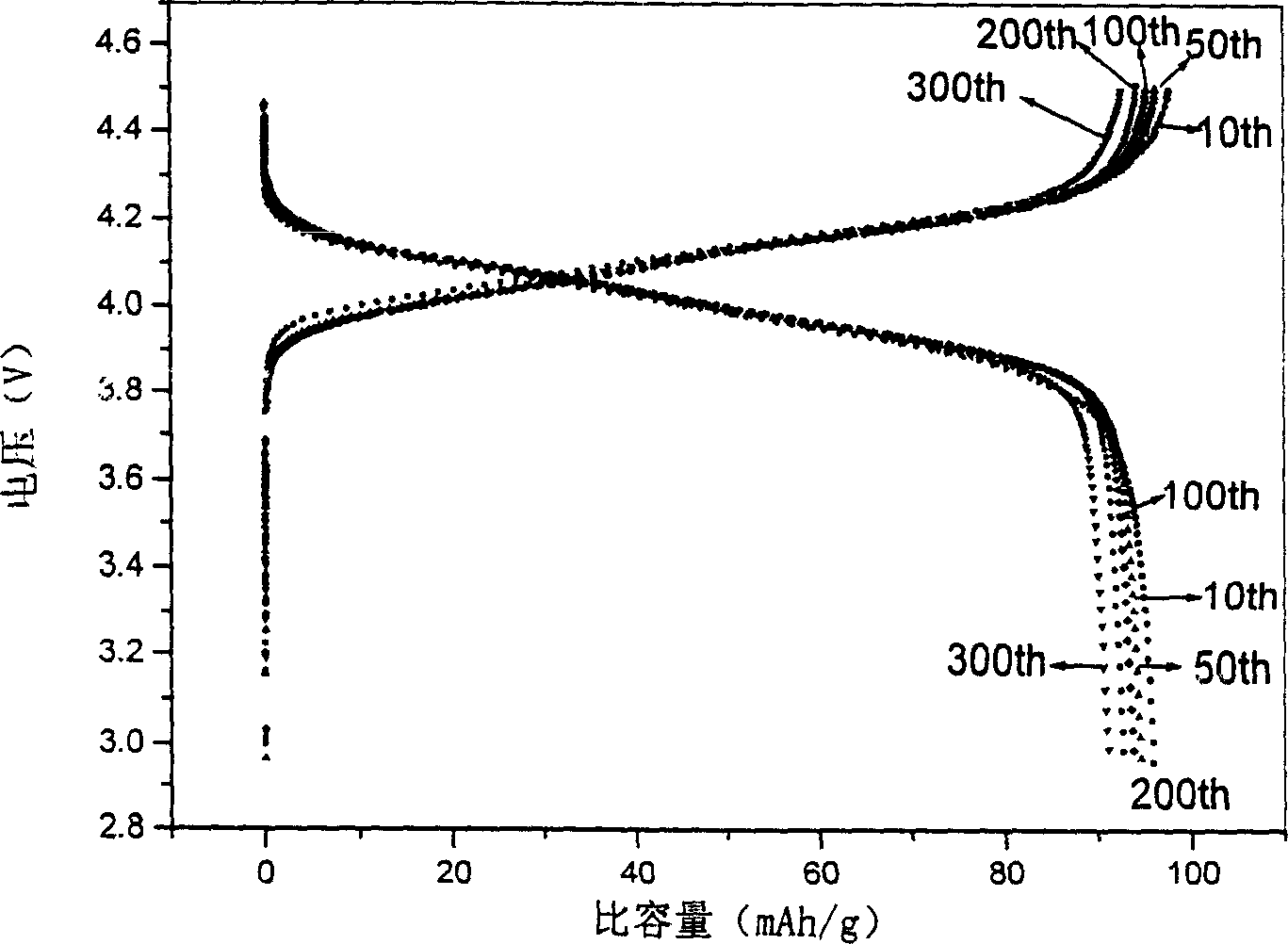

A positive electrode material for lithium secondary cell, and preparation and usage thereof

InactiveCN1595687AIncrease energy densityGood charge and discharge cycle performanceElectrode manufacturing processesIron compoundsLithiumManganese

The invention relates to positive electrode material of a lithium secondary battery, which can combine with electrolyte solution or solid electrolyte, and negative electrode active material to form lithium secondary battery. Its characteristics are: the positive electrode material of lithium secondary battery is LiMn2-zMzO4 (0<=z<=0.5.), M is chosen from Li, Mg, Co, Ni, Fe, Al, Sr, Cr, Ga, Cu and Zn. The manufacturing method for positive electrode material of the lithium 1 secondary battery, includes preparation of usher containing Mn; decorate to the covering of usher particle containing Mn; mix with lithium salt and prepare particle; sintering and other steps. By decoration of the surface of particle to usher of positive electrode containing Mn or active material itself, state of material or apparent condition of material can be changed and its capacity of powerful charge and discharge, cycle performance and thermal stability can be raised. The invention has notable advantages including low cost, capacity of powerful charge and discharge, super-long cycle performance, excellent safety, super-long circulation property and resistance to overcharge.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

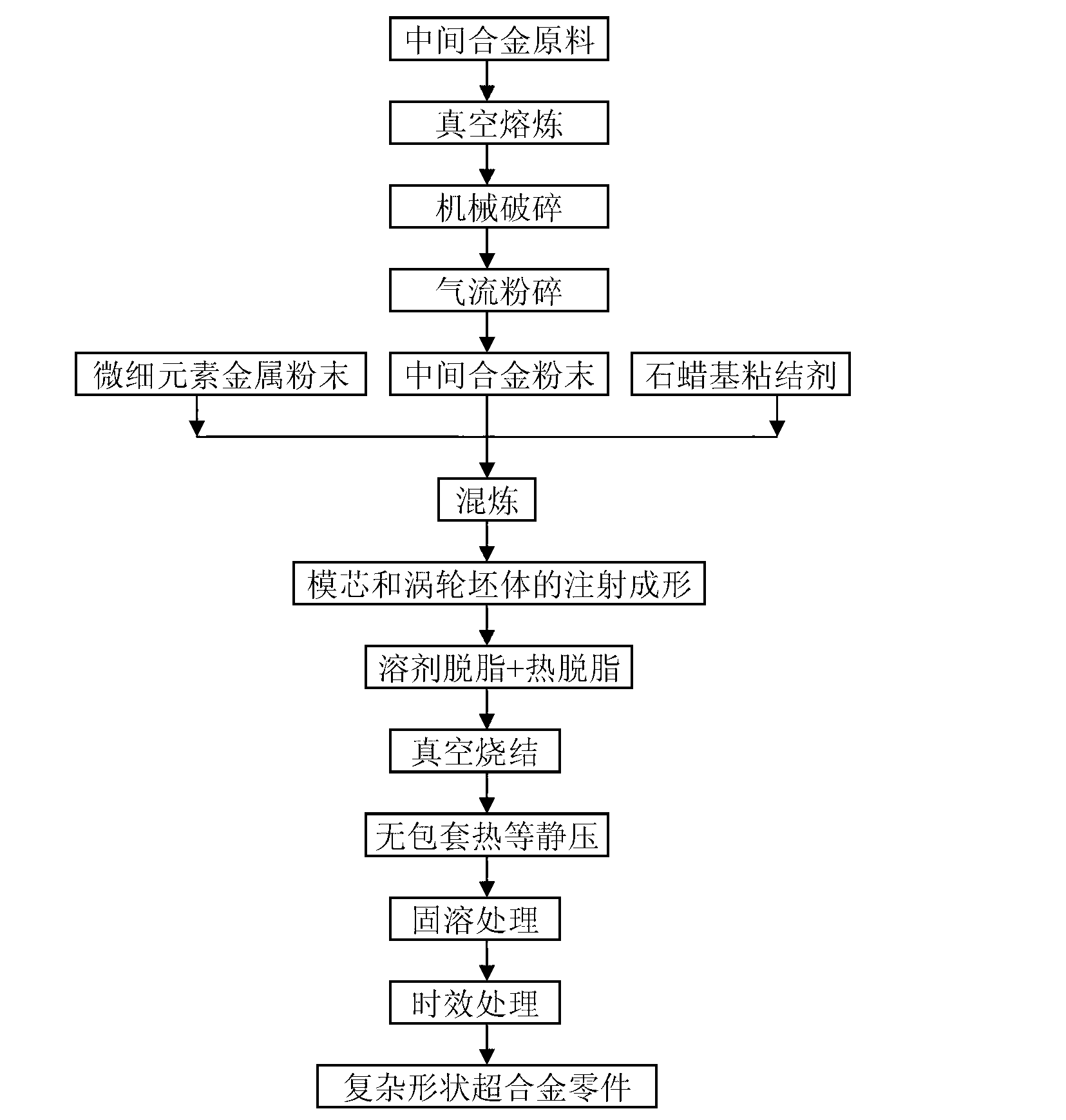

Method for preparing powder super-alloy by near net shape

Disclosed is a method for preparing powder super-alloy by a near net shape. Firstly, high-purity intermediate alloy powder is prepared by the aid of vacuum melting and air jet pulverization technology. Secondly, the intermediate alloy powder and fine particle diameter metal powder (such as carbonyl nickel powder, carbonyl iron powder, reduction tungsten powder and reduction molybdenum powder) are mixed in a high-energy ball mill with protective atmosphere to obtain mixed powder. The mixed powder and paraffin base binders are uniformly premixed, feedstock with a uniform rheological performance is obtained by mixing and is formed on an injection forming machine to obtain a blank in a complicated shape. The binders are removed from the blank in the complicated shape by the aid of solvent degreasing and hot degreasing technologies, the degreased blank is sintered in the vacuum atmosphere, the sintered blank is further compacted by the aid of unjacketed hot isostatic pressure, and finally, a super-alloy part in the complicated shape is obtained by the aid of solid solution and aging treatment. Raw material powder cost and technological energy consumption are remarkably reduced, and prepared super-alloy is almost fully compact, uniform in structure and excellent in comprehensive mechanical property.

Owner:UNIV OF SCI & TECH BEIJING

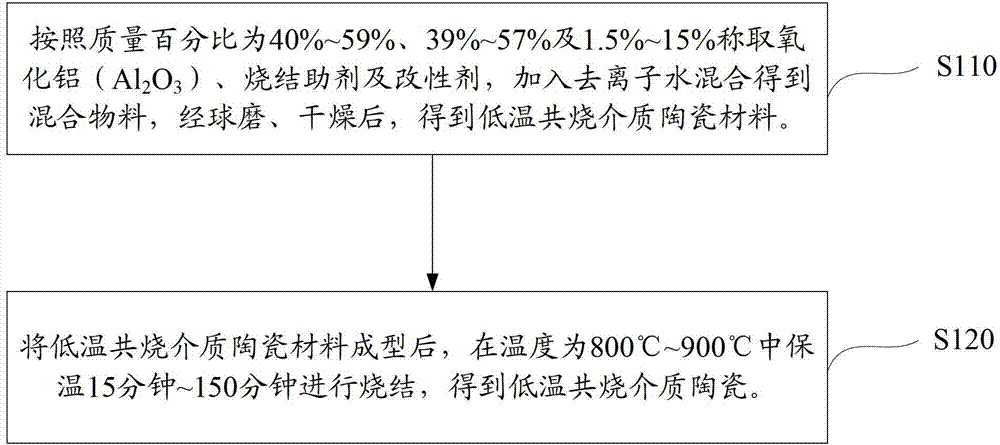

Method, sintering aid and materials for preparation of low-temperature cofired medium ceramic and application

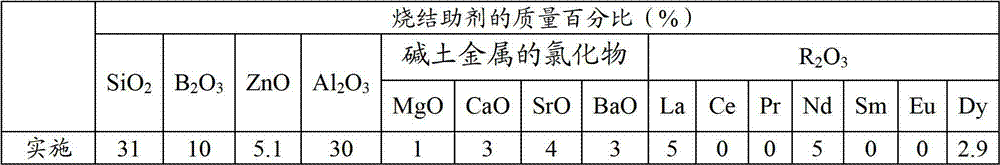

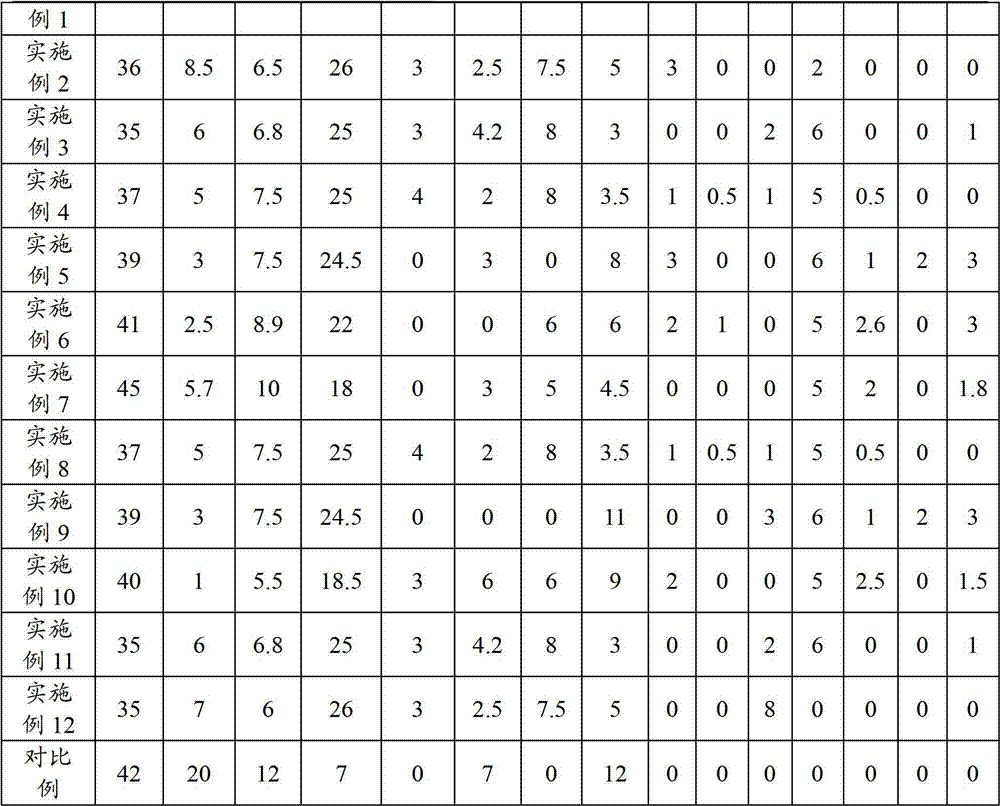

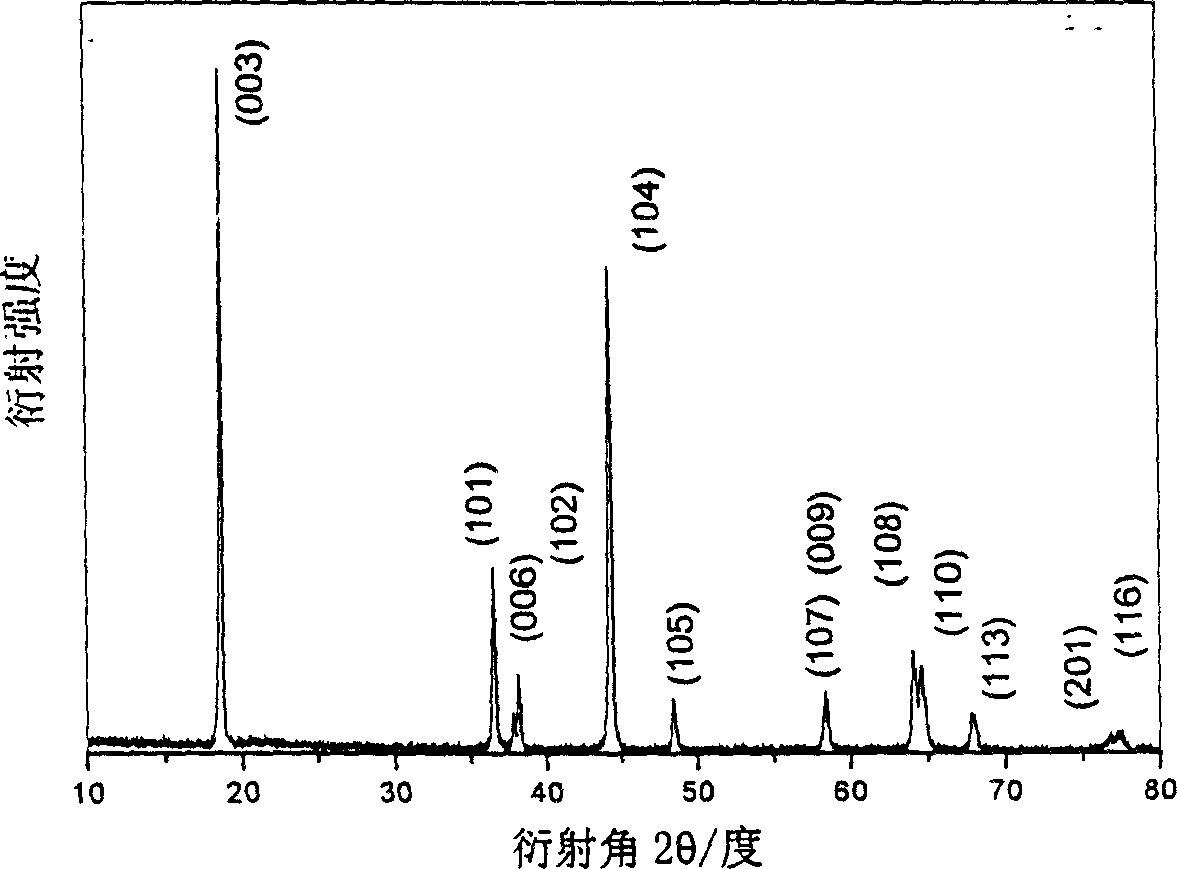

A sintering aid for a low-temperature cofired medium ceramic material is composed of, by weight, 31%-45% of silicon dioxide, 1%-10% of boron oxide, 5.1%-10% of zinc oxide, 18%-30% of aluminum oxide, 11%-24% of alkaline earth metallic oxide and 5%-15% of oxide with the general formula of R2O3, wherein R refers to at least one of lanthanum, cerium, praseodymium, neodymium, samarium, europium and dysprosium, and the alkaline earth metallic oxide refers to one of magnesium oxide, calcium oxide, barium oxide and strontium oxide. Adding the sintering aid into the low-temperature cofired medium ceramic material enables the prepared low-temperature cofired medium ceramic to have excellent thermal mechanical performance and dielectric performance. In addition, the invention provides the low-temperature cofired medium ceramic material and application thereof and a method for preparing the low-temperature cofired medium ceramic.

Owner:GUANGDONG FENGHUA ADVANCED TECH HLDG

Preparation method of high-coercivity sintered Nd-Fe-B and product

InactiveCN104505206AIncrease profitImprove liquidityInorganic material magnetismInductances/transformers/magnets manufactureRare earthNitrogen

The invention discloses a preparation method of high-coercivity sintered Nd-Fe-B. The preparation method comprises the following steps: preparing a main phase alloy powder and a grain boundary phase alloy powder; protecting the prepared main phase alloy powder and the grain boundary phase alloy powder by using nitrogen or argon in a protective medium, and uniformly mixing, wherein the mass percent of the added grain boundary phase alloy powder accounts for 0.1-10 percent; carrying out orientation profiling and cold isostatic pressing on the mixed alloy powder; in a vacuum sintering furnace, sintering a profiled magnet block for 2-4h at the temperature of 1000-1100 DEG C, then carrying out primary tempering for 2-4h at the temperature of 800-950 DEG C, and carrying out secondary tempering for 2-4h at the temperature of 450-650 DEG C to prepare the sintered Nd-Fe-B. The invention also discloses the high-coercivity sintered Nd-Fe-B. According to the preparation method disclosed by the invention, by virtue of low melting point auxiliary alloy, the wetting temperature between a grain boundary phase and a main phase is lowered, the wetting time is prolonged, the utilization ratio of heavy rare earth is increased, the used amount of rare earth is lowered, the process is simple, the cost is low, and the high-coercivity sintered Nd-Fe-B is suitable for mass production.

Owner:ZHEJIANG UNIV

Positive electrode material of manganese series, and preparation and usage thereof

InactiveCN1595689AIncrease energy densityIncrease powerElectrode manufacturing processesSecondary cellsManganeseThermal stability

The invention relates to manganese department positive electrode material of a lithium secondary battery, which can combine with electrolyte solution or solid electrolyte, and negative electrode active material to form lithium secondary battery. Its characteristics are: the positive electrode material of lithium secondary battery is LiMn1-x-y NixMyO2(x is not less than 0.2 and not larger than 0.8, y is not less than 0 and not larger than 0.6, and x+y is not larger than 1.), M is chosen from Li, Mg, Co, Ni, Fe, Al, Cr. The manufacturing method for manganese department positive electrode material of the lithium secondary battery, includes preparation of usher containing Mn; decorate to the covering of usher particle containing Mn; mix with lithium salt and prepare particle; sintering and other steps. By decoration of the surface of particle to usher 6 of positive electrode containing Mn or active material itself, state of material or apparent condition of material can be changed and its capacity of powerful charge and discharge, cycle performance and thermal stability can be raised. The invention has notable advantages including low cost, capacity of powerful charge and discharge, super-long cycle performance, excellent safety, super-long circulation property and resistance to overcharge .

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

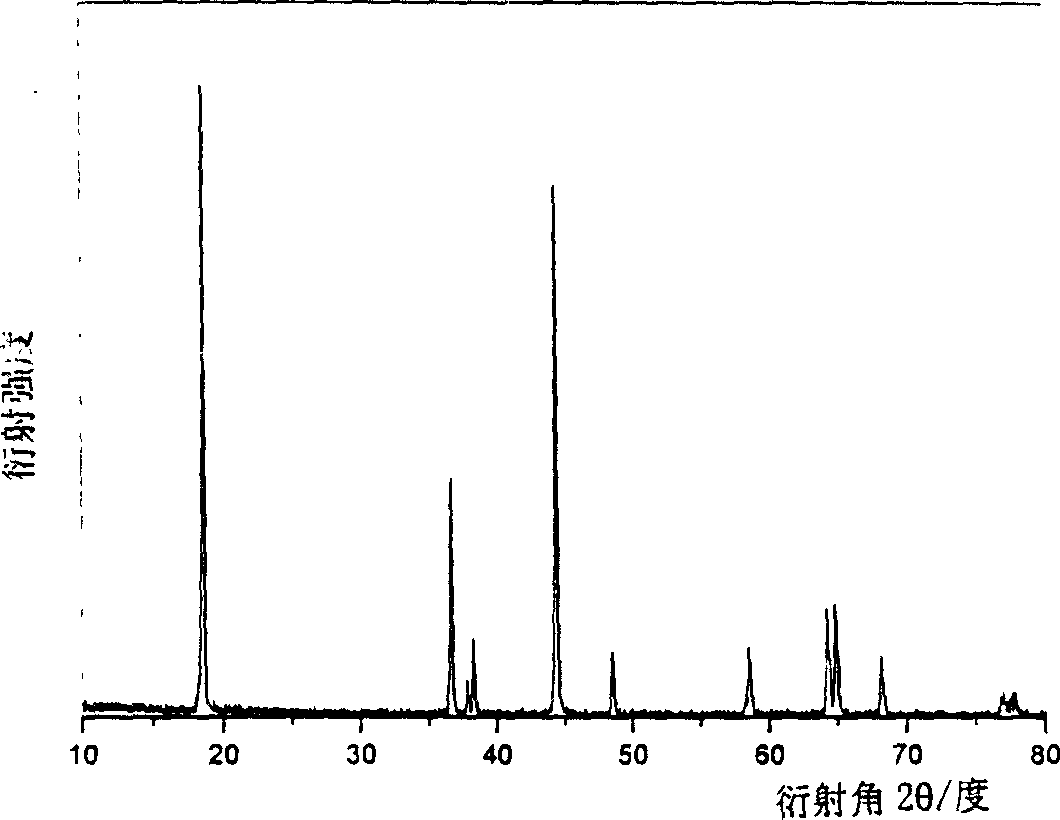

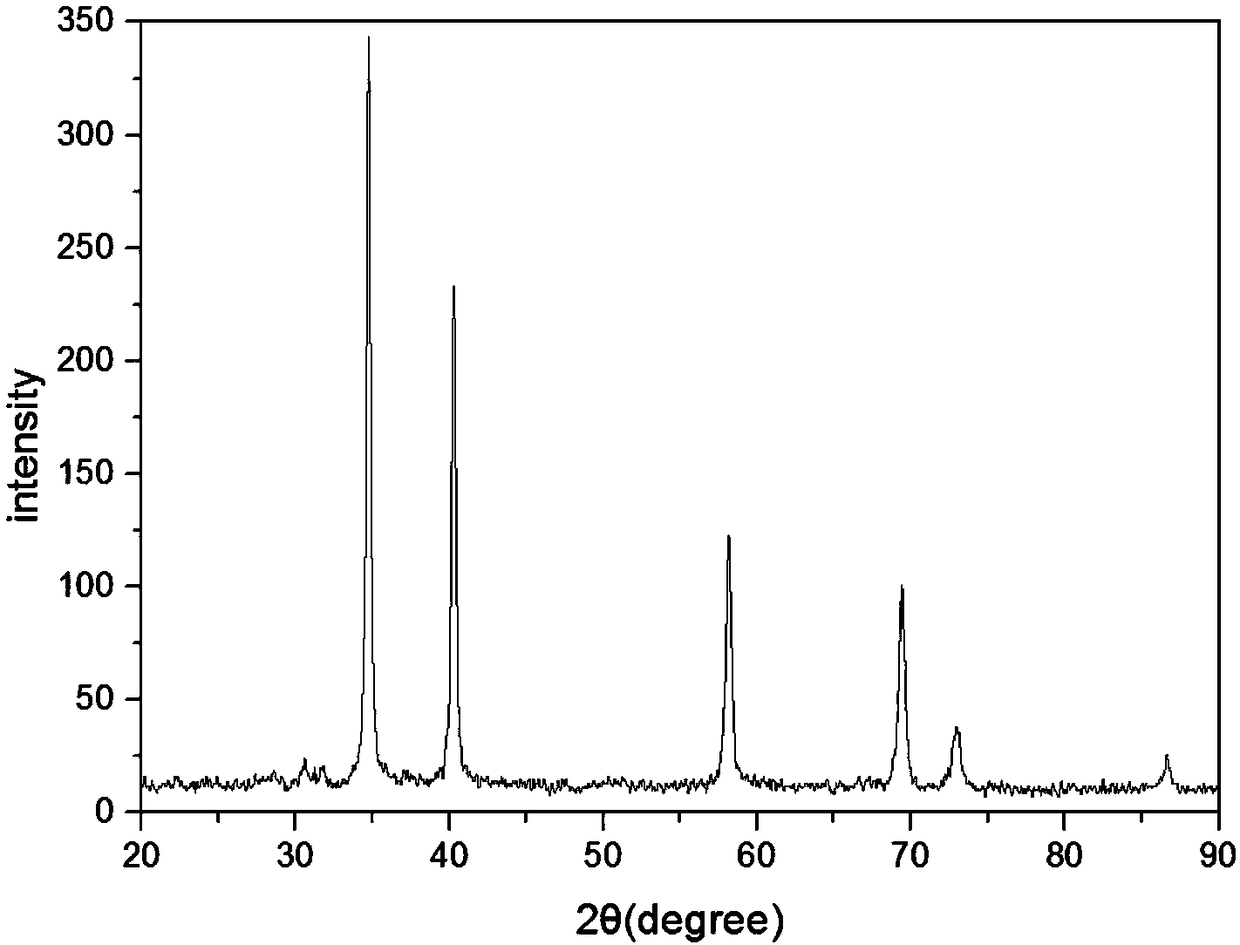

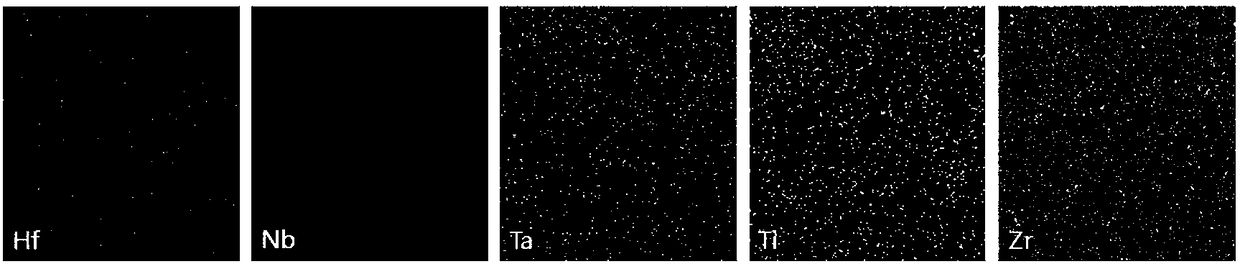

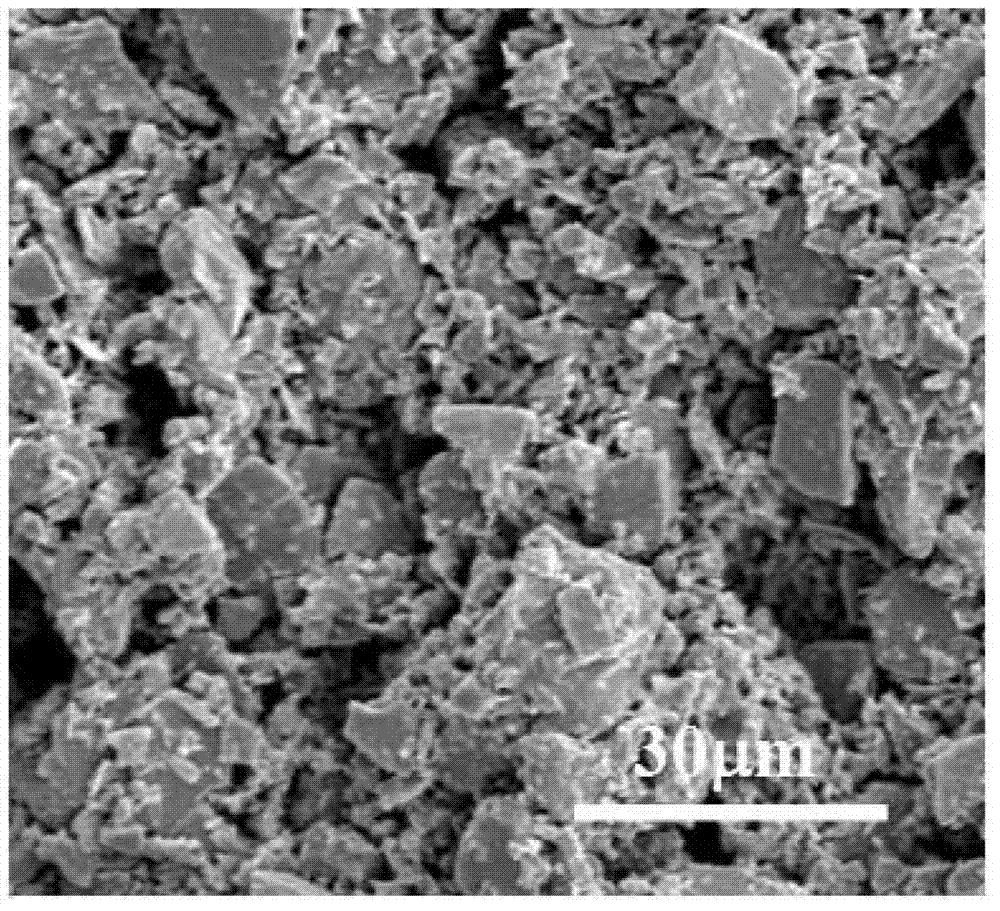

(HfTaZrTiNb) C high-entropy ceramic powder and preparation methods of high-entropy ceramic powder and high-entropy ceramic blocks

The invention relates to (HfTaZrTiNb) C high-entropy ceramic powder and preparation methods of the high-entropy ceramic powder and high-entropy ceramic blocks. Five-face centered cube (FCC) carbonizedpowder is made into ceramic powder through a high-energy ball milling method, then a discharging plasma method is adopted to realize preparation of the high-entropy ceramic blocks, and quick sintering of ceramic within a temperature range of 1700-2350 DEG C can be realized to obtain high-entropy ceramic with single-phase-face centered cube (FCC) structure. The preparation method of (HfTaZrTiNb) Chigh-entropy block ceramic is solved; the high-entropy ceramic with the FCC structure is finally obtained by strictly controlling parameters of a discharging plasma sintering furnace or a hot press furnace and characterizing XRD, so that the ceramic material system is enriched.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

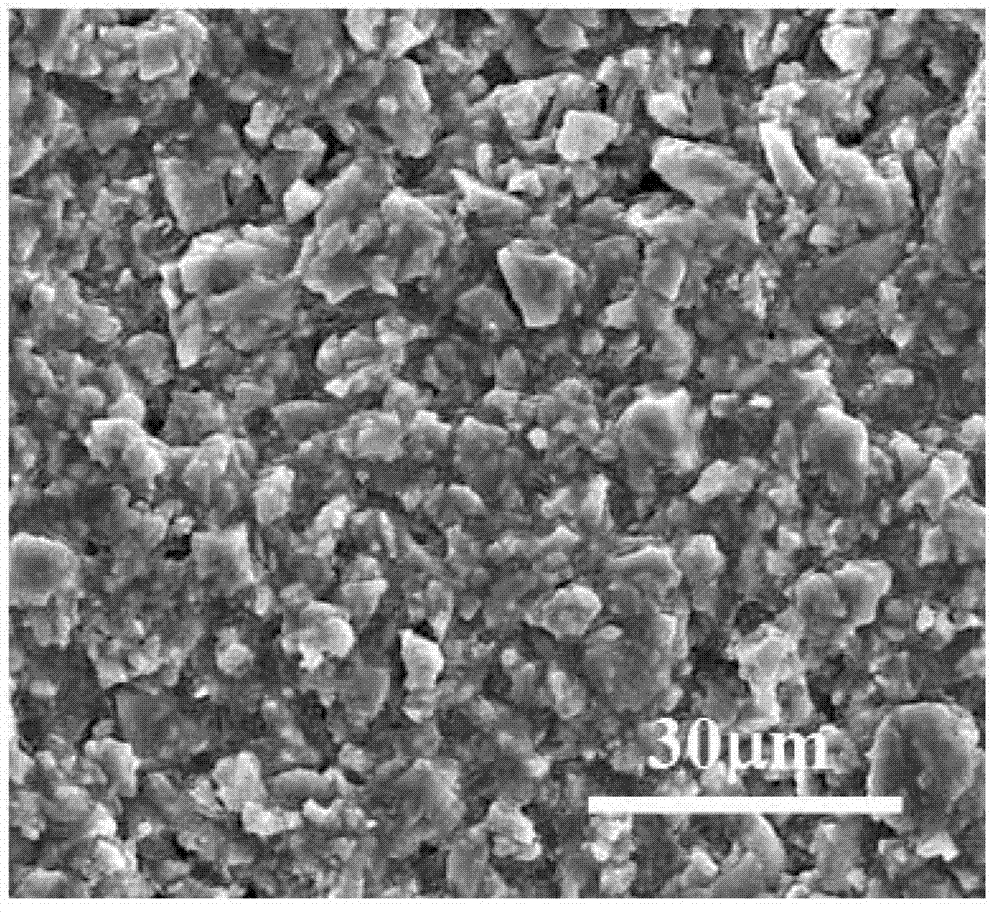

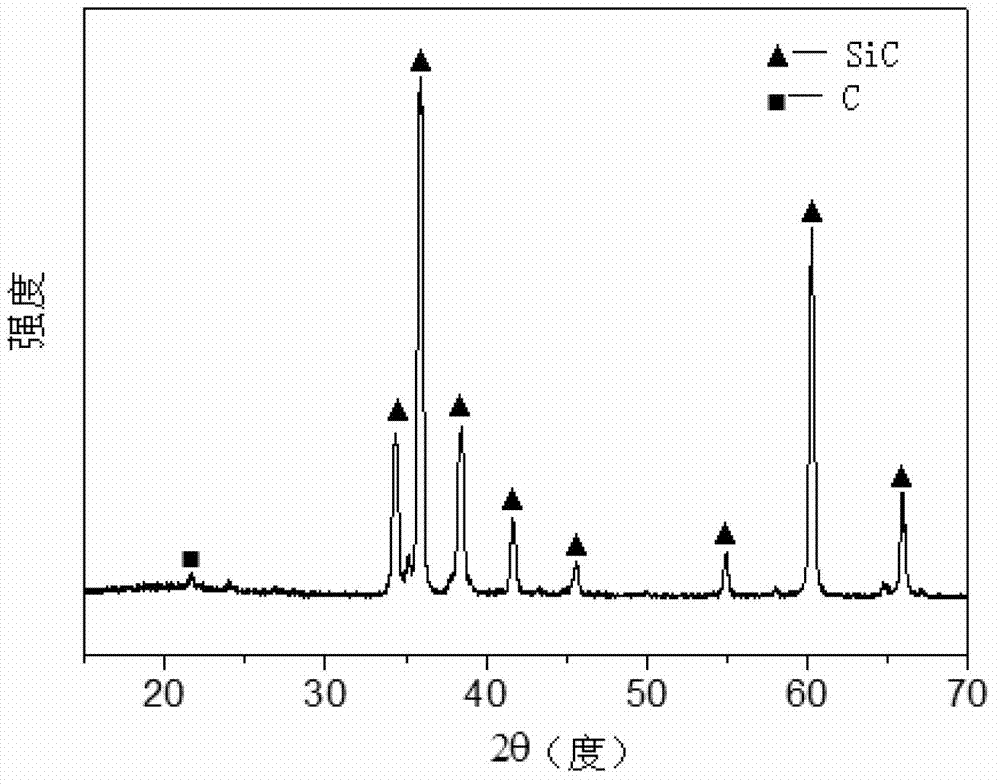

Method for preparing porous silicon carbide ceramic

ActiveCN102807391AImprove strength propertiesLow costCeramicwareSilica fumeMechanical properties of carbon nanotubes

The invention discloses a method for preparing porous silicon carbide ceramic, and relates to a method for preparing silicon carbide ceramic. The invention aims to solve the technical problems of low mechanical properties and low porosity of porous silicon carbide ceramic prepared through the existing method. The method comprises the following steps of 1, preparing pulp; 2, preparing a porous ceramic green body; 3, preparing a prefabricated body; 4, preparing carbon gel; 5, preparing a composite material of silicon carbide and the carbon gel; 6, preparing a composite material of porous silicon carbide and carbon aerogel; and 7, putting the composite material of the porous silicon carbide and the carbon aerogel and monatomic silicon powder into a sintering furnace to be sintered to obtain the porous silicon carbide ceramic. The porosity of the opening of the porous silicon carbide is 30-83 percent, the aperture size is 0.3-100m, and pore spaces can be uniformly distributed or directionally arranged. Through a three-point bending test, the bending strength of the finally prepared porous silicon carbide ceramic material with the porosity of 47.8 percent achieves 164.62 MPa.

Owner:HARBIN INST OF TECH

Cylindrical attapulgite flower ceramsite

ActiveCN102503537AHigh strengthLower sintering temperatureCeramic materials productionCeramicwareMetallurgyBentonite powder

The invention discloses cylindrical attapulgite flower ceramsite. The key points of the technical scheme are that the cylindrical attapulgite flower ceramsite consists of high-adhesion attapulgite clay powder, attapulgite clay tailing powder, red bentonite powder, sludge, diatomite tailing powder and rice husk powder. The cylindrical attapulgite flower ceramsite is produced by the following stepsof mixing the ingredients, pelleting, roasting, cooling, screening and packaging. The cylindrical attapulgite flower ceramsite has a rough and porous surface, is light in weight, high in strength andwater absorption rate, can be immersed in water throughout the year without cracking and can continuously and slowly release nutrition required by flowers. Moreover, the cylindrical attapulgite flower ceramsite is produced by comprehensively utilizing the sludge and tailings, so that the resource utilization rate is improved, waste is turned into wealth, and environment is protected. Besides, thecylindrical attapulgite flower ceramsite is applicable to cultivation of various flowers and vegetables.

Owner:江苏世澳非金属应用科技有限公司

Permanent ferrite magnetic tile and preparation method thereof

InactiveCN101202138AIncrease solid solutionImprove performancePermanent magnetsInorganic material magnetismFiberSilicon oxide

The invention relates to a permanent ferrite magnetic arc and the manufacturing method thereof, belonging to a manufacturing field of a motor permanent ferrite. Weight proportions of main material components and additive components are as the following: main materials: 8.7 to 9.0 percent of strontium oxide; 86 to 87 percent of iron oxide red; additives: 0.6 to 1.0 percent of calcium carbonate; 0.6 to 1.0 percent of aluminum oxide; 0.4 to 0.8 percent of chrome oxide; 0.3 to 0.6 percent of boric acid; 0.3 to 0.5 percent of silicon oxide; 0.2 to 0.4 percent of cobalt oxide; 0.2 to 0.4 percent of lanthanum oxide and 0.1 to 0.3 percent of silicate fiber. The invention is provided with high surplus magnetic induction strength and high intrinsic coercivity so as to enhance a mechanical strength of the magnetic arc.

Owner:CHANGZHOU DIER MAGIC MATERIALS

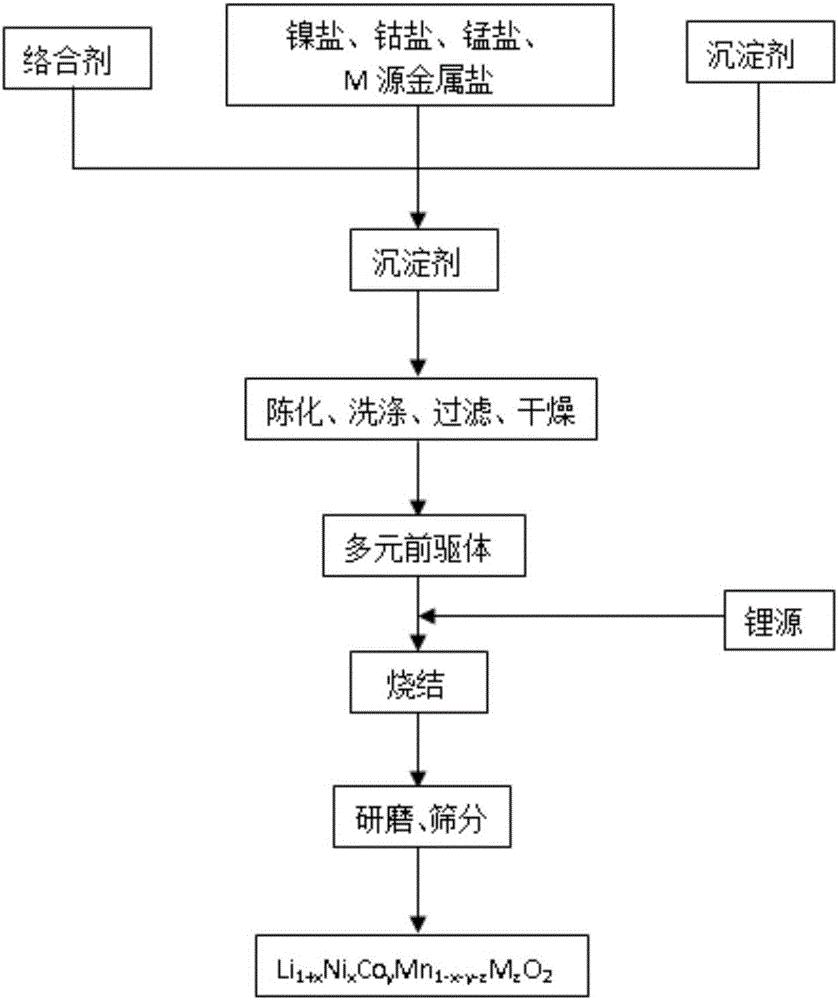

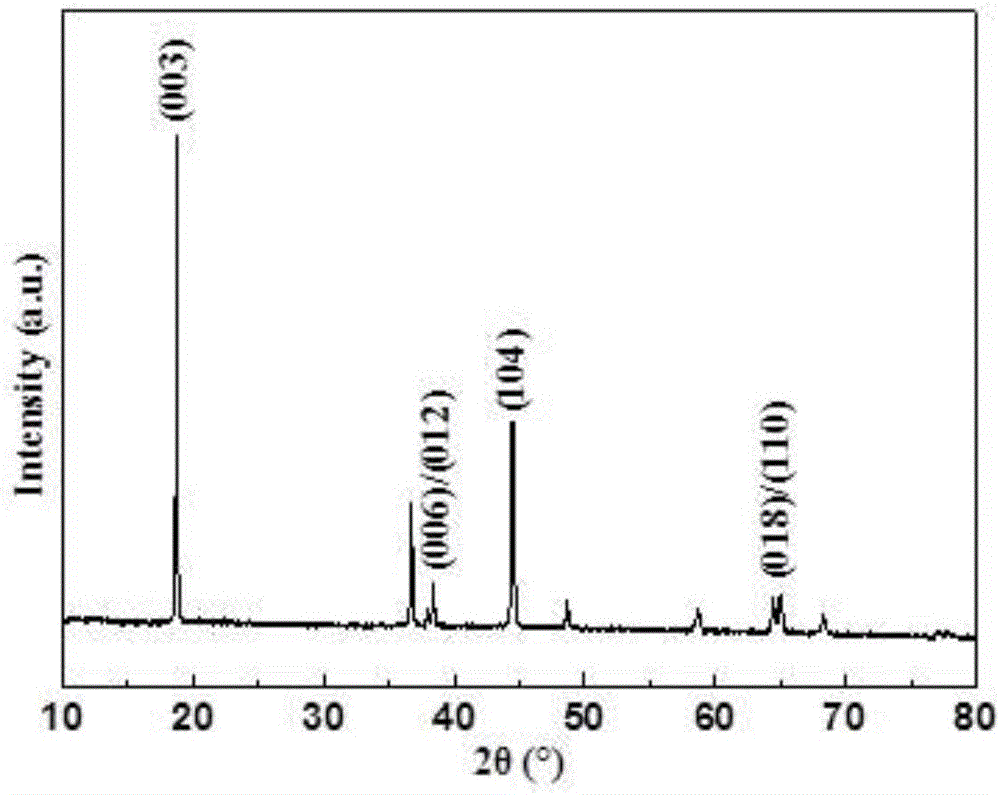

Doped monocrystal multi-component material for lithium ion batteries and preparation method of such doped monocrystal multi-component material

InactiveCN106784686AIncrease energy densityHigh tap densityHybrid capacitor electrodesCell electrodesManganeseCharge discharge

The invention belongs to the technical field of anode materials for lithium ion batteries and particularly discloses a doped monocrystal multi-component material for lithium ion batteries and a preparation method of such doped monocrystal multi-component material. The doped monocrystal multi-component material and the preparation method thereof have the advantages that nickel-cobalt-manganese ternary materials are modified, and M-source metals are doped when a precursor is prepared to decrease the material sintering temperature and improve material tapping density, so that the mixed arrangement degree of Ni<2+> in a Li<+> layer is weakened obviously; through high-temperature sintering and tempering processes, the precursor of the multi-composite material, prepared through a coprecipitation method, is more stable in crystal structure, metal ions in the material are inhibited from dissolving through surface coating, side reaction between the metal ions and electrolyte is inhibited, and stability and electrochemical performance of an active material are further enhanced; a doped monocrystal multi-component material finished product is stable in crystal structure, high in safety and compaction density and excellent in rate capability and cycle performance, so that specific capacity and charge-discharge voltage of the material are further enhanced; the preparation method is small in doping quantity, simple to operate, easy to control, widely applicable and suitable for large-scale production.

Owner:烟台卓能锂电池有限公司

Preparation method of medical porous titanium and titanium alloy

InactiveCN102747245AImprove efficiencyGood mechanical propertiesProsthesisThermal insulationRepair material

The invention discloses a preparation method of medical porous titanium and titanium alloy, which comprises the following steps: proportionally preparing titanium powder, alloy element powder and pore forming agent powder according to needs; carrying out ball milling, mixing and mechanical pressing by a powder metallurgy blank making technique to obtain a blank; putting the blank in a thermal insulation barrel, and putting the thermal insulation barrel into a microwave sintering furnace; and after vacuumizing the furnace chamber to a vacuum degree of 0.1Pa, charging argon with the purity of 99.999% to form cyclic protection, controlling the output power of the microwave sintering furnace at 0.5-3kW, heating to the sintering temperature of 800-1200 DEG C at the heating rate of 5-40 DEG C / minute, keeping the temperature for 5-30 minutes, shutting down the microwave source, and carrying out furnace cooling to obtain the medical porous titanium and titanium alloy. The invention has the advantages of simple preparation method, short sintering period, high efficiency, low sintering temperature and low energy consumption; and the sintered porous titanium and titanium alloy have excellent mechanical properties, and can be used as alternate repair material for bones, joints, artificial radix dentis and other hard tissues.

Owner:HUAIYIN INSTITUTE OF TECHNOLOGY

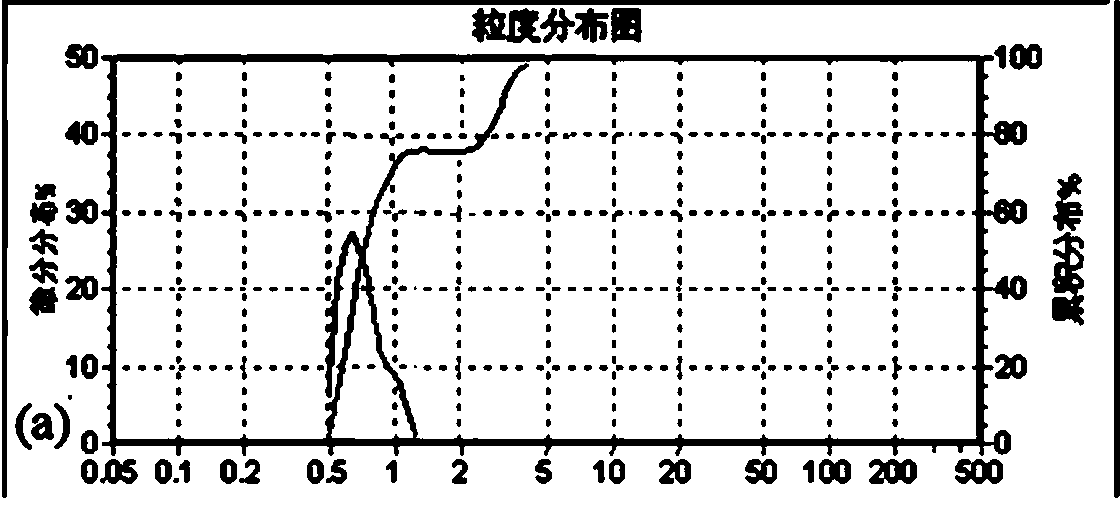

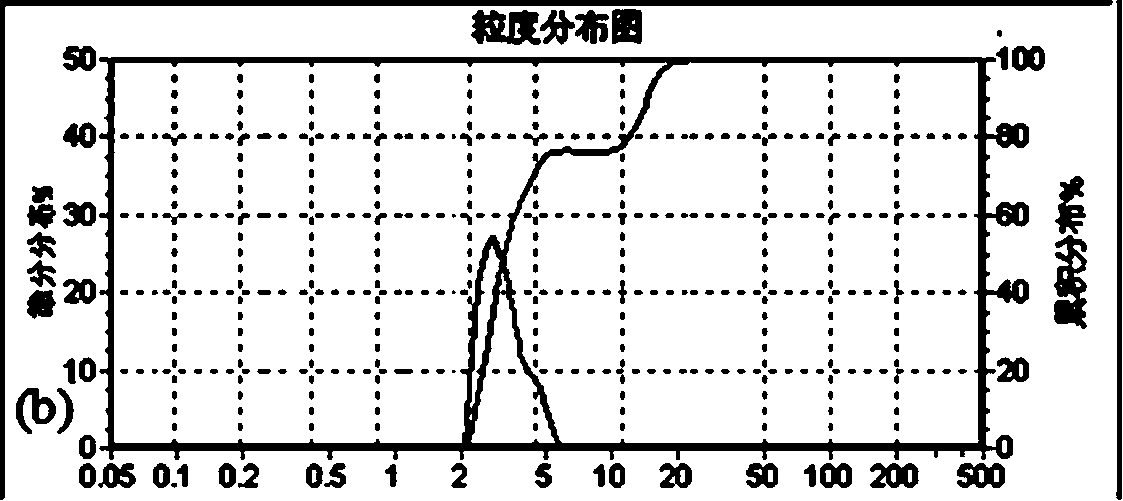

Yttria-stabilized zirconia powder and preparation method thereof

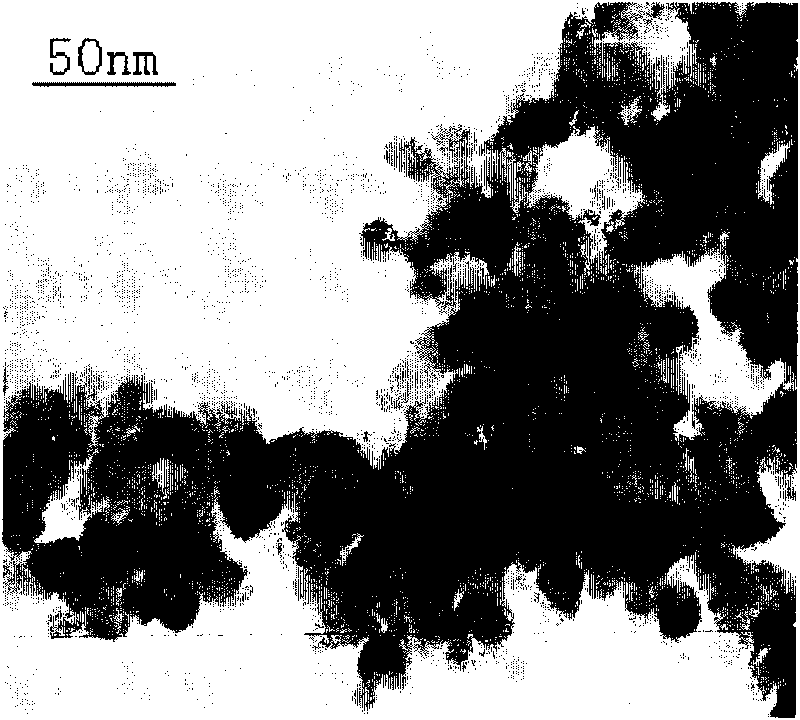

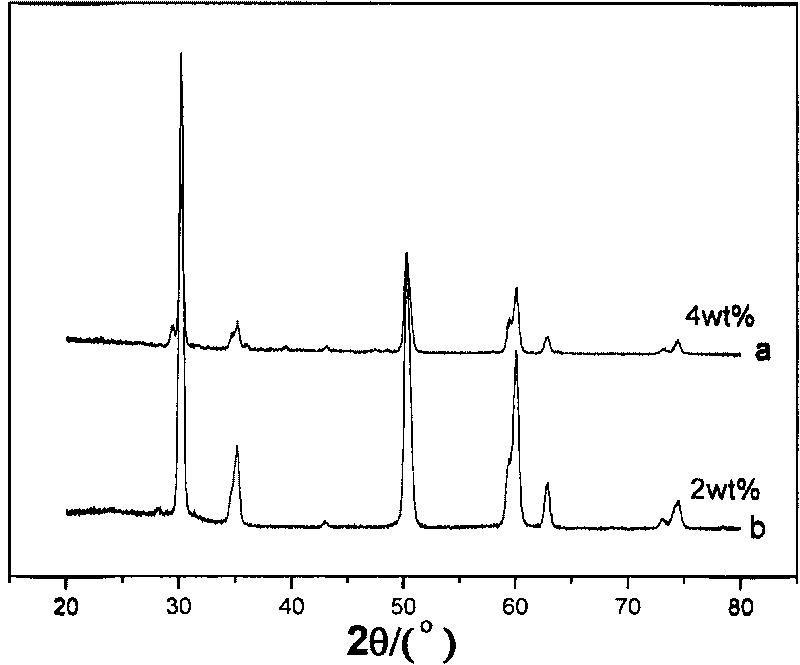

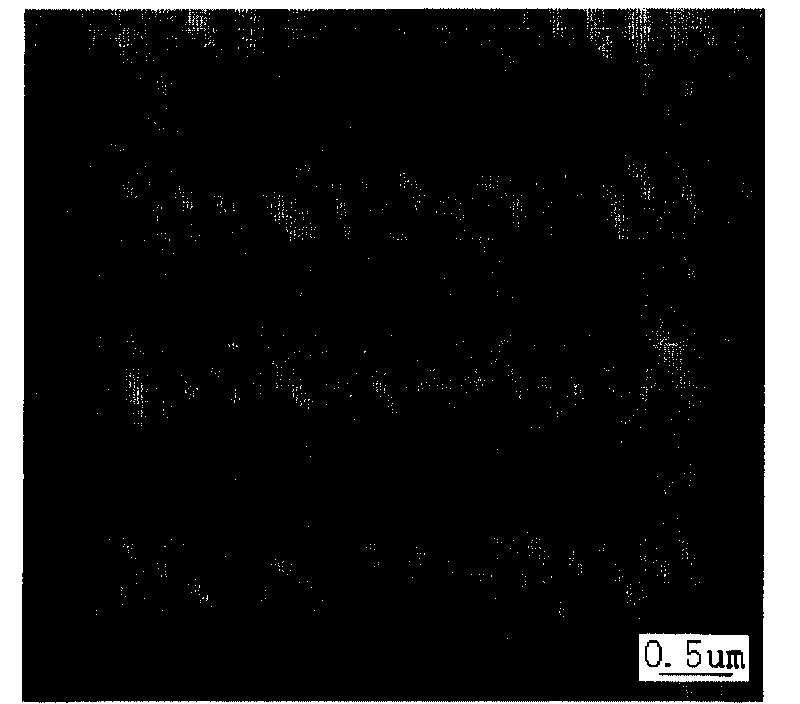

The invention relates to yttria-stabilized zirconia powder and a preparation method thereof. The yttria-stabilized zirconia powder has the composition characteristics that yttria is taken as a stabilizer of a zirconia material; the powder comprises a doping system formed by one or more following third components: alumina, ceria, lanthana, copper oxide, magnesium oxide and calcium oxide, wherein the weight of the yttria is 2-8mol%, and the total doping weight of the alumina, the ceria, the lanthana, the copper oxide, the magnesium oxide and the calcium oxide is 0-5wt%. According to the yttria-stabilized zirconia powder and the preparation method, the deficiencies of an existing liquid phase preparation process of nanometer zirconia powder are overcome, and the prepared nanometer ZrO2 composite powder has the performance of uniformity in dispersion of components, uniform grain size, super-fineness, high sintering activity, good liquidity and the like. Furthermore, the preparation method is simple in process and low in cost and is easy to industrialize.

Owner:YAAN YUANCHUANG CERAMIC

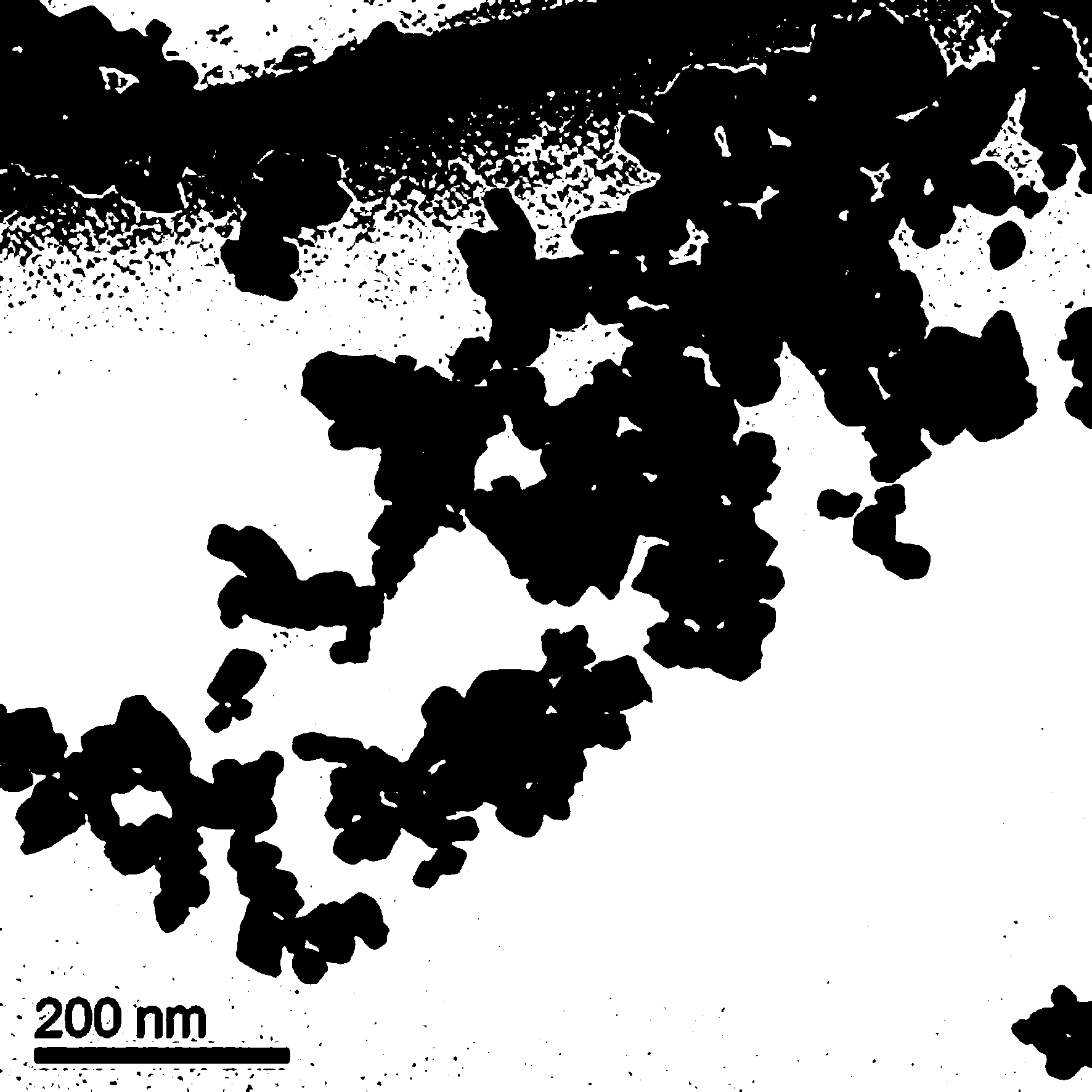

Method for preparing black zirconia ceramics at low temperature

The invention relates to a method for preparing black zirconia ceramics at the low temperature and belongs to the technical field of the preparation of high-temperature structural material. The method respectively uses a homogeneous precipitation method for synthesizing a nanometer coloring agent, and a coprecipitation method for synthesizing nanometer zirconia powder, and adopts Fe-Co-Ni-Mn as a coloring agent. The zirconia powder is not added with any sintering additive, only added with small amount of coloring agent and sintered at the temperature of 1150-1350 DEG C, thus obtaining the black zirconia ceramics with excellent performance and bright color. As the homogeneous precipitation method is adopted for synthesizing coloring agent powder, the monodisperse nanometer particles with uniform powder granules, narrow size distribution and high purity are obtained so that the coloring agent easily colors the particles. As the coprecipitation method is used for synthesizing zirconia powder, nanometer particles with small granularity, big superficial area and high activity are obtained, and can reduce the temperature of the solid-phase reaction, greatly reduce the sintering temperature and solve the problem that the black coloring agent oxide decomposes and volatiles at the high temperature. Simultaneously the method adopts the Fe-Co-Ni-Mn as the coloring agent, thus avoiding the poisonous function of Cr on the human body.

Owner:TSINGHUA UNIV

Flame-retardant ceramic silicone rubber and preparation method thereof

InactiveCN103554919ALower sintering temperatureIncreased preparation reaction speedPlatinum complexReaction rate

The invention discloses flame-retardant ceramic silicone rubber. The flame-retardant ceramic silicone rubber contains the following materials in parts by weight: 100 parts of silicon rubber, 1-100 parts of silica, 0-30 parts of silicone oil, 0.00001-10 parts of platinum in platinum complex or platinum compound, 0-10 parts of coupling agent, 1-100 parts of flame retardant, 1-150 parts of ceramic powder and 0.01-10 parts of vulcanizing agent. A preparation method of the flame-retardant ceramic silicone rubber comprises the steps of milling the materials in a kneader, vacuumizing, adding into the kneader, milling uniformly to form lumpish ceramic rubber, cooling, adding the vulcanizing agent, and carrying out open milling, thereby obtaining the flame-retardant ceramic silicone rubber. The flame-retardant ceramic silicone rubber is easy to process and low in production cost and can be ablated into a ceramic-like shell, so as to protect an ablated object from being damaged. According to the flame-retardant ceramic silicone rubber disclosed by the invention, due to the addition of the platinum complex or platinum compound, the sintering temperature for the flame-retardant ceramic silicone rubber can be lowered, and the reaction rate of preparation can be increased, so that the production efficiency is increased, and the production cost is reduced.

Owner:常州市沃科科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com