High-hardness scratch-resistant double-component waterborne polyurethane woodwork varnish and preparation method thereof

A water-based polyurethane and wood varnish technology, applied in polyurea/polyurethane coatings, anti-corrosion coatings, coatings, etc., can solve the problems of difficult construction, long drying time, hardness and wear resistance not as good as solvent-based coatings, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

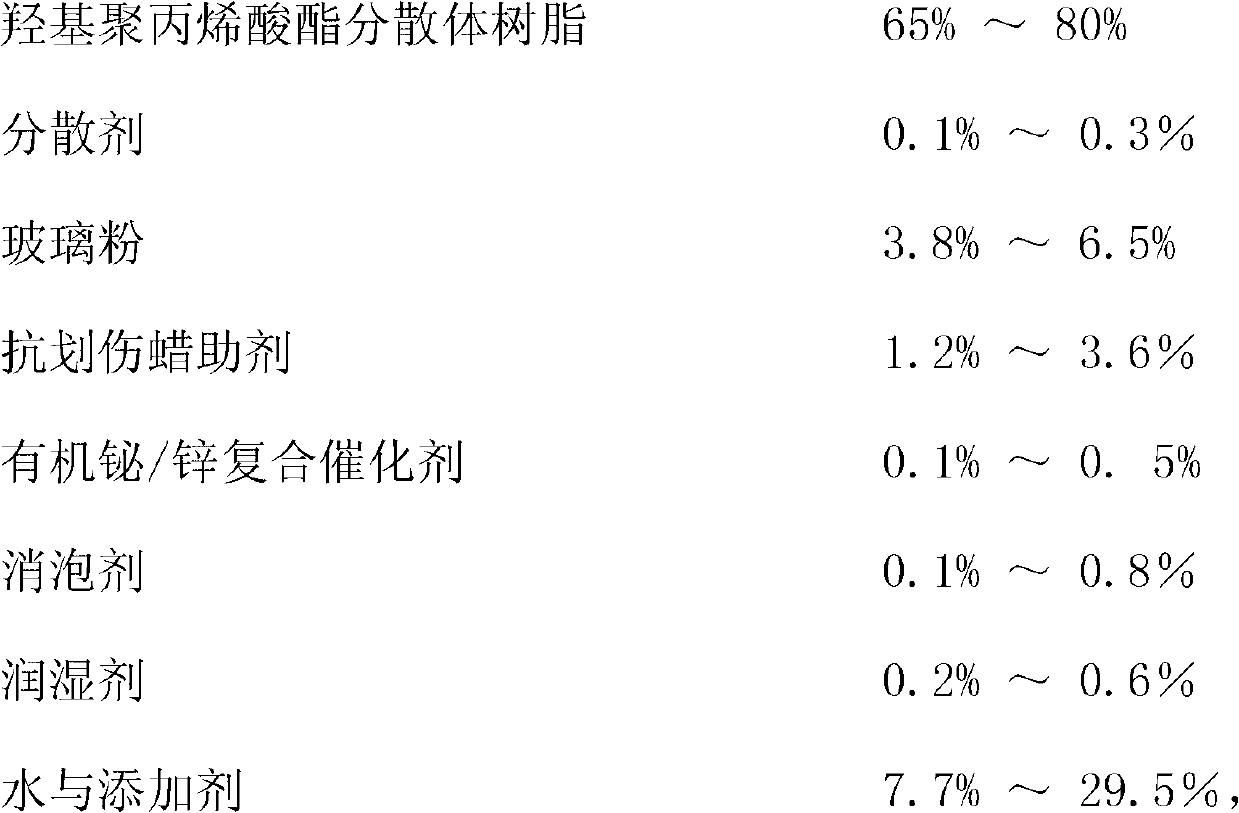

Embodiment 1

[0074] The additives include weight component content: 5% film-forming aid, 0.9% thickener, 0.3% preservative, 0.3% anti-fungal agent, 0.3% anti-blocking agent, and 0.1% leveling agent.

[0075] The preparation method of embodiment 1 is:

[0076] a. Prepare the main paint of component A: first add water and hydroxyl polyacrylate dispersion resin with a total weight of 10% of water in the dispersion tank, and carry out medium-speed dispersion at 800r / min, then evenly mix in dispersant and glass powder, After dispersing at a high speed of 1500r / min for 15 minutes, add anti-scratch wax additives, organic bismuth / zinc composite catalyst, defoamer, wetting agent and other components, and disperse at a medium speed for 15 minutes, then take a sample to test the fineness of the finished product with viscosity, filtration, canning, packaging;

[0077] b. Preparation of component B curing agent: Add propylene glycol ether acetate and allophanate modified HDI trimer in sequence in the ...

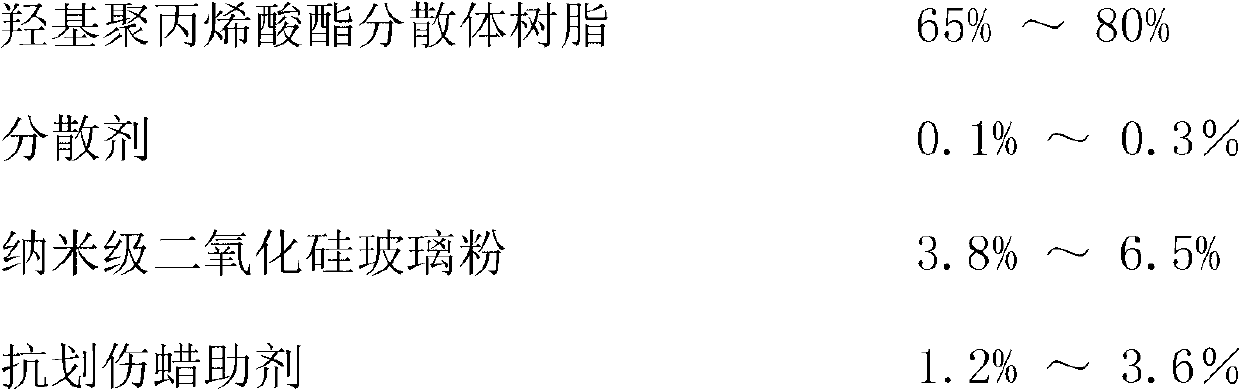

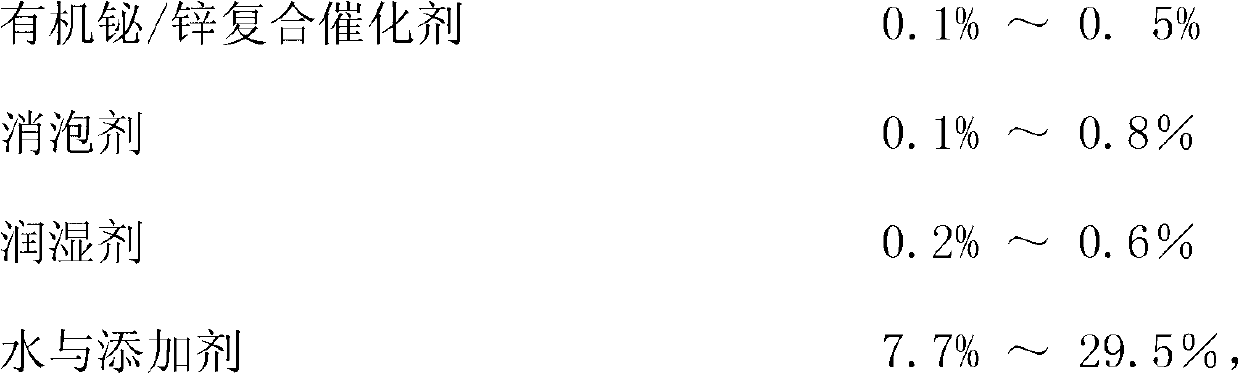

Embodiment 2

[0080] The additives include weight components: 4% film-forming aid, 0.7% thickener, 0.1% preservative, 0.1% antifungal agent, 0.2% anti-blocking agent, and 0.05% leveling agent.

[0081] The preparation method of embodiment 2 is:

[0082] a. Prepare the main paint of component A: first add water and hydroxyl polyacrylate dispersion resin with a total weight of 15% of water in the dispersion tank, and carry out medium-speed dispersion at 700r / min, then evenly mix in dispersant and glass powder, After dispersing at a high speed of l300r / min for 20 minutes, add anti-scratch wax additives, organic bismuth / zinc composite catalyst, defoamer, wetting agent and other components, and disperse at a medium speed for 20 minutes, then take a sample to test the fineness of the finished product with viscosity, filtration, canning, packaging;

[0083] b. Preparation of component B curing agent: Add propylene glycol ether acetate and allophanate modified HDI trimer in sequence in the dispers...

Embodiment 3

[0086] The additives include weight component content: 2.7% of film-forming aids, 0.5% of thickeners, 0.15% of preservatives, 0.15% of antifungal agents, and 0.15% of anti-blocking agents.

[0087] The preparation method of embodiment 3 is:

[0088] a. Prepare the main paint of component A: first add water and hydroxyl polyacrylate dispersion resin with a total weight of 20% of water in the dispersion tank, and carry out medium-speed dispersion at 600r / min, then evenly mix in dispersant and glass powder, After dispersing at a high speed of 1000r / min for 25 minutes, add anti-scratch wax additives, organic bismuth / zinc composite catalyst, defoamer, wetting agent and other components, and disperse at a medium speed for 25 minutes, then take a sample to test the fineness of the finished product with viscosity, filtration, canning, packaging;

[0089] b. Preparation of component B curing agent: Add propylene glycol ether acetate and allophanate modified HDI trimer in sequence in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com