Mold-releasing agent for oil die casting, method for setting solvent mixing ratio, casting method and spray device

A release agent, oil-based technology, applied in the field of injection units and punches, can solve the problems such as the inability of molten metal to reach the cavity, the low adhesion efficiency of water-soluble release agents, and the inability to manufacture cast products, avoiding the problem of Dunfrost phenomenon, excellent wettability, and the effect of reducing the spread

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1 to 5 and comparative example 1 to 3

[0102] (A) Components and results of measurement tests

[0103] Table 1 below shows the components, physical property values, results of the adhesion test, and results of the friction test of Examples 1, 2, 3, 4 and 5. Moreover, the following Table 1 shows the components, physical property values, results of adhesion test and results of friction test of Comparative Examples 1 to 3, that is, the water-soluble release agents prepared by the applicant of the present invention. The mold agent is water-soluble pigment release agent (trade name: Lubrolene A-704); water-soluble release agent (trade name: Lubrolene A-201); and water-soluble release agent (trade name: Lubrolene A-1609) .

Embodiment 6 to 11 and comparative example 4 to 7

[0144] Hereinafter, the release agents of Examples 6 to 11, which contain a wettability-improving additive, will be described with reference to the release agents of Comparative Examples 4 to 7.

[0145] (A) Components and test results

[0146] Table 4 below shows the components, physical property values, adhesion test results, and friction test results of the oil-based release agents of Examples 6, 7, 8, 9, 10, and 11. Table 5 below shows the physical property values of the oil-based release agents of Comparative Examples 4, 5 and 6 and the water-soluble release agent of Comparative Example 7 (trade name: Lubrolene A-1609, manufactured by AOKI SCIENCE INSTITUTE CO., Ltd.) , components, adhesion test results and friction test results.

[0147] Table 4

[0148] Example

6

7

8

9

10

11

Component (weight%)

water

0

0

0

0

0

0

solvent

...

Embodiment 12

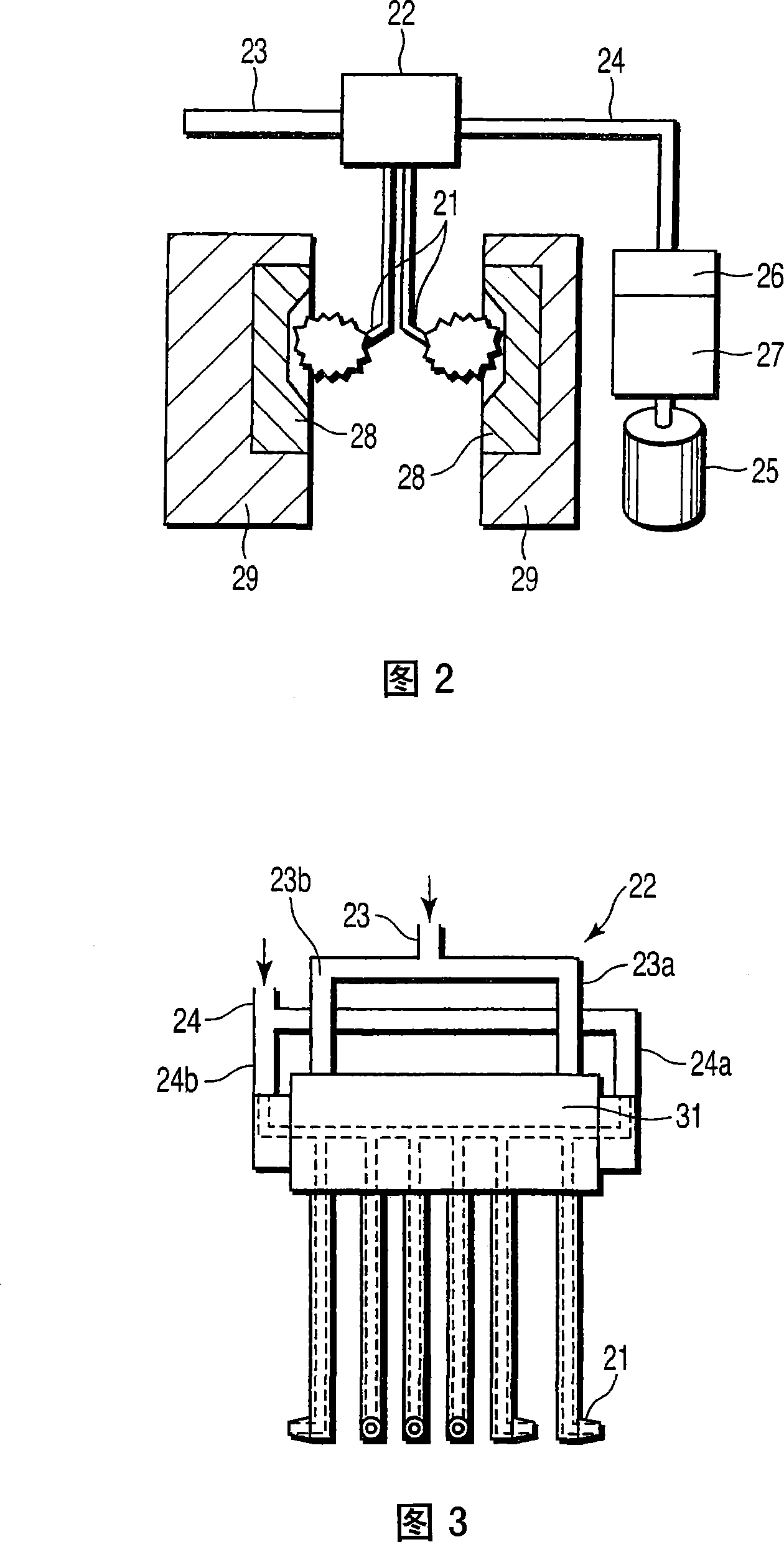

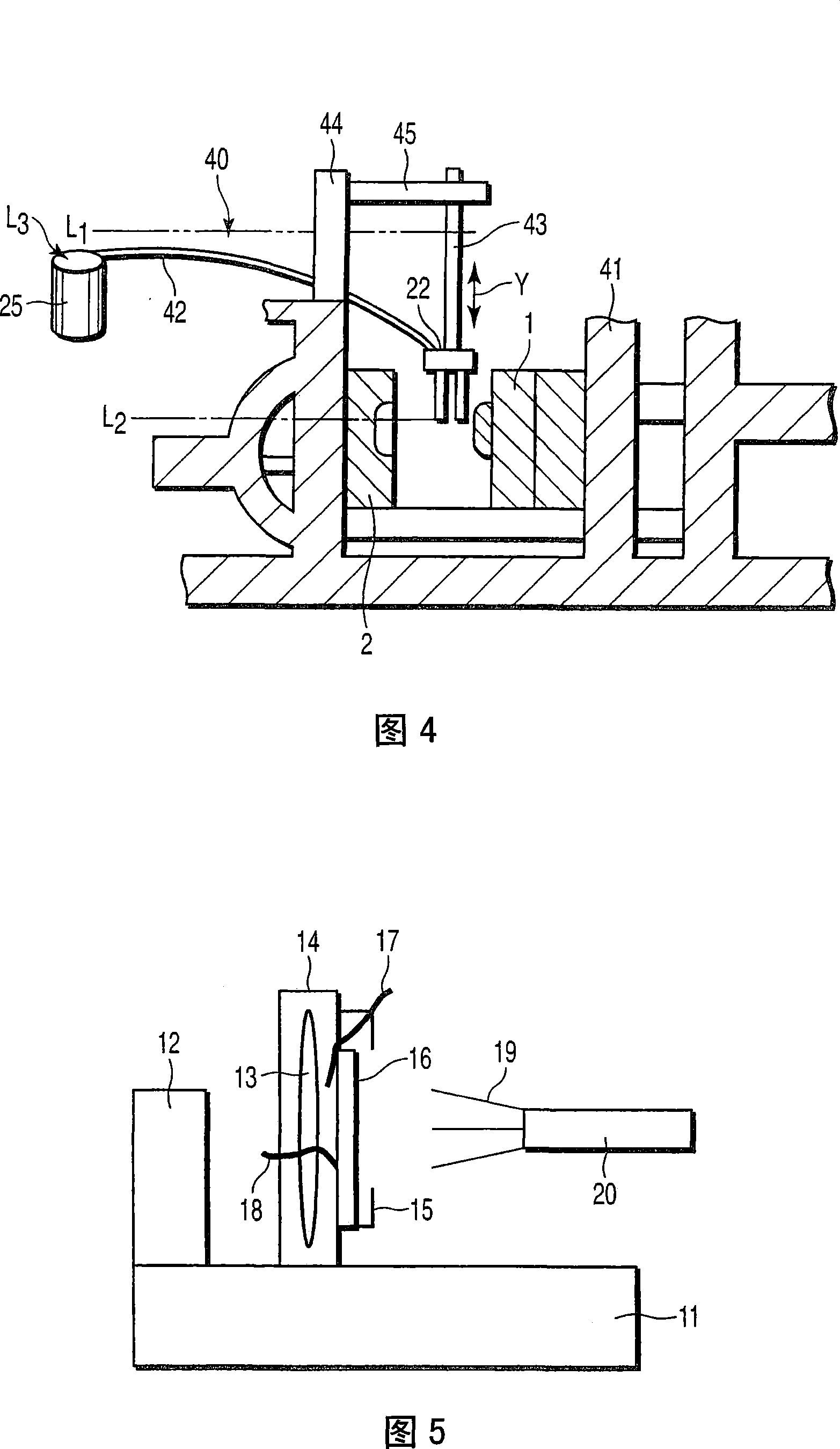

[0173] Next, a spray unit for uniformly applying the oil-based release agent of the present invention will be described. The unit is as described above. Casting quality was compared in Example 12 by using an actual machine.

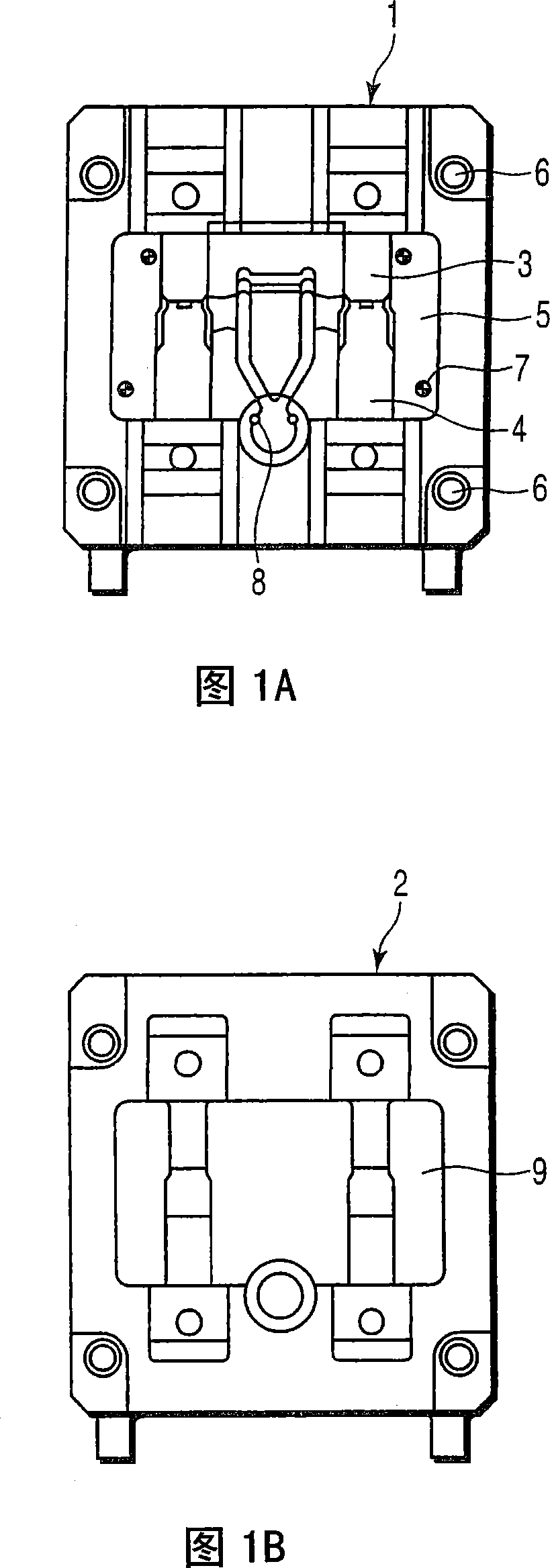

[0174] Table 7 below shows properties of products obtained by performing aluminum die casting using the release agents of Examples 13 to 16 and Comparative Examples 8, 9 and the above-mentioned injection unit. In this case, the release agent of Example 4 was used for Examples 13 and 14; the release agent of Example 6 was used for Examples 15 and 16; the release agent of Comparative Example 7 was used for Comparative Example 8; and the release agent of Comparative Example 4 was used in Comparative Example 9. As shown in Figure 1, the mold used in Example 12 can manufacture two products at the same time, and has a casting structure consisting of upper and lower sliders in the cavity, wherein the cavity consists of a movable mold and a fixed The mold is f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| friction | aaaaa | aaaaa |

| friction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com