Patents

Literature

234 results about "Allophane" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Allophane is an amorphous to poorly crystalline hydrous aluminium silicate clay mineraloid. Its chemical formula is Al₂O₃·(SiO₂)1.3-2·(2.5-3)H₂O. Since it has short-range atomic order, it is a mineraloid, rather than a mineral, and can be identified by its distinctive infrared spectrum and its X-ray diffraction pattern. It was first described in 1816 in Gräfenthal, Thuringia, Germany. Allophane is a weathering or hydrothermal alteration product of volcanic glass and feldspars and sometimes has a composition similar to kaolinite but generally has a molar ratio of Al:Si = 2. It typically forms under mildly acidic to neutral pH (5–7). Its structure has been debated, but it is similar to clay minerals and is composed of curved alumina octahedral and silica tetrahedral layers. Transmission electron micrographs show that it is generally made up of aggregates of hollow spherules ~3–5 nm in diameter. Allophane can alter to form halloysite under resilicating aqueous conditions and can alter to form gibbsite under desilicating conditions. A copper containing variety cupro-allophane has been reported.

Pseudo thin allophane and its preparation method

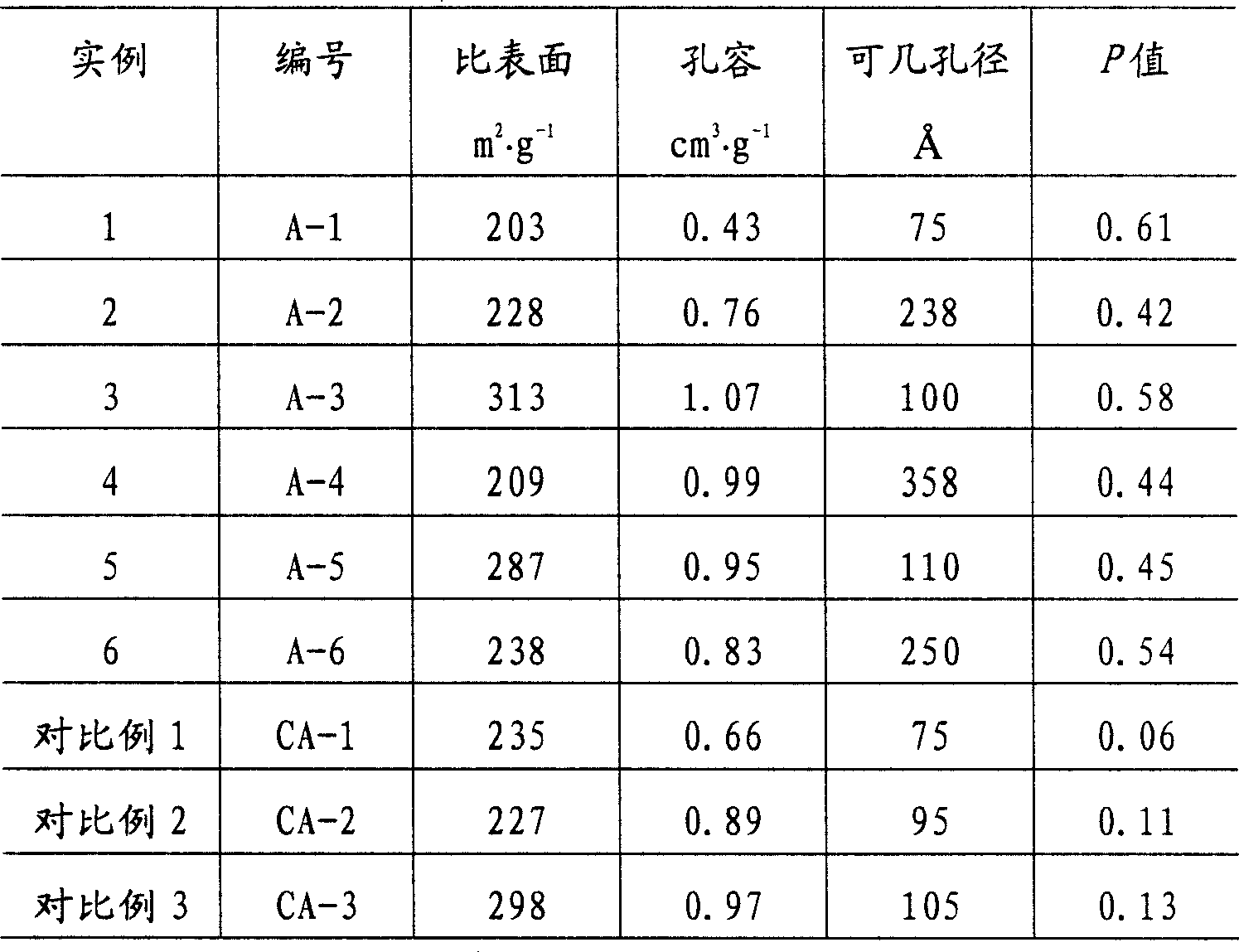

This invention discloses a pseudoboehmite and its preparation method. This pseudoboehmite is prepared by following steps: a) at acidity condition that can make aluminum precipitate, precipitate aluminum of aluminum compound water solution, separate, and get a kind of amorphous alumina hydrate; b) mix amorphous hydrated aluminum oxide with water and at least one kind of water-soluble alkali, slurry, stabilize at 20deg-90deg for 0.2-6 hours, wherein dosage of above alkali make serumal pH be 6-11. Compared with existing technique, pseudoboehmite prepared by this invention can get aluminum oxide of bore distributing localized by calcining.

Owner:CHINA PETROLEUM & CHEM CORP +1

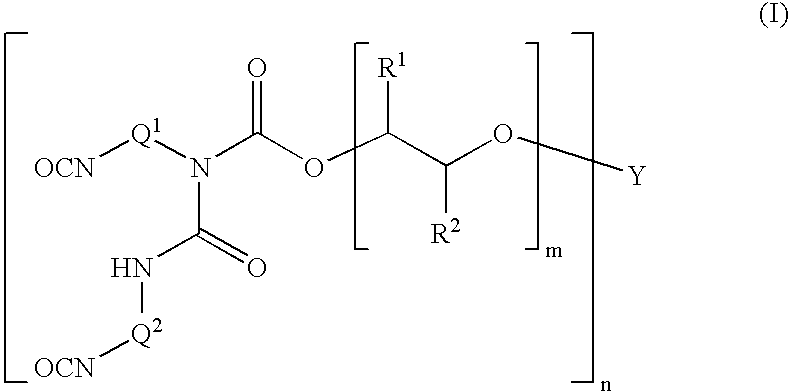

Radiation-curing binders and a process for their preparation

The invention relates to a process for preparing binders which contain 1) allophanate groups, 2) groups that react with ethylenically unsaturated compounds with polymerization on exposure to actinic radiation (radiation-curing groups) and 3) optionally NCO-reactive groups, by reacting at temperatures ≦130° C. A) one or more NCO-functional compounds containing uretdione groups with B) one or more compounds that contain isocyanate-reactive groups and groups that react with ethylenically unsaturated compounds with polymerization on exposure to actinic radiation (radiation-curing groups), and then C) with one or more saturated, hydroxyl-containing compounds other than B), at least one of these compounds having an OH functionality of ≧2, in the presence of D) a catalyst containing one or more zinc compounds, the reaction with compounds C) taking place at least proportionally with the formation of allophanate groups. The present invention also relates to the binders obtained by the process of the invention.

Owner:ALLNEX NETHERLANDS BV

Low-viscosity allophanates containing actinically curable groups

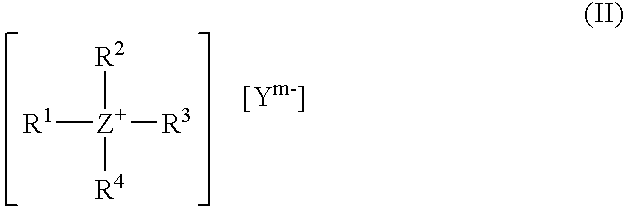

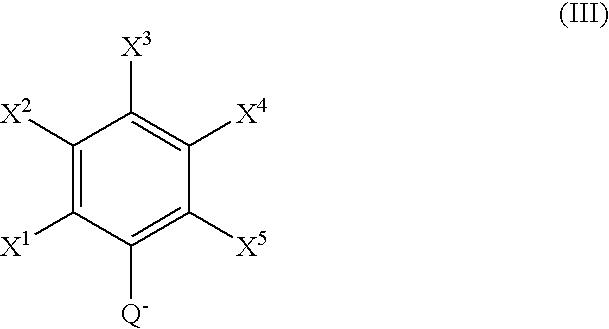

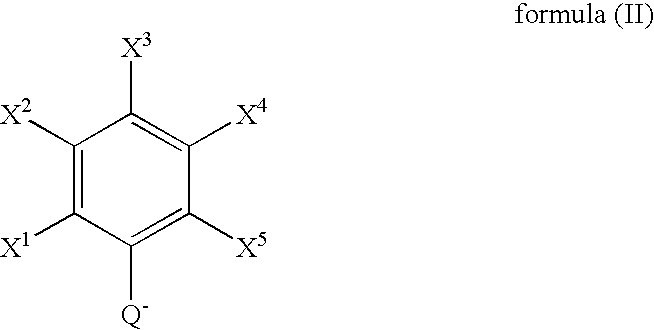

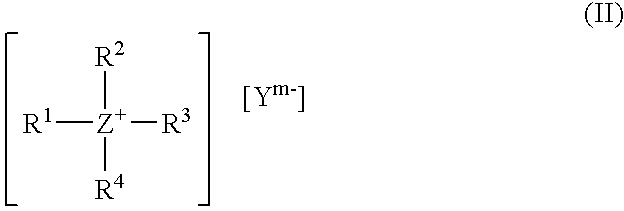

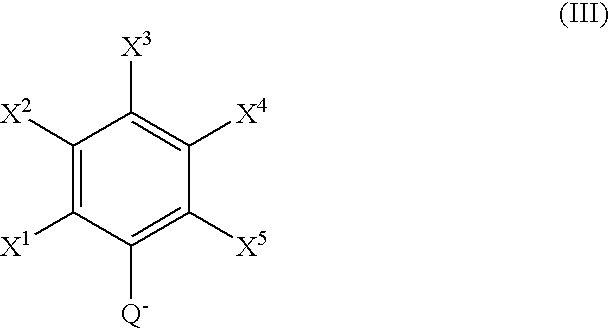

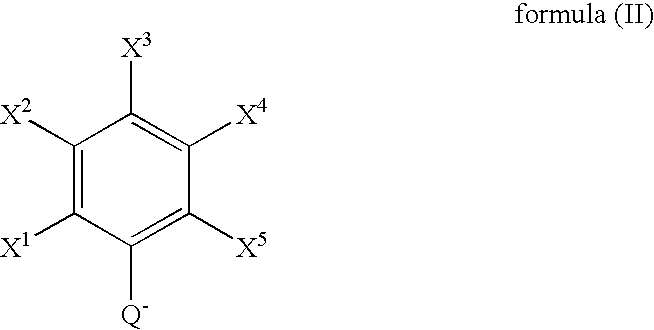

A process for preparing binders containing allophanate groups which contain, at the oxygen atom of the allophanate group that is bonded via two single bonds, organic radicals with activated groups capable of participating in a polymerization reaction with ethylenically unsaturated compounds on exposure to actinic radiation; the process includes reacting A) one or more compounds containing uretdione groups with B) one or more OH-functional compounds which contain groups capable of participating in a polymerization reaction with ethylenically unsaturated compounds on exposure to actinic radiation, and C) optionally further NCO-reactive compounds, and D) in the presence of one or more compounds containing phenoxide groups, as catalysts. The binders can be used in preparing coatings, coating materials, coating compositions, adhesives, printing inks, casting resins, dental compounds, sizes, photoresists, stereolithography systems, resins for composite materials and sealants.

Owner:ALLNEX NETHERLANDS BV

Preparation of new radiation-curing binders

Process for preparing binders including reacting A) one or more NCO-functional compounds containing uretdione groups with B) one or more compounds containing groups capable of participating in polymerization reaction with ethylenically unsaturated compounds on exposure to actinic radiation, and contain isocyanate-reactive groups, followed by C) reaction with one or more hydroxyl-containing compounds other than B), wherein at least one of these compounds has an OH functionality of≧2, D) in the presence of one or more compounds containing phenoxide groups, as catalysts, and E) optionally auxiliaries and additives, where the reaction with compounds of component C) proceeds at least proportionally with the formation of allophanate groups and where and including binders containing allophanate groups and groups capable of participating in a polymerization reaction with ethylenically unsaturated compounds on exposure to actinic radiation, and optionally also contain NCO-reactive groups. The binders are used in coating compositions used to coat substrates.

Owner:ALLNEX NETHERLANDS BV

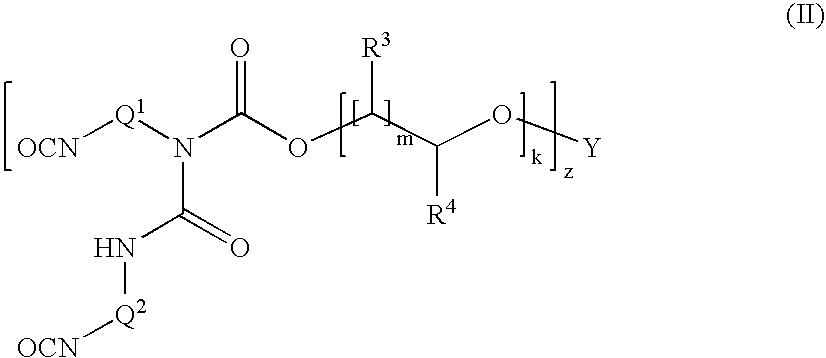

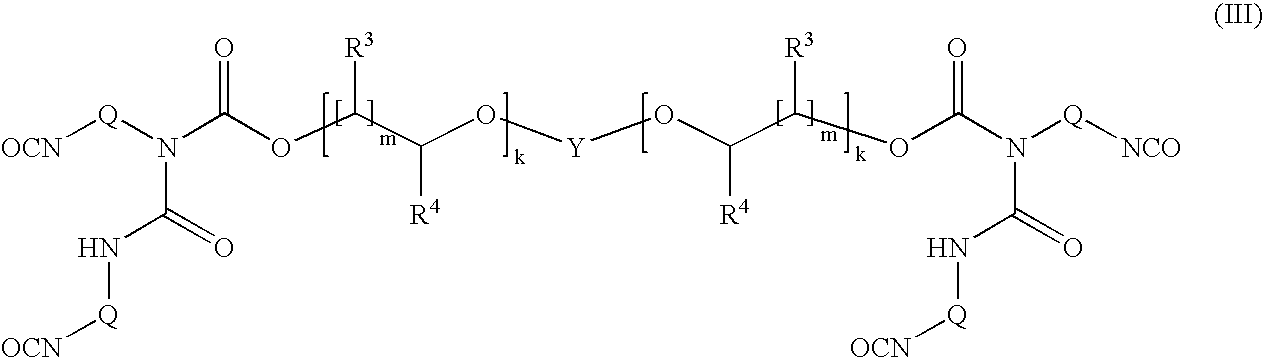

Process for preparing allophanate-containing actinically curable polyurethane prepolymers with increased resistance

The present invention relates to a process for preparing low-viscosity, allophanate-containing and NCO-free polyurethane prepolymers curable by actinic radiation, and to the products obtainable by this process. The prepolymers have residual monomer contents of less than 0.5% by weight and an NCO content of less than 1% by weight, and are prepared by a process in which A) diisocyanates, B) hydroxy-functional compounds containing groups which react with ethylenically unsaturated compounds on exposure to actinic radiation, and C) polyester, polyether or polycarbonate polyols having a functionality of at least 1.9 and a number-average molecular weight (Mn) of at least 1000 g / mol, D) optionally in the presence of a catalyst, are reacted to form NCO-group-containing prepolymers having radiation-curing groups, which are subsequently reacted E) optionally after addition of monofunctional isocyanates in the presence F) of an allophanatization catalyst to give allophanate-containing prepolymers, the ratio of NCO groups of the compounds from A) to the OH groups of the compounds from B) and C) being 1.45:1.0 to 1.1:1.0 and the ratio of the OH groups from B) to the OH groups from C) being 8.0:1 to 1.5:1.

Owner:ALLNEX NETHERLANDS BV +1

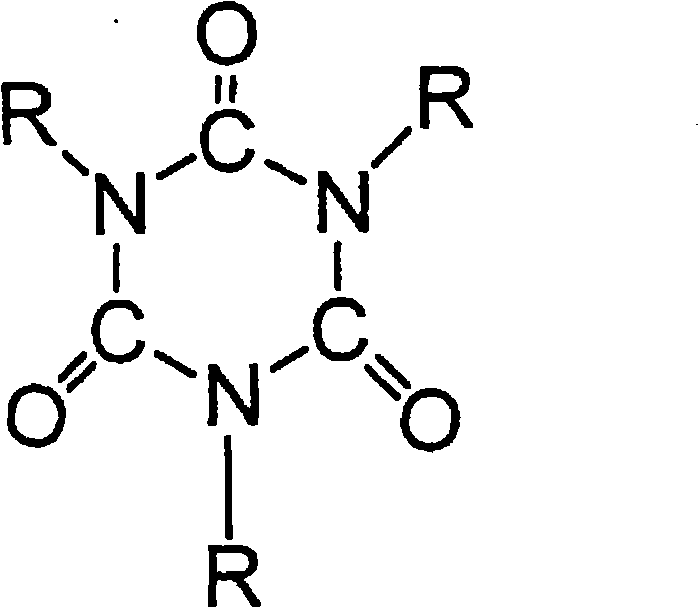

Allophanate-containing modified polyurethanes

InactiveUS20060205911A1Low viscosityBuilding componentsPolyurea/polyurethane coatingsAllophaneCarbamate

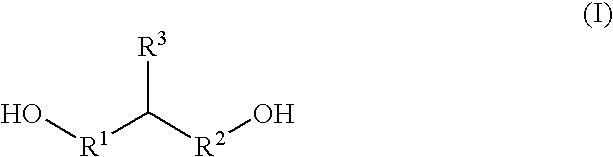

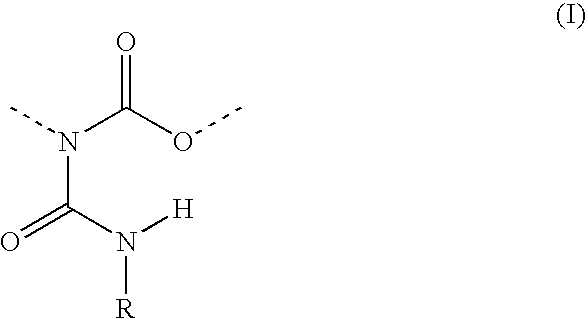

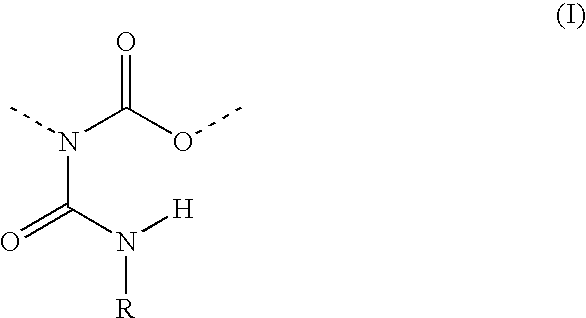

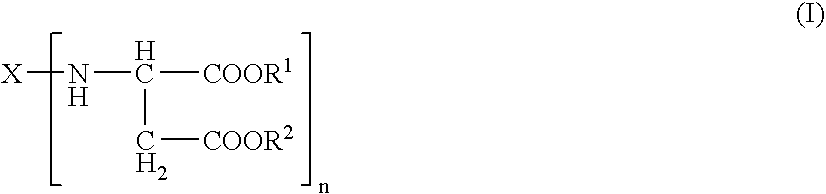

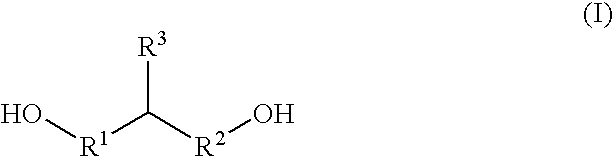

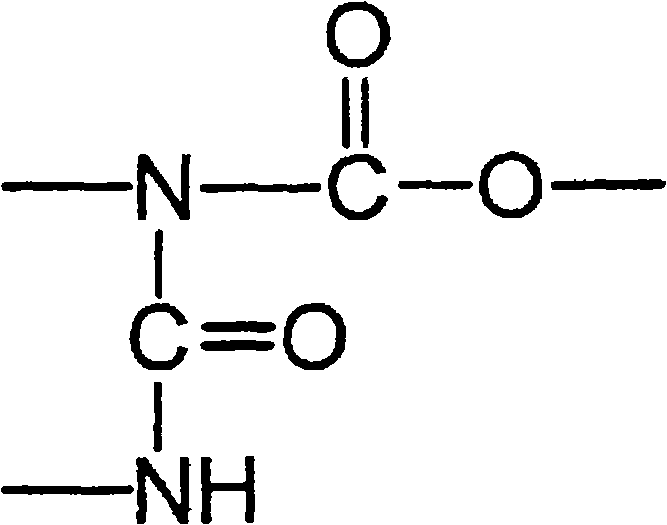

The present invention relates to a process for lowering the viscosity of compositions containing compounds having urethane groups, in which all or some of the urethane groups contained therein are reacted with monoisocyanates to form allophanate groups. The present invention also relates to compounds having allophanate groups and compositions containing such compounds, wherein at least 10 mole % of the allophanate groups contained therein correspond to formula I) wherein R is an alkyl, aralkyl or aryl radical which has up to 20 carbon atoms and optionally contains heteroatoms and wherein these radicals can also have, in addition to the NCO group present as part of the allophanate group, other functional groups which are neither isocyanate groups nor functional groups derived from isocyanate groups.

Owner:BAYER MATERIALSCIENCE AG

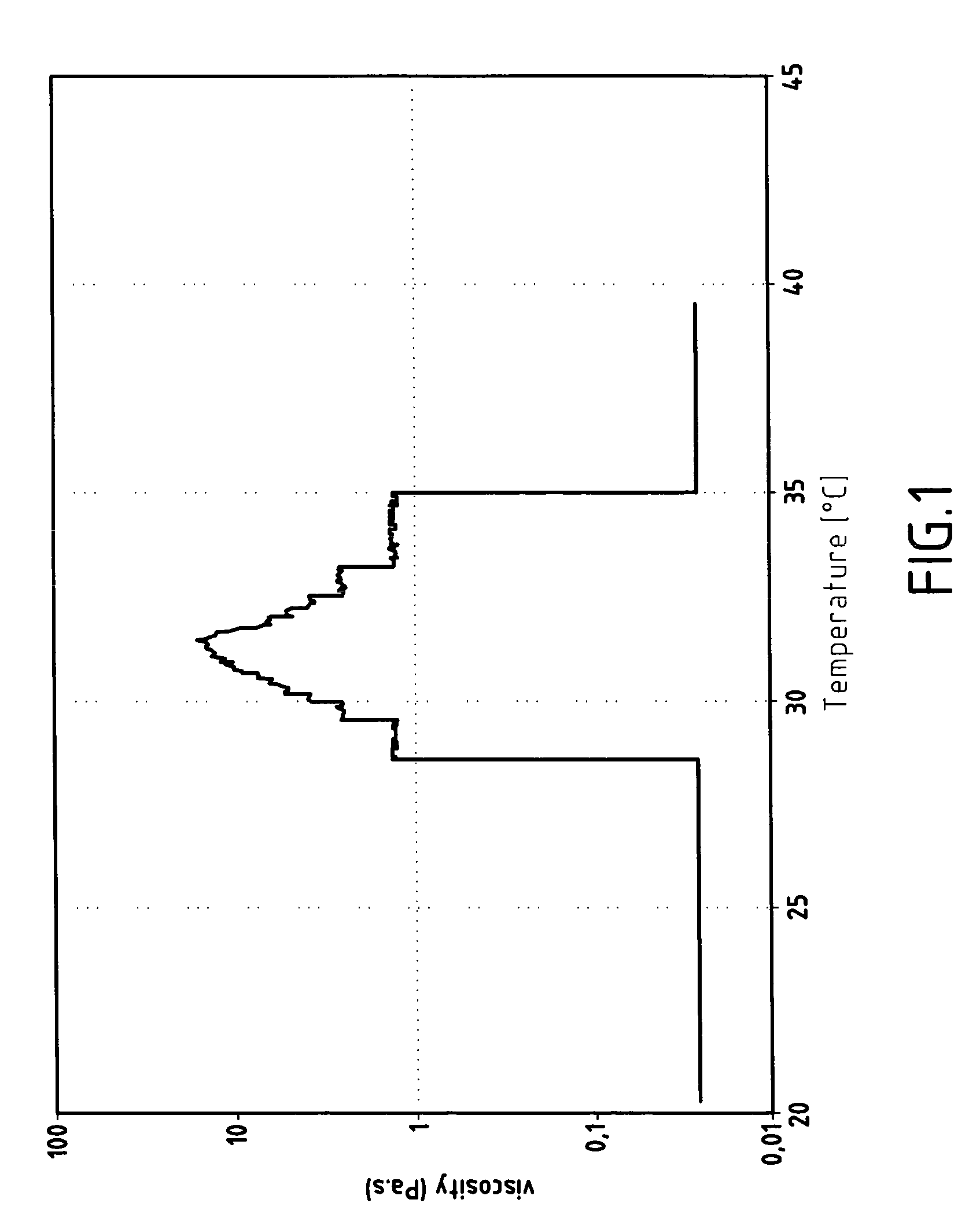

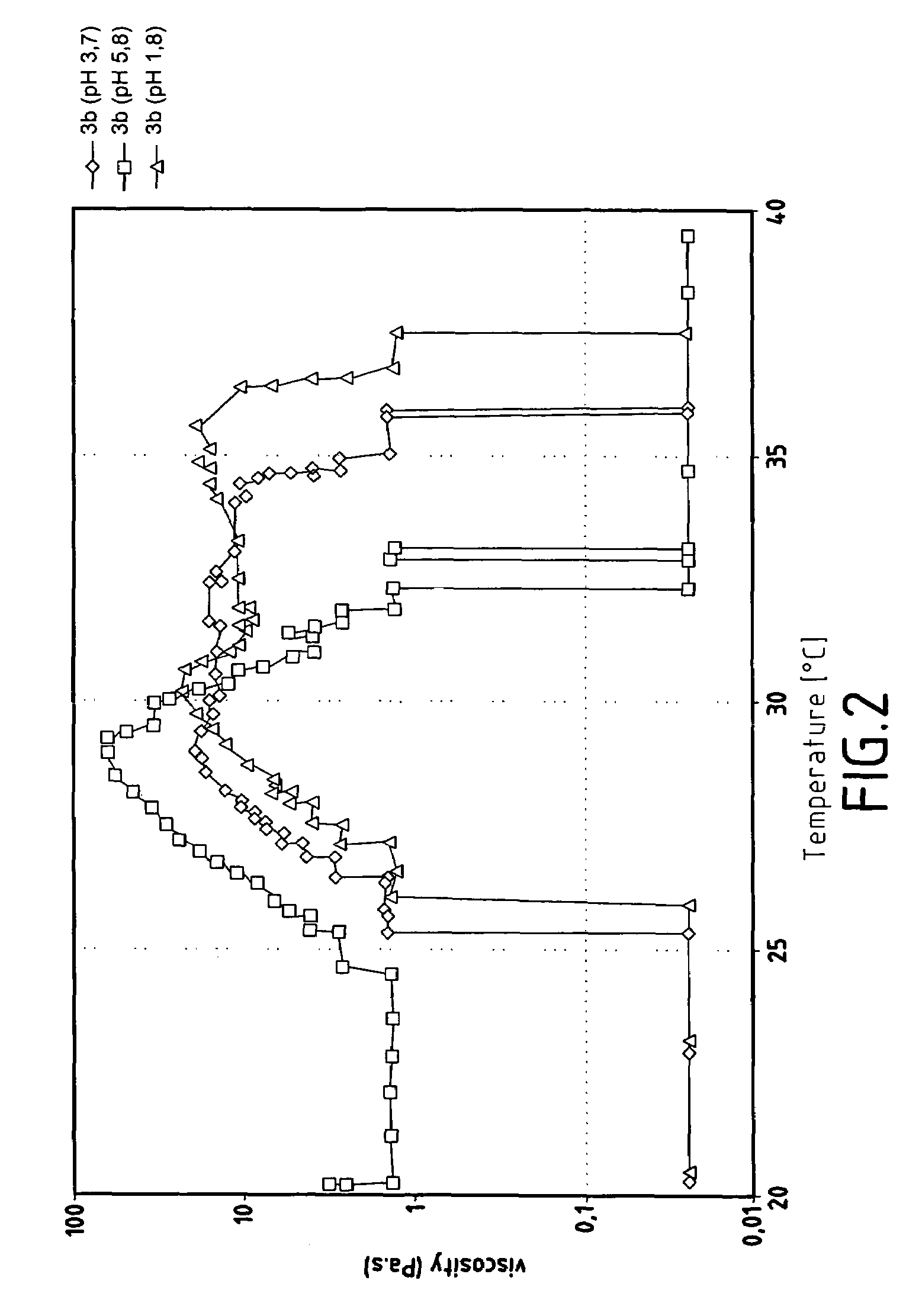

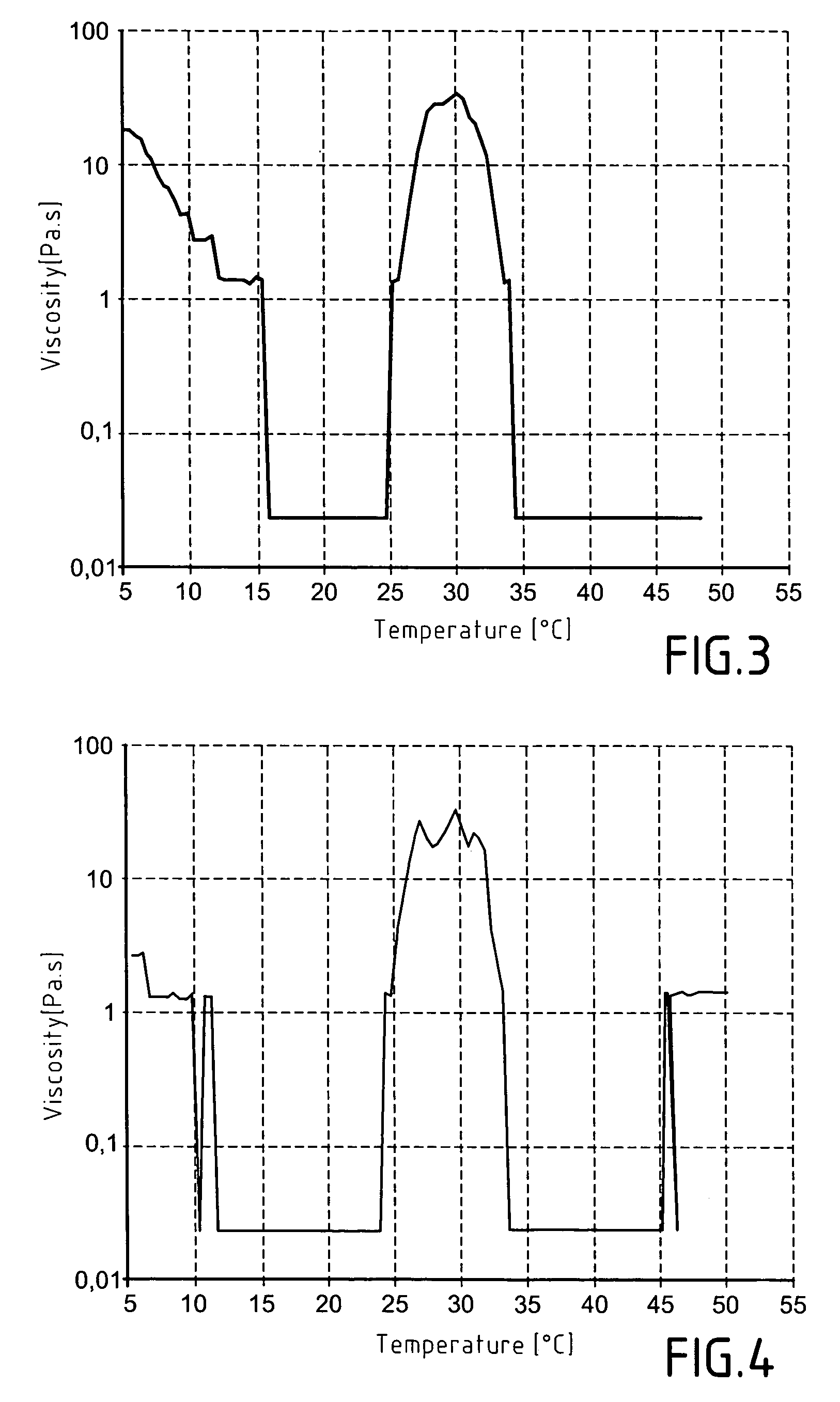

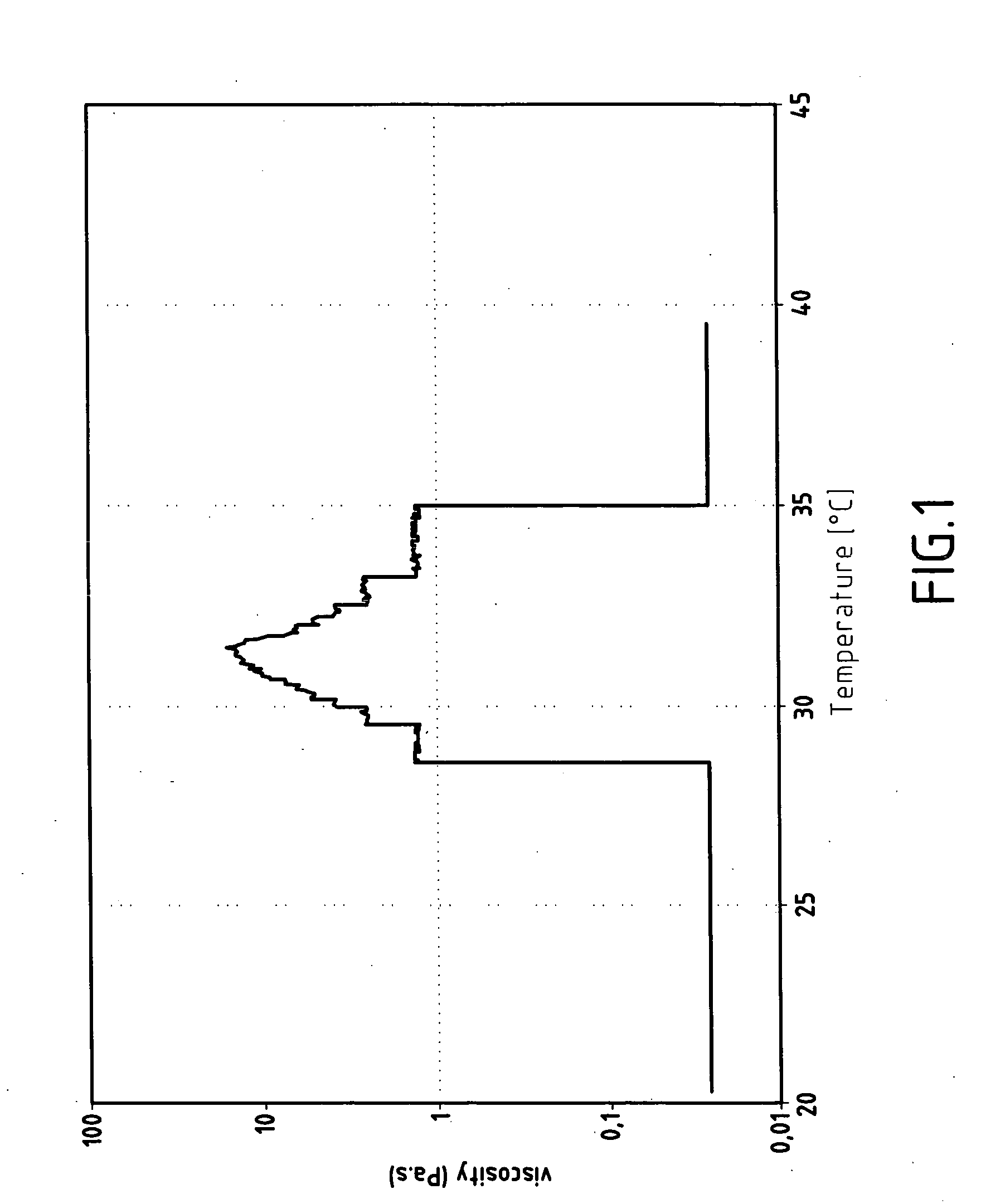

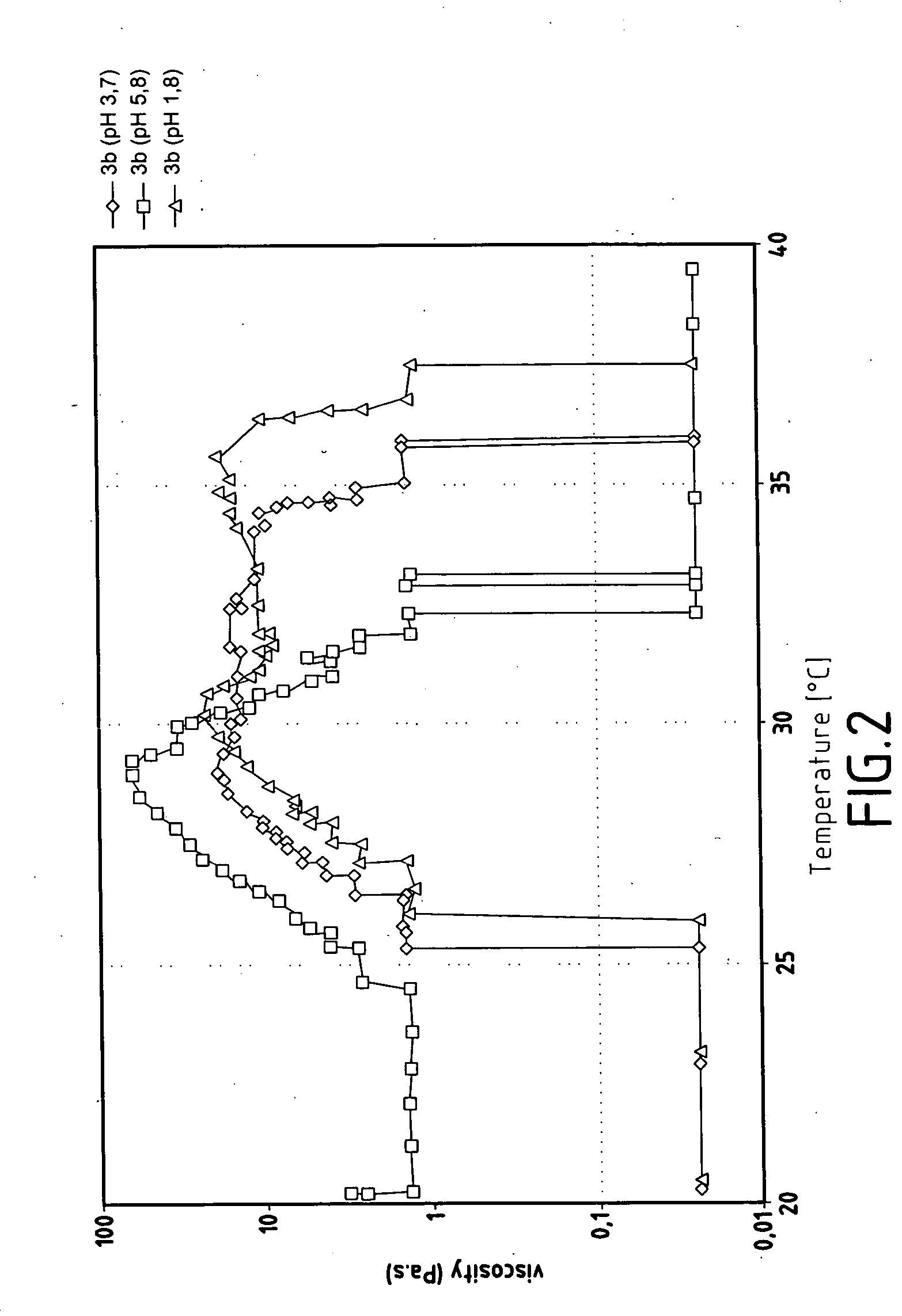

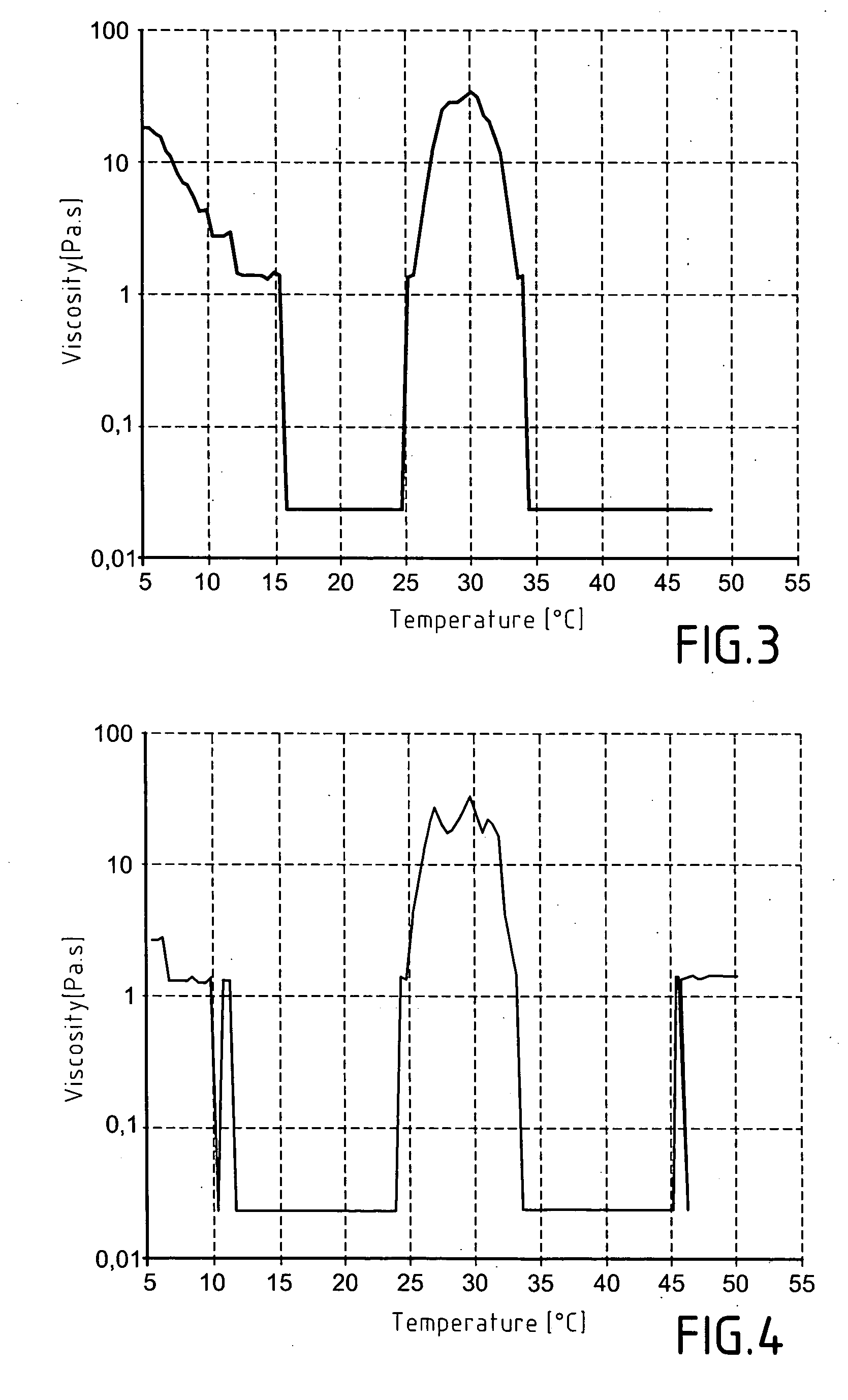

Thermosensitive polymers and thermoreversible gels obtained from these polymers

InactiveUS7339013B2High viscosity indexEffective compositionCosmetic preparationsSenses disorderAllophaneThermosensitive polymer

Polymers which comprise polymer chains of terpolymer type which are constituted by poly(ethylene oxide) (PEO) and poly(propylene oxide) (PPO) of PEO-PPO-PEO form, which are modified at their termini by groups which can essentially be other chains of PEO-PPO-PEO, acid segments, amine groups or PEOs, these chains being linked to the terpolymer chains via chemical bridges which are constituted by urethane bridges, urea bridges, allophanate bridges and biuret bridges, and which comprise more than 80% by weight of said PEO-PPO-PEO.Thermoreversible physical gels of high viscosification index, which contain these polymers, and their uses.Preparation of these polymers and of these gels.

Owner:POLYMEREXPERT

Pseudo thin allophane and its preparation method

This invention discloses a pseudoboehmite and its preparation method. This pseudoboehmite is prepared by following steps: a) at acidity condition that can make aluminum precipitate, precipitate aluminum of aluminum compound water solution, separate, and get a kind of amorphous alumina hydrate; b) mix amorphous hydrated aluminum oxide with water and at least one kind of water-soluble alkali, slurry, stabilize at 20deg-90deg for 0.2-6 hours, wherein dosage of above alkali make serumal pH be 6-11. Compared with existing technique, pseudoboehmite prepared by this invention can get aluminum oxide of bore distributing localized by calcining.

Owner:CHINA PETROLEUM & CHEM CORP +1

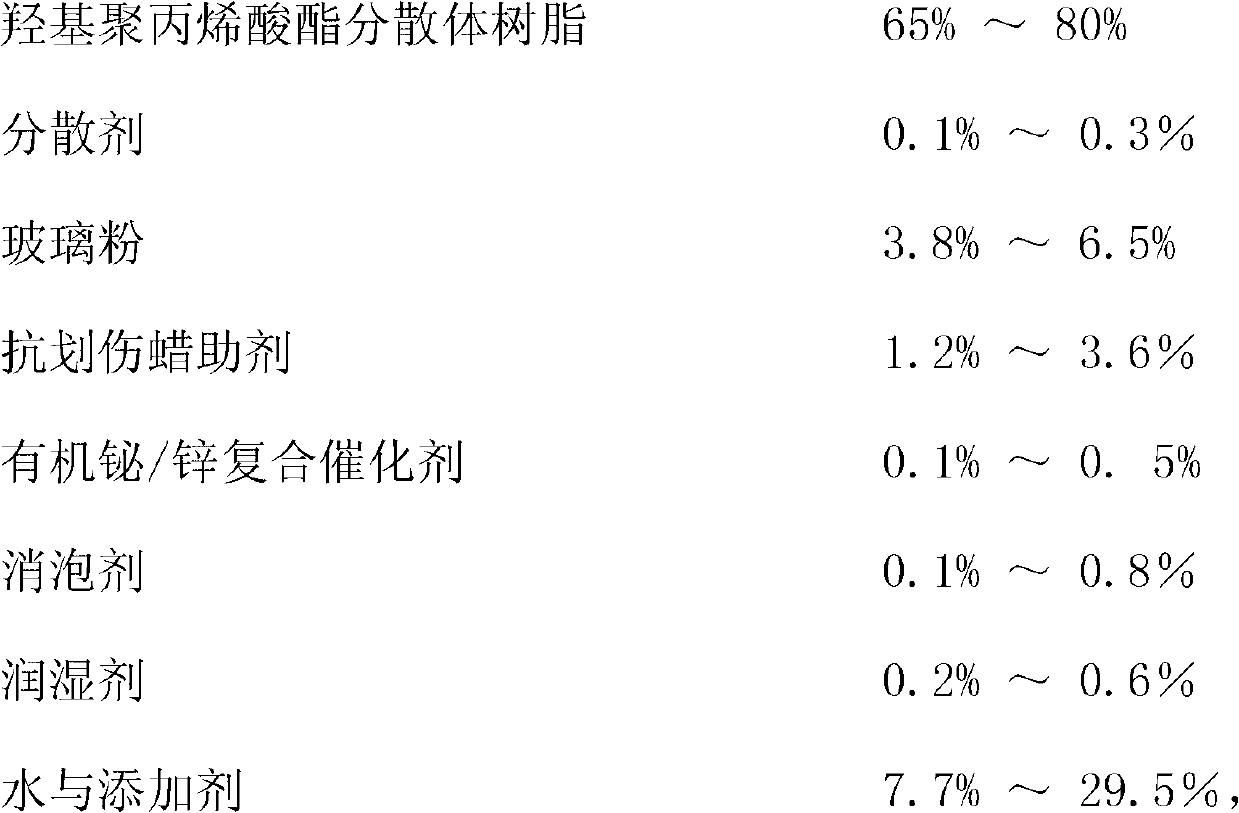

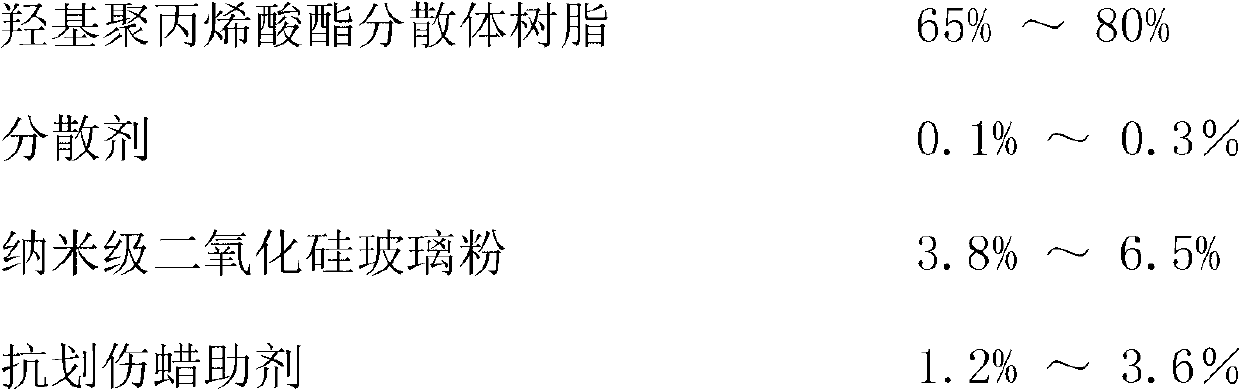

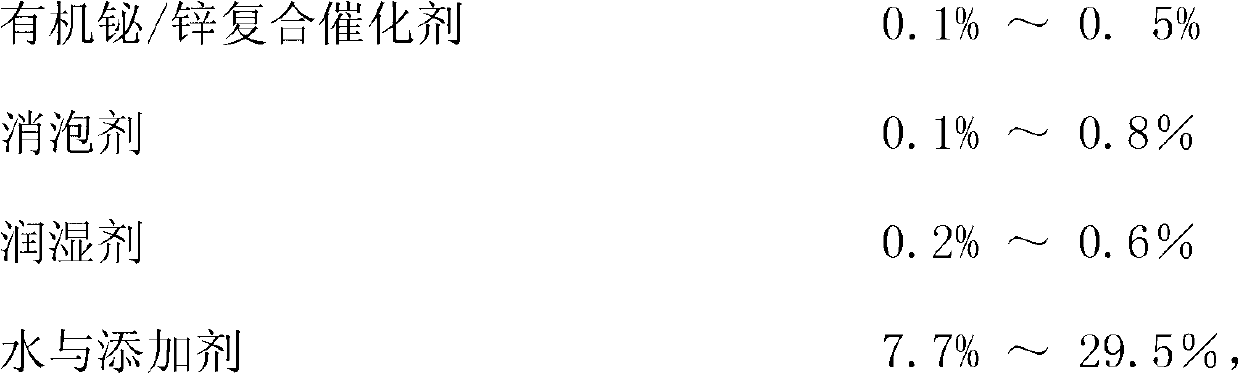

High-hardness scratch-resistant double-component waterborne polyurethane woodwork varnish and preparation method thereof

InactiveCN102898937AImprove scratch resistanceShorten the timeAnti-corrosive paintsPolyurea/polyurethane coatingsOperabilityDrying time

The invention discloses high-hardness scratch-resistant double-component waterborne polyurethane woodwork varnish and a preparation method thereof. The varnish consists of double components, i.e., a primer and a curing agent, wherein the primer consists of hydroxyl polyacrylate dispersion resin, dispersant, nano-scale silicon dioxide glass powder, a scratch-resistant wax auxiliary agent, an organic bismuth / zinc composite catalyst, an antifoaming agent, a wetting agent, water and an additive, wherein the sum of the weight percentages of the A components is 100 percent; the curing agent consists of propylene glycol ethyl ether acetate and allophanate modified HDI (Hexamethylene Diisocyanate) tripolymer; the sum of the weight percentages of the B components is 100 percent; and the A components and the B components are mixed according to the equivalent molar ratio of n-NCO:n-OH as 1.38:1.62. The varnish has the advantages of high hardness, shortened surface drying time and hard drying time, long activation period, superior performance, environmental friendliness of the product and high operability.

Owner:中山蓝海洋水性涂料有限公司

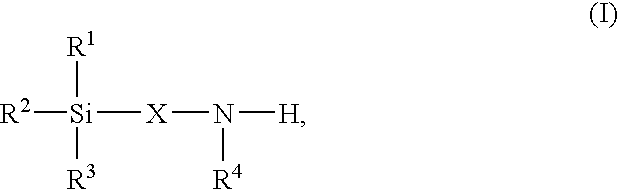

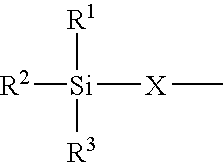

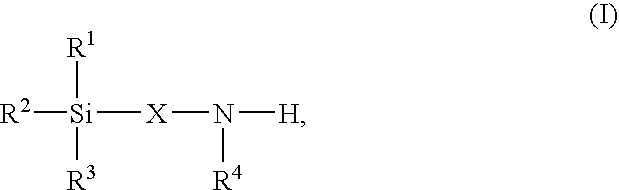

Polyisocyanates containing allophanate and silane groups

InactiveUS20090018302A1Silicon organic compoundsPolyurea/polyurethane coatingsAllophanePolymer science

The invention relates to polyisocyanates containing allophanate groups and silane groups, to a process for preparing them and to their use as a starting component in the production of polyurethane polymers, more particularly as a crosslinker component in polyurethane paints and coatings.

Owner:COVESTRO DEUTSCHLAND AG

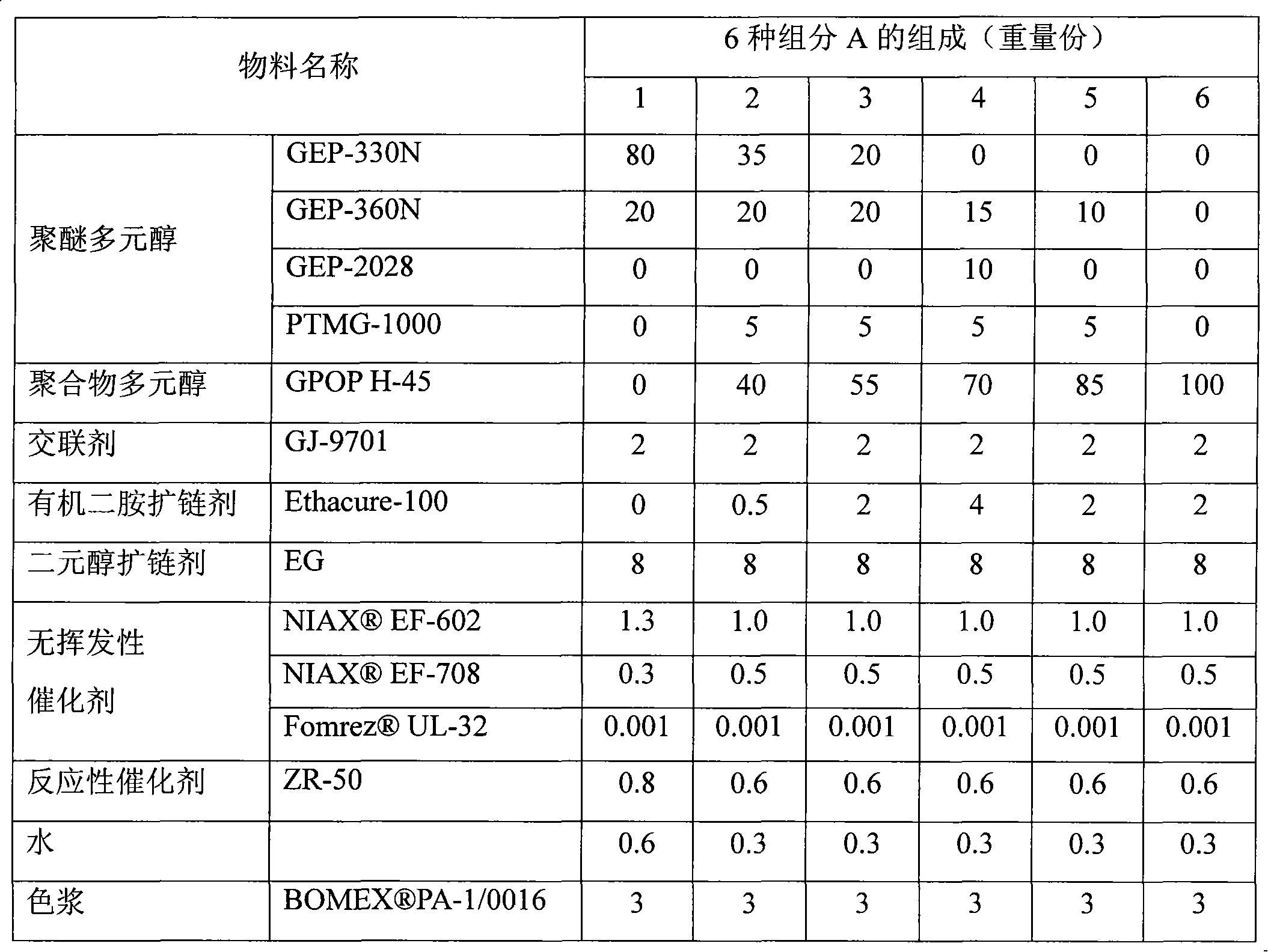

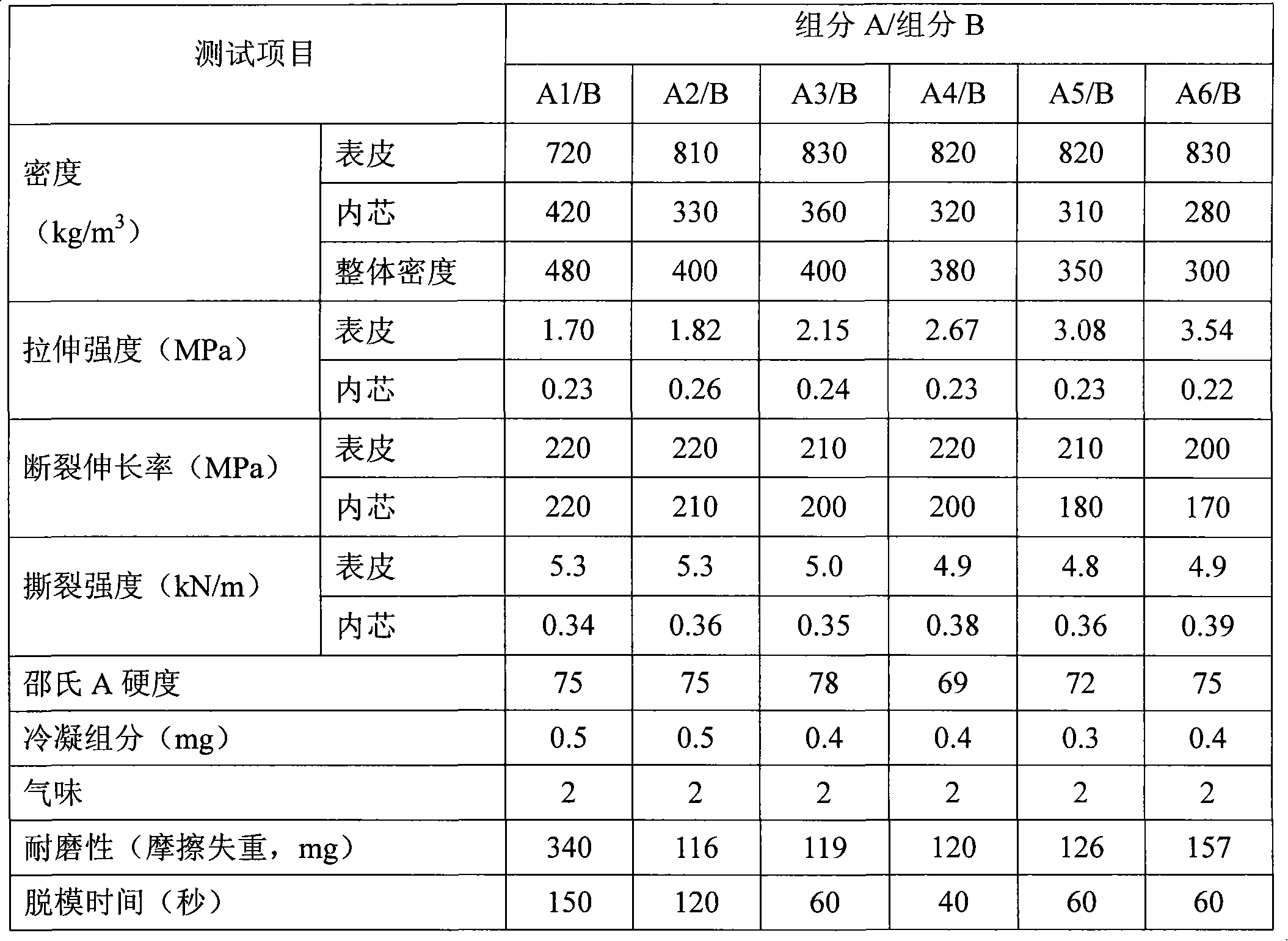

Integral skin polyurethane-urea composition, preparation method and application thereof

The invention discloses a quick demoulding water-blown low-density integral skin polyurethane-urea composition which comprises a polyalcohol mixture component A and a modified isocyanate component B, wherein the component A is a polyalcohol mixture which comprises polyether glycol, polymer polyol, a cross linking agent, organic diamine, a divalent alcohol chain extender, a nonvolatile catalyst and / or a reactive catalyst, water and color paste; the component B is allophanate modified isocyanate containing 22-31 wt percent of NCO and is formed by polymerizing methyl diphenylene diisocyanate (MDI) and polyalcohol with molecular weight of 62-3000. The component A and the component B according to a weight ratio of 100:40-100 are polymerized into integral skin polyurethane-urea with integral intensity of 260-400 kg / m, and the integral skin polyurethane-urea can be demoulded within 60 seconds.

Owner:湖州合达图宏新材料技术股份有限公司

Thermosensitive polymers and thermoreversible gels obtained from these polymers

InactiveUS20050175573A1Improve propertiesHigh viscosity indexCosmetic preparationsSenses disorderAllophanePolymer science

Polymers which comprise polymer chains of terpolymer type which are constituted by poly(ethylene oxide) (PEO) and poly(propylene oxide) (PPO) of PEO-PPO-PEO form, which are modified at their termini by groups which can essentially be other chains of PEO-PPO-PEO, acid segments, amine groups or PEOs, these chains being linked to the terpolymer chains via chemical bridges which are constituted by urethane bridges, urea bridges, allophanate bridges and biuret bridges, and which comprise more than 80% by weight of said PEO-PPO-PEO. Thermoreversible physical gels of high viscosification index, which contain these polymers, and their uses. Preparation of these polymers and of these gels.

Owner:POLYMEREXPERT

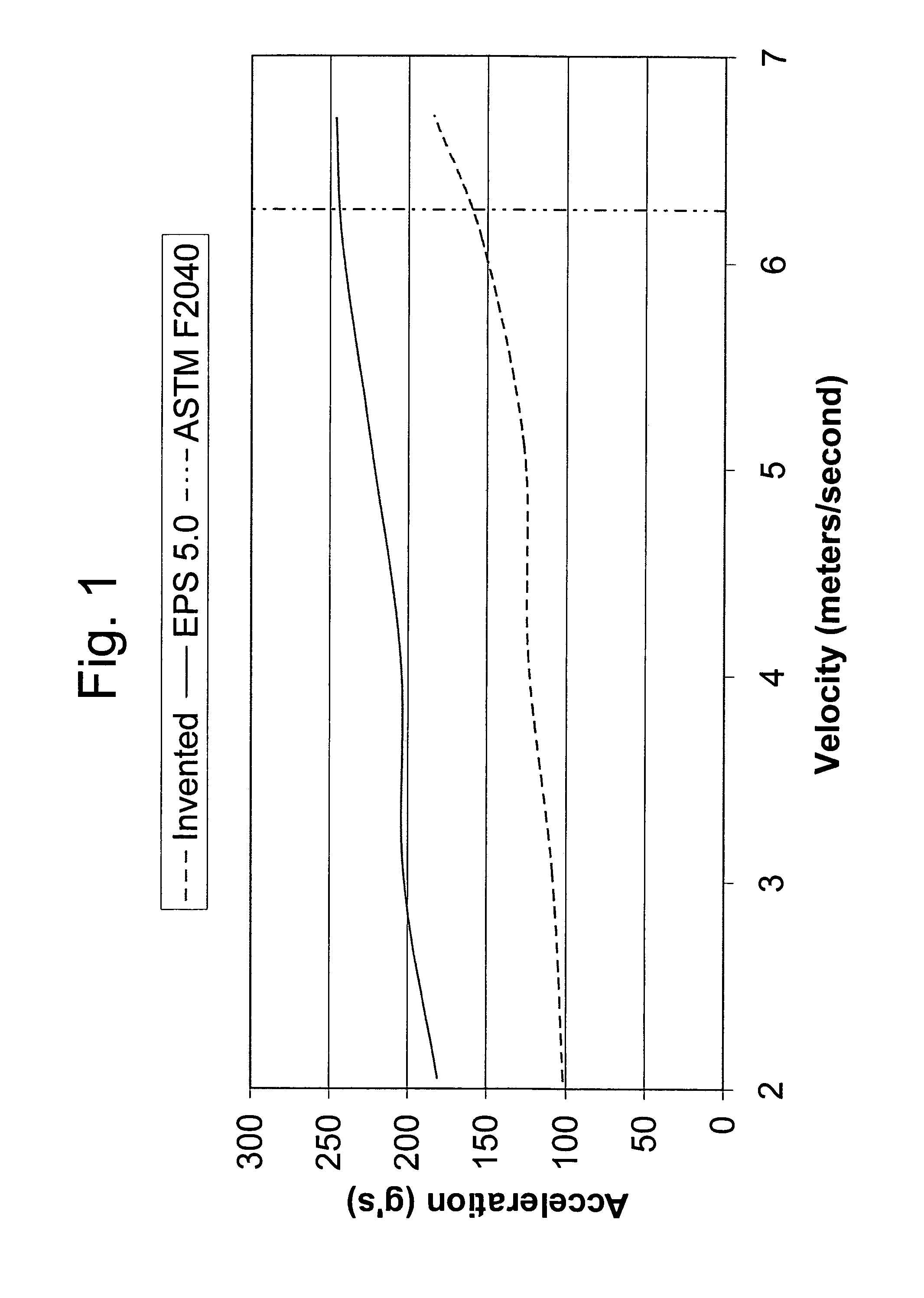

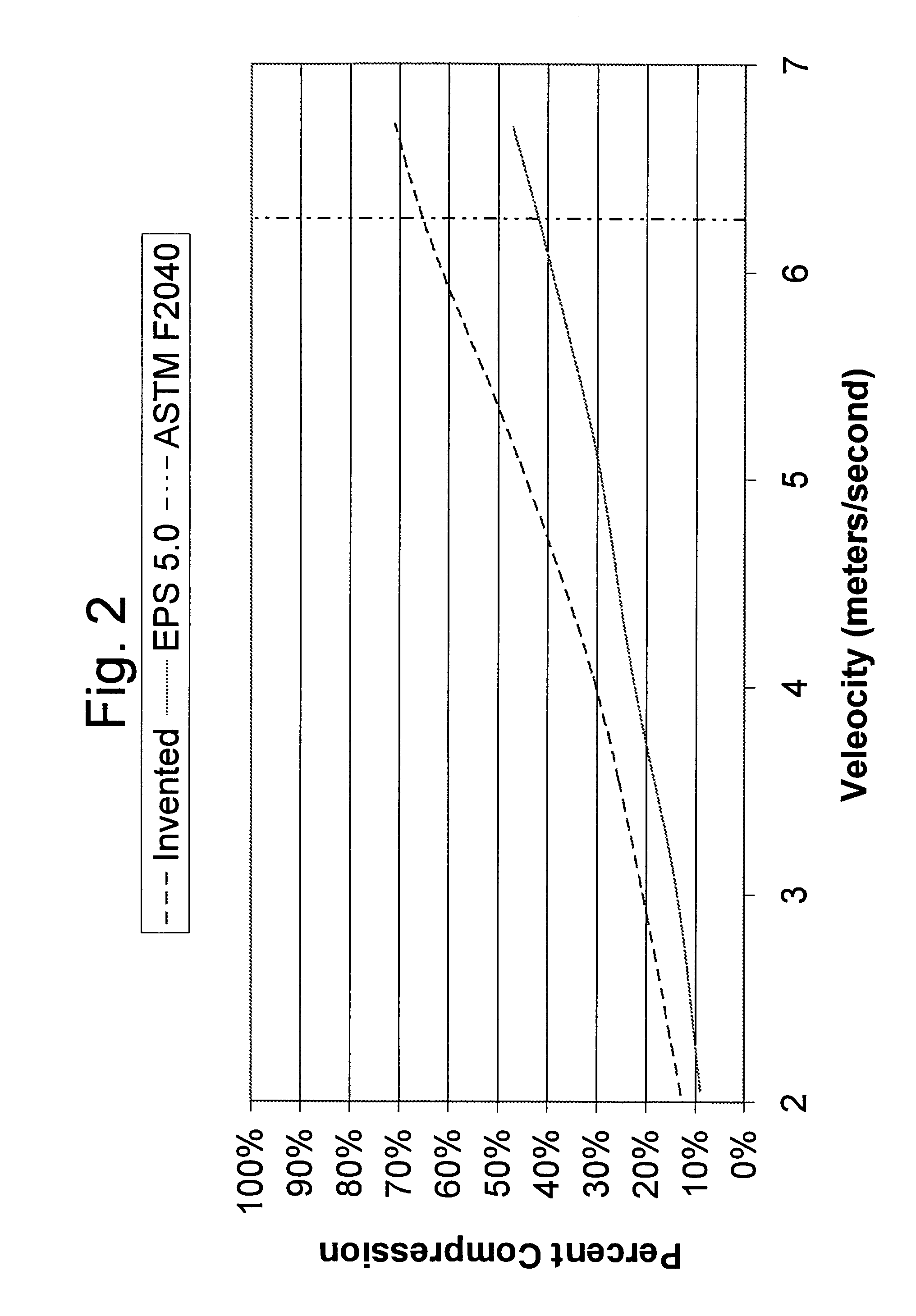

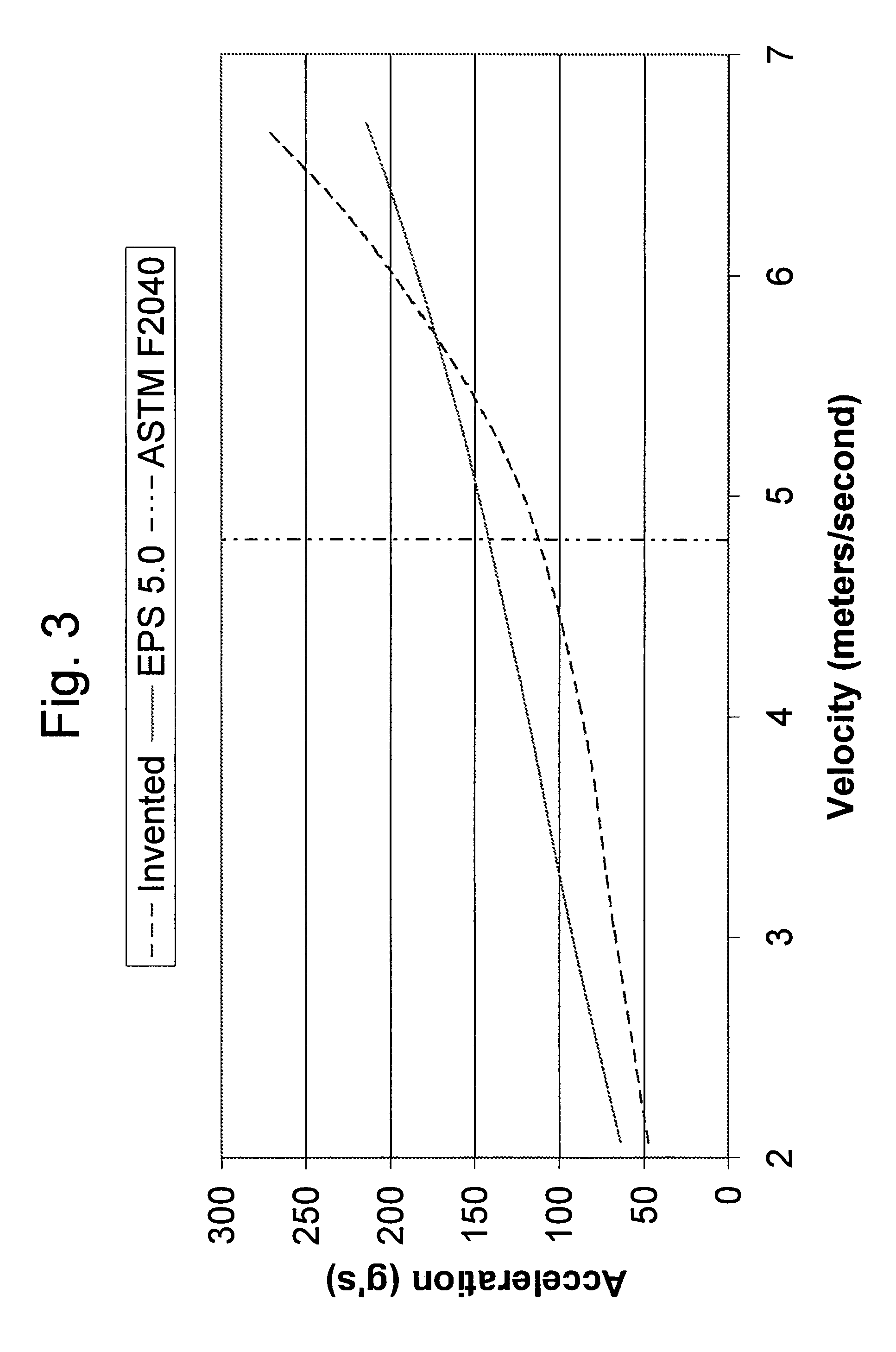

Viscoelastic foam layer and composition

A viscoelastic foam is provided having an amine-based polyol system to impart strength, recoverability and endurance to the foam, and an appropriately selected trifunctional non-amine-based polyol system to provide flexibility to the foam. The combination of amine-based and non amine-based polyols provides a viscoelastic semi-rigid foam with excellent impact and recovery properties, recovering to substantially 100% of its initial volume and shape following an impact, yet with high rigidity and stiffness so that it is effective at absorbing high as well as low-energy impacts. A method of making the above viscoelastic foam is also provided. In a preferred embodiment, the foam is made using an allophanate-modified MDI prepolymer in order to provide the isocyanate in liquid form at standard temperature and pressure in order to simplify the production of the invented viscoelastic foams.

Owner:TEAM WENDY

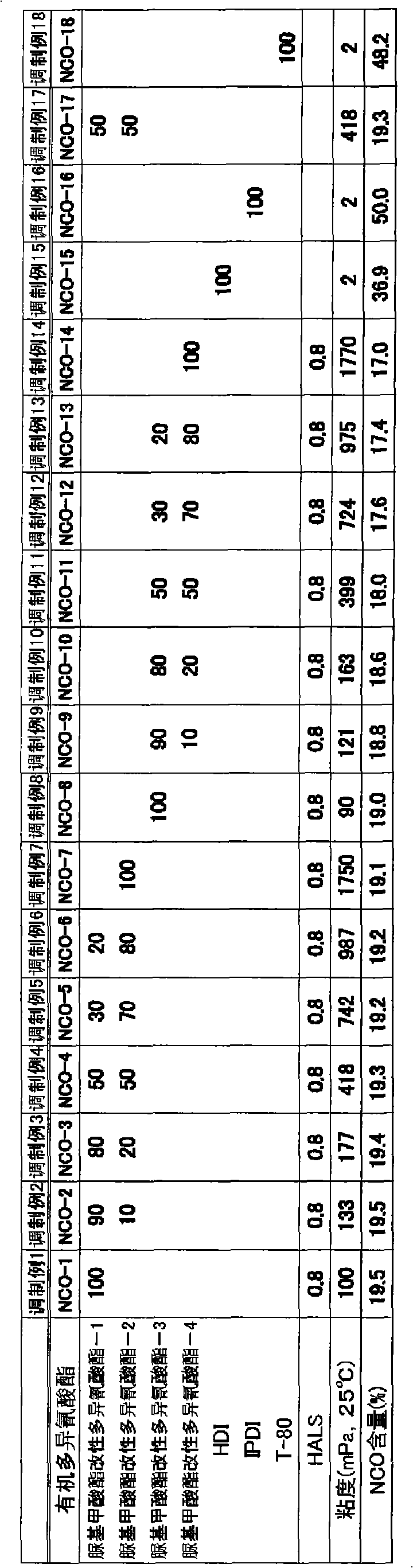

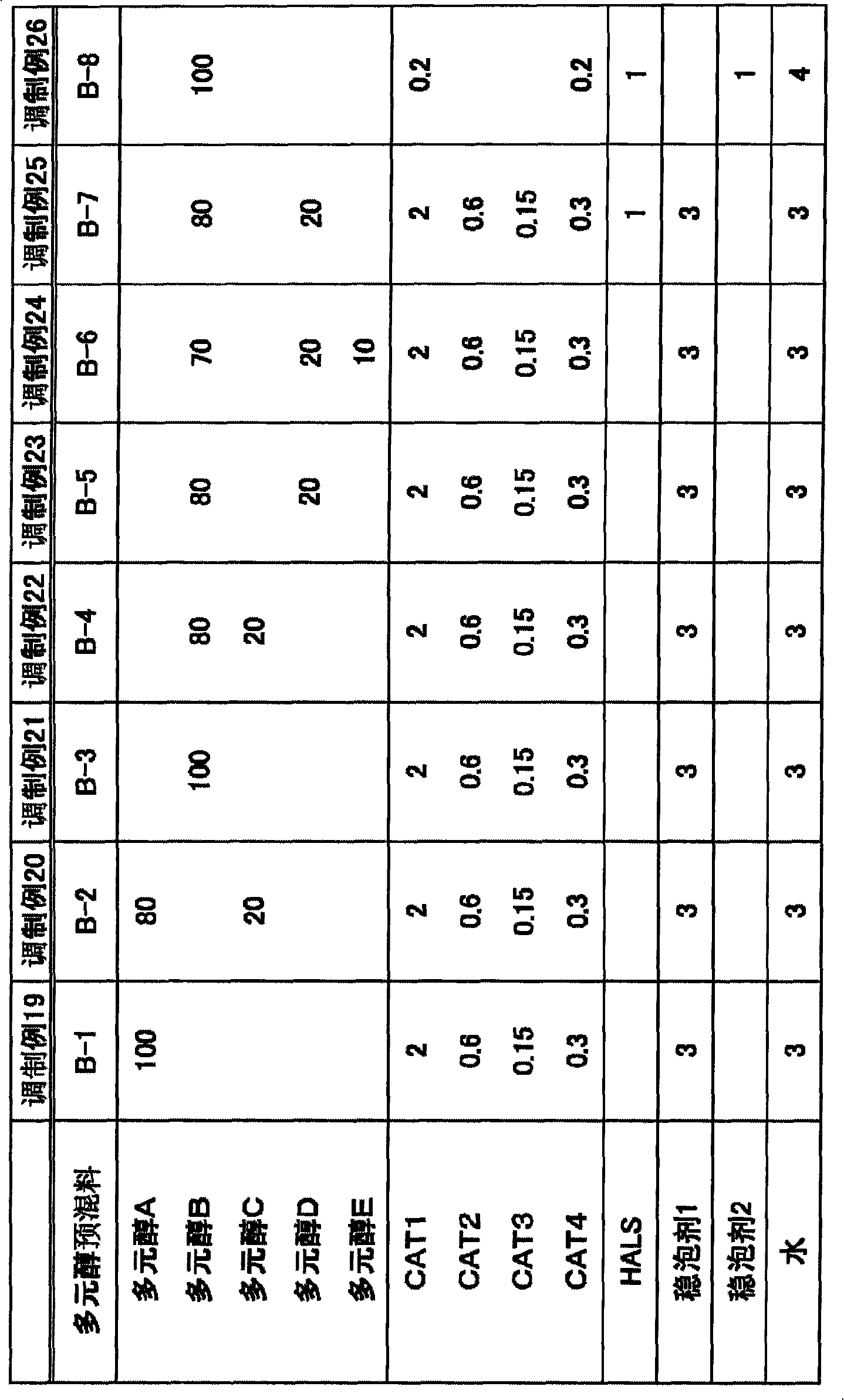

Soft polyurethane foam and its manufacture method

ActiveCN102030881AExcellent discoloration resistanceUniform and beautiful pore (cell) structurePackaging toiletriesAbsorbent padsAllophanePolymer science

The invention provides a soft polyurethane foam and its manufacture method capable of solving the above problem, characterized in that: the mixing solution of an organic polyisocyanate (A), a polyhydric alcohol (B), a catalyst (C), a foaming agent (D) and a foam stabilizer (E) reacts, foams and cures to obtain the soft polyurethane foam, wherein the organic polyisocyanate (A) uses the mixture of an organic polyisocyanate combination A1 modified by an allophanate composed of a monohydric alcohol and aliphatic and / or alicyclic ring diisocyanate and an organic polyisocyanate combination A2 modified by the allophanate composed of an alcohol with more than two hydroxyl groups and the aliphatic and / or alicyclic ring diisocyanate.

Owner:NIPPON POLYURETHANE IND CO LTD

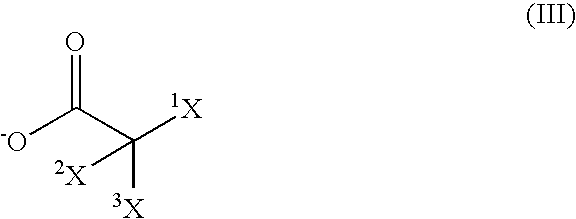

Allophanate-modified stabilizers and the polymer polyols prepared from these stabilizers

The present invention relates to allophanate-modified stabilizers and polymer polyols prepared from these stabilizers. In particular, the present invention relates to novel ethylenically unsaturated macromers, preformed stabilizers prepared from these novel macromers, stabilized from these novel ethylenically unsaturated macromers or preformed Polymer polyols prepared by agents and methods of making these compositions.

Owner:BAYER MATERIALSCIENCE AG

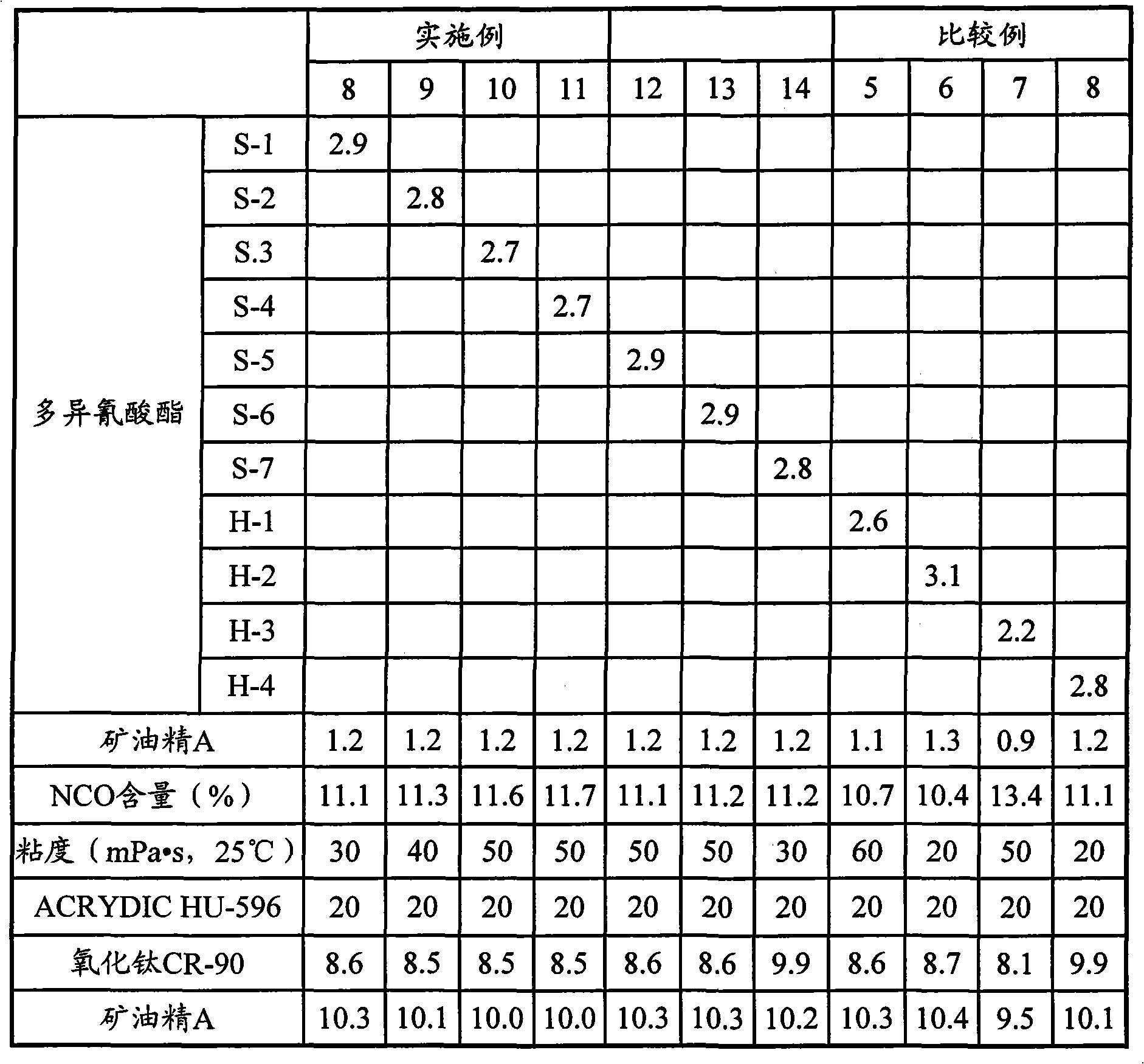

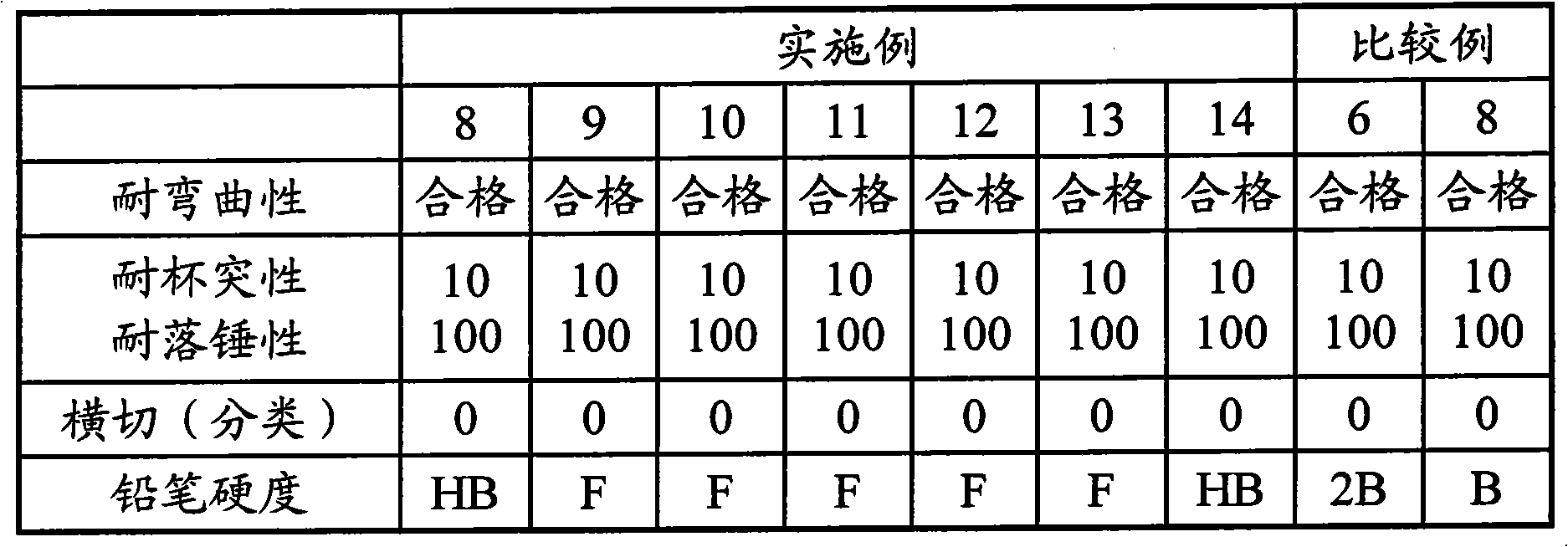

Self-repairing polyurethane resin material, self-repairing polyurethane resin, self-repairing coating material, self-repairing elastomer material, method for producing self-repairing polyurethane resin material, and method for producing self-repairing polyurethane resin

InactiveUS20170342193A1Excellent and well-balanced propertyImprove light resistancePolyurea/polyurethane coatingsAllophaneElastomer

A self-repairing polyurethane resin material is produced by reaction of a polyisocyanate compound consisting of aliphatic polyisocyanate and / or araliphatic polyisocyanate with an active hydrogen group-containing compound, used for producing polyurethane resin having self-repairing properties, has an isocyanate group at its molecular terminal, contains an allophanate group and an isocyanate trimer, and the mole ratio of the allophanate group relative to the isocyanate trimer is 0.1 to 20.

Owner:MITSUI CHEM INC

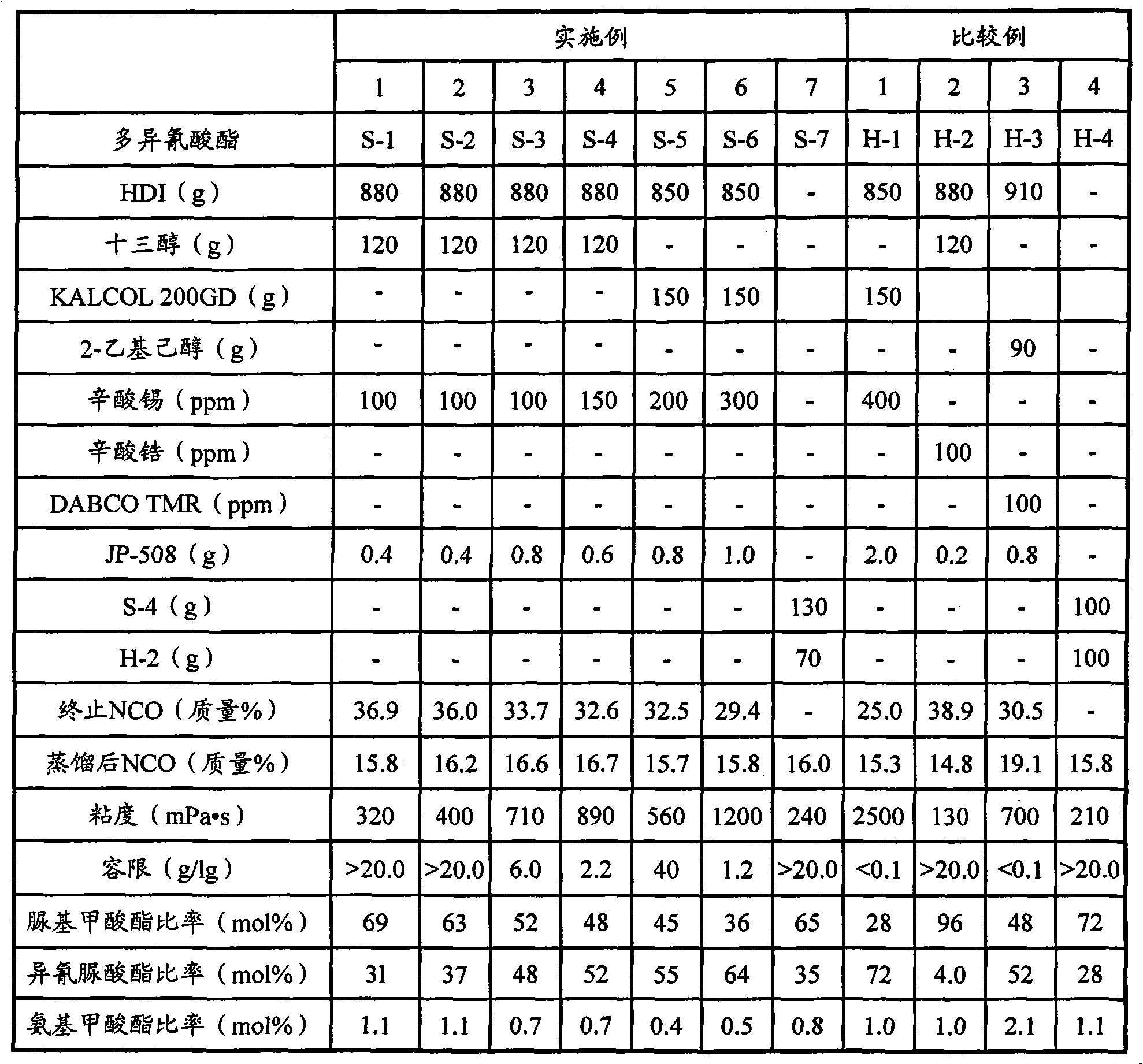

Polyisocyanates composition, coating composition, and coating method

ActiveCN105418886AGood coating appearanceImprove curing effectPolyurea/polyurethane coatingsAllophaneDiol

The present invention provides a polyisocyanates composition which expresses high curing characteristic, drying characteristic and crosslinking degree, and also has excellent performance in coating appearance such as smoothness of the coating surface, a coating composition comprising the same, and a coating method. The polyisocyanates composition is formed by more than one diisocyanate selected from aliphatic diisocyanate and alicyclic diisocyanate and more than one diol. In the polyisocyanates composition, the mole ratio of allophanate group / (isocyanurate group + allophanate group) is 0.2-0.9, and the mole ratio of allophanate group / (allophanate group + urethane group) is 0.6-1.0.

Owner:ASAHI KASEI KK

Two-component systems for producing flexible coatings

ActiveUS20070078255A1Synthetic resin layered productsPolyurea/polyurethane coatingsAllophanePolyaspartic acid

The present invention relates to two-component coating systems for producing flexible coatings. The coating systems comprise polyurethane prepolymers with allophanate structures and also amino-functional polyaspartic esters as curing agents.

Owner:COVESTRO DEUTSCHLAND AG

Low surface energy polyisocyanates and their use in one- or two-component coating compositions

The present invention is directed to a polyisocyanate mixture i) having an NCO content of 5 to 35% by weight and a monomeric diisocyanate content of less than 3% by weight, and prepared from a polyisocyanate adduct, ii) containing allophanate groups in an amount such that there are more equivalents of allophanate groups than urethane groups and such that the polyisocyanate mixture remains stable and homogeneous in storage for 1 month at 25° C. and iii) containing siloxane groups (calculated as SiO, MW 44) in an amount of 0.002 to 50% by weight, wherein the preceding percentages are based on the solids content of the polyisocyanate mixture and wherein the siloxane groups are incorporated by reacting an isocyanate group with a compound containing one or more hydroxyl groups directly attached to a carbon atom and one or more siloxane groups. The present invention is also directed to a process for the production of this polyisocyanate mixture and to its use, optionally in blocked form, as an isocyanate component in one- or two-component coating compositions.

Owner:BAYER MATERIALSCIENCE AG

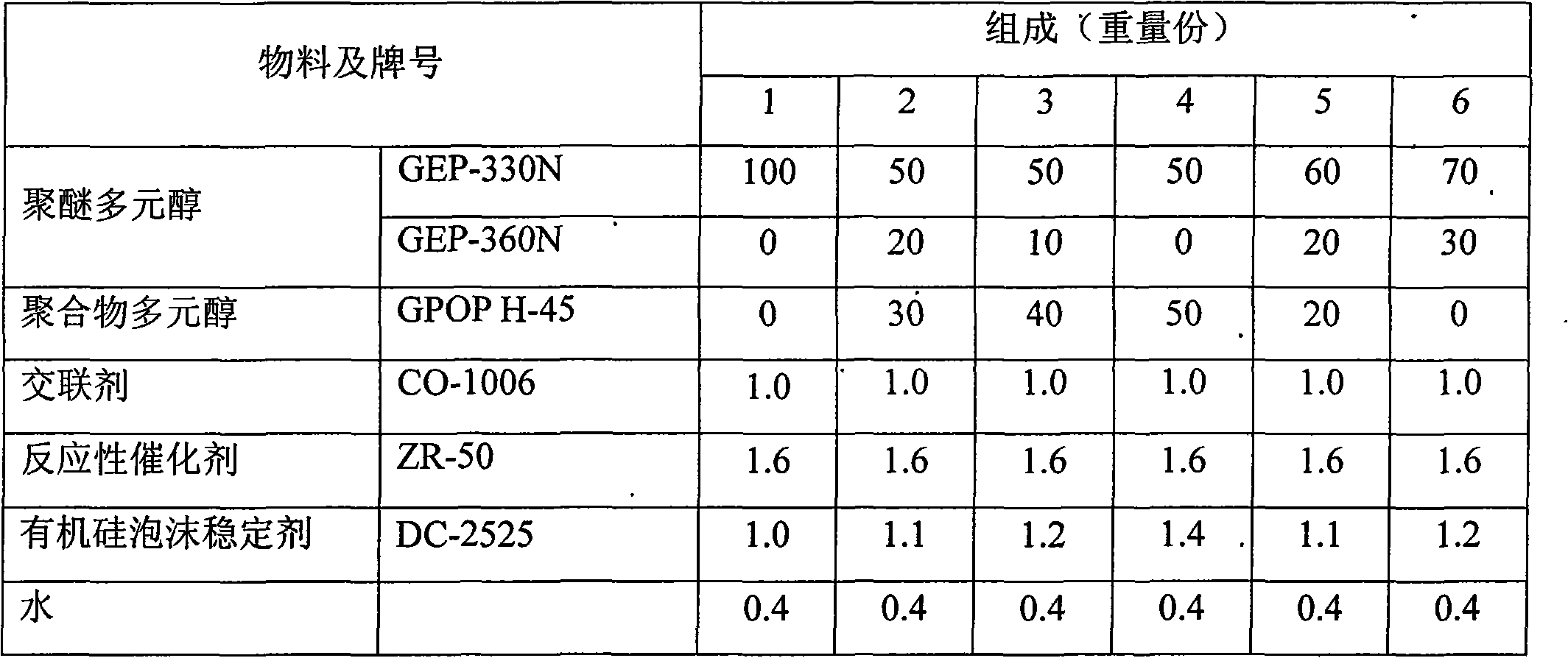

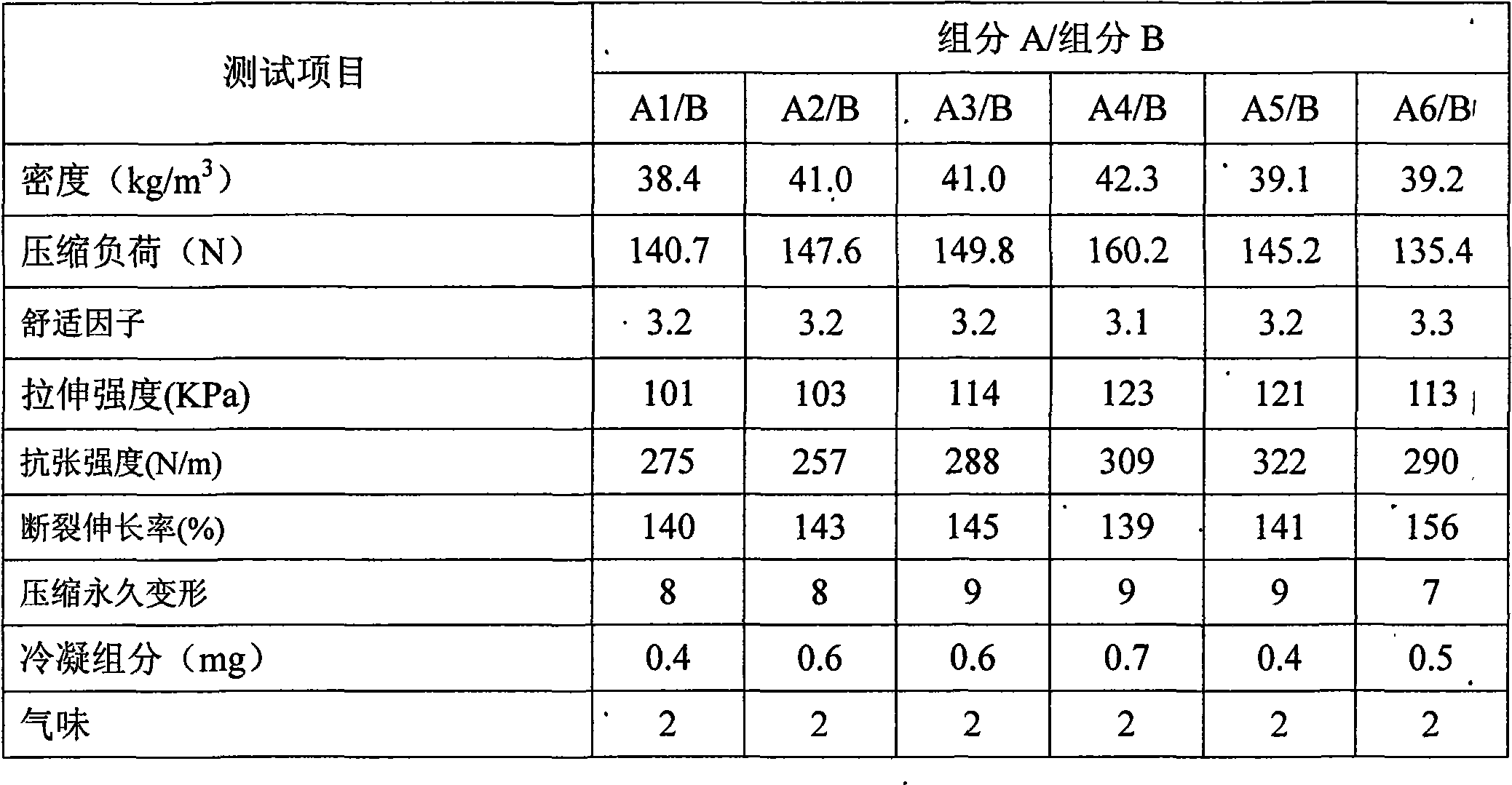

Preparation and application of low-density full diphenyl-methane-diisocyanate (MDI)-base high-resilience polyurethane foam

The invention discloses a full diphenyl-methane-diisocyanate (MDI)-base high-resilience polyurethane foam which comprises a polyatomic alcohol mixture component A and a modified MDI component B, wherein the component A is a polyatomic alcohol mixture, the component B is the mixture of carbamate modified MDI and allophanate modified MDI, and the weight ratio of the carbamate modified MDI to the allophanate modified MDI is 1:99-95:5. The high-resilience polyurethane foam prepared by polymerizing the component A and the component B in weight ratio of 100:50-100:80 has a density of 38-45kg / m<3>, and can be used for manufacturing car seats.

Owner:湖州合达图宏新材料技术股份有限公司

Low-viscosity allophanates containing actinically curable groups

A process for preparing binders containing allophanate groups which contain, at the oxygen atom of the allophanate group that is bonded via two single bonds, organic radicals with activated groups capable of participating in a polymerization reaction with ethylenically unsaturated compounds on exposure to actinic radiation; the process includes reacting A) one or more compounds containing uretdione groups with B) one or more OH-functional compounds which contain groups capable of participating in a polymerization reaction with ethylenically unsaturated compounds on exposure to actinic radiation, and C) optionally further NCO-reactive compounds, and D) in the presence of one or more compounds containing phenoxide groups, as catalysts. The binders can be used in preparing coatings, coating materials, coating compositions, adhesives, printing inks, casting resins, dental compounds, sizes, photoresists, stereolithography systems, resins for composite materials and sealants.

Owner:ALLNEX NETHERLANDS BV

Preparation of new radiation-curing binders

Process for preparing binders including reacting A) one or more NCO-functional compounds containing uretdione groups with B) one or more compounds containing groups capable of participating in polymerization reaction with ethylenically unsaturated compounds on exposure to actinic radiation, and contain isocyanate-reactive groups, followed by C) reaction with one or more hydroxyl-containing compounds other than B), wherein at least one of these compounds has an OH functionality of ≧2, D) in the presence of one or more compounds containing phenoxide groups, as catalysts, and E) optionally auxiliaries and additives, where the reaction with compounds of component C) proceeds at least proportionally with the formation of allophanate groups and where and including binders containing allophanate groups and groups capable of participating in a polymerization reaction with ethylenically unsaturated compounds on exposure to actinic radiation, and optionally also contain NCO-reactive groups. The binders are used in coating compositions used to coat substrates.

Owner:ALLNEX NETHERLANDS BV

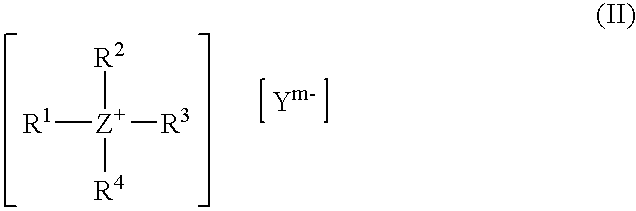

Radiation-curing binders and a process for their preparation

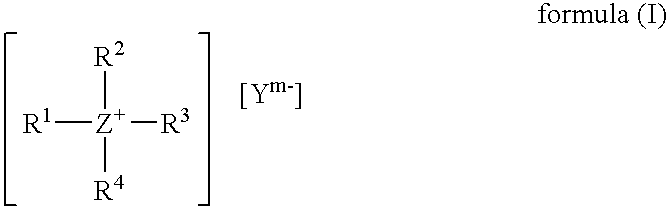

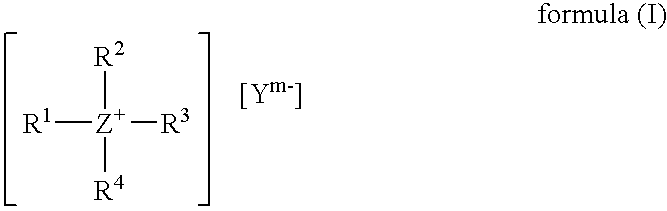

InactiveUS20060051591A1Low viscositySynthetic resin layered productsOptical articlesAllophanePhosphonium

The invention relates to a process for preparing binders which contain 1) allophanate groups, 2) groups that react with ethylenically unsaturated compounds with polymerization on exposure to actinic radiation (radiation-curing groups) and 3) optionally NCO-reactive groups, by reacting at temperatures ≦130° C. A) one or more NCO-functional compounds containing uretdione groups with B) one or more compounds that contain isocyanate-reactive groups and groups that react with ethylenically unsaturated compounds with polymerization on exposure to actinic radiation (radiation-curing groups), and then C) with one or more saturated, hydroxyl-containing compounds other than B), at least one of these compounds having an OH functionality of ≧2, in the presence of D) a catalyst containing one or more ammonium salts or phosphonium salts of aliphatic or cycloaliphatic carboxylic acids, the reaction with compounds C) taking place at least proportionally with the formation of allophanate groups. The present invention also relates to the binders obtained by the process of the invention.

Owner:ALLNEX NETHERLANDS BV

Polyisocyanate composition having allophanate group and high-solid coating material

A polyisocyanate composition comprising an allophanate group, which is obtained from an aliphatic diisocyanate(s), wherein in a state substantially free of a solvent and the aliphatic diisocyanate(s), (i) the content of components having a molecular weight of 700 or less is 20-60 weight %, (ii) the ratio of weight average molecular weight to number average molecular weight is 1.20-5.00, (iii) the ratio of viscosity (unit: mPa.s) of the polyisocyanate composition at 25 DEG C to the number average number of functional groups of isocyanate groups is represented by the following expression: viscosity (mPa.s) / number average number of functional groups ≤ 240.

Owner:ASAHI KASEI KK

Polyether allophanates stable towards discolouration

ActiveUS7038003B2Urea derivatives preparationIsocyanic acid derivatives preparationAllophaneCarbamate

A process for preparing polyisocyanate prepolymers containing allophanate structural units that includes reactinga) one or more polyisocyanates withb) one or more polyetherpolyols containing less than or equal to 0.02 milliequivalent of unsaturated end groups per gram of polyol and having a polydispersity of from 1.0 to 1.5 and / or an OH functionality of greater than or equal to 1.9 to provide an NCO-functional polyurethane prepolymer containing urethane groups that are partly or fully allophanatized by further reaction withc) polyisocyanates, which may be different from those from a), andd) catalysts and optionally addinge) acidic additives before, during and / or after the allophanatization. The polyisocyanate prepolymers can be used to produce coatings, adhesive bonds and / or seals. The coatings include one or more of the polyisocyanate prepolymers, and at least one diol or polyol and / or at least one linear and / or cyclic, aliphatic, araliphatic and / or aromatic diamine or polyamine.

Owner:COVESTRO DEUTSCHLAND AG

Polyurethane prepolymers containing alkoxysilane groups and allophanate and/or biuret groups

The present invention relates to modified alkoxysilane-functional polyurethanes containing allophanate and / or biuret groups, wherein at least 10 mol % of the allophanate and / or biuret groups are formed from a monoisocyanate of the formula R-NCO, wherein R is an optionally heteroatom-containing alkyl, aralkyl or aryl radical having up to 20 carbon atoms, provided that these radicals do not contain any other reactive groups with the exception of the NCO group that is part of the allophanate structure and any alkoxysilyl groups present. The present invention also relates to a process for preparing alkoxysilane-functional prepolymers by A) reacting some or all of the urethane groups and / or urea groups of alkoxysilane-functional polyurethane prepolymers with monoisocyanates of the formula, R-NCO to form allophanate groups and / or biuret groups, or B) reacting some or all urethane groups and / or urea groups of alkoxysilyl-free polyurethane prepolymers with monoisocyanates of the formula R-NCO to form allophanate groups and / or biuret groups, the radical R having at least one alkoxysilyl group. The present invention further relates to sealants, adhesives, primers and coatings based on the polyurethane prepolymers of the invention.

Owner:COVESTRO DEUTSCHLAND AG

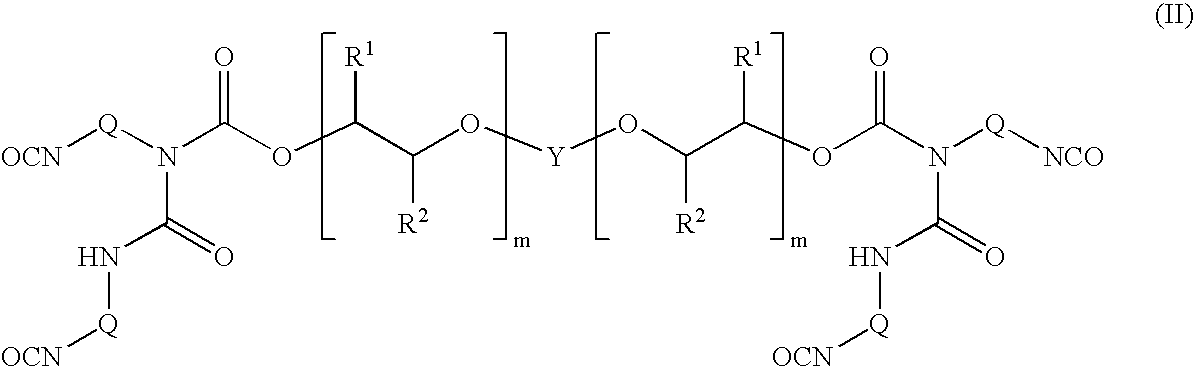

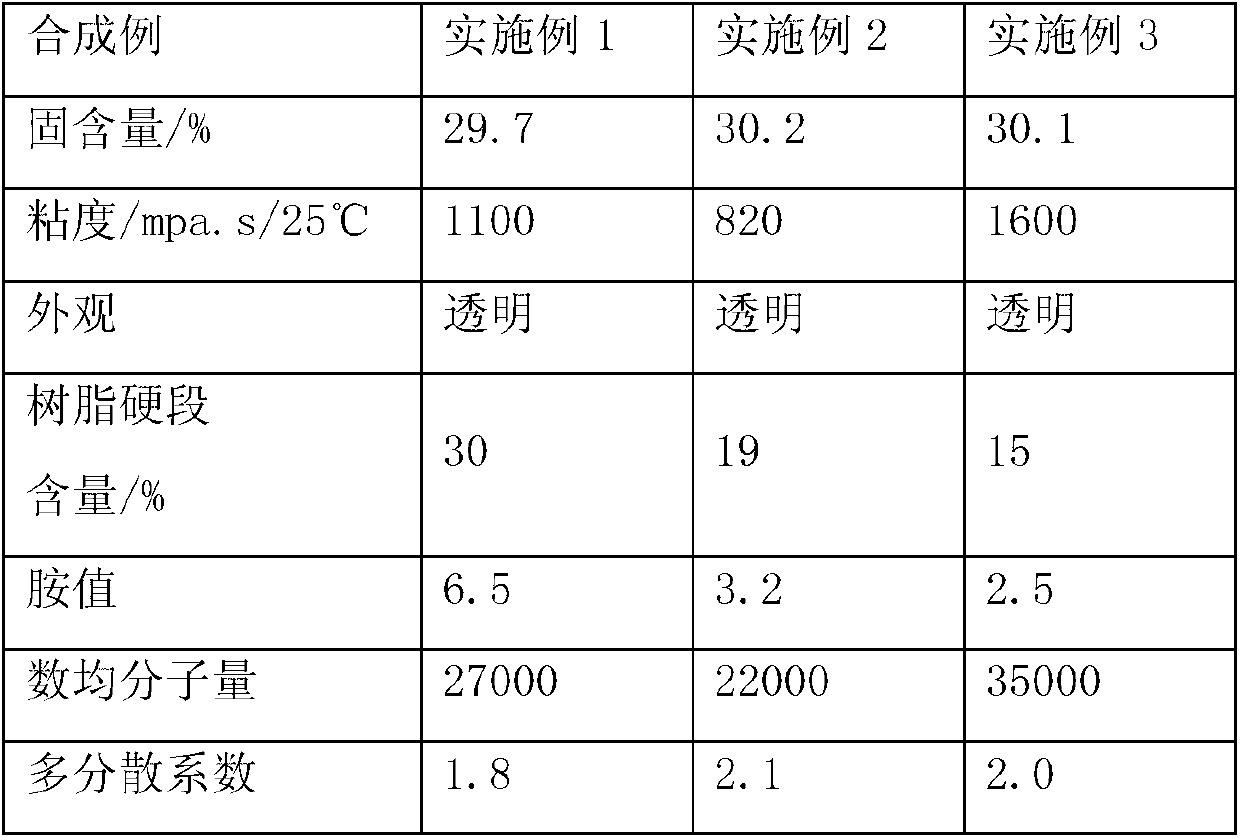

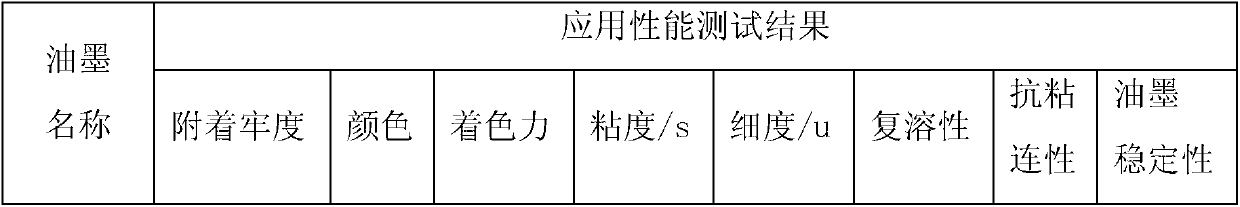

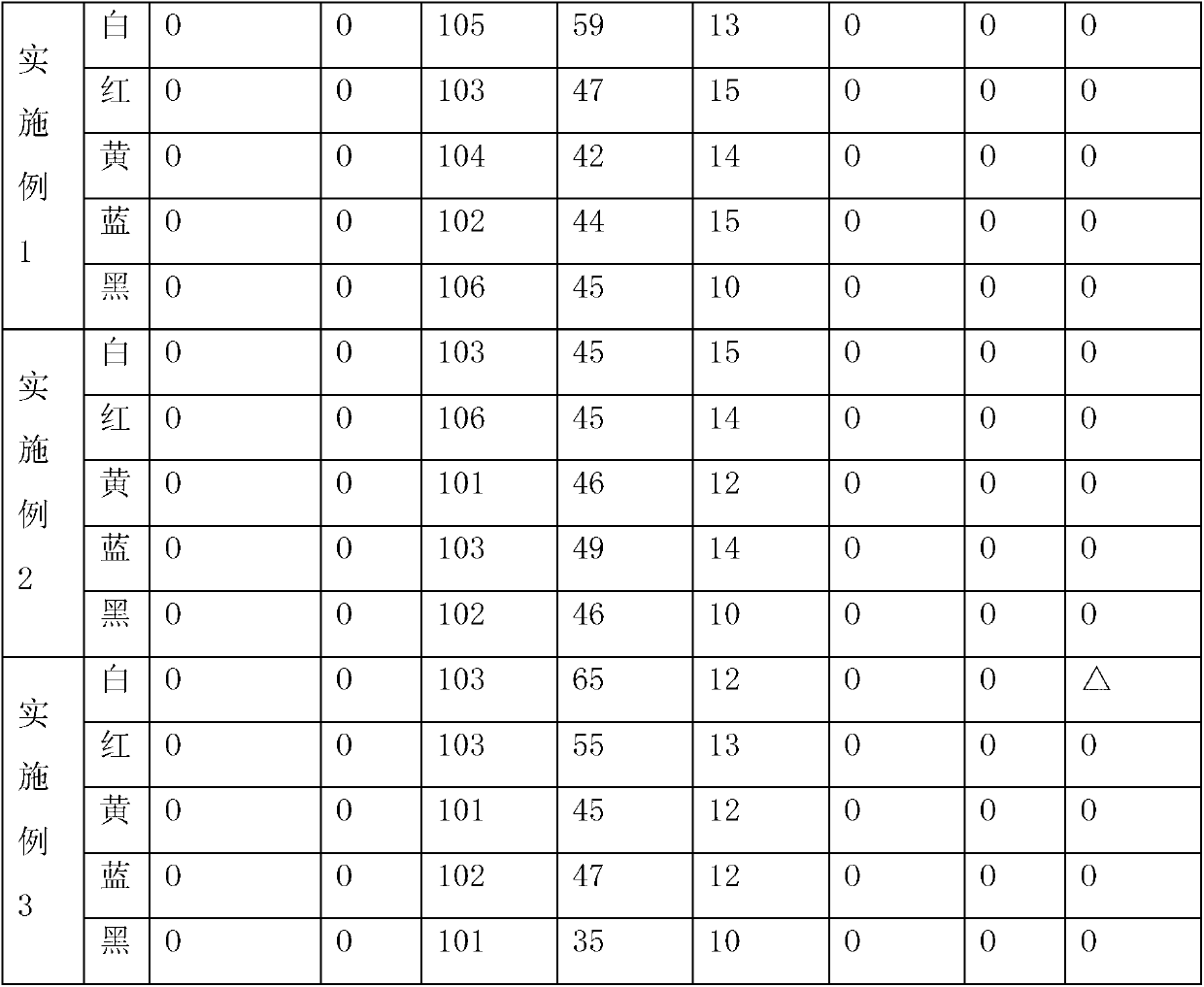

Preparation method of polyurethane resin for gravure composite ink

ActiveCN103012724AMild responseThe chain extension process is stable and controllableInksEnd-groupPolyethylene glycol

The invention discloses a preparation method of polyurethane resin for gravure composite ink, wherein the polyurethane resin is alcohol ester-soluble polyurethane resin not containing free cyanate ester radicals. Large amounts of allophanate radicals are introduced into the resin so that the ink prepared from the resin has excellent adhesion fastness to substrates such as PET (Polyethylene Glycol Terephthalate), NY (Nylon) and PP (Polypropylene) and the like. The preparation method is characterized in that diisocyanate is reacted with high-molecular polyol to generate NCO-terminated prepolymers, and then the prepolymers are added into a solvent containing an amine chain extender to achieve the polyurethane resin for the ink. The soft and hard segment of the resin has the advantages of wide adjustable range, large cohesive energy, good anti-aftertack property and good heat resistance; and the prepared ink has high binding strength to various printing substrates and has high composite strength. The preparation method provided by the invention has obvious characteristics of stable reaction in the synthesis process of the resin, easiness in control of the preparation process, narrow distribution of the molecular weight and good dissolubility of the resin.

Owner:NANTONG GAOMENG NEW MATERIAL

Polyisocyanate composition and two-package type coating composition using the same

ActiveCN102015815AImprove solubilityGood compatibilityOrganic chemistryPolyurea/polyurethane coatingsAllophaneAniline point

Disclosed is a polyisocyanate composition containing a polyisocyanate, which is obtained by reacting hexamethylene diisocyanate and an aliphatic monoalcohol having 11-20 carbon atoms, and a low-polarity organic solvent having an aniline point of 10-70 DEG C or a low-polarity organic solvent having a mixed aniline point of 5-50 DEG C. The polyisocyanate contains an allophanate group, an isocyanurate group and a urethane group in a molecule, and the molar ratio between the allophanate group and the isocyanurate group, namely allophanate group / isocyanurate group, is from 70 / 30 to 30 / 70. The composition is soluble in a low-polarity organic solvent, and has excellent compatibility with a polyol compound. Consequently, the composition can provide a coating film having excellent physical properties such as surface hardness.

Owner:NIPPON POLYURETHANE IND CO LTD

Polyisocyanate cured product, and method for producing polyisocyanate cured product

ActiveUS20170044296A1Good moisture/reflow sensitivitySemiconductor/solid-state device detailsSolid-state devicesAllophaneUnit structure

The polyisocyanate cured product according to the present invention has an isocyanurate structure, which comprises at least one diisocyanate selected from the group consisting of an aliphatic diisocyanate and an alicyclic diisocyanate, as a unit structure, the polyisocyanate cured product having an allophanate group, and the molar ratio of the isocyanurate group to the allophanate group (isocyanurate group / allophanate group) is 99 / 1 to 20 / 80.

Owner:ASAHI KASEI KK

Highly crosslinkable low-viscosity polyisocyanate composition and coating composition containing same

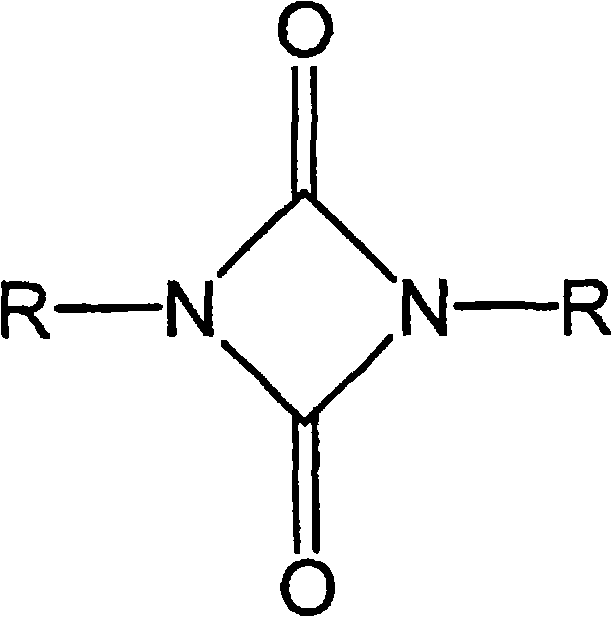

Disclosed is a polyisocyanate composition derived from an aliphatic diisocyanate monomer and an alcohol, which satisfies all the conditions below in a state not containing the aliphatic diisocyanate monomer and a solvent. 1) Isocyanurate trimer concentration: 55-95 mass%; 2) Number ratio of allophanate groups derived from the alcohol to isocyanurate groups: 1-20%; 3) Uretdione dimer concentration: 2-25 mass%; 4) Viscosity at 25 DEG C: 150-800 mPas.

Owner:ASAHI KASEI KK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com