Patents

Literature

333results about How to "Reduce injection volume" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

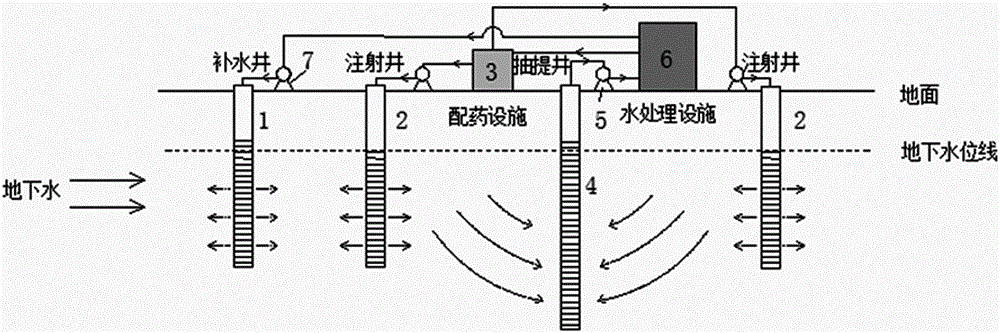

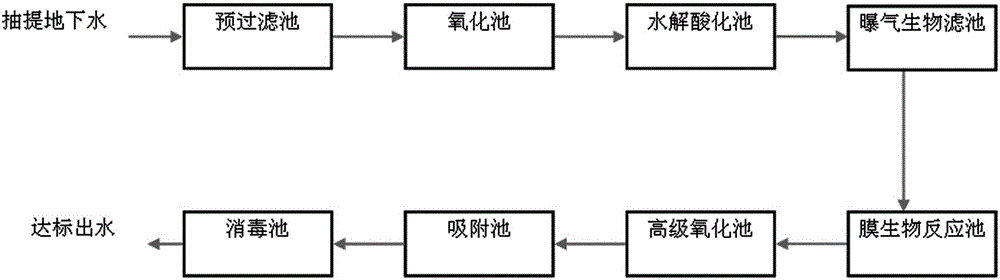

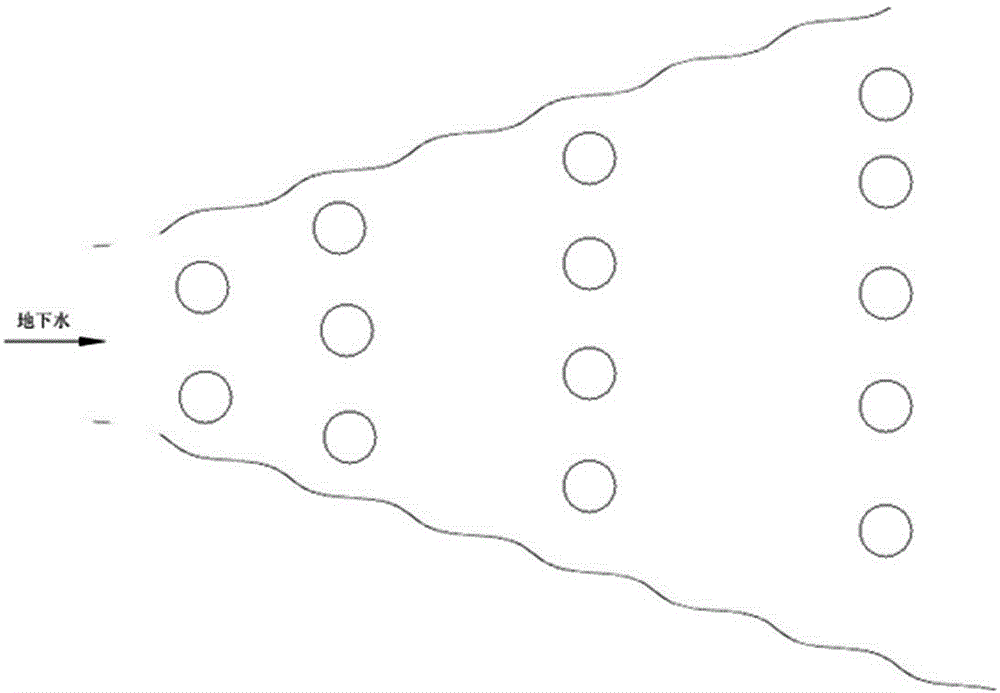

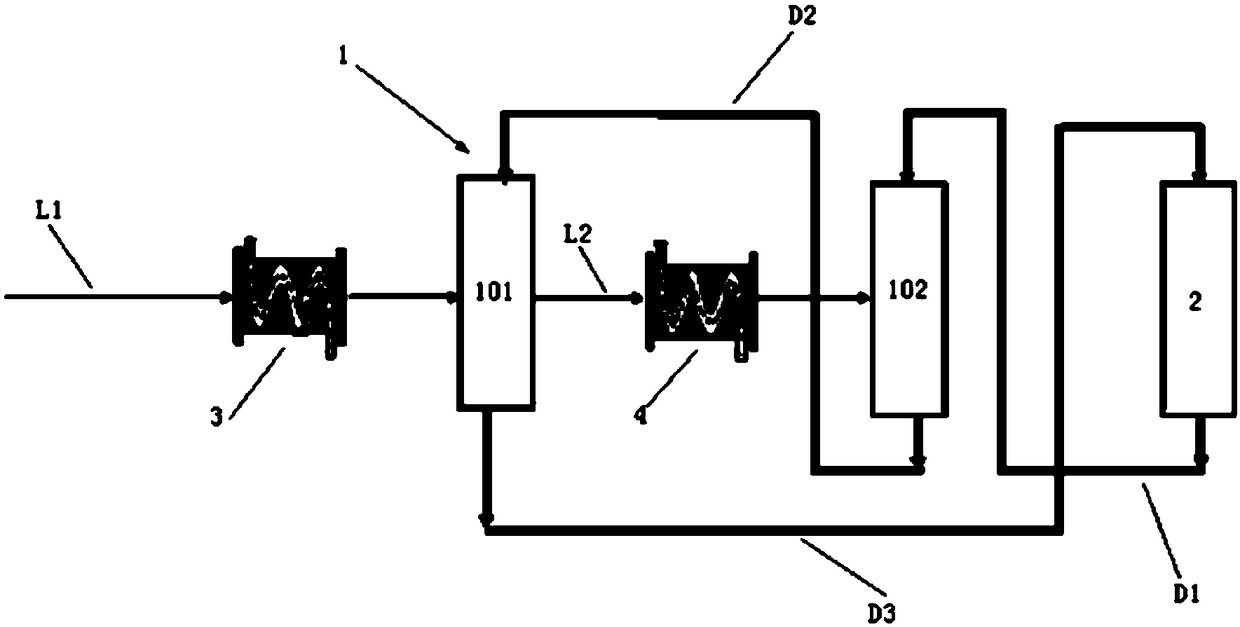

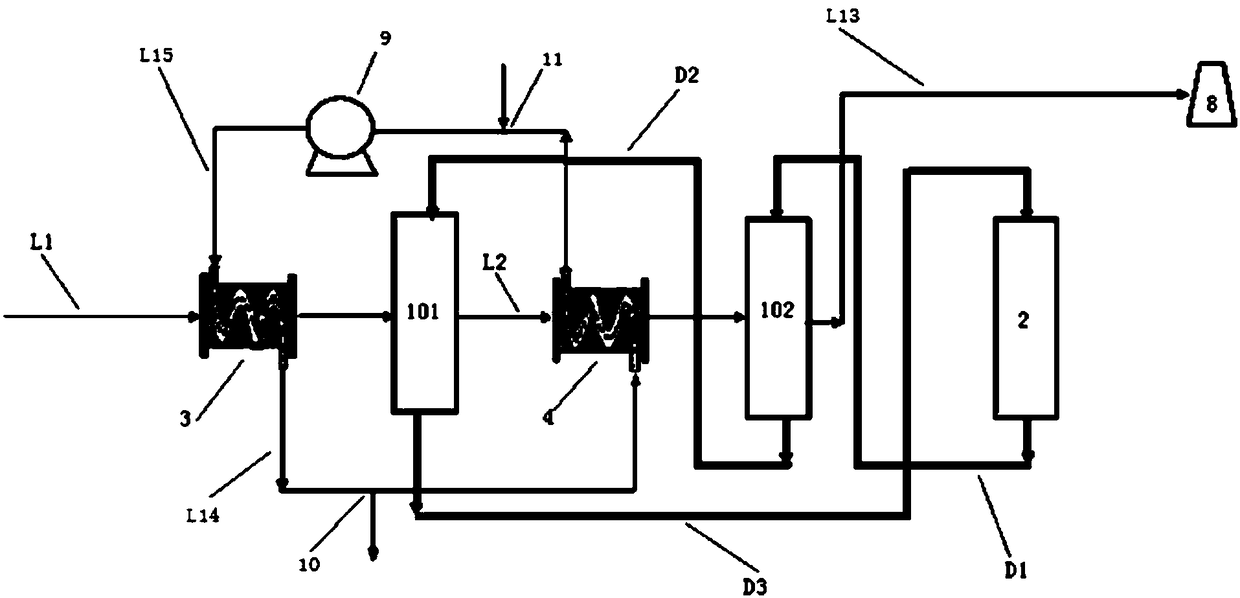

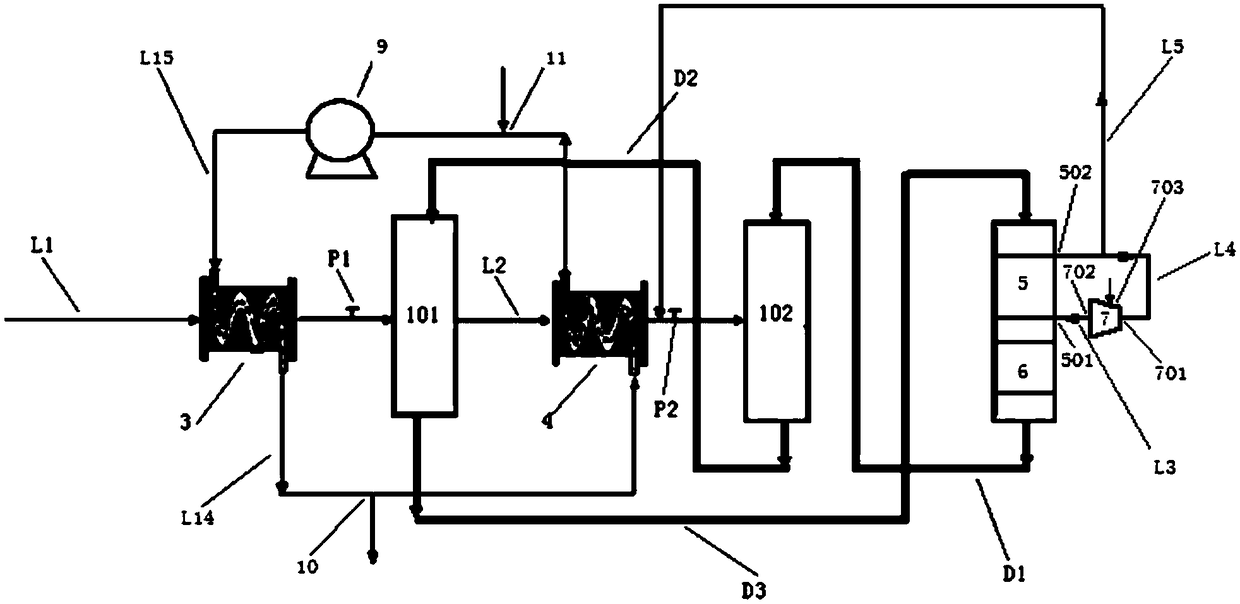

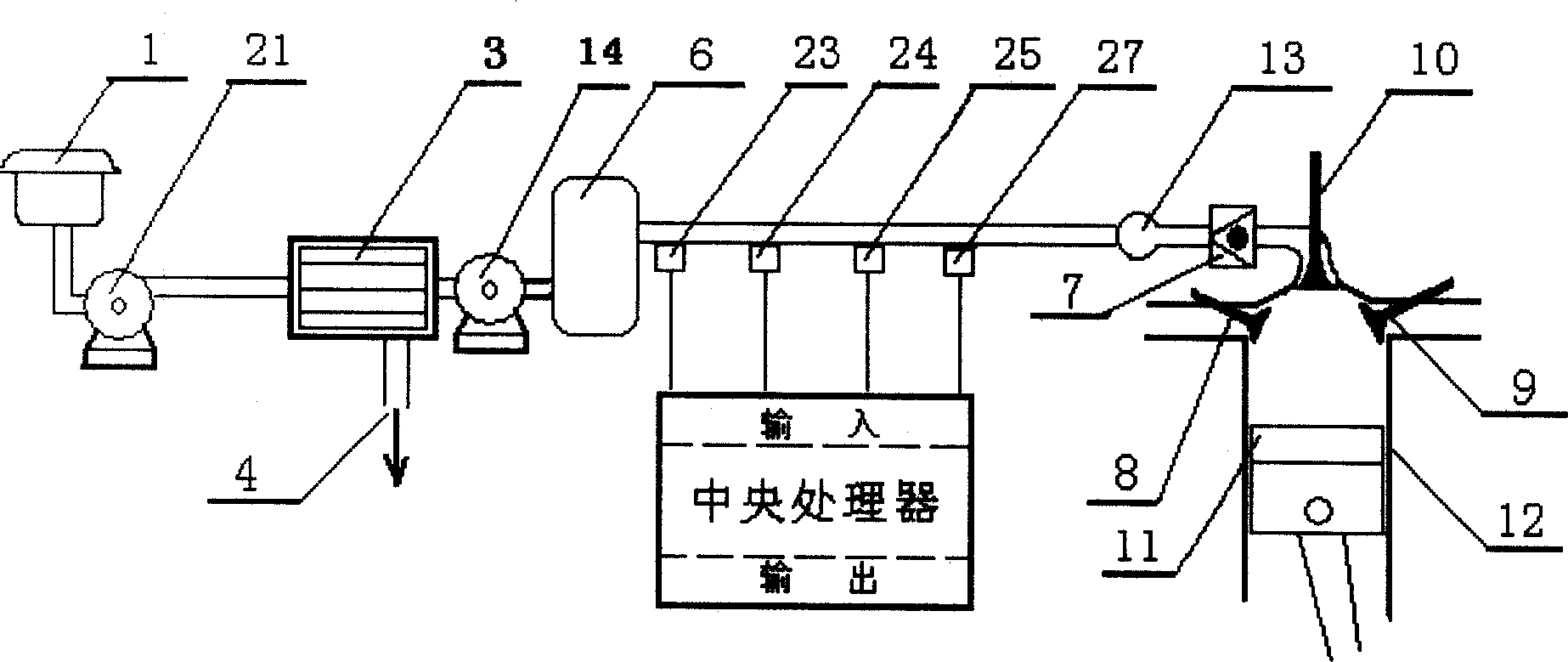

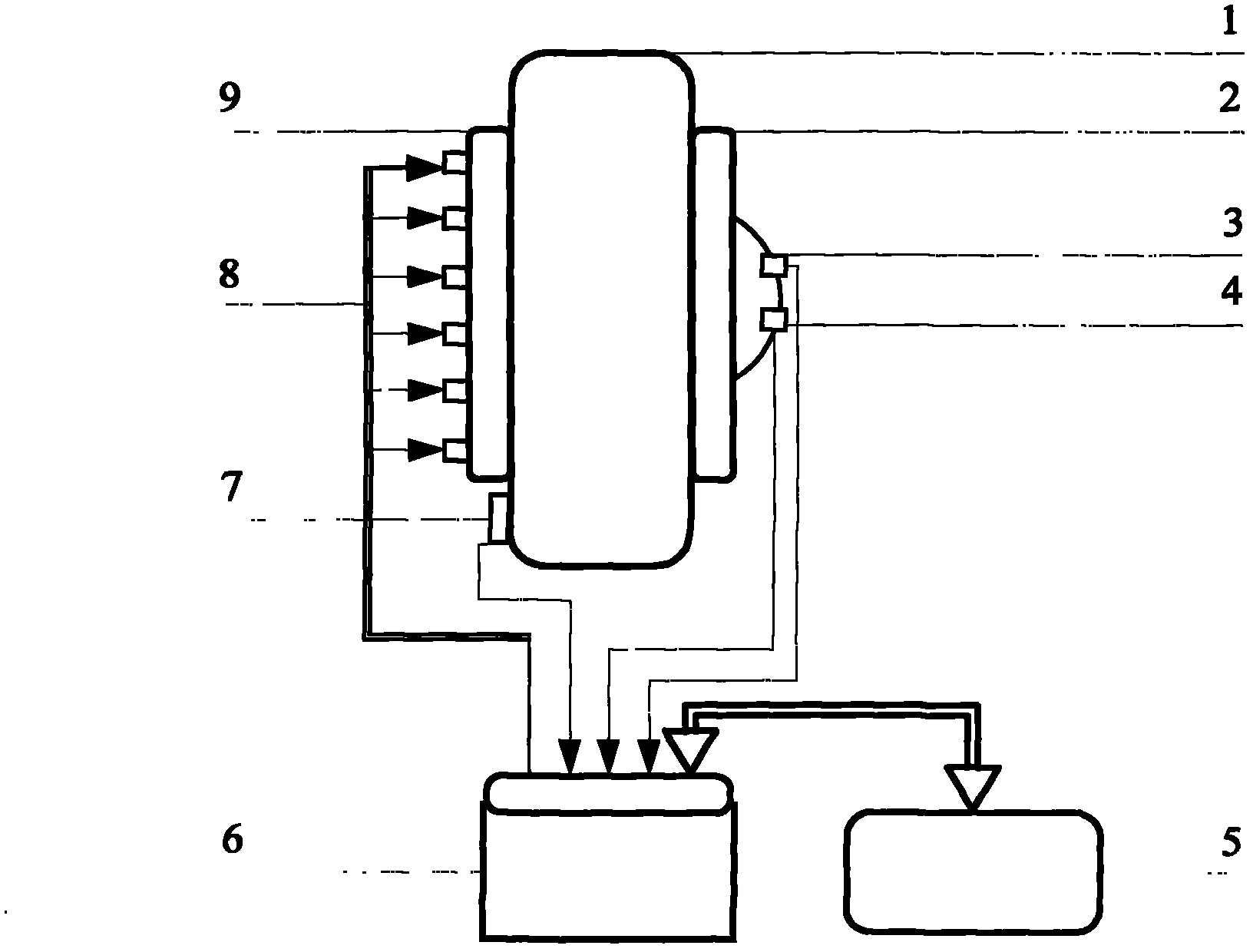

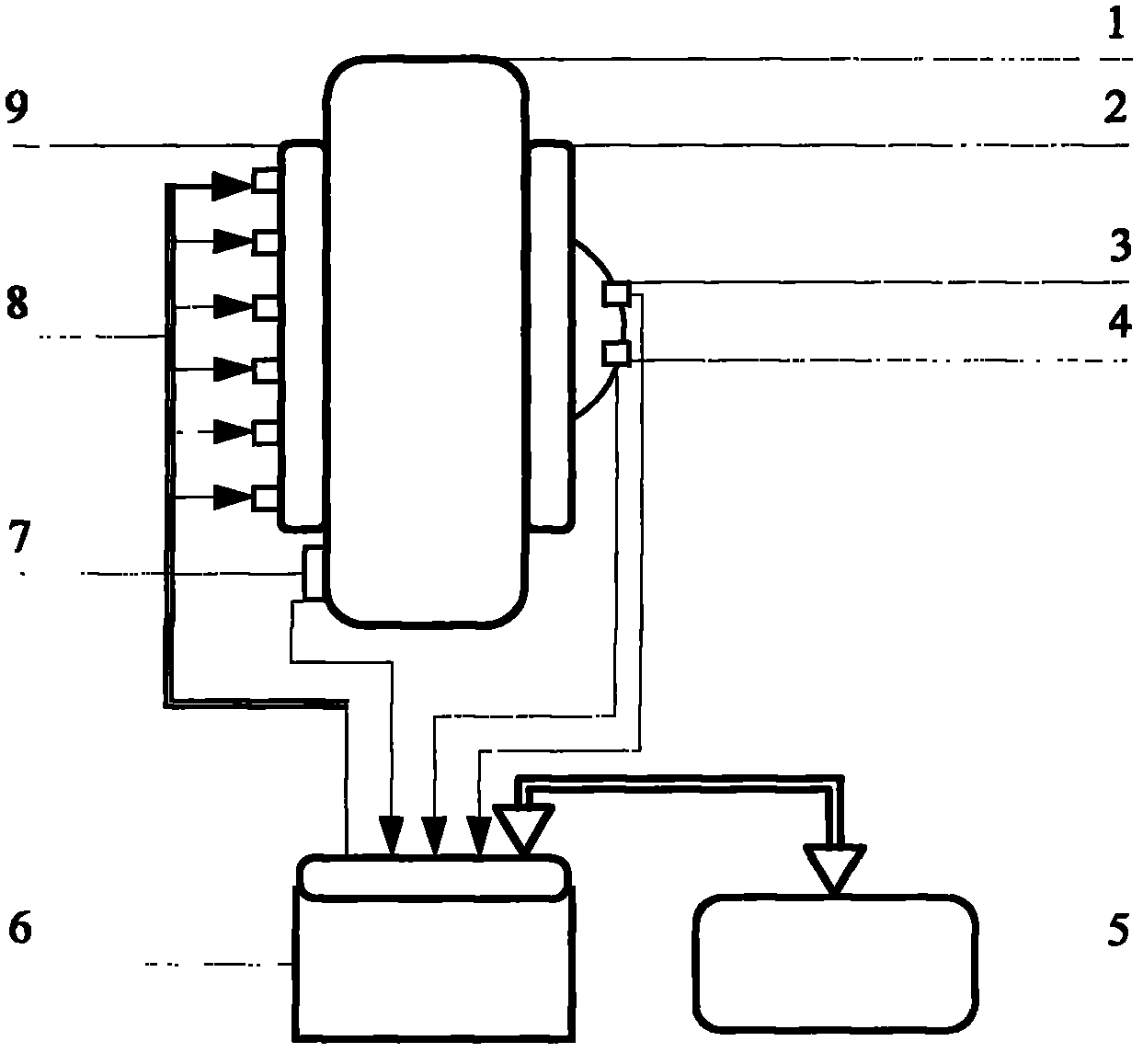

In-situ injection-extraction-water replenishing circulatory disposal system for organic contaminated soil and groundwater and combined remediation method

ActiveCN105032916ASpeed up the flowIncrease the speed of diffusionContaminated soil reclamationMultistage water/sewage treatmentInjection wellWater treatment

The invention discloses an in-situ injection-extraction-water replenishing circulatory disposal system for organic contaminated soil and groundwater and a combined remediation method. The system is consist of an injection well, an extraction well, a water replenishing well, a water treatment facility, a dispensing facility. The method comprises the following steps: extracting a pollution source or groundwater in a seriously polluted area to the ground for processing, then using the processed groundwater as a preparation drug or as replenished water to be directly injected to the underground, and injecting the drug into the underground pollution plume area through the injection well. The system and the method are used for processing the organic contaminated soil and groundwater in situ and have the advantages of being small in disturbance, environmental-friendly, short in remediation cycle and wide in range of application and has no secondary pollution.

Owner:中节能大地(杭州)环境修复有限公司

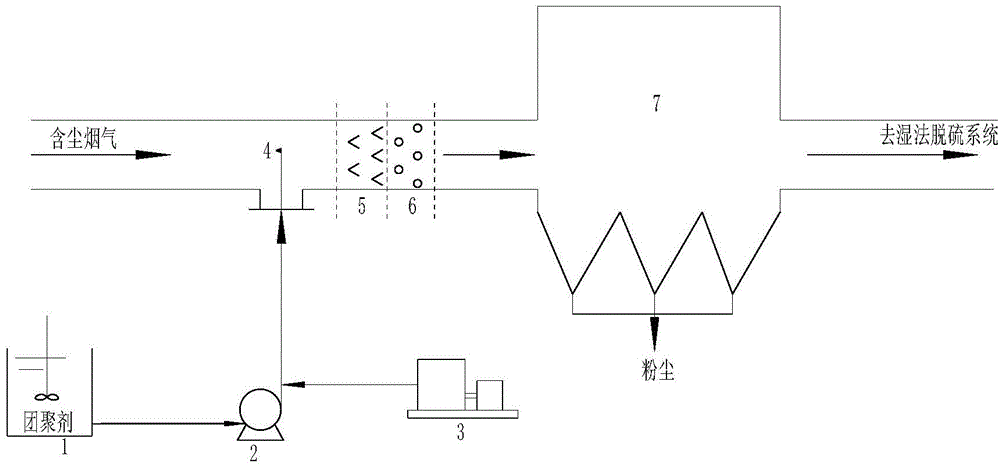

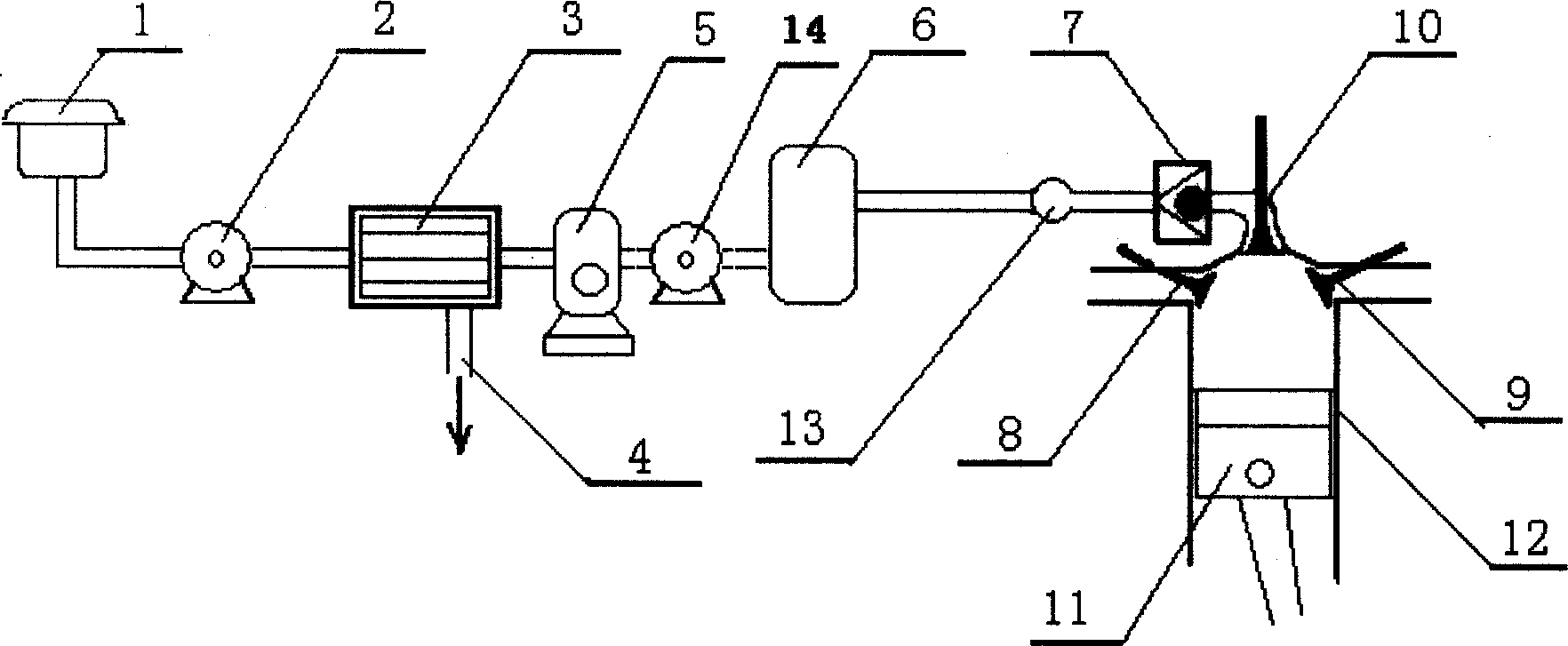

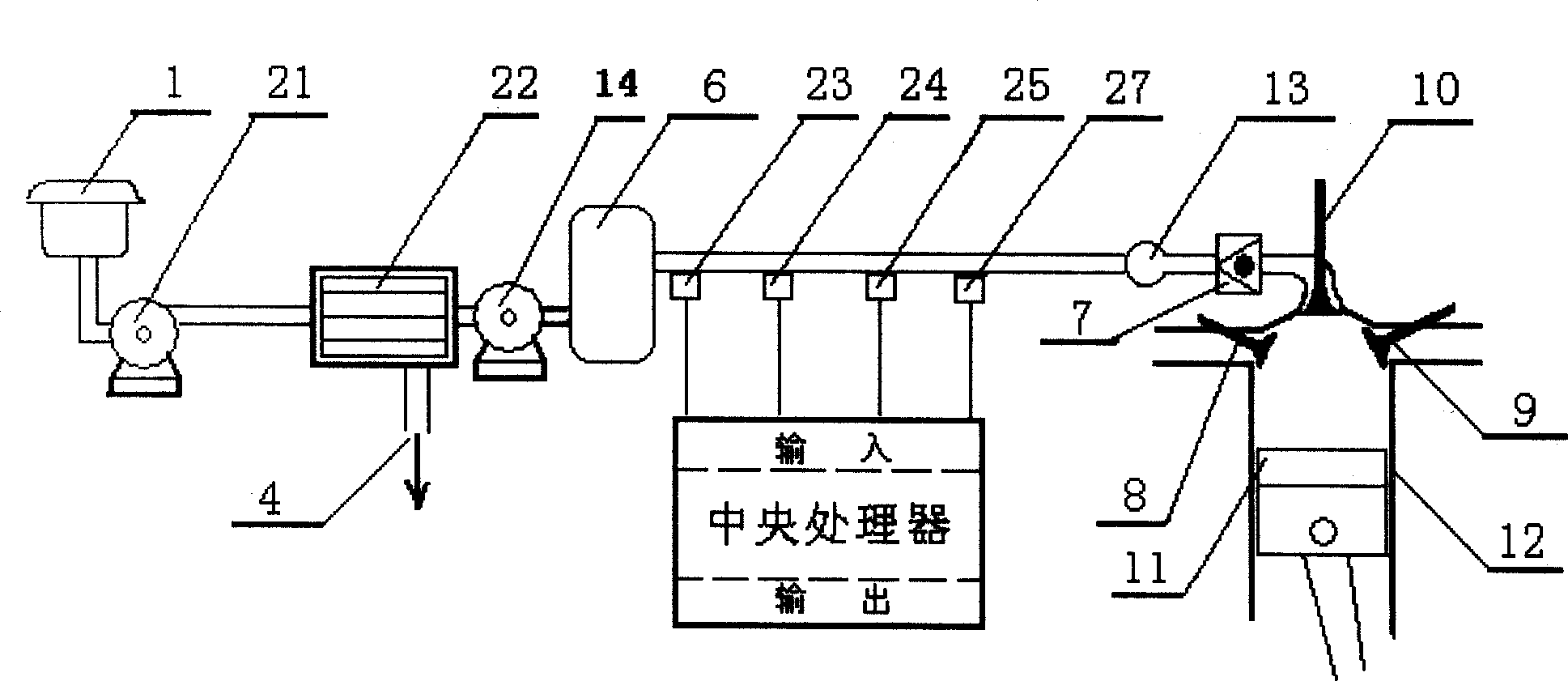

Device and method for increasing grain size of PM2.5 (particulate matter2.5) through turbulent flow and chemical agglomeration coupling

ActiveCN104801420AFacilitate collision contactImprove the growth effectElectrostatic separationParticulatesEvaporation

The invention discloses a device and a method for increasing grain size of PM2.5 through turbulent flow and chemical agglomeration coupling. Dust-containing flue gas sequentially flows through a chemical agglomeration area and a turbulent flow generation area in a flue and finally enters an electrostatic dust collector; when the dust-containing flue gas flows through the chemical agglomeration area, the PM2.5 particles in the flue gas are primarily contacted with agglomeration solution fogdrops sprayed in through a dual-fluid atomizing nozzle, agglomeration solution liquid drops are evaporated, in the evaporation process, the PM2.5 particles are connected through macromolecule chains with polar groups, and the grain size of the PM2.5 is increased; the flue gas flows through the turbulent flow area, the agglomeration solution fogdrops are promoted to collide and contact the PM2.5, the PM2.5 are promoted to collide and contact the crude dust under the turbulent flow disturbance generated by a turbulence bar, the PM2.5 are further aggregated and increased in size, meanwhile, the residence time of the agglomeration solution liquid drops in the flue is prolonged, before entering the electrostatic dust collector, the agglomeration solution liquid drops are completely evaporated, and the particles of which the size is increased through agglomeration are finally moved by the electrostatic dust collector. The agglomeration increasing effect of the PM2.5 is obviously enhanced, and the using amount of an agglomeration solution is reduced.

Owner:SOUTHEAST UNIV

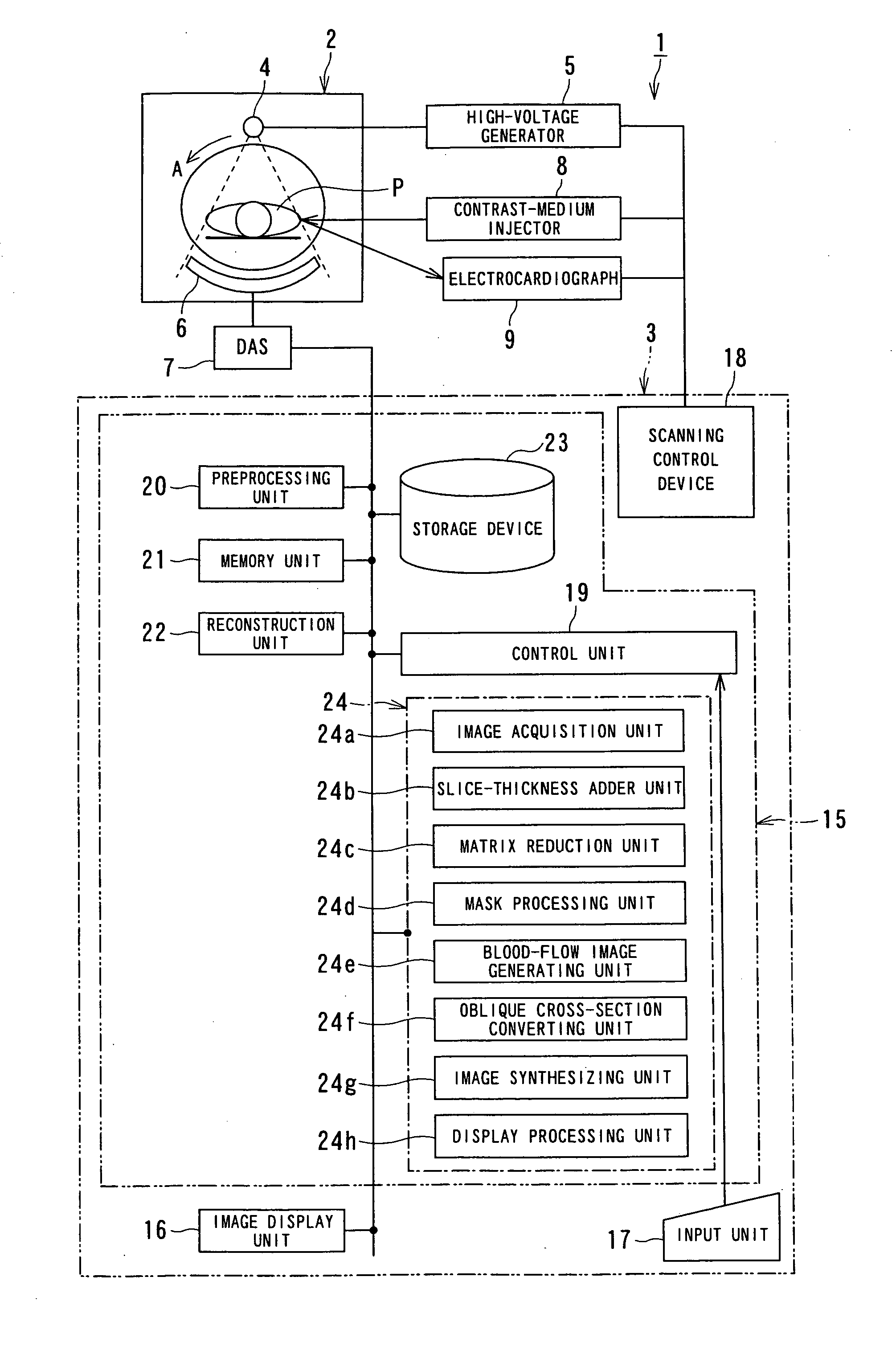

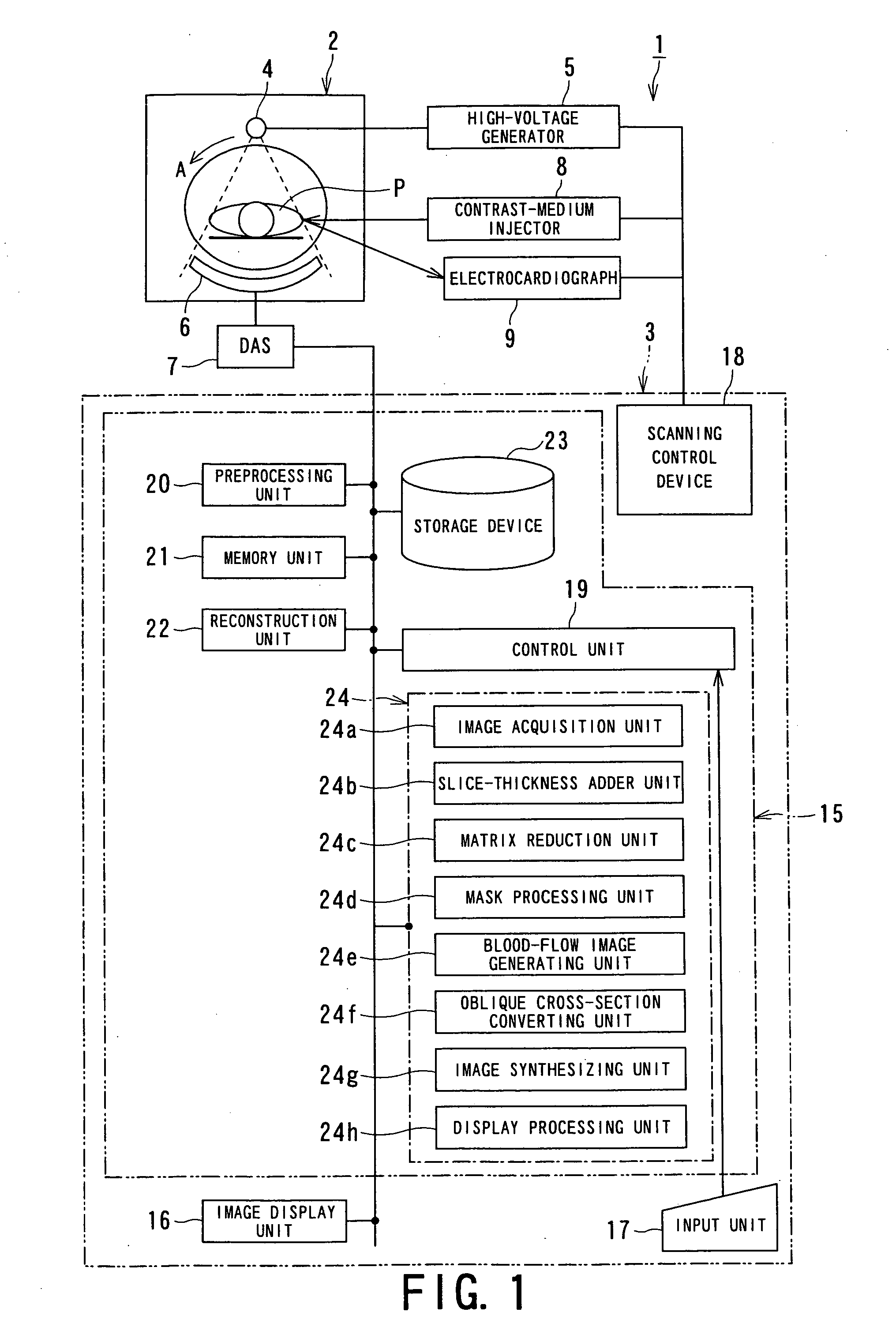

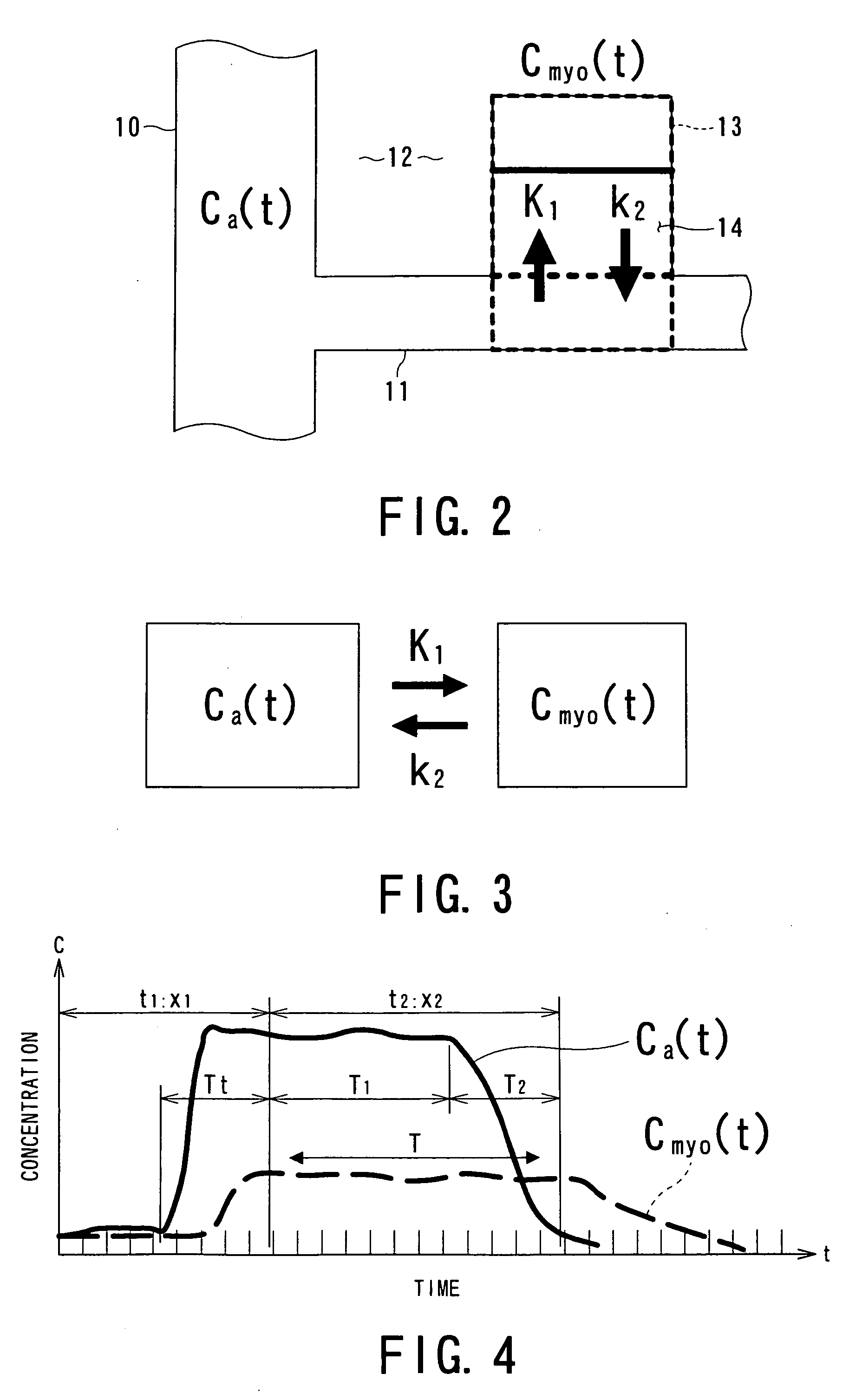

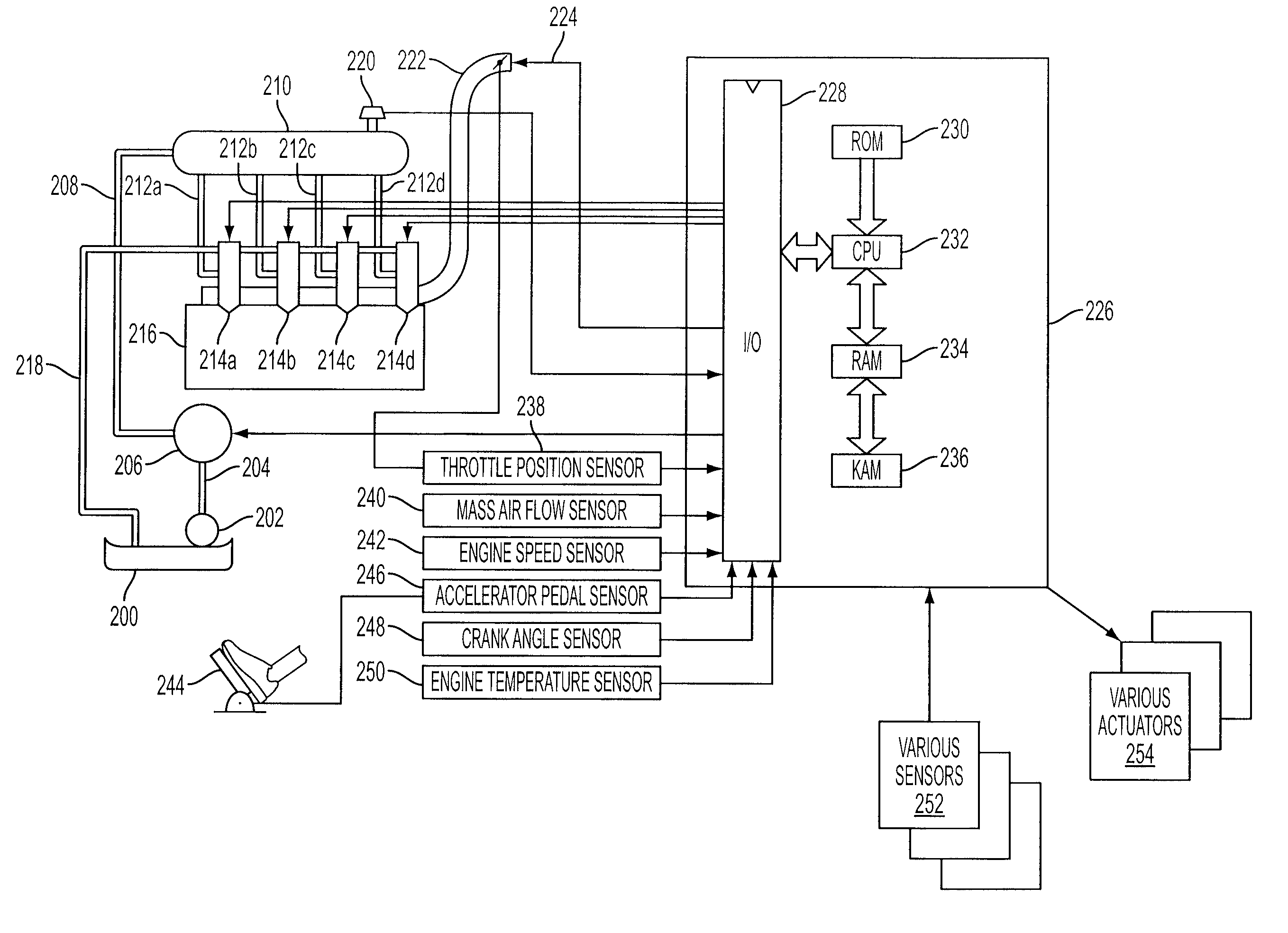

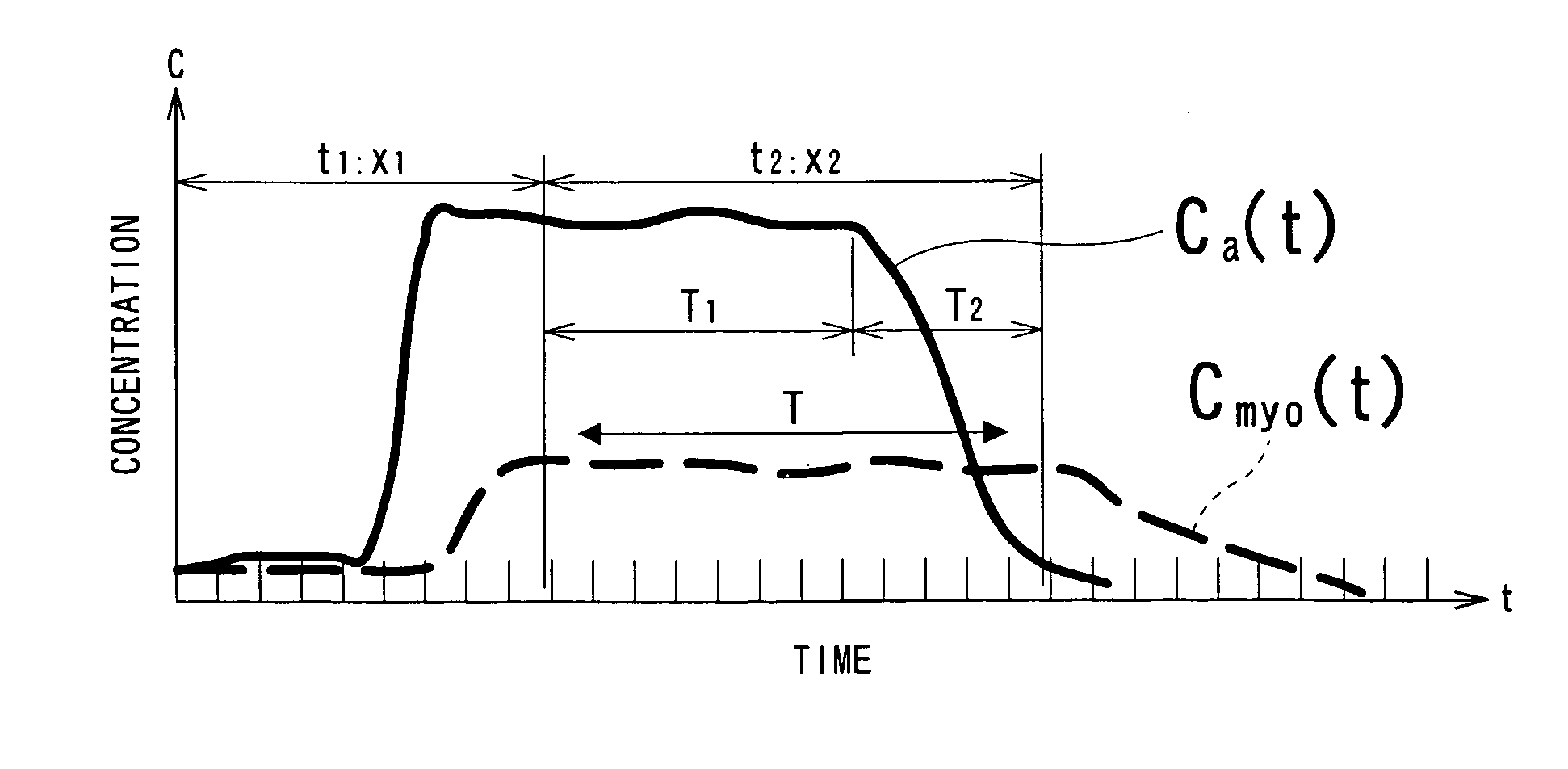

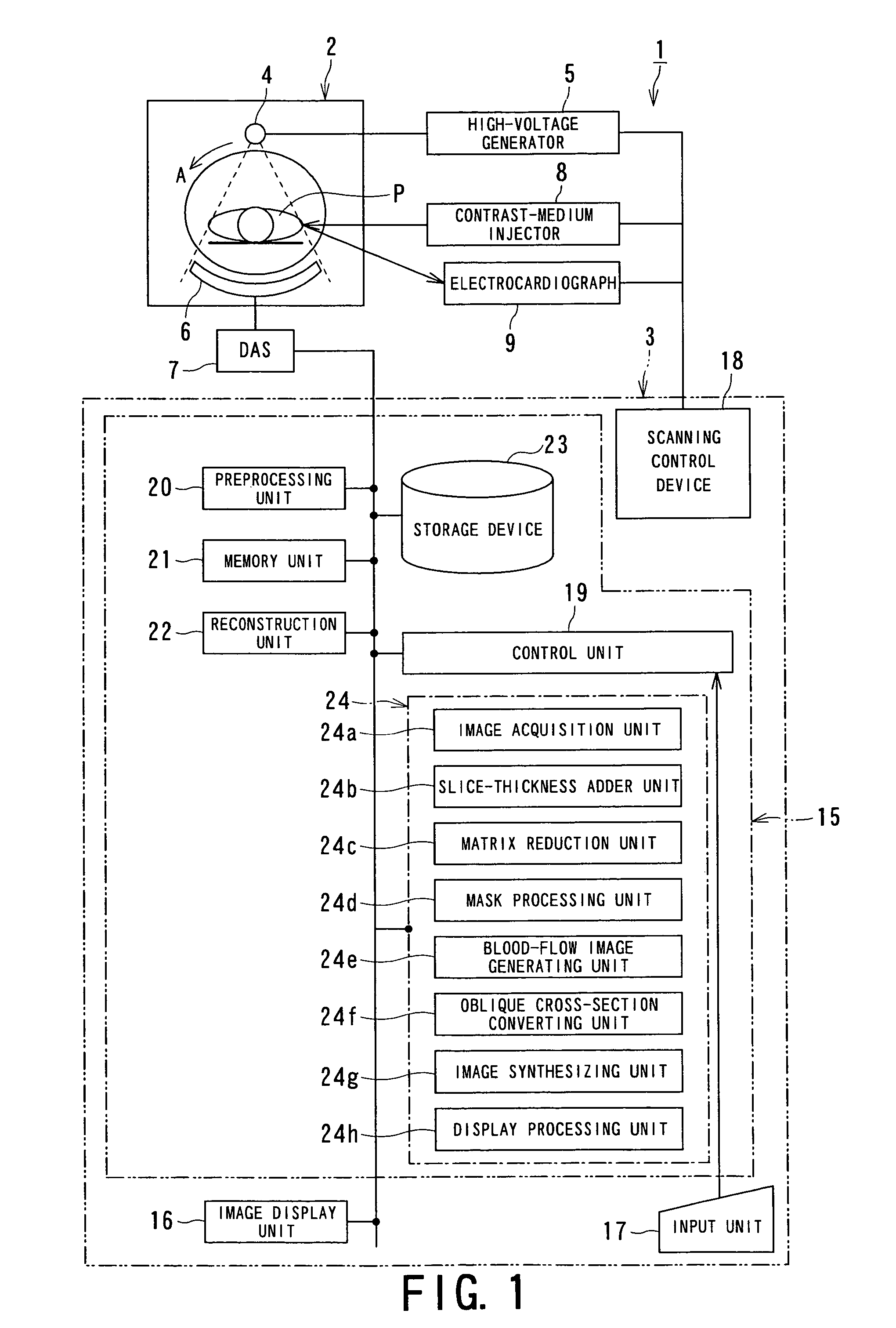

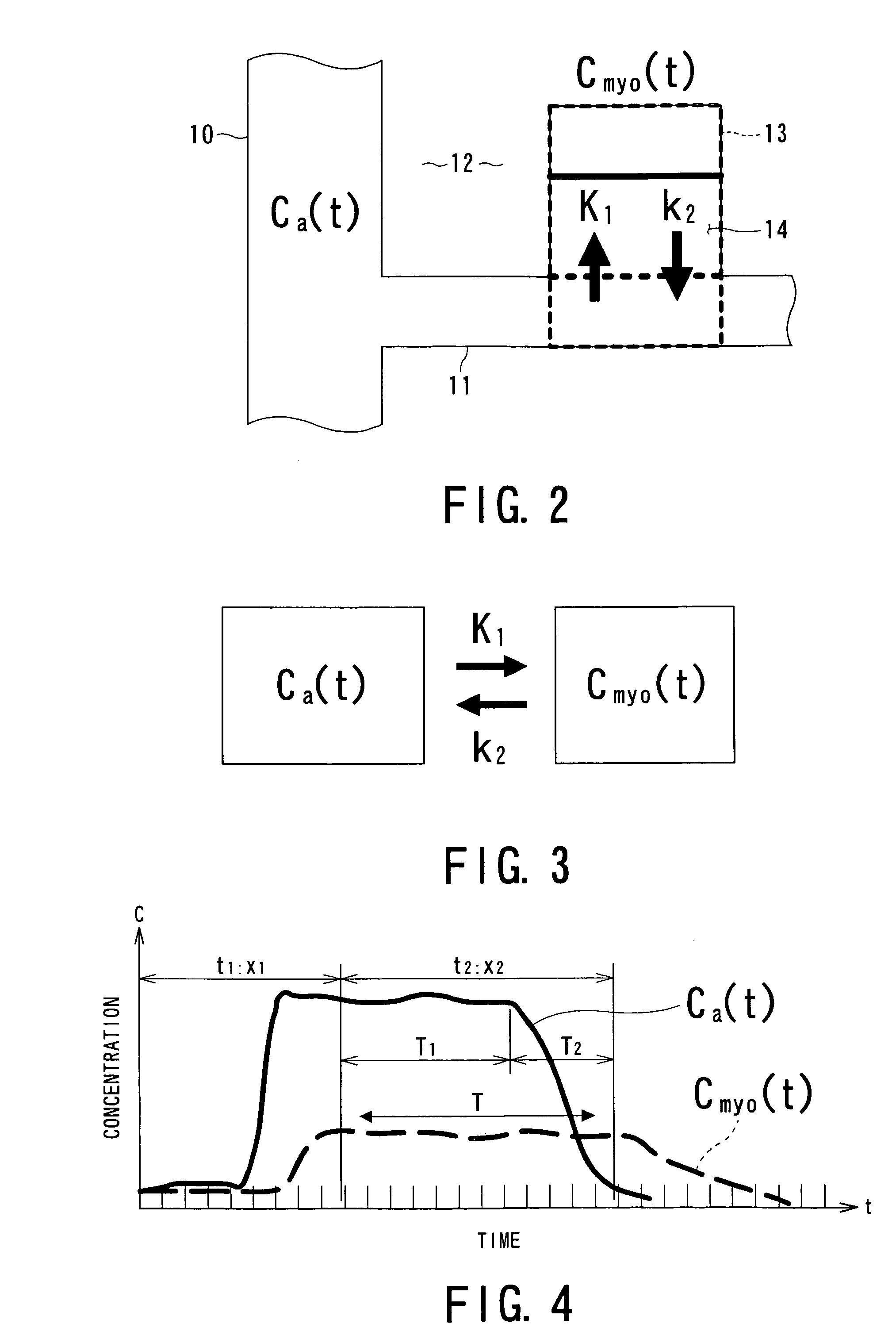

X-ray CT apparatus and myocardial perfusion image generating system

ActiveUS20060241402A1Short timeReduce injection volumeDiagnostic recording/measuringTomographyHeart muscle extractX-ray

An X-ray CT apparatus 1 comprises a blood-flow information acquisition unit, a correction value calculating unit and a blood-flow image generating unit 24 e. The blood-flow information acquisition unit obtains information of a relative blood flow rate in the myocardium of the subject P based on the CT image. The correction value calculating unit obtains a correction value based on the CT image in a concentration transition period defined to be a period from immediately after starting of a continuously injection of a contrast medium into the subject P until the contrast medium injected reaches to the myocardium, increases, and will be in a state where it can be considered that the contrast medium is saturated in a constant value. The blood-flow image generating unit 24 e generating a blood flow value image in the myocardium by correcting the information of the relative blood flow rate with the correction value.

Owner:THE JOHN HOPKINS UNIV SCHOOL OF MEDICINE +1

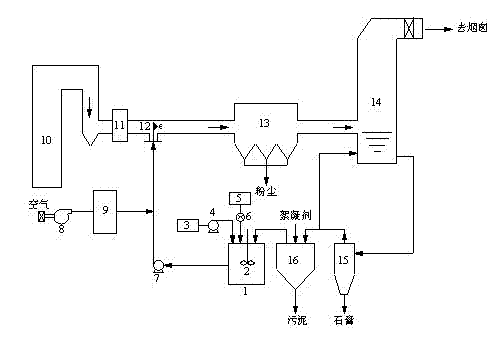

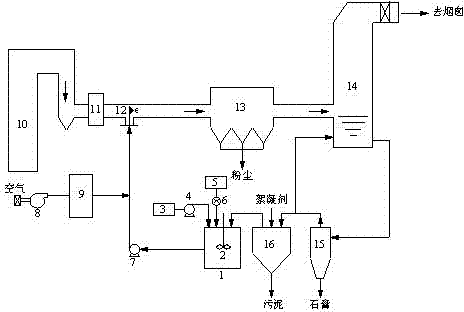

Method for cooperatively promoting agglomeration growth of PM (particulate matter) 2.5 and treating desulfuration wastewater in evaporation manner and device of method

InactiveCN102380278ALow running costConvenient sourceCombination devicesWater/sewage treatmentAir preheaterFlue gas

The invention discloses a method for cooperatively promoting agglomeration growth of PM (particulate matter) 2.5 and treating desulfuration wastewater in an evaporation manner and a device of the method. The method particularly includes steps that agglomeration liquor prepared by desulfuration wastewater, high polymer adhesive and wetting agent is sprayed into an inlet flue of an electric precipitator and is evaporated by the aid of heat of flue gas, in an evaporation process, the wetting agent promotes dust to enter drops of the agglomeration liquor, the high polymer adhesive is connected with PM2.5 via a polymer chain with polar groups, the grain diameter of the PM2.5 is prompted to be enlarged, so that the PM2.5 can be gathered by the follow-up electric precipitator, the desulfuration wastewater is evaporated completely, suspended matters and dissolvable pollutants in the wastewater are converted into solid to be dissolved out, and the suspended matters and the dissolvable pollutants in the wastewater, together with dust in the flue gas, are gathered by the electric precipitator. The device consists of a boiler, an air preheater, the electric precipitator, a desulfurizing tower, a hydraulic cyclone, a desulfuration wastewater clarification tank and an agglomeration liquor preparation tank, and a double-fluid atomizing nozzle is arranged in the flue between the air preheater and the electric precipitator.

Owner:SOUTHEAST UNIV

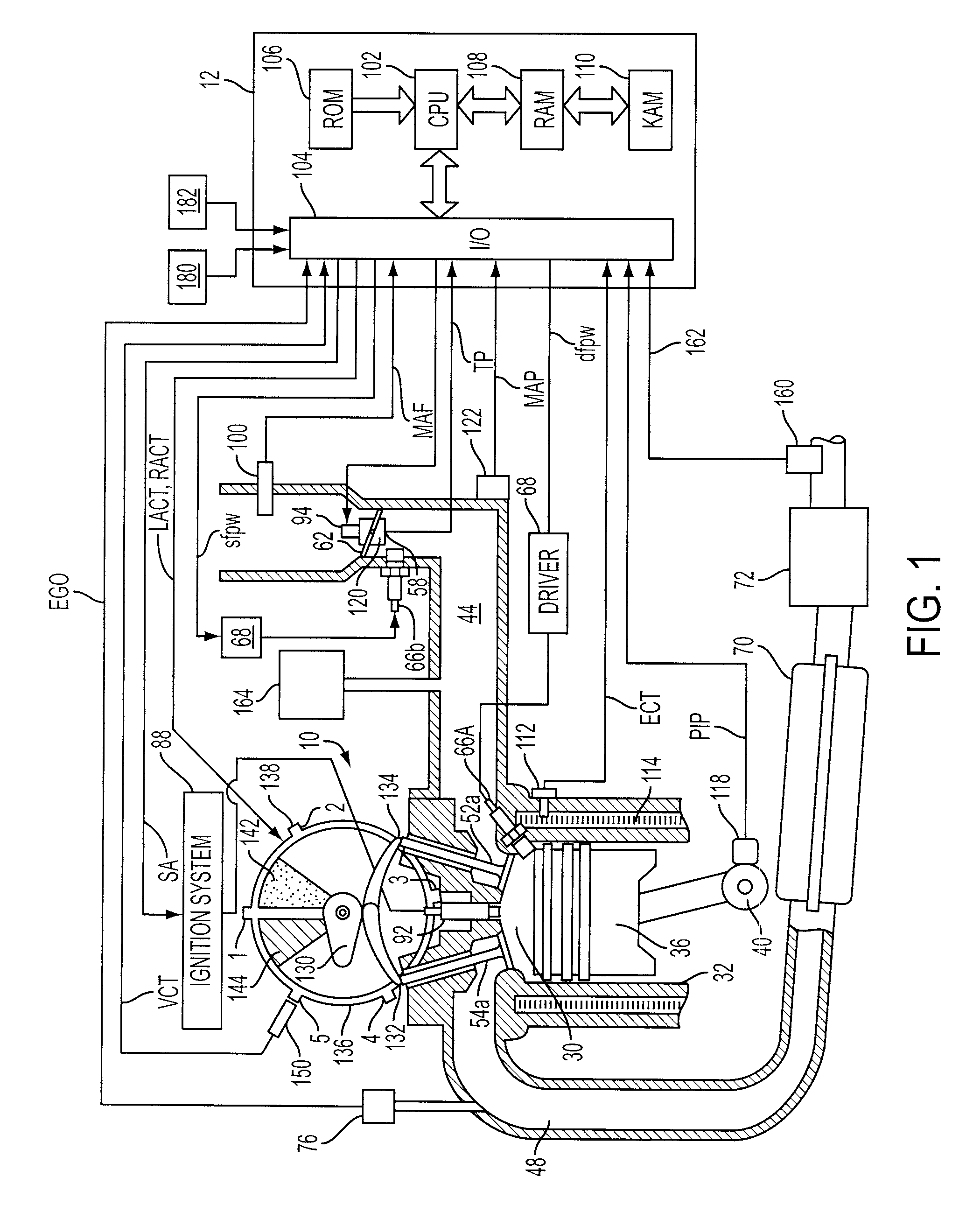

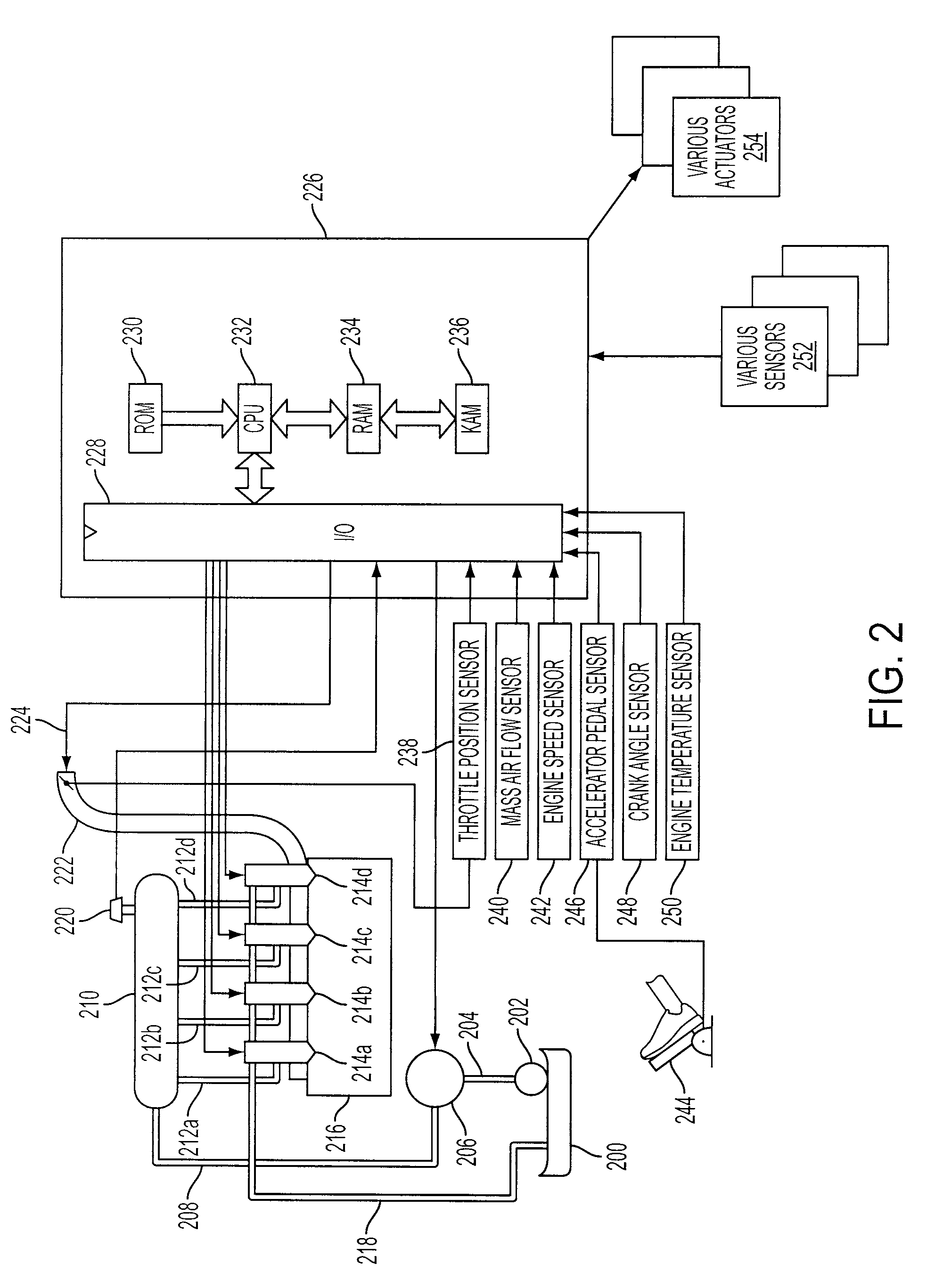

Method of detecting and compensating for injector variability with a direct injection system

ActiveUS7717088B2Improve pressure resistanceReduce temperature sensitivityElectrical controlInternal combustion piston enginesPressure decreaseEngineering

A method for controlling fuel injection of a direct injection fuel system, the fuel system having a fuel pump, the method comprising: variably operating the fuel pump to maintain a fuel pressure at a selected pressure, temporarily increasing pump operation to increase pressure sufficiently above said selected pressure and then reducing pump operation; during at least a fuel injection subsequent to the reduction in pump operation, correlating pressure decrease to injector operation, and adjusting fuel injection operation based on the correlation.

Owner:FORD GLOBAL TECH LLC

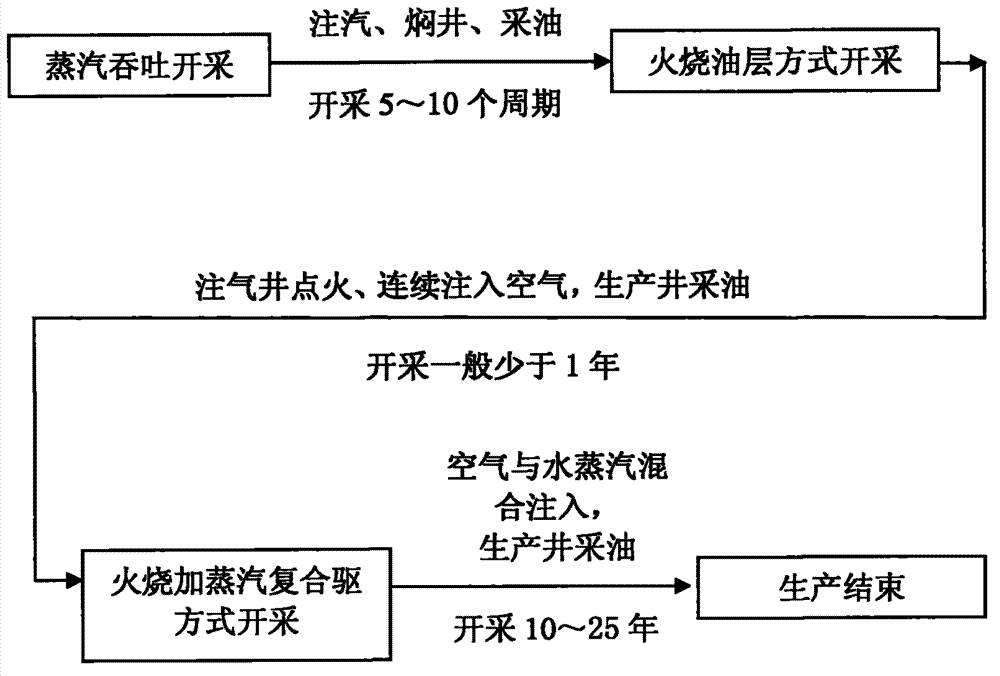

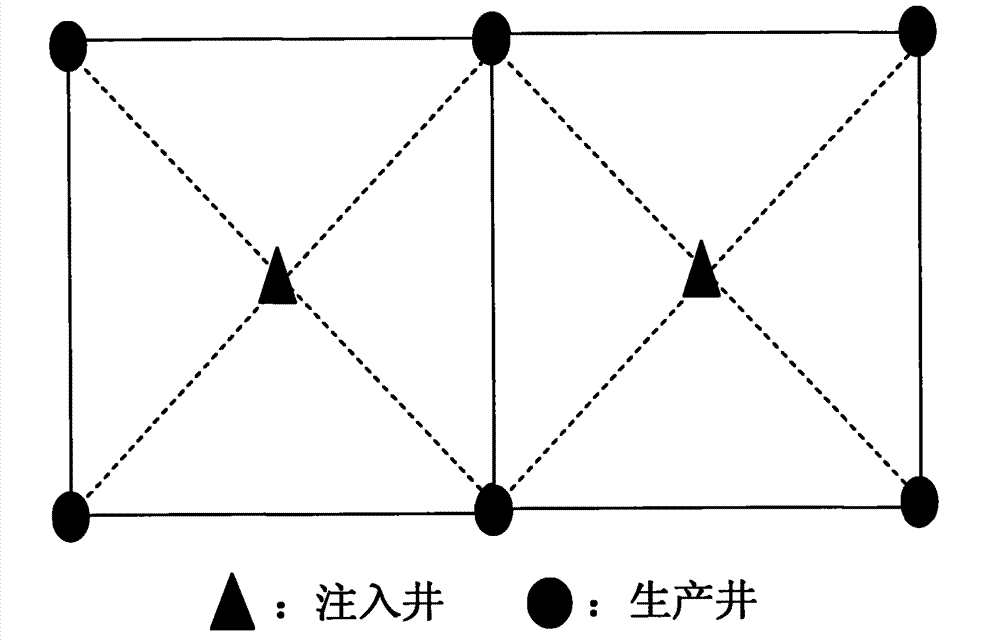

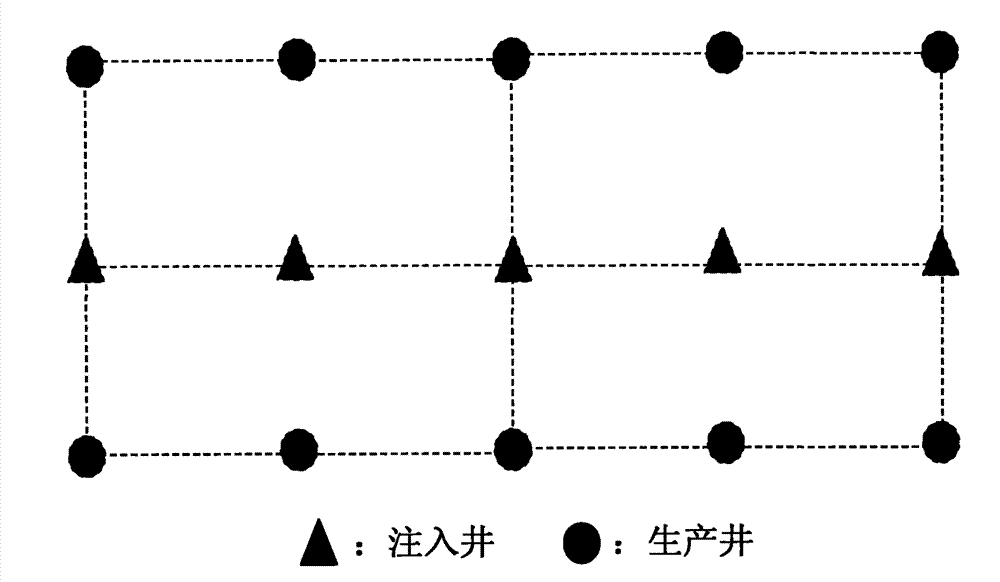

Method for using combustion and vapor combination flooding to exploit thick oil

The invention discloses a method for using combustion and stream combination flooding to exploit thick oil. The method comprises the following steps of: carrying out vapor huff and puff exploitation in a heavy crude oil reservoir; carrying out in-situ combustion exploitation after forming thermal linkage; and changing single air charging to be simultaneous charging of air and water vapor in certain proportion to carry out combination flooding exploitation. A proper optimal configuration relationship of air / vapour charging speed is selected, so as to improve combustion wave and volume of the oil reservoir and improve exploitation effects of in-situ combustion and the ultimate recovery factor.

Owner:PETROCHINA CO LTD

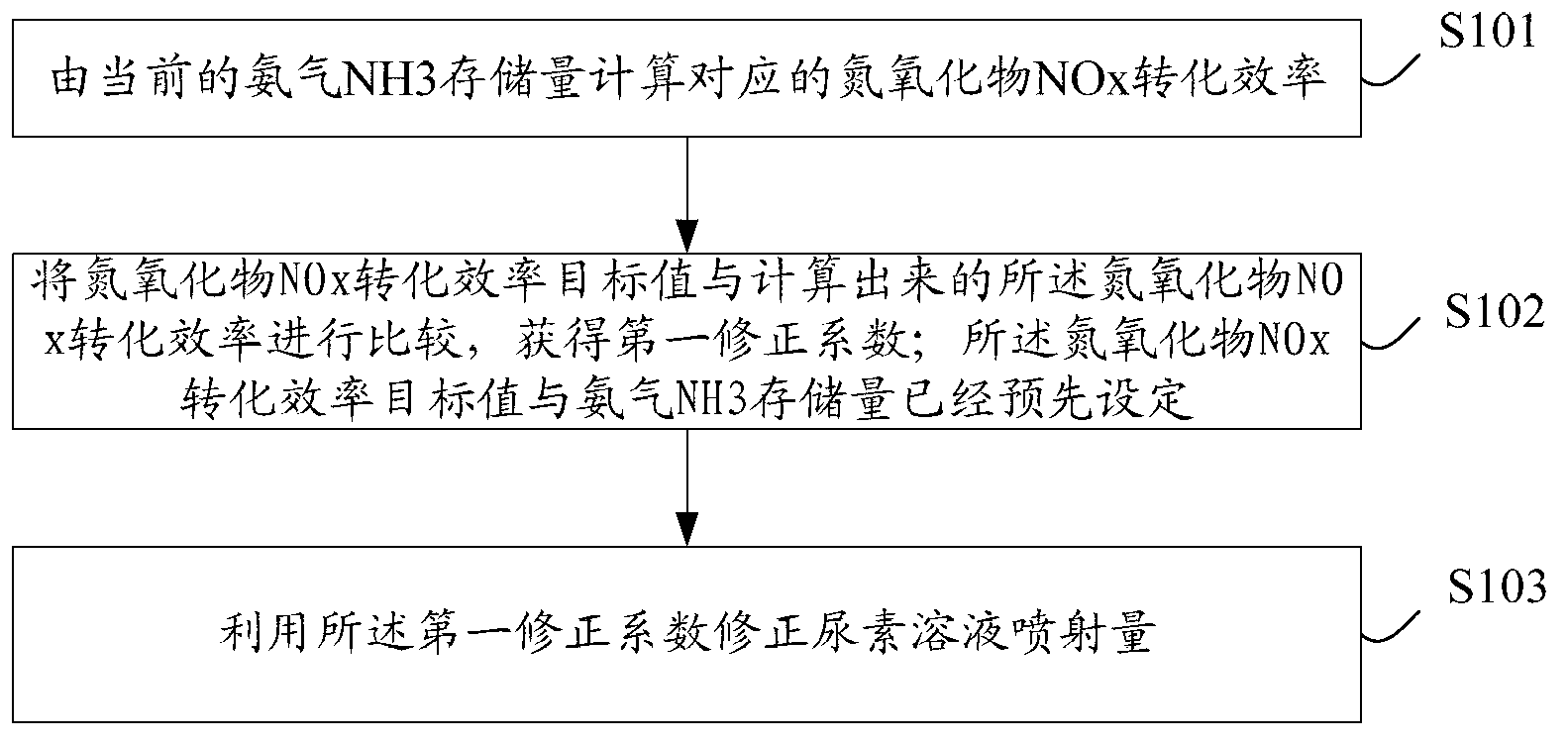

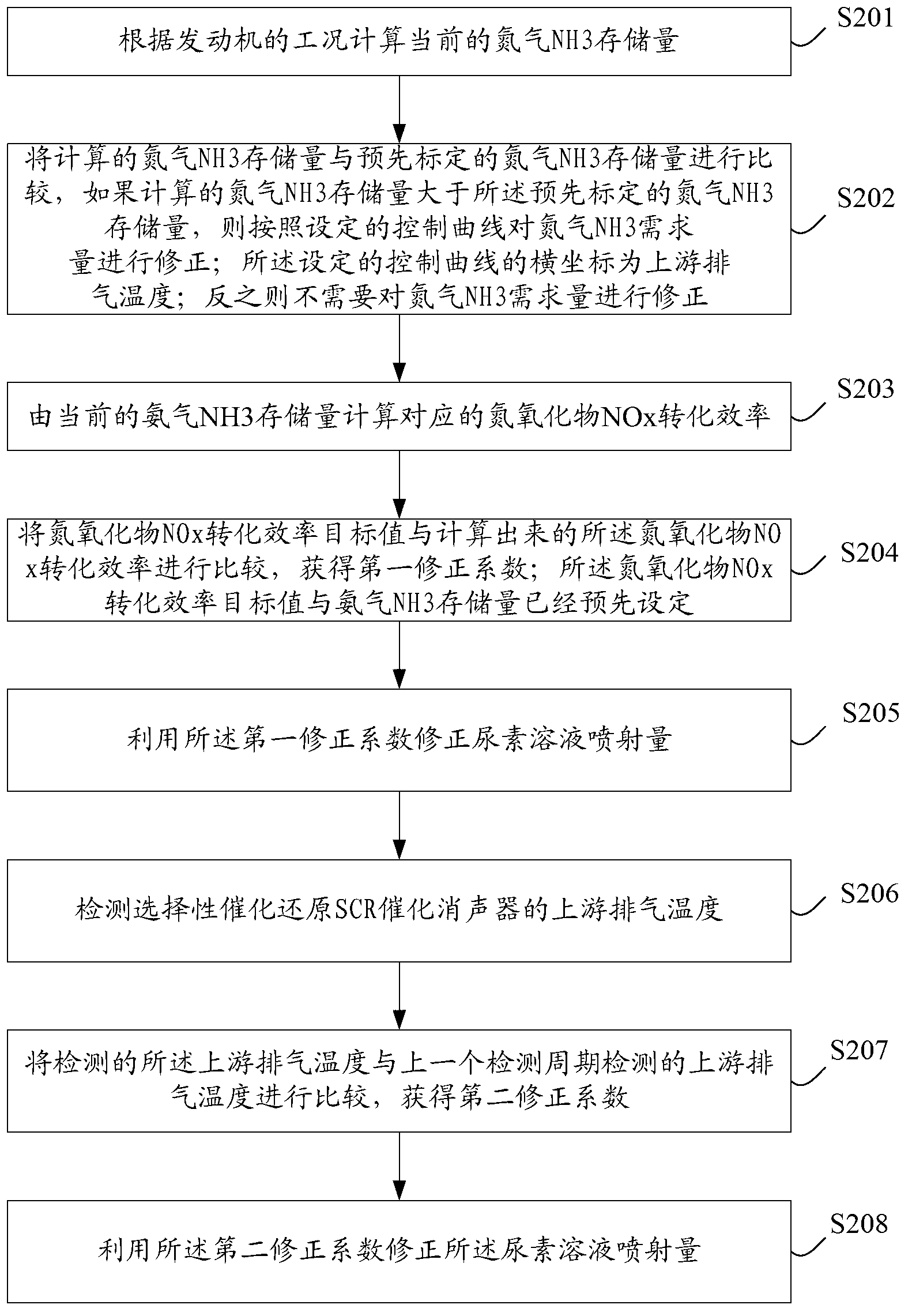

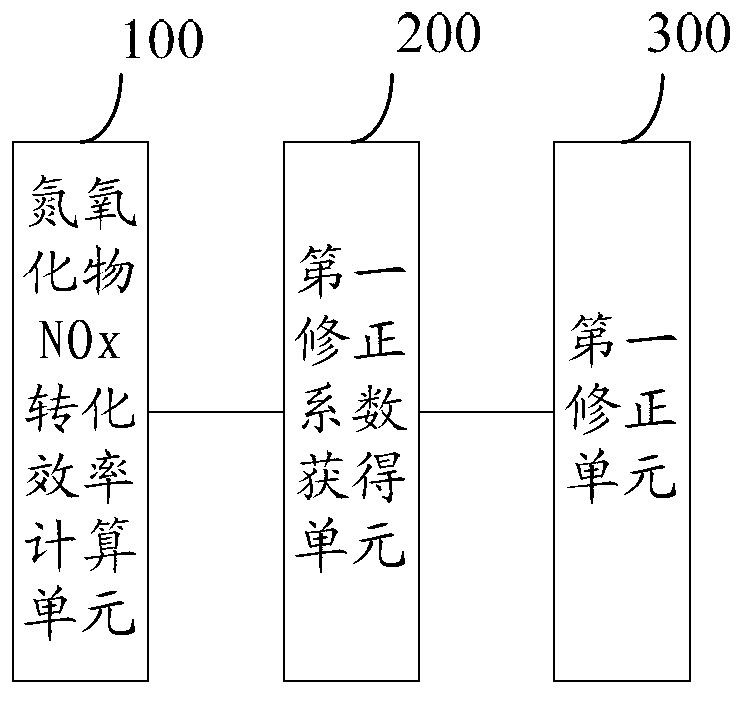

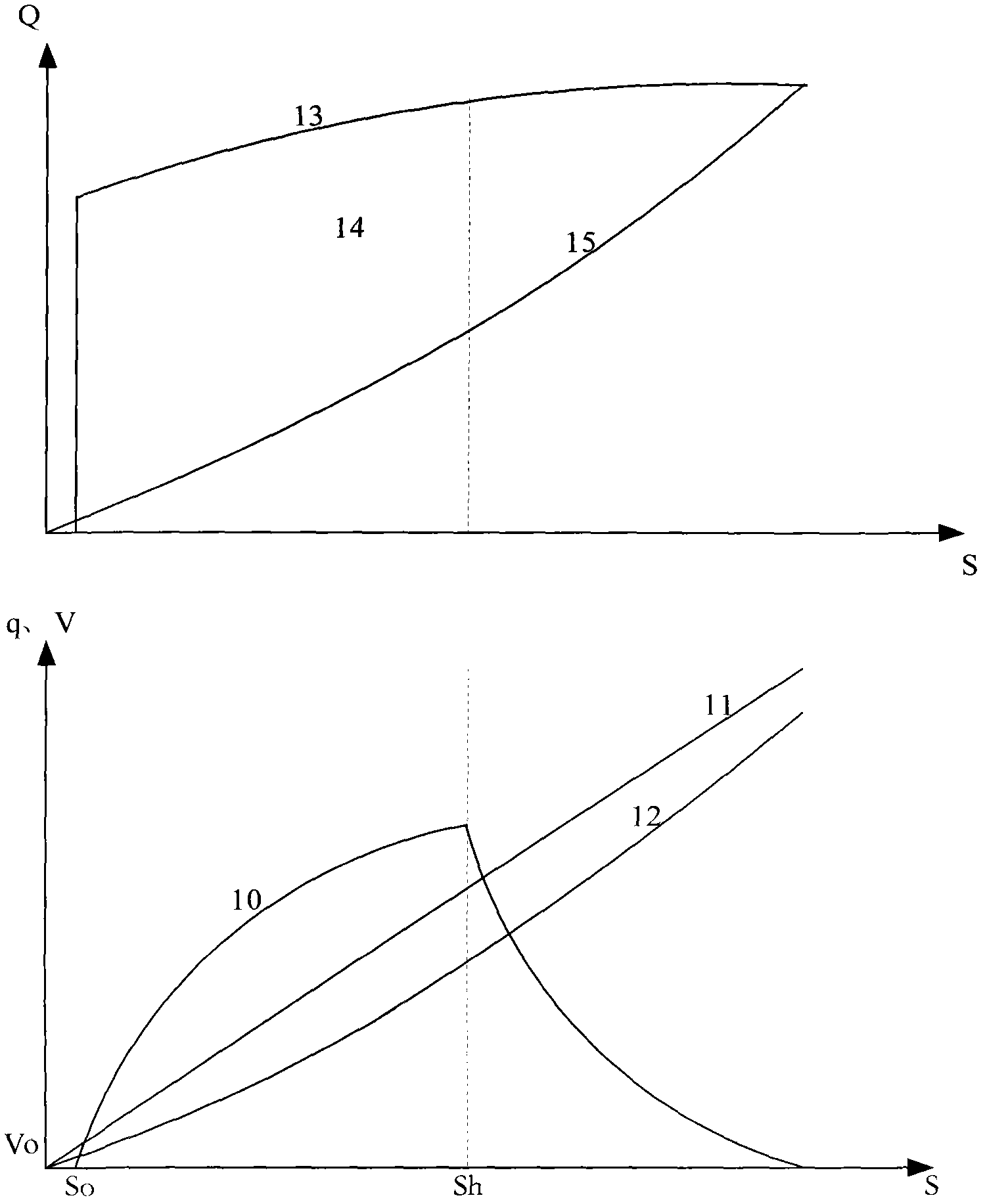

Method and system for controlling emitted dose of urea solution by SCR (Selective Catalytic reduction)

ActiveCN103016112APrecise control of injection volumeReduce injection volumeInternal combustion piston enginesExhaust apparatusReaction temperatureClosed loop

The invention provides a method and a system for controlling the emitted dose of a urea solution by SCR (Selective Catalytic Reduction) by taking three parameters, namely NH3 storage amount, NOx conversion efficiency and exhaust gas temperature into account. When the working condition of en engine instantaneously changes, the exhaust gas temperature can possibly and suddenly raise to cause increase of exhaust gas flow, and excessive NH3 escape is caused in the prior art; or when the working condition of the engine changes, the emitted dose of the urea solution is lower to cause insufficiency of the NOx conversion efficiency. Under the conditions that the requirements on the catalyst amount and the NH3 escape amount are definite, the maximum NOx conversion efficiency depends on the catalyst reaction temperature and the exhaust gas flow. According to the control method provided by the invention, a target value of the NOx conversion efficiency and the available NOx conversion efficiency based on the NH3 storage amount are added as closed-loop amendments, so that the emitted dose of the urea solution can be accurately controlled, the NOx conversion efficiency is furthest improved and the NH3 escape amount is reduced.

Owner:WEICHAI POWER CO LTD +1

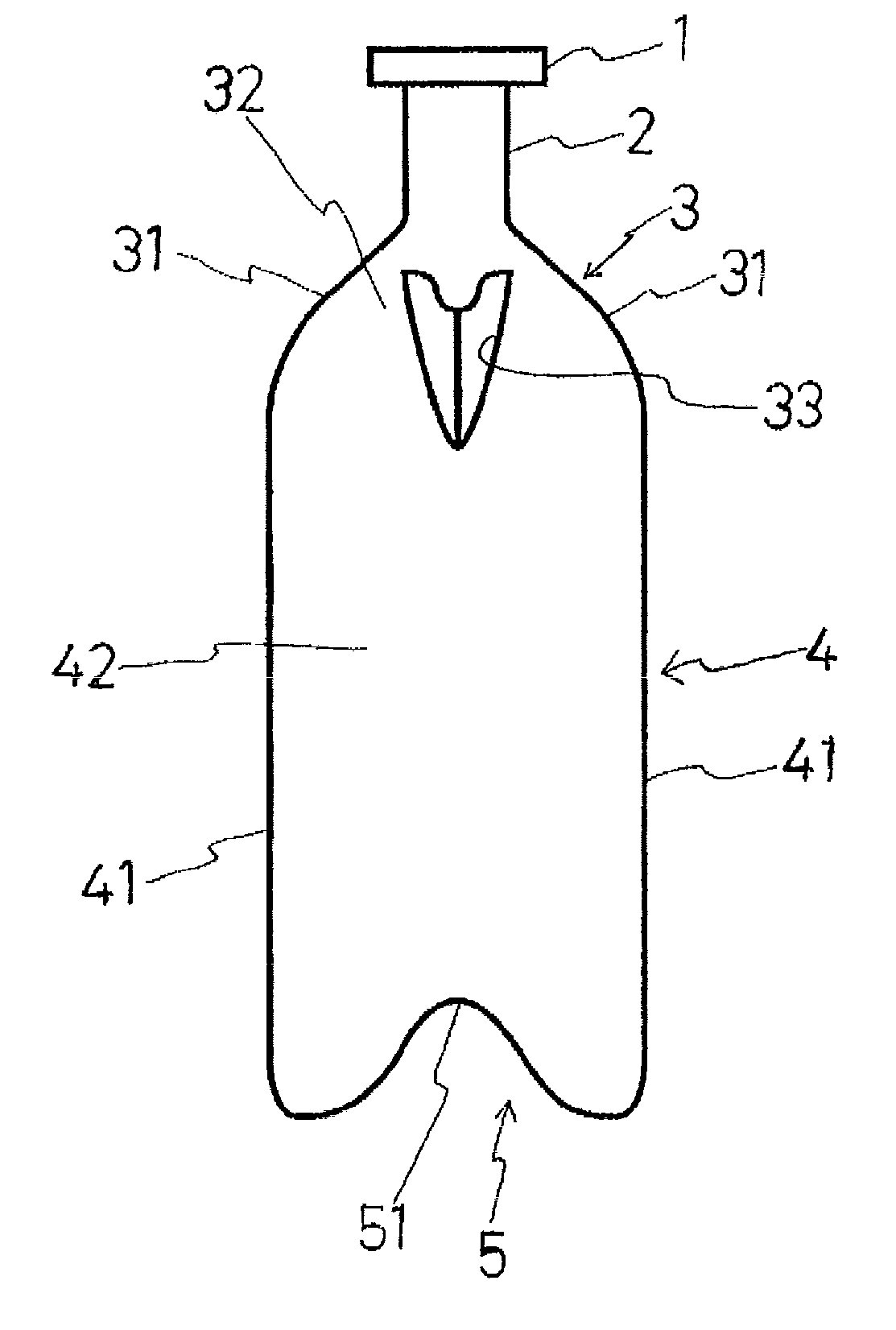

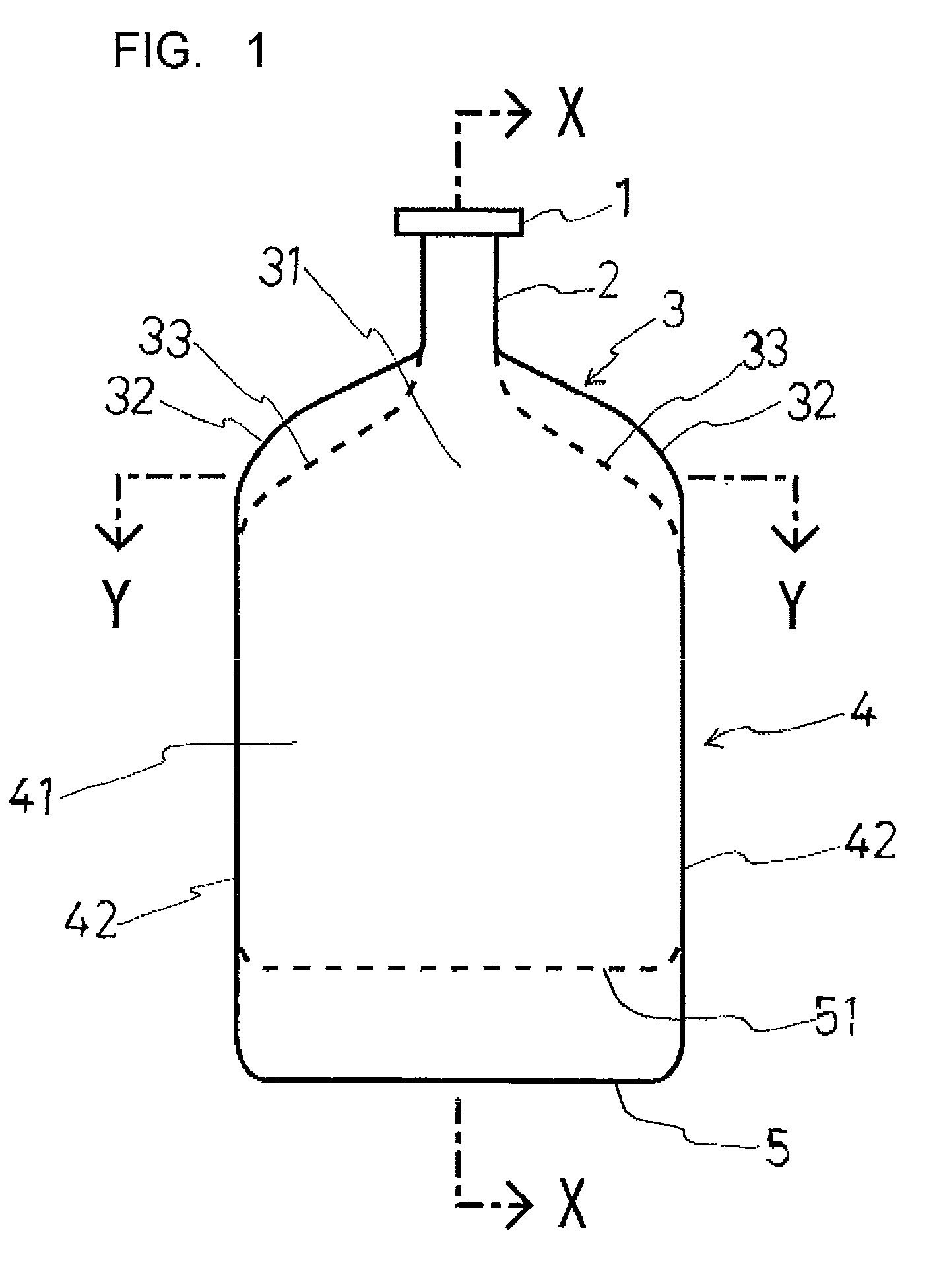

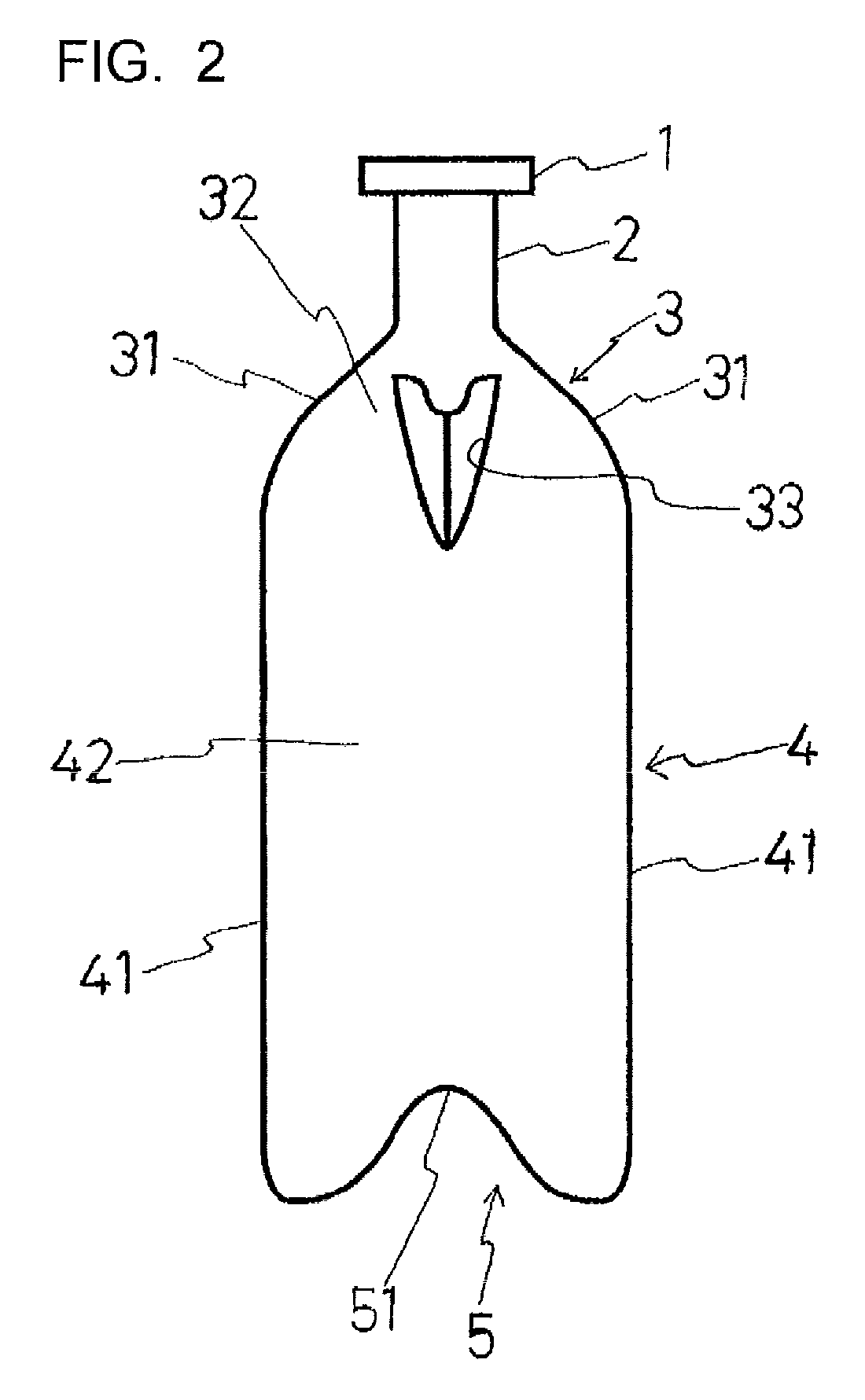

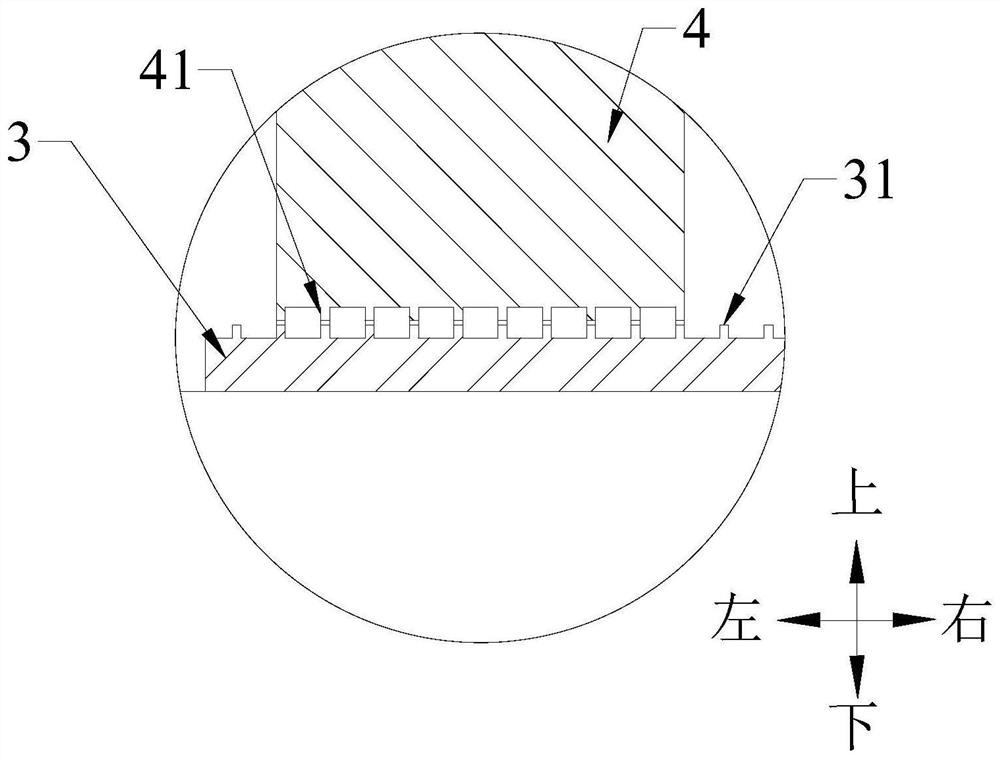

Blow-molded plastic infusion container

A bottle-type blow-molded plastic infusion container that can be set in an upright position. When liquid is discharged from the container, almost no dead space occurs in shoulder and bottom portions (required amount of air to be placed in the container to remove residual liquid is less). The blow-molded container has a mouth section (1), a neck section (2), the shoulder section (3), a barrel section (4), and the bottom section (5). The barrel section (4) has a pair of broad side faces (41, 41) and a pair of narrow side faces (42, 42). The bottom section (5) is formed in a shape symmetrical about a longitudinal axis of the bottom section (5) and bent inward in a V shape. Further, the shoulder section (3) has a pair of broad side faces (31, 31) and a pair of narrow side faces (32, 32). In the narrow side faces (32, 32) are formed grooves (33, 33) symmetrical about a longitudinal axis and bent inward in a V shape.

Owner:NIPRO CORP

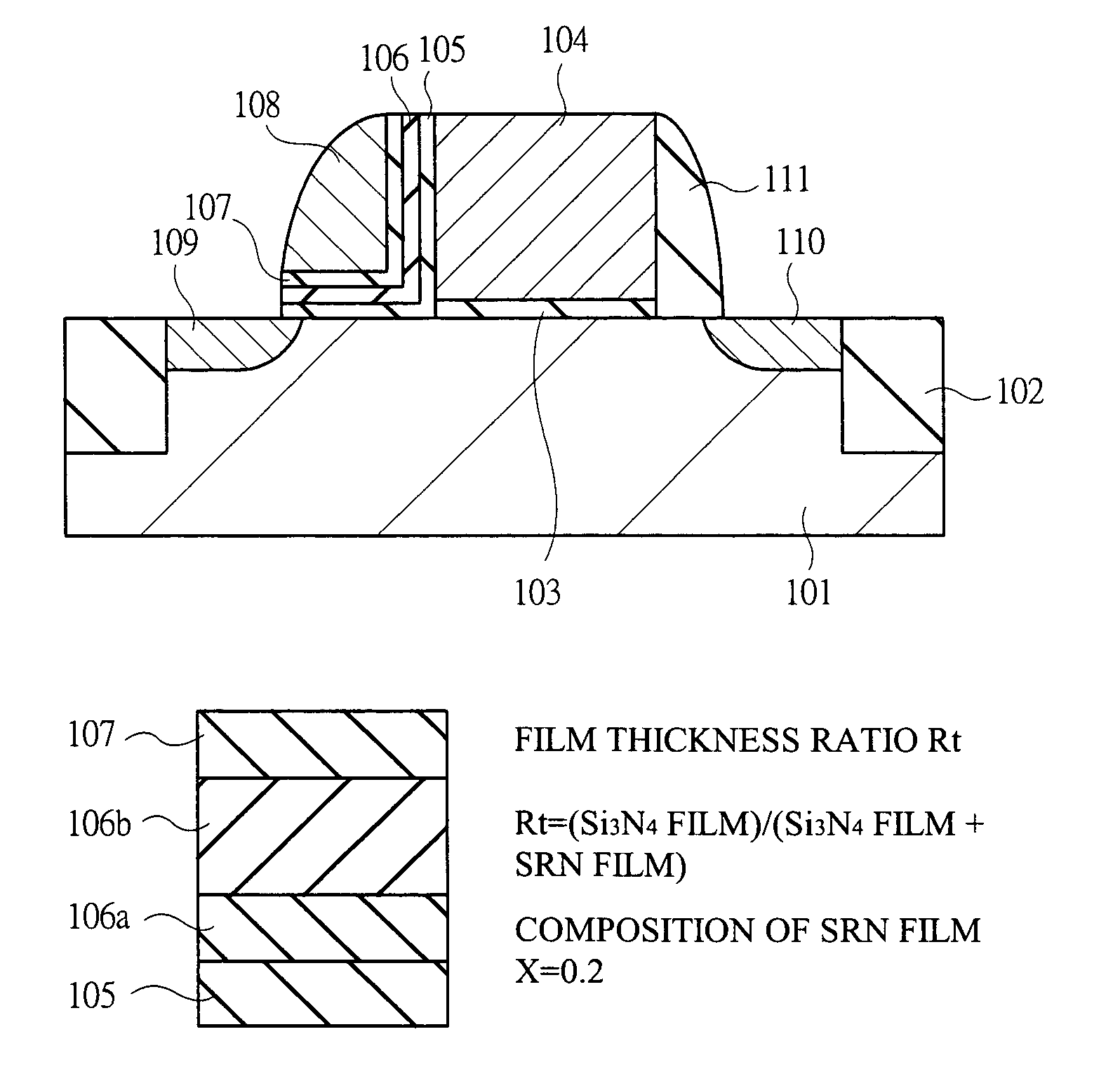

Non-volatile memory device with a silicon nitride charge holding film having an excess of silicon

ActiveUS8125012B2Increase the number ofReduce injection volumeTransistorSolid-state devicesCharge retentionSemiconductor storage devices

Performance of a non-volatile semiconductor storage device which performs electron writing by hot electrons and hole erasure by hot holes is improved. A non-volatile memory cell which performs a writing operation by electrons and an erasure operation by holes has a p-type well region, isolation regions, a source region, and a drain region provided on an Si substrate. A control gate electrode is formed via a gate insulating film between the source region and the drain region. In a left-side side wall of the control gate electrode, a bottom Si oxide film, an electric charge holding film, a top Si oxide film, and a memory gate electrode are formed. The electric charge holding film is formed from an Si nitride film stoichiometrically excessively containing silicon.

Owner:RENESAS ELECTRONICS CORP

Formulations of anti-pain agents and methods of using the same

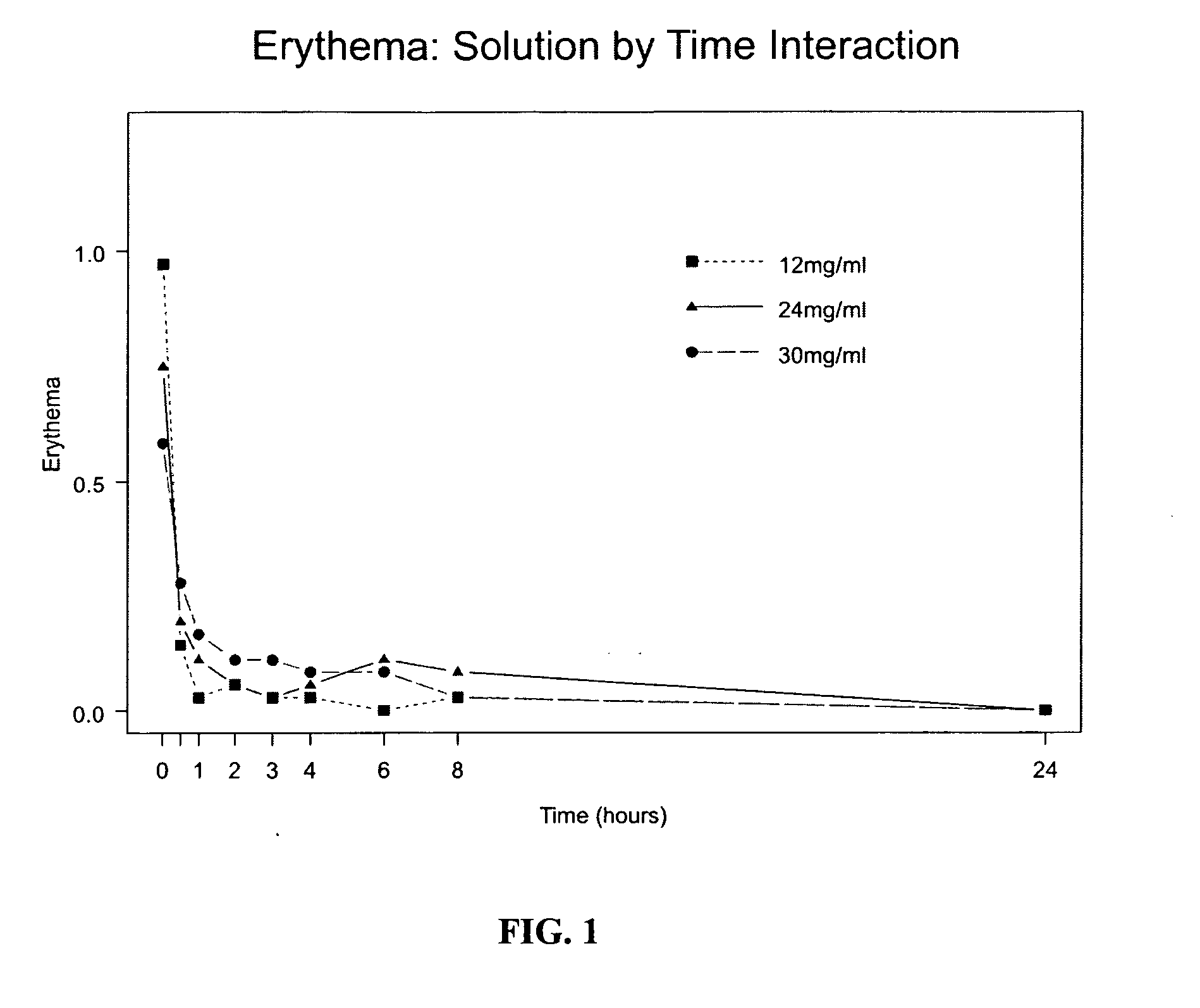

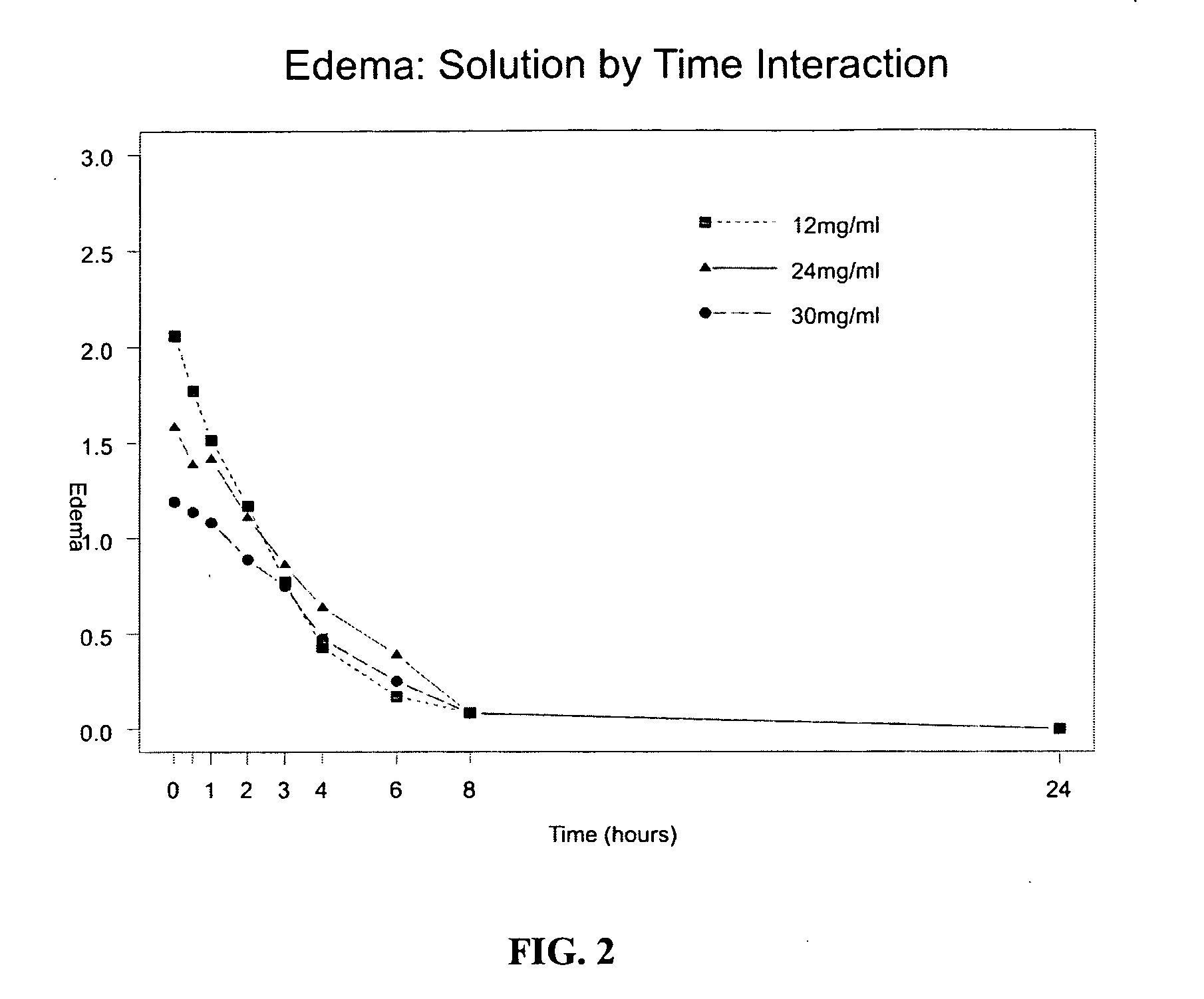

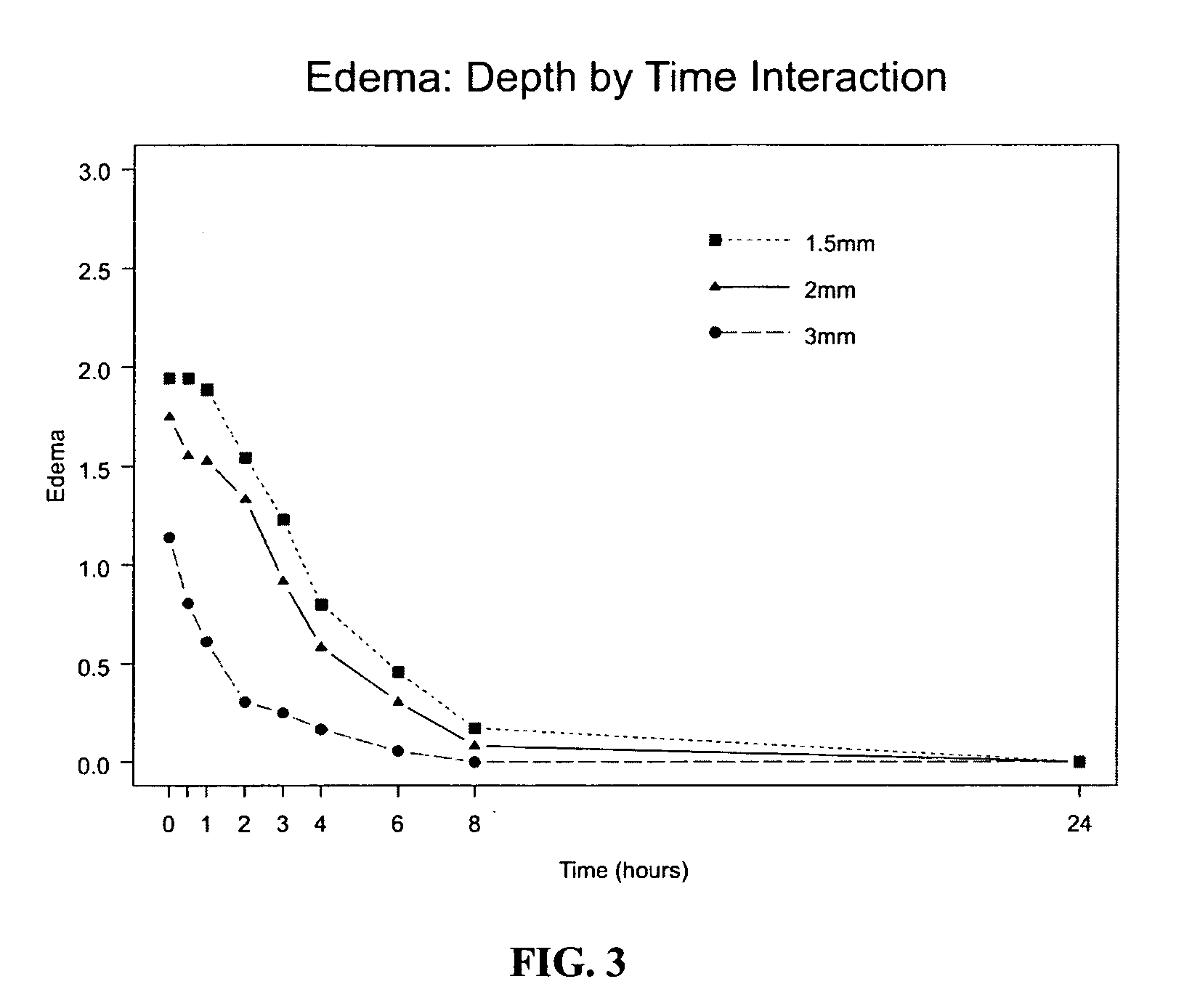

InactiveUS20050256182A1Reduce skin irritationRelieve painBiocidePharmaceutical delivery mechanismSide effectDose sparing

The present invention relates to novel anti-pain formulations and methods of their delivery. Anti-pain agents delivered in accordance with the methods of the invention have an improved clinical utility and therapeutic efficacy relative to other drug delivery methods, including oral, intramuscular and subcutaneous delivery. The methods of the present invention provide benefits and improvements over conventional drug delivery methods including dose sparing, increased drug efficacy, reduced side effects.

Owner:BECTON DICKINSON & CO

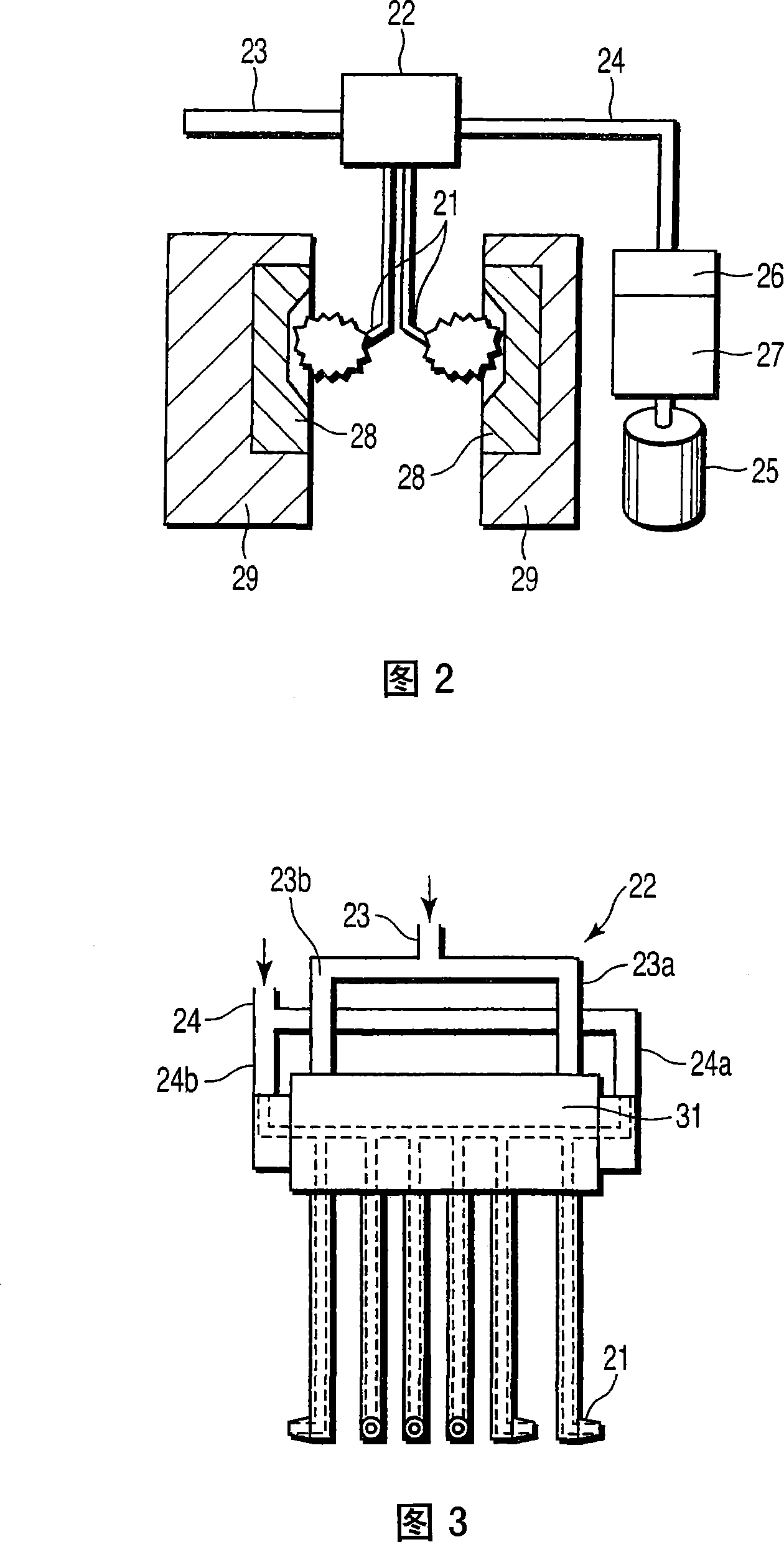

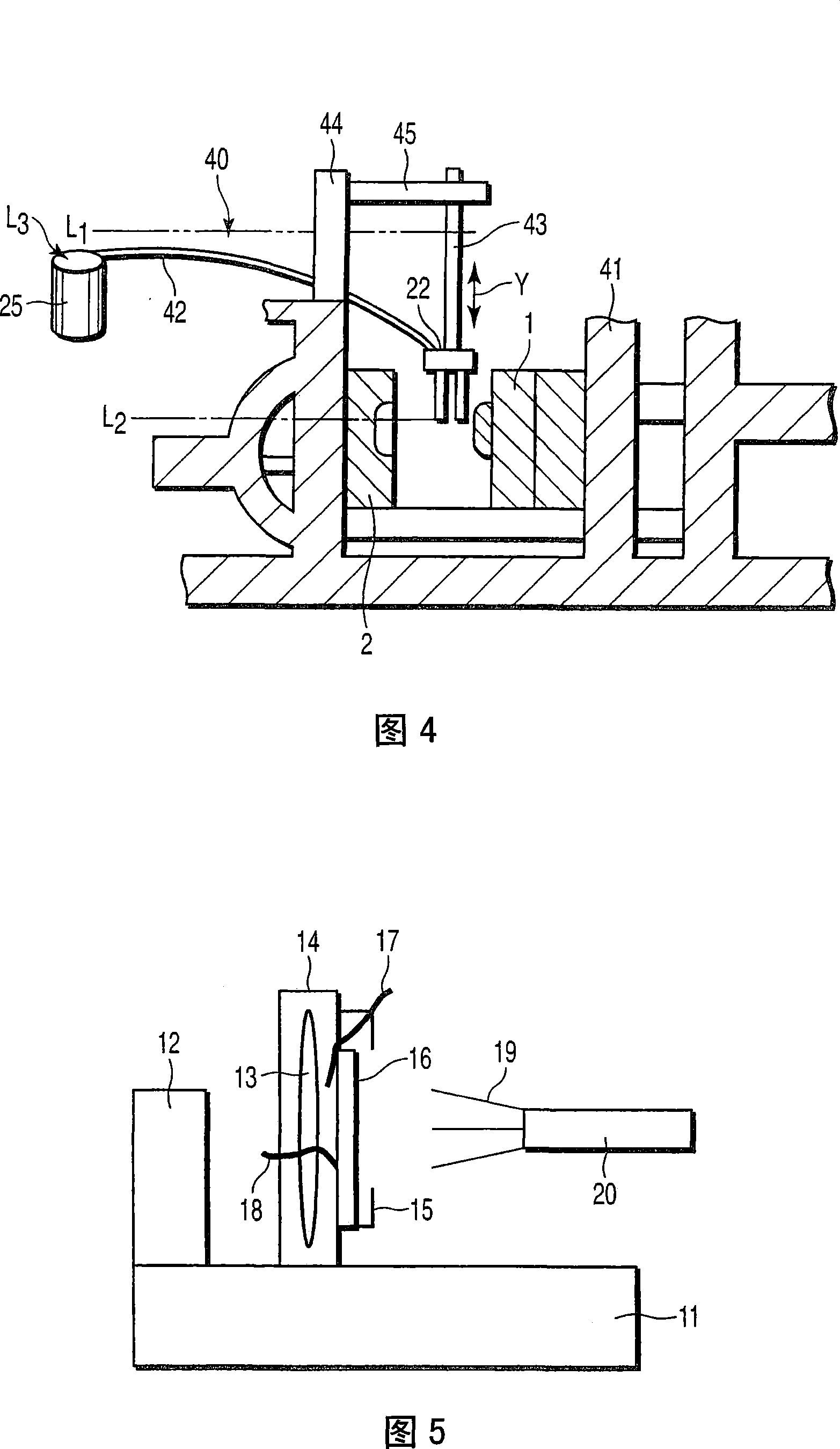

Mold-releasing agent for oil die casting, method for setting solvent mixing ratio, casting method and spray device

The invention provides an oil type release agent die casting containing 70 to 98 parts by weight of a solvent having a specified flash point, 1 to 10 parts by weight of mineral oils and / or synthetic oils having a high viscosity, 15 parts by weight or less of a silicone oil, and 1 to 5 parts by weight of additives having a lubricating function, wherein the flash point of the agent is in the range of 70 to 170 DEG C, and dynamic viscosity of the agent is 2 to 30 mm 2 / s or higher at 40 DEG C, and a method for setting a mixing ratio of the solvent, a casting method, and a spraying unit for the case of using the release agent.

Owner:AOKI SCIENCE INSTITUTE CO LTD +2

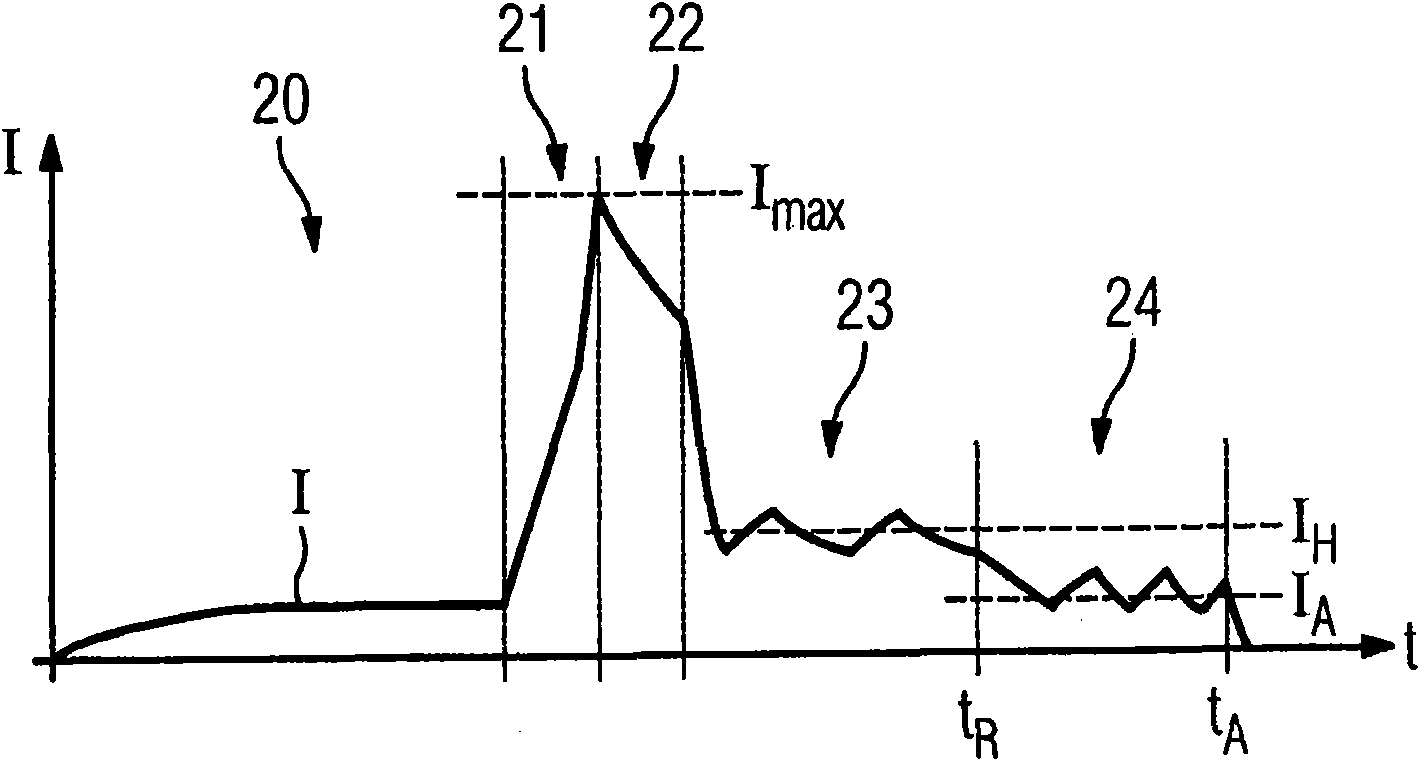

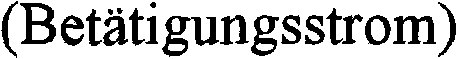

Method for actuating a solenoid valve and associated device

InactiveCN101809269AReduce latencyShort opening timeOperating means/releasing devices for valvesElectrical controlSolenoid valveEngineering

The invention relates to a method for actuating a solenoid valve (4) for generating precise opening and closing times of the solenoid valve (4). To this end, an actuating current (I) provided for actuating the solenoid valve (4) and applied to an actuating coil (5) of the solenoid valve (4) is already reducing in a reduction phase (24) prior to a switch-off point in time (tA) of the solenoid valve (4) relative to a maintained level (IH) of the actuating current (I), at which the solenoid valve (4) is reliably held in an actuating position (16).

Owner:CONTINENTAL AUTOMOTIVE GMBH

Activated carbon treatment system for improving waste heat utilization rate and denitration rate and using method thereof

ActiveCN108939808AGuaranteed temperatureImprove desulfurization and denitrification efficiencyGas treatmentDispersed particle separationActivated carbonFlue gas

The invention provides an activated carbon treatment system for improving waste heat utilization rate and denitration rate and a using method thereof. Heat exchangers are separately disposed before flue gas is input into a first-stage adsorption column and a second-stage adsorption column, the temperature of the flue gas entering the first-stage adsorption column and the second-stage adsorption column is controlled, thereby ensuring the temperature of desulfurization and denitration. The activated carbon treatment system utilizes high-temperature flue gas (about 150-170 DEG C) after a main exhaust blower, adopts a mode of heat exchange, artificially controls the temperature of the flue gas entering the first-stage adsorption column and the second-stage adsorption column, and enables the efficiency of removal of SO<2> and NO<x>; and the utilization rate of the high-temperature flue gas after the main exhaust blower is increased, and the temperature of the flue gas entering a desulfurization tower and a denitration tower is controlled to improve the efficiency of desulfurization and denitration.

Owner:ZHONGYE-CHANGTIAN INT ENG CO LTD

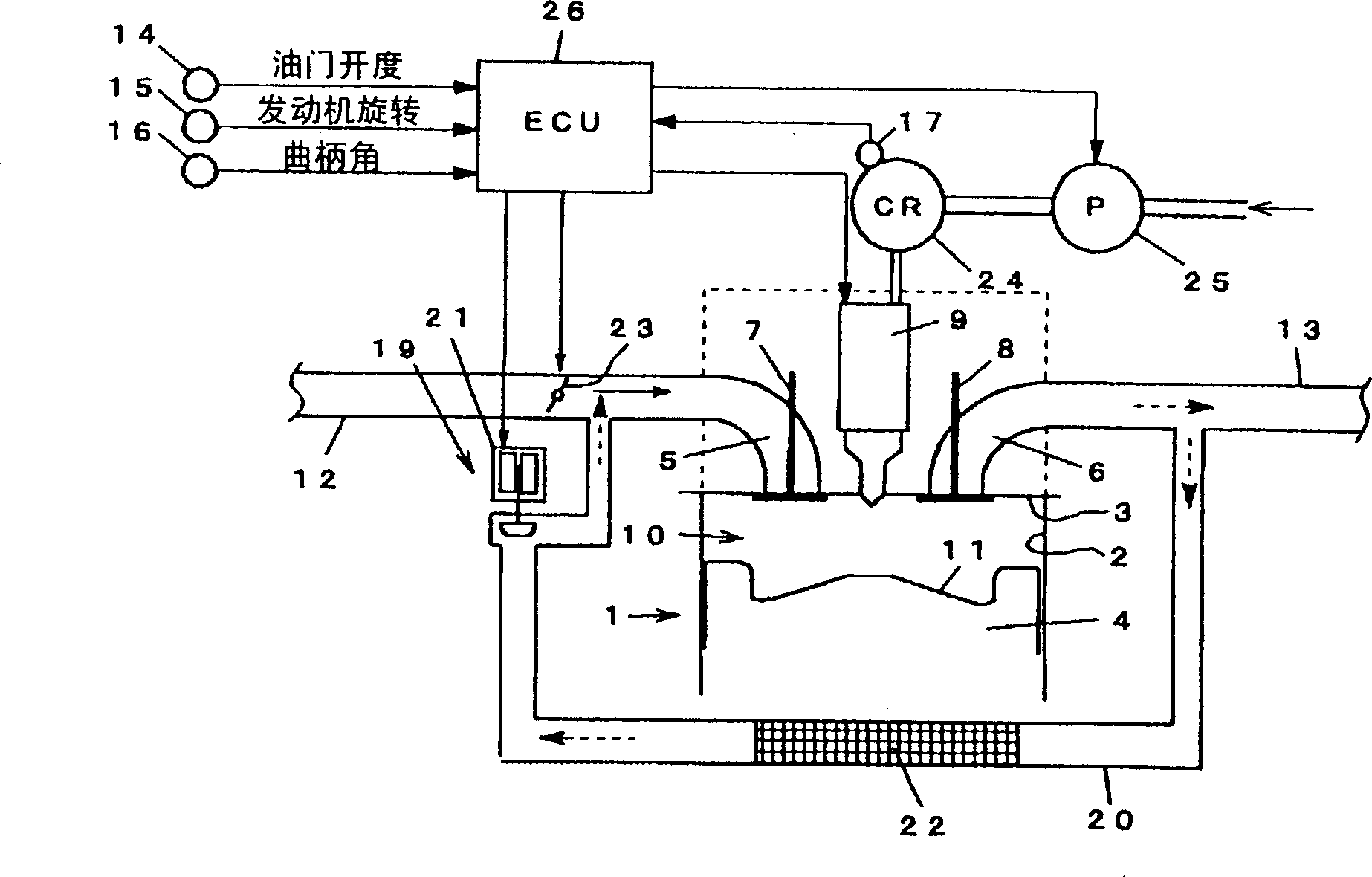

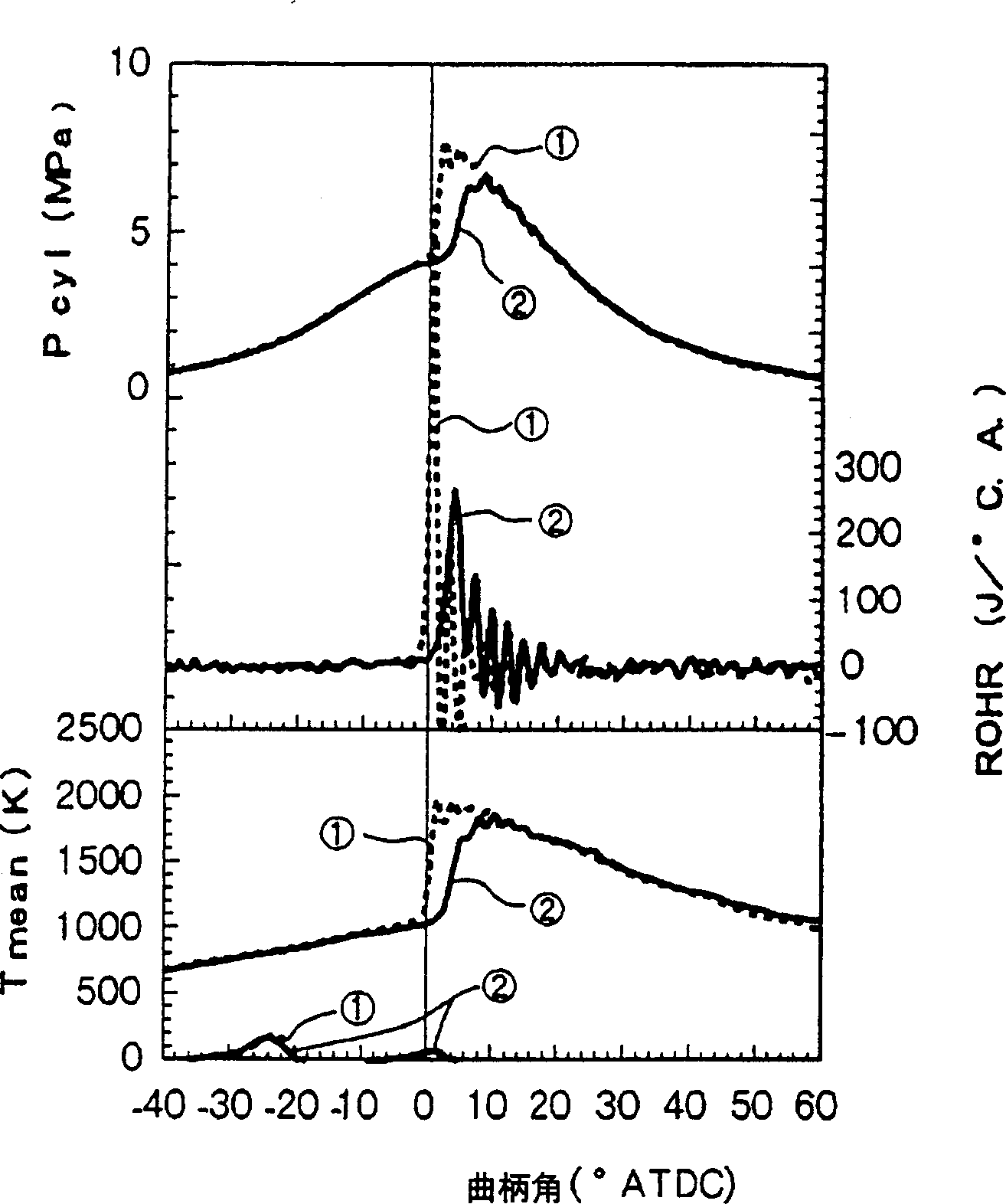

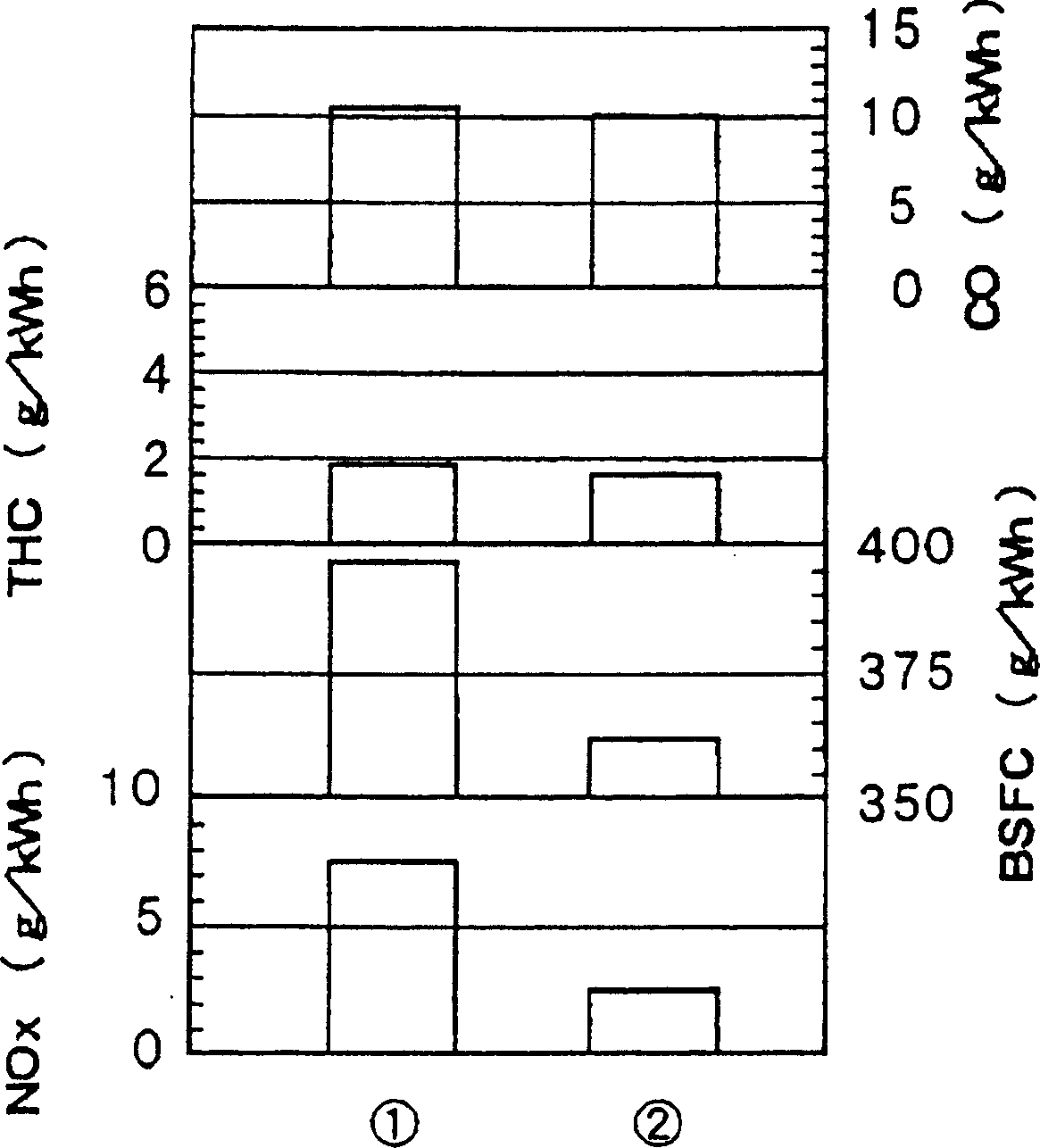

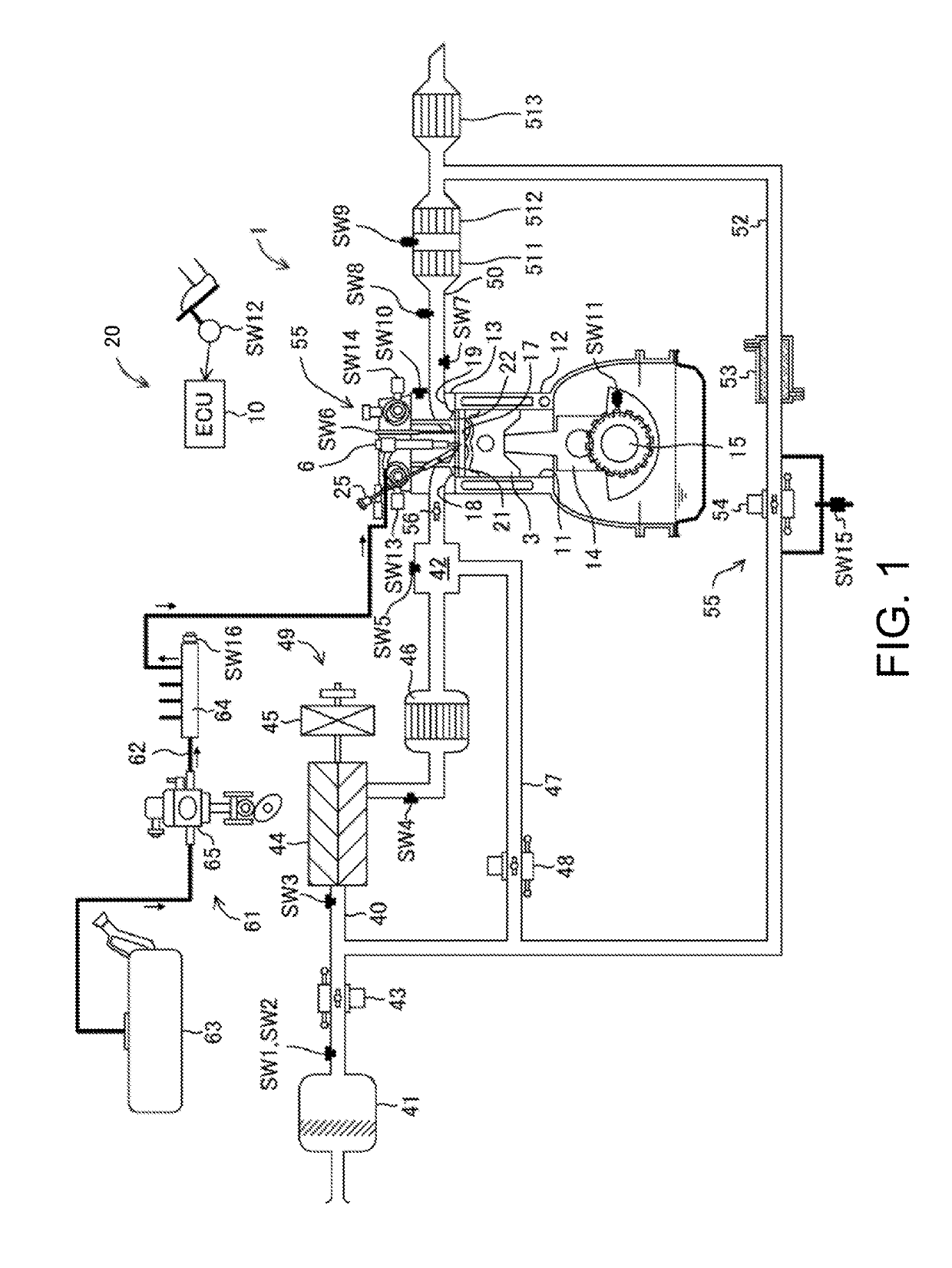

Combustion control device for an engine

InactiveCN1521394AReduce the chance of backflowReduce injection volumeElectrical controlNon-fuel substance addition to fuelTop dead centerCombustion chamber

Owner:ISUZU MOTORS LTD

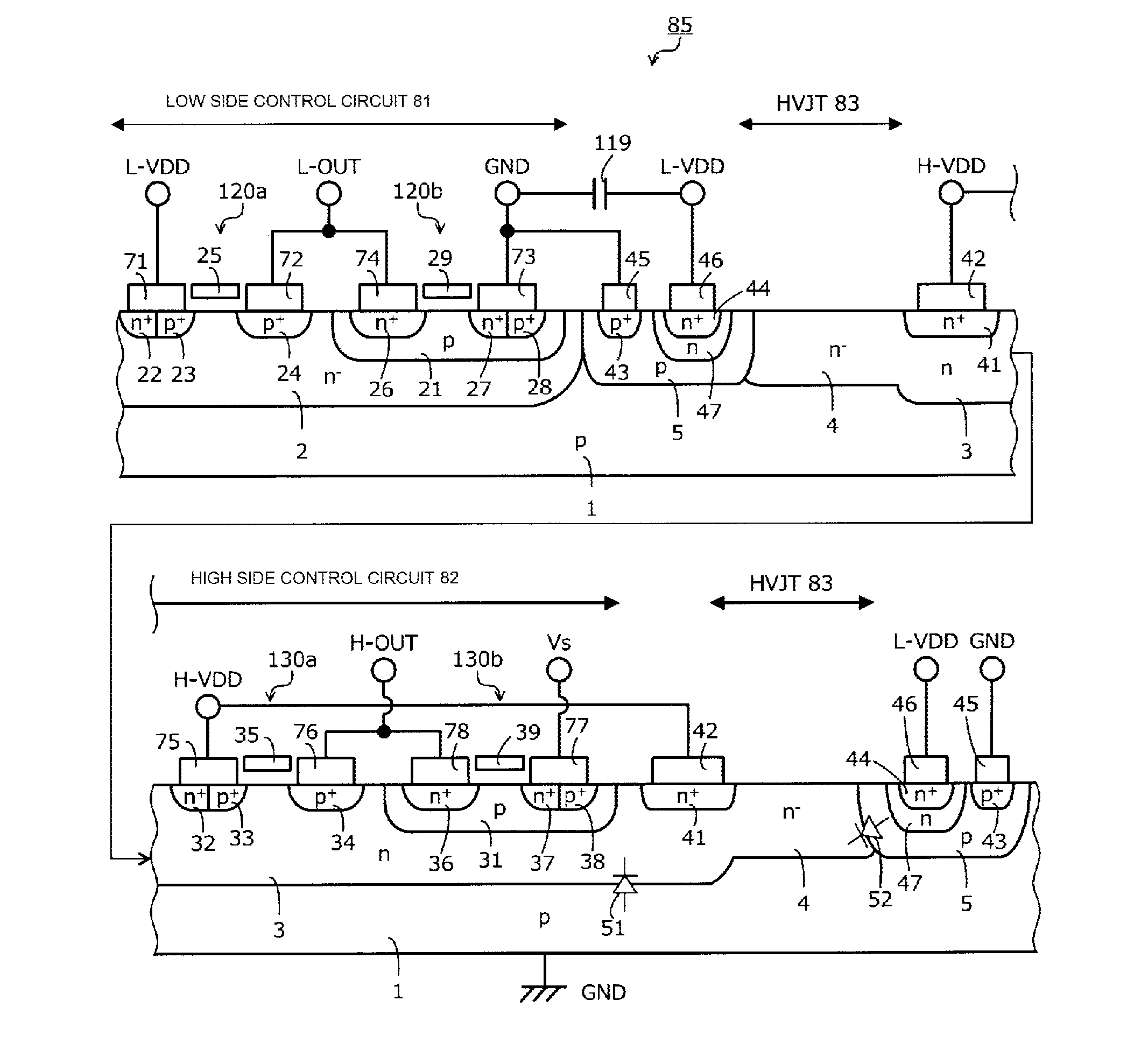

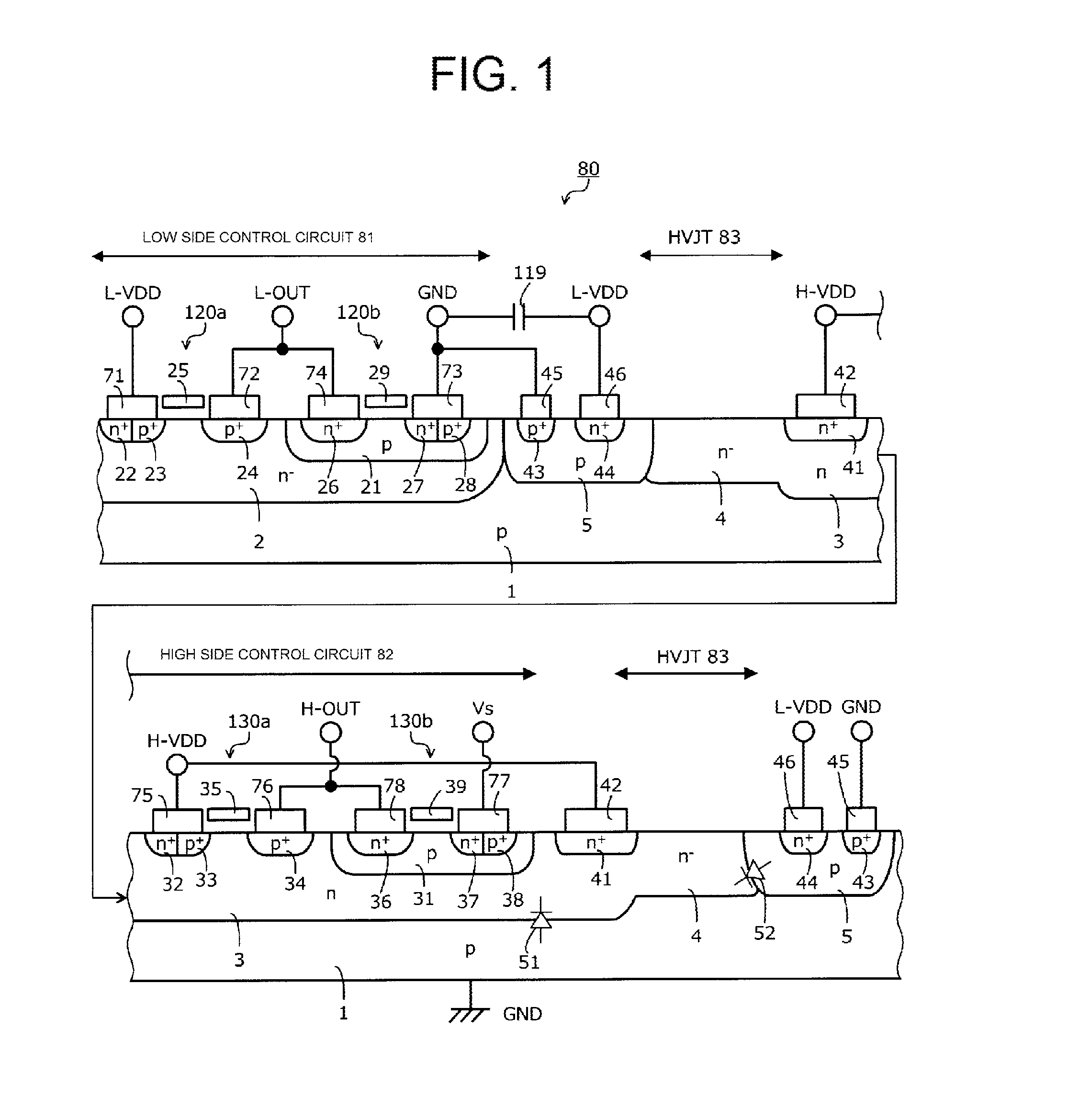

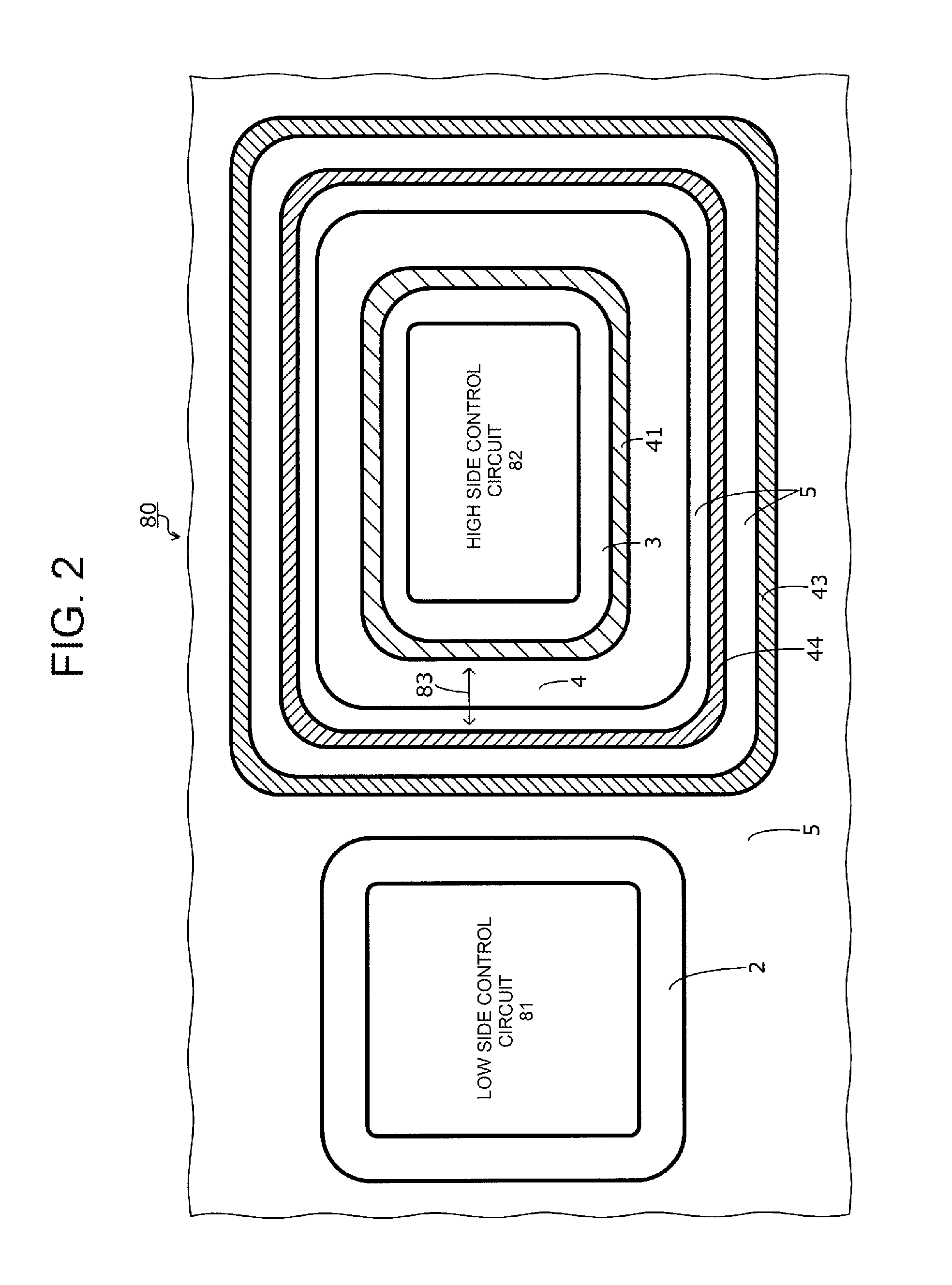

Semiconductor integrated circuit

ActiveUS20150364470A1Avoid malfunctioningPrevent breakdownTransistorSolid-state devicesControl circuitSemiconductor

A low side control circuit and a high side control circuit are disposed in first and second n type well regions, respectively. A third n type well region is formed around the second n type well region. The first n− type well region is formed outside the second n− type well region. A p type well region is formed around the third n− type well region. The third n− type well region and the p type well region constitute an HVJT between the first and second n type well regions. A p+ type contact region and a first electrode supplied with GND potential are formed in the p type well region. In the p type well region, an n+ type contact region and a second electrode supplied with L-VDD potential higher than the GND potential are formed between the HVJT and the p+ type contact region.

Owner:FUJI ELECTRIC CO LTD

Method for quickly repairing concrete pavement defects

InactiveCN108755334AAdhesive strength hasIncrease elasticityPaving detailsRoads maintainenceEpoxyEngineering

The invention relates to a method for quickly repairing concrete pavement defects. The method comprises the following steps: (1) opening a groove in a crack needing to be repaired, wherein the grooveis 2-3 mm in width and 3-5 cm in depth, blowing accumulated water in the groove, injecting epoxy slurry in the crack, covering the upper part of the groove filled with the slurry with strip-shaped plastic cloth, drilling inclined holes in one side of the crack along the length direction of the crack, pouring the epoxy slurry in each drilled inclined hole and plugging the drilled inclined holes after pouring the epoxy slurry in the inclined holes; and (2) cleaning and polishing hollow parts needing to the repaired until the hollow part is lower than the concrete surface outside the hollow partby 3-4 mm, performing epoxy slurry injection treatment on the crack on the concrete surface of the repaired part, pouring the prepared epoxy bituminous grout or epoxy bituminous mortar in the hallow part to be repaired, beating packing by using a rubber hammer until the packing is flush with the concrete surface of a pavement, covering with the strip-shaped plastic cloth after finishing leveling,and repairing after curing. The invention provides the method for quickly repairing concrete pavement defects which has the advantages that on the basis of not damaging or using the undamaged concreteon an original pavement as far as possible, the pavement repairing treatment quantity is reduced, the impact and wear resistance is high, and the repairing speed is high.

Owner:CHINA HYDROPOWER ELEVENTH ENG BUREAU ZHENGZHOU CO LTD +1

IC engine with oxygen jet in cylinder and oxygen-enriched combustion control

InactiveCN1746478AReduce demandReduce injection volumeElectrical controlNon-fuel substance addition to fuelCombustion chamberGas exchange

This is an invention of an inside cylinder oxygen injection internal combustion engine and its oxygen rich combustion control method. On each cylinder's combustion chamber installs at least one oxygen rich inlet port, the outlet of the port links to the combustion chamber, and the inlet of the port links to the outlet of a back flow valve, the inlet of the back flow valve links to the main pipe of the oxygen rich supply. The main pipe links to an oxygen generation device. By controlling the open and close of the port, injecting oxygen rich gas during the stage of inspiration or gas exchange, compressing, combustion to increase the fuel's combustion and so increase power output and decrease the exhaustion of NOx, CH, PM. This inversion consumes only 30% of oxygen rich gas of traditional engine under the same oxygen level. The oxygen generation device is of small size, light in weight, low energy consumption and low cost. It can be used in any kinds of two strokes and four strokes internal combustion engine.

Owner:贺长宏

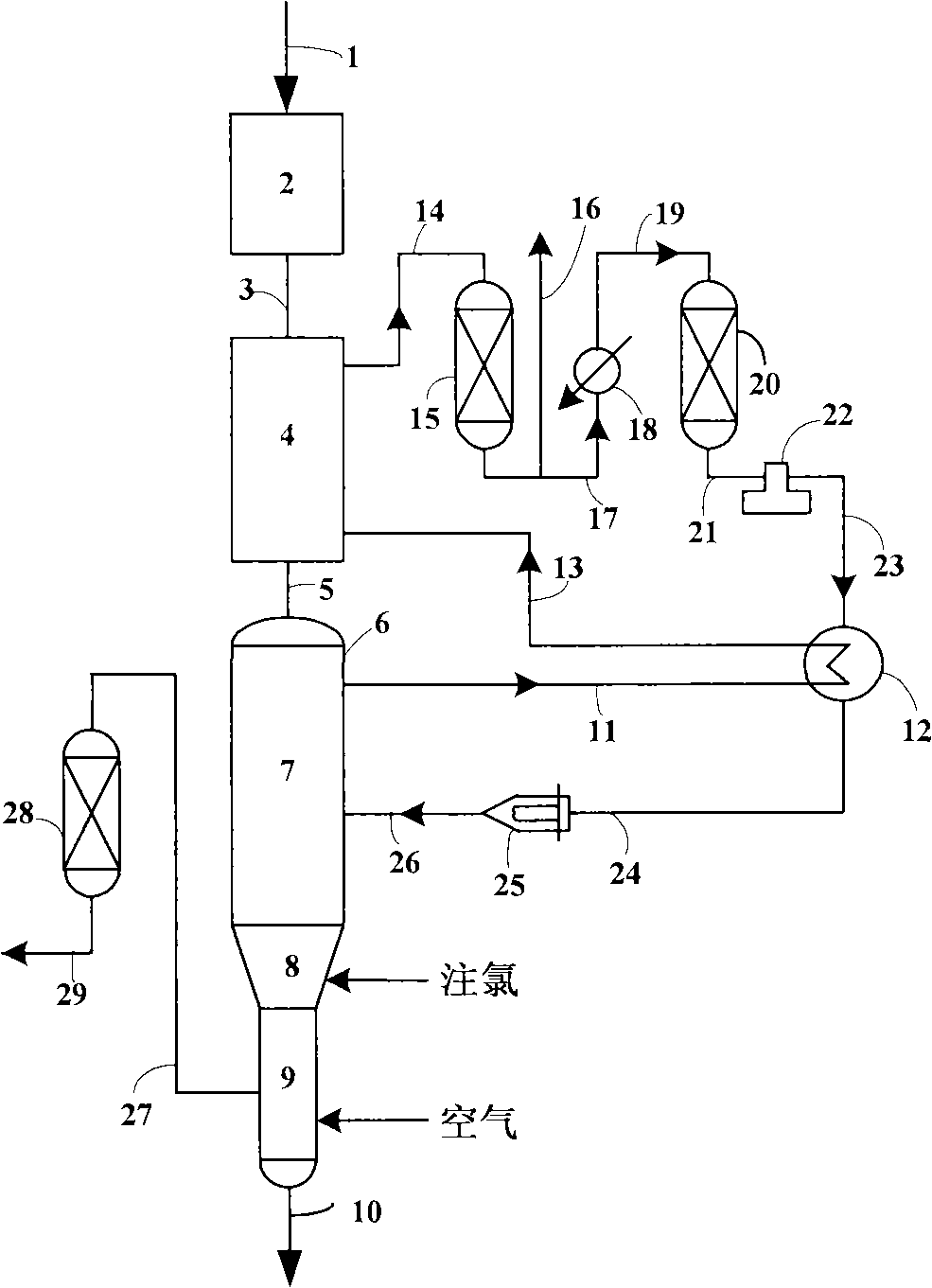

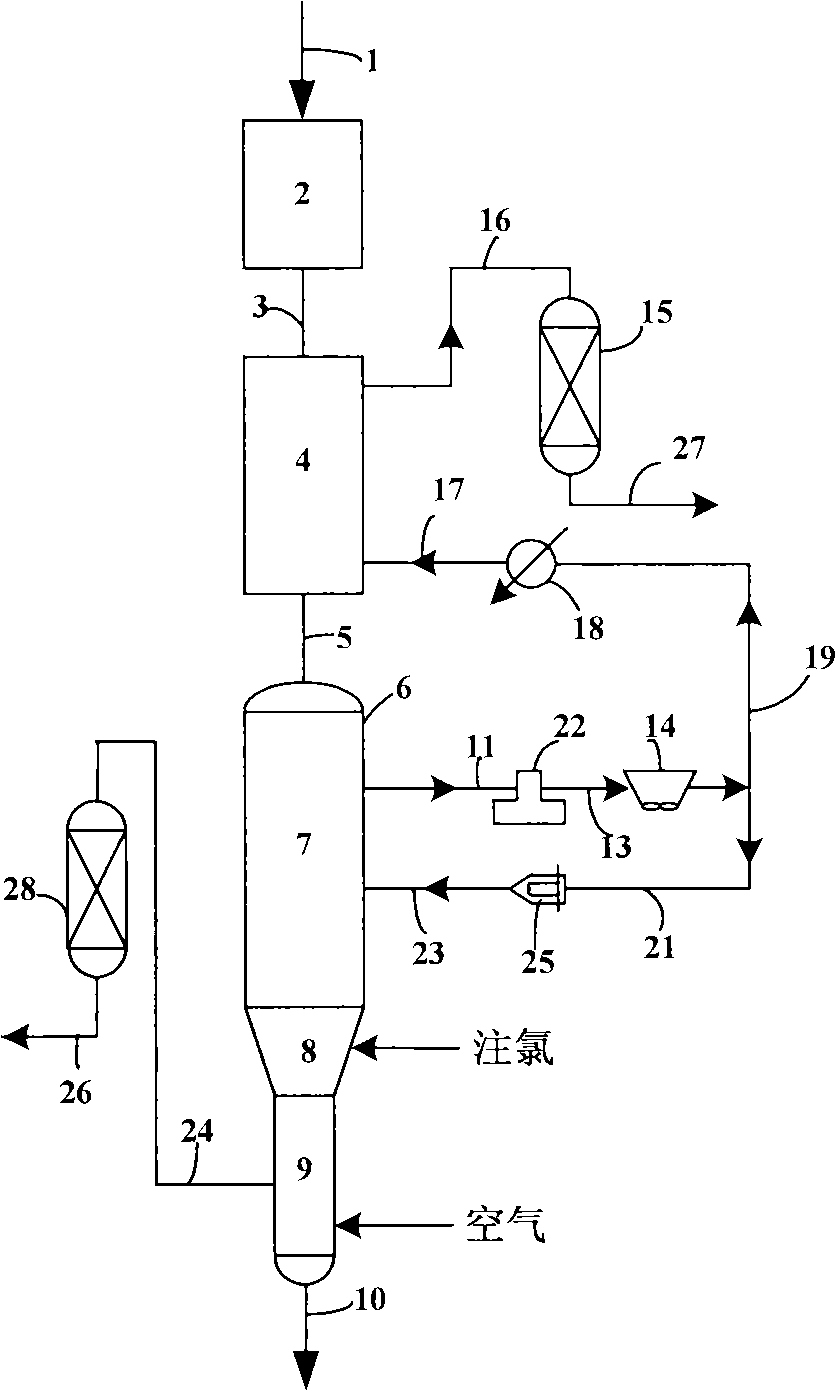

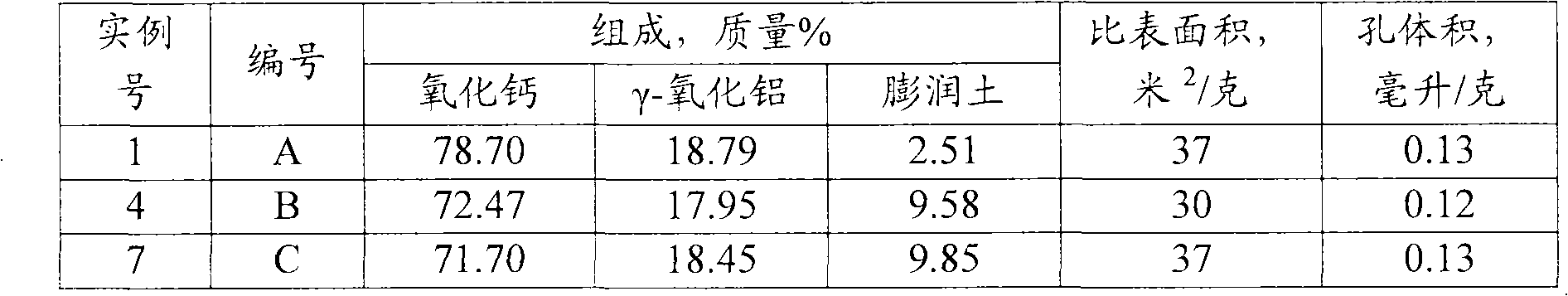

Method for dechlorinating gas discharged from continuous reforming regenerator

ActiveCN101569830AImprove stabilityNot easy to slimeCatalytic naphtha reformingDispersed particle separationSodium BentoniteEnvironmental engineering

The invention relates to a method for dechlorinating gas discharged from a continuous reforming regenerator, comprising the following steps: absorbing chloride in gas discharged from a coke-burning zone and an oxychlorination zone of the continuous reforming regenerator through a bed for catalyst to be regenerated and a bed for solid dechlorinating agent, wherein the bed for catalyst to be regenerated and the bed for solid dechlorinating agent are arranged between a gas-solid separator and a regenerator in sequence; eliminating one part of gas discharged from the bed for catalyst to be regenerated from a system, and returning the other part of the gas to the coke-burning zone of the continuous reforming regenerator; enabling gas discharged from a roasting zone of the continuous reforming regenerator to enter another dechlorinating pot filled with solid dechlorinating agent to absorb chloride therein and eliminating the gas from the system, wherein the solid dechlorinating agent comprises 50-88 percent of alkaline earth oxide by weight, 10-40 percent of alumina by weight and 2-30 percent of bentonite by weight. With the method for dechlorinating gas discharged from a continuous reforming regenerator, the gas discharged from the continuous reforming regenerator can be dechlorinated, and agent to be regenerated can absorb a certain amount of chlorine to reduce the amount of chlorine injected in the regeneration process.

Owner:CHINA PETROLEUM & CHEM CORP +1

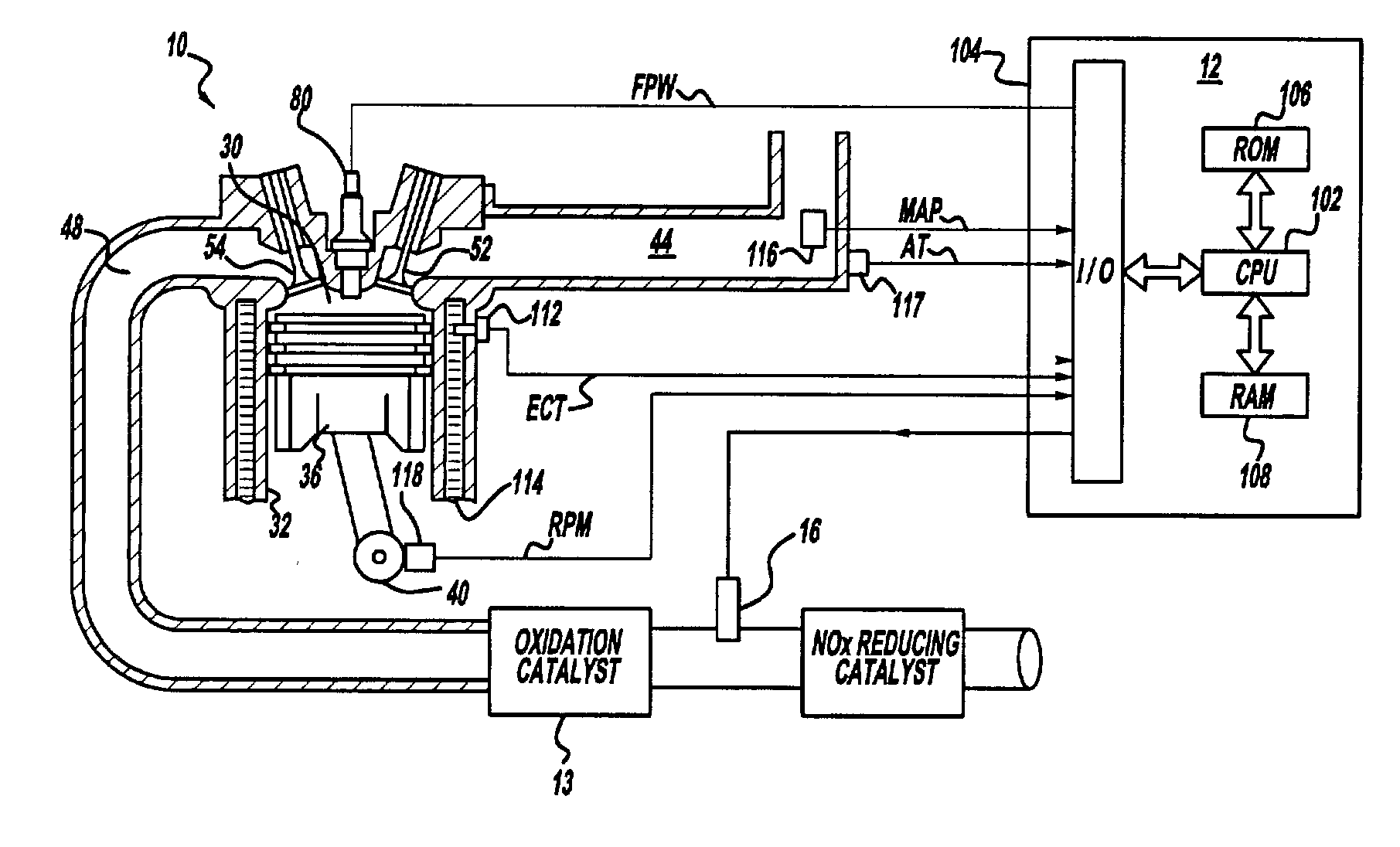

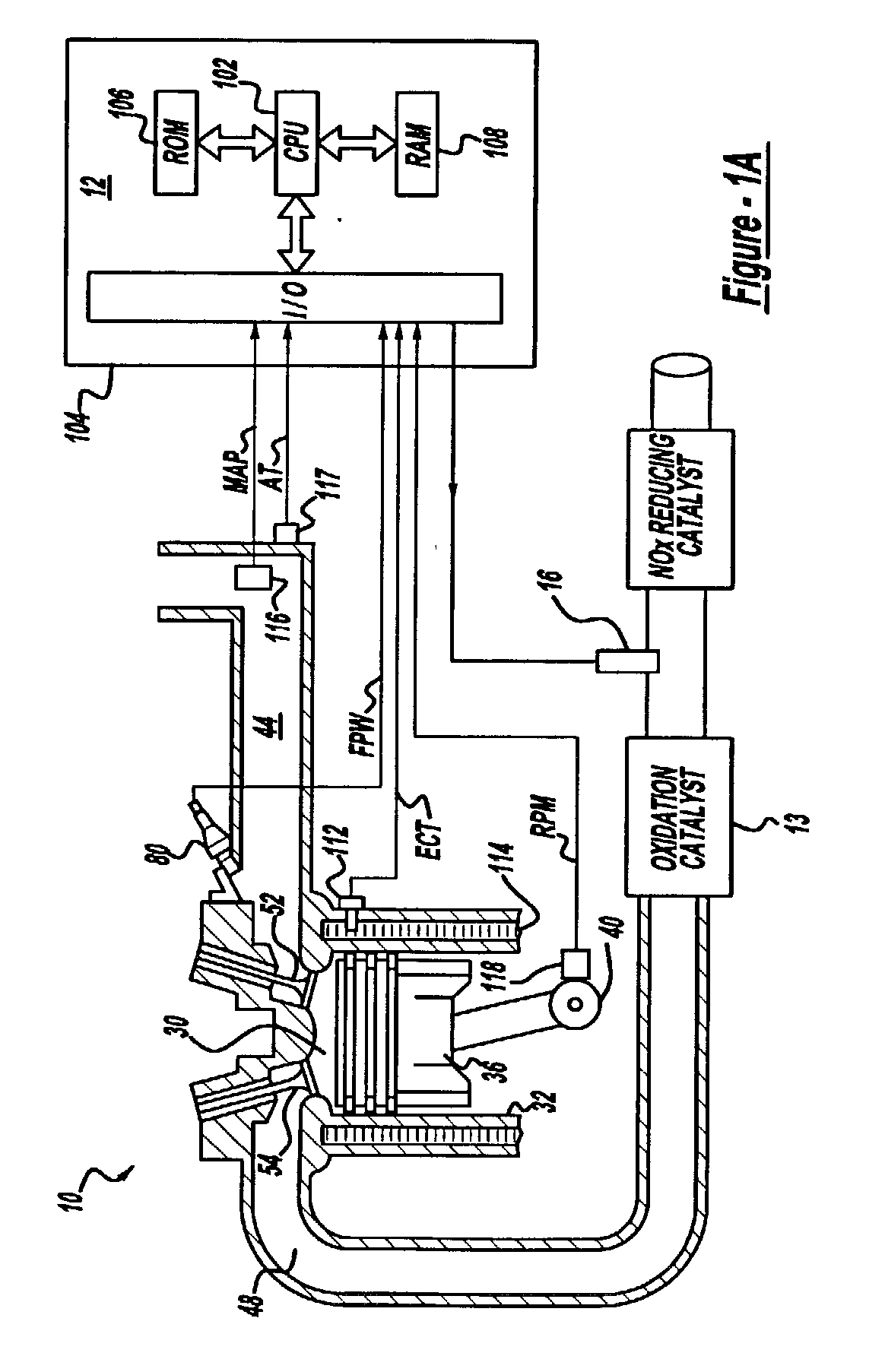

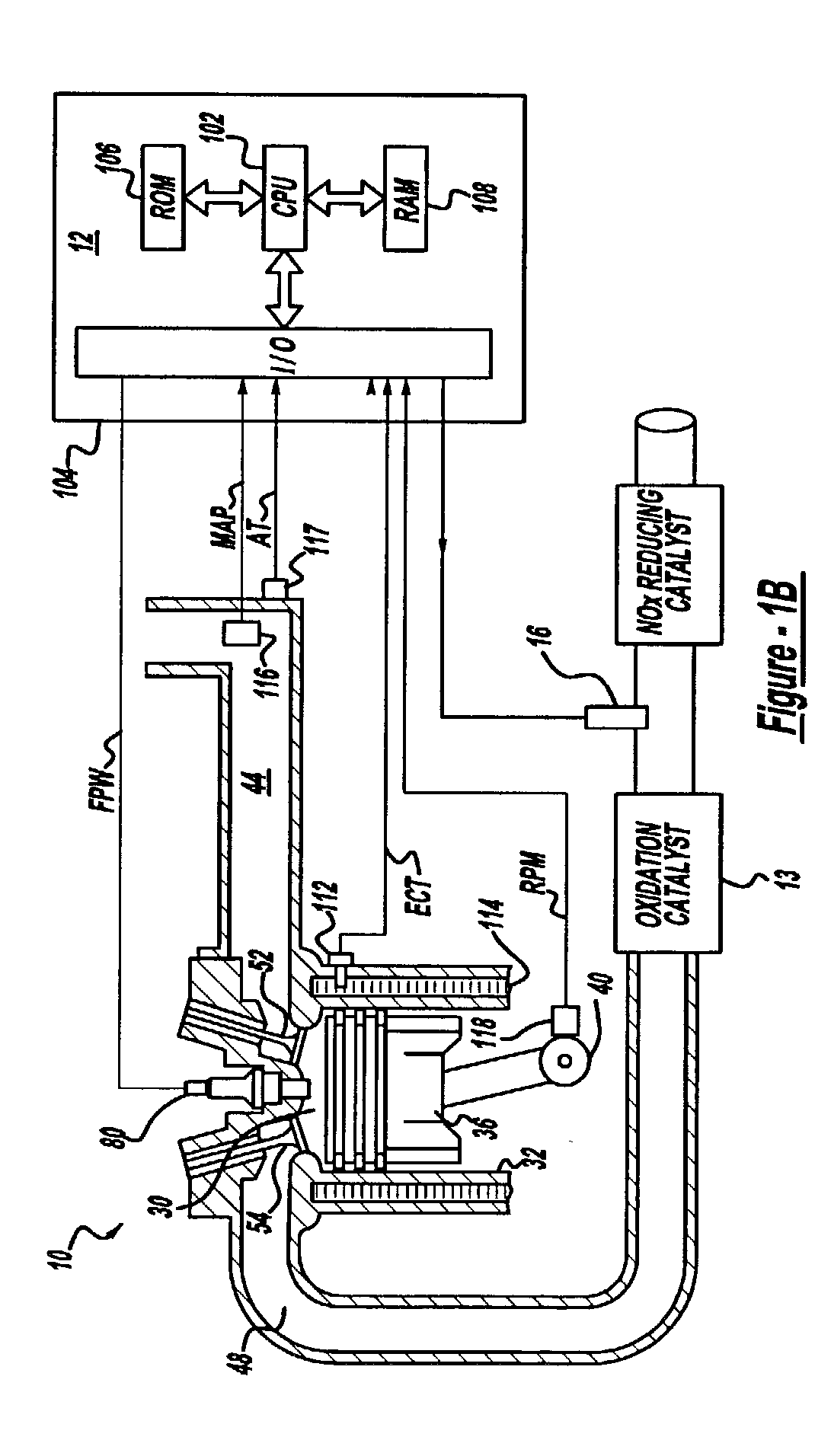

Diesel aftertreatment systems

InactiveUS20040083722A1Improve efficiencyOptimized reductant usageElectrical controlInternal combustion piston enginesEnergy conversion efficiencySteady state

A method for improving NOx conversion efficiency of a NOx-reducing catalyst by determining an accurate amount of reductant required is presented. The method includes calculating an initial reductant injection amount based on a steady state amount of NOx in the engine feedgas and adjusting the initial amount to compensate for transient NOx emissions. The compensation is initiated in response to an engine transient, such as impending acceleration or deceleration. This method further results in improved vehicle fuel economy.

Owner:FORD GLOBAL TECH LLC

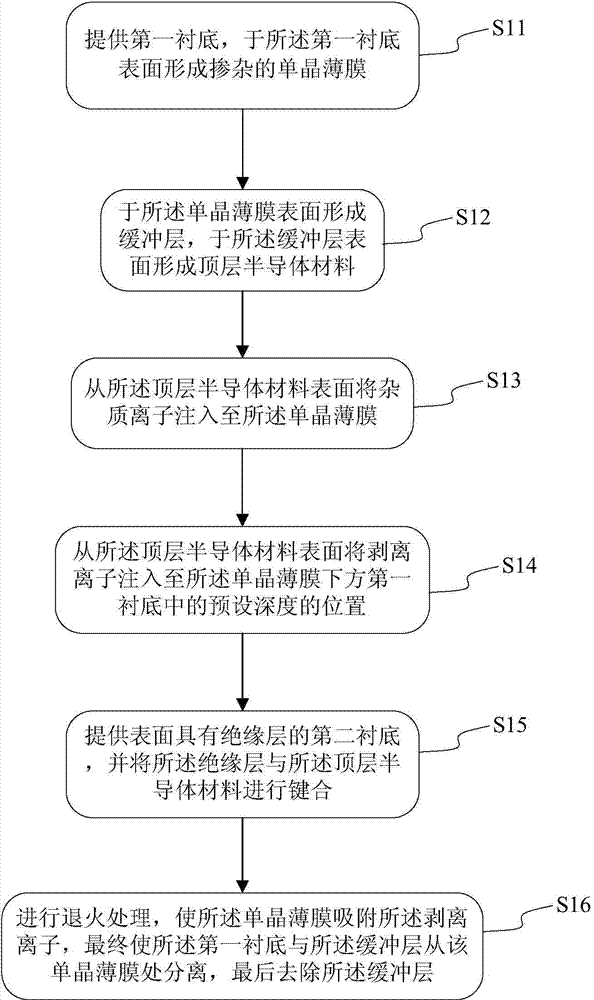

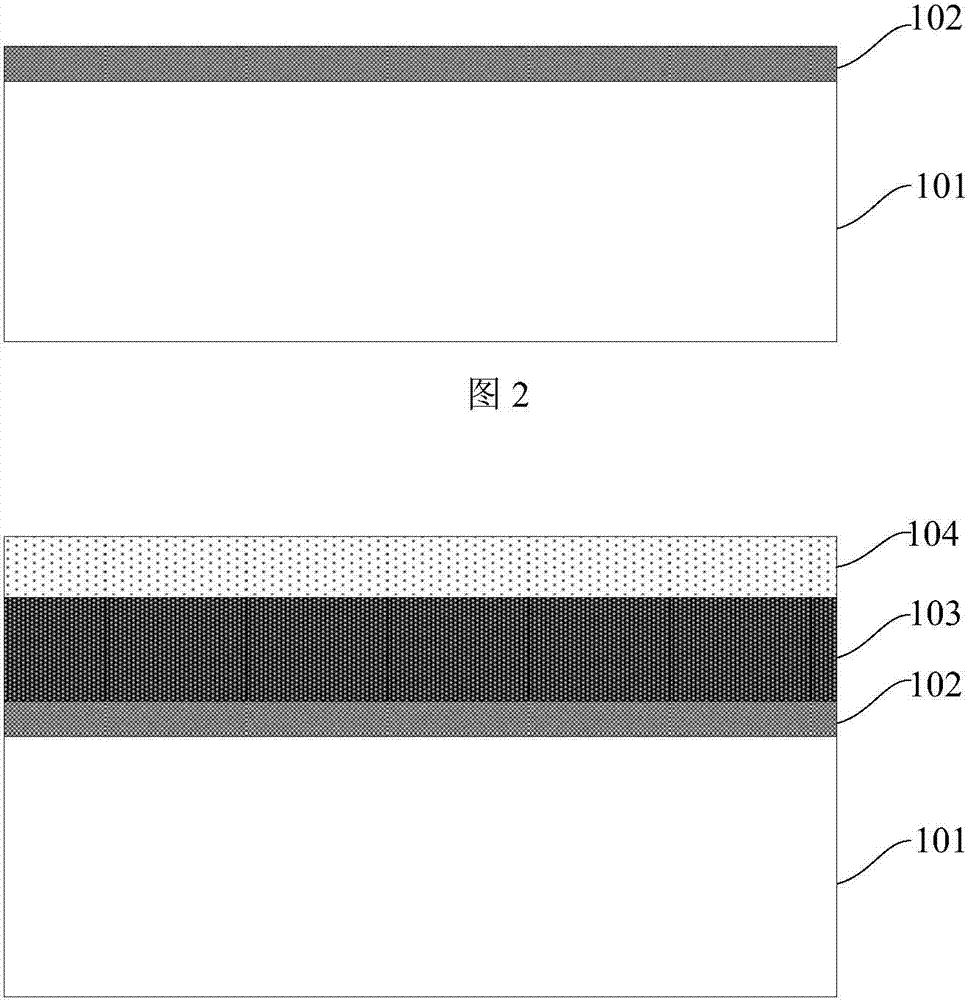

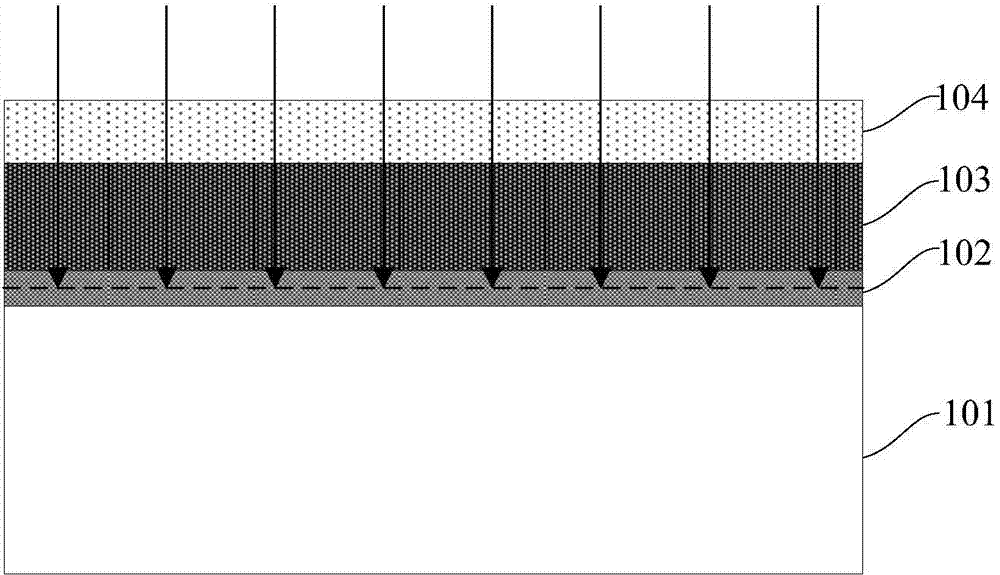

Method for preparing semiconductor-on-insulator material by utilizing ion injection technology

ActiveCN104517883AQuality improvementIncrease stressSemiconductor/solid-state device manufacturingSemiconductor materialsDual effect

The invention provides a method for preparing semiconductor-on-insulator material by utilizing an ion injection technology. The method comprises the steps that 1) a doped mono-crystal thin-film is formed on the surface of a first substrate; 2) a buffer layer and top layer semiconductor material are formed on the surface of the mono-crystal thin-film; 3) foreign ions are injected into the mono-crystal thin-film; 4) stripping ions are injected into the position of the preset depth in the first substrate below the mono-crystal thin-film; 5) bonding is performed between the top layer semiconductor material and a second substrate with an insulating layer; 6) and annealing processing is performed so that the first substrate and the buffer layer are separated from the mono-crystal thin-film, and the buffer layer is removed. Dual effect of ion co-injection and doped mono-crystal thin-film stripping is combined so that stripping dose is effectively reduced. The foreign ions are injected so that the mono-crystal thin-film is enabled to generate stress and adsorption capacity of the mono-crystal thin-film is increased. Stripping is realized after H-ion injection and annealing. Stripping occurs at the position of the ultrathin mono-crystal thin-film so that a crack is quite small, and the high-quality semiconductor-on-insulator material can be obtained.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

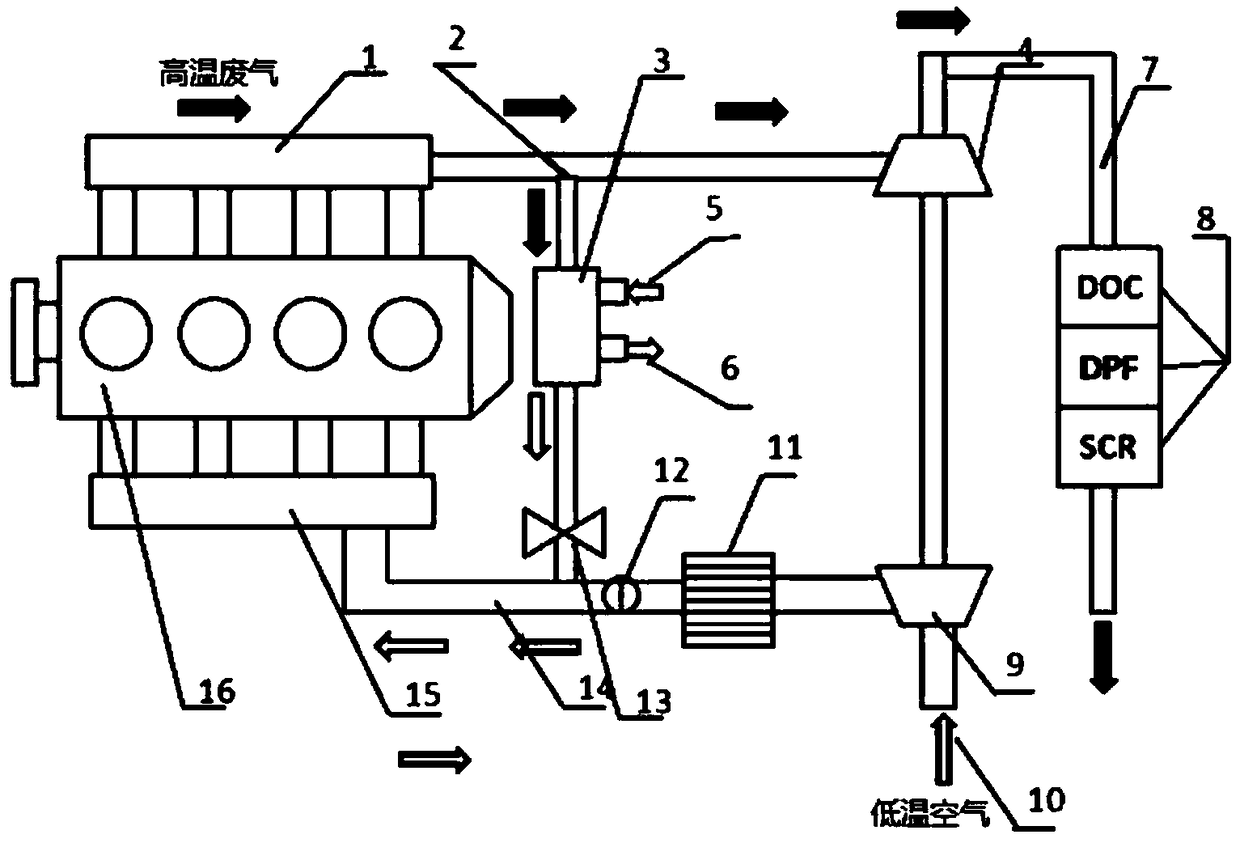

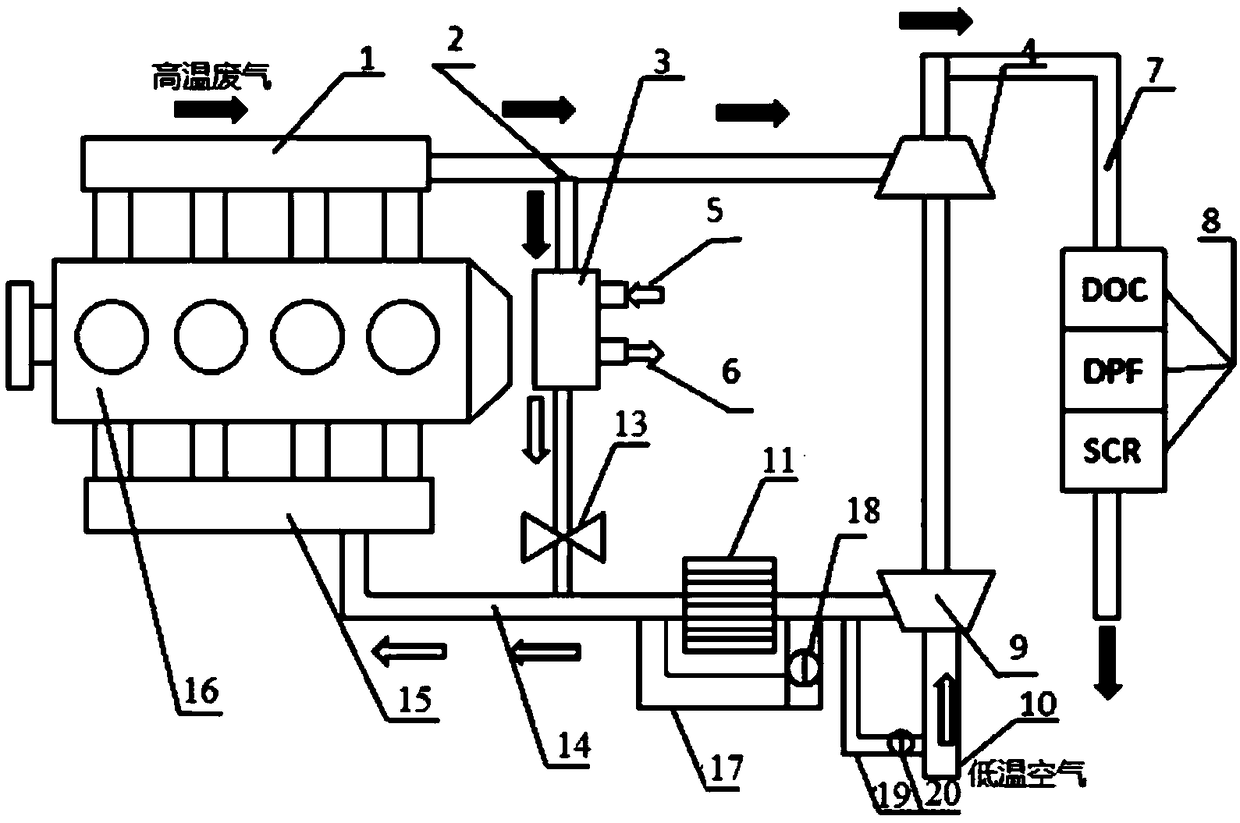

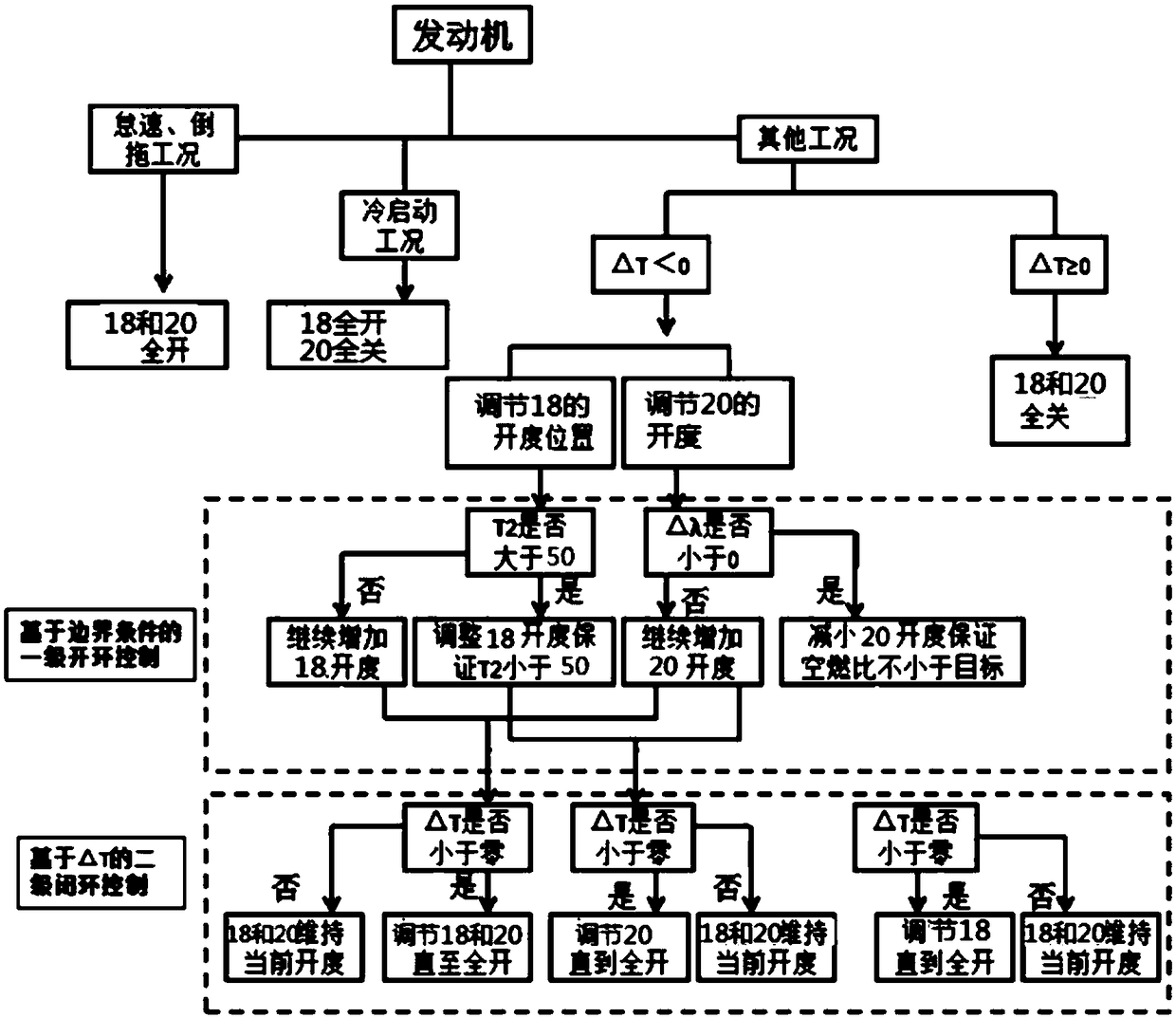

Engine thermal management system and control method thereof

ActiveCN108716433AIncrease intake air temperatureReduce fuel consumptionInternal combustion piston enginesExhaust apparatusThermal management systemIntercooler

The invention discloses an engine thermal management system. The system includes an engine air intake pipe, an engine air intake main pipe, an intercooler, and a supercharger compressor. The engine thermal management system also includes an intake air temperature control bypass pipeline, an intake air amount control bypass pipeline and a temperature sensor. The two ends of the intake air temperature control bypass pipeline are respectively connected to the inlet and outlet of the intercooler. The intake air temperature control bypass pipeline is connected in parallel with the intercooler. A first bypass proportional valve is arranged on the intake air temperature control bypass pipeline. The intake air flow bypass of different flow rates can be realized by adjusting the position ratio of the first bypass proportional valve. The two ends of the intake air amount control bypass pipeline are respectively connected to the inlet and outlet of the compressor. The intake air amount control bypass pipeline is connected in parallel with the supercharger compressor. A second bypass proportional valve is arranged on the intake air amount control bypass pipeline. The intake air flow demands ofdifferent working conditions can be met by adjusting the opening degree of the second bypass proportional valve. The temperature sensor is arranged on a pipeline of the engine air intake main pipe and is used for measuring the temperature of intake air entering the engine air intake main pipe. An EUC can collect measured values of the intake air temperature.

Owner:GUANGXI YUCHAI MASCH CO LTD

Long-acting colloidal insulin formulation and its preparation

InactiveUS20090110742A1Easy injectionEasy to fillPowder deliveryNanotechTolerabilityLong acting insulin

The invention relates to injectable long-acting insulin formulations for the treatment of types I and II diabetes in humans and animals.The essential object of the invention is to provide an injectable long-acting insulin formulation in the form of a colloidal suspension which is stable, which has a good local tolerance and toxicity compatible with the chronic treatment of diabetics, and which maintains a substantial hypoglycemic effect extending over at least 24 hours after a single administration, e.g. by the subcutaneous route.To achieve this object, the invention relates to a stable aqueous colloidal formulation of insulin-laden nanoparticles of at least one poly(Leu-block-Glu) in which the pH is between 5.8 and 7.0, the osmolarity O (in mOsmol) . . . : 270≦O≦800, and the viscosity v (in mPa.s) is low, namely v≦40. The nanoparticles of poly(Leu-block-Glu) have a mean hydrodynamic diameter Dh such that: 15≦Dh≦40.The invention relates to an antidiabetic drug based on this long-acting insulin formulation and injectable using needles of gauge 29G, 30G or 31G.

Owner:FLAMEL TECHNOLOGIES

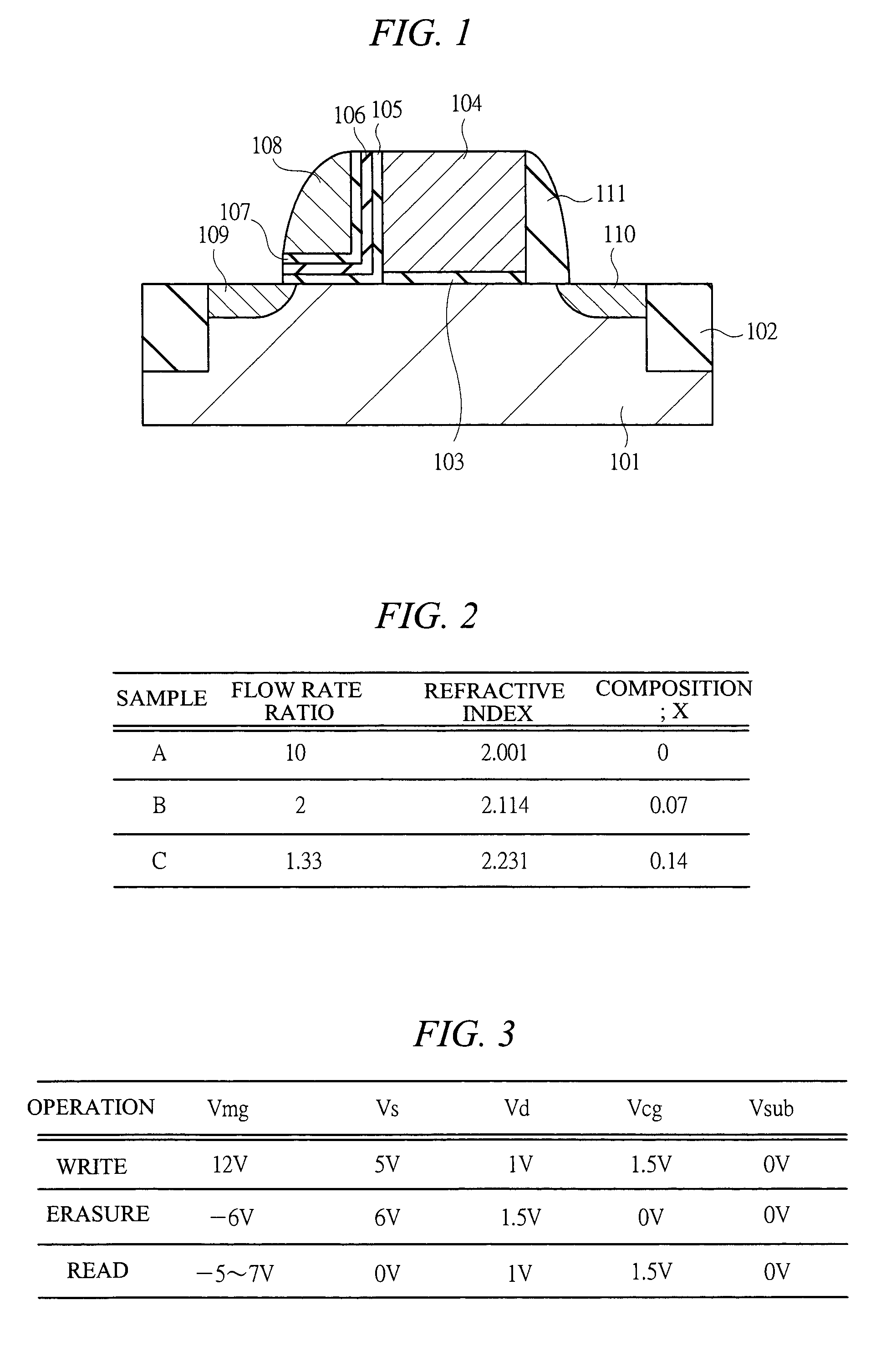

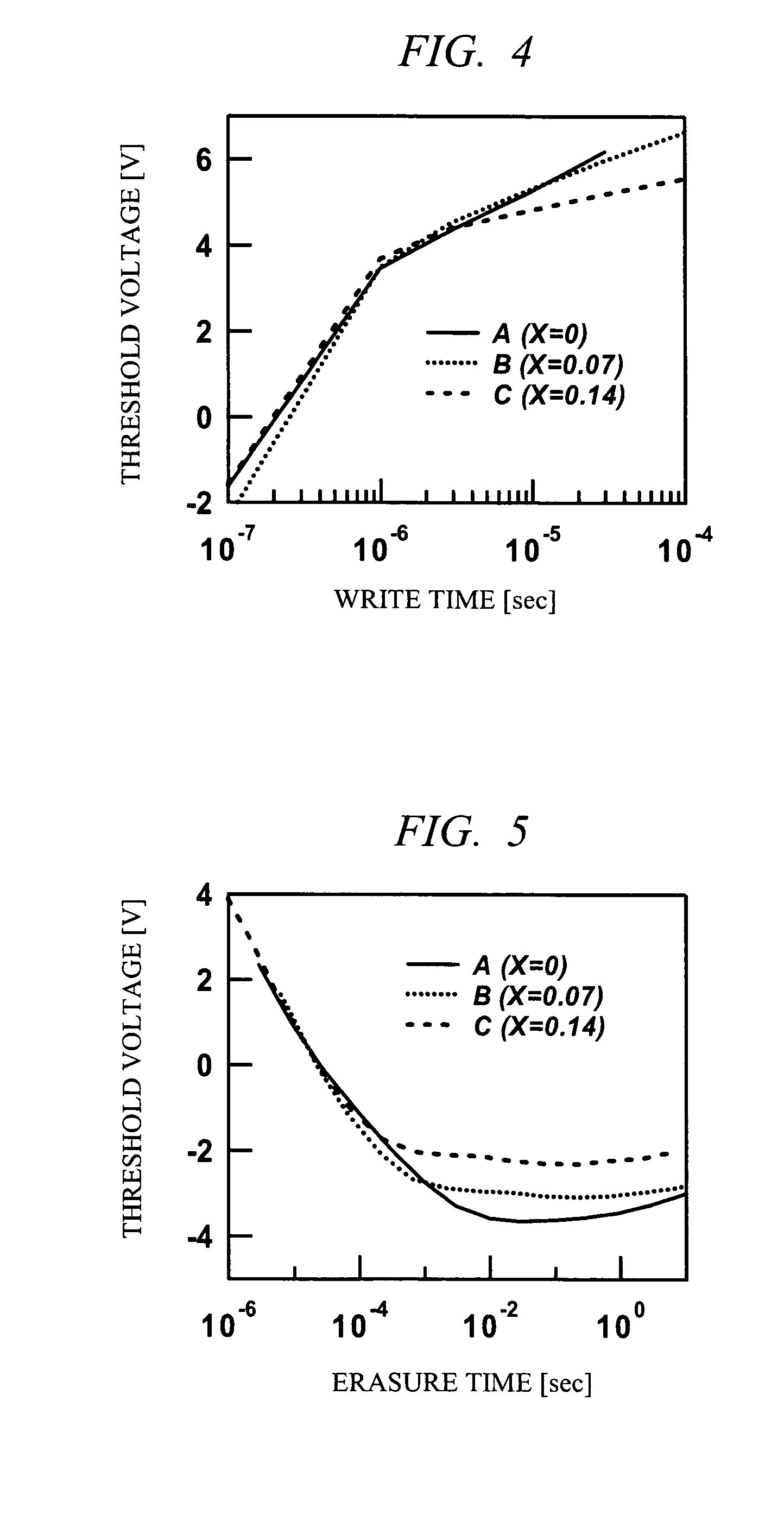

X-ray CT apparatus and myocardial perfusion image generating system

InactiveUS7840255B2Reduce injection volumeShort timeDiagnostic recording/measuringTomographySoft x rayX-ray

An X-ray CT apparatus 1 for radiating X-ray to a subject P so as to scan the subject P and reconstructing a image within the subject P based on an obtained projection data comprises an image generating unit and a blood-flow image generating unit 24e. The image generating unit generates the image based on the projection data in a state in which a concentration of a contrast medium in a myocardial portion of a subject P continuously injected the contrast medium can be considered to be constant. The blood-flow image generating unit 24e generates a blood flow image by removing components of a myocardial tissue from a portion of a myocardial region of the image generated by the image generating unit.

Owner:TOSHIBA MEDICAL SYST CORP

Concentrated human immunoglobulin composition

InactiveUS20130121991A1Easy to administer subcutaneouslyGood flexibilityAntibacterial agentsNervous disorderHuman immunoglobulinsHuman Immunoglobulin G

The invention relates to a human immunoglobulin G composition characterized in that the human immunoglobulin G concentration is at least 230 g / l, which is of use in particular for subcutaneous administration.

Owner:LABE FR DU FRACTIONNEMENT & DES BIOTECH SA

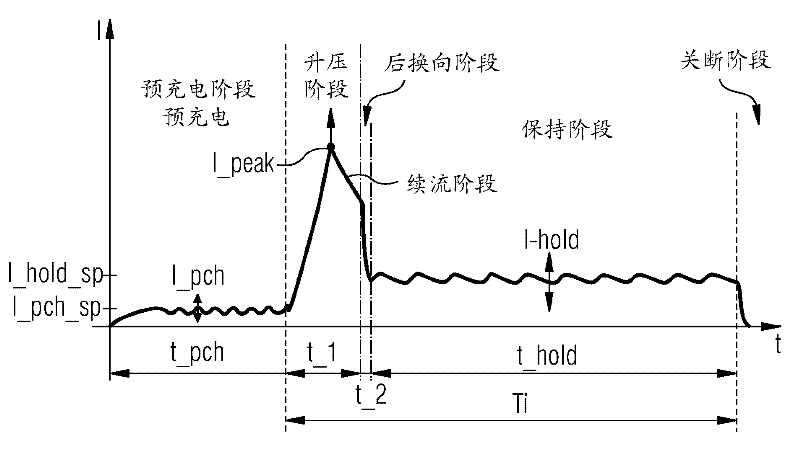

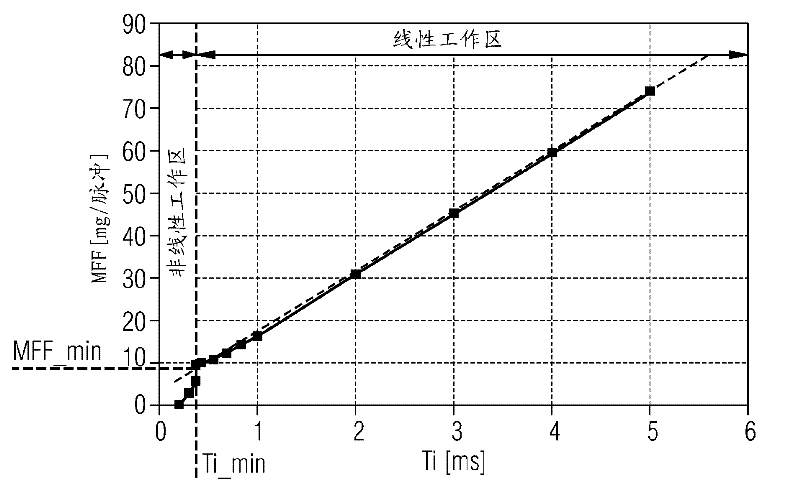

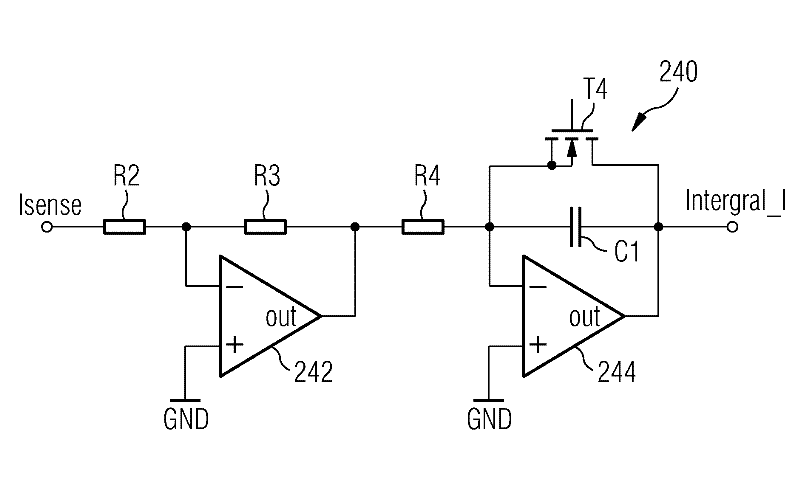

Use current integration to control the current flowing through the valve's coil drive

InactiveCN102272435AAvoid pulse-by-pulse changesAccurate settingElectrical controlMachines/enginesPhase currentsDriving current

A device and a method are provided which allow direct injection valves with coil actuation (110) in particular to reduce the pulse-to-pulse variation of the fuel quantity injected through the direct injection valves in a manner also based on Regulation of the current integral of the coil drive (110), especially during the boost phase of the current excitation spectrum of the coil drive (100). Furthermore, a computer program for carrying out the method is described.

Owner:CONTINENTAL AUTOMOTIVE GMBH

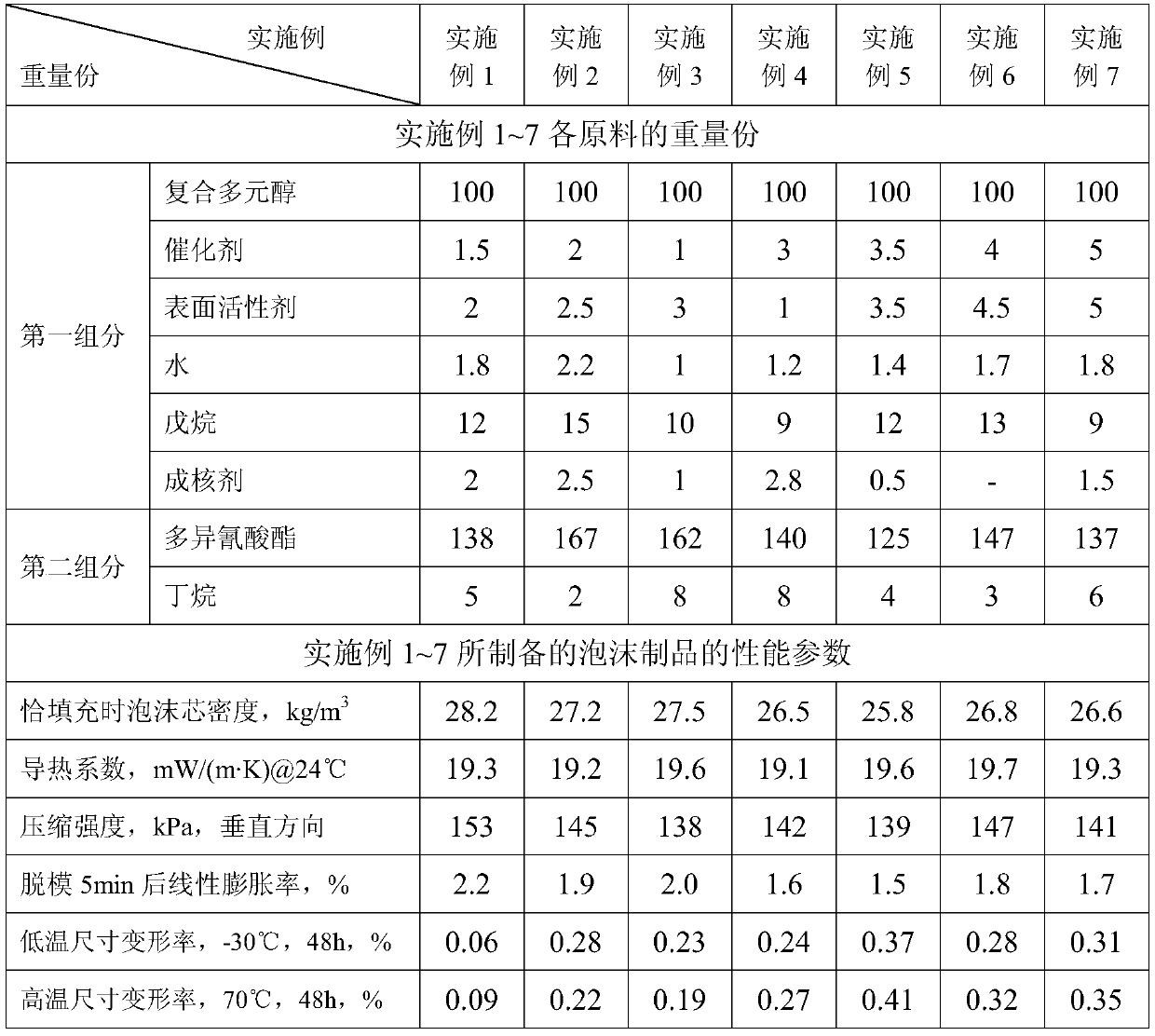

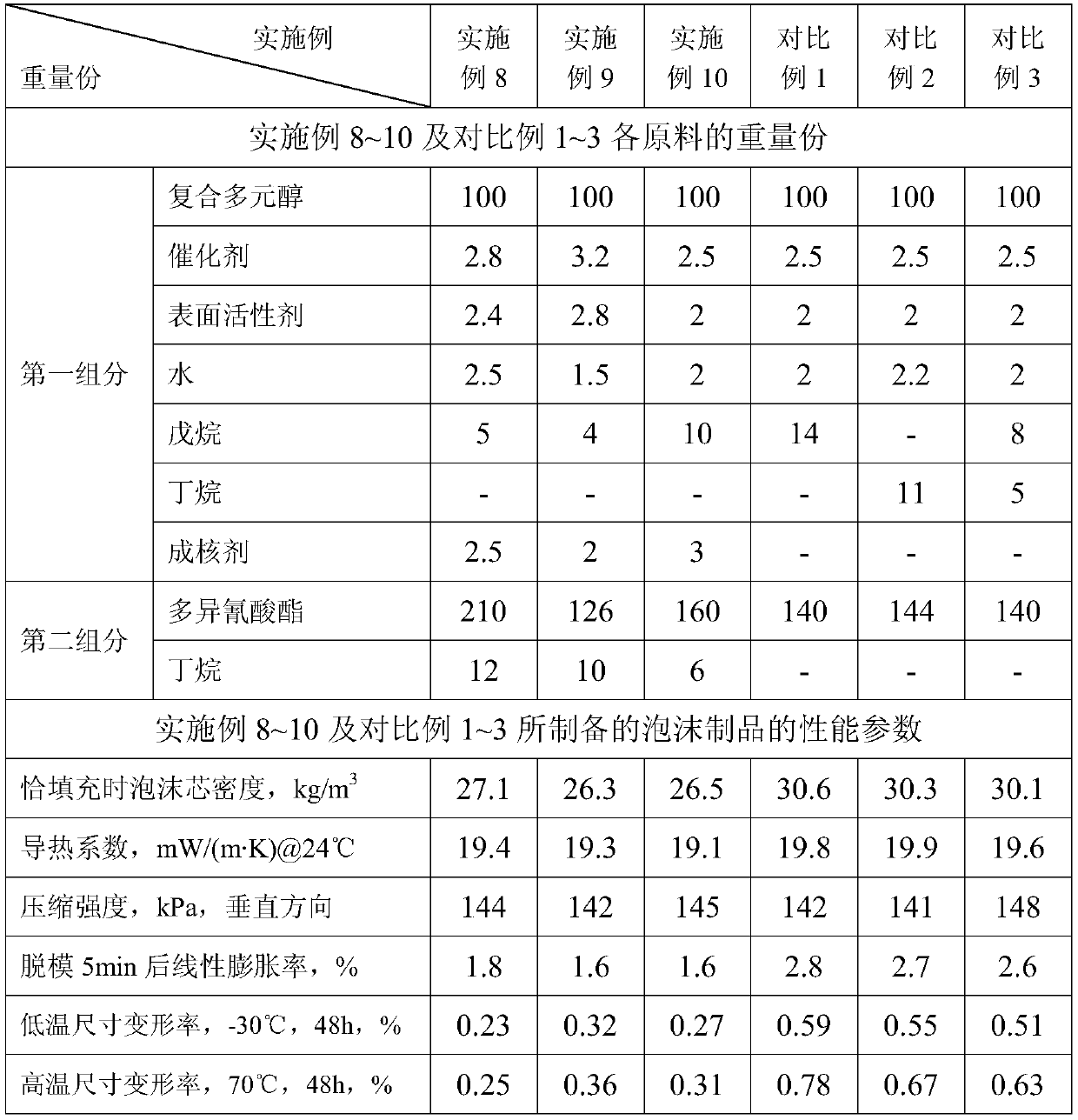

Ultra-low-density rigid polyurethane foam and preparation method thereof

The invention relates to ultra-low-density rigid polyurethane foam with pentane and butane as foaming agents. The ultra-low-density rigid polyurethane foam is prepared by well premixing a component Aand a component B, and then well mechanically mixing and foaming the component A and the component B, wherein the component A is prepared from the components in parts by weight: 100 parts of pluronicpolyols, 4-15 parts of the pentane, 1-5 parts of a catalyst, 1-5 parts of an organosilicon surfactant, 1-2.5 parts of water and 0-3 parts of a nucleating agent, the component B is prepared from the components in parts by weight: 2-12 parts of the butane and 120-210 parts of polyisocyanates, and raw materials are based on 100 parts of pluronic polyols. According to the prepared foam, foam holes arefine and uniform, the heat conductivity coefficient is small, the compression strength is high, and the overall performance is excellent. The invention further discloses a preparation method of the rigid polyurethane foam.

Owner:NANJING HONGBAOLI POLYURETHANE

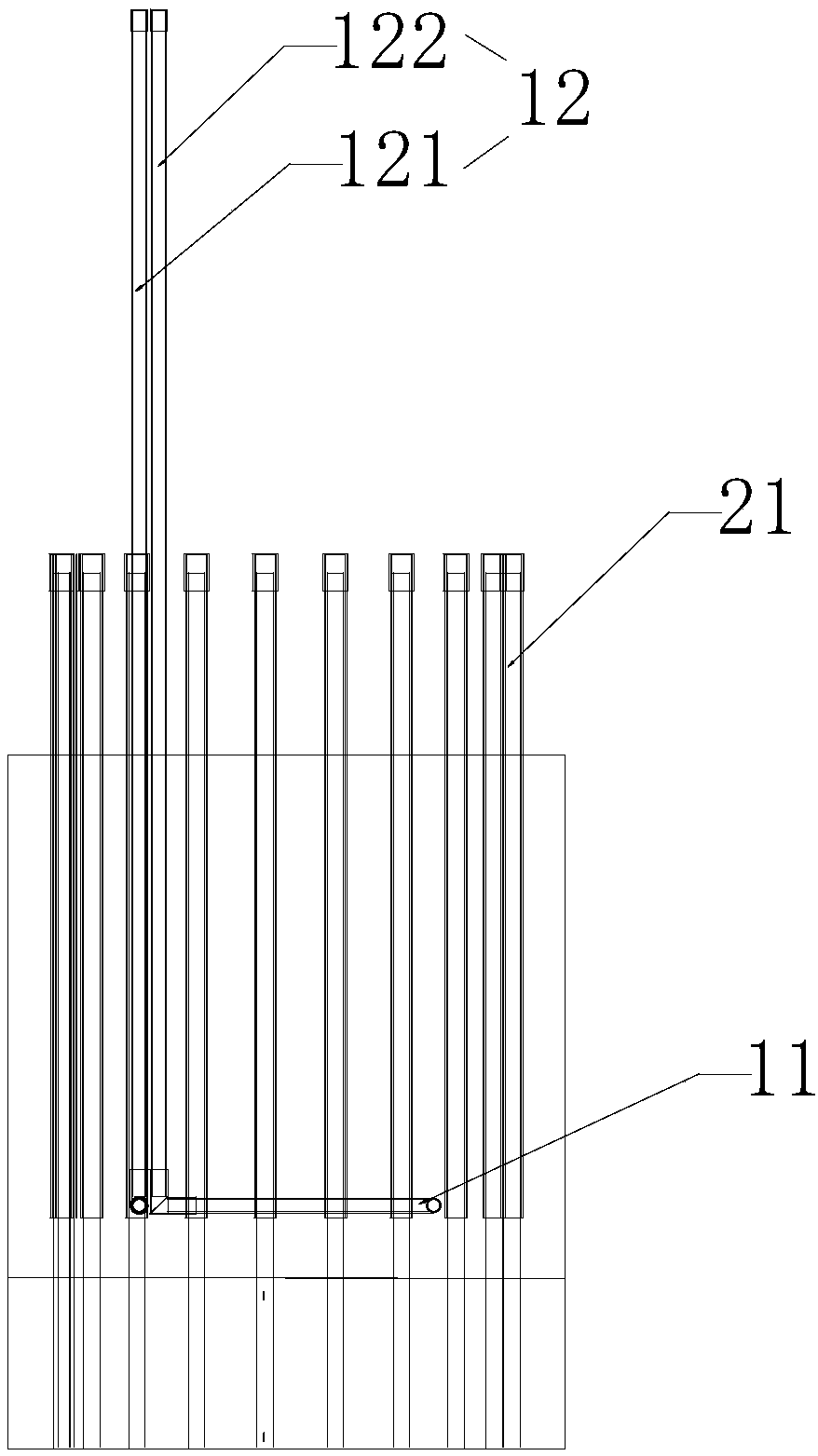

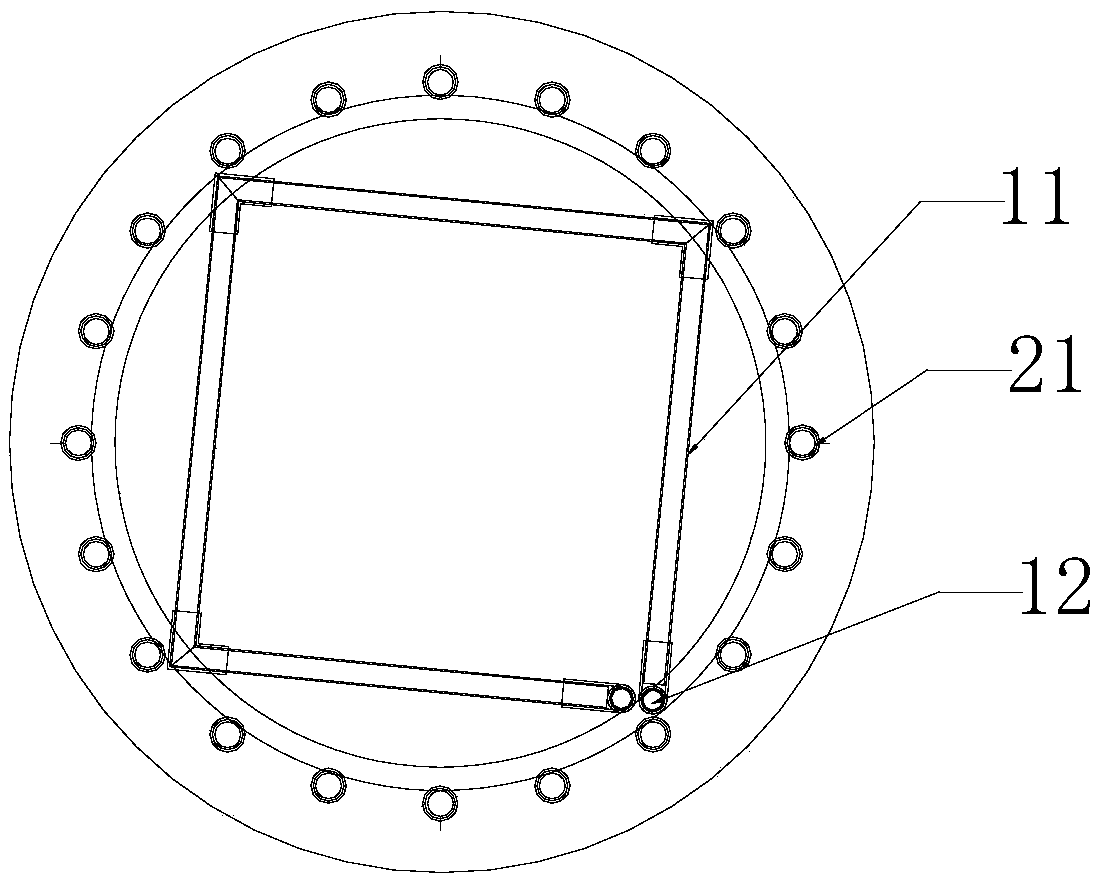

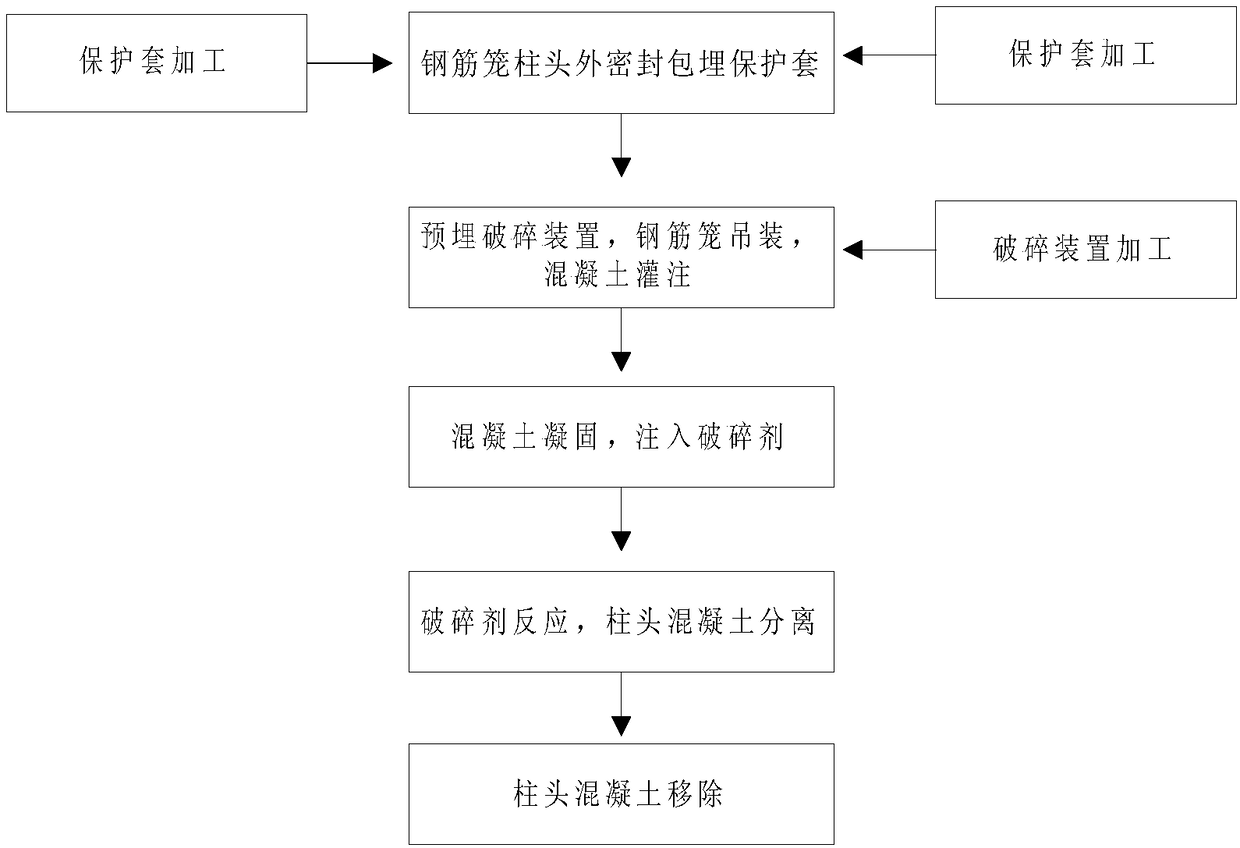

Crushing device, breaking method and application of pile head of cast-in-place bored pile

The invention discloses a crushing device, a breaking method and an application of a pile head of a cast-in-place bored pile. The crushing device of the pile head of the cast-in-place bored pile comprises the crushing device, wherein the crushing device is used for separating pile head concrete from pile body concrete through horizontal expansion force; the crushing device comprises a horizontal crushing assembly and a communicating pipe, wherein the horizontal crushing assembly is arranged at the joint position of the pile head concrete and the pile body concrete, and the horizontal crushingassembly is used for generating the horizontal expansion force to force the pile head concrete to be separated from the pile body concrete; and the communicating pipe extends out of the pile head concrete and is in communication with the inner cavity of the horizontal crushing assembly, and is used for injecting a crushing agent into the inner cavity of the horizontal crushing assembly. Accordingto the crushing device of the pile head of the cast-in-place bored pile, the structural design is simple, the crushing device of the pile head of the cast-in-place bored pile is placed at the joint position of the pile head concrete and the pile body concrete, and the separating effect can be achieved by injecting the crushing agent.

Owner:CCFEB CIVIL ENG

Diesel-alternative fuel hybrid combustion engine control method

ActiveCN102220916AReduce injection volumeReduce output torqueElectrical controlInternal combustion piston enginesInjectorHigh pressure

The invention provides a diesel-alternative fuel hybrid combustion engine control method without an electric oil pump rack actuating mechanism, belonging to the field of engine control. According to the invention, an exhaust temperature sensor, a wide-range oxygen sensor, a mixedly burning ratio information display screen, an alternative fuel injection controller, a high pressure diesel pump rack displacement sensor and an alternative fuel injector are additionally arranged on an original diesel engine with a mechanical high pressure fuel pump; a high pressure diesel pump rack is mechanically connected with a vehicle accelerator pedal; and according to the position of the high pressure oil pump rack of the diesel engine, the alternative fuel injection controller determines the injection quantity of alternative fuel in combination with estimation on the excess air coefficient of an engine and the operation intention of the driver and sends a control command to drive an alternative fuel injection valve to inject corresponding alternative fuel to an engine intake pipe. The method has the beneficial effects of lowering the cost and overcoming the adverse factors caused by the adoption of an electric oil pump rack actuator and can be widely applied to the diesel-alternative fuel hybrid combustion engines.

Owner:NANTONG YATAI ENG TECH

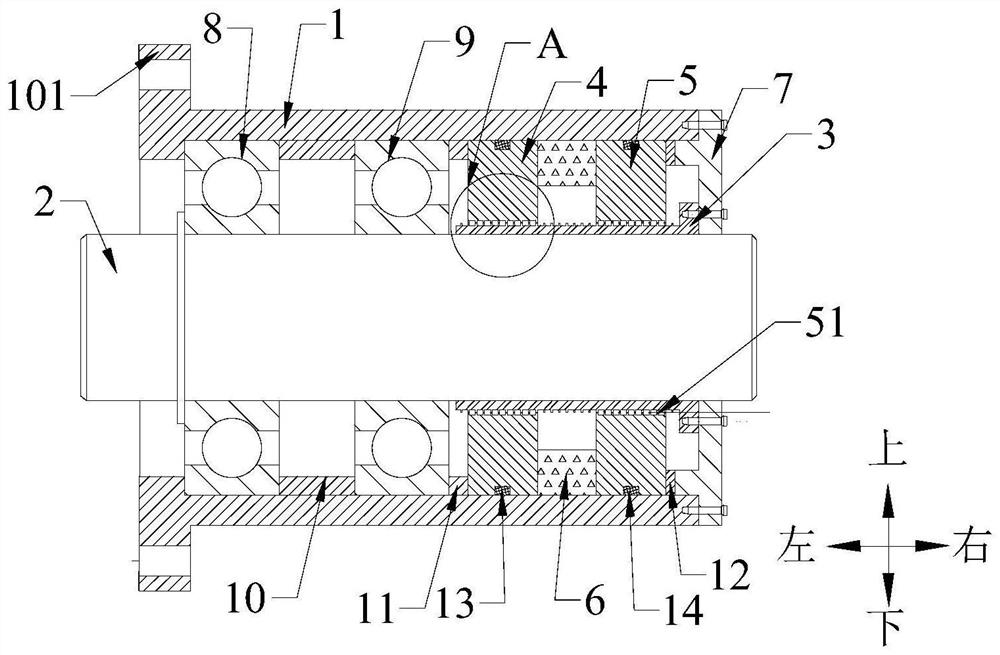

Magnetic liquid sealing device

The invention discloses a magnetic liquid sealing device. The magnetic liquid sealing device comprises a shell, a rotating shaft, a shaft sleeve, a first pole shoe, a second pole shoe, a permanent magnet and an end cover, wherein a cavity is formed in the shell; the rotating shaft is rotatably arranged in the cavity; the shaft sleeve is arranged on the rotating shaft in a sleeving mode; a plurality of protrusions are arranged on the periphery of the shaft sleeve and arranged in the axial direction of the rotating shaft at intervals; the first pole shoe and the second pole shoe are arranged inthe axial direction of the rotating shaft at intervals; a plurality of first pole teeth are arranged on the inner circumferences of the first pole shoe and arranged in the axial direction of the rotating shaft at intervals; the plurality of first pole teeth and the plurality of protrusions are oppositely arranged in the radial direction of the rotating shaft; a plurality of second pole teeth are arranged on the inner circumference of the second pole shoe and arranged in the axial direction of the rotating shaft at intervals; the plurality of second pole teeth and the plurality of protrusions are oppositely arranged in the radial direction of the rotating shaft; one end of the shaft sleeve is connected to the end cover; and the permanent magnet surrounds the rotating shaft and is arranged between the first pole shoe and the second pole shoe. The magnetic liquid sealing device can reduce a sealing gap, the injection amount of magnetic liquid, and the magnetic liquid seal starting torque.

Owner:TSINGHUA UNIV

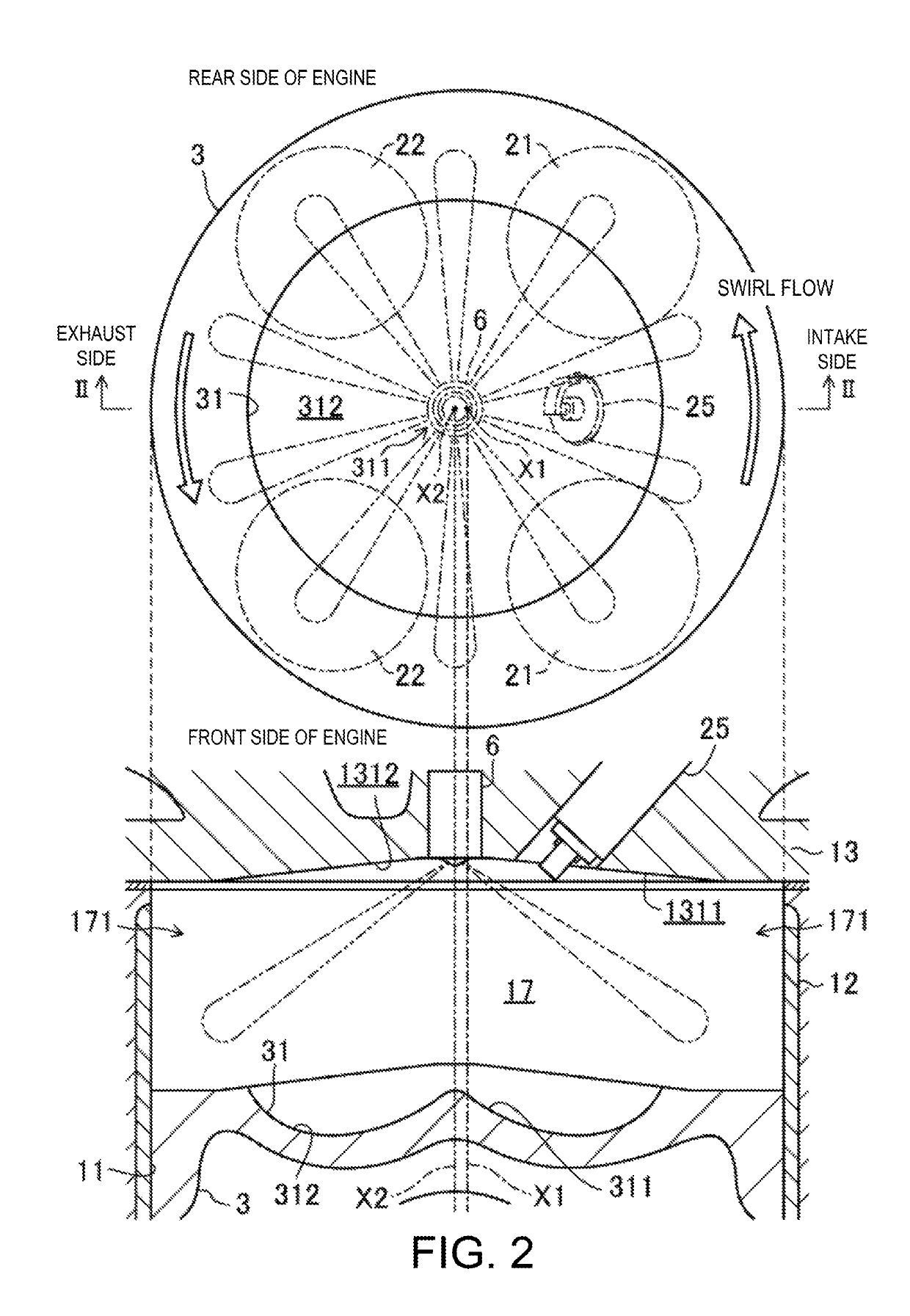

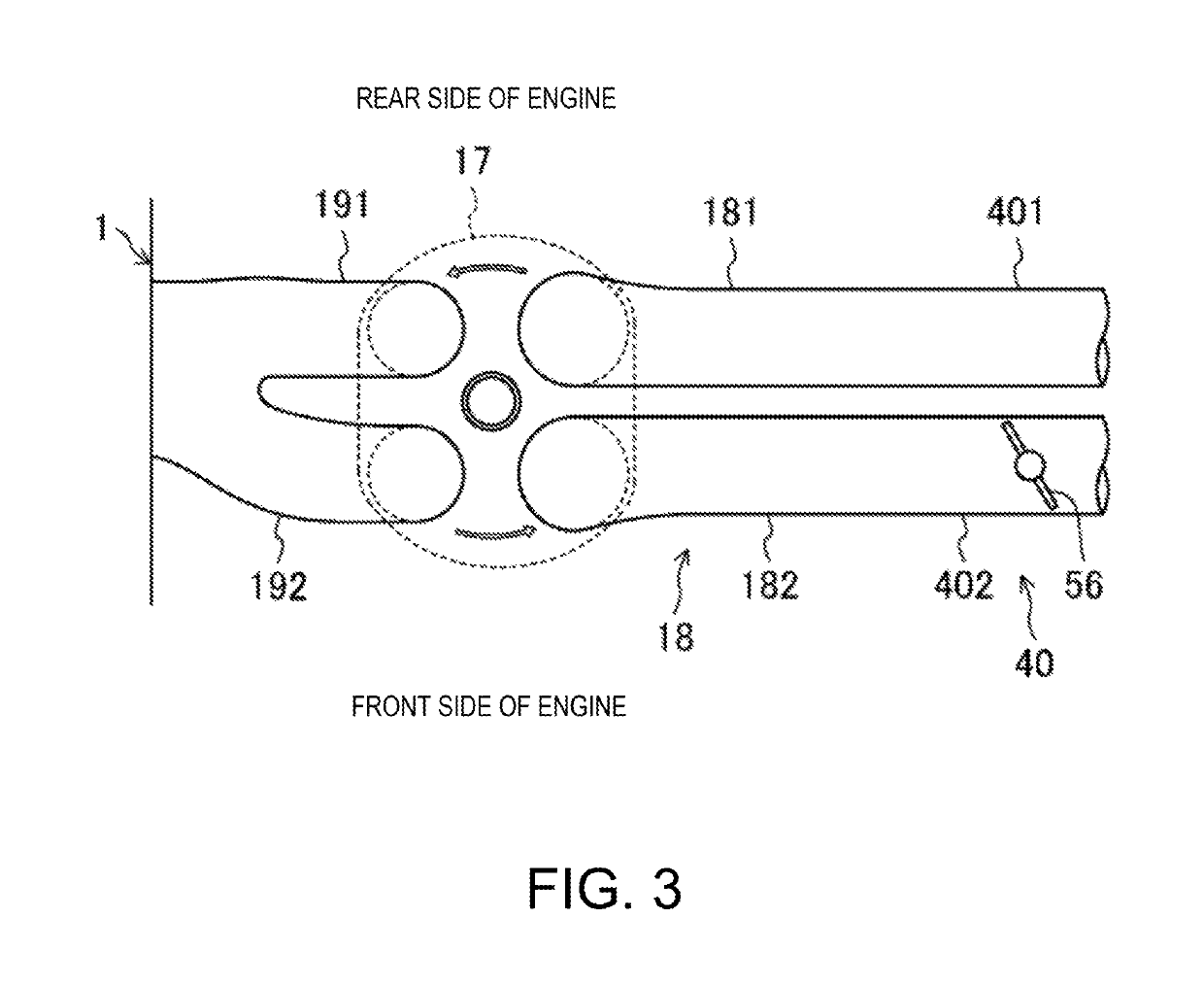

Control system of compression-ignition engine

ActiveUS10487720B2Reduce injection volumeIncrease injection volumeElectrical controlInternal combustion piston enginesCombustionControl signal

A control system of a compression-ignition engine is provided, which includes an engine, an injector, a spark plug, and a controller connected to the injector and the spark plug, and configured to operate the engine by outputting a control signal to the injector and the spark plug. After the spark plug ignites mixture gas to start combustion, unburned mixture gas combusts by self-ignition. The controller outputs the control signal to the injector to perform a first-stage injection of fuel and then a second-stage injection in which fuel is injected to at least form the mixture gas around the spark plug. The controller also outputs the control signal to the injector to control a ratio of the injection amount of the second-stage injection with respect to the injection amount of the first-stage injection to be higher at a high engine speed than at a low engine speed.

Owner:MAZDA MOTOR CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com