Method for preparing ZrO2-SiO2-SiC coated C/C composite material by adopting sol-gel method

A zro2-sio2-sic, composite material technology, applied in the field of advanced composite anti-oxidation coating materials, can solve the problems of limited service life of the coating, limited application of glass coating, low anti-oxidation temperature, etc. Antioxidant performance, high purity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

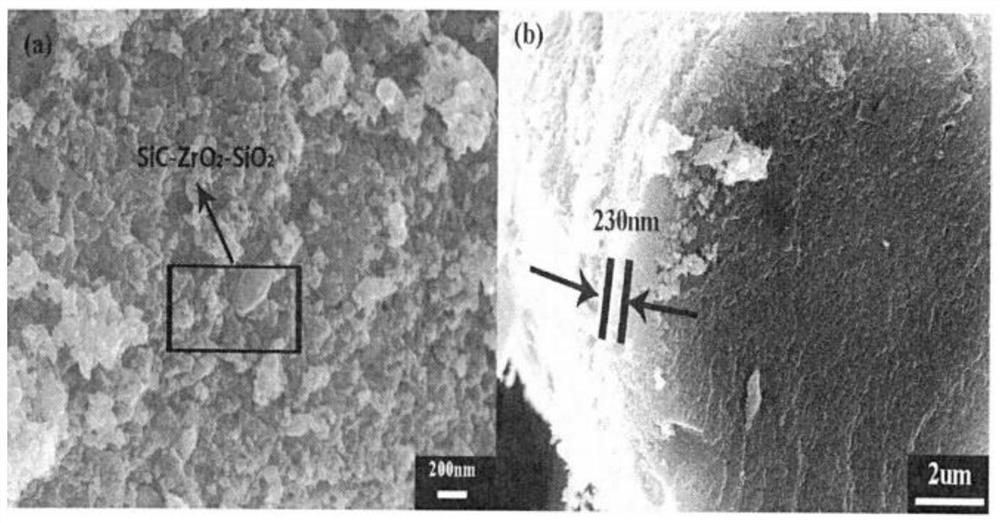

Embodiment 1

[0023] The prepared SiO 2 Sol, ZrO 2 The sol was mixed according to the Zr:Si molar ratio of 80:20, and magnetically stirred at room temperature for 1.5h. Then the SiC-coated C / C composite sample prepared by 7% MTES sol was impregnated in ZrO 2 -SiO 2 In the sol, when there are no obvious air bubbles escaping from the surface of the sample, place it in an oven at 80°C for 2 hours, and repeat this process. Put the above-mentioned C / C composite material sample into a graphite crucible, place it in a high-temperature carbonization furnace, use high-purity nitrogen as a protective atmosphere, control the temperature rise rate of the carbonization furnace to 5°C / min, and lower the furnace temperature from room temperature to Rise to 900°C for 2 hours and 1350°C for 1 hour to produce ZrO 2 -SiO 2 - SiC coating. The coating was isothermally oxidized in air at 1000°C for 1 h, and the mass loss rate was about 9.3%.

Embodiment 2

[0025] SiO 2 Sol, ZrO 2 The sol was mixed according to the Zr:Si molar ratio of 0:100, and the other conditions were the same as in Example 1. The C / C mixed coating material obtained failed to protect the C / C composite material very well.

Embodiment 3

[0027] SiO 2 Sol, ZrO 2 The sol was mixed according to the Zr:Si molar ratio of 20:80, and the other conditions were the same as in Example 1. The C / C mixed coating material obtained failed to protect the C / C composite material very well.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com