Maintenance method of water purifying device of water purifying washing machine and a washing machine adopting maintenance method

A technology of water purification device and washing machine, which is applied to the control device of washing machine, washing device, other washing machines, etc., to achieve the effect of avoiding pollution clogging, reducing production cost and improving filtering effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

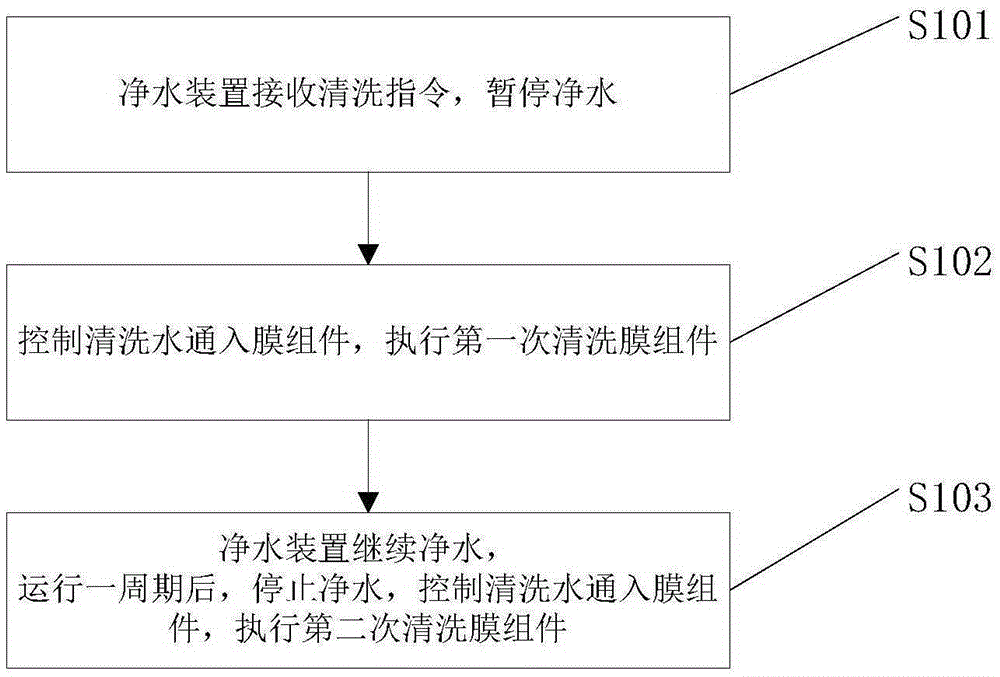

Embodiment 1

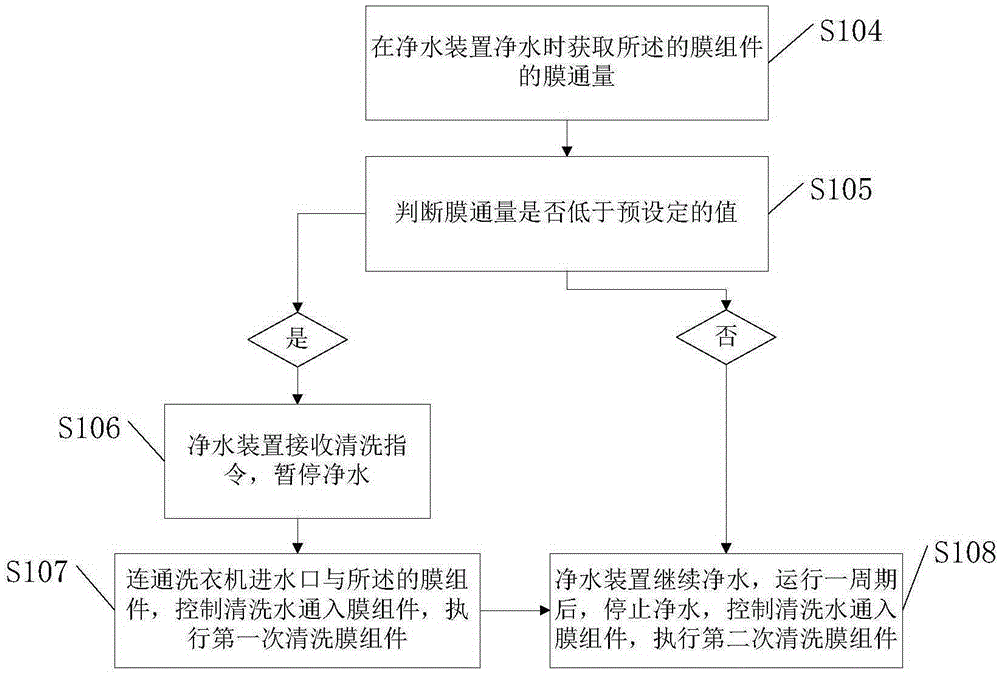

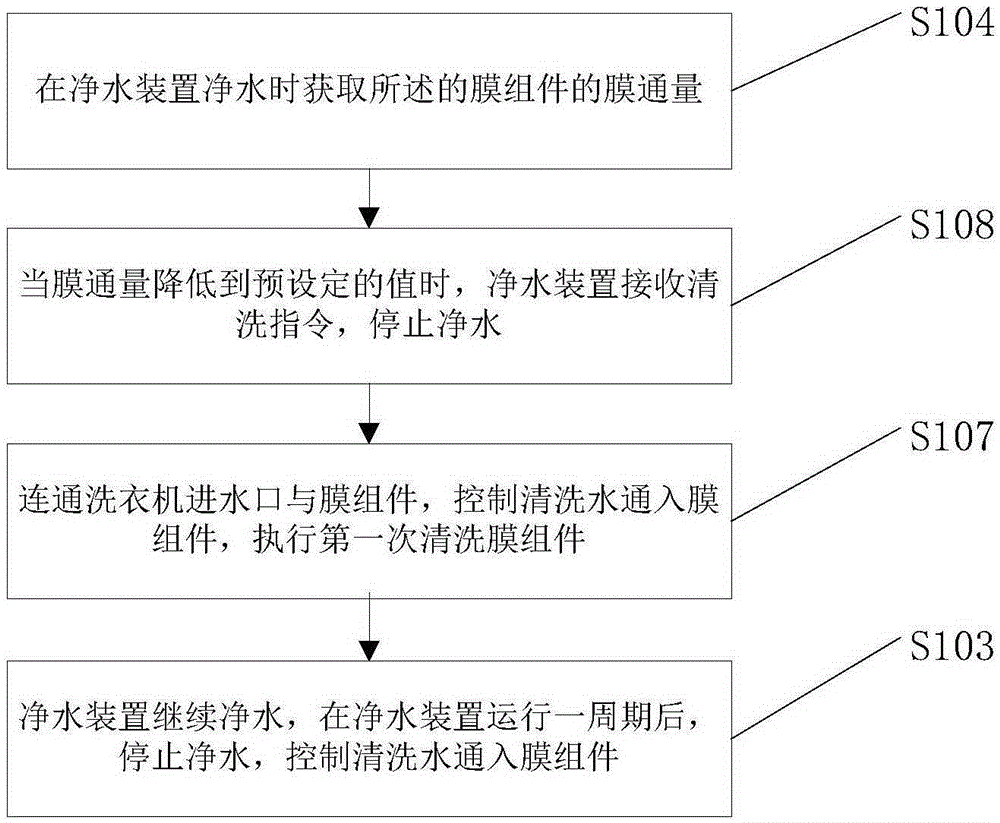

[0037] Such as figure 2 As shown, on the basis of the above-mentioned embodiments, the maintenance method for a water purification device of a water purification washing machine according to Embodiment 1 of the present invention further includes: obtaining the membrane flow rate of the membrane module when the water purification device is purifying water. When the membrane flux of the membrane module is lower than the preset value, the water purification device receives the cleaning command and suspends the water purification; step S106, connects the water inlet of the washing machine with the membrane module, controls the cleaning water to flow into the membrane module, and executes the first Clean the membrane components.

[0038] The maintenance method of the water purifying washing machine water purifying device of the present embodiment is:

[0039] First, step 104 is executed to obtain the membrane flux of the membrane module when the water purification device purifies...

Embodiment 2

[0050] Such as Figure 1-3 As shown, as a further preferred mode of the embodiment of the present invention, on the basis of the above-mentioned implementation mode, the first time t A greater than or equal to the second time t B , preferably, t A and t B The relationship is: t A = 2t B , this is because in the first stage of water purification process before time point A, the membrane module filtered more dirt in the laundry water, and as the filtration progressed, the dirt in the laundry water was gradually filtered out and decreased, so the dirt The accumulation on the membrane module is mainly concentrated in the first water purification process before time point A, so t A The setting time is longer, which can fully wash the dirt on the membrane module and maintain the performance of the membrane module more effectively. On the other hand, t B The setting time is short, which can effectively avoid the waste of water resources, and use less water while achieving the ...

Embodiment 3

[0053] Such as Figure 4 As shown, on the basis of the above-mentioned embodiments, the embodiment of the present invention provides a washing machine adopting the above-mentioned maintenance method for the water purification device of the washing machine, including: a washing tub, a circulating water pipeline, a drainage pipeline, and a membrane module, the membrane module It has a water inlet, a water production port and a sewage discharge port. The membrane module is connected to the circulating water pipeline through the water inlet and the water production port, and the membrane module is connected to the drainage pipeline through the sewage discharge port (not shown in the figure). Inlet water cleans the flushing port of the membrane module, and the flushing port communicates with the water inlet of the washing drum. Since the membrane module is cleaned with a specially set flushing port, the flushing port and the water production port do not share the same port.

[005...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com