Patents

Literature

16432 results about "Propylene glycol" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Propylene glycol (IUPAC name: propane-1,2-diol) is an organic compound with the chemical formula CH₃CH(OH)CH₂OH. It is a viscous, colorless liquid, which is nearly odorless but possesses a faintly sweet taste. Containing two alcohol groups, it is classed as a diol. It is miscible with a broad range of solvents, including water, acetone, and chloroform. In general, glycols are non-irritating, have very low volatility and very low toxicity.

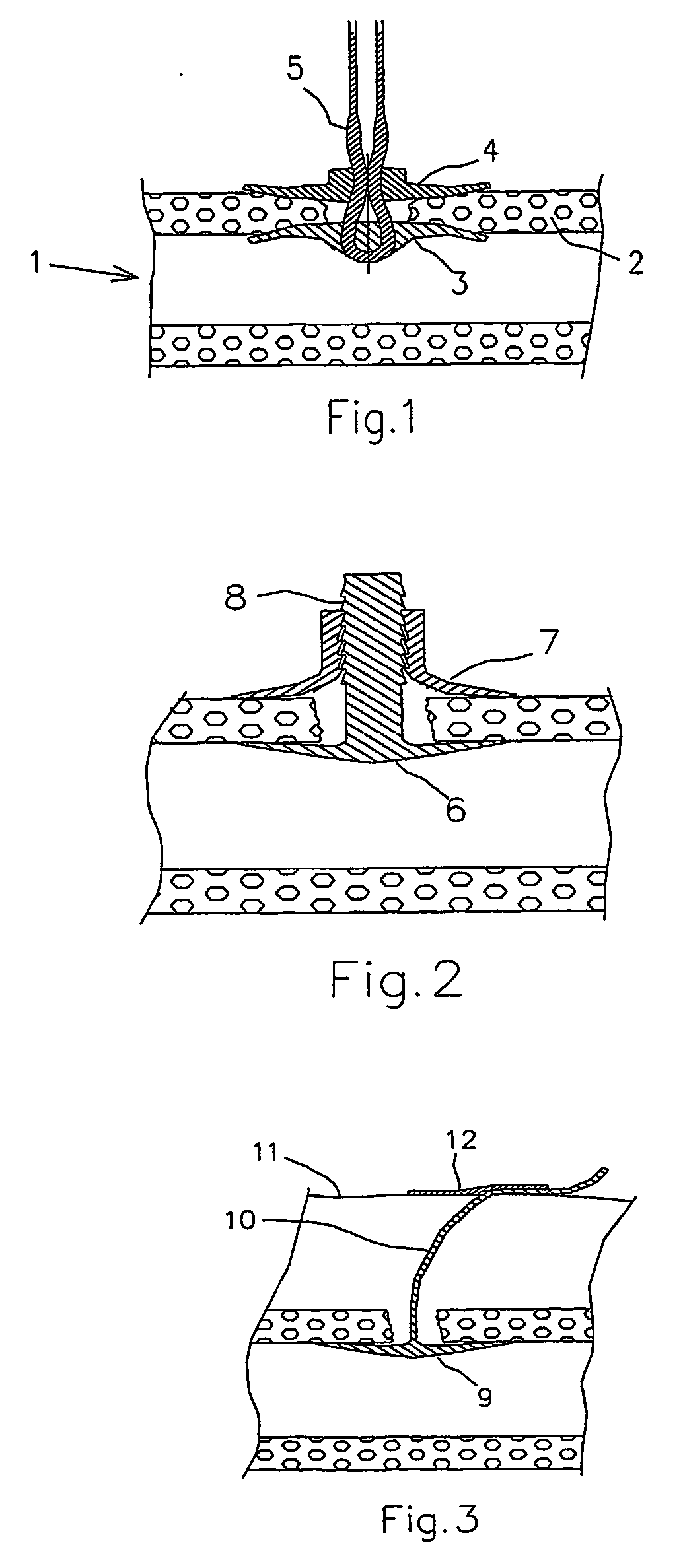

Dissolvable medical sealing device

ActiveUS20050169974A1Shorten the timeSuture equipmentsPharmaceutical delivery mechanismOrganismal ProcessPolyvinyl alcohol

The present invention provides a dissolvable medical sealing device (3, 4; 6, 7; 9) for closing a wound in vessel. A sealing device (3, 4, 6, 7, 9) according to the invention is made of a material that dissolves by means of physical processes, rather than by means of chemical or biological processes. Such a sealing device (3, 4; 6, 7; 9) can be made of polyethylene glycol, polypropylene glycol, copolymers containing ethylene glycol and propylene glycol, polyvinyl alcohol or polyvinyl pyrolidone, or any combinations thereof.

Owner:TERUMO MEDICAL CORP

Lyophilization process and products obtained thereby

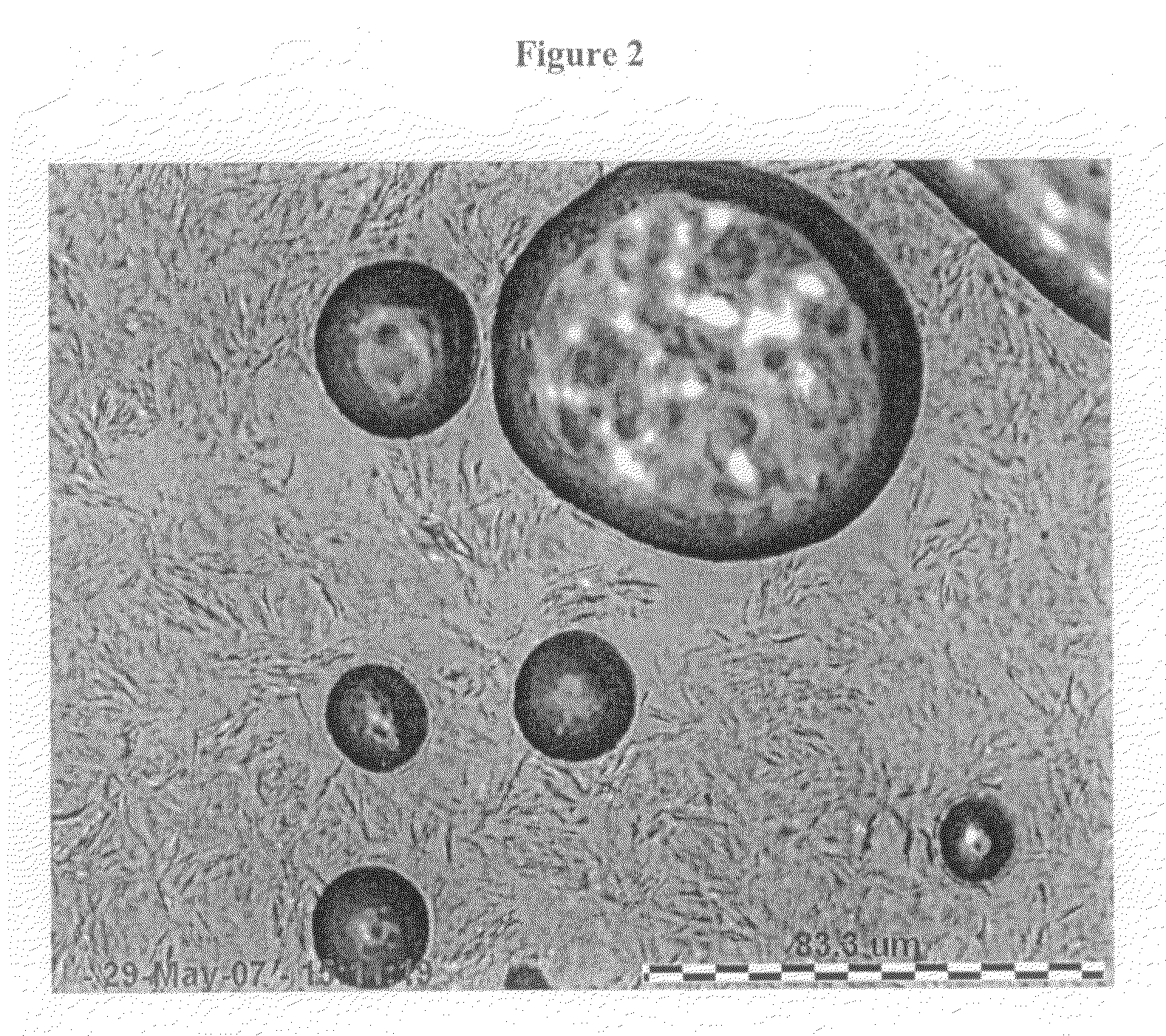

ActiveUS20070116729A1Dissolve fastSuitable for useBiocidePowder deliveryHigh concentrationFreeze-drying

A lyophilization process which comprises dissolving a material in one or more solvents for said material to form a solution; forcing said material at least partially out of solution by combining the solution and a non-solvent for the material, which non-solvent is miscible with the solvent or solvents used and wherein said non-solvent is volatilizable under freeze-drying conditions. In addition, for hydrophobic and / or lipophilic materials, the anti-solvent can be omitted, and the solution of the material in the solvent can be subjected directly to freeze drying. The lyophilizates can then be reconstituted with typical aqueous diluent in the case of hydrophilic materials. Hydrophobic and or lipophilic materials can be initially reconstituted with propylene glycol and / or polyethyleneglycol to form a high concentration solution therein and this is further diluted for use with a diluent of Intralipid, plasma, serum, or even whole blood.

Owner:SCIDOSE PHARMA +1

Oleaginous pharmaceutical and cosmetic foam

InactiveUS20070292461A1Pleasant and easy to spreadPatient compliance is goodCosmetic preparationsMetabolism disorderActive agentPolyethylene glycol

The invention relates to stable pharmaceutical or cosmetic foam compositions containing certain active agents, having unique therapeutic properties and methods of treatment using such compositions. The foamable composition includes at least one solvent comprising polyethylene glycol (PEG) or PEG derivative and mixtures thereof, or comprising propylene glycol, wherein the solvent is present at a concentration of about 70% to about 96.5% by weight of the total composition, at least a non-ionic surface-active agent at a concentration of about 0.1% to less than about 10% by weight of the total composition.

Owner:FOAMIX PHARMACEUTICALS LIMITED

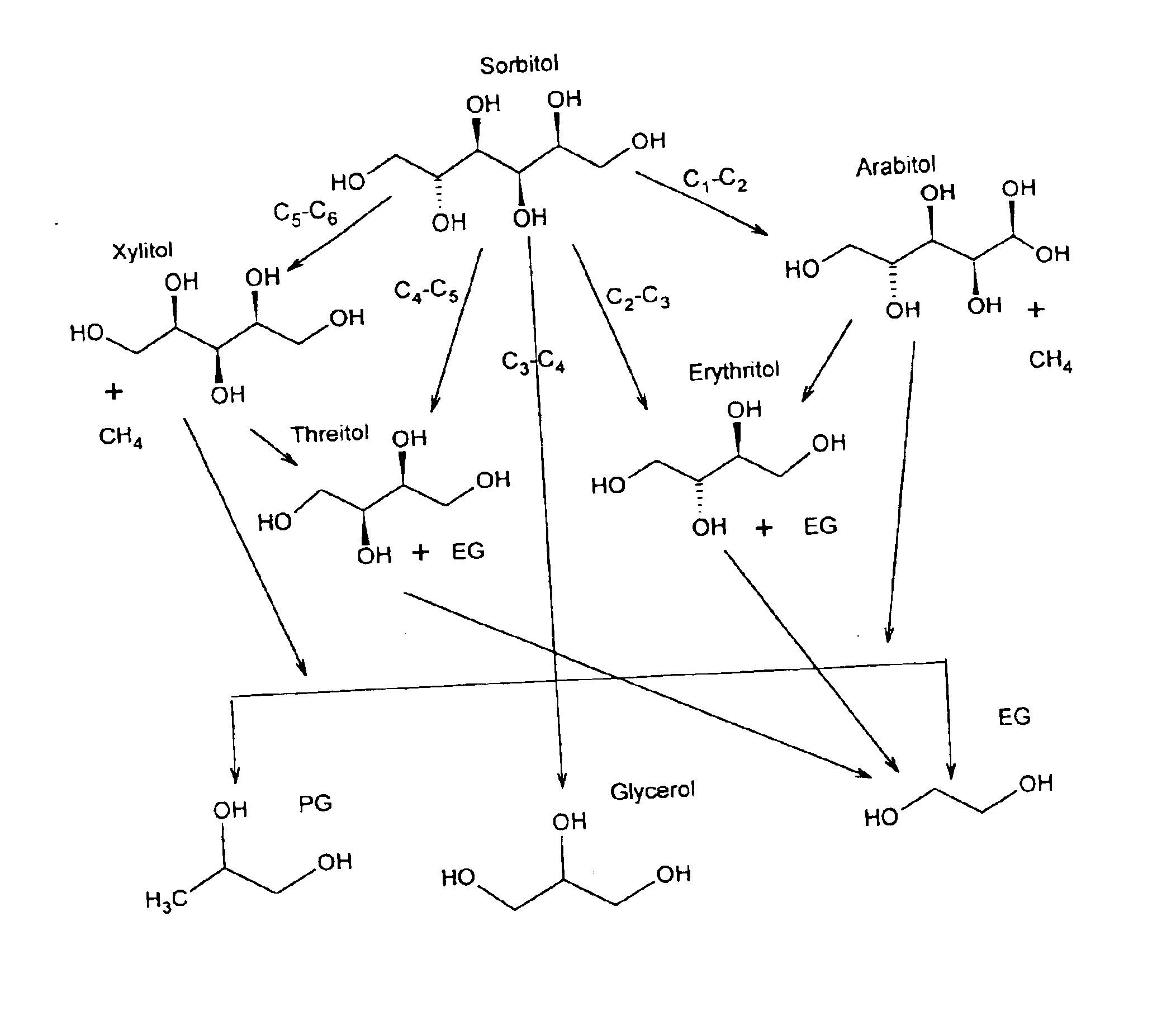

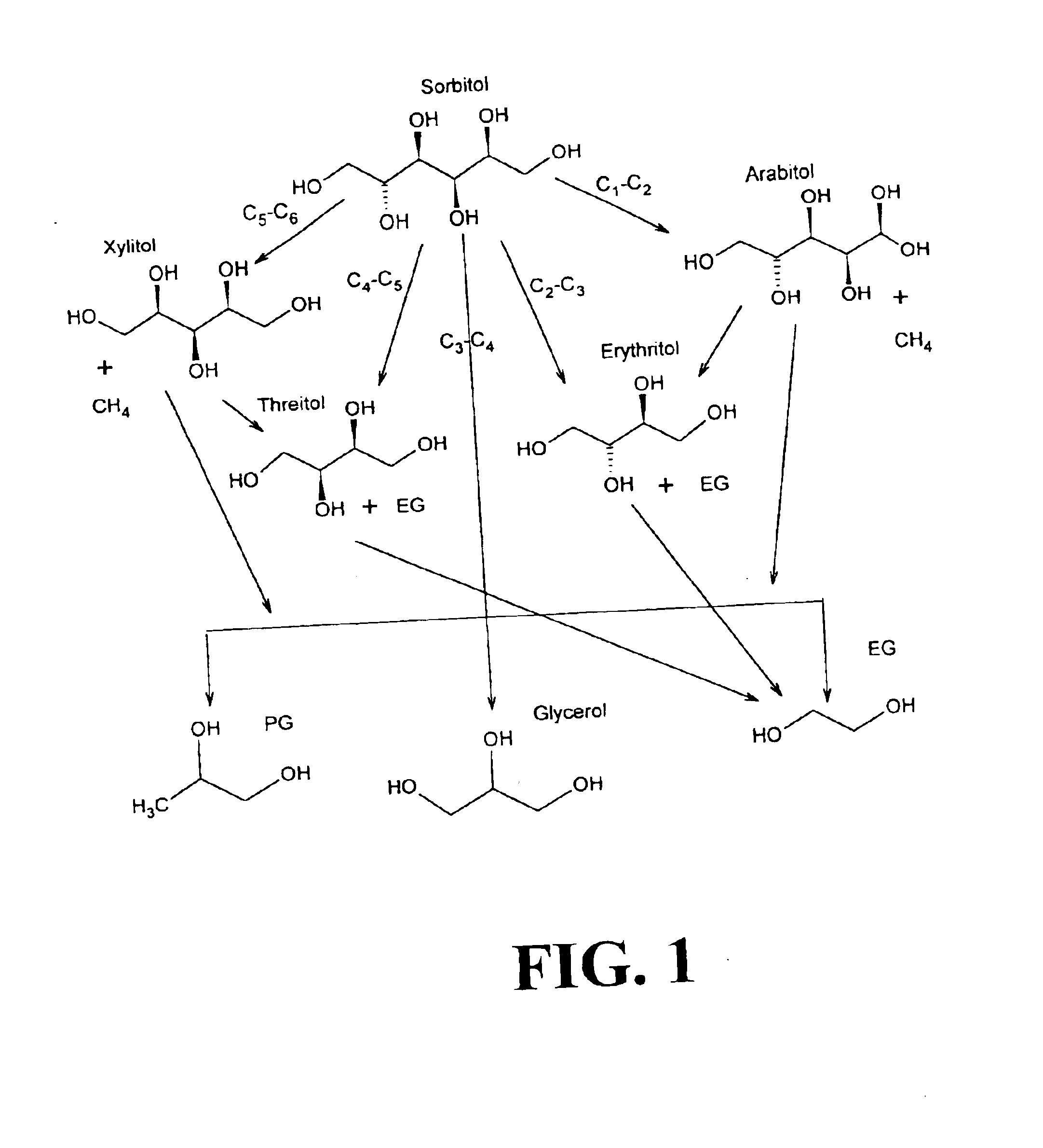

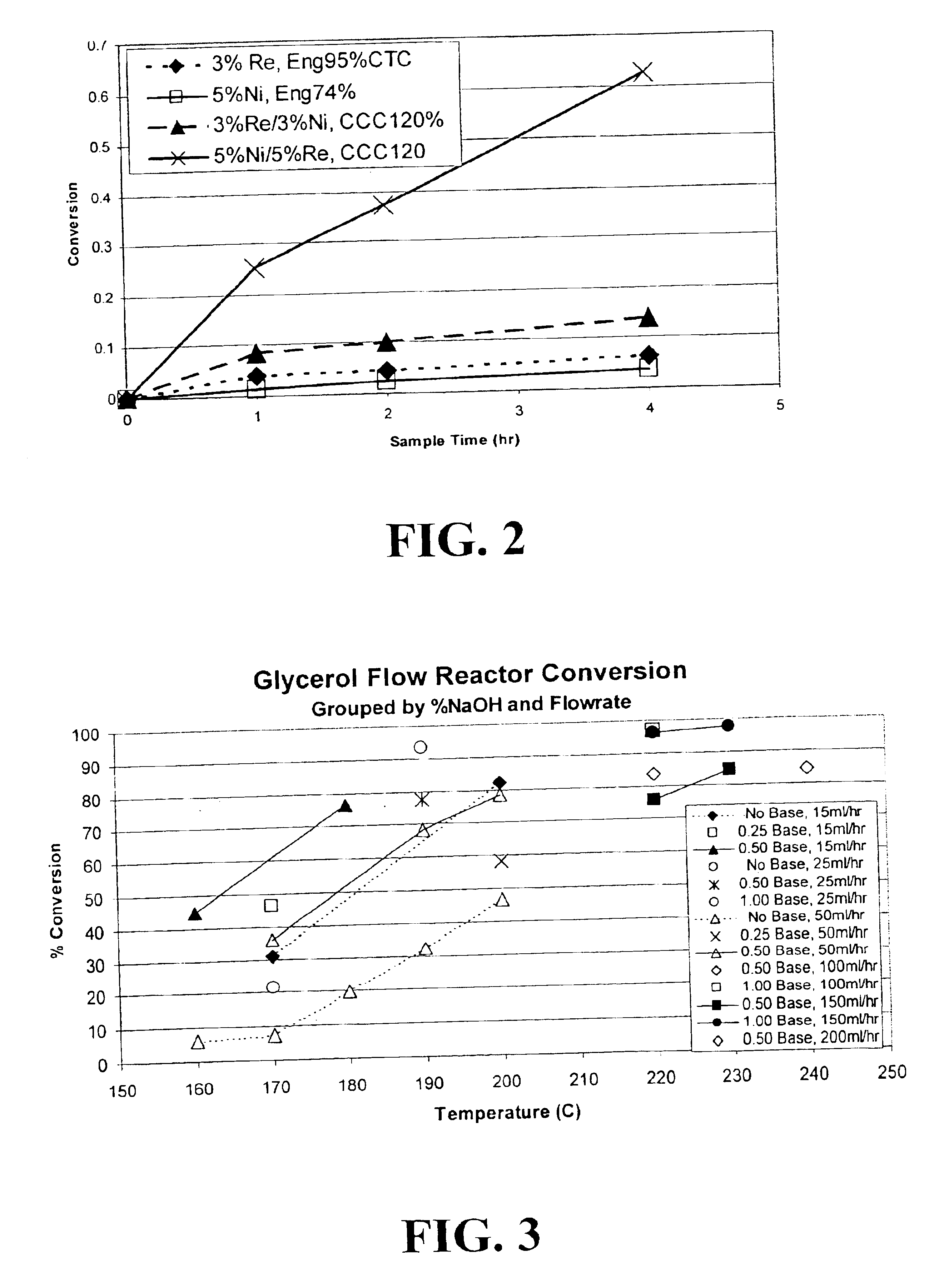

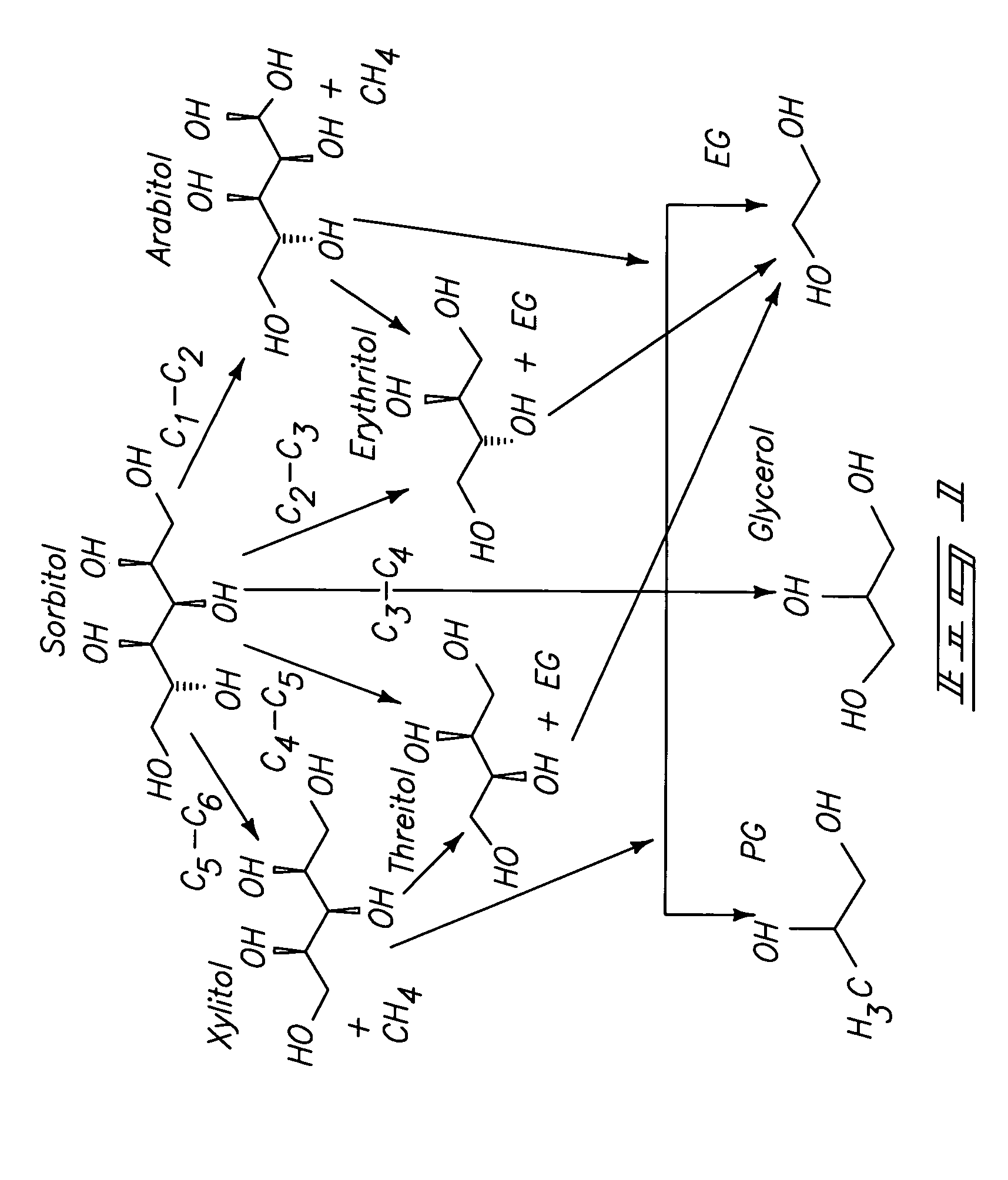

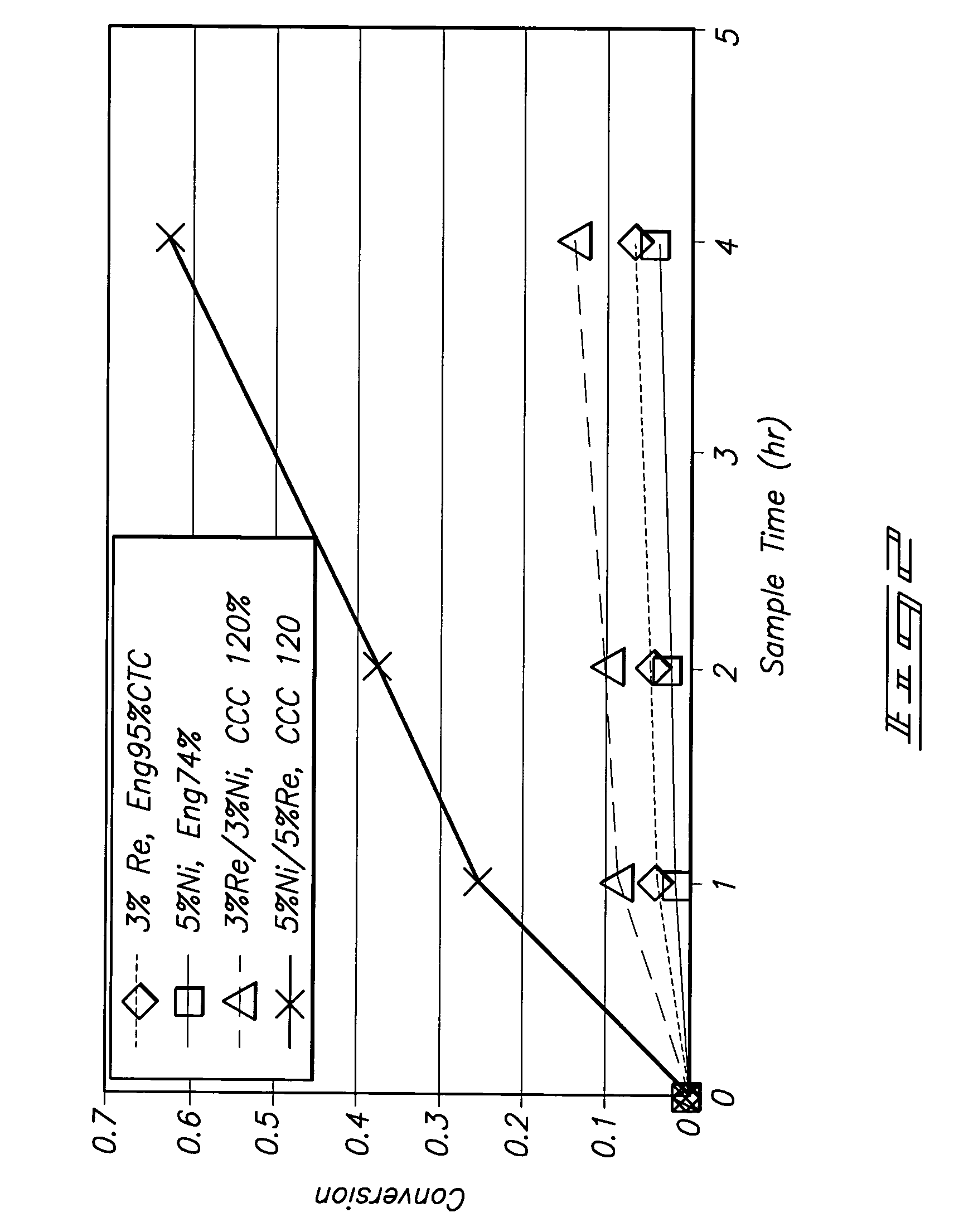

Hydrogenolysis of 6-carbon sugars and other organic compounds

InactiveUS6841085B2High selectivityHigh activityBiocideHydroxy compound active ingredientsHydrogenAlcohol sugars

Methods for hydrogenolysis are described which use a Re-containing multimetallic catalyst for hydrogenolysis of both C—O and C—C bonds. Methods and compositions for reactions of hydrogen over a Re-containing catalyst with compositions containing a 6-carbon sugar, sugar alcohol, or glycerol are described. It has been surprisingly discovered that reaction with hydrogen over a Re-containing multimetallic catalyst resulted in superior conversion and selectivity to desired products such as propylene glycol.

Owner:MICHIGAN STATE UNIV +1

Pharmaceutical composition

InactiveUS6946120B2Improve solubilityImprove abilitiesCosmetic preparationsOrganic active ingredientsAlcoholPolyol

A pharmaceutical composition for topical administration, including, as the pharmaceutically active component, at least 5% by weight, based on the total weight of the composition of a piperidinopyrimidine derivative or a pharmaceutically acceptable salt thereof; an acid in an amount to completely solubilise the piperidinopyrimidine derivative or a pharmaceutically acceptable salt thereof; a solvent composition including at least two of water, a lower alcohol and a co-solvent selected from one or more of the group consisting of aromatic and polyhydric alcohols; wherein when the co-solvent includes propylene glycol, it is present in an amount of less than approximately 10% by weight.

Owner:STIEFEL RESEARCH AUSTRALIA PTY LTD

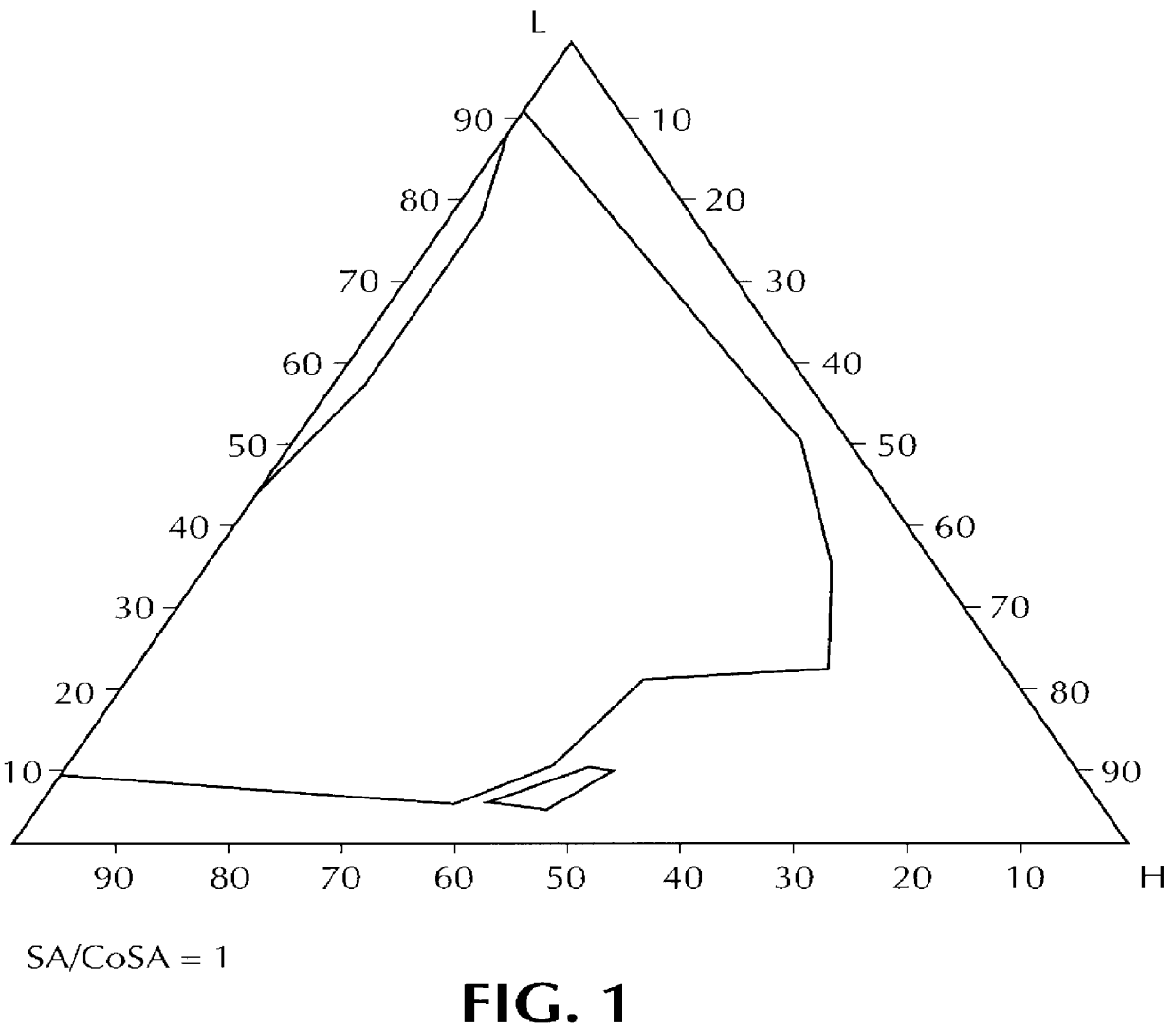

Orally administrable composition capable of providing enhanced bioavailability when ingested

InactiveUS6054136AImprove solubilityImprove bioavailabilityCosmetic preparationsToilet preparationsFatty acid esterIngestion

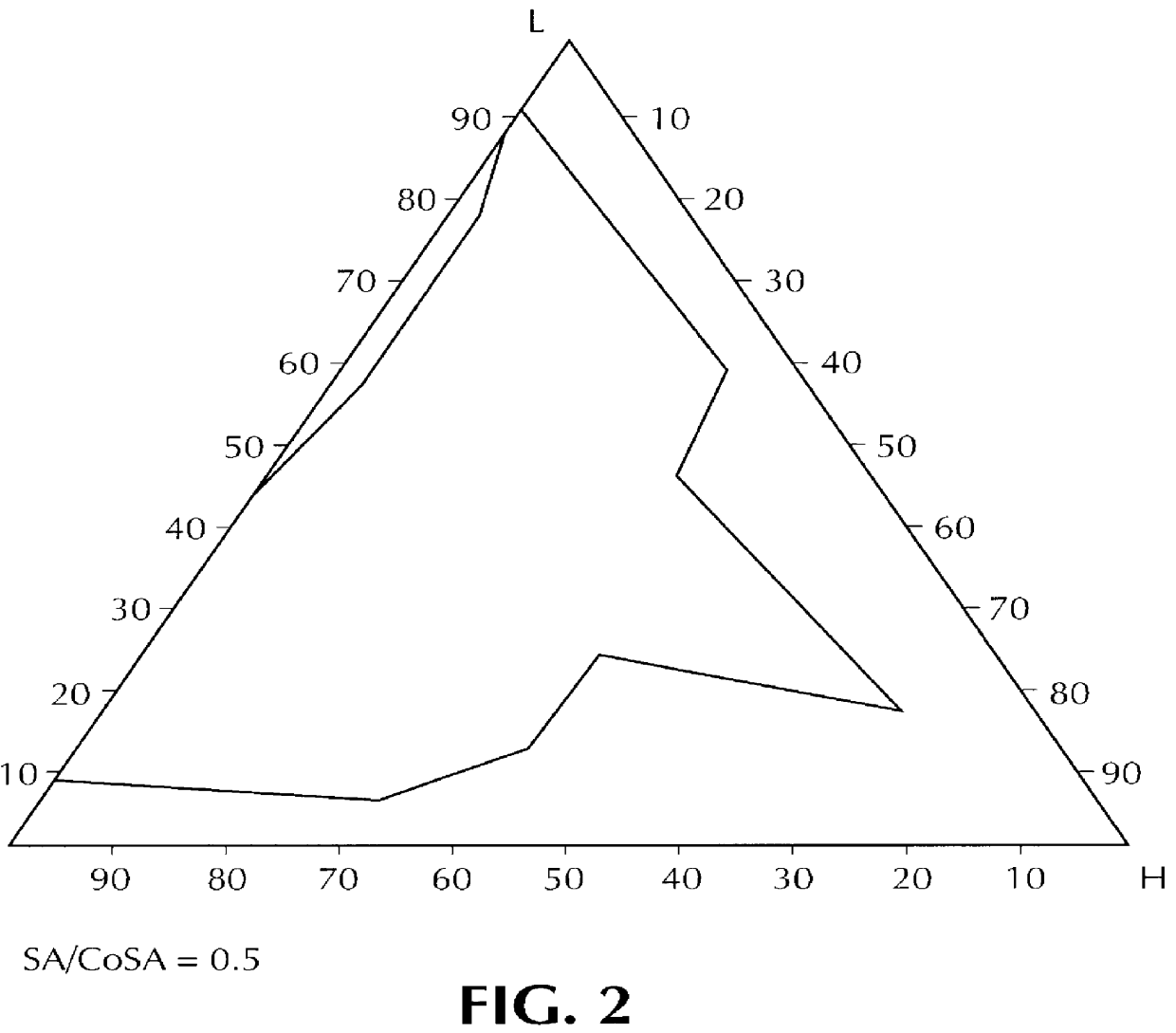

Composition for pharmaceutical or cosmetic use, capable of forming a microemulsion, comprising at least: an active principle, a lipophilic phase consisting of a mixture of fatty acid esters and glycerides, a surfactant (SA), a cosurfactant (CoSA), a hydrophilic phase, characterized: in that the lipophilic phase consists of a mixture of C8 to C18 polyglycolized glycerides having a hydrophilic-lipophilic balance (HLB) of less than 16, this lipophilic phase representing from 30 to 75% of the total weight of the composition; in that the surfactant (SA) is chosen from the group comprising saturated C8-C10 olyglycolized glycerides and oleic esters of polyglycerol, this surfactant having an HLB of less than 16; in that the cosurfactant (CoSA) is chosen from the group comprising lauric esters of propylene glycol, oleic esters of polyglycerol and ethyl diglycol; in that the SA / CoSA ratio is between 0.5 and 6; and in that the hydrophilic phase of the final microemulsion is supplied after ingestion by the physiological fluid of the digestive milieu.

Owner:GATTEFOSSE HLDG

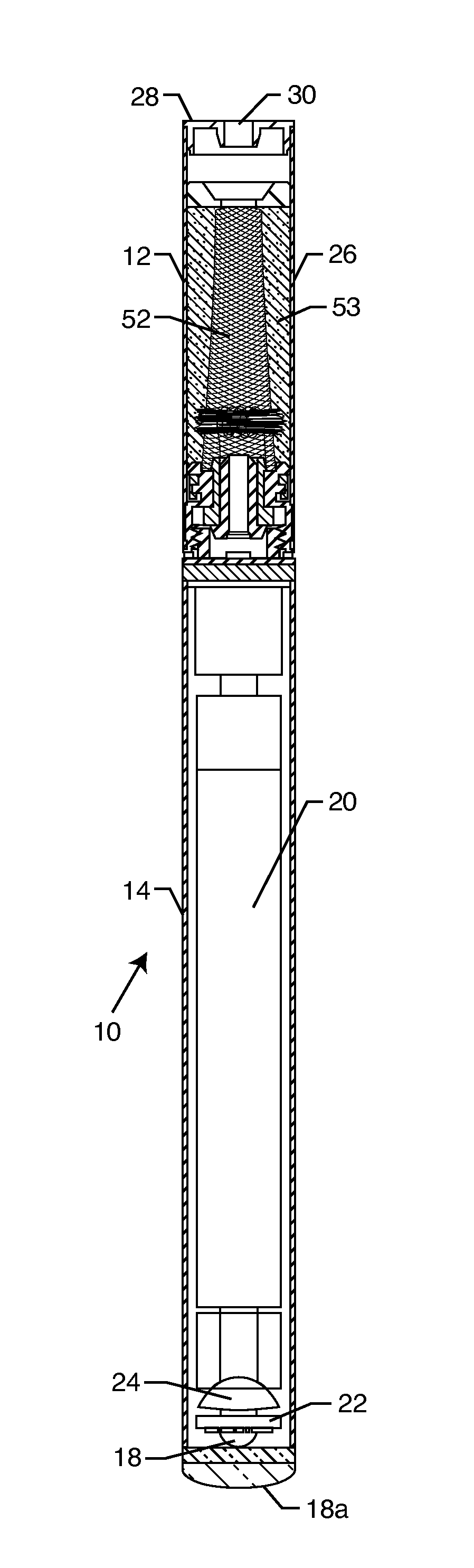

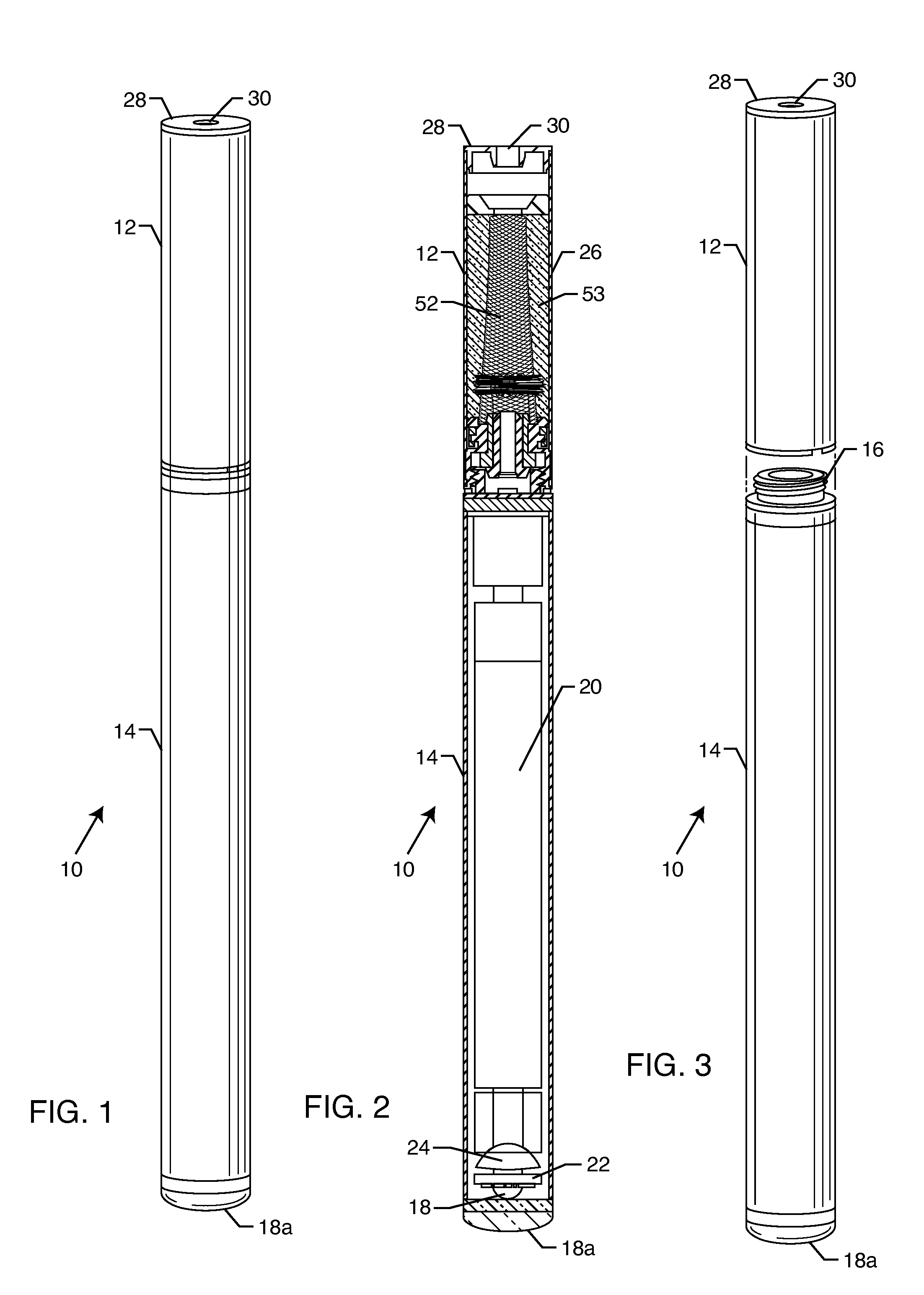

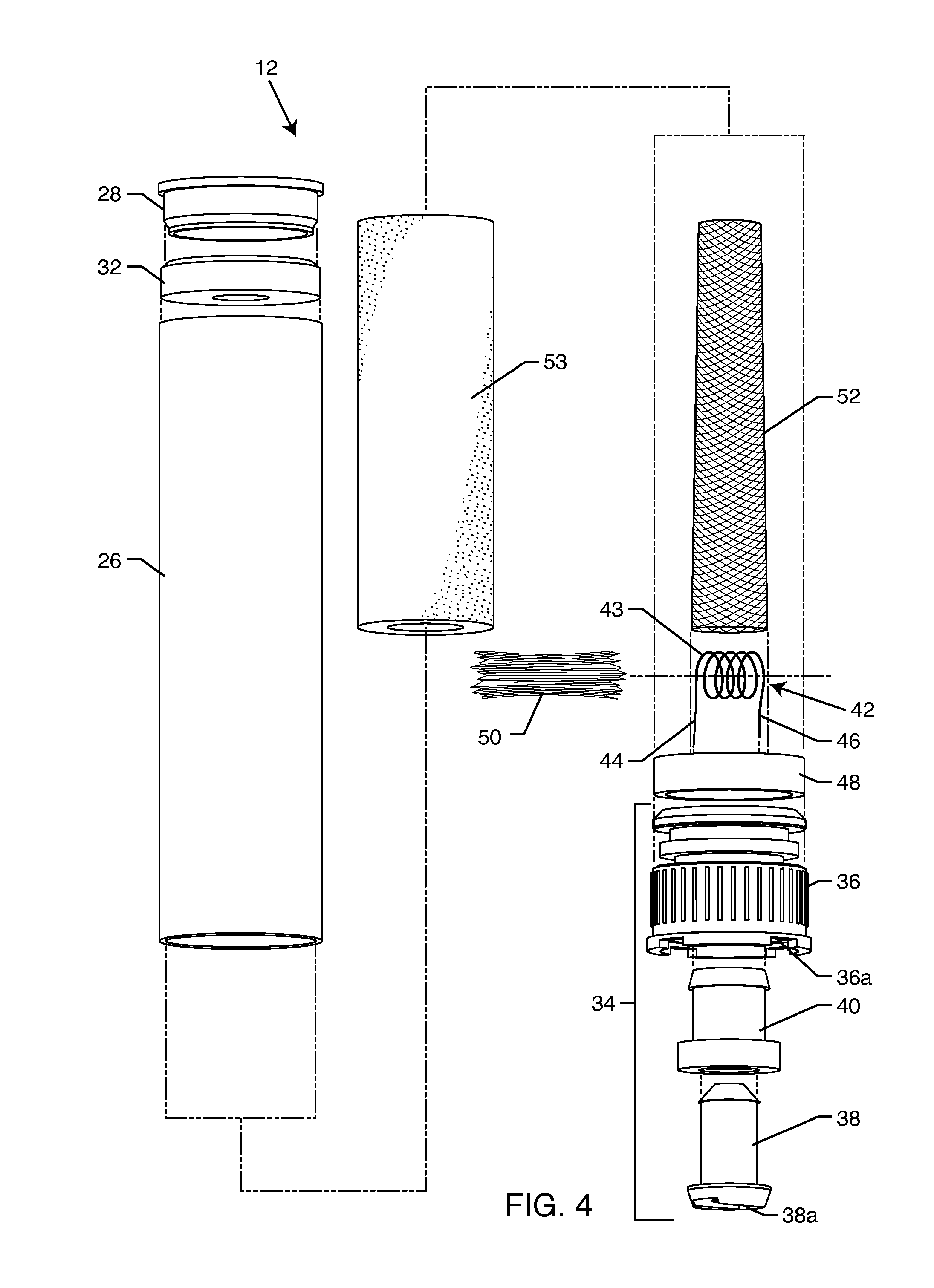

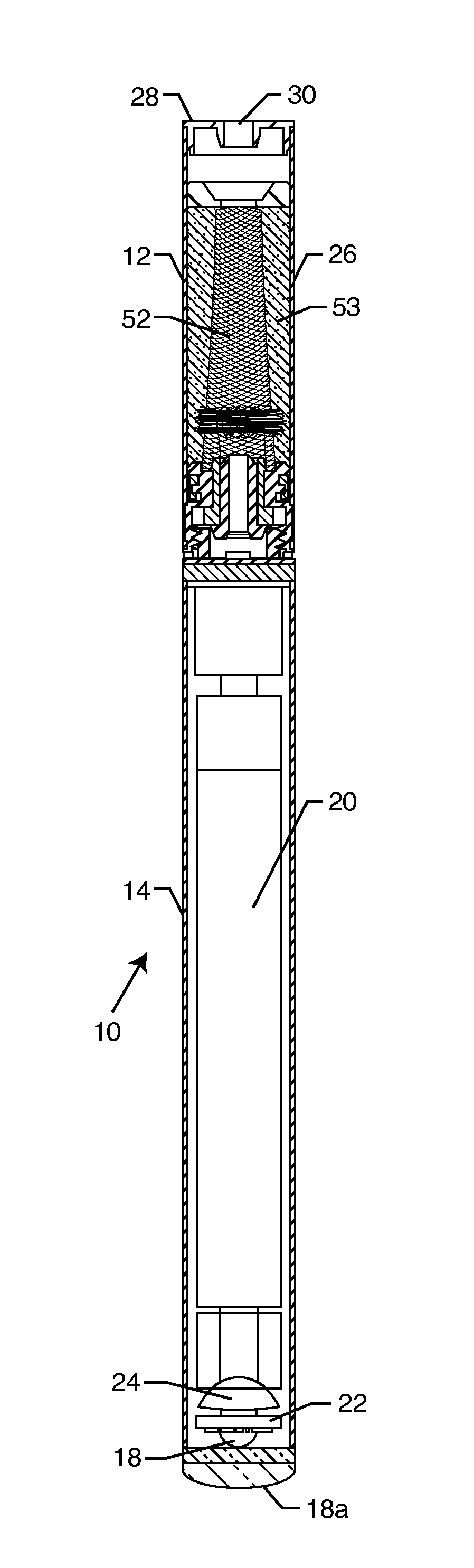

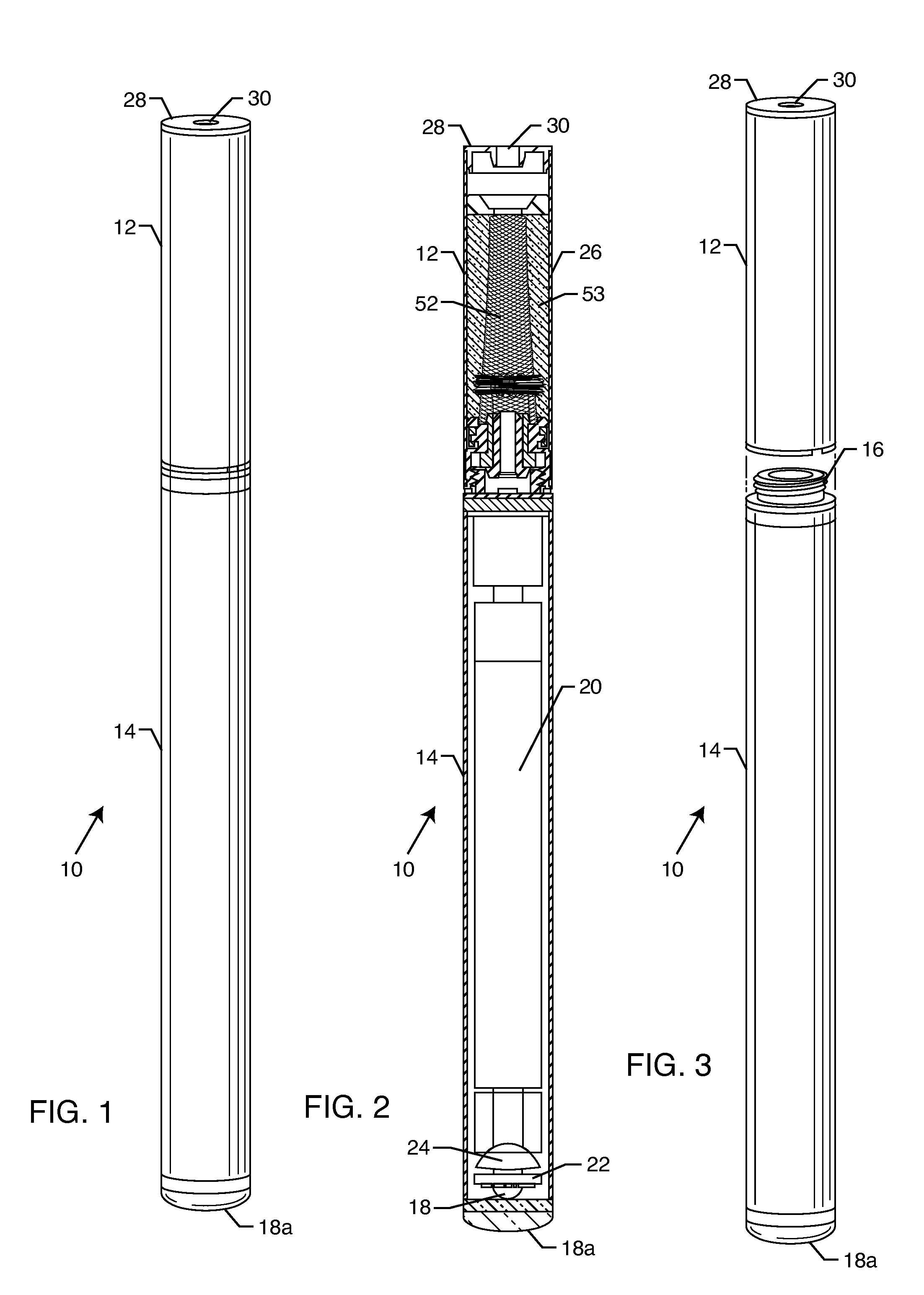

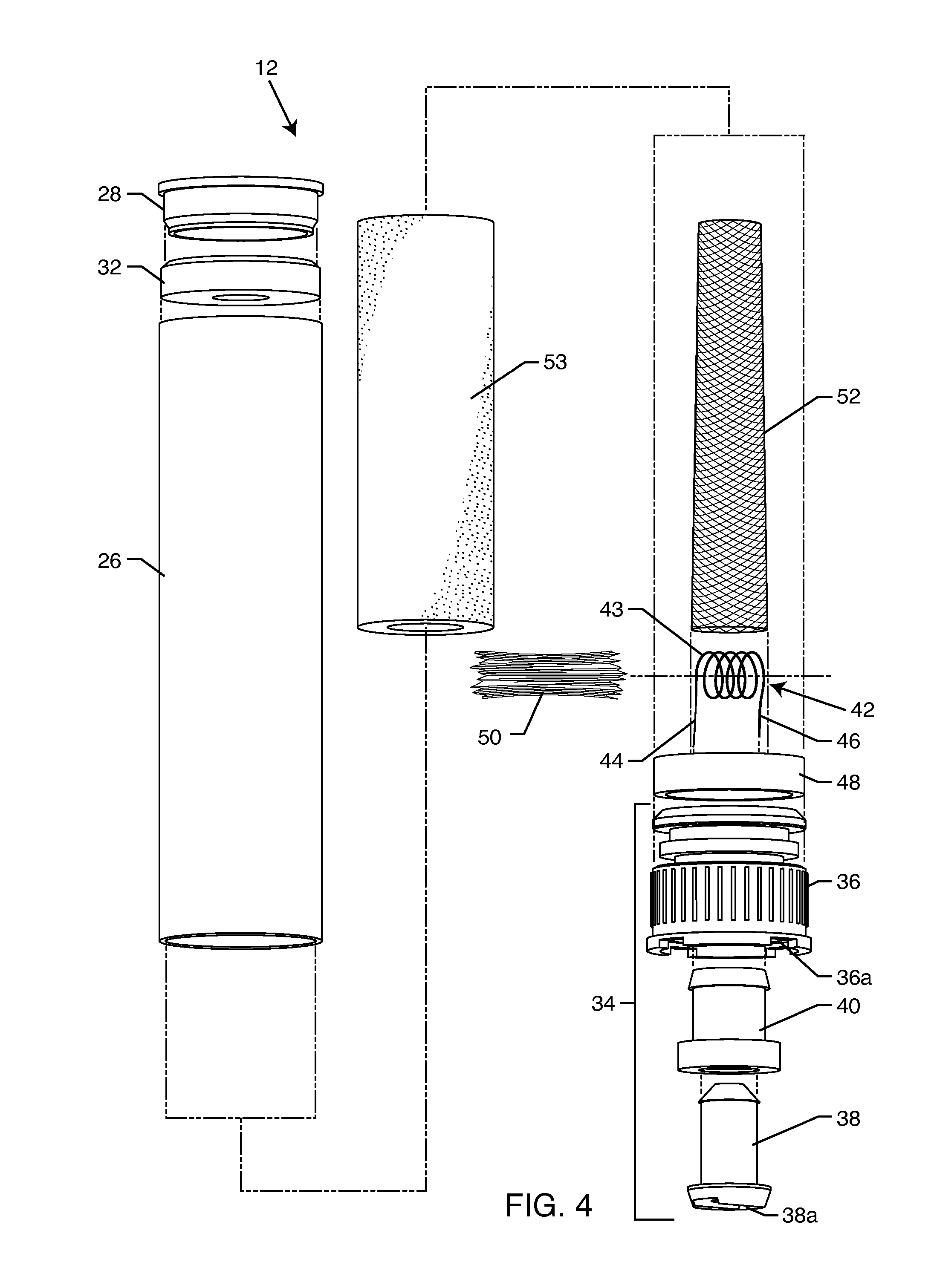

Cartomizer for electronic cigarettes

A cartomizer for an electronic cigarette having an elongated, hollow body with a mouthpiece in a first end and a battery coupling in an opposite second end. An atomizing coil is disposed in the body generally perpendicular to a longitudinal axis of the cartomizer and has positive and negative terminal leads pressfit connected to positive and negative terminals separated by an insulative spacer in the battery coupling. A fibrous wick is inserted inside the atomizing coil and a cloth tube is disposed generally parallel to the longitudinal axis of the cartomizer and extends from the atomizing coil to the mouthpiece. A volatile liquid mixture of preferably 80% propylene glycol and 20% veggie glycol with liquid nicotine and / or flavoring is disposed in the body.

Owner:KRETEK INT INC

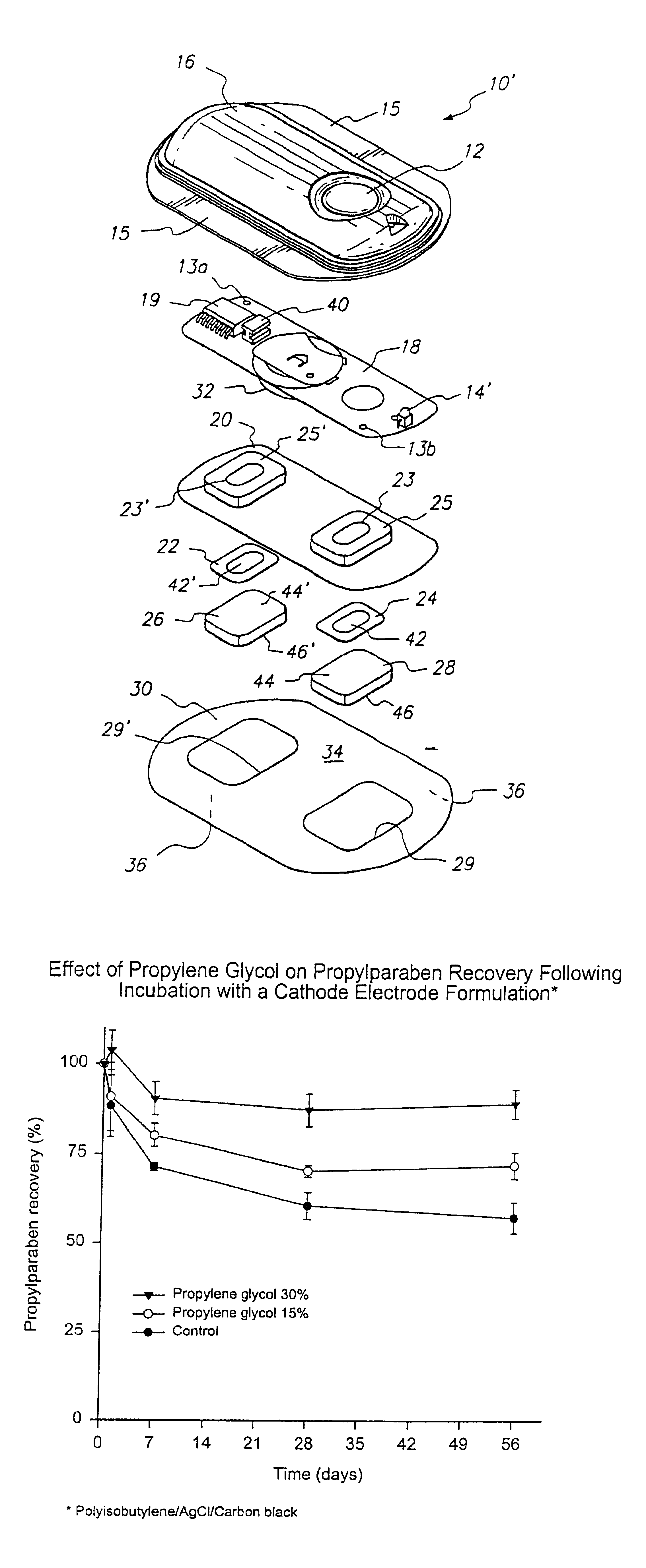

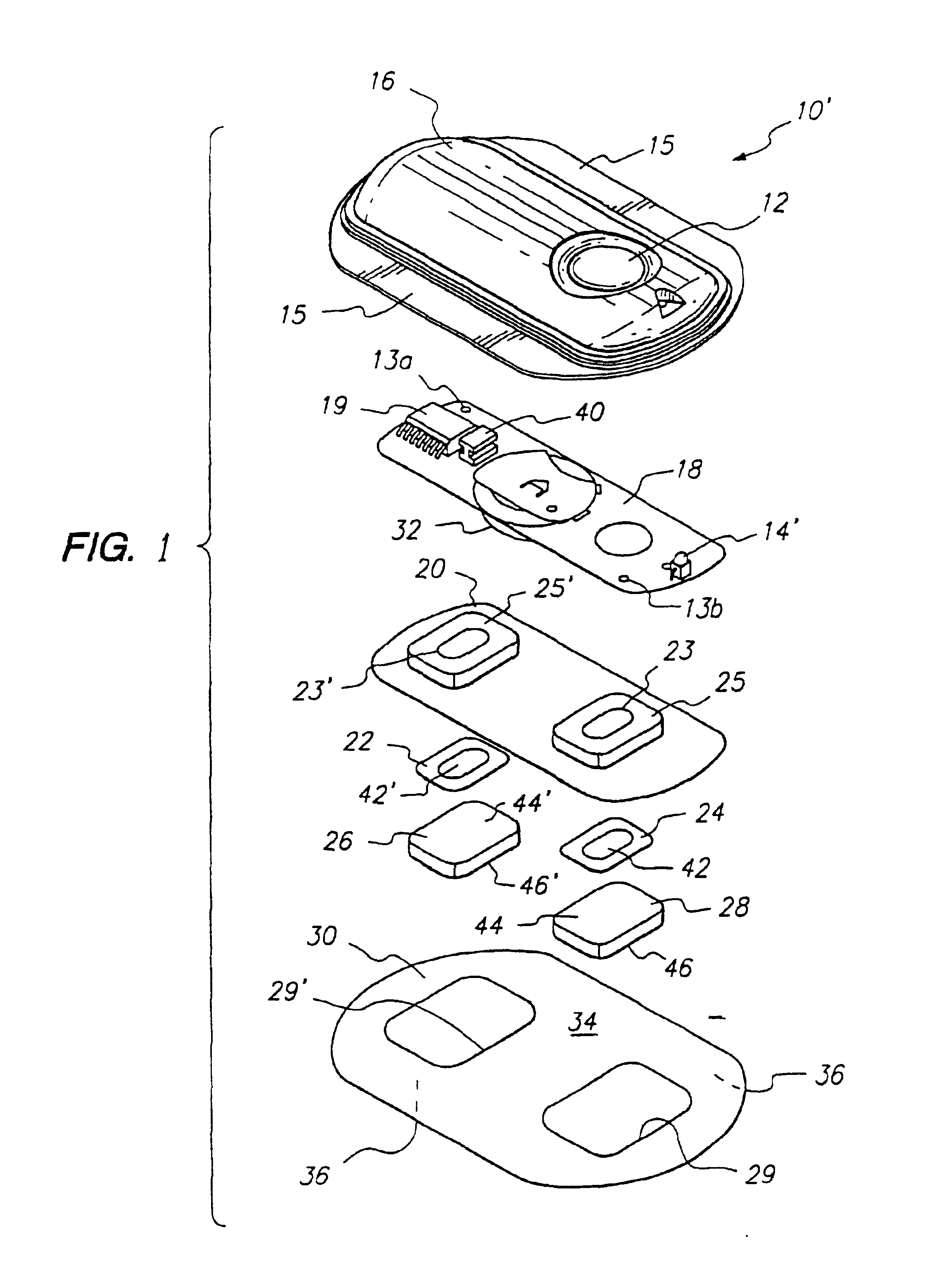

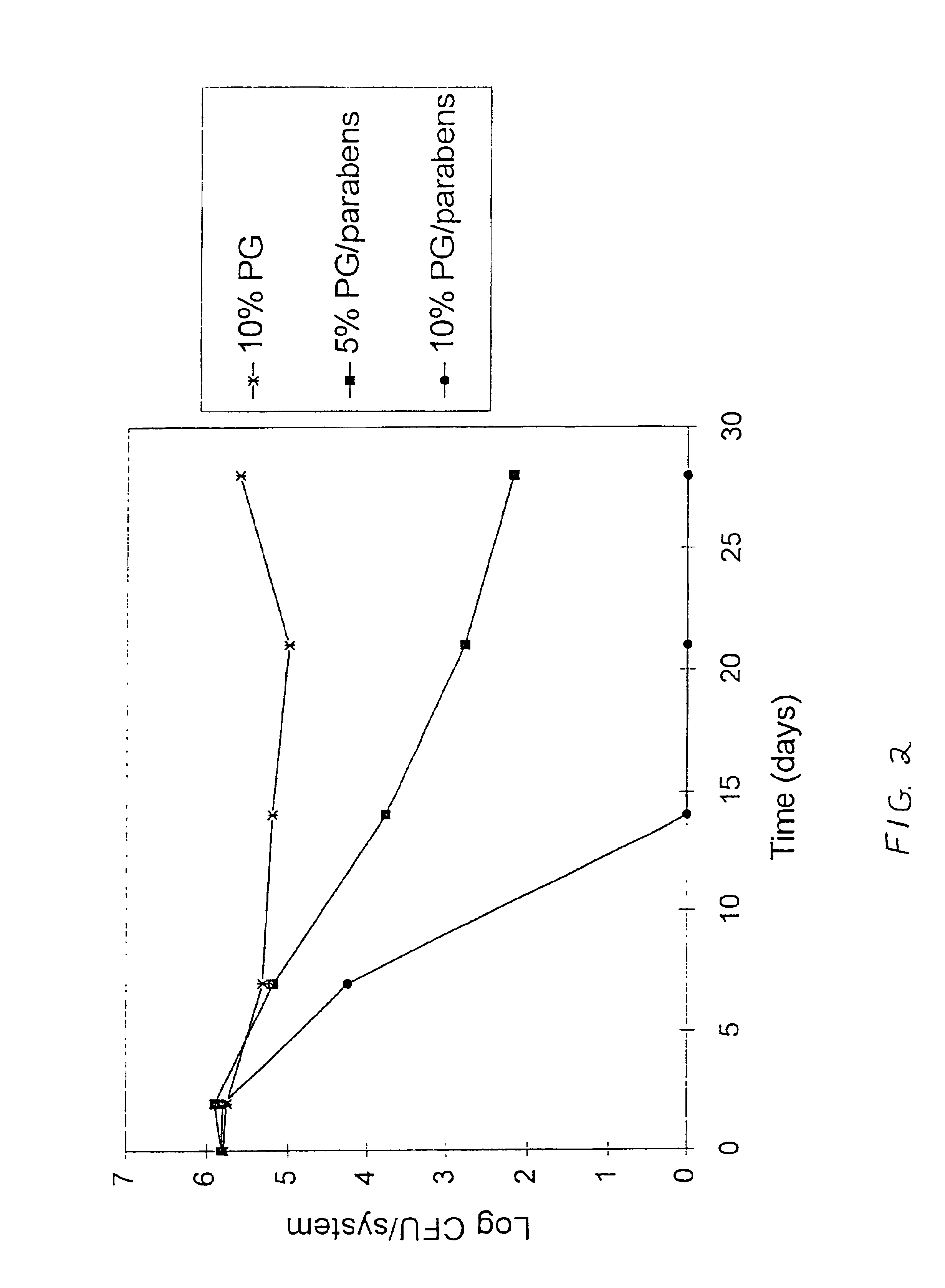

Transdermal electrotransport delivery device including an antimicrobial compatible reservoir composition

InactiveUS7054682B2Reducing its effectivenessInhibit microbial growthNervous disorderElectrotherapyMedicineAqueous medium

A transdermal electrotransport drug delivery device having an anode, a cathode and a source of electrical power electrically connected to the anode and the cathode. At least one of the anode and the cathode includes an electrode and a reservoir comprised of a housing composed of a polymeric material and an aqueous medium in contact with the housing. The aqueous medium includes (i) a drug or an electrolyte salt or a mixture thereof, (ii) propylene glycol, and (iii) an antimicrobial agent in an amount sufficient to inhibit microbial growth in the aqueous medium. The propylene glycol prevents the antimicrobial agent from being adsorbed by other materials used in the construction of the delivery device. A process for preparing a transdermal electrotransport drug delivery device is also provided.

Owner:ALZA CORP

Oleaginous pharmaceutical and cosmetic foam

InactiveUS20080063607A1Pleasant and easy to spreadPatient compliance is goodBiocideCosmetic preparationsActive agentPolyethylene glycol

The invention relates to stable pharmaceutical or cosmetic foam compositions containing certain active agents, having unique therapeutic properties and methods of treatment using such compositions. The foamable composition includes at least one solvent comprising polyethylene glycol (PEG) or PEG derivative and mixtures thereof, or comprising propylene glycol, wherein the solvent is present at a concentration of about 70% to about 96.5% by weight of the total composition, at least a non-ionic surface-active agent at a concentration of about 0.1% to less than about 10% by weight of the total composition.

Owner:FOAMIX PHARMACEUTICALS LIMITED

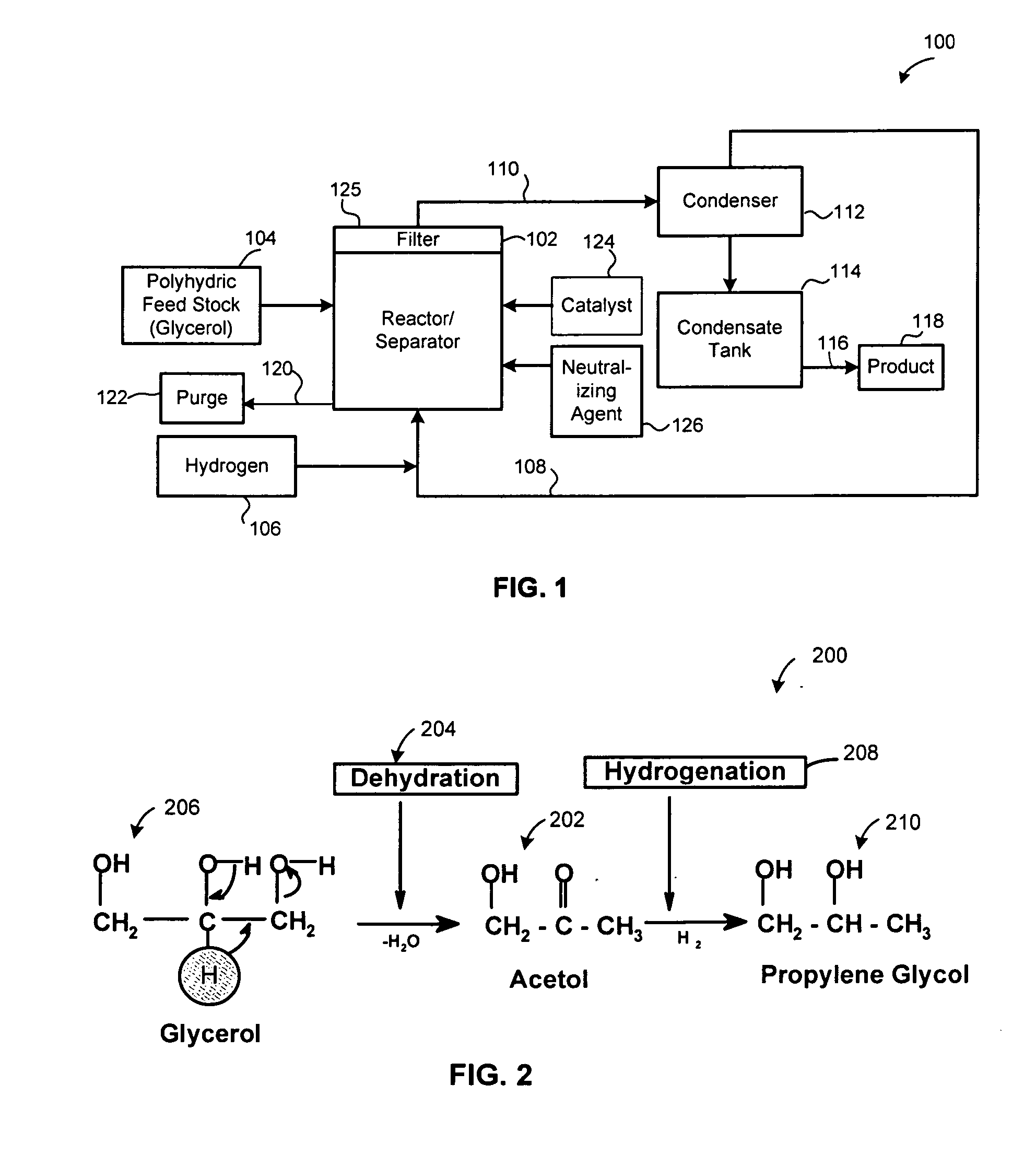

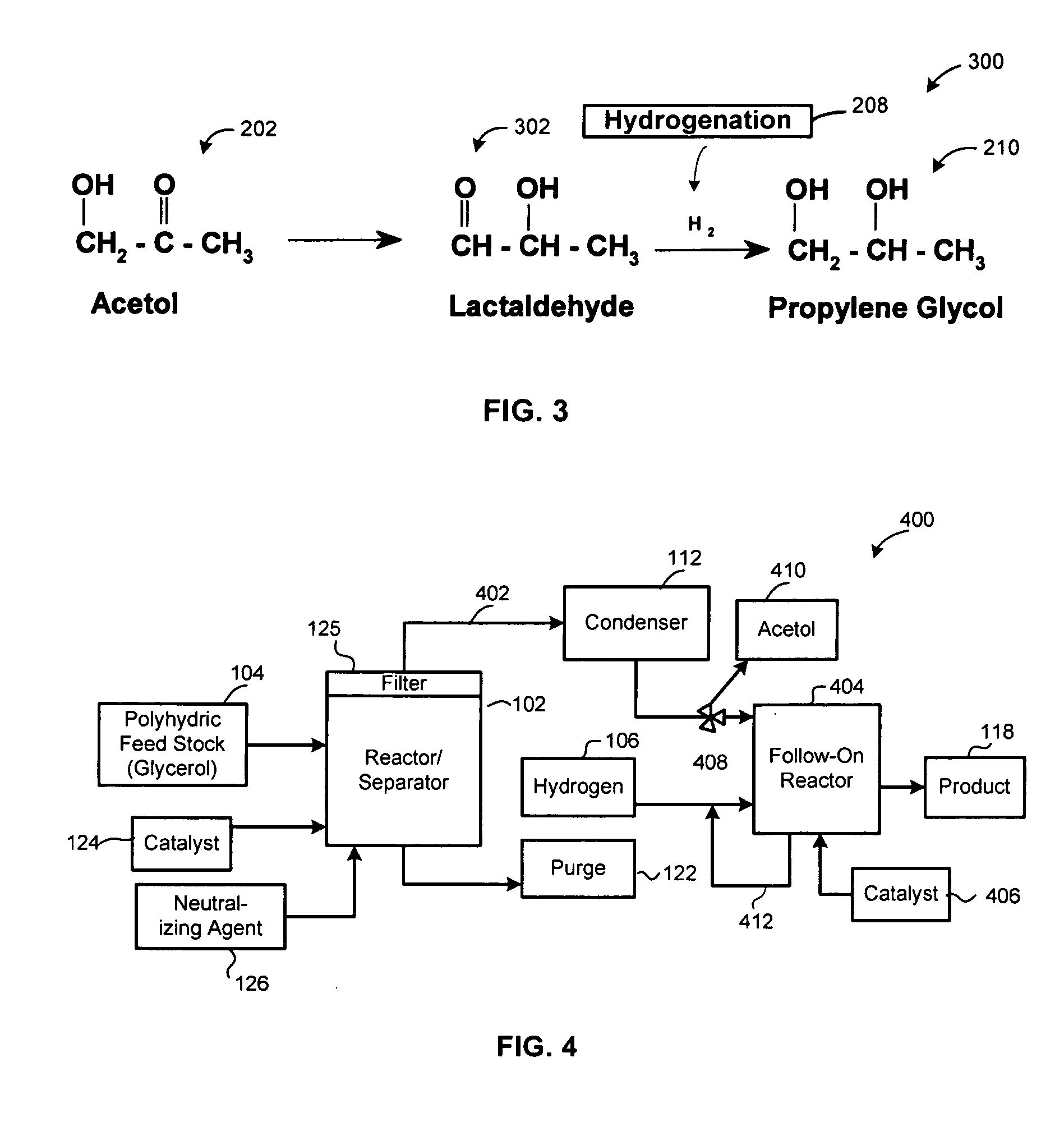

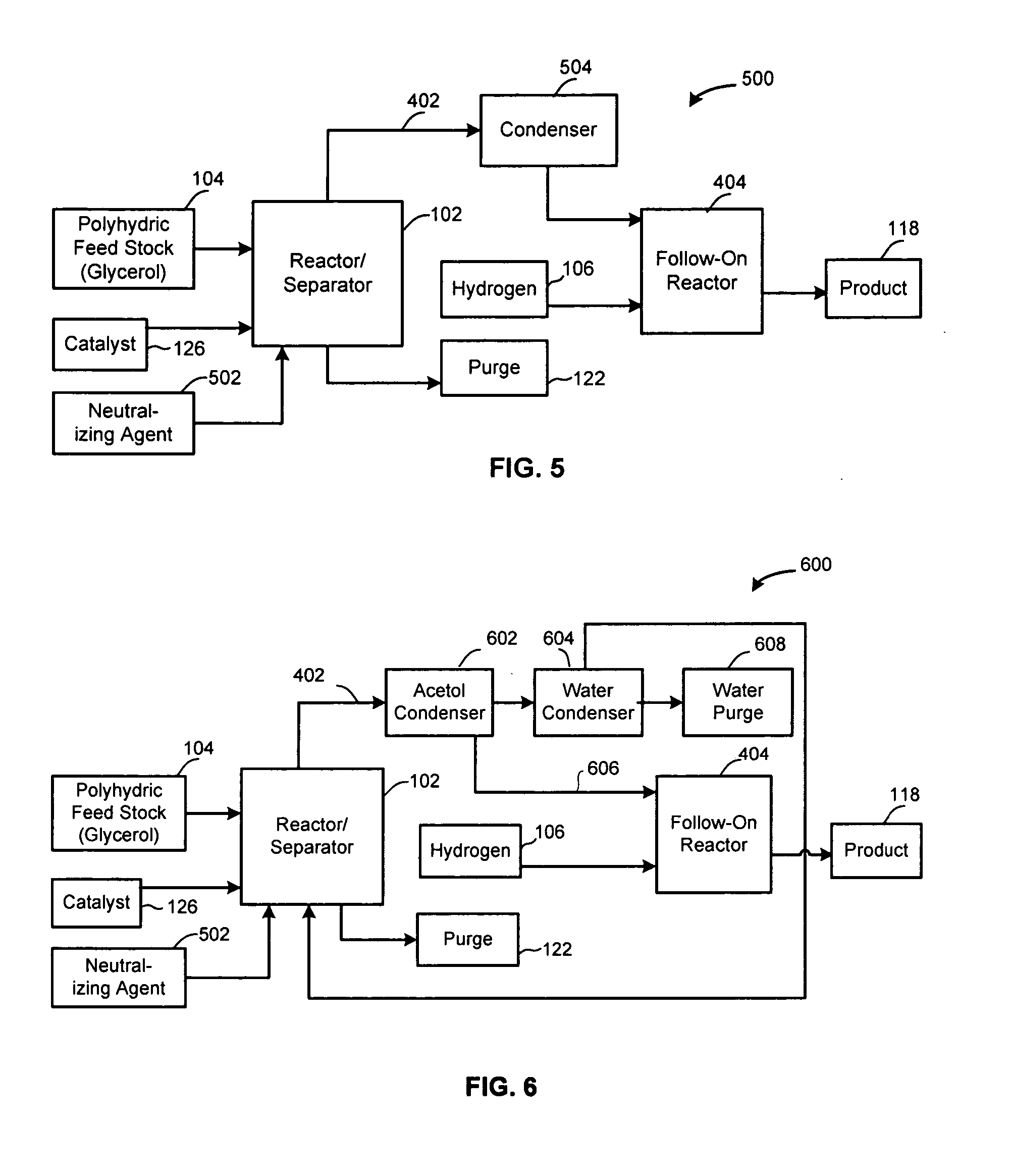

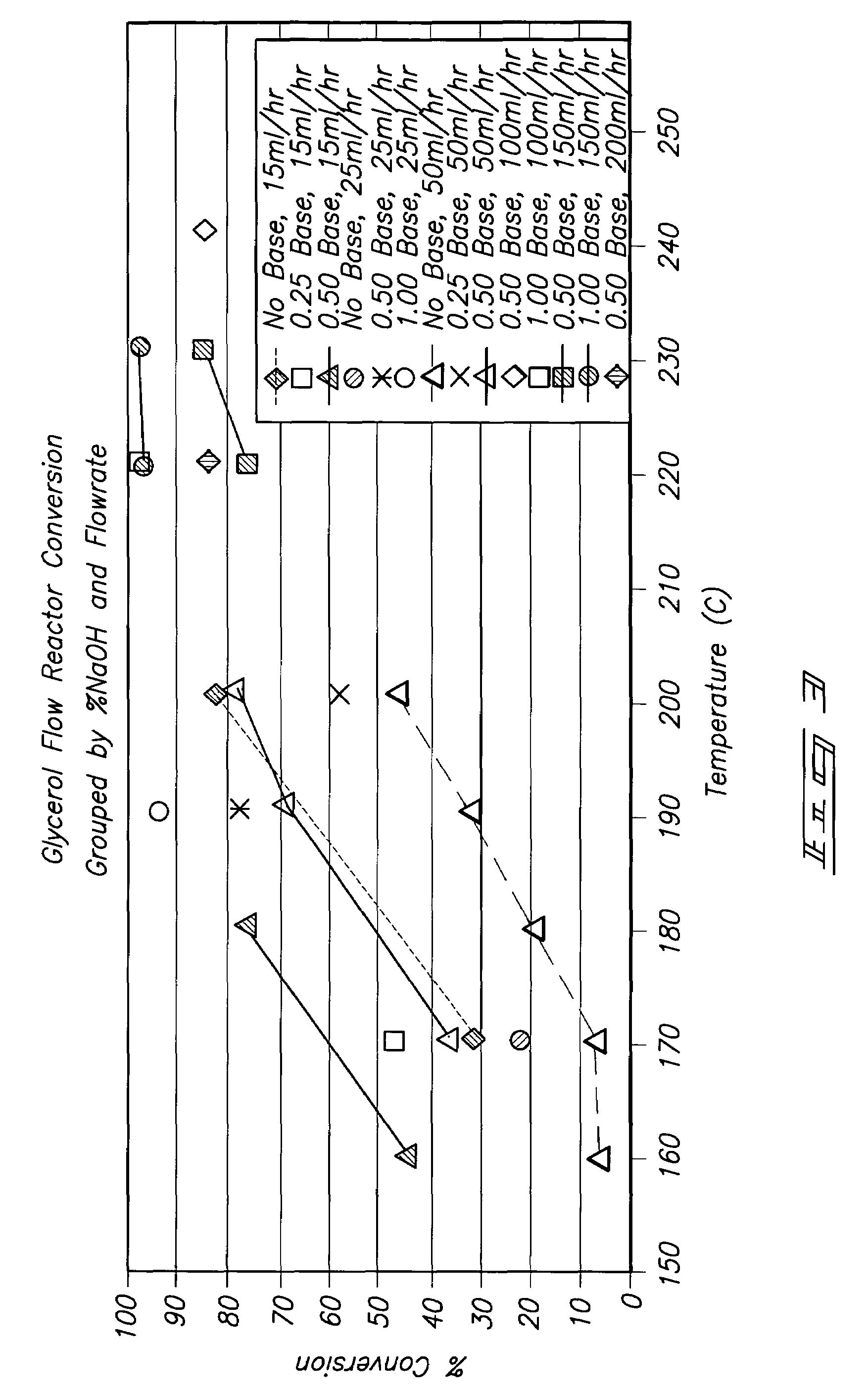

Method of producing lower alcohols from glycerol

ActiveUS20050244312A1High selectivityOrganic compound preparationOxygen compounds preparation by reductionAlcoholBoiling point

A reactive-separation process converts glycerin into lower alcohols, having boiling points less than 200° C., at high yields. Conversion of natural glycerin to propylene glycol through an acetol intermediate is achieved at temperatures from 150° to 250° C. at a pressure ranging from 1 and 25 bar. The preferred applications of the propylene glycol are as an antifreeze, deicing compound, or anti-icing compound. The preferred catalyst for this process in a copper-chromium powder.

Owner:RENEWABLE ALTERNATIVES LLC +1

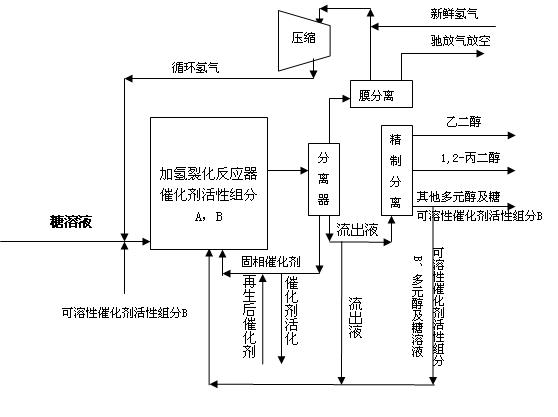

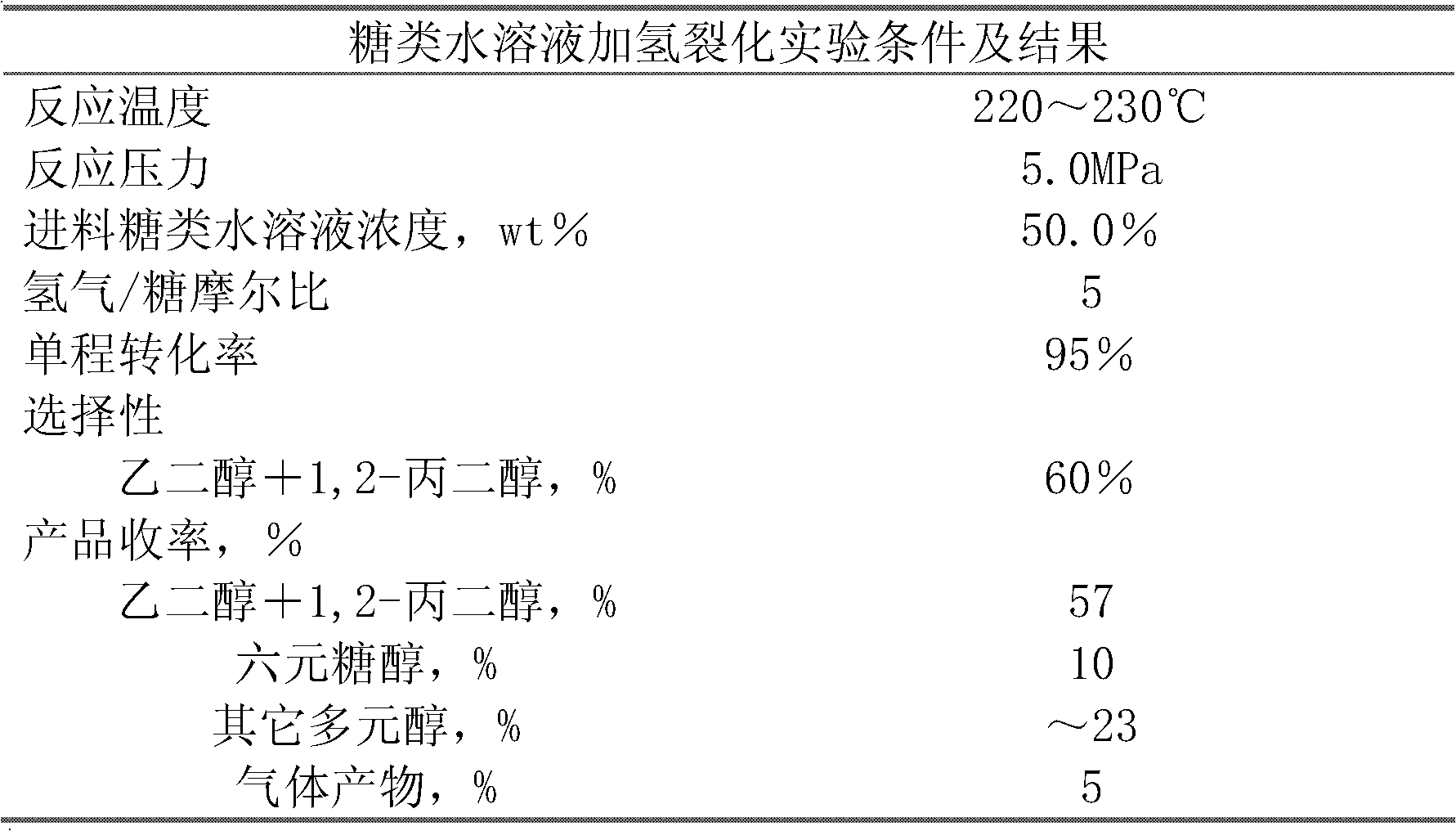

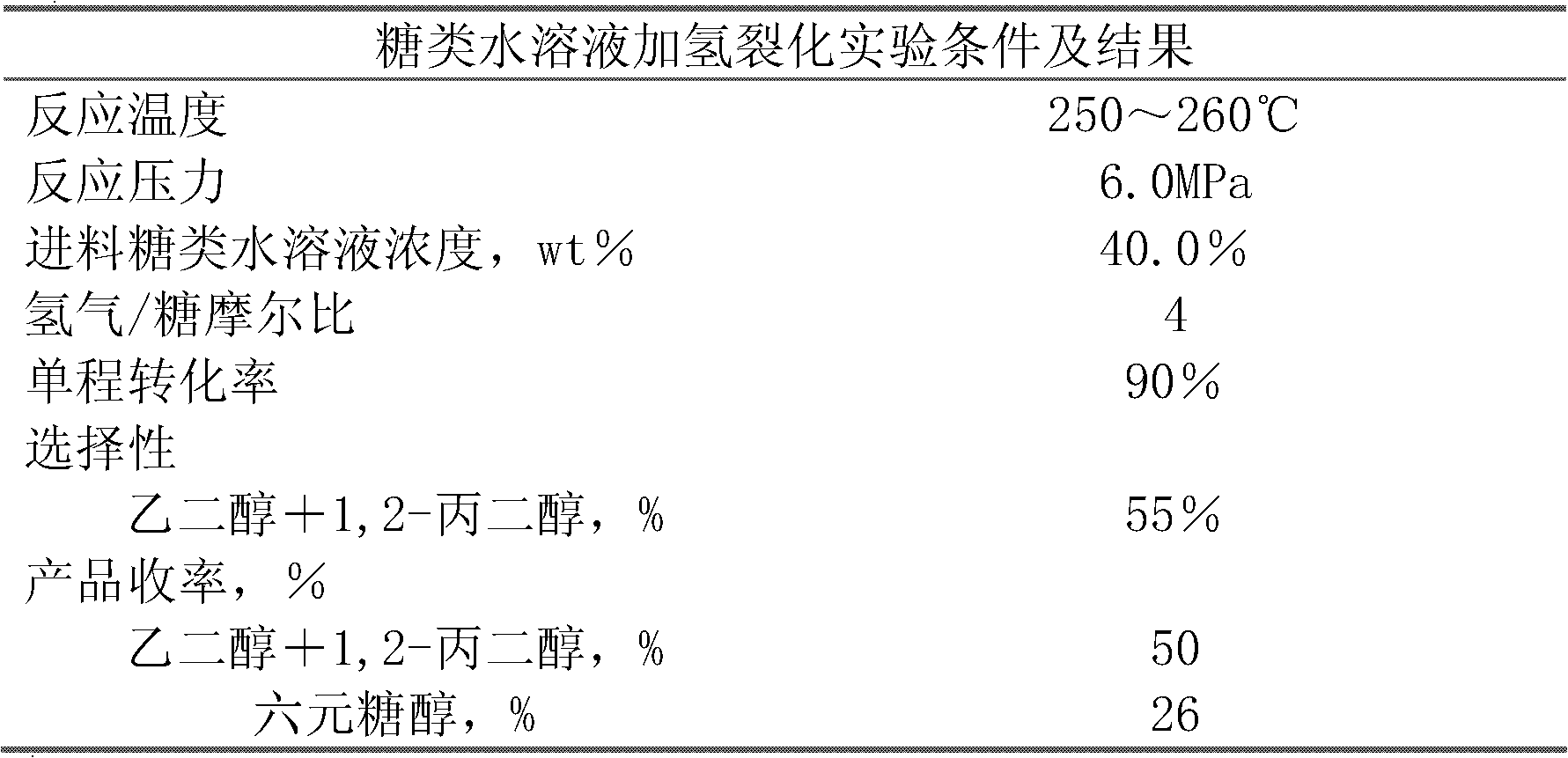

Method for producing ethylene glycol and 1,2-propylene glycol through continuous hydrocrackin of sugars

ActiveCN102643165ARealize continuous inputReduce consumptionOrganic compound preparationPreparation by OH group eliminationGas phaseOligosaccharide

The invention relates to a continuous reaction process flow for producing ethylene glycol and 1, 2-propylene glycol through continuous hydrocrackin of sugars and provides a method for producing the ethylene glycol and the 1,2-propylene glycol through continuous hydrocrackin of sugars. In the process flow, sugars (comprising one or more than two of sugar, glucose, fructose, xylose, soluble xylo-oligosaccharide and starch) are hydrocracked in the presence of a catalyst in a reactor and the hydrocracked product enters a separating system. Hydrogen gas in a gas phase is recycled by separating and recovering; a liquid phase product partially reflows to the reactor and other liquid phase products are refined and separated to form the ethylene glycol, the propylene glycol and other polyhydric alcohols; and concentrated soluble catalyst components in the refined and separated residual component liquid phase are partially returned to the reactor.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Aqueous compositions, aqueous cutting fluid using the same, method for preparation thereof, and cutting method using the cutting fluid

InactiveUS6221814B1Promote degradationSimple treatmentOther chemical processesWork treatment devicesActivated sludgeLiquid waste

An aqueous cutting fluid which can reduce the impact on working environment and the global environment, and can achieve both preventing precipitates from becoming a hard cake and keeping high dispersibility for abrasive grains is provided. Such an aqueous cutting fluid is obtained by a method comprising dispersing abrasive grains (G) in an aqueous composition comprising a dispersion medium (M) containing a hydrophilic alcohol compound such as ethylene glycol, a lipophilic alcohol compound such as propylene glycol and water, and silica colloid particles dispersed stably in the medium. The dispersion medium (M) is odorless and not flammable. The abrasive grains (G) may settle out after a time, but they do not closely contact with one another, and therefore the resulting precipitates do not become a hard cake, which allows the re-dispersion and reuse of precipitated grains. The instant aqueous cutting fluid is inherently low viscous, and the reduction of viscosity owing to the contamination of water and the increase of viscosity owing to contamination of shavings are both moderate. As a result, the cutting fluid has a long life. And articles which have been cut using the cutting fluid can be washed with water. Further, as the dispersion medium (M) is a biodegradable low molecular weight organic compound, a waste liquid from a process using the cutting fluid can be disposed with an activated sludge.

Owner:SHIN-ETSU HANDOTAI CO LTD +1

Polypropylene glycol foamable vehicle and pharmaceutical compositions thereof

InactiveUS20080152596A1Easy to useCosmetic preparationsBiocidePolypropylene glycolSurface-active agents

The present invention teaches a foamable pharmaceutical carrier comprising polypropylene glycol (PPG) alkyl ether, a surface-active agent water and a liquefied hydrocarbon gas propellant; and pharmaceutical compositions thereof.The present invention further teaches a foamable pharmaceutical carrier comprising polypropylene glycol (PPG) alkyl ether, a surface-active agent, and a liquefied hydrocarbon gas propellant; and pharmaceutical compositions thereof.

Owner:FOAMIX PHARMACEUTICALS LIMITED

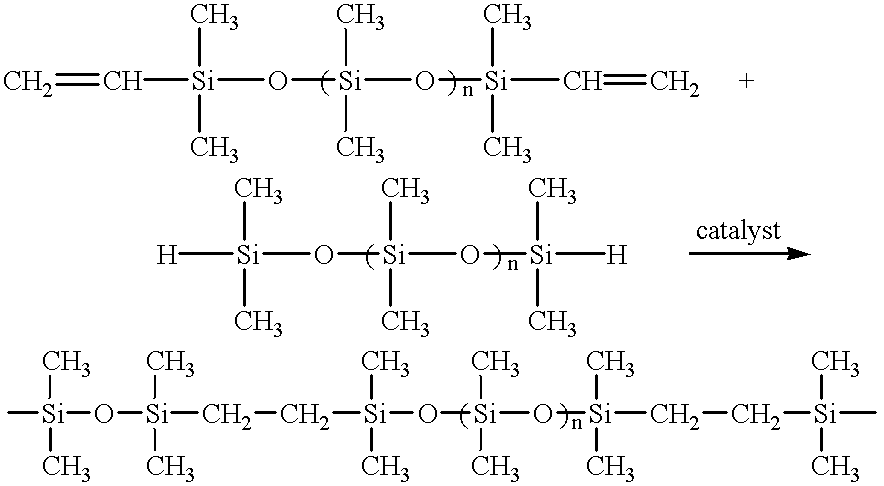

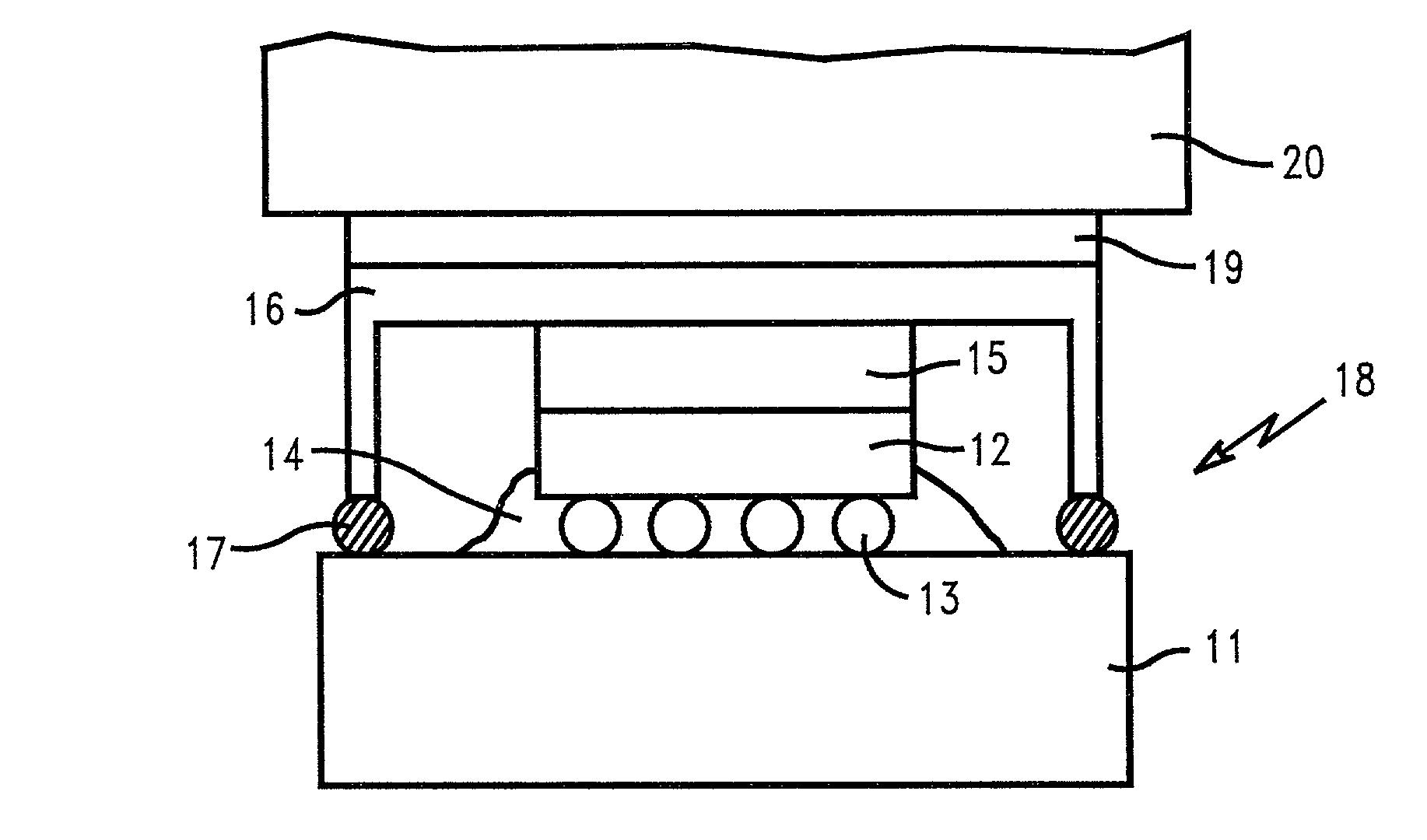

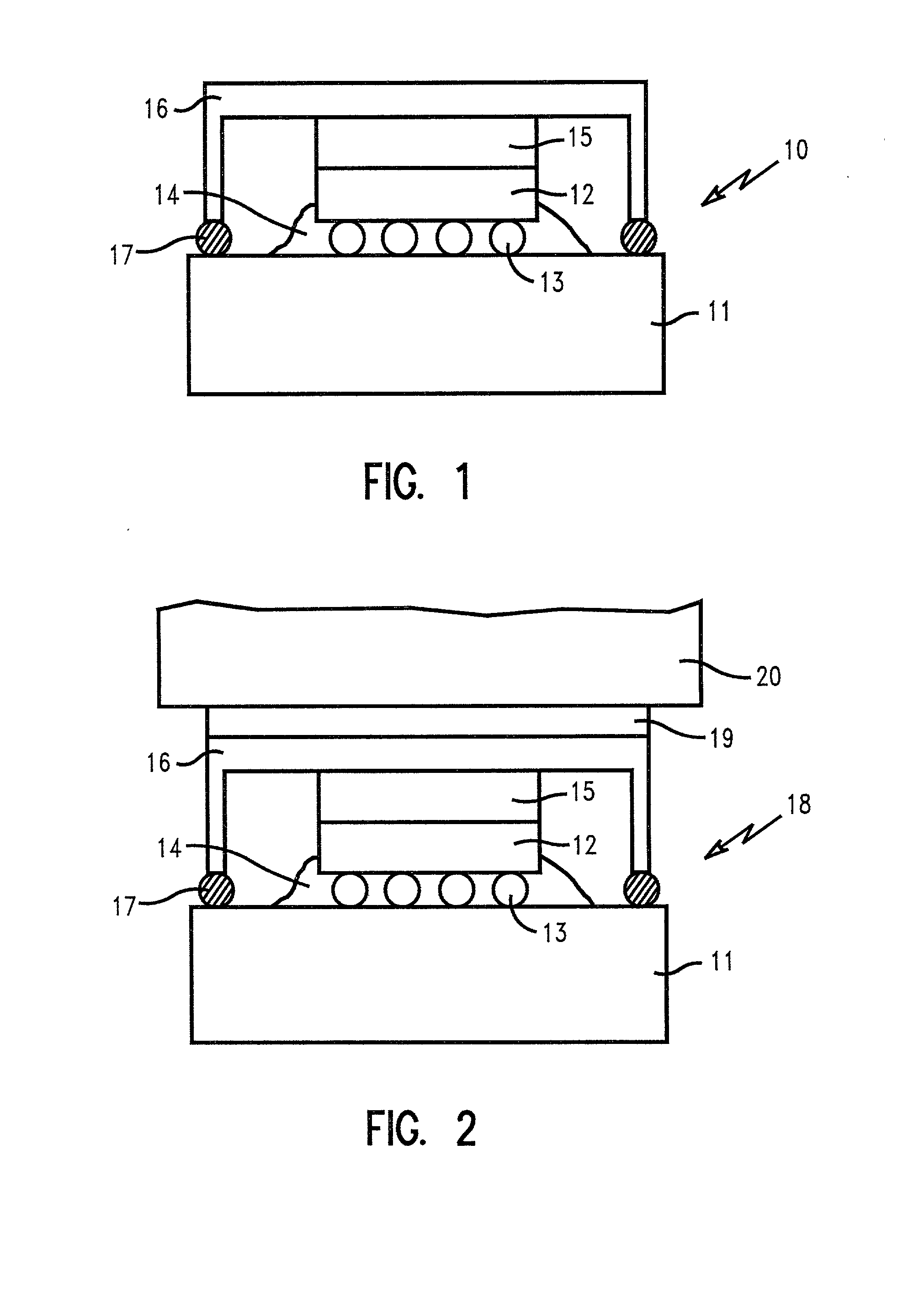

Removal of cured silicone adhesive for reworking electronic components

InactiveUS20020000239A1Inorganic/elemental detergent compounding agentsOrganic detergent compounding agentsOrganic baseSolvent

Owner:IBM CORP

Suspension formulations of nepafenac and other ophthalmic drugs for topical treatment of ophthalmic disorders

Topical aqueous suspension compositions of sparingly soluble ophthalmic drugs are disclosed. The compositions comprise a combination of a poloxamer or meroxapol surfactant and a glycol tonicity-adjusting agent such as propylene glycol.

Owner:NOVARTIS AG

Dental bleaching compositions containing sucralose

Dental bleaching compositions that include sucralose. The bleaching agent is dispersed within a carrier, which is optimally sticky and viscous such as a mixture of propylene glycol and silica fume. Anhydrous propylene glycol and / or anhydrous glycerin are especially useful in order to maintain the desired degree of hydration of the perborate being used. Flavorants may be added to enhance the taste of the dental compositions, since they will be used within a person's mouth. For best results, a flexible, thin-walled, comfortable-fitting, custom dental tray is used with the dental bleaching compositions. The dental compositions are sufficiently sticky and viscous so as to adhere and retain a dental tray against a person's teeth which is designed so as to not exert significant mechanical pressure onto the person's teeth.

Owner:ULTRADENT PROD INC

Dental bleaching compositions containing sucralose

InactiveUS6322774B1Effectively disguise the bitter taste of such agents over timeAccurate quantityCosmetic preparationsImpression capsFlavouring agentGlycerol

Dental bleaching compositions that include sucralose as a non-nutritive sweetener. The bleaching agent is dispersed within a carrier, which is optimally sticky and viscous, such as a mixture of a liquid or solvent carrier and a tackifying agent. Propylene glycol and / or glycerin are especially useful liquid or solvent carriers. Flavorants may be added to enhance the taste of the dental compositions, since they will be used within a person's mouth. For best results, a flexible, thin-walled, comfortable-fitting, custom dental tray is used with the dental bleaching compositions. The dental compositions are preferably sufficiently sticky and viscous so as to adhere and retain a dental tray against a person's teeth which is designed so as to not exert significant mechanical pressure onto the person's teeth.

Owner:ULTRADENT PROD INC

Cartomizer for electronic cigarettes

A cartomizer for an electronic cigarette having an elongated, hollow body with a mouthpiece in a first end and a battery coupling in an opposite second end. An atomizing coil is disposed in the body generally perpendicular to a longitudinal axis of the cartomizer and has positive and negative terminal leads pressfit connected to positive and negative terminals separated by an insulative spacer in the battery coupling. A fibrous wick is inserted inside the atomizing coil and a cloth tube is disposed generally parallel to the longitudinal axis of the cartomizer and extends from the atomizing coil to the mouthpiece. A volatile liquid mixture of preferably 80% propylene glycol and 20% veggie glycol with liquid nicotine and / or flavoring is disposed in the body.

Owner:KRETEK INT INC

Hydrogenolysis of 5-carbon sugars, sugar alcohols, and methods of making propylene glycol

InactiveUS7038094B2High selectivityHigh activityOrganic compound preparationOxygen compounds preparation by reductionIsopropylene glycolPropylene glycol

Methods and compositions for reactions of hydrogen over a Re-containing catalyst with compositions containing a 5-carbon sugar, sugar alcohol, or lactic acid are described. It has been surprisingly discovered that reaction with hydrogen over a Re-containing multimetallic catalyst resulted in superior conversion and selectivity to desired products such as propylene glycol. A process for the synthesis of PG from lactate or lactic acid is also described.

Owner:BATTELLE MEMORIAL INST

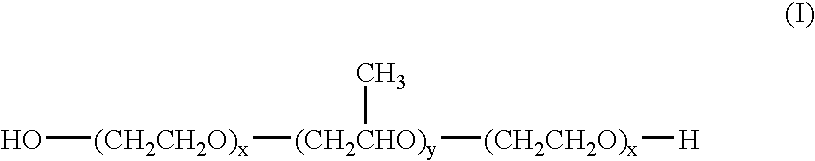

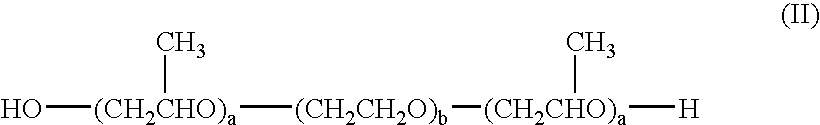

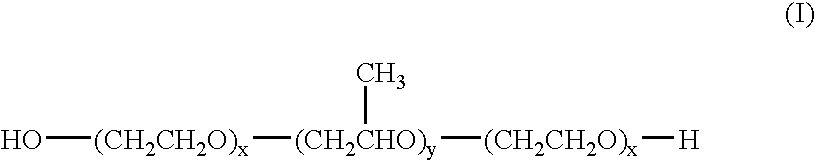

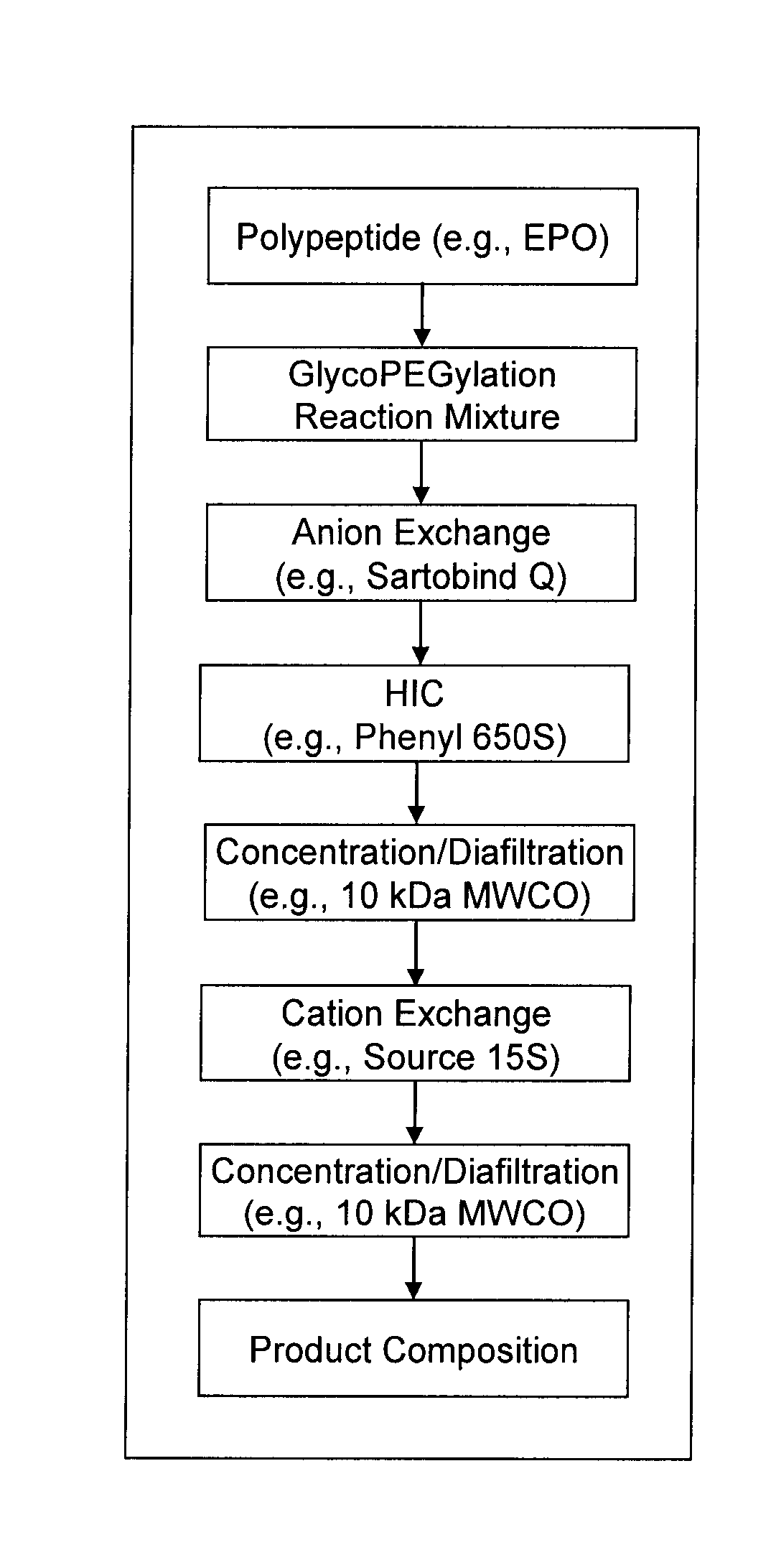

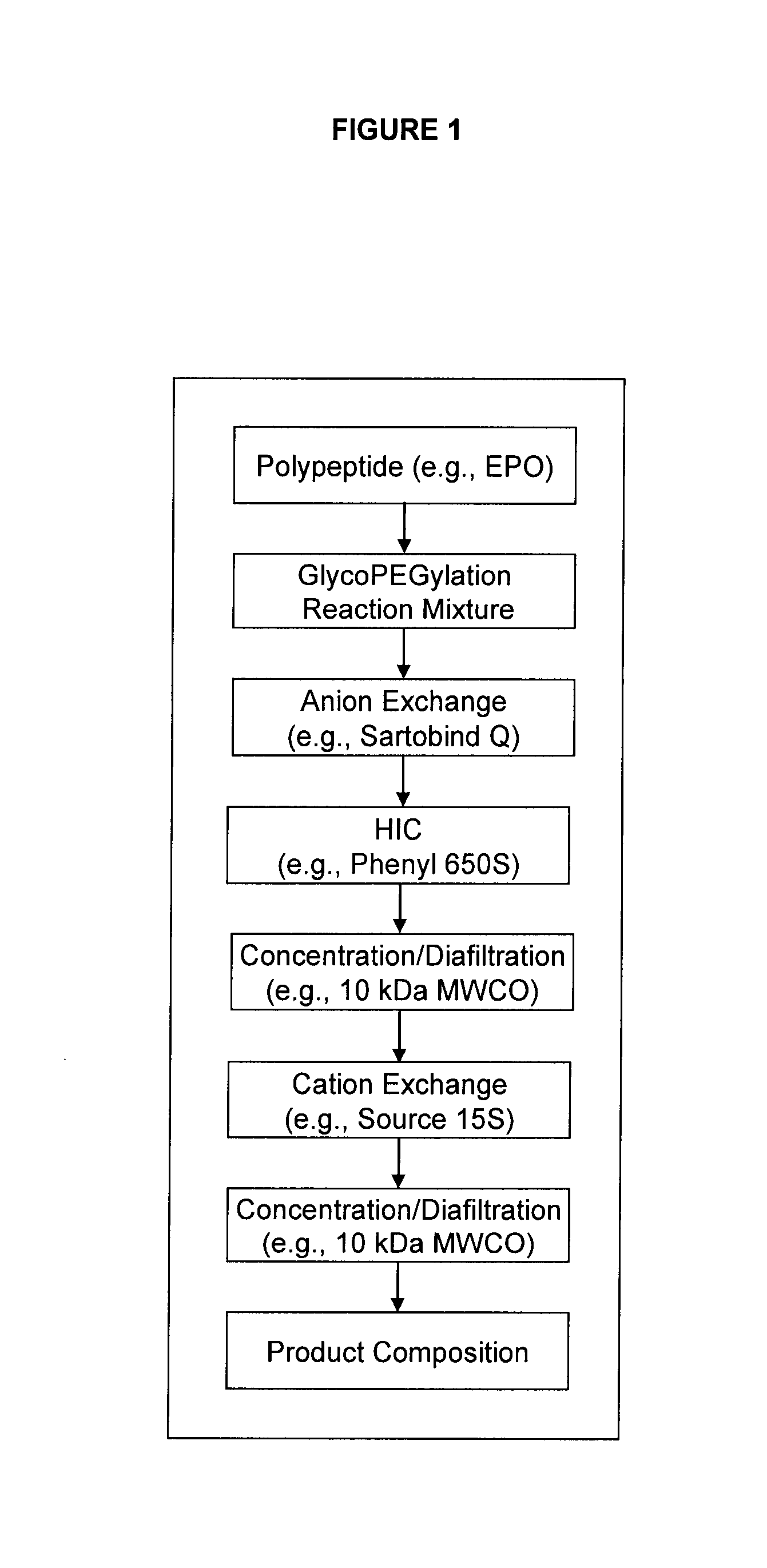

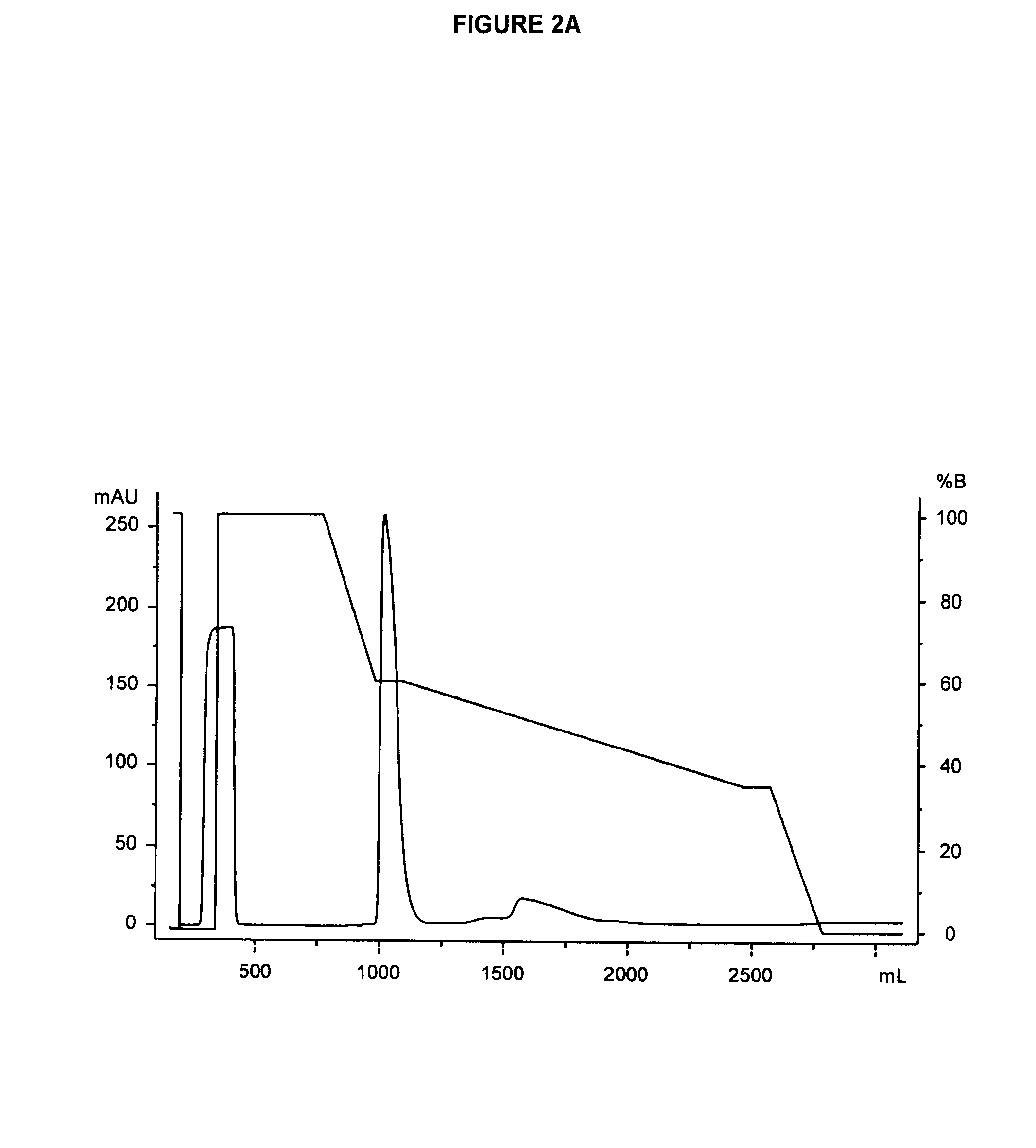

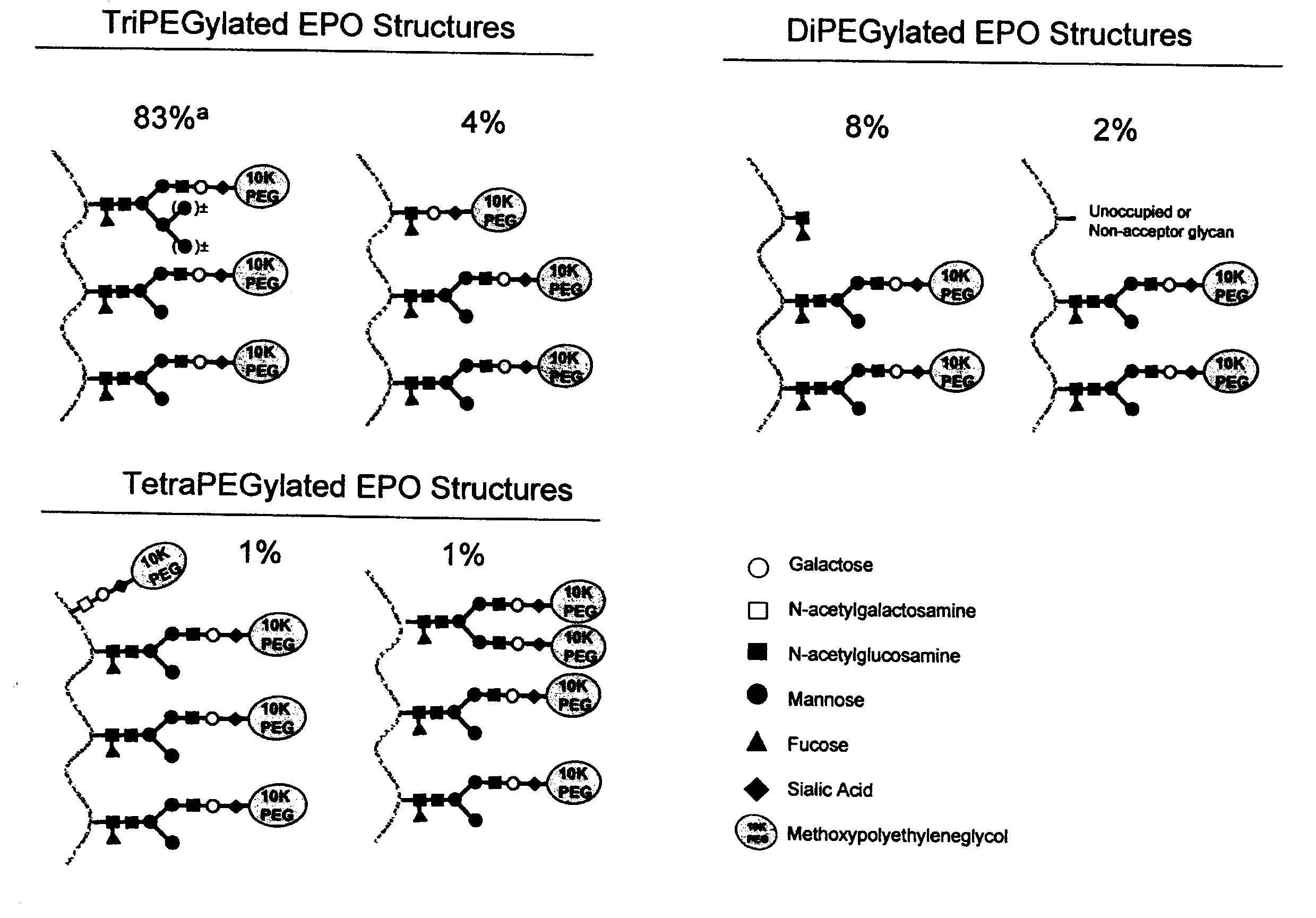

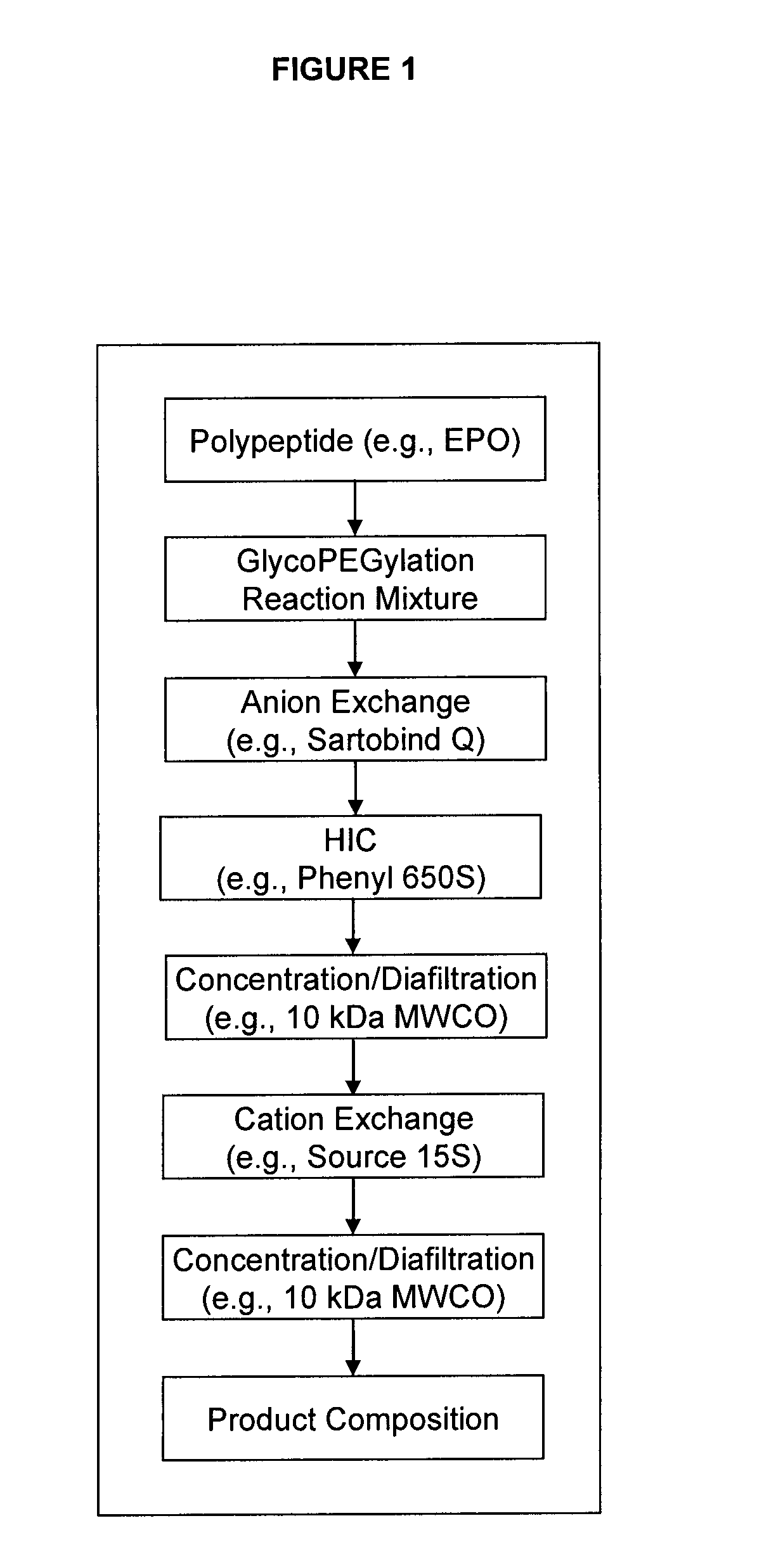

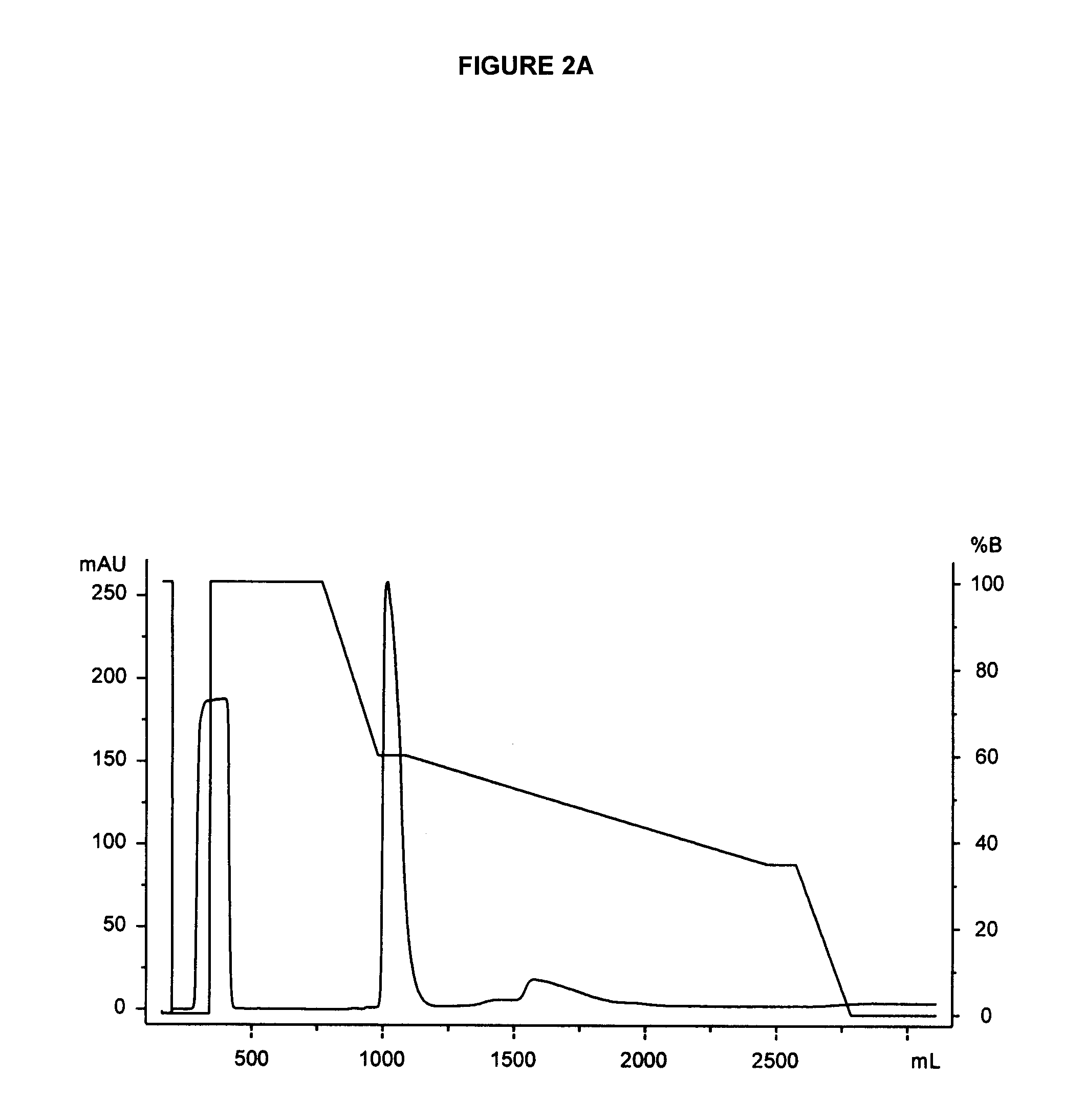

Methods for the purification of polypeptide conjugates

The present invention provides processes for the manufacturing of polypeptide conjugates. In particular, the invention provides methods for the purification of polypeptide conjugates, which include at least one polymeric modifying groups, such as a poly(alkylene oxide) moiety. Exemplary poly(alkylene oxide) moieties include poly(ethylene glycol) (PEG) and poly(propylene glycol). In an exemplary process, hydrophobic interaction chromatography (HIC) is used to resolve different glycoforms of glycoPEGylated polypeptides.

Owner:NOVO NORDISK AS

Light-fragrance electronic cigarette atomized smoke solution and preparation method thereof

The invention discloses light-fragrance electronic cigarette atomized smoke solution and a preparation method thereof. The atomized smoke solution comprises the following components in percentage by weight: 30-45 percent of propylene glycol, 20-35 percent of glycerol, 5-15 percent of deionized water, 5-15 percent of alcohol, 15-45 percent of traditional Chinese medicine liquid, 2-5 percent of tobacco flavor, 2-6 percent of tobacco extract and 0.1-2 percent of forming agent, wherein the traditional Chinese medicine liquid is extraction liquid which is obtained by extracting traditional Chinese medicine mixture through water distillation or alcohol extraction, and the traditional Chinese medicine mixture consists of tendrilleaf fritillary bulb, mint leaf, loquat leaf, dendranthema indicum, violet, sweet-scented osmanthus and green tea. The light-fragrance electronic cigarette atomized smoke solution not only can meet the smoking demands of smokers, but also can effectively reduce irritation of smoke to tracheas, bronchi, throats and lungs of bodies, and has the efficacies of clearing heat, moistening lungs, arresting coughs, expelling phlegm, refreshing and restoring consciousness, regulating qi-flowing, resolving stagnation and the like.

Owner:HUBEI CHINA TOBACCO IND +1

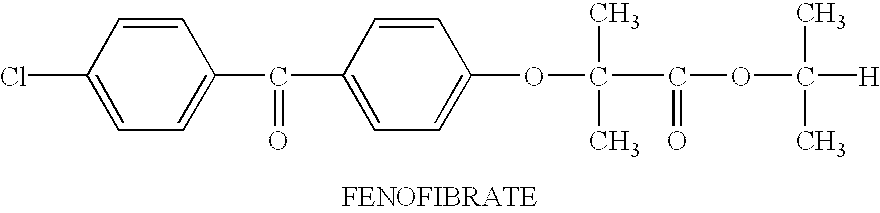

Pharmaceutical compositions and dosage forms for administration of hydrophobic drugs

Pharmaceutical compositions and dosage forms for administration of hydrophobic drugs, particularly fenofibrate, are provided. The compositions comprise a therapeutically effective amount of an active agent and a solubilizer. The solubilizer is selected to effectively solubilize active agent in the composition. The solubilizers employed as part of the invention include: a vitamin E substance; monohydric alcohol esters such as trialkyl citrates, lactones and lower alcohol fatty acid esters; nitrogen-containing solvents; phospholipids; glycerol acetates such as acetin, diacetin and triacetin; glycerol fatty acid esters such as mono-, di- and triglycerides and acetylated mono- and diglycerides; propylene glycol esters; ethylene glycol esters; and combinations thereof. The pharmaceutical dosage forms contain the compositions in a suitable dosage form unit such as a capsule. Methods of treating patients comprising administering the compositions are also provided.

Owner:LIPOCINE

Syrups containing sorbitol, a plasticizing agent and hydrogenated starch hydrolyzate, and their use in chewing gum and other confectionaries

A chewing gum including non-crystalline sorbitol and method of making the same is provided. The chewing gum composition comprises a sugarless syrup made from aqueous sorbitol, a plasticizing agent selected from the group consisting of glycerin, propylene glycol and mixtures thereof, and a hydrogenated starch hydrolyzate syrup. Other confectionaries can be made from the same sugarless syrup.

Owner:WM WRIGLEY JR CO

Liquid formulation of decitabine and use of the same

Pharmaceutical formulations, kits and vessels are provided for delivering decitabine to a patient suffering from a disease in need of treatment with decitabine. The pharmaceutical formulation comprises decitabine solvated in a non-aqueous solvent that comprises glycerin, propylene glycol, polyethylene glycol, or combinations. Such formulations are more chemically stable than conventional liquid formulations of decitabine containing more than 40% water in volume. The pharmaceutical formulations can be used for any disease that is sensitive to the treatment with decitabine, such as hematological disorders and cancer.

Owner:SUPERGEN

Methods for the purification of polypeptide conjugates

InactiveUS20100035299A1Peptide/protein ingredientsImmunoglobulinsPolymer sciencePolypropylene glycol

The present invention provides processes for the manufacturing of polypeptide conjugates. In particular, the invention provides methods for the purification of polypeptide conjugates, which include at least one polymeric modifying groups, such as a poly(alkylene oxide) moiety. Exemplary poly(alkylene oxide) moieties include poly(ethylene glycol) (PEG) and poly(propylene glycol). In an exemplary process, hydrophobic interaction chromatography (HIC) is used to resolve different glycoforms of glycoPEGylated polypeptides.

Owner:NOVO NORDISK AS

Preparation of poly(trimethylene terephthalate) with low level of di(1,3-propylene glycol)

A process of preparing poly(trimethylene terephthalate) containing less than 2.0 mole % of DPG comprising:(a) providing a molar amount of 1,3-propanediol:C1 to C4 dialkyl ester of terephthalic acid of 1.2:1 to 1.9:1,(b) reacting the 1,3-propanediol with the C1 to C4 dialkyl ester of terephthalic, acid to form bis(3-hydroxypropyl)terephthalate monomer in the presence of 10-100 ppm (as titanium metal) of an organic titanate catalyst, by weight of the poly(trimethylene terephthalate), and(c) polymerizing the bis(3-hydroxypropyl)terephthalate monomer to obtain the poly(trimethylene terephthalate); andpoly(trimethylene terephthalate) produced by the process.

Owner:DUPONT IND BIOSCIENCES USA LLC

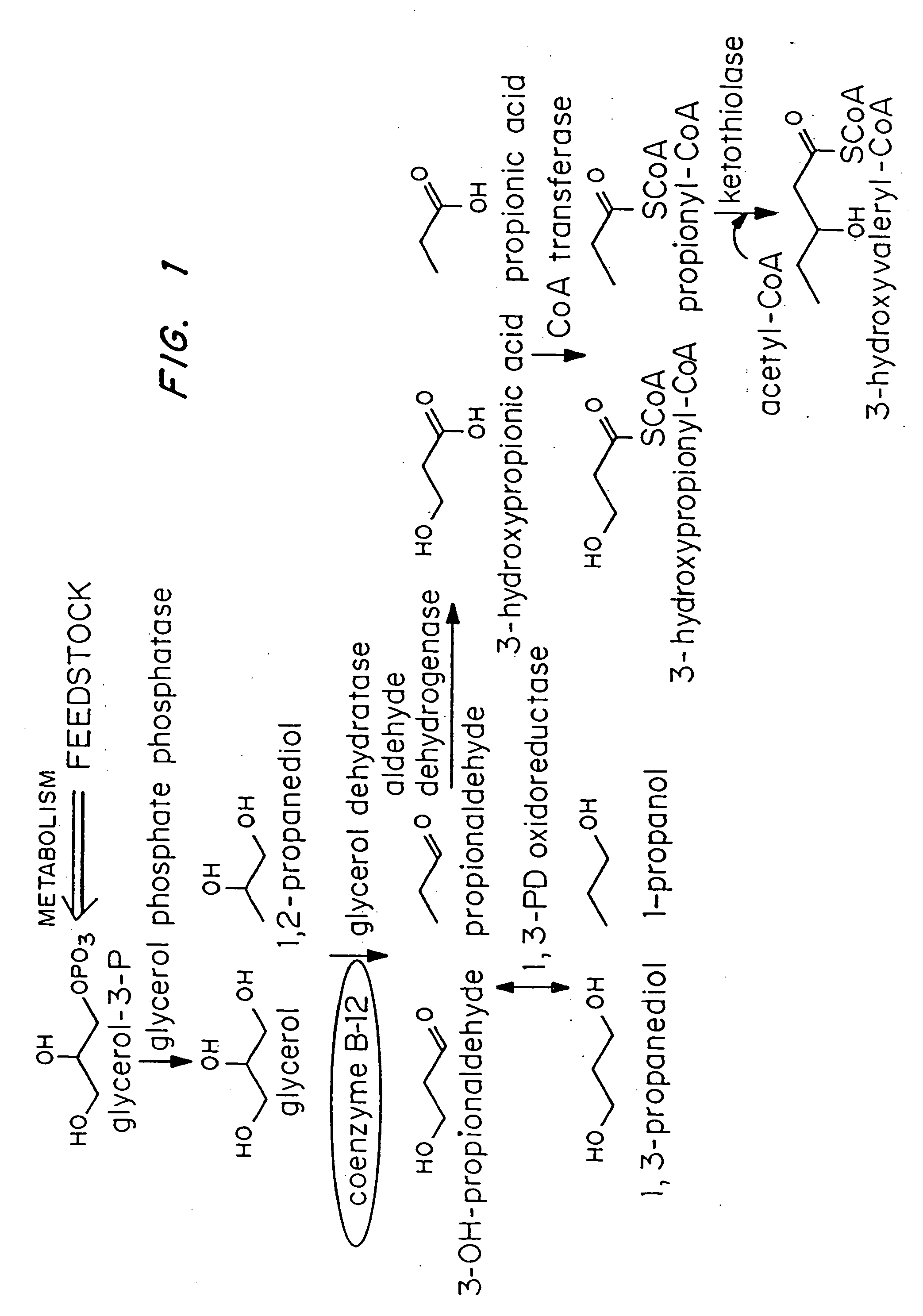

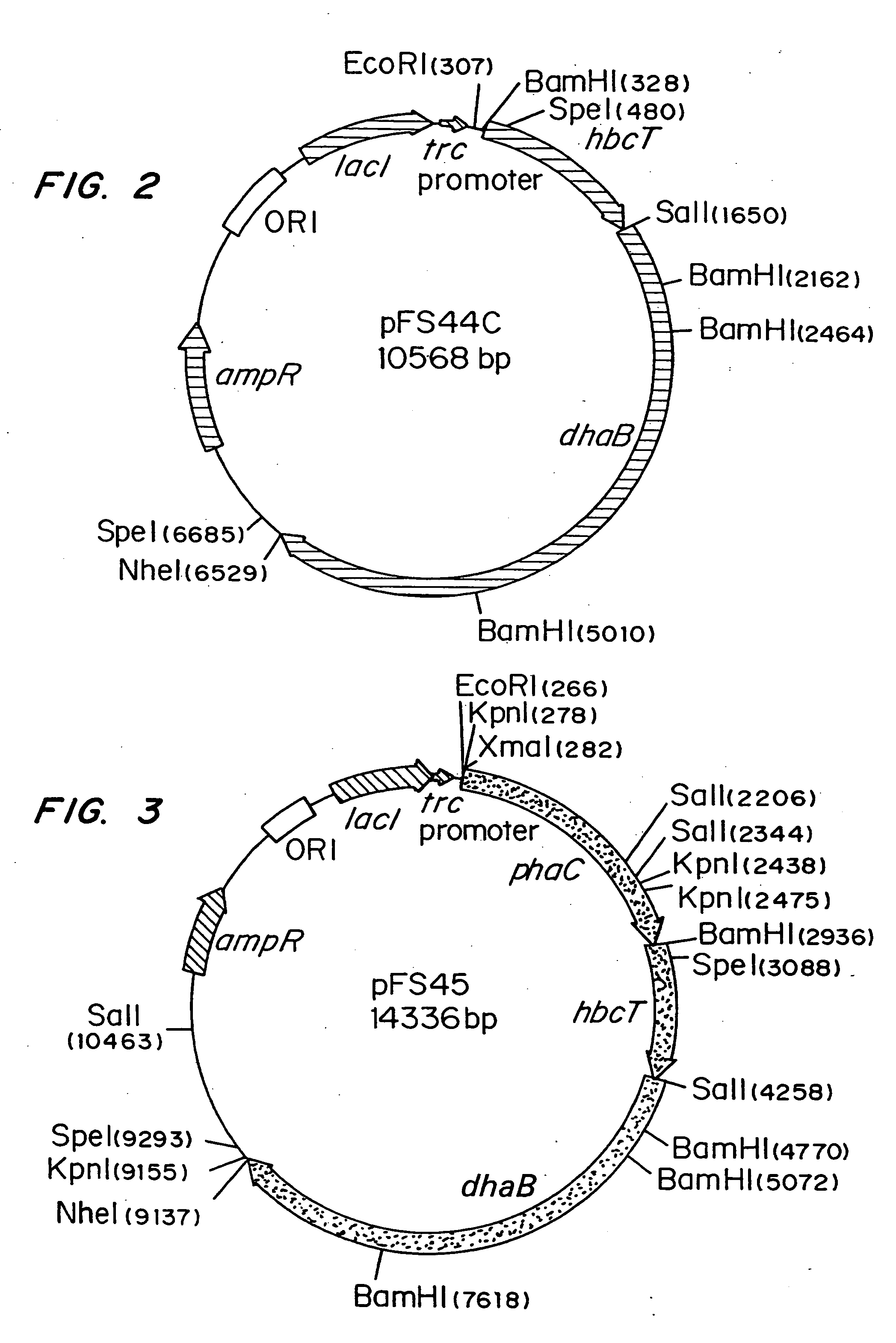

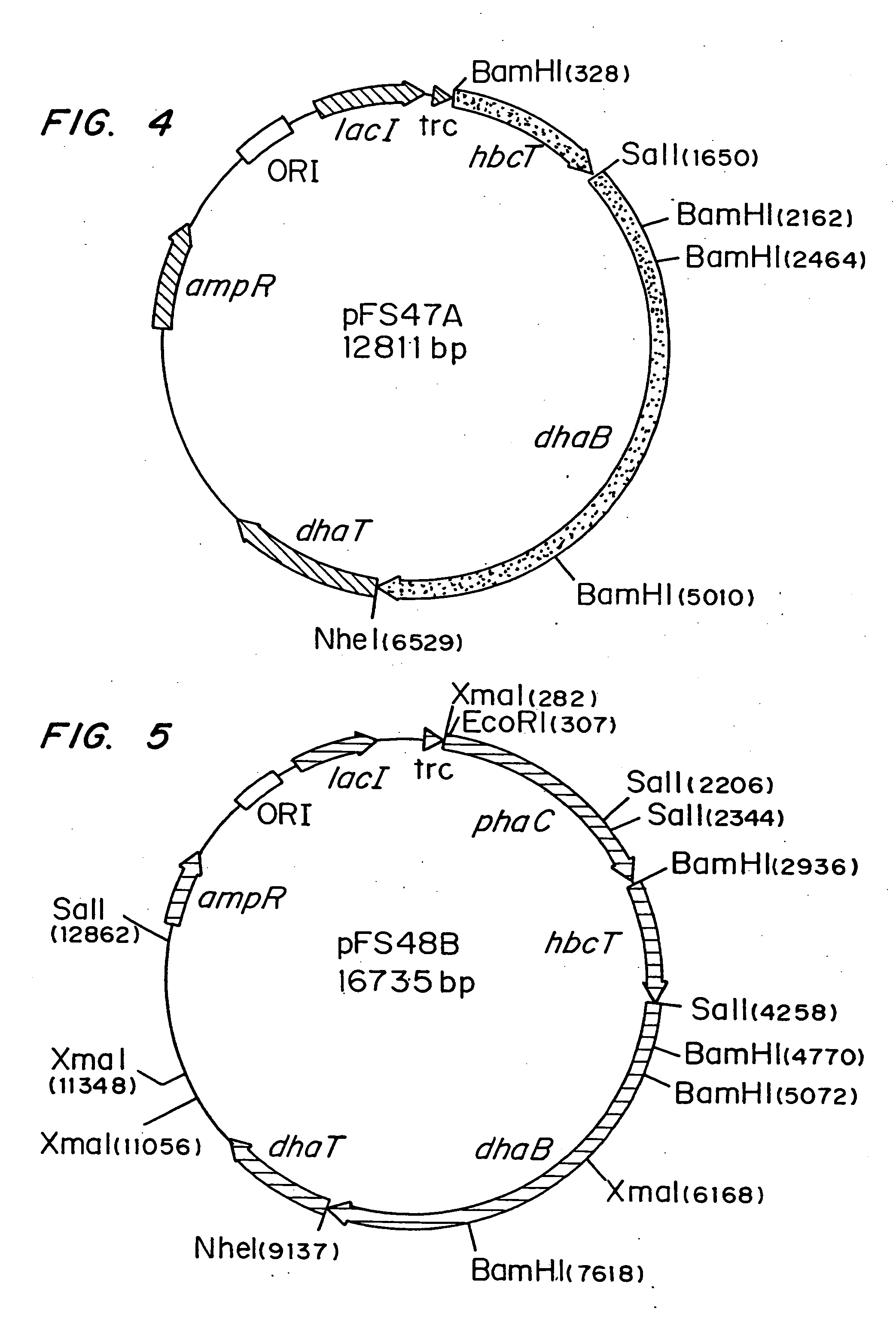

Polyhydroxyalkanoate production from polyols

InactiveUS20050239179A1Promote recoveryProduct can be usedBacteriaMicroorganism based processes3-Hydroxypropionic acidPropanoic acid

Organisms are provided which express enzymes such as glycerol dehydratase, diol dehydratase, acyl-CoA transferase, acyl-CoA synthetase β-ketothiolase, acetoacetyl-CoA reductase, PHA synthase, glycerol-3-phosphate dehydrogenase and glycerol-3-phosphatase, which are useful for the production of PHAs. In some cases one or more of these genes are native to the host organism and the remainder are provided from transgenes. These organisms produce poly (3-hydroxyalkanoate) homopolymers or co-polymers incorporating 3-hydroxypropionate or 3-hydroxyvalerate monomers wherein the 3-hydroxypropionate and 3-hydroxyvalreate units are derived from the enzyme catalysed conversion of diols. Suitable diols that can be used include 1,2-propanediol, 1,3 propanediol and glycerol. Biochemical pathways for obtaining the glycerol from normal cellular metabolites are also described. The PHA polymers are readily recovered and industrially useful as polymers or as starting materials for a range of chemical intermediates including 1,3-propanediol, 3-hydroxypropionaldehyde, acrylics, malonic acid, esters and amines.

Owner:CJ CHEILJEDANG CORP

Aerosol and injectable formulations of nanoparticulate benzodiazepine

InactiveUS20060198896A1Easy doseReduce injection volumeBiocidePowder deliveryBenzodiazepinePolyethylene glycol

Described are nanoparticulate formulations of a benzodiazepine, such as lorazepam, that does not require the presence of polyethylene glycol and propylene glycol as stabilizers, and methods of making and using such formulations. The formulations are particularly useful in aerosol and injectable dosage forms, and comprise nanoparticulate benzodiazepine, such as lorazepam, and at least one surface stabilizer. The formulations are useful in the treatment of status epilepticus, treatment of irritable bowel syndrome, sleep induction, acute psychosis, and as a pre-anesthesia medication.

Owner:ELAN PHRMA INT LTD

Fuel additive composition and method for treatment of middle distillate fuels and gasoline

InactiveUS6923838B2Increase and improvement of performanceIncrease and improvement of and lubricityLiquid carbonaceous fuelsFuel additivesVegetable oilAntioxidant

A fuel additive for middle distillate fuels is a mixture of at least one methyl, ethyl, propyl or butyl ester of a vegetable oil or a C16-C18 fatty acid, at least one alkyl ether of propylene glycol, a surfactant, and an antioxidant. A fuel additive for gasoline is a mixture of ligroin or toluene / xylene, at least one alkyl ether of propylene glycol, a surfactant, and tertiary amyl methyl ether.

Owner:ADVANCED COMBUSTION TECH

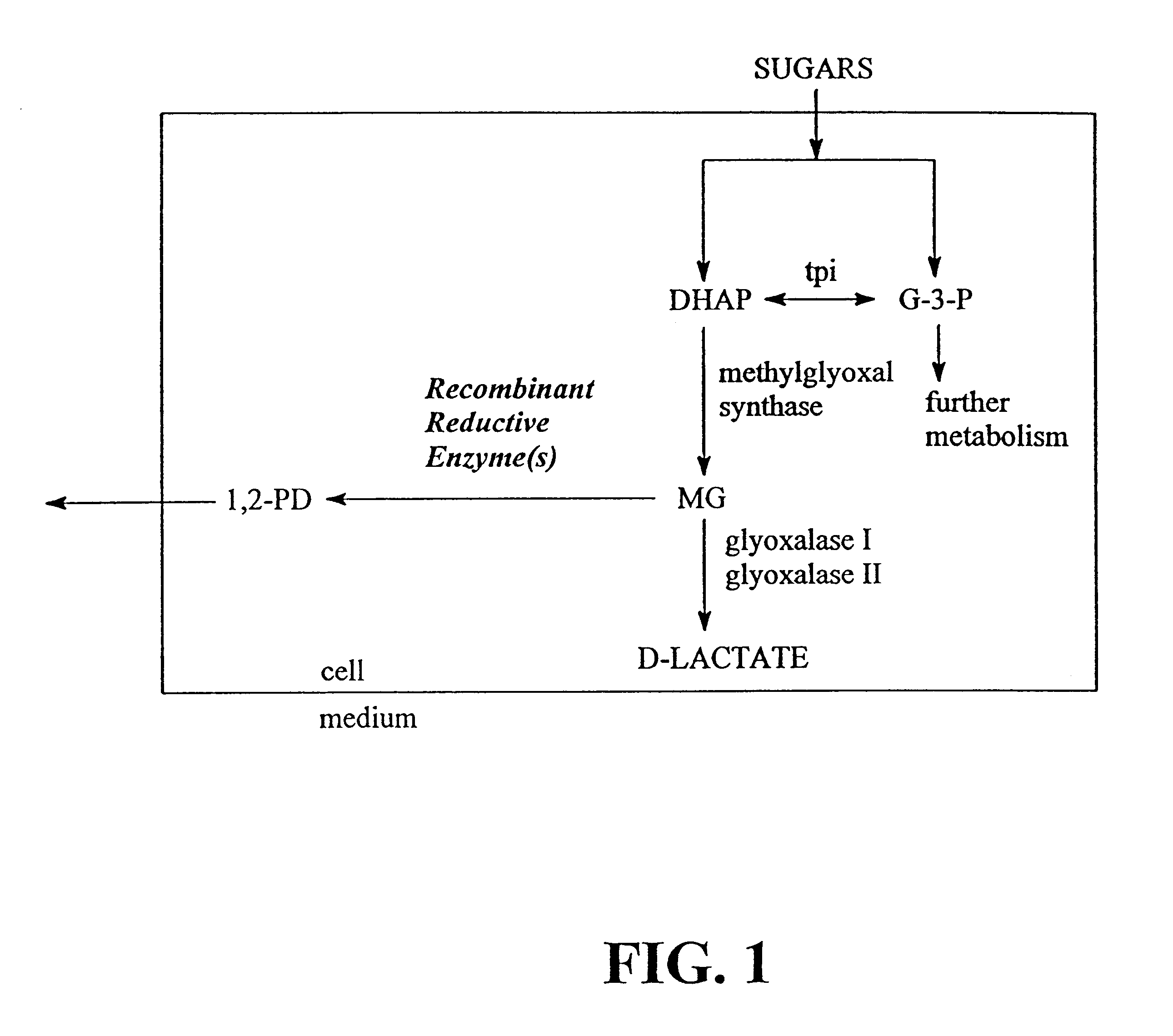

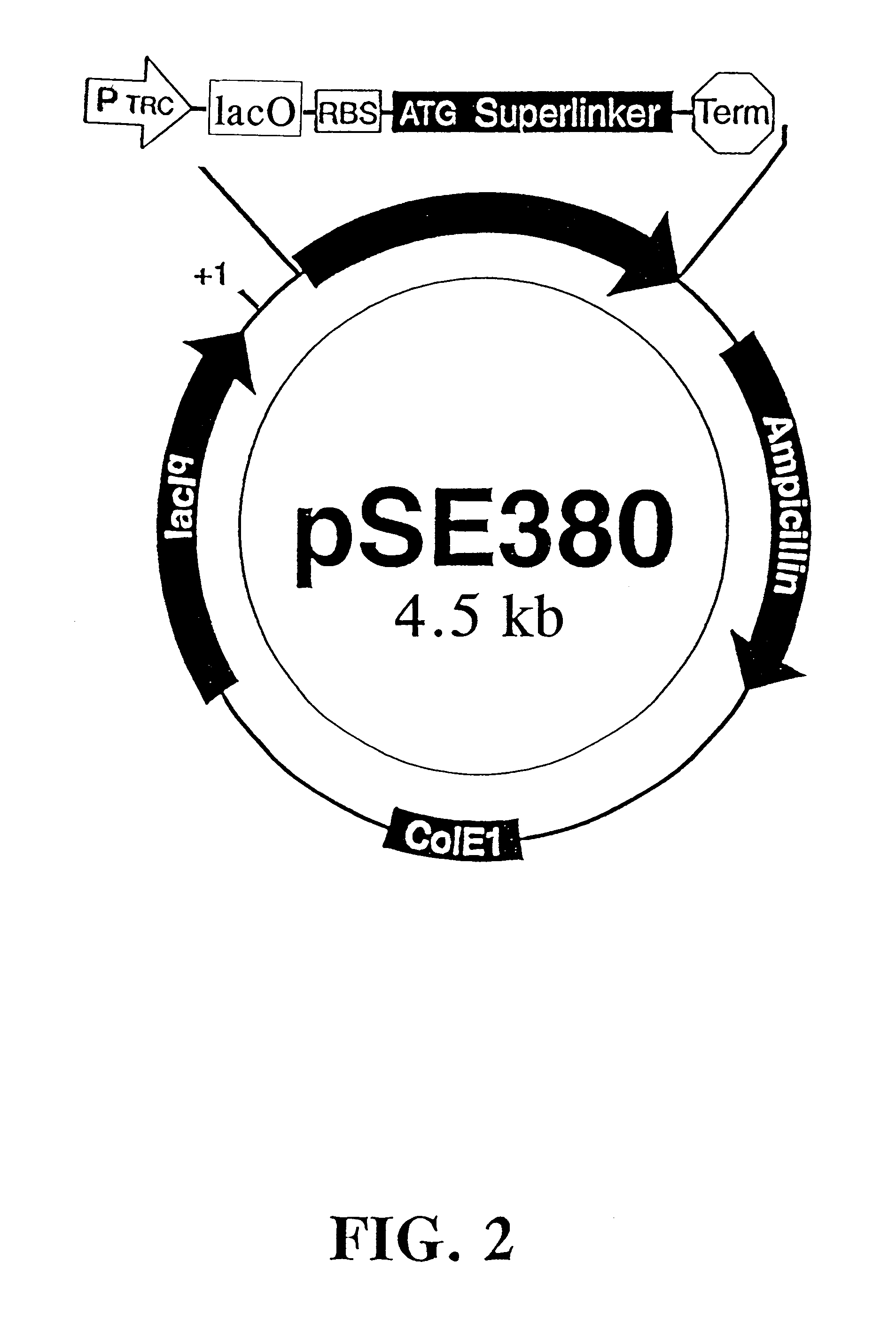

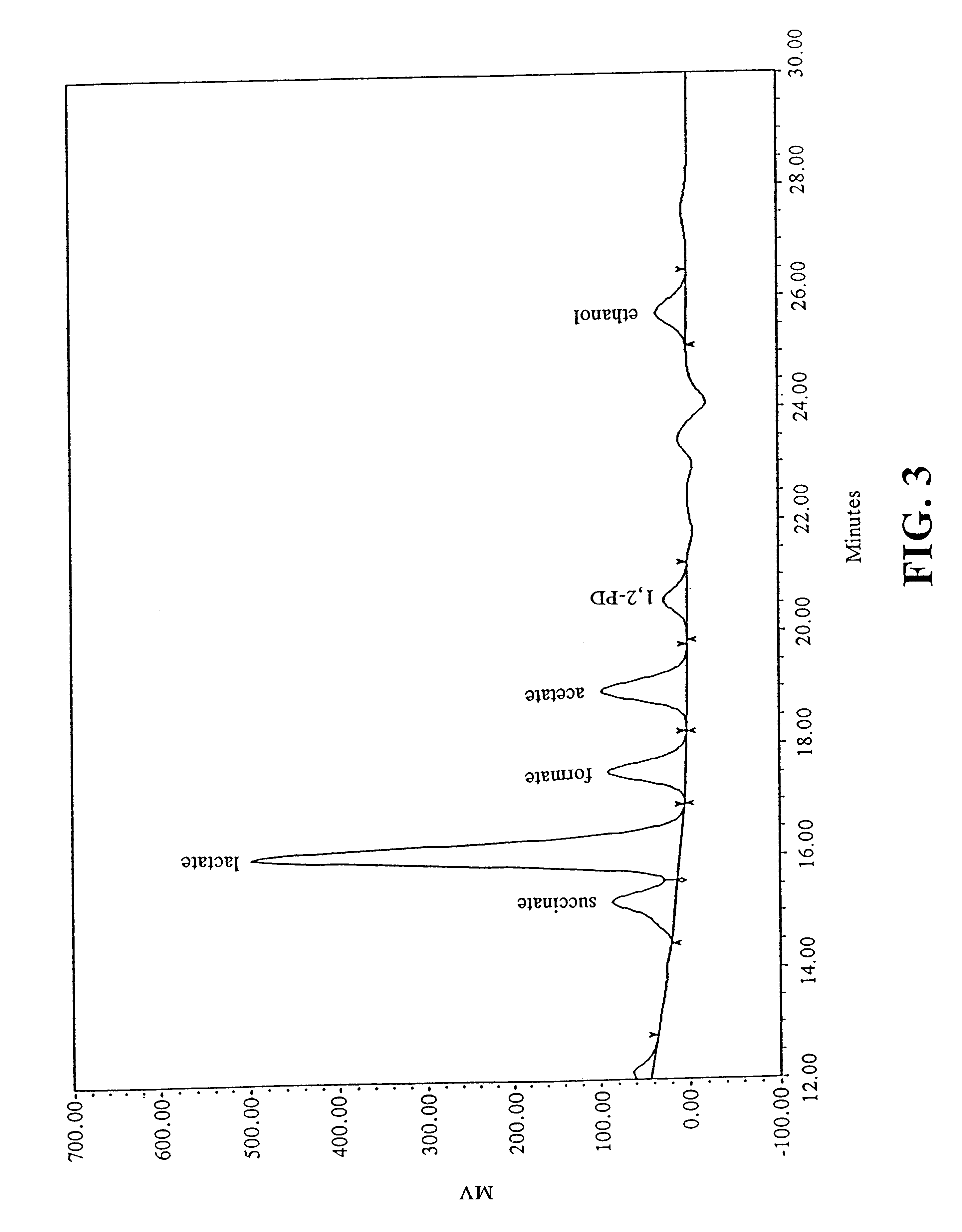

Microbial production of 1,2-propanediol from sugar

Microorganisms which ferment common sugars into 1,2-propanediol, synthetic operons to effect the transformation, and methods to produce 1,2-propanediol by fermentation of common sugars using the transformed microorganisms are disclosed.

Owner:WISCONSIN ALUMNI RES FOUND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com