Patents

Literature

44results about How to "Avoid cleaning difficulties" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Drink brewing machine and control method thereof

ActiveCN105030069AImprove heating efficiencyImprove the bactericidal effectBeverage vesselsMicrowaveEngineering

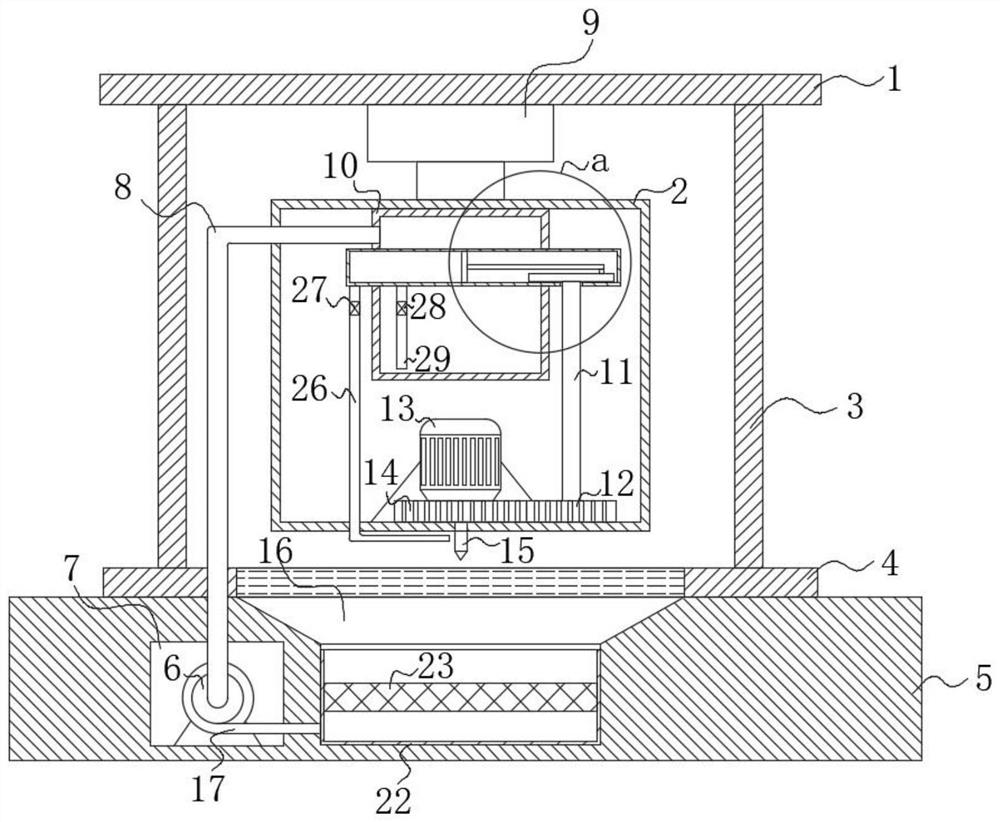

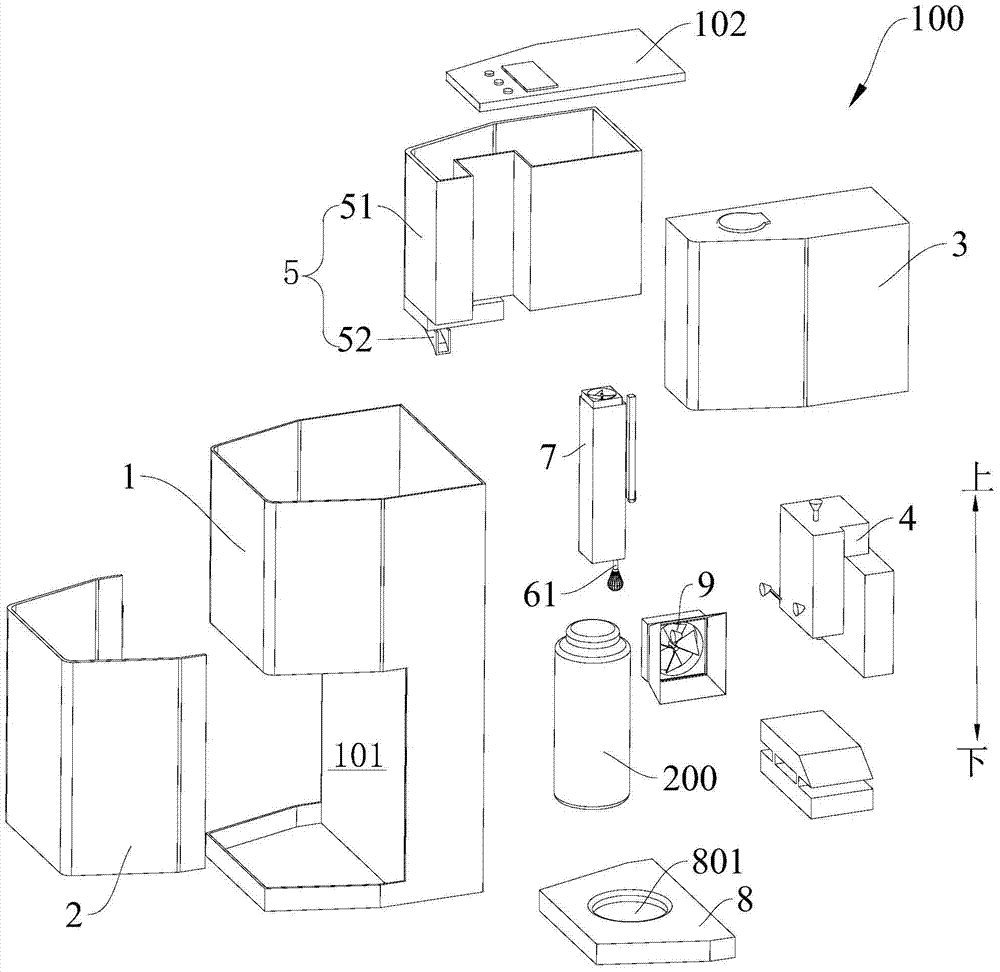

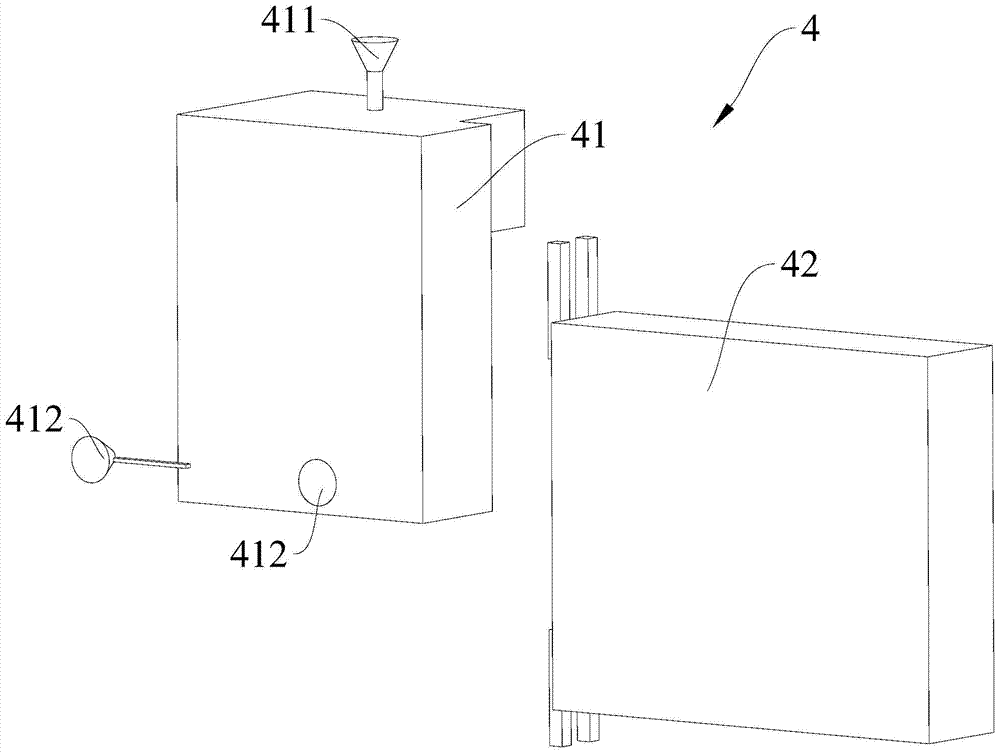

The invention discloses a drink brewing machine and a control method thereof. The drink brewing machine comprises a shell, a water tank, a microwave heating device and a drink feeding device. A container containing cavity with the side face open is formed in the outer side of the shell, and a door used for opening and closing the container containing cavity is arranged. At least part of the water tank is arranged in the shell and used for storing water. At least part of the microwave heating device is arranged in the shell and used for providing microwaves for at least one of the water tank and the container containing cavity. The drink feeding device is arranged in the shell. According to the drink brewing machine, heating efficiency can be improved, and the drink brewing machine further has the disinfection effect.

Owner:GUANGDONG MIDEA KITCHEN APPLIANCES MFG CO LTD +1

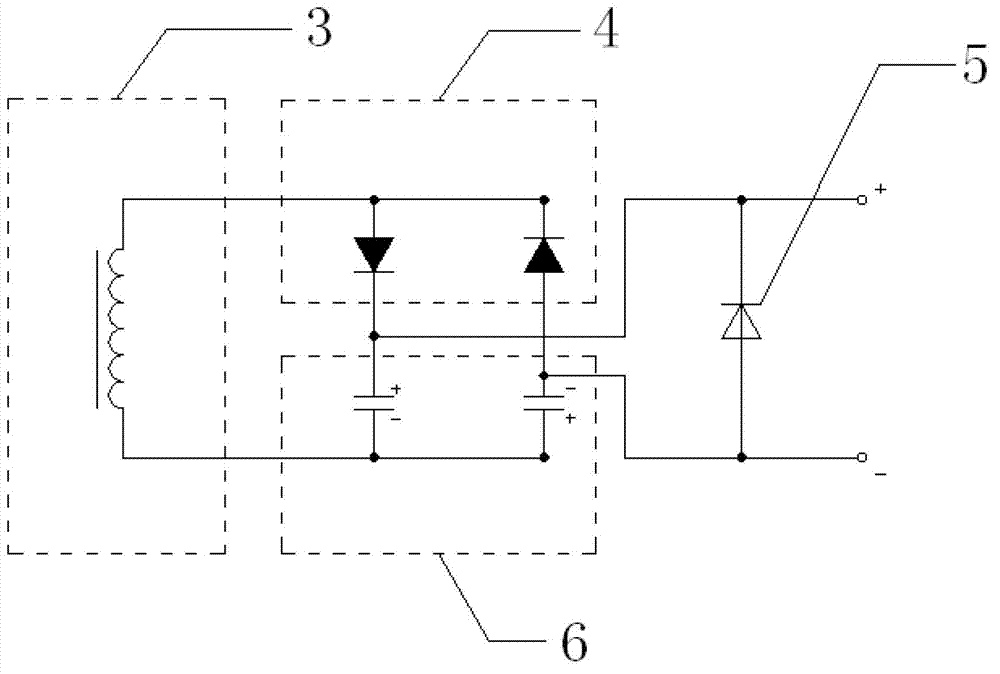

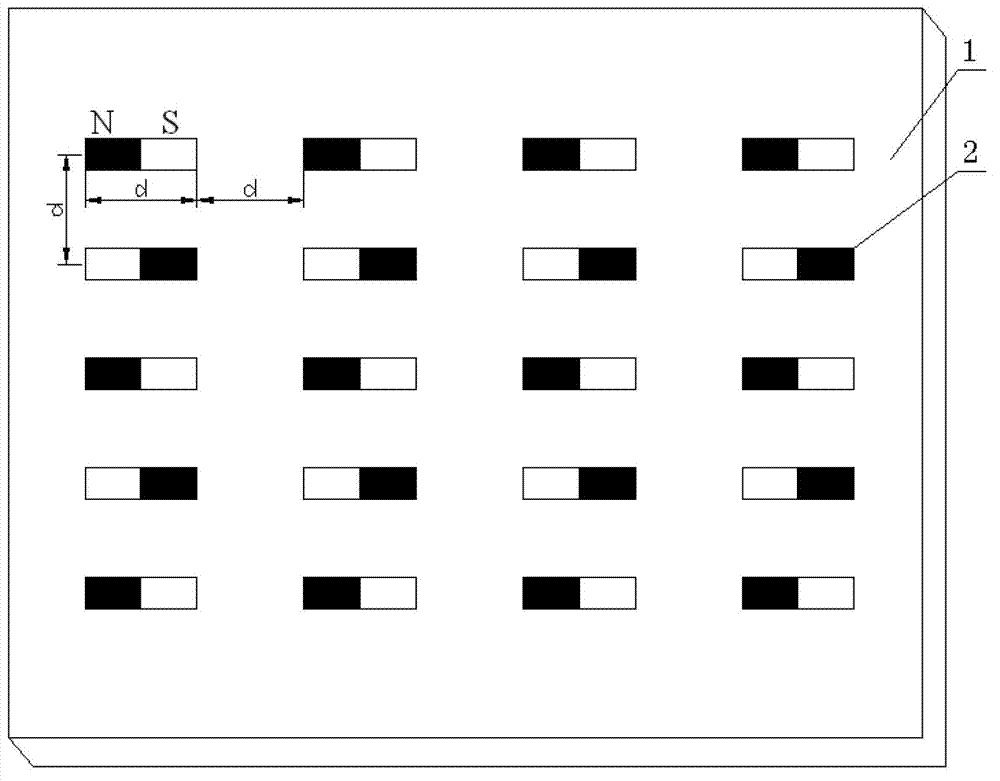

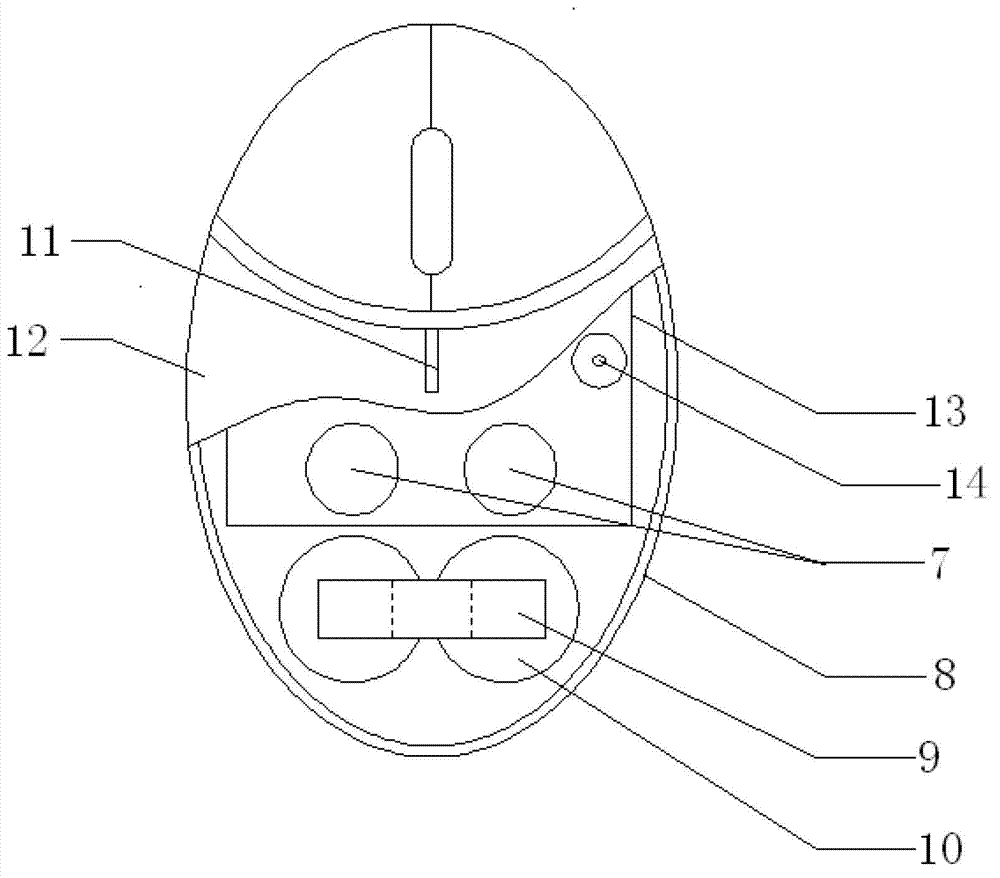

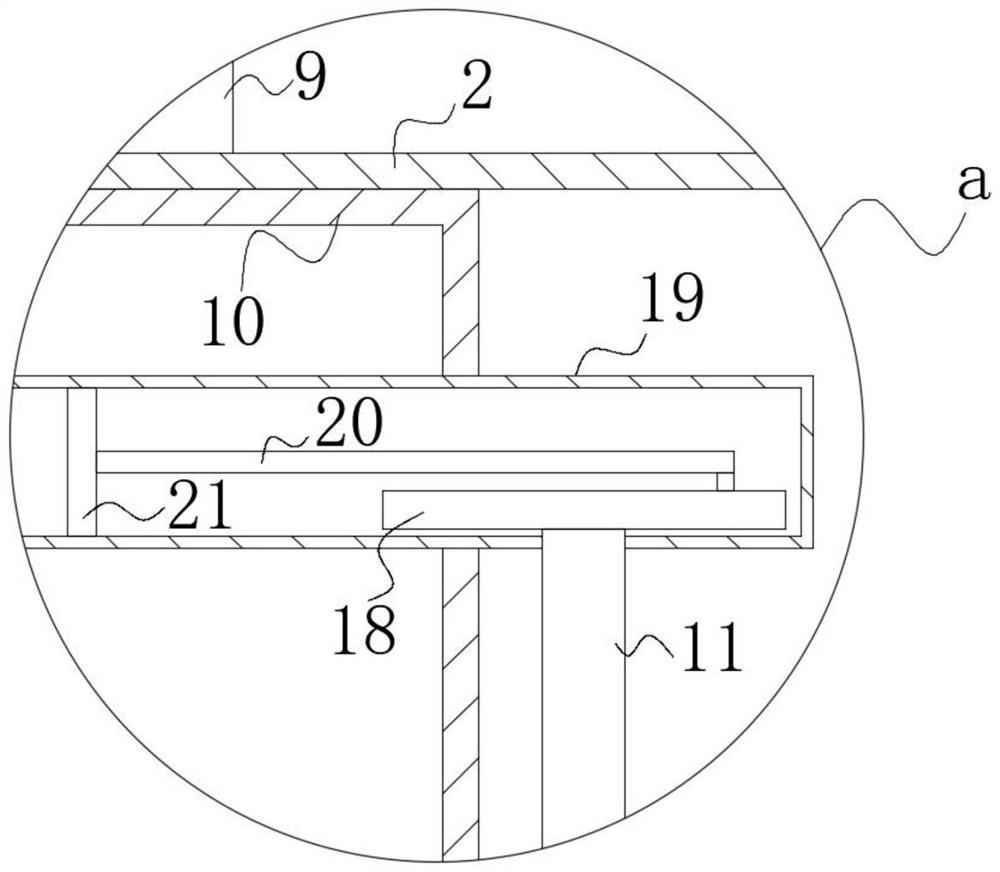

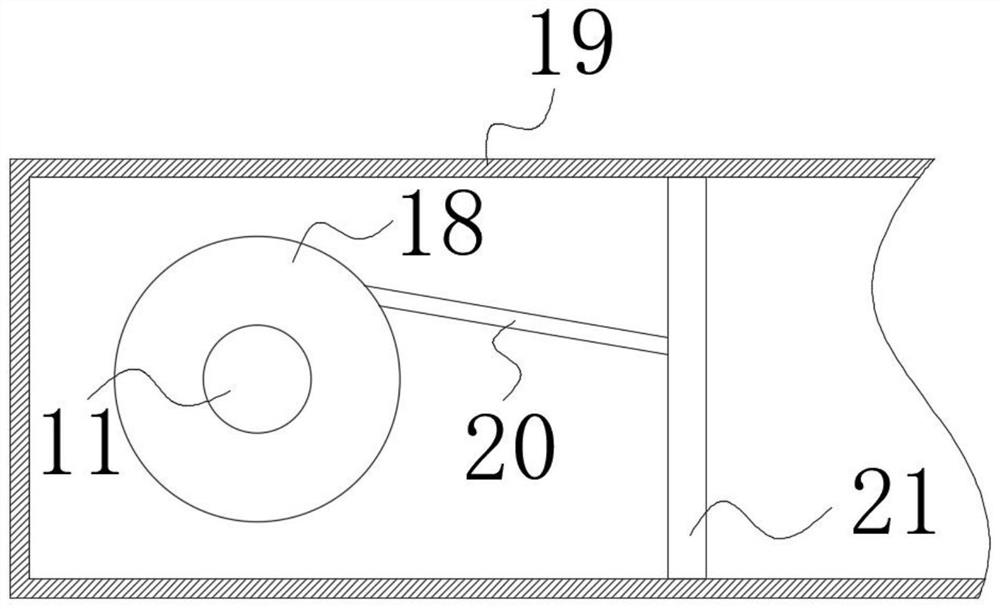

Self-generating wireless mouse and mouse pad

InactiveCN102830820AAvoid cleaning difficultiesExtended service lifeBatteries circuit arrangementsElectric powerElectrical energy storageElectric energy

The invention relates to a self-generating wireless mouse and a mouse pad. One or more magnets are arranged in the mouse pad; the magnets on the same horizontal line are identical in the NS pole direction; the magnets on two adjacent horizontal lines are opposite in the NS pole direction; a rectifier module, an electric energy storage module, an electromagnetic induction module and a voltage stabilizing diode are arranged on a circuit board in the wireless mouse; the positive output end and the negative output end of the rectifier module are respectively connected with the positive end and the negative end of the electric energy storage module; the output end of the electromagnetic induction module is connected with two ends of the rectifier module and the electric energy storage module after serially connecting the rectifier module and the electric energy storage module; and the positive connection end and the negative connection end of the voltage stabilizing diode are respectively connected with the positive end and the negative end of the electric energy storage module. The self-generating wireless mouse provided by the invention has the advantages of high charging efficiency, high self-generating voltage, and long service life of the power supply by adopting the non-contact power generation method and a novel rectifying and charging circuit, and can supply power by itself during normal movement of the mouse.

Owner:余姚市鑫大电子科技有限公司

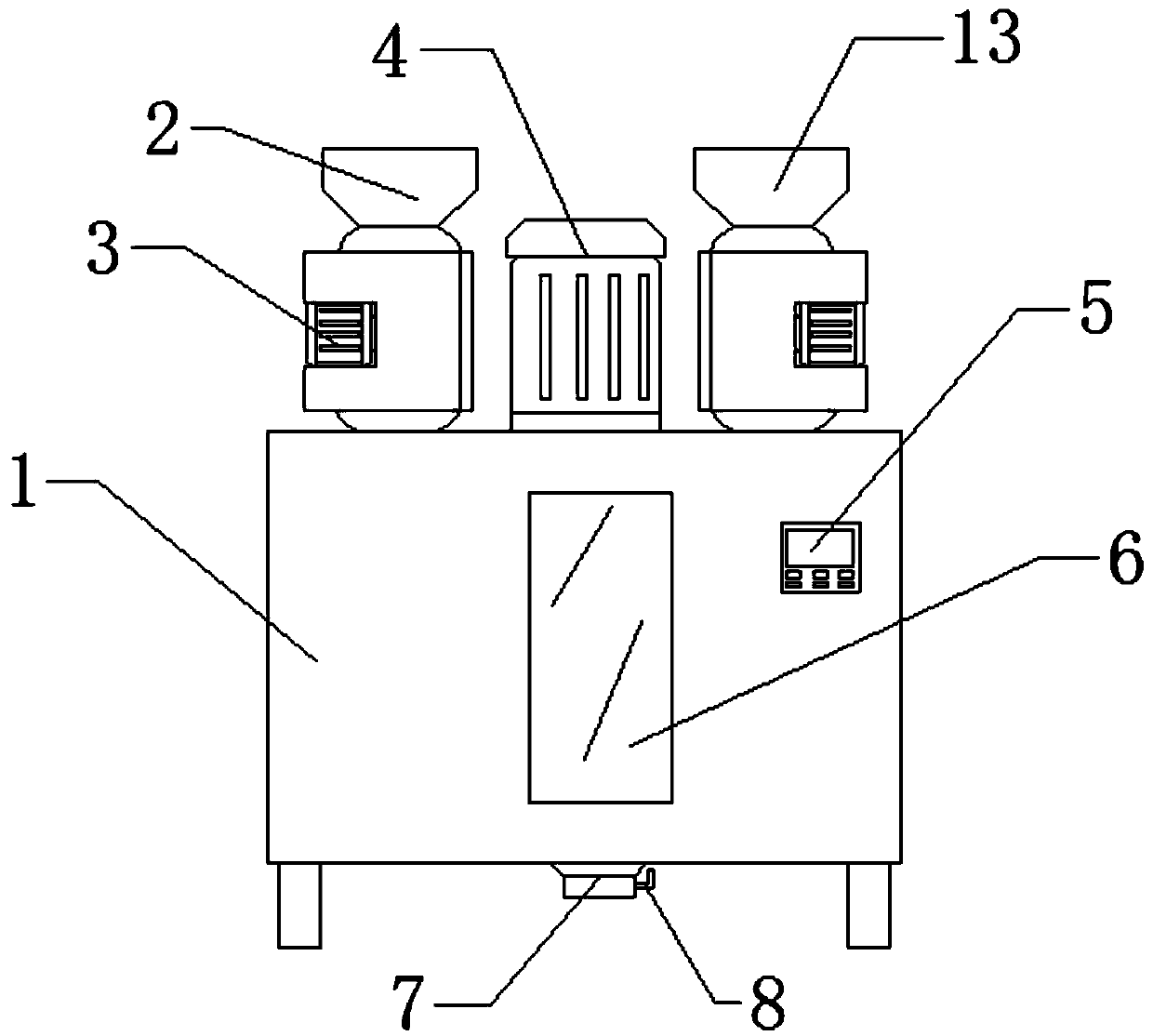

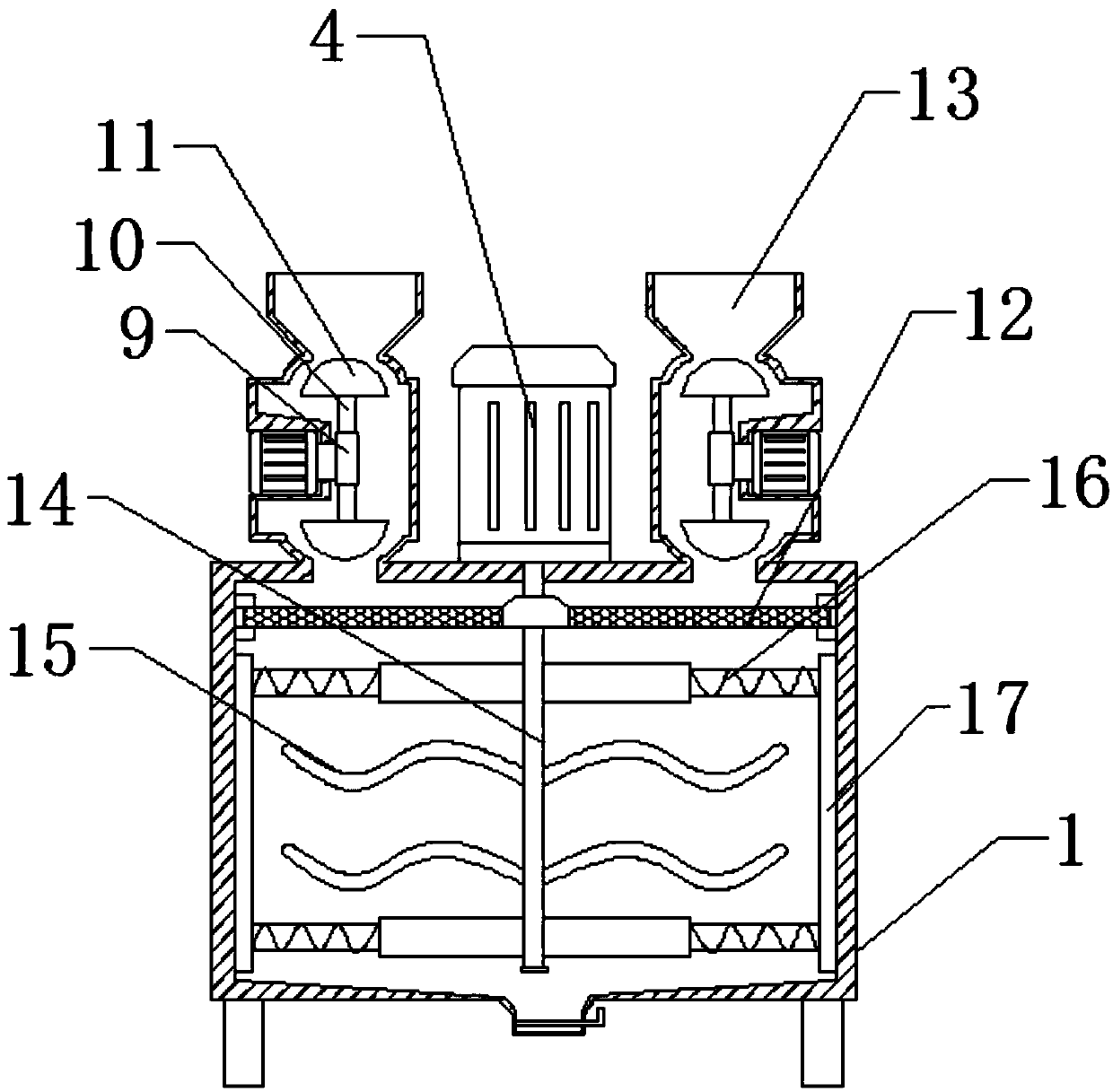

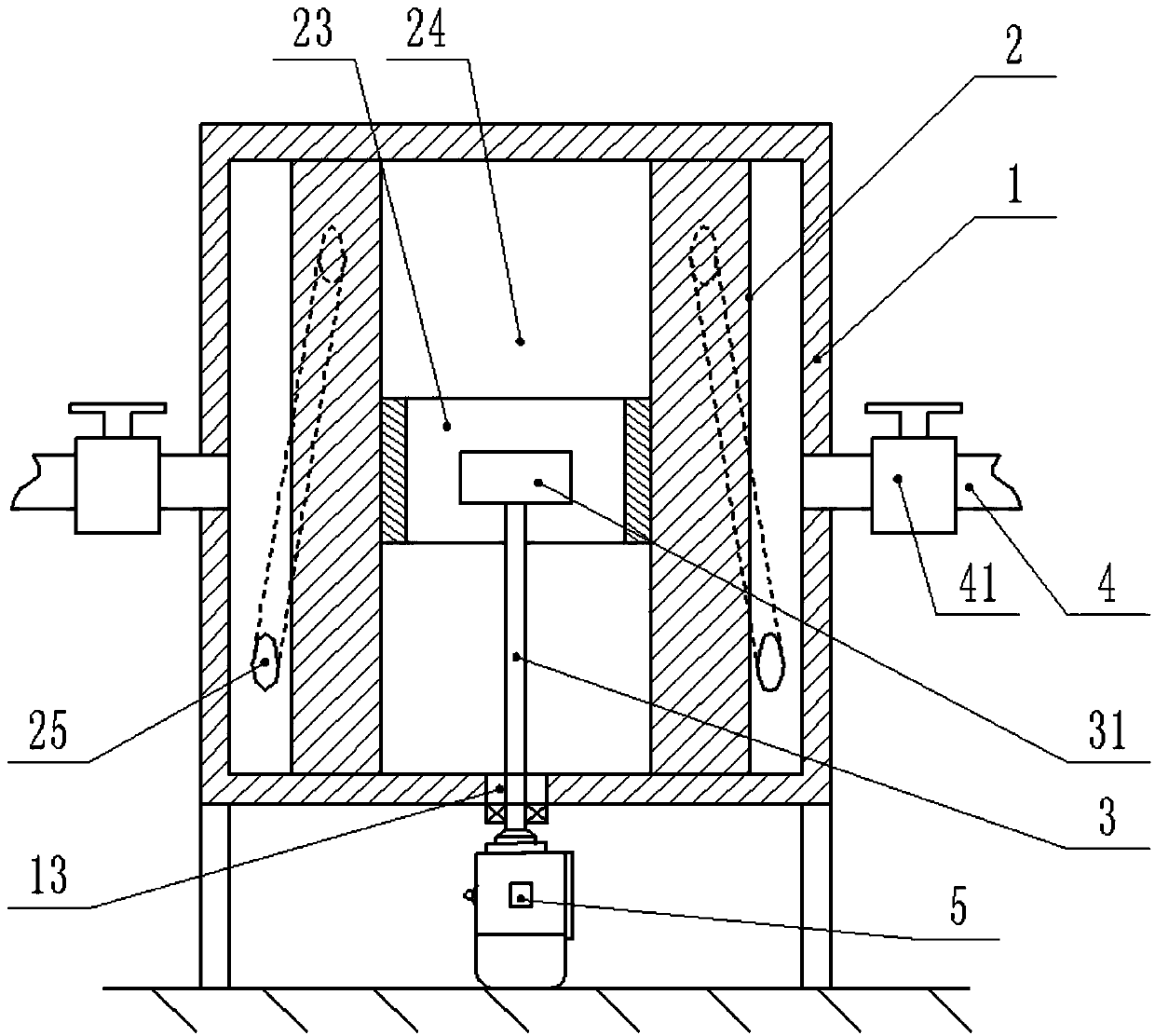

Chemical raw material stirring machine

InactiveCN109569364AStir wellImprove mix qualityRotary stirring mixersTransportation and packagingCentrifugal forceRaw material

The invention discloses a chemical raw material stirring machine. The chemical raw material stirring machine comprises a machine body, wherein a discharging opening is formed in the bottom of the machine body in a penetrating manner; a valve is arranged on one side of the discharging opening; a first feeding barrel and a second feeding barrel are separately arranged on the two sides of the top ofthe machine body in a penetrating manner; a motor is arranged on the top of the machine body; the device is further provided with a spring rod and a scraper blade; during stirring, a rotating shaft rotates rapidly, and thus, the spring rod rotates rapidly; the spring rod rotates rapidly to generate centrifugal force, thus, the spring rod is expanded, due to expansion of the spring rod, the scraperblade is closely attached to the inside of the machine body, at the moment, the spring rod rotates to drive the scraper blade to rotate, due to rotation of the scraper blade, chemical raw materials which adhere to the inner wall of the machine body are scraped off, on the one hand, the chemical raw materials cannot be wasted, and on the other hand, the problem that the chemical raw material is condensed and dried and then is difficult to clean is prevented.

Owner:深圳振业企业管理咨询有限公司

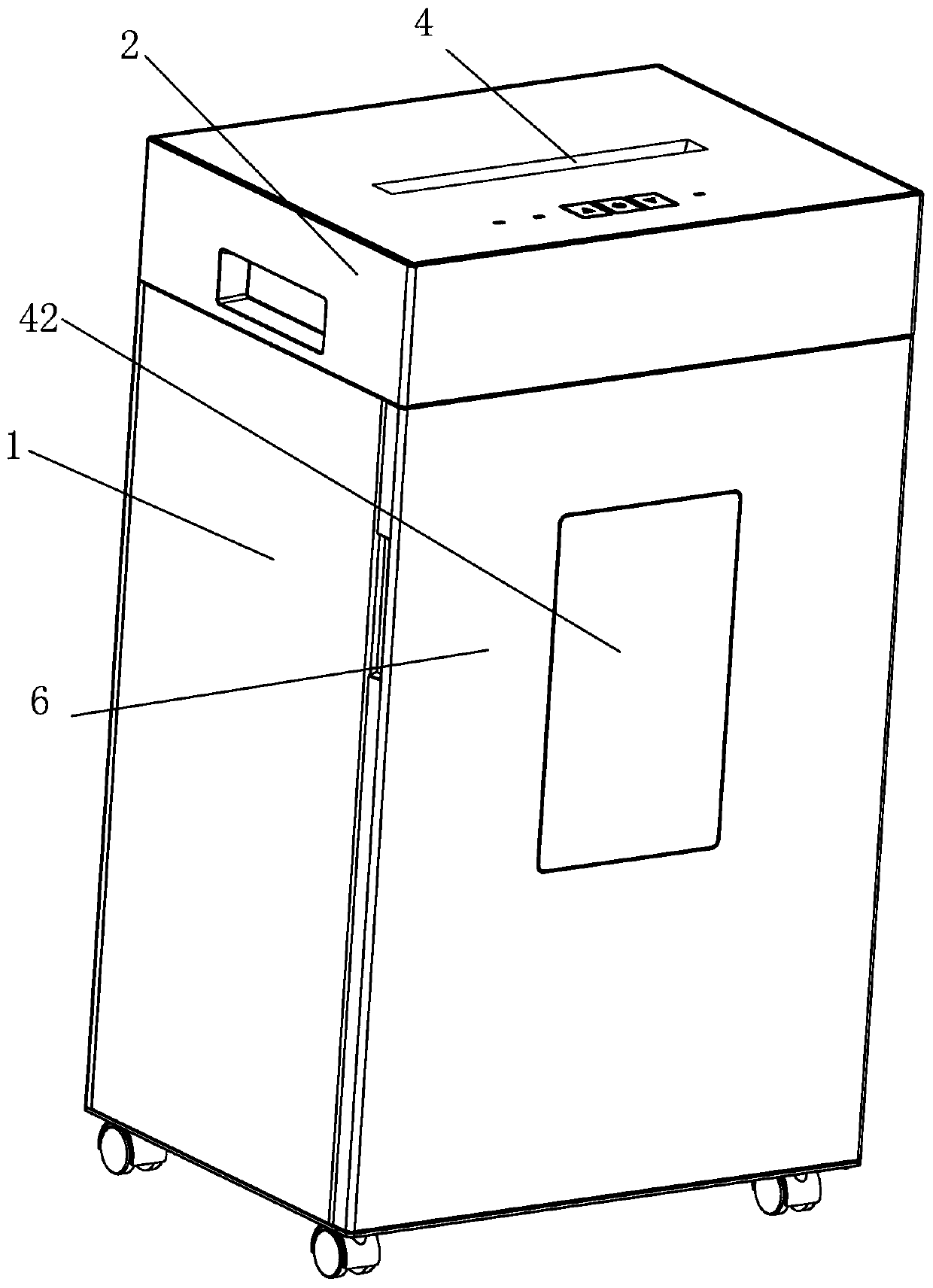

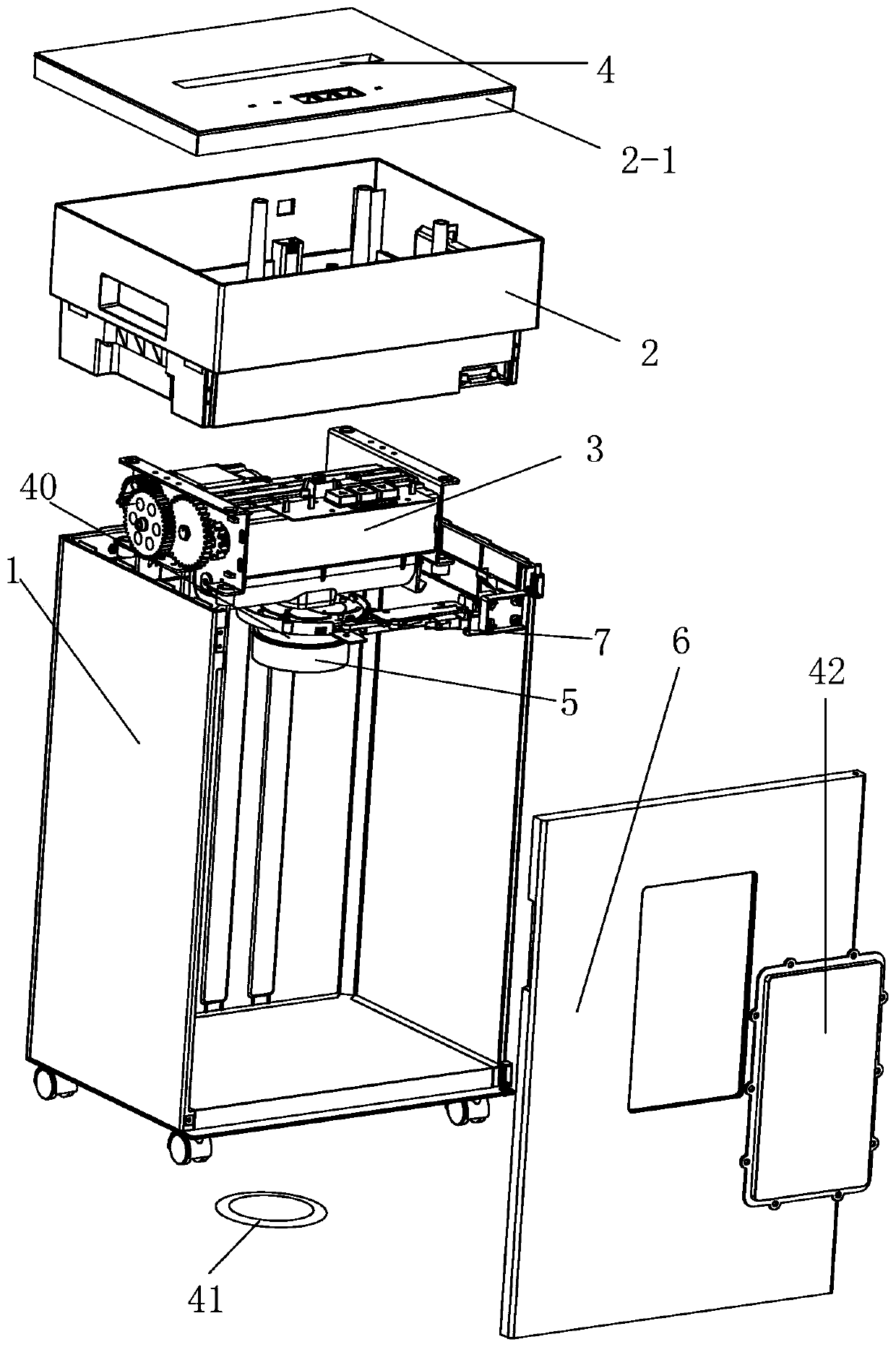

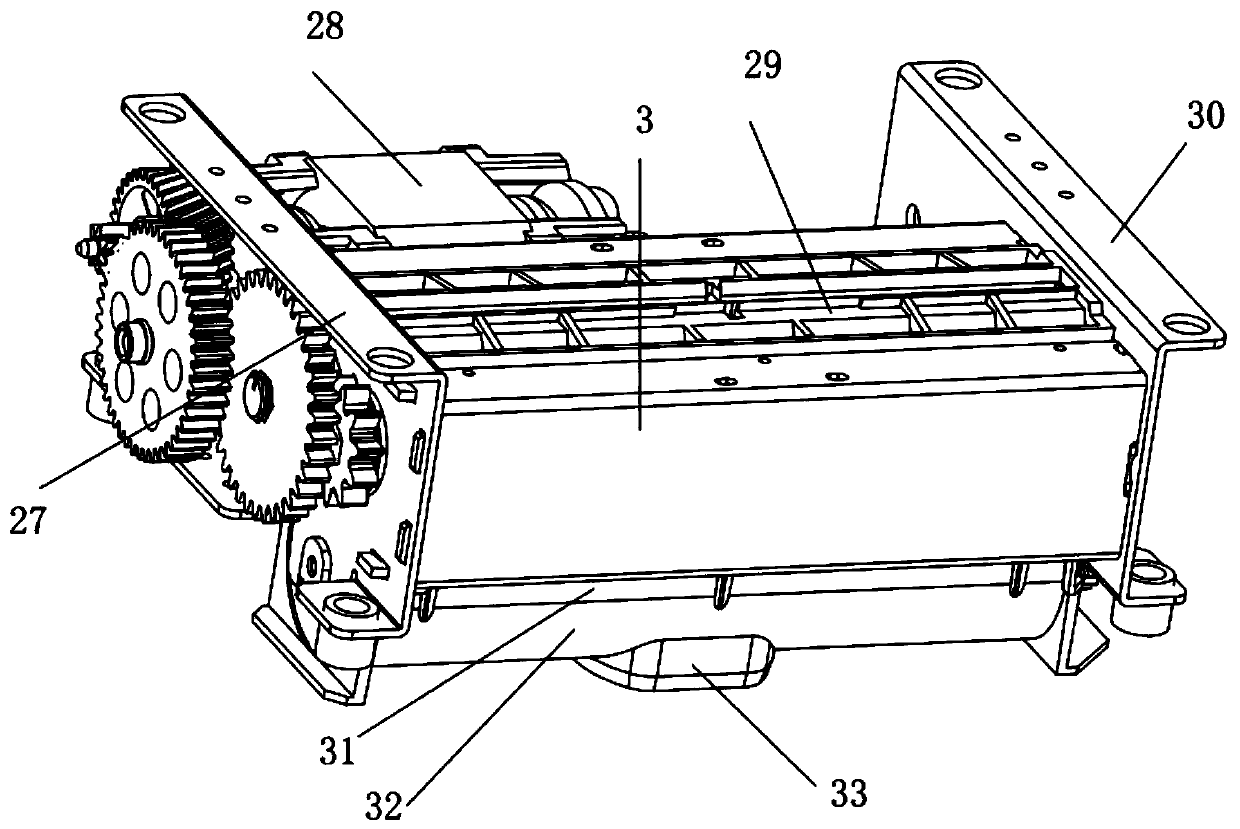

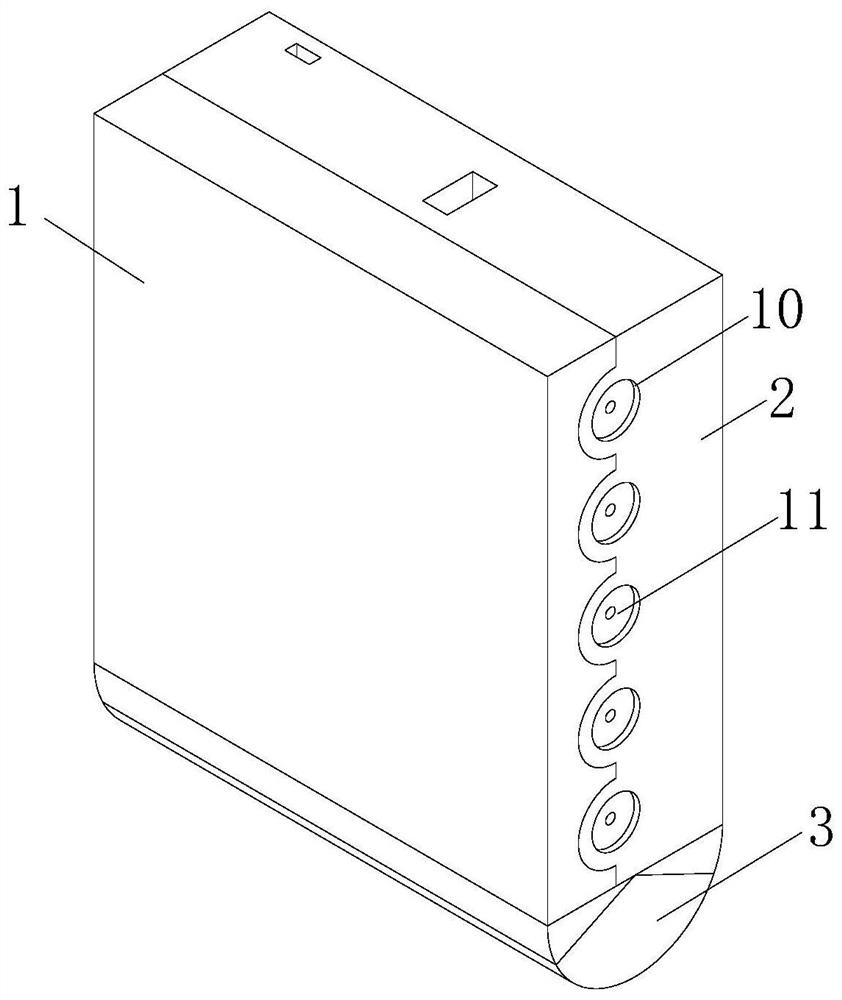

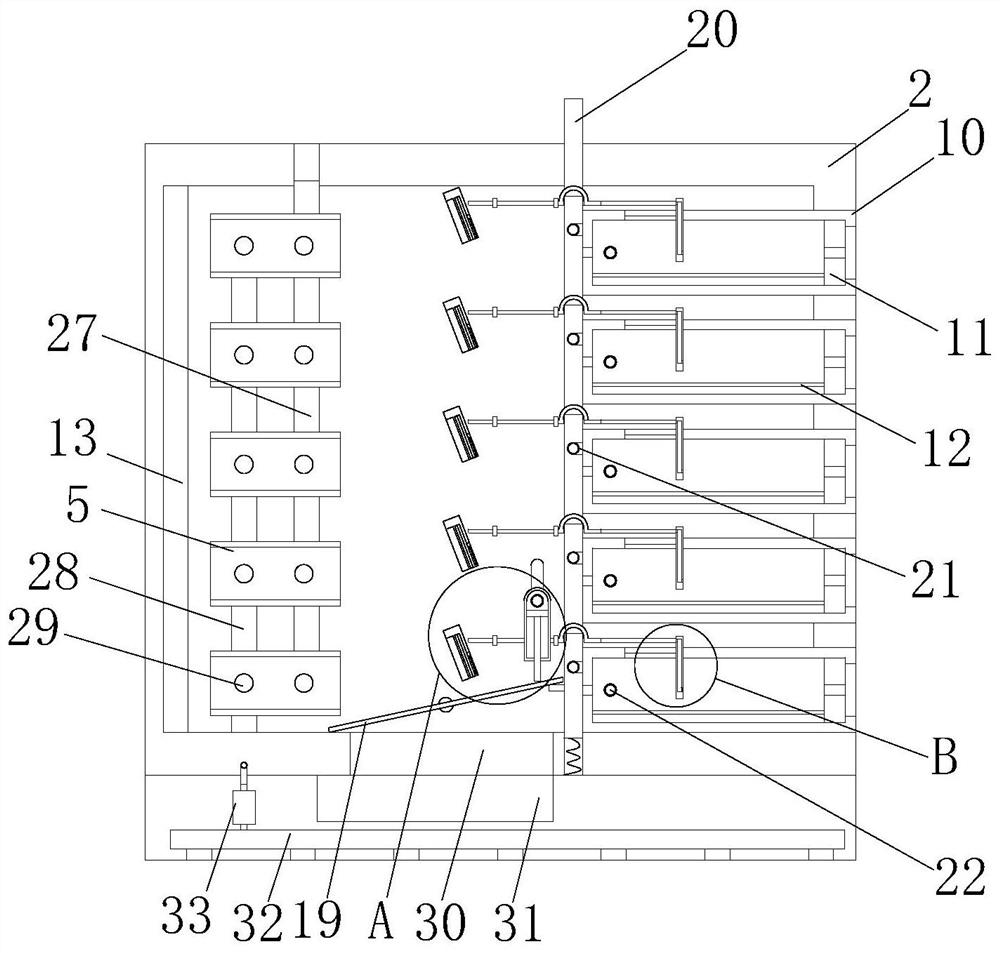

Dust-free paper shredder

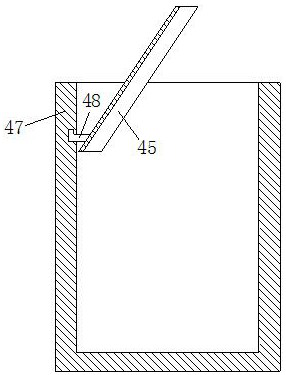

PendingCN110449239AAvoid cleaning difficultiesWill not affect the air environmentGrain treatmentsPaper dustPulp and paper industry

The invention relates to a dust-free paper shredder which comprises a box body. A crushing part is arranged above the box body, a crusher assembly is arranged in the crushing part, a paper inlet located in the top of the crusher assembly is formed in the crushing part, a paper scrap outlet penetrating the paper inlet is formed below the crusher assembly, the paper scrap outlet is located in the box body, a cover door is hinged to the side edge of the box body, a driving plate mechanism capable of opening or closing the paper scrap outlet as needed if being pulled is arranged at an upper port of the paper scrap outlet, and when the driving plate mechanism is opened, the paper scrap outlet and the paper inlet penetrate. On the contrary, when the driving plate mechanism is closed, the paper scrap outlet and the paper inlet are closed. According to the dust-free paper shredder, when a garbage bag is taken away, a condition that the air environment is affected as paper scrap dust is blown out randomly is avoided, so that a problem that it is hard to clean paper scrap dust in later stage is avoided.

Owner:NINGBO FORTEK ELECTRONICS

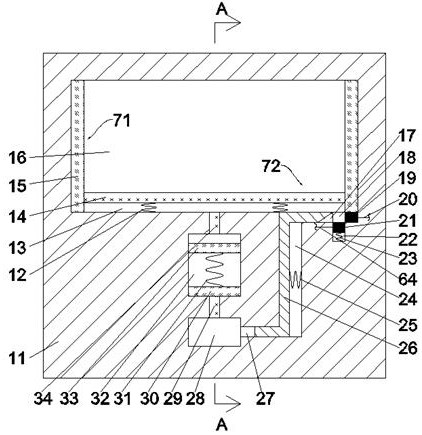

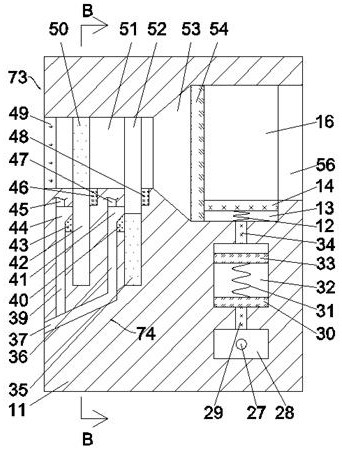

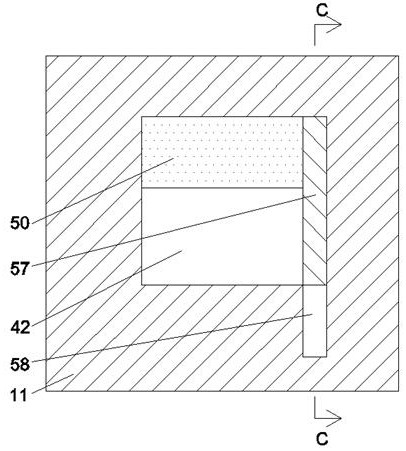

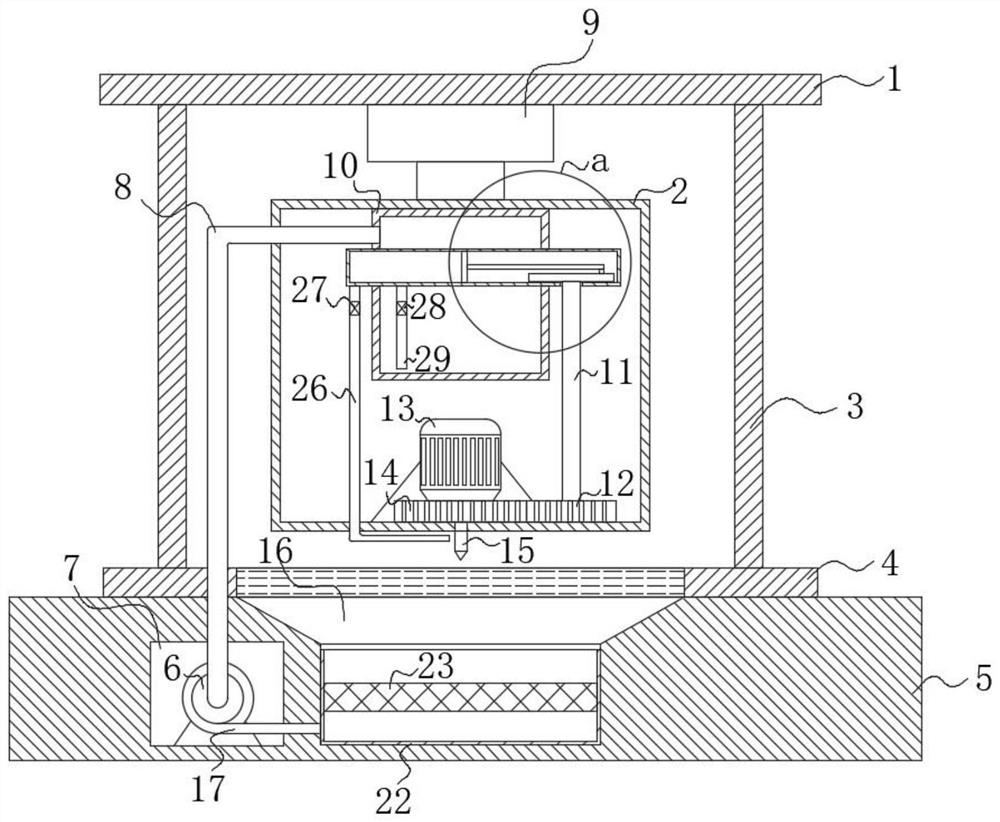

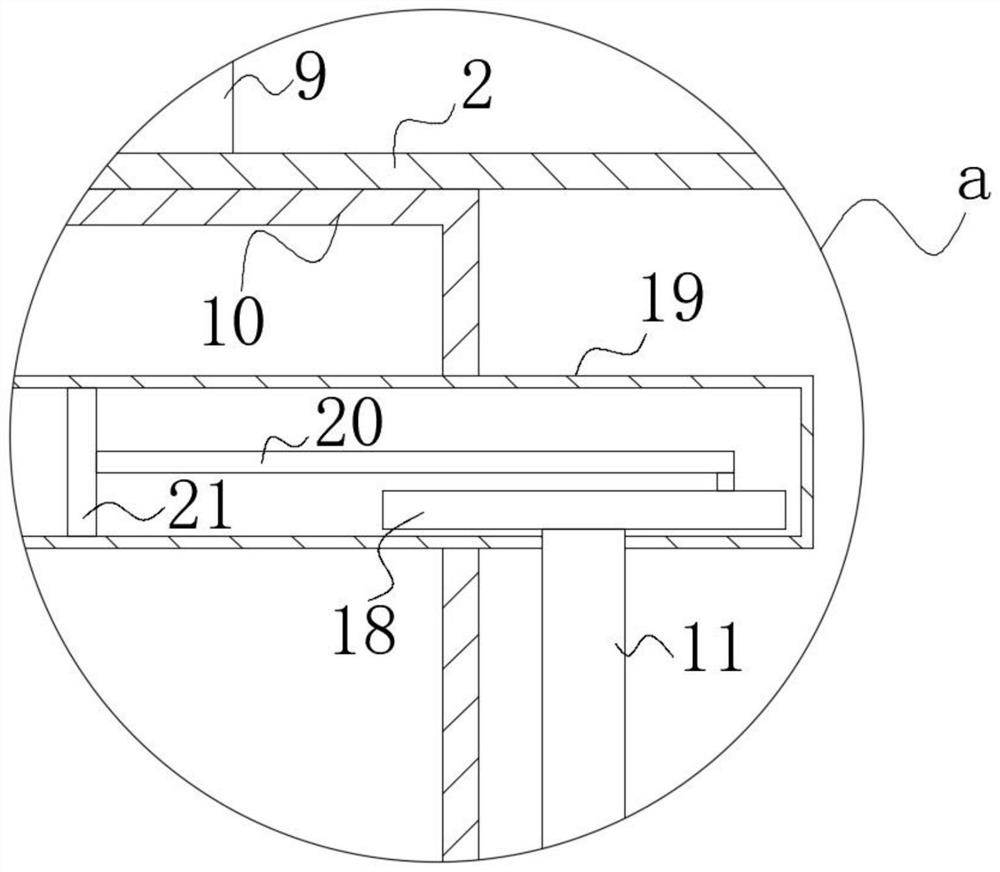

Television cabinet capable of automatically cooling and cleaning

InactiveCN112167857AAvoid cleaning difficultiesImprove cooling effectDispersed particle filtrationTransportation and packagingMechanical engineeringCable television

The invention discloses a television cabinet capable of automatically cooling and cleaning. The television cabinet comprises a box body, wherein a television cavity is formed in the box body, a cooling device is arranged in the television cavity, the cooling device comprises a bottom plate sliding cavity located on the lower side of the television cavity and provided with an upward opening, and abottom cooling plate is connected into the bottom plate sliding cavity in a sliding mode; two bottom plate springs in bilateral symmetry are fixedly arranged between the bottom cooling plate and the inner wall of the lower side of the bottom plate sliding cavity, and an overheating protection device is arranged on the lower side of the bottom plate sliding cavity. According to the invention, the dust in the device cannot enter the television and can be effectively prevented from entering the television through heat dissipation holes, so that the problems of difficult cleaning and the like areeffectively prevented, and a filter screen can be automatically cleaned; when the television is powered on, cooling is started, and the machine body temperature can be automatically detected; and whenthe temperature rises, the cooling effect is automatically improved.

Owner:兰溪太纲电子科技有限公司

Plate drilling machine

ActiveCN111906339AAvoid cleaning difficultiesAvoid wastingDrilling machinesMaintainance and safety accessoriesThermodynamicsHydraulic ram

The invention discloses a plate drilling machine which comprises a cross beam, a supporting rod, a base plate and a base. A hydraulic oil cylinder is fixedly installed at the bottom of the cross beam,the piston end of the hydraulic oil cylinder is fixedly connected with a working box, a cooling box is fixedly installed in the working box, liquid pumping mechanisms penetrate through the side wallsof the two ends of the cooling box, and a collecting cavity is formed in the base; and a processing mechanism is movably connected into the collecting cavity, a cavity is formed in one side of the processing mechanism, and a recycling mechanism is fixedly installed in the cavity. By the arrangement of a chipping and cooling liquid collecting device, a large number of chippings generated in the drilling process and used cooling liquid are collected and recycled, so that the problem that the chippings are difficult to clean can be solved, and the cooling liquid can be recycled; and meanwhile, by the arrangement of a drill bit cooling mechanism, cooling liquid is sprayed to a drill bit when the drill bit works, the temperature of the drill bit is reduced, and cutting edges can be kept sharp.

Owner:芜湖腾飞信息科技有限公司

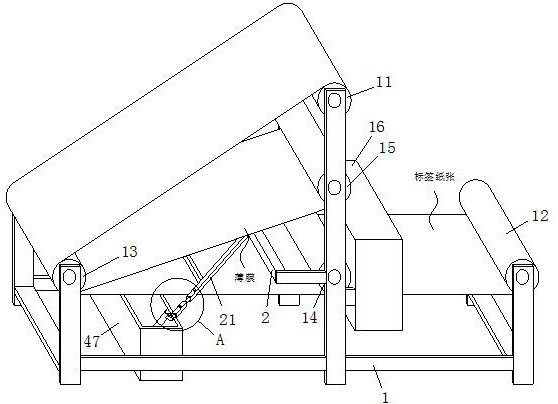

Environmentally friendly label sheet printing process and printing equipment thereof

ActiveCN111791606AImprove distribution uniformityPrevent partial swellingLaminationLamination apparatusIndustrial engineeringPaper sheet

The invention belongs to the technical field of label production and machining and particularly discloses an environmentally friendly label sheet printing process and printing equipment thereof. A fixed frame, a winding roll, an unwinding roll, a first pressing roll, a second pressing roll, an auxiliary roll and code spraying equipment are included. The unwinding roll is rotationally connected tothe left end of the fixed frame through a rotary shaft. The winding roll is rotationally connected to the middle of the fixed frame through a rotary shaft. The first pressing roll is rotationally connected to the left end of the fixed frame through a rotary shaft, and the winding roll is driven by a motor. According to the environmentally friendly label sheet printing process and the printing equipment thereof, an adhesive sticker can be flattened from the middle to two sides, thus distribution uniformity of the adhesive sticker is improved, and the problems that the adhesive sticker is not distributed evenly, consequently partial bulges appear in the label paper pasting process, the content of the adhesive sticker on the periphery is low, and the edge of label paper warps are prevented. Meanwhile, a first scraper blade is designed in an arrow shape and is matched with elastic design of a rubber block, and the conditions that high pull force is generated by a flattening plate to the label paper in the flattening process of the adhesive sticker, and consequently the label paper is damaged can be effectively reduced.

Owner:安徽华哲标签科技有限公司

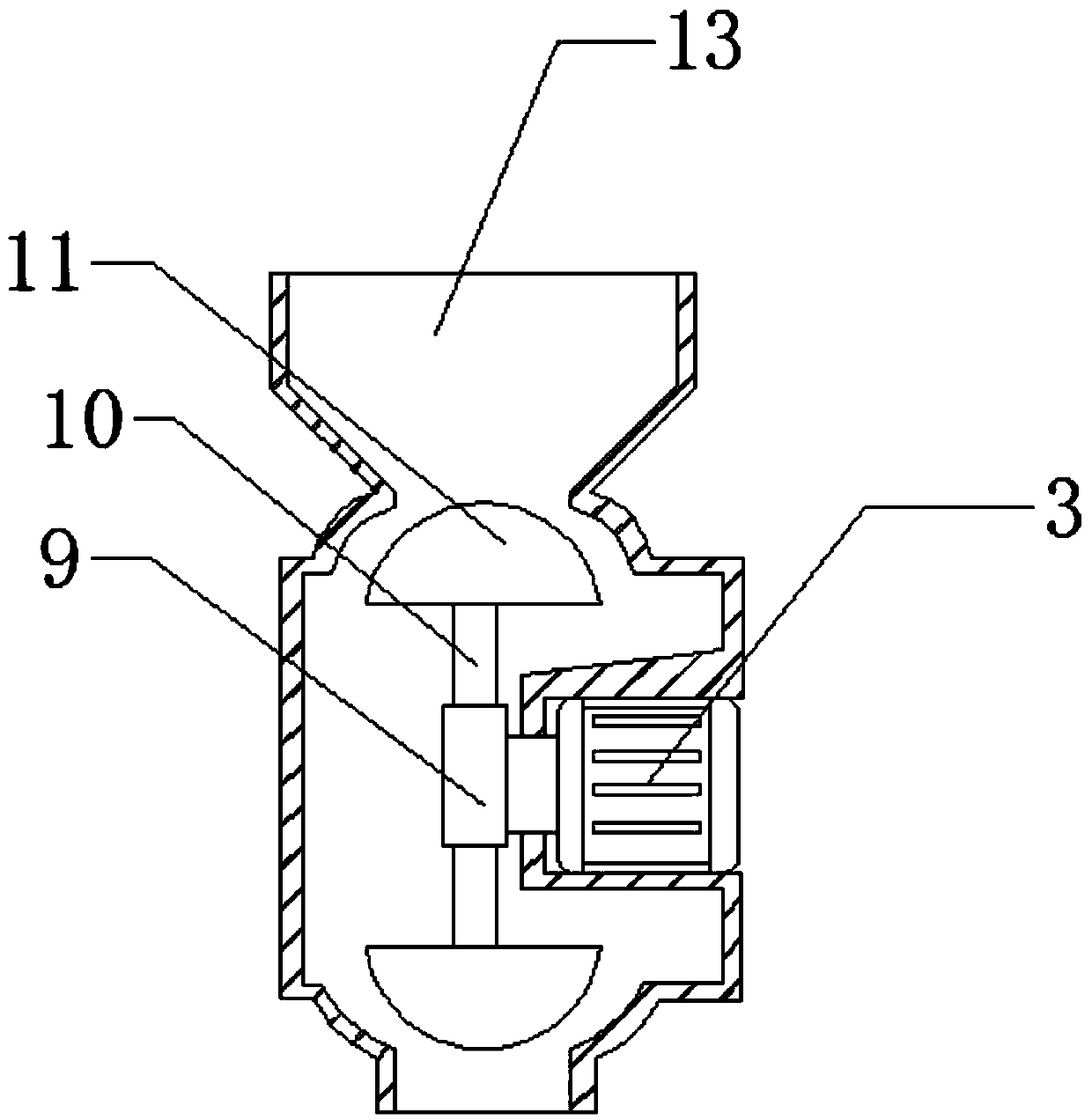

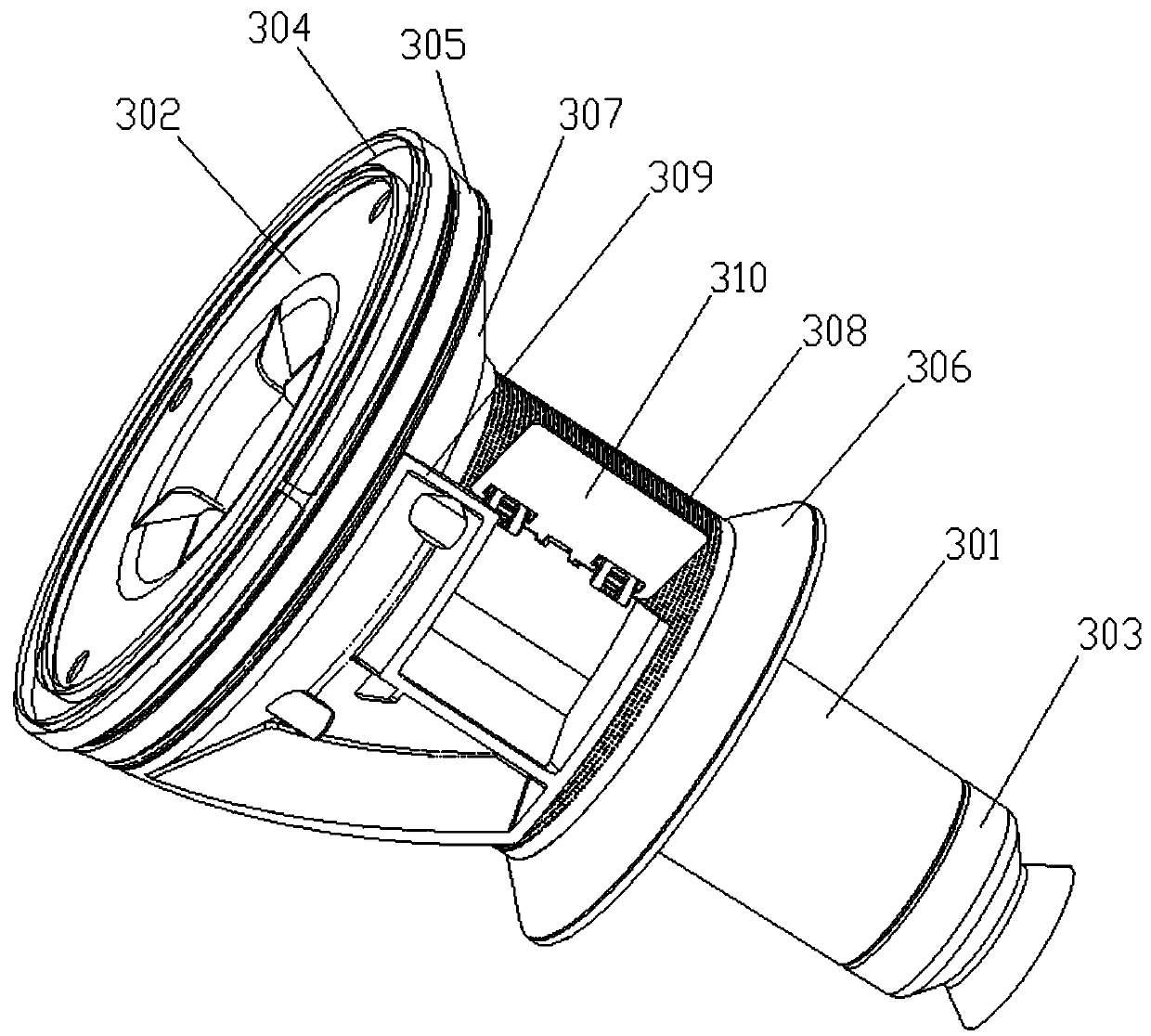

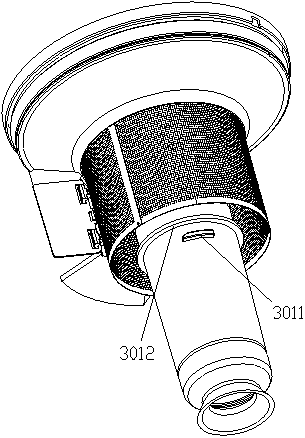

Dust cylinder with detachable filter screen for handheld dust collector

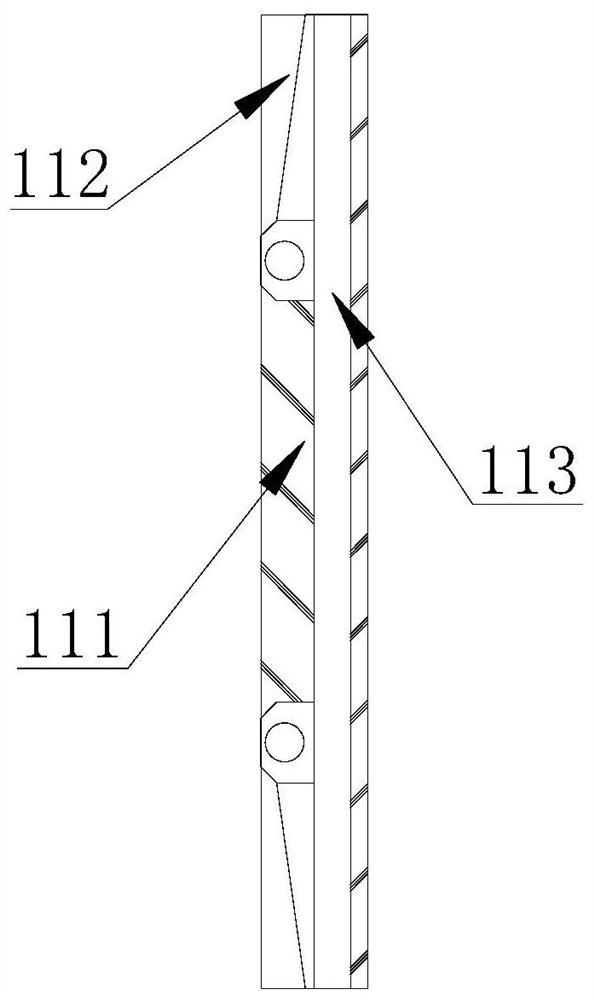

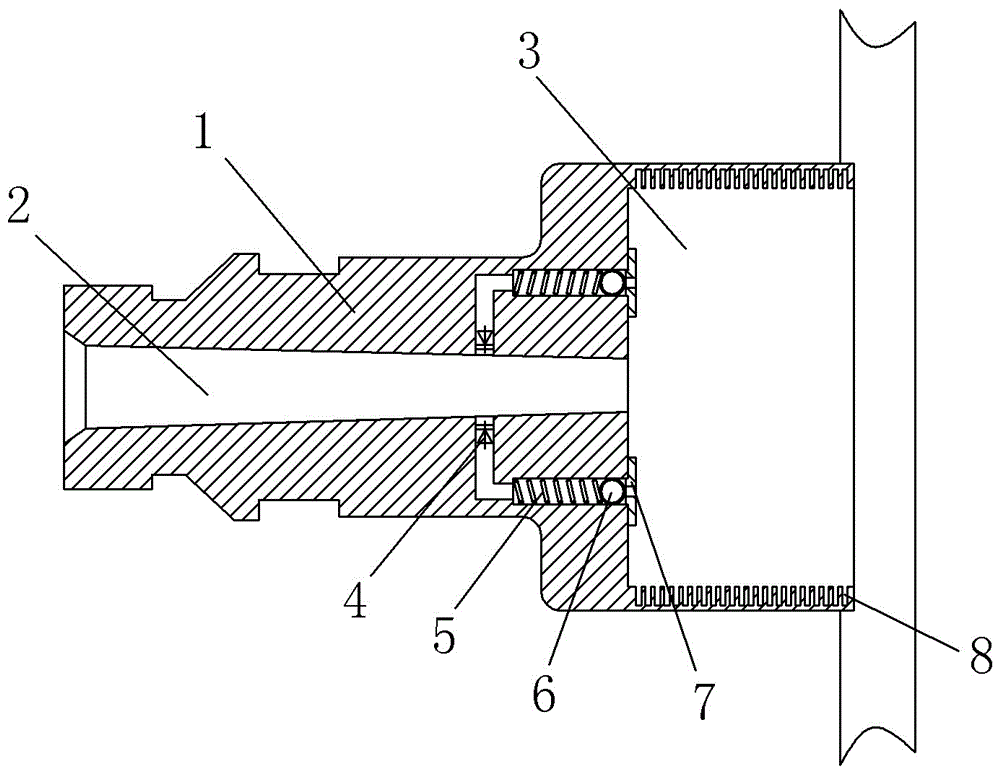

The invention particularly discloses a dust cylinder with a detachable filter screen for a handheld dust collector. The dust cylinder comprises a dust cylinder body, one end of the dust cylinder bodyis rotatably provided with a dust cylinder turning cover, and the other end is provided with an HEPA assembly. A cyclone cylinder assembly is arranged on the inner side of the dust cylinder body; thecyclone cylinder assembly comprises a cyclone cylinder; a cyclone cylinder upper cover is mounted at one end of the cyclone cylinder; a cyclone cylinder lower cover is detachably mounted in the middleof the cyclone cylinder; a cyclone middle cover is arranged between the cyclone upper cover and the cyclone lower cover; and a filter screen is arranged between the cyclone middle cover and the cyclone lower cover. The invention is reasonable in design, when the filter screen of the handheld dust collector is blocked due to long-term use, the filter screen in the dust cylinder can be detached tobe thoroughly cleaned, operation is easy and convenient, and the handheld dust collector is suitable for application and popularization.

Owner:SHENZHEN PROSCENIC TECH CO LTD

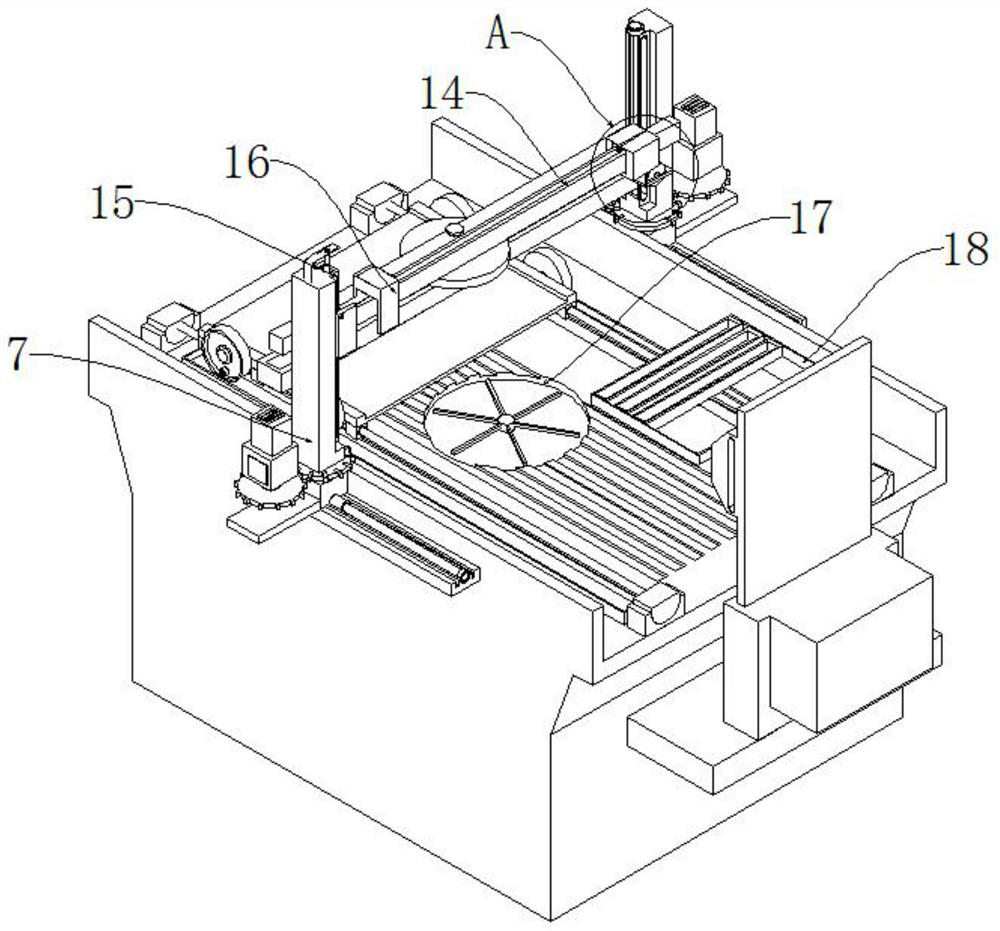

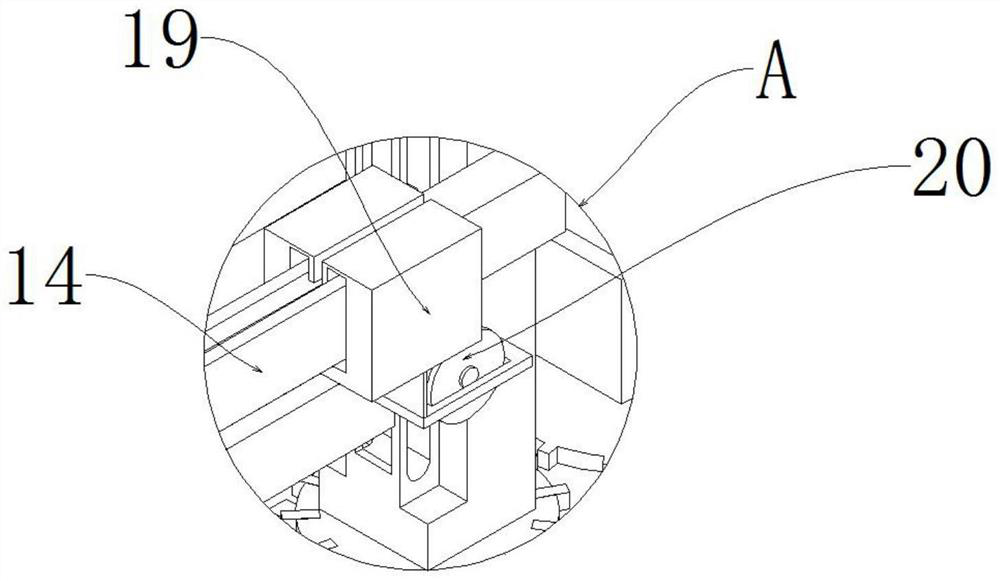

Plate drilling machine and using method thereof

InactiveCN113145888AAvoid cleaning difficultiesAvoid wastingDrilling machinesMaintainance and safety accessoriesThermodynamicsHydraulic ram

The invention discloses a plate drilling machine and a using method thereof. The plate drilling machine comprises a cross beam, supporting rods, a base plate and a base, wherein a hydraulic oil cylinder is fixedly installed at the bottom of the cross beam, the piston end of the hydraulic oil cylinder is fixedly connected with a working box, a cooling box is fixedly installed in the working box, liquid pumping mechanisms penetrate through the side walls of the two ends of the cooling box, and a collecting cavity is formed in the base; and a treatment mechanism is movably connected into the collecting cavity, a cavity is formed in one side of the treatment mechanism, and a recycling mechanism is fixedly installed in the cavity. A large amount of chippings generated in the drilling process and used cooling liquid are collected and recycled through a chipping and cooling liquid collecting device, so that the problem that the chippings are difficult to clean can be solved, and the cooling liquid can be recycled; and meanwhile, a drill bit cooling mechanism is arranged, and the cooling liquid is sprayed to a drill bit when the drill bit works, so that the temperature of the drill bit is reduced, and the cutting edge can be kept sharp.

Owner:芜湖腾飞信息科技有限公司

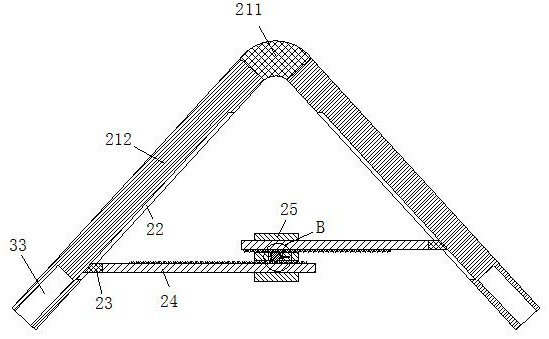

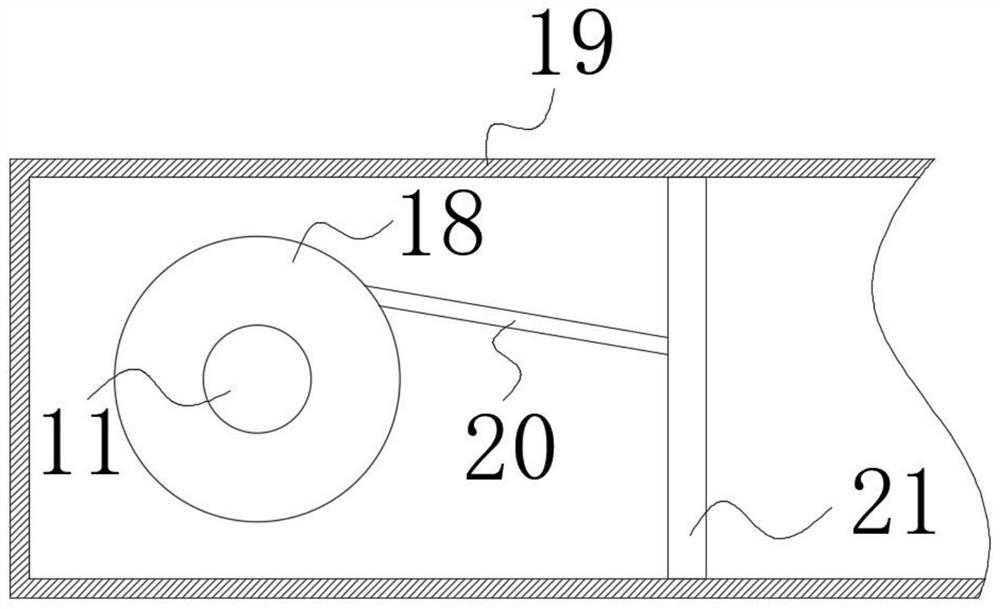

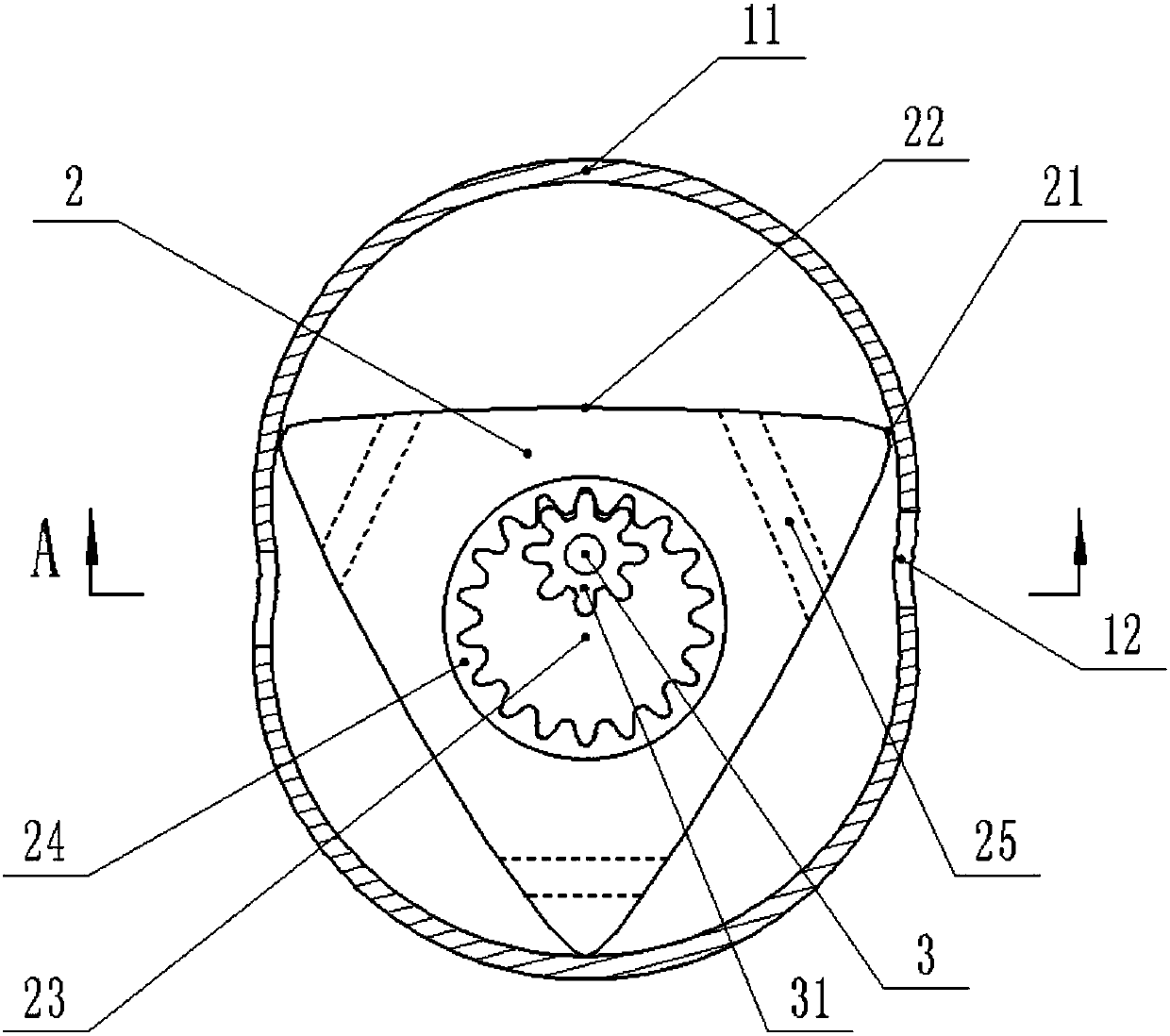

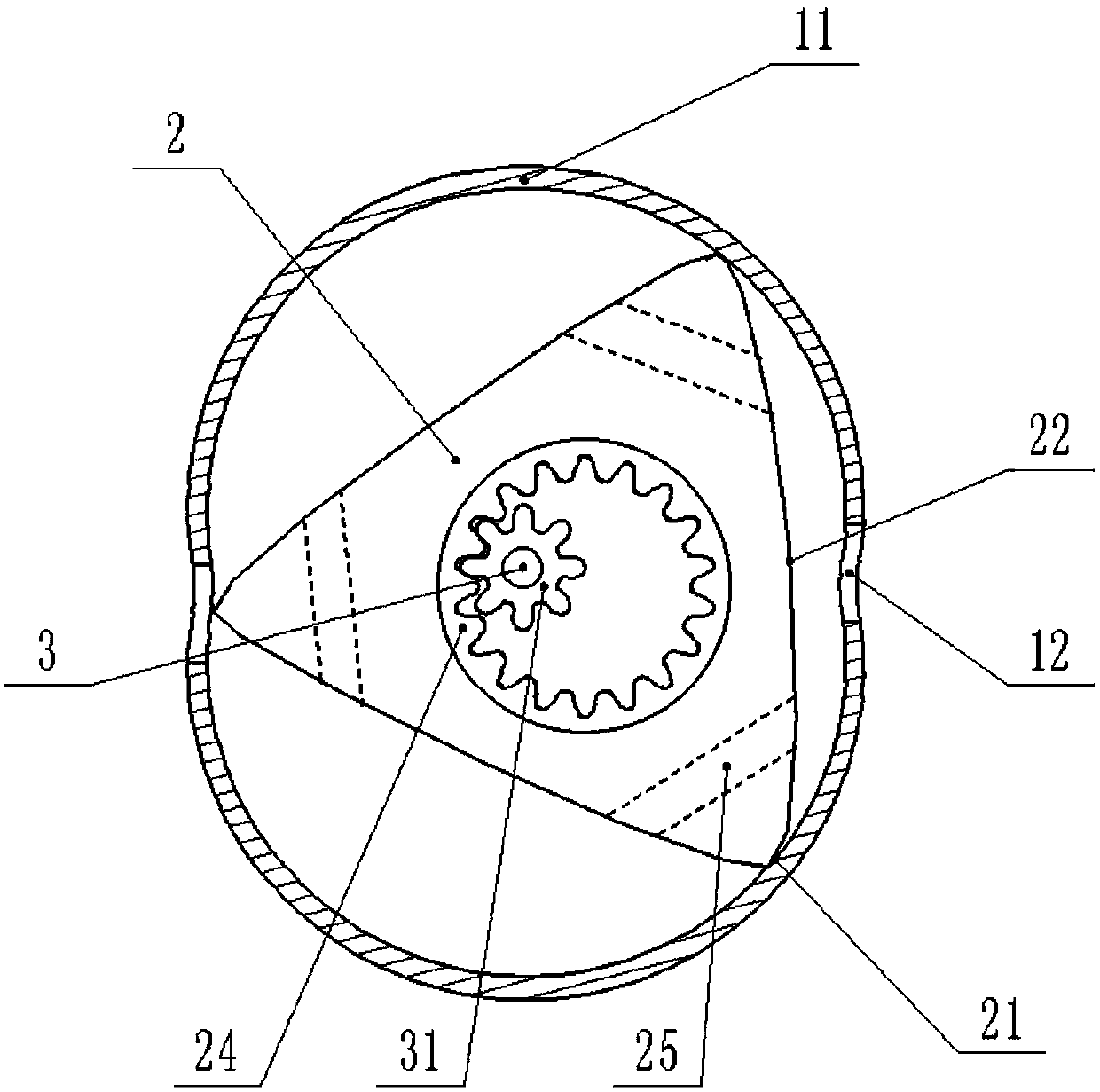

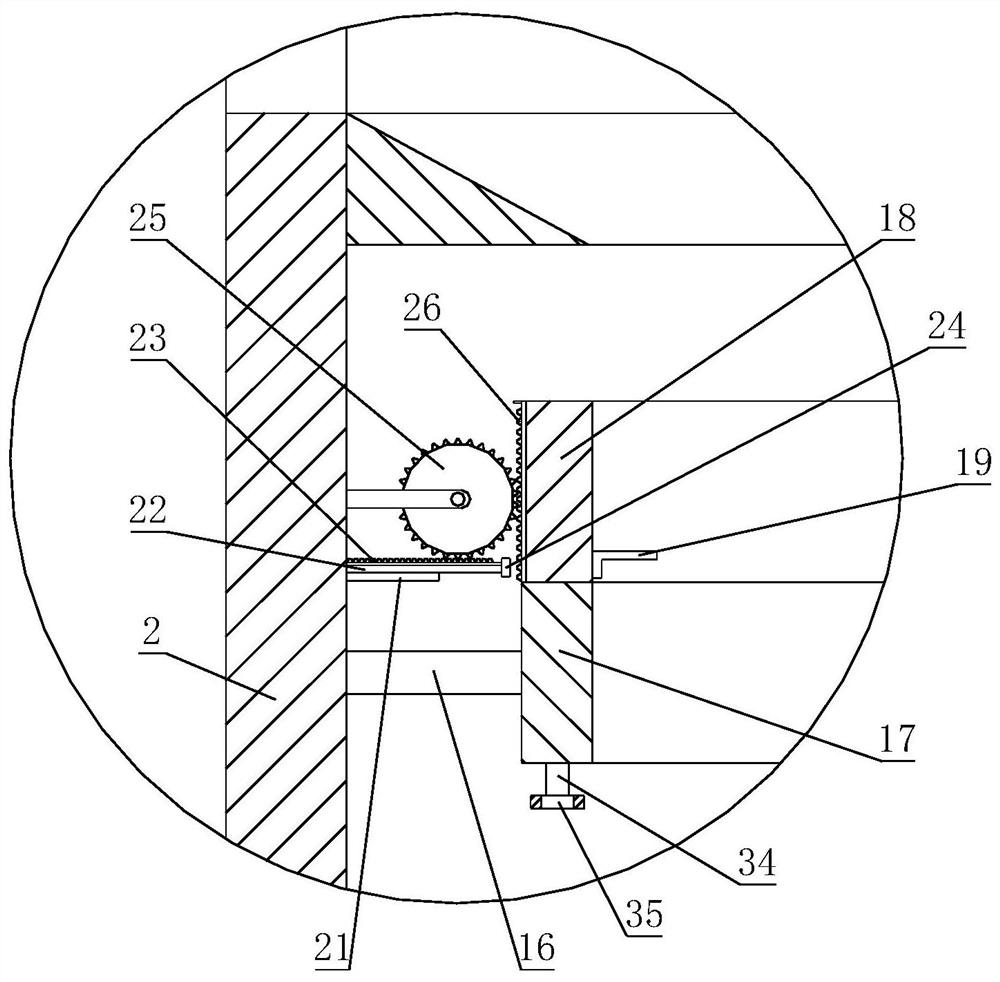

Mortar stirring cylinder

InactiveCN107899498AWell mixedAvoid cleaning difficultiesTransportation and packagingMixer accessoriesTriangular prismMixing effect

The invention relates to the technical field of mortar stirring equipment and particularly discloses a mortar stirring cylinder, comprising a cylinder body, a triangular rotor and a spindle; the cylinder body is a cycloidal cylinder body, the top wall of the cylinder body is a flat top, the bottom wall of the cylinder body is a flat bottom, the sidewall of the cylinder body is in figure-eight shape, the sidewall of the cylinder body includes two arc portions and two thin-waist portions, a discharge pipe is communicated with the thin-waist portions, the cylinder body is provided with a first through hole that is arranged in the center of the cylinder body, and the triangular rotor is in triangular prism shape, is positioned in the cylinder body and is rotationally connected with the cylinder body. The invention is intended to solve the problems that the stirring cylinder of an existing mortar tank is poor in mixing effect and mortar may consolidate on the inner wall of the cylinder body.

Owner:CHONGQING RUIXUAN HAOBANG NEW BUILDING MATERIAL

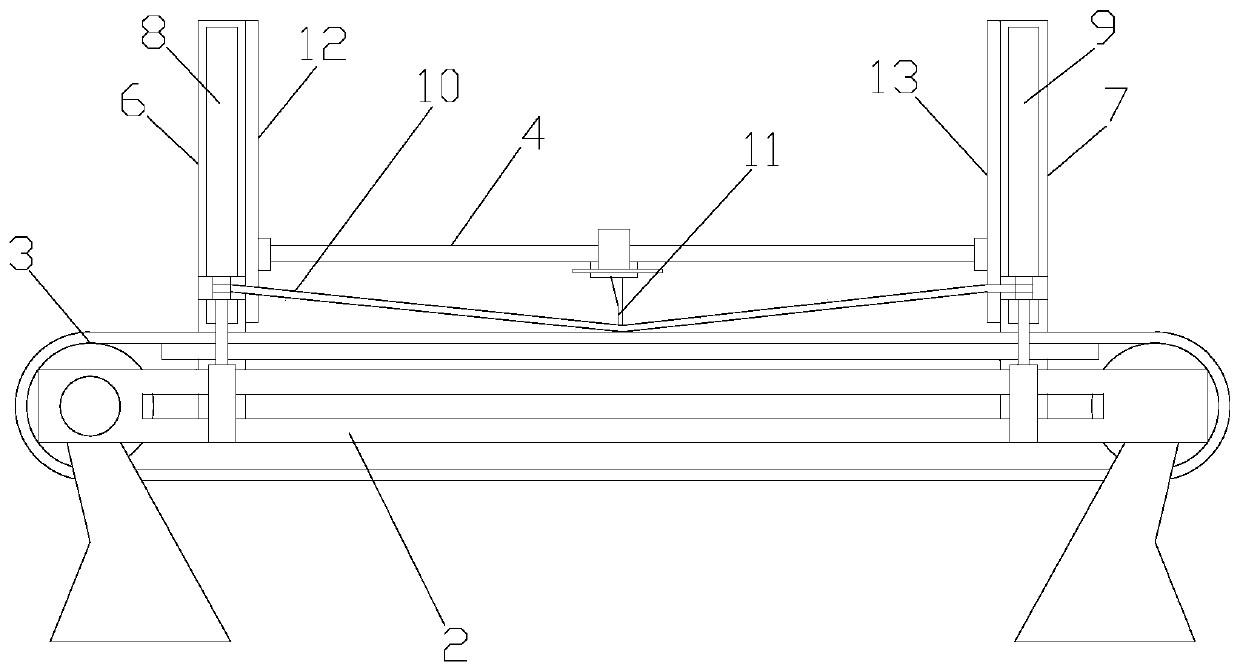

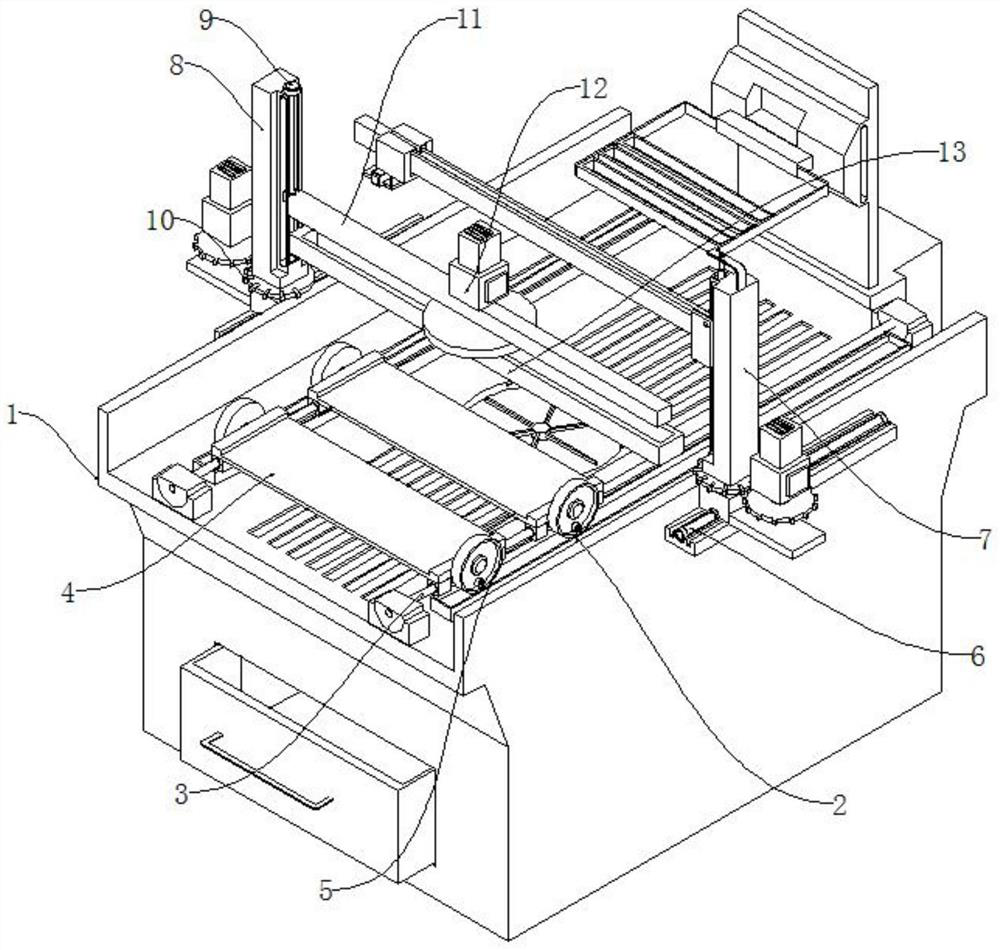

Screen printer

The invention discloses a screen printer. The screen printer comprises a net frame, a support frame, a conveyor and an electric linear guide rail, wherein a supporting plate used for supporting a conveyor belt is arranged on the supporting frame, the supporting plate is fixedly connected with the supporting frame, the conveyor is mounted on the support frame, the belt of the conveyor is clung to the supporting plate, a first connecting plate and a second connecting plate are arranged on the supporting frame, a first sliding guide rail and a second sliding guide rail are arranged on the front surface of the first connecting plate and the front surface of the second connecting plate respectively, clamps used for clamping the net frame is arranged on the first sliding guide rail and the second sliding guide rail, a net plate is arranged on the net frame, the net plate is located right above the supporting plate, the electric linear guide rail is mounted between the first connecting plateand the second connecting plate, and a scraping plate matched with the net plate is arranged on a slider of the electric linear guide rail. The screen printer can adjust the screen height so as to prevent the scraping plate from working under the condition of high load for a long time.

Owner:HUZHOU XINTIAN GREEN PACKAGE PRINTING CO LTD

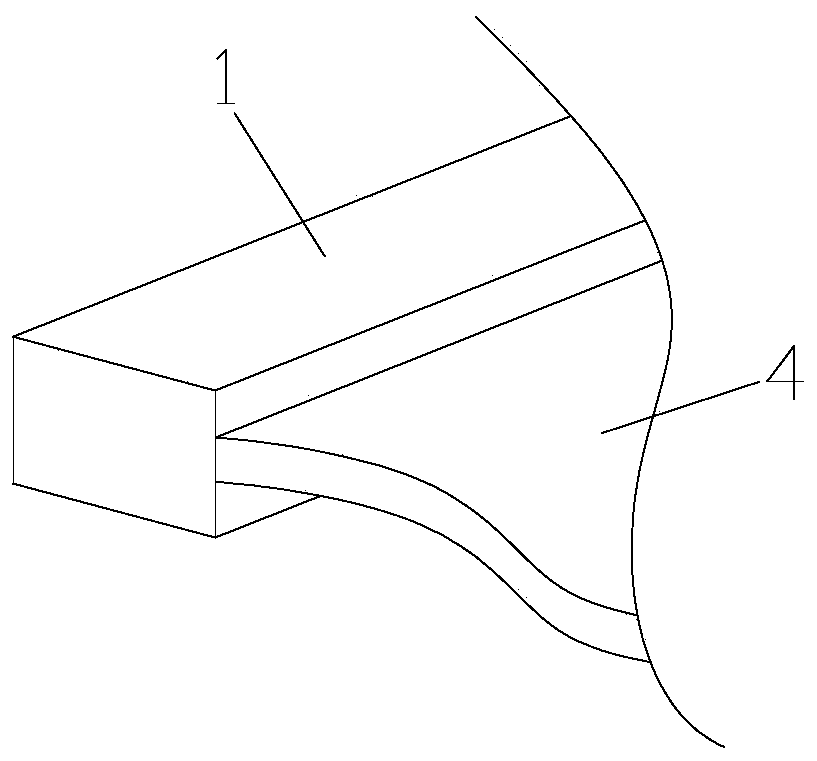

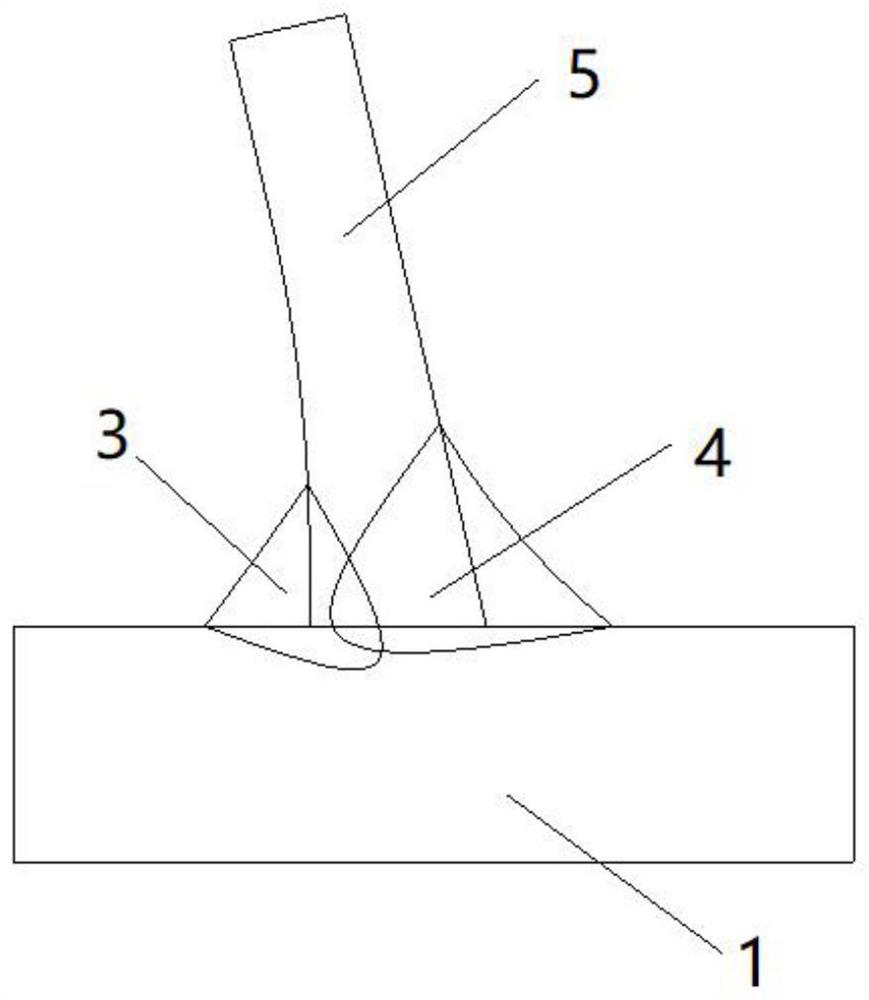

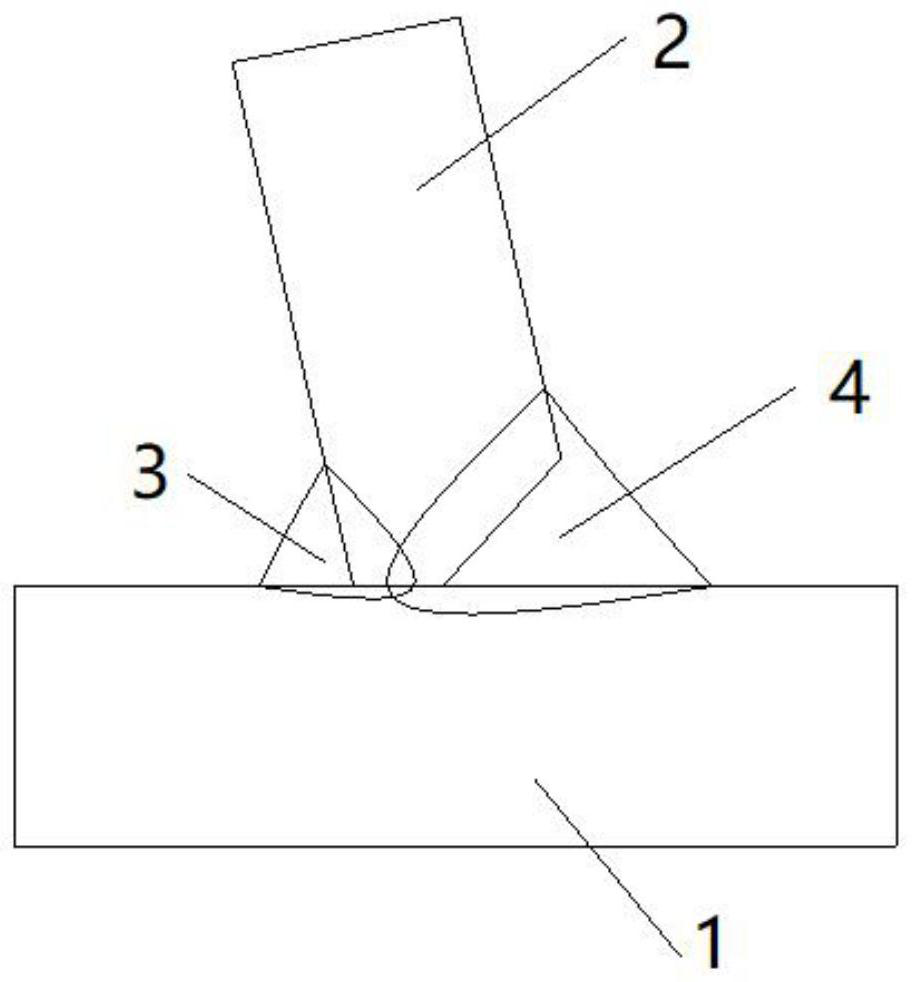

Hot-rolled U-rib double-sided welding method

PendingCN112222580AImprove welding efficiencyMeet the requirements of full penetrationWelding accessoriesBridge deckStructural engineering

The invention discloses a hot-rolled U-rib double-sided welding method which comprises the steps of grinding a to-be-welded area of a U-rib to enable the to-be-welded area of the U-rib to be a plane,grinding a to-be-welded area of a bridge deck slab to enable the to-be-welded area of the bridge deck slab after grinding to be a plane, placing the U-rib upside down on the bridge deck slab so as toenable the to-be-welded area of the U-rib to be attached to the surface of the to-be-welded area of the bridge deck slab, welding position-fixing weld seams on the outer side of the U-rib, welding theinner side of the U-rib, adopting a fine wire submerged arc welding process to perform welding at a horizontal position to form an inner side weld seam, welding the outer side of the U-rib, adoptinga double-wire and double-arc submerged arc welding process to perform welding at a ship-shaped position to form an outer side weld seam, and performing flaw detection on all the weld seams after welding is completed. According to the hot-rolled U-rib double-sided welding method, stable welding of the U-rib can be achieved under the condition that the U-rib is not provided with a welding groove oris provided with a relatively small welding groove, and the weld seams are smooth.

Owner:WUCHUAN HEAVY ENG

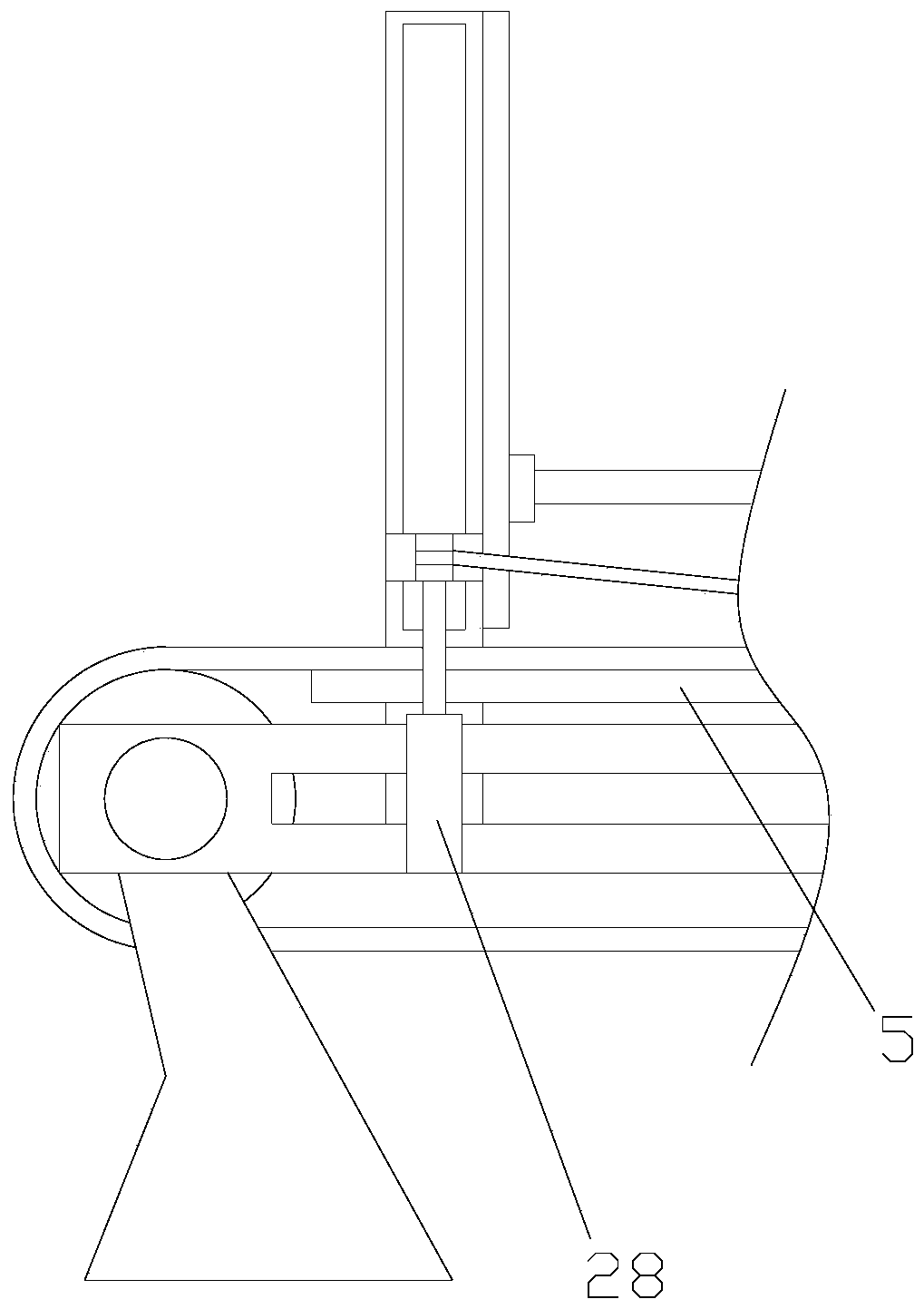

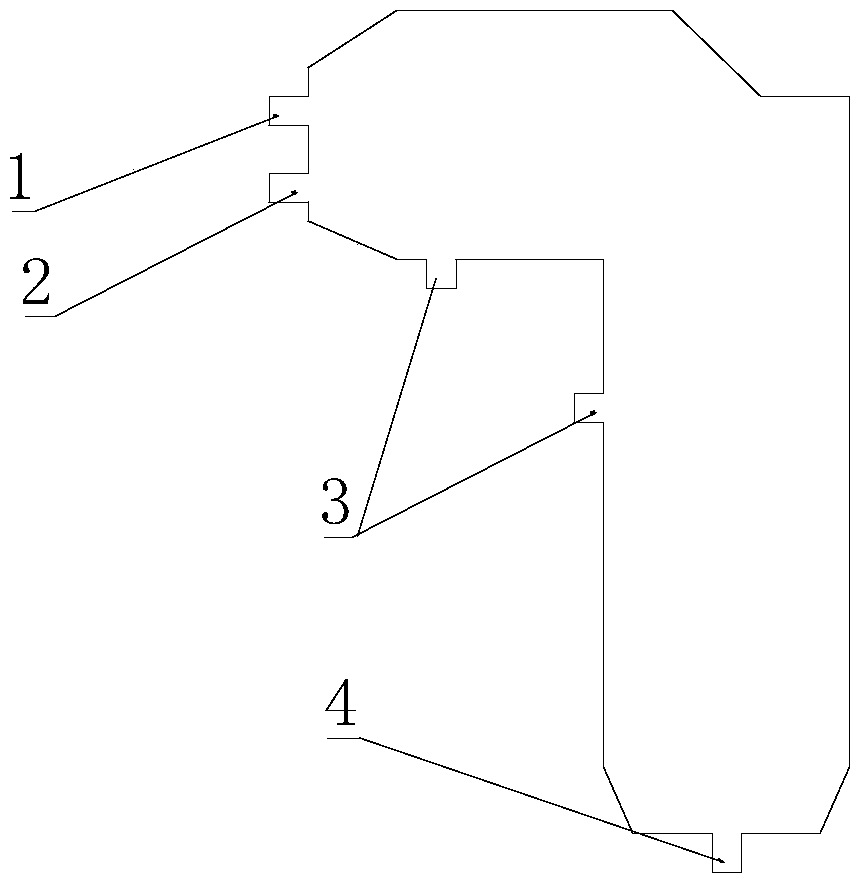

Telescopic device for hot pressing gumming machine

InactiveCN105252816ASimple structureEasy to operatePaper-makingBox making operationsSlide platePulp and paper industry

The invention relates to a telescopic device and particularly discloses a telescopic device for a hot pressing gumming machine. The telescopic device comprises an upper sliding plate and a lower sliding plate which are arranged on a machine body. The upper sliding plate and the lower sliding plate are arranged on the two sides of a channel for objects to be stuck to pass, a positioning plate is arranged at the ends, away from the machine body, of the upper sliding plate and the lower sliding plate, and the positioning plate is hinged to the lower sliding plate and can be connected to the upper sliding plate in a clamped manner. According to the telescopic device, the sizes of machined cylinders are not single, and the application range of the telescopic device can be enlarged.

Owner:CHONGQING XINSHUI MACHINERY MFG

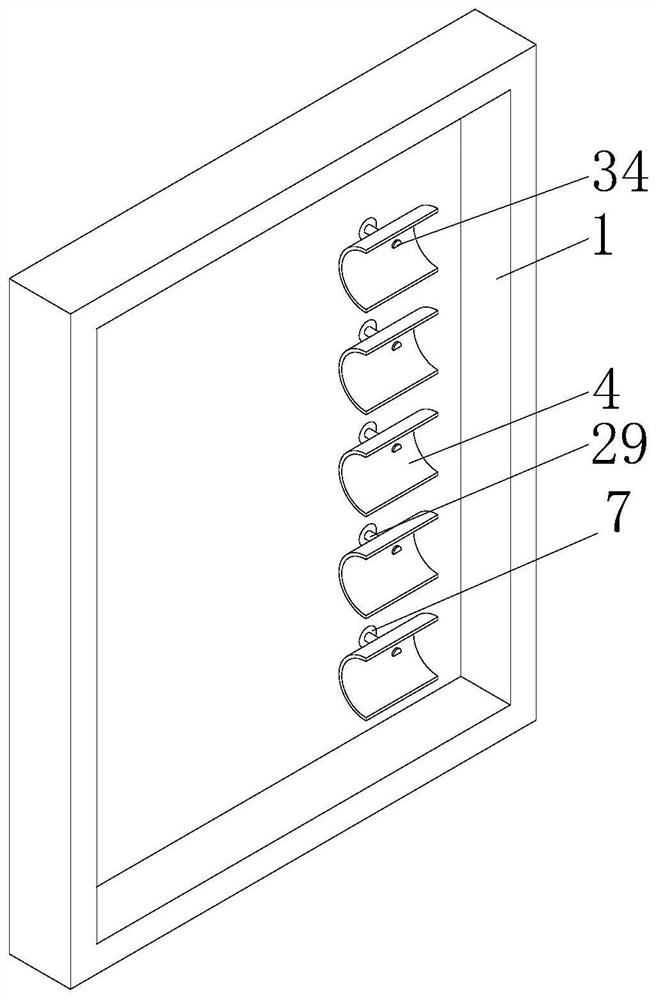

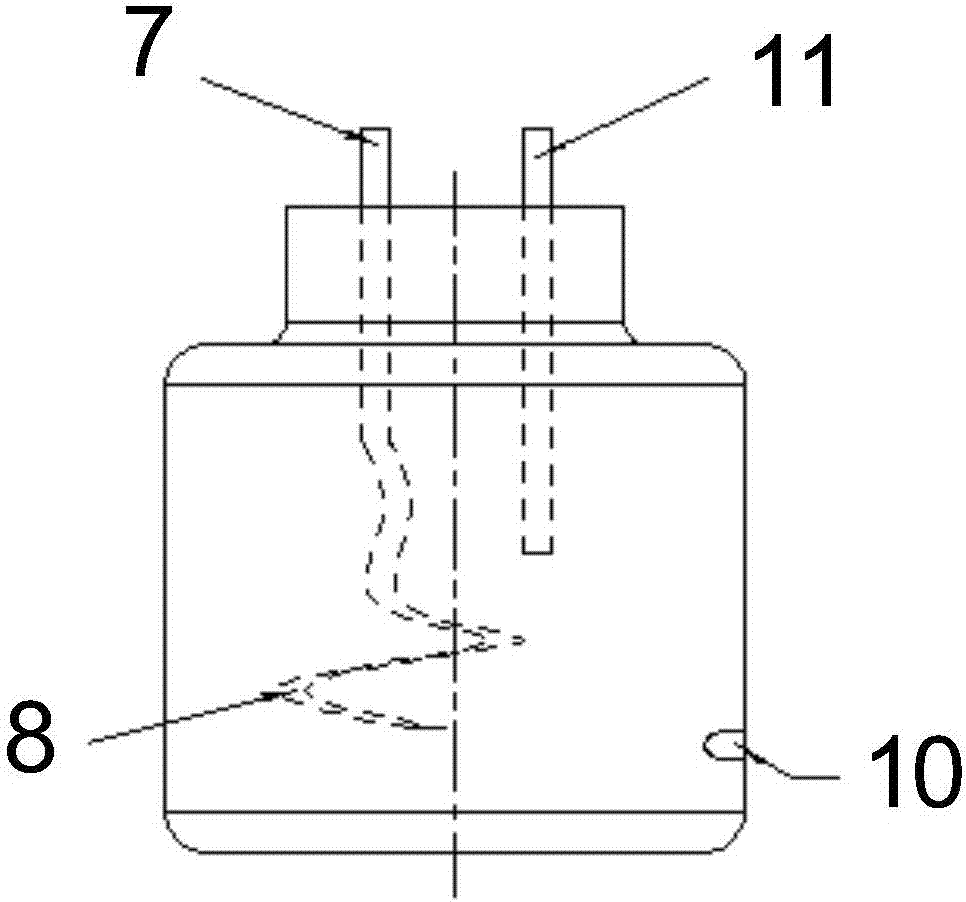

Special go-out first-aid device for anesthesiologist

ActiveCN113274198ARealize the carrying functionAvoid safety hazardsSurgical furniturePharmaceutical containersAnesthetic departmentEngineering

The invention relates to the technical field of anesthesiology departments, and discloses a special go-out first-aid device for an anesthesiologist. The special go-out first-aid device comprises a box cover A and a box cover B; the box cover A and the box cover B are rectangular, the bottom faces of the box cover A and the box cover B are connected with each other through a connecting pad, and the corresponding faces of the box cover A and the box cover B are in a hollowed-out state; five clamping rings A and five clamping rings B are arranged on the left sides of the inner walls of the corresponding faces of the box cover A and the box cover B correspondingly, the clamping rings A and the clamping rings B are both semicircular ring bodies, the concave faces of the clamping rings A and the concave faces of the clamping rings B correspond to each other, five holes are formed in the right ends of the corresponding faces of the box cover A and the box cover B correspondingly, inserting barrels are fixedly connected to the inner walls of the holes in the box cover B, and the inner walls of the inserting barrels sleeve pistons A. Through the arrangement of the box cover A and the box cover B, the anesthetic carrying function is achieved, meanwhile, an ampoule bottle can be broken and extracted in the sealed space, it is guaranteed that external pollution cannot permeate into an anesthetic, and potential safety hazards caused by anesthetic pollution are avoided.

Owner:THE SECOND HOSPITAL OF DALIAN MEDICAL UNIV

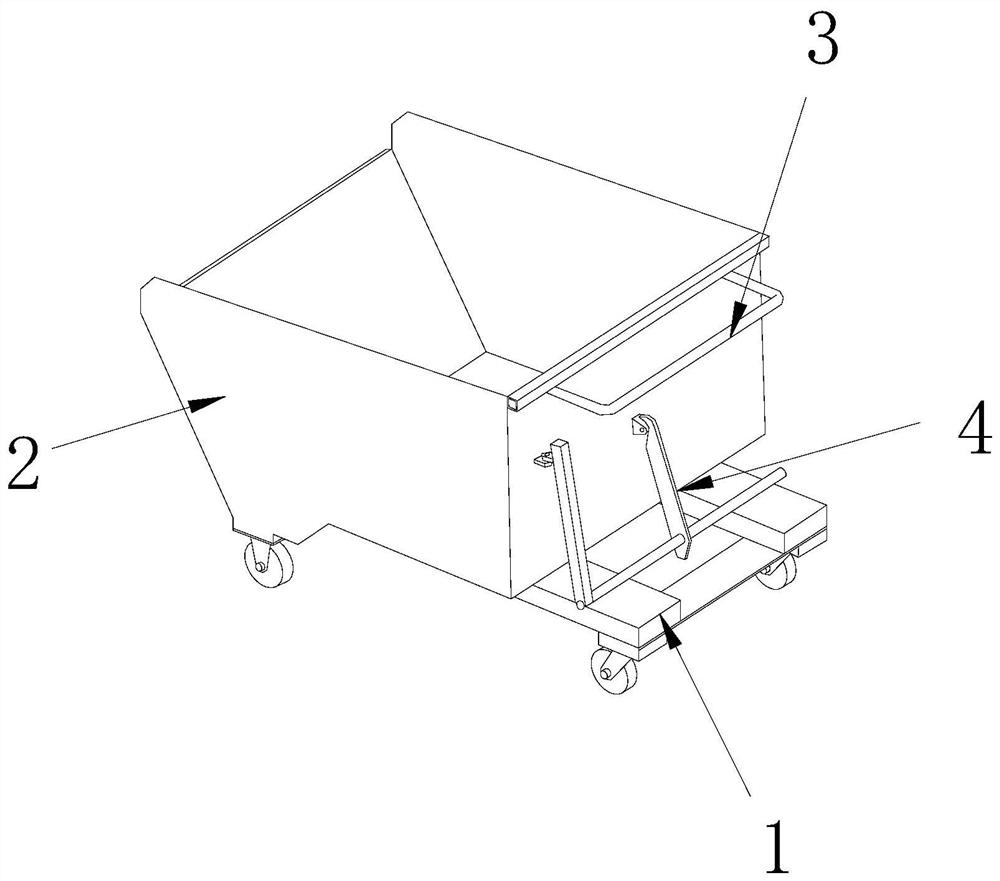

Urban traffic transportation equipment

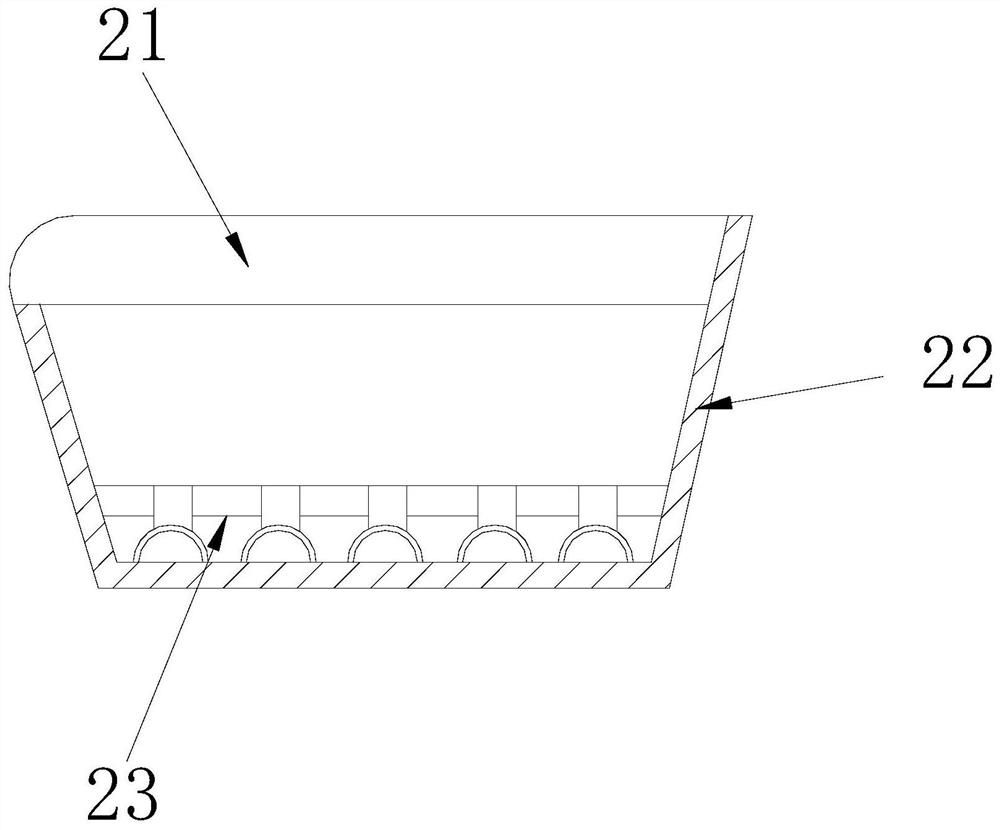

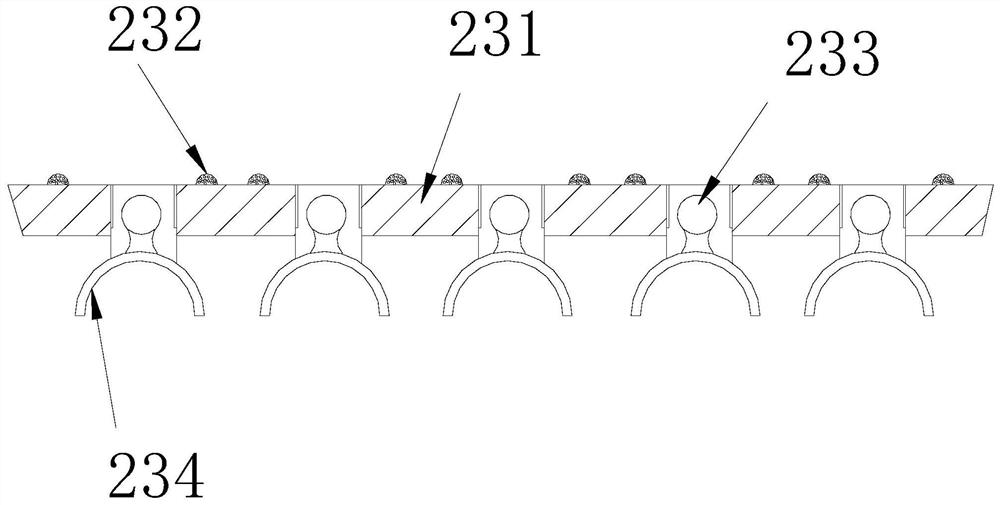

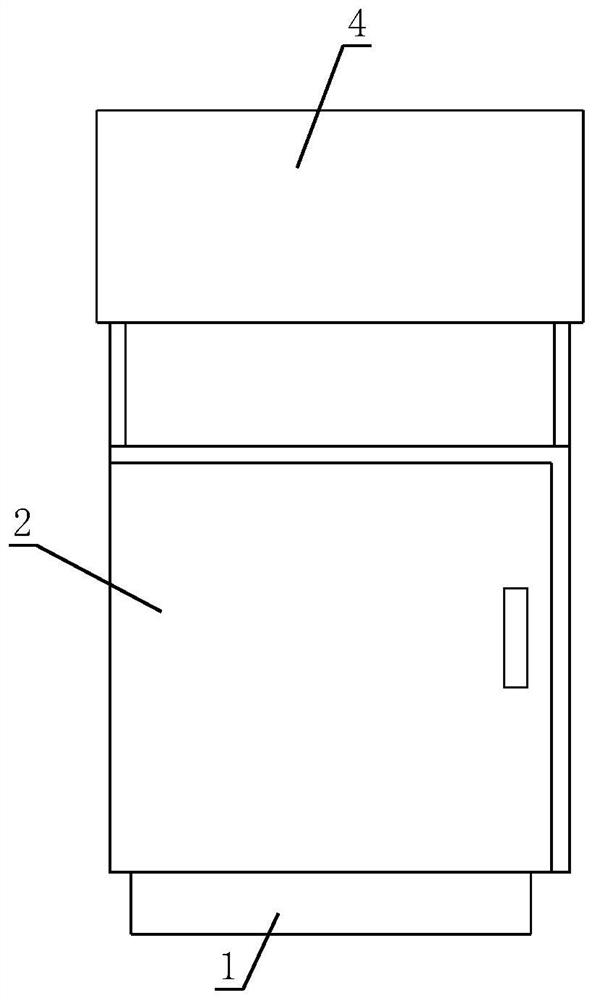

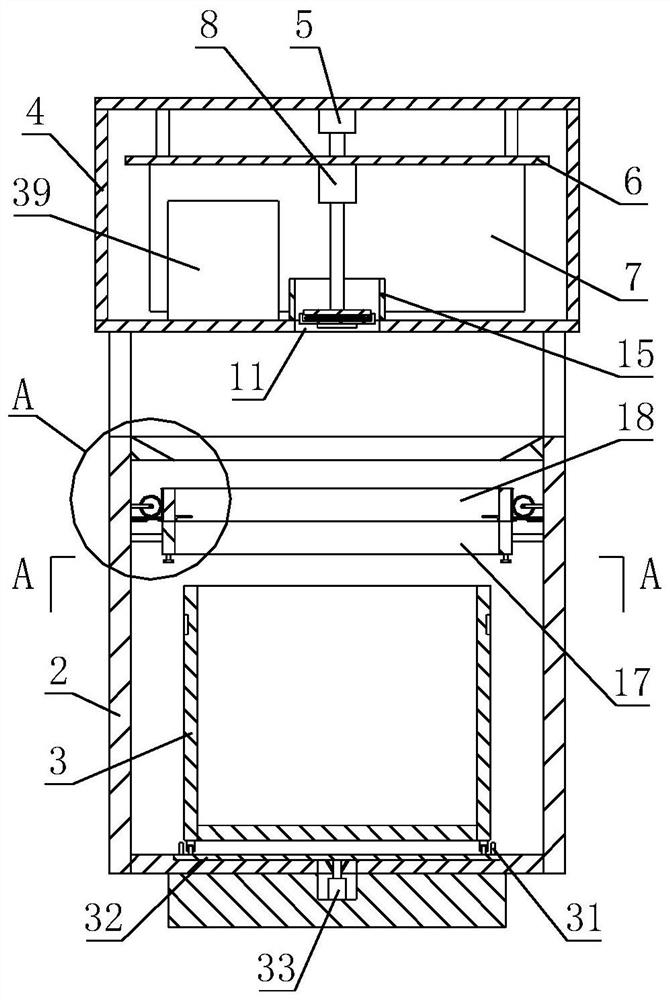

InactiveCN113060205AAvoid cleaning difficultiesGuaranteed Volumetric EfficiencySupporting partsHand carts with multiple axesEngineeringStructural engineering

The invention discloses urban traffic transportation equipment which structurally comprises a moving seat, a conveying hopper, a push handle and a lifting handle, the top face of the moving seat is movably clamped with the lower left corner of the conveying hopper, and the left side of the push handle is connected with the right side of the conveying hopper in a welded mode. According to the invention, materials are transported through the conveying hopper, in the process of transporting wet cement, the cement can be condensed into a cement layer and adhered to a supporting table; in the dumping process, a falling structure of the supporting table can move upwards through the gravity of the falling structure, the impact force of movement is increased through rolling of a heavy ball, meanwhile, an upper swinging head is lifted upwards through inertia, the cement layer is slapped with high force under the action of a stress application ball, a concentration plate stretches out of a blocking frame while the cement layer is in contact with the concentration plate, the bottom surface of the cement layer is intensively stressed, so that the cement layer is broken and falls off and can be discharged along with the dumped conveying hopper; the problem that cement is difficult to clean due to long-term accumulation and condensation is solved, and meanwhile, the conveying volume and the conveying efficiency of the transportation device are ensured.

Owner:沈阳联宏远物流有限公司

A solar intelligent garbage collection device

InactiveCN111453259BRealize intelligent detectionBlock deliveryWaste collection and transferRefuse receptaclesRefuse collectionProcess engineering

Owner:HENAN POLYTECHNIC INST

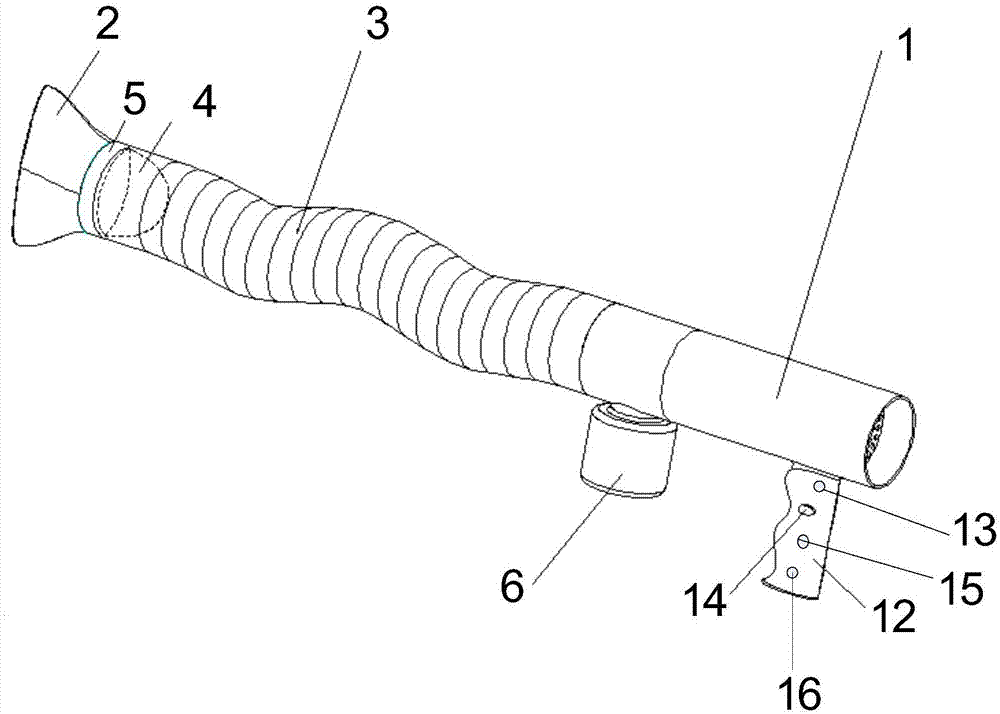

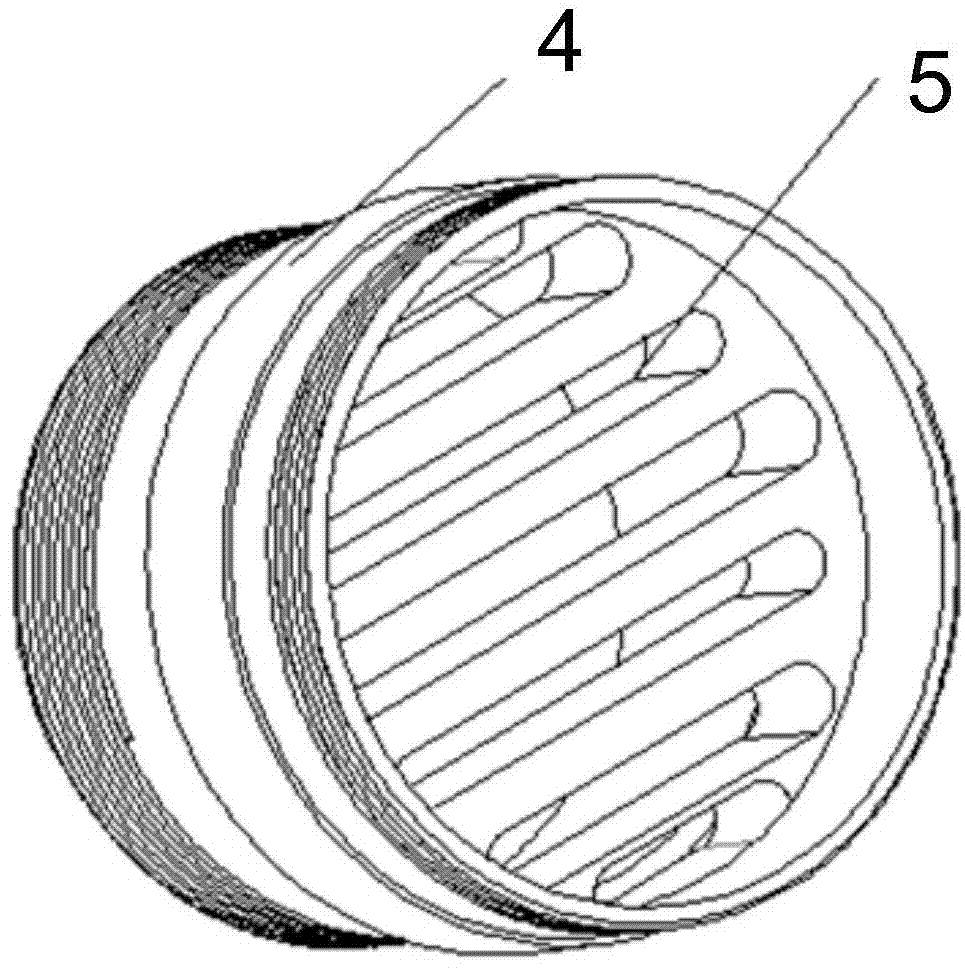

Multifunctional household appliance

PendingCN107326629AAvoid cleaning difficultiesRealize the ironing functionSuction hosesSuction nozzlesHome applianceDust collector

The invention discloses a multifunctional household appliance. The multifunctional household appliance comprises a hair dryer, an air nozzle and a steam generator. An air inlet of the hair dryer is connected with the air nozzle through a hose; a dust collection device is arranged at the position where the air nozzle and the hose are connected; the steam generator is communicated with the hose, and the rotating direction of a fan of the hair dryer can be switched between forward rotation and reverse rotation. In the use process of the multifunctional household appliance, the functions of the hair dryer, a dust collector, an evacuating device, an ironing machine and a drying machine can be achieved at the same time, and the problem that a household appliance has a single function is avoided.

Owner:GUANGDONG UNIV OF TECH

A plate drilling machine

ActiveCN111906339BAvoid cleaning difficultiesAvoid wastingDrilling machinesMaintainance and safety accessoriesHydraulic cylinderHydraulic ram

The invention discloses a plate drilling machine, which comprises a beam, a support rod, a backing plate and a base. A hydraulic oil cylinder is fixedly installed at the bottom of the beam. The piston end of the hydraulic oil cylinder is fixedly connected with a working box. A cooling box is fixedly installed in the working box. The side walls at both ends of the box are penetrated by a pumping mechanism, and a collection chamber is provided inside the base, and a processing mechanism is movably connected to the collection chamber, and a cavity is provided on one side of the processing mechanism, and a recovery mechanism is fixedly installed inside the cavity. By setting up debris and coolant collection devices, a large amount of debris generated during the drilling process and used coolant are collected and recycled, which can not only avoid the difficulty of debris cleaning, but also recycle the coolant, and at the same time through Set the drill bit cooling mechanism, spray coolant to the drill bit when the drill bit is working, so as to lower the temperature of the drill bit and keep the cutting edge sharp.

Owner:CHONGQING WANZHOU LONGLI WOOD IND CO LTD

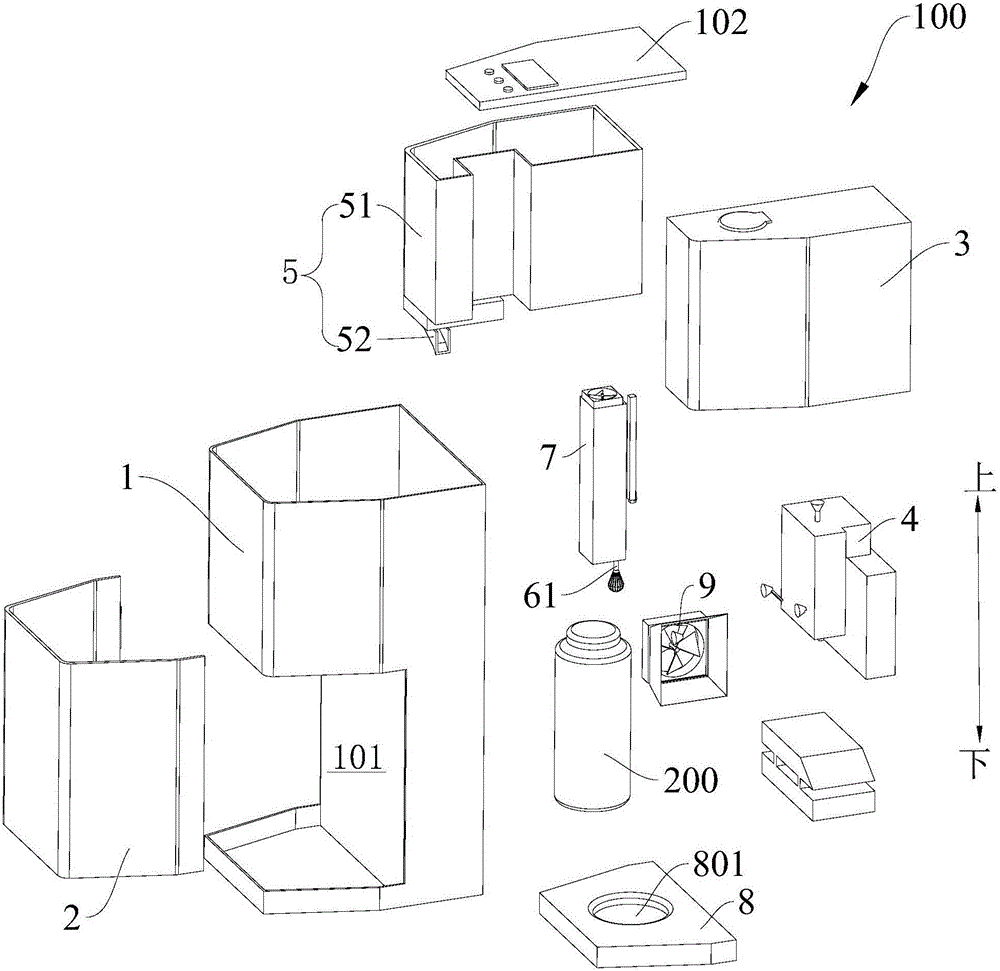

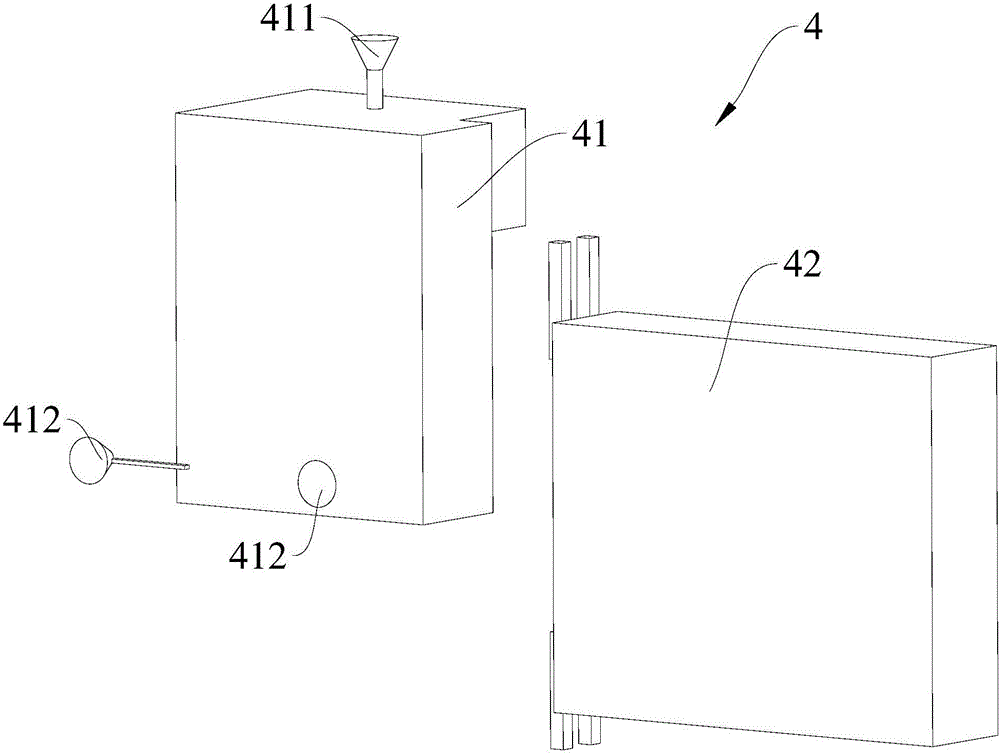

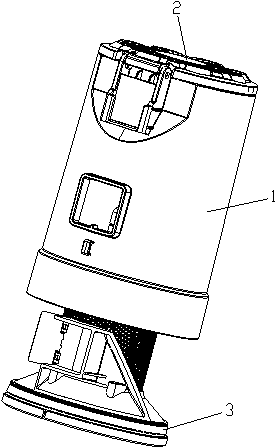

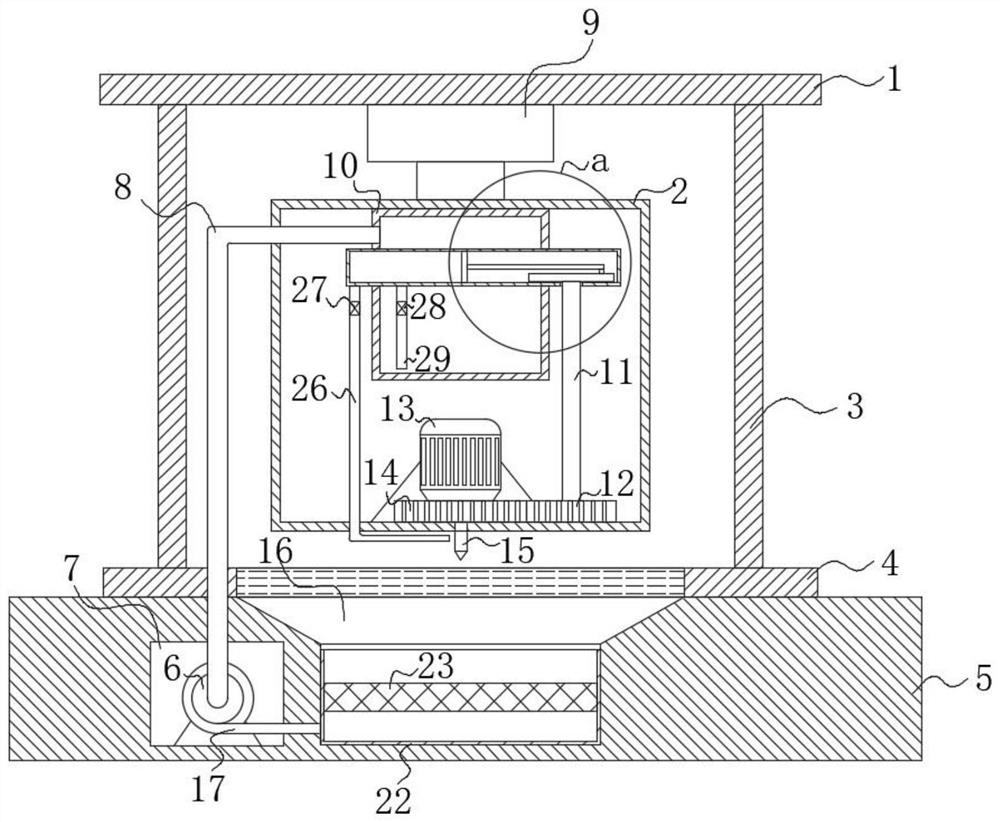

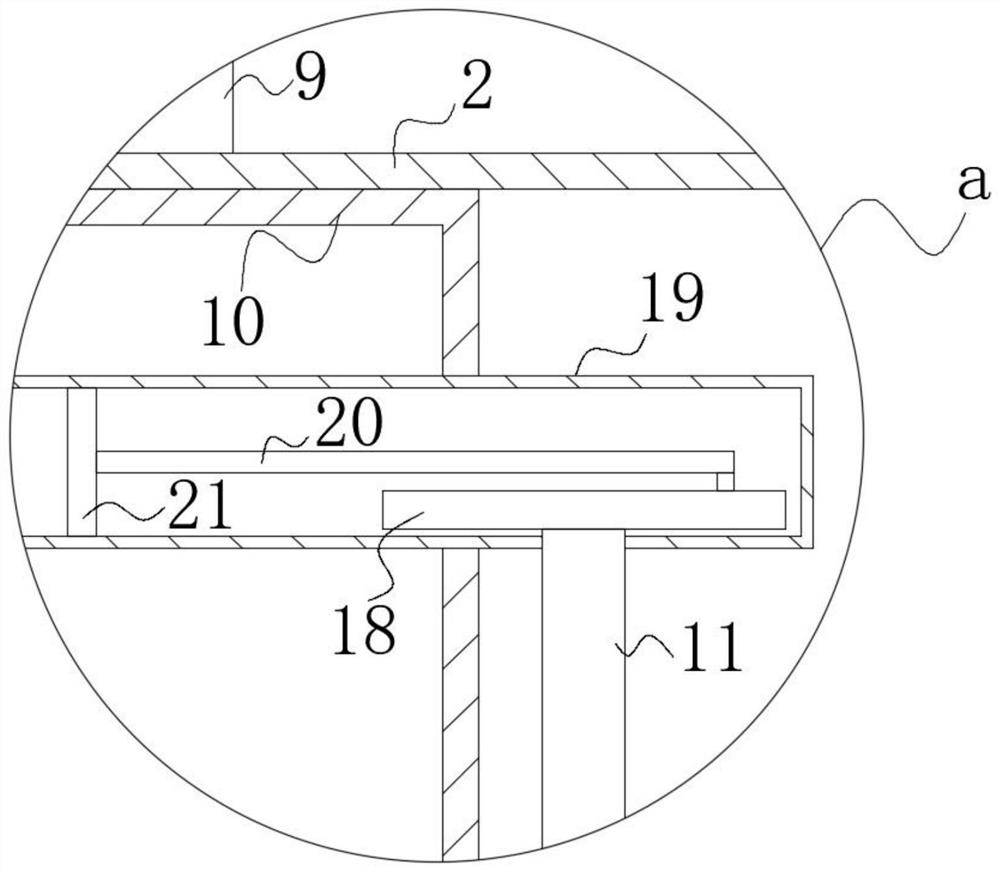

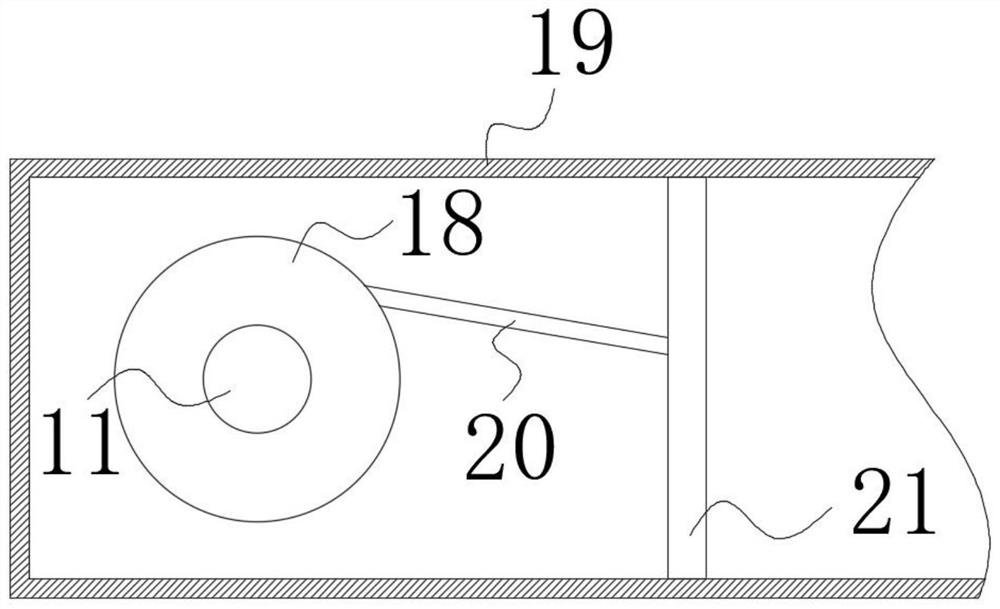

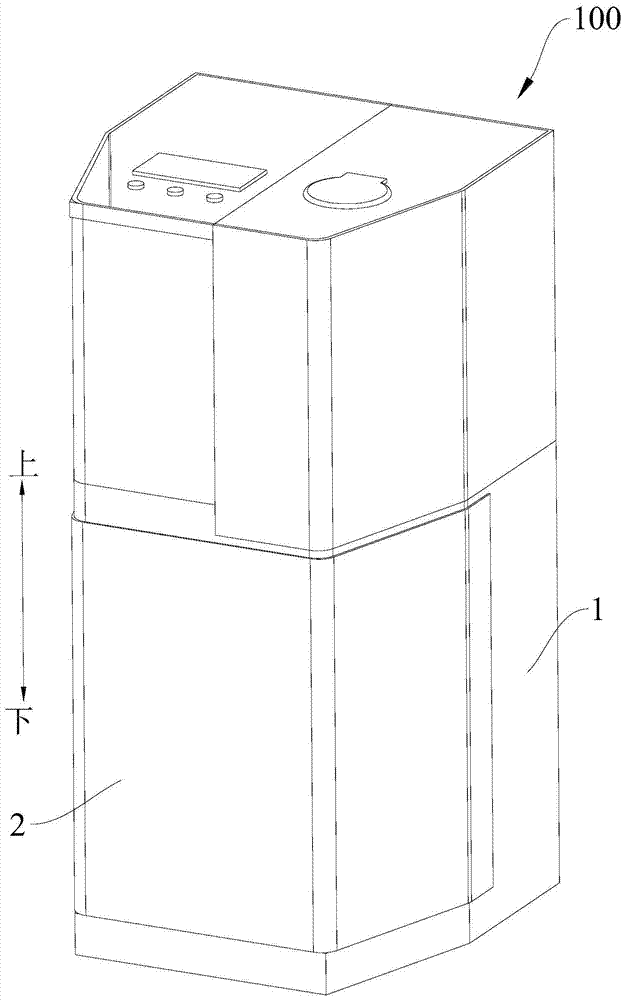

Beverage brewing machine and control method thereof

ActiveCN105030069BImprove heating efficiencyImprove the bactericidal effectBeverage vesselsMicrowaveProcess engineering

The invention discloses a beverage brewing machine and a control method thereof. The beverage brewing machine comprises: a shell, a water tank, a microwave heating device and a beverage delivery device. A container storage cavity with an open side is formed on the outside of the casing and a door body for opening or closing the container storage cavity is formed; at least a part of the water tank is arranged in the casing for storing water; at least a part of the microwave heating device is arranged in the casing for use The microwave energy is provided to at least one of the water tank and the container storage cavity; the beverage delivery device is arranged in the casing. According to the beverage brewing machine of the embodiment of the present invention, the heating efficiency can be improved, and it also has the function of disinfection and sterilization.

Owner:GUANGDONG MIDEA KITCHEN APPLIANCES MFG CO LTD +1

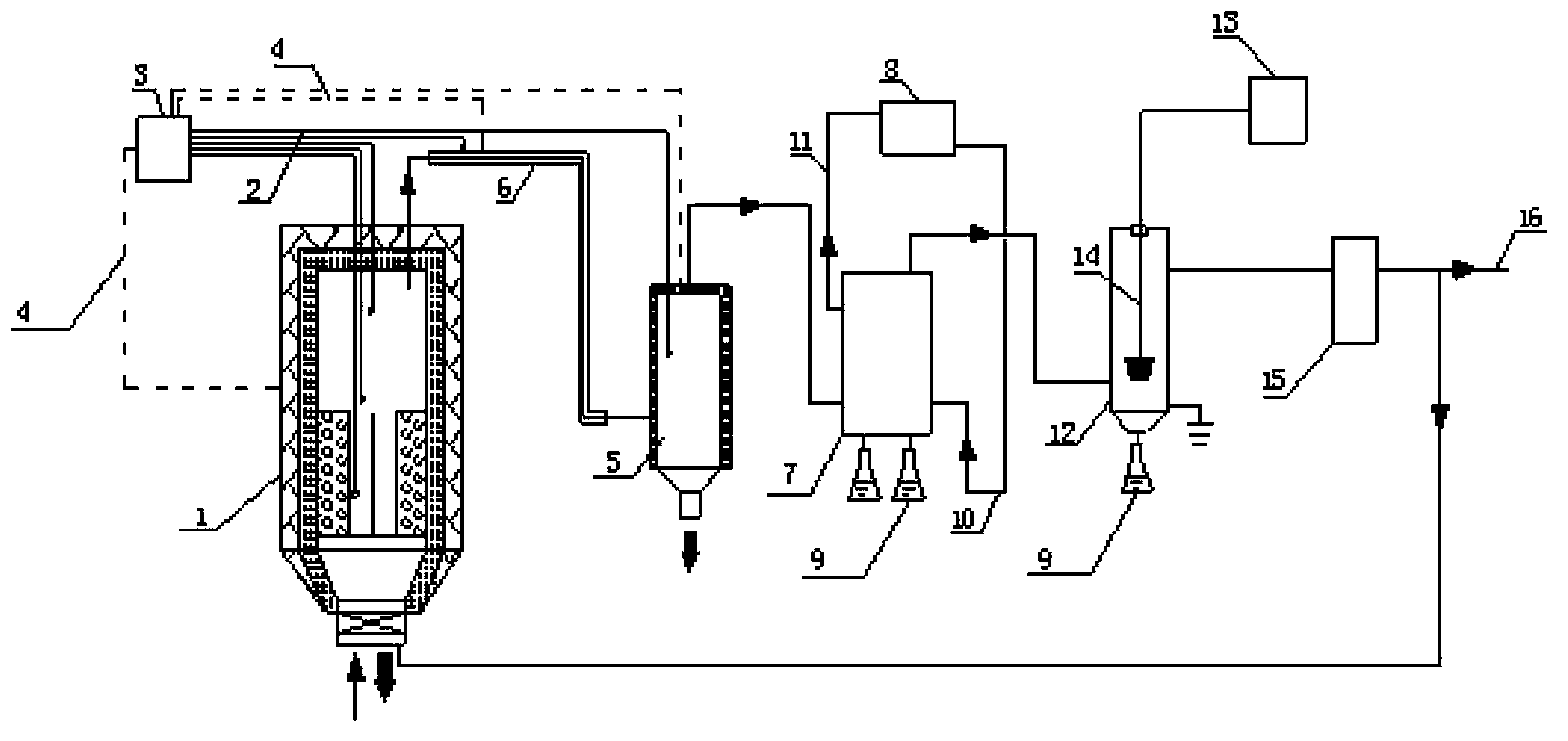

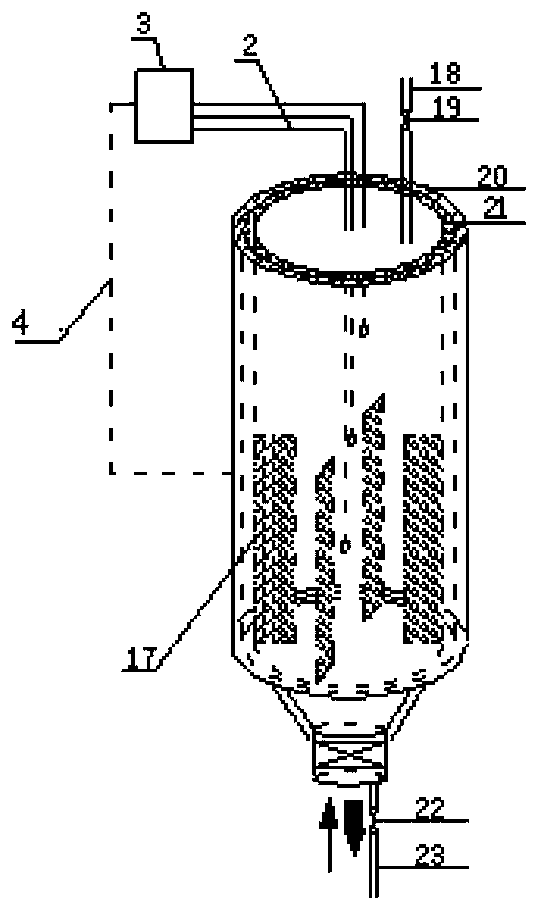

Solid waste or biomass high-efficiency pyrolysis oil-producing system

ActiveCN102719265BImprove heat transfer performanceHigh heat and mass transferLiquid hydrocarbon mixture productionElectrostatic separationHigh pressure

The invention discloses a solid waste or biomass high-efficiency pyrolysis oil-producing system. The solid waste or the biomass is charged into a pyrolyzing furnace, wherein the pyrolyzing furnace is internally provided with a thermoelectric couple, and an intelligent temperature controller controls the heating power of an electric stove wire outside a reaction pipe; a pyrolysis volatile component product enters into a semi-coke separation device from an air outlet on the top of the reaction pipe; sequentially, the pyrolysis volatile component enters into at least two levels of condensing device to be condensed; and a large number of non-condensable substances contained in pyrolysis gas continuously passes through a high-voltage electrostatic separation device, wherein the non-condensable pyrolysis oil is collected into a collecting bottle through the high-voltage electrostatic separation device. According to the system provided by the invention, the heat and mass transfer effects of the solid waste and the biomass material in the process of pyrolysis can be preferably enhanced; the volatile component can be preferably overflowed; and the semi-coke product and the gas can be effectively separated from each other, and the productivity and the quality of the liquid diesel oil product can be greatly improved. According to the different feeding varieties of the biomass, the system can obtain more than 10%-15% of the biological oil compared with a general biomass pyrolysis liquefaction process.

Owner:TIANJIN UNIV

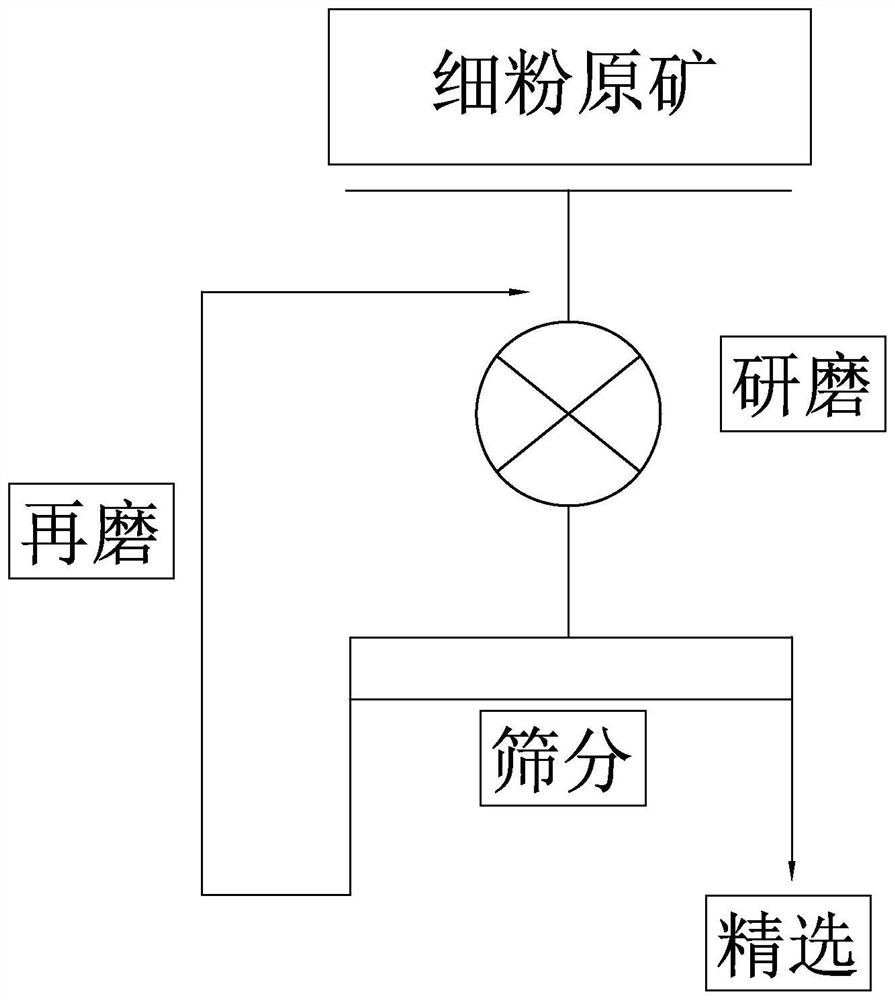

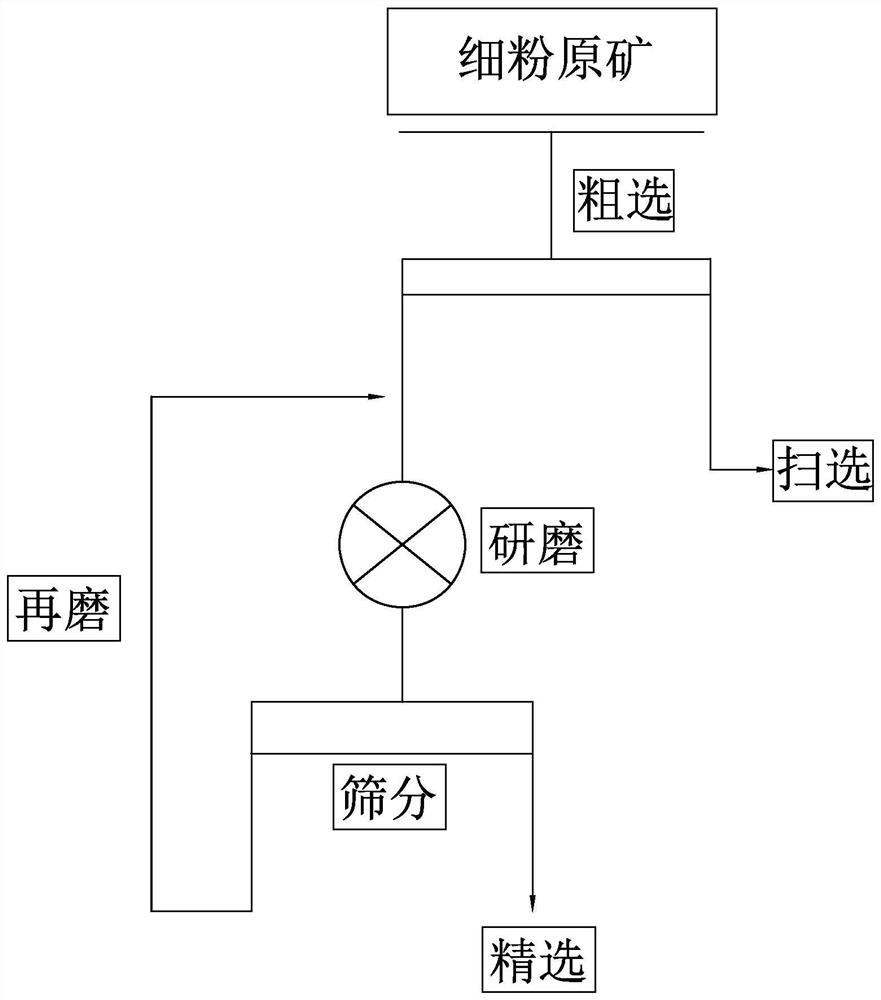

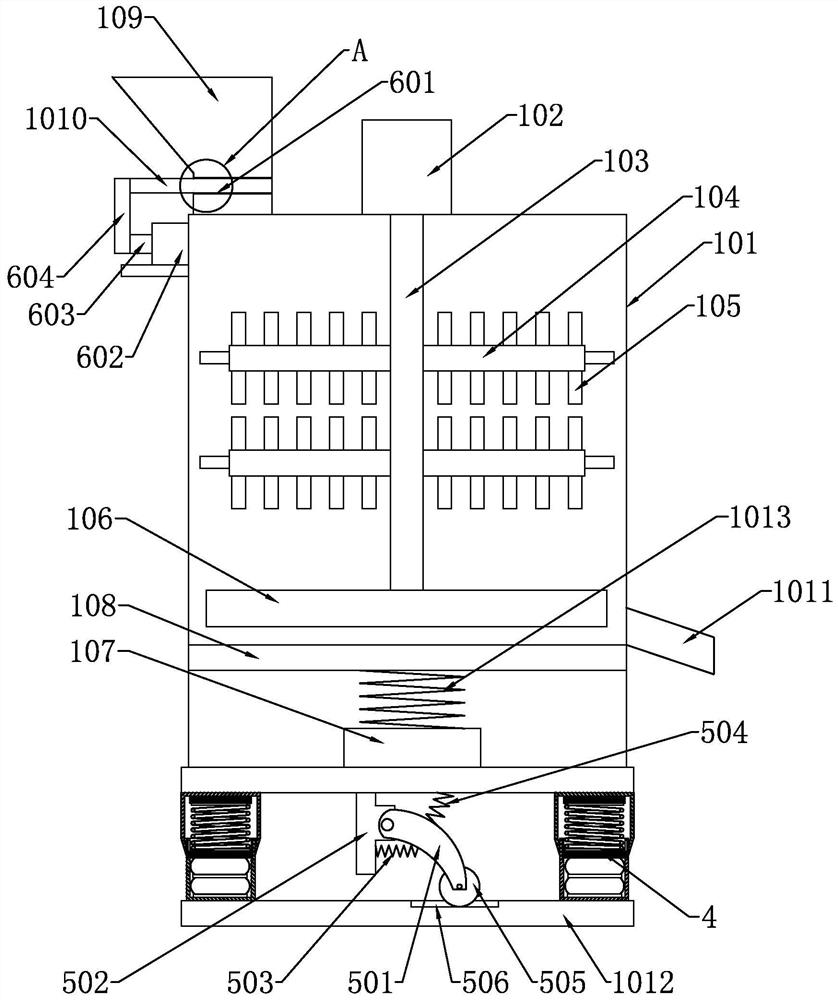

Fluorite processing production line and processing technology thereof

PendingCN112517233AStable chemical propertiesImprove corrosion resistanceFlotationProcess engineeringMachining process

The invention relates to a fluorite processing production line and a processing technology thereof. The fluorite processing production line comprises the steps of roughing, scavenging, grinding, screening, regrinding, concentrating and the like; and the current selected raw ore regrinding process is changed into the process that fine powder roughing is conducted firstly, then regrinding, screeningand concentrating are conducted on foam obtained through roughing, the load of a grinding machine in the processing process is reduced, the recovery rate of a separation plant is further improved, the selection fineness is improved, and the product quality is improved.

Owner:LONGQUAN FLUOSPAR

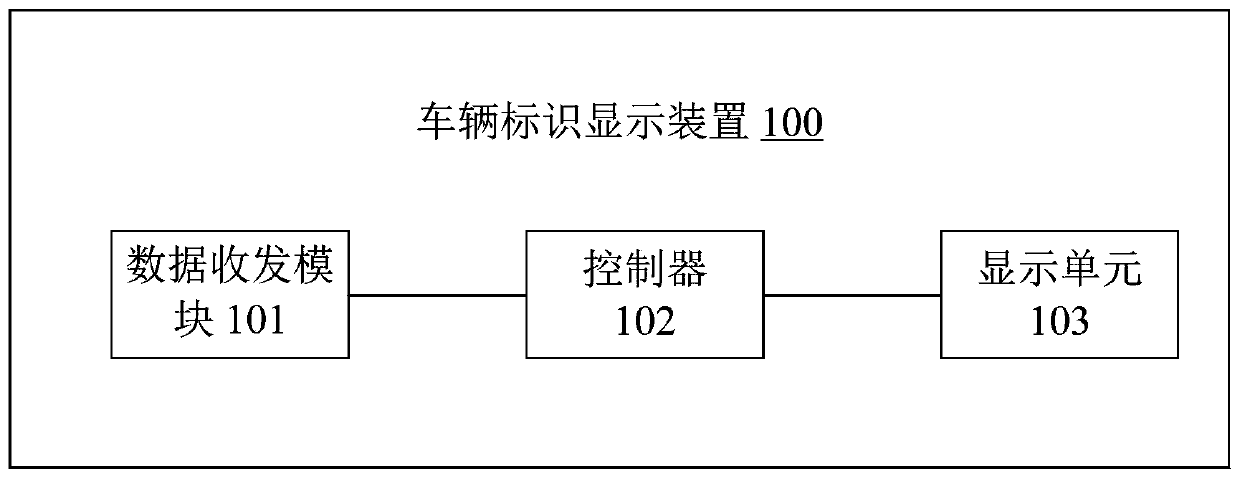

Vehicle identification display device and vehicle

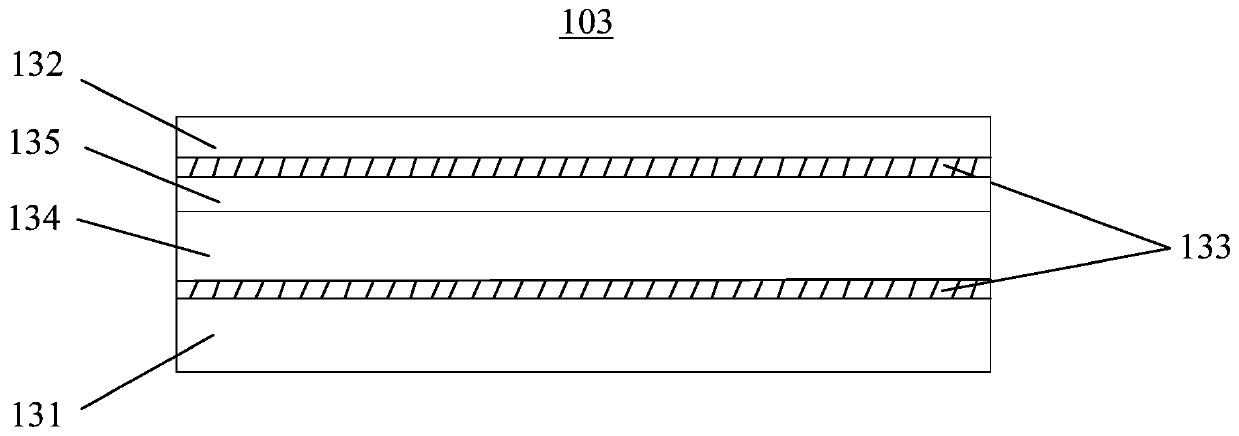

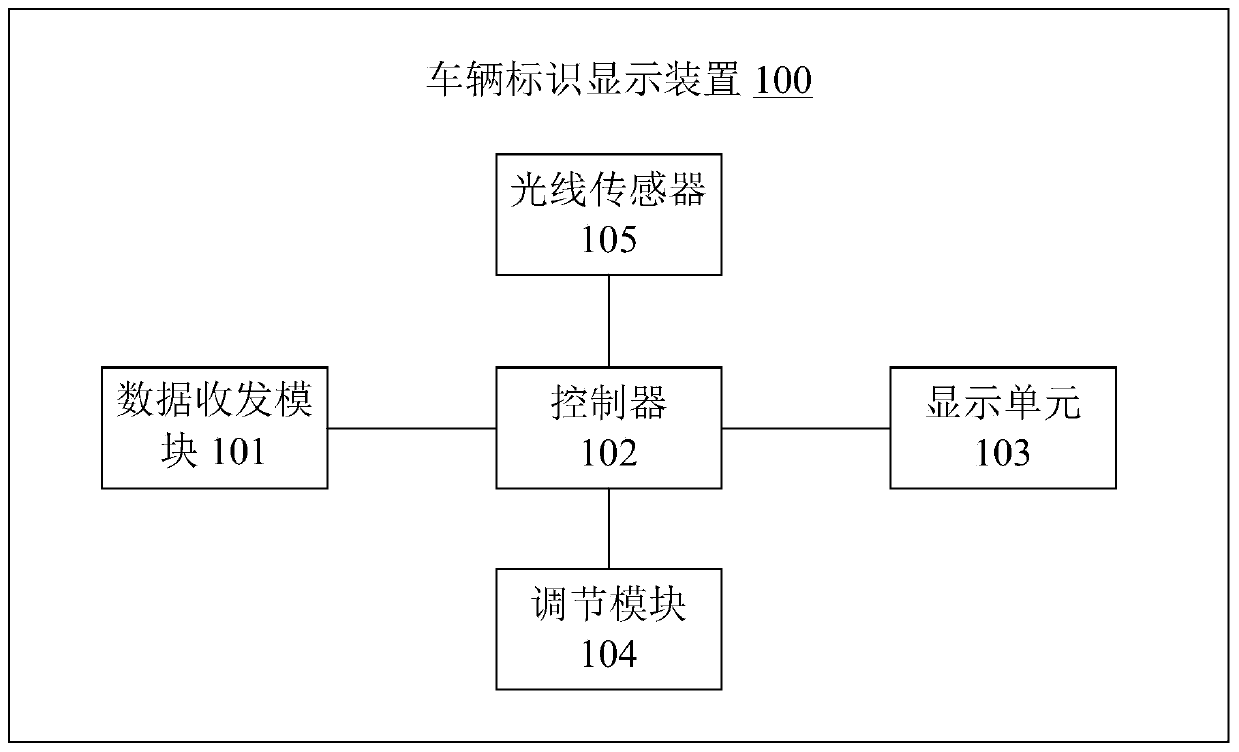

PendingCN111460013AAvoid cleaning difficultiesImprove experienceDatabase management systemsTransmissionControl signalDisplay device

The invention relates to a vehicle identification display device and a vehicle. The device comprises a data transceiving module, a controller and a display unit, and the controller is respectively connected with the data transceiving module and the display unit; the data transceiving module is used for acquiring identification information of a vehicle; the controller is used for processing the identification information and generating a corresponding control signal; and the display unit is used for displaying the identification information according to the control signal. According to the technical scheme, the problem that cleaning is difficult due to an existing paper vehicle logo is solved, paper is saved, the logo information of the vehicle can be updated at any time, the sense of science and technology is increased, and the user experience is improved.

Owner:BEIJING BORGWARD AUTOMOBILE CO LTD

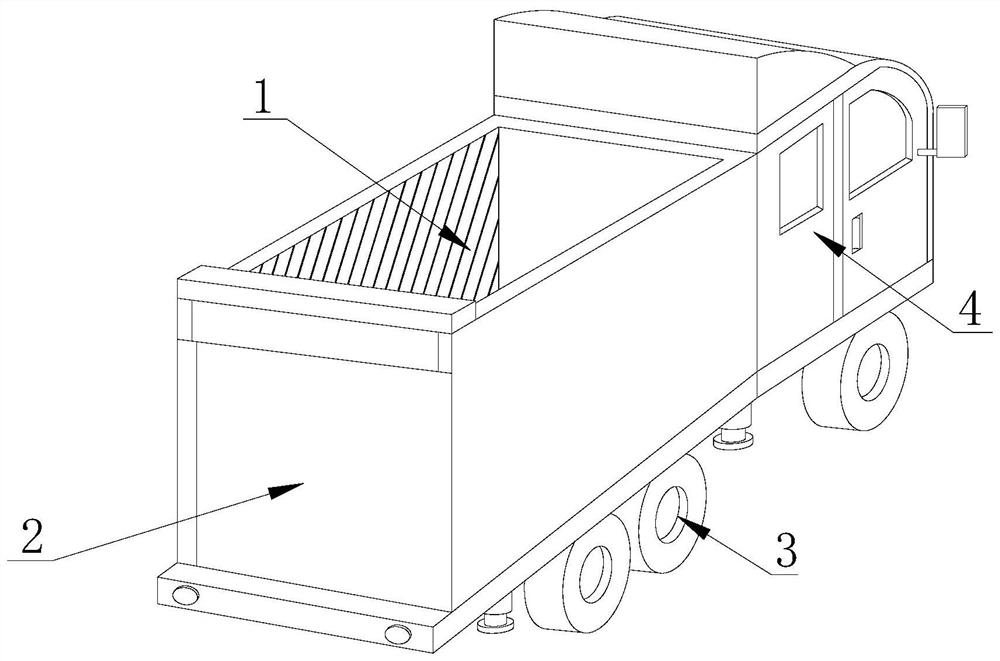

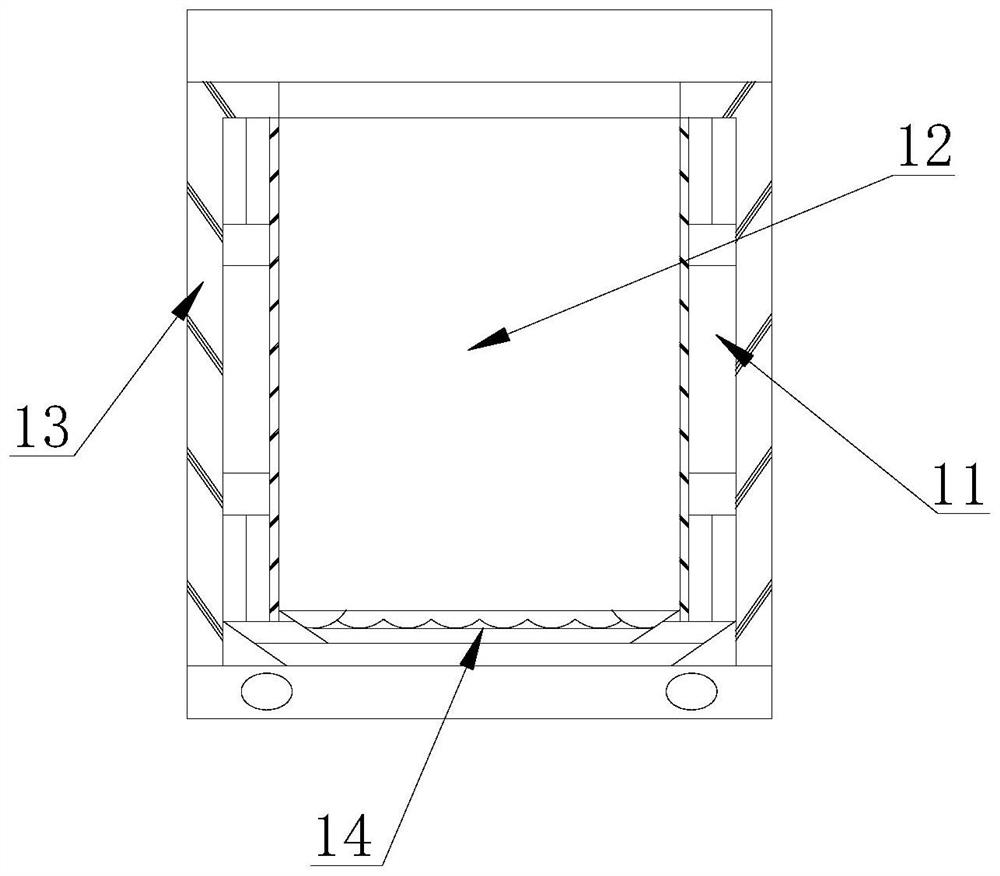

Traffic transport vehicle facilitating loading and unloading

InactiveCN113147556AScrape is effectiveAvoid cleaning difficultiesSludge treatmentVehicle cleaningDrive wheelSludge

The transportation vehicle structurally comprises a cargo carrying box, a partition bin door, driving wheels and a vehicle head, the lower surface of the cargo carrying box is in clearance fit with the tops of the driving wheels, the upper ends of the driving wheels are in clearance fit with the lower end of the vehicle head, the rear end of the vehicle head is movably matched with the top of the cargo carrying box, and the tail end of the cargo carrying box is hinged to the left side of the partition bin door; the cargo carrying box comprises a cleaning plate, a bearing bin, a box wall and a storage seat, and the inner side of the cleaning plate is fixedly connected with the inner surface of the box wall in an embedded mode. According to the invention, after stress on a pressed sliding ball disappears, a strip body connected with a fixing groove of the pressed sliding ball is driven through cooperation with elastic columns at the two ends, and the surface of the inner bin wall is scraped in the driving process; in the scraping process, in order to prevent splashing of sludge water drops, the sludge water drops are subjected to orientation flow guide through the flow guide holes so that the sludge water drops can flow downwards, the surface of the inner bin wall is effectively scraped through the pressure scraping strips during unloading, and the problem that the sludge water drops are adhered to the inner wall after being dried and are difficult to clean is effectively solved.

Owner:沈阳联宏远物流有限公司

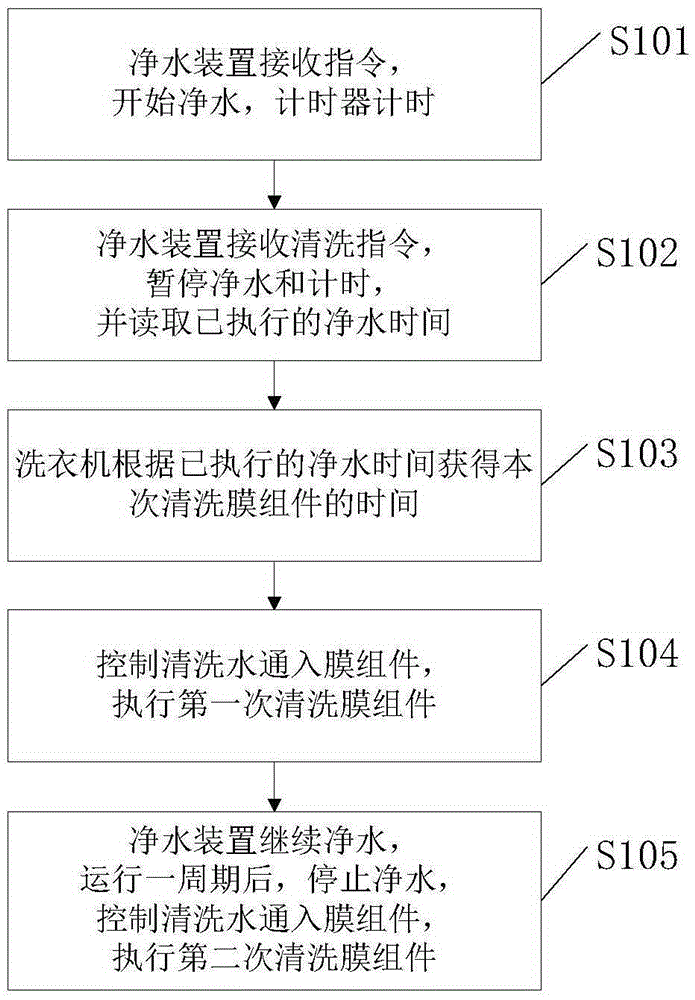

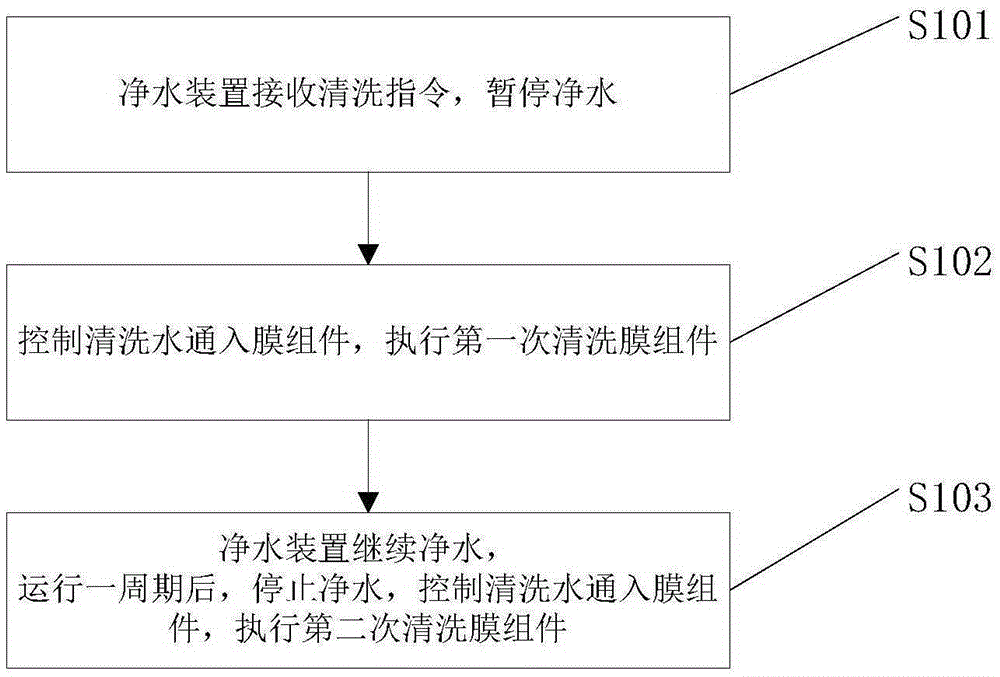

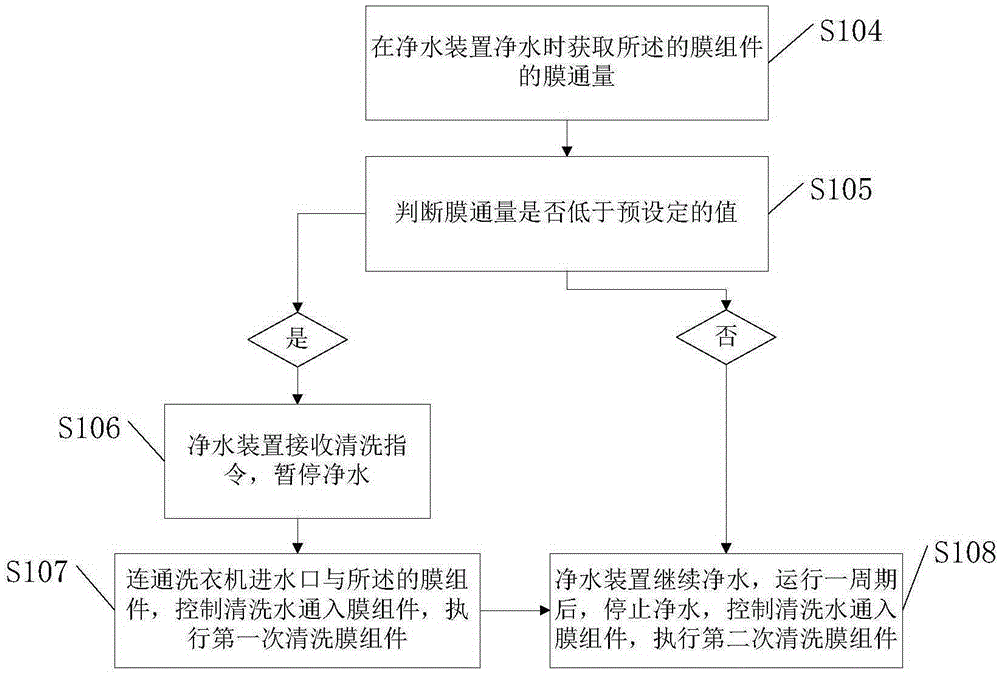

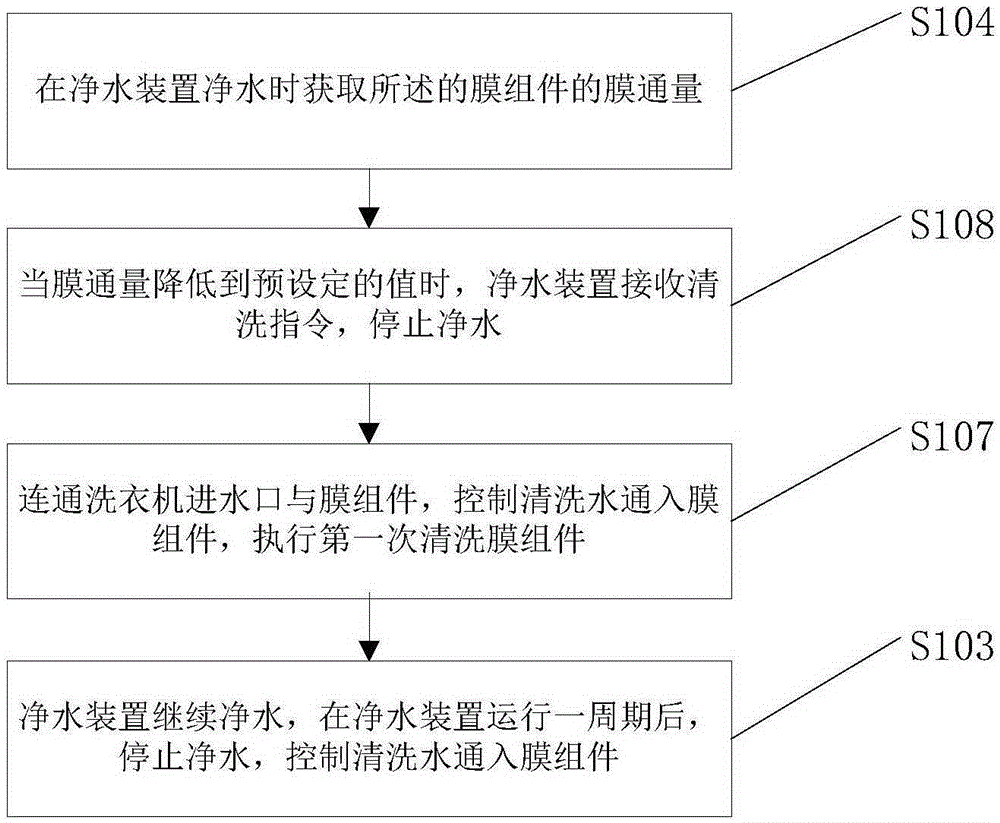

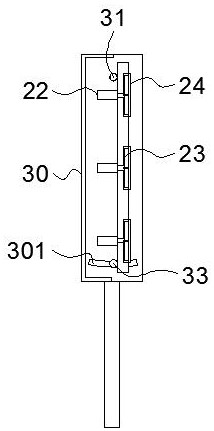

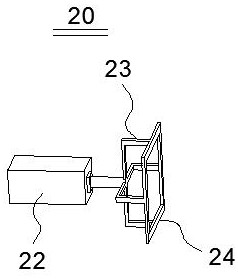

A maintenance method of a water purification device for a water purification washing machine and a washing machine therefor

ActiveCN106637806BThe simplification method is complexReduce manufacturing costOther washing machinesControl devices for washing apparatusWater dischargeEnvironmental engineering

Owner:QINGDAO HAIER DRUM WASHING MACHINE

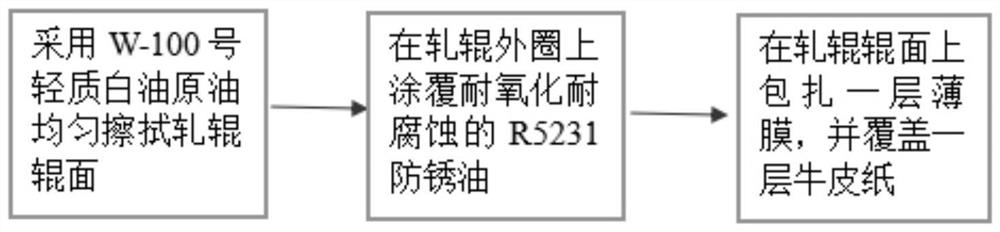

Protection method for roller surface at environment temperature of -35 DEG C to +30 DEG C

PendingCN113042537AIsolation of atmospheric ambient gasesAvoid cleaning difficultiesRolling equipment maintainenceMetal rolling arrangementsCorrosion resistantEnvironmental geology

The invention discloses a protection method for a roller surface at the environment temperature of -35 DEG C to +30 DEG C. The protection method has the following advantages that (1) the roller surface is coated with a layer of light white oil crude oil without any additive, and the situation that common alcohol and ester additives with the carbon number distributed between C12 and C16 are crystallized, separated out and bonded to the roller surface in a low-temperature environment (the temperature is lower than 20 DEG C) can be effectively avoided; and (2) the outer ring of a roller is coated with a layer of oxidation-resistant and corrosion-resistant R5231 anti-rust oil, atmospheric environment gas can be isolated, the situation that the gas directly corrodes the roller surface, and consequently rust spots are generated on the roller surface is prevented, and meanwhile the situation that the anti-rust oil makes direct contact with the roller surface, and consequently the roller surface is difficult to clean subsequently is avoided.

Owner:INNER MONGOLIA LIANSHENG NEW ENERGY MATERIALS CO LTD

Drill bit used for glass drilling and having automatic chip removing function

ActiveCN106393448AAvoid wastingAvoid cleaning difficultiesStone-like material working toolsDrill bitEngineering

The invention discloses a drill bit used for glass drilling and having an automatic chip removing function. The drill bit comprises a drill bit main body, wherein a water conveying pipeline and a drill bit inner cavity are arranged in the drill bit main body, the drill bit main body is provided with a first relief pressure groove and a second relief pressure groove, one side of the first relief pressure groove is communicated with the second relief pressure groove and the other side is communicated with a drill bit hollow cavity, one side of the second relief pressure groove is communicated with the first relief pressure groove and the other side is communicated with the water conveying pipeline, a spring and a steel ball are arranged in the first relief pressure groove, a safety valve is arranged in the second relief pressure groove, a location plate is arranged in the drill bit inner cavity, a location boss is arranged on the location plate, a communicating hole is arranged in the location plate, the steel ball is of an internal hollow structure, the steel ball comprises an outer layer and an inner layer which can mutually rotate, a plurality of first through holes are uniformly distributed in the circumference of the inner layer, and a plurality of second through holes are uniformly distributed in the circumference of the outer layer. According to the solution, water drained from the drill bit hollow cavity can be used repeatedly, and chips of glass can be effectively collected.

Owner:CHONGQING HECHUAN JINXING GLASS PROD CO LTD

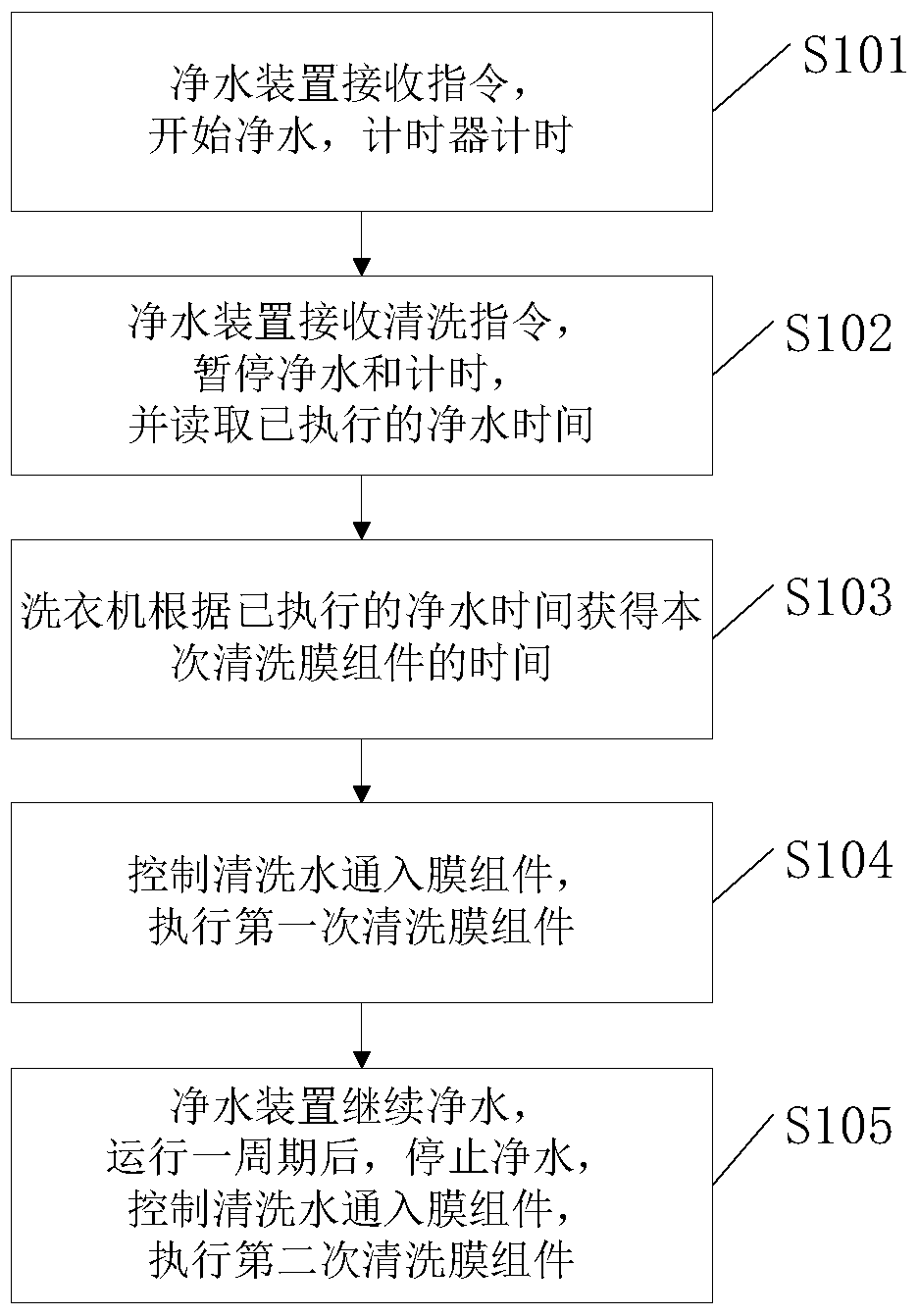

Maintenance method of water purifying device of water purifying washing machine and washing machine adopting maintenance method

ActiveCN106637806AThe simplification method is complexReduce manufacturing costOther washing machinesControl devices for washing apparatusWater dischargeEnvironmental engineering

The invention provides a maintenance method of a water purifying device of a water purifying washing machine and a washing machine adopting the maintenance method. The washing machine comprises a washing drum, a circulating water pipeline, a drainage pipeline and a membrane assembly. The membrane assembly is provided with a water inlet, a water producing outlet and a sewage discharge outlet, the membrane assembly is connected to the circulating water pipeline through the water inlet and the water producing outlet, the membrane assembly is connected to the water discharge pipeline through the sewage discharge pipeline, the membrane assembly is further provided with a washing inlet used for inputting intake to washing the membrane assembly, and the washing outlet is communicated to the water inlet of the washing machine. The maintenance method of the water purifying device comprises the steps of running the water purifying device for one cycle, executing membrane assembly washing twice, wherein the time length of executing first membrane assembly washing is related to the time in the water purifying running cycle of first membrane assembly washing. According to the water purifying device of the water purifying washing machine and the washing machine thereof, the washing problem of a filter membrane component in the existing water purifying washing machine is solved, meanwhile, the washing method of the filter membrane component is simplified, the water consumption of washing the filter membrane component is saved, and the production of the water purifying washing machine is reduced.

Owner:QINGDAO HAIER DRUM WASHING MACHINE

LCD liquid crystal screen cutting and packaging process

PendingCN114355645AAvoid cleaning difficultiesIncrease flexibilityPrinted circuit assemblingNon-linear opticsLiquid-crystal displaySolder paste

The invention discloses a liquid crystal display (LCD) cutting and packaging process, and particularly relates to the related technical field of LCDs, and the LCD cutting and packaging process comprises the following steps: S1, stably placing a series of processed LCDs on a positioning carrier plate above the inner side of a cutting table; s2, an electric cutting machine is aligned with the starting end of the marked cutting line; and S3, continuously moving the positioning carrier plate to the position of the mounting rack, adjusting the left-right position of the spot welding machine by using a bidirectional screw rod, pasting the pasted element on the bonding pad printed with the soldering paste, and packaging and connecting the circuit board and the outer lead of the liquid crystal screen device by using a conductive adhesive. The spot welding machine is combined with the two-way lead screw, the left-right position of the spot welding machine is adjusted through the two-way lead screw, the spot welding machine can flexibly conduct lead welding on a circuit board behind an LCD screen, the worm wheel is matched with the worm, the direction of force can be changed through the worm, the worm wheel drives the worm to move up and down, and the welding precision is improved. Therefore, the height of the spot welding needle is controlled.

Owner:苏州视达讯远电子科技有限公司

Maintenance method of water purifying device of water purifying washing machine and a washing machine adopting maintenance method

ActiveCN106637827AGuaranteed uptimeAvoid foulingWater treatment parameter controlSpecific water treatment objectivesEngineeringEnvironmental engineering

The invention provides a maintenance method of a water purifying device of a water purifying washing machine and a washing machine adopting the maintenance method. The washing machine comprises a washing drum, a circulating water pipeline, a drainage pipeline and a membrane assembly. The membrane assembly is provided with a water inlet, the water producing outlet and a sewage discharge outlet, the membrane assembly is connected to the circulating water pipeline through the water inlet and a water producing outlet, the membrane assembly is connected to the water discharge pipeline through the sewage discharge pipeline, the membrane assembly is further provided with a washing inlet used for inputting intake to washing the membrane assembly, and the washing outlet is communicated to the water inlet of the washing machine. The maintenance method of the water purifying device comprises the steps that the water purifying device receives a water purifying command; washing water is controlled to be input into a membrane component; after the water purifying device runs for one cycle, water purifying is stopped, and the washing water is controlled to be input into the membrane component. According to the water purifying washing machine and the washing machine adopting the maintenance method, the washing problem of a filter membrane component in the existing water purifying washing machine is solved, meanwhile, the washing method of the filter membrane component is simplified, the water consumption of washing the filter membrane component is saved, and the production of the water purifying washing machine is reduced.

Owner:QINGDAO HAIER DRUM WASHING MACHINE +1

Literary works display device and display method

ActiveCN112425962BAvoid cleaning difficultiesEasy to read and watchShow shelvesShow hangersDisplay boardDisplay device

The present invention relates to the technical field of display equipment, and provides a literary work display device and a display method, wherein the literary work display device includes a display board, and the display board has a plurality of display areas for fixedly displaying literary works, and each display area is respectively Correspondingly, a plurality of independent fixing devices are installed. The fixing device has a control button. When the control button is pressed, the fixing device is away from the display area. When the control button is released, the fixing device interferes and presses against the display area. Compared with the traditional display method of bonding literary works to the display board with glue, the literary work display device of the present invention can control the fixing device to display literary works by pressing and releasing the control button, and the operation is simple. When the display is finished, you only need to press the control button, then take off the literary works and release the control button, which effectively avoids the difficult problem of later cleaning of the literary works pasted on the display board.

Owner:JIAOZUO UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com