Patents

Literature

526 results about "Electric stove" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

An electric stove or electric range is a stove with an integrated electrical heating device to cook and bake. Electric stoves became popular as replacements for solid-fuel (wood or coal) stoves which required more labor to operate and maintain. Some modern stoves come in a unit with built-in extractor hoods.

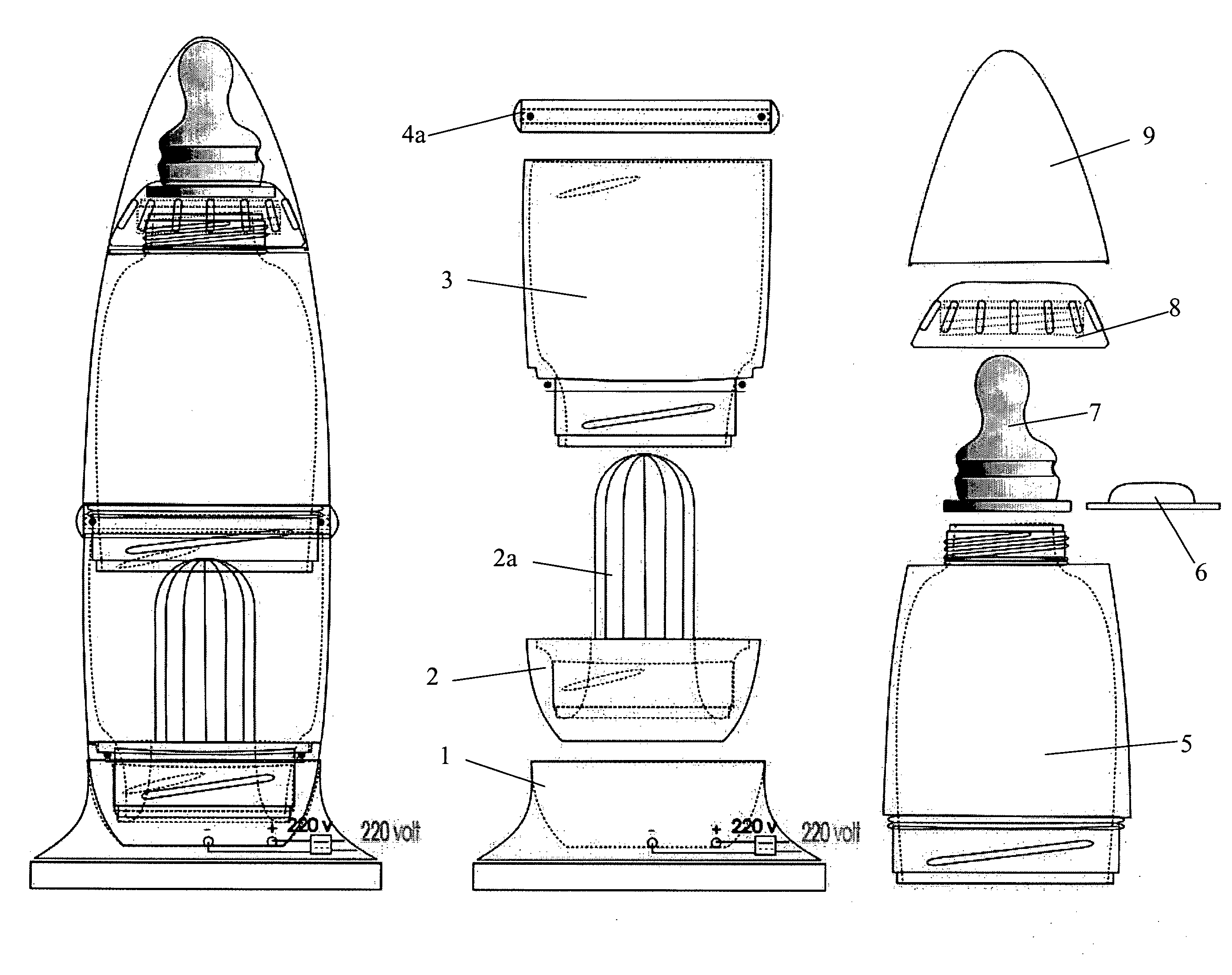

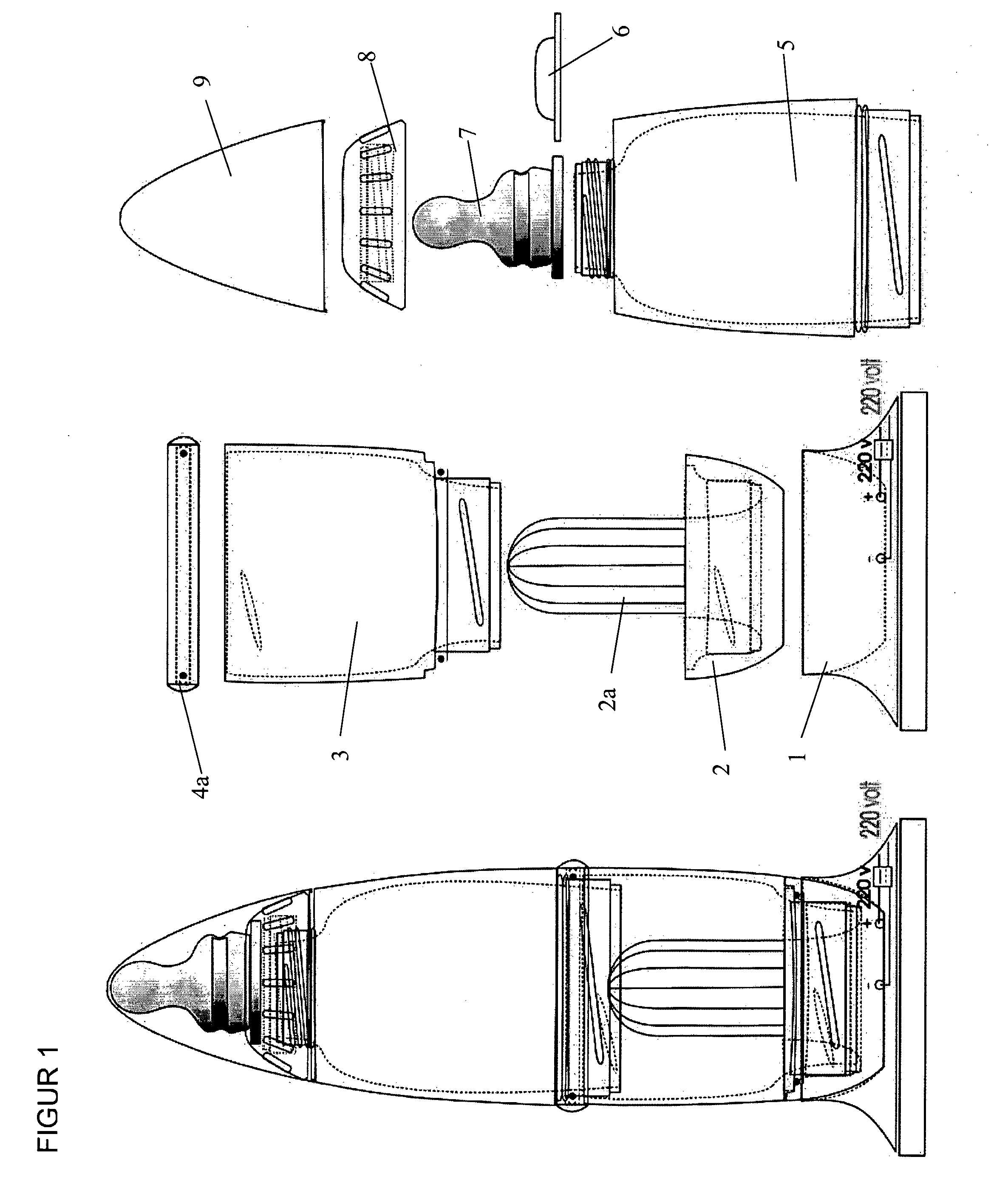

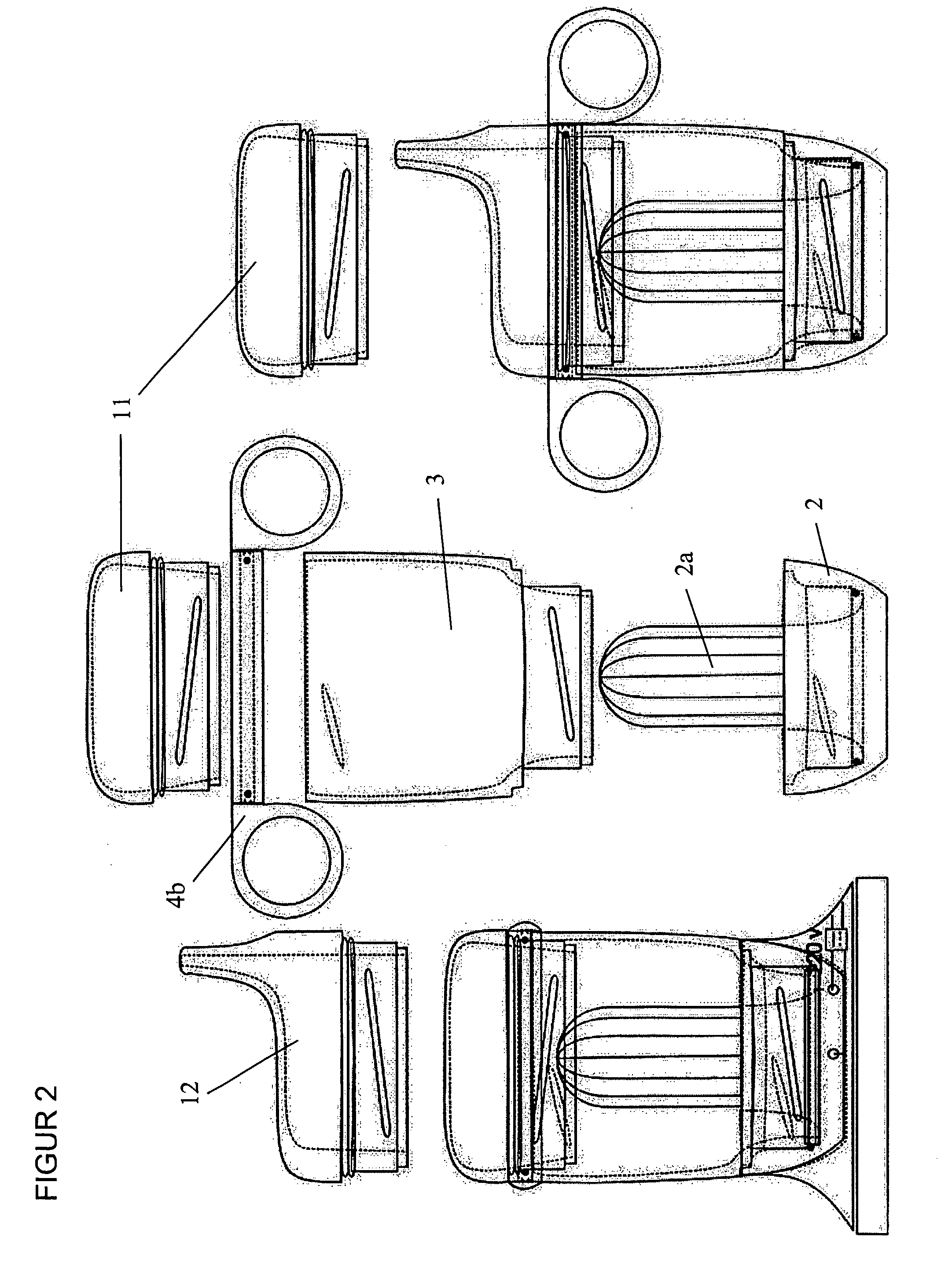

Modular Transportable Heating Device

During journeys, and at other times when no stationary heating devices such as microwave ovens or hotplates are available, providing hot foods, liquid or solid, can be problematic. By providing a container with an in-built heating arrangement, the present invention solves the problem. Furthermore, the container is of a modular design. Its parts are easily interchangeable and new configurations for different purposes can be readily put together.

Owner:TEGLBJARG CASPER

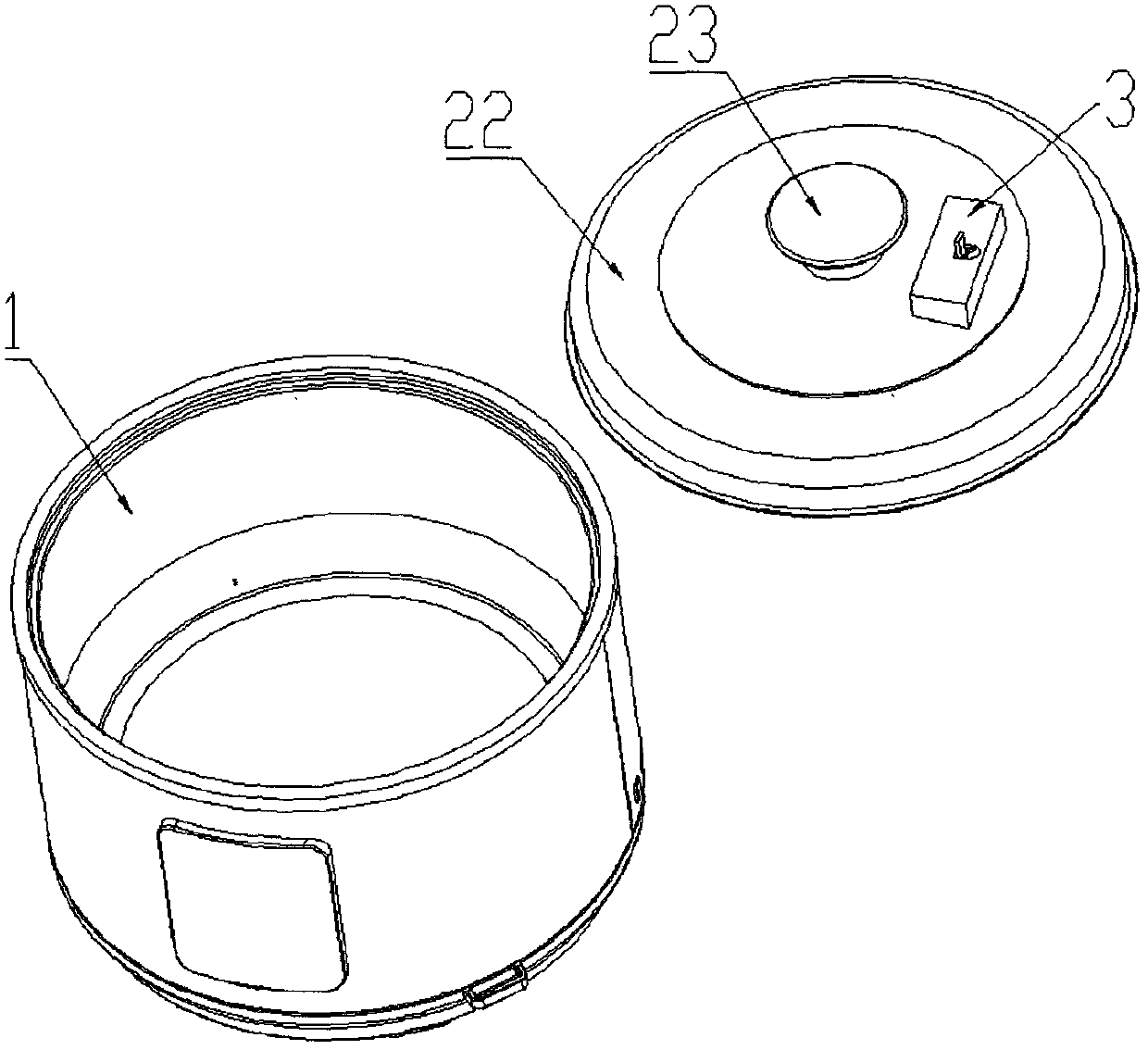

Electric heating cooking utensil with wireless steam detection device

The invention discloses an electric heating cooking appliance with a wireless steam detection device, which is a detection device for detecting the temperature, humidity, flow velocity and flow data signals of the steam flowing into the atmosphere through the pot cover in different boiling states of the liquid with wireless transmission and reception. On the pot lid of the electric cooking appliance that is detachable from the pot body or utensils and has no signal transmission wires, this effectively solves the problem that the pot lid and the pot body or utensils can be separated. The electrothermal liquid heating appliance is susceptible to product structure, heating method, and material changes , use environment, operation method, aging deformation, commercial pots of different specifications, etc., especially the changes in altitude, which cause existing problems such as electric rice cookers, electric pressure cookers, electric steamers, and electric stew pots. It has realized the intelligent judgment, adjustment and control of the cooking process when the electric heating stoves such as induction cooker, electric ceramic stove, health pot, electric tea set, and light-wave oven are performing the function of "steaming, cooking, and stewing".

Owner:谢勇

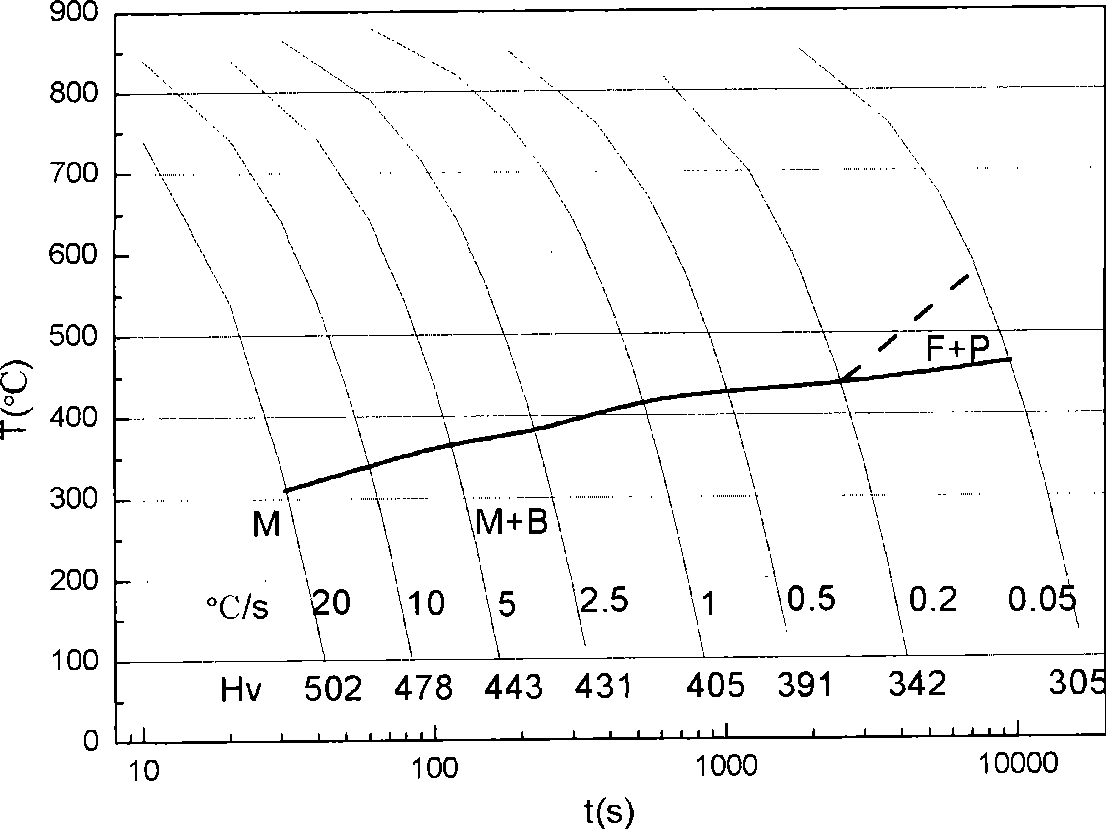

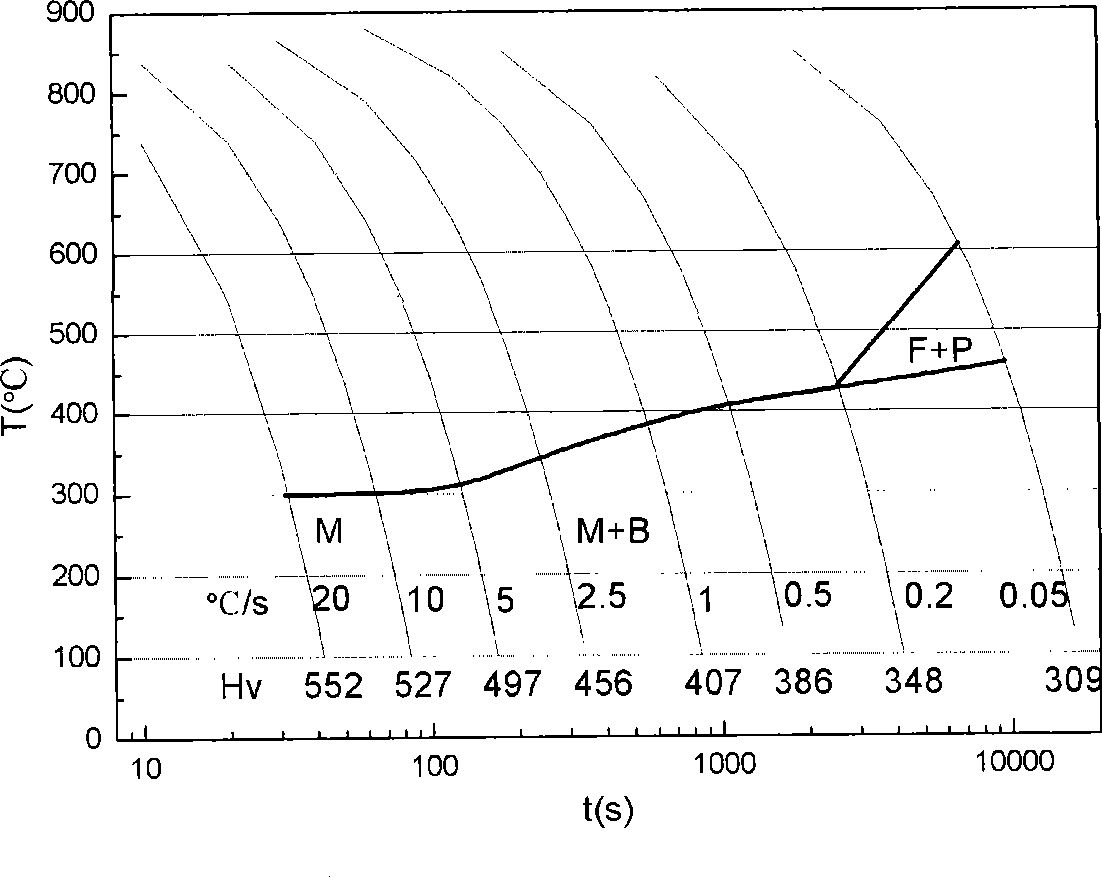

High-performance marine mooring chain steel and manufacturing method thereof

InactiveCN101519751AGood weather resistanceImprove corrosion resistanceMetal rolling arrangementsIngotHeating furnace

The invention relates to high-performance marine mooring chain steel and a manufacturing method thereof. The method comprises the following steps: a. tapping compositions comprise the following by weight percentage: C: 0.16 to 0.27, Mn: 0.40 to 1.45, Si: 0.15 to 0.50, Cr: 1.25 to 2.50, Ni: larger than 0 and less than 1.20, Mo: 0.20 to 0.60, Al: 0.01 to 0.06, N: 0.004 to 0.015, S: not larger than 0.005, P: not larger than 0.015, Cu: larger than 0 and less than 0.50, and the balance of Fe; b. a steel ingot or a continuous casting billet is casted after the steps of primary smelting in an electric stove or a converter, external refining and vacuum degassing; c. the charging temperature of a heating oven is not larger than 900 DEG C, the heating rate is not larger than 150 DEG C / h; when being raised to 1100 to 1300 DEG C, the temperature is kept for more than 40 minutes, cogging bloom or rolling by a finisher is carried out, and the finishing temperature is not larger than 1050 DEG C; and d. after heated at the temperature of 1000 to 1250 DEG C, the cogged ingot is hot-rolled or forged into round steel, the finishing temperature is not larger than 1050 DEG C, and after rolling, the steel is air-cooled, slow cooled or softening heat-treated at the temperature of not less than 600 DEG C. The performance of finished products achieves or exceeds the requirement of level 4.5 and level 5 of mooring chain steel.

Owner:BAOSTEEL SPECIAL STEEL CO LTD

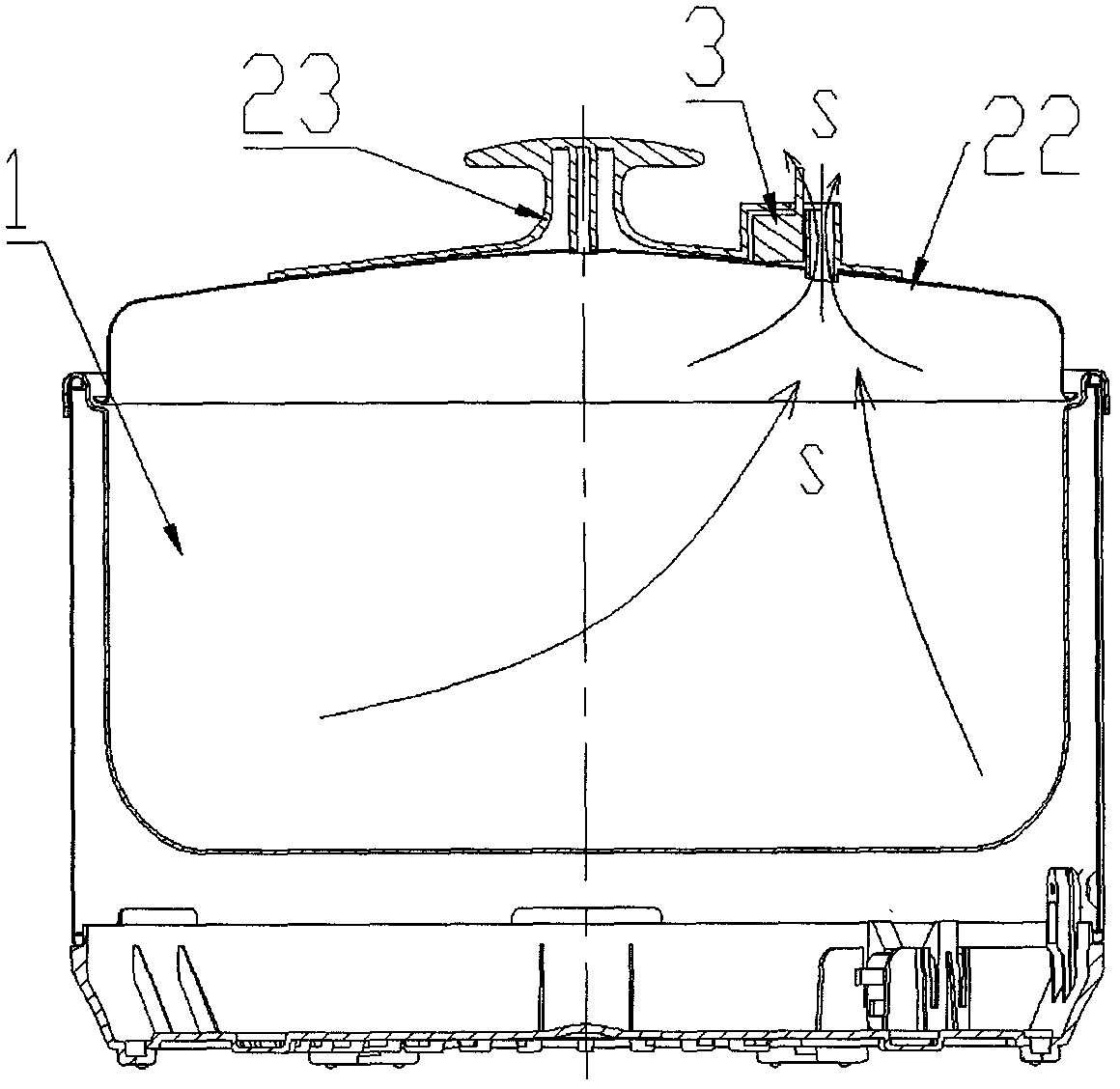

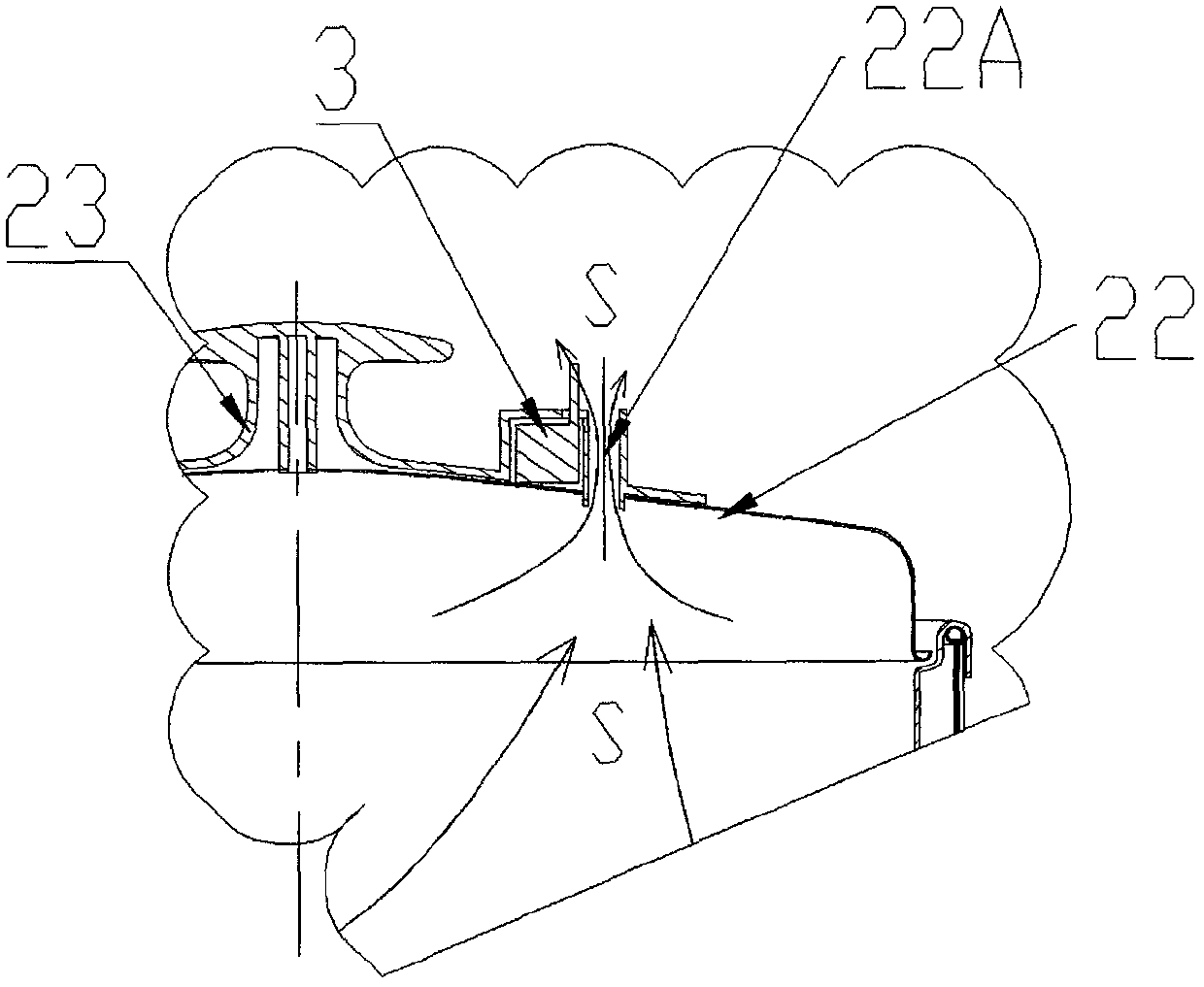

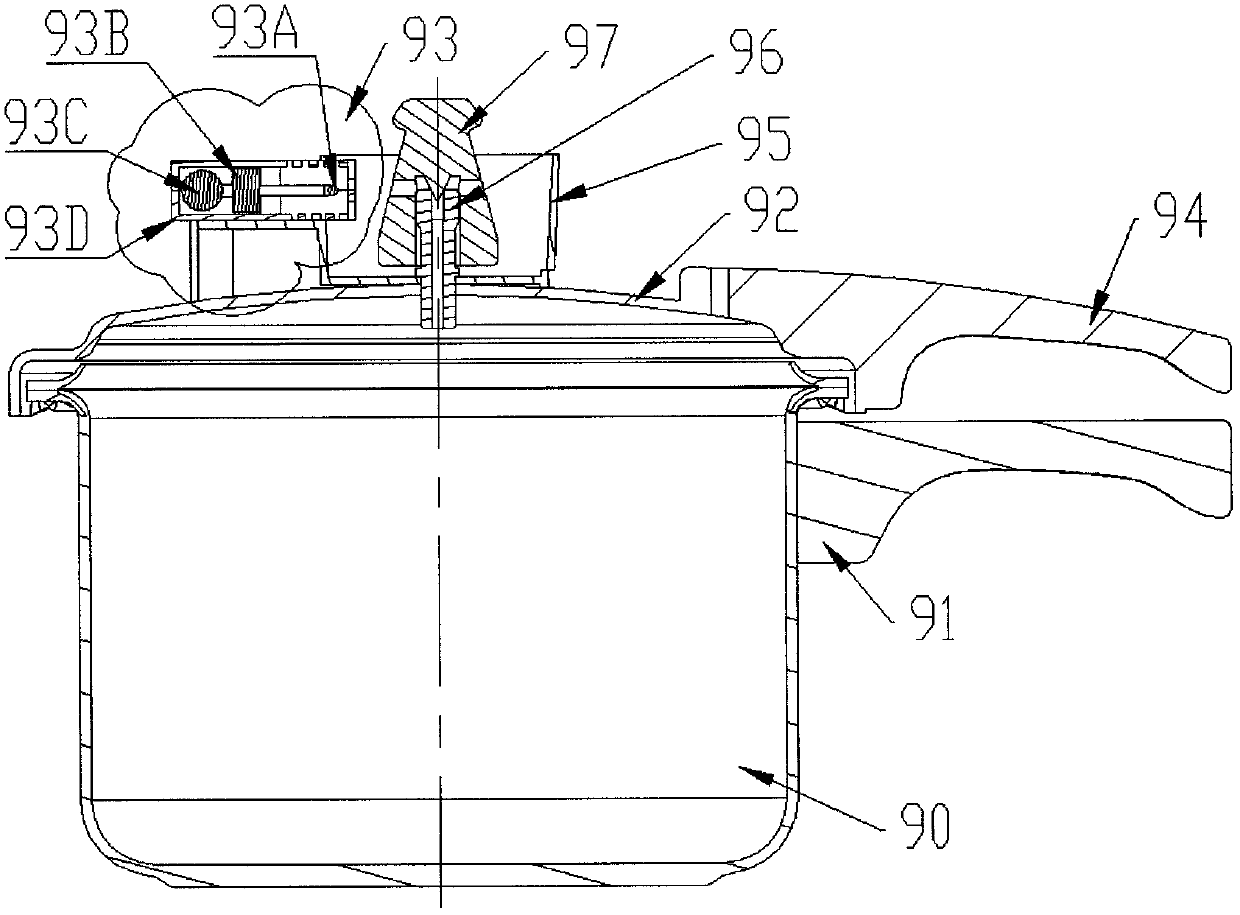

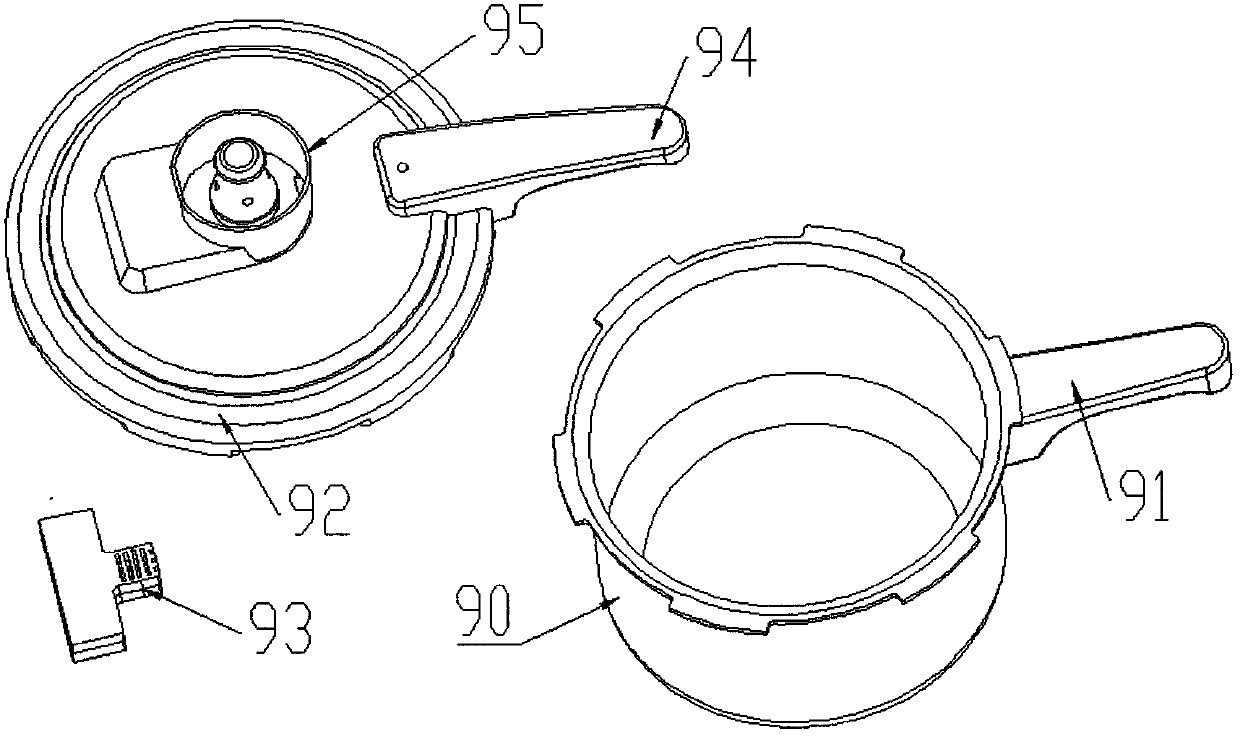

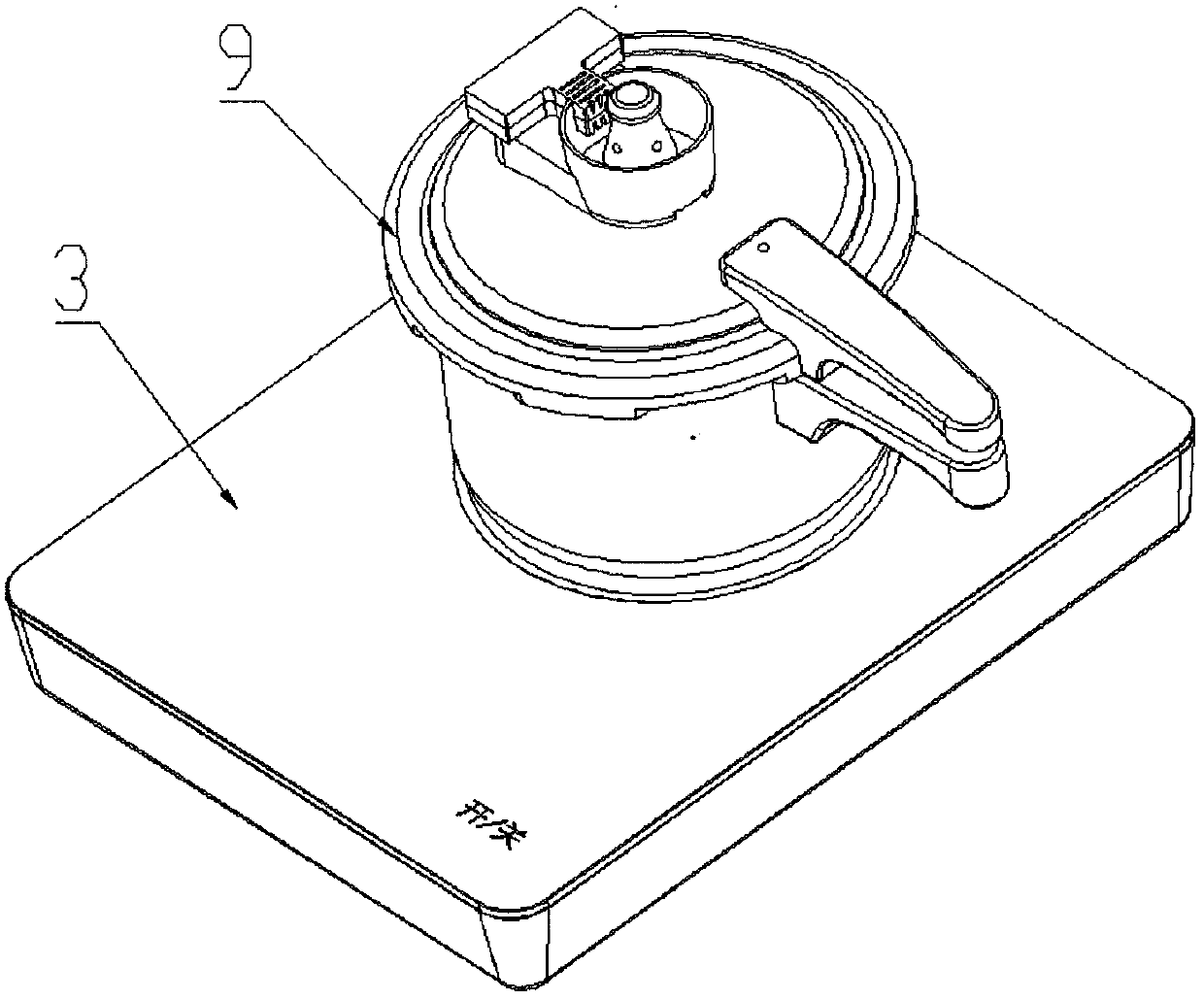

Pressure cooker with steam detector and matched electric heating stove

InactiveCN107647772ARealize matchingAvoid safety accidentsDomestic stoves or rangesLighting and heating apparatusWireless transceiverMature technology

The invention discloses a pressure cooker equipped with a steam detector and the matching electric heating stove. It combines the mature wireless transceiver technology with the steam detection technology. Detectors of temperature, humidity, flow velocity, and flow changes of steam flowing into the atmosphere through exhaust pipes and pressure limiting valves in different boiling states of liquids, providing stable, reliable, and accurate data signals for electric heating stoves equipped with matching wireless transceiver systems , realize the intelligent control when the ordinary pressure cooker is used with the electric heating stove, improve the performance of the electric heating stove, expand the application range of the electric heating stove, and effectively eliminate the safety hazard of using the pressure cooker on the electric heating stove.

Owner:谢勇

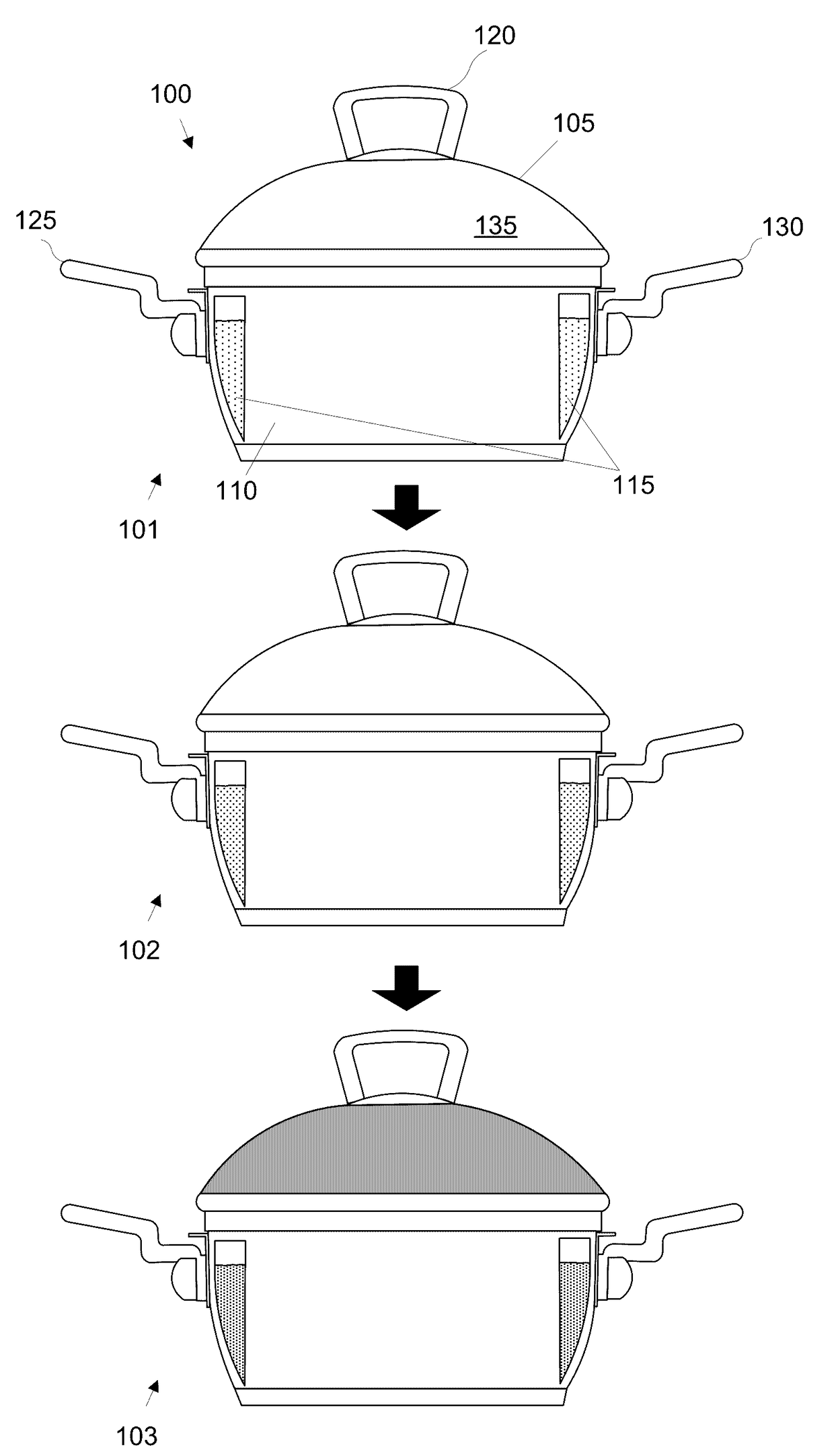

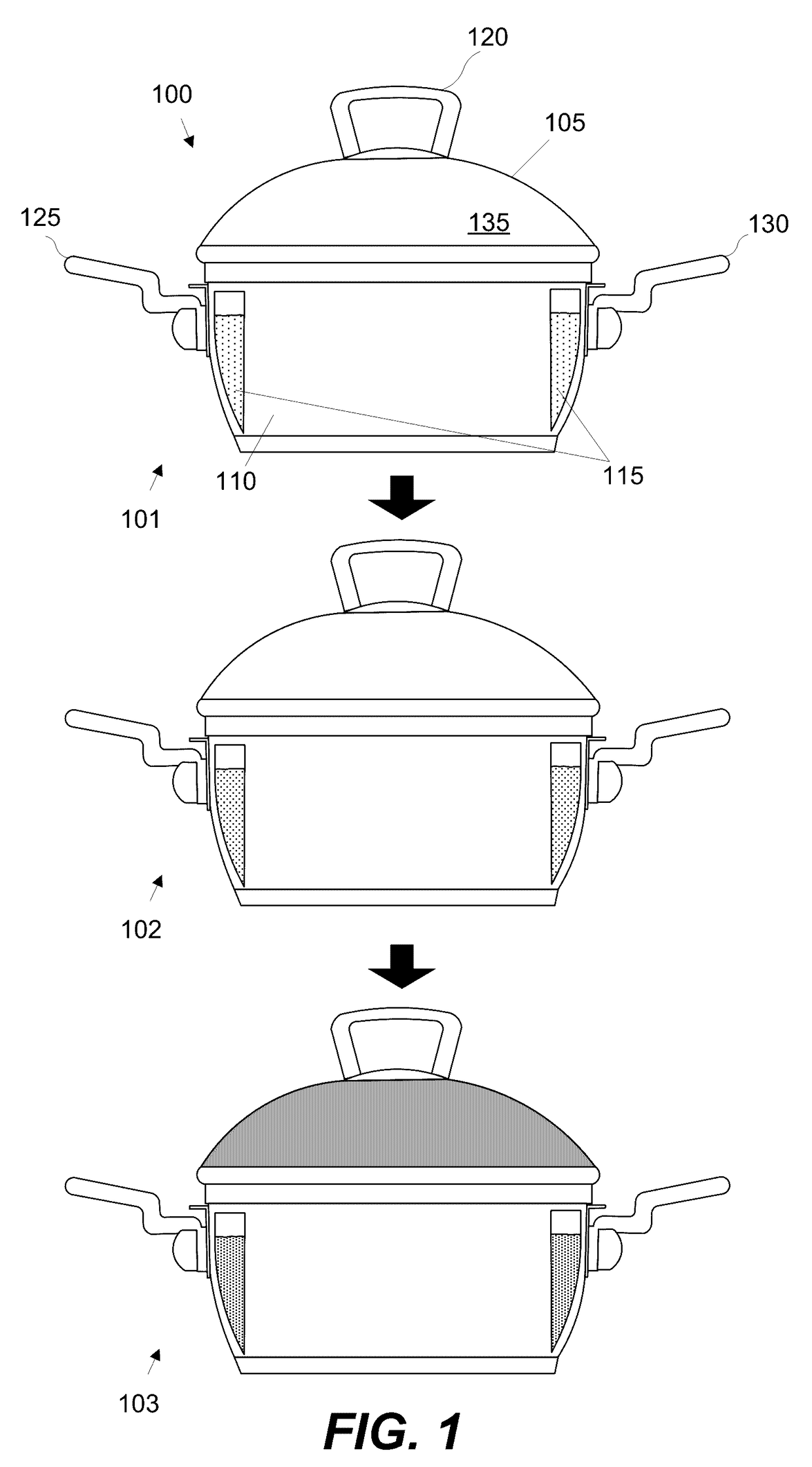

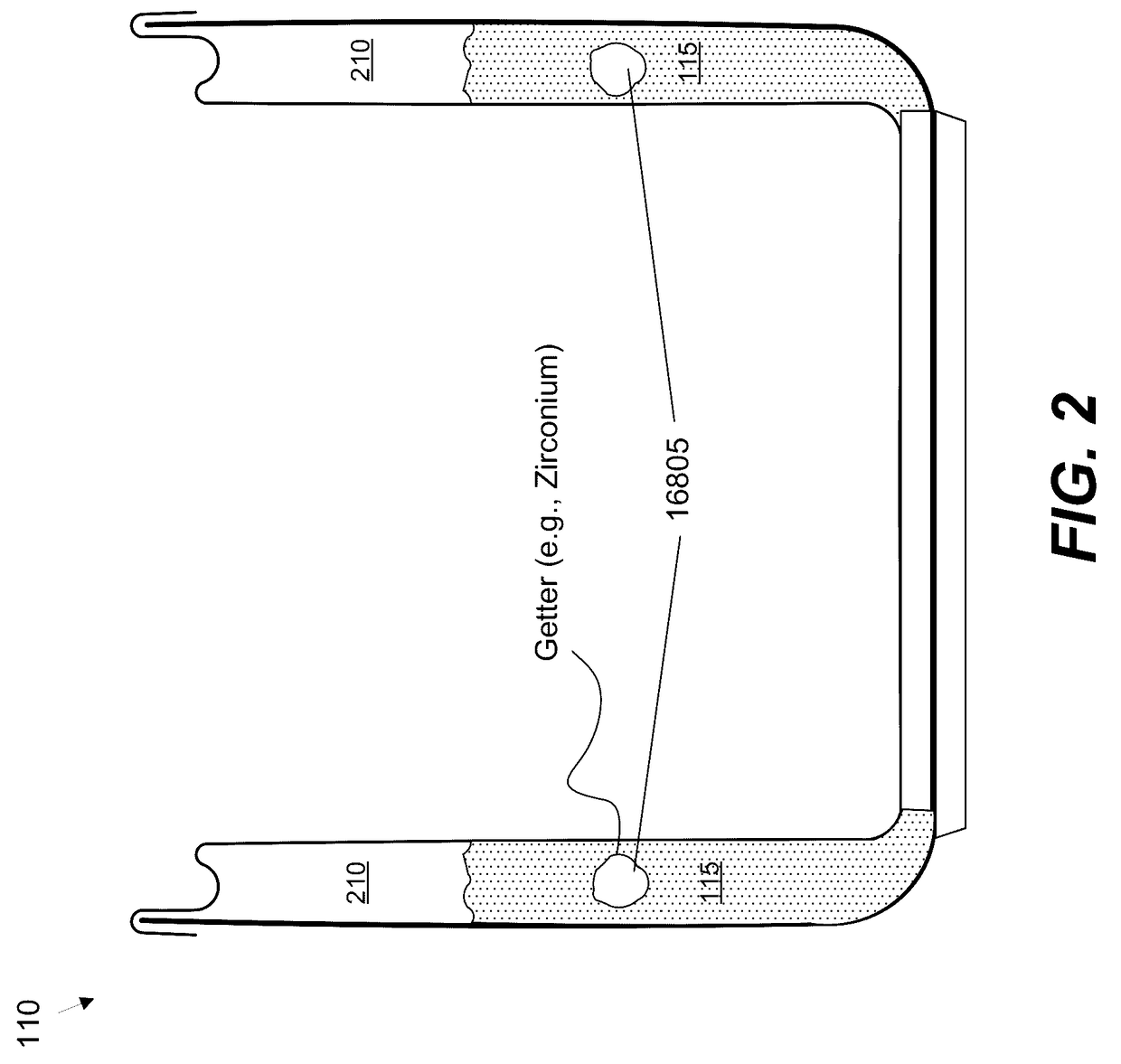

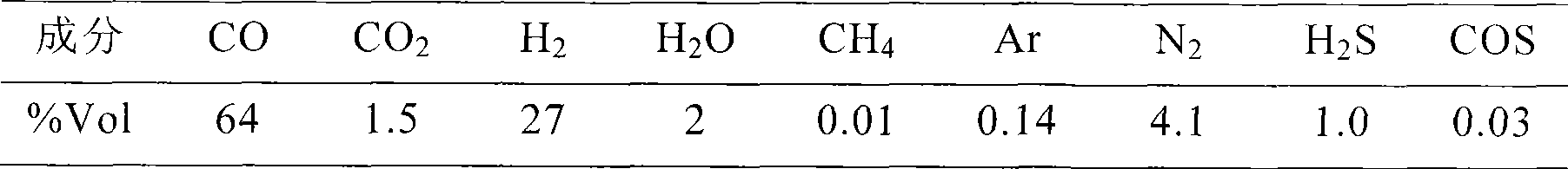

Multi-purpose double layered container

InactiveUS20170150840A1Cooking-vessel materialsCooking-vessel lids/coversInterior spaceMicrowave oven

Some embodiments provide a multi-purpose cooking and heating container. The container can be used with a variety of different cooking appliances, including a microwave oven, induction cooker, electric stove, etc. The multi-purpose container is double layered in that it has inner and outer shells. The inner shell is disposed adjacent the outer shell, and the outer edges of the shells are then hermetically sealed to form an inner space between the two shells. To transfer heat to the inner space in different cooking environment, the container's outer surface of the outer shell is coated with an exothermic enamel glaze or a exothermic ceramic coat.

Owner:PARK JONG PETER

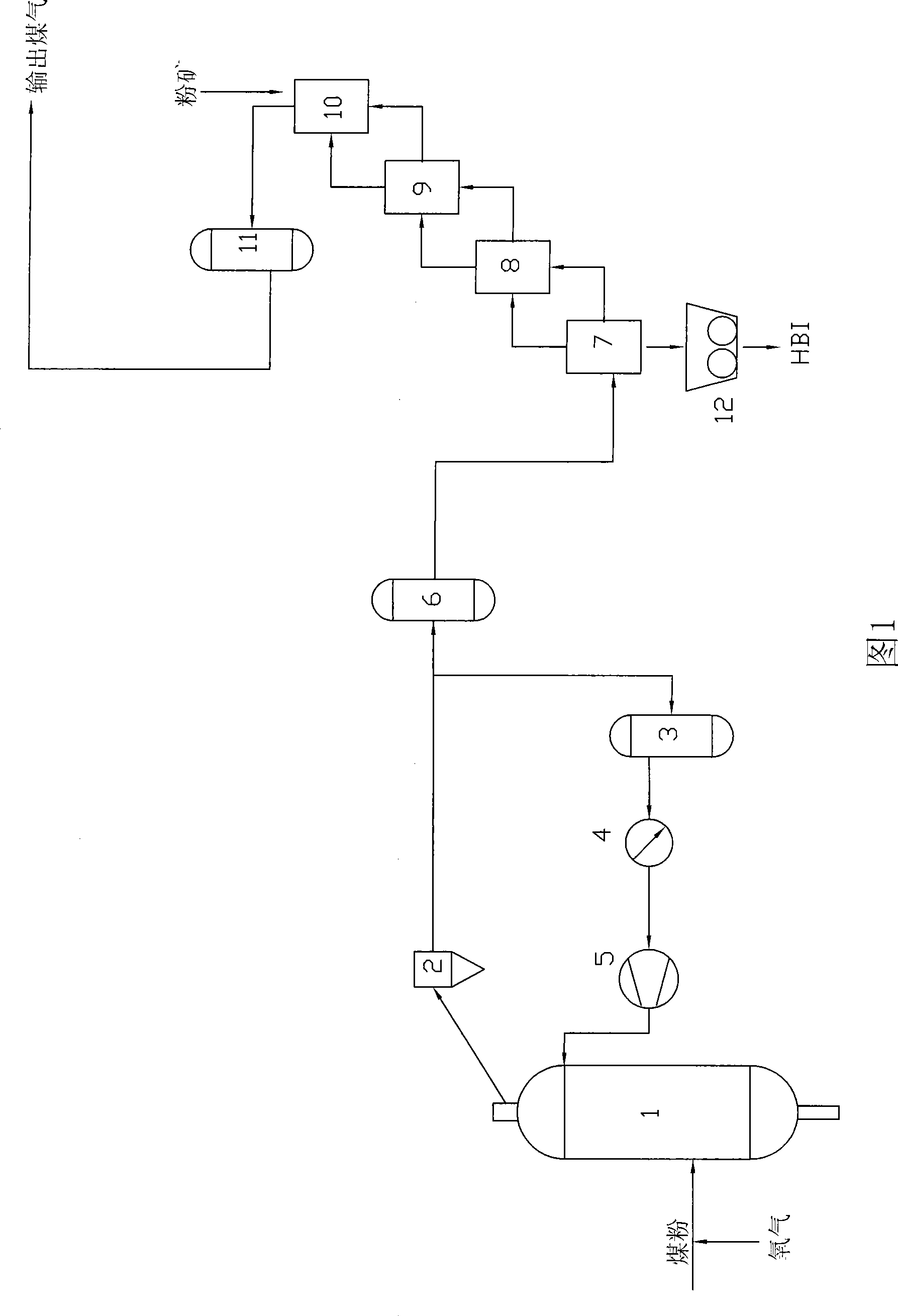

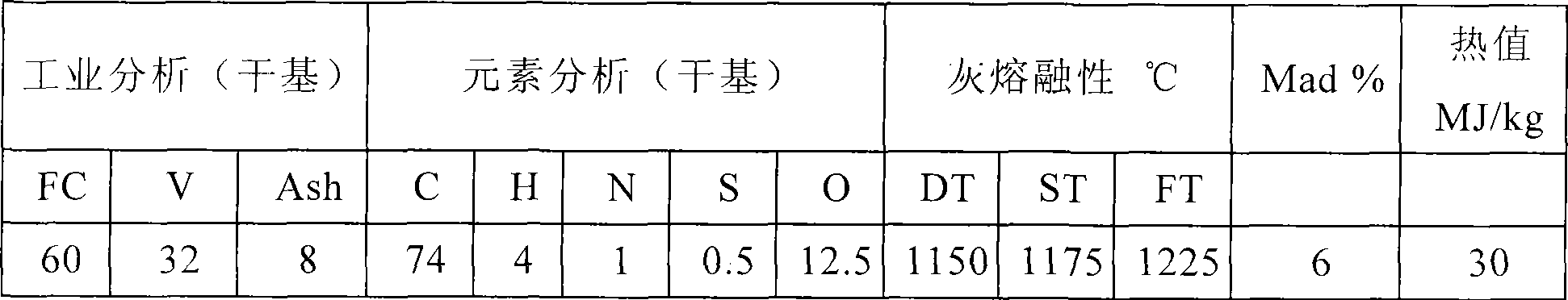

Method for producing spongy iron by direct reduction of dry coal powder gasification and hot coal gas fine ore fluidized bed

InactiveCN101397597AOvercoming gasification link limitationsGas emission reductionIron powderFluidized bed

The invention discloses a method for reducing and producing sponge iron directly by a dry coal dust gasified hot coal gas fineore fluidized bed, which comprises the following steps of: a) grinding and drying the feed coal; b) spraying the dry coal dust and pure oxygen into a pressured gasification furnace; c) chilling the hot coal gas at the top of a gasification furnace to be 900 DEG C to 950 DEG C by the cooled coal gas of 30 DEG C to 80 DEG C, then removing dust, and after washing and cooling part of the coal gas to be 30 DEG C to 80 DEG C, which then returns to the top of the gasification furnace, chilling the high-temperature coal gas; d) desulfurizing the remaining coal gas which is taken as reducing gas for entering a fluidized bed reactor; and e) introducing the hot coal gas into the last level of the multilevel fluidized bed; and then the coal gas flows in the opposite direction of the iron-containing powder lot; the coal gas flows through all levels of the fluidized bed in the reverse direction and the iron-containing powder lot flows through all levels of the fluidized bed in the forward direction, and then the iron-containing powder lot and the reduced gas countercurrent contact with each other, therefore, the sponge iron is obtained by progressive reduction and carburization. The reduced gas is produced by adopting the technology of gas generation; the energy utilization rate is improved by using the sensible heat of the hot coal gas to provide the energy which is necessary in the hematite reduction; and the generated sponge iron can be used for the electrosmelting of steel directly.

Owner:BAOSHAN IRON & STEEL CO LTD

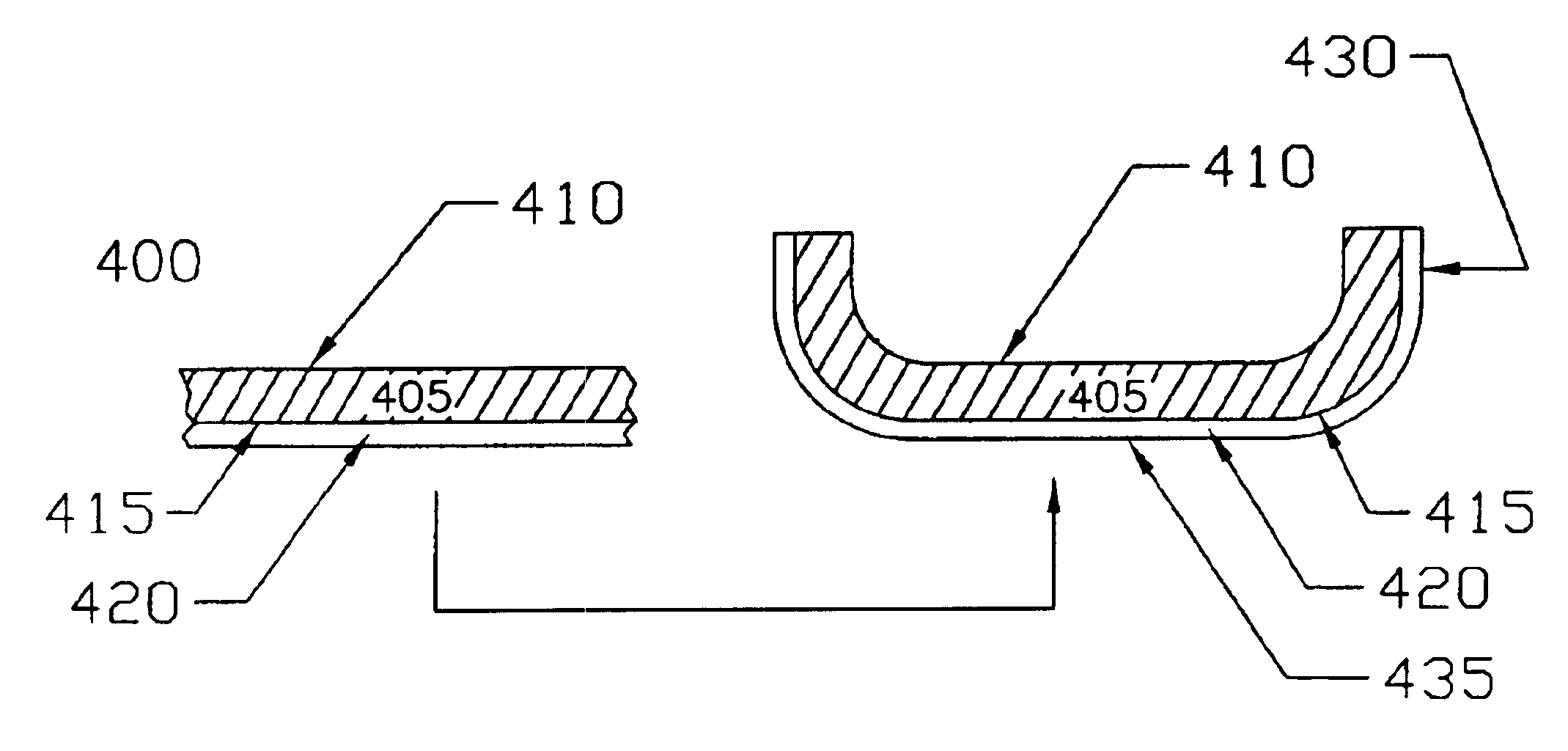

Foodware with a tarnish-resistant ceramic coating and method of making

A foodware article having a thermally stable color, tarnish-resistant ceramic coating that enables direct contact with a heat source, such as a gas flame or the heating element of an electric stove. The foodware article of the present invention includes a metal foodware article having an inner food-contacting surface and an outer heat source-contacting surface, a bonding layer deposited on a portion of the outer heat source-contacting surface, and a first ceramic layer deposited adjacent to a portion of the bonding layer, the first ceramic layer selected from (Ti,Al)N, (Ti,Al)CN, (Ti,Al,X)N, or (Ti,Al,X)CN. A top layer of TiCN can be deposited adjacent to the first ceramic layer. There may optionally be alternating layers of a third ceramic selected from (Ti,Al)N, (Ti,Al)CN, (Ti,Al,X)N, or (Ti,Al,X)CN and a fourth ceramic selected from TiN, TiCN, XN or XCN deposited adjacent to the bonding layer and below the first ceramic layer. The alternating layers can be repeated as many times as desired. A method of making such a foodware article is also disclosed.

Owner:MEYER INTPROP

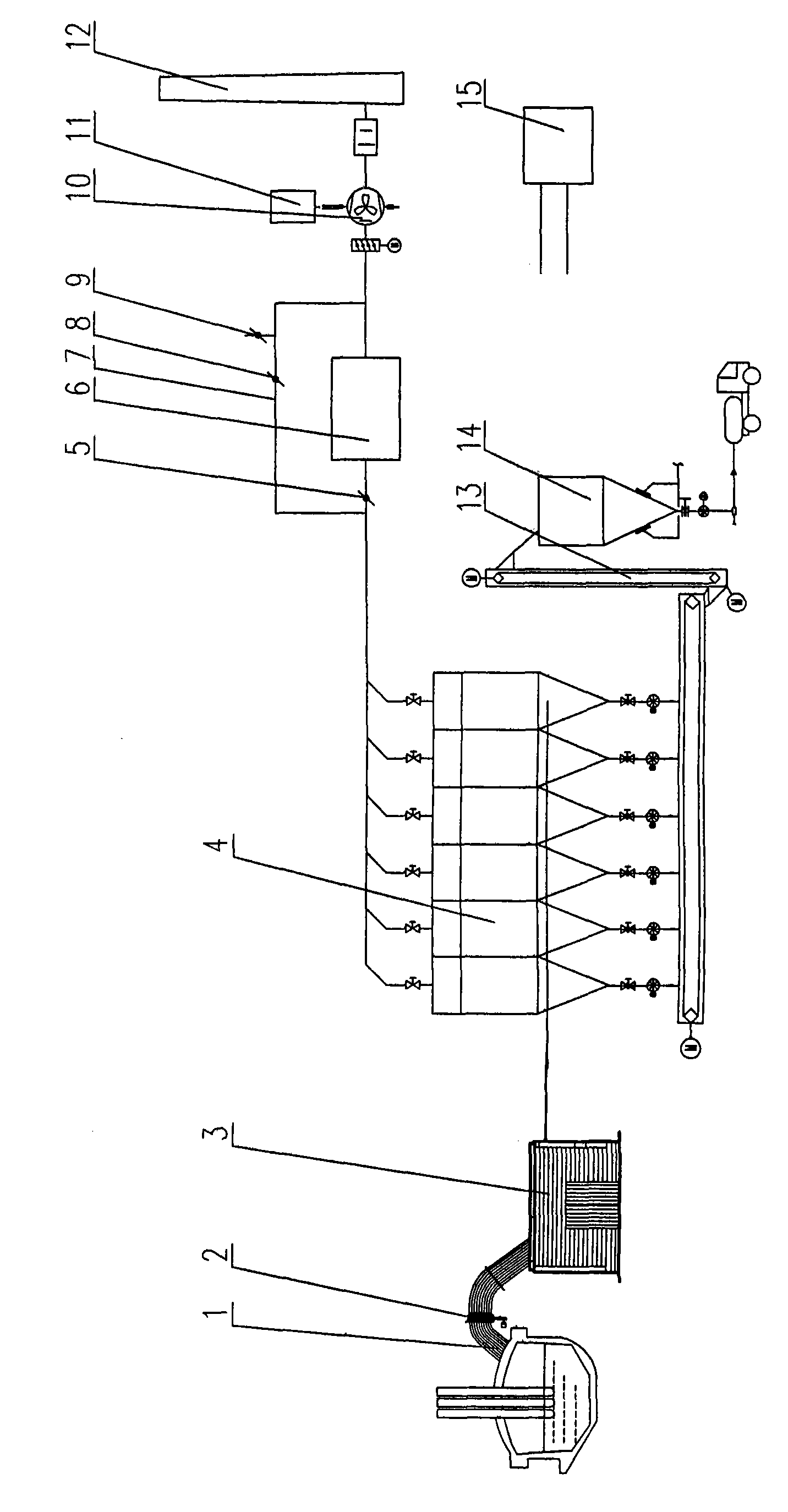

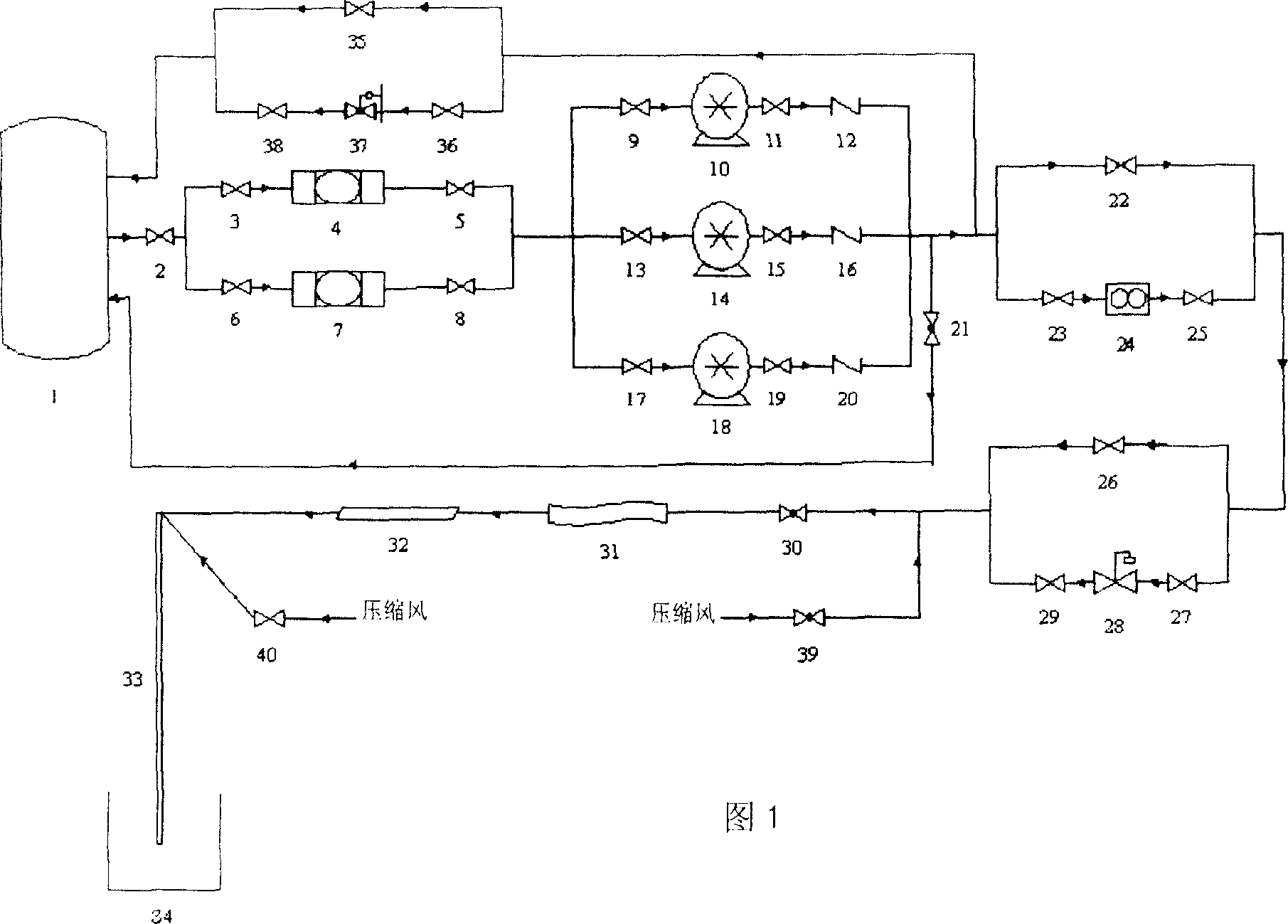

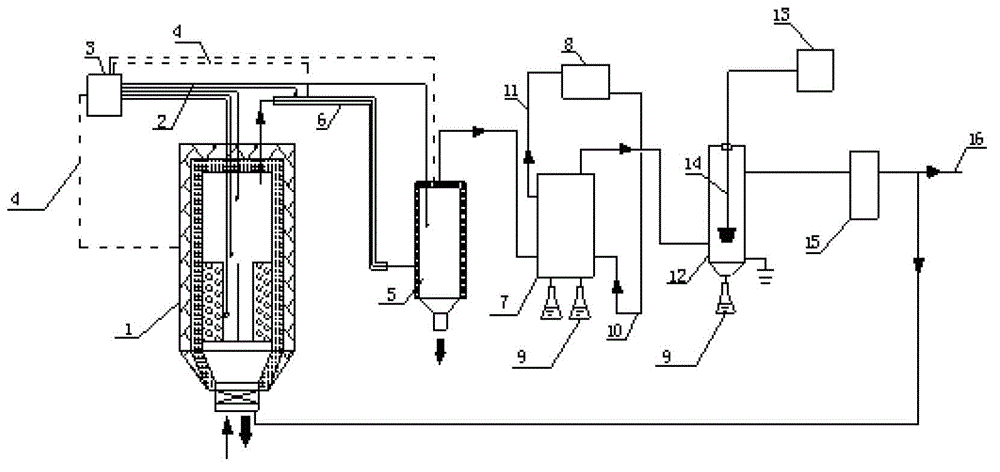

Flue gas waste heat recovery and negative energy consumption dust-removal system for electric stove

InactiveCN101539369AEasy to recycleSave on wear and maintenance costsDispersed particle filtrationIncreasing energy efficiencyCombustion chamberEvaporation

The invention relates to a flue gas waste heat recovery and negative energy consumption dust-removal system for an electric stove, comprising a first flue gas dust-removal and waste heat recovery system for the electric stove which is connected with the smoke hole of the electric stove to absorb high temperature flue gas generated by the electric stove during smelting phase and a secondary flue gas dust-removal system for the electric stove which is in charge of absorbing the flue gas generated by the electric stove during charging and tapping phase. The first flue gas dust-removal and waste heat recovery system for the electric stove comprises a water cooling travelling tube, an evaporation cooling device, a high temperature resistant dust remover, a waste heat boiler, a dust removal fan and a chimney; wherein the evaporation cooling device replaces the original water cooling flue gas path and combustor. The secondary flue gas dust-removal system for the electric stove comprises a collecting cover, a dust remover worked at normal temperature, a dust removal fan and a chimney. The invention is high in dust removal efficiency and high in vapor recovery rate, saves a first cooling device and a secondary cooling device, reduces device investment and maintenance charge and prolongs the service life of the filter pocket of the dust remover.

Owner:BAOSTEEL ENG & TECH GRP

Pre-molten low-melting point composite calcium aluminate desulfurizer and its prepn.

The invention discloses a kind of premelt-type, low-melting point, calcium aluminate complex desulfurizing agent and its preparation method, which is prepared according to the below components and proportion (weight): aluminum alum earth (calculated according to the Al2O3 content) 30-60%, and calcium oxide 40-70%. In advance perform passivating treatment on calcium oxide, then mix all the components according to the required proportion, then smelt them in the electric stove or the reflecting stove, then cool them, and by crashing, prepare the particle-shape or powder-shape desulfurizing agent. By the premelting treatment, the melting point of desulfurizing agent lowers to 1250-1400 centigrade, which obviously raises its desulfurizing rate in the molten iron molten steel and shortens the reactive time and production cycle.

Owner:盛富春

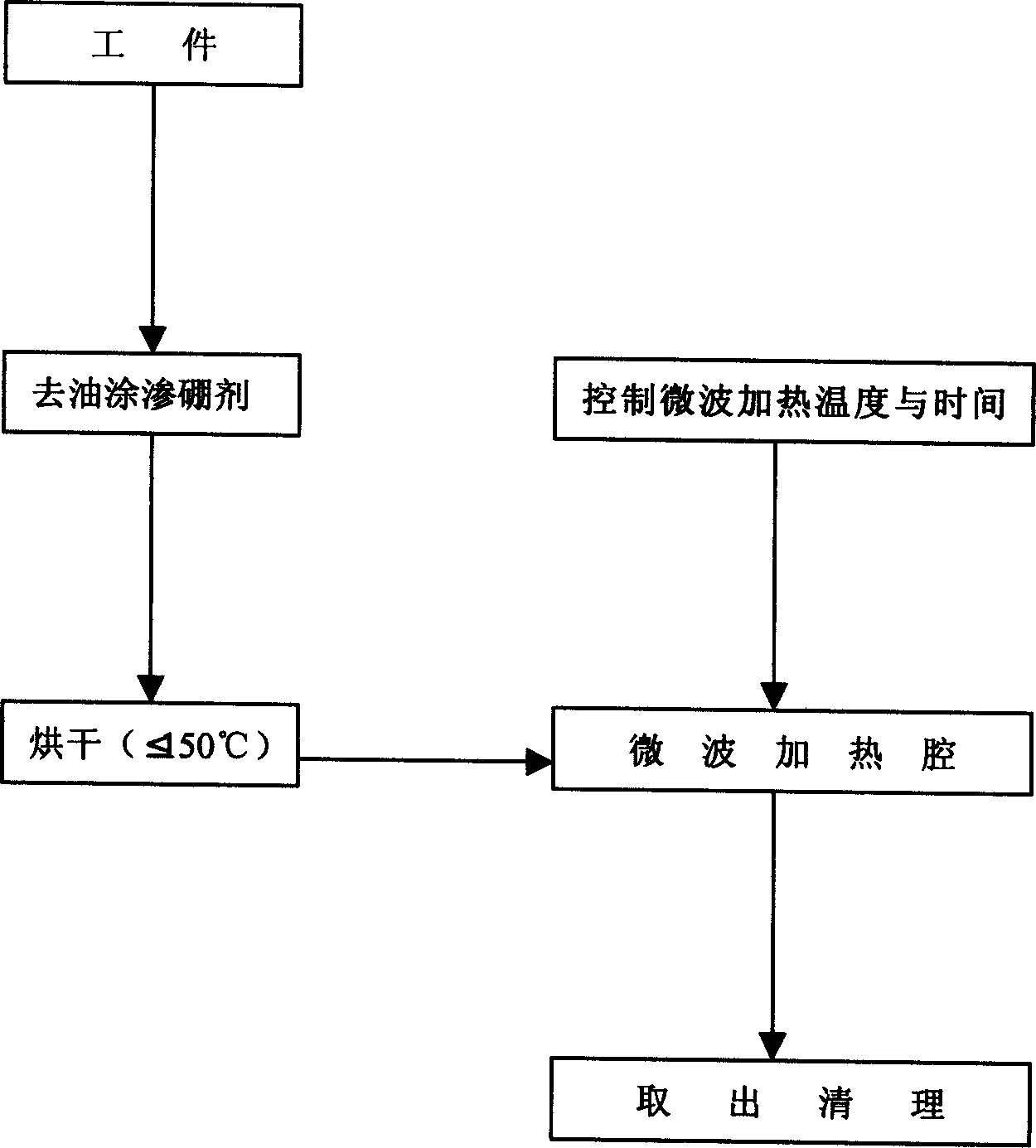

Quick preparation method of metal surface boronizing layer

InactiveCN1603452AExcellent microwave heating characteristicsFacilitate chemical reactionsSolid state diffusion coatingMicrowaveLevel structure

The invention provides a kind of superficial boronization level the fast preparation method. The method fast and the choice heats up and the acceleration chemical reaction characteristic using the microwave, in compares the low temperature and the short time intrinsic steel and iron and the metal surface preparation boronization level, it heating temperature may heat up compared to the electric stove reduces 100 DEG C about, heats up the time to reduce above three times, also the preparation boronization the level structure integrity, unifies with the substrate, the degree of hardness is high. The method broke through the traditional heat treatment to be unable in the low temperature, the short time obtained good infiltrates the level the limitation, had the significant industrial application value.

Owner:WUHAN UNIV OF TECH

Cold rolling orientation silicon steel production technology

InactiveCN101643829ALower melting temperatureExtended service lifeRoll force/gap control deviceTemperature control deviceDie castingIngot

The invention discloses a cold rolling orientation silicon steel production technology, relating to the technical field of metallurgy, and aiming to solve the technical problems of complex working procedures, high cost, high heating temperature for hot rolling plate blanks, low hit rate of controlling orientation silicon steel components, two-time operation of decarburization and annealing and thelike in the traditional cold rolling orientation silicon steel production technology. The invention comprises the following steps: controlling smelting by an electric stove; refining with an externalfurnace heating furnace and an external furnace vacuum furnace; steel tapping by crane ladle; steel ingot tapping by die casting; cogging; hot rolling; washing shot blast with acid; primary cold rolling; full decarburizing and annealing; secondary cold rolling; annealing and coating with MgO; high-temperature annealing by a bell-type furnace; smoothing a steel band and coating with an insulatinglayer; slitting for cutting edges, and packaging for putting in storage. The invention is suitable for producing cold rolling orientation silicon steel.

Owner:JIANGYOU FENGWEI NEW MATERIAL

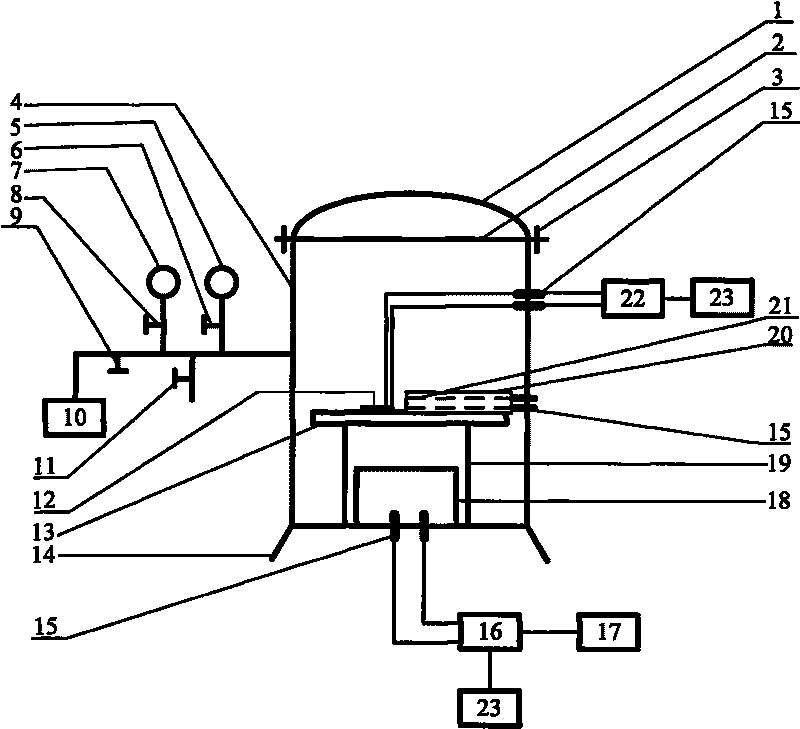

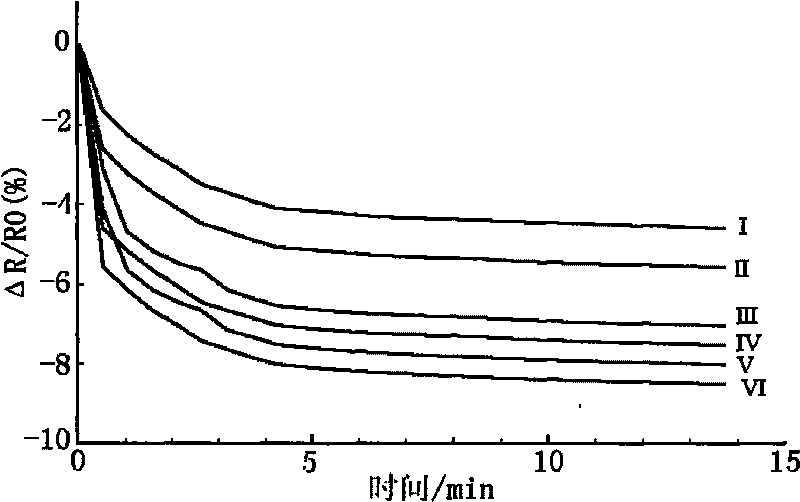

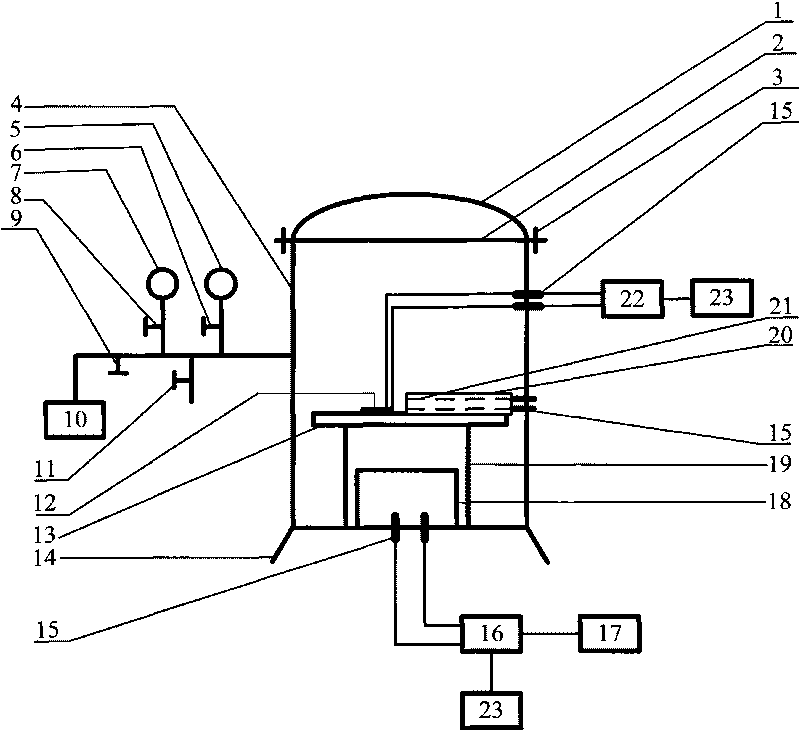

Experimental device of gas-sensitive temperature property test of carbon nano tube sensor and method

InactiveCN101694477AImprove sealingImprove accuracyMaterial resistanceCarbon nanotubeWorking temperature

An experimental device of gas-sensitive temperature property test of a carbon nano tube sensor and a method belong to the technical field of property test of the carbon nano tube sensor. The device mainly includes a cylinder, a vacuum pump, an alternating current contactor, a digital display regulator, an electric stove, a thermal resistor, an impedance analyzer and the like. By using the device, the method conducts the gas-sensitive temperature property test of the carbon nano tube on different detection gases at different temperatures. The device and the method can measure the gas-sensitive temperature property of the carbon nano tube sensor under different defected gases, find out the optimal working temperature of the carbon nano tube sensor under defected gases, have high accuracy and sensitivity of measurement, convenient operation and easy promotion and application, and the method is simple. The device and the method can be widely applied to the analysis and application of the gas-sensitive temperature property of carbon nano tube sensors for scientific research, teaching and study institutions.

Owner:CHONGQING UNIV

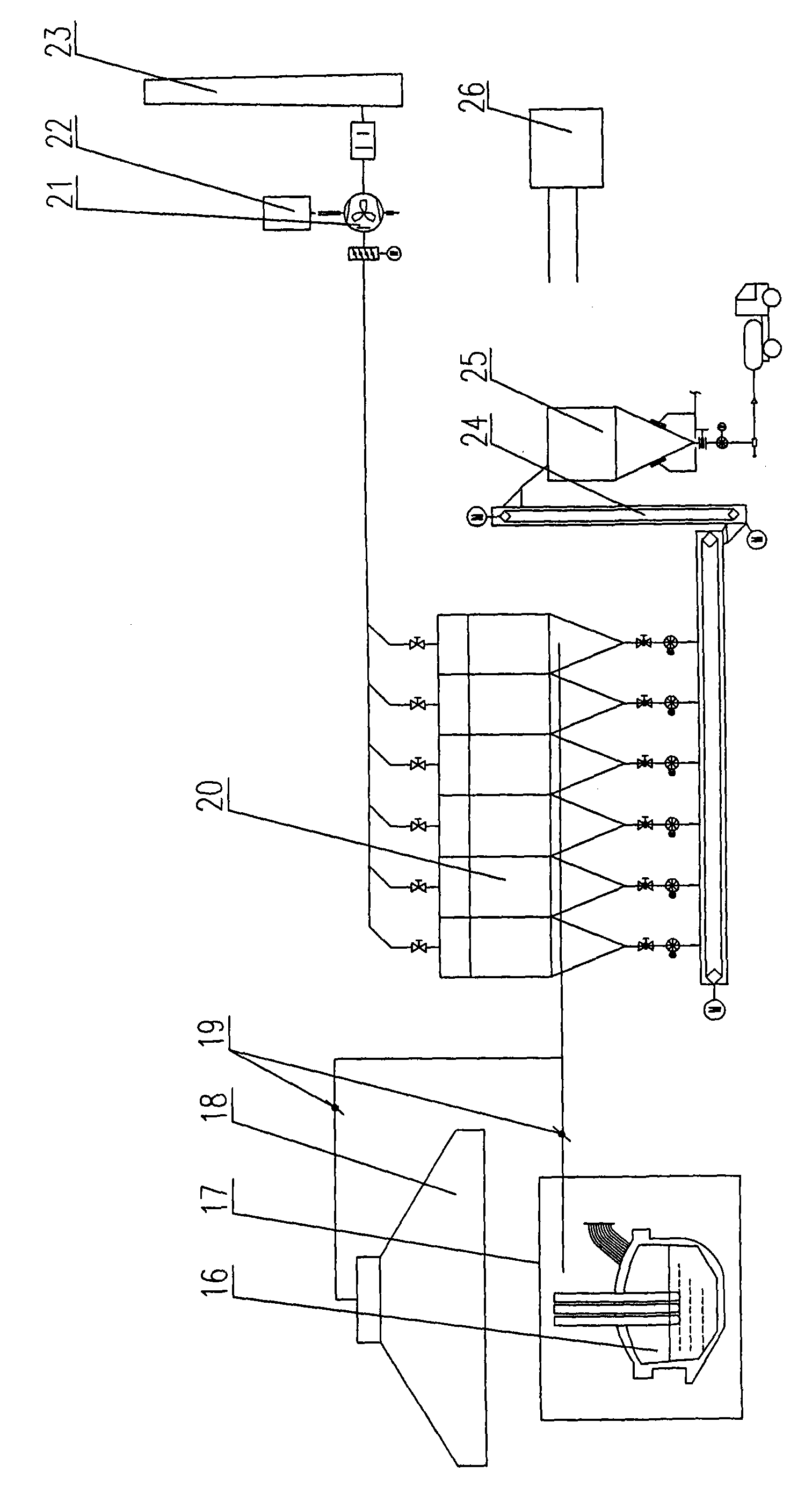

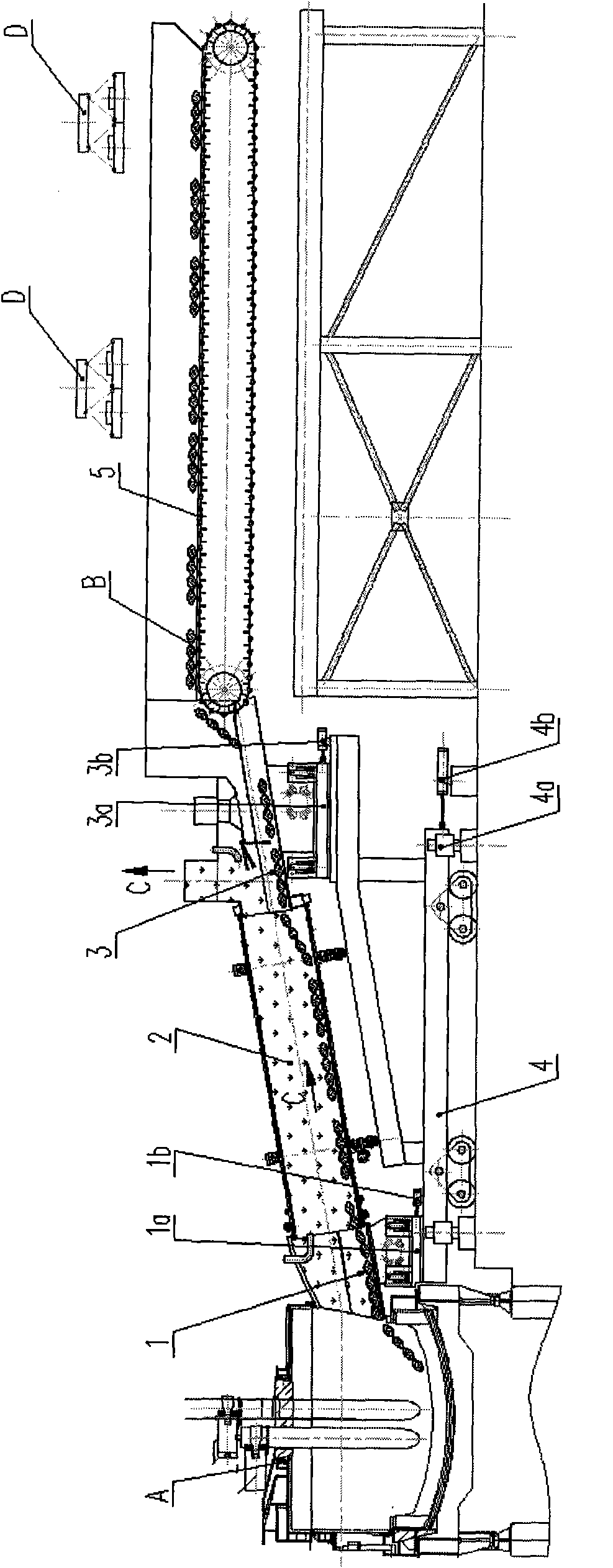

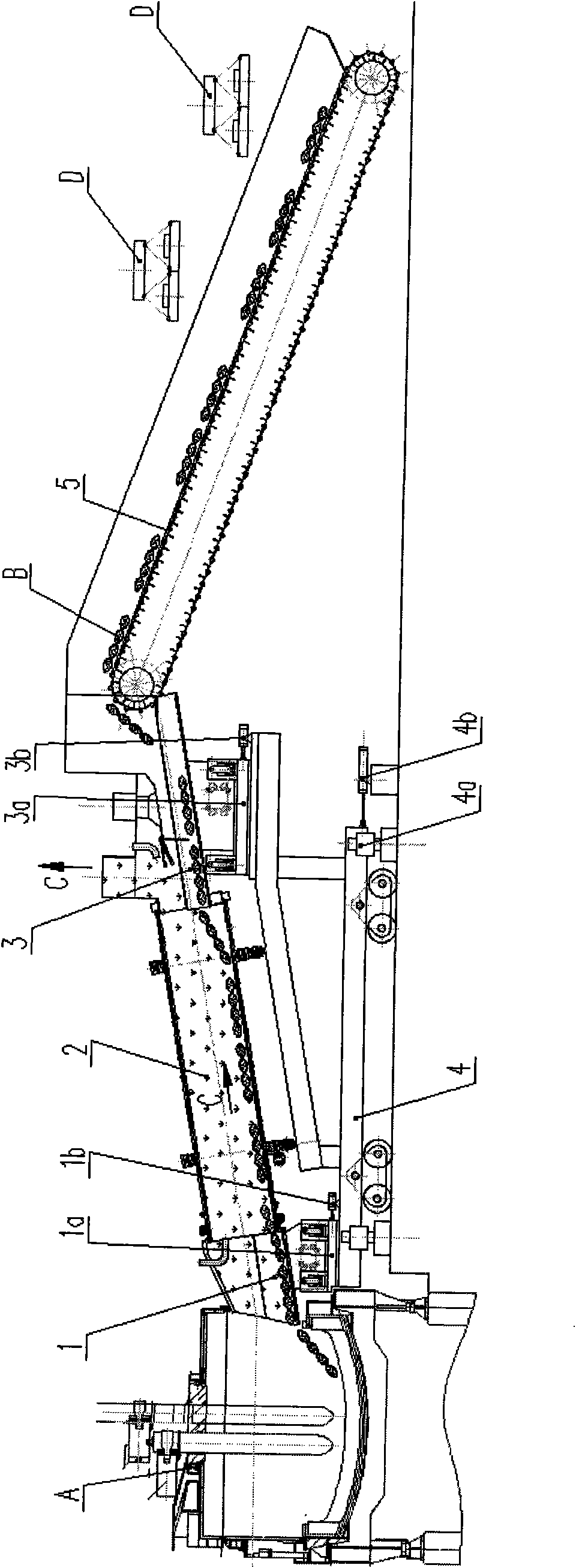

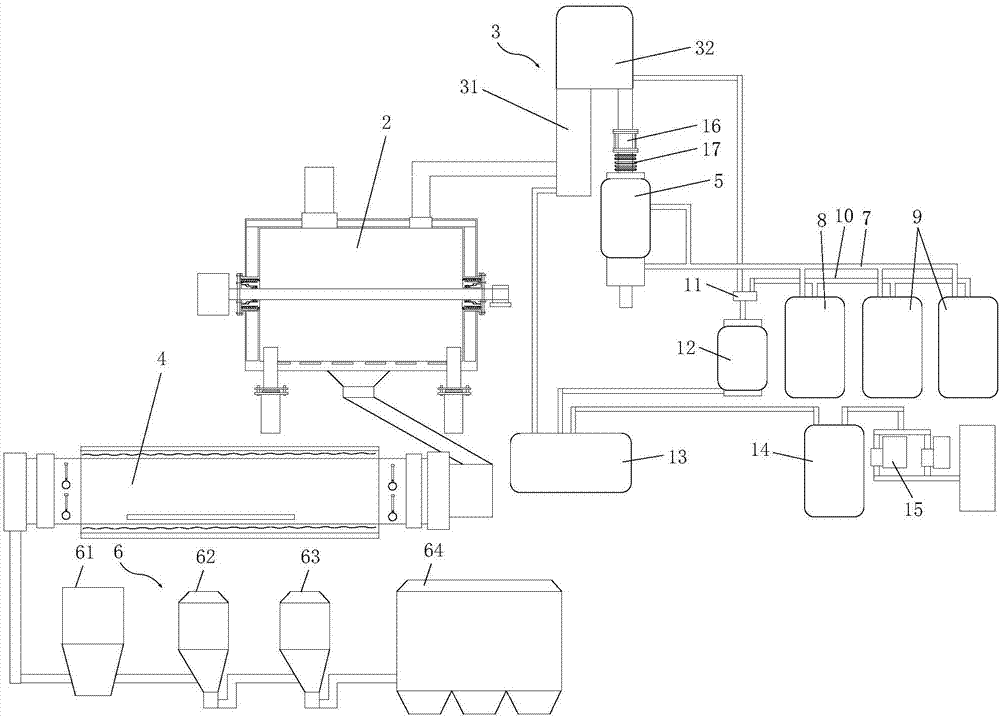

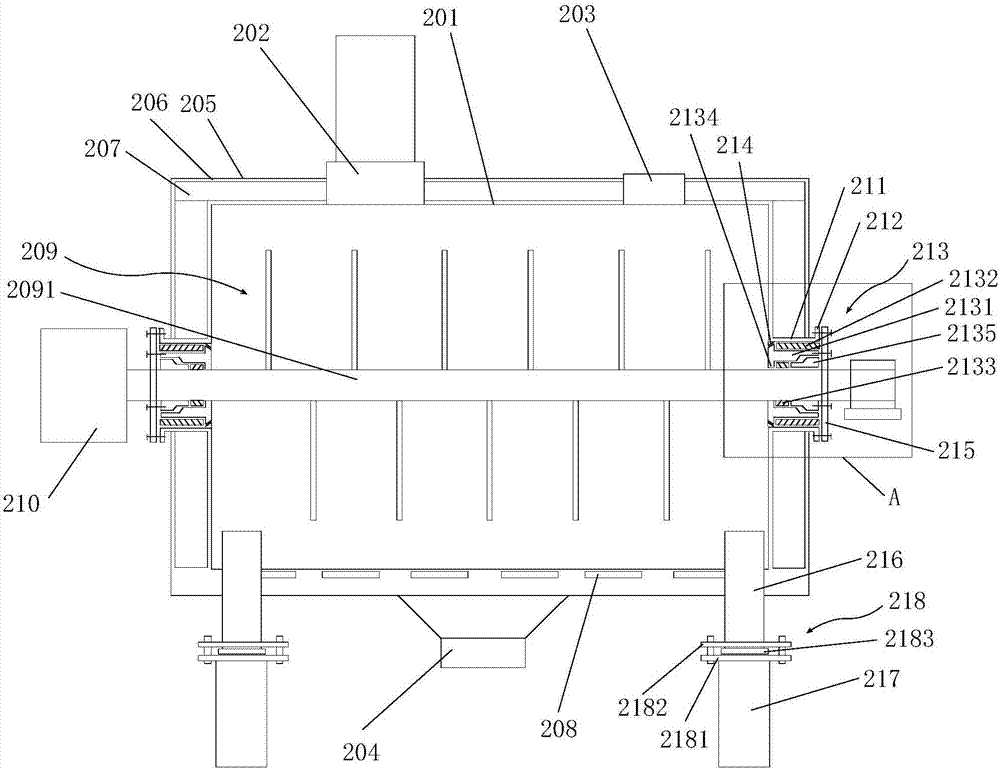

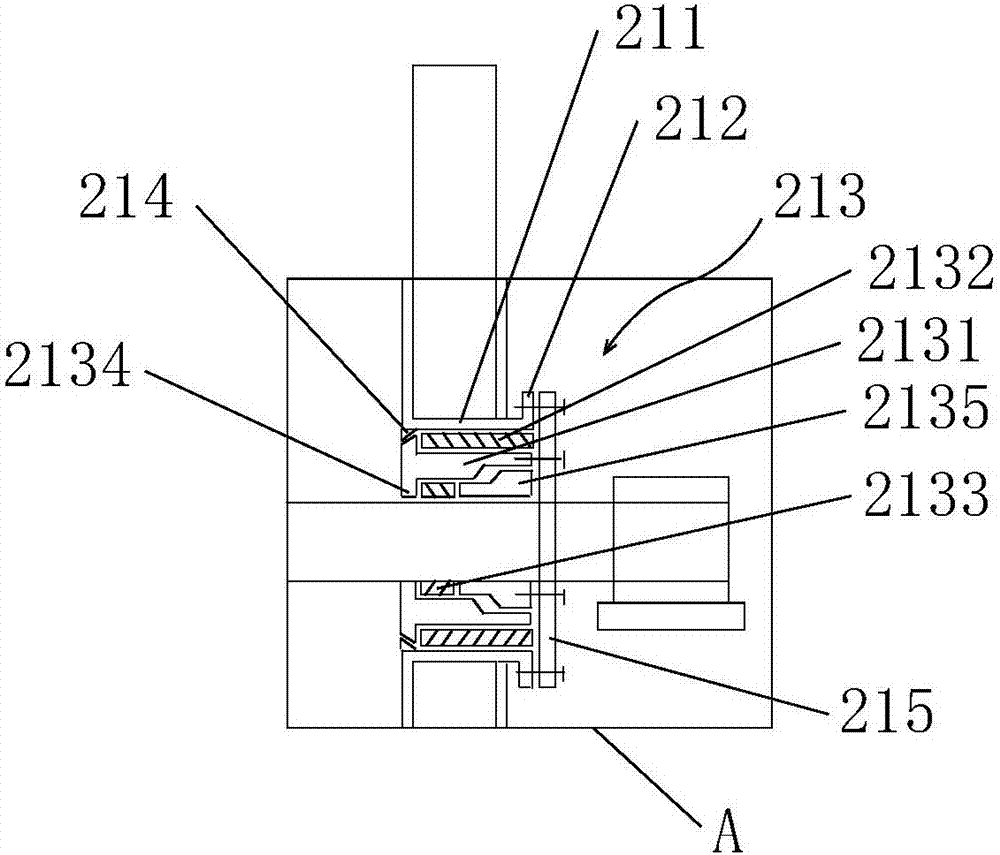

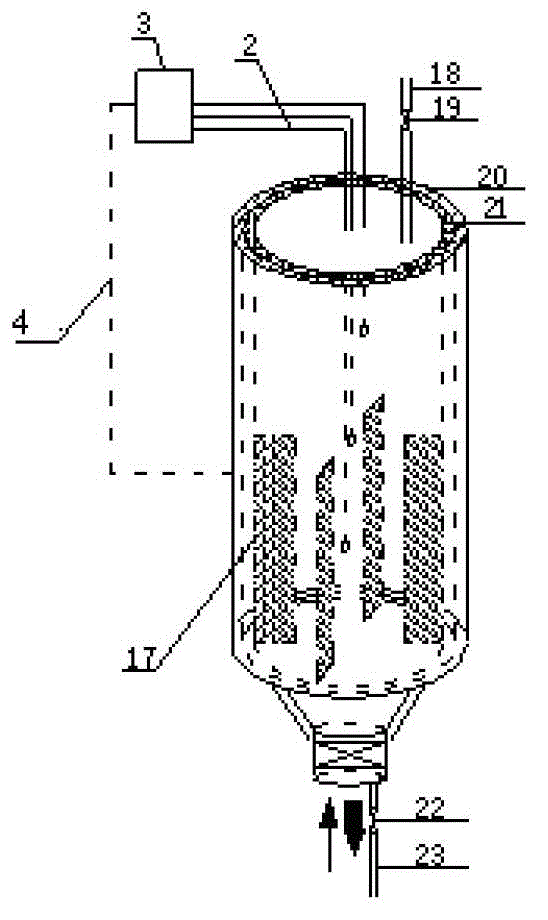

Electric stove metal bulk cargo continuous feeding and preheating device and method

InactiveCN101644539AReduce manufacturing costSave energyCharge manipulationPreheating chargesBulk cargoShortest distance

The invention belongs to the metallurgy technical field and discloses an electric stove metal bulk cargo continuous feeding and preheating device and method. The metal charge roller preheating grooveof the device is inclined with the horizontal plane, the lower end of the metal charge roller preheating groove is inserted into the inlet of a stove entering vibratory conveyor to be sheathed in short distance fit, the stove entering vibratory conveyor is connected with open pore A of the electric stove, the position of approach end is lower, the higher end of the metal charge roller preheating groove is sheathed and combined with a groove entering vibratory conveying and air sealing device, and the two are sheathed in short distance fit. The method is characterized in that metal charge is fed into the metal charge roller preheating groove to be preheated. The preheated metal charge is fed into the electric stove, and smoke of the electric stove is exhausted by the stove entering vibratory conveyor, the metal charge preheating groove and the groove entering vibratory conveying and air sealing device. The invention has the advantages of less electrical energy consumption, steady operation, high scrap preheating efficiency, high operational throughput and short total device length and is a new energy-saving and environmentally friendly technology with promotional value on electric stove or other production technologies.

Owner:CISDI ENG CO LTD

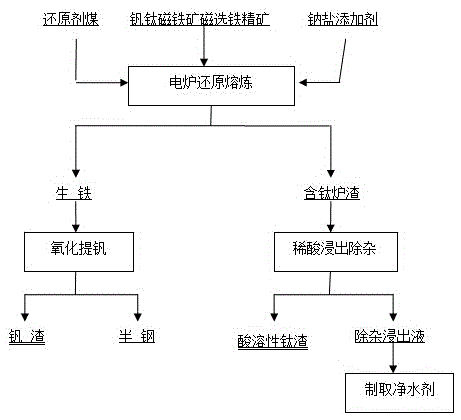

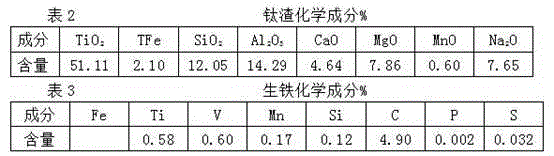

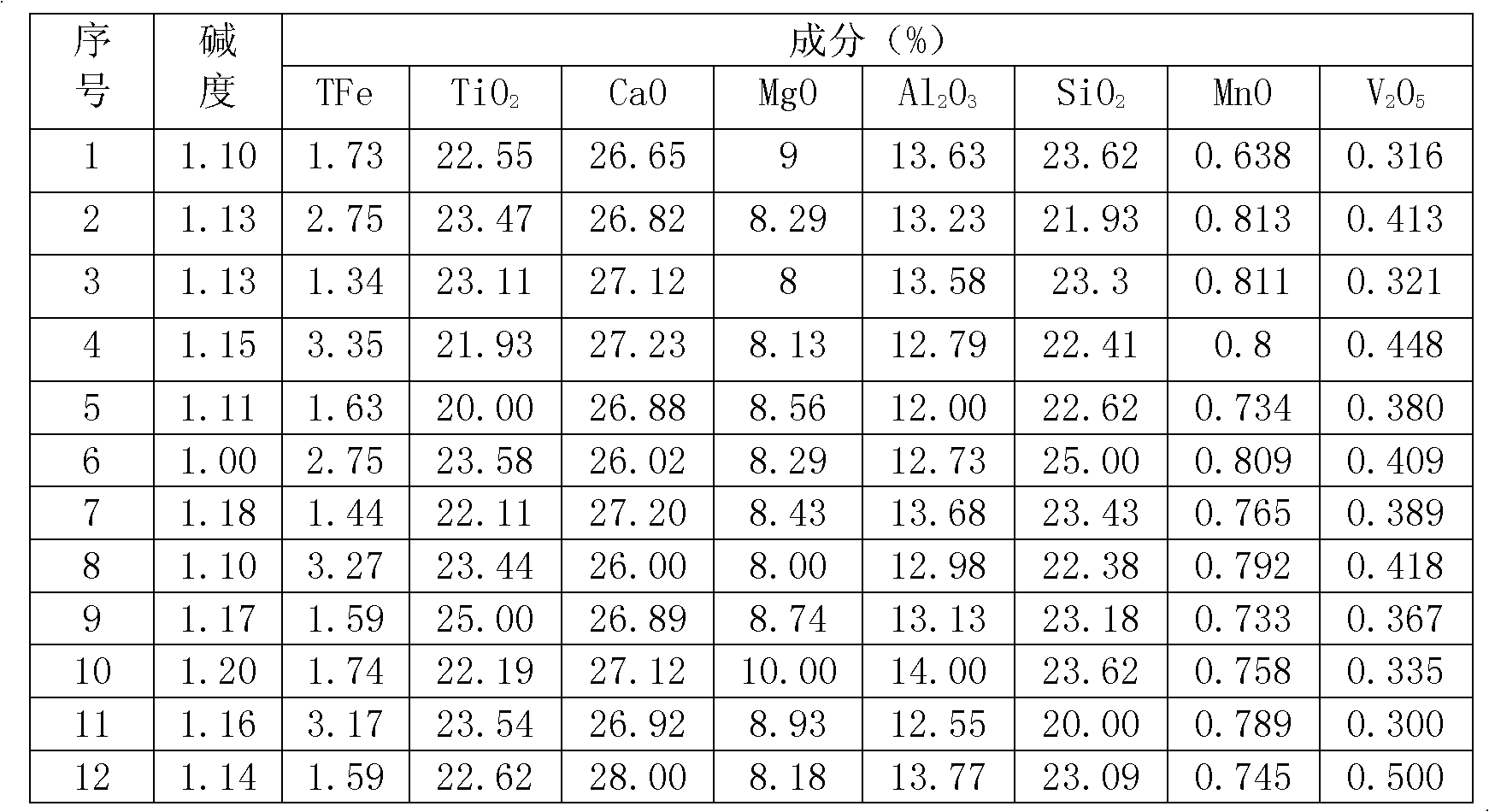

Method for extracting titanium from vanadium-titanium magnetite

InactiveCN105112689AEfficient and reasonable useSolve the technical problems of efficient separation and extractionProcess efficiency improvementElectric furnaceAluminateSmelting process

The invention discloses a method for extracting titanium from vanadium-titanium magnetite. The method comprises the following steps: adding sodium or potassium salt additive in the reduction smelting of an iron ore concentrate electric stove to obtain liquid iron and titanium-containing slag, wherein vanadium and iron are reduced to enter liquid iron, under a smelting high temperature condition, silicon and aluminum impurities form sodium aluminosilicate capable of being dissolved in dilute acid with the sodium or potassium salt additive, and enabling the sodium aluminosilicate and titanium and aluminum magnesium impurities to remain in the titanium-containing slag; purifying the titanium-containing slag by virtue of a wet-method metallurgical impurity removal method, to acquire a titanium slag product with TiO2 content more than 75 percent. For the application problem of titanium in the iron ore concentrate, the slag modification additive is added in the reduction smelting process, so that not only is the mobility of the slag improved, but also a condition is created for removing the later silicon-aluminum impurities of the slag, the high-efficiency separation and extraction problem of the titanium in the iron ore concentrate can be well solved, the resource utilization rate of the iron, titanium and vanadium is greatly increased, and the utilization rate of the titanium is increased about 3 times compared with the flow of a blast furnace.

Owner:INST OF MULTIPURPOSE UTILIZATION OF MINERAL RESOURCES CHINESE ACAD OF GEOLOGICAL SCI

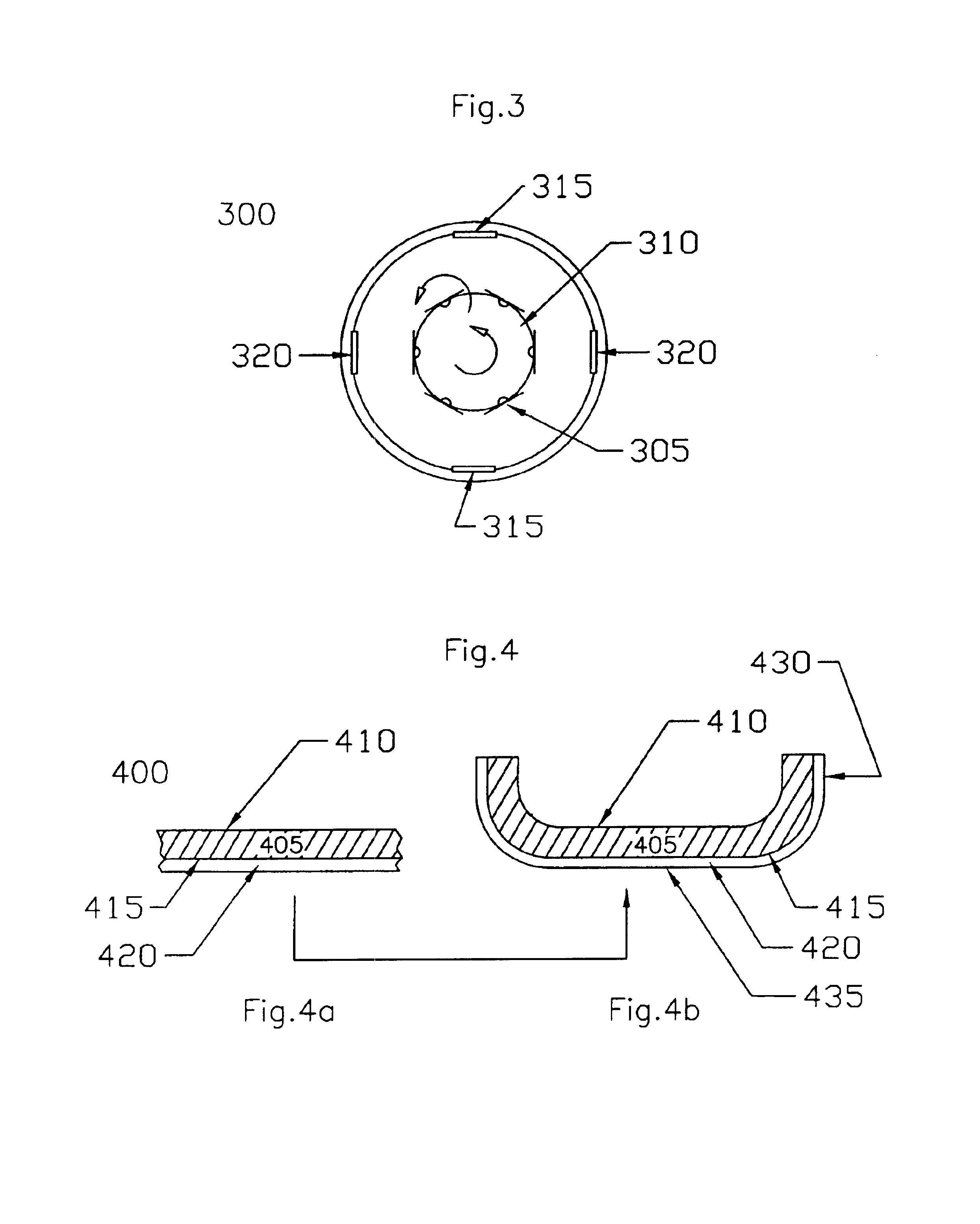

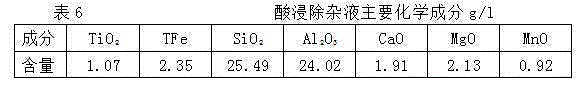

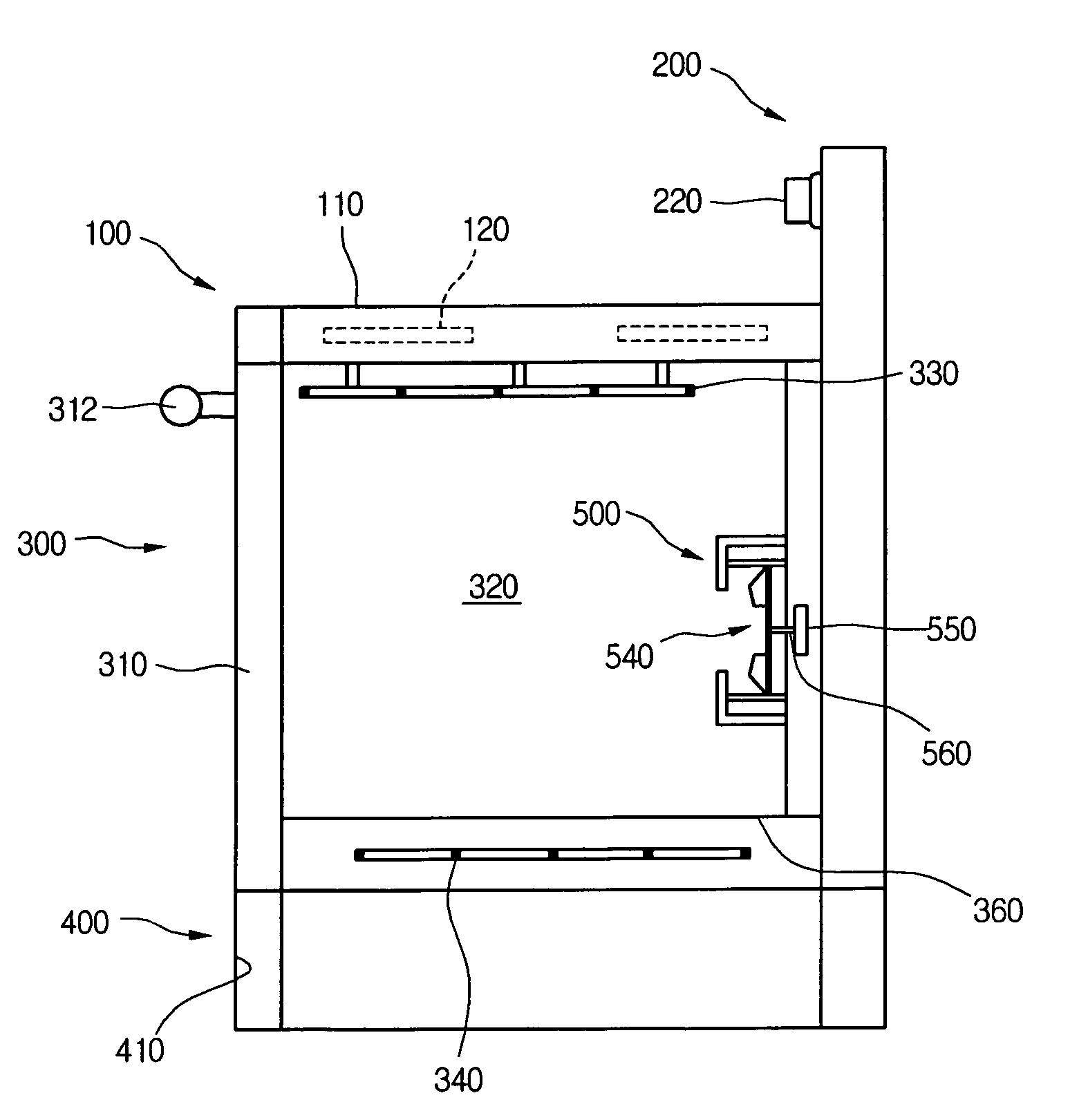

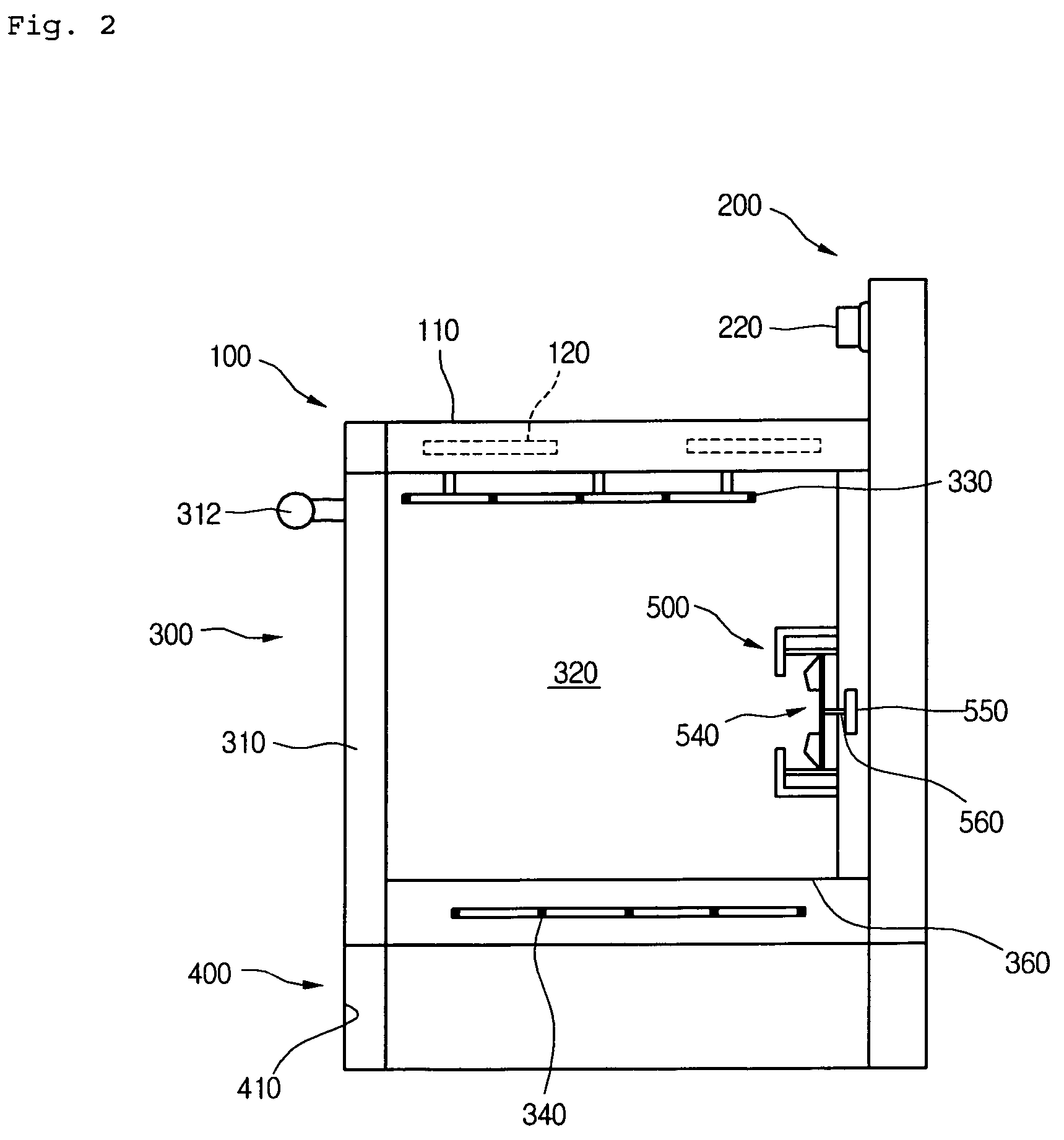

Convection part for electric oven range

InactiveUS7329838B2Simple structureEven airflowBoiling over preventionDomestic stoves or rangesControl theoryElectric stove

A convection part of an electric oven range is provided. In the convection part, a convection motor is provided, a convection fan is connected with the convection motor, and a fan housing encloses the convection fan and it includes at least one pair of discharge ducts in opposite directions.

Owner:LG ELECTRONICS INC

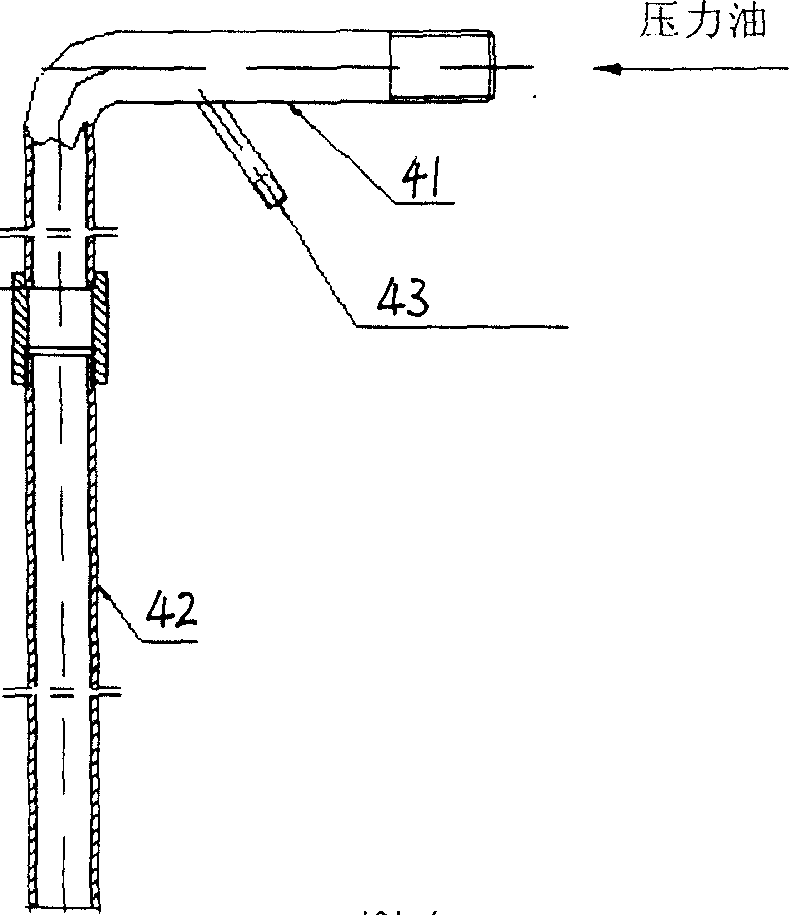

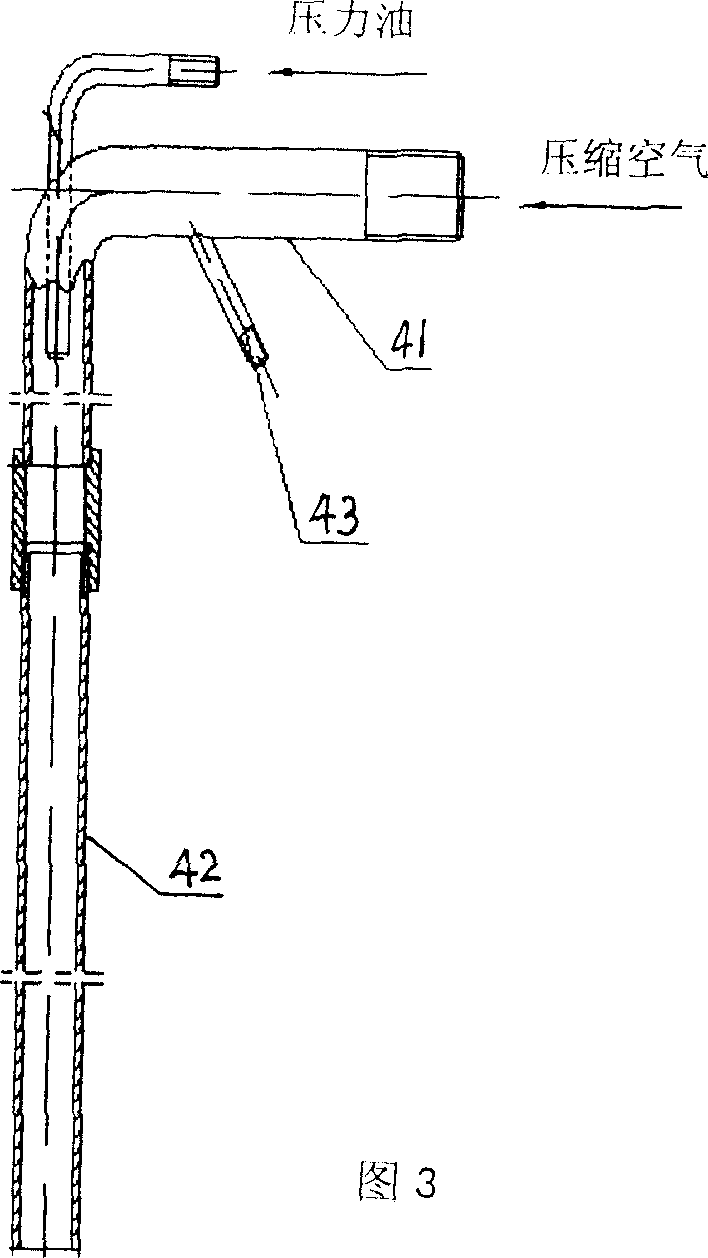

Slag cleaning furnace top-blown immersion technology

Disclosed is a slag-cleaning furnace top-blown immersion technology which comprises using the oil-gas mixture formed from 0# diesel or 0# diesel and compressed air as the reducing agent, inputting oil amount of the oil spray gun into DCS system, spraying into fondant under the control of an automatic regulating valve, inputting compressed air and regulated wind amount based on deacidizing degree and atmosphere in the furnace, conveying the reducing agent to pipes controlled by the automatic regulating valve, inserting the oil spray gun into the fused bath from the top of the furnace and immersing into the fondant, deacidizing the magnetic iron oxide through blowing the reducing agent into fondant by means of top-blowing pattern. The invention can improve deacidizing efficiency substantially.

Owner:YUNNAN COPPER CO LTD

Magnesium-based brazing filler metal alloy and preparation method thereof

InactiveCN101623800ALow costSimple manufacturing processWelding/cutting media/materialsSoldering mediaCrucibleIngot

The invention provides a magnesium-based brazing filler metal alloy with low working temperature and favorable welding performance as well as a preparation method thereof. The alloy comprises the following components in percentage by weight: 0.5-1.1 percent of Al, 51-60 percent of Mg, 0.5-3 percent of Sn, 0.001-0.003 percent of Be, 0.001-0.003 percent of Te, 0.1-0.4 percent of La, 2.6-8 percent of Bi, and the balance of Zn. The preparation method of the magnesium-based brazing filler metal alloy comprises the following steps: dispensing all materials according to weight percentage; heating and melting the dispensed materials in an electric stove crucible under the SF6 protective atmosphere, wherein the weight percentage of La in the middle alloy from Mg to La is 15 percent; preserving the temperature for 5-10 minutes when the temperature rises to 680-700 DEG C; and casting in a steel ingot mould which is preheated to 200 DEG C and then cooling to obtain the magnesium-based brazing filler meta alloy.

Owner:NANJING UNIV OF INFORMATION SCI & TECH

Production technology for melting steel by electric arc furnace converter

InactiveCN1598000AReduce consumptionReduce power consumptionProcess efficiency improvementElectric furnaceElectric arc furnaceOxygen

The invention relates to a kind of arc furnace converter steel-making technique, in the state of lacking electricity. The converter steel-making technique by using arc furnace is a kind of arc furnace converter steel-making technique of low electric power consumption and high ratio of molten iron enclosing, especially in the state of lacking electricity. Using small voltage progression, the system of oxygen blowing and loading materials realize the producing aim of arc furnace converter steel-making. The biggest advantage of the invention is that the production level can maintain normally though in the phase of low power utilization or break; avoid stop production because the break. In addition, because of the abundance low impurity content water, the ratio of iron and water arrive at above 55%; markedly decrease the residual element in the molten steel. The invention is low power consumption and electrode consumotion.

Owner:NANJING NANGANG IND DEV CO LTD

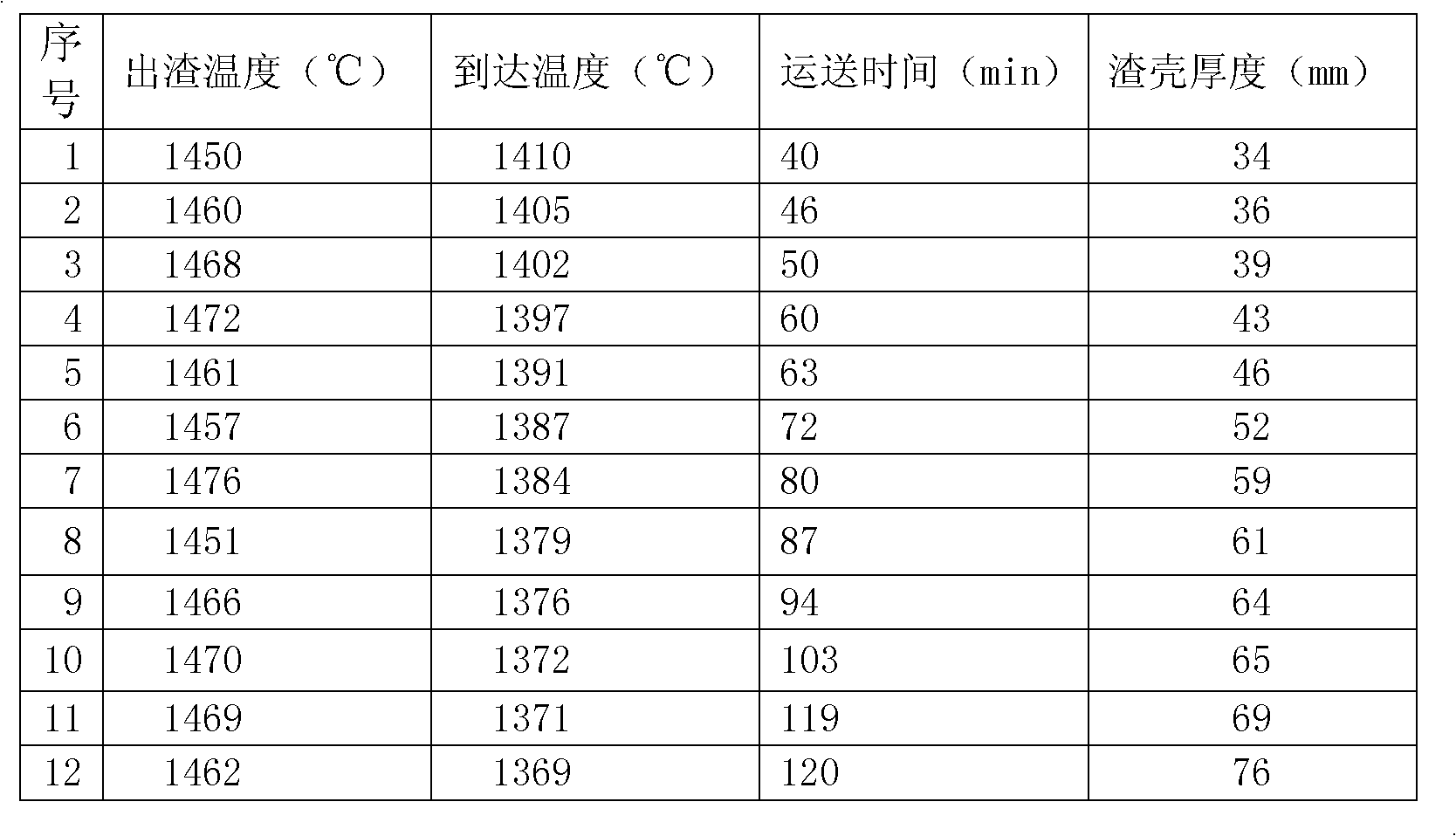

Electric furnace charging process for high-titanium blast furnace slag carbonization

The invention relates to the field of comprehensive utilization of high-titanium blast furnace slag, and provides an electric furnace charging process for high-titanium blast furnace slag carbonization. The process comprises the following steps of: 1) controlling the blast furnace tapping temperature at over 1,450 DEG C; 2) introducing liquid blast furnace slag into a slag pot car through a slag runner; 3) solidifying the blast furnace slag to form slag crust, and performing sealed heat insulation on the liquid blast furnace slag in the slag pot car; 4) conveying the slag to an electric furnace through the slag pot car for less than or equal to 2 hours; and 5) breaking the slag crust, and guiding the liquid blast furnace slag into the electric furnace through a guide plate and a guide trough. By charging the liquid slag into the furnace, the heat in the blast furnace slag is furthest kept so as to reduce the energy consumption of a blast furnace slag high-temperature carbonization process, reduce the time required for blast furnace slag high-temperature carbonization and smelting and avoid the water resource waste of the conventional water quenching slag; and meanwhile, the process has little modification on the conventional equipment, is easy to implement, and has low implementation cost. The process is suitable for charging of the high-titanium blast furnace slag carbonization.

Owner:PANGANG GROUP VANADIUM TITANIUM & RESOURCES +1

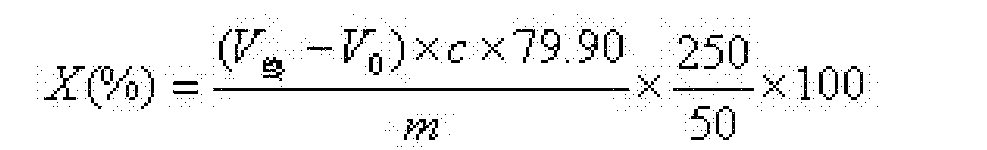

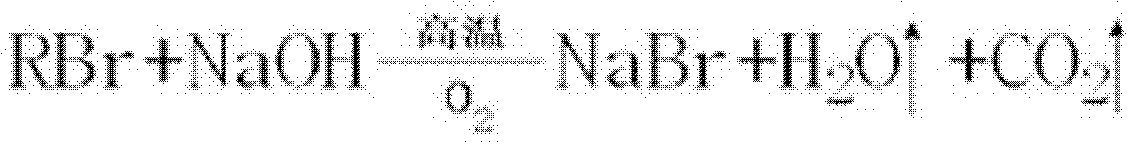

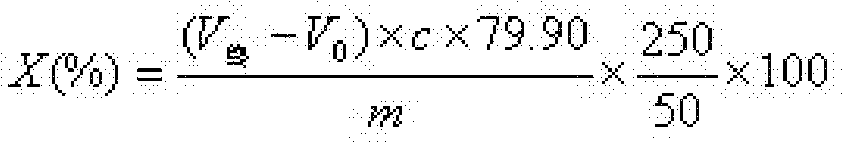

Method for detecting content of bromine in fire retardant through automatic potentiometric titration

ActiveCN102539511ALarge sampling volumeMeet the analytical precision requirementsMaterial electrochemical variablesPotassium hydroxideFire retardant

The invention discloses a method for detecting content of bromine in fire retardant through automatic potentiometric titration, which comprises the steps of 1 utilizing nickel crucible to directly weigh a sample, adding emulsifier and potassium hydroxide solution or sodium hydroxide solution into the sample, and evenly infiltrating the mixture in advance; 2 after adding small amount of ground sodium carbonate on the surface of the sample to cover the sample, adding solid sodium hydroxide to cover the surface, covering a crucible cover on the crucible with gaps reserved; 3 slowly heating the sample on a pressure regulating electric stove and enabling the sample to fuse in alkali solution and absorb the alkali solution till no white powder solid exits in the crucible; 4 turning off the electric stove, enabling the test sample to cool down, adding water into the crucible till 1 / 2-1 / 3 of the height of the crucible, heating the water, enabling fusant to be completely melt in the water, transferring the mixture into a beaker, cleaning the nickel crucible and the cover and transferring cleaning solution into the beaker together; 5 metering the volume of the solution for standby measurement; and 6 utilizing the automatic potentiometric titrimetor, utilizing a silver / bromine iron selection electrode to serve as an indication electrode and utilizing silver nitrate (AgNO3) standard solution to titrate sample solution. The method for detecting the content of the bromine in the fire retardant through the automatic potentiometric titration has the advantages of being high in weighing accuracy, safe and reliable.

Owner:KINGFA SCI & TECH CO LTD +1

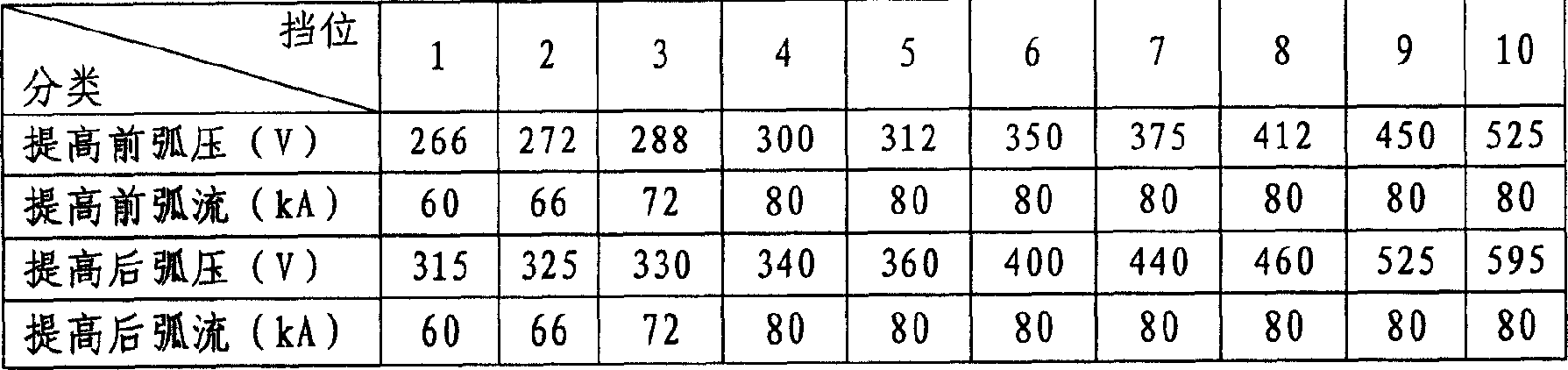

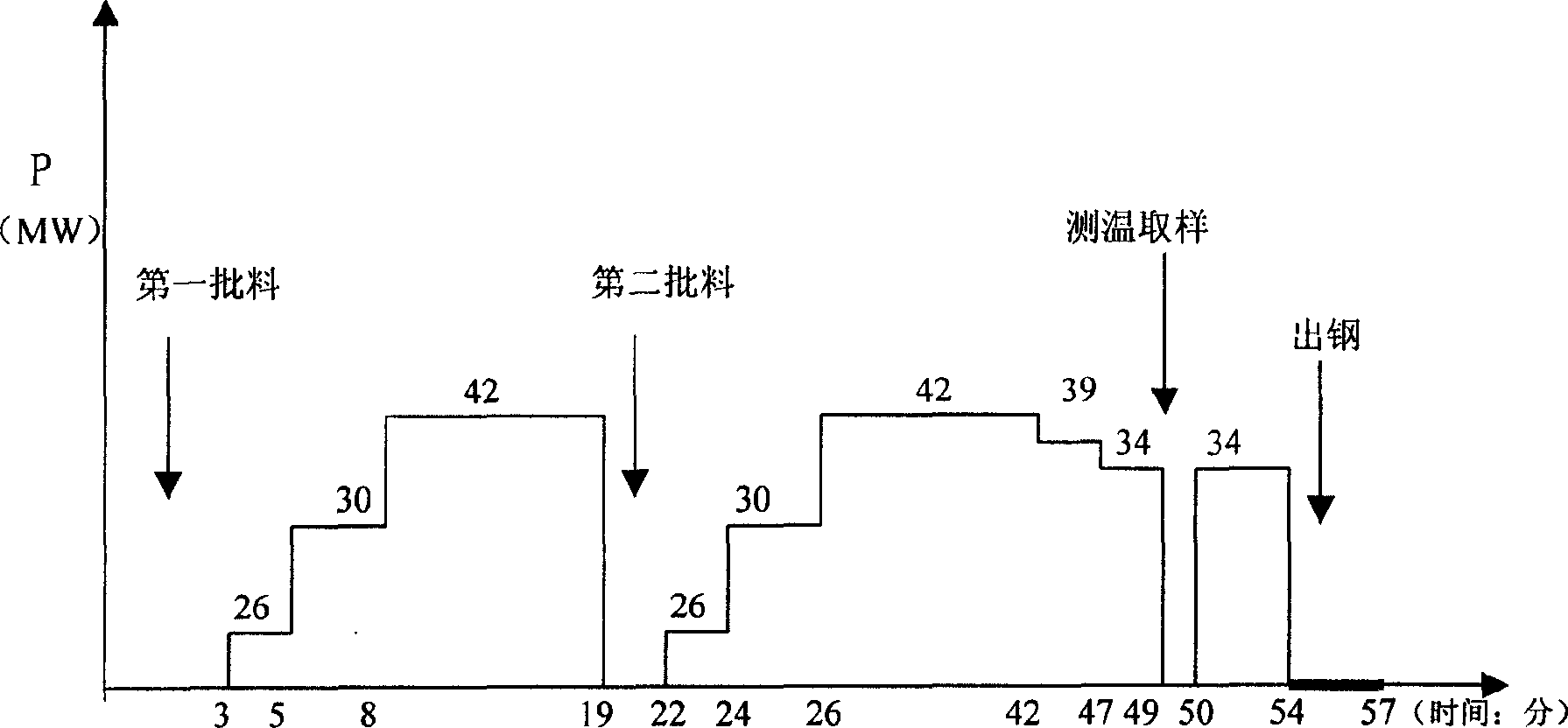

Electric furnace high voltage and large oxygen quantity foam slag smelting method

The invention discloses an electric furnace high voltage and large oxygen quantity foam slag smelting method which comprises, keeping the reactive power of the electric stove rectifier unchanged, forward leading the triggering angle, increasing the voltage on the D.C. side of the rectifier, applying a high voltage during the total procedure of electric stove smelting, charging furnace door quick smelting material into the electric stove, delivering power to the electric stove, oxygen blowing to melt the scrap steel, then inserting into molten pool for oxygen blowing, then charging a second batch of the material, delivering power, blowing oxygen immediately, adjusting scrap steel batching and molten iron proportion as well as furnace slag alkalinity, spraying carbon into the electric furnace, keeping the foam slag, measuring temperature and taking samples.

Owner:XINJIANG BAYI IRON & STEEL

High-alumina electric furnace cover pouring material and preparation method thereof

The invention relates to a castable material of high aluminum electric stove and a preparation method thereof. The technic proposal is that: 75-90wt% high aluminum bauxite clinker, 3-15wt% fine poder kyanite, 1-10wt% micro-powder aluminum oxide, 0-10wt% aluminate cement, 1-5wt% alumino silica gel are firstly mixed, and 0.10-0.25wt% water reducer of the mixture and 5.0-6.5% water are added into the mixture, and the mixture is stirred for 5-10min to be casted into a mold, and the mold is naturally conserved for 12-24h and demould, and is dried in 110 DEG C for 24h. The casting mold is either entire-cast or deblocking-cast, and finally the molds are assembled. The invention adopts high aluminum bauxite clinker as base, and the prepared products has the advantages of good thermal shock resistance, high density, which is difficult for splashing substances of high temperature cinder to penetrate, and has excellent erosion resistance as well as long service life.

Owner:WUHAN UNIV OF SCI & TECH

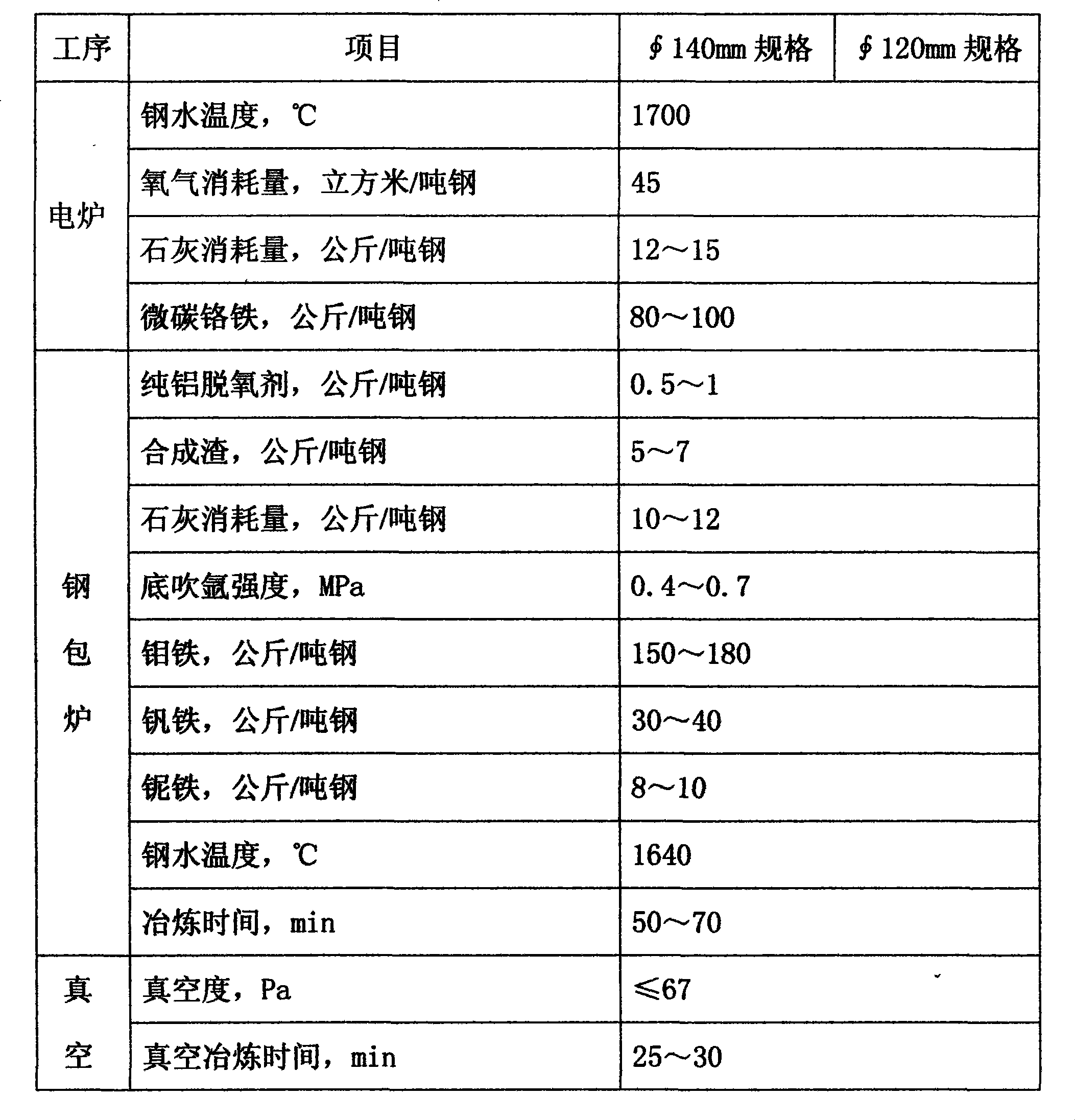

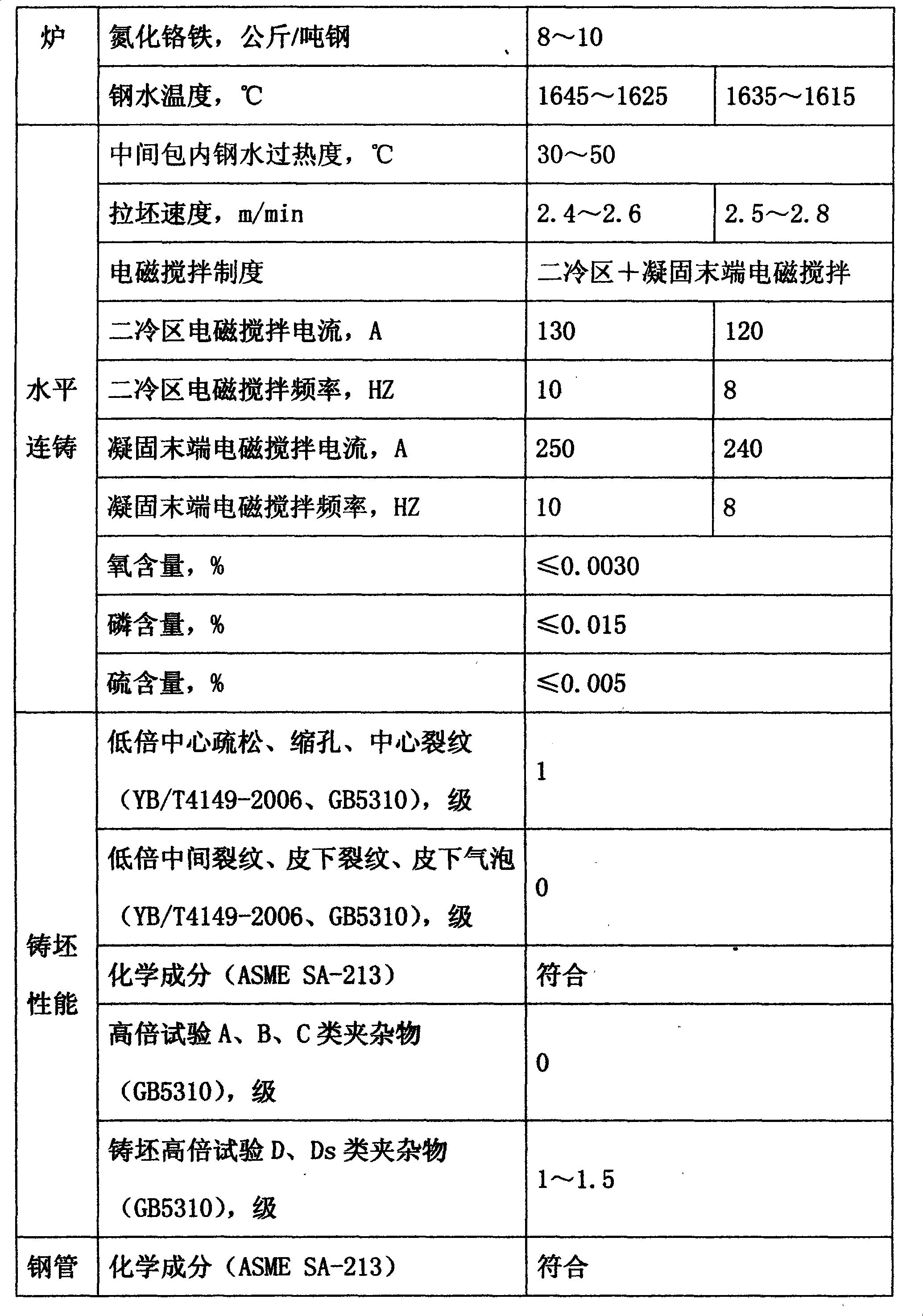

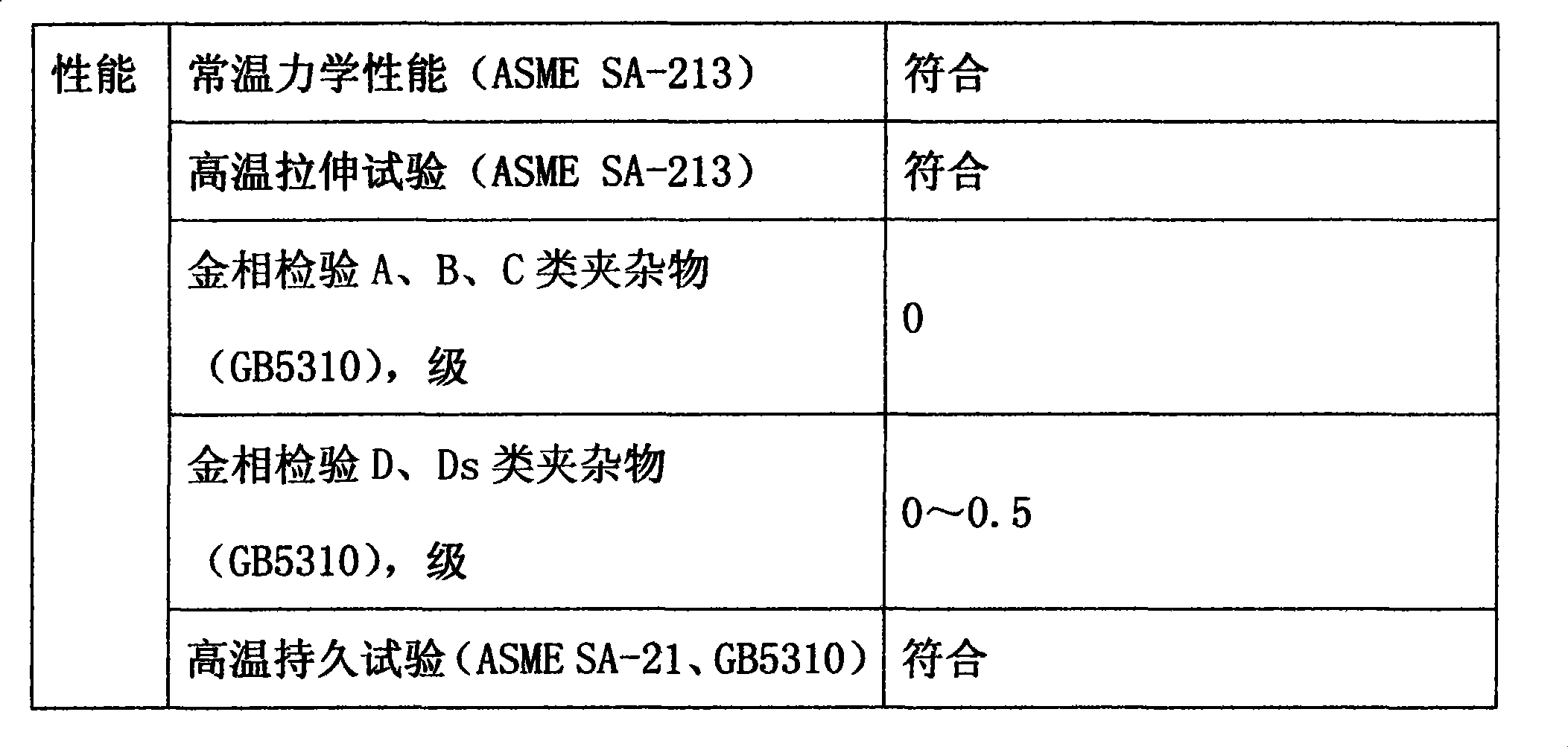

Method for horizontal continuous casting 10Cr9Mo1VNbN ferrite heat-resistant steel to tube round blank through electric stove smelting

ActiveCN101381790AEasy to controlFew linksElectric furnaceProcess efficiency improvementSlagAlternating current

The invention provides a method for smelting 10Cr9Mo1VNbN ferrite refractory steel to form a circular tube billet by horizontal continuous casting in an electric furnace. The method comprises the following process flow: primary smelting in a 30-ton alternating current electric furnace (steel is tapped from the bottom of an eccentric furnace; refined pre-smelting slag, various alloys and a deoxidizer are added), a 40-ton ladle refining furnace (the bottom is blown with argon), a 40-ton vacuum furnace for degassing and horizontal continuous casting. All the alloys are roasted; the alloy roasting is carried out through the following steps: pores are pricked on an iron barrel filled with ferrochrome nitride, ferromolybdenum, ferrovanadium and ferrocolumbium; the alloys are put in a large smoke hood of the refining furnace and are roasted; micro-carbon ferrochromium is added into a ladle ahead of 60 minutes before tapping and is roasted; and the replenished micro-carbon ferrochromium after the tapping is roasted in an offline middle ladle ahead of eight hours.

Owner:衡阳华菱连轧管有限公司

Method and system for circularly regenerating diatomite filter aid containing oil waste

ActiveCN107159103AGuaranteed negative pressureSolve the sealing problemCombination devicesOther chemical processesDesorptionBiochemical engineering

The invention belongs to the technical field of diatomite regeneration and provides a system for circularly regenerating a diatomite filter aid containing oil waste. The system comprises a regenerator, wherein the regenerator is connected with a dephlegmation device and an electric roasting rotary kiln; the dephlegmation device is connected with a condenser; the electric roasting rotary kiln is connected with a sorting device and comprises a frame body and a kiln cylinder rotationally arranged on the frame body; an electric stove wire and a heat preserving furnace shell are sequentially arranged outside the kiln cylinder; a loop cutting device is arranged in the kiln cylinder and comprises a long bar-shaped rod body; and the cross section of the rod body is a trilateral cross section formed by enclosure of three arcs which are sunken inwards. The invention also provides a method for circularly regenerating the diatomite filter aid containing the oil waste. The method comprises the following steps of desorption regeneration, regenerated diatomite roasting and sizing crushing. The problems that a diatomite regeneration process is complex, requirement on equipment is relatively high, process is complex because of separation, and quality of an oil product obtained through desorption is relatively low in the prior art are solved.

Owner:河北天诺再生资源利用有限公司

Method for preparing carbonaceous autoreduction cold pressing block and application thereof

The invention relates to a method for preparing a carbonaceous autoreduction cold pressing block by using electric stove dust-removing ash and iron scales and the application thereof. The carbonaceous autoreduction cold pressing block comprises the following raw materials by the weight percent: 40 to 50 of iron scale, 20 to 30 of electric stove dust-removing ash, 20 to 25 of carbon powder and 5 to 8 of bonding agent. The method for preparing the carbonaceous autoreduction cold pressing block comprises the following steps: the raw materials are evenly stirred in proportion and are pressed and molded by a double-roll block-press machine of 190 tons, and a mold is placed in dry environment of above 50 DEG C for 30 to 36 hours to form the high-strength carbonaceous cold pressing block which is directly used for electric stove steelmaking smelting. The method has simple technology, low energy consumption, high strength and no environmental pollution. When the carbonaceous autoreduction cold pressing block is used in an electric stove, the recovery rate of metallic iron reaches 27 percent, and the method is beneficial to increase foam residues and dephophorization effect.

Owner:SHANDONG IRON & STEEL CO LTD

High temperature resistant dust collector

InactiveCN101559307AImprove dust removal efficiencyReduce energy consumptionHuman health protectionDispersed particle filtrationMetal fibersEngineering

The invention relates to a high temperature resistant dust collector, which comprises a heat insulation shell, a dust hopper, a pulse blowing device, a metal filter cartridge, a filter chamber, a purified gas outlet, a dust containing gas inlet and a dust conveying device. The dust hopper is connected to the bottom of a tank body of the filter chamber; one side of the dust hopper is provided with the dust containing gas inlet which is communicated with the filter chamber; one side of the top of the heat insulation shell is provided with the purified gas outlet which is communicated with a clean chamber; the metal filter cartridge is arranged in the filter chamber, and is made of a high temperature resistant metal material; a nozzle of a blowing pipe in the pulse blowing device aligns to the metal filter cartridge; and the dust conveying device is connected to the lower part of the dust hopper. The filter material of the high temperature resistant dust collector is special metal fiber, and can be applied to a flue-gas at 300 to 1,000 DEG C to replace multiple cooling devices such as a water-cooling flue, an air cooler and the like in a dust removing system; and the high temperature resistant dust collector has high collection efficiency, low energy consumption, and safe and stable operation of the system, and realizes the dust removing of high temperature flue gas of equipment such as electric stoves, oxygen argon decarbonization converters and the like.

Owner:BAOSTEEL ENG & TECH GRP

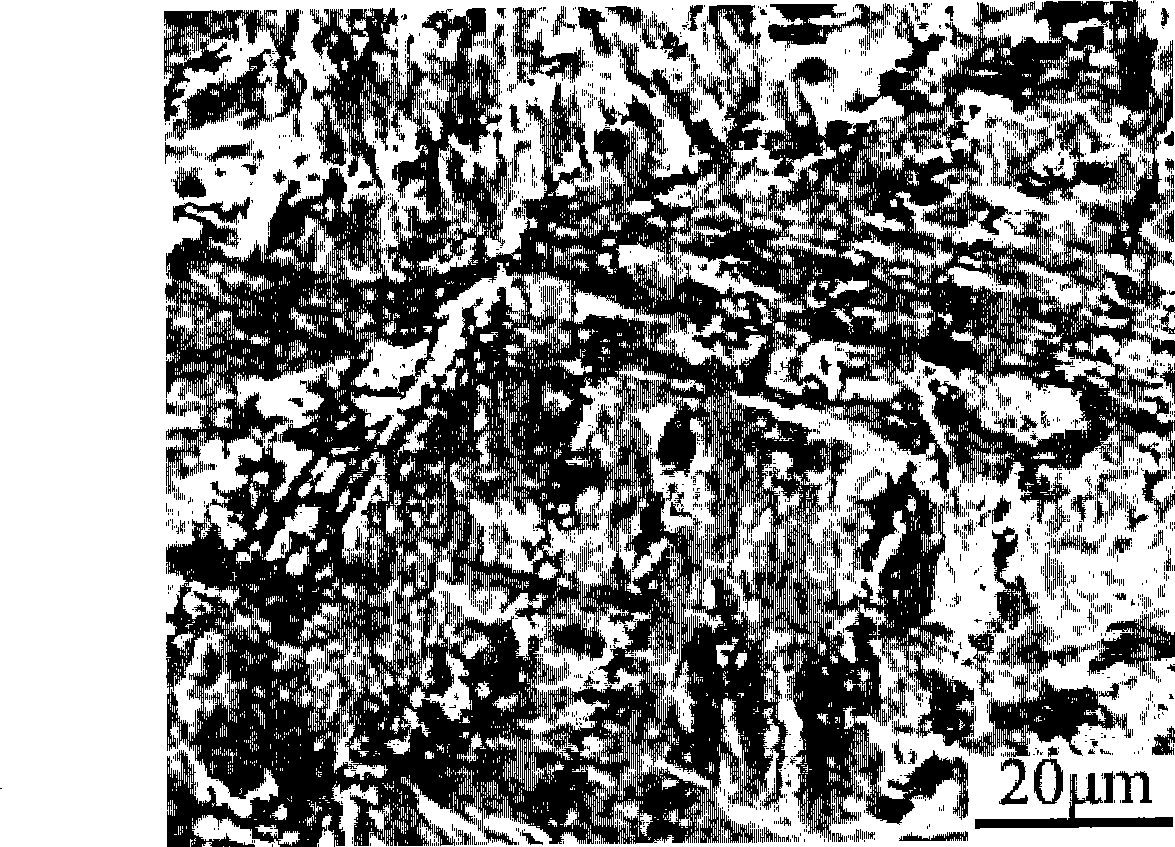

Liquid zinc corrosion resistant high-boron cast steel and preparation method thereof

The invention discloses a high boron cast steel which resists the corrosion of molten zinc and a preparation method thereof, and the chemical compositions of the high boron cast steel are (weight percentage): C is less than 0.15, Si is less than 0.40, Mn is less than 0.40, B: 5.0-7.0, Ce: 0.05-0.15, Cr: 1.5-3.0, Al: 0.80-1.50, and the rest are Fe and unavoidable microimpurity. The high boron cast steel of the invention can be produced by an electric stove, wherein, the metallographic microstructure of the high boron cast steel consists of a reticular boride, a ferrite and a metallic matrix composed of a small quantity of pearlite; the molten zinc corrosion resistance of the high boron cast steel is excellent, and the corrosion velocity in the molten zinc of 500 DEG C is 25-40g / m <2> multiplied by h. Furthermore, the high boron cast steel is characterized by good obdurability, the intensity of tension more than 400MPa and an impact ductility more than 6J / cm <2>. The invention has the advantages that the cast steel does not rupture in operating process, and the service performance is significantly better than regular molten zinc corrosion resistant material; furthermore, the manufacturing process is simple, and the production cost is low for containing no expensive alloying elements. By adopting the molten zinc corrosion resistant high boron cast steel of the invention, the device operation efficiency can be significantly improved, the production cost can be reduced, and the economic and social benefits are good.

Owner:XI AN JIAOTONG UNIV

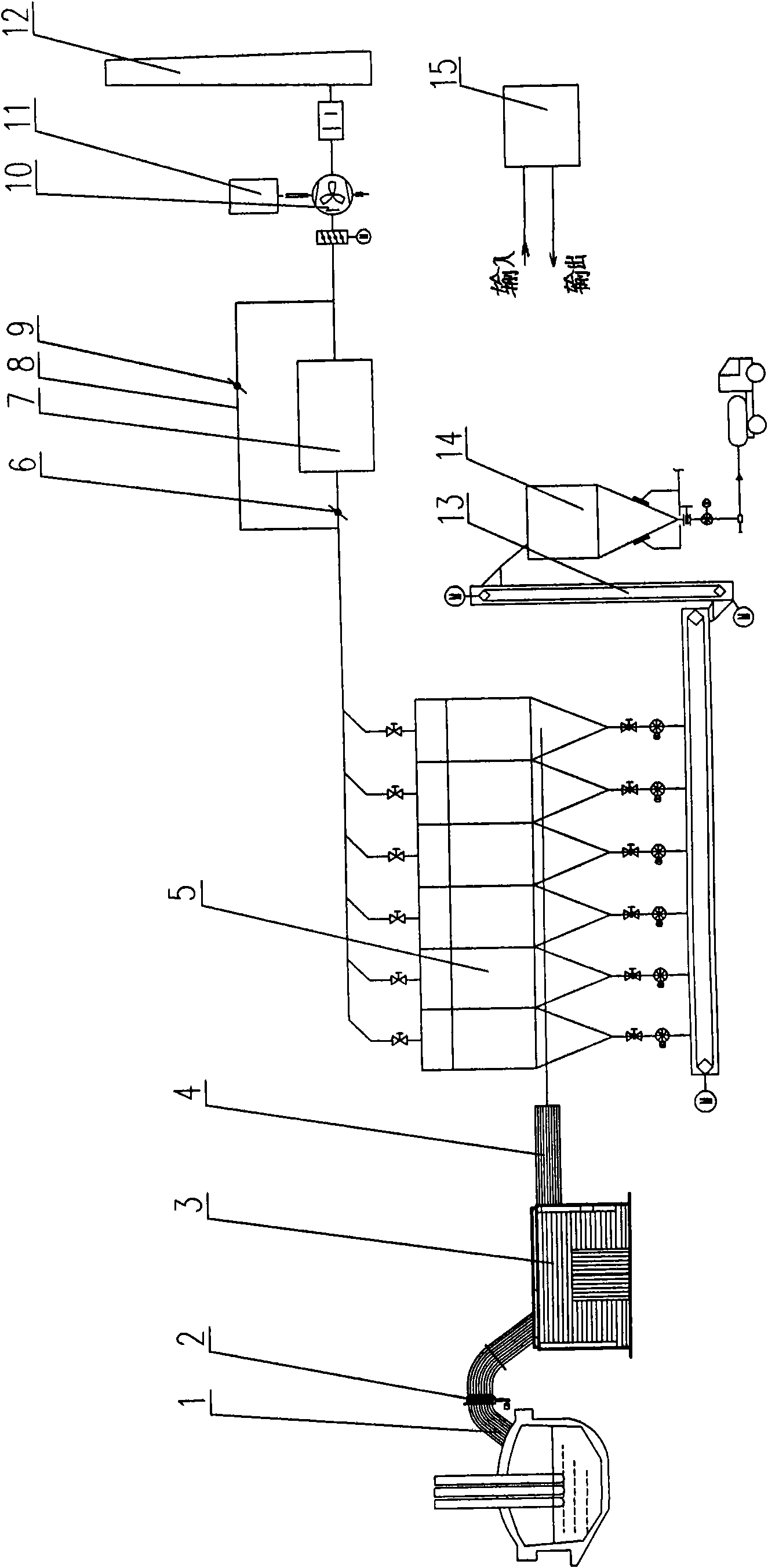

Solid waste or biomass high-efficiency pyrolysis oil-producing system

ActiveCN102719265AAvoid cleaning difficultiesPromote escapeLiquid hydrocarbon mixture productionProduct gasBottle

The invention discloses a solid waste or biomass high-efficiency pyrolysis oil-producing system. The solid waste or the biomass is charged into a pyrolyzing furnace, wherein the pyrolyzing furnace is internally provided with a thermoelectric couple, and an intelligent temperature controller controls the heating power of an electric stove wire outside a reaction pipe; a pyrolysis volatile component product enters into a semi-coke separation device from an air outlet on the top of the reaction pipe; sequentially, the pyrolysis volatile component enters into at least two levels of condensing device to be condensed; and a large number of non-condensable substances contained in pyrolysis gas continuously passes through a high-voltage electrostatic separation device, wherein the non-condensable pyrolysis oil is collected into a collecting bottle through the high-voltage electrostatic separation device. According to the system provided by the invention, the heat and mass transfer effects of the solid waste and the biomass material in the process of pyrolysis can be preferably enhanced; the volatile component can be preferably overflowed; and the semi-coke product and the gas can be effectively separated from each other, and the productivity and the quality of the liquid diesel oil product can be greatly improved. According to the different feeding varieties of the biomass, the system can obtain more than 10%-15% of the biological oil compared with a general biomass pyrolysis liquefaction process.

Owner:TIANJIN UNIV

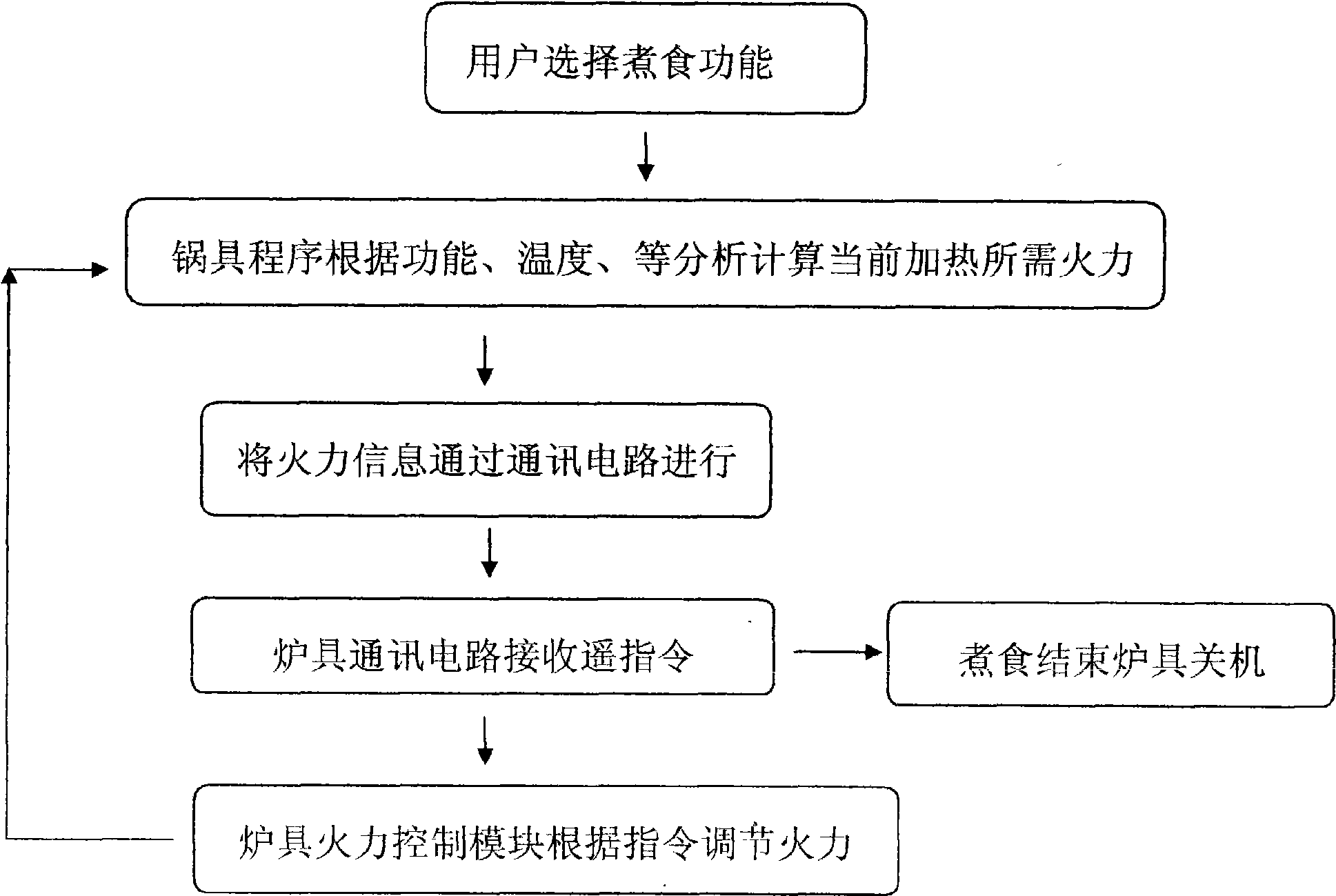

Intelligent food boiling method realized by boiler remote-control furnace

InactiveCN101507572AEasy to useSolve the shortcomings of not being able to cook food intelligentlyCooking vesselsRemote controlComputer module

The invention relates to food cooking intelligent control, belongs to the field of kitchen electric appliances, and is a method for controlling food cooking, which is realized by a pan remote controlled stove, and not only can realize intelligent control, but also can make the pan and the stove freely matched. The pan remote controlled stove consists of the pan and the stove, wherein a food cooking control module, a food cooking control program and a wireless communication circuit are installed in the pan; the pan can analyze fire power required by food cooking currently, and transmit information of the fire power in a wireless communication mode to the stove; a fire power control module and the wireless communication circuit are arranged in the stove so as to control heating fire power through the information of the fire power transmitted by the pan; and wireless communication is used between the pan and the stove, and pans and stoves with the same mode and protocol of wireless communication can be matched to be used. The pan remote controlled stove and the method overcome the defect that the prior gas stove cannot cook food intelligently, and provide infinite space for function expansion of electric stoves (such as electromagnetic ovens, infrared stoves and the like).

Owner:黄银章

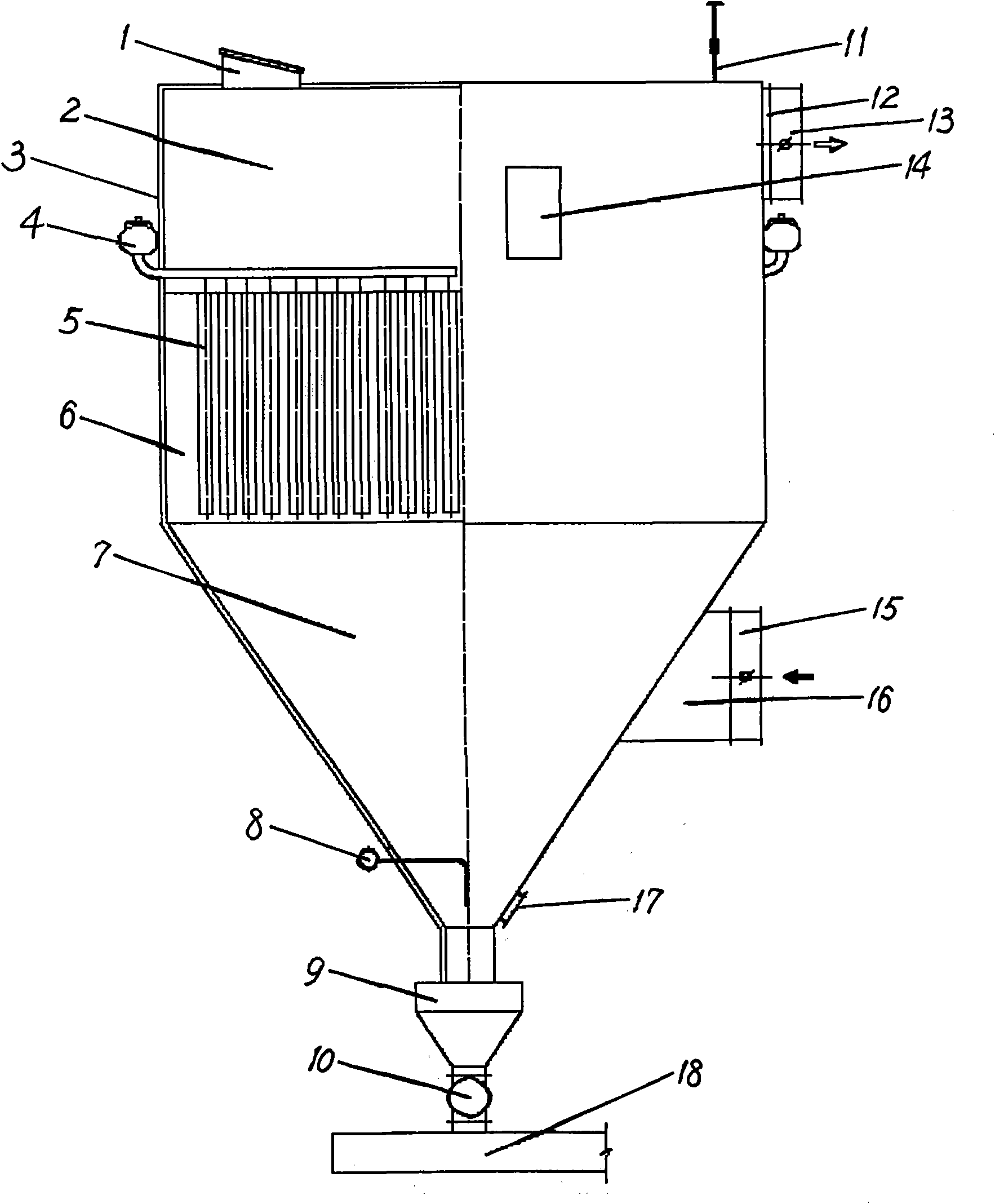

First flue gas dust removal and waste heat recovery system for electric stove

InactiveCN101539371AAchieve emission reductionRealize energy savingDispersed particle filtrationIncreasing energy efficiencyCombustion chamberElectric stove

The invention relates to a first flue gas dust removal and waste heat recovery system for an electric stove. The system is connected with the smoke hole of the electric stove and comprises a water cooling travelling tube, a combustor and a water cooling flue gas path, and the system also comprises a high temperature resistant dust remover, a waste heat recovery device, a dust removal fan and a chimney. The outlet of the combustor is communicated with the smoke hole of the electric stove by the water cooling travelling tube and the outlet of the combustor is communicated with the high temperature resistant dust remover by the water cooling flue gas path. The outlet of the high temperature resistant dust remover is communicated with the inlet pipeline of the waste heat recovery device, thus the flue gas after dust removal can be sent into the waste heat recovery device. The outlet of the waste heat recovery device is communicated with the chimney by the fan, and the waste heat recovery device is used for absorbing the heat of the flue gas. The dust removal fan is arranged on the pipeline between the waste heat recovery device and the chimney. The system of the invention has the advantages of high dust removal efficiency, strong operability, safe and steady operation, low energy consumption and steam recovery, thus realizing flue gas emission reduction and energy conversation of the electric stove.

Owner:BAOSTEEL ENG & TECH GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com