Multi-inspection-lot metallurgical crude fuel batch quality control method

A technology for inspecting batches and raw fuels, used in instruments, data processing applications, calculations, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

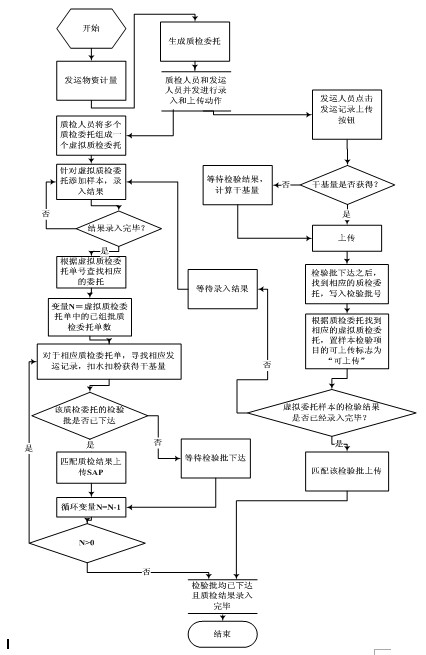

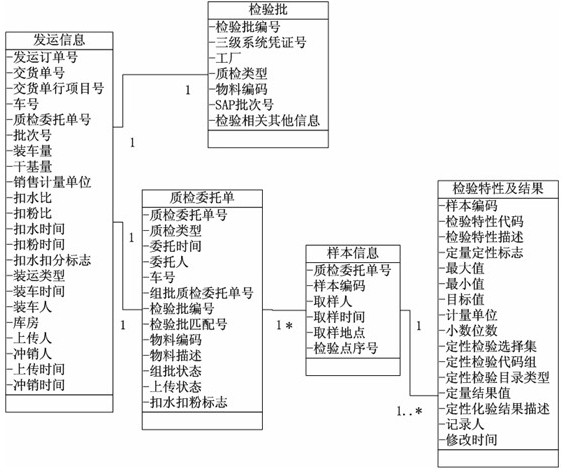

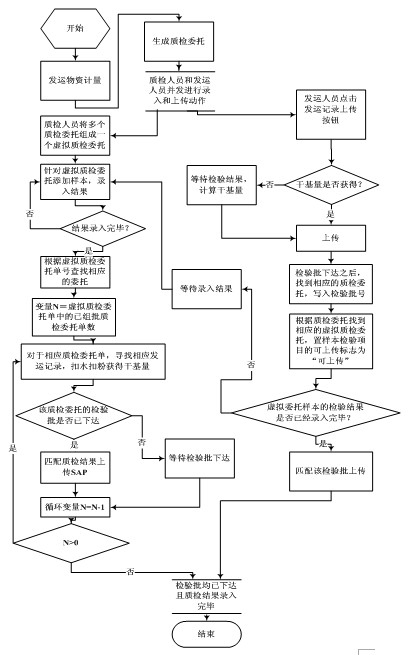

[0020] Example: figure 1 , figure 2 As shown, the system database relied on in this embodiment is ORACLE 10g, which is implemented in a browser-client mode by using the J2EE open source framework (Struts 2 + Spring + Ibatis).

[0021] The communication between the system and SAP is realized by connecting IBM MQ 6.0 and SAP XI. During the implementation process, according to different functions, the corresponding classes are stored in the following packages:

[0022] Dao (data access object), Entity (entity class), Service (class for processing business logic), Web (action class of STRUTS 2), a batch quality inspection method for metallurgical raw fuel groups under multi-inspection batches includes the following steps :

[0023] (1) A quality inspection entrustment is generated when measuring the gross weight of shipped materials, including order number, quality inspection type, entrustment time, client, vehicle number, batch quality inspection order number, inspection lot ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com