Positive electrode material of manganese series, and preparation and usage thereof

A technology of positive electrode material and negative electrode active material, which is applied in the field of battery positive electrode material and can solve the problems of inability to meet large capacity or high power density lithium secondary batteries, and the specific capacity and charge-discharge cycle performance of positive electrode materials are not ideal.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

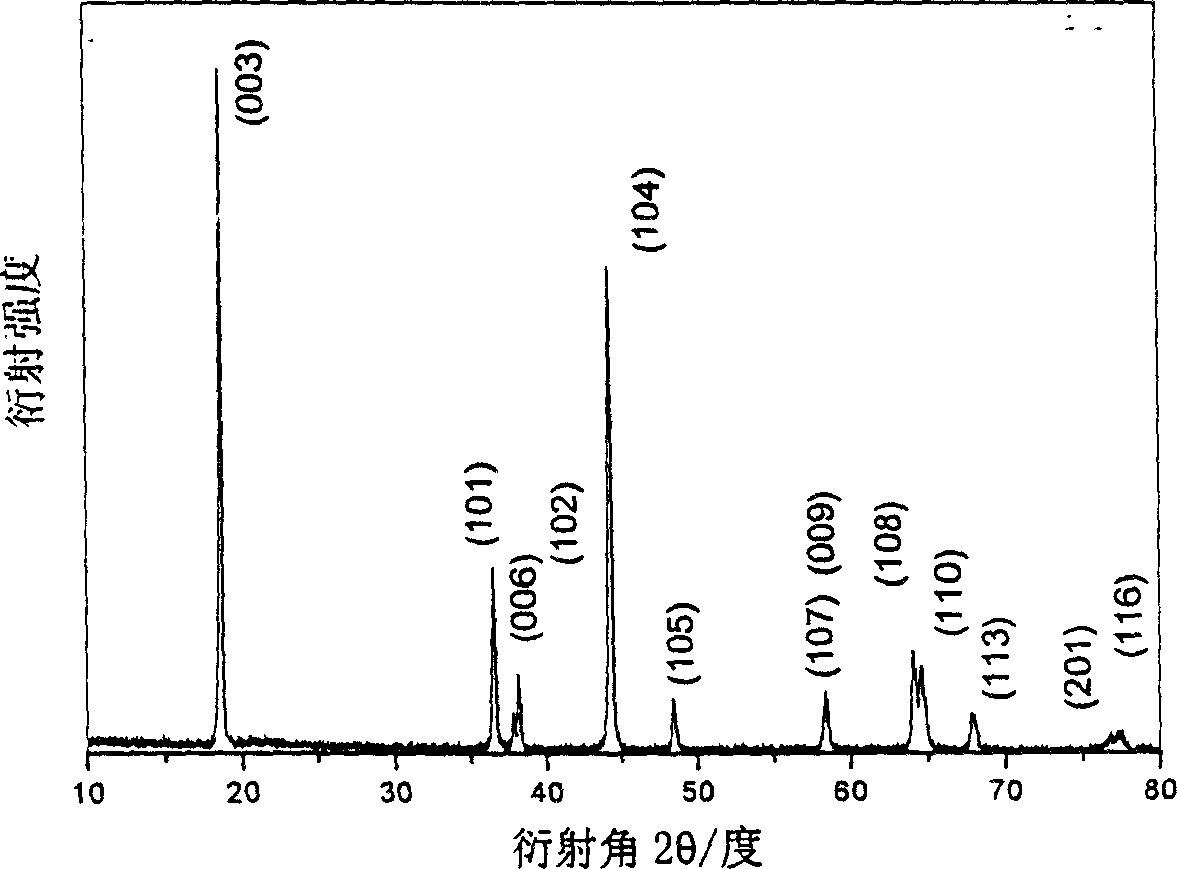

[0067] Embodiment 1, according to the preparation method of the present invention-preparation through Al 2 o 3 Modified LiMn 0.5 Ni 0.5 o 2 Manganese-based cathode materials for lithium-ion batteries

[0068] Mix nickel sulfate and manganese sulfate at a molar ratio of 1:1 to make a 2mol / l aqueous solution, then dissolve sodium hydroxide in water to make a 4mol / l solution. Add transition metal sulfate, sodium hydroxide, 25% ammonia water and hydrazine hydrate solution into the reaction kettle at the same time, control the temperature of the slurry in the reaction kettle to 50° C., pH=10, and stir for 5 hours. Then filter, wash the precipitate, and dry it.

[0069] Add 50 grams of nickel and manganese hydroxide precursors prepared by the liquid-phase precipitation technology into 2mol / l aluminum nitrate solution, wherein the molar ratio of aluminum nitrate and manganese-containing precursors is 0.1:1, and then stir At the same time, 8.0M ammonia water was added dropwise u...

Embodiment 2~21

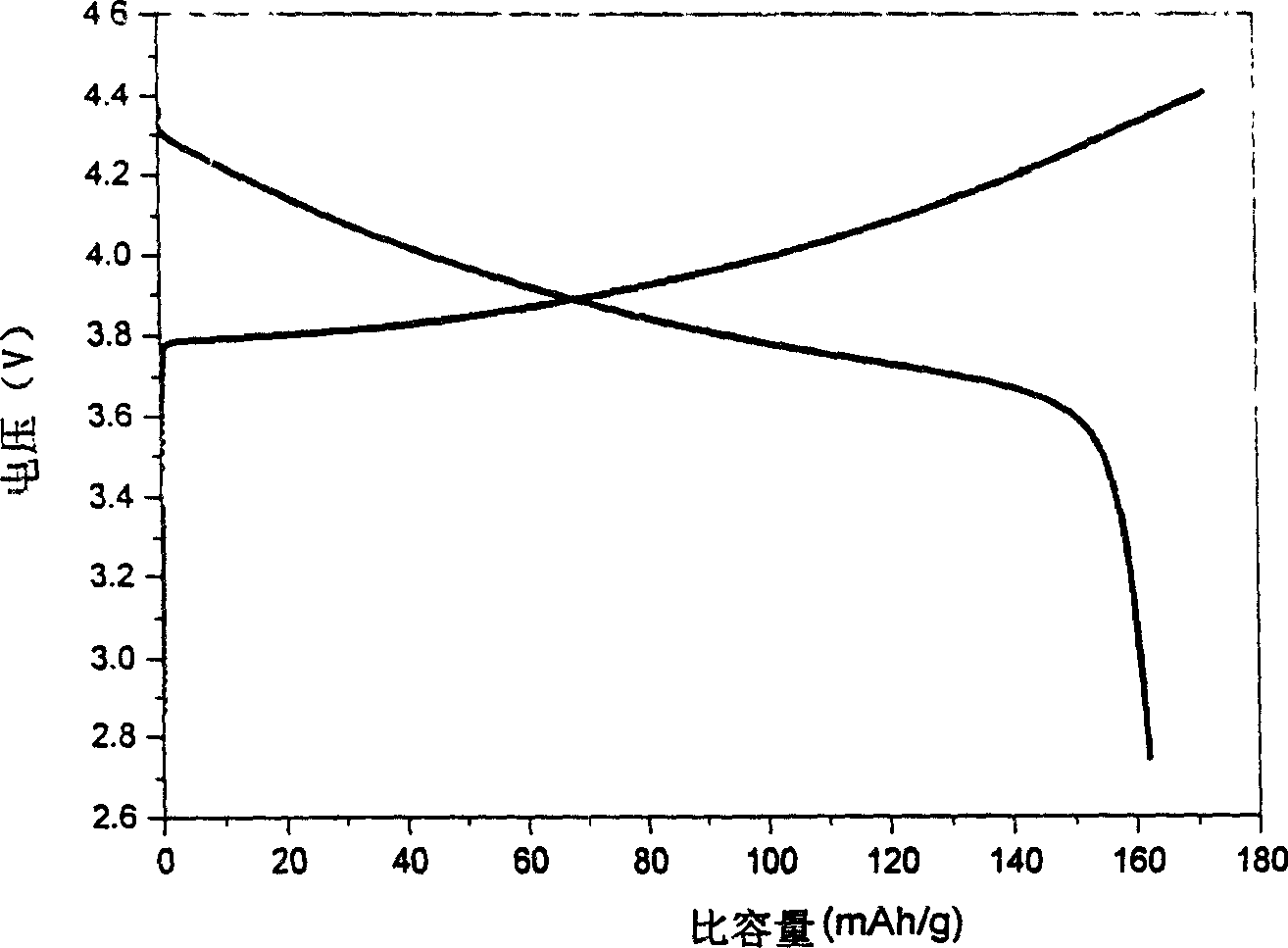

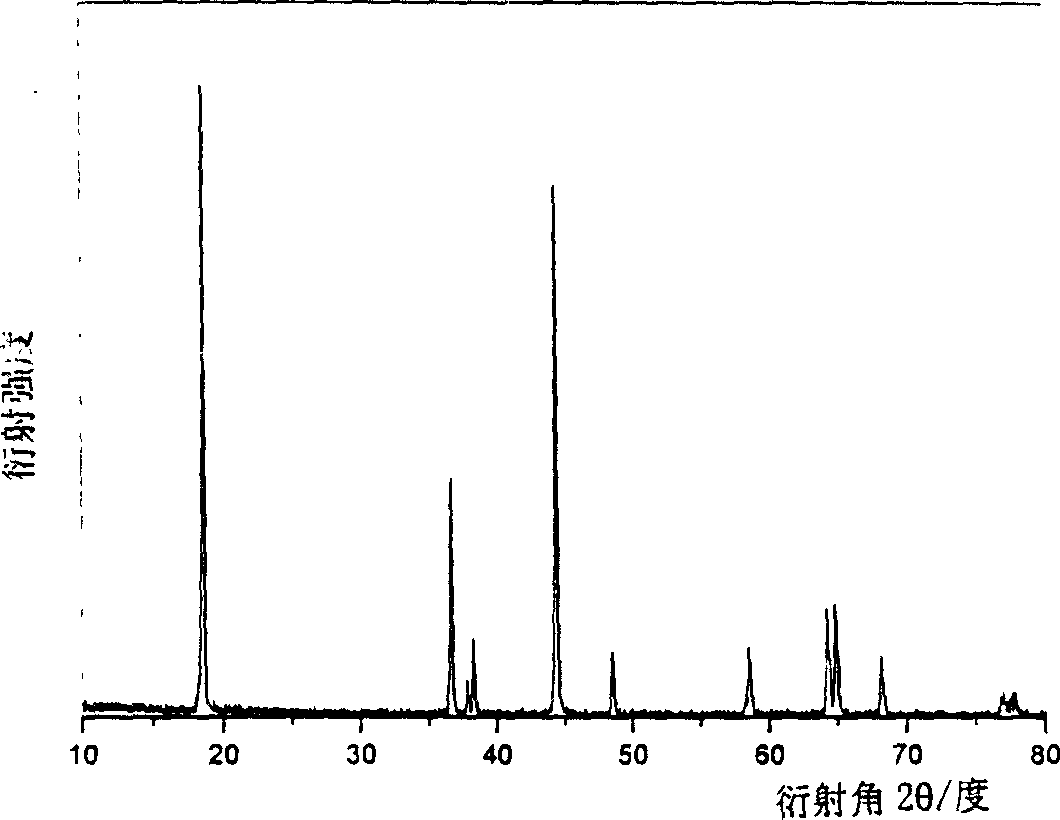

[0072] Embodiment 2~21, according to the preparation method of the present invention-synthesize a series of layered lithium manganese oxides LiMn under different conditions 1-x-y Ni x m y o 2 positive active material

[0073] According to the preparation method one provided by the present invention, under the different conditions listed in Table 1, a series of layered lithium manganese oxides LiMn were synthesized. 1-x-y Ni x m y o 2 Positive active material.

[0074]

Embodiment 22

[0075] Example 22, according to the preparation method of the present invention two synthesis process LiAlO 2 Modified LiMn 0.4 Ni 0.4 co 0.2 o 2 Lithium-ion battery cathode active material

[0076] Mix nickel sulfate, manganese sulfate and cobalt sulfate according to the molar ratio of 2:2:1 to make a 2mol / l aqueous solution, then dissolve sodium hydroxide in water to make a 8mol / l solution. Add transition metal sulfate, sodium hydroxide, 25% ammonia water and hydrazine hydrate solution into the reaction kettle at the same time, control the temperature of the slurry in the reaction kettle to 80° C., pH=13, and stir for 5 hours. Then filter, wash the precipitate, and dry it.

[0077] Mix the oxide or hydroxide precursor of nickel and manganese prepared above directly with lithium hydroxide at a molar ratio of 1:1.05, add water to adjust the viscosity of the slurry, spray dry and granulate, and the particle size after drying is 20 Micron solid powder particles were sinter...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com