Patents

Literature

81results about How to "Restore flux" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

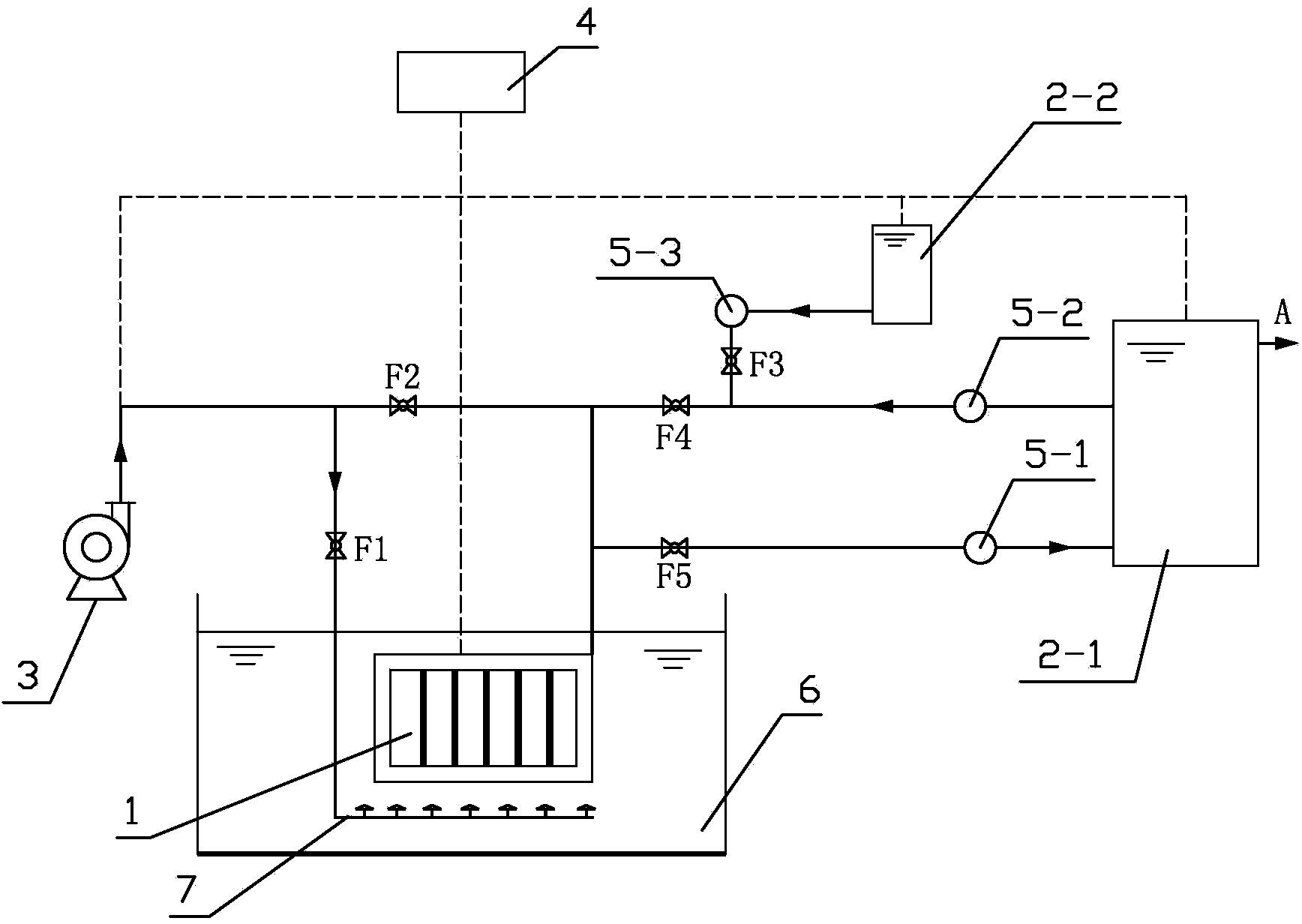

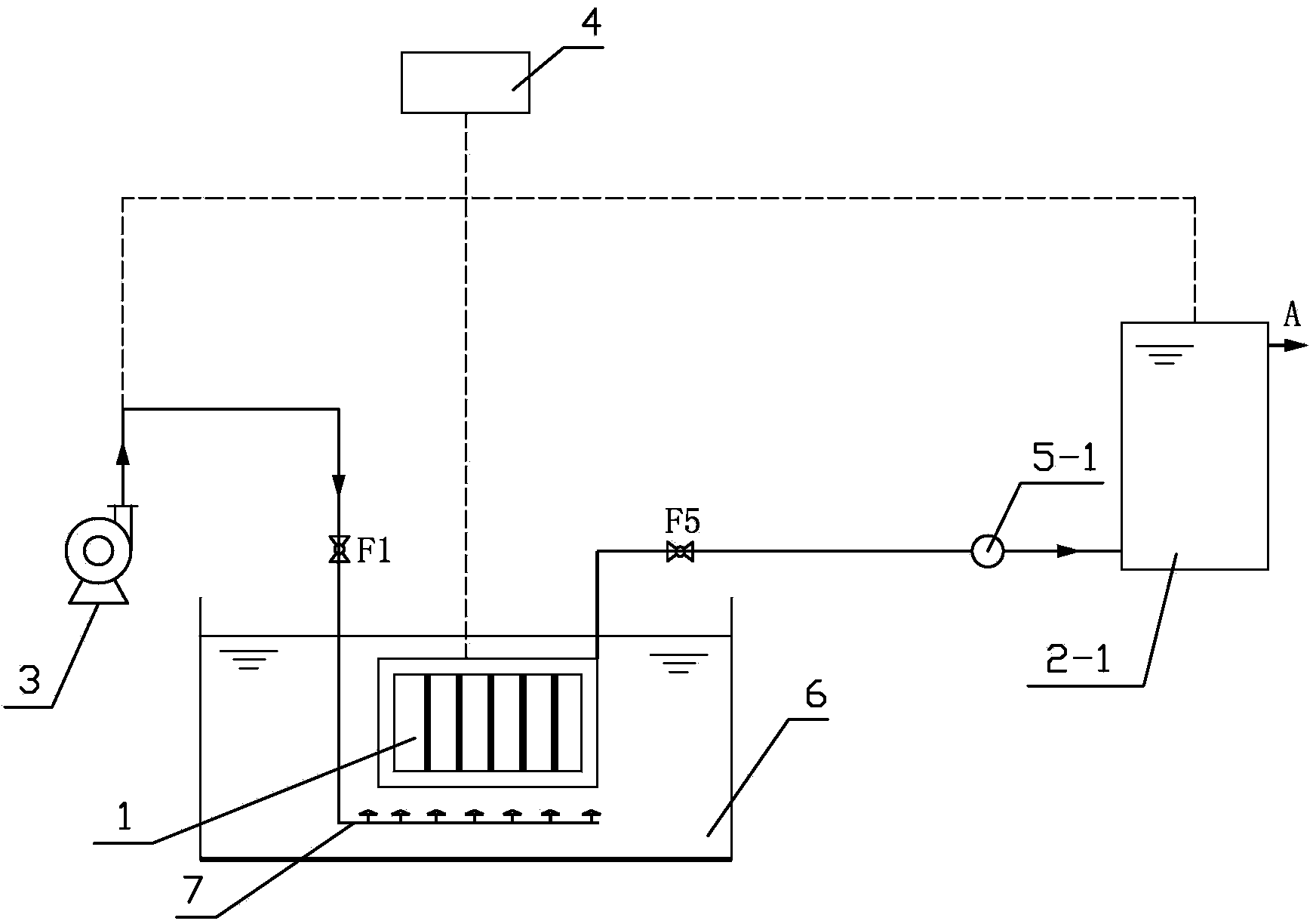

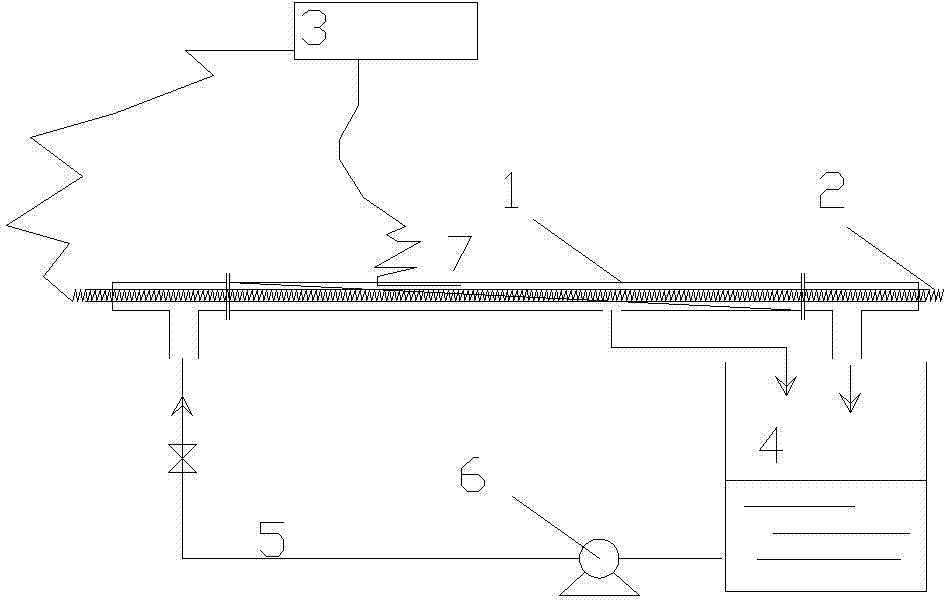

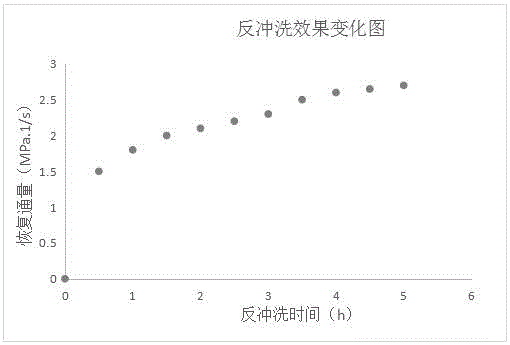

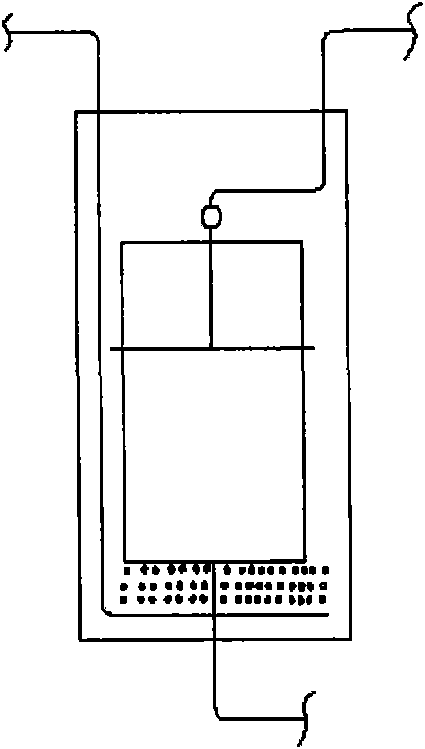

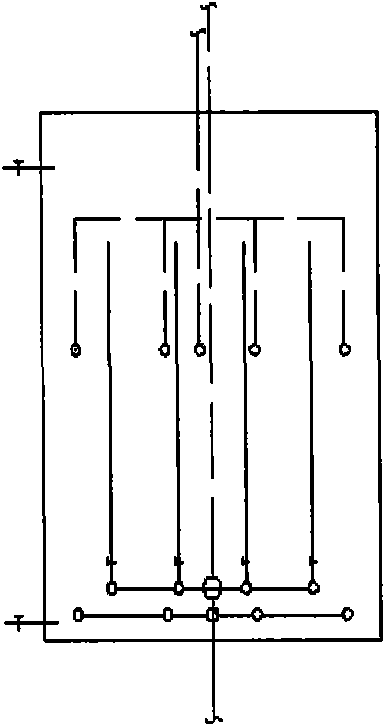

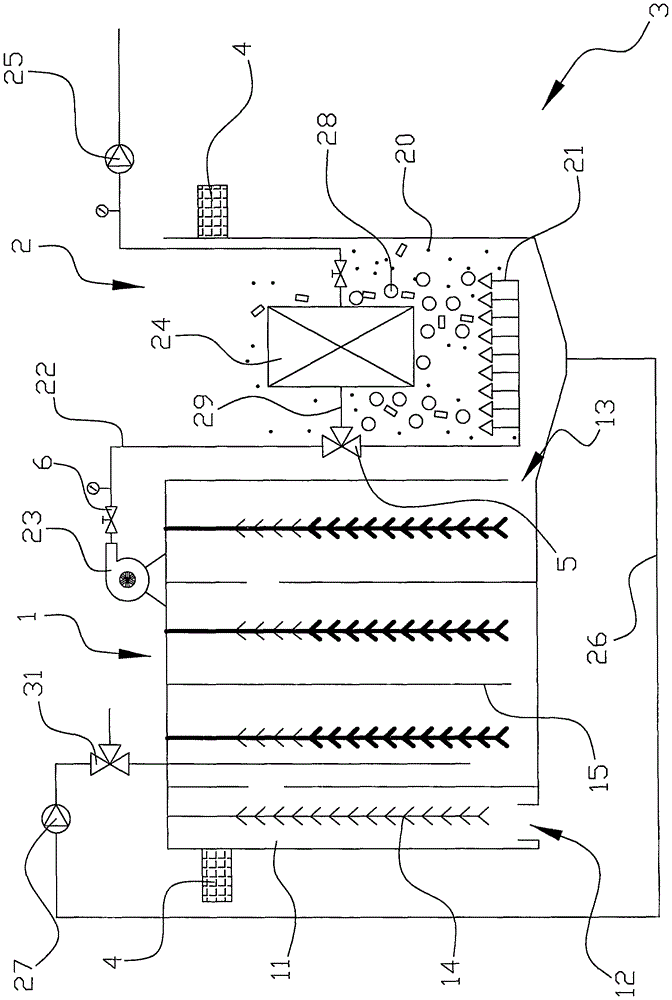

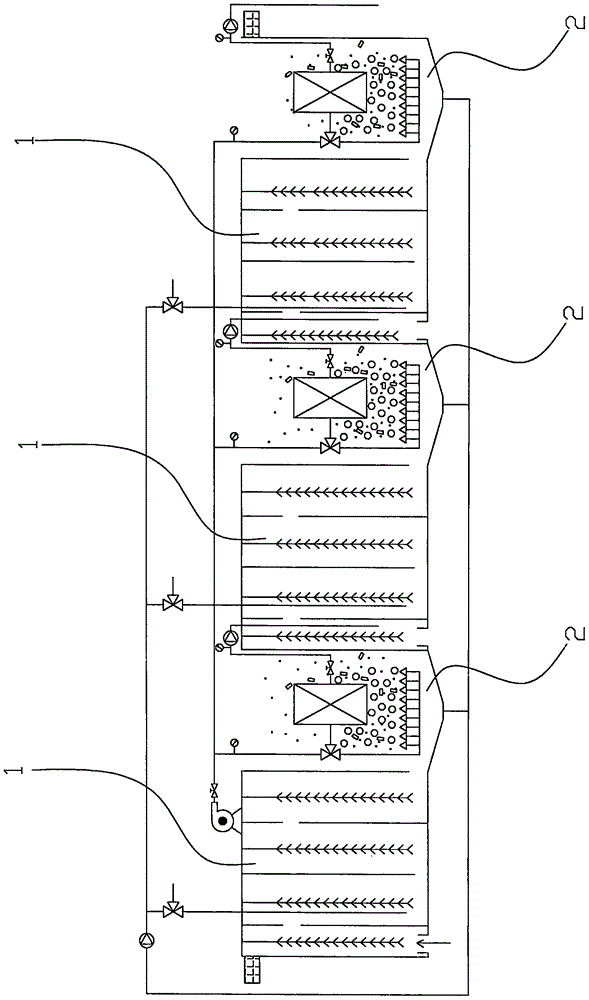

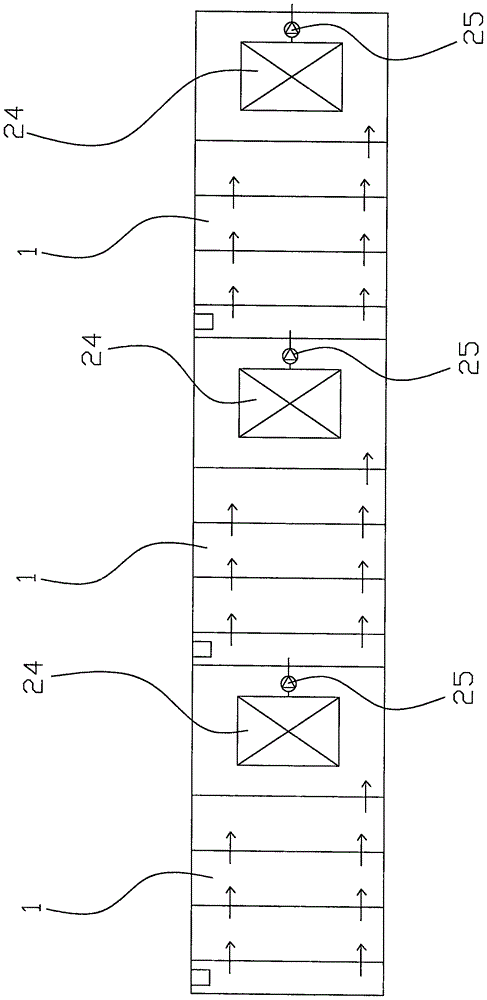

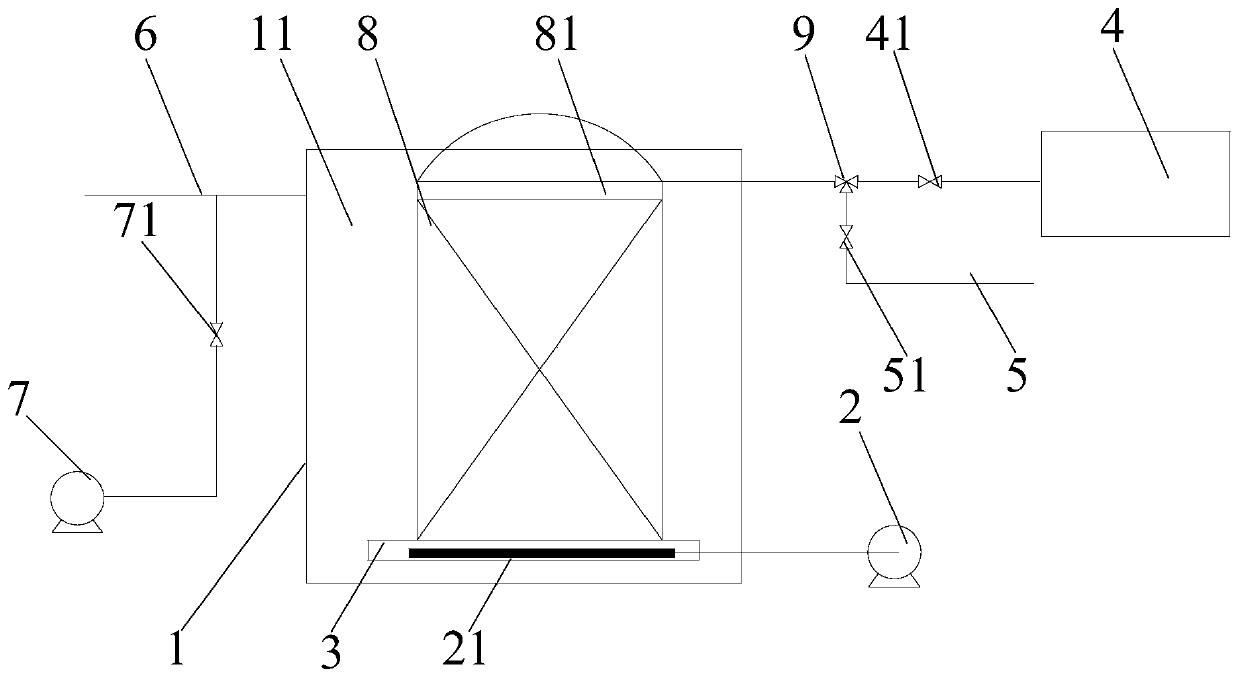

Immersed type on-line cleaning method and device for slab ceramic membrane

InactiveCN103752175AImprove cleaning effectGood system integrationSemi-permeable membranesAutomatic controlFlat panel

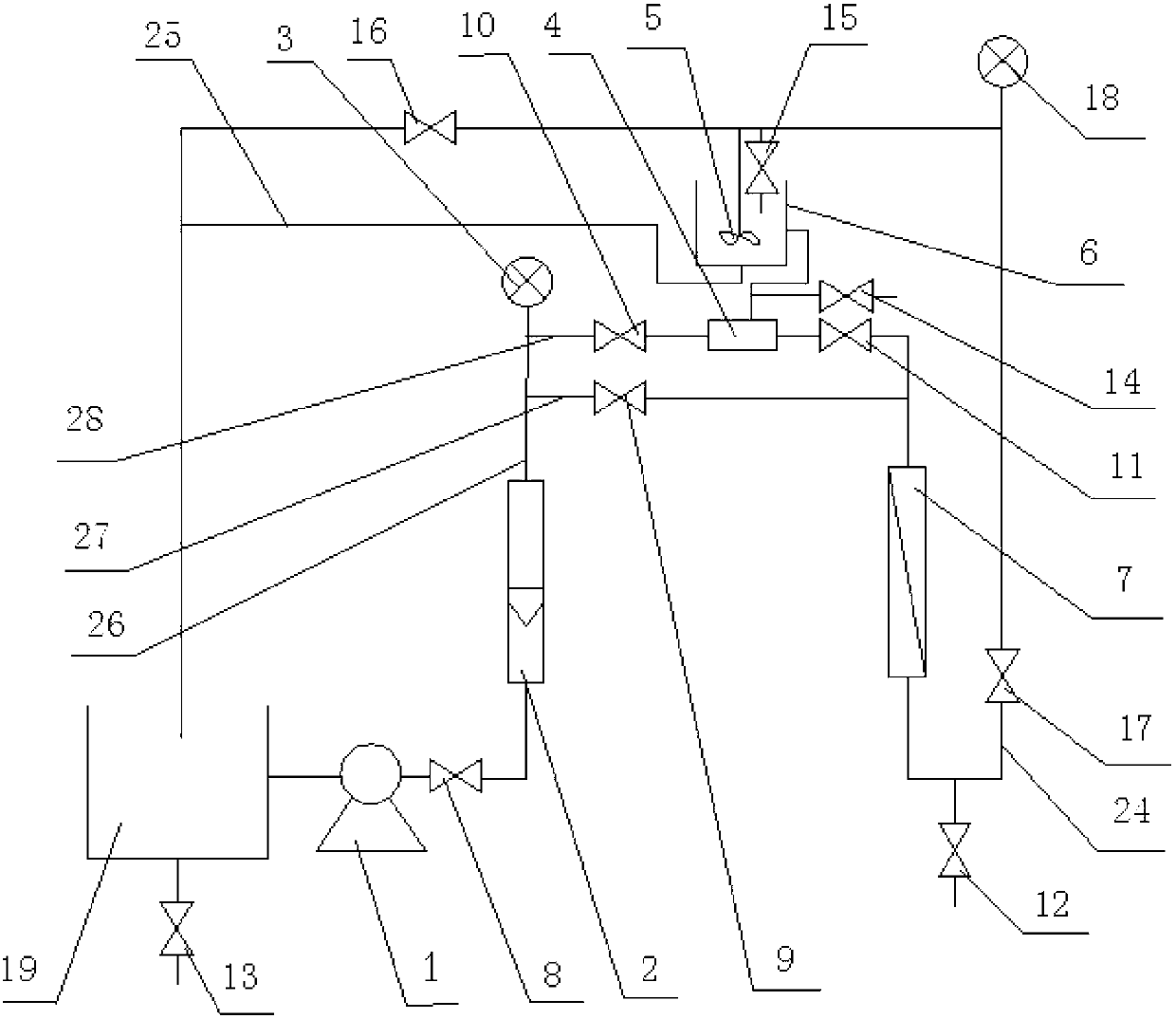

The invention relates to an immersed type on-line cleaning method and device for a slab ceramic membrane. The invention aims to provide the method which can be used for cleaning the slab ceramic membrane in an in-situ or online manner without separating the ceramic membrane and a reactor, and the method has the characteristics of high membrane flux recovery speed, low energy consumption, high cleaning efficiency, low operation cost and automatic control. The provided device has the characteristics of simple structure and convenience in use. According to the technical scheme, the immersed type on-line cleaning process for the slab ceramic membrane comprises the following steps in sequence: (1) turning on on-line cleaning; (2) back-flushing a liquid phase; (3) back-flushing gas and liquid in a combined manner; and (4) finishing the on-line cleaning. The immersed type online cleaning device for the slab ceramic membrane comprises an aeration pipeline and a control system, wherein the on-line cleaning device further comprises a liquid-phase back-flushing system; the liquid-phase back-flushing system is assorted with a back-flushing pump and is communicated with the aeration pipeline through a pipeline; a cleaning agent preparation device is communicated with the liquid-phase back-flushing system through a pipeline.

Owner:ZHEJIANG ZONE KING ENVIRONMENTAL SCI&TECH CO LTD

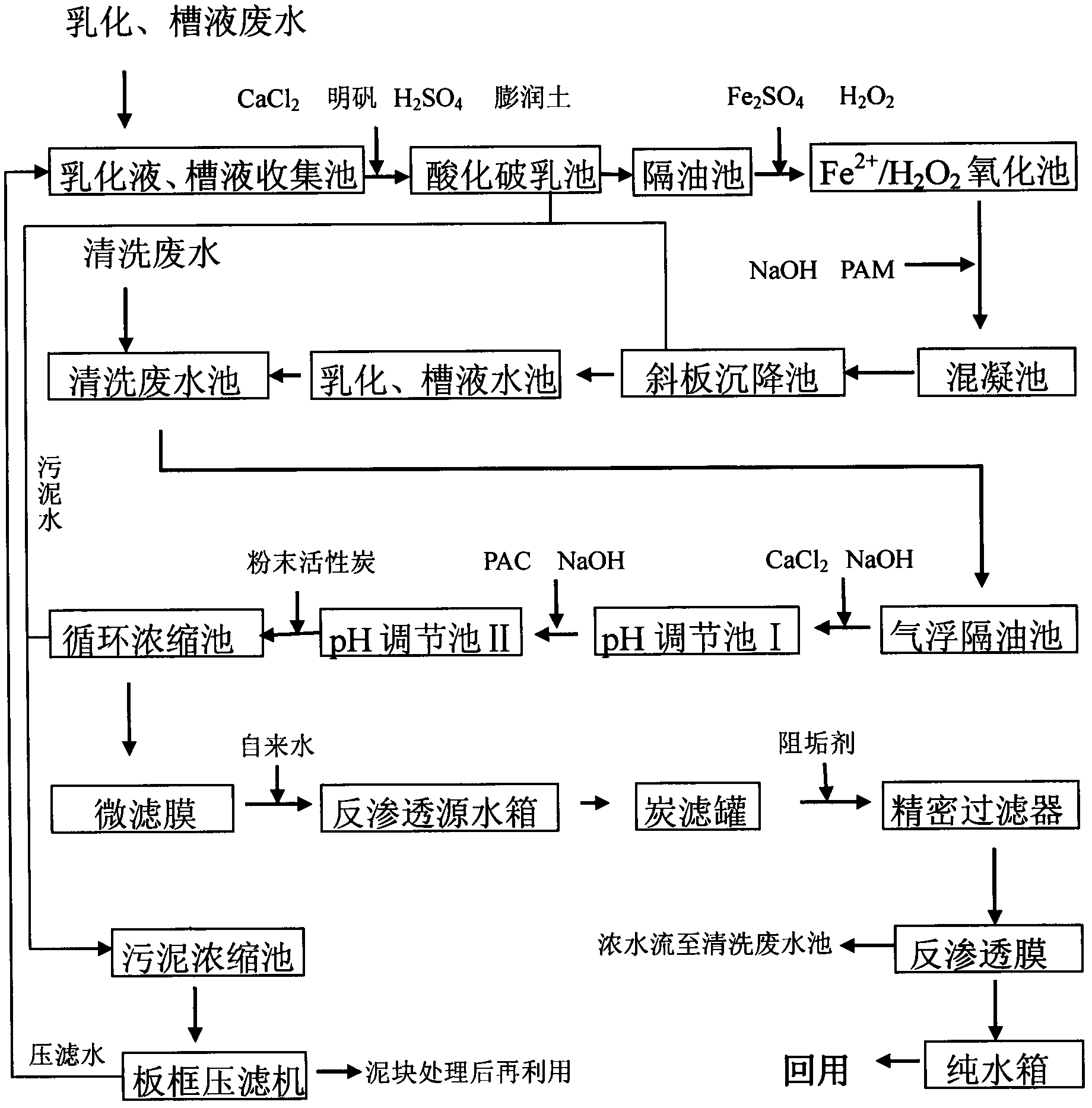

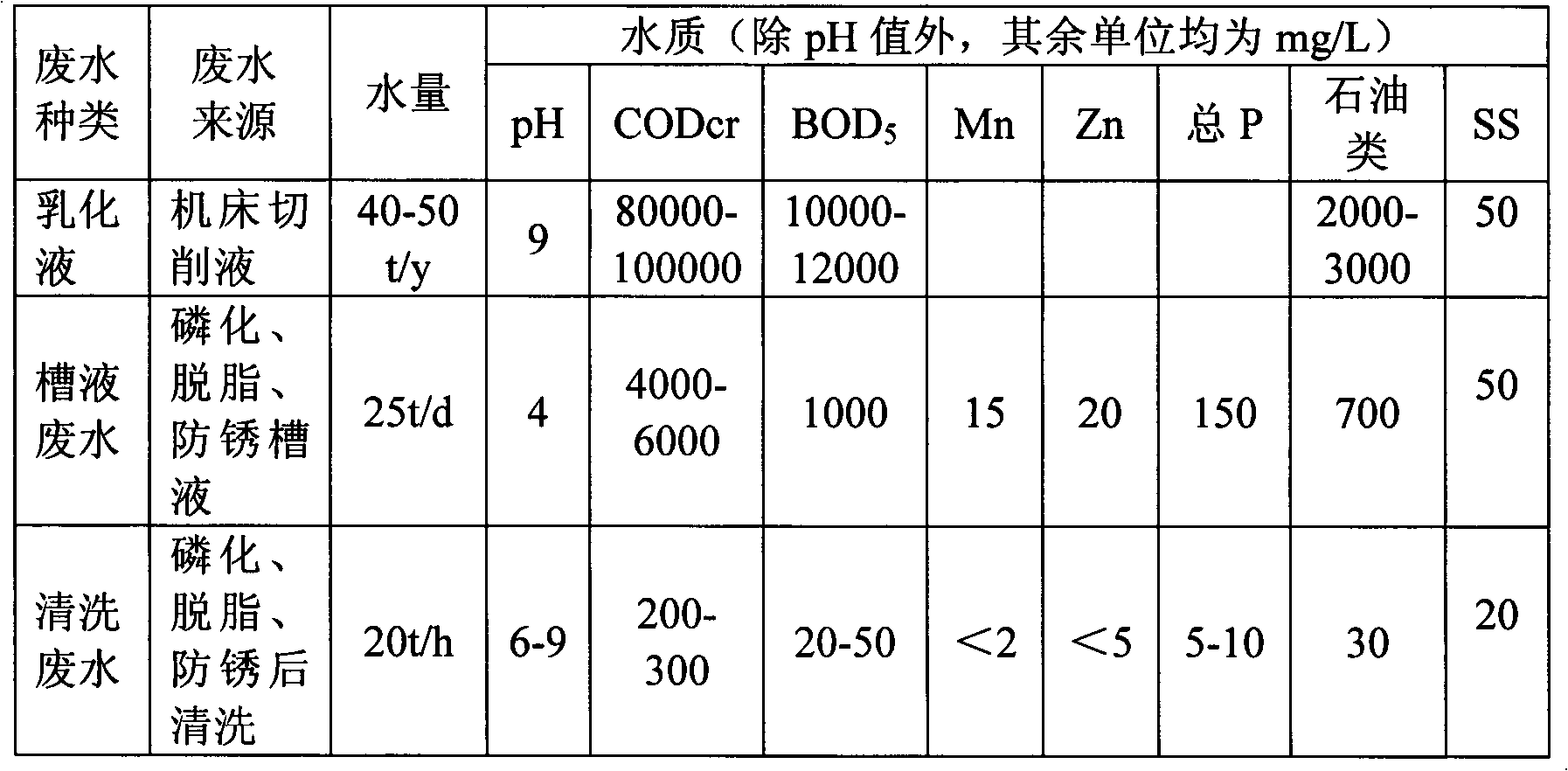

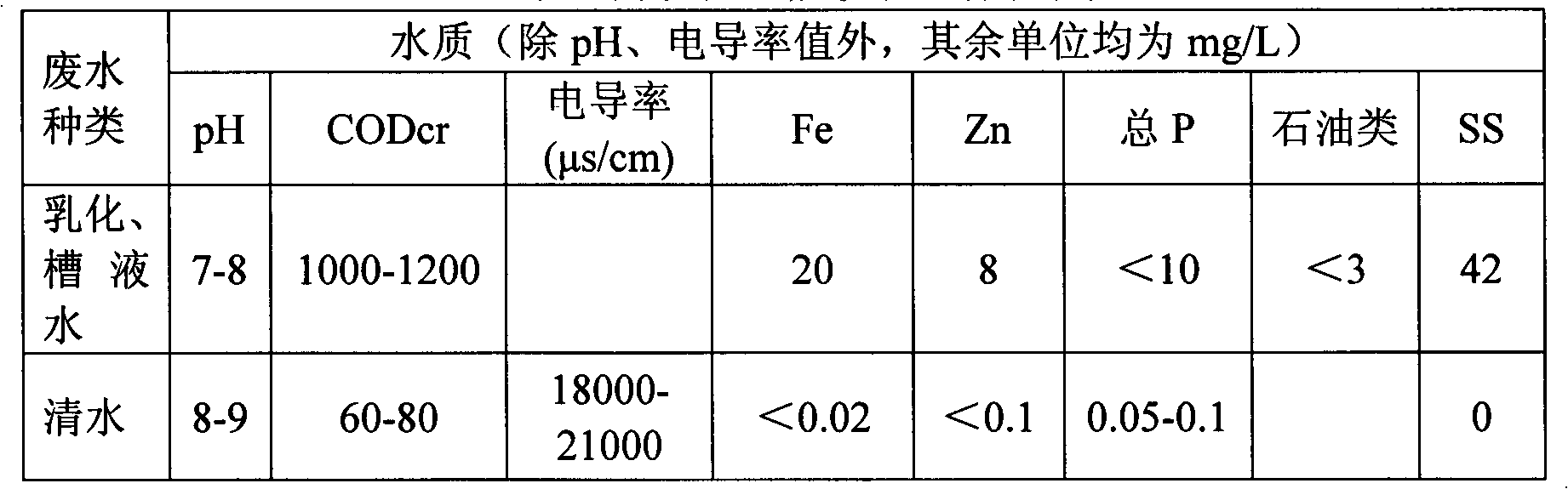

Reuse treatment method for industrial wastewater from refrigerator compressor factory

InactiveCN102642961AReduce COD valueReduce oil contentGeneral water supply conservationMultistage water/sewage treatmentWater useFiltration

The invention relates to a reuse treatment method for industrial wastewater from a refrigerator compressor factory. Firstly, independently collected emulsified bath solution wastewater is acidified and demulsified, free oil and emulsified oil in the wastewater are eliminated, and then the wastewater is subjected to Fe<2+> / H2O2 oxidation, the effluent pH is 7-8, and then coagulant aid is added forcoagulation sedimentation, and organic matter, metal salt and SS are removed, so that emulsified bath solution water is obtained. Subsequently, the emulsified bath solution water and the independently collected rinsing wastewater are uniformly mixed according to the ratio of 1:20-30 to serve as the source water for micro filter membrane treatment; the source water is subjected to air floatation oil separation dephosphorization, coagulation and activated carbon adsorption to obtain water with the pH value of 9-10 under micro filtration, and then the water under micro filtration enters the micro filter membrane, so clean water is obtained; and the clean water and tap water are mixed according to the ratio of 1:1-2, are subjected to filtering by activated carbon and 5um precise filtration and enter a reverse osmosis membrane, and then pure water is obtained after desalination, and the pure water can be reused for production. With the reuse treatment method, the water quality of reused water is stable and can reach the standard of pure water used by enterprises for production, the water is reused for a product line, so that the wastewater discharge of the enterprises is greatly reduced, the use volume of tap water is saved, and remarkable economical and social benefits are achieved.

Owner:TONGJI UNIV +1

Regeneration method of gas filter element

InactiveCN104645732AGood effect of dust removal and regenerationAvoid damageDispersed particle filtrationCombustionProduct gas

The invention relates to a regeneration method of a gas filter element. The gas filter element is integrally arranged in a combustion-supporting gas with an oxygen volume ratio of 0.01 to 20 percent, the combustion-supporting gas is enabled to have the oxidizing reaction with impurities on the surface of the gas filter element at a set temperature, and the impurities can be removed. By adopting the regeneration method of the gas filter element, not only can a good gas filter element dust removal regeneration effect be achieved, but also the damage of the gas filter element is slight, the gas filter element can be used for a long time; moreover, a flux after the gas filter element is regenerated is obviously restored, and the flux can basically reach that at an initial state of the gas filter element.

Owner:CHENGDU INTERMENT TECH

Preparation method of gourmet powder industrial waste water treatment membrane cleaning agent

InactiveCN102029113AGuaranteed uptimeRestore fluxSemi-permeable membranesCleansing AgentsFatty alcohol

The invention relates to a preparation method of a gourmet powder industrial waste water treatment membrane cleaning agent. The preparation method comprises the following steps of: mixing inorganic salt, a coupling agent, a function monomer with surface activity, a stabilizer, an addition agent, an organic solvent and deionized water, placing the materials in a reactor, and stirring at normal temperature and normal pressure to prepare the gourmet powder industrial waste water treatment membrane cleaning agent. The gourmet powder industrial waste water treatment membrane cleaning agent is prepared by using ethanol water as the medium and comprises the following components in percent by weight: 20-33% of sodium hydroxide, 0.5-5% of sodium triphosphate, 2.5-5% of sodium alkyl benzene sulfonate, 0.1-0.5% of alkyl polyglucoside, 1-5% of kieselguhr, 1-5% of sodium hypochlorite, 1-6% of sodium silicate, 0.3-0.8% of fatty alcohol polyoxyethylene ether sulfate, 0.1-0.5% of zirconium aluminum acid ester coupling agent, 0-5% of sodium sulfate, 0-8% of sodium carbonate, 0-7% of edetic acid disodium slat, 5-10% of ethanol and 35-45% of water. The gourmet powder industrial waste water treatment membrane cleaning agent is prepared by the step of stirring the components for 4-8h at room temperature and normal pressure in a reactor.

Owner:CHINA NAT OFFSHORE OIL CORP +1

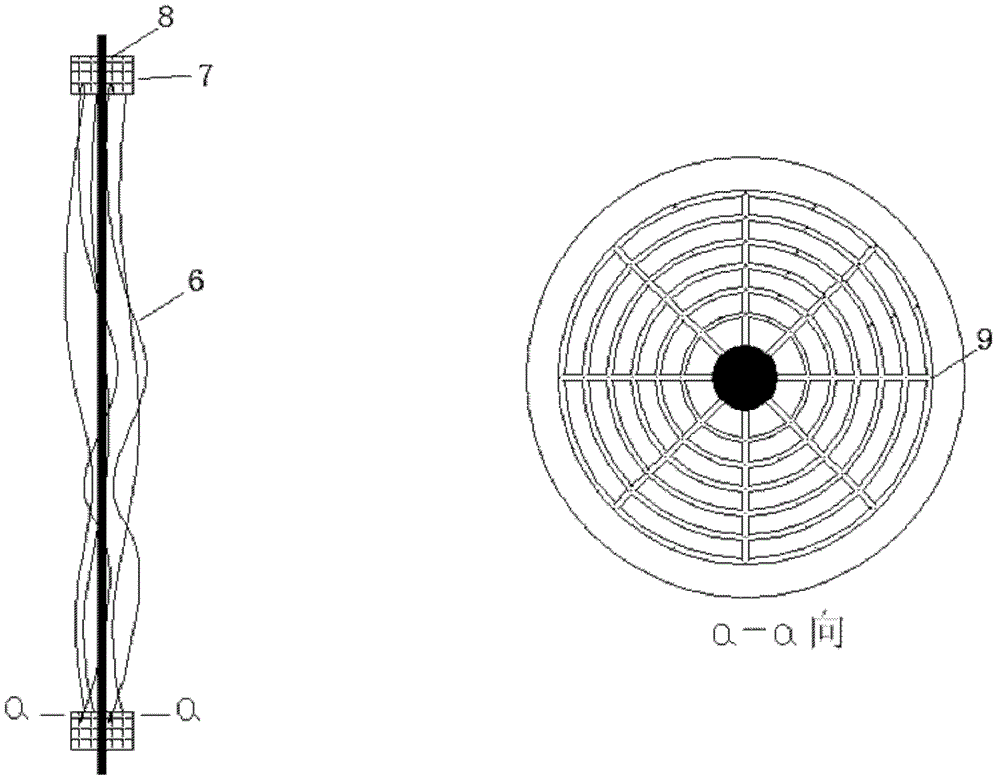

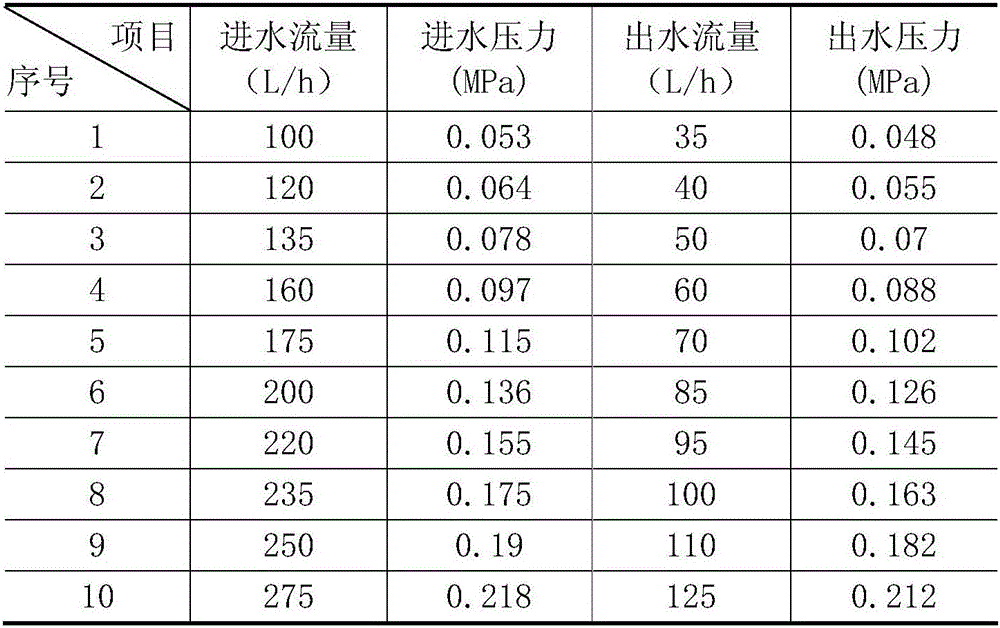

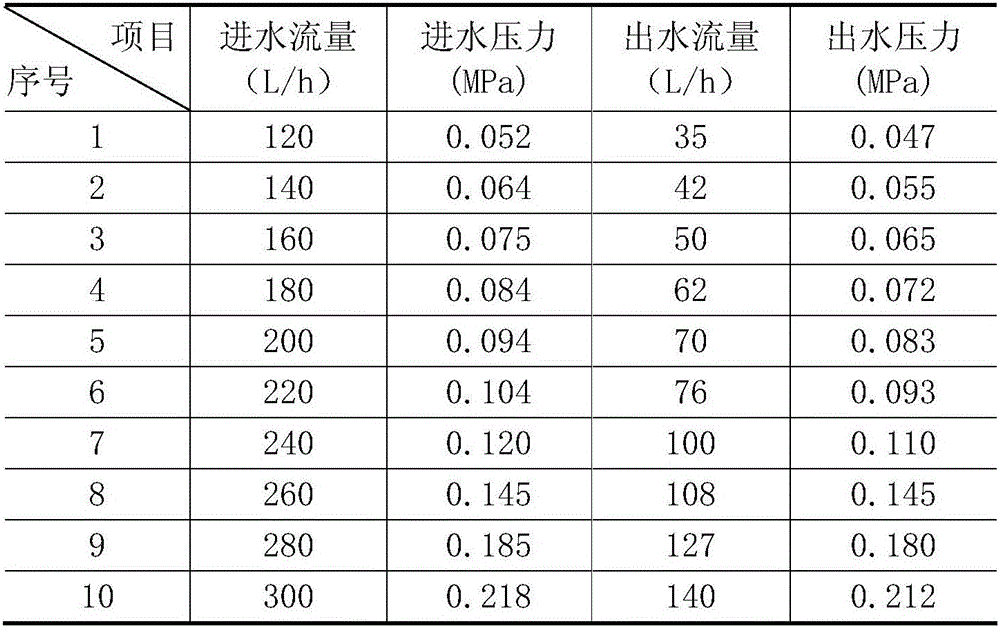

Cleanable security filter and its application

ActiveCN103055701ARestore fluxReduce differential pressureUltrafiltrationWater/sewage treatment bu osmosis/dialysisWater useParticulates

The invention relates to a security filter that can realize online automatic backwashing and its application. The invention solves the technical problems that currently used filter elements in industry have low filter precision, are easy to cause deep pollution, and cannot achieve long-term use through automatic cleaning. The security filter provided in the invention can mainly be used for a double-membrane system in the field of wastewater treatment by a membrane method, such as the security filtering measures in ultrafiltration and reverse osmosis systems, and also can be applied to circulating water replenishing and other water treatment processes with high requirements for filter precision and effluent water quality. The security filter can be used as an effective pretreatment filter means to reduce the influence of particles in water or water quality change caused by inflow water impact on stable running of follow-up processes, so that the effluent water quality can be improved to meet following water use requirements.

Owner:CHINA PETROLEUM & CHEM CORP +1

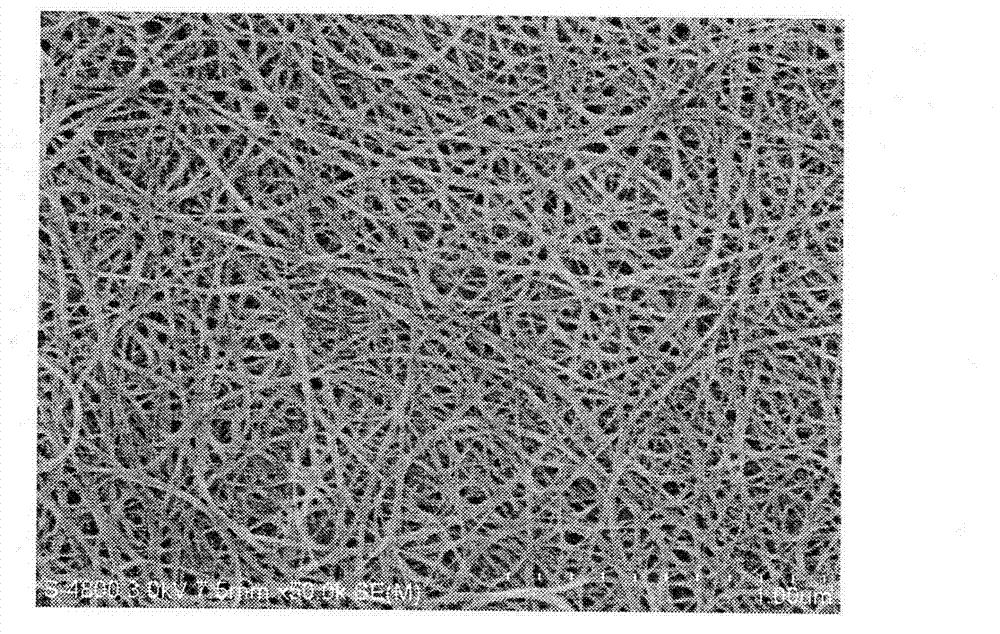

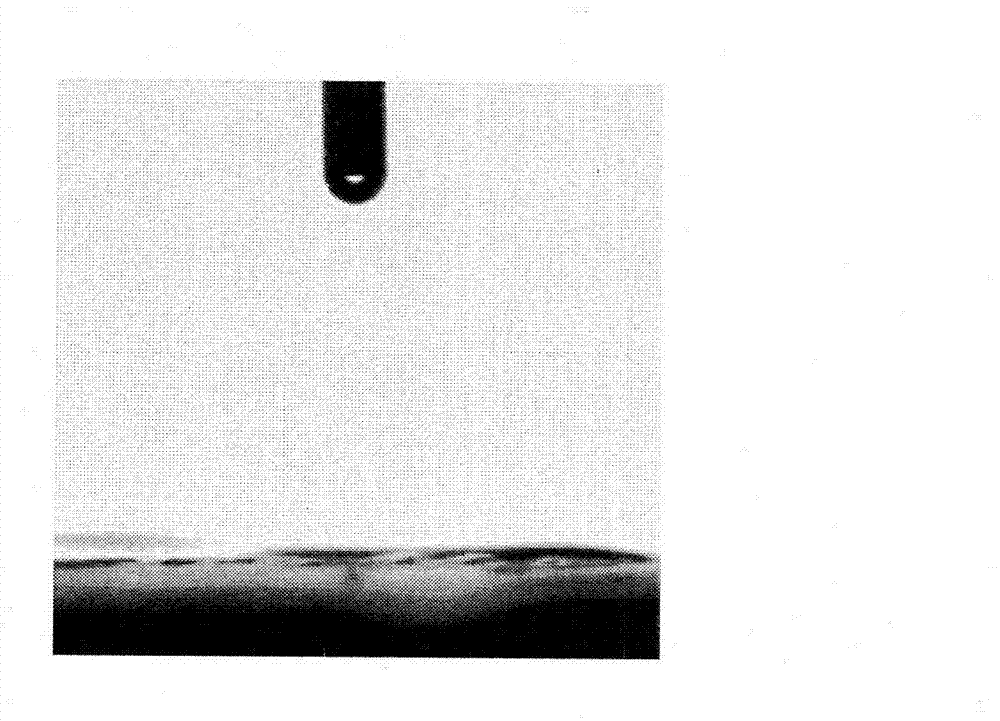

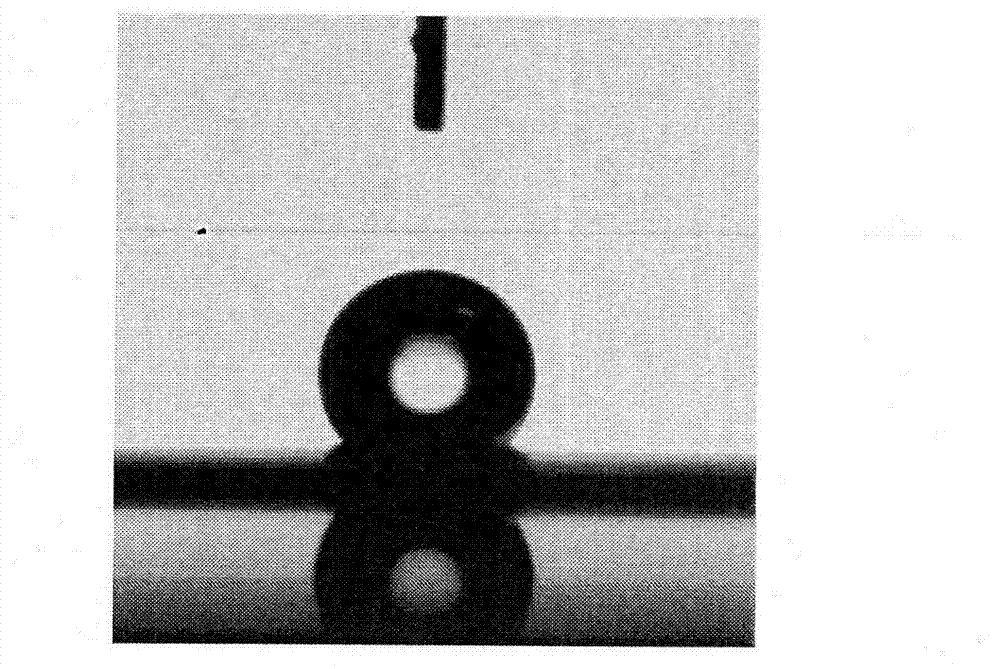

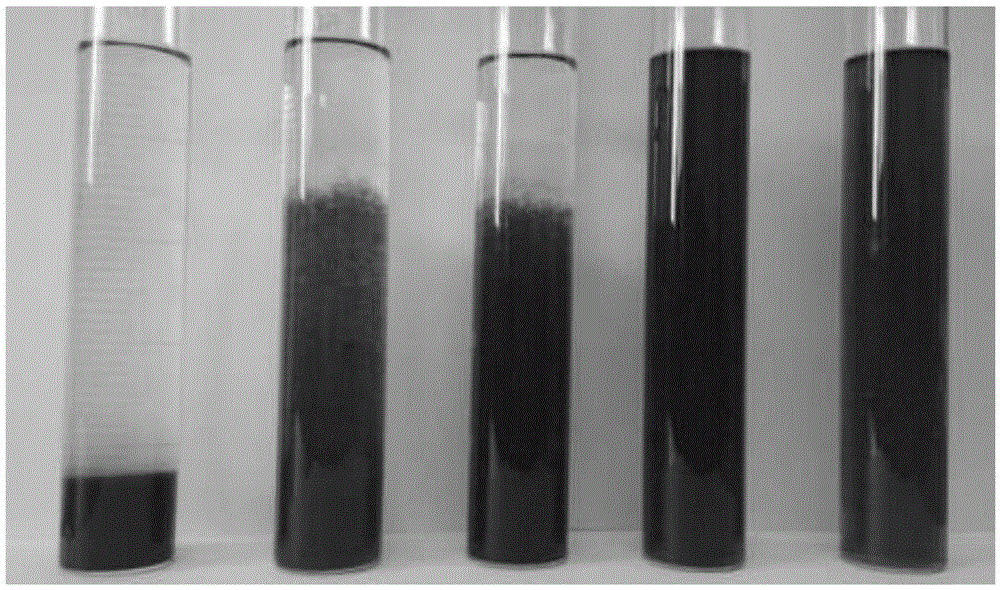

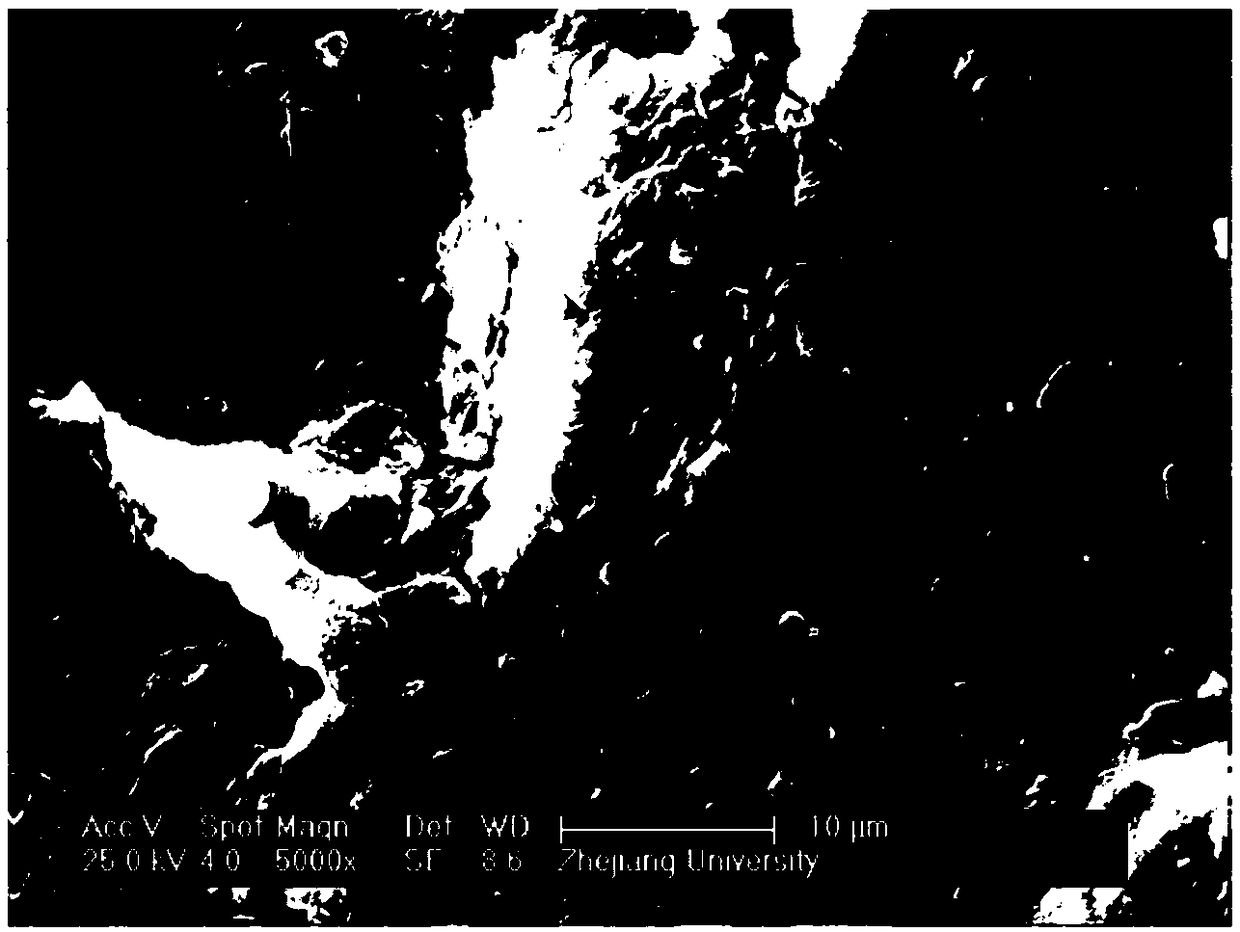

Oil-water separating device and method based on carbon nanotube film

The invention discloses an oil-water separating device and method based on a carbon nanotube film. Separation of an oil-water mixed system is realized by taking a carbon nanotube film as a filter film. The carbon nanotube film is formed by a lattice of interwoven carbon nanotubes, the film thickness is 10-500 nanometers, the film pore diameter is 2-1,000 nanometers, the film surface has hydrophobic and oleophylic properties, the film has high acid resistance and alkali resistance, and the structure and performance of the film are stable when the pH value is 1-14. The oil-water mixed system comprises a system formed by directly mixing an oil phase with a water phase or emulsified oil water (water in oil type or oil in water type). The device and the method can be applied to low-cost, high-flux, efficient and rapid separation of various oil-water mixtures in the fields of production, life, petrochemical industry, machinery and the like.

Owner:SUZHOU INST OF NANO TECH & NANO BIONICS CHINESE ACEDEMY OF SCI

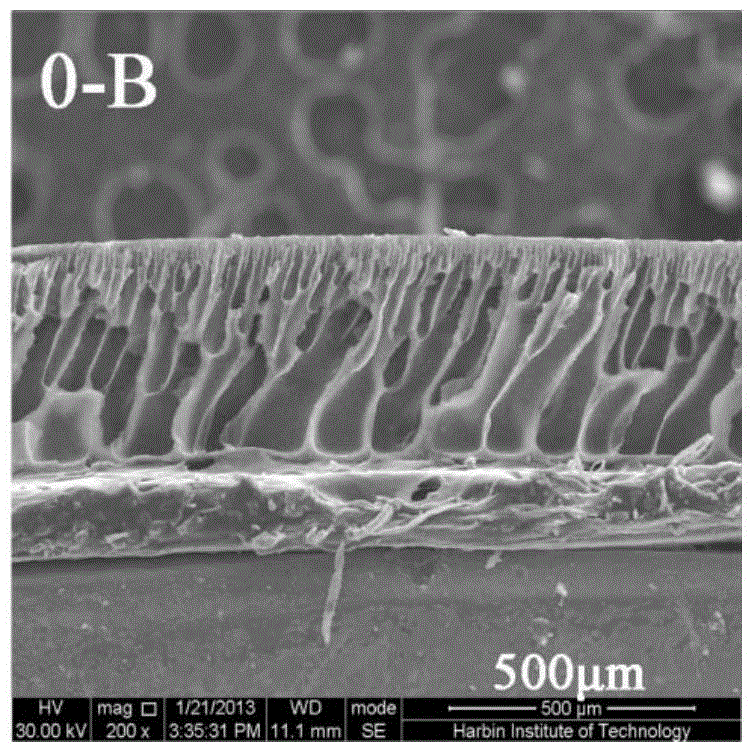

Preparation method of cheap ultra-filtration membrane for treating oil producing wastewater

ActiveCN104258742ANo post-processingSimple processSemi-permeable membranesWater bathsFiltration membrane

The invention provides a preparation method of a cheap ultra-filtration membrane for treating oil producing wastewater. The preparation method comprises the following steps: dissolving nano silicon dioxide into a polyvinyl chloride dissolving solvent under ultrasonic condition to prepare a suspension solution of nano particles; then sequentially and slowly adding a pore-forming agent, a de-foaming agent and polyvinyl chloride into the suspension solution; continuously and mechanically agitating in a water bath of 30-40 DEG C for more than 24 hours until a homogeneous membrane casting solution is formed; sufficiently de-foaming the membrane casting solution in a vacuum drying box and scraping a membrane by using a membrane scraping machine; after volatilizing the scraped new membrane in the air for 15-60 seconds, slowly putting the scraped new membrane into a coagulating bath for coagulation; and after separating the membrane from a glass plate, sufficiently immersing the membrane in pure water for 48 hours to obtain a nano silicon dioxide modified polyvinyl chloride flat plate membrane. The preparation method of the cheap ultra-filtration membrane can be used for nano silicon dioxide polyvinyl chloride hollow fiber type ultra-filtration membranes and micro-filtration membranes, reverse osmosis membranes, nano-filtration membranes, pipe type membranes, capillary tube membranes or spiral-wound membranes.

Owner:HARBIN ENG UNIV

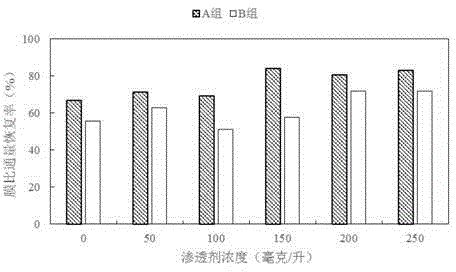

Flocculation method for prevemting membrane from pollution and maintaining flux of membrane

InactiveCN1480410AReduce accumulationLow running costSustainable biological treatmentBiological water/sewage treatmentFlocculationIron salts

A flocculating method for preventing pollution to membrane of membrane bioreactor and maintaining the membrane throughput includes adding iron salt solution to membrane bioreactor, stirring or aerating for providing turbulence while reaction to generate flocculate, and discharging sludge. Its advantages are high effect etc.

Owner:TIANJIN UNIV

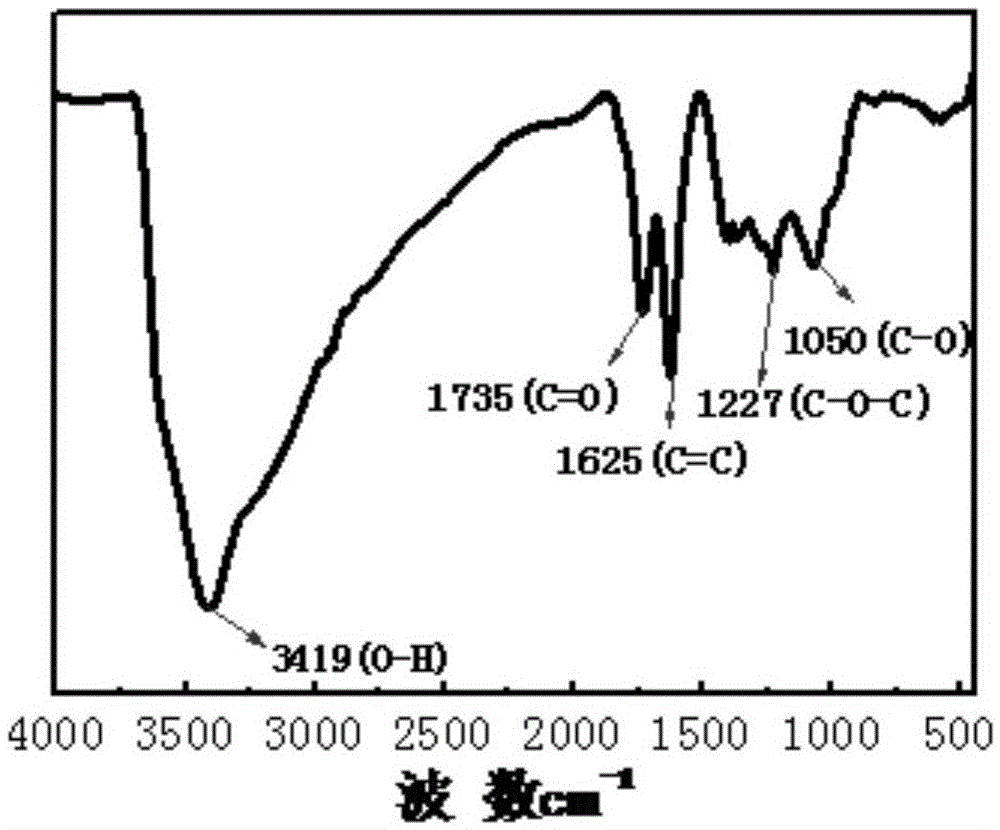

Preparation method of forward osmosis membrane modified with oxidized graphene

InactiveCN105582816AEasy to implementEase of mass industrial productionSemi-permeable membranesGrapheneOrganic solvent

The invention provides a preparation method of a forward osmosis membrane modified with oxidized graphene. The preparation method comprises the following steps: 1, firstly, conducting ultrasonic dispersion on the oxidized graphene in high-polarity organic solvent, so that homogeneous dispersion liquid is obtained; 2, adding organic solvent of raw materials of a produced membrane to the dispersion liquid; 3, sequentially adding additives and the produced membrane to the dispersion liquid obtained in step 2, and stirring the mixture till the mixture is dissolved completely, so that casting membrane liquid is obtained; 4, conducting sufficient defoaming on the casting membrane liquid in a vacuum drying box, then pouring the casting membrane liquid on a glass plate where a support layer is laid, and conducting membrane scraping; 5, after membrane pouring is ended and the casting membrane liquid is volatilized in air, putting the casting membrane liquid in a coagulation bath; 6, separating a membrane piece with the glass plate, and putting the membrane piece into pure water for immersion; 7, conducting natural drying on the membrane which is sufficiently immersed as mentioned above, so that the forward osmosis membrane is obtained. The modified forward osmosis membrane prepared through the preparation method is good in hydrophilicity and water flux and great in antipollution capability, cleaning expense of the membrane is lowered, the service life of the membrane is greatly prolonged, and mechanical properties are improved a lot.

Owner:HARBIN ENG UNIV

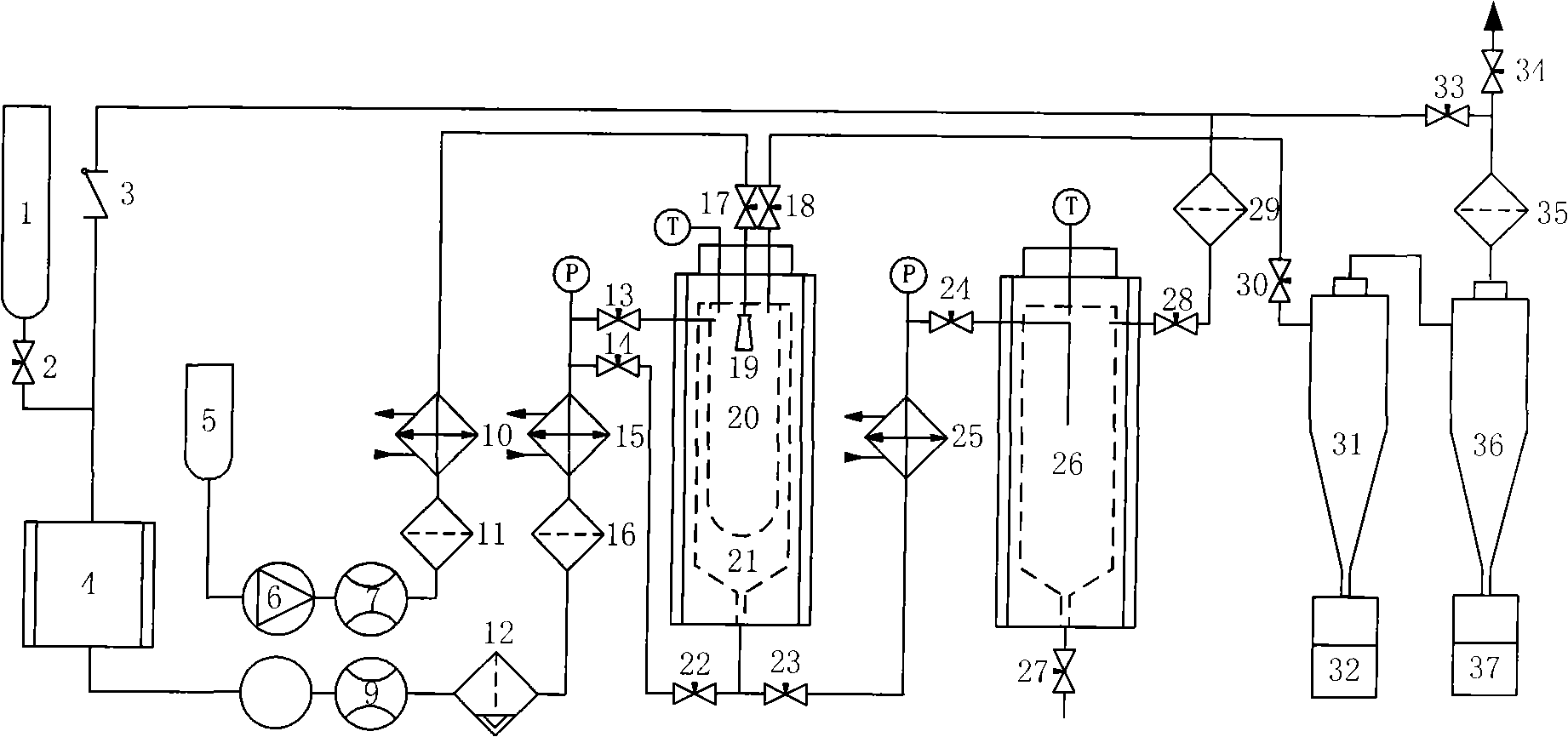

Water-soluble nano material supercritical carbon dioxide anti-solvent preparing device

InactiveCN101264431ACrystallize fastIncrease the areaCrystallization separationGranulation by liquid drop formationFiltration membraneHigh pressure

The invention relates to a preparation device for water-soluble nanometer material supercritical carbon dioxide anti-solvent, comprising a high-pressure pump for carbon dioxide, a high-pressure pump for solution, a nozzle, a crystallization reactor, a whole filtration membrane crystallizer, a separation reactor, and a cyclone separator, which is characterized in that: the nozzle and the whole filtration membrane crystallizer are arranged in the crystallization reactor, the aperture of the nozzle outlet is 1 to 1000um, the aperture of the whole filtration membrane crystallizer is 50 to 500nm, the cyclone separator is connected with the whole filtration membrane crystallizer arranged in the crystallization reactor, thus forming a closed recovery system for products. The preparation device has the advantages of large whole filtration membrane crystallizer area, fast crystallization, small particle size, uniform distribution, high crystallization rate of more than 80 percent, automatic collection of products without opening the cover of the crystallization reactor, ability to conversely blow the whole filtration membrane crystallizer utilizing carbon dioxide, and closely select products through the cyclone separator, thorough collection of products, rapid recovery of filter membrane flux, no pollution to environment, not harm to human body, less solvent consumption, high separation efficiency, fast speed, short cycle, low energy consumption, and easy operation.

Owner:NORTHEAST FORESTRY UNIVERSITY +1

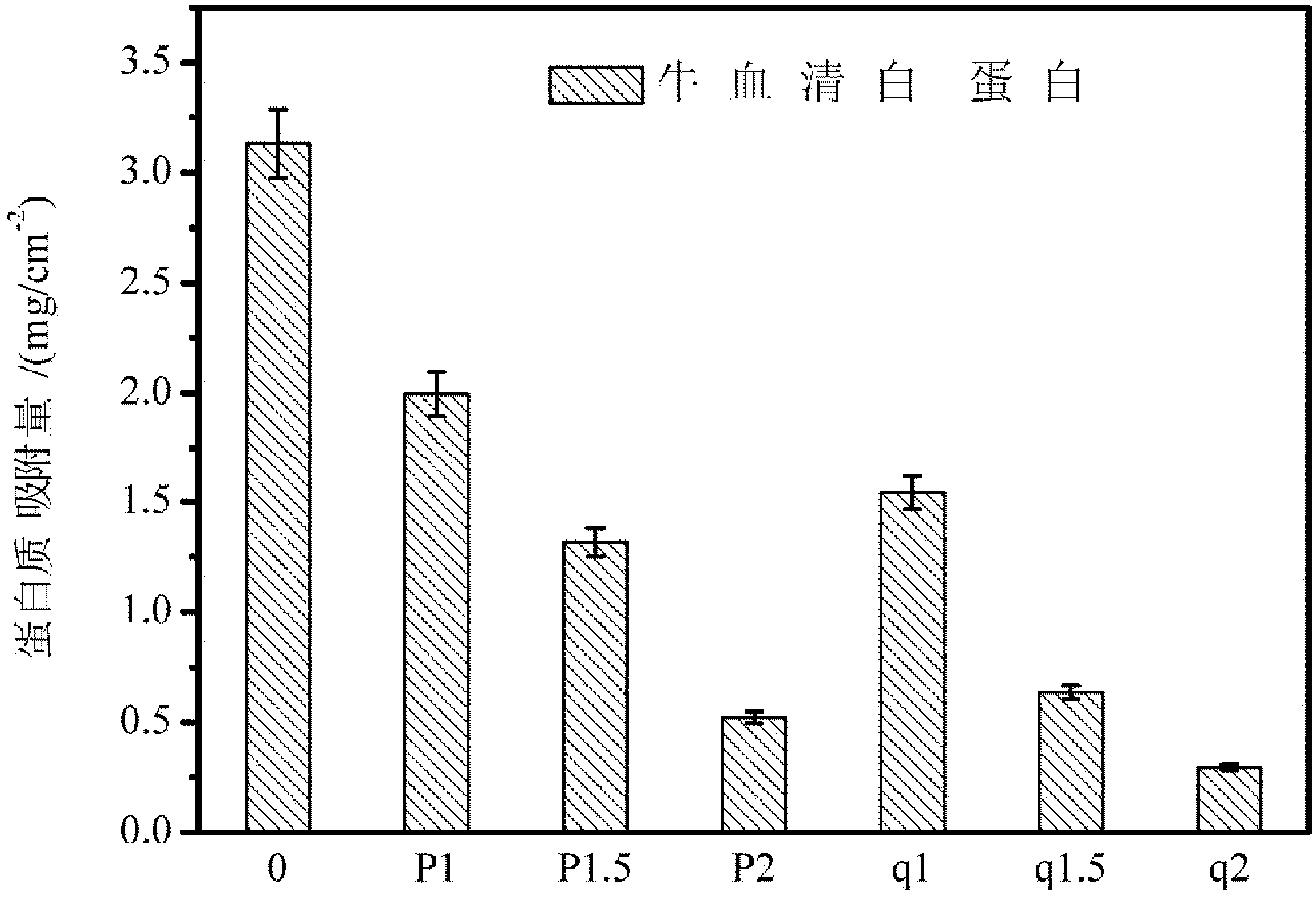

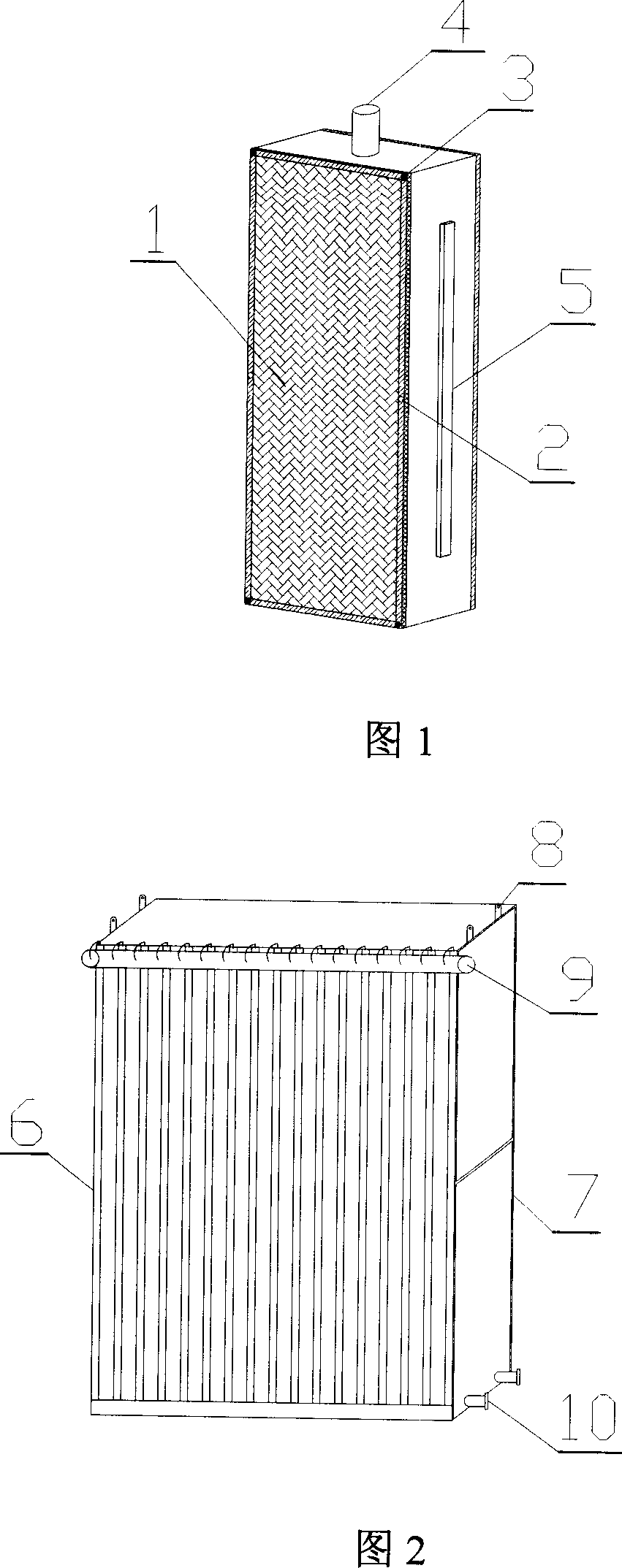

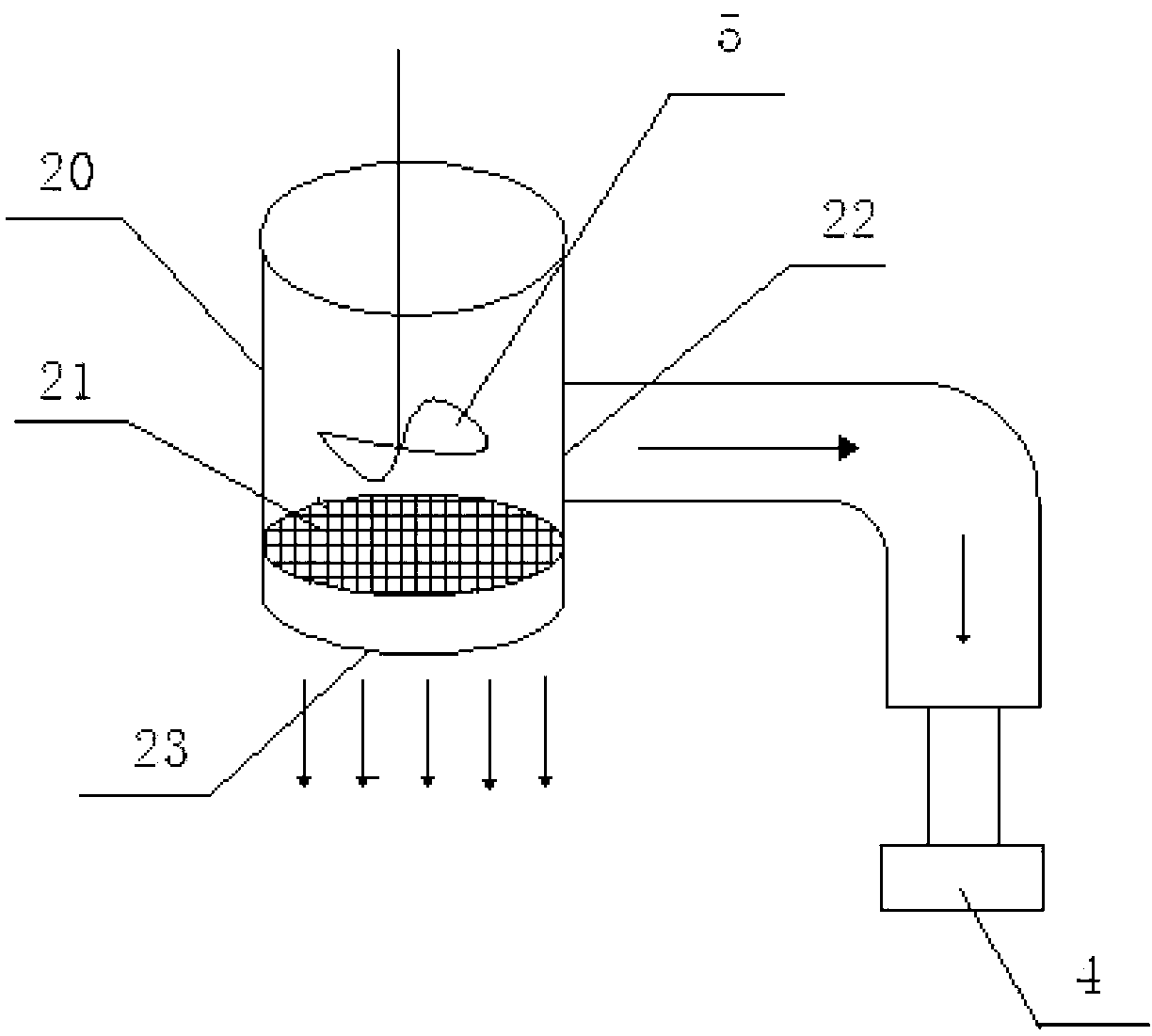

Bioreactor using polyvinyl alcohol nano microsphere dynamic film as filtration medium

InactiveCN101012082AReduce pollutionGood anti-adsorption performanceTreatment using aerobic processesSustainable biological treatmentMicrosphereFiltration

The invention discloses a filter dielectric biological reactor in the effluent processing and water recycling technical domain, which is characterized by the following: adopting industrial filter cloth as porous bottom film; emulsifying and crosslinking polyvinyl alcohol and glutaraldehyde to obtain the microball as precoating agent; depositing microball on the outer wall and pore wall; forming polyvinyl alcohol nanometer microball dynamic film; fixing the film component on the frame; placing in the biological reactor; discharging water through sucking pump.

Owner:DALIAN UNIV OF TECH

Cleaning agent, method and device for tubular membrane

The invention relates to a cleaning agent, method and device for a tubular membrane. The cleaning agent is an acid solution or an alkaline solution prepared by taking alcohols C1-C4 as a solvent and acid or alkali as a solute. The alcohols C1-C4 with good solubility are adopted as the solvent of the cleaning agent, acid, alkali, a surfactant or a complexing agent and the like are adopted as the solute, and a heating mode is adopted, so that stemming in holes of the membrane is washed out in a cleaning process like micro blasting, the membrane flux is recovered, and the service life of the membrane is prolonged.

Owner:NINGXIA QIYUAN PHARMA

Method for washing ultrafiltration membrane by combining ultrasonic waves and chemical cleaning agent

InactiveCN106268340AEnhance chemical cleaning effectRestore fluxUltrafiltrationUltrasonic assistedUltrafiltration

The invention discloses a method for washing an ultrafiltration membrane by combining ultrasonic waves and a chemical cleaning agent. The method comprises the following steps: washing the ultrafiltration membrane which is operated for a period of time, wherein the washing step is divided into physical washing and chemical washing; firstly, carrying out combined water and air backwashing on the ultrafiltration membrane and discharging all sewage in an ultrafiltration membrane assembly; preparing a sodium hypochlorite chemical washing solution and injecting the sodium hypochlorite chemical washing solution into an ultrafiltration membrane pool until the membrane assembly is immersed; immersing; then performing filtering and circulating backwashing; meanwhile, loading the ultrasonic waves to assist the chemical washing; finally, injecting a hydrochloric acid solution to immerse the membrane assembly, and immersing; then performing filtering and circulating backwashing; meanwhile, loading the ultrasonic waves to assist the chemical washing. Compared with the prior art, the method has the beneficial effects that an optimal medicament mass concentration and optimal ultrasonic frequency are obtained; ultrasonic wave assisting is added on the basis of the chemical washing to help to enhance the chemical washing effect and save medicament washing amount, so that the cost is saved.

Owner:HOHAI UNIV

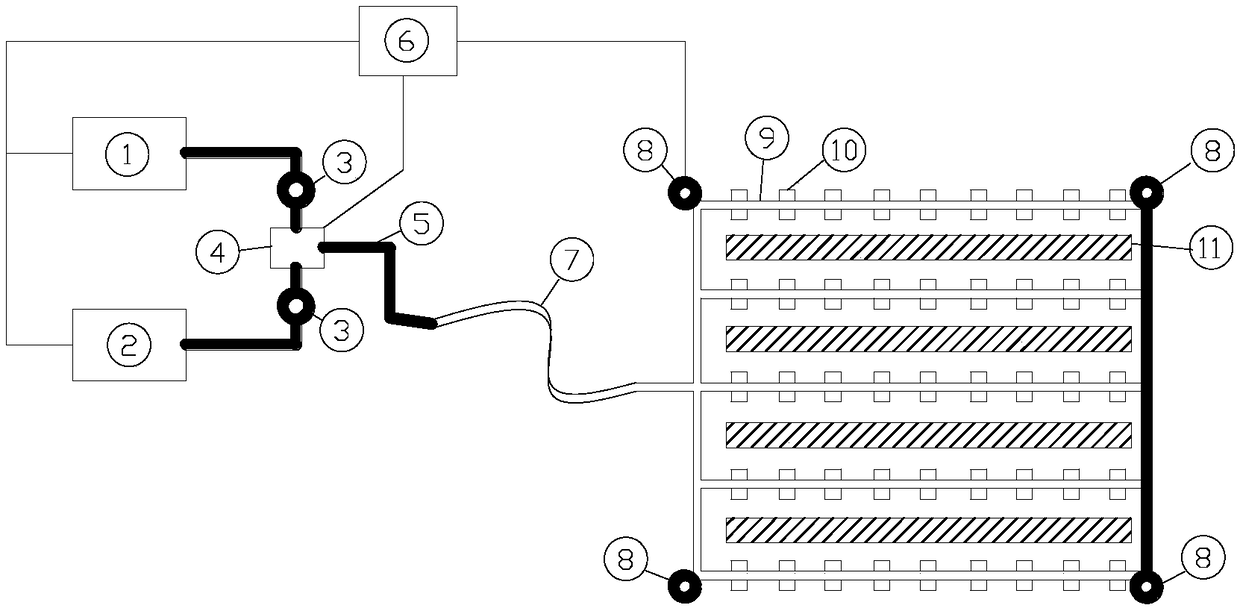

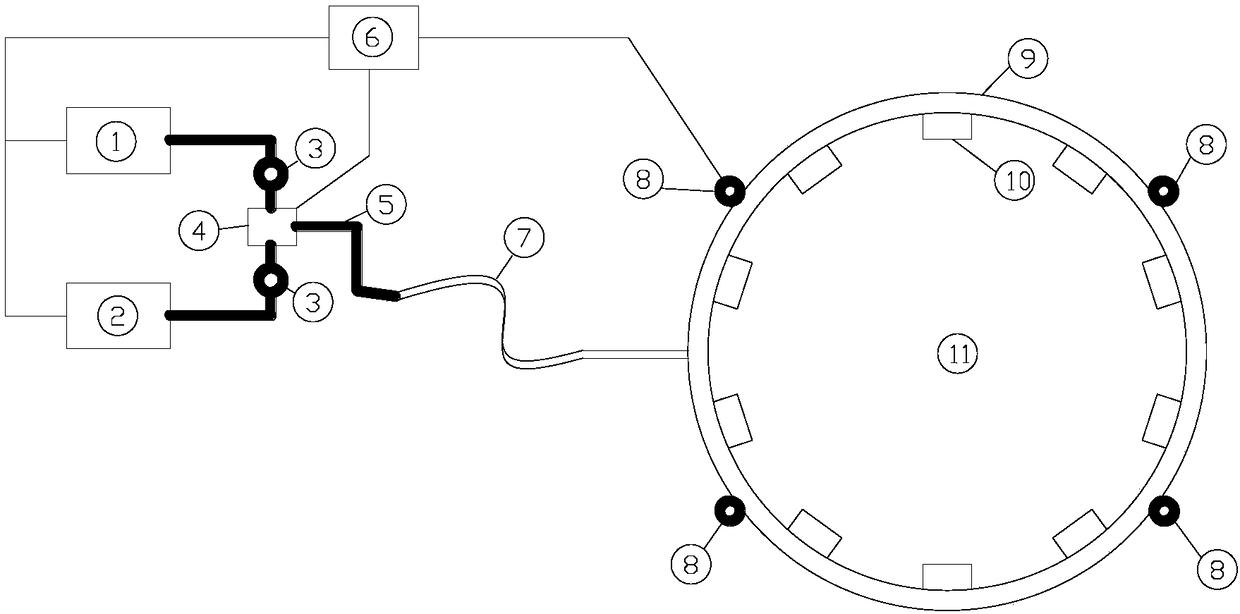

Membrane bioreactor and membrane bioreactor membrane pollution control method and device

ActiveCN108249560ASimple structureEasy to operateSemi-permeable membranesTreatment with anaerobic digestion processesGas compressorEnvironmental engineering

The invention discloses a membrane bioreactor and a membrane bioreactor membrane pollution control device and method. The membrane bioreactor comprises a fluid medium conveying device, an injection device and a movement device, wherein an exhaust port of a gas compressor of the fluid medium conveying device is communicated with an air inlet of a pipeline switching device through a gas conveying pipeline; the gas conveying pipeline is provided with a check valve; a liquid outlet of a liquid pump is communicated with a liquid inlet of the pipeline switching device through a liquid conveying pipeline; the liquid conveying pipeline is provided with a check valve; the injection device comprises an injection pipe and a plurality of nozzles; an inlet of the injection pipe is communicated with anoutlet of the pipeline switching device through a pipeline; each outlet of the injection pipe is provided with one nozzle; the movement device is installed in or out of the MBR (membrane bioreactor);the injection device is arranged on the movement device. According to the membrane bioreactor and the membrane bioreactor membrane pollution control device and method disclosed by the invention, in-situ efficient control on aerobiotic and anaerobic MBR membrane pollution can be met, operation is simple, energy consumption is low, and an application range is wide.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

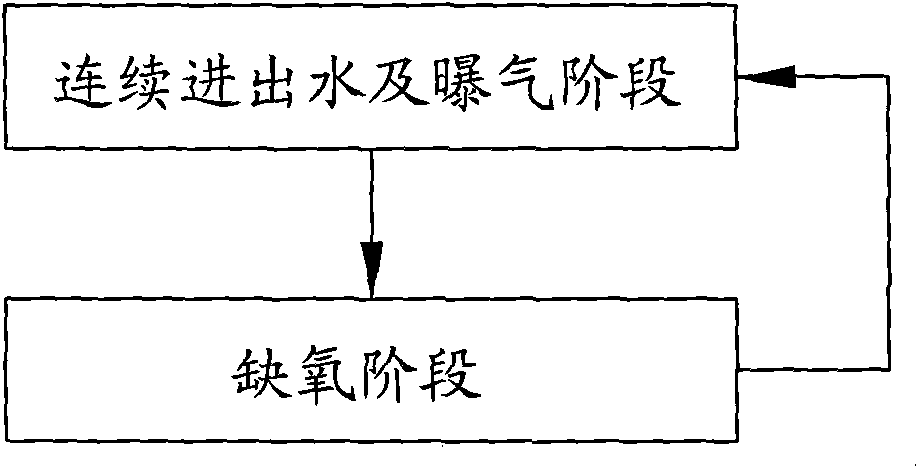

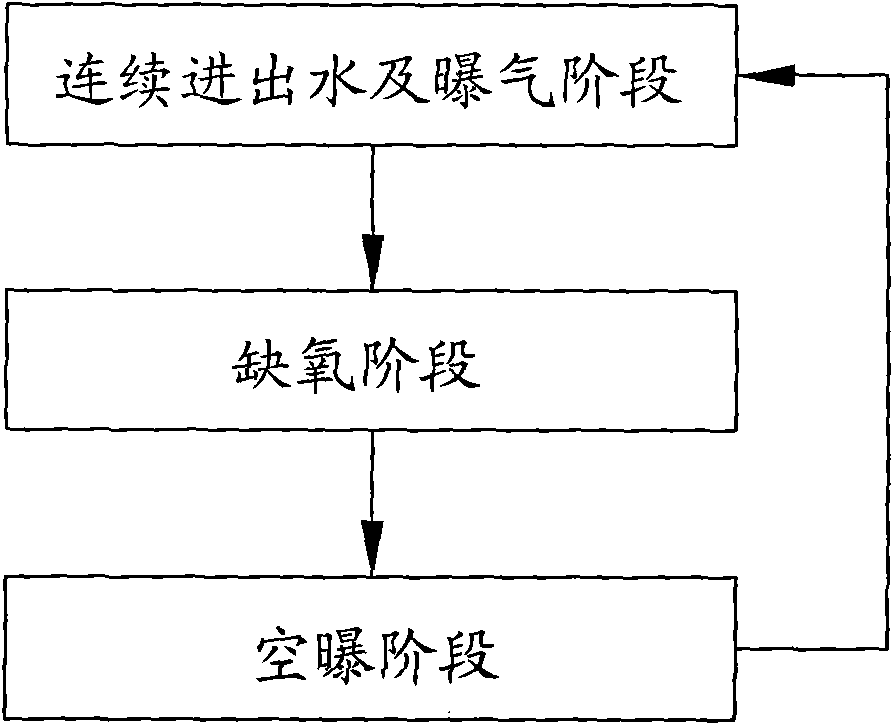

Treatment process of membrane bioreactor in nondegradable industrial wastewater

InactiveCN102001795AImprove processing efficiencyRealize resourcesTreatment with aerobic and anaerobic processesMultistage water/sewage treatmentHigh concentrationIndustrial effluent

The invention discloses a treatment process of a membrane bioreactor in nondegradable industrial wastewater, which comprises the following two stages: 1, continuous water feeding / discharge and aeration stage: while aerating, continuously feeding water into the membrane bioreactor and continuously pumping water, and entering the next stage after operating for a period of time; and 2, anaerobic stage: stopping feeding and discharging water and aerating so that the active sludge is in the anaerobic condition, and repeating the first stage after operating for a period of time. The treatment process can be used to enhance the treatment efficiency for high-concentration nondegradable wastewater, such as dyeing plant wastewater, factory finishing wastewater and the like, and increase the removalrate of total nitrogen, so that the quality of the discharged water can reach the standard for circulating cooling water, thereby converting sewage into resources.

Owner:XIAMEN UNIV OF TECH

Cleaning method and cleaning apparatus for beer filtration ceramic membrane

PendingCN109382000AAchieve immersionPromote sheddingSemi-permeable membranesCleansing AgentsCeramic membrane

The invention provides a cleaning method for a beer filtration ceramic membrane. The cleaning method comprises: (1) pre-rinsing a ceramic membrane by using clear water; (2) adding a cleaning agent, and completely immersing the ceramic membrane in the cleaning agent, wherein the cleaning agent is a mixed solution of sodium hydroxide and sodium hypochlorite; and (3) rinsing the ceramic membrane by using clear water until the aqueous solution after the rinsing is substantially neutral. The invention further provides a cleaning apparatus for a beer filtration ceramic membrane, wherein the cleaningapparatus is connected to the inlet and the outlet of a ceramic membrane assembly through pipelines, a clear water tank and a cleaning agent tank are connected to the inlet of the ceramic membrane assembly through a cleaning pump, and the cleaning pump can pump clear water or a cleaning agent into a ceramic membrane, and rinse and soak the ceramic membrane. With the cleaning method of the presentinvention, the ceramic membrane cleaning time is shortened so as to improve the production efficiency of beer and reduce the production cost. The cleaning apparatus of the present invention is easy to operate, and can save a lot of time for the whole cleaning process.

Owner:NINGBO LEHUI INT ENG EQUIP CO LTD

Method for cleaning membrane pollution in process of electrodialysis treatment on paper-making reconstituted tobacco extract liquor

InactiveCN111672326AImprove the effect of alkaline cleaning processRestore fluxTobacco preparationTobacco treatmentMembrane foulingProcess engineering

The invention discloses a method for cleaning membrane pollution in the process of electrodialysis treatment on paper-making reconstituted tobacco extract liquor, which is used for cleaning an electrodialysis system generating membrane pollution through the cleaning processes of primary water washing, reversed-pole alkaline washing, secondary water washing, reversed-pole acid washing and tertiarywater washing in sequence. According to the cleaning method, membrane pollution in the electrodialysis process can be effectively solved, the desalination rate of an electrodialysis system is remarkably recovered, and reliable operation guarantee is provided for the process of treating the paper-making process reconstituted tobacco extracting solution through electrodialysis.

Owner:CHINA TOBACCO ANHUI IND CO LTD

Cleaning method and cleaning system of tubular membrane

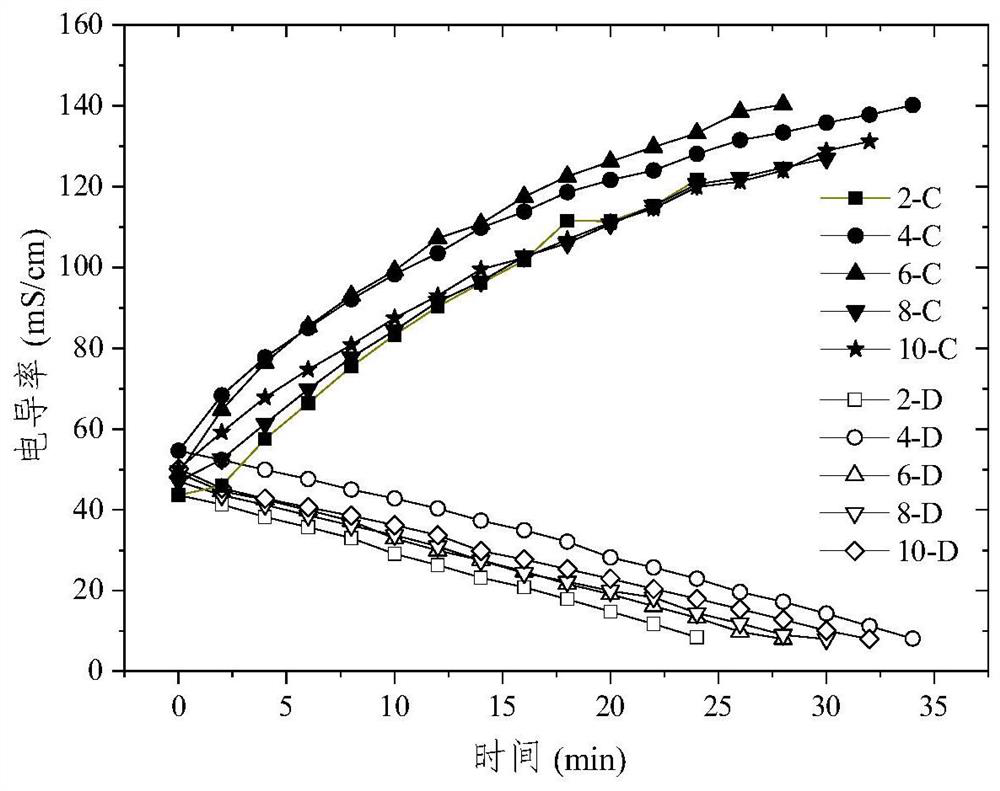

InactiveCN103341324AHigh flux recovery rateStable fluxSemi-permeable membranesParticle flowEngineering

The invention discloses a cleaning method and a cleaning system of a tubular membrane, and provides a cleaning method and a cleaning system which can recover the membrane flux. The cleaning method comprises the following steps of: cleaning with clean water; cleaning through mixing particles, clean water and air: after mixing particles, clean water and air, and cleaning the mixture of particles, clean water and air in the tubular membrane, wherein air bubbles are broken caused by the collision of air bubbles and particles, energy is released extensively to cause partial vibration, and meanwhile, the particles and air bubbles are both rubbed with the membrane so as to lead to falling of pollutants on the surface of the membrane; and discharging the pollutants to complete the cleaning process. According to the cleaning method disclosed by the invention, the step of cleaning by mixing particles, clean water and gases is added; the air bubbles generated by the gases can be collided with the particles, and energy is released extensively so as to lead to partial vibration; turbulence is formed in a membrane component; particles flow rapidly in a system; and the air bubbles and particles are both rubbed with the surface of the membrane so as to remove surface pollutants. The cleaning effect and the cleaning efficiency can be improved greatly by combining with two aspects.

Owner:TIANJIN POLYTECHNIC UNIV

Hollow fiber membrane cleaning agent and preparation method and application thereof

ActiveCN104056555AImprove cleaning effectShorten cleaning timeSemi-permeable membranesBiological water/sewage treatmentChemistrySodium hypochlorite

The invention provides a hollow fiber membrane cleaning agent and a preparation method and application thereof. The hollow fiber membrane cleaning agent comprises: sodium hypochlorite and a cleaning agent, which is at least one selected from the group consisting of a penetrating agent and a complexing agent. The hollow fiber membrane cleaning agent provided by the invention can effectively improve the cleaning effect on the hollow fiber membrane, shortens the cleaning time, is convenient to use, and does not generate secondary pollution.

Owner:TSINGHUA UNIV +1

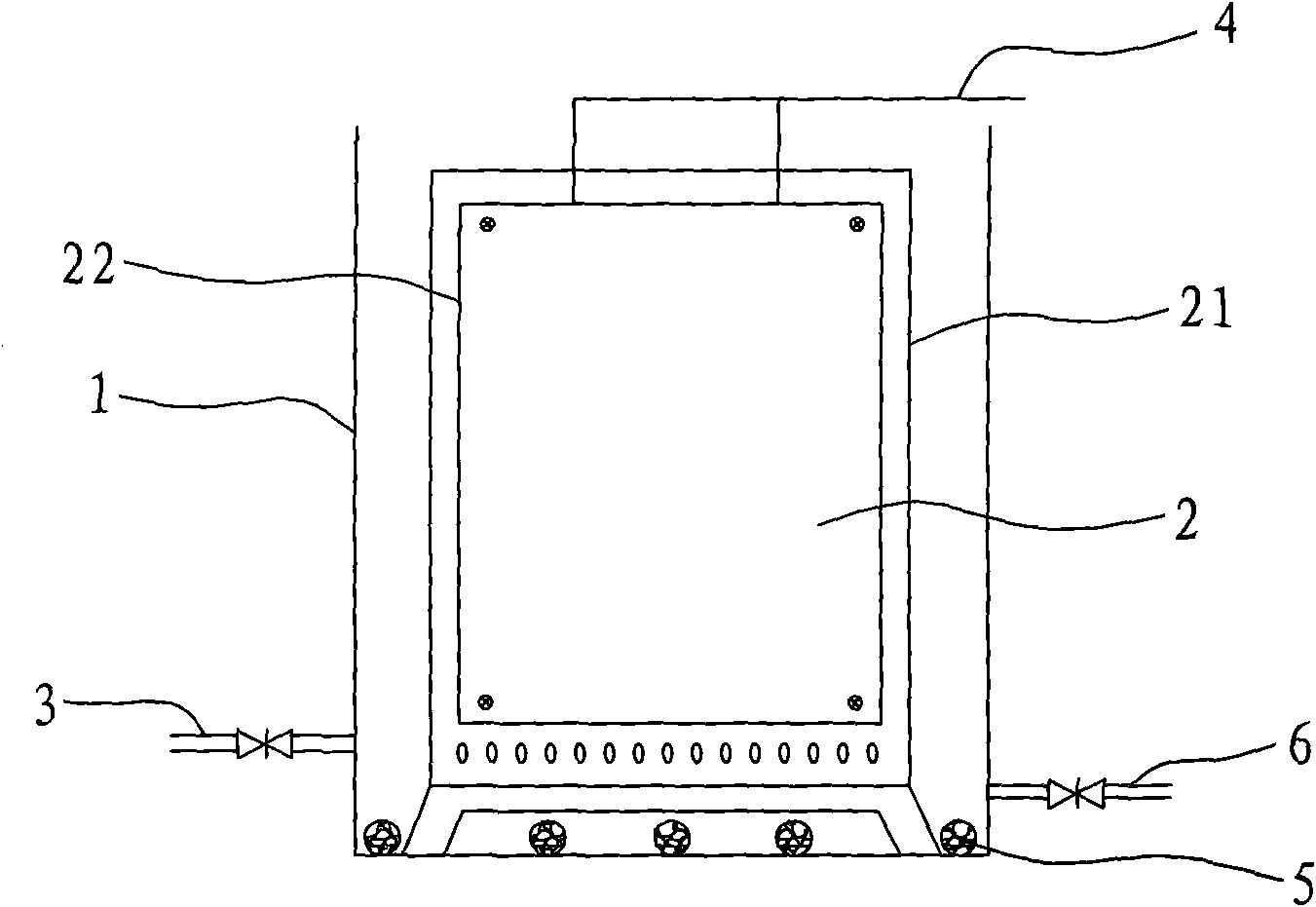

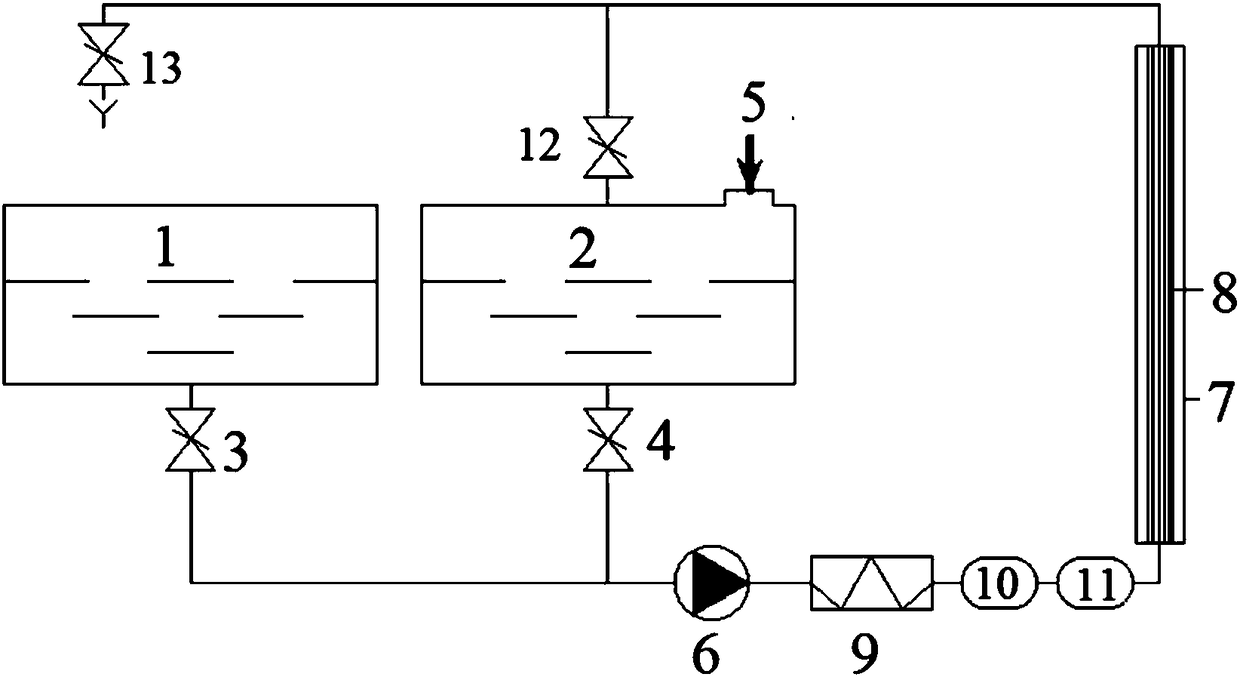

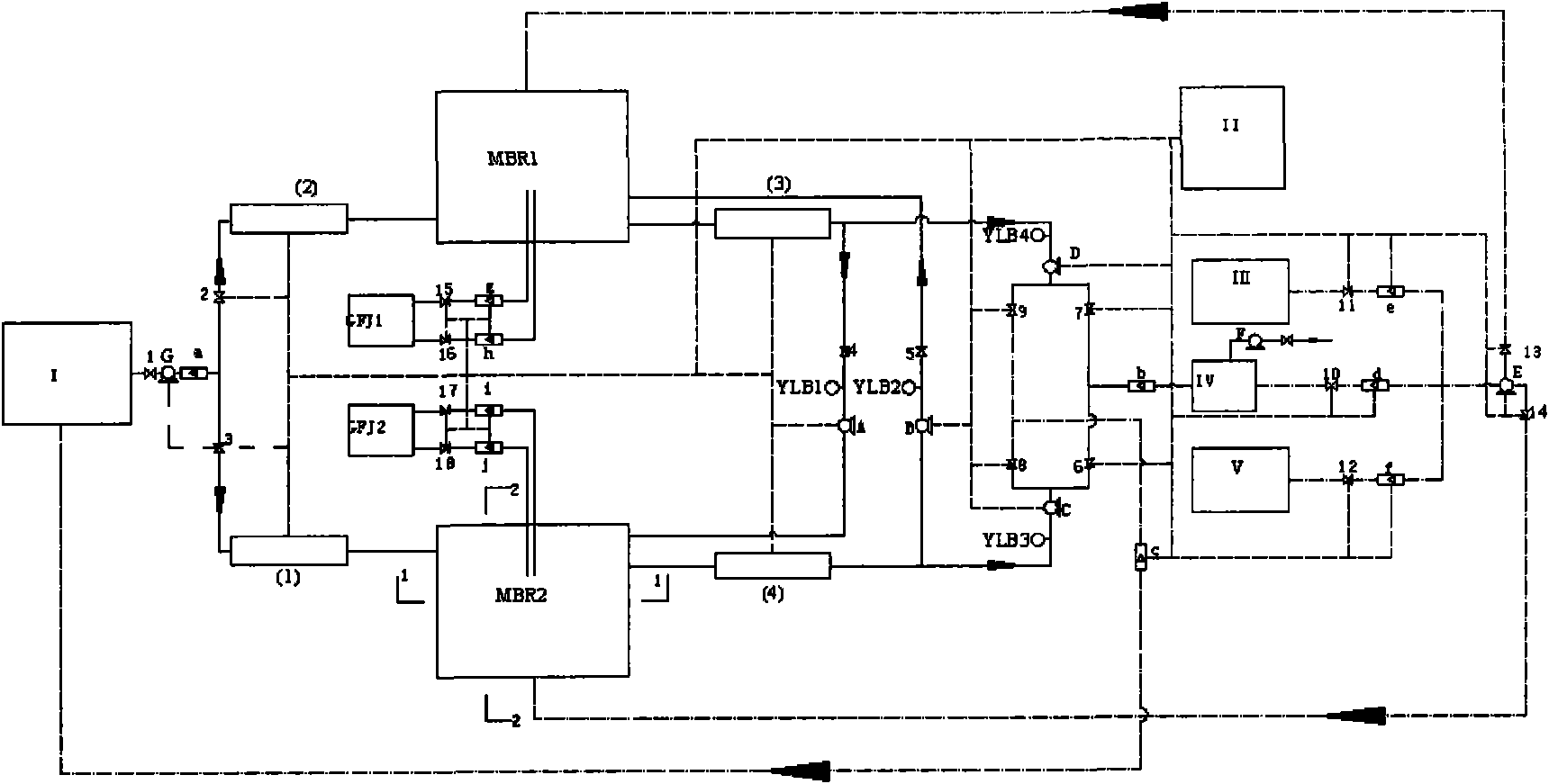

Alternate two-stage aerobic membrane bioreactor

InactiveCN101830607AMitigation of membrane foulingGuaranteed uptimeMultistage water/sewage treatmentAutomatic controlCentrifugal pump

Owner:HARBIN ENG UNIV

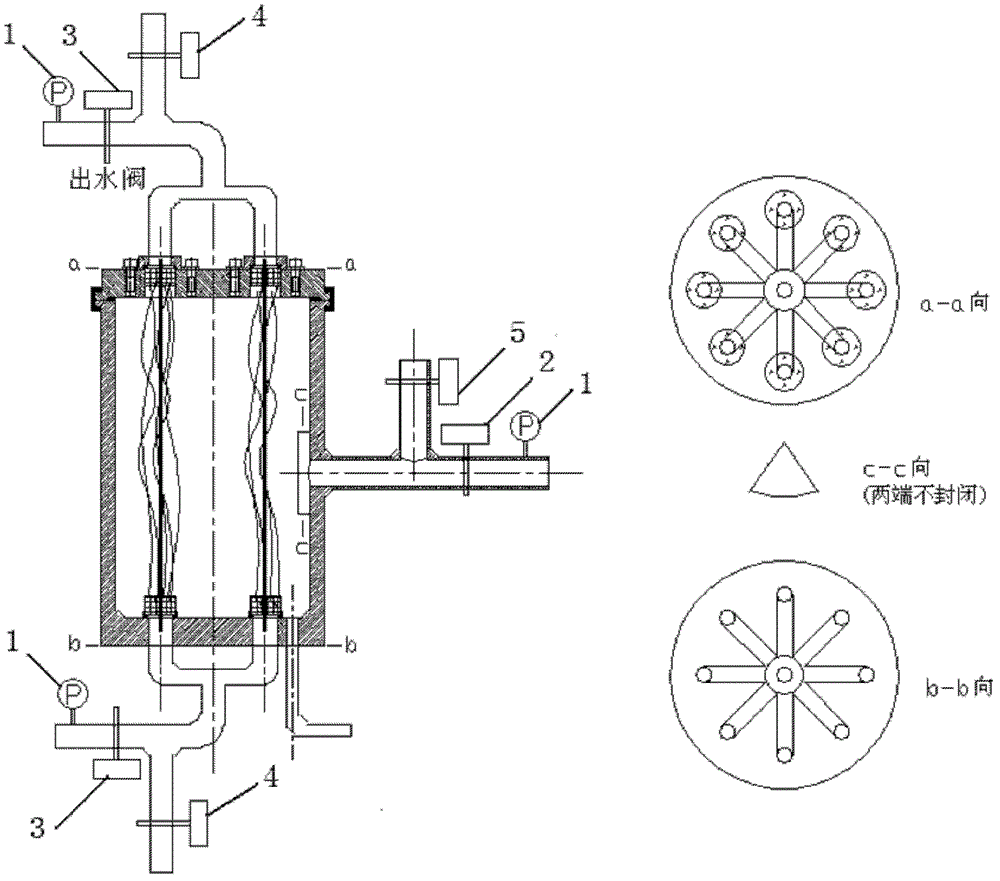

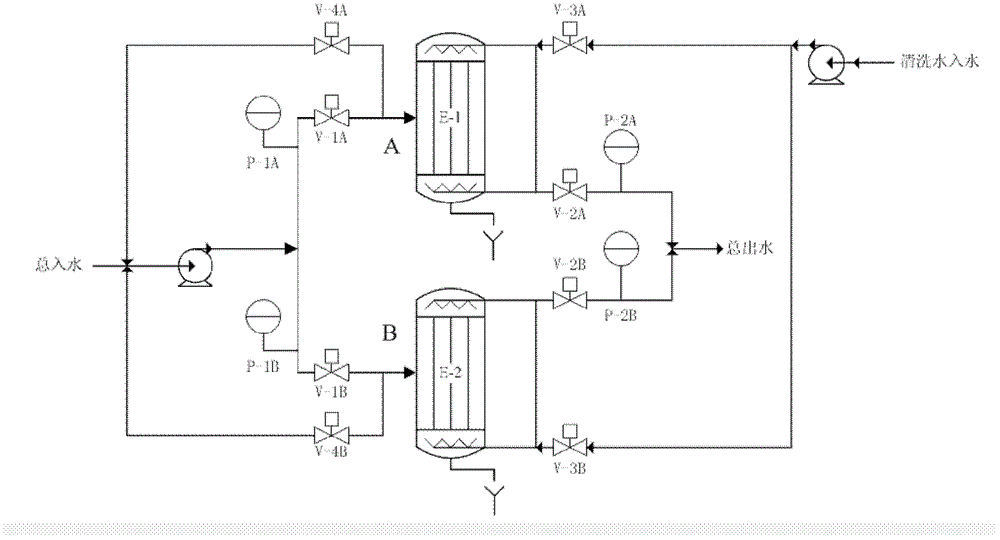

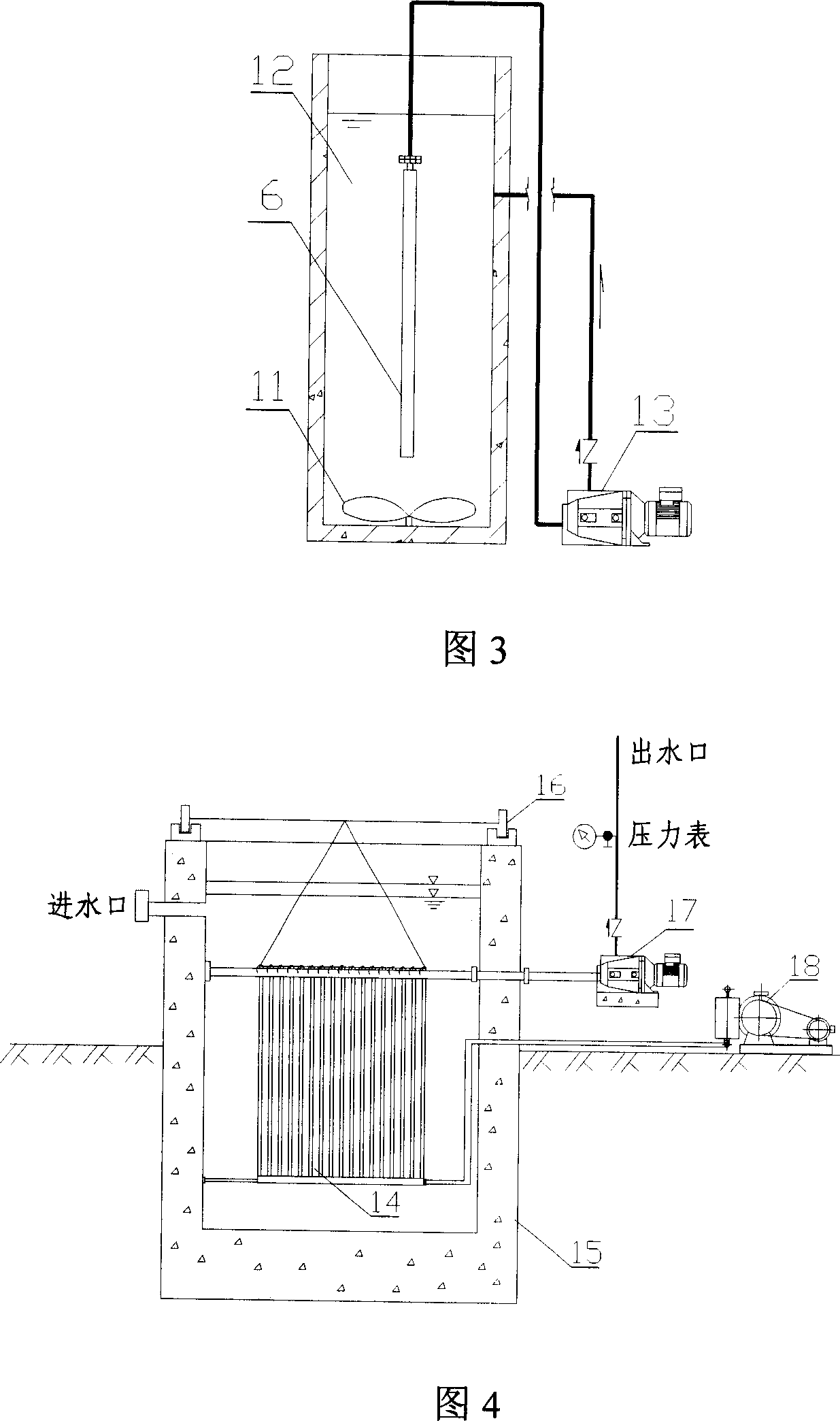

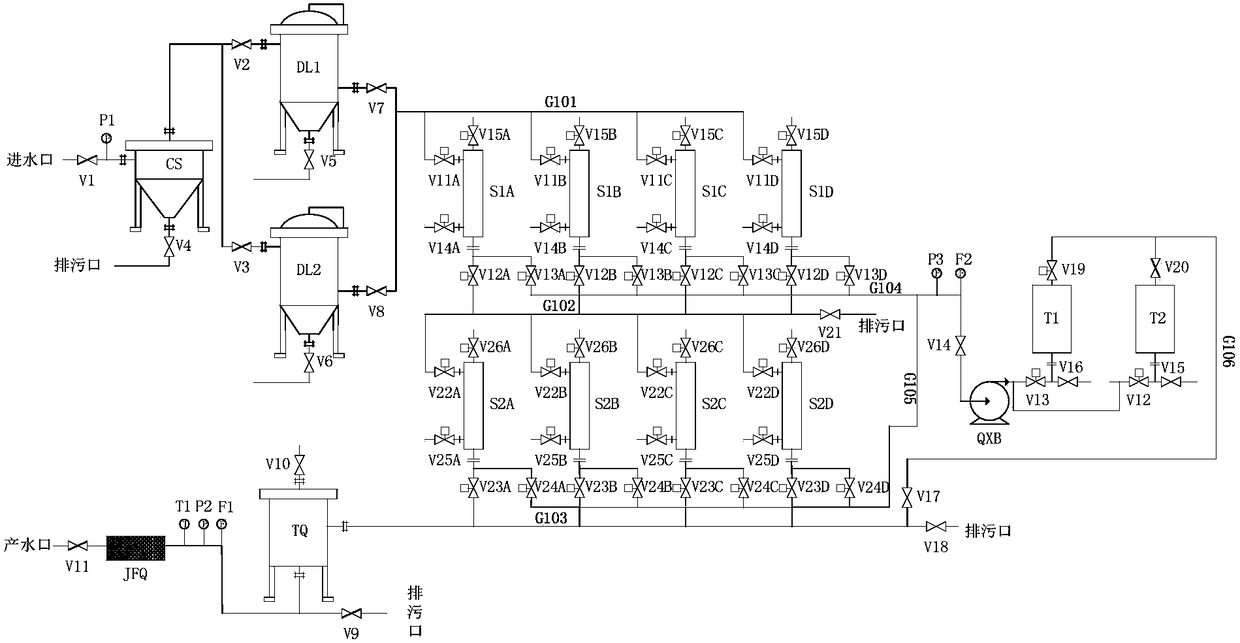

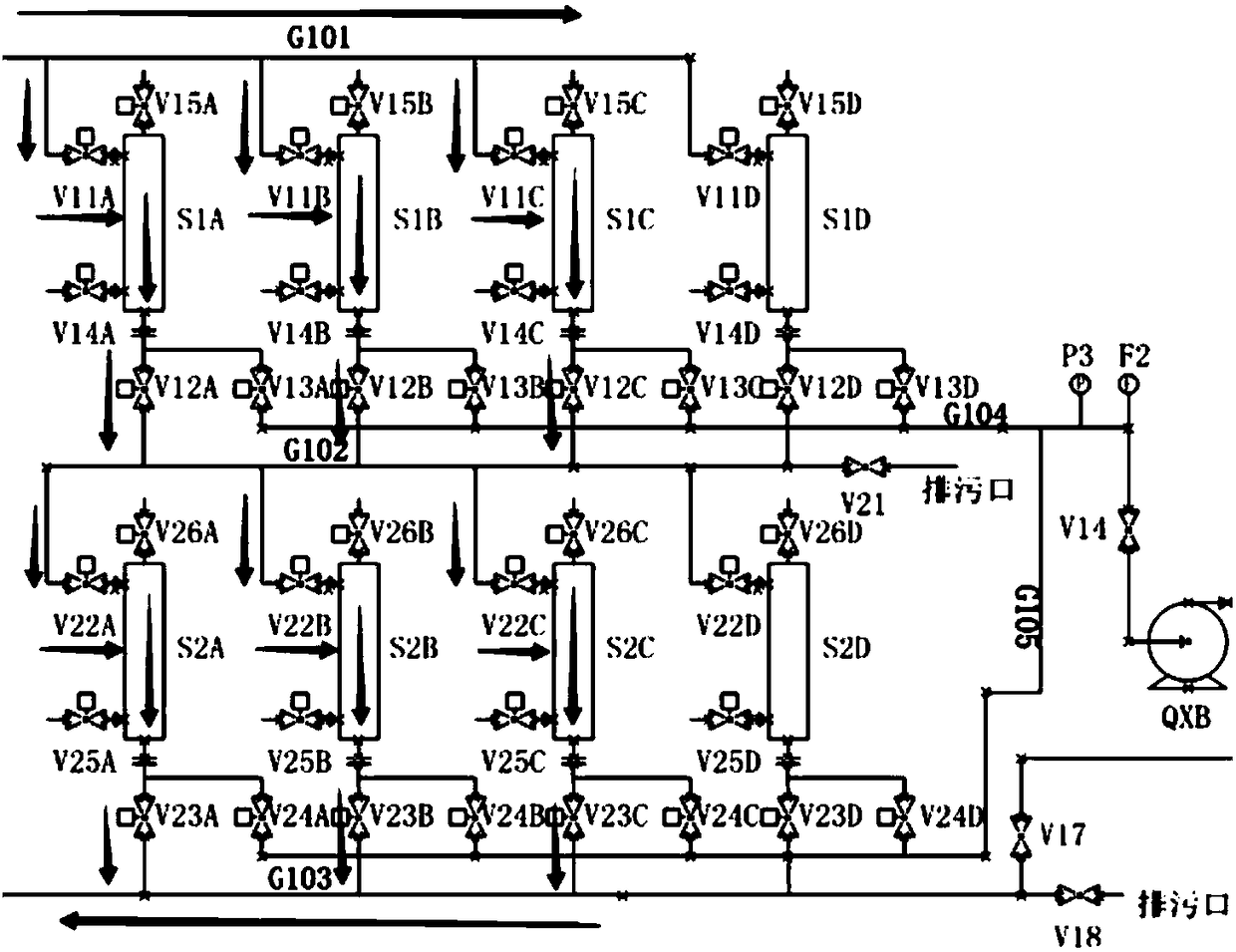

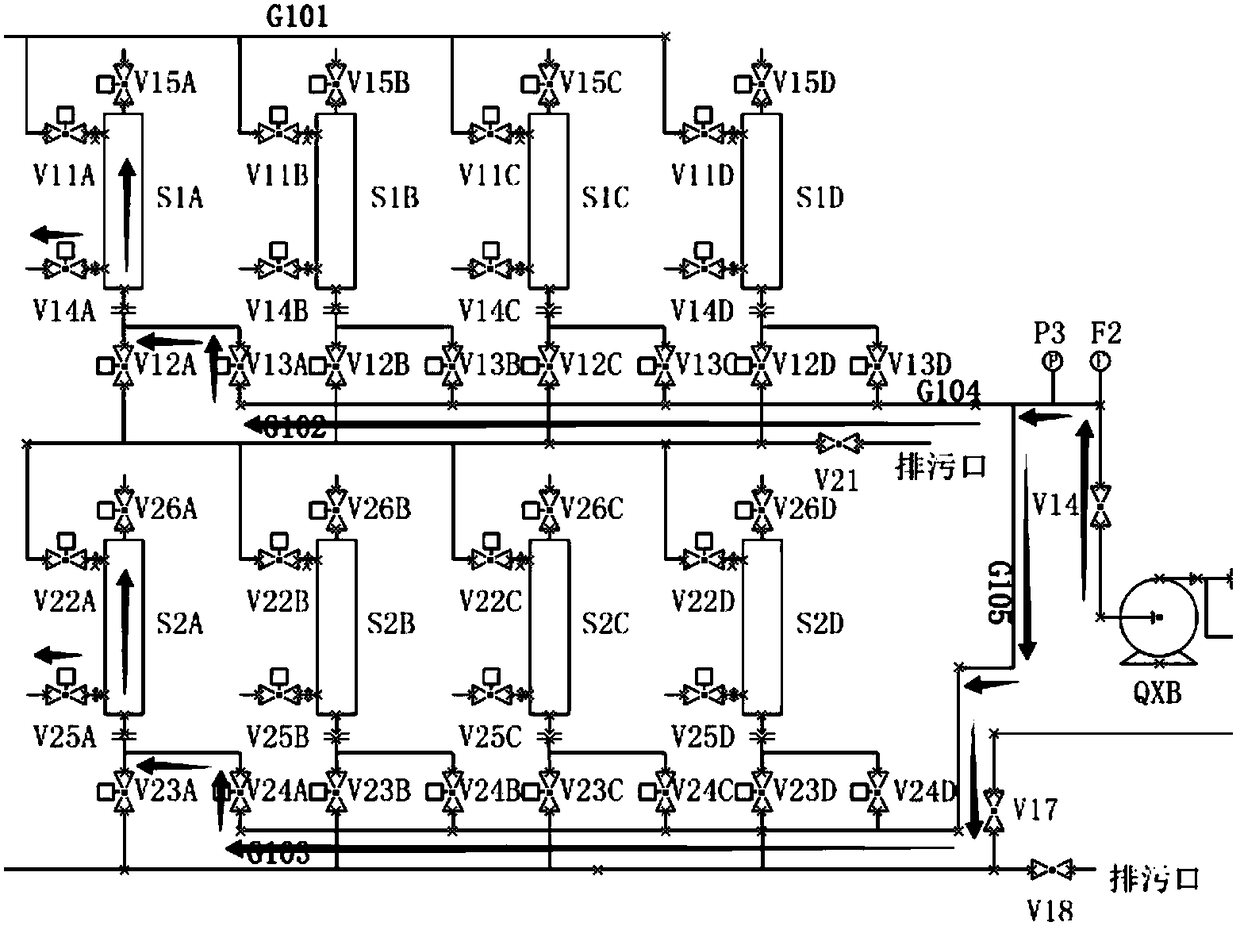

Technological system for treating terrestrial heat tail water by utilizing tubular membrane

PendingCN108314204AReduce processing costsImprove processing efficiencyWater/sewage treatment by centrifugal separationScale removal and water softeningWater treatment systemTechnological system

The invention creatively provides a technological system for treating terrestrial heat tail water by utilizing a tubular membrane. The technological system comprises a cyclone sand remover, bag type filters, a tubular membrane filtering device, a washing tank, a washing ump, a degassing tank and an electric control device; two sets of the bag type filters are arranged; one bag type filter is usedand one bag type filter is standby, and the two bag type filters are alternatively used; the tubular membrane filtering device is divided into two grades; each grade comprises four tubular membrane filters which are arranged in parallel, three tubular membrane filters are used and one tubular membrane filter is standby; the system is provided with a thermometer, a pressure meter and a flow meter;the electric control device comprises a PLC (Programmable Logic Controller) and can realize online automatic backwashing of equipment and prevent fouling and blocking, so that stable operation of equipment is ensured. The technological system takes a tubular membrane as a core and integrates equipment including the cyclone sand remover, the bag type filters and the like to form a technology of treating the terrestrial heat tail water by utilizing a set of water treatment system; the technological system has the advantages of high integration degree, high automation degree, high treatment efficiency and long service life; water treatment can reach reinjection water quality requirements and the treatment cost of reinjection water is greatly reduced.

Owner:TIANJIN HIPURE MEMBRANE TECH CO LTD

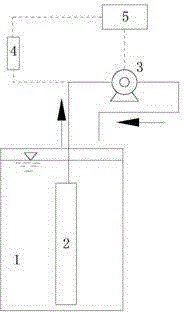

Water purification device for contaminated water body

InactiveCN106082541AEasy to makeEnhanced Nitrogen and Phosphorus RemovalWater contaminantsTreatment involving filtrationSludgeWater quality

The invention provides a water purification device for a contaminated water body. The water purification device comprises N frames which are sequentially connected with one another and floating frames connected with the frames; each frame is composed of a hypoxic reaction tank and an oxygen-enriched filter tank; a water flow turning flow cavity is formed in each hypoxic reaction tank, the lower portion of each hypoxic reaction tank is provided with a sewage inlet, each hypoxic reaction tank is provided with a communication port, and the hypoxic reaction tanks are filled with filler; the bottom of each oxygen-enriched filter tank is provided with an aeration device, a dynamic membrane filter is arranged in an inner cavity of each oxygen-enriched filter tank, water in the oxygen-enriched filter tanks enters inner cavities of the dynamic membrane filters through the dynamic membrane filters, or the inner cavities of the dynamic membrane filters are communicated with river water through pipelines and delivery pumps, the bottoms of the inner cavities of the oxygen-enriched filter tanks are communicated with openings of sludge pipelines stretching into the lower portions of the inner cavities of the corresponding hypoxic reaction tanks through the sludge pipelines and sludge reflux pumps, and the portion, located over the corresponding frame, of each sludge pipeline is provided with an excessive sludge discharge valve. The water purification device has the advantages of being convenient to manufacture, capable of effectively utilizing carbon sources in water and good in water purification effect.

Owner:浙江天韵生态环境工程有限公司 +1

Hollow fiber ultrafiltration membrane organic fouling blockage cleaning method

The invention discloses a hollow fiber ultrafiltration membrane organic fouling blockage cleaning method. The cleaning method comprises the following steps: firstly, cleaning a hollow fiber ultrafiltration membrane through a surface active agent and NaOH, and then cleaning the hollow fiber ultrafiltration membrane through a sterilizing agent. The method can achieve the cleaning of the hollow fiberultrafiltration membrane organic fouling blockage and further has the advantages of good cleaning effect, simple operation and low cost.

Owner:XIAN TPRI WATER & ENVIRONMENTAL PROTECTION

Coiled membrane separating technology and equipment with forward feeding and reversed washing processes

The invention discloses a novel coiled membrane separating technology with forward feeding and reversed washing processes. During the forward feeding process, a feeding valve is opened; a material delivering pump and a high-pressure pump are started; a membrane pile is switched to a normal feeding connection state; a break valve is adjusted, until a system pressure reaches a preset value, such that a membrane separating system operates normally; a liquid material is delivered into a circulation tank, and is delivered into the membrane pile through the material delivering pump and the high-pressure pump; substances penetrating the membrane form a penetration liquid, and substances that do not penetrate the membrane flow back to the circulation tank through the break valve and an condensation pipeline. During the reversed washing process, a water inlet vale is opened; the material delivering pump and the high-pressure pump are started; the membrane pile is switched to a state opposite to the normal feeding state; the break valve is adjusted, until a pressure required by washing is reached, such that the membrane separating system operates in a washing state. The invention also discloses coiled membrane separating equipment with forward feeding and reversed washing functions. With the technology and the equipment, material separating can easily be carried out, the service life of the membrane is prolonged, and the washing effect is improved.

Owner:SEPATEC ENVIRONMENTAL PROTECTION TECH XIAMEN

Cleaning method of immersed ultrafiltration membrane

InactiveCN111217425ARestore permeate fluxLower transmembrane pressureSemi-permeable membranesSpecific water treatment objectivesUltrafiltrationChemistry

The invention provides a cleaning method of an immersed ultrafiltration membrane. The method comprises the following steps: 1) carrying out primary alkali washing: emptying an ultrafiltration membranetank, conveying an alkaline cleaning solution into the ultrafiltration membrane tank until ultrafiltration membrane filaments are completely immersed in the cleaning solution, and carrying out soaking alkali washing on the ultrafiltration membrane; 2) backwashing the ultrafiltration membrane tank; 3) carrying out primary acid cleaning: emptying the ultrafiltration membrane tank, conveying an acidic cleaning solution into the ultrafiltration membrane tank to completely immerse ultrafiltration membrane filaments, and carrying out soaking and acid cleaning on the ultrafiltration membrane; 4) backwashing the ultrafiltration membrane tank; 5) carrying out secondary alkali washing: emptying the ultrafiltration membrane tank, conveying the alkaline cleaning solution into the ultrafiltration membrane tank until ultrafiltration membrane filaments are completely immersed, and carrying out soaking and alkali washing on the ultrafiltration membrane; 6) backwashing the ultrafiltration membrane tank; 7) carrying out secondary acid cleaning: emptying the ultrafiltration membrane tank, conveying the acidic cleaning solution into the ultrafiltration membrane tank till the ultrafiltration membranefilaments are completely immersed, and carrying out soaking and acid cleaning on the ultrafiltration membrane; and 8) backwashing the ultrafiltration membrane tank. The method has a remarkable recovery effect on cleaning of the ultrafiltration membrane polluted by multiple components at the same time and is excellent in working performance.

Owner:LUTAI TEXTILE

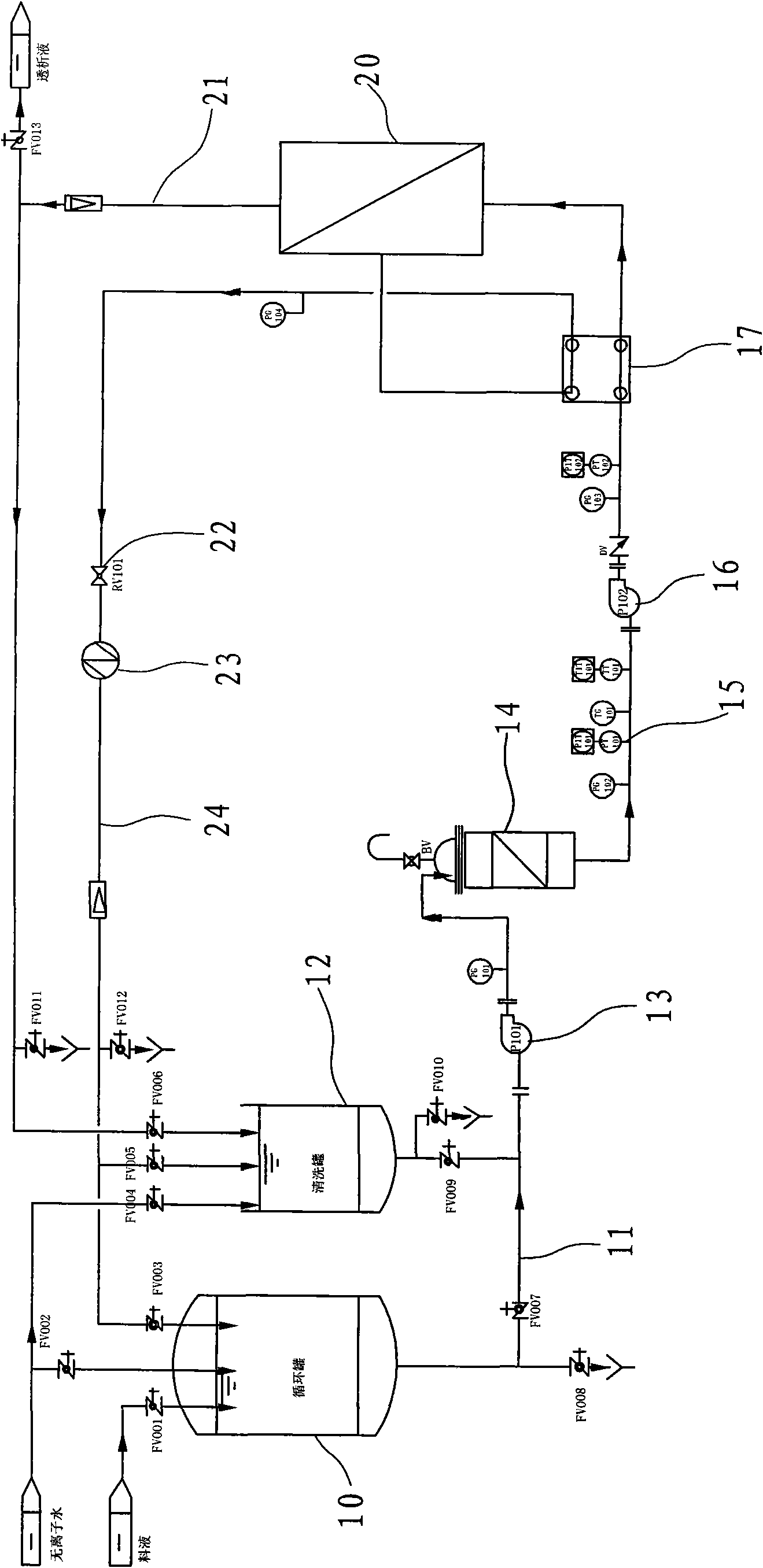

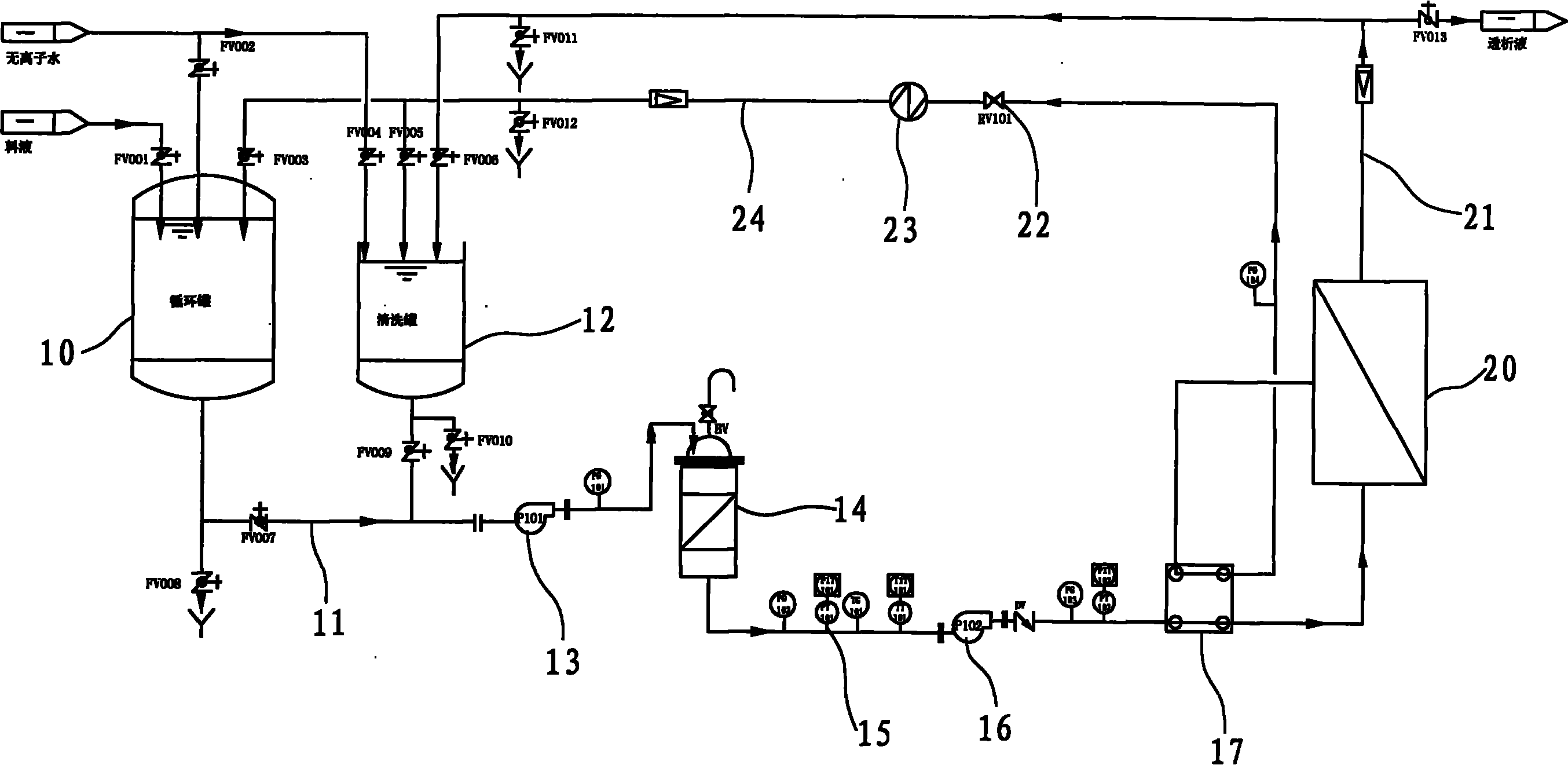

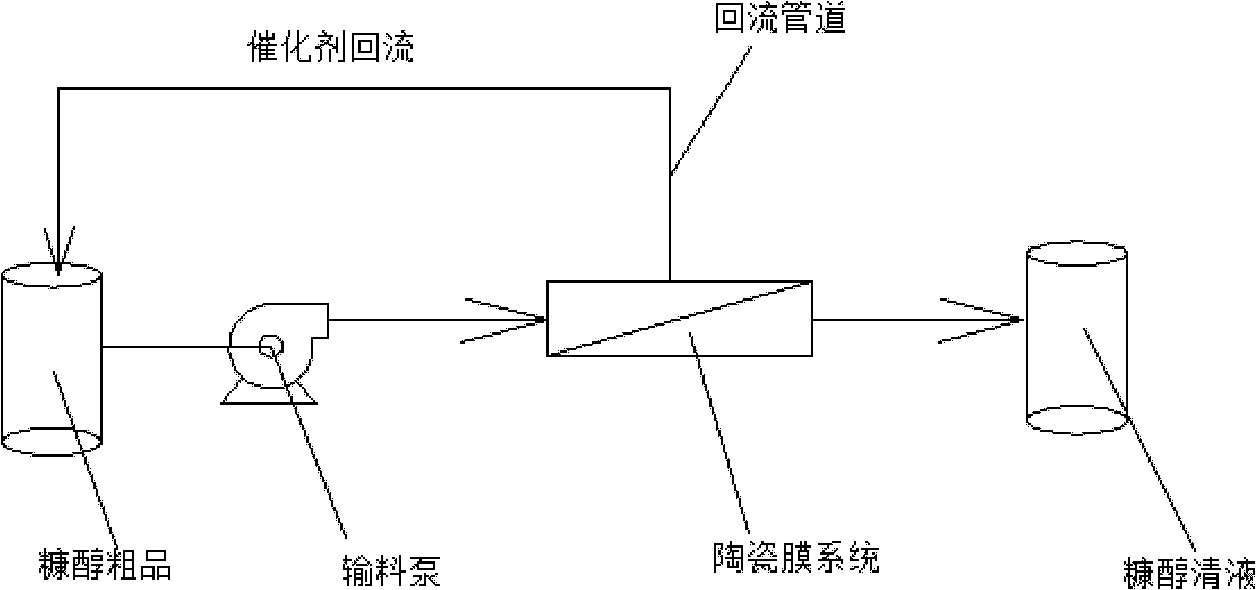

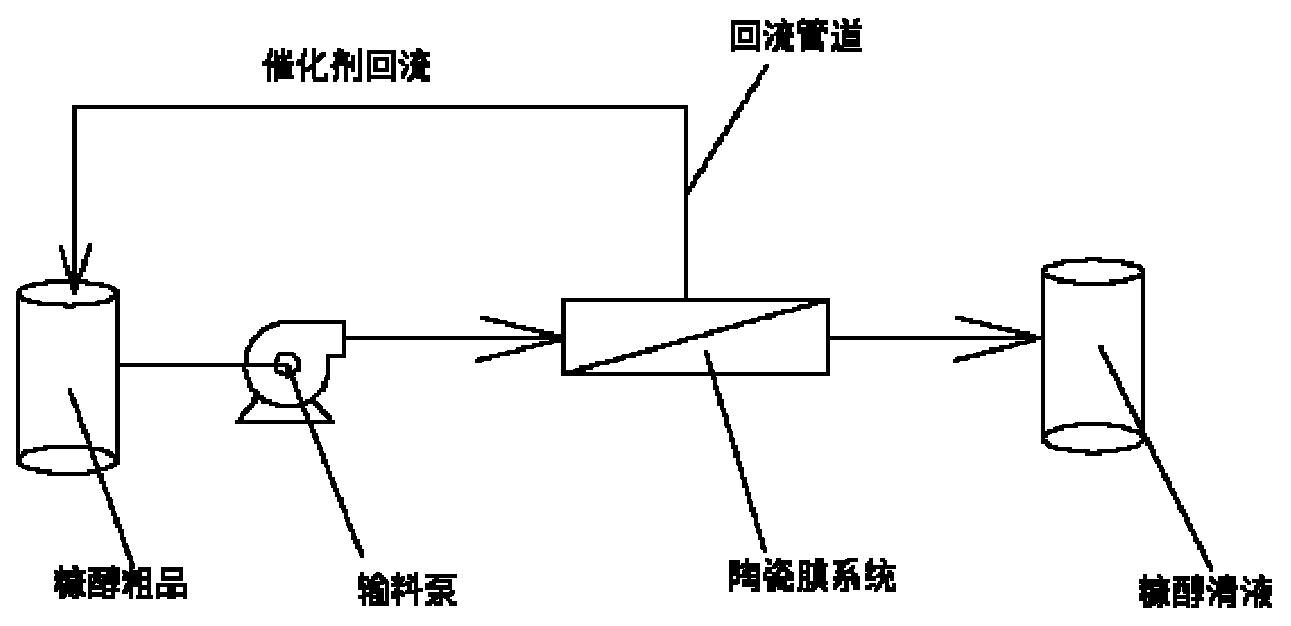

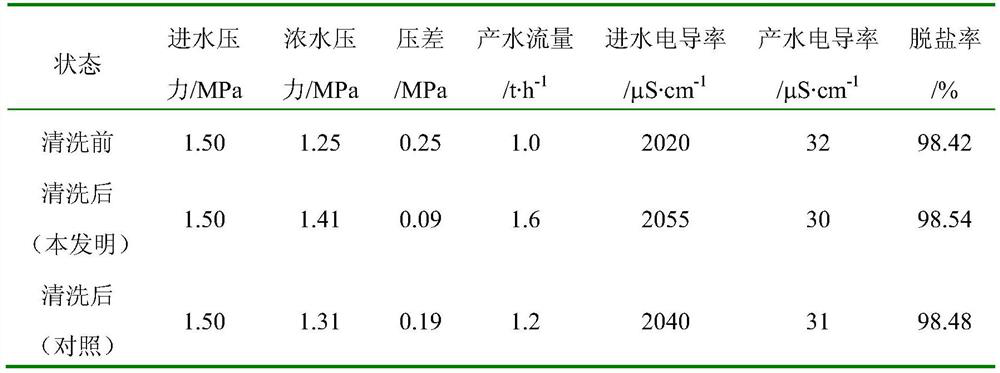

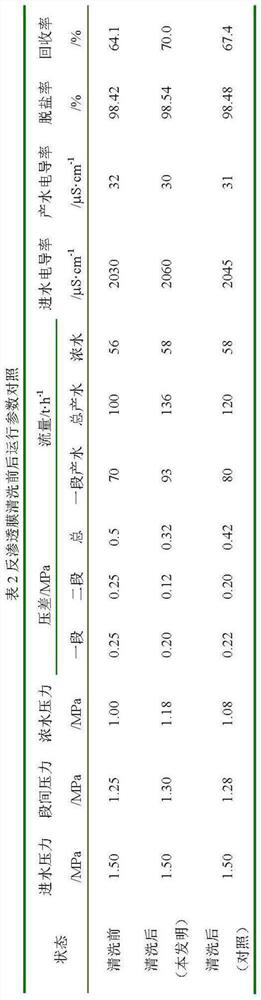

Method for catalyst recovery and furfuryl alcohol clarification during furfuryl alcohol production

InactiveCN101845031AEasy to separateReduce contentOrganic chemistryChemical industryCross-flow filtrationCeramic membrane

The invention discloses a method for catalyst recovery and furfuryl alcohol clarification during furfuryl alcohol production, which comprises the following specific steps that: rough furfuryl alcohol carrying a catalyst is delivered from a rough furfuryl alcohol storage tank to a ceramic membrane separation device through a delivery pump, reflux containing the catalyst is intercepted by the ceramic membrane system through cross-flow filtration and returns to the rough furfuryl alcohol storage tank through a return pipe, and the clear furfuryl alcohol solution penetrates through the ceramic membrane system and flows into the clear furfuryl alcohol solution storage tank. The method of the invention has the advantages of high catalyst removal rate, low energy consumption, short production cycle and the like.

Owner:厦门市威纳通膜科技有限公司

Membrane cleaning method in membrane-method sugar manufacturing technology

ActiveCN109589796AReduce dosageLow running costSemi-permeable membranesPurification by physical meansManufacturing technologyCleaning methods

The invention belongs to the technical field of membrane separation, and relates to a membrane cleaning method in a membrane-method sugar manufacturing technology. The membrane cleaning method comprises the following steps: step (1) sequentially using deionized water, a sodium hydroxide solution, a mixed solution of sodium hydroxide and sodium hypochlorite and the deionized water to clean a clarification membrane; step (2) sequentially using the deionized water, a glucanase solution and the sodium hydroxide solution to clean a decolorizing membrane; and step (3) sequentially using the deionized water, the sodium hydroxide solution and the deionized water to clean a concentration membrane. The step (1) and the step (3) are not ordered. The membrane cleaning method in the membrane-method sugar manufacturing technology is customized for different pollution mechanisms of the clarification membrane, the decolorizing membrane and the concentration membrane, can effectively remove the membrane pollution, restores the membrane flux of each level, maintains the stable operation of a membrane-method cane sugar manufacturing system, and can reduce water consumption, discharge of wastewater and consumption of chemical reagents by recycling membrane cleaning waste liquid at all levels.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Reclaimed water recycling reverse osmosis membrane cleaning agent

InactiveCN111644070AReduce usageReduce manufacturing costSemi-permeable membranesActive agentReverse osmosis

The invention discloses a reclaimed water recycling reverse osmosis membrane cleaning agent, and belongs to the technical field of membrane element cleaning. The cleaning agent comprises an acidic cleaning agent and an alkaline cleaning agent. The acidic cleaning agent comprises the following main components in percentage by weight: 0.02-0.2% of hydrochloric acid, 0.1-0.2% of organic acid and thebalance of water. The alkaline cleaning agent comprises the following main components in percentage by weight: 0.05-0.2% of sodium hydroxide, 0.01-0.1% of biosurfactant, 0.02-0.2% of metal complexingagent, 0.01-0.1% of bactericide, and the balance of water. A use method comprises the following steps: cleaning the reverse osmosis membrane with the acidic cleaning agent, then cleaning the reverse osmosis membrane with the alkaline cleaning agent, and washing the reverse osmosis membrane with clear water after cleaning with the acidic cleaning agent and the alkaline cleaning agent, wherein during on-line cleaning, a part of concentrated water and produced water need to be discharged into a wastewater pool at the initial stage of cleaning. The reverse osmosis membrane cleaning agent disclosedby the invention is an environment-friendly composite formula which is easy to biodegrade, all the components play a role in coordination and synergy during cleaning, the cleaning agent has excellentcleaning performance on a reverse osmosis membrane which is seriously polluted during reclaimed water recycling, and the usage amount of the cleaning agent is small.

Owner:HIGH & NEW TECH RES CENT OF HENAN ACAD OF SCI

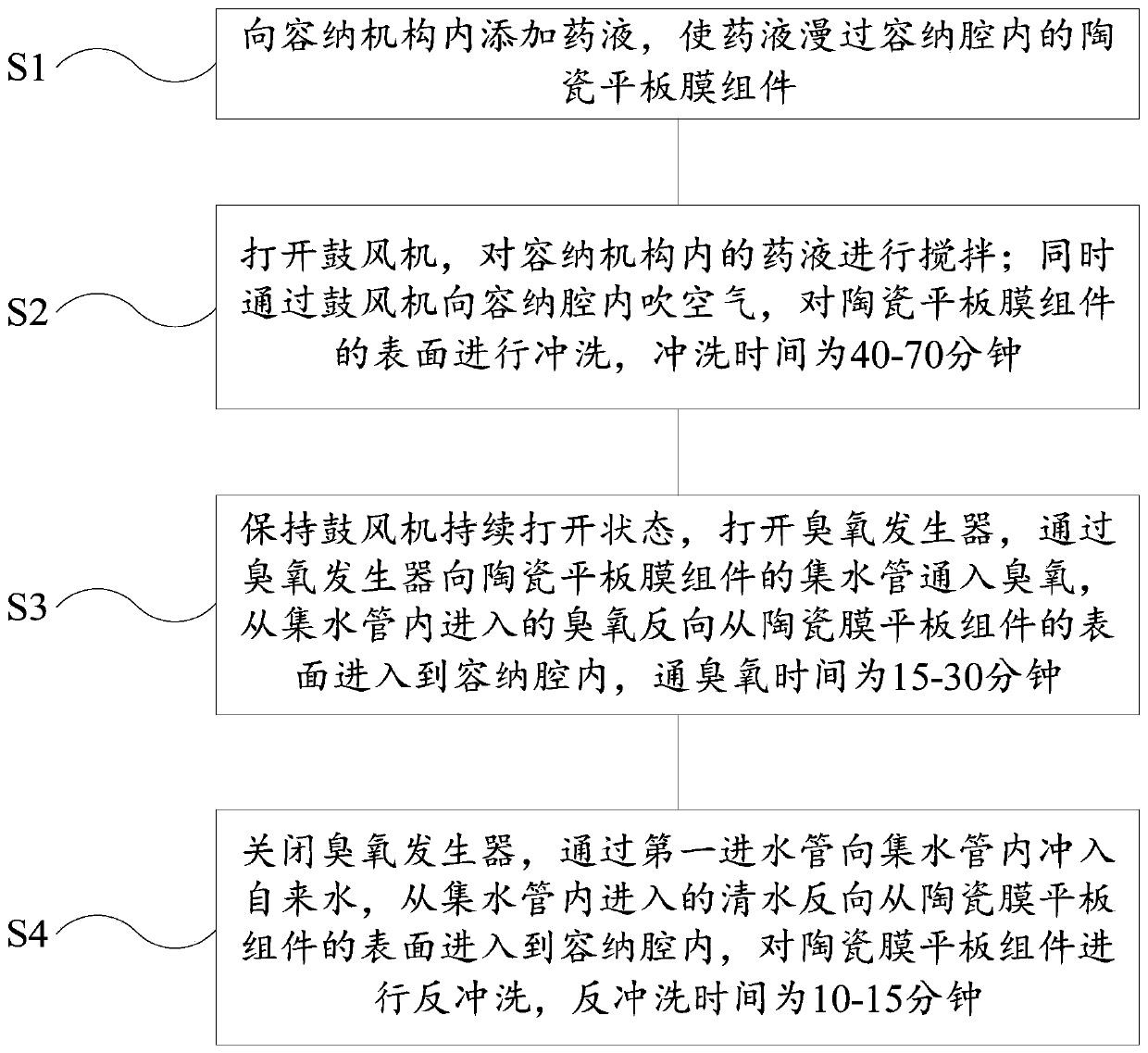

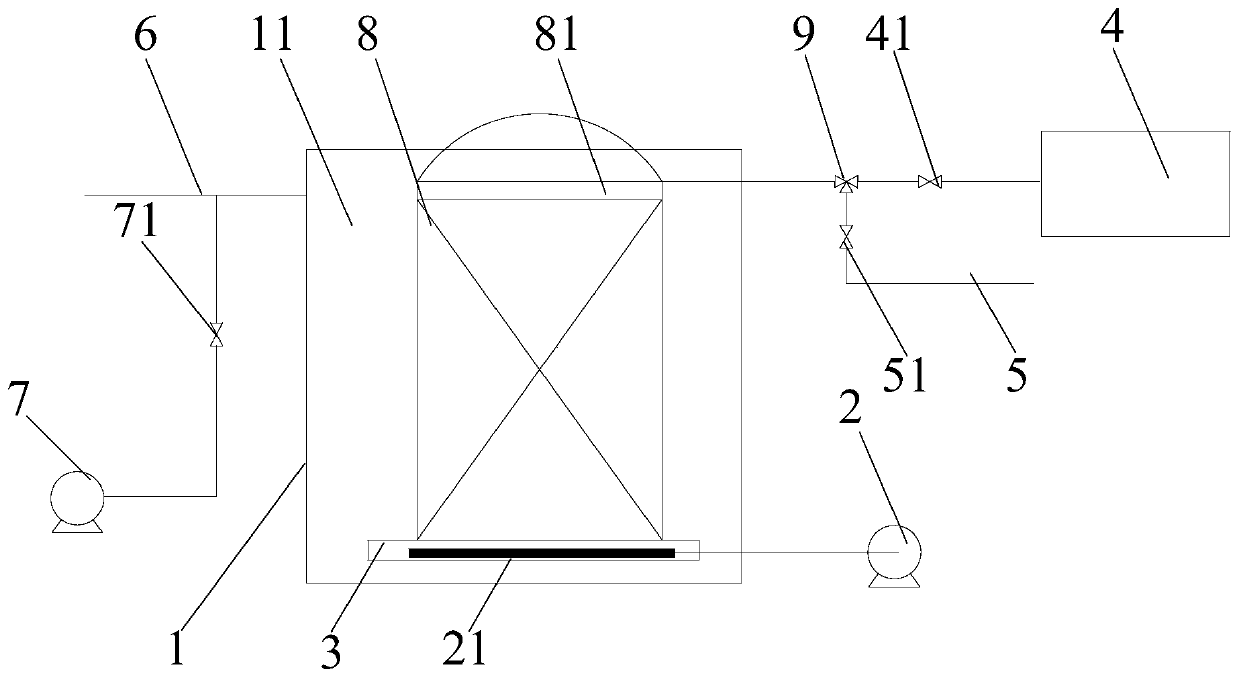

Cleaning device and cleaning method for ceramic flat sheet membrane component

PendingCN110026089AMix the medicine evenlyImprove efficiencySemi-permeable membranesWater/sewage treatment bu osmosis/dialysisPollutantAirflow

The invention relates to the technical field of sewage treatment, and specifically relates to a cleaning device and a cleaning method for a ceramic flat sheet membrane component. The cleaning device provided by the embodiment of the invention comprises an accommodating mechanism, a fixing bracket, an air blower, a first water inlet pipe and an ozone generator, a liquor is injected into an accommodating cavity first in use, the dirt on the ceramic flat sheet membrane component is soaked by the liquor, and is softened and separated, then the air is introduced to scour the dirt, the dirt cleaningefficiency is higher; the ozone is introduced into the ceramic flat sheet membrane component through an ozone generating mechanism, the pollutant in an inner channel and an aperture of a ceramic membrane is oxidized and degraded from inside to outside, the cleaning effect on the dirt at the inner part of the ceramic flat sheet membrane component is better, then tap water is used to flush back from the inner part to the outer part of a ceramic membrane sheet, the pollutant blocked in the aperture of the membrane is thoroughly removed, the membrane flux restoration effect is better, the cleaning efficiency is higher, and the cleaning time is reduced by a half or more.

Owner:广西碧清源环保投资有限公司

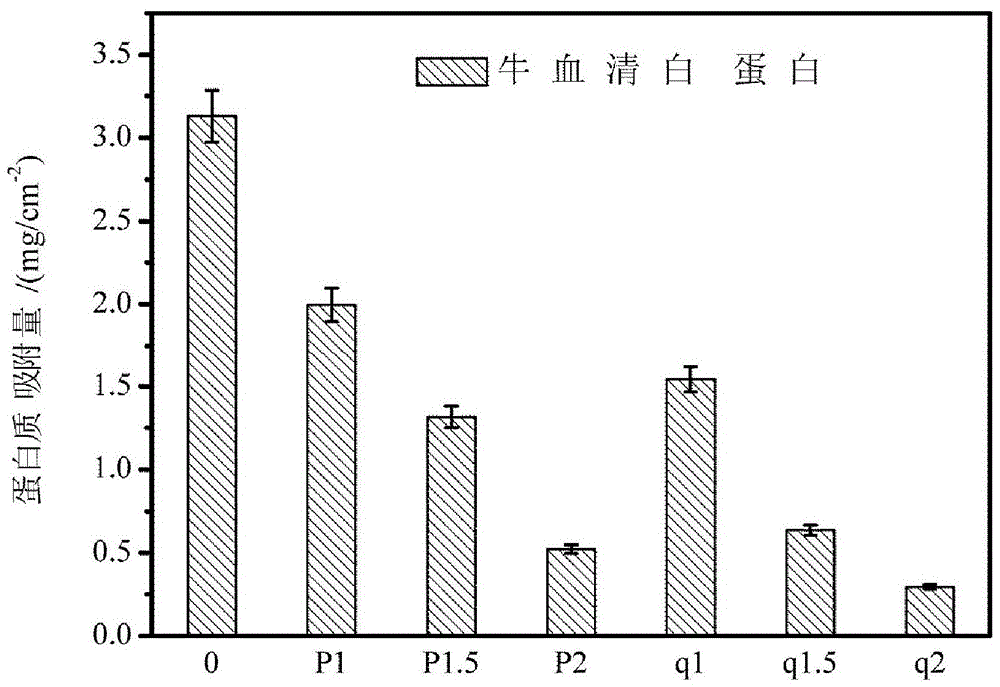

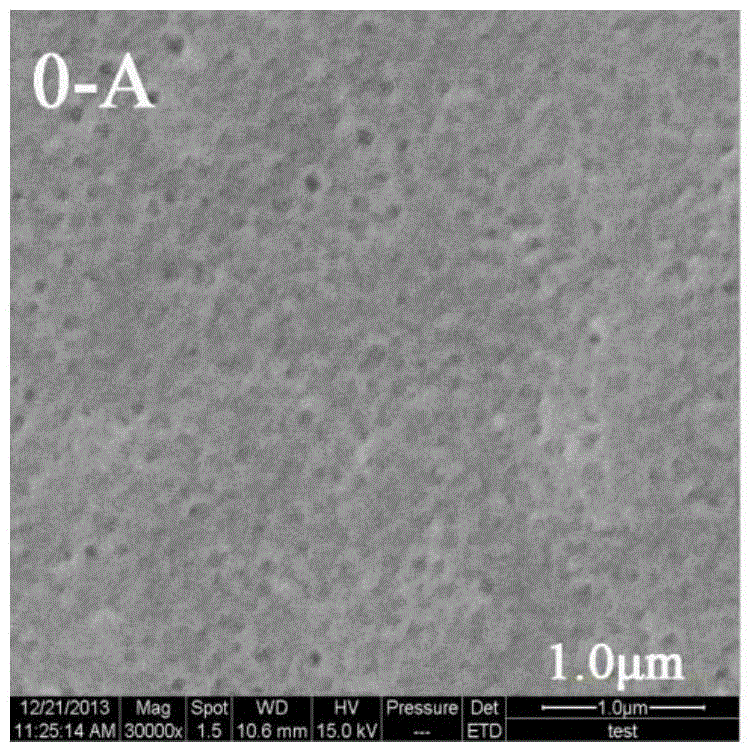

A method for preparing an inexpensive ultrafiltration membrane that can be used in the treatment of oil production wastewater

ActiveCN104258742BNo post-processingSimple processSemi-permeable membranesWater bathsFiltration membrane

The invention provides a preparation method of a cheap ultra-filtration membrane for treating oil producing wastewater. The preparation method comprises the following steps: dissolving nano silicon dioxide into a polyvinyl chloride dissolving solvent under ultrasonic condition to prepare a suspension solution of nano particles; then sequentially and slowly adding a pore-forming agent, a de-foaming agent and polyvinyl chloride into the suspension solution; continuously and mechanically agitating in a water bath of 30-40 DEG C for more than 24 hours until a homogeneous membrane casting solution is formed; sufficiently de-foaming the membrane casting solution in a vacuum drying box and scraping a membrane by using a membrane scraping machine; after volatilizing the scraped new membrane in the air for 15-60 seconds, slowly putting the scraped new membrane into a coagulating bath for coagulation; and after separating the membrane from a glass plate, sufficiently immersing the membrane in pure water for 48 hours to obtain a nano silicon dioxide modified polyvinyl chloride flat plate membrane. The preparation method of the cheap ultra-filtration membrane can be used for nano silicon dioxide polyvinyl chloride hollow fiber type ultra-filtration membranes and micro-filtration membranes, reverse osmosis membranes, nano-filtration membranes, pipe type membranes, capillary tube membranes or spiral-wound membranes.

Owner:HARBIN ENG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com