Patents

Literature

2874 results about "Oil film" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

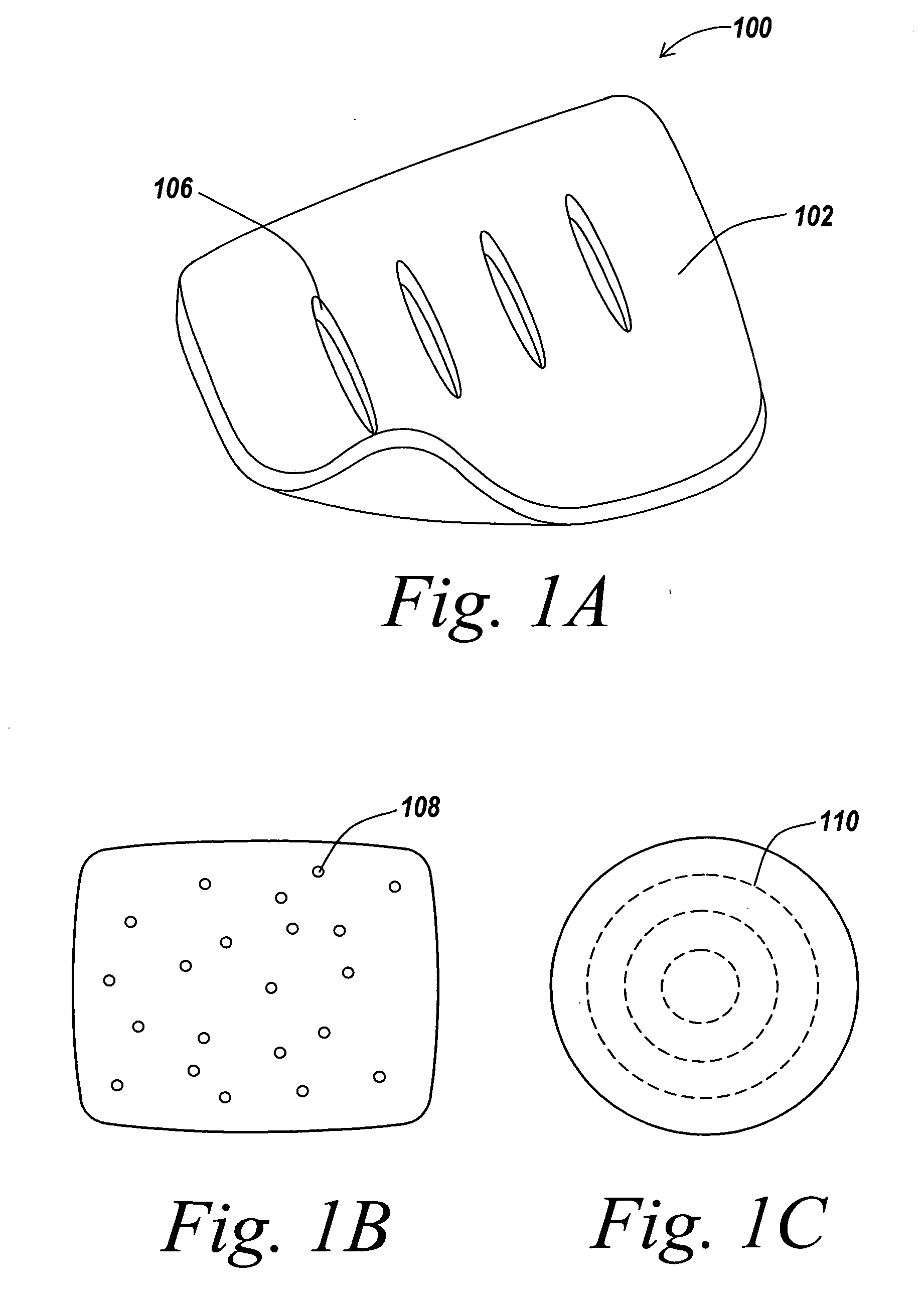

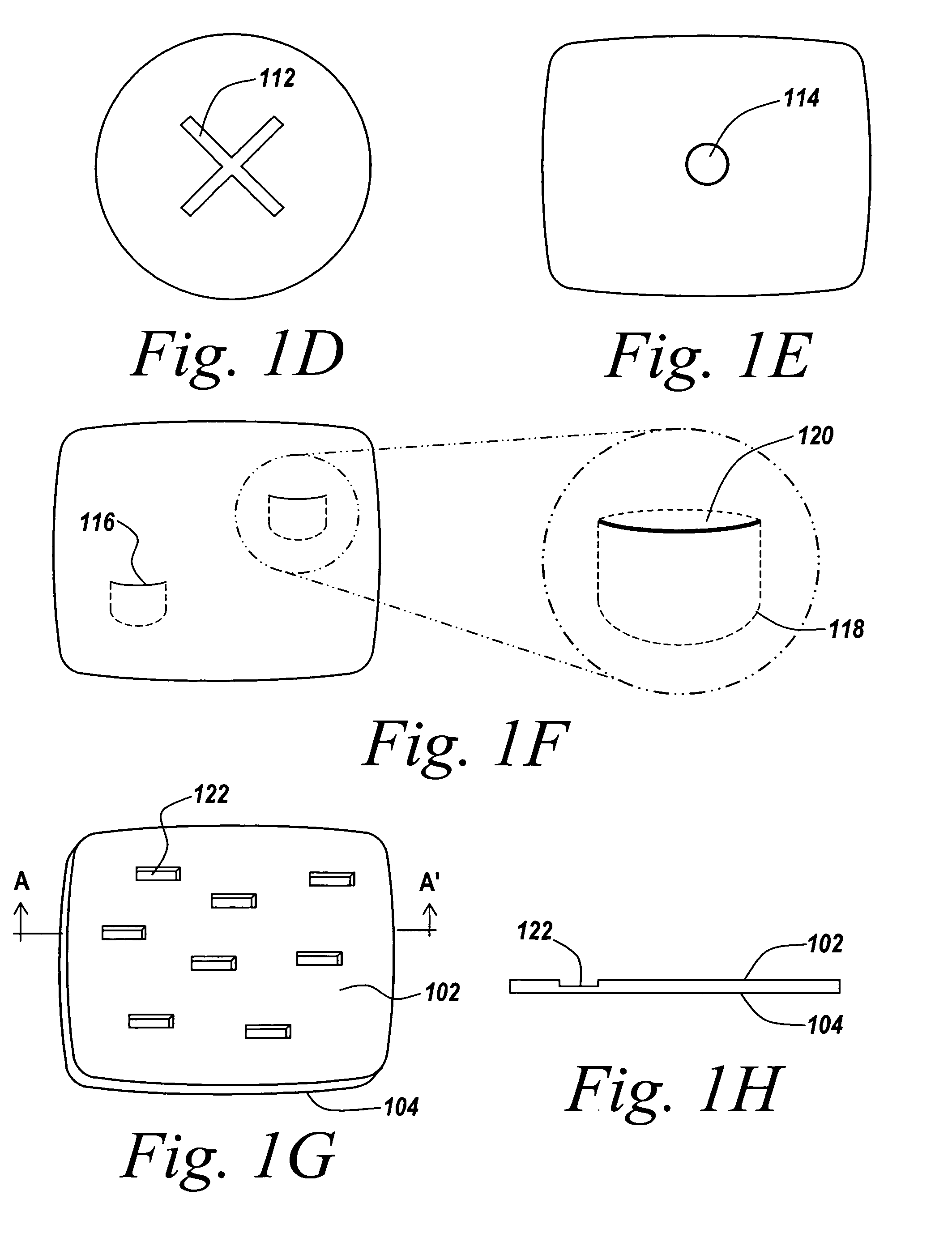

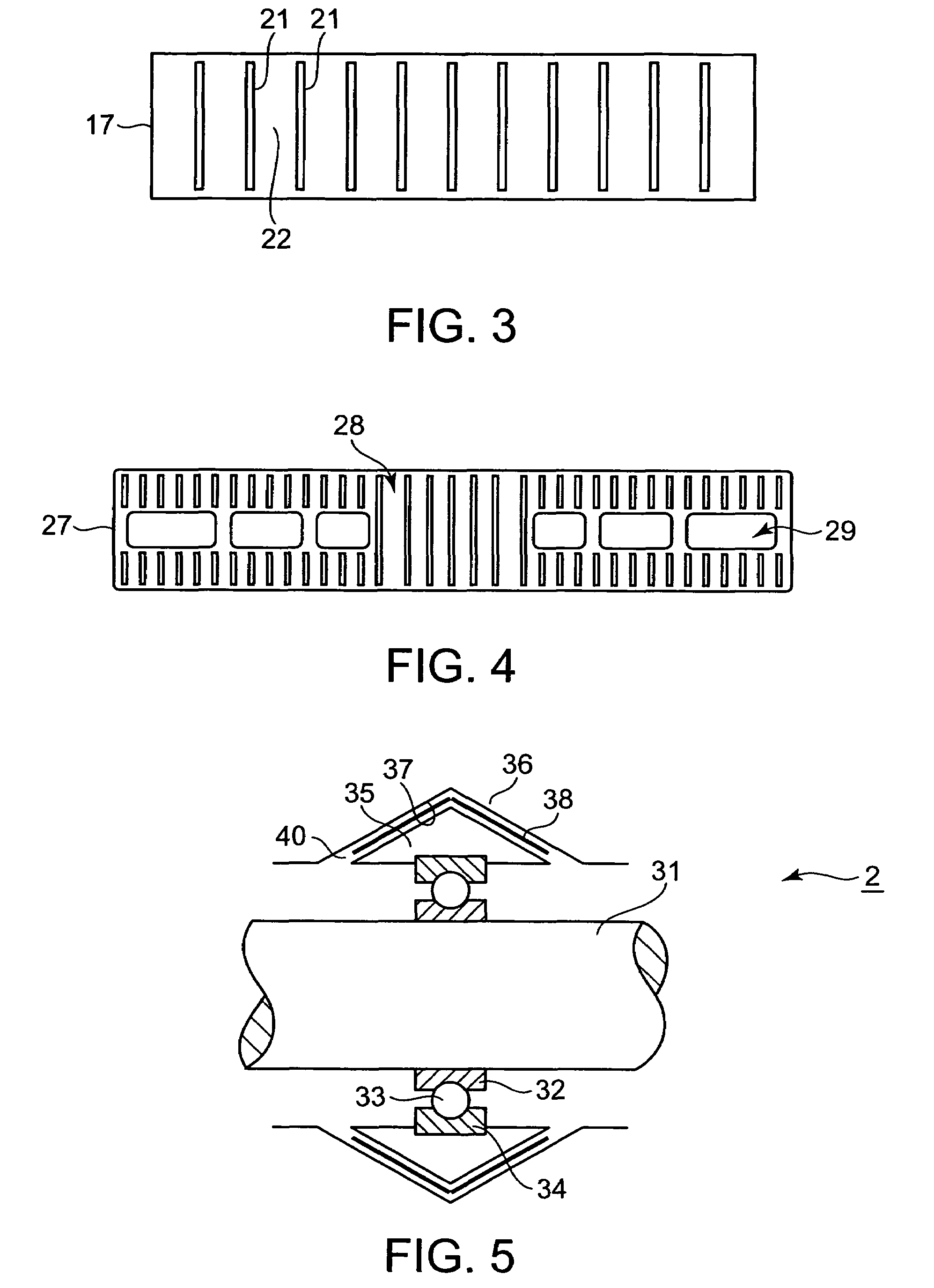

Perforated bioabsorbable oil film and methods for making the same

ActiveUS20070071798A1Improve bioabsorptionMaintain propertiesCosmetic implantsDiagnosticsWound healingMedicine

A bio-absorbable stand-alone film is derived at least in part from fatty acids. The bio-absorbable stand-alone film can have anti-adhesive, anti-inflammatory, non-inflammatory, and wound healing properties, and can additionally include one or more therapeutic agents incorporated therein. The stand-alone film has one or more perforations or depressions formed therein. Corresponding methods of making the bio-absorbable stand-alone film with one or more perforations or depressions include molding, cutting, carving, puncturing or otherwise suitable methods to create the perforations or depressions in the bio-absorbable stand-alone film. The resulting stand-alone film is bioabsorbable.

Owner:ATRIUM MEDICAL

Ultra-low resistance acid-type microemulsion plugging removal and stimulation technology for low permeability oil well

ActiveCN101691839AGood dispersionStrong solubilizationFluid removalDrilling compositionSolubilityLiquid surfaces

The invention relates to a plugging removal and stimulation method for a low permeability oil well. The ultra-low resistance acid-type microemulsion is prepared by the following components: 10%-25% of acid, 5%-20% of oil, 5%-25% of alcohol, 0.5%-5% of surfactant, 0.5%-3% of inorganic salt, 0.3-1.5% of corrosion inhibitor and the balance water. The method comprises the following steps: injecting the prepared microemulsion in the oil bearing reservoir of the oil well, closing the oil well to react for 4-10h, cleaning the oil well, flowing the reaction exhaust liquor back, and completing the oilwell to perform normal production. The ultra-low resistance acid-type microemulsion used by the invention has thermodynamic stability, is a high dispersive acid-type microemulsion with good solubilization capacity, has ultra-low surface and interfacial tensions and good solubilization capacity and can increase the dispersive capacity of crude in water and the emulsification and peeling function to oil film; the microemulsion also has good dissolubility in water or oil and good fluidity due to high carrying capability and low seepage resistances so that the oil yield of the oil well is increased and the water content is reduced; the liquid surface tension in oil reservoir is reduced and the flow resistance of the crude is lowered so that the mining rate of the crude is increased and the plugging removal and stimulation of the oil well can be realized.

Owner:陕西中孚石油信息技术有限公司 +1

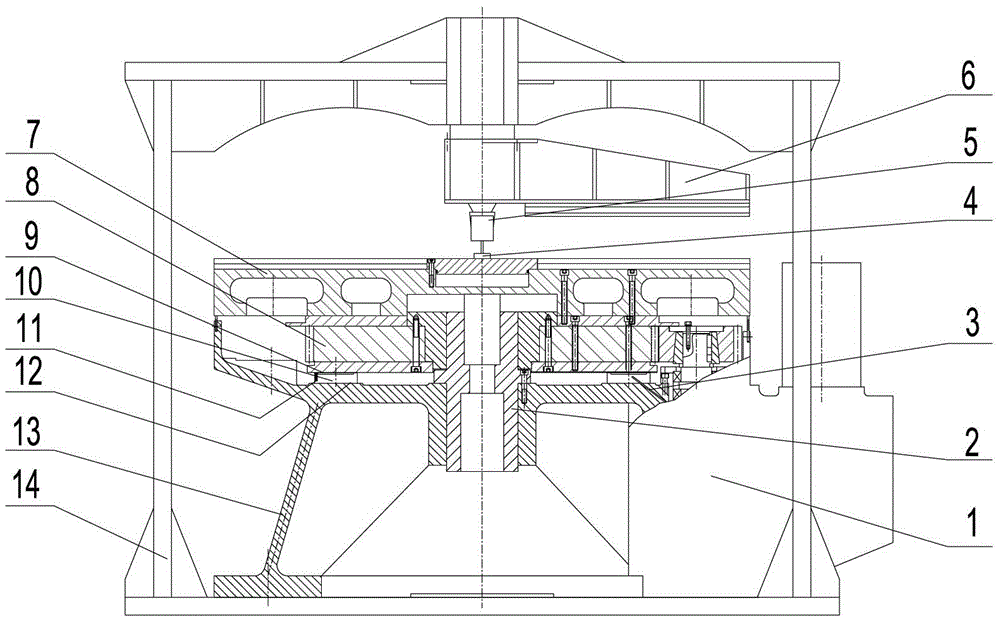

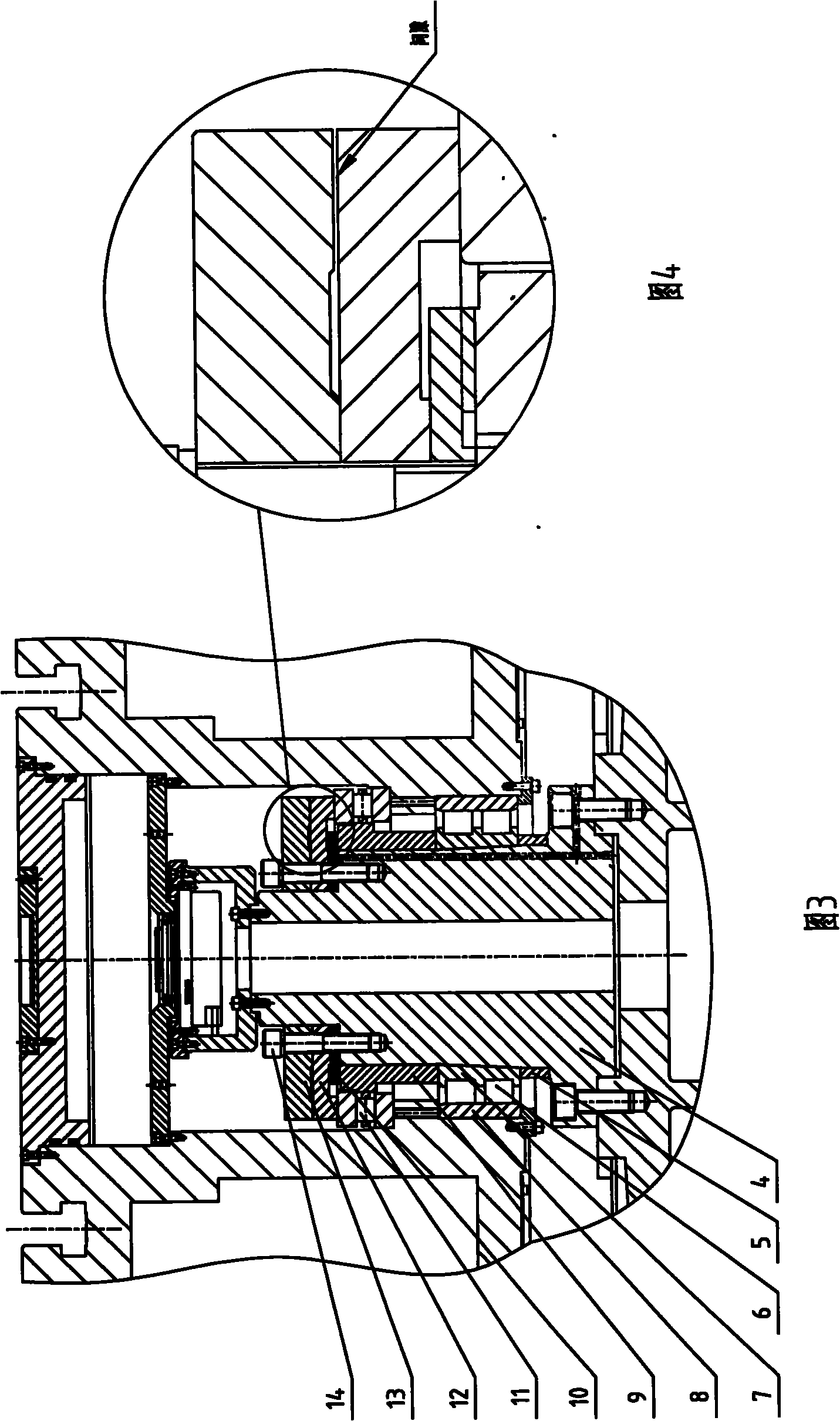

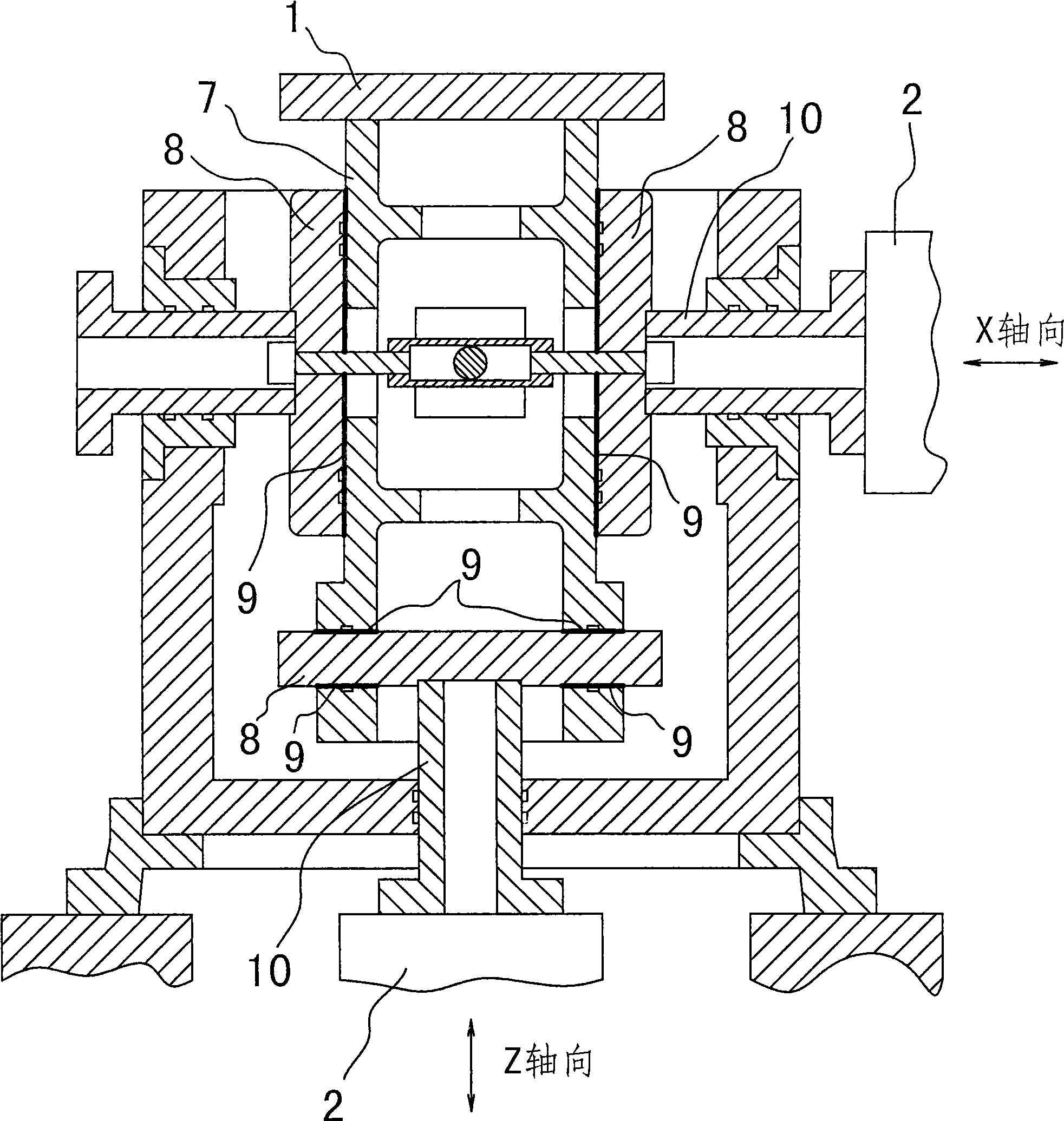

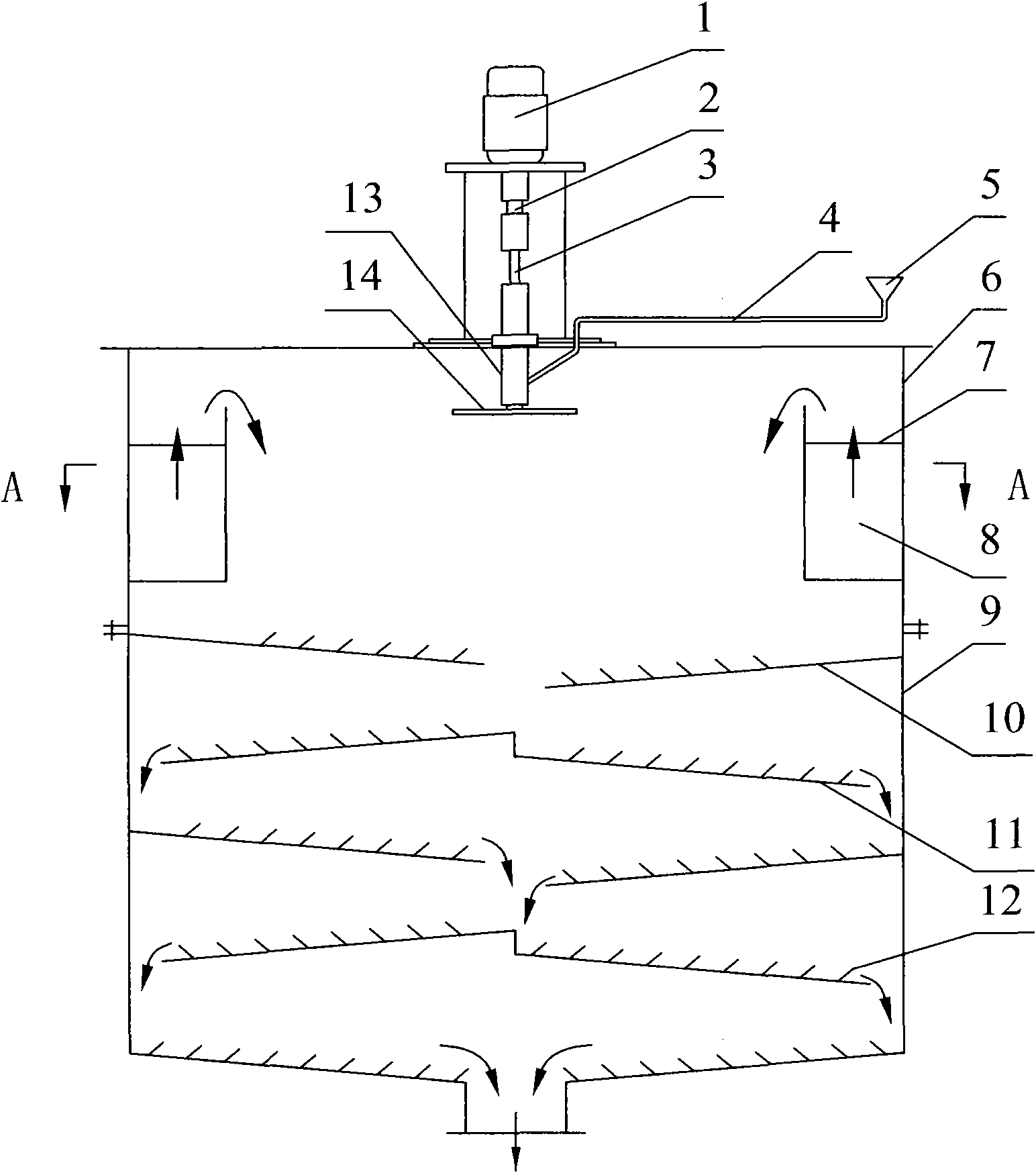

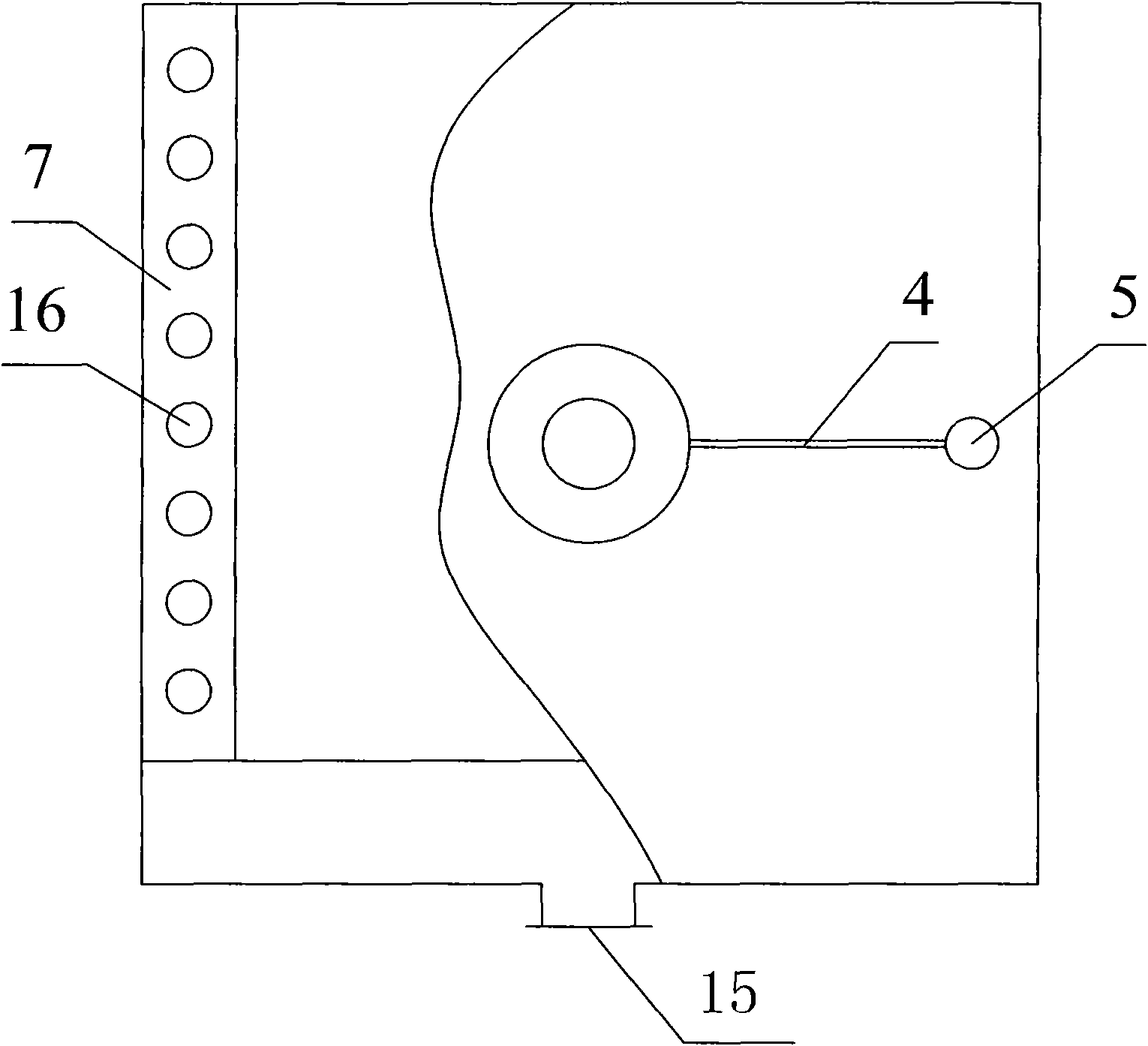

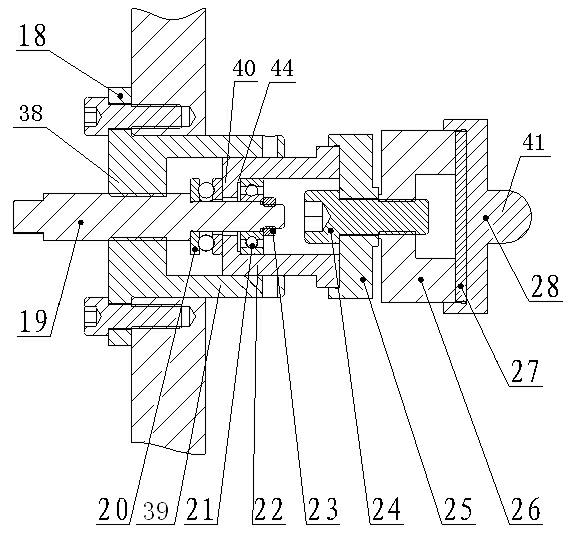

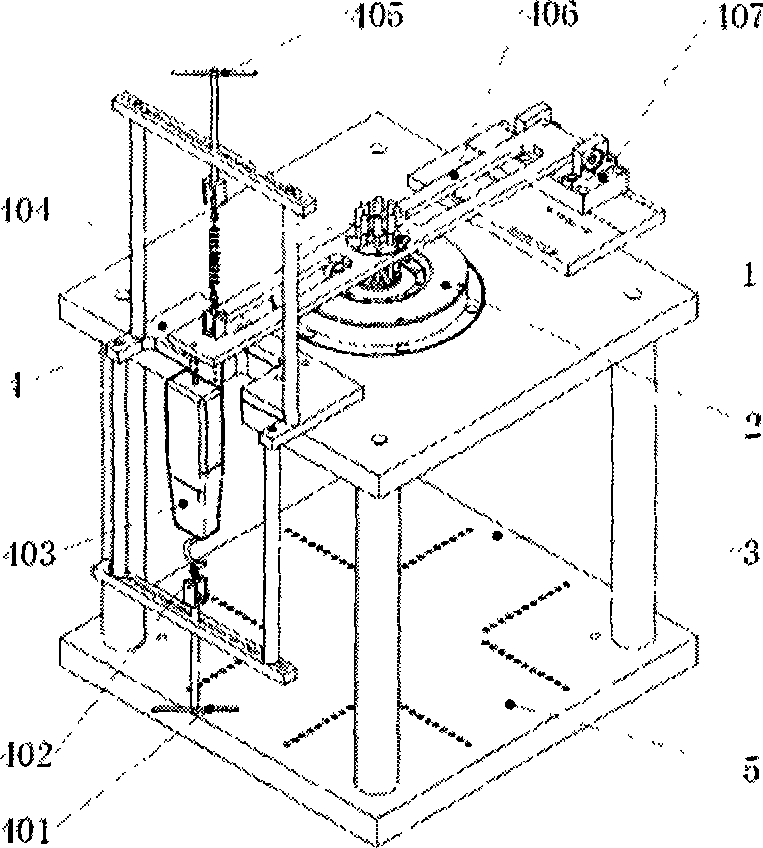

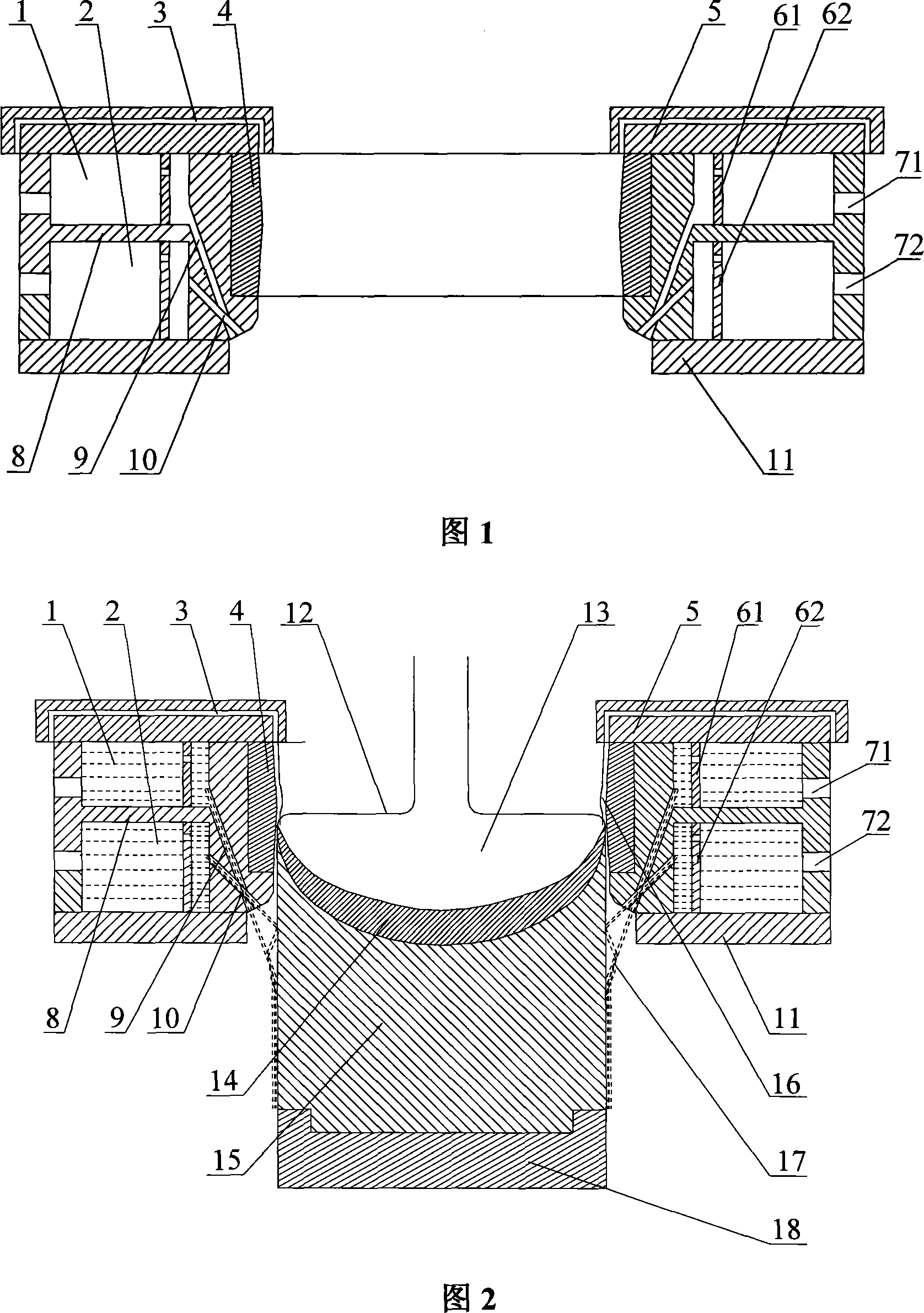

Quantitive type experimental device for dynamic and static performances of static-pressure rotary table

ActiveCN102980755AStructural parameter optimizationImprove machining accuracyMachine part testingElectricityEddy current

The invention provides a quantitive type experimental device for dynamic and static performances of a static-pressure rotary table, and belongs to the field of machinery design and manufacture. According to the experimental device, a loading device (5) and a loading arm (6) are used for changing magnitude of loads or changing oil supply pressure to control the distance between a static-pressure oil cushion (10) and a rotary table disc chuck (7), a pressure sensor (12) is used for measuring pressure in an oil cavity, an eddy current displacement sensor (11) is used for measuring the thickness of an oil film, a thermocouple temperature sensor (3) is used for measuring oil temperature, a force sensor (4) is used for obtaining magnitude of loading force, a pressure gauge a (15) on a multi-head pump at an oil inlet in the oil cavity is used for measuring pressure of the oil inlet of the oil cavity, and a pressure gauge b (16) arranged between an oil pump and the multi-head pump is used for measuring the oil supply pressure of the static-pressure rotary table. By means of the experimental device, a test of the dynamic and static performances of the static-pressure rotary table is carried out under the condition that temperature is between minus 10 DEG C and 60 DEG C and pressure is not more than 100 MPa, and the experimental device provides guarantee for solving problems in engineering, optimizing structural parameters of the rotary table, and improving machining precision of the rotary table.

Owner:BEIJING UNIV OF TECH

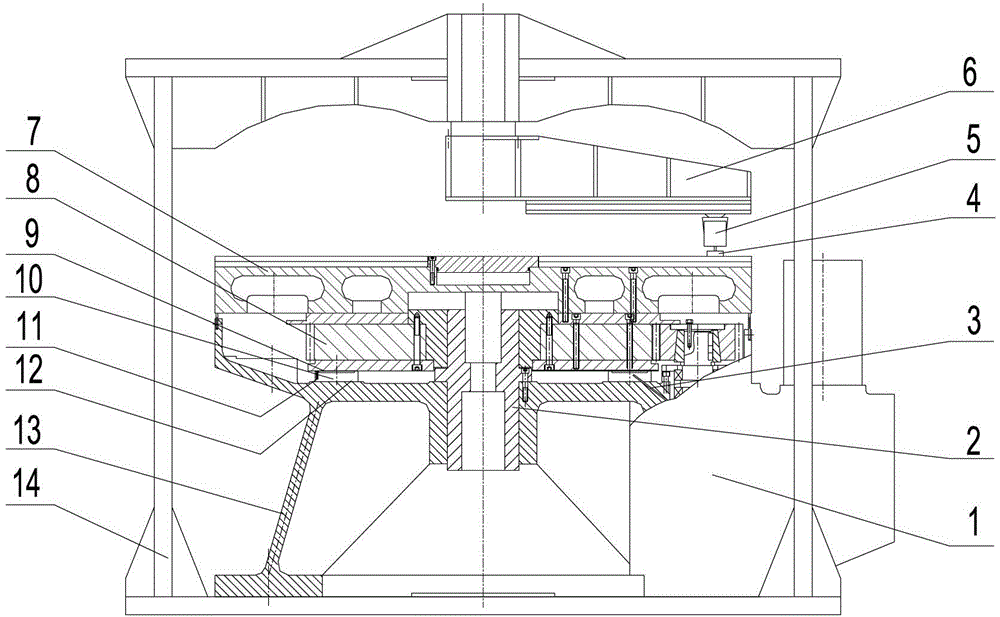

Open-type static pressure rotating table for controlling floating degree and manufacturing method thereof

ActiveCN102039527AImprove motion smoothnessHigh movement precisionLarge fixed membersBearingsThrust bearingHydrostatic pressure

The invention relates to an open-type static pressure rotating table for controlling floating degree and a manufacturing method thereof. The open-type static pressure rotating table is characterized in that: a column on the lower part of a rotary table body and the inner hole of a large gear ring forms clearance fit by a coaxial basic hole system; the large gear ring and the table are arranged ona slide carriage, and the bottom surface of the large gear ring with high planeness and roughness and a static pressure oil chamber on the upper surface of the slide carriage form a hydrostatic pressure guide rail pair; an additional axial thrust bearing structure arranged on a centering structure provides preloads for hydrostatic pressure guide rails of the table; and the bottom surface of the large gear ring is assembled and ground correctly according to design requirements till plane precision, and the upper surface of the static pressure oil chamber on the slide carriage is scraped by facing-up simultaneously to ensure the fit accuracy of the upper and lower hydrostatic pressure guide rails. In the open-type static pressure rotating table, the thrust bearing structure is adopted on the basis of a common centering shaft structure, so the initial preloads of the hydrostatic pressure guide rail pair are controlled effectively and the floating degree of the open-type static pressure rotary table is controlled effectively, the rigidity of an oil film is increased, and the motion stability, motion accuracy and unbalance load-resistant capacity of the open-type static pressure rotarytable are improved.

Owner:沈阳机床中捷友谊厂有限公司

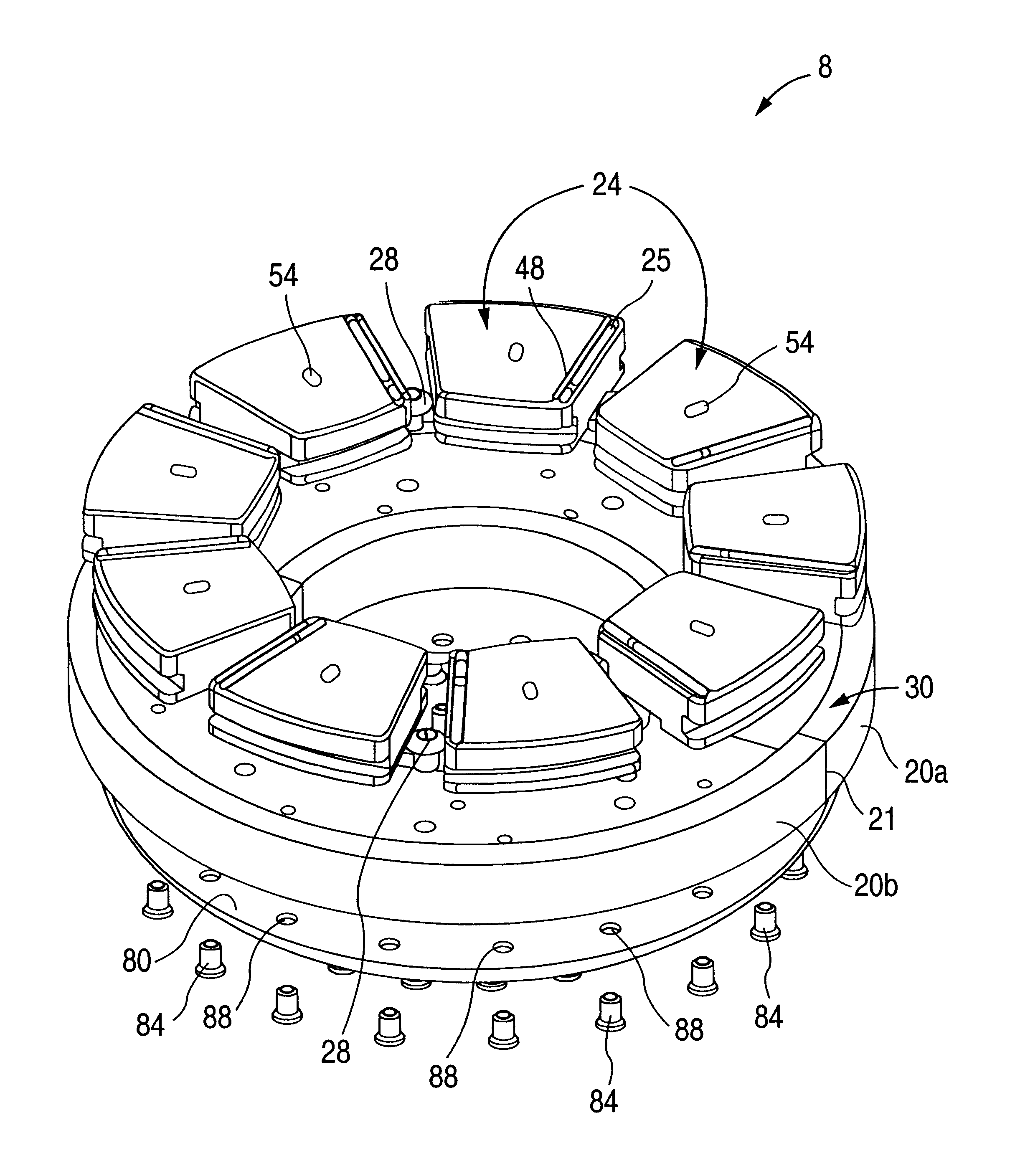

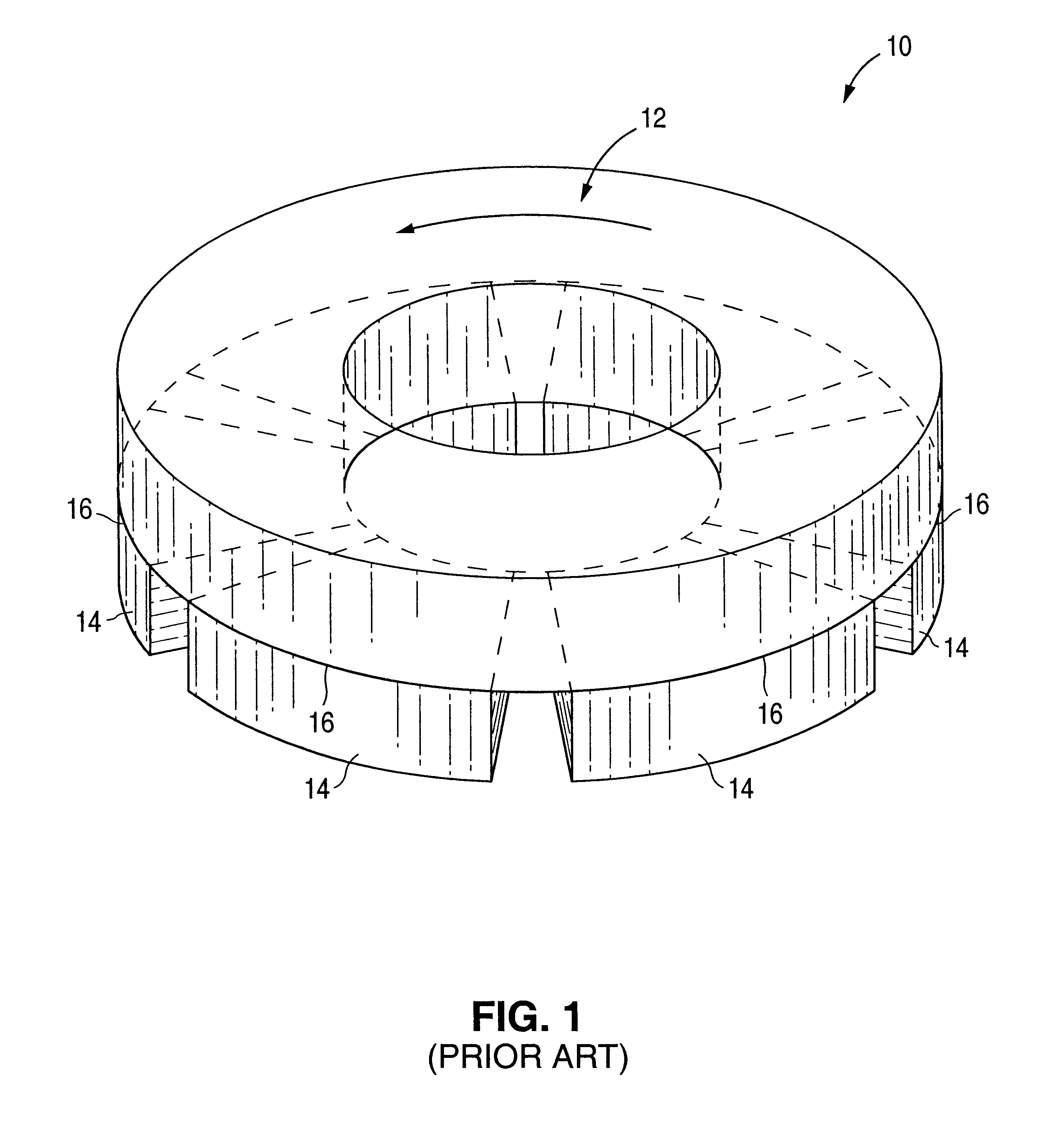

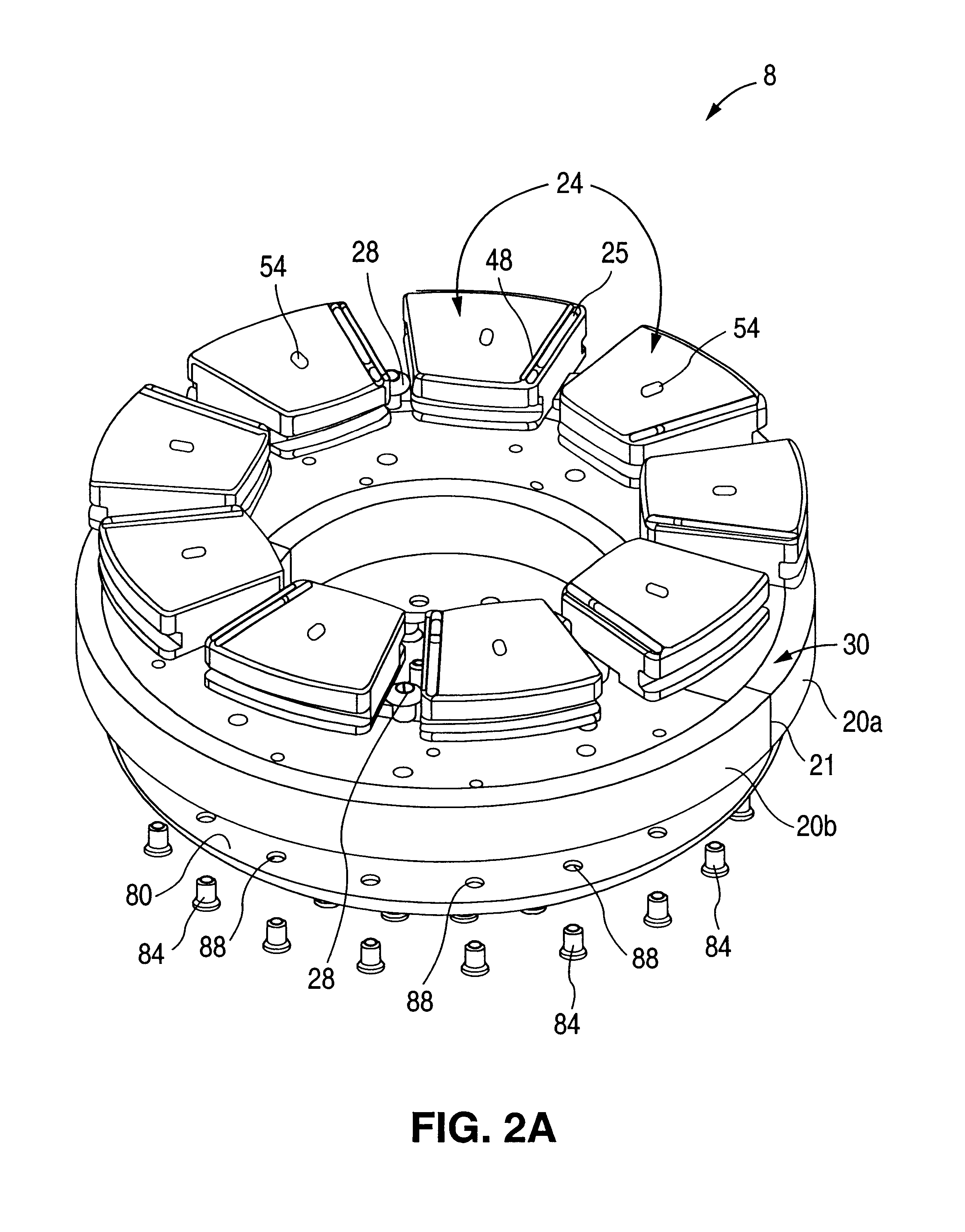

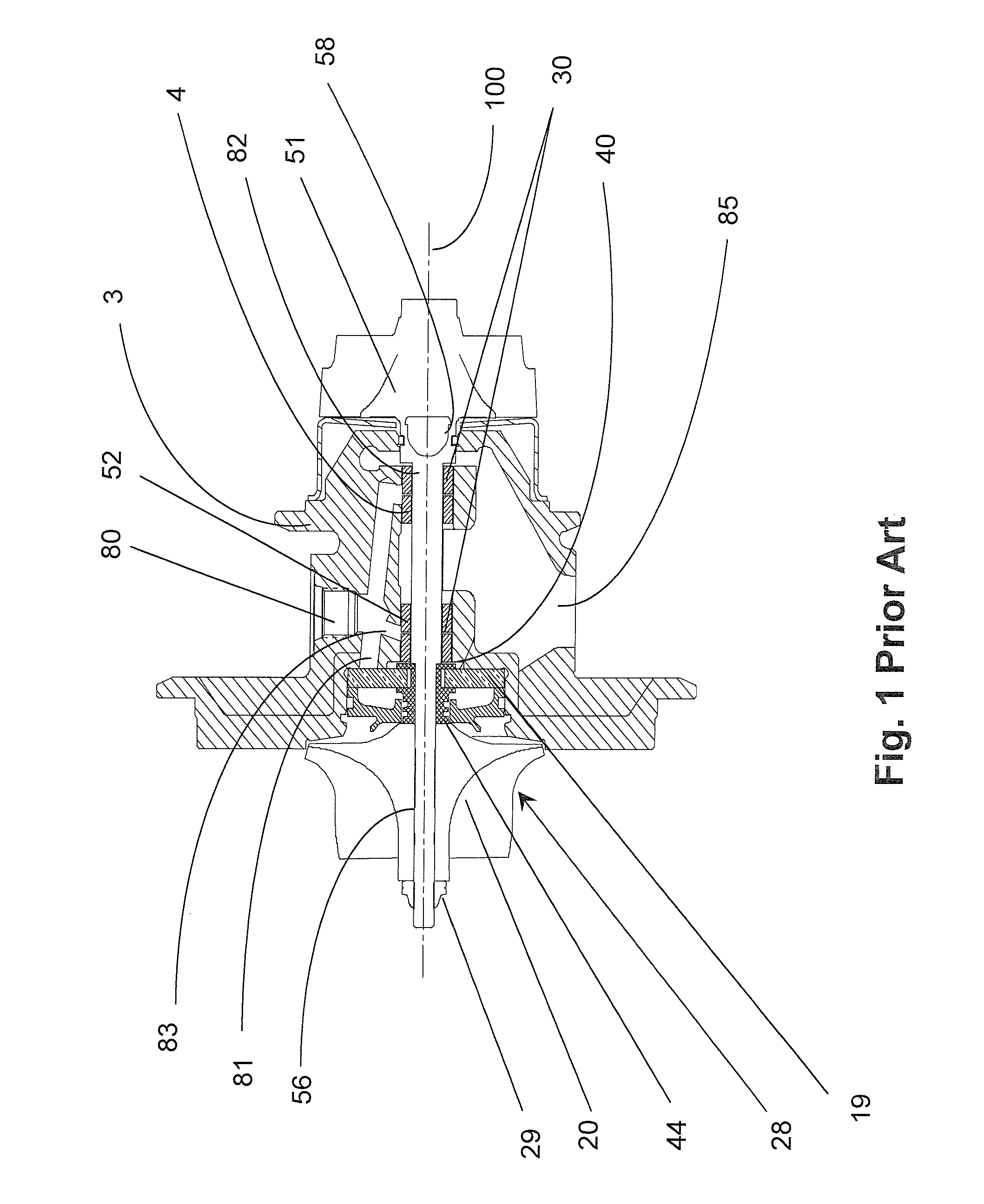

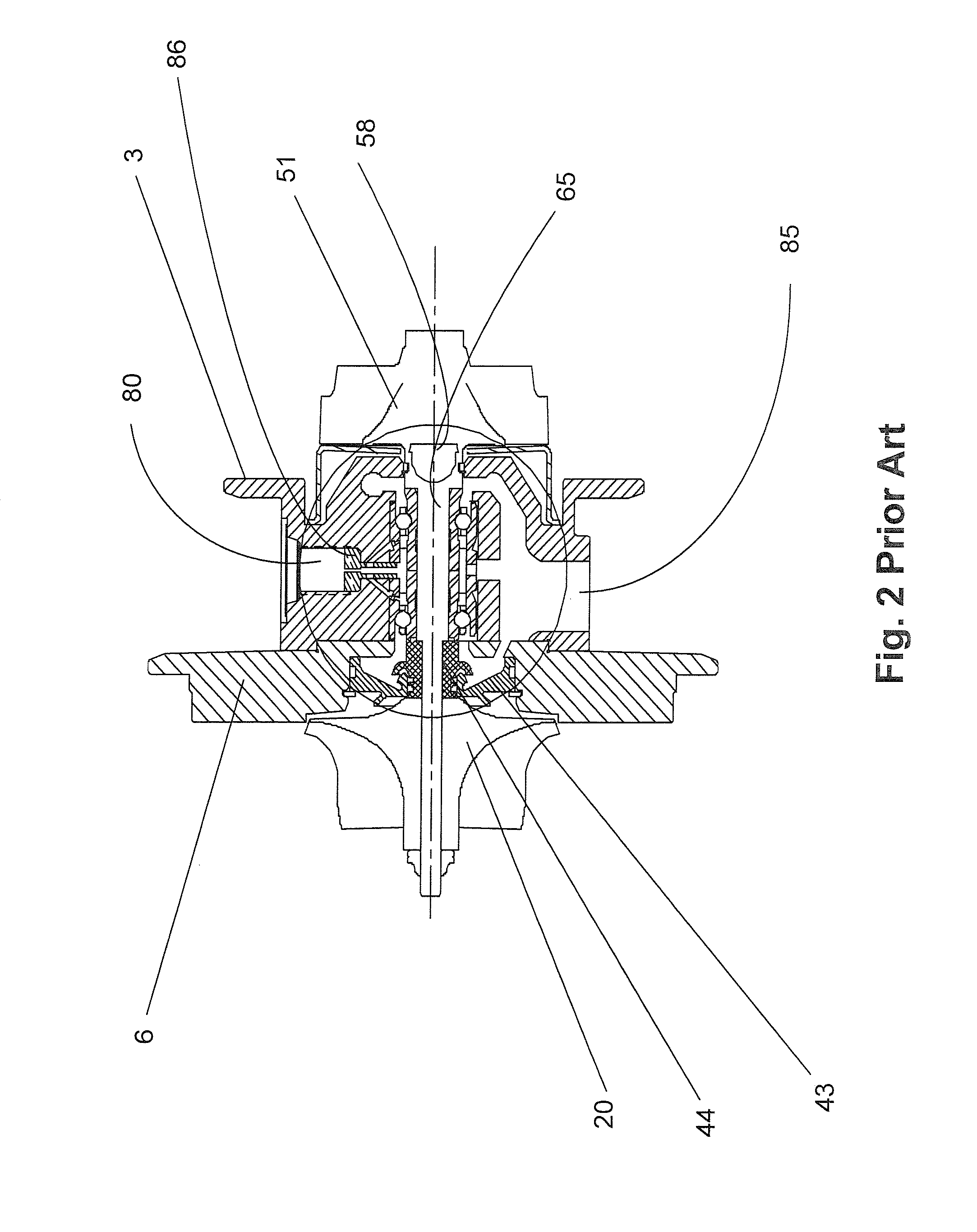

Thrust bearing and method for equalizing load

A multi-pad, fluid film thrust bearing has the pads suspended from the carrier ring on hydrostatic oil pressure regions. The oil is pressurized hydrodynamically by relative rotation between a load surface and the bearing surface of each pad; and the oil is passed through each pad to a rear cavity where the hydrostatic pressure region is established. A manifold interconnects all of the hydrostatic pressure regions for the individual pads in order to average the hydrostatic pressures and provide for static and dynamic load equalization.

Owner:PIONEER MOTOR BEARING

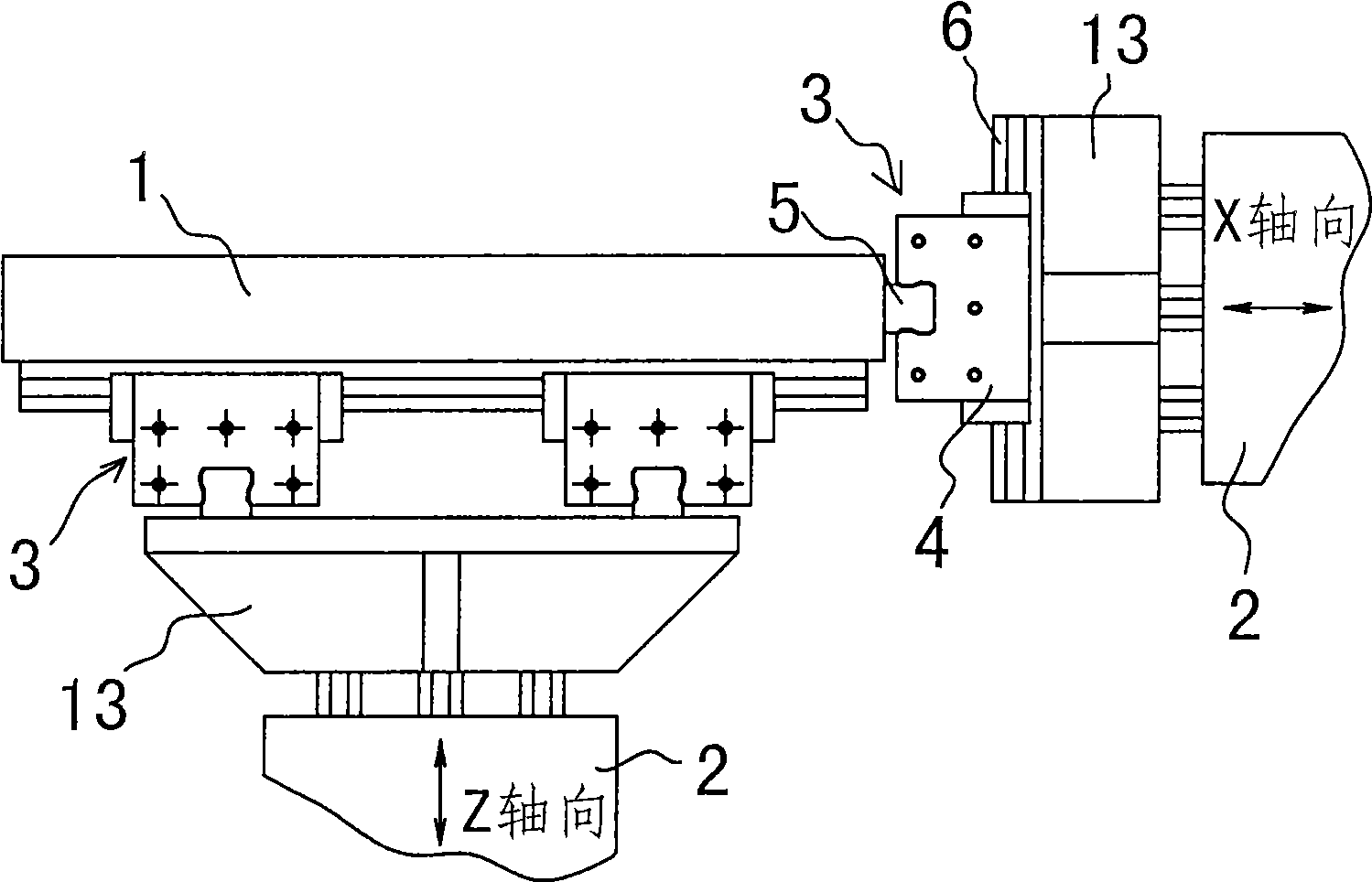

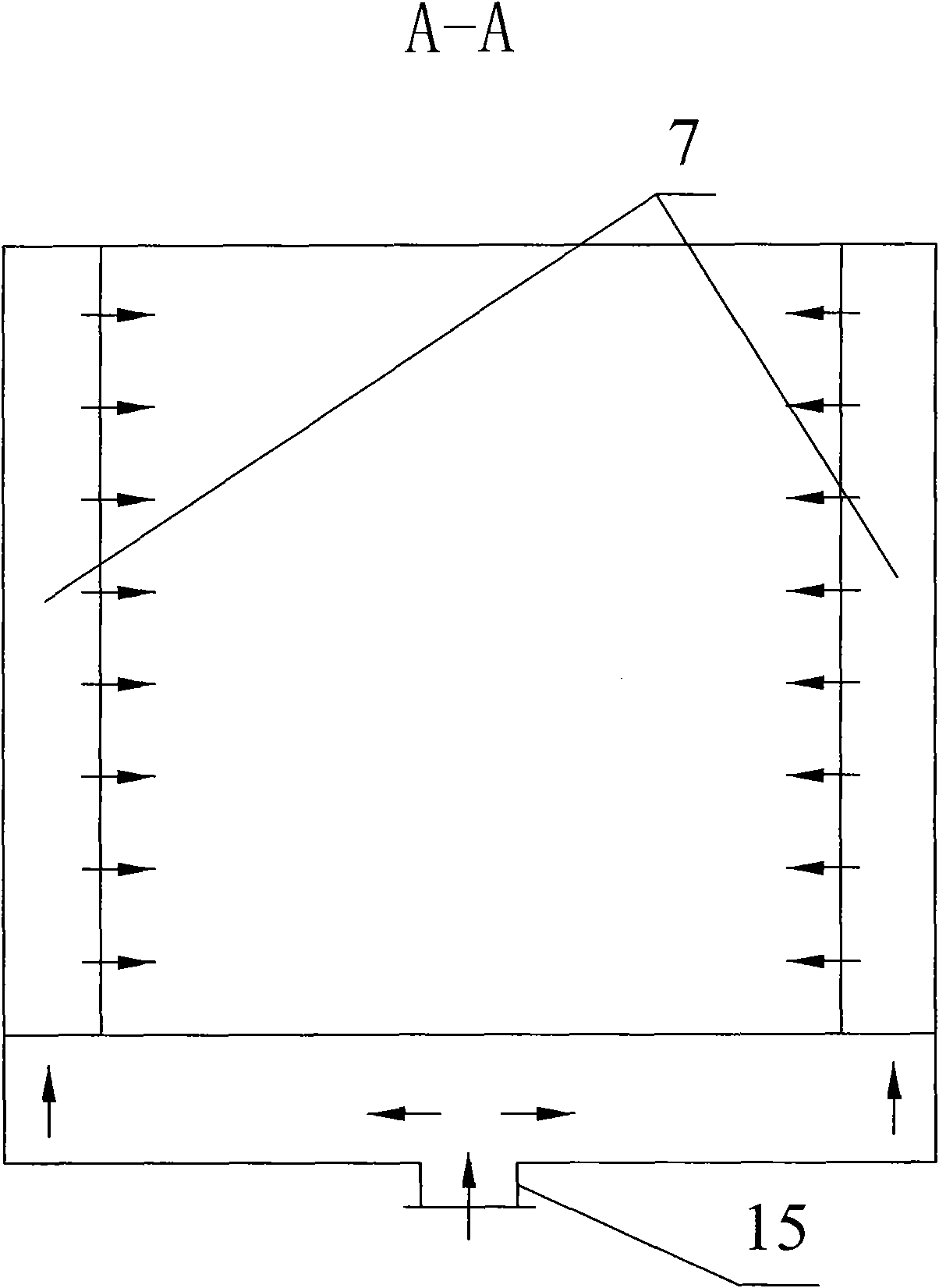

Three-axial vibration composite testing apparatus

A triaxial vibration composite testing device is provided with a worktable, and is characterized in that both a horizontal X-axis second axial transmission-vibration mechanism and a horizontal Y-axis third axial transmission-vibration mechanism are cross linear guide rail pairs, while a first axial transmission-vibration mechanism vertical to Z-axis comprises an upper clamp plate, a lower clamp plate and a central panel, wherein the upper clamp plate and the lower clamp plate are aligned vertically and arranged horizontally, the central panel is positioned between the upper clamp plate and the lower clamp plate, the upper clamp plate and the lower clamp plate oppositely clamp the central panel, the lower surface of the upper clamp plate and the upper surface of the central panel are in clearance fit to form an upper fit plane, the upper surface of the lower clamp plate and the lower surface of the central panel are in clearance fit to form a lower fit plane, and high-pressure oil is pumped into gaps of the upper fit plane and the lower fit plane to form static-pressure oil films so as to form a static-pressure plane bearing mechanism. The invention can further improve performance (working frequency in particular), improve capability of resisting capsizing moment, simplify structure, and lower manufacturing difficulty and cost.

Owner:SUZHOU SUSHI TESTING INSTR CO LTD

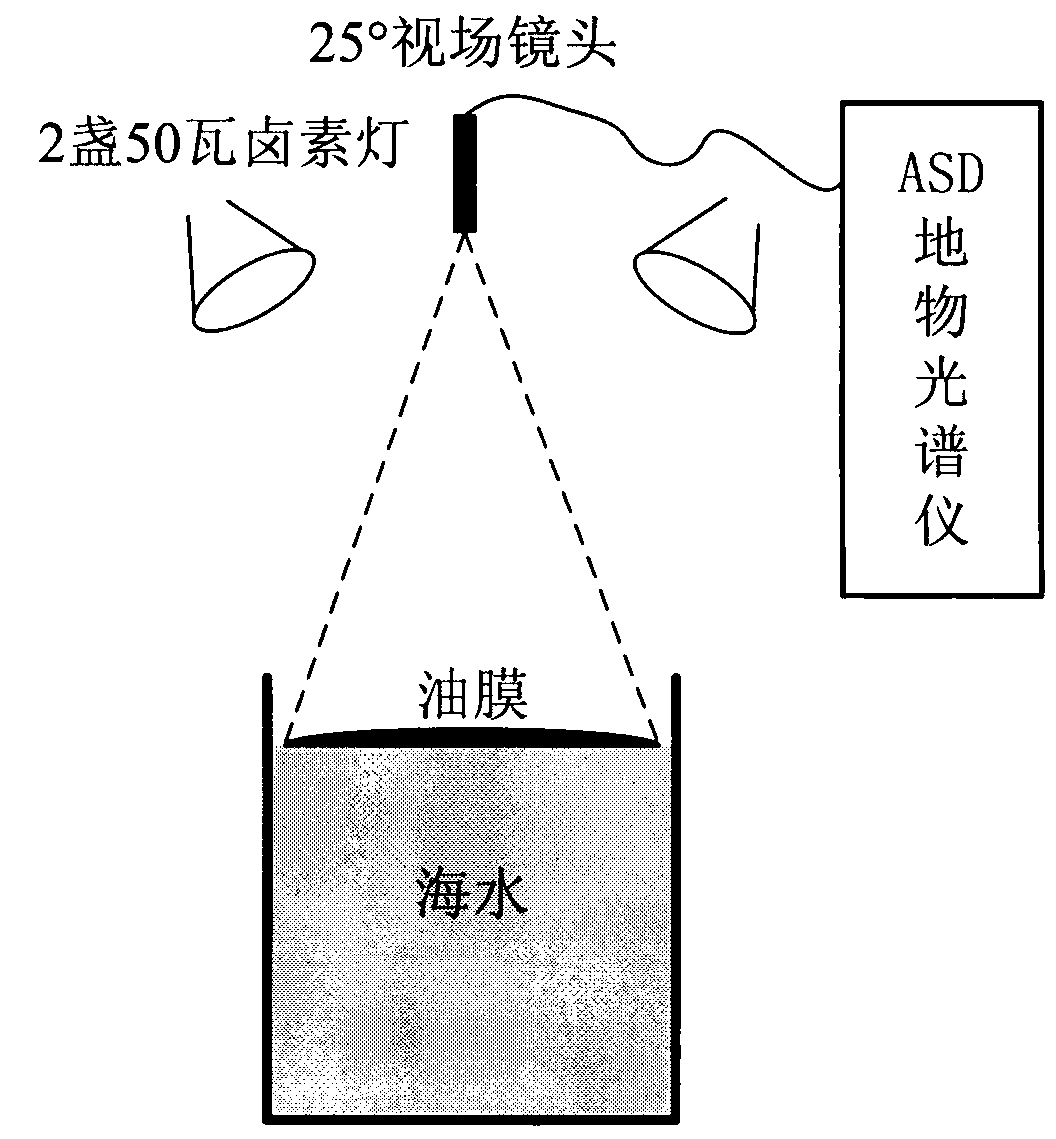

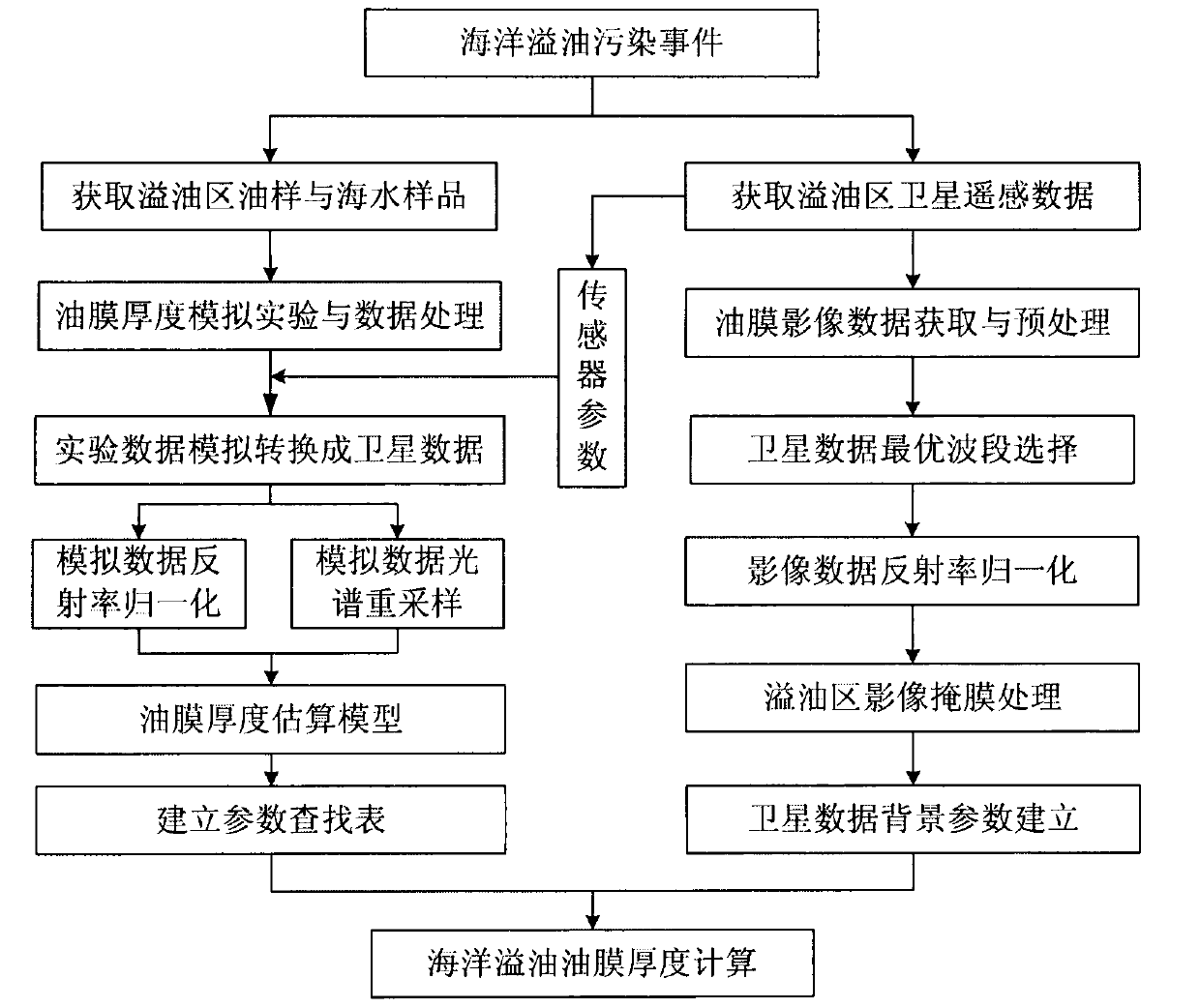

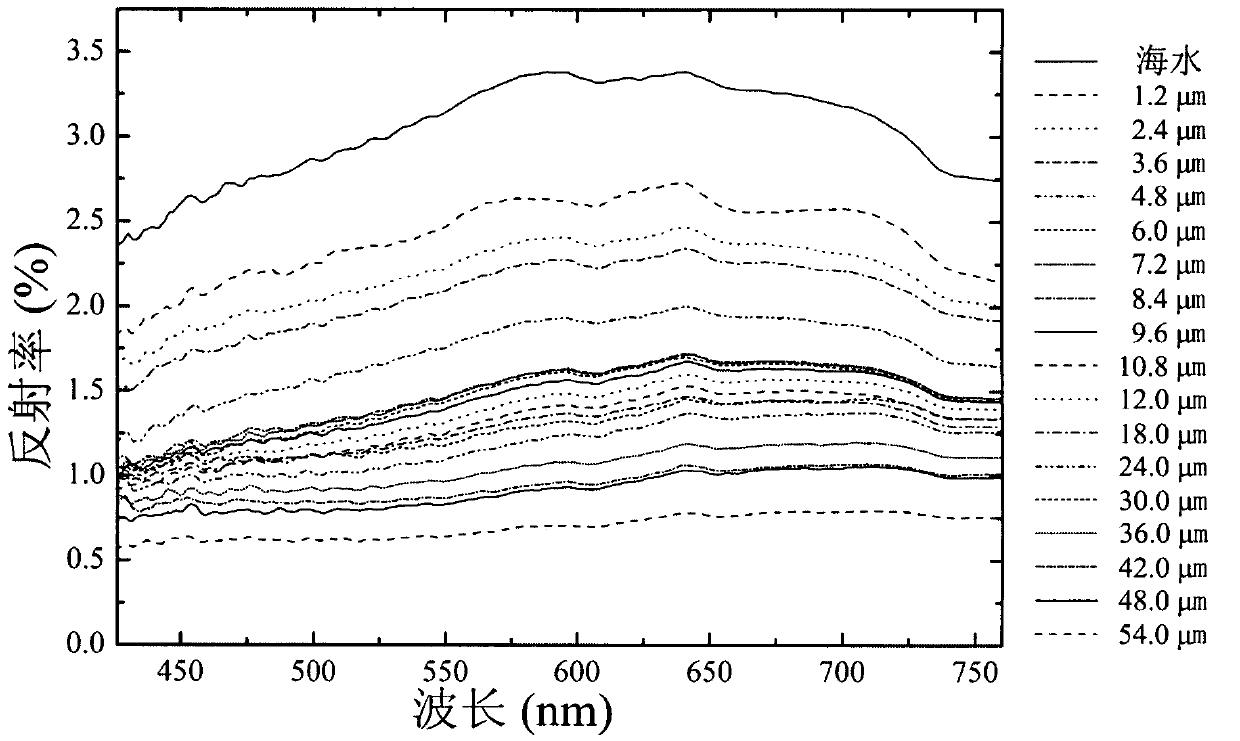

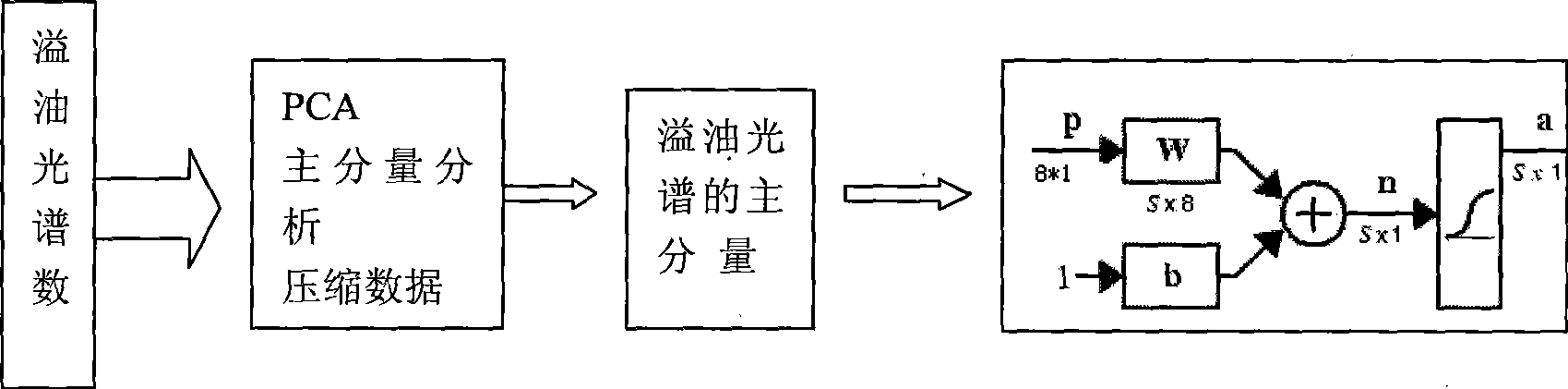

Ocean spilt oil film thickness hyperspectral remote sensing estimation method based on parameter lookup table

InactiveCN102997856AMeet the needs of emergency monitoringEstimation is objective and efficientUsing optical meansPerformance indexKnowledge Field

The invention relates to an ocean spilt oil film thickness hyperspectral remote sensing estimation method based on a parameter lookup table and belongs to the field of ocean environment monitoring research. The method includes the steps of obtaining and pre-processing standard oil film thickness continuous change hyperspectral data by designing a simulation experiment; obtaining and pre-processing ocean spilt oil satellite remote sensing data; resampling a standard oil film spectrum based on a satellite sensor performance index; normalizing spectral reflectivity; building an oil film thickness optical calculating model; building an attenuation parameter lookup table; normalizing the reflectivity of satellite data and conducting mask treatment; inquiring and building an optimal wave band of the satellite data and relevant parameters; and calculating the oil film thickness in the satellite data through the parameter lookup table and the optical model. Compared with a traditional observation means, by means of the ocean spilt oil film thickness hyperspectral remote sensing estimation method, field workload is less, the thickness of the spilt oil film can be quantized, the thickness of an oil film in a spilt oil area can be calculated without entering an ocean spilt oil pollution area, and requirements of ocean split oil emergency monitoring and evaluation can be met.

Owner:NANJING UNIV

Atomized fall type coal paste preprocessor

ActiveCN101773795AAvoid cloggingAchieve repeated dropsFlow mixersTransportation and packagingProcess engineeringSlide plate

The invention relates to an atomized fall type coal paste preprocessor. A sliding plate is fixedly connected to the two sides of a lower tank body of a fall tank, a vertical shaft of a fogging disc is connected with an output shaft of an electric motor, an upper tank body of the fall tank is provided with a central feeding pipe and an overflow launder; wherein the overflow launder is internally provided with baffle plates; a slide plate comprises an upper slide plate and a lower slide plate, a ridged bar is fixedly connected on the slide plate; the vertical shaft of the fogging disc is externally sheathed with a sleeve, the lower part of the sleeve is provided with a chemical feed pipe which is communicated with a chemical feed hopper, the lower end of the chemical feed pipe is placed above the front surface of the fogging disk; a coupler is a flexible coupler. In the invention, the front surface of the fogging disk is the working surface; floating agent automatically flows to the working surface under the action of static pressure, thus avoiding blockage caused by impurities; with the fall tank, repeated fall of coal paste is realized, so that sufficient time is provided to contact and fully mix with the floating agent having gong through atomization and dispersion, thus facilitating formation of enough and stable oil film on the surface of the fogging disk; the slide plate with ridged bars is set with different contact pretreatment time for medium-thickness and fine particles of the coal paste, thus creating fine technological conditions for coal paste pretreatment.

Owner:BEIJING GUOHUA TECH GRP LTD

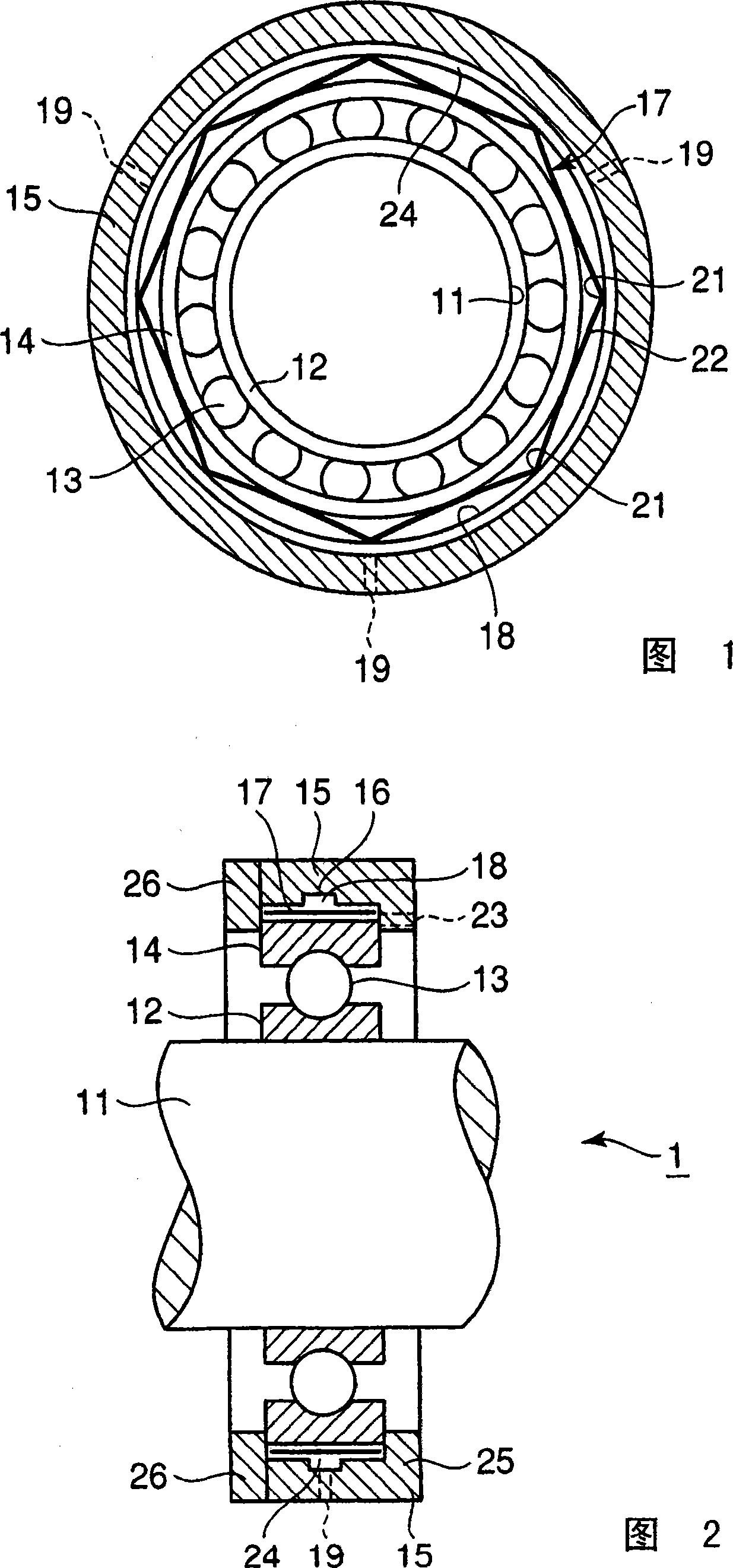

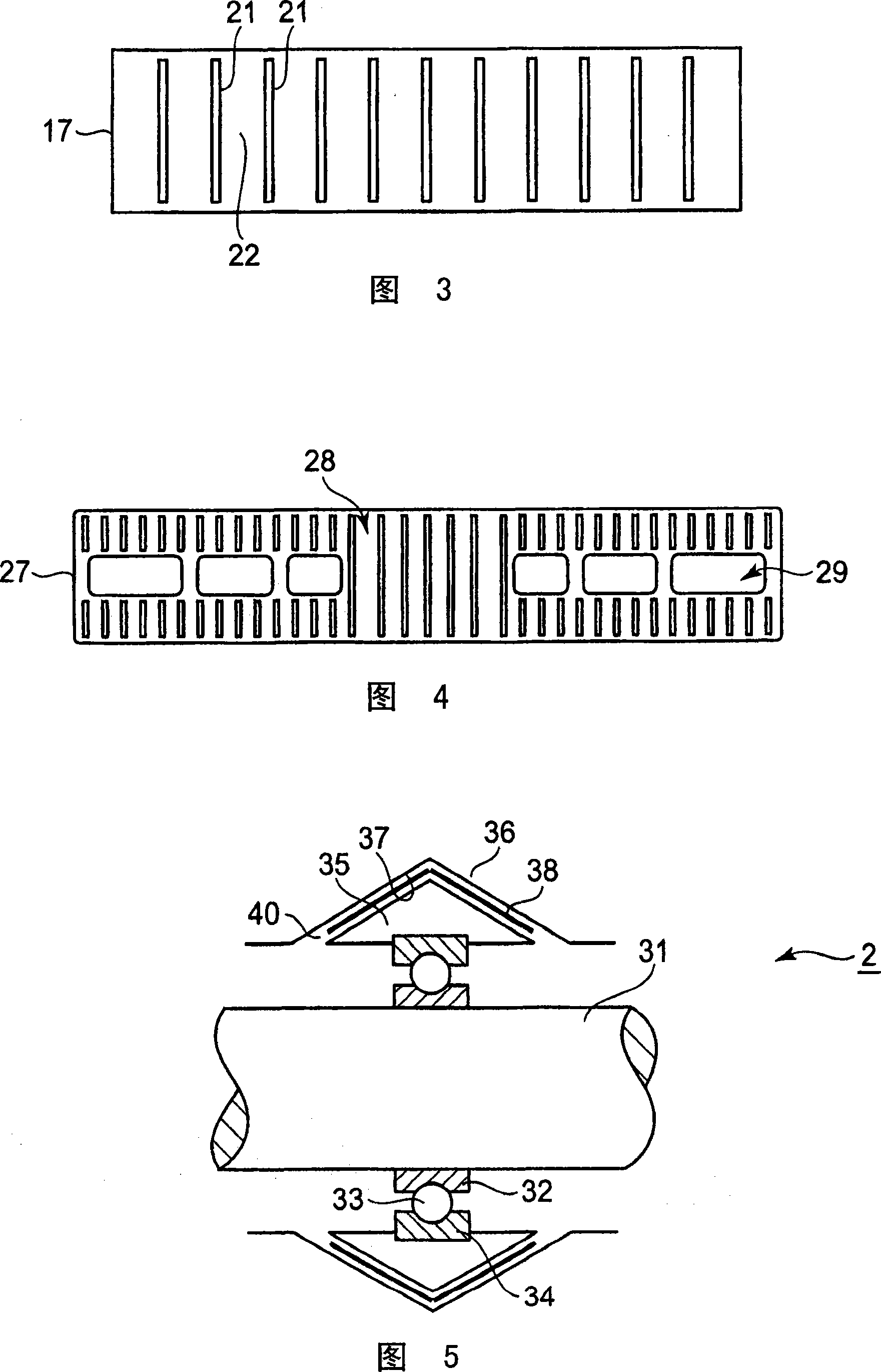

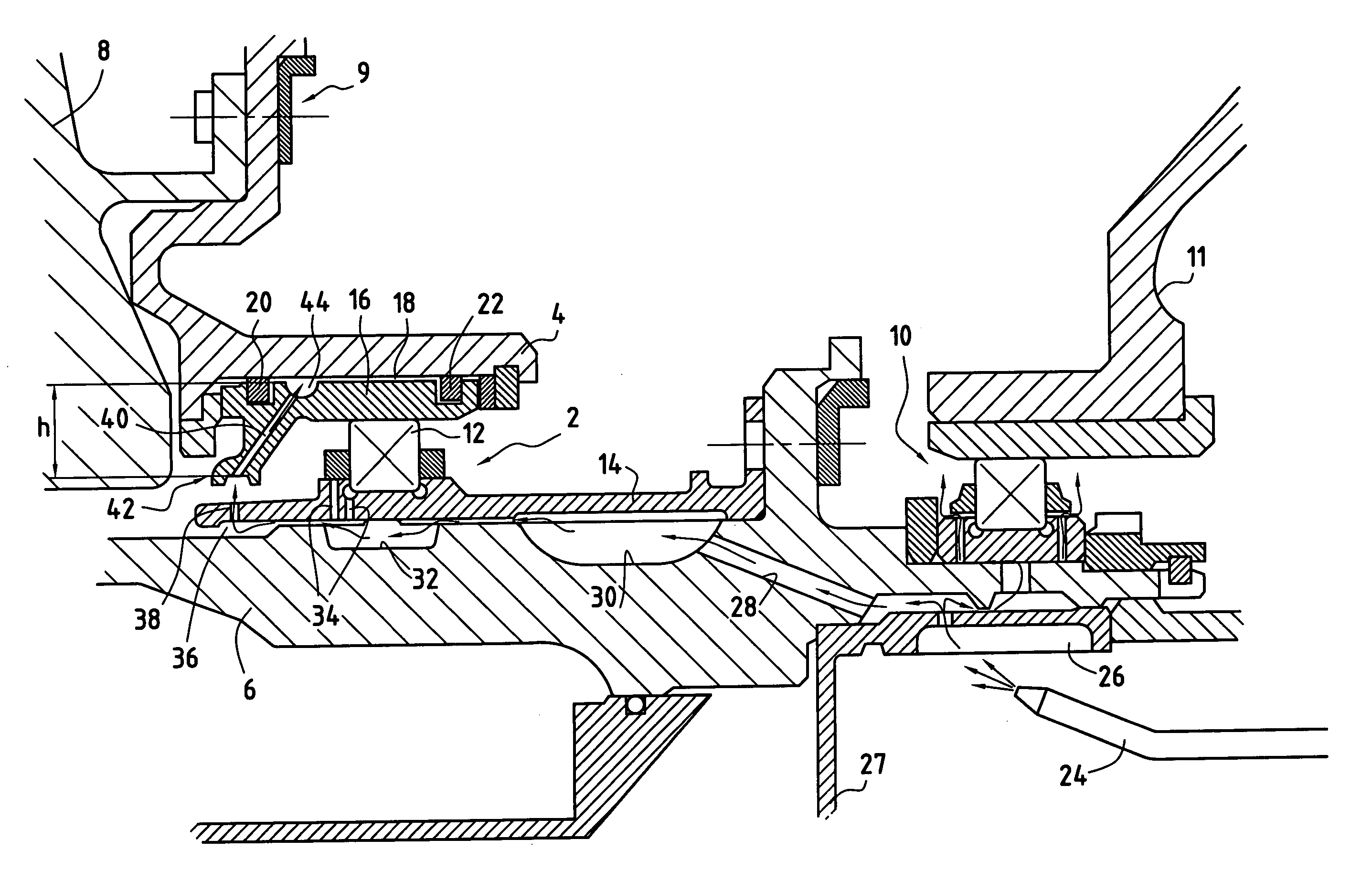

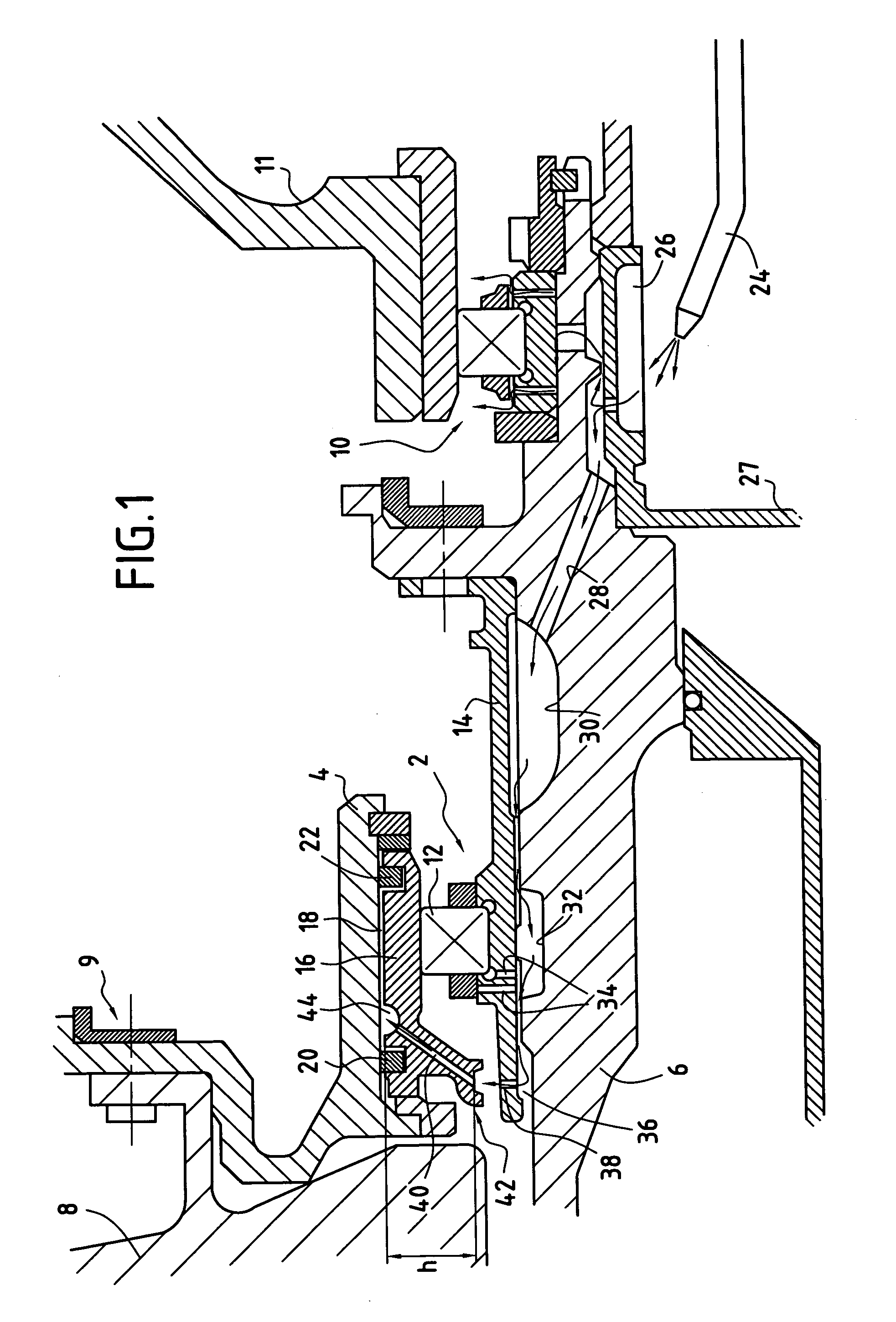

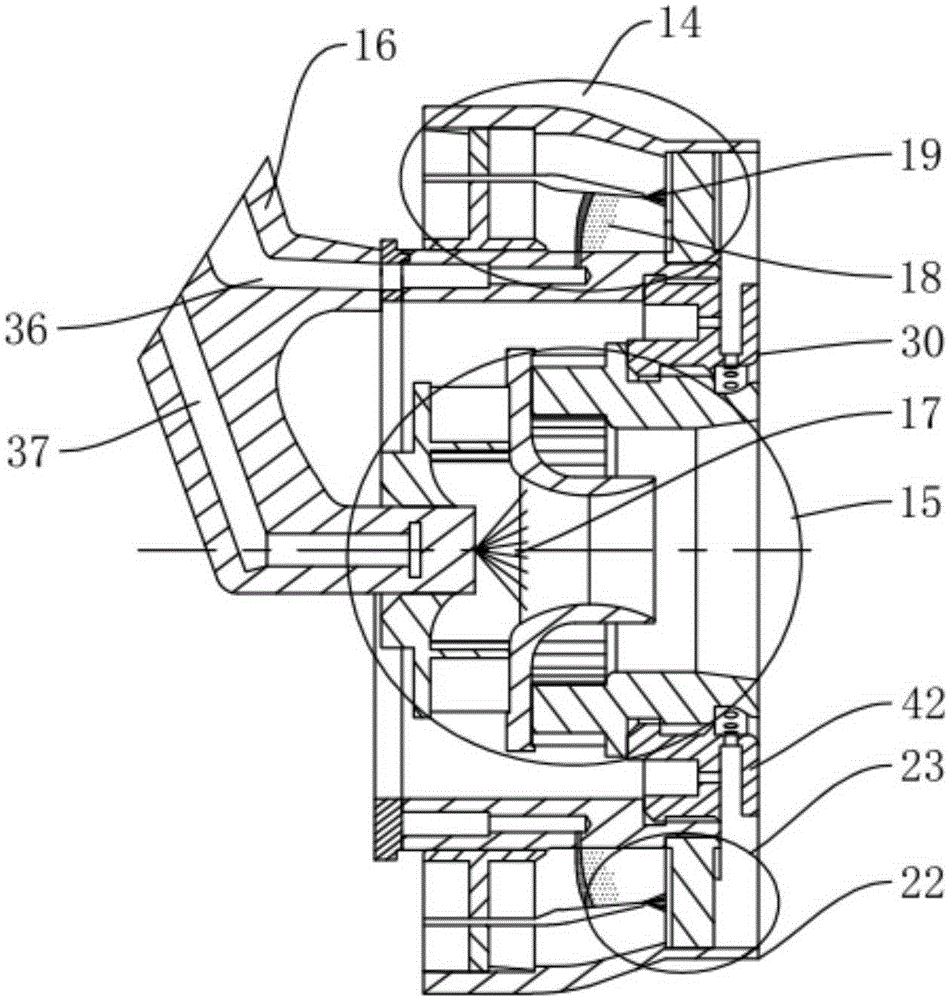

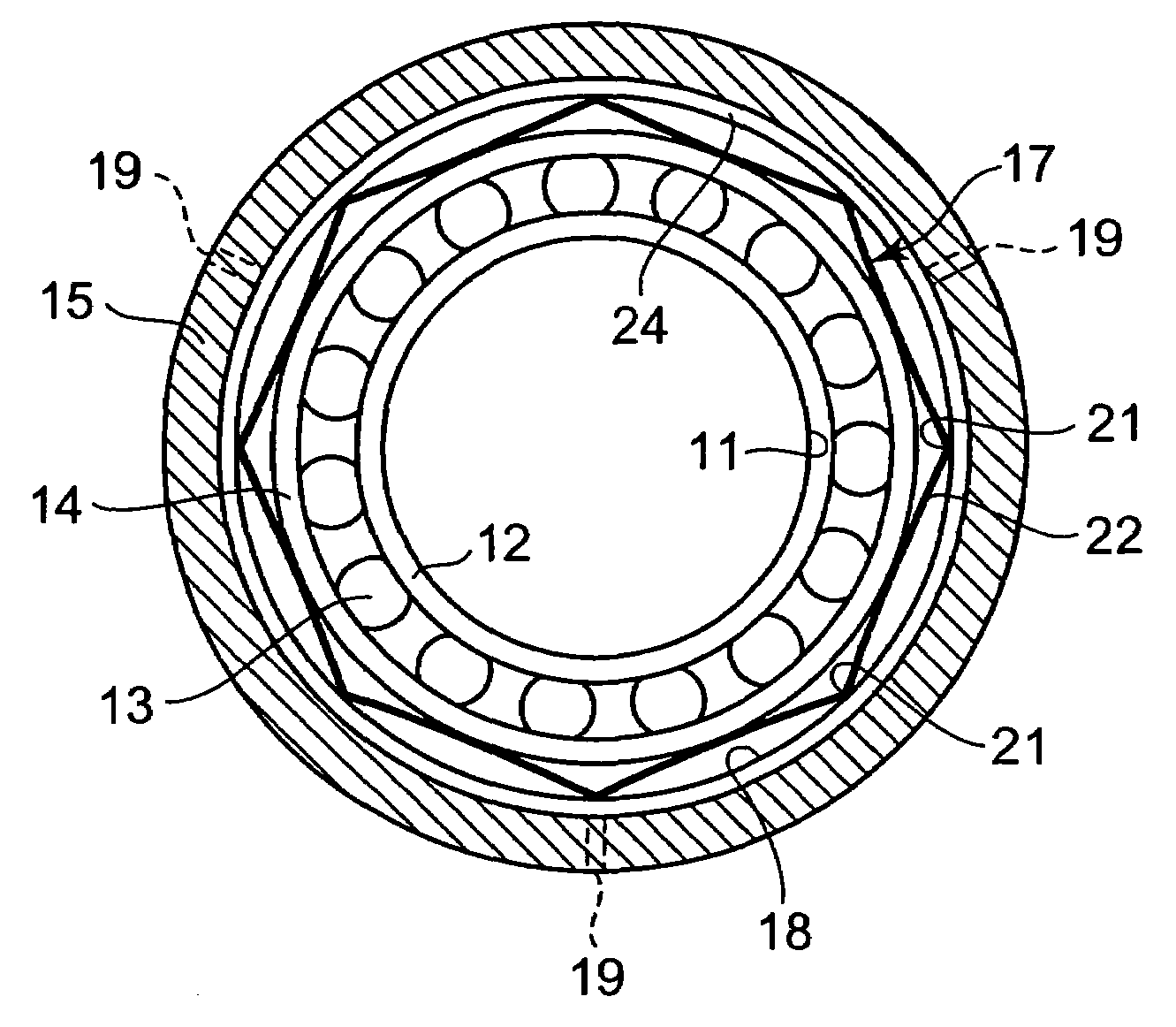

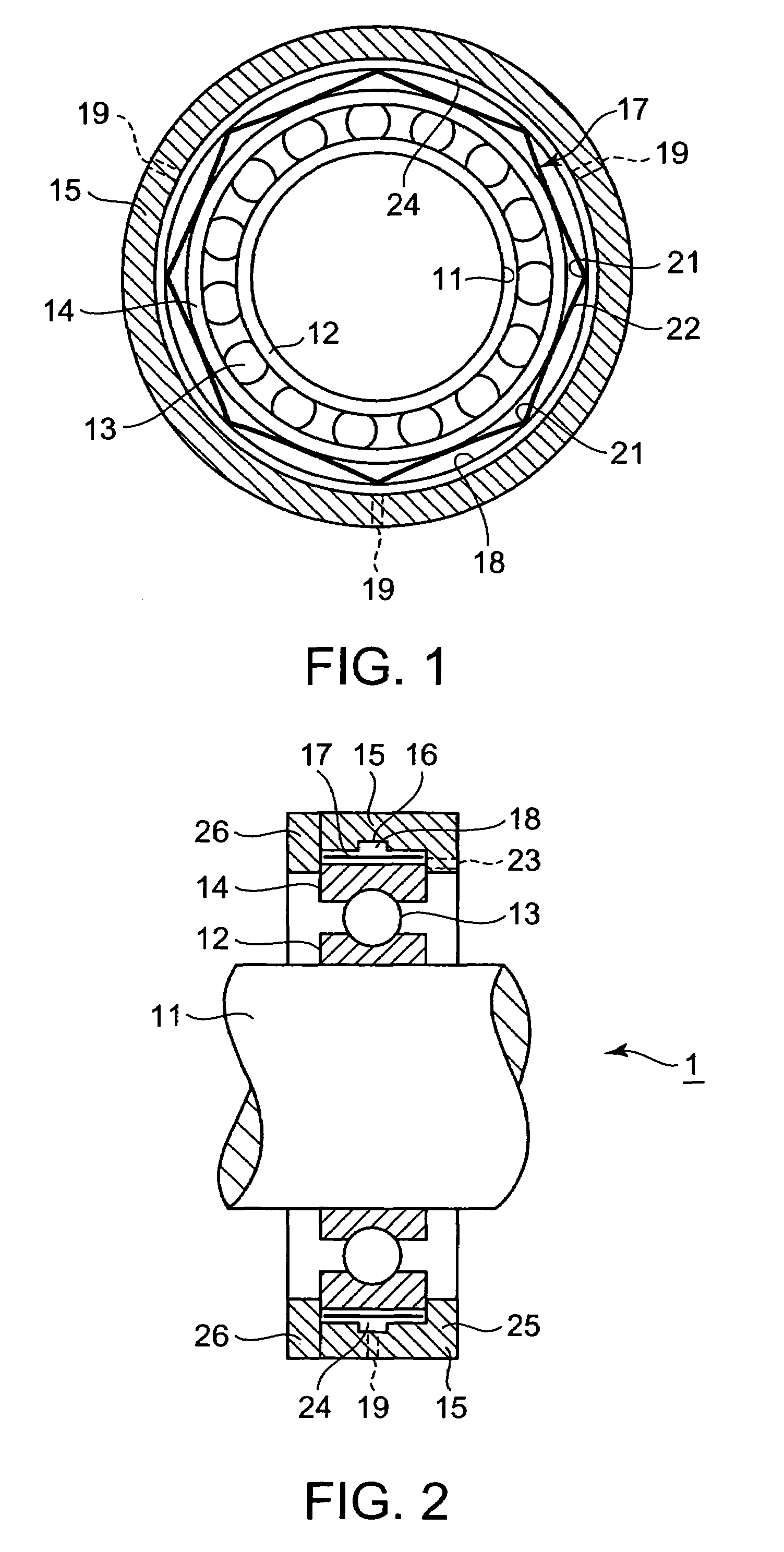

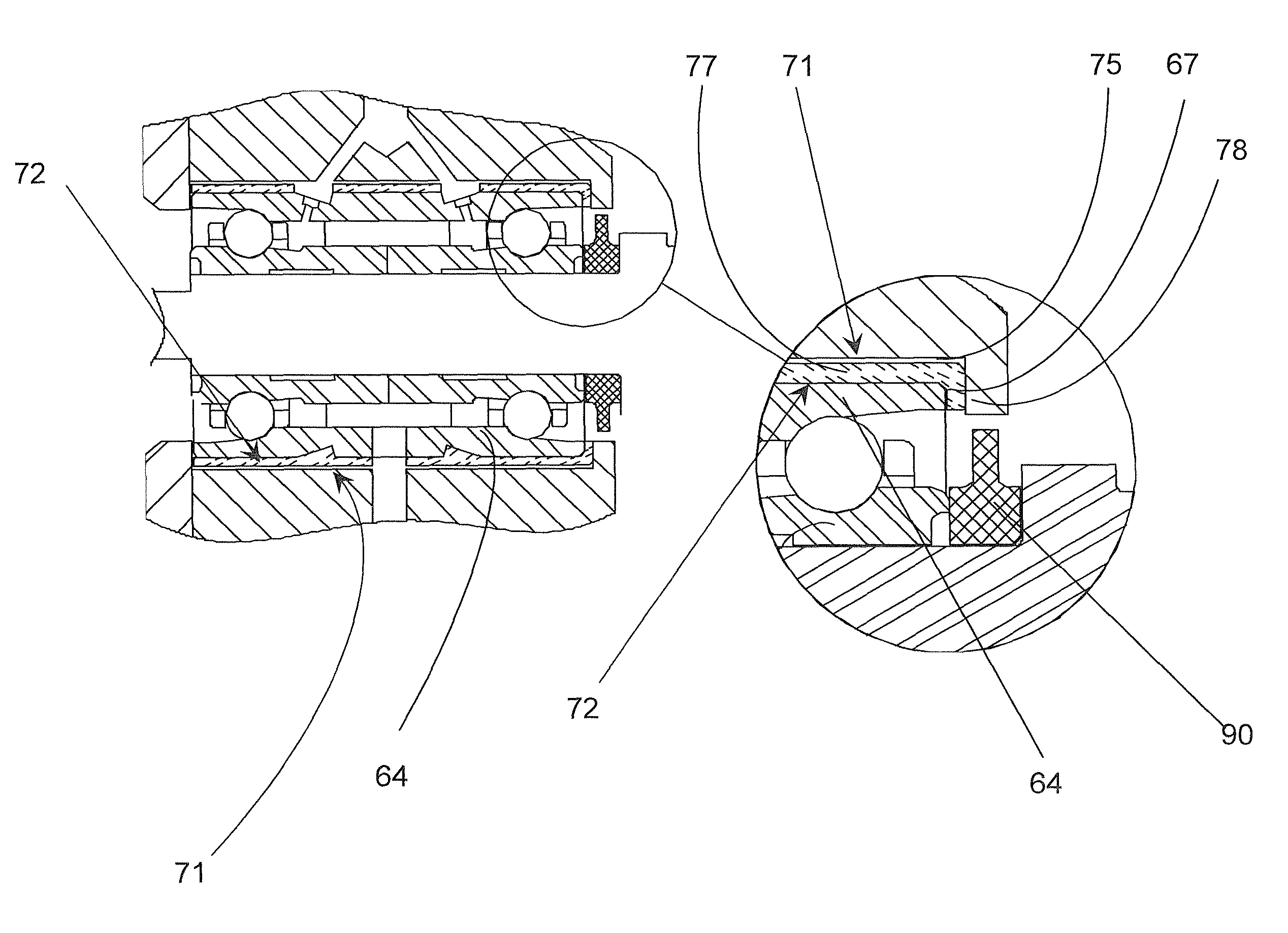

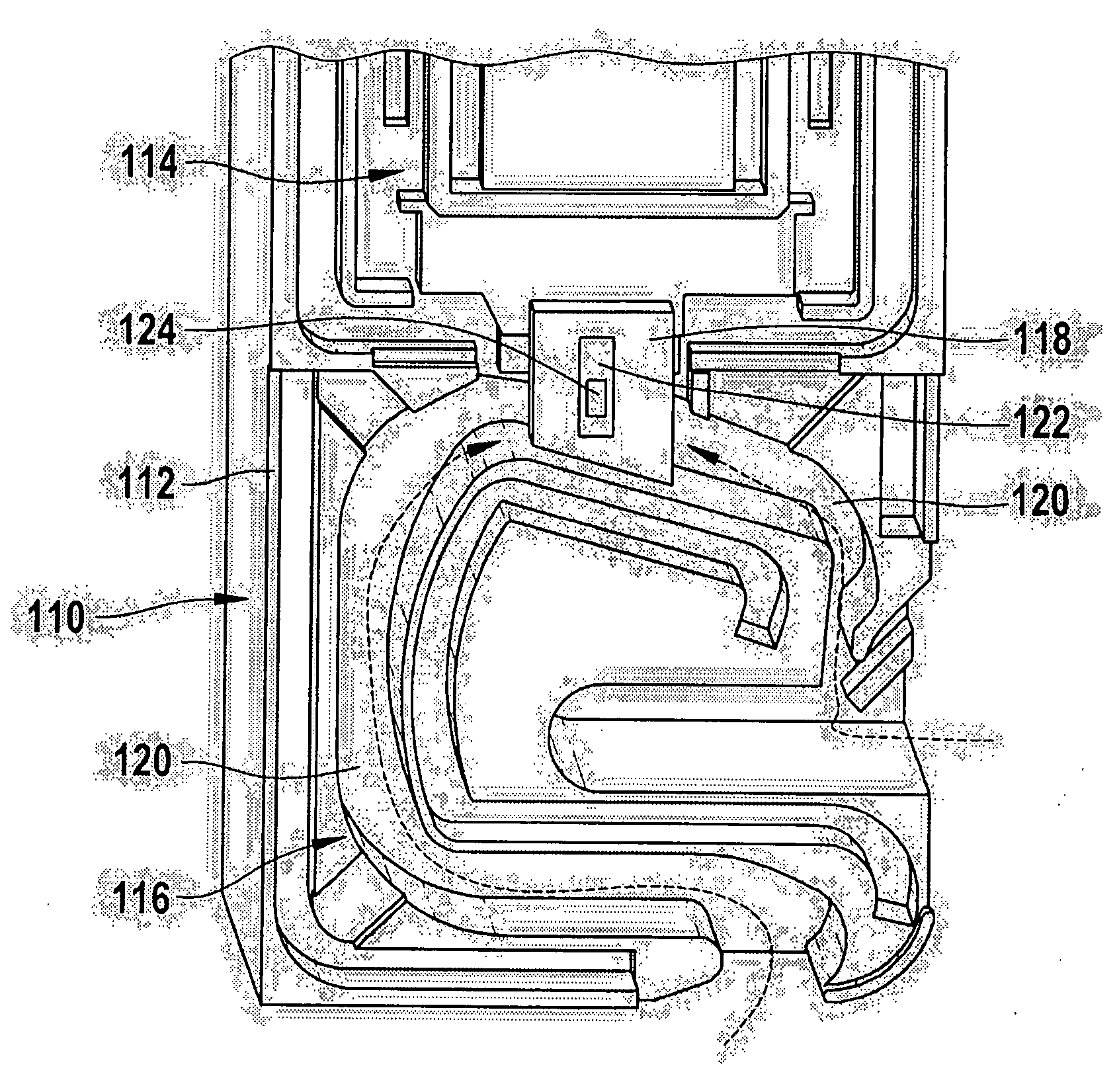

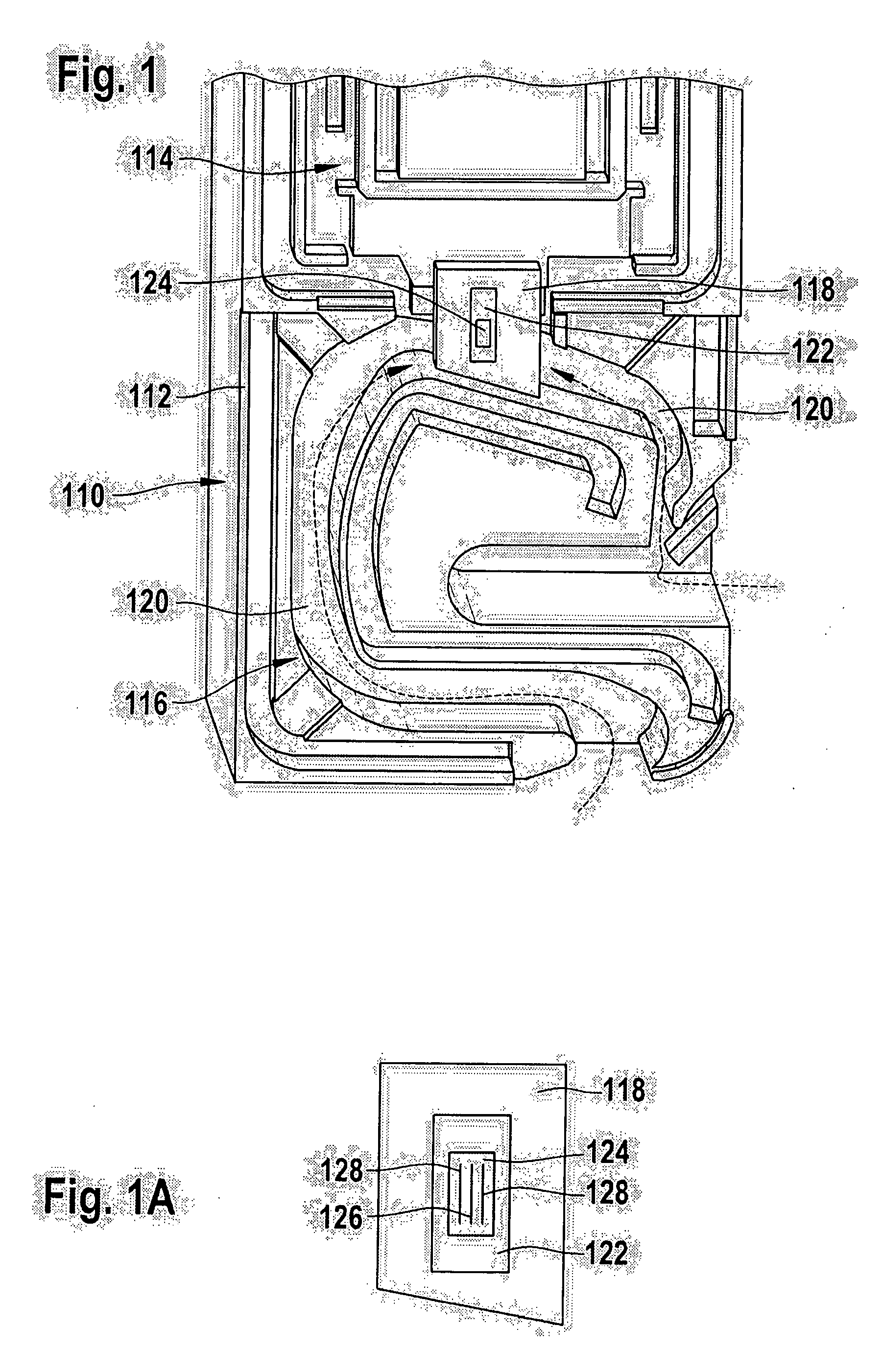

Vibration damping mechanism for bearing

ActiveCN101010521AInhibit sheddingInhibition releaseLeaf springsShaftsRolling-element bearingEngineering

A squeeze film damper bearing easily manufacturable, having excellent productivity, and reduced in size and a vibration damping mechanism for the rolling bearing capable of having an effect on loads in two of radial and thrust directions. In the vibration damping mechanism (1) for the rolling bearing, a storage hole (16) having a diameter larger than the diameter of the outer periphery (14) of the bearing is formed on the inside of a housing (15) and an oil supply hole (19) supplying an oil into the storage hole is formed in the wall of the housing (15), the bearing is inserted into the storage hole to form an annular clearance (18) on the outer periphery of the bearing, and a thin flat plate (17) having a plurality of slits is inserted into the annular clearance along the circumferential direction. The portions of the thin flat plate held by the slits are formed in an elastic beam to elastically support the bearing at a center position, and the vibration of the bearing is damped by a squeeze film action caused by an oil film generated by supplying the oil into the annular clearance.

Owner:KAWASAKI JUKOGYO KK

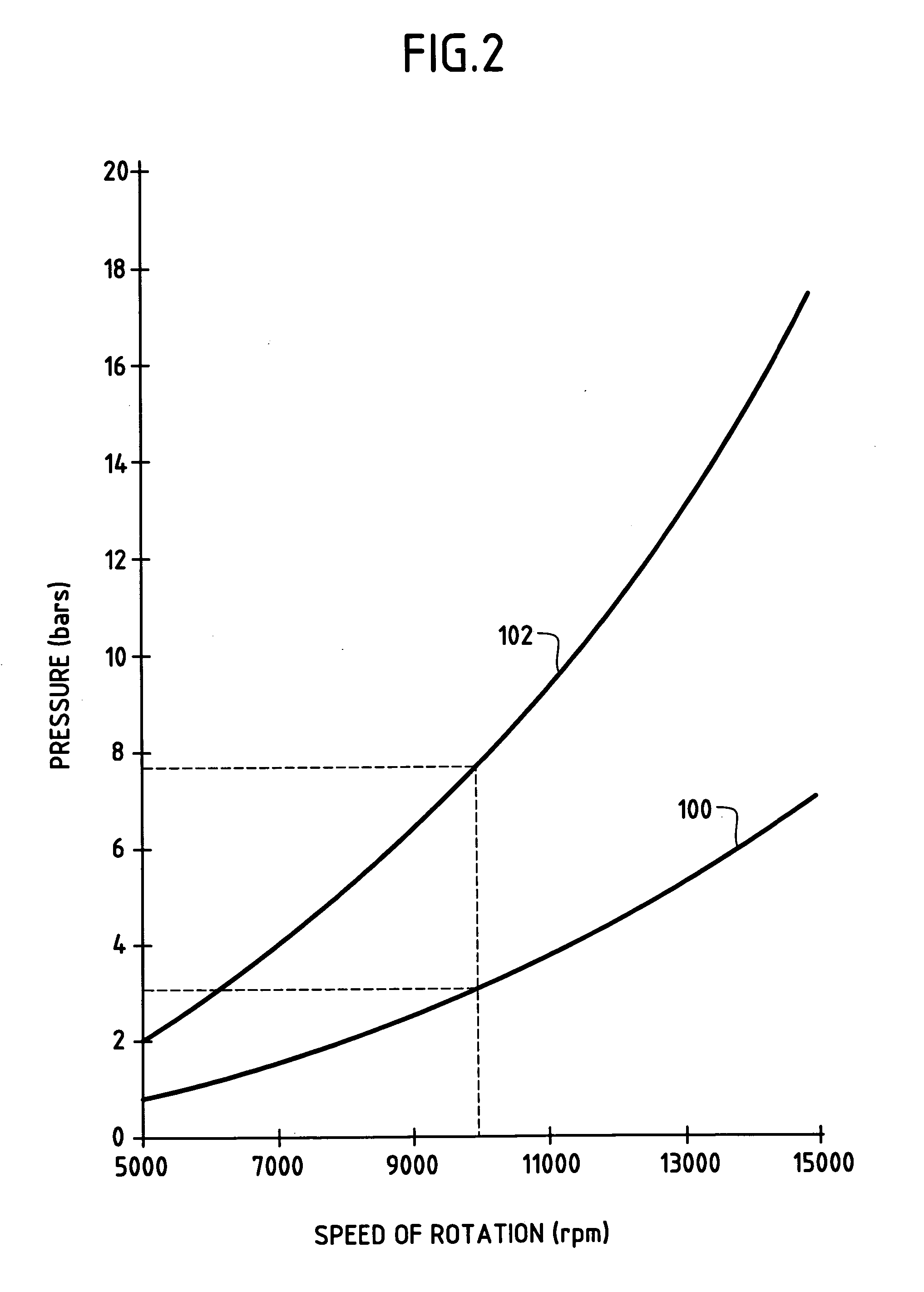

Oil-damped rolling bearing

ActiveUS20040062460A1Mitigate such drawbackRoller bearingsPump componentsRolling-element bearingEngineering

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

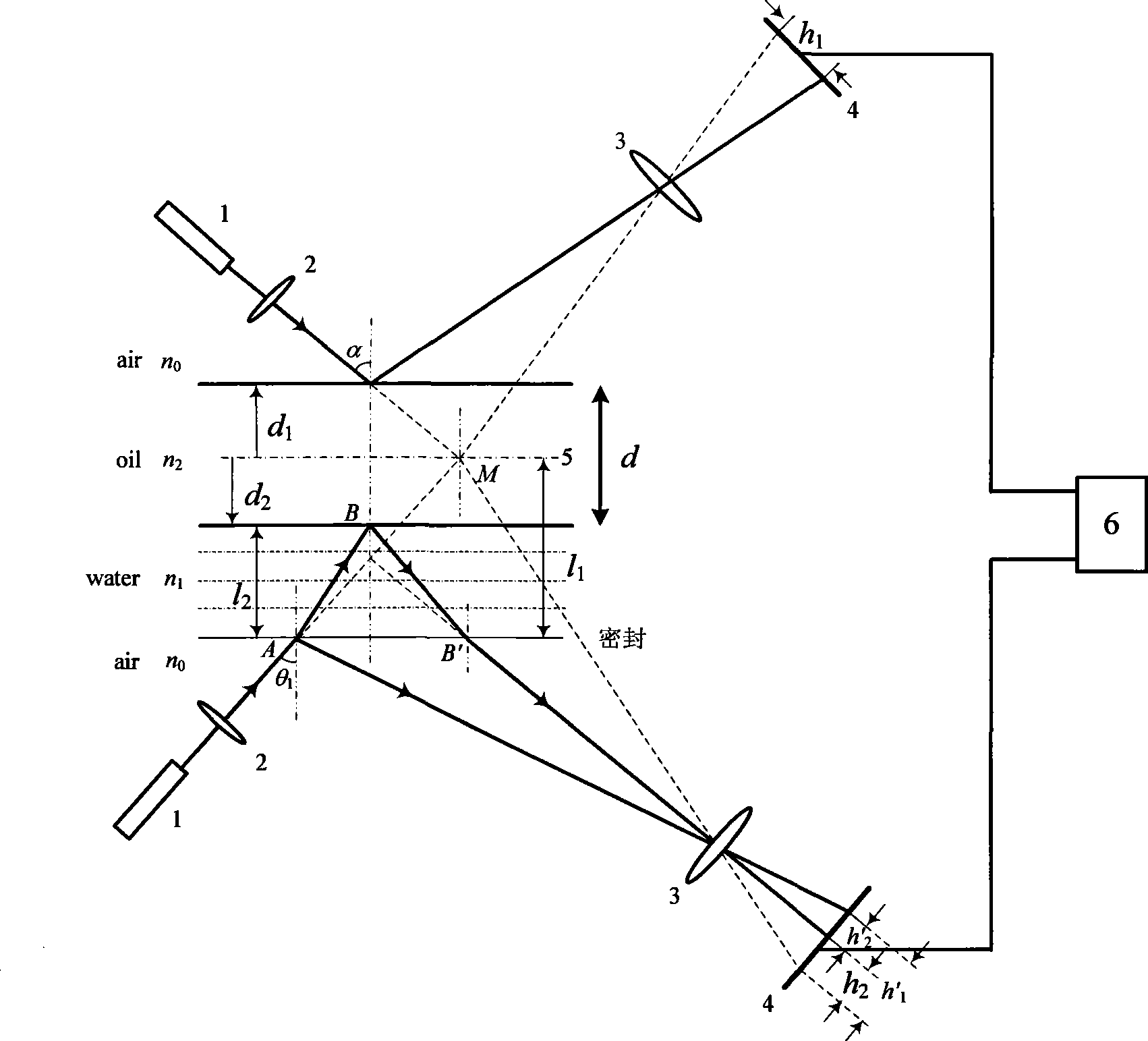

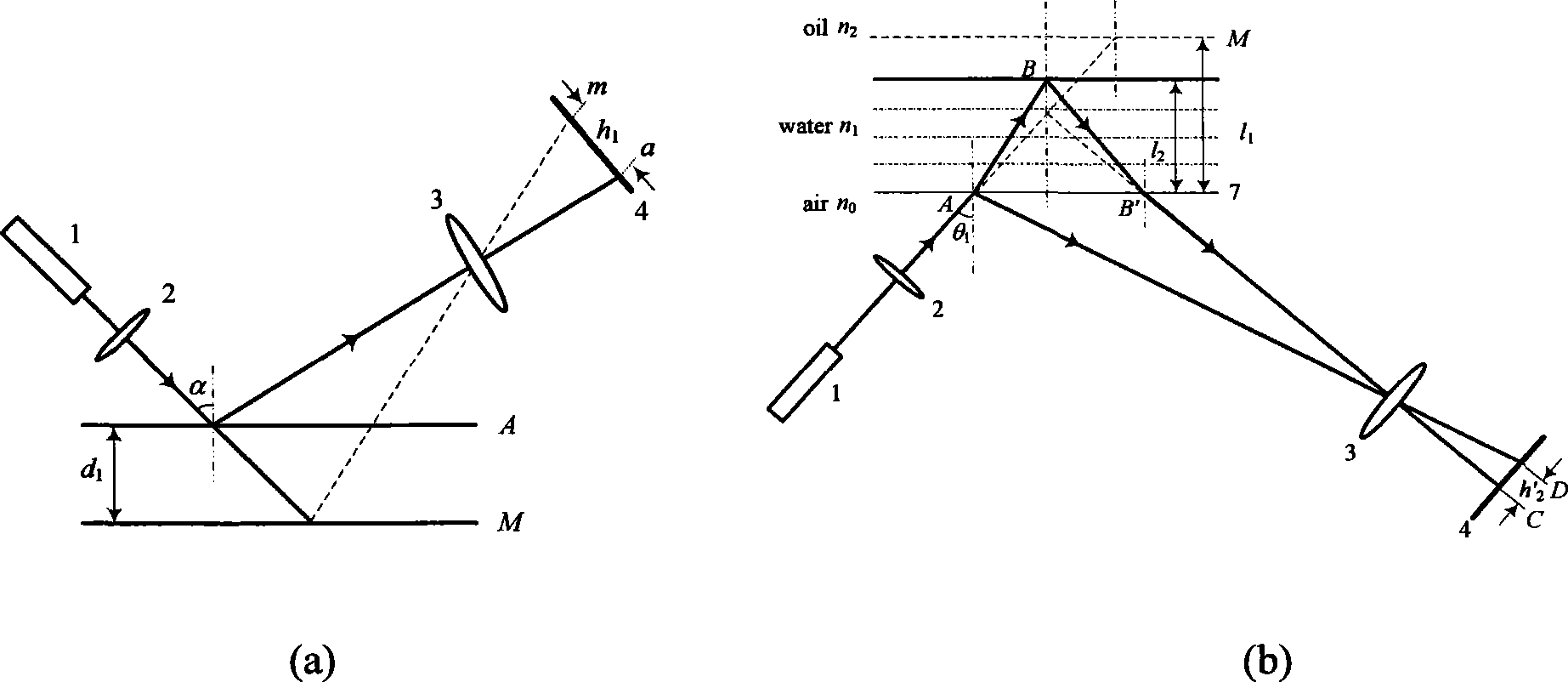

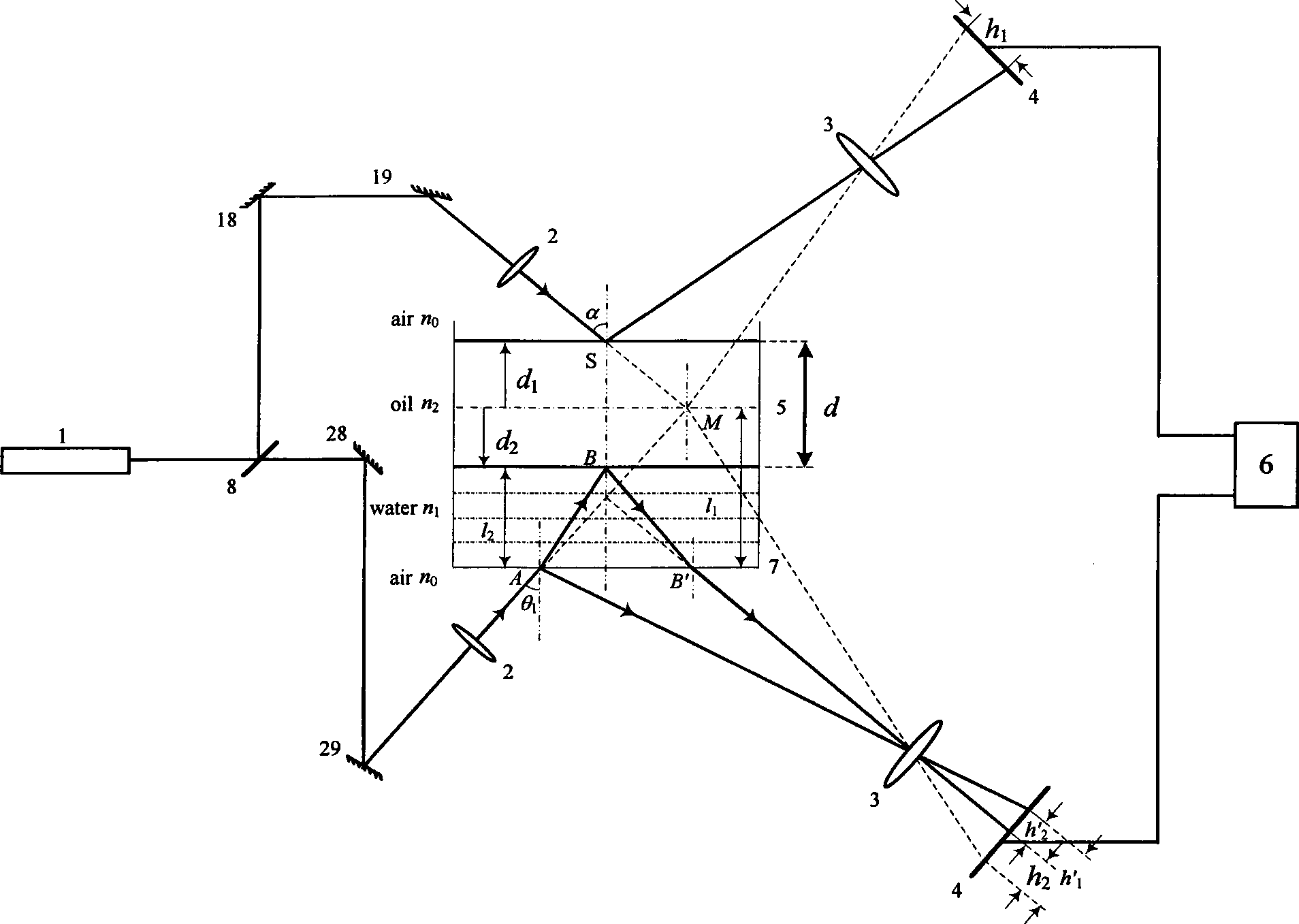

Method for measuring thickness of sea surface spilled oil film based on differential laser triangulation method

InactiveCN101532825AThe principle is simpleEasy to measureUsing optical meansAqueous solutionLaser beams

The invention relates to a method for measuring thickness of sea surface spilled oil film based on differential laser triangulation. The method uses dual laser triangulation ranging system, and laser beams emitted by two lasers are respectively irradiated to the upper and the lower surfaces of an oil film to be measured in any vertical direction; the off-plane displacements of the upper and the lower surfaces can be obtained simultaneously according to the size of image drift and configuration parameters of imaging system; the thickness of the measured oil film can be determined by subtracting; and the thickness distribution of oil film in spilled oil area can be obtained by multi-point sampling. The non-contact measuring method has the characteristics of simple theory, convenient measurement, low cost, high precision, small volume and the like, and can be applied to dynamic on-line measurement of oil film thickness at the surface of aqueous solution.

Owner:TIANJIN UNIV

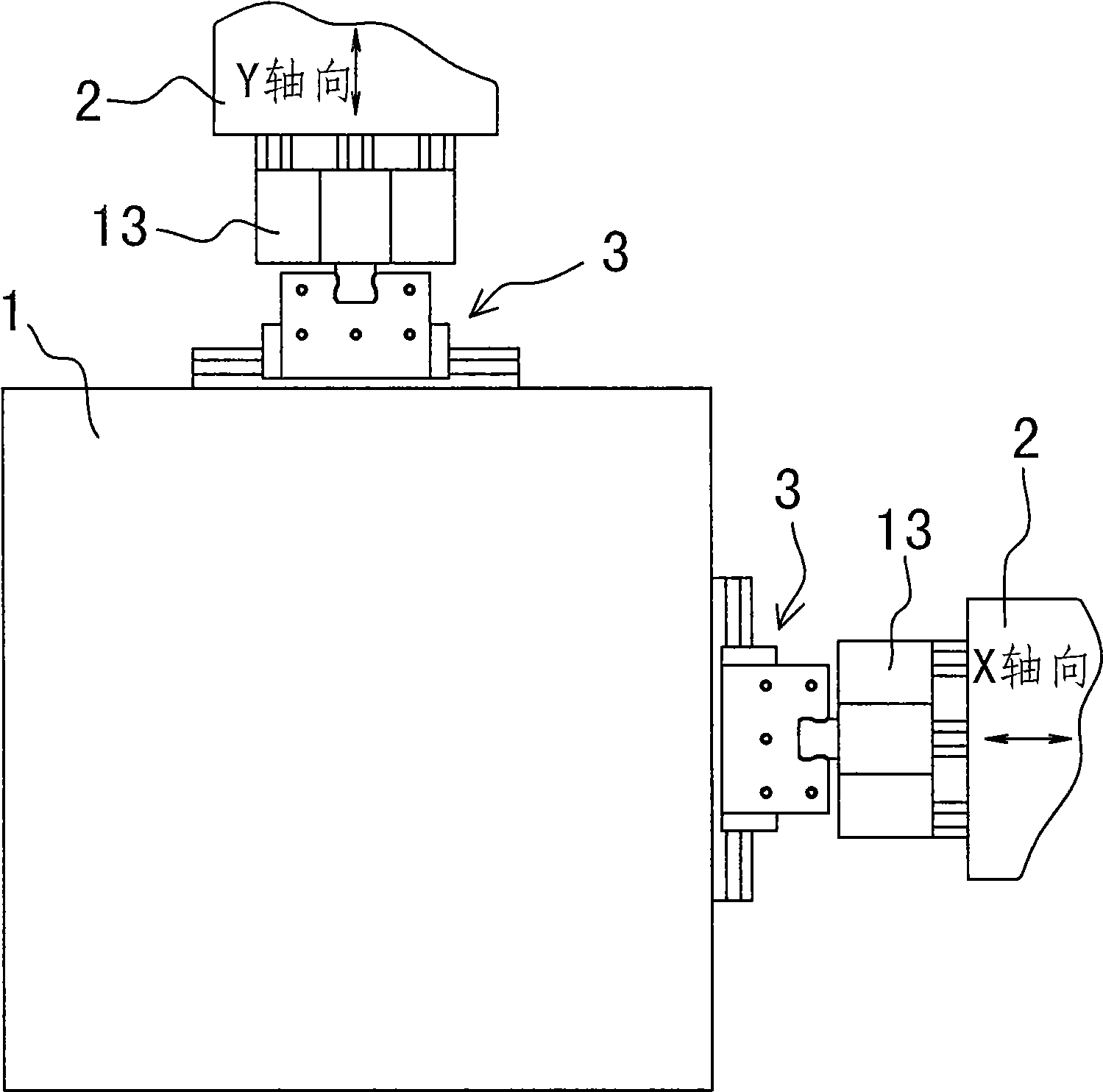

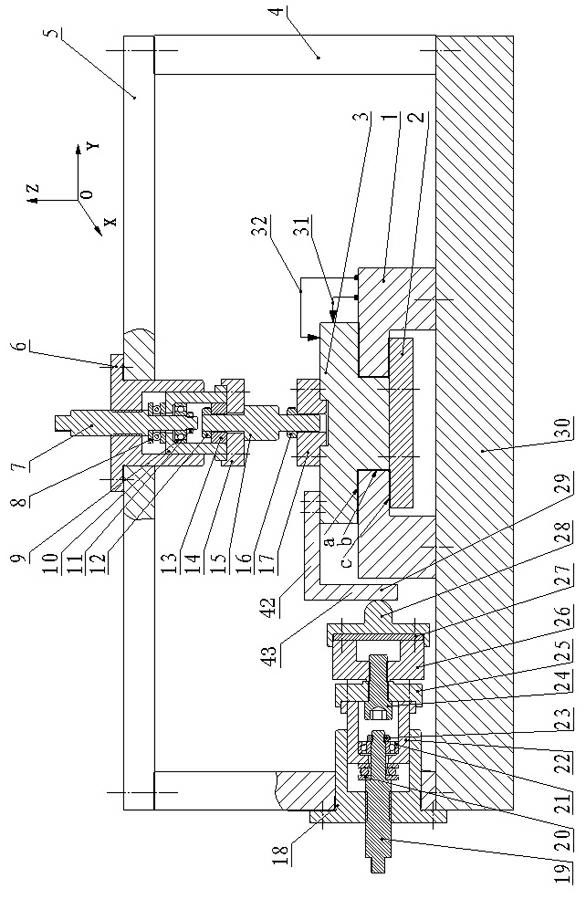

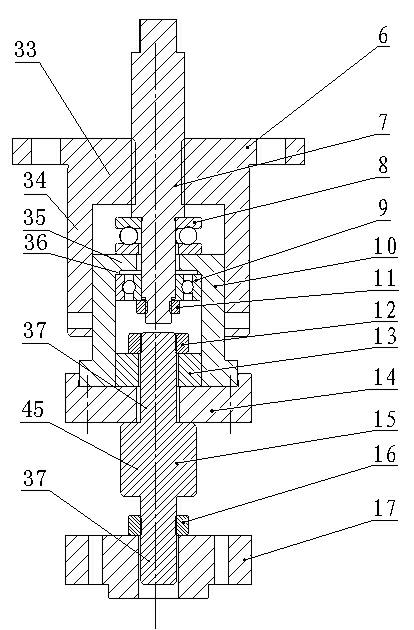

Method and device for testing axial rigidity and radial rigidity of rotary hydrostatic guide rail

The invention provides a method and device for testing axial rigidity and radial rigidity of a rotary hydrostatic guide rail. A rotary guide rail seat is fixed on a platform, a pressing plate and a rotary assembly are fixedly connected to form a rotary part, and the rotary part is used for guiding in a rotary motion way by depending on a hydrostatic guide rail pair; an axial load assembly comprises a flange sleeve, a screw rod, a thrust bearing, a radial bearing, a sleeve, a connecting piece, force sensors and a terminal pad which are vertically arranged; a radial load assembly comprises a flange sleeve, a screw rod, a thrust bearing, a radial bearing, a sleeve, a connecting piece, a force sensor, a loading piece and a connection bending plate which are horizontally arranged; and a mounting support of a displacement sensor assembly is fixed on the rotary guide rail seat, and a measuring head aligns to the rotary assembly. The method and device provided by the invention can be used for acquiring the axial and the radial rigidity data of the hydrostatic guide rail in a rotary motion and can also be used for an confirmatory experiment on a method for analyzing the rigidity of the hydrostatic guide rail in the rotary motion and the influence of oil film tangential adhesive force.

Owner:XIAN UNIV OF TECH

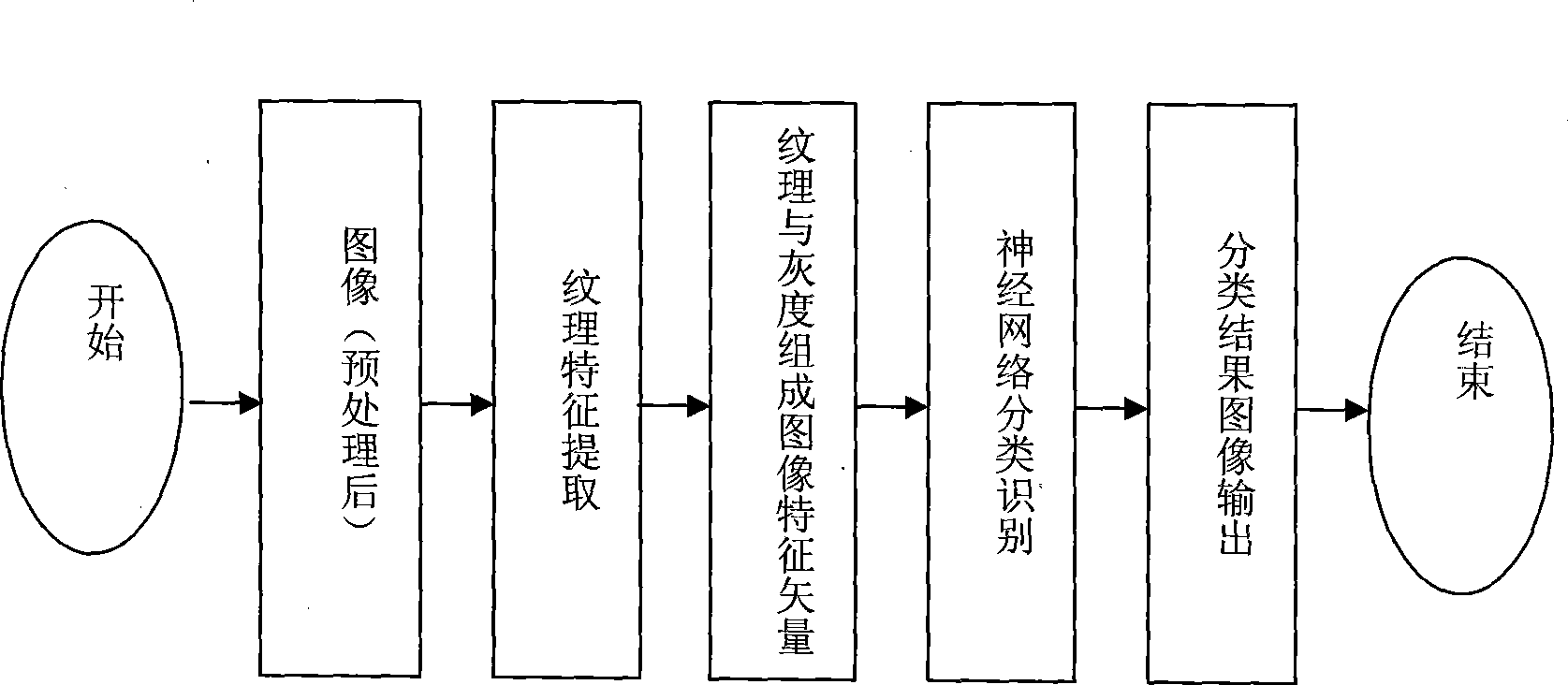

Portable airborne offshore oil overflowing remote sense monitoring system

InactiveCN101414009ASimple equipmentEstimating the amount of oil spilledOptical detectionMaterial analysis by optical meansImaging processingSoftware system

The invention provides a portable airborne marine oil spill remote sensing monitoring system, and relates to the marine pollution monitoring field. The system comprises an infrared / ultraviolet / multispectral digital camera, a central control and display system as well as a data management and image processing operation software system. The central control and display system records image information acquired by the infrared / ultraviolet / multispectral digital camera, and superposes the information with an electronic chart for on-line or off-line track playback; and the data management and image processing operation software system which is arranged in a portable industrial control computer of the central control and display system reads the image information, identifies oil spill on line, computes contaminated area on line and identifies thick oil film. The system has the advantages that the portable airborne marine oil spill remote sensing monitoring system can be expediently equipped on various ocean patrol planes without power supply from the planes; when a marine oil spill accident happens, the system can track the marine oil spill in real time, estimate oil spillage and the contaminated area, and evaluate the oil spill elimination effect.

Owner:DALIAN MARITIME UNIVERSITY

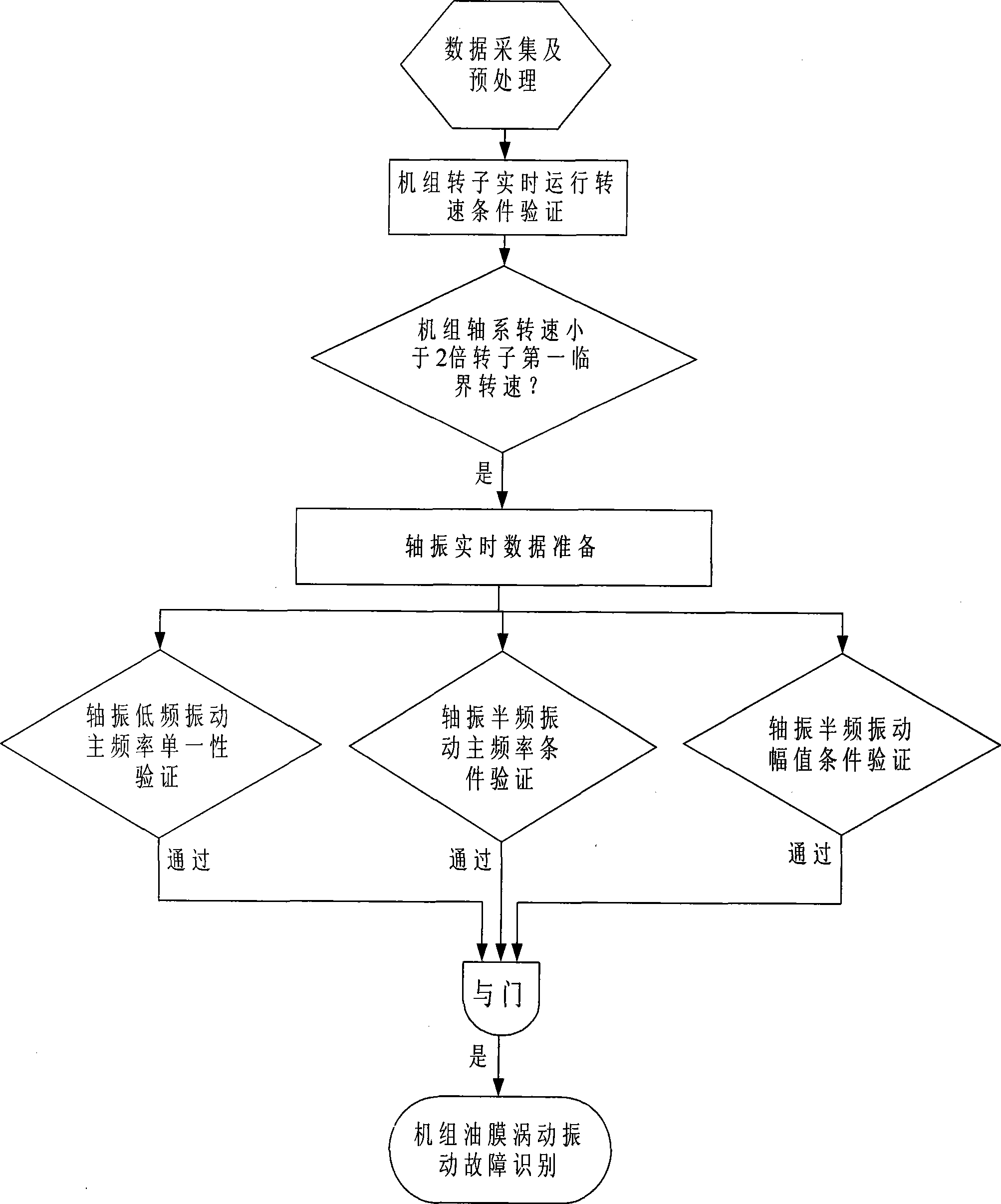

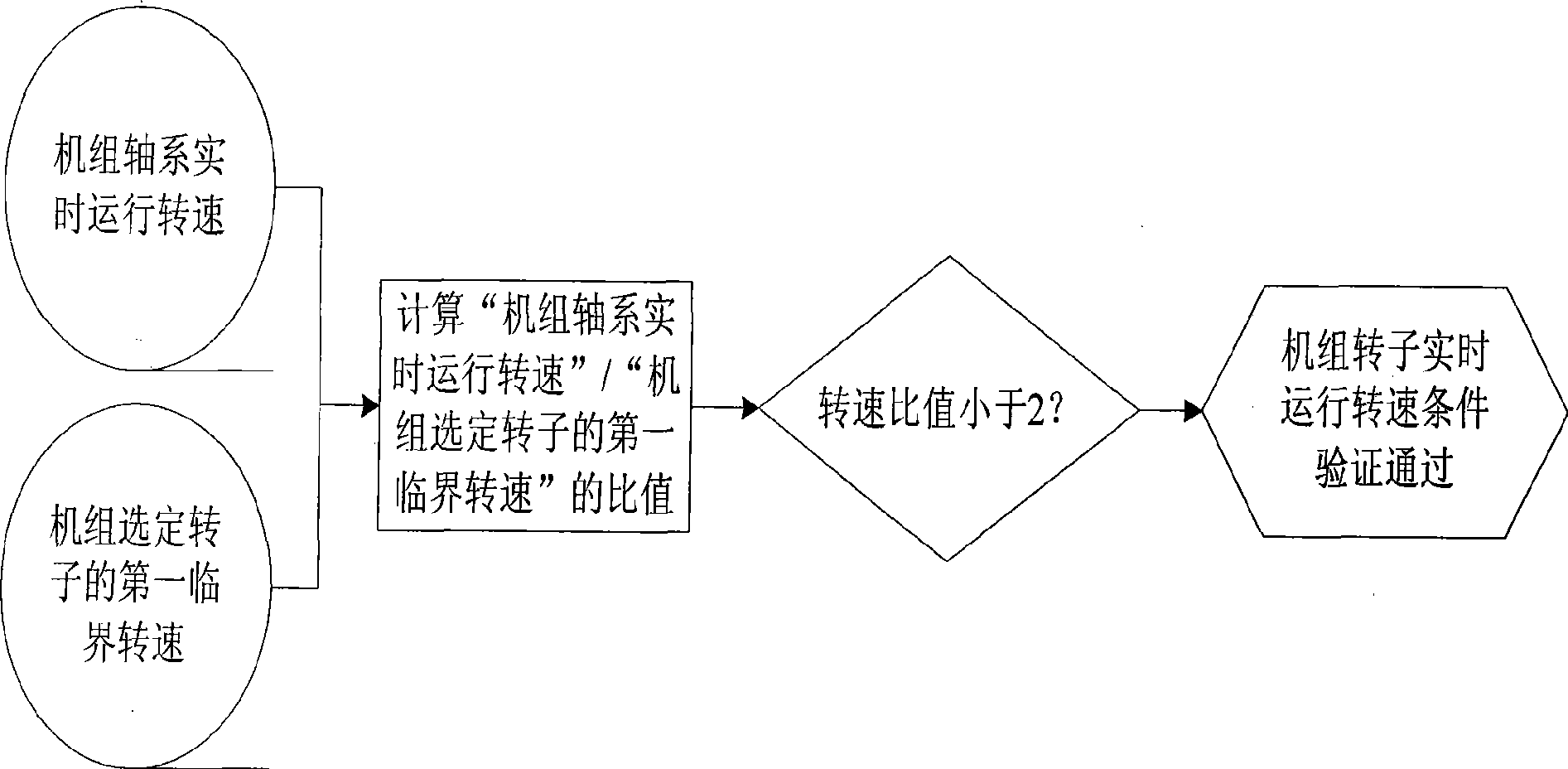

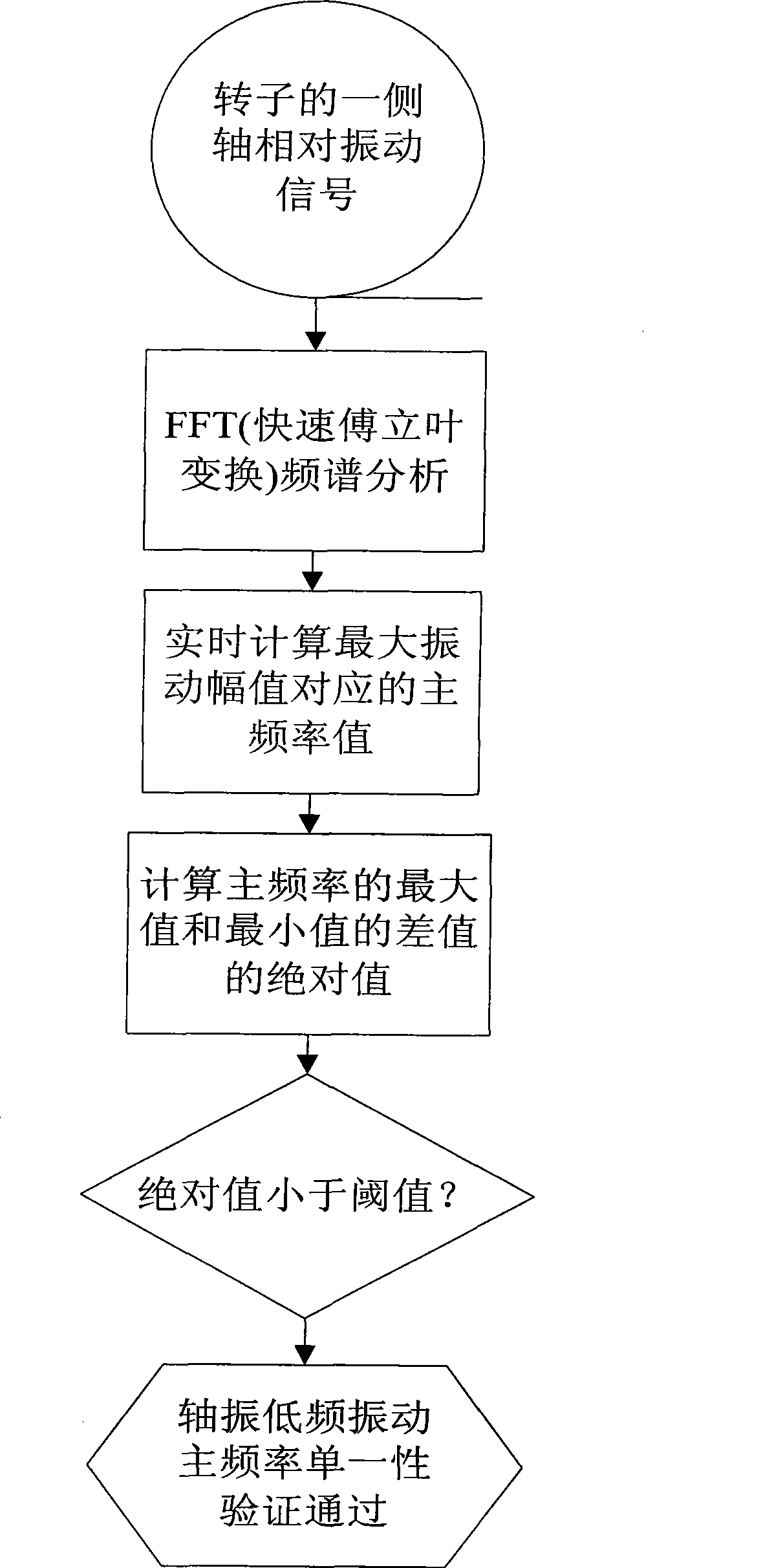

Real-time diagnosis method for oil film whirl fault of large steam turbine-generator

InactiveCN101430239AMethod scienceConclusion scienceEngine testingVibration testingVibration amplitudeFrequency spectrum

The invention discloses a real-time oil film whirling fault diagnosis method for a large steam turbine generator set, belongs to the fields of mechanical vibration state monitoring and fault diagnosis, and relates to the real-time online monitoring of the vibration state of the large steam turbine generator set. The method comprises the following steps: collecting vibration signals of a rotor shaft of a steam turbine set to carry out necessary data preprocessing on vibration data, judging that the rotating speed of a shaft system of the set is less than twice of a first critical rotating speed of a rotor, further combining the Fast Fourier Transform (FFT) spectrum analysis method to carry out the real-time quantitative computation and analysis of the shaft vibration data such as unicity verification of the main frequency for the low frequency vibration of the shaft vibration, condition verification of the main frequency for the half-frequency vibration of the shaft vibration, the condition verification of the half-frequency vibration amplitude of the shaft vibration and the like, and automatically diagnosing whether an oil film whirling fault occurs in the set based the real-time quantitative computation and analysis and in conjunction with various verification results in a real-time and online manner. The method has the advantages of scientificness, reliable conclusion, automatic realization of the real-time online monitoring and fault diagnosis and the like.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

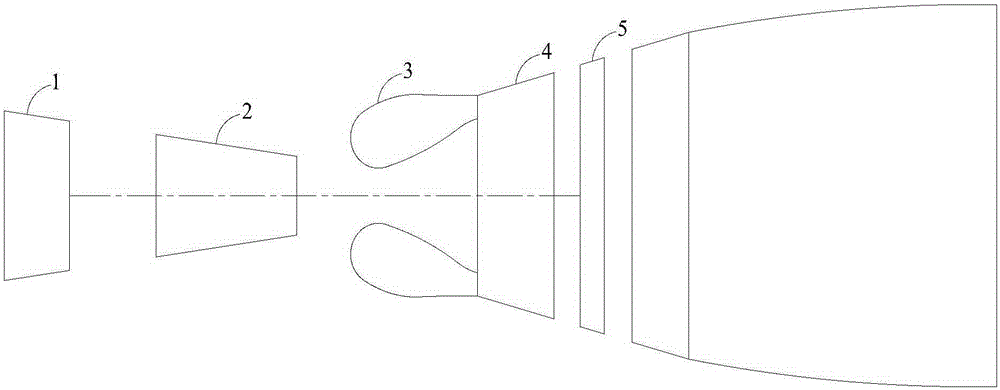

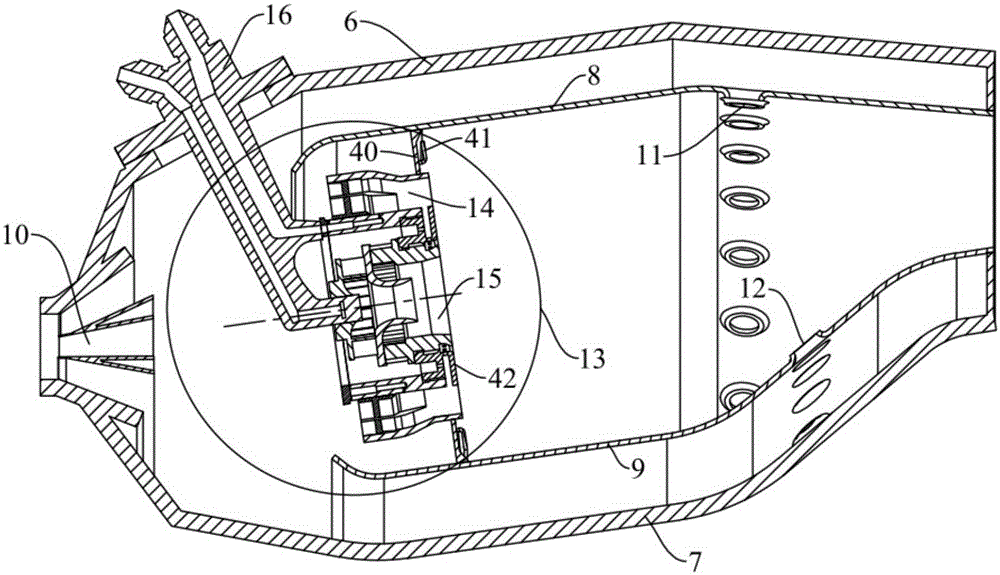

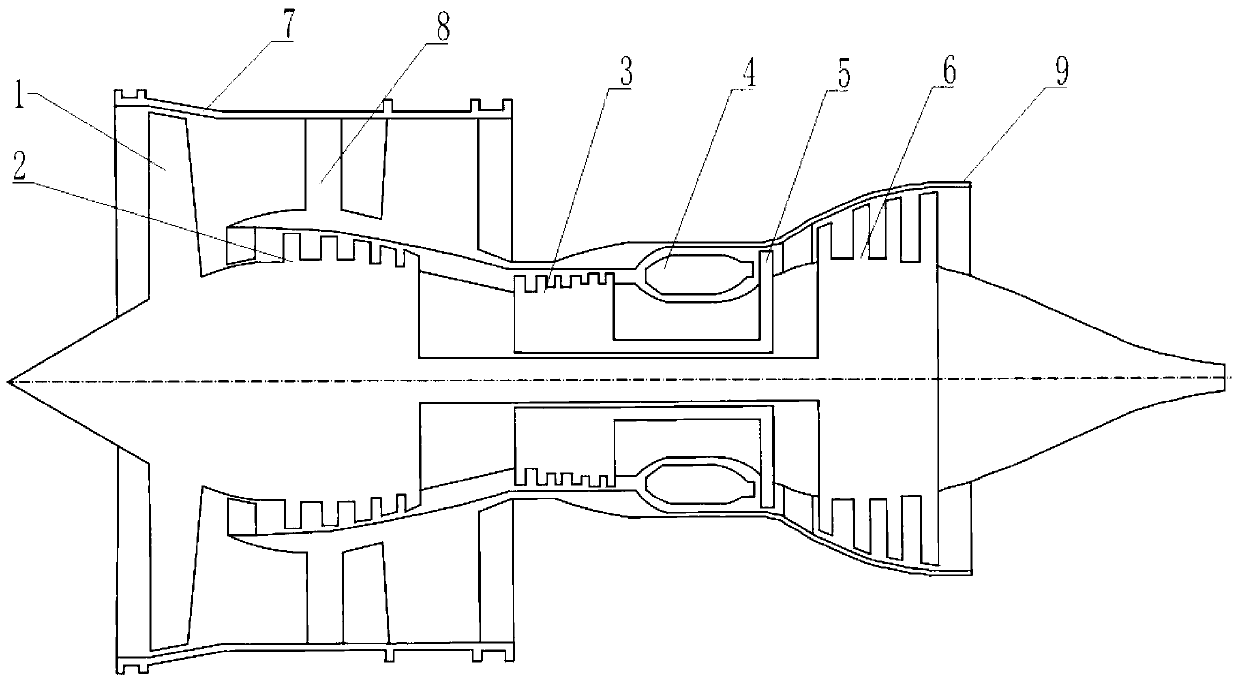

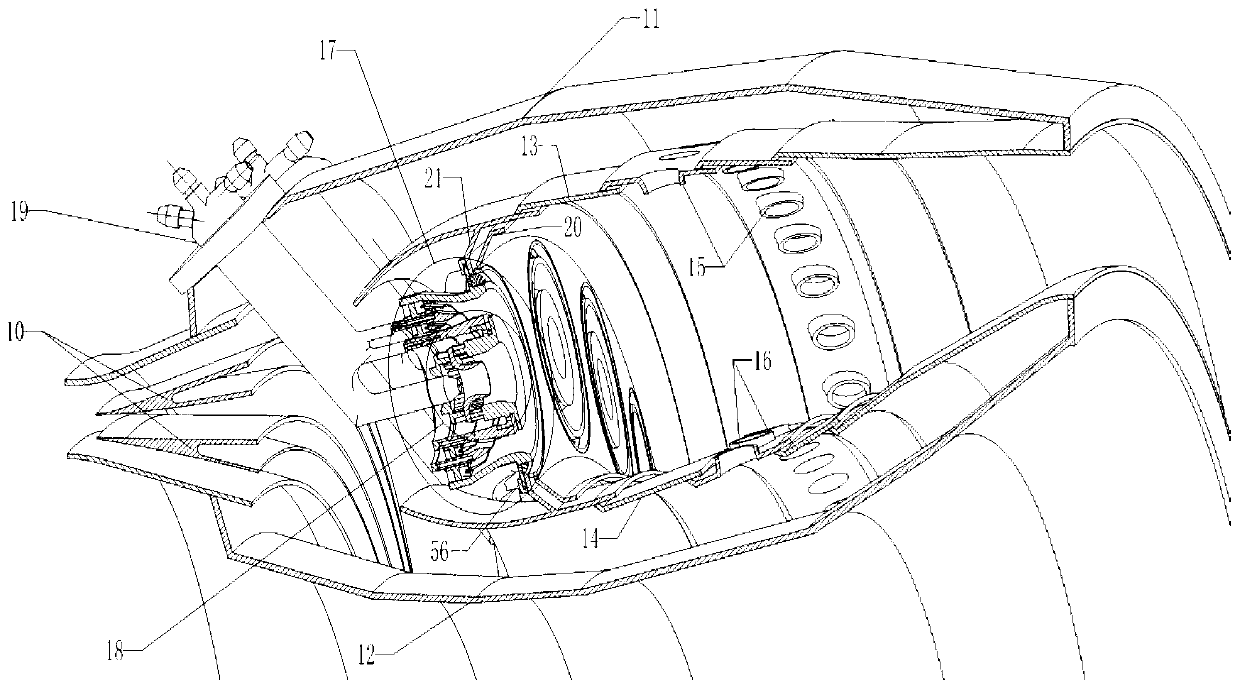

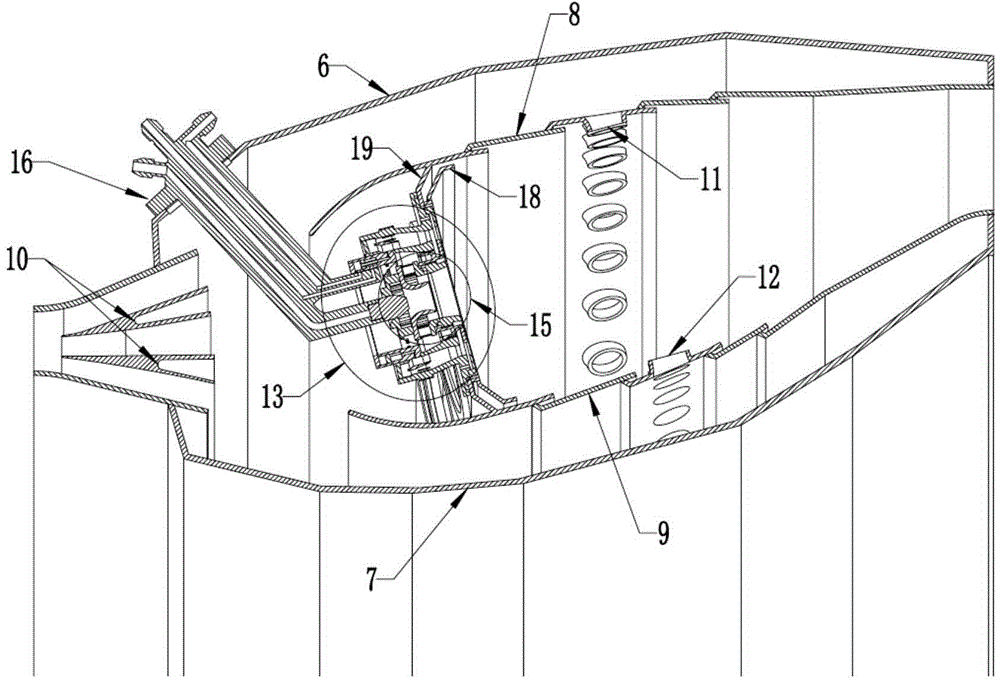

Low-pollution combustion chamber with main combustion stage adopting single-layer pre-film radial two-grade reverse rotational flow

InactiveCN105180215AImprove blending uniformityStrong shearContinuous combustion chamberAviationCyclone

The invention discloses a low-pollution combustion chamber with a main combustion stage adopting single-layer pre-film radial two-grade reverse rotational flow. The low-pollution combustion chamber adopts a single annular cavity structure, and comprises a diffuser, a combustion outdoor box, a combustion indoor box, a flame cylinder outer wall, a flame cylinder inner wall and a combustion chamber head part; the combustion chamber adopts a classification combustion scheme; the combustion head part is divided into a pre-combustion stage and the main combustion stage; the pre-combustion stage adopts a mode of combining rotational flow-stable diffusion combustion with rotational flow premixing combustion; the combustion mode reduces the pollutant discharge under small working conditions when not influencing stable combustion; and the main combustion stage adopts a premixing pre-evaporation combustion mode to be in favor of uniform combustion. The combustion chamber adopts a center classification structure; the pre-combustion stage is simple in structure; the main combustion grade adopts a two-grade reverse cyclone distributed in the radial direction; and two parts of reverse rotational flows shear an oil film, so that the atomization effect is greatly improved, the atomization of fuel of the main combustion stage and the mixing with air are enhanced, the premixing pre-evaporation of the fuel is reinforced, and the pollution discharge of whole landing and taking-off circulation of an aero-engine combustion chamber is further reduced.

Owner:BEIHANG UNIV

Bearing vibration damping mechanism

ActiveUS7628542B2Easy to produceReduce vibrationLeaf springsShaftsRolling-element bearingEngineering

A squeeze film damper for a bearing and a vibration damping mechanism capable of damping the vibration of a rolling bearing are provided. The squeeze film damper is small in construction and can be easily made by mass production. The vibration damping mechanism is capable of damping both radial and axial vibrations. A bearing housing 15 is provided with a bearing holding bore 16 of a diameter greater than the outside diameter of the outer ring 14 of a bearing, and an oil hole 19 through which oil is supplied into the bearing holding bore 16. A vibration damping mechanism 1 is formed by inserting a thin, flat sheet 17 provided with slits into an annular space formed between the inner wall of the bearing holding bore 16 and the outside surface of a bearing held in the bearing holding bore 16 so as to surround the bearing. Parts of the thin, flat sheet extending between the adjacent slits serve as elastic beams. The elastic beams center the bearing and support the centered bearing elastically. The vibration of the bearing is damped by the squeeze film effect of an oil film formed by supplying oil into the annular space.

Owner:KAWASAKI HEAVY IND LTD

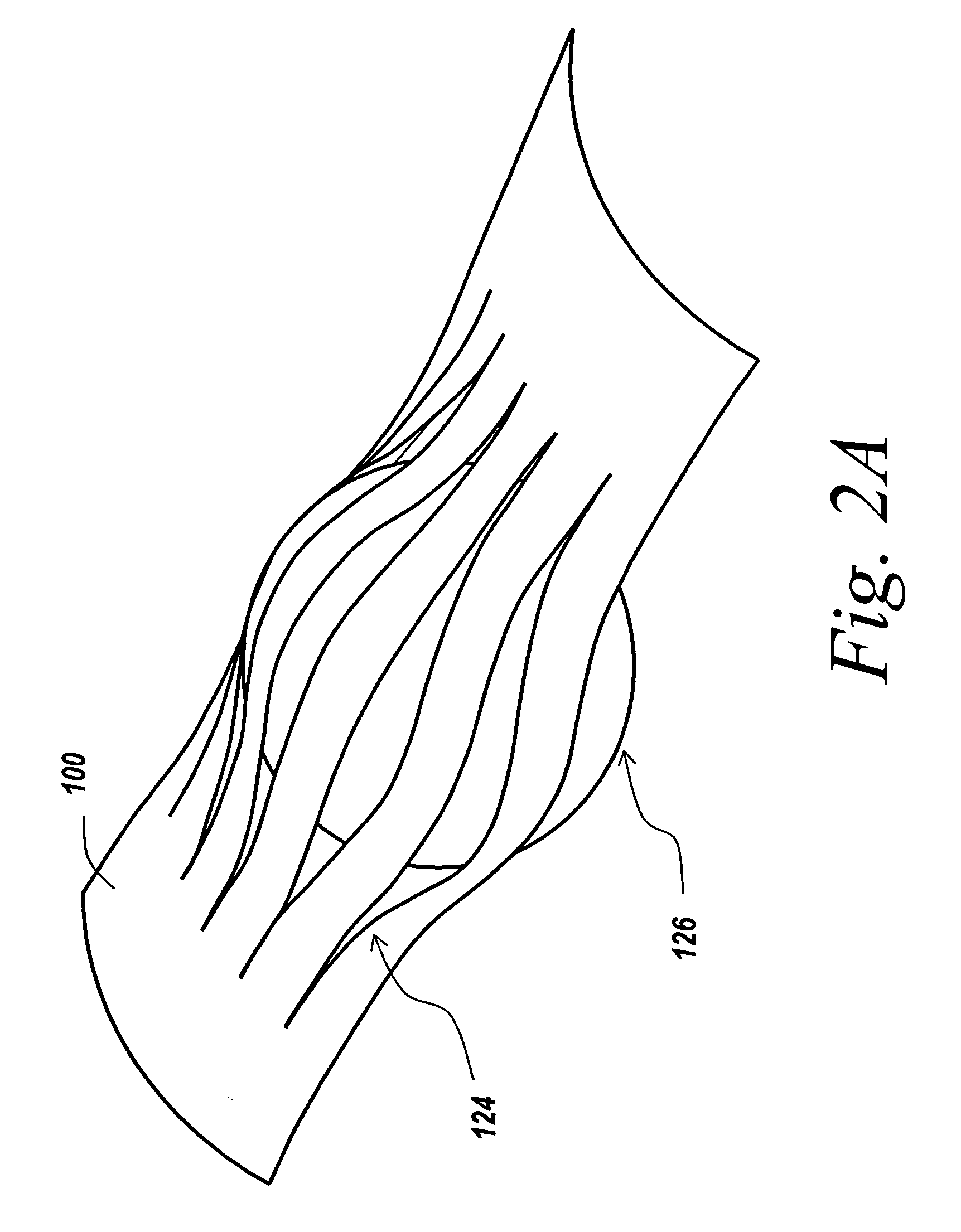

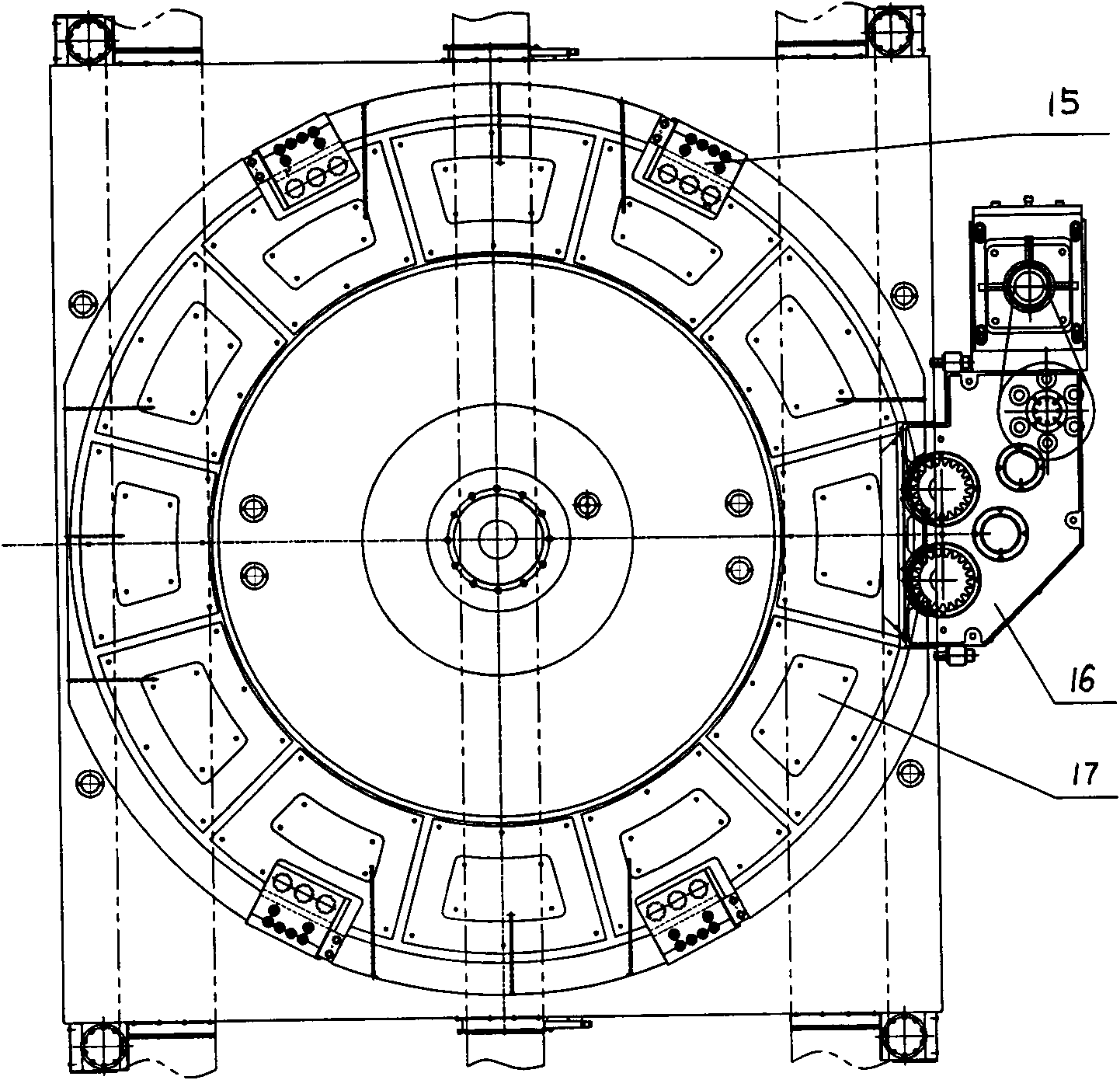

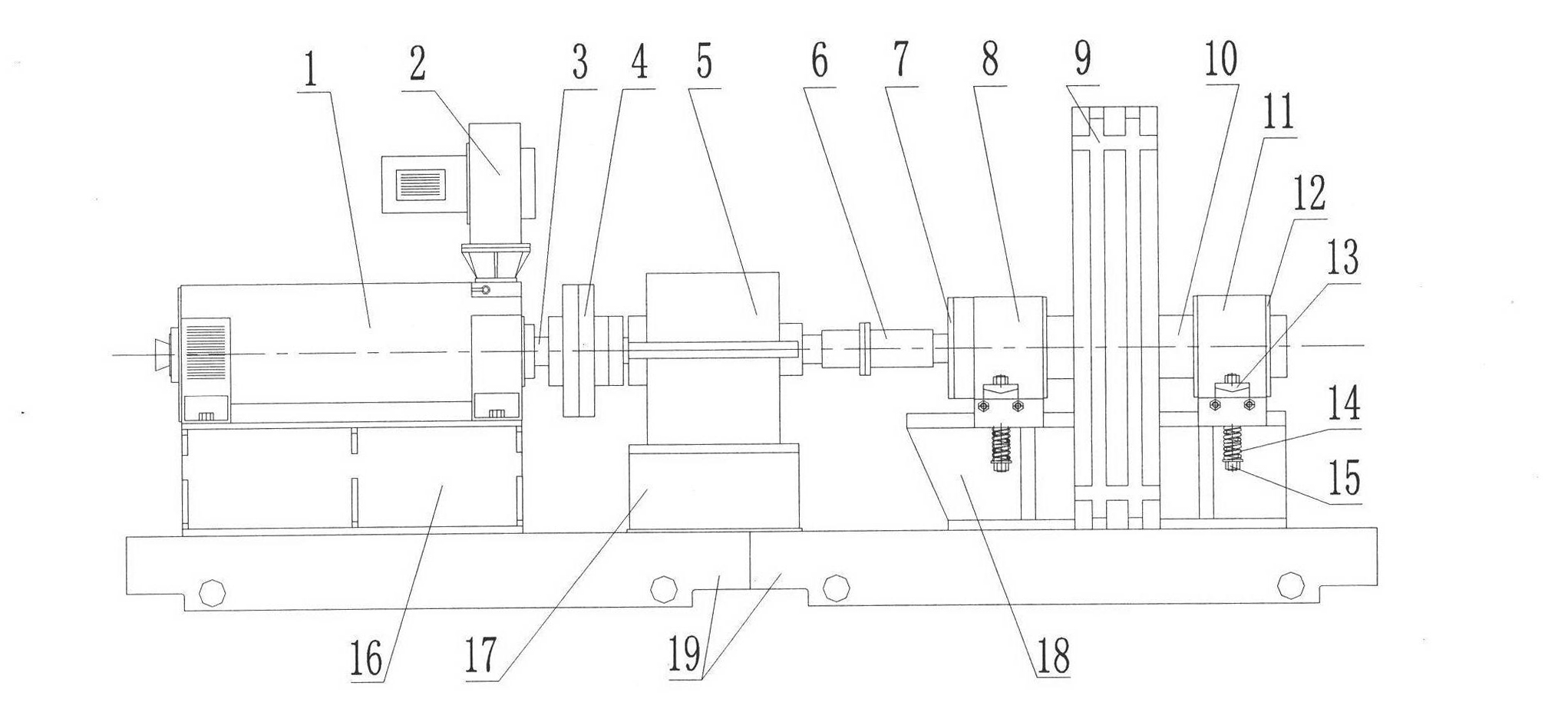

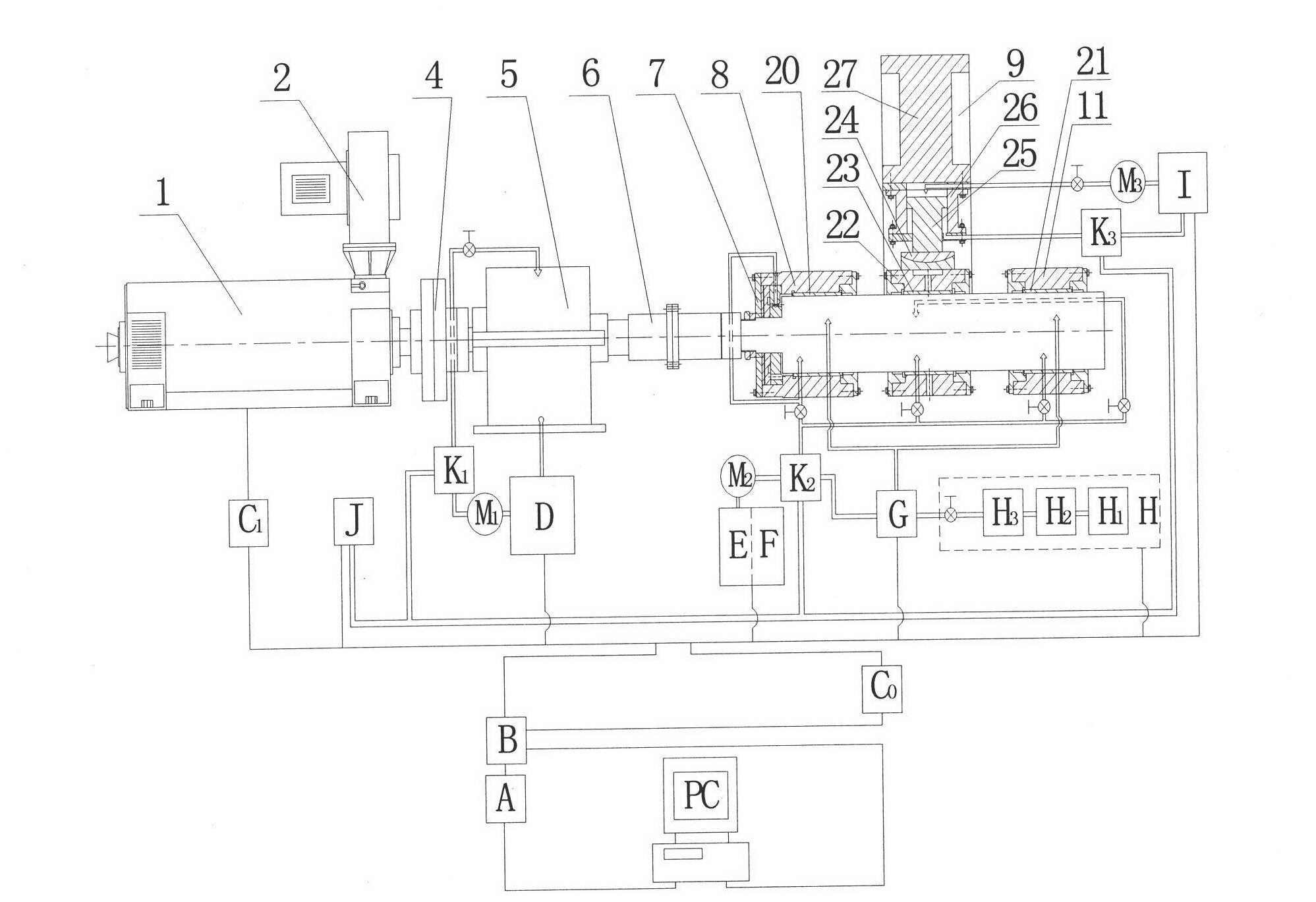

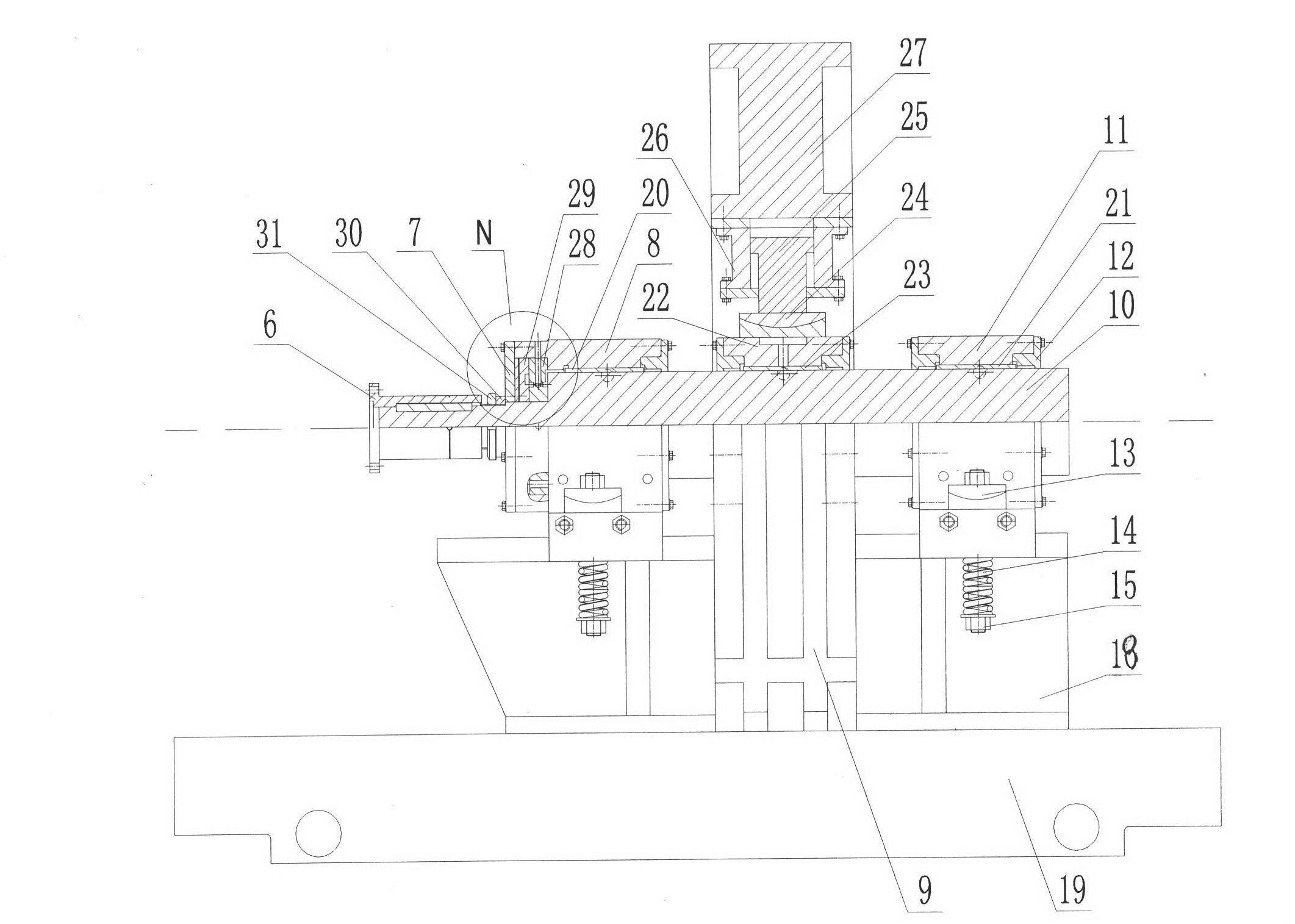

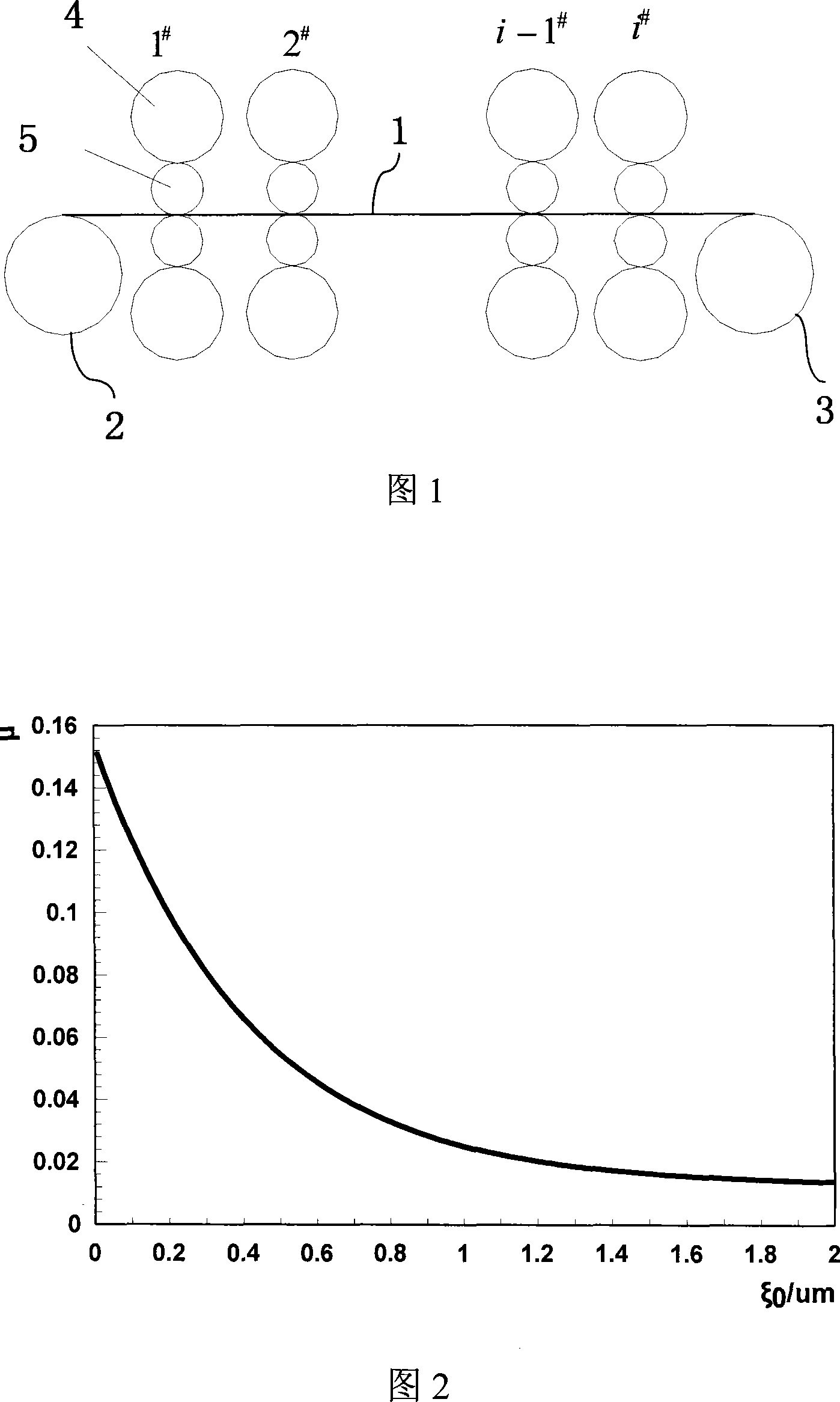

Rolling mill oil film bearing comprehensive test bench

The invention discloses a comprehensive test-bed for an oil film bearing of a rolling mill, belonging to the technical field of testing equipment of oil film bearings of rolling mills. The comprehensive test-bed is characterized by comprising a mechanical system, a motor driving system, a hydraulic loading system, a lubricating system, an air pressure control system, an electric control system and a computer data acquisition system which are combined to form an integral and uniform operation; flow sensors, temperature sensors, pressure sensors and displacement sensors mounted on the bearing and all pipelines are connected to the computer data acquisition system through a PLC (Programmable Logic Controller); and the electric control system is connected with and controls the motor driving system, the hydraulic loading system, the lubricating system and the air pressure control system. The invention realizes integration of an electromechanical hydropneumatic integral system by setting rotation speed of a motor shaft and the dynamically controlling rolling conditions of the hydraulic load and testing performance of the oil film bearing of the rolling mill by the data acquisition system. The system has the advantages of compact structure and convenience for operation, and is suitable for the fields of various teaching and scientific research.

Owner:TAIYUAN UNIVERSITY OF SCIENCE AND TECHNOLOGY

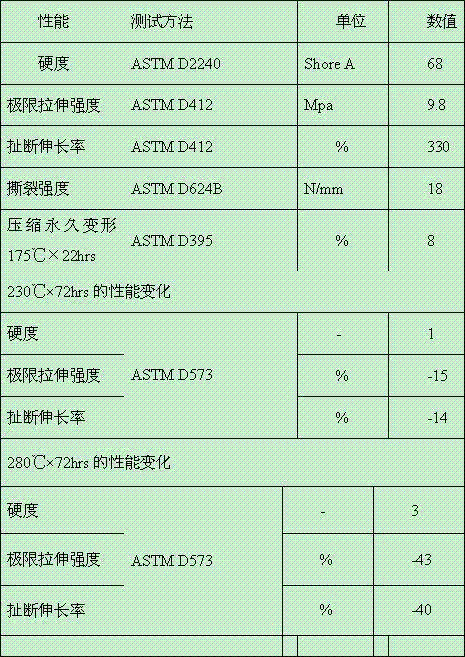

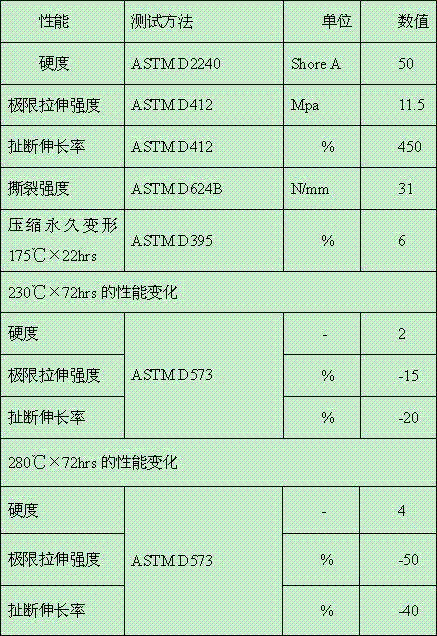

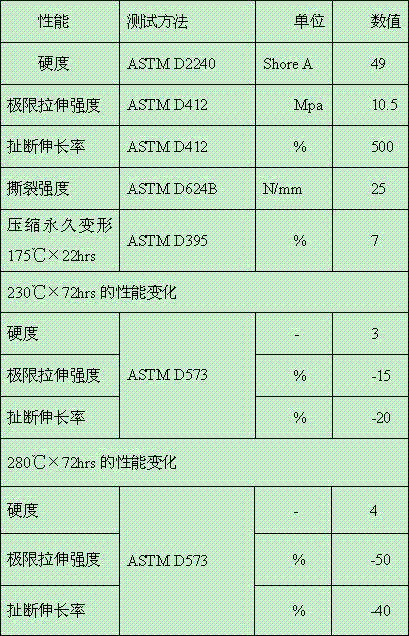

High temperature mixing silicone rubber as well as preparation method and application thereof

ActiveCN104761911AHelp with installationExtended service lifePolymer scienceLTV vinyl silicone rubber

The invention discloses high temperature mixing silicone rubber as well as a preparation method and an application thereof. According to the high temperature mixing silicone rubber disclosed by the invention, raw methyl phenyl vinyl silicone rubbers with different proportions are added in the raw methyl vinyl silicone rubber to serve as raw rubber, hydrophobic gas phase white carbon black is used as fillers, and ageing resistant additives are added, so that the obtained high temperature mixing silicone rubber has excellent high temperature ageing resistance. The high temperature mixing silicone rubber disclosed by the invention has the advantages of good high temperature ageing resistance, long service life, ultralow permanent compression deformation and is capable of automatically forming an oil film to isolate water vapor, and the like, and the high temperature mixing silicone rubber is particularly suitable for automobile sealing elements and has a good application prospect.

Owner:XINAN TIANYU SILICONE CO LTD +1

Insulating and damping sleeve for a rolling element bearing cartridge

ActiveUS8807840B2Good vibration reduction effectLow thermal conductivityRolling contact bearingsInternal combustion piston enginesRolling-element bearingTurbocharger

Owner:BORGWARNER INC

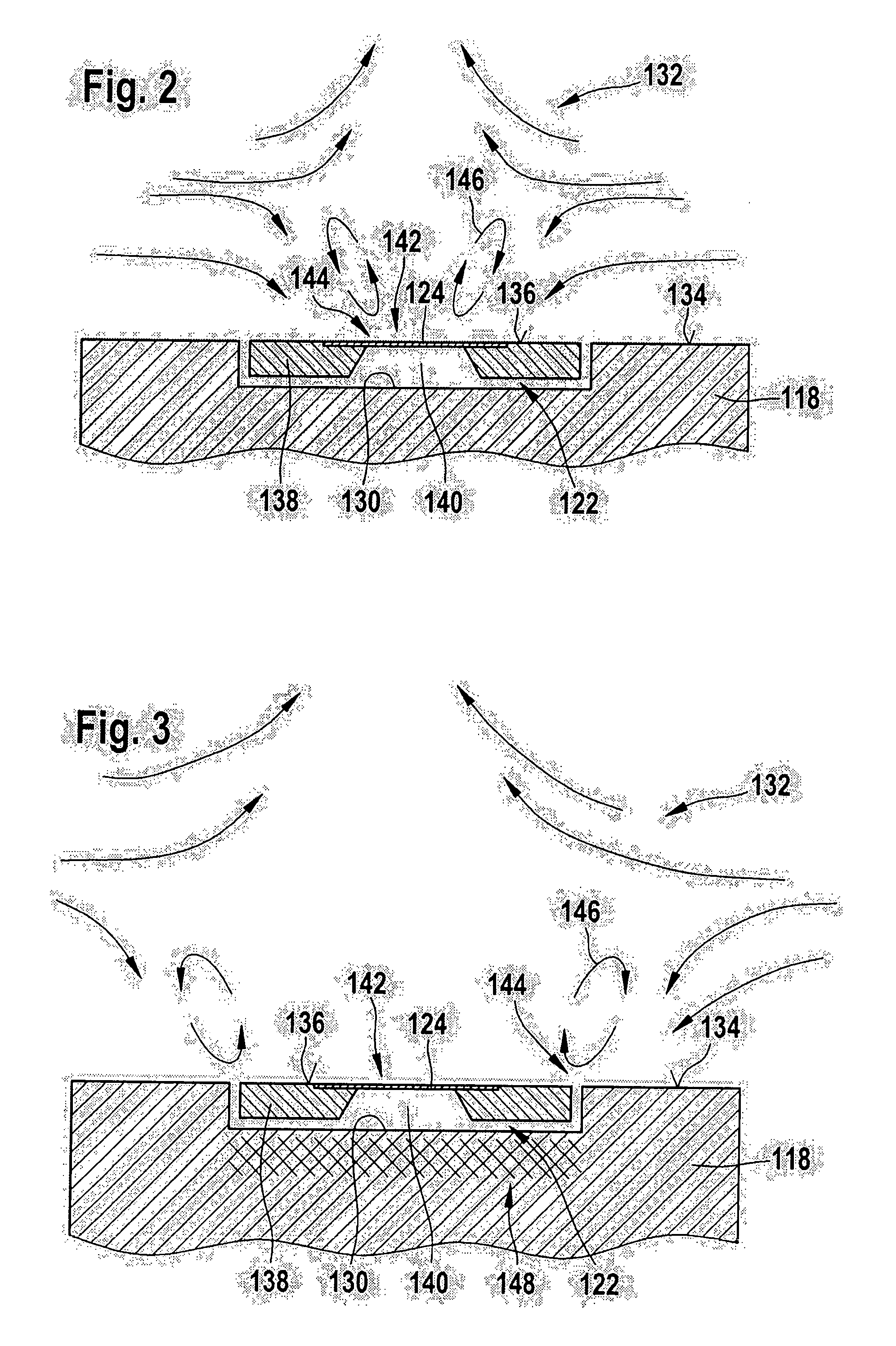

Heated Hot-Film Air-Mass Sensor

ActiveUS20090211355A1Contamination of the surface of the sensor chip is minimizedMinimize contaminationPrinted circuit assemblingElectrical controlCombustionTwo temperature

To determine air mass flows, especially for controlling internal combustion engines, a hot-film air-mass sensor is provided, which may be used especially for sensing air mass flows in the intake tract of an internal combustion engine. The hot-film air-mass sensor has a sensor chip having a sensor frame and a sensor diaphragm having at least one heating element and at least two temperature sensors. Furthermore, the hot-film air-mass sensor has a chip carrier for mounting the sensor chip, as well as at least one additional heating element. The sensor chip is able to be heated up using the at least one additional heating element, which is inserted into the chip carrier. Compared to the usual devices, the hot-film air-mass sensor has a lower susceptibility to contamination, especially by oil films.

Owner:ROBERT BOSCH GMBH

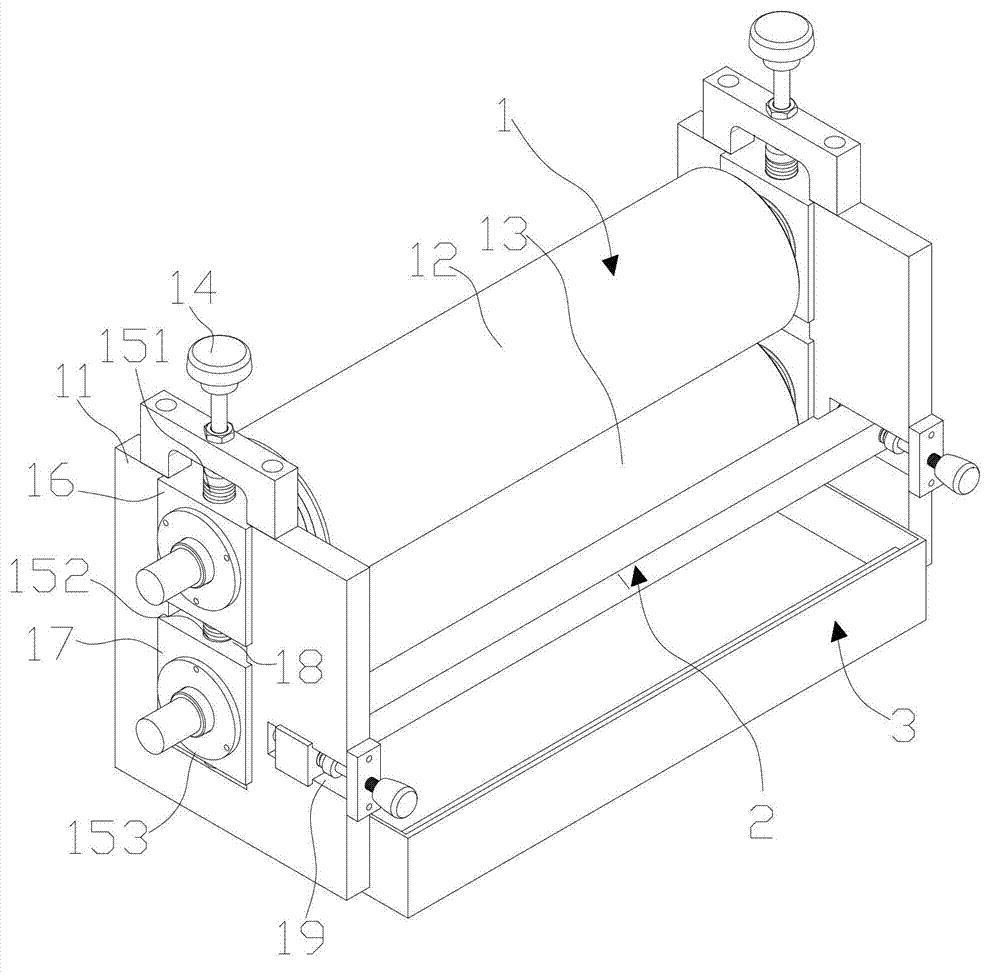

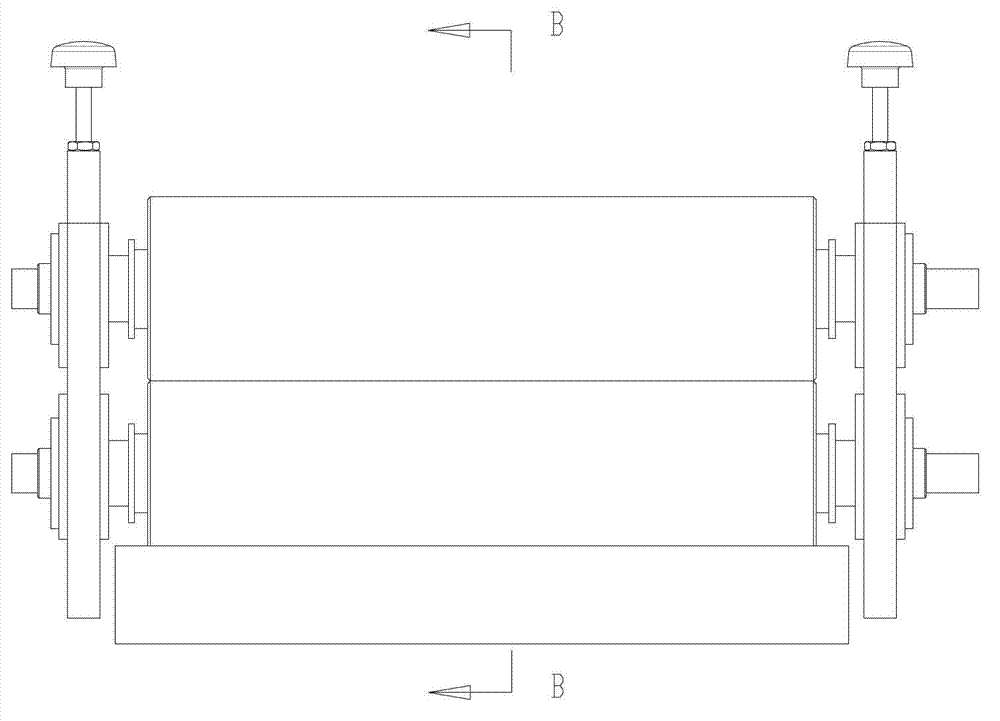

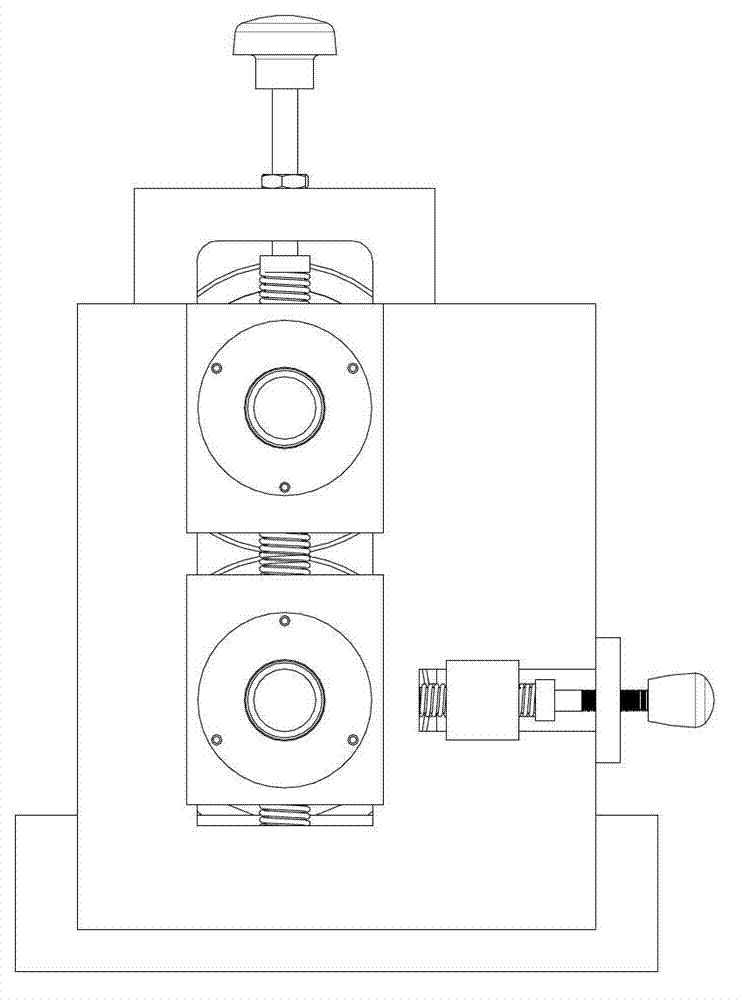

Automatic double-sided oiling machine

ActiveCN103041953AUniform thicknessEasy to adjustLiquid surface applicatorsCoatingsEngineeringPulp and paper industry

The invention discloses an automatic double-sided oiling machine which comprises an oiling roller mechanism, an oil film adjusting mechanism and an oil groove mechanism. The oiling roller mechanism comprises an oiling roller which is placed in an oil groove of the oil groove mechanism. The oil film adjusting mechanism is arranged on the oiling surface of the oiling roller. The oiling roller consists of a first oiling roller and a second oiling roller. The second oiling roller is placed in the oil groove, and the roller faces of the first and second oiling rollers are tangential in the vertical direction compress each other. The automatic double-sided oiling machine provided by the invention has the benefits that the oiling film is uniform in thickness and easy to adjust and control, the deficiency of high dependency on manual operation in the manual oiling manner in a stretching, stamping and forming process of metal sheets is thoroughly solved, and the problem that the mould is easy to abrade and short in service life due to nonuniform manually oiled film is solved. Meanwhile, oil is saved, the labor intensity is reduced, and the production cost is saved. The automatic double-sided oiling machine is in particular suitable for double-sided automatic oiling for stainless steel thin plates which are hard to stamp and stretch.

Owner:GUANGDONG ZHONGBAO KITCHENWARE

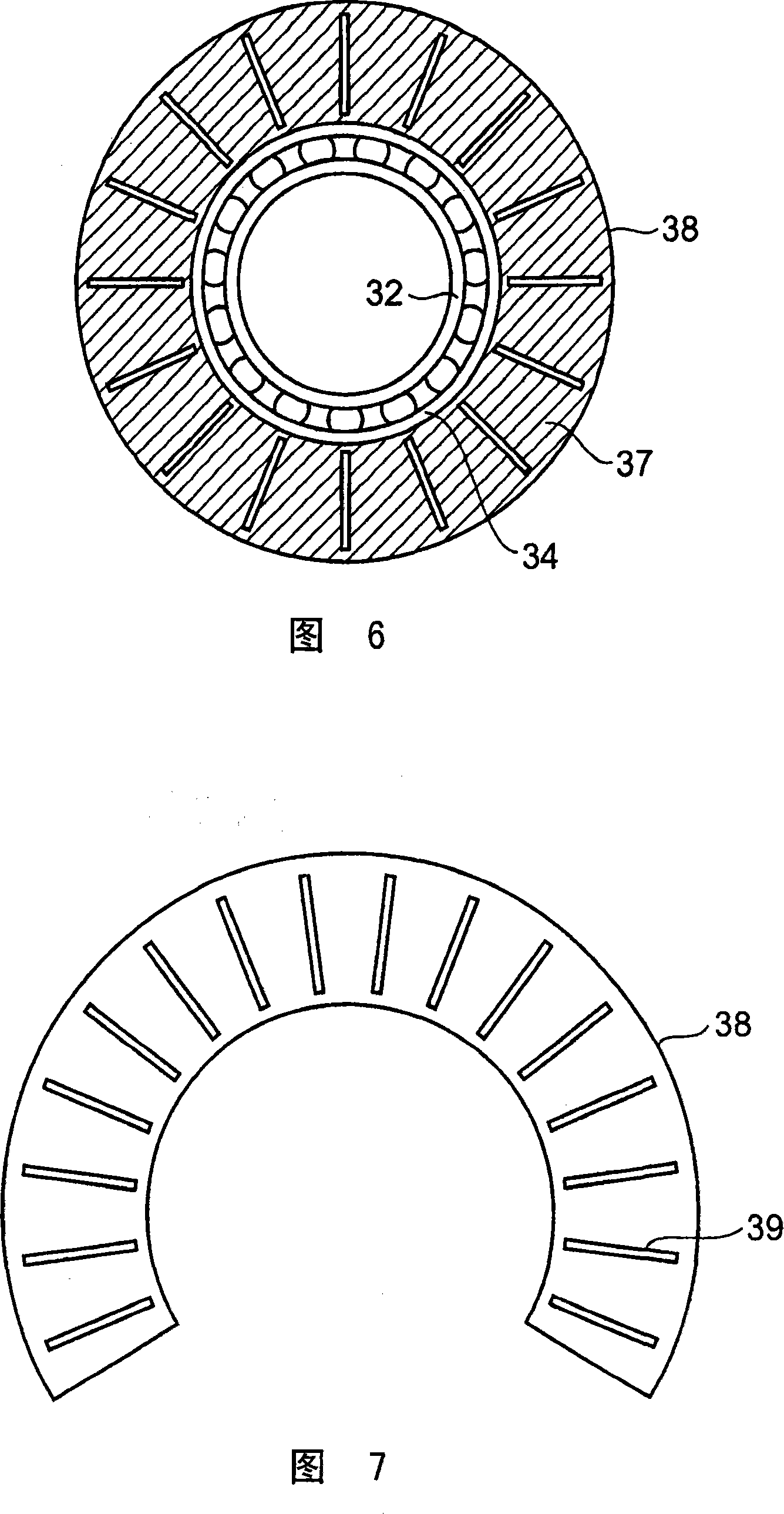

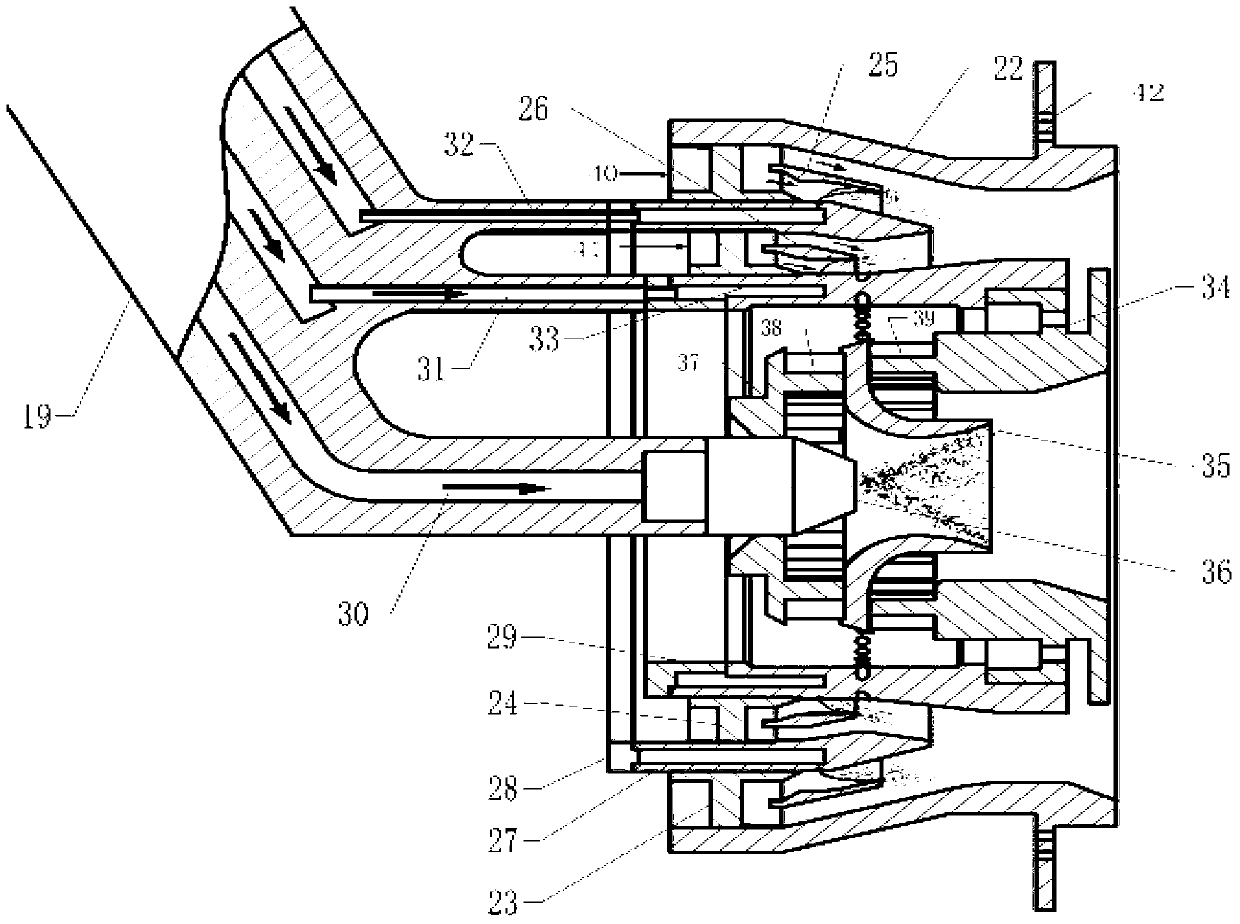

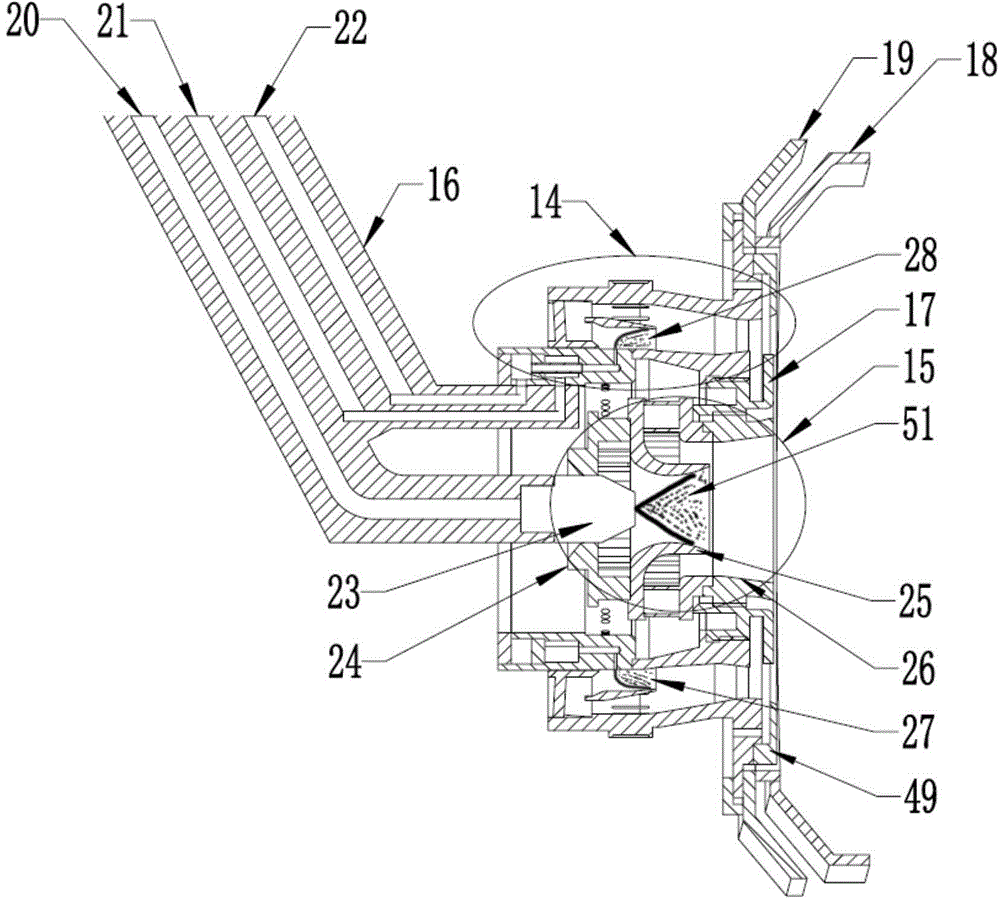

Double-pre-film pneumatic nebulization low pollution combustor head structure

The invention discloses a double-pre-film pneumatic nebulization low pollution combustor head structure. Combustion is organized in a combustor head in a center classification mode. The combustor head structure is divided into a main combustion level and a pre-combustion level. The pre-combustion level is of a double-level swirl cup structure, combustion is organized in a partially premixing mode, and the requirements for combustion stability and pollutant discharge of small working conditions are met. The main combustion level is of an axial swirler double-pre-film structure, combustion is conducted in a combustor in a premixing mode, and combustion pollutants can be effectively reduced through premixing combustion. The double-pre-film type main combustion level structure comprises two stages of independent oil collecting rings, two stages of axial swirlers and two stages of pre-film plate structures. Each stage of independent oil collecting ring is provided with a plurality of beveled fuel injection holes. Each stage of fuel is injected out through the fuel injection holes and then strikes the pre-film plates to be expanded into oil films. The structure is beneficial for fuel classification of the whole combustor under different working conditions, ensures reasonable oil-gas distribution, and further reduces the pollutant discharge level in the whole cycle of landing and taking off of the combustor of an aero-engine.

Owner:BEIHANG UNIV +1

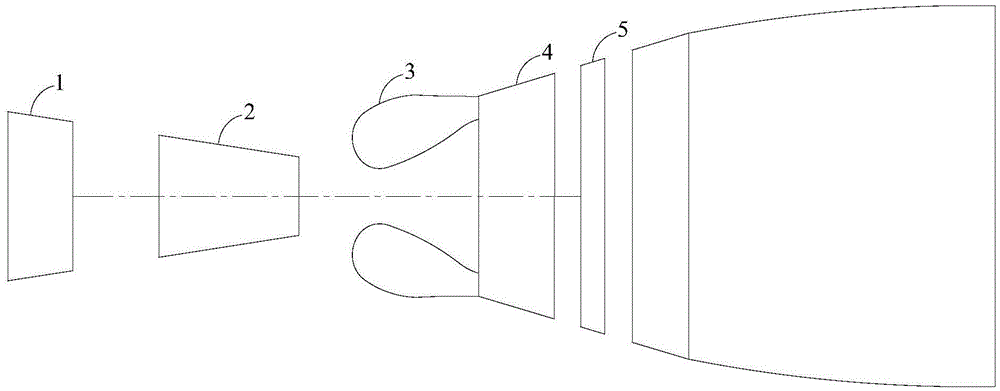

Lean oil premixing and pre-evaporating combustion chamber head structure with cyclone/pre-film plate integrated primary combustion stage

The invention relates to a lean oil premixing and pre-evaporating combustion chamber head structure with a cyclone / pre-film plate integrated primary combustion stage. A central staged combustion mode is adopted for the head structure and divided into a pre-combustion stage and the primary combustion stage, the mode of combining diffusive combustion and cyclone premixing combustion is adopted for the pre-combustion stage, the mode of premixing and pre-evaporating combustion mode is adopted for the primary combustion stage, and combustion pollutants can be effectively reduced. A cyclone / pre-film plate integrated structure is adopted for the primary combustion stage, the structure is simple and reliable, first-stage fuel and second-stage fuel form oil films on the same pre-film plate and are atomized, evaporated and mixed under the action of two strands of cyclones, an even oil and gas mixture can be easily formed at an outlet of the primary combustion stage, and the combustion pollutants are reduced. The design of dual oil paths of the primary combustion stage is beneficial to oil and gas matching of the combustion chamber under different working conditions, and the pollutant discharge level of the whole landing and take-off circulation of the combustion chamber of an aero-engine is further lowered. By means of the micro shrinkage type design of a primary combustion stage channel and the design of a backfire prevention ring, the backfire problem can be effectively solved, and the safety of the head of the combustion chamber is ensured.

Owner:BEIHANG UNIV +1

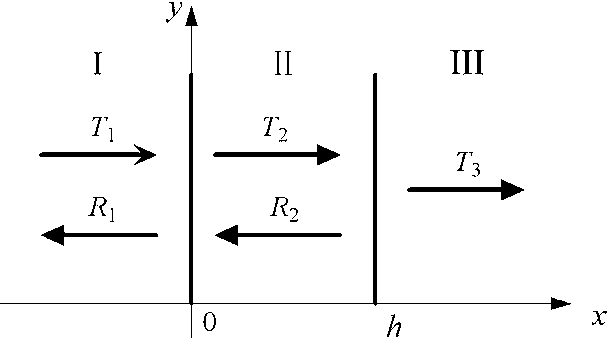

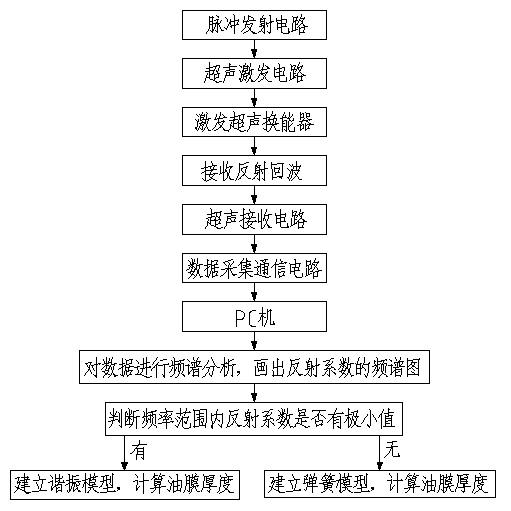

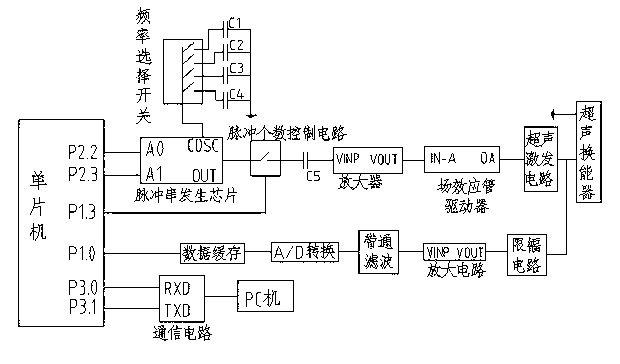

Ultrasonic film thickness measuring instrument and measuring method thereof

InactiveCN103308011AReduce volumeWill not cause missingUsing subsonic/sonic/ultrasonic vibration meansMicrocontrollerMeasuring instrument

The invention provides an ultrasonic measuring instrument and a measuring method for monitoring the thickness of an oil film between two contacted surfaces. The ultrasonic measuring instrument comprises a pulse transmission circuit, an ultrasonic excitation circuit, an ultrasonic receiving circuit, a data acquisition communication circuit and a personal computer (PC) which are sequentially connected, wherein the ultrasonic excitation circuit is further connected with an ultrasonic transducer; and the pulse transmission circuit and the data acquisition communication circuit share the same single-chip microcomputer. Compared with a traditional ultrasonic thickness measuring instrument, the size of the ultrasonic thickness measuring instrument is smaller due to a digital integrated circuit, the analog-to-digital (A / D) sampling rate is very high, radio frequency sampling is directly carried out to an ultrasonic signal, and the information is not lost. A circuit design is simpler, and corresponding data can be processed. The designed instrument adopts a new oil film thickness calculation method, can measure oil film thicknesses of nano level, and is more applicable to measuring the thicknesses of lubricating oil films.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

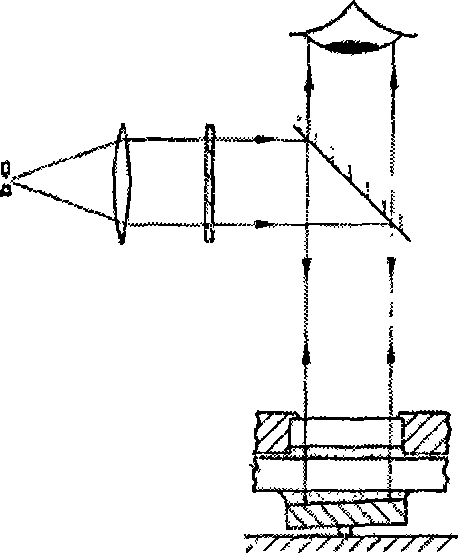

Miniature guide bearing lubricating oil film measuring apparatus and guide regulating method thereof

InactiveCN101458068AHigh inclination efficiencyHigh precisionUsing optical meansCircular discMeasuring instrument

The invention discloses a miniature slipper bearing lubricant film measuring instrument which comprises a frame, a miniature sliding block, a transparent round disk, a miniature sliding block fixing and adjusting unit, a transparent round disk revolving unit, a loading single end and a micro-interference measuring unit, wherein, a group of adjusting devices are used for adjusting and fixing the obliquity of the miniature sliding block. The instrument achieves high efficiency and high accuracy in adjusting the obliquity, and height difference of the two sides of an inclined surface has an adjustment accuracy of 0.2 micron. The utilization of the instrument can lead to the obtaining of a determined obliquity between a miniature sliding block work plane and the transparent optical round disk in a static condition. The adjustment of the obliquity includes the adjustment of size and direction.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

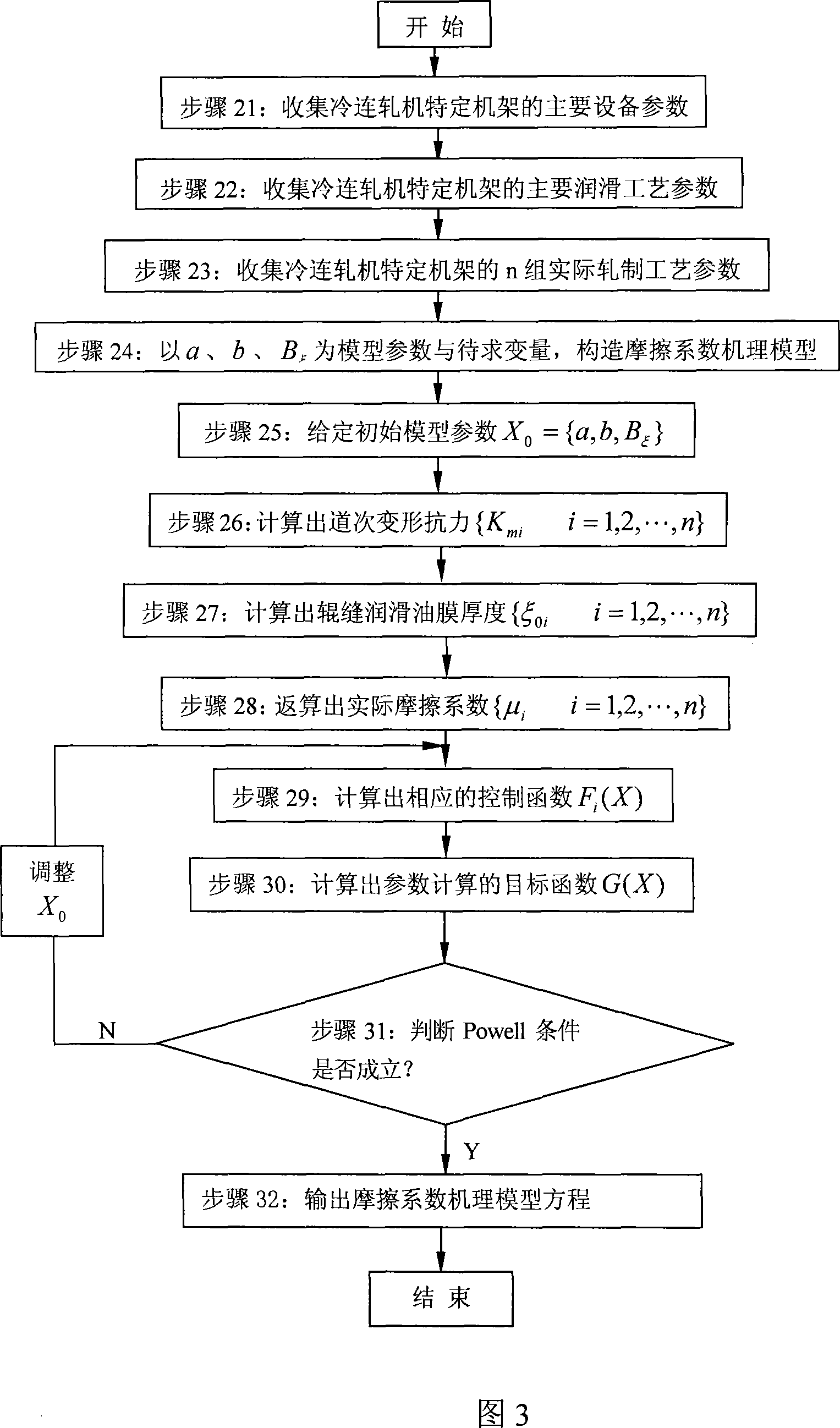

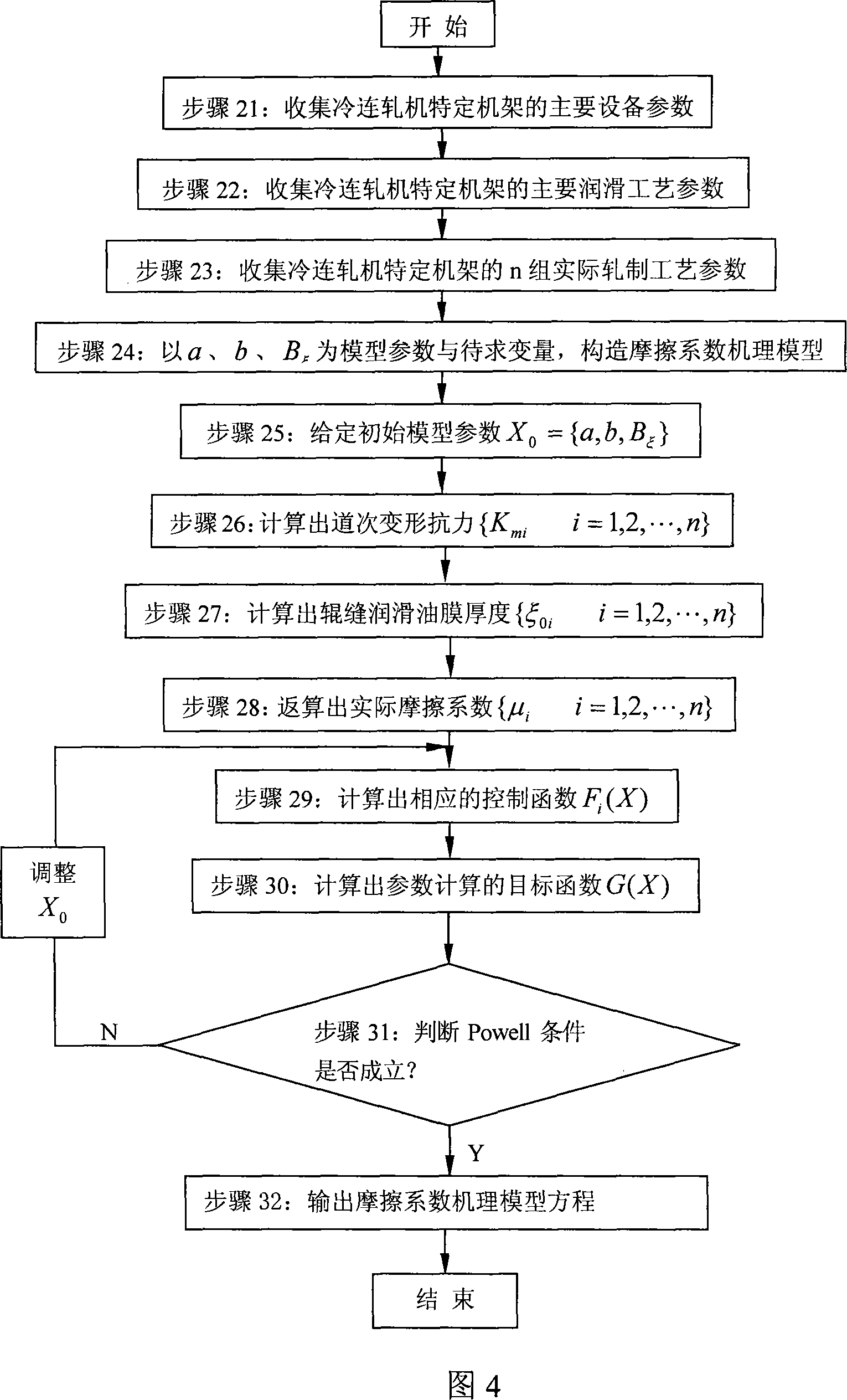

Friction coefficient forecasting and setting method for cold-continuous-rolling high-speed rolling process

InactiveCN101025767AImprove general performanceClear principleSimulator controlSpecial data processing applicationsSurface roughnessComputerized system

The invention is a method for forecasting and setting friction coefficient in the cold continuous rolling high speed rolling course, executing on computer system the following steps of: a. collecting main equipment parameters of a cold continuous roller specific frame; b. collecting main lubricating process parameters of the cold continuous roller specific frame; c. collecting n groups of actual rolling process parameters of the cold continuous roller specific frame; d. according to the field experimental data of a specific leveler, establishing a plate surface roughness forecasting model for the specific leveler; e. using a, b as friction coefficient mechanism model parameters and to-be-found variants, constructing a friction coefficient mechanism model reflecting basic function relation between friction coefficient and lubricating oil film thickness; f. substituting the friction coefficient mechanism model parameters into a function equation reflecting relation between friction coefficient and lubricating oil film thickness and obtaining a friction coefficient forecasting and setting model in the cold continuous rolling high speed rolling course; and g. on-line forecasting and setting the friction coefficient in the cold continuous rolling high speed rolling course.

Owner:YANSHAN UNIV

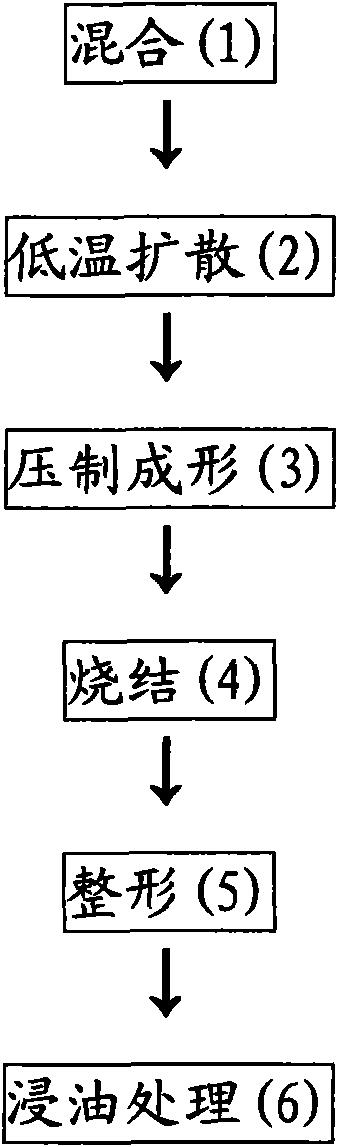

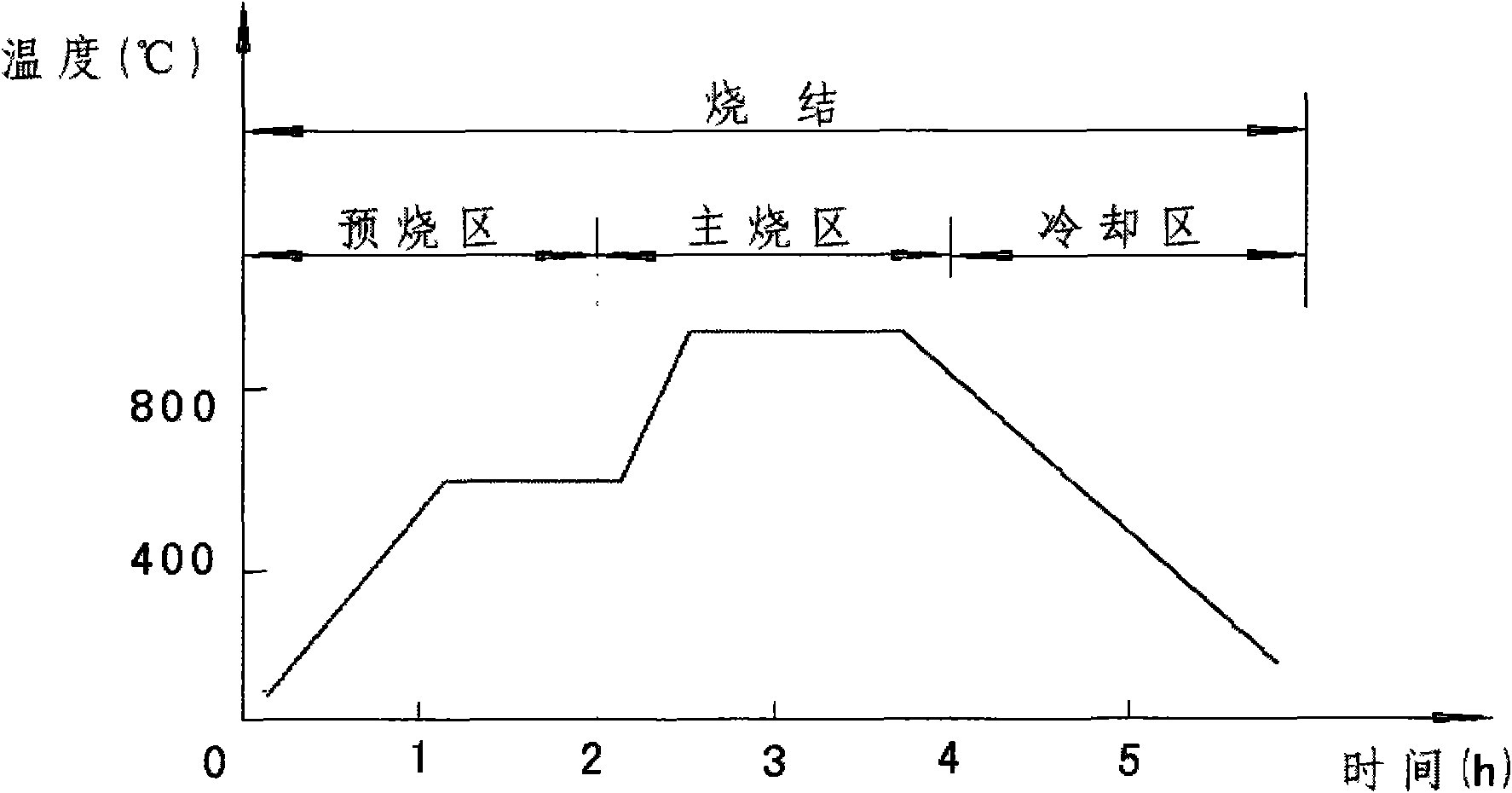

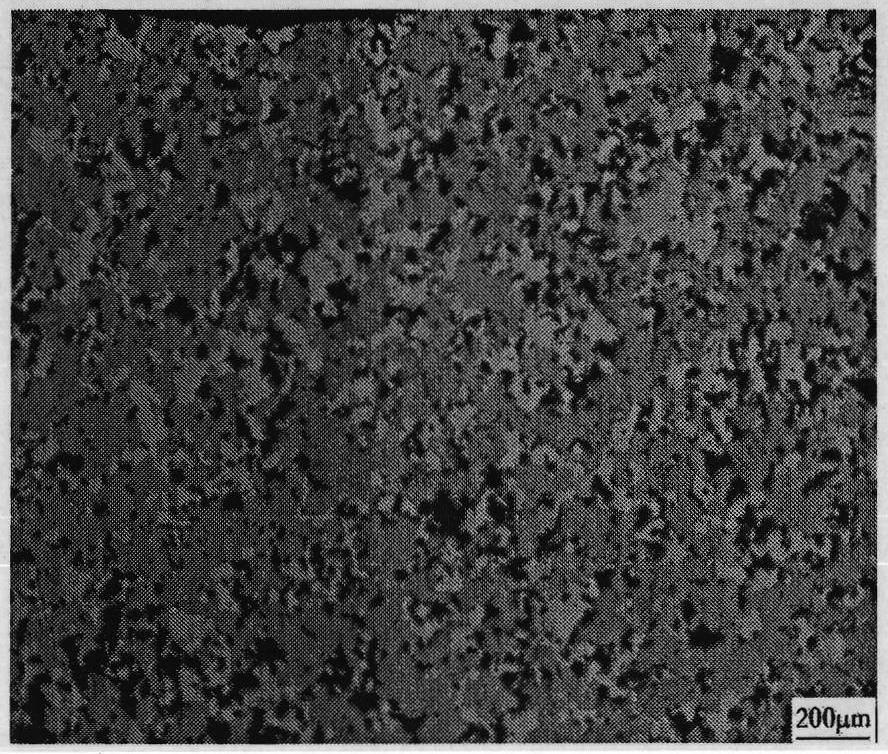

Ultrahigh rotating speed oil bearing for powder metallurgy and manufacturing method thereof

The invention discloses an ultrahigh rotating speed oil bearing for powder metallurgy and a manufacturing method thereof. The bearing comprises the following components in percentage by weight: 27-54% of Cu, 3-6% of Sn, 2.2-6% of MoS, 0.2-2% of La or Ce and the balance of Fe and inevitable impurities. The bearing is manufactured by carrying out processes of mixing, low-temperature diffusion, press forming, sintering, reshaping and oil immersion treatment on mixture formed by proportionally mixing the powders. Solid lubricant and rare earth which are used as an active catalyst and an enhancer for a basis material of the bearing are added to the bearing, thereby being benefical to grain refinement; and weeny through holes are generated on a sintering body, and the connectivity rate is more than 95 percent. When the bearing rotates at a high speed, an oil film is formed on the inner wall of the bearing by the lubricating oil, and the bearing is applicable to an ultrahigh rotating speed motor with the rotating speed being more than 34000 rpm.

Owner:JIANGSU YINGQIU GRP CO LTD

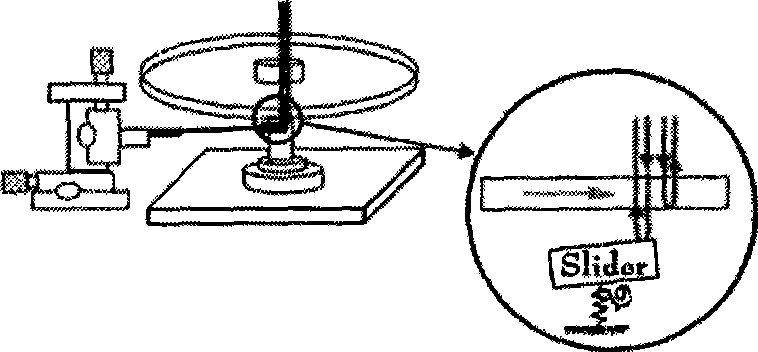

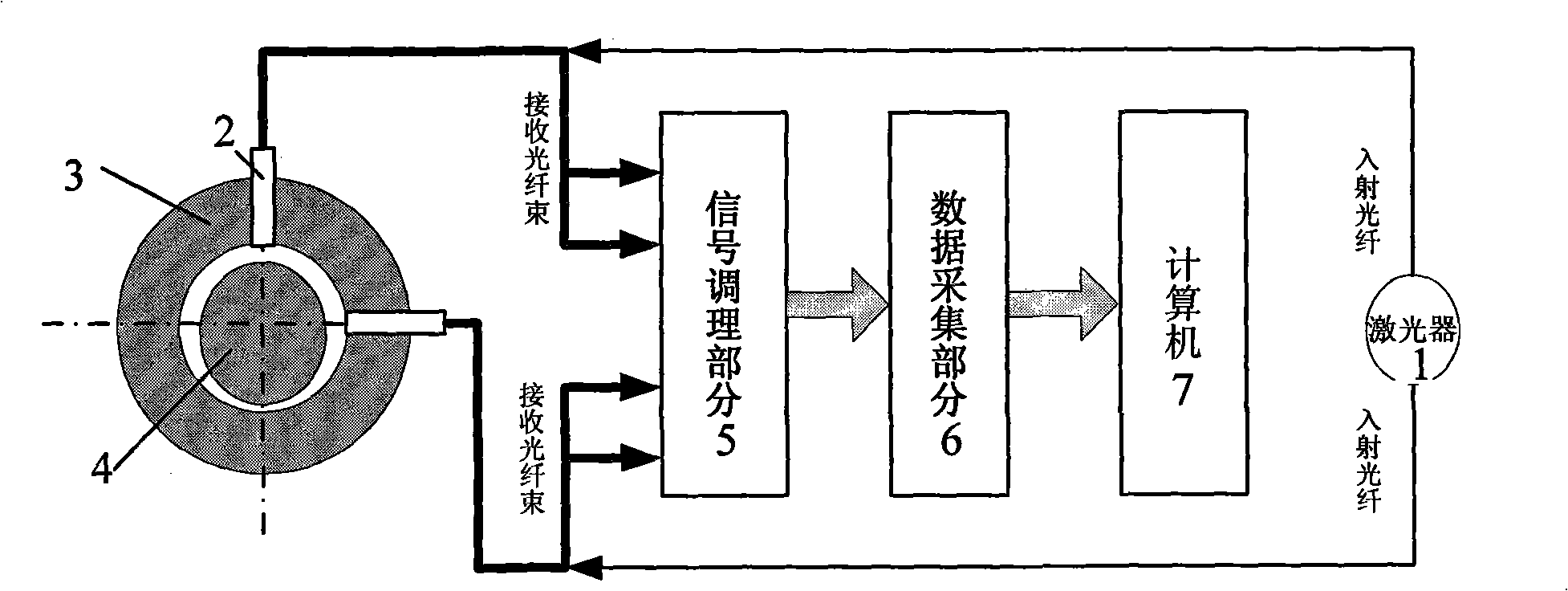

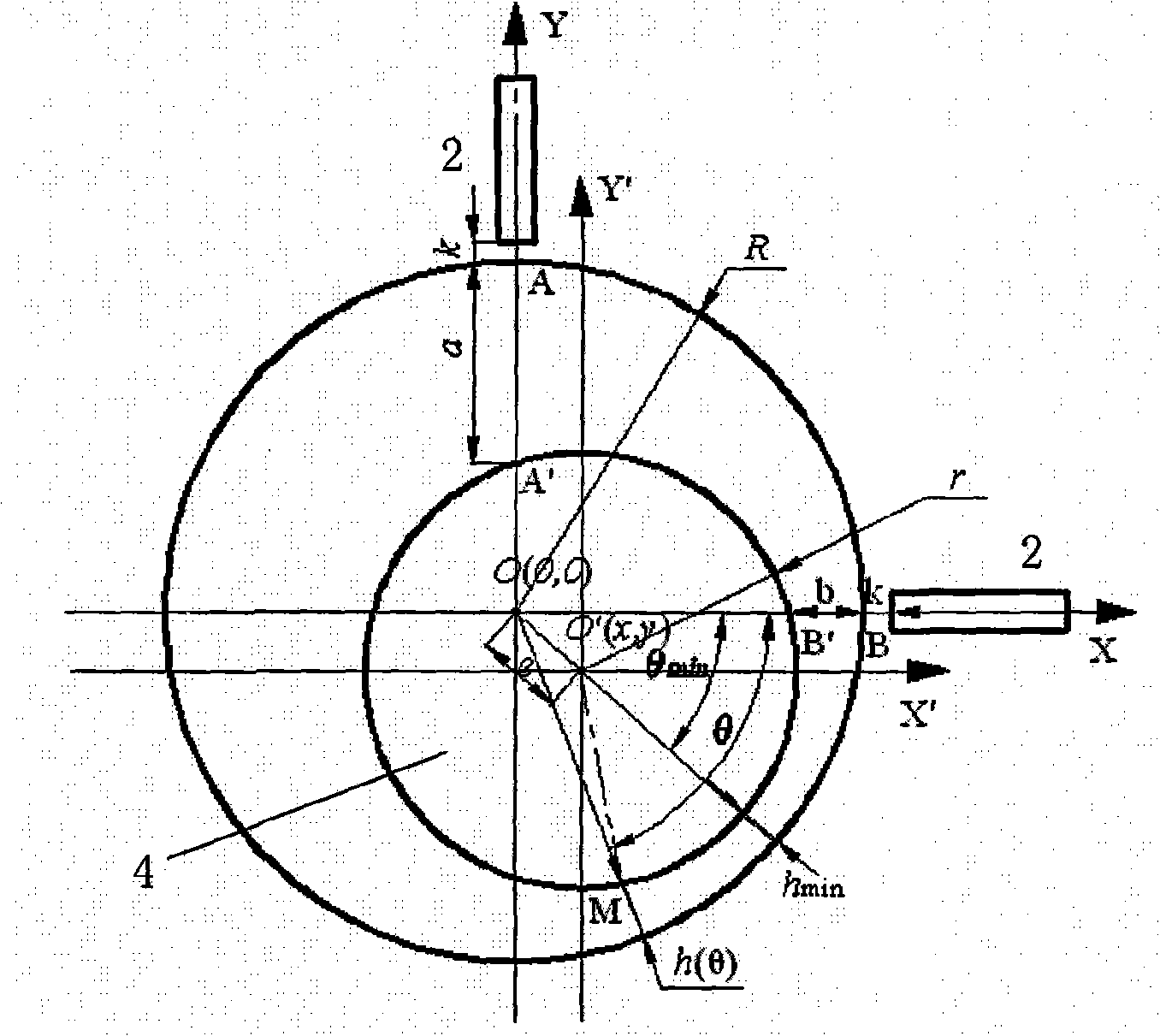

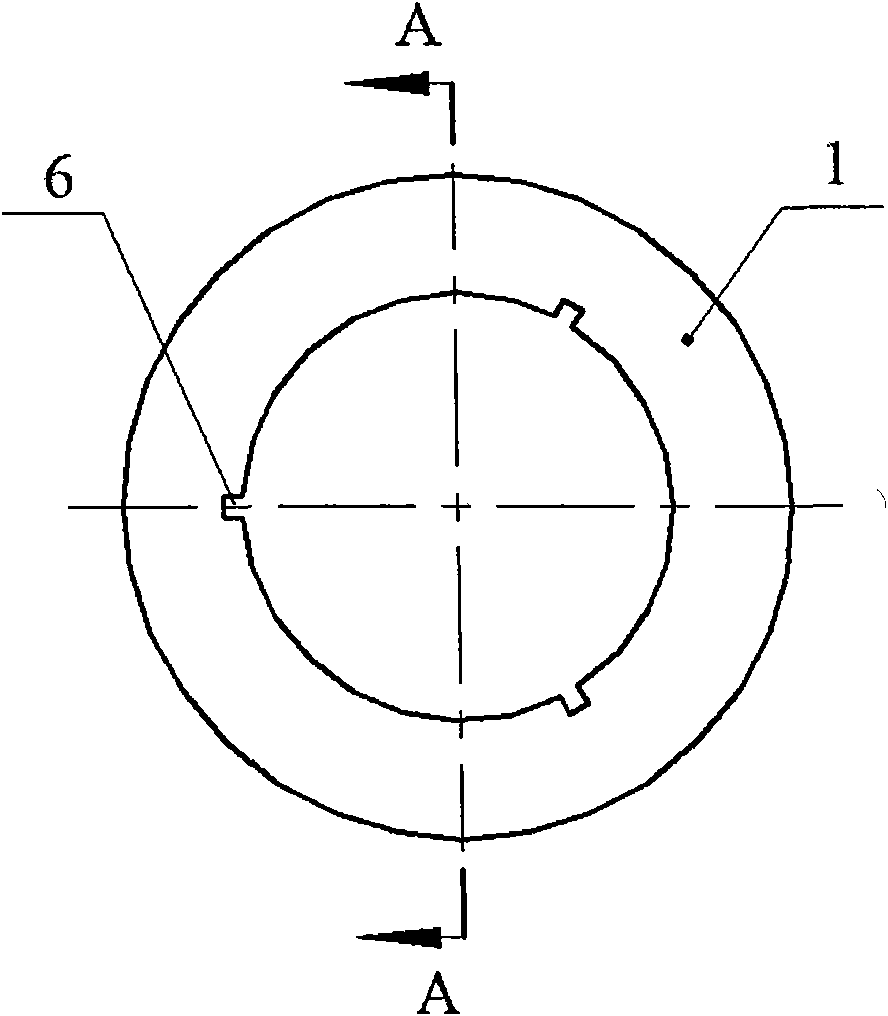

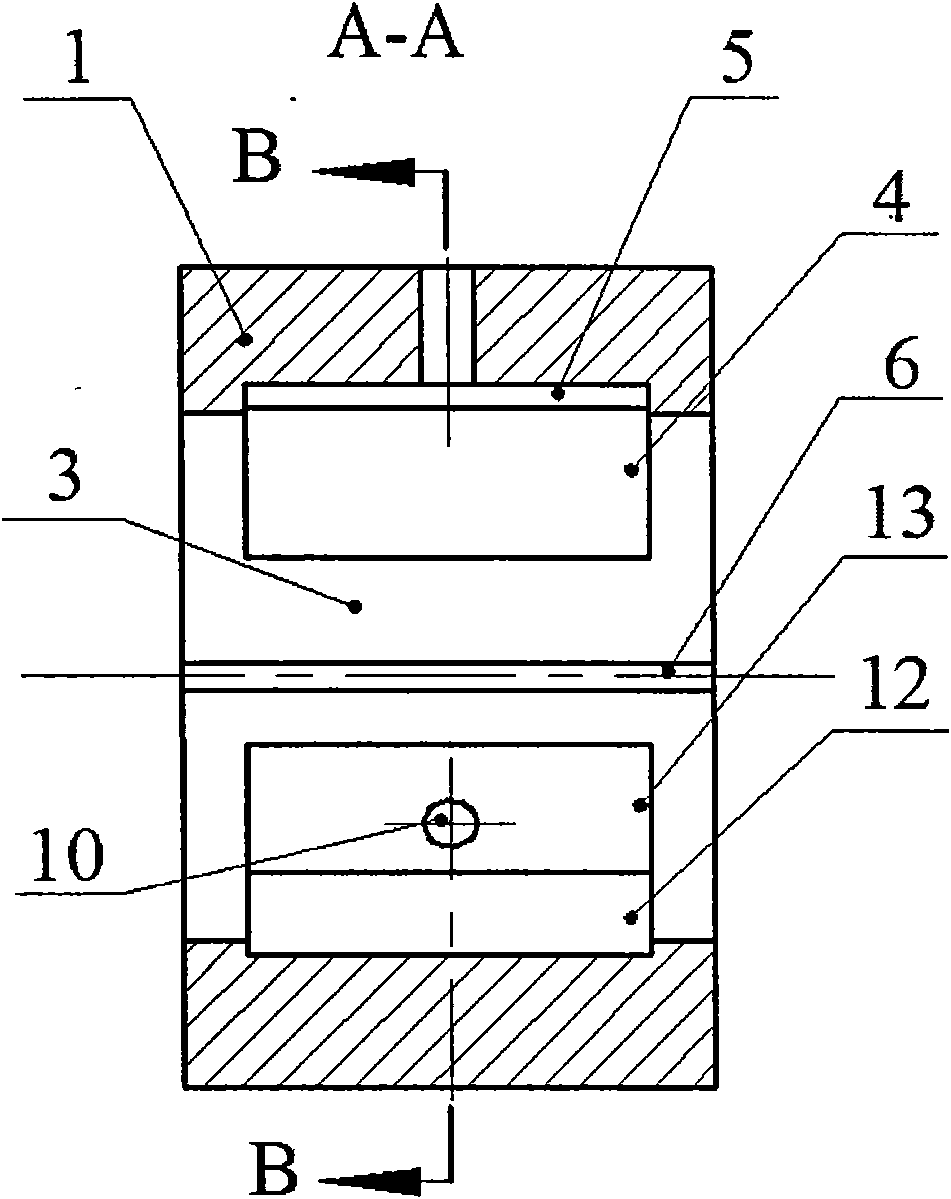

Dynamic measurement method of slide bearing lubricating film and fiber optic sensor for measurement

InactiveCN101329167AReduce usageRemove light intensityUsing optical meansBundled fibre light guidePosition angleInner loop

The invention discloses a dynamic measuring method of lubricating films of a sliding bearing, and an optical fiber sensor that is used for measurement. Two reflection-typed optical fiber sensors with coaxial double loops that form a right angle are respectively arranged at the two end faces of a bearing bush of the sliding bearing, two distances from A to A' and from B to B' are directly measured, the coordinates of the two points A' and B' that are obtained by measurement and calculation are substituted into a standard circle equation of a shaft neck so as to calculate the values of x and y of a cross section circle of the shaft neck, and consequently, the eccentric offset of the shaft neck, the smallest oil film thickness h<min>, the position angle of the smallest oil film thickness Theta<min> and the thickness of the oil films on any point along the circumferential direction of the sliding bearing h(Theta) are obtained in order; in order to implement subsequent failure diagnosis, the multi-dimensional features of the lubricating films of the sliding bearing are represented and extracted. The optical fiber sensor that is used in the dynamic measuring method comprises an optical fiber probe, an incident optical fiber and a receiving optical fiber beam, and is characterized in that two loops of receiving optical fiber beams including an inner loop and an outer loop are arranged closely and coaxially surrounding the incident optical fiber.

Owner:XI AN JIAOTONG UNIV

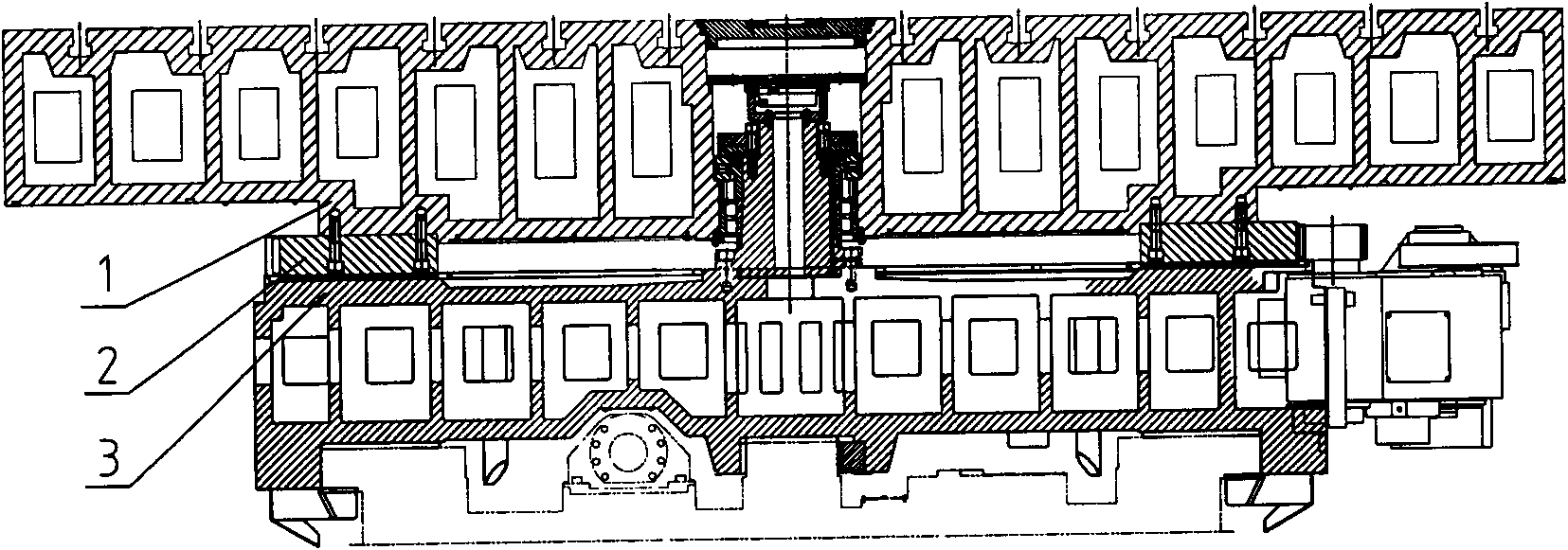

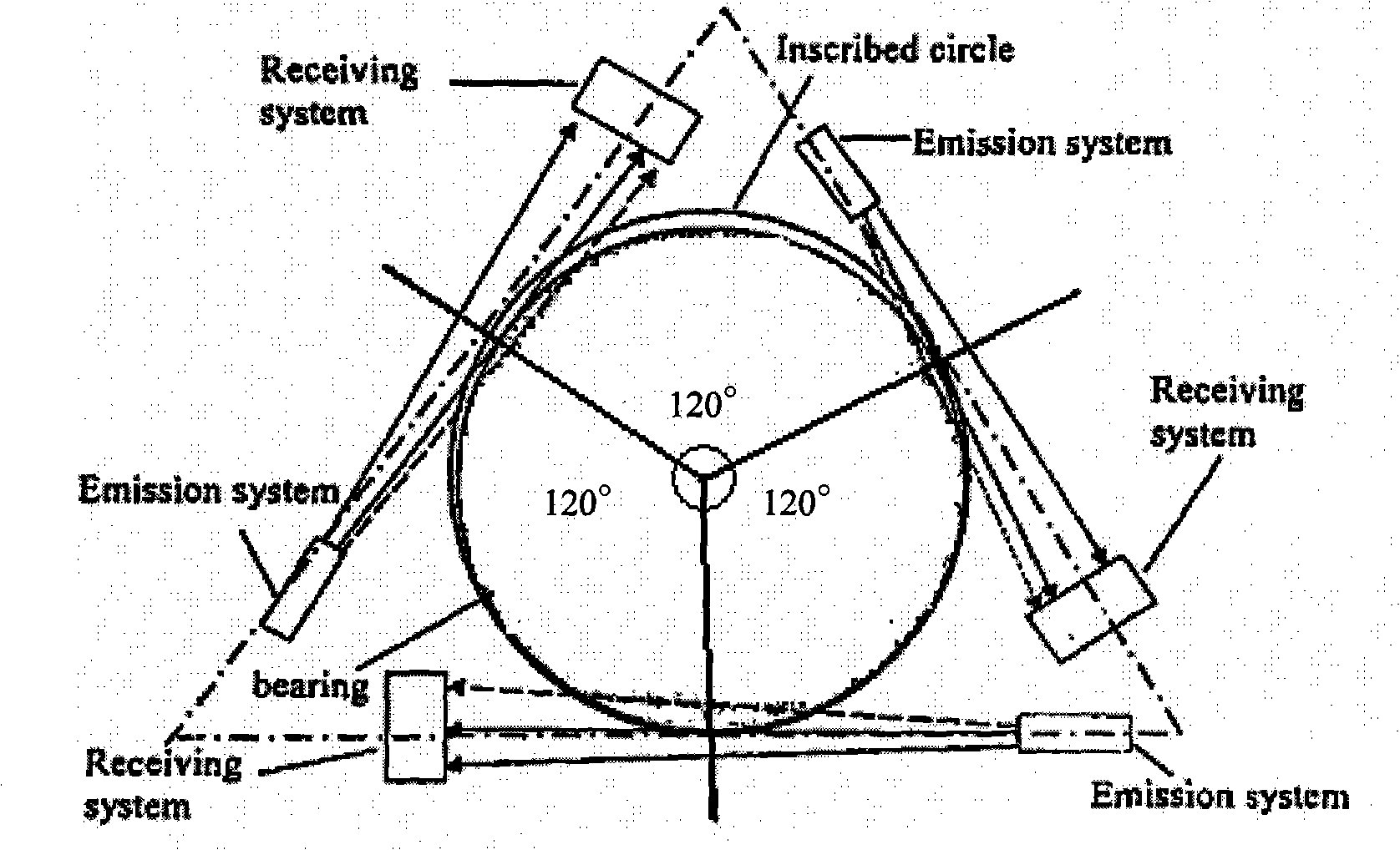

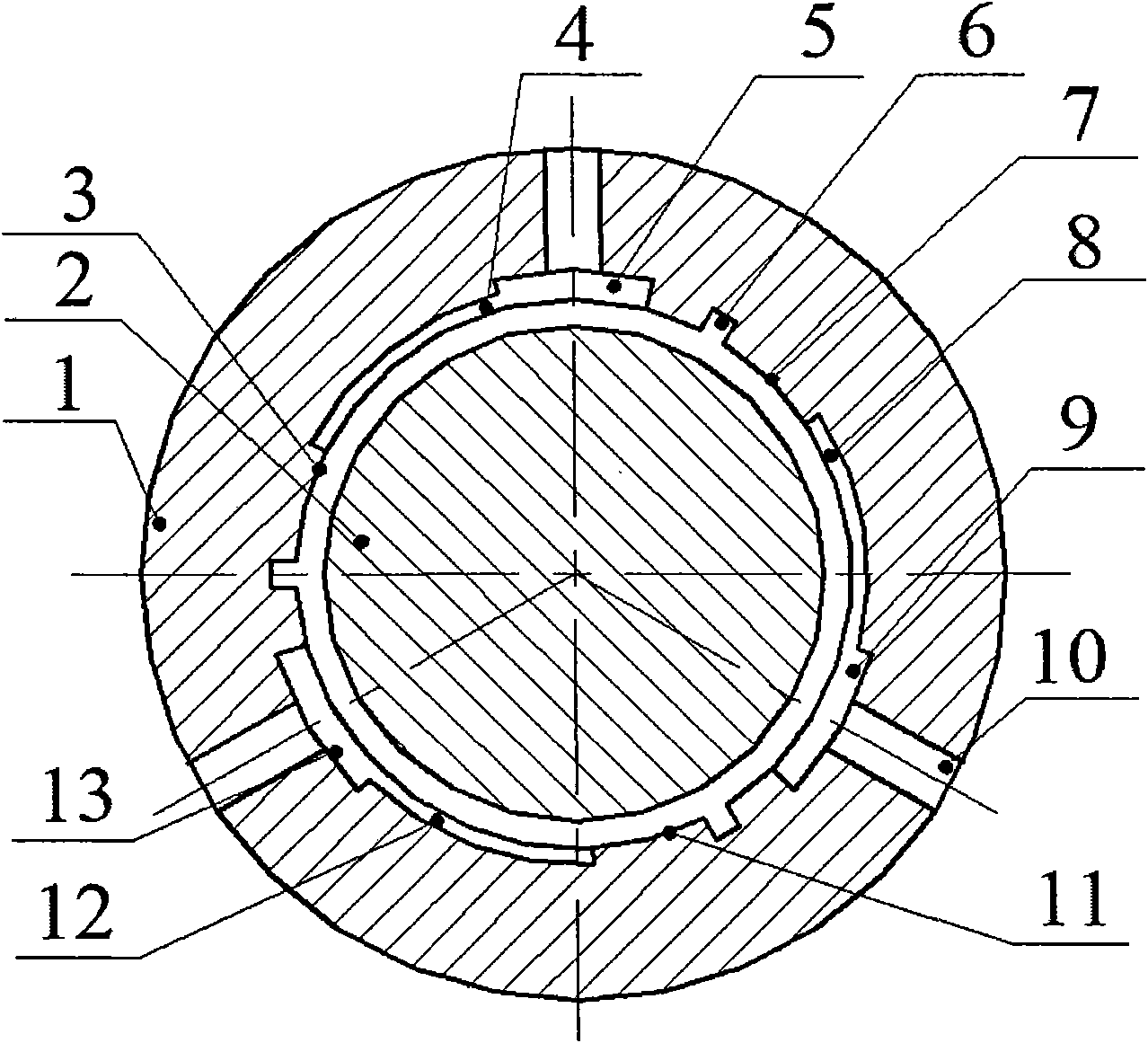

Static-dynamic mixed oil film bearing

The invention discloses a static-dynamic mixed oil film bearing, which comprises a static-dynamic mixed oil film bearing 1, a main shaft 2, a return chute 6, and an oil inlet hole 10. The static-dynamic mixed oil film bearing is characterized in that the surface of an inner hole of the static-dynamic mixed oil film bearing 1 is provided with three static cavities which mutually form 120 degrees; pressure oil enters each static cavity through the oil inlet hole 10; the pressure oil returns through three coaxial return chutes 6; three step holes mutually forming 120 degrees are arranged between the static cavities and the coaxial return chutes 6; and three dynamic cavities are formed on the oil seal surface between the step cavities and the coaxial return chutes 6. The static-dynamic mixed oil film bearing better solves the contact problem between the main shaft and the static-dynamic mixed oil film bearing when the main shaft is started, and greatly improves the dynamic pressure effect of the static-dynamic mixed oil film bearing when in operation work condition and therefore obtains an ideal dynamic pressure effect, can greatly improve the rigidity of the oil membrane and the effect of homogenizing errors, and can greatly improve the return precision of a main shaft system.

Owner:重庆西门雷森机械工程技术服务有限公司

Continuous lubricating crystallizer for aluminum alloy semi-continuous casting

The invention relates to a continuous lubrication crystallizer used for casting aluminum alloy semi-continuously, wherein the inner wall of the crystallizer is inlaid with a graphite lining, a top cover of the crystallizer is internally provided with an independent oil cavity, the graphite lining presents up-down symmetric construction with a taper, a body of the crystallizer is provided with a top water cavity and a lower cavity which are independent, the top water cavity and the lower cavity are respectively opened with an independent water inlet and are respectively provided with a splash plate, the bottom of the top water cavity is provided with a row of water passing ports, the bottom of the lower water cavity is also provided with a row of water passing ports, the angel of the water passing ports of the top water cavity is different from and presents interlaced shape with the water passing ports of the lower water cavity's, when casting, a layer of continuous oil film forms via infiltrating oil forming the oil cavity to the graphite lining, which has effects of heatproof, reducing once cooling of ingot casting at the same time when improving graphite lubricating oil effects, two independent water cavities realize the independent or double water-cavity water supply, which improves the aftercooling effect on the premise of ensuring heat cracks not to appear at the early stage of aluminum alloy ingot casting, thereby realizing a low liquid level on the inner portion of the crystallizer, and distinctively improving surface quality of the ingot casting.

Owner:CHINA NON-FERROUS METALS PROCESSING TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com