Patents

Literature

235results about How to "Ease of mass industrial production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

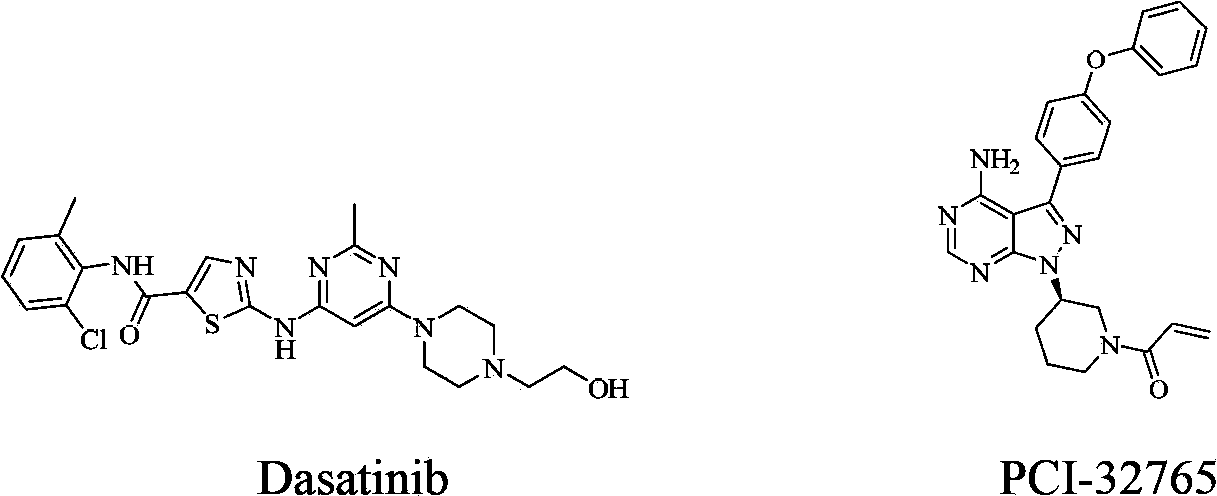

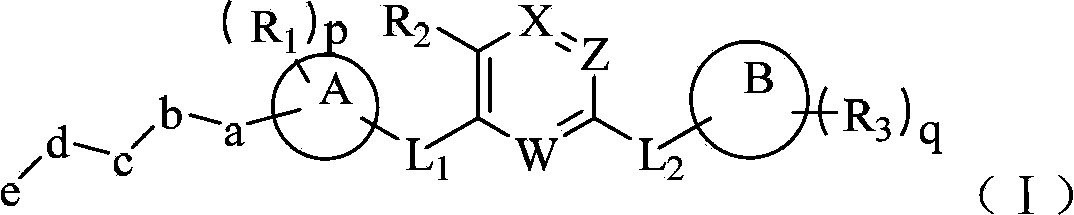

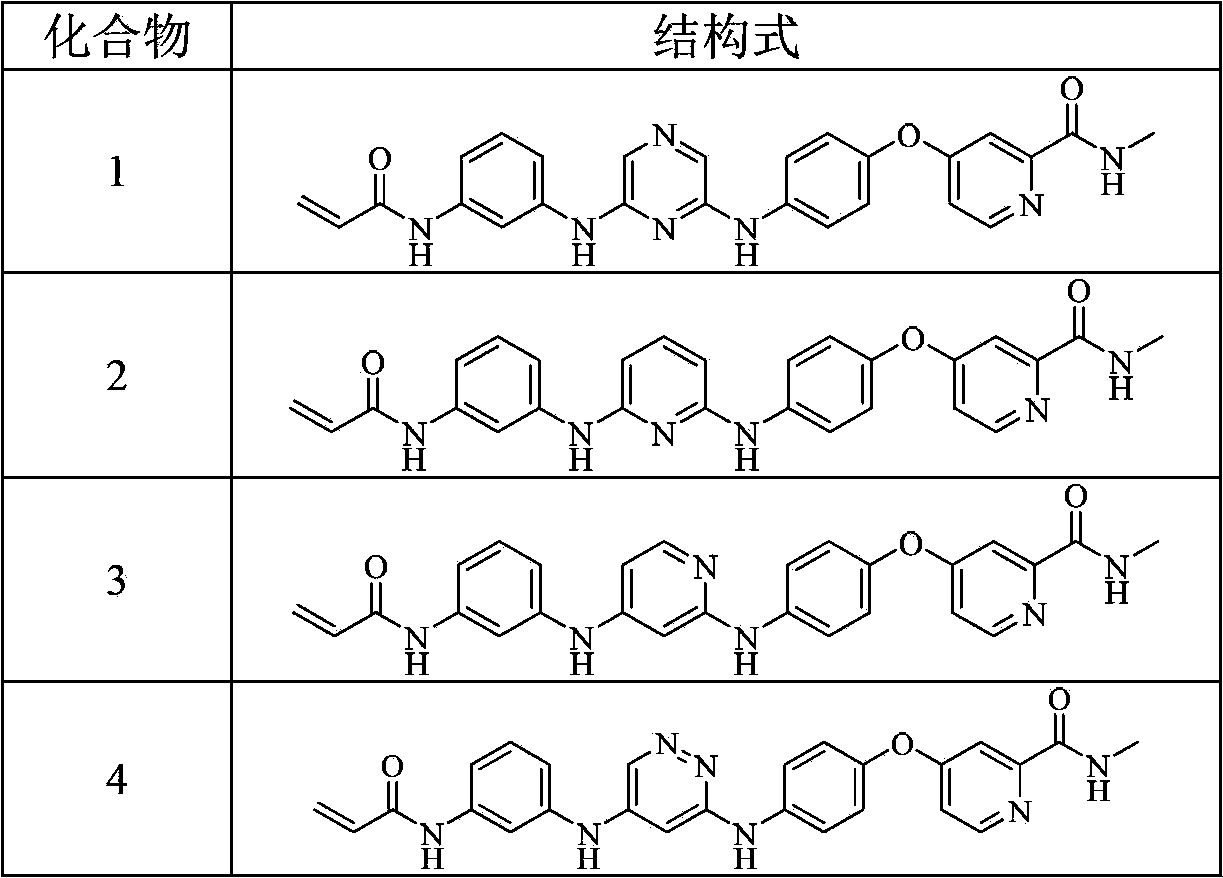

Hetero-aromatic ring and derivative type tyrosine kinase inhibitor thereof

InactiveCN103664878ABTK kinase inhibition is goodLittle side effectsOrganic active ingredientsOrganic chemistryImmunologic disordersDisease

The invention belongs to the technical field of medicaments, and in particular relates to a hetero-aromatic ring shown by a general formula (I) as well as a derivative type tyrosine kinase inhibitor, a pharmaceutically acceptable salt or a stereoisomer thereof, wherein X, Z, W, R1, R2, R3, L1, L2, a, b, c, d, e, p, q, A and B are as defined in the specification. The invention also relates to preparation methods of these compounds, a pharmaceutical preparation containing these compounds, and important functions of these compounds in preparation of medicaments for treating B cell related leukemia (such as B cell chronic lymphocytic carcinoma and non-hodgkin lymphoma) and autoimmune diseases (such as rheumatoid arthritis, systemic lupus erythematosus and the like).

Owner:KBP BIOSCIENCES CO LTD

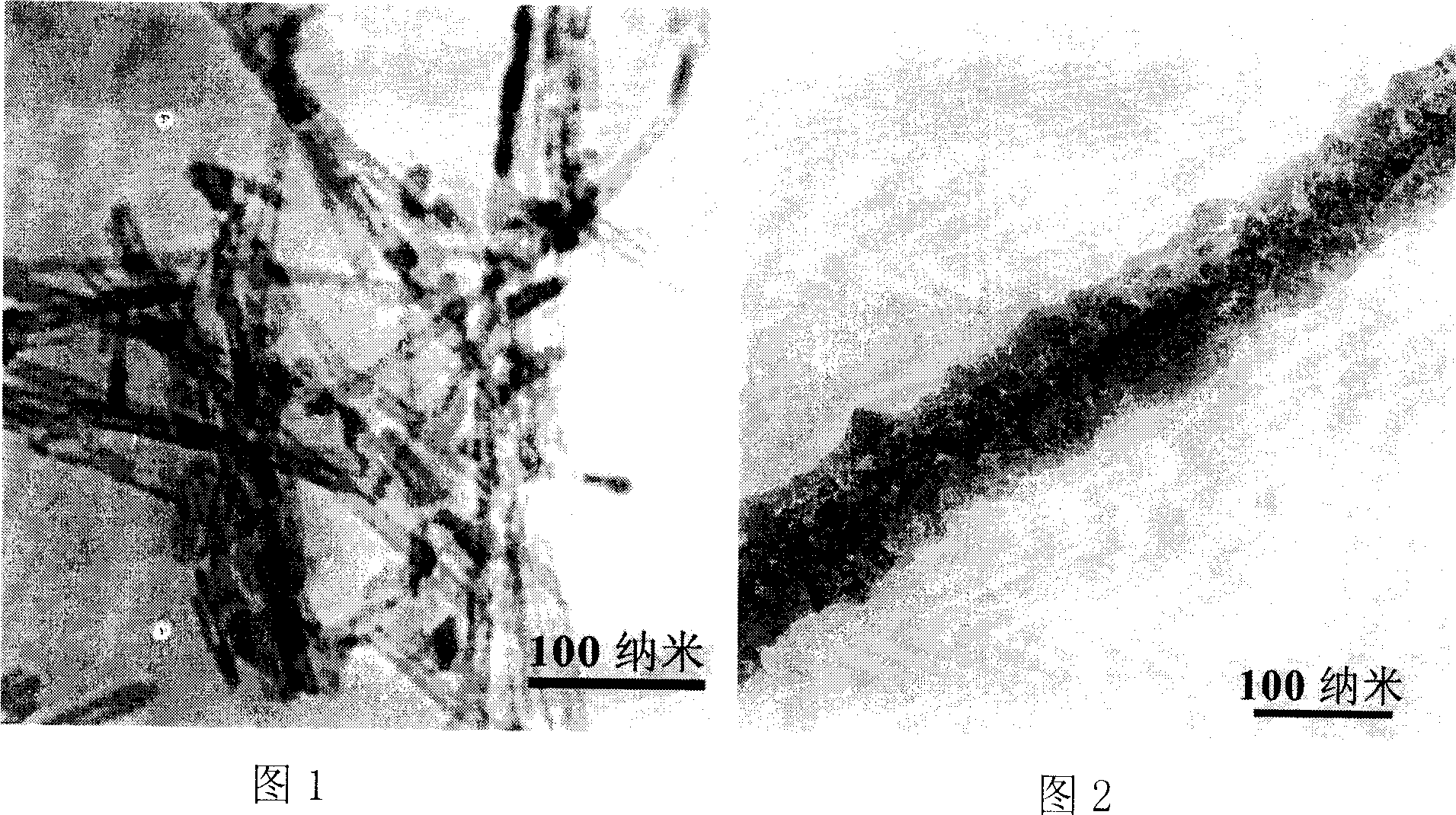

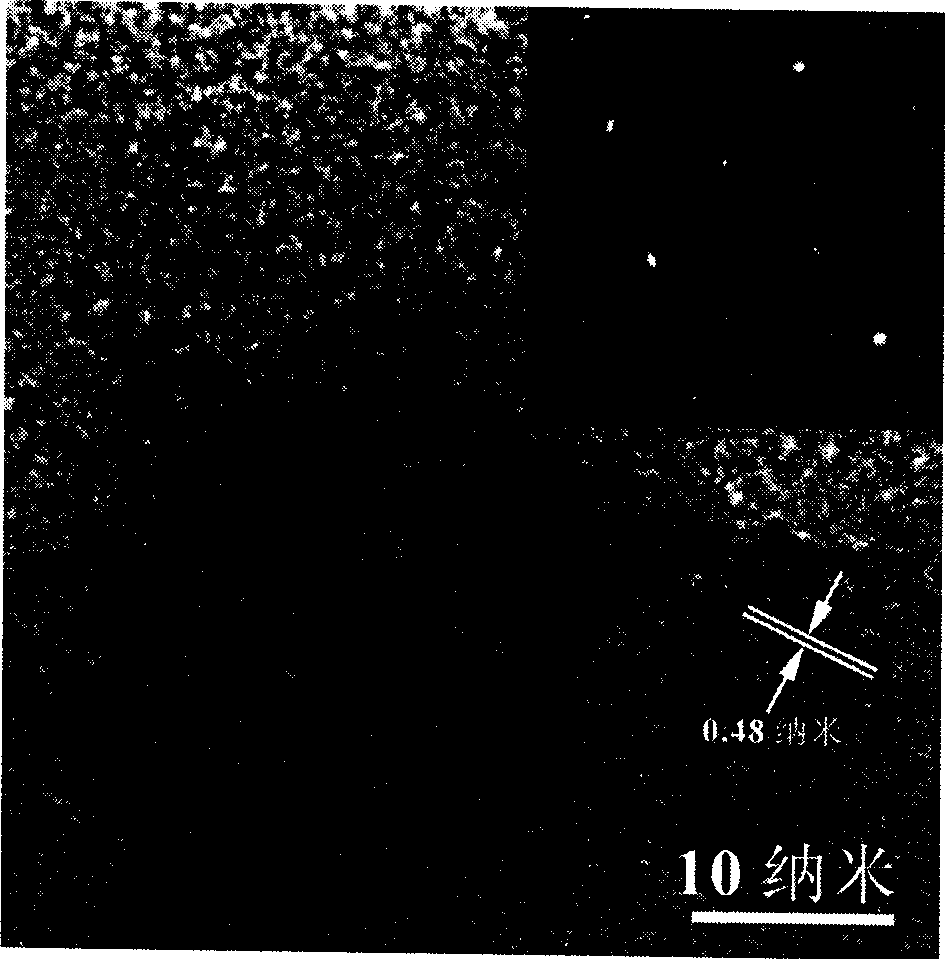

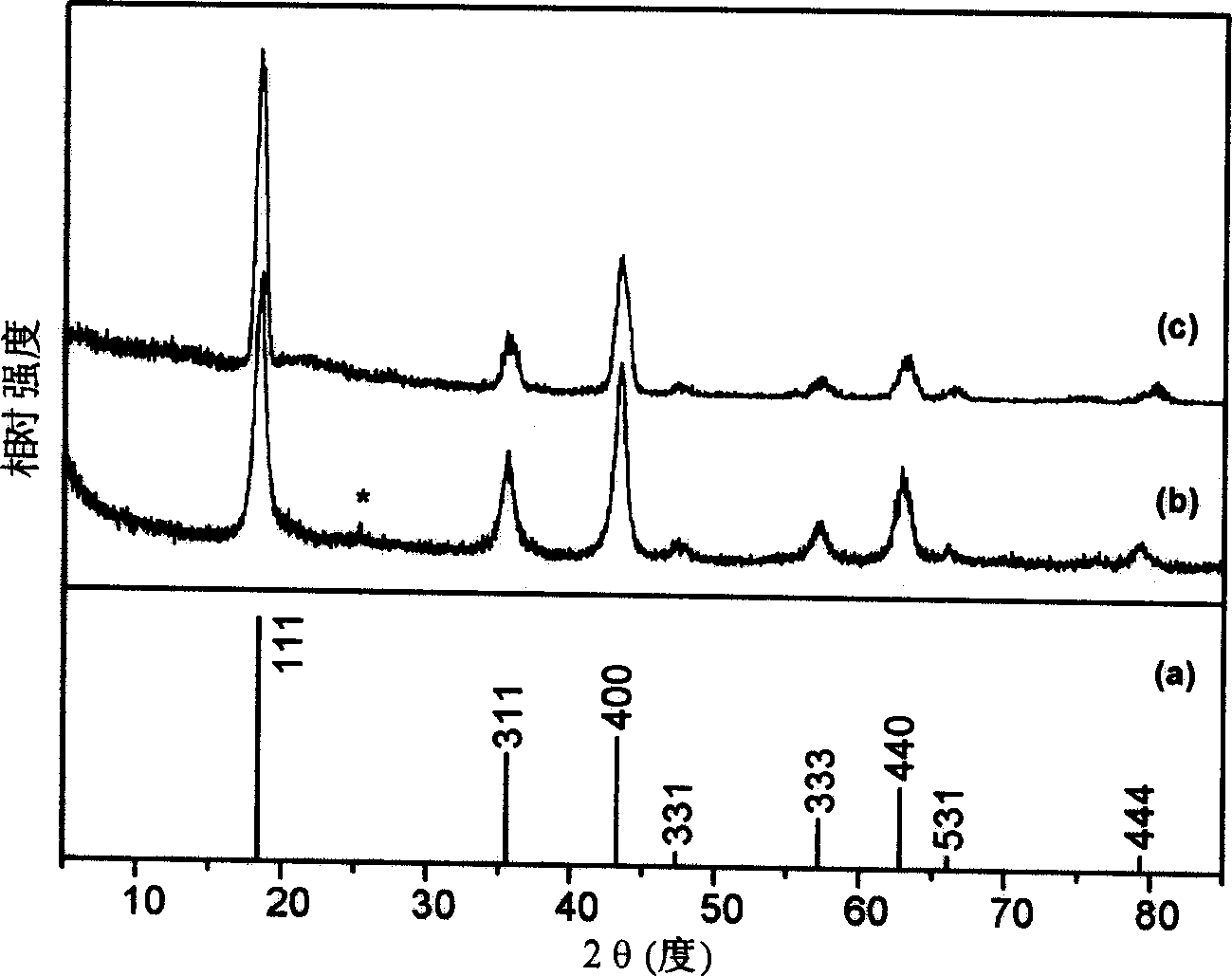

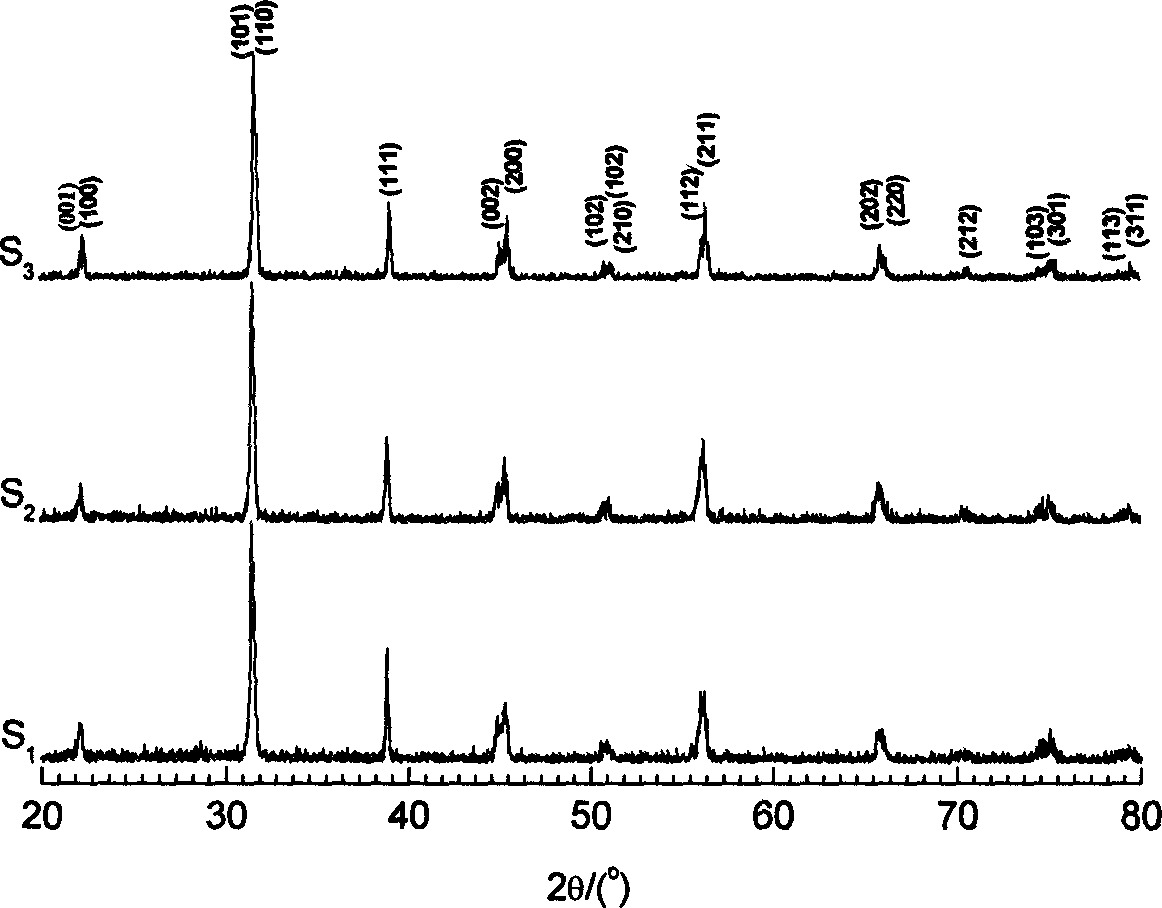

Preparation method of spinel lithium titanate nano tube/wire for lithium battery and capacitor

InactiveCN1725530AReduce energy consumptionUniform shapeNanostructure manufactureElectrode manufacturing processesNanowireIon exchange

This invention discloses a preparation method for spinel lithium titanate nm pipes / nm lines used in Li batteries and capacitors, which applies cheap industrial TiO2 as the raw material and supersonic chemical method to prepare said nm pipes / lines then takes them as the raw materials to be mixed with a certain quantity of soluble Li salt solution to be baked in air and by low-temperature hydrothermal ion exchange method to manufacture spinel lithium titanate nm pipes / lines with uniform shape, uniform diameter and even larger major diameter ratio and big ratio surface area.

Owner:TSINGHUA UNIV

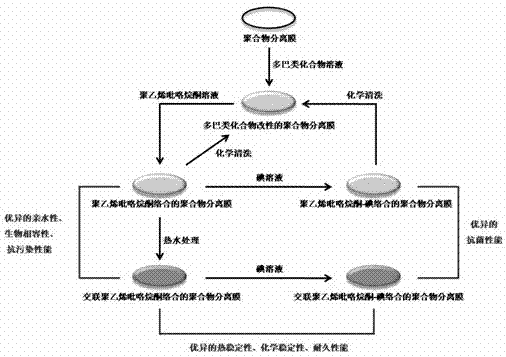

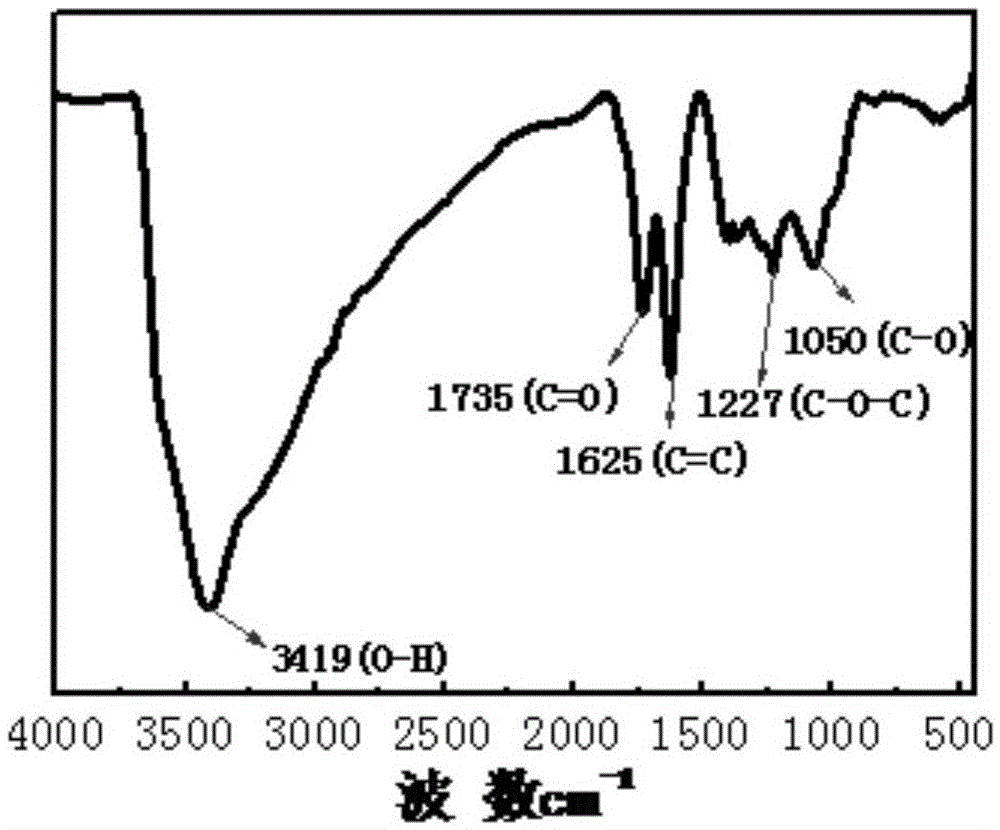

Surface modification method for polymer separation membrane

ActiveCN103041721AModification equipment is simpleShorten the production cycleSemi-permeable membranesPolymer scienceAgglutination

The invention discloses a surface modification method for a polymer separation membrane. Under the water solution condition, a dopa compound is easily oxidized by dissolved oxygen in water to generate auto-agglutination-composite reaction in order to generate a firmly attached dopa compound composite layer on the surface of the polymer separation membrane; the dopa compound composite layer contains rich catechol radicals which can form the multi-point hydrogen bonding effect with lactam radicals in polyvinylpyrrolidone, and the polyvinylpyrrolidone is firmly complexed on the surface of the separation membrane; and the polymer separation membrane immobilized with povidone-iodine on the surface can be prepared through the complexation between the polyvinylpyrrolidone and iodine. The method has simple technique, and is suitable for the polymer separation membranes with different materials and shapes; and the modified polymer separation membrane has excellent hydrophily, blood compatibility, contamination resistance and bacterial resistance, so that the important significance is given to improve the comprehensive performance of the polymer separation membrane.

Owner:ZHEJIANG UNIV

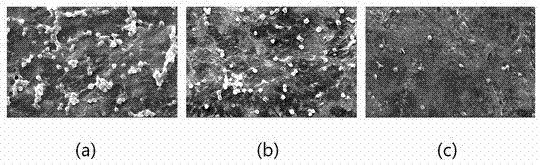

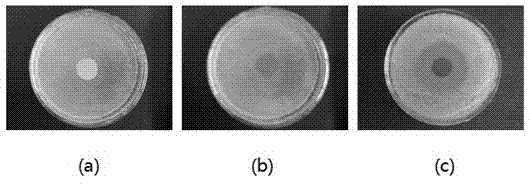

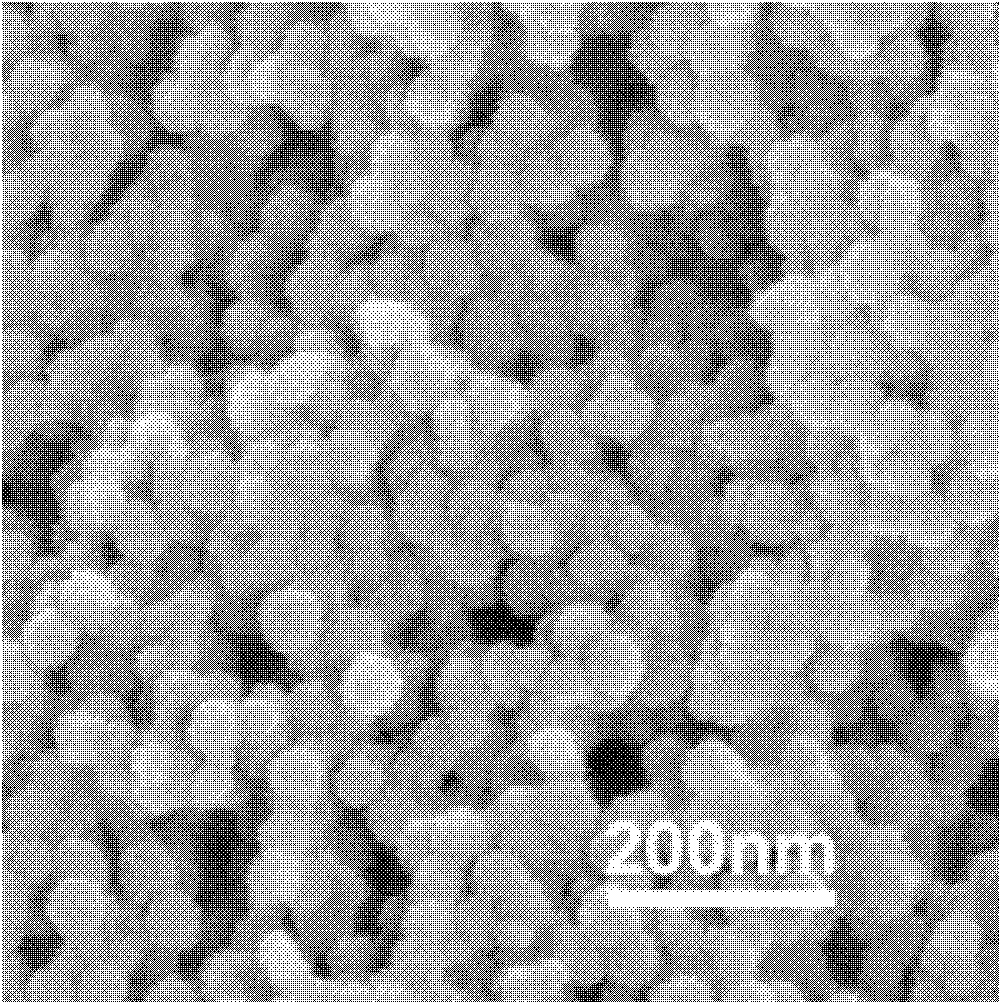

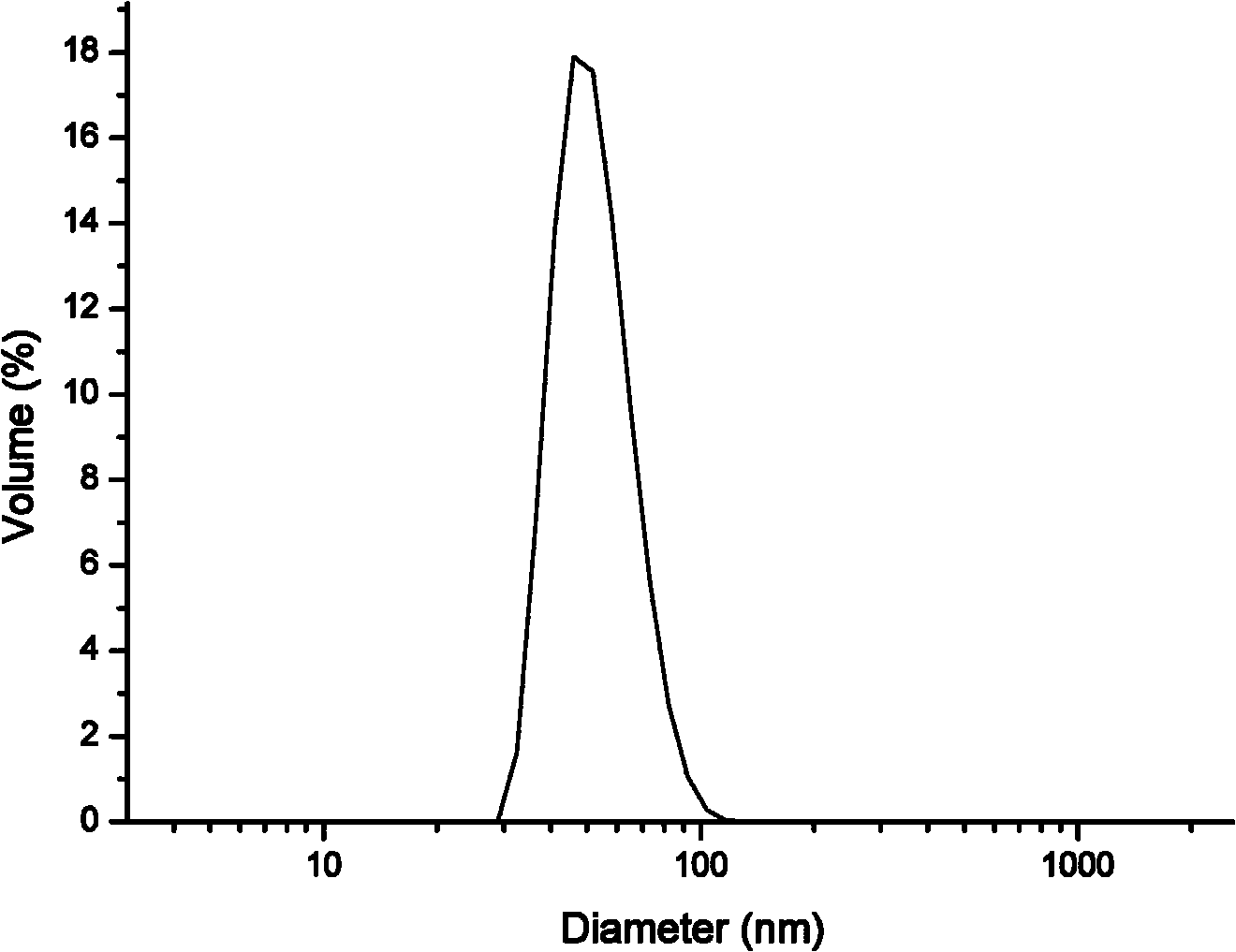

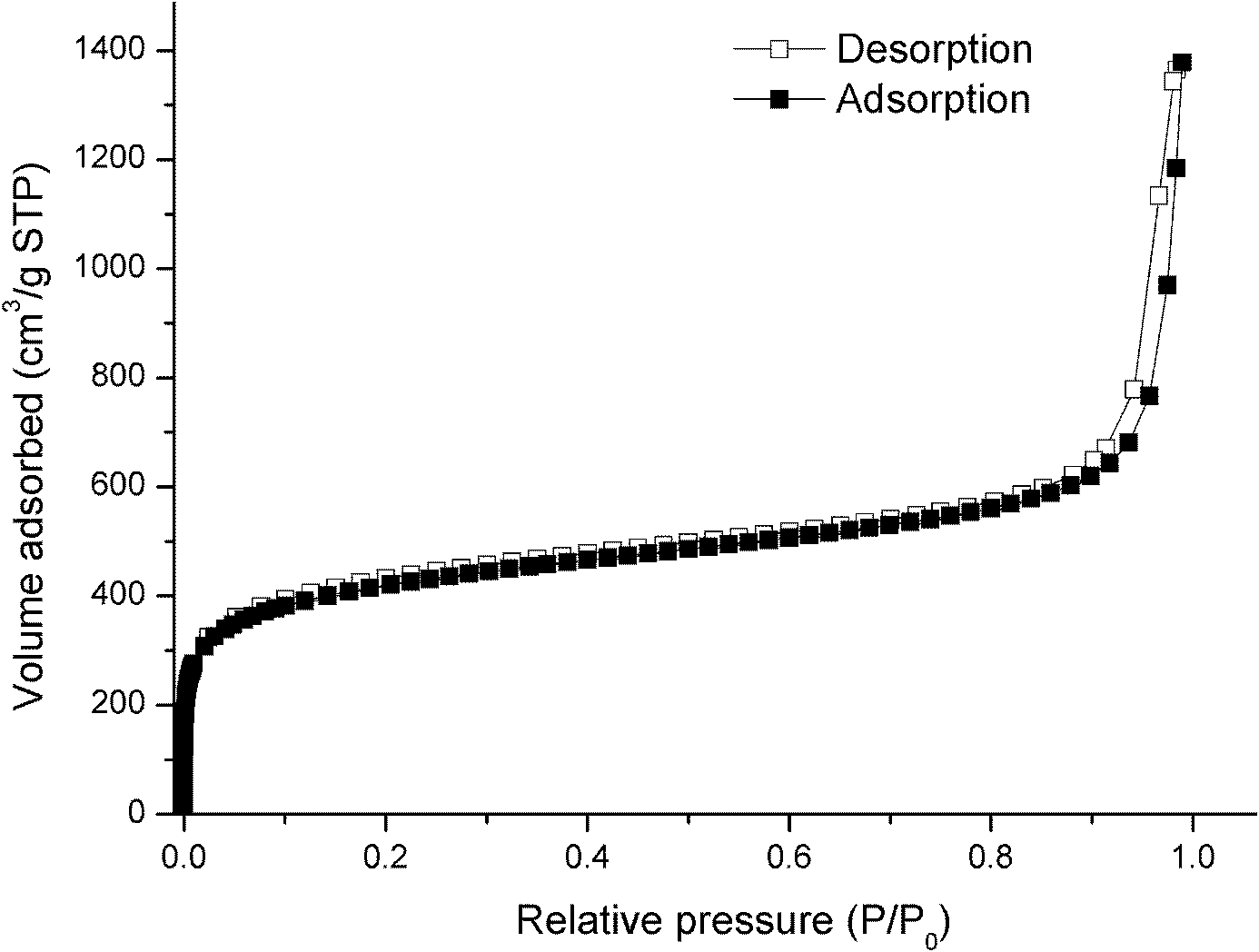

Porous polymer nanoparticles and preparation method thereof

ActiveCN101824118AEase of mass industrial productionCatalyst carriersSemi-permeable membranesNanometreDrug carrier

The invention provides porous polymer nanoparticles and a preparation method thereof. The porous polymer nanoparticles are prepared by an emulsion polymerization method, and have the adjustable porous size, the monodisperse particle size, the adjustable particles size and a high specific area. Compared with the traditional porous polymer particles, the porous polymer nanoparticles have the porous size with adjustable range of between 0.5 and 100nm, the monodisperse particle size, and the particles size with adjustable range of between 20 and 200nm, so the porous polymer nanoparticles can be used as a catalyst carrier, a separation membrane, a gas storage material, a medicament carrier of animal and plant cells, a medicament carrier of animal and plant tissues and a novel template agent of a complex structure material. The preparation method comprises the following steps of: polymerizing a styrene monomer and a divinylbenzene monomer by the emulsion polymerization method to obtain a precursor of the monodisperse porous polymer nanoparticles; and then performing ultra-crosslinking on the precursor of the monodisperse porous polymer nanoparticles by an internal crosslinking method or an external crosslinking method to obtain the monodisperse porous polymer nanoparticles.

Owner:武汉华科中英纳米科技有限公司

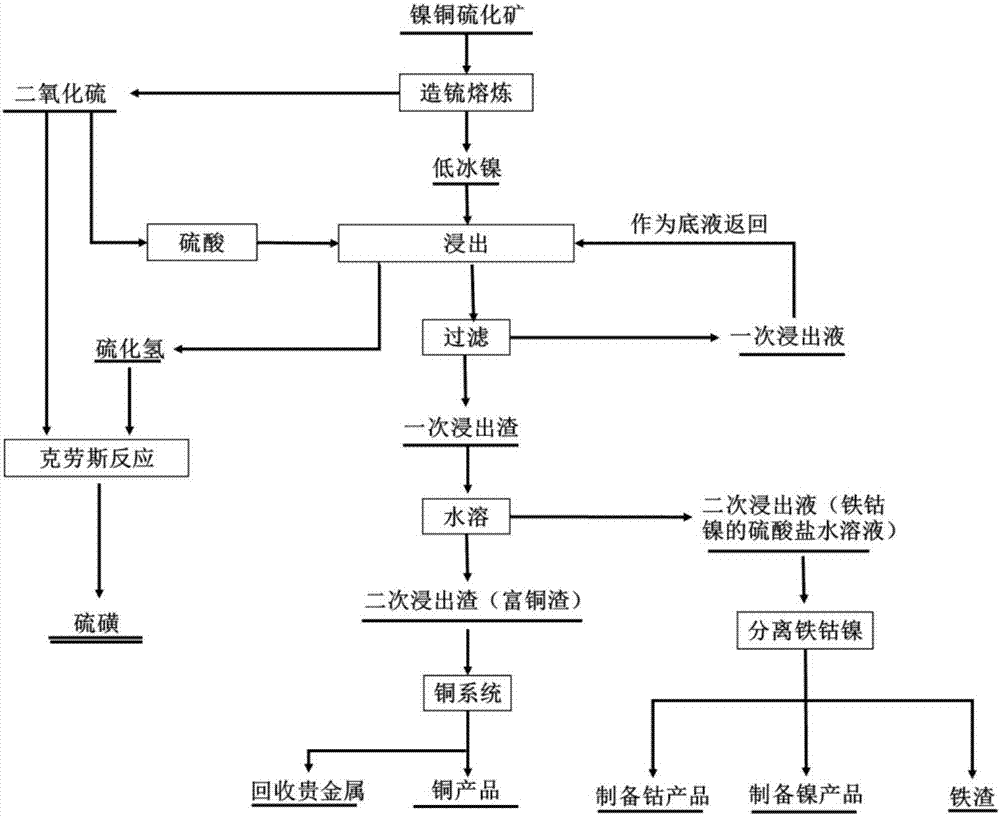

Method and system for recovering main associated elements from copper-nickel sulfide ore

ActiveCN107012324AAchieve deep separationImprove efficiencyProcess efficiency improvementSlagNickel sulfide

The invention provides a method and system for recovering main associated elements from copper-nickel sulfide ore. The method comprises the following steps: 1, continuously adding low-grade nickel matte and a leaching reaction solution into a reaction base solution, carrying out selective leaching, and collecting hydrogen sulfide gas, a first leaching solution and a first leaching residue, wherein the leaching reaction liquid is sulfuric acid with the mass fraction being 60-95%; 2, adding water into the first leaching residue for dissolving the first leaching slag, and collecting a second leaching solution and a second leaching residue; and 3, removing iron from the second leaching solution, collecting an iron-removed solution used for extracting nickel and cobalt and an iron-removed residue used for iron making, and / or sending the second leaching residue to a copper smelting device for smelting to obtain copper and noble metal. According to the method, deep separation of the nickel and the copper can be realized, and recovery of the nickel, the copper, the cobalt, the noble metal and sulfur can be effectively realized. The method is simple in process, short in flow and high in efficiency, is a clean and efficient element recovery process and is easy for large-scale industrial production.

Owner:CENT SOUTH UNIV

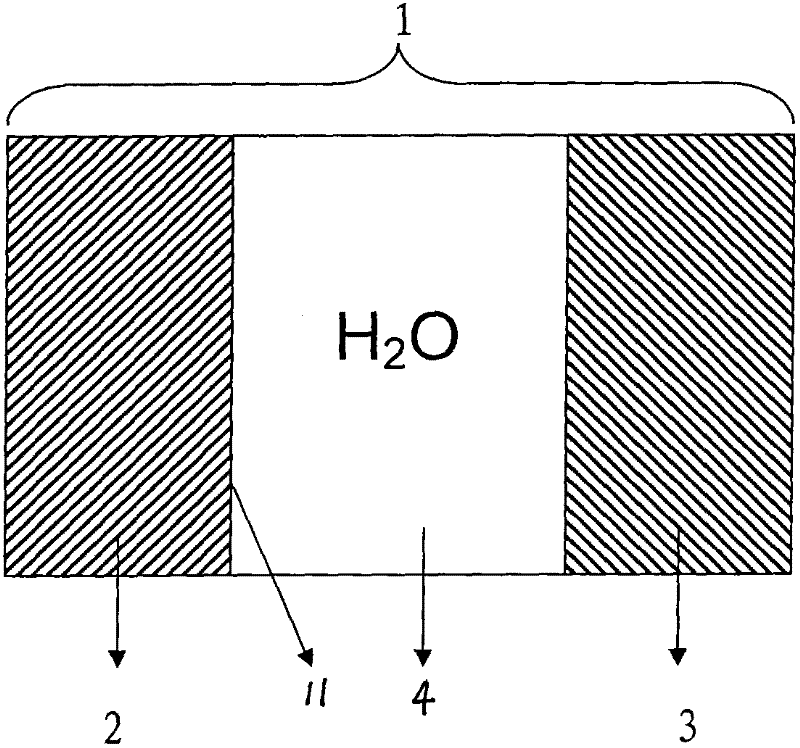

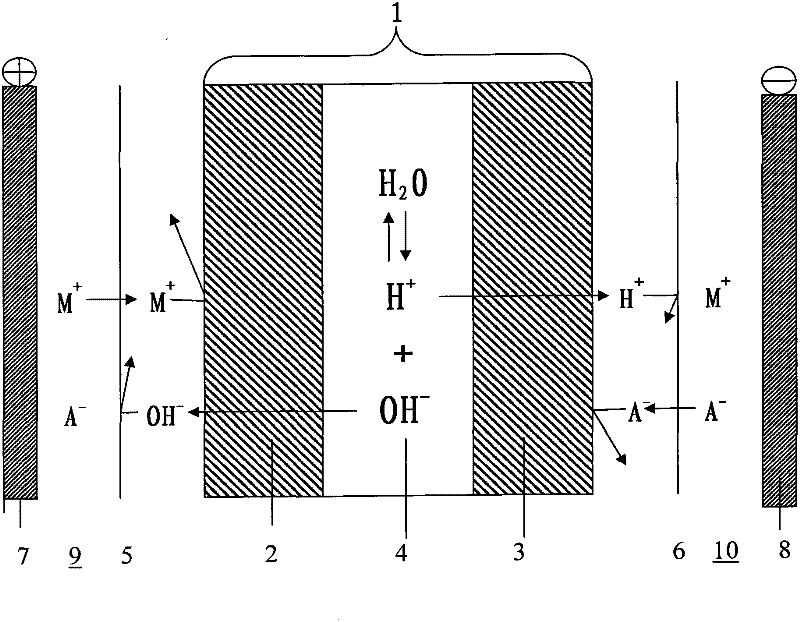

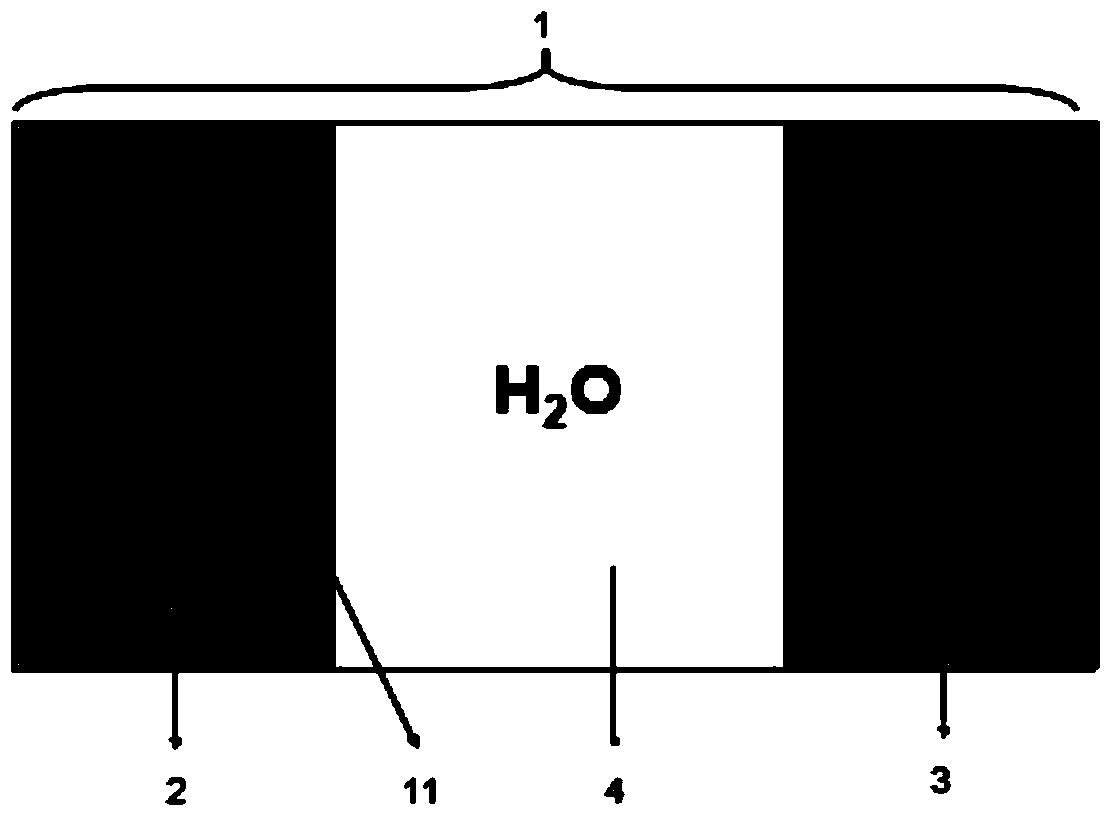

Method for manufacturing monolithic bipolar membrane

ActiveCN102061004BIncrease elasticityImprove flexibilitySemi-permeable membranesElastomerBenzoyl peroxide

The invention relates to a method for manufacturing a monolithic bipolar membrane, which comprises the following steps of: immersing a substrate membrane in a solution containing styrene, divinybenzene and benzoyl peroxide, pressurizing the immersed membrane, wherein the substrate membrane is a thin alloy membrane formed by two-element blending of polyethylene and ethylene-octylene copolymer elastomer or by three-element blending of polyethylene, ethylene-octylene copolymer elastomer and polyisobutylene rubber; and pressurizing the membrane immersed in the solution and polymerizing under the condition of heating to obtain a base membrane; sulfonating one side face of the base membrane by heating in concentrated sulfuric acid; performing chloromethylation reaction of the membrane with one sulfonated side face in chloromethyl ether containing anhydrous stannic chloride so that the other side face of the membrane is chloromethyl; and immersing the membrane in a trimethylamine aqueous solution or a trimethylamine aqueous solution containing dimethylamine to carry out an aimination or quaterisation reaction to obtain the monolithic bipolar membrane. The method has the advantages that the immersing temperature is greatly reduced, the styrene and divinybenzene solution can be repeatedly used, and the electric resistance of the bipolar membrane is low. The bipolar membrane has a catalytic layer for accelerating water decomposition, the method is simple and convenient and is easy for large-scale industrialized production.

Owner:福建省延润膜环保科技有限公司

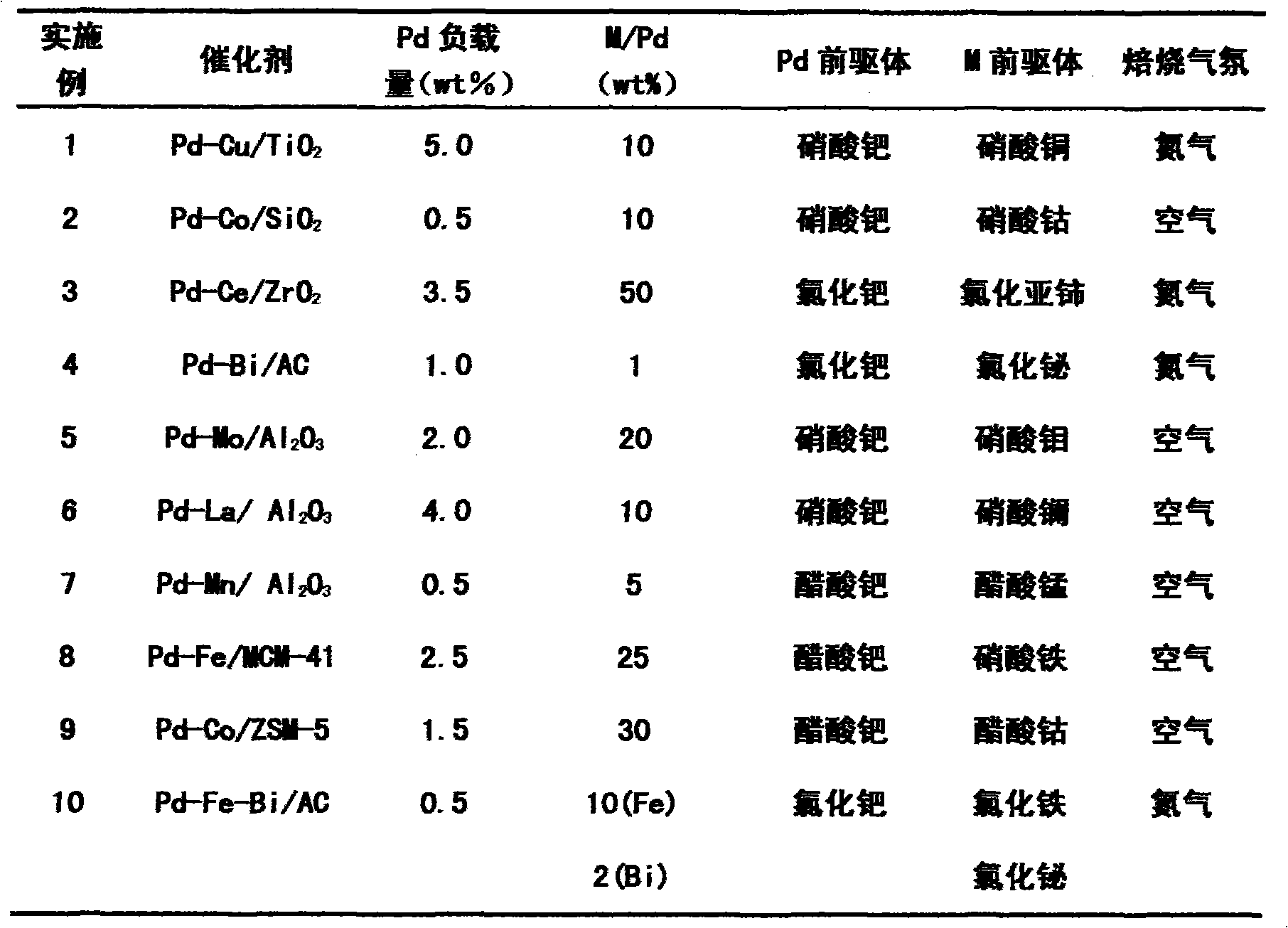

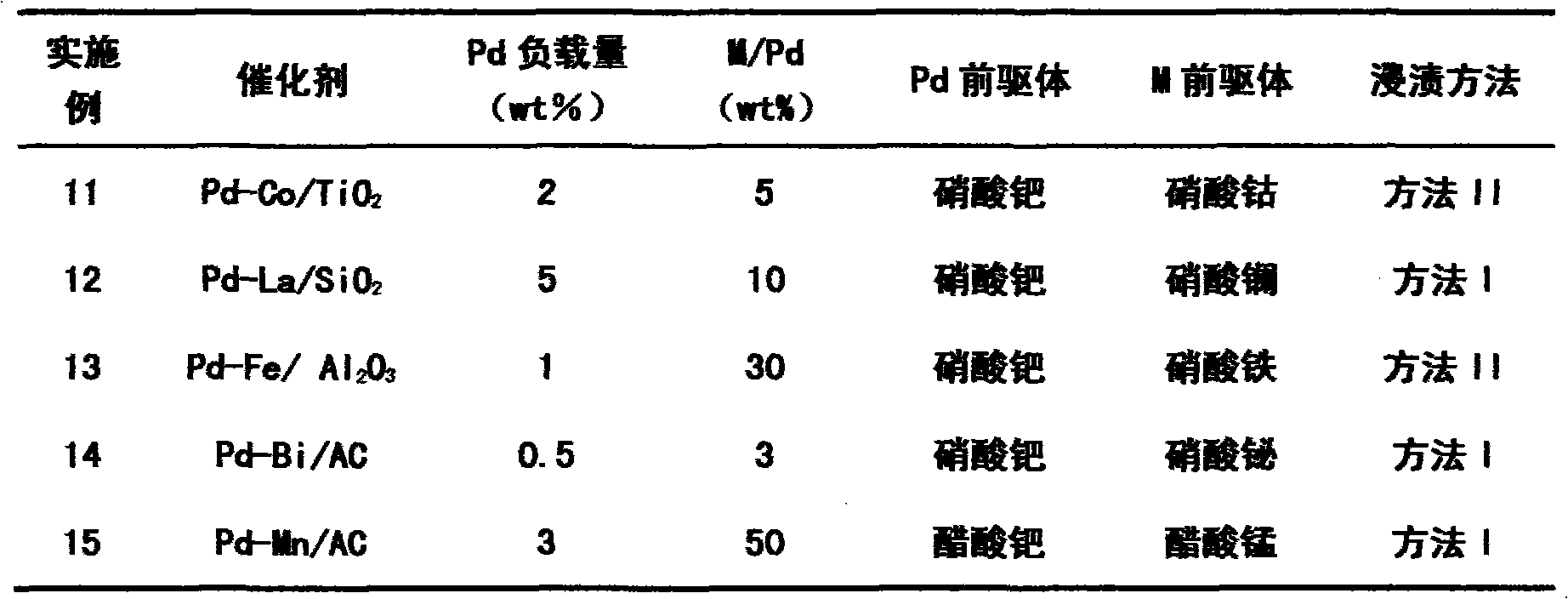

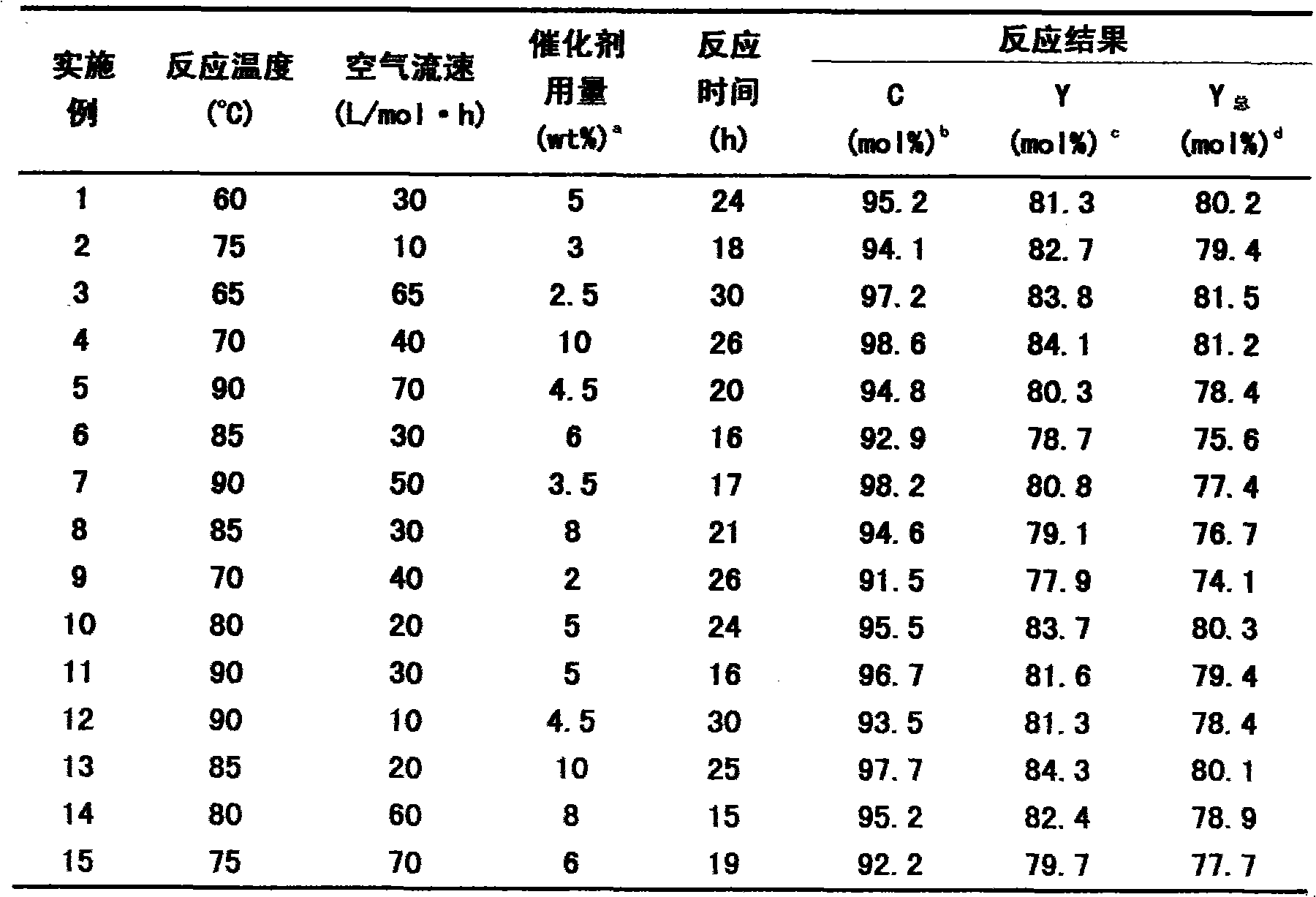

Method for preparing glutaric acid through oxidation of glutaral pentanedial

ActiveCN101570479AImprove conversion rateHigh selectivityMolecular sieve catalystsOrganic compound preparationGlutaric acidActive component

The invention provides a method for preparing glutaric acid through the oxidation of glutaral pentanedial. The method takes a load type solid catalyst containing an active component Pd, takes air as an oxidant, and oxidizes glutaral pentanedial into glutaric acid in a gas-liquid-solid three-phase intermittent or continuous reaction mode under moderate conditions. The method has high glutaral pentanedial conversion rate and high glutaric acid selectivity, easy separation of the catalyst from the raw materials and products, simple and feasible operation, the air oxidant which is easily obtainedand has low price, low production cost, green and environmental protection reaction process, and easy large-scale industrialized production.

Owner:SHANGHAI HUAYI NEW MATERIAL

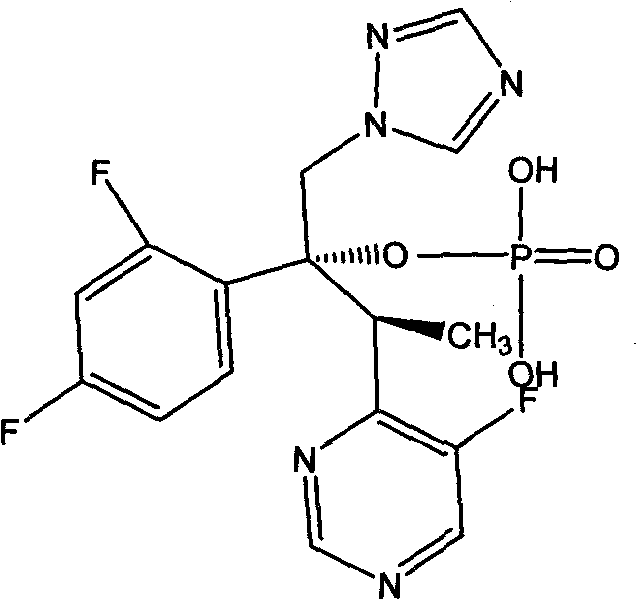

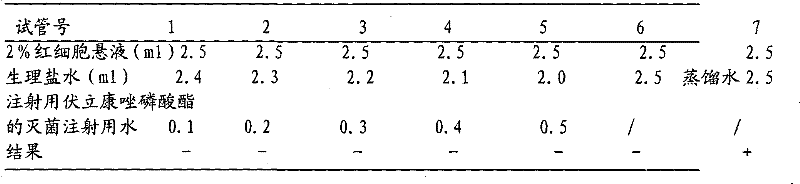

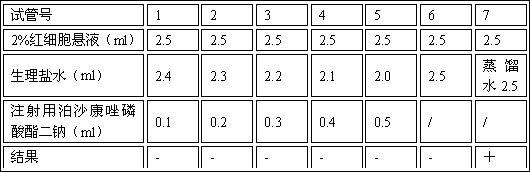

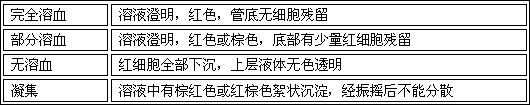

Voriconazole phosphate ester for injection and preparation method thereof

ActiveCN101744778AImprove performanceNo pollution in the processOrganic active ingredientsPowder deliveryPhosphateMedical prescription

The invention provides voriconazole phosphate ester for injection and a medicinal salt thereof and a preparation method for the voriconazole phosphate ester for injection and the medicinal salt thereof. The preparation method comprises the following steps: adding 5 to 98 percent water for injection in a liquid preparation container; adding 90 to 110 percent of the accurate formula dosage of voriconazole phosphate ester and the medicinal salt thereof in the container; stirring the mixture; slowly dropwise adding a pH value regulator; regulating pH to between 6.0 and 11; supplementing water to the full dosage and then adding 0.01 to 1.0 percent (weight in volume) medicinal carbon into the product; stirring the mixture for 15 to 60 minutes; using a sand filter stick to carry out rough filtration and decarburization on the obtained product, and using a 0.22mum millipore filter to carry out fine filtration on the product until the clarity is qualified; after determining that the content of the midbody is qualified, determining the filling quantity and subpackaging the finished product in the vial; adding the semi-plug; carrying out freezing and drying on the sample; controlling the moisture content between 1 and 8 percent; pressing the plug; and carrying out capping.

Owner:HC SYNTHETIC PHARMA CO LTD

A method of manufacturing a monolithic bipolar membrane

The invention relates to a production method of a single-sheet bipolar membrane, and belongs to the technical field of preparation of a membrane separation material in the field of chemical engineering. The production method comprises the following steps: a polyolefin membrane or a polyhaloalkene membrane is taken as a substrate membrane; the substrate membrane is immersed into a monomer solution filled with styrene-divinylbenzene, nitrogen is fed, the mixture is sealed and then placed in a radiation source chamber for radiation, and then the mixture is taken out to obtain the base membrane; one side surface of the base membrane is heated for sulfonation in concentrated sulfuric acid or chlorosulfonic acid, and a positive surface membrane of the bipolar membrane is formed; the membrane with one sulfonated side surface has a chloromethylation reaction in chlorosulfonic acid containing tin tetrachloride anhydrous to obtain the membrane with a chloromethyl group on the other side surface, the membrane is then immersed in a trimethylamine aqueous solution or a dimethylamine-containing trimethylamine aqueous solution for an amination or quaterization reaction to form a negative surface membrane of the bipolar membrane, and the single-sheet bipolar membrane is formed. The prepared bipolar membrane has low resistance and low transmembrane voltage, and the production method is simple and convenient and facilitates large-scale industrial production.

Owner:福建省延润膜环保科技有限公司

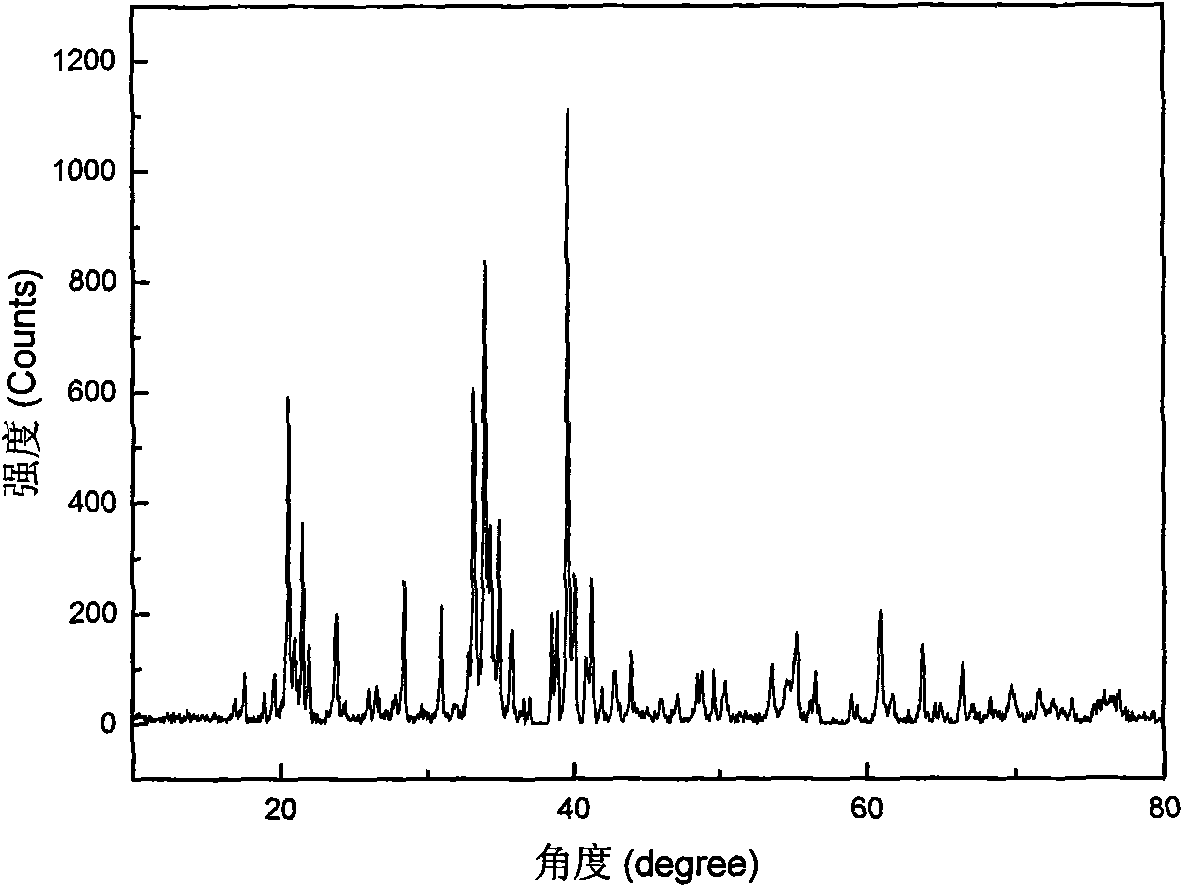

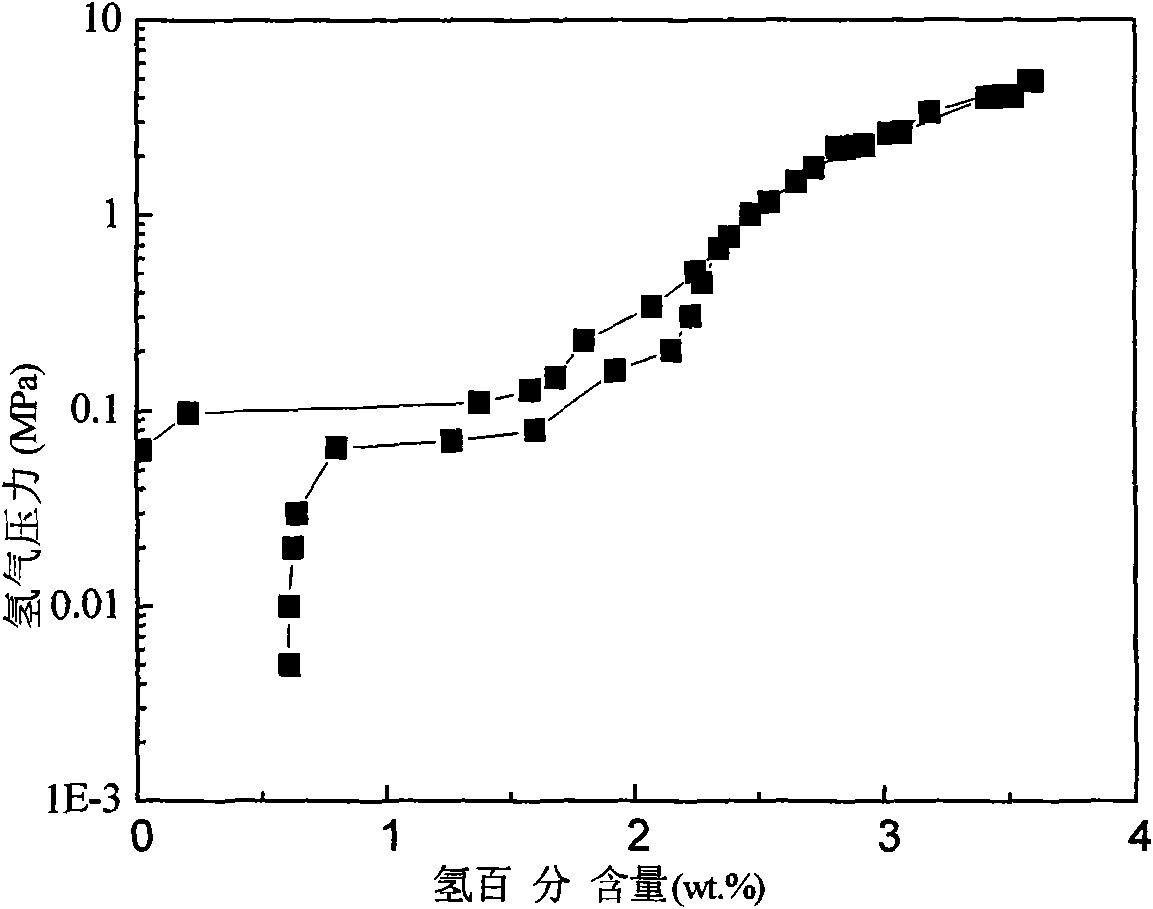

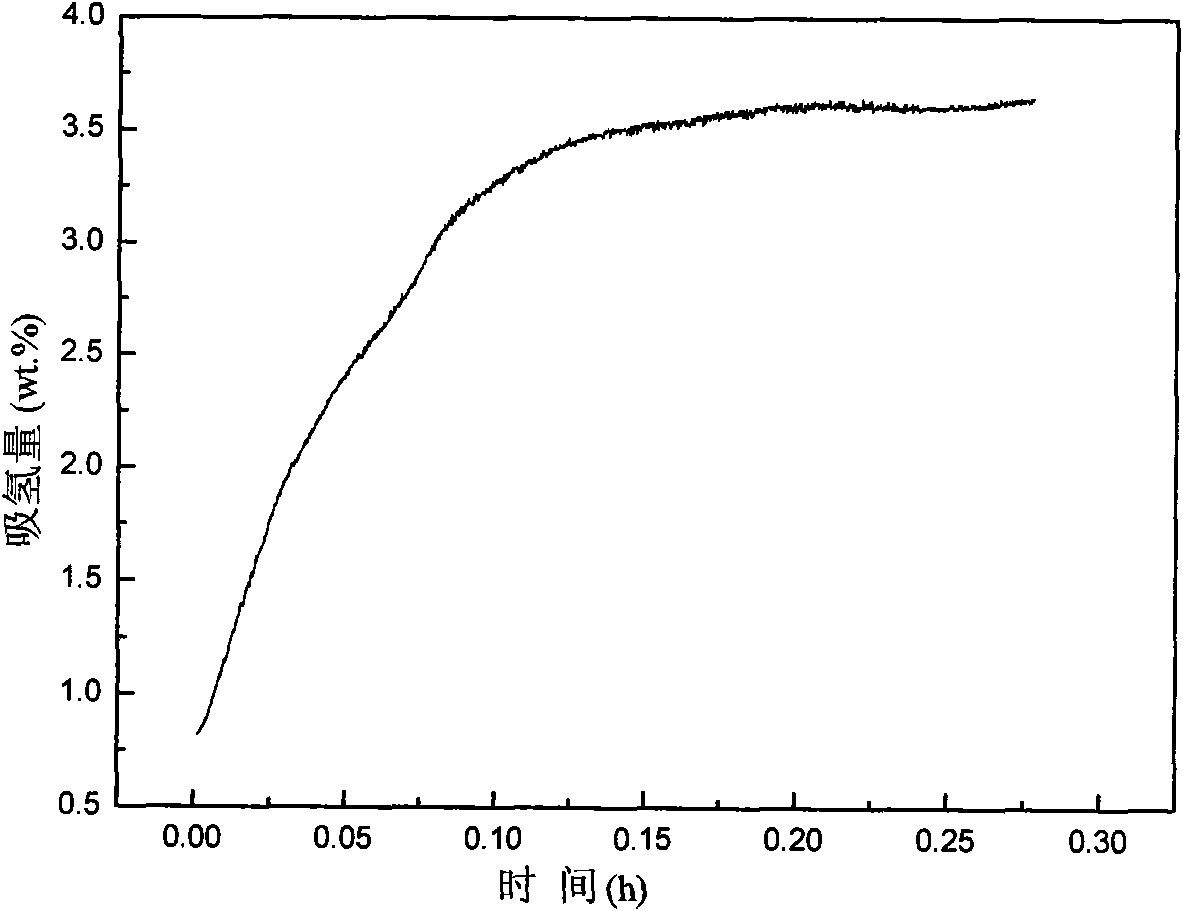

Rare earth-magnesium-transition metal base hydrogen storage metal and preparation method thereof

The invention relates to a rare earth-magnesium-transition metal base hydrogen storage metal with high hydrogen storage capacity and moderate hydrogen storage temperature and preparation method thereof. The metal is characterized in that the chemical formula thereof is REMgxMy, wherein x is more than 1 and less than 2, y is more than 1 and less than 3; RE is one or more than one of rare earth metals of La, Ce, Pr, Nd, cerium rich mish metal Mm and lanthanum rich mish metal M1; M is one or more than one of transition metals of Cu, Ni, Mn, Fe and Zn. The rare earth-magnesium-transition metal base hydrogen storage metal provided by the invention is also characterized in that the metal at least contains a multiphase structure of CeMg3 type LaMg3 phase and LaMg2Cu2 phase. The invention also provides a preparation method of the rare earth-magnesium-transition metal base hydrogen storage metal. The preparation method mainly includes that induction melting is adopted, Mg base master alloy is utilized to substitute magnesium and used as raw material, secondary charging is used for preparing the metal, and the metal is annealed. The hydrogen storage metal of the invention has the advantages that the hydrogen storage capacity at 200 DEG C is more than 3wt% and the metal can be used as solid-state hydrogen storage material.

Owner:YANSHAN UNIV

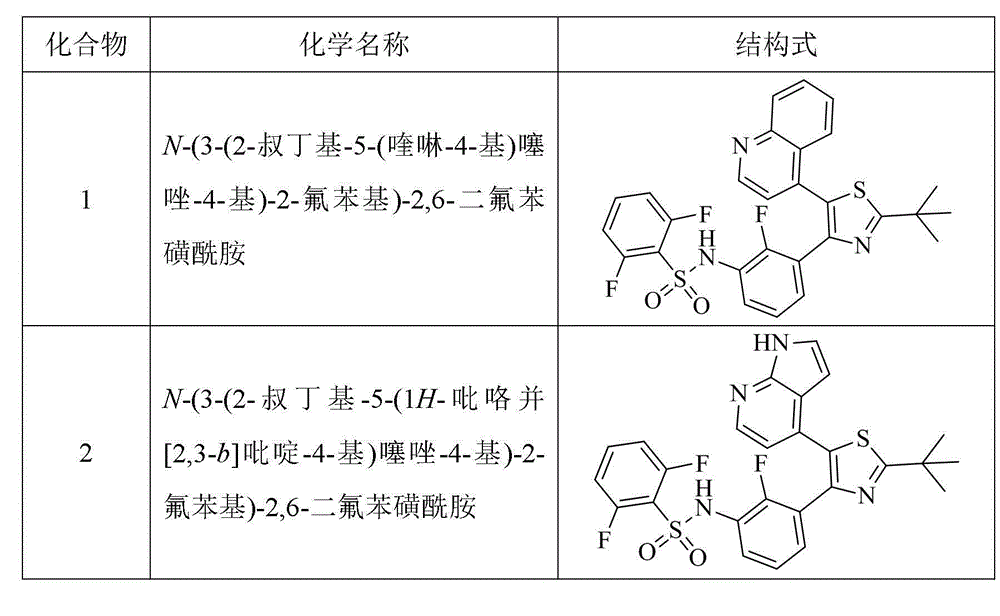

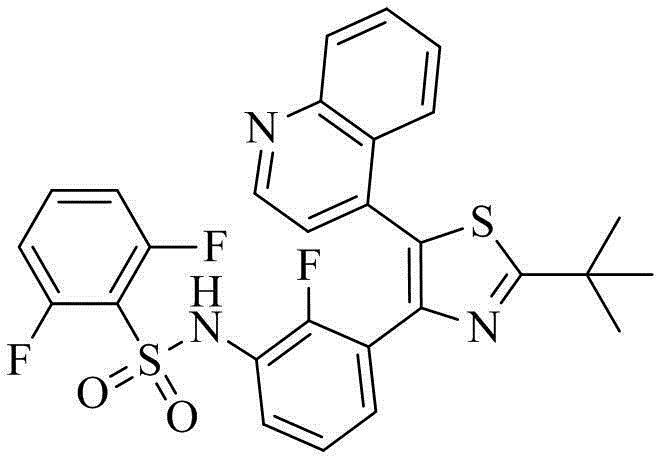

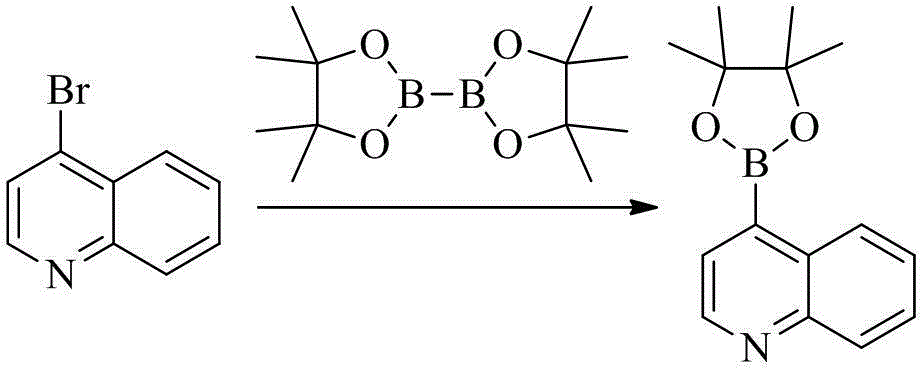

Benzenesulfonamide thiazole kinases inhibitor

InactiveCN103936730AStrong inhibitory activityGood choiceOrganic active ingredientsOrganic chemistryDrugMutation

The invention belongs to the technical field of medicines, and specifically relates to a benzenesulfonamide thiazole kinases inhibitor shown as a general formula (I), and pharmaceutically acceptable salts or other stereisomers thereof, and R1, R2, R3, R4, m, n and p are defined in the specification. The invention also relates to a preparation method of the compounds, medicine preparations and pharmaceutical compositions both containing the compounds, and application of the compounds, the pharmaceutically acceptable salts or other stereisomers to prepare medicines for treating and / or preventing cancer-correlated or non-cancer-correlated diseases caused by b-RAF mutation.

Owner:TONGHUA SIHUAN PHARM

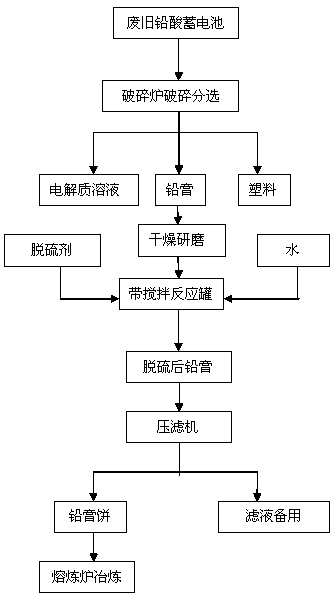

Waste diachylon desulphurization method

InactiveCN103633394AEmission reductionReduce pollutionWaste accumulators reclaimingProcess efficiency improvementProcess engineeringFilter press

The invention discloses a waste diachylon desulphurization method which comprises the following steps: A, adding waste lead-acid storage batteries into crushing and sorting system equipment to carry out crushing and sorting; B, drying sorted diachylon at a temperature of 120 DEG C for later use; C, carrying out grinding and screening on the dried diachylon; D, adding diachylon particles with the uniform size, which are obtained in the step C, into a canned reactor, then adding a desulfurizer and water and stirring to perform the reaction for certain time; E, transporting a mixture in a can, which is obtained after reaction, to a filter press to carry out filter pressing and carrying out separation to obtain a diachylon cake and a filtrate. The method disclosed by the invention has a high lead recovery rate, is low in cost, has low energy consumption and is short in time consumption.

Owner:SOUTH CHINA NORMAL UNIVERSITY

Method for preparing high-temperature sintering ceramic aluminum oxide grinding material

The invention discloses a method for preparing a high-temperature sintering ceramic aluminum oxide grinding material. The method comprises the following steps that 1, boehmite, water, aluminum chloride, oleic acid and fine grain alpha-aluminum oxide are ground, and evenly-dispersed slurry is obtained; 2, the evenly-dispersed slurry and water are mixed and stirred to be uniform, and after carbon dioxide gas is introduced for heat preservation, acid is added to form alumina sol; 3, an additive is added into the alumina sol; 4, gel is formed after the sol prepared in the step 3 is dried, drying continues to be carried out, and xerogel is obtained; 5, the xerogel is subjected to heat preservation at the temperature of 1,400 DEG C to 1,550 DEG C, cooling and crushing are carried out, and then the high-temperature sintering ceramic aluminum oxide grinding material is obtained. The prepared high-temperature sintering ceramic aluminum oxide grinding material has the advantages of resisting high-temperature secondary sintering and being high in hardness, high in abrasion resistance and good in toughness, and is simple in preparation process and low in production cost, technological parameters are easy to control, and large-scale industrial production is easy.

Owner:SUZHOU CHUANGYUAN INVESTMENT DEV

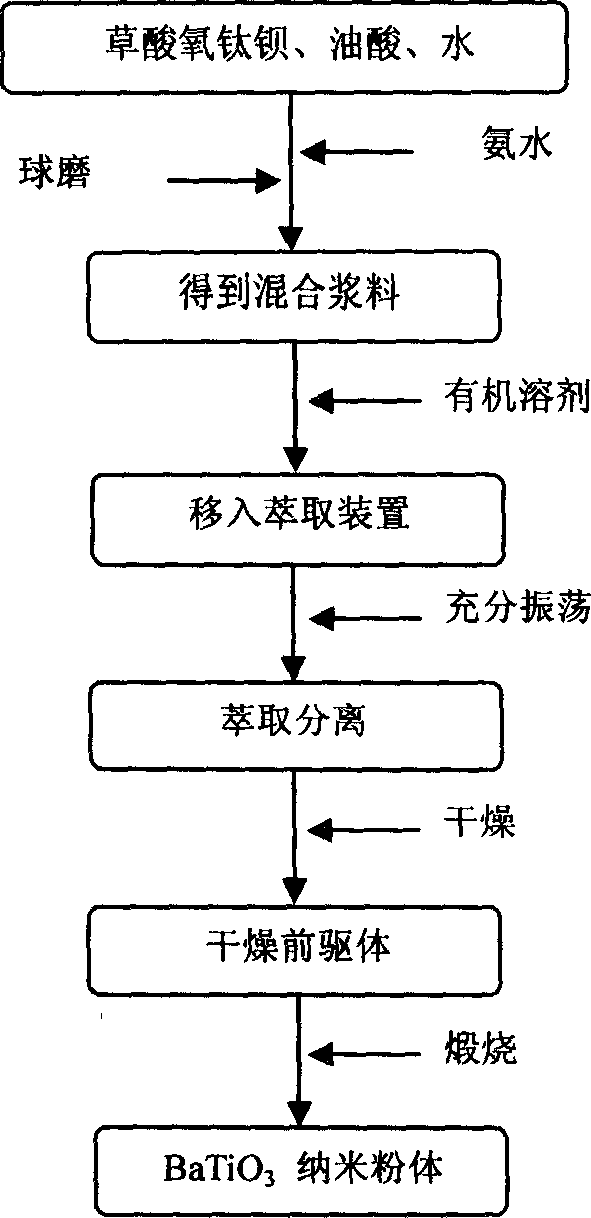

Barium titanate low-dimensional nano powder material and its preparation method

InactiveCN1699179AProcess conditions are easy to controlEase of mass industrial productionCalcium/strontium/barium compoundsTitanium compoundsOrganic solventBarium titanate

The invention discloses a barium titanate low-dimensional nano powder material and its preparation method, which comprises using commercially available super fine barium titanyl oxalate powder for barium titanate production as principal raw material, employing a hydrophobic agglomeration sorting floatation process, changing the relative proportion of the surface active agent and the organic solvent powder, and carrying out the procedures of surface active agent wet method ball grinding adsorption, organic solvent pulping, emulsified stratification, extraction separation, drying and heat treatment.

Owner:TSINGHUA UNIV

Freeze-drying composition of posaconazole prodrug and preparation method and application of freeze-drying composition of posaconazole prodrug

InactiveCN105287403AImprove performanceNo pollution in the processOrganic active ingredientsPowder deliverySolubilityCase fatality rate

The invention relates to a freeze-drying composition of a posaconazole prodrug and a preparation method and application of the freeze-drying composition of the posaconazole prodrug. The freeze-drying composition has the advantages that the freeze-drying composition is high in water solubility, and safety of the freeze-drying composition is guaranteed due to the fact that cyclodextrins auxiliary materials need not to be added during the preparation of the freeze-drying composition; the freeze-drying composition is suitable for being used for treating various amphotericin-intolerant or refractory adult invasive fungal infections; the freeze-drying composition is used as a preventive drug for high-risk patients, the freeze-drying composition is applicable to patients above 13 years old and with impaired immunity and especially applicable to patients who have graft versus host disease (GVHD) after hematopoietic stem cell transplant, patients with leukemia and patients with long-term leukopenia due to chemotherapy; compared with control drugs such as fluconazole and itraconazole, the freeze-drying composition can effectively prevent invasive aspergillosis and can lower the mortality related to the invasive fungal infections.

Owner:HC SYNTHETIC PHARMA CO LTD

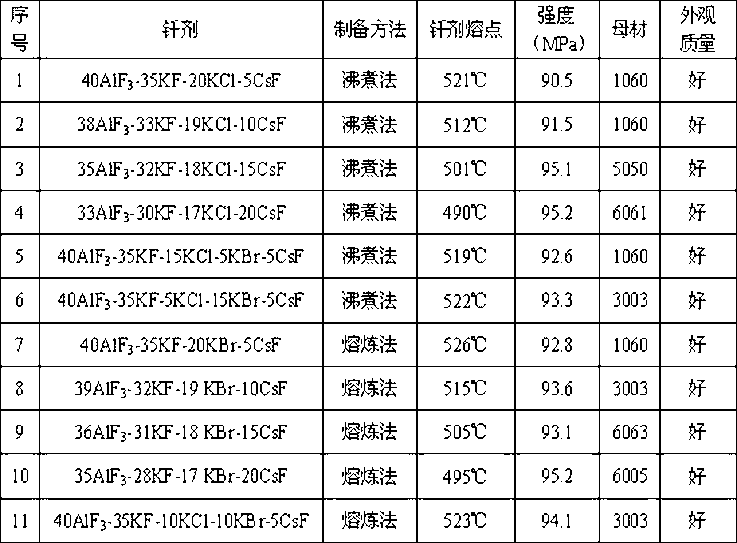

Intermediate-temperature low-cesium fluoroaluminate brazing flux and preparation method thereof

ActiveCN102699577ALow melting pointLow costWelding/cutting media/materialsSoldering mediaAluminateAluminum fluoride

The invention discloses an intermediate-temperature low-cesium fluoroaluminate brazing flux and a preparation method thereof, can be applied to furnace brazing and flame brazing of pure aluminum and an aluminum alloy, and belongs to the field of brazing materials. The brazing flux consists of 32 to 42 mass percent of aluminum fluoride, 28 to 36 mass percent of potassium fluoride, 1 to 20 mass percent of cesium fluoride and 17 to 22 mass percent of one or two of potassium chloride and potassium bromide and can be prepared by a deionized water boiling method or a deionized water smelting method. The melting point of the brazing flux is 490 to 521 DEG C, the content of precious metal salt CsF ranges from 1 percent to 20 percent; a deliquescence phenomenon cannot occur in the air; postwelding brazing flux residues do not corrode joints, the flame adaptability is good, and the brazing flux is suitable for aluminum and aluminum alloy flame brazing and furnace brazing.

Owner:UNIV OF SCI & TECH BEIJING

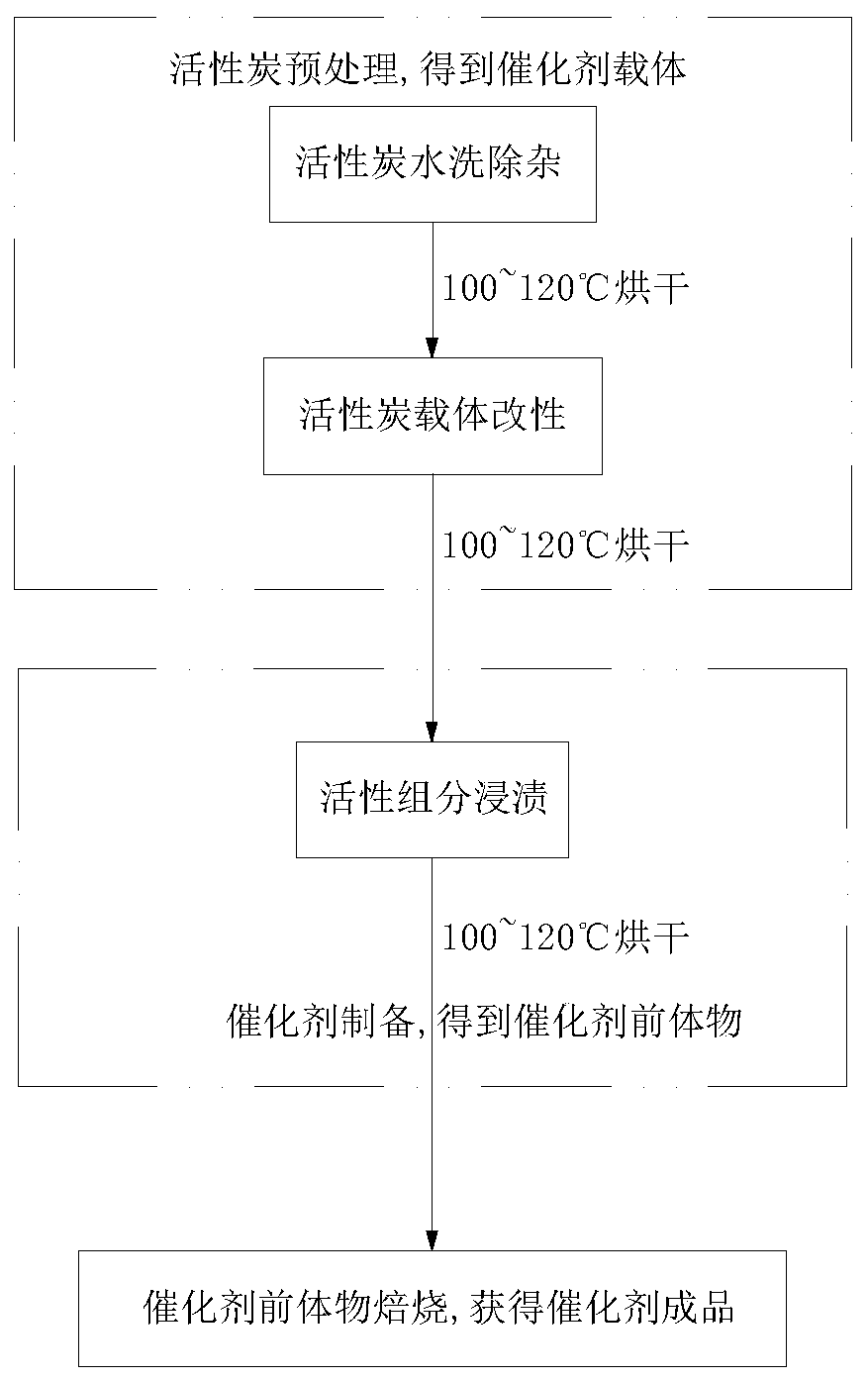

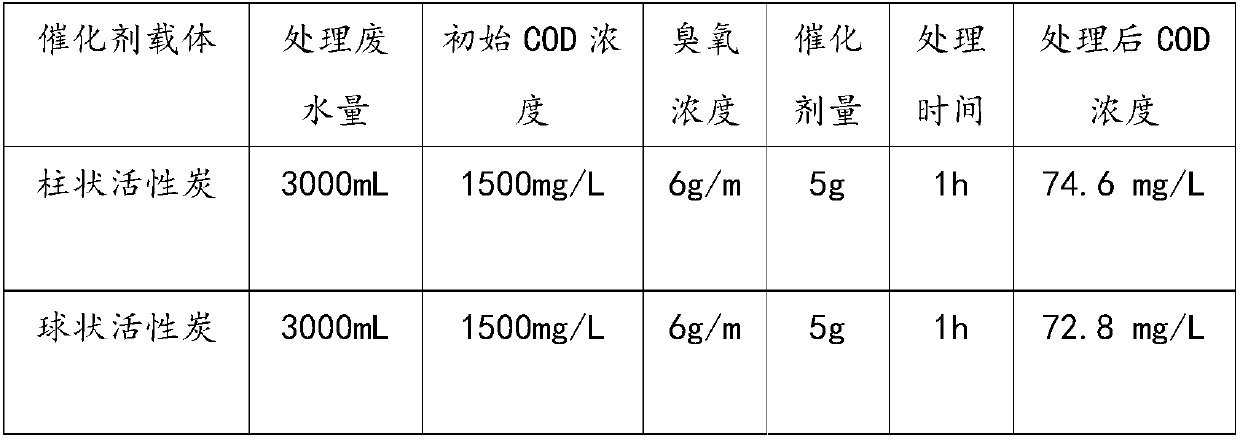

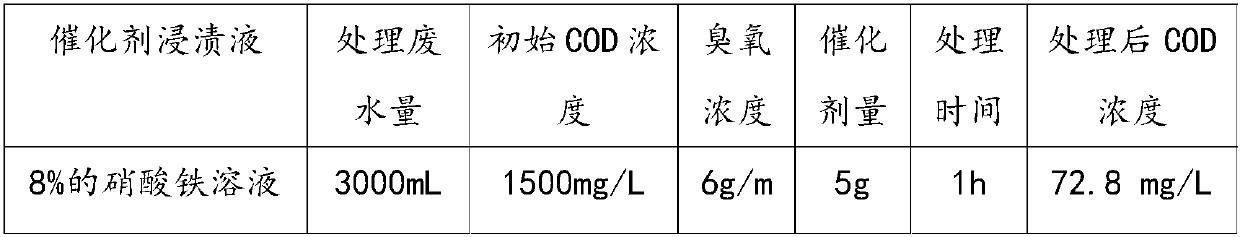

Catalytic ozonation catalyst and preparation method thereof

InactiveCN110052268AImprove catalytic oxidation performanceImprove processing efficiencyWater treatment compoundsWater contaminantsActivated carbonIndustrial effluent

The invention discloses a catalytic ozonation catalyst and a preparation method thereof. The preparation method includes following steps: (1), using activated carbon to wash for removing impurities; (2), modifying an activated carbon carrier; (3), soaking an active component to prepare a catalyst precursor; (4), calcining the catalyst precursor to obtain the catalytic ozonation catalyst. The catalytic ozonation catalyst prepared by the preparation method can be used for treating domestic sewage or industrial wastewater containing degradation-resistant organic matter, removal rate of high-degradation-difficulty organic matter in wastewater can reach higher than 95%, and the catalytic ozonation catalyst has the advantages of being efficient, environment-friendly, wide in application range and long in service life.

Owner:四川恒泰环境技术有限责任公司

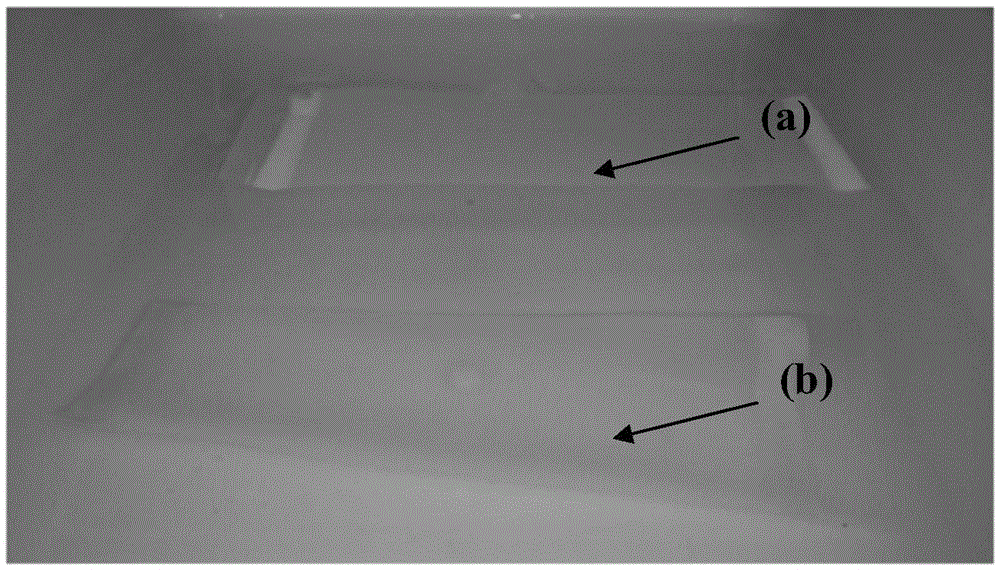

Preparation method of forward osmosis membrane modified with oxidized graphene

InactiveCN105582816AEasy to implementEase of mass industrial productionSemi-permeable membranesGrapheneOrganic solvent

The invention provides a preparation method of a forward osmosis membrane modified with oxidized graphene. The preparation method comprises the following steps: 1, firstly, conducting ultrasonic dispersion on the oxidized graphene in high-polarity organic solvent, so that homogeneous dispersion liquid is obtained; 2, adding organic solvent of raw materials of a produced membrane to the dispersion liquid; 3, sequentially adding additives and the produced membrane to the dispersion liquid obtained in step 2, and stirring the mixture till the mixture is dissolved completely, so that casting membrane liquid is obtained; 4, conducting sufficient defoaming on the casting membrane liquid in a vacuum drying box, then pouring the casting membrane liquid on a glass plate where a support layer is laid, and conducting membrane scraping; 5, after membrane pouring is ended and the casting membrane liquid is volatilized in air, putting the casting membrane liquid in a coagulation bath; 6, separating a membrane piece with the glass plate, and putting the membrane piece into pure water for immersion; 7, conducting natural drying on the membrane which is sufficiently immersed as mentioned above, so that the forward osmosis membrane is obtained. The modified forward osmosis membrane prepared through the preparation method is good in hydrophilicity and water flux and great in antipollution capability, cleaning expense of the membrane is lowered, the service life of the membrane is greatly prolonged, and mechanical properties are improved a lot.

Owner:HARBIN ENG UNIV

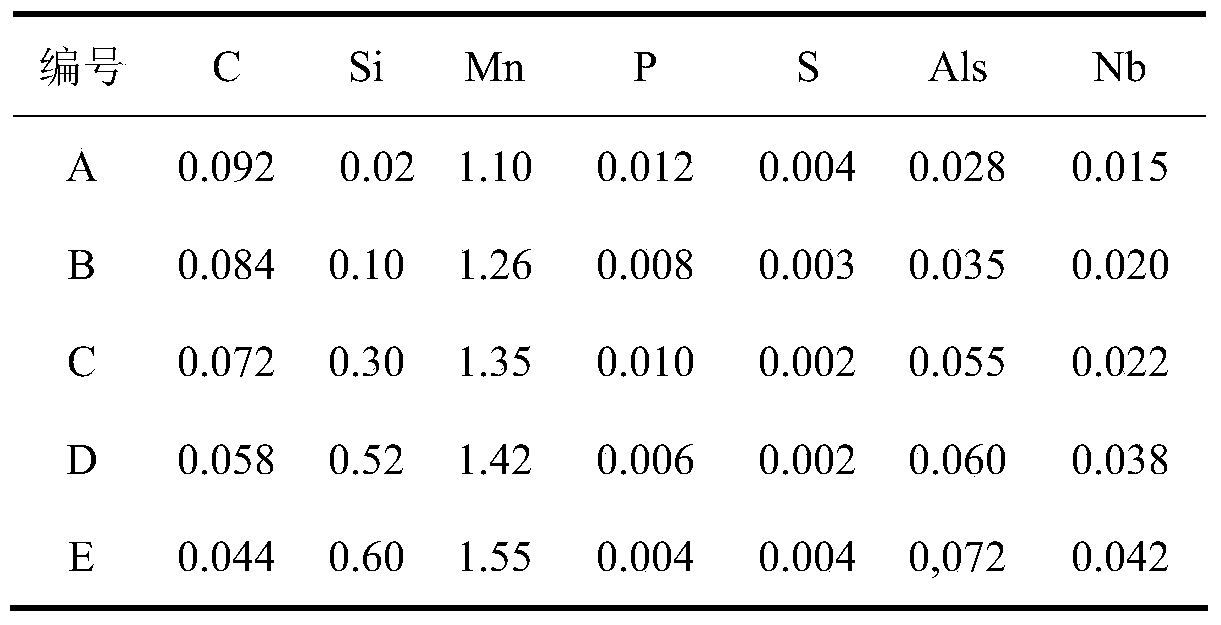

600 MPa-grade highly-chambered steel plate for automotive chassis and manufacturing method thereof

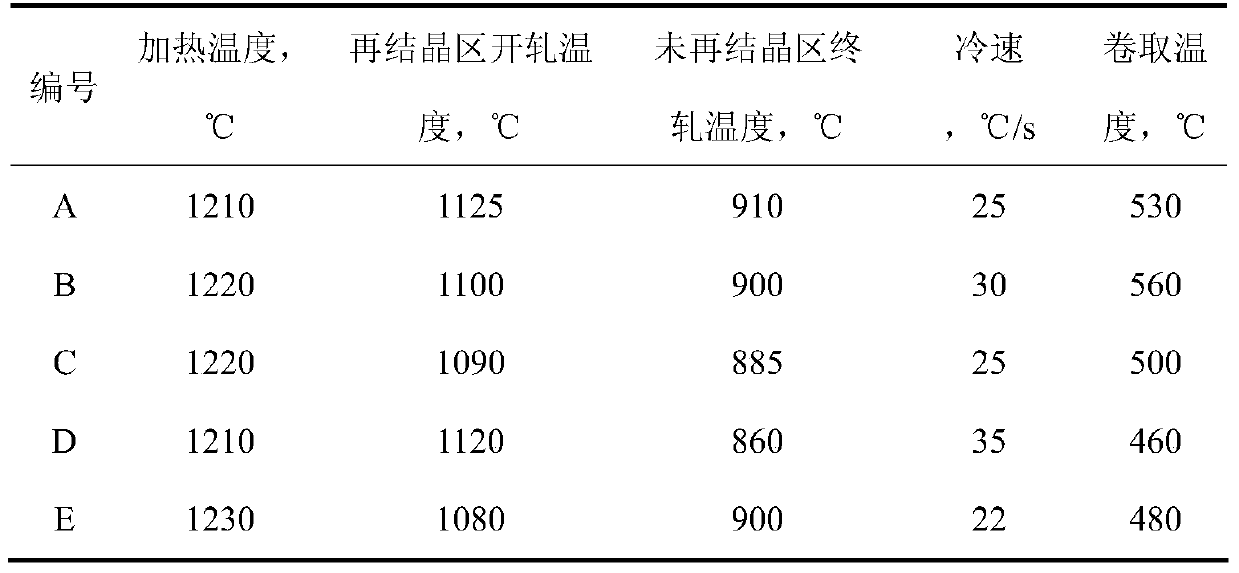

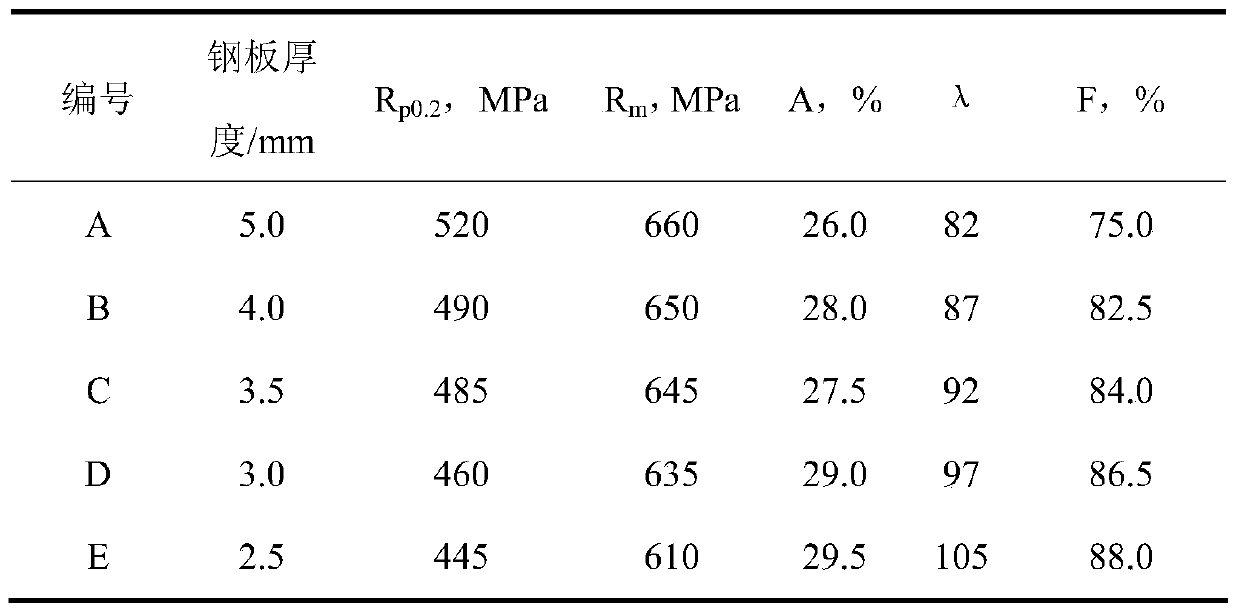

The invention provides a 600 MPa-grade highly-chambered steel plate for automotive chassis. Steel of the steel plate is composed of, in percentage by weight, 0.04-0.10% of C, Si smaller than 0.70%, 1.0-1.6% of Mn, 0.02-0.08% of Als, 0.01-0.05% of Nb, P smaller than 0.015%, S smaller than 0.005% and the balance Fe and inevitable impurities. The invention further provides a manufacturing method of the steel plate. The method comprises the steps of heating continuous casting sheet billets with the thickness ranging from 80 mm to 230 mm to 1220+ / -20 DEG C, and preserving the temperature for 1.8-3 hours; carrying out two-stage rolling, wherein the rolling temperature of the recrystallizing region is higher than 1050 DEG C, the thickness of intermediate billets ranges from 35 mm to 60 mm, the finish rolling temperature of the non-recrystallizing region ranges from 840 DEG C to 920 DEG C, and the thickness of finished products ranges from 2.0 mm to 6.0 mm; carrying out continuous laminar flow cooling after finish rolling, wherein the cooling rate is 20-40 DEG C / s and the coiling temperature ranges from 450 DEG C to 580 DEG C. According to the invention, the steel plate is high in alloy content and low in cost, the hot rolling process is simple, the rolling performance of the steel plate is uniform, and the matching performance between the strength and the hole chambering rate is good.

Owner:ANGANG STEEL CO LTD

Method of preparing phosphotungstic acid from sodium tungstate as raw material

ActiveCN106335928APhase separation effect is goodSimple processTungsten compounds preparationAlcoholSodium tungstate

The invention belongs to the technical field of heteropolyacid preparation, and particularly relates to a preparing method of sodium tungstate. Industrial sodium tungstate crystal is used as the raw material, an alcohol extraction agent is used for extracting to obtain a phosphotungstic acid water solution, phosphotungstic acid crystal can be obtained through evaporative crystallization or spray drying, organic phase and raffinate obtained after reverse extraction can be returned and used directly, and the process of organic phase regeneration is avoided. The method is short in process flow, low in manufacturing cost, high in product yield, environmentally friendly and capable of achieving large-scale industrial production.

Owner:CENT SOUTH UNIV

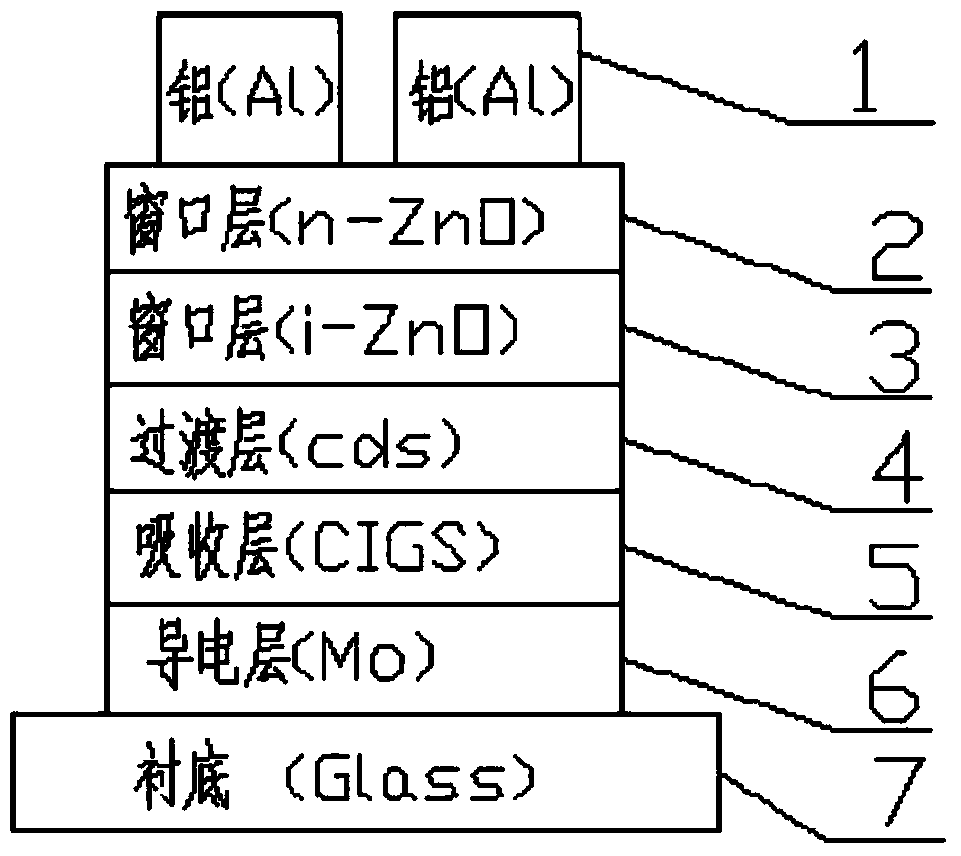

Thin-film solar cell and method for preparing same

InactiveCN103474488AReduce chance of recombinationLower internal resistanceFinal product manufacturePhotovoltaic energy generationHigh resistanceThin film solar cell

The invention provides a thin-film solar cell. Electrode grooves are formed in a low-resistance window layer, and collection electrodes are deposited in the electrode grooves respectively. On the premise that the thickness of a buffer layer and the thickness of a high-resistance window layer are large enough so that the density of a film layer of the thin-film solar cell can be ensured, the photon-generated carrier recombination probability of an interface can be effectively lowered. Due to the fact that the collection electrodes are arranged in the electrode grooves respectively, the thickness of the portions, in the perpendicular direction of the contacting areas of the collection electrodes and the electrode grooves, of the high-resistance window layer can be reduced, the internal resistance of the solar cell can be effectively reduced, the output power of the solar cell can be improved, meanwhile, the contact area between the collection electrodes and a transparent window layer composed of the high-resistance window layer and the low-resistance window layer is increased, the collection rate of the collection electrodes for photon-generated carriers is improved, and the output power of the thin-film solar cell is further improved. In addition, a method for preparing the thin-film solar cell is simple in process and allows large-scale industrial production to be easily achieved.

Owner:DONGTAI HI TECH EQUIP TECH (BEIJING) CO LTD

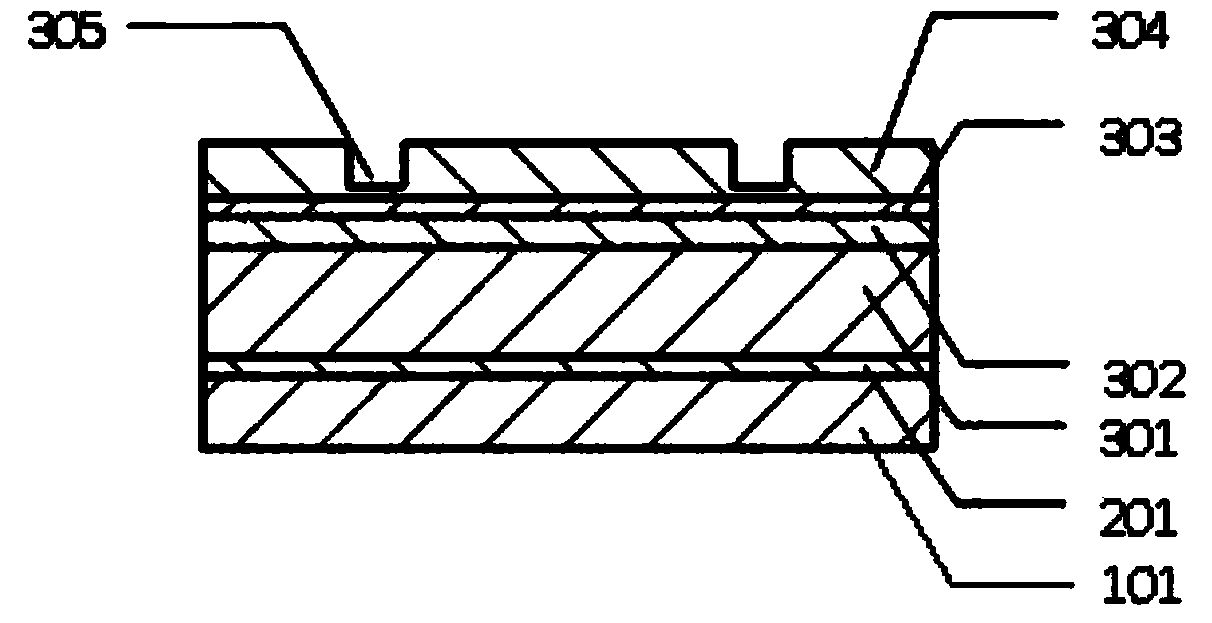

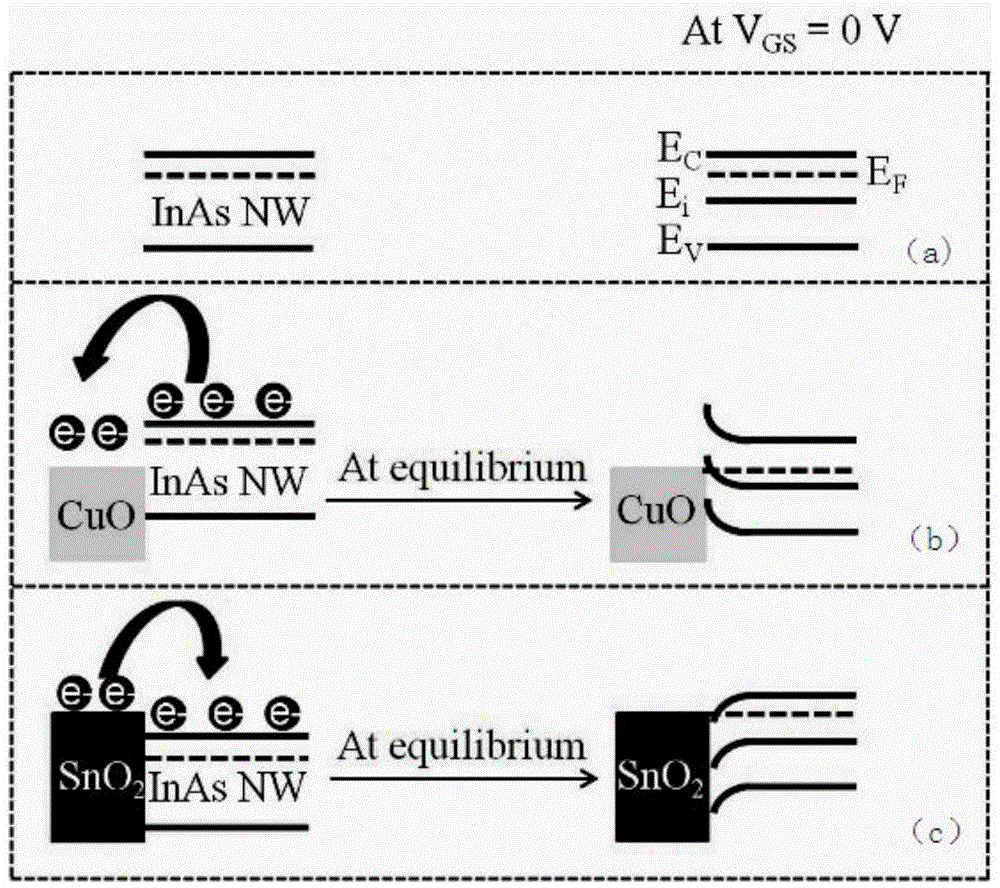

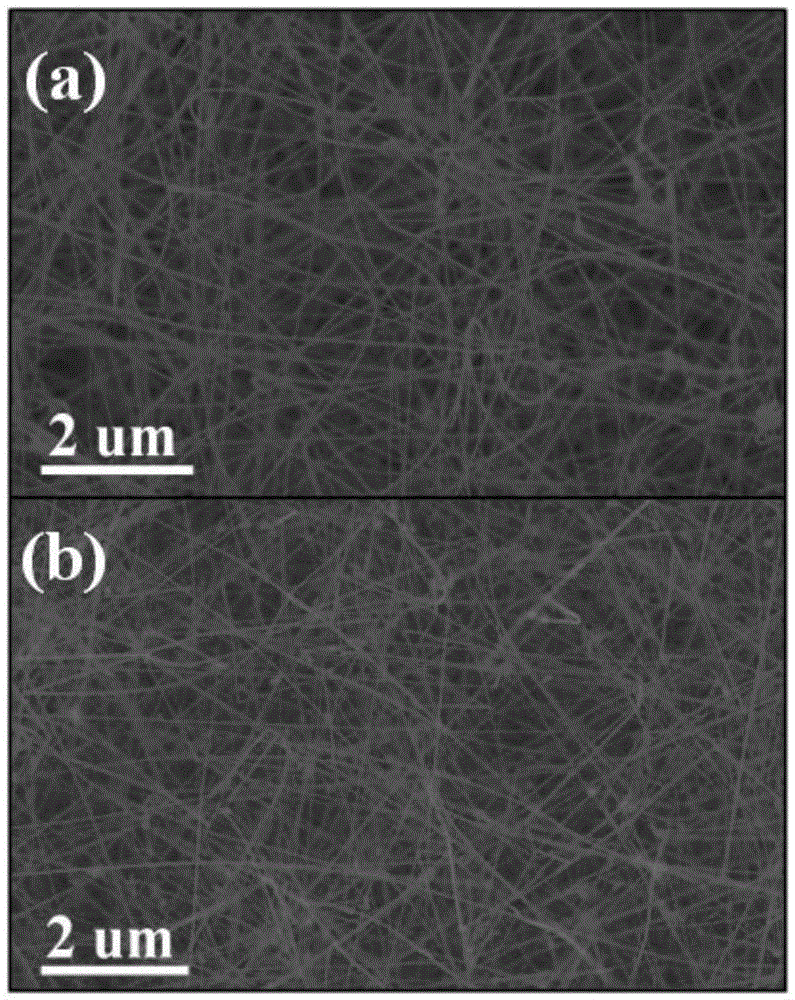

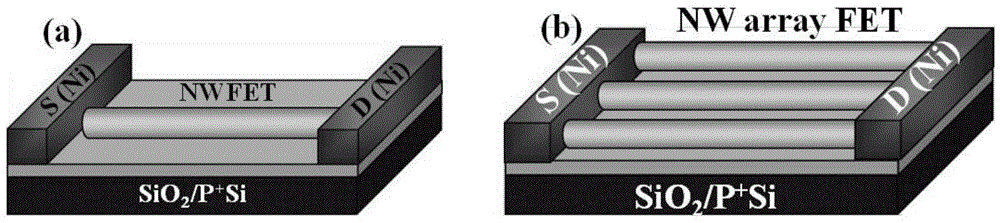

Method for regulating and controlling threshold voltage of semiconductor nanowire field effect transistor

InactiveCN105632935ASimple processSimple and fast operationSemiconductor/solid-state device manufacturingSemiconductor devicesSemiconductor materialsMetallic materials

The invention belongs to the field of transistor threshold voltage regulating and controlling technology, and relates to a method for regulating and controlling threshold voltage of a semiconductor nanowire field effect transistor. The method comprises steps of depositing metal-oxide semiconductor materials or metal materials on a prepared semiconductor nanowire field effect transistor or a prepared nanowire array field effect transistor, and carrying out film coating decoration on the surface of the semiconductor nanowire field effect transistor or on the surface of the nanowire array field effect transistor, wherein thickness of a coating film is 0.2-5 nm, thereby regulating and controlling the threshold voltage of the semiconductor nanowire field effect transistor or the nanowire array field effect transistor. According to the invention, the technique is simple; operation is simple; principles are reliable; product cost is low; the method has a wide application prospect in field of electronic switch devices, displays, and biological and chemical sensors; and large-scale industrial production can be easily carried out.

Owner:QINGDAO UNIV

Method for recycling active materials and aluminum foil from waste lithium-ion battery cathode materials

InactiveCN107130113AThe solution cannot be efficientlyResolve separabilityWaste accumulators reclaimingProcess efficiency improvementLithium-ion batteryAluminum foil

The invention discloses a method for recycling active materials and aluminum foil from waste lithium-ion battery cathode materials, and belongs to the technical field of electrode material recycling. The method comprises the steps that waste lithium-ion batteries are discharged, disassembled and then cut, and cathode sheets are obtained; the cathode sheets are put into a sulfuric acid solution to be soaked for 2 min to 10 min to enable cathode active materials to be separated from aluminum foil, wherein the concentration of the sulfuric acid solution ranges from 1.0 mol / L to 3.0 mol / L, and the temperature of the sulfuric acid solution ranges from 40 DEG C to 60 DEG C; and the aluminum foil is taken out, washed and dried, the dried aluminum foil is obtained, the solution containing the cathode active materials is filtered, filter residues are washed and dried, the cathode active materials are obtained, the cathode active materials are subjected to a wet leaching process, valuable metals in the cathode active materials are recycled, and filtrate is recycled or serves as a slurrying liquid of the wet leaching process. According to the method for recycling the active materials and aluminum foil from the waste lithium-ion battery cathode materials, the problem that the cathode active materials and the aluminum foil cannot be effectively and thoroughly separated in the waste lithium-ion battery recycling process is solved, the technology is simple, the flow is short, the recycling cost is low, large-scale industrial production is easy to achieve, secondary pollution is not generated in the recycling process, and the method is friendly to the environment.

Owner:JINCHUAN GROUP LIMITED

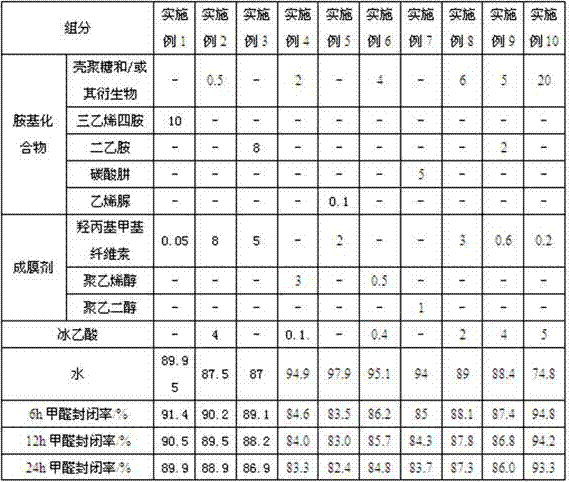

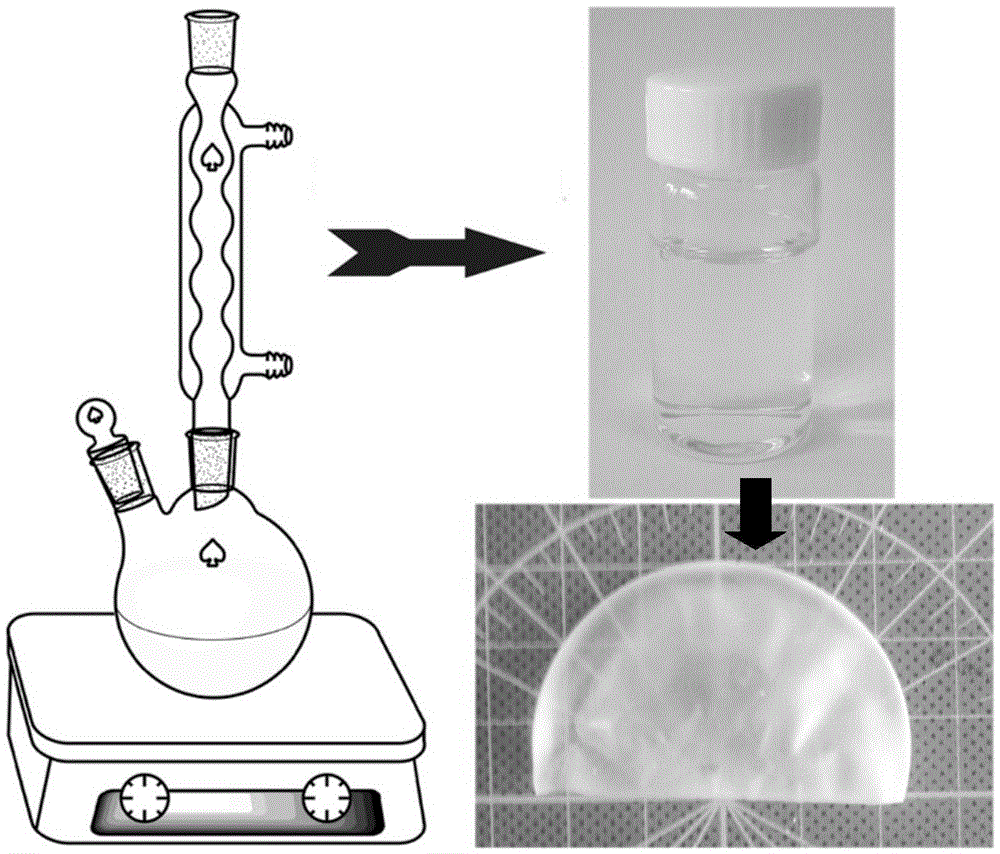

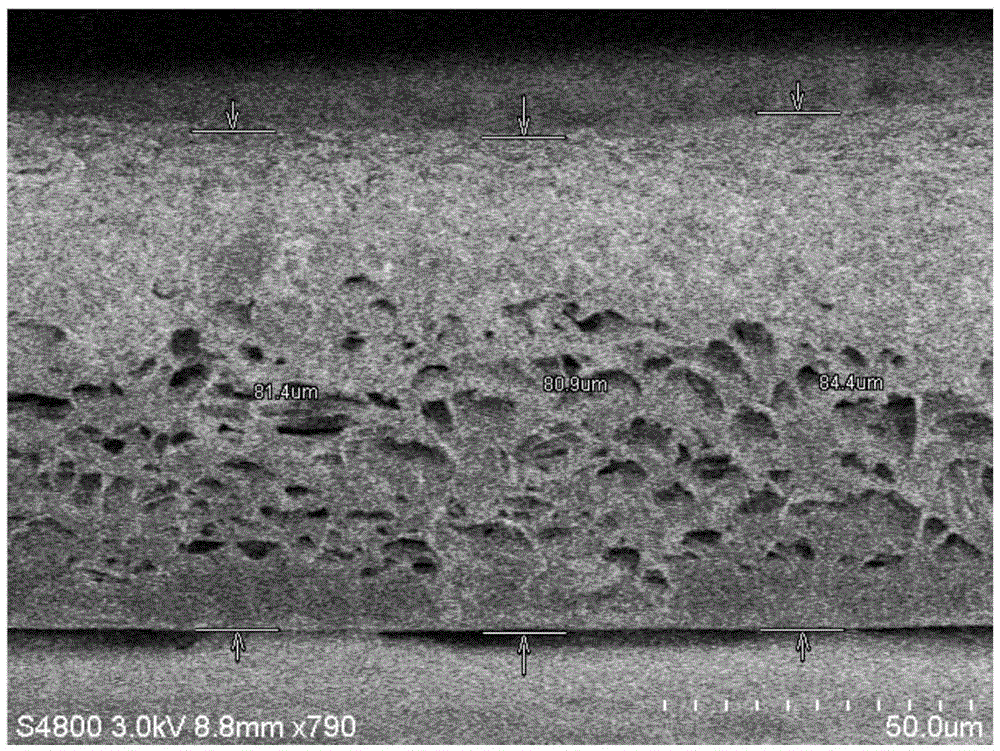

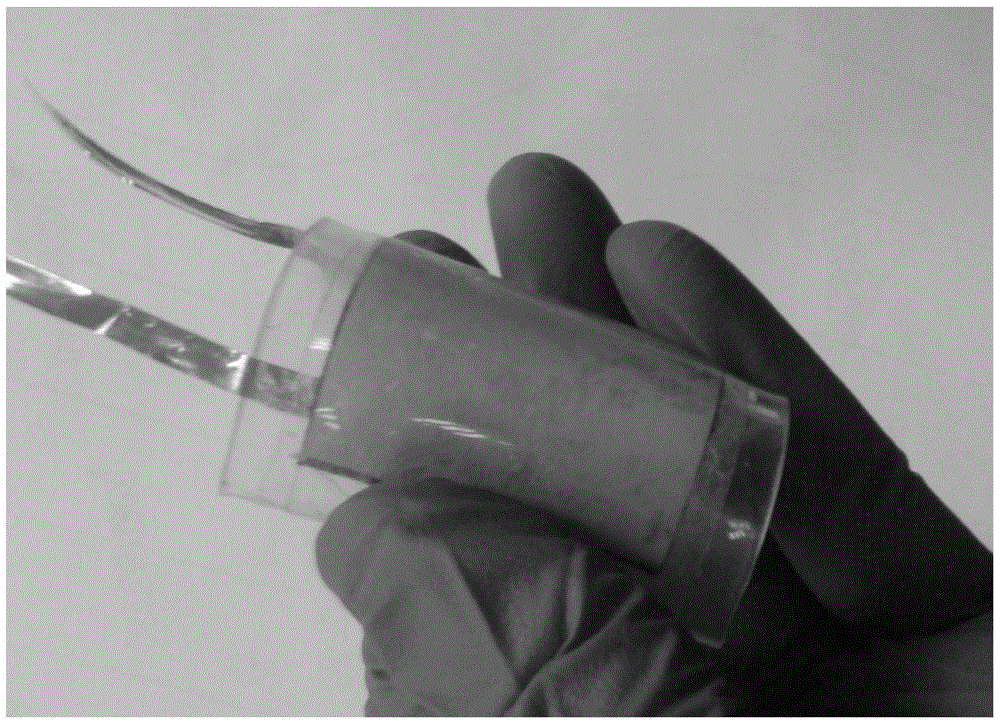

Sealing agent and preparation method thereof

InactiveCN107459874AGood film formingEasy to spreadPolyether coatingsHyaluronic acid coatingsAcetic acidFilm-forming agent

The invention discloses a sealing agent and a preparation method thereof and belongs to the field of air purification. According to the adopted technical scheme, the sealing agent is characterized by being prepared from, by mass, 0.1-20% of amido compound, 0.05-10% of film-forming agent and 0-10% of glacial acetic acid. The preparation method comprises the following steps that a reagent is measured by mass percent for usage; a dispersion solution of a solution amido compound and pre-mixed liquid of the film-forming agent and the glacial acetic acid are prepared respectively; the dispersion solution of the amido compound is poured into the prepared pre-mixed liquid, and stirring is performed for 20-40 minutes to obtain the sealing agent. The sealing agent has the advantages of being good in film-forming performance and easy to spread, quickly and efficiently sealing the surfaces of boards, furniture and the like and efficiently purifying air. The preparation method is simple and low in cost, and large-scale industrial production is promoted.

Owner:伦慧东

Modified PVA electrolyte membrane for flexible super capacitor, and preparation method and application thereof

InactiveCN107180705ASimple production processEasy to operateHybrid capacitor electrolytesHybrid/EDL manufactureInorganic saltsCapacitance

The invention discloses a modified PVA electrolyte membrane for a flexible super capacitor, and a preparation method and application thereof. The manufacturing method comprises: polyving akohol, inorganic salt and a modified filler are mixed uniformly in a solvent and reaction is carried out for no more than 50h at a temperature of 0 to 100 DEG C; a modified PVA gel electrolyte is processed to form a membrane; and then drying is carried out to form the modified PVA electrolyte membrane. According to the invention, the preparation process is simple; the operation becomes convenient; the product cost is low; the energy consumption is low; controllability is high; and large-scale industrial production of the membrane can be realized easily. Meanwhile, the modified PVA electrolyte membrane has high conductivity and good thermal stable performance. The flexible super capacitor based on the modified PVA electrolyte membrane has the improved specific capacitance value and cycling stability.

Owner:SUZHOU INST OF NANO TECH & NANO BIONICS CHINESE ACEDEMY OF SCI

Method for recycling positive electrode material of waste lithium iron phosphate battery

PendingCN113735087AHigh purityAvoid it happening againPositive electrodesWaste accumulators reclaimingIron phosphateHydrogen peroxide

The invention relates to a method for recycling a positive electrode material of a waste lithium iron phosphate battery. The method comprises the following steps of: (1) adding water into positive electrode powder of the waste lithium iron phosphate battery to prepare slurry, preheating the slurry, adding 98% sulfuric acid for leaching, and performing solid-liquid separation after the leaching is completed to respectively obtain leachate and leaching residues; (2) adjusting the pH value of the leachate, adding iron powder to replace and remove copper, continuously adjusting the pH value, removing aluminum by precipitation, and carrying out solid-liquid separation to obtain an impurity-removed solution; (3) supplementing sodium phosphate to adjust the mass ratio of iron to phosphorus; (4) introducing hydrogen peroxide below the liquid level of the base solution, spraying alkali liquor and the impurity-removed solution by using spraying equipment, adjusting the pH value, aging for 5-7 hours after iron in the solution is completely oxidized and precipitated, and performing solid-liquid separation to respectively obtain an iron phosphate precipitate and a lithium-containing solution; and (5) adjusting the pH value of the lithium-containing solution, and carrying out evaporation concentration and solid-liquid separation to obtain filtrate; and introducing carbon dioxide into the filtrate to obtain precipitated lithium. The method is simple, efficient and easy for batch industrial production.

Owner:JINCHUAN GROUP LIMITED +1

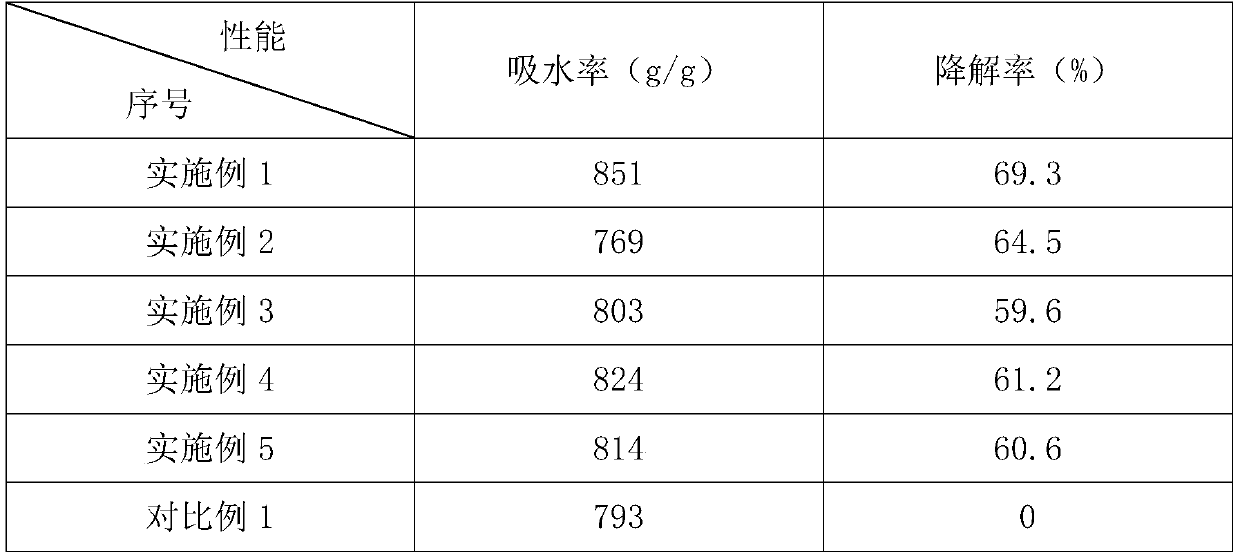

Preparation method of degradable high-performance water absorbent resin

InactiveCN109824831APromote degradationGood mechanical propertiesNitrogen gasPoly(butylene succinate)

The invention provides a preparation method of degradable high-performance water absorbent resin. The preparation method includes: smashing polybutylene succinate for standby use; weighing acrylic andpolybutylene succinate powder according to a certain mass ratio into a four-neck flask; using a sodium hydroxide water solution to neutralize the acrylic acid to obtain an acrylic acid and sodium acrylate solution; cooling to room temperature, then slowly adding an initiator and a crosslinking agent; feeding nitrogen, slowly increasing temperature, and stirring to enable the acrylic acid and sodium acrylate solution to be in grafting copolymerization reaction with polybutylene succinate; pouring anhydrous alcohol after the reaction is finished, repeatedly washing, and drying to obtain polybutylene succinate grafted sodium acrylate resin. Polybutylene succinate grafted sodium acrylate copolymerization is adopted to form the water absorbent resin, so that the water absorbent resin has highbiodegradability, good mechanical performance and high water absorbency and can be widely applied in many fields. The preparation method is simple, low in cost and easy for large-scale industrial production.

Owner:江苏常源新材料科技有限公司

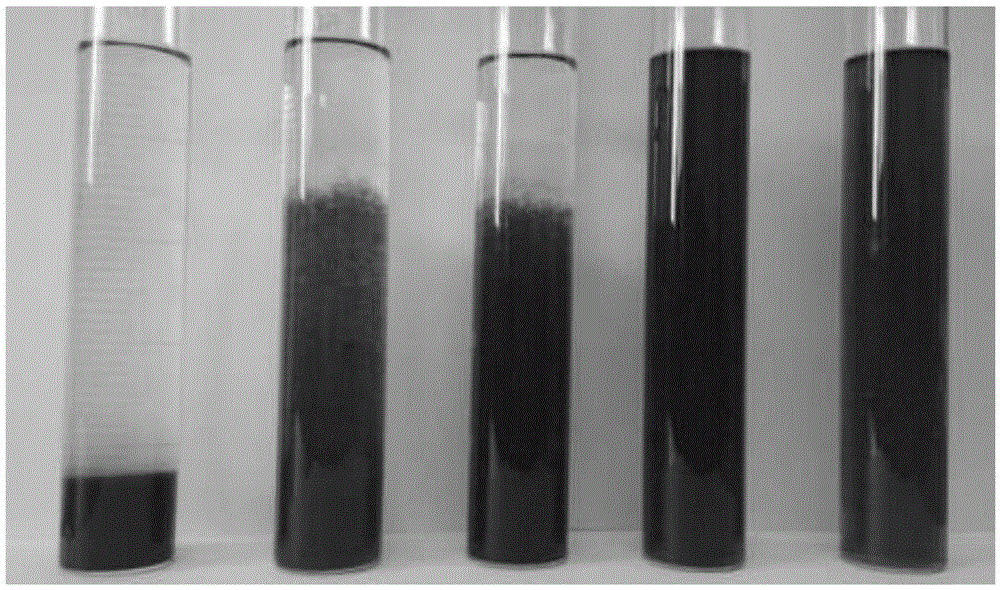

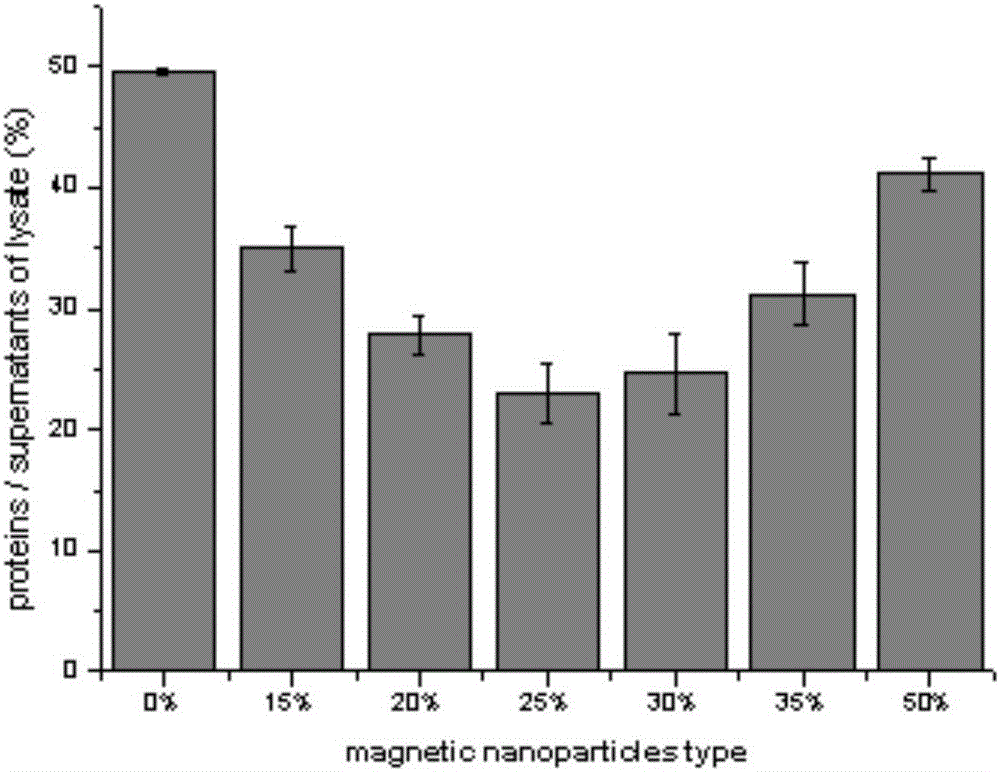

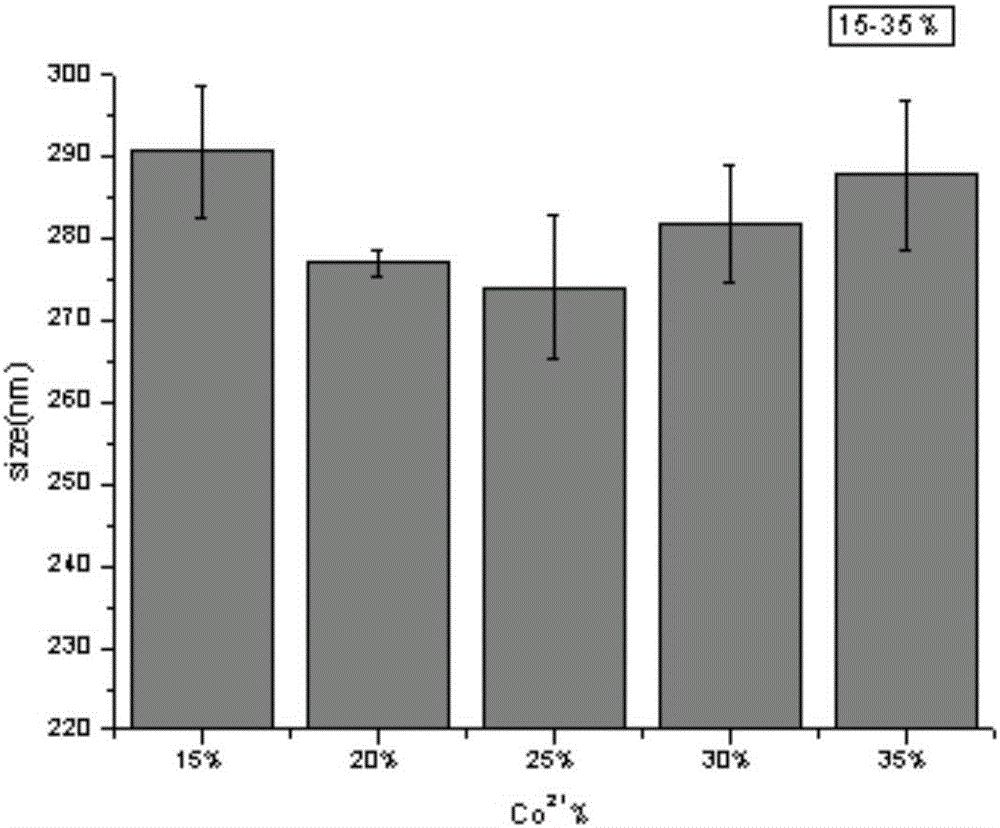

Cobalt-ion-doped iron-nickel magnetic microsphere and application thereof

InactiveCN107175089AGood dispersionThe application effect is fast and efficientIon-exchange process apparatusOther chemical processesMicrospherePolyhistidine-tag

The invention relates to a cobalt-ion-doped iron-nickel magnetic microsphere and application thereof and belongs to the technical field of chemical materials. The cobalt-ion-doped iron-nickel magnetic microsphere is mainly characterized in that cobalt ions and nickel ions are mixed and used in a magnetic sphere preparation process, the cobalt ions accounts for 20 to 30% of the total mole number of the cobalt ions and the nickel ions, and optimally, the cobalt ions accounts for 25% of the total mole number of the cobalt ions and the nickel ions. The synthesized cobalt-ion-doped iron-nickel magnetic microsphere disclosed by the invention can be directly applied to purifying target protein with a histidine tag, and other modification like antibody modification on the surface of the magnetic sphere is avoided; furthermore, the cobalt-ion-doped iron-nickel magnetic microsphere has good dispersion and quick and high-efficiency application effect and is superior to a no-cobalt-doped iron-nickel magnetic microsphere; separation performance of the cobalt-ion-doped iron-nickel magnetic microsphere is similar to that of imported coordinate-bond nickel-ion sepharose gel; the cobalt-ion-doped iron-nickel magnetic microsphere further can achieve magnetic separation and can replace imported separation materials.

Owner:DALIAN NATIONALITIES UNIVERSITY

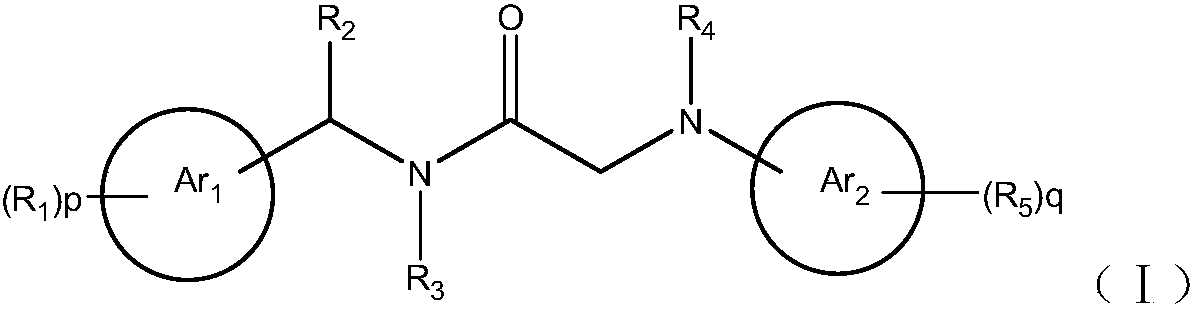

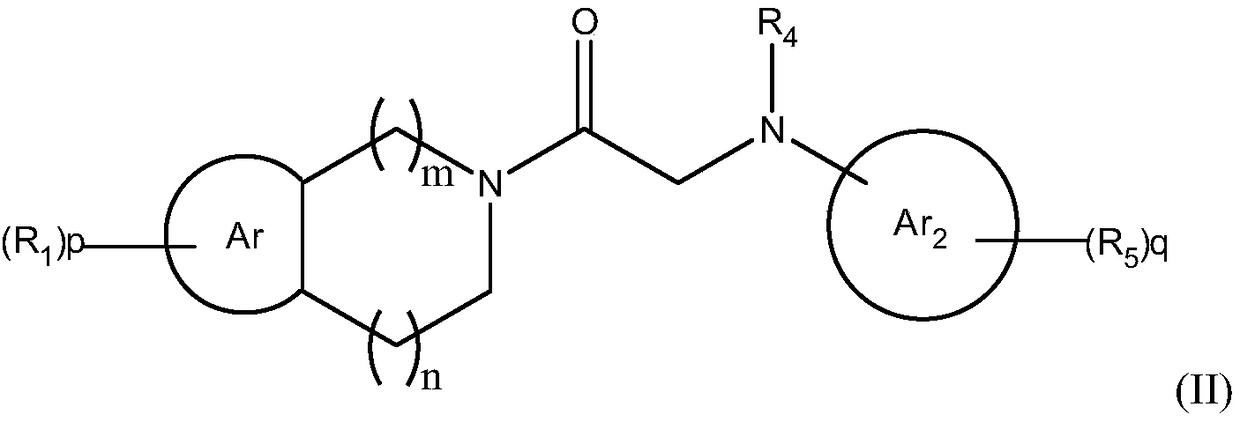

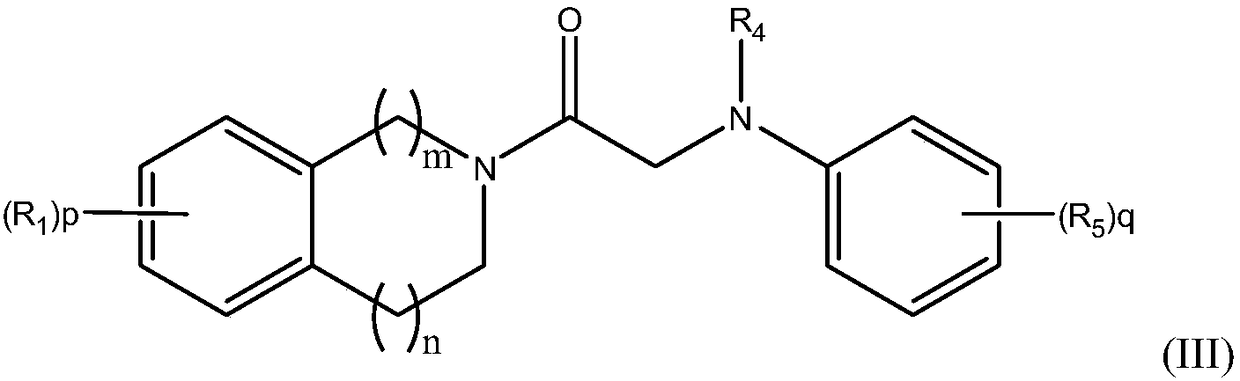

Amide compound for prevention and treatment of mental disorders

ActiveCN109020887AStrong inhibitory activityLow toxicityOrganic active ingredientsNervous disorderDrugDisease

The present invention relates to an amide compound for prevention and treatment of mental disorders, which is shown as a formula (I), a pharmaceutically acceptable salt thereof, a prodrug thereof, a solvate thereof, a deuterated substance or a stereoisomer thereof. Wherein R1, R2, R3, R4, R5, Ar1, Ar2, p and q are as defined in the specification. The invention also relates to a preparation methodof the amide compound, a pharmaceutical composition and a pharmaceutical preparation containing the amide compound, and an application of the compound in preparation of a drug for prevention or treatment of mental disorders such as depression, depression and anxiety, and schizophrenia.

Owner:SHAOXING ZEROIN BIOMEDICINES CO LTD +1

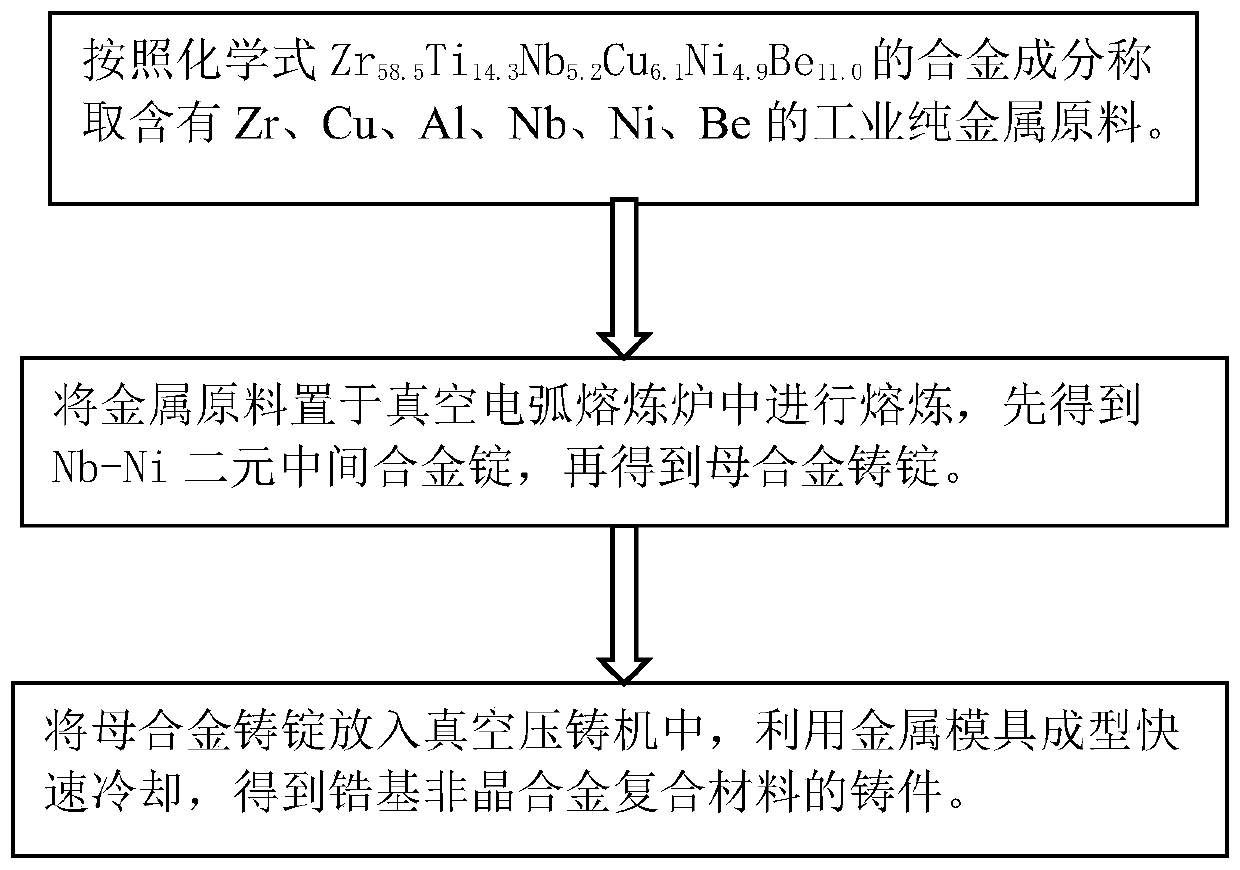

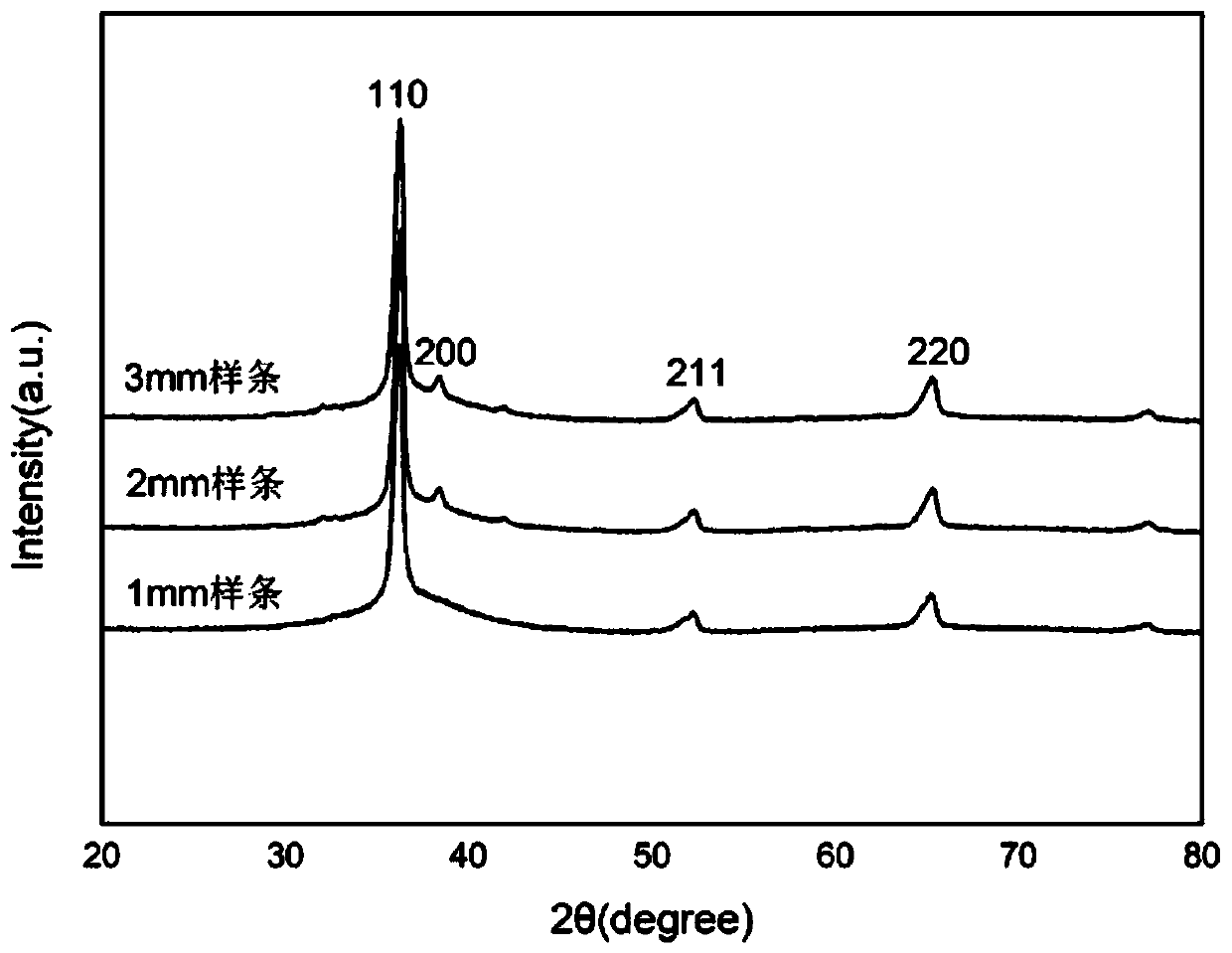

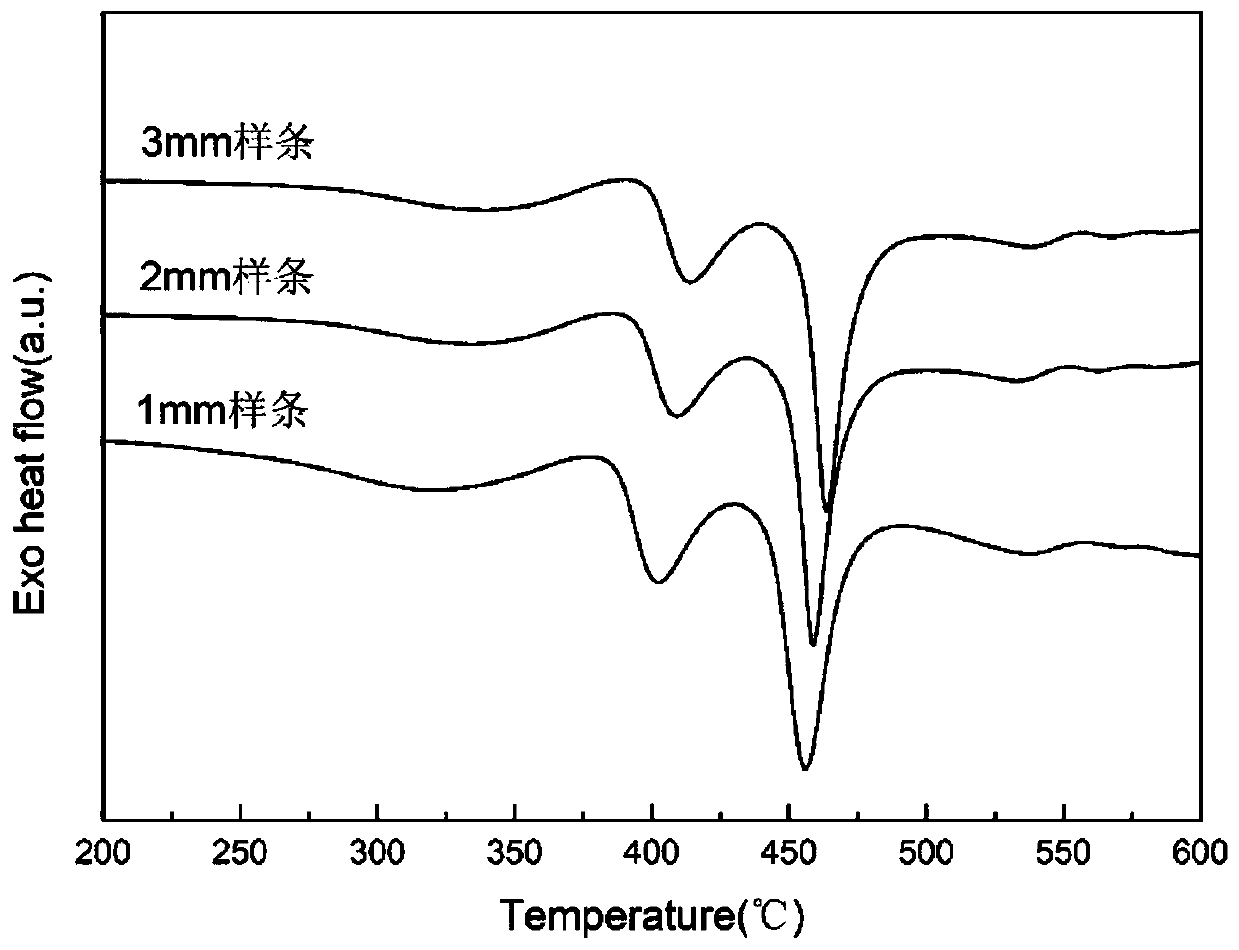

Low-cost high-strength high-plasticity zirconium-based amorphous composite and preparation method thereof

InactiveCN110592500AHave the ability to formReduce manufacturing costElectric arc furnaceAlloy composite

The invention discloses a low-cost high-strength high-plasticity zirconium-based amorphous composite. The formula of the low-cost high-strength high-plasticity zirconium-based amorphous composite is Zr58.5Ti14.3Nb5.2Cu6.1Ni4.9Be11.0. A preparation method comprises the following specific steps of A, preparing materials, wherein Zr, Ti, Nb, Cu, Ni and Be metal raw materials are weighed and fetched according to the composition and atomic percent of Zr58.5Ti14.3Nb5.2Cu6.1Ni4.9Be11.0; B smelting master alloy, wherein a vacuum arc furnace water cooling copper crucible smelting method is adopted, theabove metal raw materials are smelted into uniform master alloy ingots; C forming the composite, wherein a vacuum die casting metal die formation rapid cooling method is adopted, the master alloy ingots are made into a casting of the zirconium-based amorphous alloy composite. The low-cost high-strength high-plasticity zirconium-based amorphous composite solves the problems that an existing zirconium-based amorphous alloy is poor in indoor temperature plasticity and high in raw material cost; the prepared zirconium-based amorphous alloy composite is low in cost and high in strength and indoortemperature plasticity and can be applied to industrial production.

Owner:东莞宜安新材料研究院有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com