Inorganic doped/coated modification natural graphite, as well as preparation method and application thereof

A natural graphite and inorganic technology, applied in the field of inorganic doping/coating modified natural graphite, can solve the problems such as cycle performance can not meet market demand, high heat treatment graphitization temperature, difficult to achieve uniform coating, etc. The effect of improving high current charge and discharge performance, wide source of raw materials, and improving rate charge and discharge performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

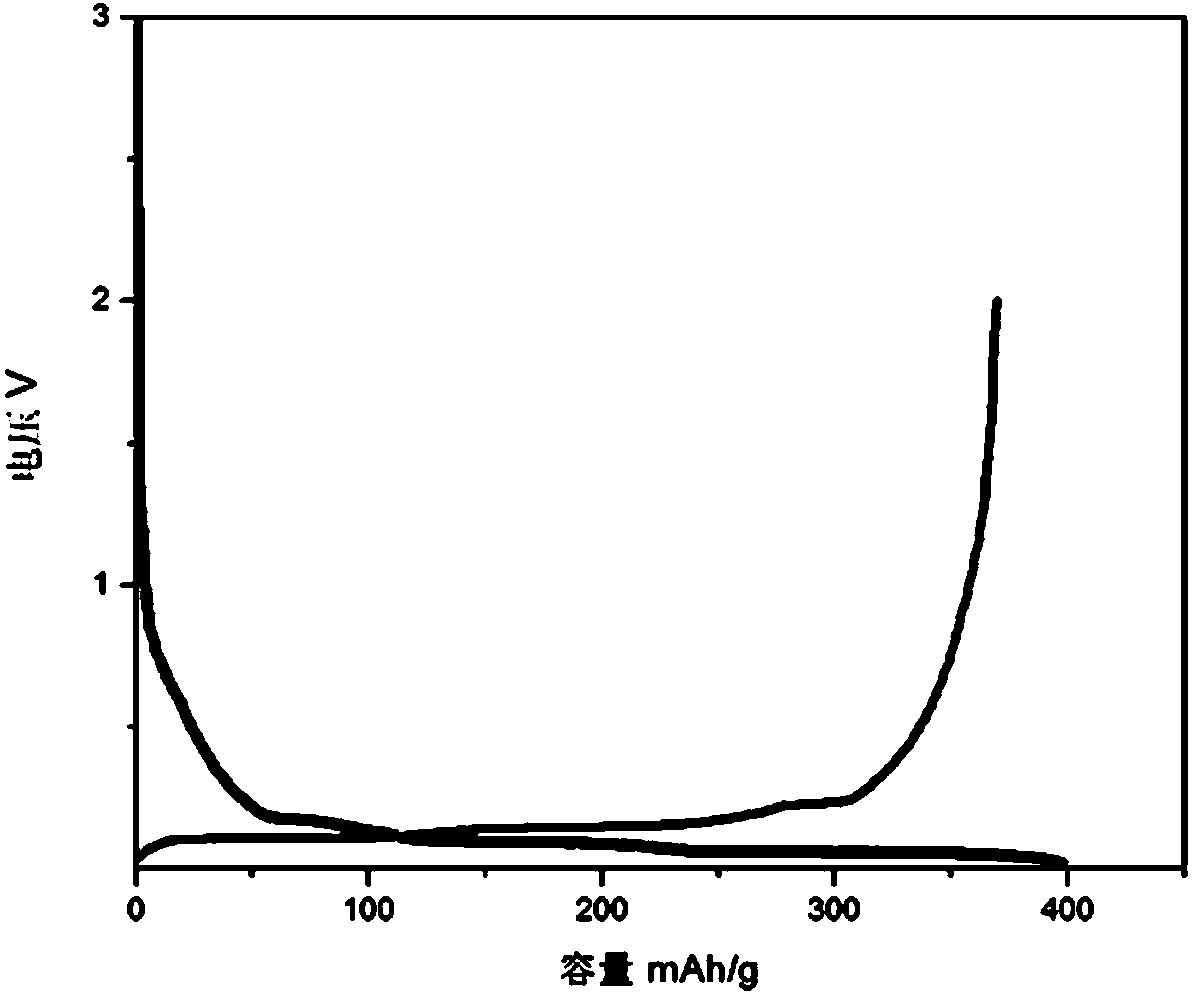

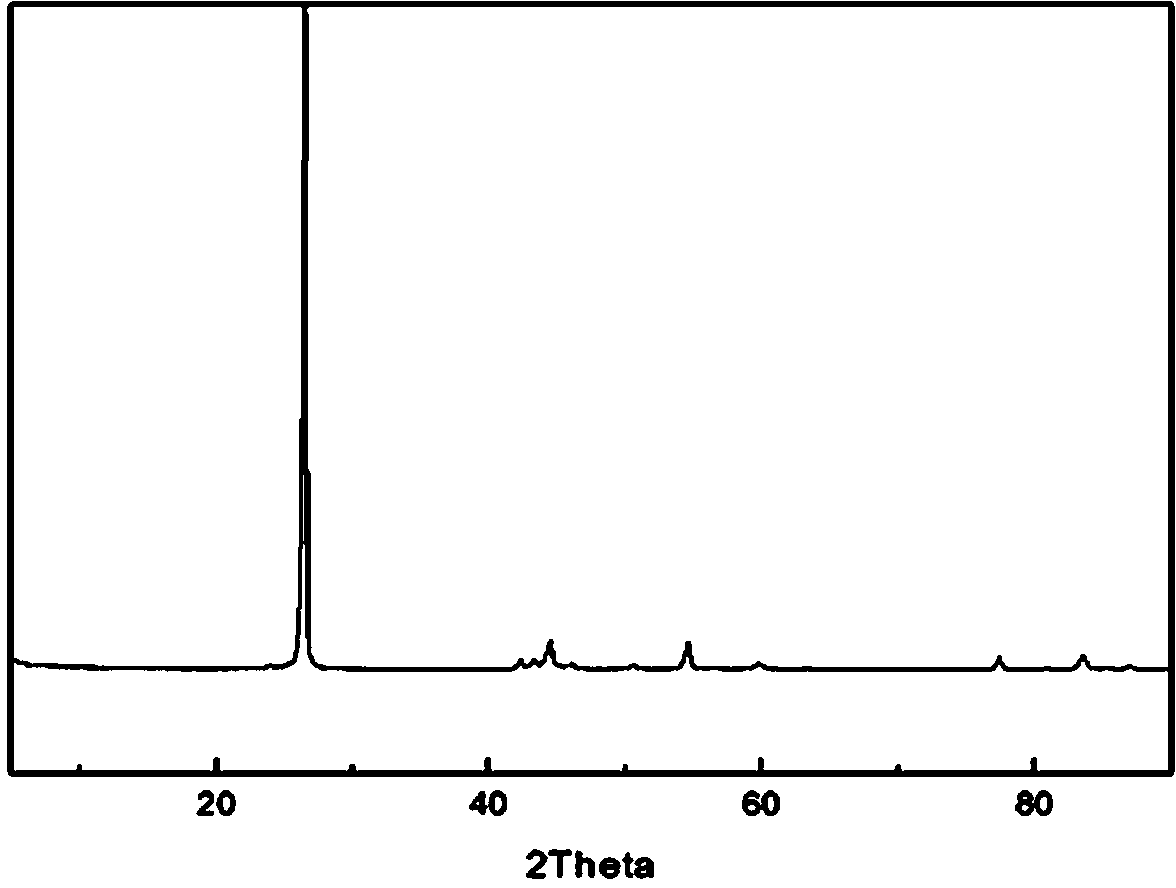

Embodiment 1

[0037] The modified natural graphite material for lithium-ion batteries in this example uses concentrated phosphoric acid and glacial acetic acid to react hydrothermally in a 100°C reactor for 10 hours, and then conducts a high-temperature treatment on the graphite obtained by the reaction, and simultaneously feeds nitrogen-containing organic matter, A nitrogen coating layer is formed on the graphite surface.

[0038] Take 12g of natural graphite and oxidize it with 1.2g of 85wt% concentrated phosphoric acid and 10ml of glacial acetic acid at 100°C for 10 hours. (Glacial acetic acid is used as an oxidizing acid, and concentrated phosphoric acid is used as both a dopant and an oxidizing acid).

[0039] After cooling naturally, the samples were dried in an oven.

[0040] The dried sample was put into a tube furnace with nitrogen, and 30ml of diethylamine was introduced at the same time, the temperature was raised to 1000°C at 16°C / min, kept for 2 hours, and naturally cooled to ...

Embodiment 2

[0046] In this example, the amount of phosphoric acid added was 2.4 g, the hydrothermal reaction was carried out at 90° C. for 12 hours, and the high temperature treatment holding time was 12 hours. Other processes and conditions were consistent with those in Example 1. The average particle diameter D of the modified graphite obtained in the present embodiment 50 -Basically consistent with Example 1. The discharge current density in the first cycle of 0.1C charge and discharge is 36mA / g, the first charge gram capacity is 406.1mAh / g, the first discharge gram capacity is 462.2mAh / g, and the first coulombic efficiency is 87.9%. At a current density of 5C, the charging capacity is 324.8 mAh / g, and the capacity retention rate is 80.0%.

Embodiment 3

[0048] In this embodiment, glacial acetic acid is used as the oxidizing acid, and the dopant added is red phosphorus in an amount of 2.4 g, and the hydrothermal reaction is carried out at 180° C. for 0.5 hours. Other than that, other processes and conditions were consistent with Example 1. The average particle diameter D of the modified graphite obtained in the present embodiment 50 -Basically consistent with Example 1. The discharge current density in the first cycle of 0.1C charge and discharge is 36mA / g, the first charge gram capacity is 335.6mAh / g, the first discharge gram capacity is 378.0mAh / g, and the first coulombic efficiency is 88.8%. At a current density of 5C, the charging capacity is 285.3mAh / g, and the capacity retention rate is 85.0%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com