ASA/PVC co-extrusion ultra-weather resisting colorful rainwater pipeline

A super weather-resistant and pipeline technology, applied in the pipeline field, can solve the problems of insufficient market segmentation of PVC rainwater pipelines, difficult to coordinate the appearance of buildings, affecting the service life of pipes, etc., to achieve improved impact resistance, long service life, and improved toughness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Embodiment 1: D50 specification (diameter is 50mm)

[0033] The formula of rainwater pipeline of the present invention is as follows:

[0034] 1) Outer layer (by weight):

[0035] ASA 100

[0036] Inorganic yellow K2001 0.20

[0037] Brilliant Orange 0.06

[0038] CPE 2

[0039] HST0.25

[0040] CaST 0.4

[0041] Ultrafine CaCO 3 5

[0042] Compound lubricant G12 0.15

[0043] UV-168 0.2

[0044] B-129 0.2

[0045] Titanium dioxide 3

[0046] 2) inner layer (by weight):

[0047] PVC 100

[0048] Chlorinated polyethylene 6

[0050] Titanium dioxide 0.15

[0051] Organotin stabilizer TM-697 0.5

[0052] PE wax 0.1

Embodiment 2

[0053] Embodiment 2: D110 specification (diameter is 110mm)

[0054] The formula of rainwater pipeline of the present invention is as follows:

[0055] 1) Outer layer (by weight):

[0056] ASA 100

[0057] Inorganic Yellow K2001 2.0

[0058] Brilliant orange 0.5

[0059] CPE 6

[0060] HST0.75

[0061] CaST 0.8

[0062] Ultrafine CaCO 3 3

[0063] G12 0.2

[0064] UV-168 0.25

[0065] B-129 0.2

[0066] Titanium dioxide 3.5

[0067] 2) inner layer (by weight):

[0068]PVC 100

[0069] Chlorinated polyethylene 8

[0070] Calcium stearate 1.5

[0071] Titanium dioxide 0.2

[0072] Organotin stabilizer TM-697 0.5

[0073] PE wax 0.15

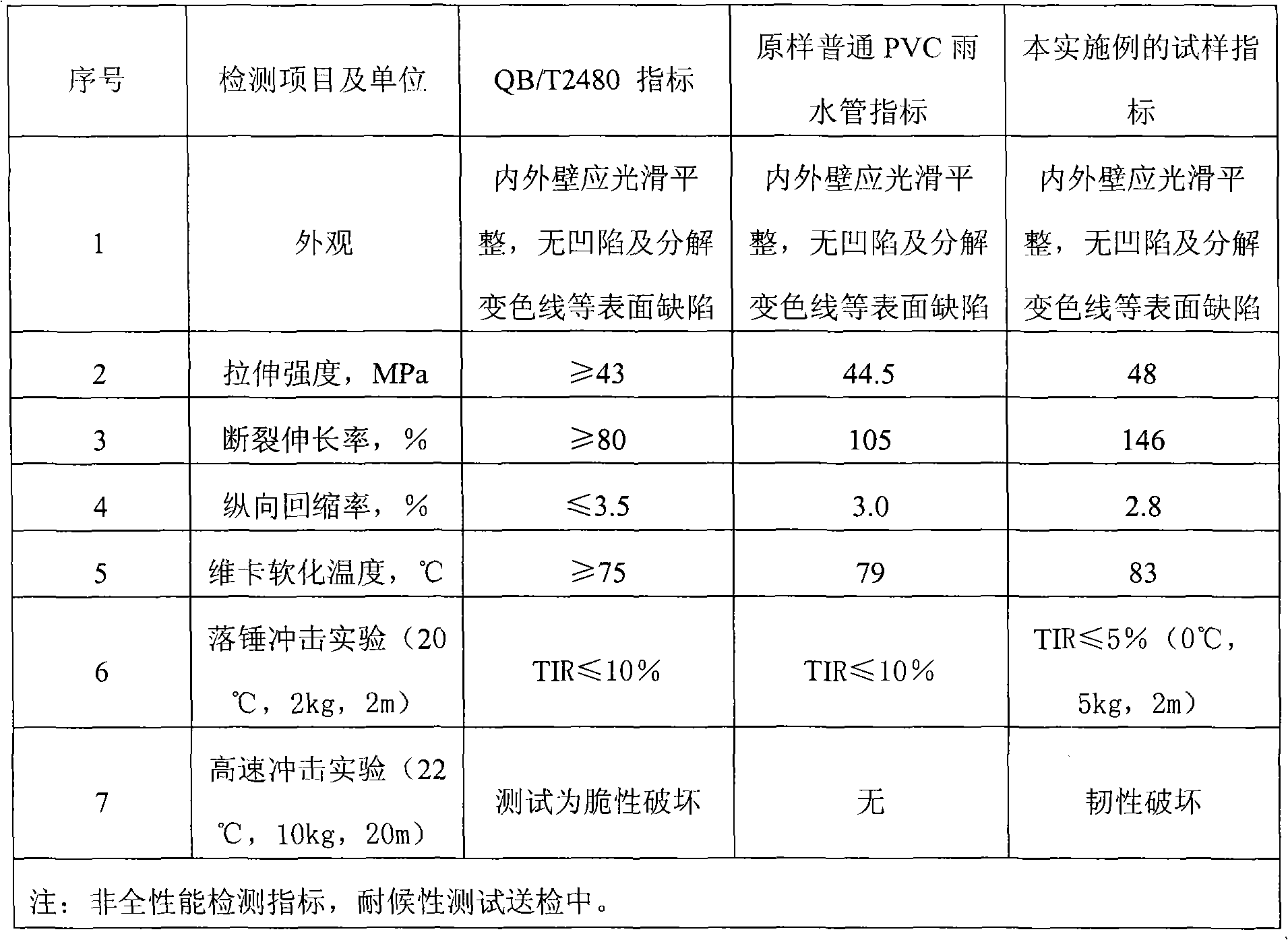

[0074] The comparative verification test result of the present invention is as follows:

[0075]

Embodiment 3

[0076] Embodiment 3: D200 specification (diameter is 200mm)

[0077] The formula of rainwater pipeline of the present invention is as follows:

[0078] 1) Outer layer (by weight):

[0079] ASA 100

[0080] Inorganic Yellow K2001 2.8

[0081] Brilliant Orange 0.7

[0082] CPE 10

[0083] HST 1.2

[0084] CaST 0.8

[0085] Ultrafine CaCO 3 1.5

[0086] G12 0.45

[0087] UV-168 0.35

[0088] B-129 0.45

[0089] Titanium dioxide 5.0

[0090] 2) inner layer (by weight):

[0091] PVC 100

[0092] Chlorinated polyethylene 10

[0093] Calcium stearate 2.5

[0094] Titanium dioxide 0.45

[0095] Organotin stabilizer TM-697 1.0

[0096] PE wax 0.5

[0097] The preparation methods of the above three examples are as follows: first mix the outer layer and the inner layer according to their respective formulas, and then place them in two mixers for mixing. The mixing process is first high-speed kneading, and the temperature is controlled at 105- 115 degrees, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com