Tobacco shred blending method and tobacco shred blending system

A technology of shredded tobacco and dispensing machine, which is applied in the direction of tobacco, prepared tobacco, conveyor objects, etc. It can solve the problems of unresolved shredded shredded cluster dispersion, difficult to realize transformation and improvement, difficult shredded tobacco blending uniformity, etc., to meet the requirements of refinement Low production requirements, low maintenance and use costs, and a simple blending system for shredded tobacco

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

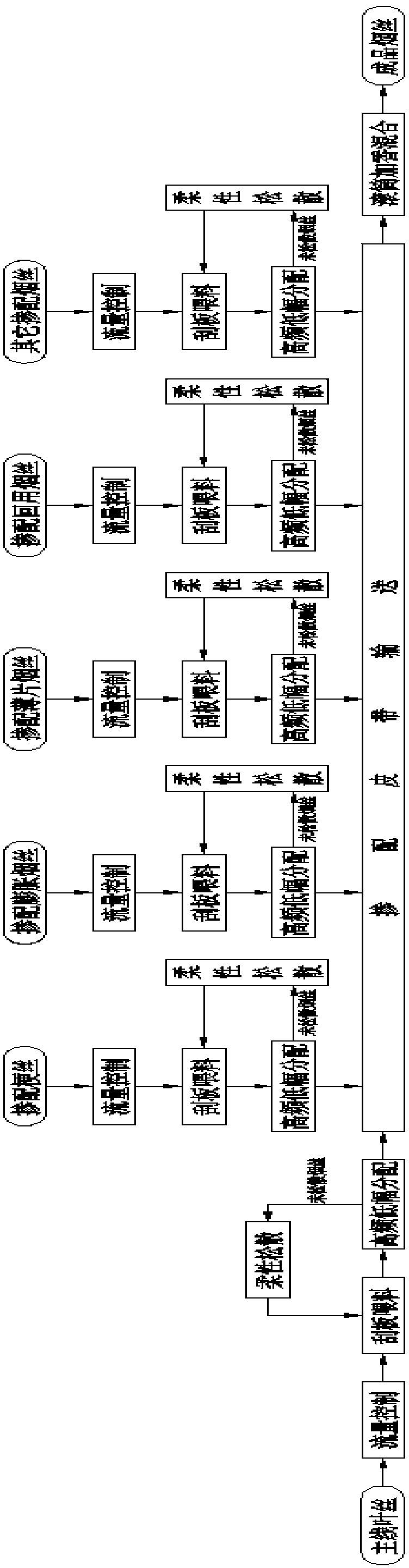

[0045] Such as figure 1 As shown, divide the main line shredded leaves, cut stems, expanded shredded tobacco, shredded shredded tobacco, recycled shredded tobacco, and other blended shredded tobacco into 5 equal parts, and arrange these 6 kinds of shredded tobacco staggered according to the parts, forming 5 groups each consisting of these 6 kinds of shredded tobacco Combination shredded tobacco, the staggered order of each group of combined shredded tobacco is: main thread shredded leaves, cut stems, expanded shredded tobacco, thin sliced shredded tobacco, recycled shredded tobacco, and other blended shredded tobacco. The staggered order of each group of combined shredded tobacco can also be different. For example, the arrangement order of one group of combined shredded tobacco is: main thread shredded leaves, cut stems, expanded shredded tobacco, thin sliced shredded tobacco, recycled shredded tobacco, and other blended shredded tobacco; The order of arrangement is: main ...

Embodiment 2

[0047] Such as figure 1 As shown, divide the main line shredded leaves, cut stems, expanded shredded tobacco, shredded shredded tobacco, recycled shredded tobacco, and other blended shredded tobacco into 6 equal parts, and arrange these 6 kinds of shredded tobacco staggered according to the parts, forming 6 groups each consisting of these 6 kinds of shredded tobacco Combination shredded tobacco, the staggered order of each group of combined shredded tobacco is: main thread shredded leaves, cut stems, expanded shredded tobacco, thin sliced shredded tobacco, recycled shredded tobacco, and other blended shredded tobacco. The 6 groups of combined shredded tobacco were mixed respectively, and then the 6 groups of mixed shredded tobacco were mixed together.

Embodiment 3

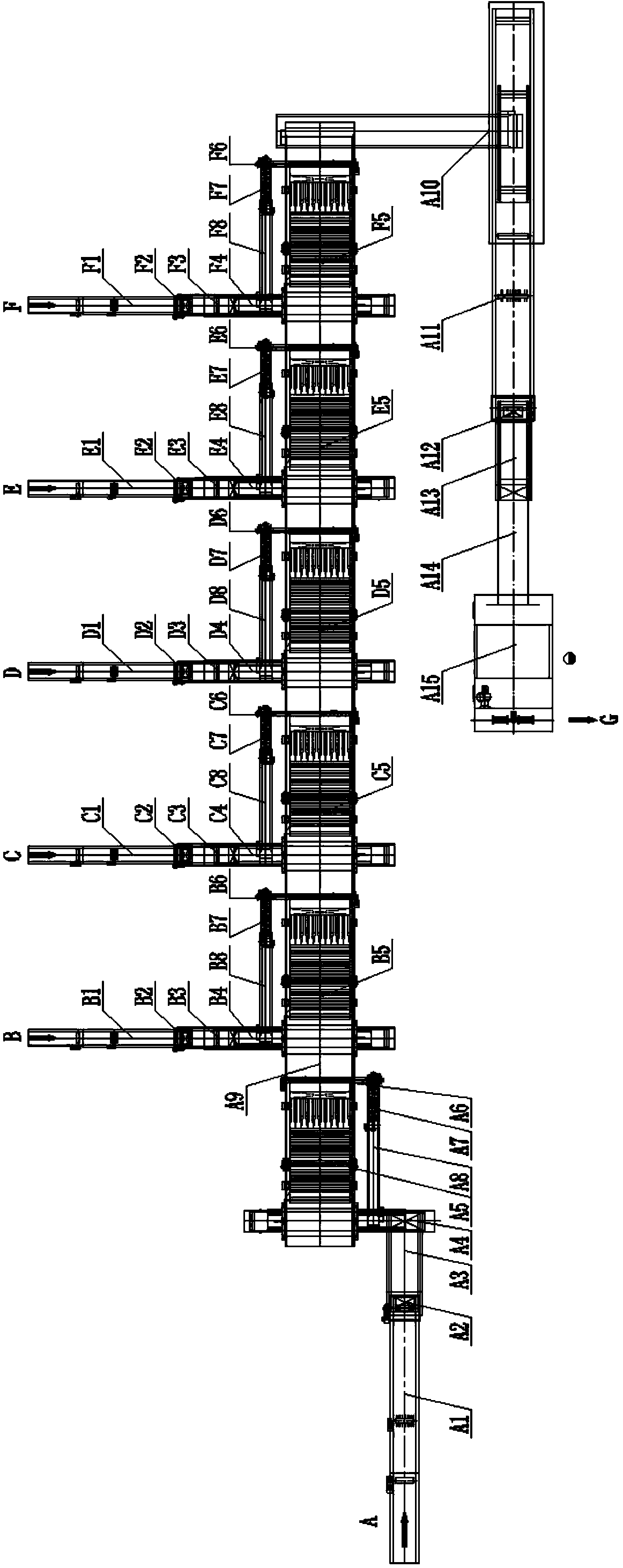

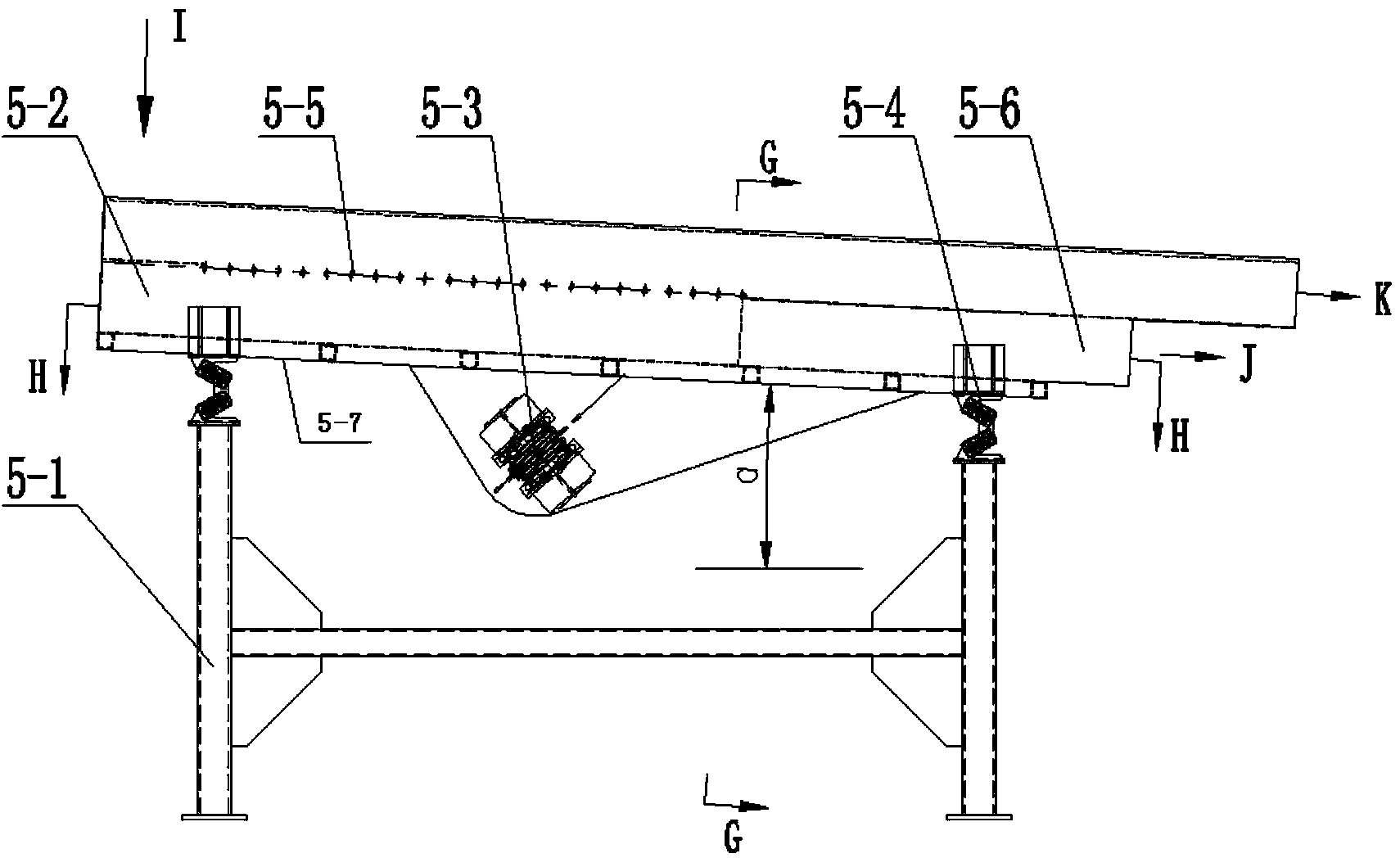

[0049] Such as figure 1 , 2 As shown in the figure, after the flow measurement and control unit composed of the feeder A1, metering tube A2 and belt scale A3 connected in sequence on the line A passes through the main line, the leaf silk is evenly spread by the scraper feeder A4 at high frequency. On the low-amplitude distributor A5, the high-frequency low-amplitude distributor A5 has the function of vibrating and loosening. The completely loose leaf silk falls to the bottom layer through the high-frequency low-amplitude distributor A5 strip screen, and then passes through the high-frequency low-amplitude distributor A5. The material dividing section evenly distributes the shredded leaves into 9 parts and then falls on the blending belt conveyor A9. The unloose leaf silk passes through the high-frequency low-amplitude distributor A5, enters the flexible loosening machine A7 through the screw conveyor A6, and then is sent back to the feed port of the scraper feeder A4 through ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com