Patents

Literature

703results about How to "Increase chance of contact" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method and application of acrylate heterozygotic emulsion

ActiveCN101787098ASmall particle sizeWide particle size distributionPolyurea/polyurethane coatingsPolymer scienceLacquer

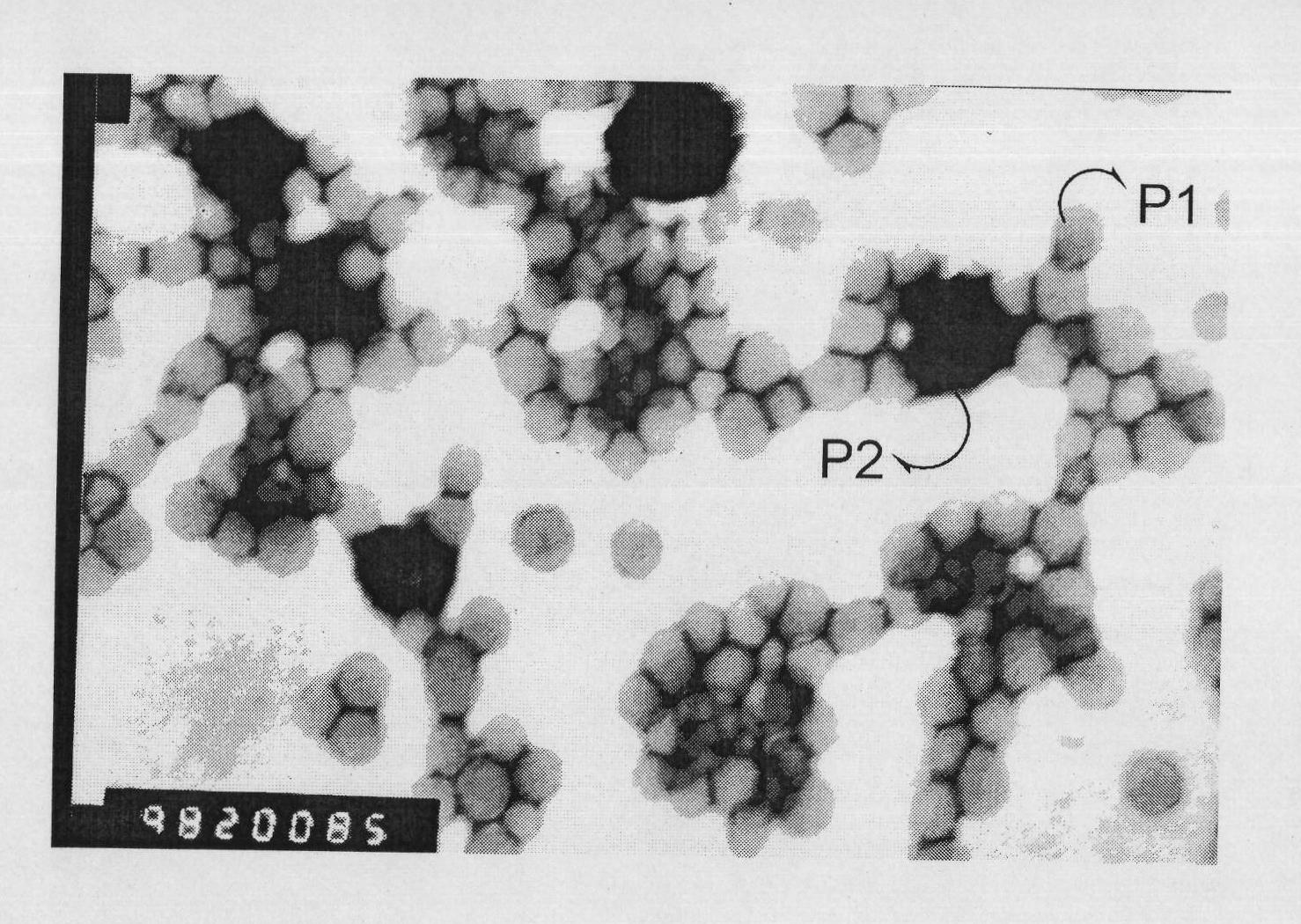

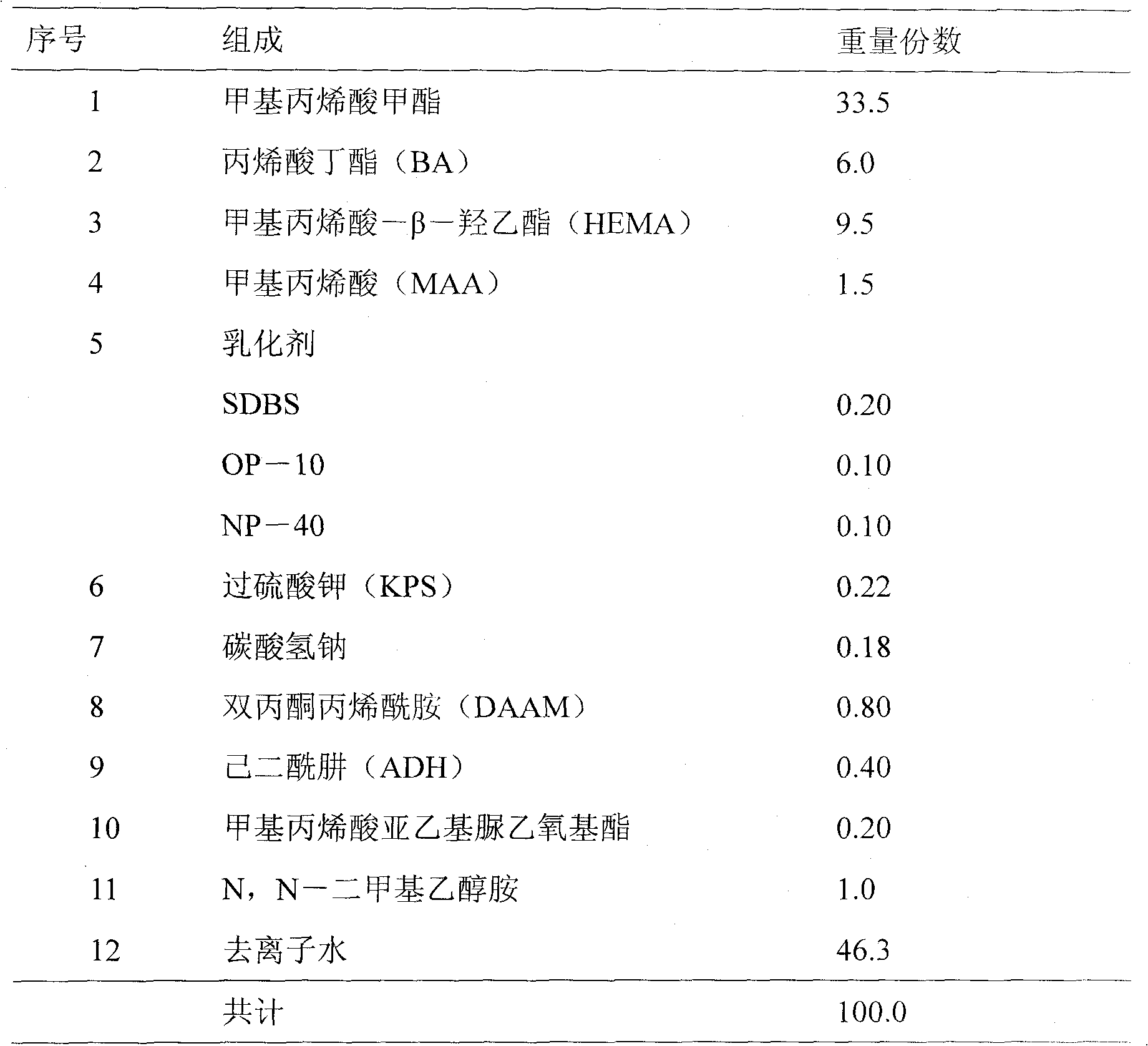

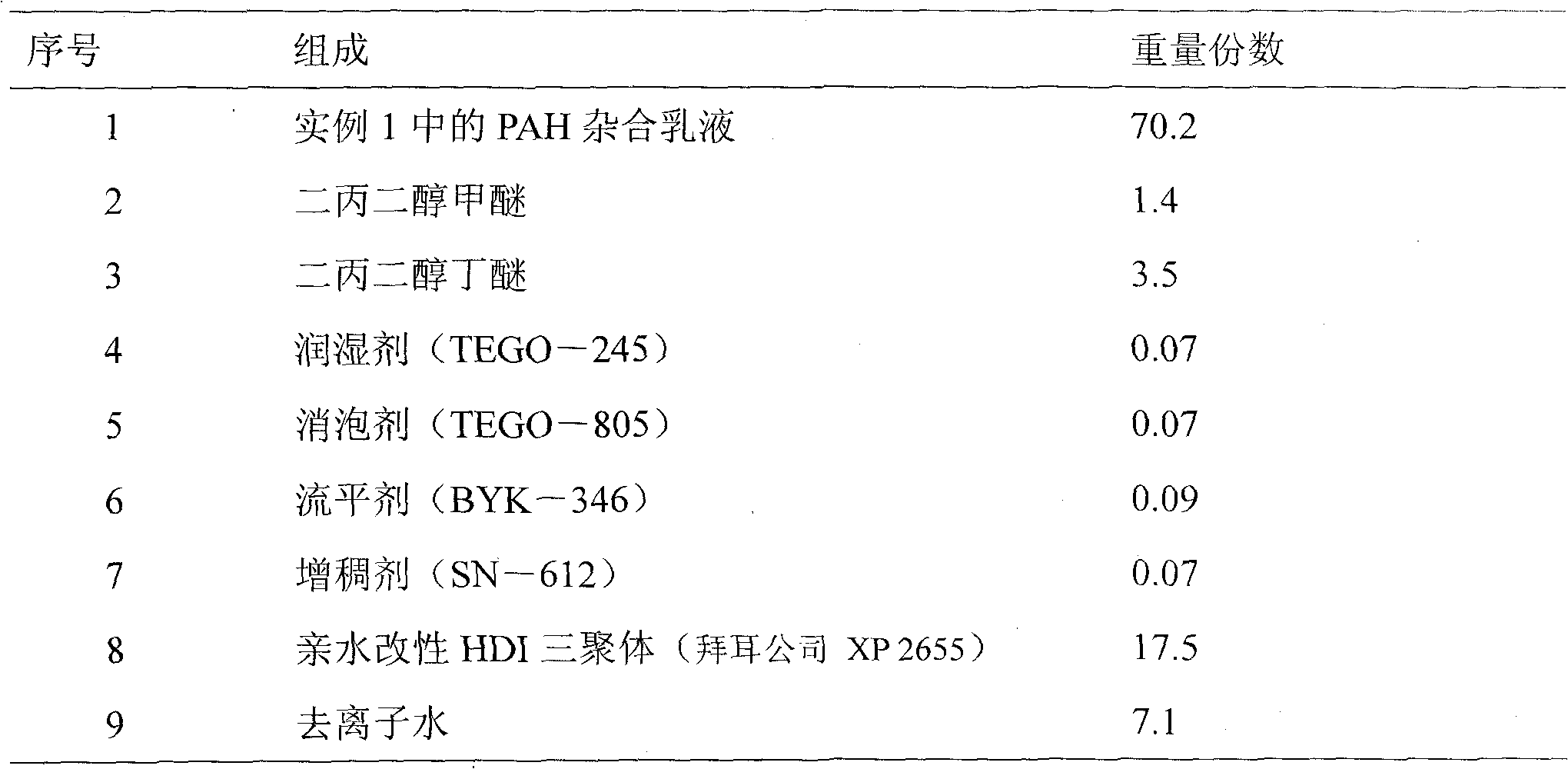

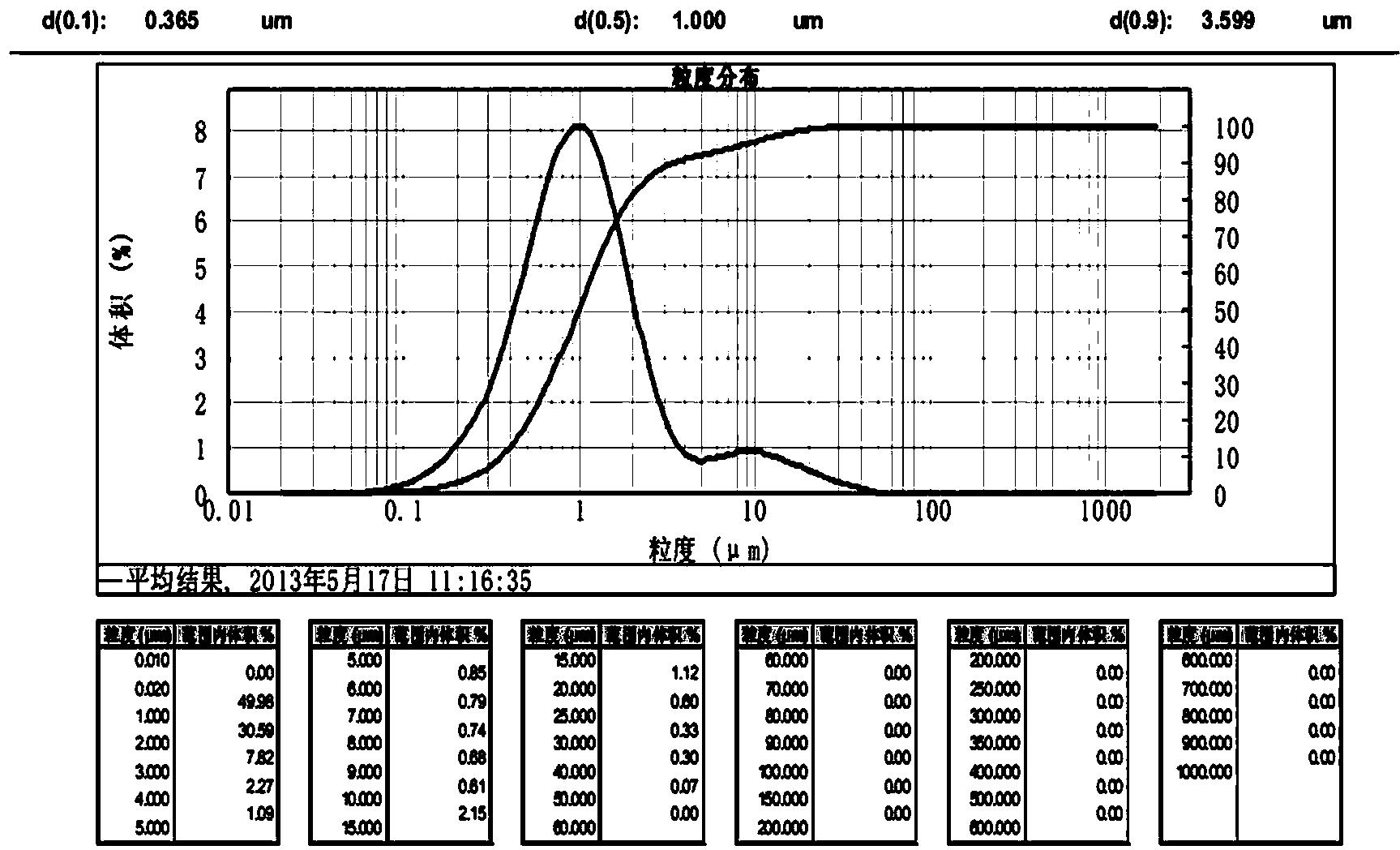

The invention discloses a preparation method and an application of an acrylate heterozygotic emulsion. In the invention, the acrylate heterozygotic emulsion is synthesized by adopting a seed emulsion polymerization process and combining a process of instantly neutralizing and segmentally adding polar monomers. The acrylate heterozygotic emulsion comprises macroparticles consisting of polymers P2 rich in hydroxyl groups on a surface layer and microparticles consisting of polymers P1 rich in carboxylate on the surface layer. Compared with a conventional hydroxy acrylate emulsion, the acrylate heterozygotic emulsion has smaller mean grain size and wider grain size distribution on emulsion particles. The acrylate heterozygotic emulsion can be adopted to prepare aqueous bi-component polyurethane wood coatings, and a coating layer of the coating has excellent property of resisting water and solvents, high crosslinking density and hardness, good mechanical property, scratching resistance and wear resistance. The acrylate heterozygotic emulsion has compact coating structure, high glossiness and better combination property, and not only can be applied to high-grade wood coatings, but also can be applied to automotive refinish paint, metallic anti-corrosion paint, other industrial protective paint, and the like.

Owner:SOUTH CHINA UNIV OF TECH

Maleic anhydride grafted polypropylene preparation method

The invention discloses a maleic anhydride grafted polypropylene preparation method, which comprises: uniformly mixing maleic anhydride, an activator and polypropylene powder in a high-speed mixer; and feeding into a multifunctional rubber-plastic processing device, and carrying out a grafting reaction on the maleic anhydride and the polypropylene powder under the co-action of microwaves and the activator to prepare the maleic anhydride grafted polypropylene. According to the present invention, by introducing the activator, the microwave reaction efficiency is promoted, and the grafting ratioof the maleic anhydride grafted polypropylene is increased, such that the compatibility, the toughness and the impact strength of the maleic anhydride grafted polypropylene product are substantially improved.

Owner:LUOYANG HEMENG TECH CO LTD

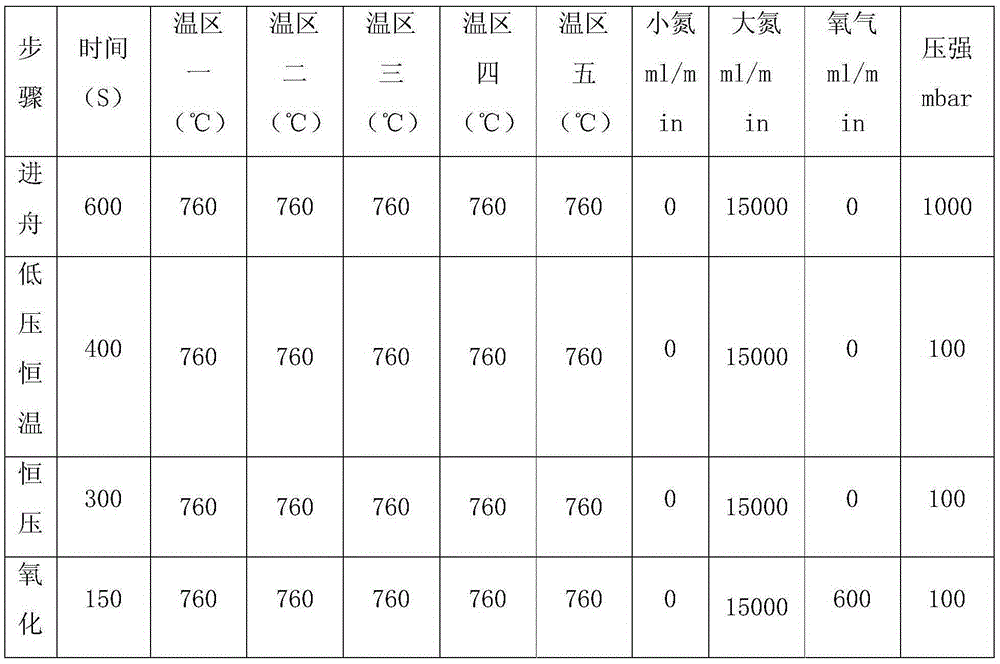

Low-pressure diffusion technology for crystalline silicon cell

ActiveCN105261670AIncrease chance of contactImprove uniformityFinal product manufactureSemiconductor/solid-state device manufacturingDiffusion methodsInternal pressure

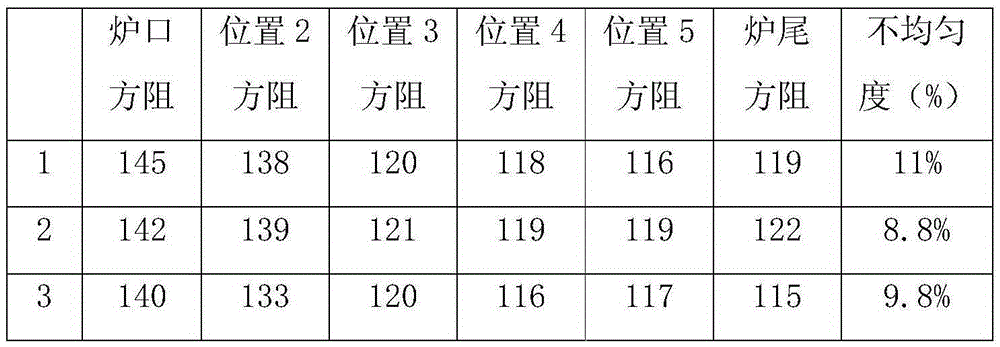

The invention discloses a low-pressure diffusion technology for a crystalline silicon cell. The technology comprises the following steps: (1) a high-temperature oxidation before diffusion; (2) a low-pressure diffusion, namely preparing a PN knot by a sub-step diffusion method; and (3) annealing, namely changing internal pressure to remove impurities. According to the low-pressure diffusion technology, the uniformity between diffusion sheets can be improved; the temperature of a temperature zone in a fire hole is lowered, namely the temperature uniformity of various temperature zones of a diffusion tube is improved; the problem of a great fluctuation of sheet resistance of the fire hole of a diffusion furnace is solved; the service lifetime of a vacuum pump is prolonged; and the production cost of a diffusion procedure is reduced.

Owner:HUNAN RED SUN PHOTOELECTRICITY SCI & TECH

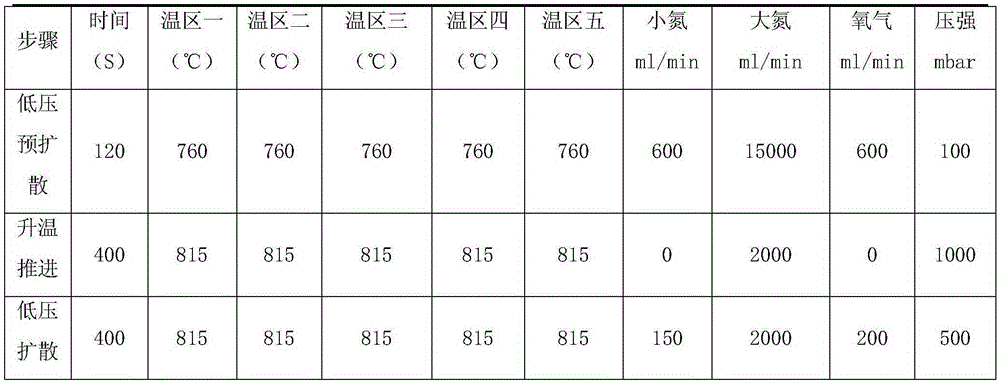

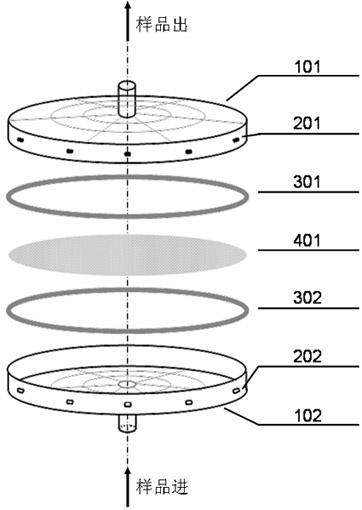

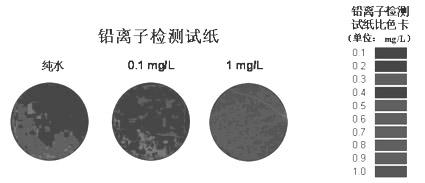

Indicator fixation test paper for heavy metal ion detection, preparation thereof and application thereof

ActiveCN102466638AEffectively fixedIncrease the chance of interactionMaterial analysis by observing effect on chemical indicatorAcetic acidSilanes

The invention relates to a preparation and an application of an indicator fixation test paper for the heavy metal ion detection. The preparation comprises three steps of silica sol gel synthesis, indicator fixation and color comparison. Tetraethoxysilane and siloxane containing hydrophobic function groups, which are adopted as a mixed silicon source, are hydrolyzed under acidic conditions to synthesize the silica sol gel. The gel is mixed with a specific hydrophobic or water-soluble metal ion indicator, is uniformly coated on a nitric acid-acetic acid mixed cellulose film and is dried under the protection of nitrogen. The test paper of the invention can be used for determining trace heavy metal ions in water and can respectively, rapidly and semi-quantitatively determine various trace heavy metal ions in water within 10min.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

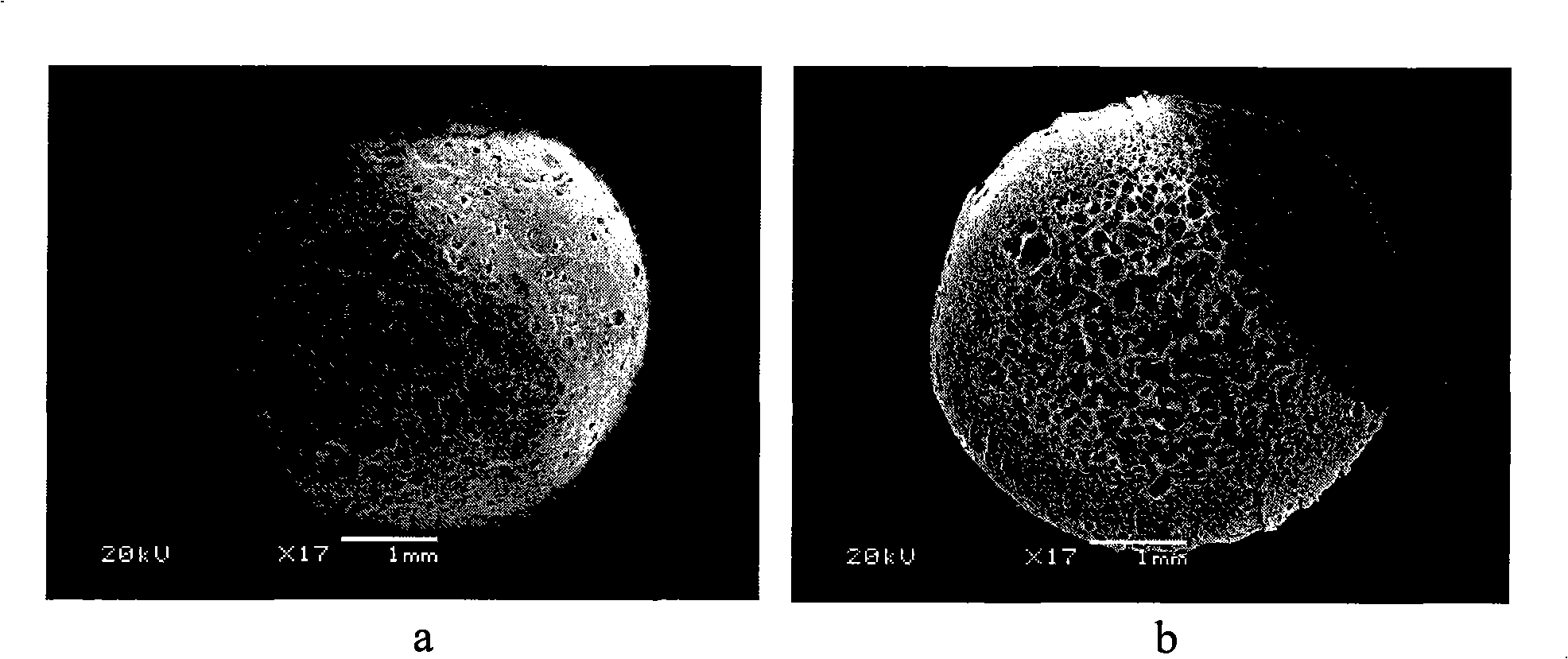

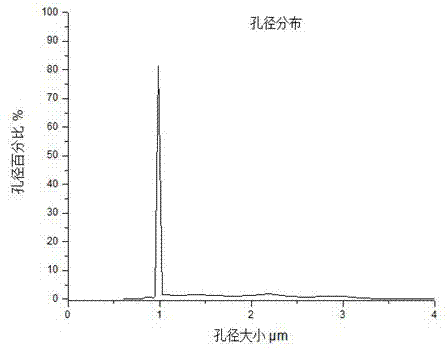

Macroreticular polyvinyl alcohol bead carrier and preparation thereof

InactiveCN101348782AIncrease the specific surface area of contactIncrease chance of contactOn/in organic carrierPeristaltic pumpDissolution

The invention provides a method for preparing a macroporous reticulated polyvinyl alcohol spherical vector. The method comprises the following steps: firstly, polyvinyl alcohol, calcium carbonate, sodium alginate and water are mixed in a certain mass proportion, and stirring is performed for full dissolution of the polyvinyl alcohol and uniform mixture, and then white PVA sol is obtained; secondly, the sol obtained is added into saturated boric acid solution containing 3 percent of calcium chloride by a peristaltic pump, and PVA gel beads are formed, cleaned by water and then placed into diluted hydrochloric acid solution for dipping until no air bubble is generated; thirdly, a spherical vector is thrown into glutaral pentanedial water solution and adjusted into acidity so as to generate crosslinking reaction to form a more stable crosslinking structure; and fourthly, the spherical vector is dipped into water and cleaned into neutrality, and then the white macroporous reticulated PVA spherical vector with elasticity is obtained. The macroporous reticulated polyvinyl alcohol vector prepared by the method has stable macroporous reticulated structure and good hydrophilicity, physical and chemical stability and anti-biological degradability, is suitable for immobilized enzymes and microorganisms so as to form a plurality of bed-shaped bioreactors, and is used in the modern bioengineering field such as sewage treatment and so on.

Owner:LANZHOU UNIVERSITY

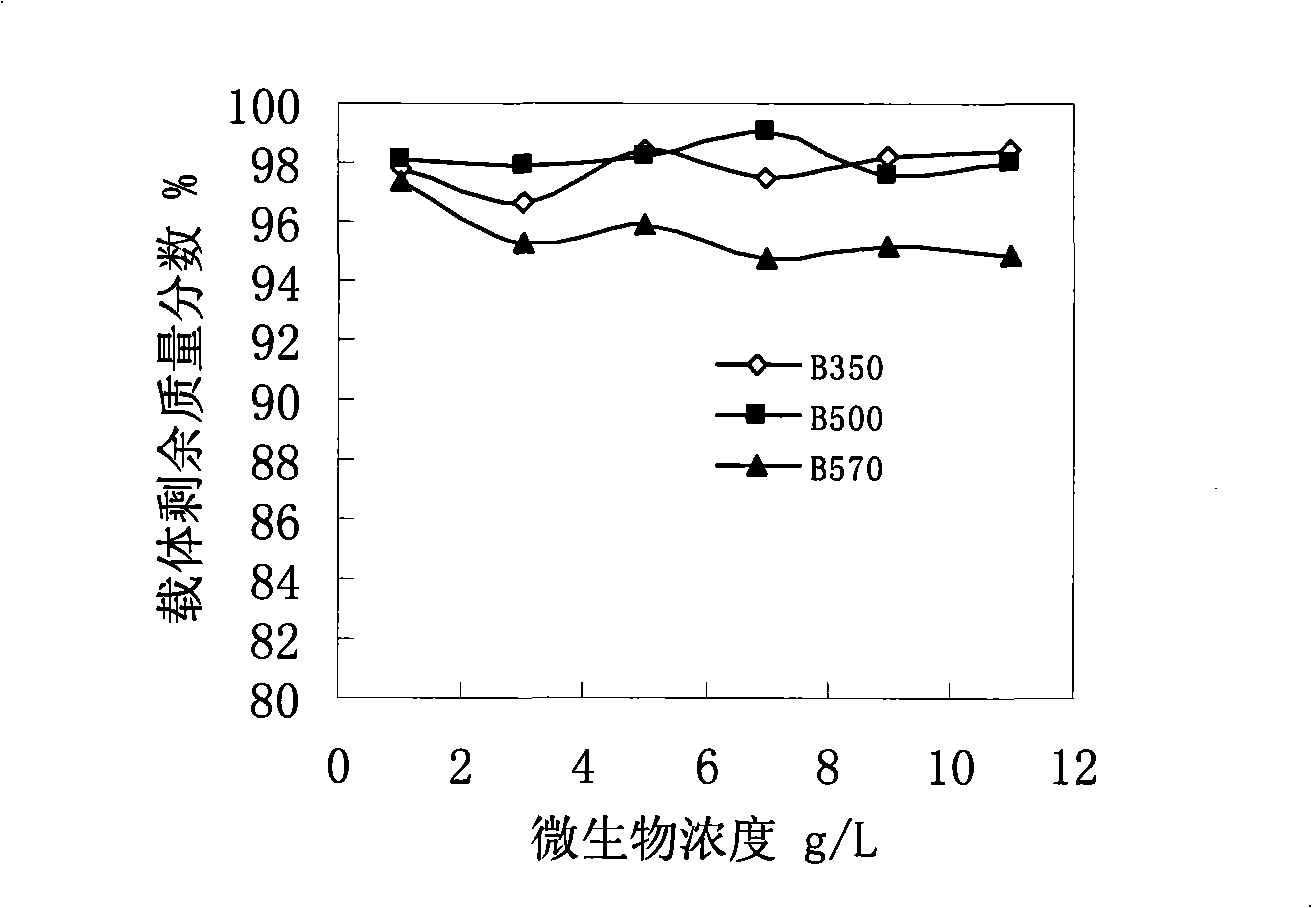

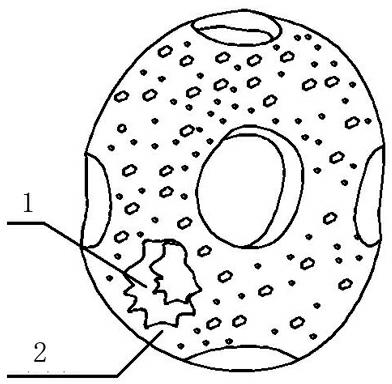

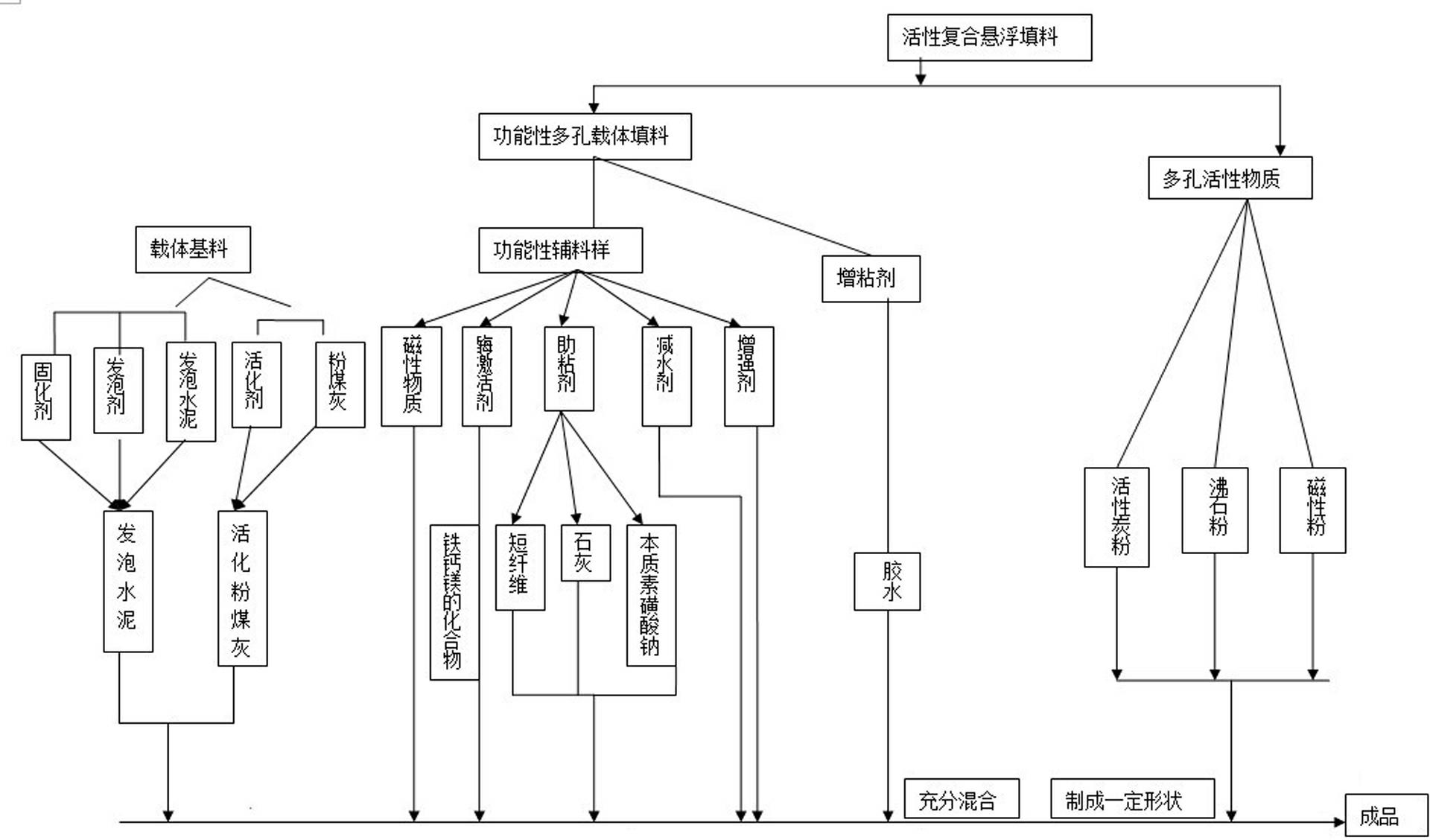

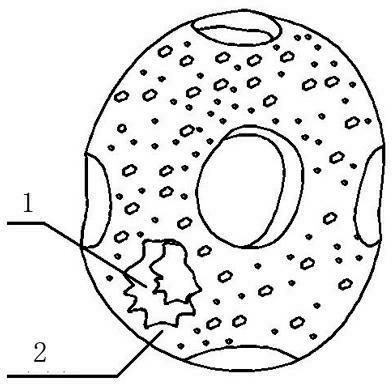

Active composite suspended filler

ActiveCN102583719AHigh activityKeep aliveTreatment with aerobic and anaerobic processesSustainable biological treatmentChemical oxygen demandHoneycomb

The invention relates to an active composite suspended filler, which is applied to the technology of biochemical treatment of organic wastewater, and discloses a porous support filler formed by a carrier basic materials and functional assistant materials. The porous support filler is in a through-hole spheroidal body or a through-hole cylindrical body, and one layer of porous active powder material layer is bonded on an outer surface of the through-hole spheroidal body or the through-hole cylindrical body. The active composite suspended filler is an inorganic suspended filler, has an uneven surface and roughness height; and pores with different sizes are distributed on the filler and are shaped like a honeycomb. The filler not only has high adsorption performance on harmful substances and dissolved oxygen, but also can form different dissolving intensity, is beneficial to improving processing efficiency for removing COD (Chemical Oxygen Demand) and ammonia nitrogen, and will be a novel high-efficient filler.

Owner:GUANGDONG LVYUAN ENVIRONMENTAL TECH CO LTD

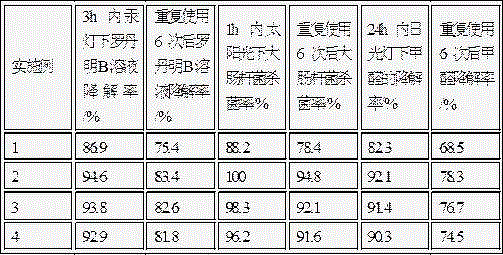

Preparation method of TiO2 photocatalyst by loading TiO2 to diatomite formed in advance and doping rare earth

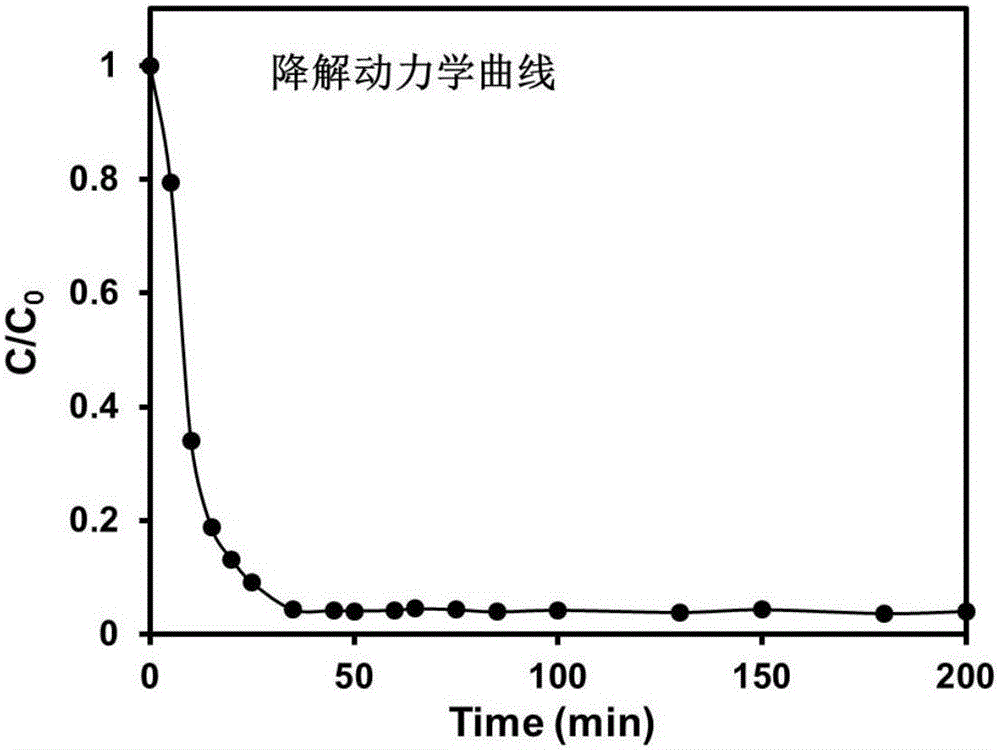

InactiveCN105080528AIncrease chance of contactImprove photodegradation efficiencyBiocideWater/sewage treatment by irradiationSol-gelMercury vapors

The invention relates to a preparation method of TiO2 photocatalyst by loading TiO2 to diatomite formed in advance and doping rare earth, and belongs to the technical field of photocatalysis. The preparation method comprises the steps of: pickling original diatomite, roasting the pickled diatomite, and uniformly mixing the roasted diatomite, a binder, a fluxing agent and the like so as to obtain molded diatomite; and using tetrabutyl orthotitanate and dehydrated alcohol as raw materials, preparing TiO2 and rare earth doped TiO2 sol by a sol-gel method, macerating the preformed diatomite in the sol, drying the macerated diatomite, and calcining the dried diatomite so as to obtain the load type photocatalyst. The photocatalyst can prevent the TiO2 from running off; besides, the rare earth is doped, so that the utilization rate of visible light by the TiO2 is increased; when a mercury-vapor lamp is used for 3 hours, 95% of a rhodamine b solution can be degraded; when the photocatalyst is illuminated for an hour under sunlight, escherichia coli can be thoroughly killed; when the photocatalyst is illuminated for 24 hours by common daylight lamps, 92% of methanal can be degraded; the photocatalyst is excellent in photocatalytic property and stability, which indicates that the photocatalyst has favorable application prospects in the respects of waste water treatment, sanitation and sterilization, air purification and the like.

Owner:NORTHEASTERN UNIV

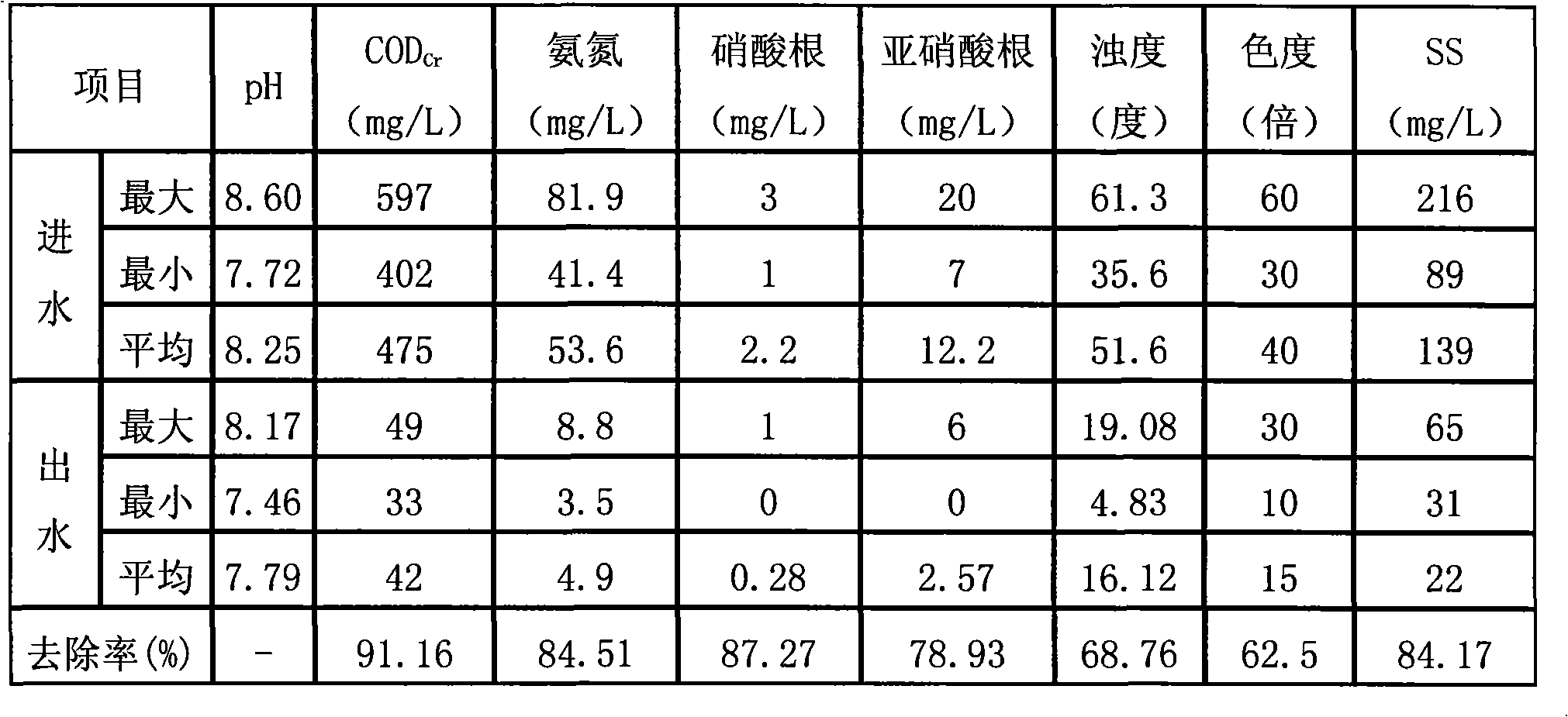

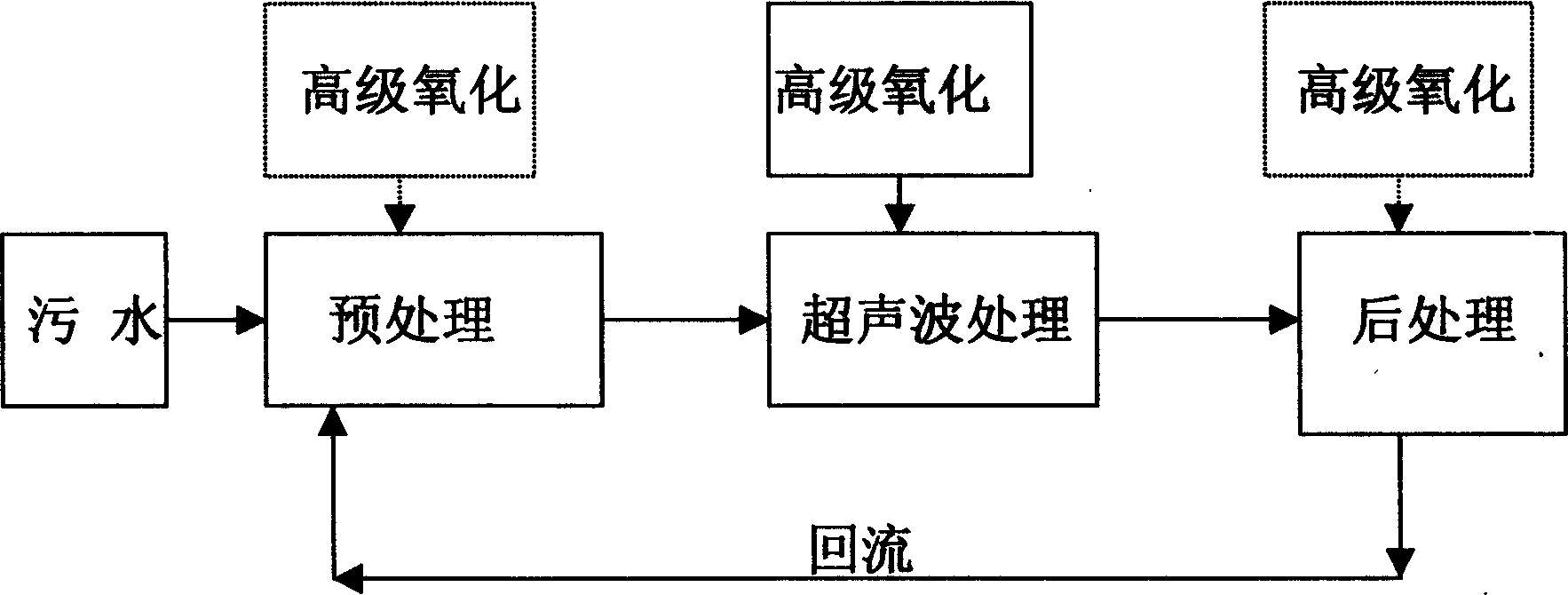

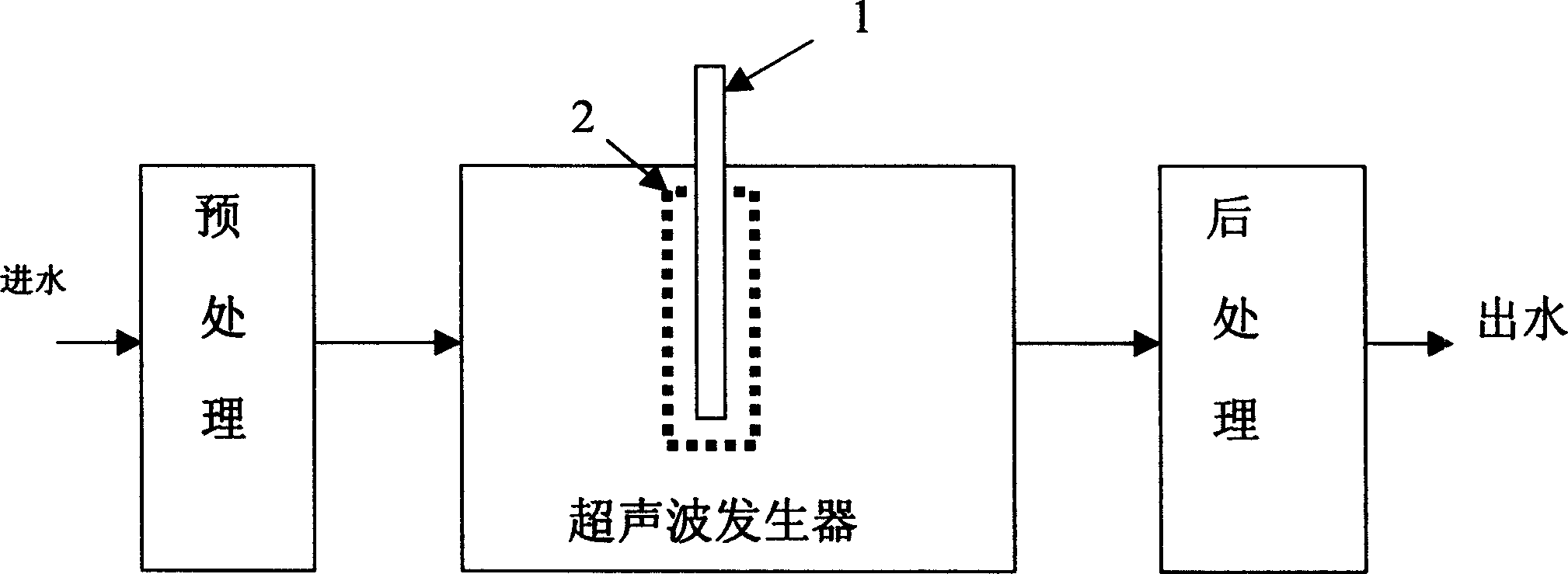

Ultrasonic wave and oxidation sewage treatment method

InactiveCN1544346AHigh yieldIncrease concentrationWater/sewage treatment with mechanical oscillationsWater/sewage treatment by oxidationAdvanced oxidation processTherapeutic effect

The invention relates to a ultrasonic oxidization sewage treatment process which is aimed at solving the problem of unsatisfactory treatment effects to COD, BOD, SS, N, P, chromaticity and various hard-degradable organics in the conventional sewage treatment methods, the process according to the invention comprises the steps of, (1) water pretreatment, (2) subjecting the pretreated water to ultrasonic treatment, (3) subjecting the treated water to post-treatment, high-grade oxidation treatment can be added to each or any one of the steps.

Owner:北京裕京电脑软件有限公司

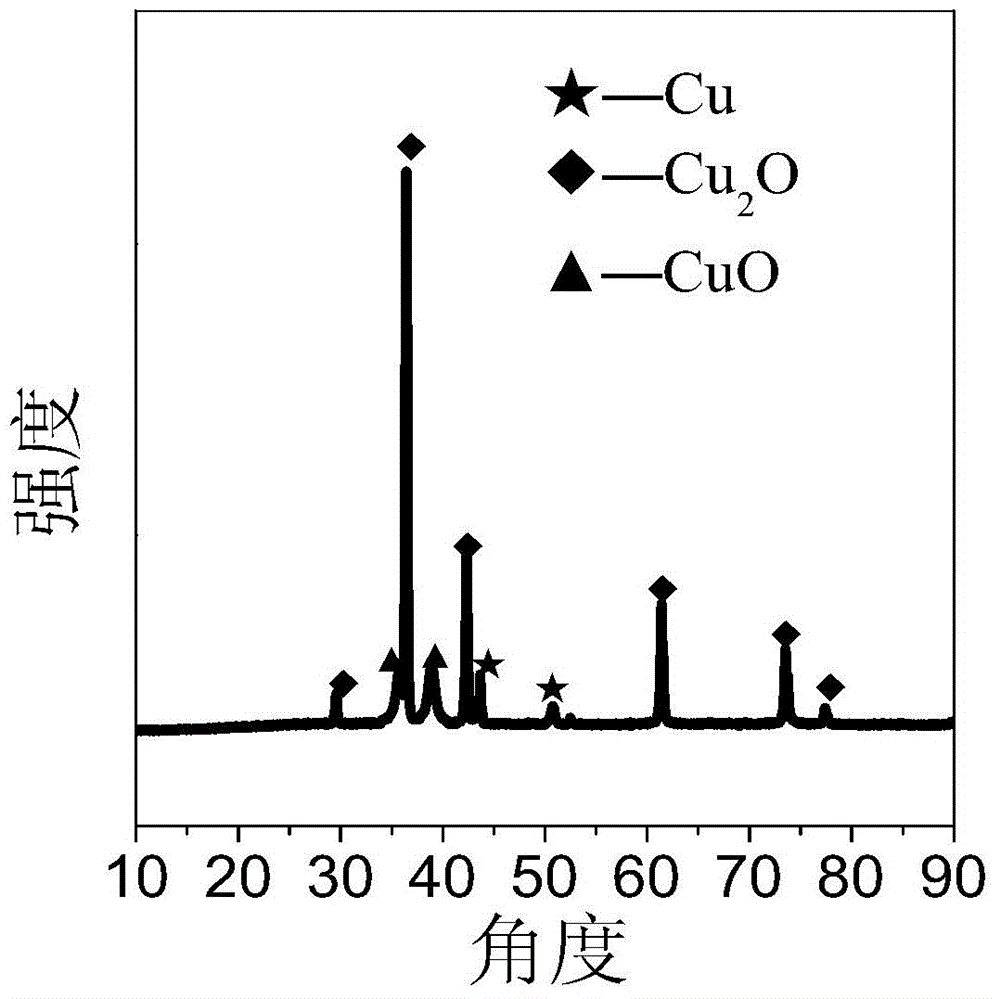

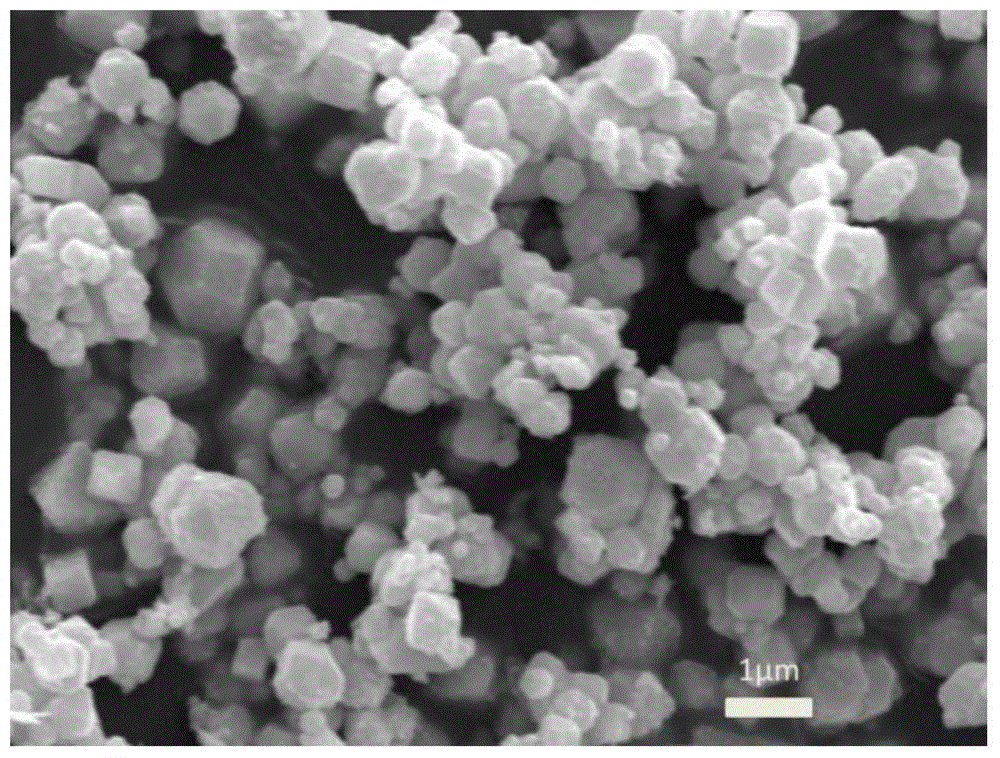

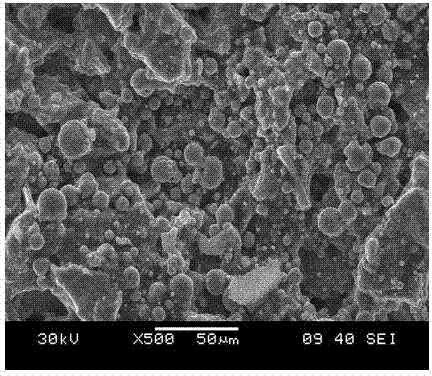

Copper-based Cu-Cu2O-CuO catalyst as well as preparation method and application thereof

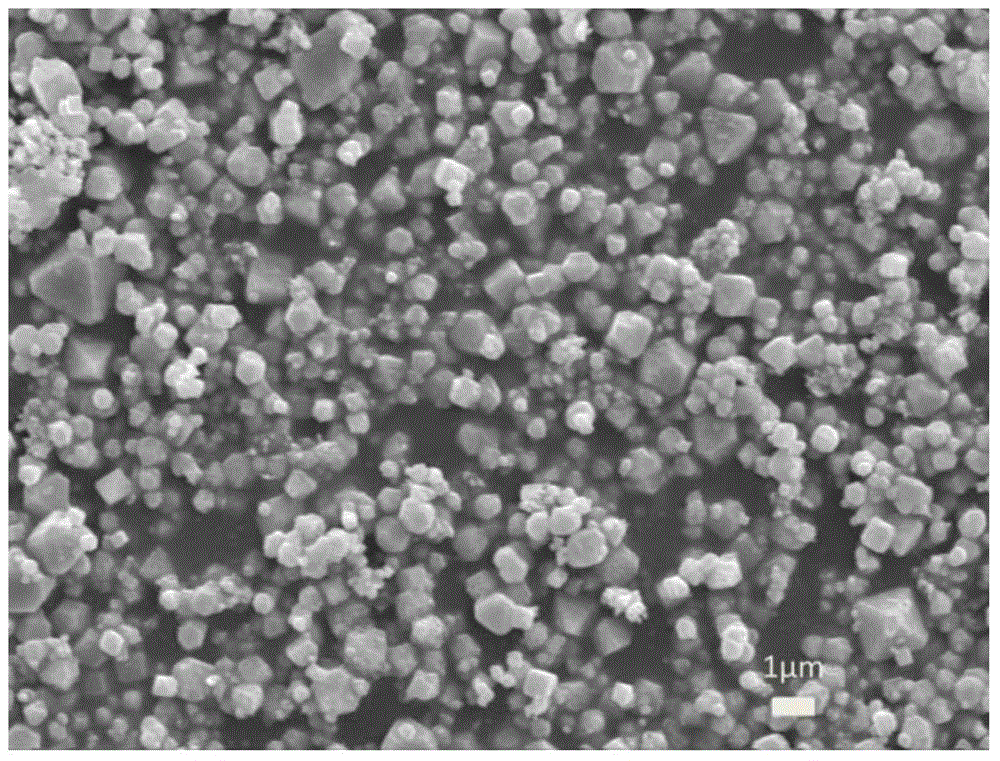

ActiveCN104857958AControllable ratioEvenly distributedGroup 4/14 element organic compoundsMetal/metal-oxides/metal-hydroxide catalystsCopper(II) oxideVacuum drying

The invention provides a copper-based Cu-Cu2O-CuO catalyst for an organic silicon monomer synthesis reaction as well as a preparation method and an application of the copper-based Cu-Cu2O-CuO catalyst. The catalyst comprises components in percentage by mass as follows: 0-40% of elementary Cu, 40%-90% of Cu2O and 0-40% of CuO, and the sum of mass percentages of all the components is 100%. The method comprises steps as follows: a copper salt is dissolved to form a copper salt solution; an alkaline solution is dropwise added to the copper salt solution, and copper hydroxide precipitate is obtained and then converted into CuO precipitate; then a certain quantity of reducing agent is dropwise added to a CuO suspension for a controllable reduction reaction; obtained reaction products are filtered, washed and subjected to vacuum drying, and then the multicomponent copper-based catalyst is obtained. The experimental process route is simple, the controllability is high, and the prepared multicomponent copper-based catalyst is smaller in particle size and evener in particle size distribution, contains controllable components and shows the higher M2 selectivity and the higher silicon powder raw material conversion ratio.

Owner:TAIXING SMELTING PLANT

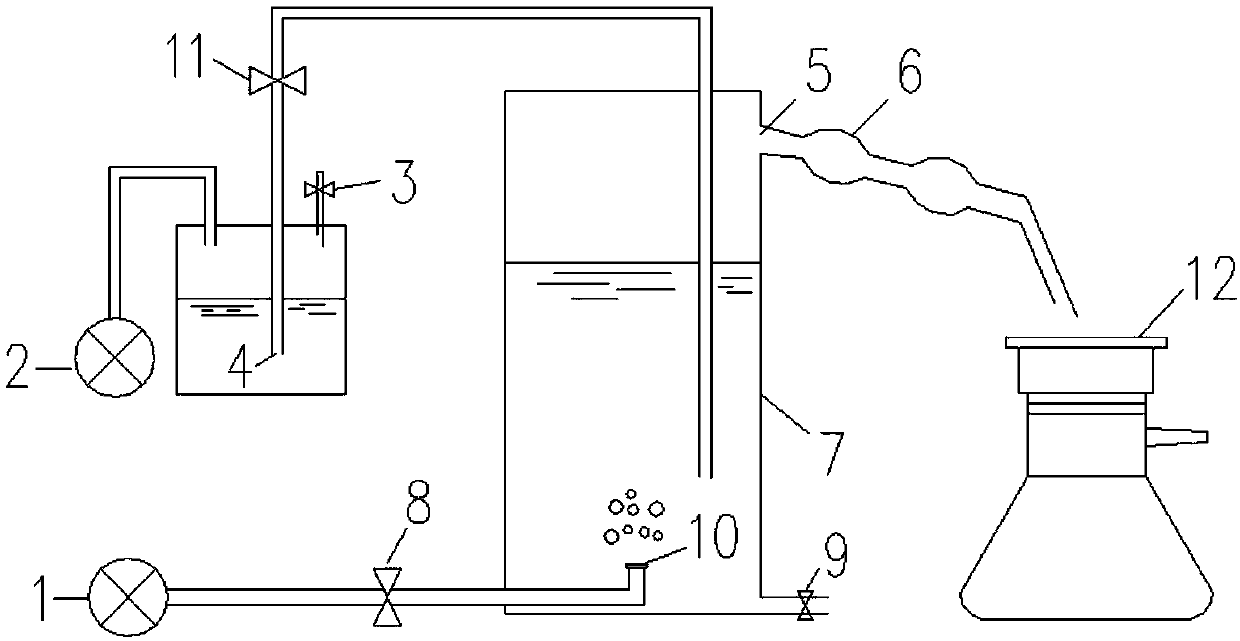

Flotation gathering device and screening method for microplastics

InactiveCN109655321AImprove extraction efficiencyReduce demandPreparing sample for investigationHigh densityAeration system

The invention discloses a flotation gathering device and a screening method for microplastics. The basic principle is that the difference of adhesion characteristics of bubbles on hydrophilic and hydrophobic materials can be changed based on a biosurfactant, and a high-density flotation solution can improve the separation effect on the high-density microplastics. The device comprises a flotation solution storage device, a separation pipe, an aeration device and a suction filtration device, wherein the aeration system is used for generating ascending gas to strengthen stirring of the system, and microplastics are coated with small bubbles to be rapidly separated. After standing, the flotation solution is pushed by a flotation solution system to overflow from an upper opening, and the separation performance of the microplastics is improved. The microplastic flotation separation device disclosed by the invention is simple and easy to operate, high in recovery rate of microplastic particlefragments, recyclable in flotation liquid, high in practicability and low in cost, and can be widely applied to gathering and screening of environmental microplastics.

Owner:TIANJIN UNIV

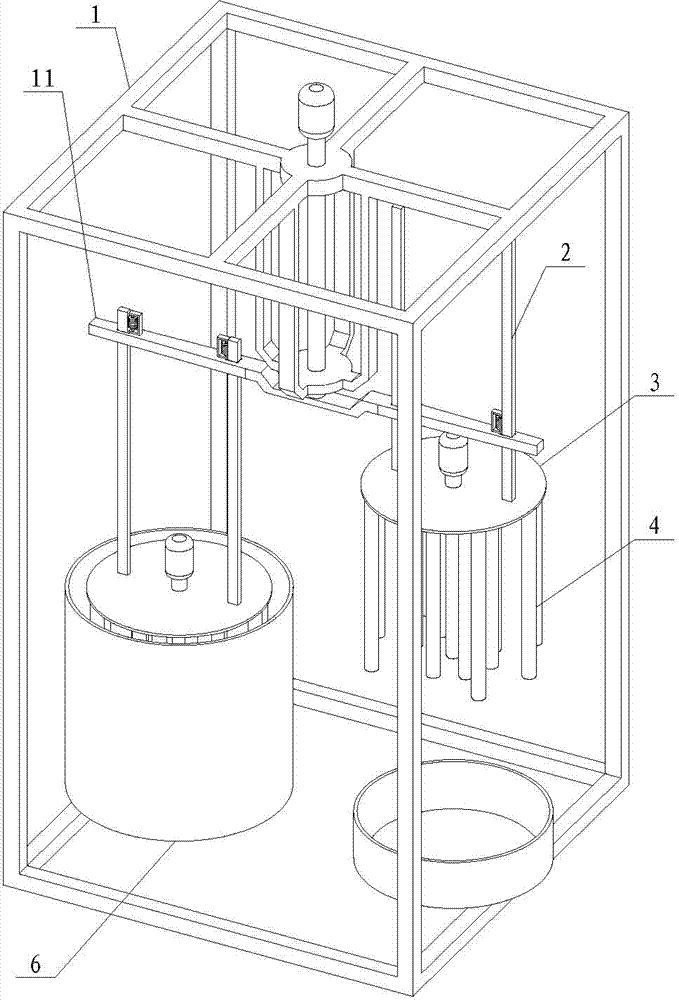

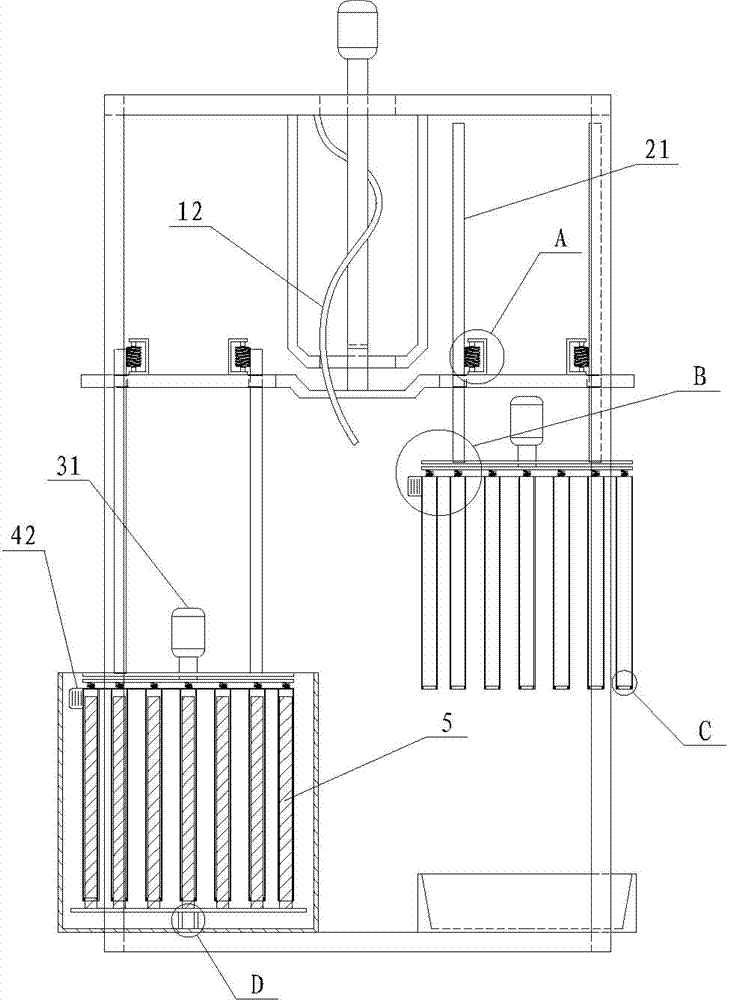

Method and equipment for eliminating iron scraps from raw materials

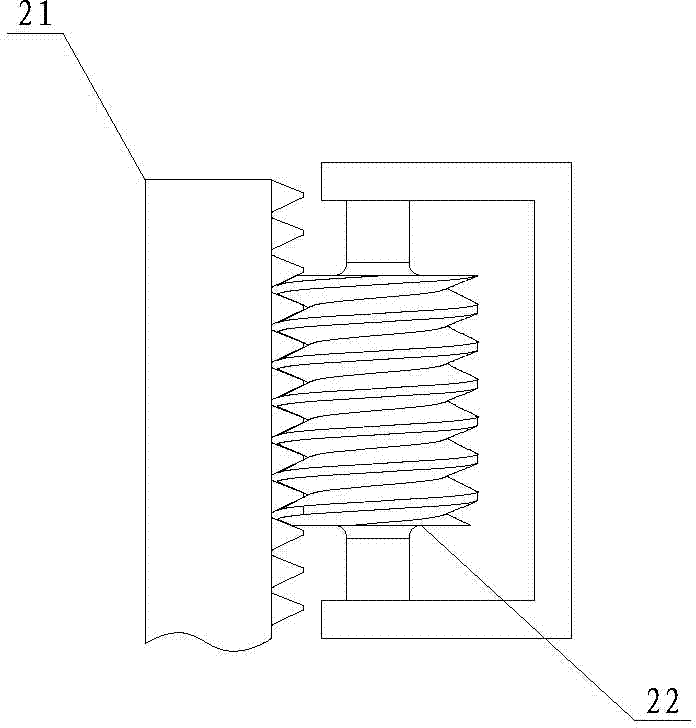

The invention discloses method and equipment for eliminating iron scraps from raw materials. The equipment comprises a rack, a charging bucket and a group of magnetic rods, and is characterized in that rotary arms are arranged on the rack and can horizontally rotate around the rack; a lifting mechanism is arranged on each of the rotary arms; rotary mechanisms are connected to the bottoms of the lifting mechanisms; a group of iron barrels are connected to the lower parts of each of the rotary mechanisms; a connection plate, a vibrator and an iron barrel connected with the connection plate are arranged in the group of iron barrels; the group of iron barrels is driven by the lifting mechanisms to sleeve iron barrels on the magnetic rods in the group of the magnetic rods; a motor, a rotary disc and a spring are arranged in each of the rotary mechanisms; each of the rotary disc is connected with each of the motors; a spring is fixed between each of the connection plates and each of the rotary discs; and vibrators are arranged on the connection plates. The method and the equipment have the beneficial effects that the iron barrels and the magnetic rods rotate in the charging bucket when irons are attracted, so that the contact probability of the iron barrels and slurries is increased, and the iron-attraction effect is improved; and when the iron barrels are subjected to iron removal, another group of iron barrels are quickly sleeved on the magnetic rods to perform the next round of iron attraction, so that the iron removal time is shortened, and the efficiency is improved.

Owner:ZIBO S & N MAGNET MFG

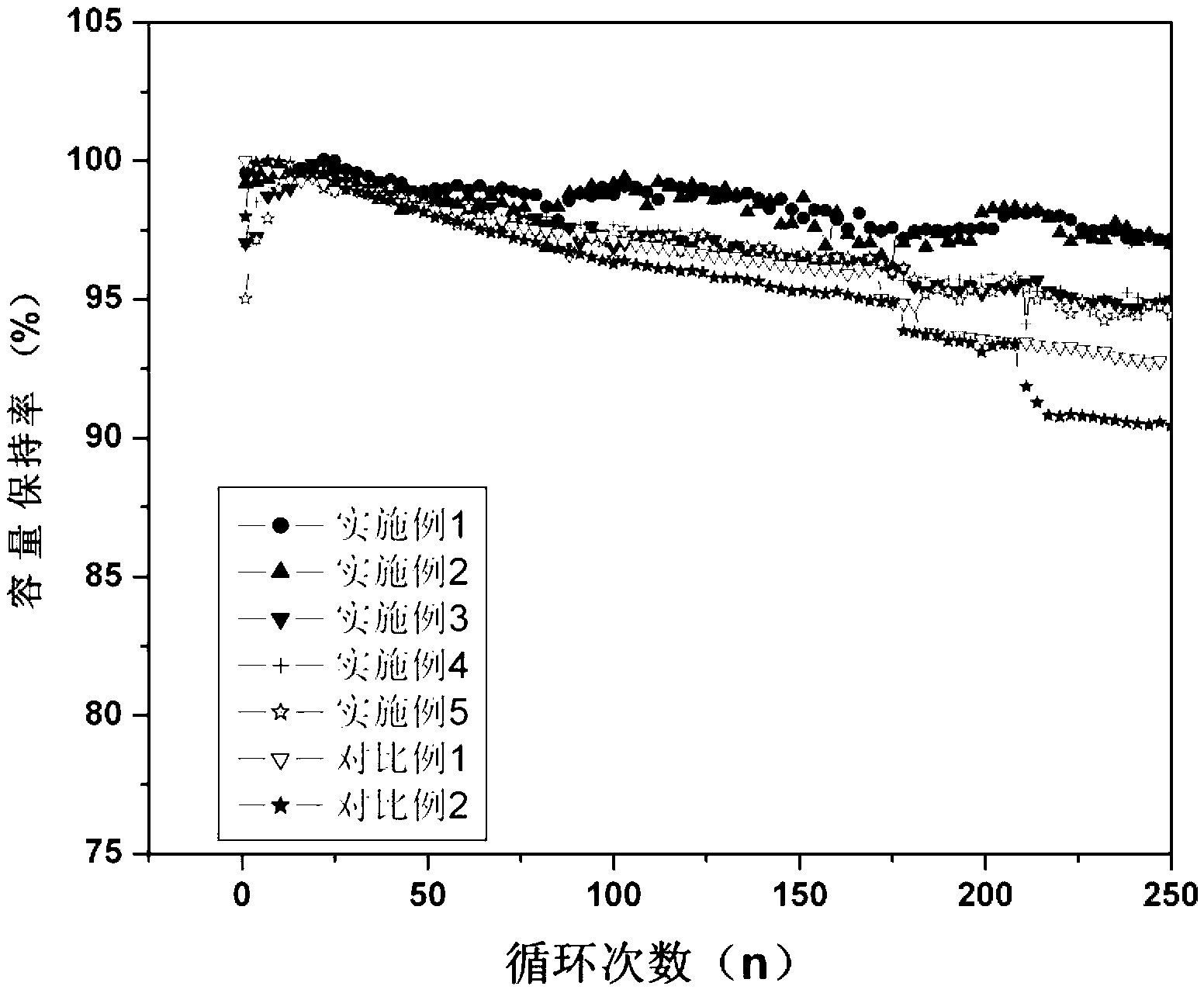

Preparation method of safety coating for positive current collector in lithium ion battery

ActiveCN103956499ALow resistivityHigh resistivityElectrode carriers/collectorsSecondary cellsElectrical batteryInternal resistance

Owner:LUOYANG YUEXING NEW ENERGY TECH

Iron-based metal organic framework (MOFs) photocatalytic material and its preparation method and use

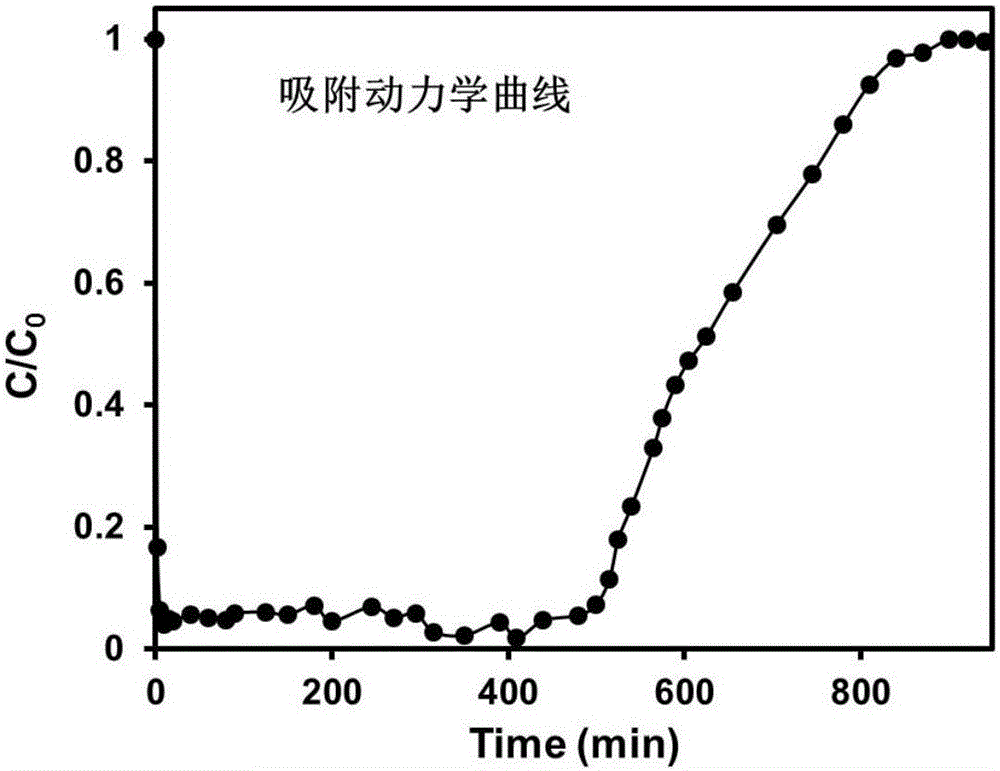

InactiveCN106064101AHigh porosityLarge specific surface areaOrganic-compounds/hydrides/coordination-complexes catalystsDispersed particle separationFiltrationMetal-organic framework

The invention discloses an iron-based metal organic framework (MOFs) photocatalytic material and its preparation method and use. The preparation method comprises dissolving FeCl3.6H2O and terephthalic acid in a DMF solution, carrying out a hydro-thermal reaction process under temperature programmed control and orderly carrying out alcohol washing, filtration and vacuum drying on the precipitated solids. The photocatalytic material has excellent adsorption and enrichment effects on volatile organic chemicals (VOCs), can efficiently degrade VOCs under visible light action and can be used in an air VOCs photocatalytic purification reaction system. The preparation method has the characteristics of simple processes, good environmental friendliness, mild reaction conditions, high catalytic efficiency and no secondary pollution and can be massively promoted in the field of environmental protection.

Owner:GUANGDONG UNIV OF TECH

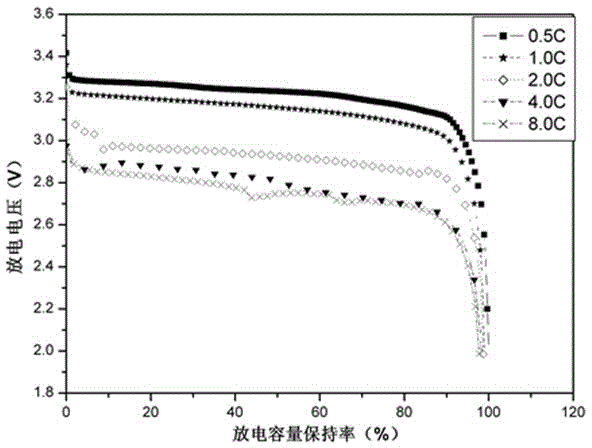

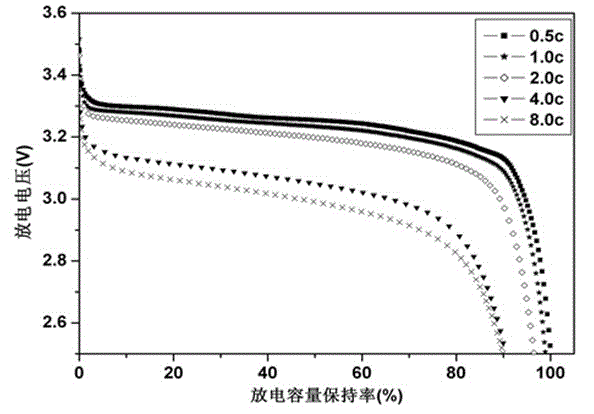

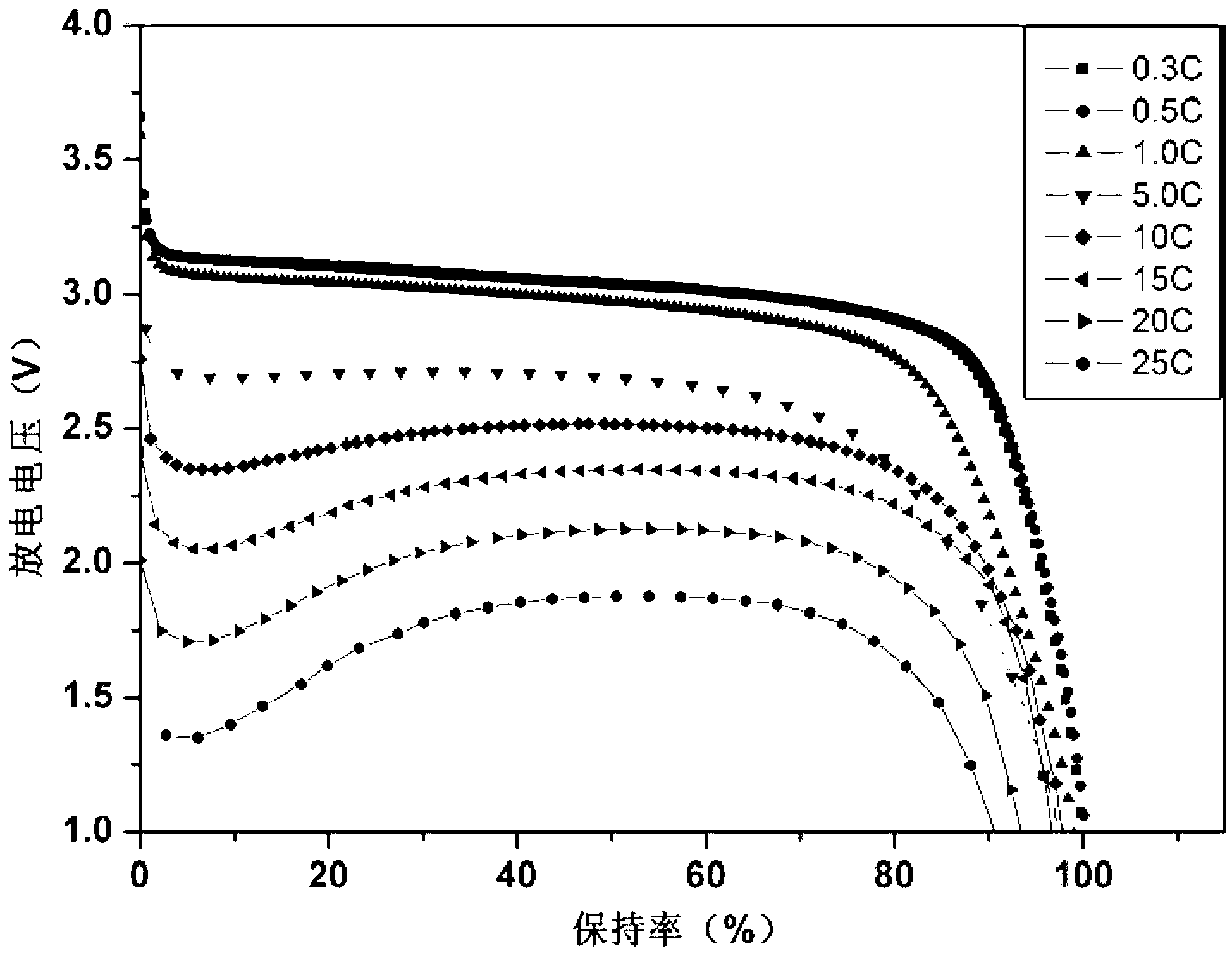

Preparation method of lithium titanate/carbon nano tube composite cathode material

The invention discloses a preparation method of a lithium titanate / carbon nano tube composite cathode material and belongs to the technical field of battery materials. A carbon nano tube grows on the surface of lithium titanate by a chemical vapour deposition method, and has the characteristics of uniform dispersion, high binding force and the like compared with a carbon nano tube directly doped in lithium titanate, the growing carbon nano tube can form a network structure on the surface of lithium titanate, and an important effect is exerted on improving structural stability of the material under the condition of high-rate discharge of a battery. The contact probability of the lithium ion battery with lithium titanate is increased and the internal resistance and polarization are reduced by using high conductivity of the carbon nano tube and the network structure formed by the carbon nano tube, the liquid absorption and keeping ability of the cathode material can be improved due to larger specific surface area of the carbon nano tube, and the high-rate discharge ability and recyclability of the battery are improved.

Owner:RIGHTFUL TECH

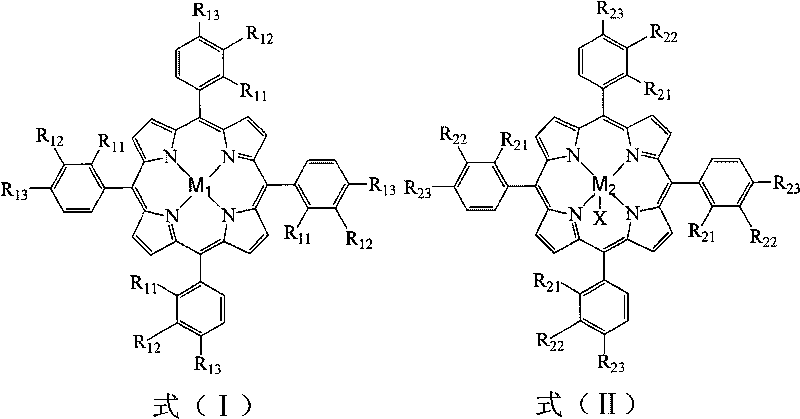

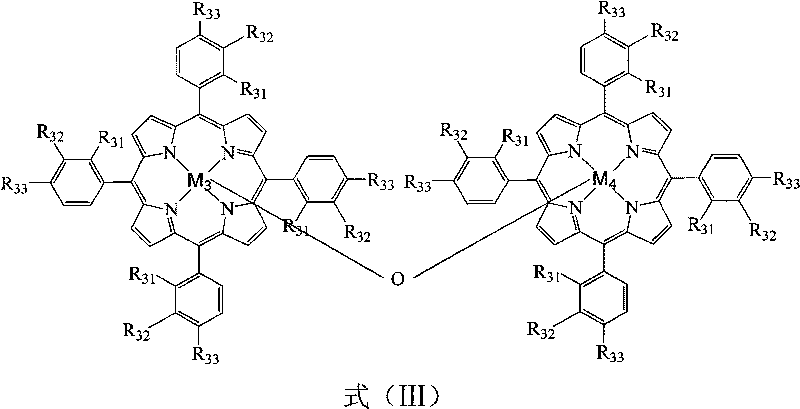

Method for preparing acetophenone by biomimetic catalytic oxidation of ethylbenzene with oxygen

InactiveCN101759542AReduce dosageAvoid separationOrganic compound preparationCarbonyl compound preparationPorphyrinCatalytic oxidation

The invention relates to a method for preparing acetophenone by biomimetic catalytic oxidation of ethylbenzene with oxygen, comprising the following steps: taking ethylbenzene as the raw material, selecting any one of 1-30ppm of mononuclear metalloporphyrin and mu-oxo-dinuclear metalloporphyrin or the composition of the two substances as the catalyst under normal pressure and in the absence of solvents, introducing oxygen at the flow rate of 10-60mL / min, initiating reaction at 130-136 DEG C and then carrying out reaction at 70-110 DEG C for 4-10h, thus obtaining the acetophenone. In the method, the way of high temperature quick initiation and low temperature reaction is adopted, thus minimizing the reaction initiation time, greatly shortening the reaction time, improving the reaction efficiency, reducing the energy consumption, lowering the operation cost and improving the reaction safety.

Owner:BEIJING UNIV OF TECH

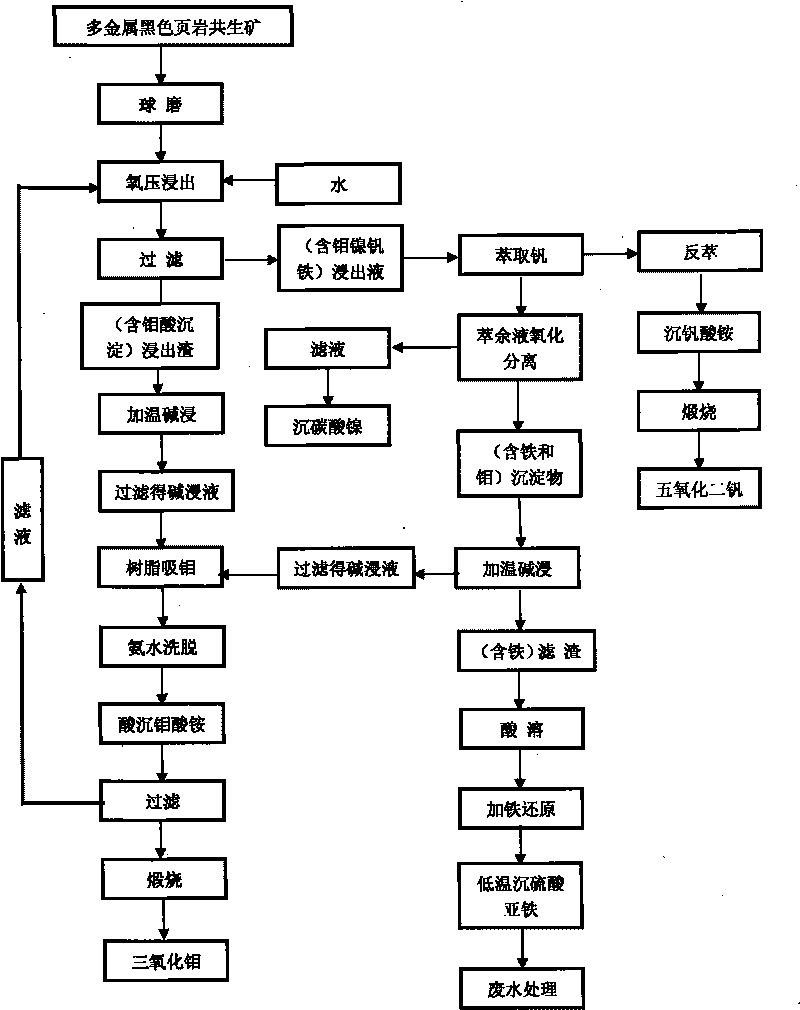

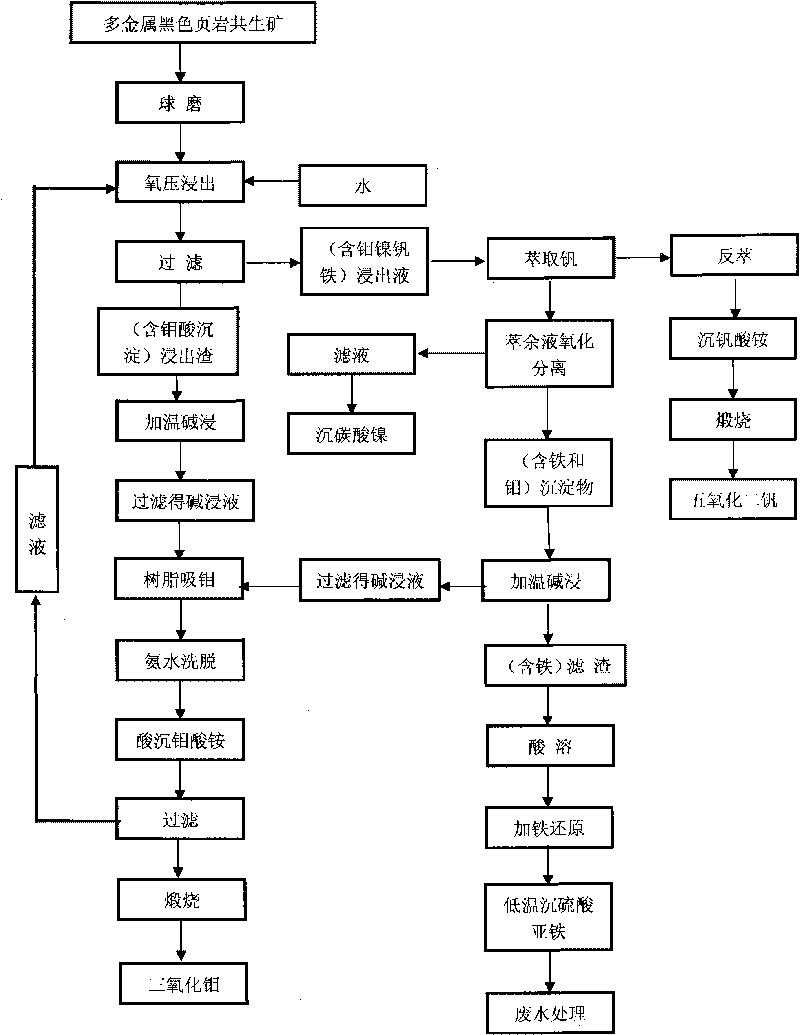

Method for extracting molybdenum, nickel, vanadium and ferrum from polymetallic black-shale paragentic minerals

InactiveCN101717858AAvoid smoke pollutionEnvironmentally friendlyProcess efficiency improvementSal ammoniacSmoke

The invention discloses a method for extracting molybdenum, nickel, vanadium and ferrum from polymetallic black-shale paragentic minerals, comprising the following steps of: ball-milling the polymetallic black-shale paragentic minerals, and then adding into a pressure kettle for oxygen pressure leaching to obtain leach liquor containing ferrous sulphate, molybdenum trisulfate acyl, vanadic acid and nickel sulfate and leach residues containing molybdic acid sediments; adding ammonia water into the leach liquor to extract the vanadium; then carrying out reextraction to obtain ammonium vanadate; generating sediments containing the molybdenum and the ferrum and a solution containing the nickel; filtering to obtain nickel carbonate; carrying out warming alkaline leach on the leach residues containing the molybdic acid sediments and the sediments containing the molybdenum and the ferrum; filtering to obtain an alkaline leach solution containing the molybdenum and filter residues containing the ferrum; after resin absorbs the molybdenum, eluting, acid-precipitating, filtering, drying and calcining to obtain molybdenum trioxide; and acid-dissolving, reducing and filtering the filter residues containing the ferrum to obtain green vitriol. The invention prevents the pollution of smoke gases, such as sulfur dioxide and the like in environment and has low production cost and high recovery rate of molybdenum, nickel and by-products of the vanadium and the ferrum.

Owner:CHONGQING TUOBITUO MOLYBDENUM IND

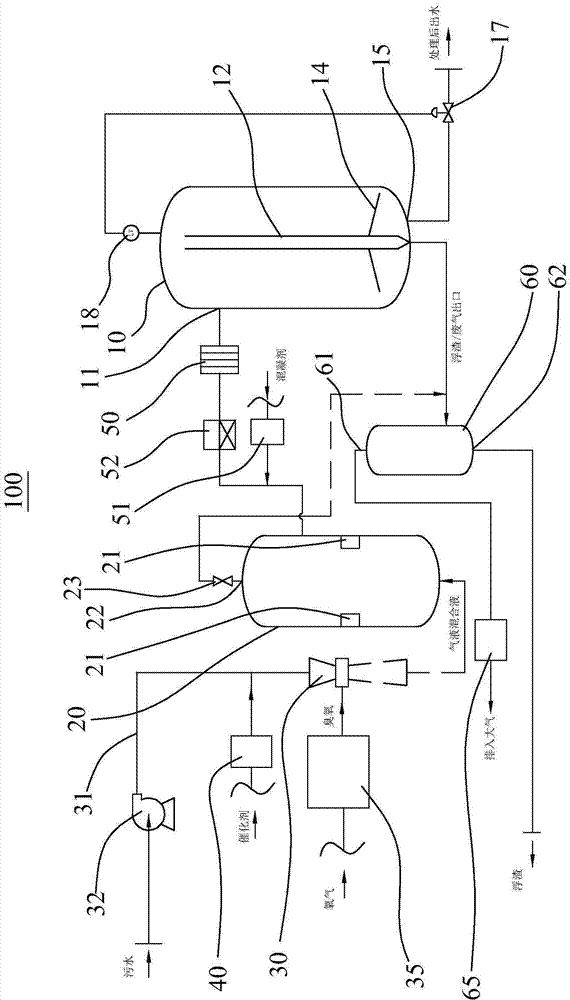

An ozone oxidation-air floatation combined treatment system and a process

ActiveCN104761088AShort stayImprove Ozone Oxidation AbilityMultistage water/sewage treatmentChemistryPollutant

The invention relates to an ozone oxidation-air floatation combined treatment system and a process. The system comprises a reaction tank, a gas liquid mixer, a catalyst adding device and a whirl stream air floating tank. Ozone-containing gas and sewage are mixed into a gas-liquid mixture containing micro bubbles by the gas liquid mixer and then fed into the reaction tank. The reaction tank is provided with at least one ultrasonic wave cavitation device. The catalyst adding device is used for feeding a catalyst, ozone and the sewage into the reaction tank together. Then a catalytic oxidation reaction is performed under the action of ultrasonic wave cavitation. A stream guide pipe is vertically disposed in the center of the whirl stream air floating tank. The upper end of the stream guide pipe is open, and the lower end of the stream guide pipe penetrates the bottom of the whirl stream air floating tank. The bottom of the whirl stream air floating tank is also provided with a sewage outlet. The bottom of the stream guide pipe is provided with vortex plates. The whirl stream air floating tank is communicated with the reaction tank, and used for allowing the gas liquid mixture reacted in the reaction tank to react continuously under the whirl stream function and to be subjected to floatation, washing and separation treatment. The contact probability of the micro bubbles generated by the system with contaminants is large, the reaction is more thorough, the ozone utilization rate is high, retention time is short, and contaminant removing effects are good.

Owner:SHENZHEN CLEAR SCI & TECH

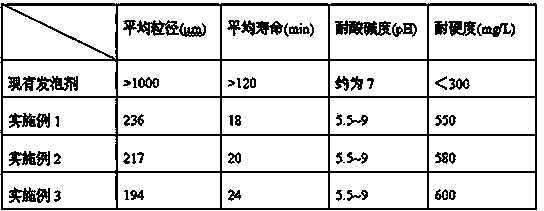

Compound foaming agent used for depositing dust and preparation method thereof

InactiveCN103361035AGood acid and alkali resistanceImprove hard water resistanceOther chemical processesDust removalRespirable dustAlkyl polyglycoside

The invention discloses a compound foaming agent used for depositing dust and a preparation method thereof. The compound foaming agent is prepared from following materials by weight: 5-8 parts of an alkyl polyglucoside, 20-25 parts of a fatty alcohol-polyoxyethylene ether, 9-14 parts of fatty alcohol polyoxyethylene ether sodium sulfate, 1-2 parts of 2-ethyl hexyl succinate sodium sulfonate and 51-65 parts of water. The compound foaming agent has advantages of good acid and alkali resistance and hard-water resistance, strong foaming capability, fine and rich foams, small bubble sizes, moderate stability, large dust contacting area, good adhesiveness and wettability, enhanced dust depositing effects, enhanced capturing capability for respirable dust in particular, no toxicity, no harm, no skin irritation, rapid and complete biodegradation, selection of raw materials common in market and low cost. The compound foaming agent has wide applicability in the field of dust deposition using foams.

Owner:CHINA UNIV OF MINING & TECH +1

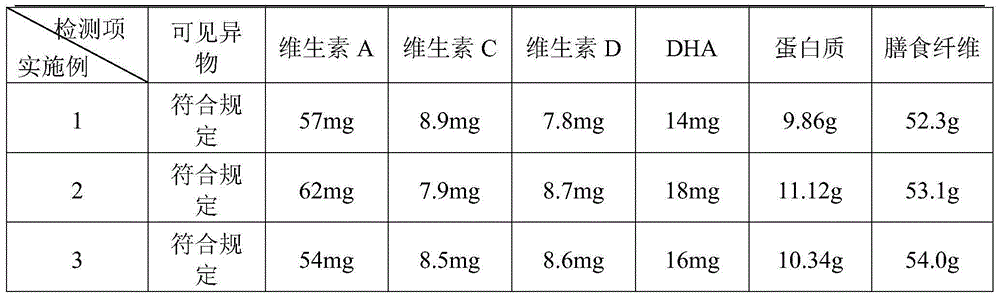

Sweet potato-based functional cake and preparation method thereof

ActiveCN104542865ANo side effectsPrevent liver function lossDough treatmentBakery productsSide effectLiver function

The invention discloses a sweet potato-based functional cake and a preparation method thereof. Most of sweet potatoes are utilized for extracting a sweet potato protein fluid and preparing a dietary fiber in the preparation process, so that the content of sweet potato protein and the dietary fiber in the obtained cake is increased; the cake prepared by the method has the efficacies of preventing and treating constipation, is rich in sweet potato protein and dietary fiber, can play a role in preventing bowel cancer and hyperlipidemia without being greatly taken, and does not cause discomfort symptoms such as abdominal distension and heartburn; meanwhile, liver function damage can be effectively prevented; the abdominal pain symptoms caused by constipation are relieved; and the sweet potato-based functional cake is abundant and balanced in nutrient, easy to digest and absorb, free of a toxic or side effect, and suitable for being taken for a long period of time.

Owner:SISHUI LIFENG FOOD PROD

Supported optical catalyst and preparation method thereof

InactiveCN101318129AImprove decomposition rateAvoid secondary pollutionPhysical/chemical process catalystsDeodrantsVolatile organic compoundActive carbon

The invention provides a supported photocatalyst and a preparation method thereof, relating to a photocatalyst and a preparation method thereof; the invention solves the problem of poor benzene removal effect of the existing photocatalyst. The supported photocatalyst is the active carbon fiber with TiO2 particles loaded on the surface. The catalyst has the preparation method that: 1. preparing solution A; 2. preparing solution B; 3. preparing and aging a titanium dioxide sol; 4. coating the titanium dioxide sol on the active carbon fiber, irradiating with microwaves, shifting to high purity nitrogen for purging, rising the temperature to 200-250 DEG C, keeping the temperature for 1-2h, heating to 350-450 DEG C, calcining at the constant temperature for 2-3h, and cooling to the room temperature. The supported photocatalyst of the invention has more than 28 percent of benzene removal efficiency under the condition of 30-70 DEG C and 1h of lighting, which is free from the influence of the benzene concentration in a gaseous environment, and can completely decompose the volatile organic compounds in an enclosed environment into non-toxic, harmless and tasteless substances after a period of time of application.

Owner:刘守新 +1

Production process for preparing high-purity quartz powder from quartzite

InactiveCN104556047ALoose structureGuaranteed structural porositySilicon compoundsStrong acidsMetal impurities

The invention discloses a production process for preparing high-purity quartz powder from quartzite. The production process comprises the following steps: 1) soaking; 2) smashing; 3) calcining; 4) water quenching; 5) grinding; 6) magnetic separation; 7) elestrostatic separation; 8) acid pickling; 9) cleaning by deionized water; 10) drying. According to the production process, the contamination particles are eluted via gradient acidity distribution; before the smashing, strong acid is used for soaking so as to remove the impurities on the surface of the quartzite; during the water quenching, medium / strong acid is used for removing the metal impurities wrapped in the quartzite; during the grinding, in order to protect the equipment from erosion, medium / weak acid is used for removing the impurities during the grinding, and a ball grinding mill is utilized to increase the contact probability and contact area between the acid liquor and the impurities so as to increase the impurity removal efficiency; during the final acid pickling, weak acid is used for further removing a small quantity of residual contamination particles which are not reacted completely; the afterheat generated during the calcination is collected and used for the final drying, so that the energy consumption is reduced and the production cost of the enterprise is decreased.

Owner:新沂市永恒熔融石英有限公司

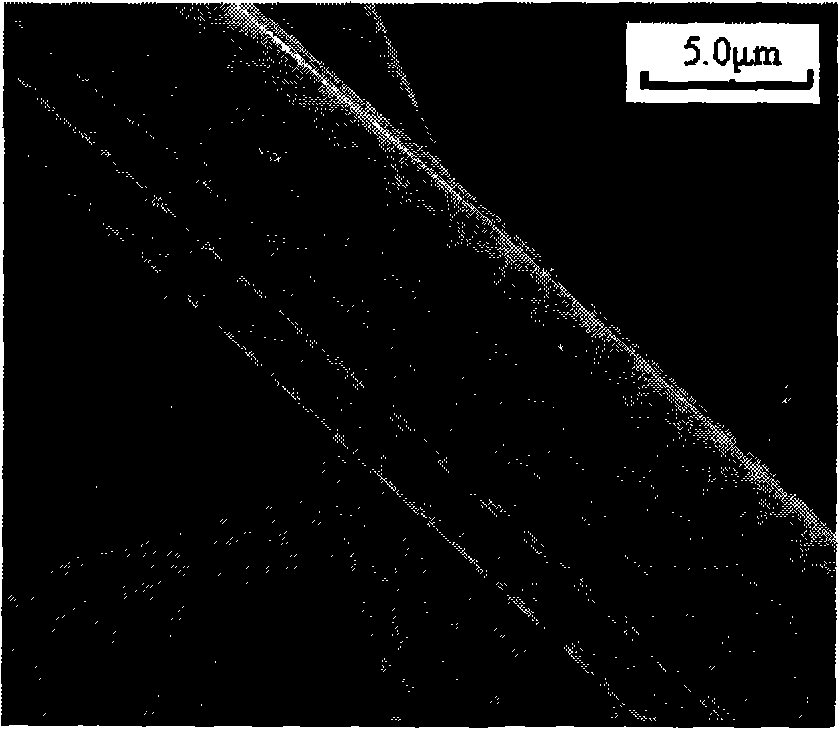

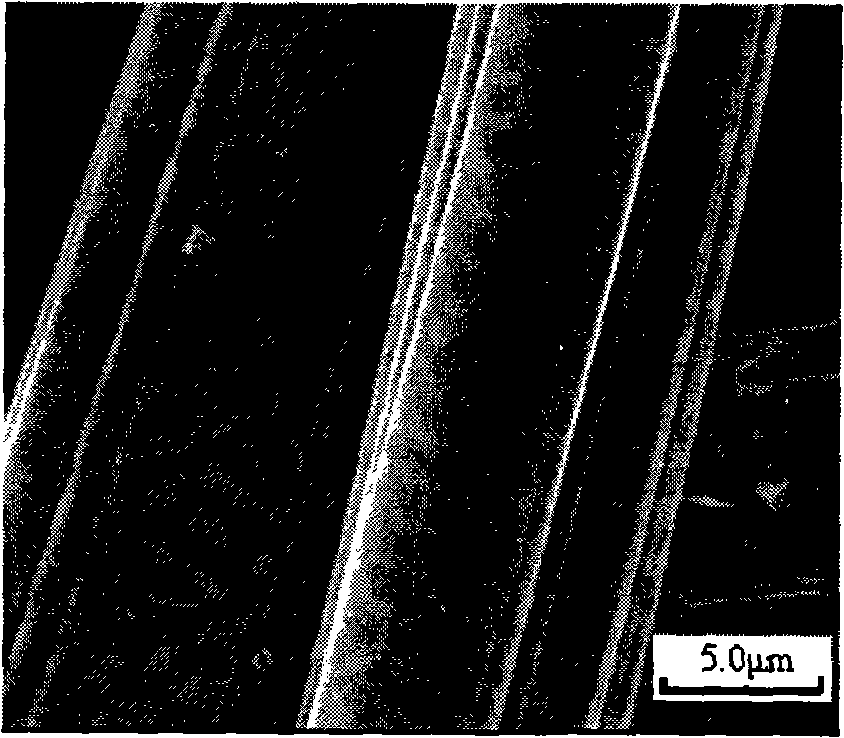

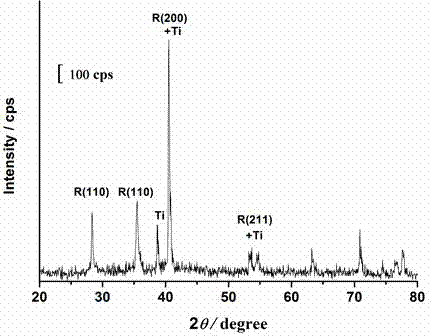

Titanium-base tubular ruthenium dioxide coating membrane electrode and preparation method thereof

InactiveCN103395865AReduce pollutionLarge specific surface areaWater/sewage treatment by electrochemical methodsWater/sewage treatment bu osmosis/dialysisCrack freeThin layer

The invention discloses a titanium-base tubular ruthenium dioxide coating membrane electrode and a preparation method thereof. According to the preparation method, a titanium filter pipe is utilized to replace a primary titanium plate to be taken as a matrix, and as numerous holes with the bore diameters of several microns are formed in the surface of the titanium filter pipe, compared with the normal titanium plate, the specific surface area is increased; and a firmly-bonded, uniformly-dispersed, surface-compacted and crack-free ruthenium dioxide thin layer is formed at the surface of the titanium filter pipe by utilizing a thermal oxidation method, and an oxide film can be firmly bonded with the titanium filter pipe after being subjected to the thermal oxidation. The electrode prepared by utilizing the preparation method has the advantages of firm coating structure, good electro-catalytic property and the like; the chlorine evolution potential of the ruthenium dioxide electrode is low, so that the chlorine is beneficially separated out; meanwhile, the operation of the preparation process is easy to control, the cost is low, the device requirements are relatively low, and the prepared electrode has double functions of electrochemical oxidation and membrane separation. Due to a diffusion action, the electrochemical oxidation efficiency can be improved, and meanwhile, the membrane pollution can be reduced due to the electrochemical oxidation, so that pollutants which are difficult to be biologically degraded can be more effectively processed.

Owner:NANJING UNIV OF SCI & TECH

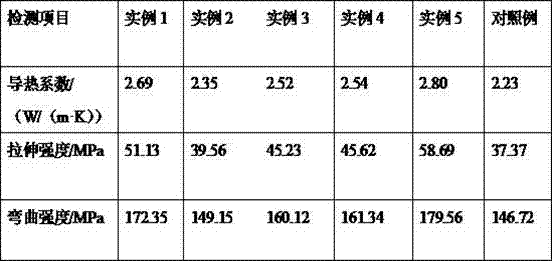

Double-component epoxy resin pouring sealant

InactiveCN107236506AIncrease spacingGood dispersionNon-macromolecular adhesive additivesEpoxy resin adhesivesEpoxyDiluent

The invention discloses a double-component epoxy resin pouring sealant and belongs to the technical field of electronic information. According to the double-component epoxy resin pouring sealant, firstly, epoxy resin, a diluent, a dispersant and a defoaming agent are mixed, fibrous filler, flaky filler and granular filler are sequentially added, high-speed dispersion and vacuum defoaming are performed, a component A is obtained, a curing agent, dibutyl phthalate, a DMP-30 epoxy accelerator, a dispersant and a defoaming agent are mixed, hydrotalcite is added, high-speed dispersion and vacuum defoaming are performed, a component B is obtained, and the component B and the component A are subjected to separate filling and mixed and blended uniformly in proportion during usage. The double-component epoxy resin pouring sealant has the benefits as follows: the double-component epoxy resin pouring sealant has higher thermal conductivity, meets the packaging requirement of high-power electronic modules and is worth popularization and use.

Owner:常州水精灵环保设备有限公司

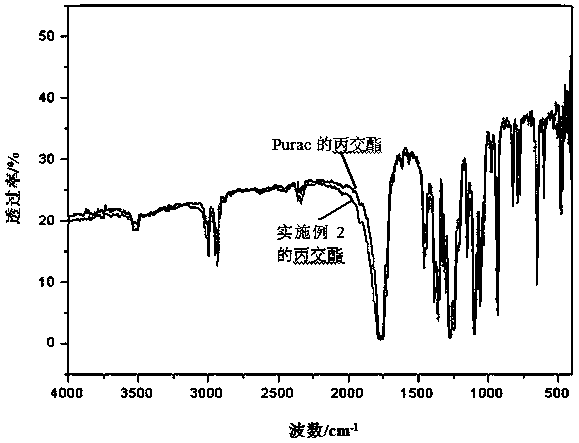

Catalyst for preparing lactides from lactic acid and method for preparing lactides from lactic acid

ActiveCN109894109AIncrease chance of contactBreak dehydration balanceOrganic chemistryCatalyst activation/preparationDepolymerizationLactide

The invention provides a catalyst for preparing lactides from lactic acid and a method for preparing lactides from lactic acid. The catalyst uses butyl titanate and zinc nitrate as raw materials; a sol-gel method is used for preparation to obtain a ZnO-TiO2 composite oxide; then, the ZnO-TiO2 composite oxide is loaded to graphene oxide; hydrothermal sealed treatment is performed to obtain a catalyst. After lactic acid dewatering, the catalyst is used for catalysis; depolymerization is performed at 5.0 to 15.0 kPa and 140 to 150 DEG C; depolymerization is performed at 500 to 100 Pa and 160 to 200 DEG C; coarse lactides are obtained; after purification, lactides are obtained. In the catalyst, the dispersion degree of ZnO and TiO2 particles is increased by graphene; the catalysis capability of active ingredients is improved. Particles with different valence states achieve mutual action in crystal lattices; the speed of the lactic acid polycondensation reaction and the oligomer depolymerization reaction is accelerated; meanwhile, the temperature required in the reaction process is lowered. The prepared lactides have high purity and high yield.

Owner:CHINA PETROLEUM & CHEM CORP +1

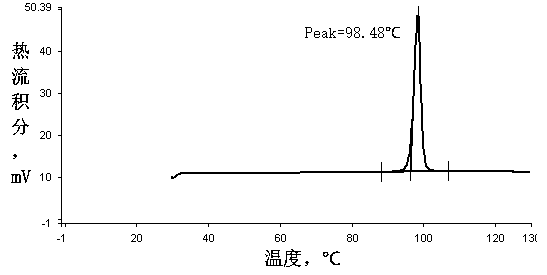

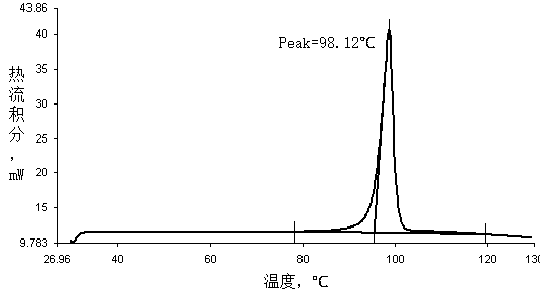

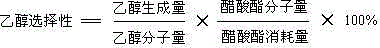

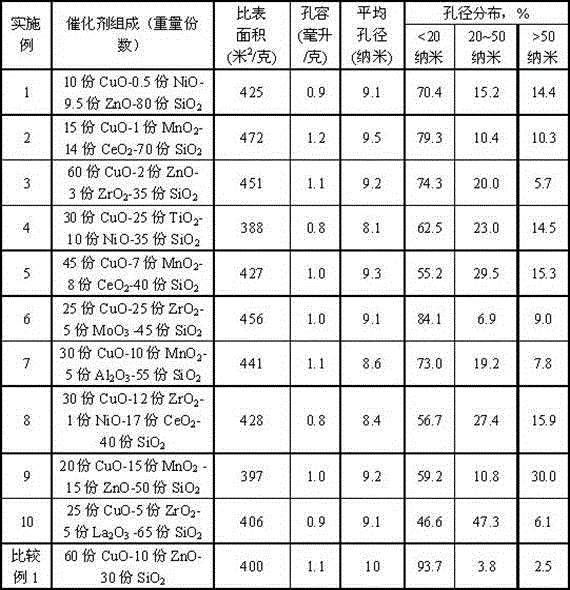

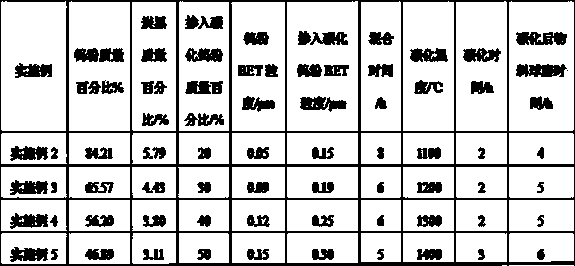

Catalyst and method for preparing ethanol by hydrogenating acetic ester

InactiveCN104148079ALarge specific surface areaIncrease chance of contactOrganic compound preparationHydroxy compound preparationHydrogenGram

The invention relates to a catalyst and a method for preparing ethanol by hydrogenating acetic ester and mainly solves the problems that in the prior art, the ratio of hydrogen to ester is too high, the conversion rate of raw materials is low and the selectivity of ethanol is poor. The catalyst is composed of the following components in parts by weight: (a) 5-80 part of metallic copper or copper oxide, (b) 0.05-60 parts of catalyst promoter and (c) 5-90 parts of silicon dioxide carrier, wherein the catalyst promoter is selected from at least one of transitional metal or oxide of the transitional metal; the specific area of the catalyst is 150-500 m<2> per gram; the total pore volume is 0.1-3.0 ml / gram; the pore volume of the diameter less than 20nm is 40-90% of the total pore volume; the pore volume of the diameter less than 50nm and larger than 20nm is 5-75% of the total pore volume; and the pore volume of the diameter larger than 50nm is 5-75% of the total pore volume. By adopting the technical scheme, the problems are well solved; and the catalyst can be used for industrial production of ethanol by hydrogenating acetic ester.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method of ultrafine tungsten carbide powder

ActiveCN103408015AImprove uniformityAvoid uneven mixingTungsten/molybdenum carbideTungstenCarbon black

The invention relates to a preparation method of ultrafine tungsten carbide powder. A mixture of ultrafine tungsten powder, carbon black and ultrafine tungsten carbide powder used as an initial reactant is subjected to carbonization reaction in a non-oxidizing atmosphere to prepare the ultrafine tungsten carbide powder. The ultrafine tungsten carbide powder prepared by the method has the advantages of small particle size, uniform particle size distribution, favorable dispersity, no pellet and high combined carbon content; and the production technique can easily control the quality and can implement mass production.

Owner:ZHUZHOU HARD ALLOY GRP CO LTD

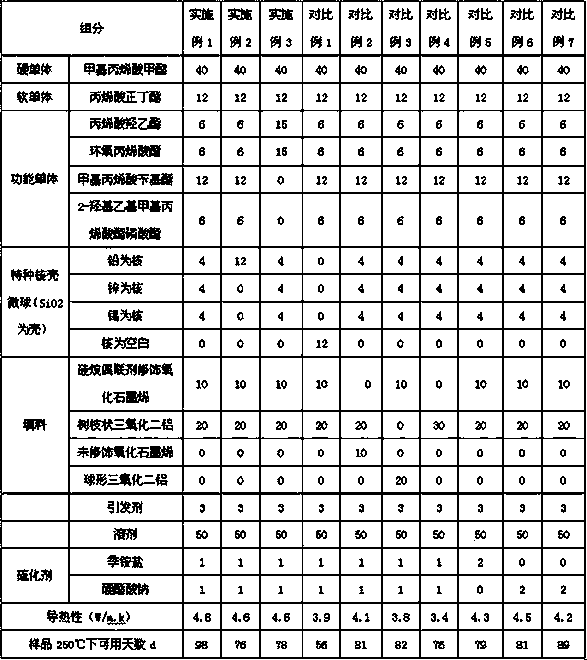

High-temperature-resisting acrylic rubber and preparation method thereof

The invention provides high-temperature-resisting acrylic rubber which is prepared from, by weight, 30-45 parts of hard monomer-methyl methacrylate, 10-15 parts of soft monomer n-butyl acrylate, 30-35 parts of functional monomers, 20-30 parts of filler, 10-15 parts of special core-shell microspheres, 2-4 parts of initiator, 1-3 parts of vulcanizing agent and 30-60 parts of solvent. The function monomers contain one or more of hydroxide radical, carboxyl, epoxy group, aryl and phosphate. Multiple ways for improving high temperature resistance are combined and matched, the acrylic rubber with the excellent high temperature resistance is obtained, and using requirements of the prior art can be met.

Owner:SHENZHEN HANYUXIN ELECTRONICS TECH

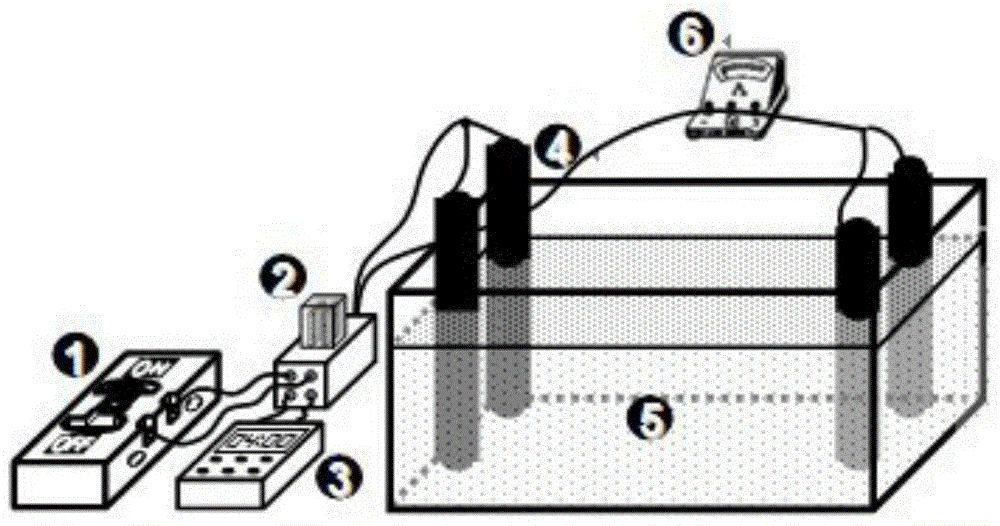

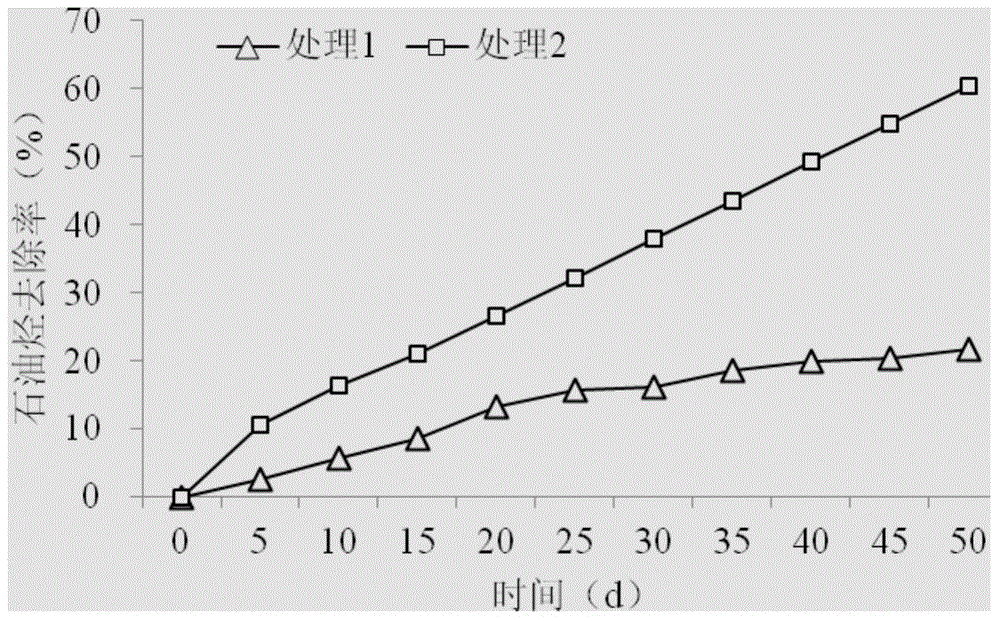

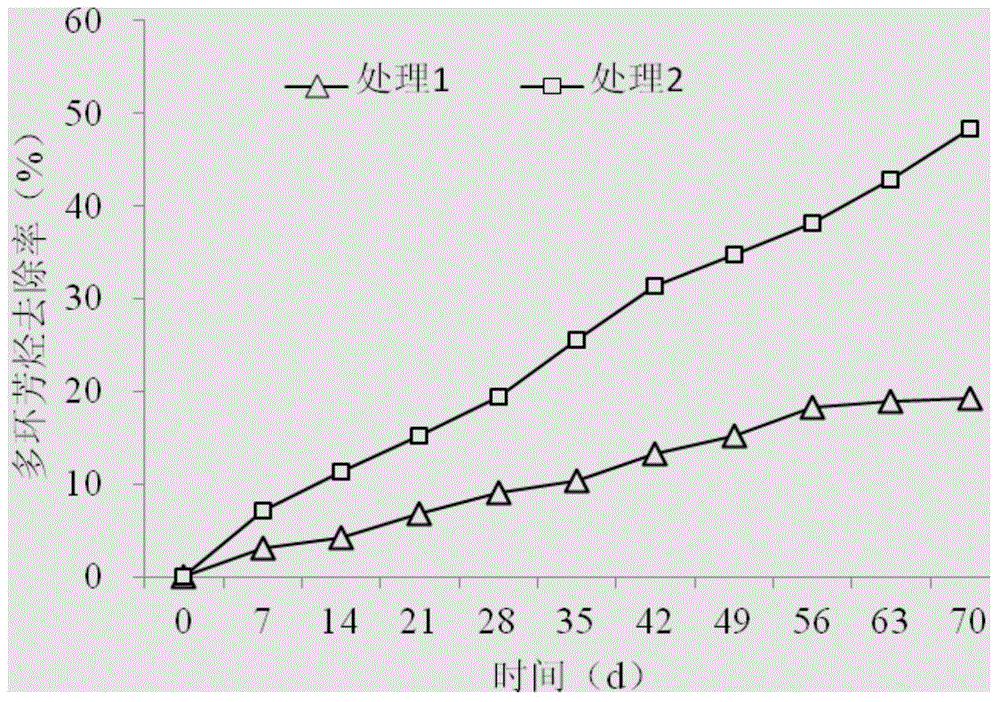

Renovating preparation for improving electric-microbial remediation of organic substance contaminated soil and using method for renovating preparation

InactiveCN104624622AHelp desorptionIncrease chance of contactAgriculture tools and machinesContaminated soil reclamationMicroorganismElectrokinetic remediation

The invention belongs to the technical field of environmental renovation, and particularly relates to a renovating preparation for improving electric-microbial remediation of organic substance contaminated soil and a using method for the renovating preparation. The preparation is prepared from the following components in percentage by weight: 10-20% of a solubilizer, 40-60% of electrolyte and the balance of water, wherein the solubilizer is one or more of Triton X-100, beta-cyclodextrin and Brij35. The renovating preparation disclosed by the invention can improve the contact efficiency of pollutants and microorganisms, and also can keep the pH of the soil unchanged, can improve the soil current intensity and can provide sufficient nutrient salts to the microorganisms, so that the electric renovating efficiency is improved by over 30%.

Owner:SHENYANG INST OF APPLIED ECOLOGY - CHINESE ACAD OF SCI

Electroconductive plastic with high electrical conductivity and preparation method thereof

InactiveCN102212244AConductiveEvenly dispersedNon-conductive material with dispersed conductive materialPolymer scienceFiltration

The invention provides an electroconductive plastic with high electrical conductivity and a preparation method thereof. The electroconductive plastic is composed of a plastic matrix, electroconductive polyaniline, a dispersant and an antioxidant. The preparation method comprises the following steps: 1. synthesis of the electroconductive polyaniline: adding aniline to distilled water on the basis of using an inorganic acid as a doping agent, dissolving ammonium persulfate in the distilled water to obtain an ammonium persulfate solution, dropwise adding the ammonium persulfate solution at a constant speed, carrying out suction filtration, washing and drying; and 2. preparation of the electroconductive plastic: firstly adding a plastic matrix resin and the dispersant to a mixing roll, mixingfor some time; then adding the plastic matrix resin; then adding polyaniline until the two components are completely mixed to obtain a mixture; introducing the mixture to a mold, hot-pressing; and cooling to room temperature. According to the invention, a hot-melting and blending method is utilized to prepare the electroconductive plastic with high electrical conductivity. The obtained electroconductive plastic can be used for overcoming the defects that the existing electroconductive plastic has large filling amount of electroconductive filler, poor compatibility of the filler and the plastic matrix and the like, the volume conductivity of the electroconductive plastic provided by the invention can be adjusted within a large range, and the retention rates of original mechanical properties and processing properties of the plastic base body are high.

Owner:HARBIN ENG UNIV

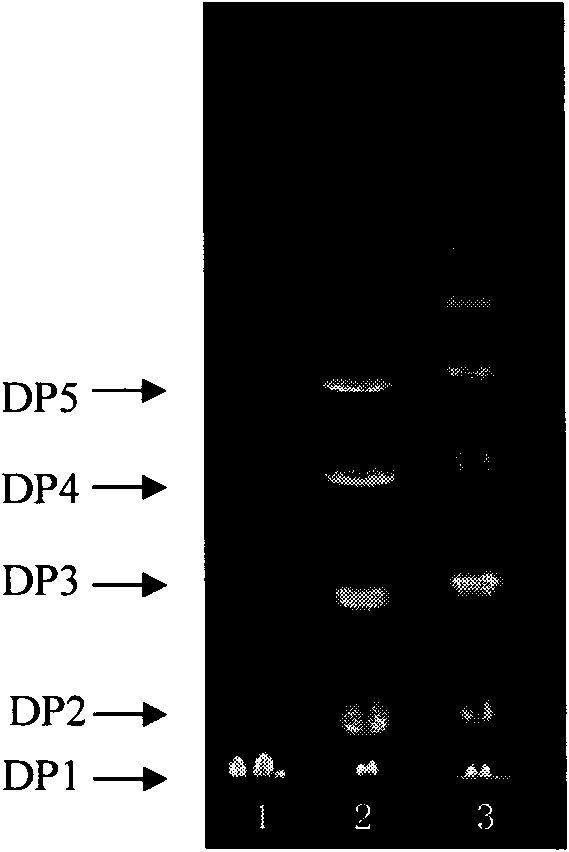

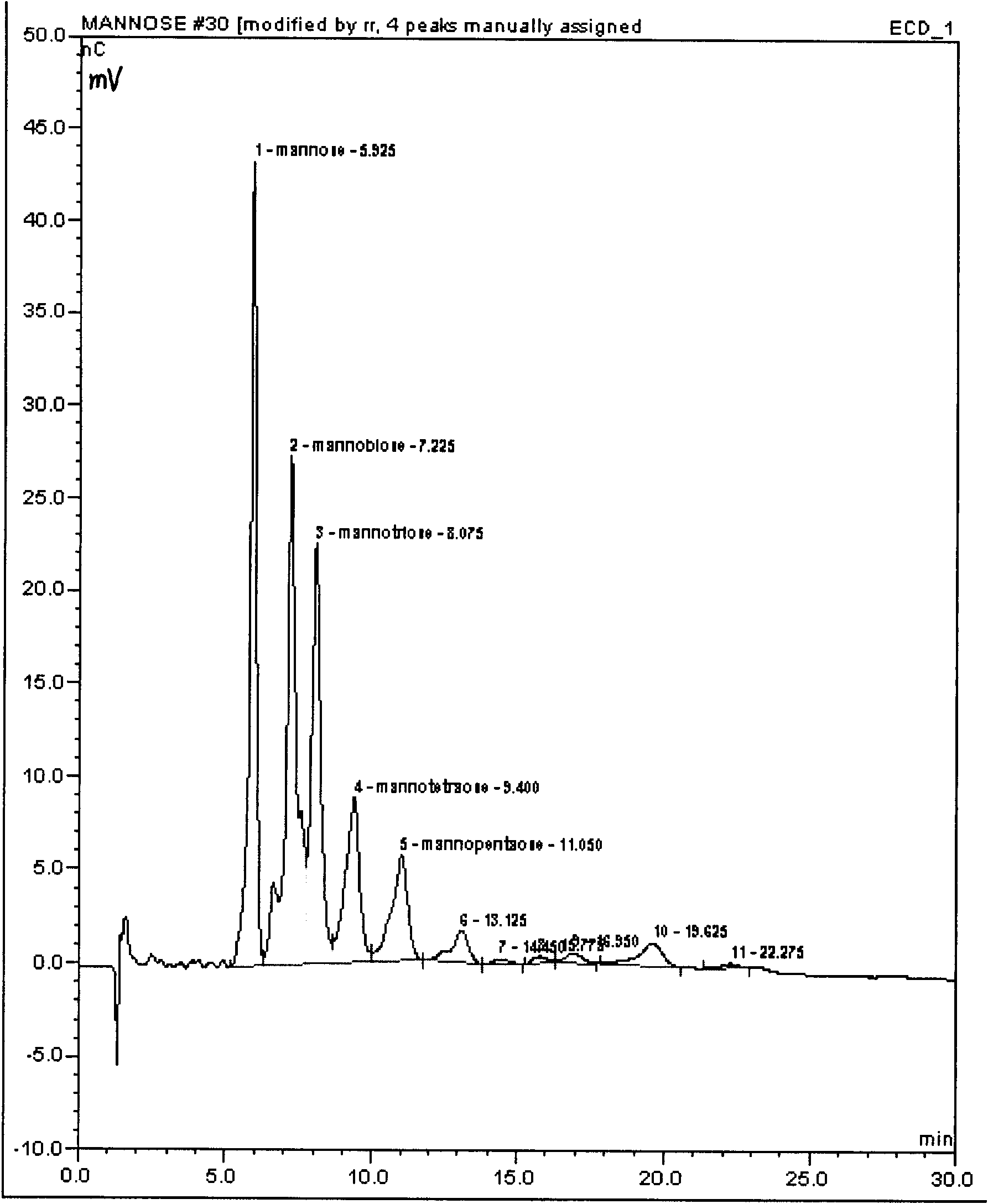

Method for preparing konjac mannan oligosaccharide

The invention discloses a method for preparing konjac mannan oligosaccharide. The method comprises the following steps of: 1) uniformly mixing konjak and water, cutting and emulsifying; homogenizing under the pressure of 160 to 250 MPa and the pressure of 450 to 650 MPa in turn; and drying to obtain coarse konjak powder; and 2) performing enzyme hydrolysis reaction on the slurry of the coarse konjak powder and endo-mannase to obtain the generation liquid of the konjac mannan oligosaccharide, and continuously taking the generation liquid of the konjac mannan oligosaccharide out; replenishing the slurry of the coarse konjak powder once every 3 to 6 hours of the reaction; after replenishing for 9 to 20 times, reacting for 3 to 6 hours and stopping; and collecting and merging the generation liquid of the konjac mannan oligosaccharide, and drying to obtain the konjac mannan oligosaccharide. By the method, the effect and utilization rate of the mannase can be improved and the target productof the mannan oligosaccharide can be obtained to the maximum extent, and the purity of the product is over 90 percent.

Owner:河北科纳生物科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com