Patents

Literature

672 results about "Bulk cargo" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Bulk cargo is commodity cargo that is transported unpackaged in large quantities.

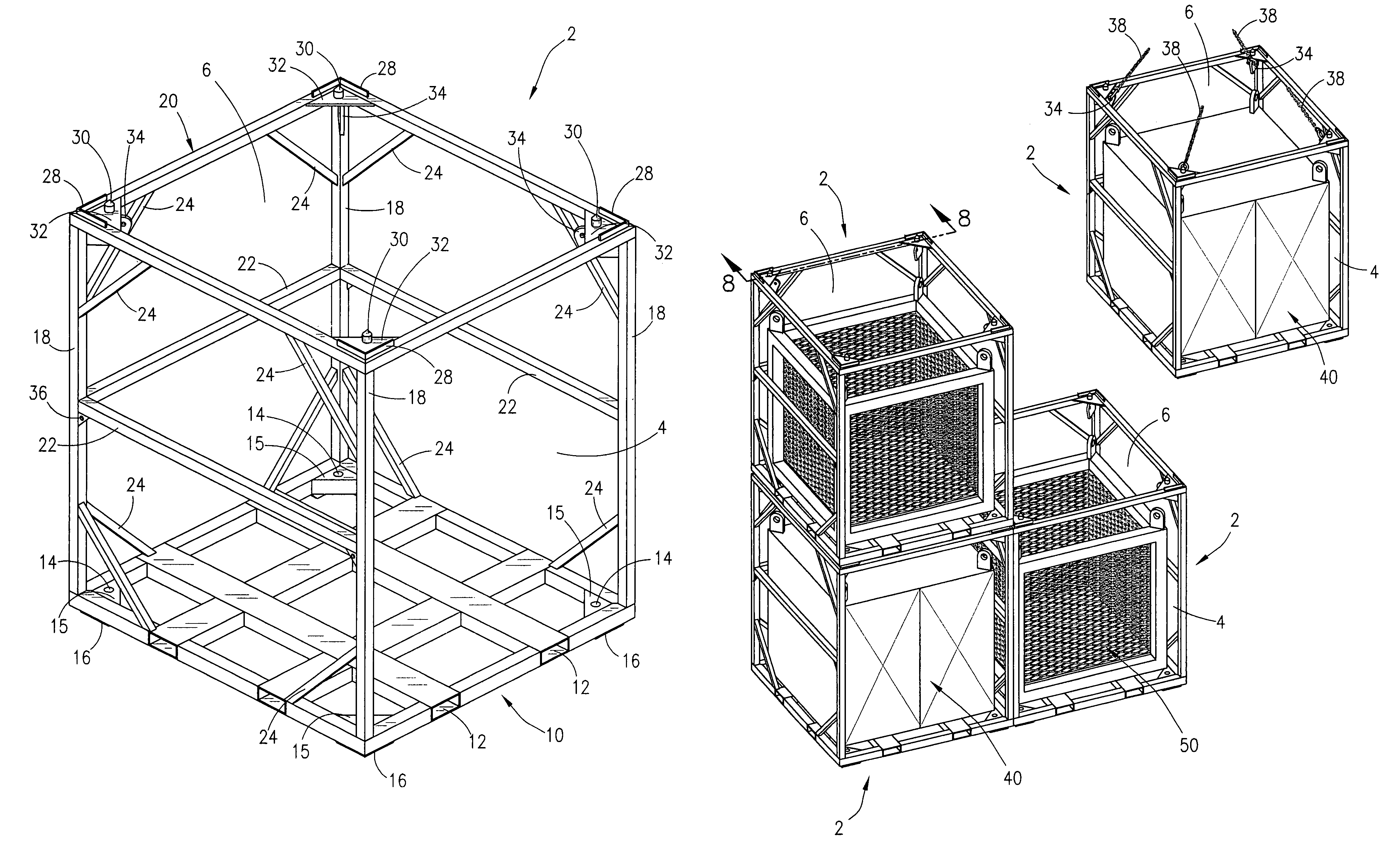

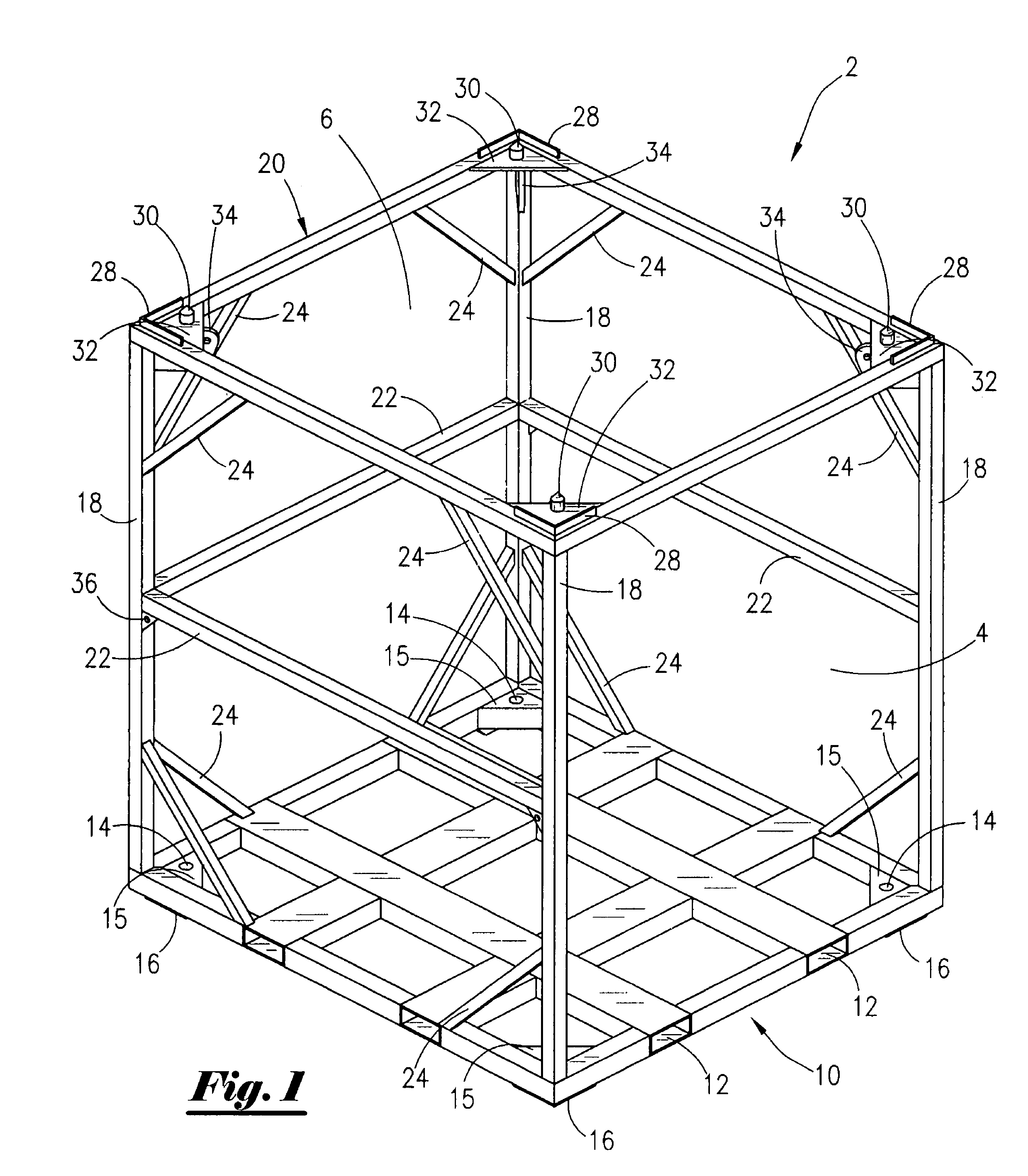

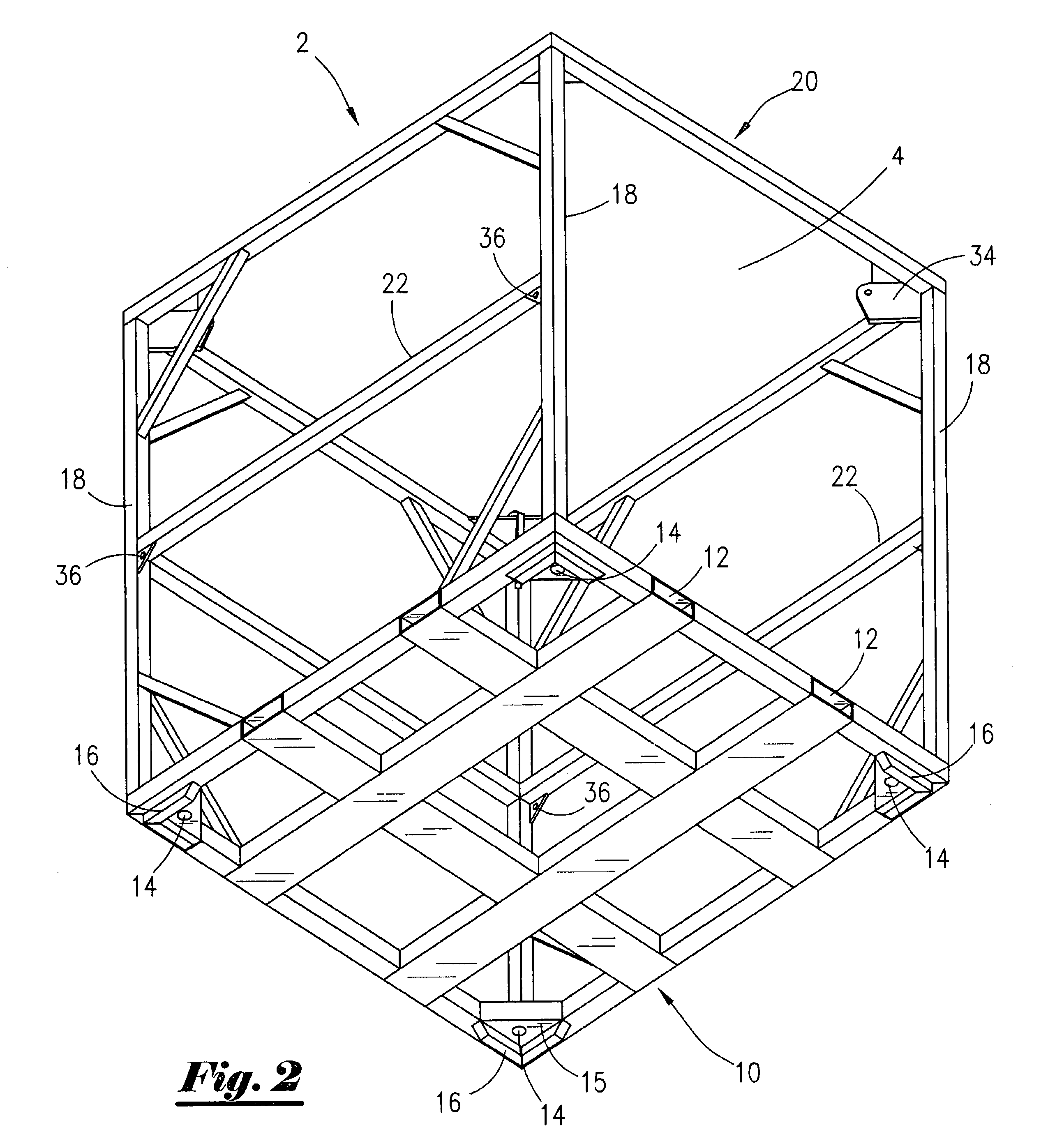

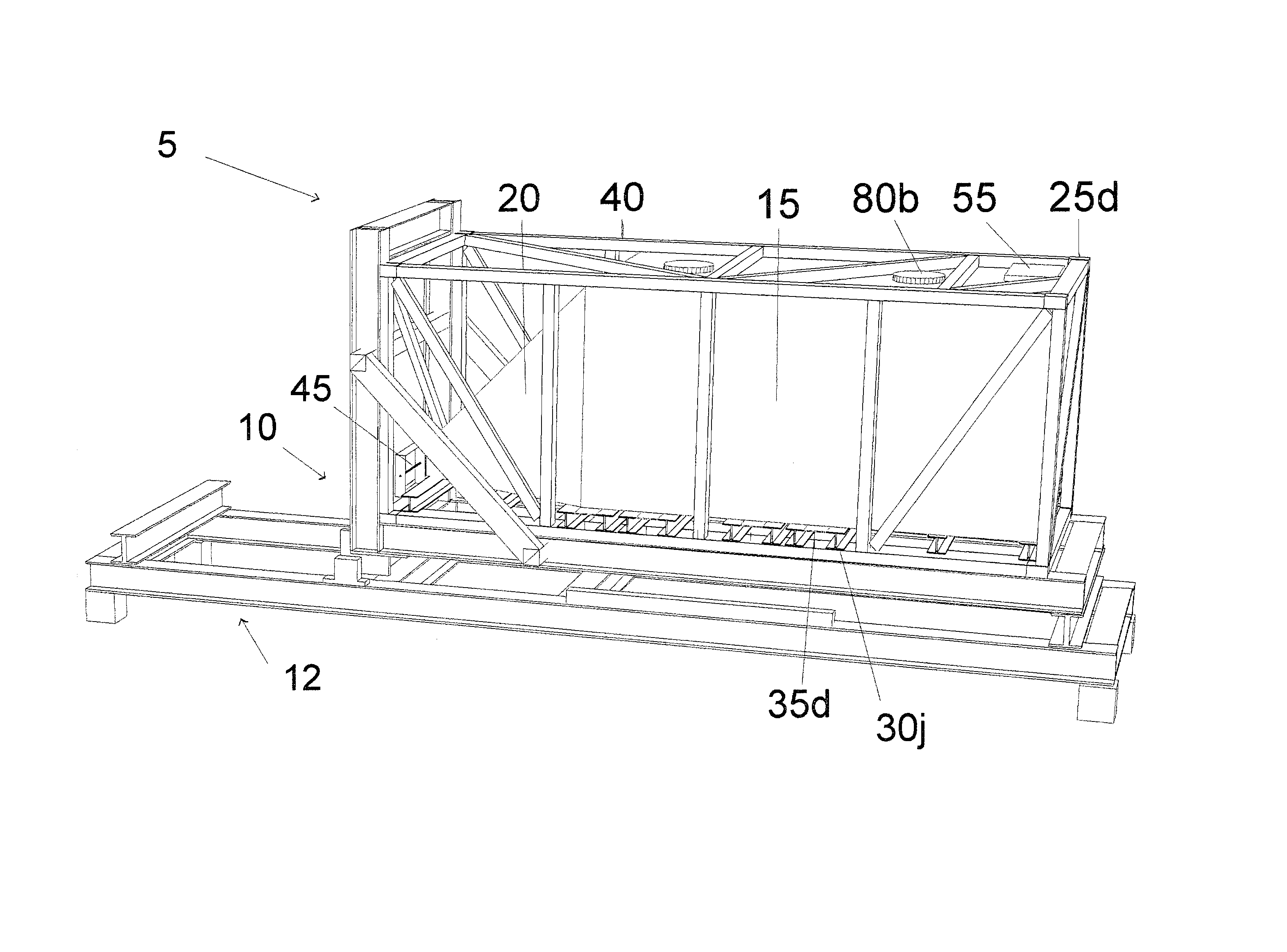

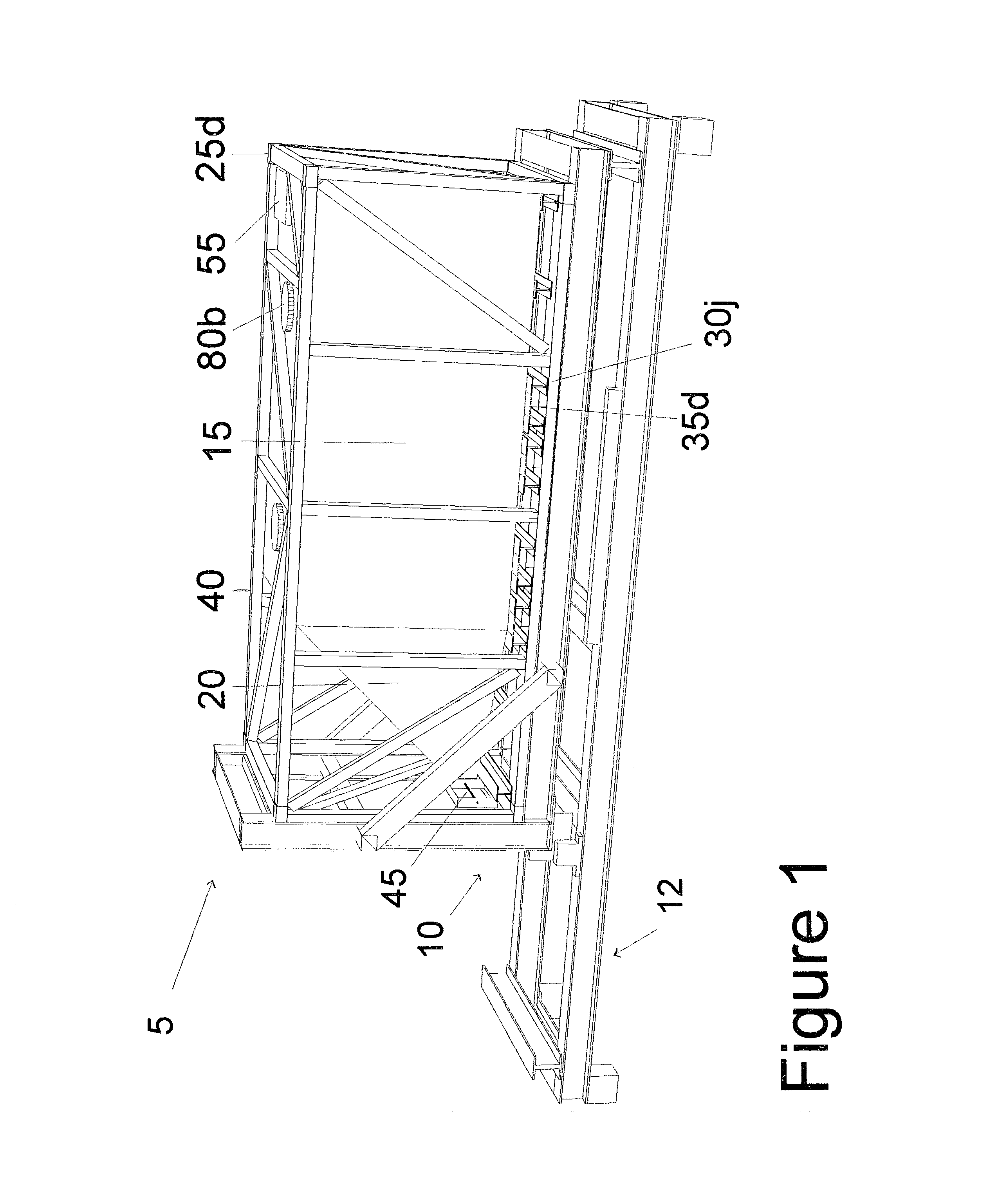

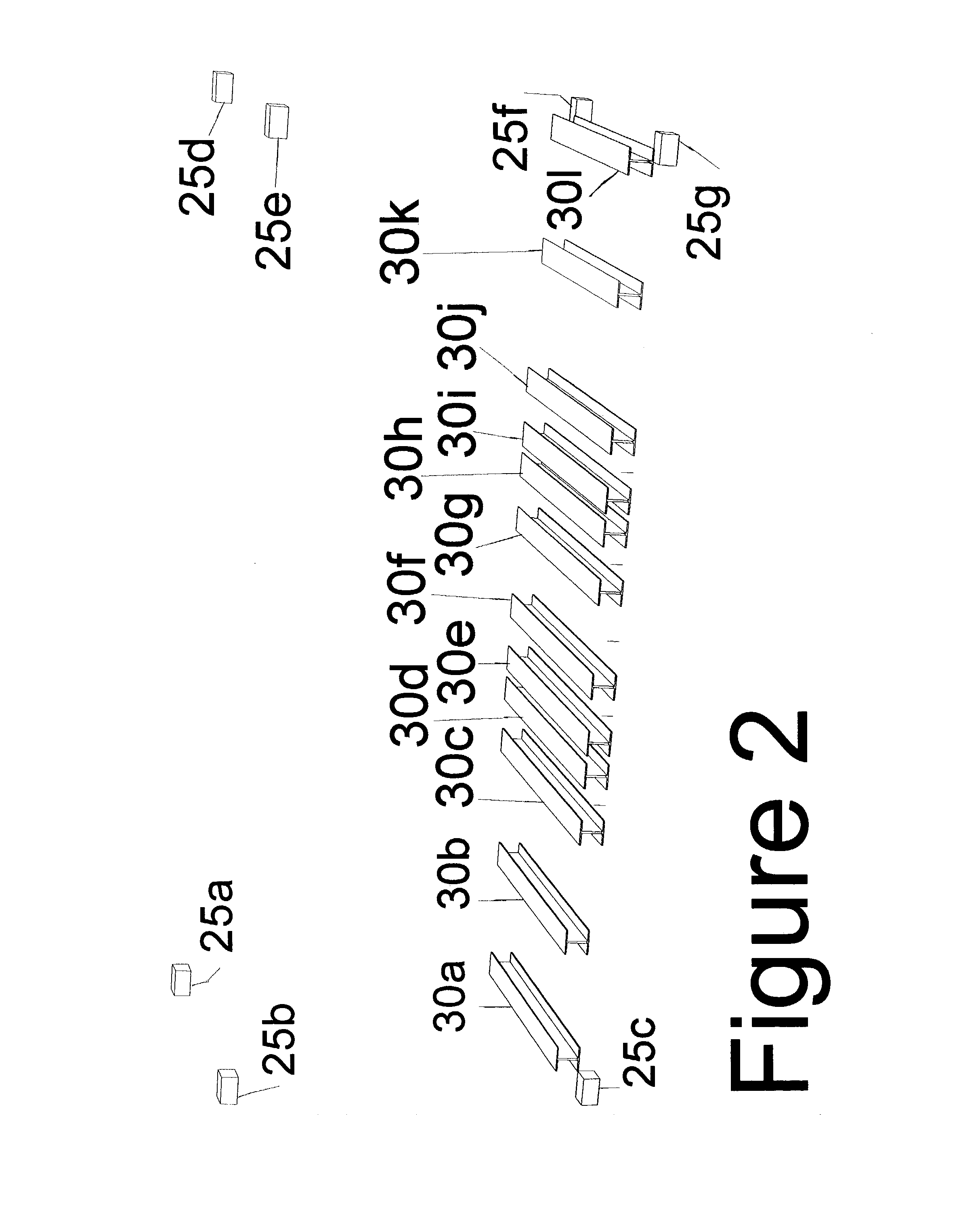

Cargo container cradle

A modular cradle for reinforcing, transporting, and stacking cargo containers used in the transportation and storage of bulk cargo in the oil and gas industry so as to allow compliance with construction and shipping standards adopted by the oil and gas industry is disclosed. The cargo cradle is comprised of a rectangular frame for holding and supporting a cargo container. The cradle has attached lifting lugs positioned within the interior of the cargo cradle for attachment of lifting cables. The lifting lugs are positioned so as to allow cradles to be stacked one upon the other. The container cradles interlock when stacked.

Owner:R3G

Intermodal bulk dry particulate cargo container and method

A method for loading and unloading of dry bulk freight containers vertically, and a device in the form of an improved intermodal dry bulk freight container for vertical loading and unloading. Standardized corner locks may be used and dimensions may be selected so as to provide a standardized cargo container.The present invention teaches that an intermodal dry bulk freight container may be loaded in either the customary horizontal orientation of such devices, or in a vertical orientation in which one end is opened and elevated. In particular, however, such a container may advantageously be emptied by elevating it into the vertical orientation. The method of the invention is thus to provide only a single hopper and yet allow one hopper to empty the entire container, as well as providing a more efficient gravity feed of bulk cargo as it is off loaded.The present invention furthermore teaches an intermodal dry bulk freight container suitable for this method of operation. In the presently preferred embodiment, the container is loaded conventionally via hatches on the top of the container when it is in a horizontal orientation, but is unloaded via a single hopper located at the lower end when the container is raised into the vertical orientation.

Owner:LE ROY CURTIS W

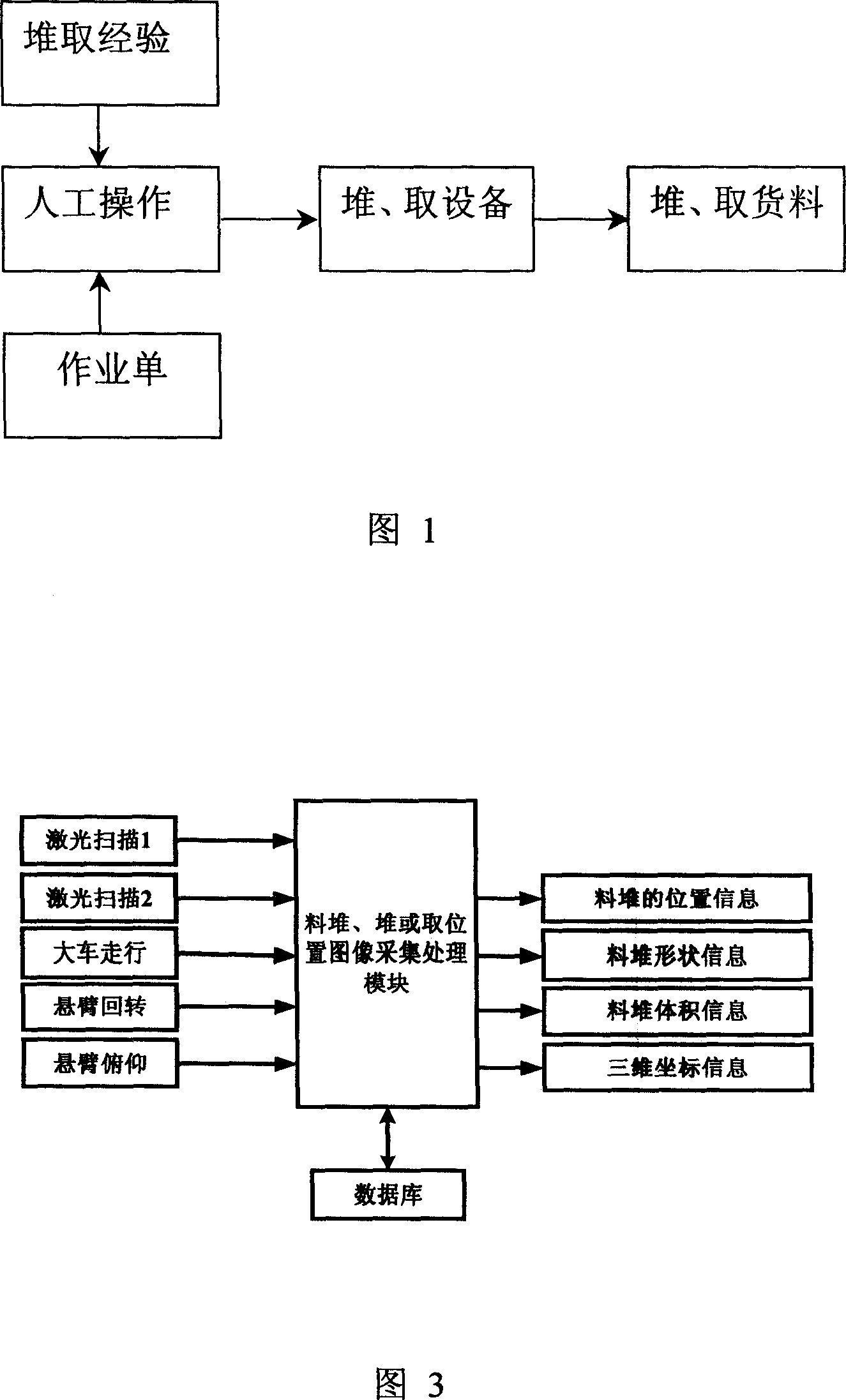

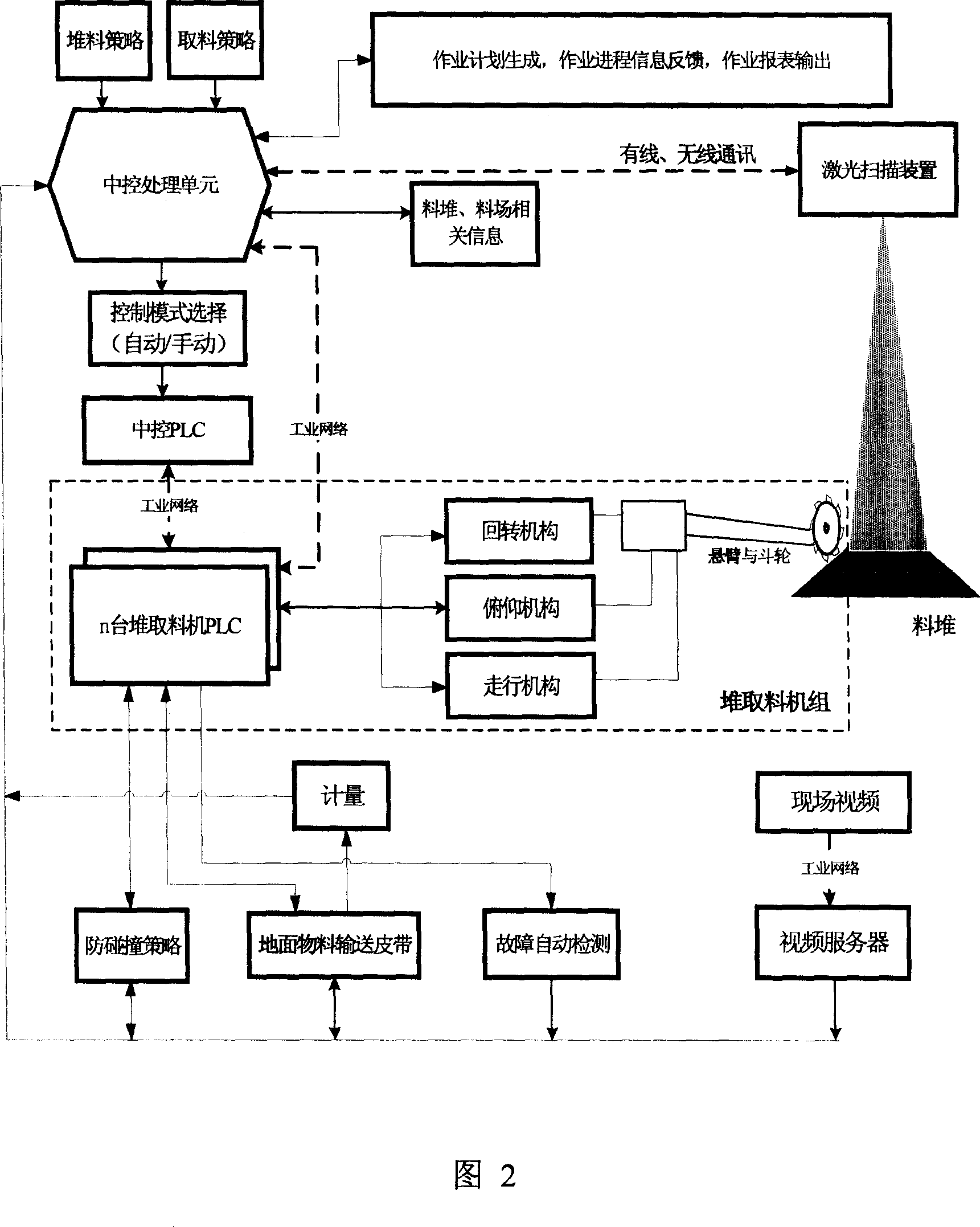

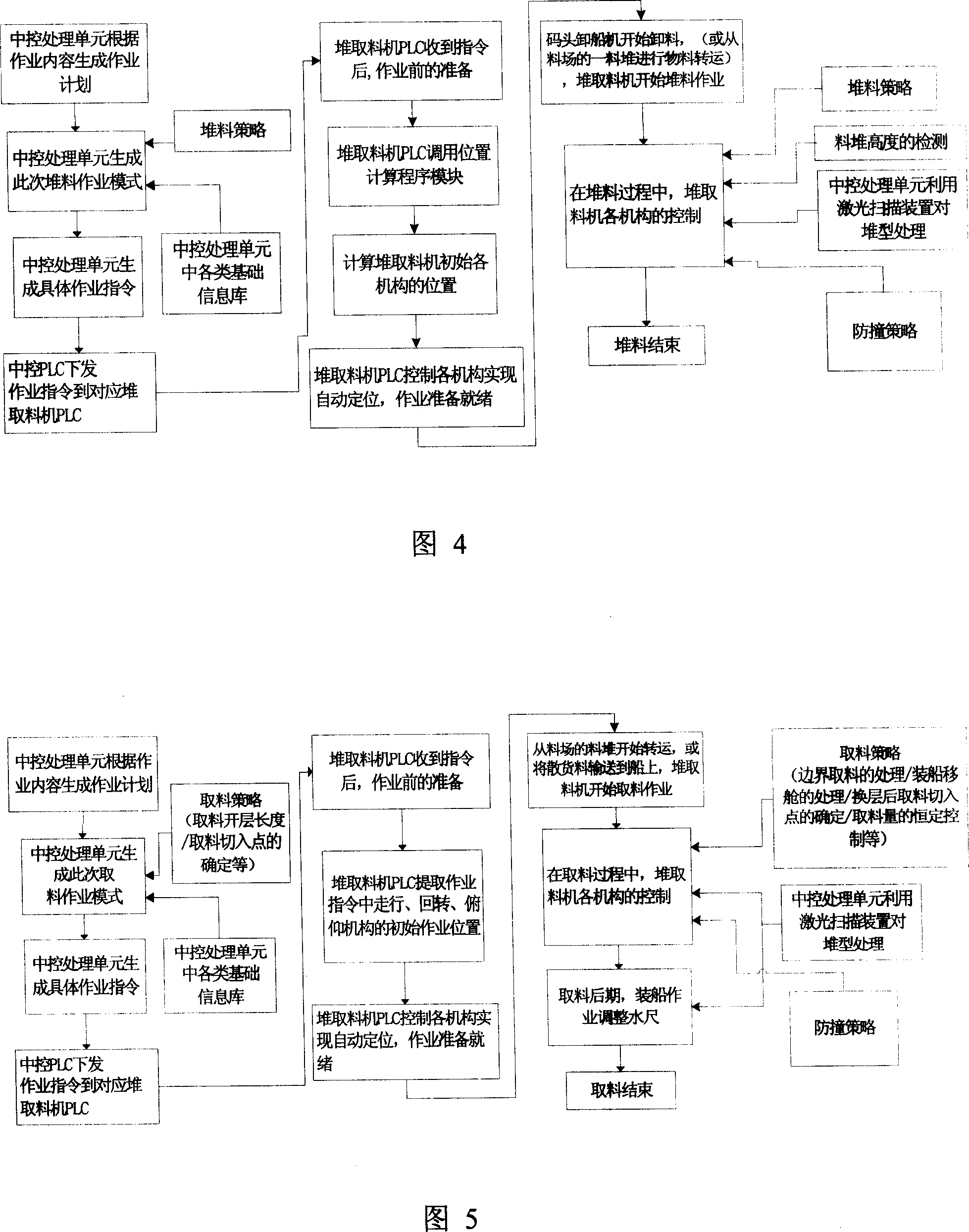

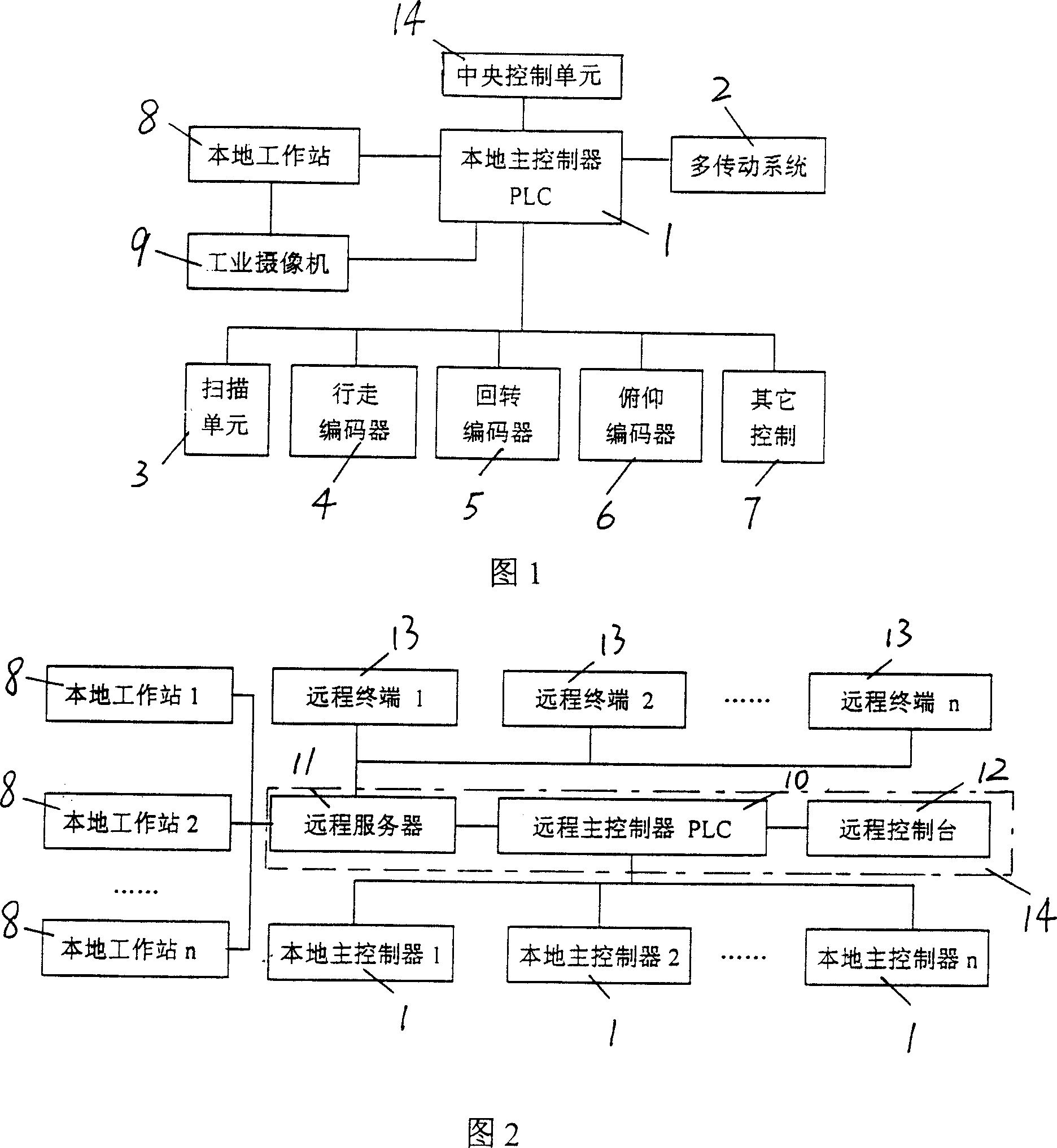

Unmanned piling and taking technique for bulk cargo stock yard

ActiveCN101104480AOvercoming automationOvercome labor intensityElectric programme controlLoading/unloadingBulk cargoLaser scanning

The invention relates to a port warehousing logistics technology, in particular to a bulk material yard unmanned stacking / reclaiming technology. Firstly, a database is established; secondly, operation instructions, automatic stacking / reclaiming operation modes and control instructions for automatic stacking / reclaiming operations are generated through input operation kinds of goods and the planning work amount; thirdly, the relevant instructions are sent to a central control PLC and then transmitted to the corresponding local stacker / reclaimer PLC through the industrial network; fourthly, the local PLC controls the operation of all components of the stacker / reclaimer to complete the local operation control. At the same time, a material stack laser scanning device is used to scan the material yard condition, and the scanned result will then be transferred to a central control processing unit through the industrial network; fifthly, the central control processing unit achieves the stack type scan data processing of the stacker / reclaimer to generate new instructions which will then be sent to the corresponding local stacker / reclaimer PLC; sixthly, a handle operating panel arranged inside a central control room can be taken as a backup means of manual operation under special circumstances. The invention can be applied to large-scale raw material yards, such as ports, wharfs, open warehouses, mine stacking yards, as well as iron and steel enterprises.

Owner:BAOSHAN IRON & STEEL CO LTD +1

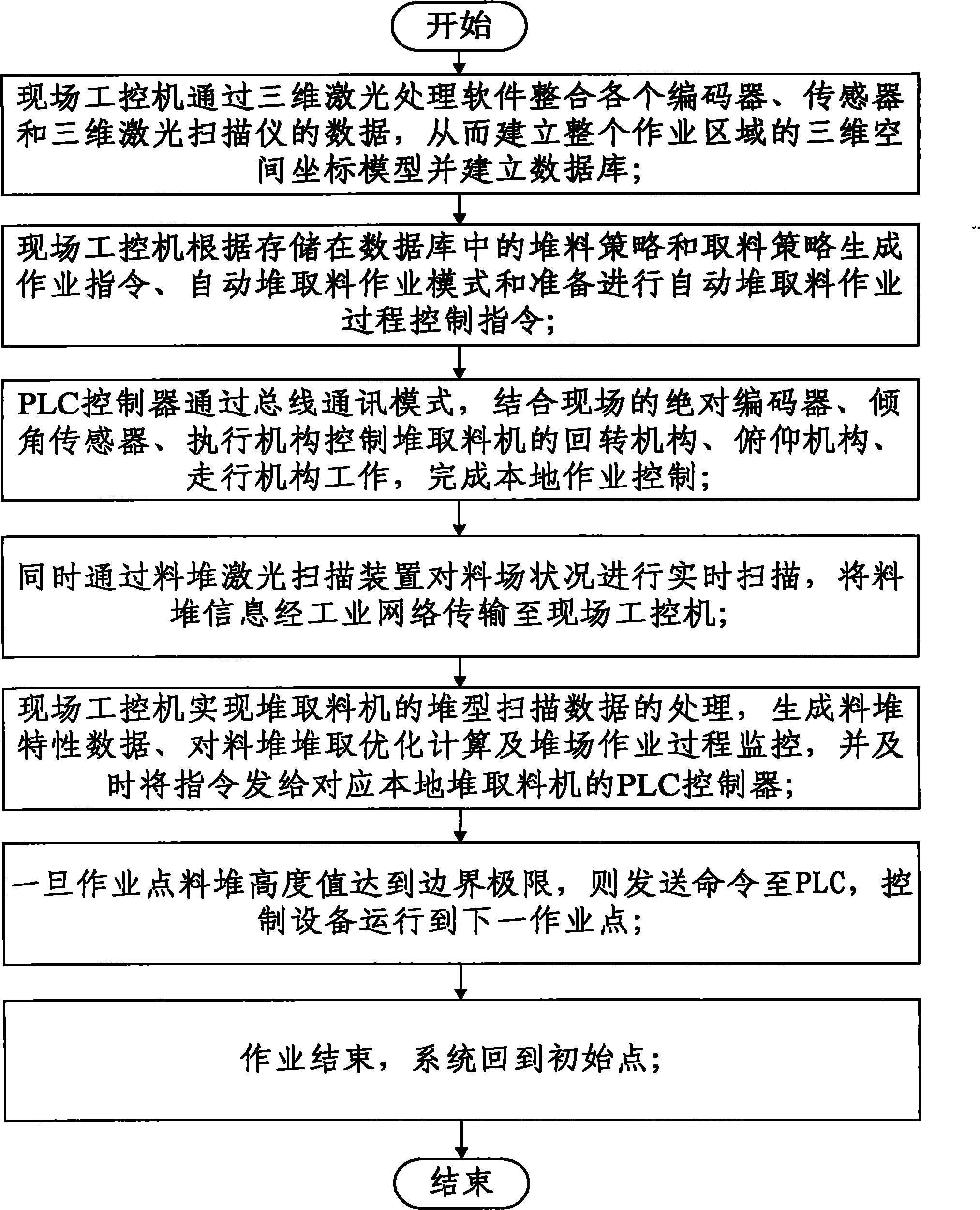

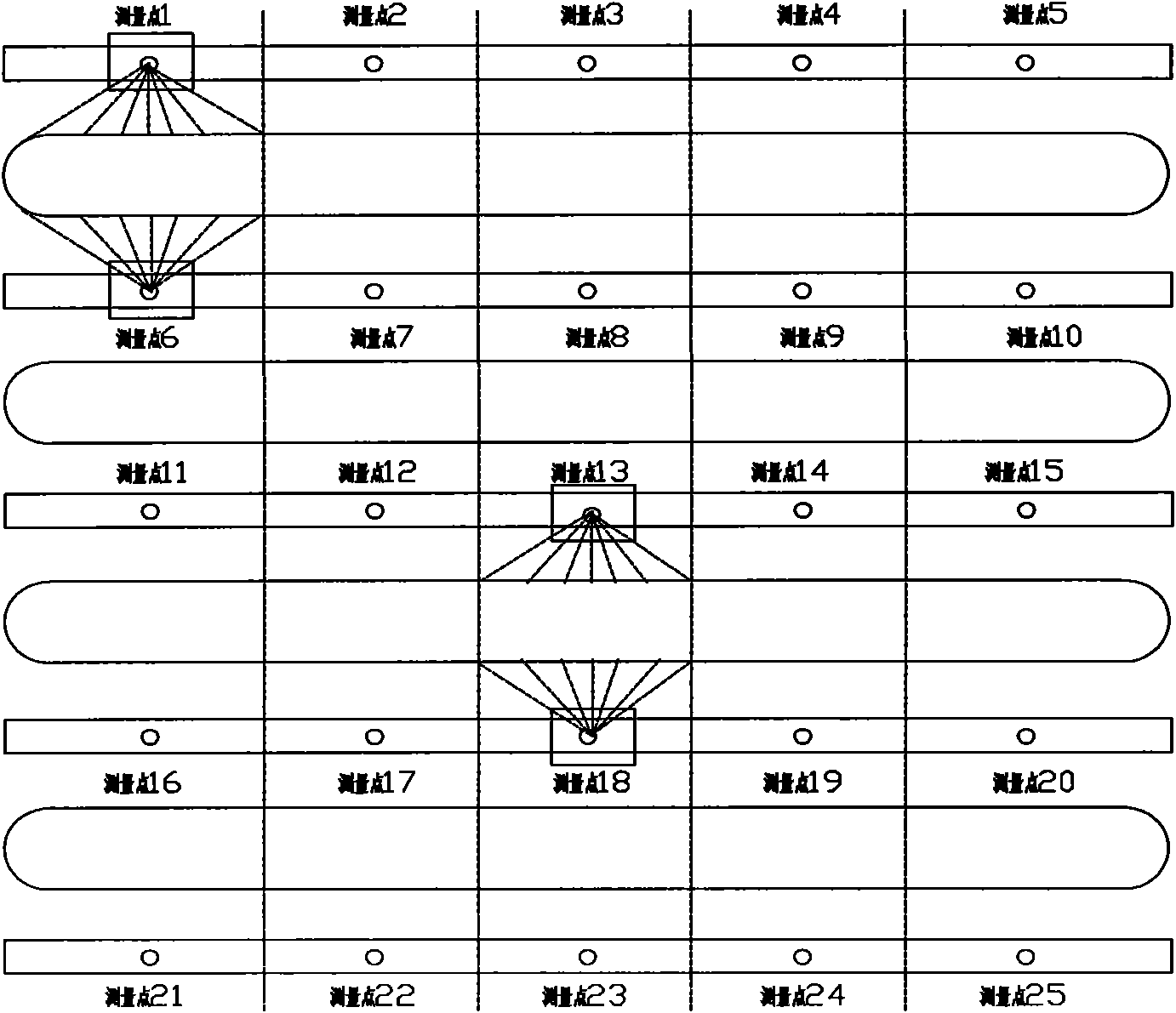

Full-automatic bulk cargo storage yard stacking and taking method

InactiveCN102336340AOvercoming automationOvercome labor intensityLoading/unloadingBulk cargoProgrammable logic controller

The invention relates to a full-automatic bulk cargo storage yard stacking and taking method applied to large port wharfs, truck stations and open storages. According to the method, when a stacking and taking machine works, an operating driver for operating and monitoring is not needed in a cab of the stacking and taking machine and a person for control and operation of the whole process is also not needed in a field industrial personal computer on the basis of fully ensuring the utilization rate of a stock yard and exerting the stacking and taking capacity and other functions of the stacking and taking machine. After the field industrial personal computer acquires an operation task from a management system, optimal calculation and security inspection are performed according to the condition of the stock yard and the state of the stacking and taking machine, and related stacking or taking mode information is automatically generated; and then the system automatically sends related control instructions to a programmable logic controller (PLC) corresponding to the local stacking and taking machine, and the stacking and taking machine performs unmanned automatic stacking and taking operation of the whole process. Therefore, the method overcomes the defects of low automation degree of the conventional bulk cargo storage yard, high labor intensity of operators, low working efficiency and low field utilization rate.

Owner:上海派恩科技有限公司

Automatic stacking/reclaiming system for bulk cargo storage yard

InactiveCN104724506ASimplify hardware configurationEasy to installLoading/unloadingBulk cargoControl signal

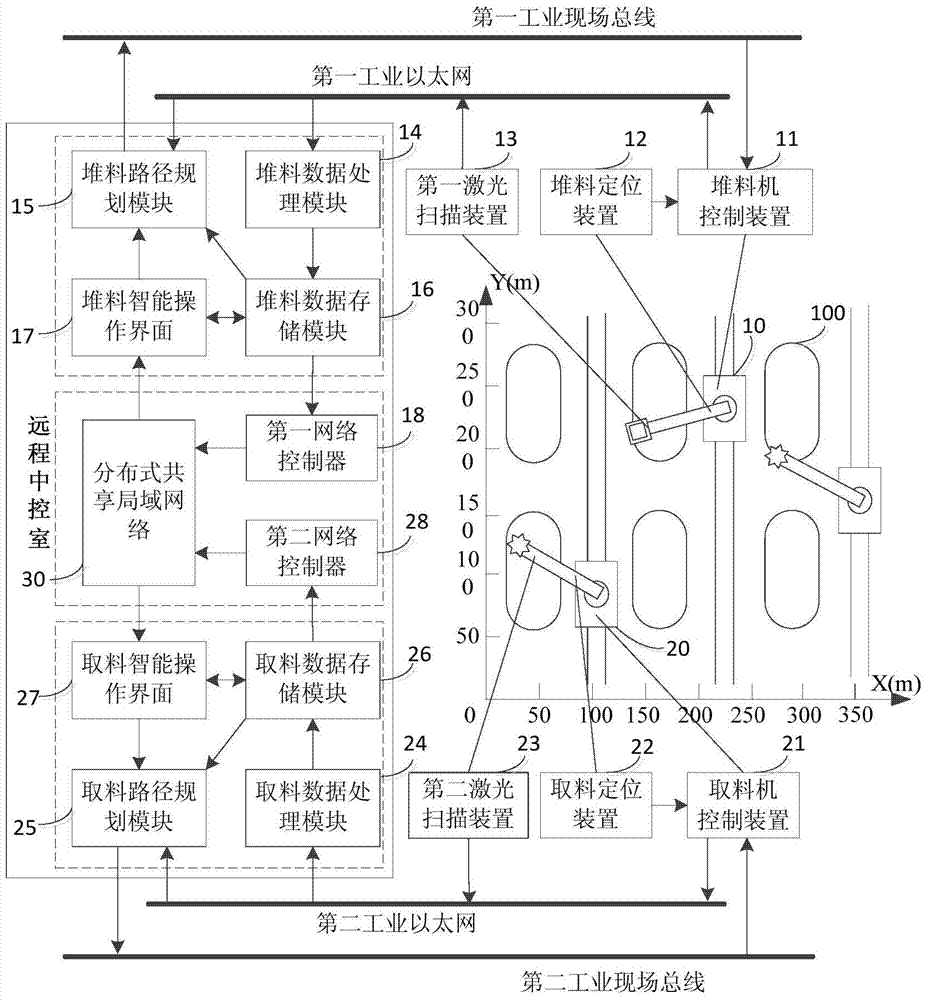

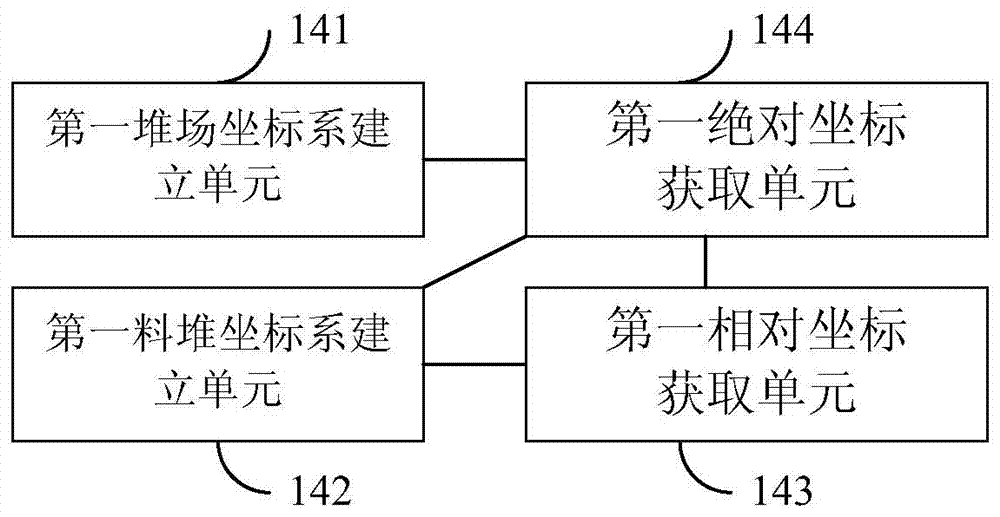

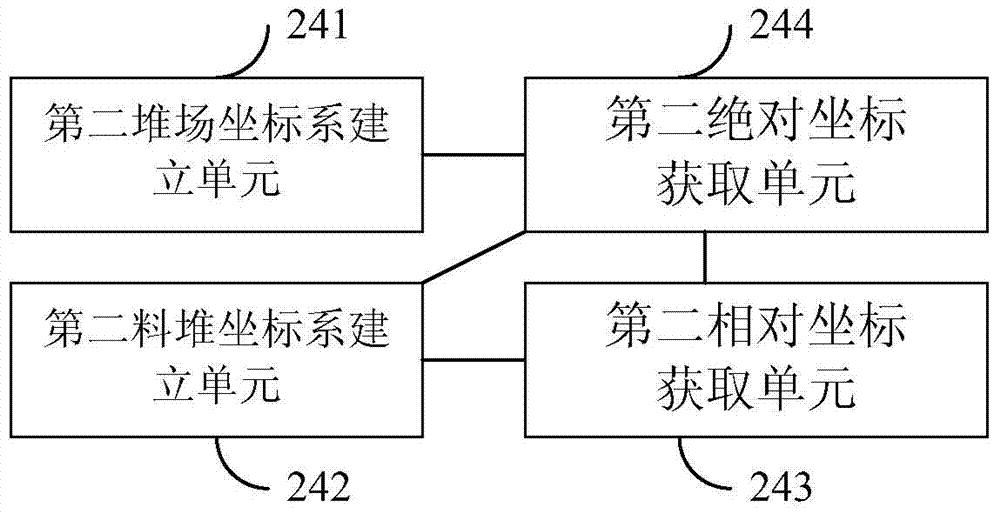

The invention provides an automatic stacking / reclaiming system for a bulk cargo storage yard. The automatic stacking / reclaiming system comprises a stacker distributed in the storage yard and provided with a stacking cantilever, a reclaimer distributed in the storage yard and provided with a reclaiming cantilever, a first laser scanning device installed on the stacking cantilever and used for acquiring scanning data of the storage yard, a second laser scanning device installed on the reclaiming cantilever and used for acquiring the scanning data of the storage yard, a stacking positioning device and a reclaiming positioning device for acquiring GNSS positioning information, a stacker control device, a reclaimer control device, a remote stacking processing device and a remote reclaiming processing device. The stacker control device and the reclaimer control device acquire and output the GNSS positioning information, receive a stacking control signal and a reclaiming control signal, and control the stacker and the reclaimer to execute corresponding stacking / reclaiming actions according to the control signals. The remote stacking processing device and the remote reclaiming processing device receive a stacking instruction and a reclaiming instruction input by a peripheral user, acquire coordinate information of the corresponding storage yard according to the instructions, the scanning data and the GNSS positioning information, and generate stacking / reclaiming path information to serve as the stacking / reclaiming control signals to be output to the stacker control device and the reclaimer control device. The automatic stacking / reclaiming system is based on GNSS positioning, and is high in accuracy and low in cost, data can be shared, and automatic operation of the bulk cargo storage yard is achieved.

Owner:CCCC THIRD HARBOR CONSULTANTS

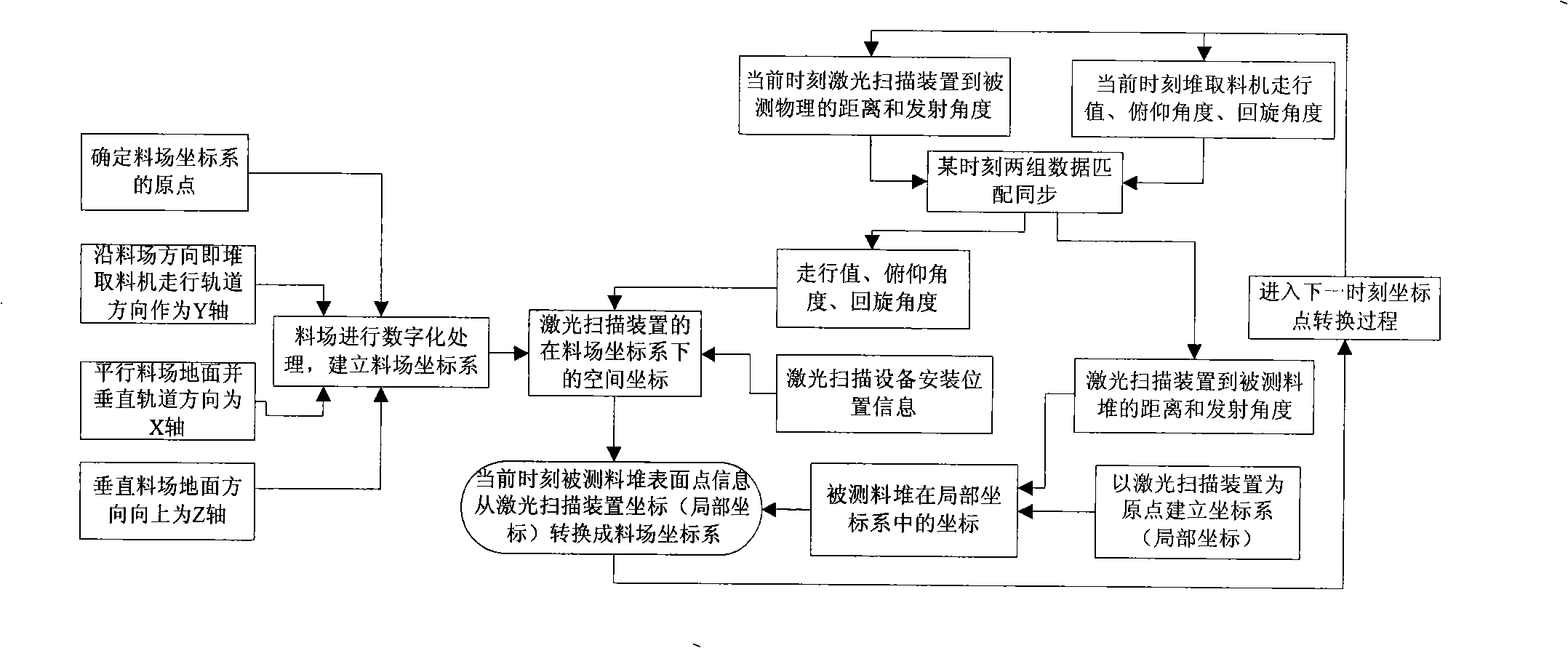

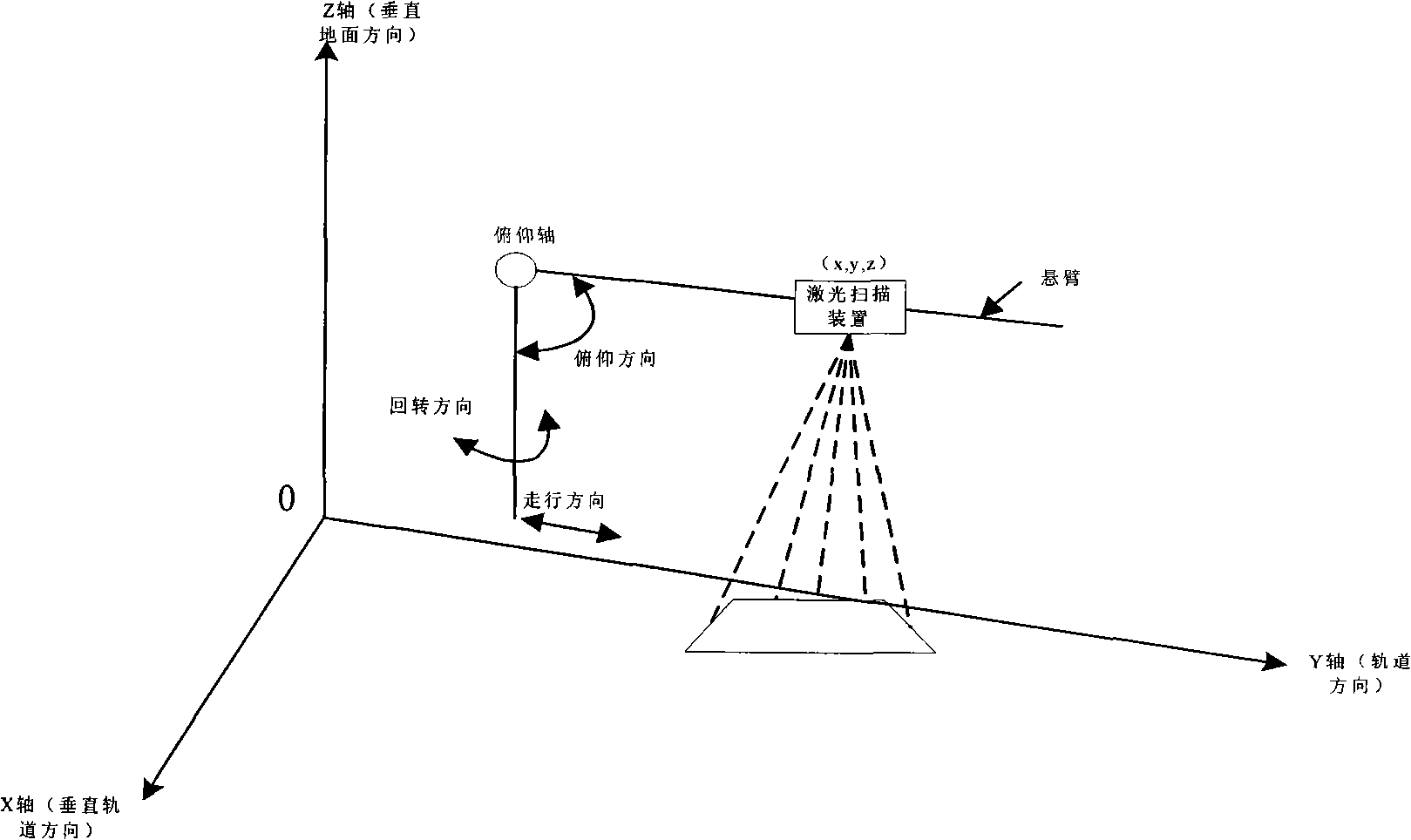

Three-dimensional imaging method for implementing material pile real time dynamic tracking

ActiveCN101334897ADynamically grasp the stacking situationStable support2D-image generationUsing optical meansBulk cargoLaser scanning

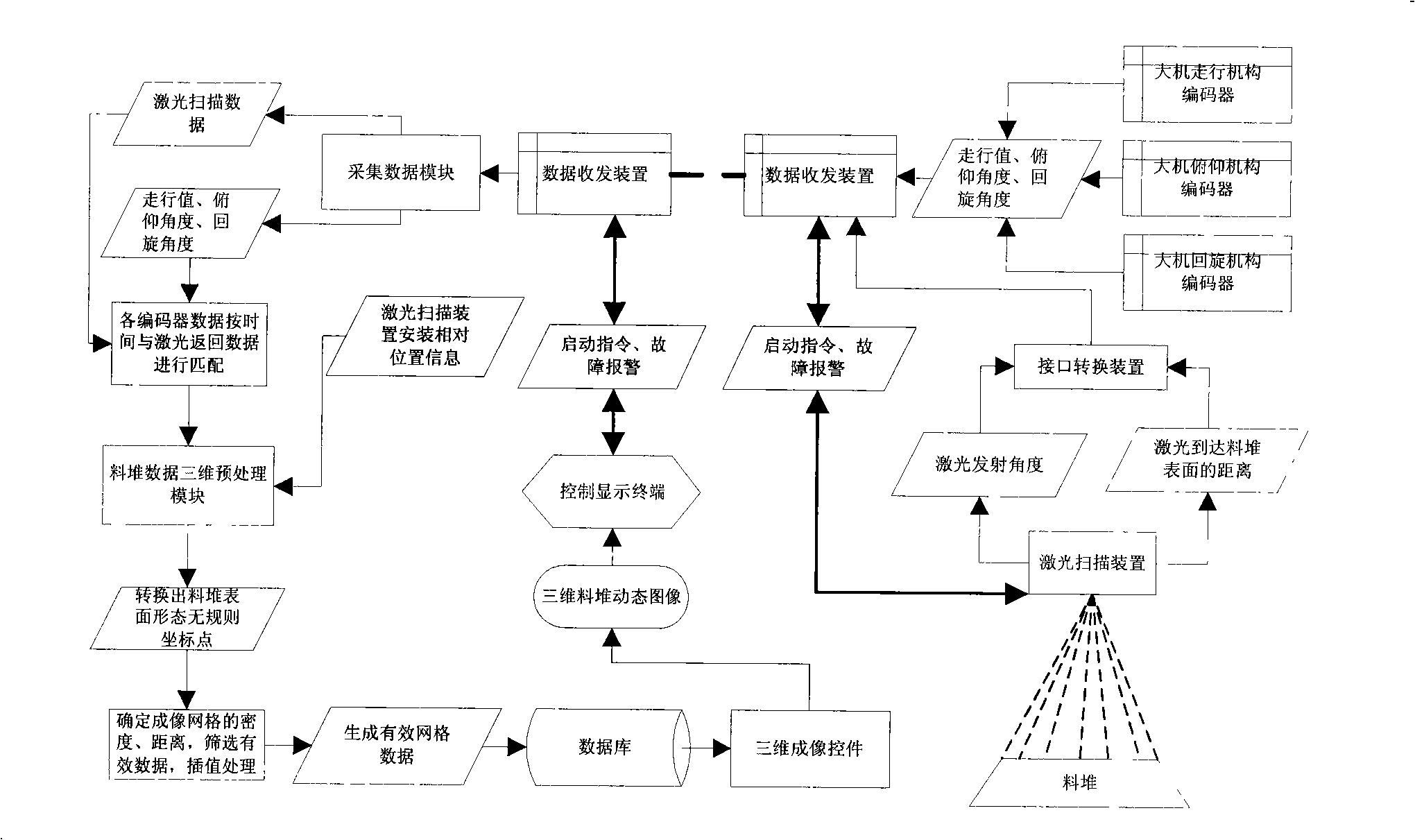

The invention relates to a stock pile identification method of a bulk-cargo stock ground. A three-dimensional imaging method for realizing the real-time dynamic tracing of a stock pile is disclosed, which drives a laser scanning device arranged at the front end of a cantilever of a material piling and taking machine to carry out a dynastic scanning to the stock pile by utilizing the running, pitching and circumnutation of the material piling and taking machine; a pretreatment, a coordinate transformation, a grid standardization processing and an interpolation are carried out to the obtained laser scanning data so as to generate regular three-dimensional data and to finally generate a complete grid data base of the whole stock ground; a three-dimensional imaging control component reads the coordinate information of the grid of the stock ground; the stock ground is taken as a display area of the image and the ground surface of the stock ground as a display base plane, thus realizing a coordinate restoration in the area and finishing the display of the three-dimensional images of the stock pile; and the content of the data in the data base is updated in a real-time manner: meanwhile, the change of the data content in the data base triggers the three-dimensional imaging control component to read the data from the data base, thus realizing the real-time dynamic updating of the three-dimensional stock-pile image displayed by a terminal.

Owner:BAOSHAN IRON & STEEL CO LTD +1

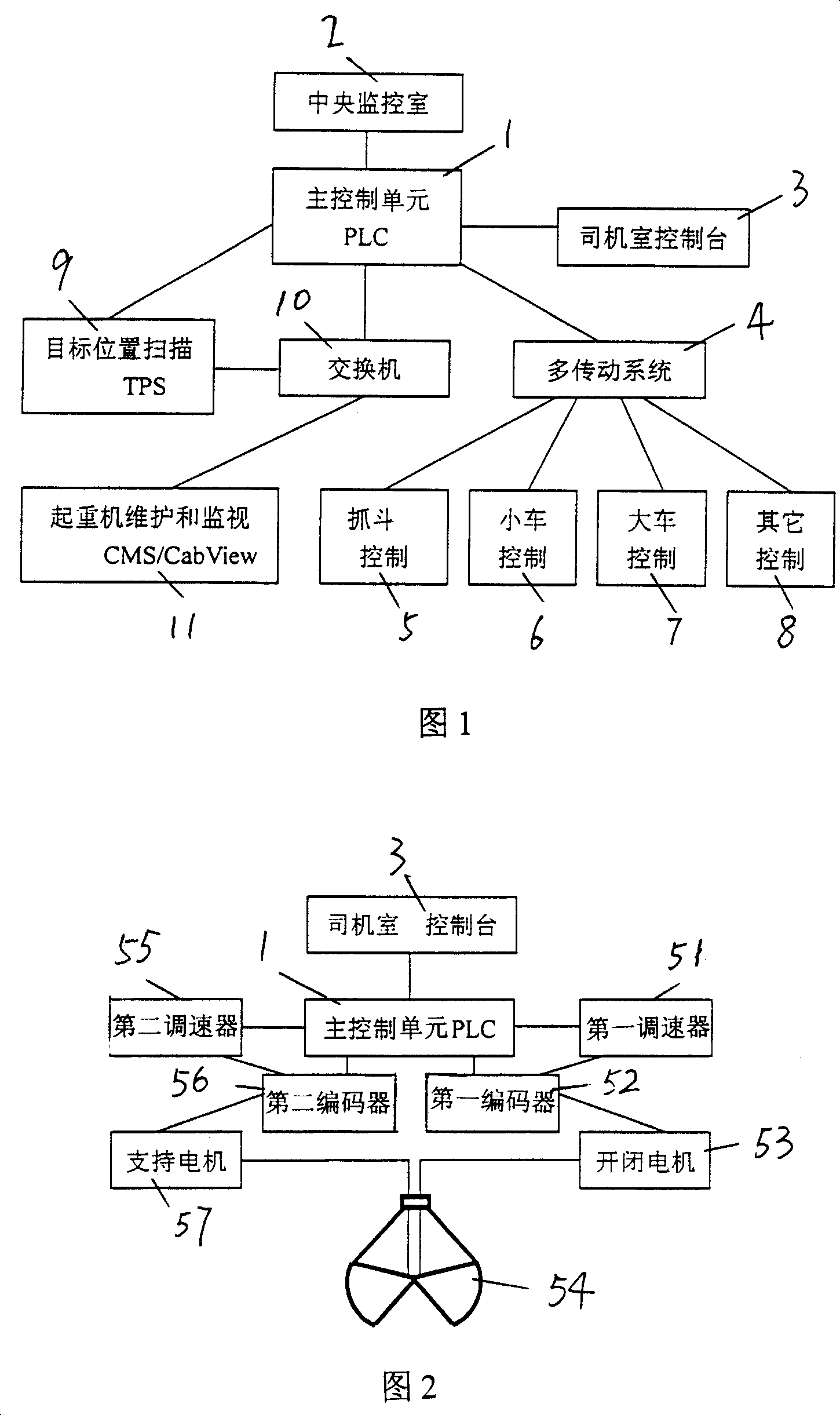

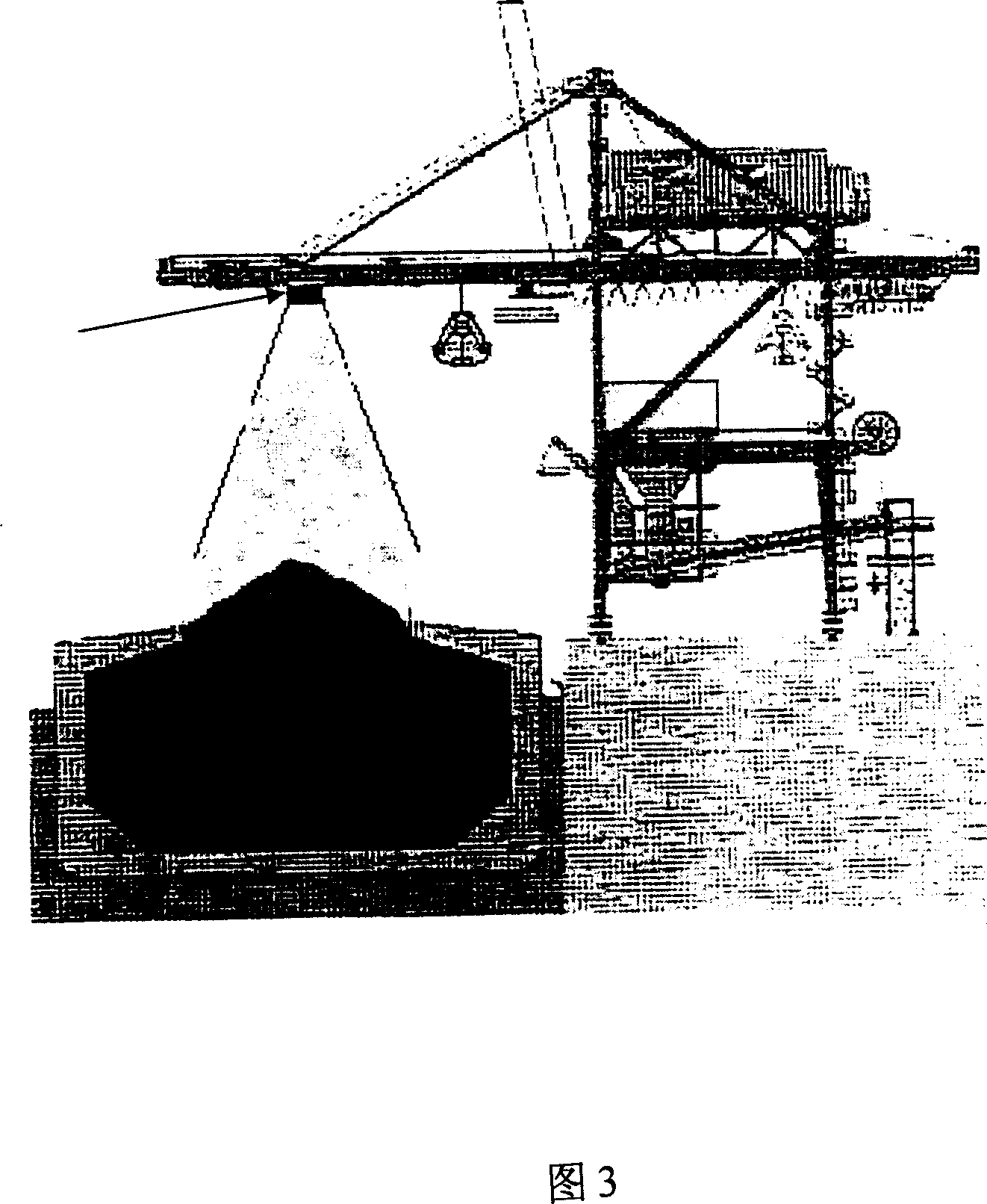

Bulk cargo automatic ship-unloading system and method thereof

InactiveCN101112961ARealize continuous automatic unloading functionFully automatedLoading/unloadingLoad-engaging elementsBulk cargoEmbedded system

The invention discloses a bulk automation boat discharging system, which is characterized in that a main control unit is connected with an object position scanning unit; the main control unit is connected with an exchanger; the object position scanning unit is connected with the exchanger which is connected with a crane maintenance and monitoring unit. In the invention, the object position scanning unit automatically scans the boat cabin and implements the automatic detection of the boat cabin position and the distribution of the material; the main control unit automatically produces the optimized boat discharging path according to the detection result and controls and executes the drive control of all mechanism motors of the boat discharging machine by a plurality of transmission units. A cab controlling platform and a central monitoring chamber are connected with the main control unit, can interrupt the automatic boat discharging process according to the actual situations, and interfaces and adjusts the devices. The invention has the advantages of implementing the continuous automatic boat discharging function of the whole cabin, improving the operation efficiency, ensuring the safety performance, and reaching the purpose of implementing full automation of the buck dock.

Owner:包起帆

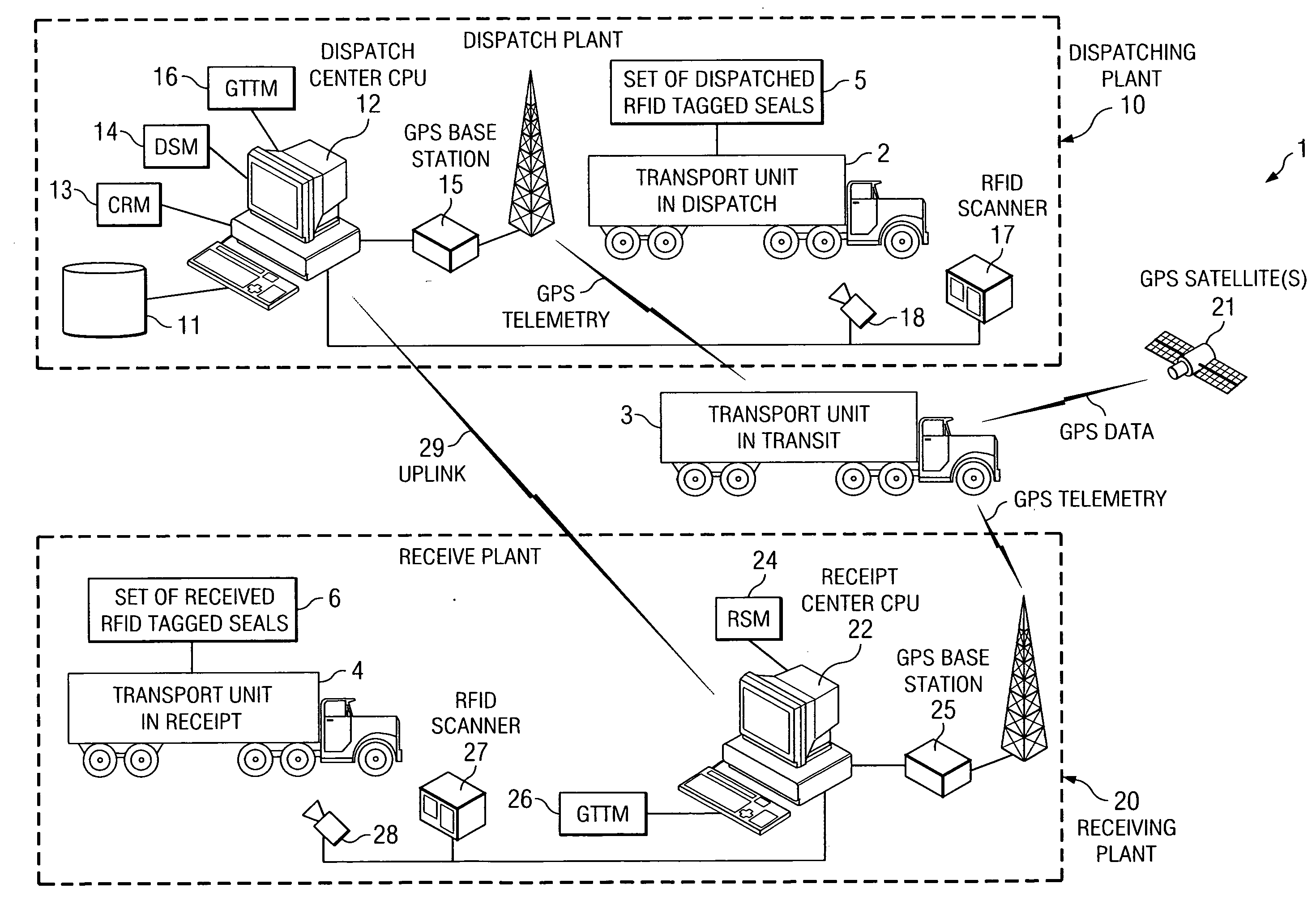

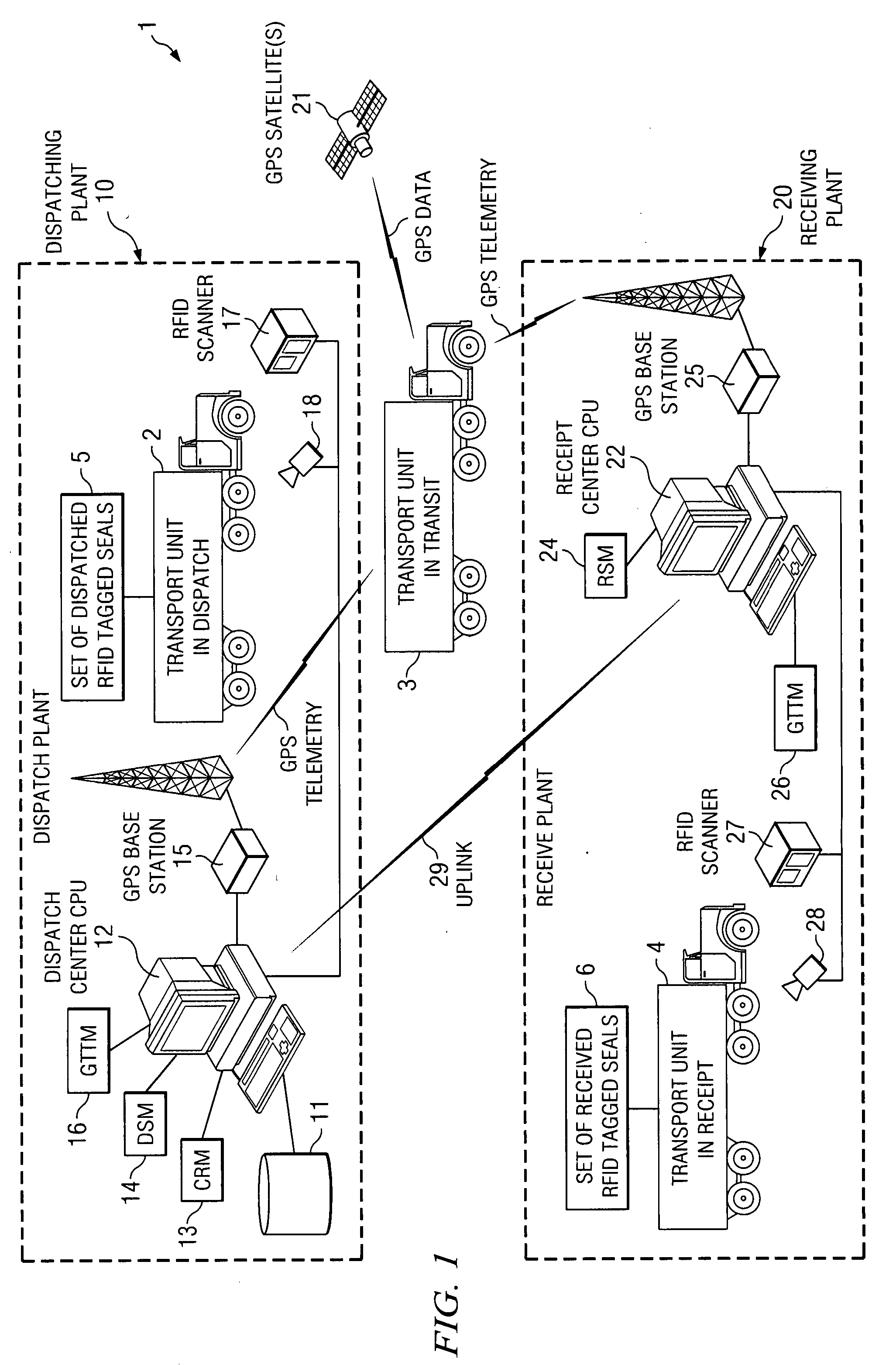

System and method for transport security control and tracking

ActiveUS20080042842A1Reduced cargo inspection timeReduce laborLogisticsBurglar alarm by hand-portable articles removalBulk cargoEngineering

The invention disclosed provides an apparatus and method to monitor and track the security of bulk cargo from a dispatch point to a receipt point. The apparatus includes a plurality of RFID antennas at a dispatch location and at a receipt location, networked software modules in communication with the RFID antennas, and disposable RFID tags used as security seals affixed to a carrier at multiple locations. The software modules include a Cargo Registration Module, a Dispatch Scanning Module, and a Receipt Scanning Module. The apparatus and method reduce cargo inspection time and labor at the points of departure and receipt. The automation of the dispatch and receipt process eliminates the human element thereby increasing the efficiency of the process. An additional embodiment includes a “single-use” disposable RFID tagged seal adapted to be attached to a transport portal unable to be removed without damaging an RFID transmitter contained within.

Owner:SURELOCK SEALS

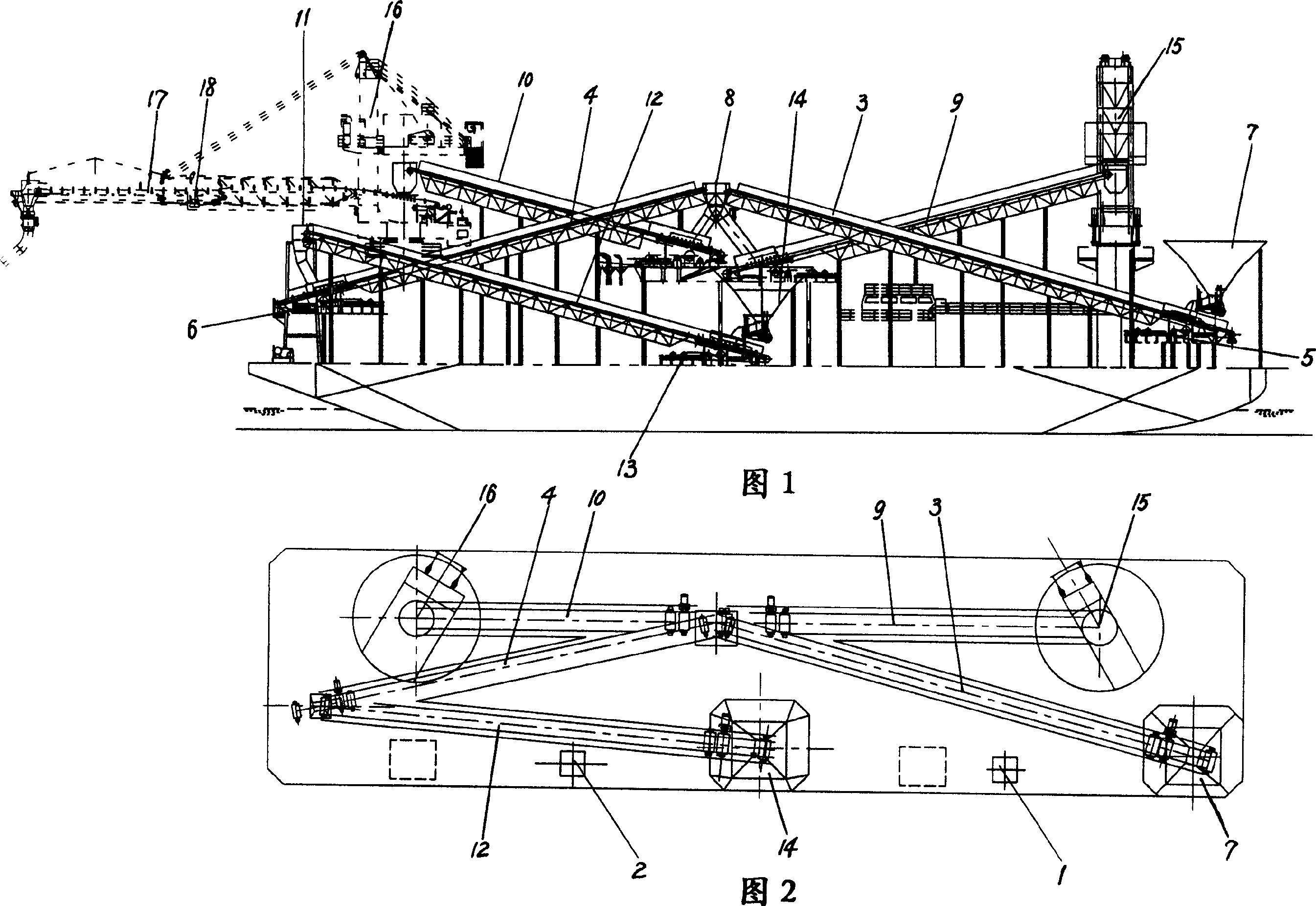

Marine bulk cargo transferring system ship

InactiveCN1884001AAdaptableLow failure rateCargo handling apparatusPassenger handling apparatusBulk cargoTransfer system

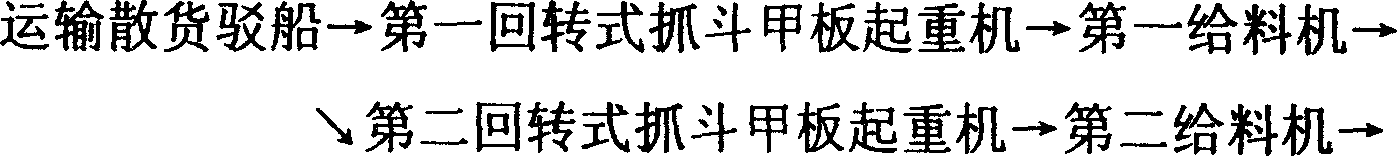

The invention relates to a maritime bulk cargo reshipment system ship, which consisted of ship hulls equipped with power and hoisting equipment. The ship hull is equipped with swinging bucket grab deck crane, belt conveyer system, retractable swinging ship-loader and power supply control system. The swinging bucket grab deck crane is immovably mounted on the hull main deck. The belt conveyer system includes five more belt conveyers, which are coupled through transfer funnels. The retractable swinging ship-loader is immovably mounted on the hull main deck, which is equipped with arm-holder belt conveyer and extending, rotating, and elevating mechanism of the arm-holder. Bulk cargo on transport barges are discharged into the funnel by said swinging bucket grab deck crane, and transported to the ship-loader by the belt conveyer system. By rotating and extending of the arm-holder, bulk cargo are loaded into the chamber of large-scale high-sea bulk ship by the ship-loader. Belt conveyer system is employed for bulk cargo conveyance, The conveyer has high adaptability, low failure rate, and high transfer capability can be achieved. Advantages are: small energy consumption, simple operation, and easy to use.

Owner:SHANGHAI GONGMAO CRANE EQUIP

Method for optimizing and screening storage locations of intelligent categorized storage system in electronic commerce

InactiveCN102663571AIncrease the function of hybrid storageNo need for manual arrangementLogisticsCommerceData streamBulk cargo

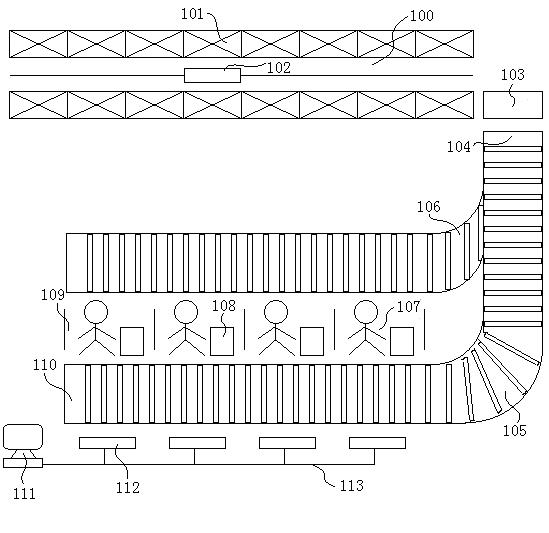

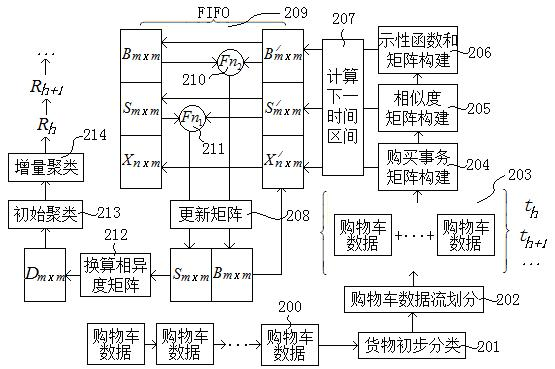

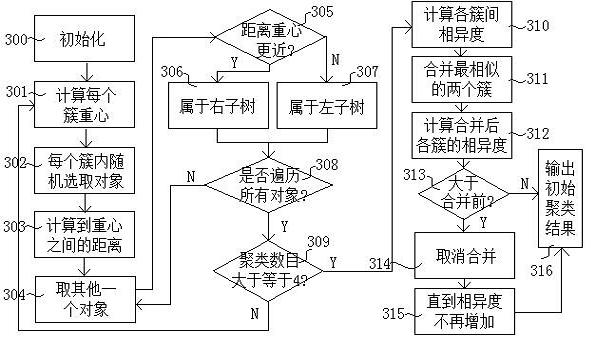

The invention discloses a method for optimizing and screening storage locations of an intelligent categorized storage system in electronic commerce. According to a dynamic sales condition of an electronic commerce company, the method applies three-dimensional storages in the same size to simultaneously store entire packages and bulk cargoes, and carries out optimization, screening, and dynamic adjustment of storage locations. The method carries out optimizing and screening of storage locations based on a data stream of a shopping cart, and applies a sliding window to dynamically record cargo similarities. And according to the similarities, the cargoes are clustered, and guided to be stored in category based on the result of clustering. In addition, the dynamic update of mixed storage is realized through a method of incremental clustering. The method adds a optimizing and screening device and an to intelligent categorized storage device to the existing full-automatic three-dimensional storage device, and enables a function of mixed storage of different sources and different categorized cargoes. The categorized storage optimizing obtained according to the shopping cart data fits the requirement of commercial acts, and the categorized storage optimizing is controlled in real time by a computer based on dynamic data in electronic commerce, so that manual arrangement is unnecessary for an operator.

Owner:ZHEJIANG GONGSHANG UNIVERSITY

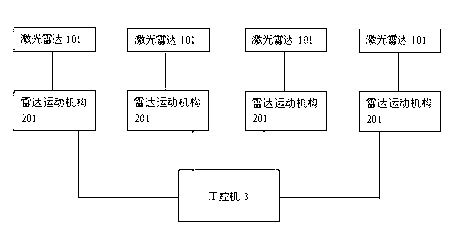

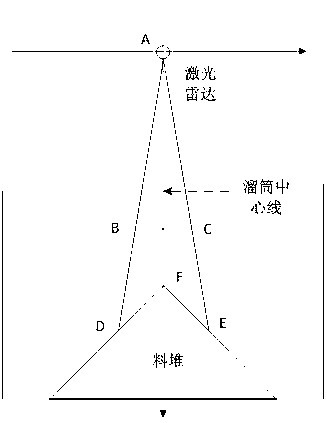

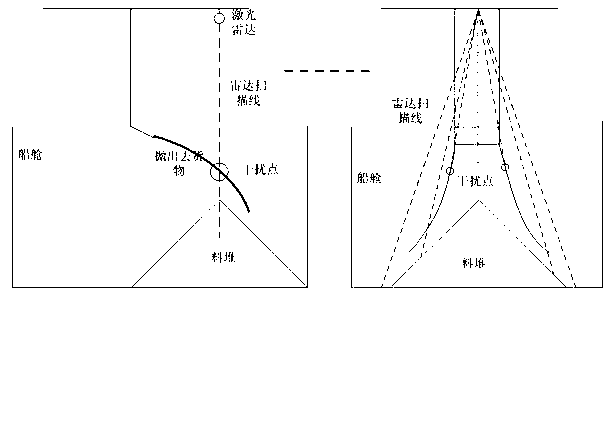

Device and method for detecting heights of material piles at material throwing positions of dock wall moving type ship loader

Provided are a device and method for detecting heights of material piles at material throwing positions of a dock wall moving type ship loader. A laser radar assembly is installed on a ship loader installing platform so as to be used for performing real-time scanning on the material throwing process and a material pile state of the current material throwing positions and then calculating the material pile heights. The device and method for detecting the heights of the material piles at the material throwing positions of the dock wall moving type ship loader are high in accuracy and good in stability, interference of various factors such as driver experience, moods and weather is removed, safety in the automatic blanking process is guaranteed well, and the ship loader can automatically finish bulk cargo shipping operation on the basis of safety in operation.

Owner:SHANGHAI MARITIME UNIVERSITY

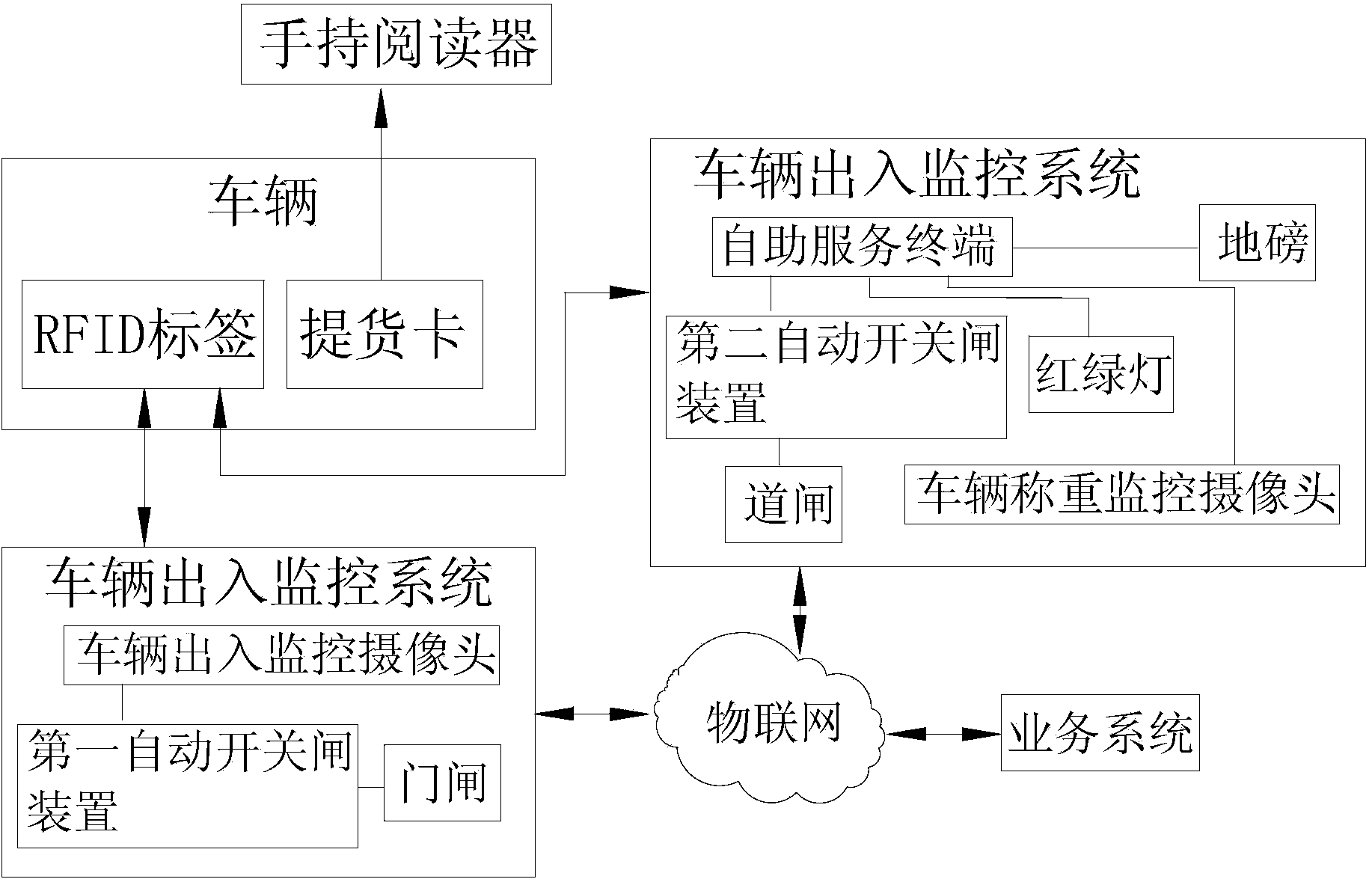

Port bulk cargo loading and unloading logistics management information system and logistics management method thereof

InactiveCN103971219AReduce working time in portReduce usageCo-operative working arrangementsLogisticsBulk cargoLogistics management

The invention discloses a port bulk cargo loading and unloading logistics management information system. The logistics management information system comprises an RFID label, a cargo picking-up card, a handheld reader, a vehicle in-out monitoring system, a wagon balance monitoring system and a service system, wherein storage yard position information of cargos picked up or unloaded by a vehicle is stored in the cargo picking-up card; the handheld reader is used for reading and manually verifying the RFID label and the information in the cargo picking-up card; the vehicle in-out monitoring system is connected into the Internet of Things and performs intercept or release operation on the vehicle; the wagon balance monitoring system is connected into the Internet of Things, weighs the weight of the cargos borne by the vehicle, writes the weight in the RFID label and writes operation document information into the RFID label; the service system is connected into the Internet of Things and used for remotely monitoring data or information obtained by the vehicle in-out monitoring system and the wagon balance monitoring system through the Internet of Things and sending out corresponding feedback instructions to the vehicle in-out monitoring system or the wagon balance monitoring system. The invention further discloses a logistics management method using the bulk cargo loading and unloading logistics management information system. The information of the bulk cargos on a general cargo wharf and the vehicle can be collected in real time, and fine automatic management is carried out.

Owner:GUANGZHOU PORT GRP

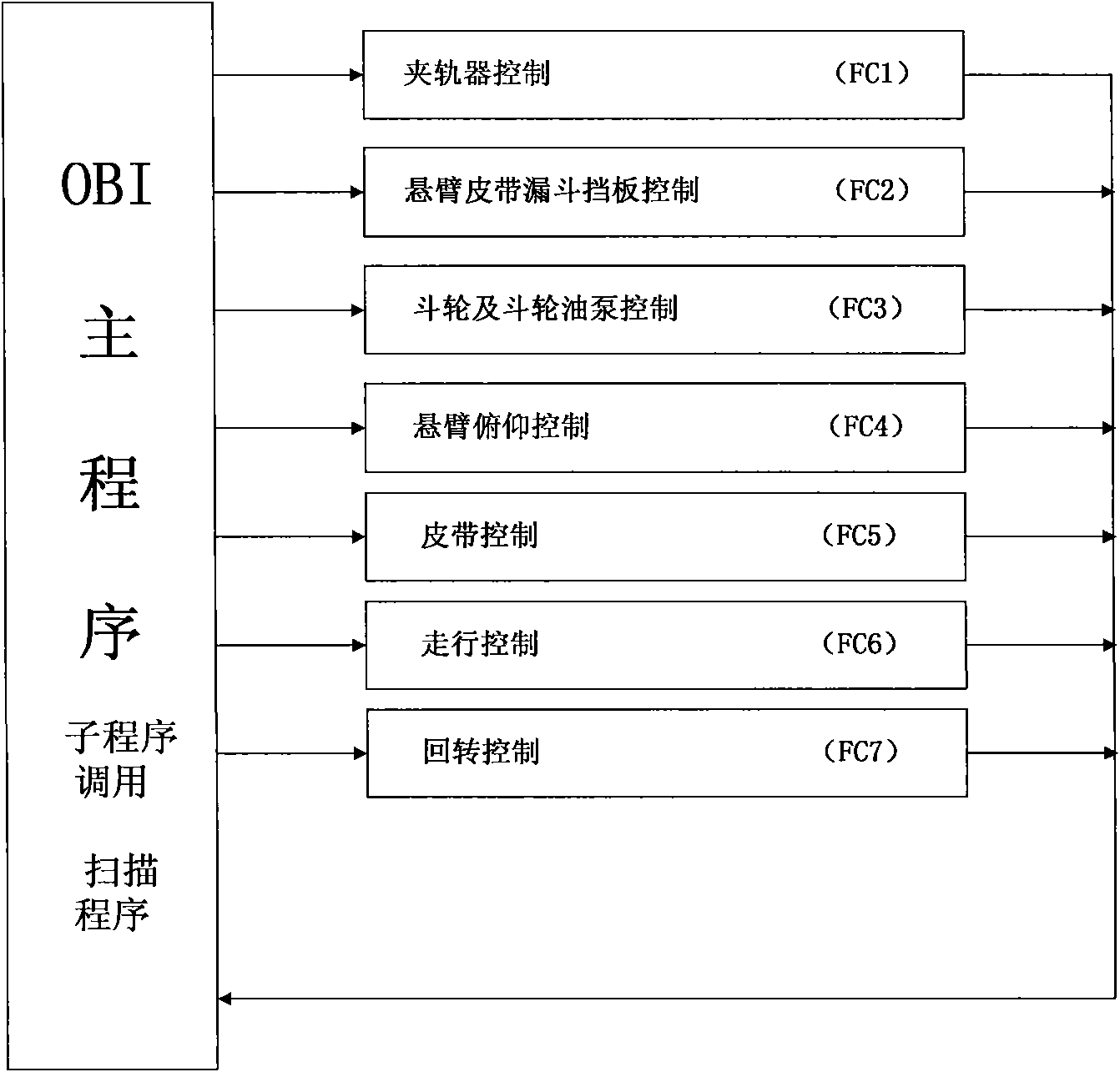

Bulk cargo automation field material stacking and fetching system and its material stacking and fetching method

InactiveCN101121469ARealize the function of fully automatic site stacking and reclaimingImprove work efficiencyLoading/unloadingTotal factory controlBulk cargoAgricultural engineering

The present invention discloses a material piling and taking system of an automatic field of the bulk cargo, connected with a material piling and taking machine. The characteristic is that the present invention comprises a local main controller and a plurality of transmission units connected with the local main controller. The local main controller is connected with a scan unit, a walk encoder, a rotary encoder, a pitching encoder, other control units and a central control unit. The central control unit comprises a remote main controller connected with a plurality of local controls. The remote main controller is connected with a remote server and a remote consol. The remote server is connected with a plurality of remote terminals and a plurality of local workstations. The advantage of the present invention is that the present invention can realize the material piling and taking function of the full automation field and improve the work efficiency in addition to ensuring the safety performance.

Owner:包起帆

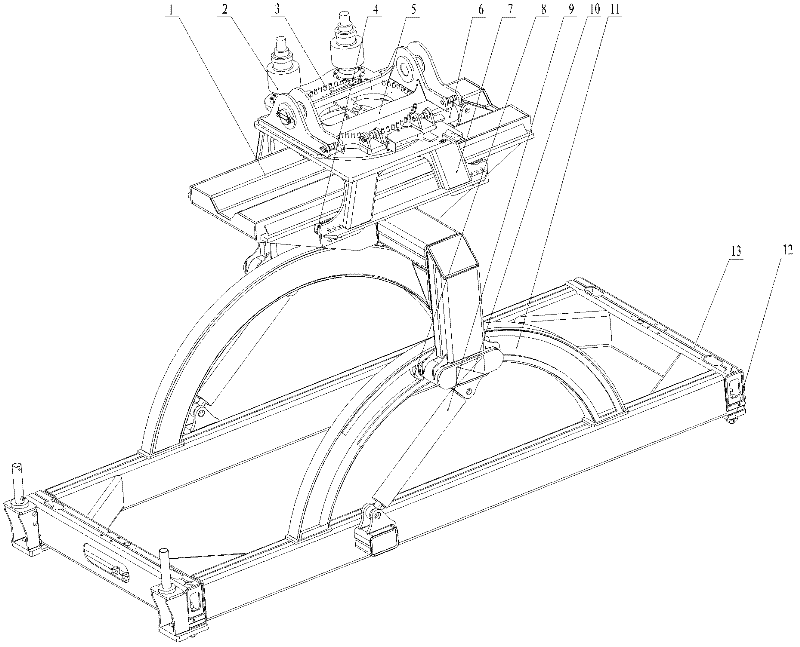

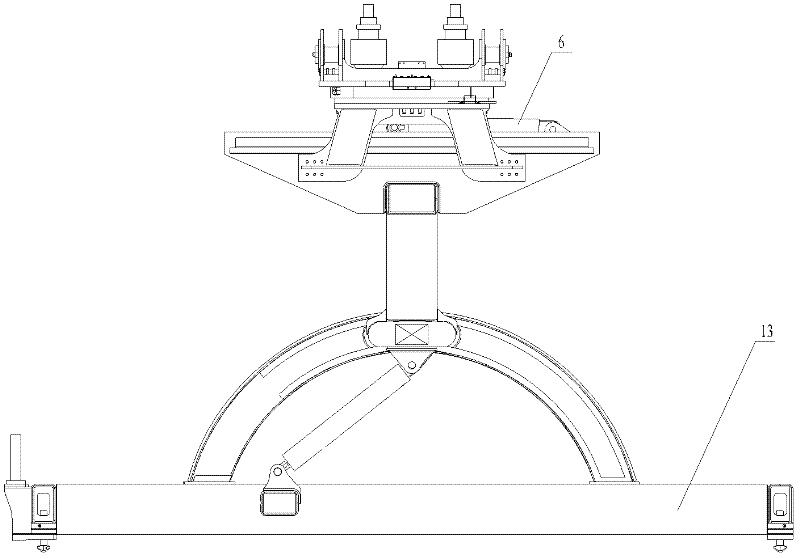

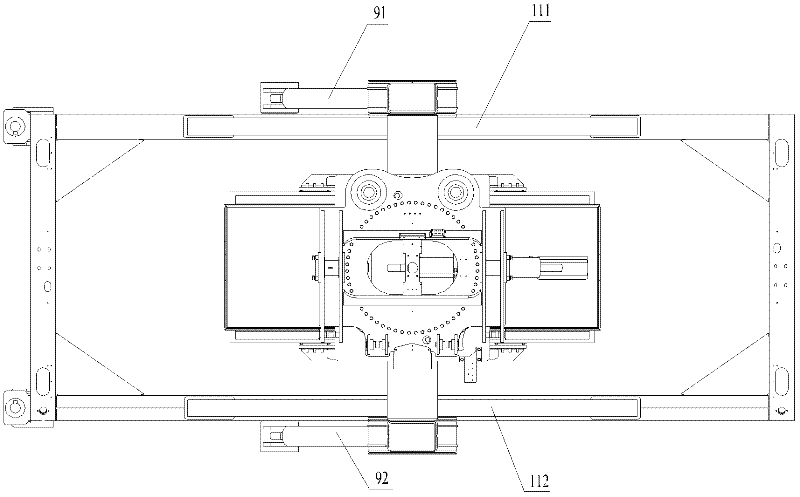

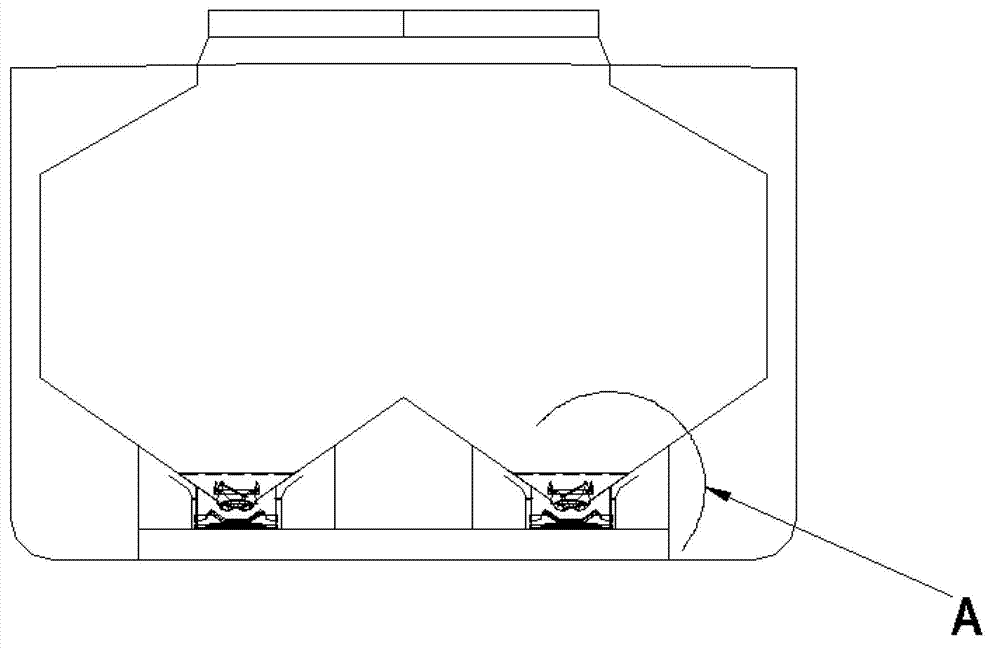

Container spreader and hoisting device

InactiveCN102229398AAutomatically adjust the center of gravityRestraint torsionLoad-engaging elementsBulk cargoEffective height

The invention relates to the technical field of containers, and discloses a container spreader which comprises an arc rail assembly, a hoisting connecting device and an elastic oil cylinder; the upper end of the hoisting connecting device is connected with a hoisting end of the hoisting device, and the lower end of the hoisting connecting device is connected with an arc rail through a rolling pair; and one end of an oblique oil cylinder is articulated with the hoisting connecting device, and the other end of the oblique oil cylinder is articulated with the arc rail assembly. A container rotates along the arc rail, the overall height of the container spreader can be reduced, and the effective height of the hositing of the container spreader can be improved greatly, thus the container spreader not only can realize bulk cargo stacking operation, but also can perform the container integral operation; meanwhile, since the container spreader has an automatic gravity center regulating function, the torsional stress of a connected host arm frame can be relieved greatly. The invention also discloses a hoisting device with the container spreader.

Owner:SANY GRP

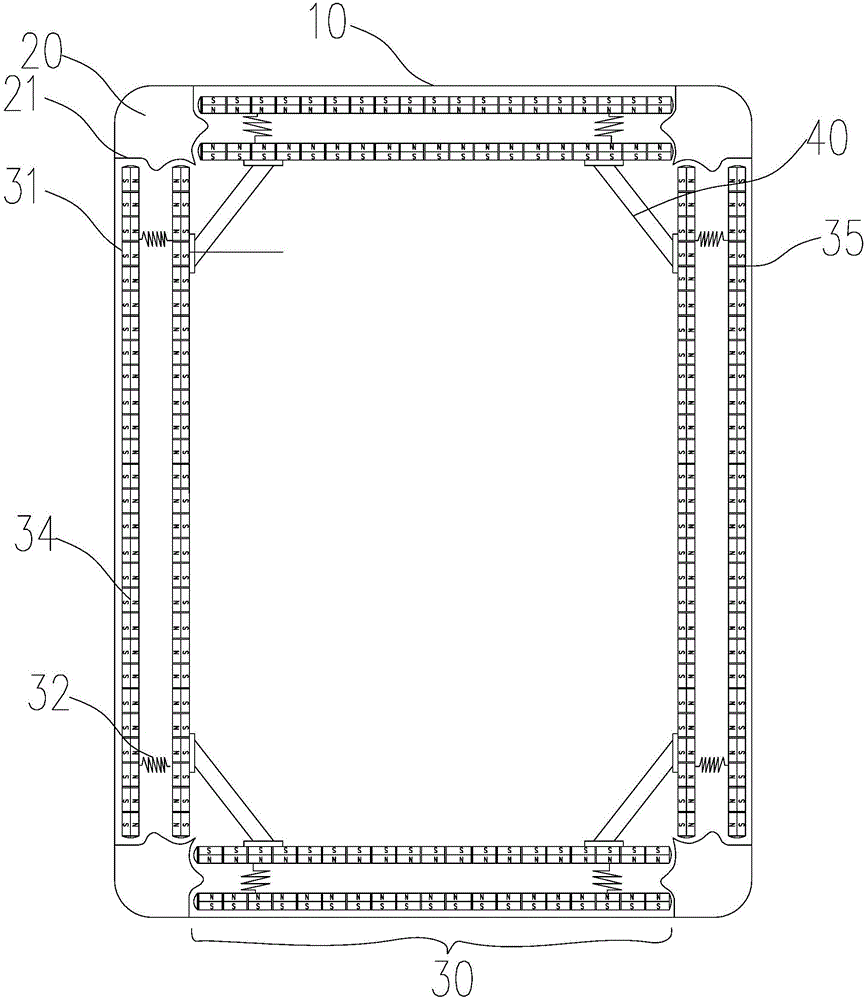

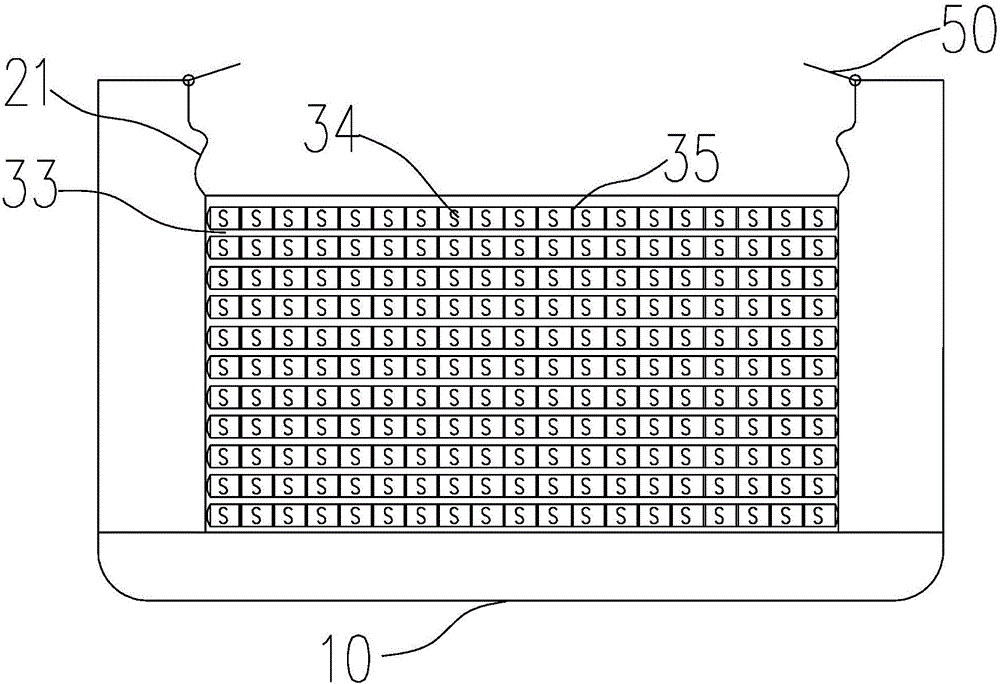

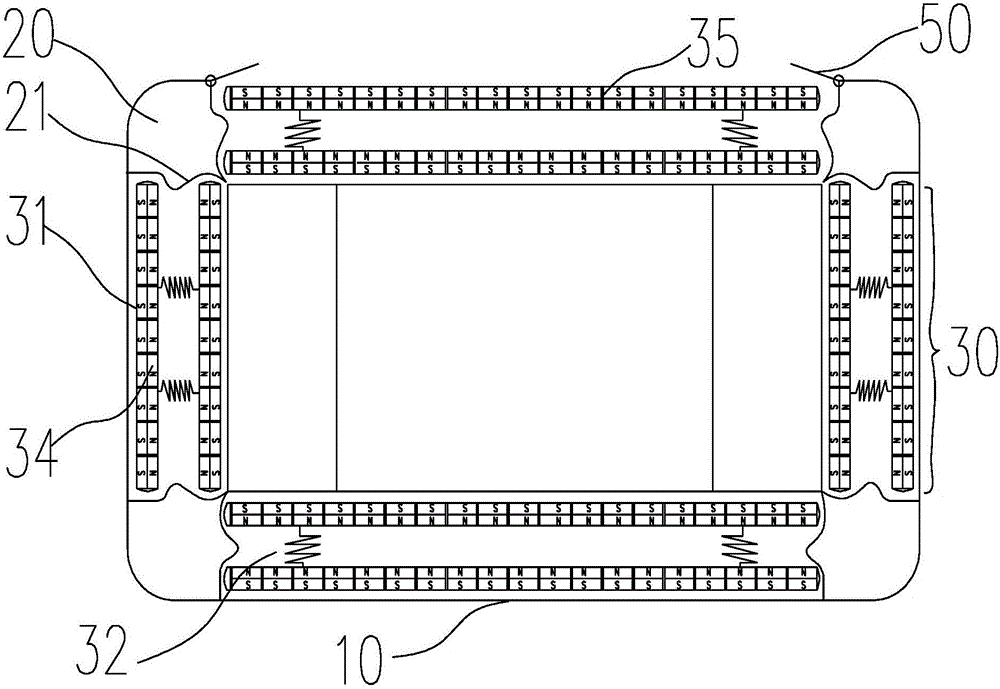

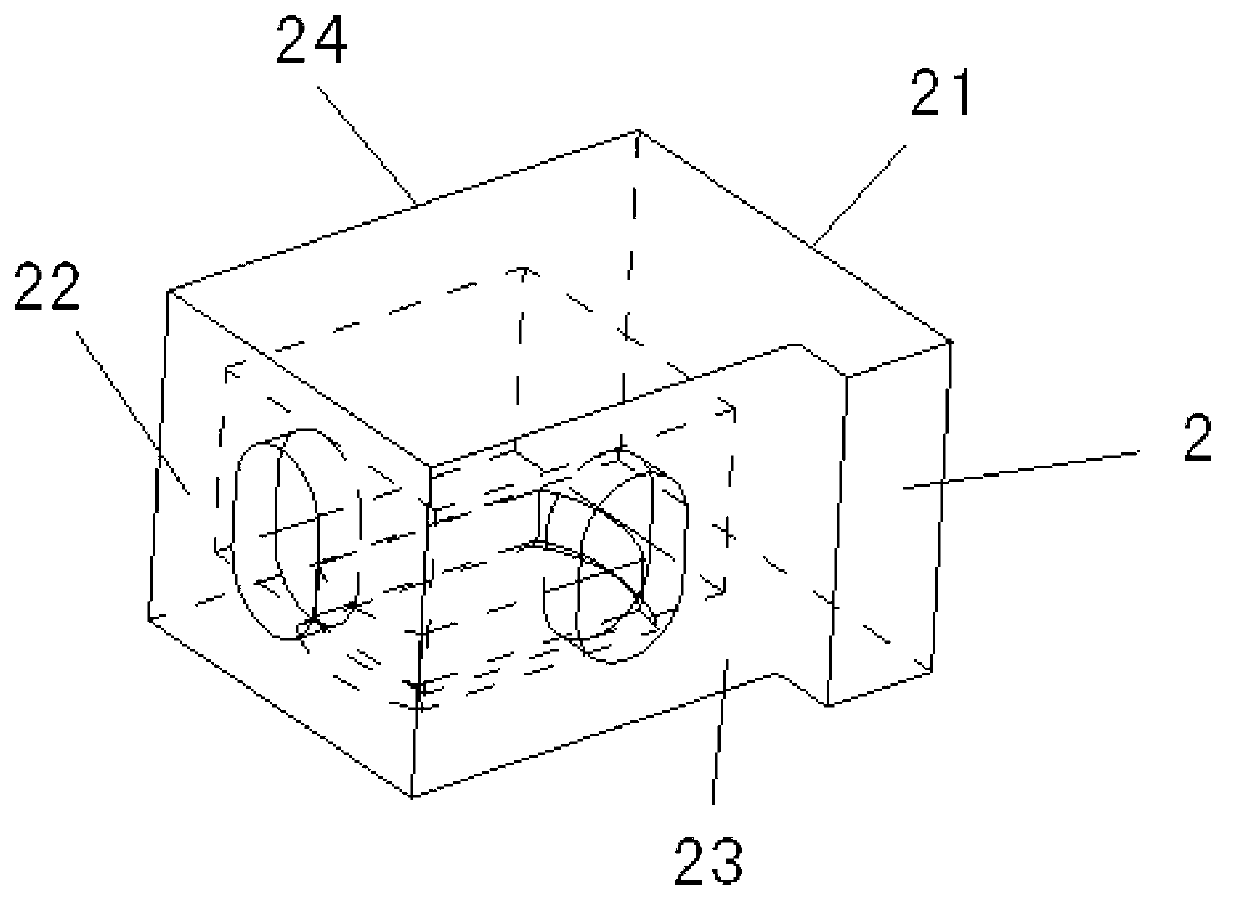

Magnetic protection box used for protecting electric automobile battery and bulk cargo

ActiveCN106042879AReduce impactHigh protection levelElectric propulsion mountingLoad securingBulk cargoAutomotive battery

The invention belongs to the technical field of object protection and particularly relates to a magnetic protection box used for protecting an electric automobile battery and bulk cargo. The magnetic protection box comprises a protection box body, limiting supports, a buffering magnetic board, force relieving push rods and a packaging door. When a battery box or a cargo box in an electric automobile is impacted and consequently deforms, magnet plates in the box are squeezed, homopolar magnets get close to one another, and instant reverse repelling force is generated according to the principle of homopolar repulsion; and the force relieving push rods are adopted for conducting multistage repelling to buffer and reduce the impact force, and therefore the protection effect on the battery or the cargo is achieved.

Owner:ANHUI UNIV OF SCI & TECH

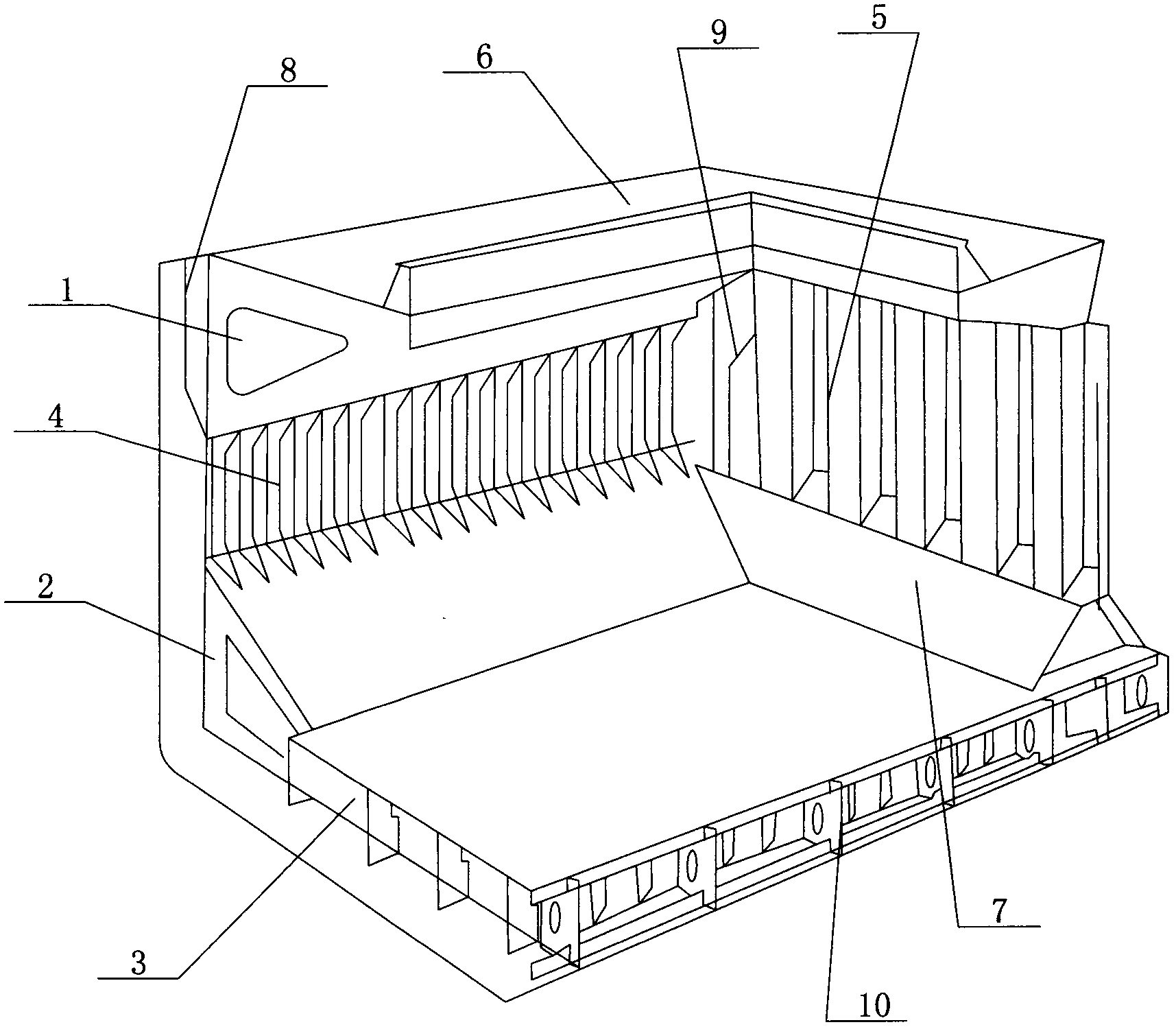

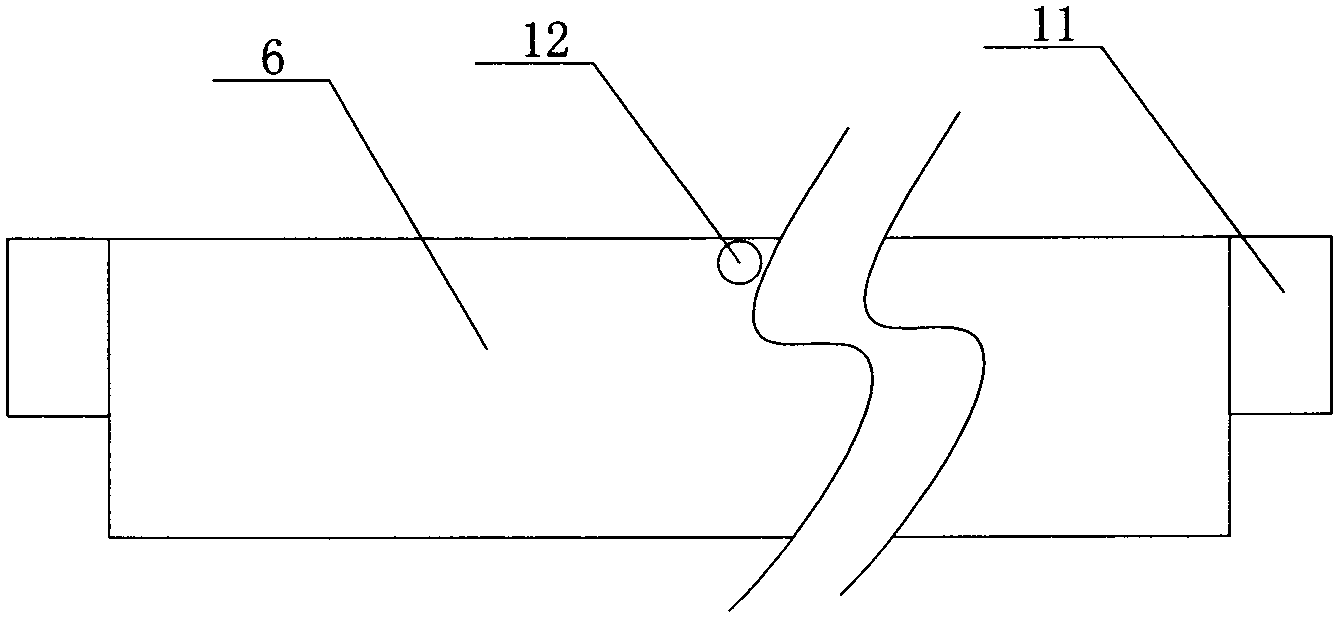

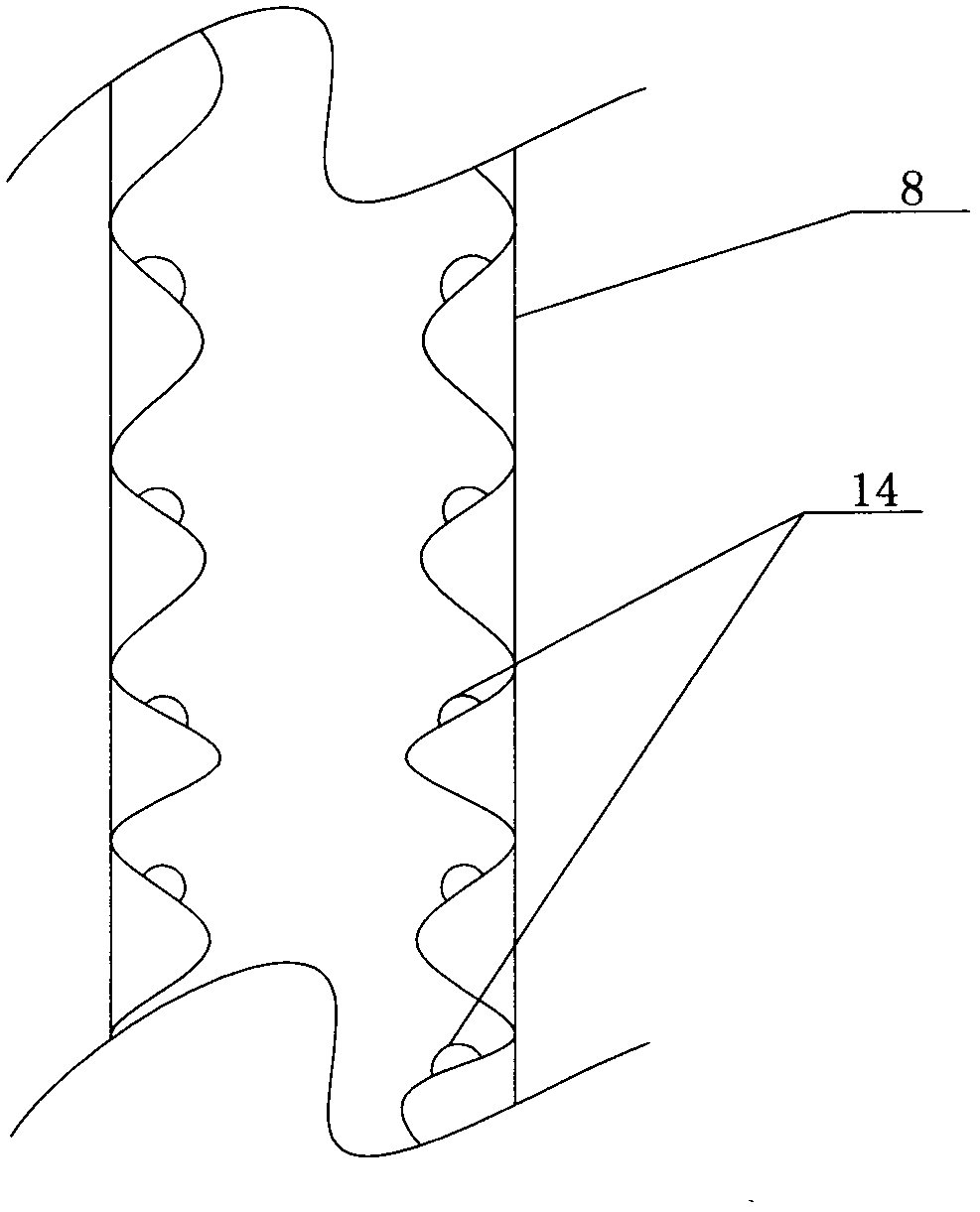

Electric stove metal bulk cargo continuous feeding and preheating device and method

InactiveCN101644539AReduce manufacturing costSave energyCharge manipulationPreheating chargesBulk cargoShortest distance

The invention belongs to the metallurgy technical field and discloses an electric stove metal bulk cargo continuous feeding and preheating device and method. The metal charge roller preheating grooveof the device is inclined with the horizontal plane, the lower end of the metal charge roller preheating groove is inserted into the inlet of a stove entering vibratory conveyor to be sheathed in short distance fit, the stove entering vibratory conveyor is connected with open pore A of the electric stove, the position of approach end is lower, the higher end of the metal charge roller preheating groove is sheathed and combined with a groove entering vibratory conveying and air sealing device, and the two are sheathed in short distance fit. The method is characterized in that metal charge is fed into the metal charge roller preheating groove to be preheated. The preheated metal charge is fed into the electric stove, and smoke of the electric stove is exhausted by the stove entering vibratory conveyor, the metal charge preheating groove and the groove entering vibratory conveying and air sealing device. The invention has the advantages of less electrical energy consumption, steady operation, high scrap preheating efficiency, high operational throughput and short total device length and is a new energy-saving and environmentally friendly technology with promotional value on electric stove or other production technologies.

Owner:CISDI ENG CO LTD

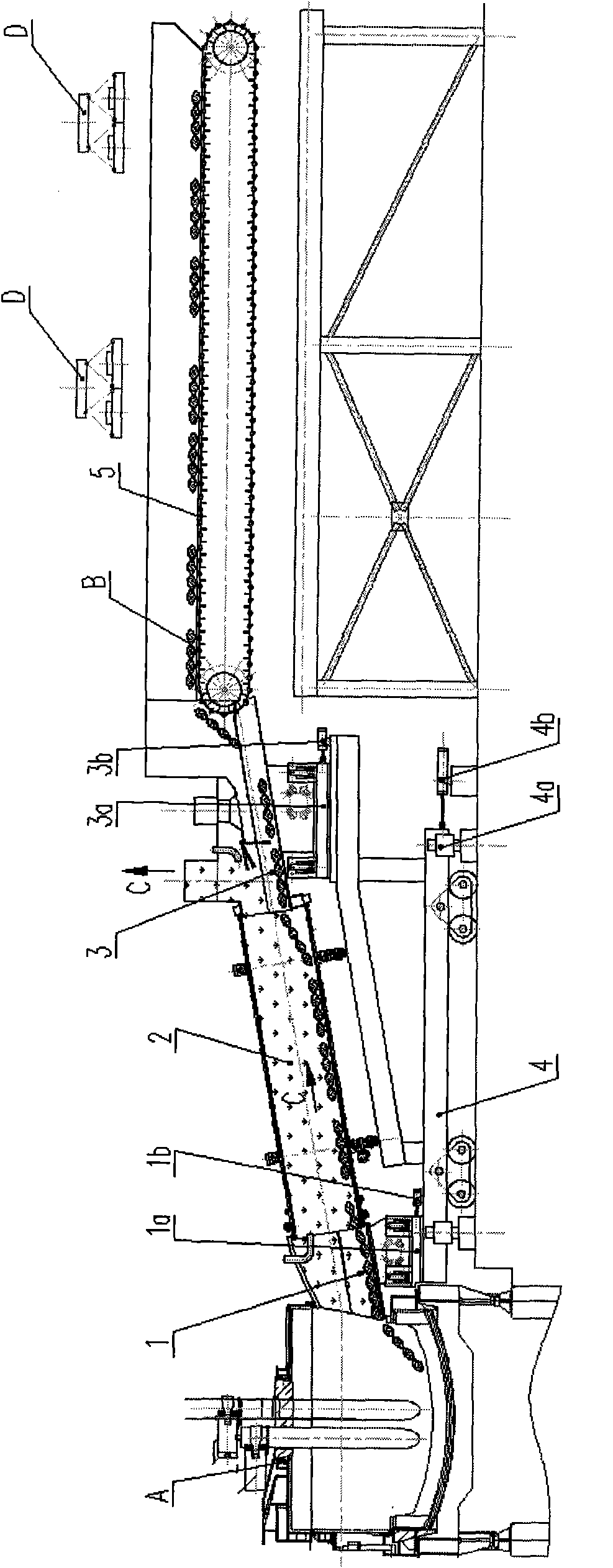

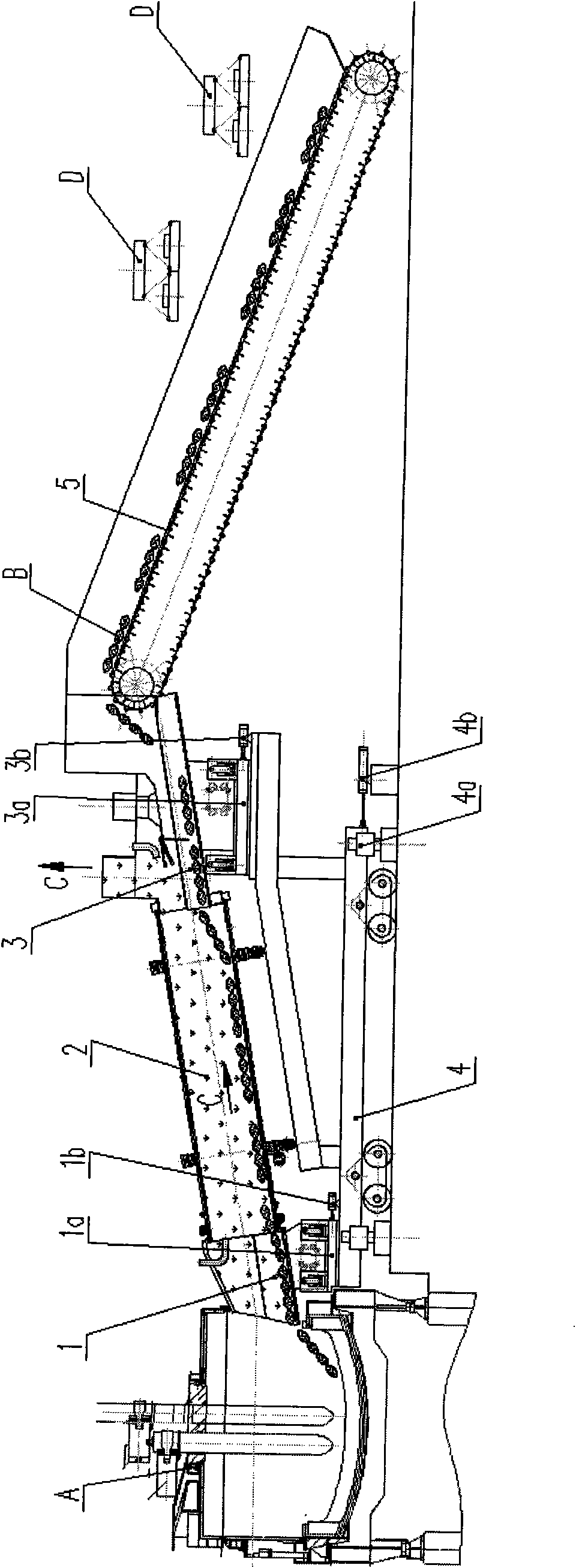

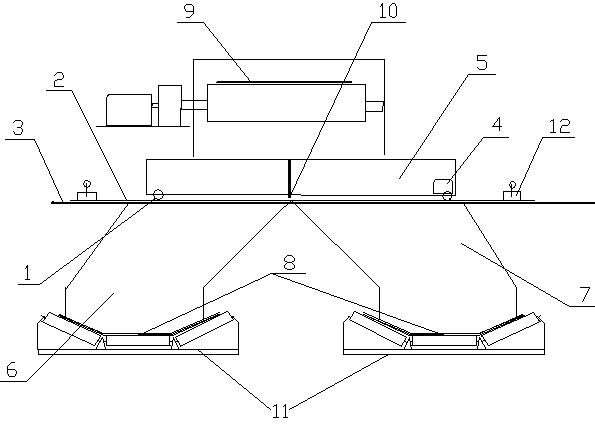

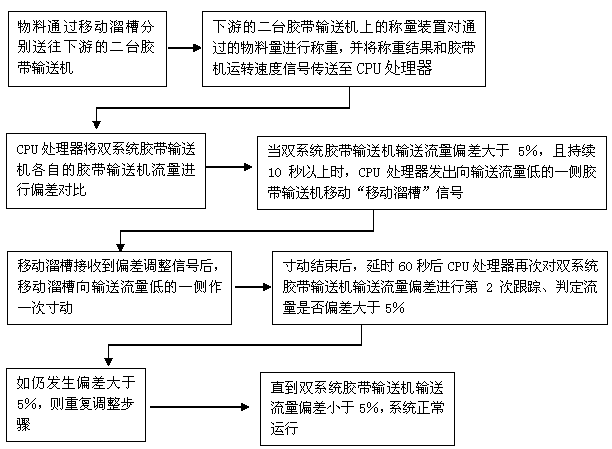

Dual-system material-smoothening automatic-balancing regulating control device and method

ActiveCN103420130AGuaranteed normal operationSimple structureControl devices for conveyorsBulk cargoTested time

The invention relates to the field of bulk cargo conveying of belt conveyor, in particular to a conveying material-smoothening control device and method of a belt conveyor. A dual-system material-smoothening automatic-balancing regulating control device comprises a moving trolley, a trolley track, a track fixing frame, a trolley traveling motor, a moving chute, a dual-system left chute, a dual-system right chute and an electronic scale. A dual-system material-smoothening automatic-balancing regulating control method comprises the steps that a unit displacement distance, a test time interval and a deviation threshold value of the moving chute are set, the electronic scale measures the flow of material on a dual-system downstream belt conveyer every other test time interval, and if deviation of the left material flow and the right material flow of the dual-system downstream belt conveyer is greater than the deviation threshold value, the moving chute moves towards the side with the lower material flow. The dual-system material-smoothening automatic-balancing regulating control device and method ensure that the locating point of the moving chute is in a dual-system material-smoothening balancing state all the time, avoid material leakage and accumulation accidents caused by flow deviation of the moving chute, guarantee that a conveying belt operates normally, and facilitate safety production and productivity improvement.

Owner:BAOSHAN IRON & STEEL CO LTD

Digital system and control method for unmanned chain bucket type continuous ship unloader

PendingCN110182621ARealize dynamic trackingEnsure safetyLoading/unloadingProduction scheduleBulk cargo

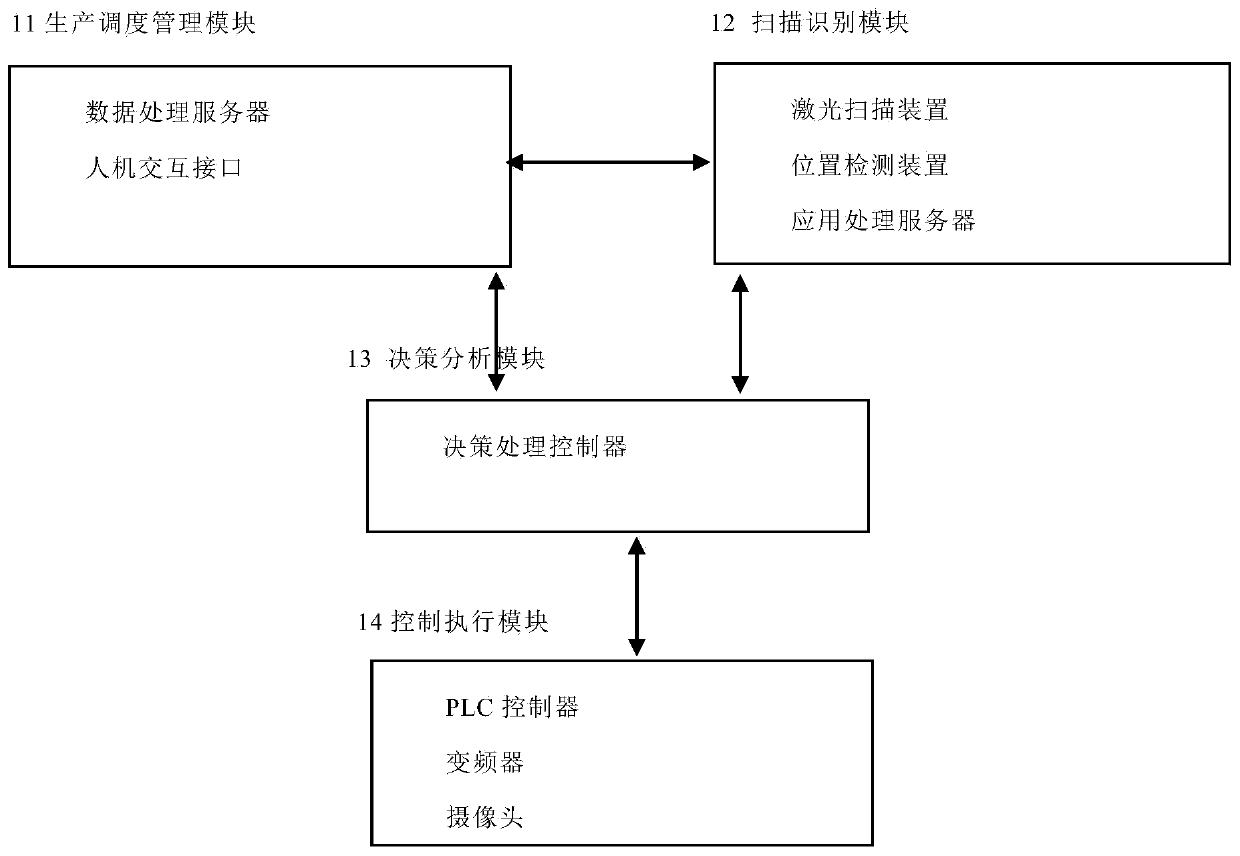

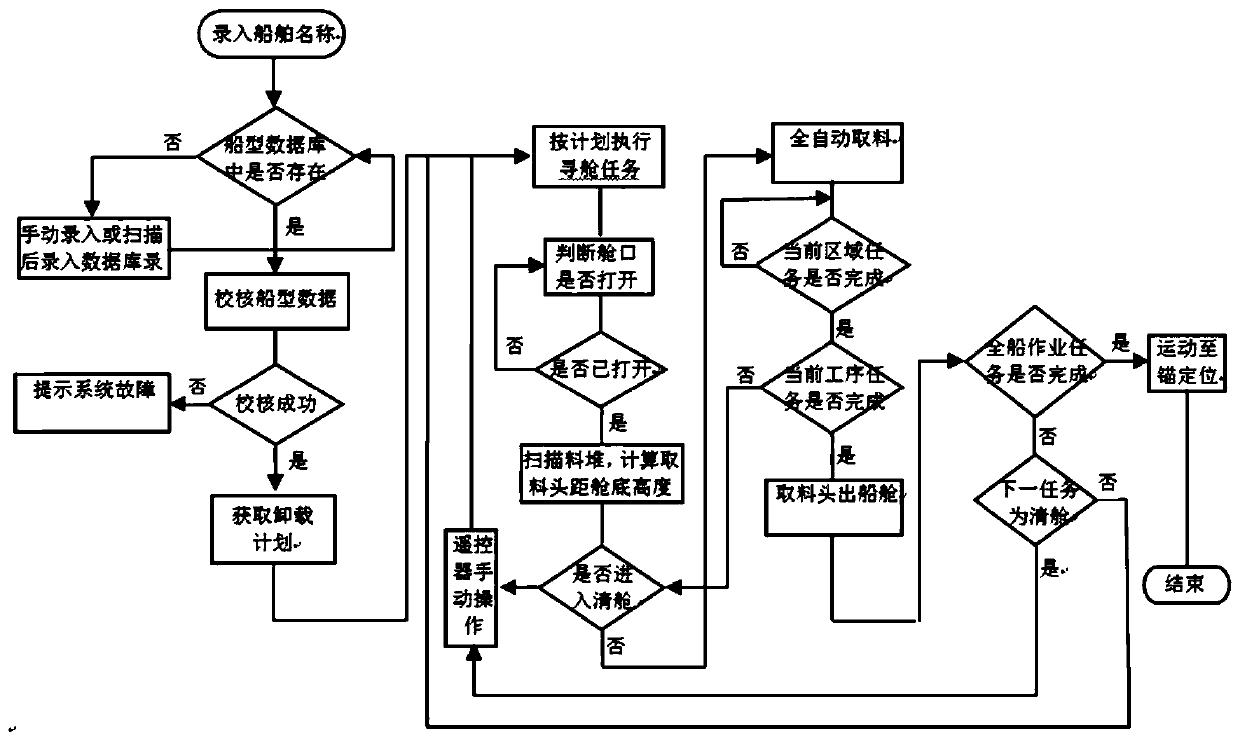

The invention provides a digital system for an unmanned chain bucket type continuous ship unloader. The digital system comprises a production scheduling management module, a scanning recognition module, a decision analysis module and a control execution module. The production scheduling management module is arranged on a wharf control room or the continuous ship unloader, and comprises a data processing server and a human-machine interactive interface; the scanning recognition module is arranged on the continuous ship unloader, and comprises a laser scanning device, a position detection deviceand an application processing server; the decision analysis module is arranged on the continuous ship unloader, and comprises a decision processing controller; and the control execution module is arranged on the continuous ship unloader, and comprises a PLC, a frequency converter and a camera. According to the digital system, the unmanned operation of the bulk cargo wharf chain bucket type continuous ship unloader can be achieved, and the real-time performance of data processing of the continuous ship unloader is ensured, so that the safety of a material fetching head to enter and exit from acabin is ensured. The number of operators is reduced, and the labor cost is decreased.

Owner:DALIAN HUARUI HEAVY IND GRP CO LTD

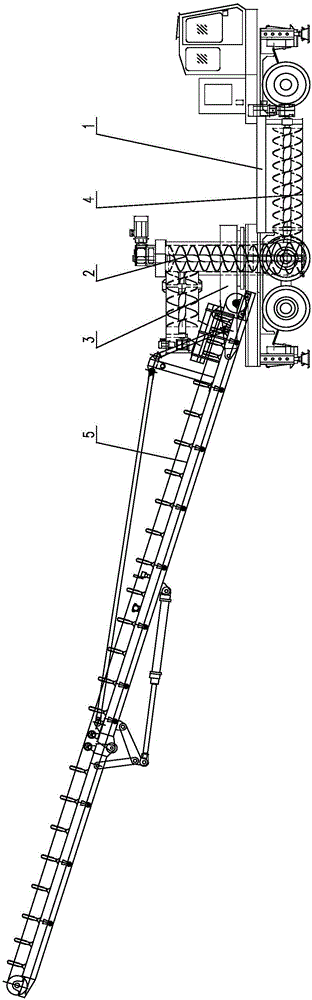

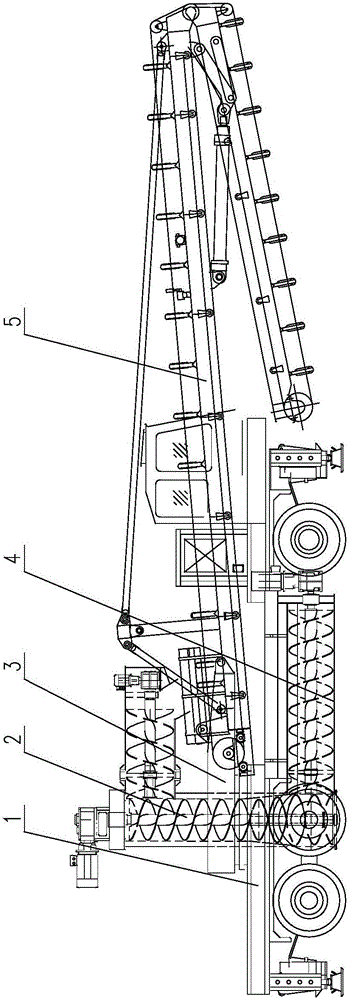

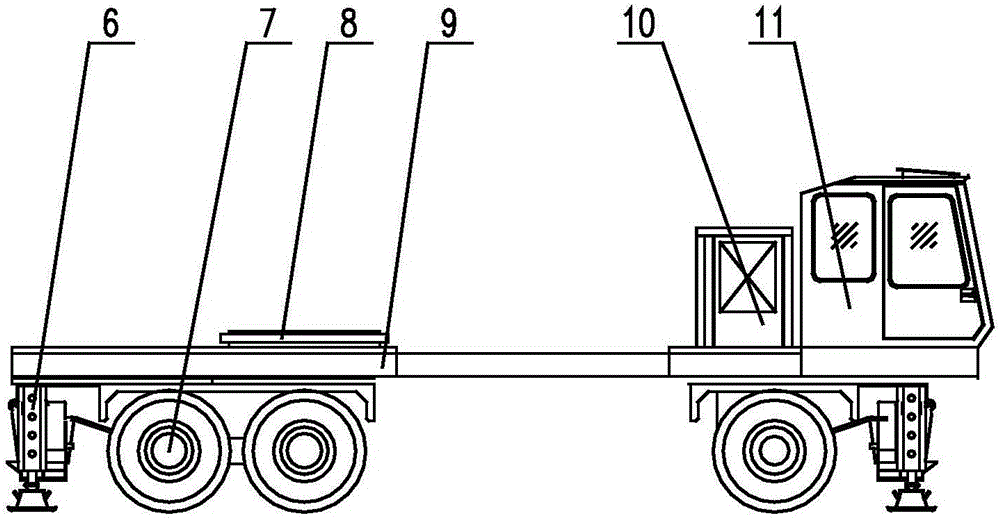

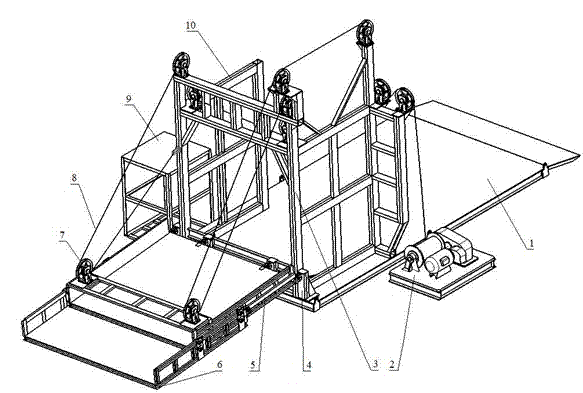

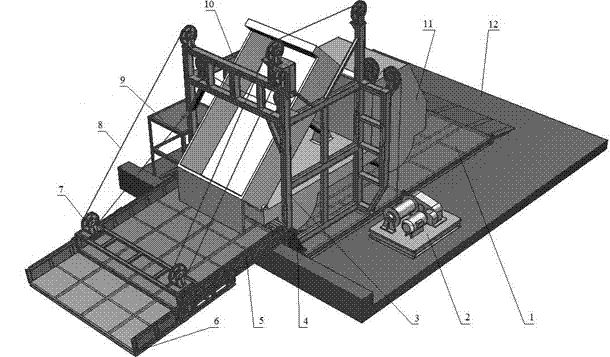

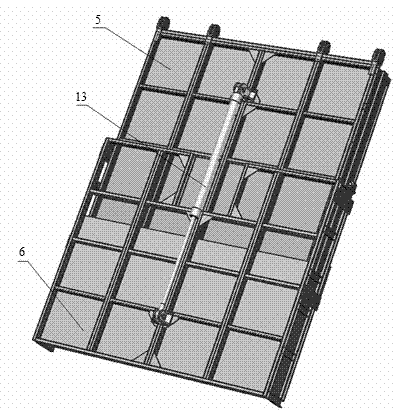

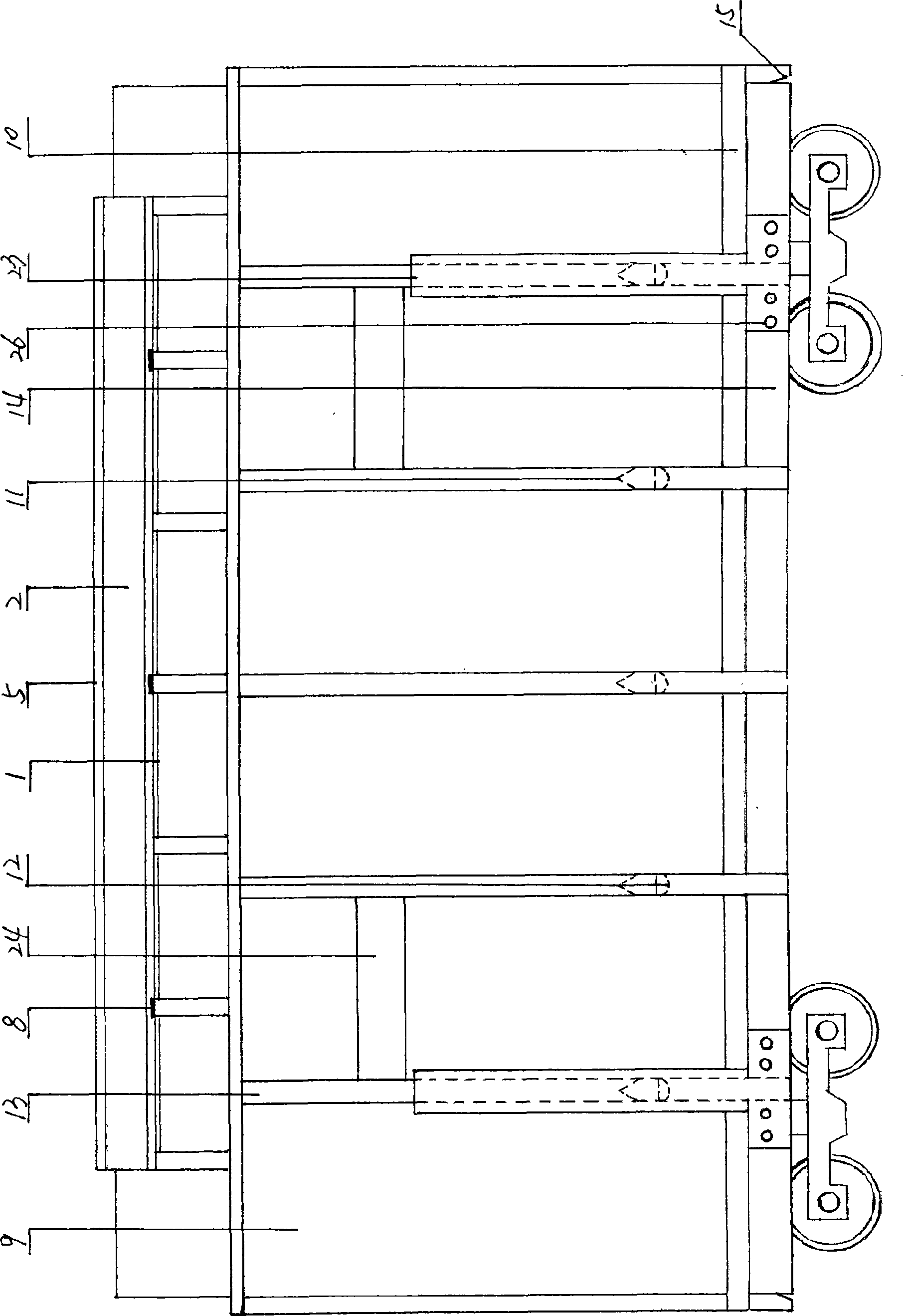

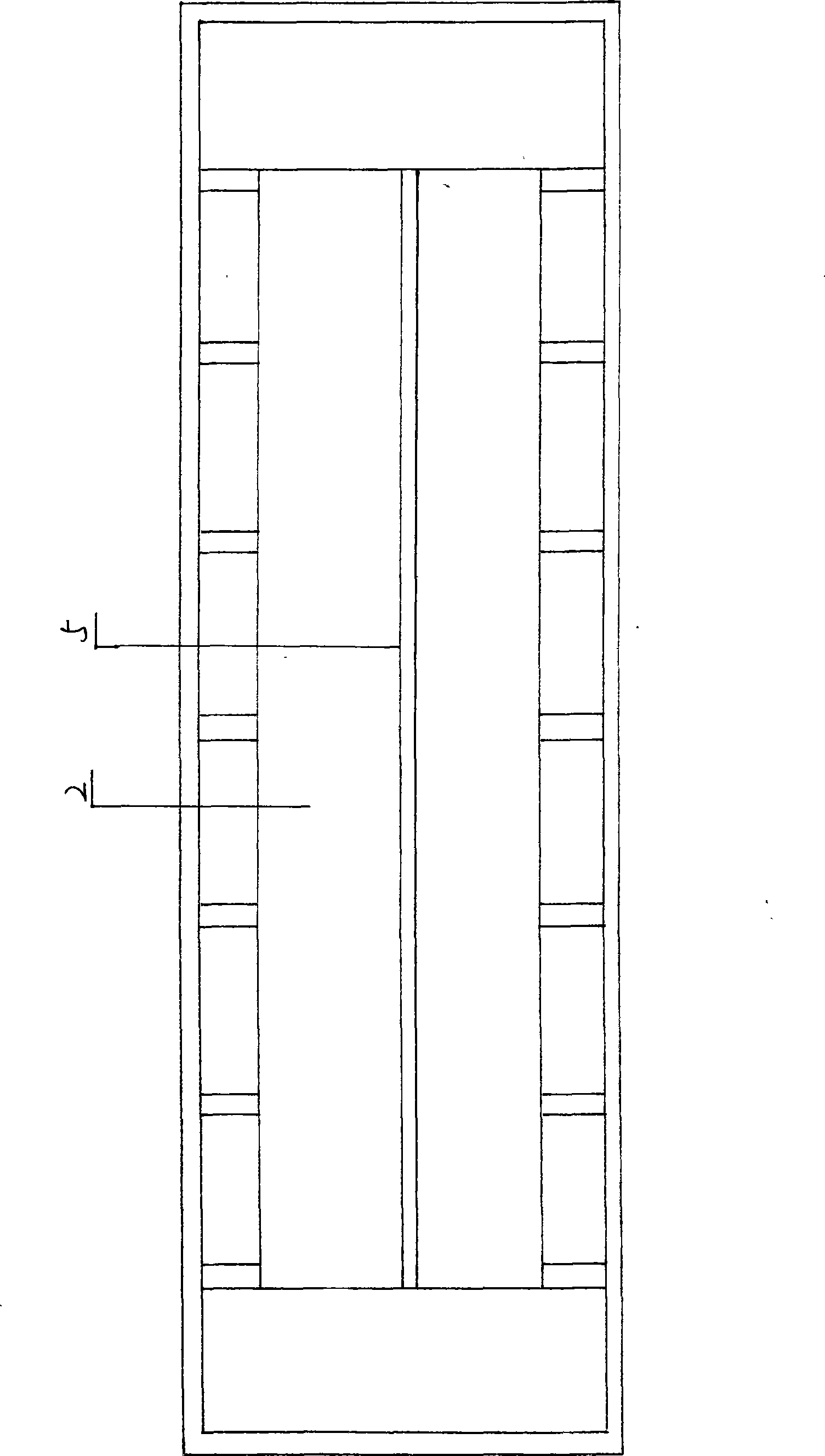

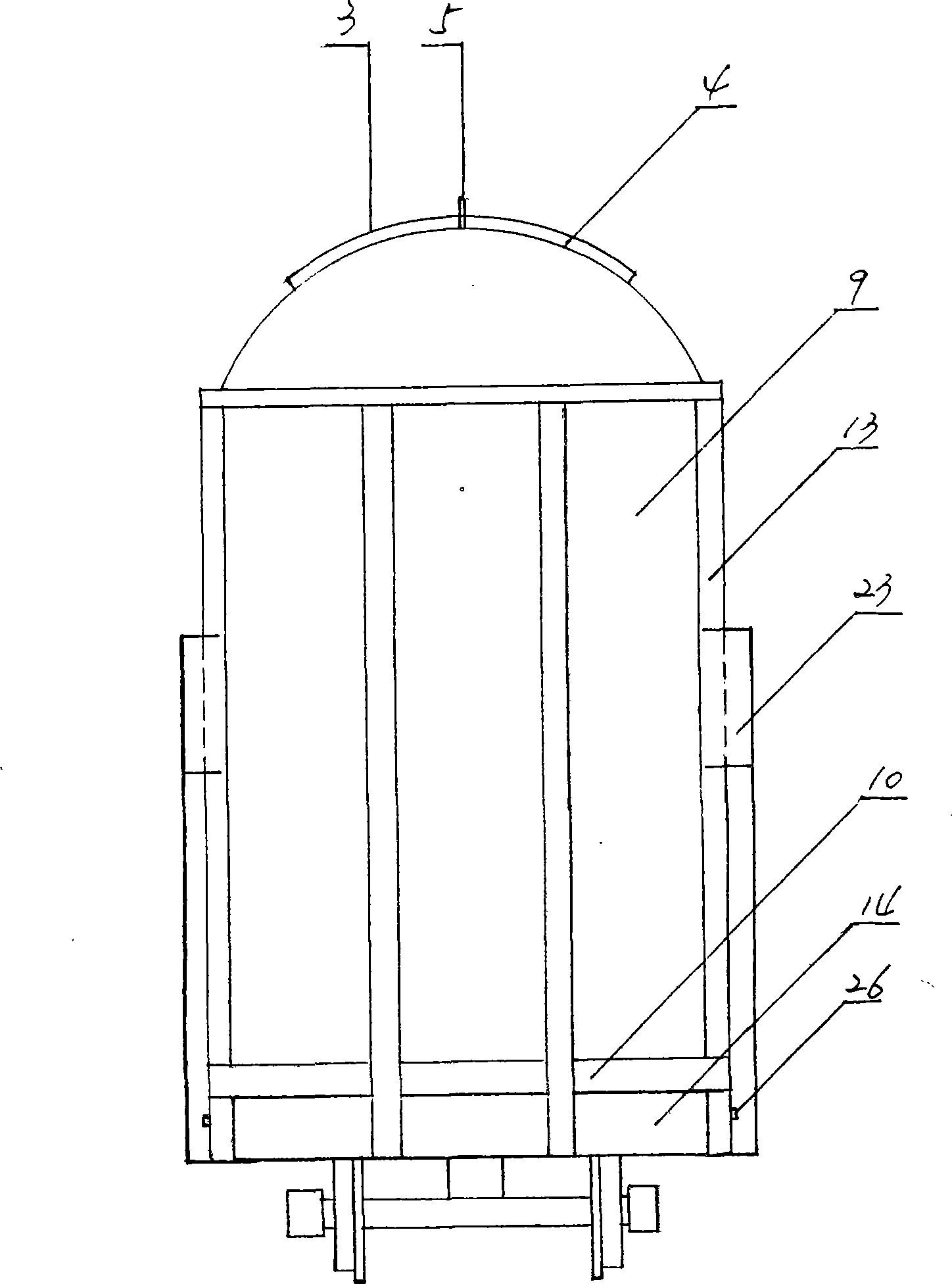

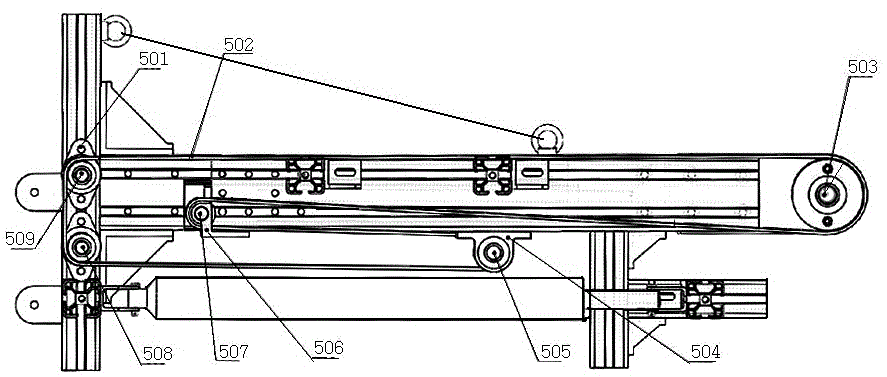

Flow-type multi-purpose bulk cargo spiral stacking machine

ActiveCN105775775AImprove stability and securityImprove passabilityConveyorsLoading/unloadingVehicle frameBulk cargo

The invention discloses a flow-type multi-purpose bulk cargo spiral stacking machine, aims to realize stacking, shipment and loading of bulk cargos. The spiral stacking machine is in contact with the ground through a vehicle body assembly; a material receiving device of the spiral stacking machine is positioned at the middle of the vehicle frame of vehicle body assembly, and can receive a material discharged from a dump truck and other devices on the two sides of the spiral stacking machine (without an unloading platform); a spiral material transferring system conveys the material in the material receiving device to a folding belt conveyor mounted on a rotating platform hinged support; and through the rotating, luffing and folding functions, rotating, luffing and wide-range stacking of the material can be realized, and then multi-purpose flow-type bulk cargo stacking operation can be realized. The spiral stacking machine is very high in trafficability and vehicle stability, and has the advantages that the operation efficiency can be improved, the higher stacking height requirement can be met, and then the stacking field utilization ratio can be improved.

Owner:WUHAN K CRANE OCEAN ELEVATORING TECH

Shipping device for port cargoes

The invention relates to a loading and unloading machine for port cargos and equipment thereof, in particular to a shipping device for the port cargos. The shipping device comprises a platform, a portal frame, a rotary sliding plate, an extension sliding plate, a winding device, a control room and the like; the rotating range of the rotary sliding plate is controlled by using the winding device for driving steel wire ropes on pulley blocks so as to be suitable for cargos with different specific weights and port conditions with different water levels; and the extension distance of the extension sliding plate is adjusted by controlling the extension movement of an oil cylinder so as to adapt to cargo ships with different tonnages and the movement requirements of stacking points of the cargo ships. The shipping device can meet the high efficiency and energy saving requirements of ship-loading operation of bulk cargos such as ores, coals and sands in the field of port transportation.

Owner:JIANGSU UNIV

Bell-type boxcar

The invention discloses a bell-type wagon compartment which can reduce the loss during the railway transportation of bulk cargo. The bell-type wagon compartment can divide the compartment into an upper and a lower part; the existing wagon shed can be adapted for use and mainly three parts are modified, including a wagon shed, a wagon compartment body and a wagon floor plate. When in loading, a door leaf on the wagon shed is opened and when in unloading, the wagon compartment body is uplifted and then the cargo discharges from the clearance between the wagon compartment body and the bottom of the wagon.

Owner:冯世英

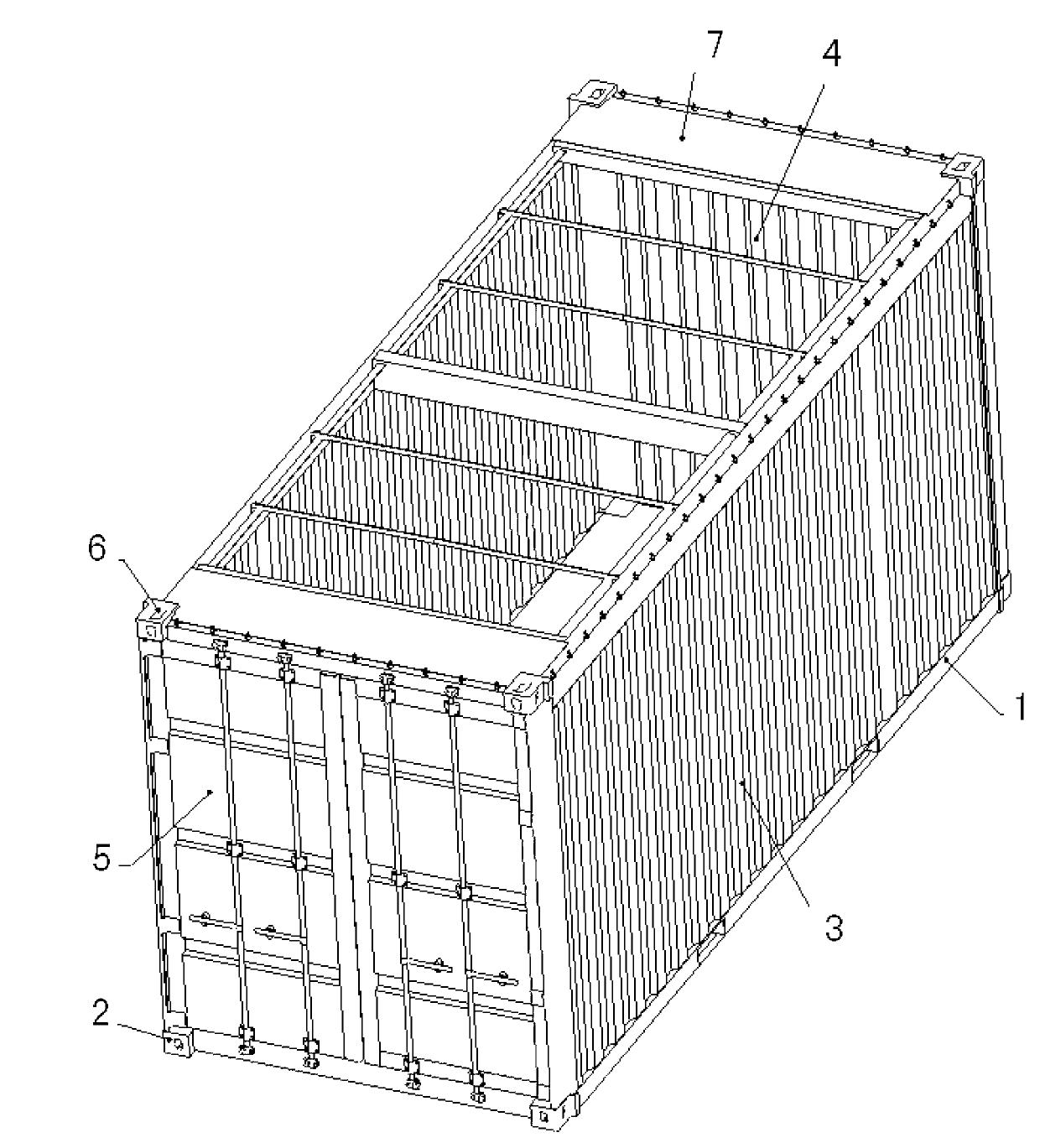

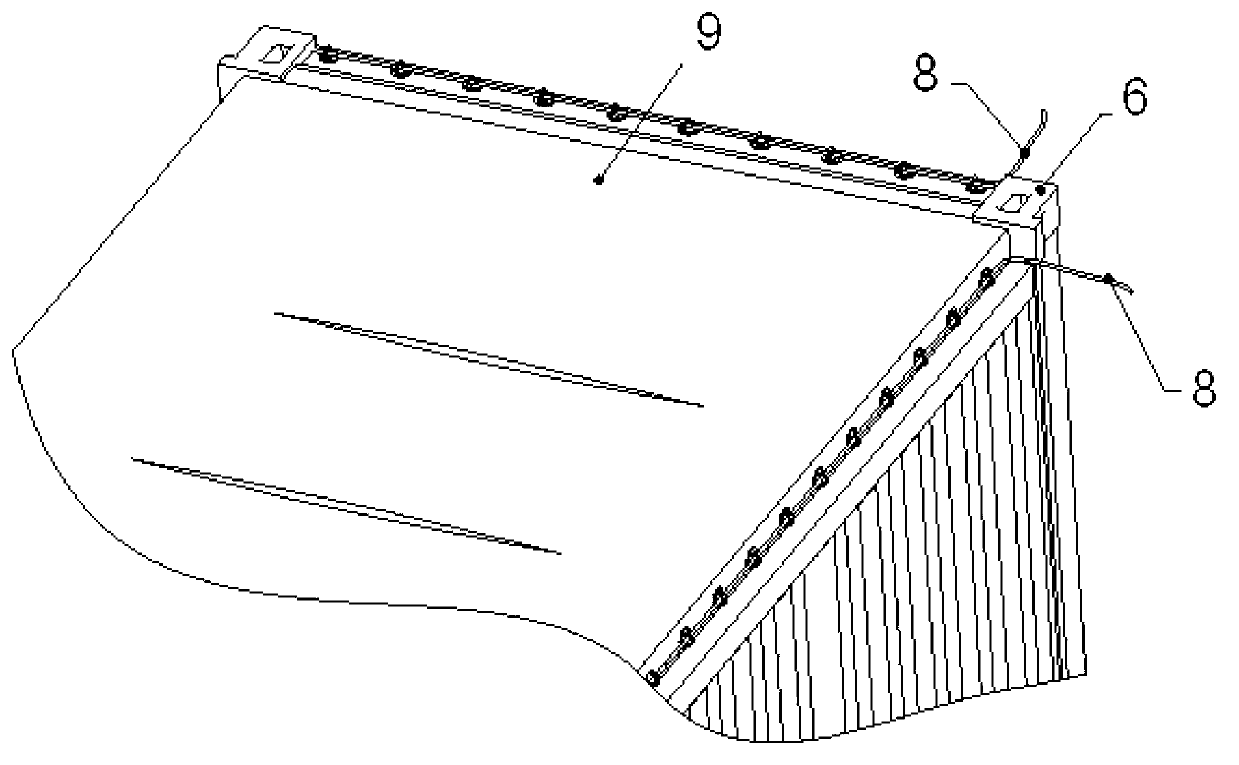

Large-volume dry bulk cargo transportation container for railway

The invention relates to a large-volume dry bulk cargo transportation container for a railway. The large-volume dry bulk cargo transportation container is characterized by comprising a container bottom assembly, four bottom corner pieces, two side wall assemblies, an end wall assembly, an end door assembly, four top corner pieces, a container top assembly, a soft rope and a PVC (poly vinyl chloride) tarpaulin, wherein the container bottom assembly is connected with the bottom parts of two side wall assemblies, the end wall assembly and the end door assembly through the four bottom corner pieces, the top parts of the two side wall assemblies, the end wall assembly and the end door assembly are connected with the container top assembly through the four top corner pieces, and the container top assembly is fixedly provided with the PVC tarpaulin through the soft rope. The large-volume dry bulk cargo transportation container has the characteristics of large volume, long service life, and good adaptability of cargo to the container. The large-volume dry bulk cargo transportation container can be widely applied to the railway transportation field.

Owner:CRRC BEIJING ERQI VEHICLE CO LTD

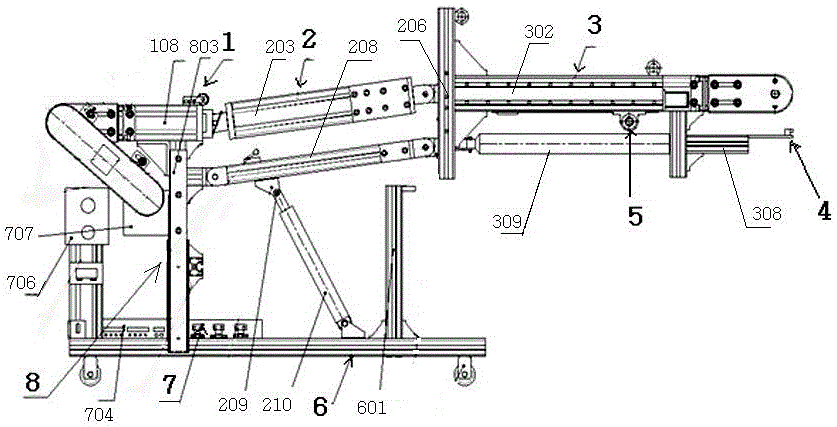

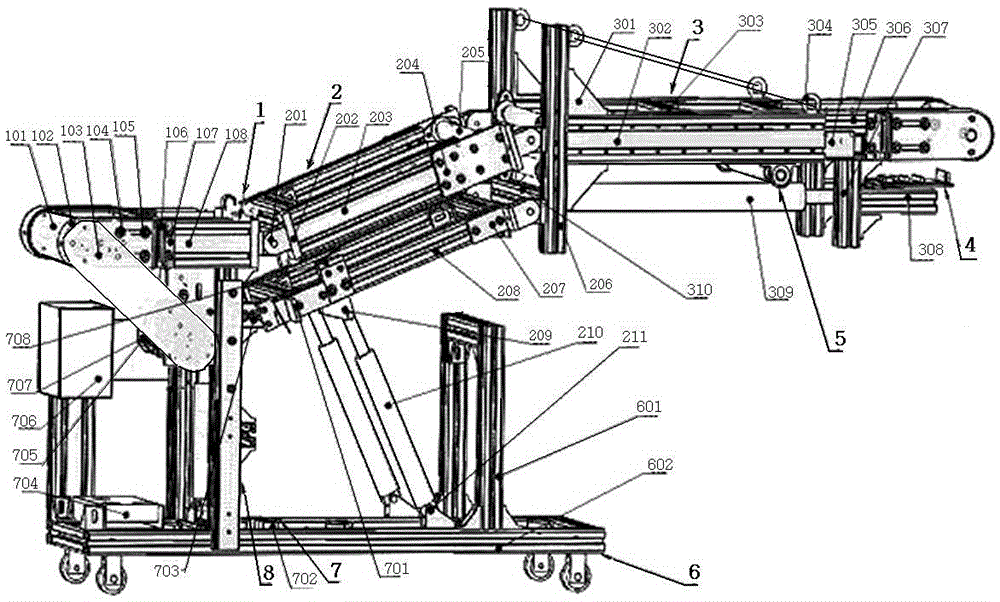

Cargo handling conveying device

ActiveCN105905630AFulfill loading and unloading requirementsLoading and unloadingConveyorsLoading/unloadingLogistics managementBulk cargo

The invention discloses a cargo handling conveying device. The cargo handling conveying device comprises a rack, an overall lifting platform, a circuit control system, a remote control system, an automatic following system, an adjustable inclined plane four-bar mechanism, a belt storage mechanism extending and retracting plane, a multi-segment integrated conveying device and a manual button controller, wherein a direct-current power supply is fixedly connected to the rack; a speed regulator is arranged at the upper side of the direct-current power supply and is fixed on the rack; the overall lifting platform, the adjustable inclined plane four-bar mechanism and the belt storage mechanism extending and retracting plane are connected in sequence through hinges; an electric push rod is used for providing powder; a speed reducing motor is used for providing power for the multi-segment integrated conveying device; the two sides of the conveying belt are planes, and the middle of the conveying belt is an adjustable inclined plane; and the automatic following system is arranged in the front of the bottom of the belt storage mechanism extending and retracting plane and is fixedly connected to a bearing platform. The cargo handling conveying device solves the technical problems such as low efficiency of handling and conveying of bulk cargos and easy damage to the cargos in a handling process; in a logistics transfer station, the front end of the cargo handling conveying device can stretch into a van-type wagon box to handle the bulk cargos, thereby greatly reducing the labor intensity of workers and improving working efficiency.

Owner:SHAOYANG UNIV

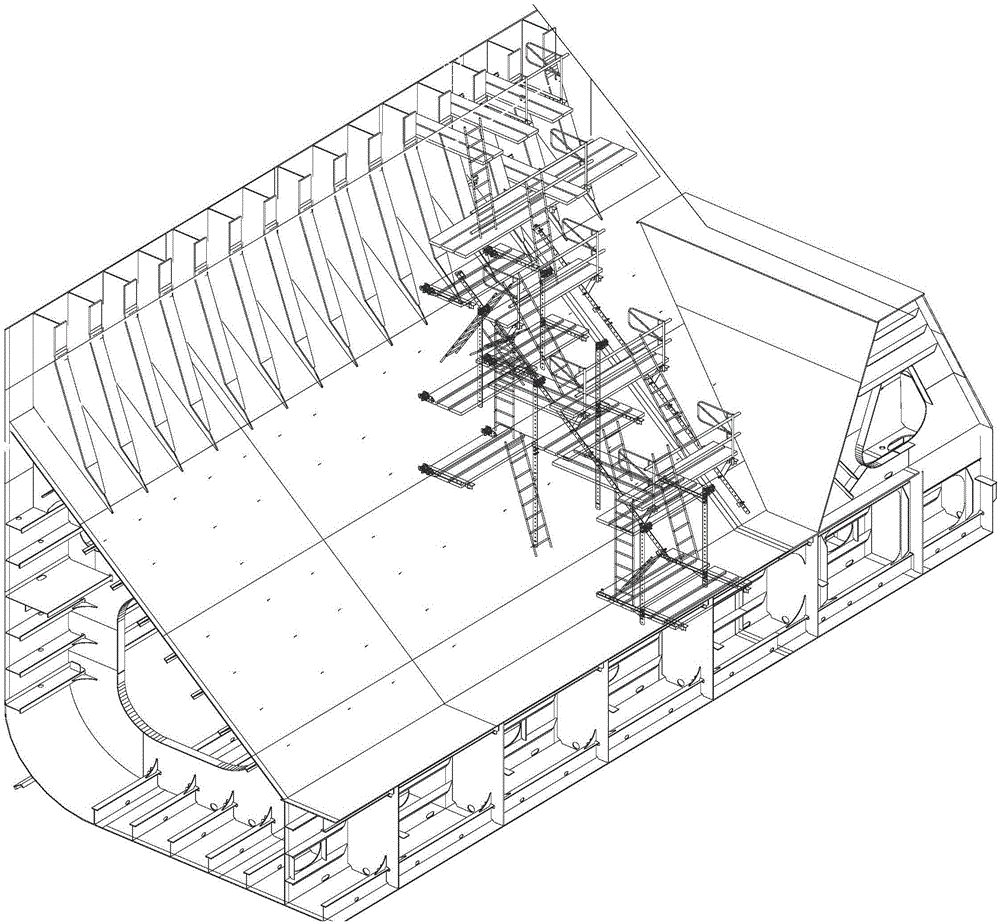

Bilge mechanism of bulk cargo ship

InactiveCN104309761AImprove stabilityImprove space utilizationHull interior subdivisionFor bulk goodsBulk cargoBilge

The invention discloses a bilge mechanism of a bulk cargo ship and relates to the technical field of shipbuilding, wherein a top side tank and a bottom side tank are connected by a ship side frame, the bottom side tank is connected with a double-layer bilge, the middle part of the double-layer bilge is respectively provided with a plurality of rib plates, an upper stool is arranged on the top side tank, the upper stool is connected with the lower stool by a transverse bulkhead, the bottom of the upper stool is arranged in a bilge way, the top of the lower stool is arranged in a glide path, both sides of the upper and lower stools are respectively provided with a clamping block, and the middle parts of the upper and lower stools are respectively provided with a height detector; the bilge mechanism adopts the fixing rib plate so as to greatly increase bearing capacity of the bilge, the flexibility of the bilge is improved by the movable internal structure and the upper and lower stools and the triangular bottom side tank has the excellent steadiness.

Owner:JIANGSU ROKEE HEAVY IND TECH

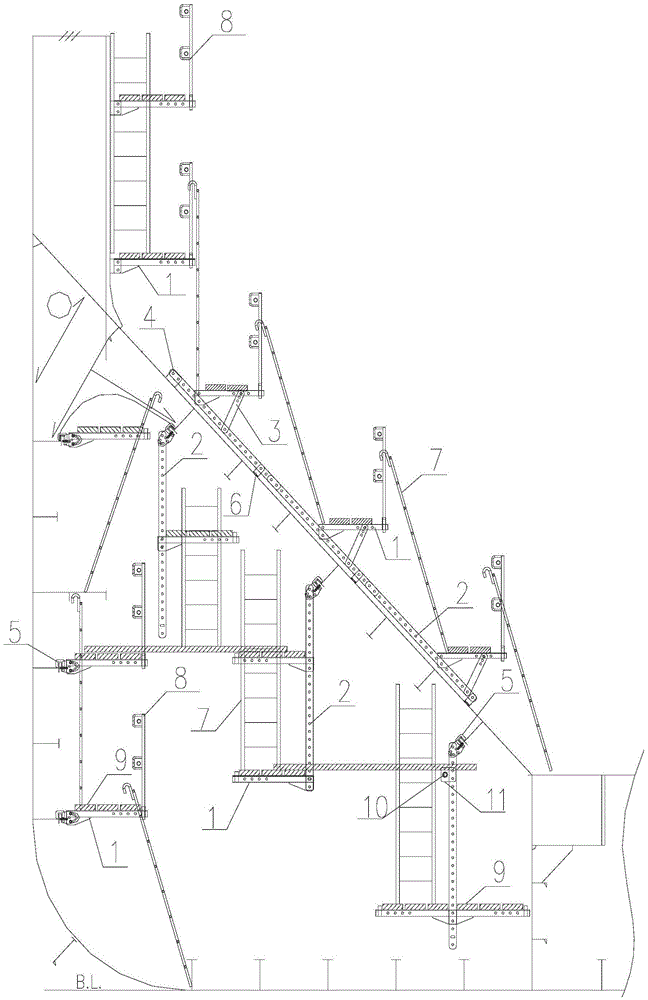

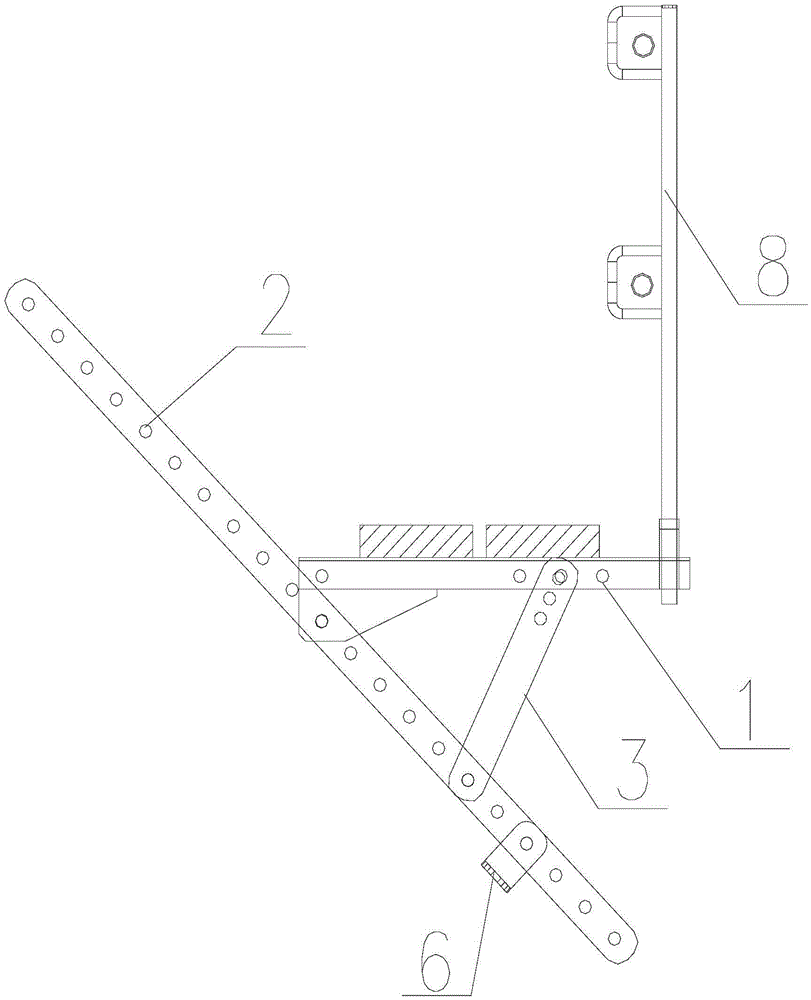

Method for building scaffolds in closing stage of bottom side tank of bulk cargo ship cargo hold

ActiveCN105539769AIncrease profitInstallation saves time and effortDry-dockingSlipwaysBulk cargoBallast tank

The invention discloses a method for building scaffolds in the closing stage of a bottom side tank of a bulk cargo ship cargo hold. Closing seams of the closing stage of the bottom side tank include ballast tank internal closing seams and bevel board closing seams. The three kinds of scaffolds are included according to the different scaffold building positions. According to the method, the tool type scaffolds are mainly adopted to meet the construction demand of the closing seams of the ship bottom side tank in the closing stage, and the prior mode with a lot of steel tube scaffolds adopted is replaced. Scaffold pore plates can be preassembled in the block stage, and part of the scaffold pore plates can be used both in the block stage and the header stage, so that the utilization rate of scaffold tools is increased.

Owner:JIANGSU MODERN SHIPBUILDING TECH

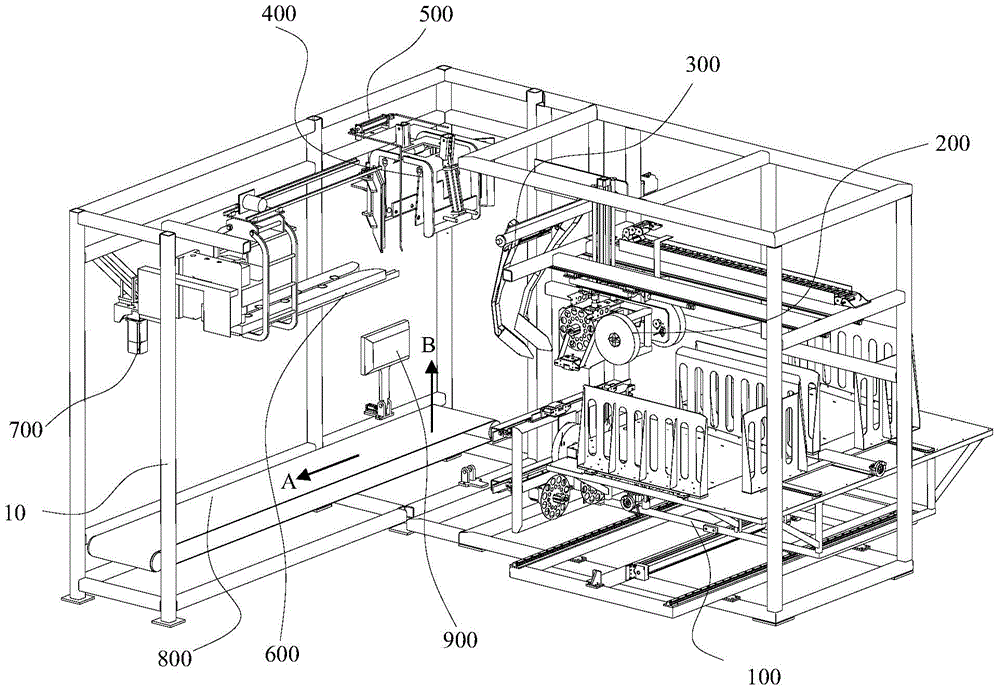

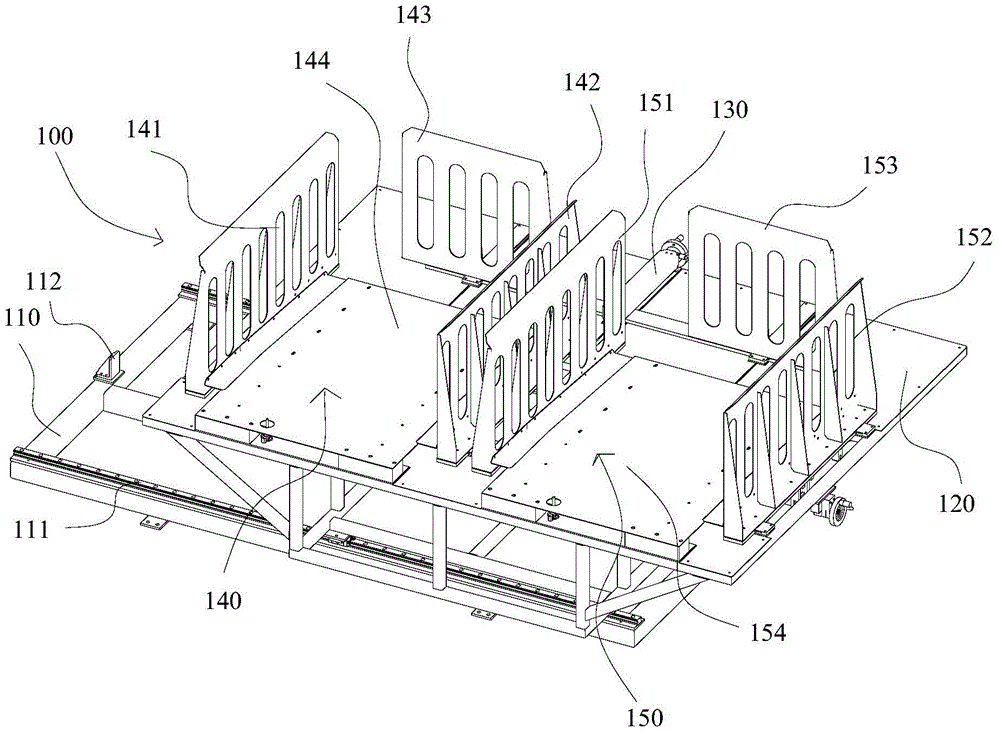

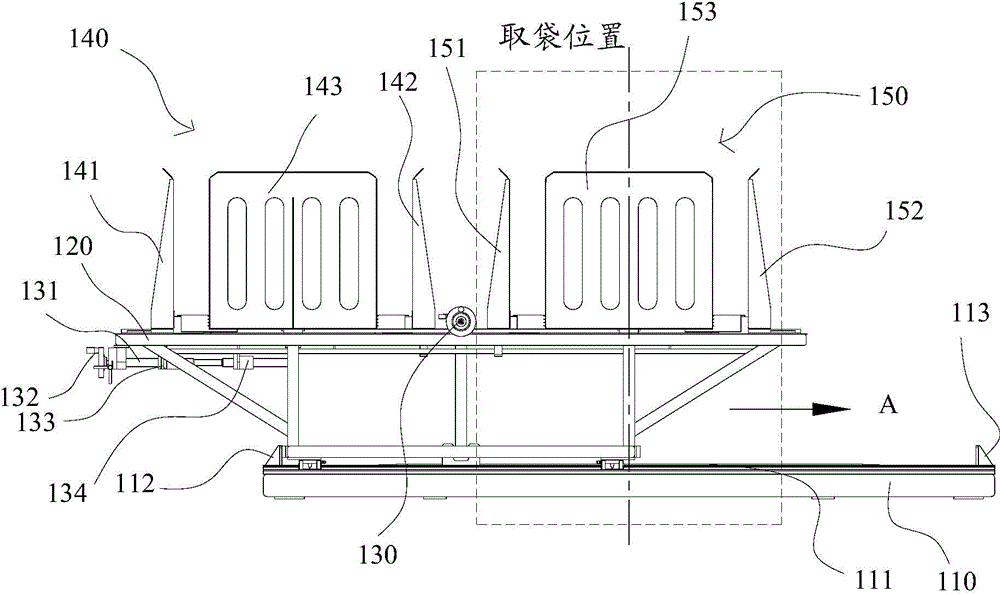

Bulk cargo bagging system

InactiveCN105984634APrevent sideways movementSuitable for large-scale automated production needsBottlesPackaging machinesLinear motionBulk cargo

The invention relates to a bulk cargo bagging system. The bulk cargo bagging system comprises a support frame, a bag magazine, bag opening and sending equipment, filling equipment, a transporting device, bag sealing equipment and a labeling device, wherein the bag magazine includes a driving mechanism, a support base moving in a linear moving direction under the effect of the driving mechanism, a bag storage box set positioned on the support base, and an adjusting mechanism for adjusting the size of at least one bag storage box; the bag storage box set includes at least two bag storage boxes arranged in the moving direction of the support base in sequence; each bag storage box can move between a bag taking position and respective bag adding position along with movement of the support base; the bag opening and sending equipment includes a bag opening device for opening openings of bags, and a bag sleeving device for further expanding the opened bags and sending to a filling position; the filling equipment is used for filling materials in the bags; the transporting device supports and transports the bags in the transporting direction; and the labeling device includes a label box, a label taking and sending mechanism for obtaining labels from the label box and sending the obtained labels to the labeled bags, and a label positioning mechanism for fixing the labels on the bags.

Owner:李雪莲

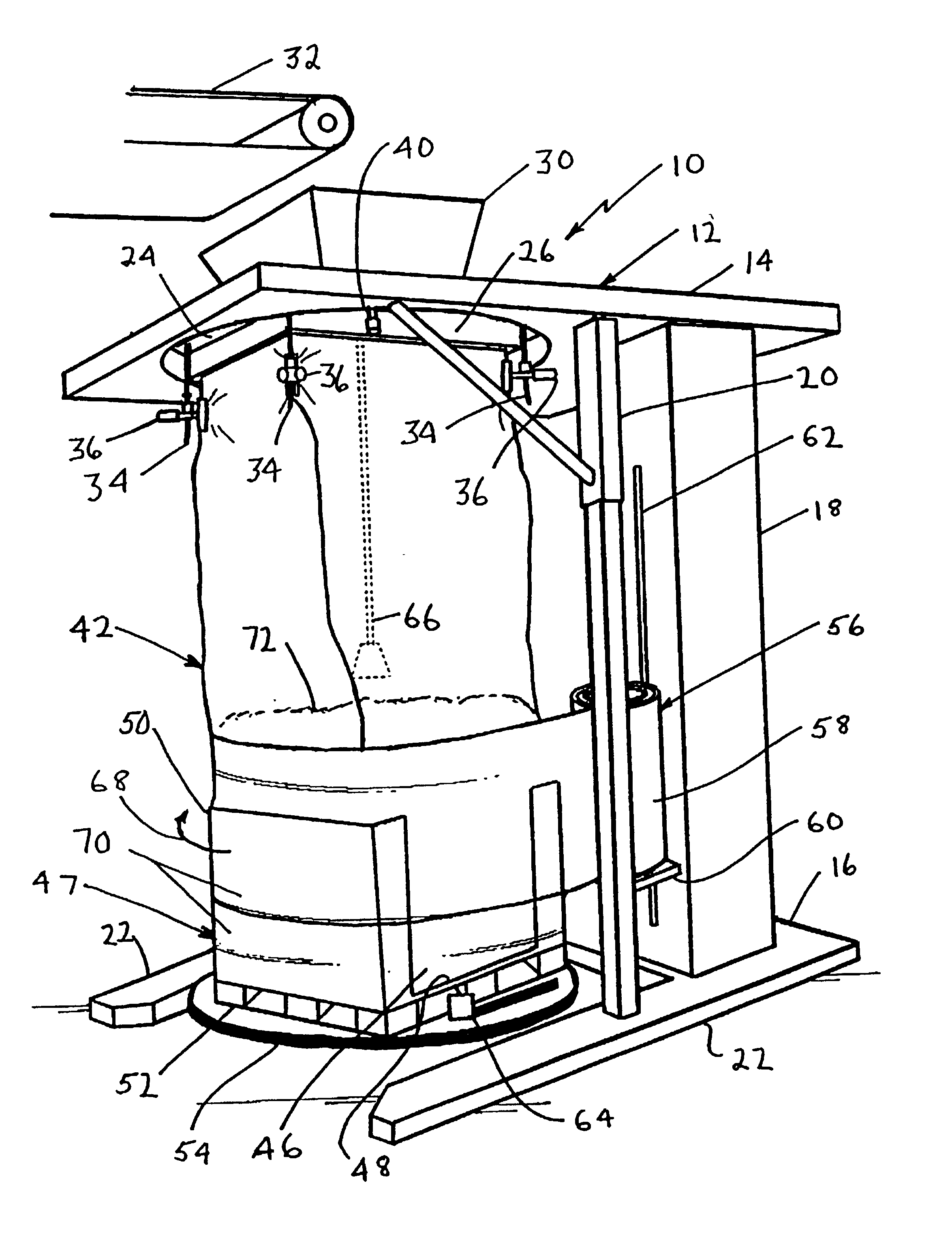

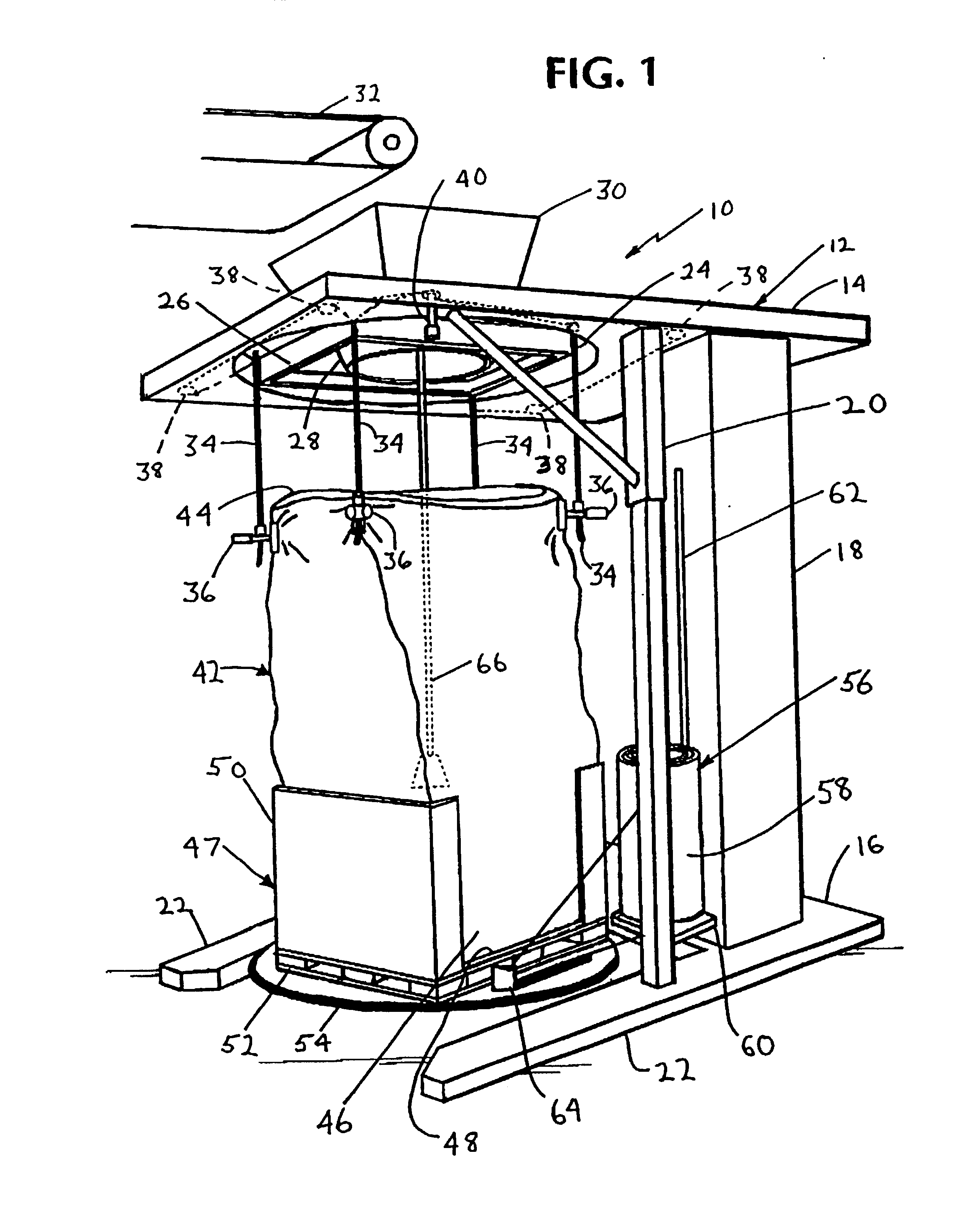

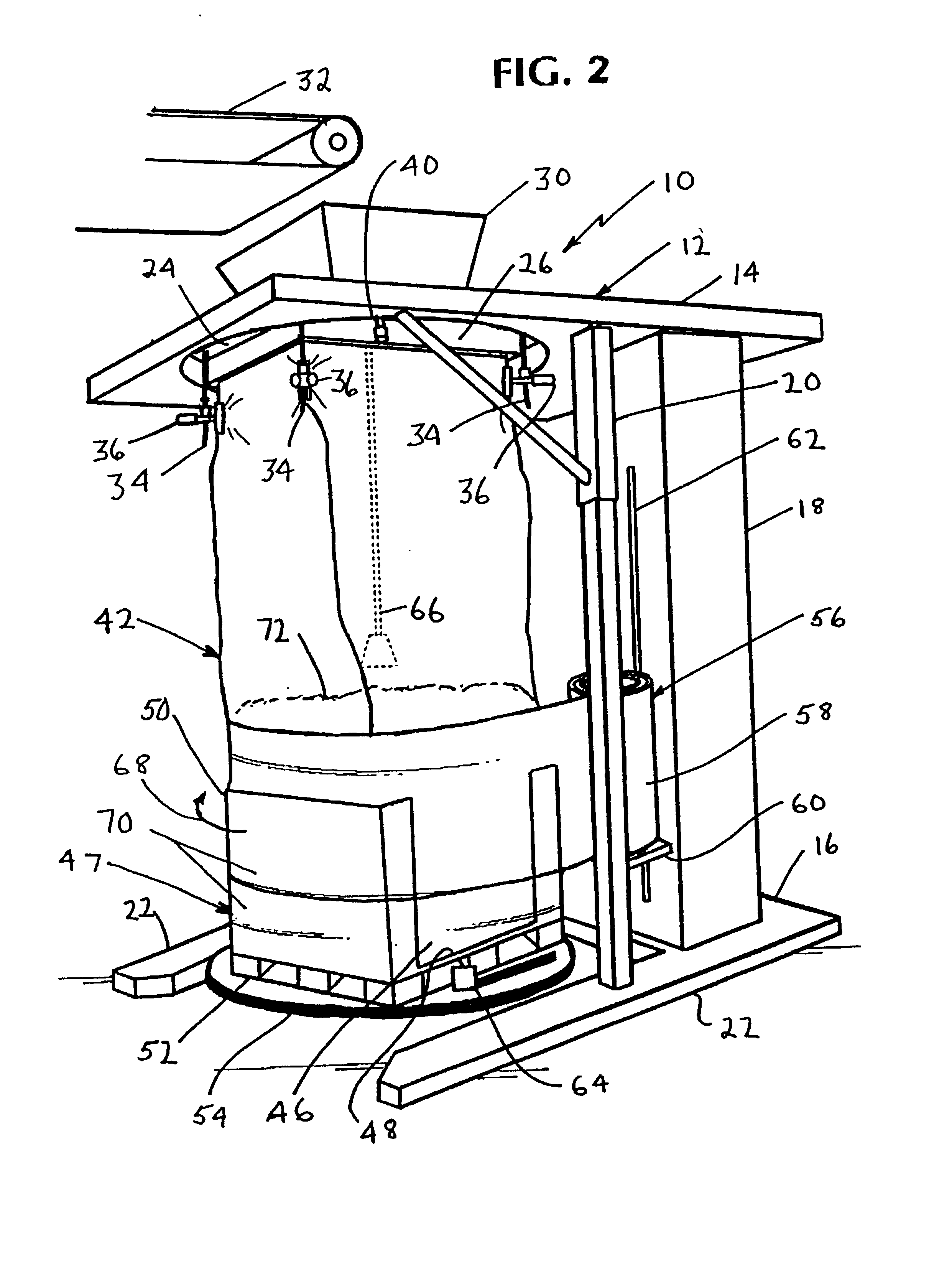

Transportable container for bulk goods and method for forming the container

InactiveUS7055293B2Avoid damaging the materialReduce particulate pollutionWrappers shrinkageMultiple wrapper applicationEngineeringParticulate material

A transportable container for bulk goods and a method for forming the container are disclosed. The transportable container is formed from a bag having a closed base and an open top. The open top is in a folded over position and a bottom support is located adjacent to the closed base. A particulate material is filled into the bag and an outer wrap is spirally wrapped around the bottom support and the bag such that the outer wrap secures the bag to the bottom support and secures the open top in the folded over position. The method for forming the transportable container includes the steps of securing the open top of the bag in an opened position and supporting a base of the bag. The bag is filled to a predetermined level with a particulate material and while being filled the fill level of the particulate material in the bag is monitored. Simultaneously with filling of the bag, an outer wrap is spirally wrapped around the bag in an upward direction to a predetermined fill level. Once the bag is completely filled the open top of the bag is released and moved into a folded over position whereupon the outer wrap is spirally wound around the bag in a downward direction to secure the open top in the folded over position thereby forming the transportable container.

Owner:KELLOGG CO

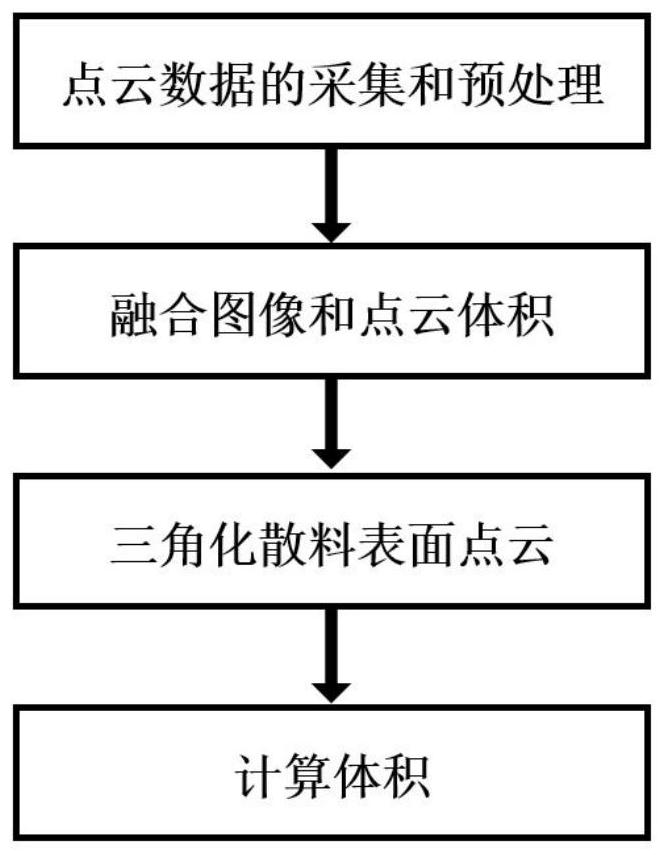

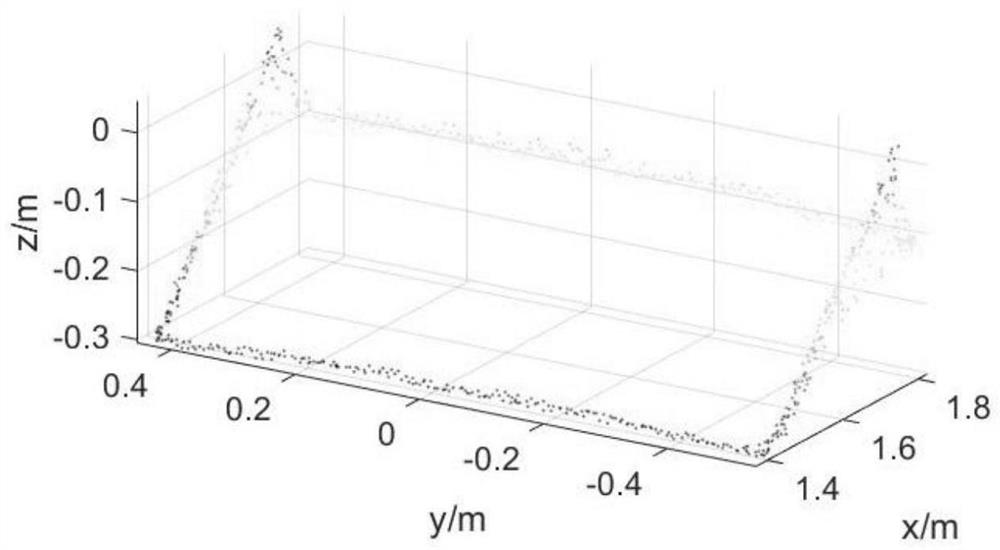

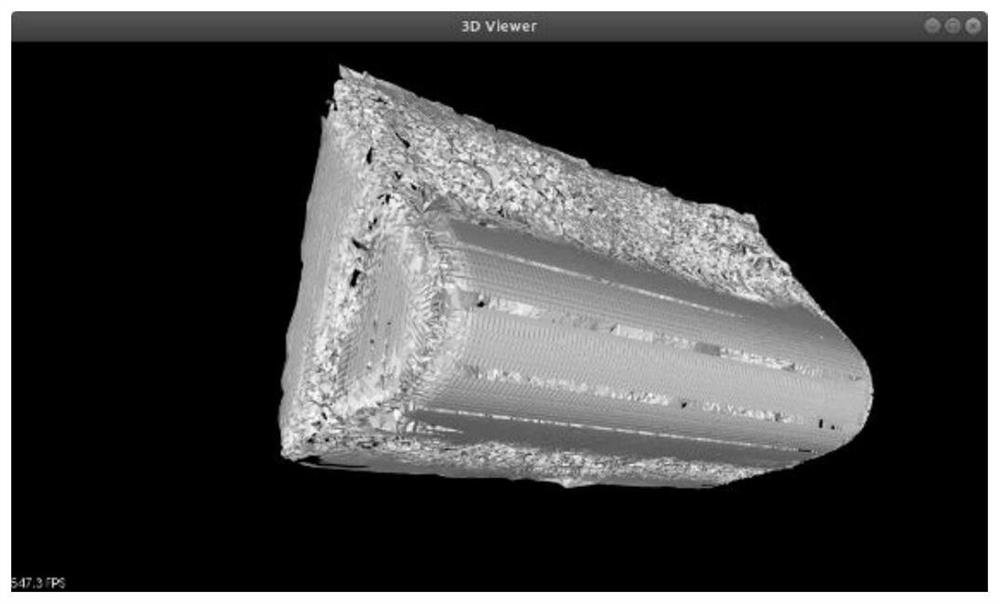

Bulk material volume measurement method based on image features and three-dimensional point cloud technology

PendingCN114419130AReduce computing pressureCalculation speedImage enhancementImage analysisBulk cargoEngineering

The invention discloses a bulk cargo volume measurement method based on image features and three-dimensional point clouds, and the method comprises the steps: fixedly arranging a three-dimensional laser radar and a digital camera on a forklift, and obtaining the full view information of a bucket and a loaded object thereof; point cloud data are collected and preprocessed, and the collected point cloud data are optimized through a filtering and clustering algorithm; fusing the image and the point cloud information, calibrating parameters between the laser radar and the digital camera, projecting the point cloud to a pixel plane, and fusing the linear features of the image and the point cloud information; acquiring a reference plane; triangularizing the point cloud on the surface of the bulk material, and dividing the point cloud after downsampling into triangular meshes through greedy triangularization; and calculating the volume: calculating the volume of the oblique triangular prism corresponding to each triangular mesh, and then performing accumulation to obtain the final bulk material volume. The method is high in calculation speed, simple in step and accurate in result; by collecting point cloud and image information of the bucket, real-time volume calculation is achieved, and the system is suitable for real-time monitoring in industrial and mining complex environments such as construction sites.

Owner:SINOHYDRO BUREAU 7 CO LTD

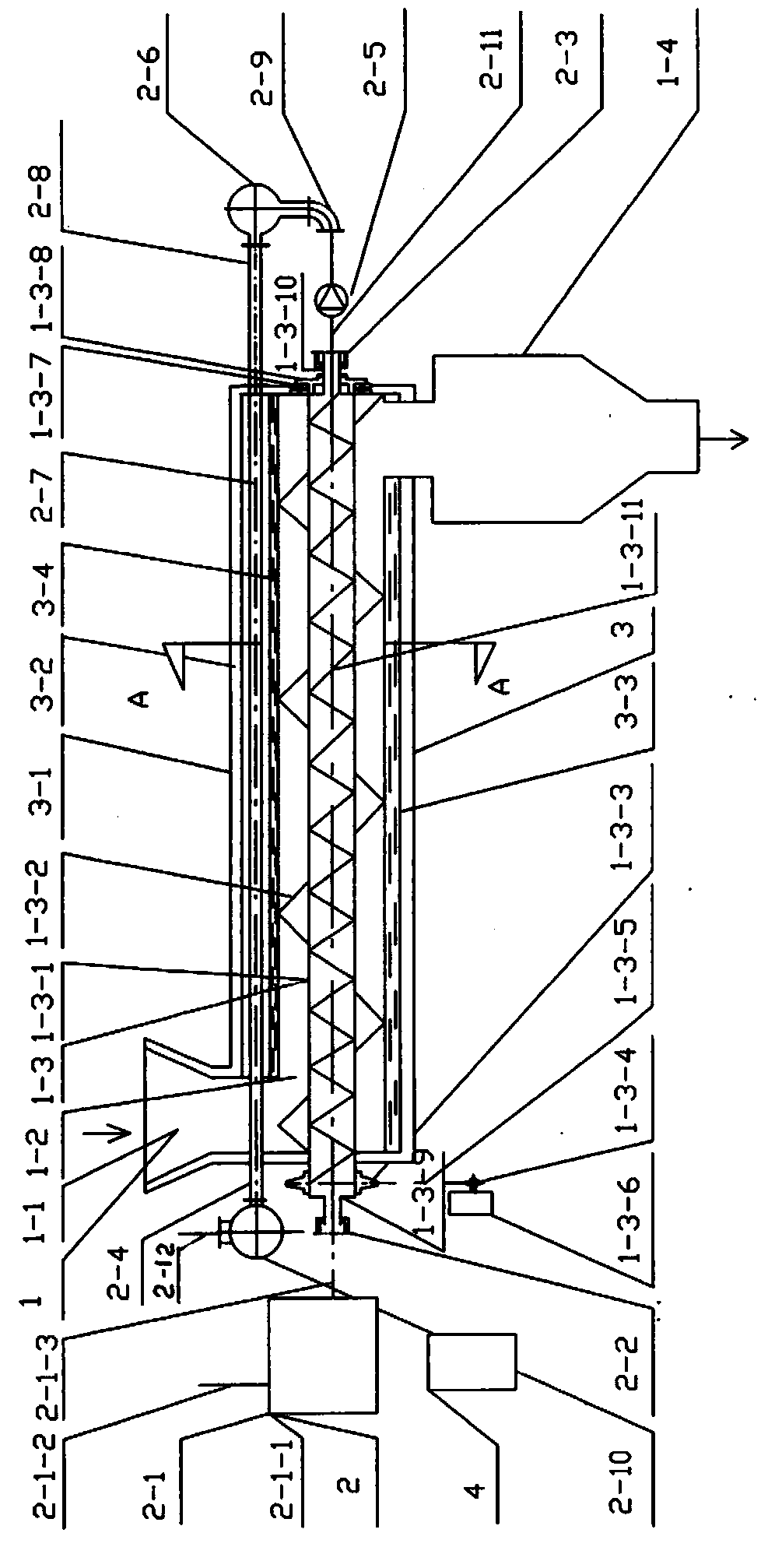

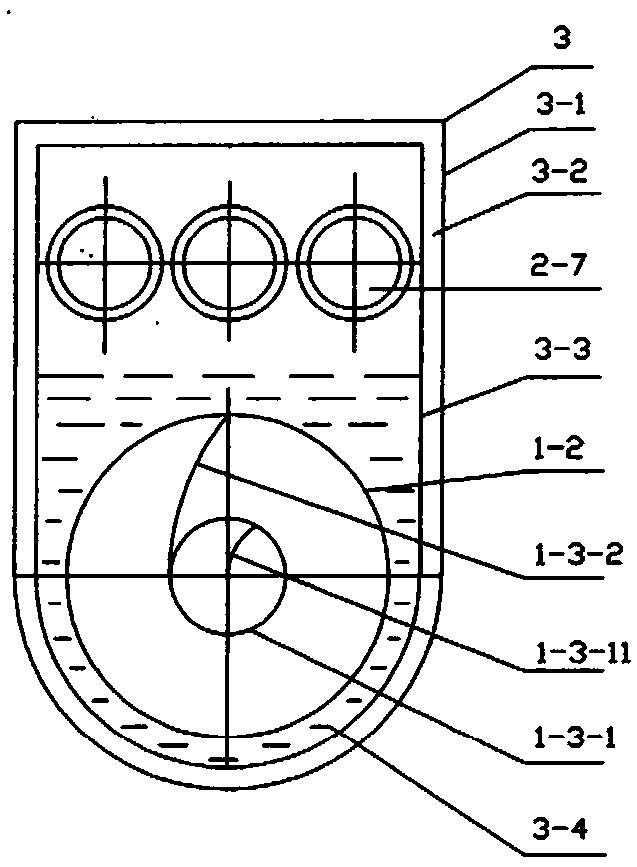

High-temperature solid bulk cargo waste heat recovery device

ActiveCN104180357AMaximize heat transfer areaMaximize the heat transfer effectSteam generation using hot heat carriersThermal energyBulk cargo

The invention discloses a high-temperature solid bulk cargo waste heat recovery device which comprises a high-temperature solid bulk cargo heat exchange system (1), a water heat exchange system (2), a high-temperature working medium heat exchange system (3) and an electric control cabinet (4). The left end and the right end of a screw propulsion cylinder (1-3-1) in the high-temperature solid bulk cargo heat exchange system (1) are connected with a water tank water outlet pipe (2-1-3) and a high-pressure water pump water inlet pipe (2-11) in the water heat exchange system (2) through a left moving seal device (2-2) and a right moving seal device (2-3) respectively, and a heat exchange bin (1-2) in the high-temperature solid bulk cargo heat exchange system (1) is welded with a high-temperature working medium box (3-3) in the high-temperature working medium heat exchange system (3). The high-temperature solid bulk cargo waste heat recovery device has the advantages that the heat exchange bin (1-2) is completely soaked in a high-temperature working medium (3-4), heat exchange effect is maximized, a screw propulsion device (1-3) is arranged in the heat exchange bin (1-2), low-temperature water flows in the screw propulsion device (1-3), so that high-temperature solid bulk cargoes exchange heat with two walls, the heating surface of a finned pipe (2-7) is large, feed hopper light pipes (2-4) are heated by the high-temperature solid bulk cargoes with the temperature of about 900 DEG C, and the output quality of heat energy is improved.

Owner:朱杰 +1

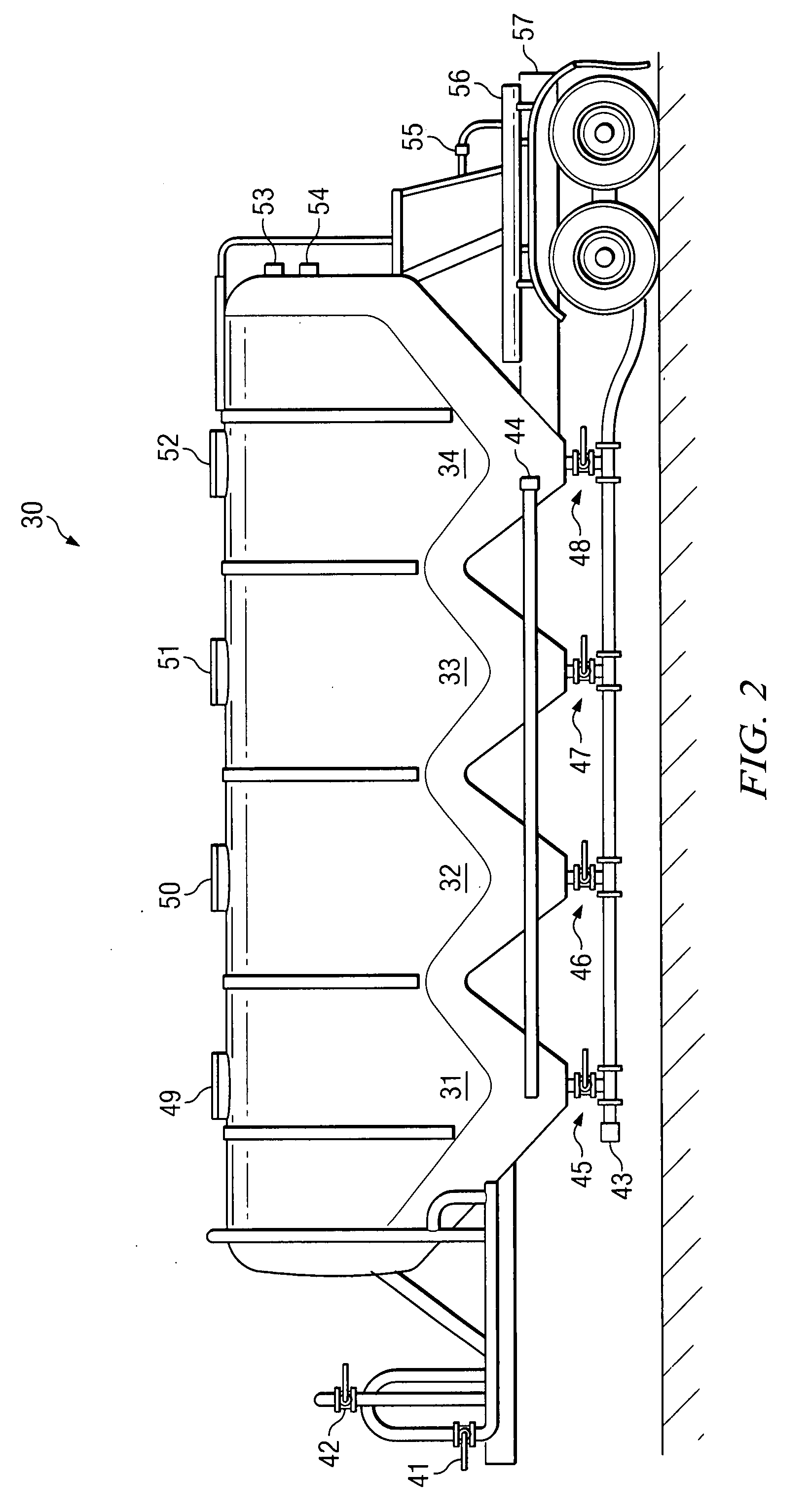

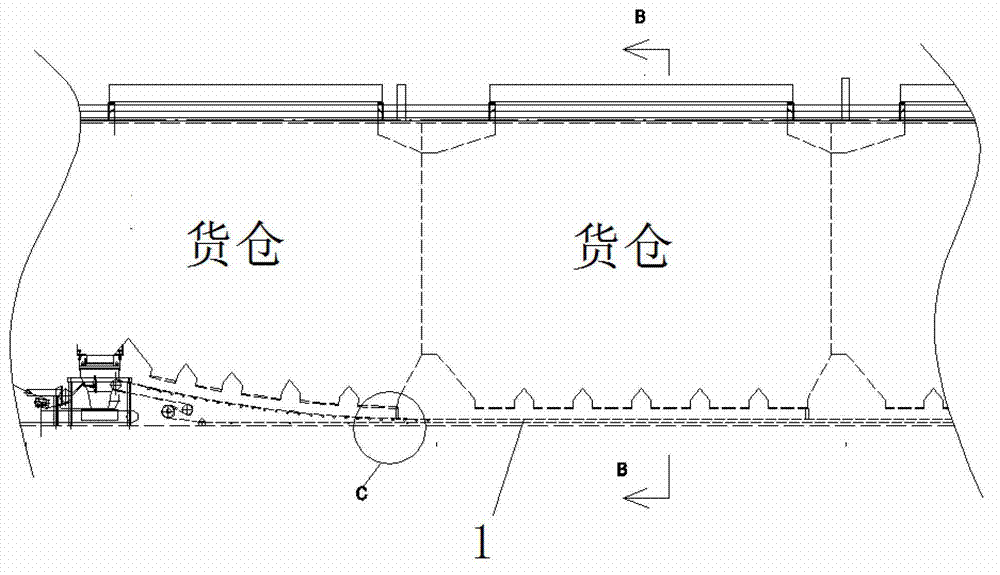

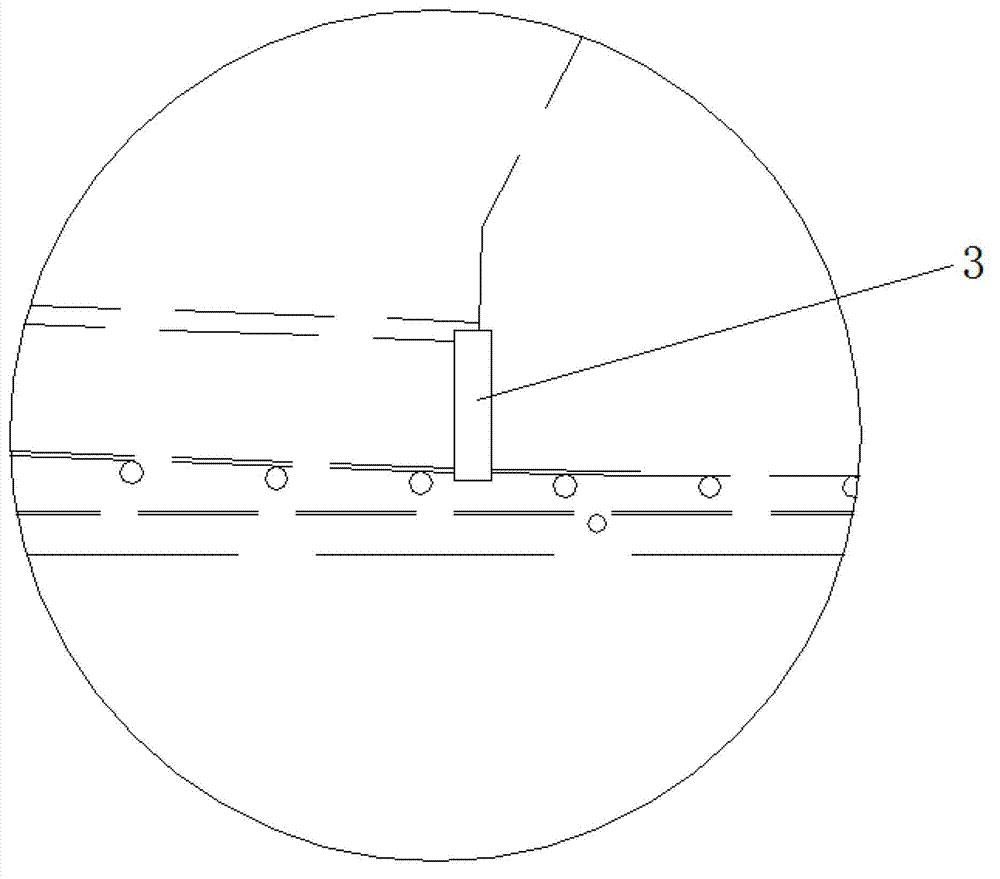

Self-unloading bulk cargo transport ship and unloading method thereof

InactiveCN103204227ASimple structureEasy to operateCargo handling apparatusPassenger handling apparatusBulk cargoConveyor belt

The invention relates to a self-unloading bulk cargo transport ship. The self-unloading bulk cargo transport ship comprises a plurality of marine cranes which are arranged above a deck, and a cargo hold grab bucket is arranged at the end of each of the marine cranes; deck hoppers which are in one-to-one correspondence to the marine cranes are arranged on the deck of a ship body and positioned on a starboard, and a longitudinal conveyor belt is arranged below the deck hoppers along the longitudinal direction of the ship body and positioned above cargo holds; a first discharge outlet is arranged on the tail portion of the longitudinal conveyor belt and corresponds to a horizontal conveyor belt, and the horizontal conveyor belt is arranged along the horizontal direction of the ship body and communicates the deck starboard and a deck larboard; a second discharge outlet is arranged on the tail portion of the horizontal conveyor belt and corresponds to an inclined conveyor belt, and the inclined conveyor belt is upwards inclined along a deck of the larboard; and a third discharge outlet is arranged at the tail end of the inclined conveyor belt and corresponds to an unloading arm of a gantry crane, the unloading arm can telescope, slew and luff, and a fourth discharge outlet is arranged at the tail end of the unloading arm.

Owner:SHANGHAI MERCHANT SHIP DESIGN & RES INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com