Patents

Literature

74results about How to "Improve rate charge and discharge performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

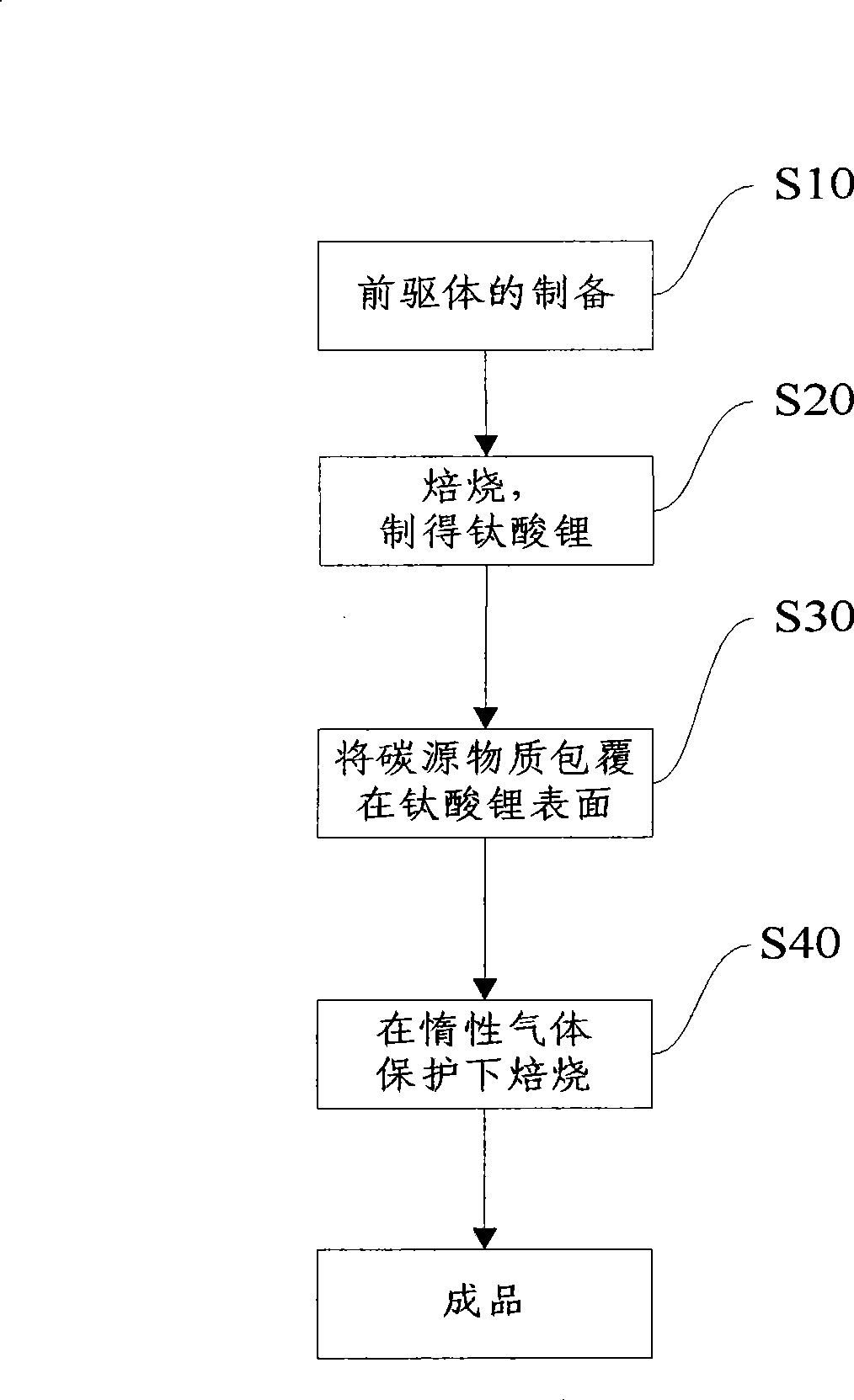

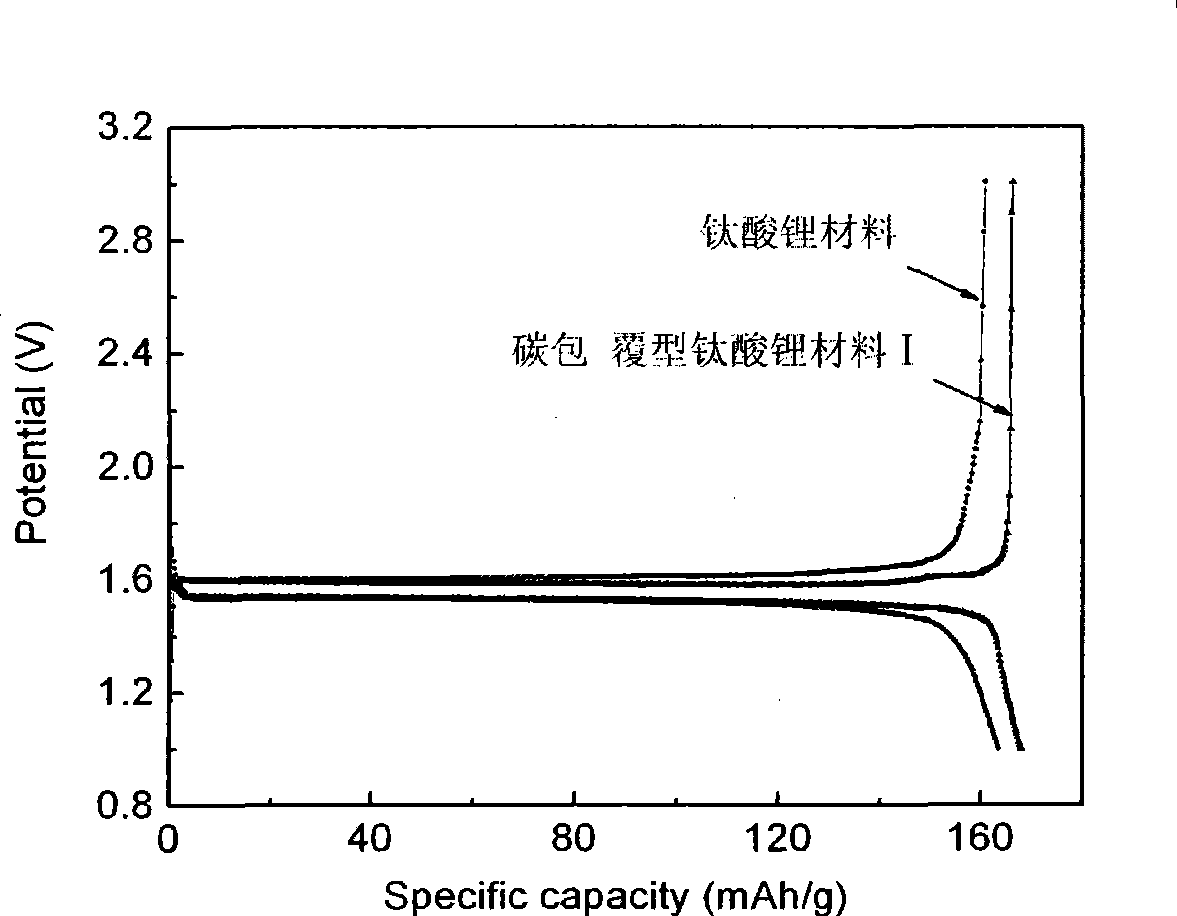

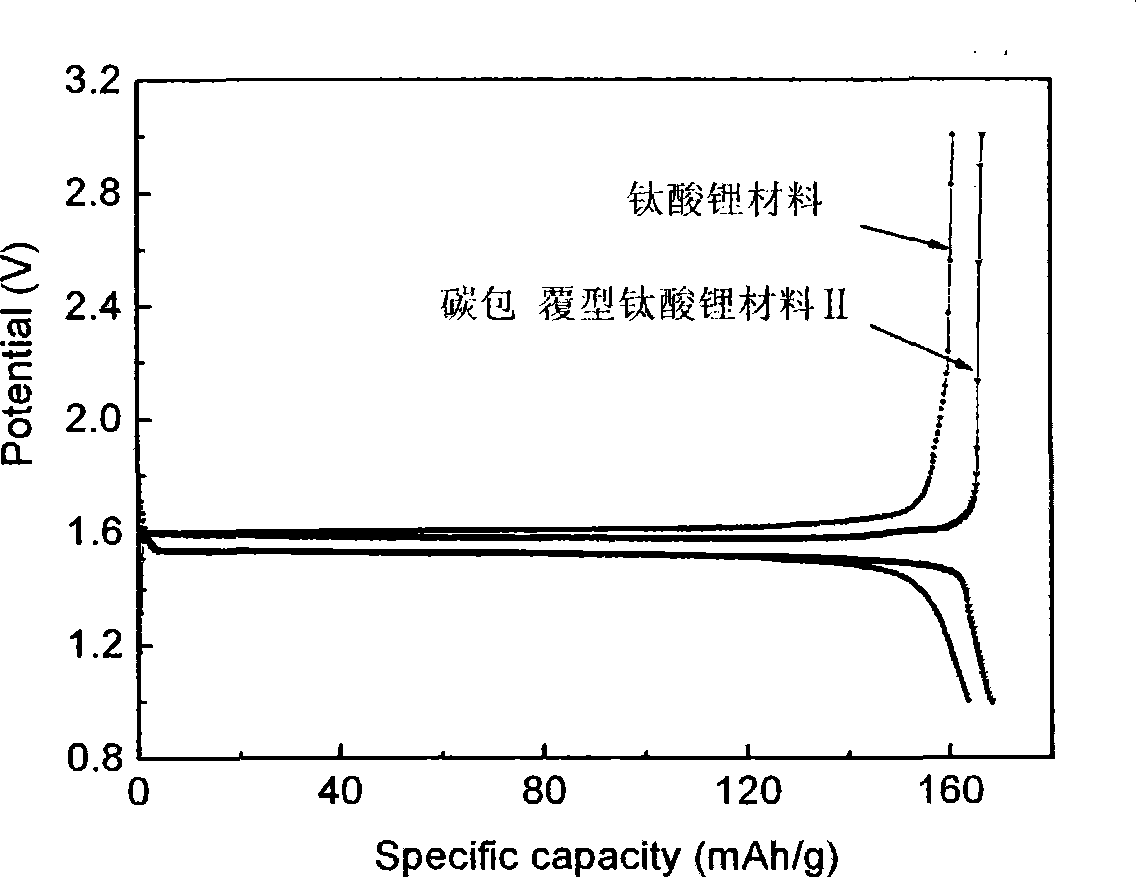

Method for preparing carbon-coating type lithium titanate for lithium ion battery

InactiveCN101378119AImprove electronic conductivityImprove rate charge and discharge performanceElectrode manufacturing processesCarbon coatedElectron

The invention discloses a preparation method of carbon-coated lithium titanate used for a lithium ion battery; the method comprises the following steps: (1) lithium salt and titanium dioxide are weighted according to proportion, a dispersing agent is added, a ball milling method is used for mixing fully and then the obtained mixture is dried in vacuum, thus obtaining a precursor; (2) the obtained precursor is roasted for 8 to 20 hours at the temperature of 750 to 1000 DEG C so as to prepare lithium titanate; (3) carbon source materials are coated on the surface of the prepared lithium titanate by a dipping and steaming method; and (4) the lithium titanate coated with the carbon source materials is placed in a tubular furnace, and is roasted for 0.5 to 5 hours at the temperature of 750 to 1000 DEG C under the protection of inert gas so as to obtain the carbon-coated lithium titanate. The preparation method of the invention forms chemically coated carbon on the surface of the lithium titanate by the pyrolytic reaction of the carbon-coated materials, and the surface contact of the coated carbon and the lithium titanate material is more firm and tight, thus improving the electron conductivity of the materials greatly and enhancing the charge and discharge performance of magnification of the materials.

Owner:TIANJIN B&M SCI & TECH

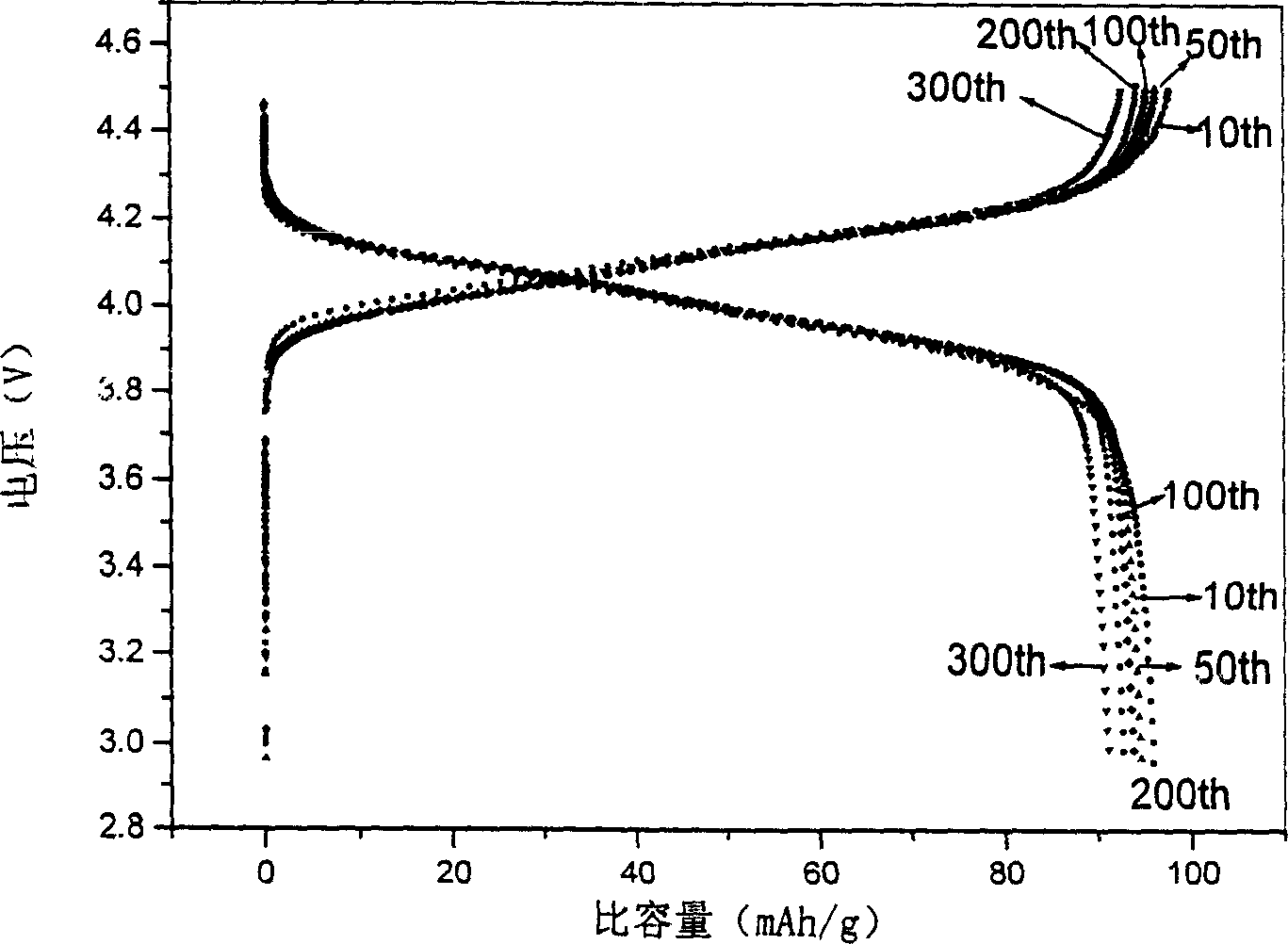

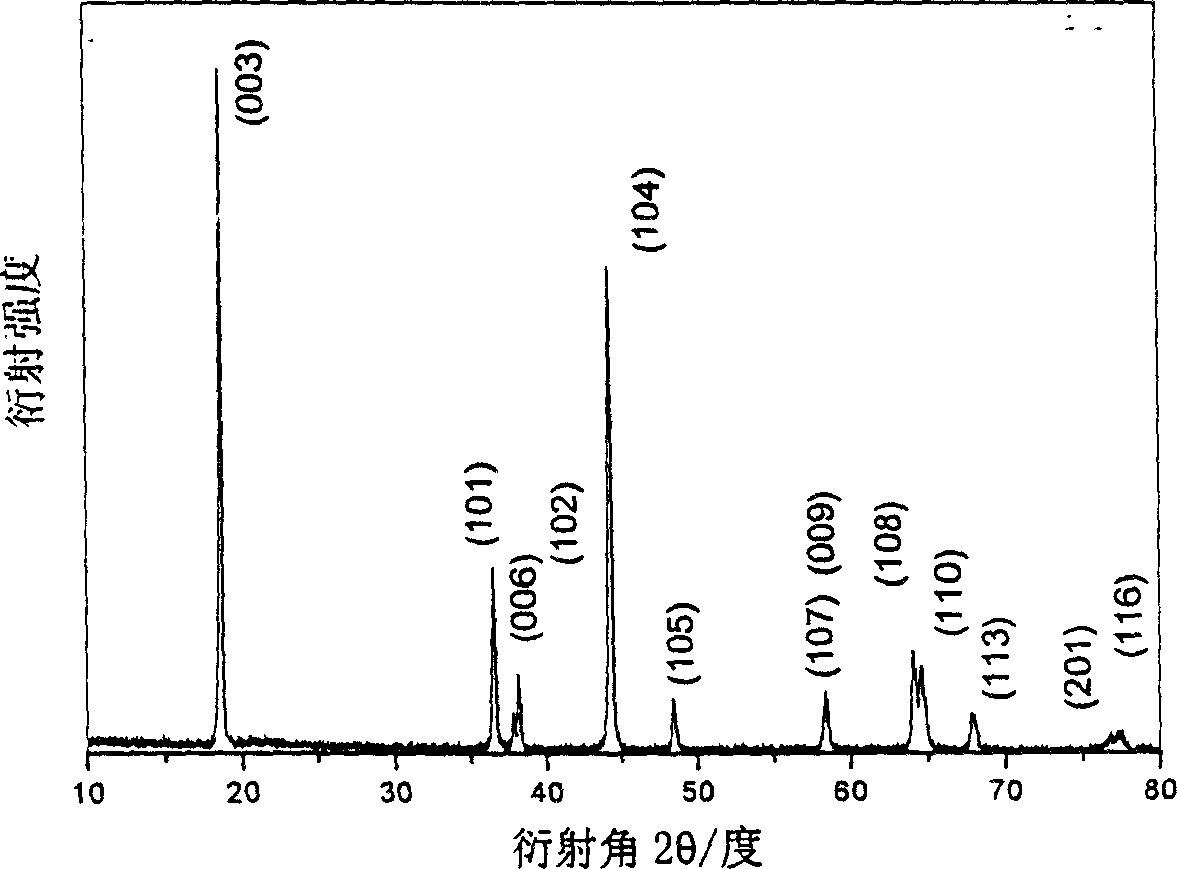

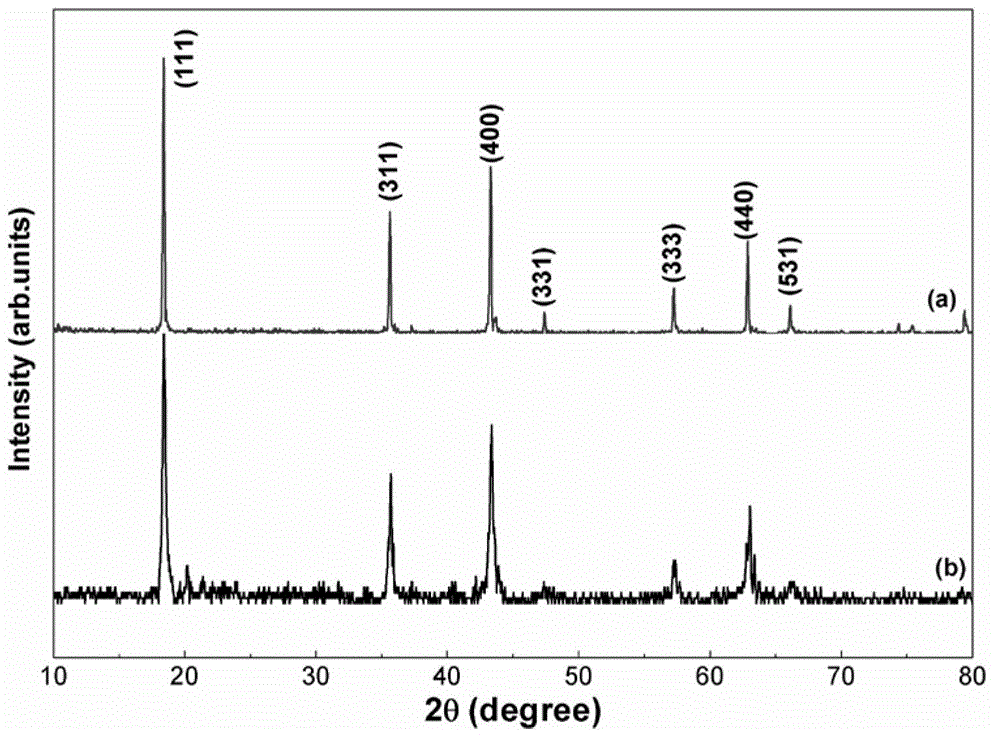

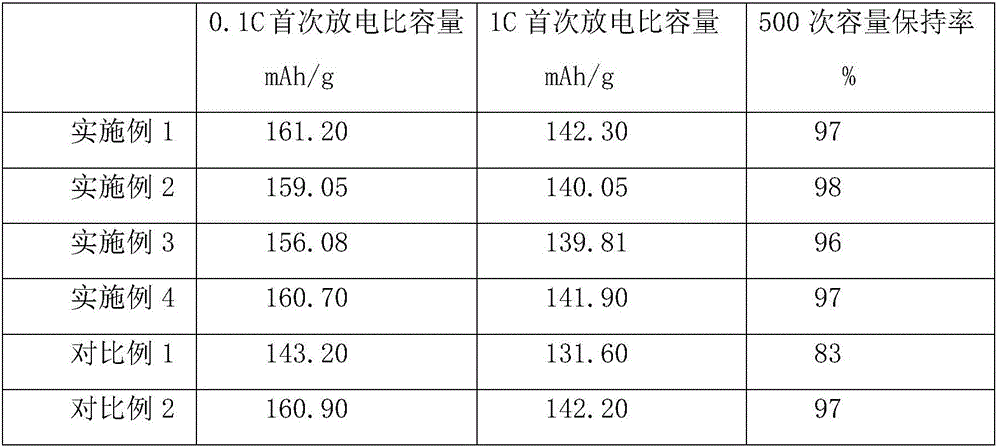

High-performance lithium ion battery cathode material and preparation method thereof

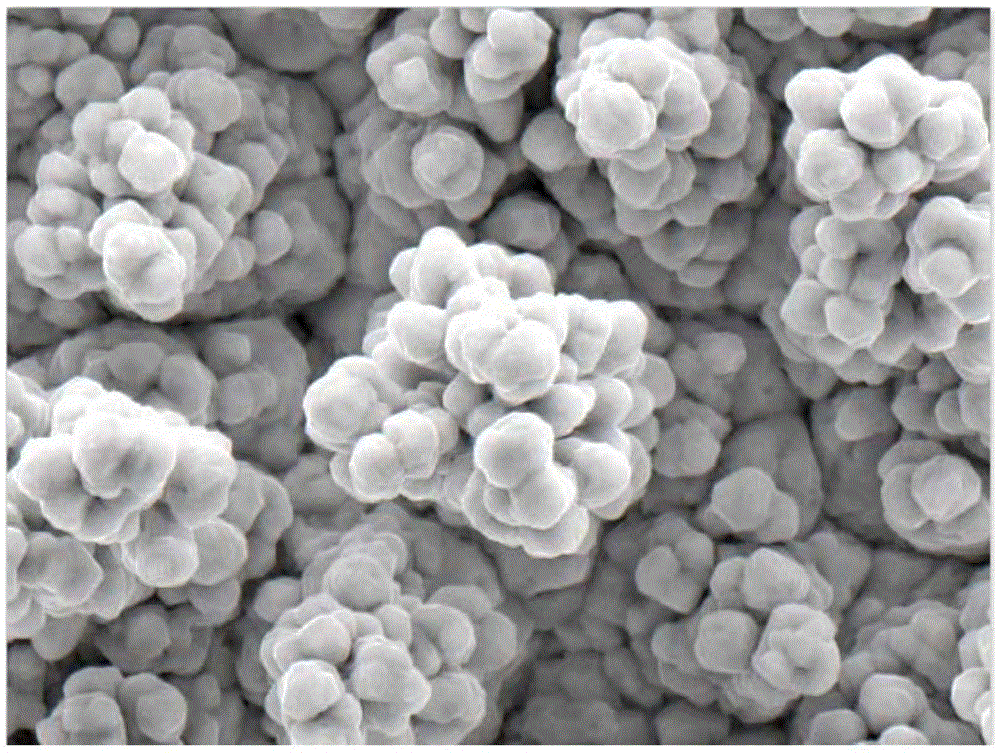

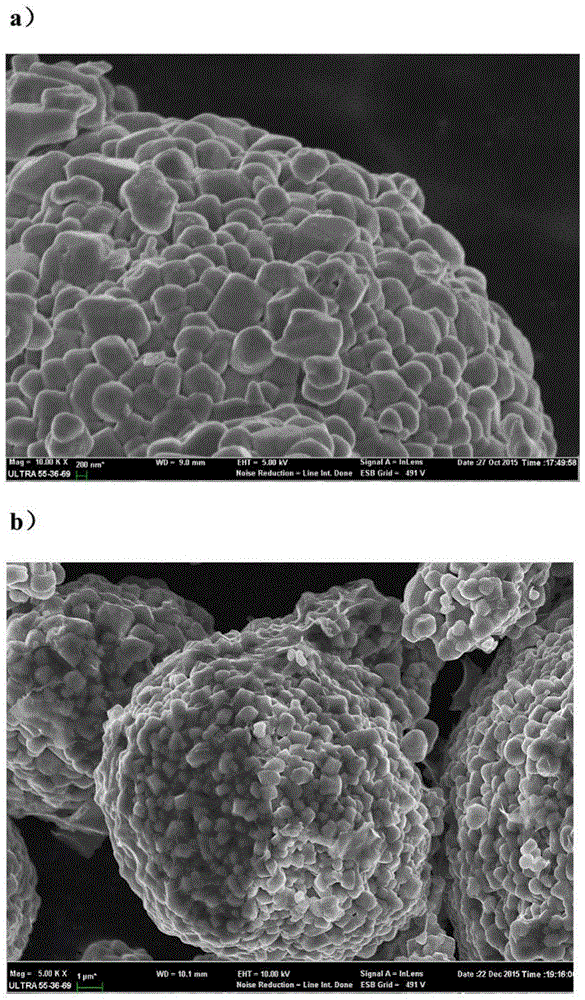

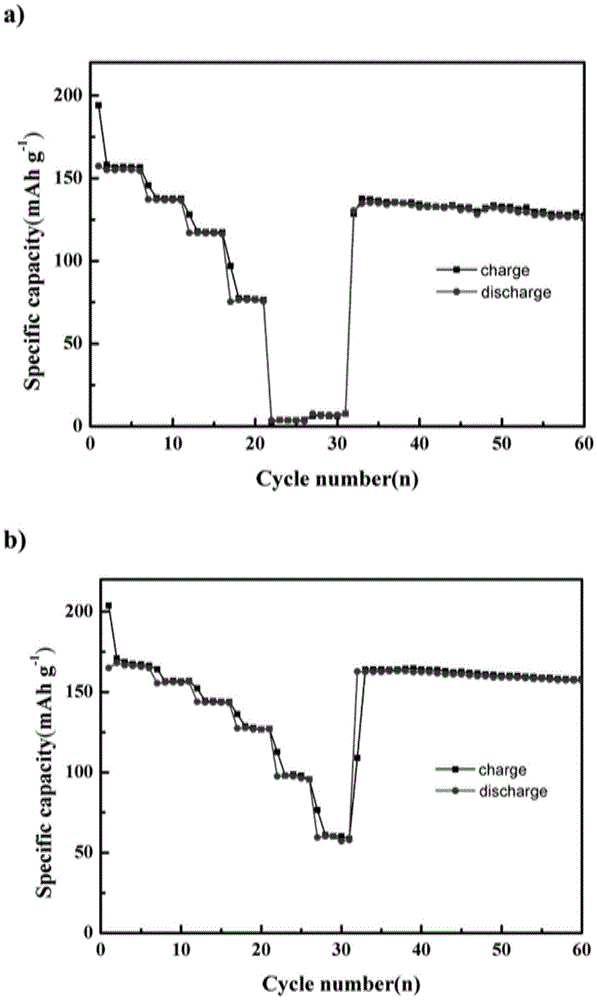

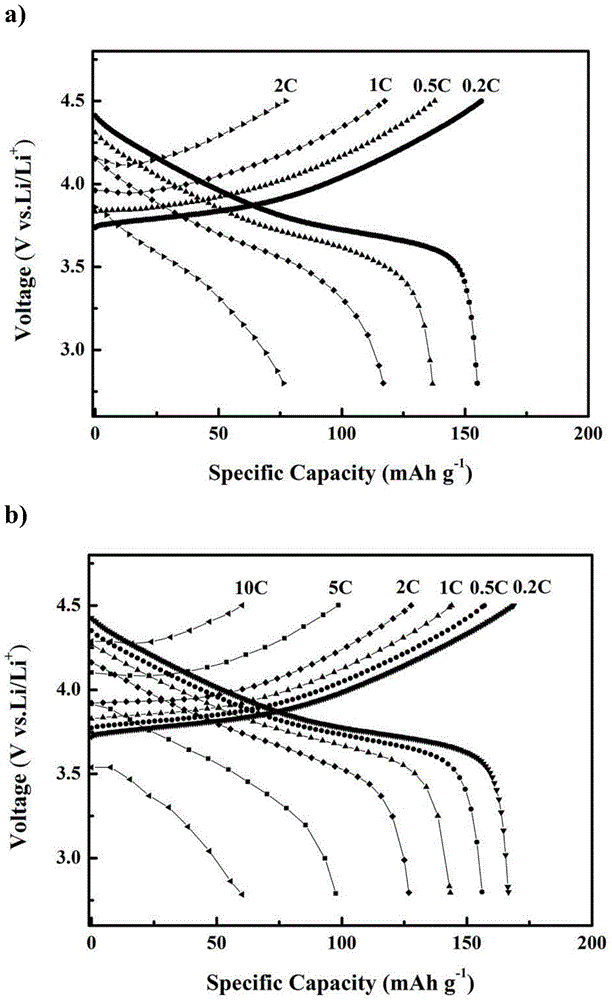

InactiveCN101847722AHigh tap densityImprove electrode processing performanceElectrode manufacturing processesNickel oxides/hydroxidesSingle crystalCobalt

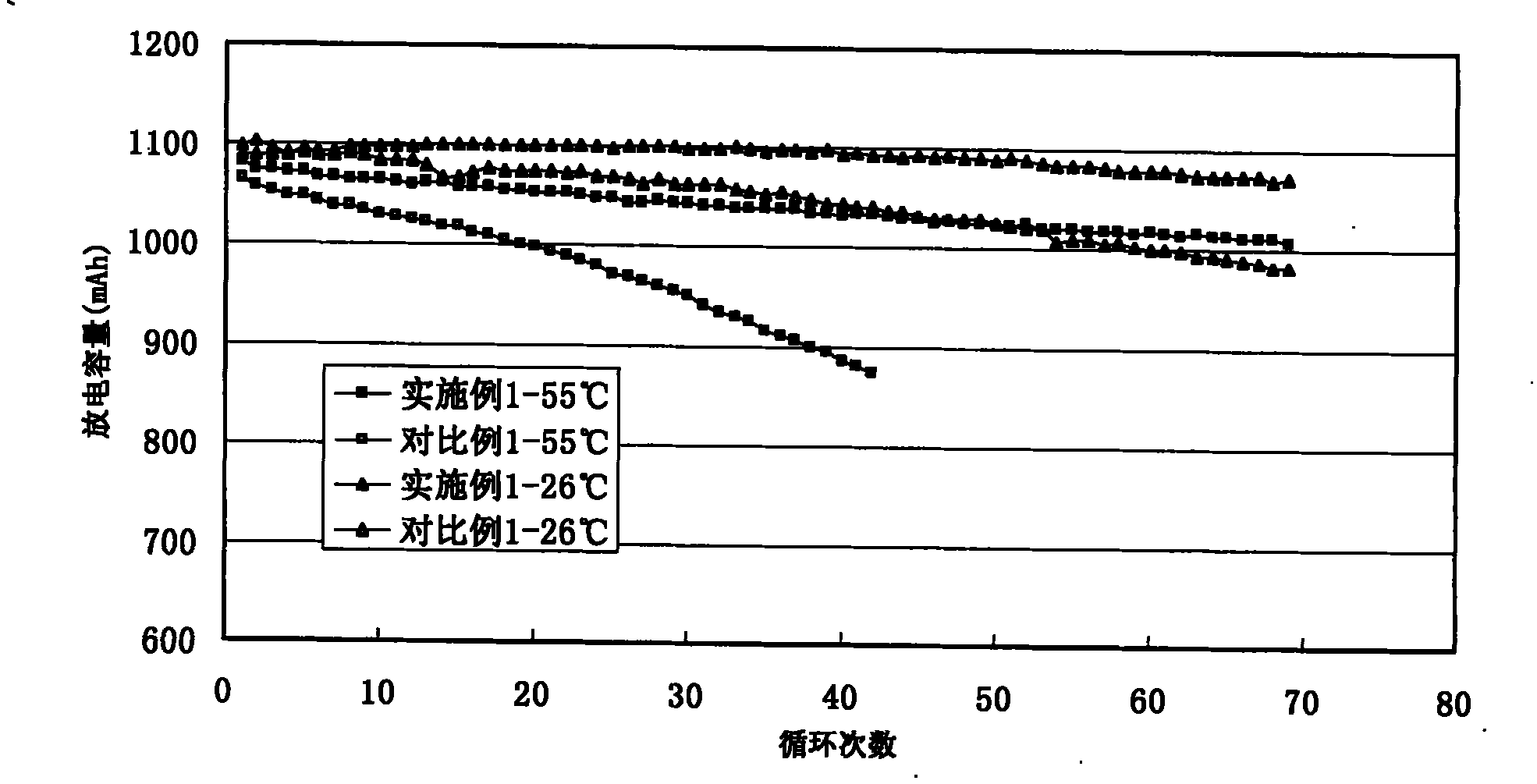

The invention relates to a lithium ion battery cathode material LiNixCoyM1-x-yO2 prepared from micron-sized single crystal particles and a preparation method thereof, wherein x is greater than 0 and is not more than 0.8, y is greater than 0 and is not more than 0.5, and M is one or two of Li, Mn, Al and Mg. The invention is characterized in that (1) composite oxide or hydroxide of transition metal nickel, transition metal cobalt and modified metal M is used as a raw material, the composite oxide or hydroxide is porous aggregate comprising nanocrystals, the average size of the aggregate is 2-50 micrometers, and the specific surface area of the aggregate is greater than 15m<2> / g (measured by BET method); (2) the composite metal oxide or hydroxide and lithium salts are milled in a ball mill, the micron-sized composite metal oxide or hydroxide is converted into nanocrystal particles to obtain a nano-sized mixed precursor of the composite metal oxide or hydroxide and the lithium salts, and the mixed precursor is sintered at uniform temperature to obtain the required lithium ion battery cathode material; and (3) the prepared lithium ion battery cathode material LiNixCoyM1-x-yO2 is basically prepared from micron-sized single crystal particles, and the average size of the single crystal particles is 2-20 micrometers. In addition, the product has excellent physical and electrochemical properties, such as ultra-low specific surface area, reasonable particle size distribution, good electrode processing properties, ultra-long cycle life, excellent rate capability, obvious high and low temperature cycling and storing properties and excellent safety; and the product can be widely used as a high-performance lithium ion battery cathode material. The invention provides the high-performance lithium ion battery cathode material and the preparation method thereof.

Owner:QINGDAO LNCM

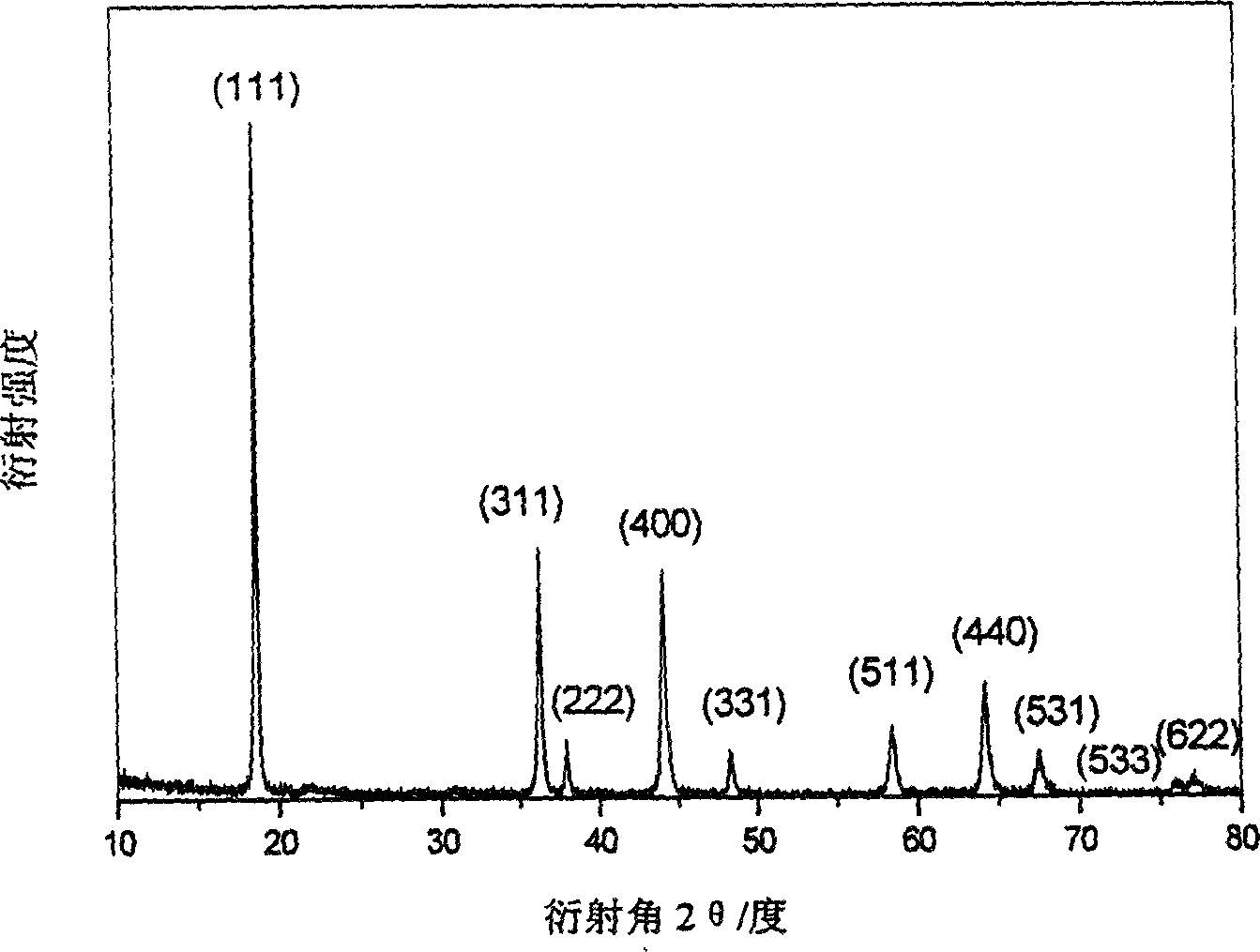

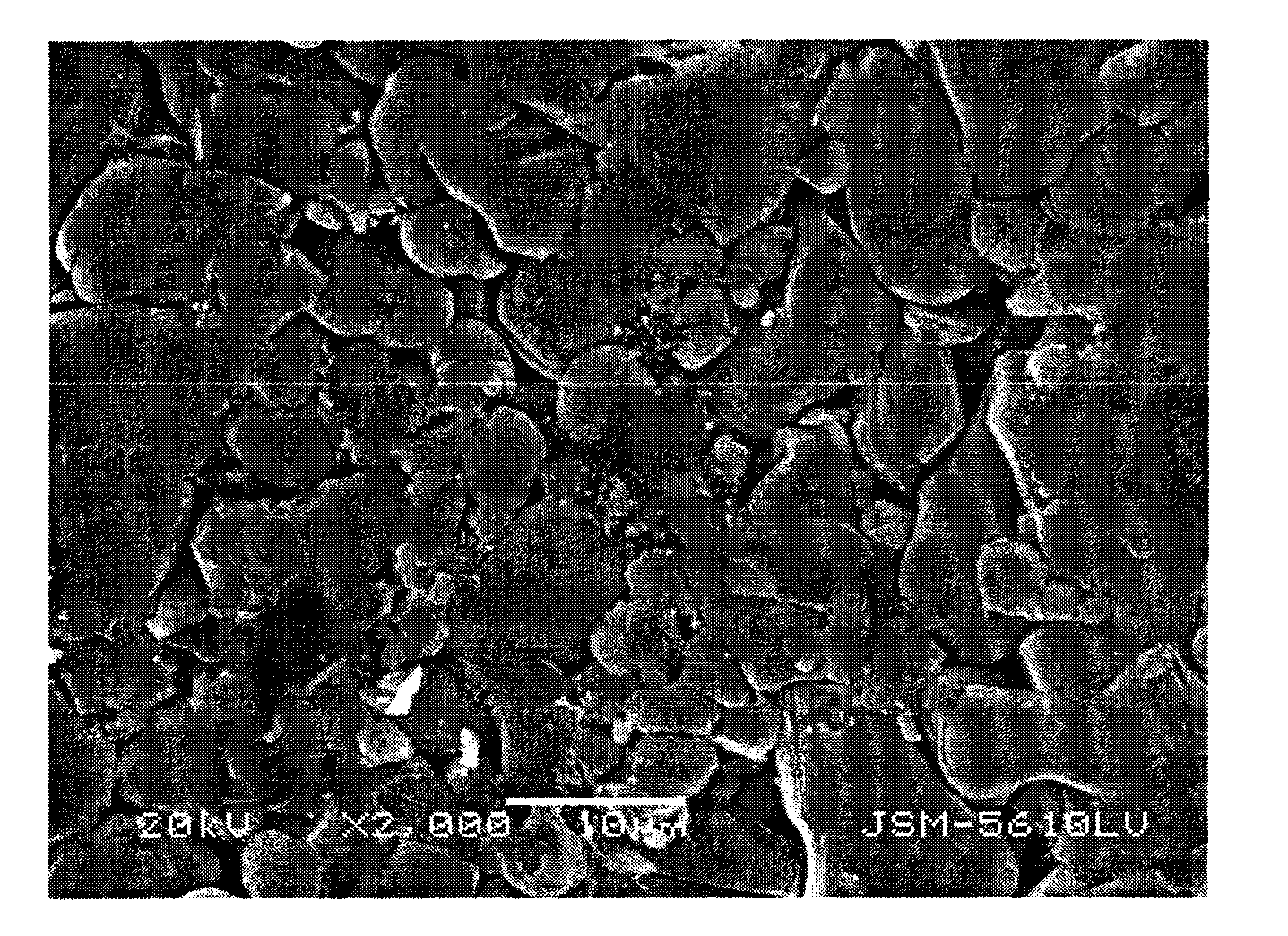

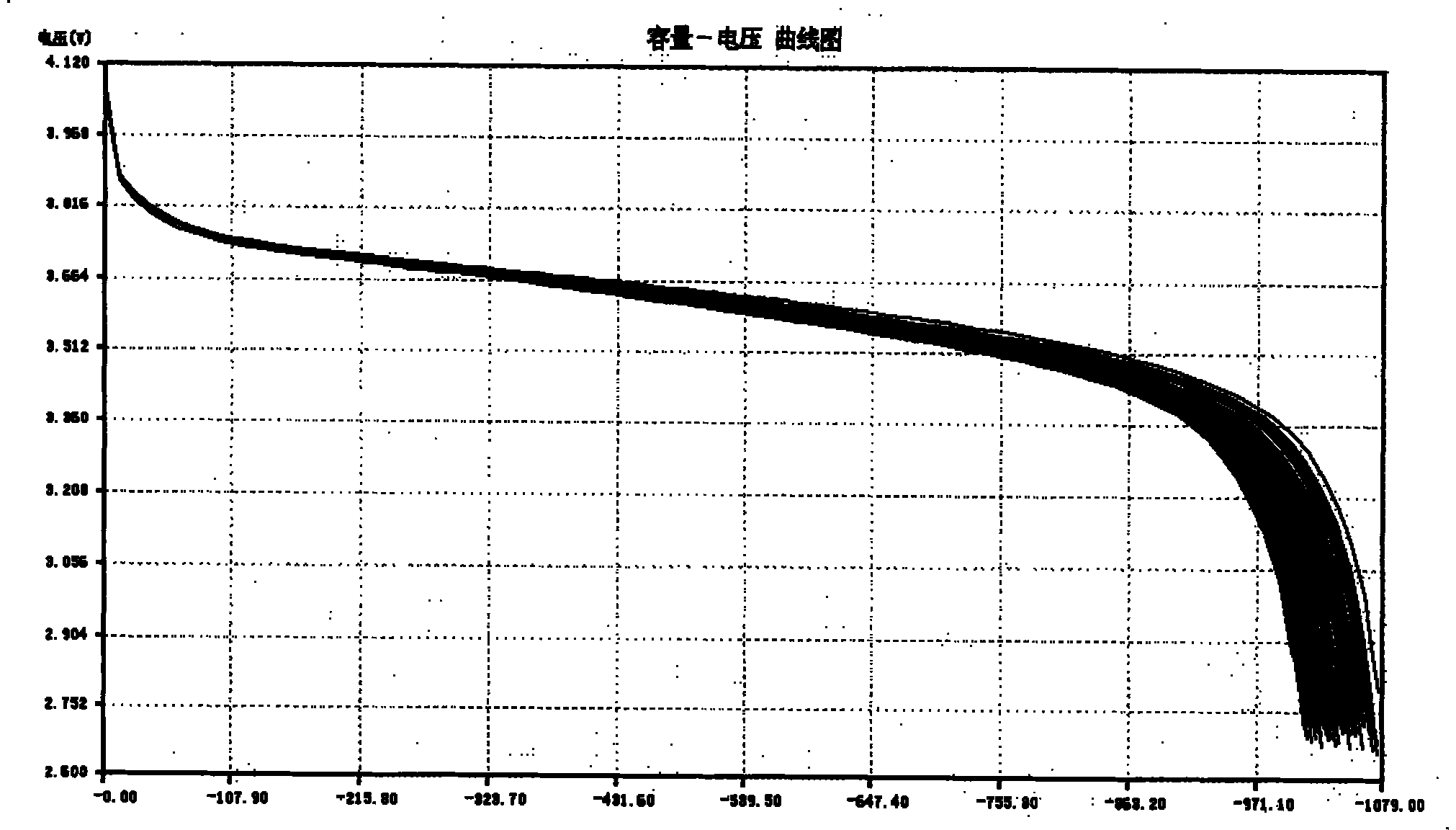

A positive electrode material for lithium secondary cell, and preparation and usage thereof

InactiveCN1595687AIncrease energy densityGood charge and discharge cycle performanceElectrode manufacturing processesIron compoundsLithiumManganese

The invention relates to positive electrode material of a lithium secondary battery, which can combine with electrolyte solution or solid electrolyte, and negative electrode active material to form lithium secondary battery. Its characteristics are: the positive electrode material of lithium secondary battery is LiMn2-zMzO4 (0<=z<=0.5.), M is chosen from Li, Mg, Co, Ni, Fe, Al, Sr, Cr, Ga, Cu and Zn. The manufacturing method for positive electrode material of the lithium 1 secondary battery, includes preparation of usher containing Mn; decorate to the covering of usher particle containing Mn; mix with lithium salt and prepare particle; sintering and other steps. By decoration of the surface of particle to usher of positive electrode containing Mn or active material itself, state of material or apparent condition of material can be changed and its capacity of powerful charge and discharge, cycle performance and thermal stability can be raised. The invention has notable advantages including low cost, capacity of powerful charge and discharge, super-long cycle performance, excellent safety, super-long circulation property and resistance to overcharge.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

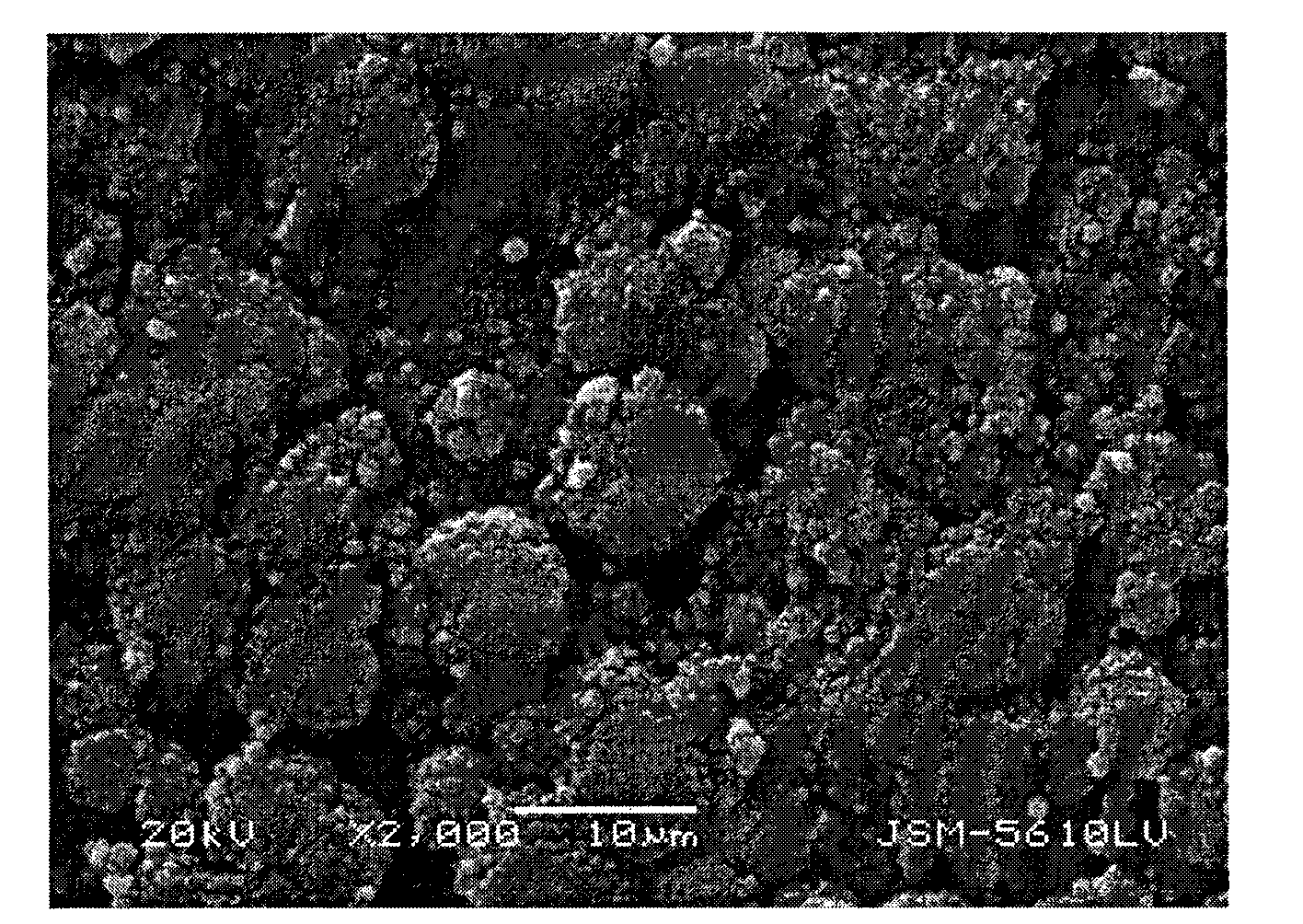

Positive electrode material of manganese series, and preparation and usage thereof

InactiveCN1595689AIncrease energy densityIncrease powerElectrode manufacturing processesSecondary cellsManganeseThermal stability

The invention relates to manganese department positive electrode material of a lithium secondary battery, which can combine with electrolyte solution or solid electrolyte, and negative electrode active material to form lithium secondary battery. Its characteristics are: the positive electrode material of lithium secondary battery is LiMn1-x-y NixMyO2(x is not less than 0.2 and not larger than 0.8, y is not less than 0 and not larger than 0.6, and x+y is not larger than 1.), M is chosen from Li, Mg, Co, Ni, Fe, Al, Cr. The manufacturing method for manganese department positive electrode material of the lithium secondary battery, includes preparation of usher containing Mn; decorate to the covering of usher particle containing Mn; mix with lithium salt and prepare particle; sintering and other steps. By decoration of the surface of particle to usher 6 of positive electrode containing Mn or active material itself, state of material or apparent condition of material can be changed and its capacity of powerful charge and discharge, cycle performance and thermal stability can be raised. The invention has notable advantages including low cost, capacity of powerful charge and discharge, super-long cycle performance, excellent safety, super-long circulation property and resistance to overcharge .

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

Composite solid-state polymer electrolyte and all-solid-state lithium battery

ActiveCN106654363AImprove electrochemical stabilityExcellent charge and discharge characteristicsSolid electrolytesSecondary cellsMicro nanoAll solid state

The invention discloses a composite solid-state polymer electrolyte and an all-solid-state lithium battery. The composite solid-state polymer electrolyte comprises organic micro-nano porous granules, a polymer having lithium ion conducting capability and a lithium salt; the composite solid-state polymer electrolyte takes the organic micro-nano porous granules as filler; and natural compatibility exists between the organic filler and the polymer matrix. The composite solid-state polymer electrolyte disclosed by the invention has high electrochemical window (4.2-5V), excellent interface stability with a lithium-based negative electrode material, and low interface impedance. The all-solid-state lithium battery, assembled by the composite solid-state polymer electrolyte disclosed by the invention, is high in cycling performance and rate capability.

Owner:UNIV OF SCI & TECH BEIJING

Coal-based composite negative electrode material used for power lithium ion battery and preparation method of composite negative electrode material

InactiveCN108054357AIncrease capacityImprove rate charge and discharge performanceCell electrodesSecondary cellsHigh rateCharge discharge

The invention discloses a coal-based composite negative electrode material used for a power lithium ion battery and a preparation method of the composite negative electrode material, and aims to solvethe technical problems for lowering production cost, protecting the environment, and adapting for large-scale industrial production. The coal-based composite negative electrode material used for thepower lithium ion battery takes graphitized anthracite coal with 75-90% of degree of graphitization as the substrate; the exterior of the substrate is coated with mesoporous carbon; and a mesoporous carbon coating layer accounts for 2.0-7.5% of the mass of the substrate. The preparation method of the coal-based composite negative electrode material used for the power lithium ion battery comprisesthe following steps of performing smashing, material preparing and mixing, blank pressing, high-temperature graphitization, coating and curing, and pyrolysis. Compared with the prior art, the coal-based composite negative electrode material used for the power lithium ion battery has high capacity, high-rate charging-discharging performance, long cycle life, environment friendliness, simple preparation method, easy control of the technological conditions, low production cost, and suitability for large-scale industrial production.

Owner:博尔特新材料(银川)有限公司

Preparation method of composite hard carbon sodium-ion battery cathode material

InactiveCN106299275AEasy to operateGood repeatabilityCell electrodesSecondary cellsMass ratioShielding gas

The invention discloses a preparation method of a composite hard carbon sodium-ion battery cathode material. The preparation method comprises the steps that boron-doped hard carbon and a carbon source precursor is mixed to be ball-milled according to the mass ratio of (8.5-9.5):(0.5-1.5), a semi-finished product obtained after mixing and ball-milling is calcined at high temperature in a shielding gas atmosphere, and then the material is obtained, wherein boron-doped hard carbon is obtained by dispersing thermoplastic phenolic resin into absolute ethyl alcohol and then adding boric acid and a curing agent through carbonizing under gradual temperature increasing and grounding, and the carbon source precursor is crosslinked starch microspheres prepared by adopting a reverse emulsification method. Compared with the prior art, the preparation method of the composite hard carbon sodium-ion battery cathode material has the advantages that the technology is simple and convenient and easy to operate, the raw materials are wide in source and low in cost, the first-time charging and discharging efficiency is high, the electrochemical performance, the cycle performance and the safety are good, and the product properties are stable.

Owner:DONGGUAN MCNAIR NEW POWER +2

A boron doping modified hard carbon coating negative electrode material with high rate performance and a liquid phase preparation method thereof

ActiveCN109148847ASimple preparation processUnique preparation processCell electrodesSecondary cellsOxygen compoundAtomic radius

The invention relates to the field of lithium batteries, and discloses a boron doping modified hard carbon coating negative electrode material with high rate performance and a liquid phase preparationmethod thereof. A hard carbon carbon layer is formed on the surface of a negative electrode substrate after carbonization by a hard carbon carbon source, boron oxide is generated by decomposing a boron-oxygen compound at a high temperature, and a composite structure such as boron-carbon bond and boron-carbon-oxygen bond is formed on the surface of the negative electrode substrate at a high temperature. On the one hand, compared with other negative electrode materials, hard carbon has larger interlayer spacing and better rate charge-discharge performance. Through hard carbon coating, the highrate charge-discharge performance of negative electrode materials can be improved. On the other hand, by doping boron into the negative electrode material, the position of carbon atom in the crystal lattice of other negative electrode materials is replaced by boron atom, and the atomic radius of boron atom itself is larger than that of carbon atom, which leads to the increase of the interlayer spacing of the negative electrode material and the magnification performance of the material.

Owner:HUZHOU CHUANGYA POWER BATTERY MATERIALS

Three-dimensional lithium ion battery and preparation method

PendingCN107819130AIncrease energy densityImprove securityFinal product manufactureElectrode carriers/collectorsPorosityAluminium-ion battery

The invention discloses a three-dimensional lithium ion battery and a preparation method and aims to manufacture lithium ion batteries. The anode and the cathode of the three-dimensional lithium ion battery are respectively made of three-dimensional foamed porous aluminum and copper foil, the thickness of the battery is 0.1-5mm, the aperture of the battery is 0.05-10mm, and the porosity of the battery is 30-80%. According to the three-dimensional lithium ion battery, three-dimensional foamed porous structured aluminum and copper foil are respectively adopted as frameworks of an anode plate anda cathode plate, one or two mixtures of nickel-cobalt lithium aluminate and nickel-cobalt lithium manganate are adopted as an anode material, one or two mixtures of a silicon-carbon anode and a silicon oxygen cathode are adopted as a cathode material, and nano Al2O3 for doping and coating is added into the anode material and the cathode material, so that the electric conductive interface of a lithium ion battery active substance is increased, the interface resistance is reduced, the multiplying power charge and discharge performance of an electrode is improved, rapid charge and discharge requirements of power batteries are met, the properties of active substances are relatively sufficiently brought into play, the thickness of an electrode piece is increased, the energy density of the battery is increased, charge migration routes of electrode pieces are changed, the security performance of the battery is improved, and the manufacturing cost of the battery is reduced.

Owner:湖北猛狮新能源科技有限公司

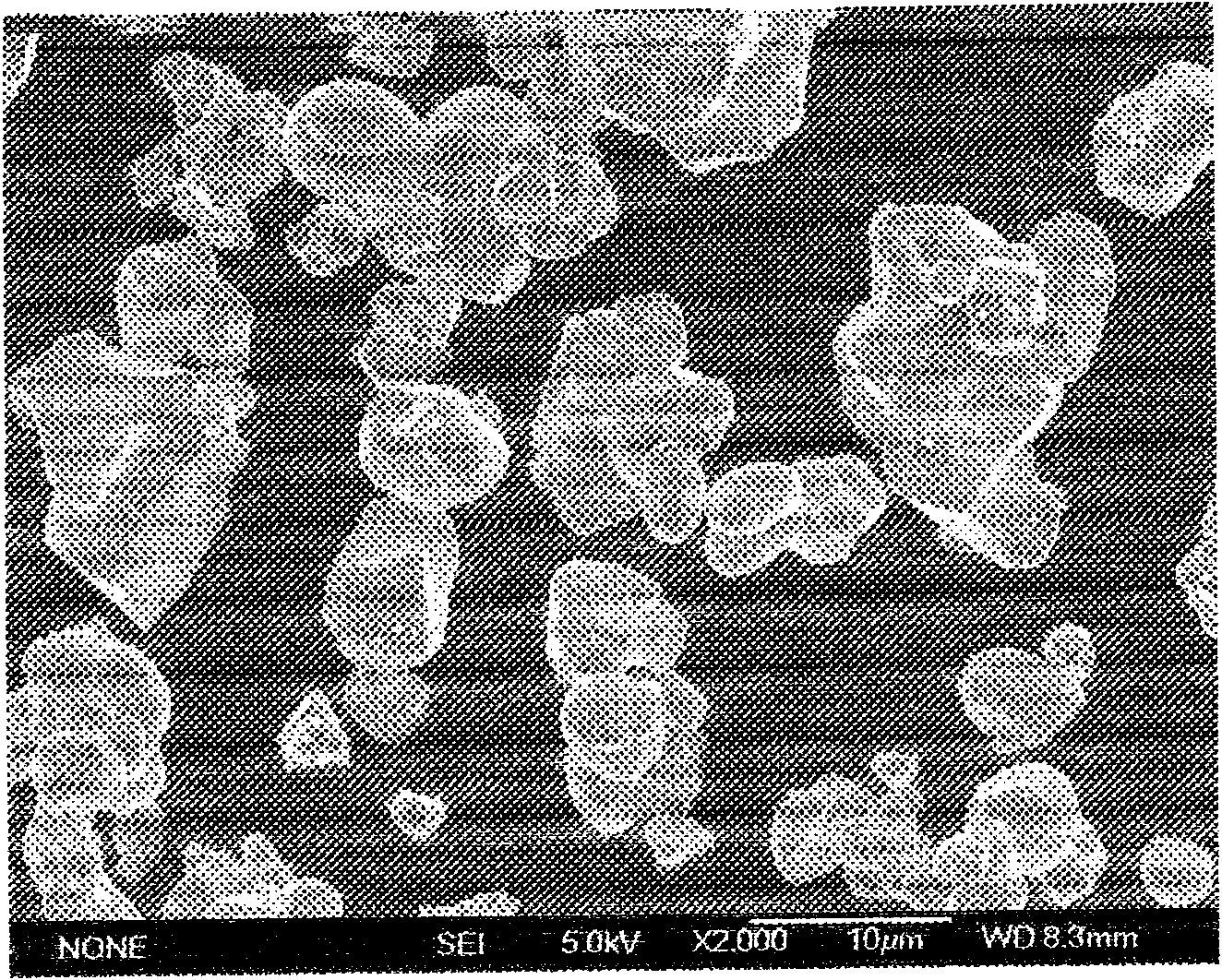

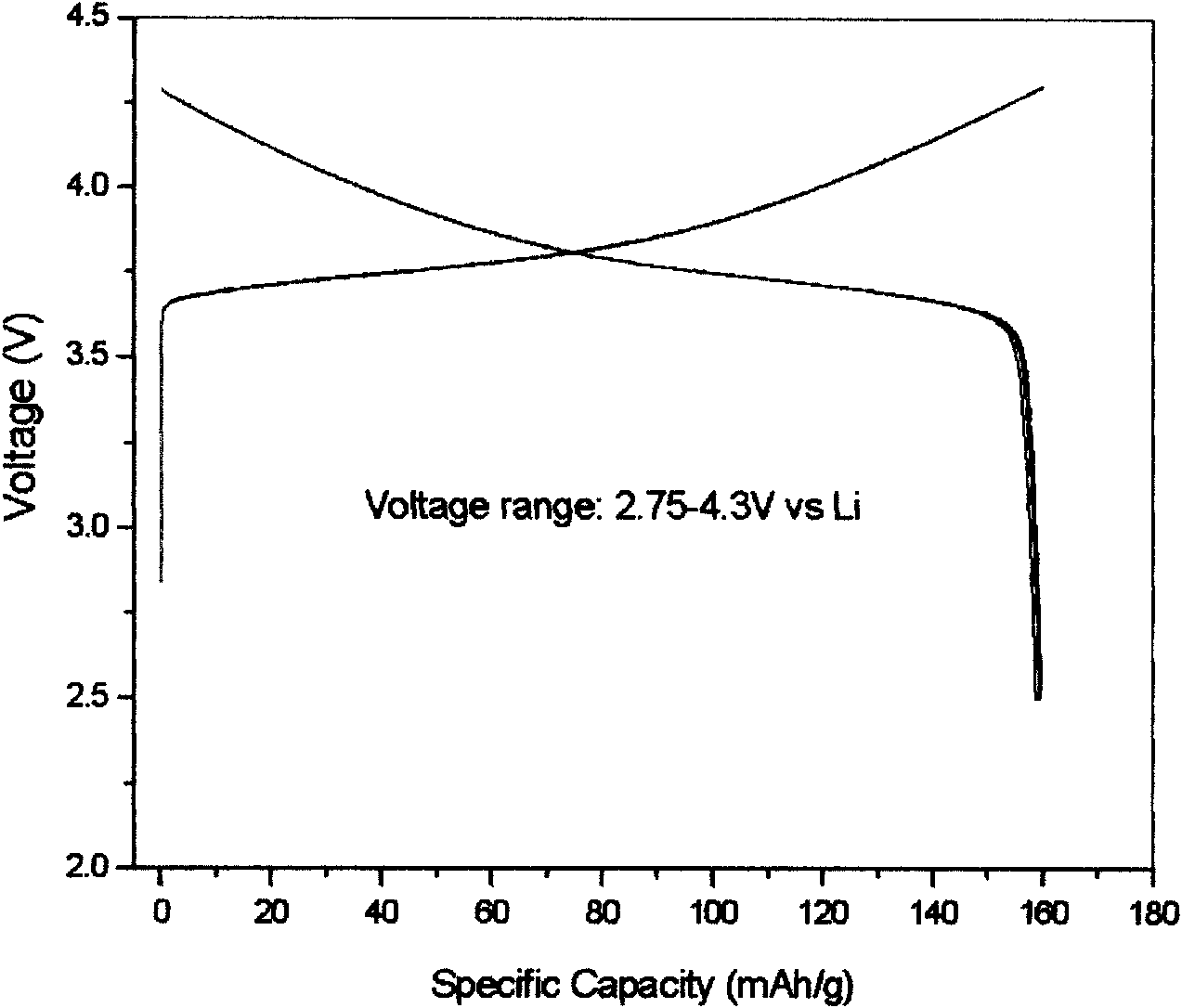

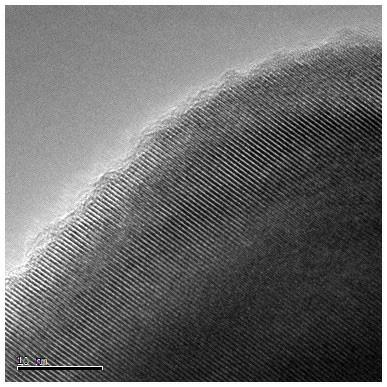

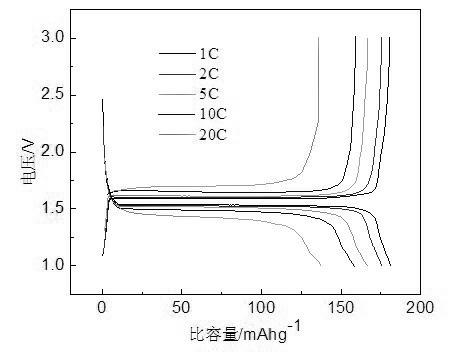

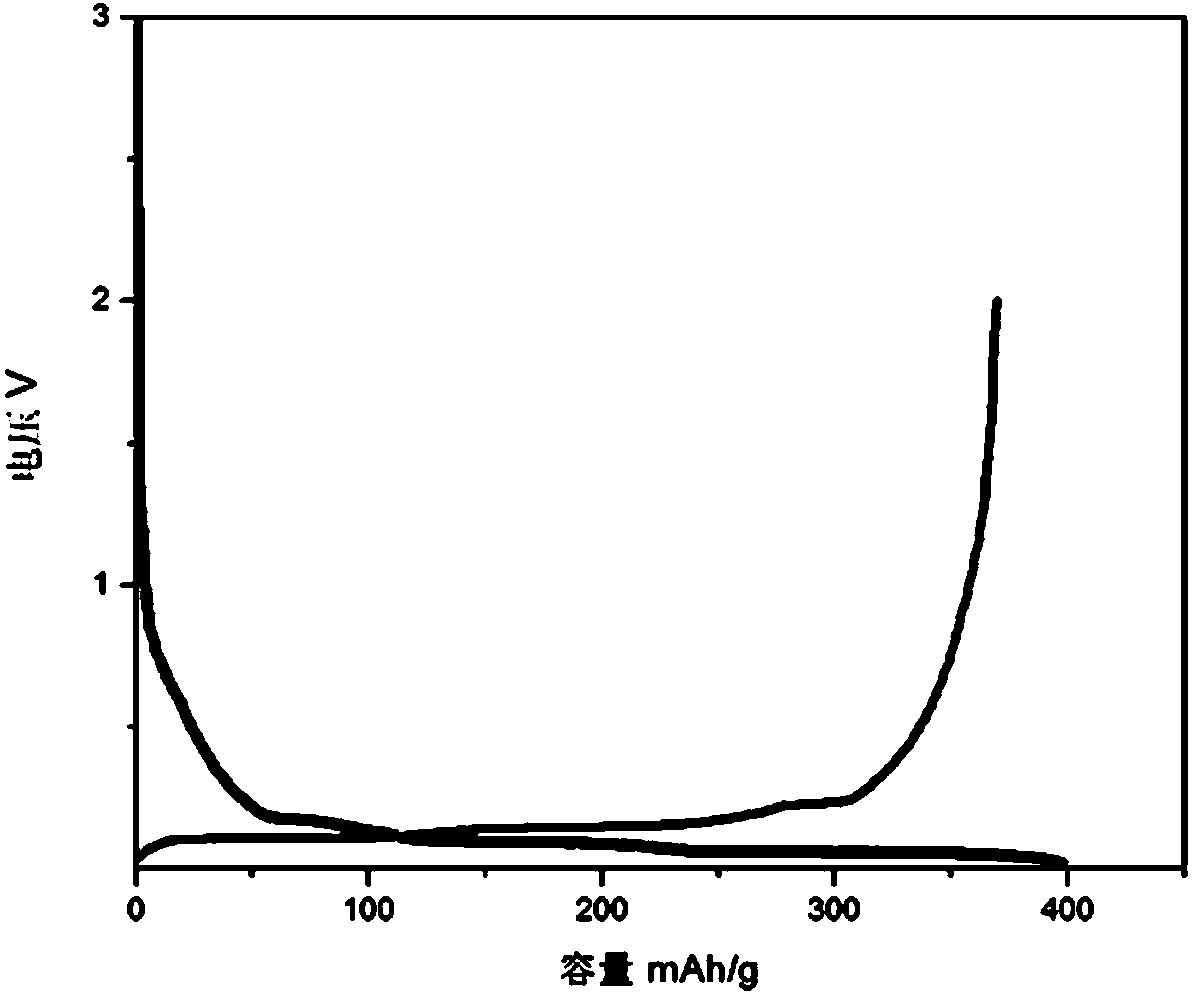

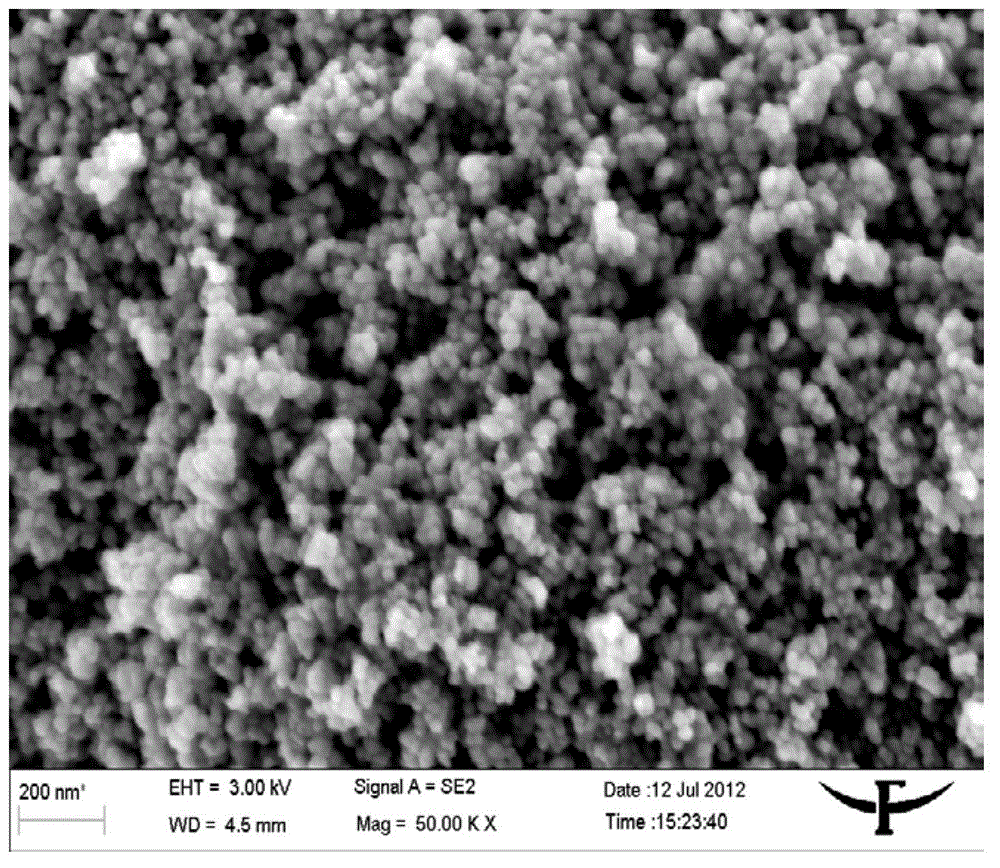

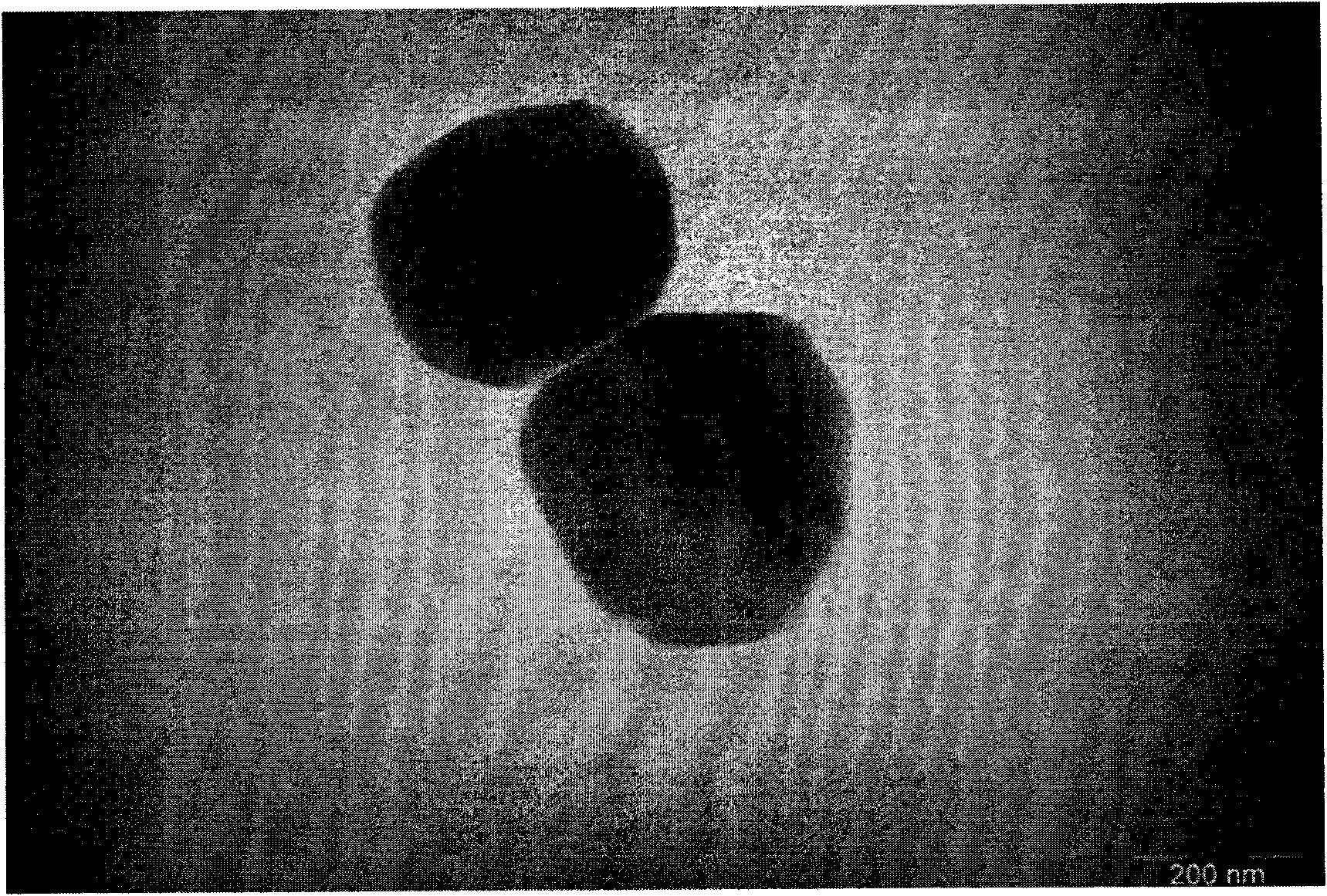

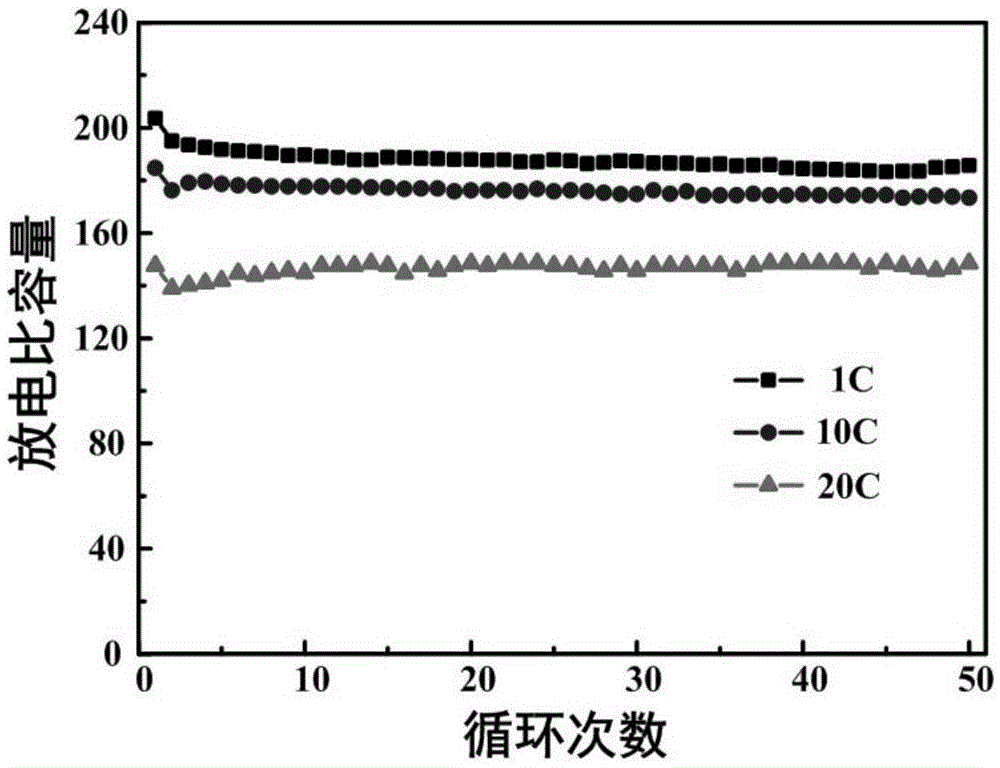

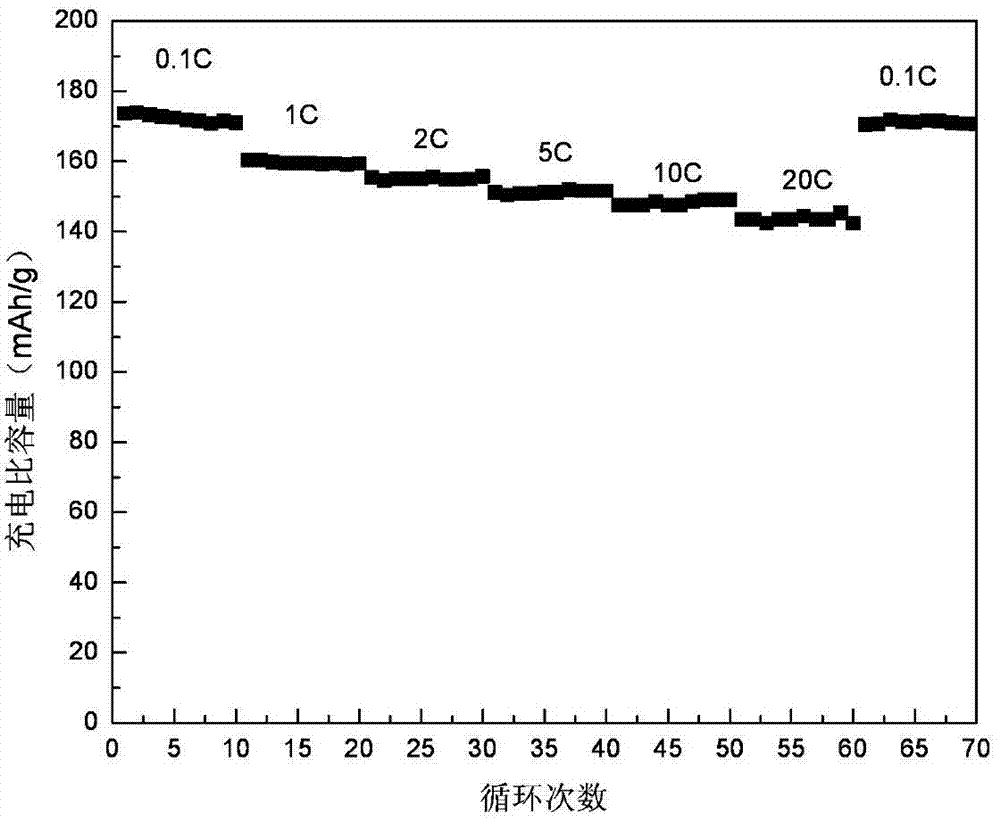

Preparation method of carbon-coated lithium titanate composite material for lithium ion power battery

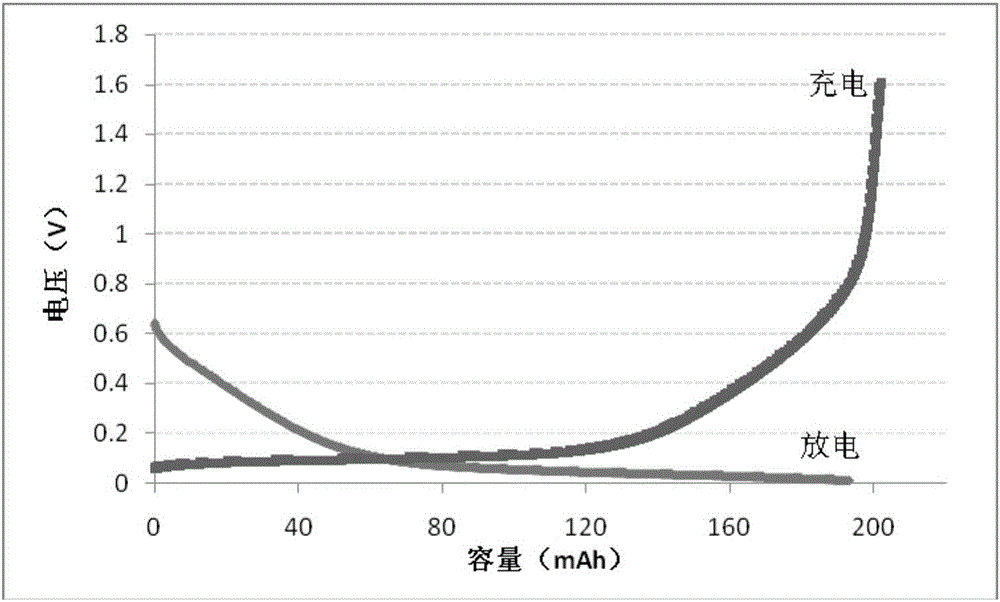

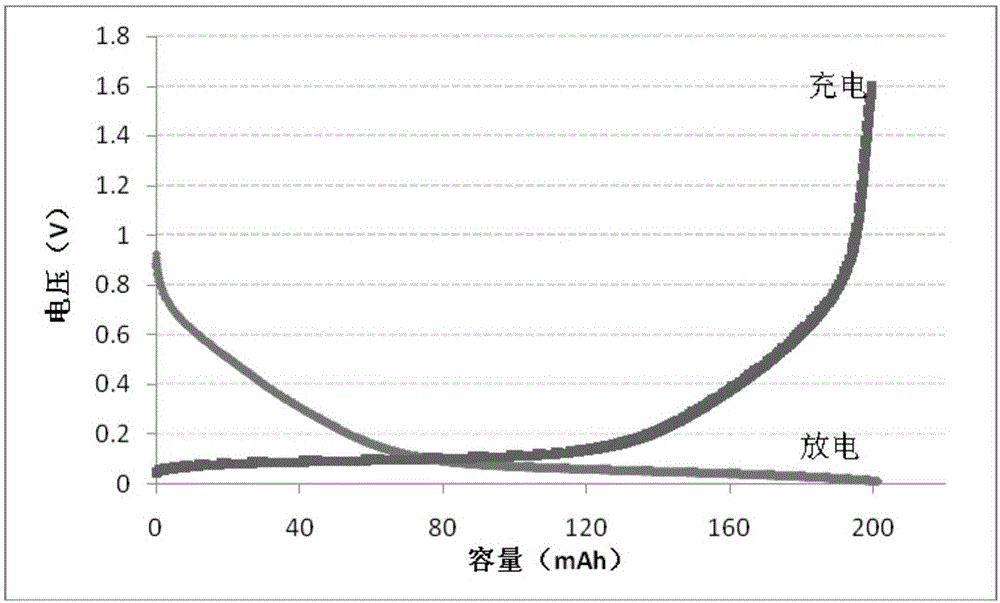

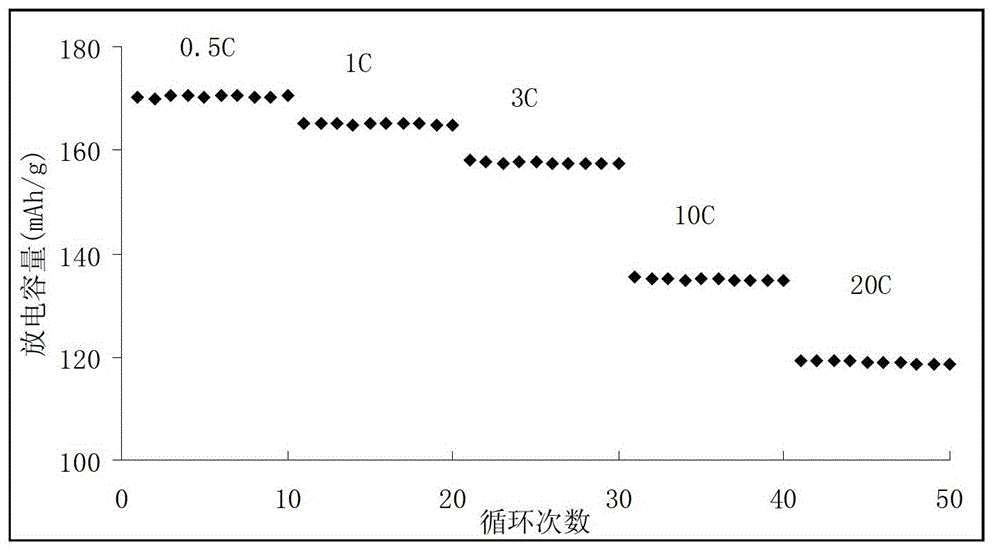

InactiveCN102610807AImprove electronic conductivityImprove rate charge and discharge performanceCell electrodesPower batteryRoom temperature

The invention discloses a preparation method of a carbon-coated lithium titanate composite material for a lithium ion power battery. The method comprises the following steps of: dissolving an amphiphilic carbon material into water at room temperature to prepare suspension, adding lithium titanate and mixing uniformly; heating to 80-90 DEG C, evaporating to dryness, and drying; performing constant-temperature thermal treatment for 0.5-10 hours at 500-1,000 DEG C to obtain the lithium titanate with a particle size of 100-400nm serving as a kernel; and coating the kernel with an amphiphilic carbon material with thickness of 3nm. The preparation method disclosed by the invention is environment-friendly, has a simple preparation process and is easy to realize large-scale production. The prepared material has large charge / discharge capacity, excellent heavy-current charge / discharge performance and stable cycle performance when used as a lithium ion battery cathode material, wherein the 10C discharge / charge capacity is 160mAh / g, the 20C discharge / charge capacity reaches 143mAh / g, and the capacity retention rate reaches 91% after 100 times of heavy-current 20C discharge and charge.

Owner:TIANJIN UNIV

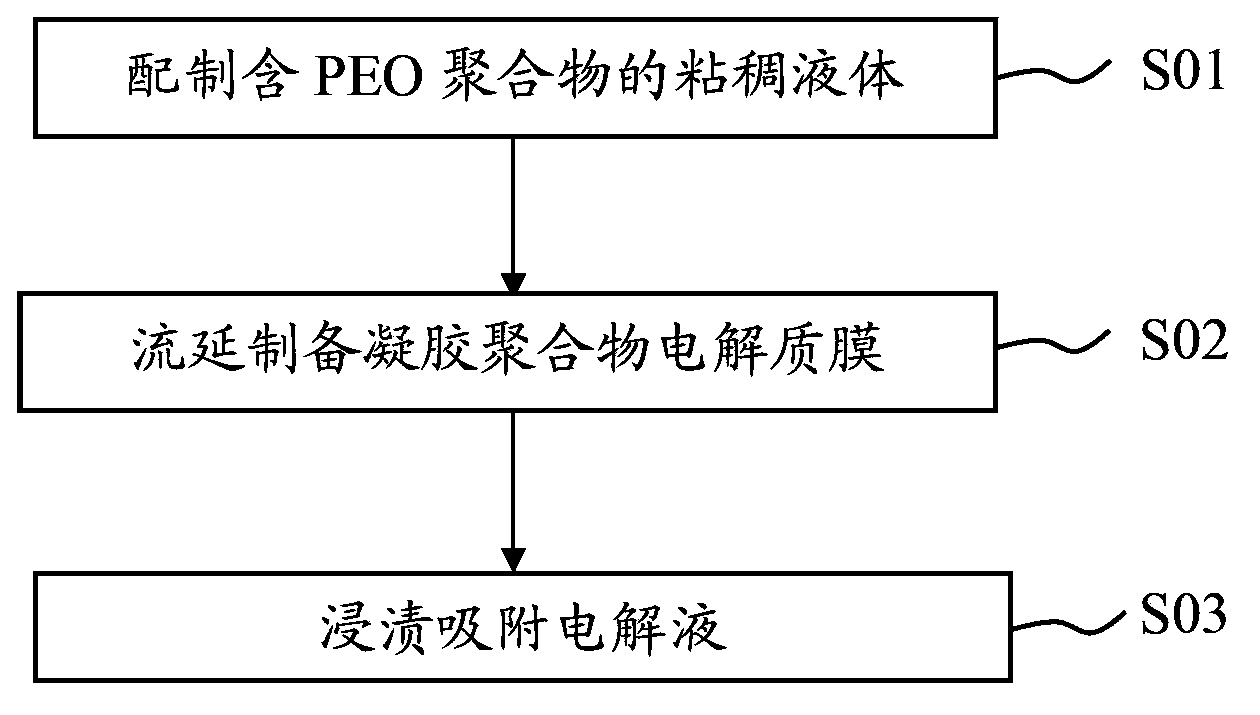

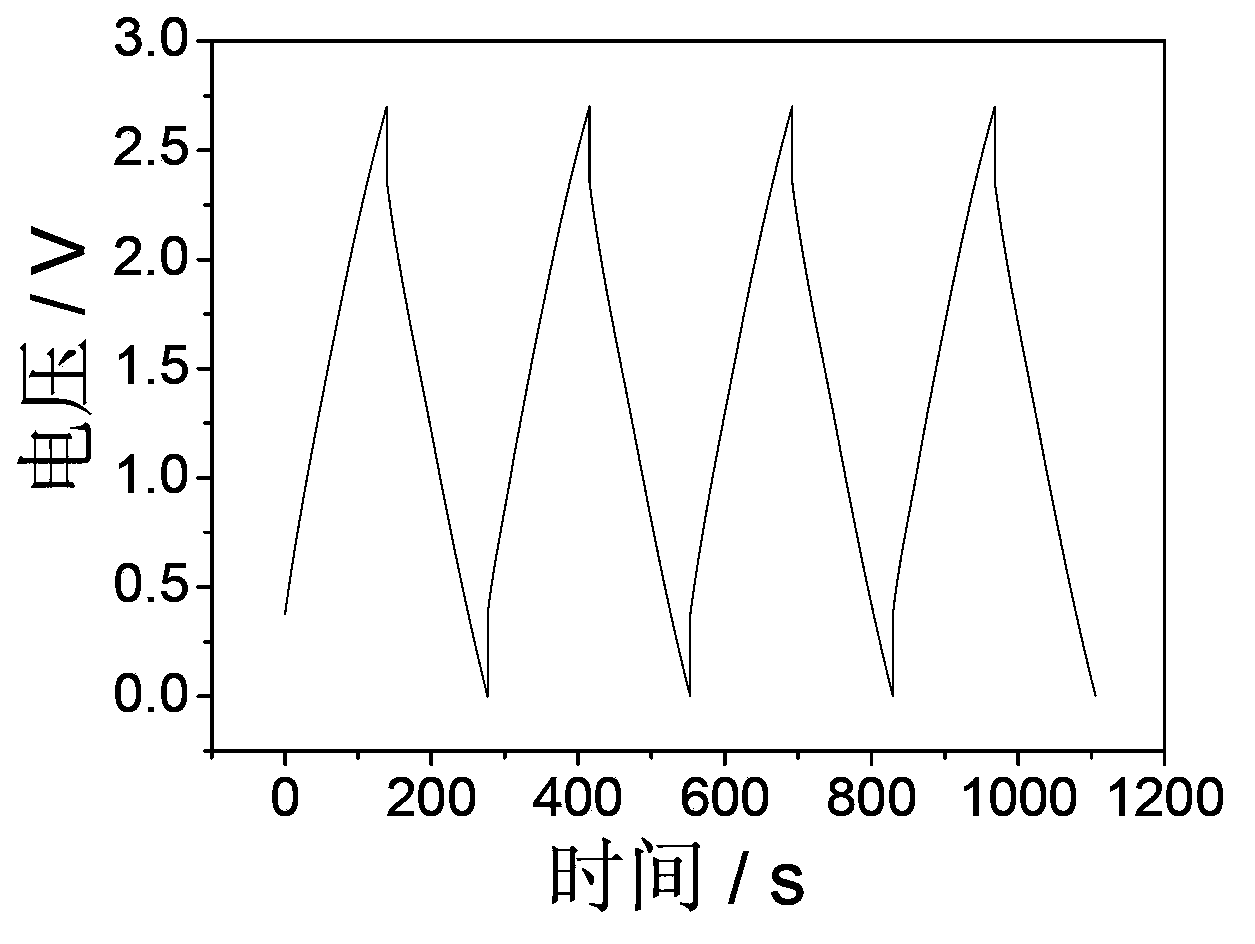

Gel polymer electrolyte, preparation method for the same, super capacitor and application thereof

InactiveCN103680968AImproves ability to absorb electrolytesImprove conductivityCapacitor electrolytes/absorbentsViscous liquidPolymer electrolytes

This invention discloses a gel polymer electrolyte, a preparation method for the same, a super capacitor and an application thereof. The gel polymer electrolyte preparation method includes steps of preparing viscous liquid containing PEO polymer, preparing gel polymer dielectric films through curtain coating and dipping and absorbing the electrolyte. The super capacitor contains the gel polymer electrolyte. The preparation method for the gel polymer electrolyte is simple in preparation, mature in technology and high in rate of finish products and efficiency, and effectively reduces the production cost. The gel polymer electrolyte prepared by the method has strong mechanical strength and high conductivity. The super capacitor containing the gel polymer electrolyte is high in the rate of finished products and low in production cost, and has excellent chemical properties and expands the application range of the super capacitor.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +2

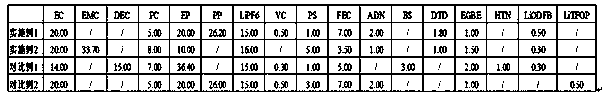

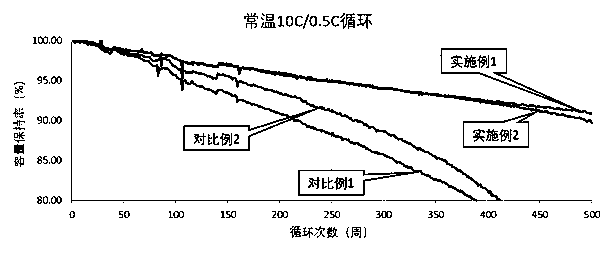

Electrolyte of high-voltage fast-charging lithium ion battery and lithium ion battery

InactiveCN111193071ALow viscosityImprove wettabilityFinal product manufactureSecondary cells servicing/maintenanceElectrolytic agentLithium-ion battery

The invention discloses an electrolyte of a high-voltage fast-charging lithium ion battery and the lithium battery. The electrolyte comprises a non-aqueous organic solvent, an electrolyte salt and anadditive, and the mass percentages of the non-aqueous organic solvent, the electrolyte salt and the additive in the electrolyte are 65%-90%, 10%-20% and 0-15% respectively. The electrolyte can improvethe normal-temperature quick charge cycle performance, the high-temperature storage performance and the low-temperature discharge performance of the high-voltage battery at the same time. The lithiumion battery prepared by adopting the electrolyte has lower surface density, is beneficial to reducing the impedance of the lithium ion battery, is smoother in lithium ion migration, can effectively improve the rate charge-discharge performance, and obviously improves the low-temperature discharge performance at the same time; the electrolyte of the high-voltage fast-charging lithium ion battery has the relatively high charging cut-off voltage, the capacity of the lithium ion battery can be improved by about 15%, and energy density reduction caused by surface density reduction is made up; andcompared with a conventional battery, the lithium ion battery has wider tabs, so that the ohmic impedance of the lithium ion battery is effectively reduced to facilitate electron transmission.

Owner:CHONGQING VDL ELECTRONICS

Inorganic doped/coated modification natural graphite, as well as preparation method and application thereof

ActiveCN103972508AWide variety of sourcesLow costCell electrodesSecondary cellsReaction temperatureNitrogen

The invention belongs to the technical field of energy materials and electrochemistry and in particular relates to inorganic doped / coated modification natural graphite, as well as a preparation method and application of the inorganic doped / coated modification natural graphite. The preparation method comprises the following steps: adding natural graphite, oxidizing acid and inorganic doped raw materials in a reaction kettle to carry out hydrothermal reaction for 0.5-12 hours at the reaction temperature of 90-180 DEG C and thus obtaining a product which is expanded graphite A; drying the expanded graphite A in a drying box to obtain dried and expanded graphite B; treating the expanded graphite B at the high temperature of 600-1600 DEG C under the protective atmosphere, simultaneously introducing nitrogenous organic compounds to form a nitrogen coated layer on the surface of the expanded graphite B, finally obtaining modified natural graphite. The preparation method is simple in process, easy to control, wide in sources of raw materials and low in cost. The prepared materials is excellent in repeatability, has the advantages of doping and coating modification, is excellent in material property and can be used as the negative electrode material of the lithium battery.

Owner:SHANGHAI SECOND POLYTECHNIC UNIVERSITY

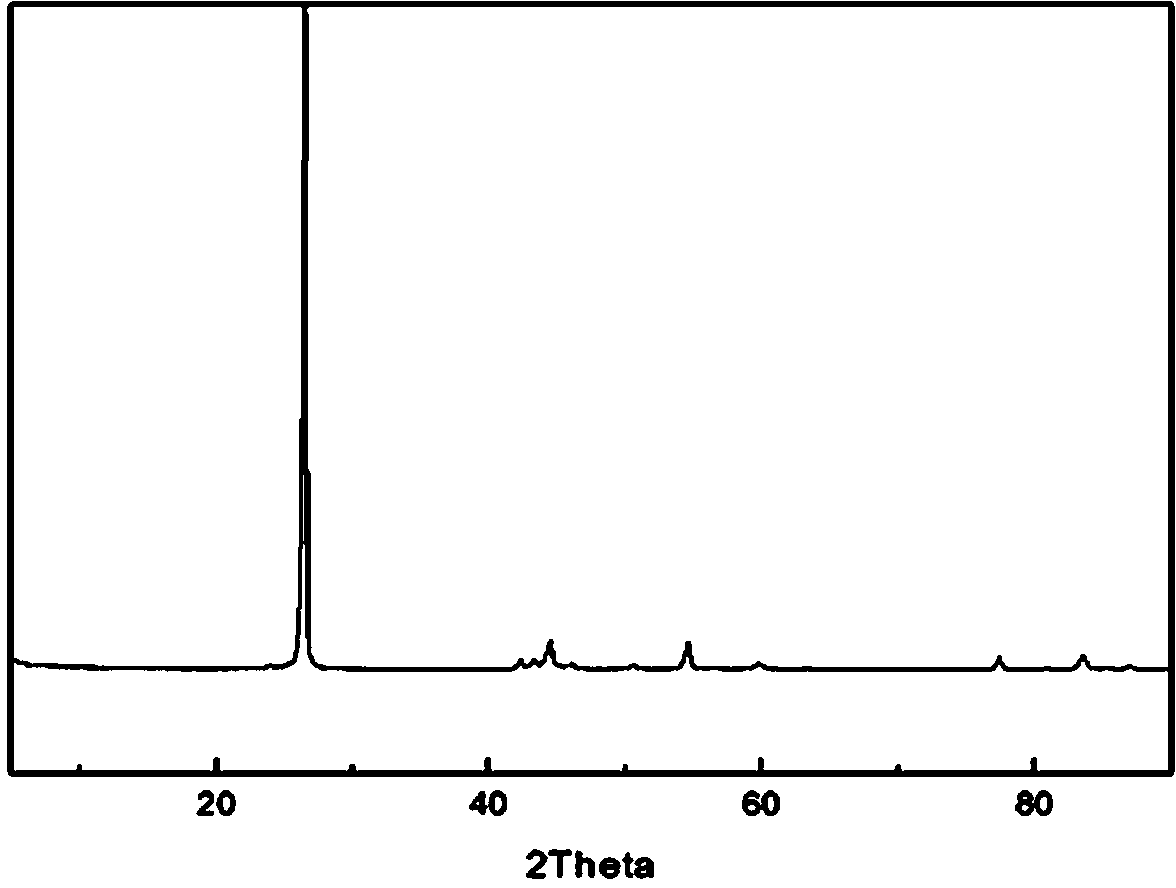

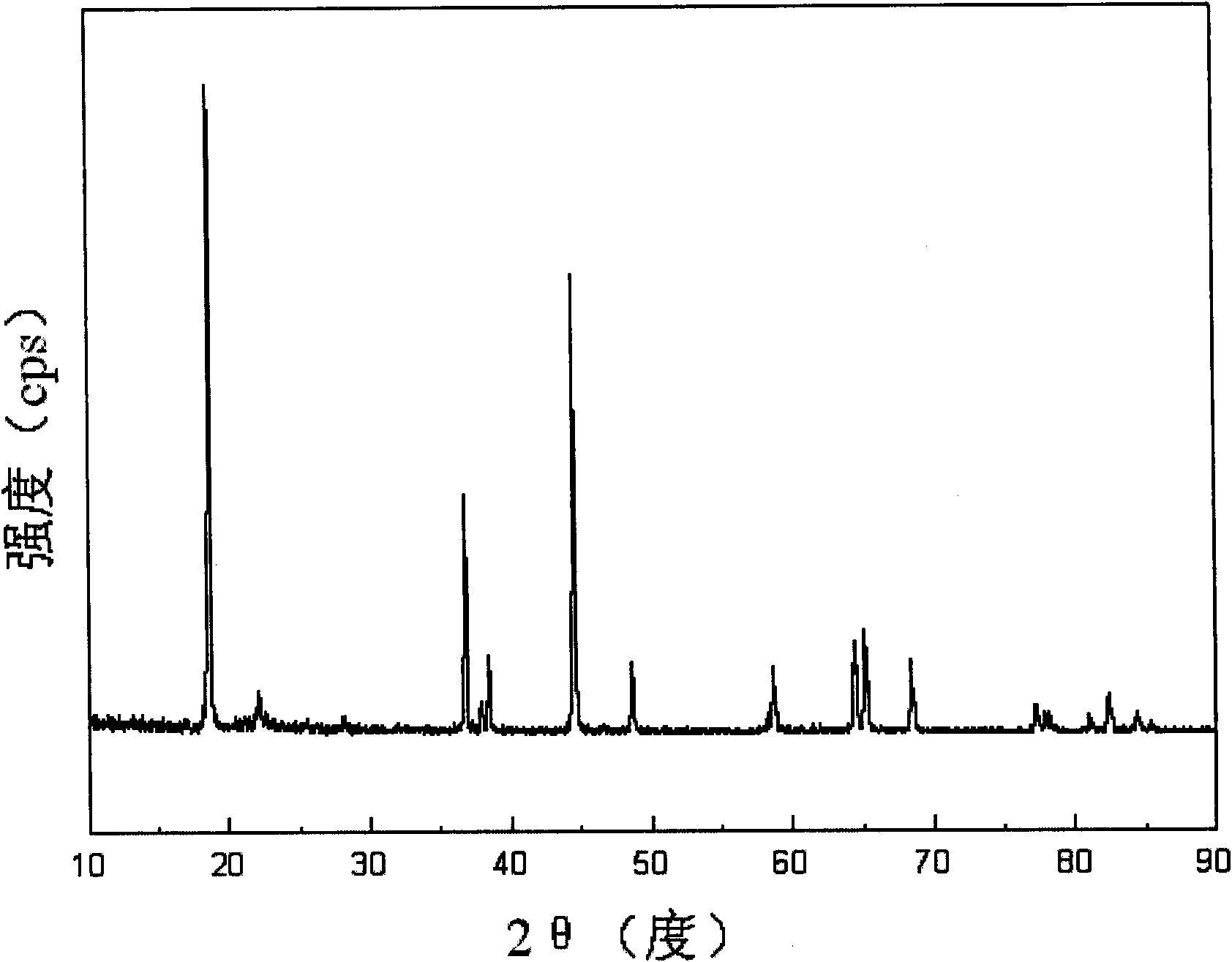

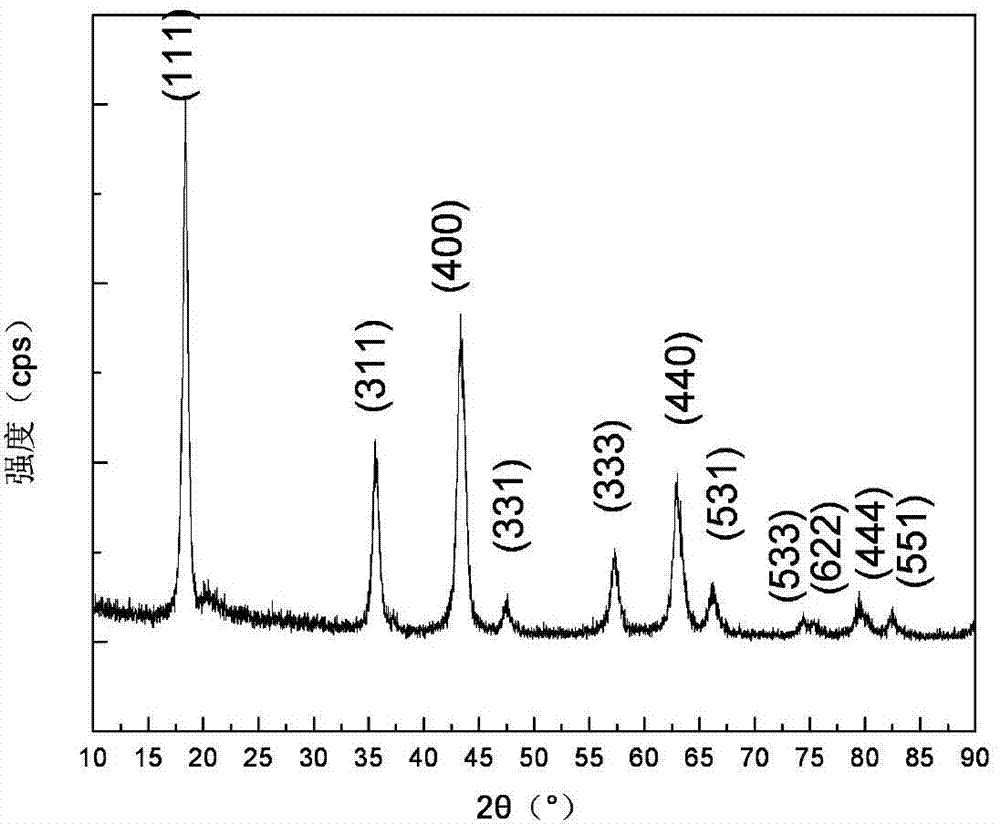

Method for preparing carbon-coated nano-particle lithium titanate electrode material

ActiveCN102916170AShorten the diffusion pathImprove electrochemical performanceMaterial nanotechnologyCell electrodesCarbon coatedAtmosphere

The invention discloses a method for preparing a carbon-coated nano-particle lithium titanate electrode material, wherein the method comprises the following steps of: (1), adding a lithium source compound, nano-TiO2 and macromolecular hydrocarbon into a dispersing agent to prepare into a mixed solution; (2), adjusting pH of the mixed solution obtained in the step (1) to 7.0-8.5, after continuously stirring, spraying and drying to prepare a precursor, drying in vacuum at 120 DEG C, and preparing precursor powder; and (3), sintering the precursor powder obtained in the step (2) under the protection of atmosphere, sieving through a 300-mesh sieve after cooling, and then obtaining the carbon-coated nano-particle lithium titanate material. According to the invention, the carbon-coated lithium titanate electrode material with uniform nano size and particle morphology is prepared; the electrical conductivity of lithium titanate is improved; the rate charging and discharging performances of the material are increased; therefore, the material has high specific capacity and good rate capability and cycle performance; and the preparation method disclosed by the invention is simple in process and easy for control and automatic operation and is applied to scale production.

Owner:DO FLUORIDE NEW ENERGY TECHNOLOGY CO LTD

High-rate lithium titanate battery and production method thereof

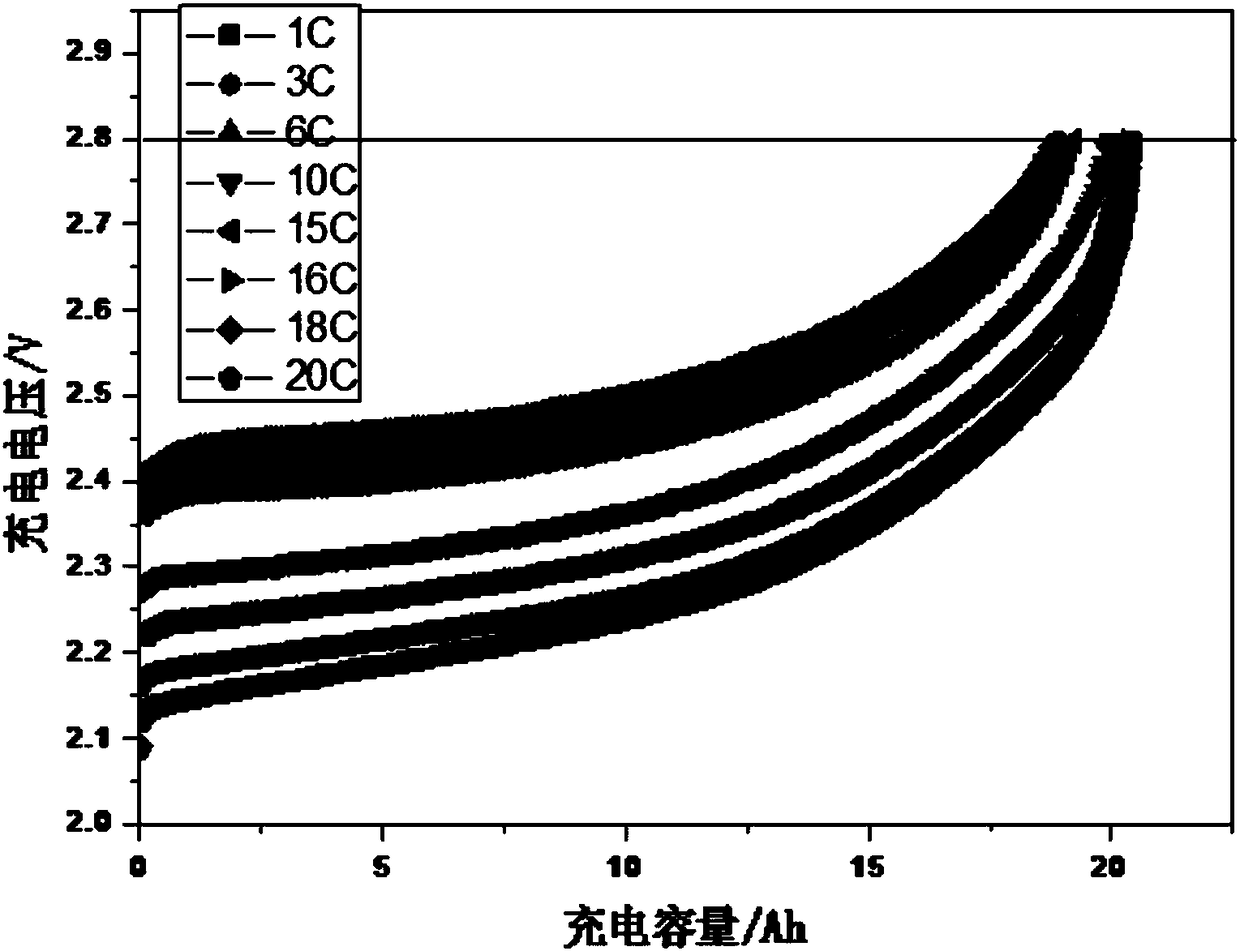

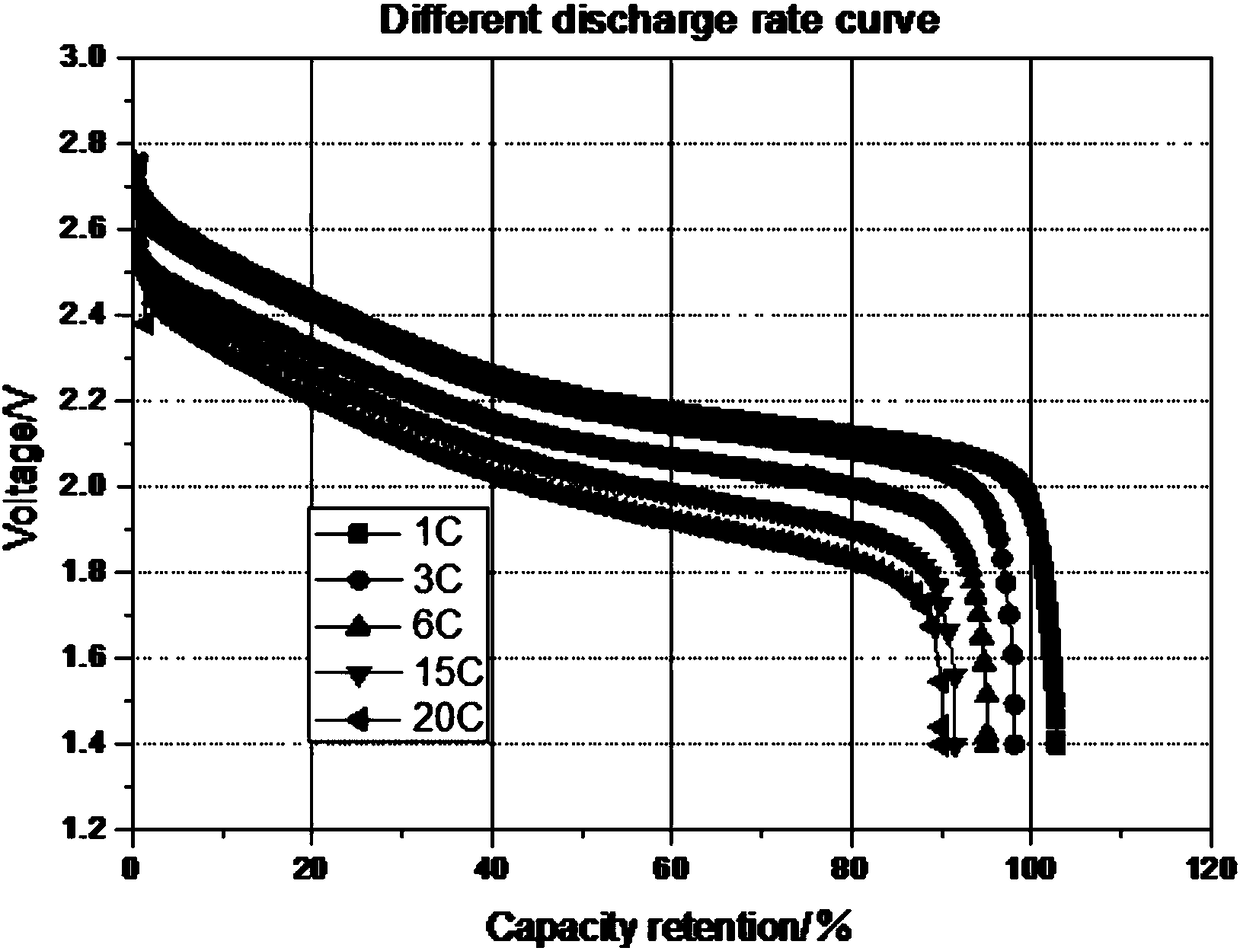

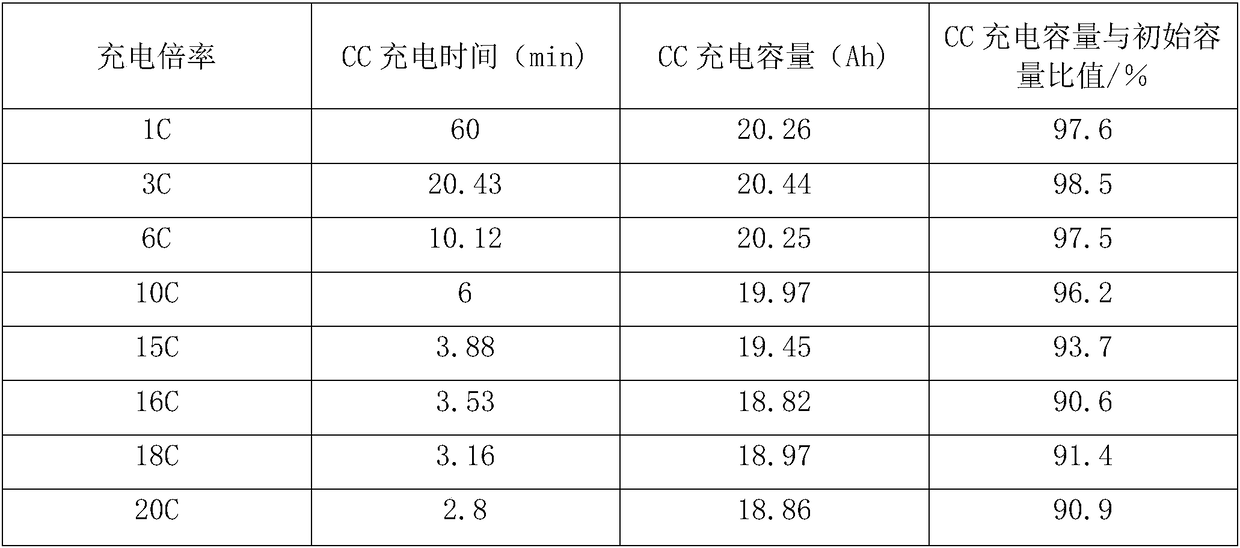

ActiveCN108232285APreventing Magnification Drop ProblemsImproved magnification performanceFinal product manufactureElectrolytesPorosityHigh rate

The invention relates to the field of lithium batteries, in particular to a high-rate lithium titanate battery and a production method thereof. The lithium titanate battery comprises a positive plate,a negative plate, a separator, an electrolyte and an outer package. A carbon-coated aluminum foil current collector is coated with positive and negative active substances, a binder and a conductive agent, lamination, packaging and injection are performed by use of the special high-porosity separator and the high-rate electrolyte system, the high-rate lithium titanate battery is prepared with high-temperature and high-pressure formation and aging technologies, and the problems of long charge time, poor rate charge and discharge performance and low safety of the lithium titanate battery are effectively solved.

Owner:CAMEL GRP NEW ENERGY BATTERY CO LTD

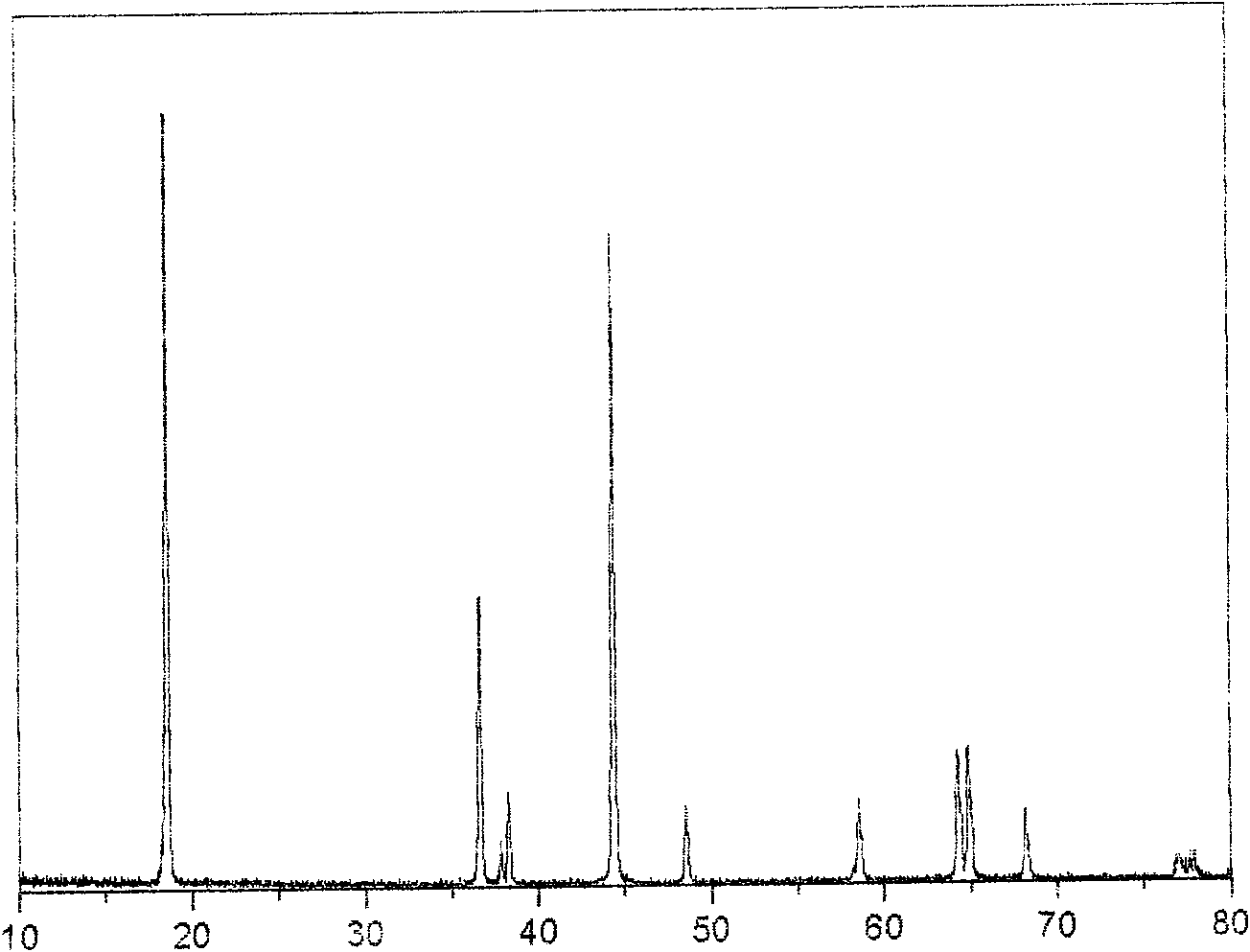

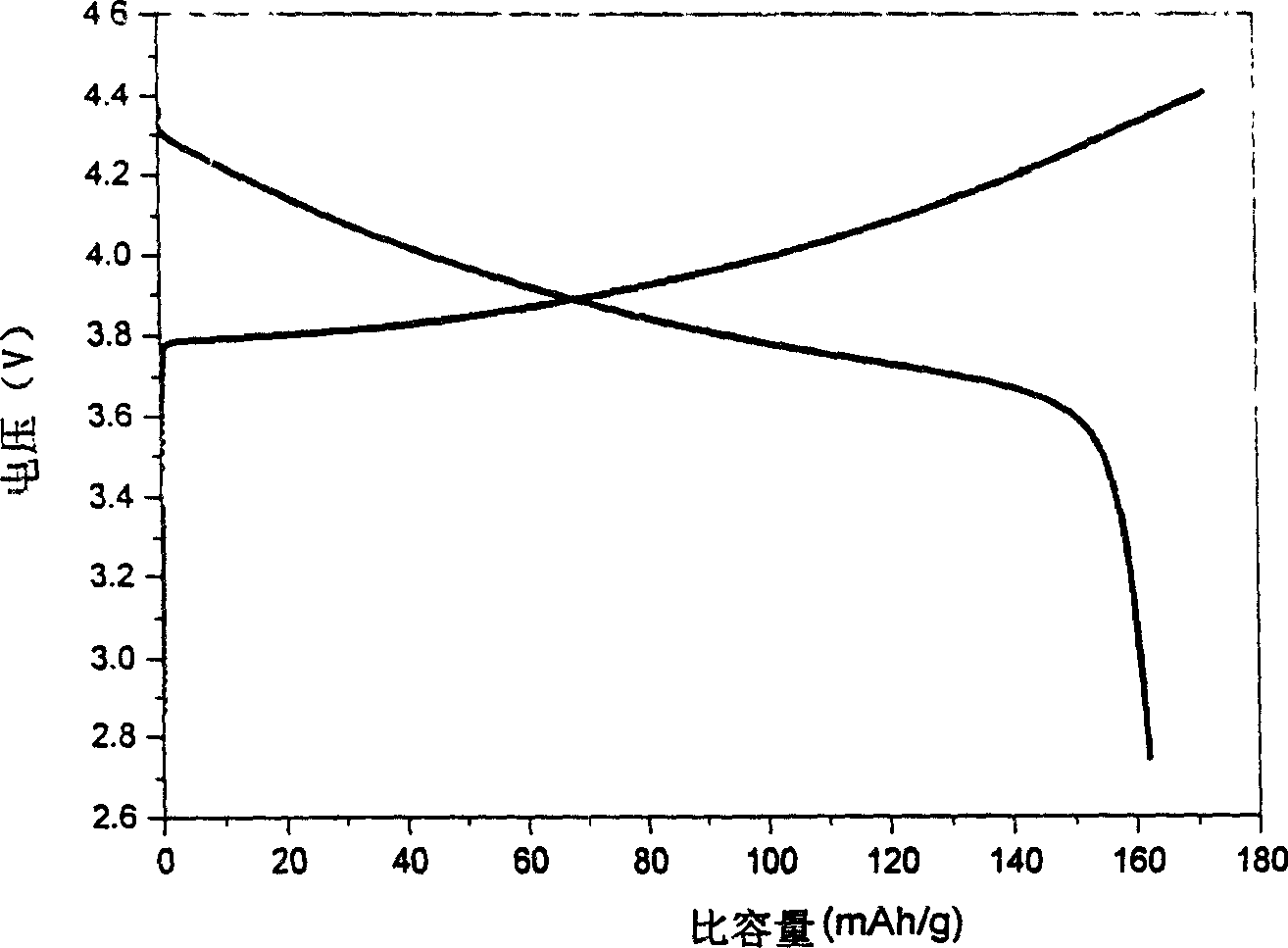

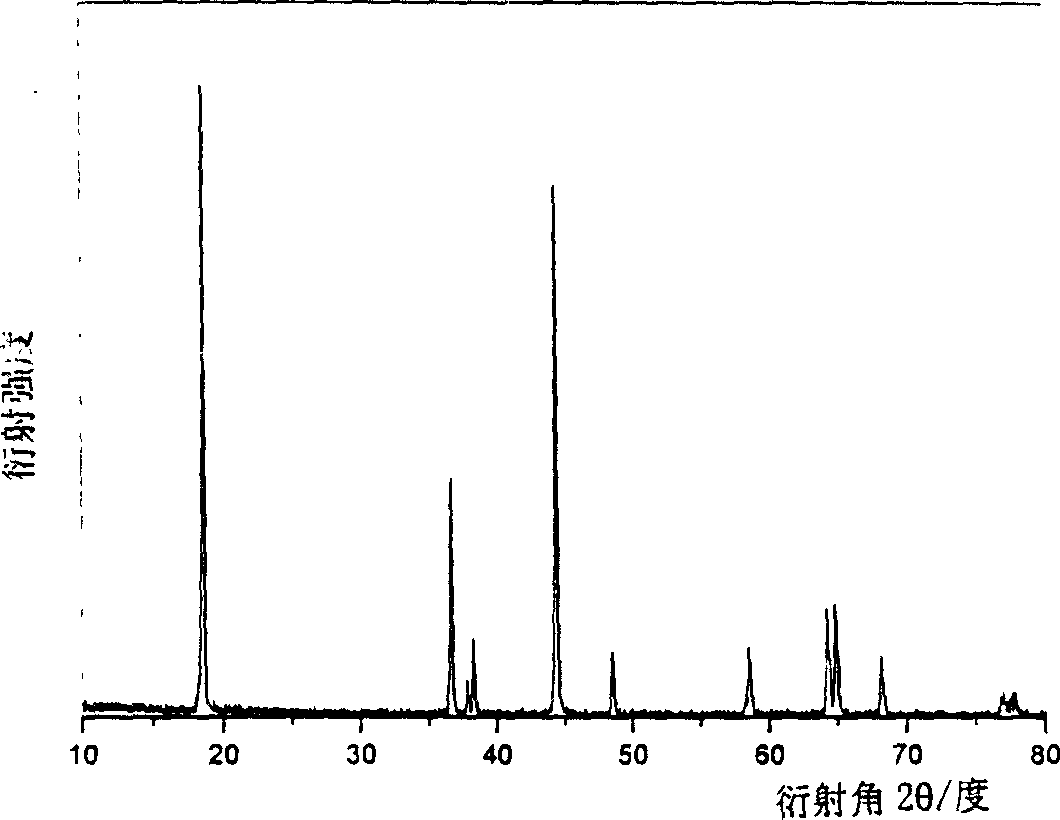

Method for preparing submicron-sized anode material LiCoxNiyMnzO2 of lithium-ion battery

InactiveCN101582499AReduce sizeImprove cycle performanceElectrode manufacturing processesNickel oxides/hydroxidesNickel saltCobalt salt

The invention relates to a method for preparing an anode material of a lithium-ion battery, in particular to a method for preparing a submicron-sized anode material LiCoxNiyMnzO2 of a lithium-ion battery. The invention solves the problem that the rate charge / discharge performance of the material is greatly affected by the micron-sized anode material with larger particle size of a battery. The method of the invention comprises the following steps: (1), dissolving cobalt salt, nickel salt and manganese salt in distilled water to obtain a system 1; (2), dissolving sodium hydroxide and chelator in distilled water to obtain a system 2; (3) adding the system 1 and the system 2 in a reaction kettle placed in a mixture of ice and water, then, filtering and further drying the filter residue to obtain precursor powder; (4) ball-milling and mixing the lithium resource and the precursor powder and sintering to obtain the anode material of the lithium-ion battery. Compared with the micron-sized anode material of the lithium-ion battery, the submicron-sized anode material of the lithium-ion battery prepared by the method of the invention reduces the particle size, thereby improving the rate charge / discharge performance.

Owner:HARBIN NORMAL UNIVERSITY

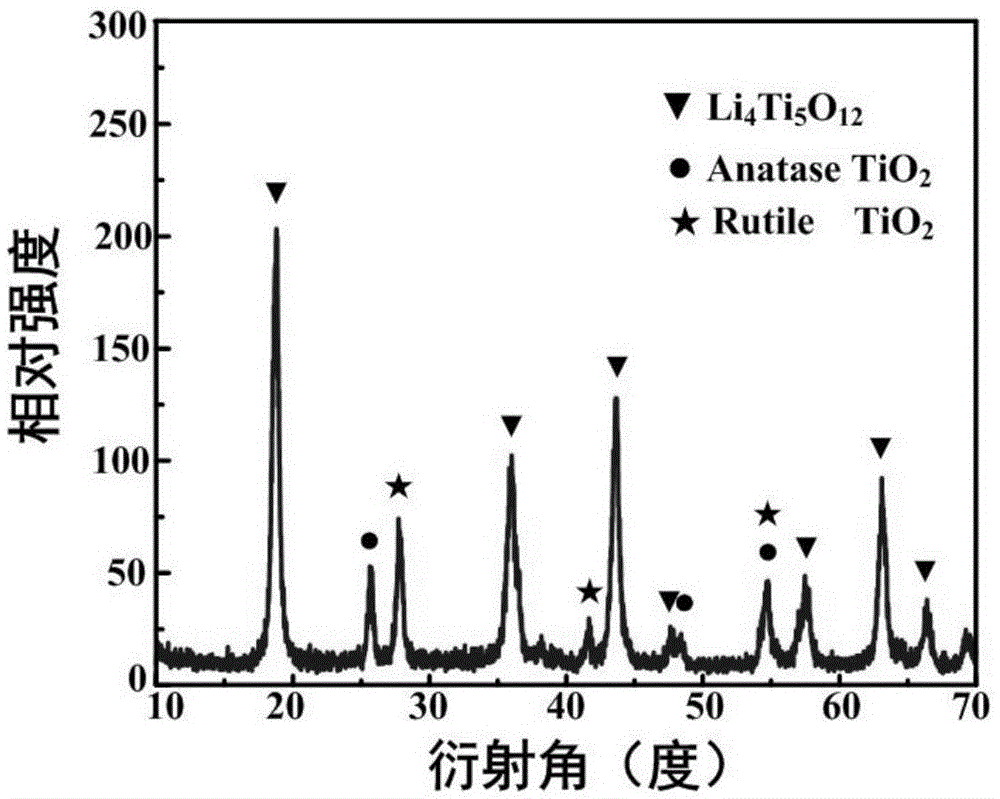

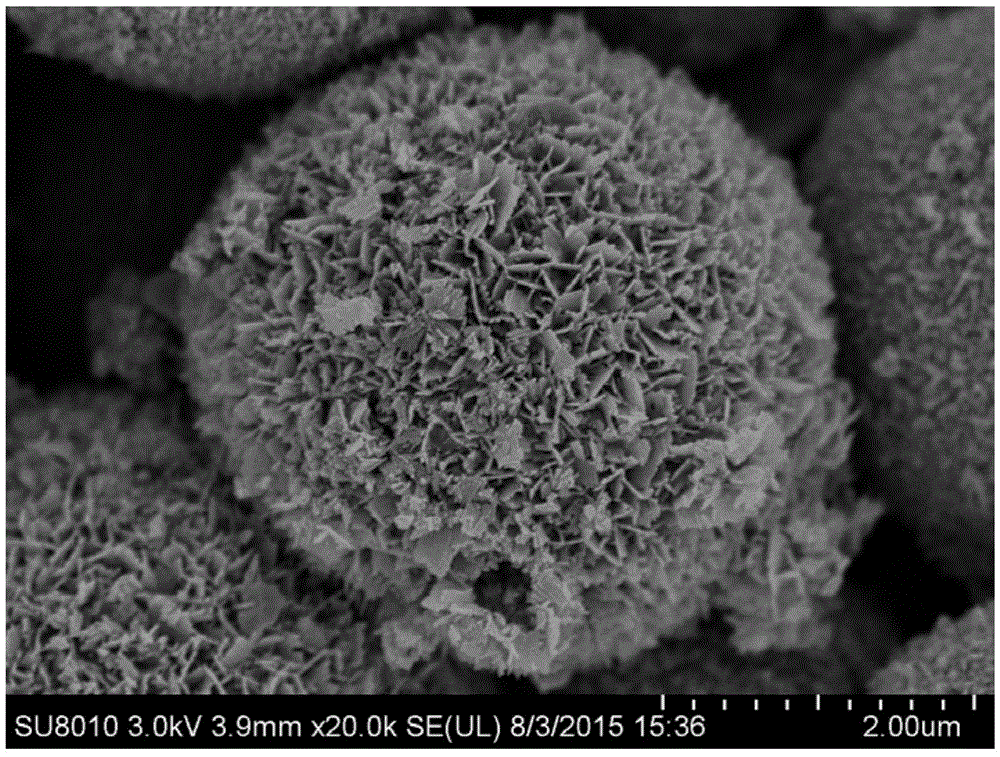

Preparation method of flower-like lithium titanate-titanium dioxide composite electrode material

InactiveCN105489858AIncrease contact areaImprove rate charge and discharge performanceMaterial nanotechnologyCell electrodesCharge dischargeLithium titanate

The invention discloses a preparation method of a flower-like lithium titanate-titanium dioxide (Li<4>Ti<5>O<12>-TiO<2>) composite electrode material. The method comprises the following steps: (a) adding a titanium source to an organic solvent under agitation to obtain a titanium-containing solution; (b) dissolving the taken surfactant into deionized water; (c) weighing a lithium source, and dissolving the lithium source into the water solution obtained in the step (b) to obtain a lithium-containing water solution; (d) adding the lithium-containing water solution obtained in the step (c) to the titanium-containing solution obtained in the step (a) under agitation to obtain a mixed solution; (e) transferring the mixed solution obtained in the step (d) into a reaction kettle for reaction; (f) cooling the product to a room temperature after reaction is ended, washing the obtained sediments, and drying the sediments to obtain white powder; and (g) roasting the white powder obtained in the step (f) to prepare the flower-like lithium titanate-titanium dioxide composite electrode material. The Li<4>Ti<5>O<12>-TiO<2> composite material with a flower-like structure prepared by the method has relatively large specific surface area and pore volume and is good in rate charge-discharge performance; the preparation method has the advantages of being simple in process, low in energy consumption and the like; and the shape and the dimension of a product are easy to control.

Owner:NANYANG NORMAL UNIV

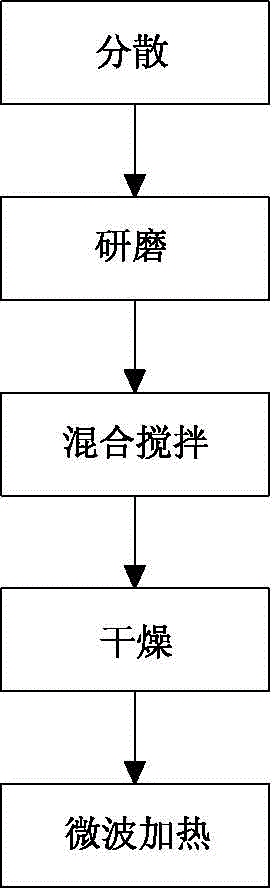

Preparation method of low-cost high-performance lithium iron phosphate material

InactiveCN106099103ALow costHigh cycle capacityCell electrodesSecondary cellsPhosphateMixed materials

The invention discloses a preparation method of a low-cost high-performance lithium iron phosphate material. The preparation method comprises the steps that an iron source, a phosphorus source and a lithium source are mixed according to the molar ratio of 1:(0.85-1):(0.9-1), a carbon source of which the weight accounts for 3%-10% of the total weight of the mixture is added, and mixing is continuously conducted to obtain a mixed material, wherein a mixture of ferric oxide and ferric orthophosphate is adopted as the iron source, lithium dihydrogen phosphate is adopted as the phosphorus source, lithium carbonate is adopted as the lithium source, and saccharose or maltose is adopted as the carbon source; the mixed material is added into a solvent to be ground for 10 hours to 20 hours, drying is conducted, and then a lithium iron phosphate precursor is obtained; a modifying agent solvent and the lithium iron phosphate precursor are mixed and then added into tartaric acid, stirring is conducted for 5 hours to 10 hours, and then drying is conducted at 60 DEG C to 80 DEG C to obtain lithium iron phosphate powder; the lithium iron phosphate powder is subjected to two-phase sintering under protection of inert gas to obtain the lithium iron phosphate material. According to the preparation method, the mixture of ferric oxide and ferric orthophosphate is adopted as the iron source, and therefore the raw material cost is reduced; meanwhile, cladding is conducted through a modifying agent, and therefore the electrical conductivity of the material is improved.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY CO LTD CO LTD

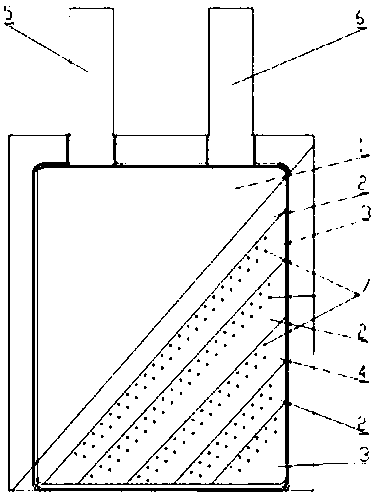

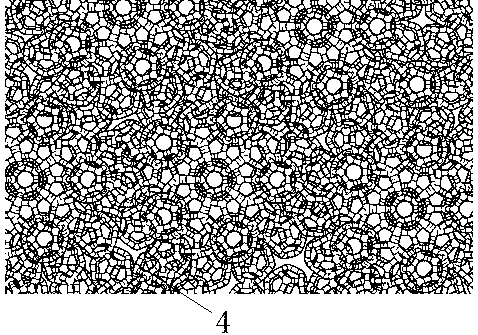

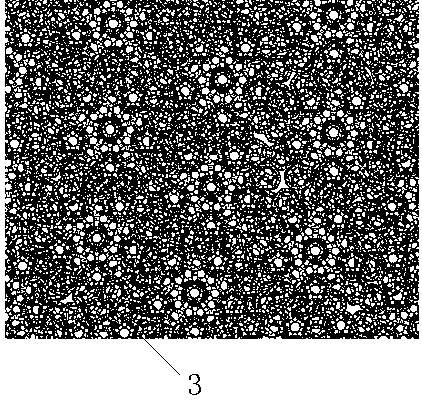

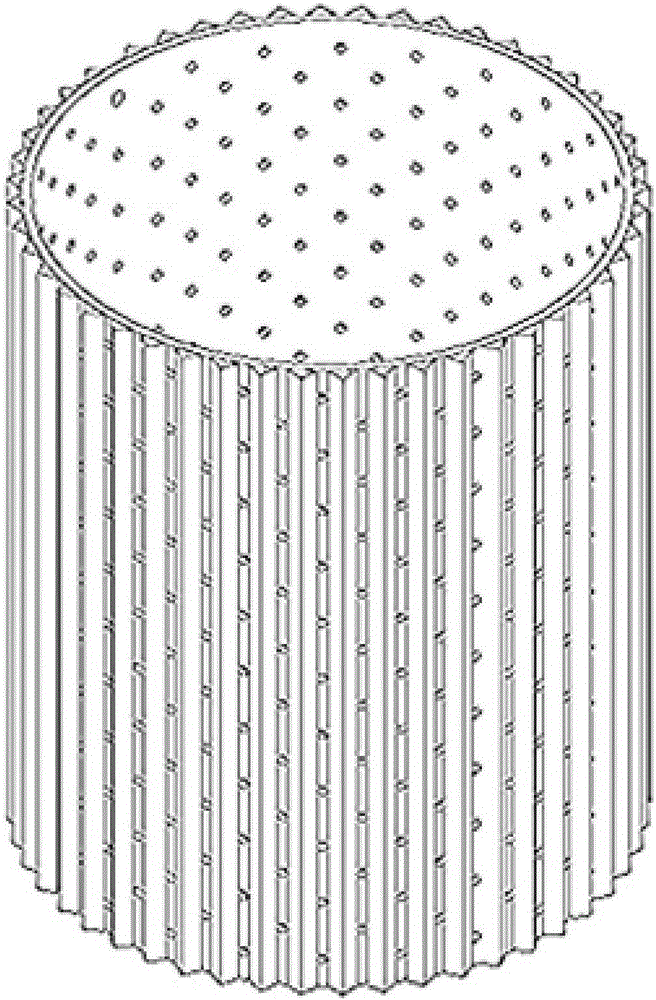

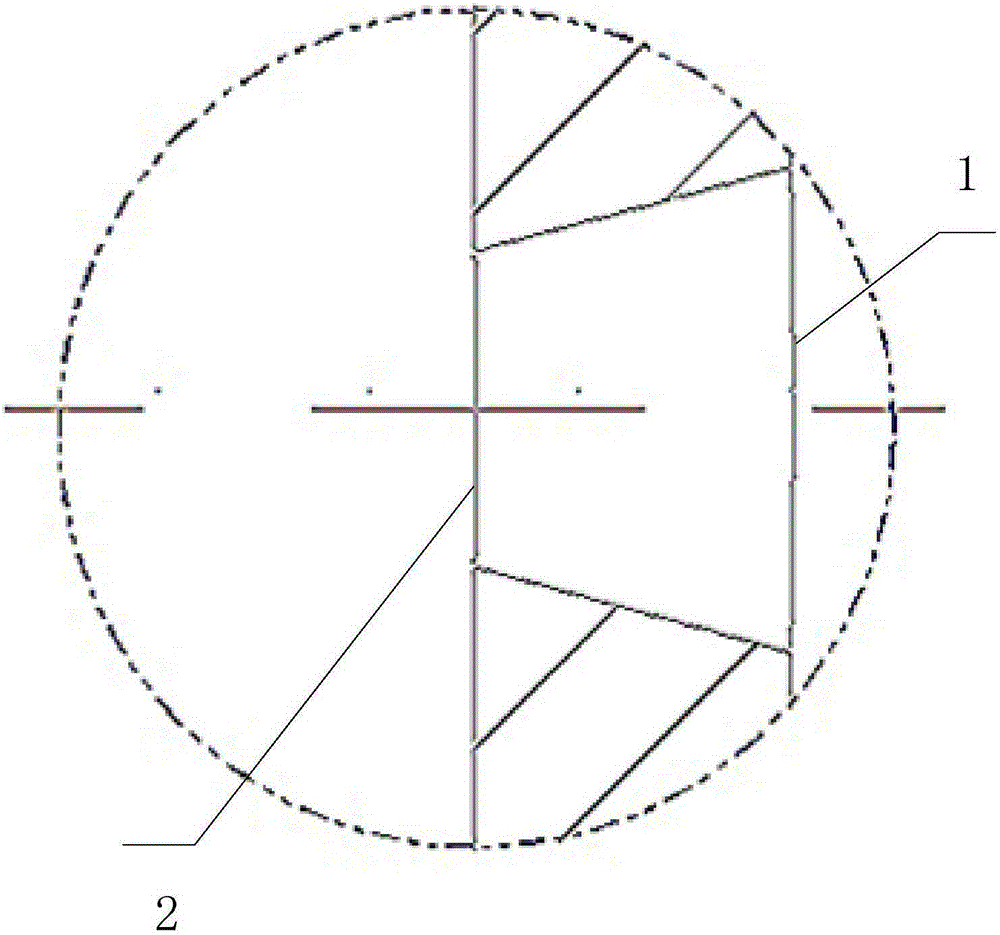

High speed dispersing equipment, slurry, battery pole piece and lithium ion battery

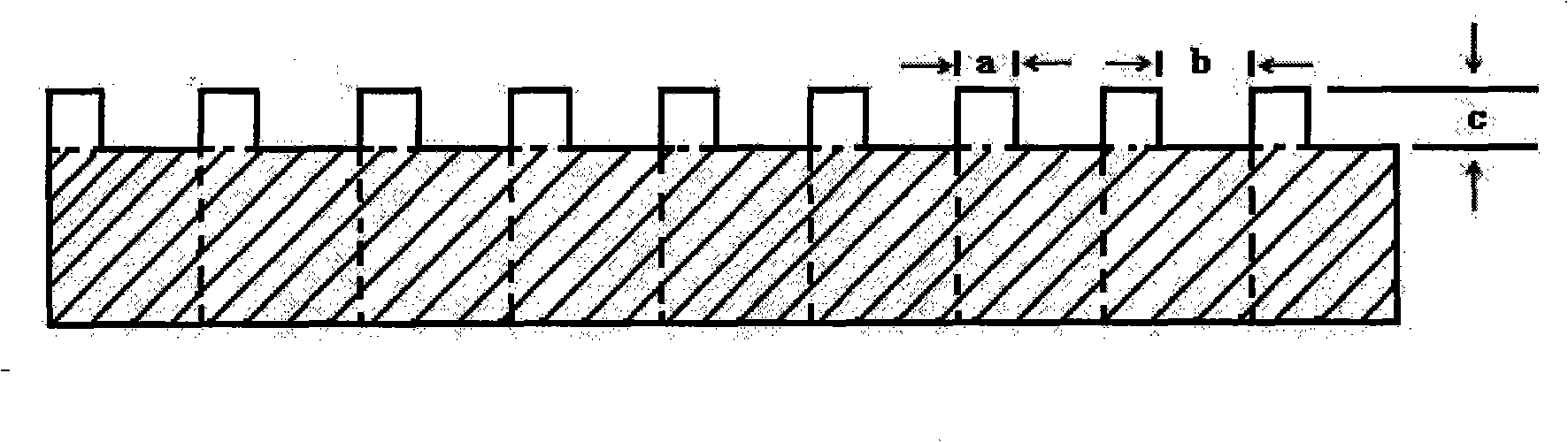

ActiveCN105170002AGood dispersionInhibition of agglomerationRotating receptacle mixersTransportation and packagingElectrical batteryPole piece

The invention belongs to the technical field of slurry preparation and battery preparation, particularly relates to high speed dispersing equipment, slurry, a battery pole piece and a lithium ion battery. The high speed dispersing equipment comprises a dispersing barrel and a dispersing wheel which are coaxially arranged, wherein the dispersing wheel is positioned in the dispersing barrel; the dispersing barrel comprises a side wall provided with a spiral track, and the spiral track is positioned on the inner surface of the side wall; the dispersing wheel comprises a barrel and holes, a plurality of tooth-like bumps are formed on the outer surface of the wall of the barrel, and the holes are of frustum structure and are arranged in the barrel wall. The dispersing capacity of the equipment for the slurry can be effectively improved as a result of the design. Inner substances of the slurry prepared by using the equipment are more uniformly dispersed, so that the agglomeration phenomenon of the active substances is remarkably mitigated. The battery pole piece prepared by using the slurry has smaller impedance, so that the electric property of the lithium ion battery prepared by using the slurry or the electrode pole piece is obviously improved.

Owner:DALIAN CBAK POWER BATTERY CO LTD

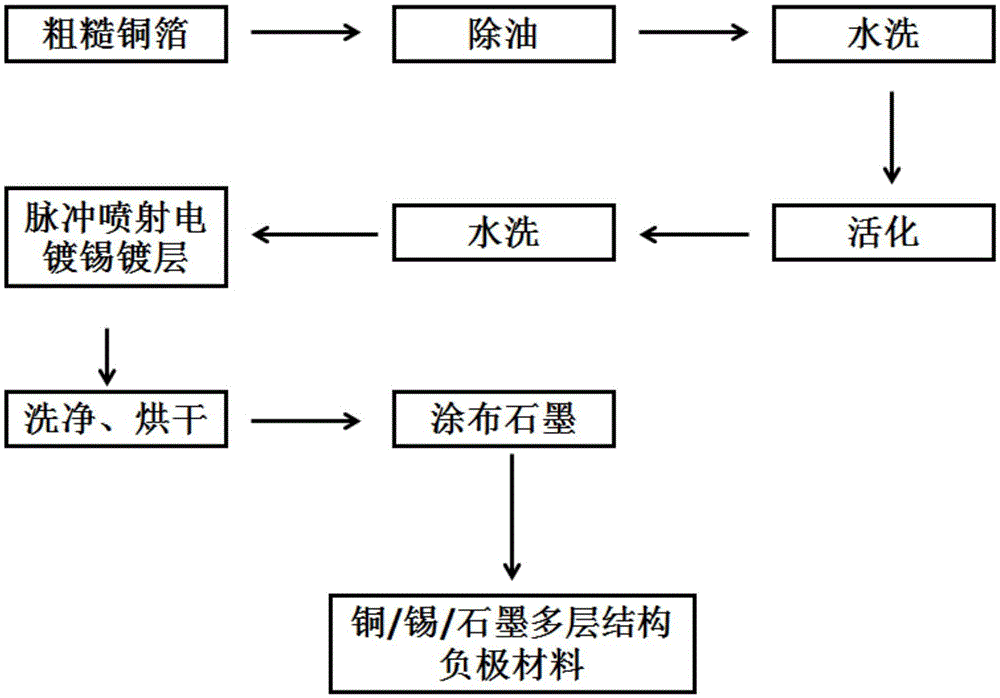

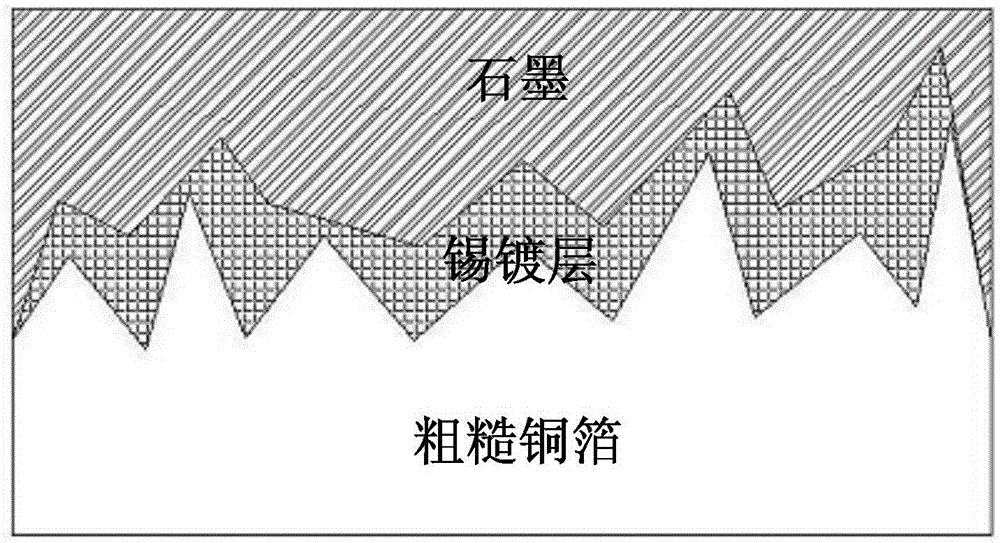

Copper/tin/graphite multi-layer structure anode material for lithium-ion battery and preparation method of copper/tin/graphite multi-layer structure anode material

InactiveCN105470487AImprove bindingIncrease migration rateCell electrodesSecondary cellsElectricityCopper foil

The invention discloses a copper / tin / graphite multi-layer structure anode material for a lithium-ion battery and a preparation method of the copper / tin / graphite multi-layer structure anode material, and belongs to the field of anode materials for lithium-ion batteries. The method comprises the following steps: with coarse copper foil or porous copper foil as a base, sequentially platingone surface with tin and further coating the surface with graphite to obtain a two-layer film structure; and after the copper foil is electrolyzed, unoiled and activated, preparing a tin coating by a pulse jet method, coating the tin coating with a layer of graphite, and carrying out thermal treatment at 80-150 DEG C, so as to prepare the copper / tin / graphite multi-layer structure anode material. Compared with the prior art, the copper / tin / graphite multi-layer structure anode material has better cycle performance than a tin anode material, and a higher specific capacity than a graphite anode material; and meanwhile, the technological process is simple. Therefore, the application prospect is very wide.

Owner:XIANGTAN UNIV

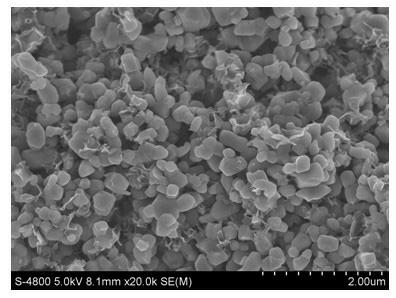

Battery electrode, preparation method thereof and battery

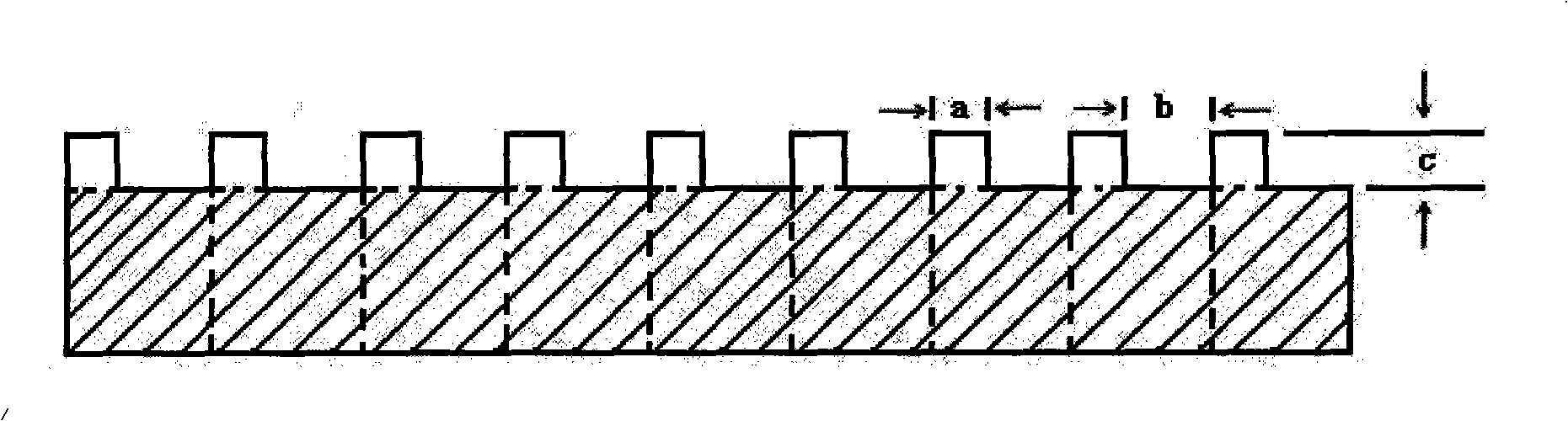

ActiveCN102054979ALower internal resistanceImprove rate charge and discharge performanceElectrode carriers/collectorsLi-accumulatorsMicro nanoPower flow

The invention provides a battery electrode, a preparation method thereof, and a battery. The battery electrode comprises a current collector and an active substance layer coated on the current collector; a micro-nano particle layer is adhered to the surface of the active substance layer; the active substance layer comprises electrode active substance and electrode binder; the micro-nano particle layer comprises micro-nano dry powder particles; and the micro-nano dry powder particles comprise dry powder particles of the micro-nano electrode active substance. Interface impedance between the electrode and electrolyte is reduced and rate discharge performance of the battery is improved; a micro-nano active material reduces serious volume effect of the material; and specifically, the micro-nano particle layer may not comprise the binder preferably, so that the large-current discharge characteristic of the battery is improved further. The method is simple and is easy to implement; and the combinability between the micro-nano particle layer and the active substance layer is high, and the surface of the active substance layer is not polluted by the substances of an upper layer.

Owner:SHANGHAI BYD

Method for improving electrochemical performance of nickel-cobalt lithium manganate by chemically reducing oxidized graphene/magnesium

ActiveCN105489884AImprove performanceImprove rate charge and discharge performanceCell electrodesSecondary cellsMagnesium saltCharge discharge

The invention relates to a method for improving electrochemical performance of nickel-cobalt lithium manganate by chemically reducing oxidized graphene / magnesium. The method includes the steps that oxidized graphene and soluble magnesium salt are mixed and dissolved in water to form a treatment solution, nickel-cobalt lithium manganate powder is added, and a conducting composite layer of magnesium ions and the oxidized graphene reduced chemically is formed on the surface of the nickel-cobalt lithium manganate powder through one-time dispersion operation by using combination of the magnesium ions and the functional group on the oxidized graphene. Reaction conditions of the method are mild, the operation process and technology are simple, it is unnecessary to add organic solvent, a surfactant, a reducing agent and an oxidizing agent in the formation process of the composite layer, and production cost is low. Due to formation of the conducting composite layer, the rate charge-discharge performance of nickel-cobalt lithium manganate can be improved obviously.

Owner:SHANGHAI JIAO TONG UNIV

Lithium ion power battery and preparation method thereof

ActiveCN101409371AImprove cycle performanceImprove high rate charge and discharge performanceElectrode manufacturing processesFinal product manufactureFiberMixed materials

The invention discloses a lithium ion power battery which comprises an anode and a cathode; the anode thereof is mixed material of LiFePO4, nanometer carbon fiber and caking agent which are mixed with Mn and La cations as well as F anions and the surface of the mixed material is coated and modified by carbon. The preparation method thereof is as follows: after the LiFePO4, the nanometer carbon fiber and the water-soluble caking agent which are mixed with elements and the surfaces of which are coated and modified by carbon are added into de-ionized water and uniformly stirred, the mixture is coated on an aluminum foil with a single side not coated; then the mixture is dried and continuously rolled and pressed; then continuous rolling and cutting are carried out on the part of the aluminum foil that is not coated for forming a squaring current collecting body provided with a single-side current collecting body and manufacturing an anode plate; then the anode plate is coiled and assembled with a spacing membrane and a cathode provided with the squaring current collecting body; an electrolyte is injected for manufacturing the battery. The lithium ion power battery has the advantages of excellent high magnification discharging performances, stable circulating performances, long service life and good safety. The lithium ion power battery can be applied to the traffic tools like hybrid electric vehicles, electric tools, electric toys, and the like.

Owner:ZHEJIANG GBS GREEN ENERGY CO +1

Electrode plate and application thereof

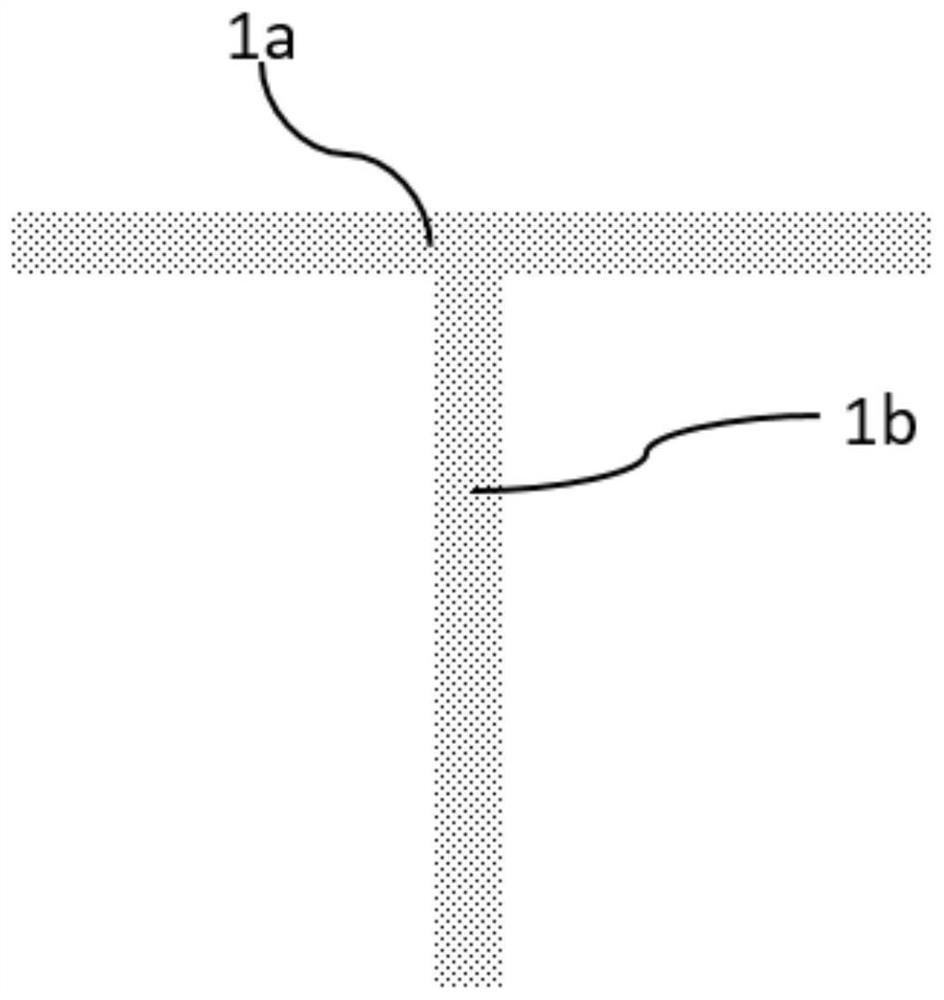

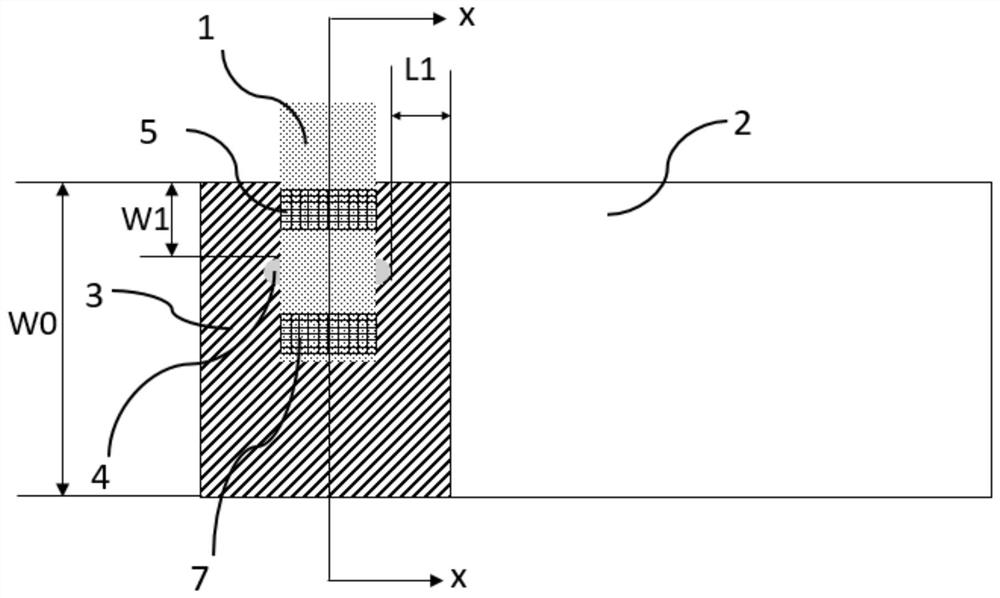

PendingCN113285055AAvoid crackingImprove mass energy densityFinal product manufactureElectrode carriers/collectorsEngineeringLithium-ion battery

The invention provides an electrode plate and an application thereof. A first functional surface of a current collector in the electrode plate comprises a first active layer area and a first tab area, and a second functional surface of the current collector comprises a second active layer area opposite to the first active layer area and a second tab area opposite to the first tab area. The active layer is arranged in the first active layer area and / or the second active layer area; n through holes penetrating to the second tab area are formed in the first tab area, a T-shaped tab passes through the through holes, one end of a first section of the T-shaped tab is connected with the first tab area to form a first connecting area, and the other end of the first section of the T-shaped tab is connected with the first tab area to form a second connecting area; the second section of the T-shaped tab is connected with the second tab area to form a third connecting area, and N is greater than or equal to 1; and the current collector comprises a first conductive layer, an insulating layer and a second conductive layer which are stacked. The lithium ion battery prepared from the electrode plate has relatively high mass energy density and safety performance.

Owner:ZHUHAI COSMX BATTERY CO LTD

Nitrogen-doped carbon nanotube/rare earth metal ion-doped lithium iron phosphate composite cathode material and preparation method thereof

PendingCN112607725ALarge specific surface areaImprove hydrophilicityCarbon compoundsCell electrodesElectrical batteryLithium hydroxide

The invention discloses a nitrogen-doped carbon nanotube / rare earth metal ion-doped lithium iron phosphate composite positive electrode material and a preparation method thereof, and is applied to the field of lithium ion batteries. The preparation method of the material comprises the following steps: mixing hydrazine hydrate and carbon nanotubes, and then carrying out reflux, suction filtration and freeze drying to prepare nitrogen-doped carbon nanotubes; preparing rare earth metal ion doped lithium iron phosphate by taking lithium hydroxide, ferric phosphate, oxalic acid, glucose and rare earth metal oxide as raw materials; and finally, adding the nitrogen-doped carbon nanotube and the rare earth metal ion-doped lithium iron phosphate into dispersion liquid for dispersion, and performing ball milling to obtain a final product. Compared with the traditional lithium iron phosphate, the nitrogen-doped carbon nanotube / rare earth metal ion-doped lithium iron phosphate composite positive electrode material prepared by the method has excellent rate charge-discharge performance.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY CO LTD CO LTD

Hard carbon composite material, as well as preparation method and application thereof

InactiveCN113422052AImprove the first Coulombic efficiencyImprove cycle performanceCell electrodesCarbon compositesLithium-ion battery

The invention provides a hard carbon composite material as well as a preparation method and application thereof. The hard carbon composite material comprises a hard carbon core, a pre-lithiation layer and a coating layer, wherein at least part of the surface of the hard carbon inner core is coated with the pre-lithiation layer, at least part of the surface of the pre-lithiation layer is coated with the coating layer, and the coating layer at least comprises a carbon material. The hard carbon composite material can improve the cycle performance and the first coulombic efficiency of the lithium ion battery.

Owner:KUNSHAN BAOTRON NEW ENERGY TECH CO LTD

Lithium ion battery cathode material of anatase TiO2 mixed carbon nanotube

ActiveCN104795553AImprove conductivityImprove mechanical propertiesCell electrodesSecondary cellsDischarge efficiencyCarbon nanotube

The invention discloses a lithium ion battery cathode material of an anatase TiO2 mixed carbon nanotube. The lithium ion battery cathode material is prepared from the following raw materials in parts by weight: 360-390 parts of anatase TiO2, 50-60 parts of carbon nanotubes, 45-55 parts of graphite, 6-8 parts of gallium powder, 4-6 parts of caesium powder, 4-6 parts of lithium cobalt oxide, 2-4 parts of cerium oxide and 2-3 parts of ammonium persulfate. With the combination of anatase TiO2 and the carbon nanotubes, and due to the adoption of the formula disclosed by the invention, the lithium ion battery cathode material of the anatase TiO2 mixed carbon nanotube replaces the conventional cathode material, namely titanium dioxide (B), the conductivity and the mechanical property are greatly improved, and due to the improvement of the conductivity and the mechanical property, the circulation property, the multiplying power charge / discharge property and the first charge / discharge efficiency of the lithium ion battery cathode material are further improved, and in addition, the preparation method is simple in process, relatively low in production cost, and simple and feasible in preparation process.

Owner:SHENZHEN XIANGFENGHUA TECH CO LTD

Lithium ion battery negative plate, preparation method thereof and lithium ion battery

ActiveCN110828779AHigh affinityFacilitate conductionCell electrodesFinal product manufactureElectrolytic agentButadiene-styrene rubber

The invention belongs to the technical field of lithium ion batteries, and particularly relates to a lithium ion battery negative plate. The lithium ion battery negative plate comprises a negative current collector and a negative active material layer coated on the surface of the negative current collector. The negative active material layer comprises a negative active material, a conductive agent, a dispersing agent, a binding agent and a thickening agent. The dispersing agent, the binding agent and the thickening agent are acrylic polymers of which the relative molecular masses are sequentially increased respectively. According to the invention, the dispersing agent sodium carboxymethyl cellulose, the binding agent styrene butadiene rubber and the thickening agent sodium carboxymethyl cellulose are changed into acrylic polymers with sequentially increased relative molecular mass respectively; the affinity of the negative active material layer to an electrolyte is improved, which facilitates the conduction of metal ions, and promotes the transmission of lithium ions in an electrode-electrolyte interface; the rate charge-discharge performance of the lithium ion battery is improved;besides, under a low-temperature condition, the acrylic polymers can accelerate the transmission of lithium ions by improving the affinity to the electrolyte; and the low-temperature performance of the lithium ion battery is improved.

Owner:东莞维科电池有限公司 +1

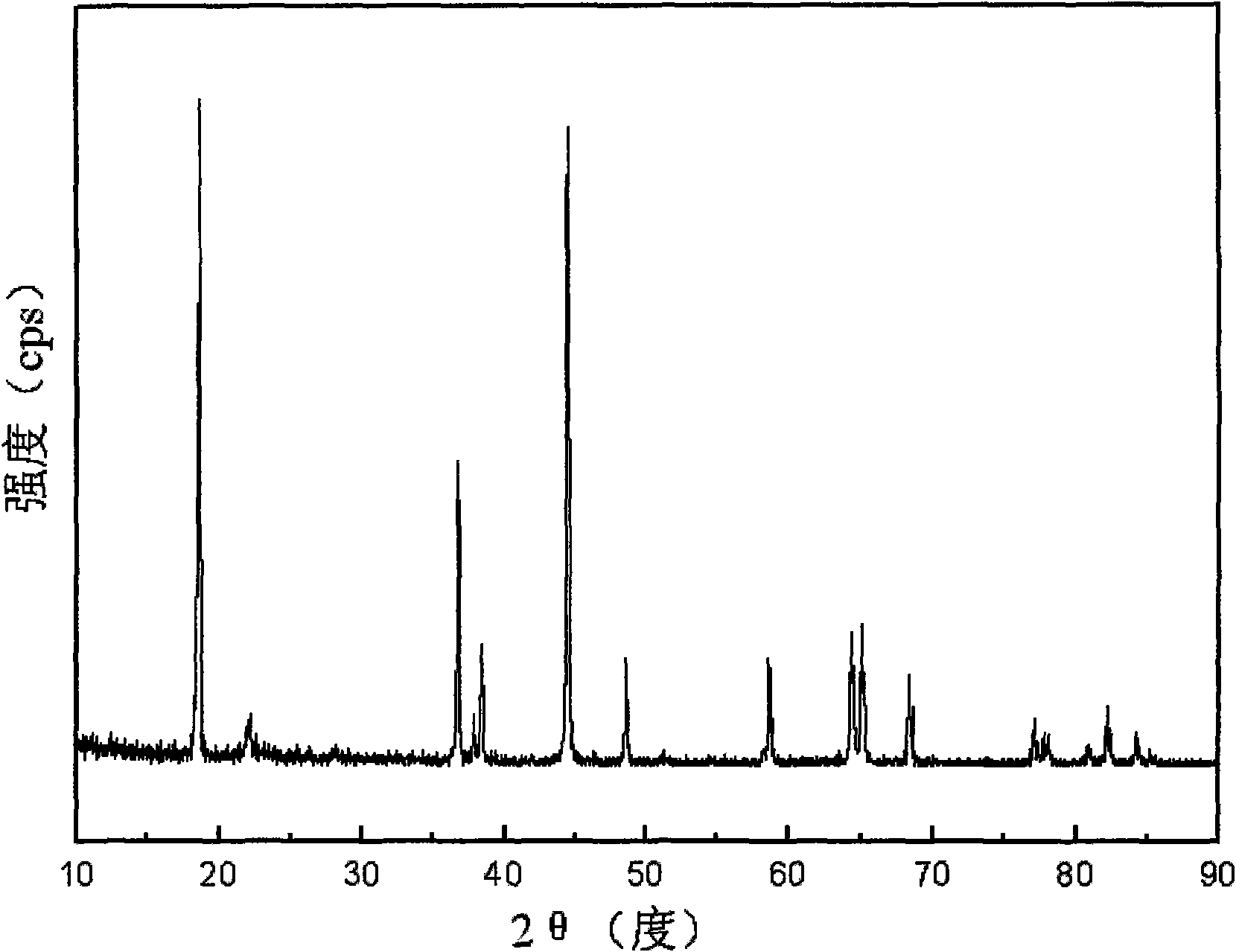

Method for preparing carbon modified lithium ion battery Li4Ti5O12 cathode material in one step

InactiveCN103779551AReduce energy consumptionImprove controllabilityAlkali titanatesCell electrodesMetallic lithiumHigh rate

The invention relates to a method for preparing a carbon modified lithium ion battery Li4Ti5O12 cathode material in one step, belonging to the technical field of manufacturing processes of chemical electrode materials. According to the method for preparing the carbon modified lithium ion battery Li4Ti5O12 cathode material in one step, a soluble metallic titanium salt and a soluble metallic lithium salt are selected as raw materials, and a carbon source is added to a precursor solution directly, so that carbon is introduced in the process of forming an LTO precursor; the purpose of modifying the rate performance of the Li4Ti5O12 cathode material is achieved through subsequent heat treatment. The carbon modified lithium ion battery Li4Ti5O12 cathode material prepared by using the method has excellent electrochemical performance. Meanwhile, the conductivity of the material is enhanced due to the introduction of the carbon; the carbon modified lithium ion battery Li4Ti5O12 cathode material has high rate charging / discharging performance.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY +1

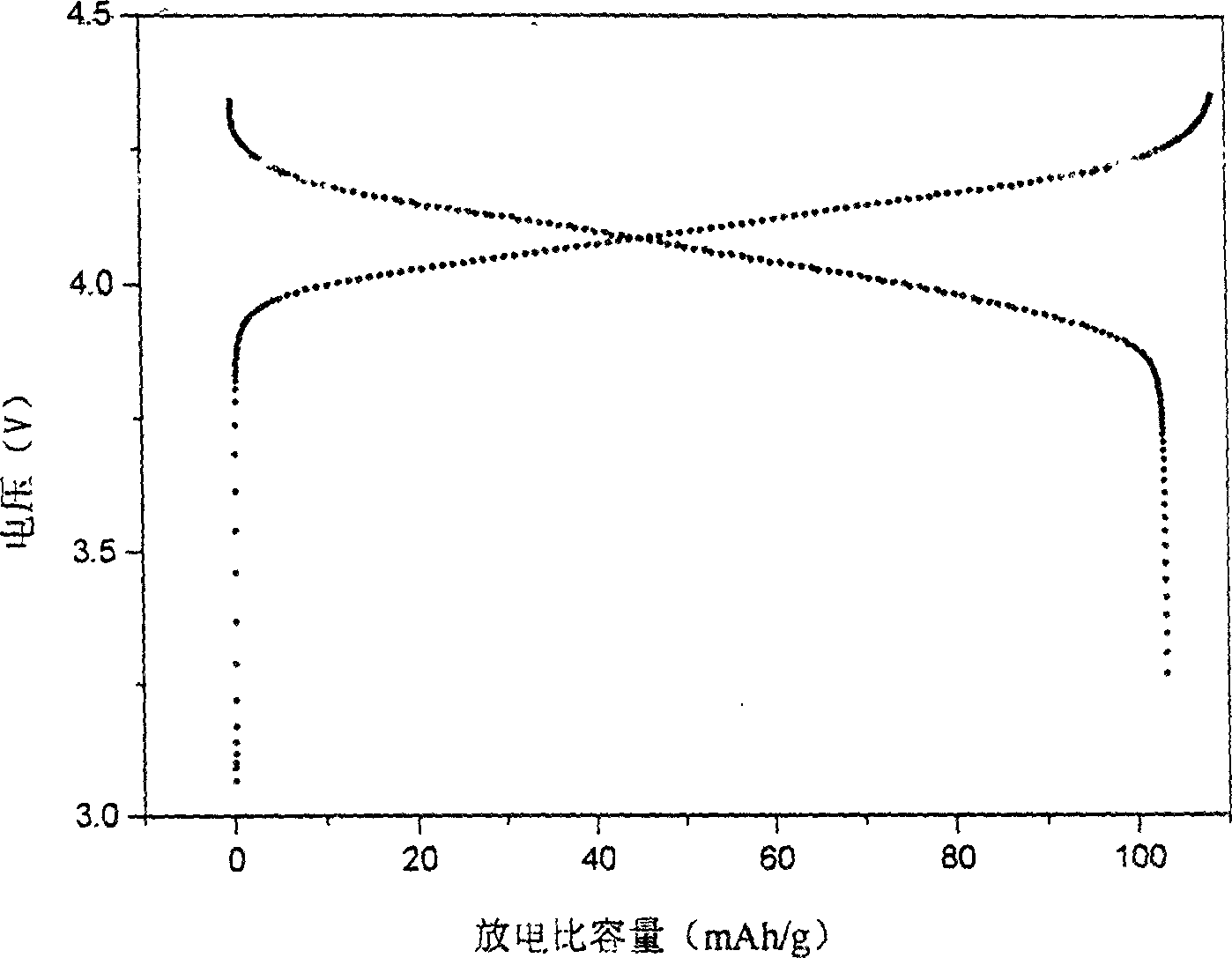

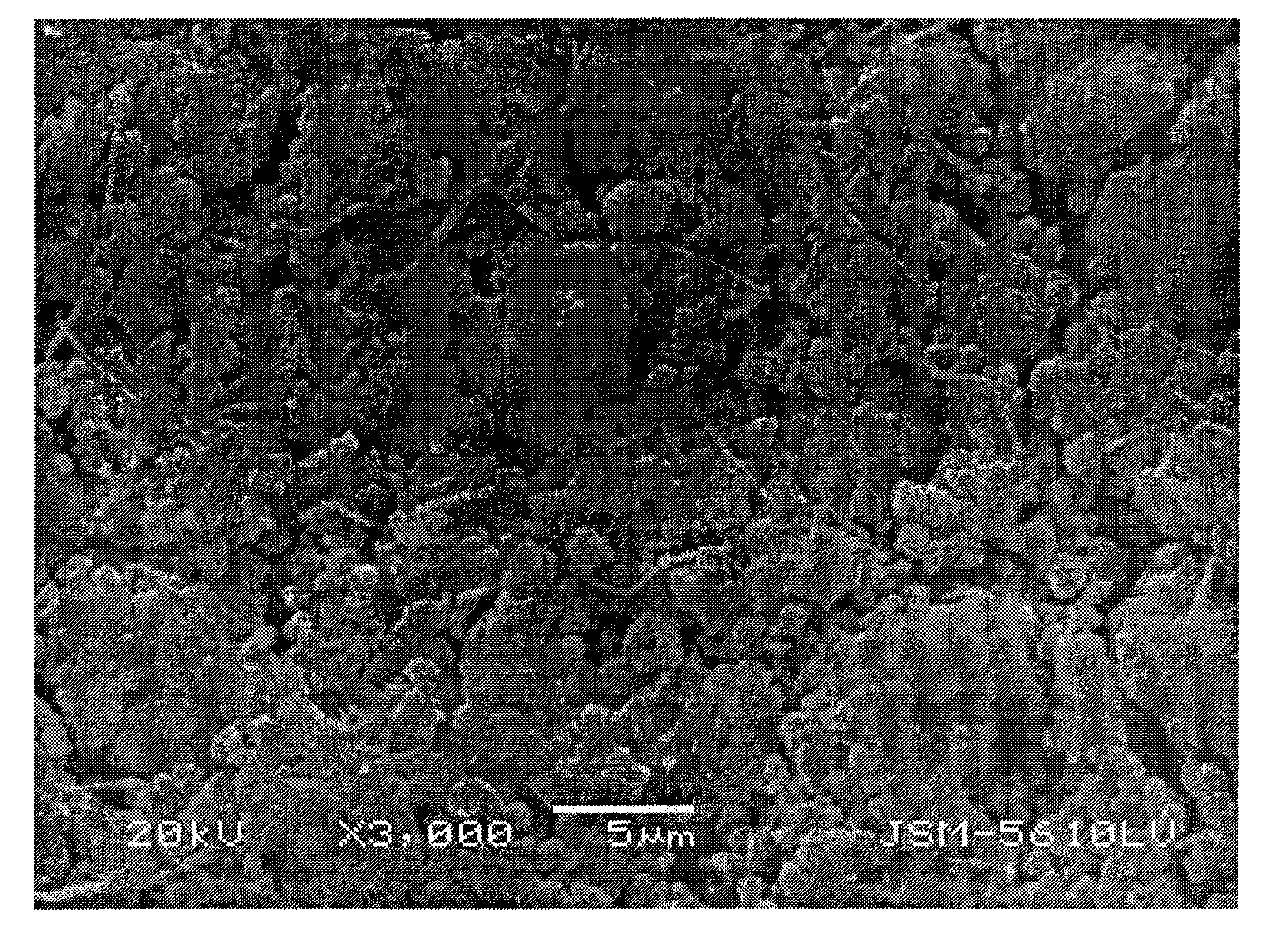

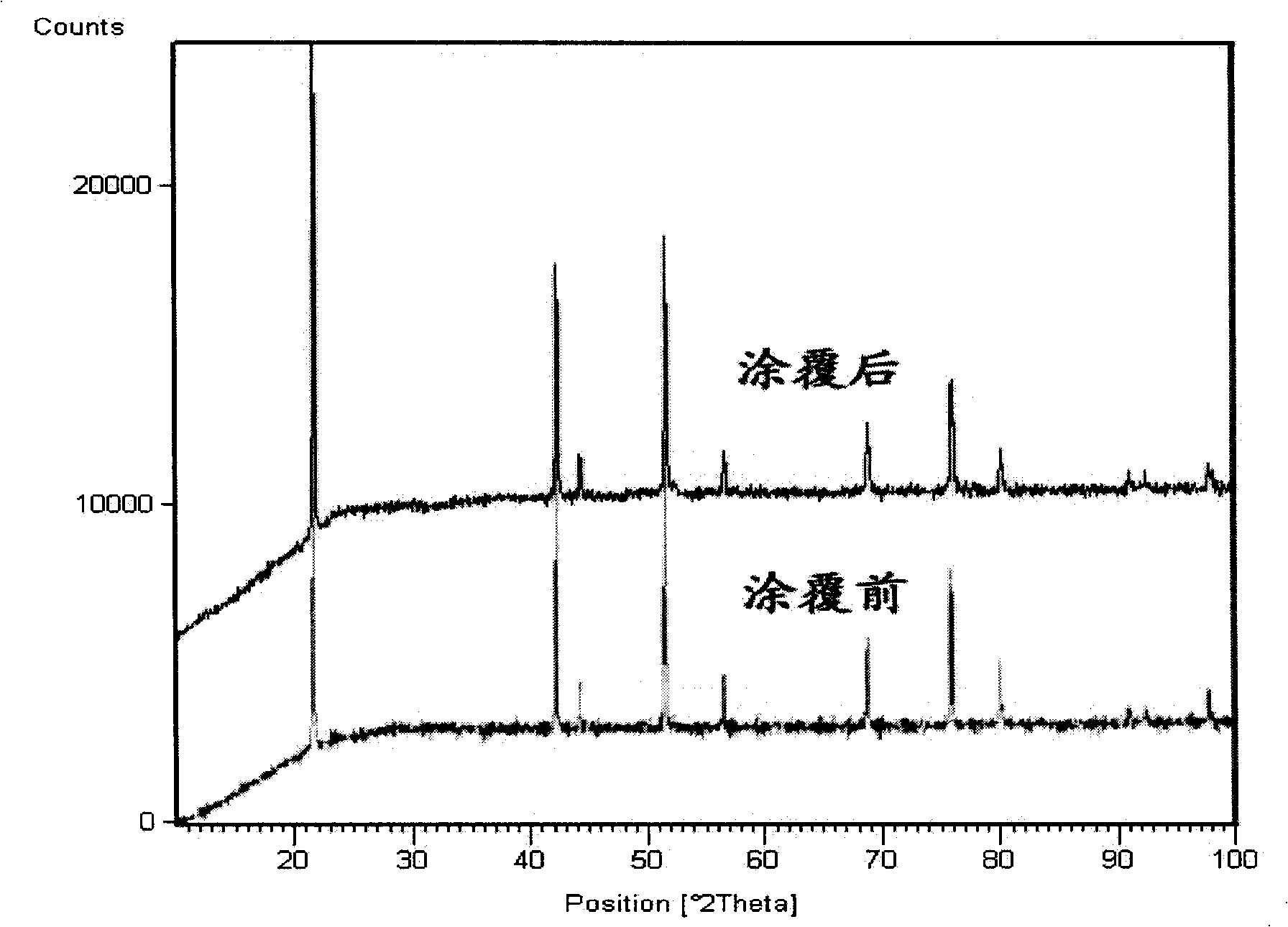

Complex Li-Mn-oxide, manufacture method and battery made of this material

ActiveCN101060173BImprove rate charge and discharge performanceEasy to prepareElectrode manufacturing processesSecondary cellsPhosphateCharge discharge

The present invention discloses a Li-Mn composite oxide for positive of secondary Li cell comprising the core LiaMn2-bXbO4 and a coating layer, wherein 0.97<=a<=1.06; 0 <=b<=0.5; X is a metallic element except Li and Mn or a nonmetallic element Si; the coating layer comprises one of more of Li-B composite oxide, Li-Co oxide, Li-V oxide, Al oxide, Al phosphate, Ti oxide, Cr. Oxide, Mg oxide, and Ca oxide. The Li-Mn composite oxide for positive of secondary Li cell provided by the present invention improves multiplying power charge-discharge performance of the material and reduces salvation of Mn<3+> in the electrolyte in the material and improves circulation, specially the multiplying power circulation performance at high temperature.

Owner:SHENZHEN BAK POWER BATTERY CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com