Patents

Literature

101results about How to "Microstructure is easy to control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Low-density ablation thermal insulation type composite and preparation method thereof

The invention relates to a low-density ablation thermal insulation type composite and a preparation method thereof. The composite adopts phenolic aerogel of the nanometer particle structure as a matrix and adopts a flexible fiber blanket or a fiber weaving body as a reinforcement body, and the composite is obtained through the steps of phenolic resin preparation, phenolic resin solution preparation, thermal treatment of the flexible fiber blanket or the fiber weaving body, steeping of the flexible fiber blanket or the fiber weaving body with the phenolic resin solution, a sol-gel reaction, aging, drying and curing of the composite and the like. Compared with the prior art, the composite is excellent in thermal protective performance, good in mechanical performance, high in designability, simple in preparation technology, low in cost and easy to process and mold, promotes later-period dimensional cutting, meets different thermal protective needs under the medium heat flow and medium and low heat flow environments, and can be applied to manned space flight and deep space detection aircrafts, outer thermal protective layers of various tactic and strategic weapons working for a short time, and inner ablation heat insulation and thermal protective layers of engines, disposable hypersonic vehicles and the like.

Owner:EAST CHINA UNIV OF SCI & TECH

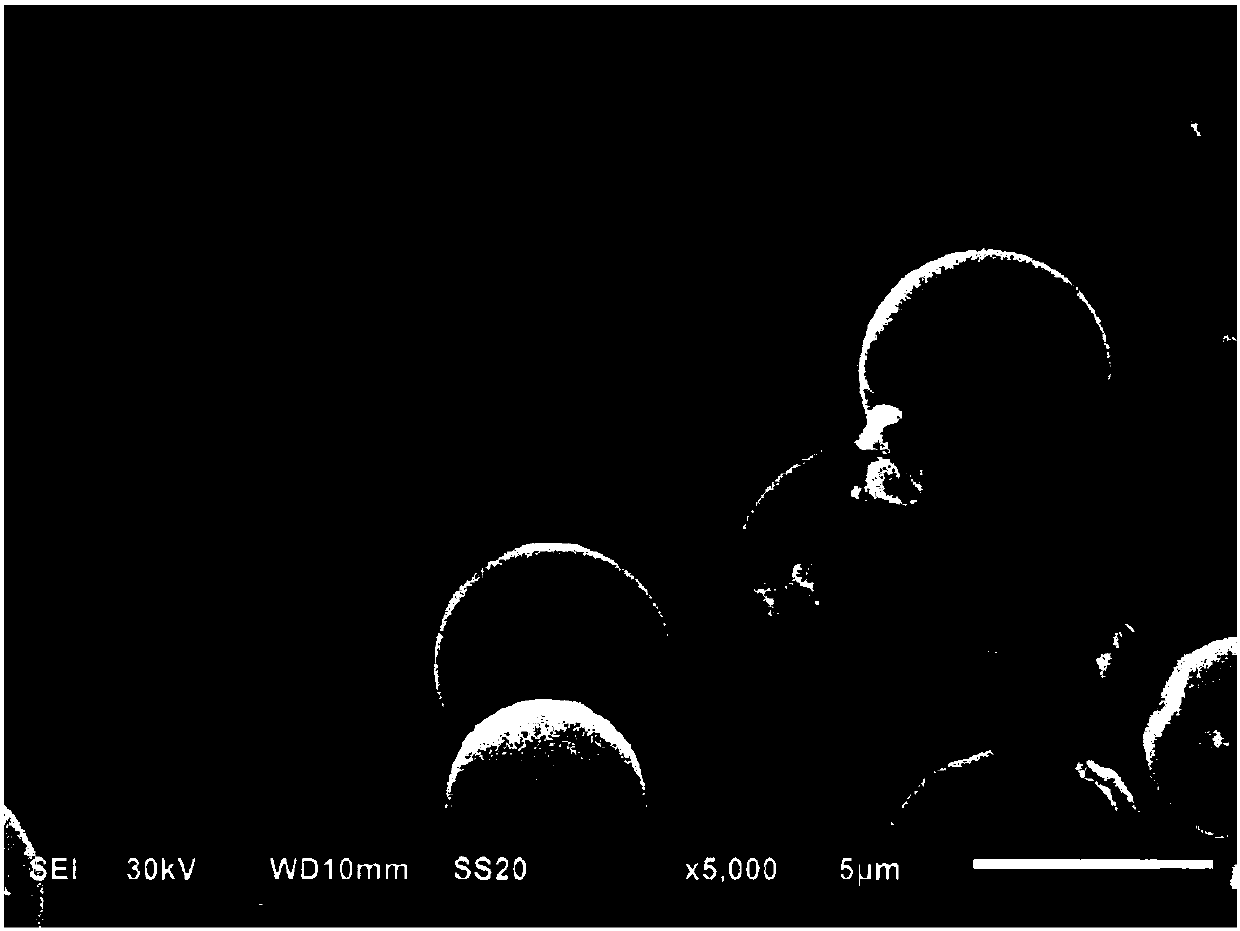

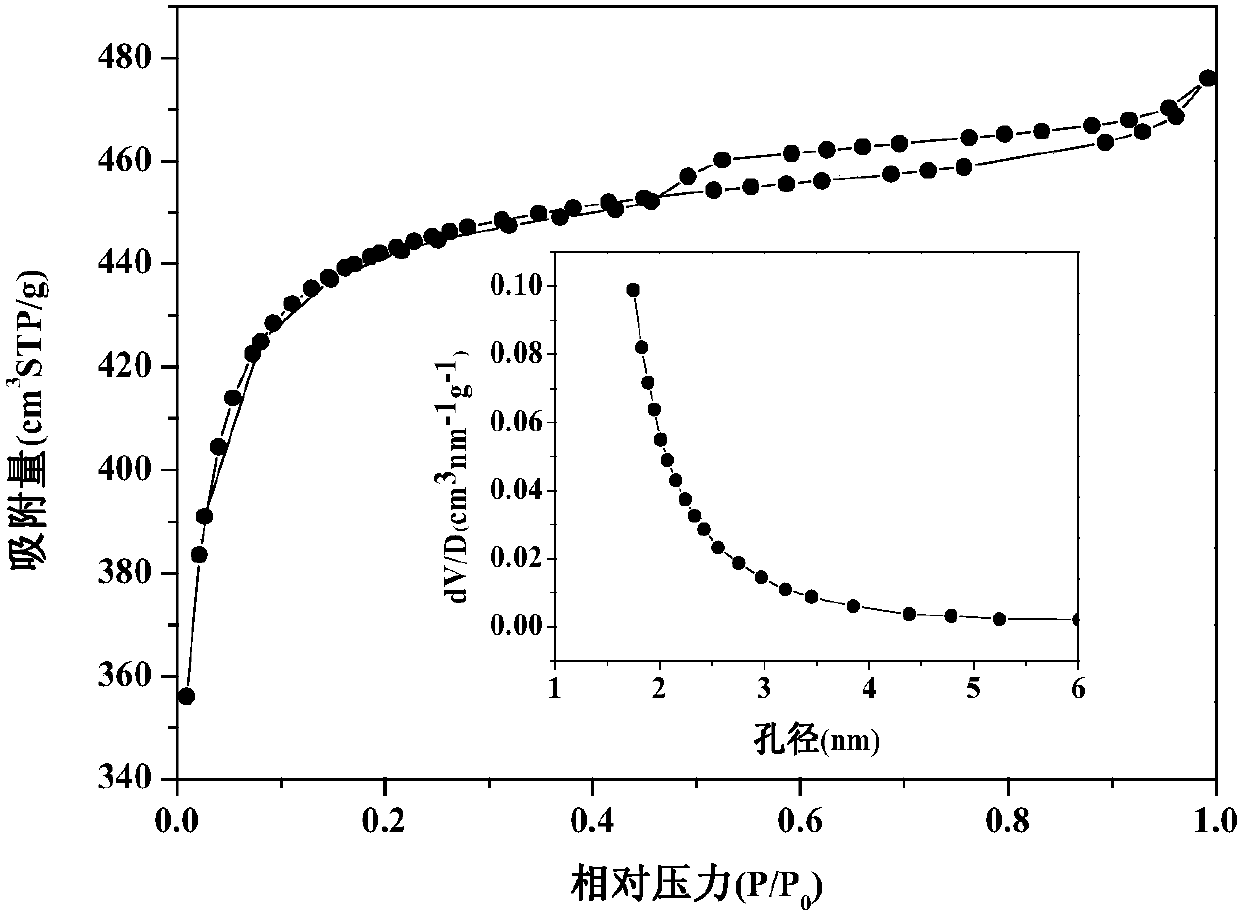

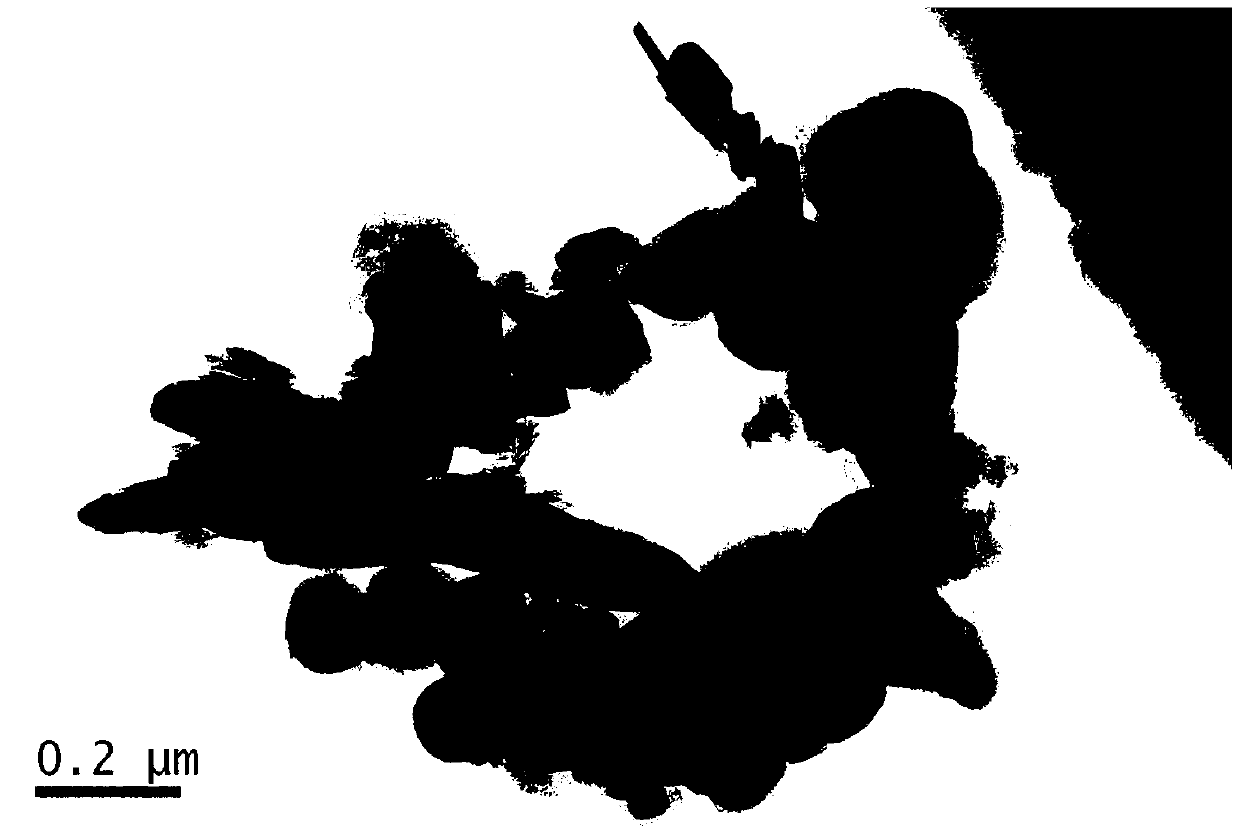

Preparation method and application of nitrogen-doped starch-based activated carbon microsphere material

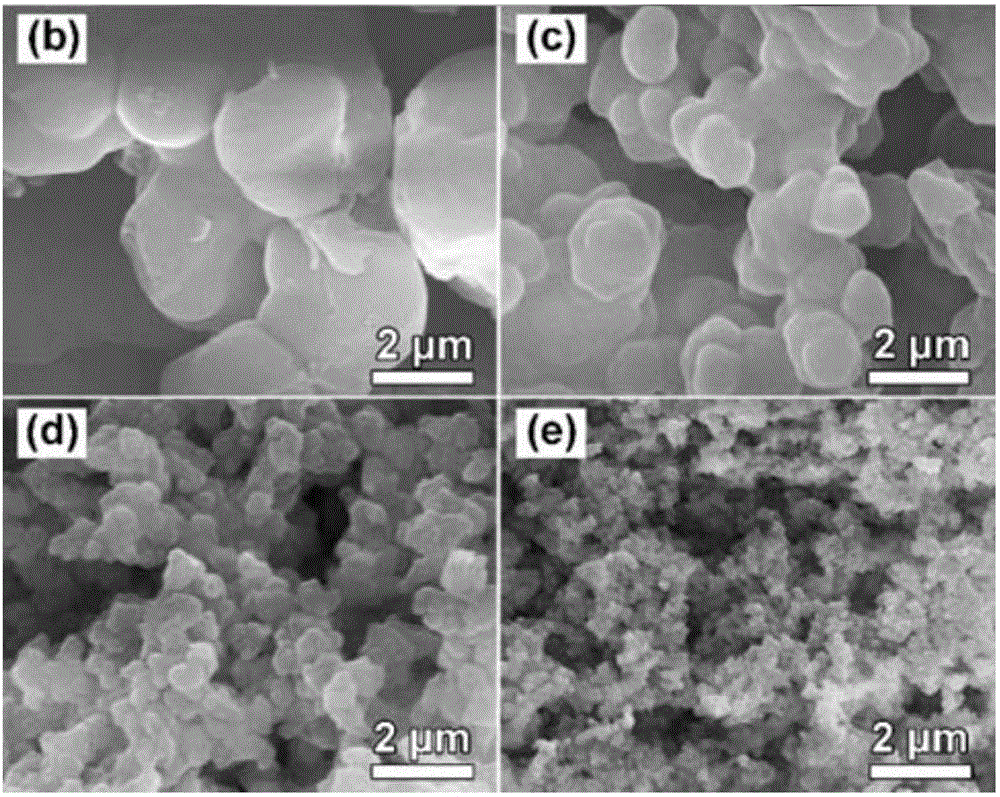

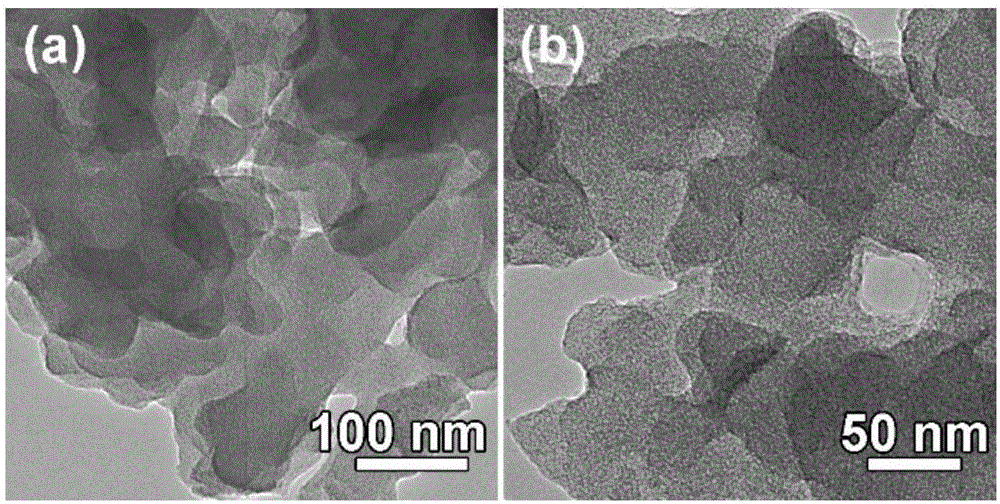

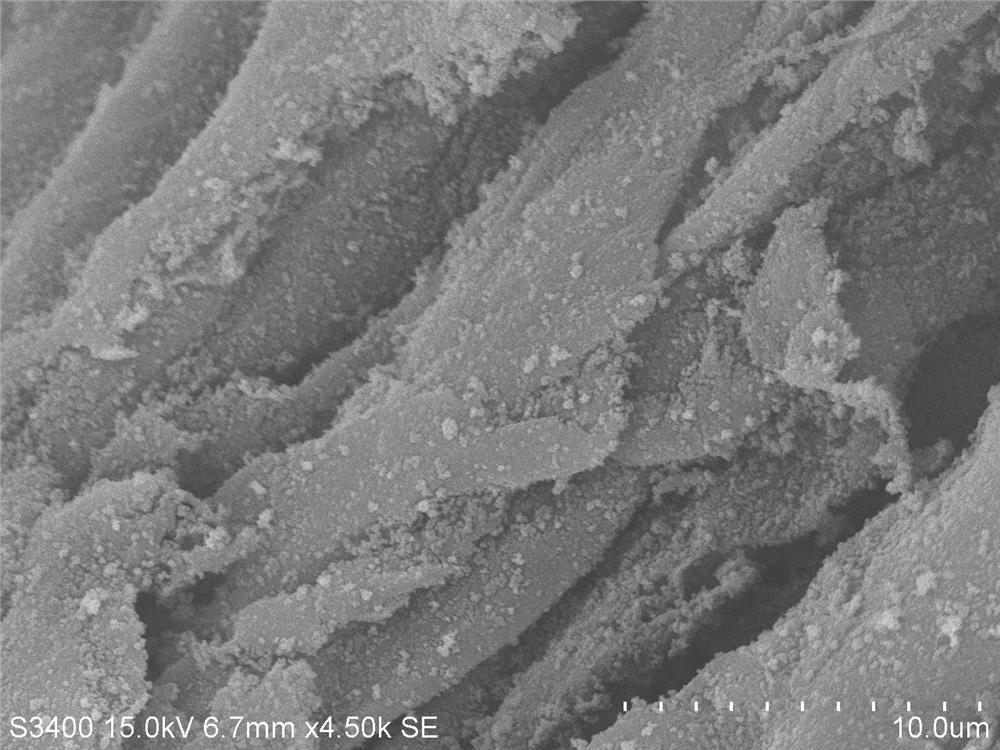

ActiveCN105948045AMicrostructure is easy to controlGood dispersionHybrid capacitor electrodesDispersityMicrosphere

The invention discloses a preparation method and application of a nitrogen-doped starch-based activated carbon microsphere material. The nitrogen-doped starch-based activated carbon microsphere material is prepared by taking starch as the carbon source and taking a nitrogen-containing compound as the nitrogen source through the steps of gelatinization, hydrothermal treatment, carbonization, activation and the like. The diameters of prepared carbon microspheres range from 0.5 micrometer to 10 micrometers, the particle size is controllable, the dispersity is good, the specific surface area ranges from 1,000 m<2> / g to 3,000 m<2> / g, and the nitrogen content ranges from 0.2% to 15%. The prepared material relates to the application fields of electrochemical energy storage, adsorption separation, catalyst carriers, drug carriers and the like and is particularly applicable to electrochemical energy storage. Green biomass is adopted as the carbon source, sources are wide, the price is low, and the preparation technology is simple, easy to control, environmentally friendly and suitable for large-scale production.

Owner:XIANGTAN UNIV

Preparation method of coal tar-based mesocarbon microbead

InactiveCN102653397AHigh content of phase carbon microspheresControl granularityCarbon preparation/purificationMicrosphereQuinoline

The invention discloses a preparation method of a coal tar-based mesocarbon microbead, comprising a process flow of pretreatment of raw materials, pyrocondensation polymerization reaction, separation and drying. The preparation method specifically comprises the following steps of: extracting, separating and removing primary quinoline insolubles of coal tar, as the raw materials, by using a mixed solvent to obtain coal tar refined soft pitch; then polymerizing the coal tar refined soft pitch for 1-8 hours at 350-450 DEG C under the rotating speed of 100-500 r / min and under the protection of inert gases by using anthracene oil or silicone oil as a reaction system viscosity regulator to obtain carbon microbead-containing mesophase pitches; and extracting by using a solvent, and drying to obtain the mesocarbon microbead. The particle diameter of the coal tar-based mesocarbon microbead prepared by using the method is 1-150 mu m, and the mass percent can reach 20-50%. The preparation method of the coal tar-based mesocarbon microbead has the characteristics of high product yield, controllable particle diameter, good sphericity, simple and convenient process, rich raw material sources, low cost and the like.

Owner:UNIV OF SCI & TECH LIAONING

Al2O3-MgO refractory castable and preparation method thereof

The invention discloses an Al2O3-MgO refractory castable and a preparation method thereof. Specifically, the refractory castable comprises: 55-75wt% of corundum grains, 10-25wt% of corundum fine powder, 5-25wt% of light burned spinel fine powder, 0.8-5wt% of magnesia fine powder, 3-6wt% of calcium aluminate cement, 1-4wt% of alpha-Al2O3 micropowder, 0.2-2wt% of silicon oxide micropowder, additional water accounting for 4.5-6wt% of the refractory castable and 0.1-1wt% of a water reducer. The preparation method includes: stirring the raw materials of the refractory castable evenly, conducting pouring vibration molding, letting the molded refractory castable green body dry naturally for 24h, and then conducting drying at 110DEG C for 12-36h, thus obtaining the Al2O3-MgO refractory castable. The refractory castable has the characteristics of controllable microstructure and controllable spinel crystal structure parameters, and the high temperature volume stability and slag resistance of refractory castable are effectively improved. The preparation method has the advantages of simple process, energy saving and environmental protection, and low cost.

Owner:SHANGHAI BAOSTEEL IND TECHNOLOGICAL SERVICE +1

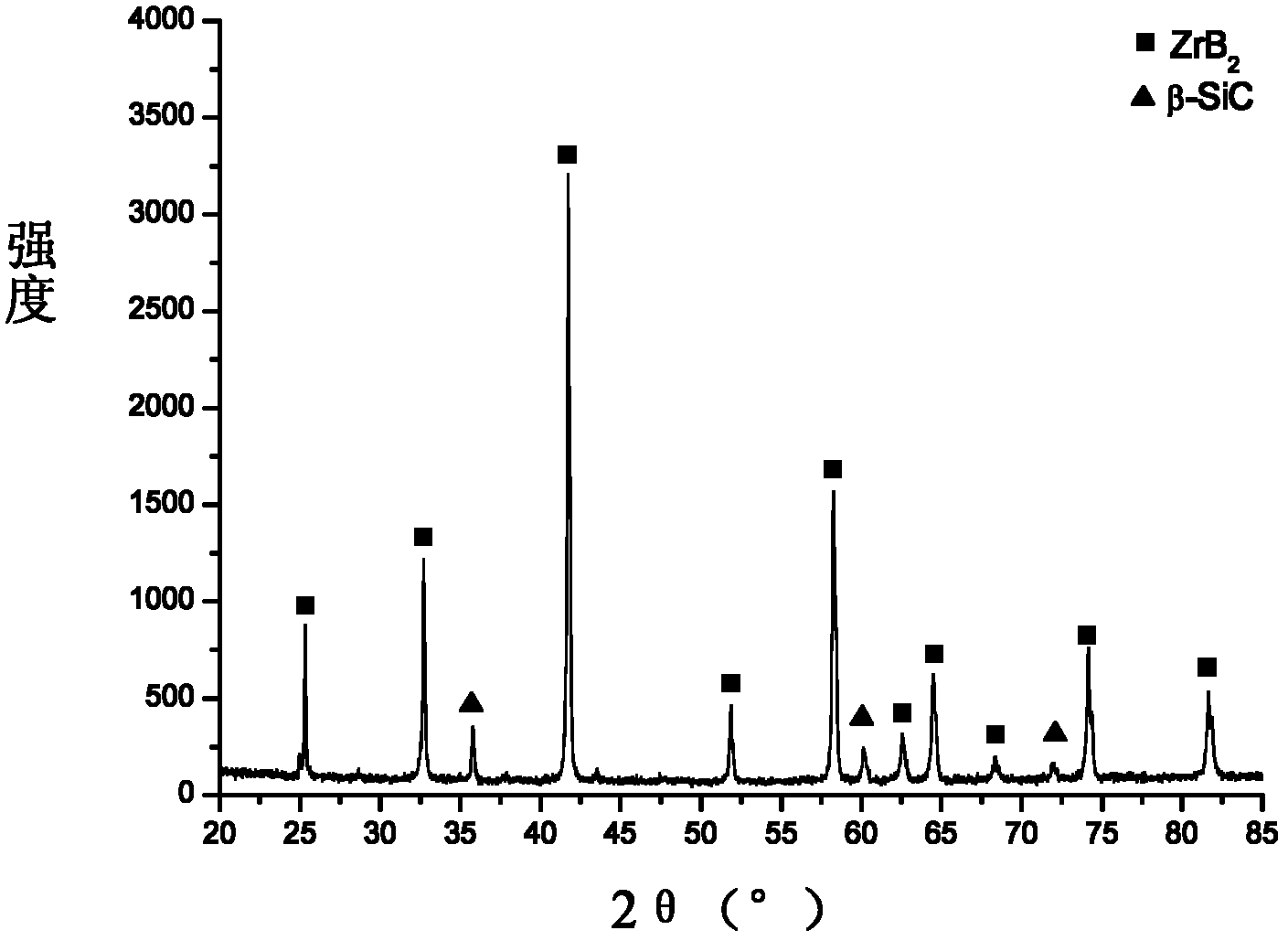

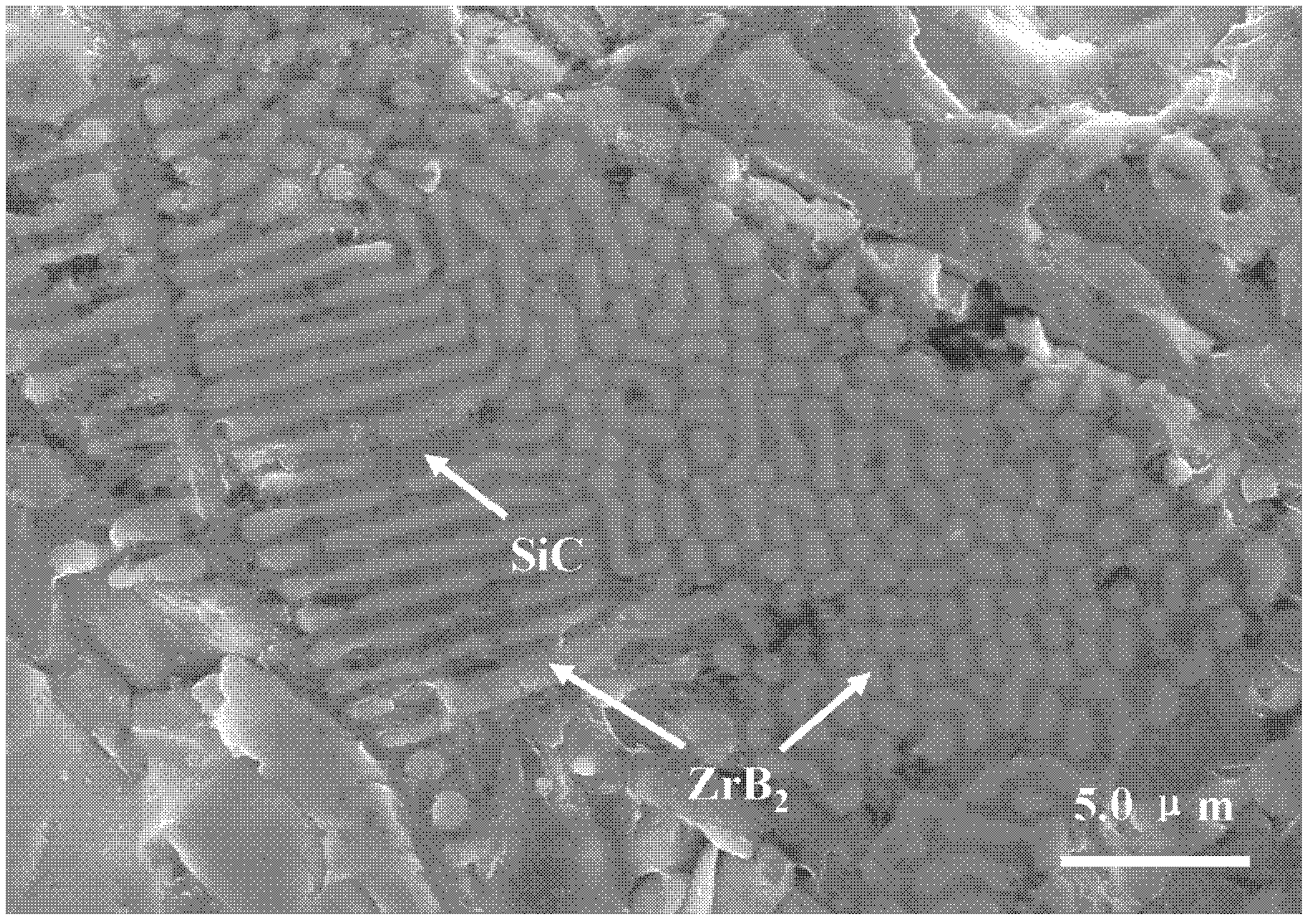

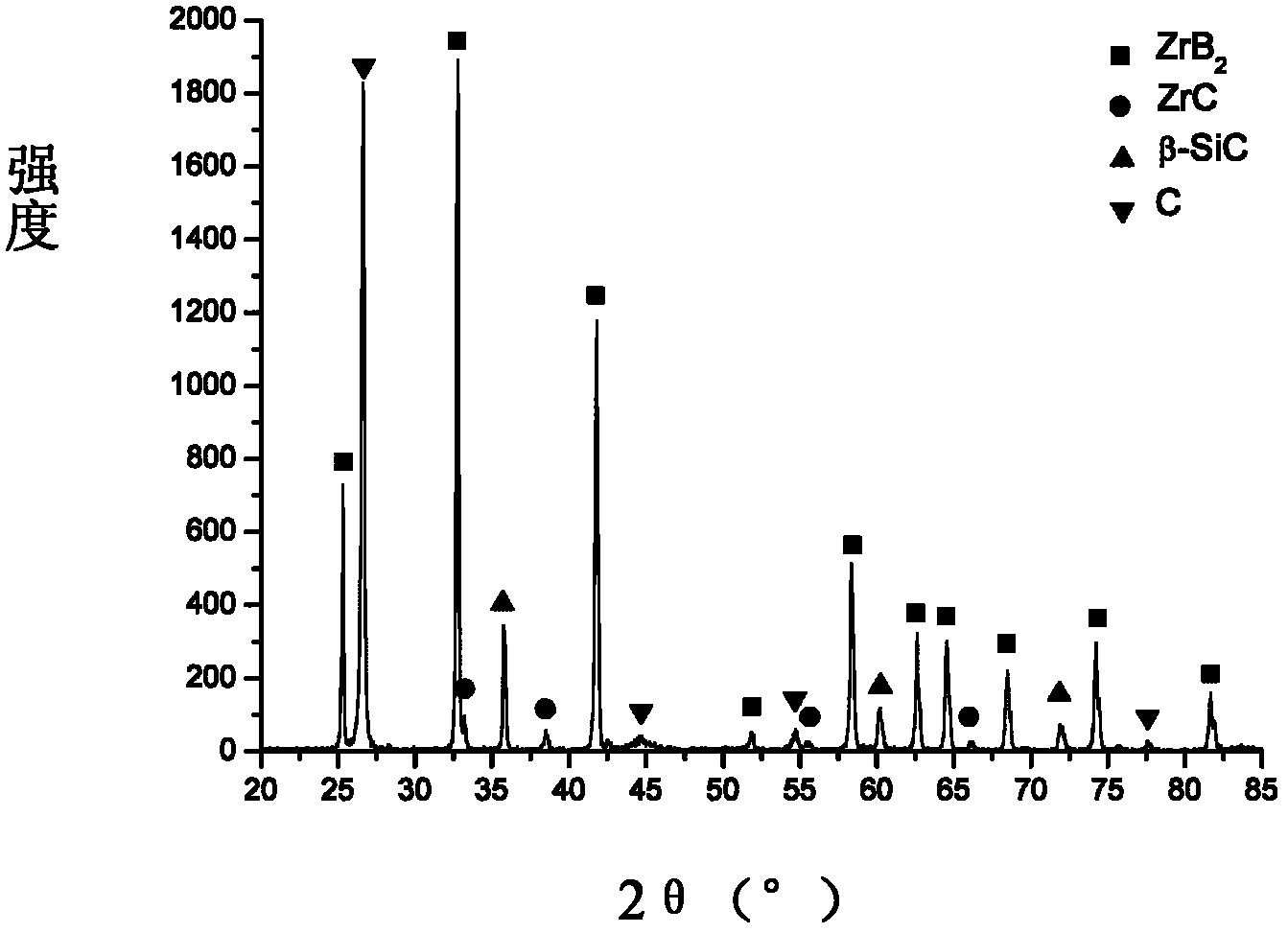

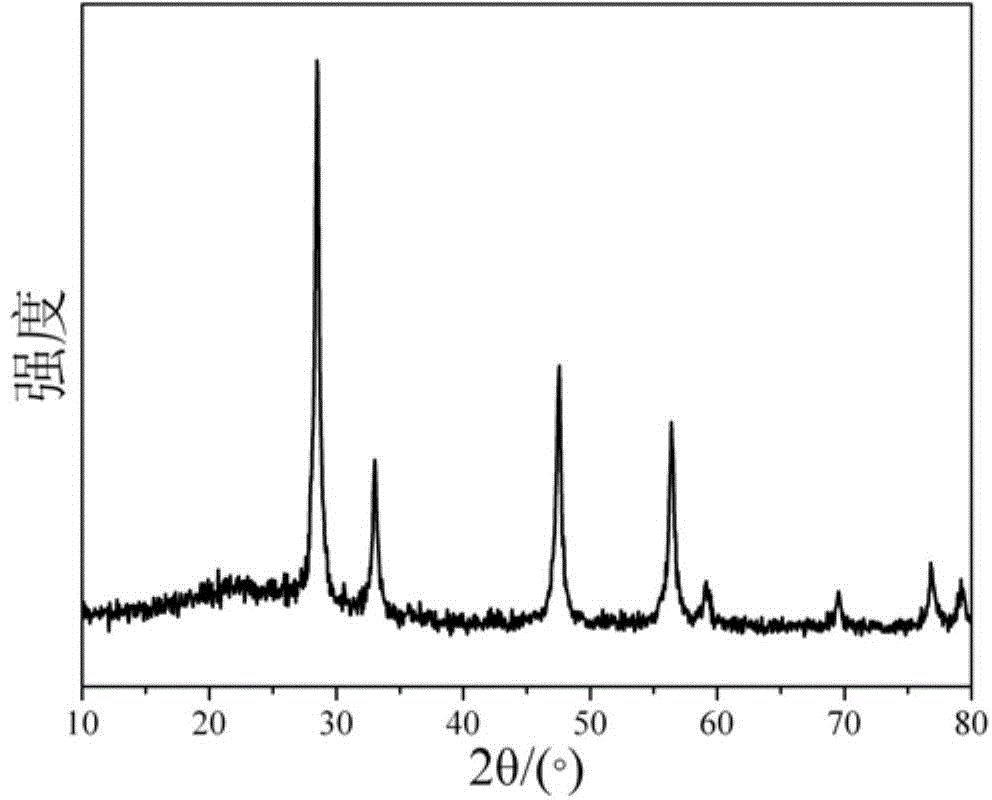

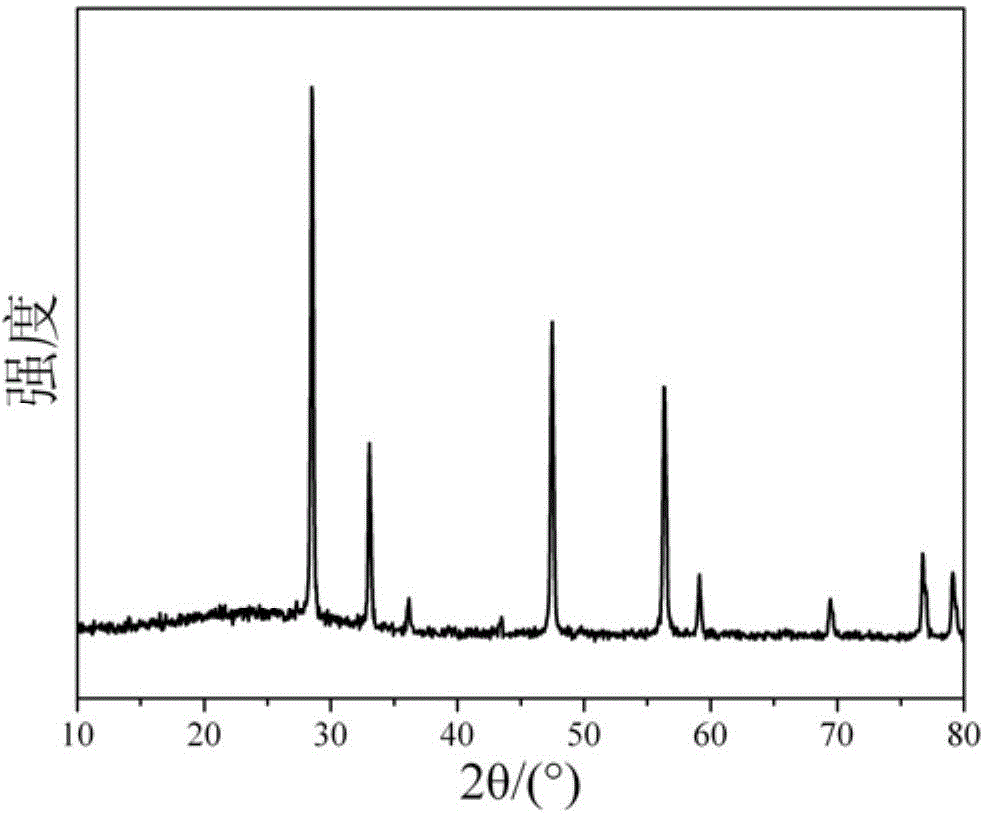

Zirconium diboride/silicon carbide composite material and method for preparing same by means of arc melting in-suit reaction

The invention discloses a zirconium diboride / silicon carbide composite material and a method for preparing the same by means of an arc melting in-suit reaction. Raw materials for reaction comprise zirconium powder, carbon boride powder and silicon carbide powder; the dried mixed powder is melted by electric arcs under the protection of argon so that the mixed powder reacts; and then the target material can be formed through solidification and crystallization. The zirconium diboride / silicon carbide composite material prepared by the arc melting in-suit reaction method has a microhardness of 24.0+ / -0.8 GPa and a breaking tenacity of 6.7+ / -0.7 MPa m<1 / 2>; the obdurability of the composite material is obviously higher than that of the zirconium diboride / silicon carbide composite materials prepared by other methods. Furthermore, the melting solidification preparation method employed in the invention is capable of solving the problems of high requirements for initial materials, complex preparation method, low material density and mechanical performance, high cost and the like in the preparation of the ZrB2-based composite material through solid-state sintering.

Owner:TIANJIN UNIV

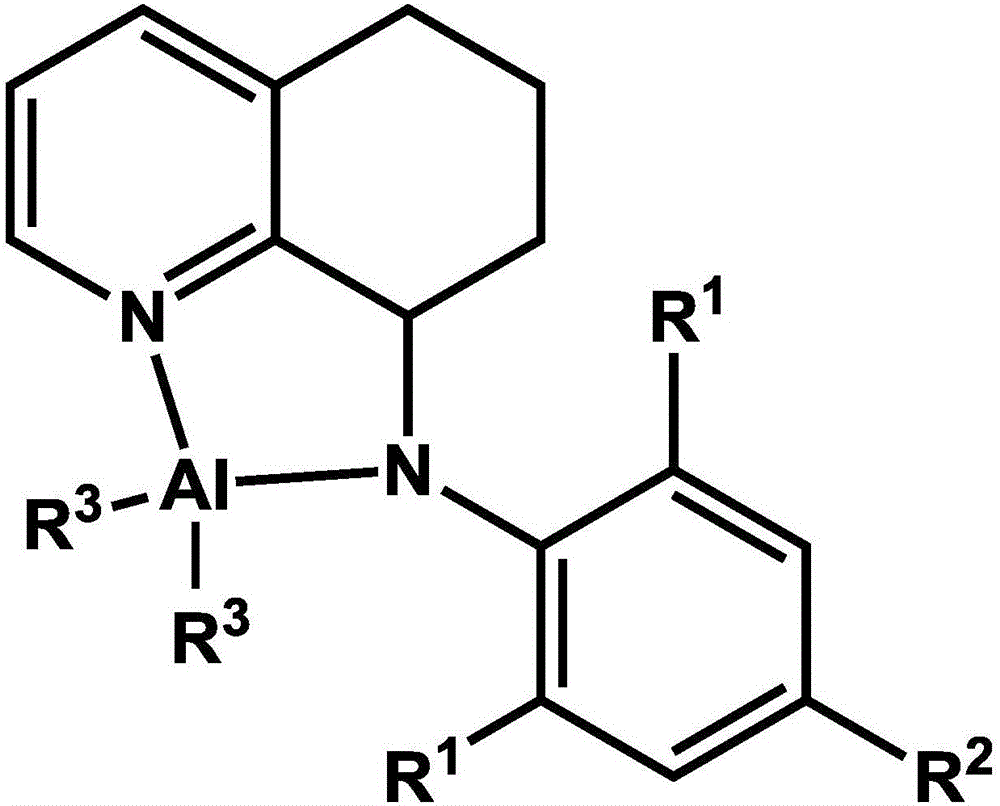

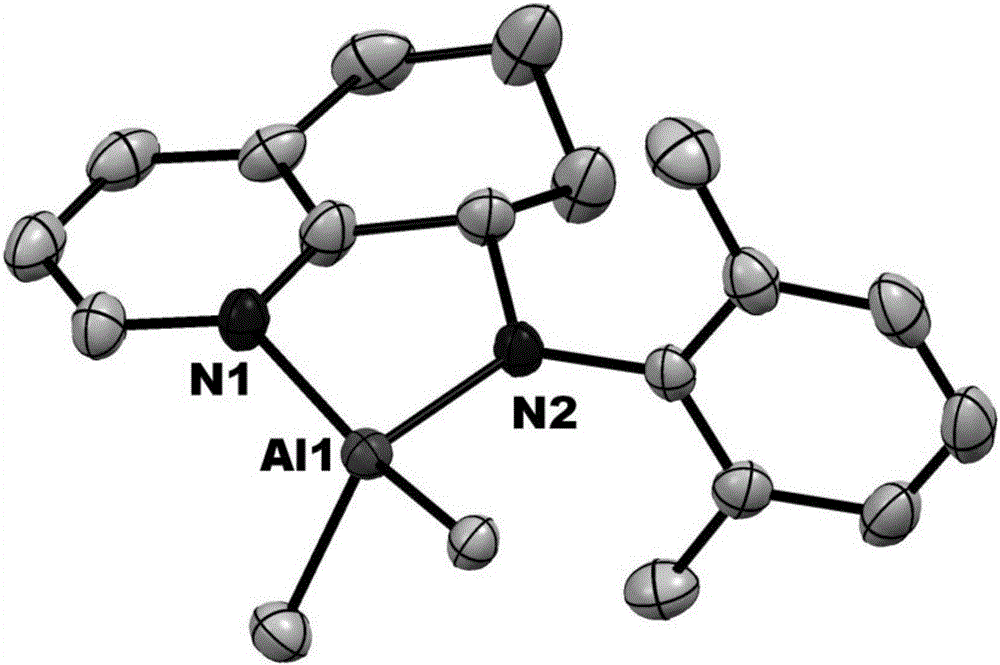

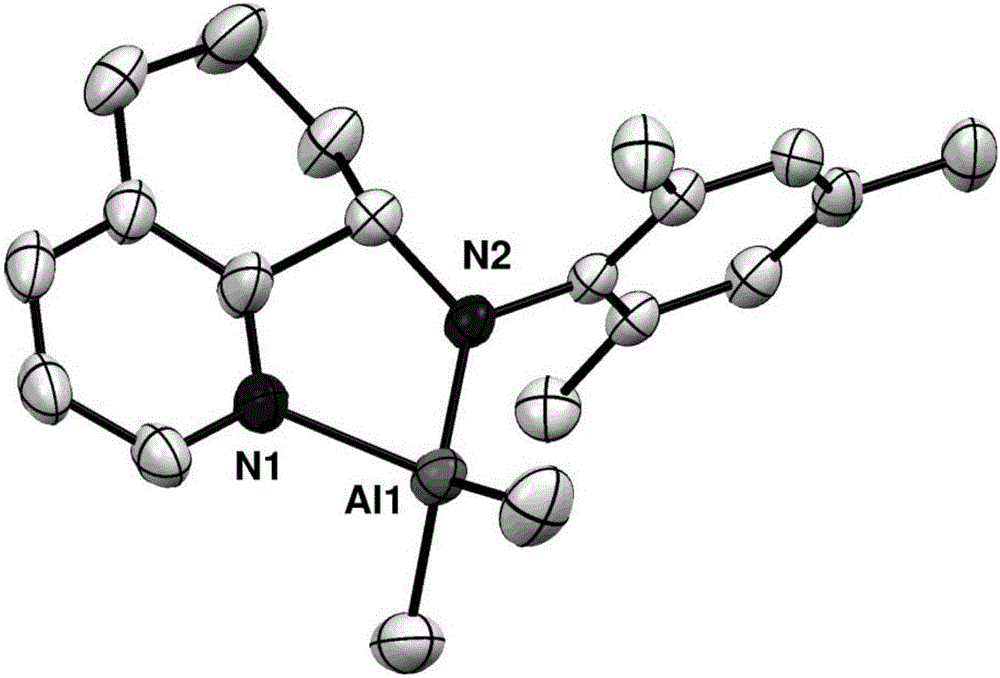

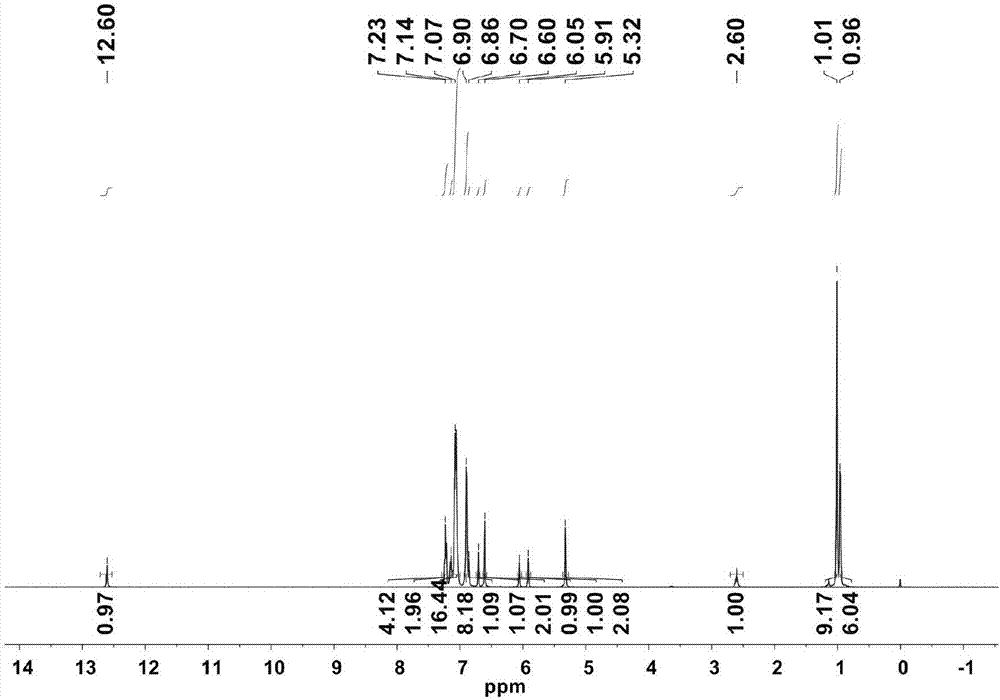

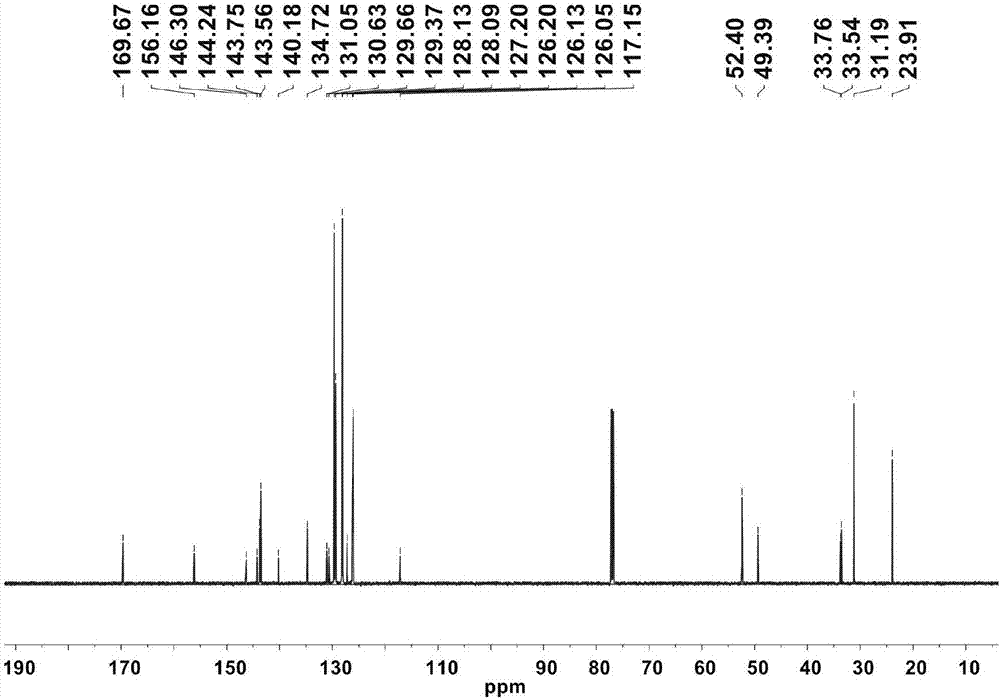

8-N-arylamine-hydrogenation quinoline complexation aluminum alkyl compound and preparation method and application thereof

ActiveCN106046038ARaw materials are cheap and easy to getMeet the requirements of ring-opening polymerizationGroup 3/13 element organic compoundsPolyesterLactide

The invention discloses an 8-N-arylamine-hydrogenation quinoline complexation aluminum alkyl compound and a preparation method and application thereof. The preparation method of the 8-N-arylamine-hydrogenation quinoline complexation aluminum alkyl compound comprises the following steps that 8-N-arylamine-hydrogenation quinoline ligand is dissolved in an anhydrous solvent, aluminum alkyl is added, stirring is carried out under protection of nitrogen at the room temperature, the solvent is removed through decompression, a poor solvent is used for carrying out washing for three times, and the target aluminum alkyl compound is obtained. The 8-N-arylamine-hydrogenation quinoline complexation aluminum alkyl compound is an efficient lactone and lactide ring-opening polymerization catalyst and can be used for lactone and lactide ring-opening polymerization reaction. According to the 8-N-arylamine-hydrogenation quinoline complexation aluminum alkyl compound, the raw materials are low in price and easy to get, the synthetic route is simple, the product yield of high, characters are stable, the prepared product is abundant and changeable in structure, the catalytic performance is easy to regulate, the requirements of different kinds of lactone and lactide ring-opening polymerization can be met, prepared aliphatic polyester high polymer material is controllable in structure and performance, and requirements of industrial departments can be met.

Owner:QINGDAO UNIV OF SCI & TECH

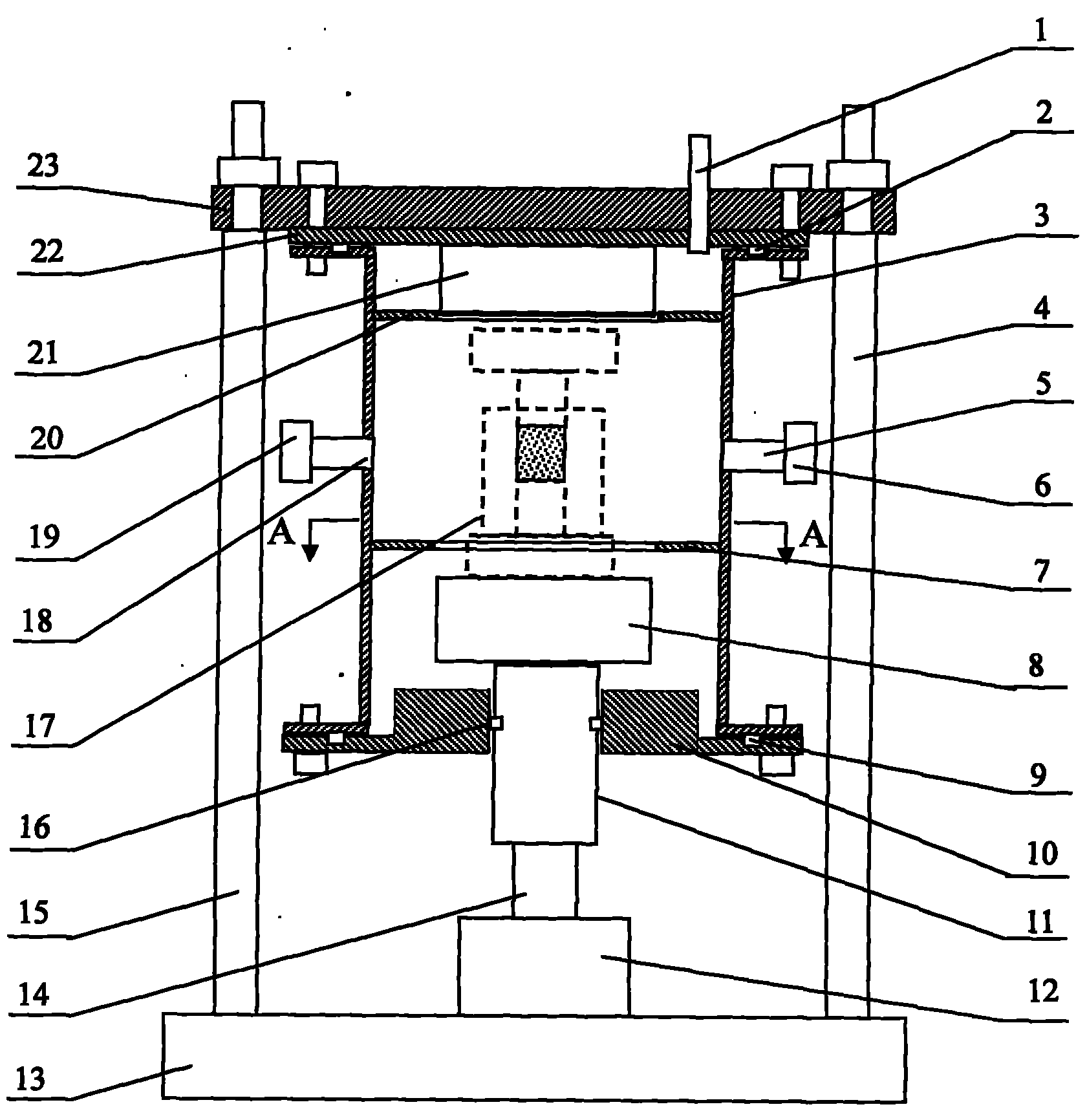

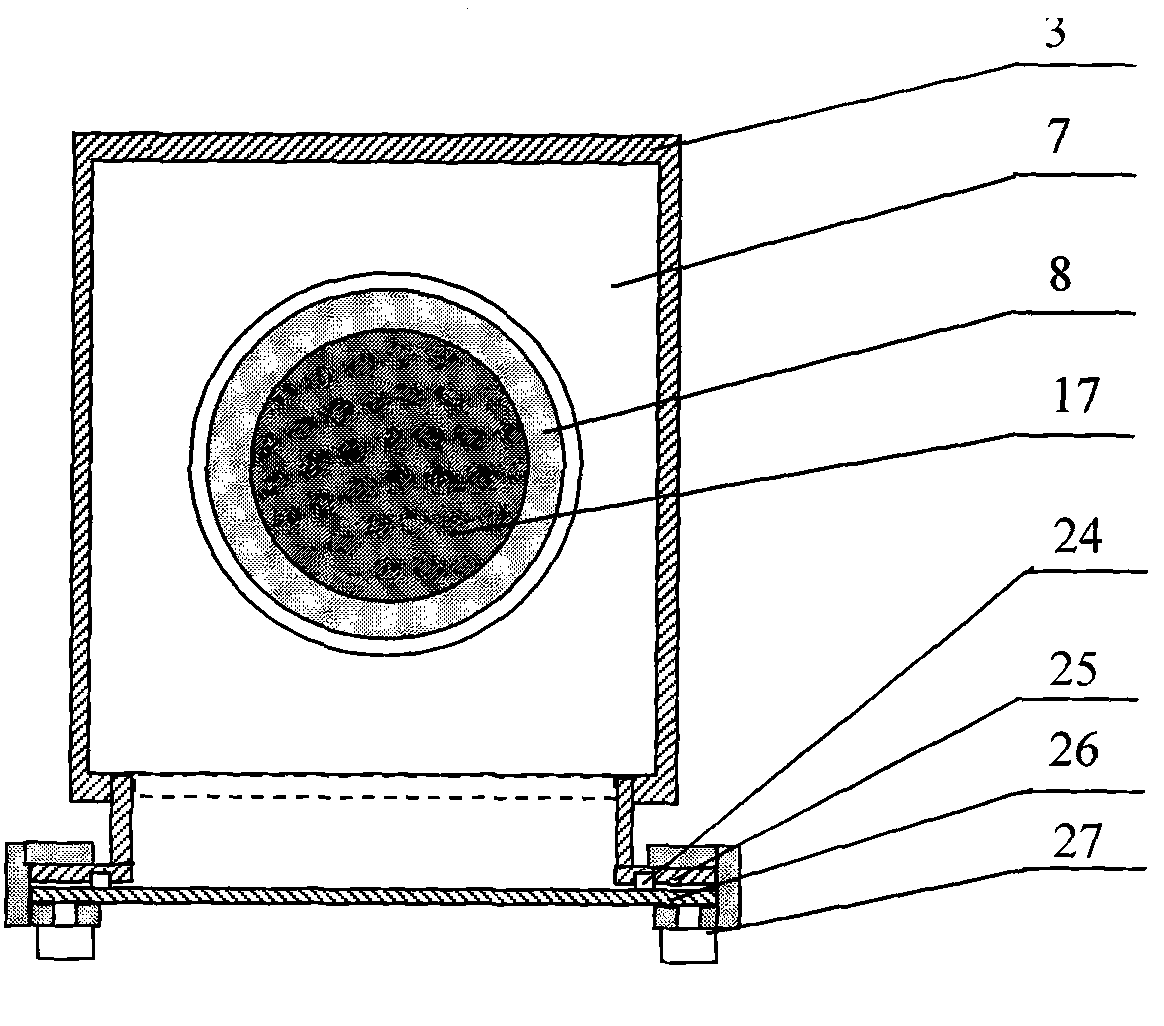

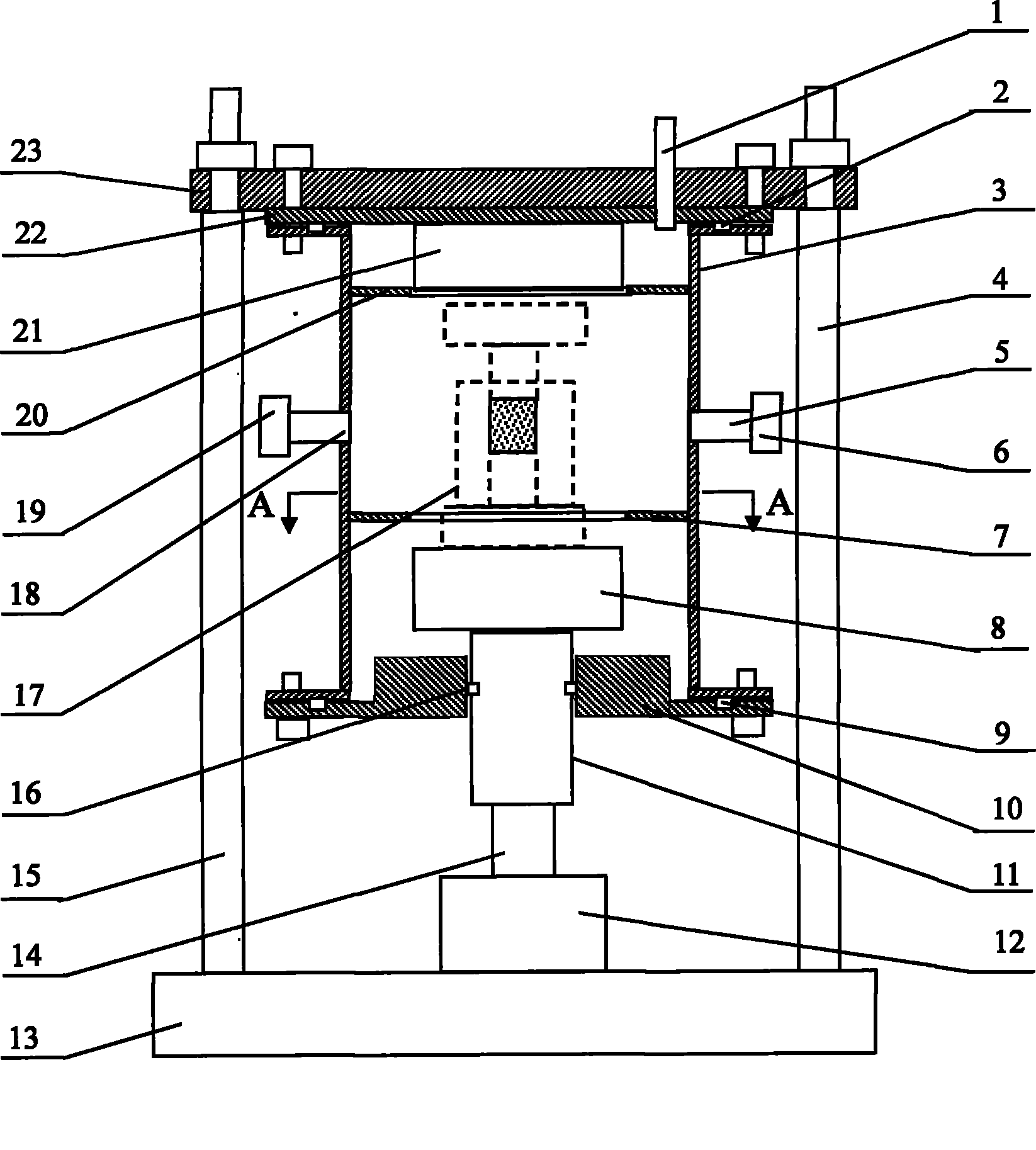

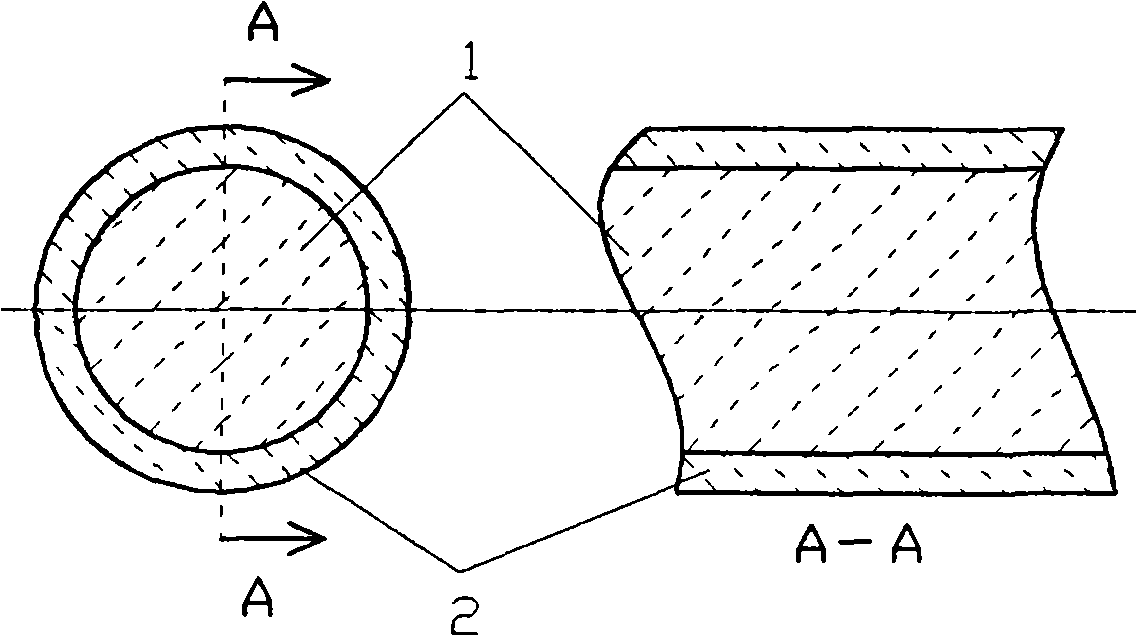

Microwave irradiation pressurized sintering equipment and use method thereof

InactiveCN101786161AIncreased diffusion rateLower sintering temperatureHydraulic cylinderMicrowave oven

The invention relates to microwave irradiation pressurized sintering equipment and a use method thereof, which have the technical scheme that an upper pressing head (21) is fixedly arranged in the center of the inner wall of an upper oven cover (22) of a microwave oven, the upper part and the lower part of the inner wall of a side plate (3) of the microwave oven are respectively and fixedly provided with an upper microwave reflecting plate (20) and a lower microwave reflecting plate (7), a first waveguide tube (5) is embedded in the right side of the side plate (3) of the microwave oven, a second waveguide tube (18) is embedded in the left side of the side plate (3) of the microwave oven, the first waveguide tube (5) and the second waveguide tube (18) are respectively and fixedly connected with a first permatron (6) and a second permatron (19), a hydraulic cylinder (12) is vertically fixed in the center of a base (13), a slide block (11) passes through a chute hole of a lower oven cover (10), and a lower pressing head (8) is arranged on the upper part of the slide block (11). The invention has the characteristics that the sintering temperature can be effectively reduced, the sintering time can be shortened, microstructures of materials are convenient to control, crystal grains are thinned, the investment is saved, and the cost is low.

Owner:WUHAN UNIV OF SCI & TECH

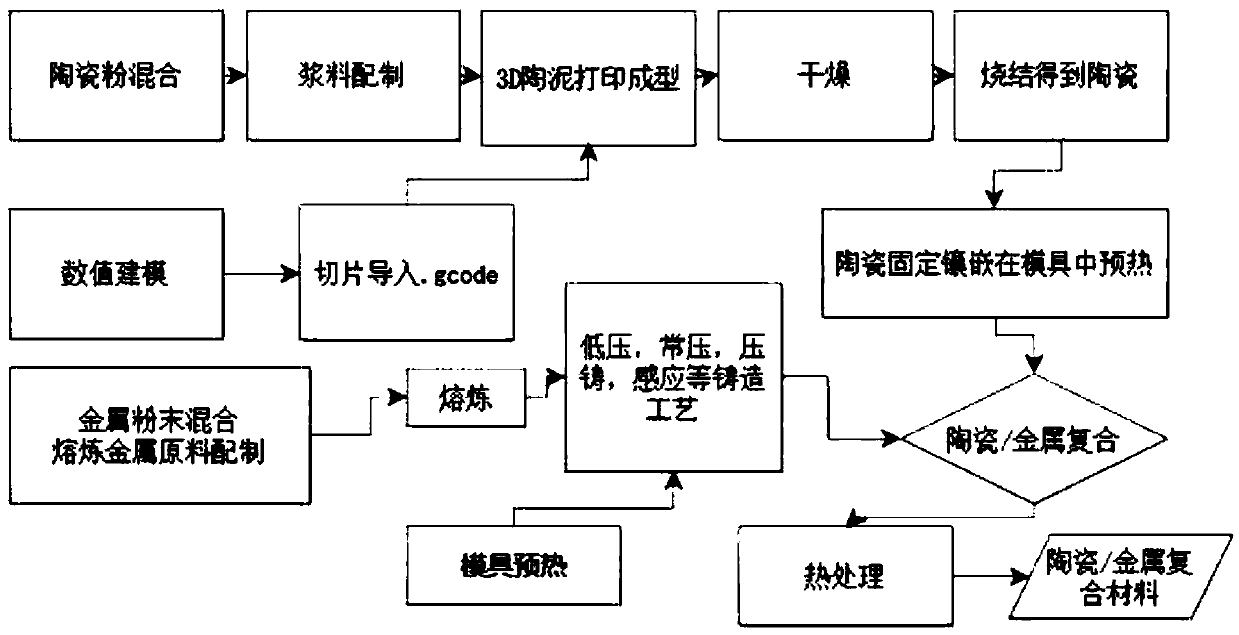

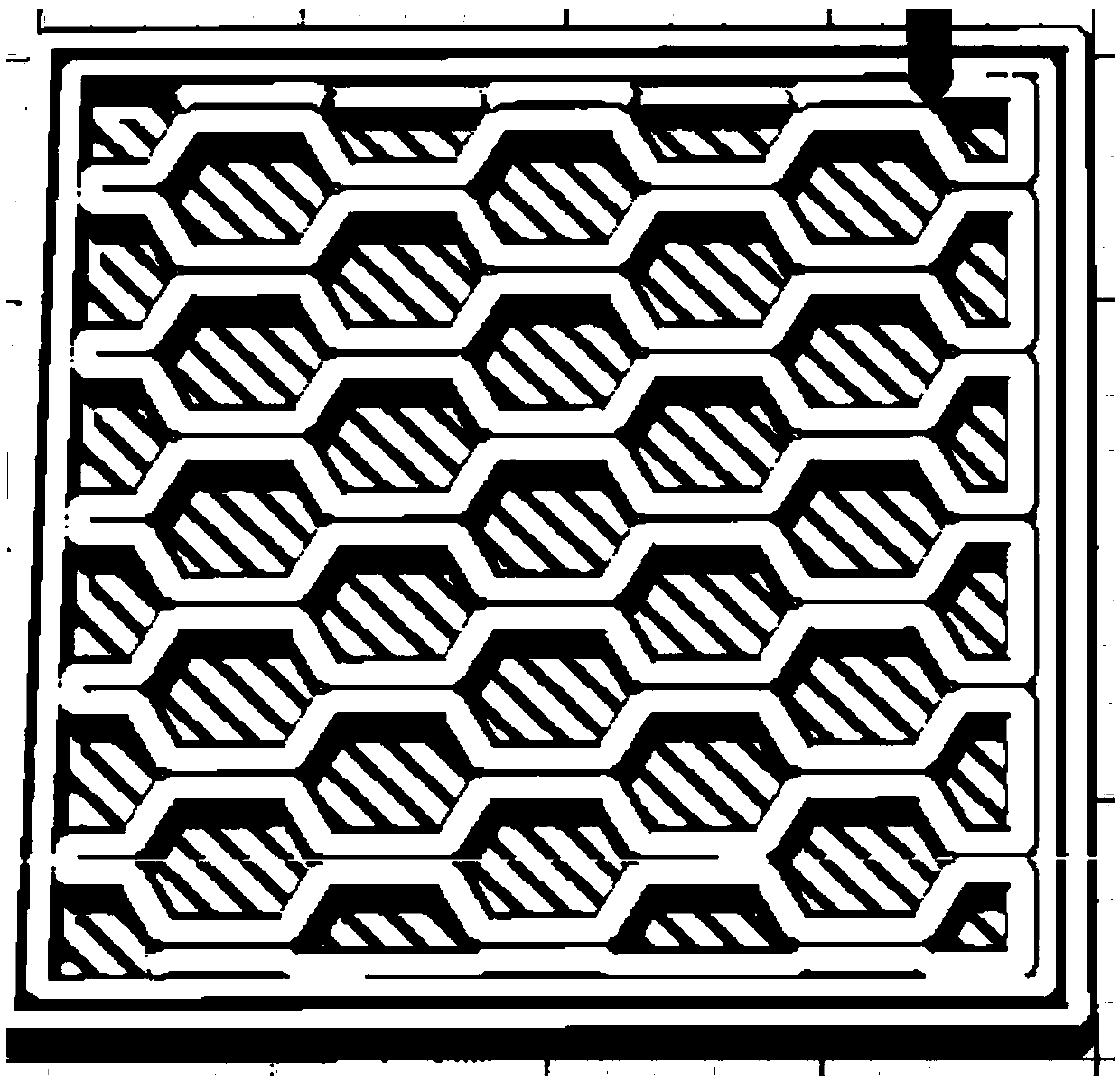

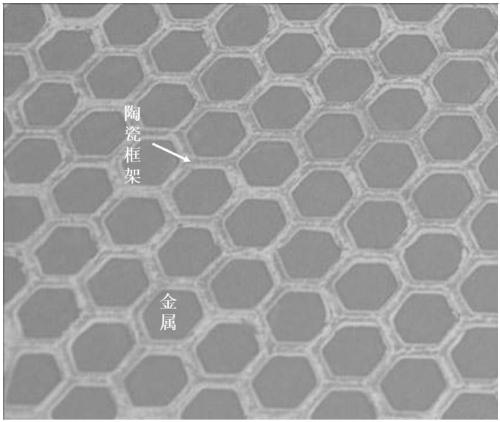

Spatially ordered frame structure ceramic-metal composite material and preparation method thereof

InactiveCN109678526AMicrostructure is easy to controlImprove rigidityCeramic shaping apparatusCeramic moldingSlurry

The invention provides a spatially ordered frame structure ceramic-metal composite material and a preparation method thereof, and belongs to the technical field of a ceramic-metal composite material.The preparation method comprises the following steps: acquiring 3D printing slicing data according to a predetermined ceramic forming structure; preparing ceramic powder slurry to perform 3D clay printing to form a blank; sintering the blank to obtain a ceramic substrate and performing surface film covering treatment; and compounding a metal material and the ceramic substrate with a metal castingmethod or a powder metallurgy method. By the 3D clay rapid integrated formation printing method, spatially ordered frame structure ceramic with high size precision, high surface quality and excellentmechanical property can be manufactured; and the method is suitable for formation of various single-phase or complex-phase ceramic materials. The ratio of the ceramic to the metal can be adjusted randomly, the microstructure can be controlled, the properties of the composite material can be designed, the advantages of high rigidity, high hardness and high impact toughness are achieved, and excellent friction resistance and heat resistance are shown up.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

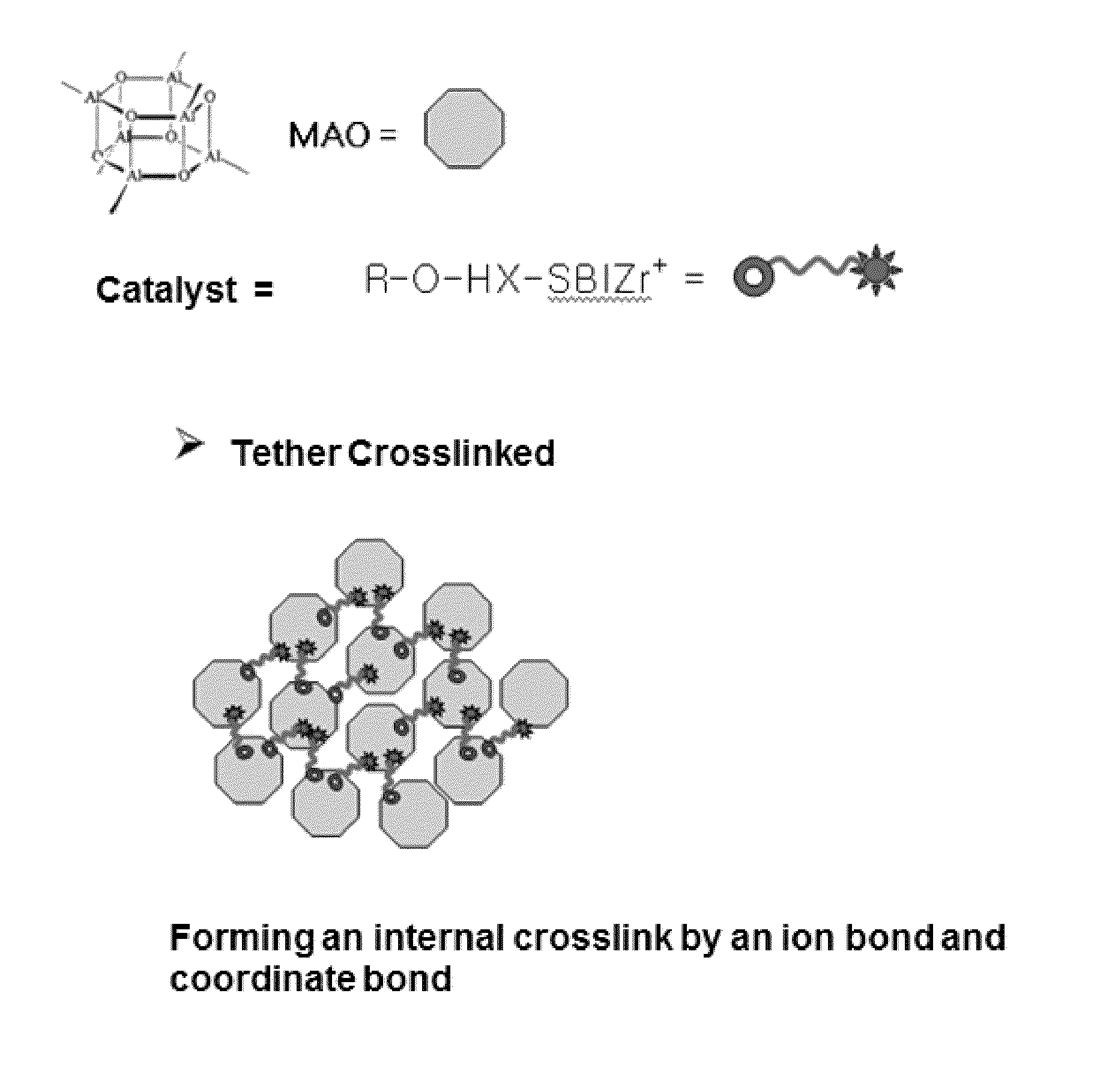

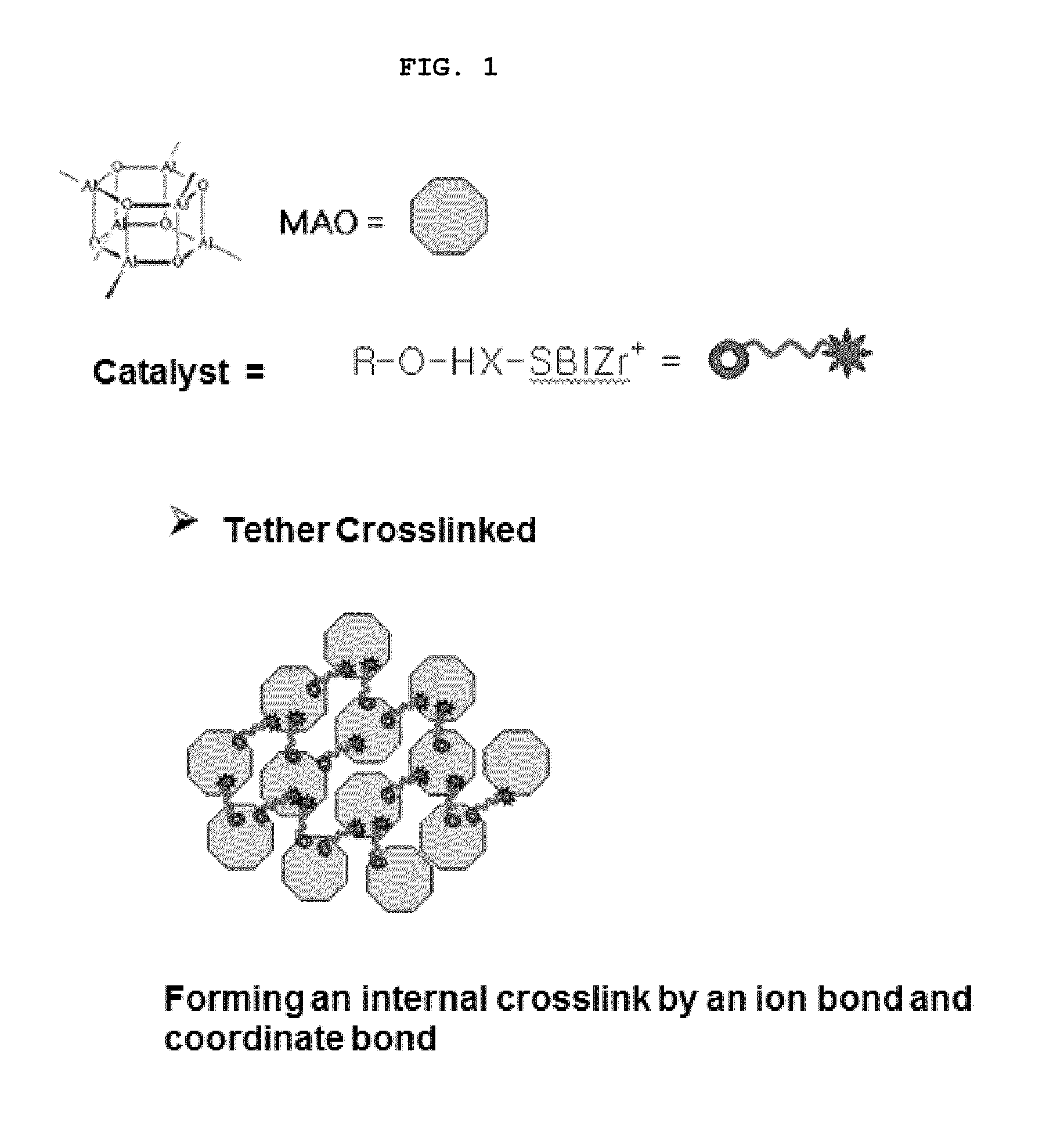

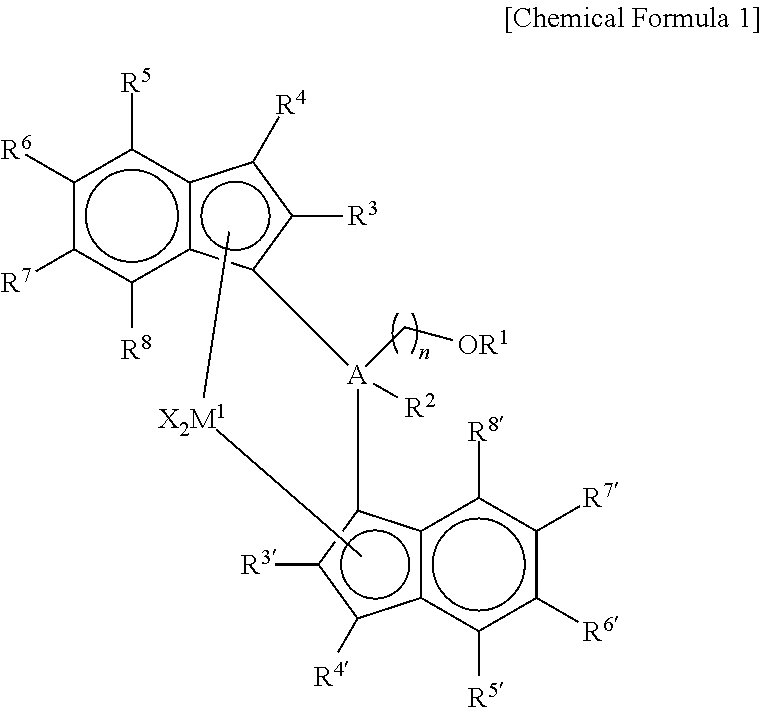

Non-supported heterogeneous polyolefin polymerization catalyst composition and method for preparing same

ActiveUS20150031844A1Microstructure is easy to controlHigh catalytic activityOrganic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationPolyolefinMicrostructure

Disclosed is a metallocene catalyst composition for polyolefin polymerization. The metallocene catalyst composition is in a non-supported, heterogeneous form where an ansa-metallocene is bound to a cocatalyst without a support. Also, a method for preparing the catalyst composition, and a method for preparing polyolefin using the catalyst are disclosed. Capable of readily controlling microstructures of olefin polymers in addition to having high catalytic activity, the non-supported heterogeneous catalyst composition can be applied to the preparation of polyolefin polymers at high yield without altering preexisting processes.

Owner:LG CHEM LTD

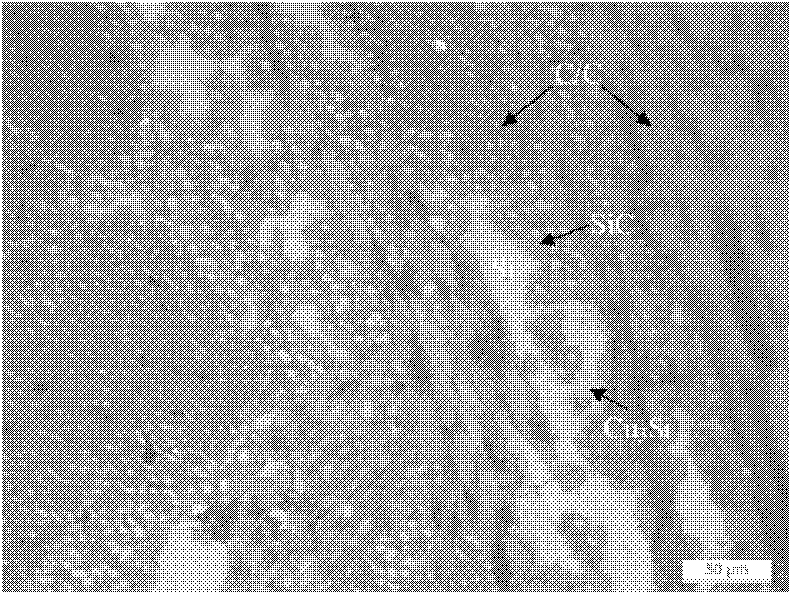

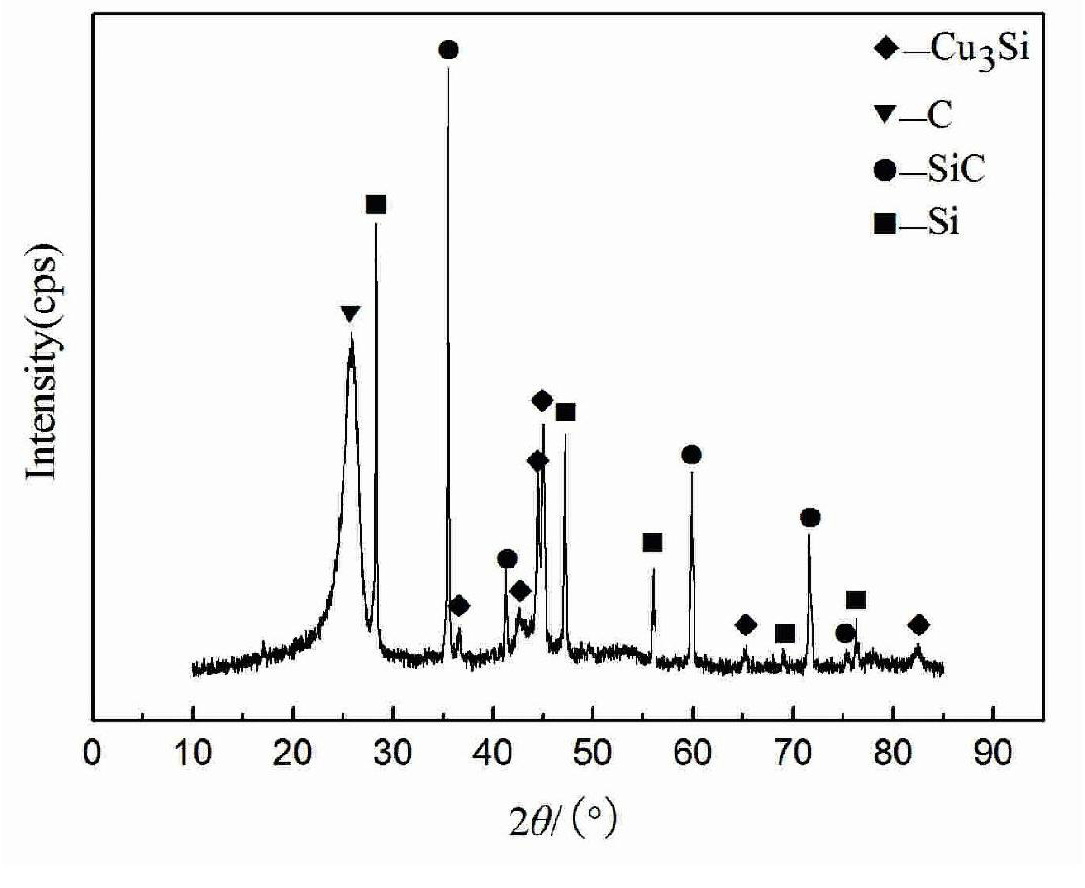

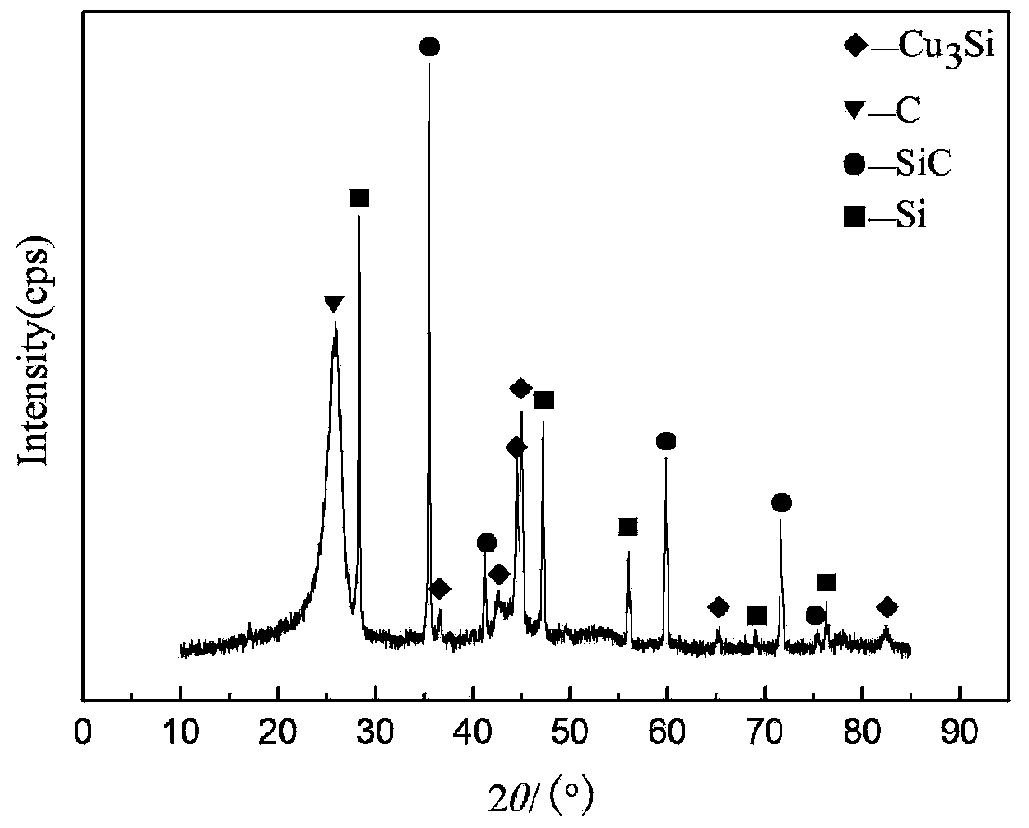

Method for preparing copper silicon alloy modified carbon/ceramic friction material

ActiveCN101818048AStress reliefFacilitate subsequent processingOther chemical processesJet aeroplaneSilicon alloy

The invention discloses a method for preparing a copper silicon alloy modified carbon / ceramic friction material, which comprises the following steps of: 1, thermally treating a carbon fiber prefabricated body at high temperature; 2, performing chemical vapor infiltration and (or) resin impregnation / carbonization densification treatment on the thermally-treated carbon fiber prefabricated body to obtain a low-density carbon fiber reinforced matrix carbon (C / C) porous material; 3, preparing Cu and Si infiltration powder; and 4, placing the Cu and Si infiltration powder into a graphite crucible, spreading the C / C porous material on the powder in the graphite crucible, performing non-immersion smelting infiltration in a high-temperature vacuum furnace, and compounding the C / C porous material and the powder to form the copper silicon alloy modified carbon / ceramic friction material through the reaction of Si and C, Si and Cu. The method has the advantages of simple and easily-controlled production process and low preparation cost; the prepared material has controllable microstructure and performance and excellent heat conducting performance; and the method can realize industrialized production, and has broad application prospect in the civil and military fields of airplanes, rapid trains, automobiles and the like.

Owner:HUNAN SHIXIN NEW MATERIALS CO LTD

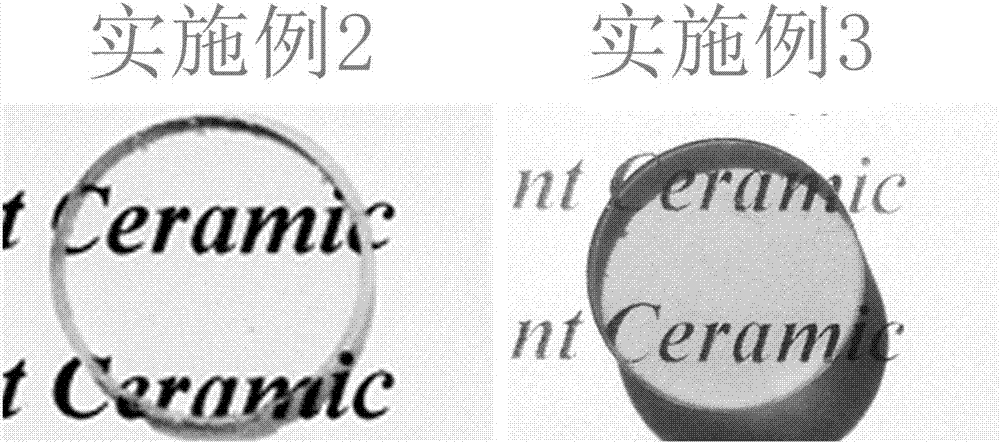

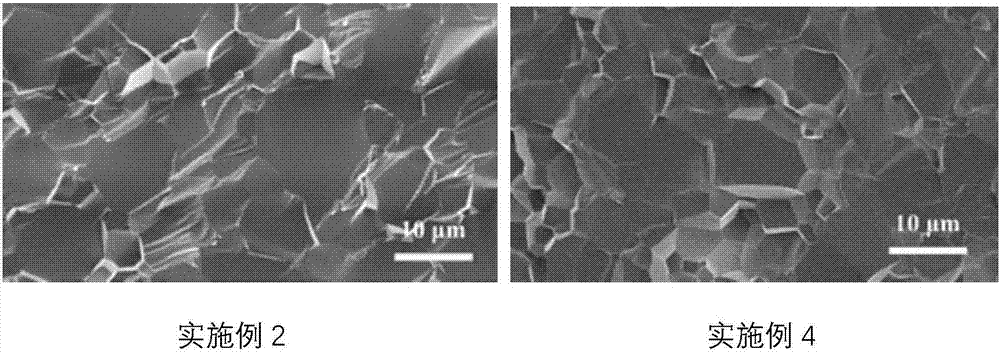

Method for preparing YAG-based transparent ceramics under Mg aid system

The invention provides a method for vacuum sintering preparation of yttrium aluminium garnet (Y3Al5O12, YAG)-based transparent ceramics under a non-annealing mechanism based on a few Mg single sintering aid system. A small quantity of Mg is taken as a single sintering aid, and a single-step vacuum sintering method is adopted to prepare the YAG transparent ceramics with favorable optical quality and fine grains without later-stage annealing treatment.

Owner:XUZHOU NORMAL UNIVERSITY

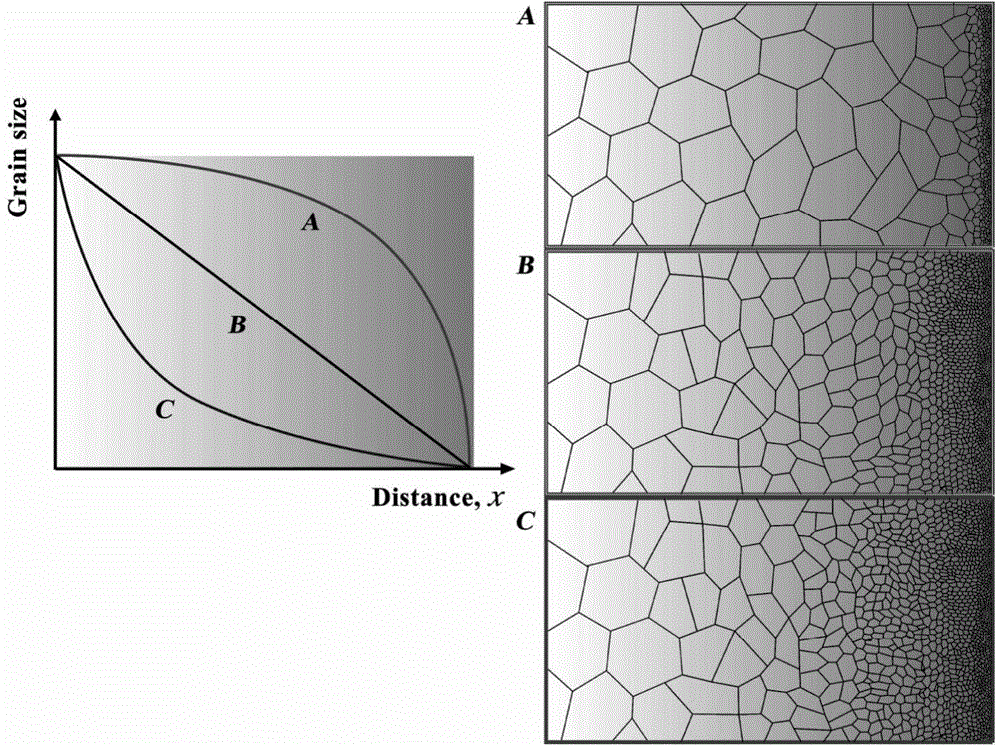

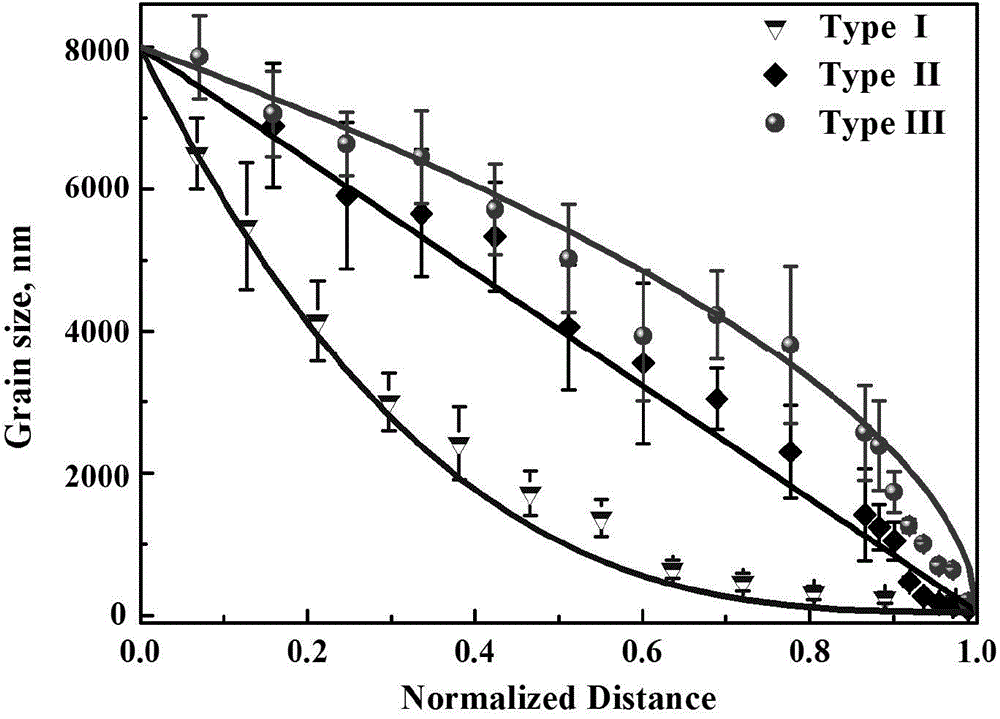

Crystalline grain scale gradient metallic nickel and controllable preparation method thereof

ActiveCN104862748AUnlimited sizeEasy to operateCellsVolumetric Mass DensityUltimate tensile strength

Aiming to the defect of a preparation method of a gradient metal material at present, the invention provides gradient metallic nickel being low in cost and easier in industrial production, and a preparation method of the gradient metallic nickel. The controllable preparation method is characterized in that an electroplating method is adopted to prepare the gradient metallic nickel, nickel is taken as a sacrificial anode, the variation of current density, additive concentration along with the time is controlled by a computer according to different microstructures or mechanical property requirements, nickel deposits under direct-current action to form crystalline grain scale gradient metallic nickel. The size of the gradient metallic nickel is almost not limited, the gradient distribution form is controllable, the size of a crystalline grain is gradually increased from 10-100 nm to 1-30 micron; no interfaces exist among hierarchical structure parts; the gradient metallic nickel is excellent in mechanical property, larger than or equal to 750 MPa in yield strength, 3-4 times of a traditional coarse grain in grain size, reaches more than 10% in tensile plastic deformation, and larger than or equal to 99.5% in overall sample density.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

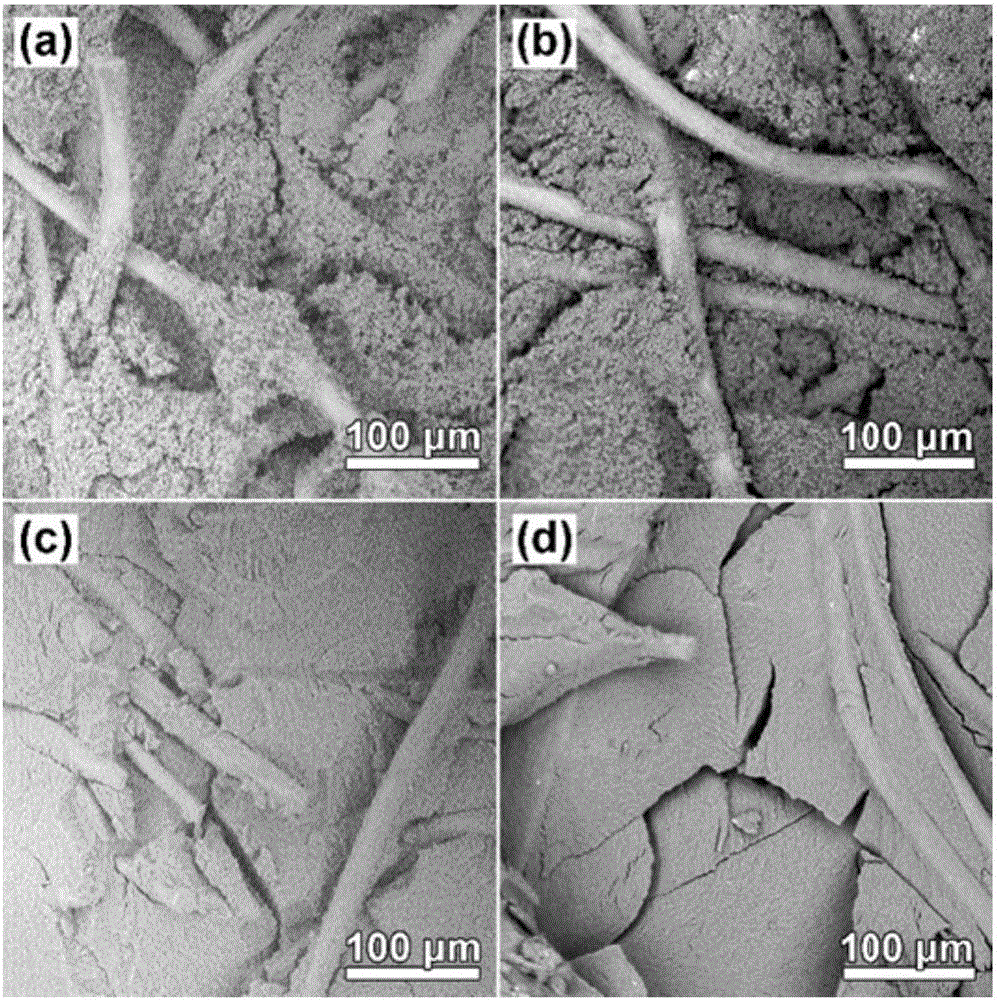

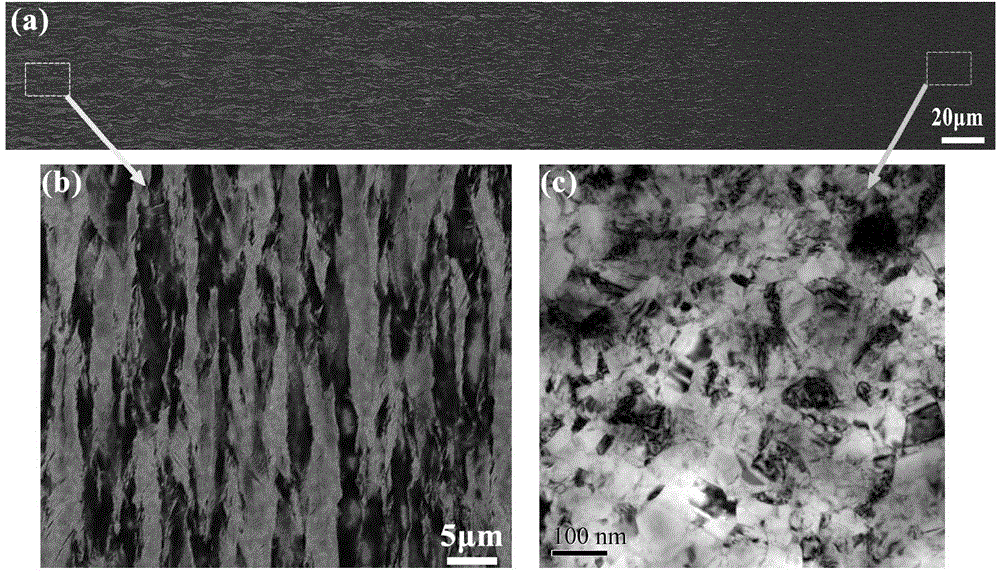

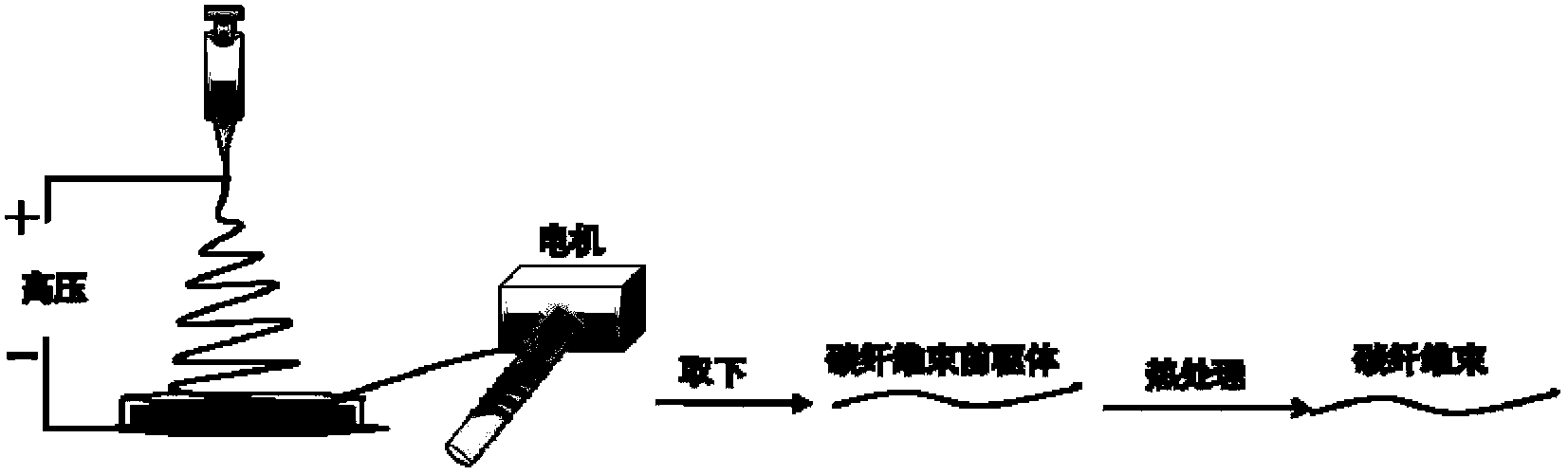

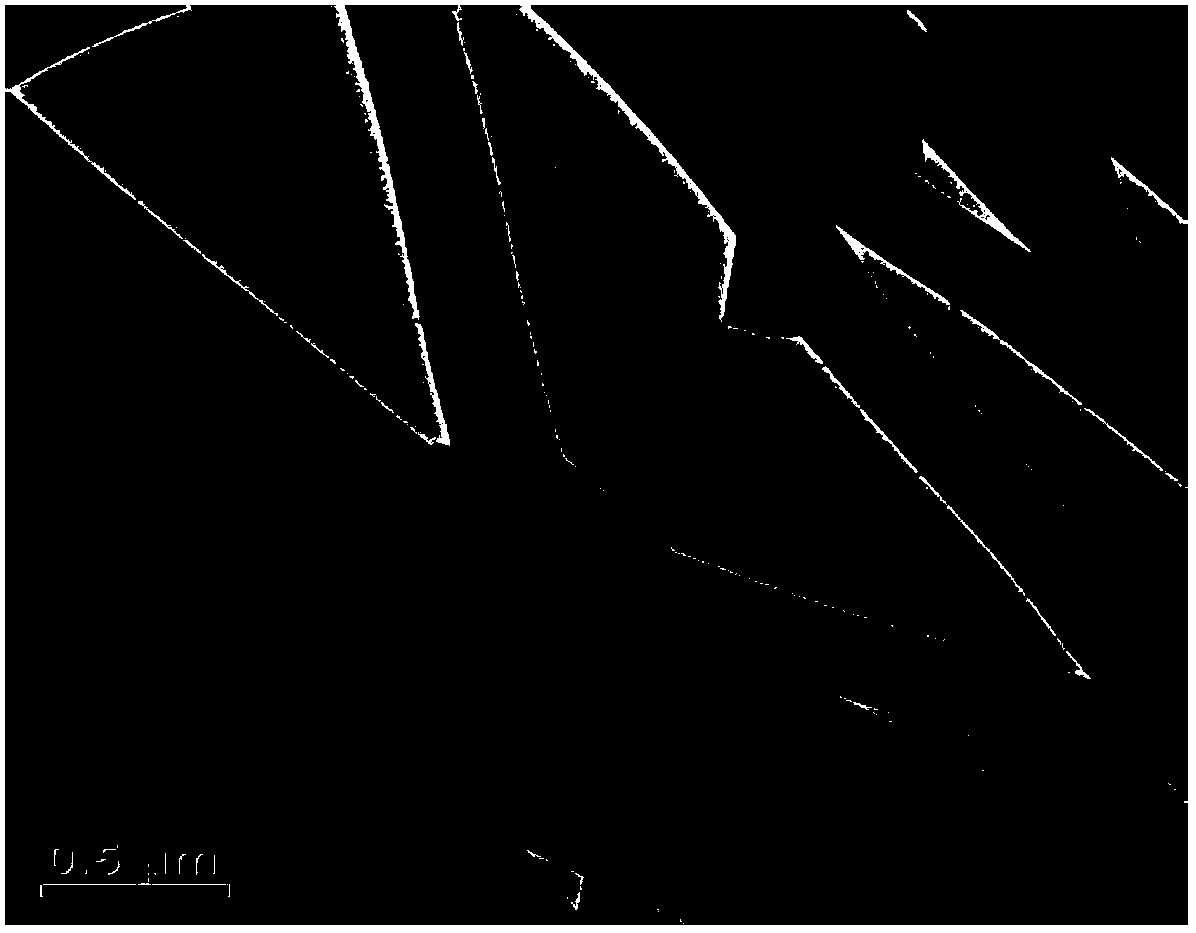

A nanometer or nanometer porous carbon fiber bundle, a preparing method thereof and applications of the bundle

InactiveCN104342783AControllable diameterMicrostructure is easy to controlHybrid capacitor electrodesFibre chemical featuresFiber bundlePorous carbon

A preparing method of a nanometer or nanometer porous carbon fiber bundle is disclosed. The method includes following steps of: (1) suspending precursor fiber prepared by a solution or a melt containing spinnable polymer through electrostatic spinning into a liquid carrying plate; (2) extracting the precursor fiber in the liquid carrying plate at a speed of 5-60 r / min and winding the precursor fiber onto a fiber taking shaft to obtain a continuous directionally arranged precursor fiber bundle; and (3) heating the precursor fiber bundle by sections and charing. The method integrates electrostatic spinning, continuous wiredrawing and heating and charing, and obtains the continuous nanometer or nanometer porous carbon fiber bundle. The diameter, the length and the microstructure of the obtained nanometer or nanometer porous carbon fiber bundle are controllable. The nanometer or nanometer porous carbon fiber bundle prepared by the method shows good electrochemical performance when being applied in the field of energy storage devices, especially as an electrode material of supercapacitors.

Owner:THE NAT CENT FOR NANOSCI & TECH NCNST OF CHINA

Rare-earth doped spinel ferrite/aluminum-doped zinc oxide composite fiber and preparation method thereof

InactiveCN101545159AHigh purityOptimizing Control ParametersInorganic material artificial filamentsFiberAluminum doped zinc oxide

The invention discloses a rare-earth doped spinel ferrite / aluminum-doped zinc oxide composite fiber and a preparation method thereof. The composite fiber is in a sandwich structure by coating an interlayer outside a core which is a rare-earth doped spinel ferrite fiber and has the diameter of 5 microns to 20 microns, and the interlayer is an aluminum-doped zinc oxide coating with the thickness of 50nm to 100nm. The method used for preparing target products has the advantages of high preparation purity, controllable process parameters and microstructures, simple technology, convenient operation, and the like and has important practical meanings on the premise that practical performance is not reduced, such as lower cost, little pollution, and the like. The composite fiber has favorable mechanical and optical performance, is a novel structure-function integrated material, is suitable for multiband absorption, function enhancement, and the like and satisfies the equipment requirements, such as thinness, lightness, width and strength.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Preparation method of carbon/carbon-boron nitride anti-friction composite material

ActiveCN109665855AImprove mechanical propertiesImprove friction and wear propertiesFiberCarbon fibers

The invention discloses a preparation method of a carbon / carbon-boron nitride anti-friction composite material. The preparation method comprises acidizing a graphitized C / C blank, washing the acidizedC / C blank to be neutral to obtain a preprocessed C / C blank, immersing the preprocessed C / C blank into a solution containing modifier for reaction to obtain a functionalized C / C blank, impregnating the functionalized C / C blank with h-BN (hexagonal boron nitride) slurry, then drying the impregnated C / C blank to obtain a C / C-BN precursor, and performing carbonizing densification and graphitization on the C / C-BN precursor with a carbon source to obtain the C / C-BN anti-friction composite material; the modifier is selected from silane coupling agent or polyvinyl alcohol (PVA). According to the preparation method of the carbon / carbon-boron nitride anti-friction composite material, a slurry impregnation method is applied for the first time to produce a BN matrix, and after the C / C blank is functionalized, a slurry impregnation process can effectively introduce BN powder into the C / C blank. The preparation method of the carbon / carbon-boron nitride anti-friction composite material can effectively avoid damage of carbon fiber and ensure excellent structural strength of the C / C-BN composite material; the prepared C / C-BN composite material has excellent friction-wear properties.

Owner:CENT SOUTH UNIV

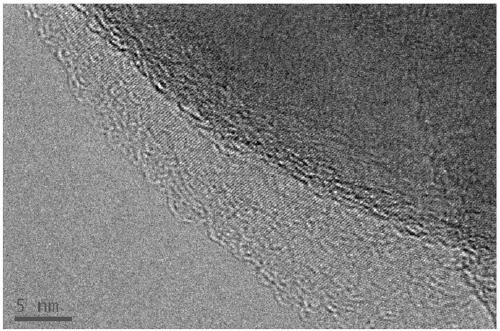

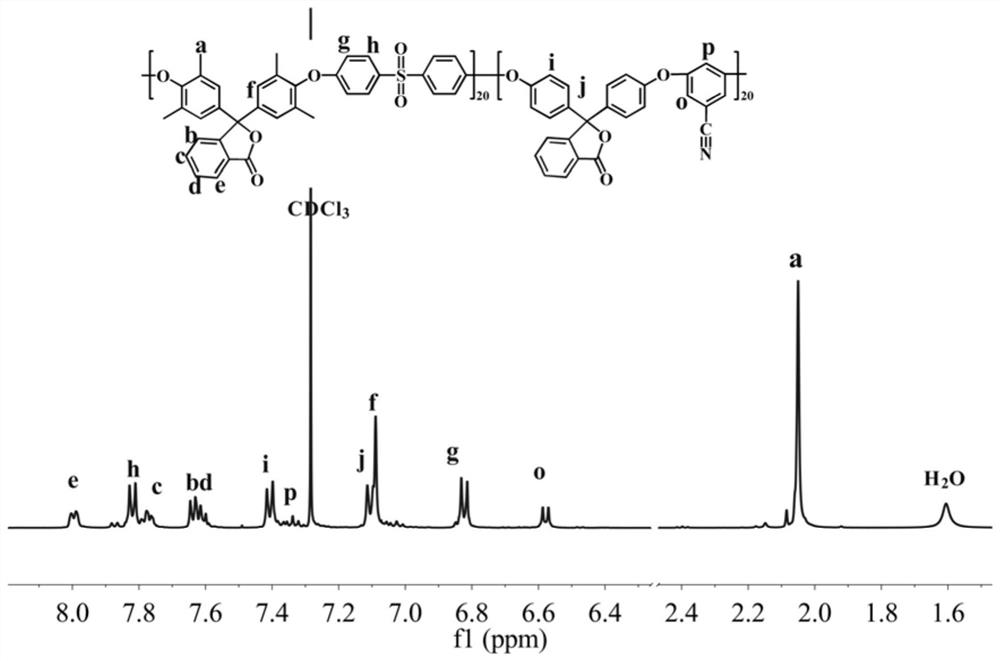

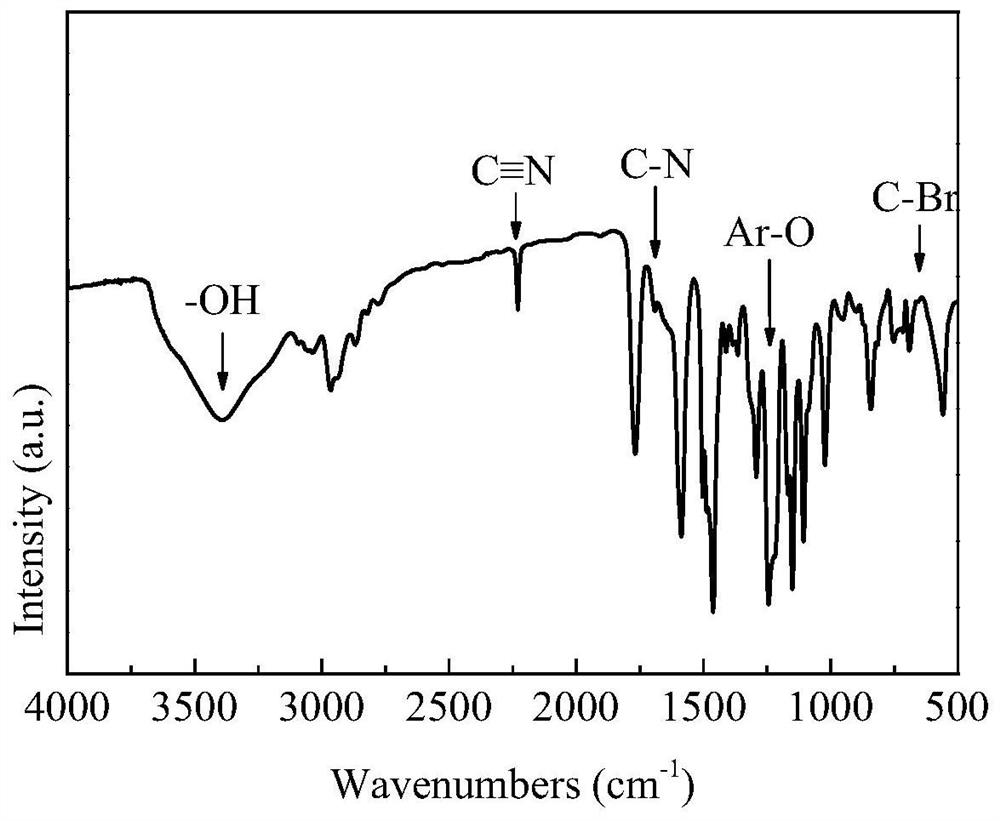

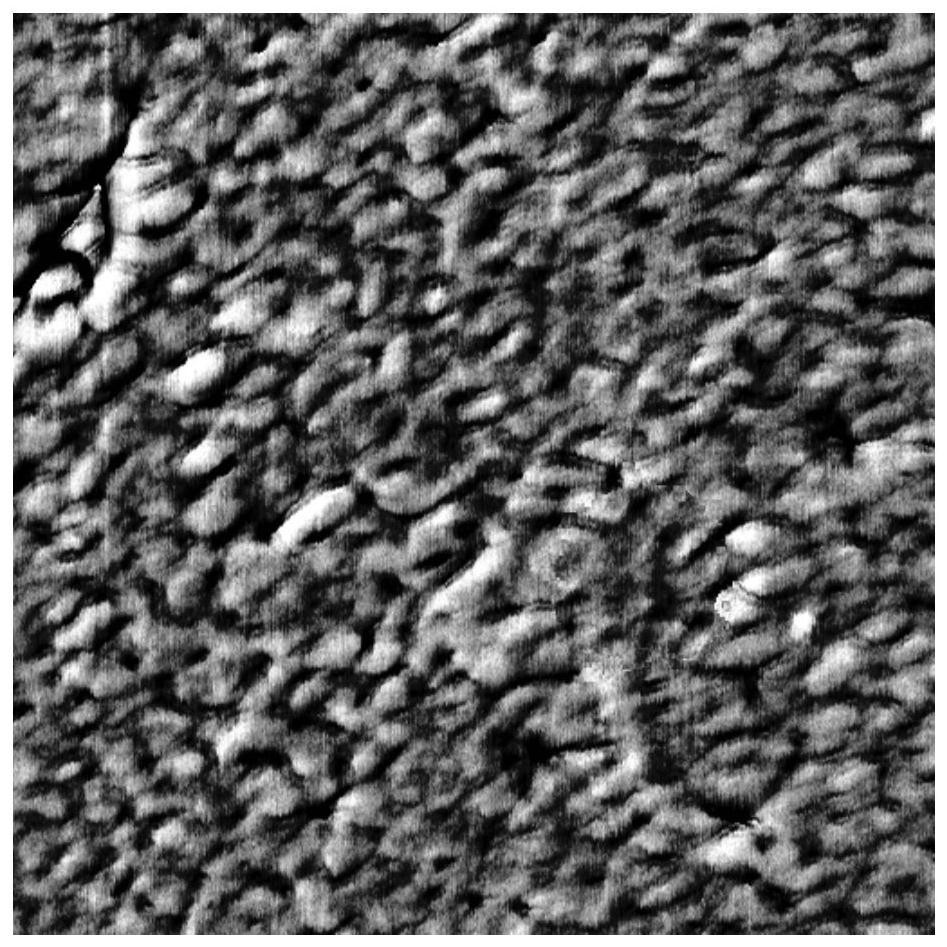

Block type anion exchange membrane containing dense ion strings, and preparation method thereof

InactiveCN111793230AIncrease moisture contentObvious microphase separationFuel cellsFuel cellsChloromethyl Ether

The invention provides a block type anion exchange membrane containing dense ion strings, and a preparation method thereof, wherein the block type anion exchange membrane can be used for an alkaline fuel cell, and is structurally characterized in that a plurality of ion strings are densely grafted on a hydrophilic segment of a block copolymer to serve as functional groups. The preparation method mainly comprises the following steps: (1) preparing a hydrophilic segment containing tetraphenylmethyl and a hydrophobic segment containing a suspended nitrile group; (2) preparing a block copolymer, and carrying out bromination modification; and (3) preparing the block type anion exchange membrane containing the dense ion strings. According to the invention, the anion exchange membrane prepared bythe method has a developed ion transmission channel, has the characteristics of high water content and low swelling rate, and overcomes the defect that the existing anion exchange membrane cannot have high water content, high conductivity and low swelling rate at the same time; and a highly toxic carcinogenic chloromethyl ether reagent is not used in the preparation process, so that the membranehas a wide application prospect in the field of alkaline fuel cells.

Owner:HUAQIAO UNIVERSITY

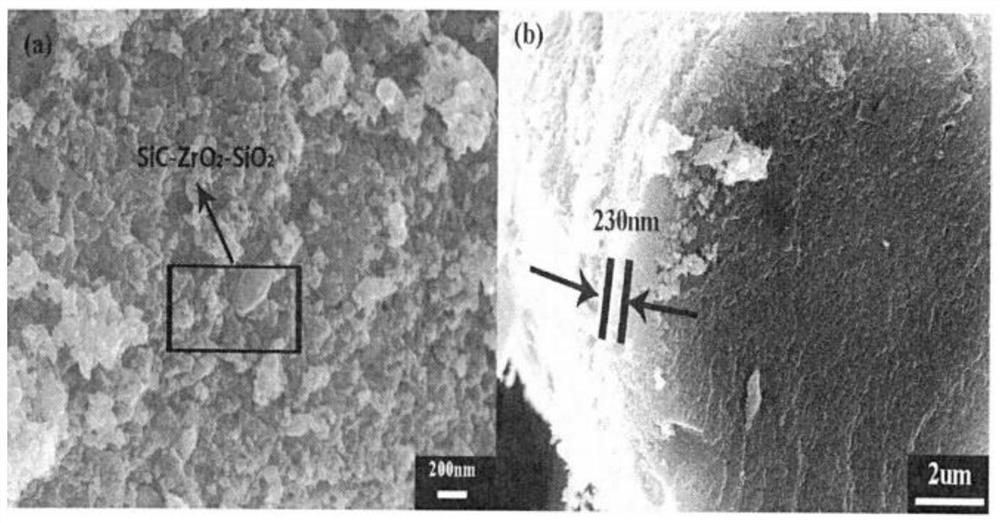

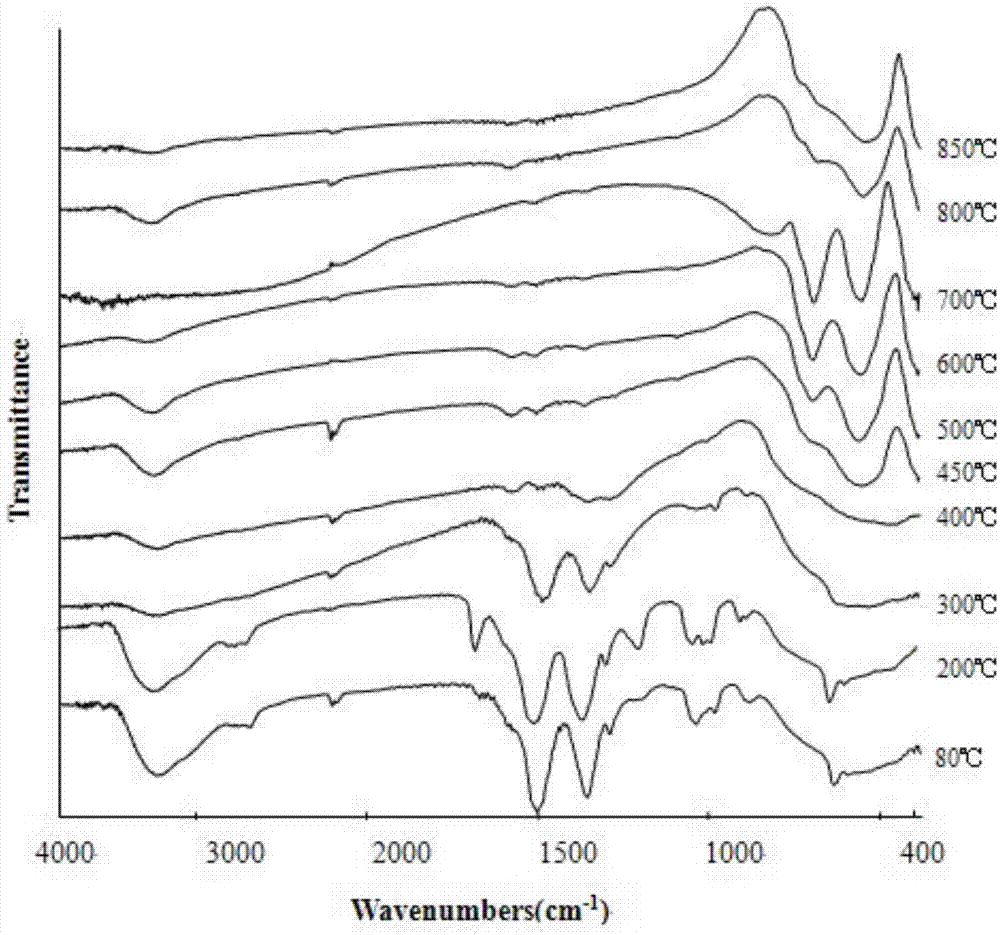

Method for preparing ZrO2-SiO2-SiC coated C/C composite material by adopting sol-gel method

The invention discloses a method for preparing a ZrO2-SiO2-SiC coated C / C composite material by adopting a sol-gel method, and belongs to the technical field of advanced composite anti-oxidation coating materials. The method comprises the following steps: firstly, preparing a SiC coating uniformly coating the surface of a C / C composite material, and then preparing a ZrO2-SiO2 binary mixed sol coating by adopting a sol-gel method; and dipping a SiC coated C / C composite material sample in ZrO2-SiO2 sol at normal pressure, and then carrying out drying and high-temperature heat treatment processes to prepare the high-purity ZrO2-SiO2-SiC ternary mixed sol coating. The composite coating can uniformly and compactly cover the C / C composite material, so the oxidation resistance of the C / C composite material is greatly improved. Defects such as micropores and cracks on the surface of the single-layer SiC coating are filled with SiO2 and ZrO2, so that the compactness of the coating is greatly improved, and the composite coating material with extremely high oxidation resistance is obtained.

Owner:BEIJING UNIV OF CHEM TECH

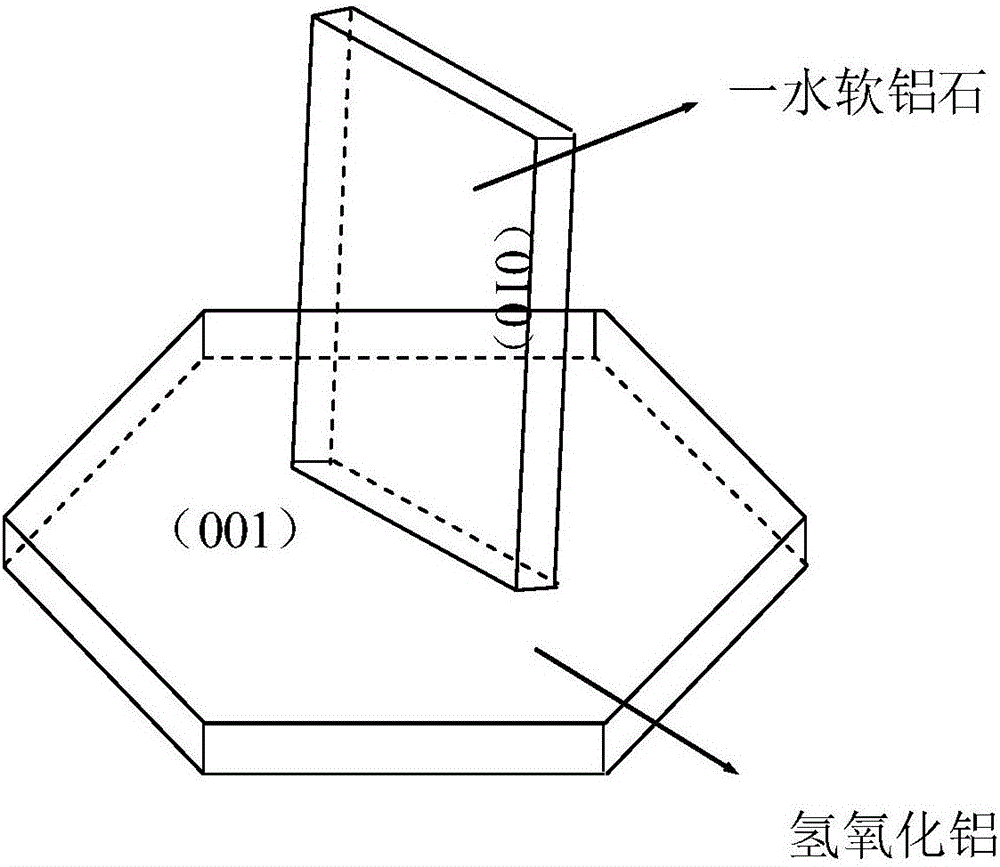

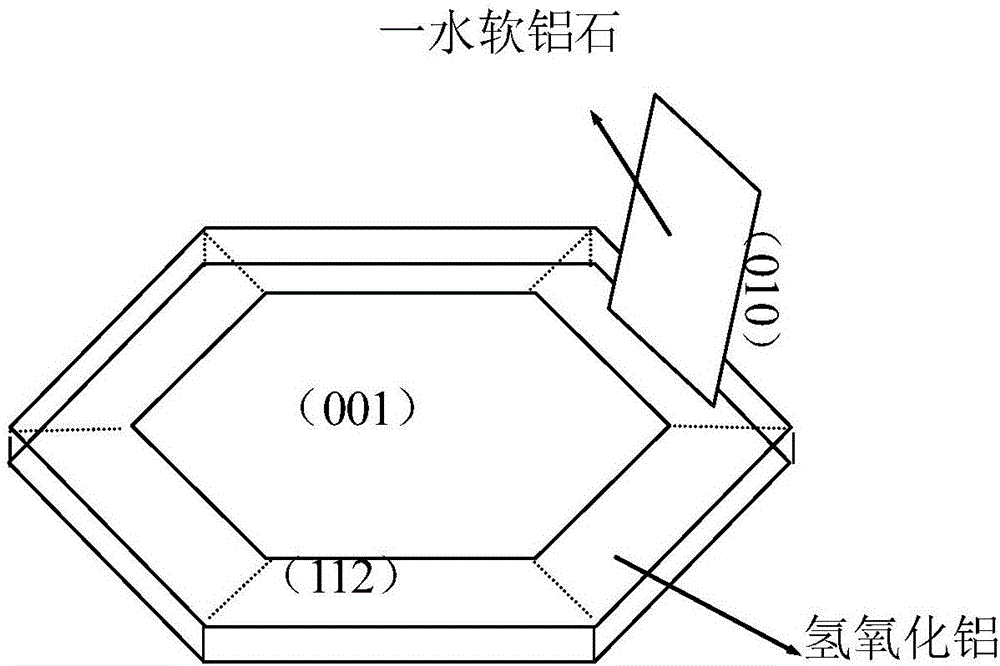

Method for preparing ultrafine alumina powder with vertical faces

ActiveCN106517278AGood lookingMicrostructure is easy to controlAlkali-metal aluminates/aluminium-oxide/aluminium-hydroxide preparationAlumina hydrateDouble phase

The invention discloses a method for preparing ultrafine alumina powder with vertical faces. The method comprises the following steps: (1) adding aluminum hydroxide to a sodium aluminate solution for seed precipitation, and partially dissolving aluminum hydroxide to precipitate boehmite; (2) performing solid-liquid separation on the mixture obtained in step (1) to obtain an alumina hydrate double-phase precursor with flaky boehmite perpendicular to or approximately perpendicular to flaky aluminum hydroxide; (3) calcining or sintering the alumina hydrate double-phase precursor to obtain the ultrafine alumina powder with the vertical faces. The alumina powder prepared with the method has the advantages that the product morphology is consistent, the micro-structure is easy to control, the production cost is low and the like, and has good application prospect in alumina-based adsorbents, catalysts and catalyst carrier inorganic films and 3D printing alumina-based materials.

Owner:CENT SOUTH UNIV

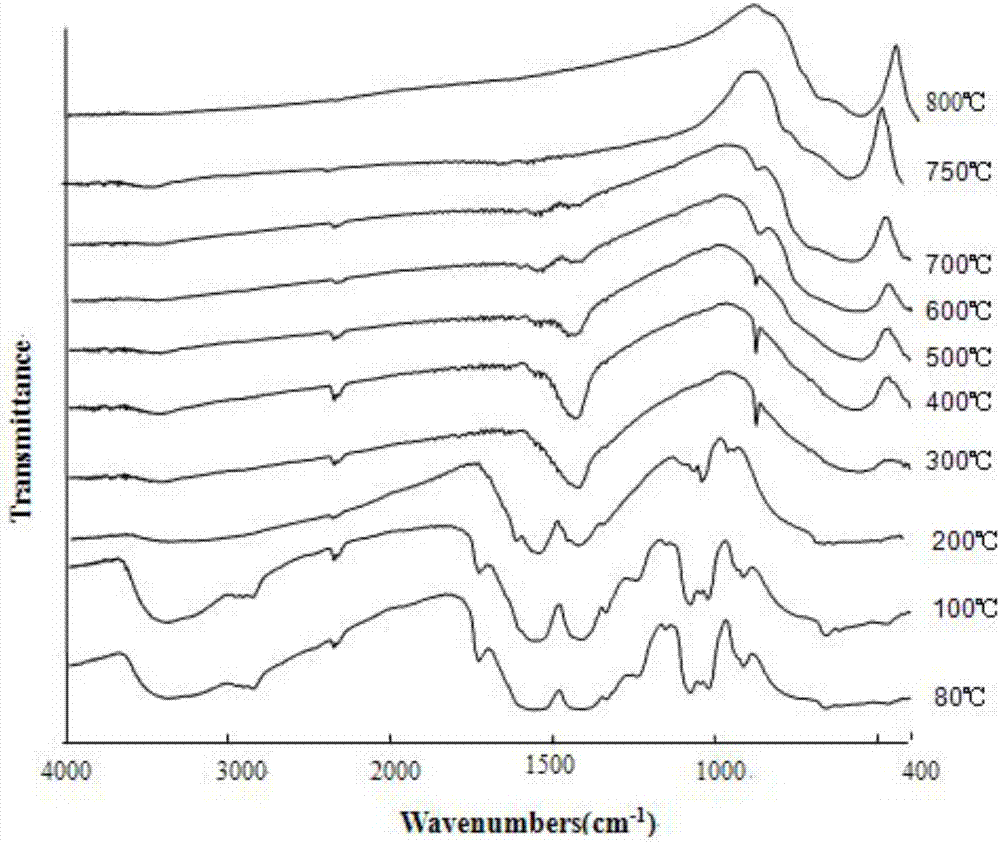

Preparation method of calcium doped lead titanate ceramic fiber

InactiveCN107164841AImprove uniformityMicrostructure is easy to controlFibre chemical featuresFiberHigh density

The invention relates to a preparation method of calcium doped lead titanate ceramic fiber, and the preparation method is characterized by comprising the following specific steps: (1) preparation of stable sol; (2) drawing and drying; (3) decomposition of dry gel fiber; and (4) sintering. The sintering conditions are as follows: the sintering temperature is 750 DEG C, the sintering time is 60min, and the heating rate is 2 DEG C / min. The preparation method has scientific and reasonable design, simple process, easy operation, low cost, and other advantages, the ceramic fiber prepared by the method has high strength, superior performance, smooth surface, high density, low tendency to fragmentation and other advantages, and the method has the advantages of convenient operation and easy implementation, and is a highly innovative preparation method of the calcium doped lead titanate ceramic fiber.

Owner:HEBEI CHEM & PHARMA COLLEGE

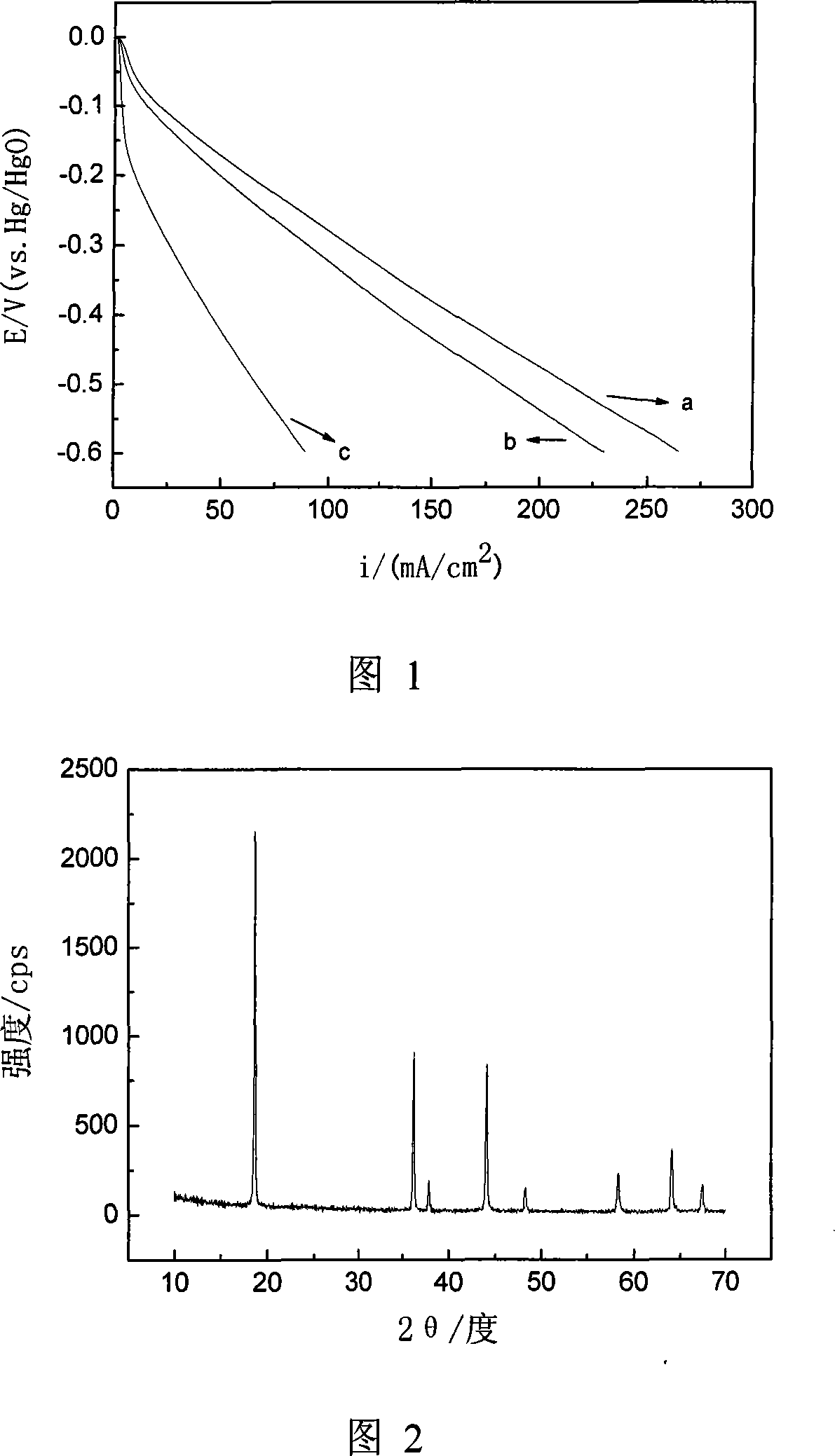

Electro-catalyst of zinc-air battery and method for making same

InactiveCN101114714AImprove electrocatalytic activityGood chemical stabilityCell electrodesCatalyst activation/preparationMolecular levelZinc–air battery

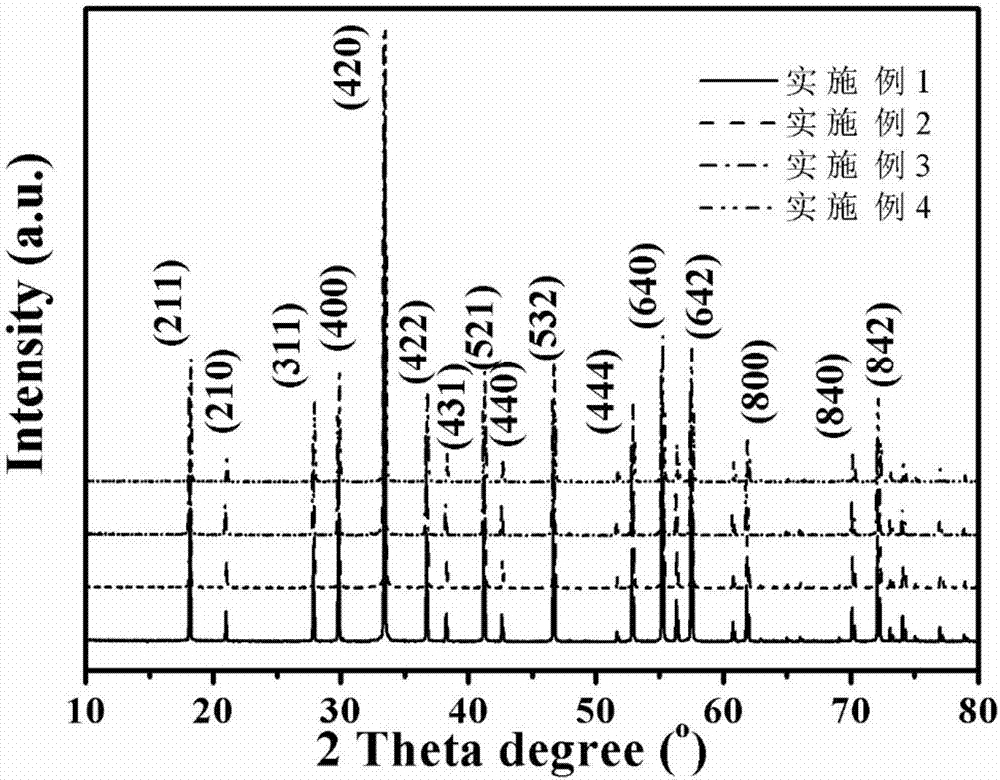

The invention discloses a clectrocatalyst for zinc-air batteries and a preparation method. The general formula of the clectrocatalyst is LiNixCoyFezMn2-x-y-zO4, wherein x is more than or equal to 0.10 and less than or equal to 0.50, y is more than or equal to 0 and less than or equal to 0.50, and z is more than or equal to 0 or less than or equal to 0.50. The crystalline structure of the clectrocatalyst is spinel-type crystalline structure. The clectrocatalyst of the invention has high electro-catalytic activity and good chemical stability, and the raw materials needed for the preparation of the clectrocatalyst has rich reserves and low prices; and the uniform doping of different metals in the clectrocatalyst outcome can be realized and an outcome with uniform structure at the molecular level can be obtained within a short time. The clectrocatalyst of the invention requires low heat treatment temperature and short heat treatment time, and the obtained outcome has high purity and narrow particle size distribution. And the reaction process and the microstructure of the sol-gel are easy to be controlled, resulting in little side effects, high outcome conversion rate, and thus having high outcome quality and production efficiency.

Owner:SOUTH CHINA UNIV OF TECH

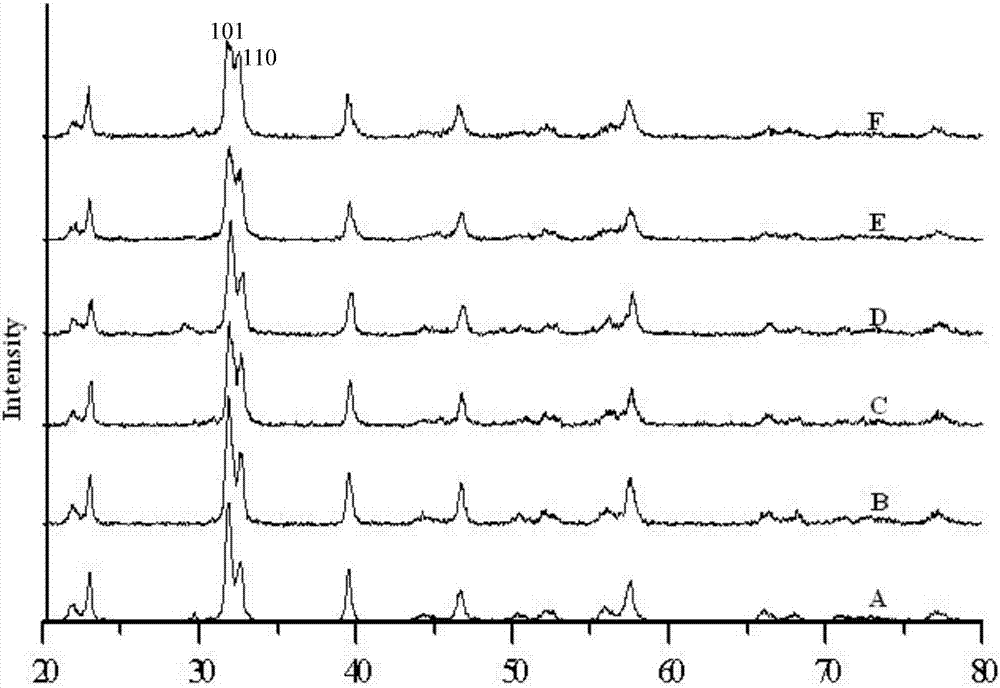

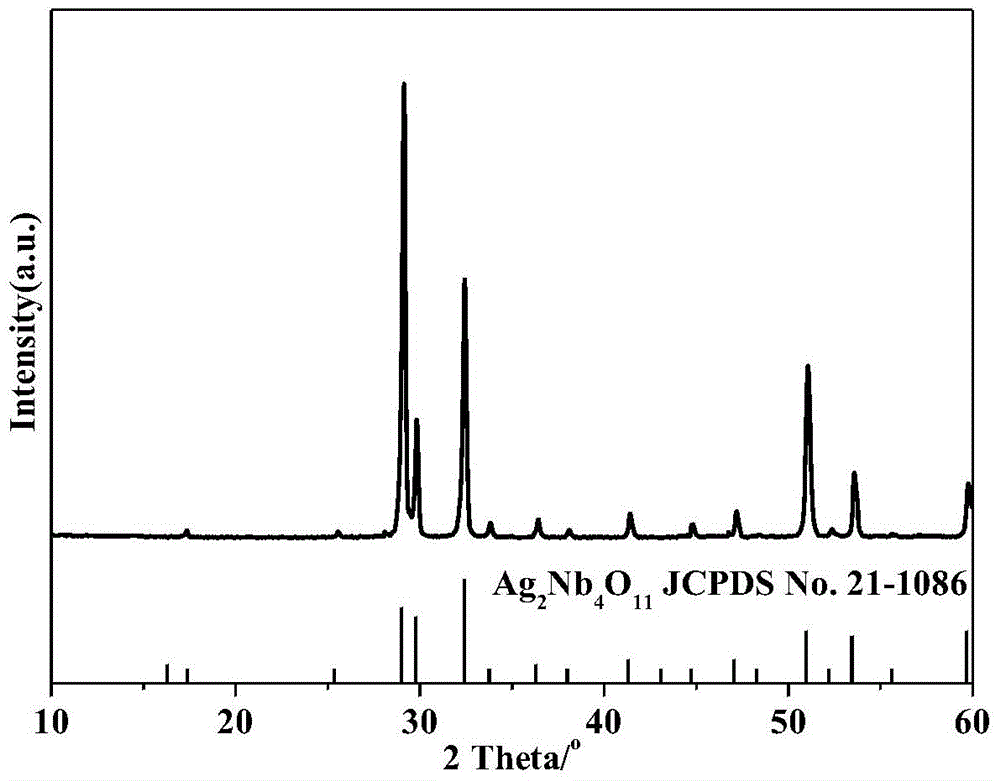

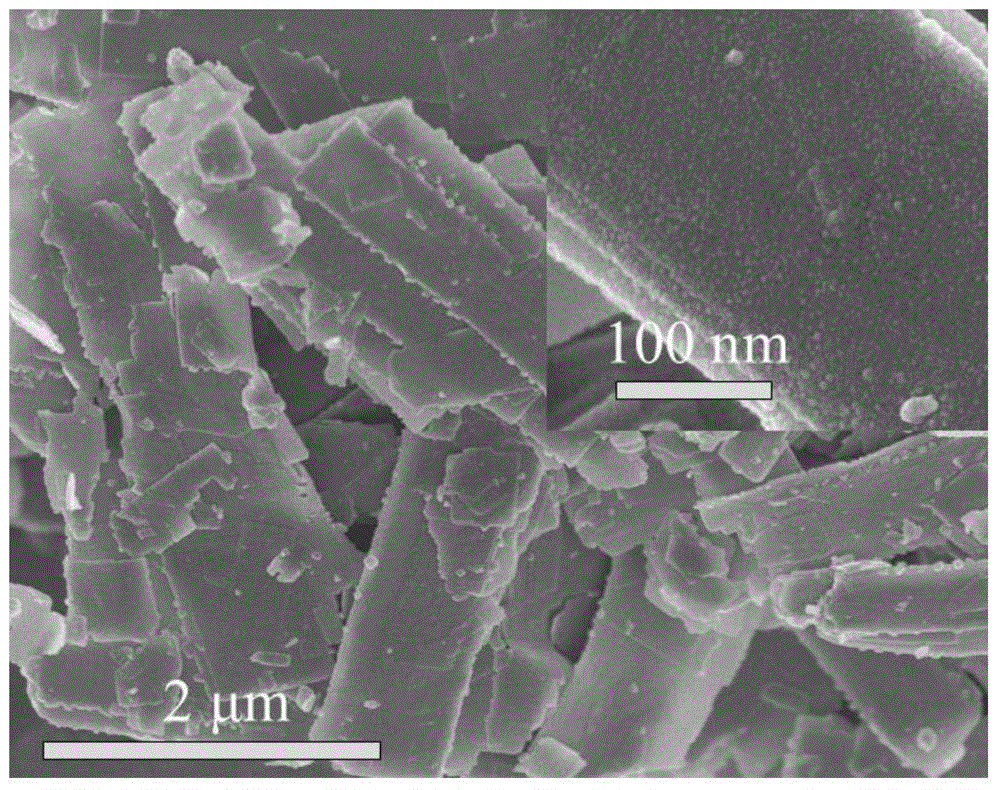

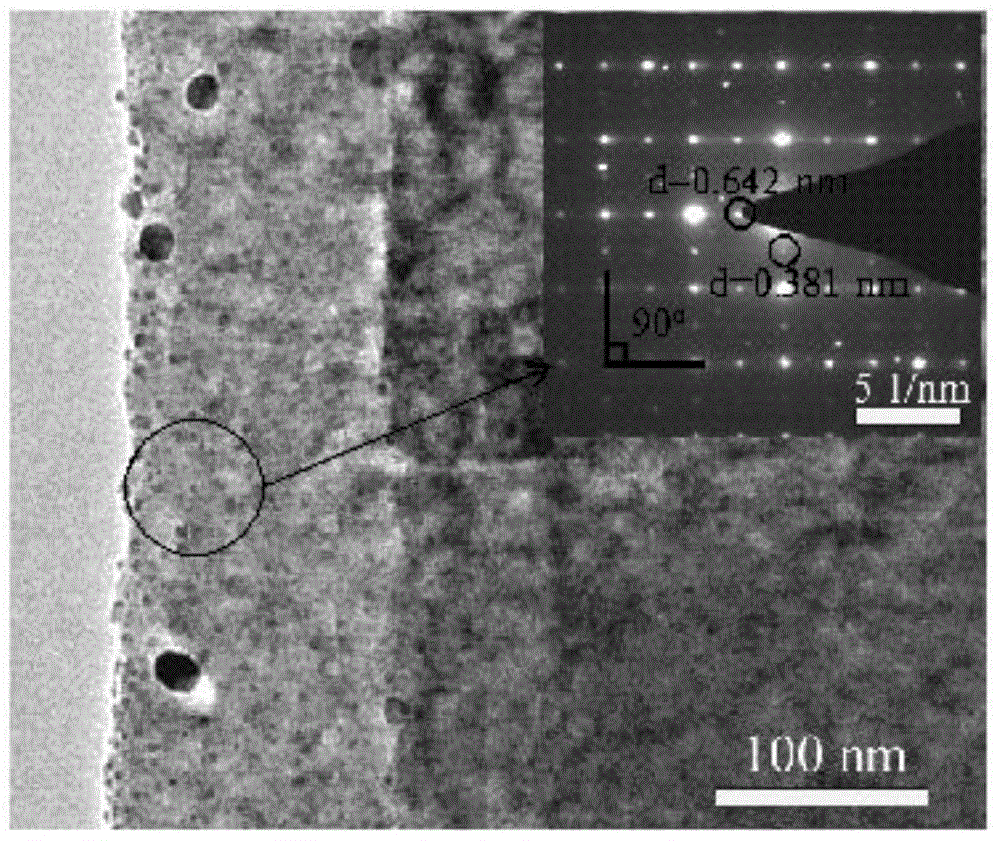

Ag2Nb4O11 nano-textured sheet particle and preparation method thereof

ActiveCN105668626AMild reaction conditionsEasy to operateMaterial nanotechnologyNiobium compoundsChemistryMicrostructure

Belonging to the technical field of nano-material preparation, the invention discloses an Ag2Nb4O11 nano-textured sheet particle and a preparation method thereof. The method includes the steps of: 1) adding layer structure H4Nb6O17 sheet particles into an AgNO3 solution according to a material-liquid ratio of 1g:80-150mL, fully stirring the substances to carry out reaction, then performing filtering, washing and drying to obtain precipitate; 2) adding the precipitate obtained in step 1) into a freshly prepared AgNO3 solution according to a material-liquid ratio of 1g:80-150mL, further stirring the substances fully to carry out reaction, then performing filtering, washing and drying to collect precipitate; 3) repeating the operation of step 2) 2-4 times to obtain layer structure Ag3HNb6O17; and 4) conducting heat treatment on the layer structure Ag3HNb6O17 at 400-800DEG C for 2-4h, thus obtaining Ag2Nb4O11 nano-textured sheet particles. The method provided by the invention is simple to operate and has high repeatability, and the sheet structure Ag2Nb4O11 prepared by the method has the advantages of good crystallization performance, high purity, and controllable shape and microstructure.

Owner:重庆泛锐科技有限公司

Preparation method of lactide and caprolactone random copolymer

ActiveCN107216447ALow costHigh activityGroup 3/13 element organic compoundsBiocompatibility TestingMicrostructure

The invention discloses a preparation method of a lactide and caprolactone random copolymer. The preparation method is characterized in that a nitrogen and oxygen two-tooth coordination aluminum compound with different substituted groups is used as a catalyst, and structurally contains a salicylaldiminato ligand and two alkyls X; the nitrogen and oxygen two-tooth coordination aluminum compound has the advantages of simple and convenient preparation method, low cost, stable property, higher catalyzing activity and excellent random co-polymerizing property, and is especially suitable for catalyzing the random co-polymerizing of lactide and caprolactone; by introducing large substituted groups into the ligand, and adjusting the reactivity ratio in the co-polymerizing of the lactide and the caprolactone, the random co-polymerizing of the lactide and the caprolactone is realized. The nitrogen and oxygen two-tooth coordination aluminum compound has the characteristics that the cost is low, the activity is high, and the controllability is good. The prepared random copolymer has the characteristics that the microstructure can be controlled and degraded, and the biocompatibility is good; the requirements of industrial departments are met.

Owner:QINGDAO UNIV OF SCI & TECH

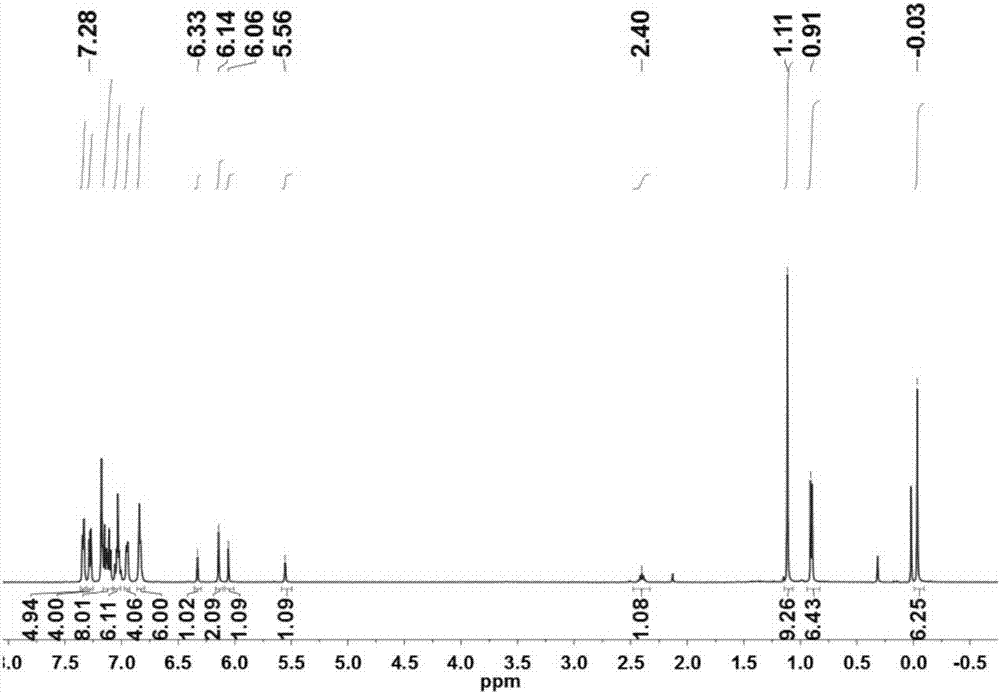

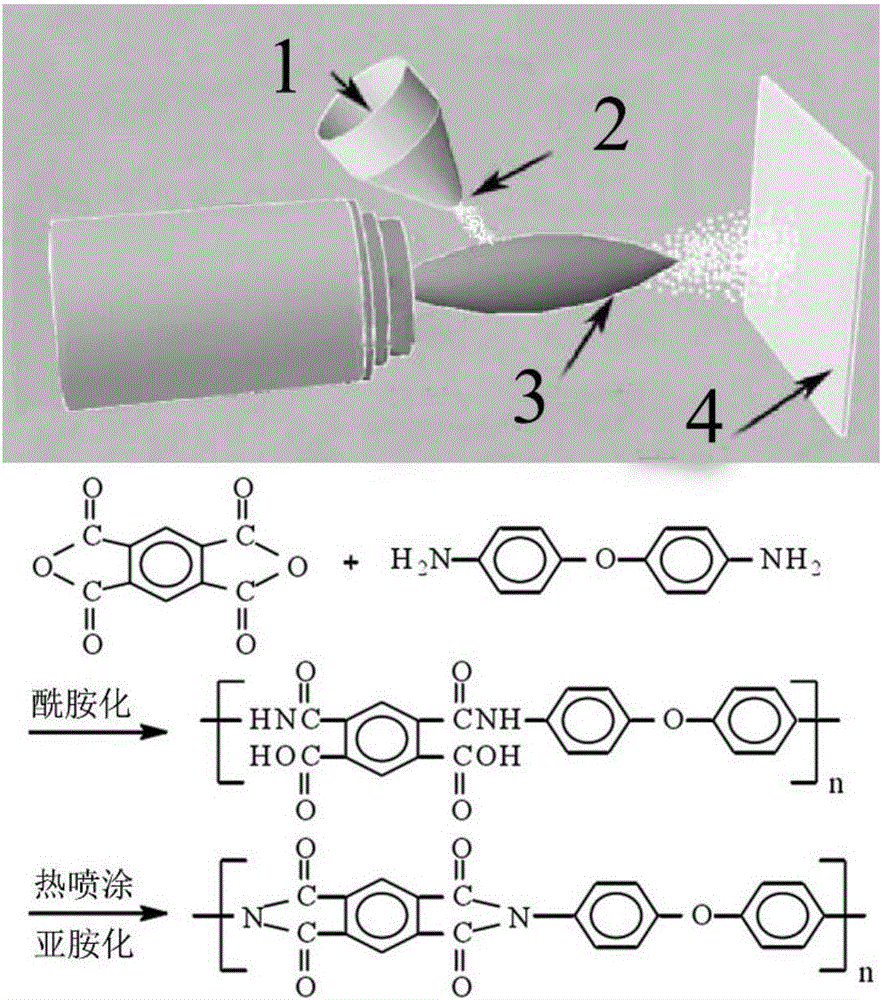

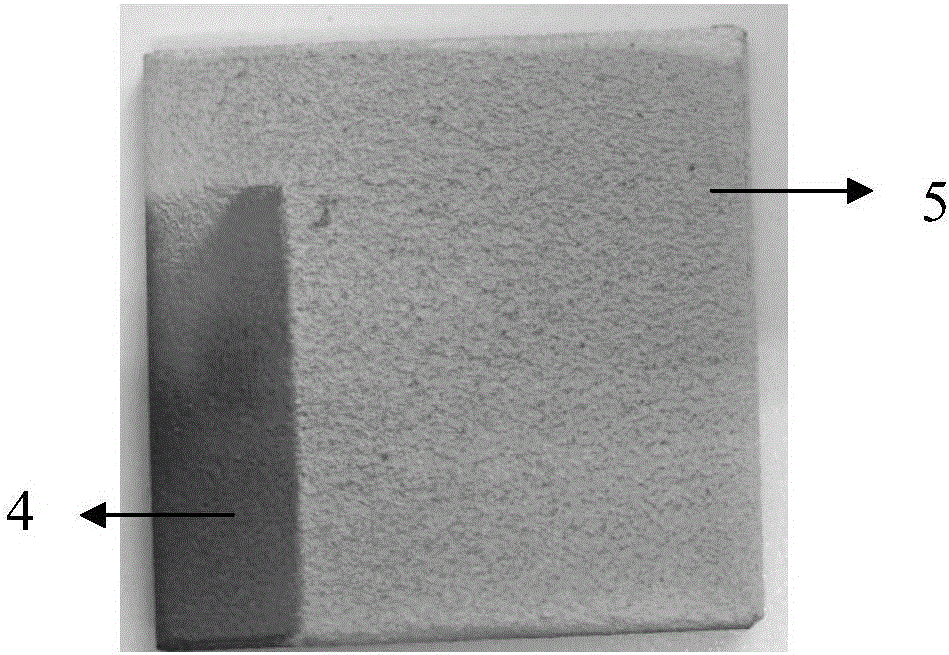

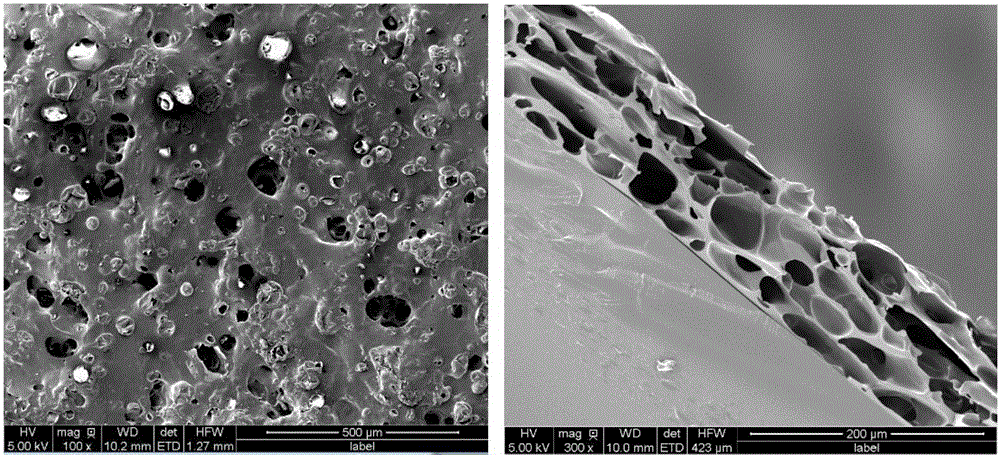

Method utilizing thermal spraying technique for preparing polyimide coating and product of method

ActiveCN105903650AImprove bindingSimple processLiquid surface applicatorsCoatingsThermal sprayingSizing

The invention discloses a method utilizing a thermal spraying technique for preparing polyimide coating and a product of the method. The method includes steps of 1, preparing polyimide spray material which is a thermosetting polyimide precursor sizing agent, a thermoplastic polyimide precursor sizing agent or a thermoplastic polyimide powder; 2, performing surface deoiling and roughening on a substrate; 3, sending the spray material prepared in step 1 into thermal spraying flame flow and forming the polyimide coating on the processed substrate surface through spraying. The method is simple in technique, high in efficiency and suitable for field construction. Spray limits of work piece sizes and shapes are removed and the cost is low. The prepared polyimide composite coating can be combined well with the substrate and the microstructures are adjustable. The method can be applied to fields of electrics, mechanics, thermotics, anti-radiation and medical science and the like.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

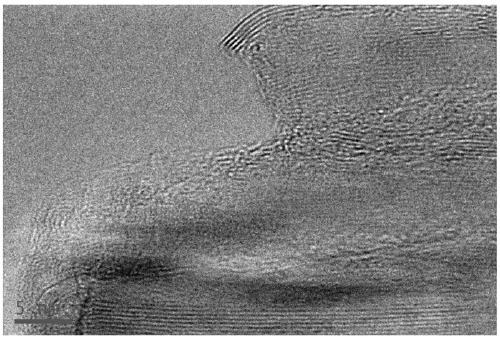

Preparation method of zirconic acid lanthanum ceramic fiber

ActiveCN103553596BSmall diameterEvenly distributedInorganic material artificial filamentsFiberSpinning

The invention relates to a preparation method of a zirconic acid lanthanum ceramic fiber. The method comprises the following steps: preparing a gel fiber through a colloidal sol centrifugal fiber forming technology by using zirconium nitrate as a zirconium source, lanthanum nitrate as a lanthanum source, citric acid as a chelating agent, and water as a solvent, and calcining the gel fiber to form the zirconic acid lanthanum ceramic fiber. A precursor prepared by the invention has stable colloidal sol property and is good in filamentation property with no need of adding a polymer spinning additive. The prepared zirconic acid lanthanum ceramic fiber is good in flexibility, compact in microstructure, good in phase stability an low in heat conductivity coefficient and can be used for high-temperature thermal-insulation material, and the crystal form of the zirconic acid lanthanum ceramic fiber is pyrochlore form.

Owner:SHANDONG UNIV

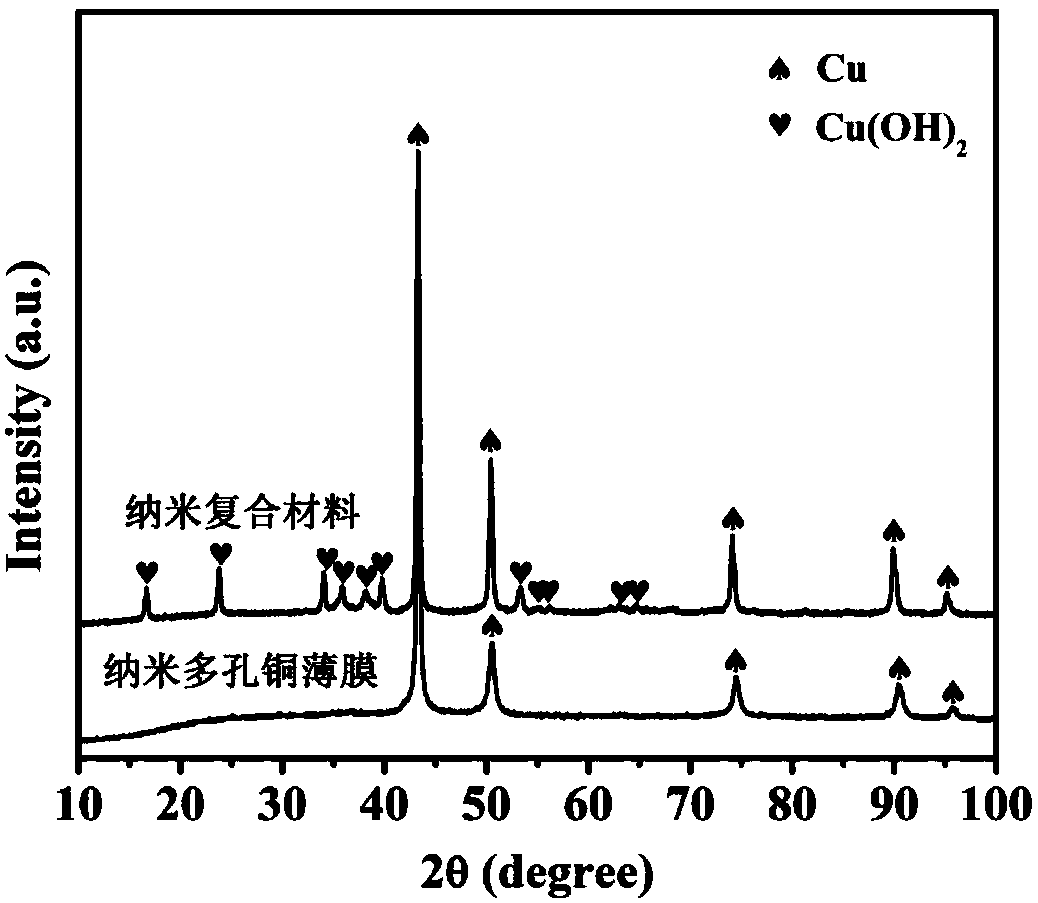

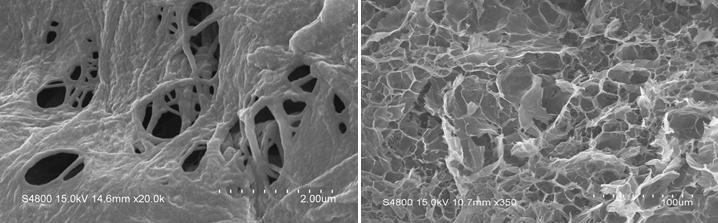

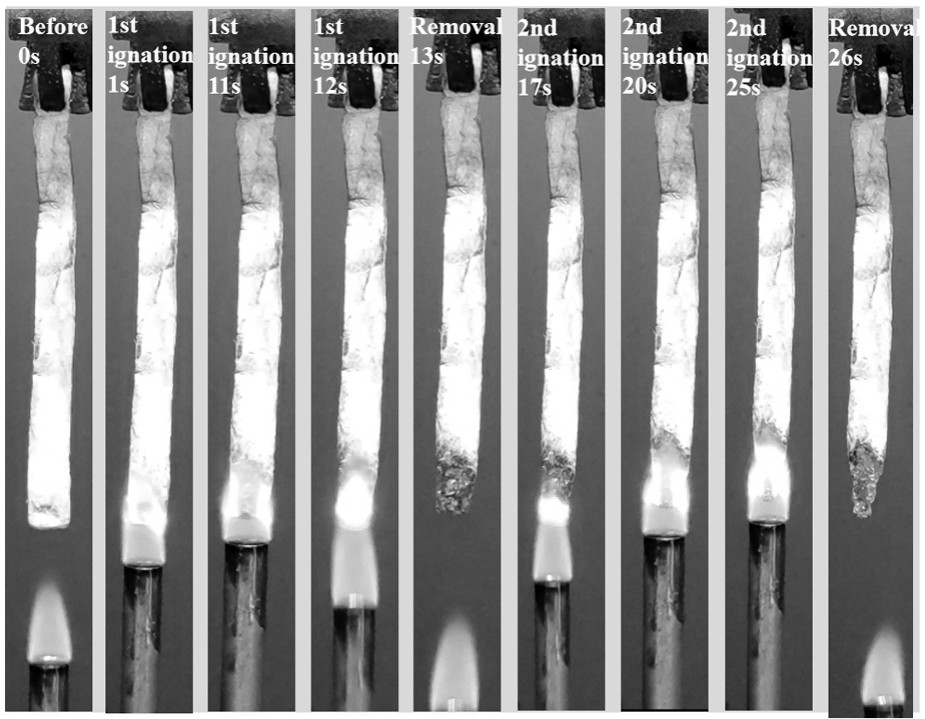

Nanoporous copper/cu(oh)2 nanowire array sensor electrode material and preparation method thereof

ActiveCN106226382BThickness is easy to controlEasy to prepareMaterial nanotechnologyMaterial electrochemical variablesGlucose sensorsComposite electrode

The invention discloses a nano porous copper / Cu(OH)2 nanowire array sensor electrode material and a preparation method thereof, and belongs to the technical field of micro-sensation. The preparation method of the nano porous copper / Cu(OH)2 nanowire array sensor electrode material mainly comprises the following two steps: by taking Cu-Zr-Al amorphous alloy as a precursor, preparing a flexible nano porous copper film of a double-continuous through hole structure by using a chemical alloy removing method; performing controllable growth on a Cu(OH)2 nanowire array on a nano porous copper film substrate by using an alkali oxidation method. The nano composite electrode material disclosed by the invention is of a structure similar to 'sandwich', Cu(OH)2 nanowires are uniformly and densely distributed on the nano porous copper substrate, have directivity and are uniform in morphology, large in internal specific surface area and very high in electric catalytic activity, the nano composite material can be directly used as an electrode material of a non-enzyme glucose sensor, the linear response range for glucose is 0.2-9 mM, the detection sensitivity is 2.09 mA / cm<2>.mM, the detection limit is 200 nM (S / N=-3.6), and the current response time is less than 1 second.

Owner:UNIV OF SCI & TECH BEIJING

Preparation and application of light, heat-insulating and flame-retardant PIPD nanofiber aerogel

InactiveCN112679793AReduce forceClose distanceMonocomponent synthetic polymer artificial filamentFiberPolymer science

The invention relates to the technical field of aerogel materials, and provides light, heat-insulating and flame-retardant PIPD nanofiber aerogel as well as preparation and application thereof. The PIPD nanofiber aerogel is prepared by taking high-molecular-weight PIPD as a raw material, stripping the PIPD into PIPD nanofibers by adopting an acid mixing method, and performing solvent exchange, freeze drying and high-temperature heat treatment in an inert atmosphere. The PIPD nanofiber aerogel is formed by assembling PIPD nanofibers serving as construction modules, the PIPD nanofibers are mutually staggered to form a layered network, and the layered network forms a honeycomb pore structure. The aerogel provided by the invention is adjustable in density of 6.90-17.95 kg / m < 3 >, high in porosity (80-99.8%), good in heat-insulating property, good in flame retardant property (UL-94, V-0 grade) and strong in interface bonding force, and can be used as a flame-retardant heat-insulating material. The preparation method provided by the invention is simple in steps and easy to implement.

Owner:EAST CHINA UNIV OF SCI & TECH

Catalyst for preparing acrylic acid through propane selective oxidation and preparation method of catalyst

ActiveCN103691457ASmall particlesLarge specific surface areaPhysical/chemical process catalystsOrganic compound preparationActive componentPetrochemical

The invention belongs to the technical field of petrochemical engineering, in particular relates to a catalyst for preparing acrylic acid through propane selective oxidation and a preparation method of the catalyst. The catalyst has a formula of MoaVbTecNbdOx, wherein Mo, V, Te and Nb are active components; a : b : c : d is 1 : (0.2-0.3) : (0.2-0.3) : (0.1-0.2). When the catalyst is adopted to prepare the acrylic acid, the conversion rate of the propane and the once-through yield of the acrylic acid are high.

Owner:临沂星火知识产权服务有限公司

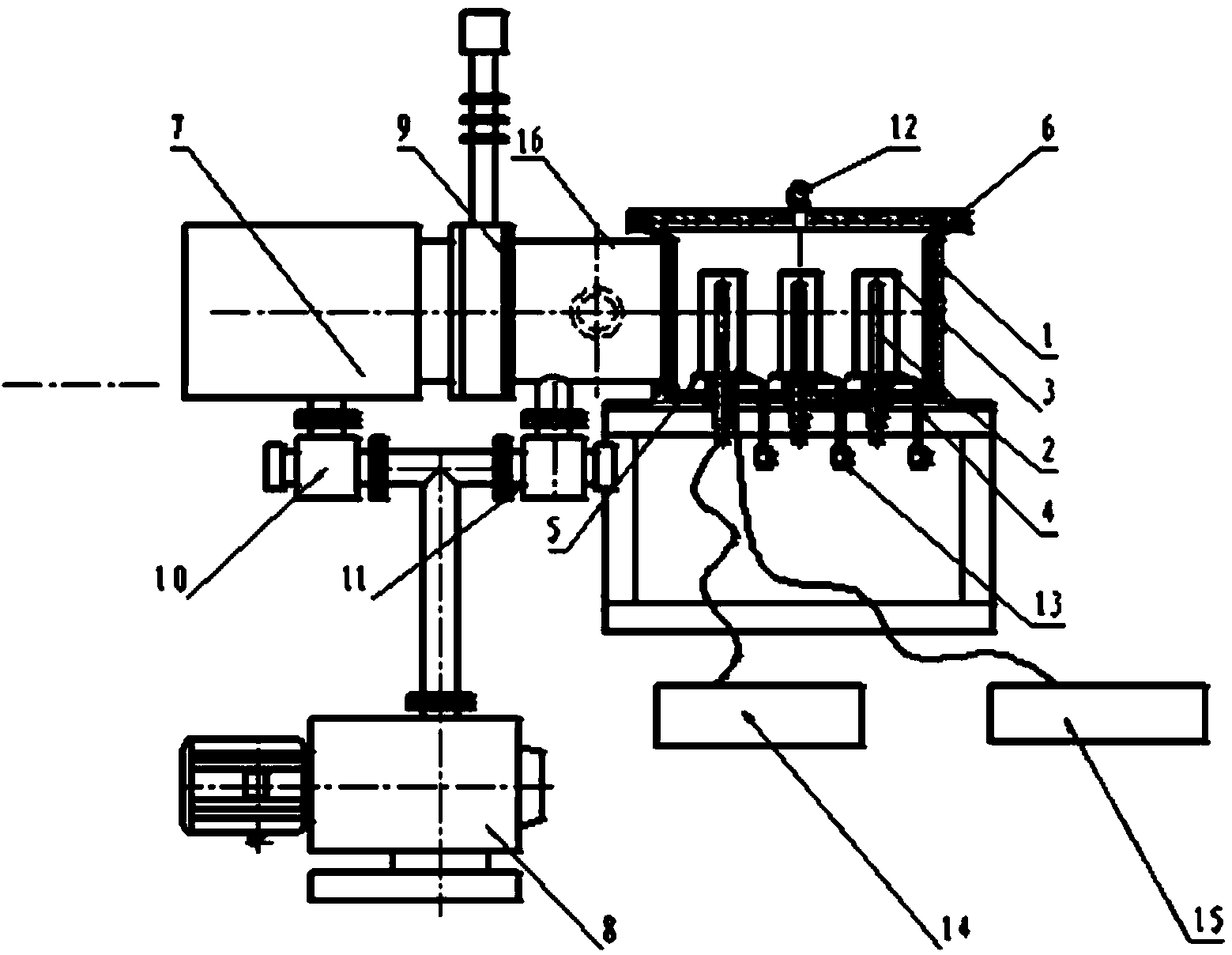

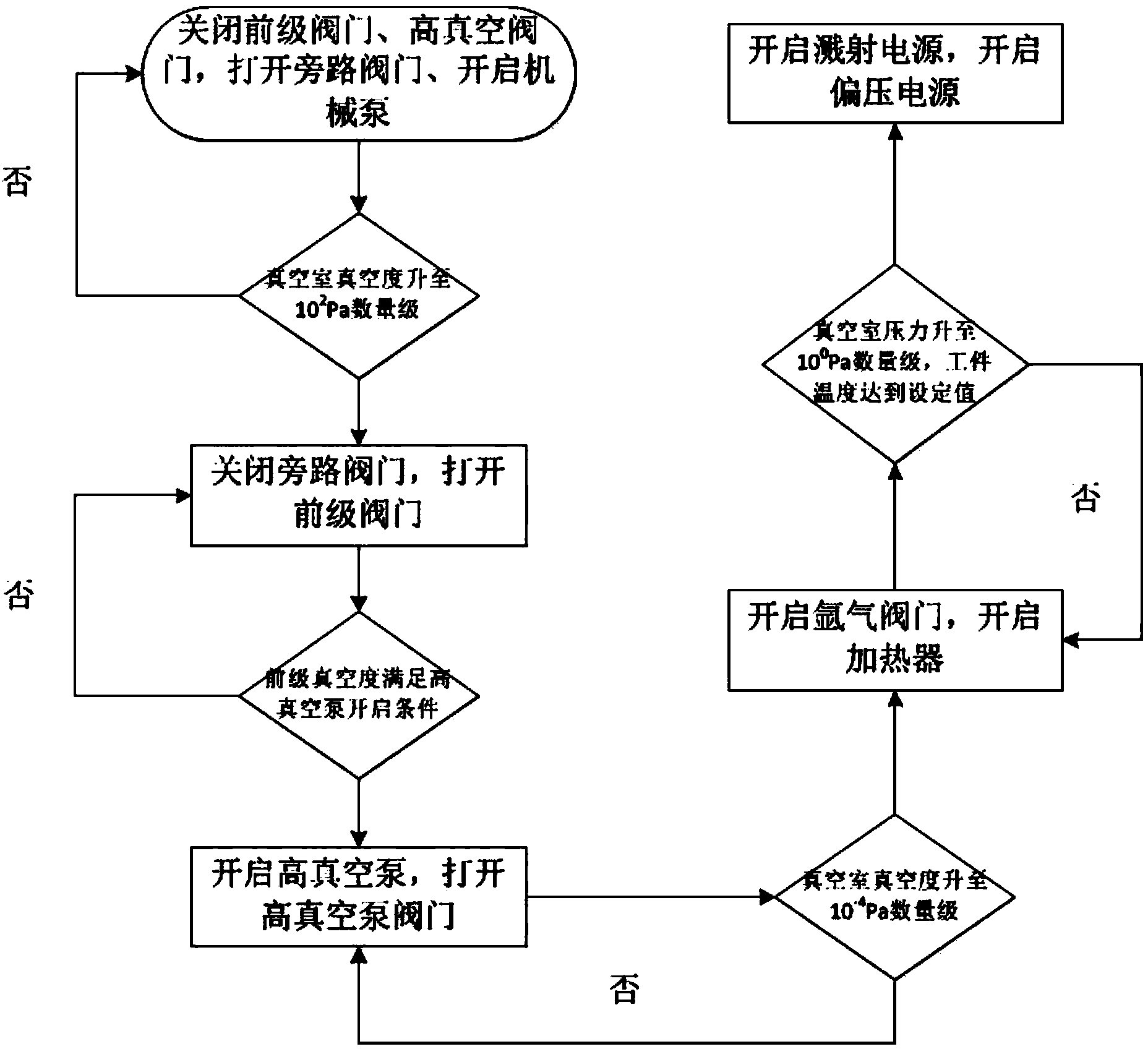

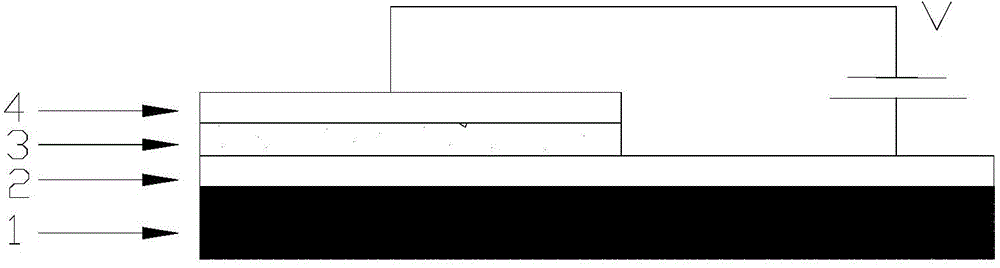

Diode sputtering coating equipment used for coating inner wall of vacuum cup

ActiveCN104388905AReduced free pathMicrostructure is easy to controlVacuum evaporation coatingSputtering coatingSputteringDeposition temperature

The invention discloses diode sputtering coating equipment used for coating the inner wall of a vacuum cup. The diode sputtering coating equipment comprises a support, a sputtering coating device and a vacuum device, wherein the sputtering coating device is arranged on the support, the vacuum device is connected with one end of the sputtering coating device, and a plurality of cup tools are arranged in the sputtering coating device and can be matched with different sputtering electrodes. The diode sputtering coating equipment has the benefits that the diode sputtering coating equipment is suitable for vacuum cups in different sizes and shapes and is simple in structure, easy to maintain and good in continuity; multiple workpieces can be machined in the same parameter, the production efficiency is high, and the quality consistence of coatings is good; additionally, due to the fact that the sputter electrodes can be replaced freely, the deposition temperature and other key parameters can be adjusted at will, and the quality and the components of the coatings can be adjusted; besides, once a more developed anti-bacteria coating is developed in the future, the equipment is very favorable for updating of the novel anti-bacteria coating and quick building of industrialization.

Owner:BEIJING TECHNOL SCI

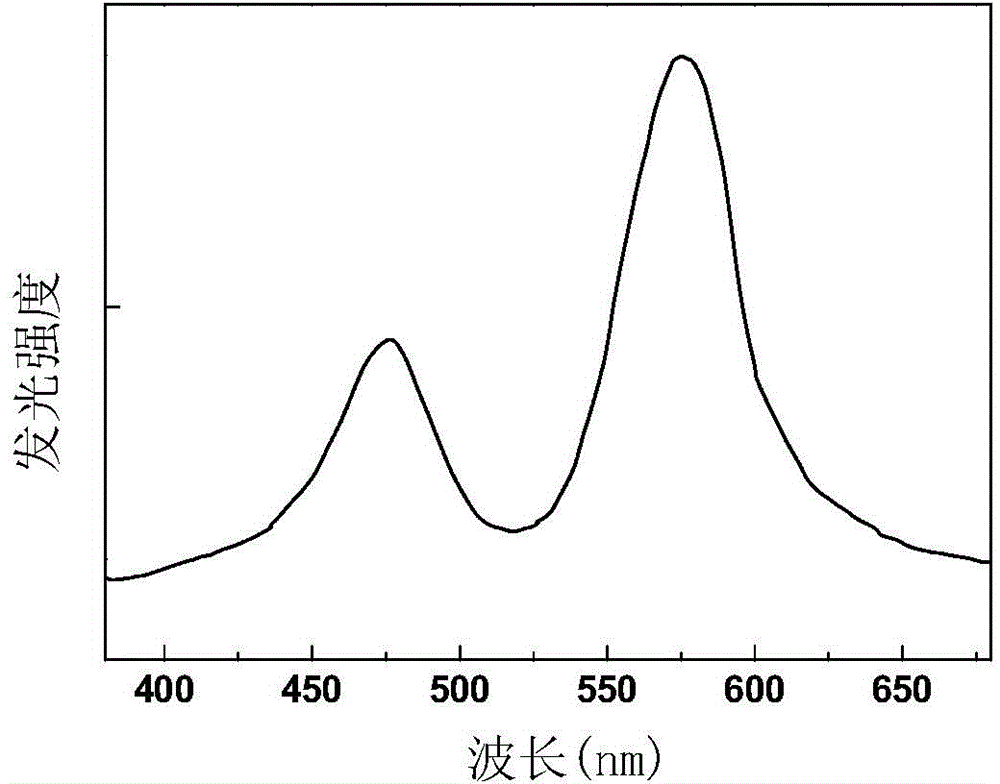

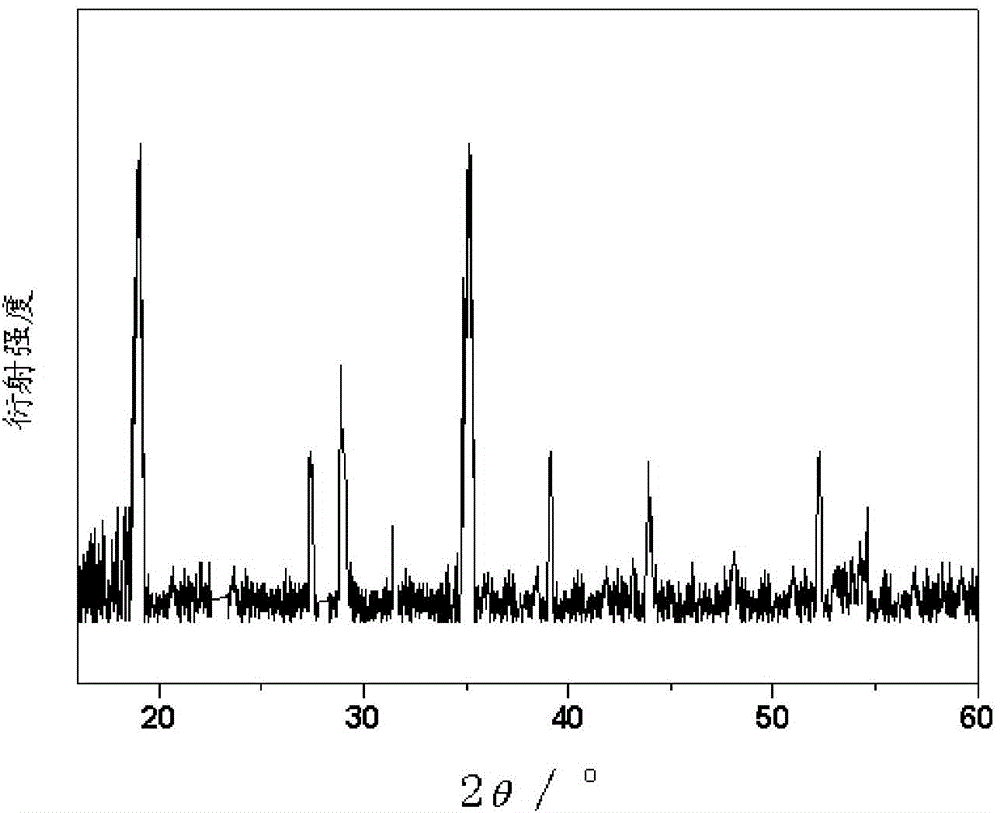

Antimony/terbium-codoped plumbite antimonate luminescent material, and preparation method and application thereof

InactiveCN104673302AGood thermal and chemical stabilityGood processing performanceLuminescent compositionsSemiconductor devicesChemistryTerbium

The invention discloses an antimony / terbium-codoped plumbite antimonate luminescent material of which the molecular expression is RPb[4-x-y]Sb6O24:xSb<3+>,yTb<3+>, wherein RPb[4-x-y]Sb6O24 is the matrix, Sb<3+> and Tb<3+> are active elements, R is Mg, Ca, Ba or Sr, x is 0.01-0.05, and y is 0.01-0.08. The luminescent material matrix plumbite antimonate has the advantages of favorable heat stability, favorable chemical stability and favorable processability. The active elements antimony and terbium are doped in the plumbite antimonate matrix as the main luminescent center, so that the obtained luminescent material has strong light-emitting peaks at 490nm and 580nm in the electroluminescent spectrum (EL). The invention also discloses a preparation method of the antimony / terbium-codoped plumbite antimonate luminescent material and application of the antimony / terbium-codoped plumbite antimonate luminescent material in film electroluminescent devices.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +2

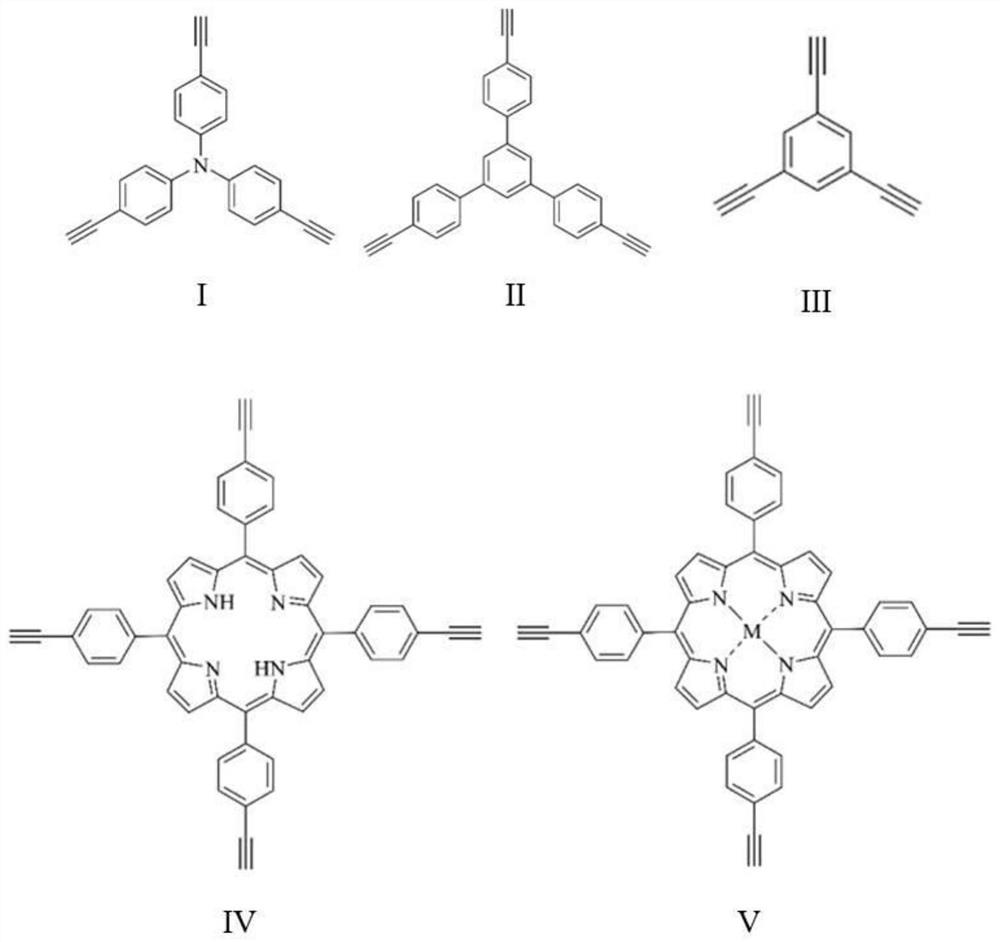

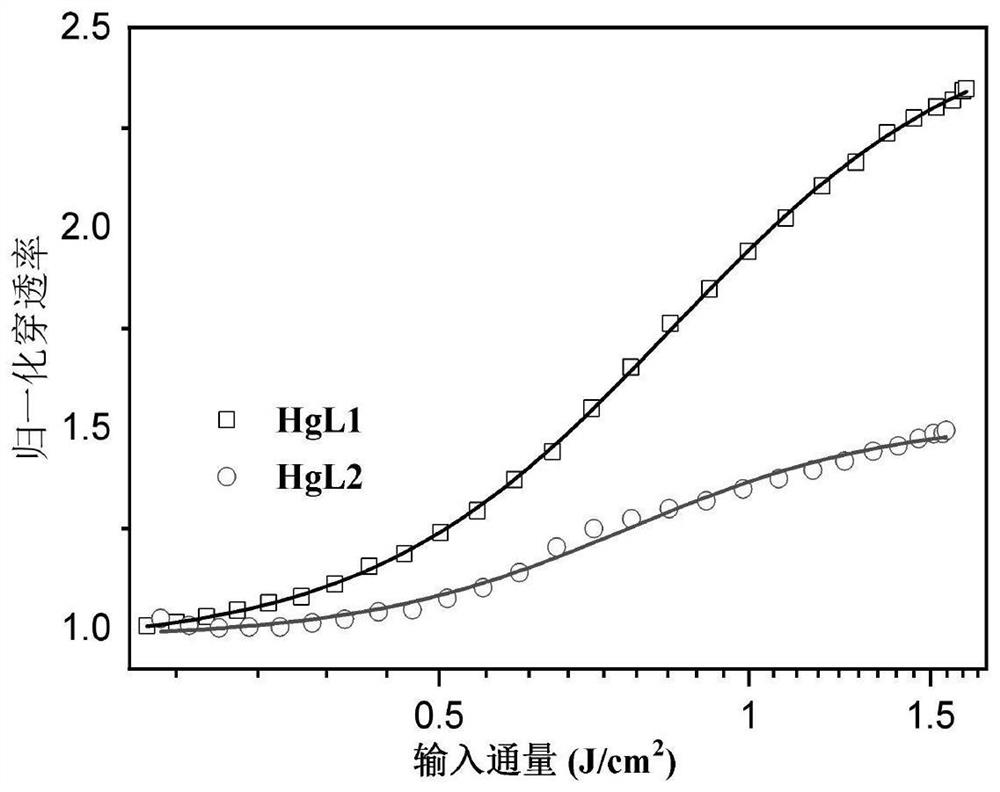

Two-dimensional metal organic alkyne nanosheet as well as preparation method and application thereof

PendingCN112500576AControllable thicknessStable performanceMaterial nanotechnologyLaser detailsBenzenePolymer chemistry

The invention provides a two-dimensional metal organic alkyne nanosheet, and the structural general formula of the two-dimensional metal organic alkyne nanosheet is shown in the specification, and inthe formula, R is an organic alkyne ligand at least containing three alkynyl groups and one benzene ring, M is a metal ligand containing divalent or higher metal ions, 3<=m<=6, and n>=3. Alkynyl in the organic alkyne ligand can react with the metal ligand to be in bonding connection, a stable cross-linked net structure is formed, and then the regularly repeated planar two-dimensional metal organicalkyne nanosheet with the cross-linked structure is formed. Due to the fact that the added organic alkyne ligand is single in structure and fixed to a specific metal ligand bonding reaction site, thethickness of a formed net-shaped structure is controllable, and therefore the prepared planar two-dimensional metal organic alkyne nanosheet is controllable in thickness, stable in performance and beneficial to follow-up use.

Owner:THE HONG KONG POLYTECHNIC UNIV SHENZHEN RES INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com