Patents

Literature

140 results about "Composite sample" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Composite sampling involves combining the individual samples into one “composite” sample (for example, combining pond water samples taken over the course of two days into one large container). This method has several drawbacks: It loses information about individual samples making it difficult to detect unknown waste variations.

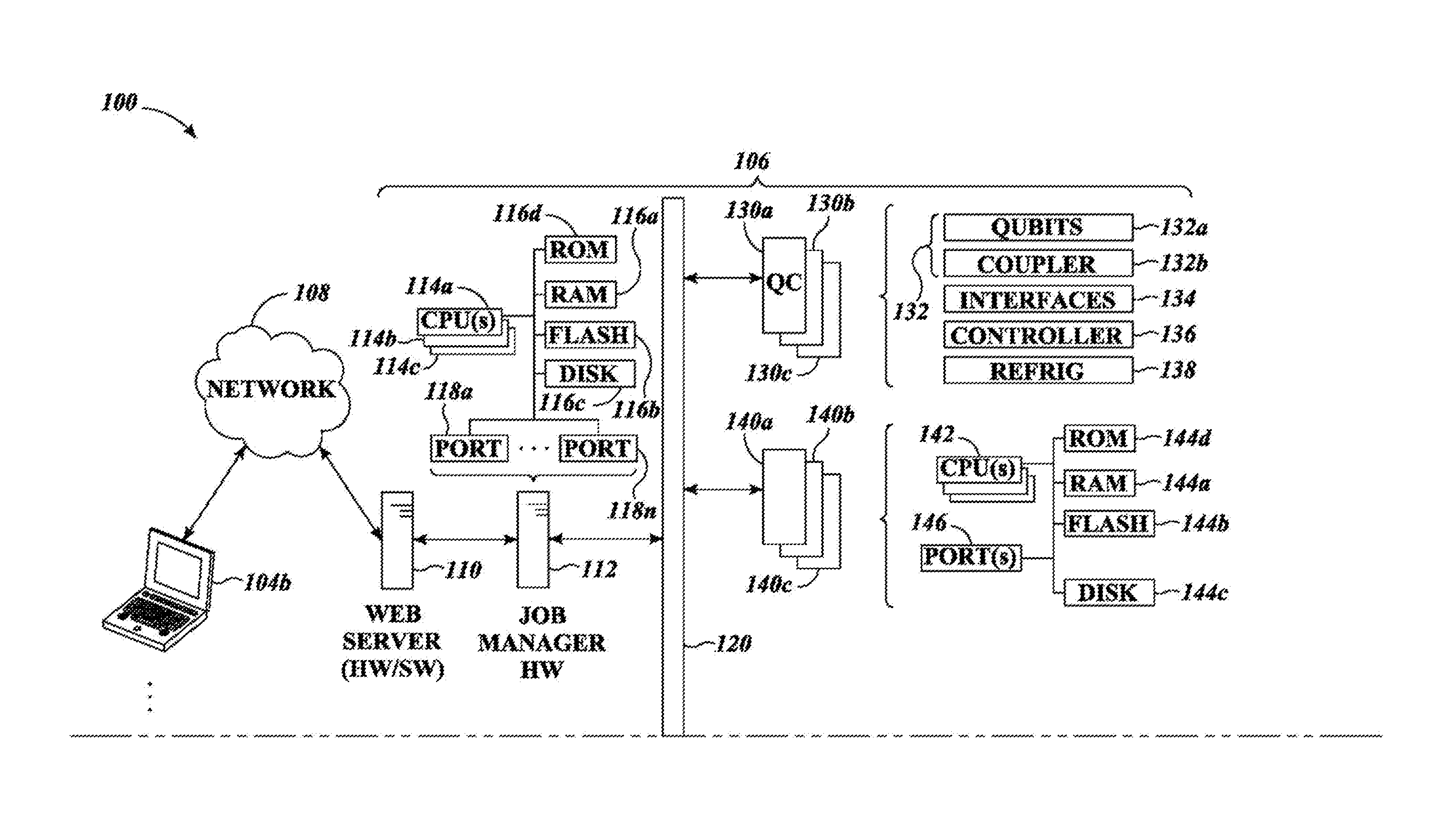

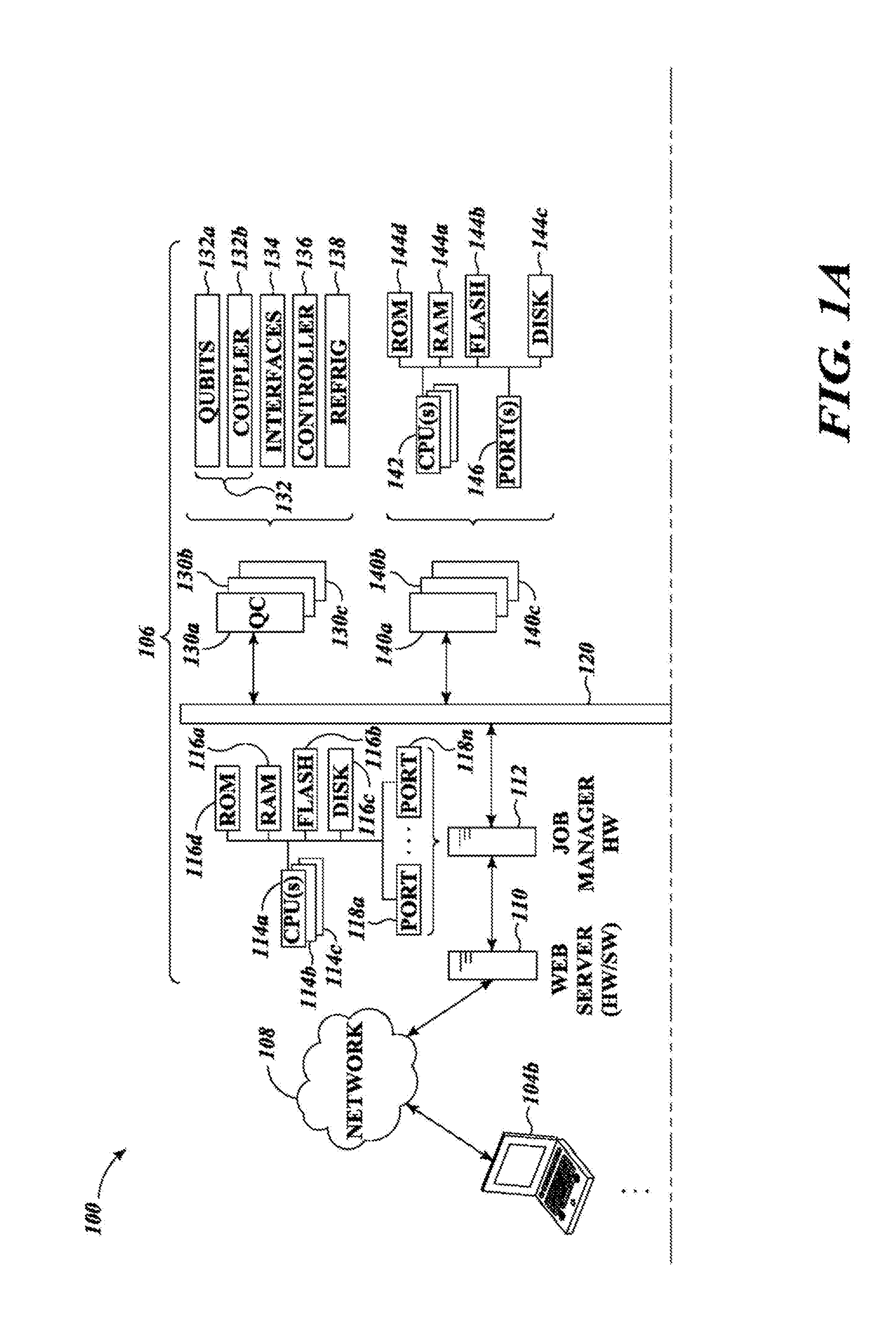

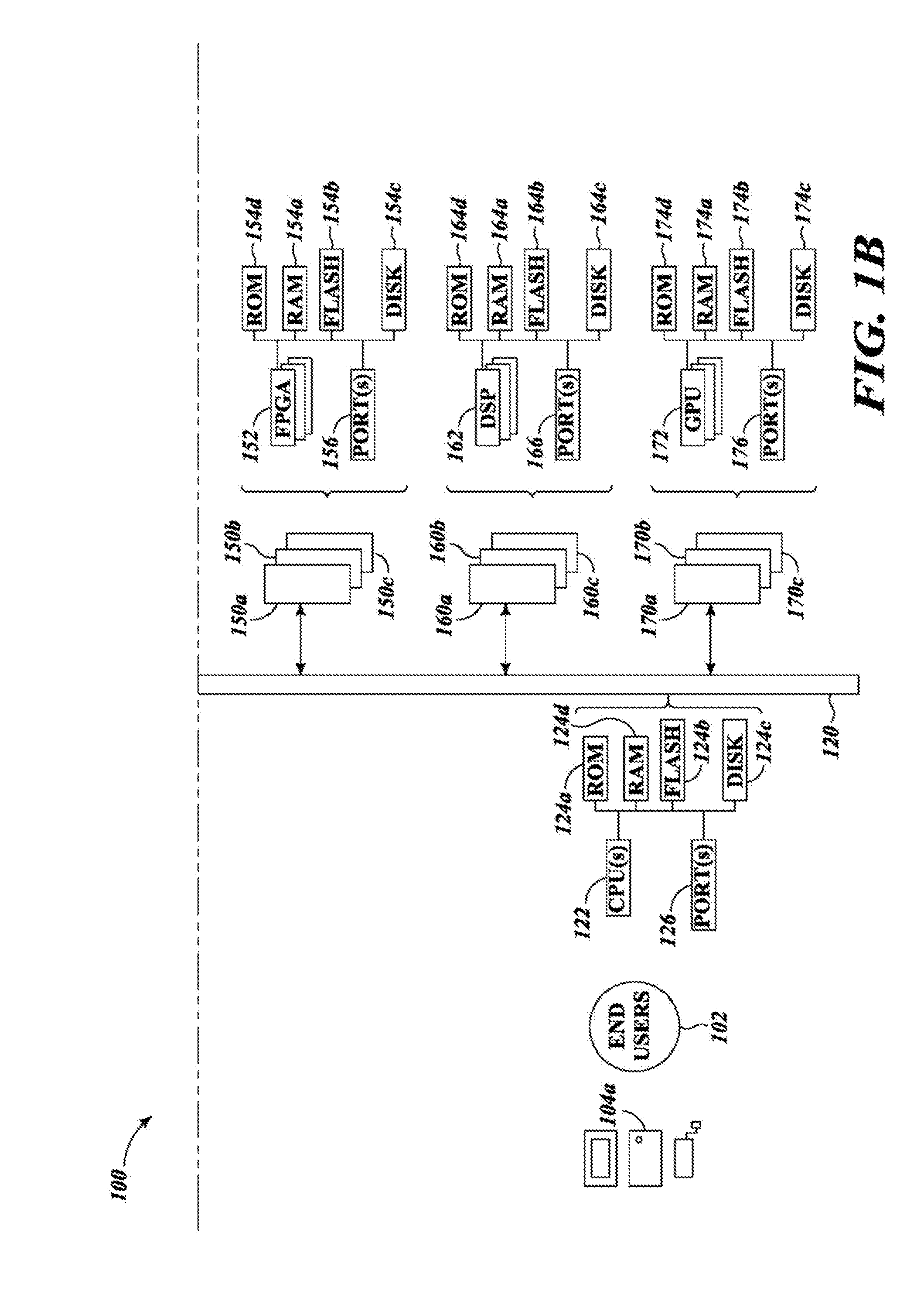

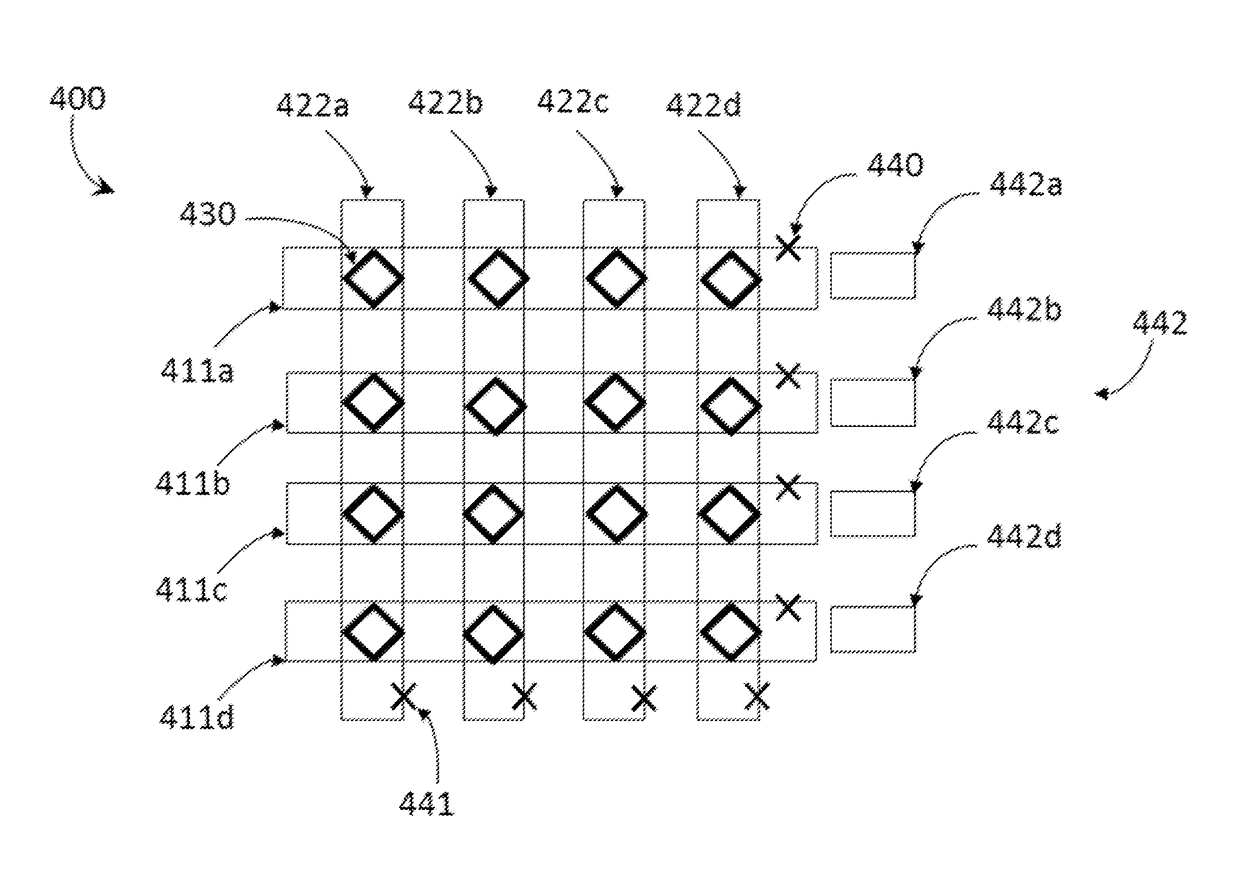

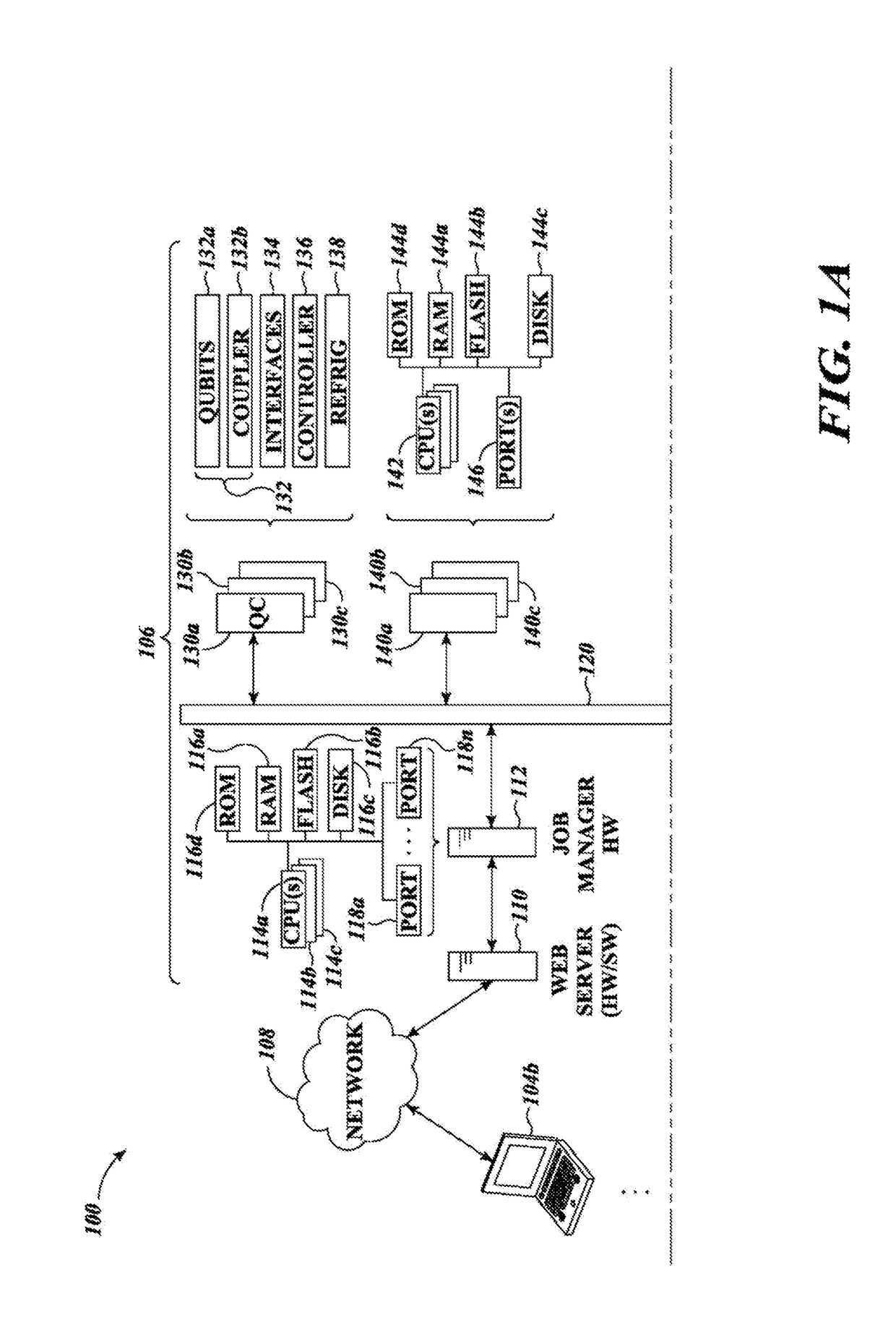

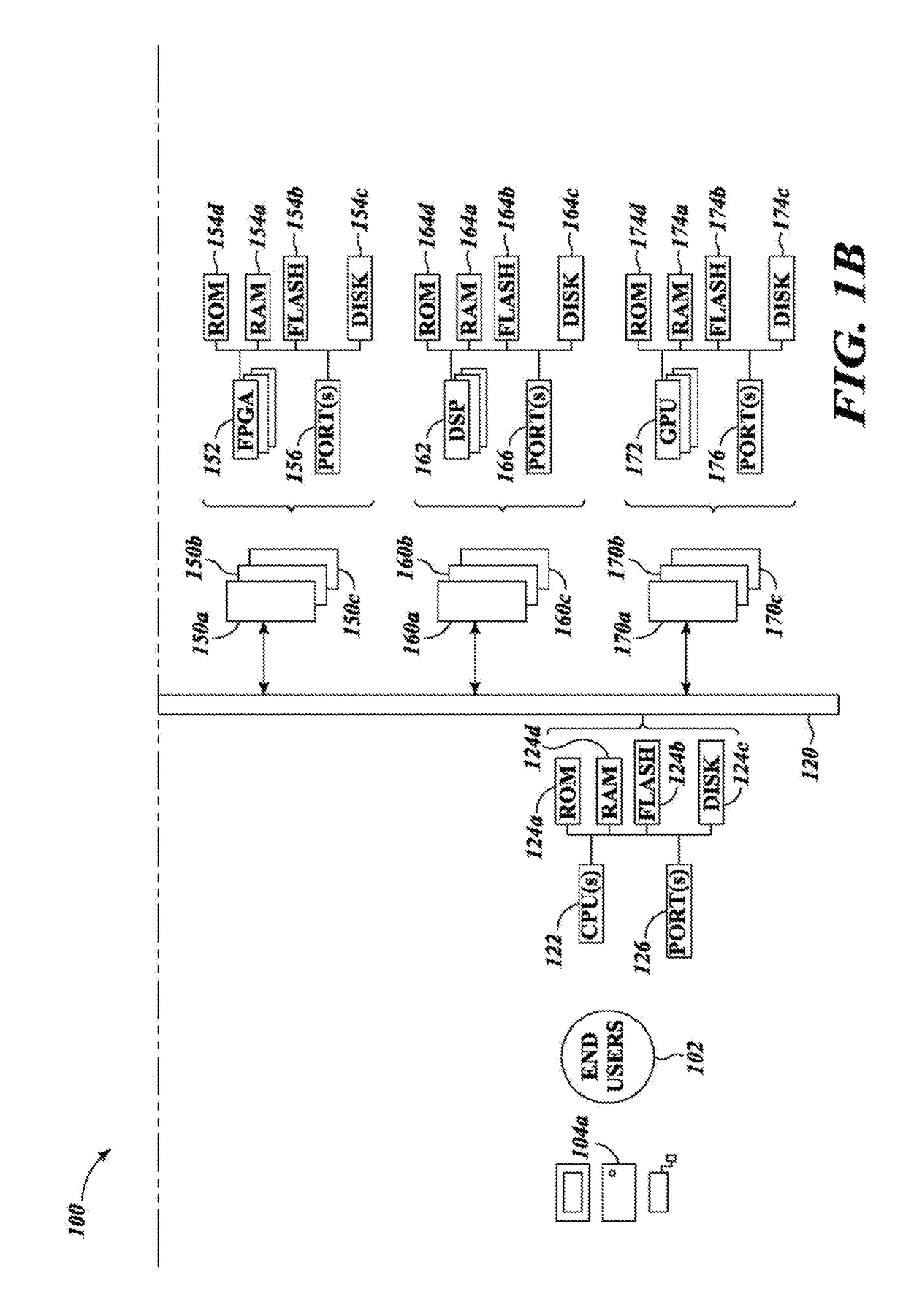

Systems and methods for improving the performance of a quantum processor via reduced readouts

ActiveUS20160071021A1Quantum computersGeneral purpose stored program computerComposite sampleComputer science

Techniques for improving the performance of a quantum processor are described. The techniques include reading out a fraction of the qubits in a quantum processor and utilizing one or more post-processing operations to reconstruct qubits of the quantum processor that are not read. The reconstructed qubits may be determined using a perfect sampler to provide results that are strictly better than reading all of the qubits directly from the quantum processor. The composite sample that includes read qubits and reconstructed qubits may be obtained faster than if all qubits of the quantum processor are read directly.

Owner:D WAVE SYSTEMS INC

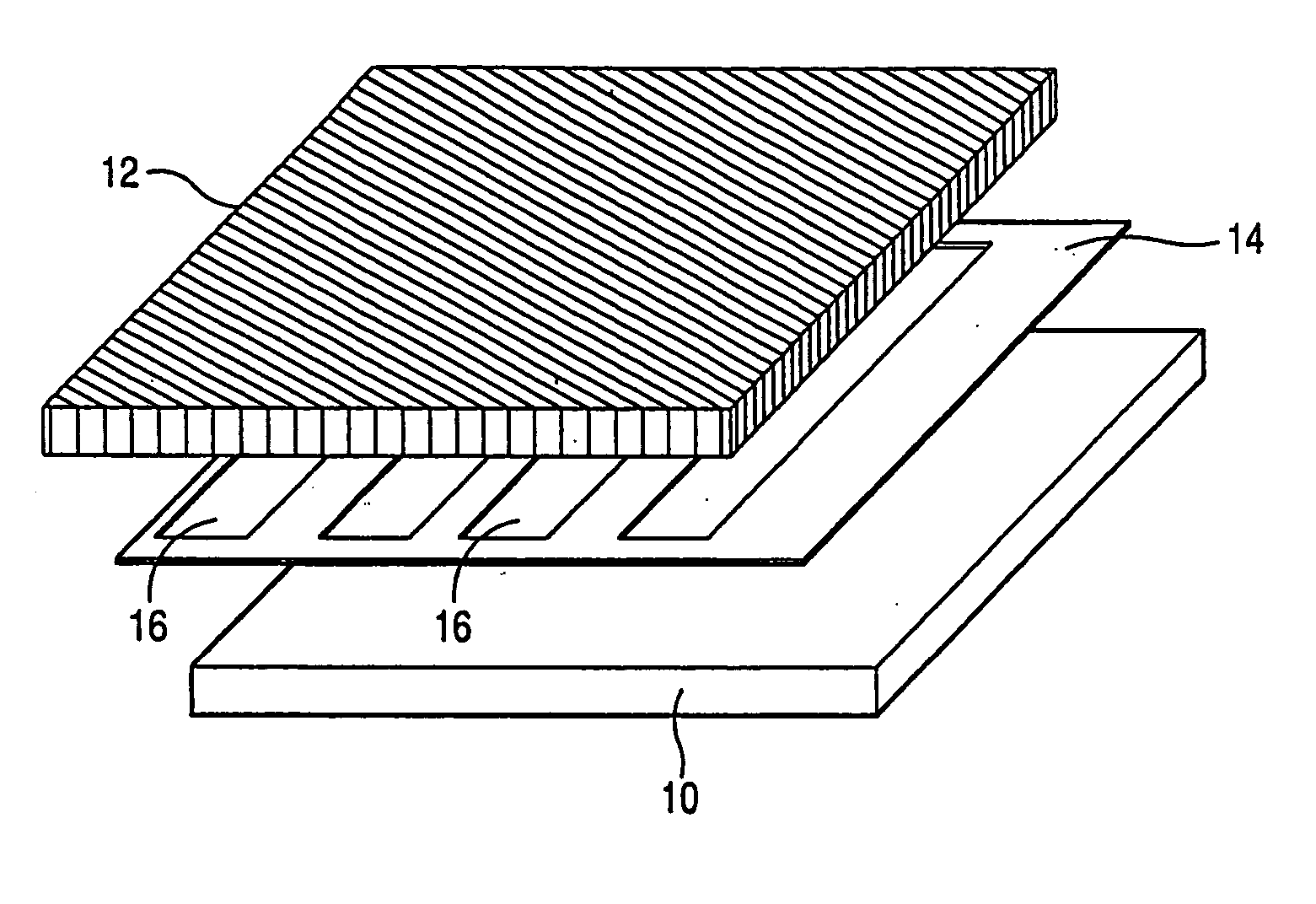

Combinatorial synthesis

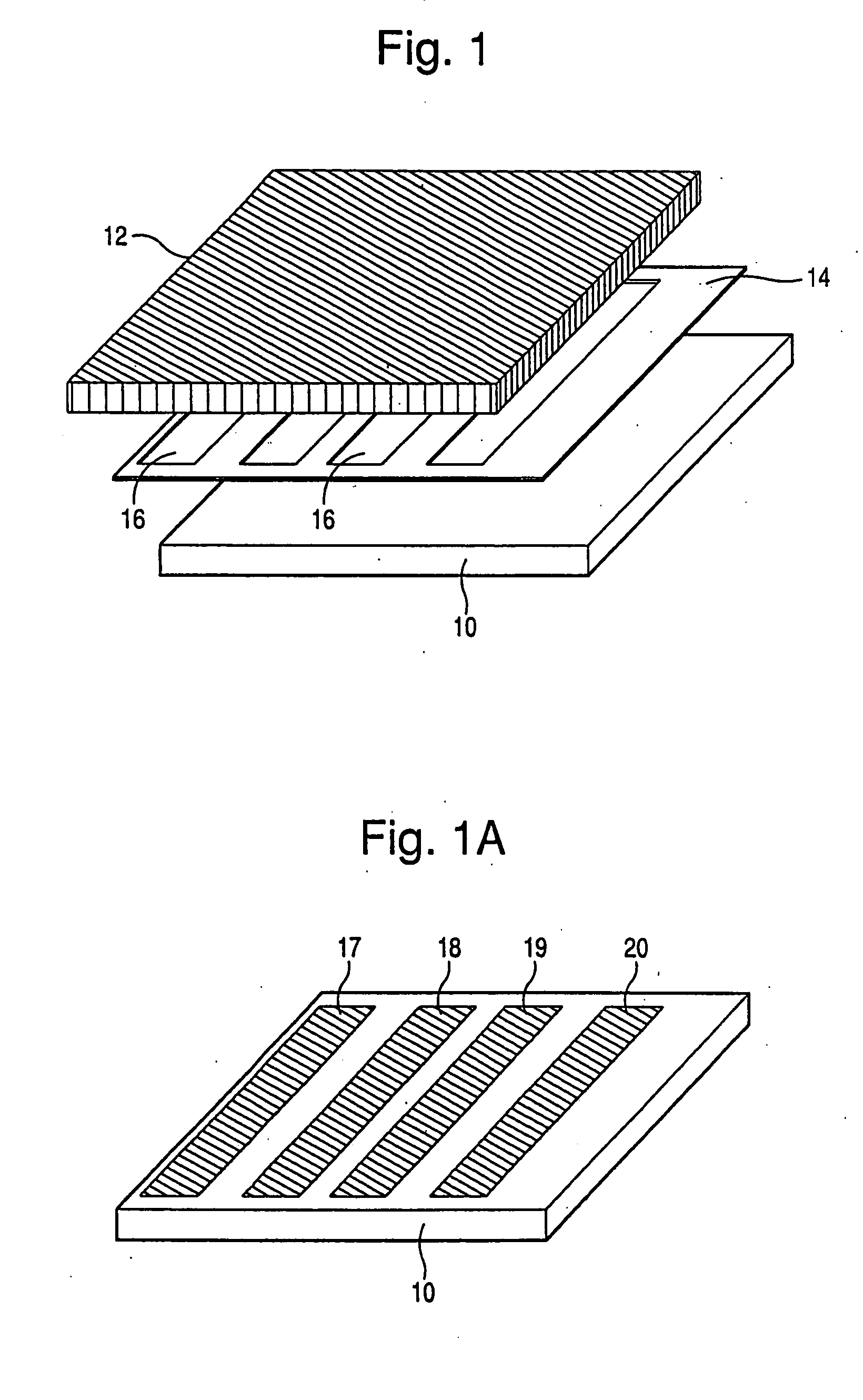

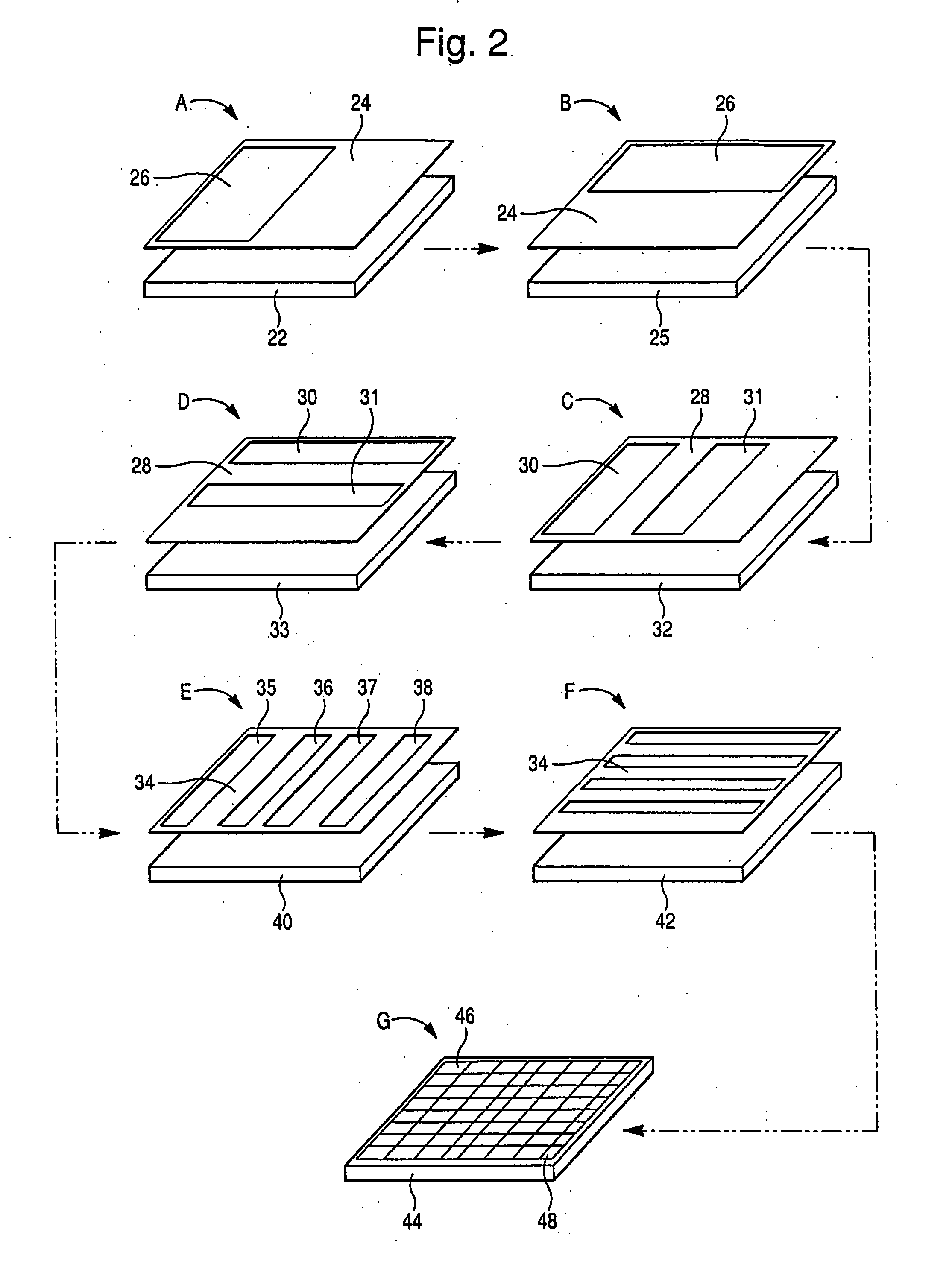

InactiveUS20050271795A1Liquid surface applicatorsSequential/parallel process reactionsConcentration gradientComposite sample

Methods are disclosed for providing a library of composite compositions on a support. The method involves depositing one or more components onto the support on either discrete spaced regions of the support or as a continuous concentration gradients on the surface of the support. The composite samples can be removed from the support by drilling out portions of the coated support so as to yield individual composite tablets containing the support with one or more component layers thereon. By using this method, a vast number of composites can be made and tested simultaneously.

Owner:MOINI AHMAD +2

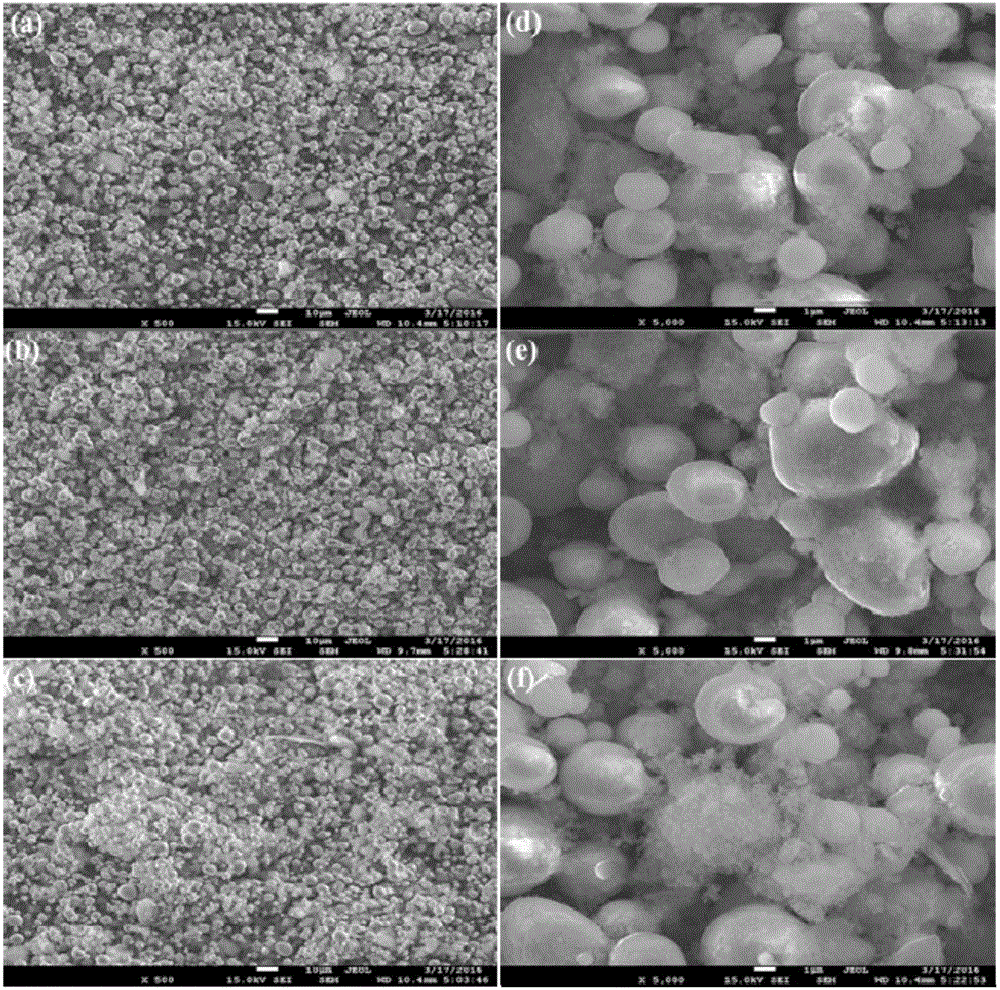

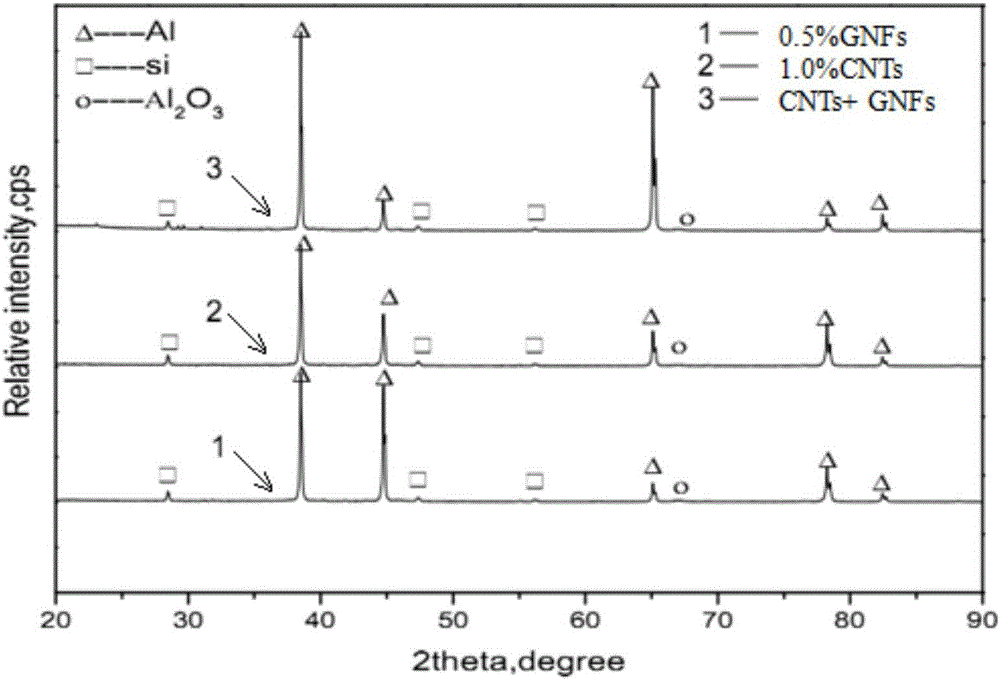

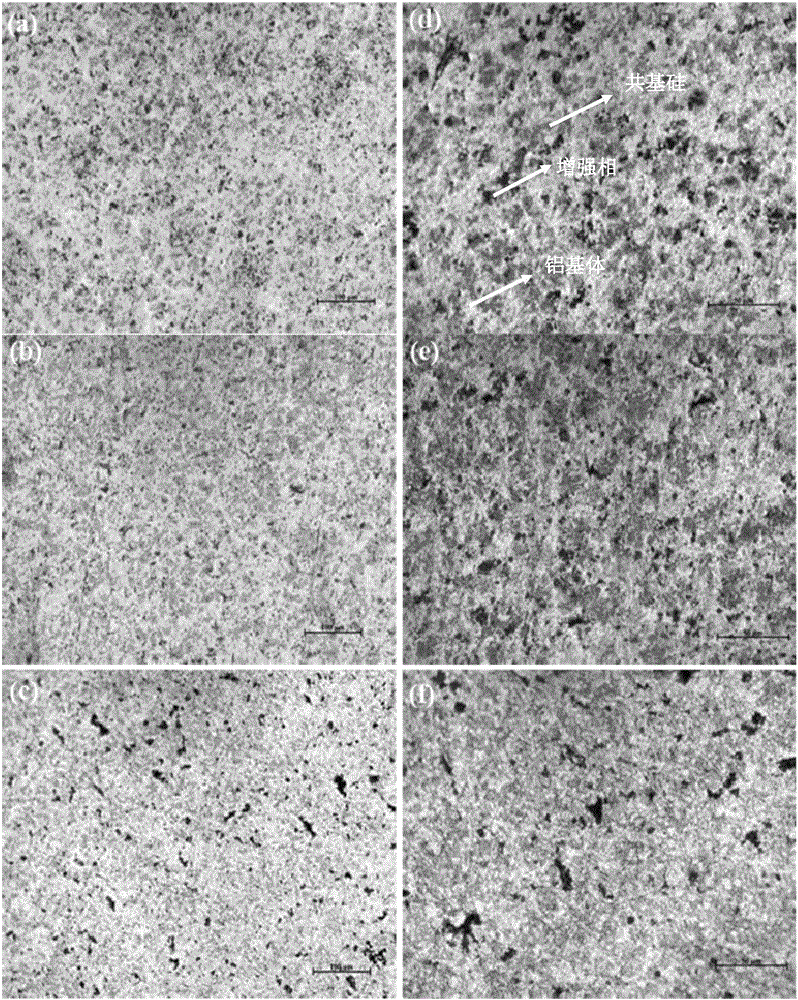

Carbon nano tubes (CNTs) and graphene nano flakes (GNFs) synergetic enhanced aluminum-based composite and preparation method

The invention discloses a GNFs / CNTs synergetic enhanced Al / Si / Al2O3 composite. The aluminum-based composite sample is mainly prepared from one or more of Al, SiO2, CNTs and GNFs. The CNTs and the GNFs are subjected to surface modification through gallic acid and rutin, and through combination with an in-situ reaction and a powder metallurgy technology, a CNTs independently enhanced aluminum-based composite, a GNFs independently enhanced aluminum-based composite and the CNTs and GNFs mixing enhanced aluminum-based composite with an Al / Si alloy as a matrix are prepared. The results show that 1, among the three composites, the 1% CNTs enhanced composite has the most excellent mechanical properties as well as the highest compactness, hardness and tensile strength; and 2, strengthening mechanisms of the CNTs enhanced aluminum-based composite mainly include the thermal expansion coefficient mismatch enhancement, Orowan enhancement and load transfer enhancement. The invention further discloses a preparation method of the aluminum-based composite. According to the method, the process is simple, production is easy, and broad application prospects are achieved.

Owner:SOUTHWEST JIAOTONG UNIV

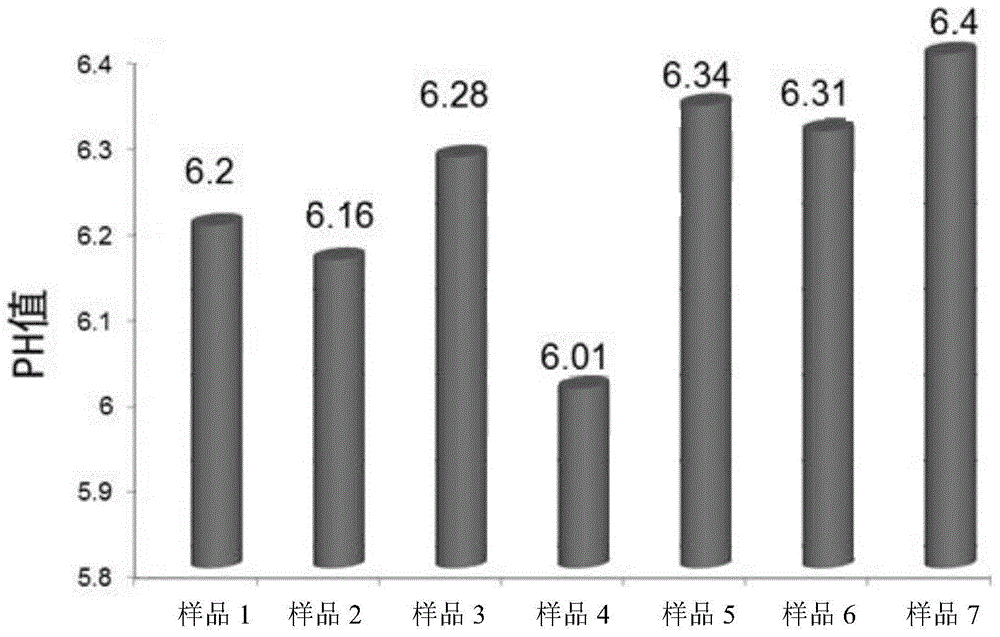

Testing method for color fastness to saliva of textile

ActiveCN103033480AReasonable configurationEnsure safetyColor/spectral properties measurementsColour fastnessFiber

The invention relates to the technical field of color fastness testing of textile, in particular to a testing method for color fastness to saliva of the textile. The testing method comprises the following steps of preparing artificial saliva, bonding a to-be-tested sample cut to a given size with multi-fiber accompanying fabric to form a composite sample, soaking in the artificial saliva, extruding the composite sample with a glass rod after soaking, pressing the composite sample with a counter weight, placing the composite sample in a drying oven simulating human body temperature, drying, placing the composite sample under standard atmospheric conditions with the temperature of 18-22 DEG C and the relative humidity of 61-69%, humidifying for at least four hours, and conducting an evaluation test on discoloring of the to-be-tested sample and staining of the accompanying fabric with a standard discoloring gray card and a standard staining gray card respectively. With the adoption of the testing method, the degree and the grade of the color fastness to saliva of the textile can be evaluated, deficiencies of the traditional staining test with filter paper are overcome, preparation of the artificial saliva is more reasonable, and the testing method is simple and easy to operate.

Owner:SGS STANDARD TECHNICAL SERVICES SHANGHAI CO LTD

Systems and methods for improving the performance of a quantum processor via reduced readouts

ActiveUS10031887B2Quantum computersGeneral purpose stored program computerComposite sampleComputer science

Techniques for improving the performance of a quantum processor are described. The techniques include reading out a fraction of the qubits in a quantum processor and utilizing one or more post-processing operations to reconstruct qubits of the quantum processor that are not read. The reconstructed qubits may be determined using a perfect sampler to provide results that are strictly better than reading all of the qubits directly from the quantum processor. The composite sample that includes read qubits and reconstructed qubits may be obtained faster than if all qubits of the quantum processor are read directly.

Owner:D WAVE SYSTEMS INC

Detection method for interface bonding strength of aluminum-steel composite material

ActiveCN104155237ASolve the defect that the leader part cannot be madeAccurate detection of interface peel fastnessPreparing sample for investigationUsing mechanical meansComposite sampleInterface bond

The invention discloses a detection method for the interface bonding strength of an aluminum-steel composite material. The detection method comprises the following steps: cutting a rolled aluminum-steel composite sample into wafer samples, selecting or preparing two metal rods of which the diameters are the same as those of the wafer samples, and cleaning the wafer samples and the to-be-bonded surfaces of the metal rods; then, grinding the to-be-bonded surfaces; next, respectively bonding the aluminum-steel surface of each wafer sample with one end surface of one of the two metal rods by using epoxy resin AB glue, and standing for over 24 hours at normal temperature to prepare specimens; and finally, performing a peeling test on the specimens on a stretching machine and calculating the interface bonding strength of the aluminum-steel composite material. The invention provides the feasible method for the quantitative measurement on the interface bonding strength of an ultrathin metal composite material. According to the method, the specimens are prepared easily and conveniently; by adopting the method, the interface peeling fastness of the aluminum-steel composite material can be accurately detected, and the interface bonding strength of the aluminum-steel composite material for brazing can be quantitatively represented.

Owner:银邦(安徽)新能源材料科技有限公司

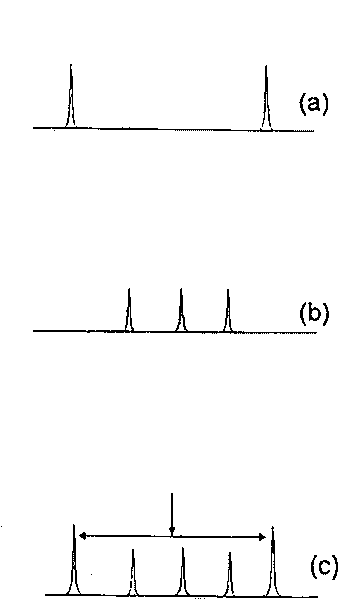

Method of measuring a physical function using a composite function which includes the physical function and an arbitrary reference function

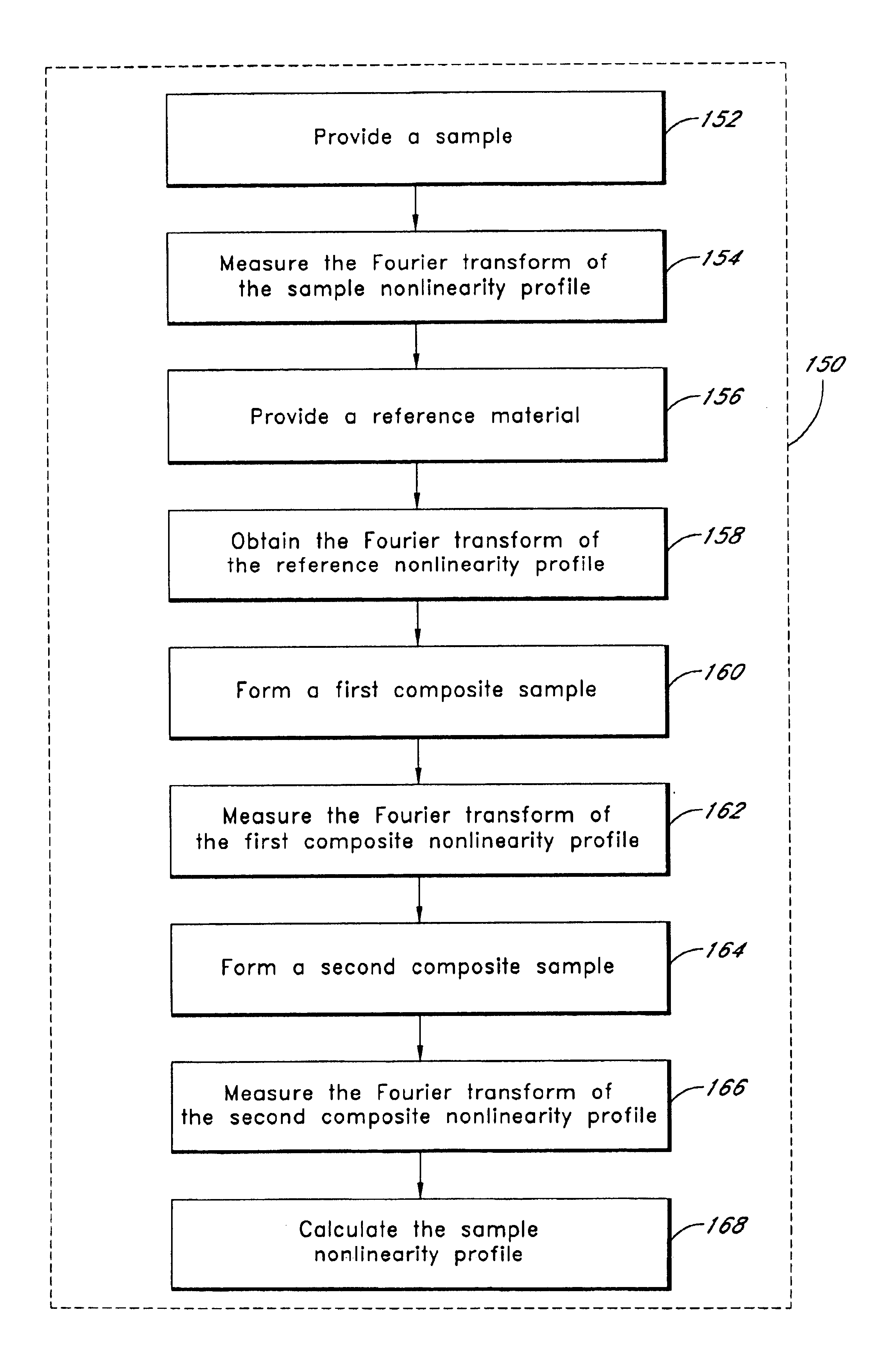

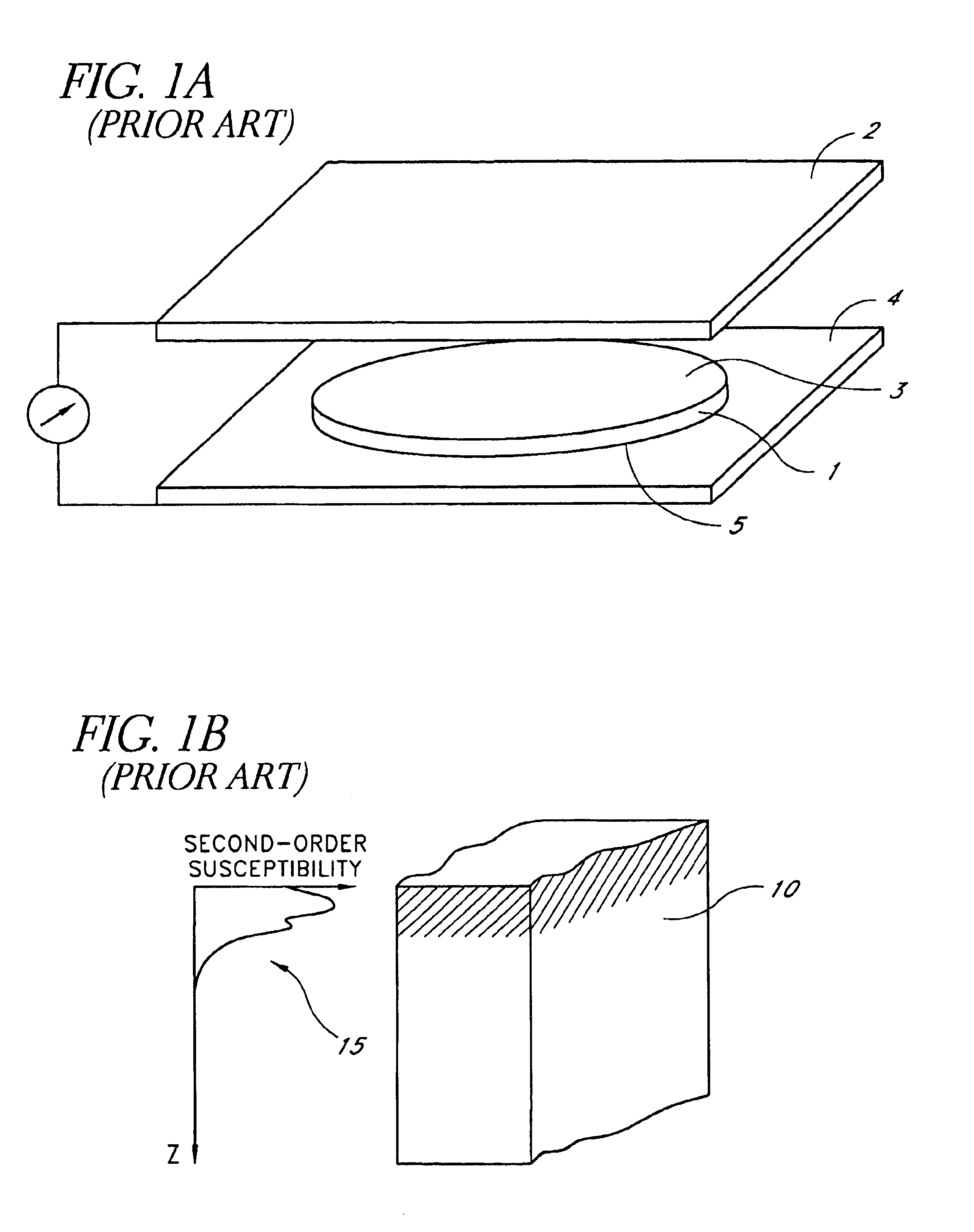

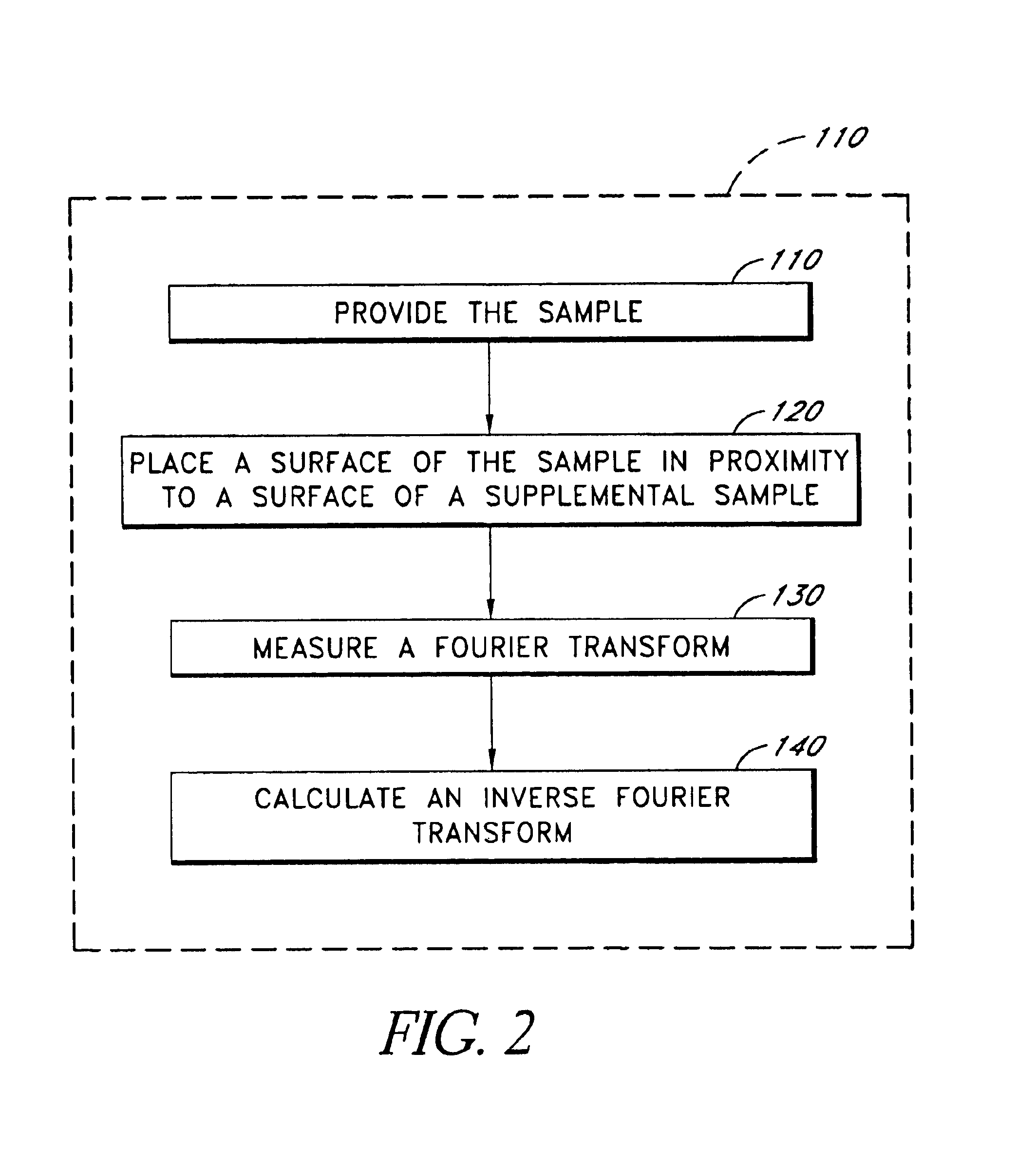

A method measures a nolinearity profile of a sample with at least one sample surface and having a sample nonlinearity profile along a sample line through a predetermined point on the sample surface. The sample line is oriented perpendicularly to the sample surface. The method includes measuring a Fourier transform of the sample nonlinearity profile and obtaining a reference nonlinearity profile from a reference material. The method includes forming a first composite sample having a first composite nonlinearity profile and forming a second composite sample having a second composite nonlinearity profile inequivalent to the first composite nonlinearity profile. The method further includes measuring a Fourier transform of the first composite nonlinearity profile and measuring a Fourier transform of the second composite nonlinearity profile. The method further includes calculating the sample nonlinearity profile using the Fourier transforms of the sample nonlinearity profile, the reference nonlinearity profile, the first composite nonlinearity profile, and the second composite nonlinearity profile.

Owner:THE BOARD OF TRUSTEES OF THE LELAND STANFORD JUNIOR UNIV

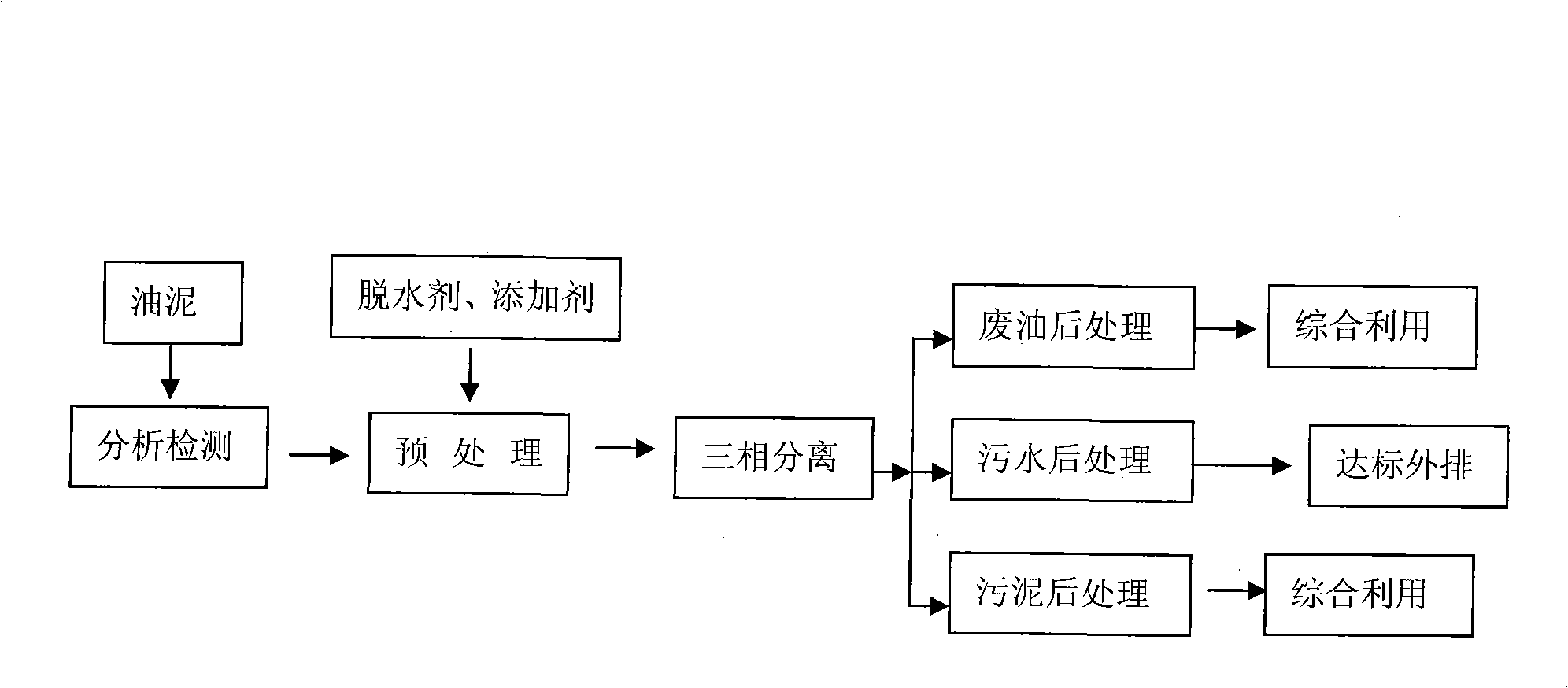

Sludge high-pressure three-phase separation method

InactiveCN101302074AReduce interfacial tensionImprove separation efficiencySludge treatmentFiltrationComposite sample

The invention relates to a method for treating the waste, in particular to a sludge high-pressure three-phase separating method, comprising the following steps that: an oil sludge composite sample to be separated is tested, added with a dehydrating agent and additives according to the oil sludge test result and then mixed evenly; the oil sludge after the pretreatment undergoes three-phase separation in a high-pressure three-phase separator, pressure filtration is carried out under the high pressure of between 10 and 50 MPa, the filtrate is collected; when no filtrate flows out, the pressure is relieved and the material is discharged, the water content of the treated oil sludge can reach between 10 and 20 percent; the collected filtrate undergoes oil-water separation, the sewage is sent to a sewage treatment system for water treatment; waste oil can be comprehensively utilized after treatment; and filter residue can be taken as industrial secondary fuel to be comprehensively utilized. Compared with other oil sludge treatment technologies, the method has the characteristics of high separation efficiency, no secondary pollution, simple and convenient operation flow, high reliability, strong practicability and so on, and has obvious social benefits and economic benefits.

Owner:DALIAN DONGTAI INDAL WASTE TREATMENT

Preparation method for iron lithium phosphite anode material simultaneously doped with fluorine ion and metallic ion

InactiveCN101345309ALow costHigh fluorine doping efficiencyCell electrodesPhosphorus compoundsComposite sampleAnode

The invention provides a preparation method used for lithium iron phosphate anode material mixed with Fl ions and iron ions. In order to achieve the object, the technical proposal adopted by the invention is that reaction compositions consisting of lithium salt, ferrite, P2O5 or P2O3 and fluorinc source are weighed and uniformly mixed according to the mol ratio of x: y: z: k: m of Li ion, ferrous iron, P ion, Fl ion and mixed ion. Carbon compound or carbon powder, with the mass equal to 1 to 20 percent of that of lithium iron phosphate, which is calculated according to the mass of reaction matter, and wet grinding matter with the volume equal to 1 / 10 to 10 of that of the reaction mixture, are added into the mixture and ball-grinded for 3 to 15 hours under the rotation ranging from 100 to 1000 r / min, and are dried in vacuum condition under the pressure of 10 to 10132Pa and any temperature ranging from 70 to 120 DEG C. The dried powder is used for preparing the composite sample containing the mixing iron phosphate by a program temperature increasing-sintering method or a combination sintering method.

Owner:FUJIAN NORMAL UNIV

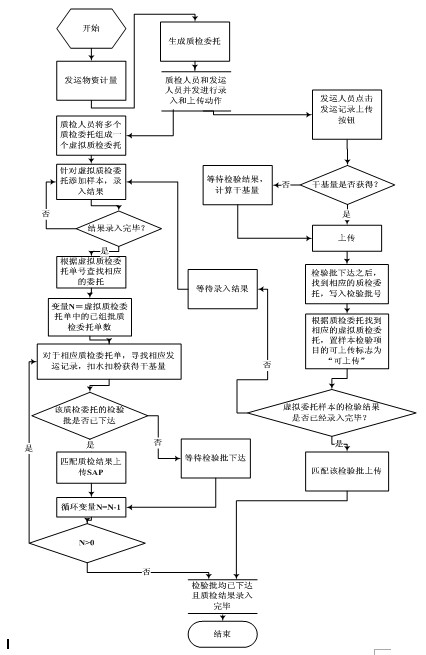

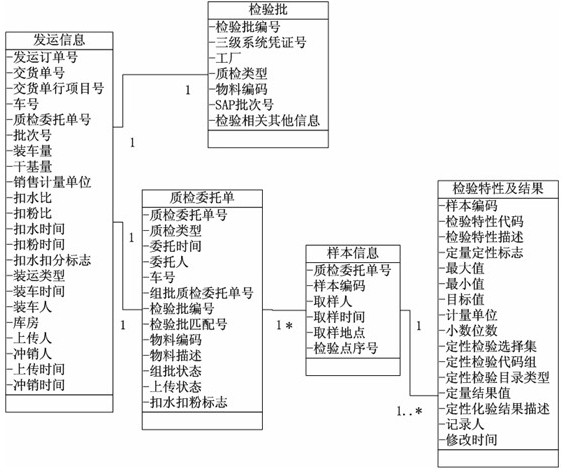

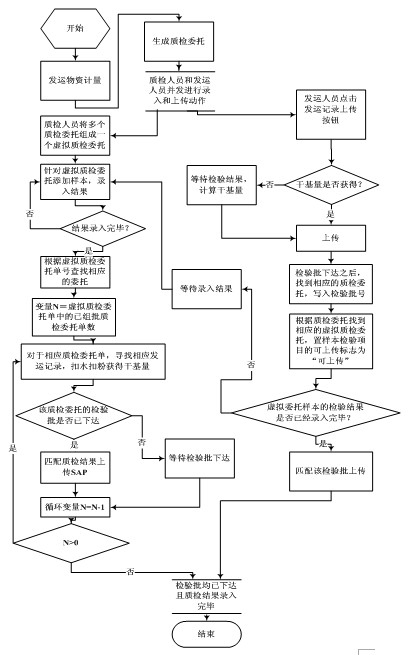

Multi-inspection-lot metallurgical crude fuel batch quality control method

InactiveCN102136107ACooperate with remote logistics managementData processing applicationsLogistics managementTest sample

The invention relates to a multi-inspection-lot metallurgical crude fuel batch quality control method which is mainly used for minerals logistics inspection and comprises the following steps: a quality control authorization is generated when gross weight measurement is carried out in materials forwarding; and the authorization needing batch quality control forms a new virtual quality control authorization, after batching is finished, a quality control authorization needing batching is changed into a batched quality control authorization. Test samples from multiple vehicles are mixed to generate a composite sample which is subordinate to the virtual quality control authorization, inspection and test are carried out to the composite sample, and a result is loaded; and the batched quality control authorization corresponding to the virtual quality control authorization is found after the result loading is finished, all batched quality control authorizations subordinating to the virtual quality control authorization all adopt the inspection and test result of the composite sample as the final inspection and test result, and the final inspection and test result is matched with a SAP (systems applications and products in data processing) inspection batch generated after a forwarding result is uploaded to the SAP. In the invention, by setting the virtual quality control authorization, independent measurement of bulk commodity such as minerals for each vehicle and independent SAP uploading are realized, while the problem that multiple inspection batches are difficult to match one group test results owning to inspection of multiple vehicle sets to one composite sample is brought, so as to realize SAP uploading of weight and inspection information of each vehicle and be well coordinated with SAP to carry out remote logistics management.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

Modular compositing-multiple lot screening protocols for detection of pathogens, microbial contaminants and/or constituents

ActiveUS7534584B2Microbiological testing/measurementPreparing sample for investigationValidation testMicroorganism

Particular aspects provide a method of sampling, testing and validating test lots (e.g., single-unit production lots), comprising: assembling a plurality of product portions from each of a plurality of test lots and combining the collected product portions to provide a corresponding set of test lot samples (wherein each test lot sample is attributed to a particular corresponding test lot); enriching the set of test lot samples; removing equal portions of each enriched sample, and combining the removed portions to provide a modular composite sample; and testing of the modular composite sample for the target agent / organism, wherein where such testing is positive, individual test lots may nonetheless yet be validated by further testing of a respective enriched test lot sample and obtaining a negative test result. The methods have broad utility for monitoring all sort of test lots (e.g., environmental lots, production lots, pharmaceutical lots, etc.) and for efficiently affecting informed, targeted remedial measures.

Owner:INST FOR ENVIRONMENTAL HEALTH

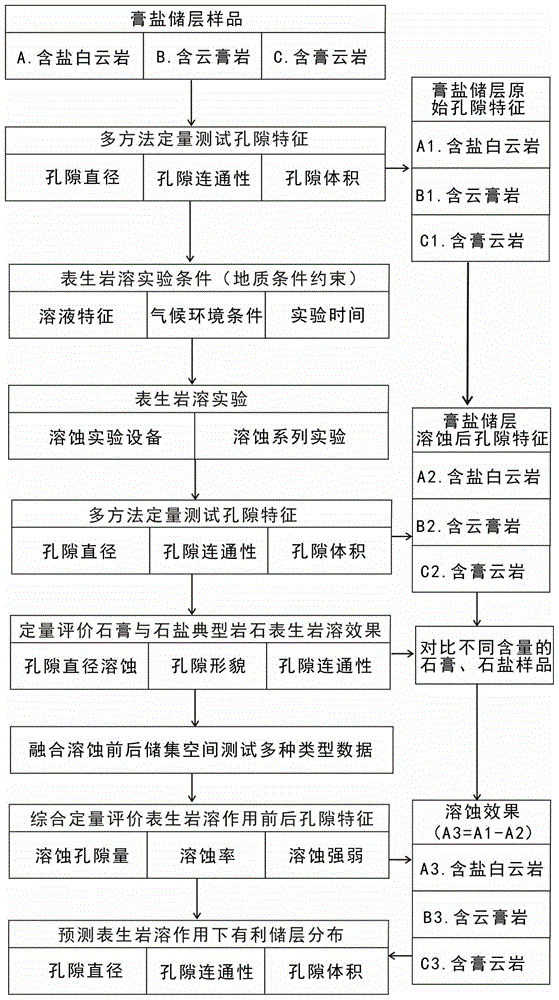

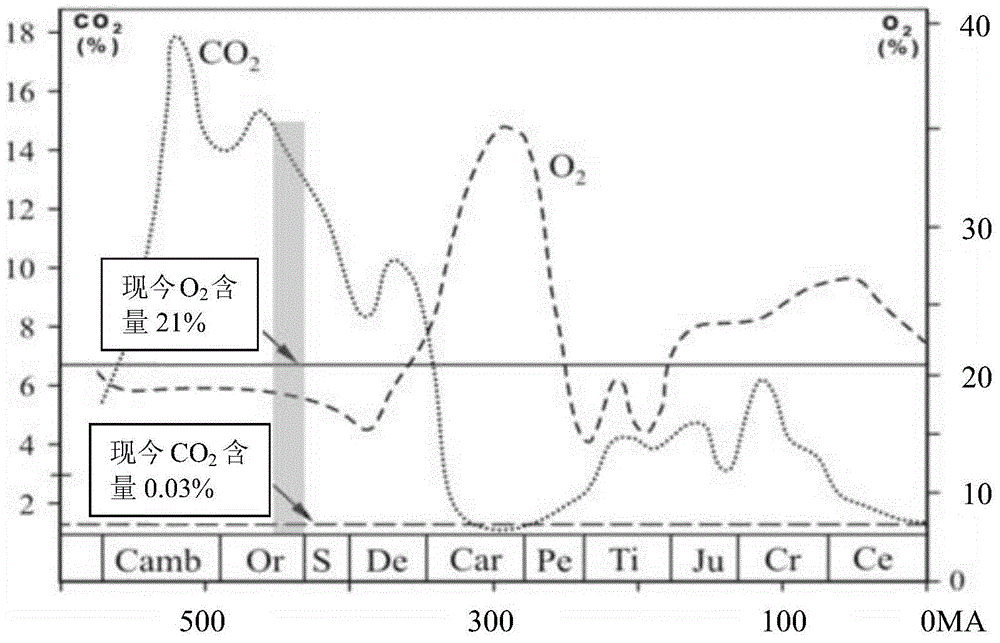

Gypsum salt-carbonate reservoir rock supergene karst effect quantitative evaluation method and device

The invention provides a gypsum salt-carbonate reservoir rock supergene karst effect quantitative evaluation method and a device. The gypsum salt-carbonate reservoir rock supergene karst effect quantitative evaluation method comprises following steps: gypsum salt-carbonate rock composite samples with different gypsum and rock salt contents are selected; gypsum salt mineral and reservoir characteristics before karstification are detected; karst conditions are determined; a supergene karst test is carried out; gypsum salt mineral and reservoir characteristics after karstification are detected; porosity characteristics before and after corrosion are determined via a plurality of methods; gypsum and rock salt marked rock is used for evaluating reservoir characteristics before and after the supergene karst test; and supergene karst conditions are analyzed. The gypsum salt-carbonate reservoir rock supergene karst effect quantitative evaluation method is used for gypsum salt-carbonate special lithological combination, and is carried out based on real geological environments; a plurality of experiment laboratory facilities are adopted for evaluating gypsum salt-carbonate reservoir rock supergene karst effects; and pore diameter test data fusion algorithm is adopted so as to realize accurate quantification of supergene karst effects, and pore diameter nanometer range to millimeter range seamless quantitative evaluation before and after karsting.

Owner:PETROCHINA CO LTD

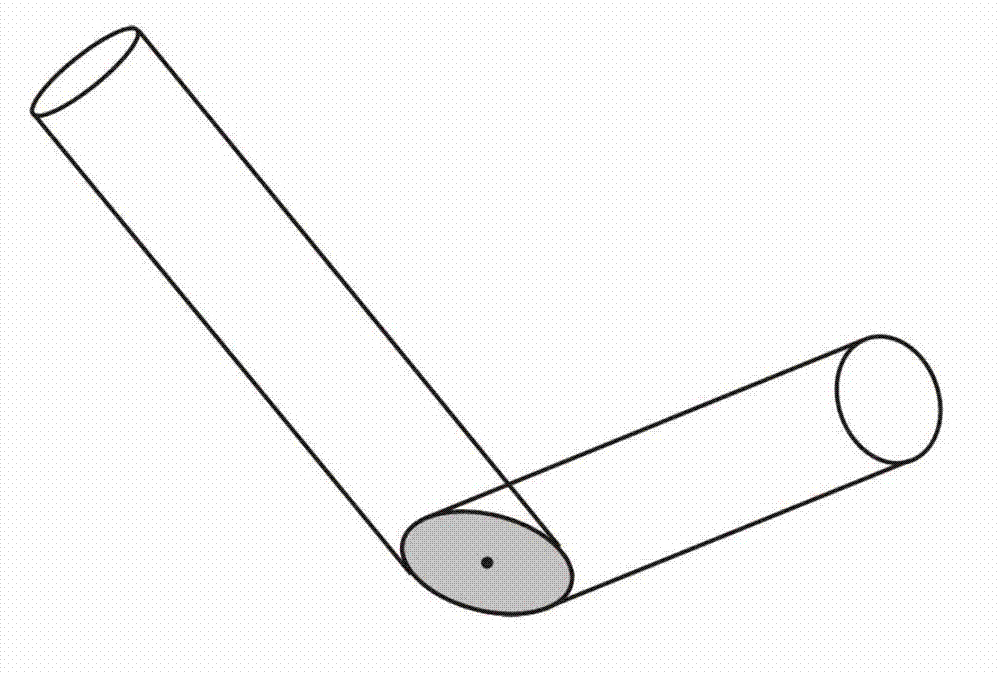

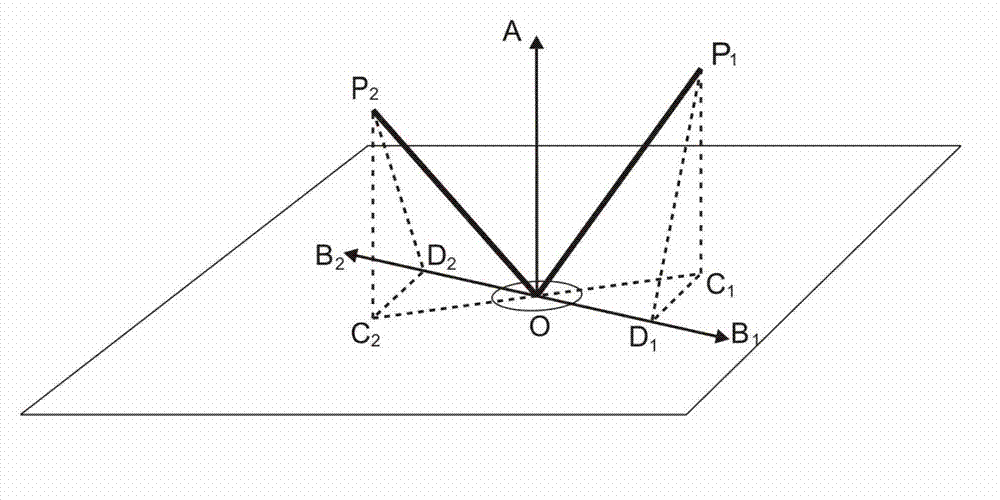

Method for quantitatively evaluating orientation degree of short fiber reinforced composite fibers

ActiveCN102768181AAvoid ultrathin sectionsEliminate calculation errorsWithdrawing sample devicesMaterial analysis by optical meansEllipseCalculation error

The invention relates to a method for quantitatively evaluating orientation degree of short fiber reinforced composite fibers, which is characterized by selecting and determining a sectioning surface and sectioning a composite sample; acquiring a micrograph via an optical microscope or a scanning electron microscope; repainting the elliptic fiber section in the micrograph in graphic image software; extracting the lengths of long axis and short axis and an angle between the elliptic long axis and a coordinate axis in the repainted picture; calculating the direction vectors of the fibers corresponding to the ellipses according to the extracted parameters of the elliptic section; and calculating the parameters of the orientation degree of the composite along a specific direction. According to the method, the proper sectioning surface is selected so as to eliminate the calculation errors caused by condition that the same elliptic section corresponds to two fiber directions. In addition, a calculated mode given by the method considers the probability of sectioning the fibers, and the calculating result is more accurate in comparison with the calculated mode which does not consider the probability of sectioning the fibers.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Graphene-ceramic composite material and preparation method thereof

The invention discloses a preparation method of a graphene-ceramic composite material. The preparation method comprises the following steps of: (1), penetrating cerate (or zircon salt), auxiliaries and graphene oxide through alcohol dissolving auxiliaries, ultrasonically dispersing the materials uniformly for co-decomposing into metal oxides to obtain a composite material; (2), adding organic adhesive solvent to the graphene-metal oxide composite material for sufficiently mixing and grinding; pressing the mixture into a strip-shaped composite sample by adopting a dry-press process, placing the composite sample in a vacuum tube furnace; and controlling the sintering condition by ventilating a gas mixture of a certain proportion, cooling to the room temperature to obtain the graphene-ceramic composite material. The preparation method of the graphene-ceramic composite material disclosed by the invention can be used for improving the dispersibility and cycling stability of ceramic oxide particles, increasing a three-phase interface among the ceramic oxide particles and improving the electrochemical activity of the composite material, so that the ceramic material has the advantages of being low in density, high in strength, excellent in oxidation resistance, thermal scouring resistance, corrosion resistance and the like.

Owner:SHAANXI COAL & CHEM TECH INST

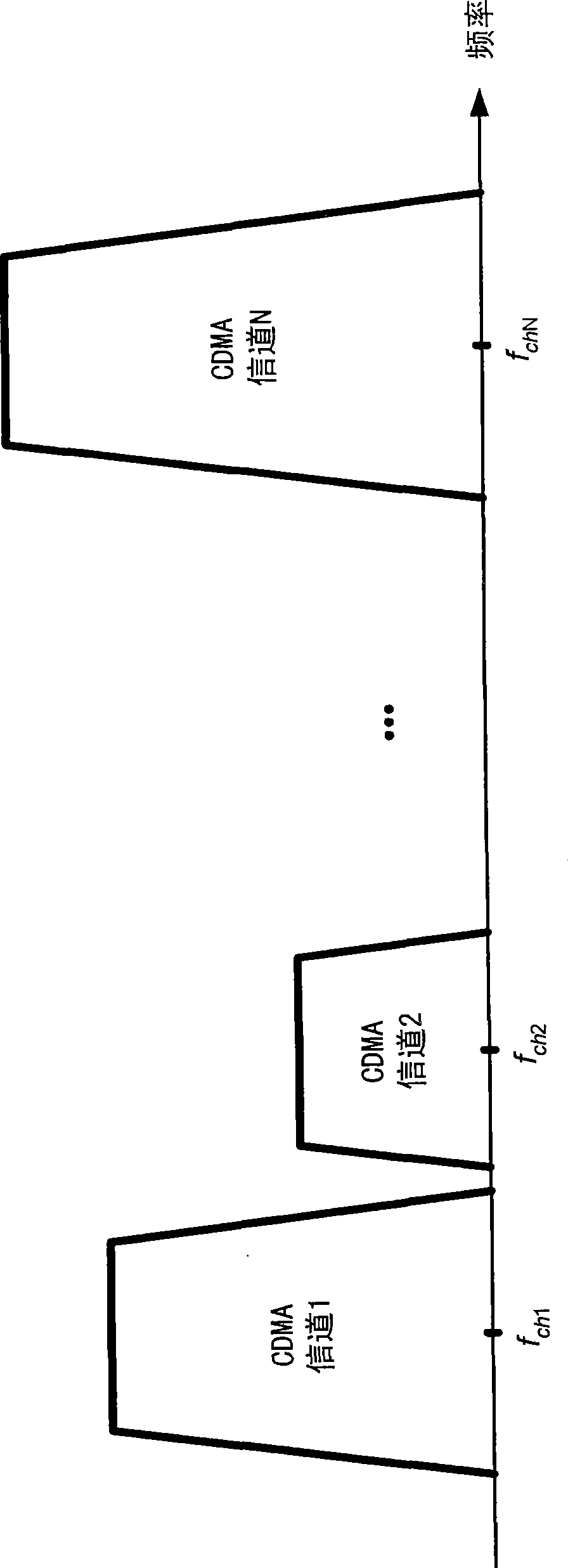

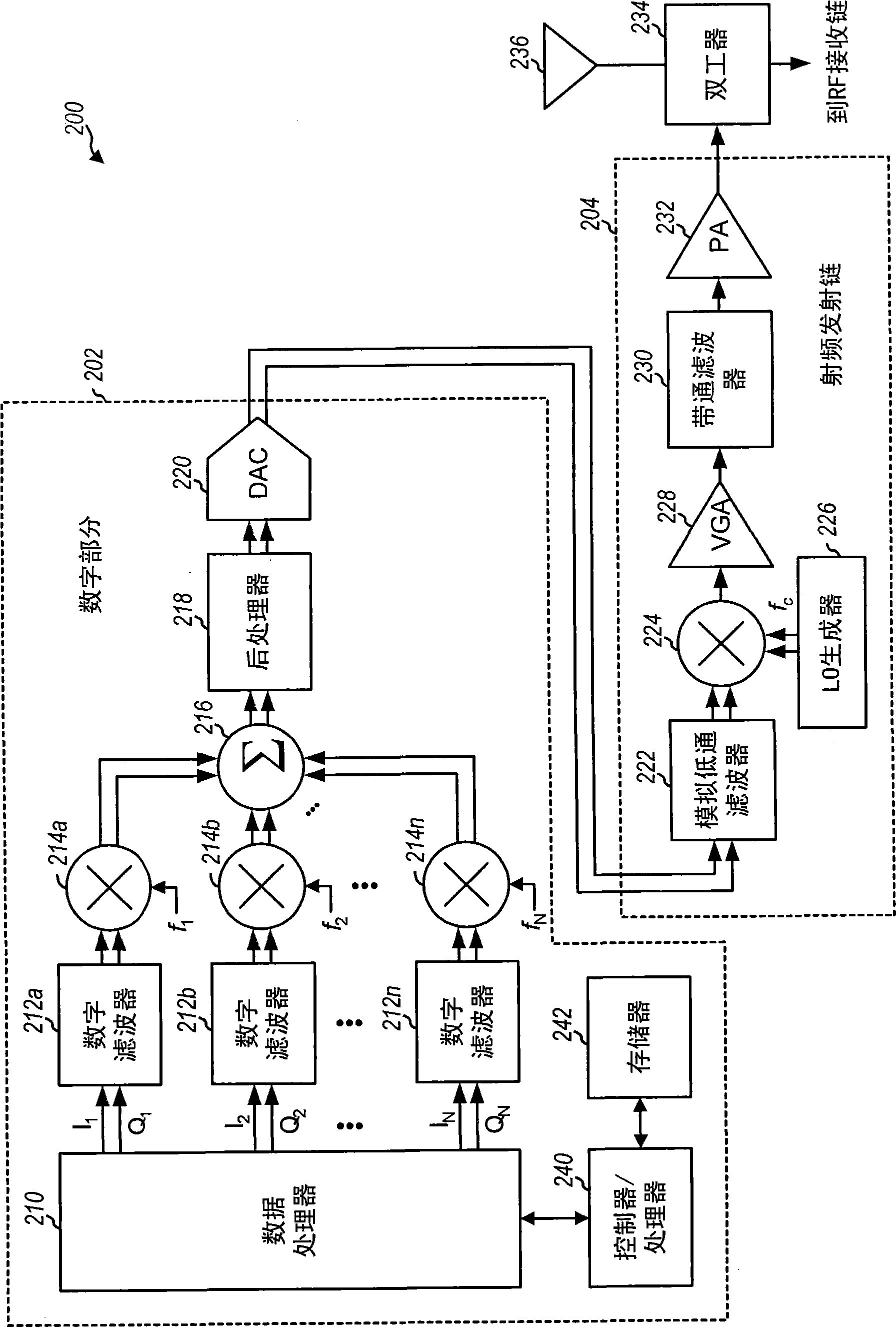

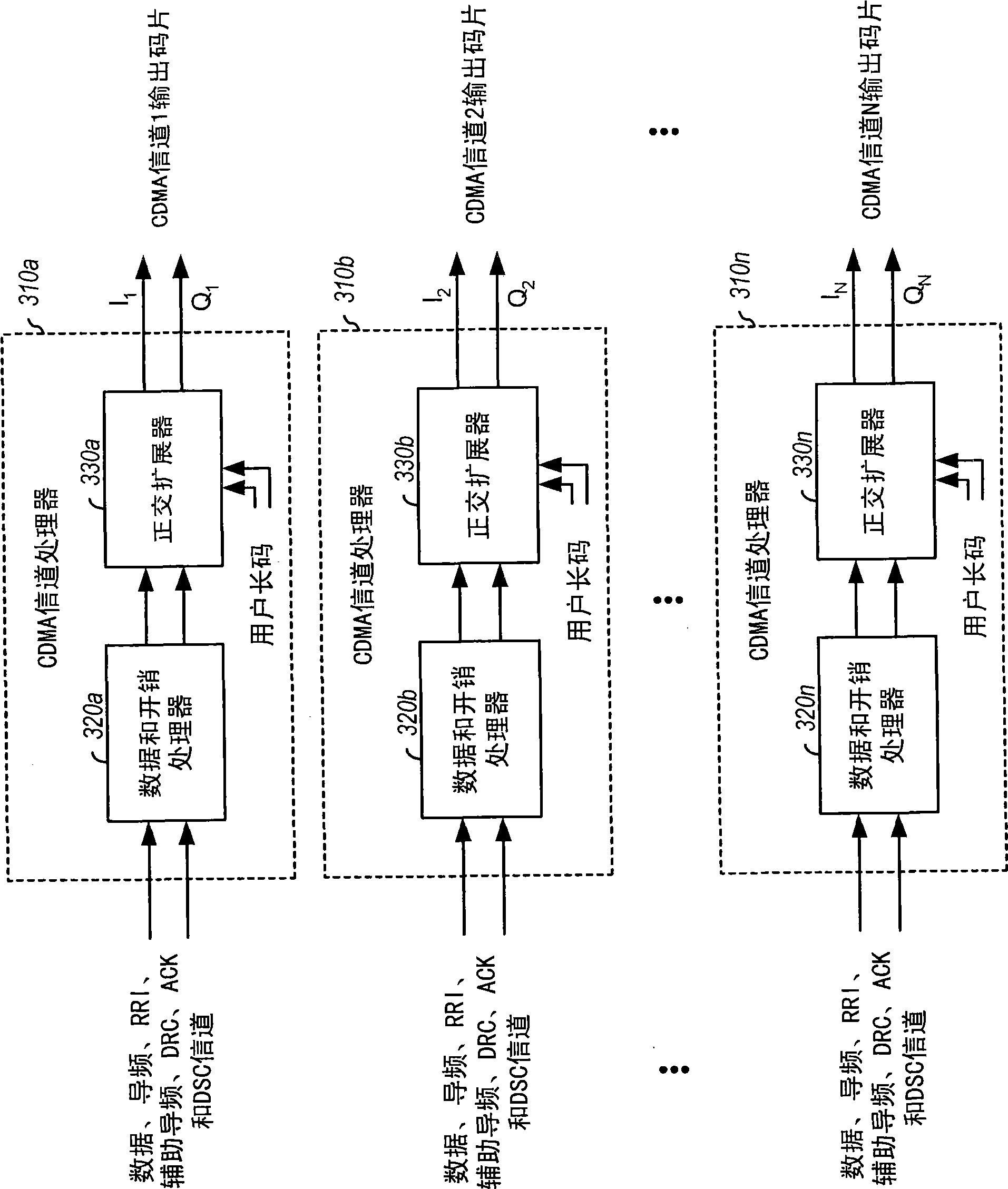

Apparatus for transmitting multiple CDMA channels

A multi-carrier transmitter capable of transmitting on one or multiple frequency channels simultaneously is described. In one design, the multi-carrier transmitter includes at least one processor and a single radio frequency (RF) transmission chain. The processor(s) may generate output chips for each of multiple frequency channels, digitally filter and upsample the output chips for each frequency channel to obtain filtered samples, and digitally upconvert the filtered samples for each frequency channel to a different frequency to obtain upconverted samples. The processor(s) may then combine the upconverted samples for the multiple frequency channels to obtain composite samples, perform pre-distortion on the composite samples for I / Q mismatch compensation, and upsample the pre-distorted samples to obtain output samples. The output samples may be converted to an analog signal with a wideband DAC. The RF transmit chain may process the analog signal to generate an RF output signal.

Owner:QUALCOMM INC

Method for detecting terbium oxide content

InactiveCN101196483AReduce intensityReduce human errorMaterial analysis using wave/particle radiationPreparing sample for investigationFluorescenceVolumetric Mass Density

A testing method of terbia content is provided, which firstly makes generatrix, terbia and water mixed to get a series of composite samples, and then dries and presses to a series of samples. According to the series of standard samples, standard curve is made. The procedures are as follows: the intensity of the character line of analyzed element terbium is measured by the X Rays fluorescence analysis to the prepared series of standard samples, and the density of the known element in intensity value and standard samples are fitted into a smooth curve, namely the standard curve; according to standard curve, the test value of the sample is counted, which means that simultaneously, the intensity A of the character line of analyzed element terbium are measured. Then the intensity is fit on the best standard curve, according to the intensity value A of the tested element, and the terbium content of the sample can be obtained from the standard curve formula A equals to f(c). By using the method, the measuring time is short, the precision is high, and the invention can quickly and accurately make feedback of the quality information, which is an accurate, convenient and quick testing method.

Owner:CAIHONG GRP ELECTRONICS CO LTD

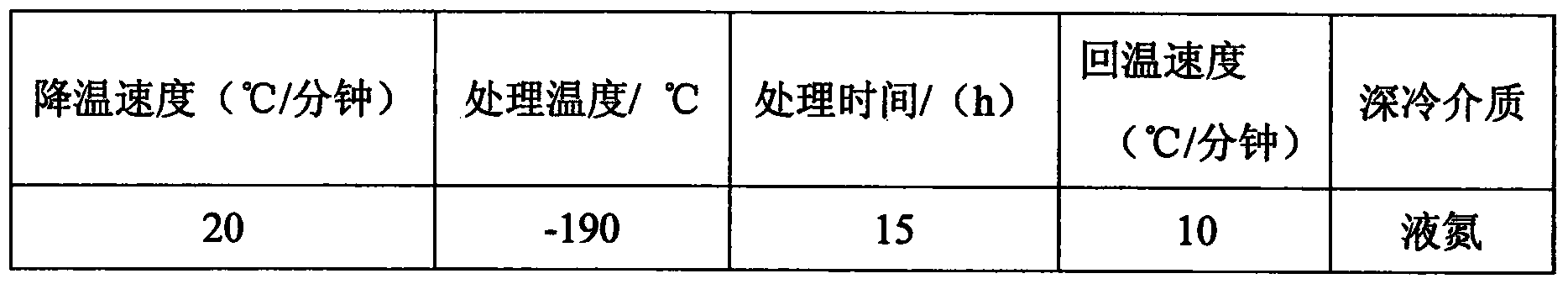

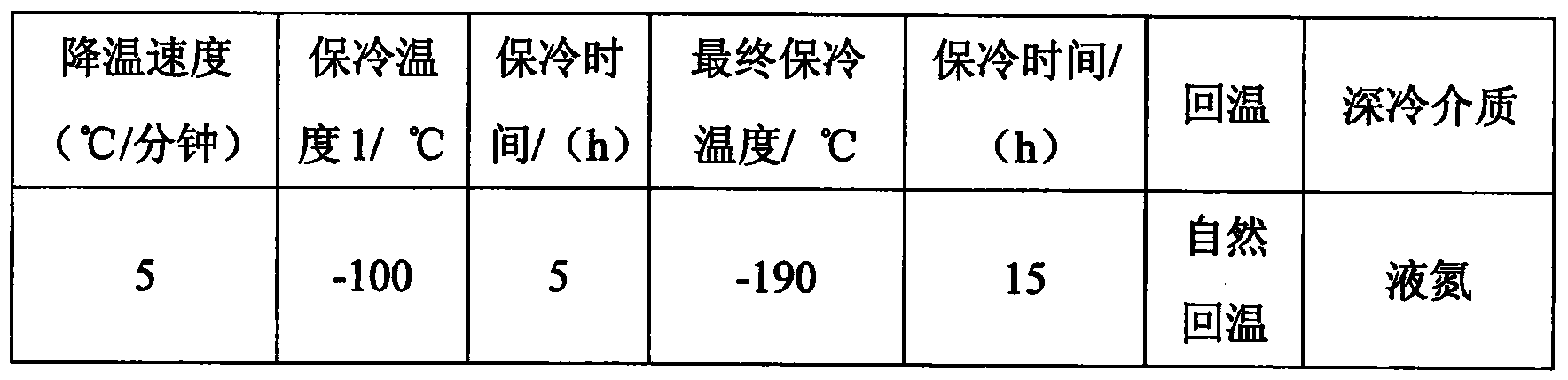

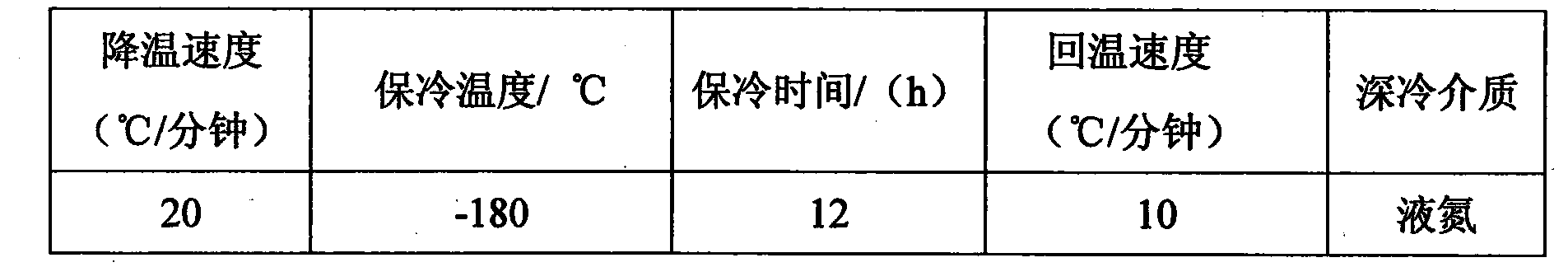

Method for modifying aramid fiber composite by subzero treatment

The invention provides a method for modifying an aramid fiber composite by subzero treatment. The method is characterized by specifically comprising the following steps: placing an aramid fiber composite sample in subzero treatment equipment with a subzero medium, closing a container for performing subzero treatment, wherein the subzero treatment temperature is constant temperature from -100 DEG C to -200 DEG C, and the subzero treatment time is 1-15 hours; and after subzero treatment, performing temperature returning by program warming or taking the sample out from the subzero treatment equipment and naturally performing temperature returning. The tensile property, the bending property, the interlaminar shear property and the wear resisting property of the aramid fiber composite subjected to the subzero treatment are improved, the comprehensive performance is relatively excellent, the application requirements in different fields can be met, and the service life of the aramid fiber composite is prolonged.

Owner:DONGHUA UNIV

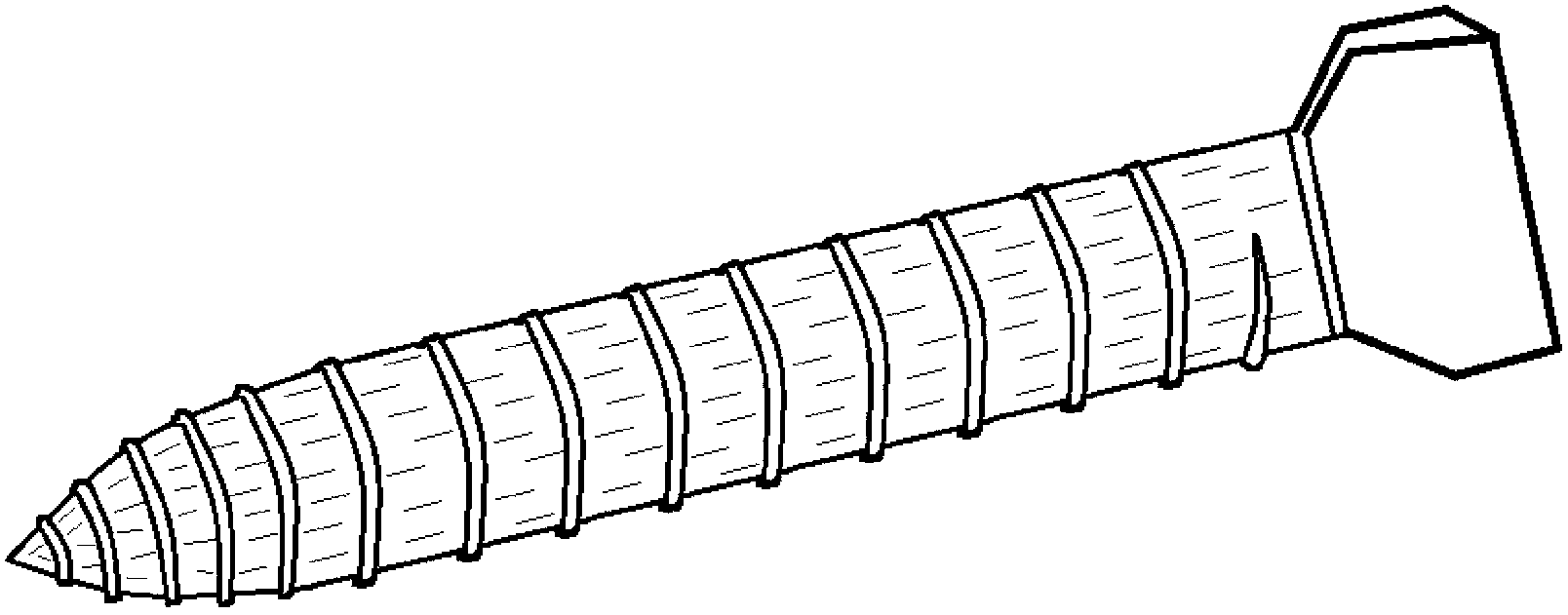

PLA absorbable bone screw with PBC as toughening agent, and preparation method thereof

InactiveCN102935248AGood biocompatibilityPromote degradationSurgeryBiocompatibility TestingComposite sample

The invention relates to a PLA absorbable bone screw with PBC as a toughening agent, and a preparation method thereof. The bone screw is a screw prepared from a composite material, wherein the composite material is a blend of a substrate material PLA, a toughening agent PBC, and an additive HAP. The preparation method comprises the steps that: (1) PBC, PLA, and HAP are respectively bake-dried, such that water content is removed; (2) the dried PBC, PLA, and HAP are heated and blended according to a certain ratio; and a cylindrical PBC / PLA / HAP composite sample bar is obtained by injection molding; (3) the composite sample bar is stretched under hot air; and (4) the stretched sample bar is subjected to cutting machining, such that a screw is prepared, wherein the screw is the PLA absorbable bone screw with PBC as the toughening agent. The bone screw provided by the invention has excellent mechanical performances and good biocompatibility, such that re-injury to patient caused by secondary operation is avoided. The degradation product of the product provided by the invention causes no toxicity or harm. The preparation method is simple and is suitable for industrialized productions.

Owner:DONGHUA UNIV

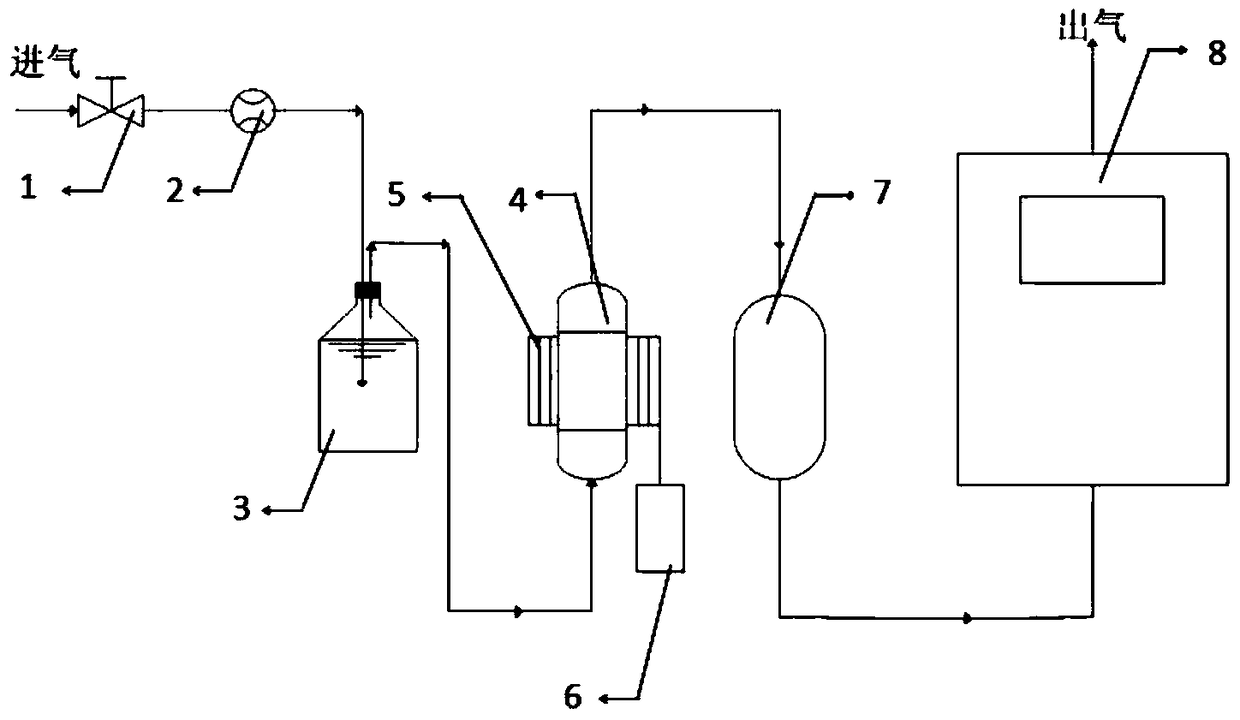

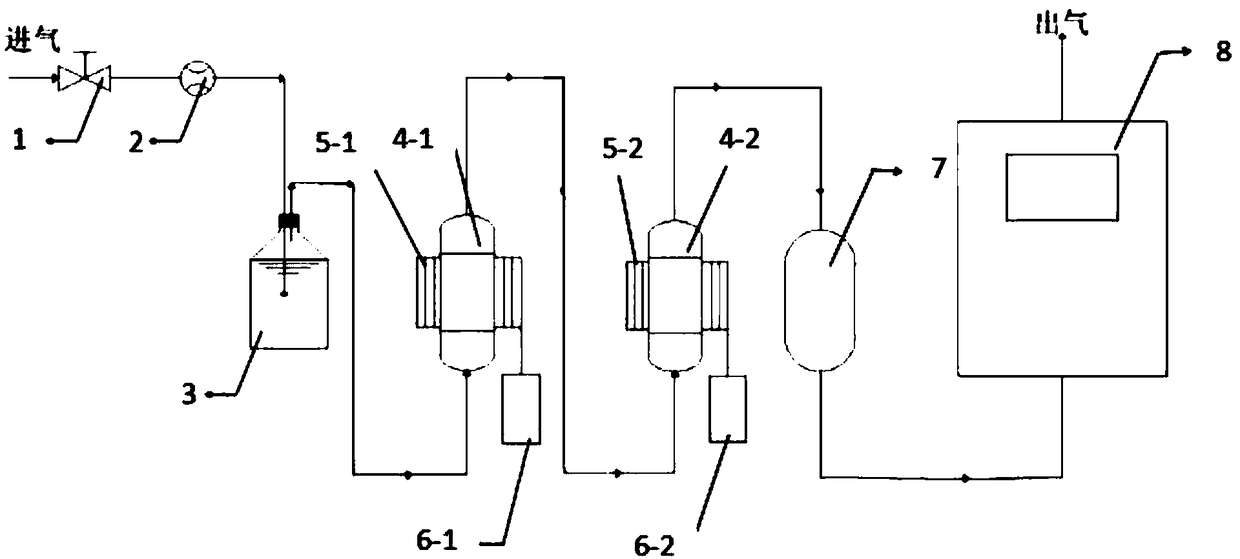

Detecting device for total sulfur content in natural gas and detecting method thereof

PendingCN108717106ASimple structureEasy to operateFuel testingColor/spectral properties measurementsComposite sampleSulfide

The invention relates to a detecting device for total sulfur content in natural gas and a detecting method thereof. The detecting device comprises a gas delivering pipeline, a pipeline valve, a vaporsaturator, a hydrolysis reactor and a hydrogen sulfide measuring device, wherein the pipeline valve, the vapor saturator, the hydrolysis reactor and the hydrogen sulfide measuring device are sequentially arranged on the gas delivering pipeline, the pipeline valve is connected with a gas inlet of the gas delivering pipeline, a gas outlet is formed in the hydrogen sulfide measuring device, the hydrolysis reactor is filled with an organic sulfur hydrolyzing catalyst, and the hydrolysis reactor is connected with a heater. By the aid of the detecting device, sulfide in the natural gas can be hydrolyzed into hydrogen sulfide, then the total hydrogen sulfide content in a composite sample can be measured by the hydrogen sulfide measuring device, and the total sulfur content in an original naturalgas sample can be obtained by calculation. The detecting device is simple in structure, simple and safer to operate, low in cost and high in precision, overcomes the deficiency that the semiconductorlaser absorption spectrum technology cannot be used for online measurement of the total sulfur content in the natural gas and provides a novel effective measurement means for the total sulfur contentin the natural gas, and the detecting method is mild in condition.

Owner:WUHAN MIZI ENERGY SCI & TECH CO LTD

Evaluation method for uniformity of continuous-fiber-reinforced composite resin

The invention provides an evaluation method for the uniformity of continuous-fiber-reinforced composite resin. According to a technical scheme in the invention, the method comprises the following main steps: step 1, acquiring a continuous-fiber-reinforced composite, cutting out samples at to-be-detected positions, wherein when the samples are to be cut out, it is required that the axial direction of most fibers on each selected cross section is perpendicular to the cross section; step 2, randomly selecting a sample, selecting test areas on a polished cross section; and step 3, after selection of the test areas, successively testing the nanometer mechanical hardness of each test area, wherein when one test area is to be tested, a nanometer indentation probe is used for scanning the three-dimensional morphology of the test area, then test points are selected from the test area, and the nanometer hardness of each test point is tested successively. Thus, the method can test the performance of the composite resin in a nano-scale microscopic level for evaluation of microscopic uniformity of the resin; and the method has a wide application scope and is applicable to acquisition of microscopic mechanical data of samples located at different areas and positions, so multiple information of integral, local and microscopic uniformity of composite samples can be obtained.

Owner:AVIC BEIJING AERONAUTICAL MFG TECH RES INST +1

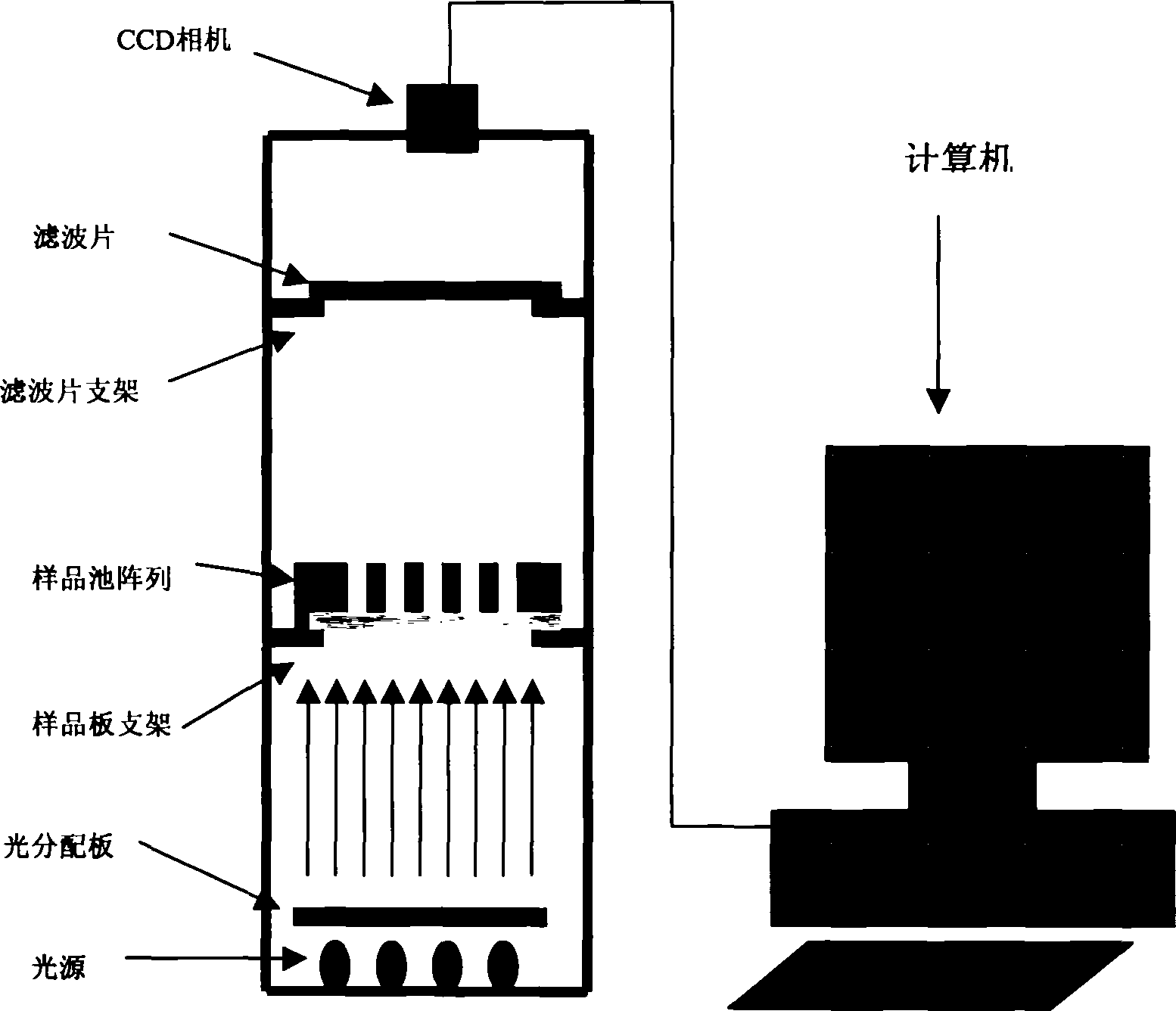

Combined chemical spectral detection system

The invention discloses a spectro-detecting system, which is characterized by the following: realizing synchronous multi-group detection for multiple samples in the composite sample library through different frequency optical sources; containing variable frequency or utility serial filtrate light source, detecting plate with M*N transmission sample pools (M and N is between 2 and 100 or more) and high-resolution CCD digital detector for device (as picture displays); detecting transmission information through high-resolution CCD digital camera; calculating the density of specific material in kinds of samples according to background and data through self-designed software; analyzing quantatively for hundreds of samples within several seconds for combined chemical samples.

Owner:MICROVAST POWER SYST CO LTD

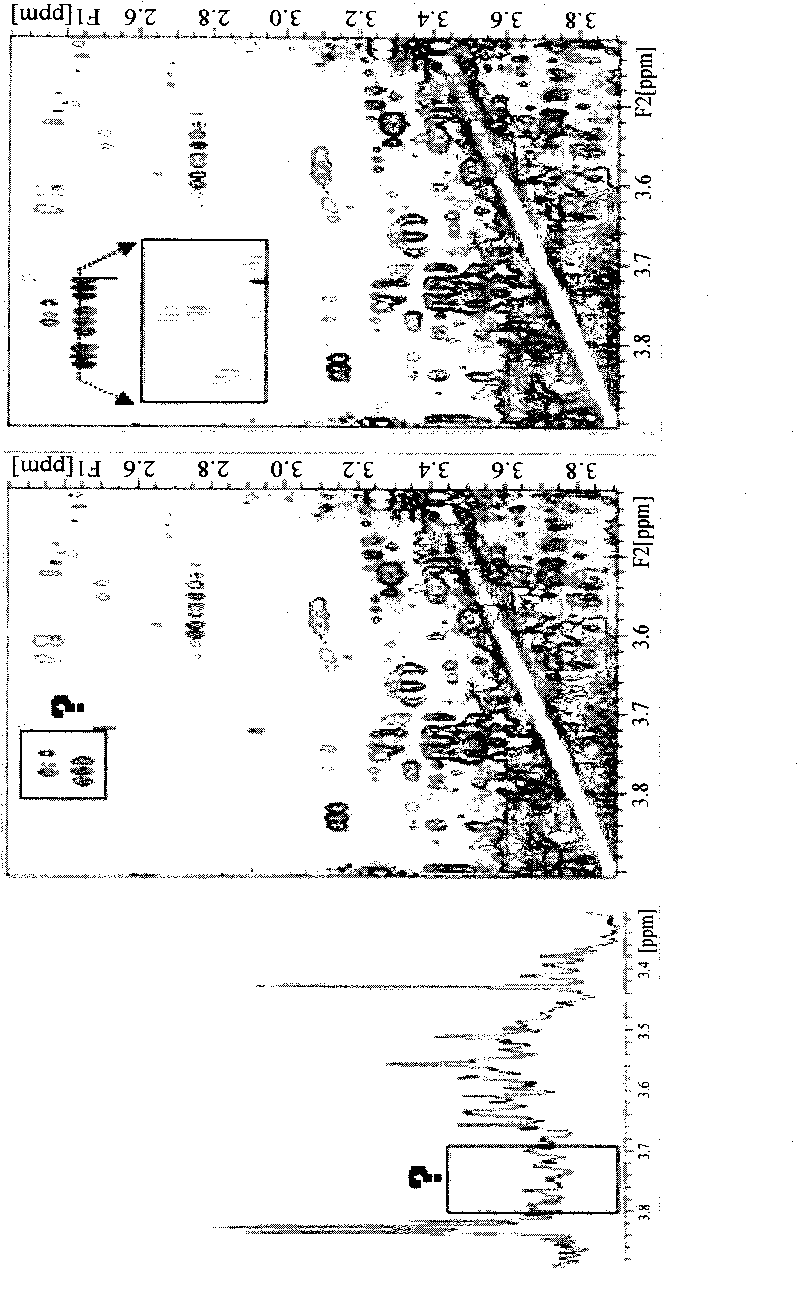

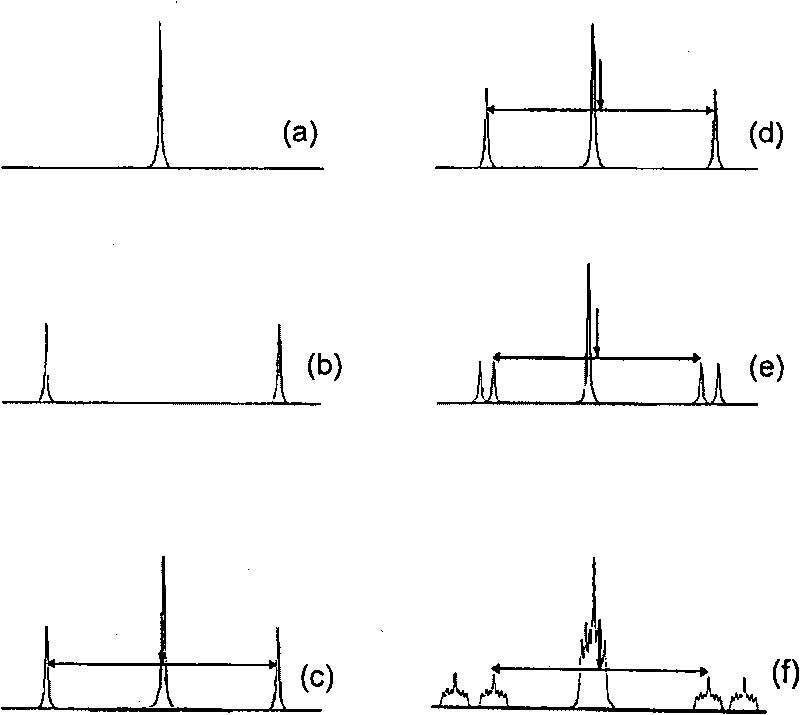

A method for detecting a target substance by nuclear magnetic resonance

InactiveCN101730842AMeasurements using NMR spectroscopyAnalysis using nuclear magnetic resonanceSolid-state nuclear magnetic resonanceNMR - Nuclear magnetic resonance

A method for detecting a known target substance in a sample by means of nuclear magnetic resonance (NMR) of a preselected nuclear species contained in the target substance is described. The method comprises the steps of: a) providing a starting sample known or suspected to contain the target substance; b) adding to the starting sample an amount of isotope-labeled target substance, thus obtaining a composite sample, the isotope-labeled target substance being obtainable from the target substance by replacing at least one nucleus thereof by another isotope thereof, wherein said replacing induces a change in the position or multiplicity of at least one NMR signal of the target substance; c) acquiring NMR signals of the preselected nuclear species from the composite sample; d) determining actual positions of an auxiliary set of NMR signals of the isotope-labeled target substance; e) calculating actual positions of a principal set of NMR signals of the target substance from the actual positions of the auxiliary set of signals and from a predetermined relationship between relative positions of the signals of the isotope-labeled target substance and of the signals of the target substance; f) detecting at least one signal of the target substance located at an actual position calculated by step e).

Owner:F HOFFMANN LA ROCHE & CO AG

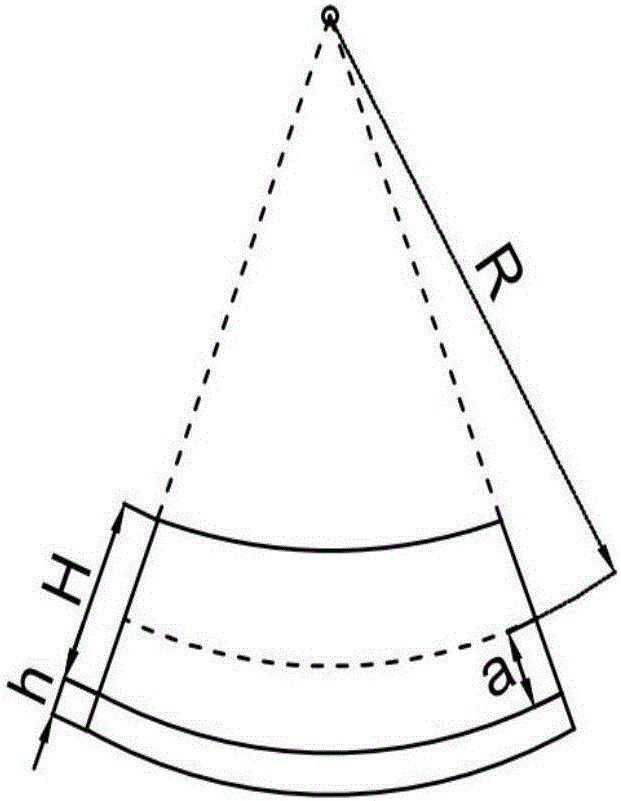

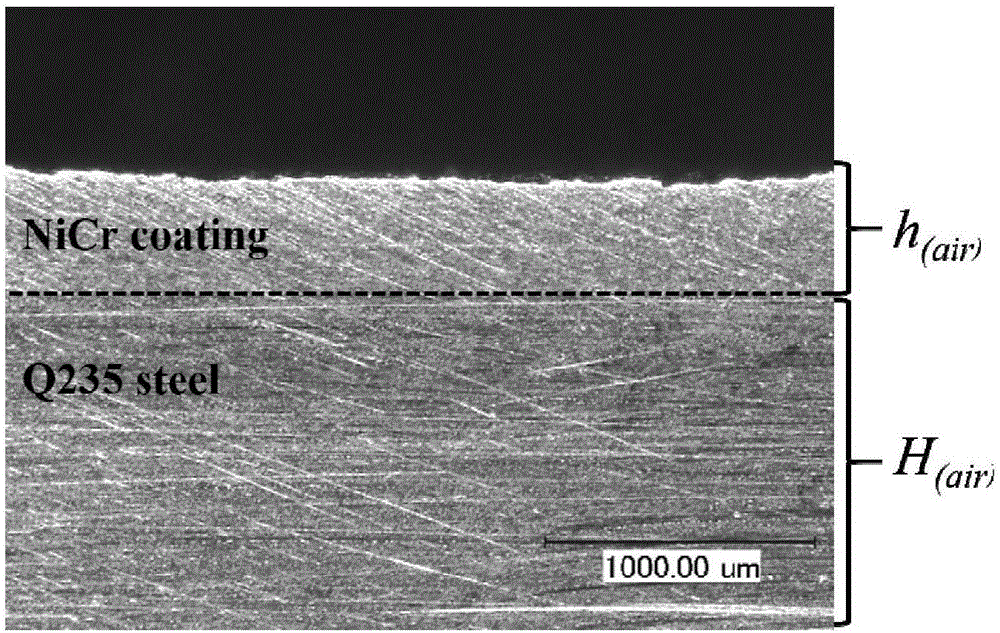

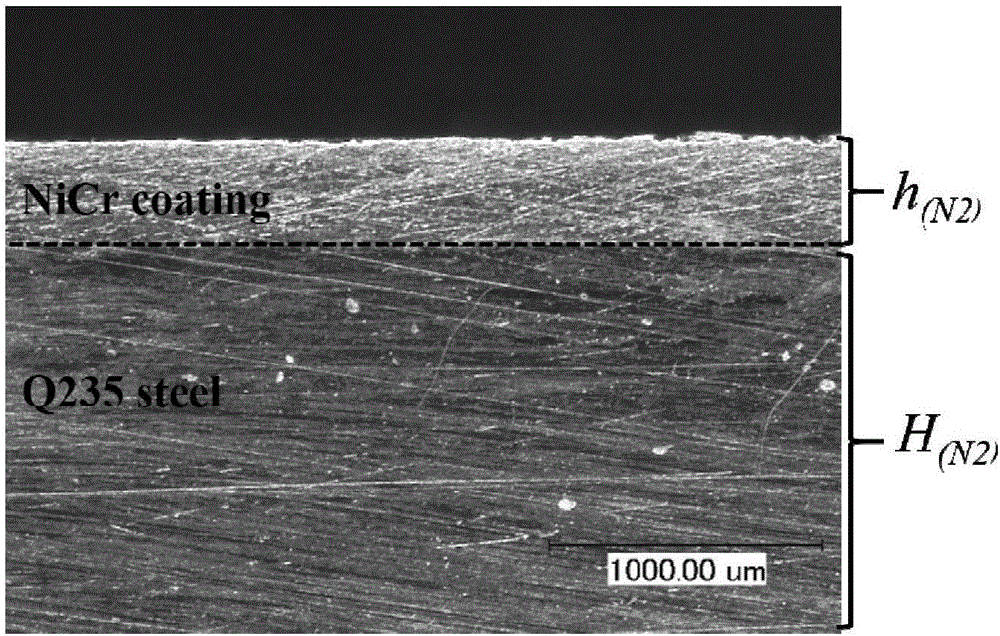

Method for measuring elastic modulus of coating

The invention discloses a method for measuring the elastic modulus of a coating. When the coating is a single-layer coating, the method comprises the following steps: acquiring the elastic modulus Eq of a coating composite sample to be measured; acquiring the elastic modulus Es of a matrix material of the coating sample to be measured; respectively acquiring the thickness H of the matrix of the coating sample to be measured and the thickness h of the coating; and calculating the elastic modulus Ec of the coating of the coating sample to be measured according to a formula shown in the description, wherein A in the formula is h<4>, B in the formula is 4EsHh<3> + 4EsH<3>h + 6EsH<2>h<2> - Eq(H+h)<3>h, and C in the formula is Es<2>H<4> - EqEsH(H+h)<3>. The method uses a pulse excitation technology to realize rapid and accurate measurement of the elastic modulus of the coating sample.

Owner:CHINA TEST & CERTIFICATION INT GRP CO LTD

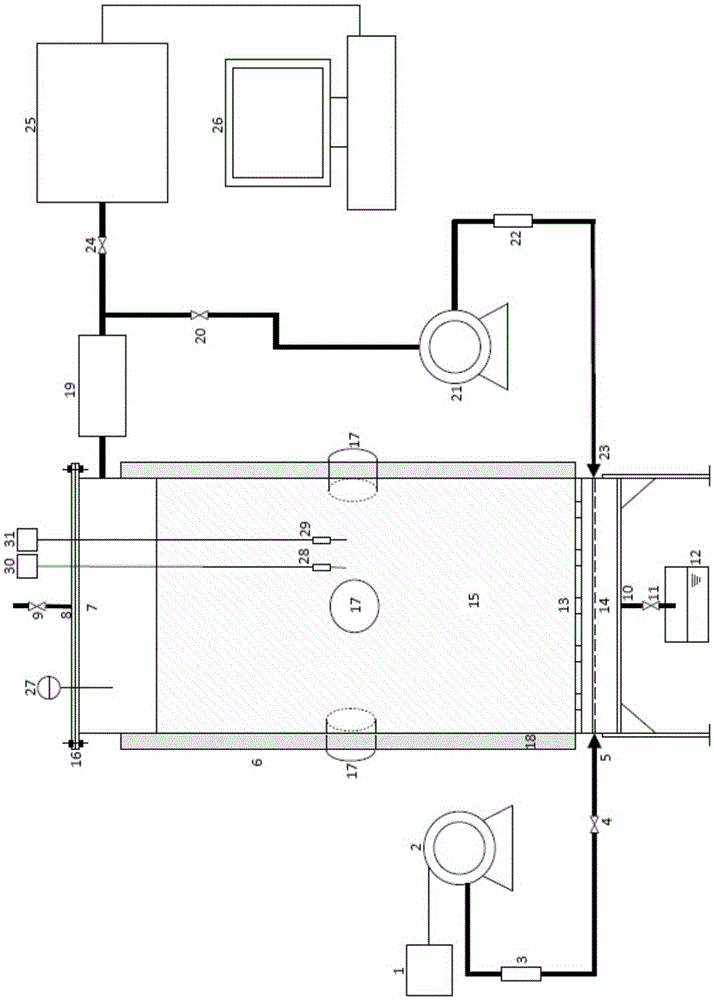

Aerobic composting stink in-situ monitoring device and operation method thereof

ActiveCN105294187AEnsure air qualityRealize self-circulationBio-organic fraction processingOrganic fertiliser preparationControl systemEcological analysis

The invention discloses an aerobic composting stink in-situ monitoring device and an operation method thereof. The aerobic composting stink in-situ monitoring device comprises an aerobic composting system, a stink gas in-situ control system, a stink gas online monitoring system and an environmental condition online monitoring system. The device can be used for composting raw materials and auxiliary materials in different kinds, different technological parameters or a stink self-circulation mode is adopted, and efficient low-cost stink in-situ control research in the aerobic composting process is carried out; the composting stink pollution in-situ control effect can be monitored online, and the stink in-situ control operating process can be adjusted according to a monitoring result; compositing samples can be collected, the changing law of the compositing physical and chemical properties is researched, ecological analysis of pile body microorganisms becomes possible, and activity optimization and regulation and control of deodorization relevant microorganisms in a pile body are further achieved.

Owner:HANGZHOU NORMAL UNIVERSITY

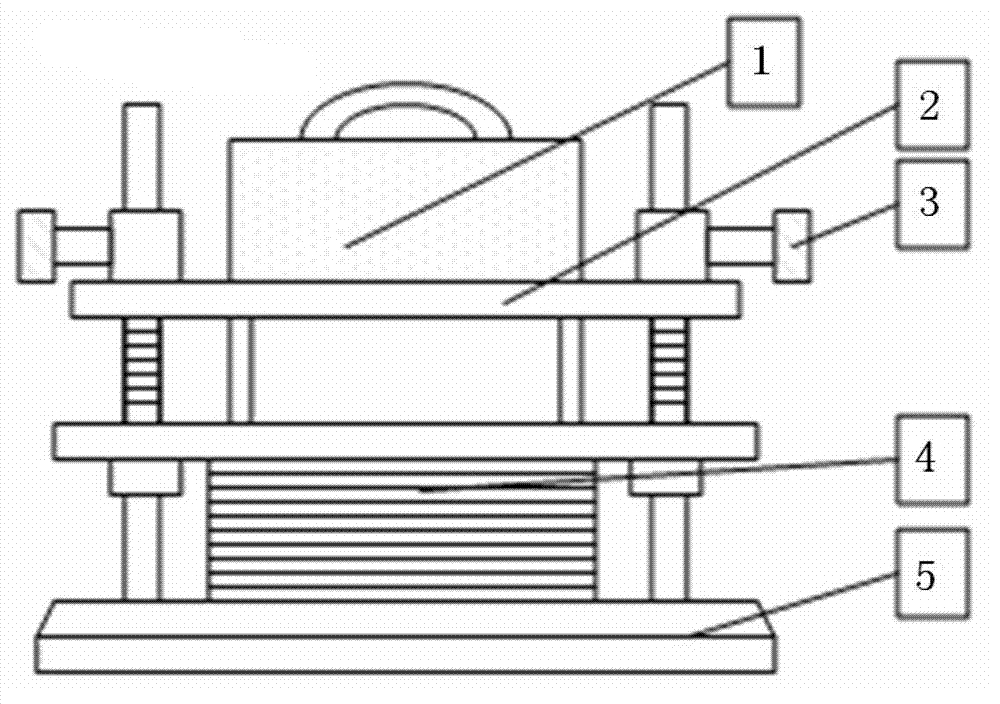

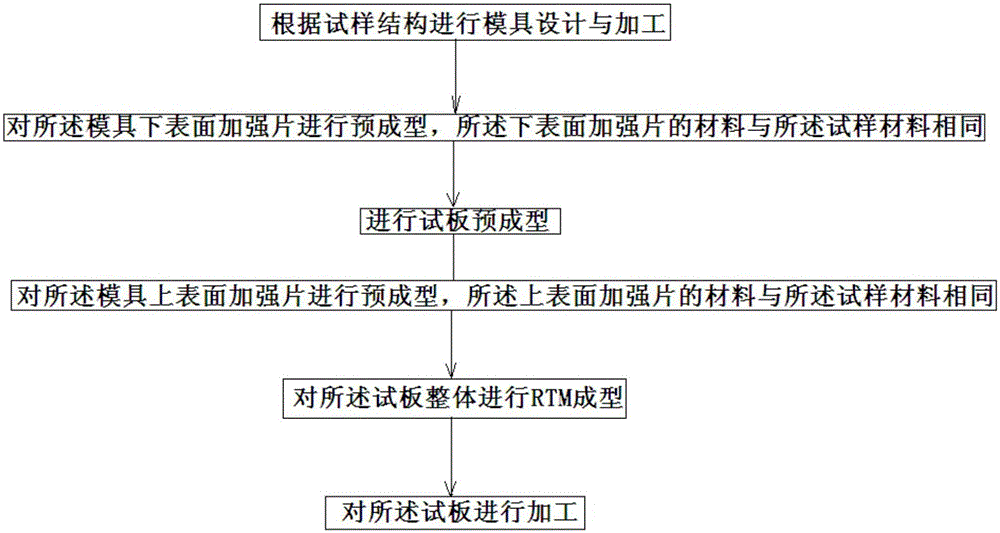

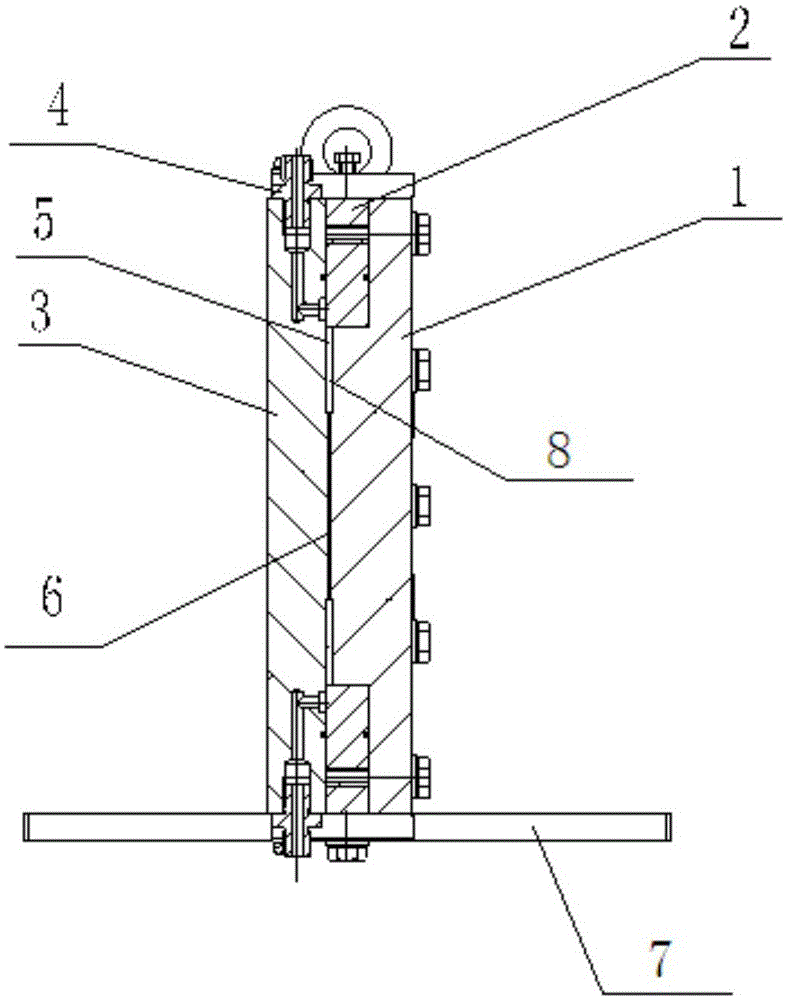

Preparation method of high-temperature composite material sample

ActiveCN105021434AConsistent strengthAvoid the phenomenon of destructionPreparing sample for investigationComposite sampleUltimate tensile strength

The present invention discloses a preparation method of a high-temperature composite sample and belongs to the technical field of composite materials. The preparation method of the high temperature composite material comprises the steps of: designing and processing a mold according to the sample structure; pre-forming a reinforcement sheet on the lower surface of the mold, wherein the reinforcement sheet on the lower surface is made of the same material as the sample; pre-forming a test board; pre-forming the reinforcement sheet on the upper surface of the mold, wherein the reinforcement sheet on the upper surface is made of the same material as the sample; conducting RTM forming on the whole test board to obtain high-temperature composite material sample; and processing the on test board. The reinforcement sheets and the body do not have adhesive secondary curing interface, the adhesive surface shear strength is consistent with test piece body material layer, so as to avoid the destruction of the adhesive surface in the test process.

Owner:HUBEI SANJIANG AEROSPACE GRP HONGYANG ELECTROMECHANICAL

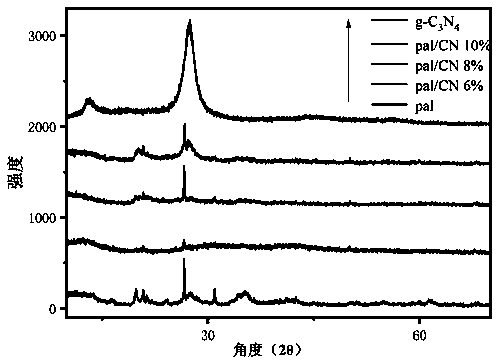

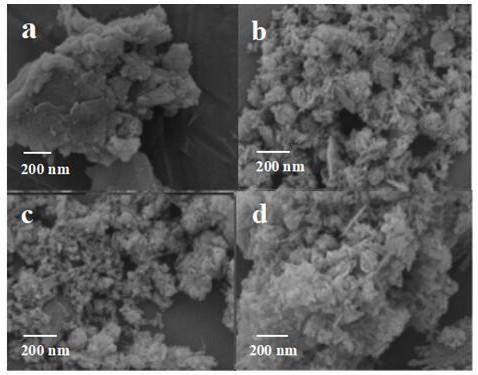

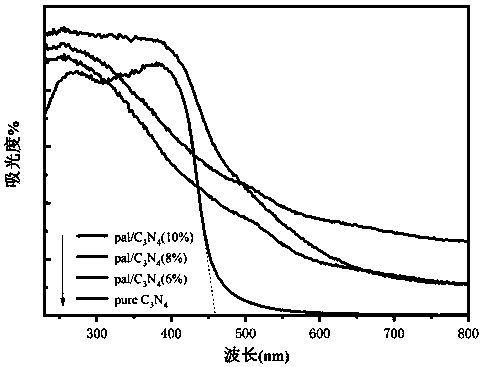

Preparation and application of palygorskite/graphite phase carbon nitride compound composite material

InactiveCN110252379AIncrease light absorption intensityEfficient removal effectPhysical/chemical process catalystsWater/sewage treatment by irradiationWater bathsTetracycline Hydrochloride

The invention discloses preparation and application of a palygorskite / graphite phase carbon nitride compound composite material. The preparation method of the pal / g-C3N4 composite material includes: subjecting palygorskite to ultrasonic dispersion in distilled water, adding dicyandiamide and mixing the substances evenly, and then performing ultrasonic treatment for 0.5-1h; conducting heating to 45-50DEG C, and further performing stirring till complete dryness by evaporation, conducting grinding into powder, placing the product in a muffle furnace, and conducting calcination at 520-550DEG C for 3.5-4h; performing cooling to room temperature, and then conducting grinding into powder, thus obtaining the pal / g-C3N4 composite material. The invention adopts water bath method to compound dicyandiamide and palygorskite to successfully prepare the pal / g-C3N4 composite material, the catalytic activity of g-C3N4 is combined with the adsorption performance of palygorskite, and the two substances cooperate to enhance the light absorption intensity of the composite sample, thus improving the photocatalytic efficiency, and reaching the effect of efficient removal of pollutants. Experiments show that the composite catalytic material has high catalytic oxidation rate on tetracycline hydrochloride, and the total removal rate reaches 85%.

Owner:NORTHWEST NORMAL UNIVERSITY

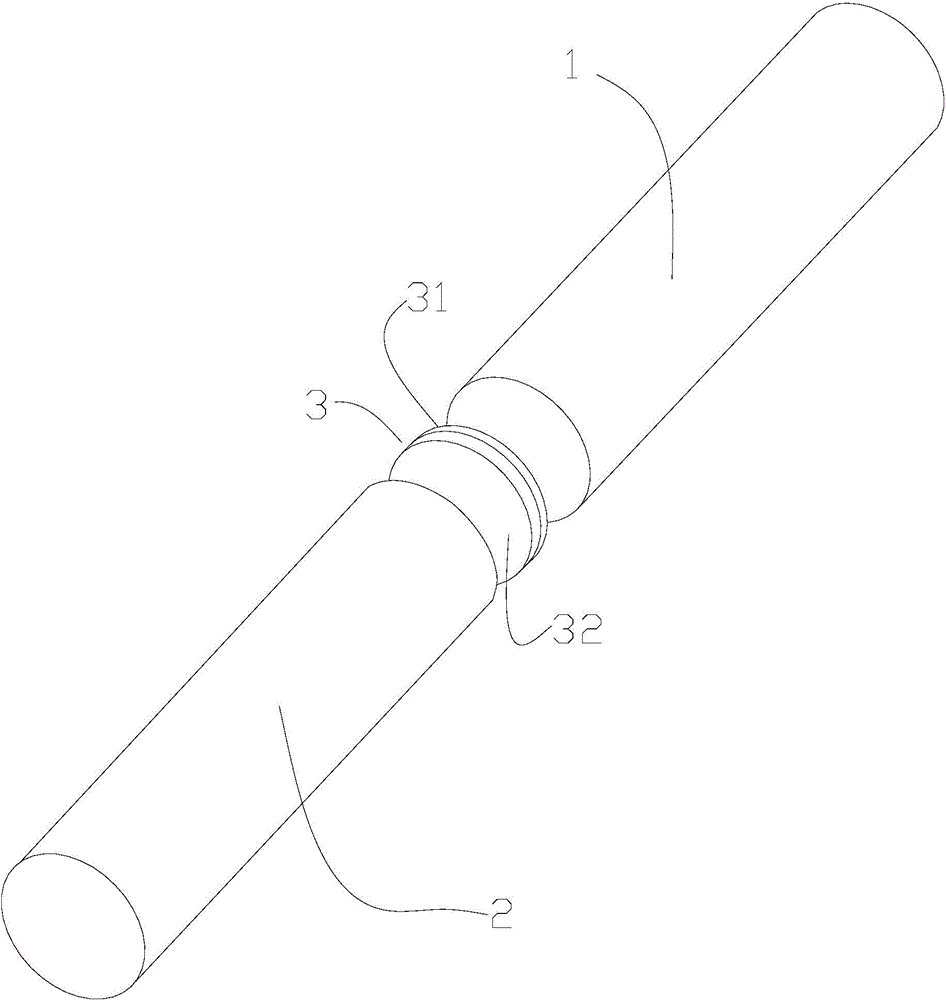

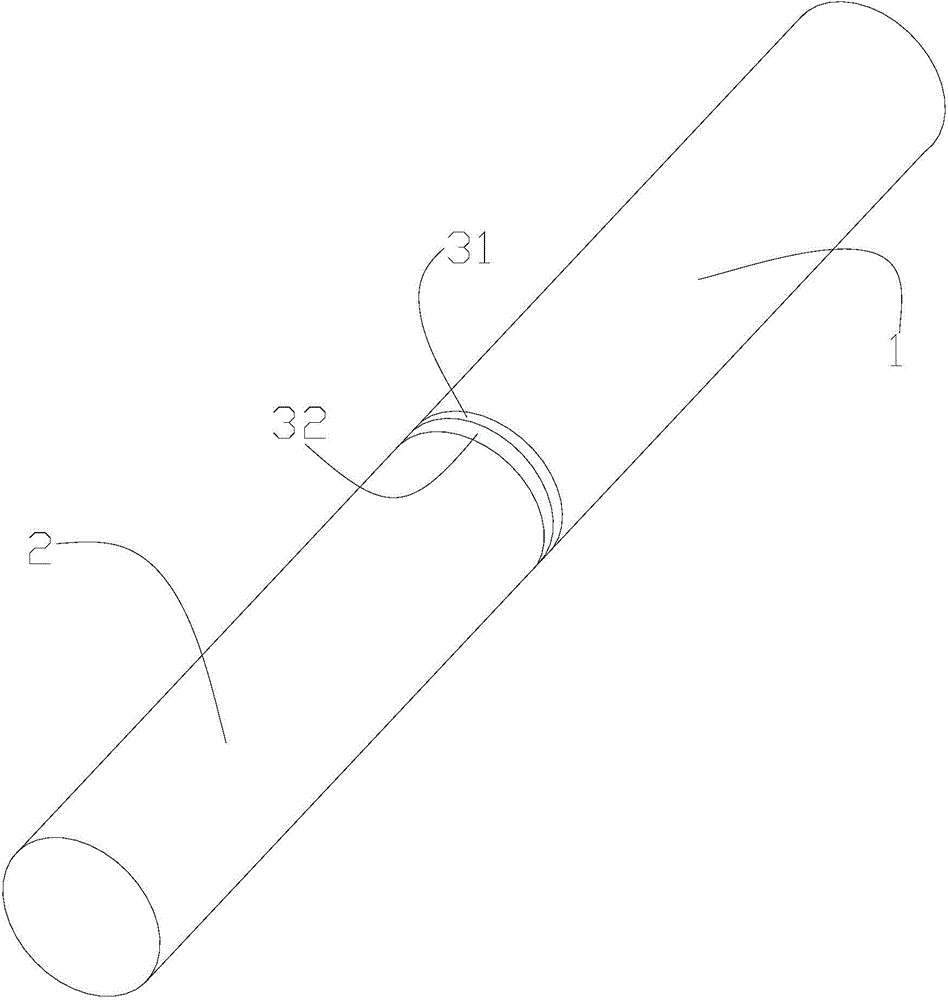

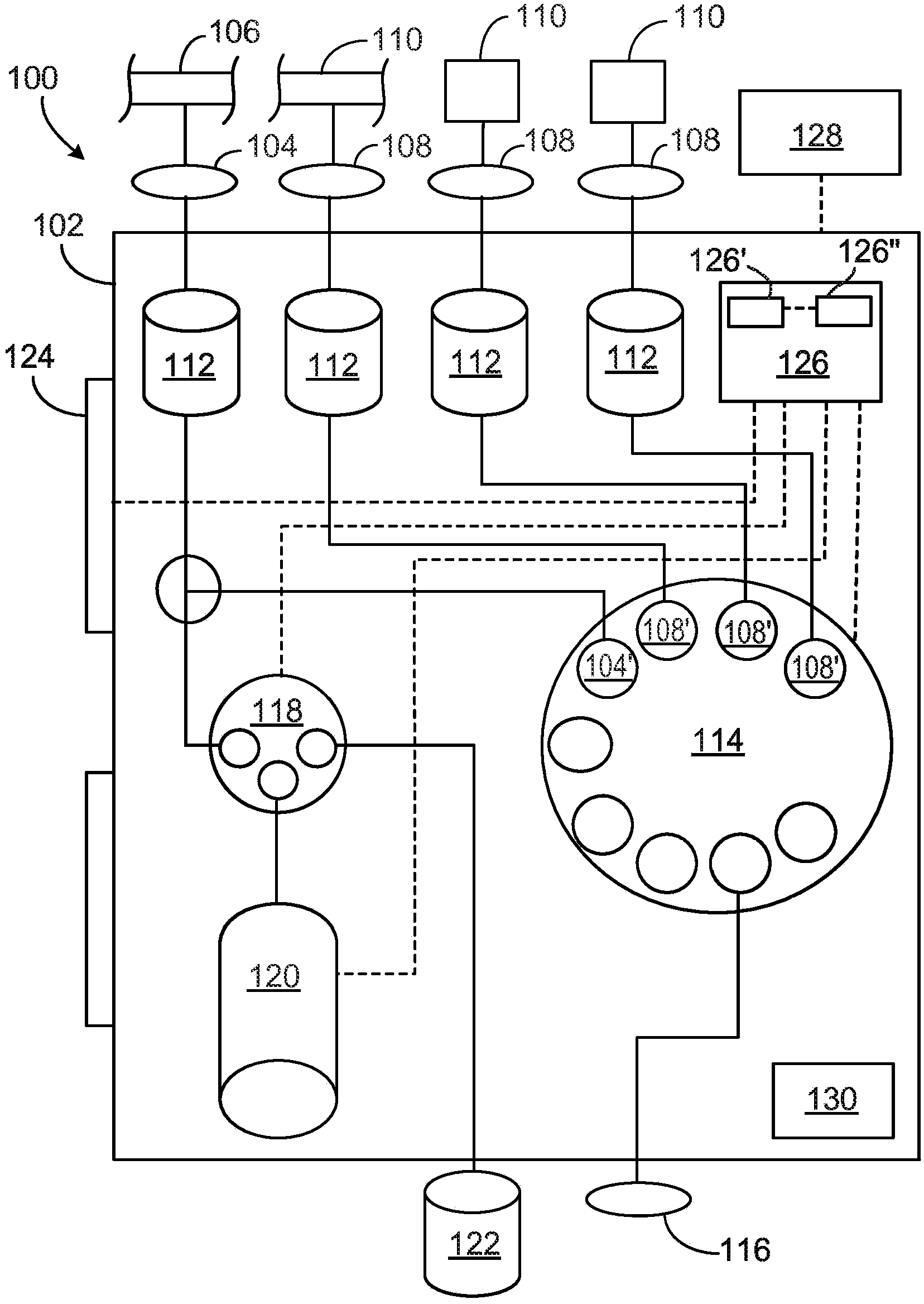

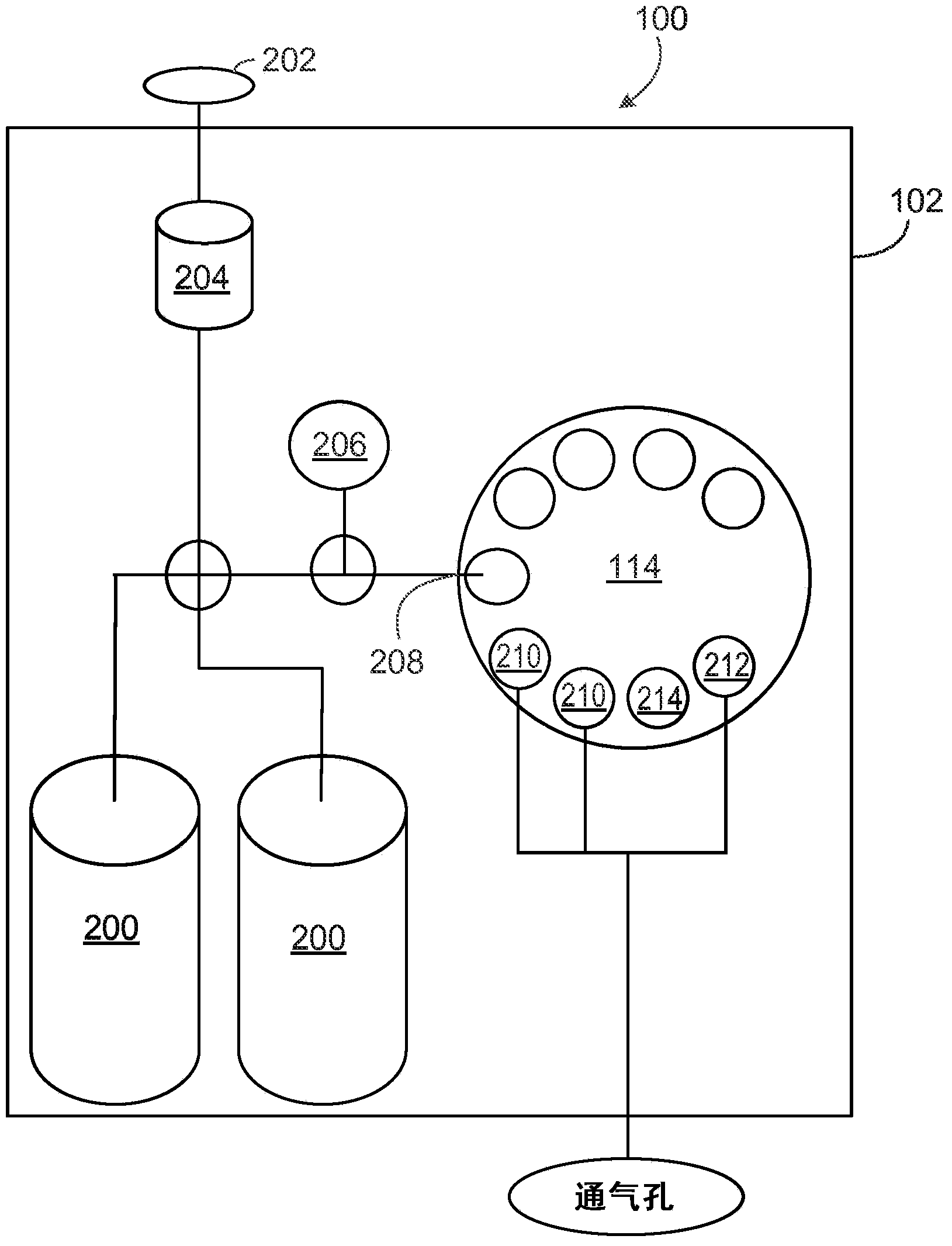

Composite sampling of fluids

InactiveCN104321647AAutomatic collectionReal-time collectionComponent separationWithdrawing sample devicesComposite sampleEngineering

Composite sampling of a fluid flowing through a conduit includes collecting, in a vessel coupled to the conduit through which the fluid is flowing, a first discrete sample of fluid from the conduit, the first discrete sample having a first selected volume, and collecting, in the vessel and at a first interval from the first sample, a second discrete sample of the fluid from the conduit, the second discrete sample having a second selected volume, thereby forming a composite sample in the vessel while the vessel is coupled to conduit. The composite sample includes the first discrete sample and the second discrete sample, and may include one or more additional discrete samples. An apparatus for collecting the composite sample includes a gas chromatograph, and is arranged such that the composite sample is provided to the gas chromatograph without removing the composite sample from the apparatus or transporting the composite sample.

Owner:SGS NORTH AMERICA INC

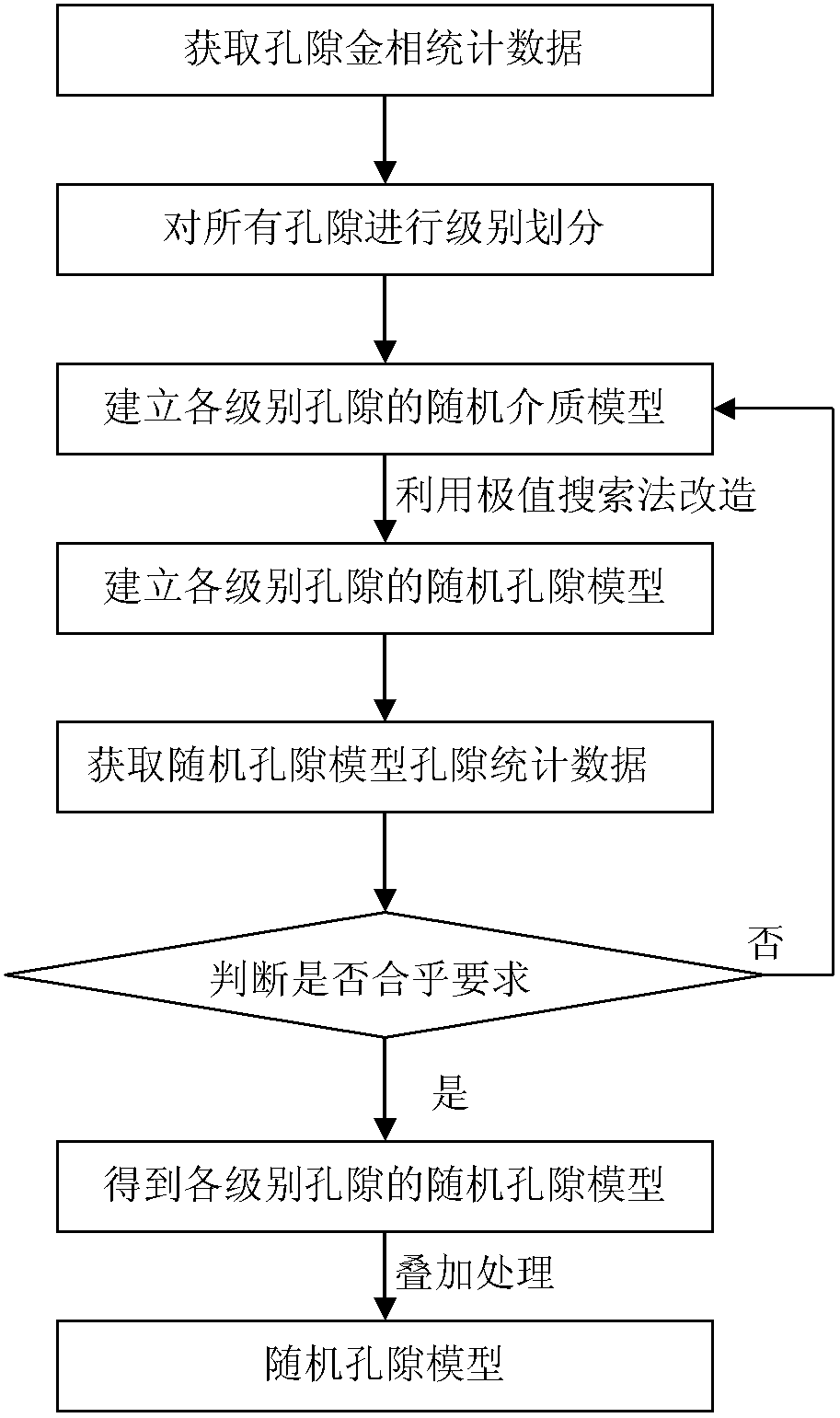

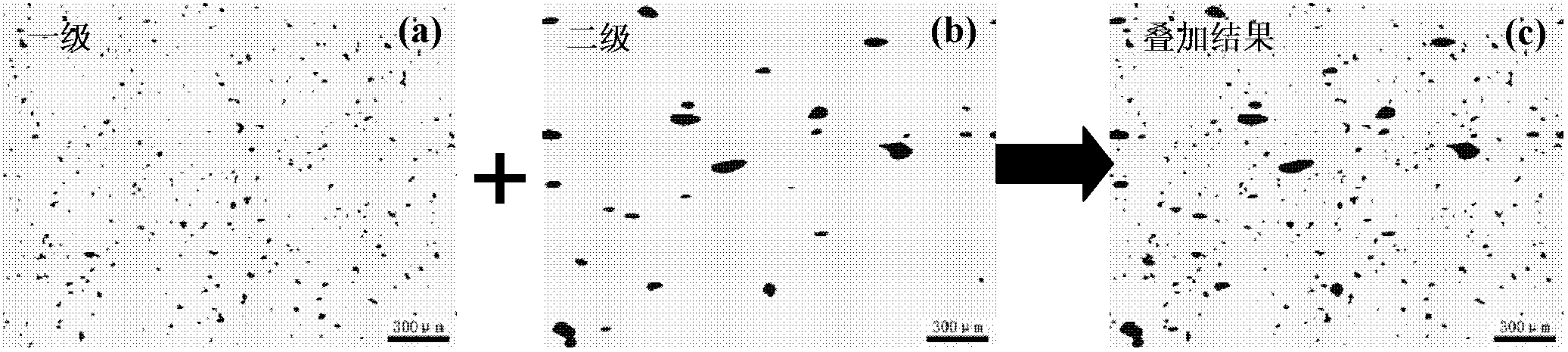

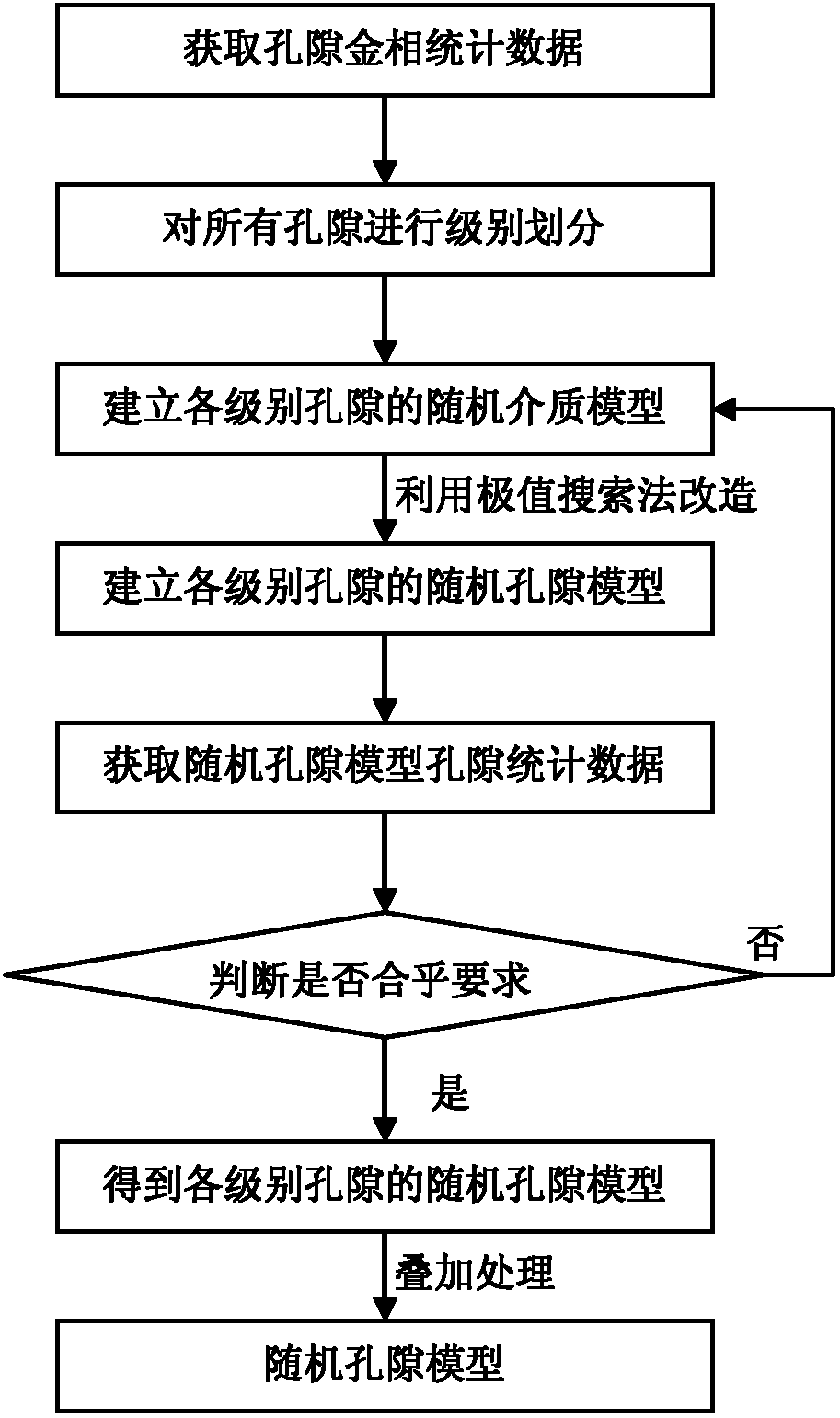

Method for establishing two-dimensional stochastic pore model of fiber reinforced composite with large dispersion pore size

A method for establishing a two-dimensional stochastic pore model of fiber reinforced composite with large dispersion pore sizes belongs to the field of composite nondestructive examination and evaluation. The method for establishing the model includes steps as follows: firstly dissecting a to-be-tested composite sample, counting the porosity and size characteristics of all pores through the metallographic method, grading the pores according to pore lengths, and establishing stochastic pore models of each grade; comparing the models with counting results, obtained through the metallographic analysis, of pore size characteristics of each grade, and obtaining the stochastic pore models of each grade as long as the difference between the models and the results are less than 2%; and finally, superimposing model images of the pores of each grade to obtain a stochastic pore model of the to-be-tested sample. The method can accurately establish the two-dimensional stochastic pore model of the fiber reinforced composite with the large dispersion pore sizes; and further, by utilizing the model, the base for the ultrasonically nondestructive examination of the composite porosity can be provided, and the model base for analyzing the performances of the composite can be provided.

Owner:DALIAN UNIV OF TECH

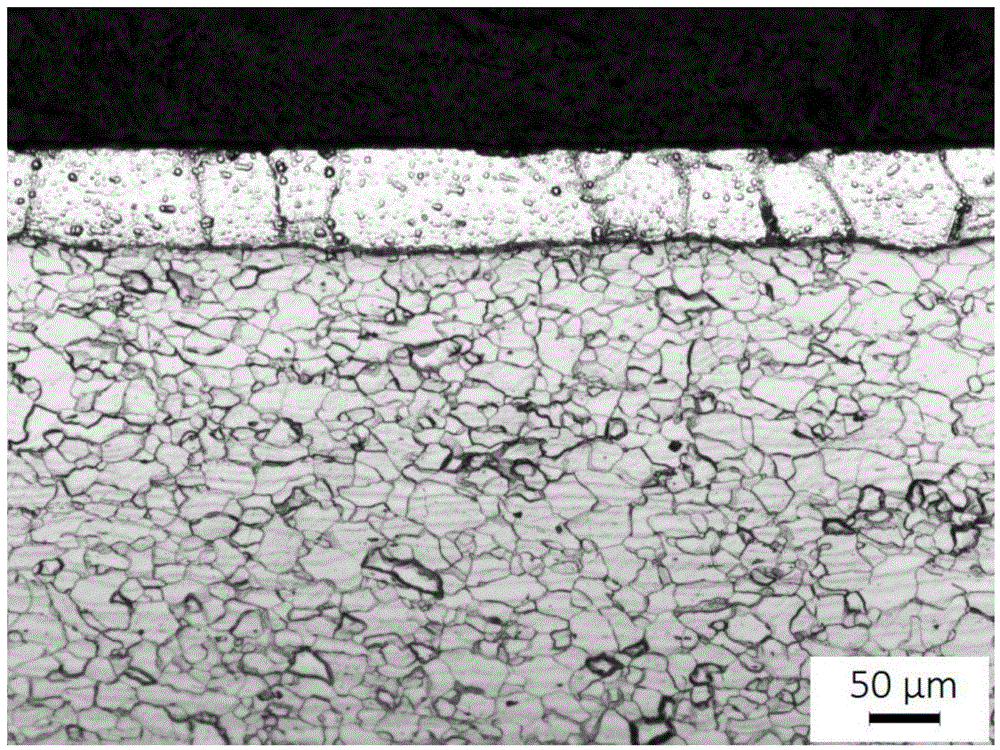

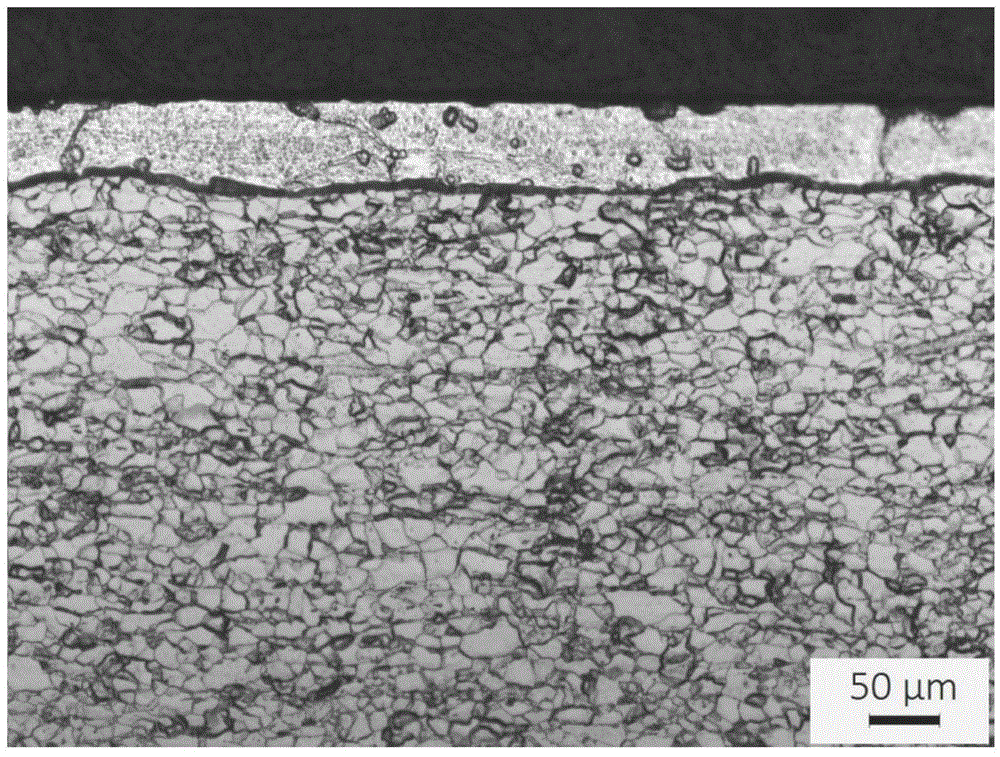

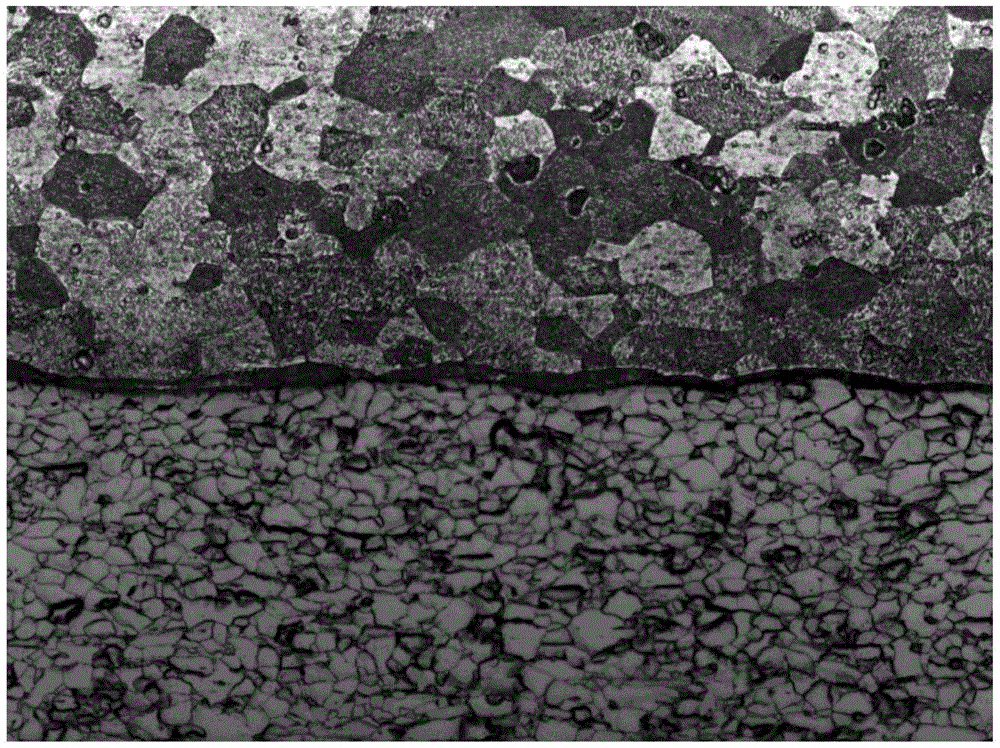

Preparation method of aluminum steel composite grain structure, sample, reagent and preparation method

ActiveCN105628474AConvenient and efficient observation and measurementPreparing sample for investigationHydrofluoric acidElectrolysis

The invention relates to a preparation method of an aluminum steel composite grain structure, a sample, a reagent and a preparation method. The preparation method of the grain structure comprises the steps that an aluminum steel composite sample is prepared; an aluminum side grain structure is prepared, wherein the composite sample is subjected to electrolysis for 1-3 min at constant potential (-1.0 V)-(-0.7 V) in 0.5%-2.5% parts by weight of hydrofluoric acid aqueous solution electrolytic solution at the temperature ranging from 50 DEG C to 70 DEG C; a steel side grain structure is prepared, wherein the composite sample subjected to electrolysis is wiped and cleaned for 30-60 s with a room-temperature nitric acid ethanol solution containing 1.0%-2.5% parts by weight of nitric acid; the aluminum steel composite sample is prepared through grinding through 200-400#, 500-700# and 1,000-1,400# waterproof abrasive paper in sequence and polishing. According to the technical scheme, the grain structures of the two sides of the aluminum steel composite can be displayed simultaneously, and observation and measurement of a composite metallographic structure are more convenient, rapid and efficient.

Owner:YINBANG CLAD MATERIAL

Modular compositing-multiple lot screening protocols for detection of pathogens, microbial contaminants and/or constituents

ActiveUS20090258359A1Microbiological testing/measurementPreparing sample for investigationMicroorganismAssay

Provided are methods for sampling, testing and validating test lots, comprising: assembling a plurality of product portions from each of a plurality of test lots and combining the portions to provide a corresponding set of test lot samples; enriching the test lot samples; removing portions of each enriched sample, and combining the removed portions to provide a modular composite sample; and testing of the modular composite sample, and individual testing of the enriched test lot samples, using at least one suitable detection assay for a target microbe or organism, wherein when such testing is negative all test lots are validated, and wherein when such testing is positive with respect to the modular composite sample, or with respect to an individual enriched test lot sample, individual test lots may nonetheless yet be validated by further testing of a portion of respective initially-negative enriched test lot samples and obtaining negative results.

Owner:INST FOR ENVIRONMENTAL HEALTH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com