Patents

Literature

51results about How to "Phase separation effect is good" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for performing extraction separation on cobalt and nickel by using microfluid technology

The invention provides a method for performing extraction separation on cobalt and nickel by using a microfluid technology. The method comprises the following steps of: uniformly mixing an extraction agent and diluent which are subjected to homogeneous phase saponification by using a mixed material liquid of Co<2+> and Ni<2+>, using 2-ethyl cthylhexyl phosphonate mono 2-ethyl cthylhexyl ester as the extraction agent and using No.260 solvent oil and using the extraction agent and the diluent as an oil phase; introducing the water phase and the oil phase into a micro-reactor by virtue of two flow pumps; mixing the two phases in the micro-reactor and performing extraction reaction at 25-50 DEG C; and collecting a product at an outlet of the micro-reactor and standing for separating the phases to ensure that Co<2+> enters the oil phase and Ni<2+> stays in the water phase so as to realize extraction separation of cobalt and nickel. According to the method, continuous flow micro-reactor with an enhanced hybrid channel structure is adopted, the extraction separation of cobalt and nickel is carried out, and the reaction time is shortened to be within a micro-second level range, so that single-level cobalt extraction efficiency is obviously improved, and the extraction levels are reduced; and moreover, standing layering on the water phase and the oil phase can be quickly carried out without any emulsion phenomenon.

Owner:KUNMING UNIV OF SCI & TECH

Colorless transparent cordierite microcrystalline glass and preparation method thereof

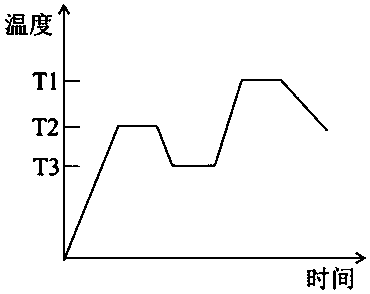

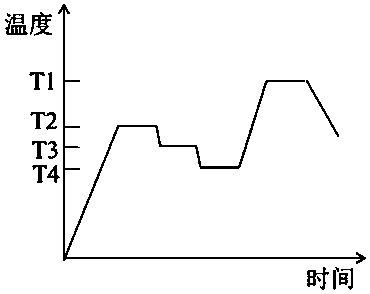

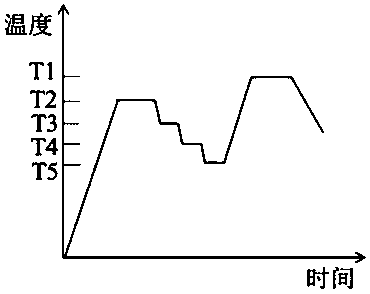

The invention relates to colorless transparent cordierite microcrystalline glass and a preparation method thereof, and the microcrystalline glass comprises the following components in percentage by mole: 15%-25% of MgO, 10%-20% of Al2O3, 62%-73% of SiO2 and 2%-6% of B2O3. The preparation method comprises the following steps: carrying out phase-splitting heat treatment on the base glass for many times, and then carrying out crystallization heat treatment. A large number of nucleation sites are formed in the base glass through multiple times of split-phase heat treatment, and crystal nucleuses grow into nanocrystals with small sizes in a controlled manner; therefore, high light transmittance and good mechanical strength of the microcrystalline glass are guaranteed, and the problems that a nucleating agent needs to be added in an existing cordierite transparent microcrystalline glass preparation process, and microcrystalline glass coloring, principal crystalline phase change, comprehensive performance reduction and the like are caused are solved. The microcrystalline glass obtained by the method belongs to a magnesium-aluminum-silicon system, alpha-cordierite is the only crystalline phase, and is colorless, transparent, high in bending strength, high in surface hardness and low in expansion coefficient.

Owner:JINGDEZHEN CERAMIC INSTITUTE

Extracting agent for extracting germanium and gallium and extraction method using same

ActiveCN102433435AEasy extractionPhase separation effect is goodProcess efficiency improvementChemistryMagnesium

The invention provides an extracting agent for extracting germanium and gallium and an extraction method using the same, relates to a hydrometallurgy extracting agent and in particular relates to an organic extracting agent for extracting germanium and gallium and an extraction method using the same. The extracting agent is characterized in that the extracting agent is O,O-dihydrocarbyl phosphorus hydroxamic acid the molecular formula of which is (RO)2P(O)NHOH, wherein in the formula, R is C5-C18 straight chain or branched chain alkyl, or C4-C14 straight chain or branched chain alkyl-substituted phenyl. The extracting agent provided by the invention has excellent extraction property, strong selectivity, high extraction rate and good phase splitting property on scattered metals such as germanium, gallium and the like. In the invention, O,O-dihydrocarbyl phosphorus hydroxamic acid is used as the extracting agent, so that germanium in an acidic aqueous solution can be extracted and enriched, or gallium in the acidic aqueous solution can be extracted and enriched, thereby realizing the separation of scattered metal germanium or gallium and elements such as zinc, iron, arsenic, manganese, calcium, magnesium and the like; and germanium and gallium in the acidic aqueous solution can also be extracted and separated step by step, thereby realizing the separation and enrichment of germanium and gallium.

Owner:BEIJING GENERAL RES INST OF MINING & METALLURGY

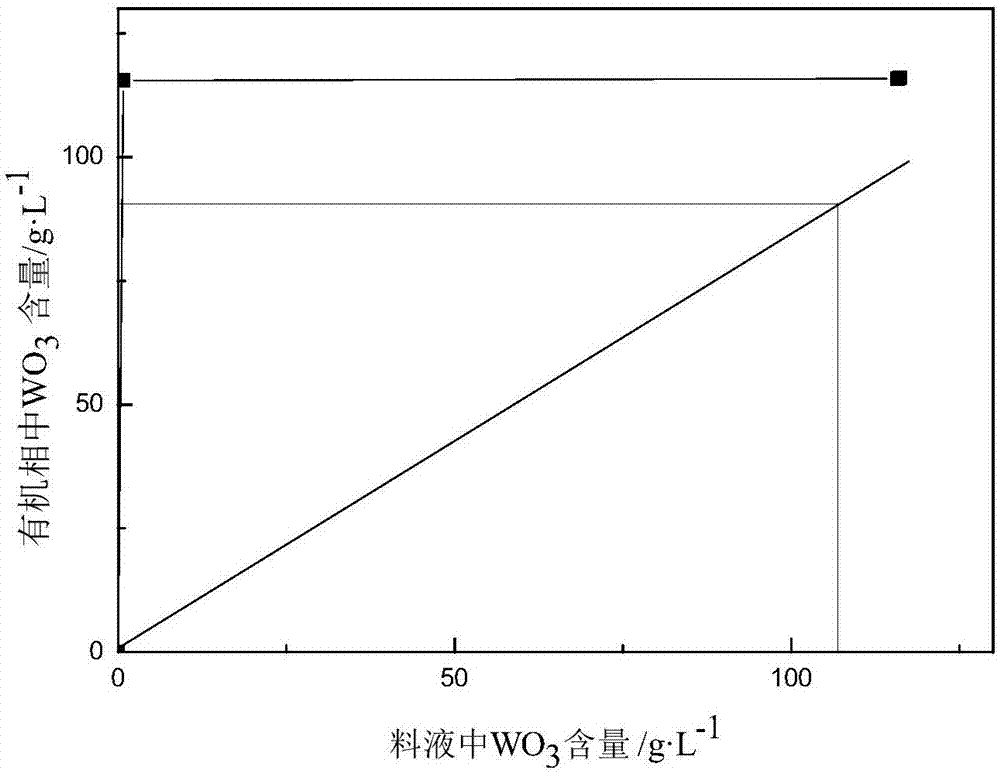

Method of preparing phosphotungstic acid from sodium tungstate as raw material

ActiveCN106335928APhase separation effect is goodSimple processTungsten compounds preparationAlcoholSodium tungstate

The invention belongs to the technical field of heteropolyacid preparation, and particularly relates to a preparing method of sodium tungstate. Industrial sodium tungstate crystal is used as the raw material, an alcohol extraction agent is used for extracting to obtain a phosphotungstic acid water solution, phosphotungstic acid crystal can be obtained through evaporative crystallization or spray drying, organic phase and raffinate obtained after reverse extraction can be returned and used directly, and the process of organic phase regeneration is avoided. The method is short in process flow, low in manufacturing cost, high in product yield, environmentally friendly and capable of achieving large-scale industrial production.

Owner:CENT SOUTH UNIV

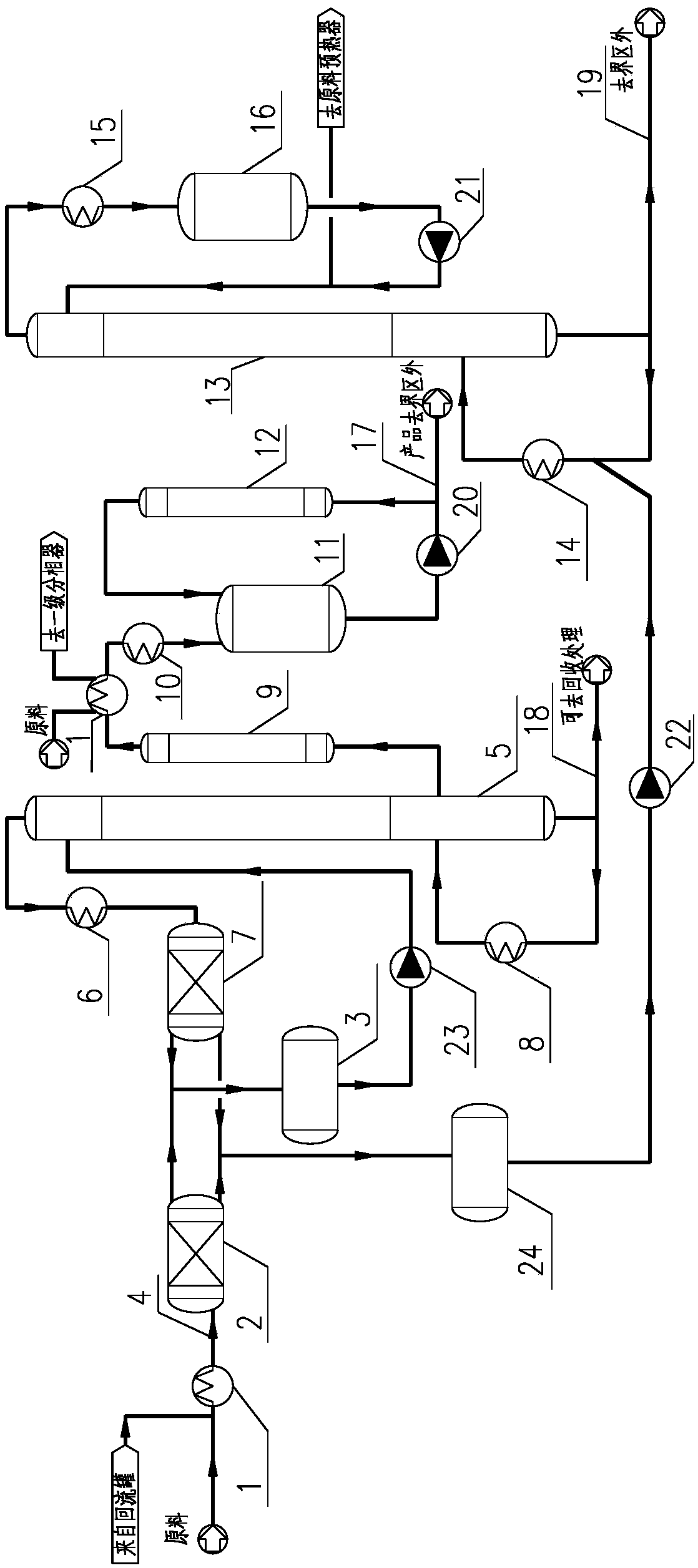

Technological method and apparatus for separating triethylamine in industrial waste solution

PendingCN109369419AReduce moistureReduce lossAmino compound purification/separationLiquid wasteOil phase

The invention relates to a technological method and apparatus for separating triethylamine in industrial waste solution. Raw materials are preheated to 50 to 70 DEG C by virtue of a raw material preheater, and the preheated materials are separated by virtue of a primary phase separator to obtain a water phase and an oil phase. An azeotrope enters an azeotropic rectifying tower to remove water dissolved in triethylamine from the top of the aceotropic rectifying tower, and is condensed by virtue of a condenser and then enters a secondary phase separator, after the phase separation, an oil phaseand a water phase are obtained respectively, the oil phase is recycled to the azeotropic rectifying tower, and steam of a tower kettle is condensed by virtue of a product separation tower, a heat exchanger and the condenser and then enters a product receiving tank. The product is dried by a drying dehydration tower to obtain anhydrous triethylamine product. The water phase from the primary phase separator and the secondary phase separator is treated through a water phase treatment tower to remove the triethylamine dissolved in the water, the recycled triethylamine is returned to the raw material preheater, and the water of the tower kettle can be directly biochemically treated. The triethylamine product steam exchanges the heat with the raw materials, so that the heat energy loss can be reduced, the triethylamine can be well separated from the water, and the water content in the separated triethylamine product is low.

Owner:烟台国邦化工机械科技有限公司

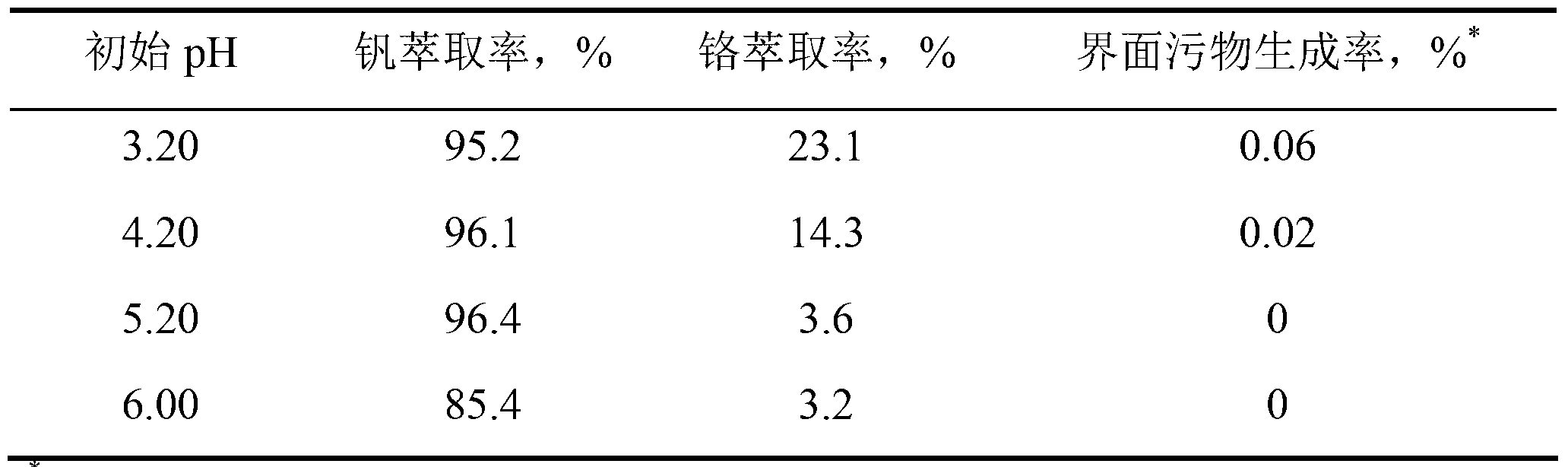

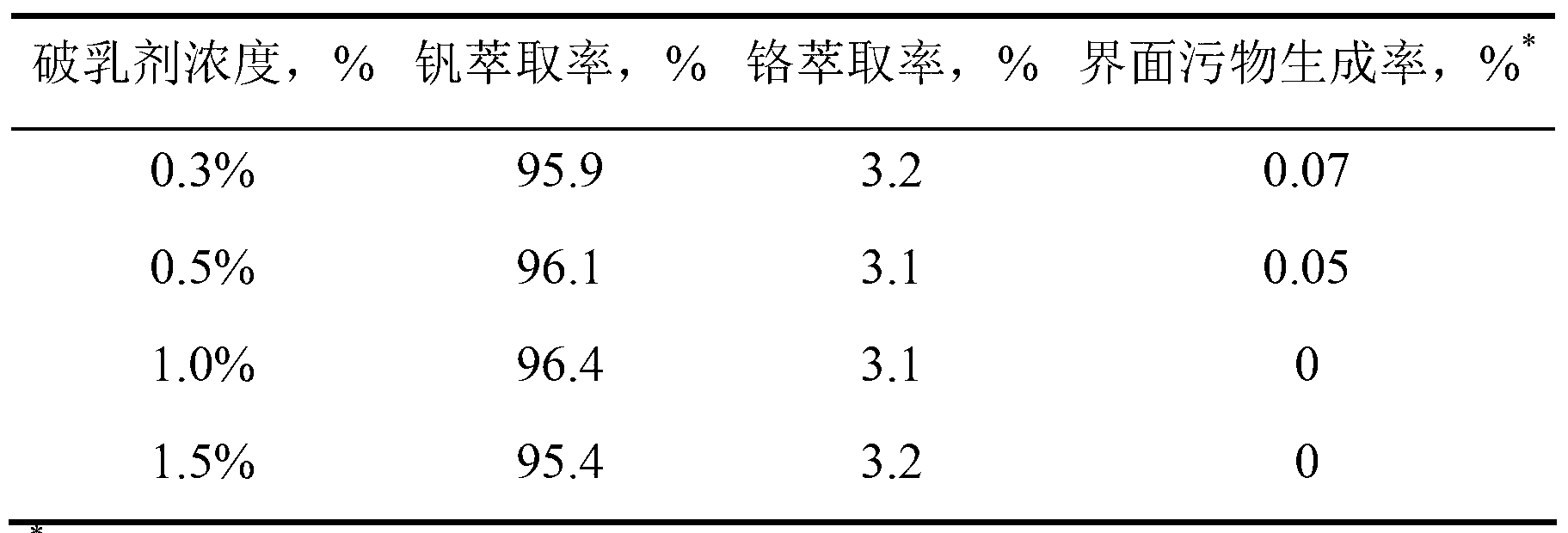

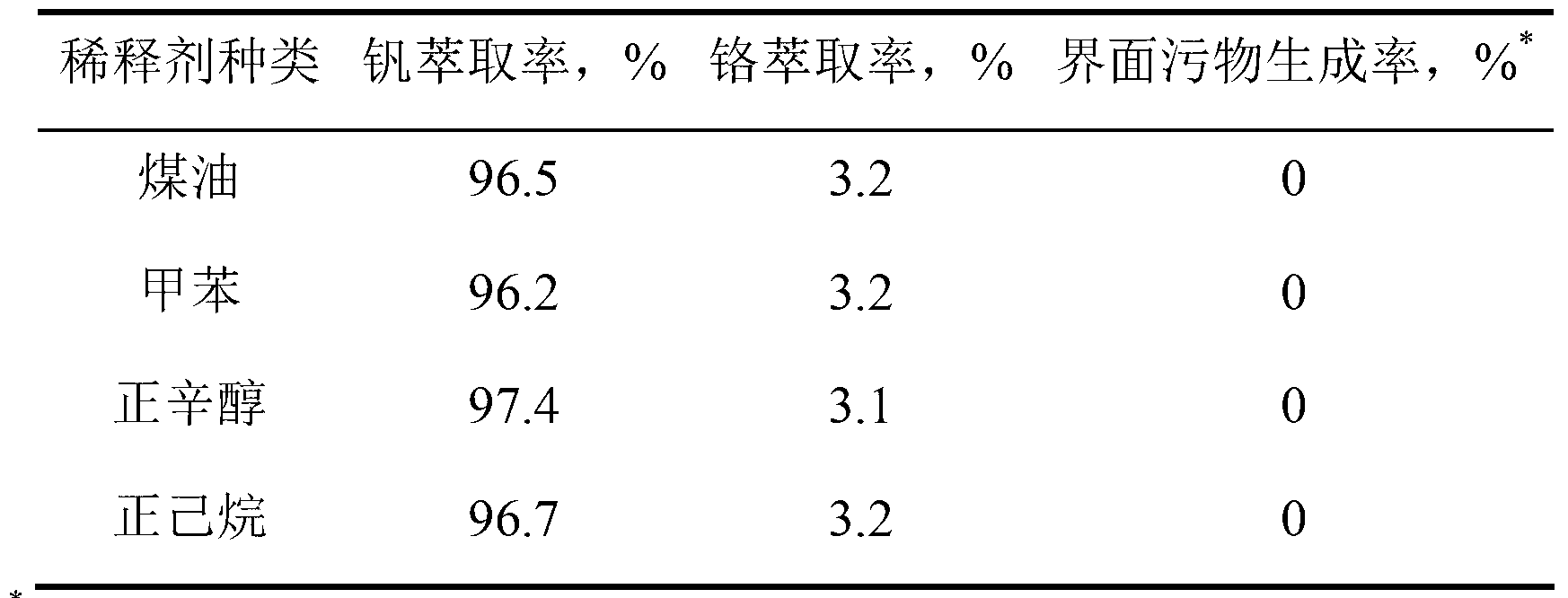

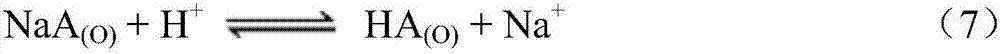

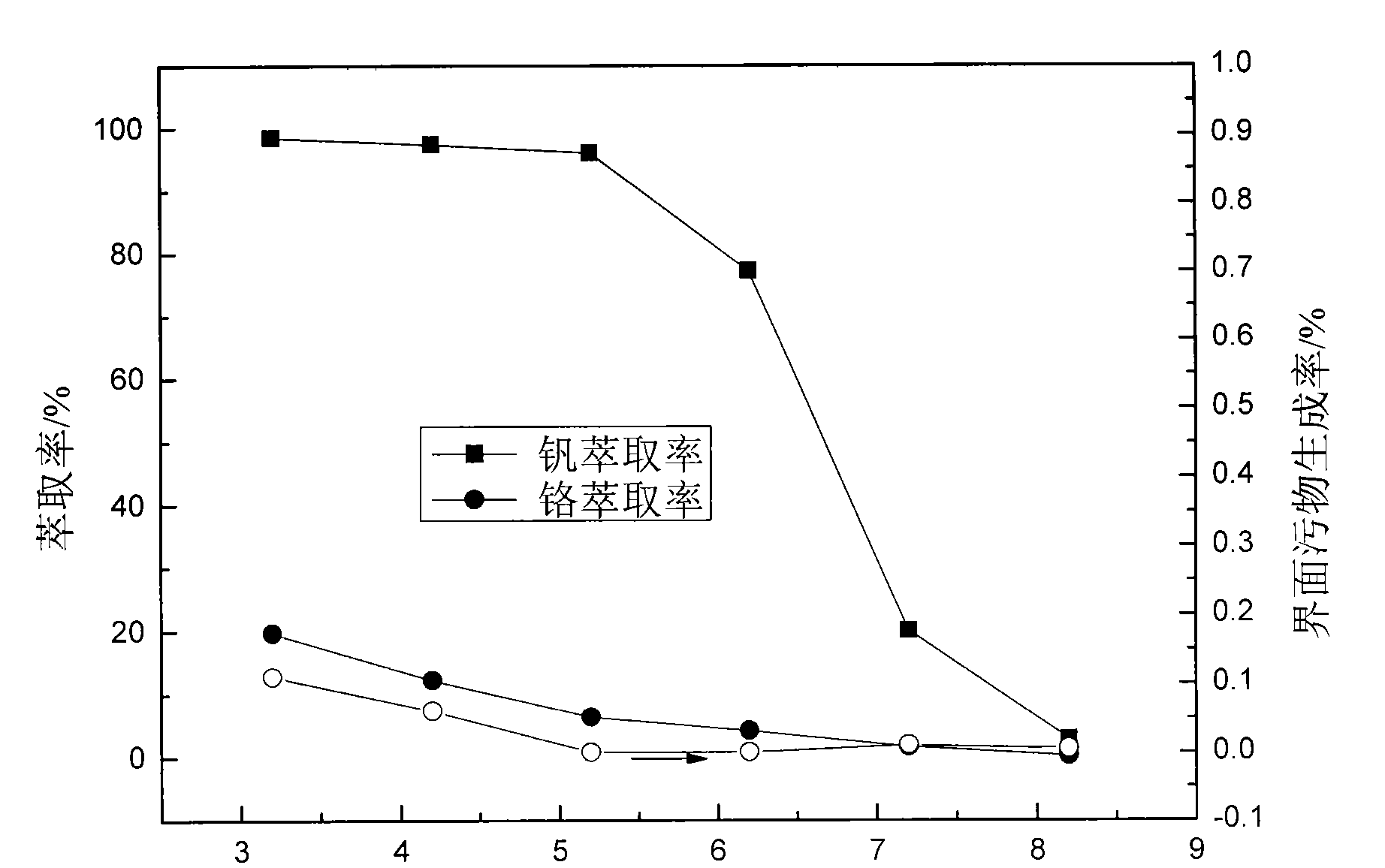

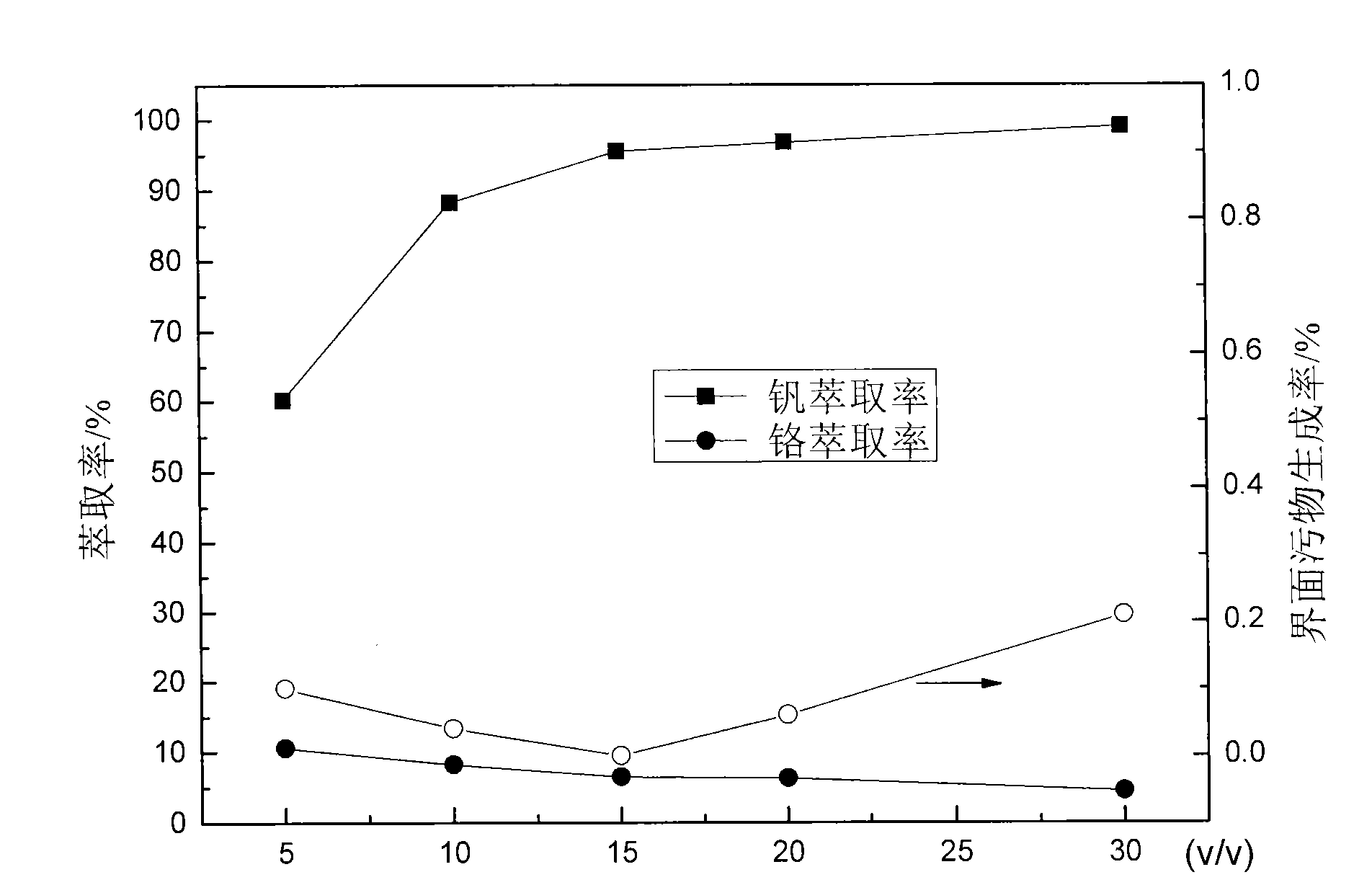

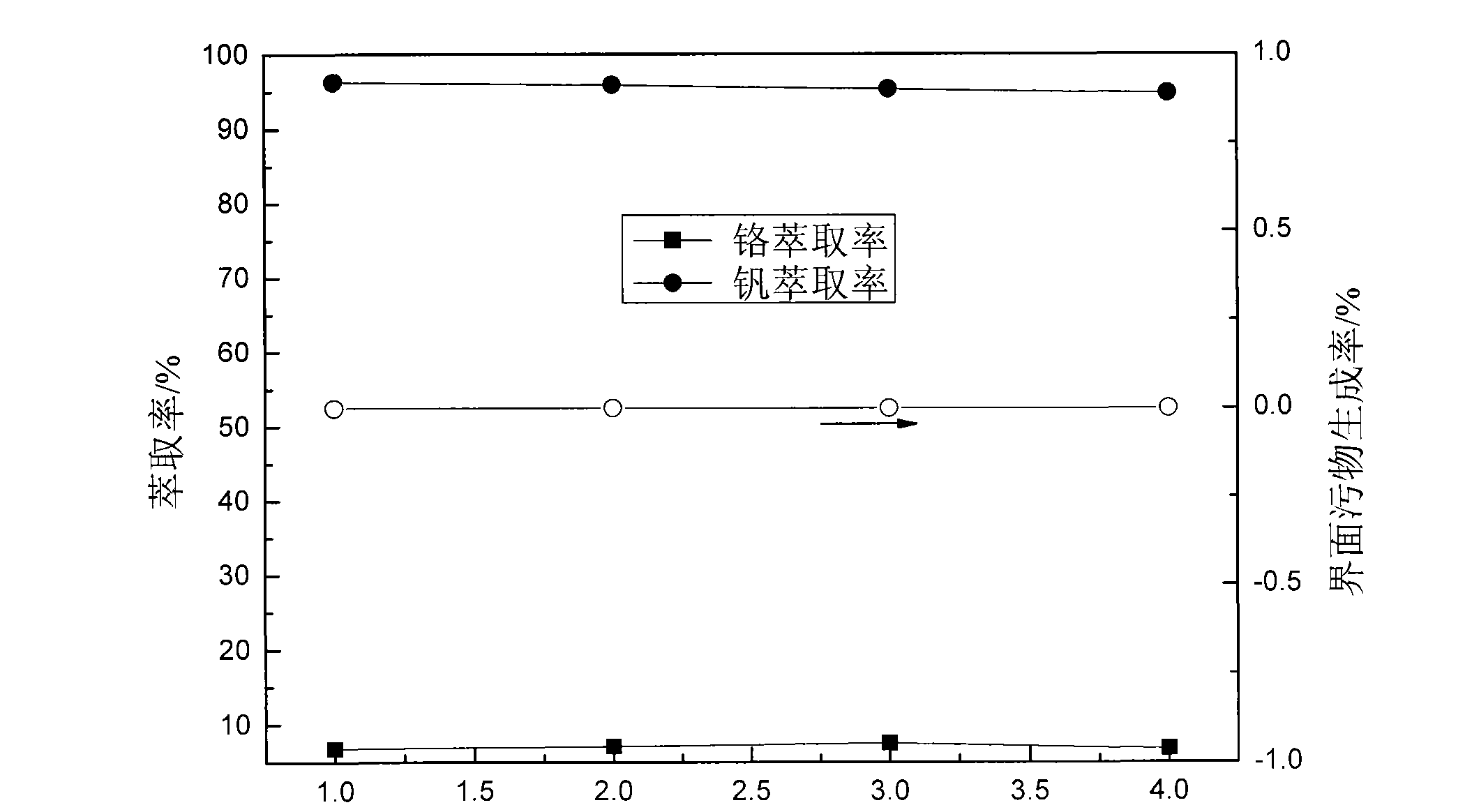

Method of preventing interphase impurity in vanadium-chromium extraction separation process

ActiveCN103305693AEasy to separatePrevent interface contaminationProcess efficiency improvementSolid particleImpurity

The invention discloses a method of preventing interphase impurity in a vanadium-chromium extraction separation process. The method is characterized by comprising the following steps of: deeply removing impurities in an extracted solution before extraction, such as phosphorus, silicon, calcium, iron, and the like; extracting the purified extracted solution through a mixed solution of an efficient composite amine extracting agent, a demulsifier and a thinner, regulating the pH of the extracted solution, controlling the extraction temperature, the extraction time, the concentration of the extracting agent and the concentration of the demulsifier in the extraction process. According to the method, solid particles possibly generating emulsification in the solution are deeply removed and the demulsifier is added to reduce the emulsification interphase stability when the extraction is finished so as to reduce the probability of inorganic salts in crystallizing on the interphase to form solid interphase membranes. The method can effectively eliminate the interphase impurity in the vanadium-chromium extraction separation process, improve the extraction equilibrium phase splitting speed, reduce the organic phase loss, save the operating cost and ensure the long-term circulation of the extraction system.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Extraction vanadium recovery process

ActiveCN107245586AImprove extraction capacityIncrease profitProcess efficiency improvementAir quality improvementVanadium oxideImpurity

The invention discloses an extraction vanadium recovery process. Spent vanadium catalysts are subjected to water leaching and reductive acid leaching treatment to obtain VOSO4-containing extracted raw liquid, the raw liquid is subjected to the single-stage extraction, tail liquid concentration, separate reextraction and back extraction vanadium recovery process, vanadium precipitation is carried out with ammonium hydroxide, and roasting is conducted to produce vanadium pentoxide. Saponified P204 is adopted as a main extraction agent, it is ensured that the pH value of the whole system is within the optimal pH value range in the extraction process, the extraction system can maintain a stable pH value, and the single-stage extraction rate of vanadium is greatly improved to above 96.4%; tetravalent vanadium obtained through extraction can be directly subjected to vanadium precipitation without oxidation, a high-purity vanadium product is produced, the technological process is simplified, and atmosphere pollution caused by chlorine generated by chlorate vanadium oxide is avoided; meanwhile, the selectivity characteristic of the saponified P204 is utilized, the influences of iron, phosphorus and arsenic on purity of extracted vanadium are effectively avoided, a part of impurity removal work is reduced, raw material consumption is reduced, enterprise cost is reduced, and economic benefits are remarkable.

Owner:KAIFENG UNIV

Method for preventing interfacial crud during vanadium-chromium extraction and separation

InactiveCN101665870AInterface contamination preventionEfficient separationProcess efficiency improvementSlagSodium hydroxide

The invention discloses a method for preventing interfacial crud during vanadium-chromium extraction and separation, which is characterized in that during extraction, vanadium and chromium are extracted and separated by use of amine-type extractant in an organic phase containing the amine-type extractant and diluent composition; an aqueous phase adopts a leaching solution which contains vanadium-chromium slag and has acidity adjusted through dilute sulfuric acid or sodium hydroxide solution; and the method comprises the steps of mixing the aqueous phase with the organic phase in a separating funnel at a certain temperature, fixing the separating funnel on an oscillator, oscillating for a certain time, taking out and standing the separating funnel for demixing. The method has the advantagesof effectively preventing interfacial crud produced during vanadium-chromium extraction and separation, improving extraction equilibrium phase-separation speed, reducing the loss of organic phase andsaving operation cost.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

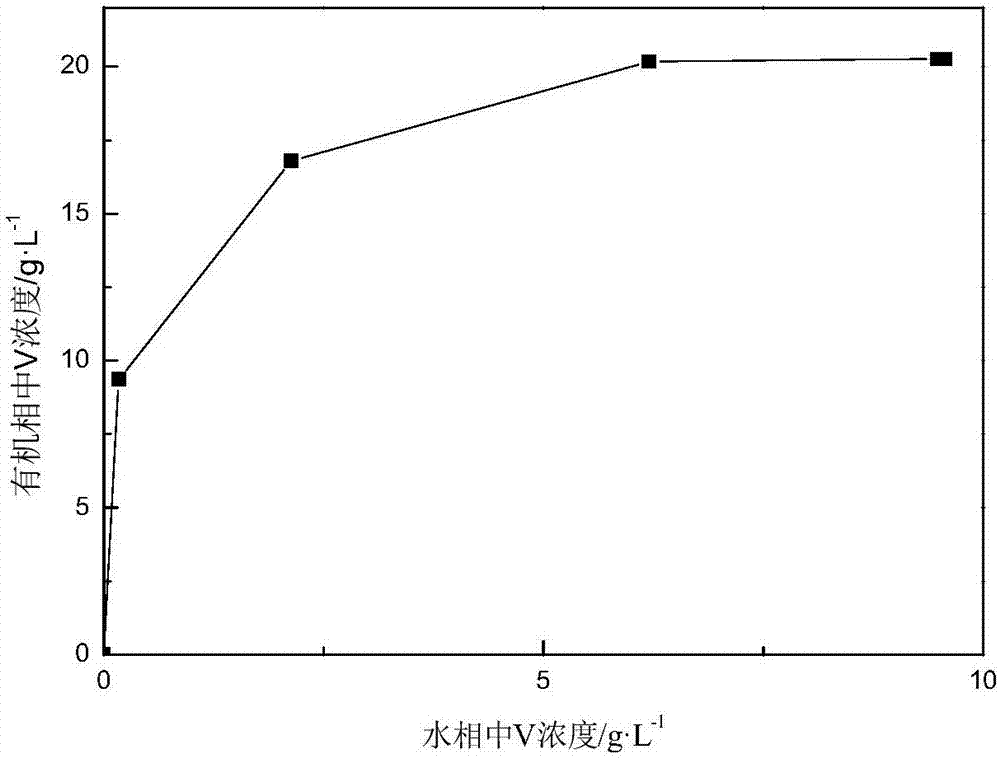

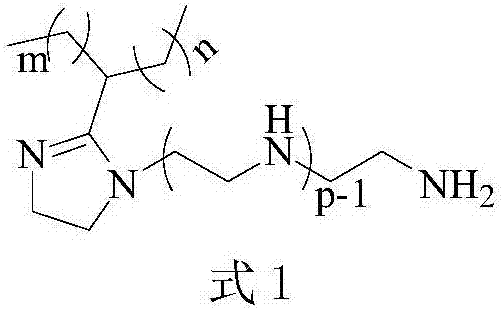

Branched-chain long-chain fatty acid base imidazoline extraction agent and preparing method and application thereof

ActiveCN107385211AImprove extraction abilityLarge saturated capacityOrganic chemistryChemical recyclingLong chain fatty acidPhase splitting

The invention discloses a branched-chain long-chain fatty acid base imidazoline extraction agent and a preparing method and application thereof. The imidazoline extraction agent comprises multiple N atoms and long-branch-chain alkyl groups. The preparing method of the imidazoline extraction agent comprises the steps that in the normal pressure, carboxylic acid and polyethylene polyamine are subjected to the reaction under the action of a solid catalyst, after the reaction is finished, the solid catalyst is recycled through solid-liquid separation, the liquid mixture is distilled, the raw material incompletely reacted is recycled, and then the branched-chain long-chain fatty acid base imidazoline extraction agent is obtained. The preparing method has the beneficial effects that reaction conditions are moderate, the catalyst can be repeatedly used, and equipment investment and operation cost are low; the imidazoline extraction agent is used for extraction negative ions including tungsten, molybdenum and vanadium, the beneficial effects that the extraction volume is high, the phase splitting time is short, and the extraction and reverse extraction performance is excellent; and good industrial application prospects are achieved.

Owner:CENT SOUTH UNIV

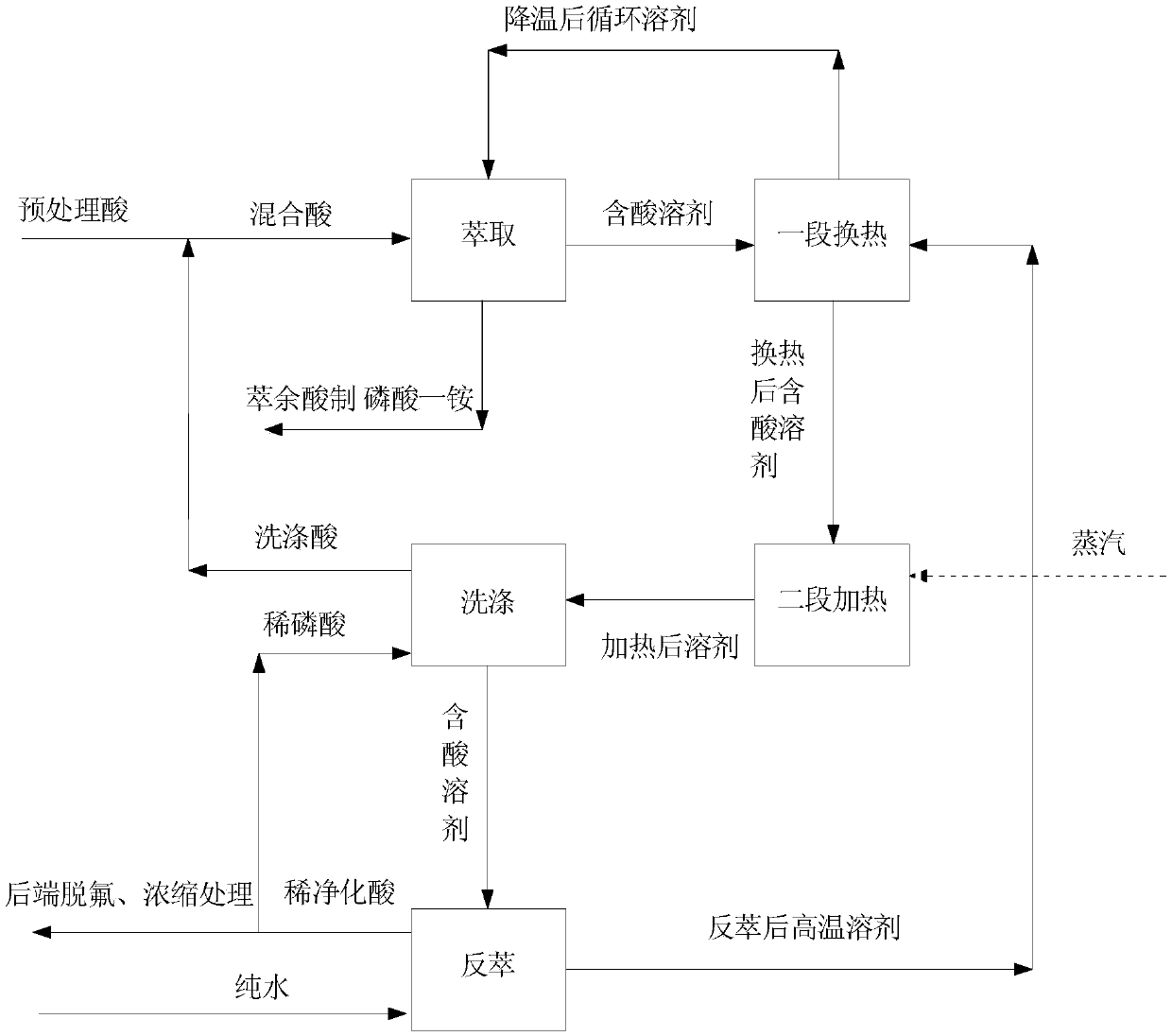

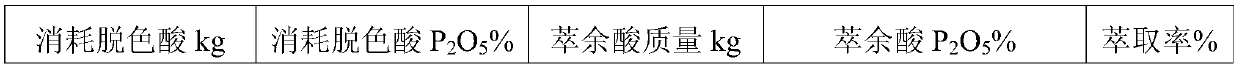

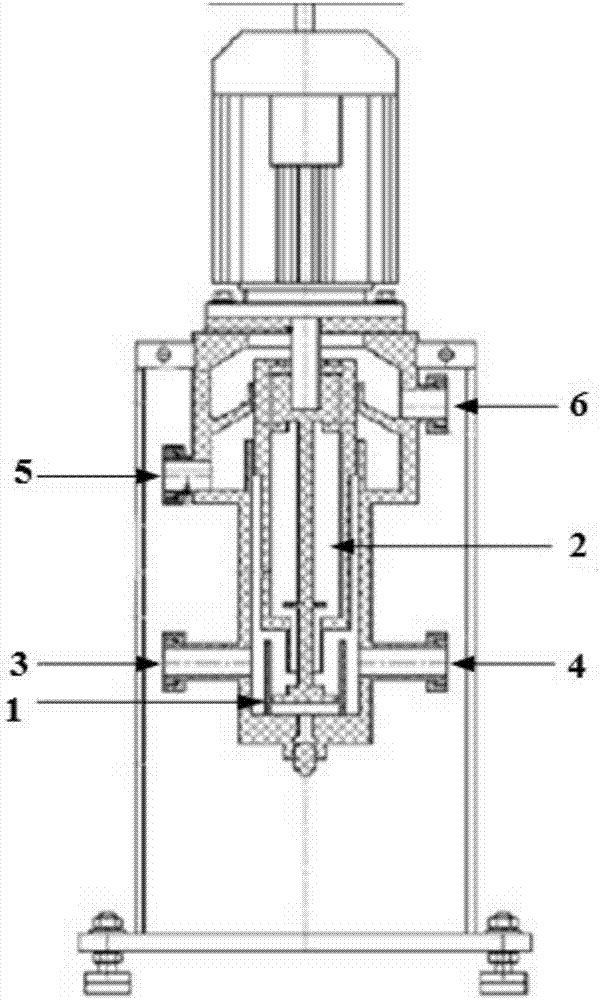

Method for purifying wet-process phosphoric acid by using centrifugal extractor

InactiveCN109650362ALow concentration requirementNo energy consumptionLiquid solutions solvent extractionPhosphorus compoundsPhosphoric acidPhase ratio

The invention discloses a method for purifying wet-process phosphoric acid by using a centrifugal extractor in the technical field of chemical production. The method mainly includes several phases ofpretreatment, extraction, washing, back extraction, desulphurization and condensation; and the main improving point is the extraction, washing and back extraction phases which adopt a centrifugal extractor. The centrifugal extractor can be used as extraction equipment which has low requirement for the phosphoric acid concentration of raw materials, only 30-40% is needed for the content of P2O5, requirements can be met by only performing simple treatment of ordinary semi-aqueous wet-process phosphoric acid without extra energy consumption, but the requirements in the prior art for the phosphoric acid concentration have to be controlled at 40-58%; extra control on the temperature of an extraction section is not needed, normal temperature reaction can be performed, the extraction rate of morethan 75% can be achieved when a phase ratio is 4 : 1, and compared with a rotating disc column, 6-8 : 1 has to be achieved; and through the centrifugal extractor, two phases can be fully mixed undera high-speed condition, so that high extraction efficiency and good split-phase effects can be realized, equivalent phase ratio with the rotating disc column can be achieved, and rapid split-phase andno entrainment can be realized.

Owner:CHANHEN ECO TECH CO LTD

Method for removing nitrotoluene in high-concentration waste acid

InactiveCN102557179ASimplified processing stepsGood processing effectWater contaminantsWater/sewage treatment by extractionSolubilityHigh concentration

The invention relates to a method for removing nitrotoluene in high-concentration waste acid. The method comprises adding an extractant into the high-concentration waste acid at a certain temperature, extracting, and separating the extractant from the waste acid; and recovering the extractant. Compared with the prior art, the invention has significant advantages that the invention has simple treatment steps, significant treatment effect and mononitrotoluene (MNT) and dinitrotoluene (DNT) removal rate up to above 99%, the treated high-concentration waste acid has high purity and can be directly used for other chemical processes, and the invention is suitable for industrialization; a perfluoro solvent serving as the extractant has good fluidity, chemical inertness and good phase separation performance, and has solubility for nitrotoluene compounds at a temperature higher than a critical temperature, thus it can be reutilized and maintains high removal rate; the invention directly treats the high-concentration waste acid without diluting with water, avoids subsequent wastewater treatment, and lowers the cost; and the inventive method has few apparatus, low manufacture cost, low investment and low running cost.

Owner:NANJING UNIV OF SCI & TECH +1

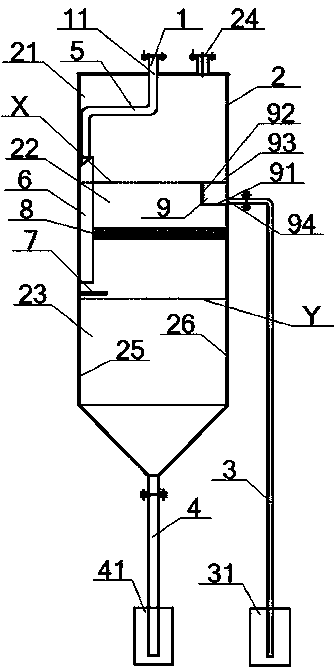

Solvent separating unit used for evaporation and recovery of solvent system and application method thereof

ActiveCN103520956AAvoid emulsificationHigh speedNon-miscible liquid separationPhase splittingEvaporation

The invention provides a solvent separating unit used for evaporation and recovery of a solvent system. A feed pipe arranged at the top of a barrel included by the solvent separating unit is communicated with a vertical condensate conduit through a transition pipe; the lower part of the vertical condensate conduit is provided with a horizontal condensate guide plate which is arranged to be slightly higher than a two-phase line; the central part of the vertical condensate conduit penetrates a metal phase-splitting mesh; an organic phase overflow groove with an upper opening is arranged above the metal phase-splitting mesh; and the top of the organic phase overflow groove is aligned with a liquid level line. In usage, a condensate successively flows through the transition pipe, the vertical condensate conduit and the horizontal condensate guide plate and then into the barrel for phase splitting; a water phase flows into a water phase discharging pipe, and an organic phase successively flows through the metal phase-splitting mesh and the organic phase overflow groove and then into an organic phase discharging pipe; and an inverted Y-shaped pipe can be arranged out of the barrel so as to adjust the two-phase line and prevent siphonage. According to the invention, the solvent separating unit has the advantages of an improved phase splitting effect, an improved phase splitting speed, a simple structure, convenience in operation, a wide application scope and capacity of preventing siphonage.

Owner:吴杰

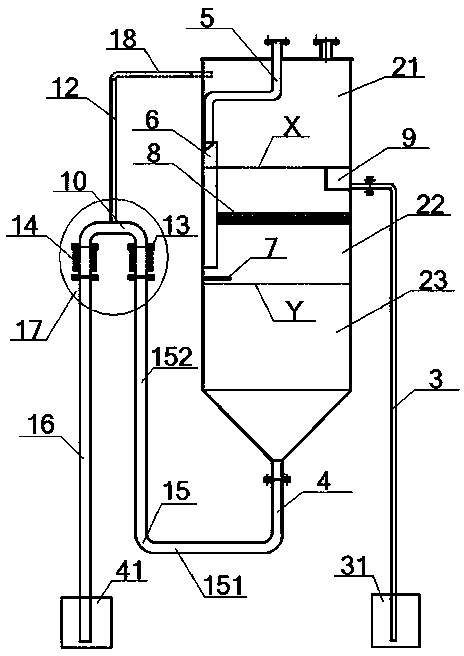

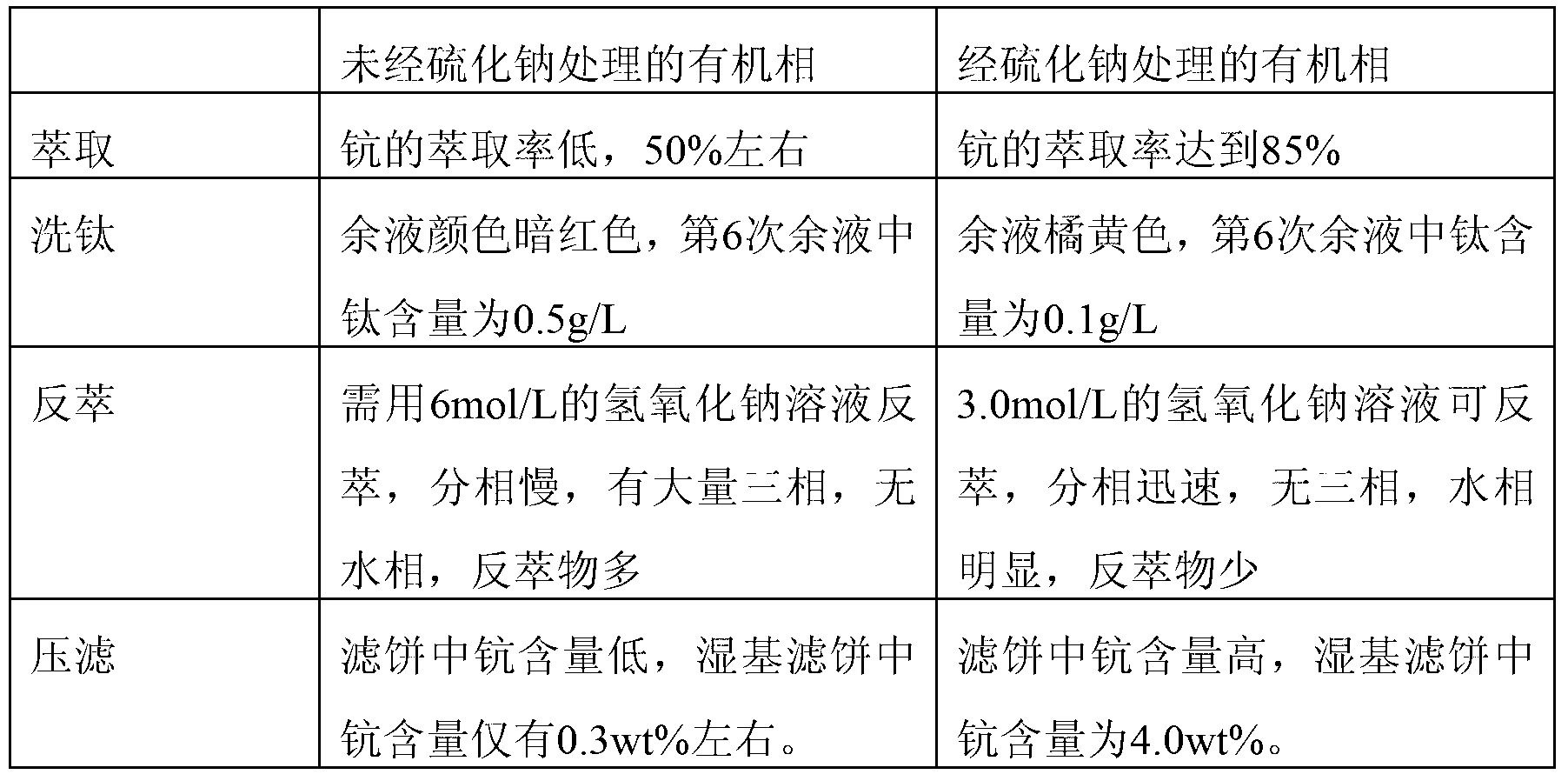

Recycling method of organic phase used for extracting scandium

ActiveCN103233134AHigh extraction performanceLong cycle lifeProcess efficiency improvementPhase splittingTitanium

The invention relates to a recycling method of an organic phase used for extracting scandium. The method comprises the following steps of: adding a sodium sulfide solution into the organic phase and mixing; performing phase splitting; discharging a water phase; adding a sulfuric acid solution into the rest of organic phase; washing the acidified organic phase with water; and using the acidified organic phase to extract scandium. The organic phase treated by using the method can be recycled, the subsequent efficiencies of titanium washing and reverse extraction processes also can be improved, most of titanium impurities can be washed off from the organic phase, and the efficiency of reverse extraction can be obviously improved; and the organic phase can be totally reversely extracted by using 3mol / L of industrial alkali, the phase splitting efficiency is rapid, and the scandium content of an obtained alkali cake is high.

Owner:桃江瑞龙金属新材料有限责任公司

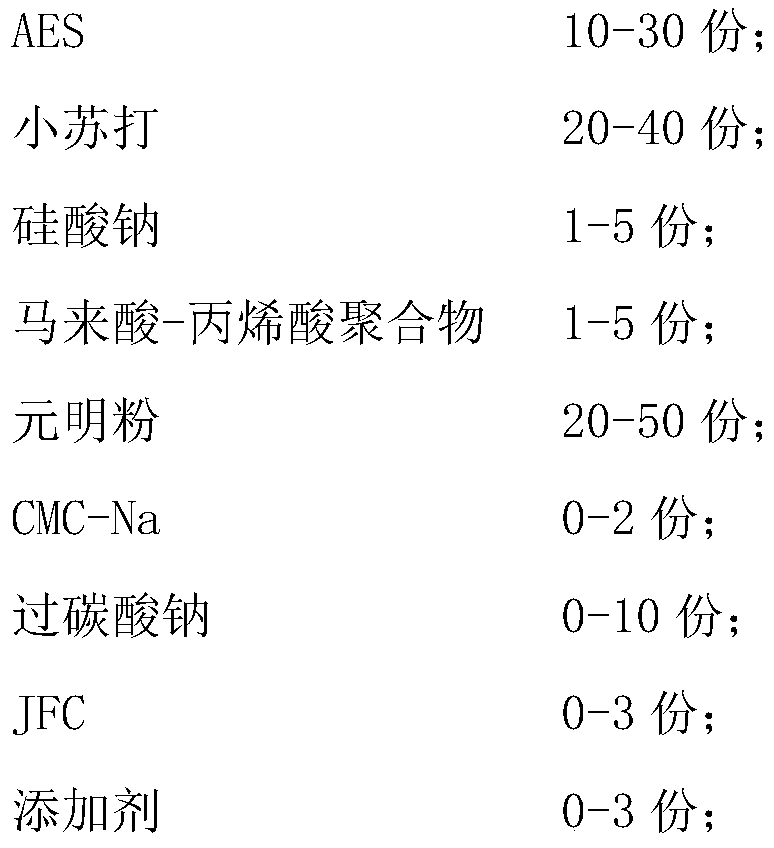

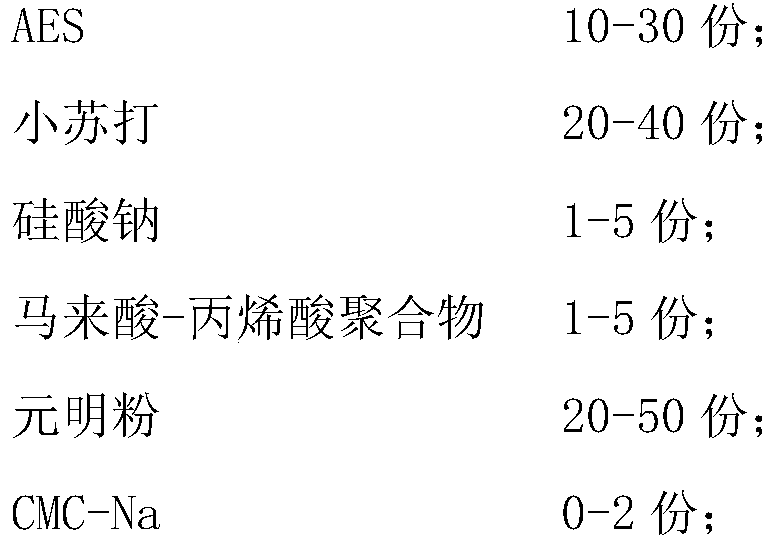

Environment-friendly phosphorus-free washing powder and preparation process thereof

ActiveCN111548866AImprove washabilityEnvironmentally friendlyInorganic/elemental detergent compounding agentsNon-ionic surface-active compoundsPhysical chemistrySodium silicate

The invention relates to an environment-friendly phosphorus-free washing powder and a preparation process thereof, and belongs to the technical field of washing powder. The environment-friendly phosphorus-free washing powder comprises the following components in parts by weight: 10-30 parts of AES; 20 to 40 parts of baking soda; 1-5 parts of sodium silicate; 1-5 parts of a maleic acid-acrylic acidpolymer; 20 to 50 parts of anhydrous sodium sulfate; 0 to 2 parts of CMC-Na; 0-10 parts of sodium percarbonate; 0 to 3 parts of JFC; and 0-3 parts of an additive; wherein sodium percarbonate is coated with a stabilizer for improving the stability of sodium percarbonate. The washing powder is more environment-friendly on the premise that the dirt-removing performance is guaranteed.

Owner:浙江美生日化用品有限公司

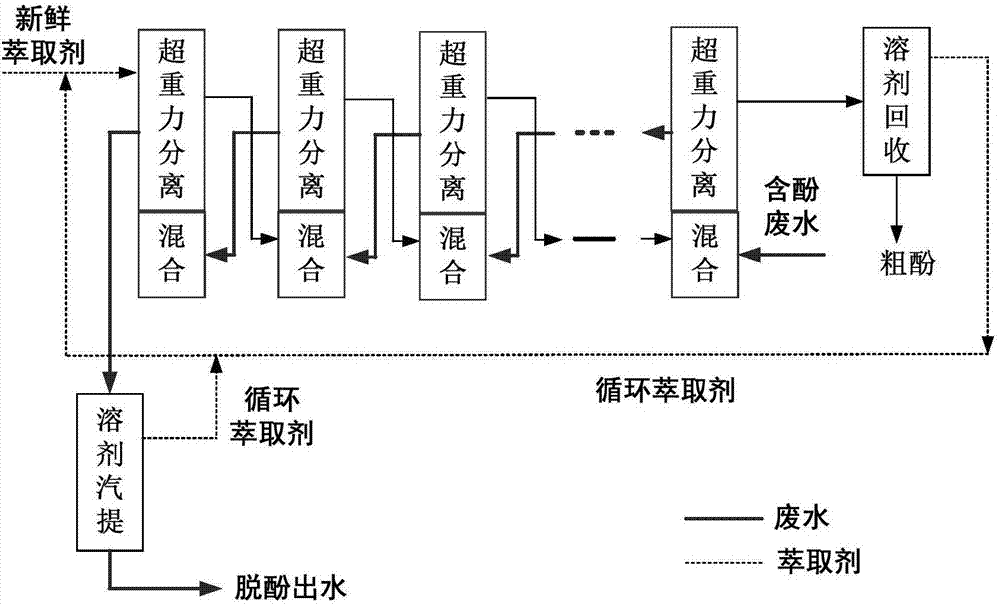

Method for dephenolization of phenolic wastewater through multi-stage mixed intensified separation

ActiveCN106865674AGood phase separation performanceImprove processing powerWater contaminantsLiquid solutions solvent extractionCounter currentChemistry

The invention discloses a method for dephenolization of phenolic wastewater through multi-stage mixed intensified separation. The method comprises the following steps: (1) conveying an extraction agent and phenolic wastewater into a multi-stage extraction device consisting of a plurality of supergravity extractors in an opposite direction, performing multi-stage counter-current extraction, and collecting a final extraction phase and a final raffinate; and (2) feeding the final raffinate into a solvent recycling tower, performing solvent recycling I so as to obtain crude phenol and an extraction agent I; feeding the final raffinate into a solvent steam stripping tower, performing solvent recycling II so as to obtain wastewater after dephenolization and an extraction agent II; continuously introducing the extraction agent I and the extraction agent II into the multi-stage extraction device, and performing multi-stage counter-current extraction with the phenolic wastewater. By adopting an extraction process, two-phase separation is achieved through supergravity, and good phase separation properties and large treatment capacities can be achieved; by adopting a powerless spiral or eddy mixer, rapid mass transfer balance of two phases can be achieved, the mass transfer efficiency is high, and the stage efficiency is approximate to 100%.

Owner:CCTEG CHINA COAL RES INST

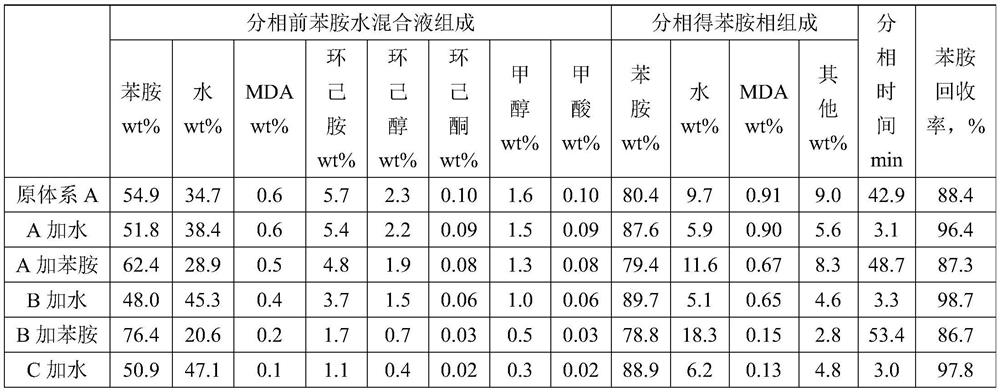

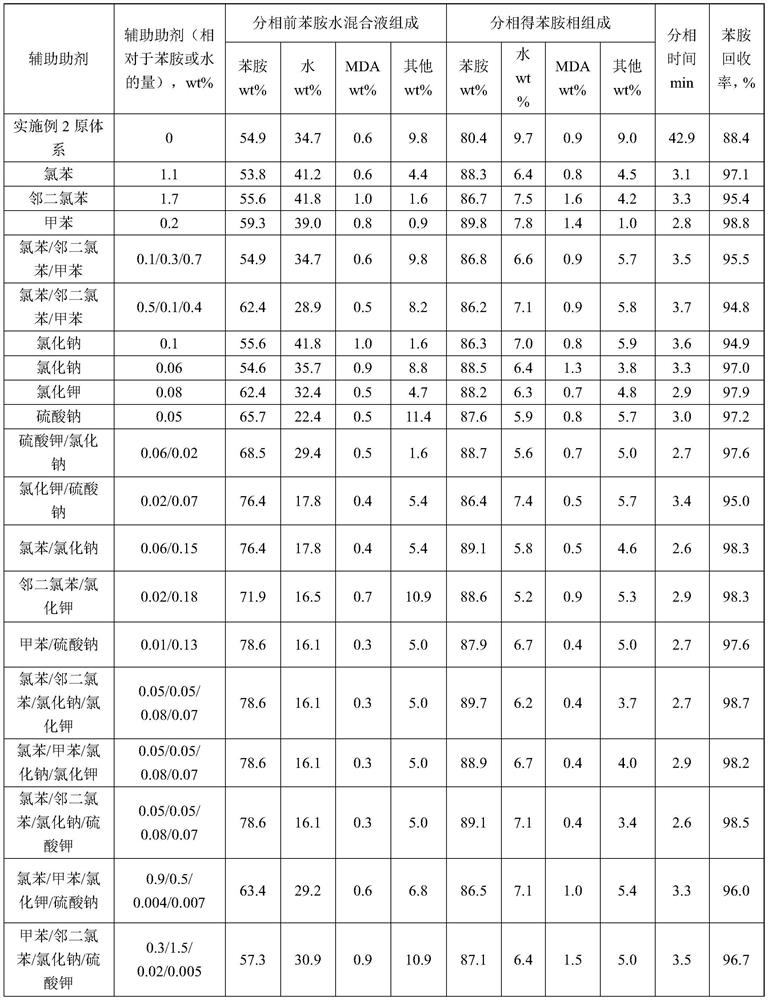

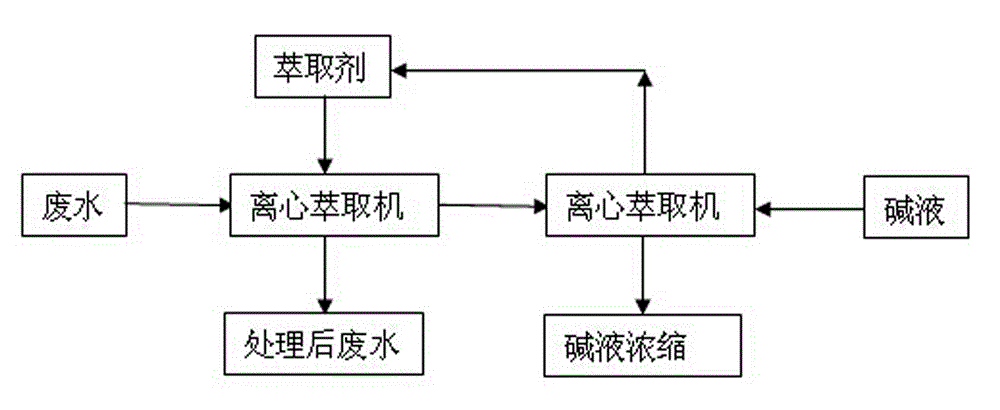

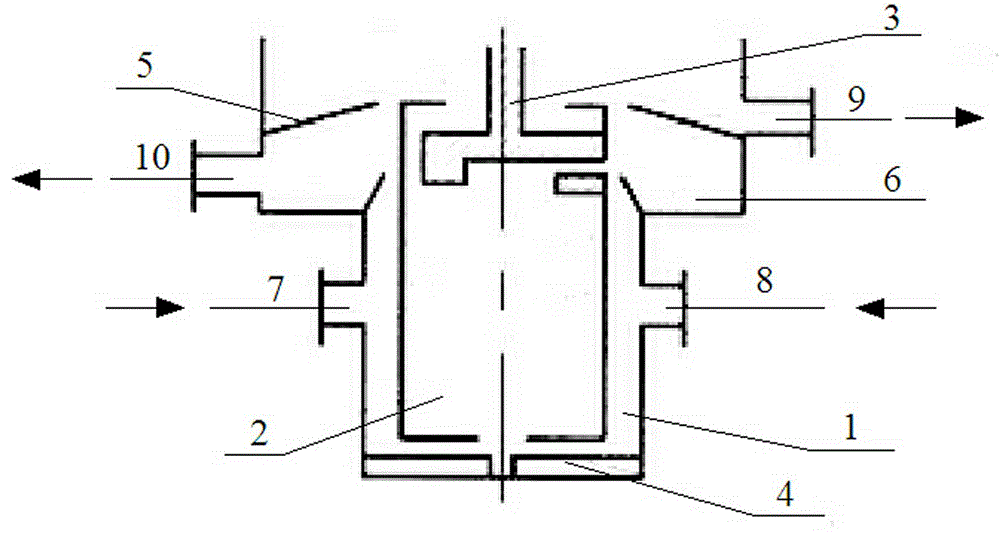

Method for recycling aniline in preparation process of diphenylmethane series diamine and polyamine

PendingCN112250584ASolve emulsification problemsPhase separation effect is goodAmino compound purification/separationDiphenylmethaneAniline

The invention relates to a method for recycling aniline in a preparation process of diphenylmethane series diamine and polyamine. The method is used for recycling aniline from an aniline-water mixed solution generated in a DAM refining process through liquid-liquid two-phase standing layering, wherein particularly the aniline content of 53 wt% in the aniline-water mixed solution is taken as a boundary value, when the aniline content is less than 53 wt%, the aniline-water mixed solution is directly layered, and when the aniline content is more than or equal to 53 wt%, the aniline content in theaniline-water mixed solution is adjusted to be less than 53 wt% and then layering is performed, or an auxiliary aid is added into the aniline-water mixed solution and then layering is performed, wherein the auxiliary aid is one or more of water-insoluble micromolecular aromatic hydrocarbon or chlorinated aromatic hydrocarbon and hydrochloride or sulfate of alkali metal. The method has the advantages of being simple, high in separation efficiency, high in recovery rate, high in recovered aniline concentration and the like, stable phase splitting of aniline water generated by the DAM refining unit can be achieved, and recovered aniline can be directly used as a raw material for producing DAM.

Owner:WANHUA CHEM GRP CO LTD +1

Cast iron aventurine glaze and method for preparing cast iron aventurine glaze ceramic product by using same

The invention relates to the technical field of ceramic preparation, and particularly relates to cast iron aventurine glaze and a method for preparing a cast iron aventurine glaze ceramic product by using the same. The cast iron aventurine glaze is prepared from the following raw materials in parts by weight: 23-28 parts of kaolin, 18-22 parts of potassium feldspar, 11-24 parts of boron frit, 14-19 parts of titanium oxide, 5-8 parts of calcium oxide, 3-8 parts of sodium oxide, 1-3 parts of magnesium oxide, 15-21 parts of quartz and 12-15 parts of waste iron slag. The preparation method comprises the steps of S1, glaze preparation; S2, slurry preparation; S3, glazing; and S4, sintering. According to the invention, green and healthy environment-friendly raw materials are adopted, and meanwhile, a better glaze effect is obtained at a lower cost.

Owner:福建省德化县新宇陶瓷有限公司

Novel process for treating maleic anhydride wastewater

ActiveCN104926024ASimple processEasy to operateMultistage water/sewage treatmentMaleic anhydrideAutomatic control

The invention relates to a novel process for treating maleic anhydride wastewater. Aiming at the characteristics of high salinity, high COD, high oil content and low biodegradability, most of organic matters and oils can be effectively removed; the influence on a treatment mode of a physical method is smaller compared with an anaerobic treatment process, an extraction effect cannot be influenced by the change of materials, and the organic matters and the oils can be efficiently and stably removed; the method is simple in process and easy to operate, devices can be intermittently operated in an individual manner or in a series connection manner according to process requirements, the number of the devices is unlimited, the devices are easy to mount, operate and maintain, the number of needed staff is small, the labor intensity of workers can be remarkably alleviated, and the labor environment can be improved; moreover, starting up and shutdown are convenient, and online analysis and automatic control are easily implemented.

Owner:PUYANG SHENGYUAN ENERGY TECH

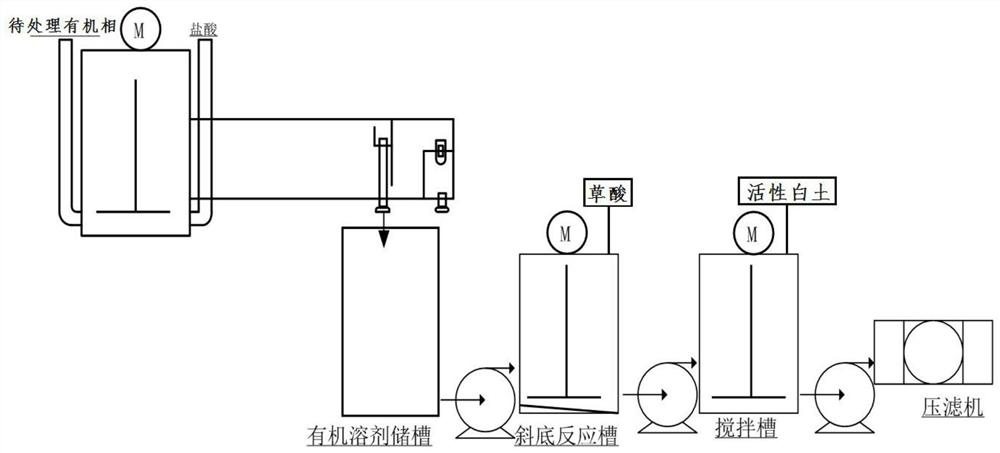

Method for purifying and regenerating P204 and P507 extraction agents

InactiveCN112063838AEasy to handleEasy to operateProcess efficiency improvementOXALIC ACID DIHYDRATEProcess engineering

The invention relates to a method for purifying and regenerating P204 and P507 extraction agents. The method comprises the following steps: collecting the P204 and P507 extraction agents on a production line to an anti-ferro section, performing reverse extraction by using 6.0-8 mol / L hydrochloric acid, and enabling the treated P204 and P507 extraction agents to flow into a storage tank; pumping apretreated organic solution into a reaction tank, adding a 10% oxalic acid solution, carrying out stirring at room temperature for 30 minutes, stopping stirring, leaving the solution standstill for layering, and then discharging a water phase, wherein the volume ratio of the oxalic acid solution to the pretreated organic solution is 10: 1; after the treated extraction agent is clarified and does not contain the water phase, pumping the treated extraction agent into a stirring reaction storage tank, and adding activated clay of which the weight volume ratio is 1%; carrying out stirring at roomtemperature for 10 minutes, and immediately pumping the stirred material into a filter press for filter pressing operation; and returning the filtered and clarified organic solution to the reverse extraction section on the extraction line for production and use. According to the purification and regeneration method disclosed by the invention, the extraction agents can be continuously treated on line, so that the extraction agents always keep excellent extraction and reverse extraction performance and phase splitting performance, and the circumstance that the performance is reduced and production is influenced due to long-time use of the extraction agents is avoided.

Owner:ZHEJIANG TIANNENG NEW MATERIAL CO LTD

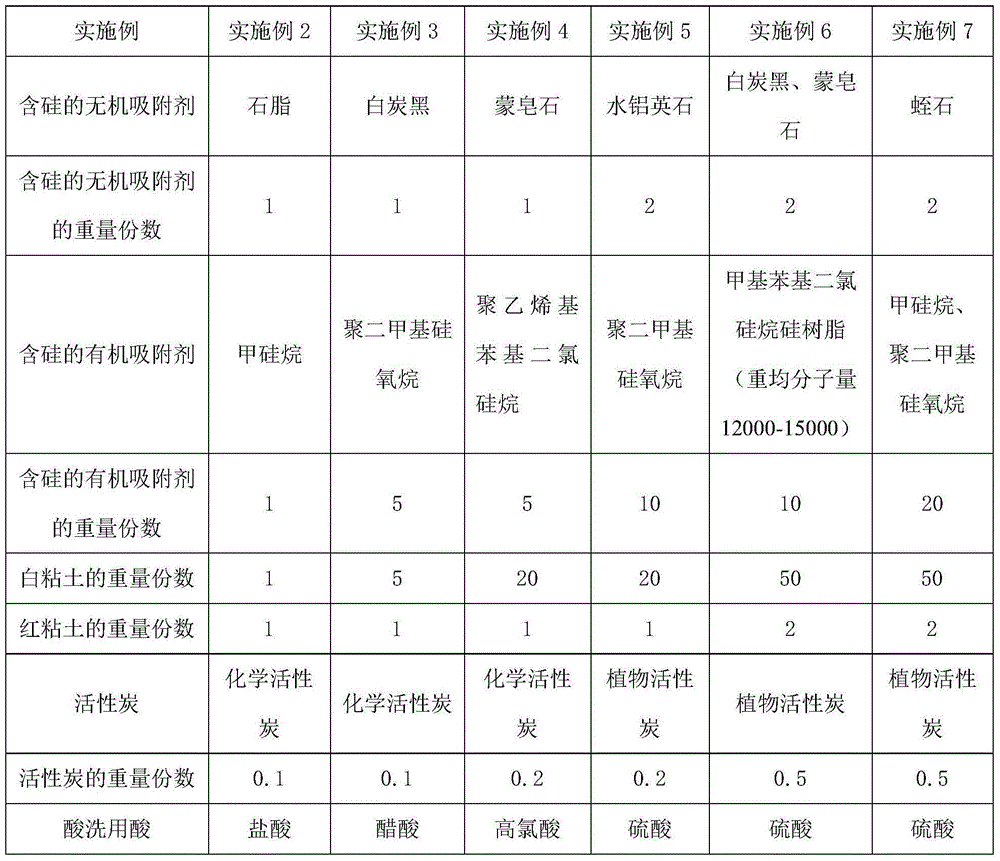

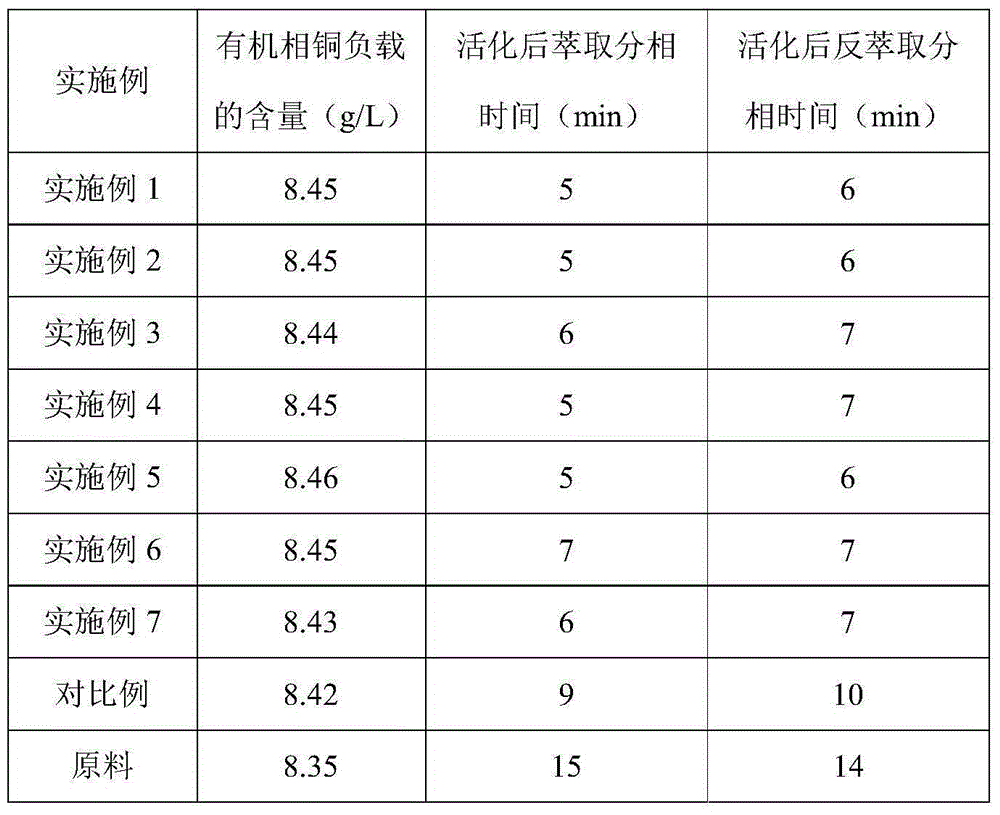

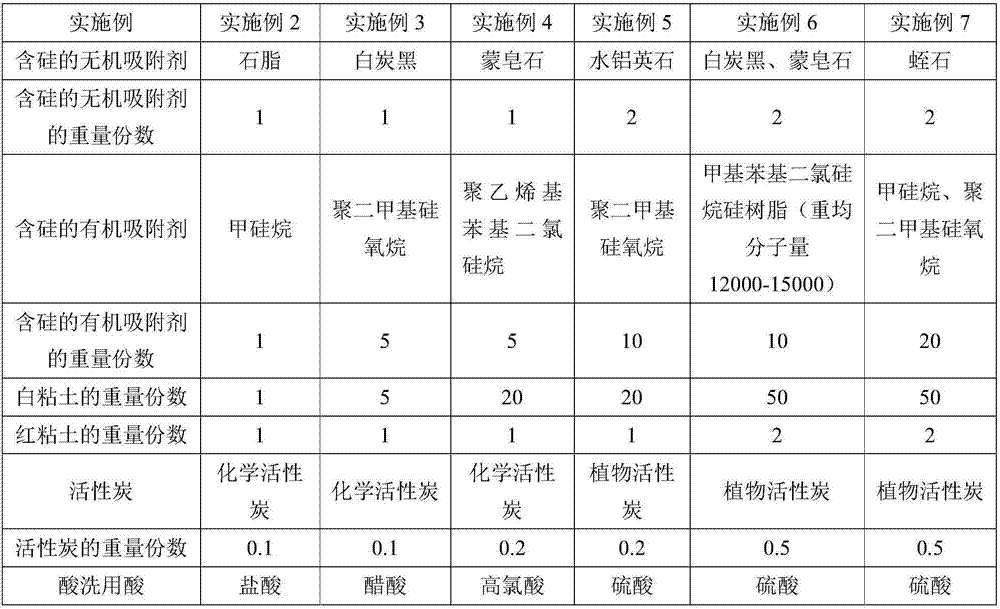

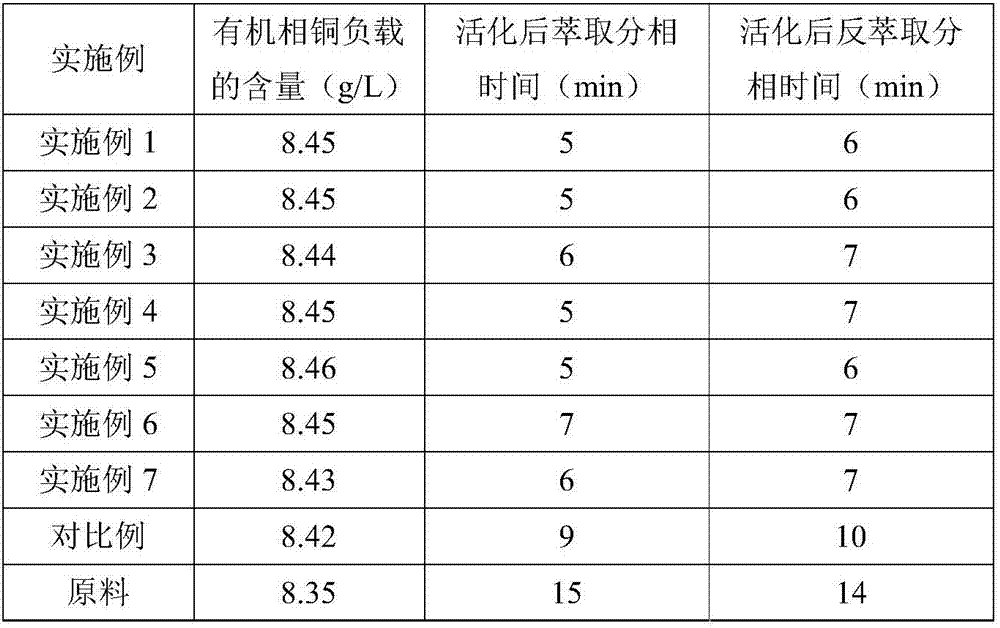

Complexing agent special for copper extracting agent and preparation method thereof

ActiveCN105039696APhase separation effect is goodImprove efficiencyProcess efficiency improvementFlocculationAllophane

The invention relates to a complexing agent special for a copper extracting agent and a preparation method thereof, and belongs to the technical field of wet metallurgy of copper. The complexing agent special for the copper extracting agent comprises, by weight parts, 1-2 parts of silicon-containing inorganic adsorbents, 1-20 parts of silicon-containing organic adsorbents, 1-52 parts of clay and 0.1-0.5 part of activated carbon. The silicon-containing inorganic adsorbents are one or more of gedanite, white carbon black, smectite, allophane and vermiculite. The silicon-containing organic adsorbents are one or more of silane, polysiloxane, polysilane and silicon resin. According to the complexing agent special for the copper extracting agent, the elimination rate of flocculation dirt in the copper extracting agent reaches over 90%, the extraction phase splitting efficiency is improved over 50%, and the use cycle of the copper extracting agent is obviously prolonged.

Owner:平顶山德源精细化学品有限公司

Special complexing agent for copper extractant and preparation method thereof

ActiveCN105039696BPhase separation effect is goodImprove efficiencyOther chemical processesProcess efficiency improvementAllophaneActivated carbon

The invention relates to a complexing agent special for a copper extracting agent and a preparation method thereof, and belongs to the technical field of wet metallurgy of copper. The complexing agent special for the copper extracting agent comprises, by weight parts, 1-2 parts of silicon-containing inorganic adsorbents, 1-20 parts of silicon-containing organic adsorbents, 1-52 parts of clay and 0.1-0.5 part of activated carbon. The silicon-containing inorganic adsorbents are one or more of gedanite, white carbon black, smectite, allophane and vermiculite. The silicon-containing organic adsorbents are one or more of silane, polysiloxane, polysilane and silicon resin. According to the complexing agent special for the copper extracting agent, the elimination rate of flocculation dirt in the copper extracting agent reaches over 90%, the extraction phase splitting efficiency is improved over 50%, and the use cycle of the copper extracting agent is obviously prolonged.

Owner:平顶山德源精细化学品有限公司

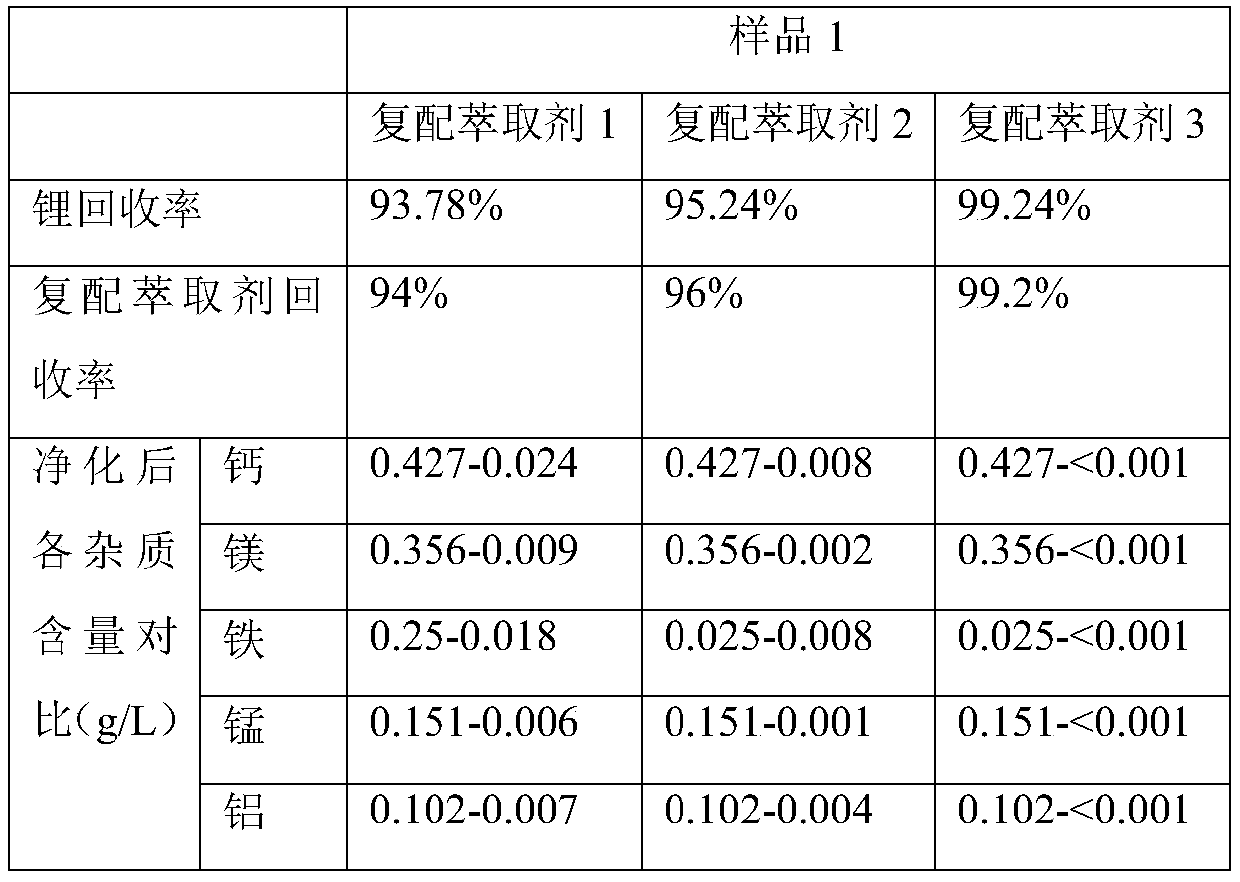

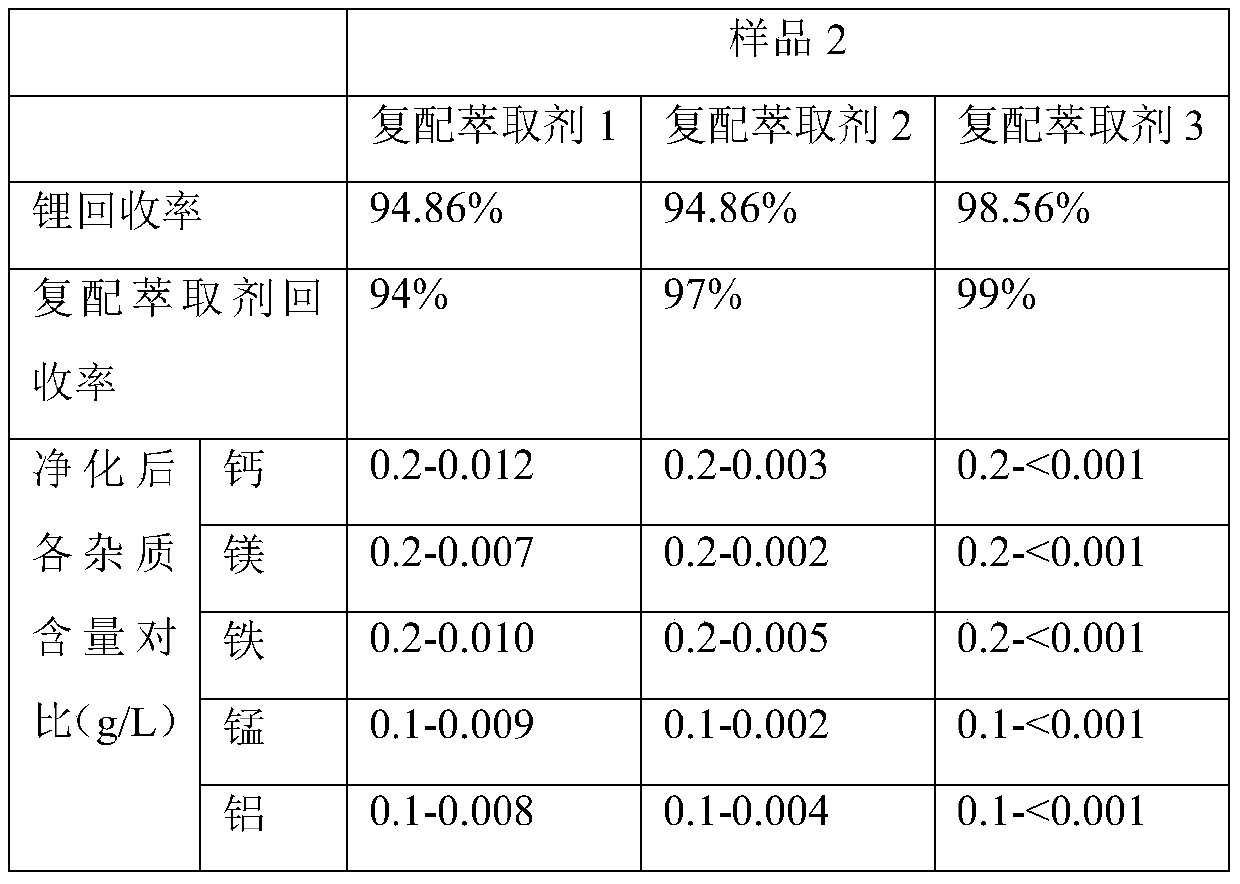

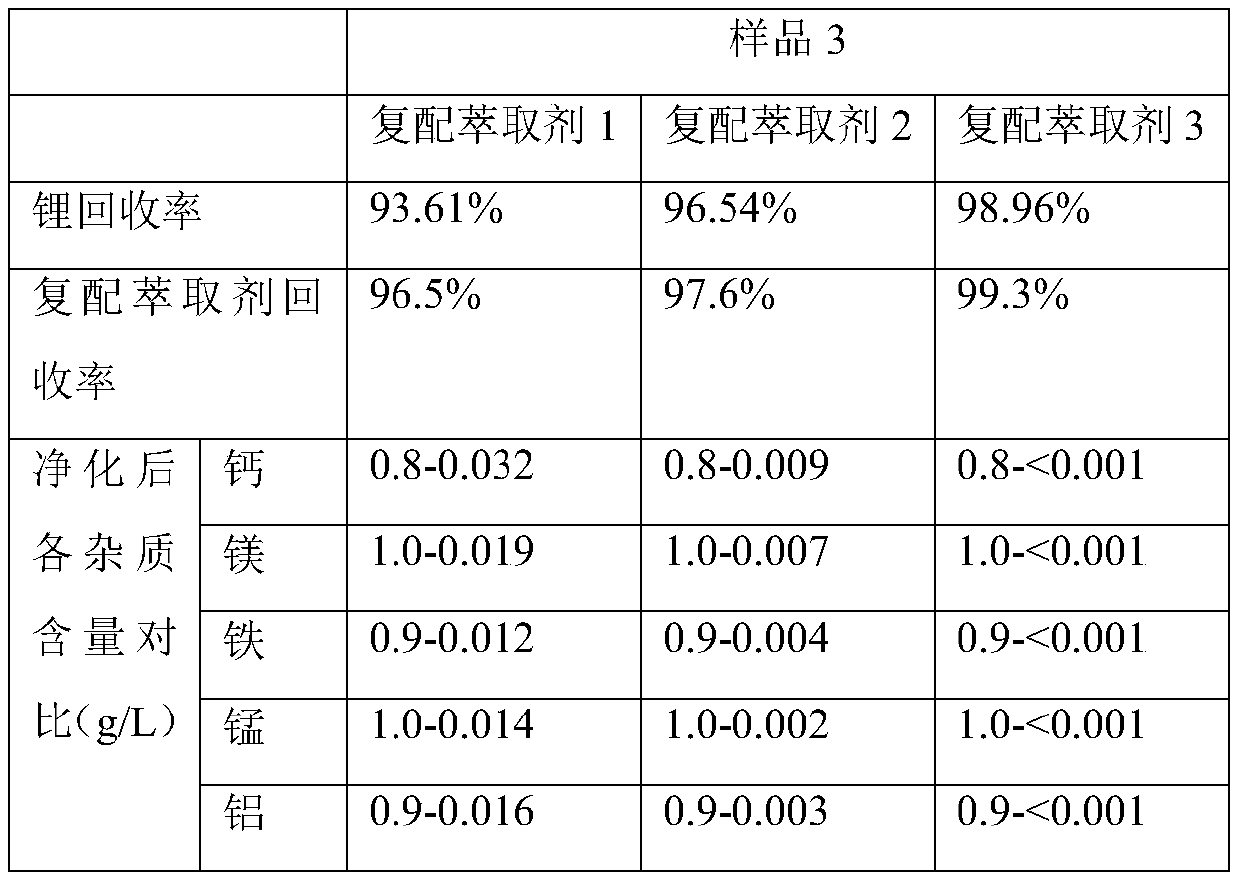

Compound extractant for deep purification of lithium ore leachate and purification process

InactiveCN111363919AImprove purification efficiencyEasy extractionProcess efficiency improvementPregnant leach solutionElectrical battery

The invention belongs to the technical field of metal smelting, and particularly relates to a compound extractant for deep purification of lithium ore leachate and a purification process. The raw material of the compound extractant for deep purification of the lithium ore leachate comprises an acidic phosphorus extractant AD290, and the volume fraction of the acidic phosphorus extractant AD290 is5%-20%. The compound extractant for deep purification of the lithium ore leachate can remove impurities such as iron, manganese, aluminum, calcium and magnesium at the same time, so that the content of the impurities in the purified lithium ore leachate is reduced to 1 ppm or below, and the compound extractant can be directly used for preparing battery-grade lithium carbonate.

Owner:ZHENGZHOU TIANYI EXTRACTION TECH

A kind of method for preparing phosphotungstic acid with sodium tungstate as raw material

ActiveCN106335928BPhase separation effect is goodSimple processTungsten compounds preparationAlcoholSodium tungstate

The invention belongs to the technical field of heteropolyacid preparation, and particularly relates to a preparing method of sodium tungstate. Industrial sodium tungstate crystal is used as the raw material, an alcohol extraction agent is used for extracting to obtain a phosphotungstic acid water solution, phosphotungstic acid crystal can be obtained through evaporative crystallization or spray drying, organic phase and raffinate obtained after reverse extraction can be returned and used directly, and the process of organic phase regeneration is avoided. The method is short in process flow, low in manufacturing cost, high in product yield, environmentally friendly and capable of achieving large-scale industrial production.

Owner:CENT SOUTH UNIV

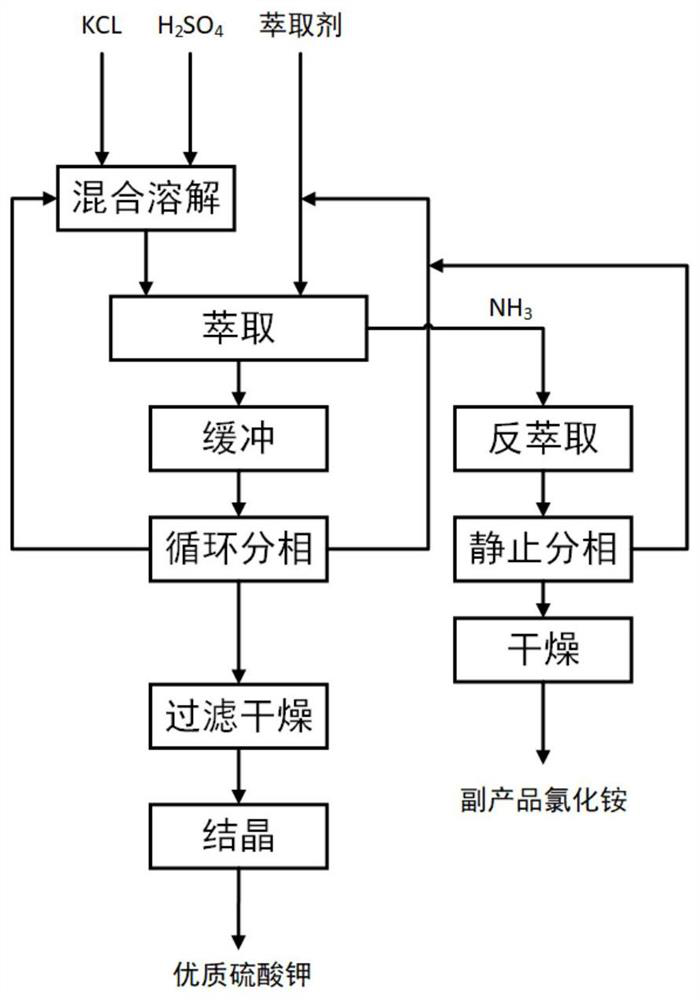

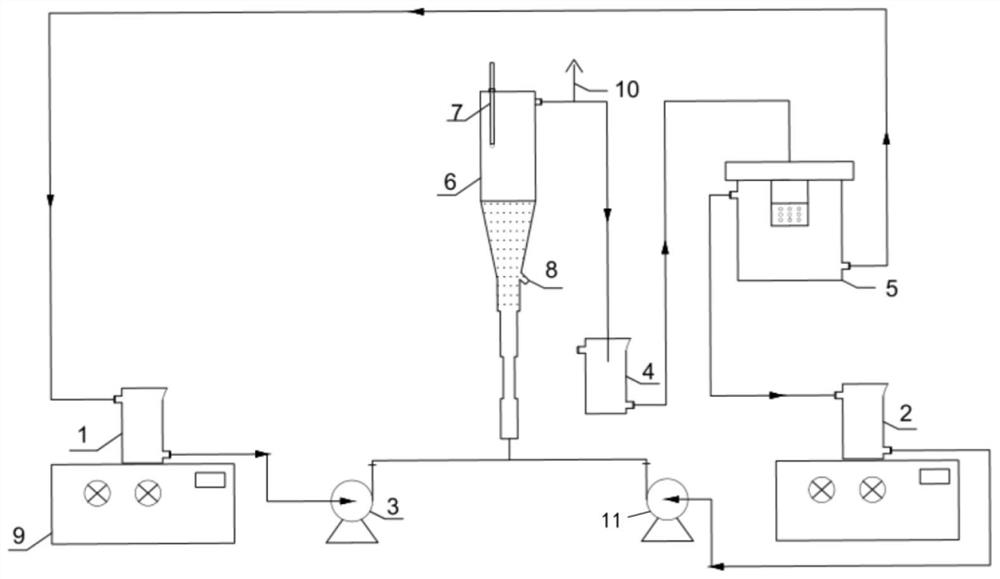

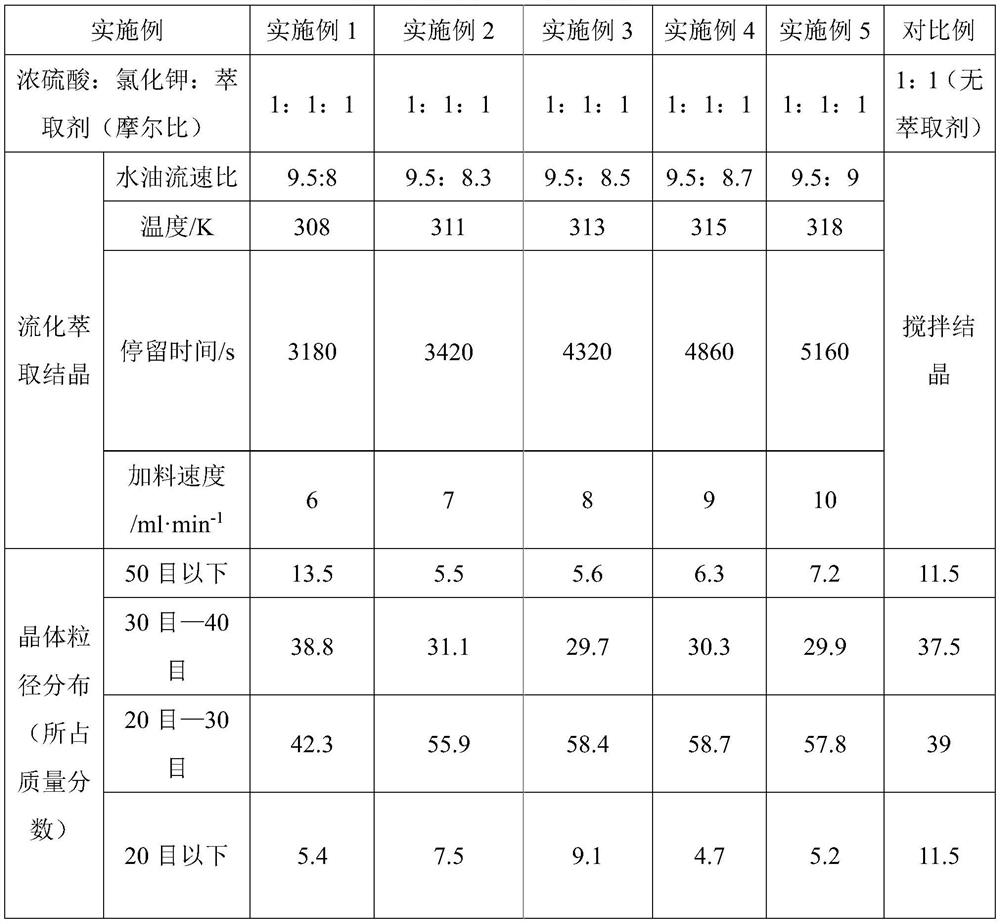

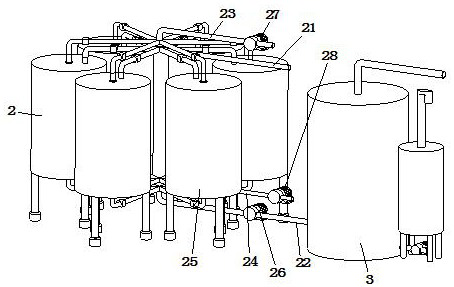

Novel extraction crystallization method for preparing potassium sulfate crystals, fluidization device and application of fluidization device

ActiveCN111960439AGood crystal shapeQuality improvementAlkali metal sulfites/sulfates preparation formAlkali metal sulfite/sulfate purificationPhysical chemistryPotassium sulfate

The invention discloses a novel extraction crystallization method for preparing potassium sulfate crystals, a fluidization device and application of the fluidization device. A fluidization method is adopted to replace stirring to generate driving force to enable crystals to grow on the surfaces of seed crystals, so that the environment is more uniform and stable, all crystal faces of the crystalsare uniformly supplied with solutes in a supersaturated solution, a solution continuously flows, the super-saturation degree of the solution in a bed is basically kept unchanged, and the obtained crystals are good in crystal form and high in quality. According to the fluidized bed fractional crystallization process production device for coupling extraction crystallization, the contact probabilityof crystals in the fluidization crystallizer and the contact probability of the crystals and the wall of the crystallizer are greatly reduced, and therefore secondary nucleation can be effectively reduced, and the crystals with a large size are obtained. Due to the application of the device, the production process is greatly simplified, the operation is coherent and convenient, a small amount of waste residues in the crystallizer are removed regularly, no three wastes are discharged, and the technological process is extremely environment-friendly.

Owner:SICHUAN UNIVERSITY OF SCIENCE AND ENGINEERING

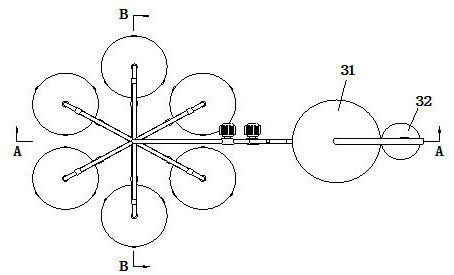

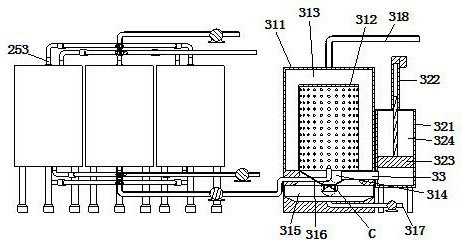

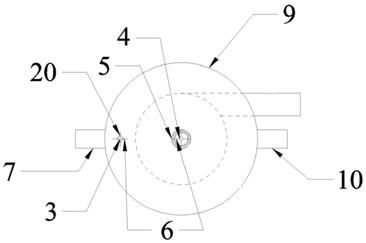

Tetrabromobisphenol A filtering and phase-splitting device

ActiveCN112791504APhase separation effect is goodImprove applicabilityOrganic chemistryOrganic compound preparationStructural engineeringTetrabromobisphenol A

The invention discloses a tetrabromobisphenol A filtering and phase-splitting device, and relates to the technical field of phase-splitting devices. The tetrabromobisphenol A filtering and phase-splitting device comprises a phase-splitting mechanism and a filtering mechanism; the phase-splitting mechanism and the filtering mechanism are arranged at an interval and are communicated through a pipeline, and the phase-splitting mechanism comprises a liquid inlet header pipe, a liquid outlet header pipe, an adjusting header pipe, a liquid discharge header pipe and a plurality of phase-splitting assemblies; each phase splitting assembly is communicated with a liquid inlet header pipe, a liquid outlet header pipe, an adjusting header pipe and a liquid discharge header pipe, and the liquid outlet header pipe, the adjusting header pipe and the liquid discharge header pipe are respectively provided with a liquid outlet pump, an adjusting air pump and a liquid discharge pump; the filtering mechanism comprises a filtering assembly and an auxiliary assembly; the auxiliary assembly is positioned beside the filtering assembly, and an auxiliary pipeline for communicating the auxiliary assembly with the filtering assembly is arranged between the auxiliary assembly and the filtering assembly. Through the arrangement of the phase splitting blocks in the phase splitting assembly, the phase splitting effect of the tetrabromobisphenol A solution is effectively improved, through the arrangement of the auxiliary assembly, the filtering assembly can be cleaned in time, and the production efficiency is improved.

Owner:山东金宜善新材料有限公司

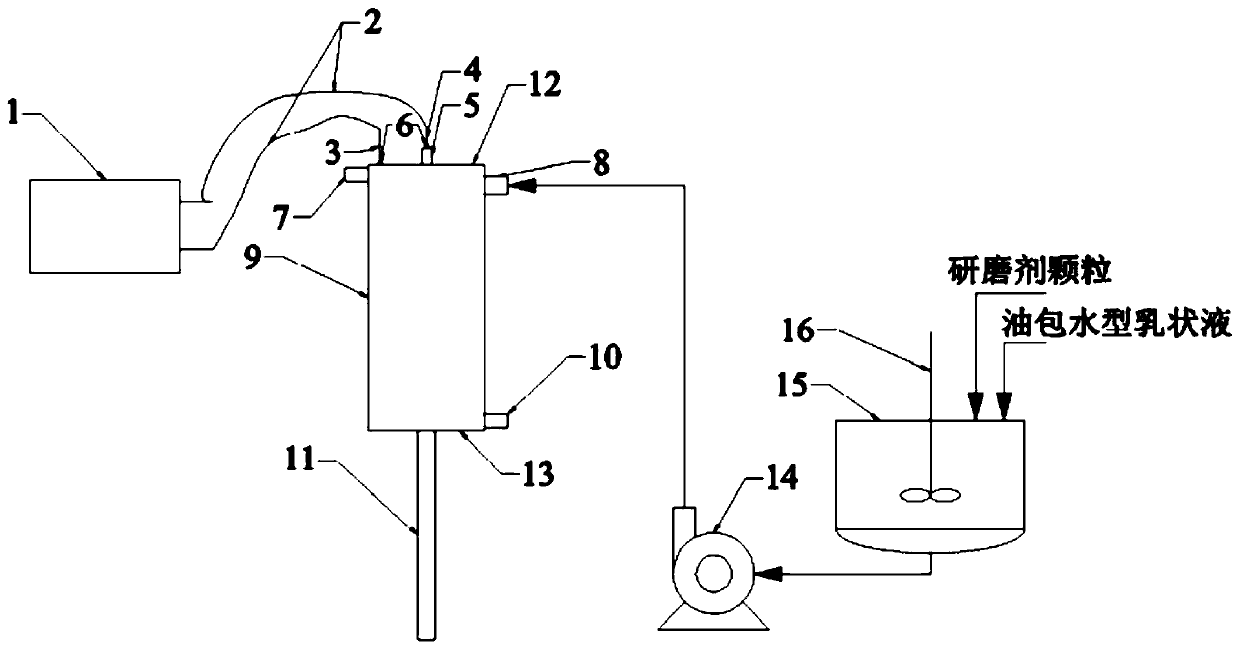

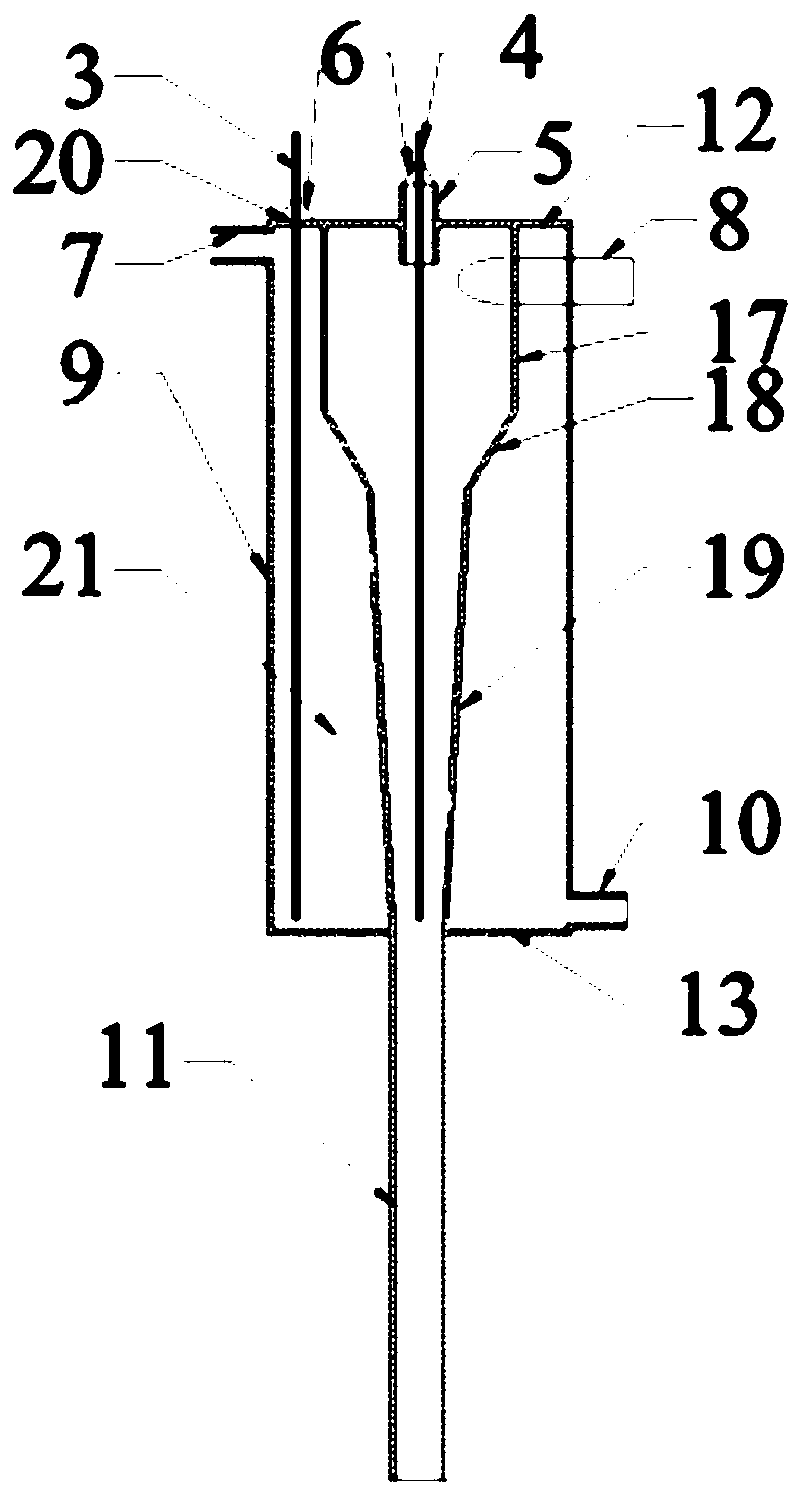

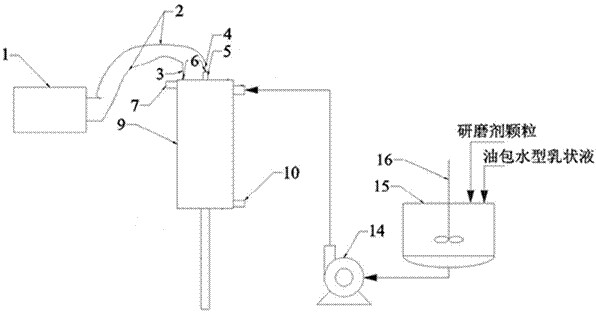

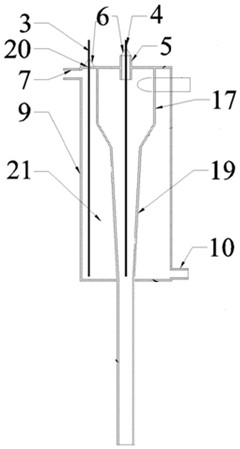

W/O emulsion demulsification method

ActiveCN111450578ALarge process capacityReduce processing costsLiquid separation by electricityNon-miscible liquid separationPolymer scienceAqueous droplet

The invention discloses a demulsification method of a W / O emulsion. The demulsification operation method of the W / O emulsion comprises the following steps that: hydrophilic and oleophobic abrasive particles are uniformly distributed in the W / O emulsion through a stirrer; a rotational flow field is generated in the mixture of the abrasive particles and the W / O emulsion by using a rotational flow device; an electrostatic field is generated in a mixture of the abrasive particles and the W / O emulsion by using a power generation device; under the synergistic effect of a rotational flow field, an electrostatic field and abrasive particles, collision is generated between the water drops, between the water drops and the abrasive particles and between the abrasive particles, the water drops are broken and coalesced and get close to the inner wall face of the rotational flow device to be gathered to form a continuous water phase, the continuous oil phase is gathered to the axis of the rotationalflow device to form an oil core, and finally oil-water phase separation is achieved. The method has the beneficial effects that special harsh conditions are not used, the work is reliable, the treatment capacity is large, the treatment cost is low, and continuous treatment can be realized; the abrasive particles are cheap and easily available, can be easily separated from a water phase, can be recycled, and have wide application prospects.

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY

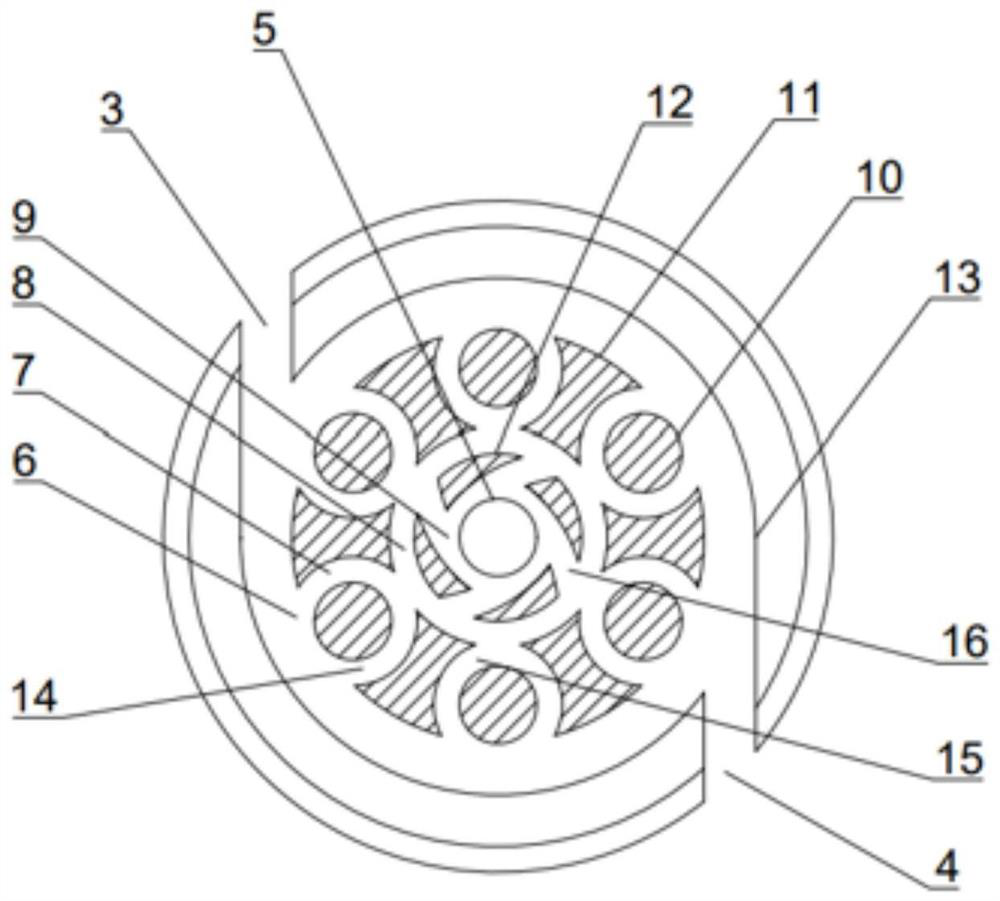

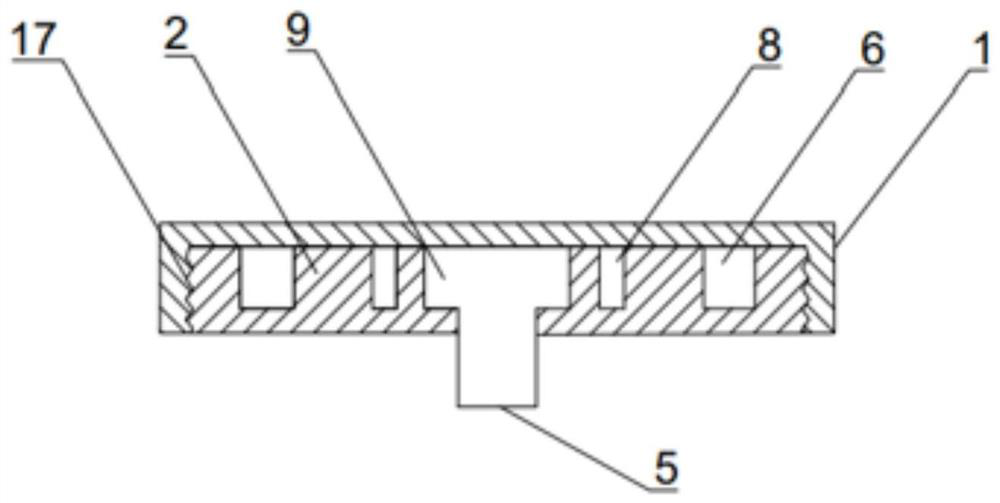

A multi-channel swirling automatic liquid control device

ActiveCN113062711BExtend working lifeImprove integrityFluid removalWell/borehole valve arrangementsThermodynamicsAutomatic control

The invention provides a multi-channel swirl automatic liquid control device, which relates to the technical field of petroleum and natural gas exploitation. It includes a valve cover (1) and a valve body (2), the valve body (2) has two liquid inlets (A(3), B(4)), one liquid outlet (5) and multi-stage flow channels; The flow channels include an outer swirl flow channel (6), a tangential flow channel (7), an intermediate flow channel (8) and an inner swirl flow channel (9). Using different inertial forces generated by different fluids in the flow channel, the fluid can flow through the multi-stage flow channel in sequence to generate multiple split flows, and form multi-circle swirl flow in the flow channels at all levels, resulting in a large pressure loss of the target controlled fluid. It solves the problem of uneven fluid production profiles in oil and gas reservoirs, can automatically control the output of different fluids, meets the requirements of balanced control of fluid production profiles in horizontal wells, can effectively reduce the water content of horizontal wells, prolong the water breakthrough time of oil and gas wells, and improve oil and gas production. Yield.

Owner:SOUTHWEST PETROLEUM UNIV

A kind of environment-friendly phosphorus-free washing powder and its preparation process

ActiveCN111548866BImprove washabilityEnvironmentally friendlyInorganic/elemental detergent compounding agentsNon-ionic surface-active compoundsSodium silicateAcrylic polymer

The invention relates to an environment-friendly and phosphorus-free washing powder and a preparation process thereof, belonging to the technical field of washing powder, and comprising the following components in parts by weight: 10-30 parts of AES; 20-40 parts of baking soda; 1-40 parts of sodium silicate 5 parts; 1-5 parts of maleic acid-acrylic acid polymer; 20-50 parts of Yuanming powder; 0-2 parts of CMC-Na; 0-10 parts of sodium percarbonate; 0-3 parts of JFC; 0-3 parts of additives; , the sodium percarbonate is coated with a stabilizer for improving its stability. The invention has the advantage of being more environmentally friendly under the premise of ensuring decontamination capability.

Owner:浙江美生日化用品有限公司

A kind of demulsification method of w/o emulsion

ActiveCN111450578BLarge process capacityReduce processing costsLiquid separation by electricityNon-miscible liquid separationPolymer scienceAqueous droplet

The invention discloses a demulsification method for W / O emulsion. The operation method for demulsification of W / O emulsion comprises: uniformly distributing hydrophilic and oleophobic abrasive particles in the W / O emulsion through a stirrer; Using a swirl device to generate a swirl field in the mixture of abrasive particles and W / O emulsion; using a power generating device to generate an electrostatic field in the mixture of abrasive particles and W / O emulsion; Under the synergistic action with abrasive particles, collisions occur between water droplets, between water droplets and abrasive particles, and between abrasive particles and abrasive particles. The water phase and the continuous oil phase gather at the axis of the cyclone to form an oil core, and finally realize the oil-water phase. The beneficial effects of the invention are that no special harsh conditions are used, the work is reliable, the processing capacity is large, the processing cost is low, and the processing can be continuously processed; the abrasive particles are cheap and easy to obtain, easy to separate from the water phase, and can be recycled, and has wide application prospects .

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY

Method for performing extraction separation on cobalt and nickel by using microfluid technology

The invention provides a method for performing extraction separation on cobalt and nickel by using a microfluid technology. The method comprises the following steps of: uniformly mixing an extraction agent and diluent which are subjected to homogeneous phase saponification by using a mixed material liquid of Co<2+> and Ni<2+>, using 2-ethyl cthylhexyl phosphonate mono 2-ethyl cthylhexyl ester as the extraction agent and using No.260 solvent oil and using the extraction agent and the diluent as an oil phase; introducing the water phase and the oil phase into a micro-reactor by virtue of two flow pumps; mixing the two phases in the micro-reactor and performing extraction reaction at 25-50 DEG C; and collecting a product at an outlet of the micro-reactor and standing for separating the phases to ensure that Co<2+> enters the oil phase and Ni<2+> stays in the water phase so as to realize extraction separation of cobalt and nickel. According to the method, continuous flow micro-reactor with an enhanced hybrid channel structure is adopted, the extraction separation of cobalt and nickel is carried out, and the reaction time is shortened to be within a micro-second level range, so that single-level cobalt extraction efficiency is obviously improved, and the extraction levels are reduced; and moreover, standing layering on the water phase and the oil phase can be quickly carried out without any emulsion phenomenon.

Owner:KUNMING UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com