Patents

Literature

3593 results about "Prepared Material" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The amount of material produced by an activity.

Information display

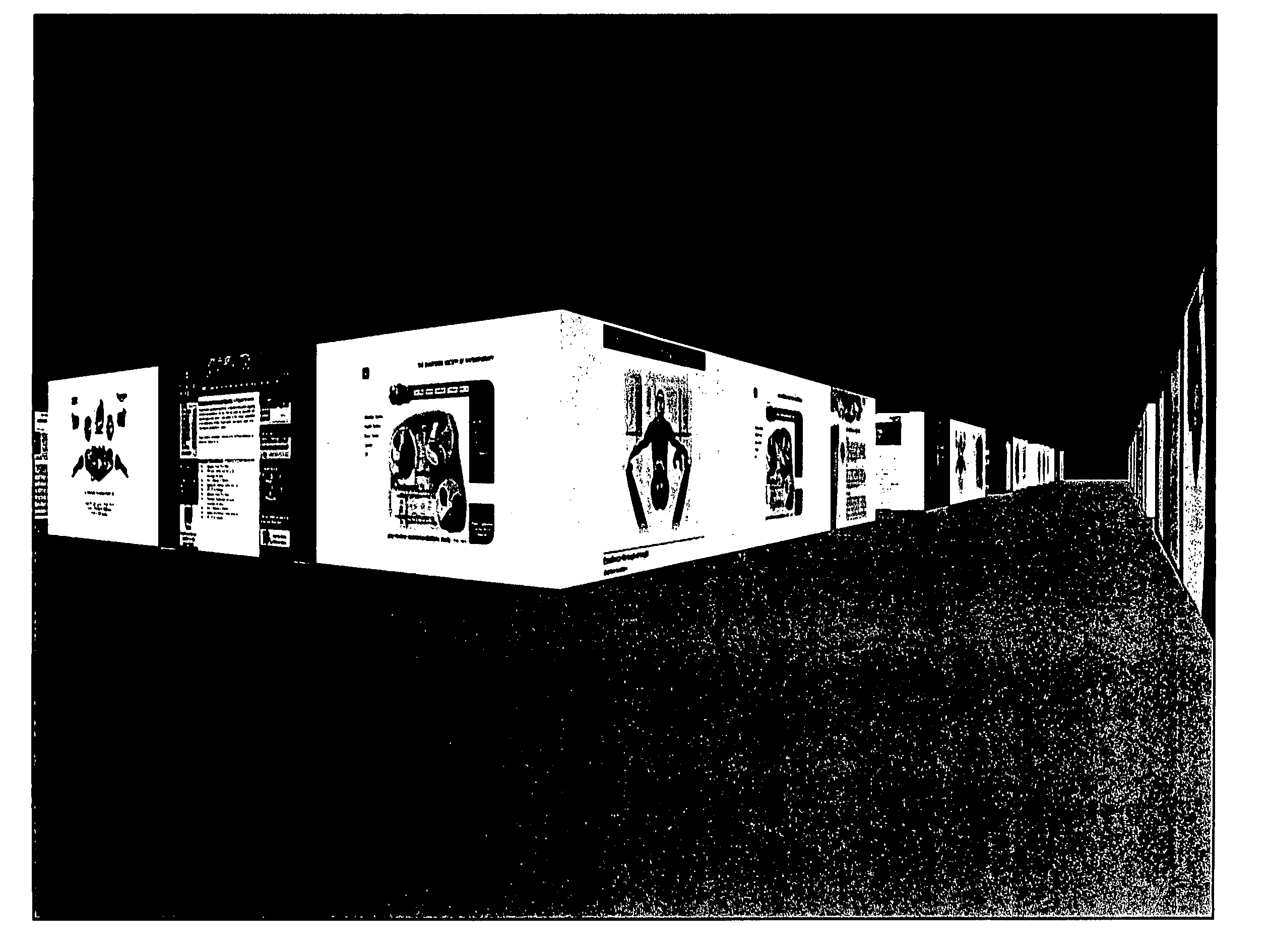

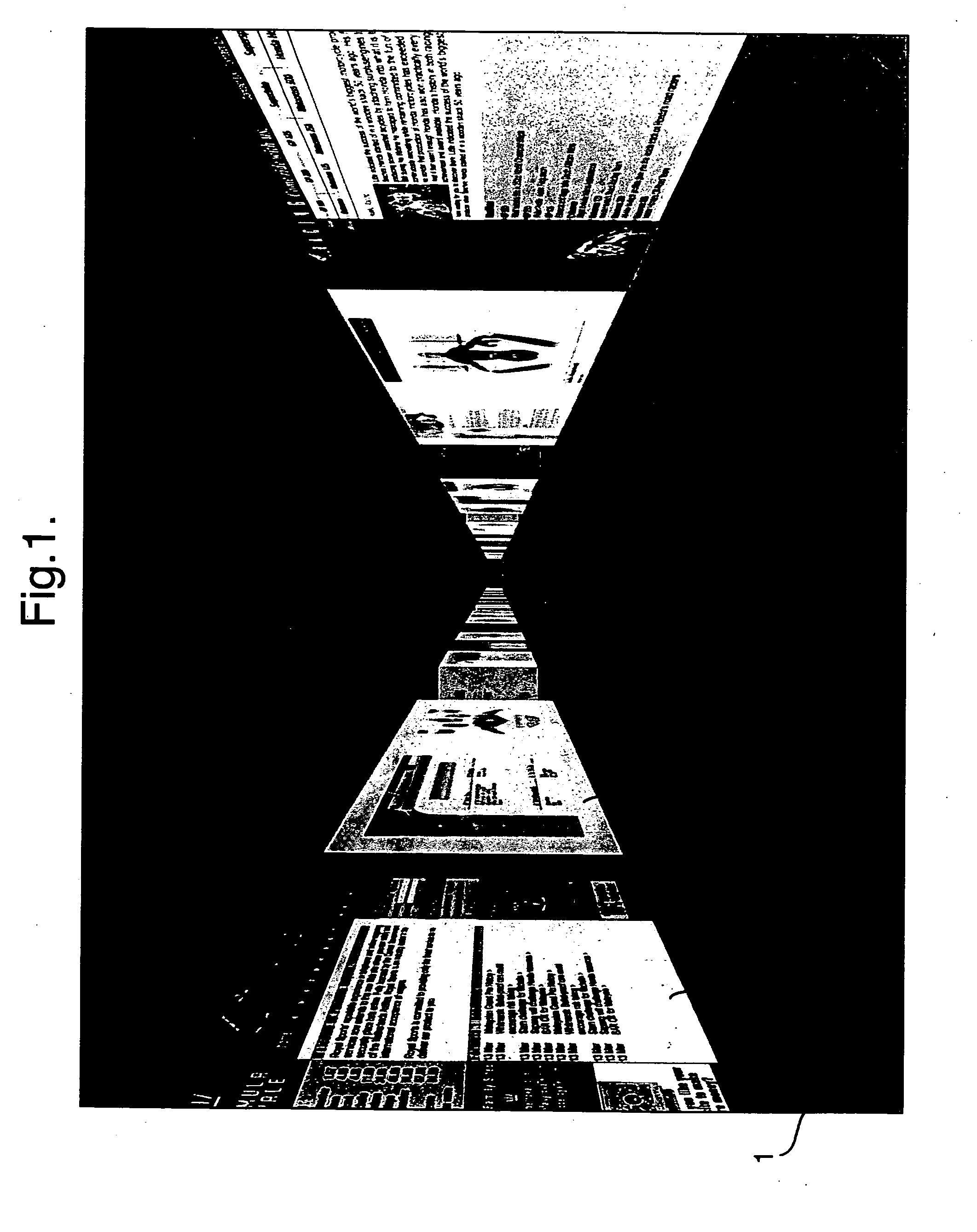

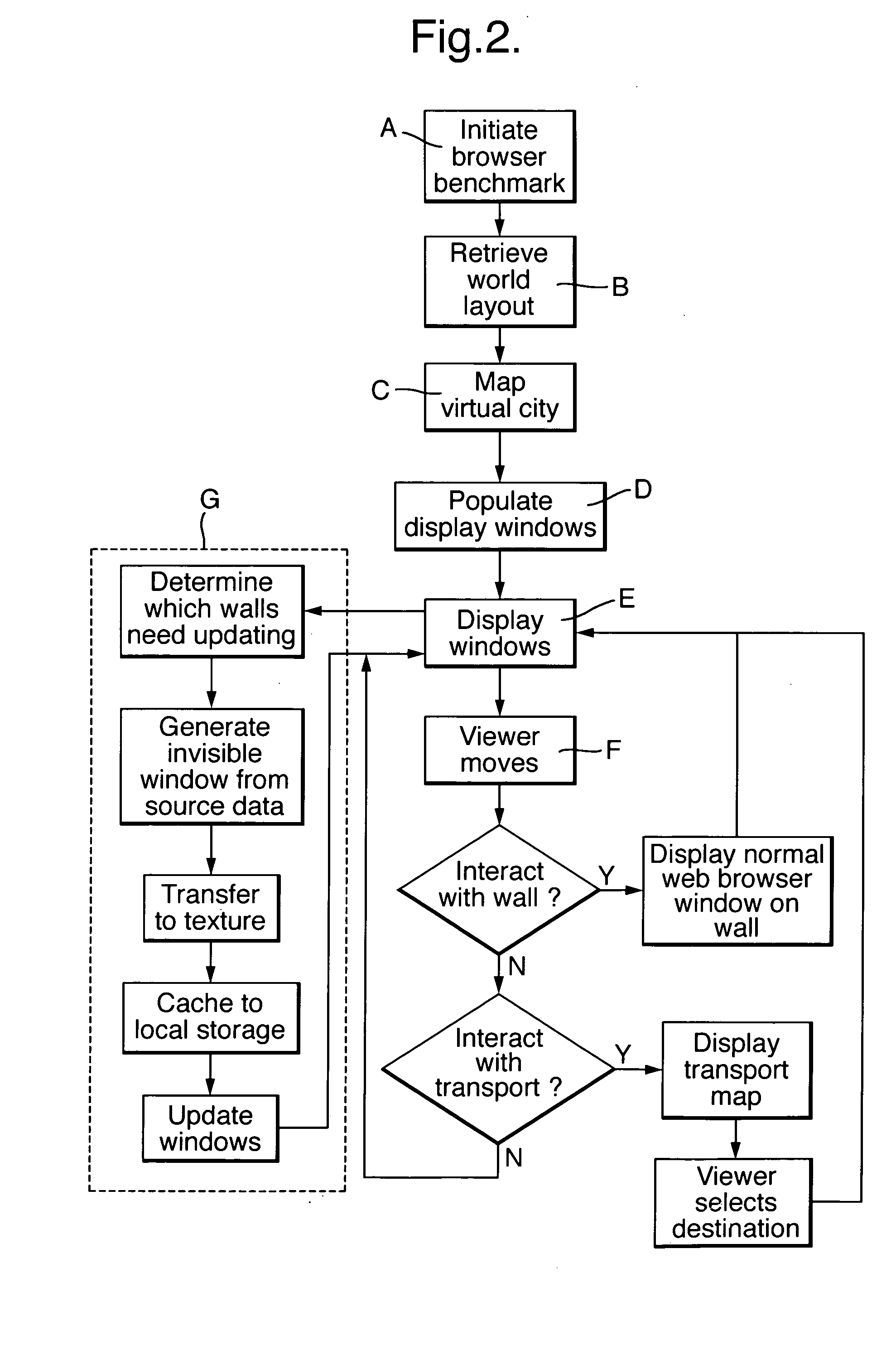

InactiveUS20050022139A1Precise positioningCathode-ray tube indicatorsWeb data navigationComputer graphics (images)Virtual space

A method for organizing and presenting material content on a display to a viewer, the method comprising: mapping a plurality of display windows within a virtual three-dimensional space so that each display window is allocated a specific and predetermined position in the space, rendering each display window in three-dimensional perspective according to its position and angle relative to a viewer's virtual position in the virtual space, cross-referencing the position of each display window to a storage location of the material content that is designated to be rendered in that particular display window at a particular time based on at least one predetermined condition, allocating at least part of the three-dimensional virtual space to display windows whose content is not chosen or determined by the viewer, selecting, retrieving and preparing material content for possible subsequent display according to a predetermined algorithm, selecting and rendering prepared material content within its cross-referenced display window according to a predetermined algorithm, providing a means of virtual navigation that changes the viewer's position in the space in such a manner as to simulate movement through a plurality of predefined channels in the virtual space.

Owner:THREE B INT

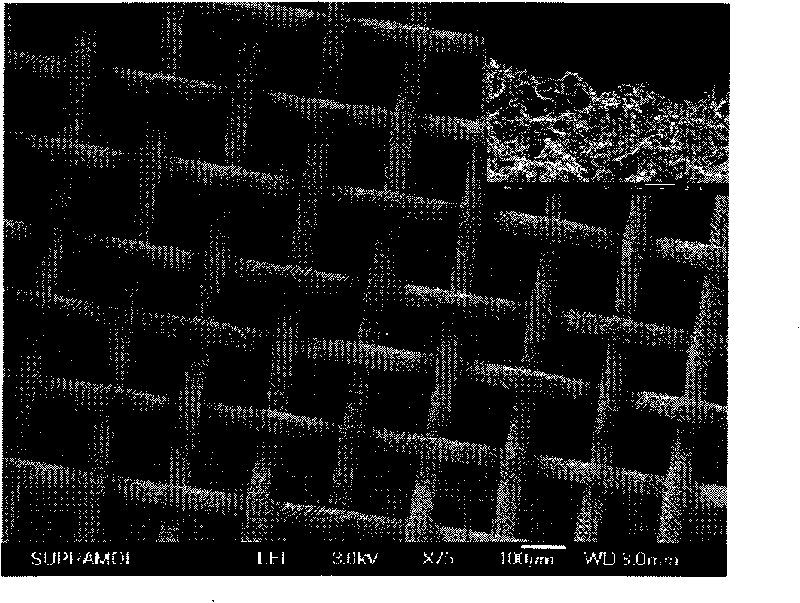

Method for preparing metal mesh for oil-water separation

InactiveCN101708384AAchieve the purpose of separationAcid resistantFiltration separationLiquid separationChemical industryNanoscopic scale

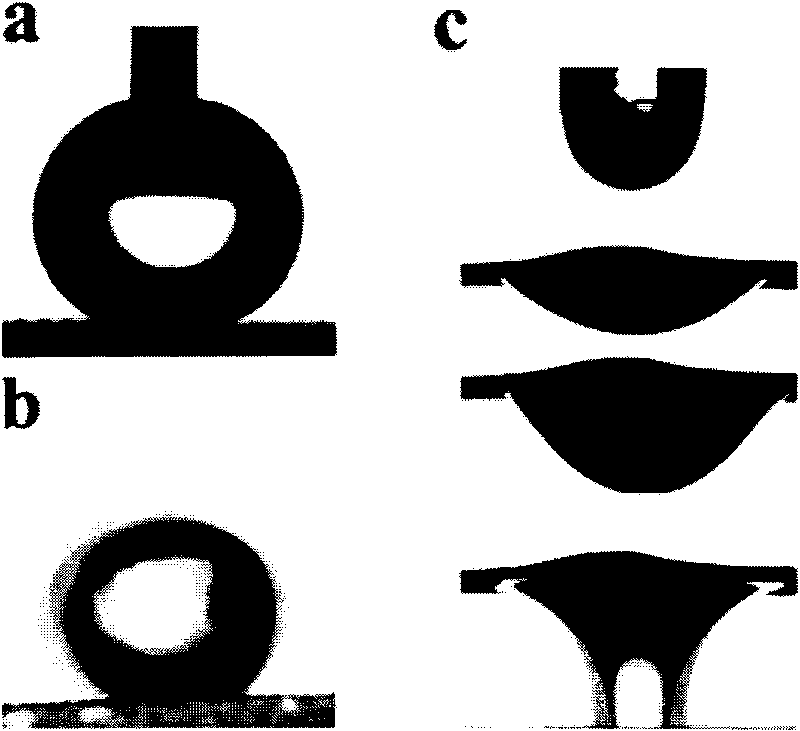

The invention belongs to the technical field of chemistry and chemical industry and functional materials, and relates to a method for preparing a metal mesh which has special wetting properties and is used for oil-water separation. The method adopts simple wet-method chemical etching technology, nano-scale microscopic bulges are prepared on the surface of a metal mesh with micron-grade pore diameters, and then a compound which does not contain fluorine and has low surface energy is modified on the surfaces of the microscopic bulges. For the surface of the prepared material, a contact angle of a water drop is more than 150 degrees, and a contact angle of oil is close to 0 degree. Due to the specific wetting properties, the material can allow the oil to pass through the metal mesh smoothly, but the water cannot permeate through the metal mesh completely, so that the property of effectively separating oil-water mixtures is realized. Particularly, the specific wetting properties of the surface of the material can keep stable in acid solution, alkali solution and salt solution, and thus the functional metal mesh can be excellently applied in aspects of metal corrosion prevention and the like. A mesh membrane does not contain the fluorine, and has the advantages of simple preparation method, high permeability of pore space and good oil-water separation effect, and corrosion resistance.

Owner:JILIN UNIV

Highly heat-conducting insulation engineering plastic and preparation method thereof

InactiveCN102174254AIncrease China UnicomImprove thermal conductivityPlastic/resin/waxes insulatorsHeat-exchange elementsFiberAntioxidant

The invention discloses highly heat-conducting insulation engineering plastic, which consists of the following components in part by weight: 100 parts of plastic substrate, 100 to 900 parts of heat-conducting filler, 1 to 45 parts of compatibilizer, 1 to 90 parts of toughening agent, 1 to 45 parts of reinforcing agent, 1 to 36 parts of lubricating agent and 0.3 to 5.4 parts of antioxidant. The invention also discloses a preparation method of the engineering plastic, which comprises the following steps of: drying the plastic substrate and the heat-conducting filler in a 60 to 100 DEG C air dry oven for 4 to 8 hours; putting the components into a high-speed mixer and mixing for 3 to 5 minutes; performing internal mixing on the mixture in an internal mixer for 10 to 30 minutes; and uniformly grinding the mixture in a grinder, transferring to a charging hopper of a double-screw extruder, feeding fiber fillers through a fiber inlet of the double-screw extruder, melting, mixing, extruding, cooling, drying, and pelletizing. The prepared material has high heat-conducting property and mechanical property, and is easily subjected to injection molding.

Owner:GUANGDONG JANUS SMART GRP CO LTD

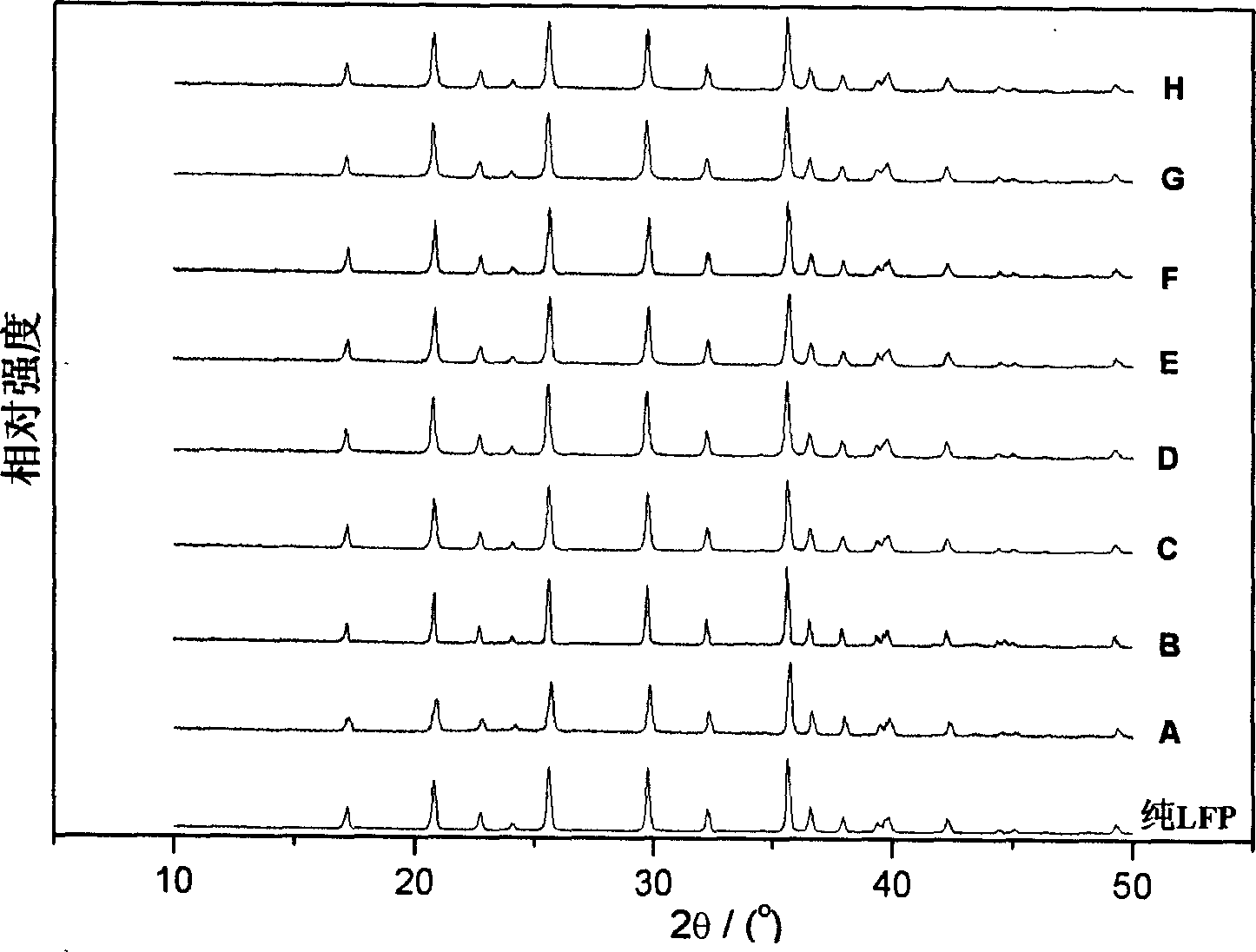

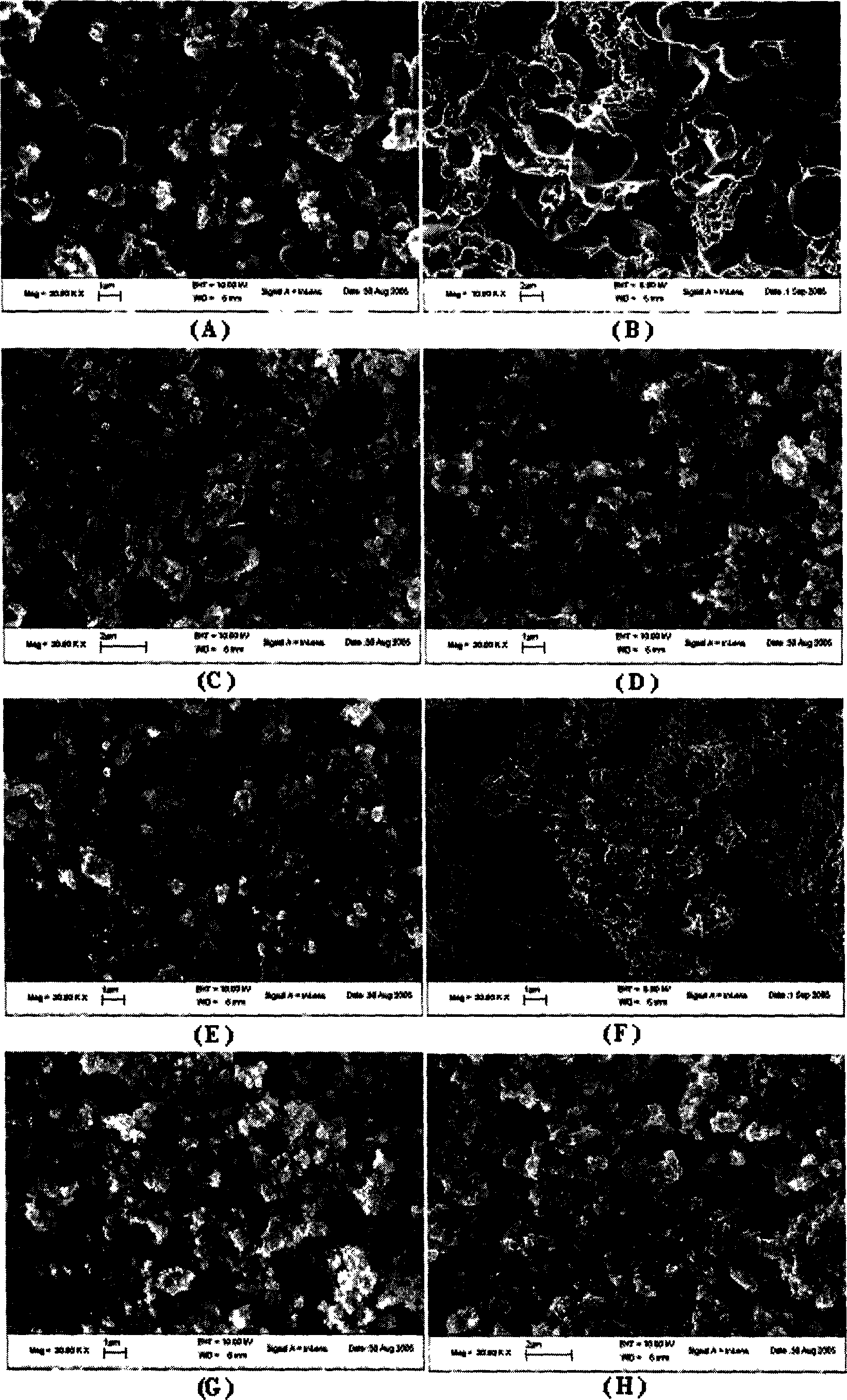

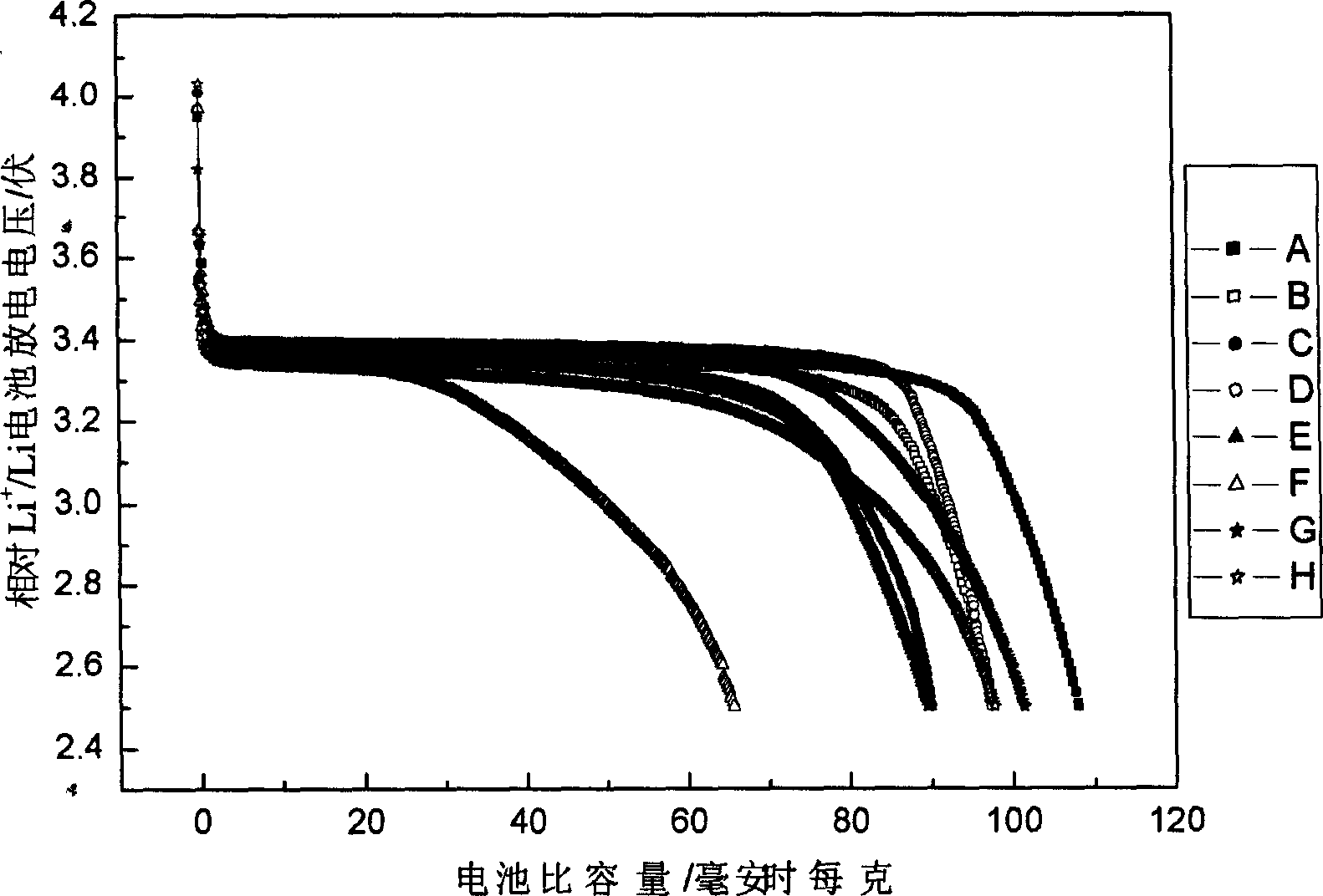

Prepn process of oxygen place doped lithium ferric phosphate powder

InactiveCN1772604AIncrease base capacityImprove cycle electrical performanceCell electrodesPhosphorus compoundsDopantLithium iron phosphate

The present invention belongs to the field of electrochemical power source material preparing technology, and is especially preparation process of oxygen place doped lithium ferric phosphate powder. The oxygen place doped lithium ferric phosphate as positive pole material in lithium ion cell has the molecular expression LiFeP(MxO4-x), and is prepared through mixing the dopant and the mother body material and sintering the mixture, or through solid phase reaction of the dopant and the mother body material. The preparation process has effective doping in the oxygen place of mother body material and the prepared material can raise the capacity and the circular discharge performance of the cell effectively and thus can find its wide application as positive pole material in secondary lithium ion cell and power cell.

Owner:TSINGHUA UNIV

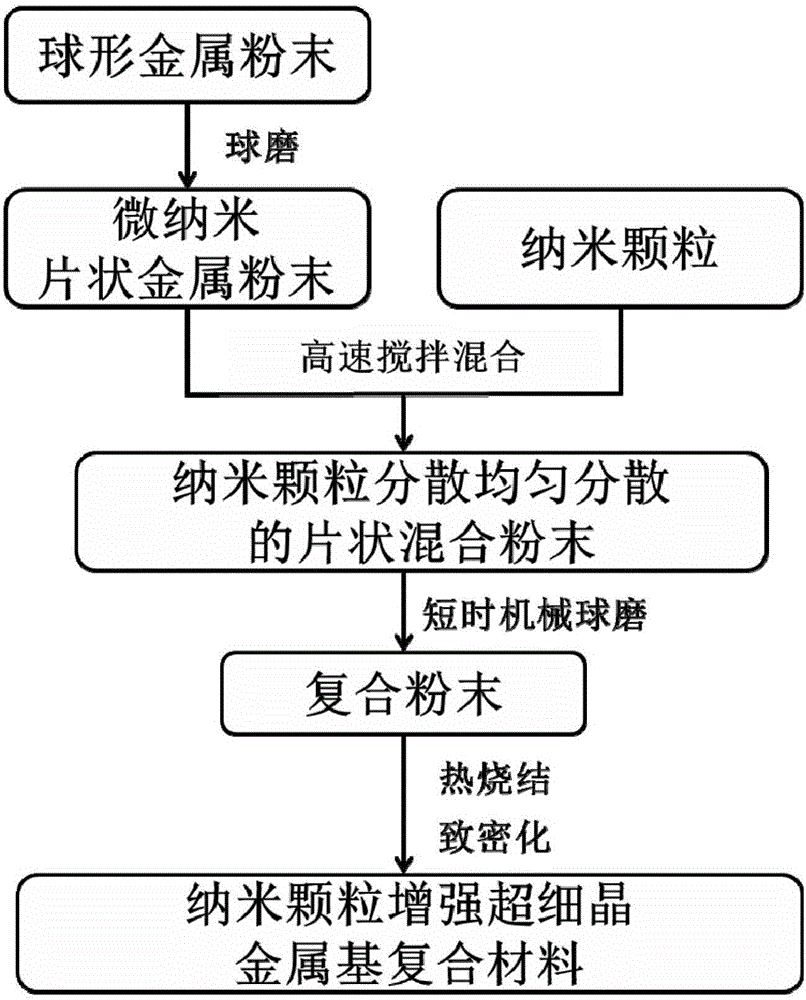

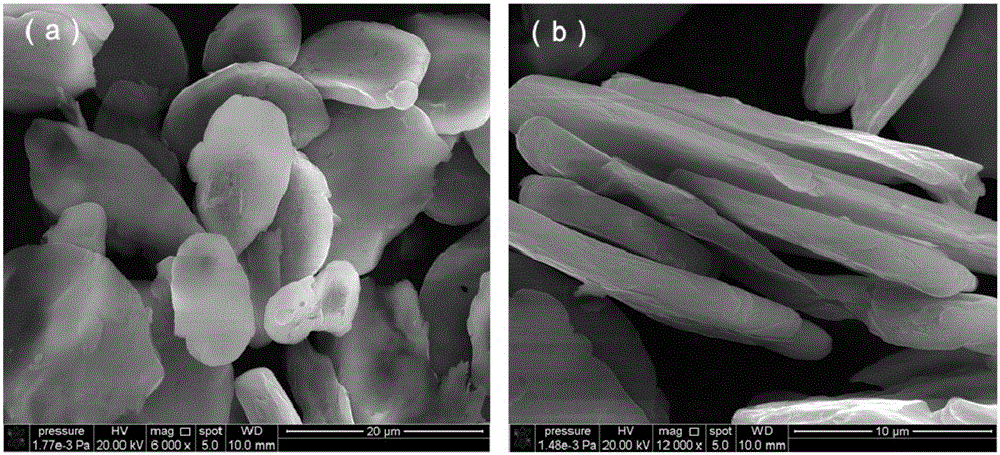

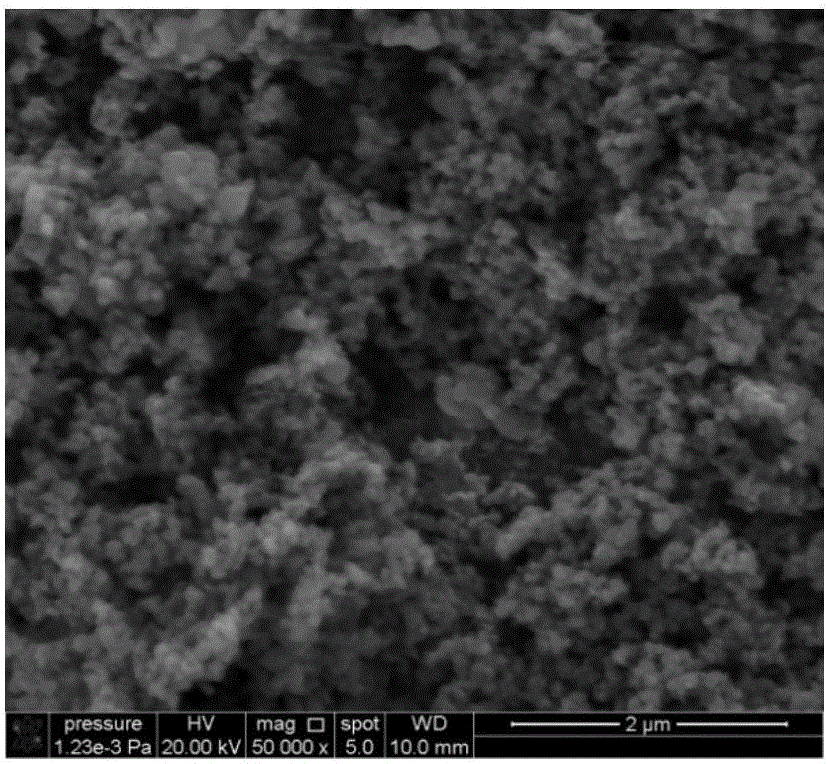

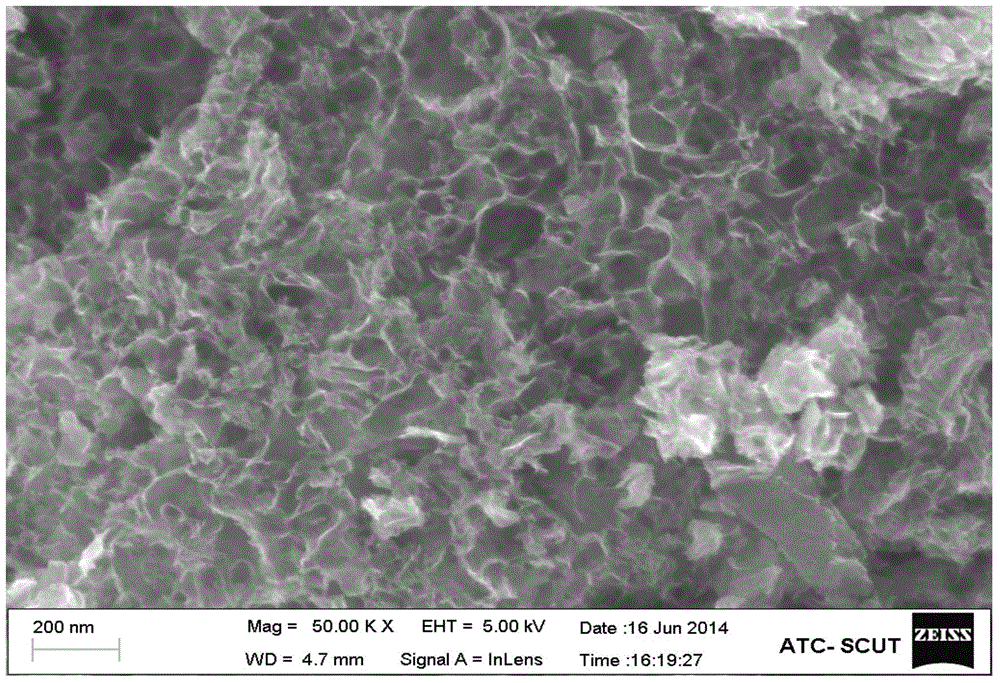

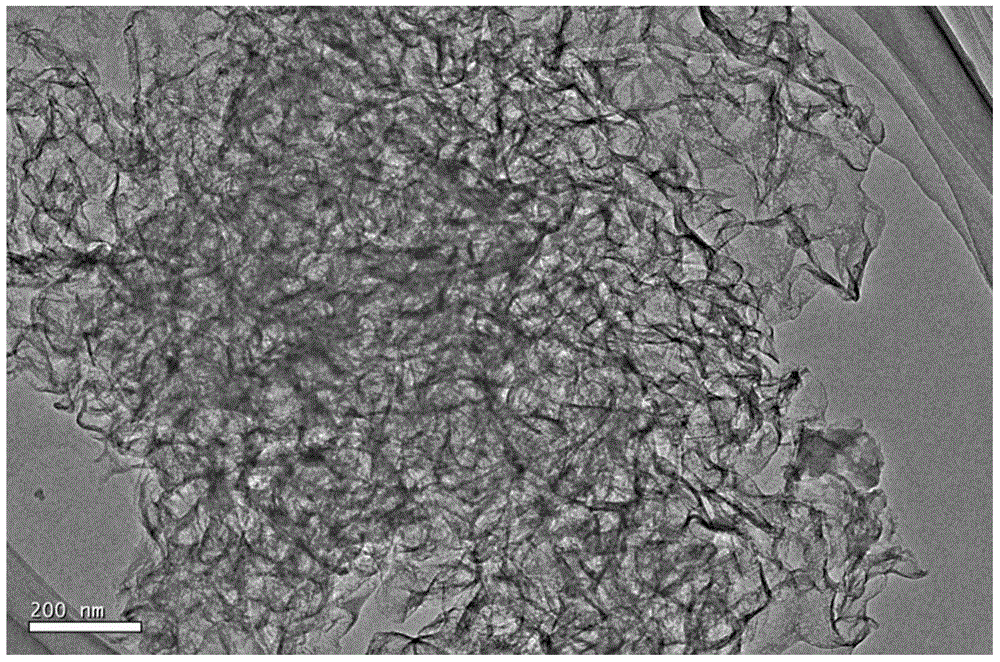

Powder metallurgy preparation method for nano-particle reinforced ultra-fine grain metal-matrix composite

The invention provides a powder metallurgy preparation method for a nano-particle reinforced ultra-fine grain metal-matrix composite. According to the method, a metal-matrix grain refining process and a nano-particle dispersing process are carried out in steps. The method comprises the steps that firstly, micro-nano flaky metal-matrix powder is prepared in advance; nano-particles and the flaky metal-matrix powder are stirred and mixed in a stirrer at the high speed under protective atmosphere, and by means of high shear force and pressure generated between stirring blades and a tank body, the nano-particles are uniformly dispersed to the surface of the micro-nano flaky metal-matrix powder; through short-time mechanical ball-milling treatment, the nano metal particles are embedded into the micro-nano flaky metal-matrix powder, so that composite powder of nano-particle reinforced metal is obtained; and compression moulding, sintering and compacting treatment are conducted, so that the ultra-fine grain metal-matrix composite with the nano-particles uniformly dispersed is obtained. By means of the powder metallurgy preparation method, time and energy are saved; cost is low; the application range is wide; and the prepared material is high in comprehensive mechanical performance and has large-scale application potential.

Owner:SHANGHAI JIAO TONG UNIV

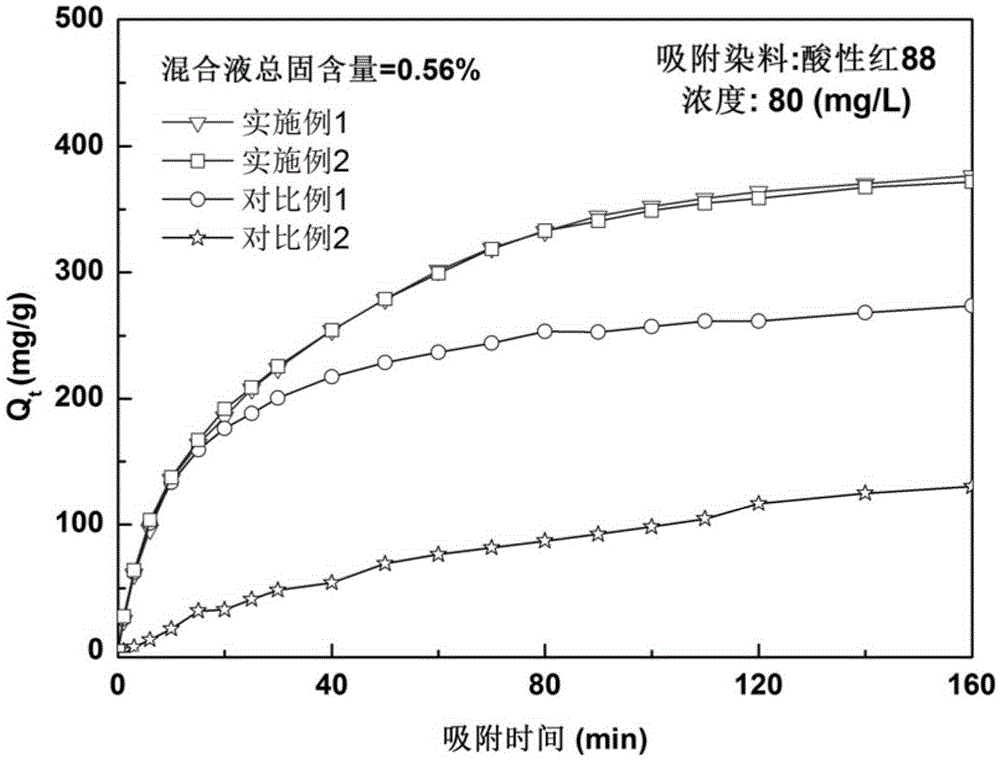

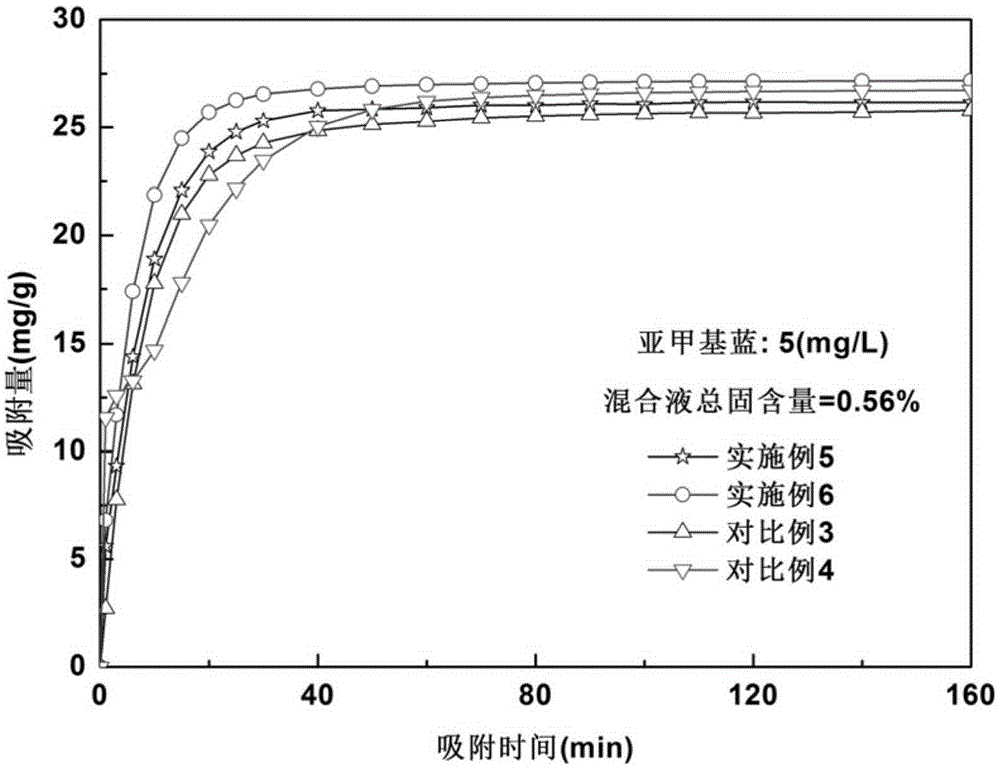

Preparation method of nano-crystalline cellulose-based composite aerogel type organic dye absorption material

ActiveCN105148868AAdsorption is widely applicableOther chemical processesColloidal chemistry detailsPorosityPretreatment method

The invention discloses a preparation method of a nano-crystalline cellulose-based composite aerogel type organic dye absorption material. The method comprises the following steps: preparing nanofibers having functional surfaces by combining a chemical pretreatment method and a mechanical treatment method; and mixing the nanofibers and a natural absorption material to prepare composite aerogel which is used as the organic dye absorption material, wherein the porosity of the prepared composite aerogel is up to 99% or more, the decolourization ratio of the prepared material on organic dyes can exceed 90%, and the prepared material can be widely applied to absorbing the various water-soluble organic dyes.

Owner:ZHEJIANG FORESTRY UNIVERSITY

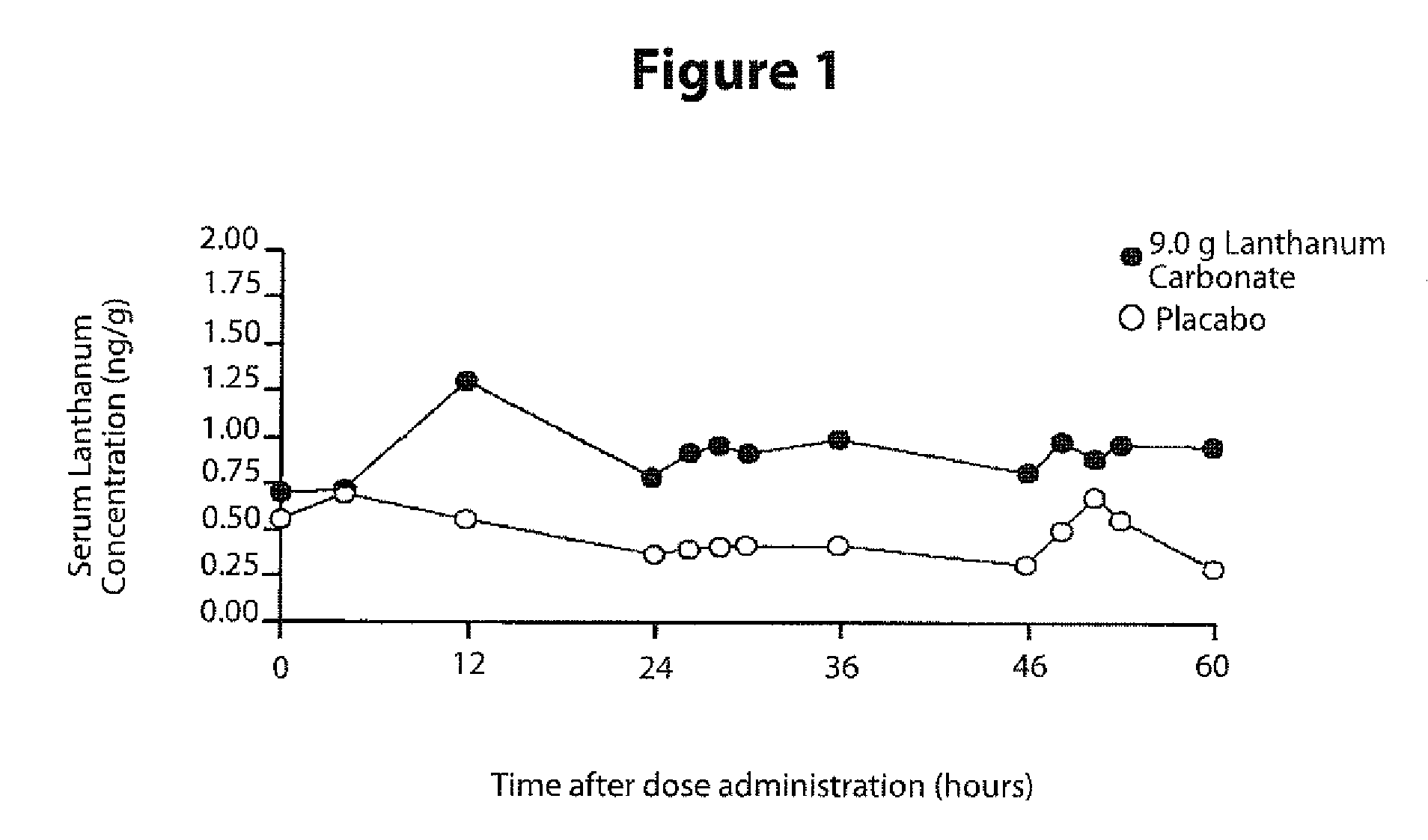

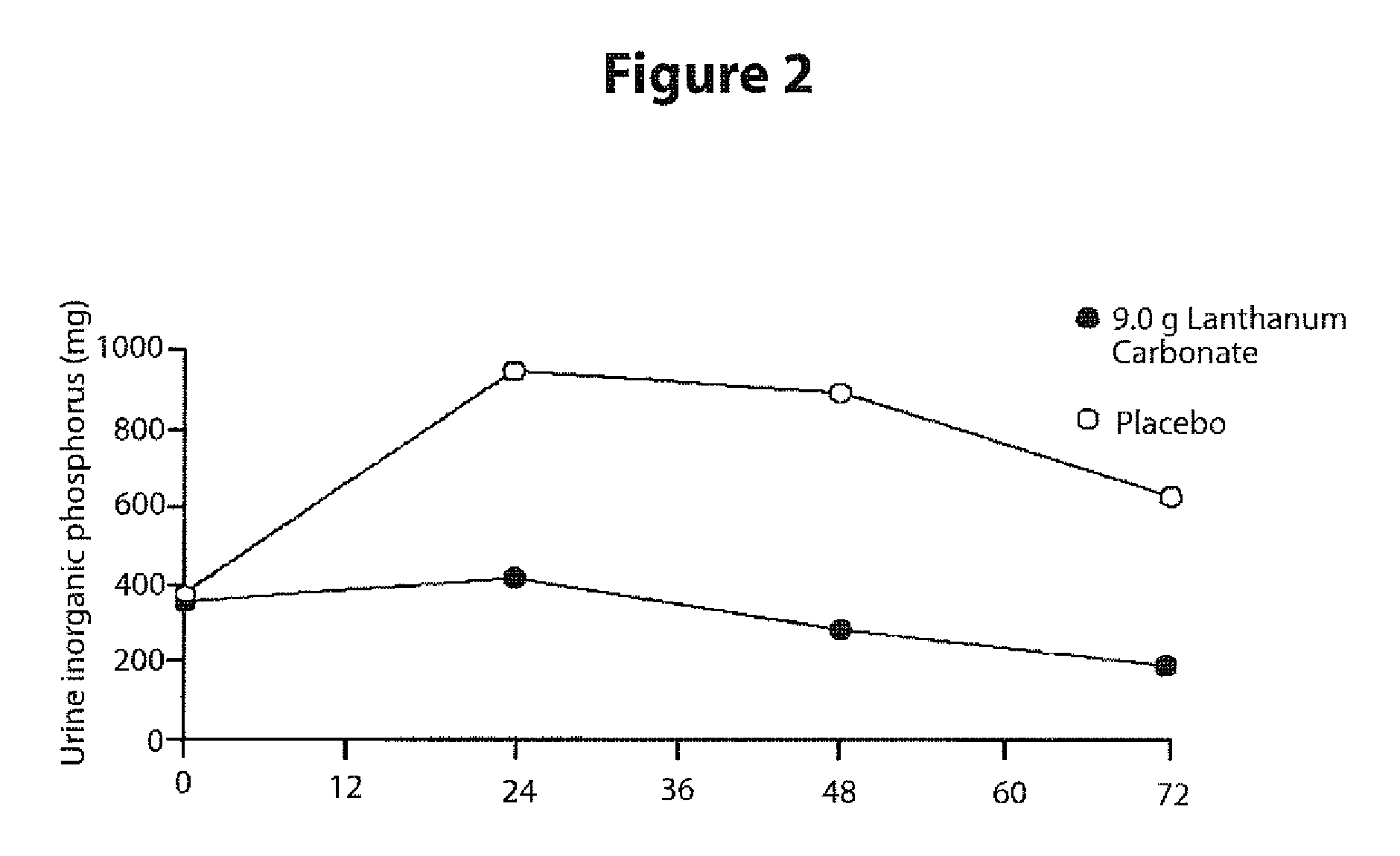

Pharmaceutical formulation comprising lanthanum compounds

ActiveUS7465465B2Extended shelf lifeRestrictive dietBiocideHeavy metal active ingredientsCompound (substance)Lanthanum

This invention relates to a chewable lanthanum formulation comprising a pharmaceutically effective amount of a lanthanum compound; and at least one chewable pharmaceutically acceptable excipient. This invention also relates to a pharmaceutical formulation in a tablet or in a powder comprising a pharmaceutically effective amount of a lanthanum compound produced by a process which comprises the steps of: a) powder blending the lanthanum compound and at least one pharmaceutically acceptable excipient in a mixer to form a mixture; or b) powder blending the lanthanum compound and excipients, compressing the resulting combination into a slug material or roller compacting the resulting combination into a strand material, and milling the prepared material into a free flowing mixture; and c) compressing the resulting mixture into a tablet or filing up the resulting mixture in a appropriate container.

Owner:SHIRE CANADA INC +1

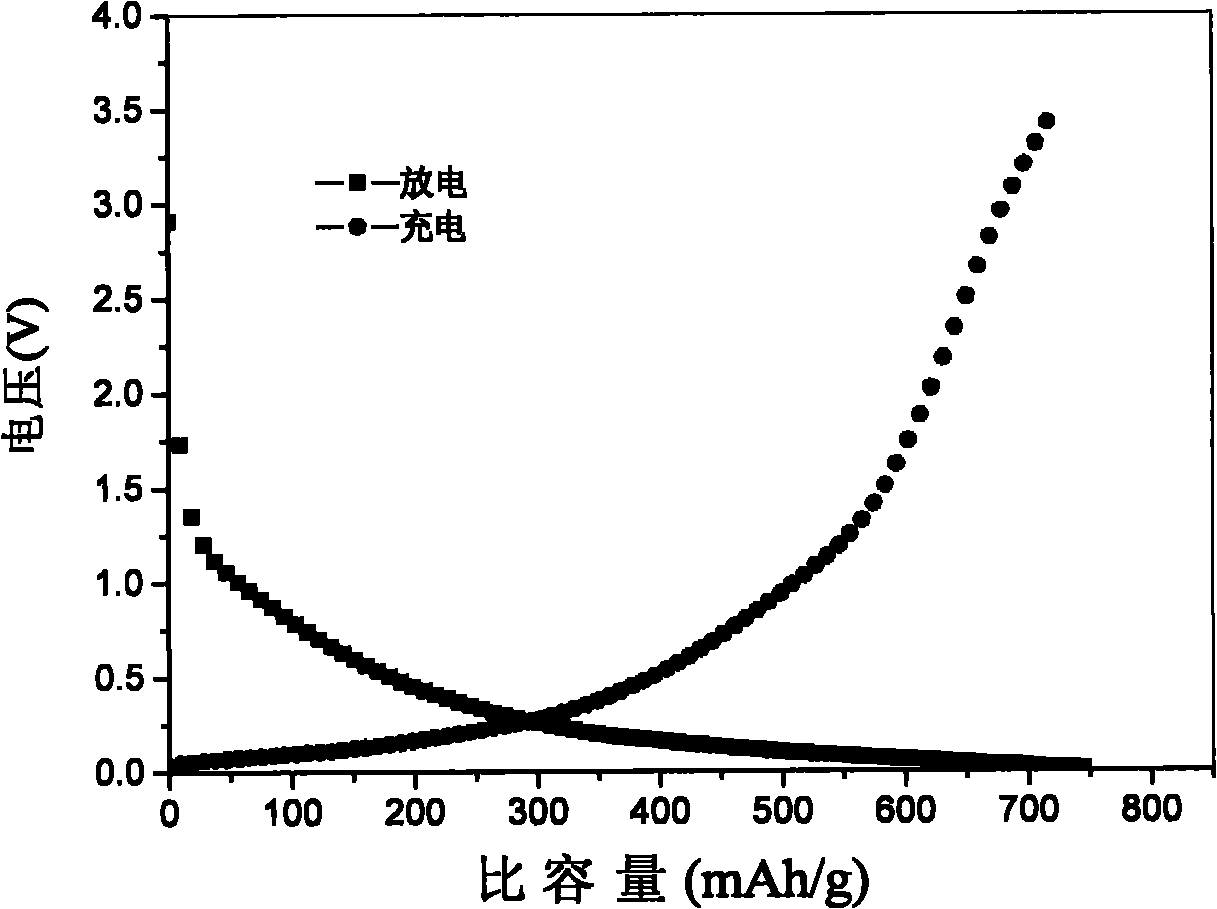

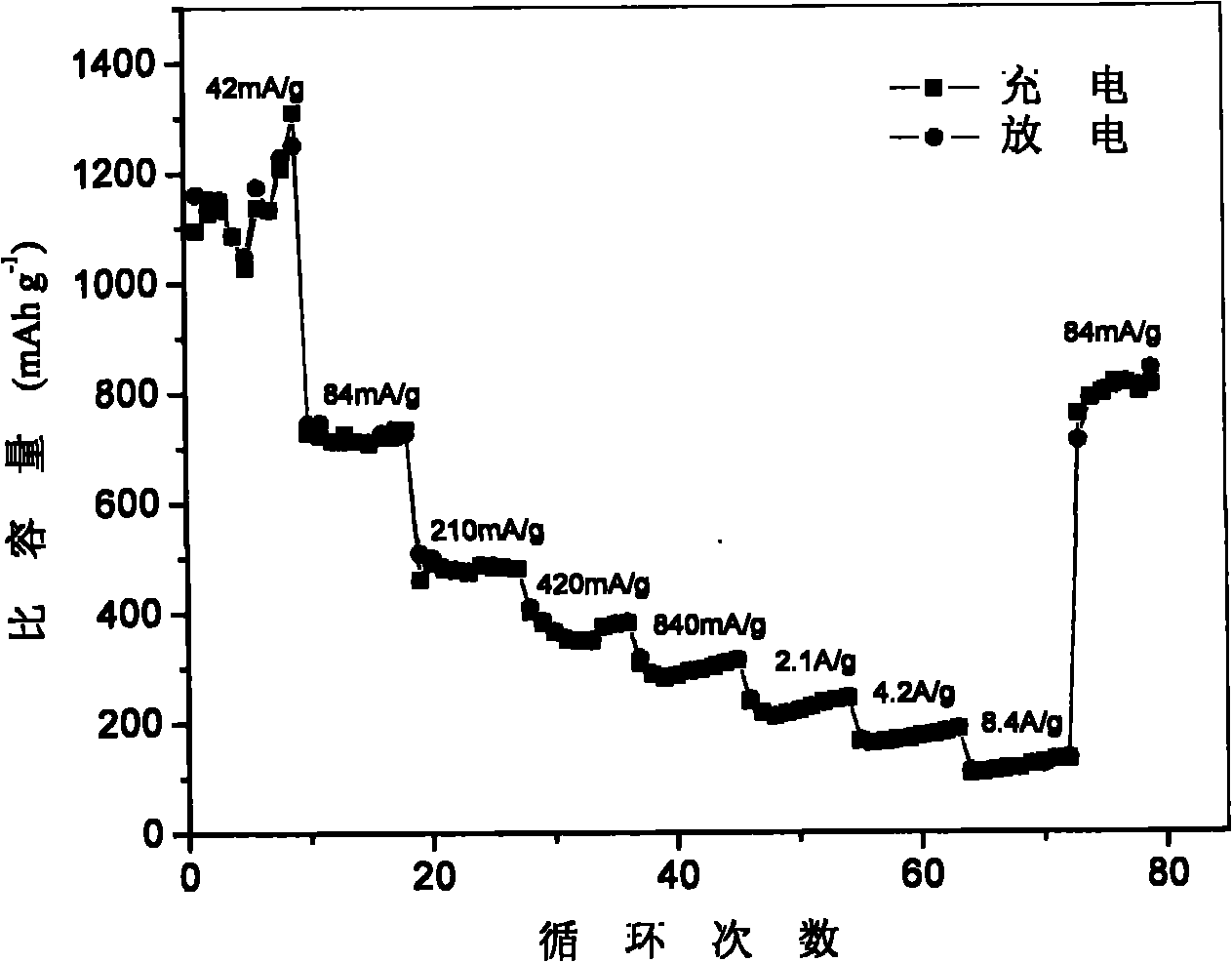

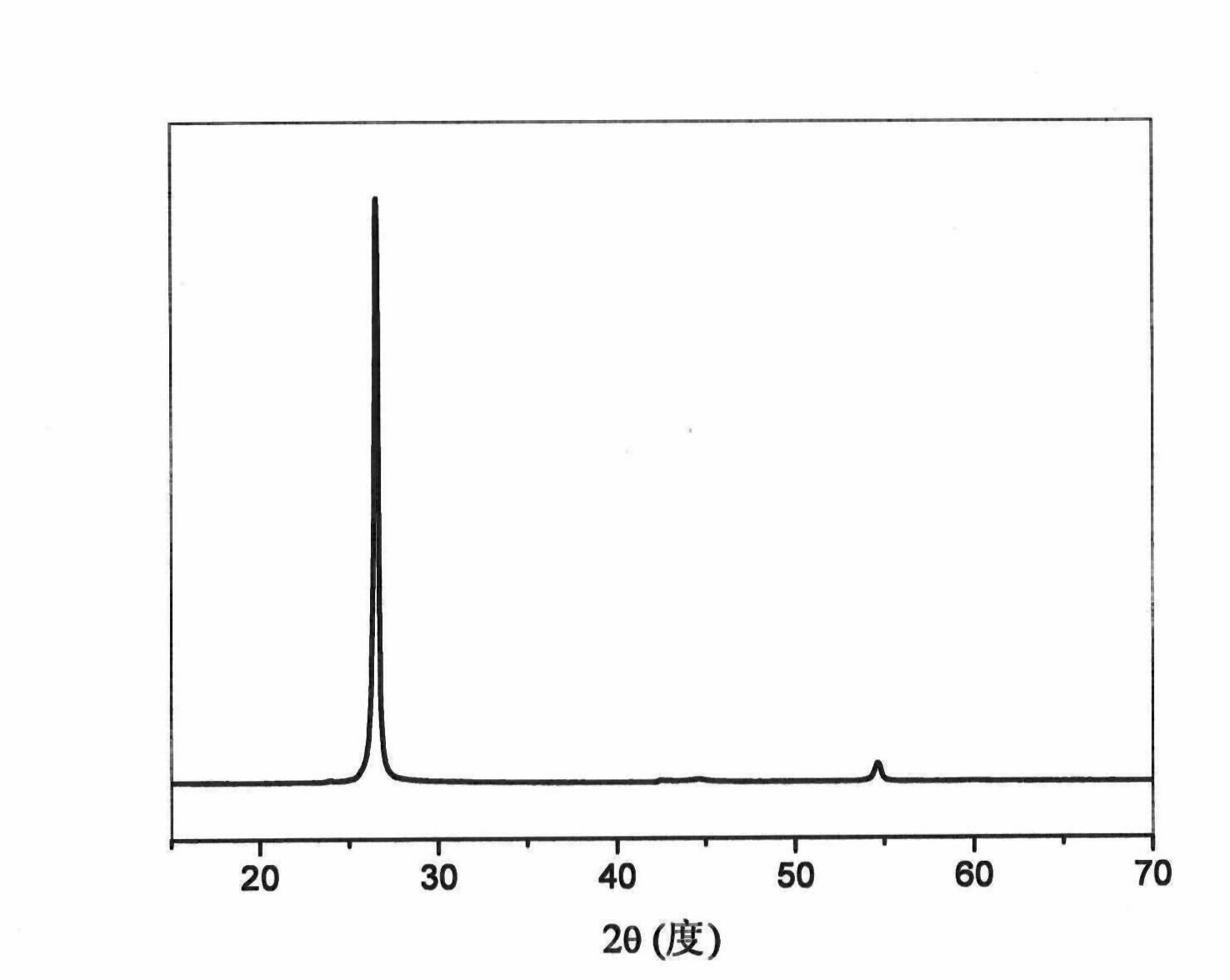

Nitrogen-doped graphite carbon serving as anode material of lithium ion battery, and preparation method and application thereof

The invention discloses a nitrogen-doped graphite carbon, which is obtained by calcining a graphite carbon material in a nitrogen-containing micromolecule material or atmosphere of the nitrogen-containing micromolecule material. When a pole piece which is prepared from the nitrogen-doped graphite carbon material is used as an electrode material of the lithium ion battery, the specific capacity of the material reaches 450 to 1,100mAh / g, and the material has high multiplying power performance and cycle performance. A preparation method of the nitrogen-doped graphite carbon is convenient to operate, and is easy and practicable; the prepared material has stable and excellent performance, and is the anode material of the lithium ion battery, which has good application prospect.

Owner:QINGDAO INST OF BIOENERGY & BIOPROCESS TECH CHINESE ACADEMY OF SCI

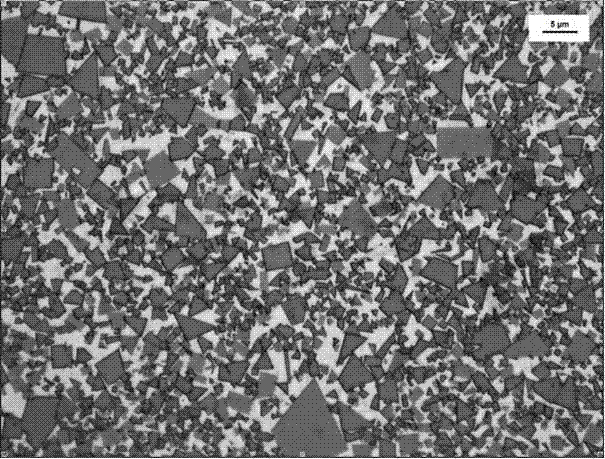

Toughened hard alloy and preparation method thereof

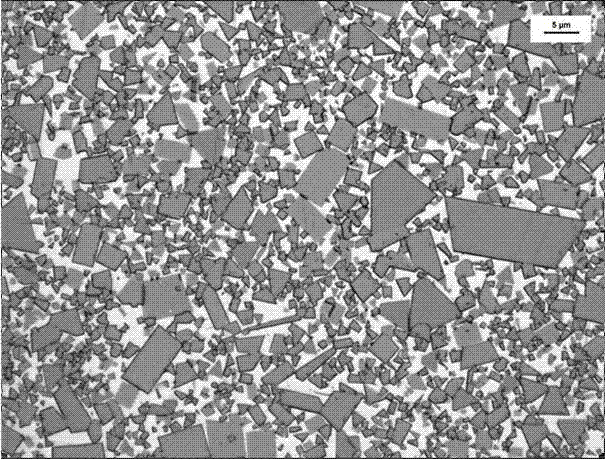

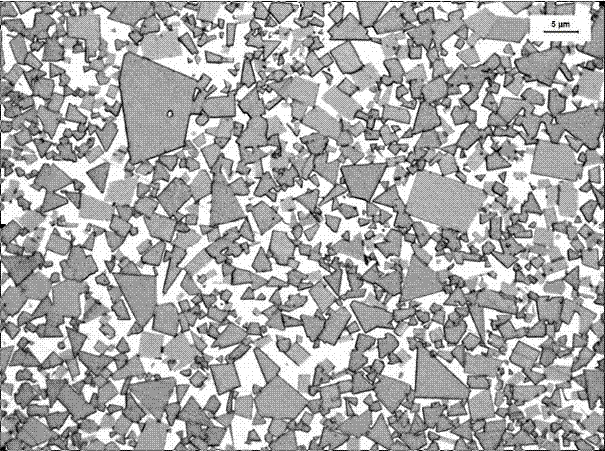

The invention discloses a high-toughness toughened hard alloy which comprises 10%-30% of Co or Co and Ni serving as a binding phase, 0-1.5% of Cr3C2 serving as an inhibitor, and the balance of hard phase WC, wherein the hard phase consists of WC crystalline grains with coarse, medium and fine grain sizes, the grain size of coarse grains is 9-15 mu m, the grain size of medium grains is 4-7 mu m, the grain size of the fine grains is less than 2 mu m, and the mean grain size of the hard phase WC is 1.6-3.2 mu m. The preparation method of the toughened hard alloy comprises the following steps of: preparing materials including 10%-30% of cobalt powder or cobalt powder and nickel powder, 0-1.5% of chromium carbide powder, and the balance of tungsten carbide powder, wherein Fsss grain size of the coarse grains WC is 9.0-11.0 mu m, the coarse grains WC account for 20%-42% of the prepared powder, the Fsss grain size of the medium grains WC is 4.0-6.0 mu m, the medium grains account for 10%-25% of the prepared powder, the Fsss grain size of the fine grains WC is 1.0-2.0 mu m, and the fine grains account for 20%-40% of the prepared powder; grinding, wherein a liquid paraffin forming agent which accounts for 2% of the prepared materials is added, mixed with absolute ethyl alcohol in a liquid-solid ratio of 300 ml / kg-350ml / kg, wet-ground for 20-28 hours according to the condition that the ratio of grinding media to material is 4:1, and sprayed and dried to obtain mixed materials; pressing; vacuum-sintering and isostatic-pressing and sintering. According to the invention, the toughness is improved on the premise of ensuring the hardness of the alloy, so that the operation field is expanded, special requirements of a cold-heating and cold-punching mould and a holt-rolling hard alloy roller ring are satisfied, and the service life of the high-toughness toughened hard alloy is prolonged.

Owner:ZHUZHOU HARD ALLOY GRP CO LTD

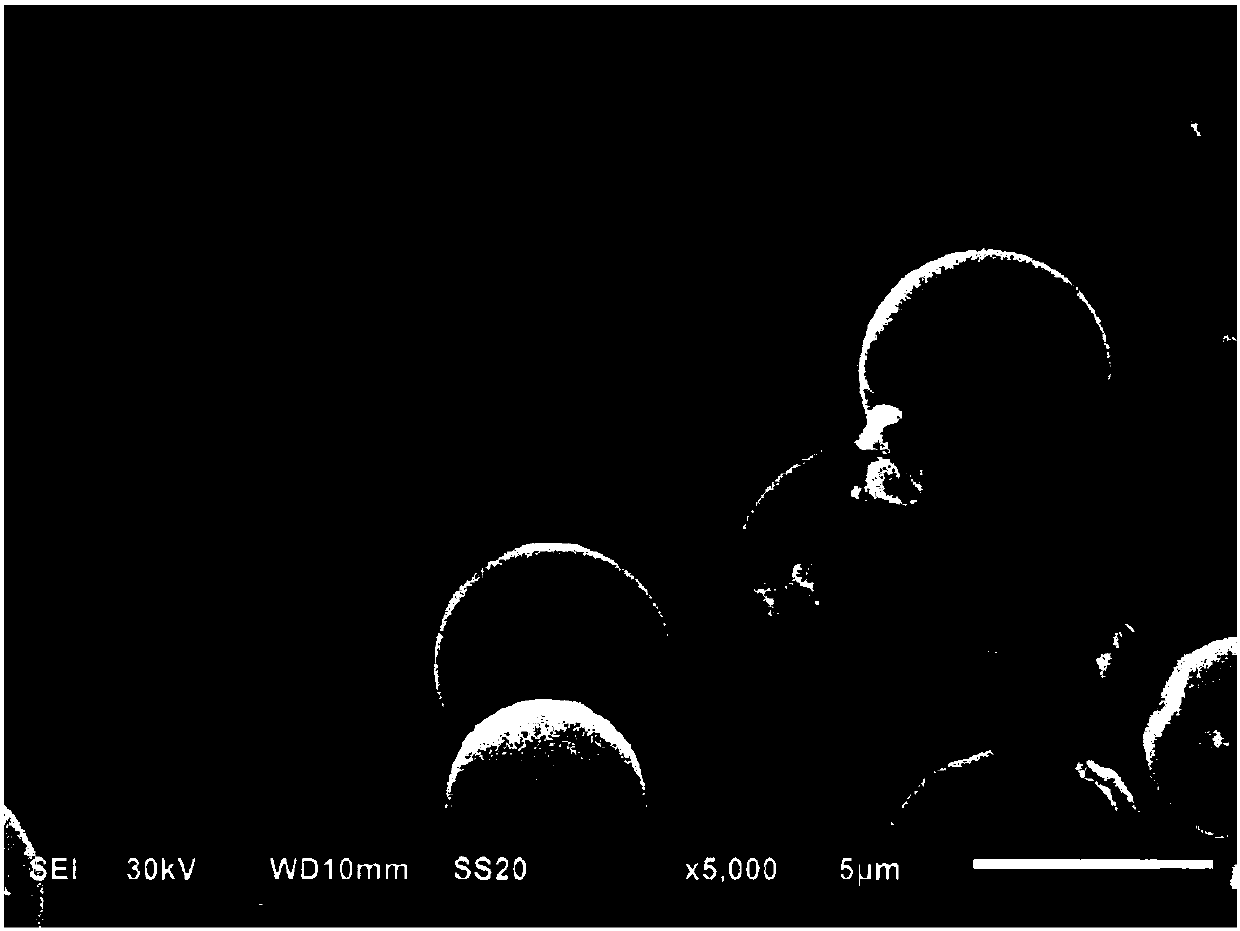

Preparation method and application of nitrogen-doped starch-based activated carbon microsphere material

ActiveCN105948045AMicrostructure is easy to controlGood dispersionHybrid capacitor electrodesDispersityMicrosphere

The invention discloses a preparation method and application of a nitrogen-doped starch-based activated carbon microsphere material. The nitrogen-doped starch-based activated carbon microsphere material is prepared by taking starch as the carbon source and taking a nitrogen-containing compound as the nitrogen source through the steps of gelatinization, hydrothermal treatment, carbonization, activation and the like. The diameters of prepared carbon microspheres range from 0.5 micrometer to 10 micrometers, the particle size is controllable, the dispersity is good, the specific surface area ranges from 1,000 m<2> / g to 3,000 m<2> / g, and the nitrogen content ranges from 0.2% to 15%. The prepared material relates to the application fields of electrochemical energy storage, adsorption separation, catalyst carriers, drug carriers and the like and is particularly applicable to electrochemical energy storage. Green biomass is adopted as the carbon source, sources are wide, the price is low, and the preparation technology is simple, easy to control, environmentally friendly and suitable for large-scale production.

Owner:XIANGTAN UNIV

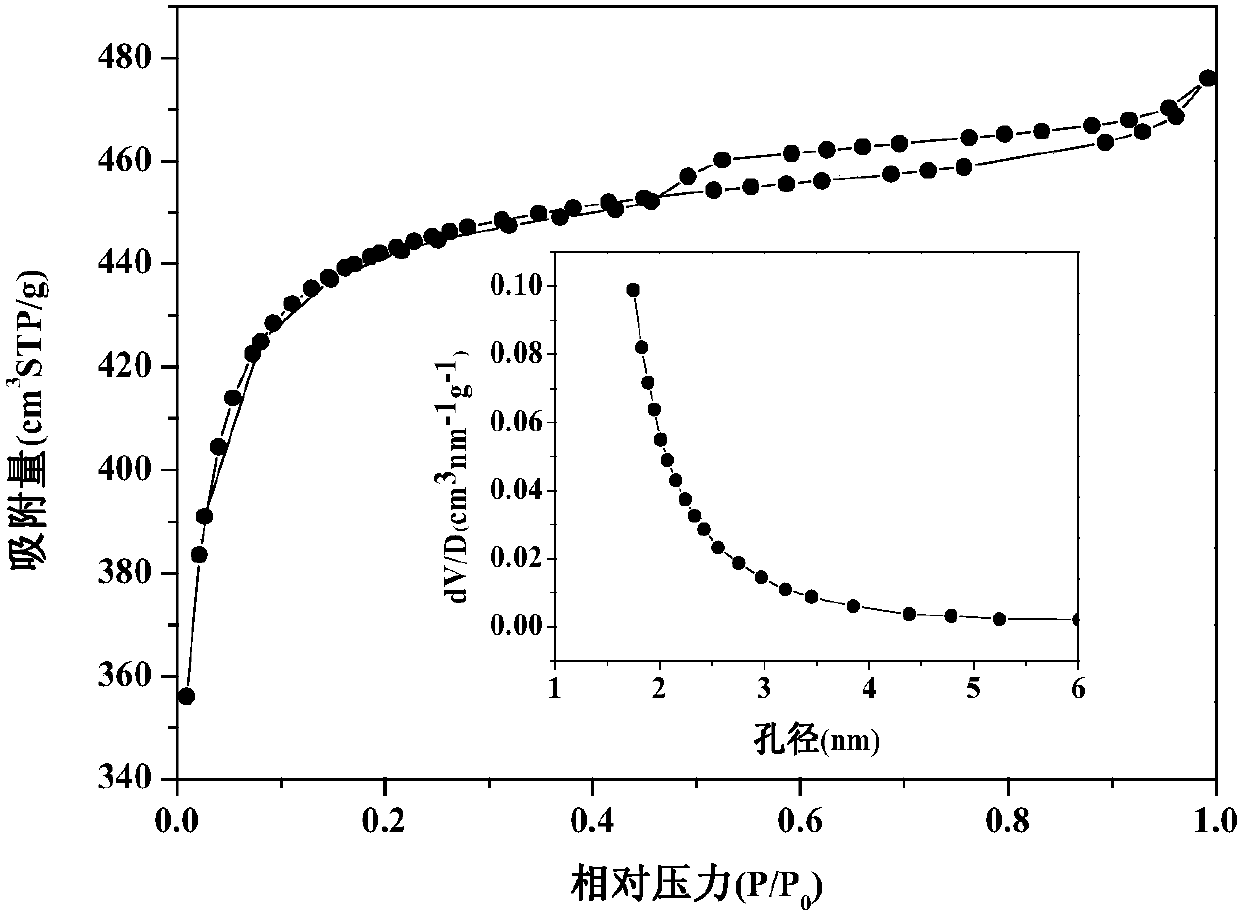

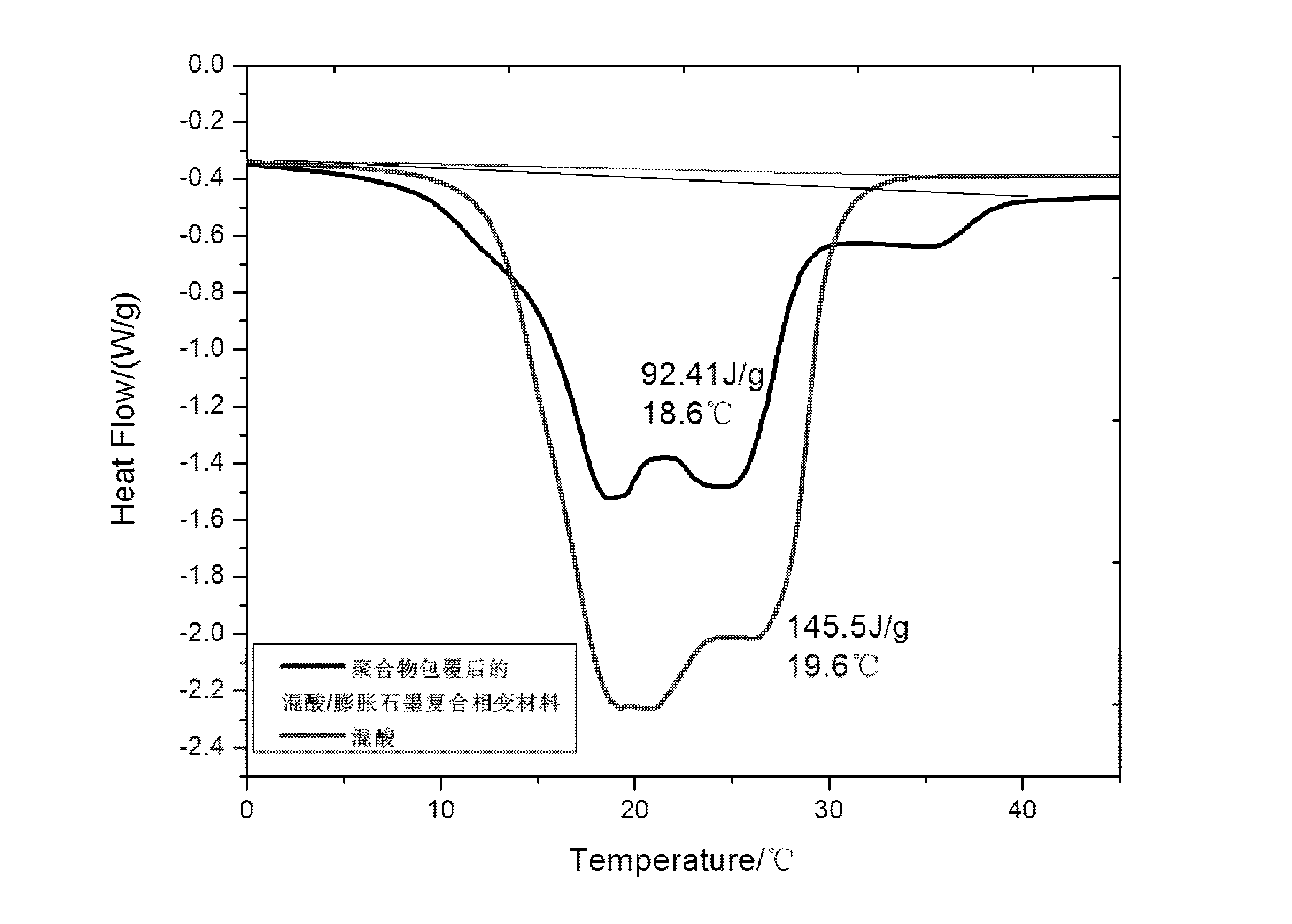

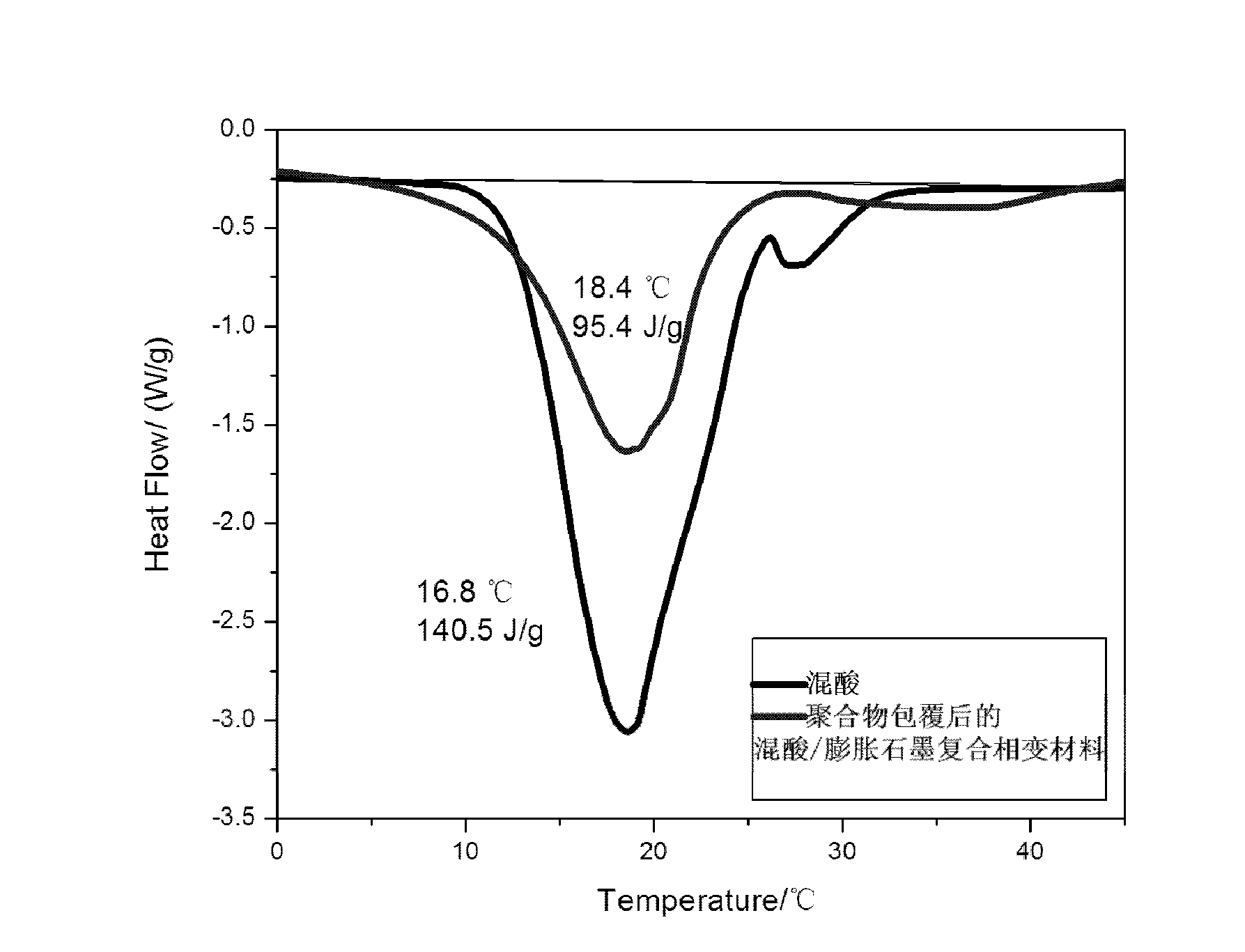

Phase change material for thermal energy storage and preparation method thereof.

InactiveCN102977858AImprove thermal conductivityLarge energy storageHeat-exchange elementsOrganic acidThermal energy storage

The present invention relates to a phase change material for thermal energy storage and a preparation method thereof. The phase change material for thermal energy storage adopts expanded graphite phase as a carrier to adsorb organic fatty acids of different ratios, and then a composite coating agent is coated on the outside of the prepared material. The adsorption of organic fatty acids into the expanded graphite carrier improves the thermal conductivity of the organic acids as the phase change material, and suppresses the liquid leakage problem of the organic acids when the organic acids are applied in thermal storage techniques; and the composite coating agent further performs reinforcing and shaping functions.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Regenerated wire drawing modified material of waste polypropylene woven bags and preparation method thereof

The invention provides a regenerated wire drawing modified material of waste polypropylene woven bags, comprising the following components in percentage by weight: 1-35 percent of polyolefin fresh material, 25-95 percent of waste polypropylene material, 1-55 percent of enhanced modifier, 1-30 percent of toughening modifier, 0.01-5 percent of activator, 0.1-3 percent of antioxidant, 0.01-6 percent of lubricant and 0.01-6 percent of dispersing agent. The invention also provides a preparation method of the regenerated wire drawing modified material of the waste polypropylene woven bags. In the preparation method, based on the arecovery treatment on the waste polypropylene woven bags, the new wire drawing modified material of woven bags are produced by adding proper amount of other raw materials and auxiliary materials and can be directly used for producing polyolefine flat fibers with stable performance. The performance of a new polypropylene woven tape produced from the prepared material and a small quantity of fresh material is equivalent to a woven bag wholly produced by carrying out granulation and wire drawing on the fresh material. The new polypropylene woven tape can completely satisfy the use performance requirements, dramatically lower the product production cost and provide a proper way for waste recycling utilization and environmental pollution reduction.

Owner:丁飞鹏 +1

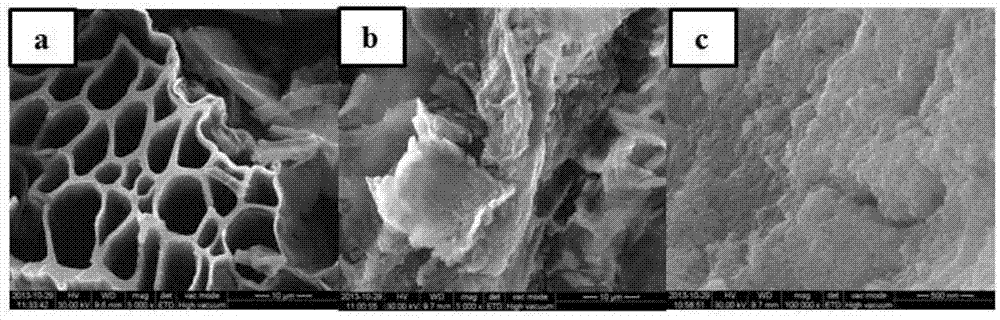

Method for preparing three-dimensional porous graphene material by solution

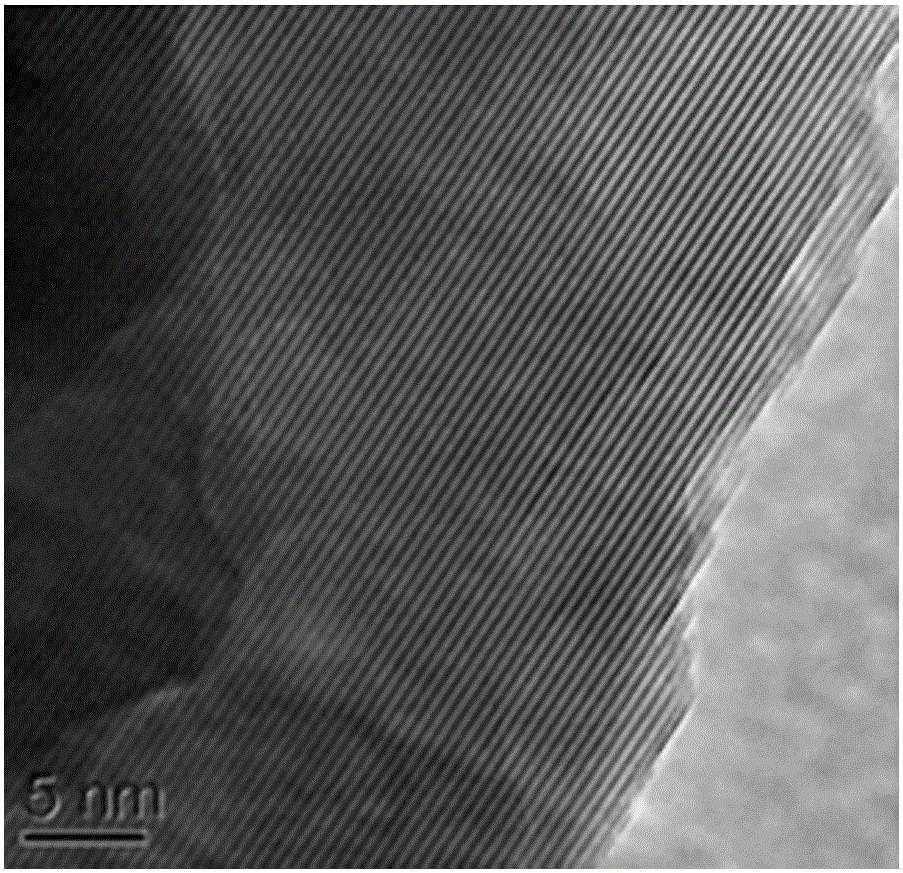

InactiveCN102701188AMass production availableAvailable for mass productionGrapheneStretchable electronicsPorous graphene

The invention discloses a method for preparing a three-dimensional porous graphene material by solution. The method comprises the following steps of: immersing a three-dimensional porous template into a graphene oxide solution, and then depositing the graphene oxide on the template to realize three-dimensional assembling of the graphene oxide on the template, and then preparing the three-dimensional porous graphene material containing the template by reduction; removing the template from the three-dimensional porous graphene material containing the template, and then washing to obtain the three-dimensional porous graphene material. The aperture of the three-dimensional porous graphene material can be regulated and controlled by using the templates with different apertures the material prepared by the invention has the advantages of low density, high specific surface area, high heat conductivity, high-temperature resistance, and corrosion resistance; the preparation method is economical and simple and suitable for large-scale production. And the prepared material is applicable to aspects such as catalytic carriers, preparation of flexible conductors, and stretchable electronics.

Owner:HUAZHONG UNIV OF SCI & TECH

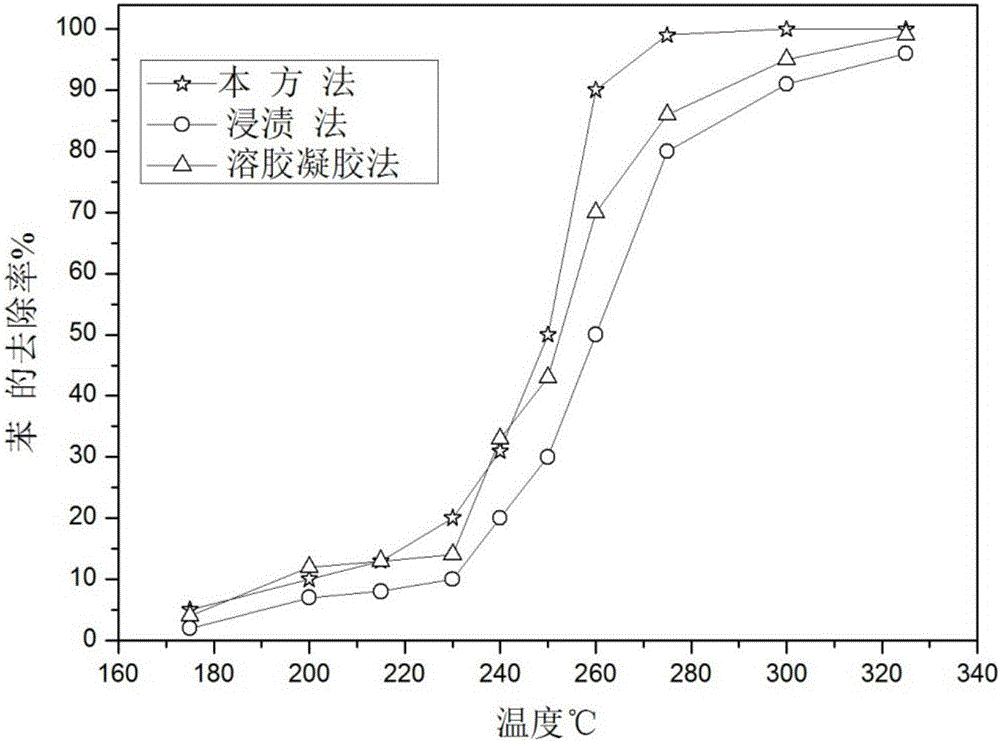

Method for preparing VOCs catalytic combustion catalyst

ActiveCN106064087AIncrease loadEvenly distributedMolecular sieve catalystsHeterogenous catalyst chemical elementsCarboxylic acidIon

A method for preparing a VOCs catalytic combustion catalyst comprises the following steps: preparing a solution A containing at least one metal compound, preparing a solution B contain organic ligand, adding the solution B to the solution A, and stirring the solution B and the solution A to obtain a mixed solution, wherein the organic ligand is at least one of carboxylic acid or imidazole organic matters; putting a carrier in the mixed solution, and carrying out 50-200DEG C constant temperature impregnation for 2-8h to obtain an MOF / carrier material; preparing a solution C containing at least one metal compound, and loading the treated MOF / carrier material in the solution C to carry out loading; ageing the above prepared material for 12h, drying the aged material at 60-100DEG C for 3-5h, and roasting the dried material in 500-800DEG C air for 4-8h; and washing the roasted material with distilled water or deionized water, and drying the washed material at 60-110DEG C for 8-24h to obtain the metal oxide catalyst.

Owner:南京朗科环保科技有限公司

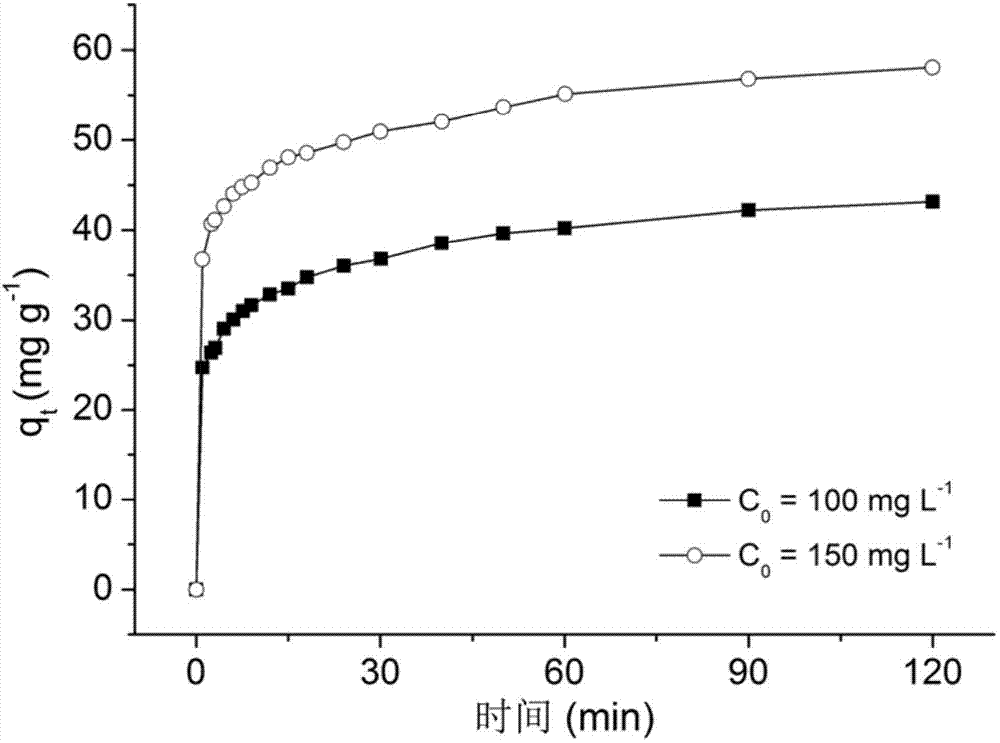

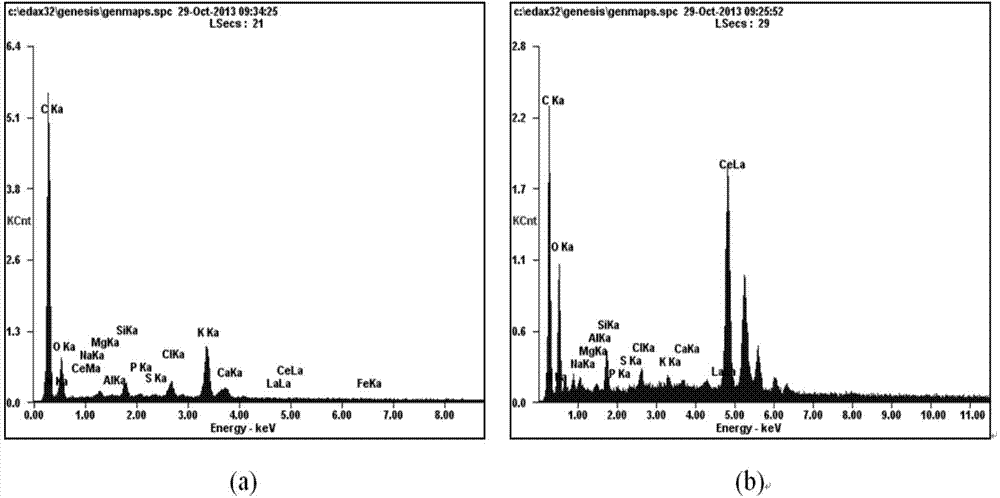

Improved charcoal-based phosphorous removal adsorbent and preparation method thereof

ActiveCN103877937AImprove adsorption capacityEfficient removalOther chemical processesWater/sewage treatment by sorptionRare-earth elementSorbent

The invention discloses an improved charcoal-based phosphorous removal adsorbent and a preparation method of the improved charcoal-based phosphorous removal adsorbent. The method comprises the following steps: loading light rare earth elements to charcoal under optimized conditions, and preparing a high-efficiency environment-friendly charcoal-based phosphorous removal adsorbent; impregnating the cleaned and dried plant powder by using a cerium chloride solution with a certain concentration, and regulating a mass ratio of the original material of charcoal to Ce element to be 5-15 percent; adding an alkaline solution to control the pH value of the system to be more than 10, stirring, washing by using ethanol, centrifuging and drying; putting the prepared material into a muffle furnace, performing temperature programming and pyrolysis under anoxic conditions through the sealing measure, and controlling the pyrolysis temperature and pyrolysis time; washing the material by using distilled water after the pyrolysis is ended and cooling is performed, centrifuging, drying, screening, and obtaining the final product. The phosphorous removal adsorbent prepared in the invention has excellent adsorptive property on phosphate radical, the adsorptive property can reach 77.52mg / g, and a charcoal-based material which is environment-friendly and excellent in adsorptive property is provided for adsorbing and purifying phosphorous-containing wastewater.

Owner:JIANGSU ACADEMY OF AGRICULTURAL SCIENCES

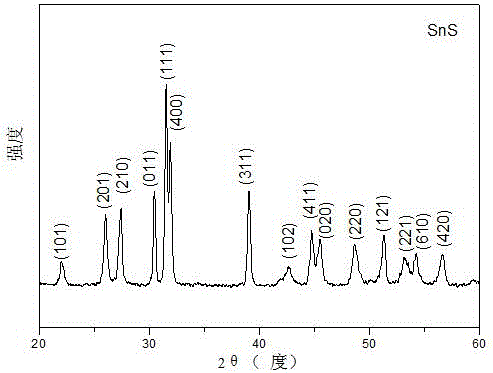

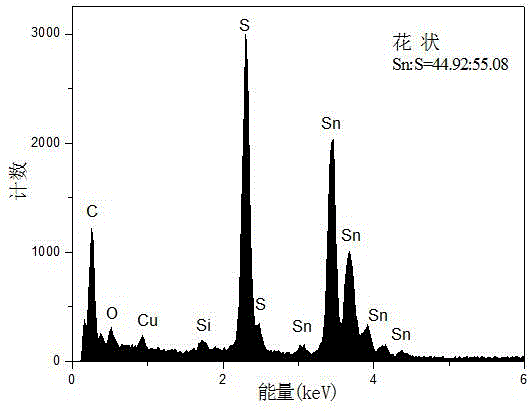

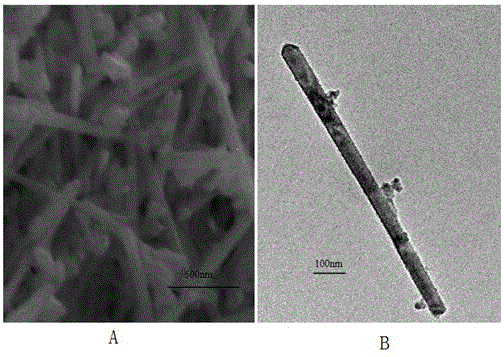

Preparation method and application of tin sulfide material

ActiveCN105800674ASimple methodMild reaction conditionsMaterial nanotechnologyPhysical/chemical process catalystsActive agentReaction temperature

The invention discloses a preparation method of a tin sulfide material. A solvothermal method is adopted, dehydrate-stannous chloride is used as a tin source, the morphology and particle size of the synthetic material are controlled by controlling a sulfur source, the reaction temperature, reaction time, the solvent variety and the surfactant variety, and the SnS photocatalytic material with controllable morphology and high quality is prepared. The method is simple in preparation and easy to carry out, the yield is high, consumed time is short, cost is low, reaction conditions are mild, good development prospects are achieved, industrial production is easy to achieve, and the prepared material has high photocatalytic activity and has good industrial application prospects when serving as the photocatalytic material.

Owner:KUNMING UNIV OF SCI & TECH

Aqueous zinc-ion battery positive electrode material

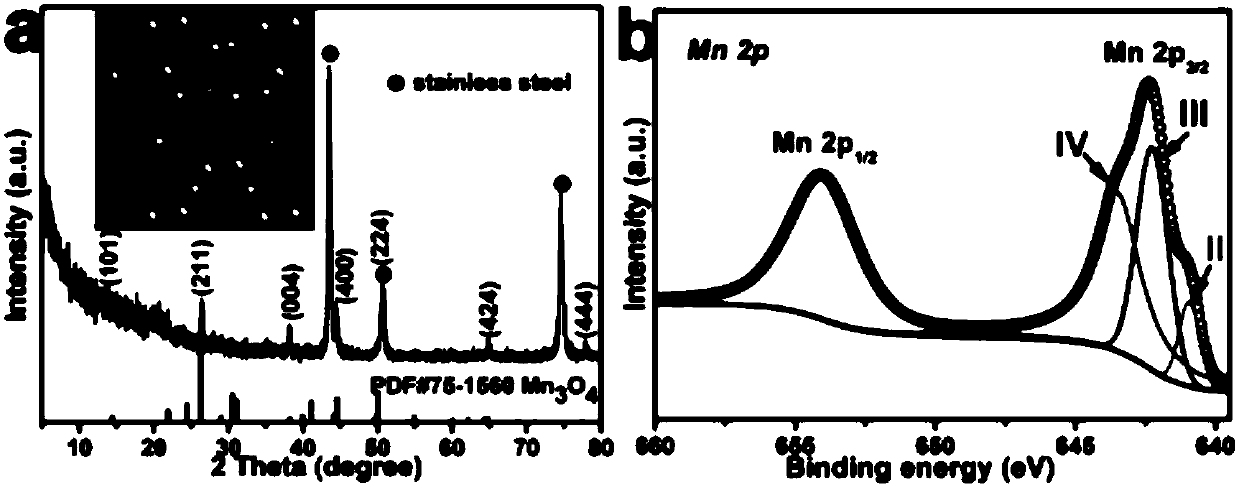

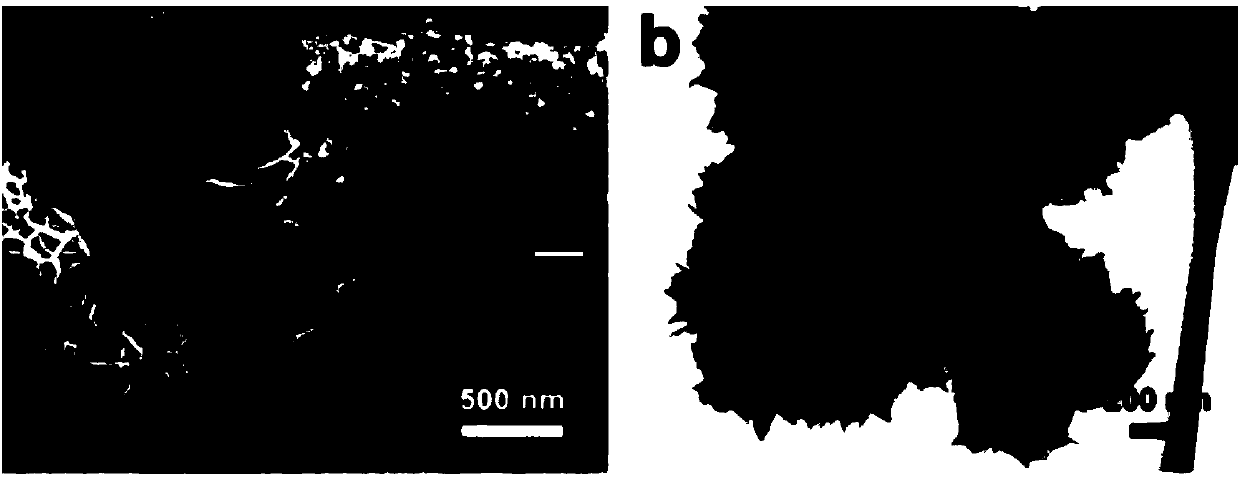

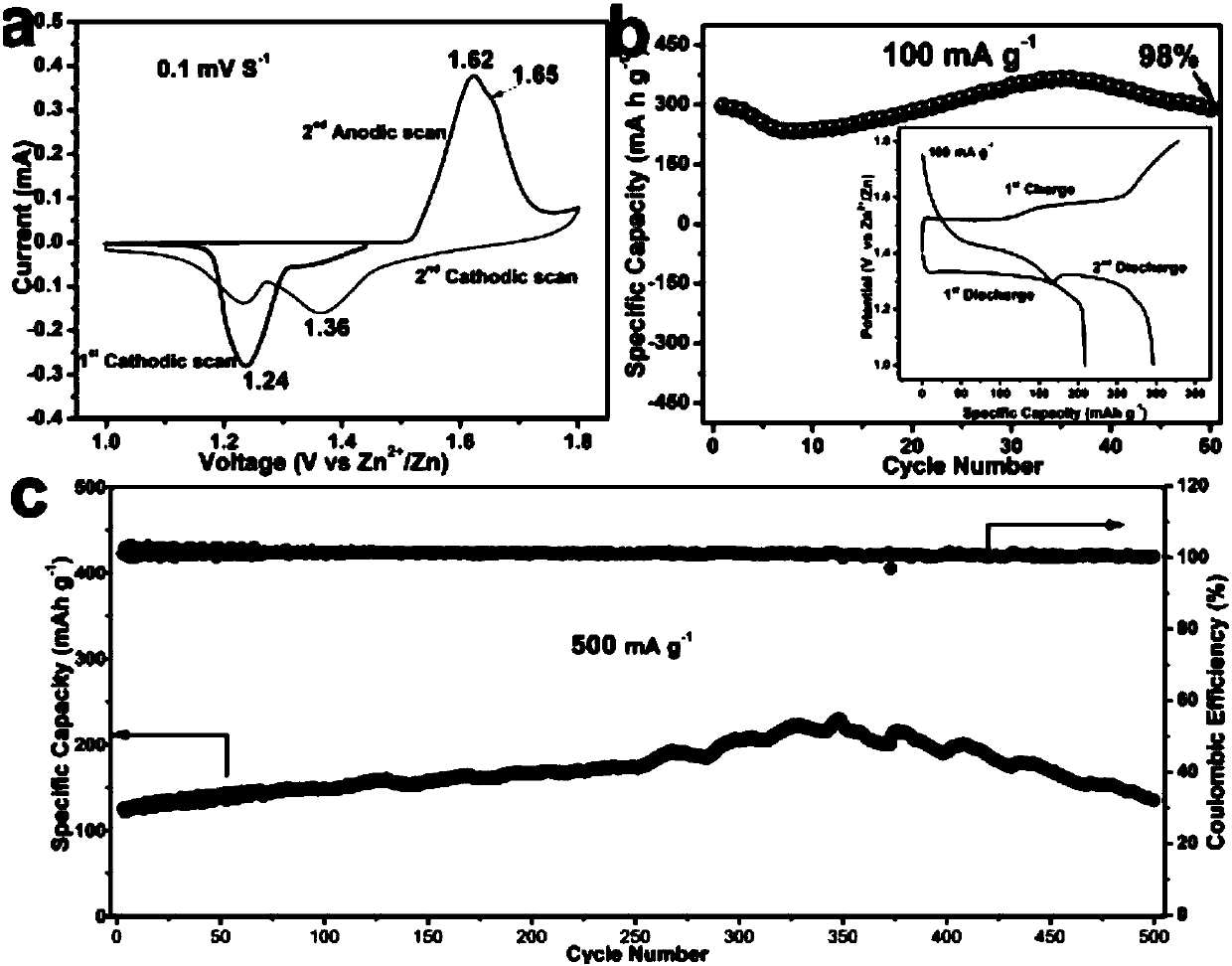

ActiveCN107863485AImprove conductivityImprove electrochemical performanceMaterial nanotechnologyElectrode thermal treatmentHigh pressurePotassium permanganate

The invention discloses an aqueous zinc-ion battery positive electrode material. A preparation method of the material is a one-step hydrothermal method and comprises the steps of adding a certain amount of potassium permanganate into deionized water, performing stirring under a room temperature to obtain a deep violet solution, transferring the solution into a high-pressure kettle, and adding a three-dimensional substrate material into the solution for hydrothermal solution; washing the three-dimensional substrate material for many times after cooling of hydrothermal solution, and performing drying in a baking oven to obtain a uniform nanometer flower spherical Mn3O4 material grown on the three-dimensional substrate material. The prepared material is initially applied to prepare the aqueous zinc-ion battery positive electrode material, has high specific capacity and favorable cycle stability, is moderate in reaction condition and simple in process and is suitable for production on a large scale.

Owner:CENT SOUTH UNIV

Method for making ferrous lithium phosphate/carbon compound material of high active disorderly ferric phosphate

InactiveCN101237043AHigh activitySmall particle sizeElectrode manufacturing processesPhosphorus compoundsCarbon compositesPhosphate

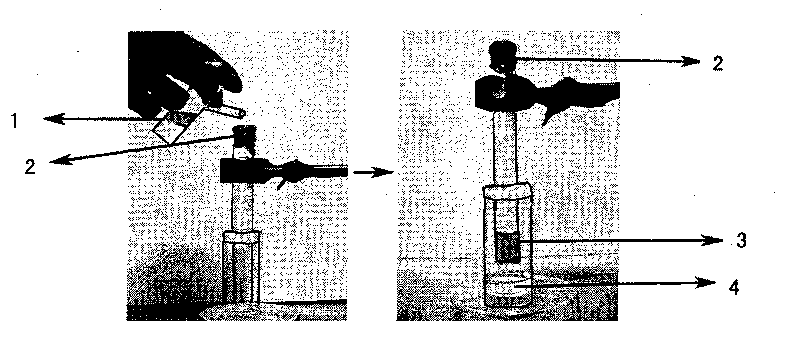

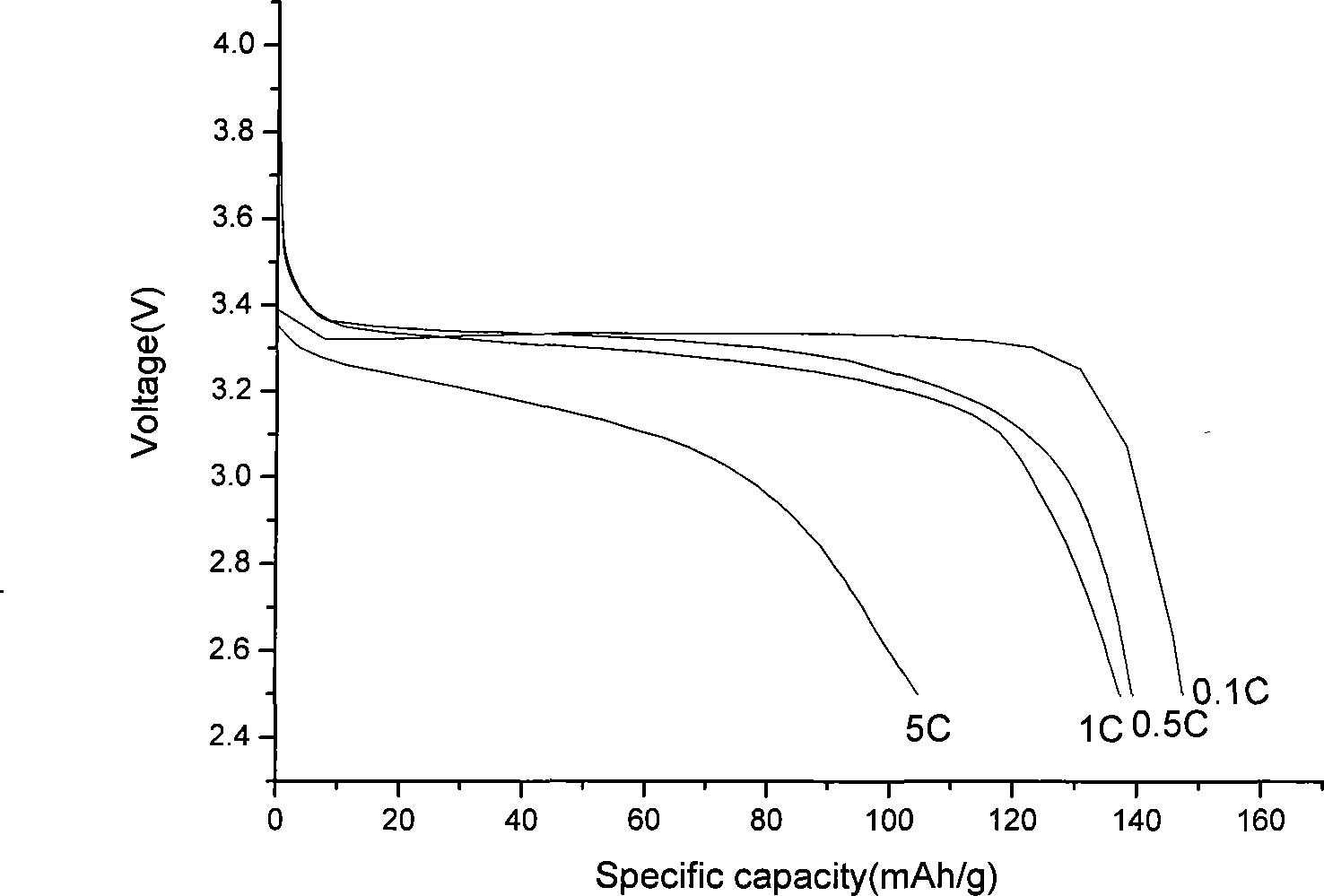

The present invention belongs to energy material, and in particular relates to a method of using high-activity disordered iron phosphate to prepare ferrous phosphate lithium / carbon composite material. A ferrous iron source is mixed with phosphorus source solution according to stoichiometric ratio, has hydrogen peroxide added in, has pH value controlled and is stirred so as to prepare high-activity disordered iron phosphate. iron phosphate, a lithium source and a carbon source are mixed pro rata, ball-milled uniformly, spray-dried and treated via high temperature under protective atmosphere, so as to obtain high specific capacity ferrous phosphate lithium / carbon composite material of which the average particle diameter is 200-500nm, 0.25C rate specific discharge capacity reaches 145-150mAh / g, 1C rate specific discharge capacity reaches 130-140mAh / g, and 5C rate specific discharge capacity reaches 105-110mAh / g. The method is low in cost and simple in process. Prepared material is good in electrochemical performance and especially excellent in rate performance, which is applicable to battery anode material of electric vehicles and other large-scale mobile devices.

Owner:NORTHEAST NORMAL UNIVERSITY

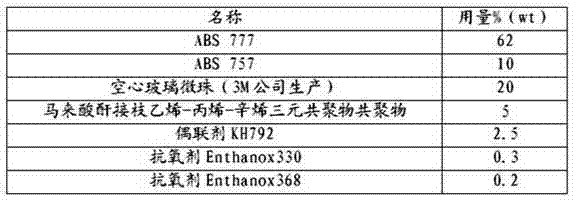

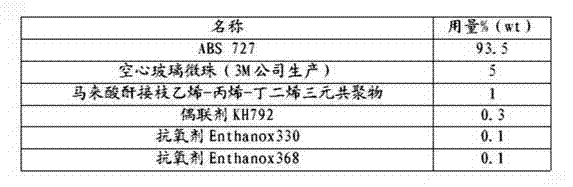

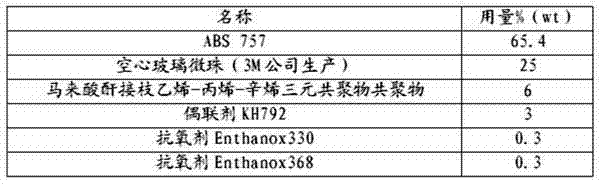

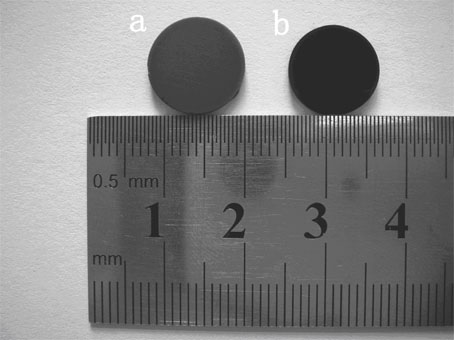

Lightweight noise-reduction modified ABS (Acrylonitrile Butadiene Styrene) material and preparation method thereof

The invention relates to a lightweight noise-reductio modified ABS (Acrylonitrile Butadiene Styrene) material which comprises the following raw materials in percentage by weight: 39-93.5% of ABS resin, 5-45% of inorganic filler, 1-10% of dispersing agent, 0.3-5% of coupling agent and 0.2-1% of antioxygen, wherein the inorganic filler is a hollow inorganic particle. Since the hollow inorganic particle is added to the formula of the material, the low density of the material is maintained while the mechanical property of the material is improved; meanwhile, the material is endowed with a certainnoise reduction function because of the special hollow particle structure, therefore, the material has a very high application value in lightweight automobile manufacture, damping and noise reductionand the like. The lightweight noise-reduction modified ABS material is prepared by the step of processing the inorganic filler fed into a screw extruder respectively from multiple lateral feeding ports arranged at different positions, so that the hollow structure of the inorganic filler is not damaged when the inorganic filler is melt and extruded, the inorganic filler can be dispersed more evenly in a substrate, and the prepared material is endowed with better properties.

Owner:辽宁金发科技有限公司

Reduction and utilization method of dedusting ash of stainless steel

InactiveCN101705333AReduce pollutionHigh recovery rateRotary drum furnacesProcess efficiency improvementMixed materialsMolten steel

The invention relates to a reduction and utilization method of dedusting ash of stainless steel, comprising the following steps of: (1) preparing materials: uniformly stirring and mixing raw materials into a mixed material according to following proportions: 90-95 dedusting ash, 2-4 reducing agent and 3-6 bonding agent; (2) extrusion formation: pressing the mixed material into dedusting ash pressure balls; (3) maintaining: naturally drying and maintaining the dedusting ash pressure balls, wherein the measured intensity of the pressure balls is 2420N / each ball-2820N / each ball; (4) sintering: adding the dedusting ash pressure balls into a rotary kiln, sintering at 650+ / -50 DEG C for no less than 20 minutes, and discharging; (5) preparing materials for an electric furnace according to the following proportions: 70-80 stainless steel waste steel, 35-40 high-carbonferrochrome, 40-45 pig iron containing chromium and nickel, 3-5 dedusting ash pressure balls, 6-8 slag former and 0.3-0.5 reducing agent; and (6) melting: adding the prepared materials into the electric furnace for melting, and tapping when the temperature and the components of the molten steel meet the requirement. The reduction and utilization method of the dedusting ash of stainless steel has the advantages of low cost and little pollution to the environment.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

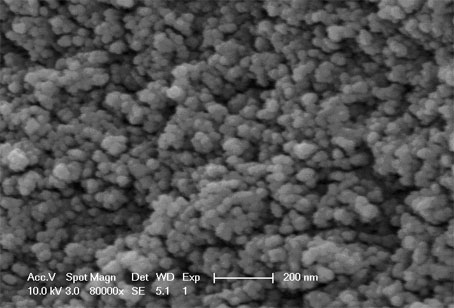

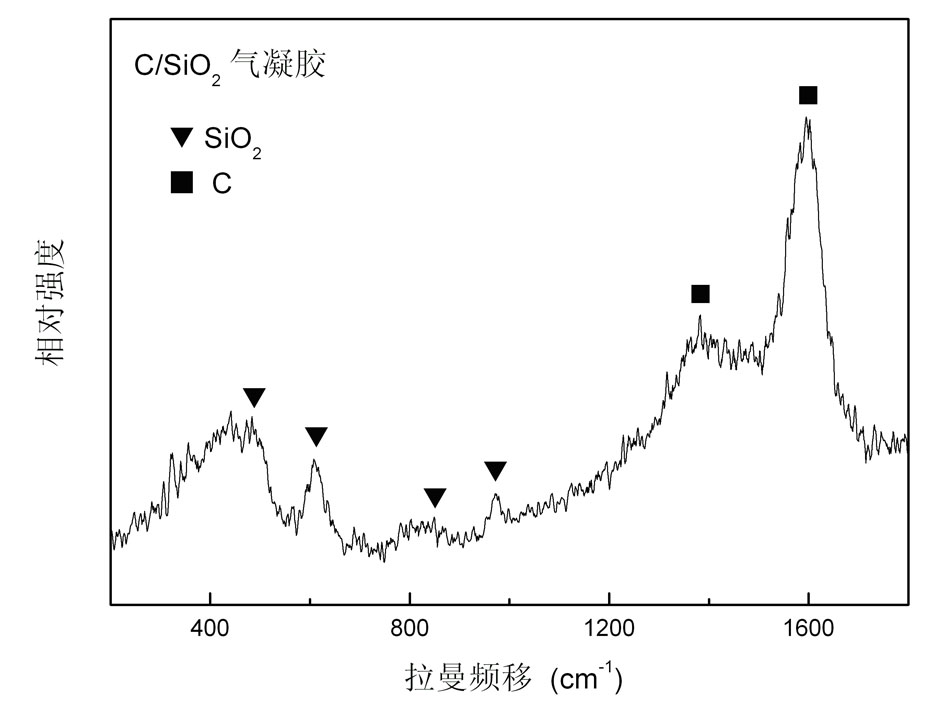

Method for quickly preparing carbon-silicon dioxide composite aerogel

The invention relates to a method for quickly preparing carbon-silicon dioxide composite aerogel. In the method, resorcinol, formaldehyde and tetraethoxysilane are taken as reactants, and a low-density and high-porosity carbon-silicon dioxide composite aerogel material is prepared by combining a sol-gel method under the catalysis of composite acid in an adjustable proportion with a special drying and carbonizing process. Compared with the conventional method for preparing similar materials under the catalysis of alkali, the preparation method has the advantages that: by a one-pot sol-gel synthesis process, the solation and gelation processes of two precursors, namely carbon and silicon dioxide are performed simultaneously, and the components of the material are more uniformly compounded; and gelation time and ageing time are short, preparation efficiency is high, the preparation process is simple, the method can be operated at room temperature, and the like. The prepared material can be used for the fields of adsorption filtration, catalysis, energy, aerospace, laser inertial confinement fusion target materials and the like.

Owner:TONGJI UNIV

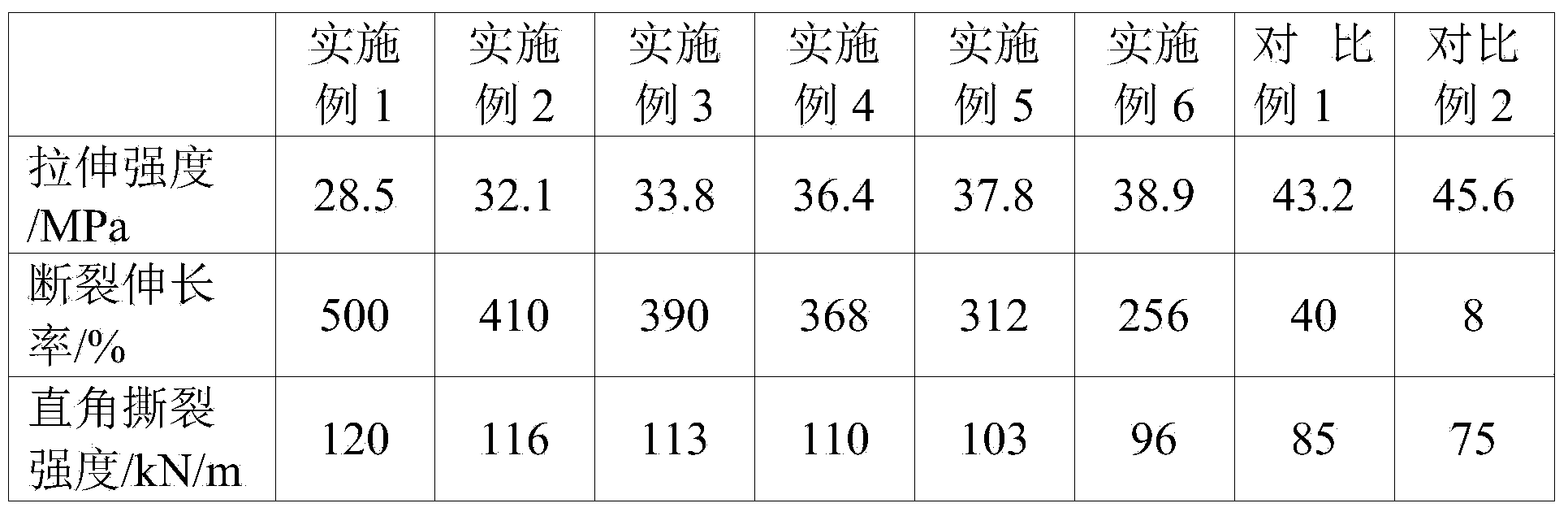

PLA (polylactic acid) modified material, preparation method thereof and PLA biodegradable mulching film

The invention discloses a PLA (polylactic acid) modified material, a preparation method thereof and a PLA biodegradable mulching film. The modified material contains the following raw materials in percentage by weight: 58-80wt% of PLA, 15-40wt% of PBAT (poly(butylene adipate-co-terephthalate)), 0.1-5wt% of modified talcum powder, 0.1-2wt% of antioxidant, 0.1-1wt% of ultraviolet absorption agent, 0.1-2wt% of light stabilizer, 0.1-2wt% of antiblocking agent, 0.1-1wt% of chain extender and 0.0005-0.05wt% of initiator. The PBAT is added into the PLA, and meanwhile the chain extender is used to compatibilize the polymer, so that the prepared material keeps the characteristics of high strength, high transmittancy and high cost performance of the PLA after blow molding and film forming, and meanwhile, the flexibility is enhanced.

Owner:ANHUI JUMEI BIOLOGICAL TECH

Ultra-light magnetic oil absorption material and preparation method thereof

InactiveCN103965835AEasy to prepareMild reaction conditionsOther chemical processesFreeze-dryingMagnetite Nanoparticles

The invention discloses a preparation method of an oil absorption material which is ultra-light in weight and has magnetic field response performance. The method comprises the following concrete preparation processes: dispersing magnetic nanoparticles, a porous material and a functional polymer into a dispersion medium; ultrasonically dispersing, and then drying by a freeze-drying method or a supercritical fluid drying method, and carrying out high-temperature treatment so as to obtain the magnetic oil absorption material which is very low in mass and has a porous structure. The method has the characteristics of being simple in preparation process, simple and feasible in reaction condition, and easy to achieve large-scale production; the prepared material can be applied to treatment of marine oil leakage, and separation of hazardous organic compounds in industrial sewage. The ultra-light magnetic oil absorption material floats on water to adsorb crude oil or organic matters when being used due to light weight, and quick magnetic separation and enrichment can be achieved after adsorption is ended.

Owner:SOUTHWEST PETROLEUM UNIV

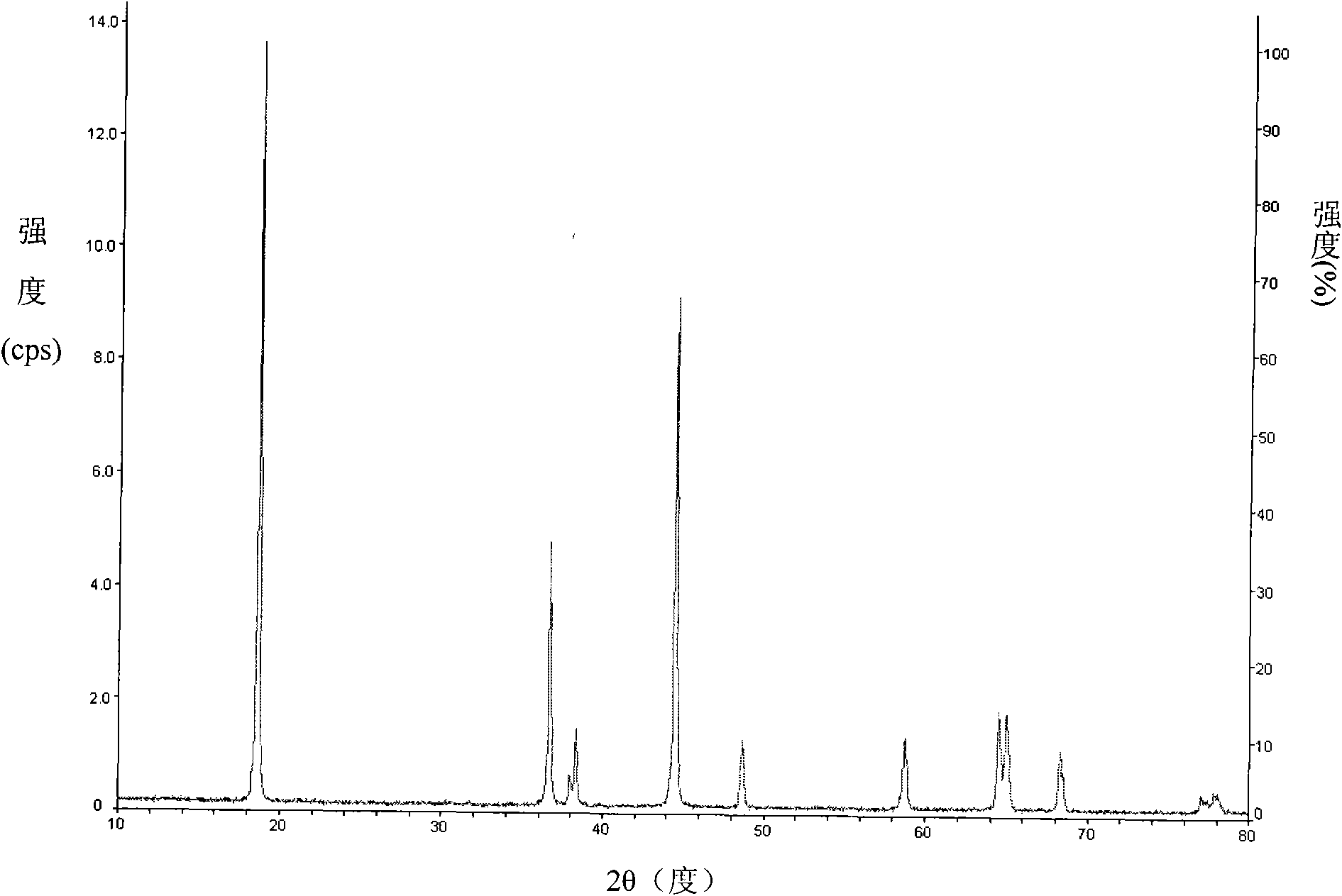

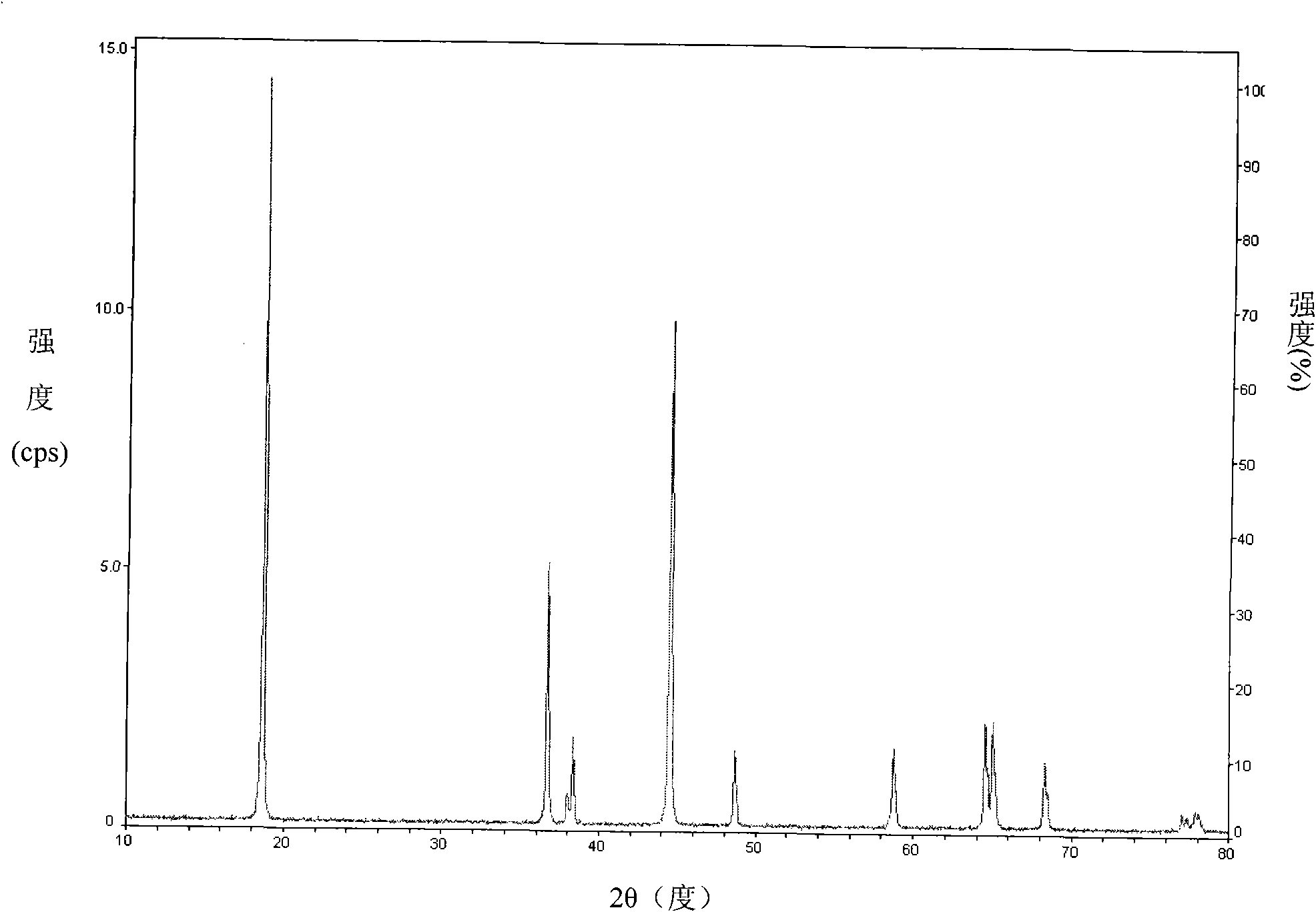

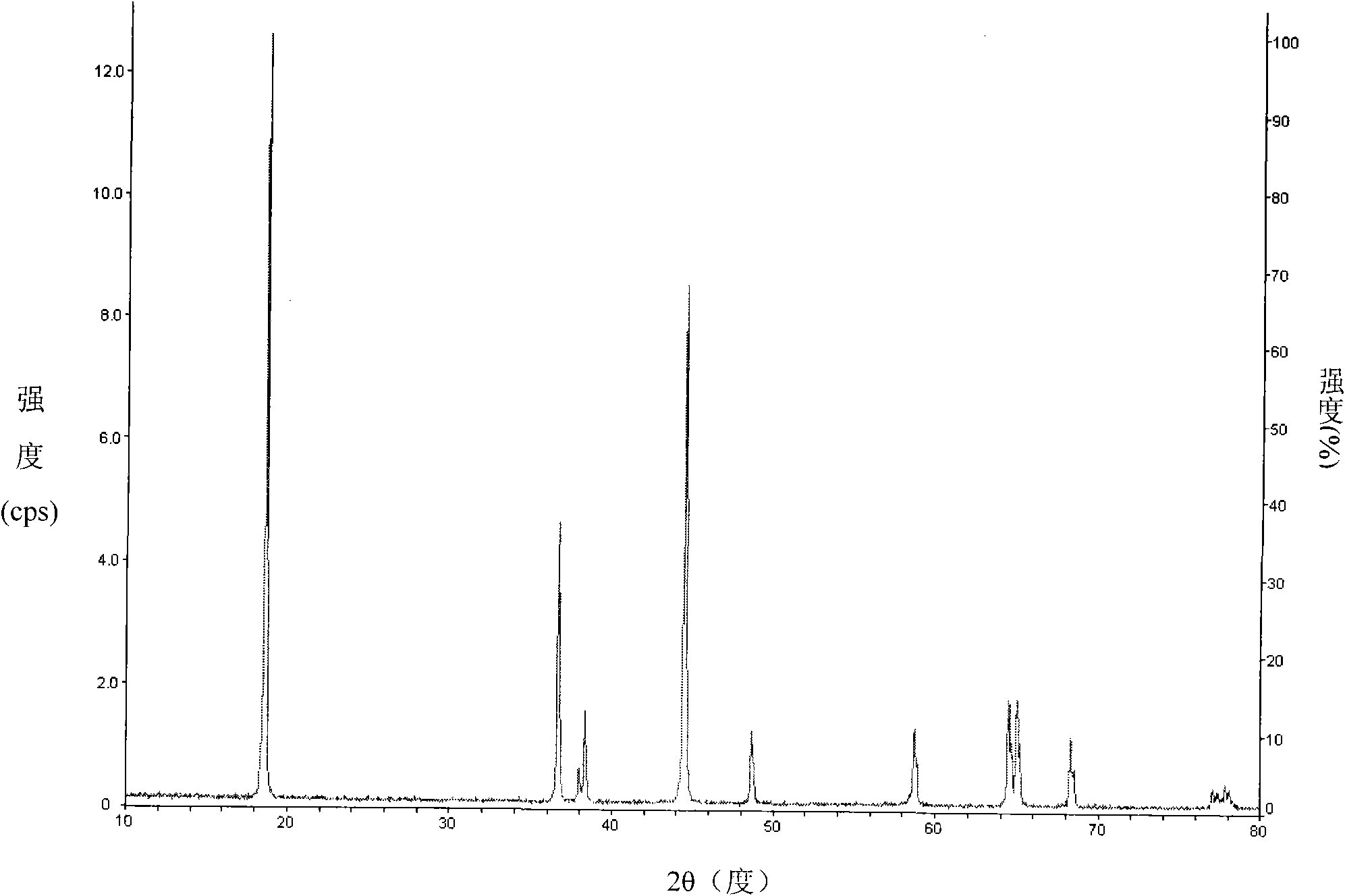

Lithium ion battery anode material as well as preparation method and battery thereof

ActiveCN101585560AIncrease production capacityHigh specific capacityCell electrodesFinal product manufacturePrepared MaterialMaterials science

The invention relates to a lithium ion battery anode material LiNi 1-x-y Cox My O2 as well as a preparation method and a battery thereof. In the formula of the material, x is not less than 0.01 and not more than 0.20, y is not less than 0 and not more than 0.10, and M is one or the composite of Mn, Al, Ti, Cr, Mg, Ca, V, Fe and Zr. The lithium ion battery anode material is characterized in that the ratio of the intensity I 003 of the (003) crystal face diffraction peak and the intensity I 104 of the (104) crystal face diffraction peak of LiNi 1-x-y Cox My O2, namely I003 / I104, is 1.21 to 1.26, and the difference value delta 2 theta of (108) crystal face diffraction peak and (110) crystal face diffraction peak is 0.520 to 0525. The prepared material has the advantages of high output, difficult agglomeration and higher discharge specific capacity.

Owner:BYD CO LTD

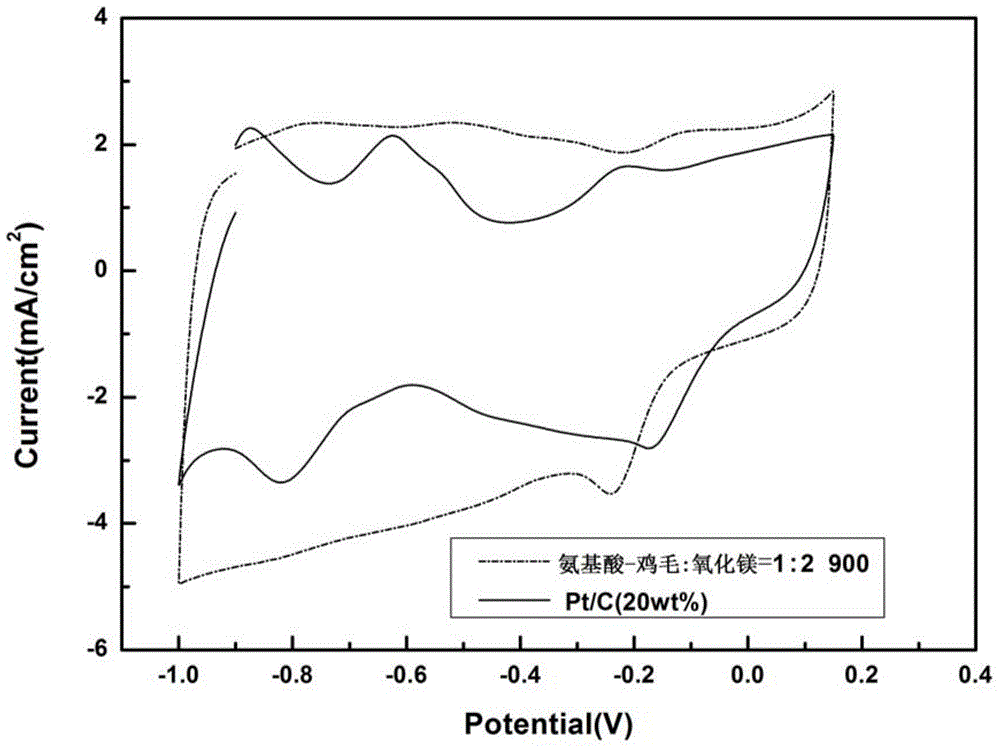

Nitrogen-sulfur co-doped carbon material with electro-catalytic oxygen reduction activity and preparation method of carbon material

InactiveCN104399508AAvoid synthetic stepsGood removal effectPhysical/chemical process catalystsCell electrodesOxygenOxygen reduction

The invention provides a nitrogen-sulfur co-doped carbon material with an electro-catalytic oxygen reduction activity and a preparation method of the carbon material, and belongs to the technical field of new material application. The technologic process comprises the following steps: performing ultrasonic cleaning on hairs with acetone, then shearing and crushing the hairs, pouring the hairs into a liner of a reaction kettle, adding analytically pure ammonia water, carrying out a hydrothermal degradation reaction, drying the solution obtained from hydrothermal degradation to obtain solid amino acid, mixing the solid amino acid with a template agent uniformly, thermally decomposing the mixture under an inert atmosphere, removing the template agent with diluted hydrochloric acid from the obtained sample, washing and drying, so as to prepare the nitrogen-sulfur co-doped carbon material. As the carbon material is prepared by taking hairs as the raw materials, the raw materials are simple and accessible, and low in cost; the selected template agent is low in cost and easy to remove; the preparation method is simple in technology; the prepared material is high in nitrogen and sulfur content, and has larger specific surface area, and is rich in pore structures; the nitrogen-sulfur co-doped carbon material prepared by the method shows up excellent properties in fuel cell cathode oxygen reduction and catalysis.

Owner:SOUTH CHINA UNIV OF TECH

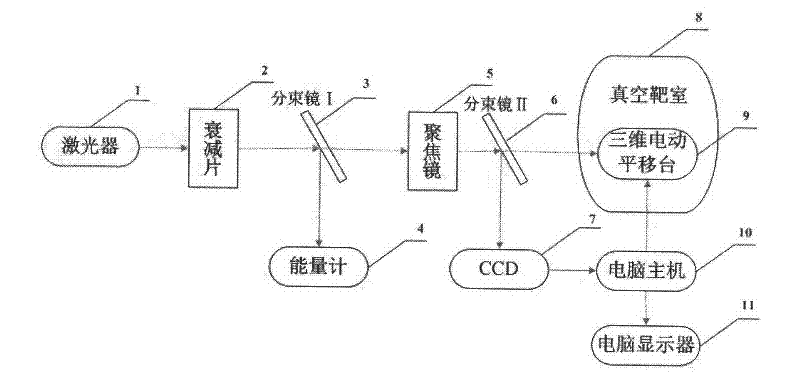

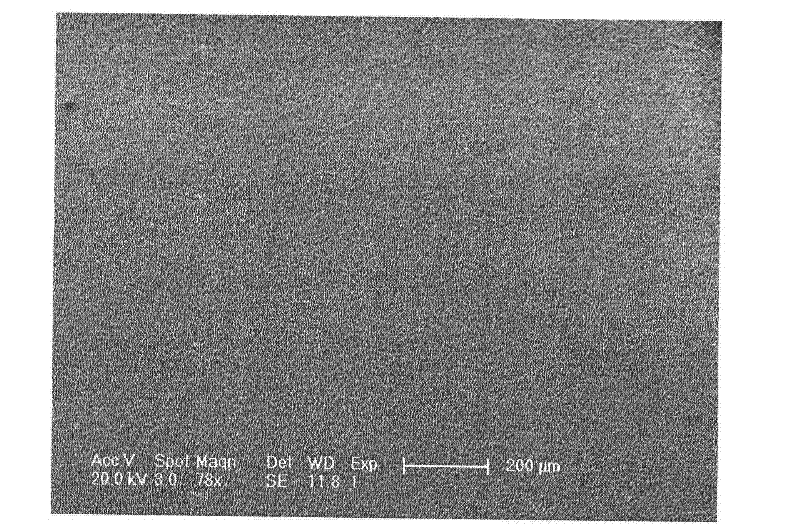

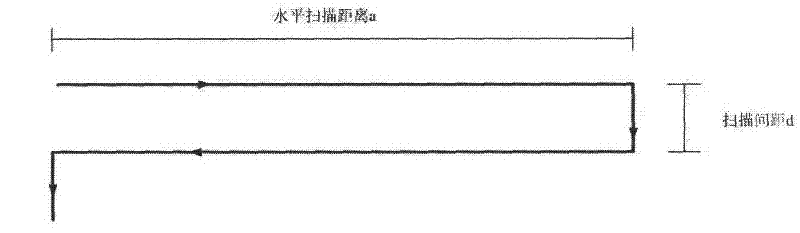

Preparation device for preparing functional micro-nano materials on silicon surfaces based on femtosecond laser and method

InactiveCN102500923AReduce heat damageEasy to processDecorative surface effectsChemical vapor deposition coatingField emission deviceSolar cell

The invention provides a preparation device for preparing functional micro-nano materials on silicon surfaces based on femtosecond laser and a method. When the device is used for preparation, scanning speed reaches 4mm / s, and is increased by 20 times as compared with scanning speed when micro-nano materials are prepared in a traditional method. Simultaneously, supersaturation doping of the silicon material surface and preparation of micro-nano structures of the surfaces are realized during preparation, prepared micro-nano materials can absorb 90% of light with wavelength ranging from 200nm to 2500nm, and silicon materials without scanning traces on surfaces can be obtained. The preparation device and the method are exquisite in design and easy to control, and the prepared materials can be applied to solar cells, detectors, field emission devices and the like in the photoelectric industry.

Owner:CHANGCHUN UNIV OF SCI & TECH

Polymer electrolyte, its preparation method and battery comprising the same

ActiveCN103700797AImprove electrochemical performanceGood flexibilityCell seperators/membranes/diaphragms/spacersFinal product manufactureFiberComposite electrolyte

The invention provides a polymer electrolyte, its preparation method and a battery comprising the polymer electrolyte. The polymer electrolyte contains a stance phase and an ionic conductive phase adsorbed on the stance phase. The stance phase is an electrostatic spinning fiber film, and the ionic conductive phase includes a polymer able to undergo complexation with lithium ions and a lithium salt. The polymer able to undergo complexation with lithium ions contains an ether oxygen functional group. A bi-continuous phase composite electrolyte film characterized by high mechanical strength, good flexibility, high ionic conductivity, good thermal stability, high interface stability and good electrochemical stability can be obtained, and the preparation process is simple and is low in cost. The prepared material can be widely used in mobile phones, notebook computers and other mobile devices, as well as electric vehicles and other fields, and has strong practical significance to development of the battery industry. The polymer battery involved in the invention is different from liquid or gel state batteries, is free of plasticizer, does not cause leakage and other potential safety hazards, so that it can be used in high temperature environment, and does not have combustion, explosion and other hidden dangers.

Owner:BYD CO LTD

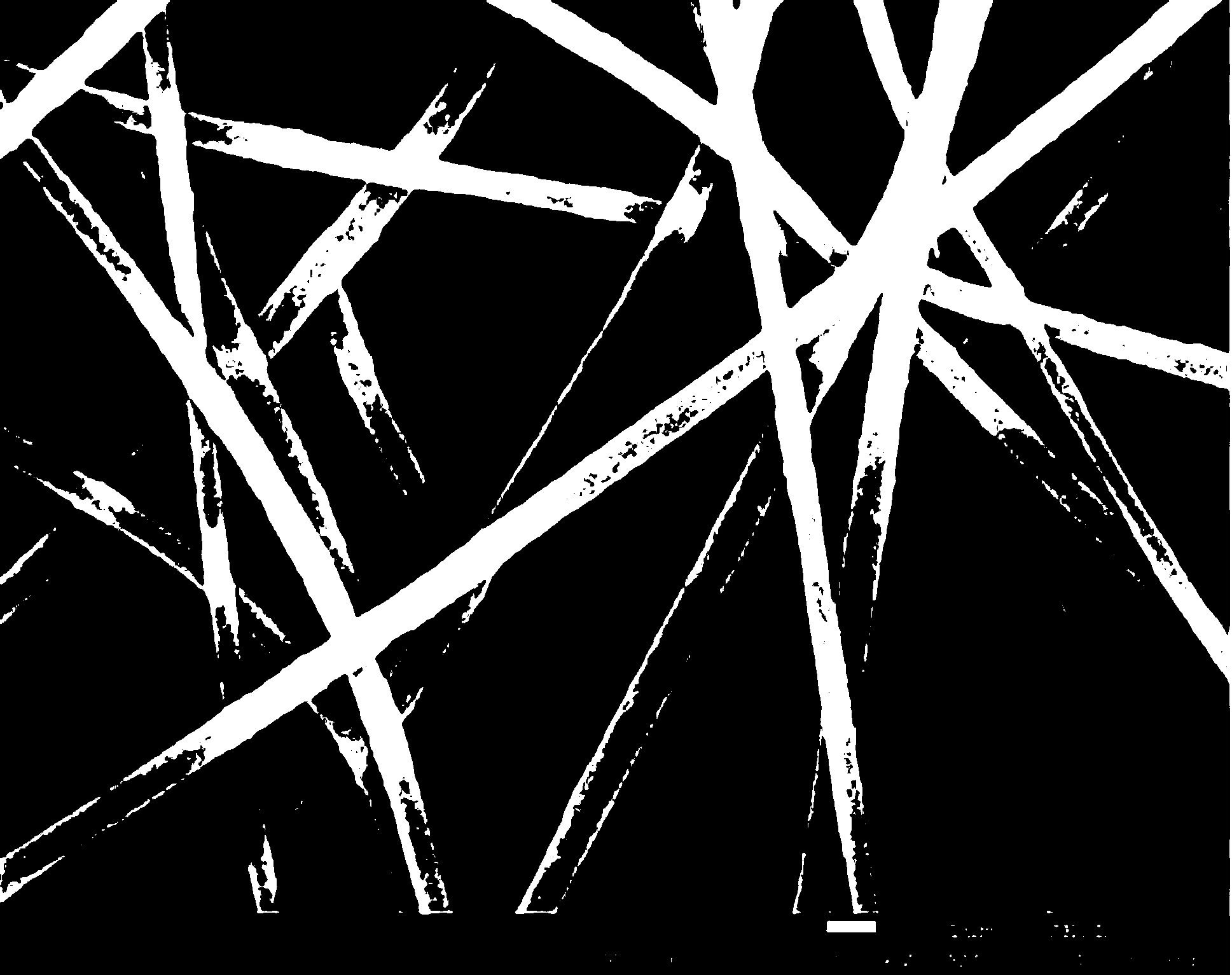

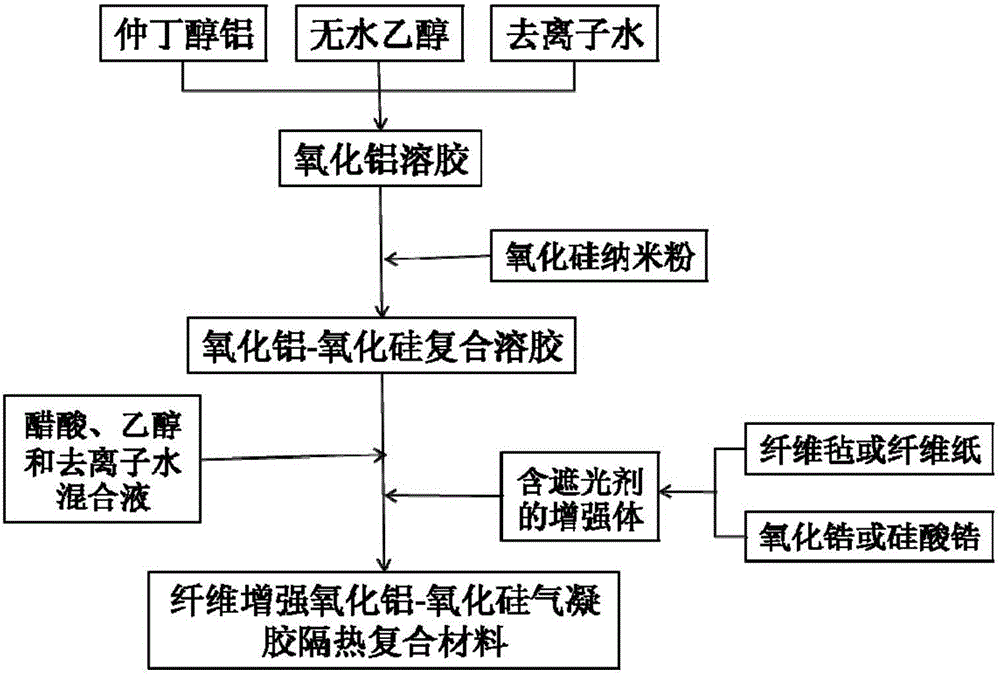

Fiber-enhanced Al2O3-SiO2 aerogel efficient heat isolation composite material and preparation method thereof

The invention relates to a fiber-enhanced Al2O3-SiO2 aerogel efficient heat isolation composite material and a preparation method thereof. The composite material is prepared from the following ingredients in percentage by mass: 25 percent to 90 percent of Al2O3-SiO2 aerogel base bodies, 5 percent to 45 percent of enhanced fiber and 5 percent to 30 percent of light-shielding agents, wherein the light shielding agents are zirconium dioxide or zirconium silicate. The highest use temperature of the prepared material can reach 1200 DEG C; good heat insulation performance is realized in the range of 25 DEG C to 1200 DEG C.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

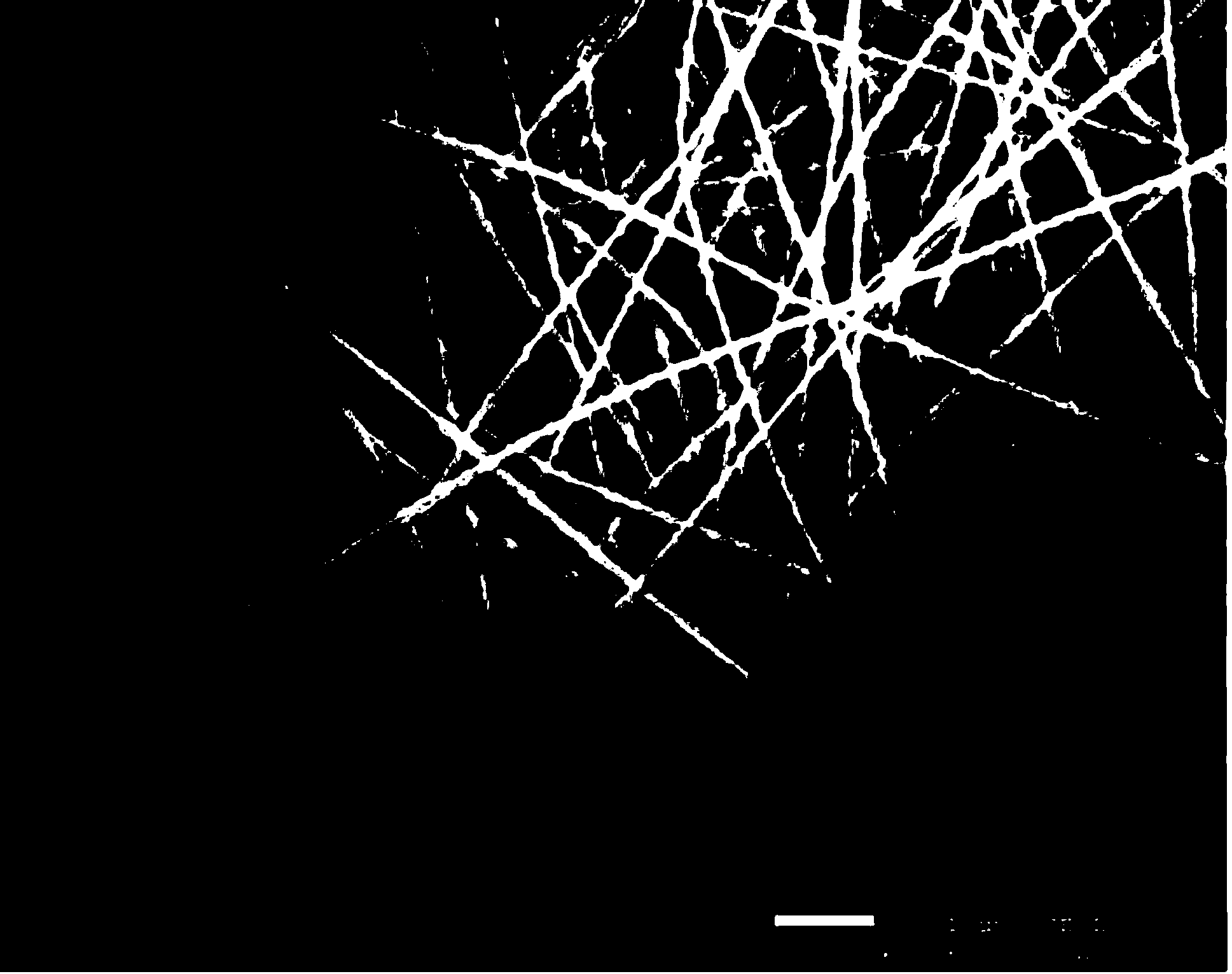

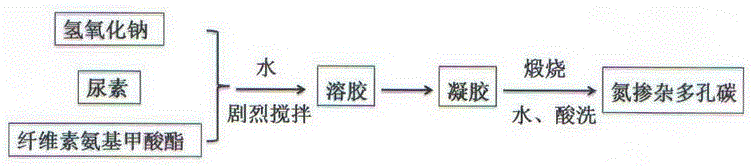

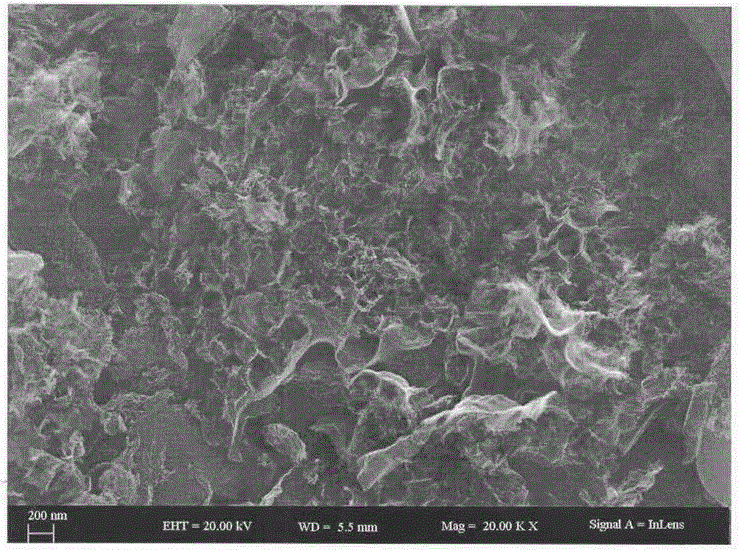

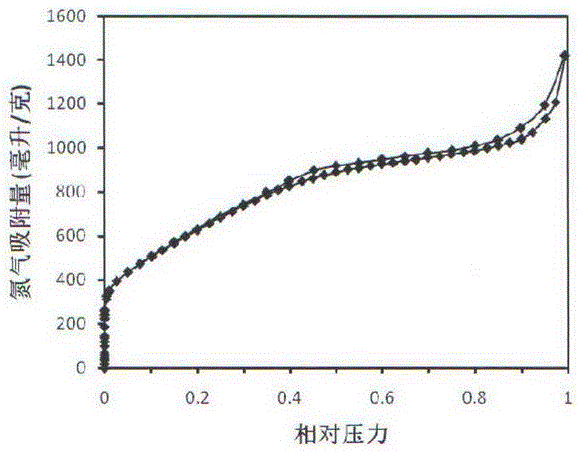

Application and preparation method of biomass-based nitrogen-doped porous carbon

InactiveCN106629655ASimple processImprove stabilityHybrid capacitor electrodesCarbon preparation/purificationCelluloseCarbamate

The invention discloses application and a preparation method of biomass-based nitrogen-doped porous carbon. The method includes: taking cheap cellulose carbamate as a raw material and urea as a nitrogen source, well mixing with sodium hydroxide solution, drying to form sol, and performing high-temperature calcination to obtain the porous-structure biomass-based nitrogen-doped porous carbon high in specific surface area and pore volume. According to electron microscopy images, the prepared material is in a three-dimensional inner-crosslinked porous structure; according to XPS and elemental analysis, nitrogen is successfully doped into a carbon substrate, the nitrogen content is 7.7-15.5%, and the specific surface area is 700-3700m<2> / g; according to supercapacitor experiments, the biomass-based nitrogen-doped porous carbon is great in electrochemical performance; according to pollutant adsorption experimental data, the material is high in adsorption rate and adsorption capacity in adsorption of dye pollutant methylene blue, and the adsorption capacity reaches 1520mg / g. The method is simple in preparation, the raw materials are renewable, and low cost is realized. In addition, sodium carbonate which is a by-product is obtained by washing of calcined samples, so that cost can be effectively reduced, and economic benefits are increased.

Owner:XINJIANG TECHN INST OF PHYSICS & CHEM CHINESE ACAD OF SCI

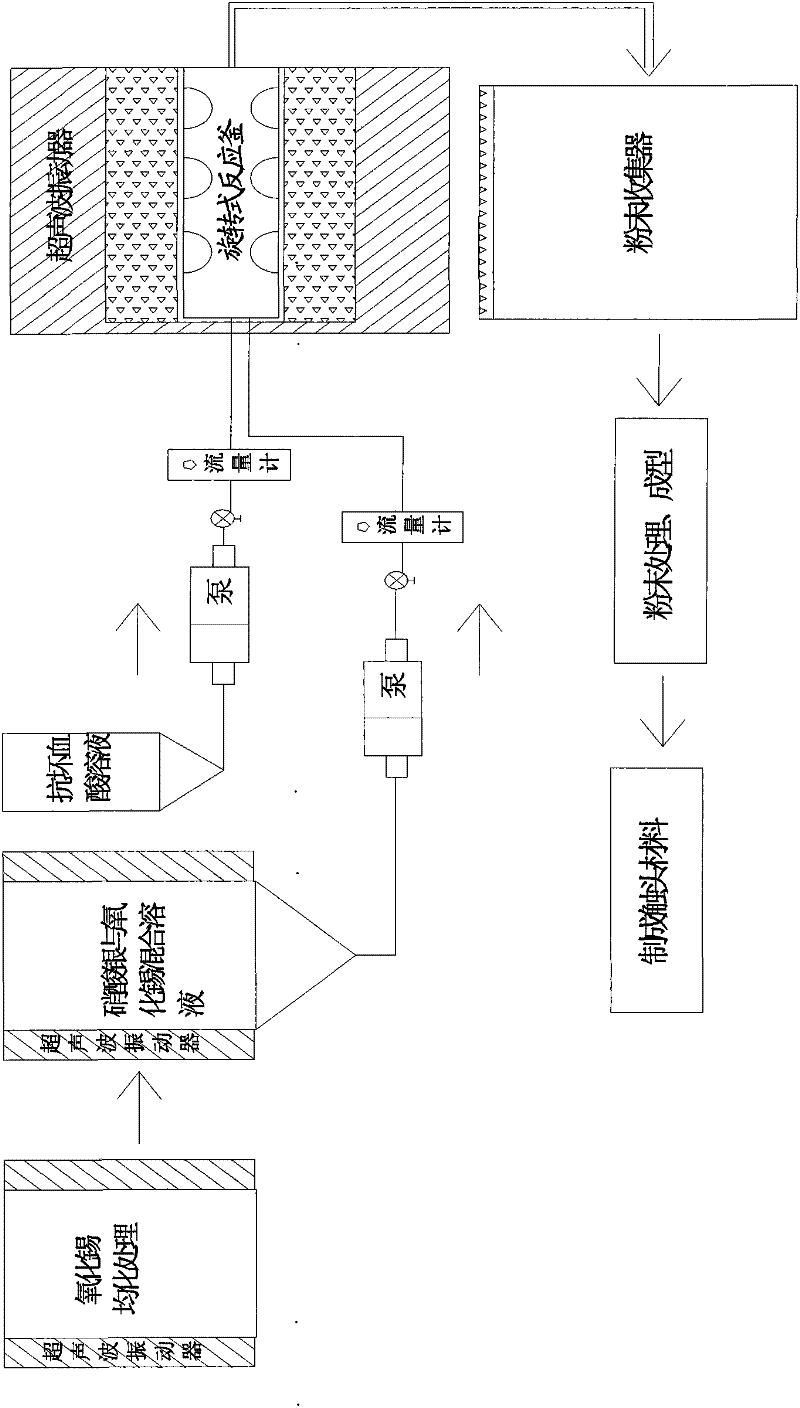

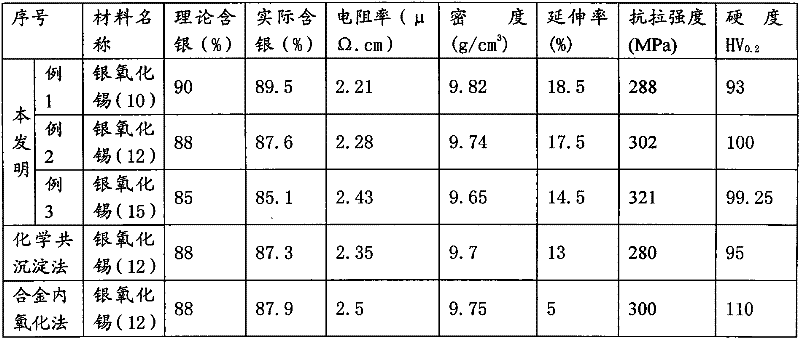

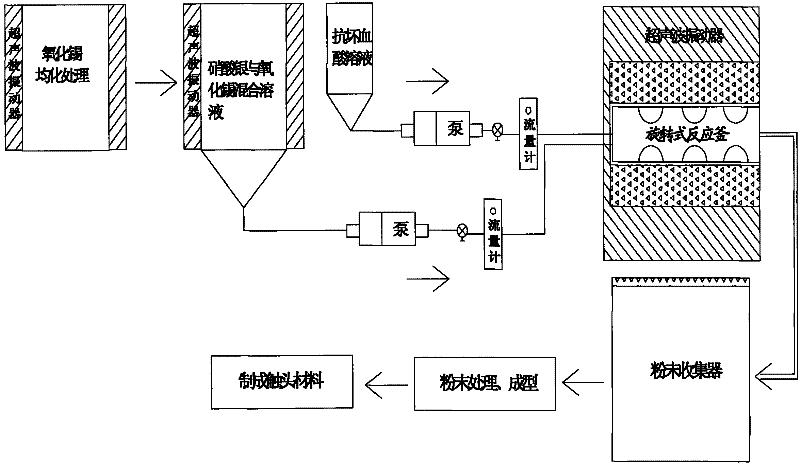

Method for continuously and homogeneously preparing silver tin oxide material

InactiveCN102389981AImprove plastic processing performanceImprove performanceElectric switchesElectric propertiesSizing

The invention discloses a method for continuously and homogeneously preparing a silver tin oxide material, and the method comprises the following steps: firstly, homogenizing a tin oxide sizing agent; preparing a silver nitrate solution according to a content ratio of silver and tin oxide; mixing the silver nitrate solution with the tin oxide sizing agent; respectively injecting a sizing agent mixture and an ascorbic acid solution into a rotary type reaction kettle; reacting while splashing and rotating, and additionally utilizing an ultrasonic vibrator to homogenize, thereby acquiring uniformly distributed silver tin oxide powder; and molding and then preparing into an electrical contact. The method can be used for overcoming the difficulties that distribution of tin oxide grains in a silver substrate is not uniform enough, processing and electric properties are unstable, and the like. According to the method, the probability of powder conglobation is efficiently reduced, the distribution of the acquired silver tin oxide powder is more uniform, and the processing property and electric property of the prepared material are better and stable. The process of the method is simple. The method can be applied to continuous production, thereby acquiring products with stable property. The method is suitable for batch production and industrialization production. Preparing processes all meet the environmentally-friendly demand.

Owner:佛山通宝精密合金股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com