Patents

Literature

65 results about "Membrane flow" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

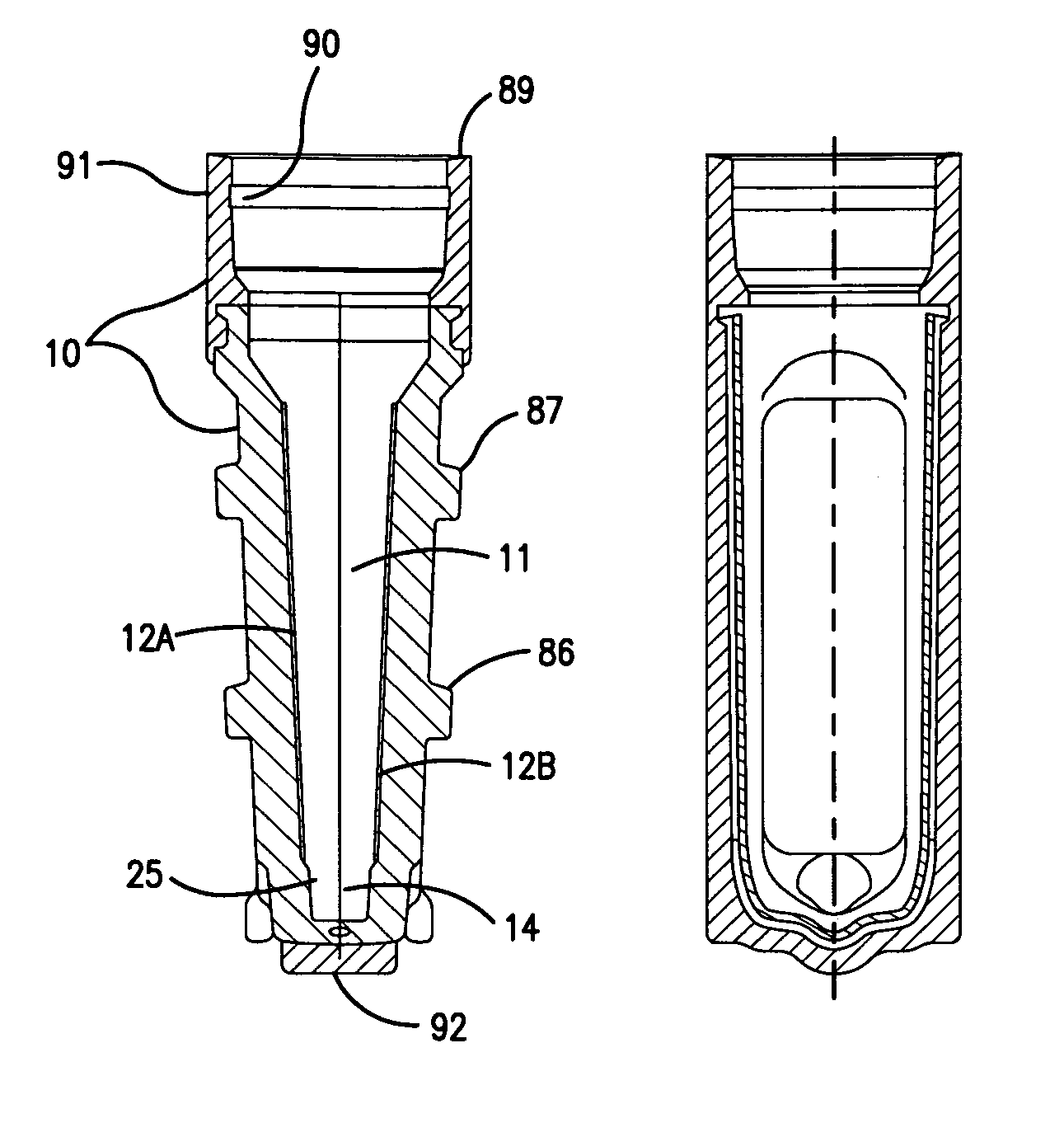

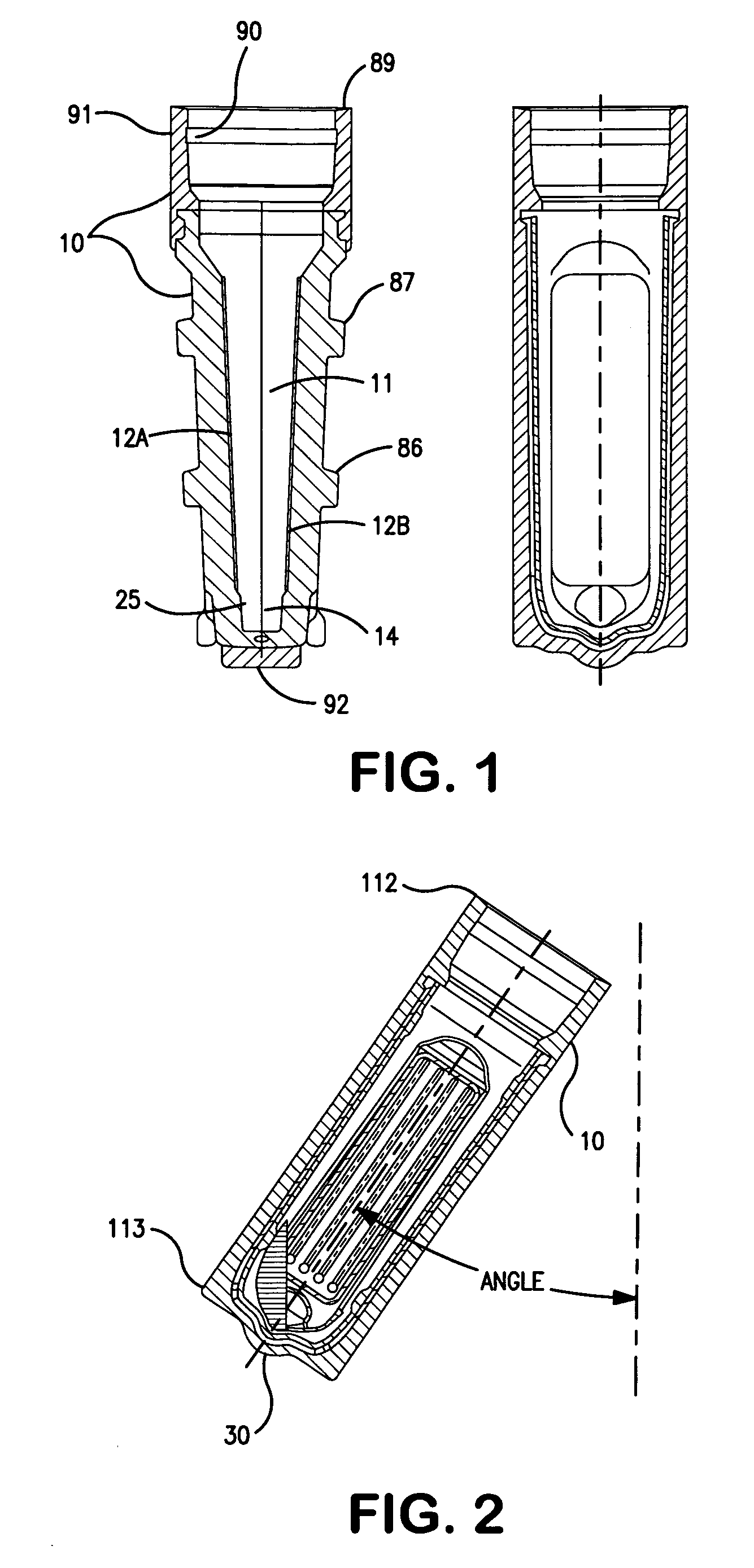

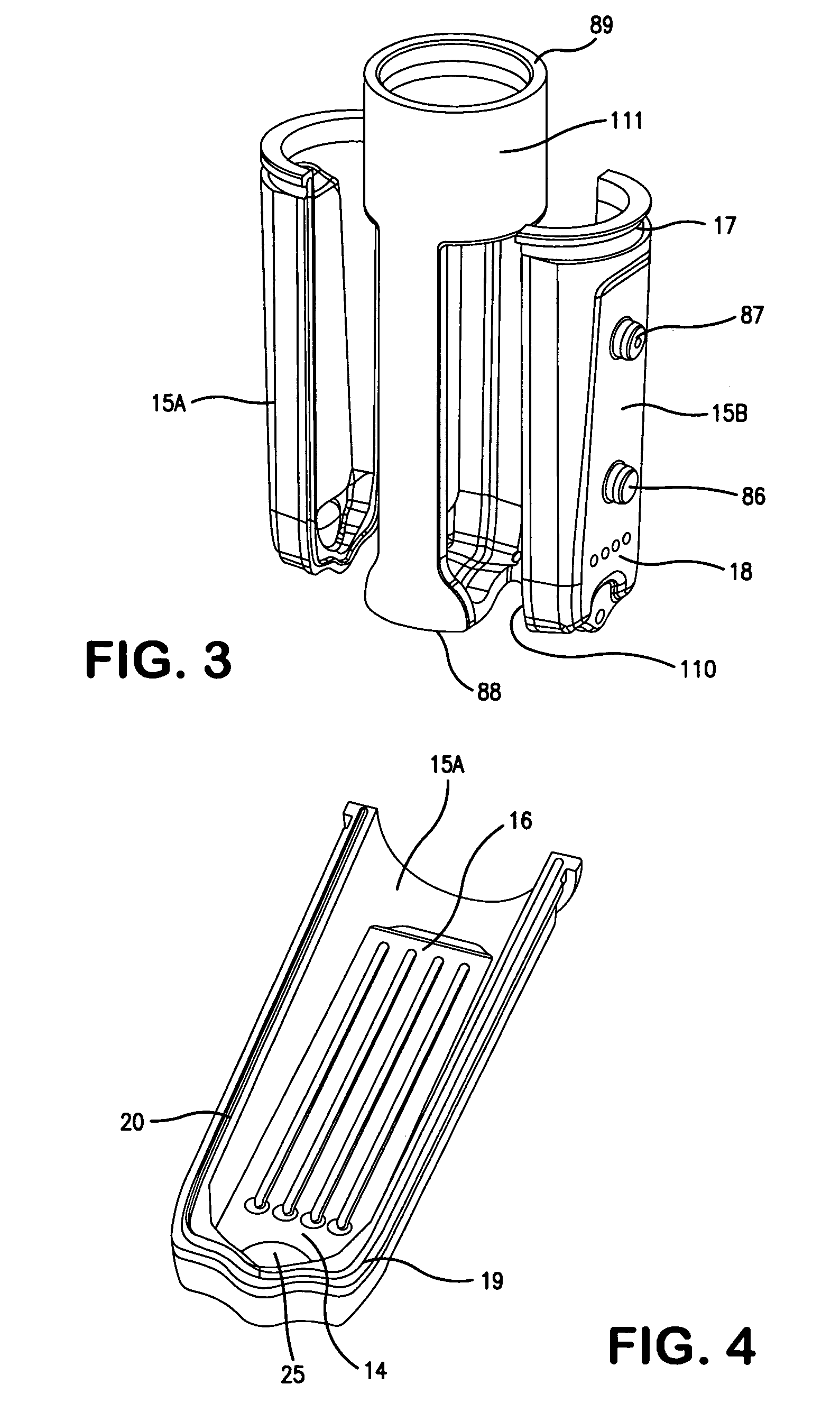

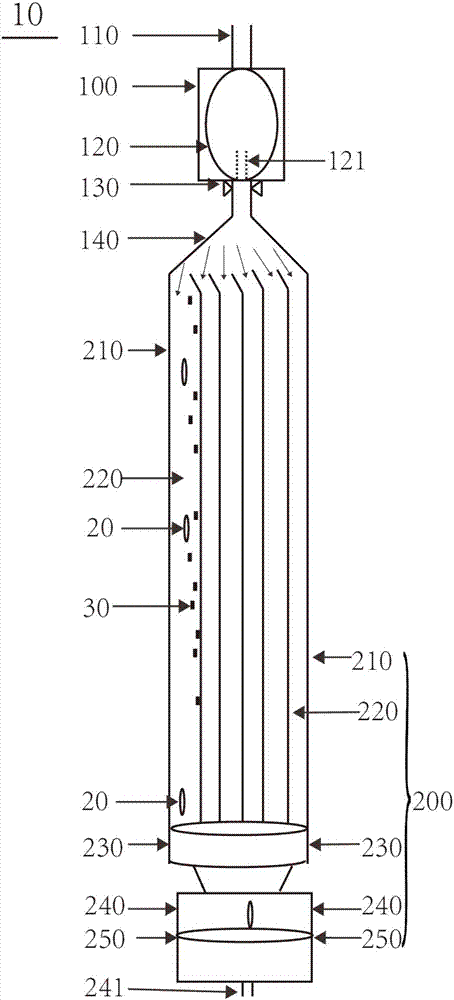

Centrifugal filter

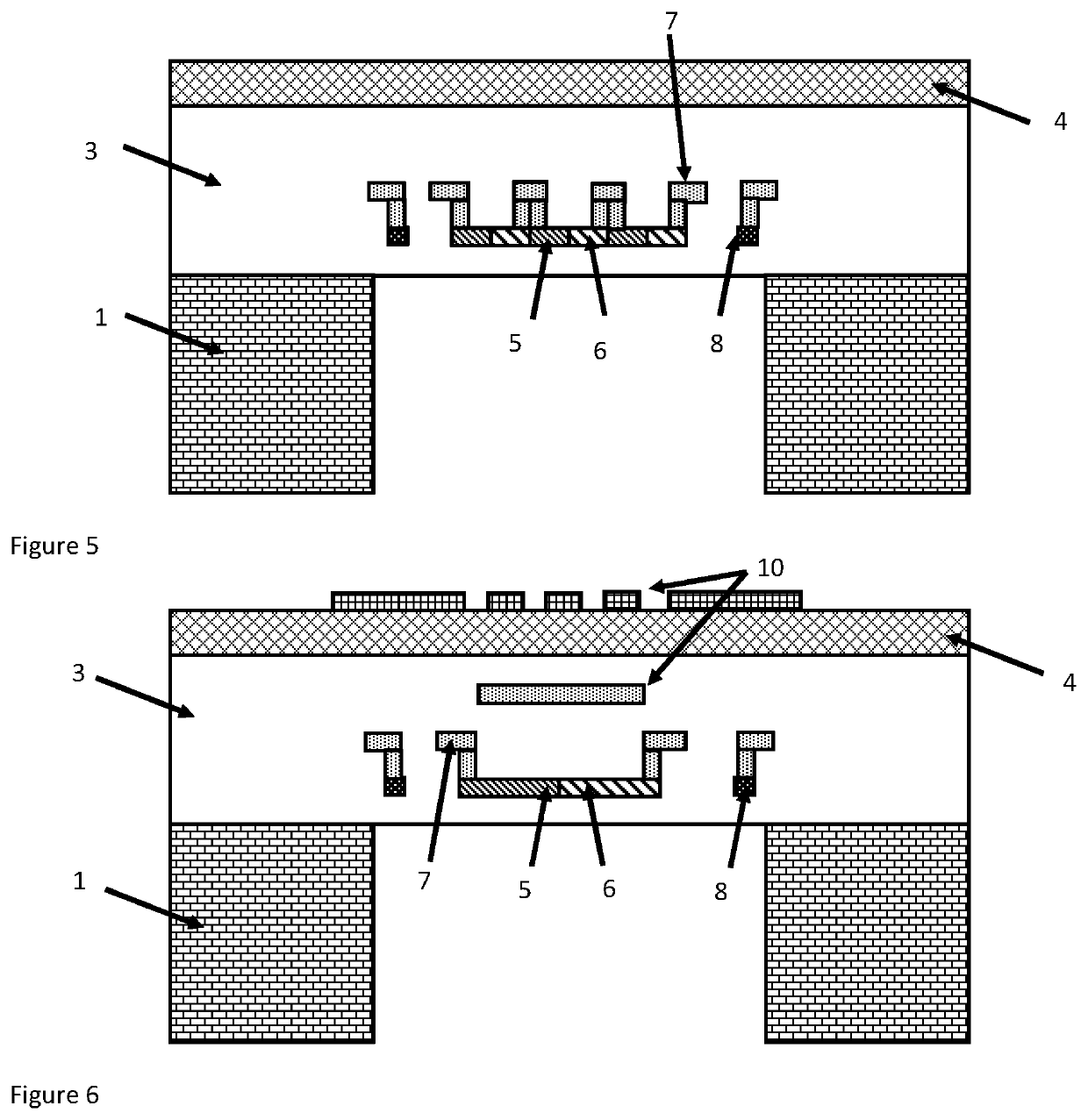

ActiveUS20090078638A1Increase membrane areaReduce the overall heightMembranesUltrafiltrationCounter rotationMembrane configuration

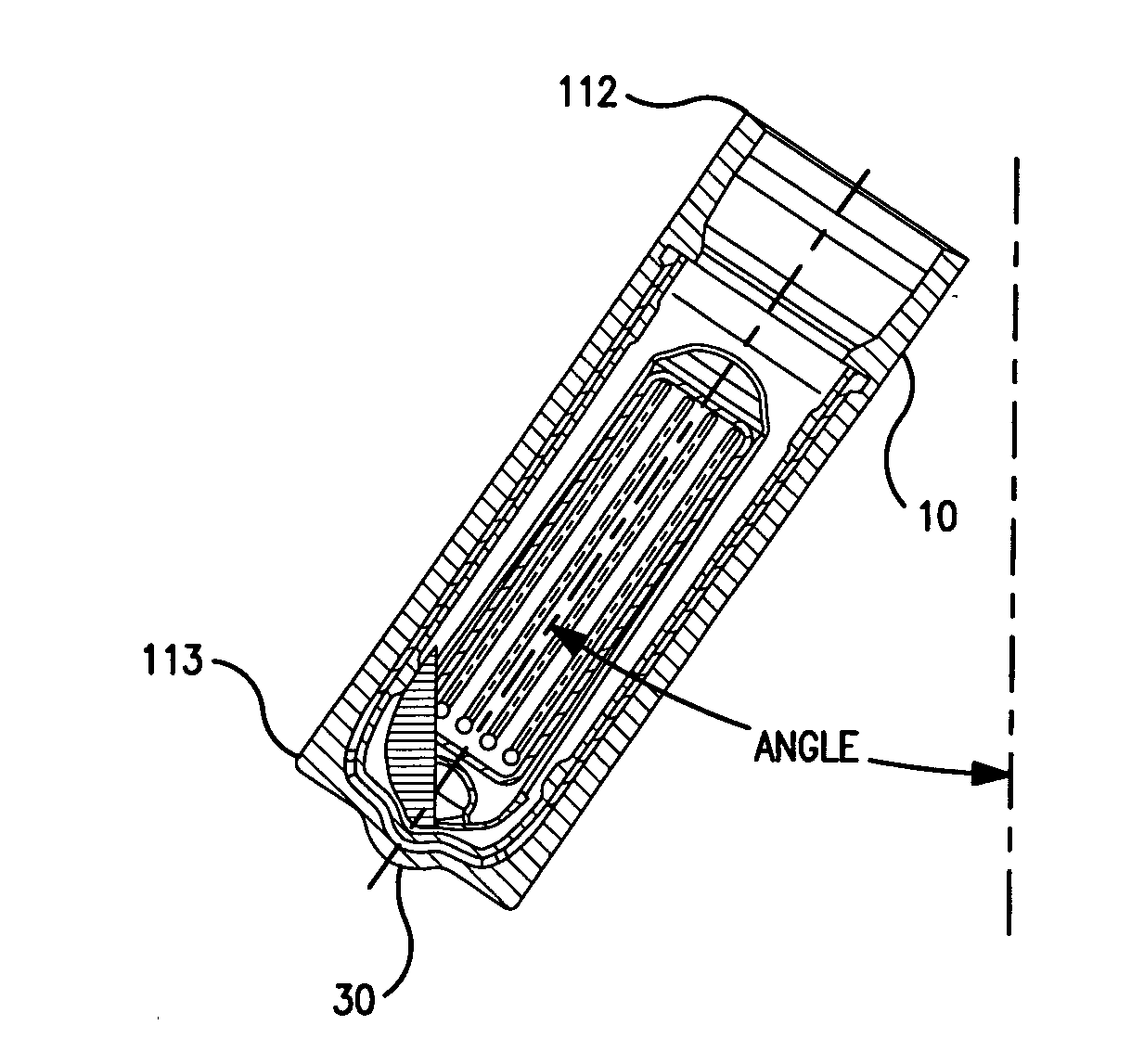

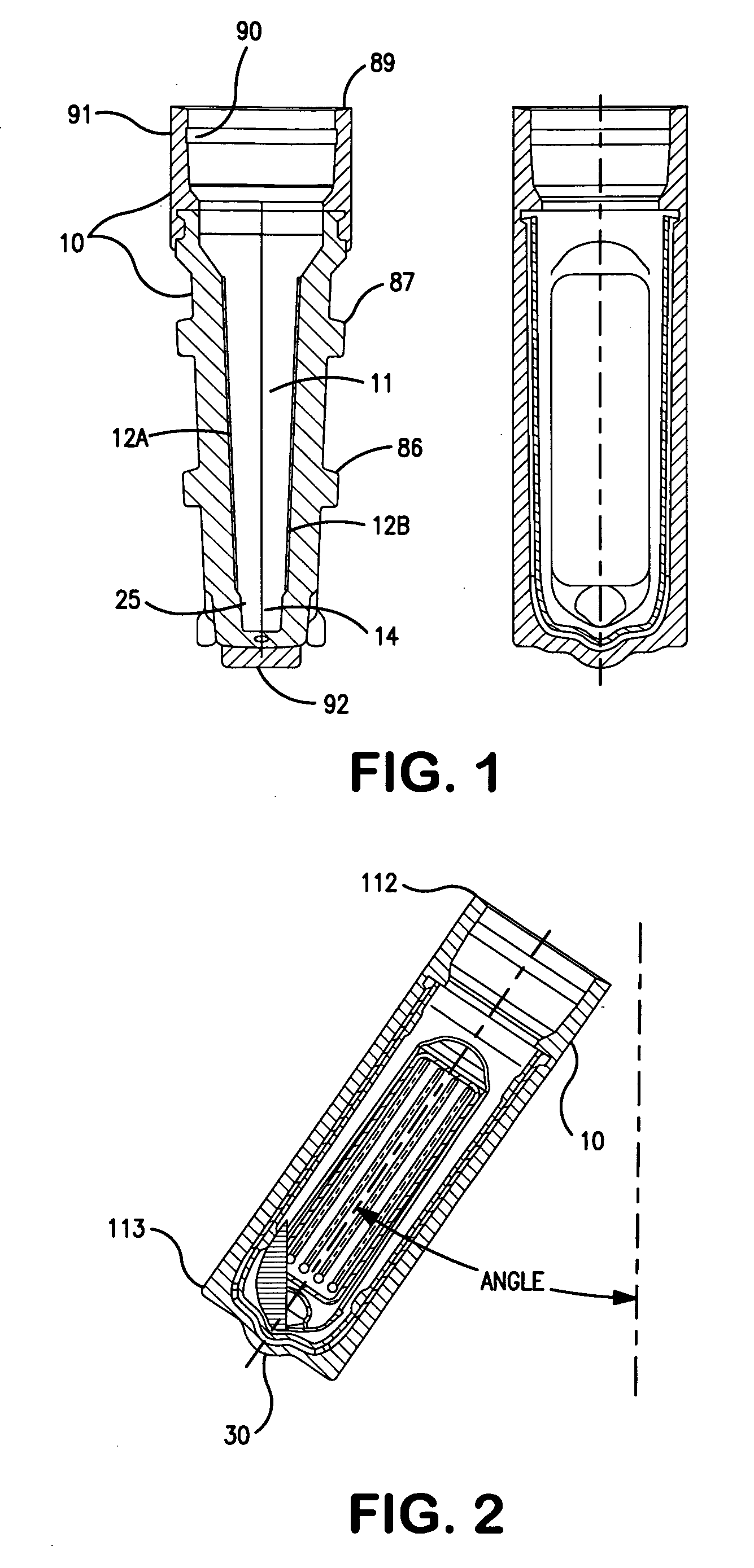

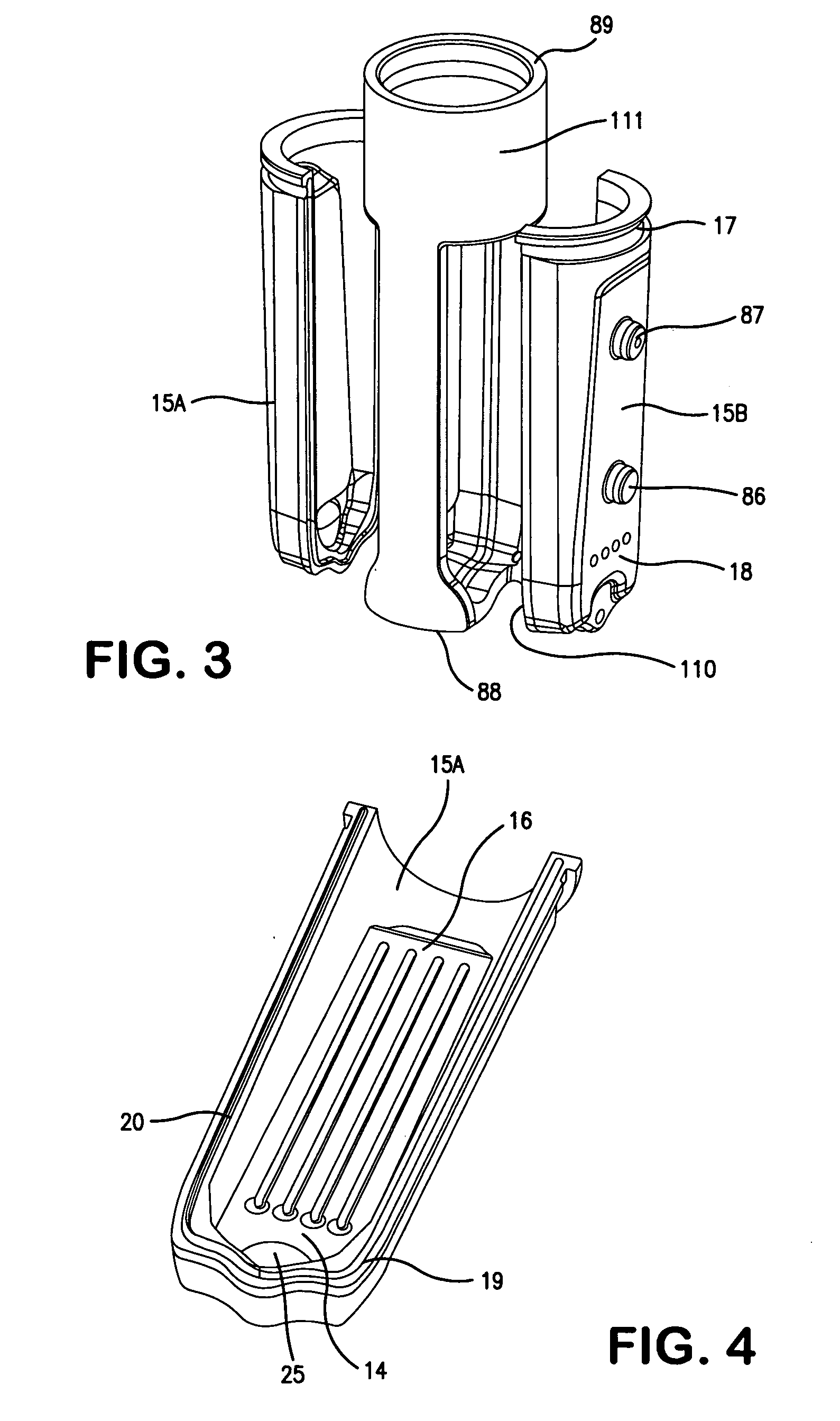

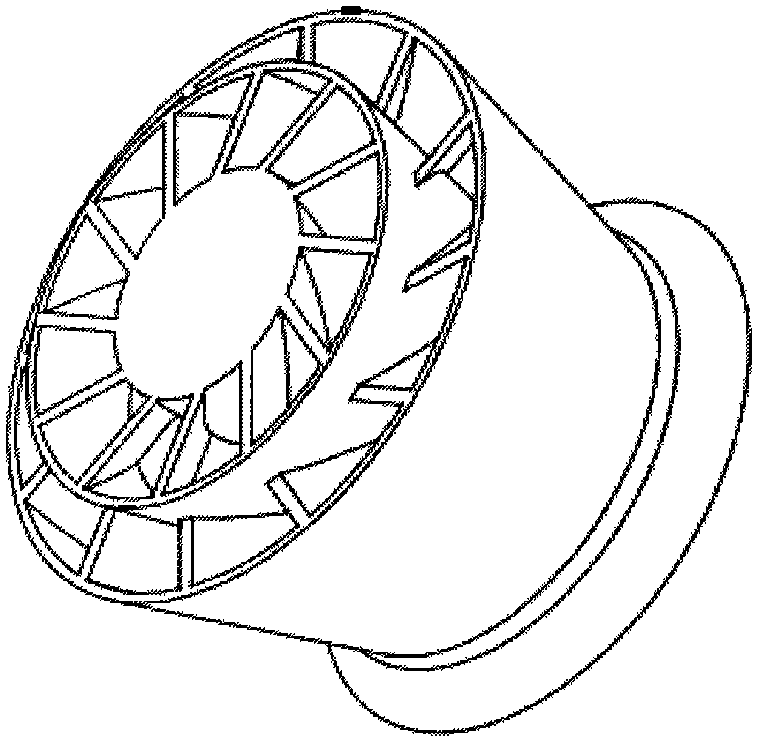

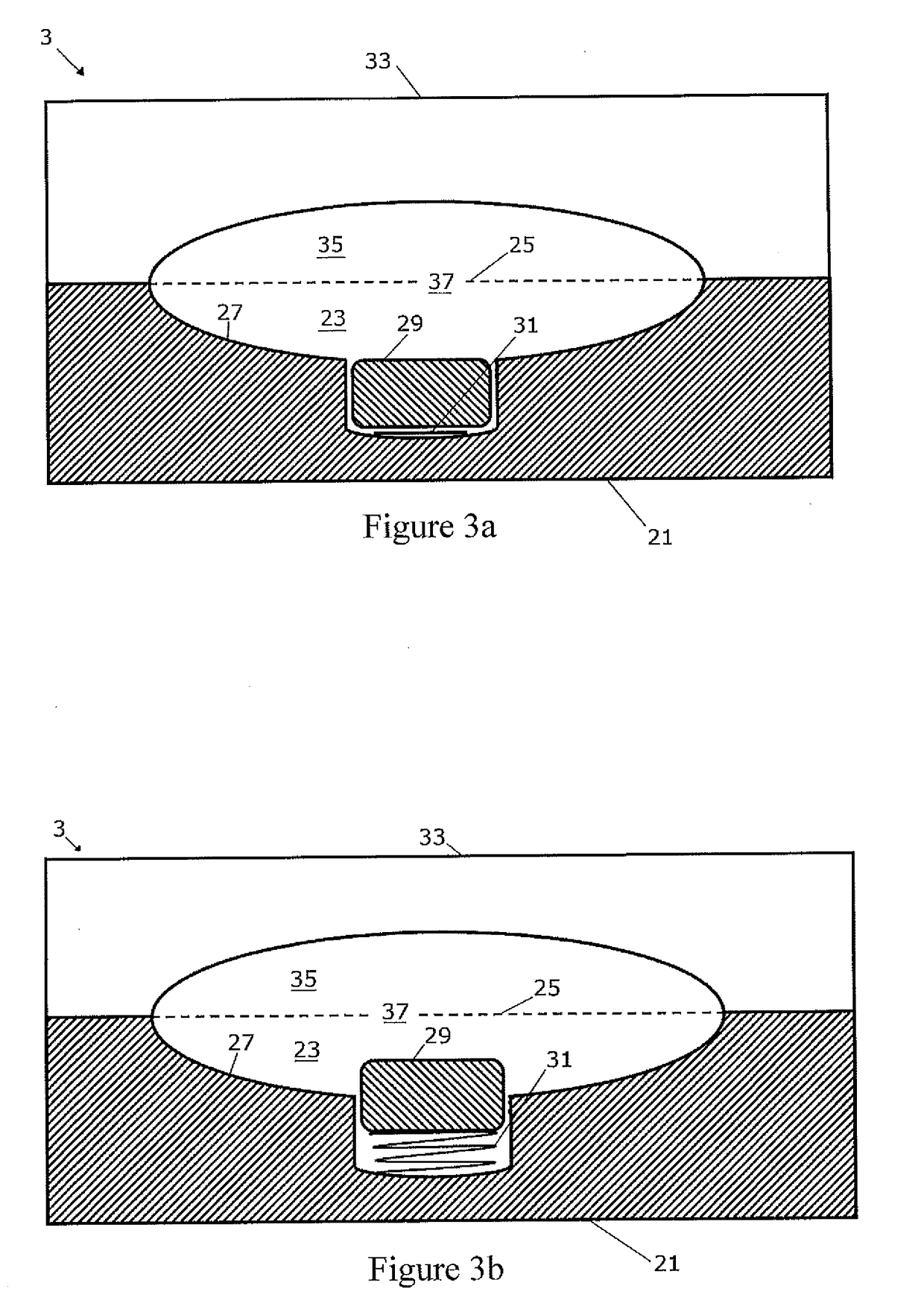

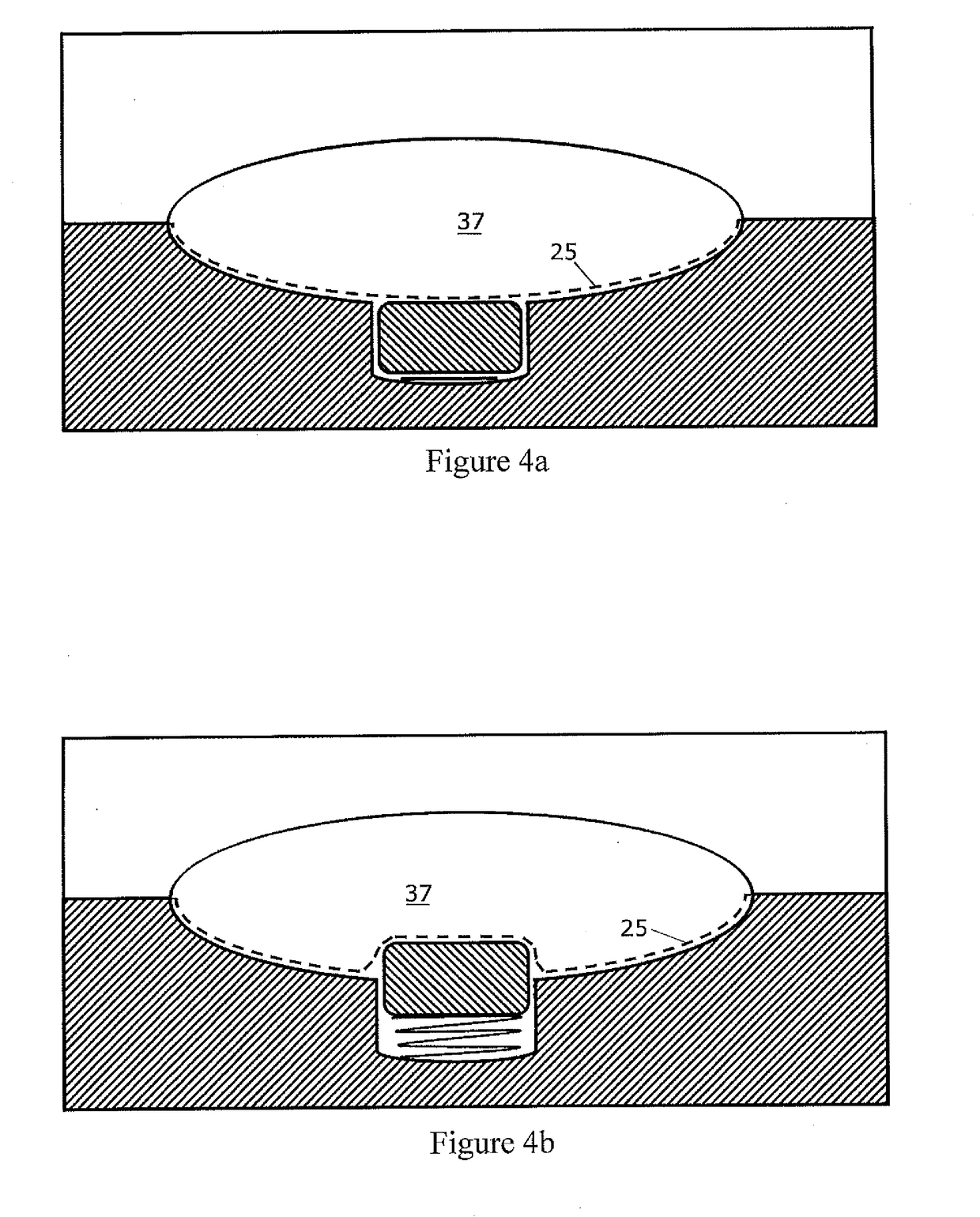

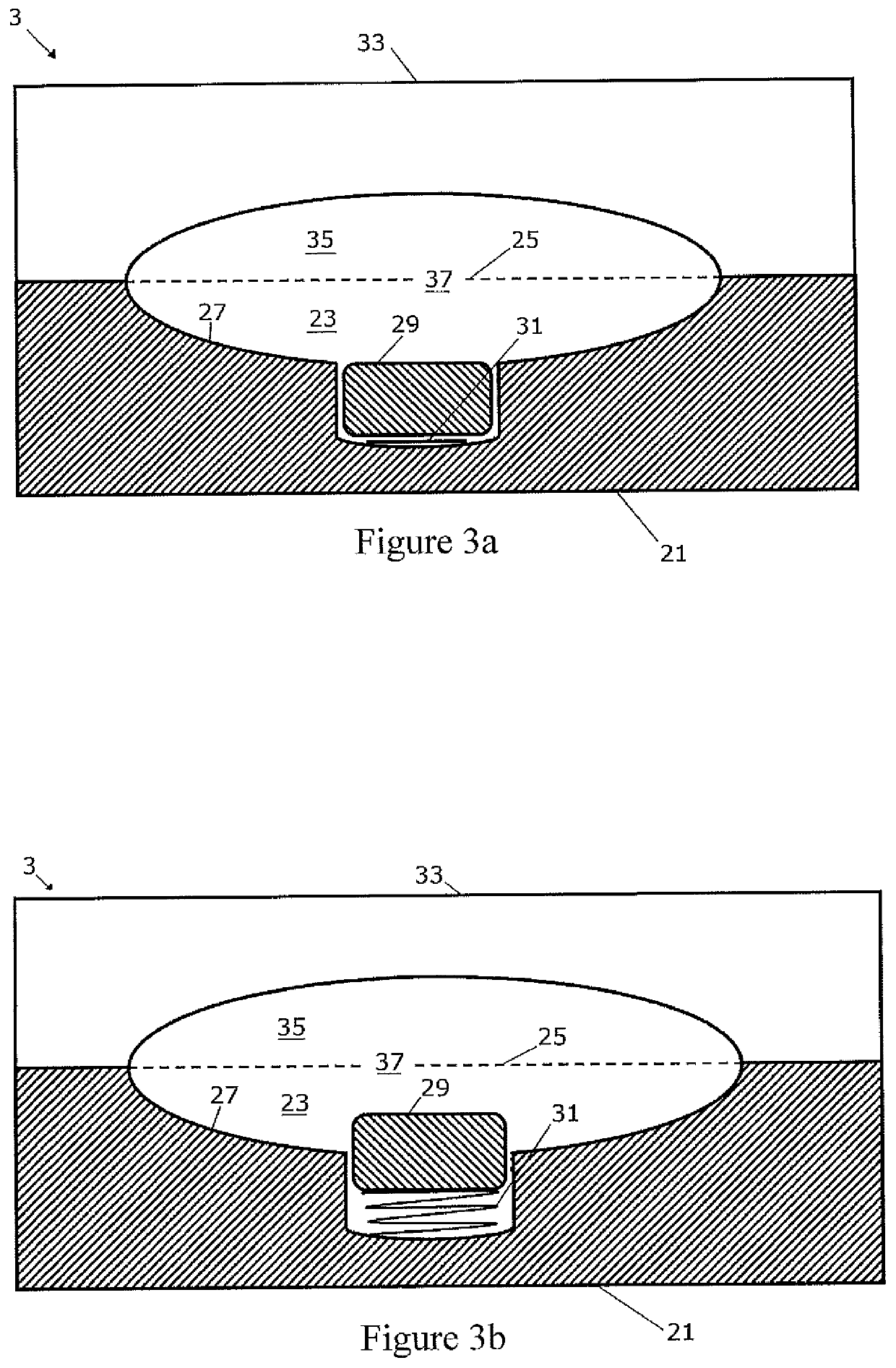

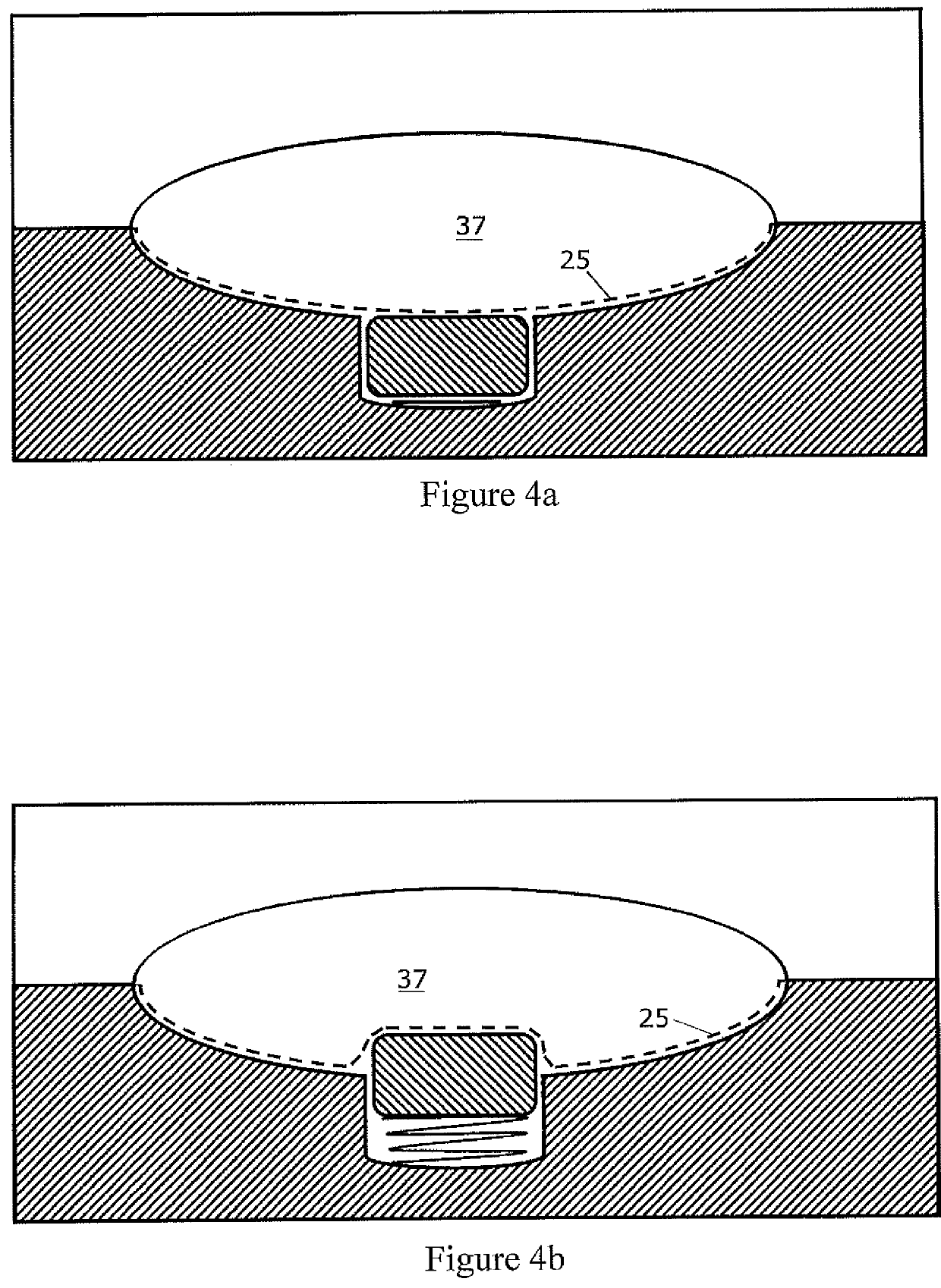

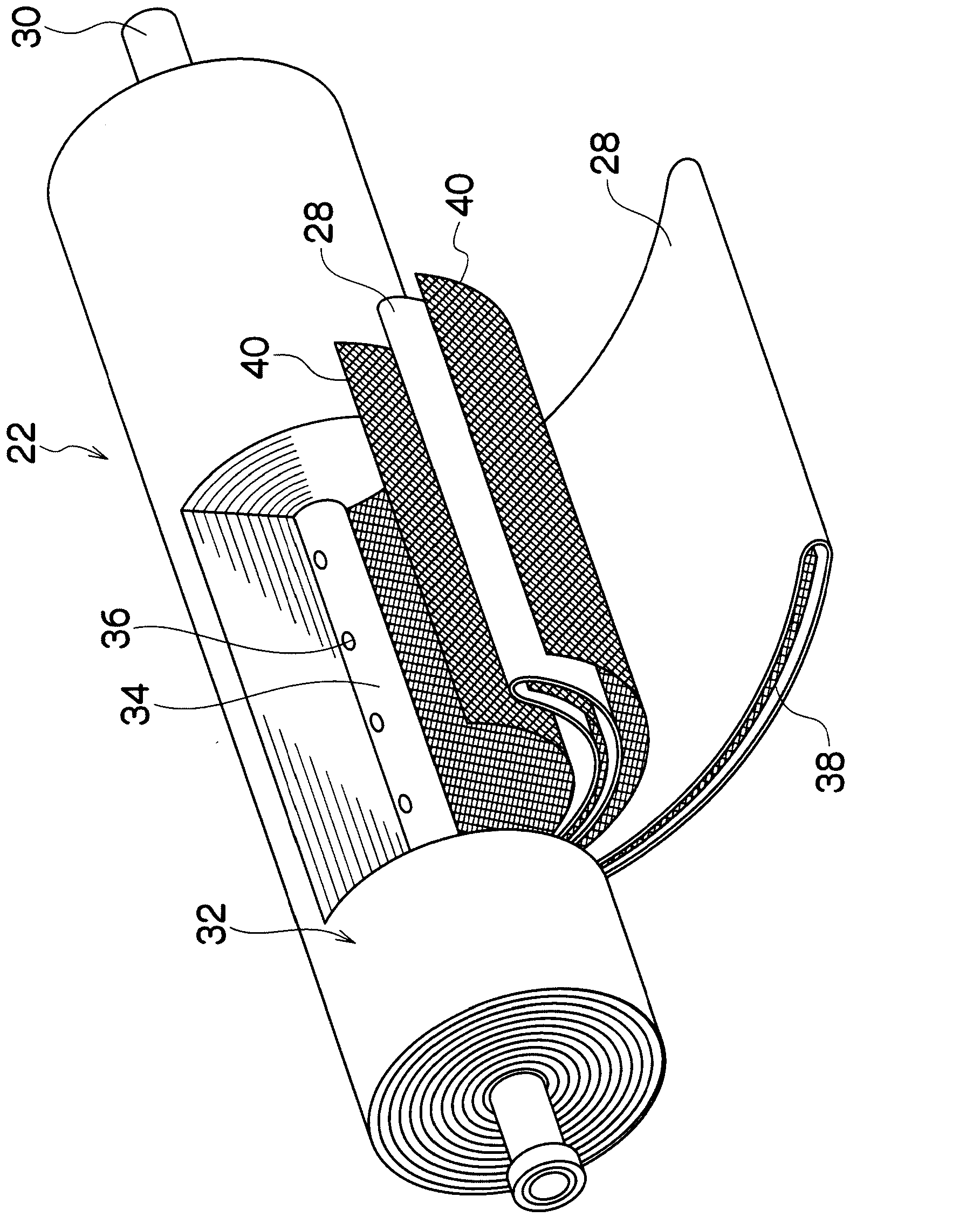

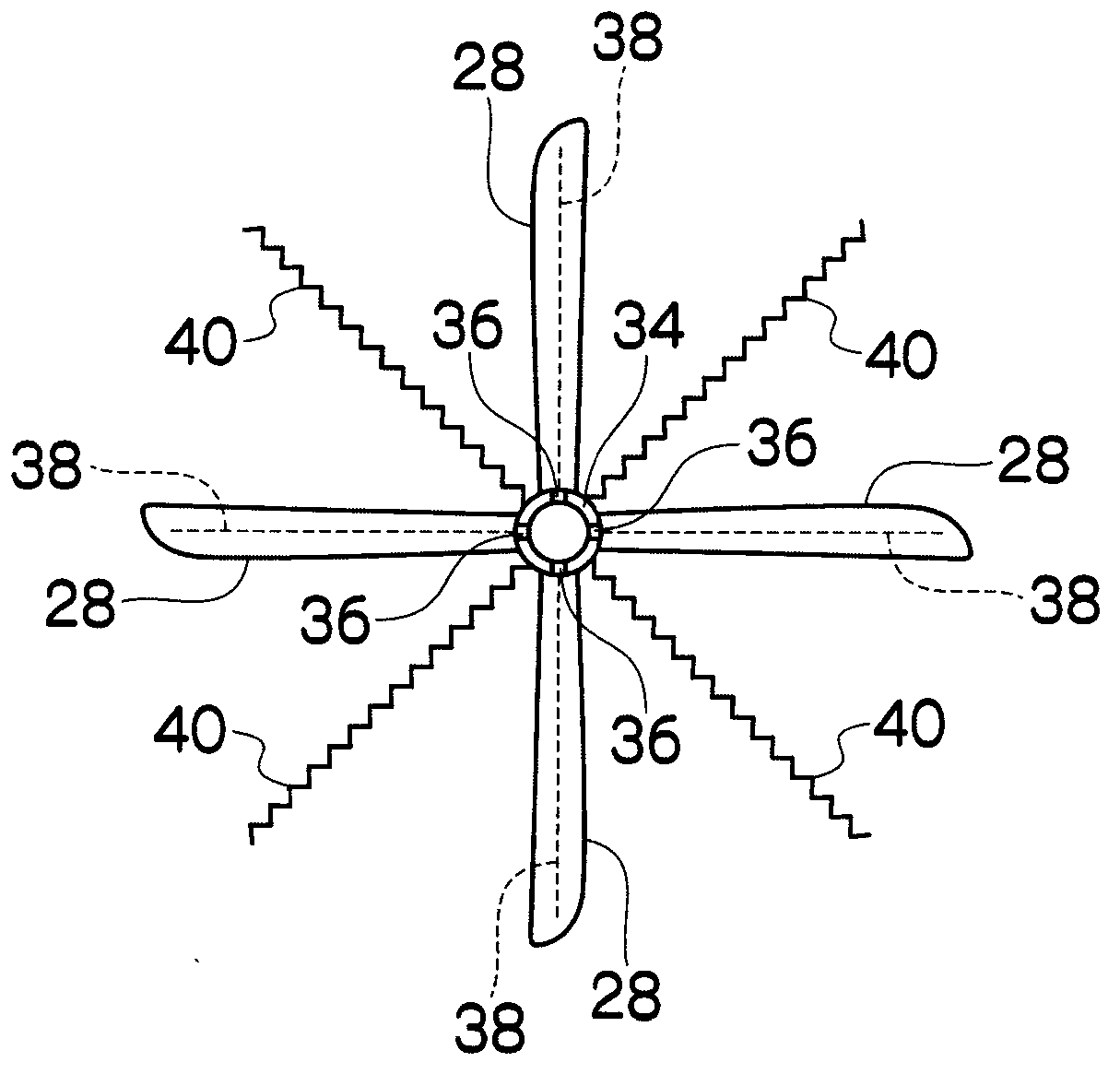

Filtration device suited for concentration of liquid samples, particularly biomolecules, and a method of concentrating, desalting, purifying and / or fractionating liquid samples. In certain embodiments the device includes a housing having a sample reservoir, and two substantially vertically oriented and spaced apart membranes disposed in the housing. An underdrain is associated with each membrane such that fluid passing through each membrane flows through a respective underdrain into a filtrate collection chamber. The fluid that does not pass through the membrane is collected in the retentate collection chamber, and can be recovered such as by a reverse spinning step, achieving recoveries greater than about 90%. The substantially vertical orientation of the membranes increases the available membrane area by at least 2.7 times the area available in a conventional filter device. The two-panel configuration also maintains more available membrane area in use during the last stages of filtration than a one-panel configuration.

Owner:MILLIPORE CORP

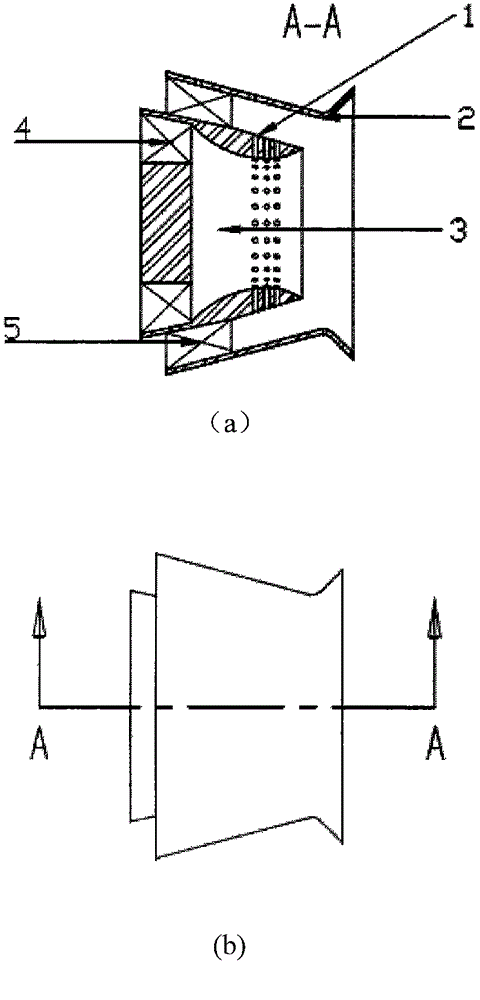

Venturi apparatus for strengthening liquid-membrane crushing effect

InactiveCN104676647AWell mixedImprove combustion efficiencyContinuous combustion chamberDual stageEngineering

The invention provides a Venturi apparatus for strengthening liquid-membrane crushing effect. Multiple rows of bosses or holes for turbulent flow are arranged in the area between a Venturi throat and a Venturi outlet and feature in disturbing flowing of the a liquid membrane and strengthening atomization effect. When the liquid membrane flows through the area at a high speed, the complete liquid membrane is disturbed, and liquid drops are atomized effectively and efficiently by reasonably arranging the holes or the bosses in position according to different dual-stage swirlers. The Venturi apparatus has the advantages that the atomization effect can be strengthened by slight improvement on the basis of a traditional Venturi, and practical value is achieved.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

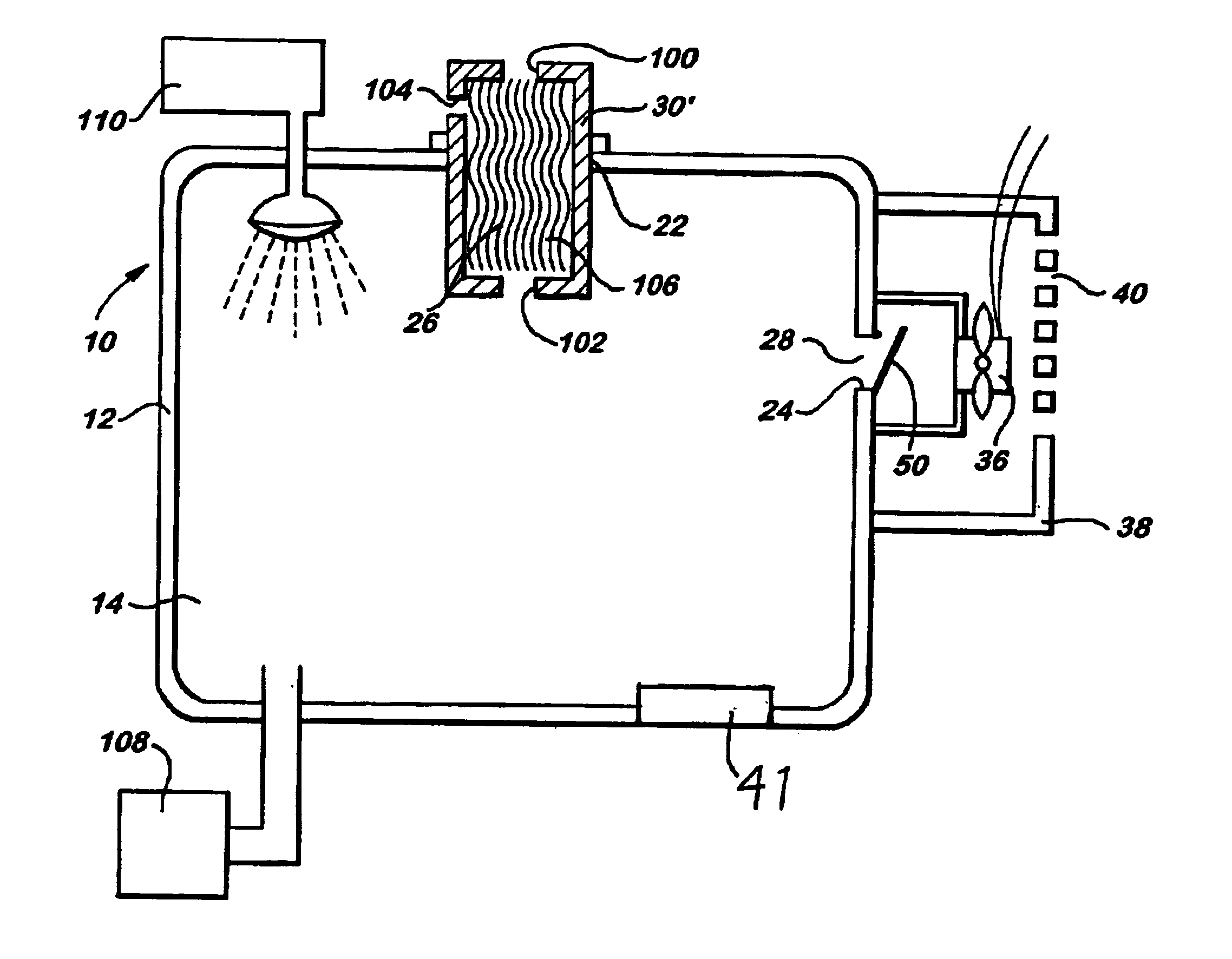

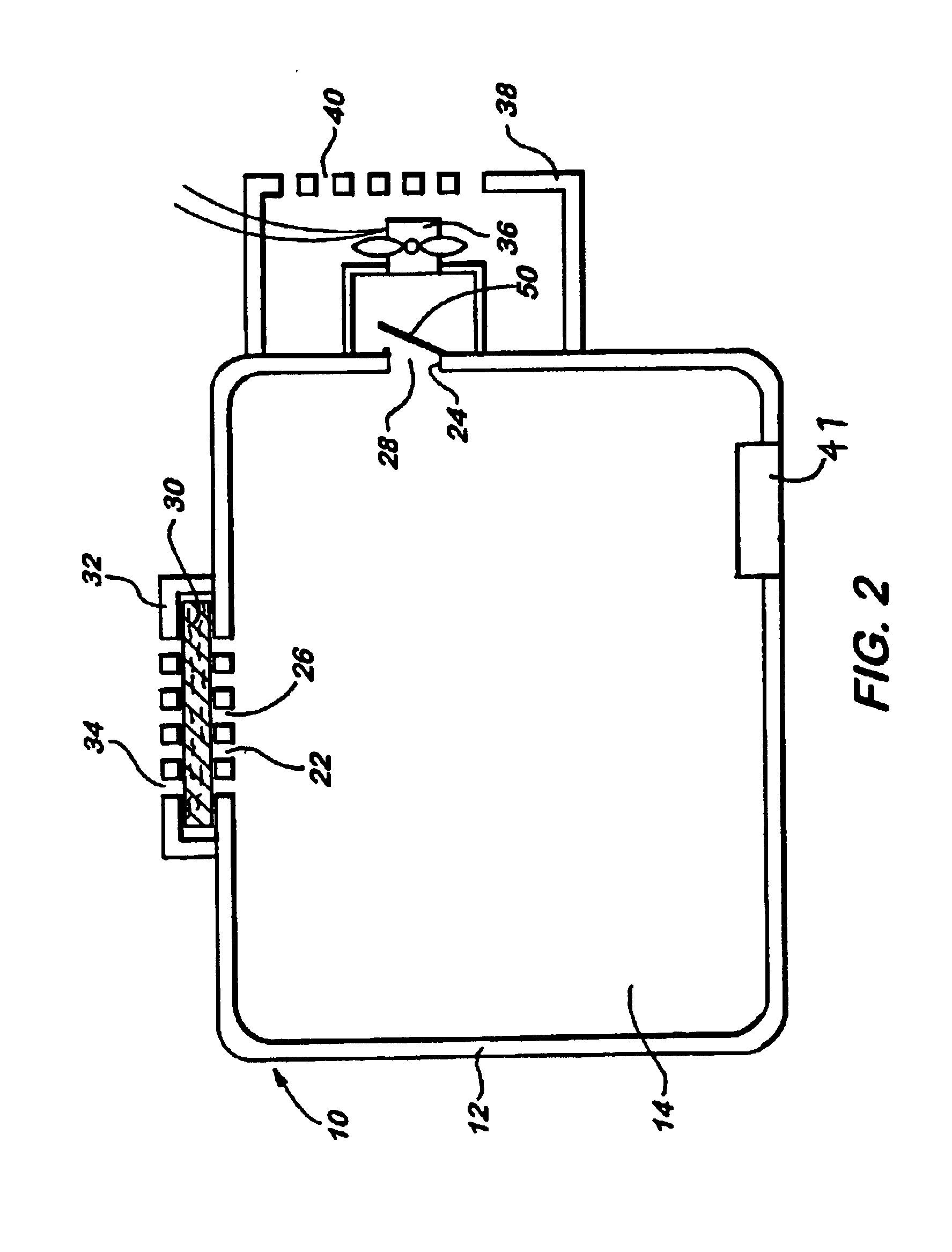

Storage device utilizing a differentially permeable membrane to control gaseous content

InactiveUS6840982B2Extended shelf lifeInhibit ripeningCombination devicesAuxillary pretreatmentProduct gasOxygen

A storage device for the preservation of oxidizable materials is provided. The storage device includes a storage chamber enclosing a storage space where oxidizable materials may be placed and a differentially permeable membrane. The differentially permeable membrane allows at least one selected gas to pass therethrough while inhibiting at least oxygen from passing therethrough. The differentially permeable membrane is in fluid communication with the storage chamber such that the at least one selected gas is allowed to pass through the differentially permeable membrane flows into the storage chamber. An air mover, preferably a compressor, feeds gases to the differentially permeable membrane. A cooling element is provided for cooling the temperature within the storage chamber below that of the ambient temperature. The level of oxygen within the storage chamber is thus reduced relative to the level of oxygen in the atmosphere.

Owner:AMERICAN MOXIE

Centrifugal filter

ActiveUS8357296B2Increase membrane areaReduce the overall heightSpecific gravity using centrifugal effectsUltrafiltrationMembrane flowChemistry

Filtration device suited for concentration of liquid samples, particularly biomolecules, and a method of concentrating, desalting, purifying and / or fractionating liquid samples. In certain embodiments the device includes a housing having a sample reservoir, and two substantially vertically oriented and spaced apart membranes disposed in the housing. An underdrain is associated with each membrane such that fluid passing through each membrane flows through a respective underdrain into a filtrate collection chamber. The fluid that does not pass through the membrane is collected in the retentate collection chamber, and can be recovered such as by a reverse spinning step, achieving recoveries greater than about 90%. The substantially vertical orientation of the membranes increases the available membrane area by at least 2.7 times the area available in a conventional filter device. The two-panel configuration also maintains more available membrane area in use during the last stages of filtration than a one-panel configuration.

Owner:MILLIPORE CORP

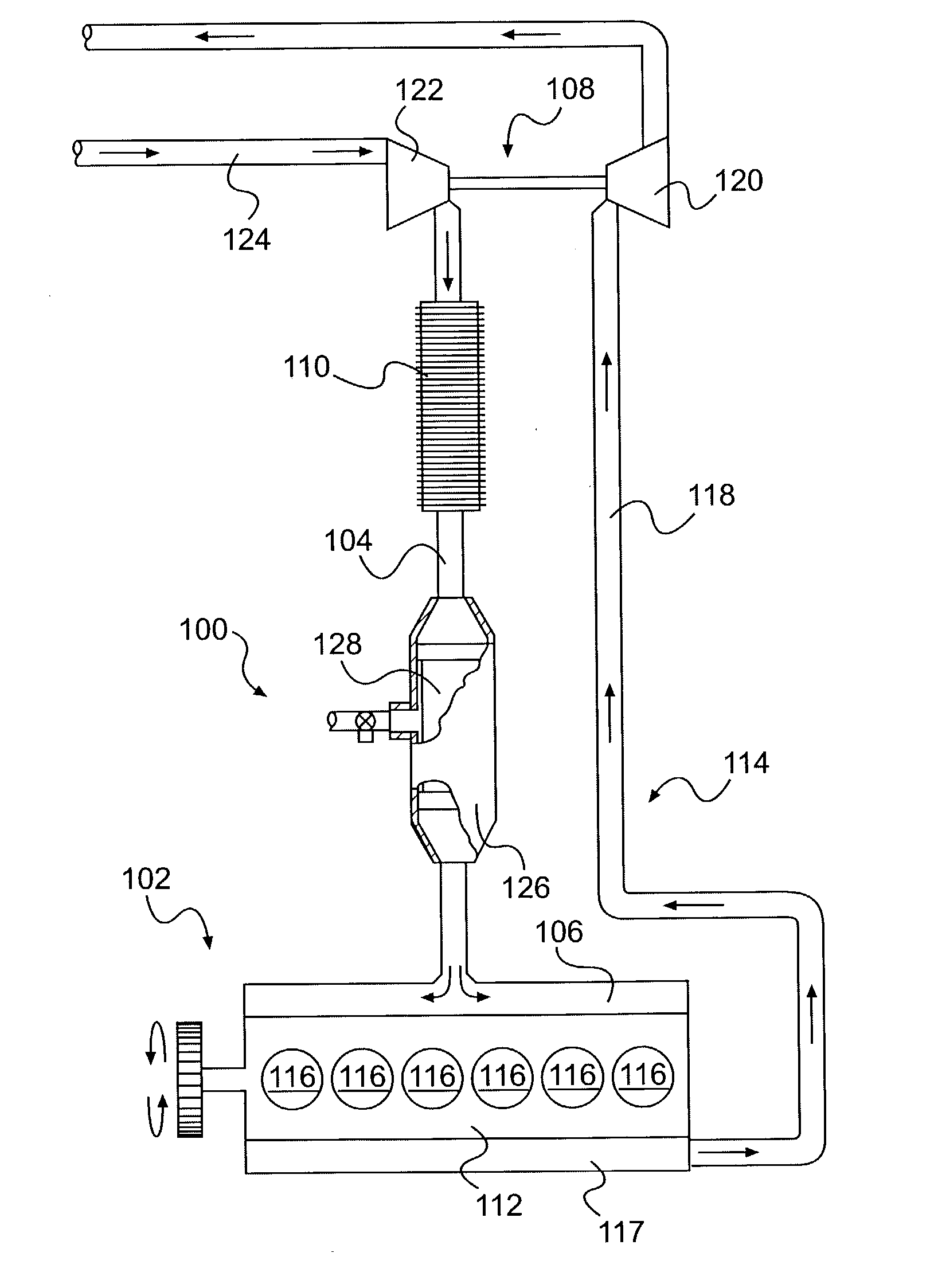

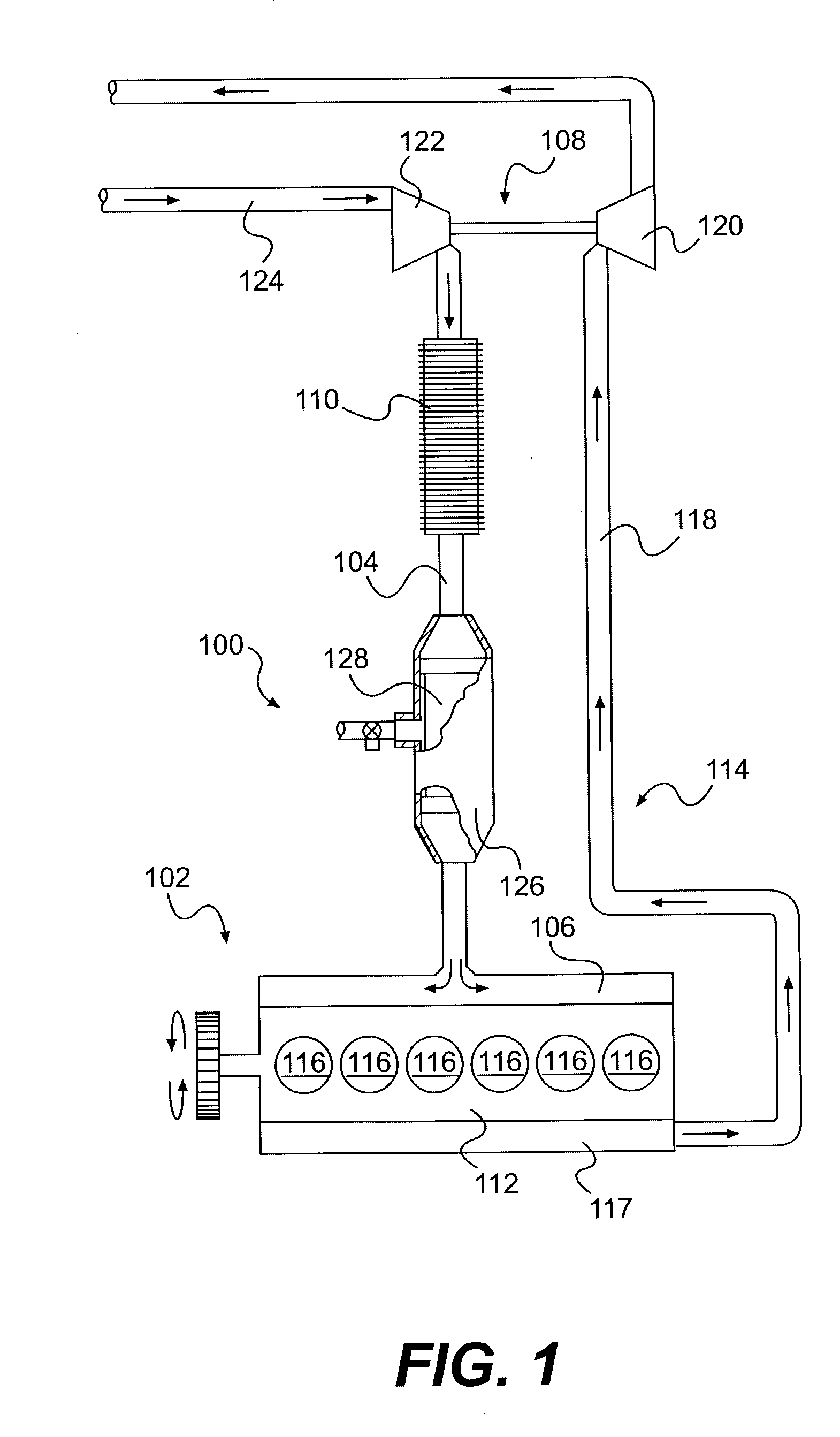

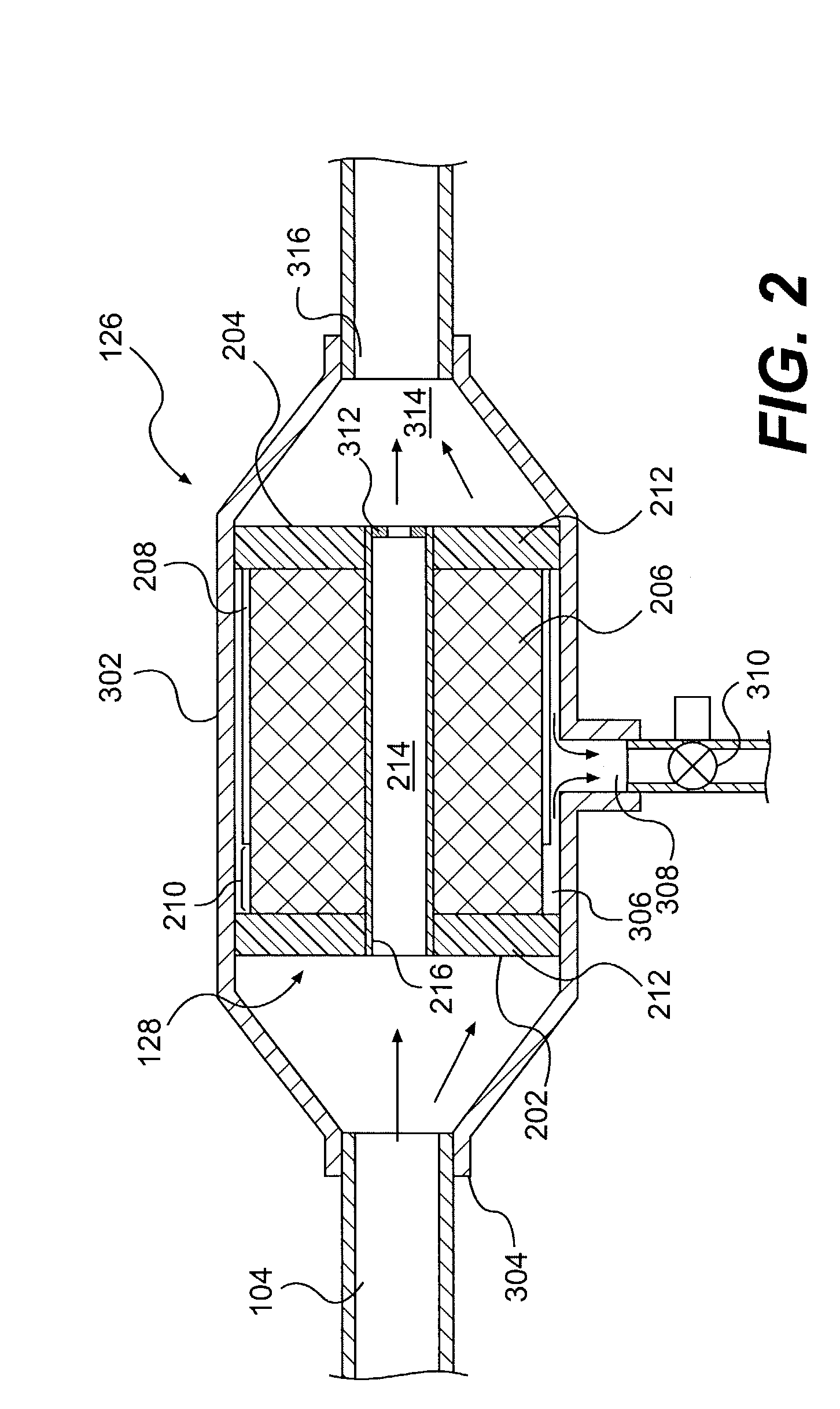

Separation membrane cartridge with bypass

A separation membrane cartridge is configured to separate an intake air flow of an engine into a membrane flow and a bypass flow. The membrane cartridge includes a fibrous section including a plurality of fibers extending from a first end of the membrane cartridge to a second end of the membrane cartridge. The fibers are configured to separate at least a portion of the membrane flow into a permeate flow and a retentate flow. The membrane cartridge also includes a bypass passage extending from the first end to the second end to allow passage of the bypass flow through the membrane cartridge.

Owner:CATERPILLAR INC

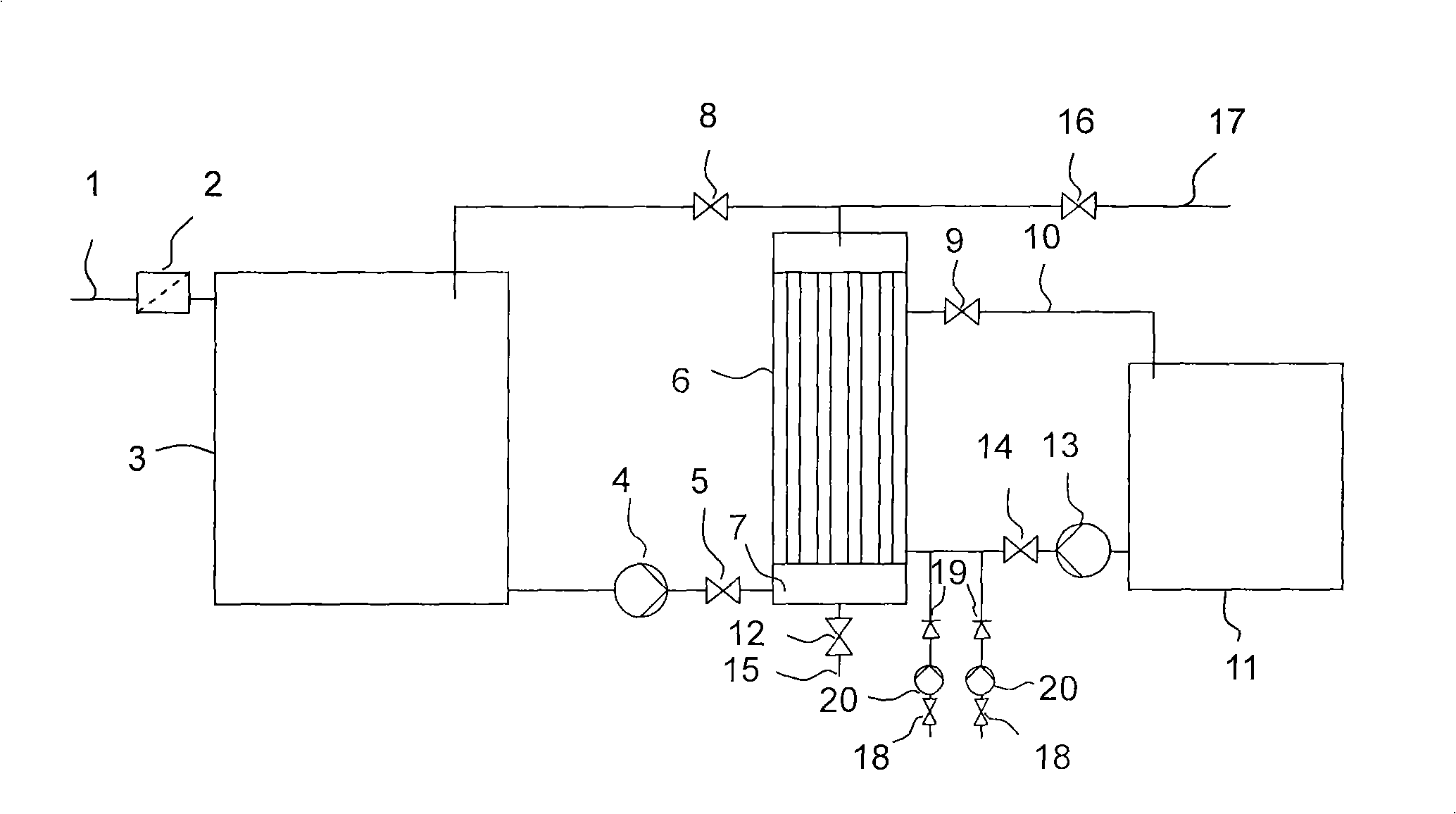

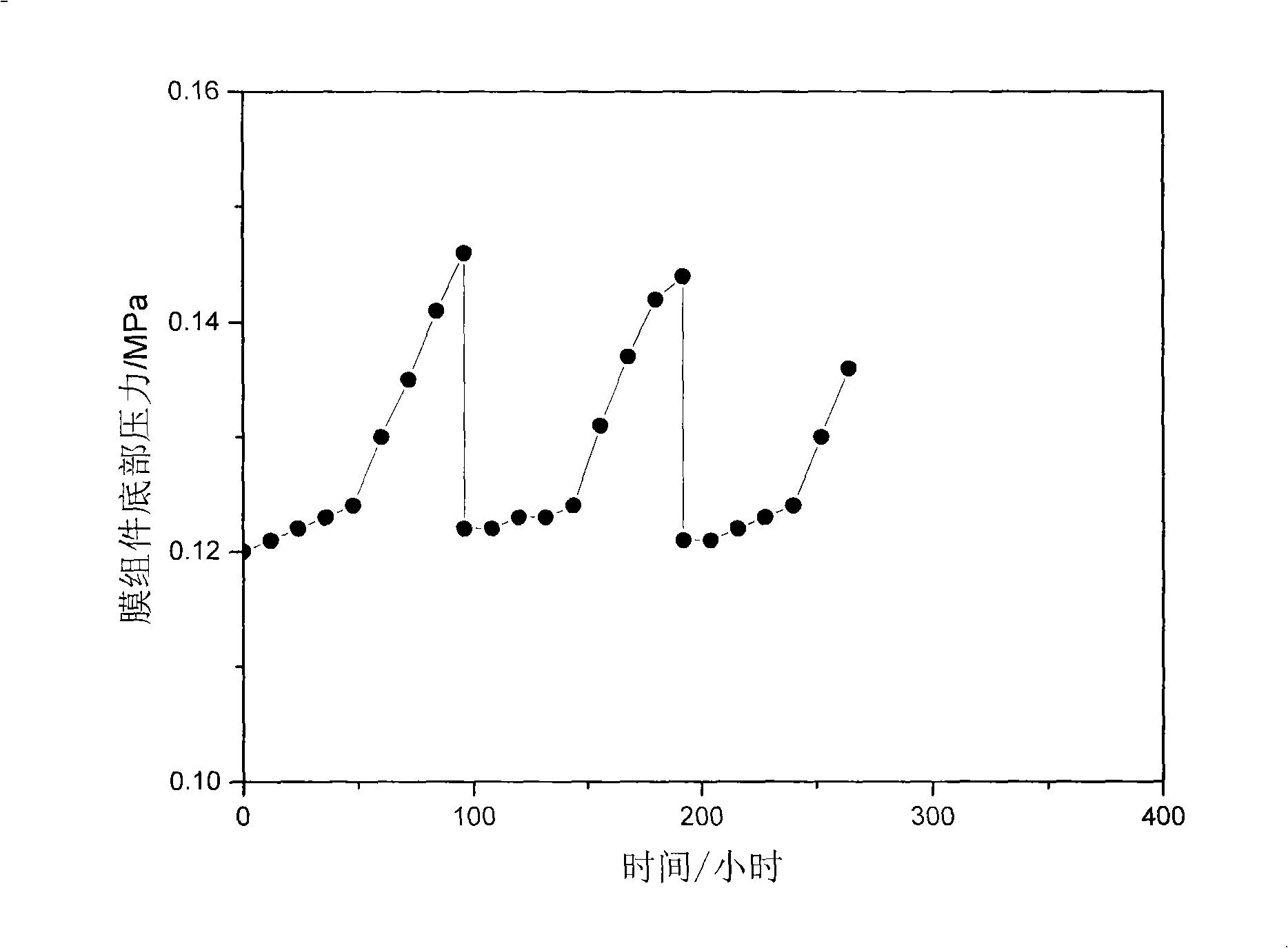

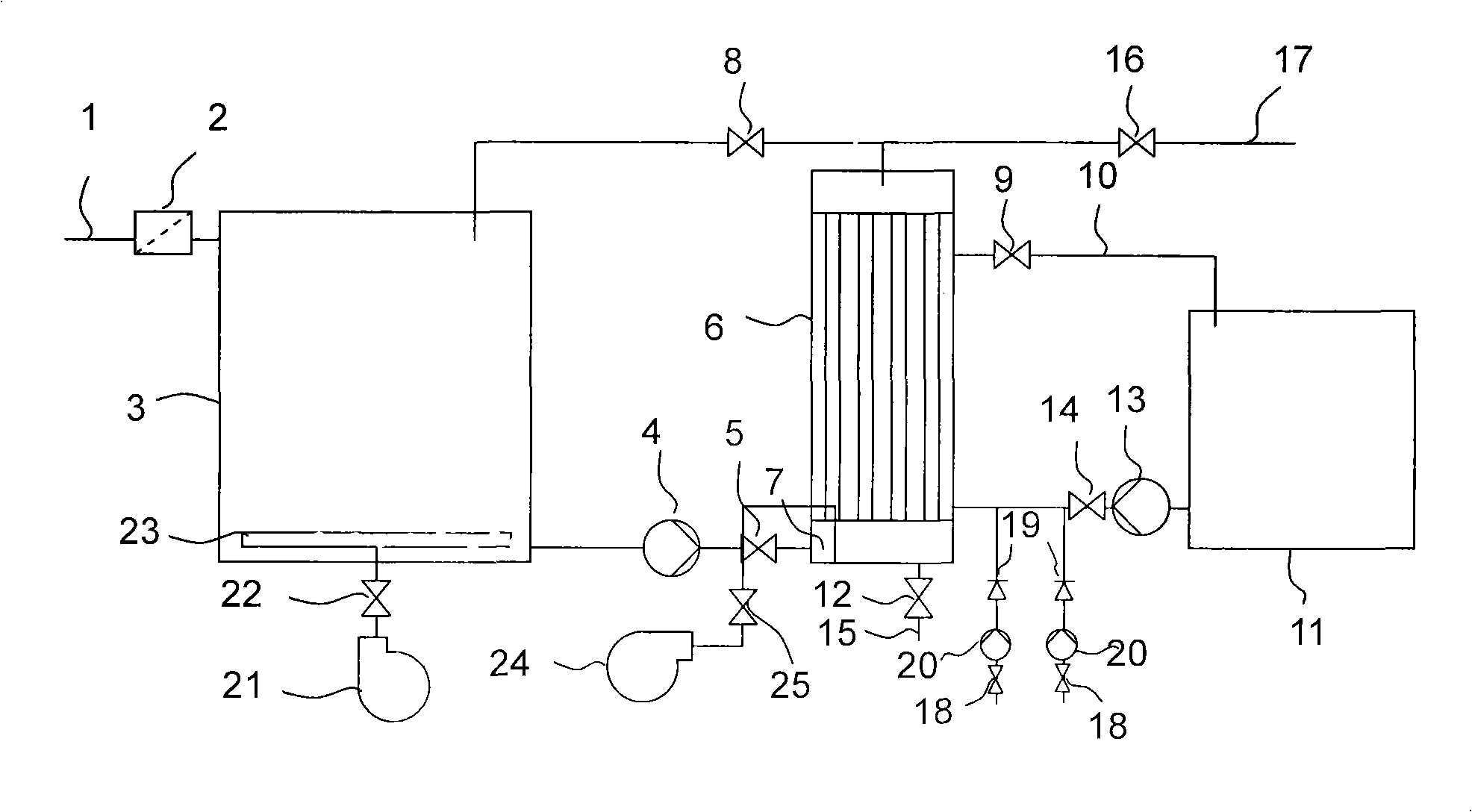

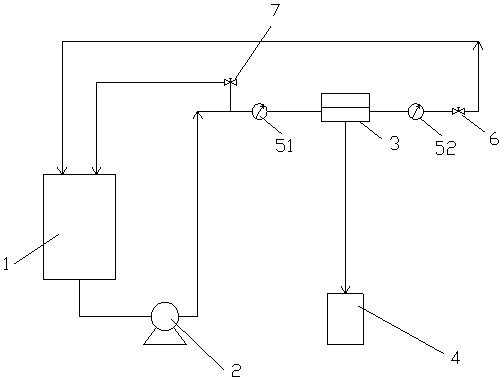

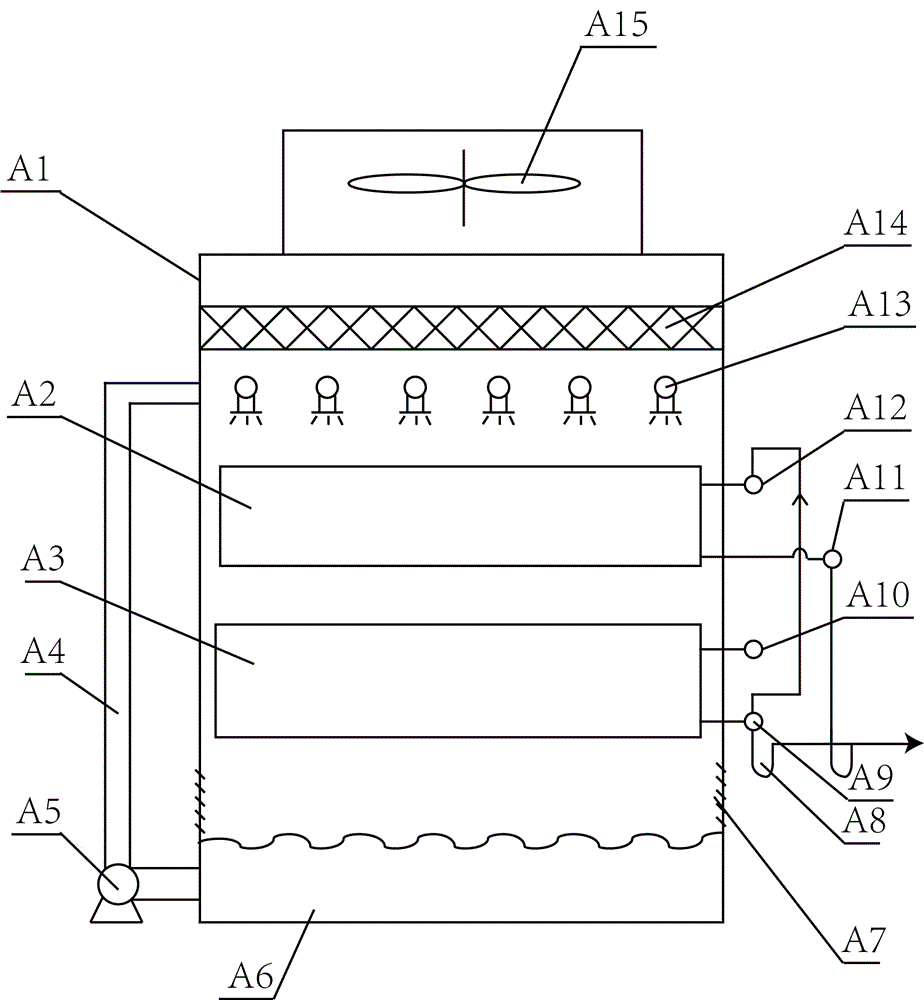

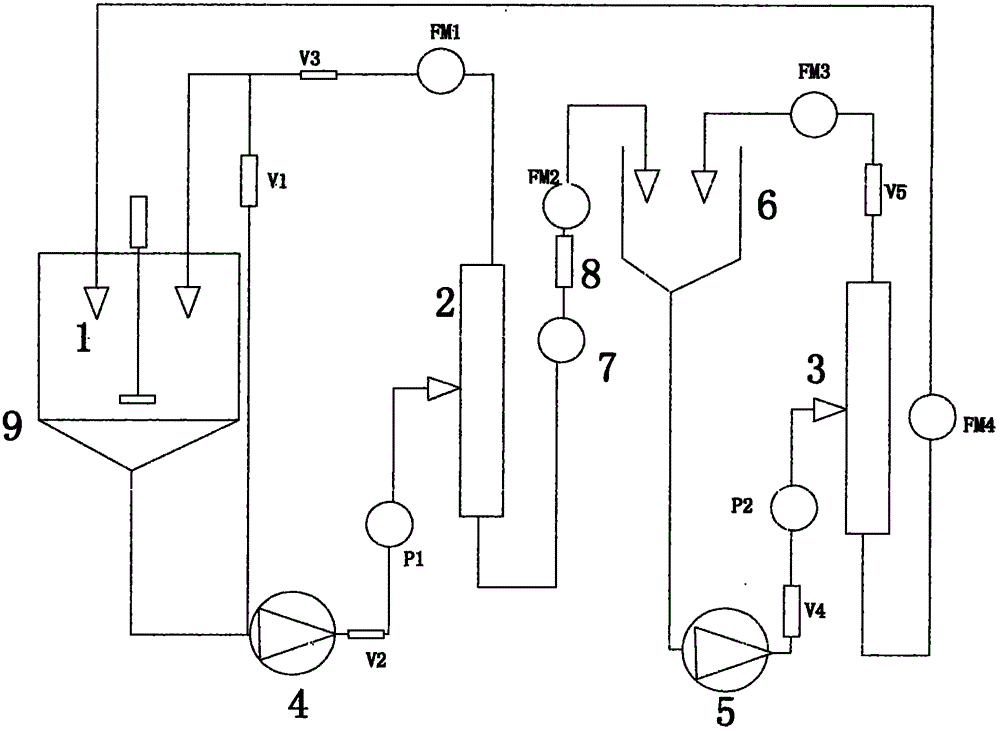

Cleaning method of porous separation membrane

InactiveCN101524625AAvoid cloggingExtend the period of stable operationSemi-permeable membranesSeparation technologyCleaning methods

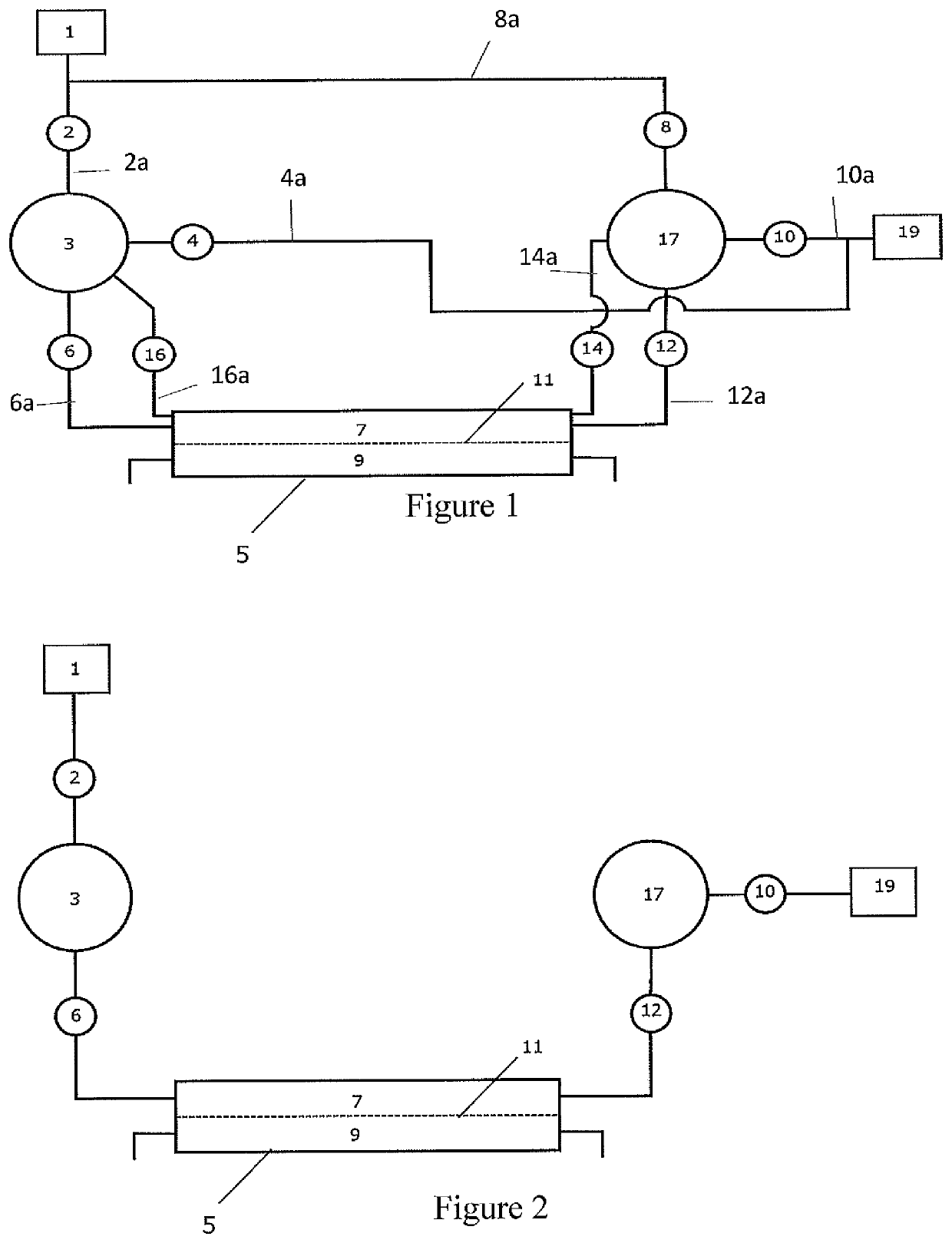

The invention relates to a cleaning method of a porous separation membrane, belonging to the technical field of membrane separation. The cleaning method of the porous separation membrane is characterized in that a membrane module bottom cleaning unit is applied in the membrane separation process of treating materials with high solid content, i.e., a start parameter is activated, a circulating pump (4) and valves (5), (9) and (14) are closed, and valves (8) and (12) are opened; liquid in a membrane module flows out of the membrane module under the action of the weight and flushes contaminants deposited at the bottom of the membrane module out of the membrane module; the start parameter can be one of a filter counter, a filter time interval, start pressure and a trans-membrane pressure difference or all or part of the same; and the membrane module bottom cleaning unit singly runs or is integrated to the backflushing process to enhance the cleaning effect. The invention has the advantages that the cleaning method effectively prevents a membrane flow passage and a flow passage entry from being blocked, prolongs the stable operation period of the membrane separation process and is widely suitable for a membrane biological reactor, and the like in the membrane separation process of treating the materials with high solid content.

Owner:DALIAN UNIV OF TECH

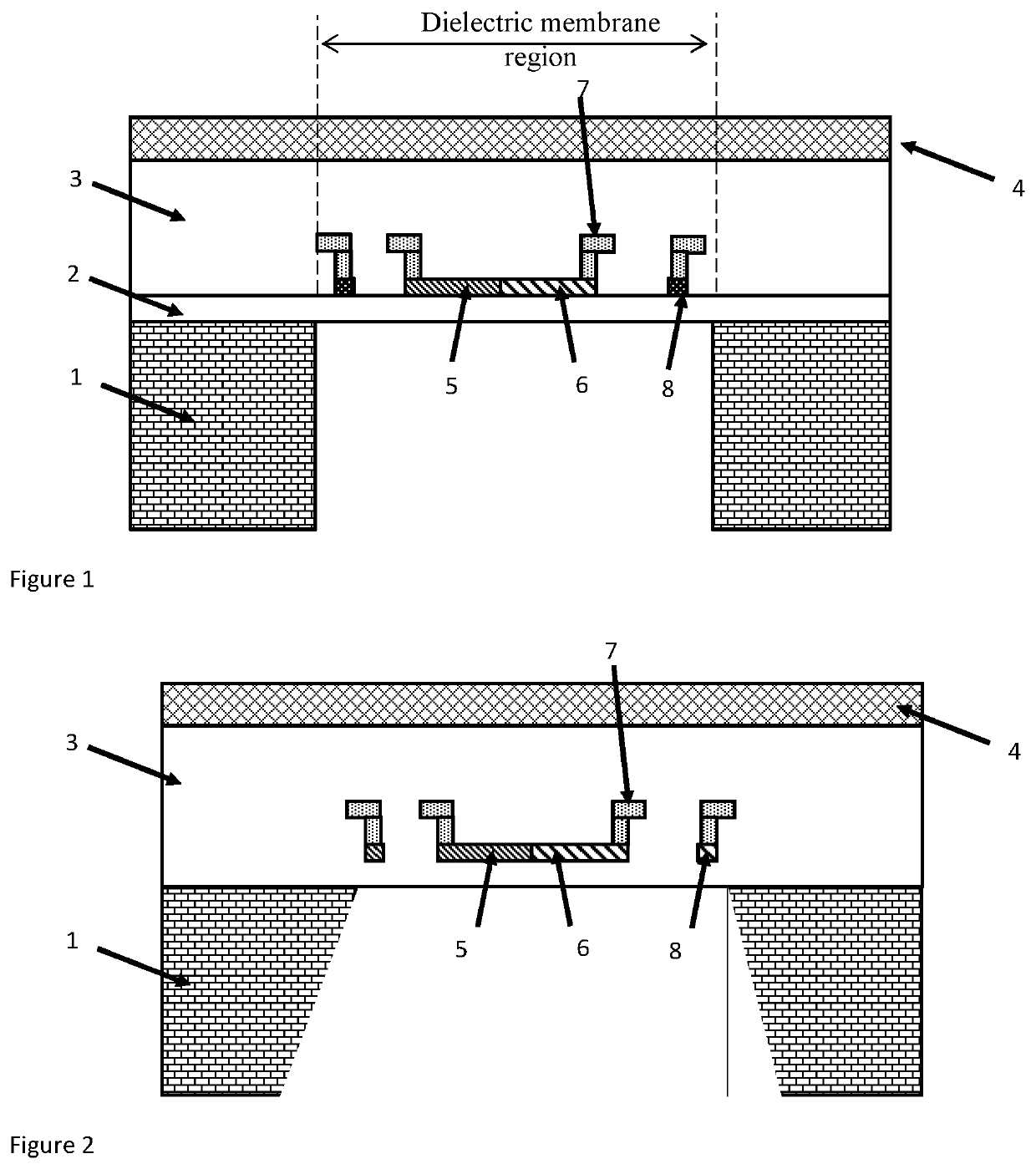

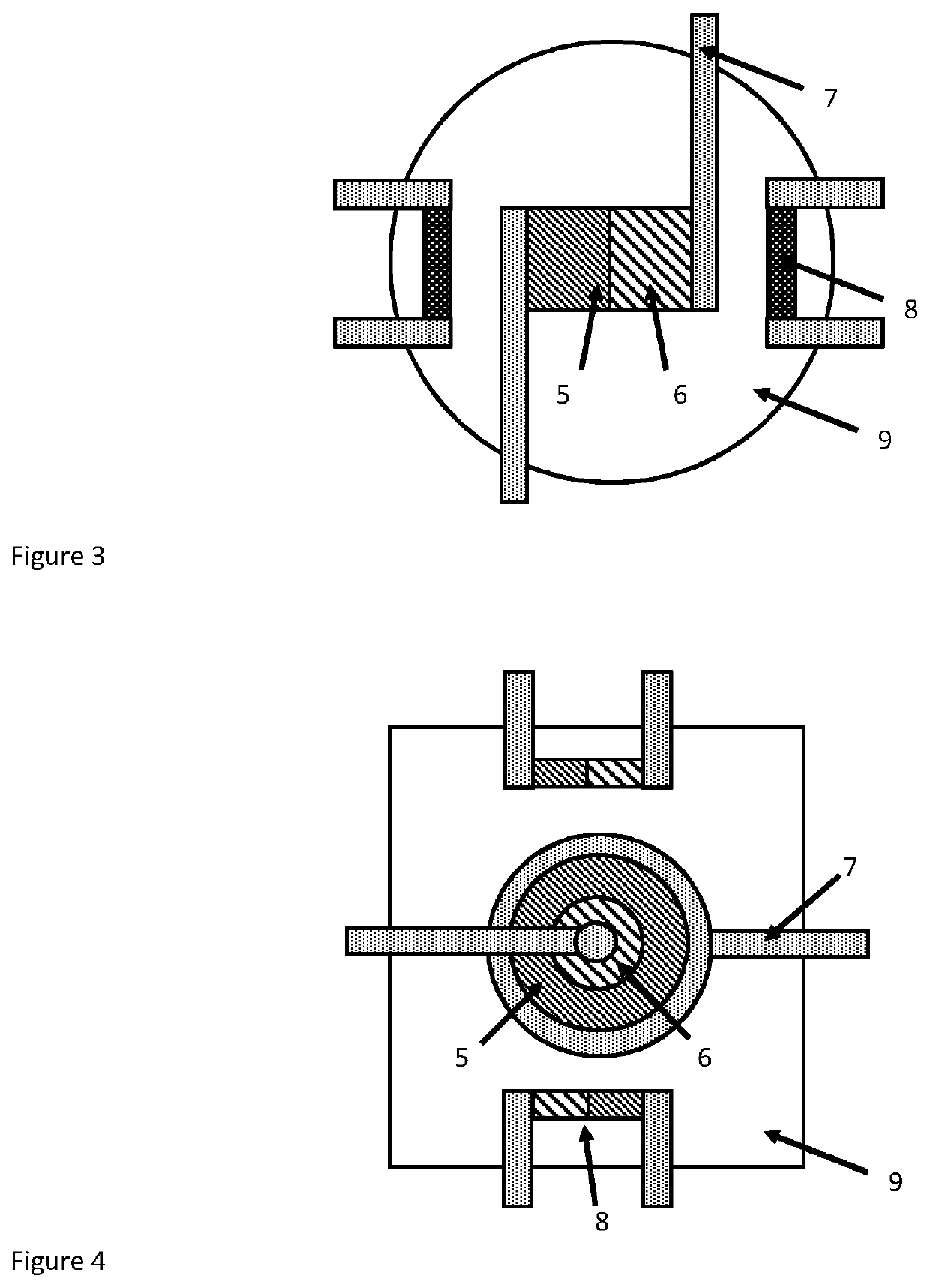

A single membrane flow-pressure sensing device

ActiveUS20200049539A1Improve sensor performanceImprove integrityThermoelectric device with peltier/seeback effectThermoelectric device manufacture/treatmentCMOSFlow transducer

We disclose herein a CMOS-based sensing device comprising a substrate comprising an etched portion, a first region located on the substrate, wherein the first region comprises a membrane region formed over an area of the etched portion of the substrate, a flow sensor formed within the membrane region and a pressure sensor formed within the membrane region.

Owner:FLUSSO LTD

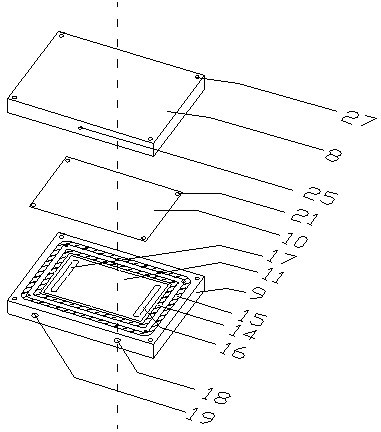

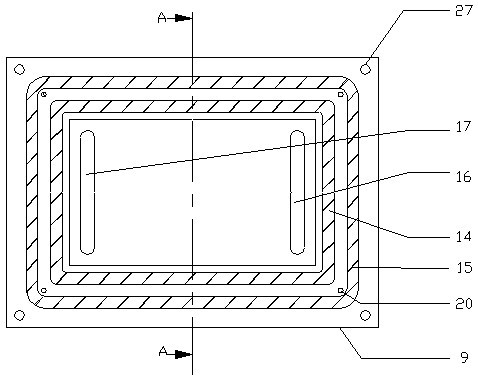

Experiment system and method for tangential filtration of high pressure resistant flat reverse osmosis (RO) membrane

The invention discloses an experiment system and an experiment method for tangential filtration of a high pressure resistant flat reverse osmosis (RO) membrane. The experiment system comprises a material feeding pot, a pressure pump, a flat RO membrane filtration device, a storage pot, a pressure gauge, an adjustment valve and a safety valve. The experiment method comprises the following steps of: (1) arranging an RO membrane between a top plate and a base plate, and fastening the top plate and the base plate together through bolts; (2) connecting equipment; (3) keeping the safety valve closed and the adjustment valve opened, and starting the high-pressure pump; (4) gradually turning down the opening degree of the adjustment valve, so that the liquid feeding pressure of the flat RO membrane filtration device is raised until material liquid flowing through the membrane flows out; and (5) finishing collecting the filtered material liquid, stopping the pump, and opening the adjustment valve and the safety valve to release pressure. The experiment system is feasible in a laboratory and can bear high pressure required by tangential filtration of the flat RO membrane so as to finish an RO filtration experiment; and according to the experiment method, the pollution situation of the membrane in each filtration stage can be observed conveniently, and researches on a pollution control technology is facilitated.

Owner:YANCHENG SILU INFORMATION TECH SERVICE CO LTD

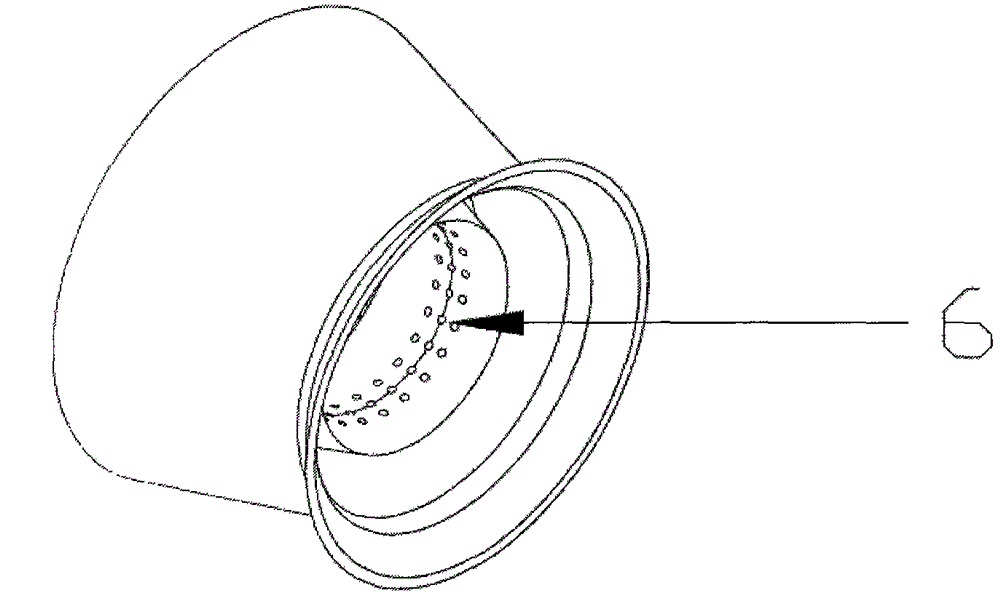

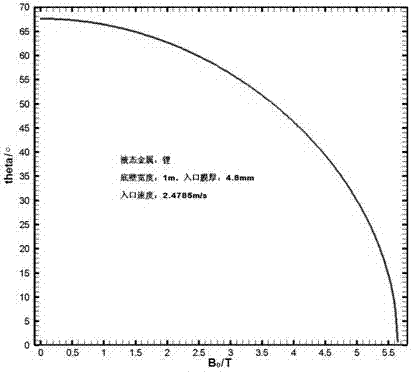

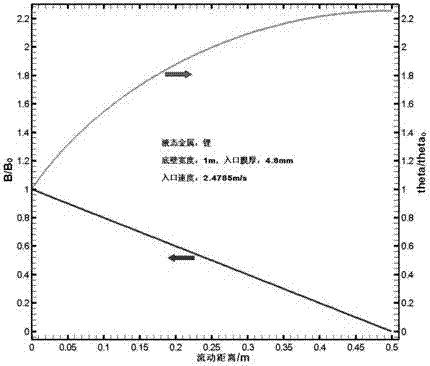

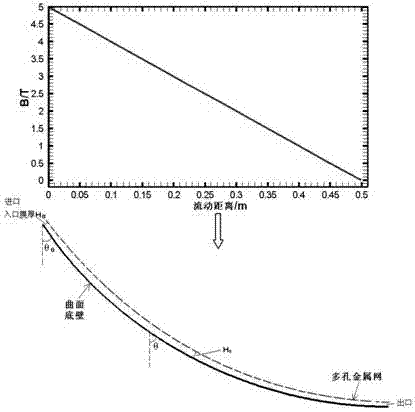

Method for establishing liquid curved membrane flow system of fusion reactor divertor flow stability

ActiveCN104751901APrevent splashAddressing Ferrofluid Instability IssuesNuclear energy generationMetal layered productsInstabilityLiquid metal

The invention relates to the technical field of liquid membrane flow control, and specifically relates to a method for establishing a liquid curved membrane flow system of fusion reactor divertor flow stability. The method comprises the following steps: step one, finding a relationship between a local magnetic field strength and an inclination angle under stable flow status of a liquid metal membrane, changing local inclination angles at different flow distances of the membrane flow to adapt variations of a gradient magnetic field, controlling a magnetofluid instability caused by a strong gradient magnetic field, i.e., utilizing the shape of a curved bottom wall to adapt the variations of the strong gradient magnetic field; step two, utilizing a method of fixing a metal screen above the curved bottom wall to ensure the liquid metal to flow along the curved bottom wall having a greater curvature variation; and step three, obtaining a stable membrane flow on the metal screen by regulating the sizes of metal meshes at different flow distances as well as regulating the distance between the metal screen and the curved bottom wall. By the method for establishing the liquid curved membrane flow system of the fusion reactor divertor flow stability, the instability of the magnetofluid of the liquid metal membrane flow under the strong gradient magnetic field environment having greater magnetic field strength variations is solved.

Owner:SOUTHWESTERN INST OF PHYSICS

Intermediate liquid discharge type efficient condensation system

The invention provides an intermediate liquid discharge type efficient condensation system. The rear end of a heat exchange tube of a front-stage heat exchanger is connected with a front-stage leading-out end header, the front end of the heat exchanger of a rear-stage heat exchanger is connected with a rear-stage inlet end header, and the rear end is connected with a rear-stage leading-out end header. The front-stage leading-out end header is connected with the rear-stage inlet end header through a pipeline so as to lead gas discharged by the front-stage heat exchanger into the rear-stage heat exchanger. The front-stage heat exchanger and the front-stage heat exchanger are located in the same box body or located in different boxes respectively, the lower end of the box body is provided with an air inlet, and the upper end of the box body is provided with an axial flow fan. According to the intermediate liquid discharge type efficient condensation system, intermediate liquid discharge is conducted at the tail end of the front-stage heat exchanger, the gas discharged by the front-stage heat exchanger is led into the rear-stage heat exchanger, flow of fluid in the heat exchange pipeline is facilitated, and the liquid membrane discharge speed in the heat exchange pipeline is increased, so that the heat exchange coefficient is increased greatly; due to the fact that the flow velocity of steam in the liquid membrane flow direction is increased, the liquid membrane can form the turbulent flow and is blown away from the wall surface, and thus the heat exchange coefficient is increased.

Owner:烟台珈群高效节能设备有限公司

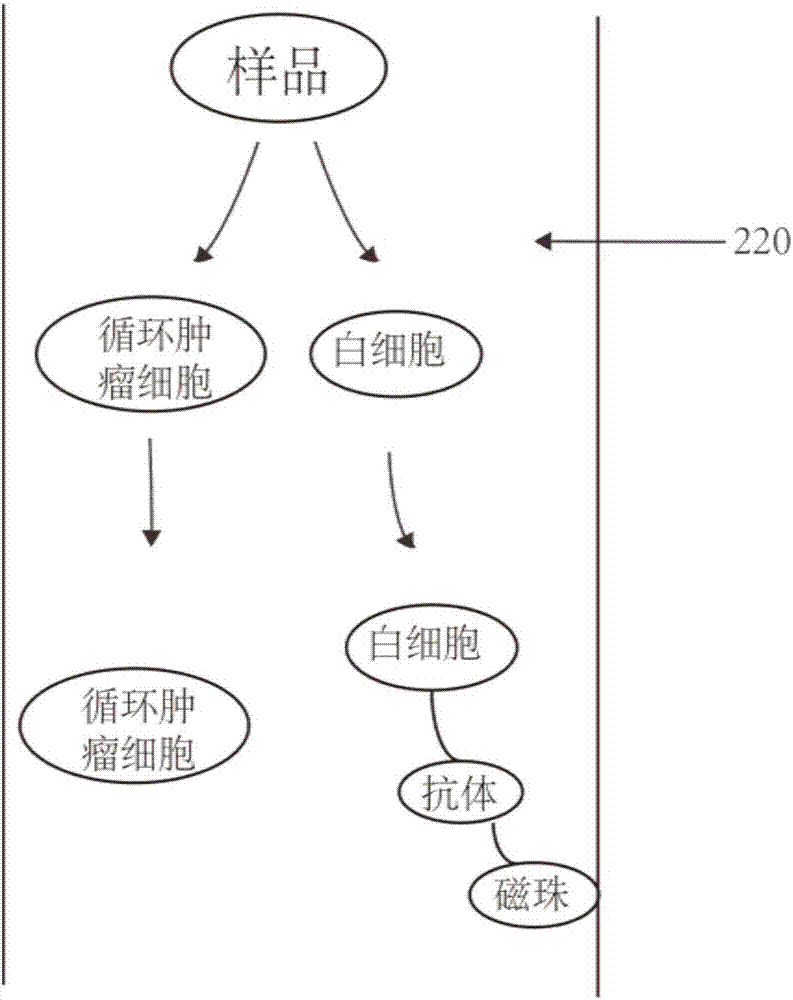

Circulation tumor cell separation and enrichment micro-fluidic chip and enrichment method thereof

ActiveCN107402303AEfficient fully automatic separation and purificationFast automatic separation and purificationMaterial analysisEnrichment methodsMagnetic bead

The invention discloses a circulation tumor cell separation and enrichment micro-fluidic chip and an enrichment method thereof. The circulation tumor cell separation and enrichment micro-fluidic chip comprises a sample treatment chamber and a separation purification chamber, wherein the separation purification chamber comprises a micro channel, a magnetic field adsorption part, a magnetic collection chamber, a cell collection chamber and a filtering membrane; a sub-channel is formed inside the micro channel; the magnetic field adsorption part is arranged on the inner wall of the sub-channel; one end of the micro channel is communicated with the sample treatment chamber; the other end of the micro channel is communicated with the magnetic collection chamber and the cell collection chamber in sequence; the magnetic collection chamber is used for collecting magnetic beads which are not adsorbed by the inner wall of the sub-channel; the filtering membrane which is capable of retaining circulation tumor cells is arranged inside the cell collection chamber; and a liquid outlet from which a liquid filtered by the filtering membrane flows out is formed in the cell collection chamber. The circulation tumor cell separation and enrichment micro-fluidic chip is efficient, rapid, good in specificity and high in accuracy.

Owner:SUREXAM BIO TECH

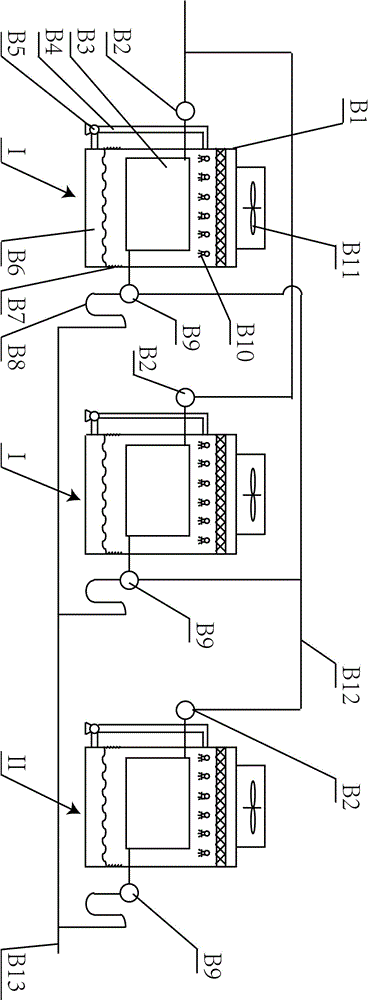

Physical simulation experiment method and experiment device for evaluating matching relation of chemical oil-displacing agent and reservoir permeability

ActiveCN104005744AQuickly find permeability conditionsSimulation is accurateFluid removalMicropore FilterSoftware system

The invention discloses a physical simulation experiment method and a series micropore filter membrane flow experiment device for evaluating the matching relation of a chemical oil-displacing agent and the reservoir permeability. The series micropore filter membrane flow experiment device comprises a pressure difference control and measurement assembly, a module combined type series filter membrane unit assembly and a data real-time collecting and processing assembly. The pressure difference control and measurement assembly comprises an air oil-less compressor, a stabilized pressure pump and a pressure sensor. The module combined type series filter membrane unit assembly comprises a liquid storage device and a micropore filter membrane mounting device. The data real-time collecting and processing assembly comprises a balance and a weight and pressure measuring software system, wherein the balance and the weight and pressure measuring software system are connected with a computer. The weight and pressure measuring software system is used for recording the size of pressure and the mass of flow-out liquid and collecting data. The micropore filter membrane mounting device is used for mounting micropore filter membranes with the diameters of 47 mm. The pressure difference control and measurement assembly, the module combined type series filter membrane unit assembly and the data real-time collecting and processing assembly are connected through hoses and are used for controlling series experiments through valves.

Owner:SOUTHWEST PETROLEUM UNIV

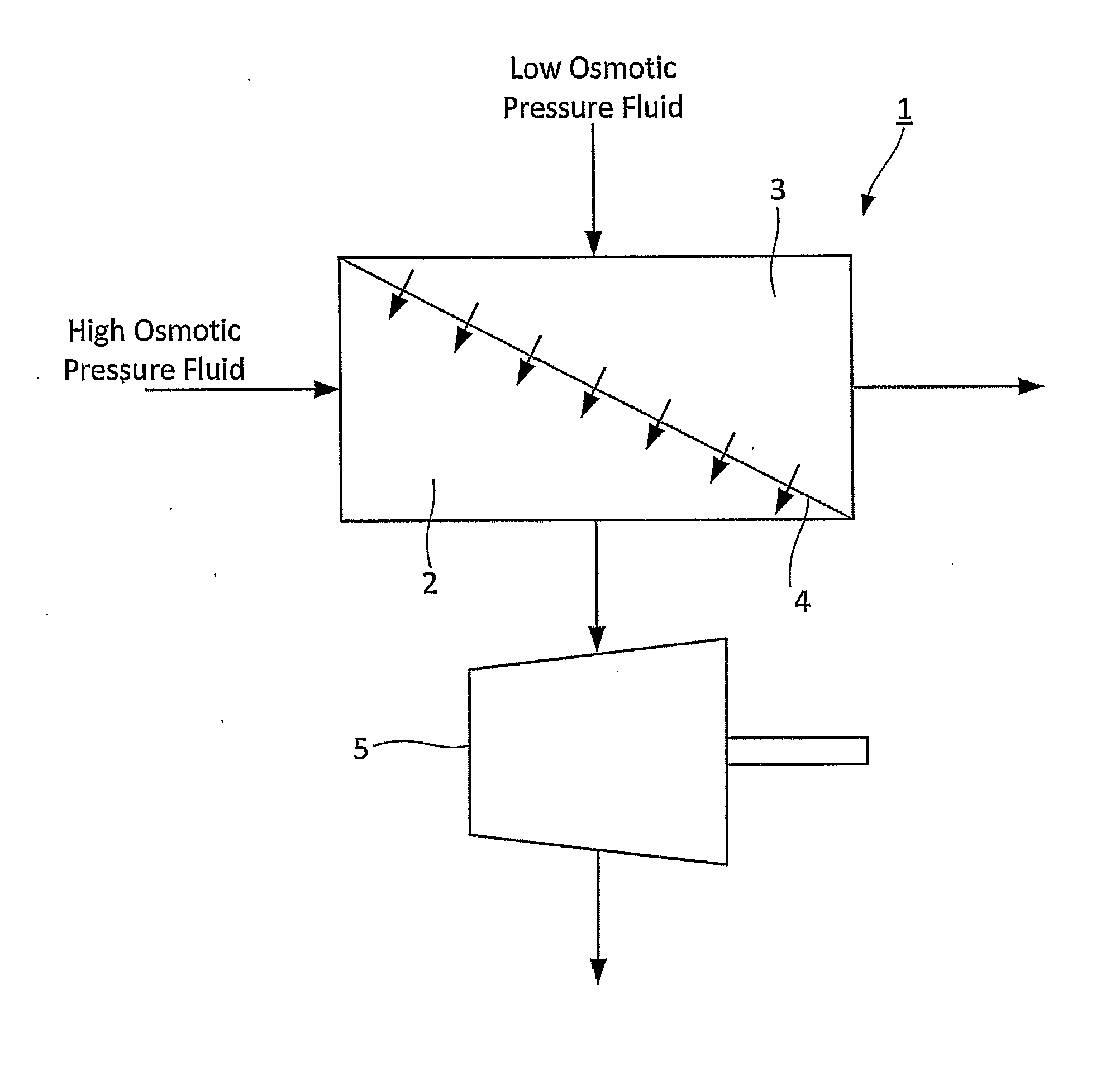

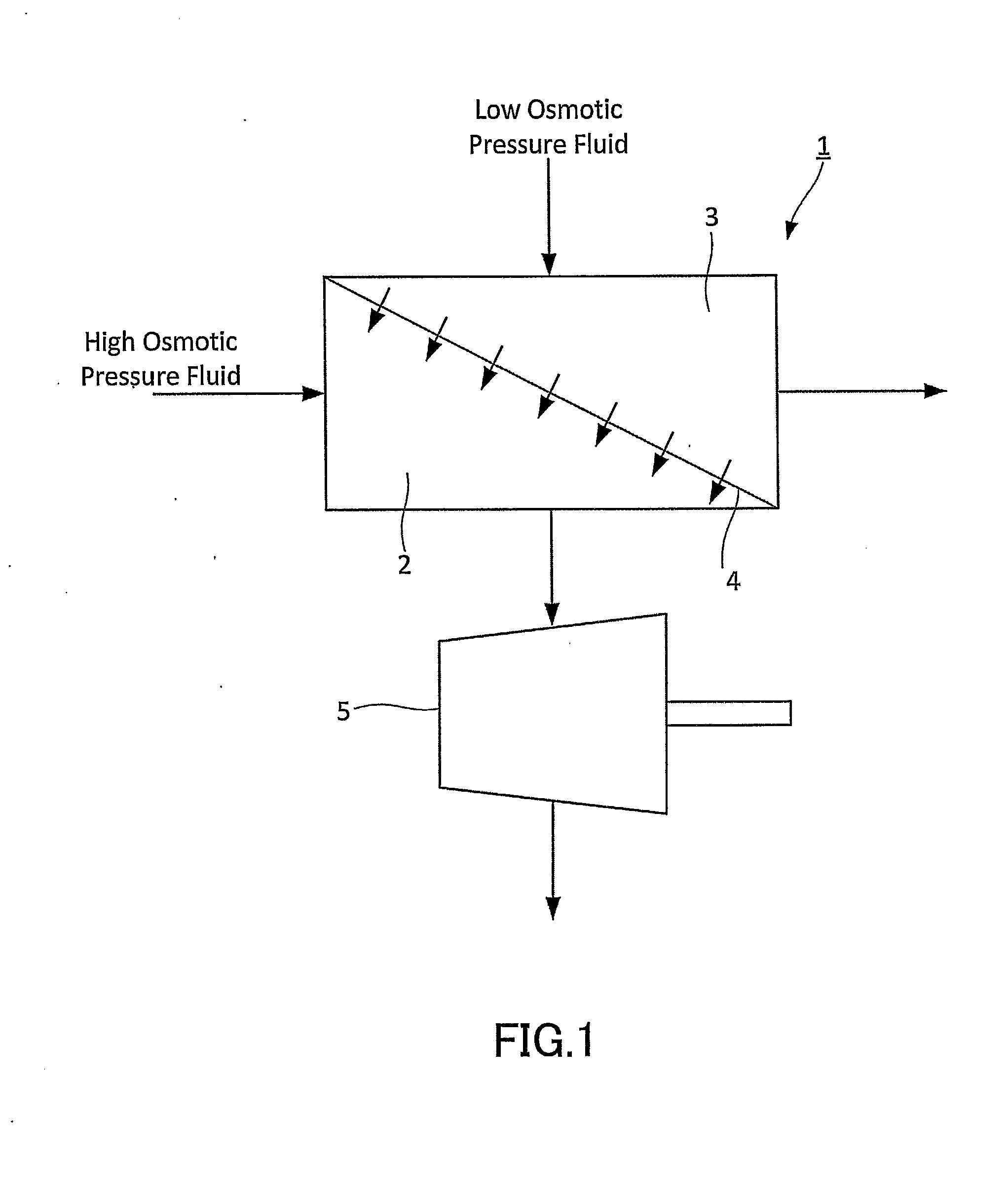

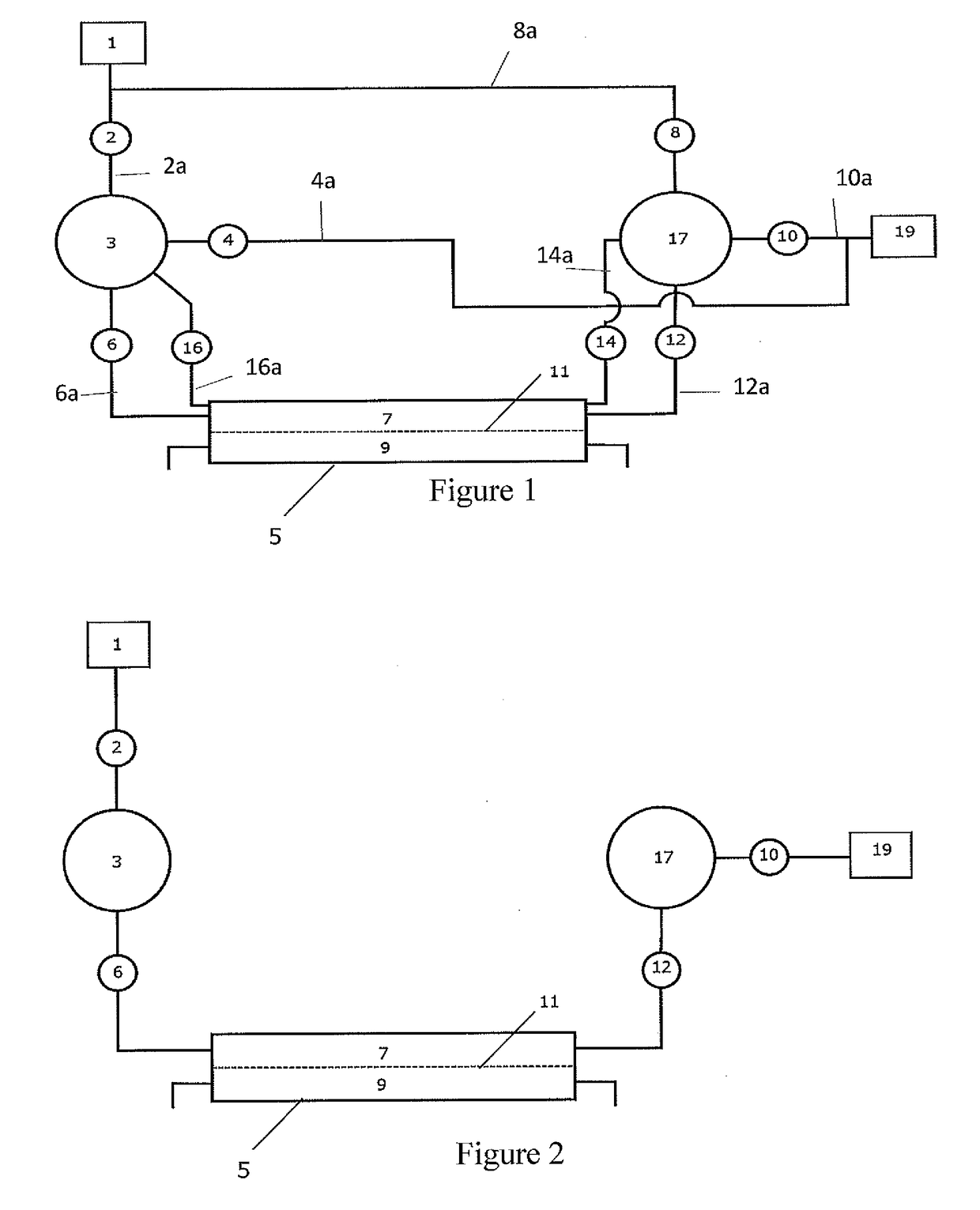

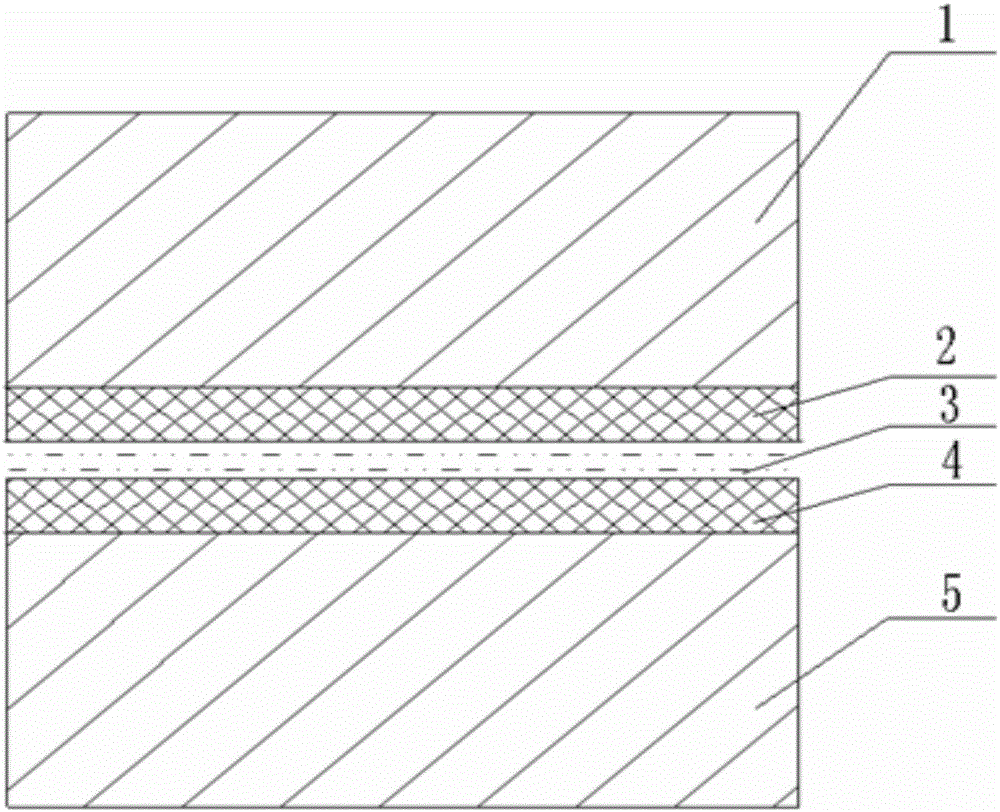

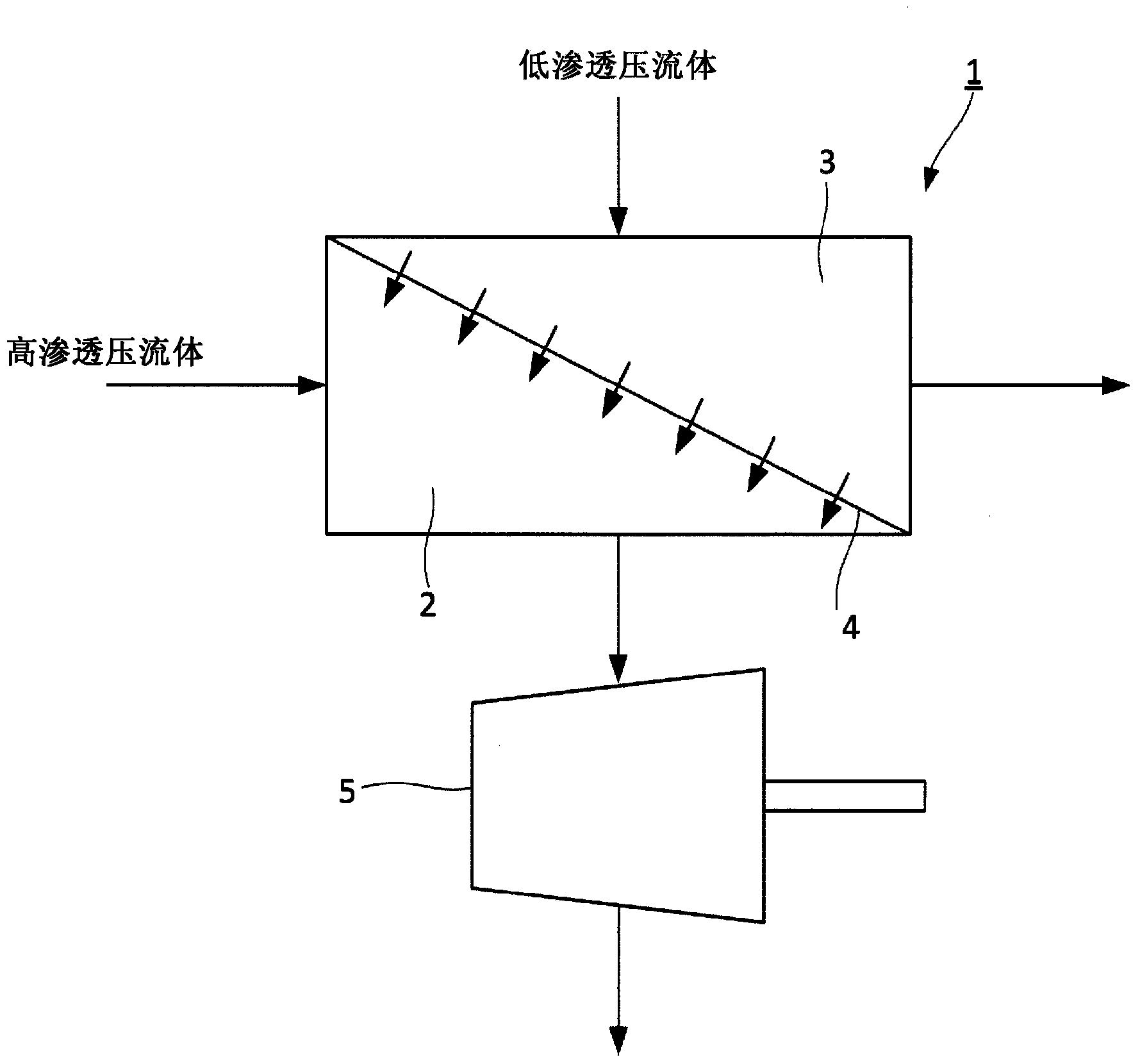

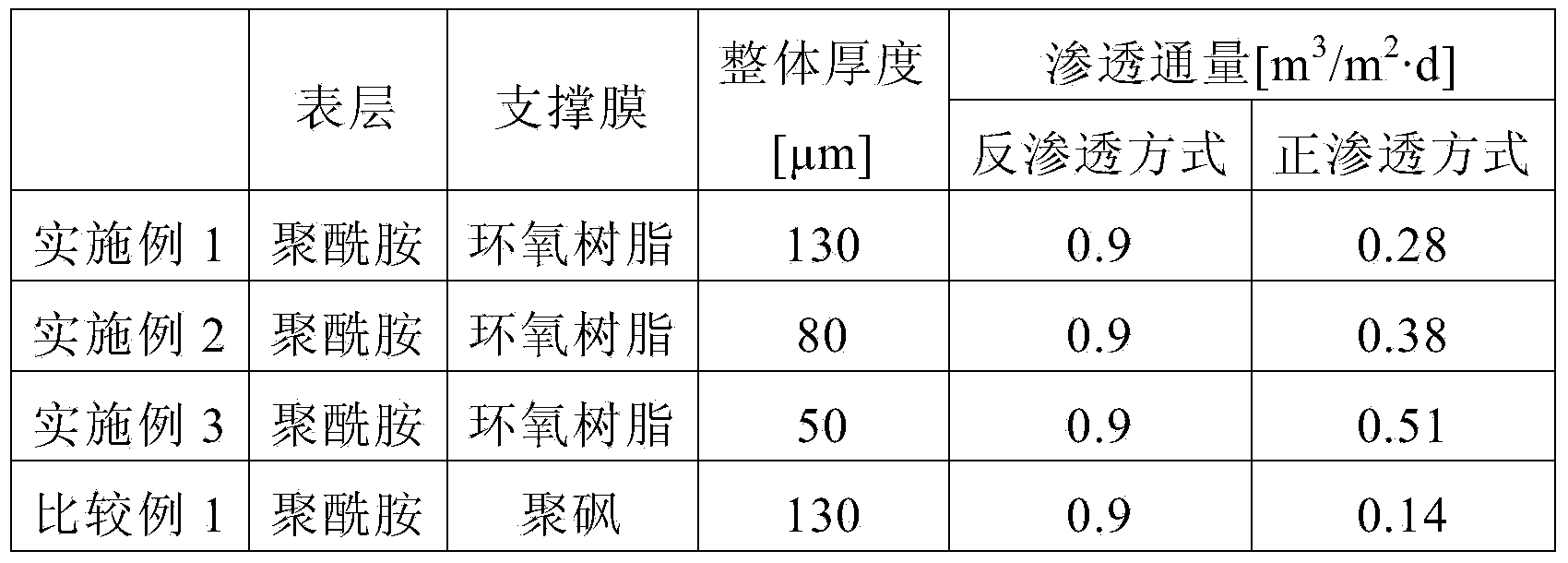

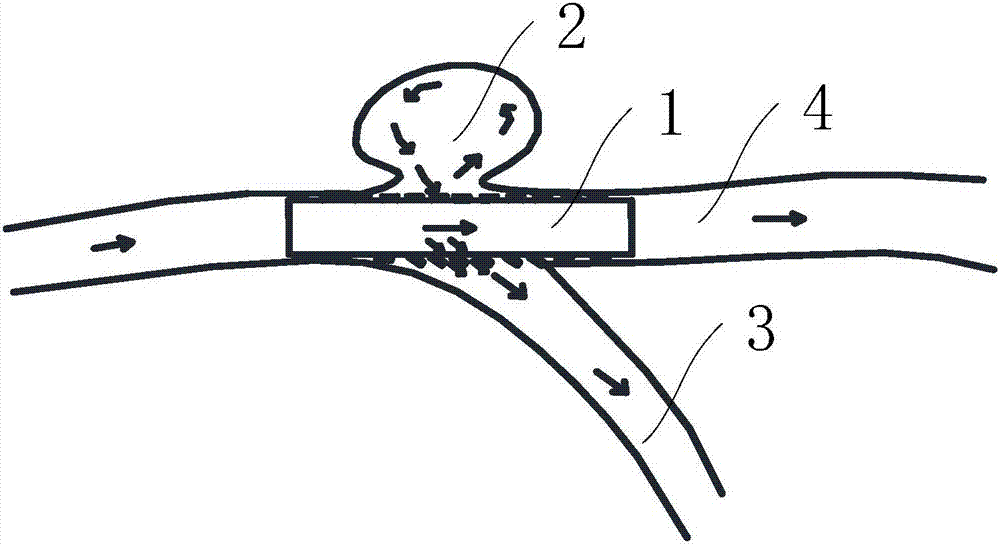

Forward osmosis membrane flow system and composite semipermeable membrane for forward osmosis membrane flow system

InactiveUS20140110328A1Improve efficiencyHigh permeation fluxSemi-permeable membranesHydro energy generationEpoxyFluid migration

The forward osmosis membrane flow system (1) includes a high osmotic pressure fluid flow section (2) to which a high osmotic pressure fluid is supplied, a low osmotic pressure fluid flow section (3) to which a low osmotic pressure fluid with a lower osmotic pressure than that of the high osmotic pressure fluid is supplied, and a semipermeable membrane (4) that separates the high osmotic pressure fluid flow section and the low osmotic pressure fluid flow section from each other. A flow rate in the high osmotic pressure fluid flow section (2) is increased by an occurrence of fluid migration from the low osmotic pressure fluid flow section (3) into the high osmotic pressure fluid flow section (2) through the semipermeable membrane (4). The semipermeable membrane (4) is a composite semipermeable membrane with a polyamide-based skin layer formed on a porous epoxy resin membrane.

Owner:NITTO DENKO CORP

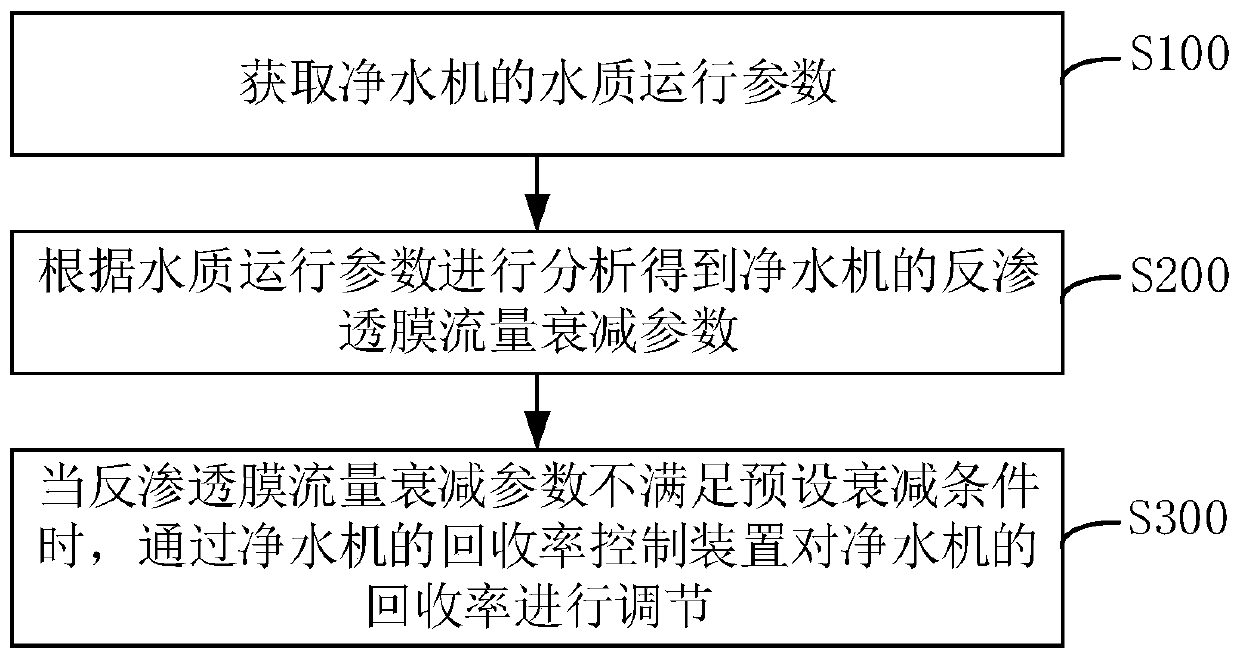

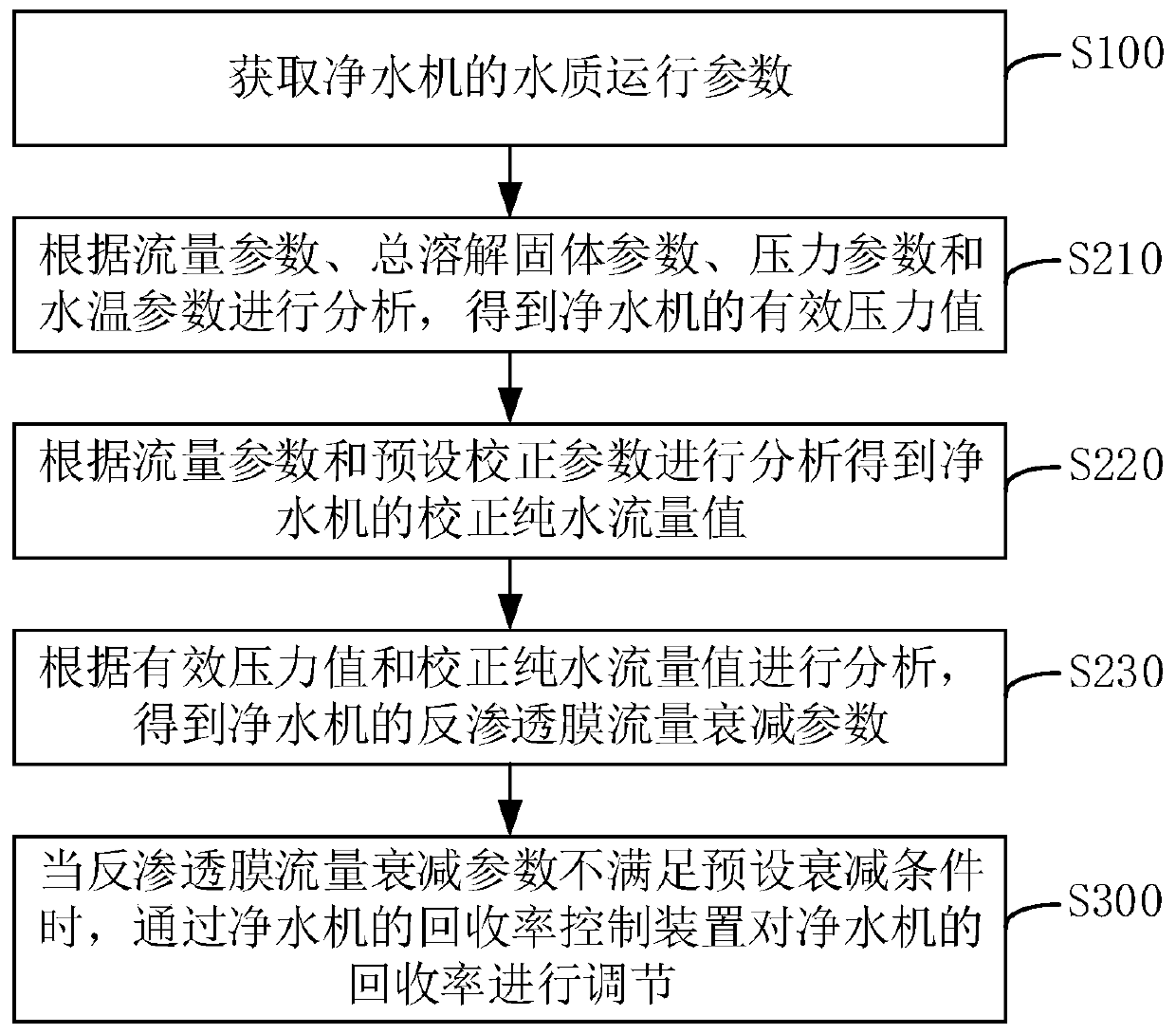

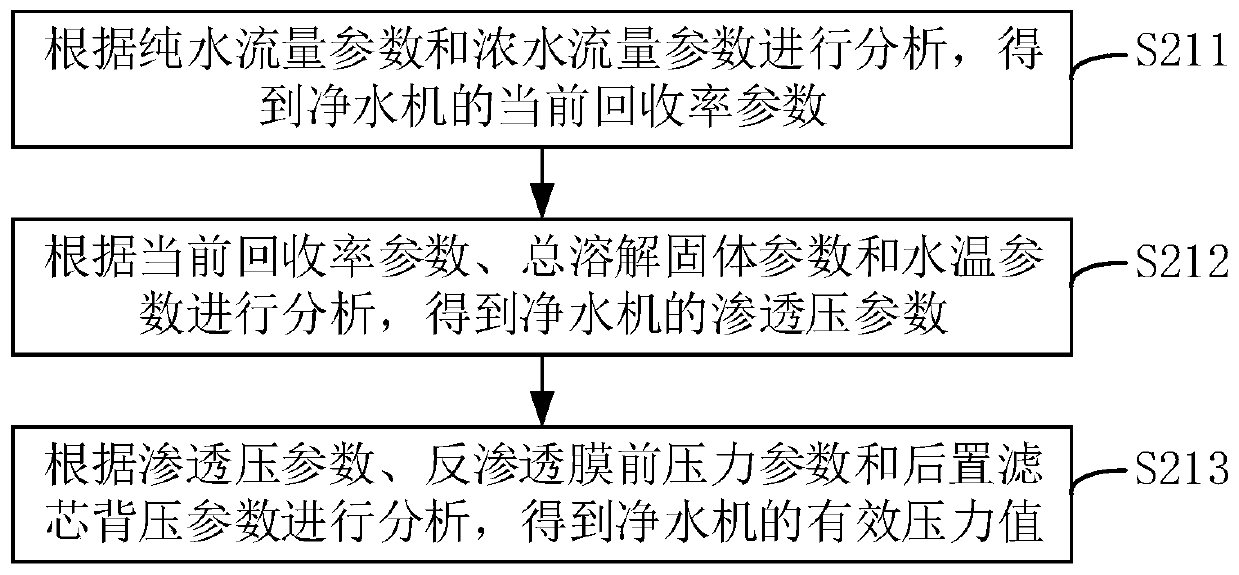

Water purifier recovery rate control method, device and system and water purifier

ActiveCN110713276AGuaranteed water productionAvoid wastingWater treatment parameter controlTreatment involving filtrationReverse osmosisWater production

The invention relates to a water purifier recovery rate control method, device and system and a water purifier. A data acquisition device of the water purifier can be used for acquiring and sending water quality operation parameters in real time; a data processing host performs analysis according to the water quality operation parameters to obtain reverse osmosis membrane flow attenuation parameters, so that when the reverse osmosis membrane flow attenuation parameters do not meet preset attenuation conditions, the recovery rate of the water purifier is adjusted through the recovery rate control device. By means of the scheme, the attenuation degree of a reverse osmosis membrane filter element of the water purifier can be truly reflected in real time according to the water quality characteristics in the water purifier in the operation process of the water purifier, and then the recovery rate of the water purifier is adjusted to be in the state matched with the current water quality inreal time according to the attenuation degree of the reverse osmosis membrane filter element. Therefore, the water yield of the water purifier is guaranteed, scaling of a reverse osmosis membrane produced by the water purifier is avoided, waste of raw water can be effectively prevented, and high water purification reliability is achieved.

Owner:GREE ELECTRIC APPLIANCES INC

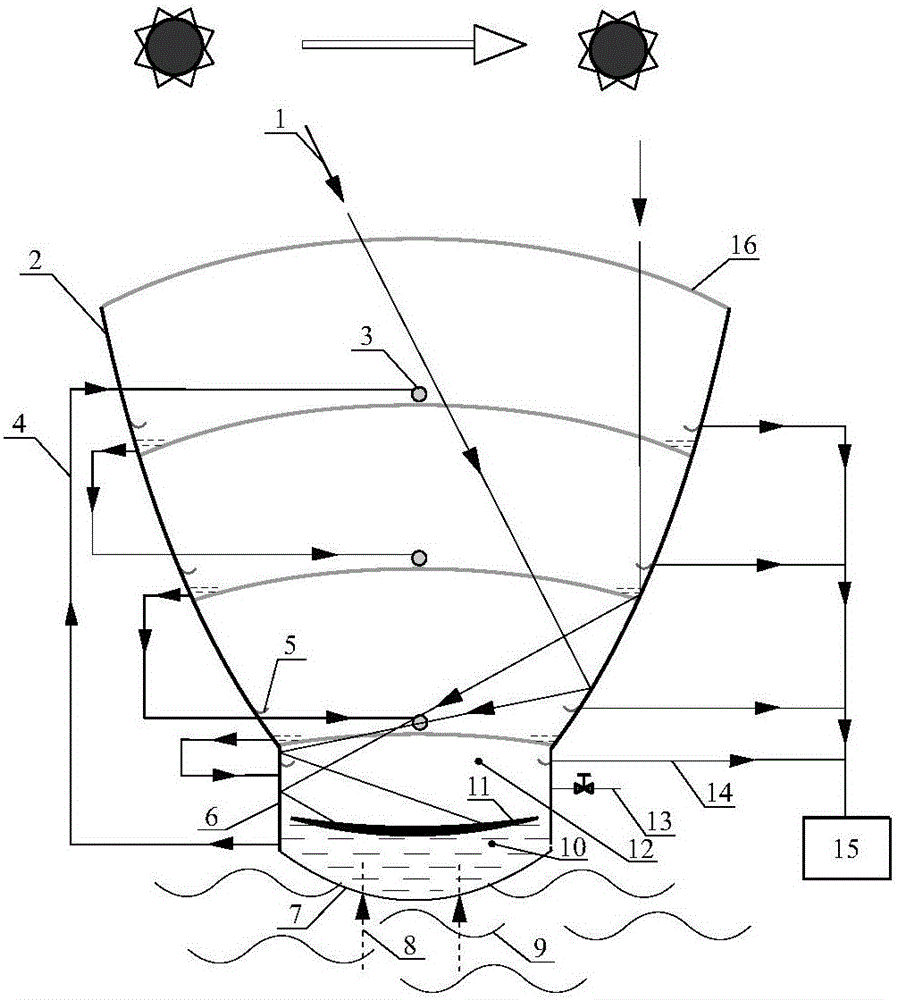

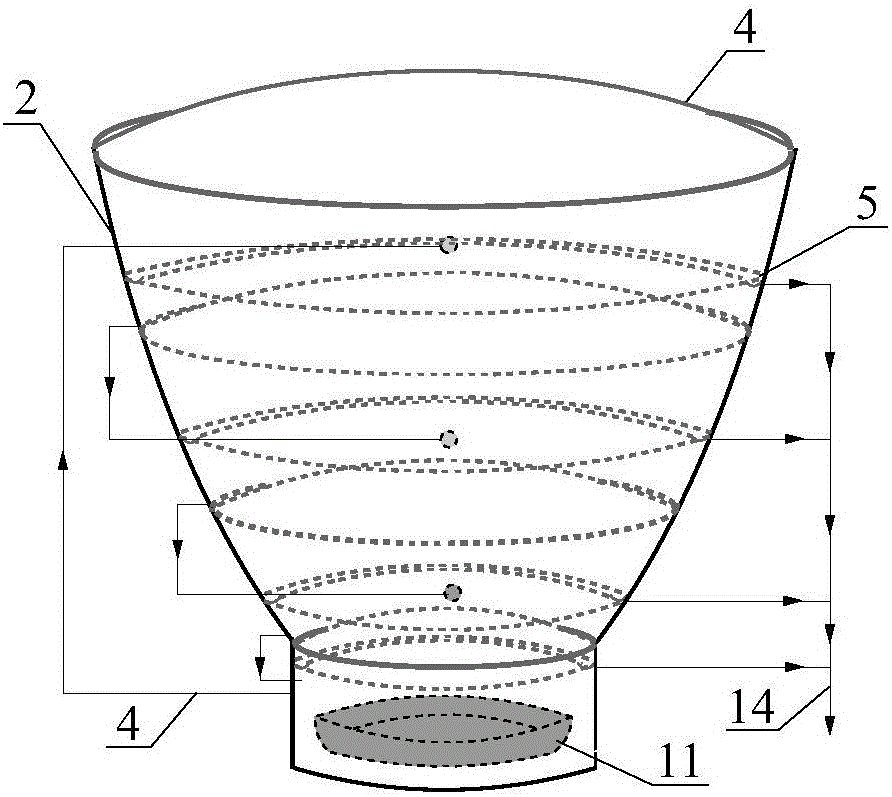

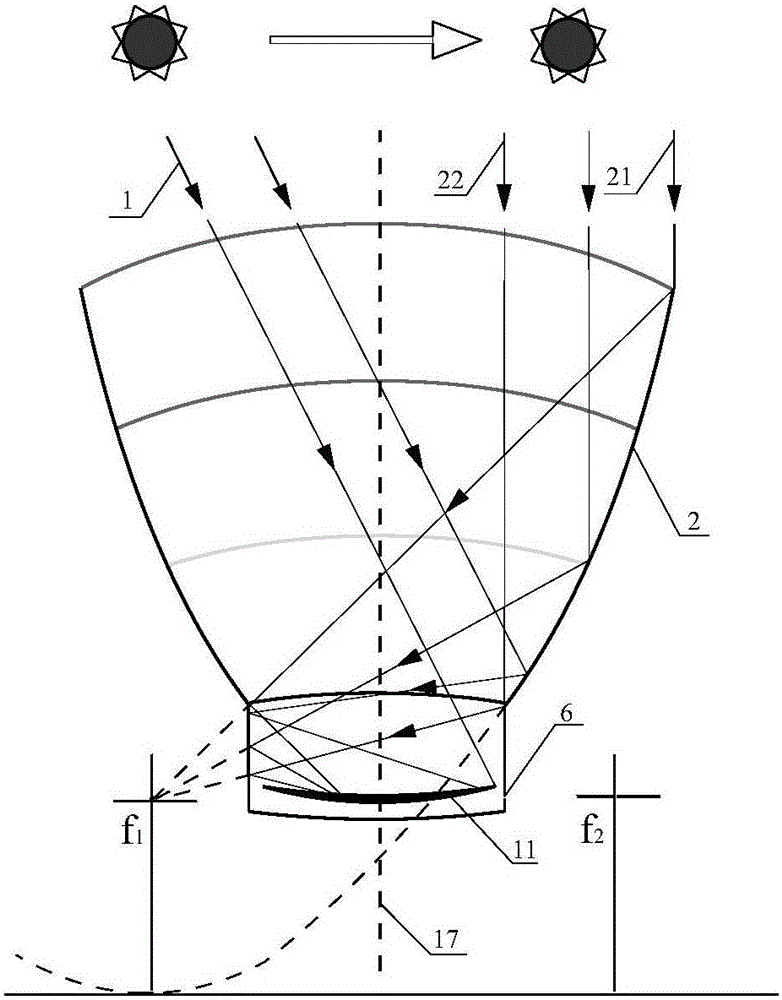

Paraboloid condensation and hot steam pulsation combined multistage falling-membrane seawater desalination device

InactiveCN105923677AImprove performanceImprove efficiencyGeneral water supply conservationSeawater treatmentSemipermeable membraneFresh water

The invention discloses a paraboloid condensation and hot steam pulsation combined multistage falling-membrane seawater desalination device. The paraboloid condensation and hot steam pulsation combined multistage falling-membrane seawater desalination device comprises a compound parabolic concentrator, a convex transparent material, water distributors, a heat receiver and a semipermeable membrane. Light rays are focused on the heat receiver after entering the compound parabolic concentrator and being subjected to reflection of the inner surface and secondary reflection of the vertical wall face, and with temperature rising continuously, the heat receiver heats seawater. A bottom chamber is similar to a cytomembrane structure, the seawater evaporates continuously, and pressure in the chamber increases to enable bottom hot seawater to be pumped from a guide pipe into the top water distributor by means of pulsation and then form falling-membrane flowing on the upper surface of a convex. Steam close to a lower chamber condensates on the lower surface of the convex, and heat is transferred to a falling-membrane water body on the upper surface to enable the steam to evaporate. The seawater flows down stage by stage under the action of gravity, the concentration of the seawater in the bottom chamber increases, and external seawater is supplied due to the fact that pure water decreases in the chamber under the action of the semipermeable membrane on the bottom side of the chamber. Fresh water tanks disposed on reflection surfaces of evaporation chambers in all layers are used for outputting fresh water.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

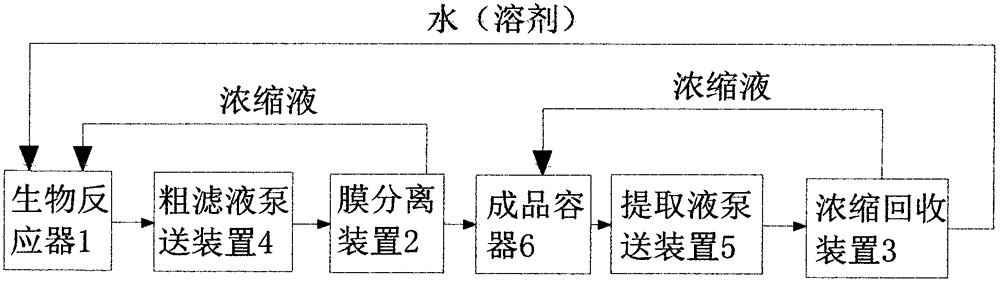

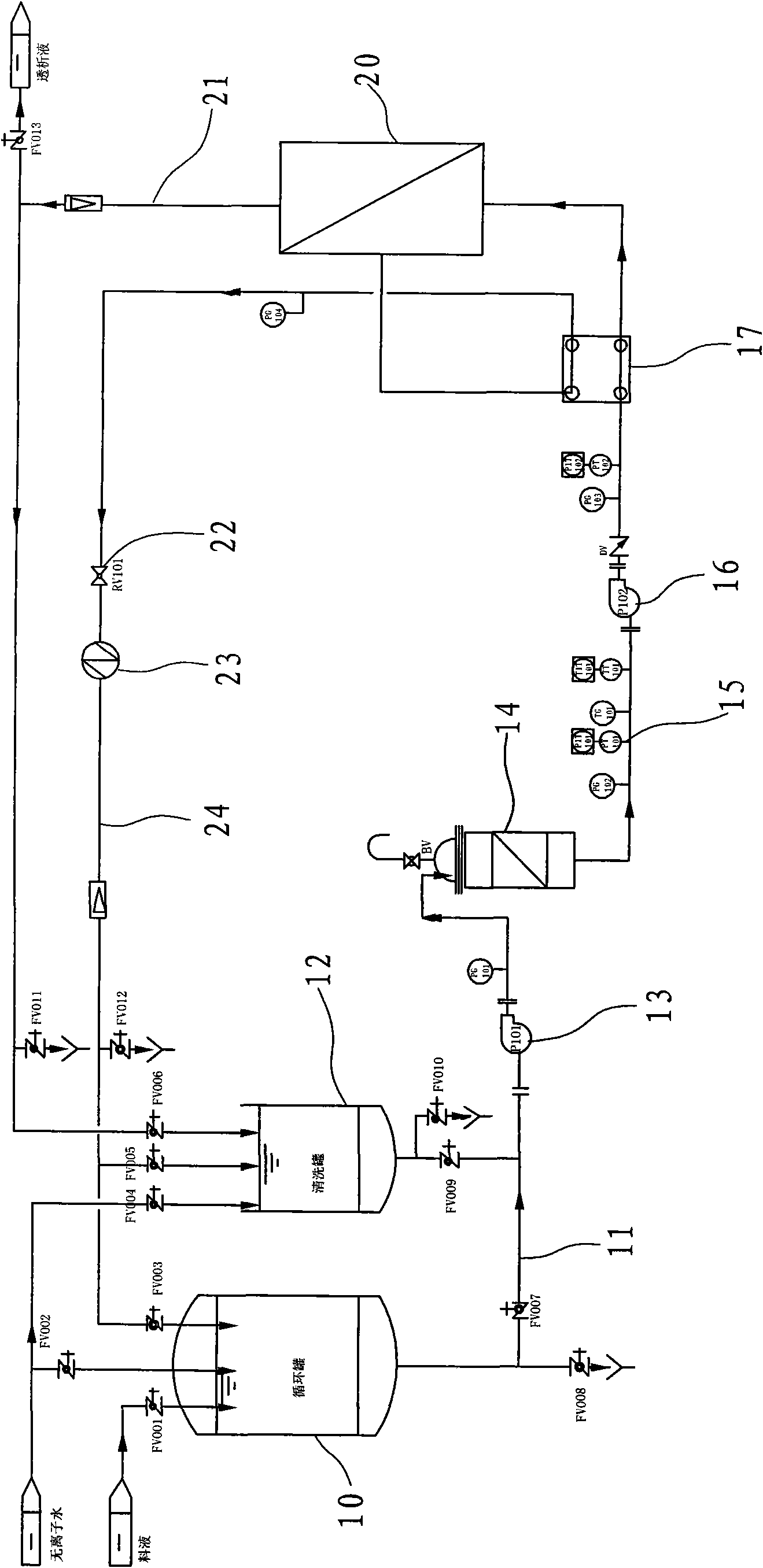

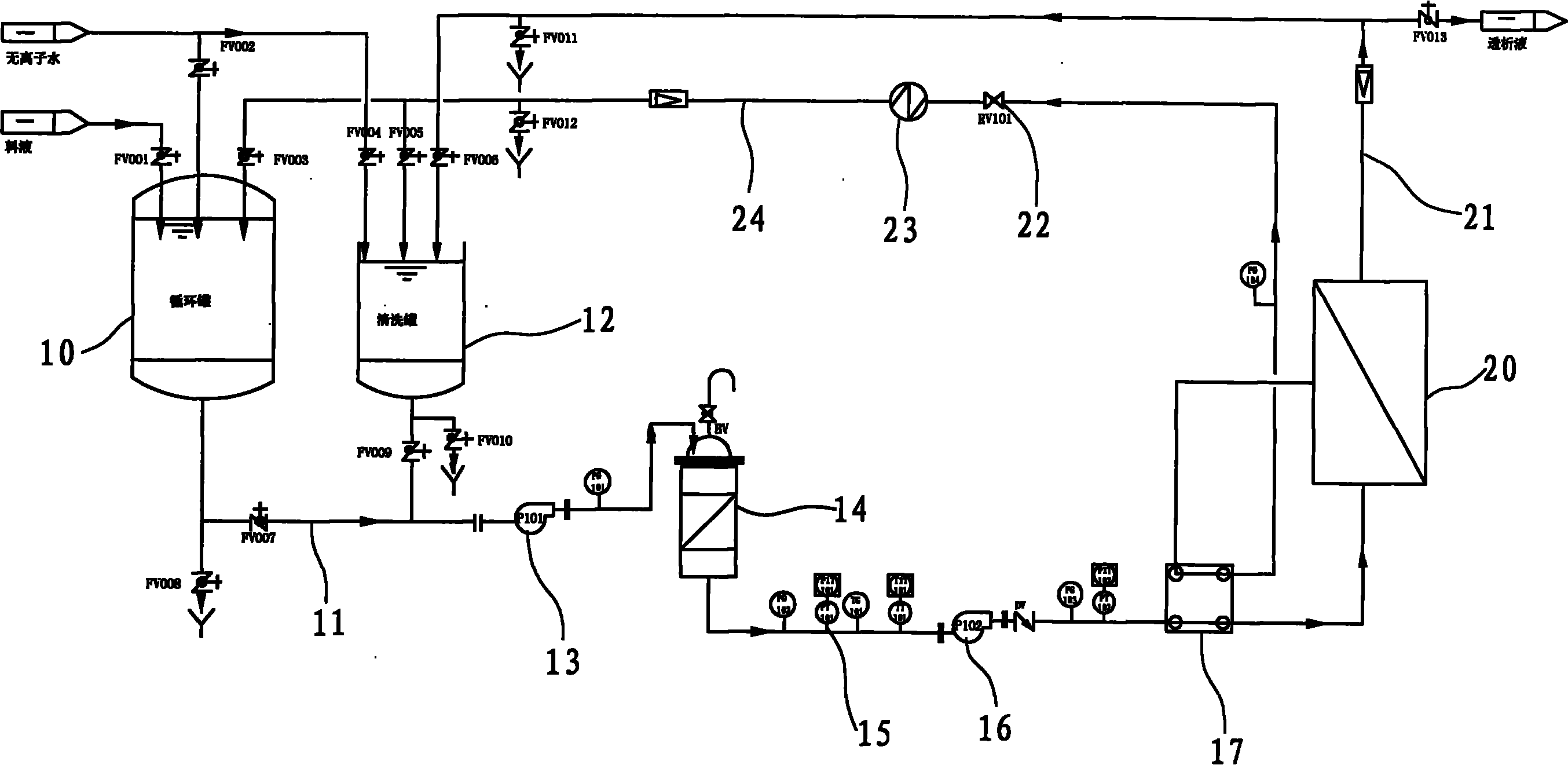

Process and device for recovering reverse osmosis-nanofiltration combination membrane separation material of fermentation liquor

InactiveCN104805008ASimplify the biochemical extraction processHigh extraction rateBioreactor/fermenter combinationsBiological substance pretreatmentsProcess systemsReverse osmosis plant

The invention discloses a process for recovering a reverse osmosis-nanofiltration combination membrane separation material of fermentation liquor. The process comprises the steps of circulating extraction in a bioreactor, membrane separation, finished product concentration and water recovery, and the steps are sequentially connected and closed to form a circulating process system. The process comprises the following specific steps: the preprocessed reverse osmosis-nanofiltration combination membrane separation material of the fermentation liquor enters the bioreactor to be extracted and coarsely filtered, coarse filter liquor is pumped into a membrane separation device by using a coarse filter liquor pumping device to be subjected to membrane separation extraction, extract liquor penetrating through a separation membrane enters a finished product container, and residue liquor not penetrating through the separation membrane flows back to the bioreactor for reaction and enzymolysis; the extract liquor is pumped into a concentration and recovery device through an extract liquor pumping device to be subjected to concentration and solvent recovery, a part incapable of penetrating through the membrane is concentrated liquor flowing back to the finished product container, water penetrating through the membrane flows back to the bioreactor for continuously dissolving enzymatically hydrolyzed effective ingredients, and circulation is stopped until the effective ingredients are extracted completely, wherein lysozyme is fibrinoclase with the concentration of 5-7%, and the extraction temperature is 42-43 DEG C.

Owner:ZHEJIANG FORESTRY UNIVERSITY

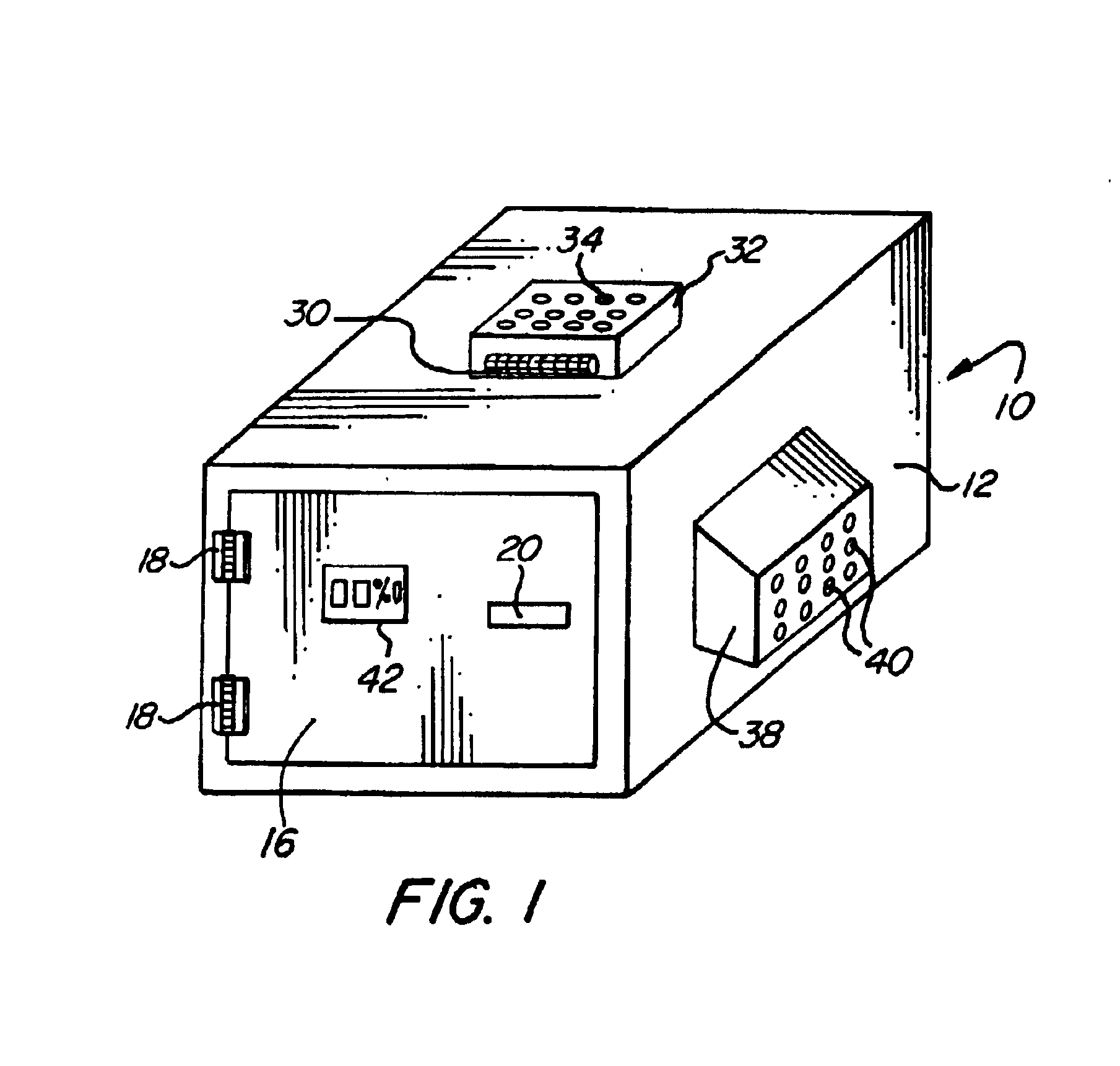

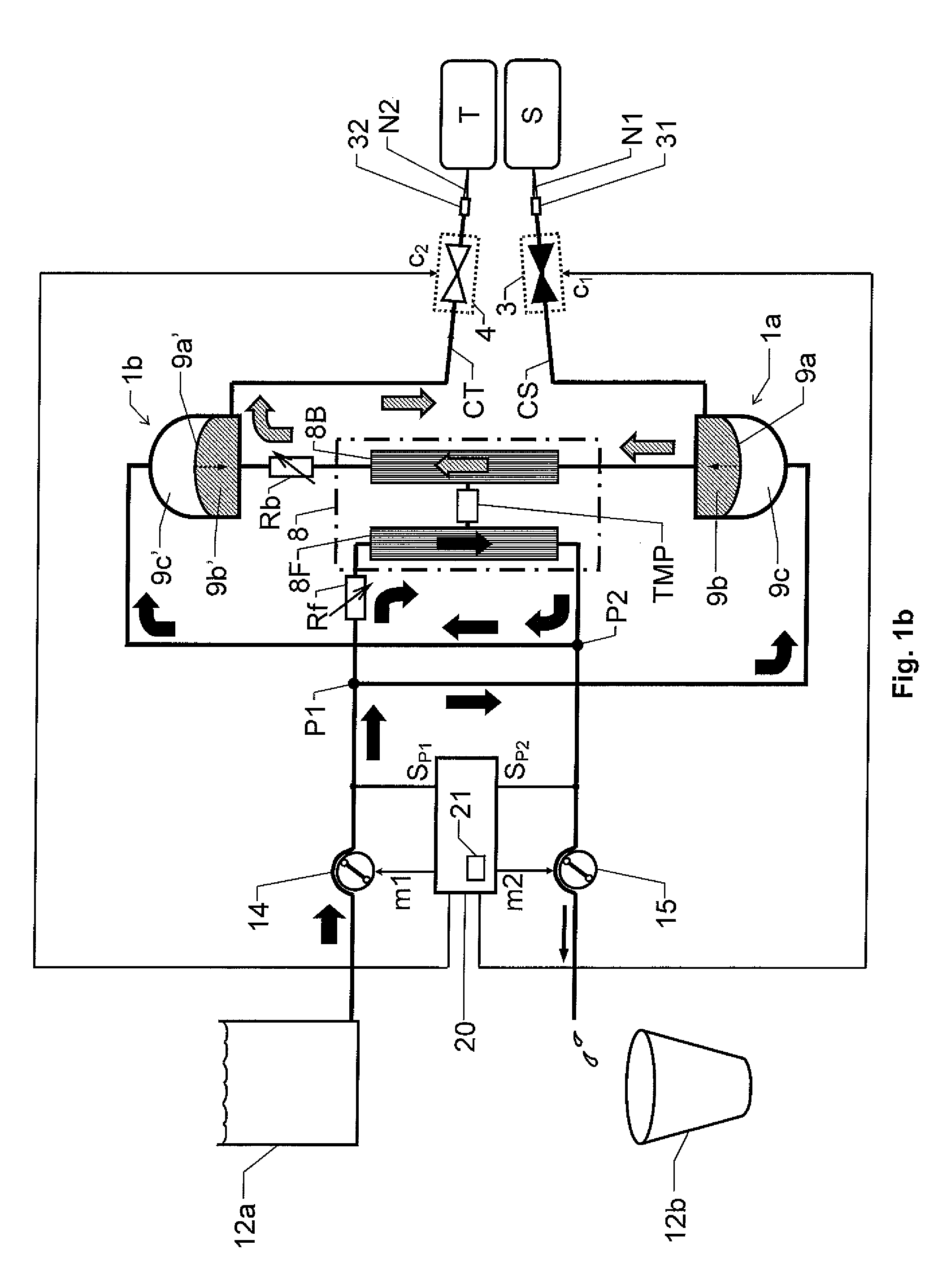

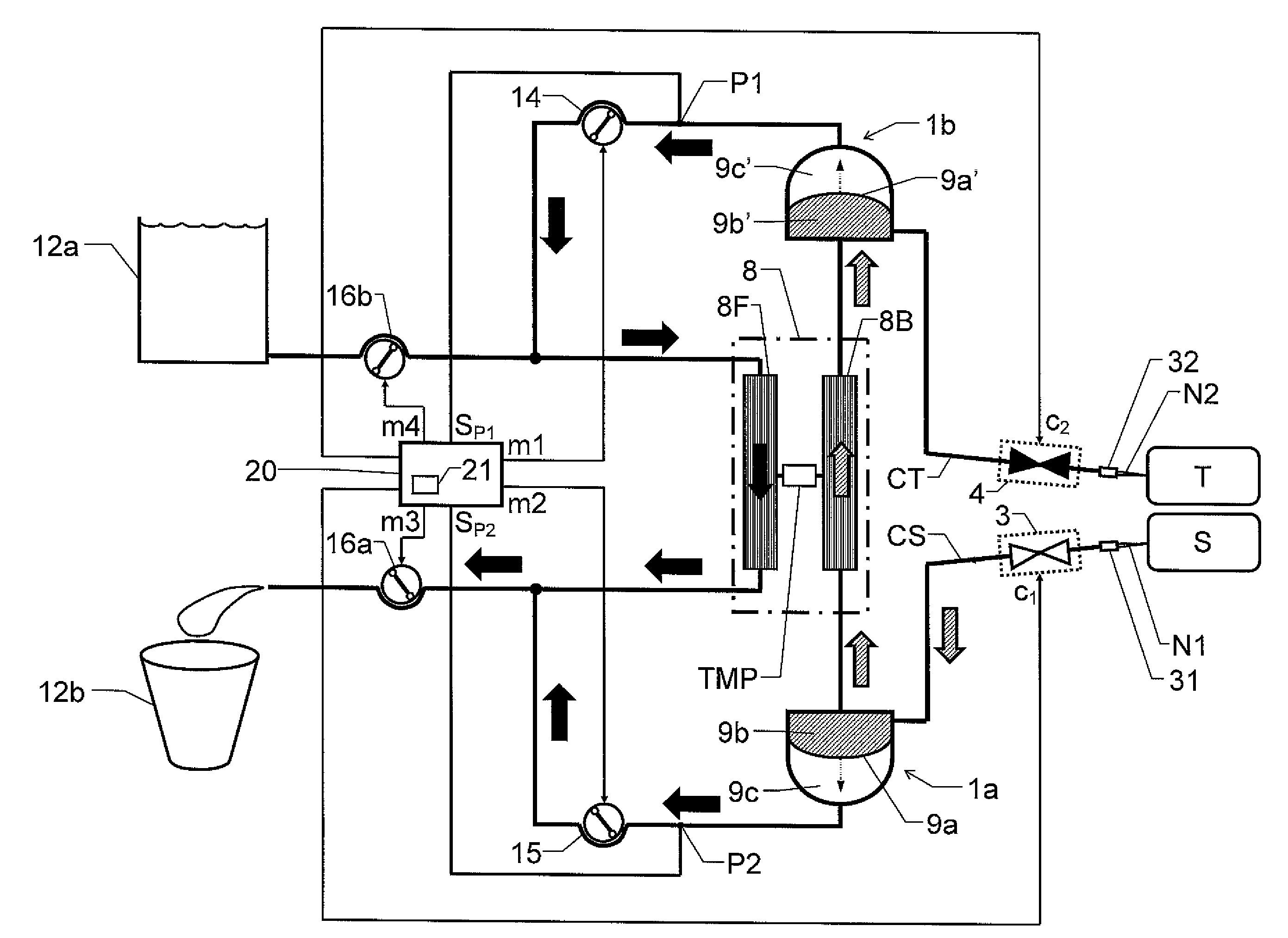

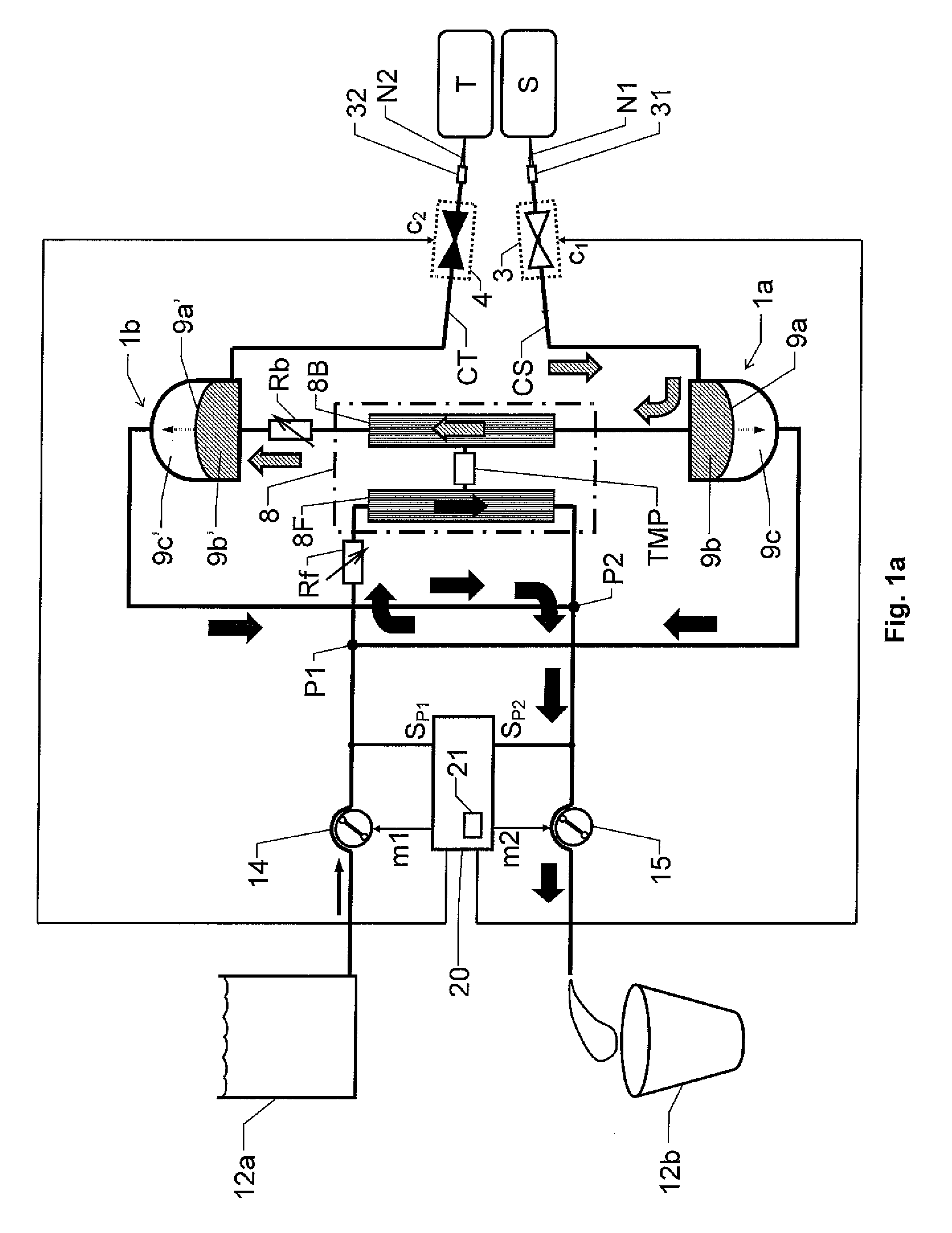

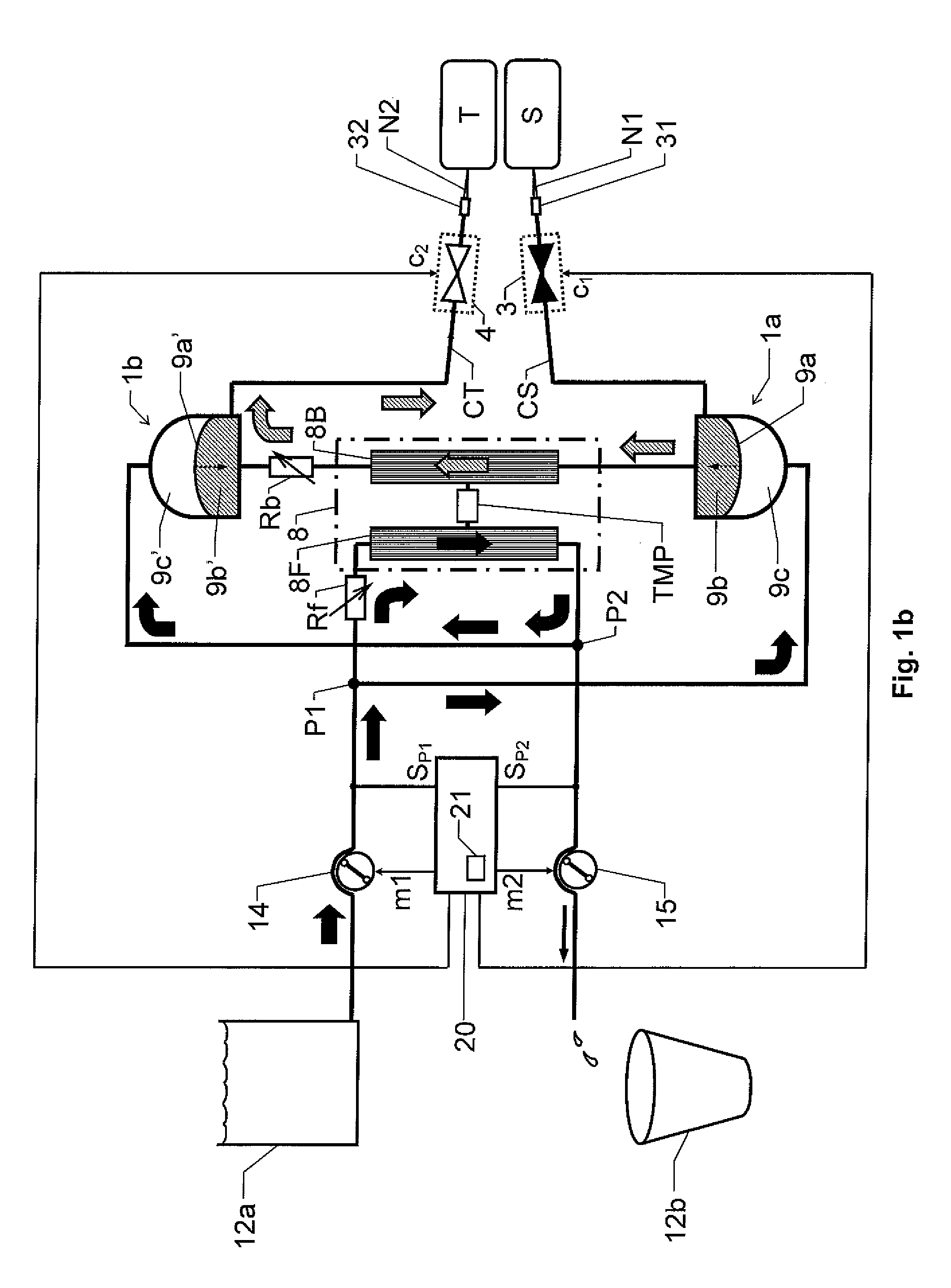

Dialysis machine and ultrafiltration

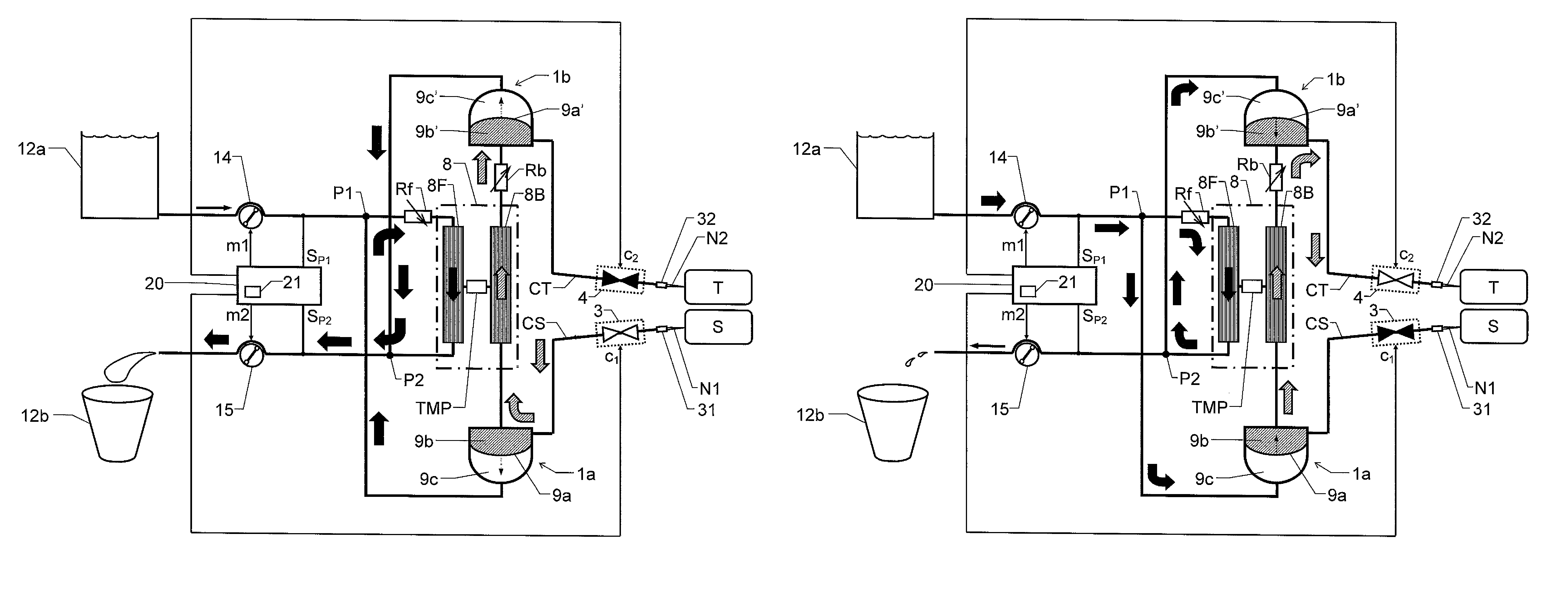

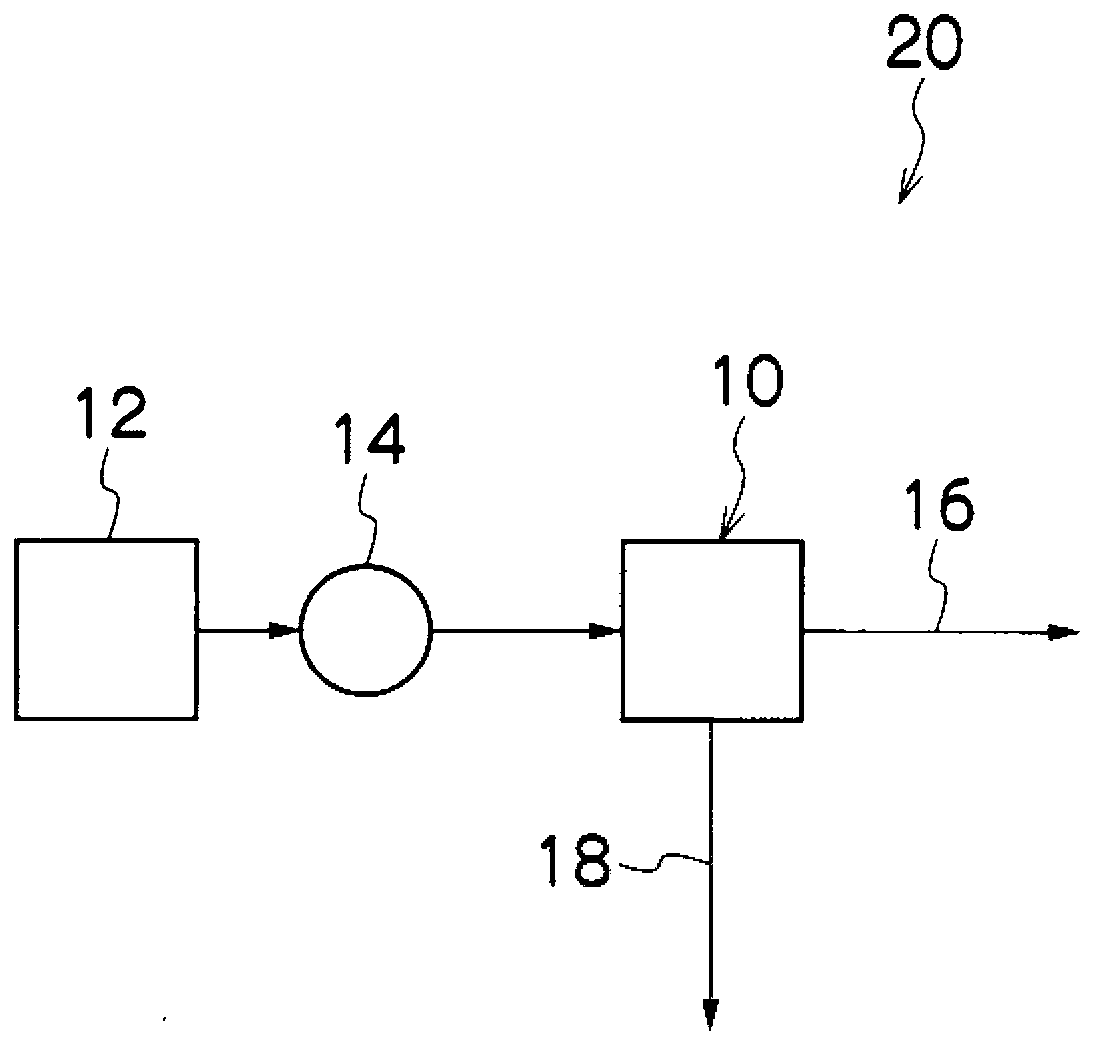

ActiveUS20180344915A1Control volumeDialysis systemsMedical devicesDialysis fluidIntensive care medicine

The invention relates to a dialysis machine capable of performing ultrafiltration without the need for a dedicated ultrafiltration pump. The system uses a pair of membrane flow balance pumps wherein the operation and / or the volume flow rate of the pumps can be modified during operation to bring about a net movement of dialysate either into or from the dialyser. The direction of flow of the dialysate in the dialyzer is reversible and the dialyzer can comprise two dialysate inlets, one at each end, and two dialysate outlets, one at each end.

Owner:QUANTA DIALYSIS TECH LTD

Blood treatment apparatus

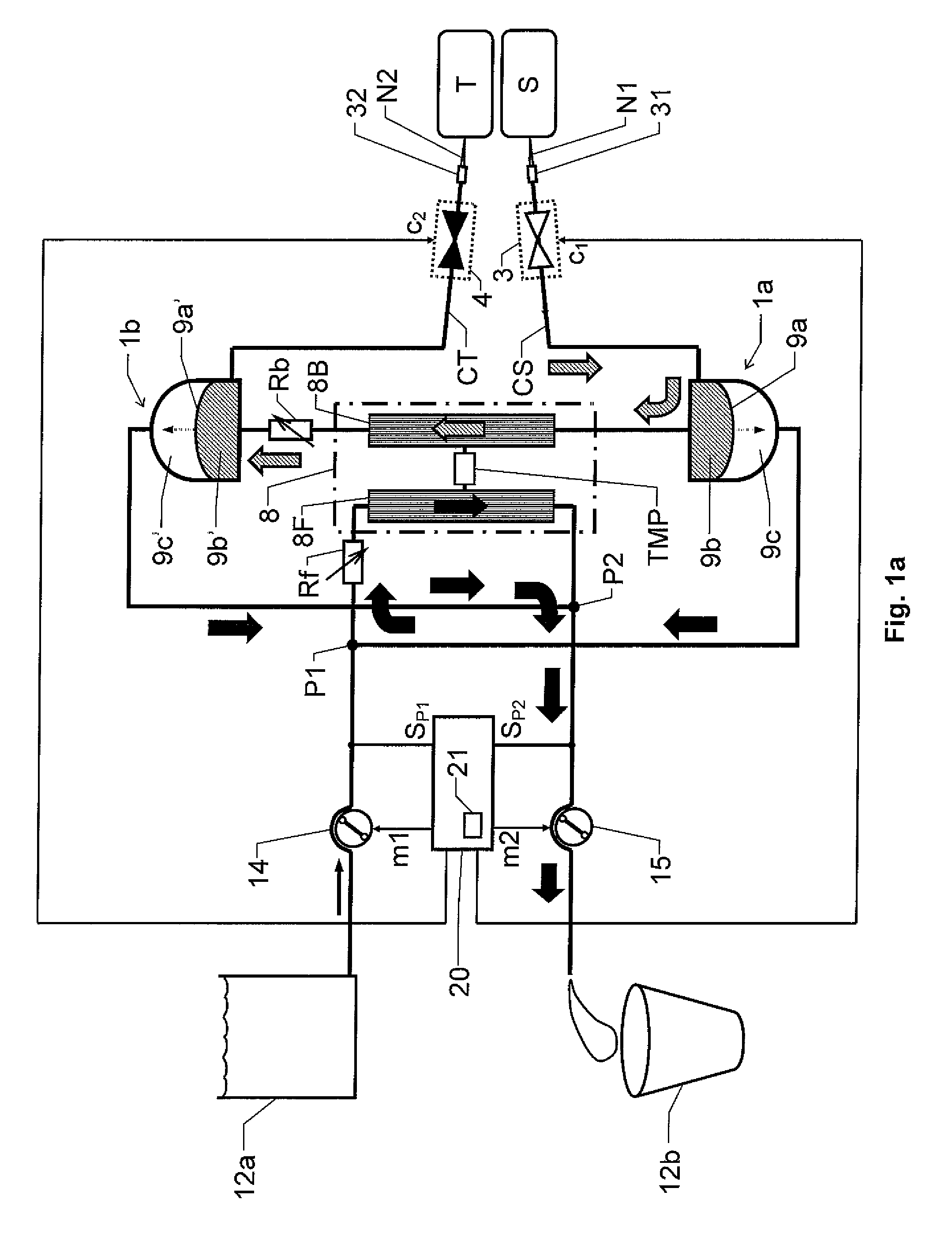

ActiveUS8580110B2Efficient and yet uncomplicatedHaemofiltrationDialysis systemsBlood treatmentsUltrafiltration

A proposed blood treatment apparatus includes: a blood treatment unit, a pair of fluid pumps and a pair blood pumps. The blood treatment unit is configured to receive untreated blood and fresh blood treatment fluid, and emit treated blood and used blood treatment fluid. The fluid pumps are configured to pass blood treatment fluid through the blood treatment unit. The blood pumps are configured to extract untreated blood from a blood source, pass extracted blood through the blood treatment unit and deliver treated blood to a target vessel. Additionally, the fluid pumps are configured to control the operation of the blood pumps via the blood treatment fluid. Moreover, a flow control device is configured to control a trans-membrane flow between the blood side and the a fluid side of the blood treatment unit. Hence, for instance ultrafiltration can be adjusted to a desired level in a very straightforward manner.

Owner:GAMBRO LUNDIA AB

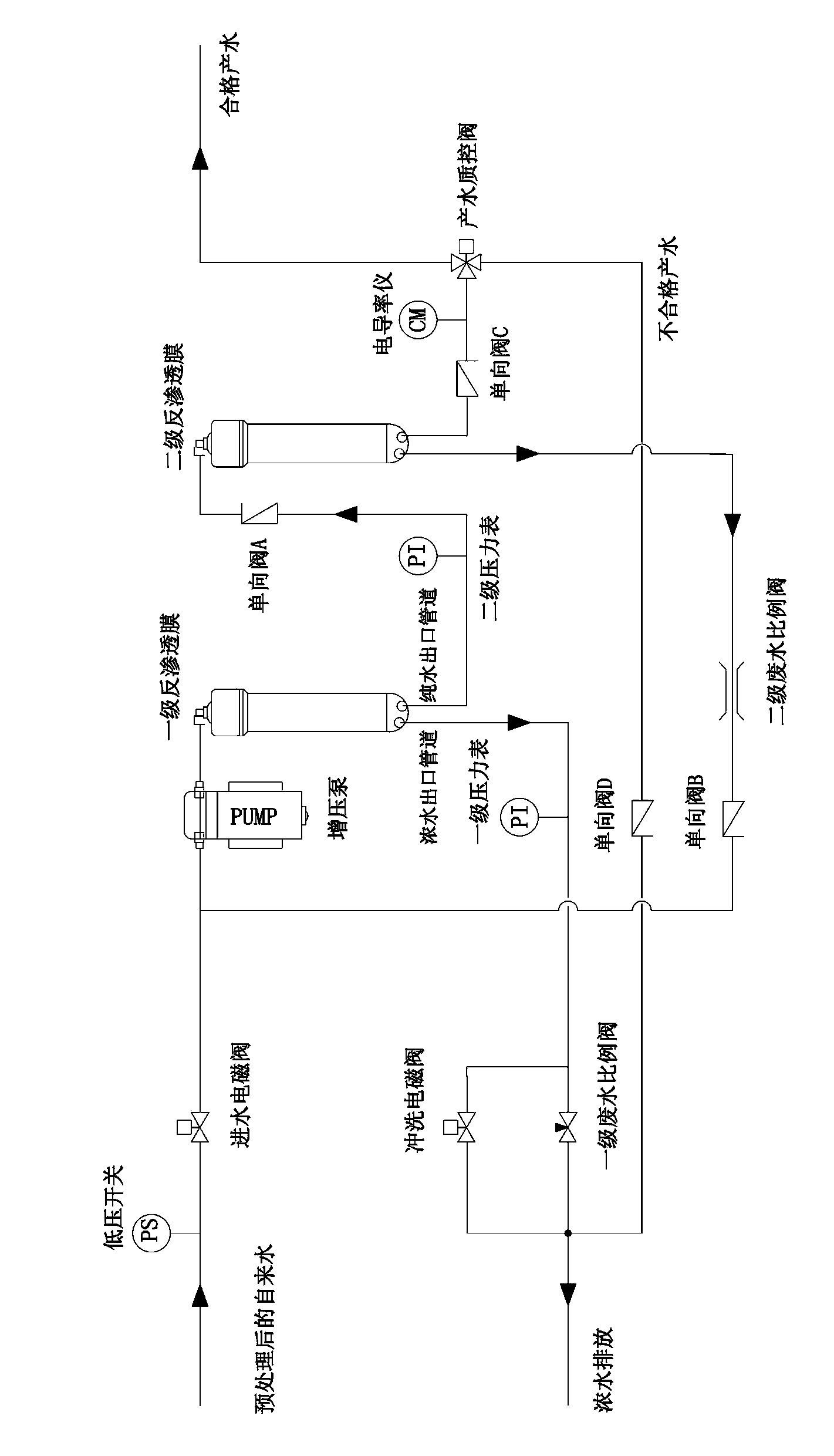

Low-yield single-pump two-stage reverse osmosis system

InactiveCN103626311AIncrease hardware costSolve the problem of changing the processReverse osmosisWater/sewage treatment bu osmosis/dialysisPurification methodsReverse osmosis

The invention relates to a low-yield single-pump two-stage reverse osmosis system. Pretreated running water is connected with a first-stage reverse osmosis membrane through a first-stage booster pump. A concentrated water outlet pipeline of the first-stage reverse osmosis membrane is sequentially and serially connected with a first-stage pressure gauge and a first-stage waste water proportional valve. The first-stage waste water proportional valve is in parallel connection with a washing electromagnetic valve and then connected with a concentrated water outlet. A pure water outlet pipeline of the first-stage reverse osmosis membrane is sequentially and serially connected with a second-stage pressure gauge and a one-way valve A and then connected with a water inlet of a second-stage reverse osmosis membrane. Waste water of the second-stage reverse osmosis membrane flows back to a water inlet of the booster pump through a second-stage proportional valve. A second-stage pure water outlet pipeline of the second-stage reverse osmosis membrane is sequentially and serially connected with a water quality monitoring instrument and a producing water quality control valve. By employing the low-yield single-pump two-stage reverse osmosis system, producing water quality can reach standards fast, long-term stability of the producing water quality is achieved, recovery reaches at least 20%, complex pretreating processes are not needed, salt removing rate can stably reach more than 99%, and double reduction of producing cost of ultrapure water produced by using DI (desorption ionization) (ion exchange) as post-stage purification.

Owner:岳勇斌

Blood treatment apparatus

ActiveUS20110024353A1Efficient and yet uncomplicatedSolvent extractionHaemofiltrationBlood treatmentsUltrafiltration

A proposed blood treatment apparatus includes: a blood treatment unit, a pair of fluid pumps and a pair blood pumps. The blood treatment unit is configured to receive untreated blood and fresh blood treatment fluid, and emit treated blood and used blood treatment fluid. The fluid pumps are configured to pass blood treatment fluid through the blood treatment unit. The blood pumps are configured to extract untreated blood from a blood source, pass extracted blood through the blood treatment unit and deliver treated blood to a target vessel. Additionally, the fluid pumps are configured to control the operation of the blood pumps via the blood treatment fluid. Moreover, a flow control device is configured to control a trans-membrane flow between the blood side and the a fluid side of the blood treatment unit. Hence, for instance ultrafiltration can be adjusted to a desired level in a very straightforward manner.

Owner:GAMBRO LUNDIA AB

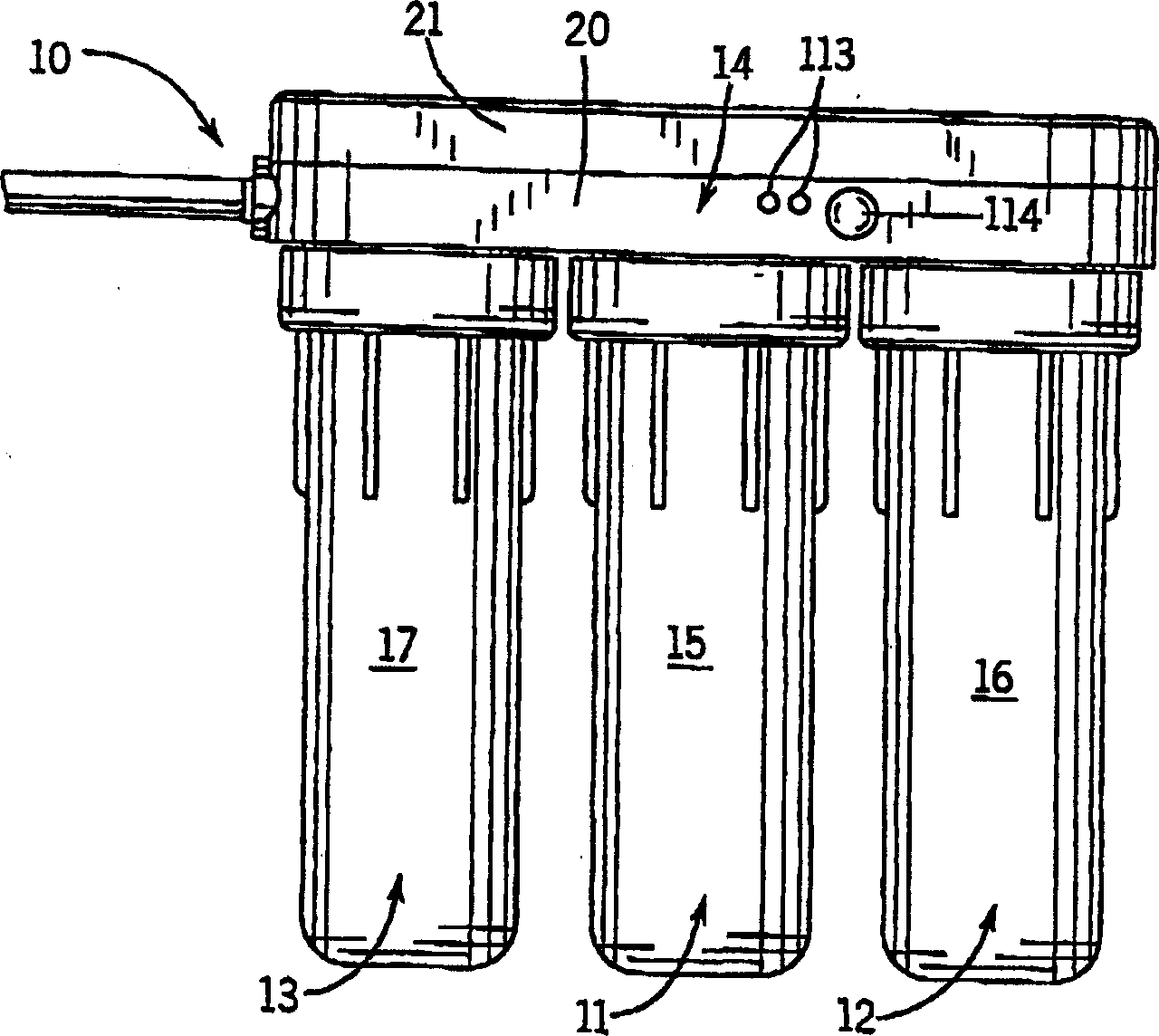

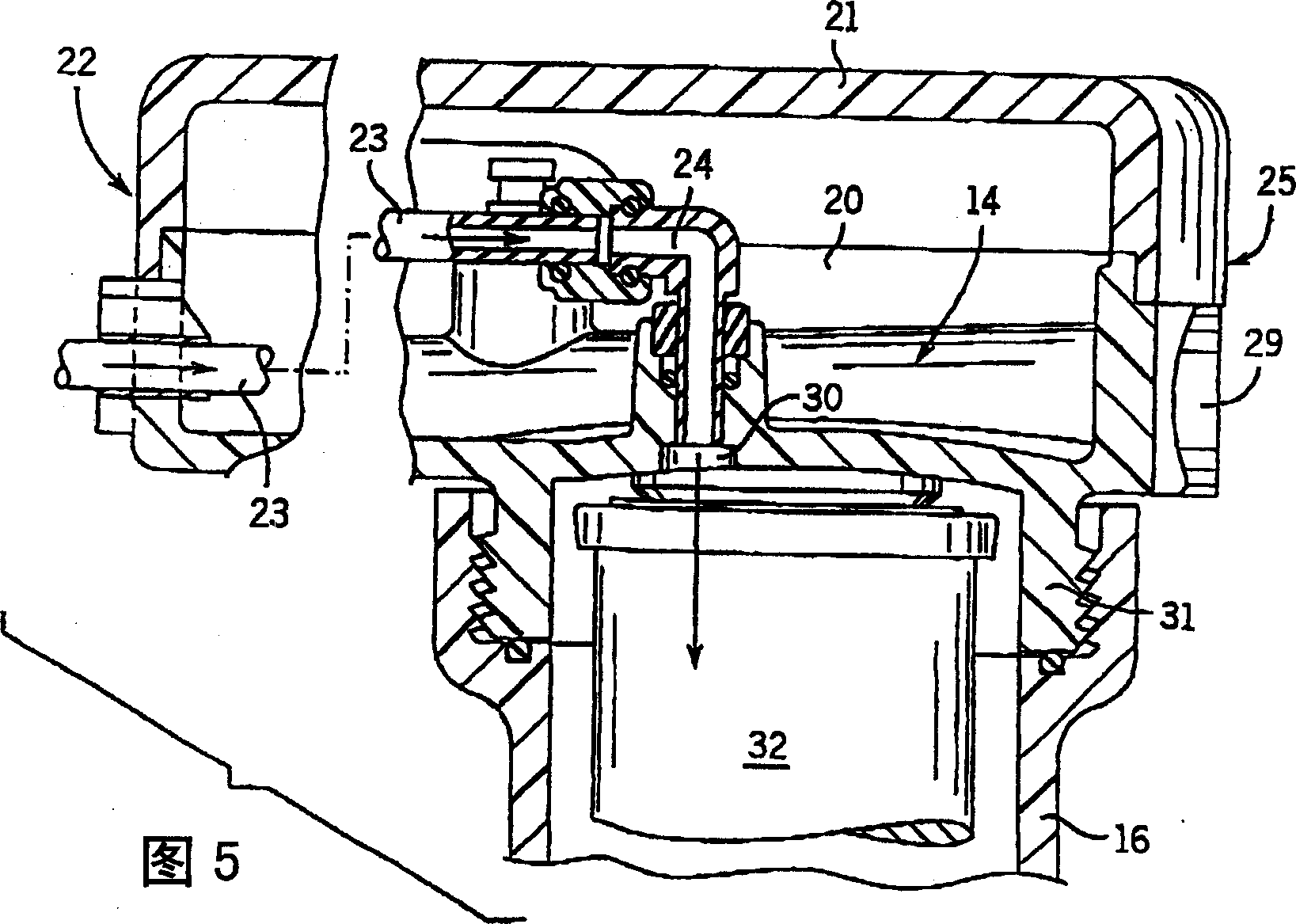

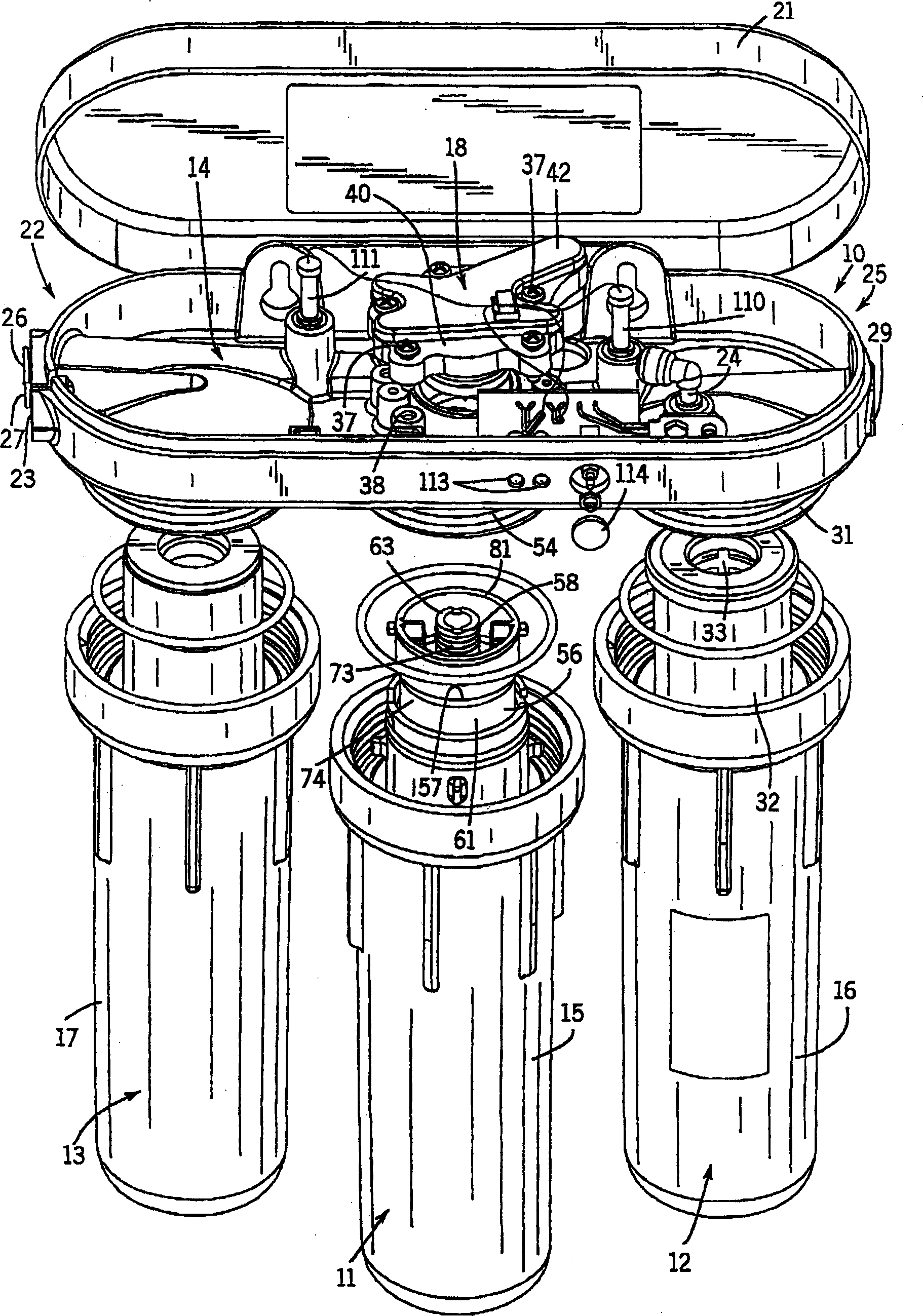

Flow control module for RO water treatment system

A unitary multi-function control module for a reverse osmosis water purification system provides all of the necessary flow control functions in a single removable and easily replaceable unit. The module connects directly with a unitary injection molded manifold, provides all of the interconnections between the manifold and the supply, permeate, and brine flow paths, and houses the supply flow shutoff valve, the RO membrane flow control, and the permeate back flow check valve.

Owner:卡立根国际公司

Membrane-oil composite lubrication method

InactiveCN105909963ALubrication method expansionLong lubrication lifeGear lubrication/coolingPortable liftingEngineeringVibration absorption

The invention provides a membrane-oil composite lubrication method and relates to a lubrication method. The invention aims to solve problems that requirements of high speed high load working condition and changing working conditions cannot be met when prior solid membrane lubrication or oil lubrication is used separately and material selection is limited and the lubrication effect is poor when the prior solid membrane lubrication and oil lubrication are in mixed use. The method includes processing a solid lubrication membrane after pretreatment of work piece surface; soaking the surface of the solid lubrication membrane with lubrication oil or injecting lubrication oil to the a friction interface of the solid lubrication membrane, so that membrane-oil composite lubrication is realized. According to the invention, the solid lubrication membrane is spaced with oil lubrication, so that abrasion of the solid lubrication membrane is slow down, the solid lubrication membrane is protected and the lubrication service lifetime is prolonged. Mutual complementation in lubrication is realized. Through solid lubrication membrane carrying, lubrication coordination of lubrication and vibration absorption of the lubrication oil is realized. Through the solid lubrication membrane carrying, the lubrication oil on the solid lubrication membrane flows so as to realize heat dissipation. The technical condition requirements are not high, the application range is wide and the lubrication effect is good.

Owner:HARBIN INST OF TECH

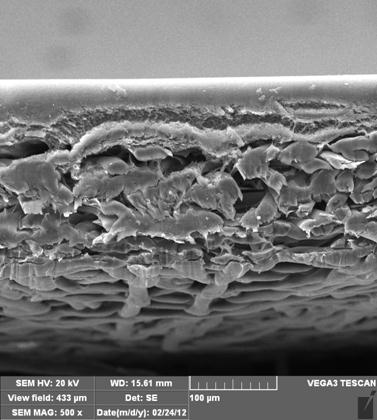

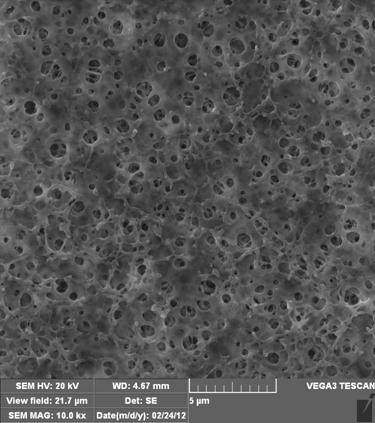

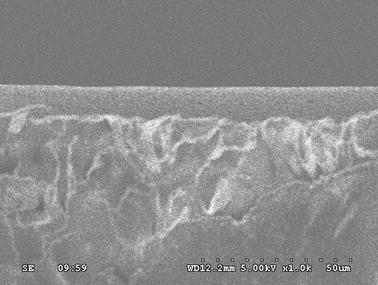

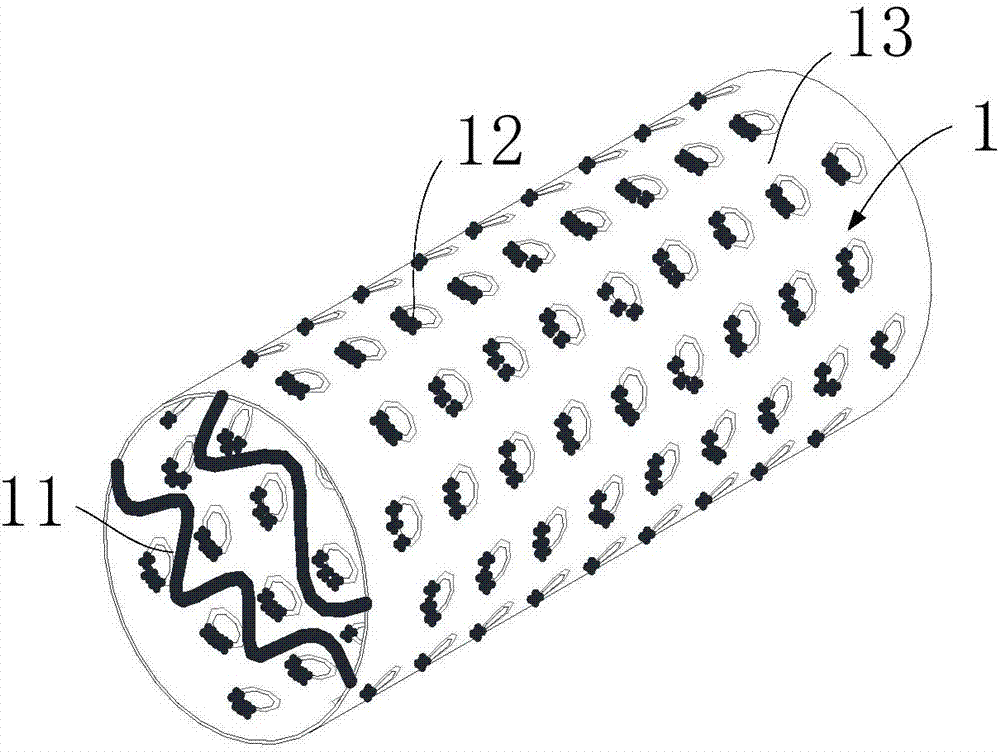

Method for preparing hydrophilic macromolecule microporous composite membrane

InactiveCN102614787AIncrease membrane fluxGood pollution resistanceSemi-permeable membranesPolyesterNonwoven fabric

A method for preparing a hydrophilic macromolecule microporous composite membrane is characterized by comprising the steps: (1) adding polyvinyl formal into 5-30% by mass of hydrochloric acid or sulfuric acid aqueous solution to be heated to the temperature of 40-100 DEG C and dissolved, performing standing and defoaming, wherein the adding amount of the polyvinyl formal is 8-20% by mass of polyvinyl formal in feed liquid; and (2) performing blade coating to coat the feed liquid on polyester non-woven fabrics, submerging the polyester non-woven fabrics in an alkaline aqueous solution with the temperature of 20-50 DEG C, and forming the microporous membrane through phase separation and solidification. In the preparation process, an organic solvent is not used so that the method is environment-friendly and safe. Hydrophilic functional group-OH in a polyvinyl alcohol structure is utilized, and the problem that polyvinyl alcohol is difficultly and directly prepared into the microporous membrane is solved. The composite membrane prepared by means of the method is made of a hydrophilic membrane material which has high membrane flow under the lower pressure and good fouling resistant performance and is used as a flat membrane material, and can remarkably improve processing capability and efficiency of a membrane bioreactor.

Owner:NANCHANG UNIV

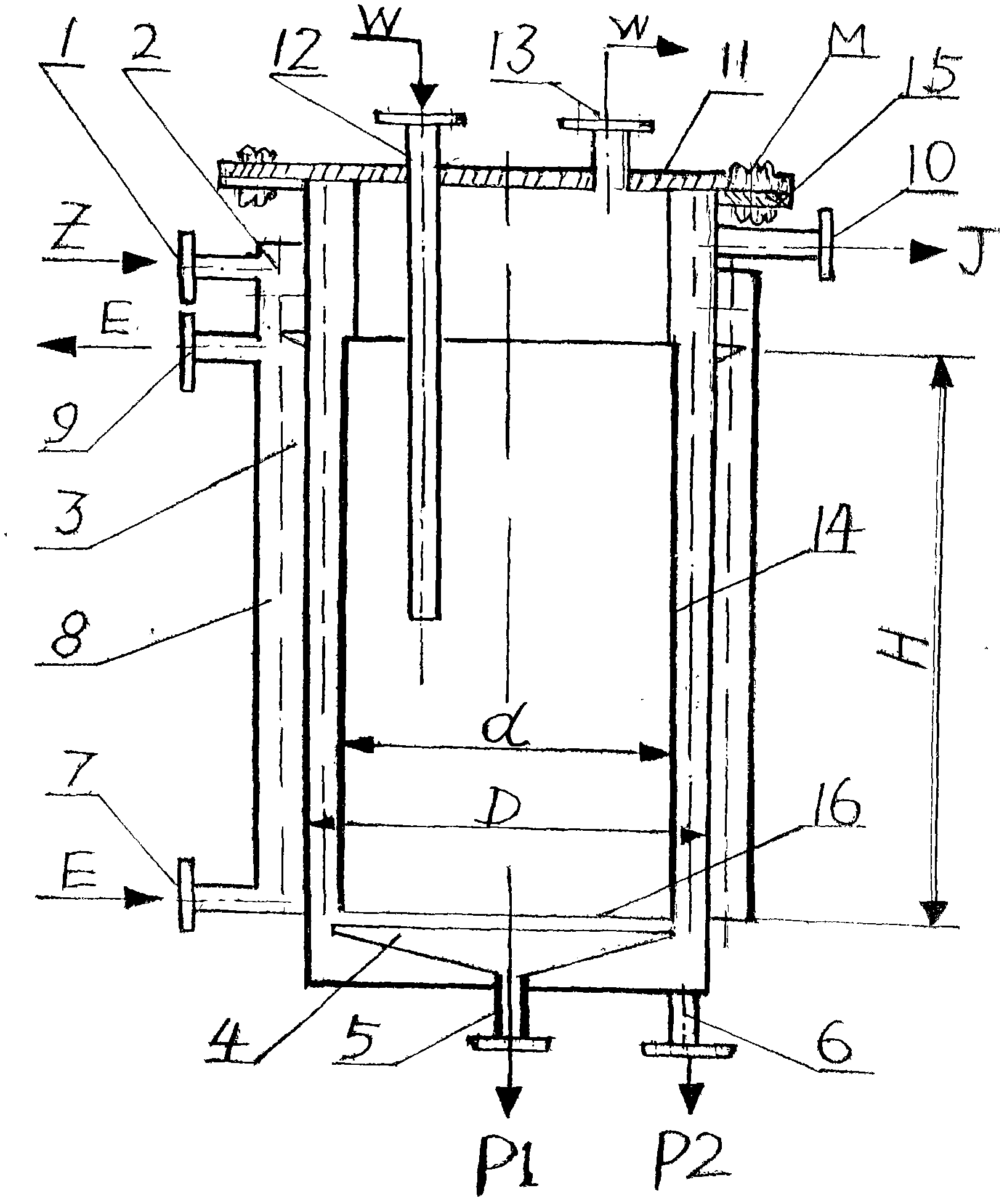

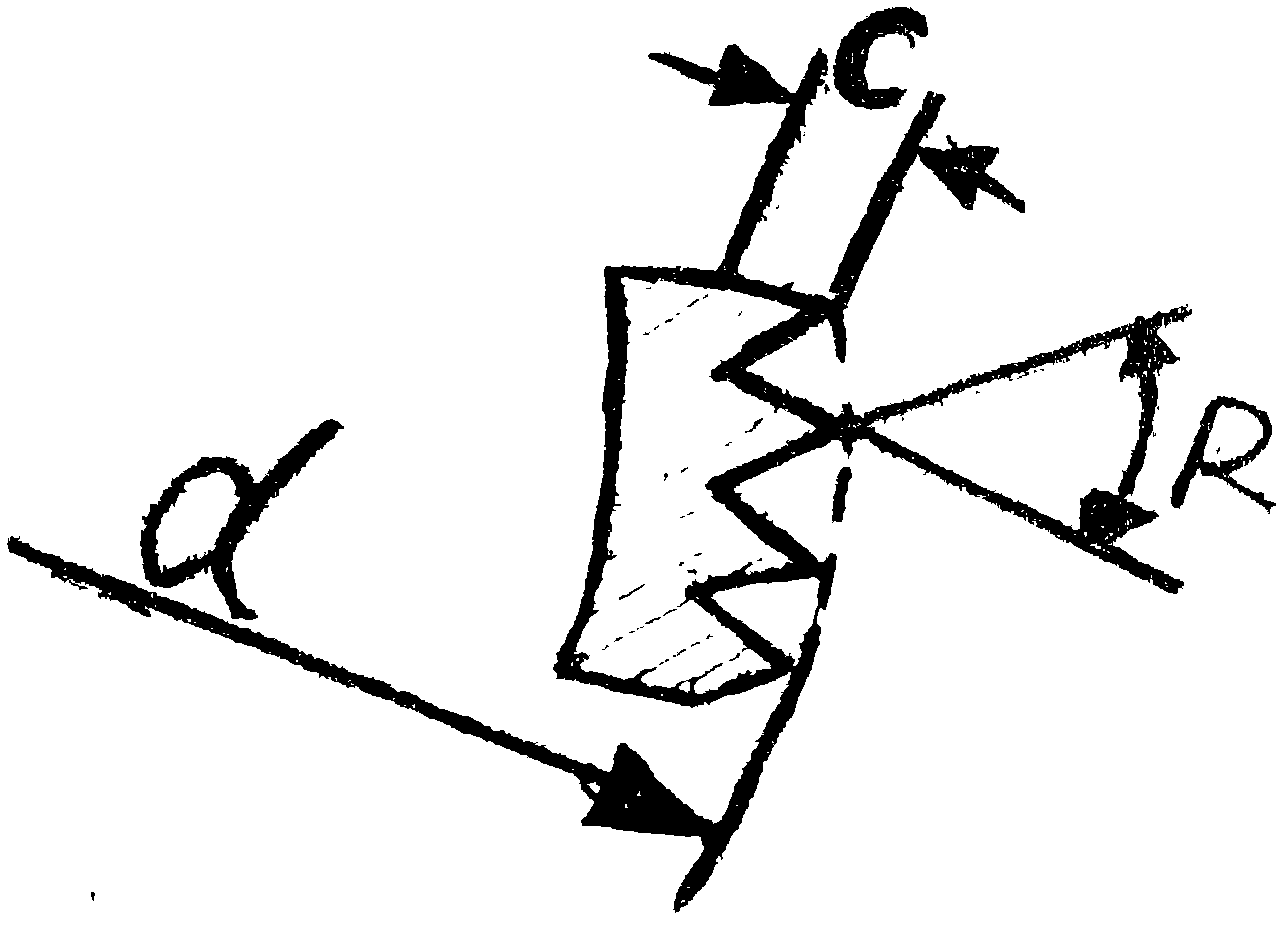

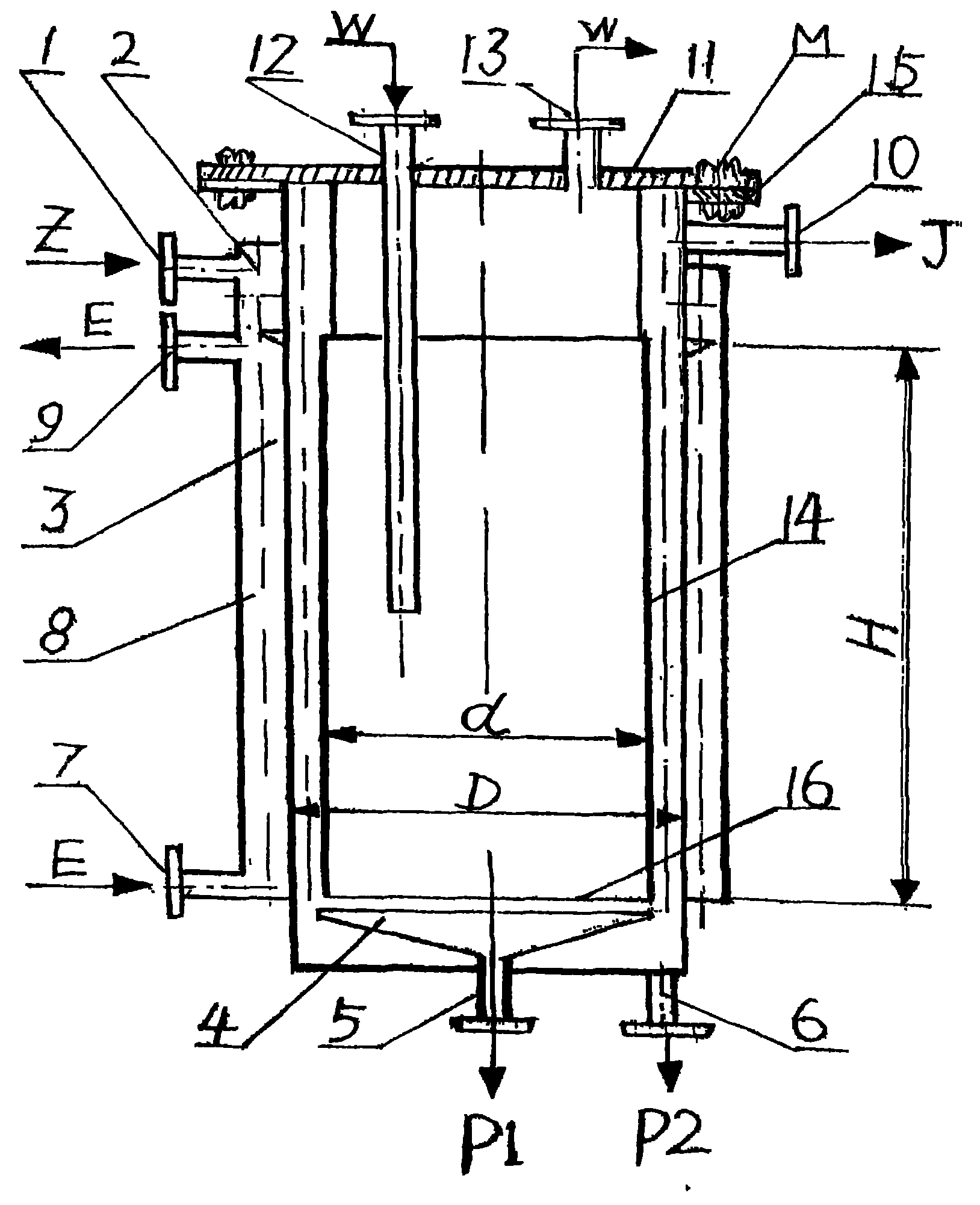

Resin short path distiller and resin distillation process

ActiveCN102321436ALower distillation temperatureReduce volumeTurpentine spiritsNatural resin purificationThermal energyDistillation

The invention relates to a resin short path distiller and a resin distillation process. The distiller comprises a feed opening 1, a resin liquid distribution ring 2, a molecule evaporation surface 3, a turpentine tray 4 and an outlet 5, a rosin outlet 6, a heating jacket 8, a molecule evaporation tube consisting of a vacuum interface 10 and a flange 11, and a molecule cooler consisting of a waterinlet 12, a water outlet 13, a tooth-shaped corrugated molecule cooling surface 14, a flange 15 and a seal bottom. The evaporation surface is preheated to 130DEG C to 140DEG C, and vacuumized to 50Pato 100Pa; after cooling liquid is injected into the cooler, the pre-heated resin liquid is put into the resin liquid distribution ring; the resin liquid is distributed into a liquid membrane which flows downwards along the molecule evaporation surface and is heated by the evaporation surface, so that molecule distillation is carried out; turpentine molecules escape from the liquid surface and arecooled by the molecule cooling surface into turpentine which flows down to the tray and flows into a storage tank P1 from the outlet 5; and the rest rosin of the liquid membrane flows into a storage tank P2 from the outlet, and the distillation process lasts for 10s to 15s. The resin distillation process provided by the invention is simple and easy to operate, saves above 70 percents of heat compared with a distillation process, so that the color of the rosin is lighter.

Owner:陆让先

Forward osmosis membrane flow system and composite semipermeable membrane for forward osmosis membrane flow system

InactiveCN103582520AImprove efficiencyAvoid smallSemi-permeable membranesPump componentsFluid migrationPorous membrane

Owner:NITTO DENKO CORP

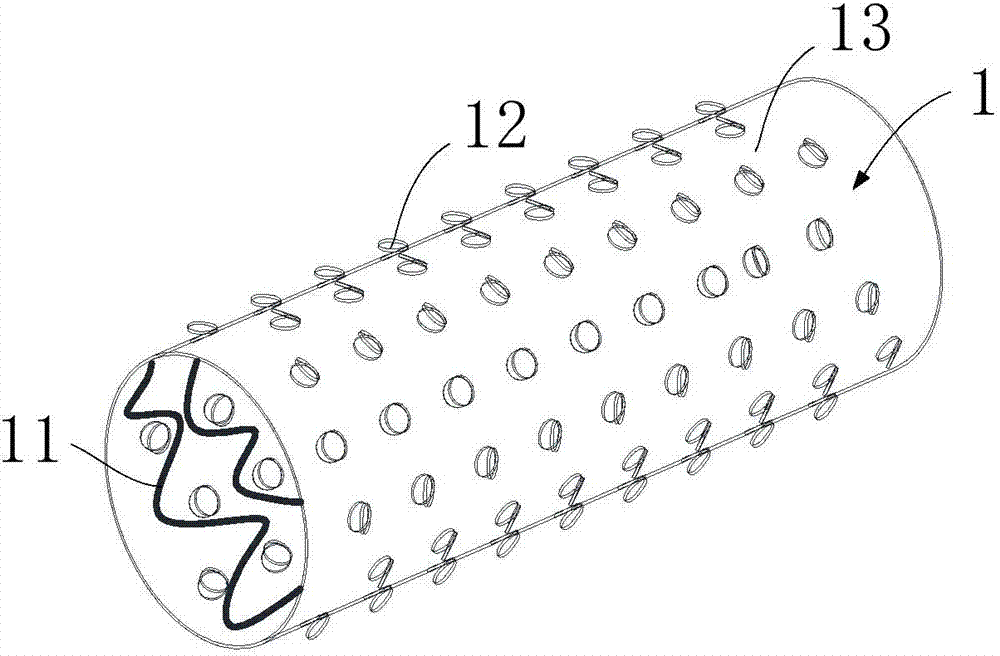

Check valve membrane coated stent

PendingCN107334561AReduces the chance of vortex formationReduces the chance of eddy currentsStentsBlood vesselsCheck valveBlood vessel

The application of the invention discloses a check valve membrane coated stent. The check valve membrane coated stent comprises a coating membrane, a stent main body and a periosteal flap, a through hole is formed in the coating membrane, the stent main body is used for supporting the coating membrane, the periosteal flap is connected to the through hole of the coating membrane, blood in the coating membrane flows into an arterial aneurysm and a collateral branch of a blood vessel through the open periosteal flap, and the periosteal flap is closed when the blood in the arterial aneurysm flows back. The check valve membrane coated stent is easy to manufacture, convenient to operate, easy to realize and low in cost, a one-way membrane stops the blood flowing into the artery blood vessel from the arterial aneurysm, and the breathing and the internal and external gas interaction of the blood vessel are not affected.

Owner:ZHUHAI TON-BRIDGE MEDICAL TECH CO LTD

Coiled membrane separating technology and equipment with forward feeding and reversed washing processes

The invention discloses a novel coiled membrane separating technology with forward feeding and reversed washing processes. During the forward feeding process, a feeding valve is opened; a material delivering pump and a high-pressure pump are started; a membrane pile is switched to a normal feeding connection state; a break valve is adjusted, until a system pressure reaches a preset value, such that a membrane separating system operates normally; a liquid material is delivered into a circulation tank, and is delivered into the membrane pile through the material delivering pump and the high-pressure pump; substances penetrating the membrane form a penetration liquid, and substances that do not penetrate the membrane flow back to the circulation tank through the break valve and an condensation pipeline. During the reversed washing process, a water inlet vale is opened; the material delivering pump and the high-pressure pump are started; the membrane pile is switched to a state opposite to the normal feeding state; the break valve is adjusted, until a pressure required by washing is reached, such that the membrane separating system operates in a washing state. The invention also discloses coiled membrane separating equipment with forward feeding and reversed washing functions. With the technology and the equipment, material separating can easily be carried out, the service life of the membrane is prolonged, and the washing effect is improved.

Owner:SEPATEC ENVIRONMENTAL PROTECTION TECH XIAMEN

Dialysis machine and ultrafiltration

The invention relates to a dialysis machine capable of performing ultrafiltration without the need for a dedicated ultrafiltration pump. The system uses a pair of membrane flow balance pumps wherein the operation and / or the volume flow rate of the pumps can be modified during operation to bring about a net movement of dialysate either into or from the dialyser. The direction of flow of the dialysate in the dialyzer is reversible and the dialyzer can comprise two dialysate inlets, one at each end, and two dialysate outlets, one at each end.

Owner:QUANTA DIALYSIS TECH LTD

Reverse osmosis processing device

InactiveCN103328077ARelieve pressureSmall inner diameterMembranesWater/sewage treatment bu osmosis/dialysisWater dischargeReverse osmosis

This reverse osmosis processing device (10) is provided with: a pressurized vessel (24); an inlet tube (56) that supplies water to be processed to one end of the pressurized vessel (24); a concentrated water discharging tube (62) that discharges concentrated water to the other end of the pressurized vessel (24); a plurality of reverse osmosis membrane elements (22) disposed within the pressurized vessel (24) and provided with a reverse osmosis membrane; a water collecting piping (34) that connects the plurality of reverse osmosis membrane elements (22) in series within the pressurized vessel (24) and through which permeated water that has passed through the reverse osmosis membrane flows; a first discharge tube (58) that discharges the permeated water on the concentrated water discharging tube (62) side of the pressurized vessel (24); and a resistance piping (90) on the inlet tube (56) side within the water collection piping (34).

Owner:HITACHI LTD

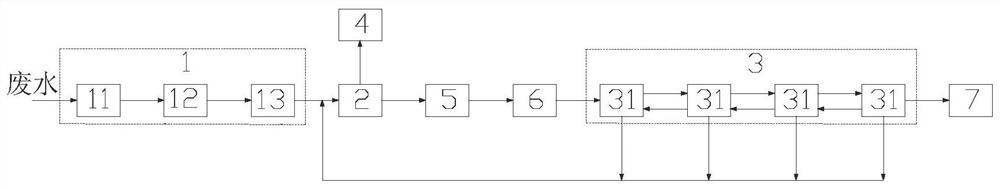

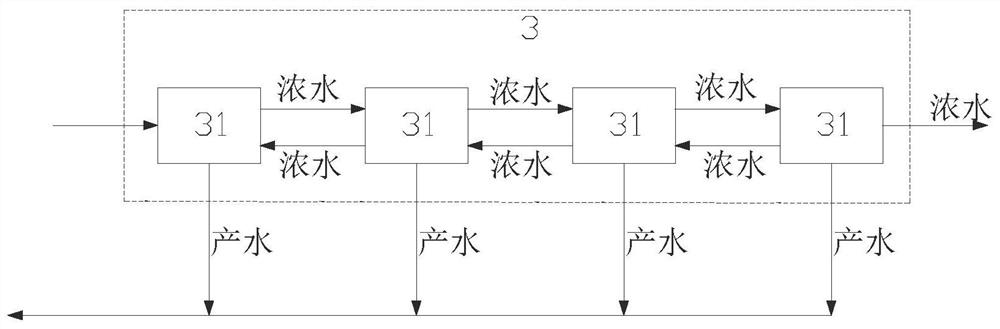

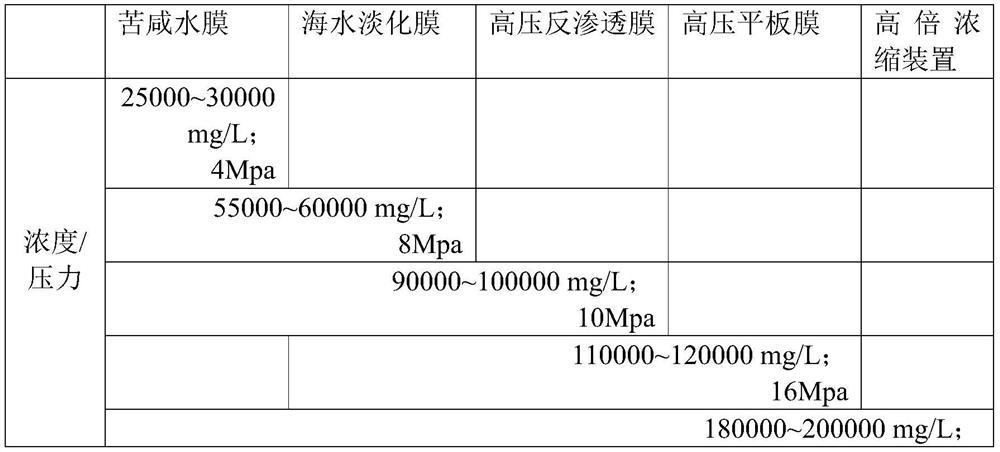

Novel membrane concentration system, process thereof and high-power concentration device

PendingCN113998793ALow running costReduce energy consumptionWater treatment parameter controlSeawater treatmentInorganic saltsThermodynamics

The invention discloses a novel membrane concentration system which comprises a pretreatment device, a reverse osmosis device, a high-power concentration device, an ion exchange device and an advanced oxidation device, wherein high-multiple concentration can be realized; besides, the operation pressure is low, and the operation energy consumption of the system is greatly reduced. According to the novel membrane concentration process, the characteristics of reverse osmosis membranes are fully utilized, and part of concentrated water of a next-stage weak reverse osmosis membrane flows back to the water production side of a previous-stage weak reverse osmosis membrane, so that the inorganic salt content of the water production side of the previous-stage weak reverse osmosis membrane is increased, and the osmotic pressure difference between the concentrated water side and the water production side of the weak reverse osmosis membrane is reduced; furthermore, high-multiple concentration is realized under relatively low operation pressure. The invention further discloses a high-power concentration device, and the content of inorganic salt in concentrated water is gradually increased through a multi-stage weak reverse osmosis membrane; wherein, a backflow water inlet is formed in the water production side of each previous-stage weak reverse osmosis membrane, so that part of concentrated water flows back, and finally, high-multiple concentration is realized.

Owner:INNER MONGOLIA JIUKE KANGRUI ENVIRONMENTAL TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com