Maintenance method of water purifying device of water purifying washing machine and washing machine adopting maintenance method

A technology of water purification device and washing machine, which is applied to the control device of washing machine, washing device, other washing machines, etc., to achieve the effects of reasonable configuration, saving water for cleaning membrane modules, and avoiding fouling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

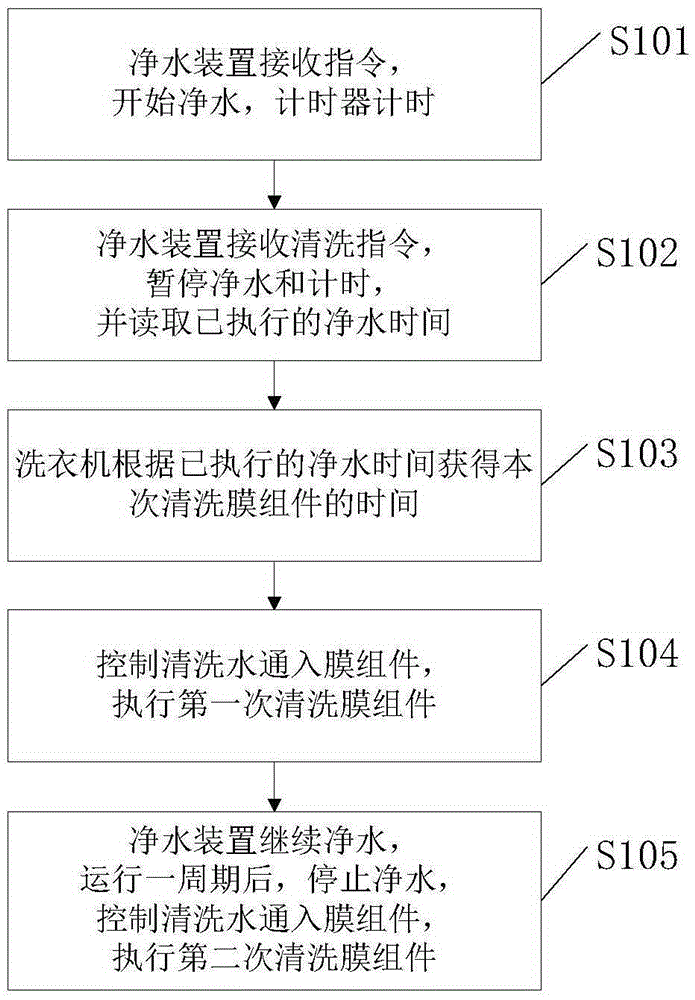

[0036] On the basis of the above-mentioned embodiments, the maintenance method of a water purification device of a water purification washing machine according to Embodiment 1 of the present invention, wherein a cycle of operation of the water purification device includes at least three time periods, and the first cleaning of the membrane module is performed When the time point of the water purification device is running in different time periods, the time for cleaning the membrane components for the first time is different.

[0037]For washing water with different levels of dirt, in order to facilitate the determination of the different durations for performing the first cleaning of the membrane module, the method provided by Embodiment 1 of the present invention is to divide the operation cycle of the water purification device into several time stages, in different The first cleaning of the membrane components is carried out in the time period of , indicating that the degree ...

Embodiment 2

[0041] On the basis of the above embodiments, the second embodiment of the present invention provides a maintenance method for a water purification device of a washing machine, wherein the durations t1, t2 and t3 for cleaning the membrane module are sequentially decreased. After a lot of experiments, the inventor preferred that the operation cycle of the water purification device be the first time period, the second time period and the third time period in sequence. When the membrane module is cleaned for the first time in the first time period, it means that the degree of dirtiness of the washing water is the highest, and the time t1 required for cleaning the mold module is the longest; when the membrane module is cleaned for the first time in the third time period, it means that the laundry water The degree of contamination of the water is the lowest, and the time t3 needed to clean the module is the shortest; therefore, the time t1, t2 and t3 for cleaning the membrane module...

Embodiment 3

[0044] On the basis of the above-mentioned embodiments, the maintenance method for a water purification device of a washing machine according to Embodiment 3 of the present invention, wherein the membrane flux of the membrane module is automatically detected and obtained during the water purification of the water purification device, and pre-set Set a membrane flux value. As the water is purified, the dirt intercepted by the membrane module increases, and the membrane flux gradually decreases. When it is automatically detected that the membrane flux of the membrane module decreases to the preset membrane flux value, Perform the first cleaning of the membrane module, which can effectively maintain the performance of the membrane module.

[0045] Further, automatically detect and obtain the membrane flux of the membrane module and preset a membrane flux value when the water purification device purifies water, or it can be replaced by automatically detecting and obtaining the wate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com