Electric stove metal bulk cargo continuous feeding and preheating device and method

A metal material and electric furnace technology, applied in the field of metallurgy, can solve the problems of poor preheating effect of scrap steel, increased height of electric furnace equipment, low mechanical reliability, etc., and achieves short workshop, small equipment vibration, and good preheating effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

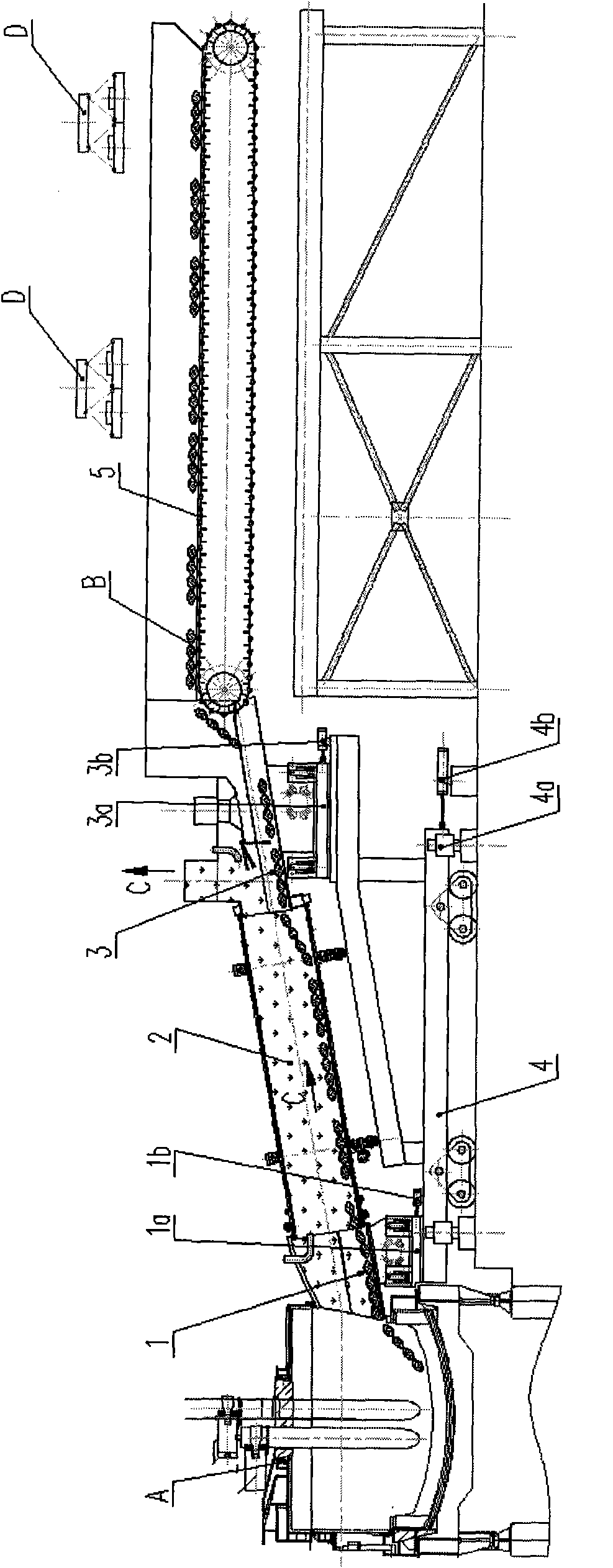

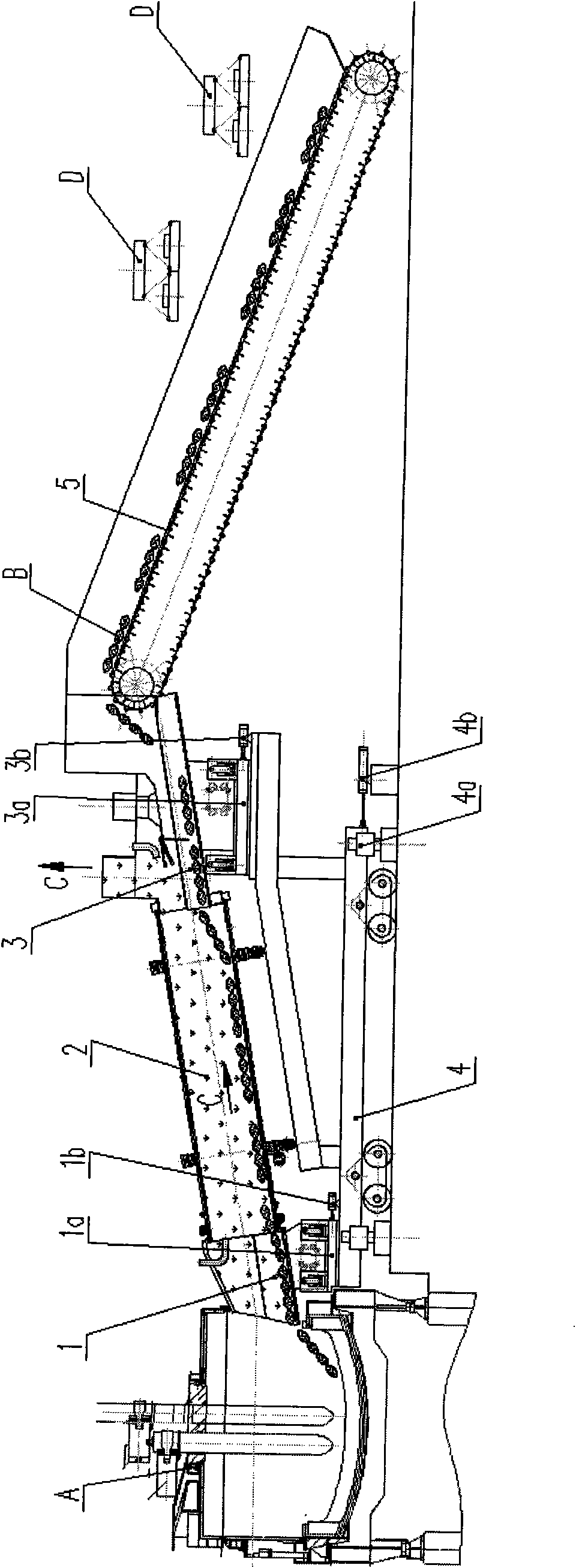

[0012] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

[0013] The metal material B is loaded onto the plate chain material receiving conveyor 5 through the disk crane D, and in addition to improve the operation rate of the disk crane D, the plate chain material receiving conveyor 5 can be installed obliquely.

[0014] In order to meet the actual factory layout and material receiving operation requirements, plate chain material receiving conveyors 5 can be arranged in combination, and one is allowed to form a certain angle with the other on the plane.

[0015] The plate chain material receiving conveyor 5 tail is installed in the inlet groove of the groove-entry vibration conveying and air sealing device 3 . The plate chain material receiving conveyor 5 transports the metal material B into the inlet groove of the vibrating conveying and air sealing device 3, and the material outlet of the vibrating con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com