Patents

Literature

620 results about "Acrylic rubber" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Acrylic rubber, known by the chemical name alkyl acrylate copolymer (ACM) or the tradename HyTemp, is a type of rubber that has outstanding resistance to hot oil and oxidation. It belongs to specialty rubbers. It has a continuous working temperature of 150 °C (302 °F) and an intermittent limit of 180 °C (356 °F). ACM is polar and doesn't contain unsaturation. It is resistant to ozone and has low permeability to gases. Its disadvantage is its low resistance to moisture, acids, and bases. It should not be used in temperatures below −10 °C (14 °F).

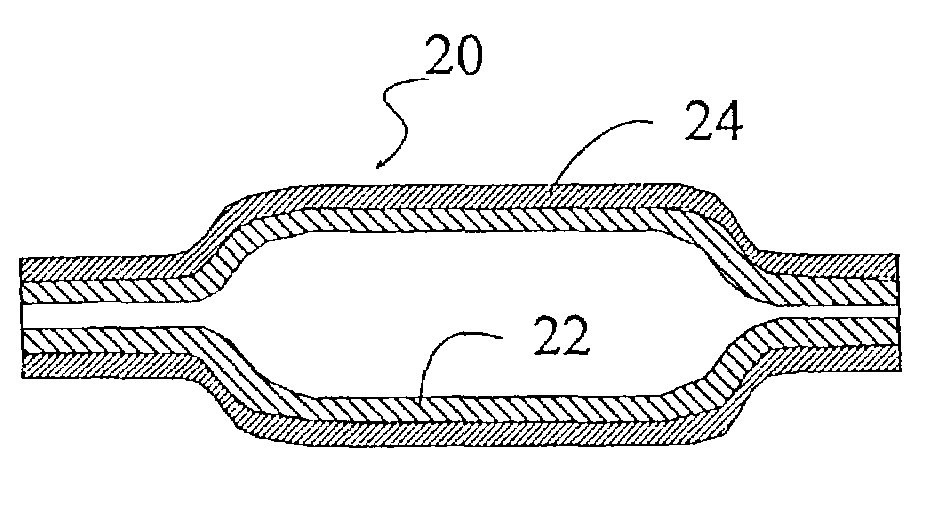

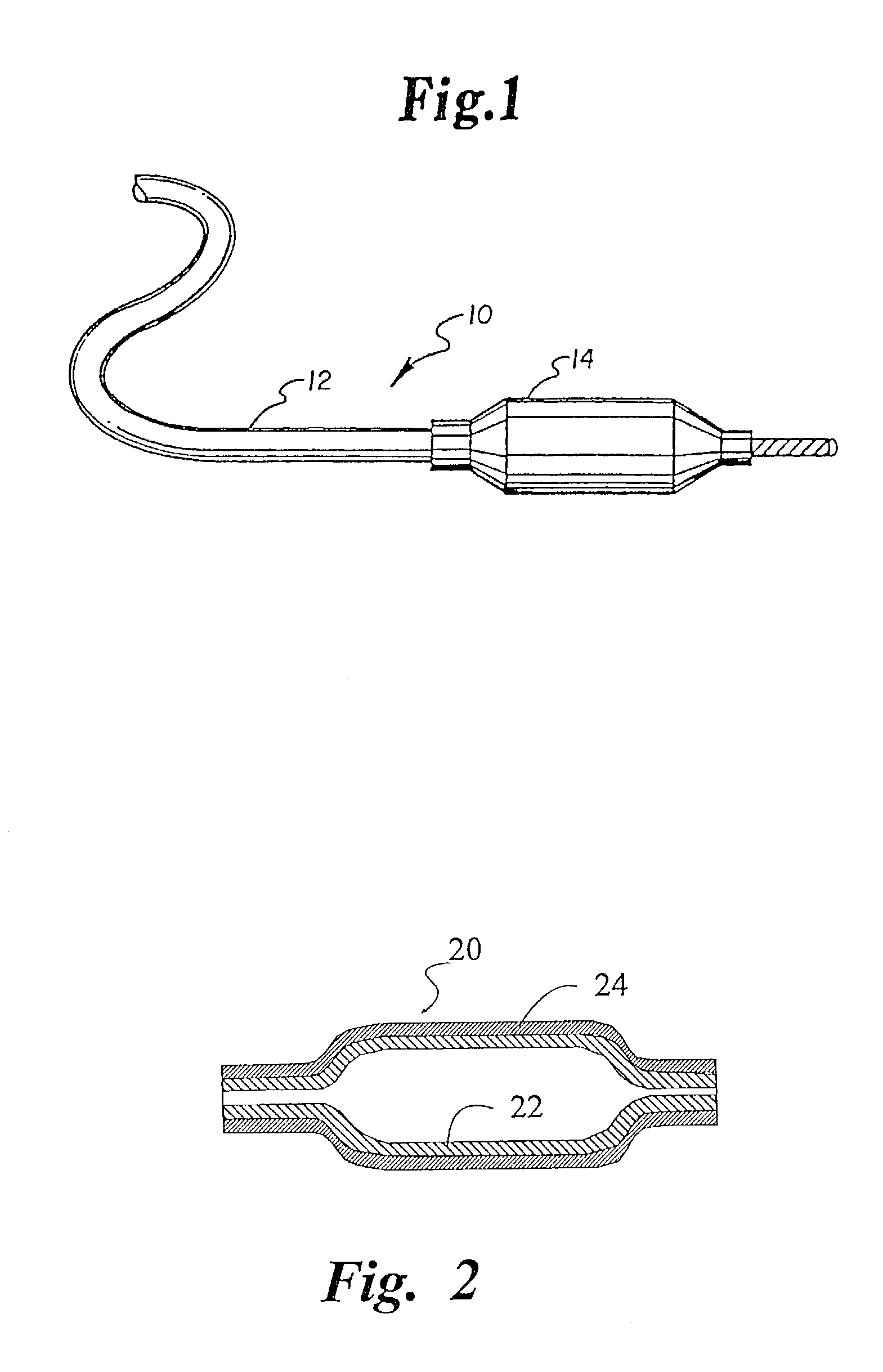

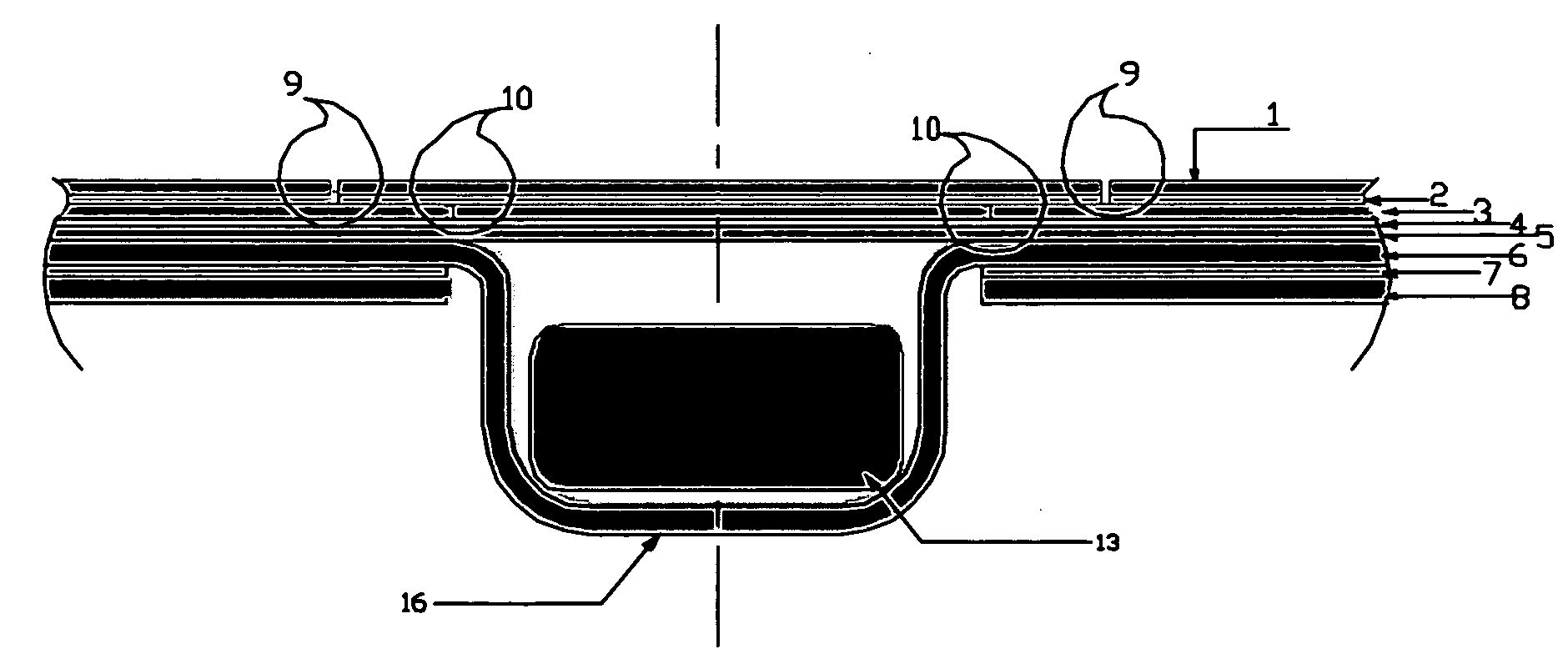

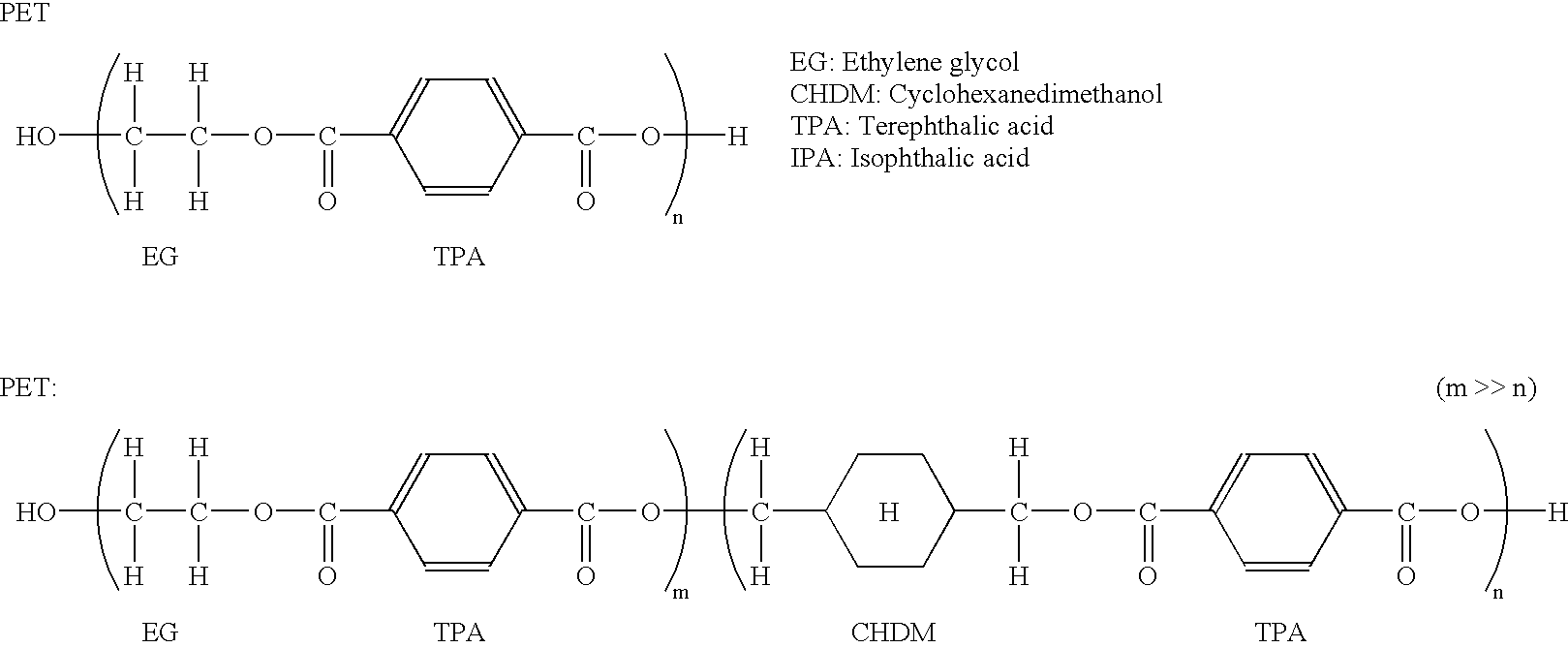

Balloons made from liquid crystal polymer blends

Balloons for use on medical devices such as catheter balloons are formed from polymer blend products which include a liquid crystal polymer (LCP), a crystallizable thermoplastic polymer, especially thermoplastic polyesters such as PET, and a compatabilizer. The compatabilizer may be an ethylene-maleic anhydride copolymer, an ethylene-methyl acrylate copolymer, an ethylene-methyl acrylate copolymer, an ethylene-methyl acrylate-maleic anhydride terpolymer, an ethylene-methyl-methacrylic acid terpolymer, an acrylic rubber, an ethylene-ethyl acrylate-glycidyl methacrylate terpolymer or a mixture of two or more such polymers.

Owner:BOSTON SCI SCIMED INC

Emulsion particles as reinforcing fillers

InactiveUS6780937B2Great tractionIncrease in the tangent deltaLaminationLamination apparatusPolymer scienceEmulsion

Owner:THE GOODYEAR TIRE & RUBBER CO

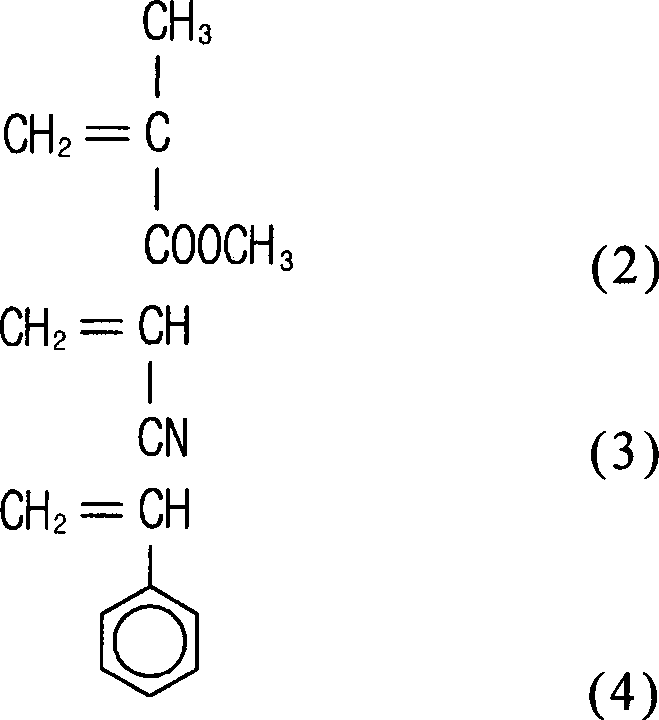

Olefinic thermoplastic elastomer and moldings thereof

An olefinic thermoplastic elastomer with improved properties can be obtained by melting and kneading a graft copolymer, acrylic rubber, a crosslinking agent, and a co-crosslinking agent. The graft copolymer is composed of an olefin polymer segment formed from a nonpolar α-olefin monomer and a vinyl polymer segment formed from a vinyl monomer, with particles of one segment being dispersed in the other segment. The particle diameter is 0.01 to 1 μm. The acrylic rubber can be obtained by polymerizing a monomer mixture containing methoxyethyl acrylate.

Owner:NOF CORP

Dynamic vulcanization of non-nitrile rubbers in fluoroplastic polymers

Processable rubber compositions contain a cured elastomer dispersed in a matrix comprising a thermoplastic material. The cured elastomer is present at a level of greater than or equal to 35% by weight based on the total weight of cured elastomer and thermoplastic material. The thermoplastic material comprises a fluorine containing thermoplastic polymer, and the cured elastomer comprises a non-nitrile rubber selected from the group consisting of acrylic rubber, EPDM rubber, butyl rubber, silicone rubber, butadiene rubber, isoprene rubber, and natural rubber. Methods for preparing the compositions involve dynamic vulcanization of the elastomer and thermoplastic components.

Owner:FREUDENBERG NOK GEN PARTNERSHIP

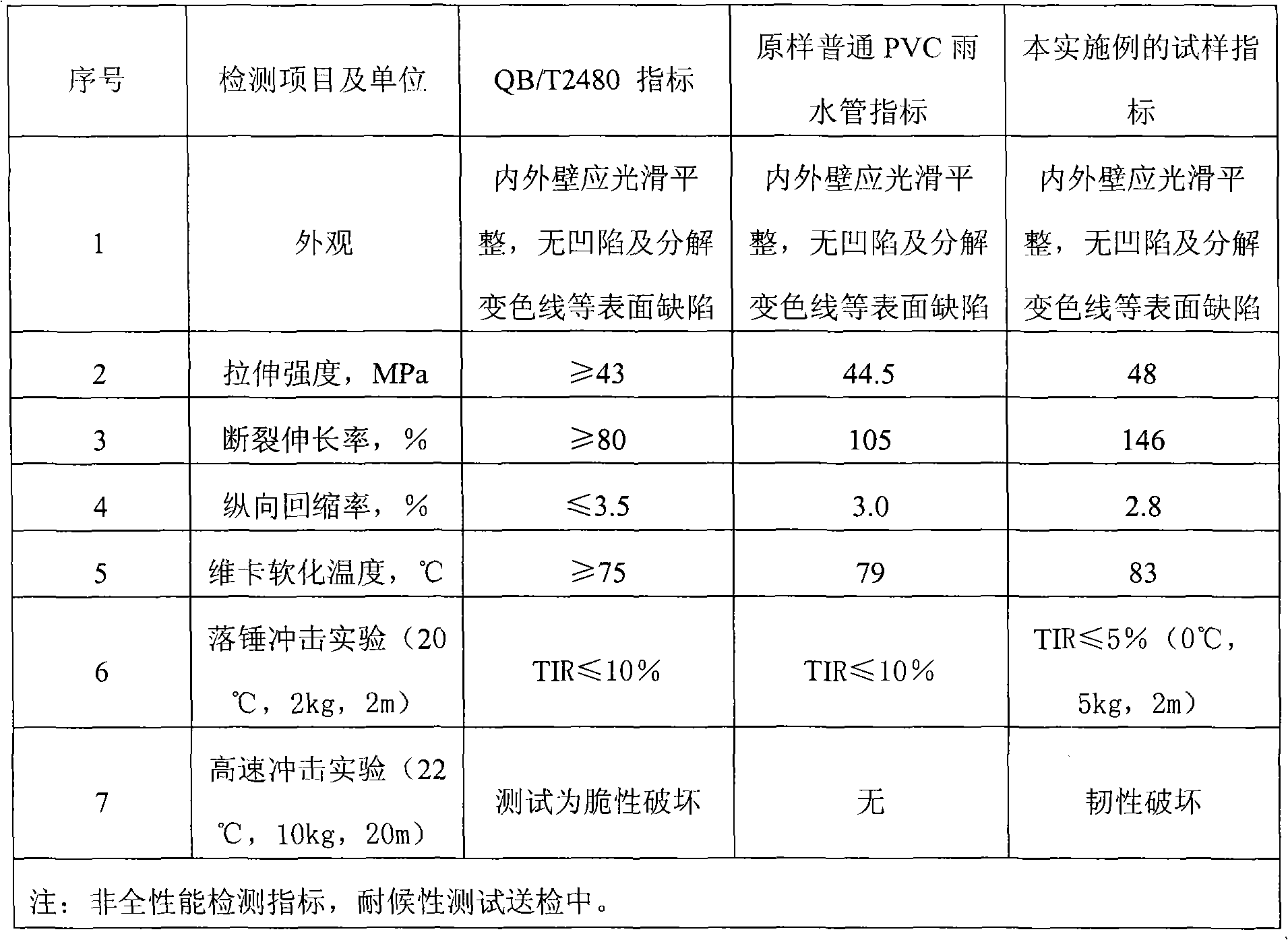

ASA/PVC co-extrusion ultra-weather resisting colorful rainwater pipeline

InactiveCN101581138AImprove toughnessImprove impact resistanceSynthetic resin layered productsRoof drainageAcrylic rubberAcrylonitrile

The invention discloses an ASA / PVC co-extrusion ultra-weather resisting colorful rainwater pipeline special for outdoor rainwater drainage. The traditional VPC rainwater pipelines are white, and are hard to be harmonized with the appearance of a building or be applied to western high altitude areas. The pipeline consists of an internal layer and an external layer, and is characterized in that the external layer is made of an ASA modified material, and comprises the following compositions: acrylonitrile, styrene, acrylic rubber terpolymer, complex pigment, chlorinated polyethylene, stearic acid, calcium stearate, nanometer calcium carbonate, compounded lubricant, titanium pigment, UV absorbent and antioxidizer; the internal layer is prepared by the following compositions: polyvinyl chloride, chlorinated polyethylene, calcium stearate, titanium pigment, organic stabilizer and PE wax. The external layer made of the ASA material has ultra-weather resistance and multiple colors to meet the requirement on the colorful pipeline in the market currently; and the internal layer greatly improves the toughness of the pipeline.

Owner:浙江中财管道衍生产品有限公司

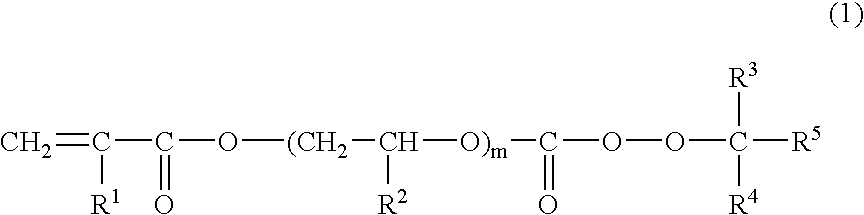

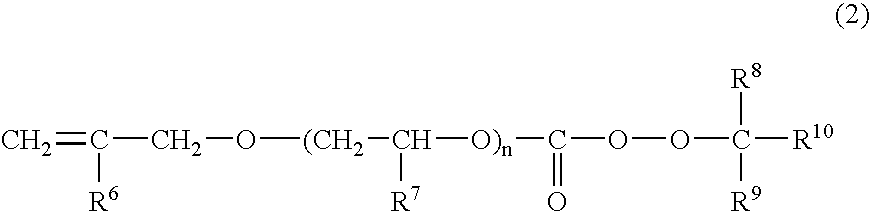

Anisotropic conductive adhesive composition and anisotropic conductive film comprising the same

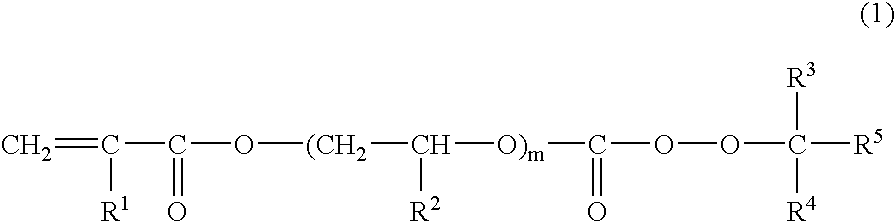

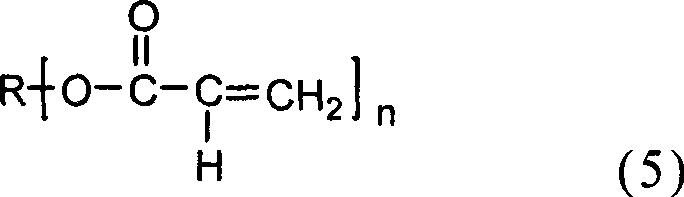

The present invention relates to an anisotropic conductive adhesive composition with high reliability and an anisotropic conductive film. The anisotropic conductive adhesive composition includes an acrylic rubber binder having a weight average molecular weight of about 100,000 to about 1,000,000, a first component including at least one of a mono(meth)acrylate compound and a di(meth)acrylate compound, a second component including at least one of a tri(meth)acrylate compound and a compound having more than three (meth)acrylate groups, an organic peroxisde, and conductive particles. The second component is present in an amount of about 1 to about 10% by weight, based on the total weight of the acrylic rubber, the first component, the second component, the organic peroxide, and the conductive particles.

Owner:KUKDO ADVANCED MATERIALS CO LTD

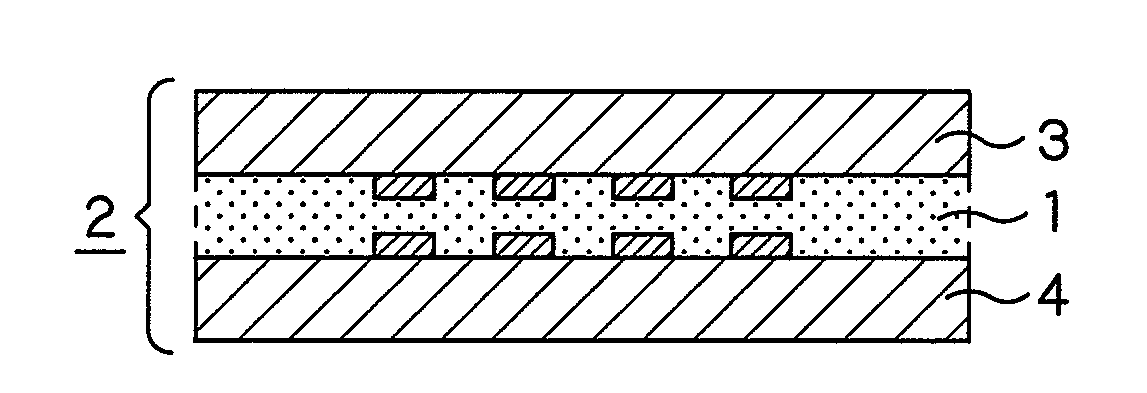

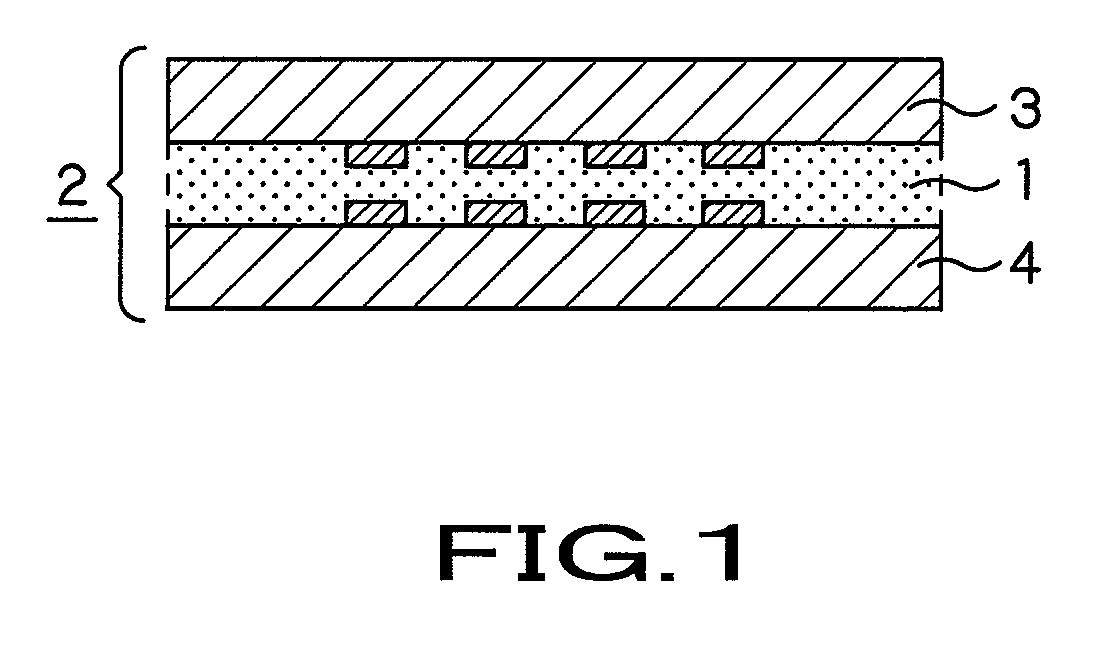

Anisotropic electrically conductive film and connection structure

ActiveUS20090178834A1High bonding strengthImprove reliabilityPrinted electric component incorporationSynthetic resin layered productsAnisotropic conductive filmAcrylic resin

An anisotropic electrically conductive film formed by a thermosetting acrylic resin composition is disclosed. The composition contains at least a thermosetting agent (A), a thermo-settable ingredient (B), an acrylic rubber containing hydroxyl groups (C), organic fine particles (D) and electrically conductive particles (E). The thermo-settable ingredient (B) may include a phosphorus-containing acrylic ester (b1). The weight averaged molecular weight of the acrylic rubber containing the hydroxyl groups (C) is not less than 1000000. The organic fine particles (D) include polybutadiene-based fine particles (d1).

Owner:DEXERIALS CORP

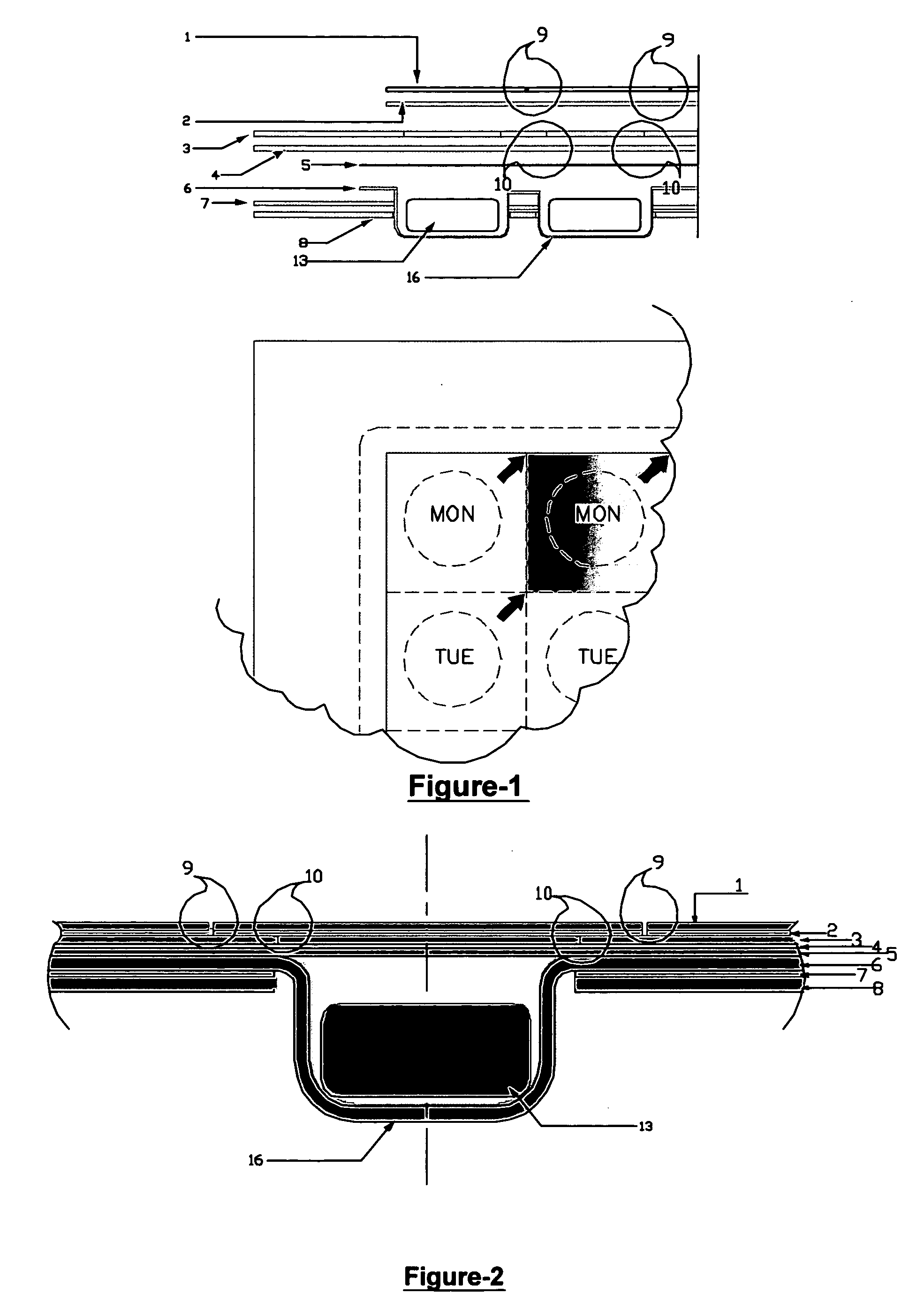

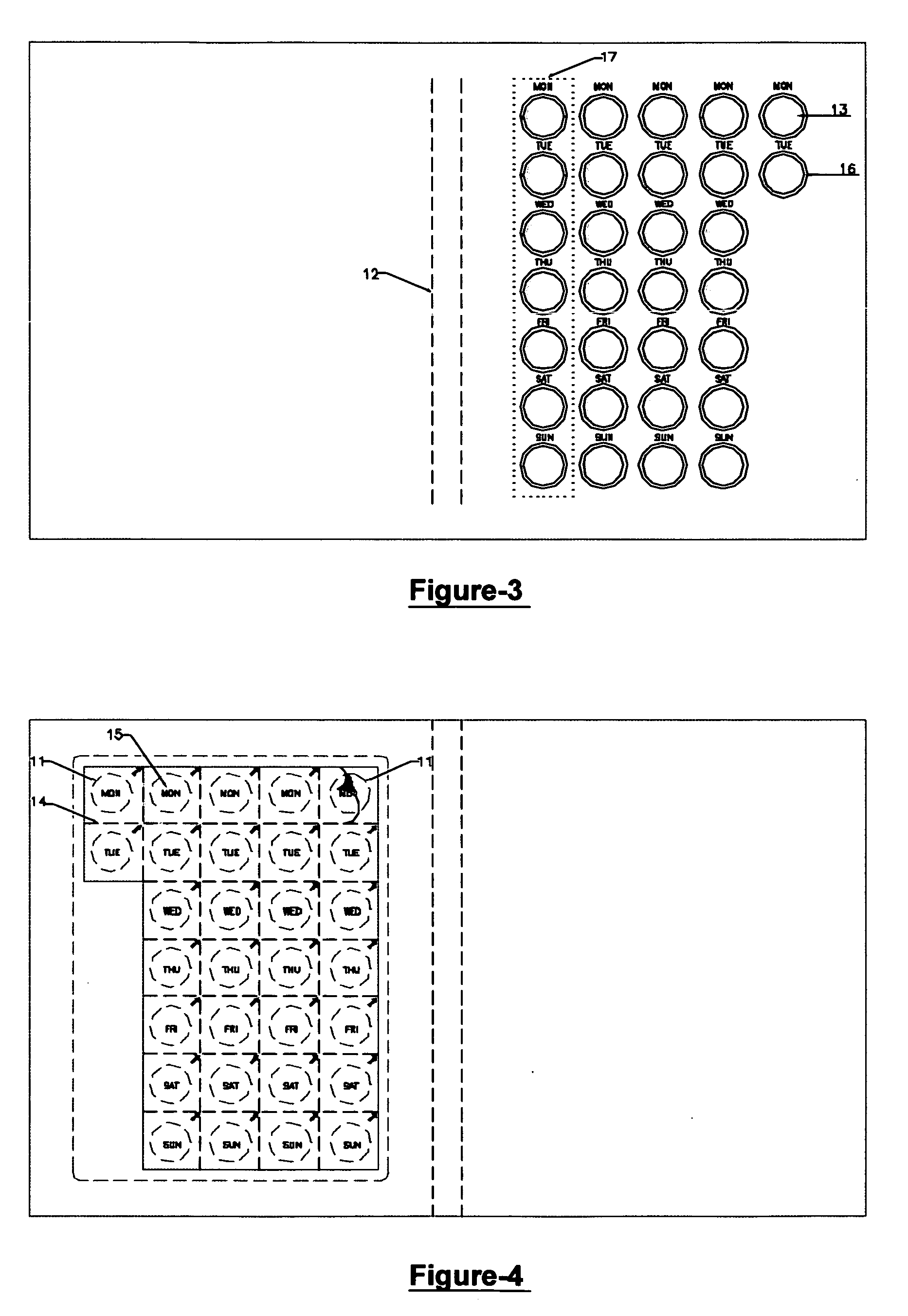

Child resistant unit dose pack

The present invention provides a child resistant blister pack for packing pharmaceutical solid dosage form comprising a blister sheet having a pattern of cavities / blisters, a rupturable cover foil laminated to the blister sheet covering and sealing the blisters and blister sheet containing the unit dosage forms is enfolded into a non-tearable paper / laminate card with an intrinsic pressure-sensitive permanent acrylic / rubber based adhesive, a polymeric film / laminate containing an intrinsic pressure-sensitive permanent acrylic / rubber based adhesive is placed on a non-tearable paper / laminate card in a precise manner, such that it corresponds with the individual cavities of the blister.

Owner:CADILA HEALTHCARE LTD

Thermoplastic polymer composition

InactiveUS6140418AEfficient productionMaintain good propertiesOther chemical processesVehicle sealing arrangementsPolymer scienceAcrylic rubber

PCT No. PCT / JP97 / 03523 Sec. 371 Date May 21, 1998 Sec. 102(e) Date May 21, 1998 PCT Filed Oct. 2, 1997 PCT Pub. No. WO98 / 14518 PCT Pub. Date Apr. 9, 1998Described are a thermoplastic polymer composition comprising (A) a block copolymer formed of a polymer block composed mainly of an aromatic vinyl compound and another polymer block composed mainly of isobutylene; and (B) a crosslinked rubber of at least one rubber selected from natural rubber, diene polymer rubber, olefin polymer rubber, acrylic rubber and fluorine rubber at a weight ratio of 90:10 to 10:90; and molded or formed products and hermetically sealing materials produced using the composition. The above thermoplastic polymer composition is excellent in moldability or formability, gas barrier properties, compression set resistance, hermetically sealing properties, sealing properties, flexibility, mechanical properties, oil resistance, safety, hygienic properties and the like. By melt molding or forming of the composition under heat, general-purpose molded or formed products, hermetically sealing materials such as sealant, packing material or gasket, particularly, stopper or gasket for syringe for the medical use can be produced smoothly.

Owner:KURARAY CO LTD

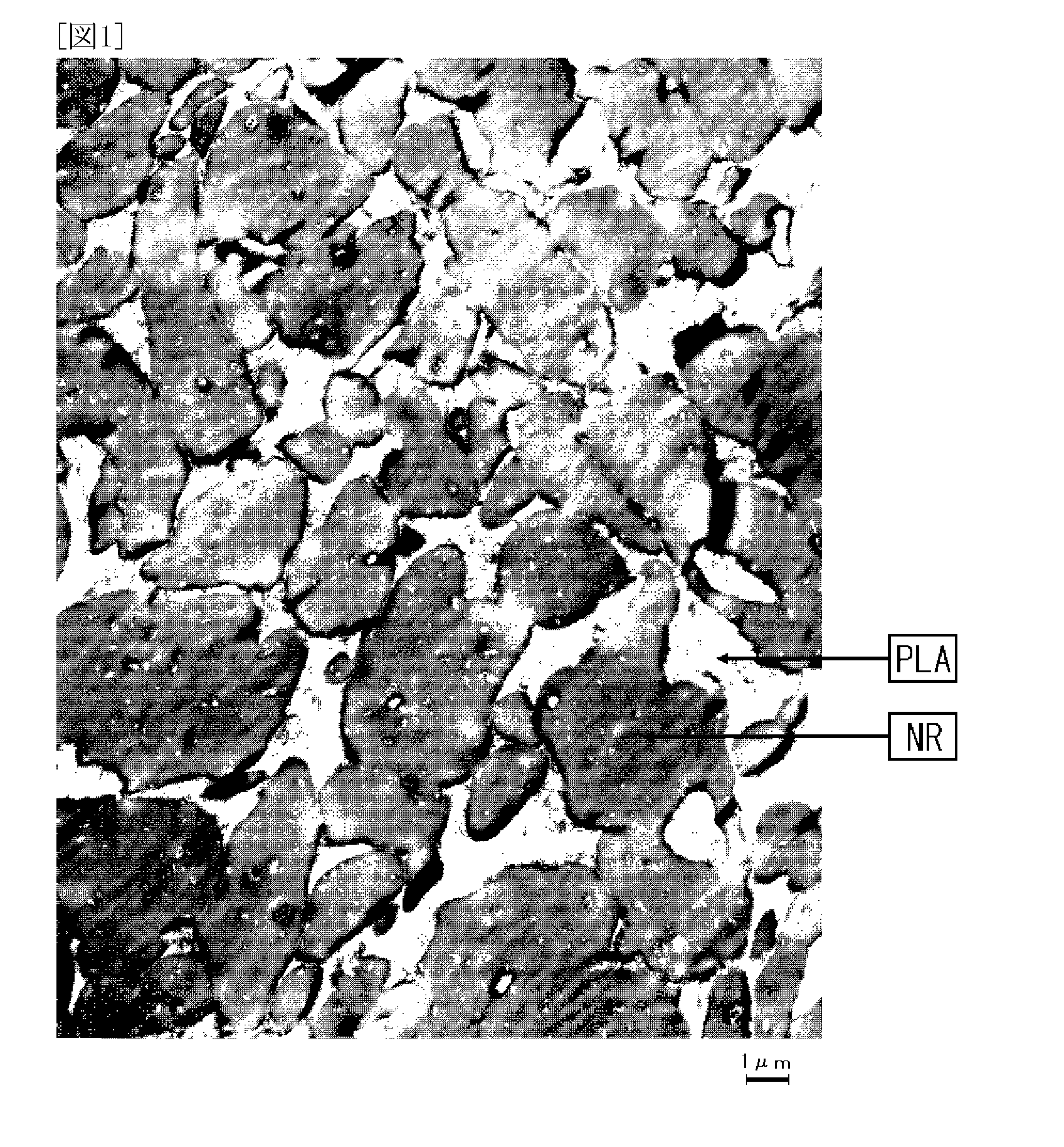

Thermoplastic elastomer composition

An object of the present invention is to provide: a thermoplastic elastomer composition, which is accompanied by less environmental burden, and which has flexibility, rubber elasticity, formability and recyclability; and a molded product obtained using the same. The present invention is directed to a thermoplastic elastomer composition comprising a thermoplastic resin (A) derived from a non-petroleum source, and at least one rubber (B) selected from a natural rubber, a diene polymer rubber, an olefin polymer rubber, an acrylic rubber and a silicone rubber, the thermoplastic elastomer composition being obtained by allowing the rubber (B) to be dynamically crosslinked with a crosslinking agent (C) in the presence of the thermoplastic resin (A). Preferred (A) is a polylactic acid, or a poly(3-hydroxybutyrate), and preferred (B) is a natural rubber.

Owner:KANEKA CORP

Transparent thermoplastic resin compositions and process for preparing the same

The present invention relates to a transparent thermoplastic resin composition which characteristically contains A) 20-80 weight % of graft copolymer composed of a) conjugated diene rubber latex; b) intermediate layer prepared by copolymerization of acrylic acid alkylester derivative and aromatic vinyl derivative with the above a); and c) graft layer prepared by copolymerization of methacrylic acid alkylester derivative or acrylic acid alkylester derivative, a romatic vinyl derivative and vinyl cyan derivative with the above b) and B) 20-80 weight % of MSAN copolymer prepared by copolymerization of methacrylic acid alkylester derivative or acrylic acid alkylester derivative, aromatic vinyl derivative and vinyl cyan derivative. The transparent thermoplastic resin composition of the present invention has enhanced transparency, impact strength, surface gloss, weather resistance and color by being prepared by the method of the invention which is characterized by the steps of forming an intermediate layer by adding acrylic rubber to polybutadiene rubber, grafting, and regulating refractive indices of each monomers of a copolymer.

Owner:LG CHEM LTD

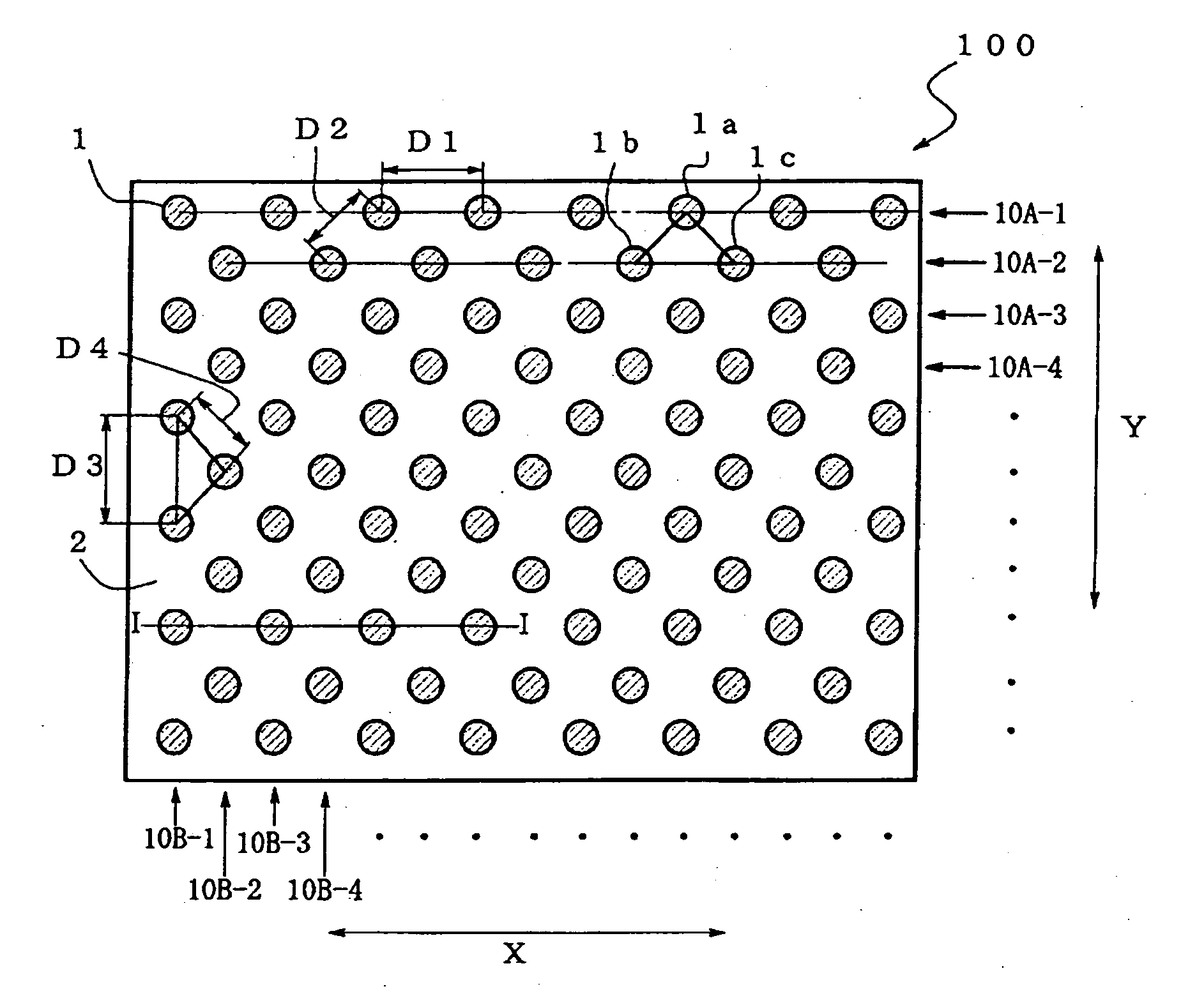

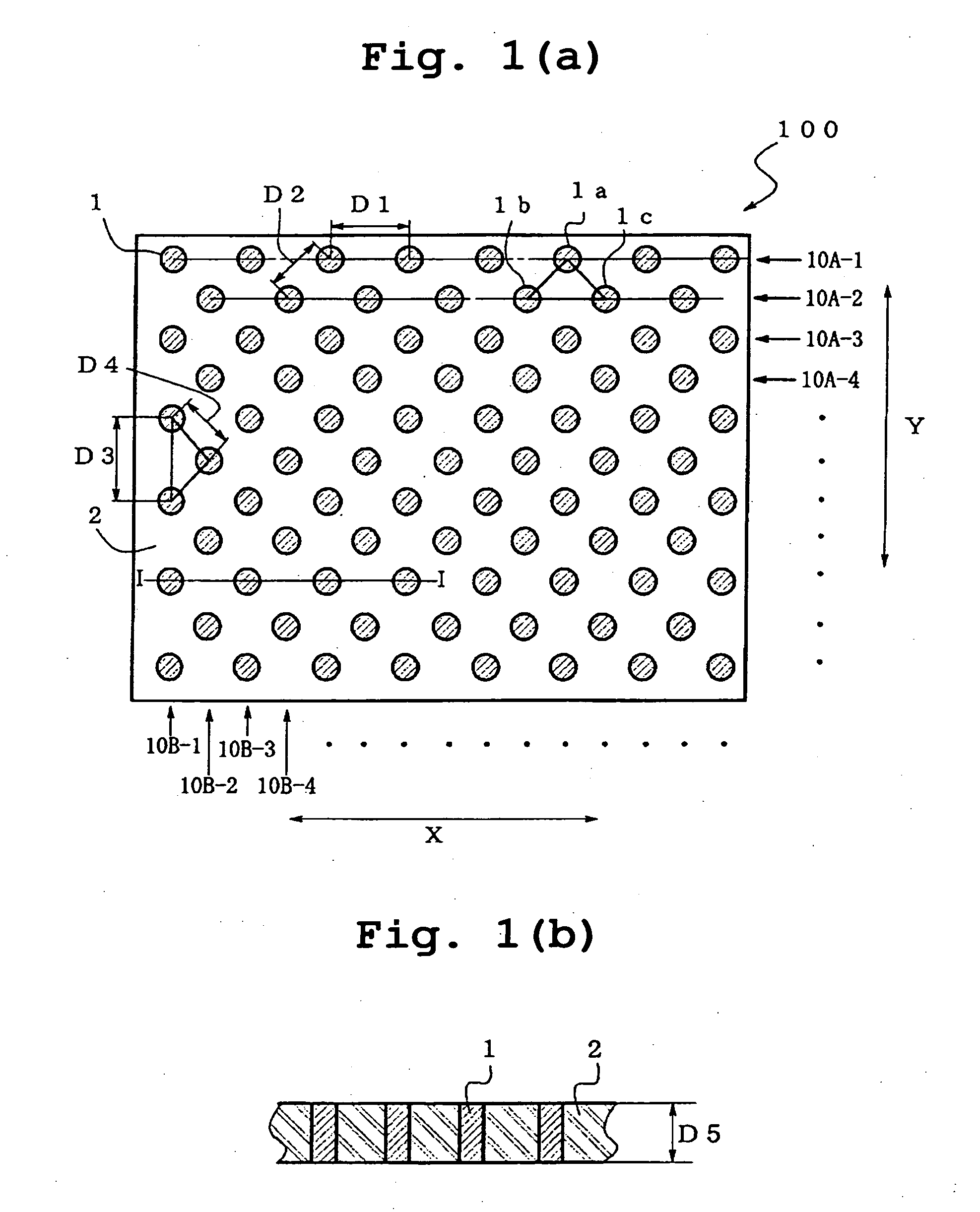

Anisotropic conductive film, production method thereof and method of use thereof

InactiveUS20050077542A1Improve reliabilitySemiconductor/solid-state device detailsSecuring/insulating coupling contact membersEpoxyAnisotropic conductive film

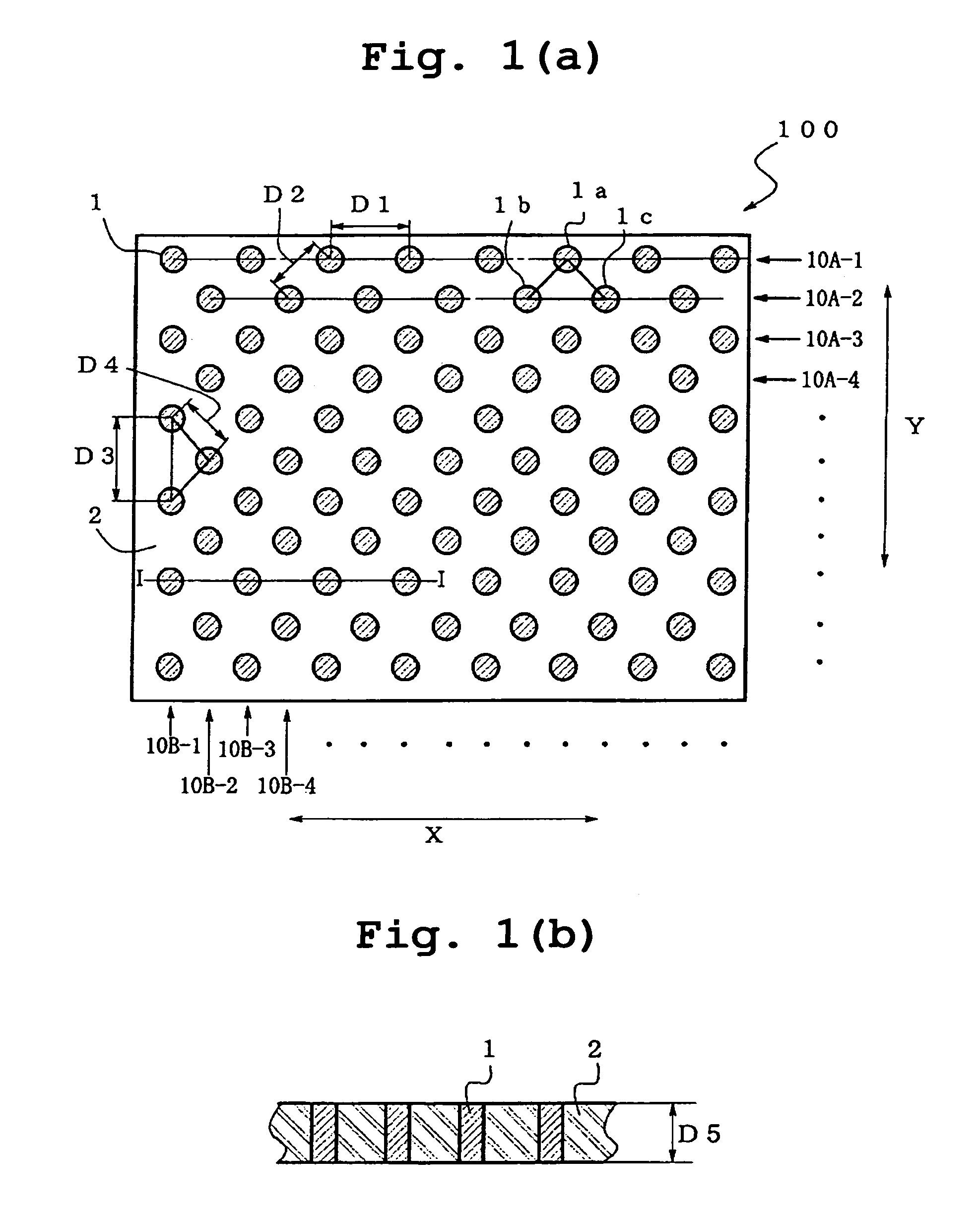

The present invention provides an anisotropic conductive film for testing an electronic component, which comprises a film substrate comprising an insulating resin and plural conductive paths insulated from each other and penetrating the film substrate in the thickness direction, preferably, an anisotropic conductive film wherein the plural conductive paths are disposed in a houndstooth check pattern and the distance between conductive paths between adjacent rows of conductive paths is smaller than the distance between conductive paths within a row of conductive paths. In another preferable embodiment, the insulating resin comprises a naphthalene skeleton epoxy resin crosslinked with a phenol resin and an acrylic rubber, and both ends of the plural conductive paths are exposed on both the front and the back surfaces of the film substrate.

Owner:NITTO DENKO CORP

Glass fiber-reinforced PBT/PET (Polybutylece Terephthalate/Polyethyleneglycol Terephthalate) composite material and preparation method thereof

The invention discloses a glass fiber-reinforced PBT / PET (Polybutylece Terephthalate / Polyethyleneglycol Terephthalate) composite material and a preparation method thereof. The glass fiber-reinforced PBT / PET composite material consists of the following components in percentage by weight: 10-93.3 percent of PBT, 0.5-20 percent of PET, 0.5-20 percent of low shrink high molecular filler, 0.5-8 percent of compatilizer, 5-60 percent of glass fiber, 0-10 percent of toughening agent and 0.2-5 percent of aids, wherein the low shrink high molecular filler is one or more of an acrylonitrile-styrene-butadiene copolymer, an acrylonitrile-styrene-acrylic rubber copolymer and polycarbonate. The warping rate of glass fiber-reinforced PBT / PET composite material can be lowered effectively, and the performance of the material is improved; and the glass fiber-reinforced PBT / PET composite material can be widely applied to products such as automobile parts, electronic apparatuses and the like, and meets the requirements of large-sized thin-wall parts.

Owner:深圳市欧力隆科技有限公司

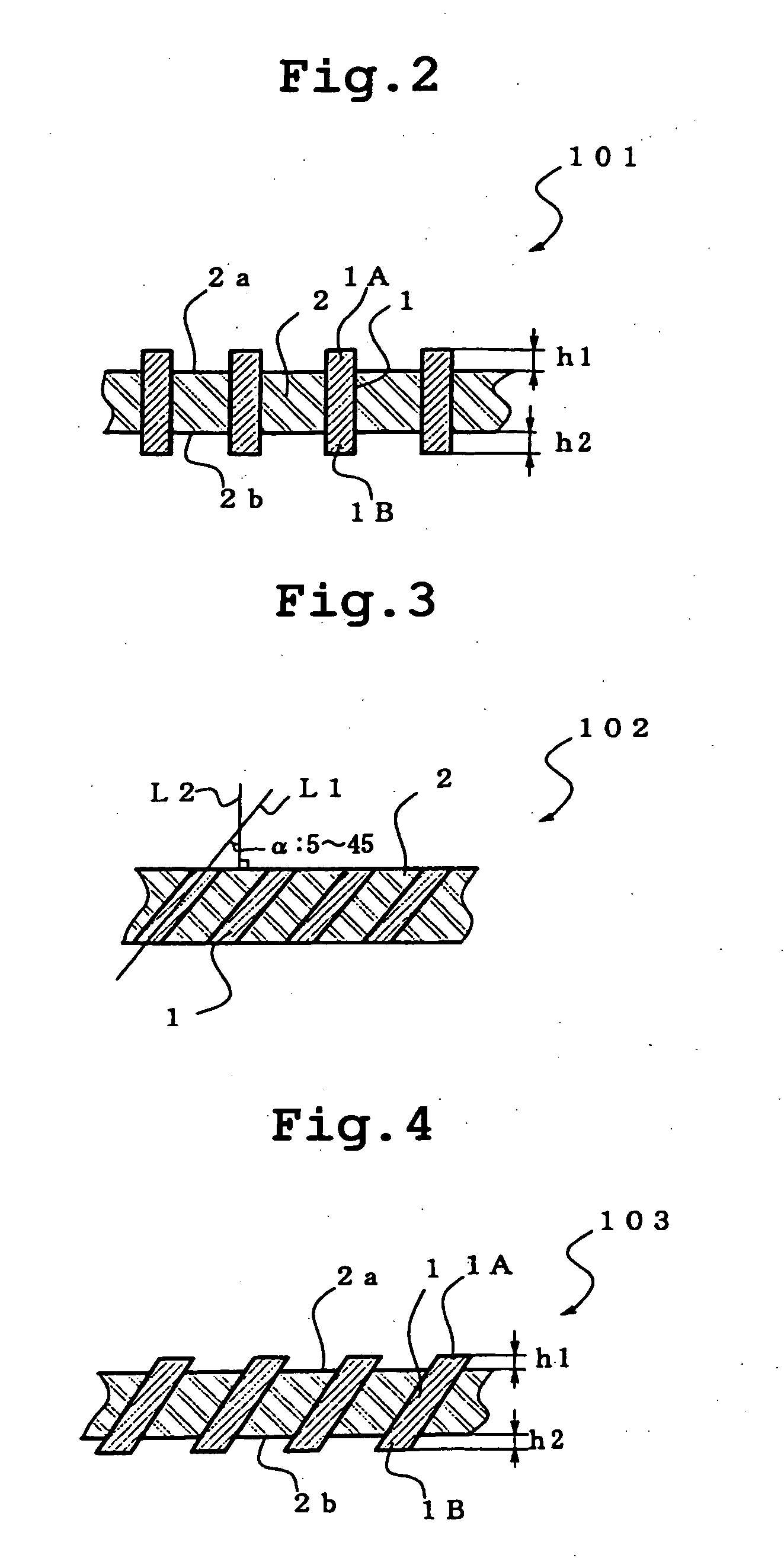

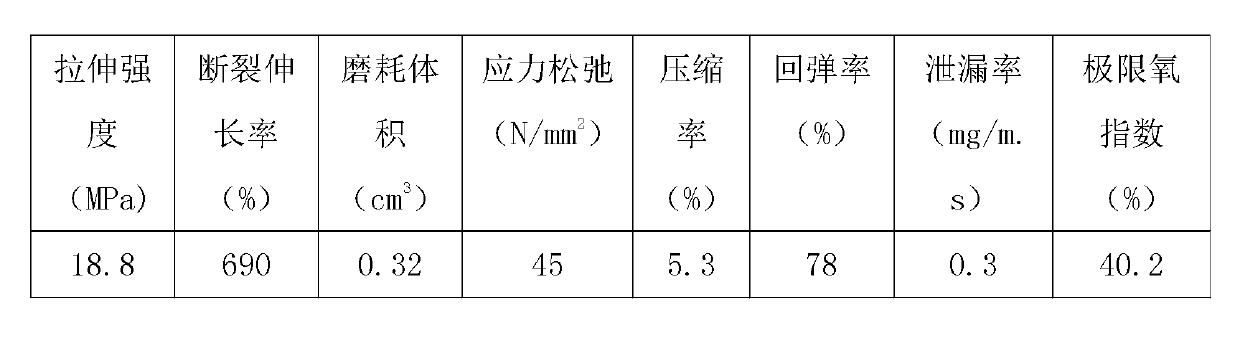

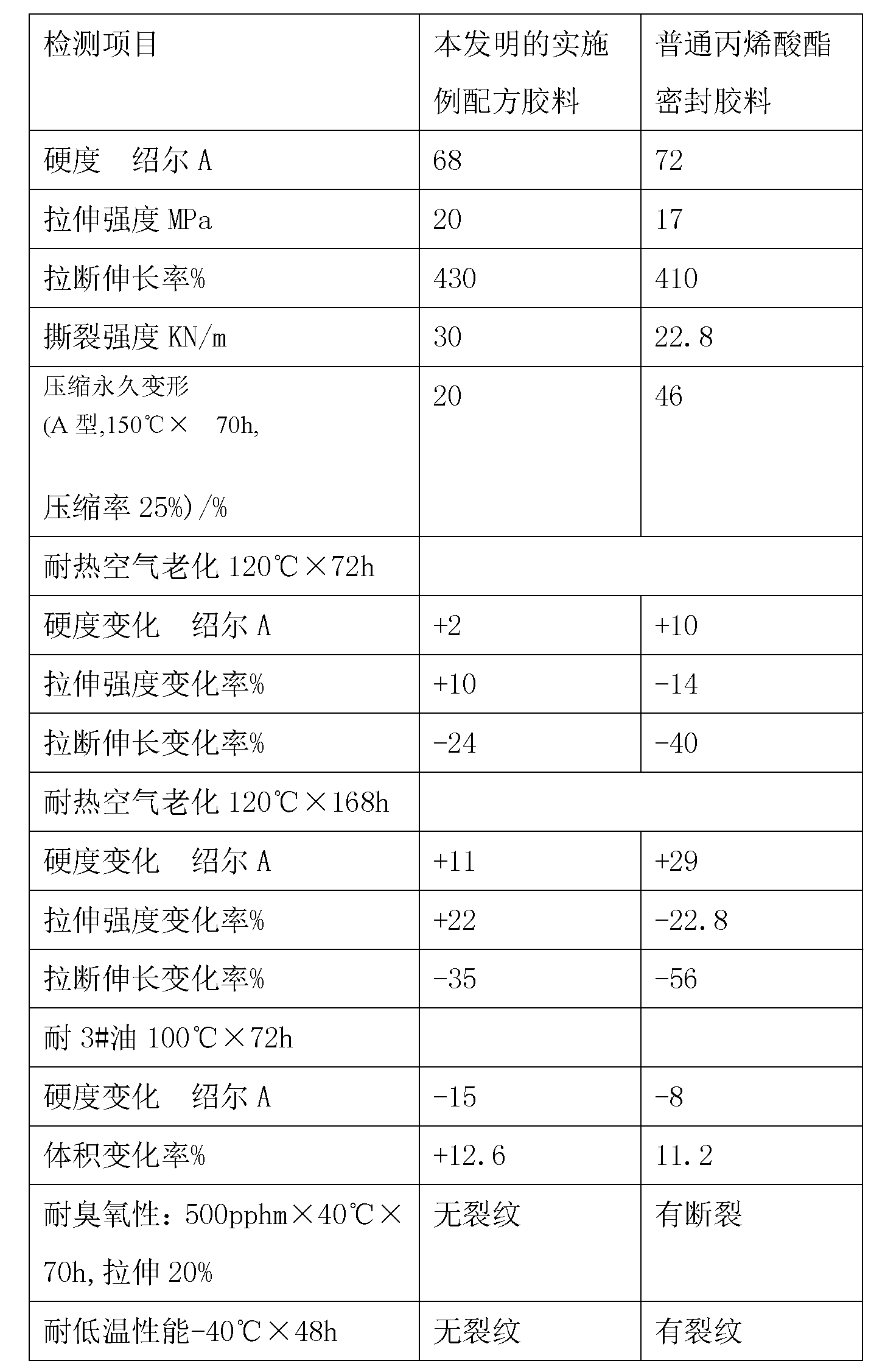

High-temperature oil resistant nitrile rubber gasket and preparation method thereof

The invention discloses a high-temperature oil resistant nitrile rubber gasket, comprising the following ingredients in parts by weight: 35-145 parts of nitrile rubber N411, 30-35 parts of active chloride type acrylic rubber, 10-15 parts of SG-1 type polyvinyl chloride, 2-5 parts of triethyl citrate, 3-5 parts of epoxy butyl oleate, and 2-5 parts of n-butyl methacrylate. The nitrile rubber gasket disclosed by the invention has excellent oil resistance and solvent resistance, also has excellent compressibility and rebound resilience and weak permanent deformation, does not soften and not decompose at high temperature, does not harden and not crack at low temperature, has excellent corrosion property, can work for a long time in mediums of acid, alkali, oil and the like, has small change in volume and rigidity and can adhered on metal surfaces, and has the following advantages of low friction coefficient, excellent wearing resistance, flexibility of being combined with a seal surface, excellent weather aging and ozone aging resistance, endurance, and the like.

Owner:ANHUI RONGDA VALVE

Elastomer compositions for use in a hydrocarbon resistant hose

InactiveUS20060263556A1High-temperature and pressure resistanceImproved hydrocarbon fluid resistanceLayered productsFibre treatmentElastomerAcrylic rubber

A vinyl ester composition; a tubular structure such as a hose for conveying fluids in an automotive engine cooler, transmission oil cooler, power transmission cooler, radiator or heater; and a method for preparing the tubular structure are described. The tubular structure includes a single layer of a heat tolerant, pressure resistant, hydrocarbon fluid impermeable composition comprising a copolymer of a first vinyl ester and a second vinyl ester, and one or more additives. The composition may, optionally contain a second polymeric component such as an ethylene-vinyl ester of a C2 to C6 carboxylic acid, chlorinated polyolefins, chlorosulfonated polyolefins, polychloroprene, ethylene-acrylic rubber, alkyl acrylate copolymer, polyvinyl acetate, acrylonitrile-butadiene rubber, hydrogenated acrylonitrile-butadiene rubber, ethylene-propylene-diene terpolymer, styrene-butadiene rubber, ethylene-propylene rubber, butyl rubber, cis-polybutadiene, cis-polyisoprene, polyurethane, polyamide and combinations thereof.

Owner:YH AMERICA

Acrylic rubber graft copolymer and thermoplastic resin composition

[Object] To provide acrylic rubber graft copolymers capable of giving thermoplastic resin compositions exhibiting excellent impact resistance, rigidity and appearance, and to provide thermoplastic resin compositions including the acrylic rubber graft copolymers.[Solution] An acrylic rubber graft copolymer is obtained by graft polymerizing a vinyl monomer in the presence of a rubbery polymer including acrylate ester monomer units and polyfunctional monomer units, wherein the total amount of the polyfunctional monomer units in the rubbery polymer is 0.3 to 3 parts by mass with respect to 100 parts by mass of the acrylate ester monomer units, and the polyfunctional monomer units include 30 to 95 mass % of polyfunctional monomer units having two unsaturated bonds and 5 to 70 mass % of polyfunctional monomer units having three unsaturated bonds with respect to 100 mass % of the total of the polyfunctional monomer units. A thermoplastic resin composition includes the acrylic rubber graft copolymer.

Owner:TECHNO UMG CO LTD

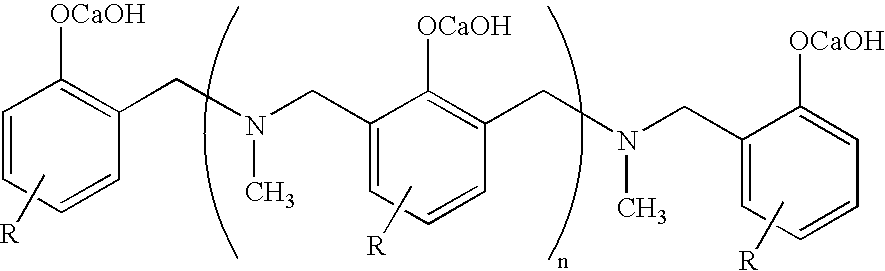

Method of improving the acrylic rubber sealant compatibility in an internal combustion engine

InactiveUS20070184992A1Improve compatibilityAdditivesFoam dispersion/preventionSimple Organic CompoundsAcrylic rubber

It has been discovered that a lubricating oil composition containing a certain combination of a nitrogen-containing dispersant and a metal-containing detergent of an alkali metal salt of alkylphenol derivative having a Mannich base structure, together with a phosphorus-containing organic compound, can be effectively employed in a method for improving the acrylic rubber sealant compatibility in an internal combustion engine, if the ratio of the nitrogen-containing dispersant and a metal-containing detergent of an alkali metal salt of alkylphenol derivative having a Mannich base structure is adjusted to a specific range, i.e., in the range of from 1:0.005 to 1:2 in terms of the nitrogen contents.

Owner:CHEVRON JAPAN

Acrylic rubber composition and crosslinked object

InactiveUS20060167159A1Improve mechanical propertiesImprove heat resistanceSpecial tyresEmulsion paintsMethacrylatePolymer science

An acrylic rubber composition comprising (A) 100 weight parts of an acrylic rubber comprising 80-99.9 weight % of units of a monomer selected from acrylic acid ester monomers and methacrylic acid ester monomers, and 0.1-20 weight % of units of an α,β-ethylenically unsaturated carboxylic acid monomer, (B) 5-200 weight parts of synthetic silica, and (C) 0.05-20 weight parts of a crosslinking agent. The acrylic rubber composition preferably further comprises 5-200 weight parts of aluminum silicate containing at least 5 weight % of Al2O3 wherein the total amount of Al2O3 and SiO2 is at least 60 weight %. The rubber composition has good storage stability and gives a crosslinked object having good heat aging resistance, reduced compression set and good mechanical properties.

Owner:ZEON CORP

Resin composition, and method for producing the same

A resin composition having excellent impact resistance and heat resistance, comprising a poly-3-hydroxybutyrate, and a core-shell latex rubber comprising an acrylic rubber and / or silicone-acrylic rubber copolymer as a core component and polymethyl methacrylate as a shell component, or a specific thermoplastic polyurethane, is disclosed. The resin composition satisfies the following requirements (c) and (d): (c) a crystallization temperature when heated from room temperature to 180° C. at a temperature rising rate of 80° C. / min by a differential scanning calorimeter, maintained at 180° C. for 1 minute, and then cooled at a temperature lowering rate of 10° C. / min is 110-170° C.; and (d) a weight average molecular weight (Mw) in terms of polystyrene conversion when a chloroform soluble component is measured with a gel permeation chromatography is 100,000-3,000,000.

Owner:TOSOH CORP

Anisotropic conductive film

InactiveUS7156669B2Improve reliabilityLine/current collector detailsElectrical measurement instrument detailsEpoxyAnisotropic conductive film

Owner:NITTO DENKO CORP

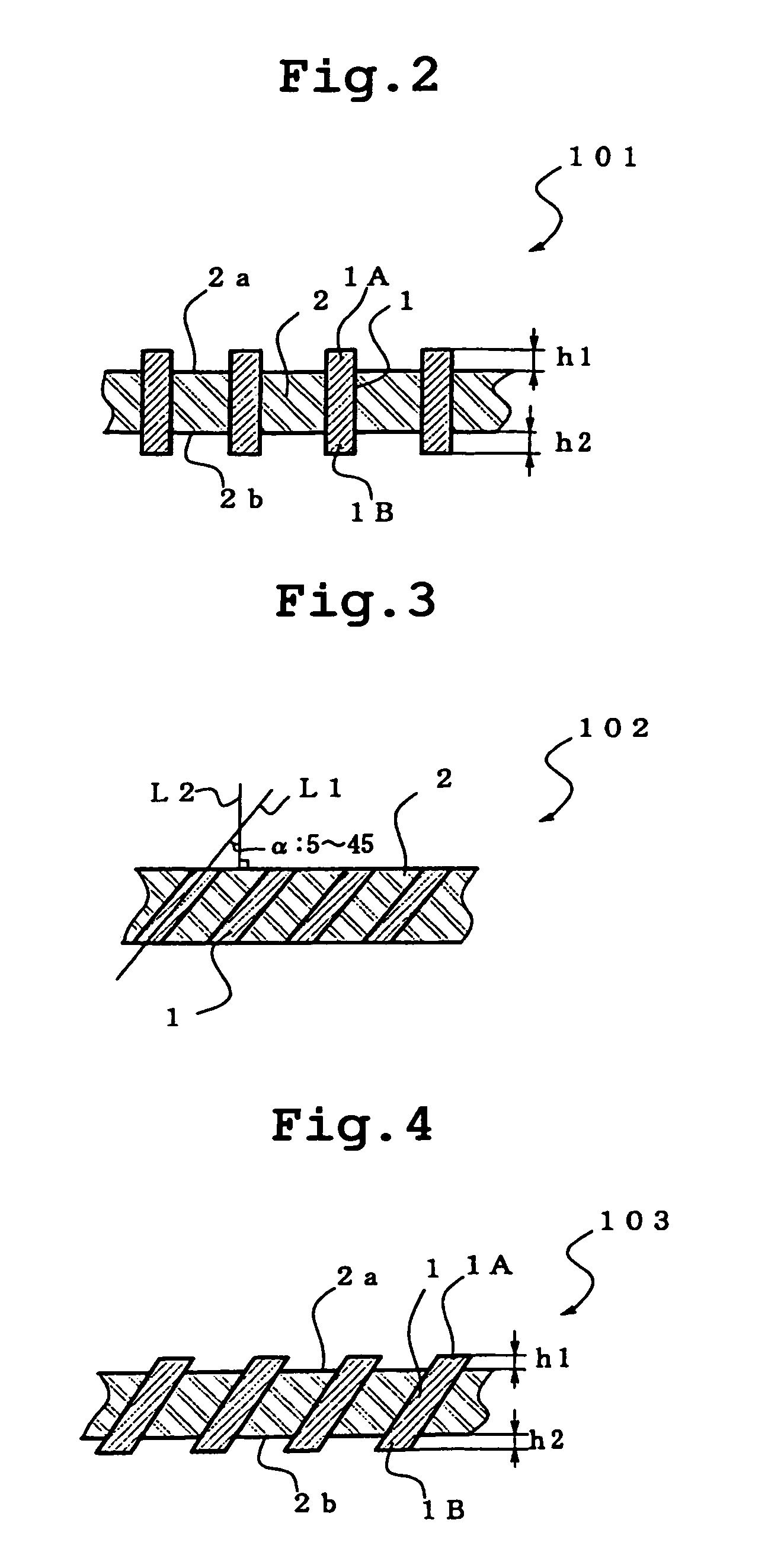

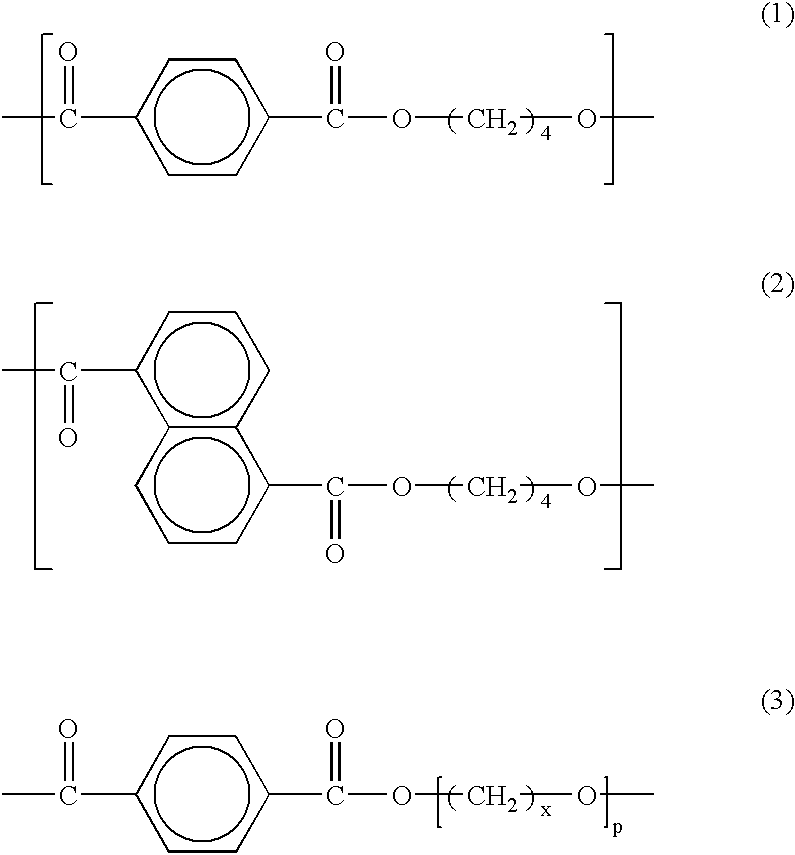

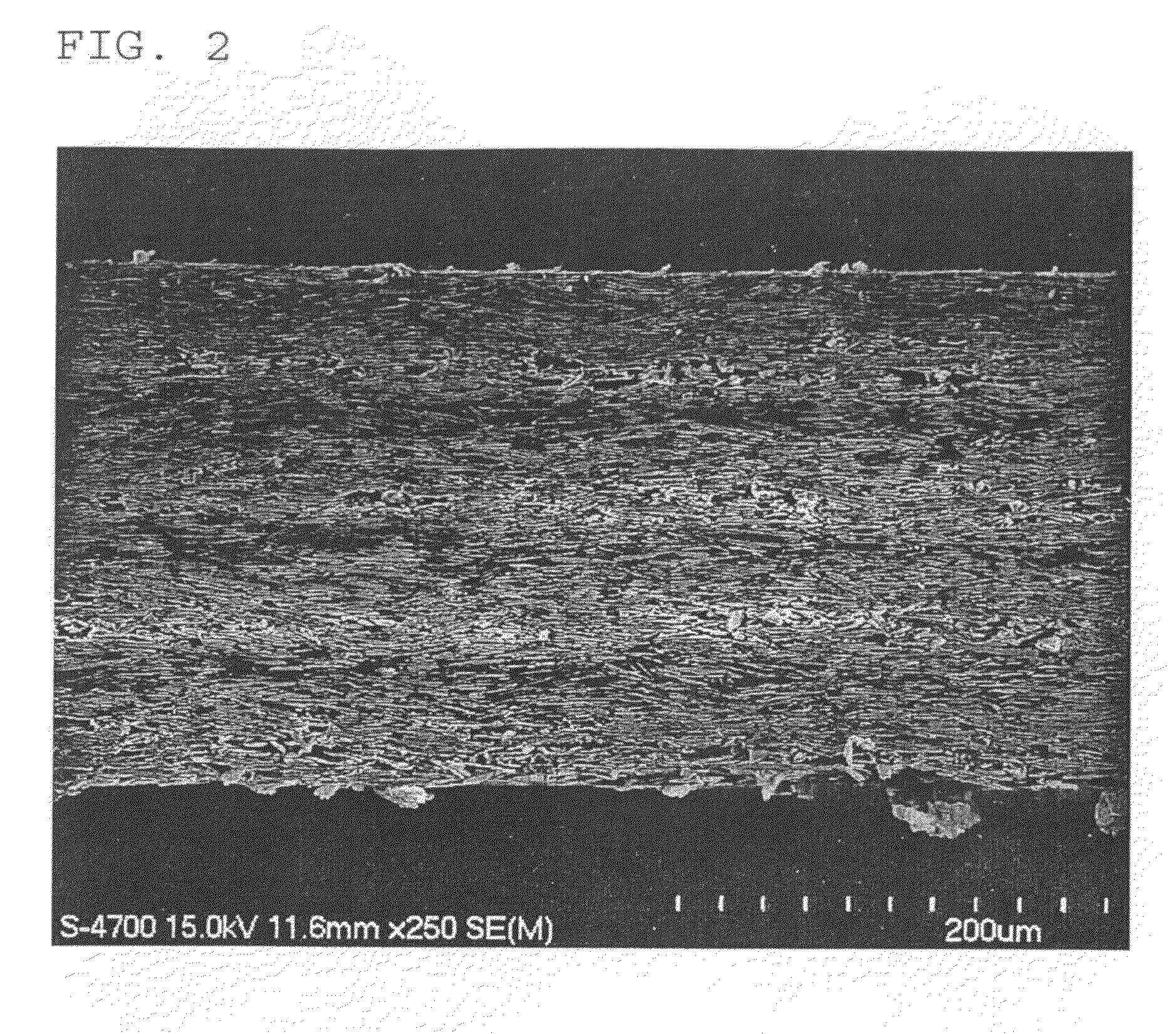

Sheet-like soft magnetic material and production method thereof

ActiveUS20100001226A1Improve heat resistanceGood dimensional stabilityShielding materialsTransportation and packagingEpoxyIn plane

The present invention is to impart, to a sheet-like soft magnetic material, a configuration in which sheet thickness change is suppressed and in which fluctuation in magnetic permeability is small even under a high-temperature or a high-temperature, high-humidity environment, even when a plurality of thin curable soft magnetic sheets produced by a coating method are laminated. The sheet-like soft magnetic material is formed from a soft magnetic composition which is formed by mixing at least a flat soft magnetic powder, an acrylic rubber, an epoxy resin, a curing agent for the epoxy resin, and a solvent. The flat soft magnetic powder is arranged in an in-plane direction of the sheet-like soft magnetic material. An acrylic rubber having a glycidyl group is used for the acrylic rubber. The weight ratio of the flat soft magnetic powder with respect to the total amount of the acrylic rubber, the epoxy resin, and the curing agent for the epoxy resin is 3.7 to 5.8.

Owner:SONY CORP

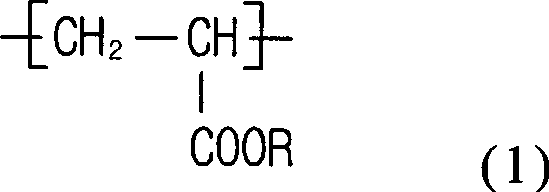

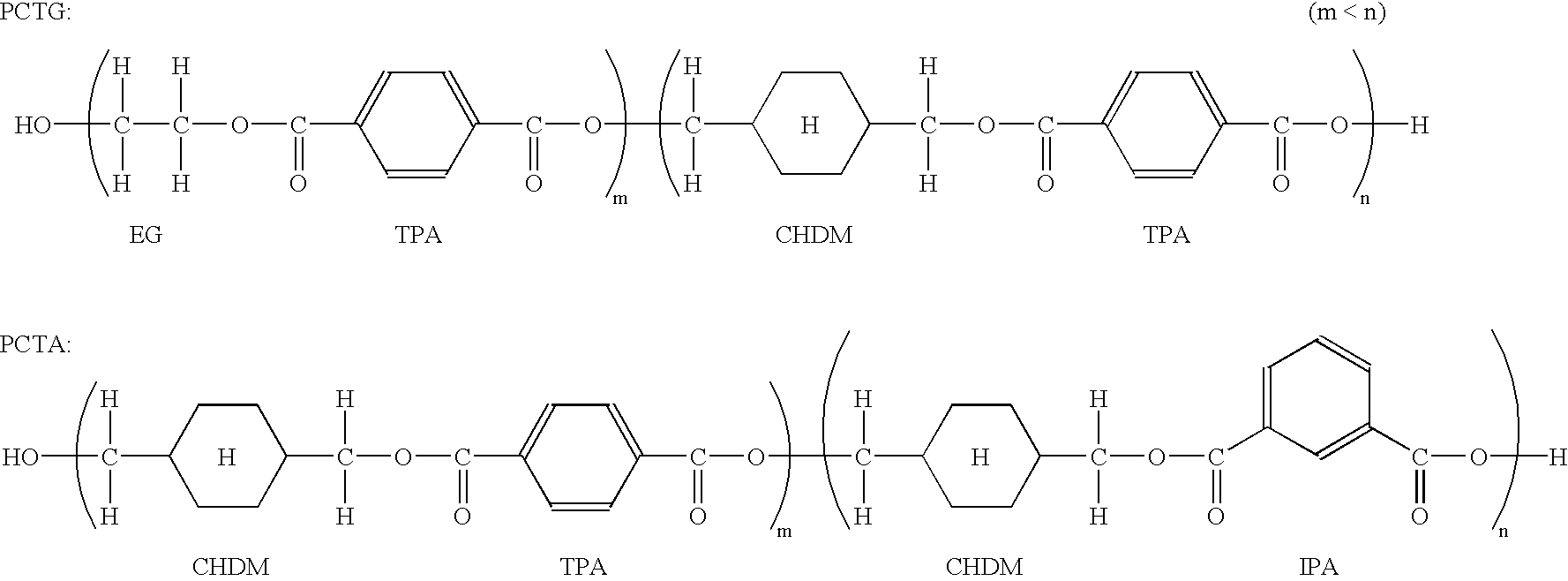

Resin composition and resin sheet

InactiveUS6433081B1High mechanical strengthSuperior V-cut propertySynthetic resin layered productsWood layered productsMethacrylateAcrylic rubber

The present invention provides a resin composition comprising 50 to 99 percent by weight of a completely amorphous polyester resin (A), and 1 to 50 percent by weight of a graft copolymer (B) obtained by graft-polymerizing a methacrylic acid ester and a vinyl aromatic compound with conjugated diene rubber particles and / or a graft copolymer (C) obtained by graft-polymerizing a methacrylic acid ester and a vinyl aromatic compound with acrylic rubber particles. According to the present invention, a resin composition and a resin sheet specifically suitable for membrane pressing, vacuum pressing, air pressing, and the like are provided, in which the resin composition and the resin sheet have superior properties, such as workability, moldability, impact resistance, transparency, and the like. In addition, plate-out is not significantly observed and whitening during embossing and heat-sealing is unlikely to occur.

Owner:RIKEN TECHNOS CORP

Elastomer compositions for use in a hydrocarbon resistant hose

InactiveUS20050059763A1High-temperature and pressure resistanceIncrease fluid resistanceSpecial tyresFlexible pipesElastomerPolyolefin

A vinyl ester composition; a tubular structure such as a hose for conveying fluids in an automotive engine cooler, transmission oil cooler, power transmission cooler, radiator or heater; and a method for preparing the tubular structure are described. The tubular structure includes a single layer of a heat tolerant, pressure resistant, hydrocarbon fluid impermeable composition comprising a copolymer of a first vinyl ester and a second vinyl ester, and one or more additives. The composition may, optionally contain a second polymeric component such as an ethylene-vinyl ester of a C2 to C6 carboxylic acid, chlorinated polyolefins, chlorosulfonated polyolefins, polychloroprene, ethylene-acrylic rubber, alkyl acrylate copolymer, polyvinyl acetate, acrylonitrile-butadiene rubber, hydrogenated acrylonitrile-butadiene rubber, ethylene-propylene-diene terpolymer, styrene-butadiene rubber, ethylene-propylene rubber, butyl rubber, cis-polybutadiene, cis-polyisoprene, polyurethane, polyamide and combinations thereof.

Owner:DAYCO PROD INC

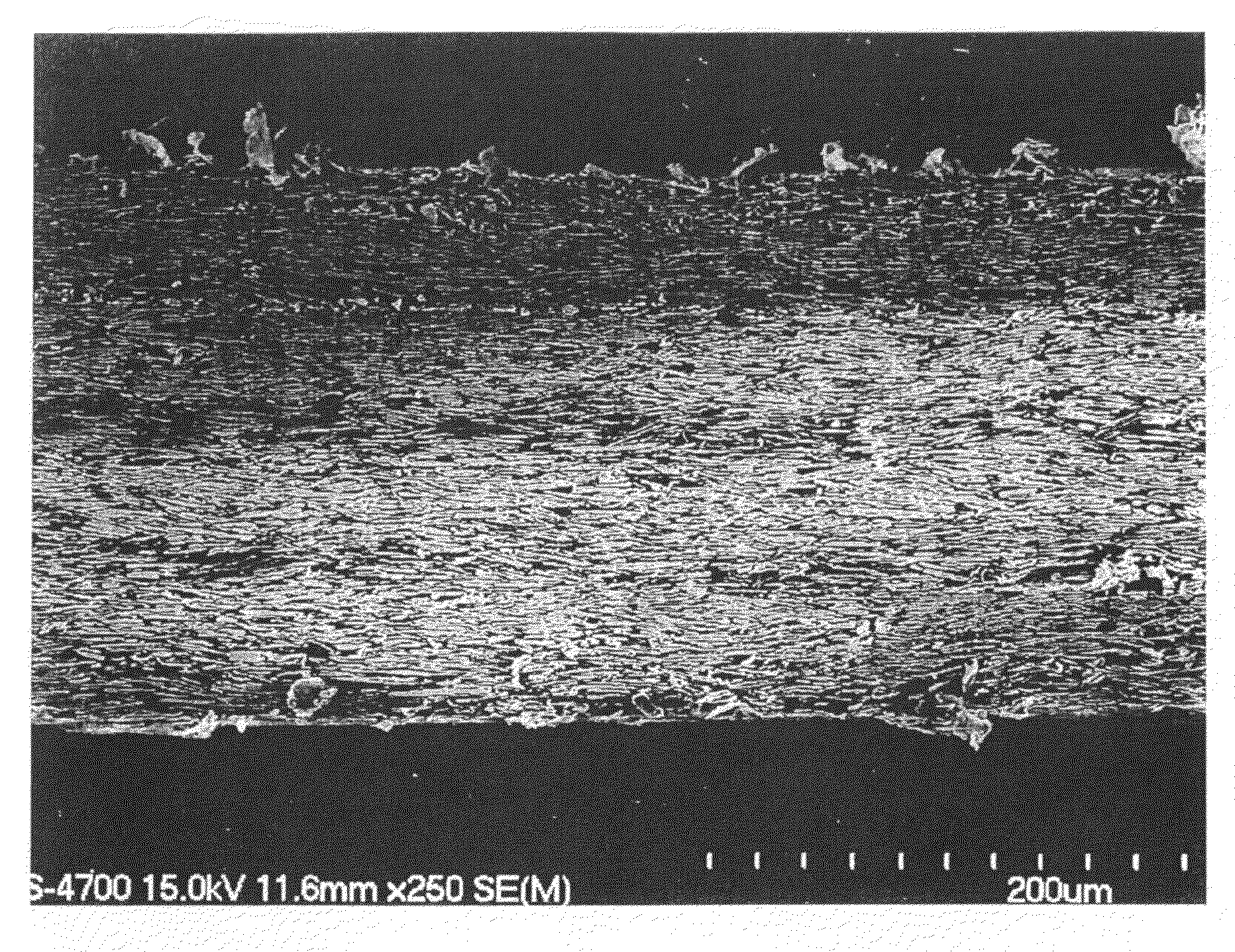

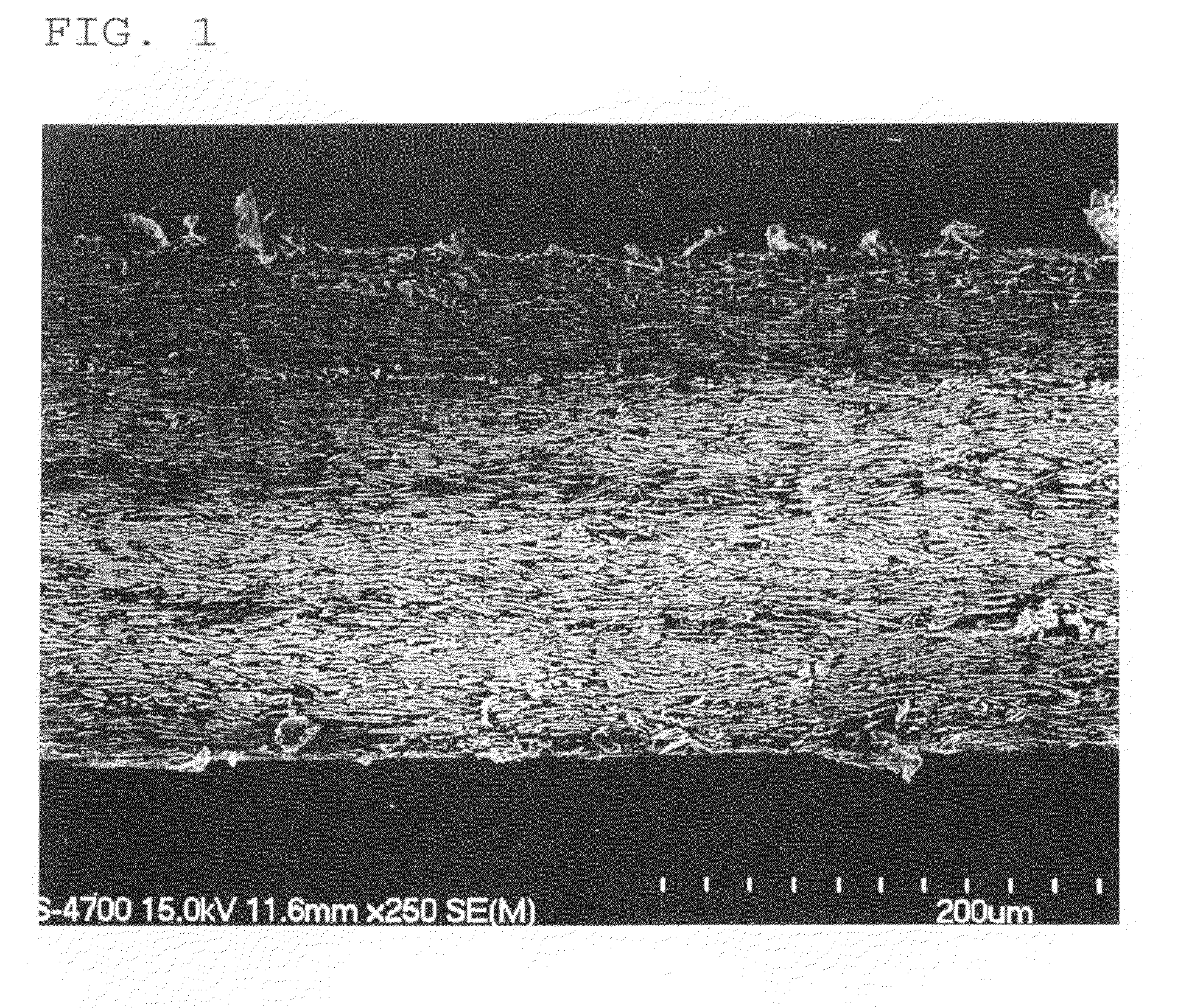

Method for manufacturing laminated soft-magnetic sheet

ActiveUS20090110587A1Reduce penetrationAvoid changeMetal-working apparatusInorganic material magnetismEpoxyAcrylic rubber

A method for producing a laminated soft-magnetic sheet is provided by laminating thin soft-magnetic sheets produced by an application method. A change in sheet thickness can be suppressed and variations in the magnetic permeability are small. The method for manufacturing a laminated soft-magnetic sheet includes the step (A) of obtaining curable soft-magnetic sheets, each of the curable soft-magnetic sheets being produced by applying to a release base a soft-magnetic composition prepared by mixing at least a flat soft-magnetic powder, an acrylic rubber having a glycidyl group, an epoxy resin, a latent curing agent for the epoxy resin, and a solvent, drying the applied soft-magnetic composition at a temperature T1 at which curing reaction of the soft-magnetic composition does not substantially take place, and removing the release base; the step (B) of obtaining a laminate of the curable soft-magnetic sheets by laminating at least two of the curable soft-magnetic sheets; the step (C) of compressing the obtained laminate at a temperature T2 at which the curing reaction does not substantially take place, using a laminator for applying a linear pressure thereon while the linear pressure is sequentially changed from a linear pressure P1, to a linear pressure P2, and to a linear pressure P3 (wherein P1<P2<P3); and the step (D) of obtaining a laminated soft-magnetic sheet by compressing the compressed laminate at a temperature T3 at which the curing reaction takes place, using a press for applying surface pressure thereon to final cure the laminate.

Owner:DEXERIALS CORP

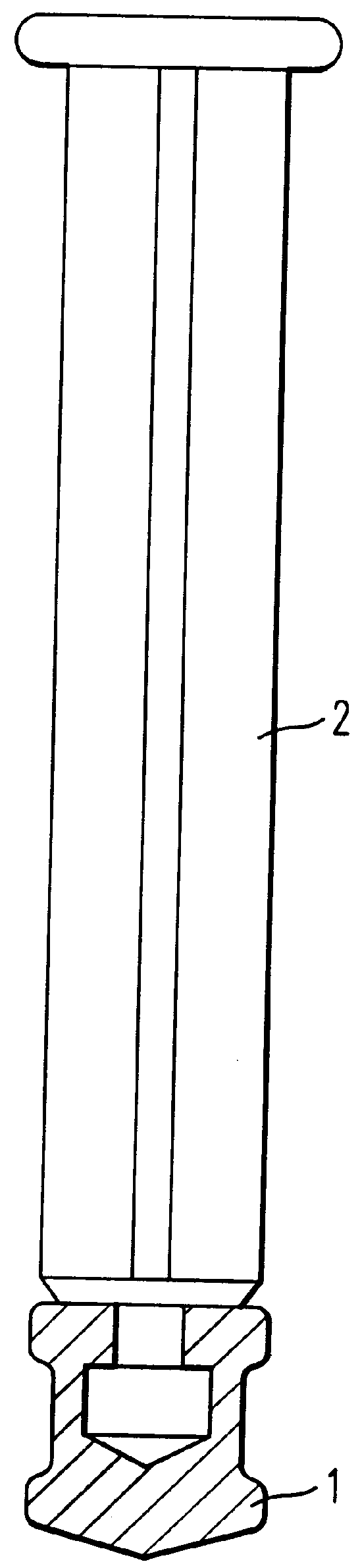

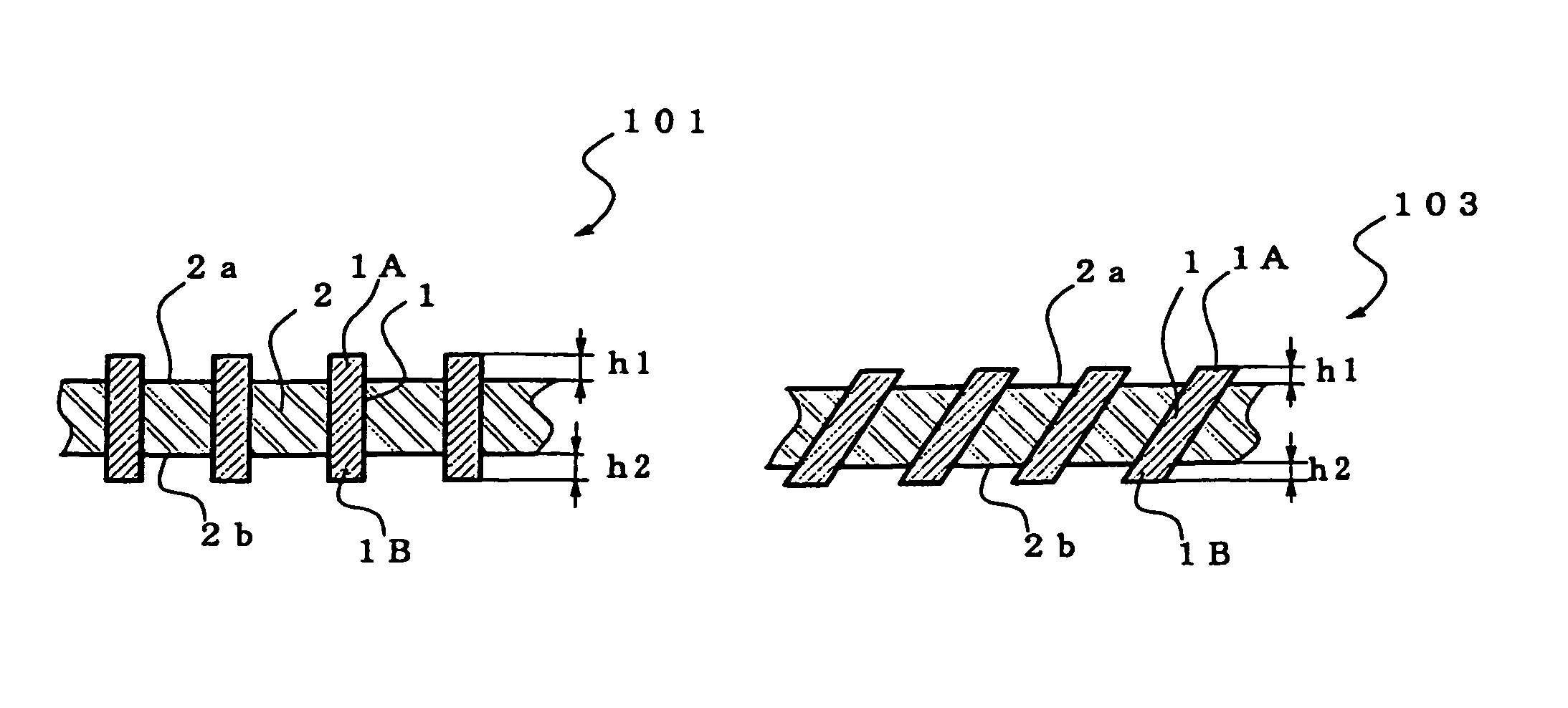

Weather-resistant synthetic wood material

InactiveUS20070128428A1Improve adhesionSynthetic resin layered productsGlass/slag layered productsWeather resistanceAcrylic rubber

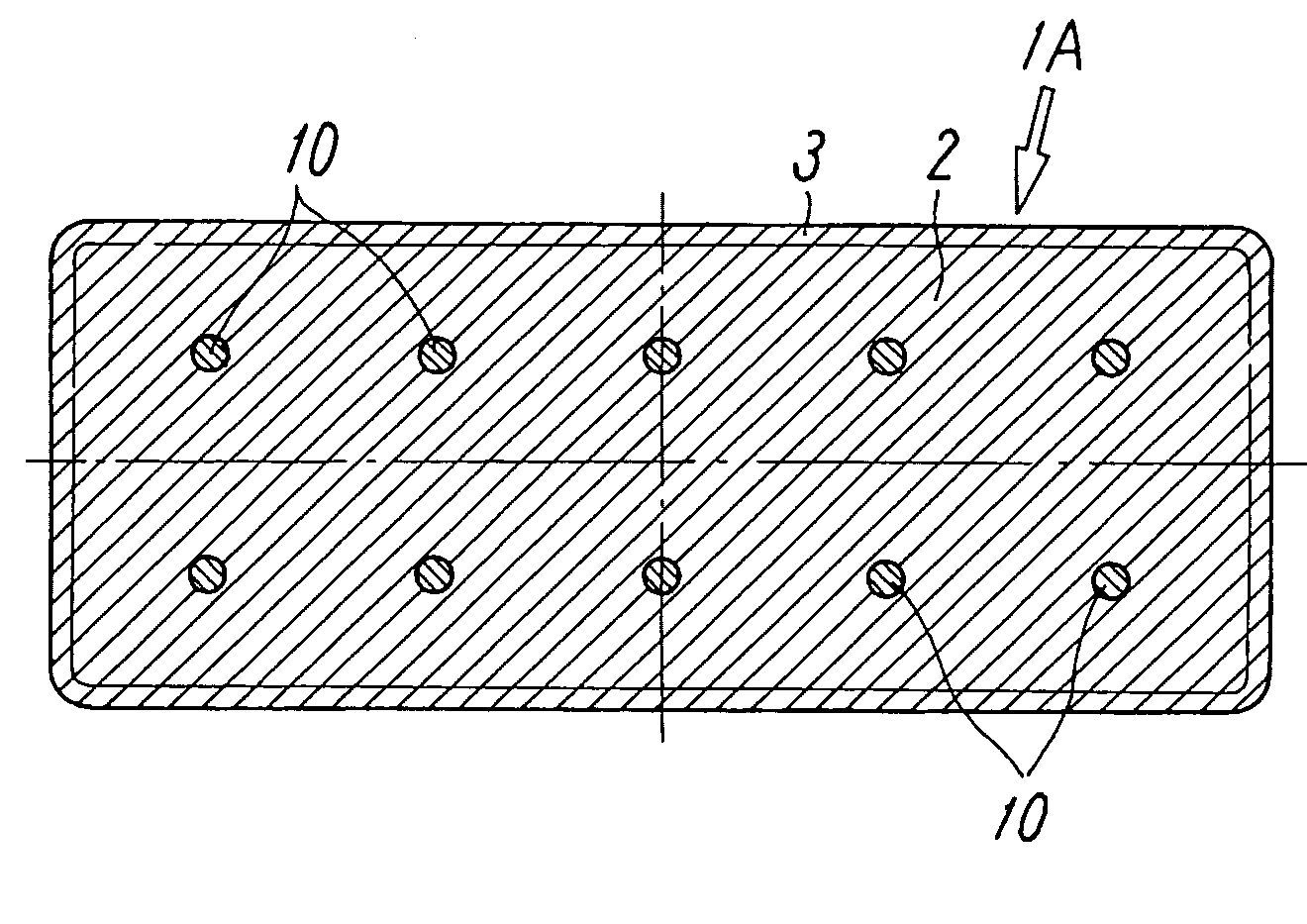

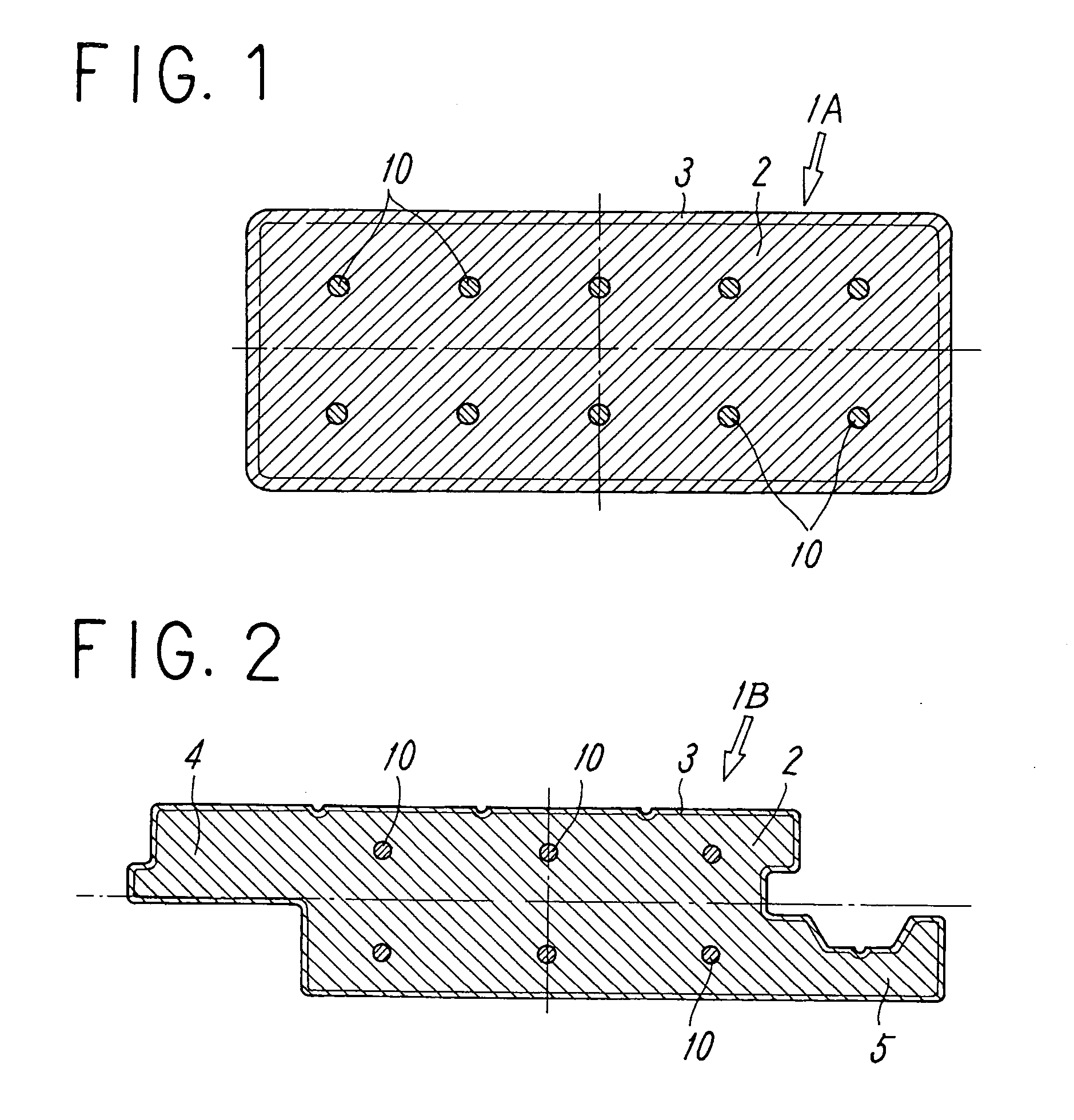

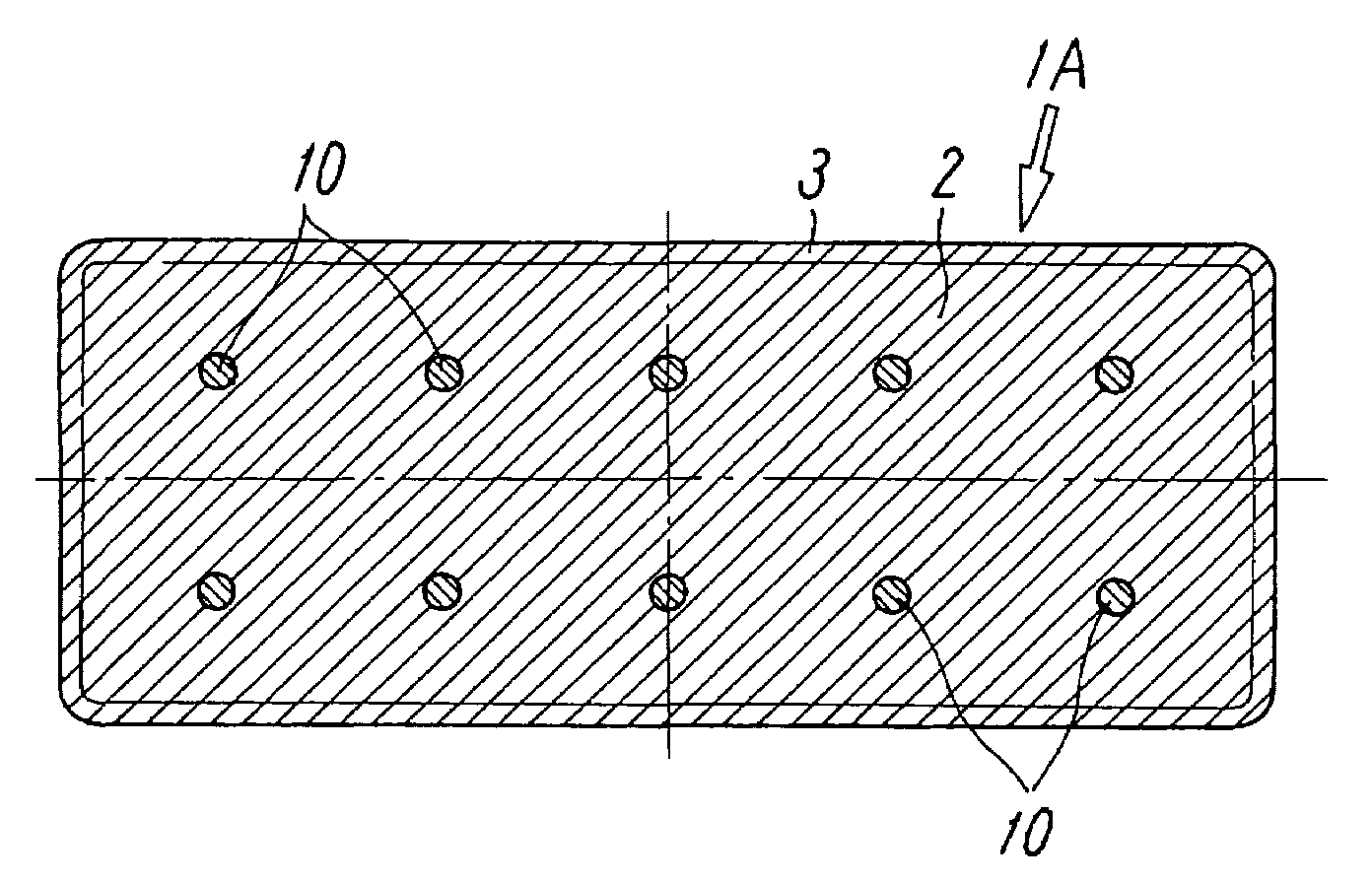

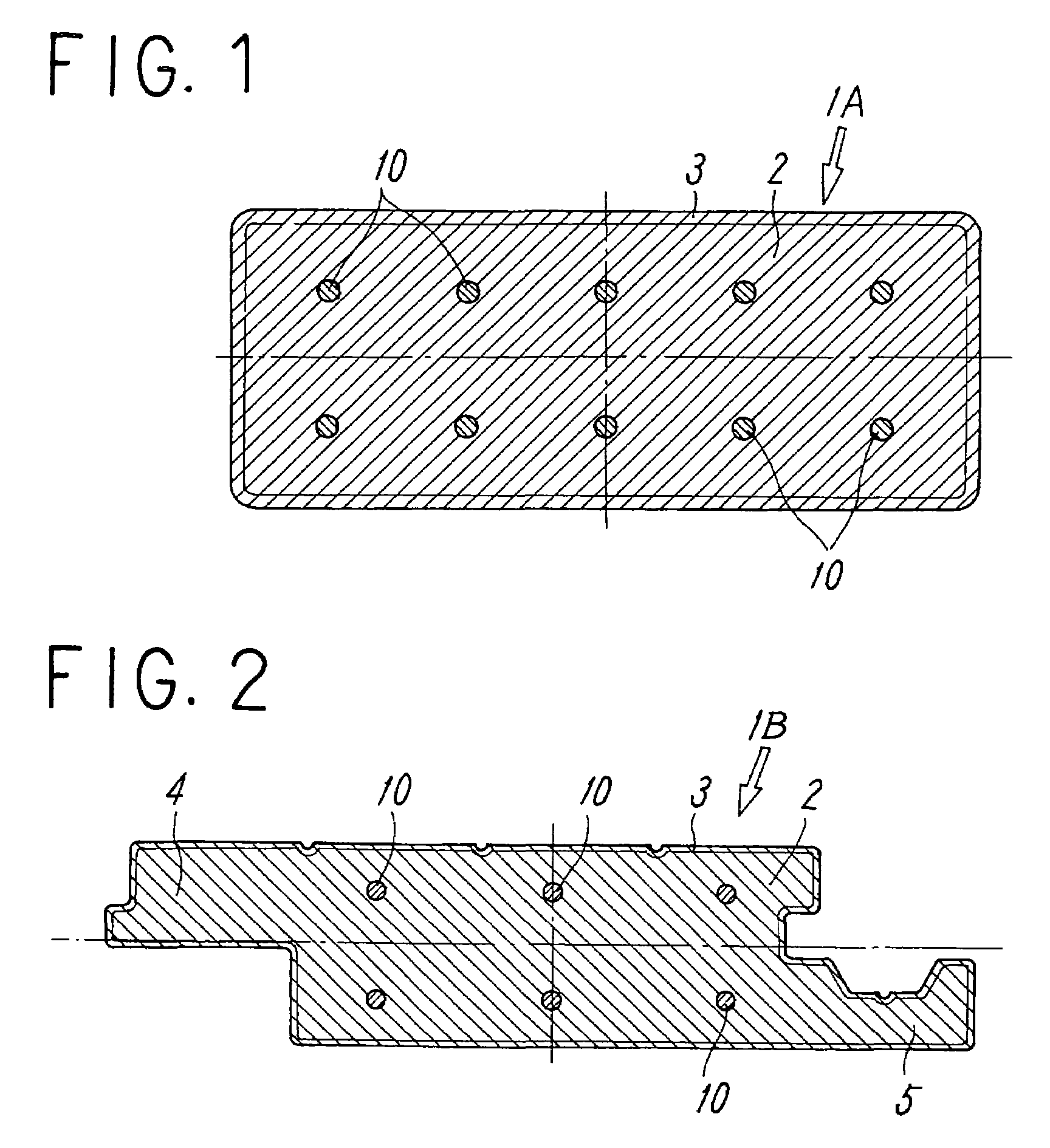

The present invention provides a synthetic wood including a body containing a polystyrene- or polypropylene-based resin as the major component and a weather-resistant outer layer with excellent adhesion to the body. A synthetic wood 1A includes a body 2 defining a core thereof and formed of a polystyrene or polypropylene foam and an outer layer 3 covering the body and formed of a weather-resistant synthetic resin that is unfoamed or foamed at a low expansion rate. The body and the outer layer are integrally bonded by coextrusion. The body contains a polystyrene- or polypropylene-based resin as the major component. The outer layer contains an acrylonitrile-acrylic rubber-styrene copolymer and / or an acrylonitrile-ethylene propylene rubber-styrene copolymer, which are weather-resistant resins, as the major component. The outer layer further contains the major component resin of the body as a minor component in such an amount that the minor component contributes to the enhancement of the adhesion between the body and the outer layer without impairing weather resistance.

Owner:SEIKI IND

Weather-resistant synthetic wood material

InactiveUS7445840B2Synthetic resin layered productsGlass/slag layered productsWeather resistanceAcrylic rubber

The present invention provides a synthetic wood including a body containing a polystyrene- or polypropylene-based resin as the major component and a weather-resistant outer layer with excellent adhesion to the body. A synthetic wood 1A includes a body 2 defining a core thereof and formed of a polystyrene or polypropylene foam and an outer layer 3 covering the body and formed of a weather-resistant synthetic resin that is unfoamed or foamed at a low expansion rate. The body and the outer layer are integrally bonded by coextrusion. The body contains a polystyrene- or polypropylene-based resin as the major component. The outer layer contains an acrylonitrile-acrylic rubber-styrene copolymer and / or an acrylonitrile-ethylene propylene rubber-styrene copolymer, which are weather-resistant resins, as the major component. The outer layer further contains the major component resin of the body as a minor component in such an amount that the minor component contributes to the enhancement of the adhesion between the body and the outer layer without impairing weather resistance.

Owner:SEIKI IND

Seal rubber for water pump of automobile and preparation method of seal rubber

The invention discloses a seal rubber for a water pump of an automobile. The seal rubber comprises the following raw materials by weight: 50 to 60 parts of acrylic rubber, 10 to 15 parts of fluorinated silicone rubber, 10 to 15 parts of epichlorohydrin rubber T3100, 10 to 15 parts of butyl bromide rubber 221, 30 to 36 parts of high wear-resisting carbon black N330, 20 to 24 parts of precipitated white carbon black, 4 to 6 parts of light calcium carbonate, 5 to 10 parts of wollastonite in powder, 3 to 5 parts of zirconium tetrafluoride, 5 to 7 parts of barium sulfate, 3 to 5 parts of molybdenum disulfide, 9 to 11 parts of modified iron tailings powder, 1 to 2 parts of vulcanizing agent DCBP, 1 to 2 parts of antioxidant TPPD, 0.5 to 1 parts of accelerant H, 4 to 6 parts of magnesium oxide, 1 to 2 parts of 2-thiol benzimidazole, 1 to 2 parts of paraffin, 1 to 2 parts of isopropyl tri(dioctylpyrophosphate) titanate, and 17 to 19 parts of tri(2-ethylhexyl) acetocitrate. The rubber compound is excellent in ozone resistance, low-temperature resistance and heat resistance, wide in operating temperature wide and environment-friendly in process, and can be used for manufacturing various sealing gaskets.

Owner:马鞍山市中澜橡塑制品有限公司

Oil-resistant thermoplastic elastomer composition and moldings using the same

InactiveUS6815506B2Excellent characteristicsIncrease flexibilityLayered productsThin material handlingElastomerPolymer science

A thermoplastic elastomer composition having excellent heat aging characteristics, weather resistance, low-temperature physical properties, oil resistance and flexibility, and moldings using the same, such as hoses, are disclosed. The thermoplastic elastomer composition is obtained by dynamically heat treating a mixture containing (A) an olefin resin, (B) an unsaturated group-containing acrylic rubber, and (D) an inorganic filler in the presence of (E) a crosslinking agent, the component (B) comprising (B1) from 55 to 94.99% by weight of a structural unit derived from an acrylic acid alkyl ester monomer and / or an acrylic acid alkoxyalkyl ester monomer, (B2) from 0.01 to 20% by weight of a structural unit derived from a monomer having a carbon-carbon double bond in a side chain thereof, (B3) from 5 to 30% by weight of a structural unit derived from an unsaturated acrylonitrile monomer, and (B4) from 0 to 30% by weight of a structural unit derived from a monomer copolymerizable therewith, provided that the sum of (B1), (B2), (B3) and (B4) is 100% by weight.

Owner:JSR CORPORATIOON

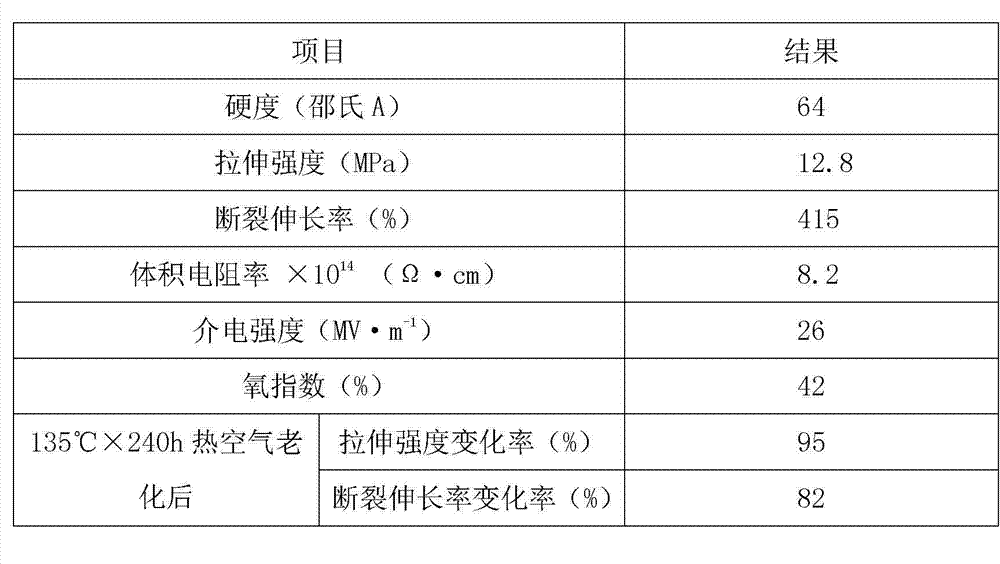

High cold-resistance ethylene propylene diene copolymer insulated cable material and preparation method thereof

ActiveCN102964698AImprove flame retardant performanceImprove cold resistancePlastic/resin/waxes insulatorsPolymer scienceBenzoyl peroxide

The invention discloses a high cold-resistance ethylene propylene diene copolymer insulated cable material and a preparation method thereof. The cable material is made of the following raw materials in parts by weight: 100-120 parts of Lanxess Deutschland 9650 ethylene propylene diene copolymer, 20-30 parts of active chlorine type acrylic rubber AR-400, 10-15 parts of duprene rubber CR121, 10-15 parts of di-butyl nylonic acid ester, 5-10 parts of trioctyl trimellitate, 5-10 parts of triethyl phosphate, 1-2 parts of sulphur, 2-4 parts of benzoyl peroxide, 1-2 parts of triallyl isocyanurate and the like. The cable material not only has excellent flame retardance and incombustibility, but also has the advantages of good high and low temperature resistance, corrosion resistance, water resistance, wear resistance, ozone resistance, ageing resistance and the like at the same time, and is durable in use.

Owner:ANHUI CHUNHUI INSTR CABLE GROUP

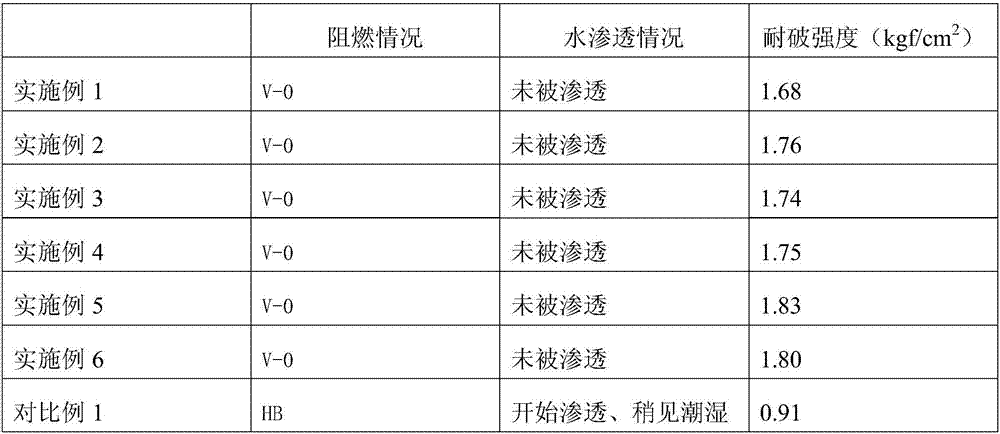

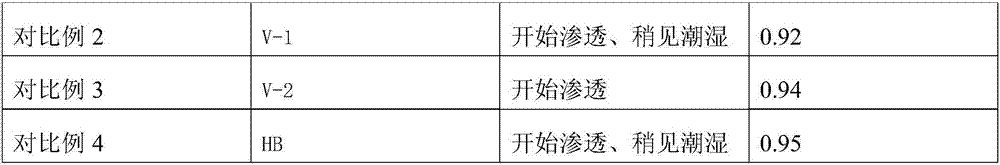

Waterproof and flame-retardant paper cone

ActiveCN106948211AHigh bromine contentImprove thermal stabilityWater-repelling agents additionReinforcing agents additionSodium metasilicateSodium Bentonite

The invention discloses a waterproof and flame-retardant paper cone, belonging to the technical field of electroacoustic products. The slurry of the paper cone is prepared by mixing and sitrring the following main raw materials in parts by weight: wood pulp, sisal hemp, cotton pulp, kapok, bulletproof fiber, wool, glass fiber, a dye, table salt, a hardening agent, a flexibilizer, a regulator, a waterproofing agent and a flame retardant, wherein the waterproofing agent is prepared through the following steps: adding acrylic rubber latex, hydroxyethyl cellulose, bentonite and sodium metasilicate according to a weight ratio of 1: (0.1-0.5): (0.2-0.5): (0.05-0.2) into water, carrying out mixing under stirring so as to form an emulsion, placing the emulsion in a stirring reflux device, and carrying out a reflux reaction for 3 to 4 hours; and the flame retardant is prepared by uniformly mixing kaolin with decabrominated dipheny ethane and antimonous oxide or magnesium hydroxide with a weight ratio of 1: (1-5) under stirring. The waterproof and flame-retardant paper cone provided by the invention has subdued sound effect and good dampproof and waterproof performances, flame retardance and mechanical performance, and is improved in use safety and prolonged in service life.

Owner:广西玉林市禹力音响配件有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com