High-temperature-resisting acrylic rubber and preparation method thereof

A technology of acrylate and methyl methacrylate, which is applied in the field of high-temperature-resistant acrylate rubber. It can solve the problems that the high-temperature resistance of acrylate rubber is difficult to meet the requirements, so as to improve resin dispersion and contact stability, and increase cross-linking density. , The effect of improving heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

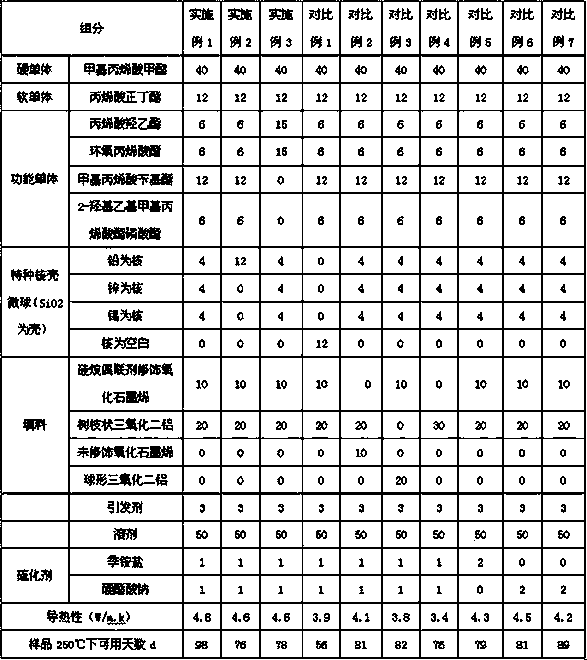

[0021] Embodiment 2-3 and comparative example 1-7

Embodiment 2-3

[0022] The preparation methods of Examples 2-3 and Comparative Examples 1-6 are the same as those of Example 1, the only difference being the difference in components and dosage, see the table below for details. In the preparation method of Comparative Example 7, the filler and the core-shell microspheres were added at the same time, and the components and dosage were the same as in Example 1.

[0023]

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com