Patents

Literature

67results about How to "Improve blending uniformity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

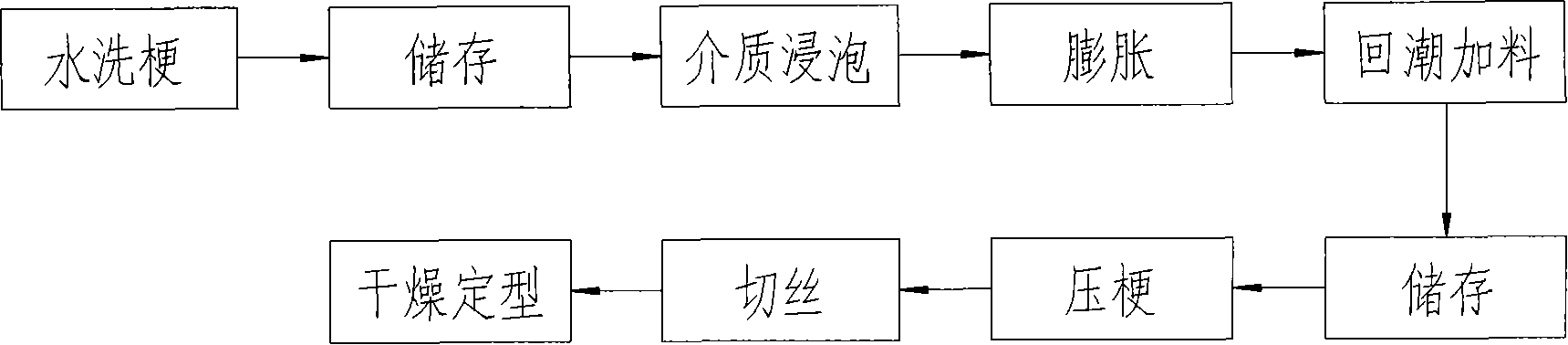

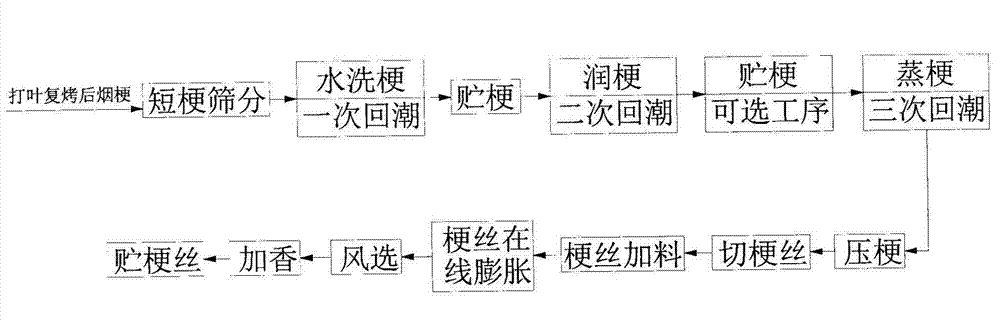

Technique of pre-expanding treating cabo

ActiveCN101108028AFully removedLarge specific surface areaTobacco preparationTobacco treatmentFilling materialsEngineering

A tobacco stalk pre-expending processing technics is provided, which is characterized in that: the technics comprises the following procedures: washing, storing, expanding in liquid and marinating with interface the tobacco stalk, expanding the stalk strips, moisture regaining and feeding, storing, pressing sticks and drying for shaping. The technics method of the invention changes the expanding of cut rolled stem into expanding the tobacco stick by using marinating with high temperature and low pressure and then expanding with high temperature and reduced preddure, thus sufficiently eliminating the bad flatus in the tobacco stick as the flatus of the wood or the corrupt straws; the tobacco stick after expanded has increased cells and remarkably enhanced ratio surface, thus the material liquid can filter into the tobacco sticks sufficiently to becoming a natural filling material and adaptation carrier for adjusting the cigarette fragrance and style; the cigarette stick after expanded is large in volume, which, after pressed, is easy being cut into silkiness (similar as the physical behavior of tobacco shred); after dried and shaped normally, the cut rolled stem can crisp naturally, thus increasing the filling capacity. The cut rolled stem processed by the technics method of the invention is basically similar with tobacco shred in color and shape and the alloying evenness of the tobacco shred is increased; besides, the tobacco shred has no bad aftertaste when smoking, but has strong filling capacity and enhanced internal quality.

Owner:ZHENGZHOU TOBACCO RES INST OF CNTC

Tobacco stem shred preparation method

A tobacco stem shred preparation method includes steps of pretreatment of tobacco stems, microwave expansion of tobacco stems, moisture regaining of expanded tobacco stems, tobacco stem shredding, stem shred screening and winnowing, stem shred feeding, second tobacco shred expansion, stem shred flavoring and the like. The prepared tobacco stem shreds are similar to tobacco shreds in appearance and shape, have the advantages of high filling performance, soft flavor and low stimulation in sensing quality and the like and are good in suitability for smoke.

Owner:YUNNAN REASCEND TOBACCO TECH GRP

Production method of elastic denim fabric with low shrinkage rate

ActiveCN107012564AReduce weft shrinkageIncrease elasticitySucessive textile treatmentsWoven fabricsShrinkage rateViscose

The invention discloses a production method of elastic denim fabric with a low shrinkage rate. The method includes the specific steps of spinning, dyeing, sizing, weaving and after-finishing. The spinning process includes the procedures of blowing, carding, drawing, roving, spinning and spooling; the dyeing process includes the procedures of ball warping and bundle type dyeing. By means of the method, the weft shrinkage rate of the elastic fabric is reduced, the elastic property of the fabric is improved, and the effects of improving the wearability of pure cotton denim fabric and improving the wearing comfort are achieved; cotton / viscose blended warp is adopted for weaving the denim fabric, a reasonable spinning technology is adopted, and thus the blending uniformity is improved; through production technology optimization, the performance of the product is improved; an air loose softening finishing machine is adopted for loose softening finishing in the after-finishing stage, so that the weft shrinkage rate of the denim fabric is greatly reduced, and the elastic property of the denim fabric is improved.

Owner:ZAOZHUANG HIYOUNG DYNASTY TEXTILE

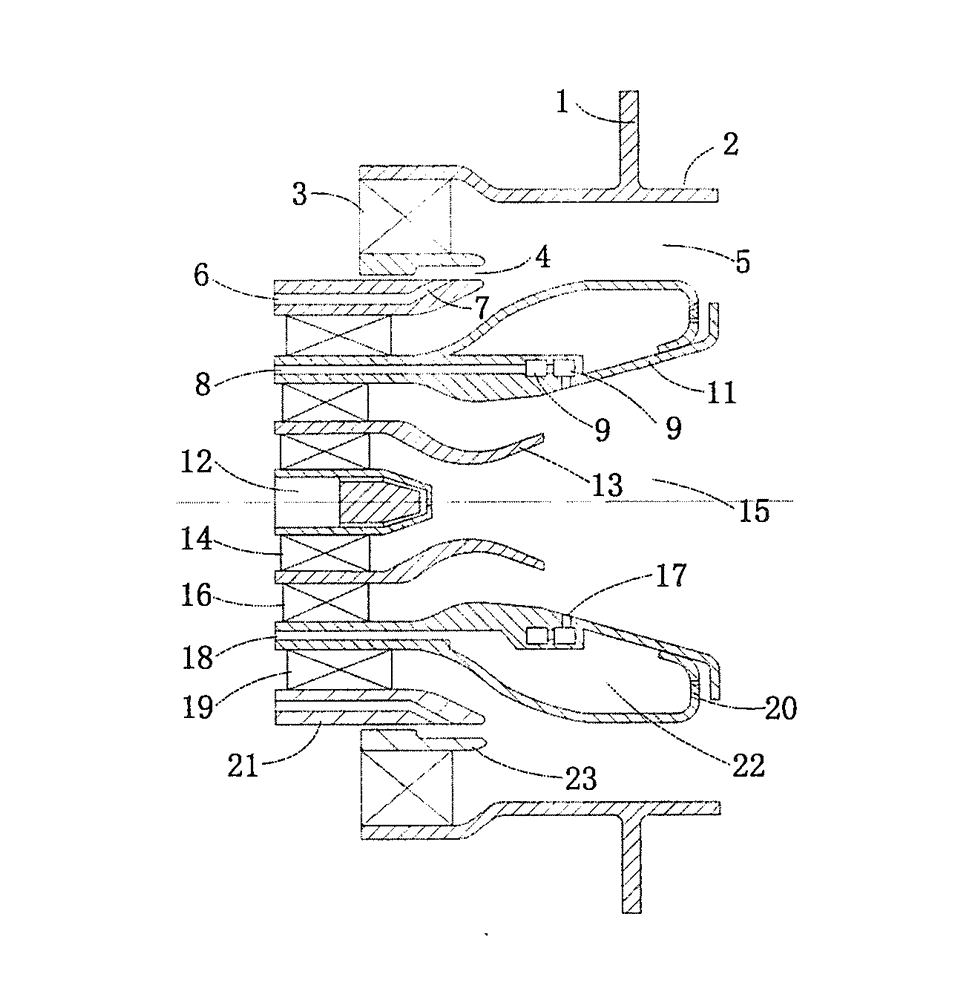

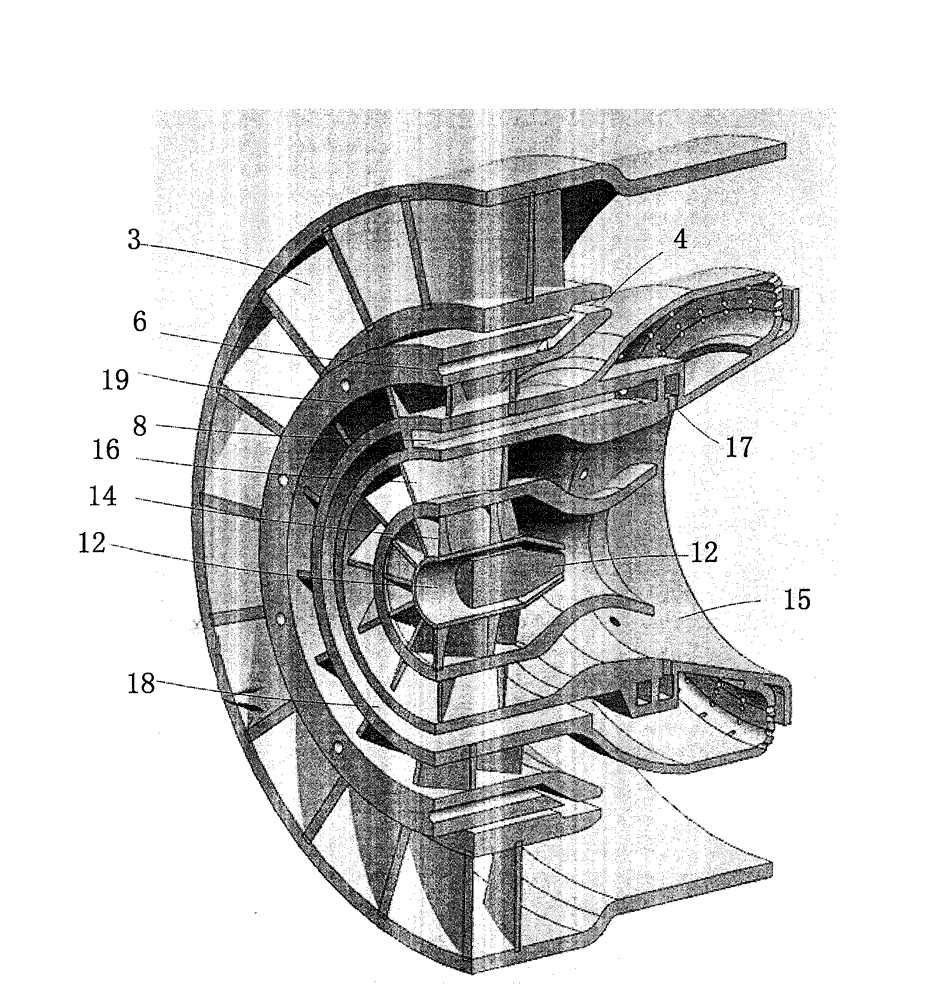

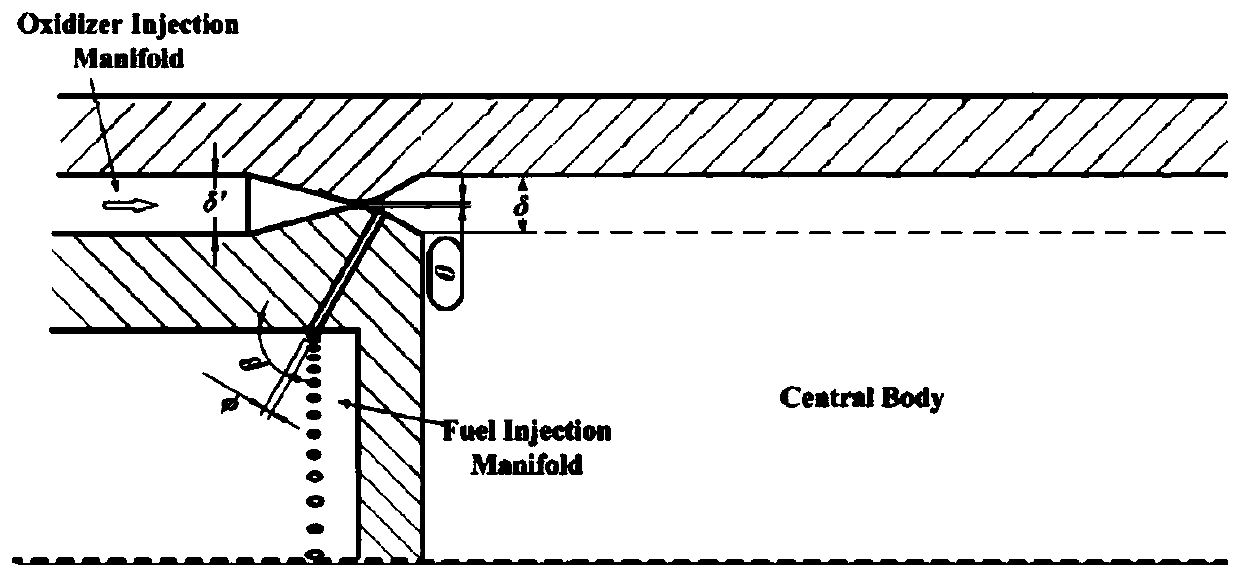

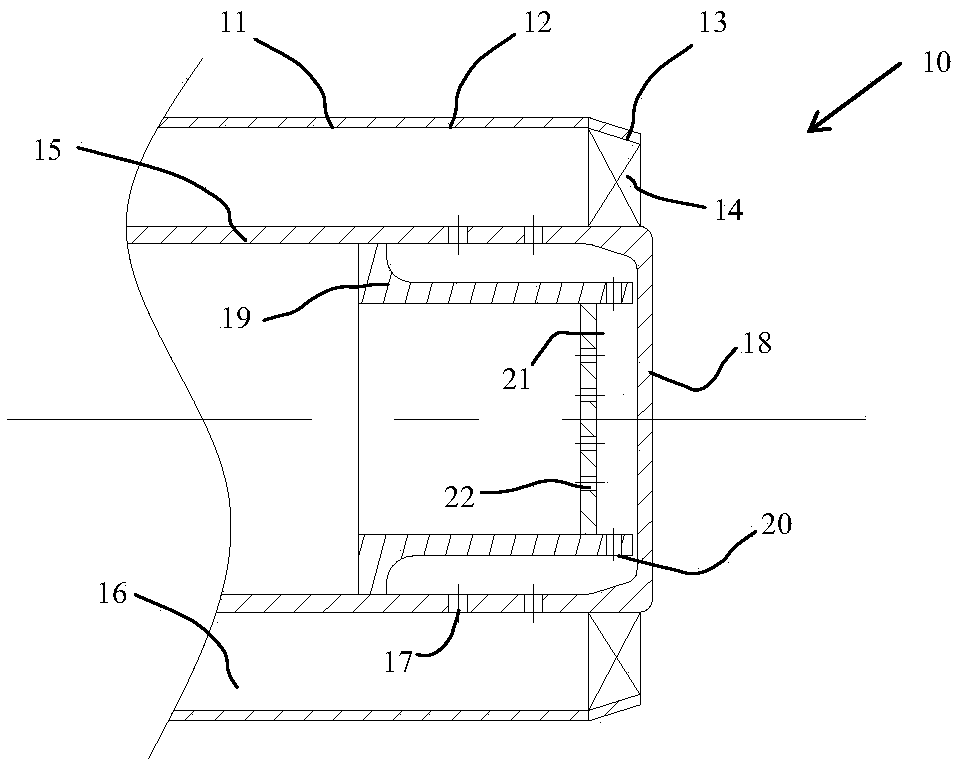

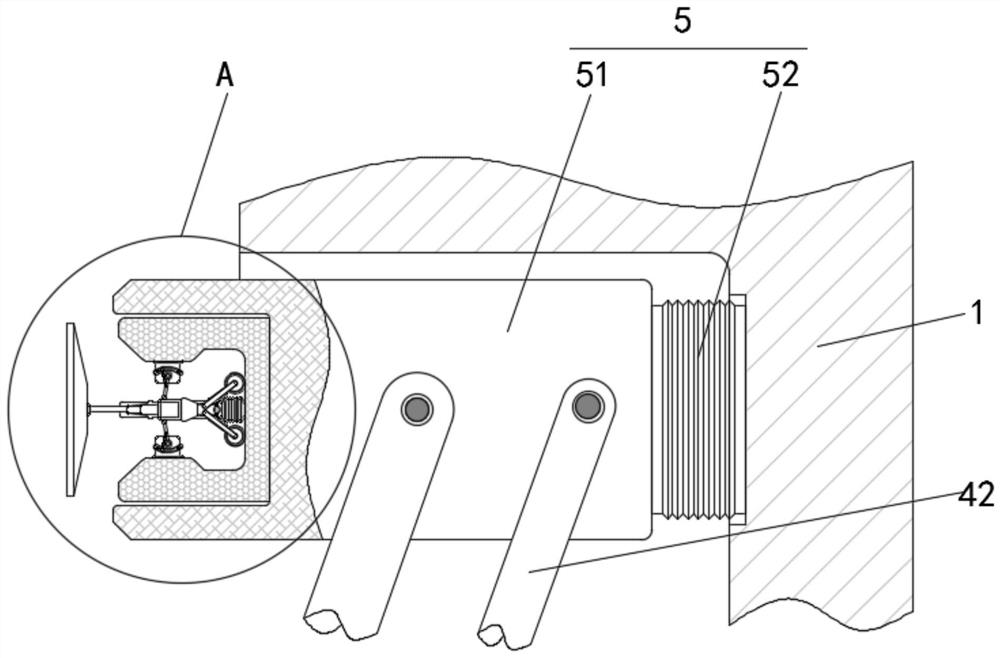

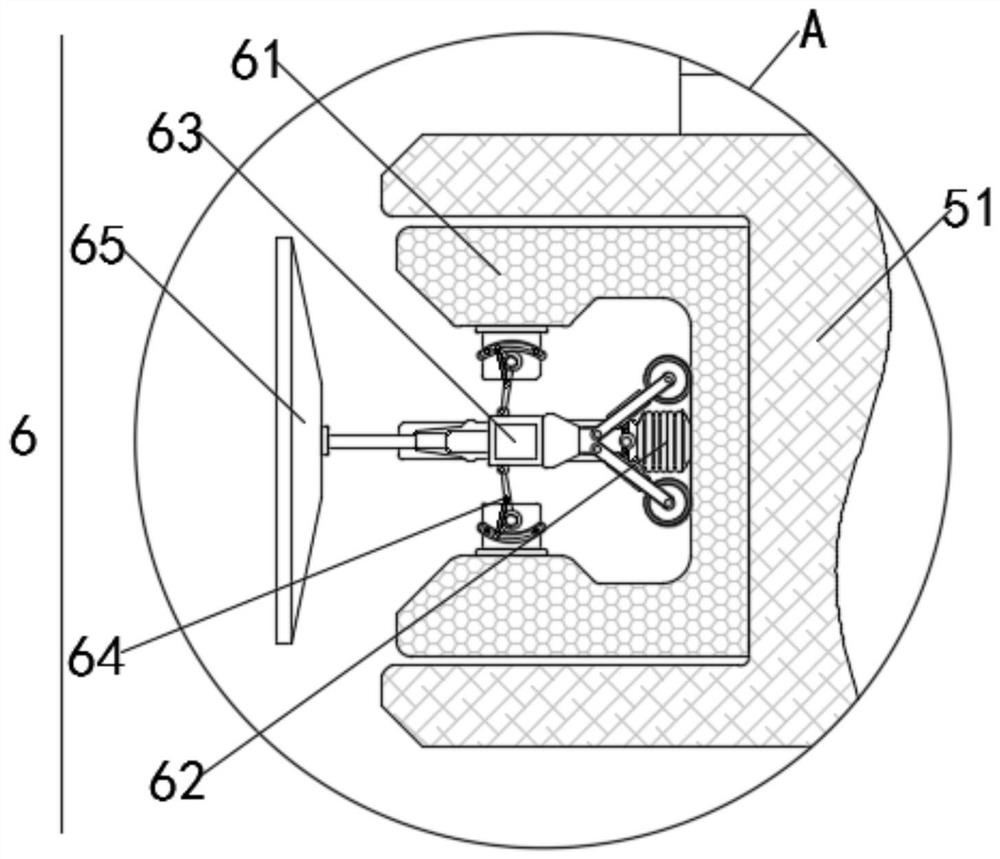

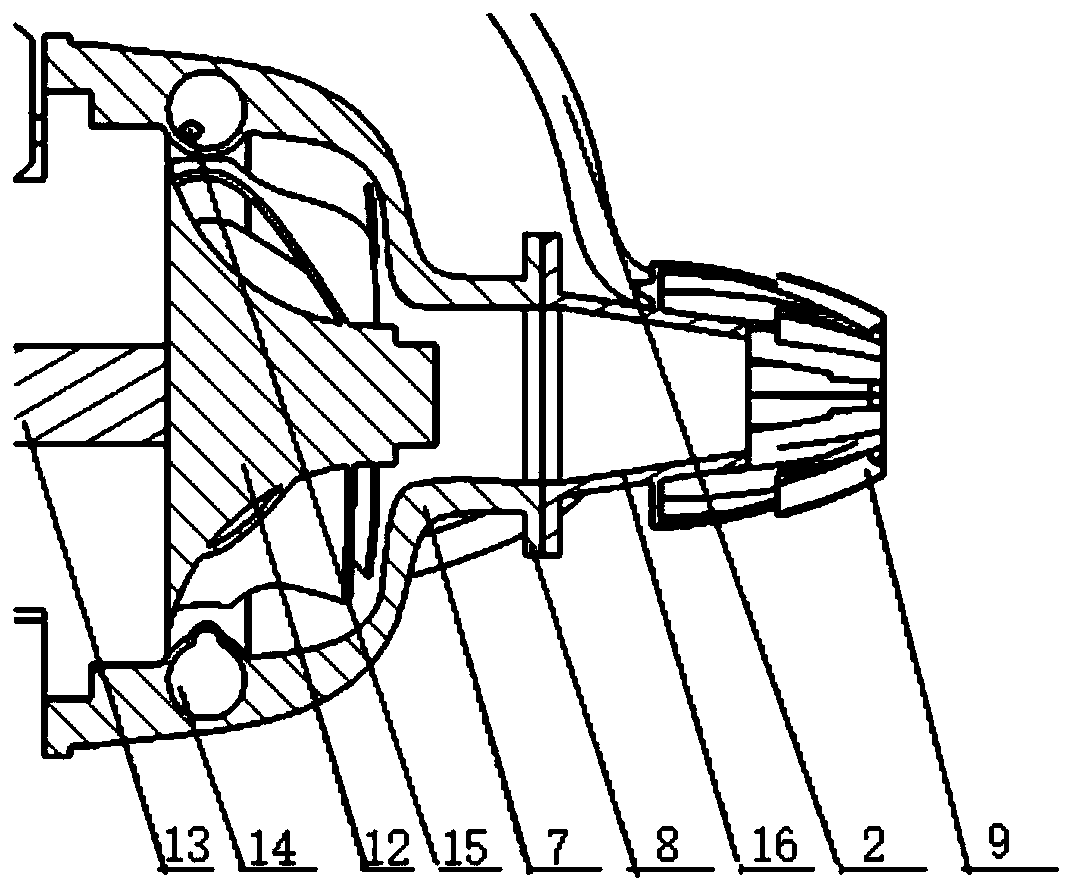

Combustor fuel injection and mixing device

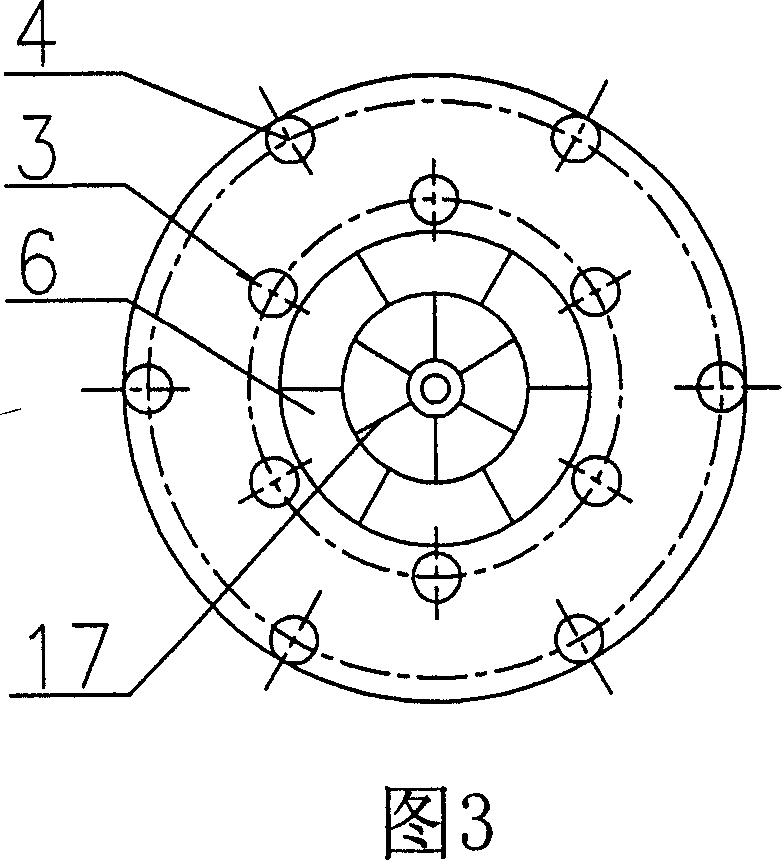

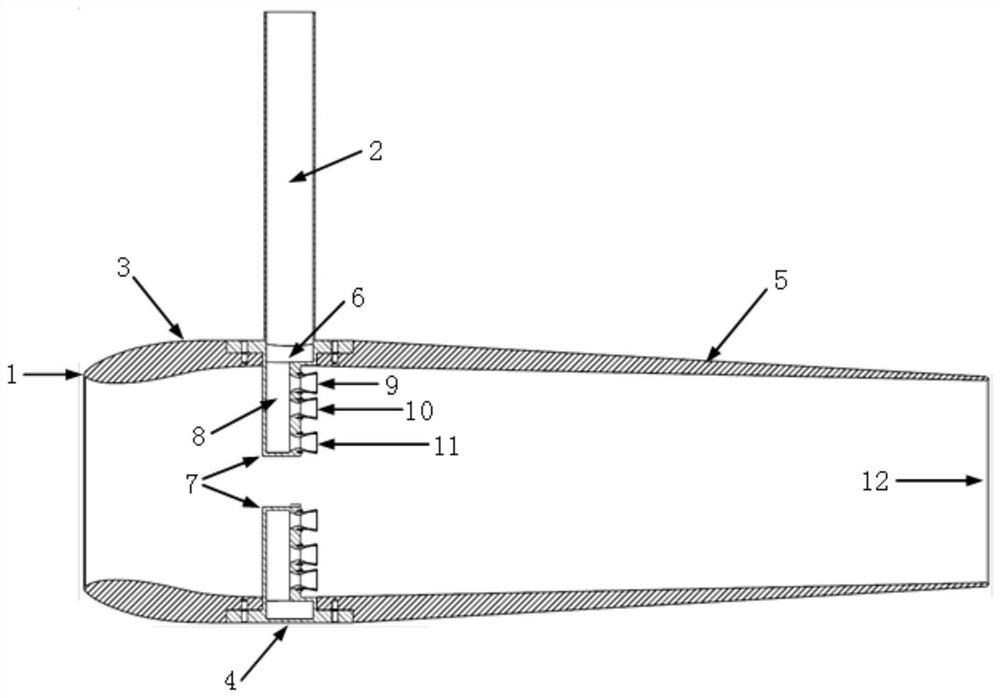

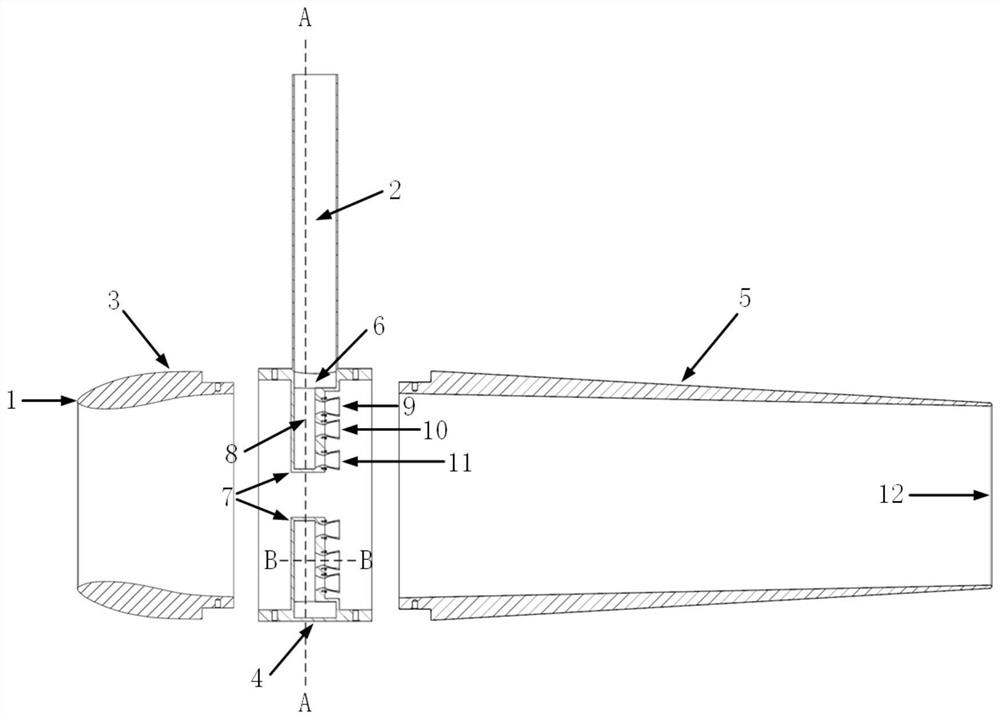

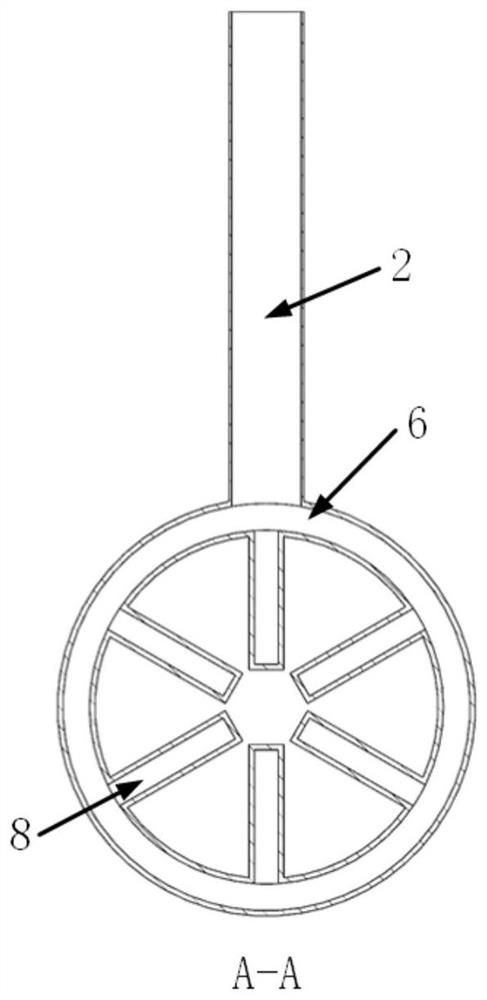

ActiveCN103062798AImprove blending uniformityImprove temperature distributionContinuous combustion chamberCombustion chamberCombustor

Disclosed is a combustor fuel injection and mixing device. A main combustion level, a middle combustion level, and a pre-combustion level are sequentially arranged from outside to inside of the combustor fuel injection and mixing device. Fuel respectively flows into oil pipelines of the main combustion level, the middle combustion level and a pre-combustion level through a main combustion level oil inlet hole, a middle combustion level oil inlet hole and a pre-combustion level oil inlet hole. The fuel in the oil pipelines are injected into a main combustion level channel, a middle combustion level channel and a pre-combustion level channel through a main combustion level nozzle, a middle combustion level nozzle and a pre-combustion level nozzle. The main combustion level nozzle is a pre-film type nozzle. Wall surface of two sides of the main combustion level nozzle is an assembling surface for assembling. The main combustion level oil pipe after a curve section is gradually expanded into a slit to enable the fuel in the main combustion level oil pipeline to form a layer of oil film behind the outer side wall of the main combustion level nozzle. Swirler components capable of shearing and atomizing the fuel injected into the main combustion level channel under the act of swirling are arranged around the main combustion level nozzle. The combustor fuel injection and mixing device is capable of improving mixture evenness of fuel and gas in the main combustion level and further improving temperature distribution of the outlet of the combustor.

Owner:AECC COMML AIRCRAFT ENGINE CO LTD

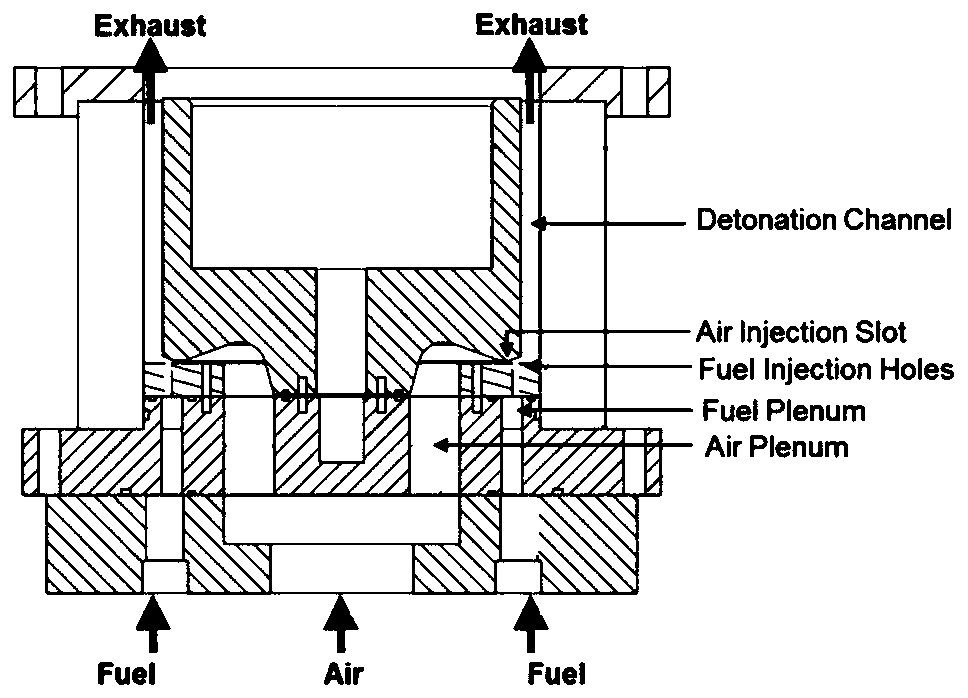

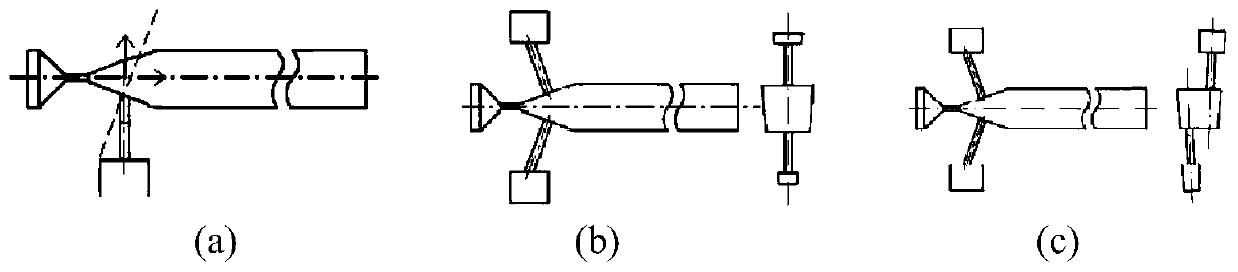

Ring cavity rotational flow opposite spraying structure based on RDE combustion chamber

The invention provides a ring cavity rotational flow opposite spraying structure based on an RDE combustion chamber. An axial symmetry hook face circular seam is adopted in a circular seam of an RDE,an included angle of the obtuse angle is formed between the transverse jet flow and the main jet flow direction of RDE, single-row annular cavity array cylindrical fuel spraying holes are evenly distributed in the inner and outer wall faces of the head of the RDE combustion chamber, and on the basis of the two-dimensional deflection, circumferential deflection is added on the fuel spraying holes.The structure has the advantages that non-linear circular seam configuration is adopted, pressure losses are reduced, and the outlet flow field is more stable. The upstream area of the transverse jetflow is decelerated, the sufficient fuel penetrating and mixing can be achieved, and the mixing efficiency is improved.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

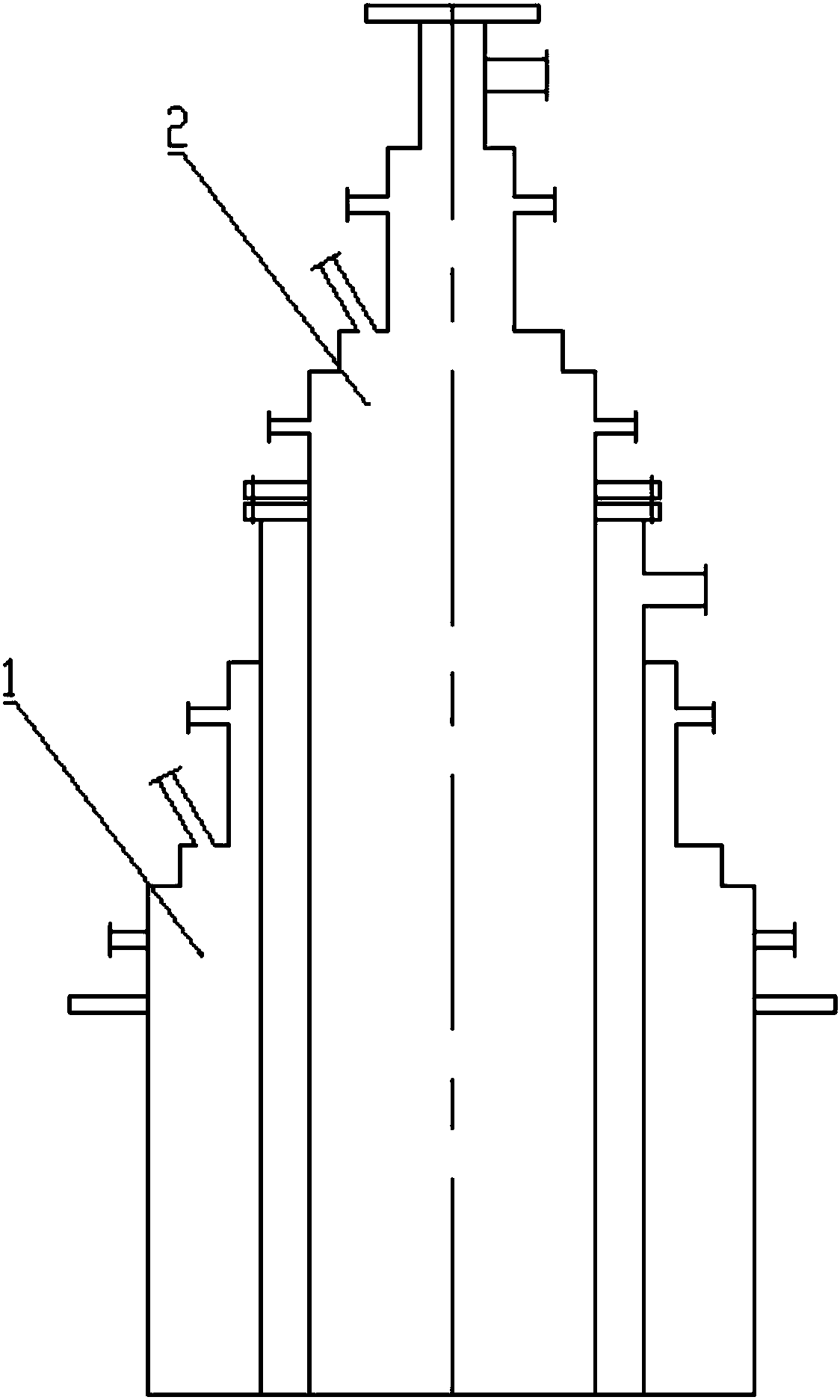

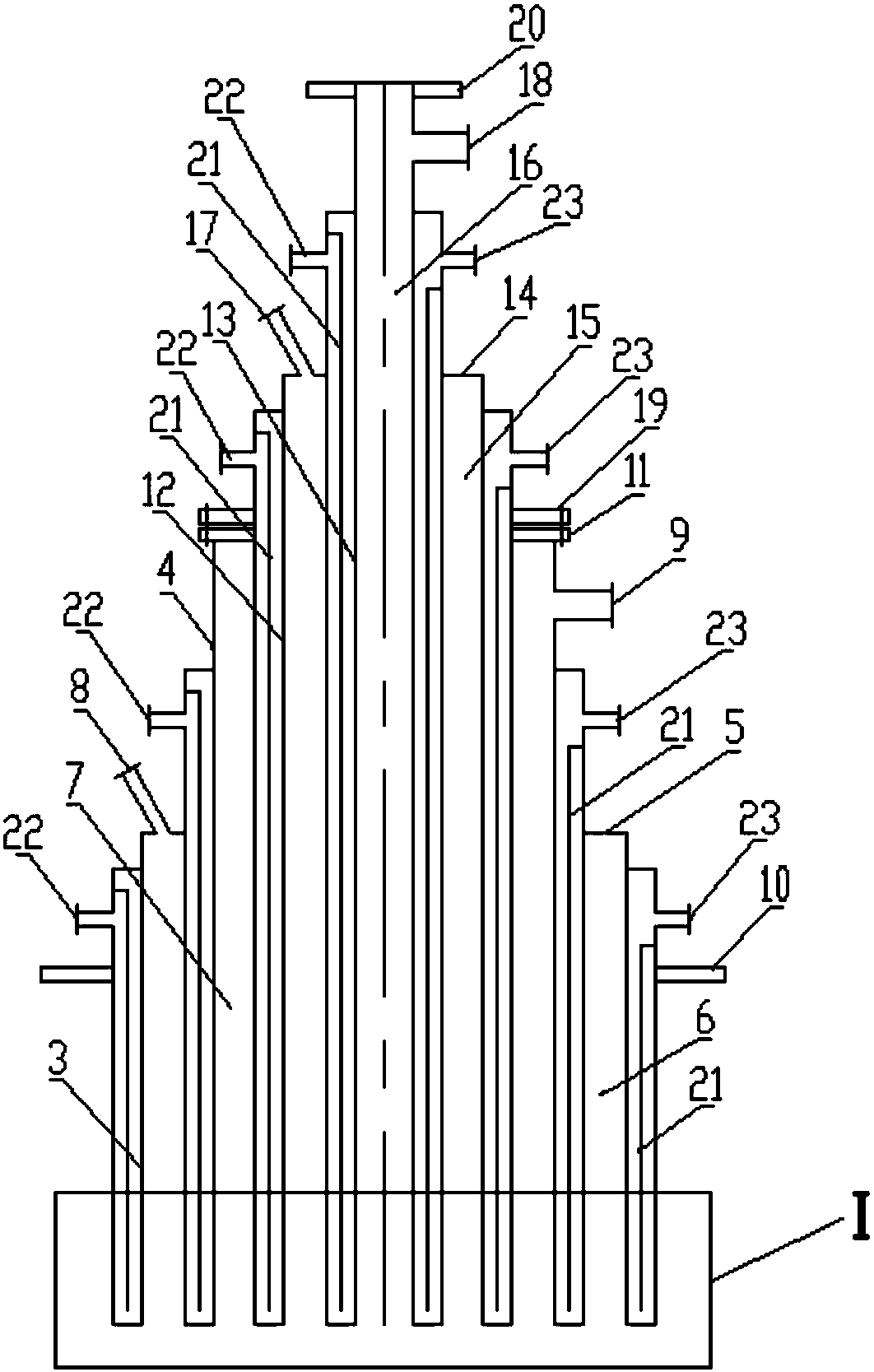

Gasification burner

PendingCN108728168AAdjust operating loadImprove conversion rateGasifier mechanical detailsGasification processes detailsCombustionReaction rate

The invention relates to a gasification burner. The gasification burner comprises a mother burner, N levels of sub-burners are arranged on the inner side of the mother burner, wherein N is an integergreater than or equal to 1, the mother burner and the sub-burners of each level are equipped with independent fuel channels and oxidant channels respectively, and the mother burner and the sub-burnersof each level are arranged to be a coaxial suit structure from the outside to the inside; the inner diameter of the mother burner is larger than the outer diameter of a first level sub-burner, and the inner diameter of the sub-burner of each level is larger than the outer diameter of the sub-burner of a next level; in a limited reaction space and residence time, the sufficient and uniform mixingof a fuel and an oxidant can be ensured, and the combustion reaction rate is accelerated, so that the fuel conversion rate and the gasification performance of a device are improved; in addition, through the adjustment of the load of the mother burner and the sub-burners of each level, the flame shape can be flexibly adjusted without reducing the load of a gasifier, so that the overheating of a gasifier furnace is effectively avoided, and different production load requirements of a project site can be met.

Owner:CHANGZHENG ENG

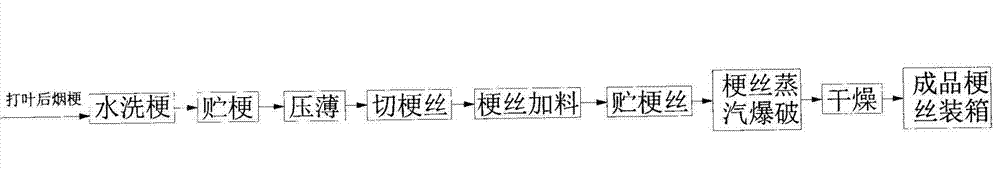

Tobacco stem cutting process by threshed tobacco stems

InactiveCN102783705AImprove qualityImprove blending uniformityTobacco treatmentIndustrial engineeringCigarette smoke

The invention discloses a tobacco stem cutting process by threshed tobacco stems. The process is characterized in comprising the following technical steps: washing stem, storing stem, thinning, cutting stem, carrying out steam explosion for cut stem, drying and so on. The process has the advantages that color and shape of the cut stem processed by the technical method are close to that of the cut tobacco; the breakage rate in the cut stem process is low; the blending uniformity is improved; when smoked, the tobacco is free from harmful wood flavor; the cigarette smoke is harmonized; the comfort of the tobacco is improved; the cut stem is strong in filling capability; and the internal quality of the cigarette is further improved. The power consumption of the corresponding tobacco stem processing enterprise can be reduced. At present, a threshing redrying factory usually stores a lot of tobacco stems, so that the direct stem cutting process provides a new method for comprehensive utilization of the tobacco stems for the redrying factory, and provides a technical economic scheme for forward leading the stem cutting process of a cigarette factory to the redrying factory.

Owner:ZHENGZHOU TOBACCO RES INST OF CNTC

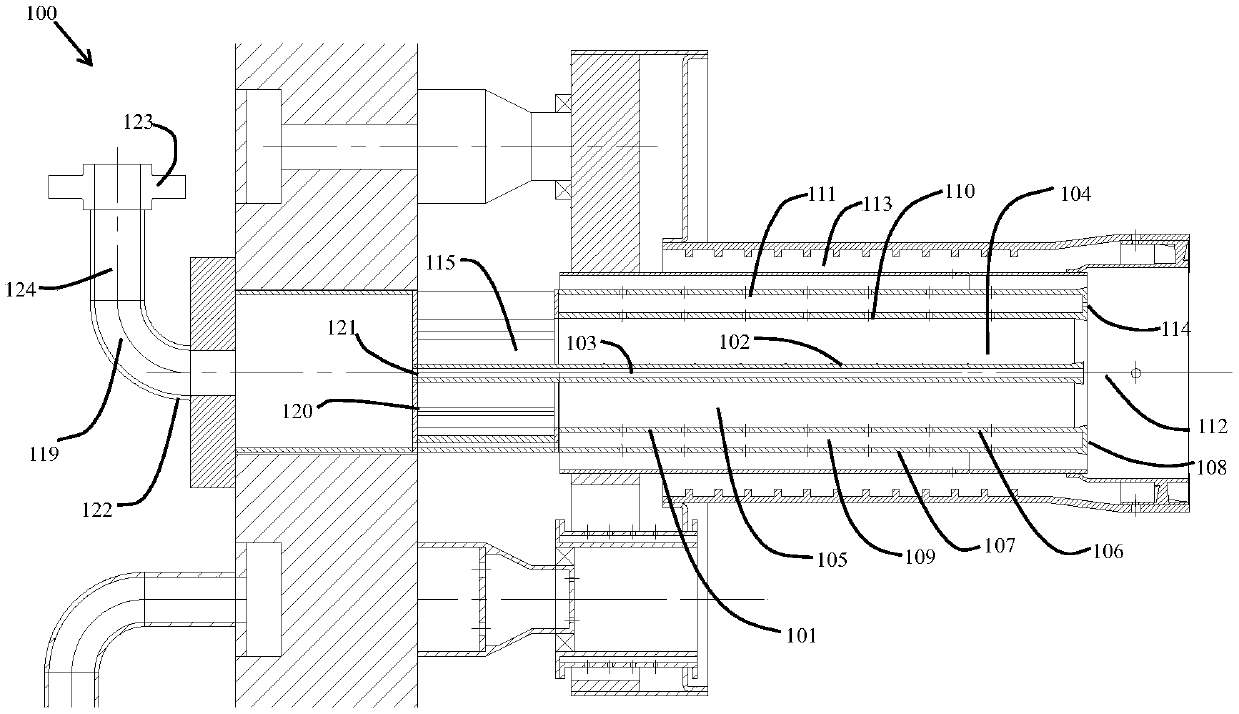

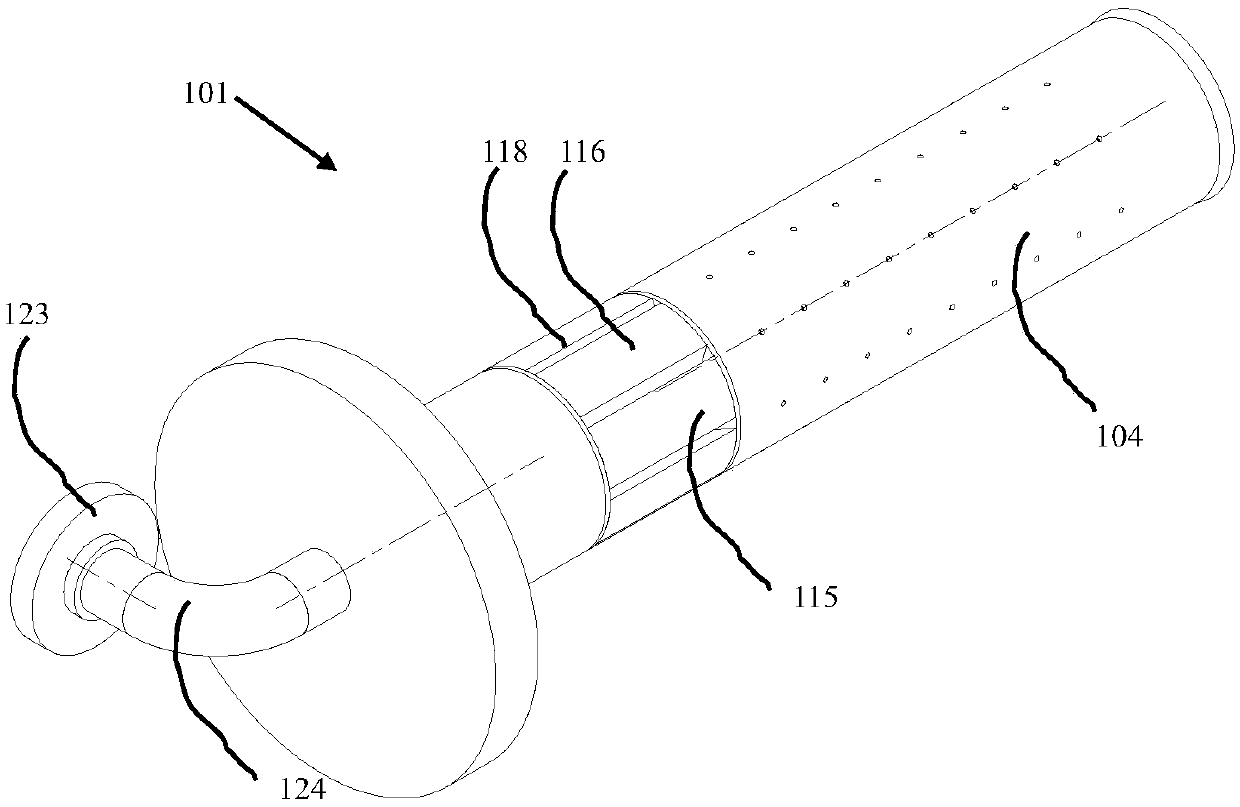

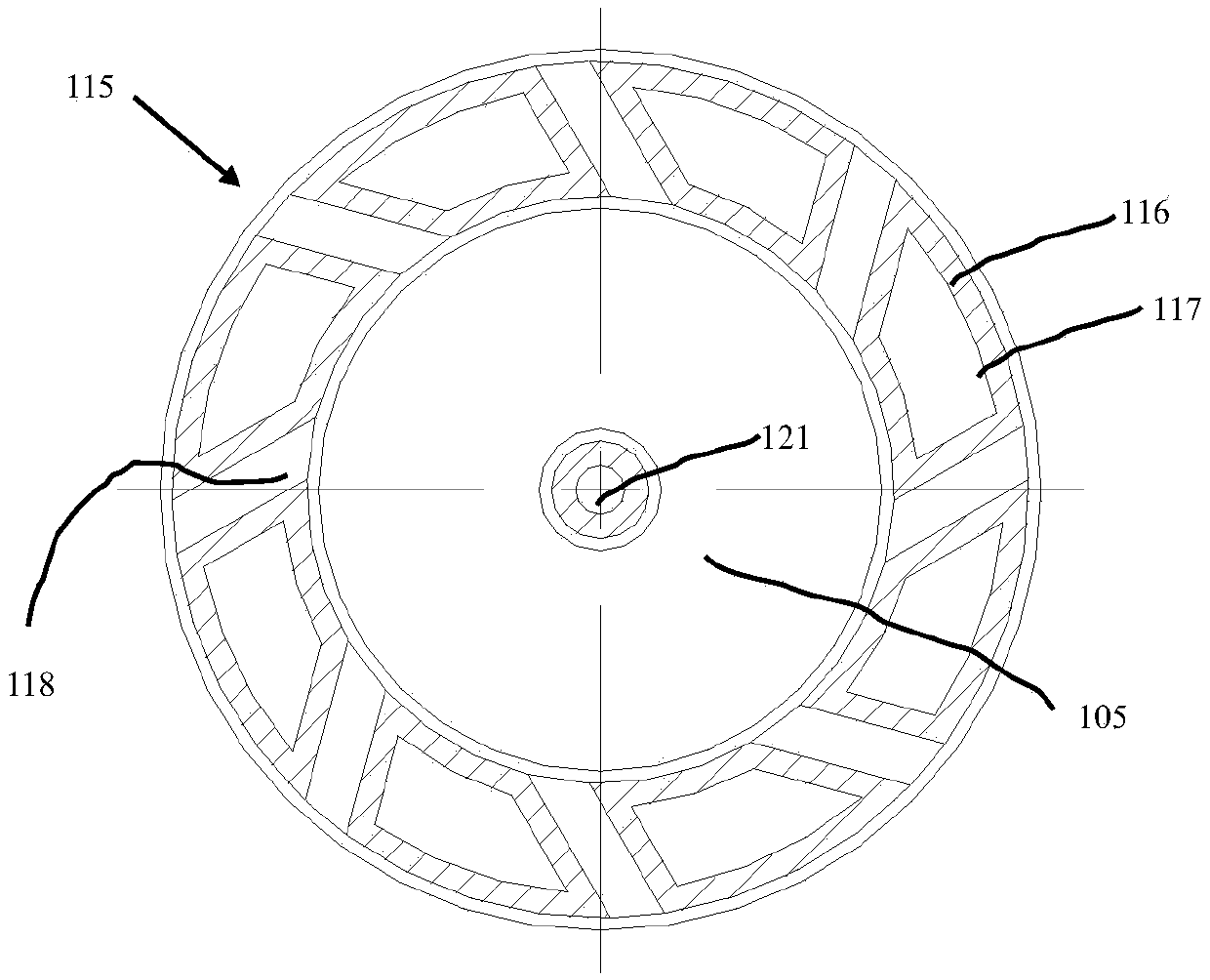

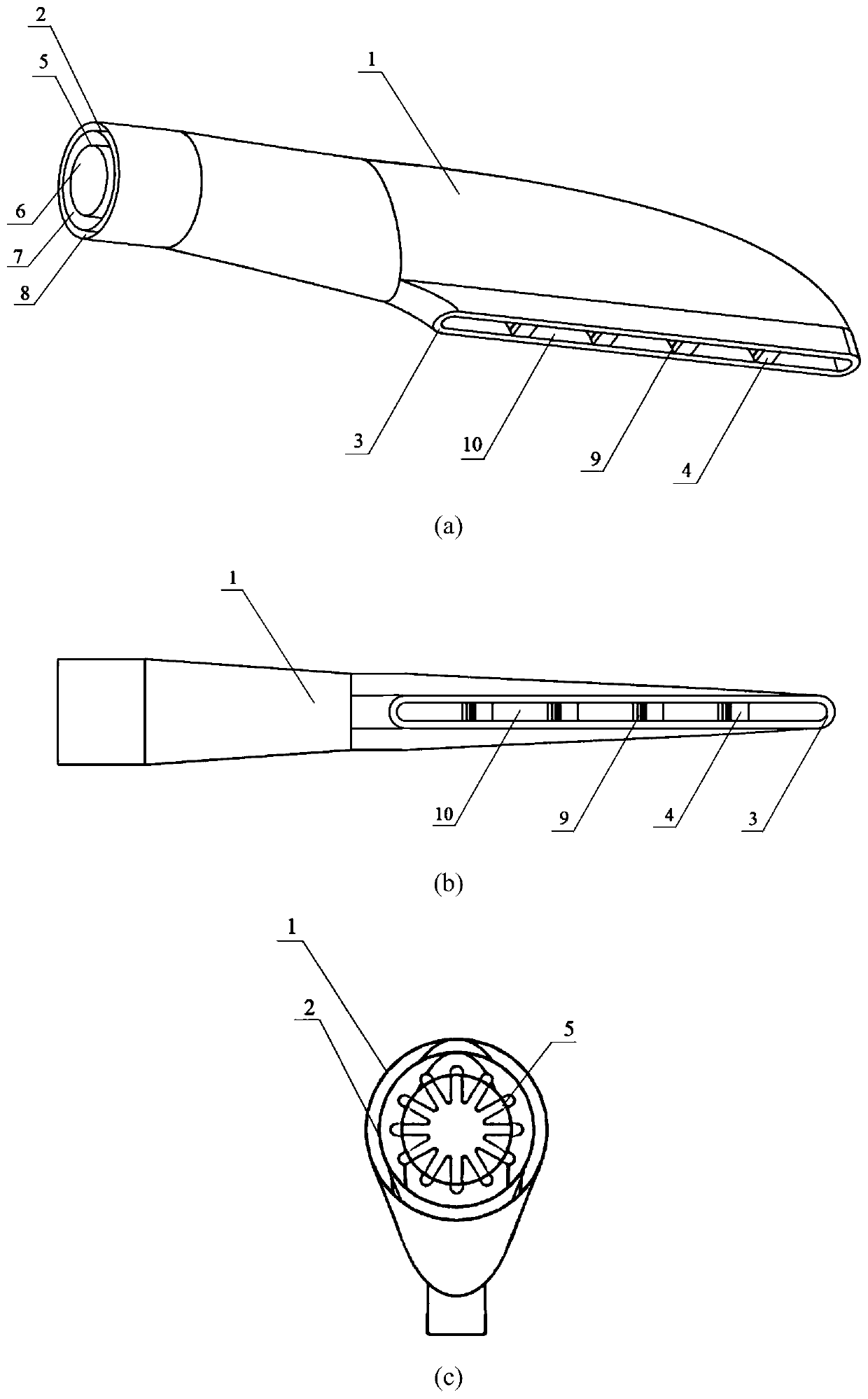

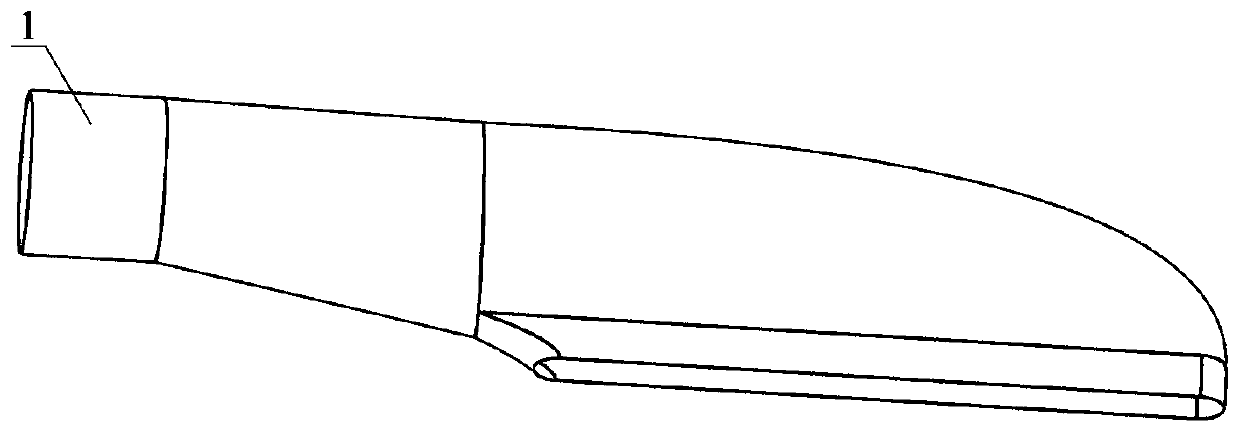

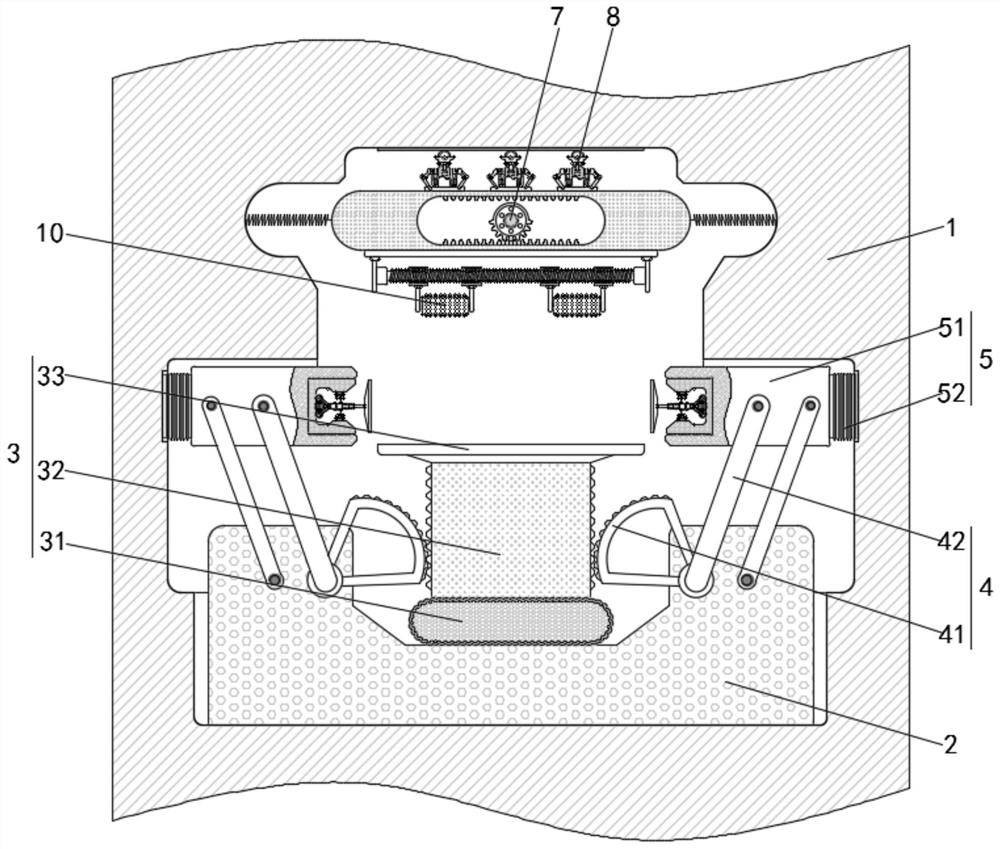

Center fuel nozzle

ActiveCN109654537AEnhanced blending uniformityReduce emissionsContinuous combustion chamberAutomotive engineeringGas turbines

The invention belongs to the technical field of turbine engines, and particularly relates to a center fuel nozzle. The center fuel nozzle (101) is arranged in a gas turbine combustion chamber (100), and comprises an on-duty fuel pipe (102), a fuel distributing pipe (104), a rotational flow pipe (115) and an inlet segment (122). According to the center fuel nozzle, the design of a traditional fuelspraying rod is omitted, through an inner fuel hole and an outer fuel hole, multi-point fuel putting is carried out, the mixed uniform degree of fuel and air can be reinforced, the emission amount ofthe combustion chamber can be reduced, the inner fuel hole and the outer fuel hole replace the fuel spraying rod in a pre-mixed channel to prevent back traces, and tempering risks of the combustion chamber are prevented.

Owner:AECC SHENYANG ENGINE RES INST

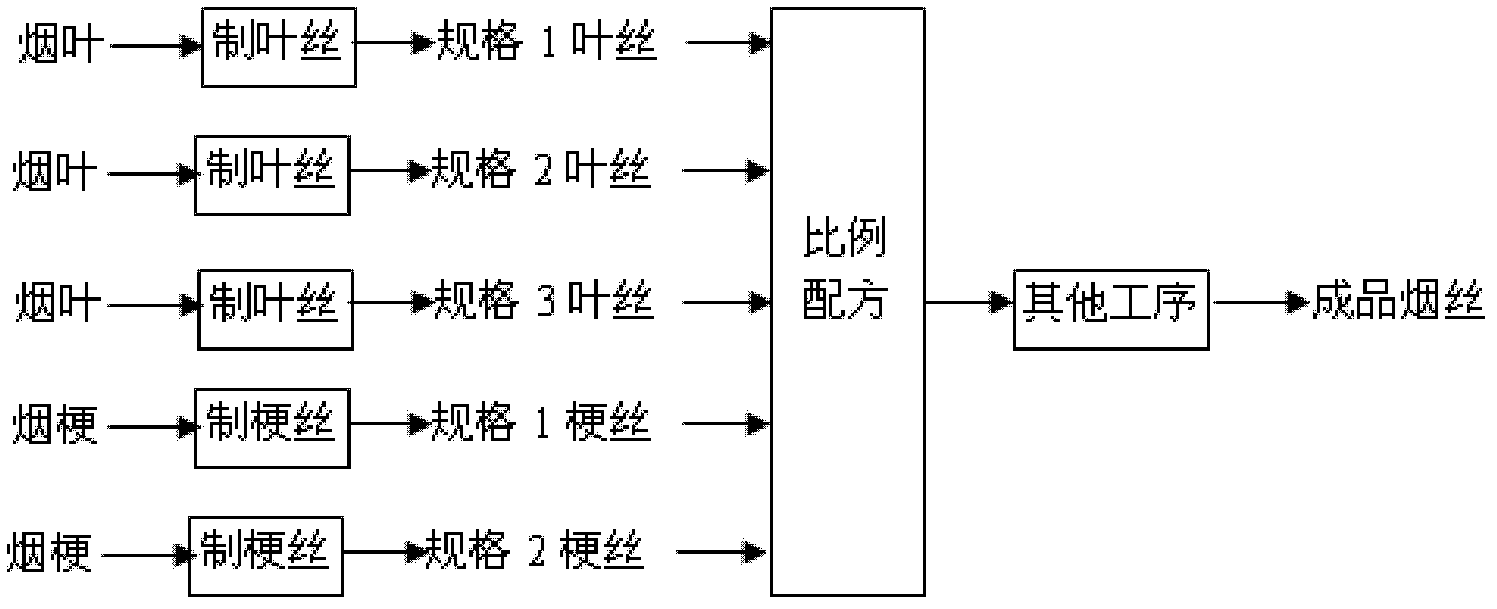

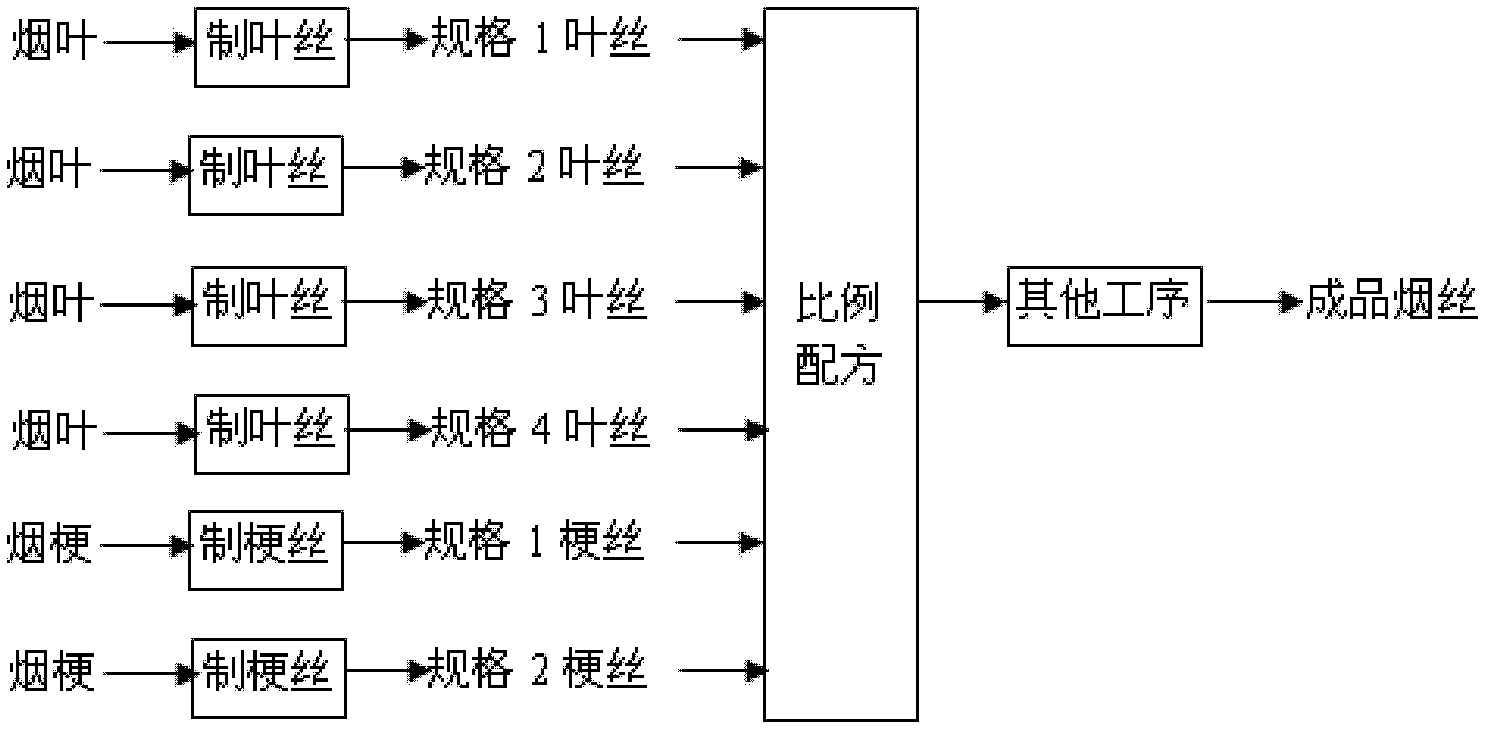

Matching method based on physical form of tobacco shred

InactiveCN102631018AQuality improvementImprove stabilityTobacco preparationDensity distributionEngineering

The invention discloses a matching method based on the physical form of tobacco shred. The method comprises the following steps of: according to size, respectively preparing the tobacco into leaf shred and stalk shred which are different in length and width by using different tobacco shred preparing processes, mixing the leaf shred and the stalk shred which are different in length and width according to the formula proportion design of cigarette, and finally processing into the finished tobacco shred by follow-up processing steps. According to the method, the differential selection of the cigarette trade mark to the tobacco shred structure can be realized, so that the even distribution of the tobacco shred in the cigarette can be improved, the stability of the physical quality and the chemical constituents of the cigarette can be effectively improved, and the loss in the process of processing can be reduced. A tobacco shred classifying working procedure is performed after the tobacco shred is baked, so that the mixing evenness of the tobacco shred and the other components in the formula can be improved. The tobacco shred structure of the cigarette can be effectively improved, so that the evenness of the tobacco shred density distribution in the cigarette can be improved, and the physical quality of the cigarette can be improved. The method is convenient to operate, and good in application prospect.

Owner:HONGYUN HONGHE TOBACCO (GRP) CO LTD

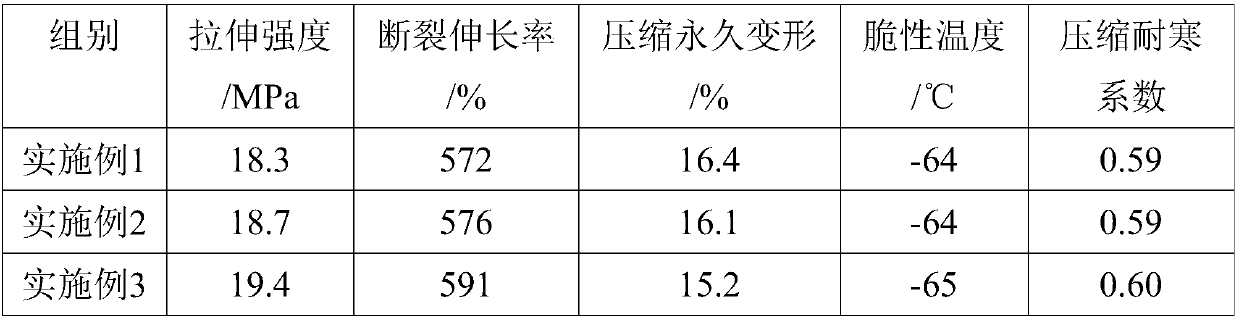

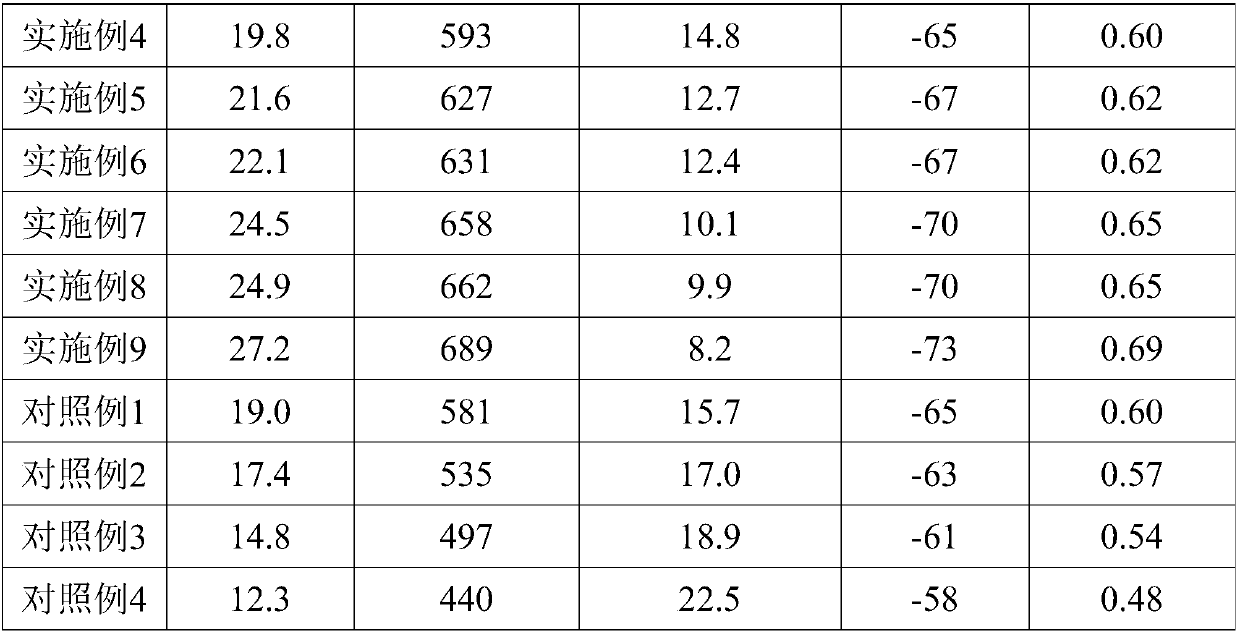

Processing method of low temperature resistant and oil resistant rubber sealing ring

InactiveCN108676210AImprove blending uniformityImprove mechanical propertiesDomestic articlesNitrile rubberCompressive deformation

The invention discloses a processing method of a low temperature resistant and oil resistant rubber sealing ring, and relates to the technical field of sealing ring processing. The method comprises the following technical steps: (1), batching, (2), mixing, (3), vulcanizing, (4), freezing, (5), performing additional vulcanization, and (6), performing finish machining. The method has the advantagesthat nitrile rubber and rear earth butadiene rubber are taken as rubber main materials, and are matched with kaoline, sea-foam stone powder and various functional additives, so that the sealing ring is formed, the sealing ring has excellent mechanical property, and particularly has excellent low temperature resistance, oil resistance and compressive deformation resistance, the sealing effect of the sealing ring in low-temperature environment is guaranteed, and the service life of the sealing ring in the low-temperature environment is prolonged.

Owner:安徽龙行密封件有限公司

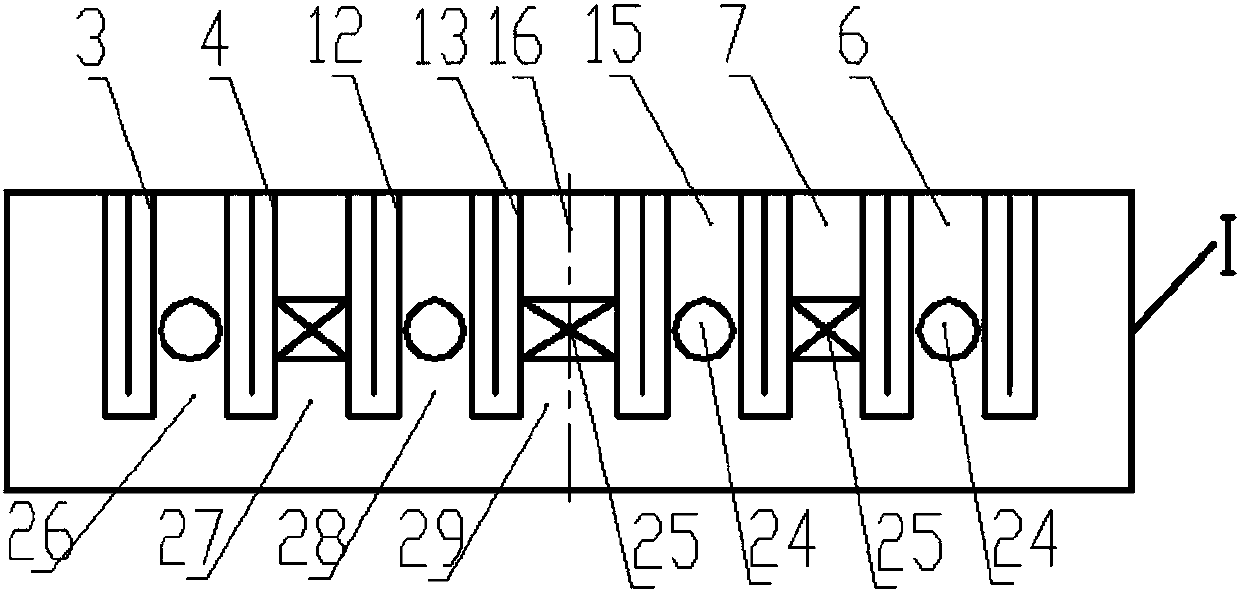

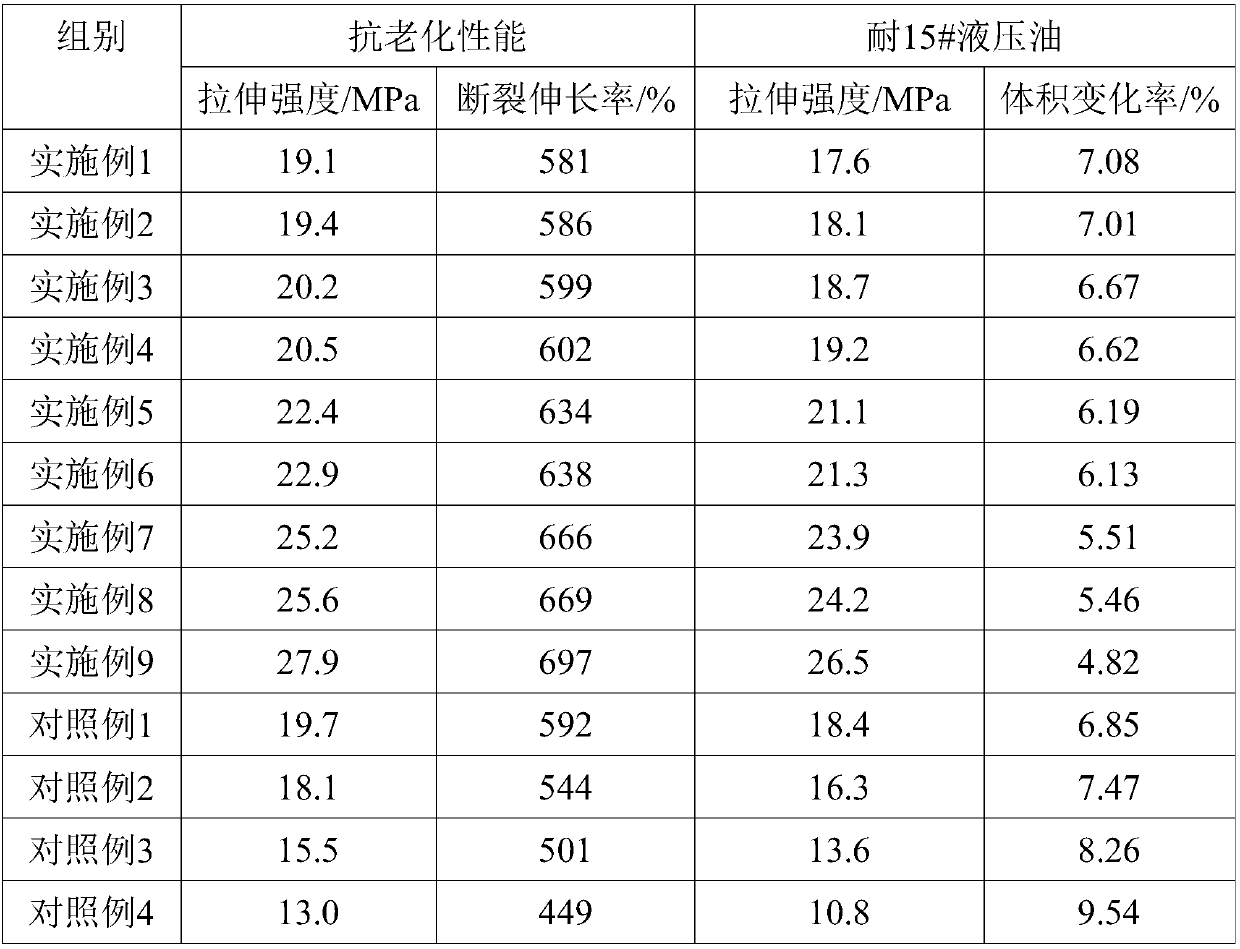

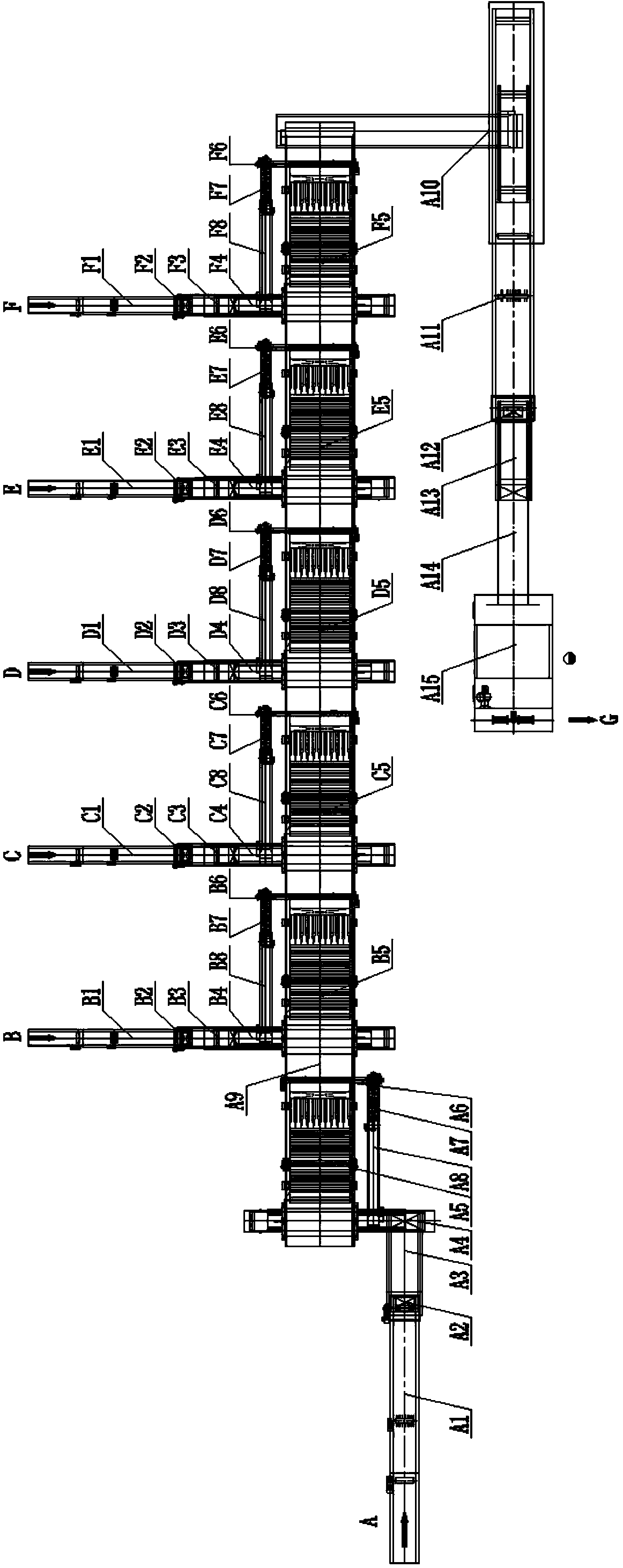

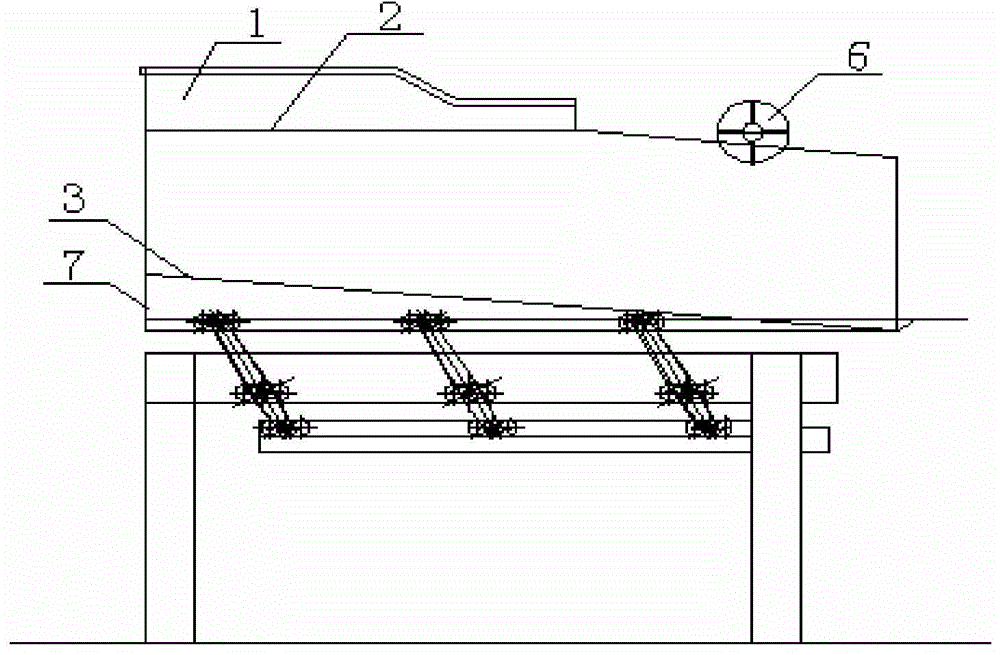

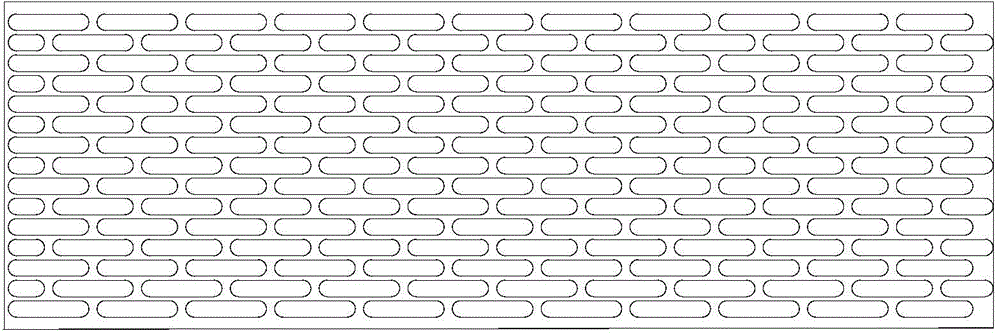

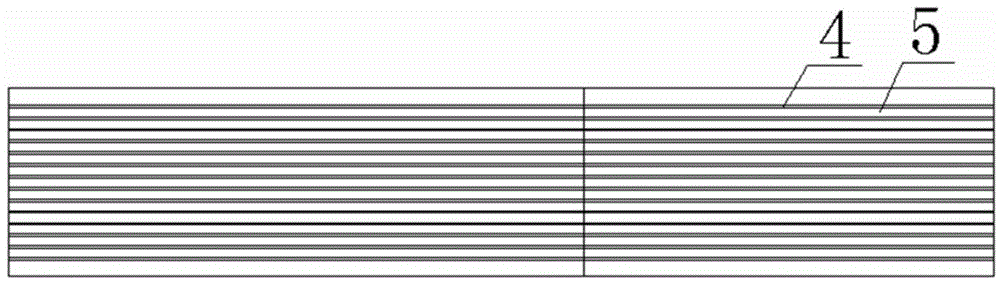

Device for sorting tobacco stems before shredding and using method thereof

InactiveCN104770855AReasonable structureAchieve the purpose of straightening outConveyorsTobacco treatmentControl systemEngineering

The invention relates to a tobacco stem sorting device for tobacco stem shredding. The device is composed of a vibrating feeder 1, a stem sorting screen plate 2, a longitudinal partition board 4, a material level control system 6 and a stem sorting machine vibrating groove 7. When the tobacco stem sorting device is matched with a tobacco stem shredding machine, tobacco stem sorting is achieved before shredding, cut stems are proper in length and are neither too long nor too short, thickness is even, cut stems are more reasonable in structure and more close to cut tobacco in form, and blending uniformity is high in cigarettes.

Owner:GUANGDONG GOLDEN LEAF TECH DEV

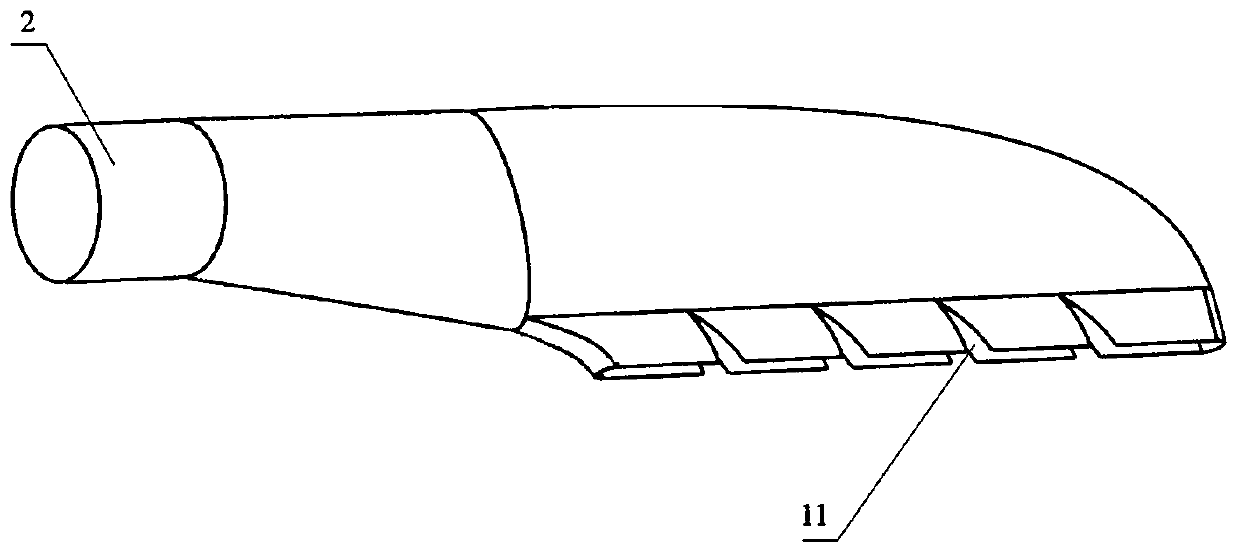

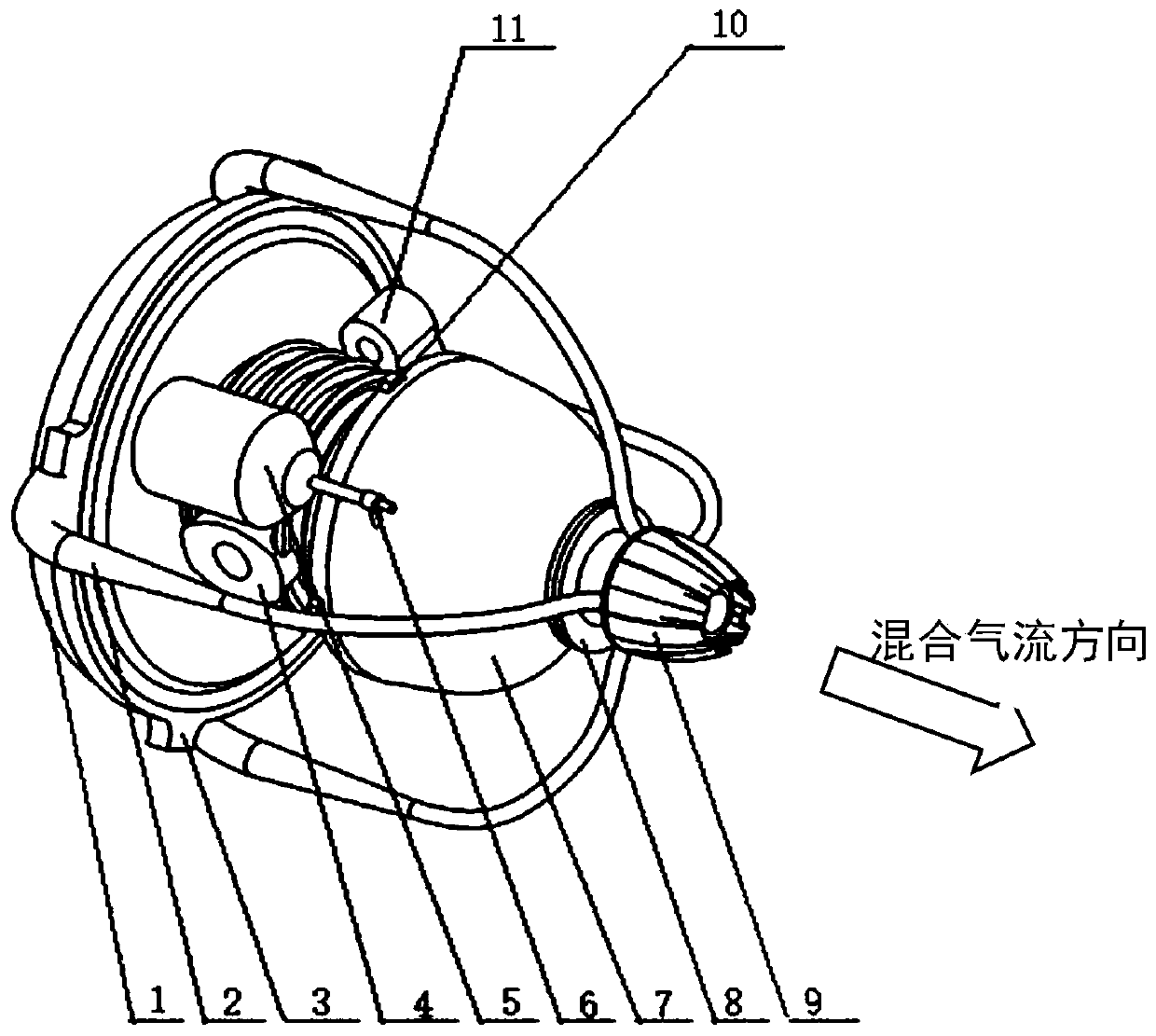

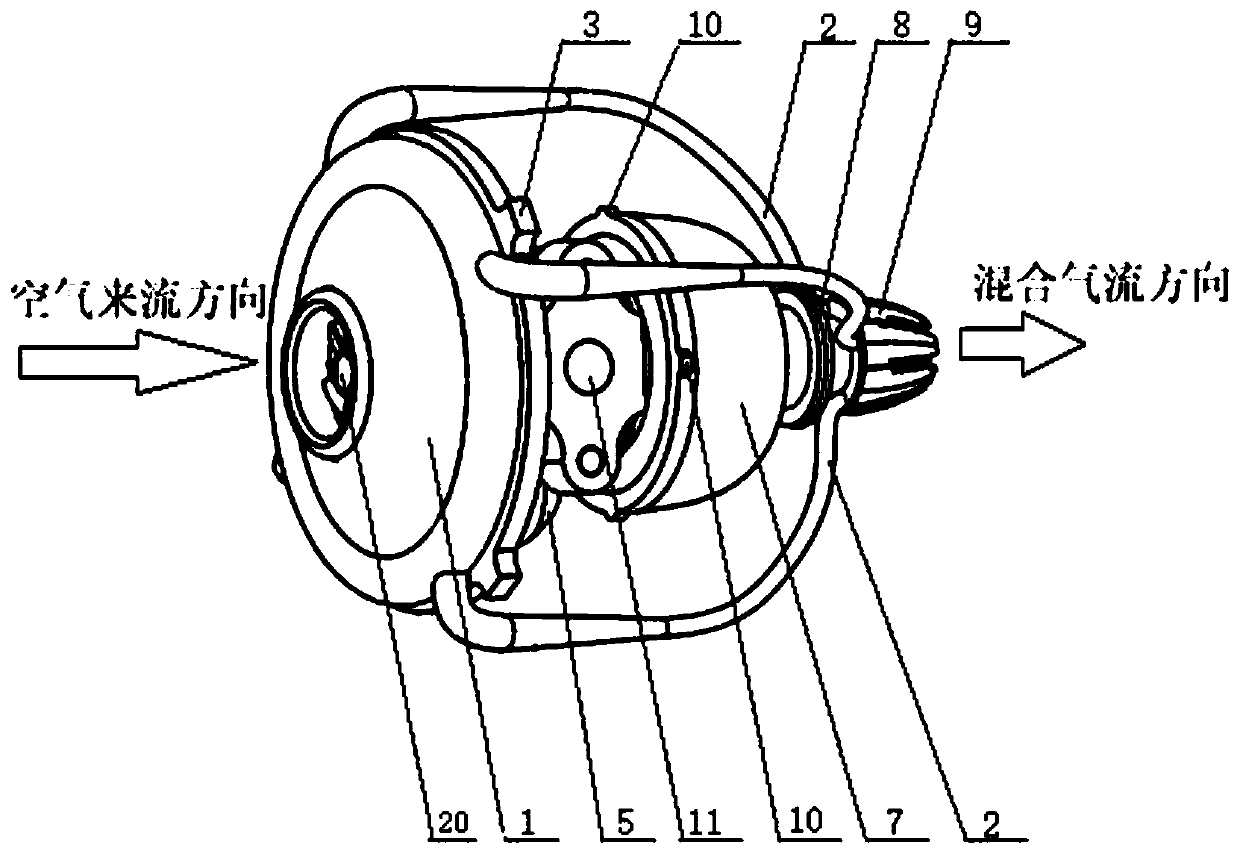

Ejection type infrared suppressor with double layer cooling mixed tubes

InactiveCN110748436AReduce the intensity of infrared radiationImprove blending uniformityJet propulsion plantsCold airEngineering

The invention provides an ejection type infrared suppressor with double layer cooling mixed tubes. The infrared suppressor comprises the inner and outer double layer mixed tubes, a lobe nozzle and a hollow flow director with a slit. According to the infrared suppressor, the upper and lower asymmetric lobe nozzle is adopted, so that the high-temperature exhaust gas at each part can just attach thewall at outlets of the mixed tubes, the high-temperature exhaust momentum is utilized to the maximum extent, and the outside cold air is guided as much as possible; forced cooling air flow is introduced into a forced air inlet of the double-layer mixed tube, the forced cooling airflow flows through an interlayer between the double layer mixed tubes, and the wall surfaces of the mixed tubes are cooled; the forced cooling airflow flows into the inner layer mixed tube through the slit of a hollow diversion guide plate and is blended with the hot exhaust gas, so that the exhaust temperature is further reduced; the hot exhaust gas in the double layer mixed tubes generates multiple streams through the hollow diversion guide plate, and the mixing uniformity of the high-temperature exhaust gas andthe injection cooling airflow is improved; and the temperature and the exhaust temperature of the wall surfaces of the mixed tubes can be greatly reduced by adopting the injection type infrared suppressor with the double layer cooling mixed tubes, and the infrared radiation intensity is reduced.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

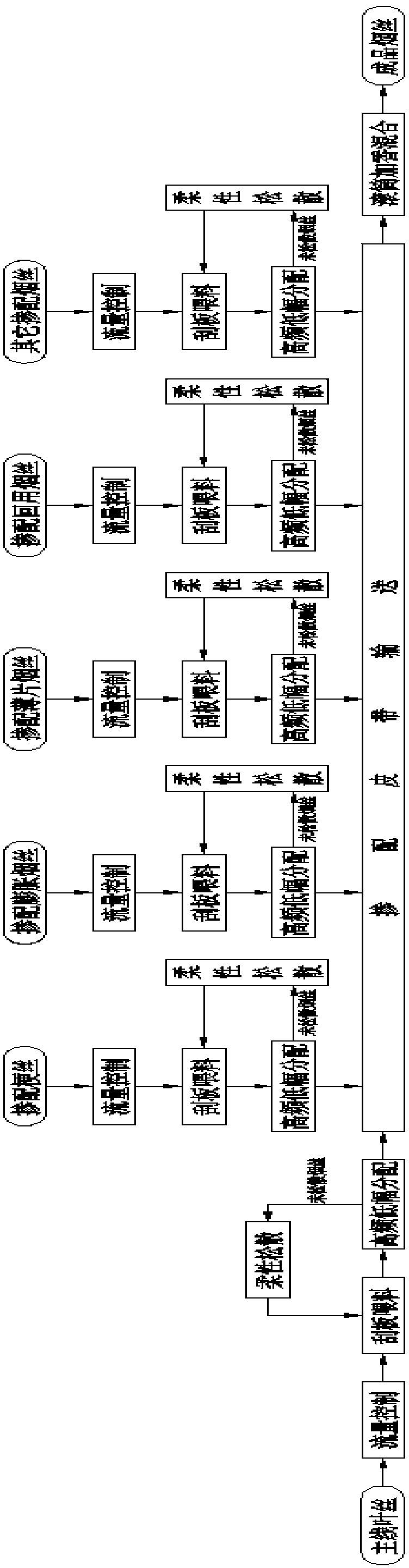

Tobacco shred blending method and tobacco shred blending system

ActiveCN104336750AImprove uniformityIncrease chance of contactTobacco preparationConveyor partsEngineeringBelt conveyor

The invention provides a tobacco shred blending method. The tobacco shred blending method comprises the following steps: dividing different kinds of tobacco shreds into N equal parts; alternately arranging the different kinds of tobacco shreds on a blending belt conveyor in parts to form N groups of different kinds of alternately arranged combined tobacco shreds; then mixing the N groups of combined tobacco shreds together. According to the method provided by the invention, the uniformity of tobacco shred blending can be improved, the method is simple and reliable, the fine production requirement of tobacco is met, and meanwhile various problems that an existing tobacco shred blending process cannot solve are well solved.

Owner:ZHISI HLDG GRP

Cigarette processing method through papermaking-method reconstituted tobacco based on fine cigarettes

ActiveCN108244687AImprove the pass rate of shreddedReasonable structureTobacco preparationTobacco treatmentEngineeringTobacco product

The invention provides a cigarette processing method through papermaking-method reconstituted tobacco based on fine cigarettes. The method comprises the following steps that (1) the papermaking-methodreconstituted tobacco is loosed and dampened, the moisture content of the reconstituted tobacco is adjusted to be 14.0-16.0%, and shredding is conducted; (2), after the physical characters of reconstituted tobacco shreds are changed through temperature and humidity increase, and then the moisture content of the reconstituted tobacco shreds turns to be 12.5-13.5% after roller drying; (3) long shreds are cut into short shreds through a shred cutting device, and the structures of the reconstituted tobacco shreds meet the requirement of the fine cigarettes; (4) the smoking quality of papermaking-method reconstituted tobacco products is improved through roller feeding; (5) flexible winnowing, feeding, measurement and binning are conducted, and residual substances with a large proportion are removed; (6) finally the reconstituted tobacco shreds are grouped and blended with rolling bags according to cigarette composition demands. According to the cigarette processing method, the blending uniformity and effective utilization rate of the papermaking-method reconstituted tobacco in the fine cigarettes are improved, and the aims of improving the quality of the fine cigarette products and lowering the processing loss are achieved.

Owner:HUBEI CHINA TOBACCO IND

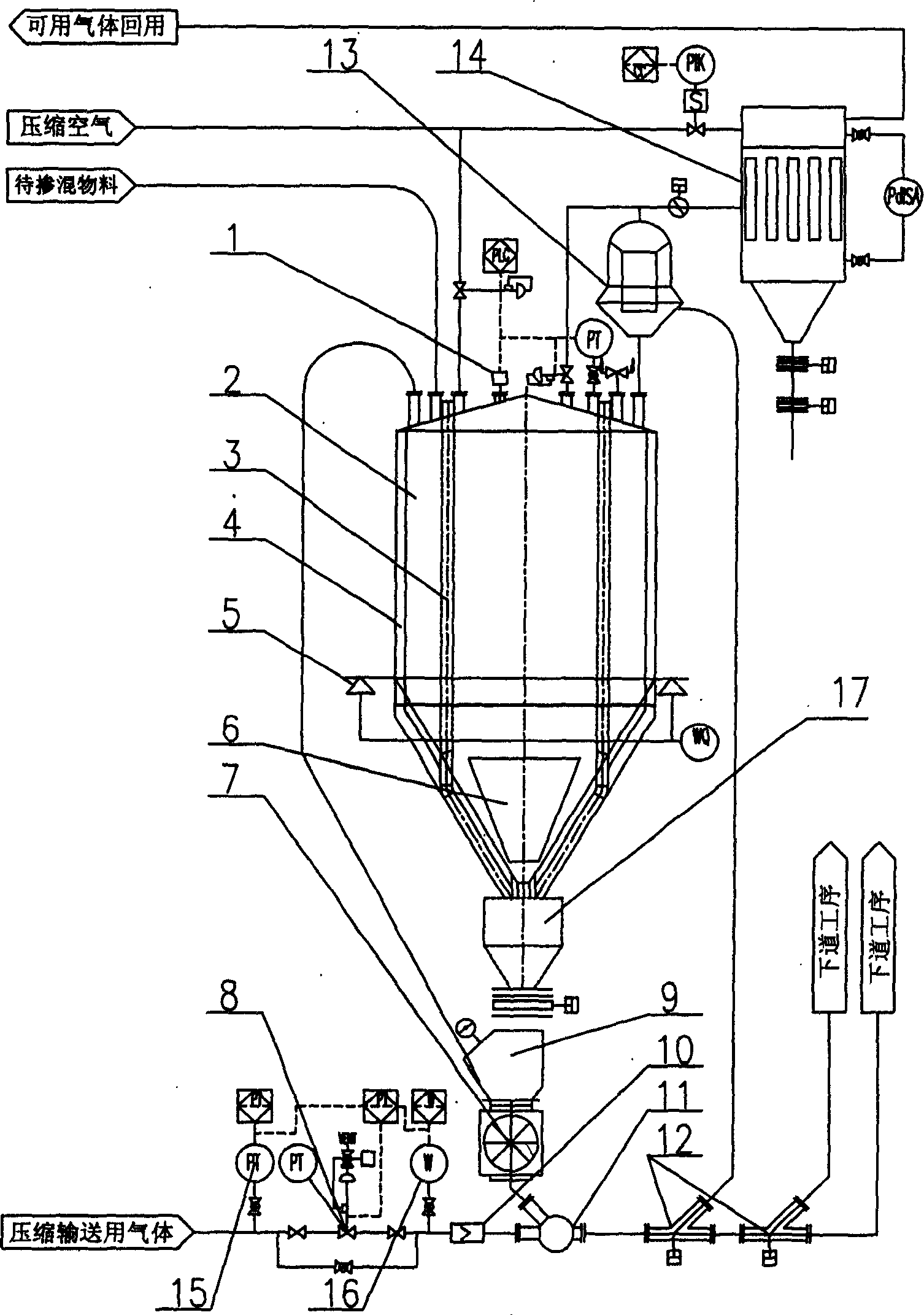

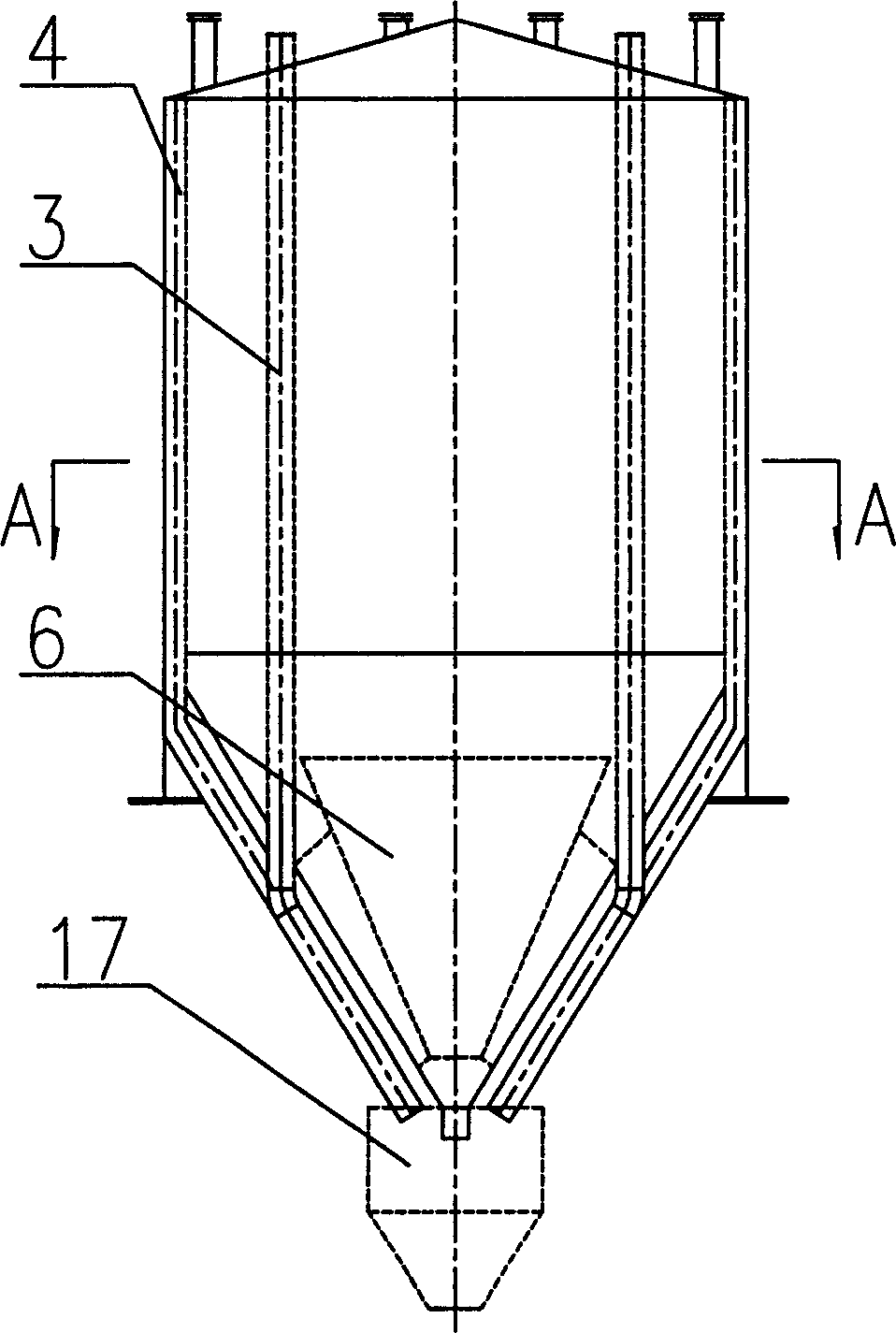

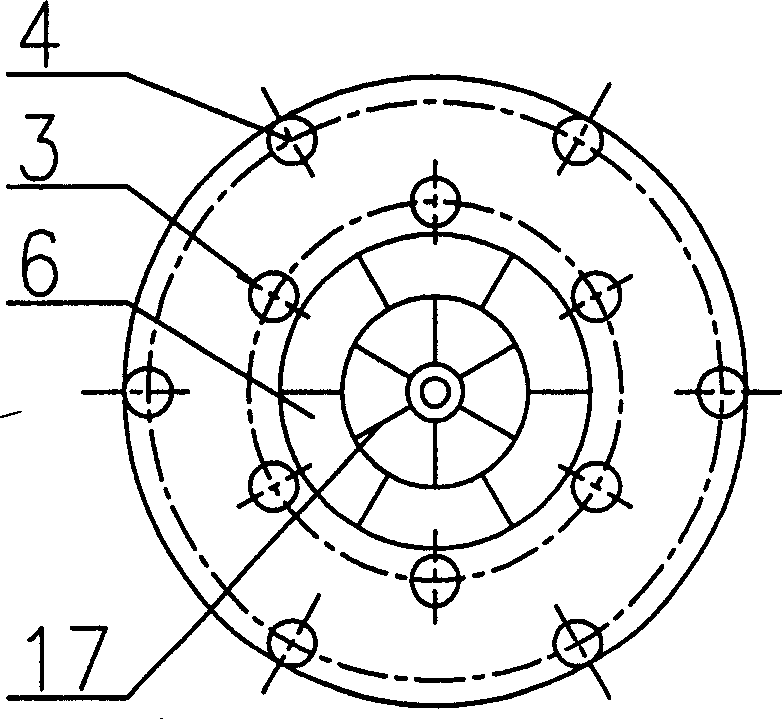

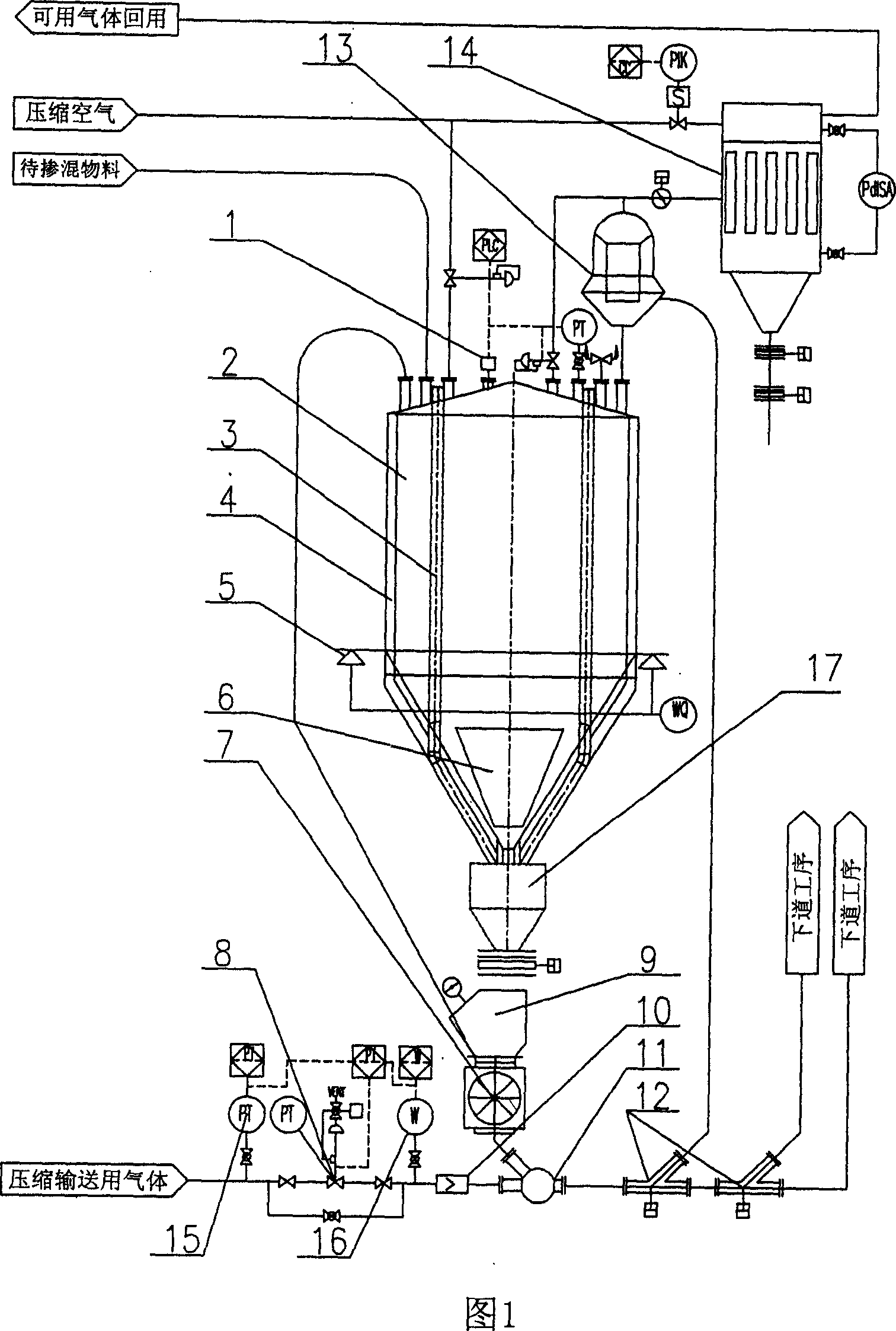

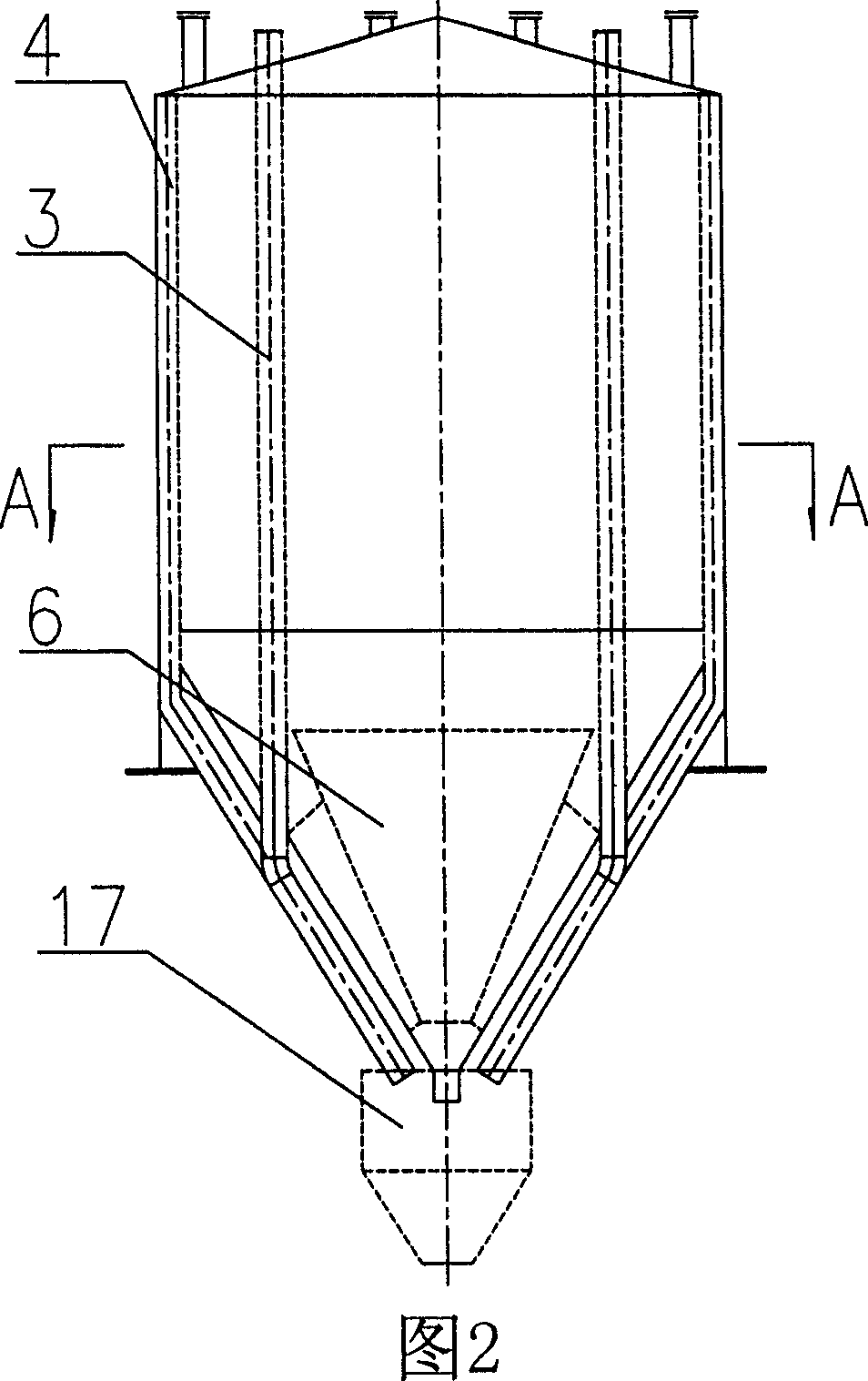

Intelligent energy mixer

InactiveCN1712117AGuaranteed fluidized movementIncrease the mixing ratioFlow mixersTransportation and packagingLine tubingEngineering

An intelligent pneumatic mixer is composed of raw material mixing cabin with multiple central pipes and multiple peripheral pipes close to wall, jet spray pipe, material delivering pipeline, high-pressure feeder, valve for high-pressure delivering pipe, multi-stage multi-conic diffusion separator with volute casing, and high-pressure pulse duster.

Owner:JIANGSU NDZ TECH

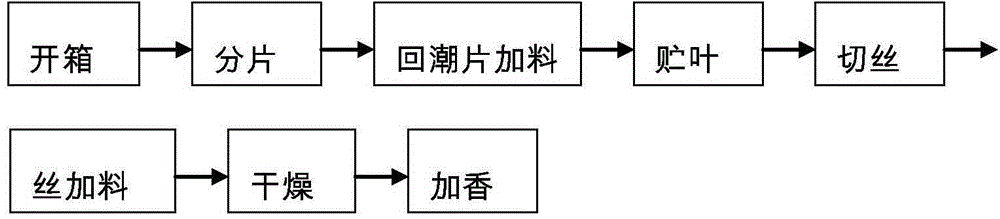

Tobacco leaf shredding method capable of improving sensory quality of tobaccos

ActiveCN104824825AIncreased Uniformity and FlexibilityImprove sensory qualityTobacco preparationEngineeringThin sheet

The present invention relates to a tobacco leaf shredding method capable of improving the sensory quality of tobaccos. Tobacco leaves are paper-making process sheet tobacco. The process comprises the following steps: unpacking, slicing, feeding dampened sheets, storing the leaves, shredding, feeding shreds, drying and improving the aroma. According to the method disclosed by the present invention, the step of shredding adopts a shredding method and a shredding blade, which can control the length distribution of thin sheet shreds. The paper-making process sheet tobacco in the method is not processed by a high-strength treatment process; the absorption efficiency of the paper-making process sheet tobacco to material liquid is improved by adopting a two-dimensional feeding mode of sheet feeding and shred feeding, so that the sensory quality of the regenerated tobacco leaves is improved; and meanwhile, the shredding method capable of controlling the length distribution of the regenerated tobacco shreds is adopted so that the doping uniformity of the regenerated tobacco shreds is improved. According to the method, style characteristics of the paper-making process sheet tobacco are enriched by the blending step, so that the sensory quality of the paper-making process sheet tobacco is improved, and the application value of the low-grade paper-making process sheet tobacco is increased.

Owner:CHINA TOBACCO YUNNAN IND

Filling material with PET and PTT composite filament as raw materials and manufacturing method thereof

InactiveCN104532416AGood flexibilityFluffy goodOakum treatmentNon-woven fabricsFiberFilling materials

The invention discloses a filling material with PET and PTT composite filament as raw materials and a manufacturing method. The down jacket and the cold protective clothing adopting the filling material are low in cost, good in heat insulation performance and free of odor. At the moment, the PET and PTT composite filament fiber are curly and have elasticity, and the stable filling material with good quality is obtained. The filling material includes the PET and PTT composite filament fiber and mixed fiber components which are mixed, then opened or pelletized to make the filling material. The content of the PET and PTT composite filament fiber is larger than 0 and smaller than 100%. The content of the mixed fiber components is larger than or equal to 0 and smaller than 100%. The manufacturing method of the filling material is further disclosed and includes the following steps of (1) mixing, (2) cotton feeding; (3) opening and (4) pelletizing.

Owner:福建省海兴凯晟科技有限公司

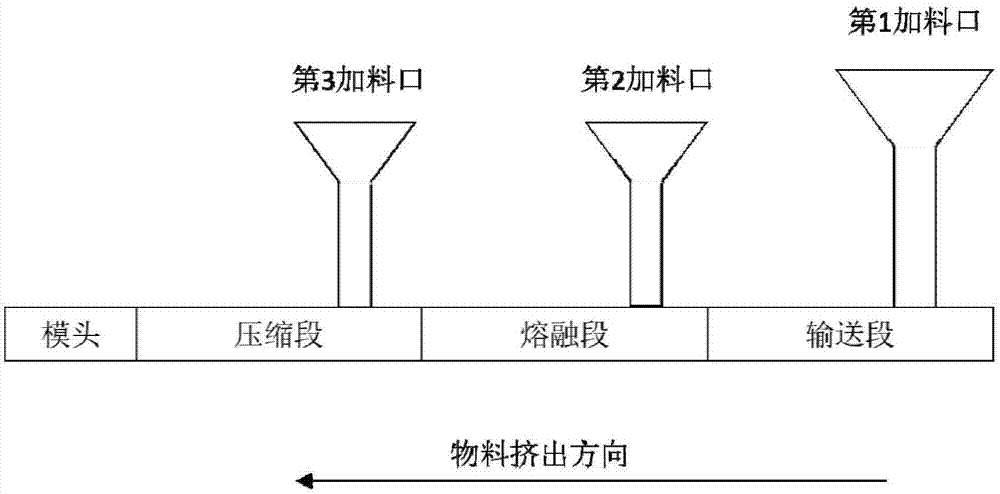

Aging-resistant easy-welding thermoplastic polyolefin waterproof roll material and preparation method thereof

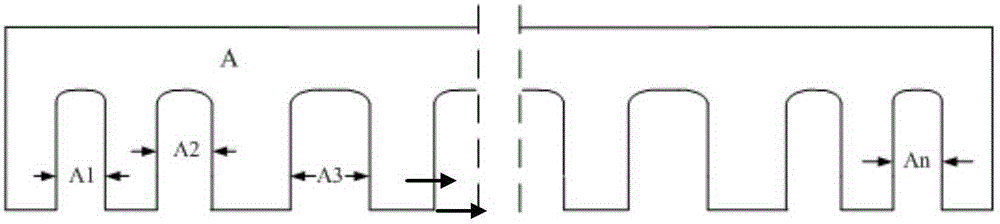

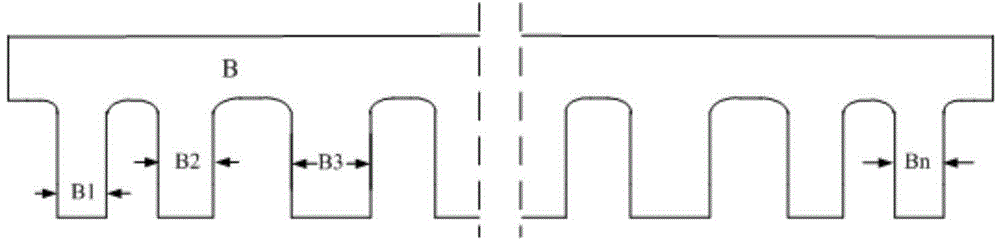

The invention discloses an aging-resistant easy-welding thermoplastic polyolefin waterproof roll material and a preparation method thereof. The aging-resistant easy-welding thermoplastic polyolefin waterproof roll material consists of the following raw materials in parts by mass: 40-60 parts of polyolefin elastomer, 20-40 parts of polypropylene, 10-30 parts of filling masterbatch, 0.2-0.5 part ofantioxidant, 0.2-0.6 part of light stabilizer, and 1-4 parts of titanium dioxide. The aging-resistant easy-welding thermoplastic polyolefin waterproof roll material is prepared through a two-step method, and the preparation method comprises a first step of raw material extrusion granulation and a second step of particle press polish molding. The prepared thermoplastic polyolefin waterproofing rollmaterial has excellent aging resistance and long-term weather resistance, has good high and low temperature performance, is easy welding, has good waterproof performance, is not easy to crack, is green and environmentally friendly, has good construction performance, and can be applied to areas with larger environment temperature changes.

Owner:广州大禹防漏技术开发有限公司

Micro-premixing combustion chamber used for natural gas turbine and applied to wet air circulation

PendingCN111765491AImprove scalabilityImprove blending uniformityContinuous combustion chamberAir cycleCombustion chamber

The invention discloses a micro-premixing combustion chamber used for a natural gas turbine and applied to wet air circulation. The micro-premixing combustion chamber used for the natural gas turbineand applied to wet air circulation comprises a combustor main body, a flame tube and a combustion chamber cartridge, wherein the combustor main body is arranged on the head part of the combustion chamber; the flame tube is arranged in the combustion chamber cartridge, and is a cylindrical wall surface wrapping the combustion chamber, and the inner side of the wall surface is a combustion area of the combustion chamber; a main fuel inlet and an on-duty fuel inlet are formed in the front end of the combustor main body, and the main fuel inlet is used for inputting a fuel into a main nozzle of acombustor; the on-duty fuel inlet is used for inputting the fuel into an on-duty nozzle of the combustor; and an air chamber is formed in the bottom of the combustion chamber, the air chamber is wrapped with a gas turbine cartridge, communicates to a gap which is formed by a lining of the combustion chamber and the flame tube, and feeds air which comes from an upstream air compressor outlet into an air bin of the combustor through the gap.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

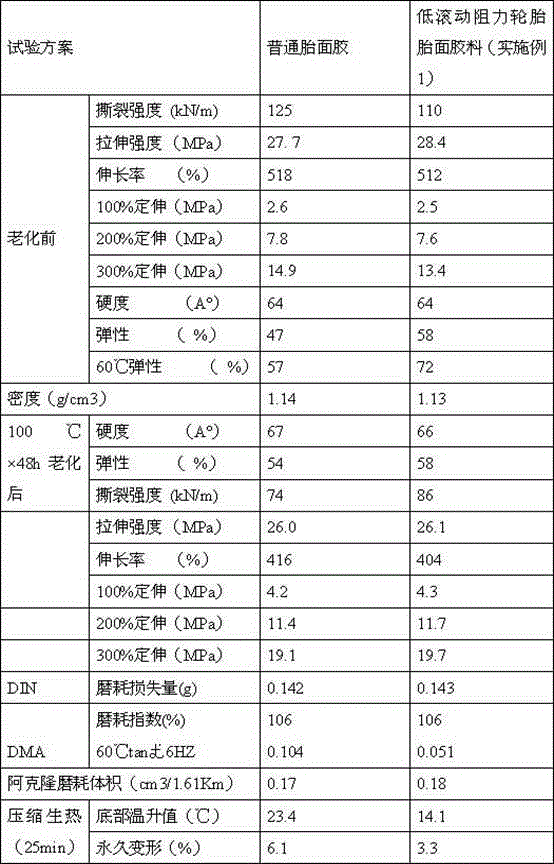

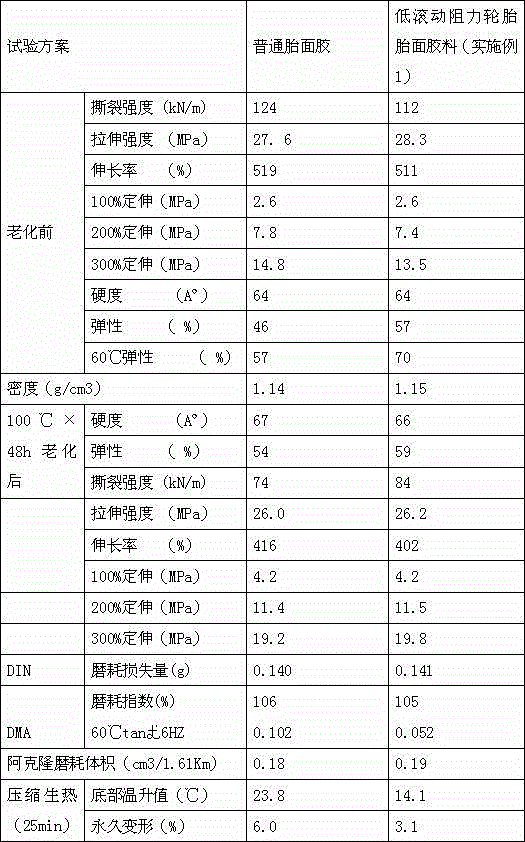

Modified low-resistance tire rubber compound and preparation method thereof

InactiveCN104419022AHigh strengthGood dispersionRolling resistance optimizationRolling resistanceToluene diisocyanate

The invention discloses a modified low-resistance tire rubber compound and a preparation method thereof. The modified low-resistance tire rubber compound comprises, by weight, 50-60 parts of natural rubber SIR20, 5-6 parts of butadiene styrene rubber, 5-6 parts of chloroprene rubber, 8-10 parts of N234 carbon black, 7-8 parts of white carbon black, 1-2 parts of a silane coupling agent X50S, 2-3 parts of polyethylene glycol, 2-3 parts of toluene diisocyanate, 2-3 parts of a tin salt catalyst, 1-2 parts of hydroxy-terminated polybutadiene, 3-4 parts of a softening plasticizer aromatic oil, 2-3 parts of stearic acid, 3-4 parts of an antioxidant, 1-2 parts of tackifier 204 resin, 1-2 parts of a homogenizing agent UB4000, 1-2 parts of sulfur, 1-2 parts of a promoter TBBS and 0.3-0.5 parts of an anti-scorching agent CTP. The preparation method improves the compatibility between rubber and water-absorbent resin and improves the strength of the rubber compound. Carbon black is partially substituted by the white carbon black, so the rolling resistance of a tire is reduced, and oil consumption reduction, exhaust gas discharge reduction and environmental protection are achieved. The modified low-resistance tire rubber compound has the advantages of strong adhesion between laminated rubbers, good dispersion and good thermo-oxidative aging resistance.

Owner:QINGDAO LANNONGGU AGRI PROD RES & DEV

Method for producing stalks by expanded stems

ActiveCN104872811AReasonable structureGood uniformity of stemsTobacco treatmentHorticultureMouthfeel

The invention relates to a method for producing stalks by expanded stems. The method includes steps of pretreating the expanded stems, arranging the stalks and slicing, ordering and cutting the stalks, burdening, drying, sorting and flavoring and the like. The stalks are mixed into cigarette, tar and CO release can be effectively reduced, the cigarette is little irritant, soft in smoke and comfortable in taste, smoking quality is greatly improved, stability of the cigarette is improved remarkably, cigarette quality is improved, application range of the stalks in the cigarette is broadened, utilization rate is increased, cost is reduced and effect is improved.

Owner:GUANGDONG GOLDEN LEAF TECH DEV

Tire rubber compound with strong viscosity, anti-aging and low resistance

InactiveCN104419021AReduce coefficient of frictionReduce rolling resistanceSpecial tyresRolling resistance optimizationRolling resistanceAntioxidant

The invention discloses a tire rubber compound with strong viscosity, anti-aging and low resistance. The tire rubber compound comprises, by weight, 50-60 parts of natural rubber, 10-15 parts of styrene butadiene rubber, 5-7 parts of N234 carbon black, 10-15 parts of white carbon black, 1-2 parts of a silane coupling agent X50S, 3-5 parts of softening plasticizer aromatic oil, 1-2 parts of zinc oxide, 2-3 parts of stearic acid, 3-5 parts of an antioxidant, 1-2 parts of tackifier 204 resin, 1-2 parts of a homogenizing agent UB4000, 1-2 parts of sulfur, 1-2 parts of a promoter TBBS, and 0.3-0.5 parts of an anti-scorching agent CTP. The tire rubber compound reduces the rolling resistance of a tire, improves the bonding performance between rubber layers, improves the blending uniformity and dispersibility of different kinds of rubbers, and has he advantages of strong viscosity, anti-aging, low resistance, effectively prolonged fatigue life.

Owner:QINGDAO LANNONGGU AGRI PROD RES & DEV

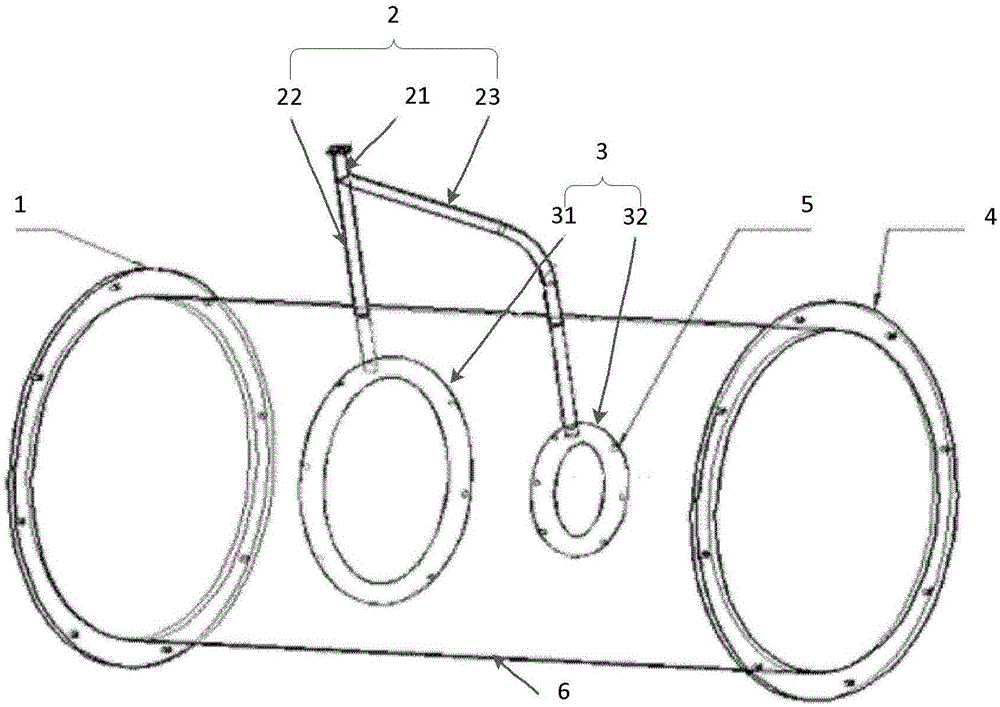

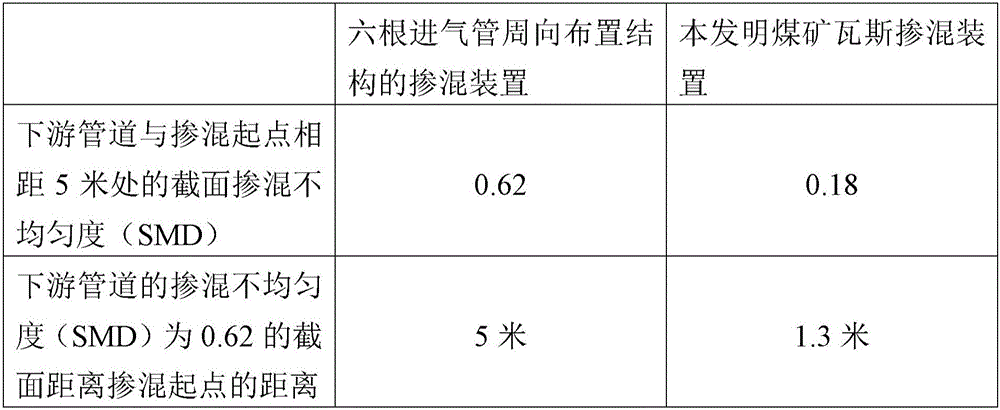

Coal mine gas blending device

InactiveCN106237880ASimple structureEasy to processFlow mixersTransportation and packagingExternal energyProcess engineering

The invention provides a coal mine gas blending device which comprises an inlet flange, a blending gas inlet pipe, an annular pipe nest, an outlet flange and a pipeline body. Ventilation gas in an upstream ventilation gas pipeline can flow into the pipeline body via the inlet flange, extraction gas can flow into the pipeline body via the blending gas inlet pipe and annular pipes, the extraction gas and the ventilation gas are blended with each other in the pipeline body, and blended gas can flow into a downstream ventilation gas pipeline from the outlet flange. The coal mine gas blending device has the advantages that the coal mine gas blending device is simple in structure, easy to machine and manufacture and convenient to assemble in engineering fields; consumption of external energy can be omitted; the coal mine gas blending device is high in blending speed and blending uniformity, the uniform blending speeds can be increased, the blending distances can be shortened to a great extent, and the accuracy of downstream methane concentration detection and flow detection, the stability of oxidizing devices and the safety of systems can be powerfully guaranteed.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

Intelligent energy mixer

InactiveCN1313192CGuaranteed fluidized movementIncrease the mixing ratioFlow mixersBulk conveyorsLine tubingHigh pressure

An intelligent pneumatic mixer is composed of raw material mixing cabin with multiple central pipes and multiple peripheral pipes close to wall, jet spray pipe, material delivering pipeline, high-pressure feeder, valve for high-pressure delivering pipe, multi-stage multi-conic diffusion separator with volute casing, and high-pressure pulse duster.

Owner:JIANGSU NDZ TECH

Single-duct ejector device for aero-engine

PendingCN113339332AImprove adherenceInhibition of boundary layer separationGas-turbine engine testingJet pumpsPhysicsJet flow

The invention discloses a single-duct ejector device for an aero-engine. Six flow stabilizing supporting plates are evenly distributed and fixed in an ejector middle section, and the airflow inlet end of each flow stabilizing supporting plate is made to communicate with an annular high-pressure air source plenum chamber on the ejector middle section. Three variable Mach number nozzles are installed on one surface of each flow stabilizing supporting plate, and outlets of the variable Mach number nozzles all face the ejector rear section. According to the single-duct ejector device, the air inlet channel of the ejector is designed into the subsonic air inlet channel, the smooth wall surface increases the wall adhesion of inlet airflow, the boundary layer separation of the air inlet wall surface is inhibited, and the quality of an air inlet flow field is improved. Each flow stabilizing supporting plate with the oval head is adopted, so that disturbance vortex caused by the flow stabilizing supporting plate is reduced, the nozzles spray in a low-pressure area behind the supporting plates, and noise generated when the ejector works is reduced. Centrosymmetric multi-point distributed ejection is adopted, so that the ejection area between a high-energy ejection flow and a low-energy ejected flow is greatly increased, and the ejection efficiency is improved.

Owner:NORTHWESTERN POLYTECHNICAL UNIV +1

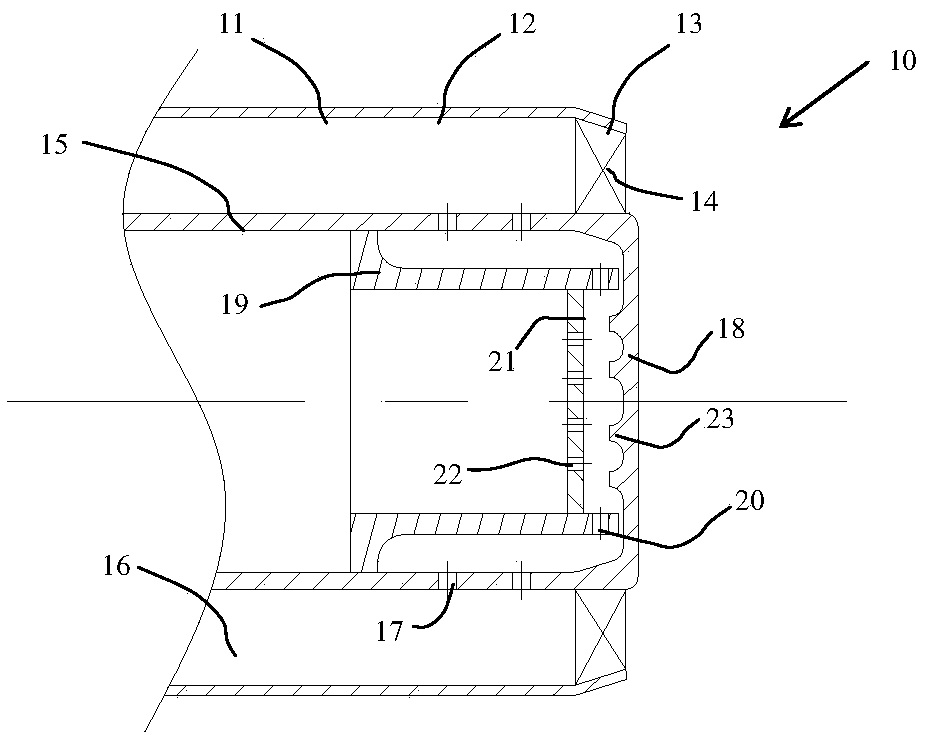

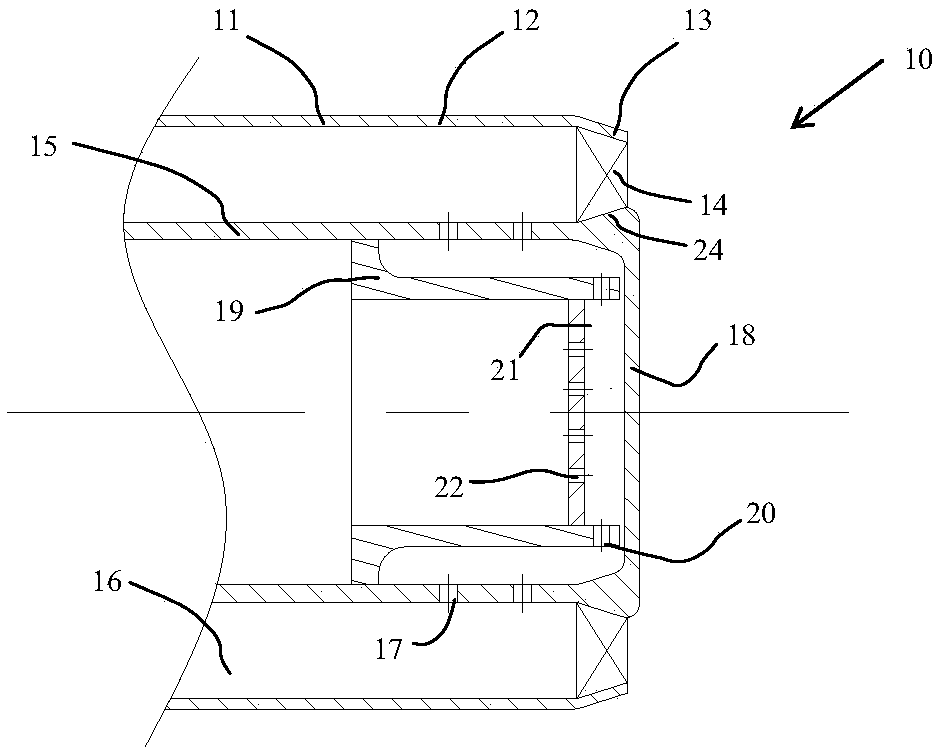

Gas fuel nozzle assembly

ActiveCN109611889AIncrease temperatureIncrease the premix strokeContinuous combustion chamberSpray nozzleCooling effect

The invention belongs to the technical field of gas turbine engines, and particularly relates to a gas fuel nozzle assembly. The gas fuel nozzle assembly (10) comprises an outer guiding cover (11), aswirler (14), an inner guiding cover (15), an end plate (18), a lining (19) and an impact plate (21). Fuel can penetrate through an impact hole (22), a through hole (19) and a mixing hole (17) in sequence, pass through a primary fuel passage and a secondary fuel passages, and reach an air passage (16) to sufficiently premix with air. According to the gas fuel nozzle assembly, the premixing strokeof fuel and the air is increased by premixing the fuel with the air in the air passage, and the mixing uniformity of the fuel and the air is intensified; meanwhile, the turbulence of fuel flow is increased through the primary fuel passage and the secondary fuel passage, and the mixing effect of the fuel and the air is intensified; and the fuel can impact and cool a nozzle end plate before premixing with the air, the nozzle cooling effect is intensified while the fuel temperature is improved, and the energy waste is reduced.

Owner:AECC SHENYANG ENGINE RES INST

Small furniture surface uniform painting equipment based on furniture manufacturing

InactiveCN113399162AIncrease productivityAvoid harmSpraying apparatusIndustrial engineeringFurniture manufacturing

The invention provides small furniture surface uniform painting equipment based on furniture manufacturing. The small furniture surface uniform painting equipment comprises a main body, wherein a driving movable assembly is arranged in the main body, a fixed bracket is fixedly arranged on the lower side of the driving movable assembly, a uniform painting assembly is arranged on the lower side of the fixed bracket, the uniform painting assembly comprises an outer shell and an inner shell, a movable shaft is installed at the center axis of the inner shell, uniform blades are movably installed on the outer side of the movable shaft, and an absorption bag is installed between the outer shell and the inner shell. According to the small furniture surface uniform painting equipment based on furniture manufacturing, the production efficiency of a manufacturer is effectively improved through automatic operation, meanwhile, the uniform painting effect is improved, manual assistance is not needed in the whole operation process of the equipment, the situation that a worker inhales a large amount of paint mist in the paint spraying process, and consequently the body is harmed is effectively avoided, and the practicability of the equipment is further improved.

Owner:义乌市凌起家具有限公司

Device for providing air and rich combustion fuel gas and engine of deice

PendingCN109826721AWell mixedImprove combustion efficiencyGas turbine plantsRam jet enginesCombustion chamberTurbine

The invention discloses a device for providing air and rich combustion fuel gas. The device comprises a supercharger, a turbine assembly, an air conveying pipeline, a fuel gas generator and a mixer; the turbine assembly is arranged at the rear end of the supercharger; one end of the air conveying pipeline is connected with the supercharger, and the other end of the air conveying pipeline is connected with the mixer; the air conveying pipeline is used for conveying air; the fuel gas generator is connected with the turbine assembly and is used for conveying the rich combustion fuel gas; and themixer is arranged on the rear portion of the turbine assembly and communicates with the turbine assembly. The invention further provides an air turbine rocket engine. Due to the device, the air and the rich combustion fuel gas can be mixed uniformly, and the combustion efficiency of an engine combustion chamber is improved to a very large extent.

Owner:CENT SOUTH UNIV

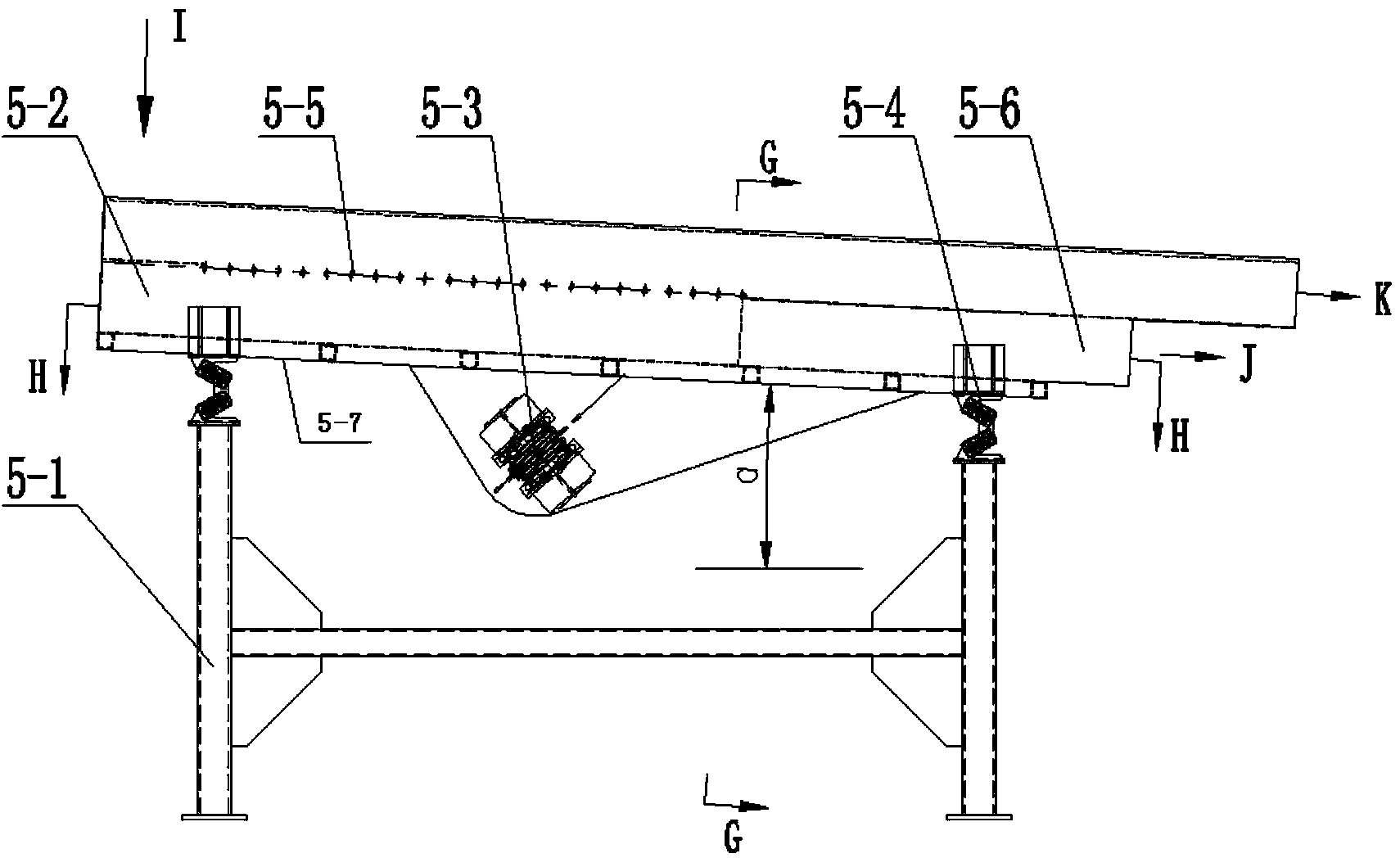

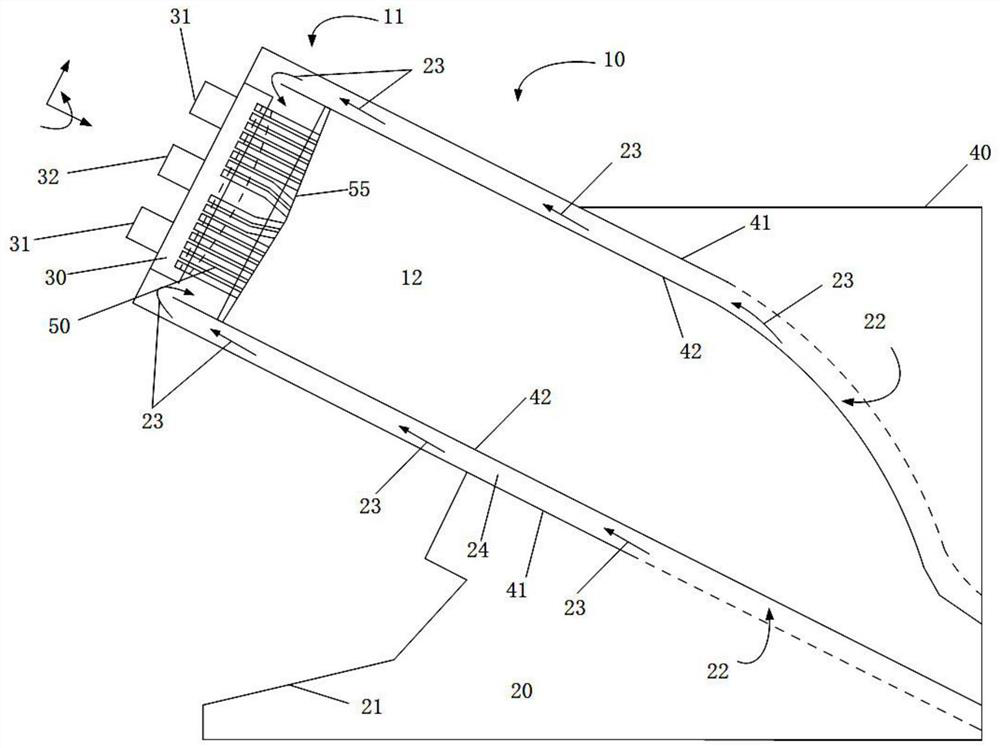

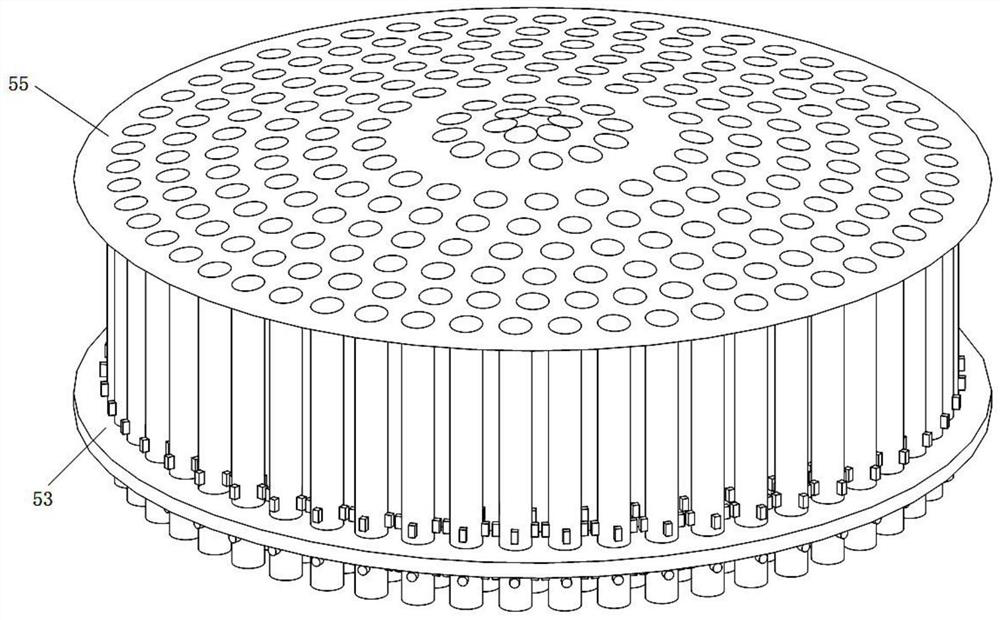

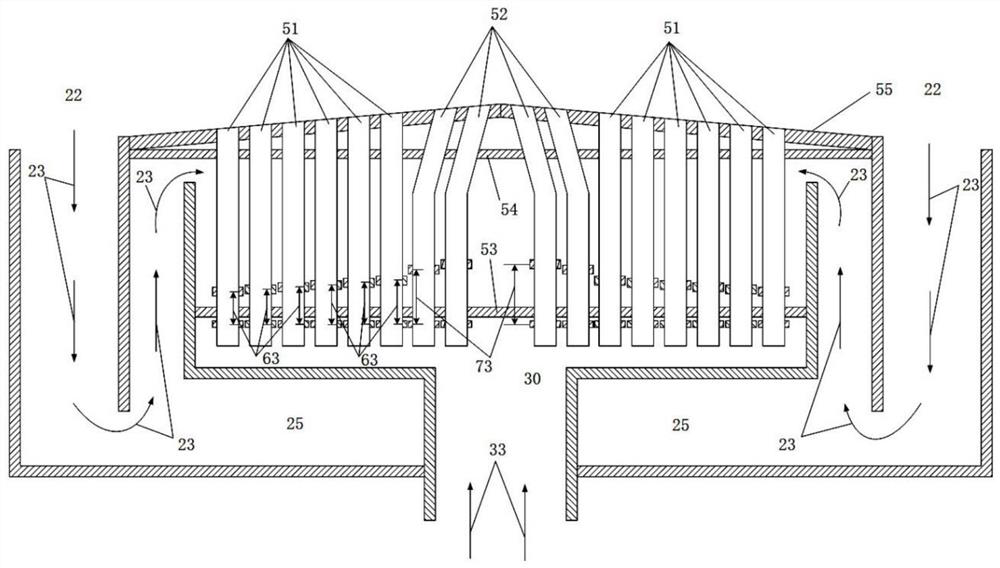

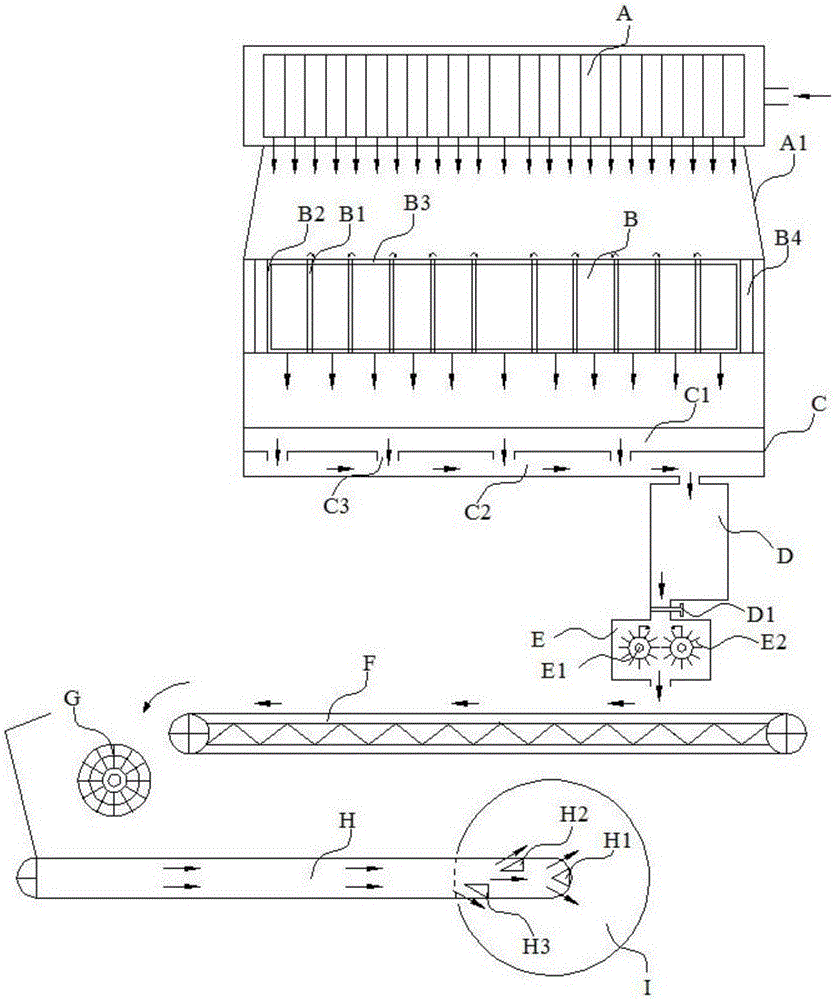

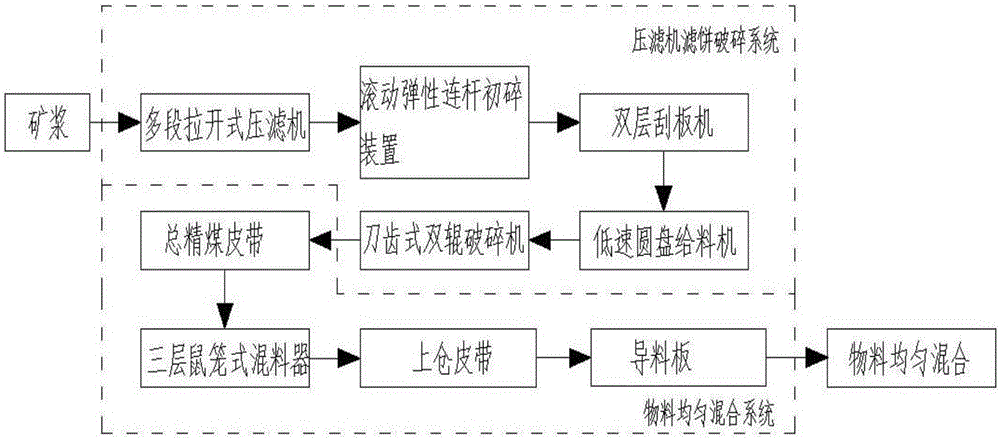

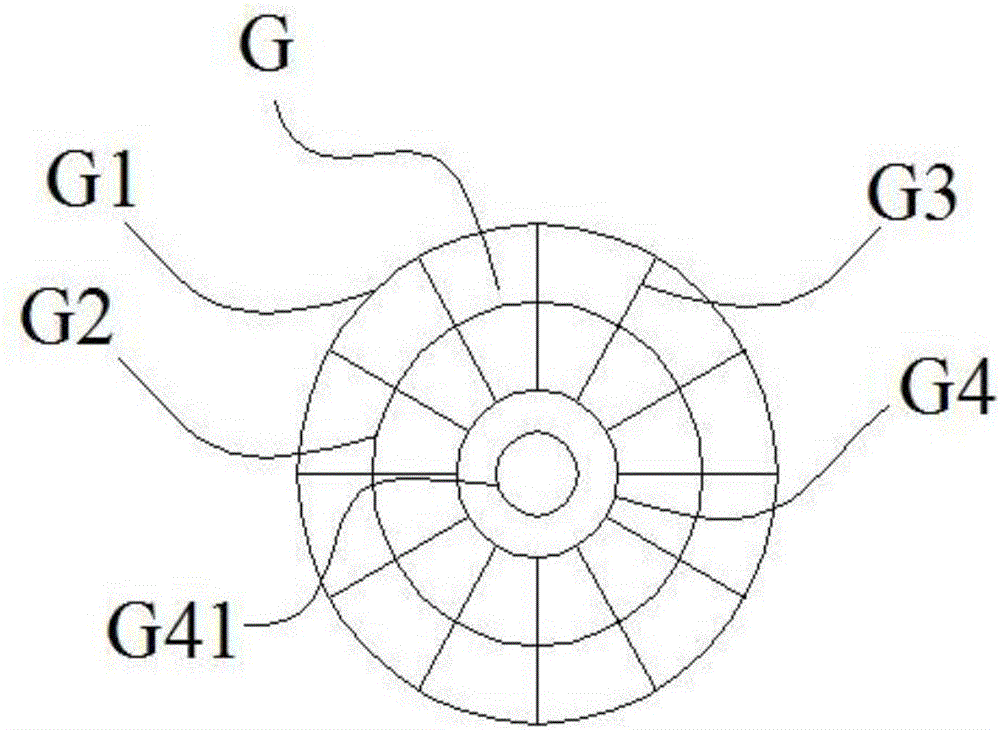

System and method for uniformly mixing fine crushed coal slime with coarse grain lump coal

ActiveCN106512769AReasonable designEliminate stickingFlow mixersTransportation and packagingHybrid systemMixed materials

The invention relates to the technical field of uniform mixing of coal slime and lump coal of a coal preparation plant and specifically relates to a system and method for uniformly mixing fine crushed coal slime with coarse grain lump coal. The system comprises the following working systems: the fine crushed coal slime uniformly falls onto a continuously running total clean coal belt; three layers of squirrel cage type mixers are arranged along the motion track of the materials on the inclined lower side of a discharging end of the total clean coal belt; under the combined action of an outer layer of stirrer, a middle layer of stirrer, an inner radial rib and a central sleeve of the three layers of squirrel cage type mixers, the uniform mixing of the materials is realized; the uniformly mixed materials are transferred and conveyed to a product cabin through an upper cabin belt; and a left material guiding plate, a middle material guiding plate and a right material guiding plate are respectively arranged on the left, middle and right positions along the motion direction of the belt at the discharging end of the upper cabin belt and have the function of dispersing the falling points. The system provided by the invention is reasonable in process layout, equipment selection and structure design, is capable of uniformly mixing the materials and is reliable and stable in effect.

Owner:ANHUI UNIV OF SCI & TECH

A kind of production method of elastic denim fabric with low shrinkage

ActiveCN107012564BReduce weft shrinkageIncrease elasticitySucessive textile treatmentsWoven fabricsYarnAdhesive

The invention discloses a production method of elastic denim fabric with low shrinkage rate. The specific steps include spinning, dyeing, sizing, weaving and post-finishing; Process, spinning process, winding process; the dyeing process includes the ball warping process and the bundle dyeing process. The invention reduces the weft shrinkage rate of the elastic fabric, improves the elastic performance of the fabric, improves the wearing performance of the pure cotton denim fabric, and improves the effect of wearing comfort. , Improve the uniformity of blending, and improve the performance of the product through the optimization of the production process. In the post-finishing stage, the air loose soft finishing machine is used for loose soft finishing, which greatly reduces the weft shrinkage of the denim fabric and improves the denim fabric. elastic properties.

Owner:ZAOZHUANG HIYOUNG DYNASTY TEXTILE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com