Patents

Literature

18641 results about "Nonwoven fabric" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Non-woven fabric is a fabric-like material made from staple fibre (short) and long fibres (continuous long), bonded together by chemical, mechanical, heat or solvent treatment. The term is used in the textile manufacturing industry to denote fabrics, such as felt, which are neither woven nor knitted. Some non-woven materials lack sufficient strength unless densified or reinforced by a backing. In recent years, non-woven have become an alternative to polyurethane foam.

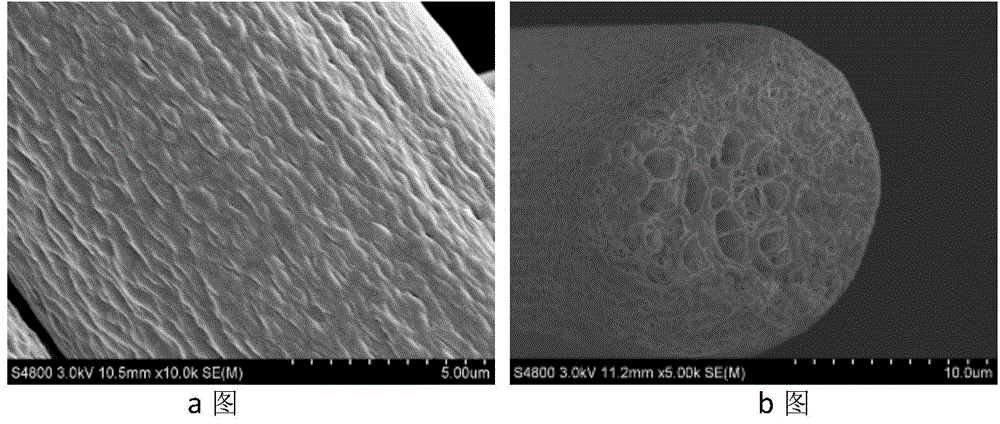

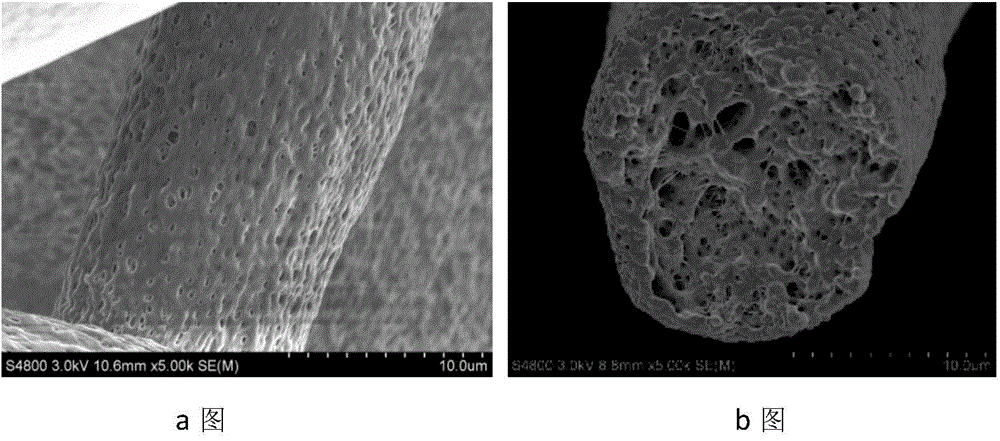

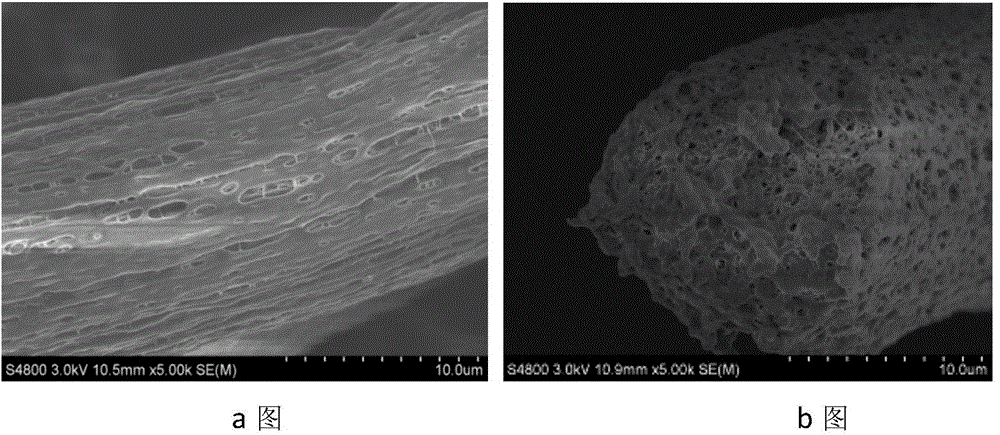

Preparation method of porous fiber non-woven fabric

ActiveCN103981635AReduce melt viscosityReduce degradationFilament forming substance formingMelt spinning methodsDiluentNonwoven fabric

The invention relates to a preparation method of a porous fiber non-woven fabric. The aim of the preparation method is to improve the product performance of the conventional non-woven fabric, so that the non-woven fabric meets the requirements on high-precision and high-performance filter. The technical scheme is that the preparation method of the porous fiber non-woven fabric comprises the following steps in sequence: (1) uniformly mixing a polymer and a diluent to obtain a blend with 10 to 60 percent of polymer; (2) melting and extruding the blend in the step (1) by adopting a screw extruder granulator, and directly cooling and granulating in air; (3) producing master batches in the step (2) by melt-down equipment to obtain a primary non-woven fabric; (4) extracting to remove the diluent from the primary non-woven fabric in the step (3), performing pore-forming on fibers in the non-woven fabric, and drying to obtain the porous fiber non-wave fabric; (5) recovering mixed waste liquid of the diluent and an extraction agent for reuse.

Owner:浙江省轻工业品质量检验研究院

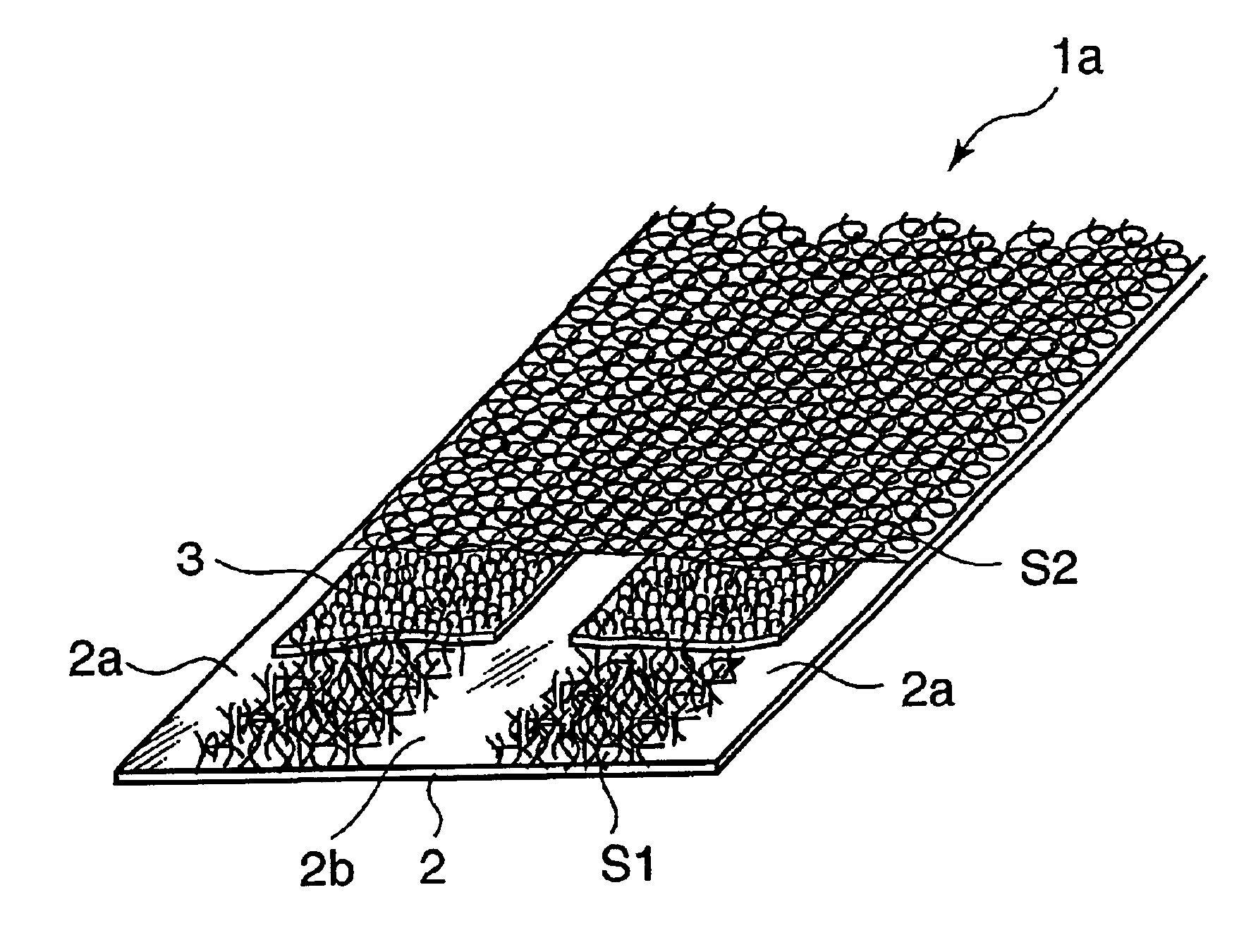

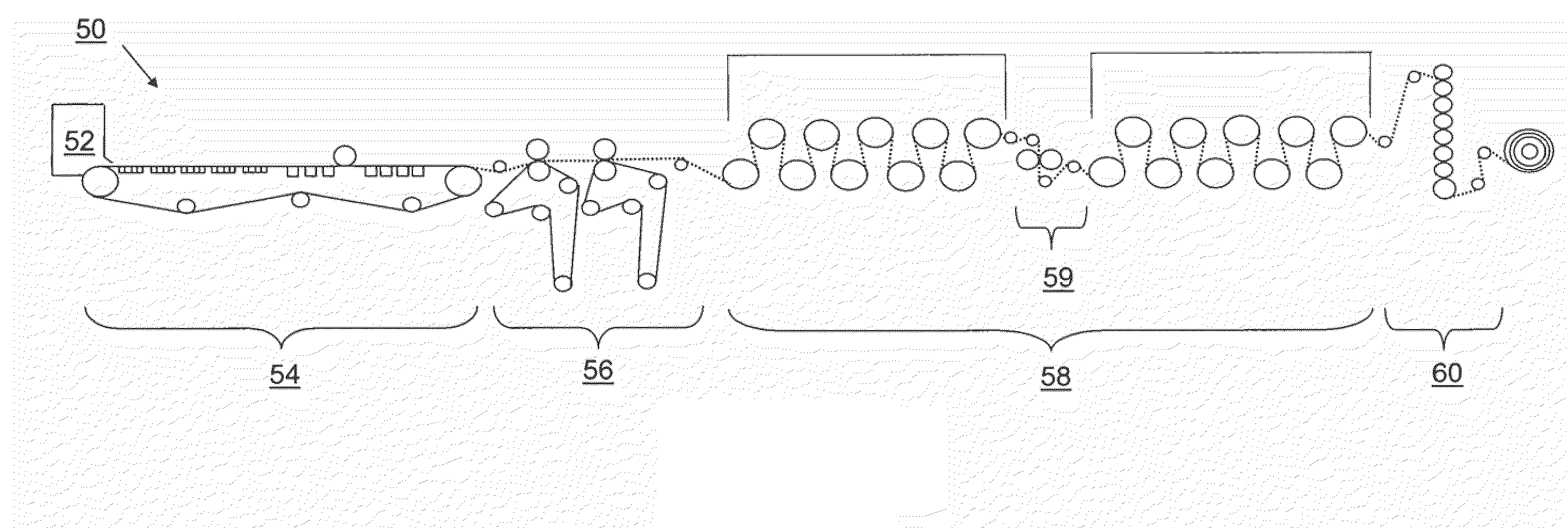

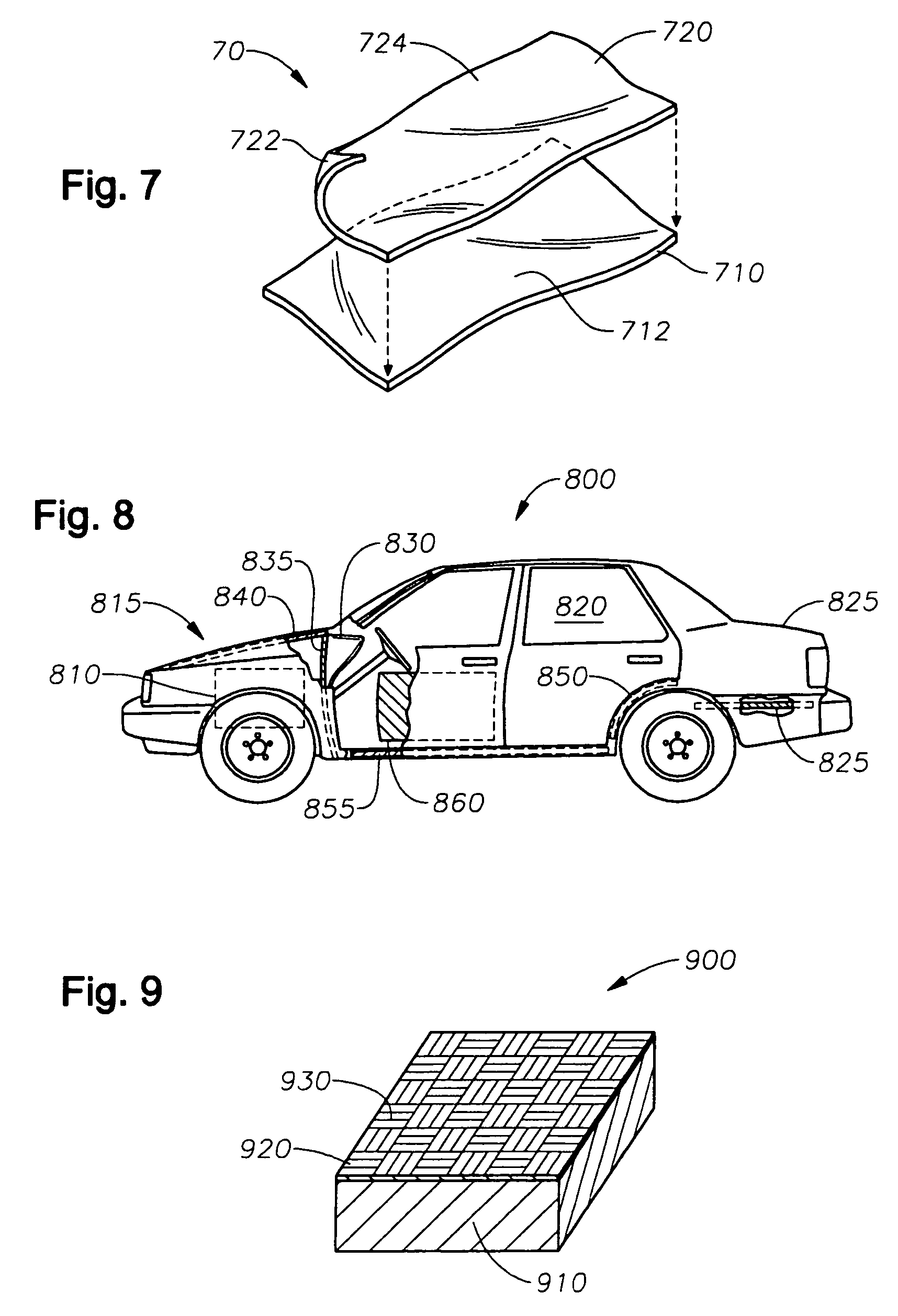

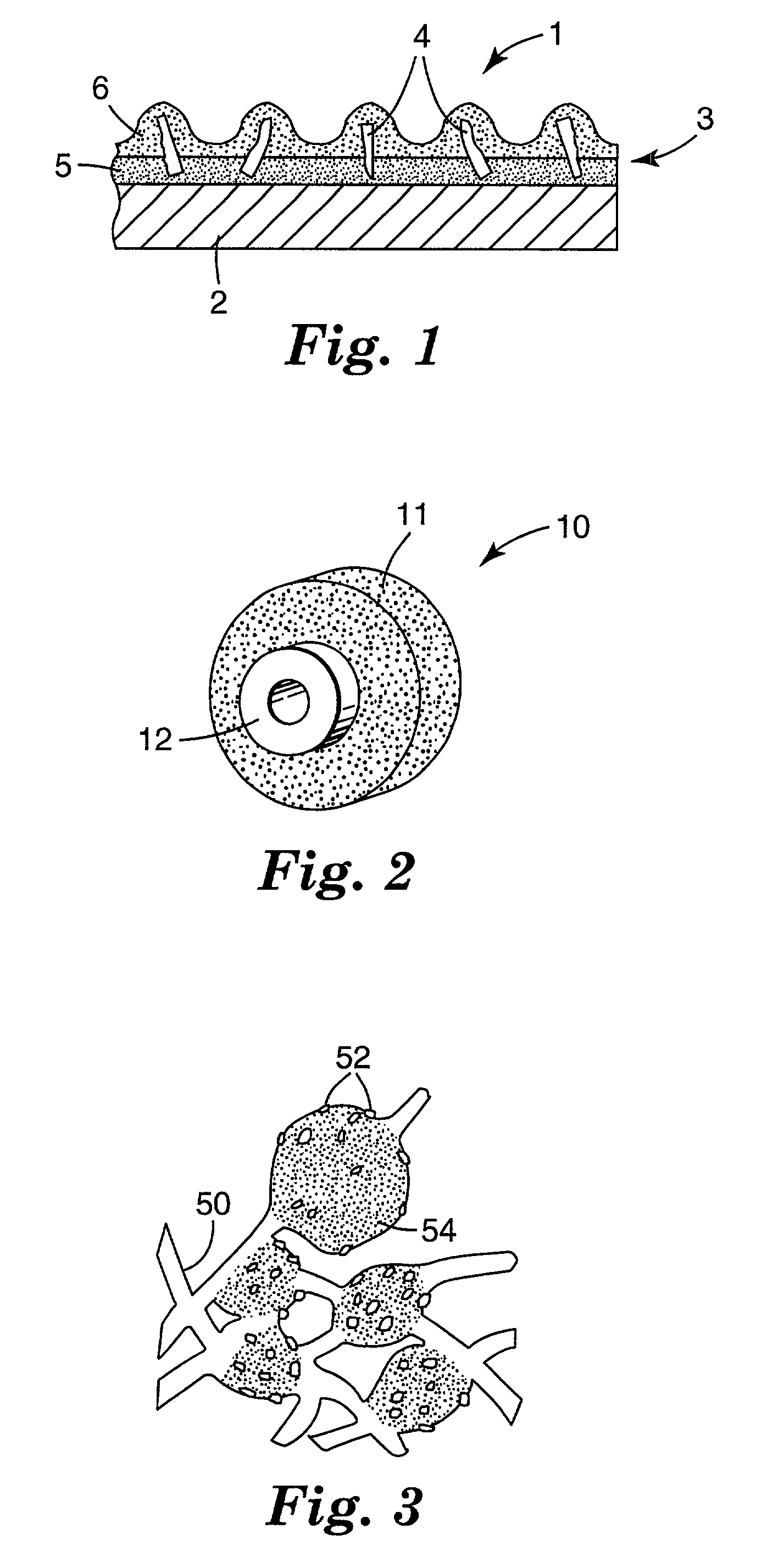

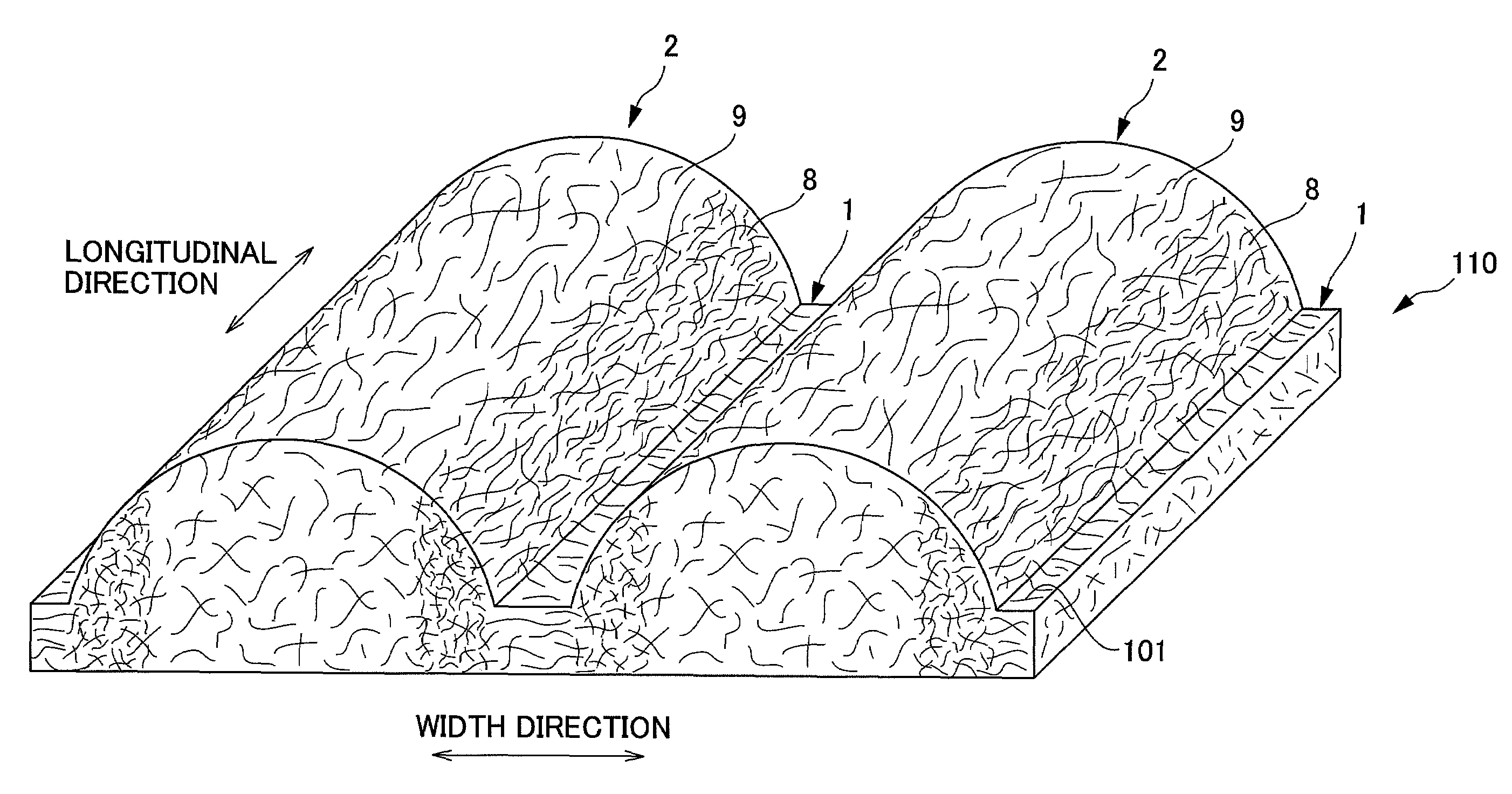

Ultra-thin absorbing sheet body, disposable absorbent article provided with ultra-thin absorbing sheet body and production device for ultra-thin absorbing sheet body

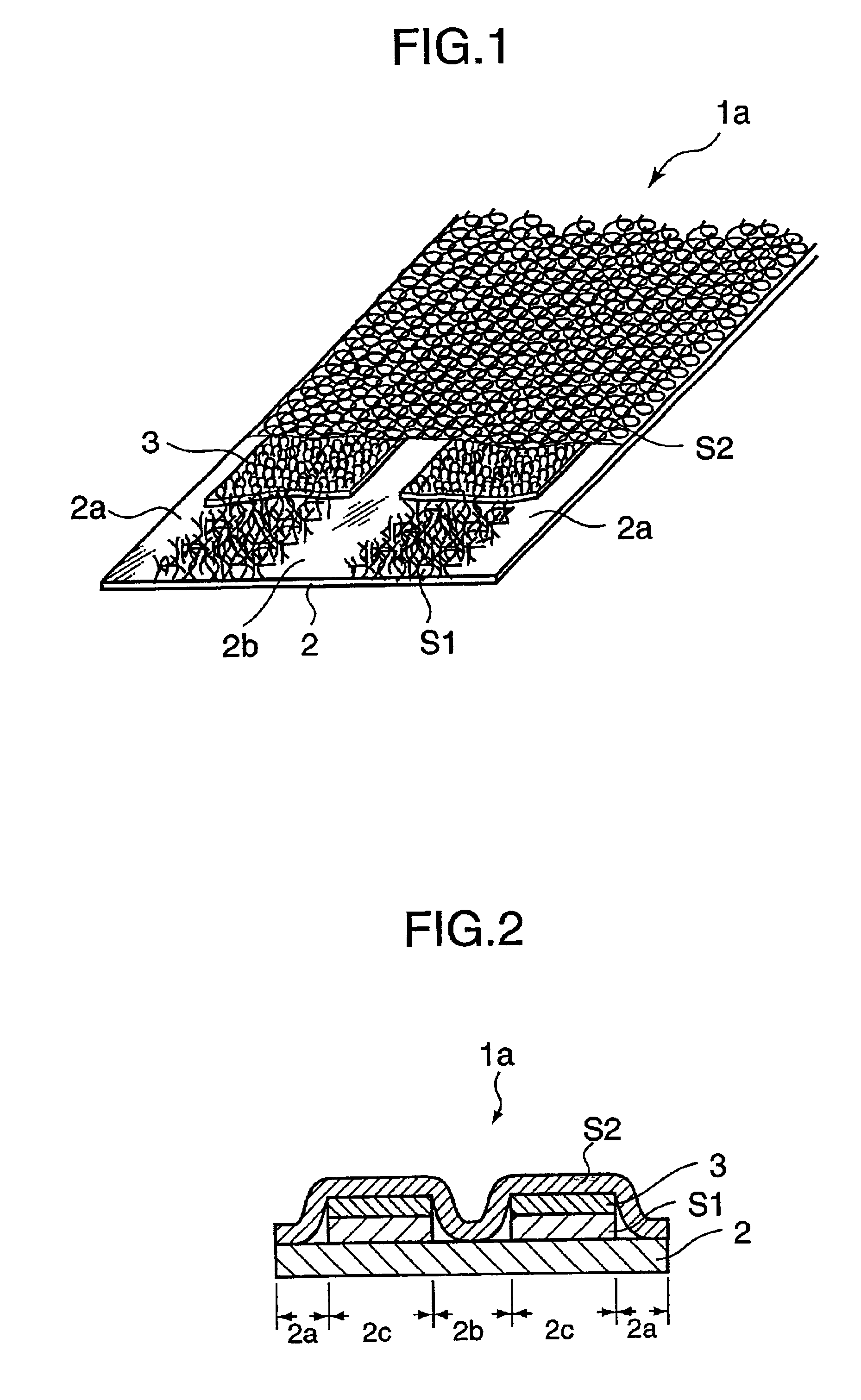

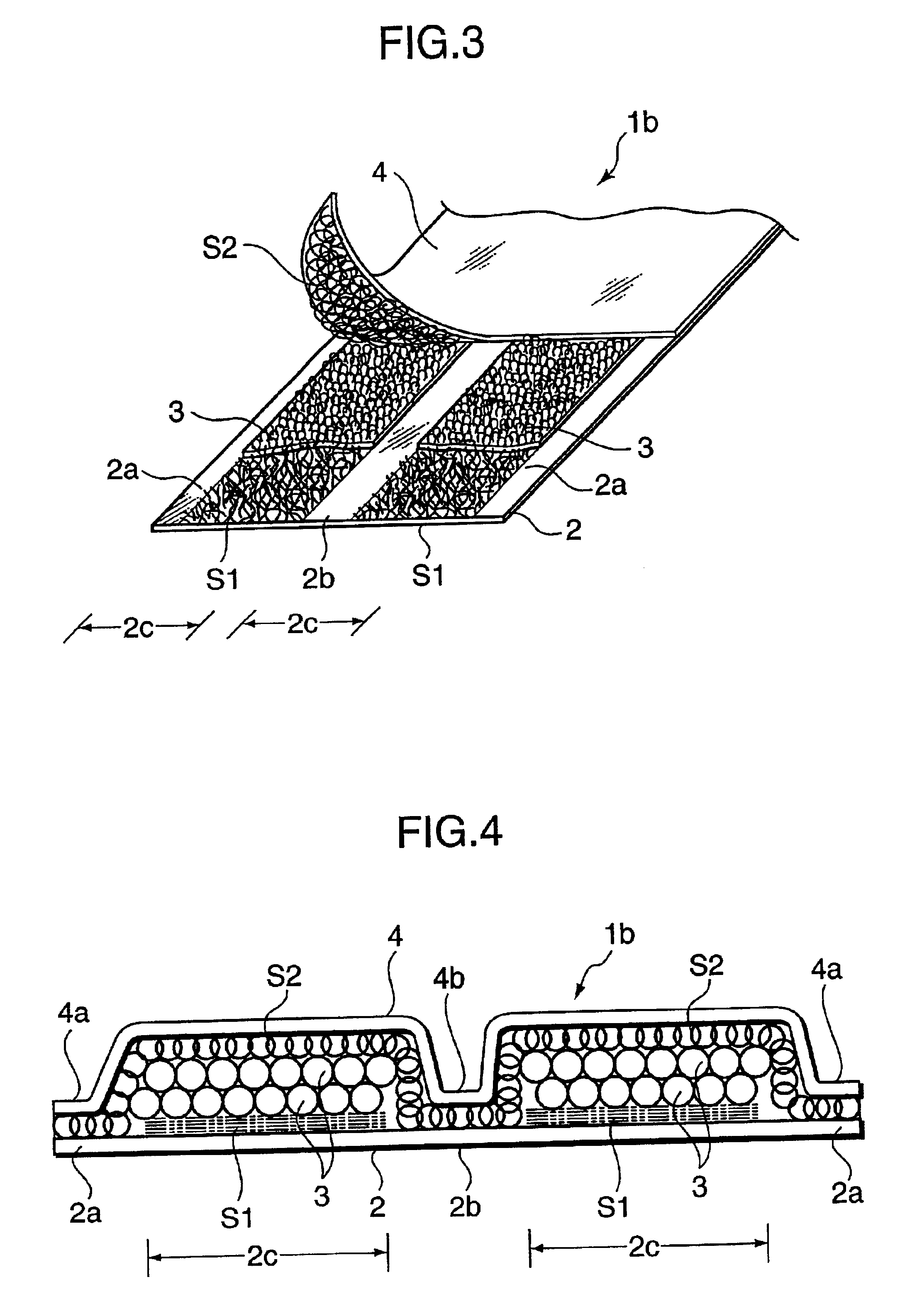

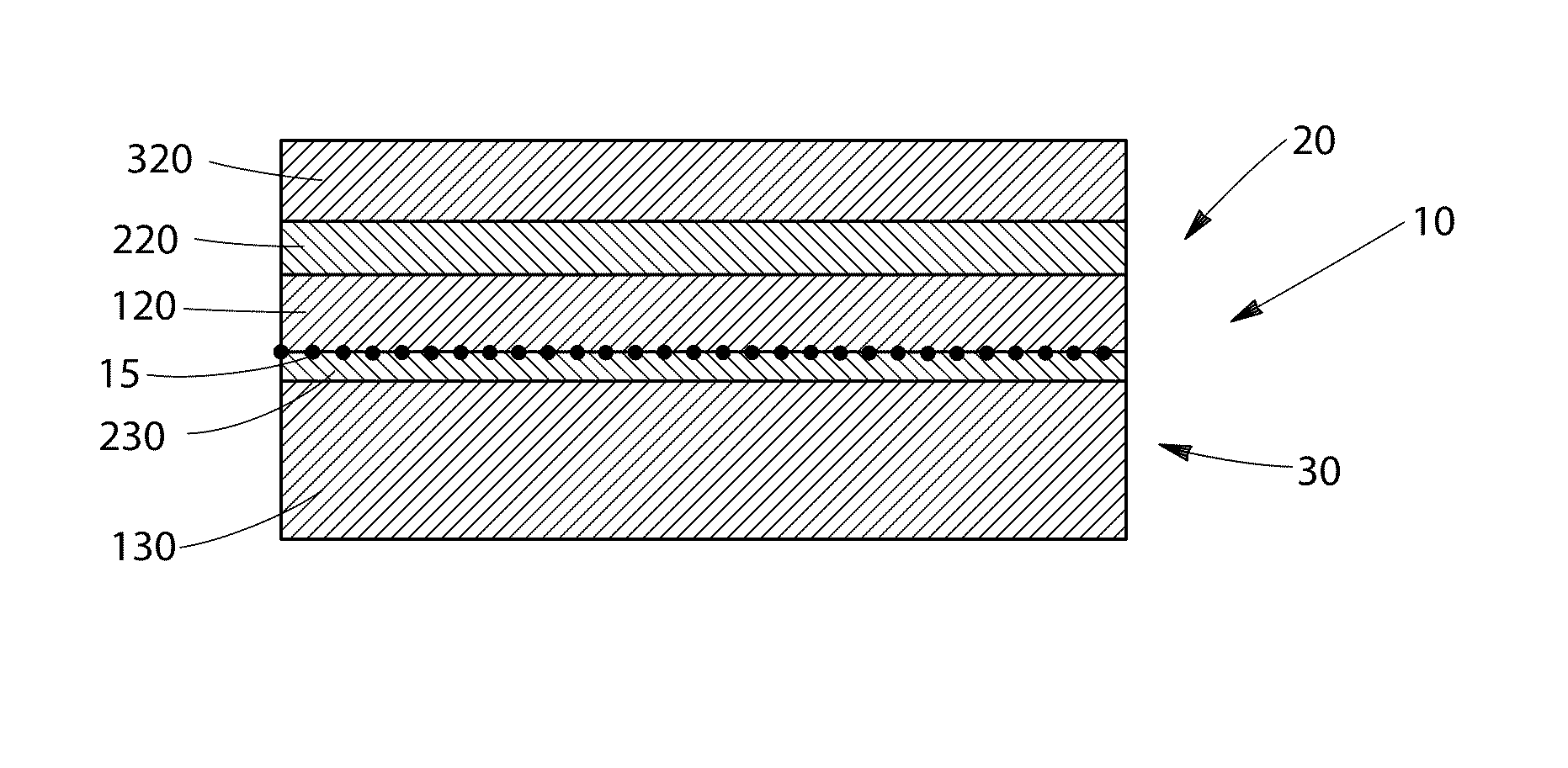

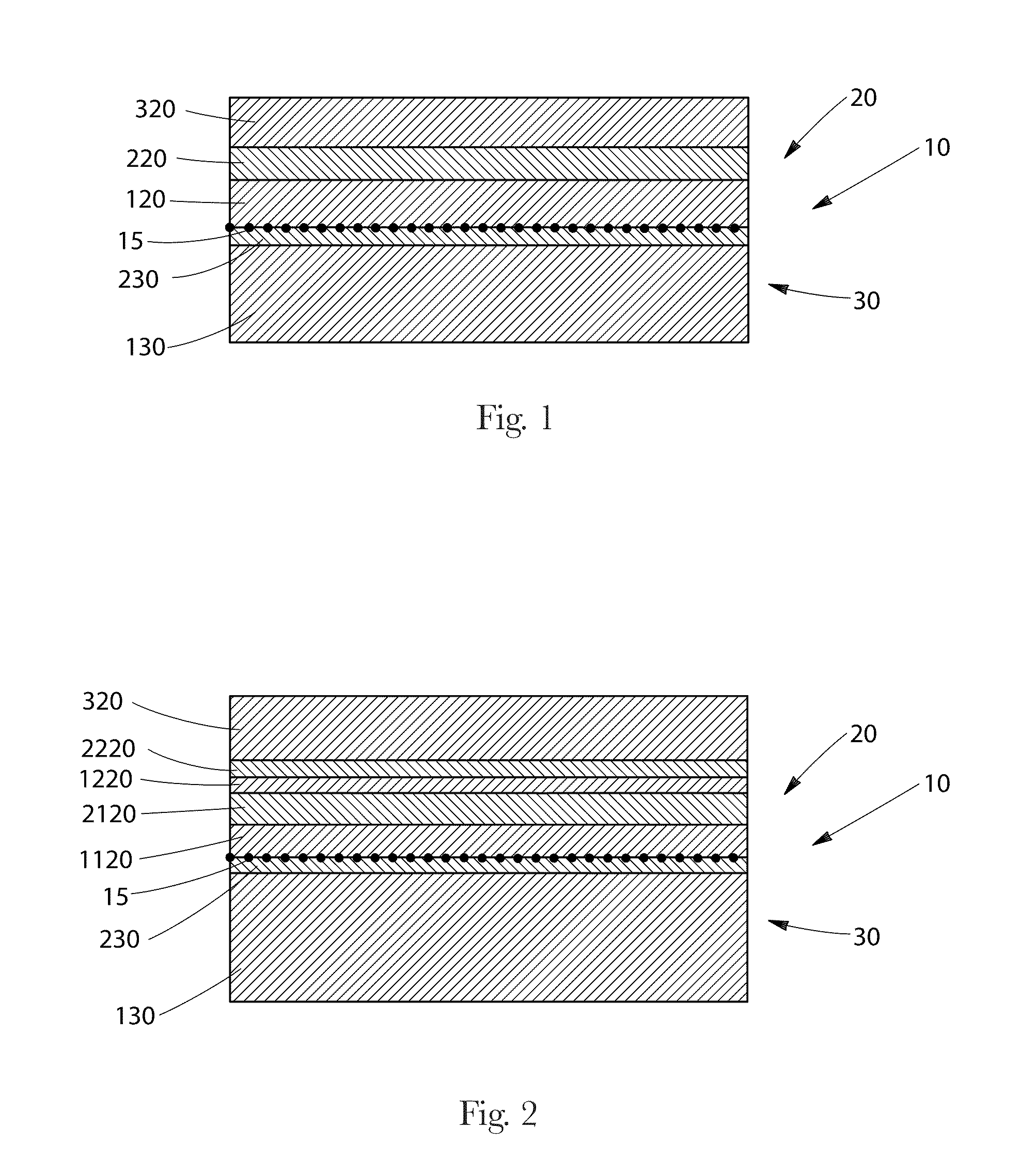

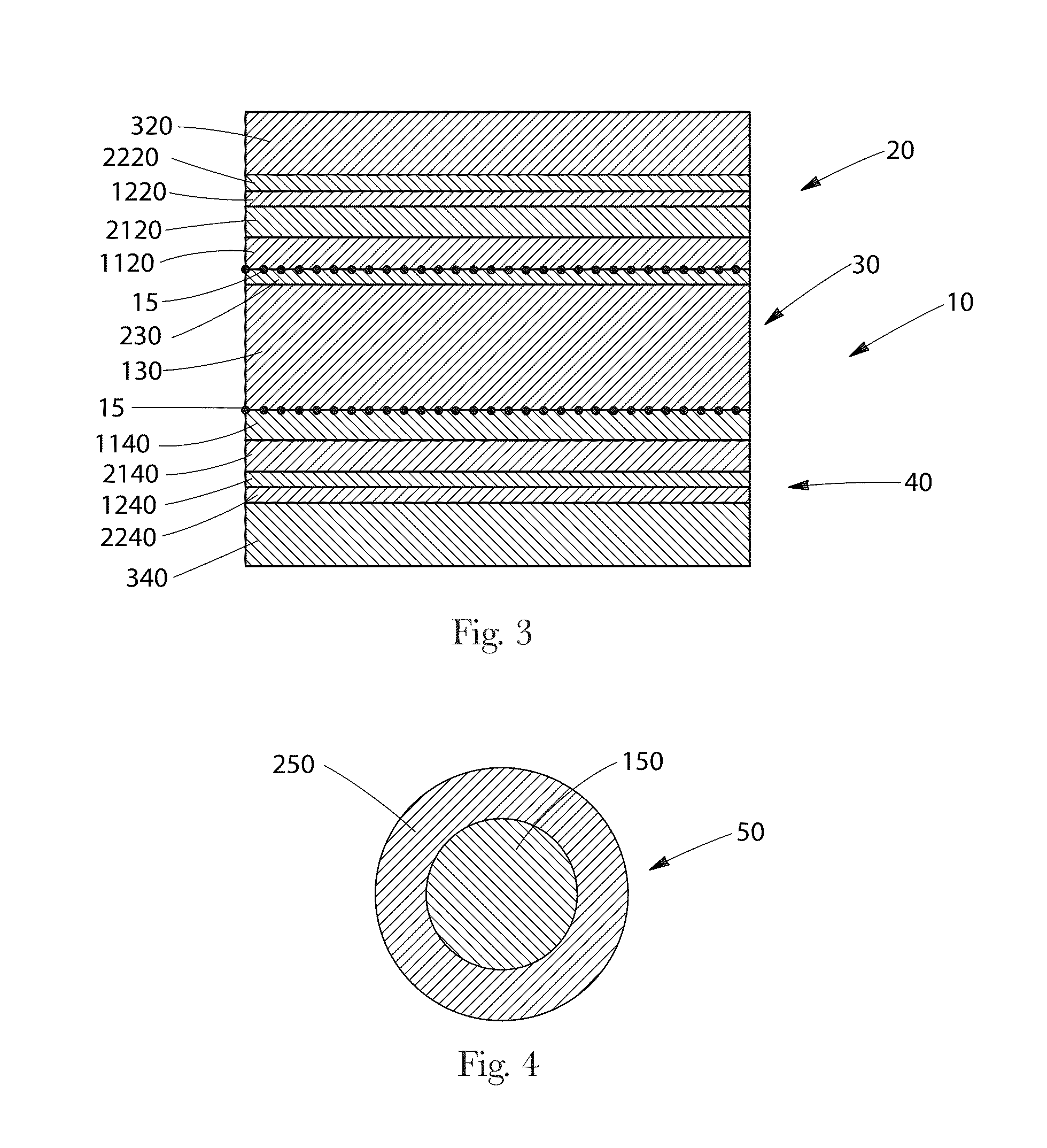

In an ultra-thin absorbent sheet member 1a in which an absorbent polymer powder 3 is adhered to one surface of a first nonwoven fabric 2 by a hotmelt adhesive such that absorbent polymer powder present areas 2c and absorbent polymer powder absent areas 2a, 2b exist; the absorbent polymer powder absent areas are present at opposite widthwise ends (2a) of the ultra-thin absorbent sheet member and at least one position (2b) between the opposite ends; the absorbent polymer powder 3 is bonded to the first nonwoven fabric 2 by first hotmelt adhesive layers S1 formed on an upper side of the first nonwoven fabric 2 and on a lower side of the absorbent polymer powder 3 and a second hotmelt adhesive layer S2 formed to cover upper sides of the absorbent polymer powder present areas 2c and the absorbent polymer powder absent areas 2a, 2b; and the first hotmelt adhesive layer S1 and the second hotmelt adhesive layer S2 are both made of an aggregate of linear hotmelt adhesive pieces.

Owner:TOOYOO EIZAI

Absorbent articles comprising hydrophilic nonwoven fabrics

InactiveUS7521587B2Hydrophilic lastingIncrease surface tensionFibre treatmentSynthetic resin layered productsPolymer scienceHydrophile

The present invention relates to absorbent articles comprising nonwoven fabrics, which are made hydrophilic by polymers chemically bonded to the surface of the nonwoven fabrics.Moreover, the invention relates to a process for making hydrophilic fibers, which can be formed into a nonwoven fabric.

Owner:THE PROCTER & GAMBLE COMPANY

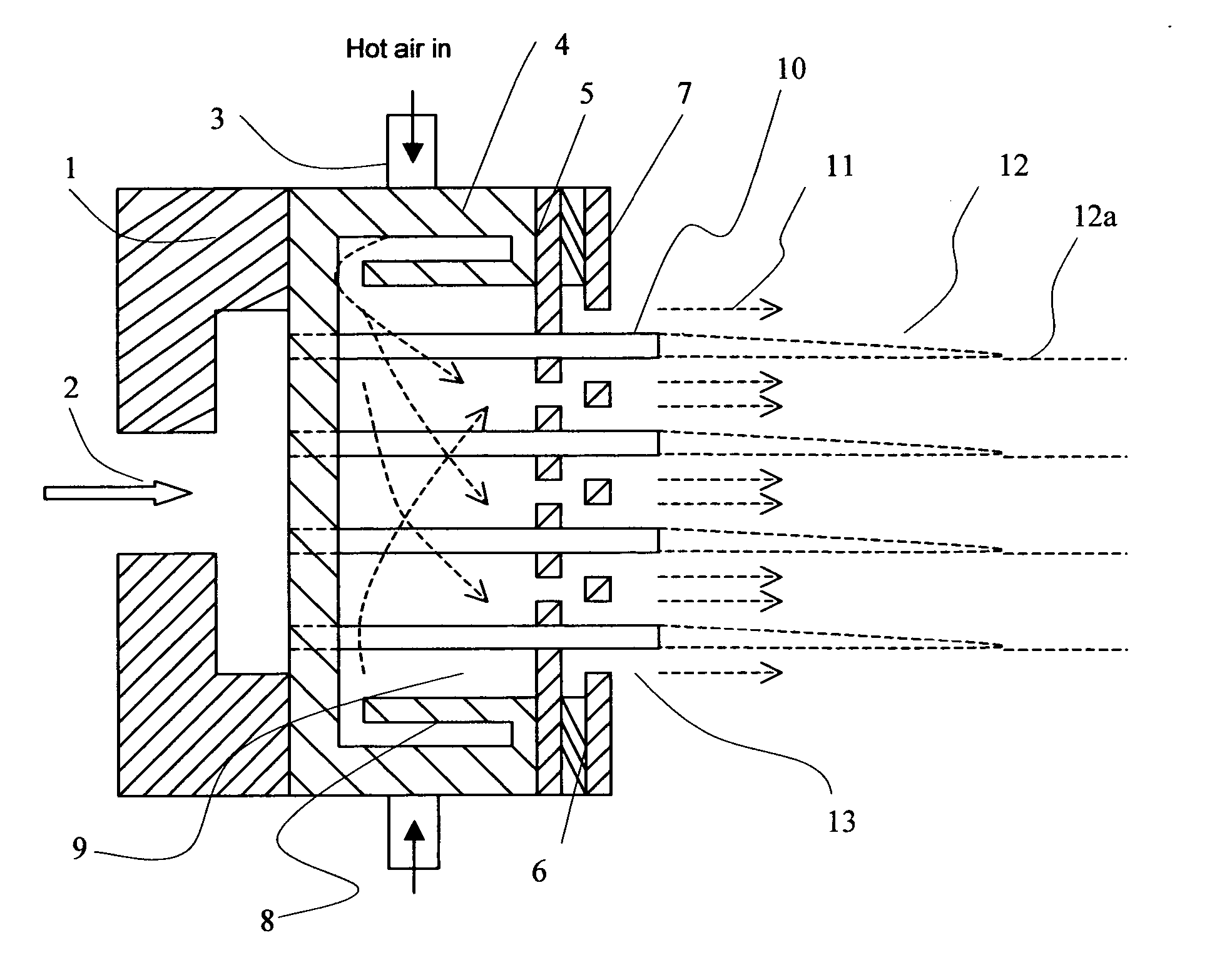

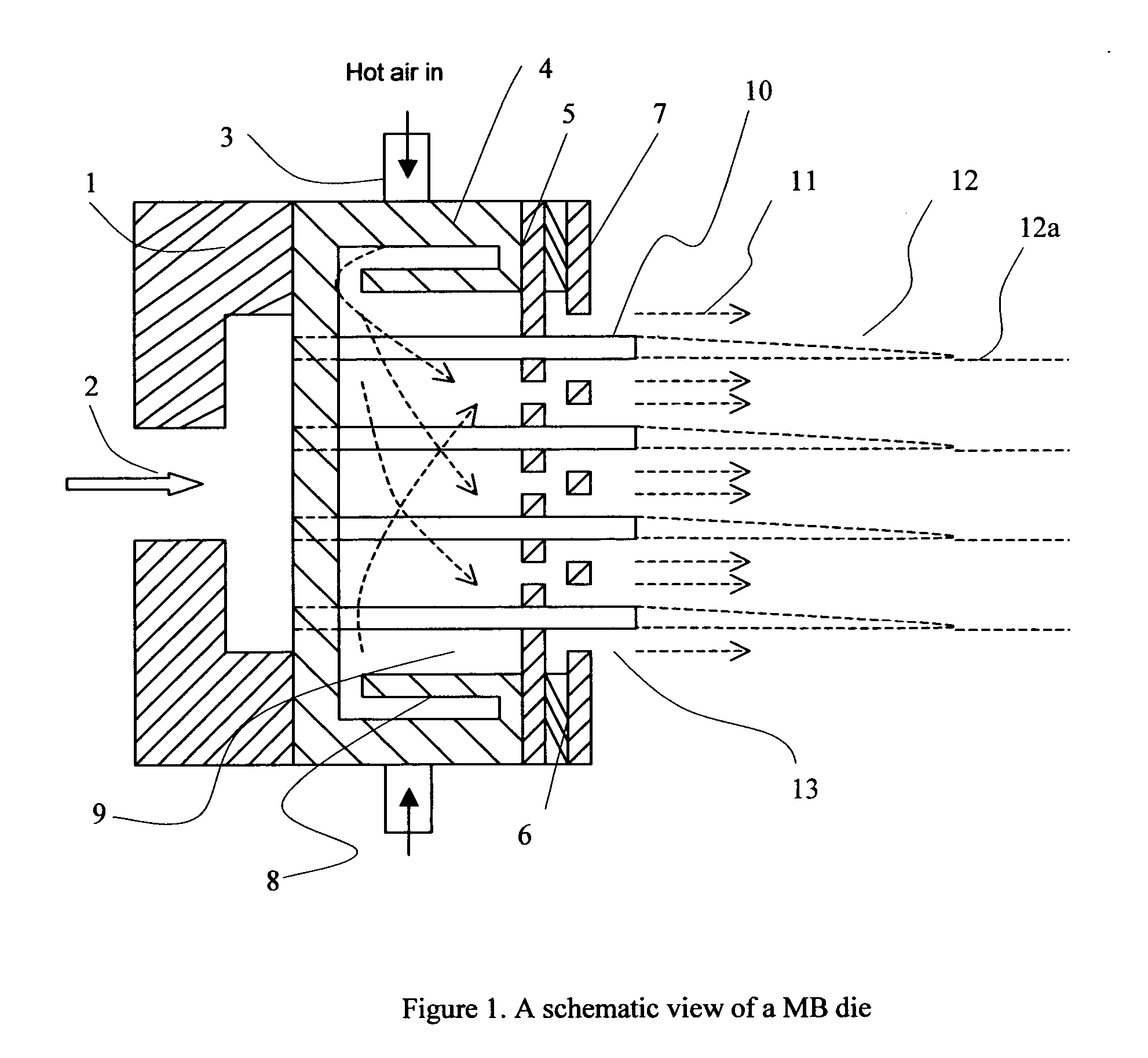

Process for forming micro-fiber cellulosic nonwoven webs from a cellulose solution by melt blown technology and the products made thereby

InactiveUS20050056956A1Artificial filament washing/dryingLoose filtering material filtersNon solventEngineering

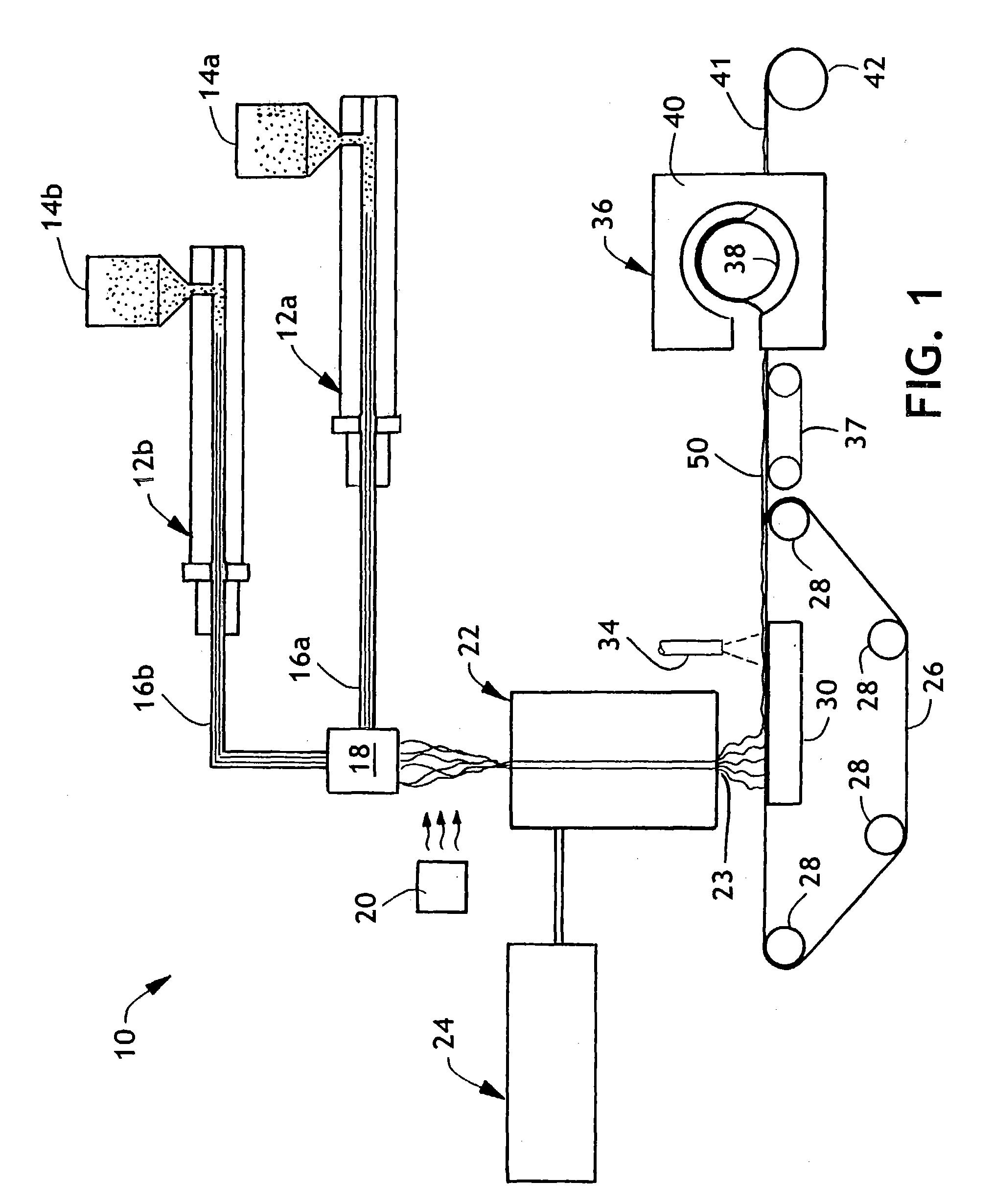

This invention relates to a process of melt blowing a cellulose solution through a concentric melt blown die with multiple rows of spinning nozzles to form cellulosic microfiber webs with different web structures. The process comprises the steps of (a) extruding a cellulose solution (dope) through a melt blown spinneret with multiple rows of spinning nozzles; (b) drawing each individual extrudate filament to fine fiber diameter by its own air jet; (c) coagulating and entangling the fine fibers with a series of pressured hydro needling jets of recycling solution of the mixture of cellulose solvent and non-solvent in the spin-line; (d) collecting the stream of microfibers, air and needling jets on a moving collecting surface to form cellulosic fiber web; (e) hydro-entangling the said pre-bonded web downstream with at least one set of hydro needling jets of recycling solvent / non-solvent solution for forming well bonded nonwoven web; (f) regenerating the fine fibers in at least one bath for at least 5 seconds; (g) further regenerating and washing the fine fibers in another bath for at least 5 seconds; (h) pinching the well bonded melt blown cellulosic nonwoven with pressure rollers to remove major portions of the non-solvent; (i) drying the nonwoven web by heat, or vacuum or both, and (j) winding the nonwoven web into rolls.

Owner:BIAX FIBERFILM CORP

Nonwovens produced from multicomponent fibers

InactiveUS20080311815A1Reduce blockingReduce fusionNon-fibrous pulp additionNatural cellulose pulp/paperPolymer scienceSlurry

A water non-dispersible polymer microfiber is provided comprising at least one water non-dispersible polymer wherein the water non-dispersible polymer microfiber has an equivalent diameter of less than 5 microns and length of less than 25 millimeters. A process for producing water non-dispersible polymer microfibers is also provided, the process comprising: a) cutting a multicomponent fiber into cut multicomponent fibers; b) contacting a fiber-containing feedstock with water to produce a fiber mix slurry; wherein the fiber-containing feedstock comprises cut multicomponent fibers; c) heating the fiber mix slurry to produce a heated fiber mix slurry; d) optionally, mixing the fiber mix slurry in a shearing zone; e) removing at least a portion of the sulfopolyester from the multicomponent fiber to produce a slurry mixture comprising a sulfopolyester dispersion and water non-dispersible polymer microfibers; and f) separating the water non-dispersible polymer microfibers from the slurry mixture. A process for producing a nonwoven article is also provided.

Owner:EASTMAN CHEM CO

Hydraulically-Formed Nonwoven Sheet with Microfibers

InactiveUS20100272938A1Non-fibrous pulp additionNatural cellulose pulp/paperNonwoven fabricMedical device

In a first embodiment, a hydraulically-formed nonwoven sheet, a package comprising such sheet, a method of packaging a medical device using a package with such sheet and a method of manufacturing such sheet are provided. This nonwoven sheet comprises first and second non-cellulosic polymeric fibers. The first non-cellulosic polymeric fibers have an average diameter less than about 3.5 micron, an average cut length less than about 3 millimeters and an average aspect ratio of about 400 to about 2000; the second non-cellulosic polymeric fibers have an average diameter greater than about 3.5 micron and an average aspect ratio of about 400 to about 1000. In a second embodiment, a hydraulically-formed nonwoven sheet is provided. This nonwoven sheet comprises binding material, non-cellulosic polymeric fibers and cellulosic based materials. The non-cellulosic polymeric fibers have an average diameter less than about 3.5 micron, an average cut length less than about 3 millimeters and an average aspect ratio of about 400 to about 2000. The second nonwoven sheet has a bacterial filtration efficiency of at least about 98%.

Owner:BEMIS COMPANY INC

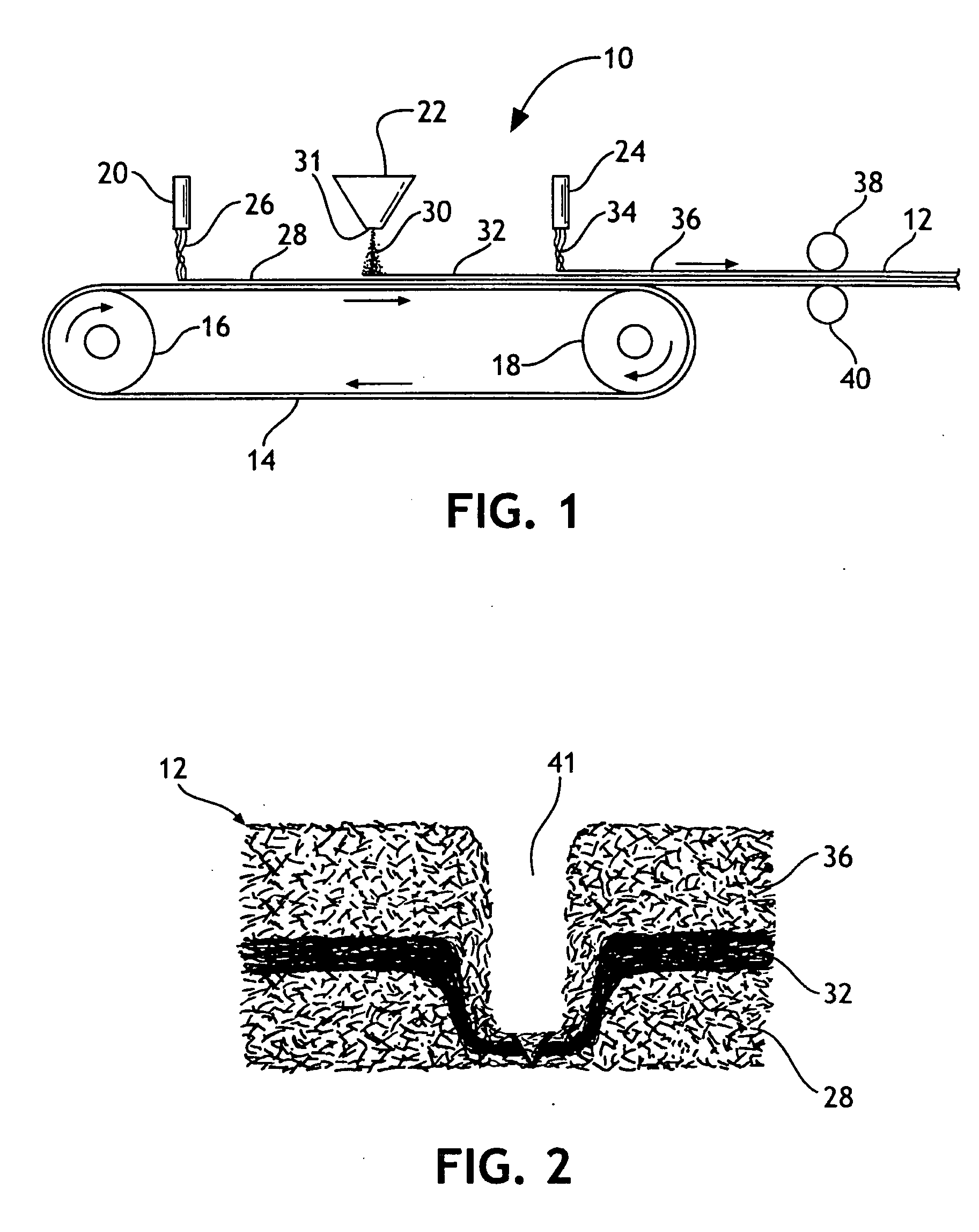

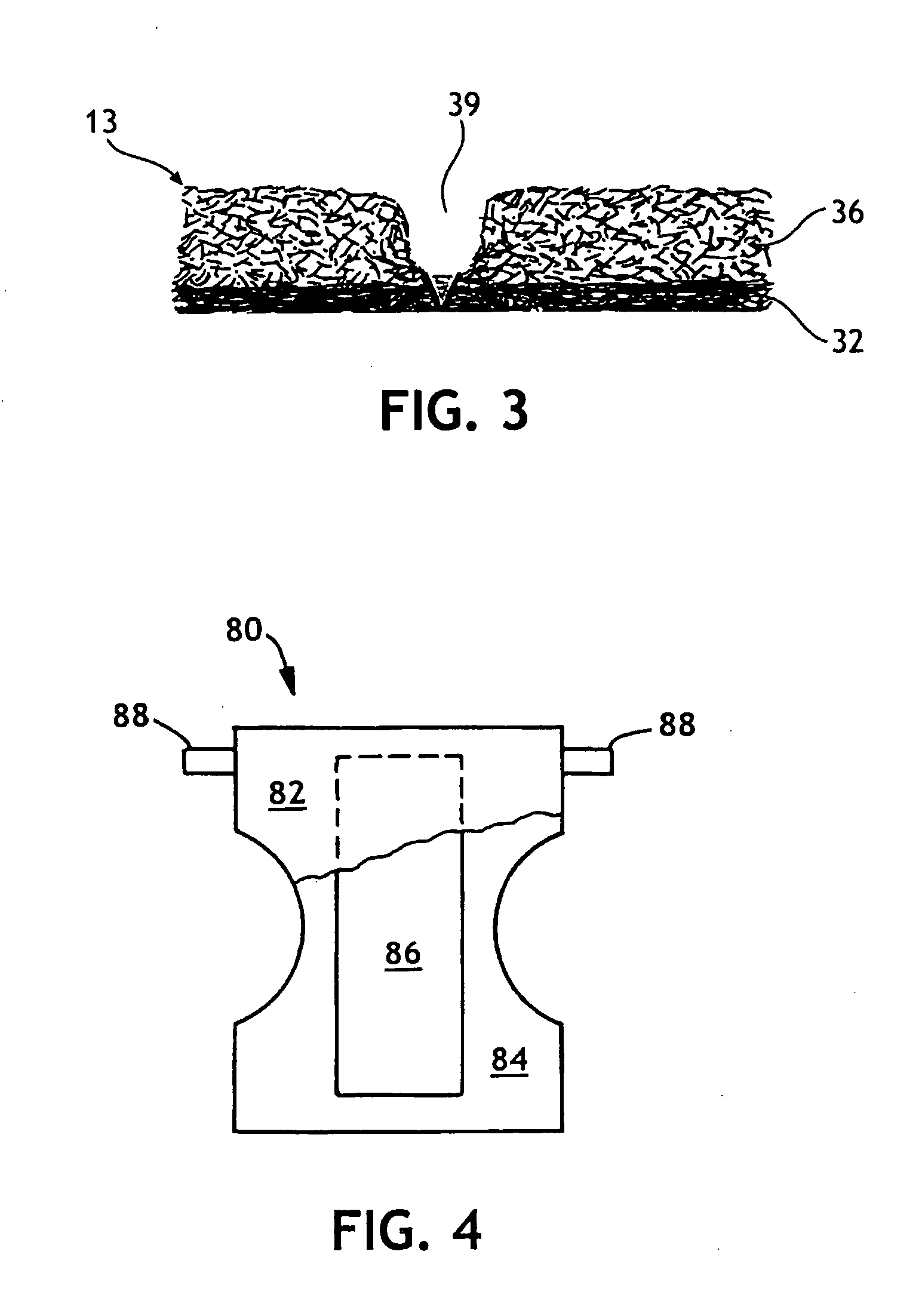

Nonwoven fabric liner and diaper including a nonwoven laminate liner

The present invention provides a bodyside liner for a disposable absorbent article that is a nonwoven fabric laminate that includes a thin layer of fine fibers that has a basis weight of less than 2.5 grams per square meter. The present invention also provides disposable absorbent garments, such as diapers, that in such a nonwoven fabric laminate to reduce the migration of particles in absorbent garments.

Owner:KIMBERLY-CLARK WORLDWIDE INC

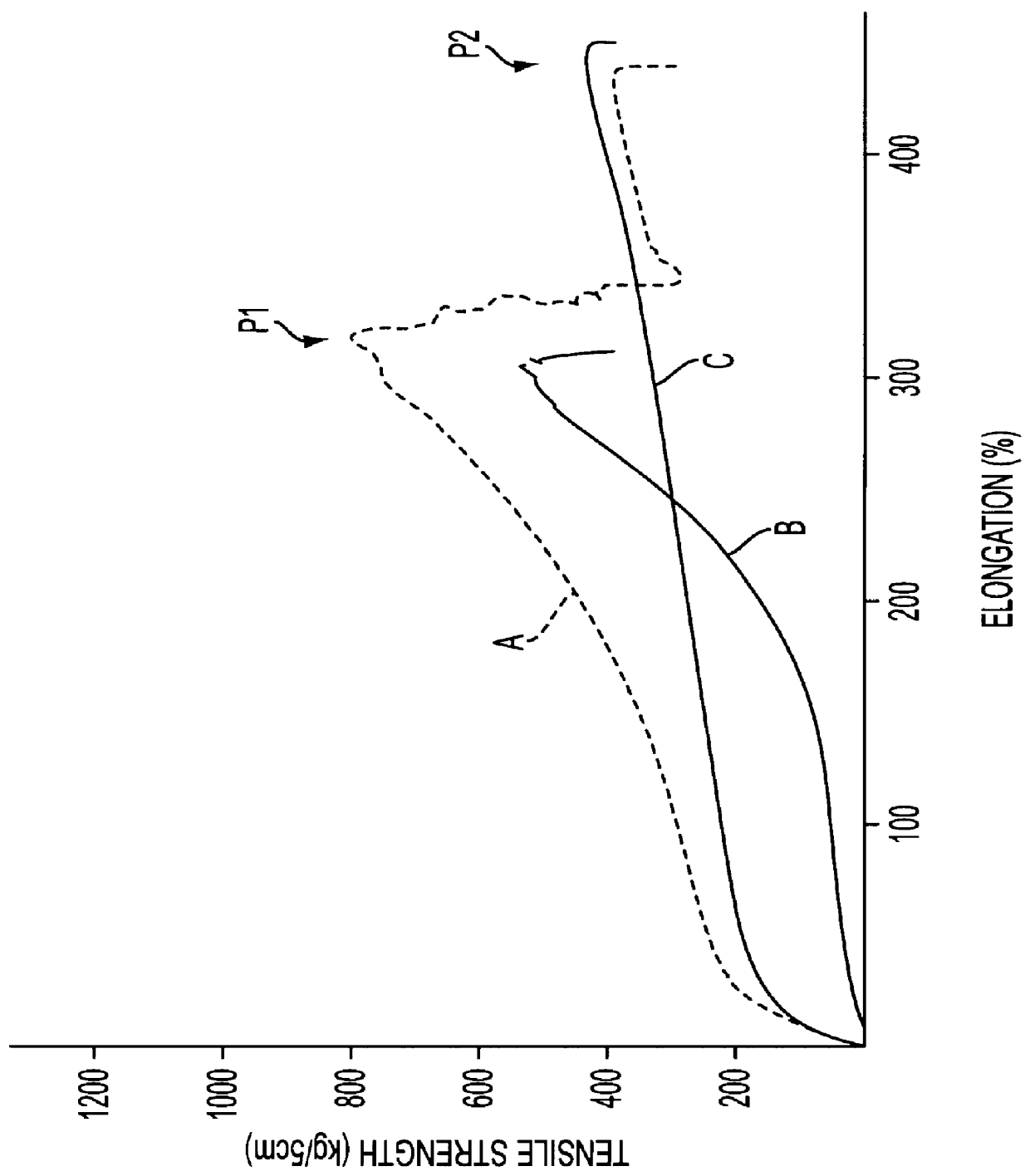

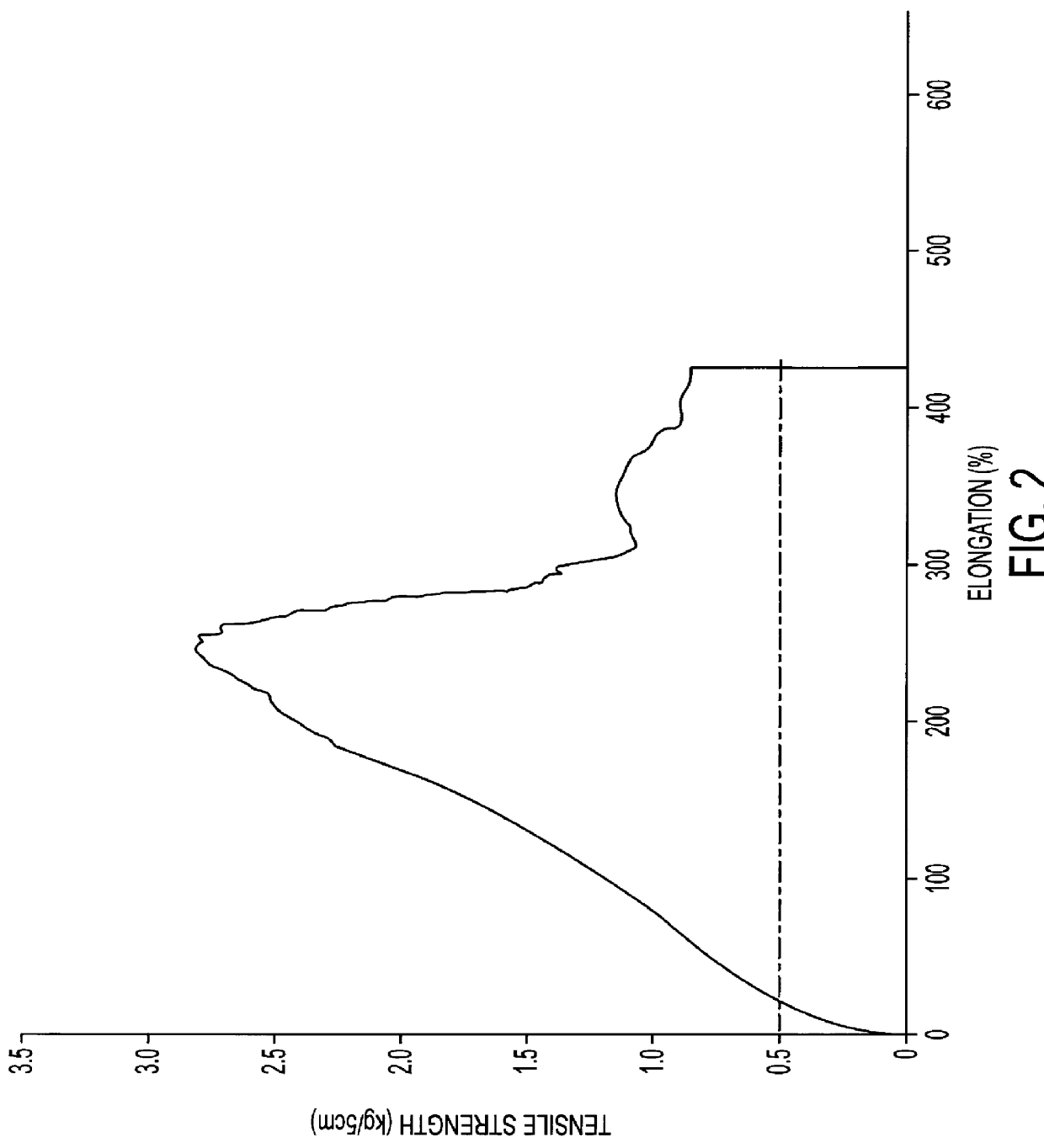

Composite elastic material having multistage elongation characteristics and method of manufacturing the same

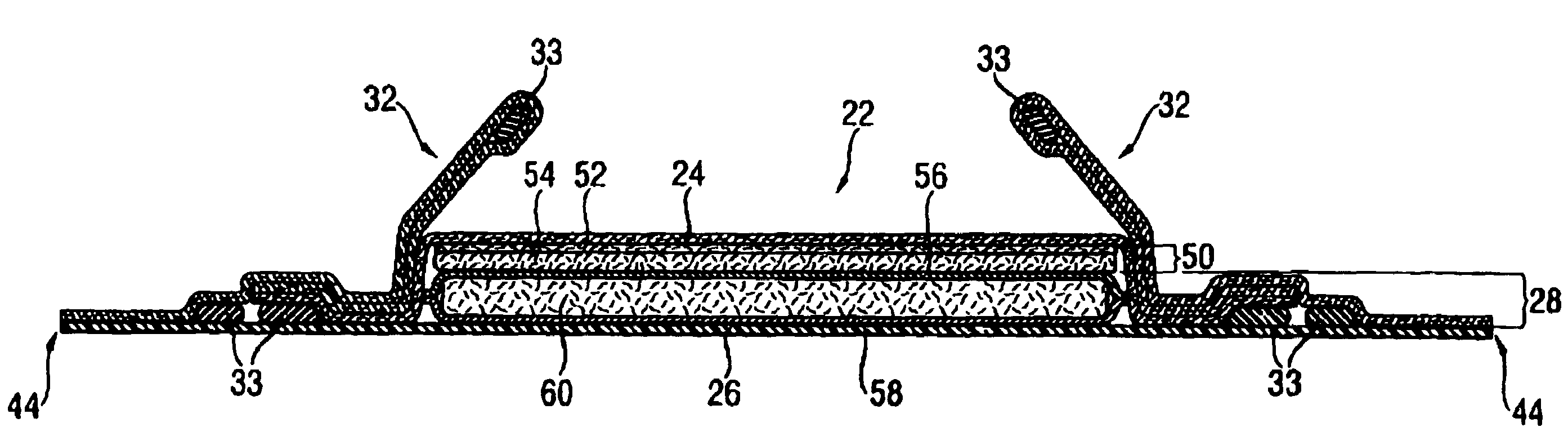

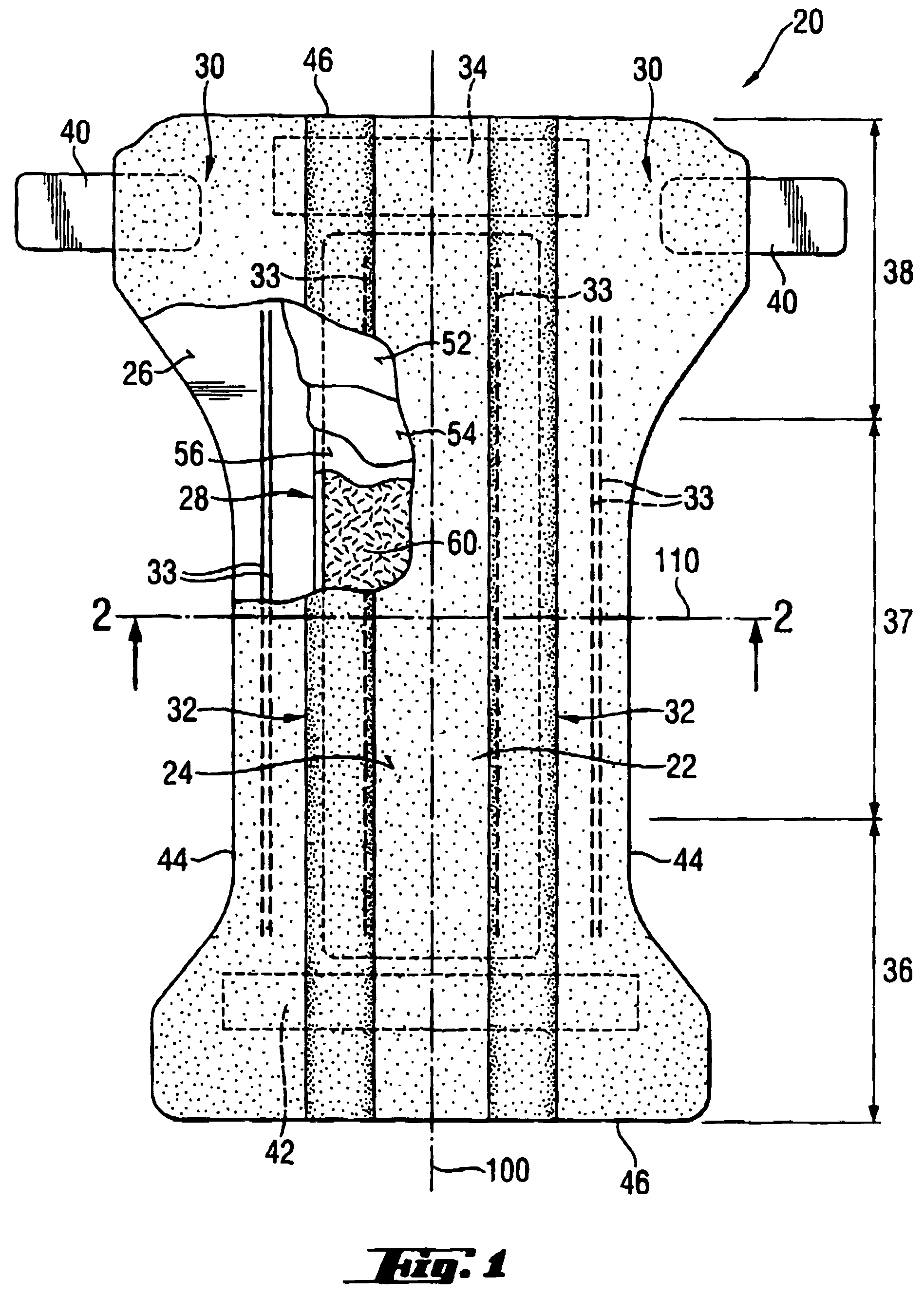

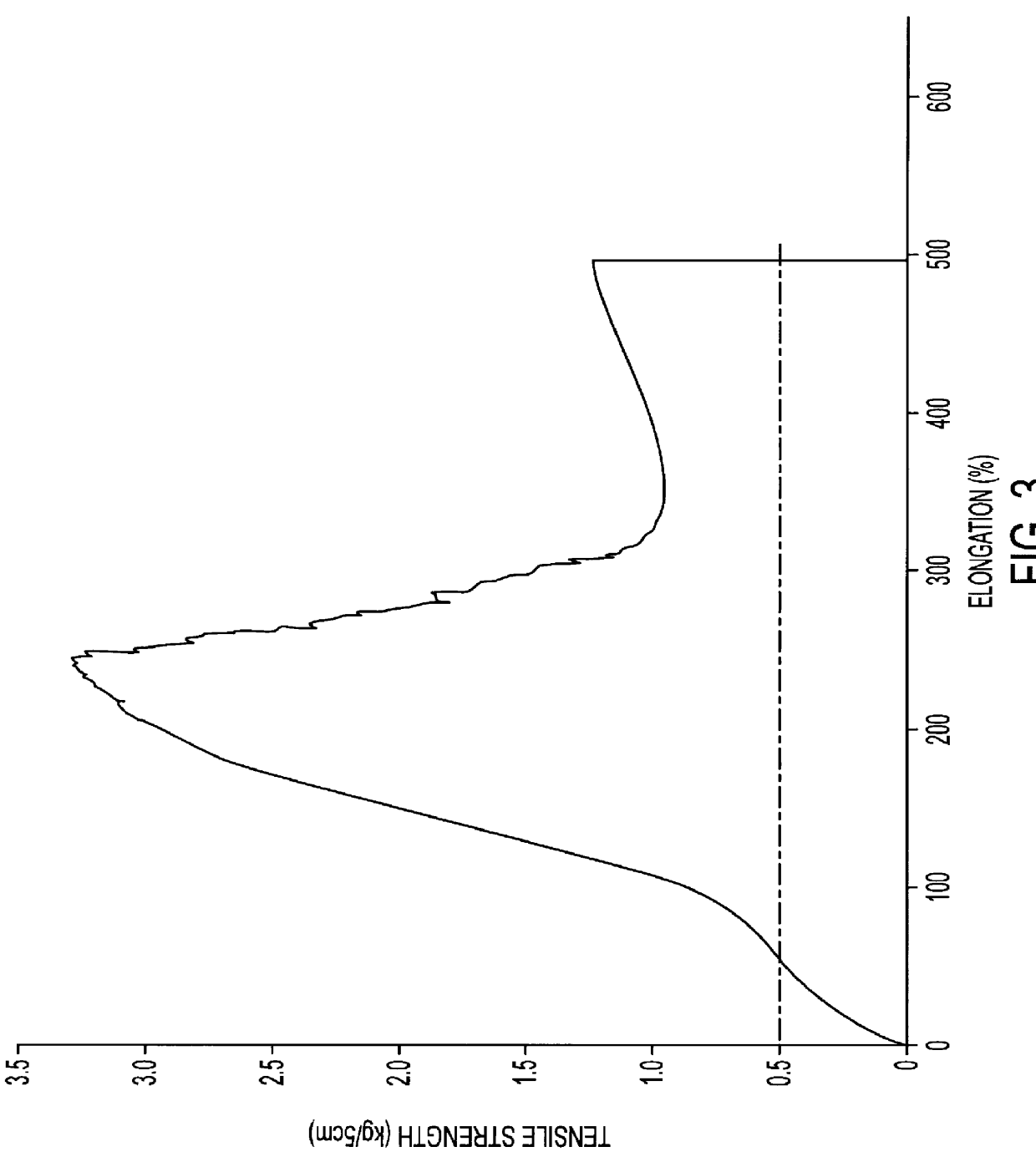

PCT No. PCT / JP96 / 00041 Sec. 371 Date Sep. 16, 1997 Sec. 102(e) Date Sep. 16, 1997 PCT Filed Jan. 12, 1996 PCT Pub. No. WO96 / 21760 PCT Pub. Date Jul. 18, 1996A composite elastic material comprises a non-woven fabric secured to an elastic member. The non-woven fabric is elastically stretchable by about 100% or more. The sheet-like elastic member has an elastic recovery of about 60% or more and a break-down elasticity of about 200% or more. The elastic member and the non-woven fabric are secured together at a plurality of points in the stretchable direction of the non-woven fabric. The composite elastic material has multiple-stage elongation characteristics including a first stress lowering point caused by changes in the structure of the non-woven fabric, and a second stress lowering point occurring at an elongation larger than that of the first stress lowering point, caused by the fracturing of the sheet-like elastic member. The elastic material clearly shows a break-down point when stretched, and increases the flexibility of designing various products.

Owner:PARAGON TRADE BRANDS

Lyocell nonwoven fabric

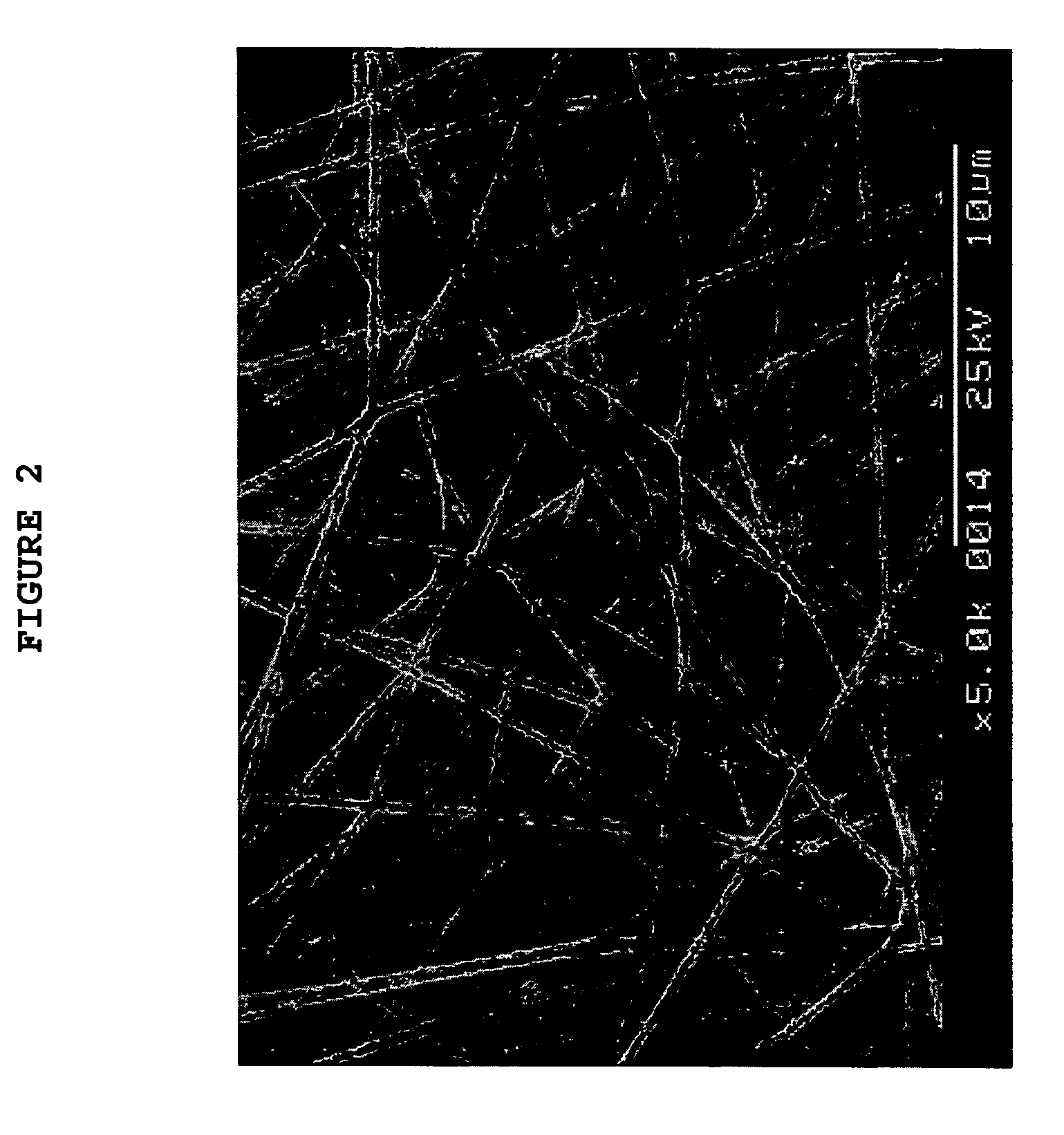

InactiveUS7067444B2Powerful solventLow tendency to fibrillatePulp properties modificationMonocomponent cellulose artificial filamentMelt blowingNonwoven fabric

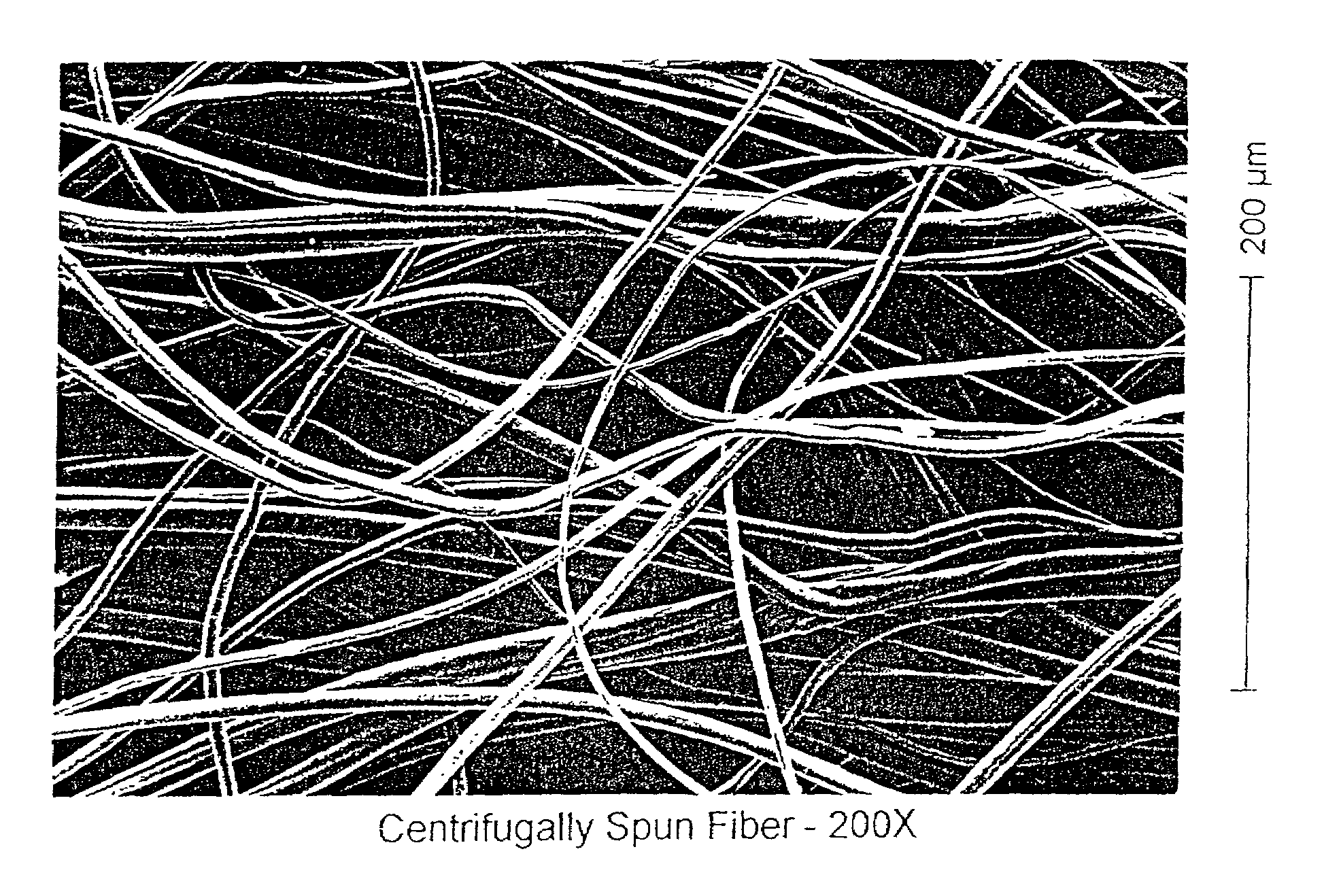

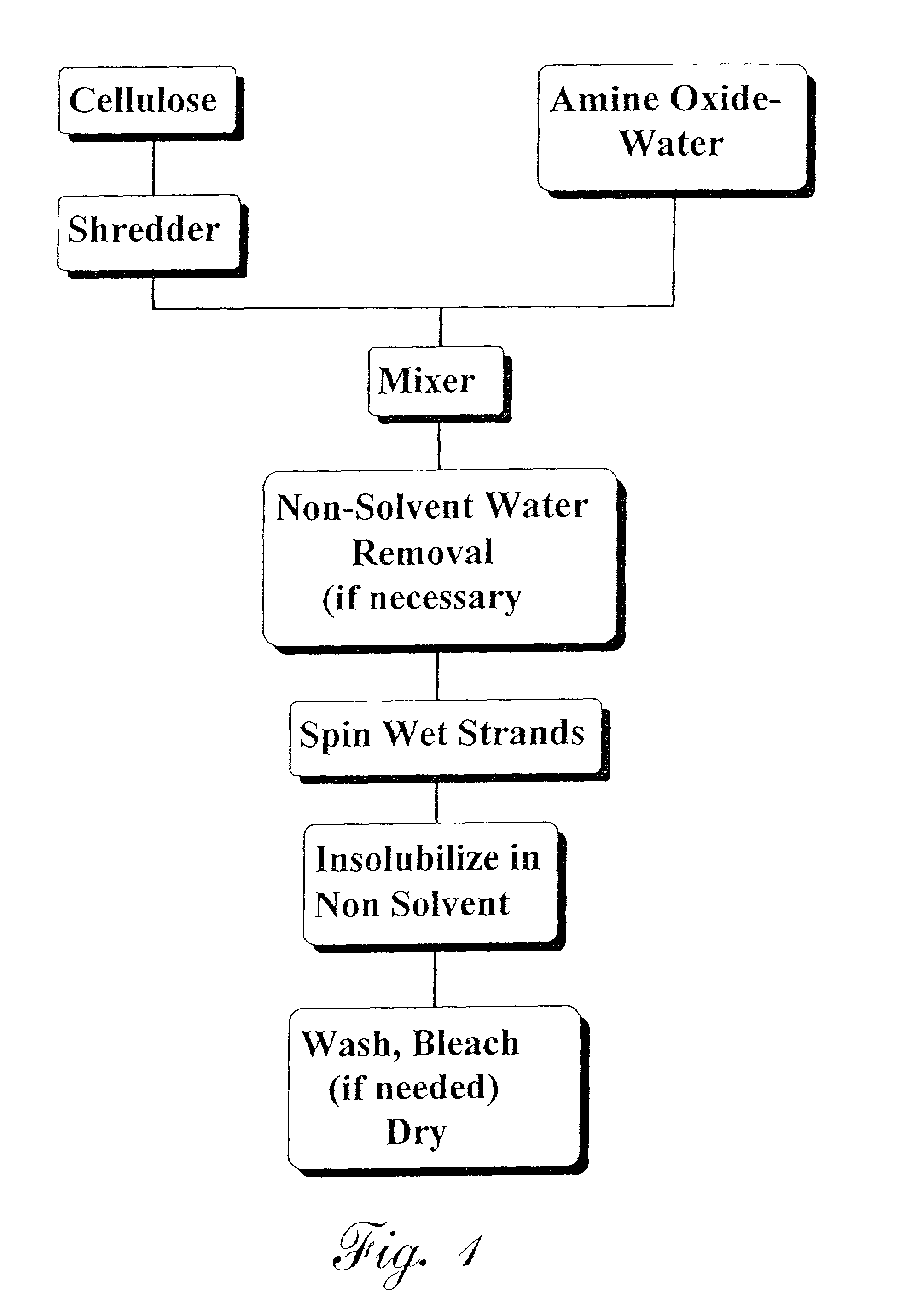

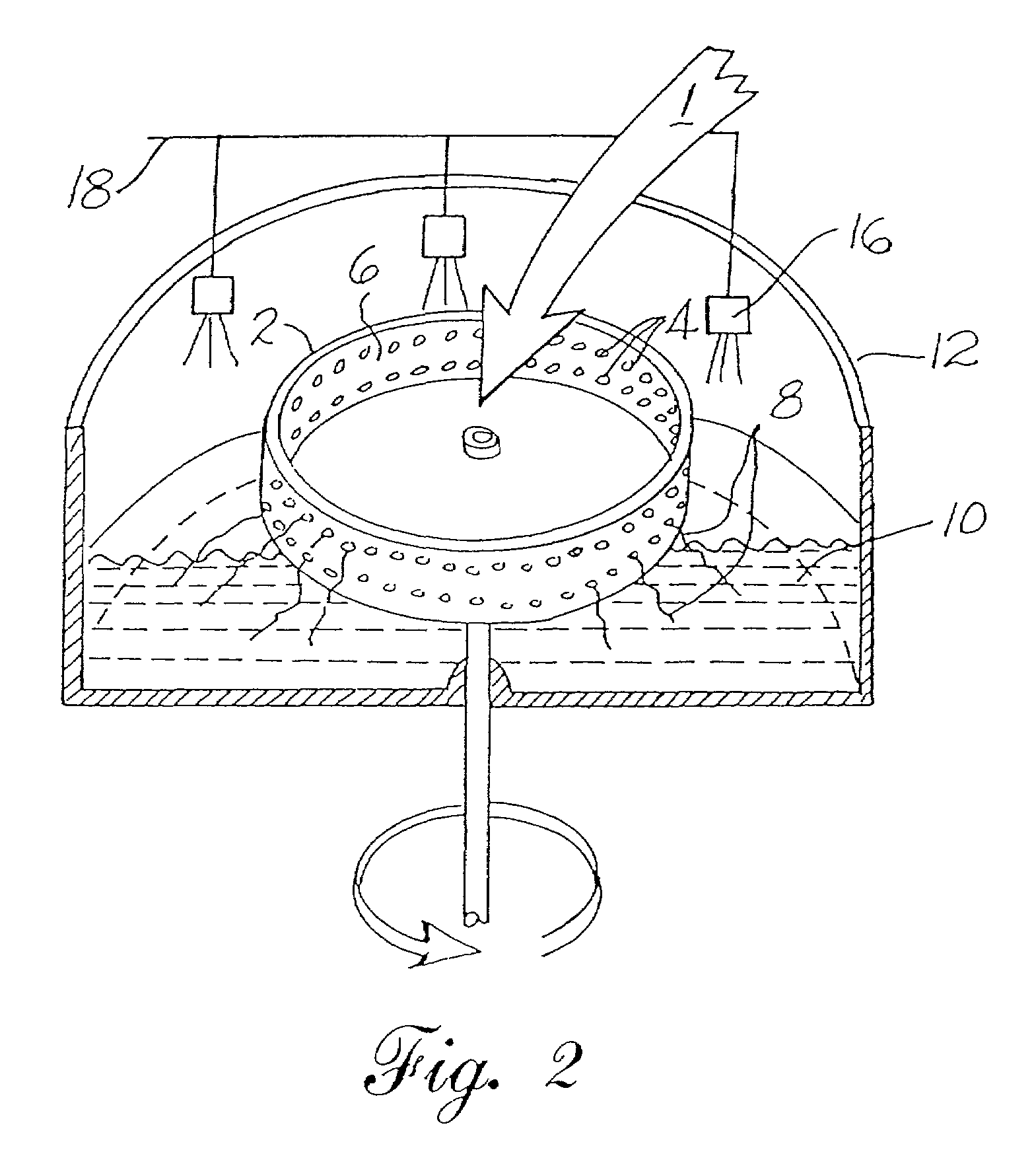

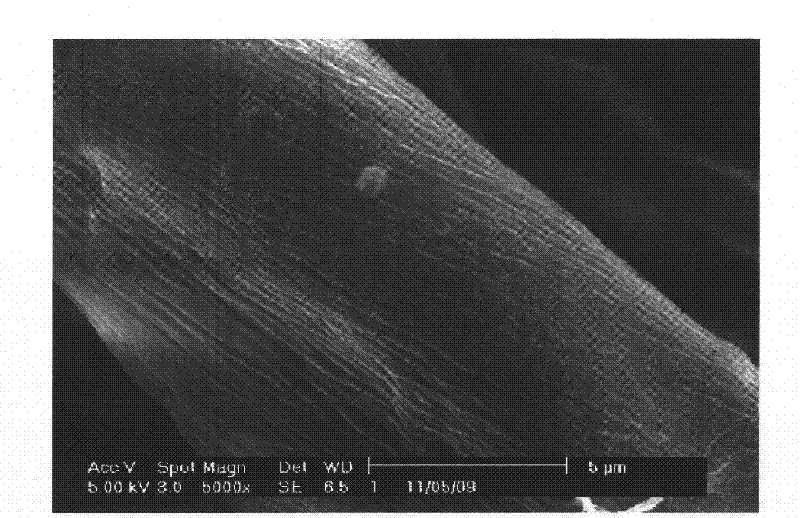

A lyocell nonwoven fabric having fibers characterized by pebbled surfaces and variable cross sections and diameters along the fibers and from fiber to fiber, is disclosed. The lyocell nonwoven fabric is produced by centrifugal spinning, melt blowing or spunbonding. The lyocell nonwoven fabric has fibers that can be made in the microdenier range with average weights as low as one denier or less. The lyocell nonwoven fabric has fibers with low gloss, a reduced tendency to fibrillate and have enhanced dye receptivity.

Owner:INT PAPER CO

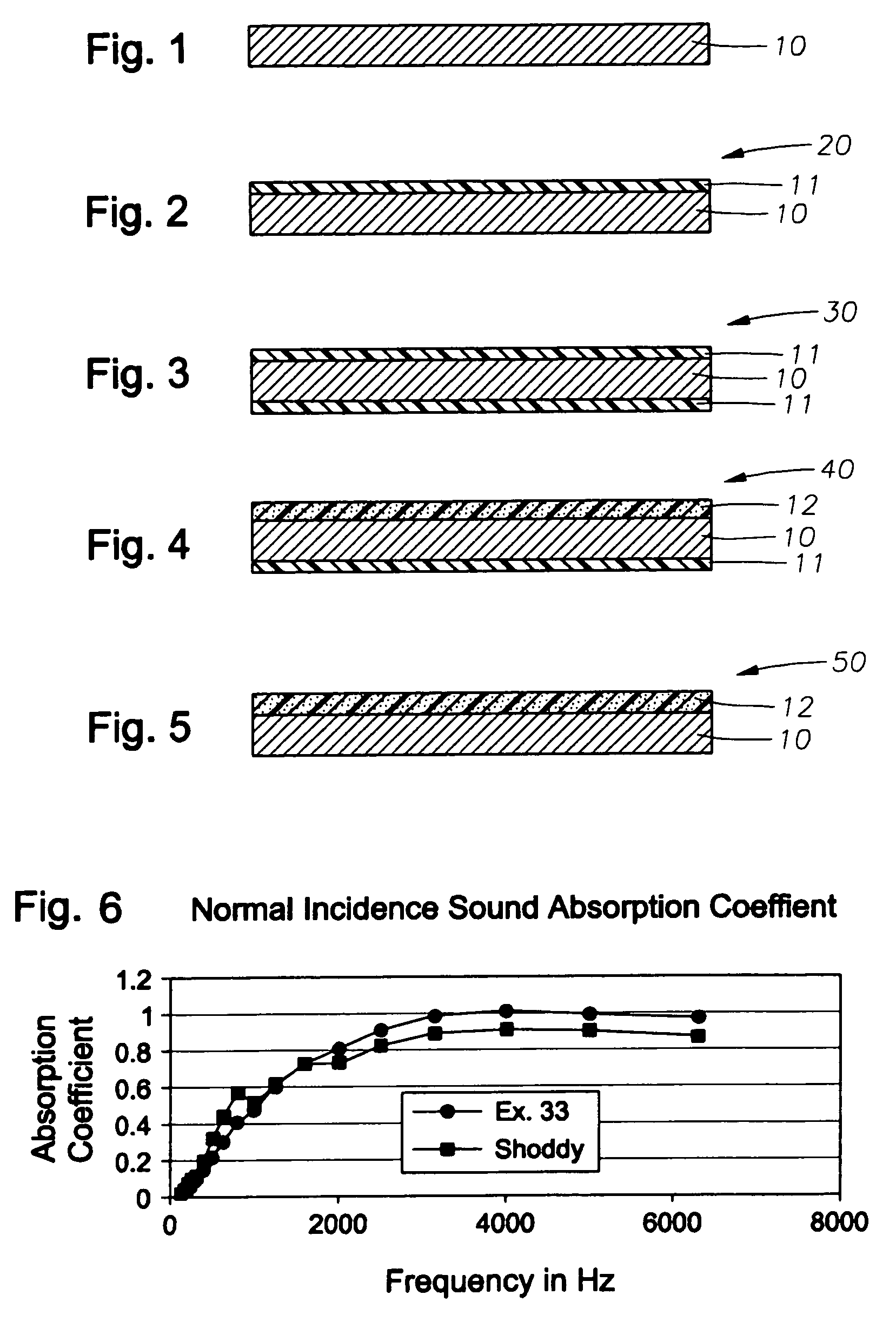

Nonwoven material for acoustic insulation, and process for manufacture

An improved acoustically and thermally insulating composite material suitable for use in structures such as buildings, appliances, and the interior passenger compartments and exterior components of automotive vehicles, comprising at least one airlaid fibrous layer of controlled density and composition and incorporating suitable binding agents and additives as needed to meet expectations for noise abatement, fire, and mildew resistance. Separately, an airlaid structure which provides a reduced, controlled airflow therethrough useful for acoustic insulation is provided, and which includes a woven or nonwoven scrim.

Owner:GLATFELTER CORP

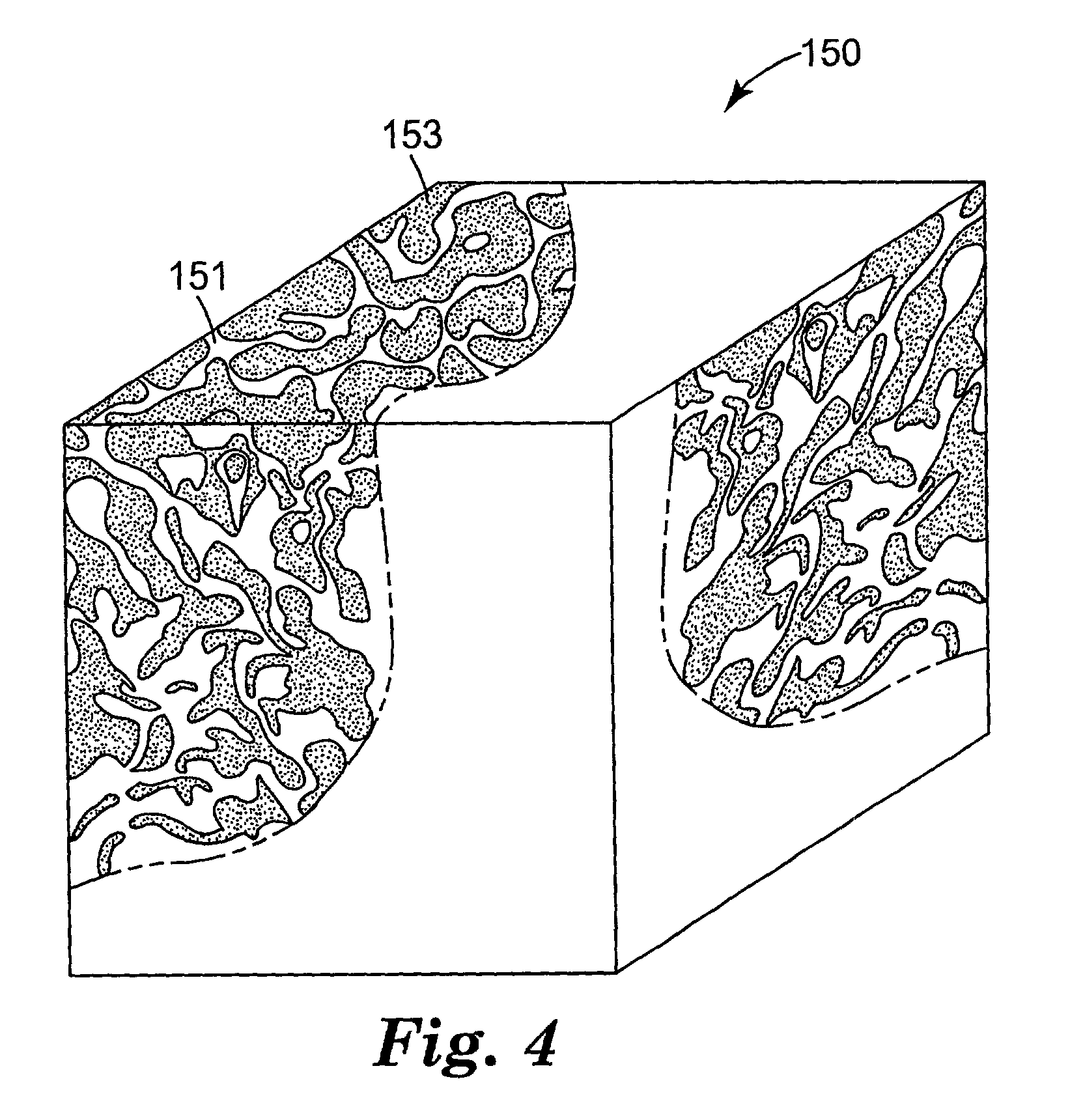

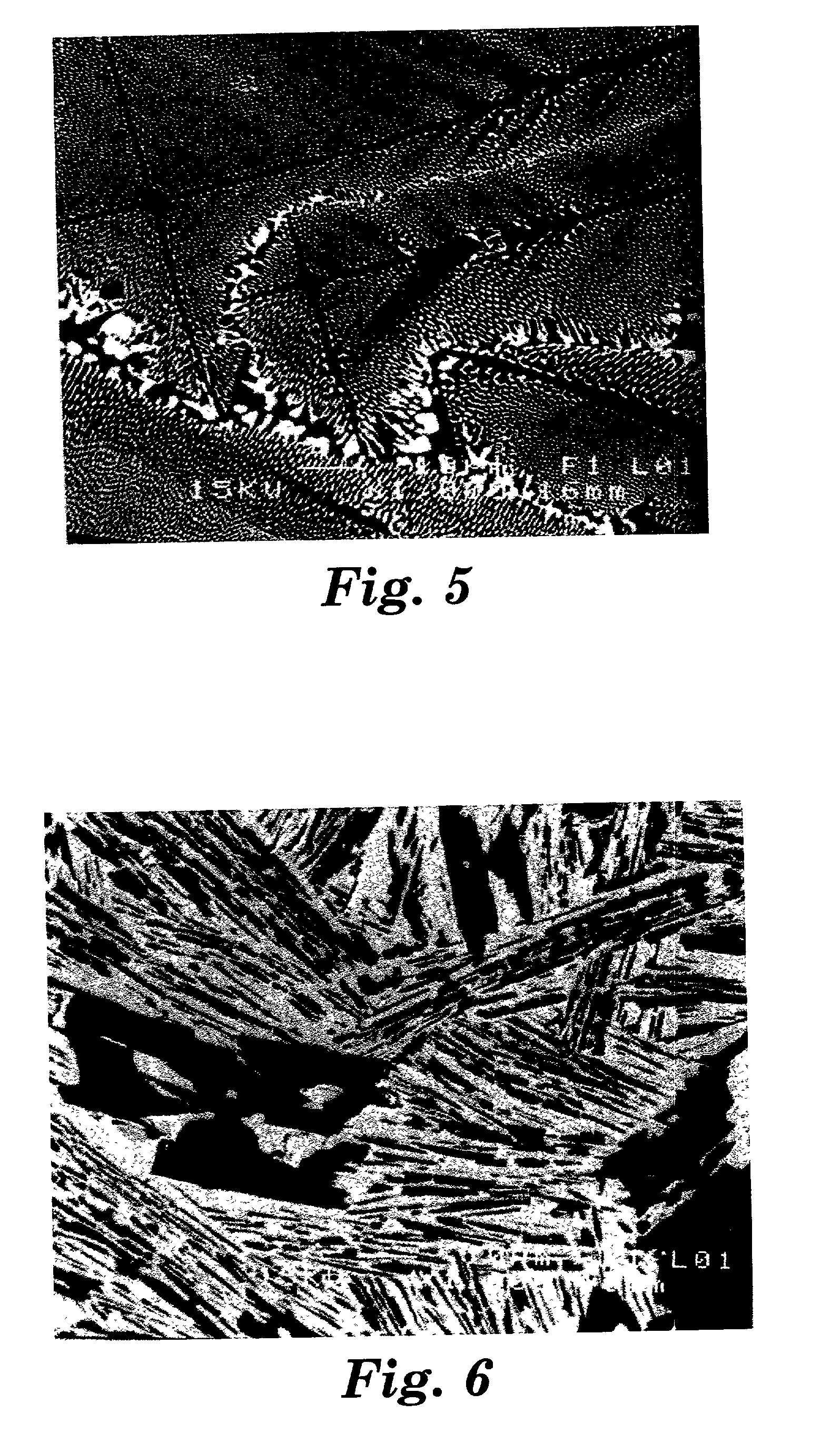

Fused Al2O3-MgO-rare earth oxide eutectic abrasive particles, abrasive articles, and methods of making and using the same

InactiveUS20010027623A1Improve grinding performanceLower performance requirementsPigmenting treatmentMangesium aluminatesRare earthAbrasive

Owner:3M INNOVATIVE PROPERTIES CO

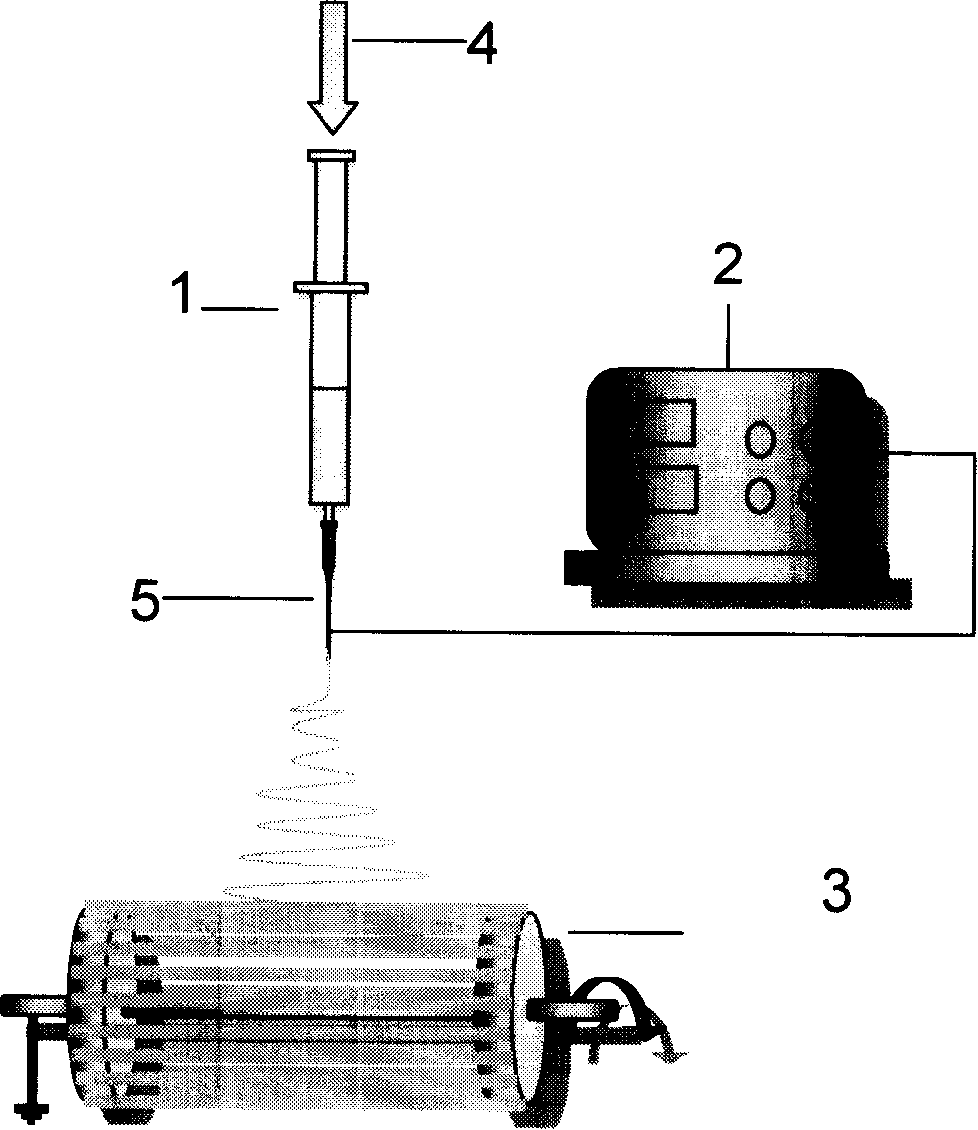

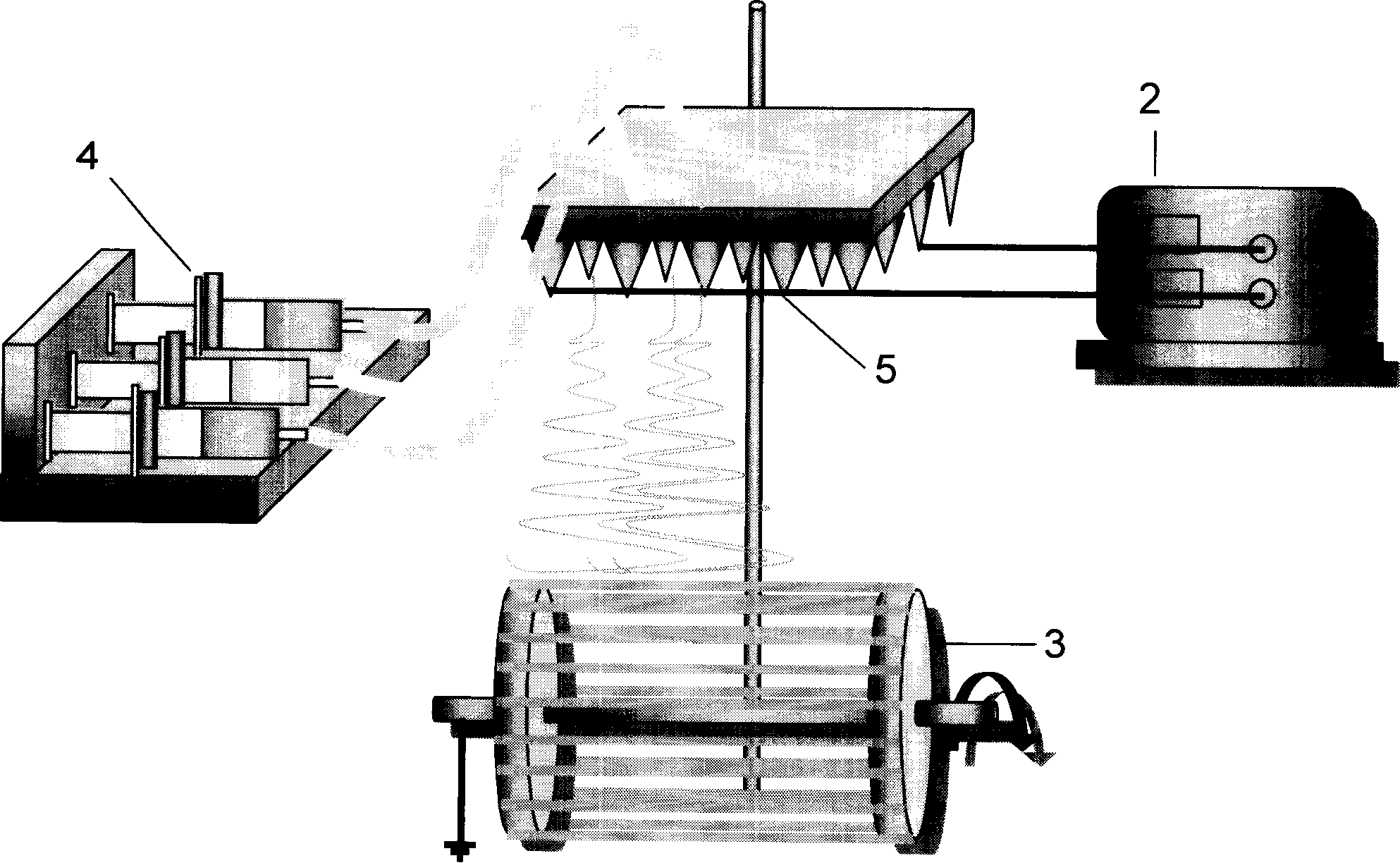

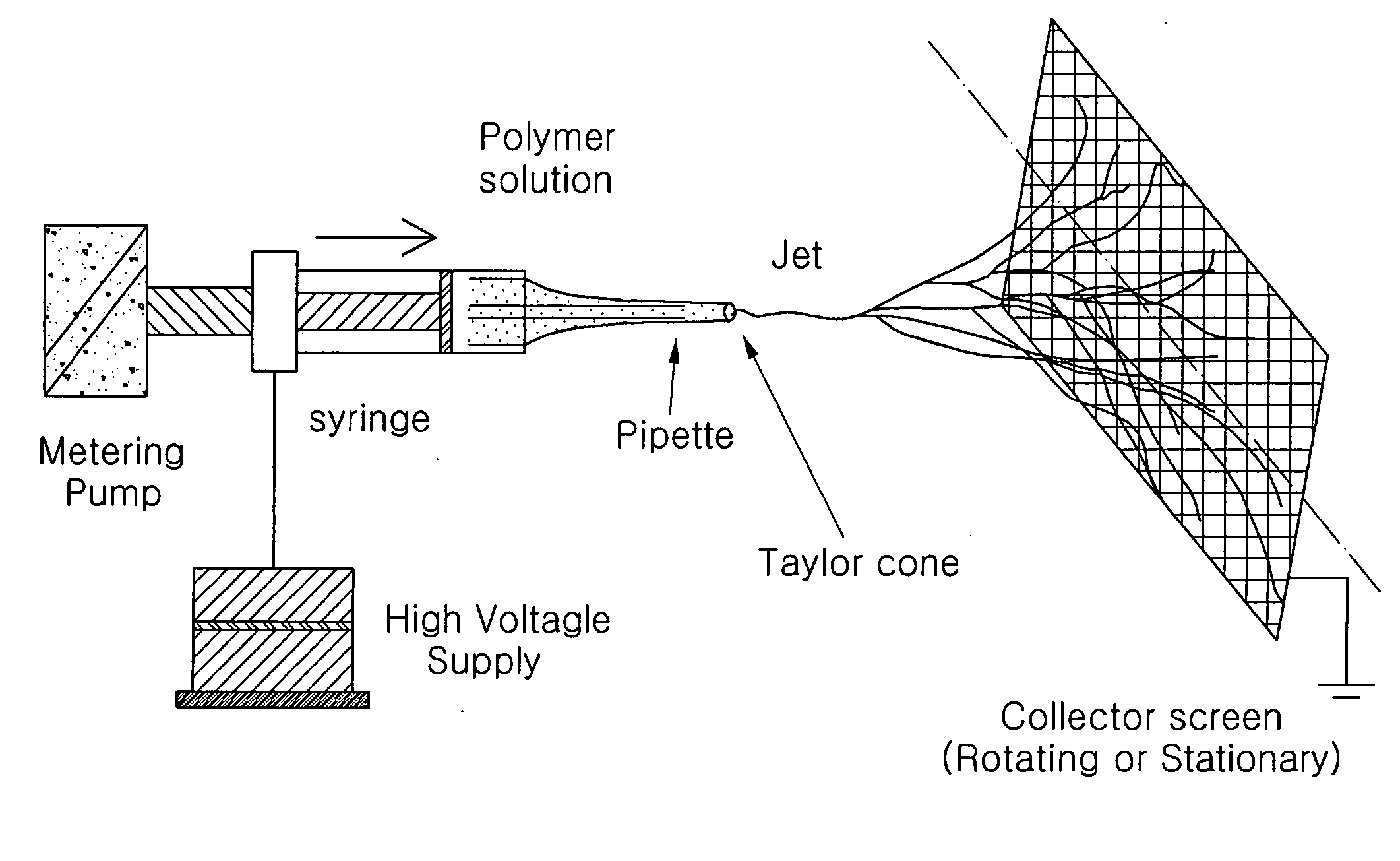

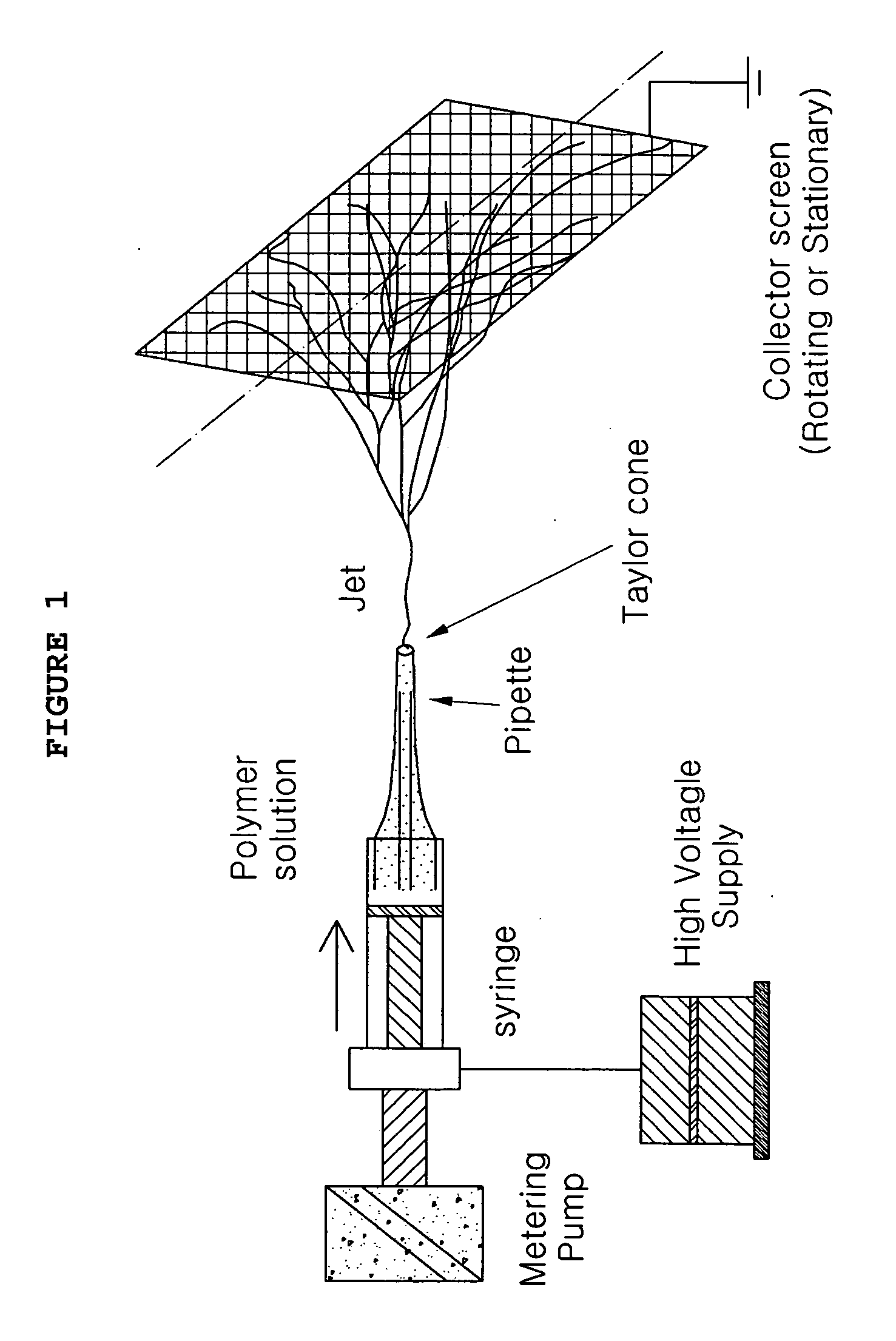

Biopolymer nano tunica fibrosa material capable of being biological degraded and absorbed, preparing method and uses of the same

InactiveCN101172164AGood biocompatibilityPromote degradationSurgeryFilament/thread formingFiberCellulose

The invention relates to compound millimicron fibrous membrane material of cellulose and cellulose matrix which can perform the biological degradation and the biological absorption and a preparation method thereof and an industry and medical purpose, and belongs to the biological macro-molecule non woven fabric material field which can perform the biological degradation and the biological absorption. Electrostatic spinning equipment is used to obtain the fibrous membrane material which can perform the biological degradation and the biological absorption, the weight of the cellulose is taken as basic reference, the component of the material comprises cellulose more than 0 and less than or equal to 100 weight parts, other biomacromolecule more than and equal to 0 and less than 100 weight parts, 0 to 10 weight parts of curative drug or 0 to 50 weight parts of inorganic catalyzer and / or 0 to 50 weight parts of inorganic strengthening agent. The material of the invention has good biological compatibility, biological degradation property and degradation absorptivity, and can be used for haemostasia material, wound cladding material, organization engineering supporting rack material, the transportation and release of medicine, artificial skin and blood vessel, and postoperation anti blocking material, beauty material and catalyzer carrier, filtering membrane and radiation protection material and so on.

Owner:INST OF CHEM CHINESE ACAD OF SCI

Nonwoven containing acoustical insulation laminate

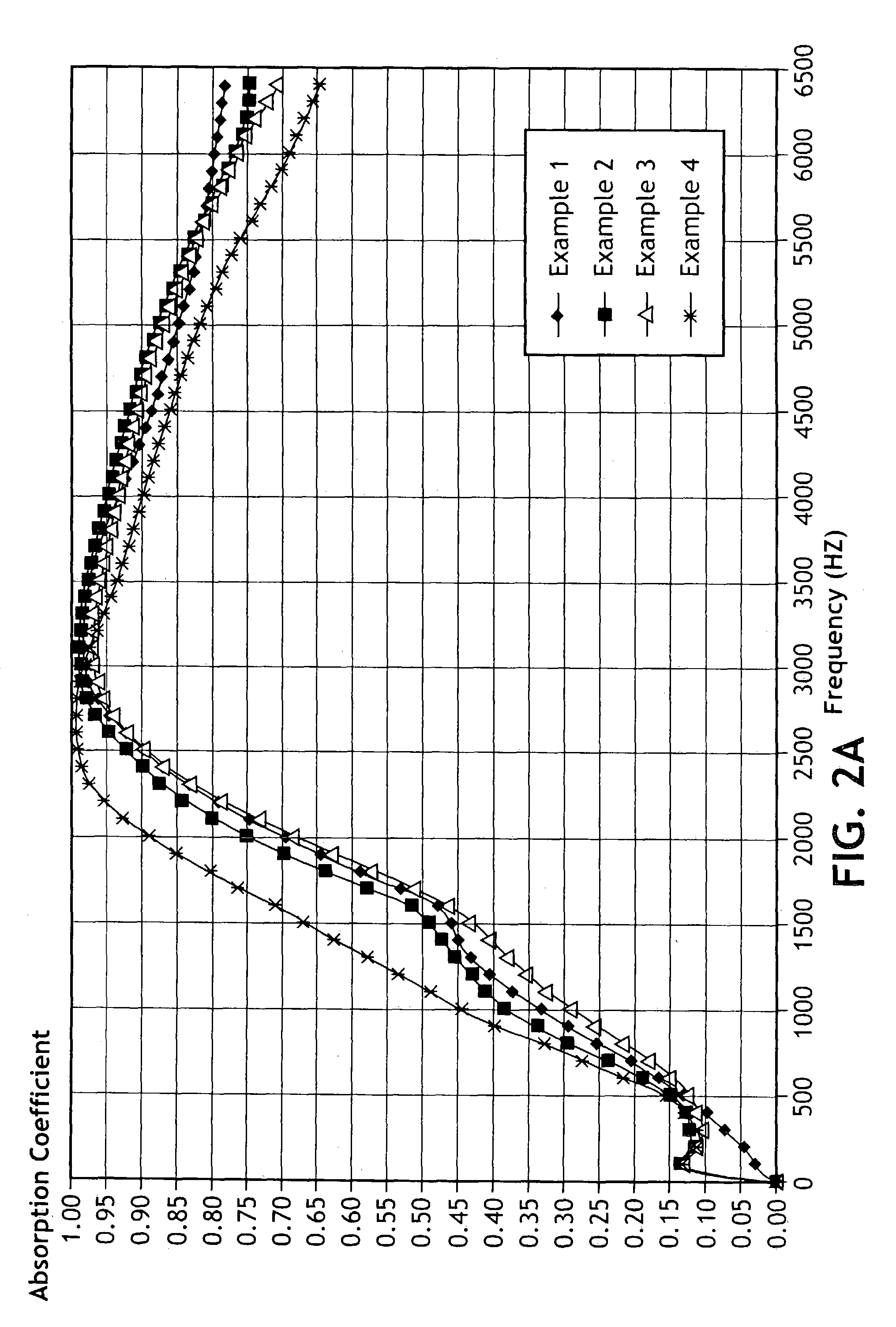

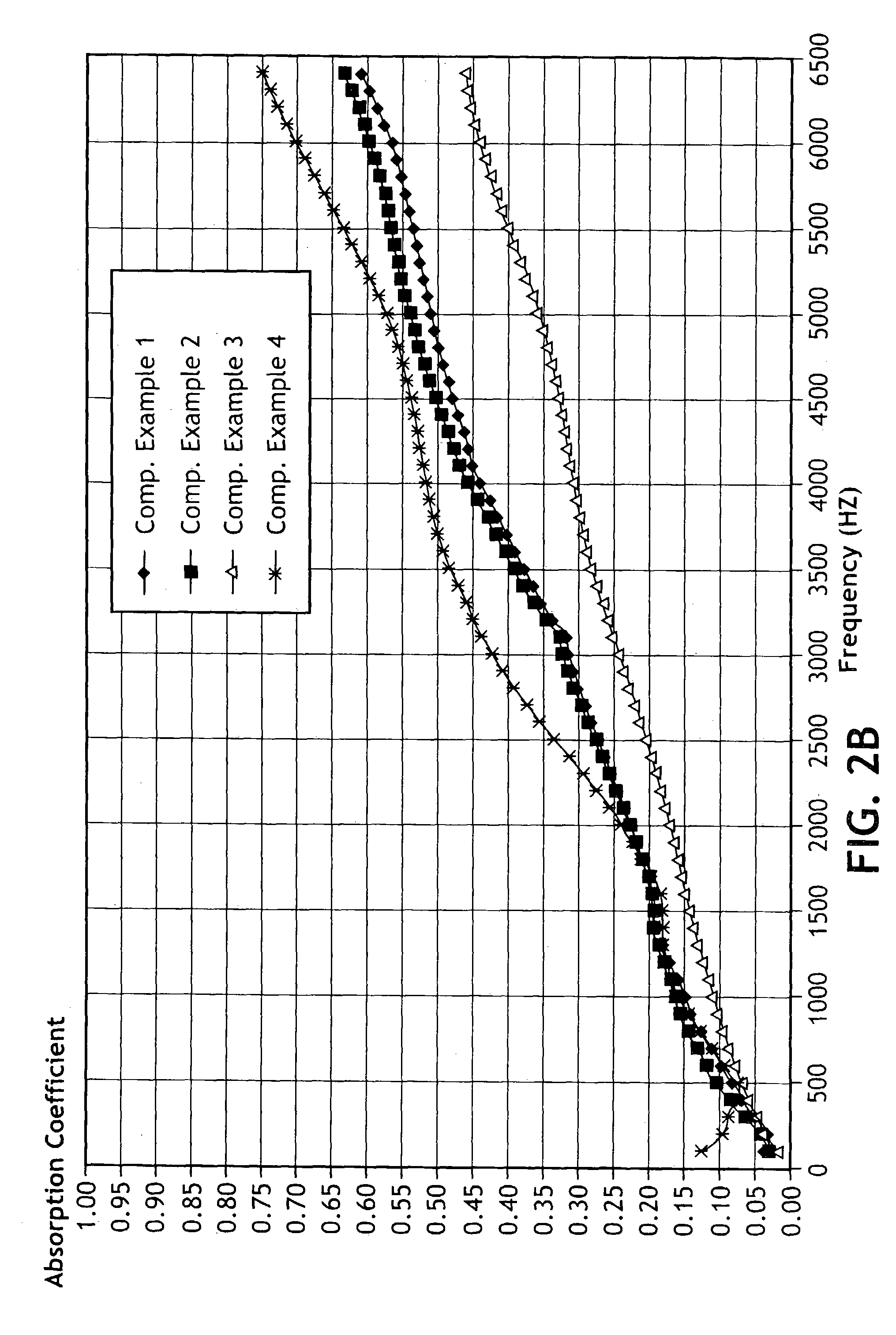

The present invention relates to an acoustical insulation material containing a first layer formed from a nonwoven web having a density of at least 50 kg / m3 wherein the nonwoven web is formed from thermoplastic [meltblown] fibers having an average fiber diameter of less than about 7 microns; and a second layer of a high loft material. The high loft material of the present invention provides bulk to the first layer and may or may not have sound attenuating properties. Examples of the high loft material include, for example, fiberglass and high loft nonwoven webs. Also disclosed in a method of attenuating sound waves passing from a sound source area to a second area. The method includes positioning an acoustical insulation material containing a first layer formed from a nonwoven web having a density of at least 50 kg / m3 wherein the nonwoven web is formed from thermoplastic [meltblown] fibers having an average fiber diameter of less than about 7 microns; and a second layer of a high loft material, between the sound source area and the second area.

Owner:KIMBERLY-CLARK WORLDWIDE INC

Polypropylene based fibers and nonwovens

InactiveUS20060008643A1Great contributionSynthetic resin layered productsWoven fabricsFiberPolyolefin

The present invention relates to fibers and nonwovens made from plasticized polyolefin compositions comprising a polyolefin, a non-functionalized hydrocarbon plasticizer and a slip agent.

Owner:EXXONMOBIL CHEM PAT INC

A kind of antibacterial composition and its application

InactiveCN102258064AExtended cleaning cycleTo achieve the effect of saving waterBiocideAntifouling/underwater paintsSodium PyrithioneNonwoven fabric

The invention relates to an antibacterial composition, comprising an organic antibacterial component containing at least one pyrithione salt, a pyrithione complex or an adduct thereof, an aqueous solution containing one or more metal ions or its The inorganic antibacterial component of the complex aqueous solution or its nanometer metal hydrosol or its nanometer metal oxide hydrosol and its composition, and the mass ratio of the organic antibacterial component to the inorganic antibacterial component is 1:100-50:1, It also includes other auxiliary agents, and its mass percentage in the antibacterial composition described in the patent is 0.001-20%. The antibacterial composition of the present invention can form a nanoparticle film on the surface of base materials such as natural fabrics, non-woven fabrics, clothing, bedding, toiletries, household items, medical care supplies, and filter screens, and realize its antibacterial properties through the nanoparticle film. Antibacterial, anti-mite, deodorizing and self-cleaning functions. The antibacterial composition of the invention is safe to use and can be used in medical treatment and life to protect people's health.

Owner:赵正坤

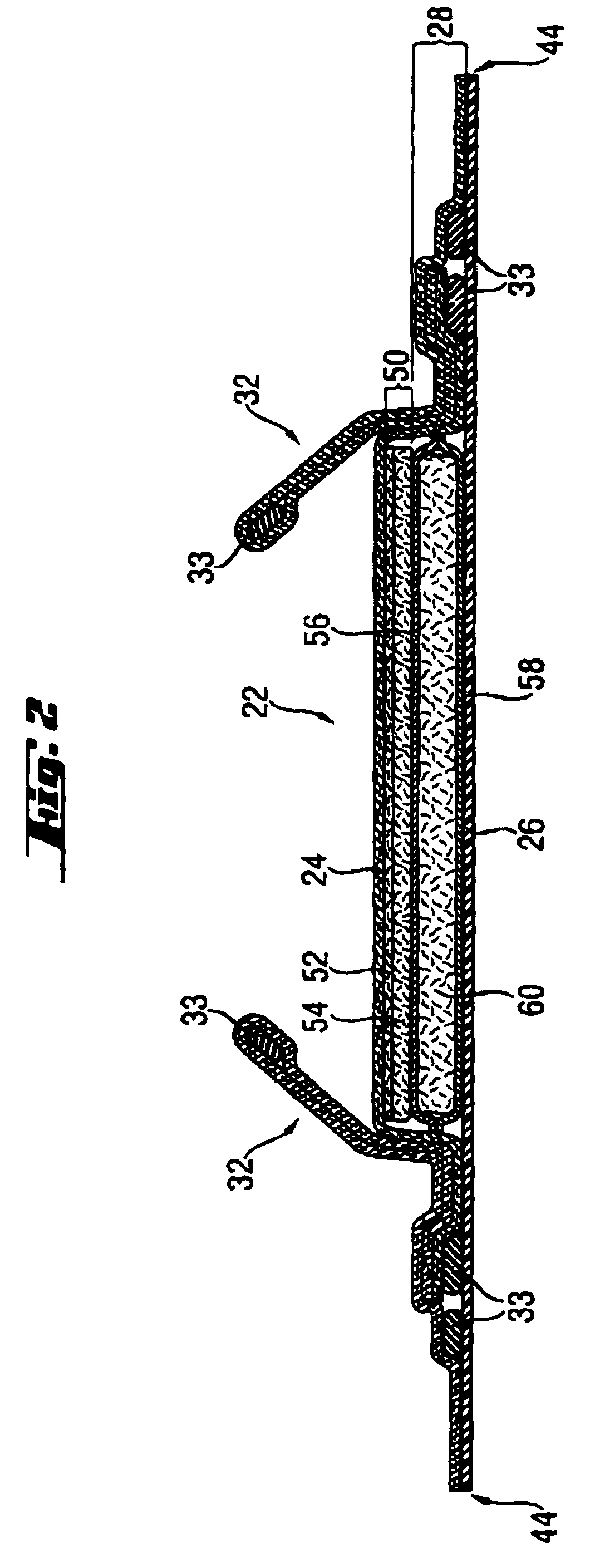

Stretchable laminates of nonwoven web(s) and elastic film

A stretchable laminate, a process of making a stretchable laminate and a disposable absorbent article that includes a stretchable laminate are disclosed. The stretchable laminate includes a nonwoven web and a web of elastomeric material. The nonwoven web includes two layers of spunbond fibers and one layer of meltblown fibers. Some of the meltblown fibers are present in the interstices formed by the spunbond fibers of one of the layers.

Owner:PROCTER & GAMBLE CO

Extensible Nonwoven Fabric

ActiveUS20140276517A1High elongationImprovement in one or moreBaby linensWoven fabricsExtensibilityNonwoven fabric

Extensible nonwoven fabrics having improved elongation, extensibility, abrasion resistance and toughness. In particular, embodiments of the invention are directed to extensible spunbond fabrics comprising a polymeric blend of a metallocene catalyzed polypropylene, polyethylene, and a third polymer component.

Owner:FITESA GERMANY +1

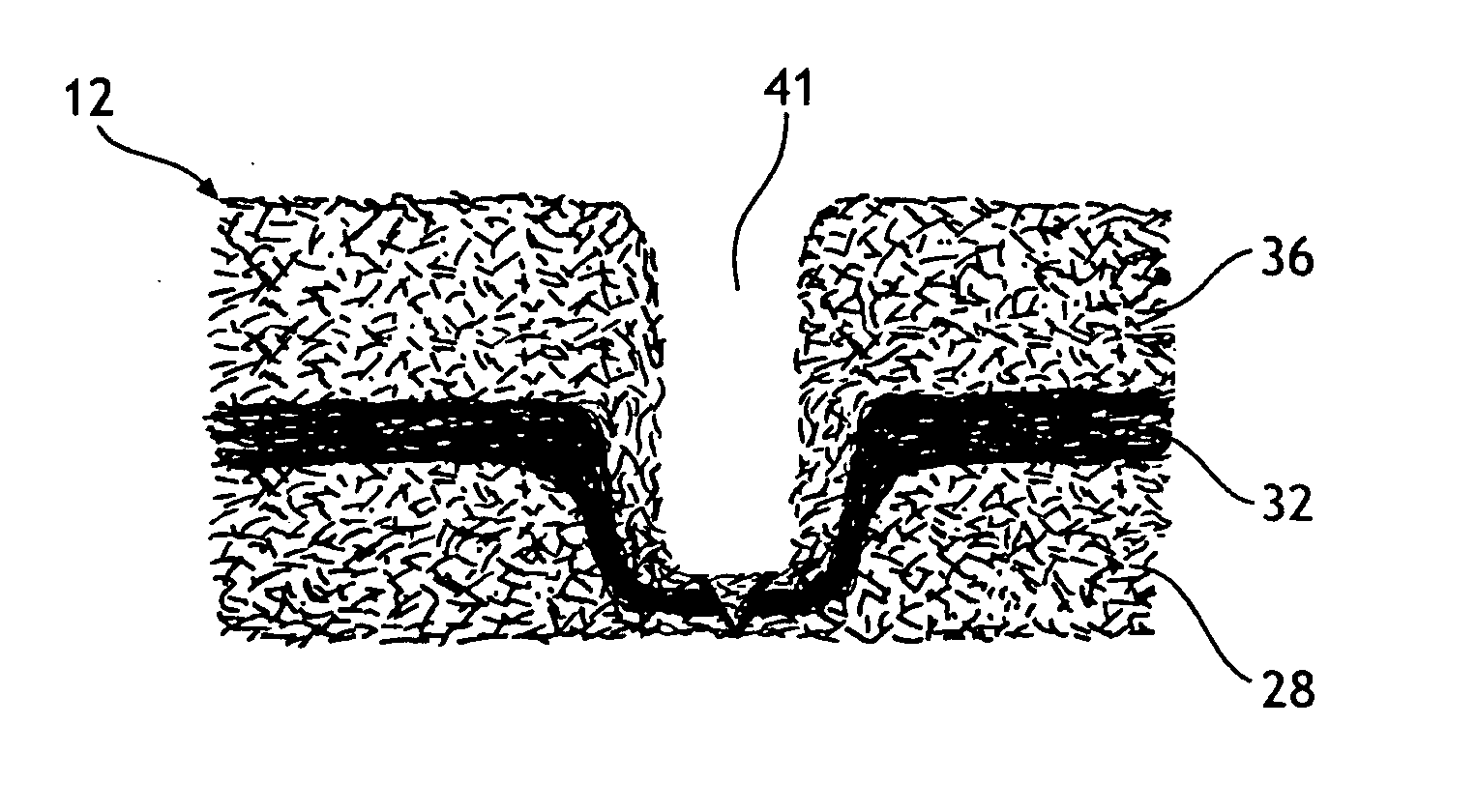

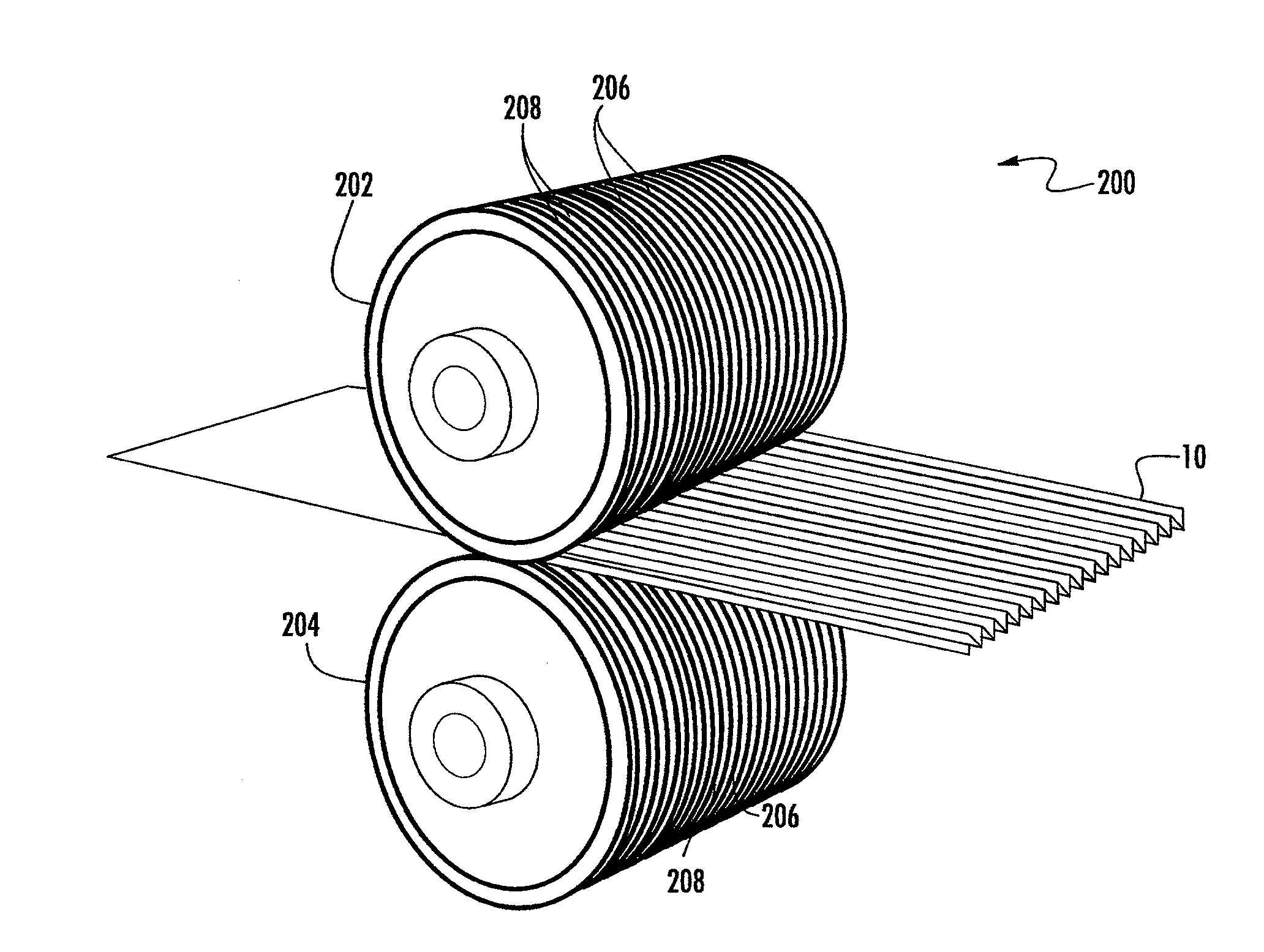

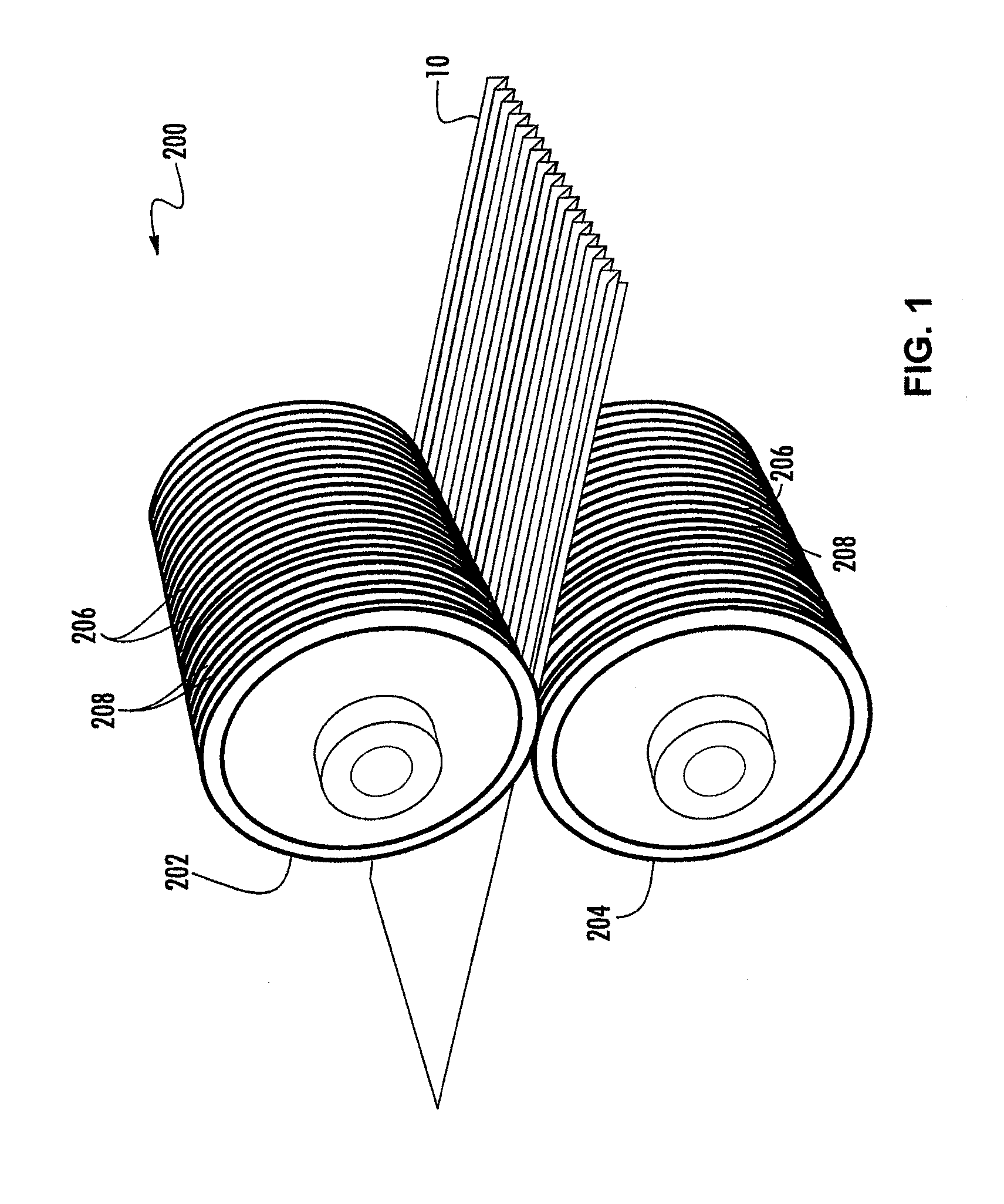

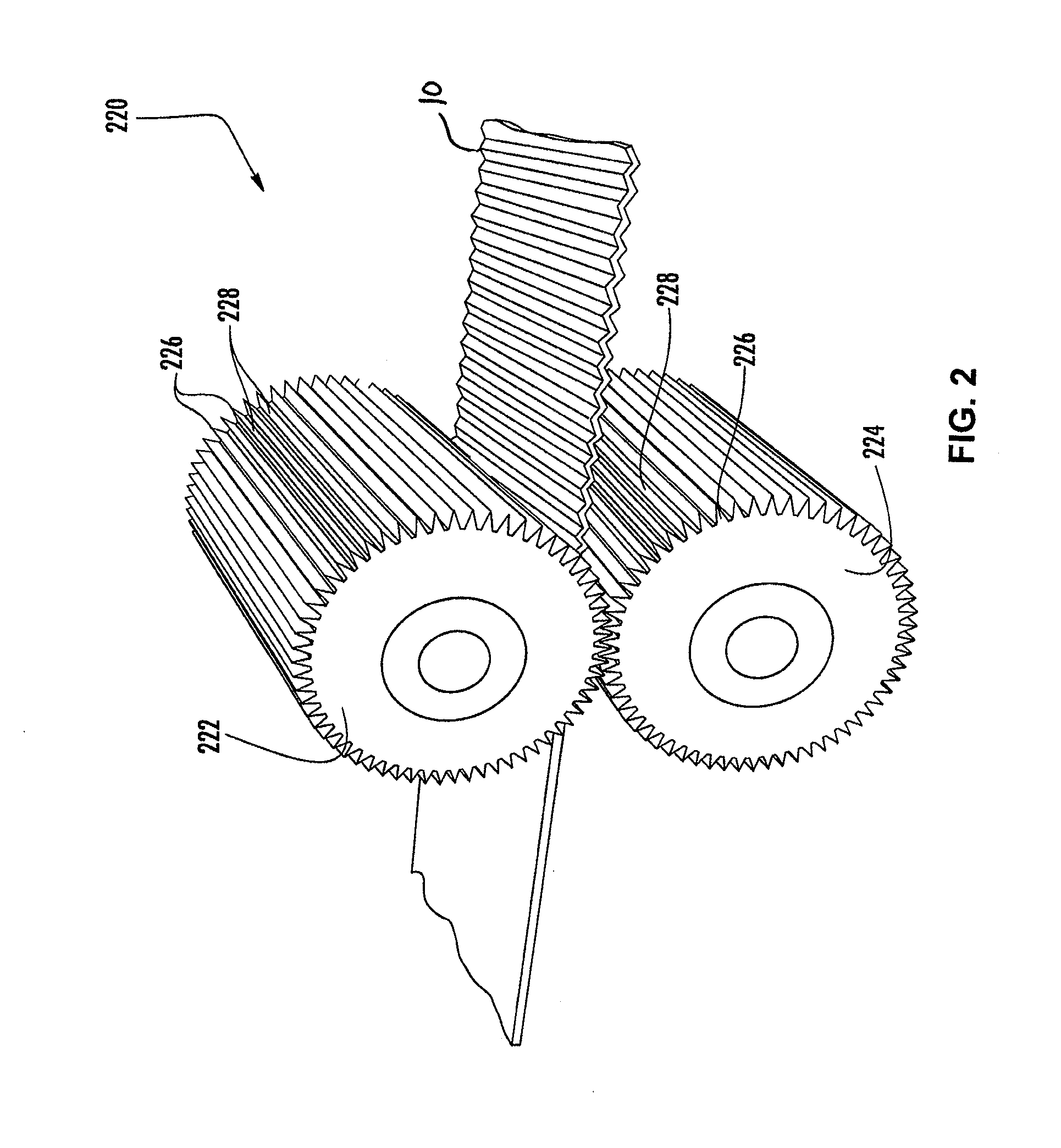

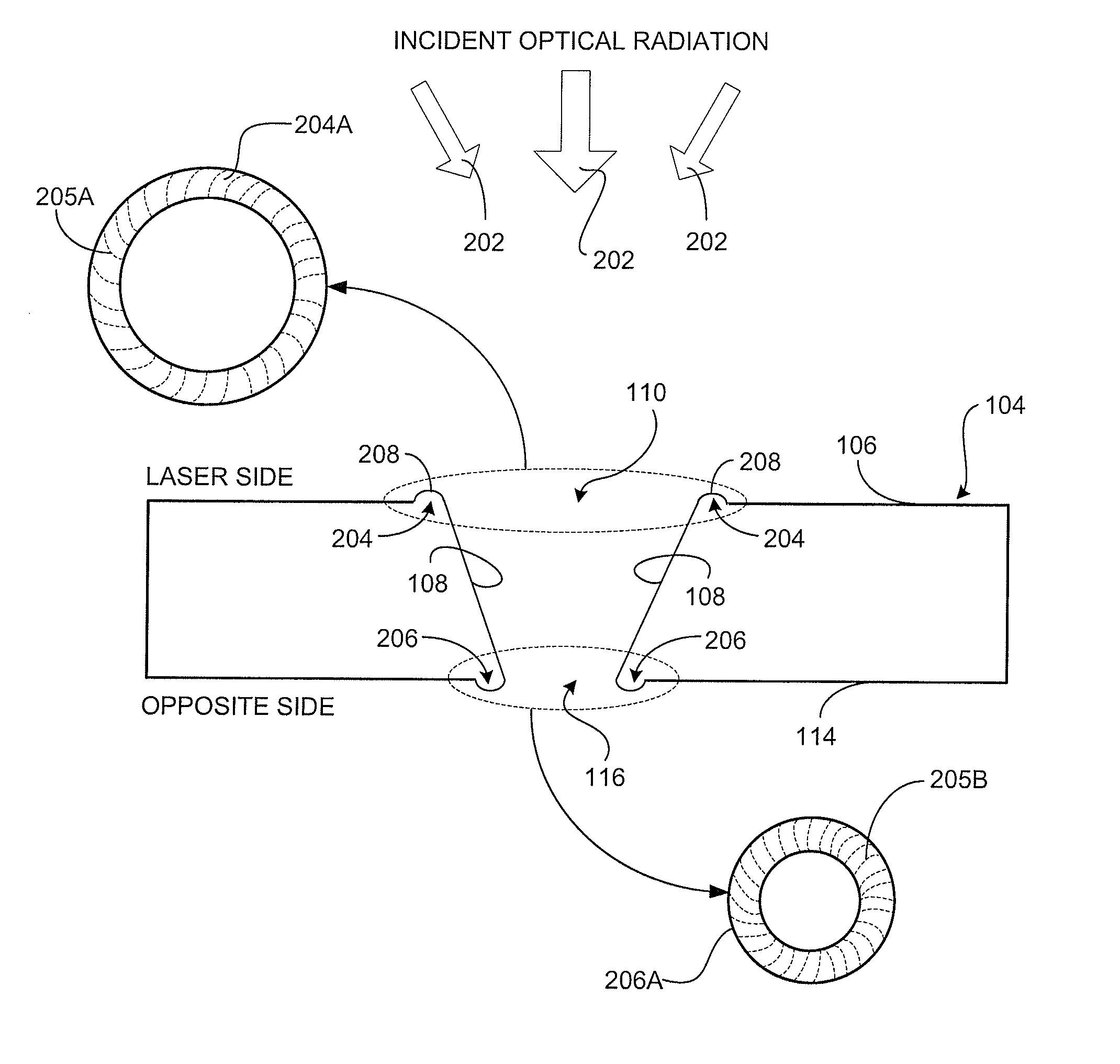

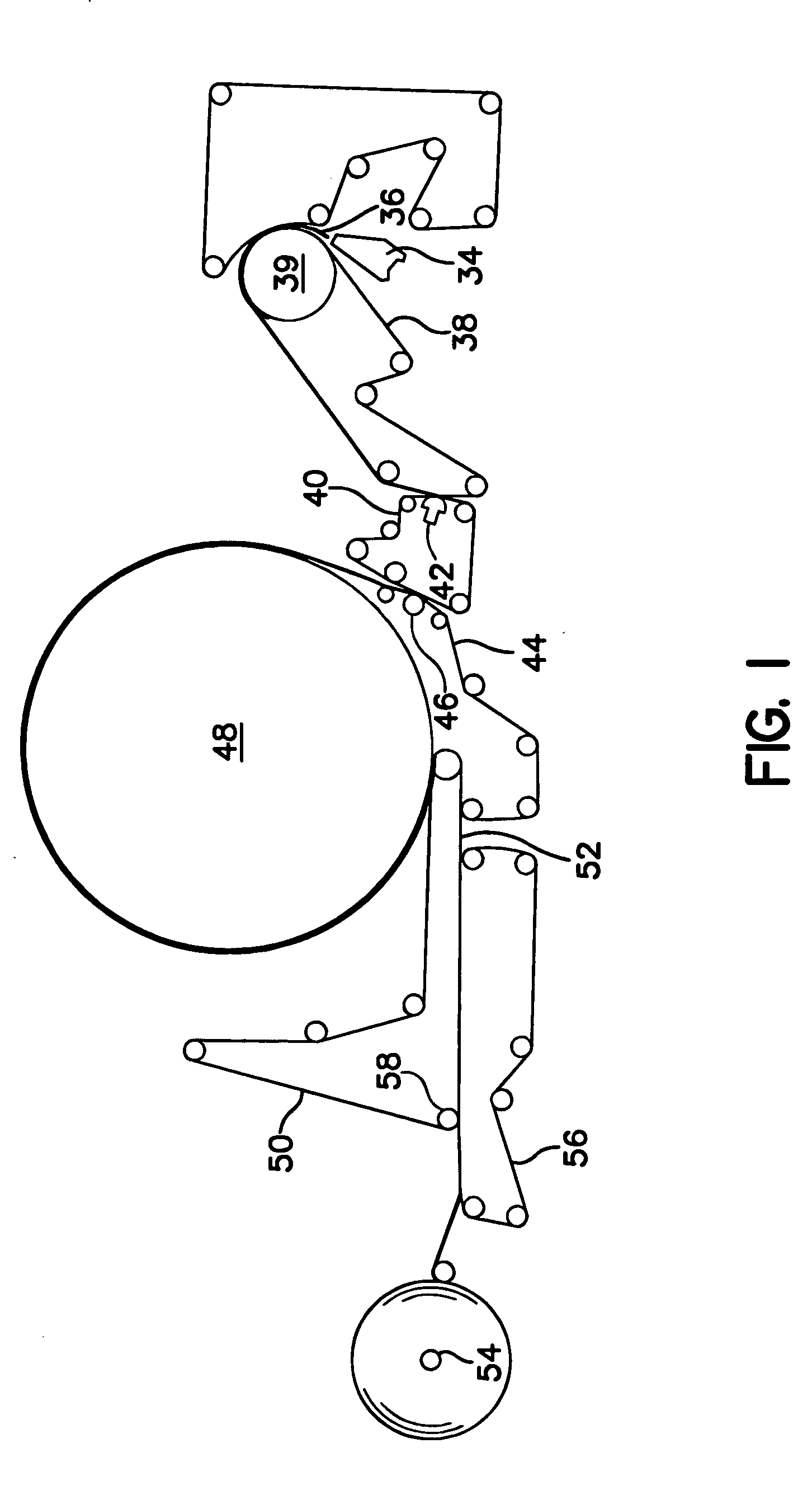

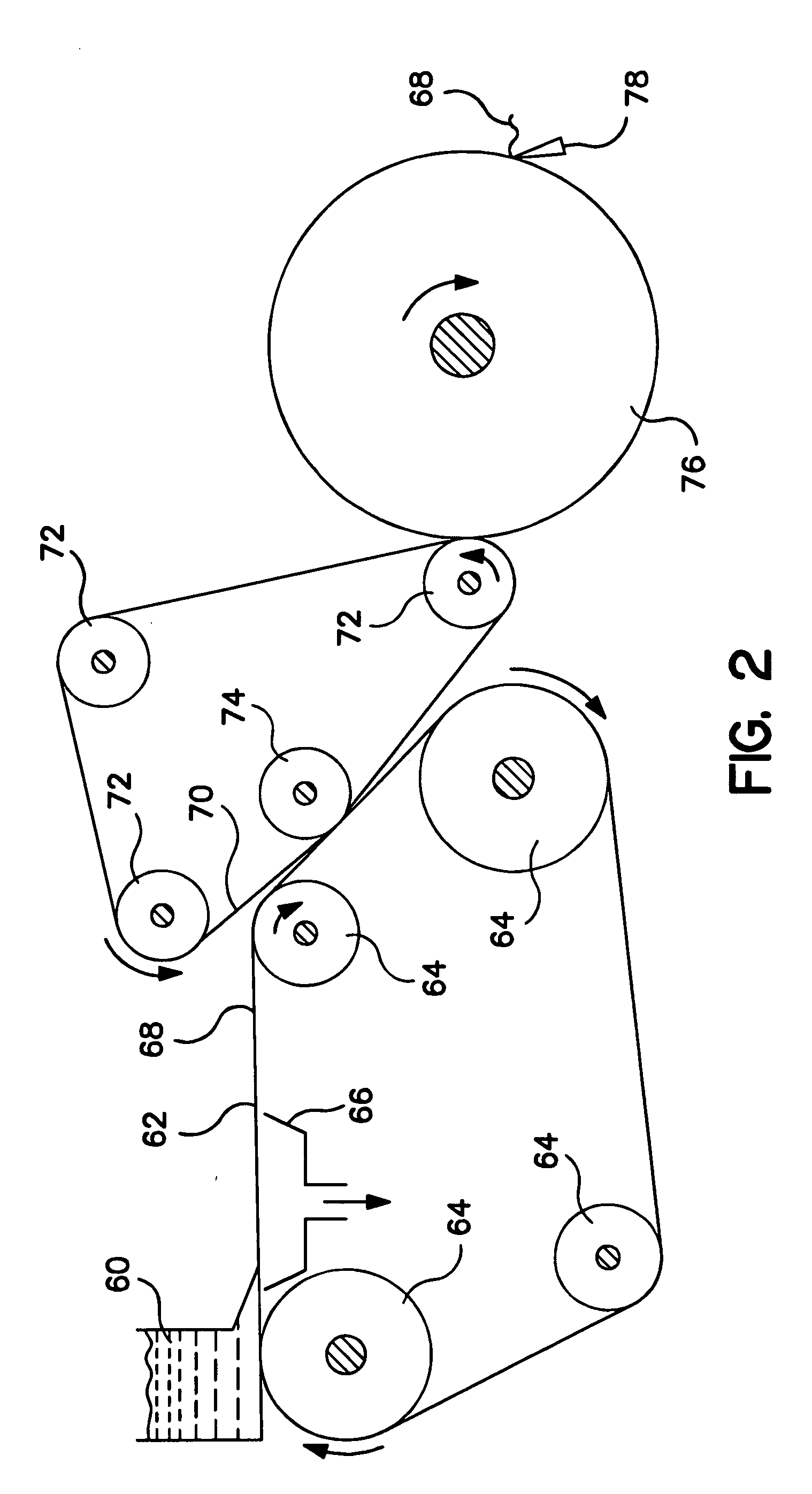

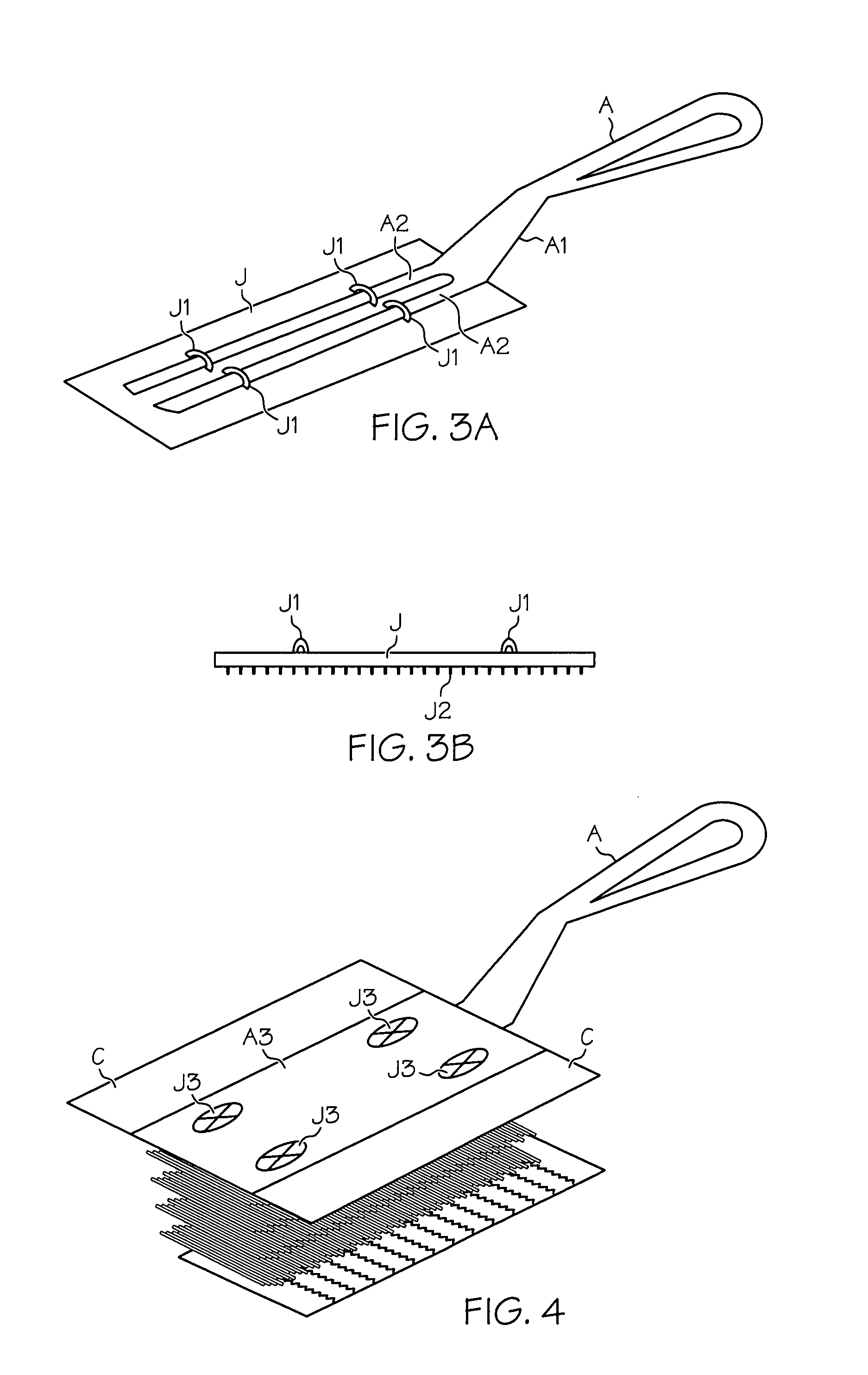

Industrial fabric for producing tissue and towel products, and method of making thereof

ActiveUS8454800B2Reduce the amount of solutionIncrease rangeNon-fibrous pulp additionNatural cellulose pulp/paperEngineeringNonwoven fabric

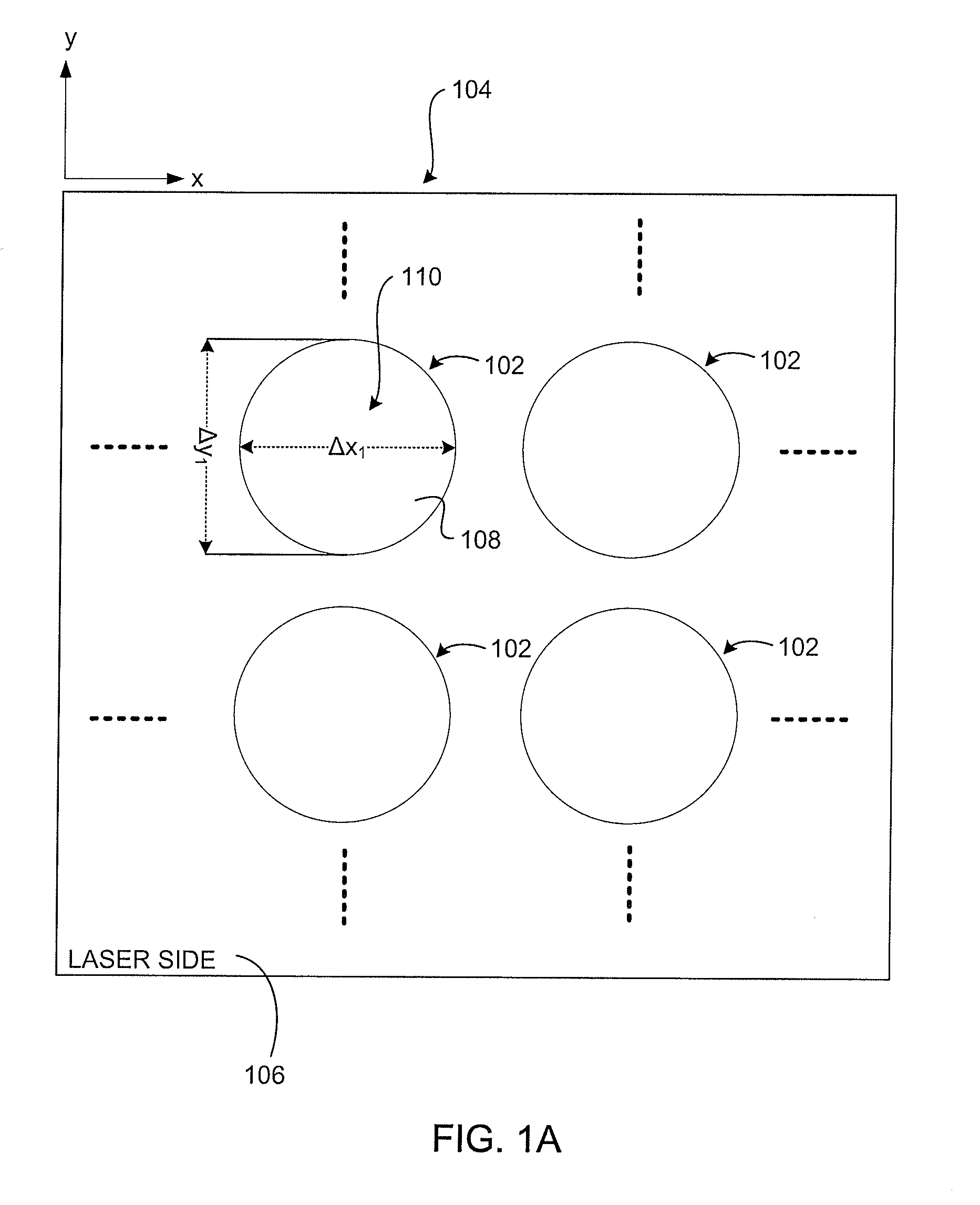

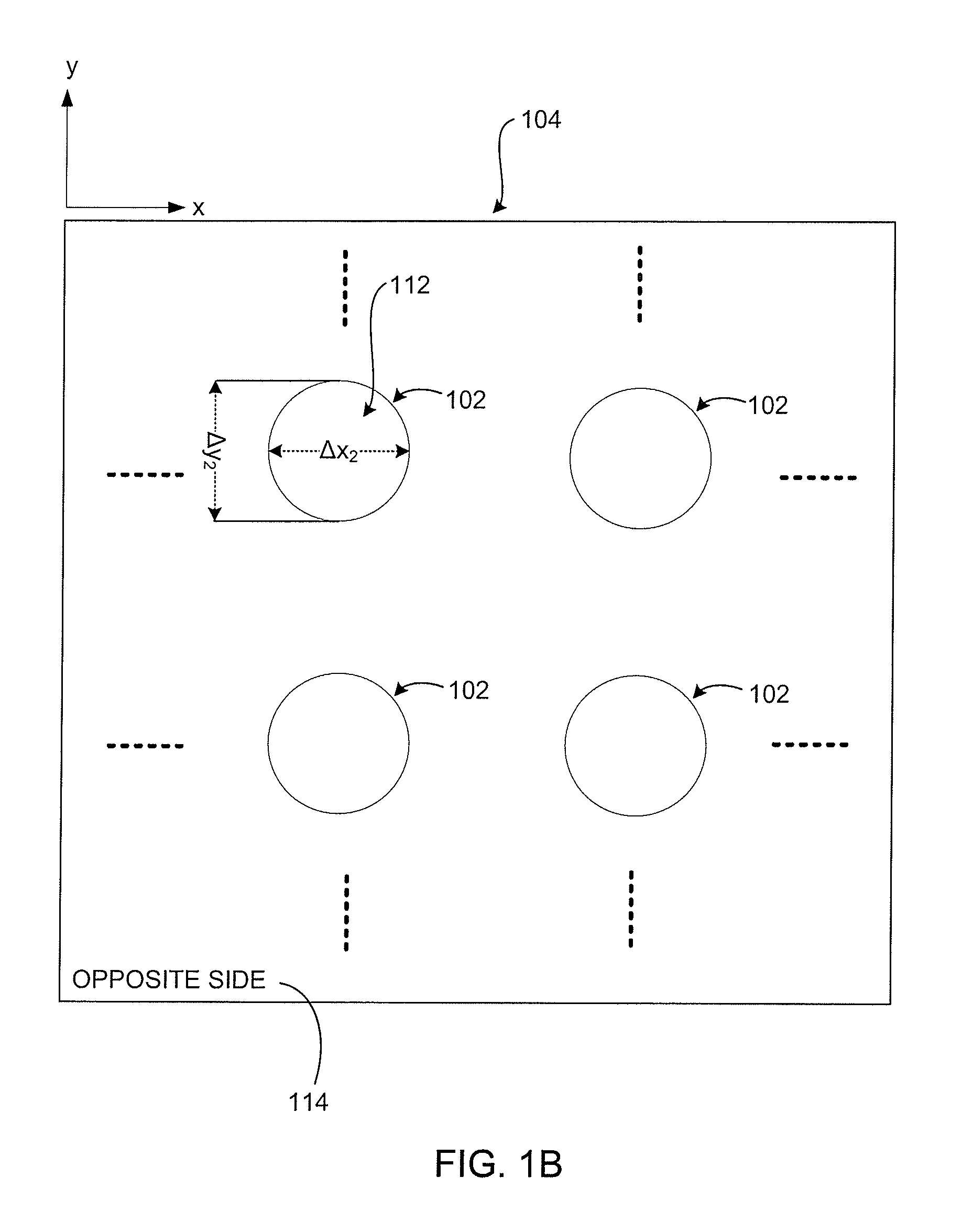

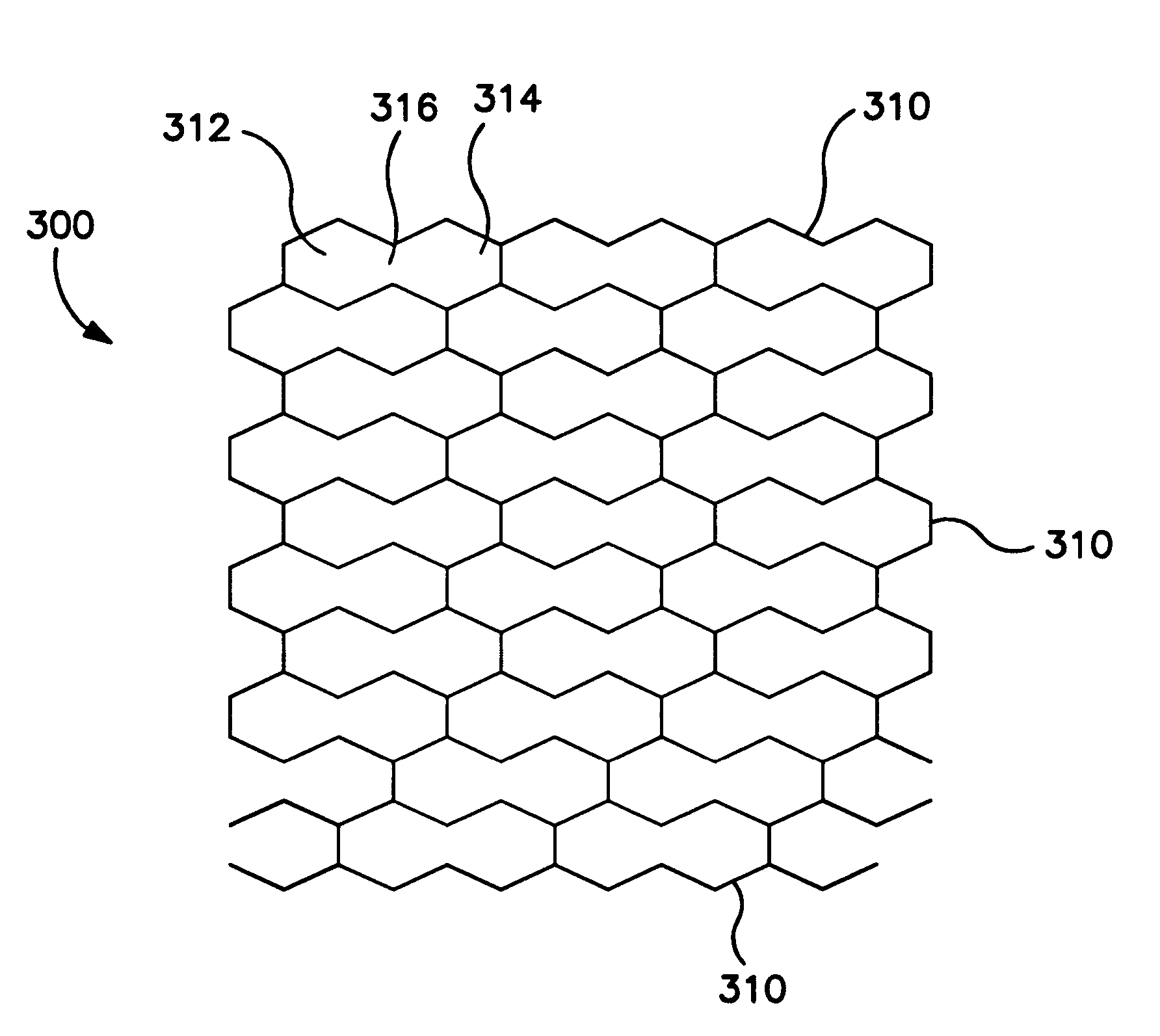

A nonwoven fabric includes a plurality of through voids, where each of the voids has a first opening associated with a top surface of the fabric and a first raised edge circumferentially adjacent to the first opening. The voids may each further include a second opening associated with a bottom surface of the fabric and a second raised edge circumferentially adjacent to the second opening, such that the first opening may have a surface area that is larger than or the same as the second opening.

Owner:ALBANY INT CORP

Separator for nonaqueous electrolyte batteries, nonaqueous electrolyte battery using it, and method for manufacturing separator for nonaqueous electrolyte batteries

InactiveUS6511774B1High tear strengthEnhanced penetration strengthNon-aqueous electrolyte accumulatorsCell seperators/membranes/diaphragms/spacersHigh energyEngineering

The present invention provides a separator for non-aqueous electrolyte batteries which neither breaks nor slips off at the time of fabrication of battery, gives excellent battery fabricability, causes no internal short-circuit caused by contact between electrodes even if the electrodes are externally short-circuited, can inhibit ignition of battery and produces high energy density and excellent cycle life, and further provides a non-aqueous electrolyte battery using the separator and a method for manufacturing the separator. That is, the present invention relates to a separator for non-aqueous electrolyte batteries which comprises a porous base containing at least one member selected from a porous film, a woven fabric or nonwoven fabric containing an organic fiber and a paper and an organometallic compound applied to the porous base; a method for the manufacture of the separator for non-aqueous electrolyte batteries which comprises allowing said porous base to contact with a solution of organometallic compound by impregnation, coating or spraying, followed by drying or curing with heating to apply the organometallic compound to the porous base; and a non-aqueous electrolyte battery using the separator.

Owner:MITSUBISHI PAPER MILLS LTD

Nonwovens having reduced poisson ratio

InactiveUS20050142331A1Reduces Poisson ratioNegative Poisson ratioNon-fibrous pulp additionNatural cellulose pulp/paperEngineeringNonwoven fabric

Owner:KIMBERLY-CLARK WORLDWIDE INC

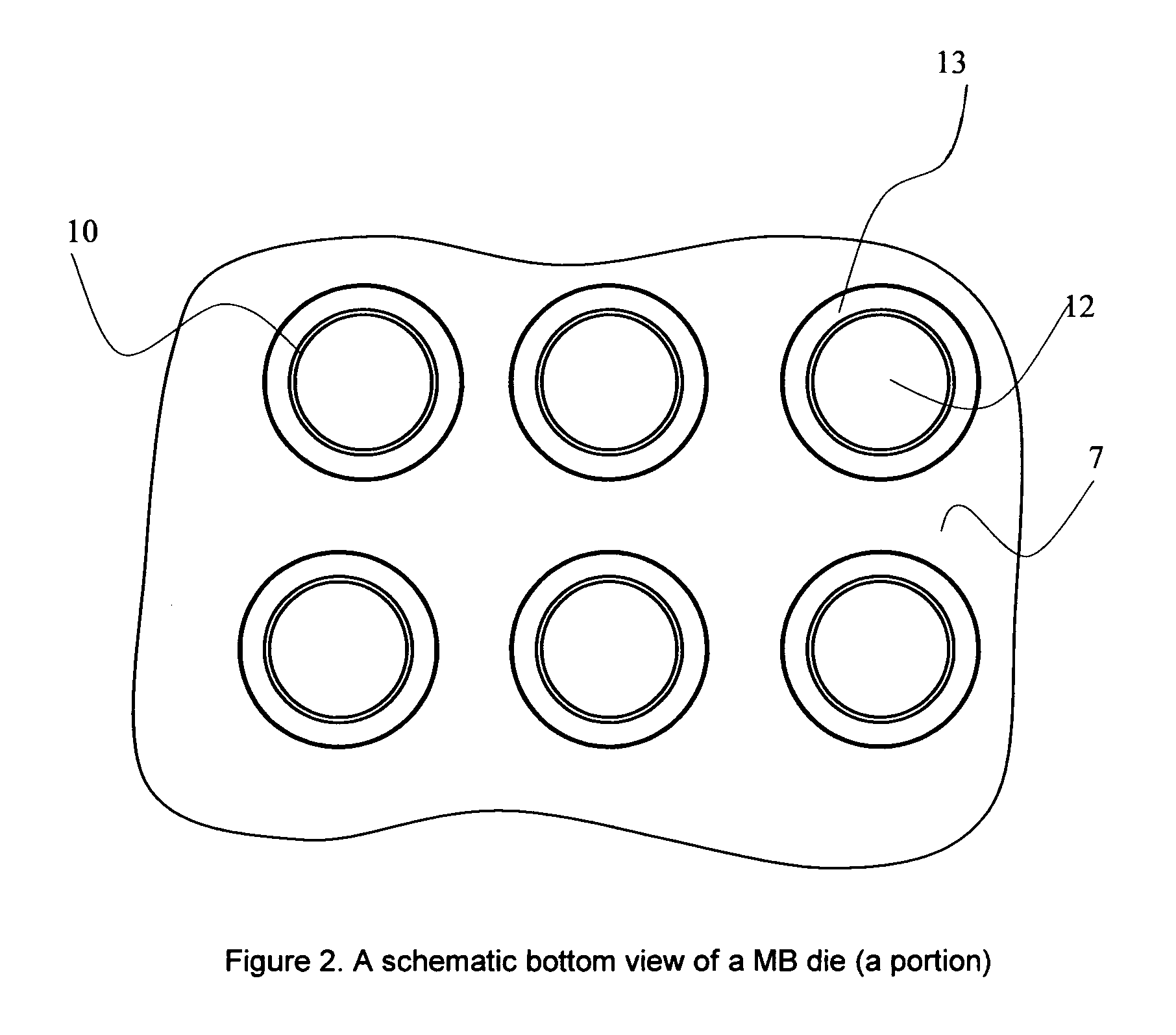

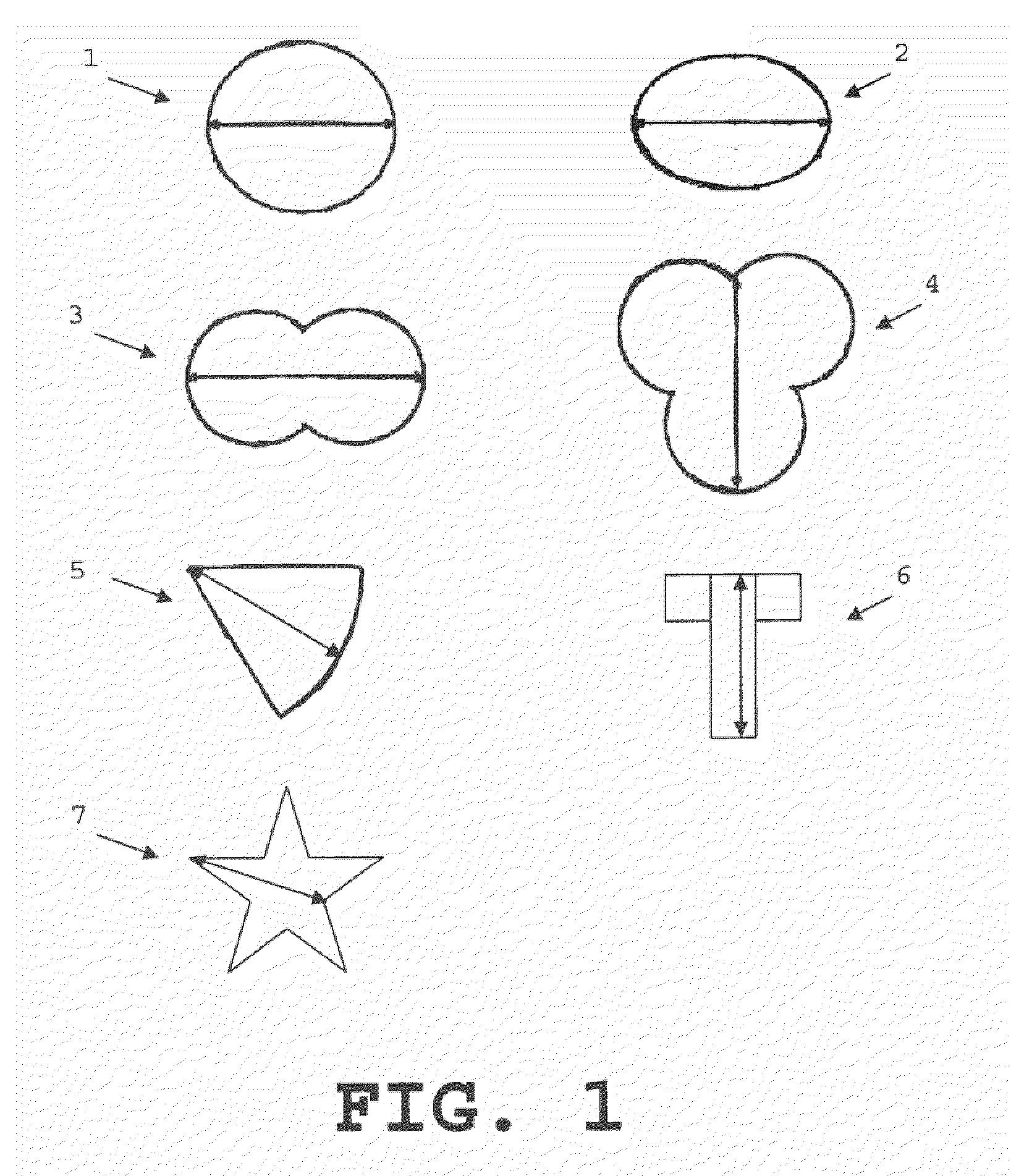

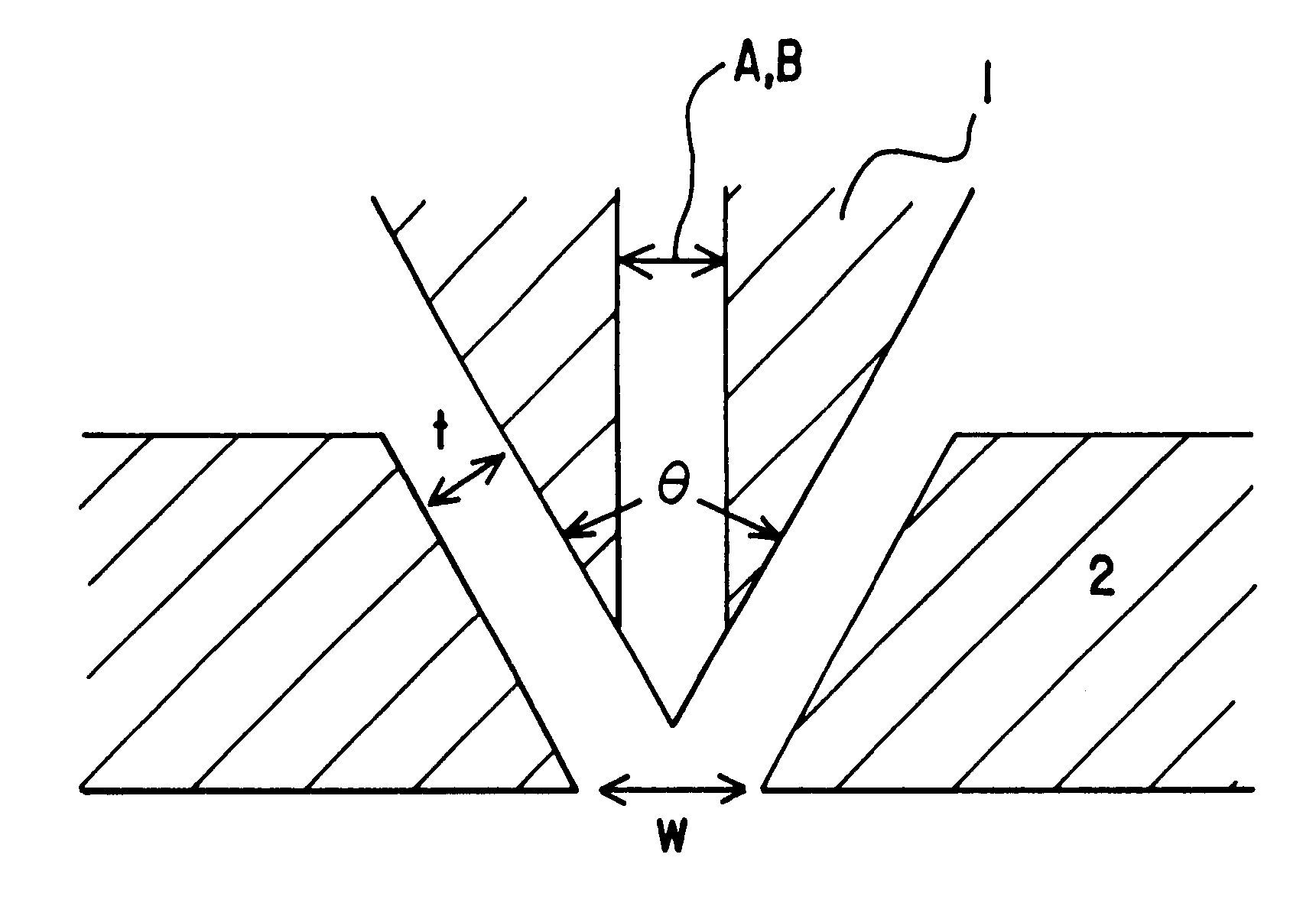

Melt-blown non-woven fabric, and nozzle piece for producing the same

InactiveUS6319865B1Efficient productionLayered productsMelt spinning methodsEngineeringFiber diameter

The nozzle piece of the present invention is provided with circular cross sectional nozzles having different sizes disposed in a row in front of the die, with n-numbered smaller nozzles B (hole diameter: Db) between adjacent larger nozzles A (hole diameter: Da). It gives melt-blown non-woven fabric of monolithic structure in one step, composed of fine fibers having a diameter in a range from 1 to 10 mum diameter Variance ratio F of 2.0 or more and wide fiber diameter distribution.

Owner:TONEN TAPYRUS

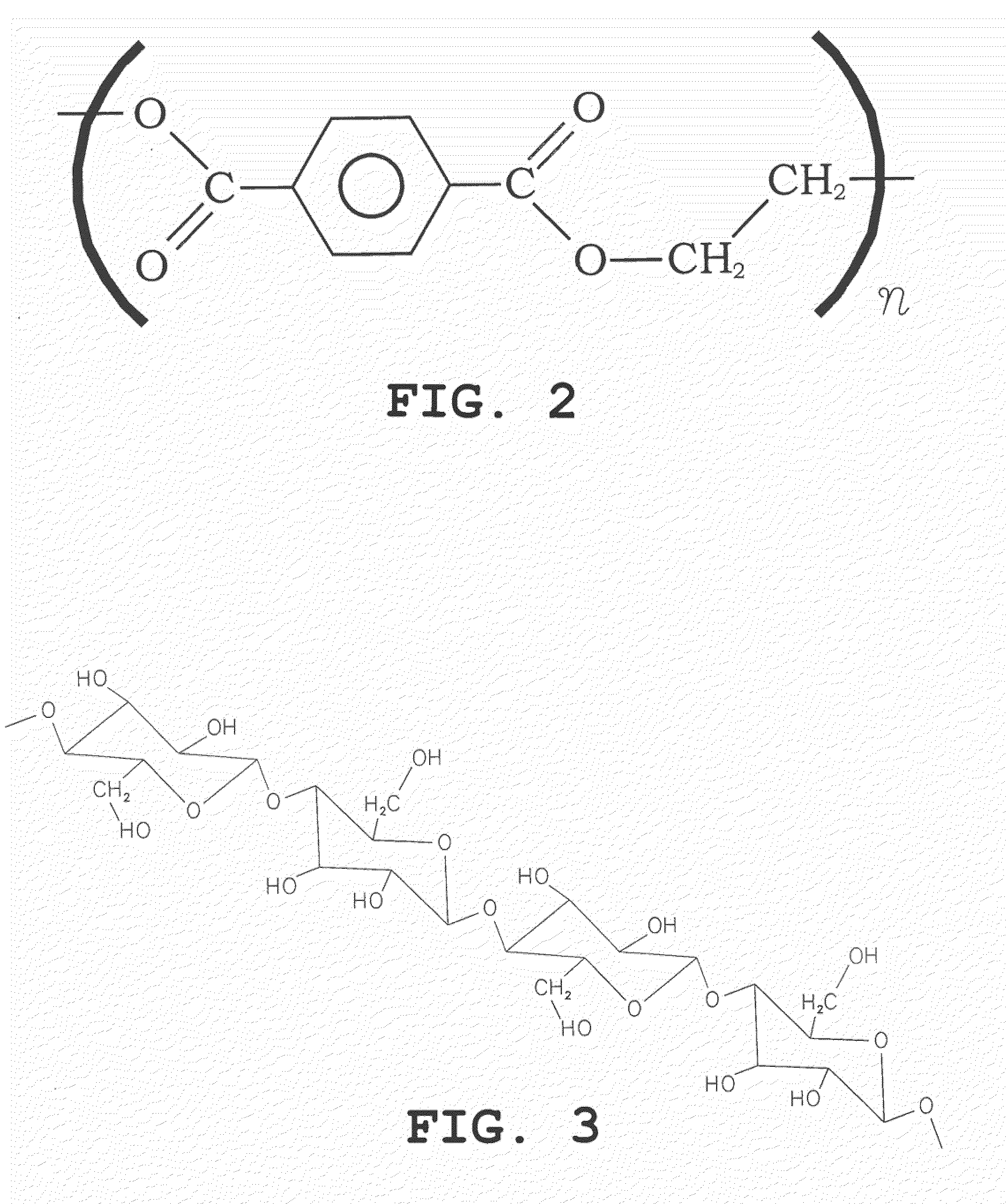

Melt-blown nonwoven fabric, process for producing same and the uses thereof

InactiveUS6207601B1Avoid undesirable oxidative processEliminate useLayered productsTobacco smoke filtersMean diameterPolymer science

The disclosure relates to a melt-blown non-woven fabric based on cellulose esters, with fibers of mean diameter less than about 10 microns. The fabric contains 0-10 wt. % extractable softener, has a reflection factor determined according to DIN 53 145 Part I (1992) of more than 60% and the cellulose ester has a degree of substitution DS of about 1.5-3.0. The softener is preferably water-extractable. A melt-blown non-woven fabric is produced with the cellulose ester as follows: a cellulose ester, cellulose acetate, with a DS of about 1.5-3.0, in particular 1.7-2.7, is mixed with softener in a weight ratio of about 2:1 to 1:4 and simultaneously heated and melted. The mixture of softener and cellulose ester has a melting index MFI (210 / 2.16) according to DIN 53 735 of about 400 to 5 g / 10 min., in particular 300 to 50 g / 10 min. The melt is worked in a melt-blown spinning device into a melt-blown non-woven fabric and the softener is then extracted with a softener solvent to leave a proportion of 0-10 wt. %. The melt-blown non-woven fabric is especially suitable as a filter material.

Owner:RHODIA ACETOW AG

Method for ecological remediation on acid tailing pond

ActiveCN109526523APrevent infiltrationSolve environmental problemsContaminated soil reclamationGrowth substratesWoody plantGround water pollution

The invention provides a method for ecological remediation on an acid tailing pond. By removing acids from soil, and by laying nonwoven cloth and a sealing layer, good partitioning is achieved, and byfurther laying a water reservation layer and a coated seed layer, the purpose of re-greening an acid tailing pond is achieved. The method has the beneficial effects that rainwater can be reserved tothe maximum extent, the sealing layer is capable of preventing the rainwater from infiltrating into tailings, the problems of underground water and ground water pollution can be substantially solved,the construction method is simple, and the construction cost is low; by using a seed coating technique, a set of rapid nursery stock breeding technique is formed, a stable ecological remediation system is cultured, the target of completely re-greening woody plants within 90 days is achieved, and environment problems of acid tailing ponds are solved for good.

Owner:杰瑞(莱州)矿山治理有限公司

Fully elastic nonwoven-film composite

InactiveUS20050106980A1Excellent abrasion resistanceImprove conformitySynthetic resin layered productsLaminationEngineeringNonwoven fabric

This invention concerns an elastic multilayer composite, comprising an elastic film layer sandwiched between a first elastic nonwoven layer and an optional second elastic nonwoven layer, and a process for making the same. The laminate is stabilized via bonding according to either: adhesive bonding between the film and nonwoven layer(s), direct extrusion lamination of the film to one or more nonwoven layer(s), or attachment of the film to one or more of the nonwoven layers at a plurality of points via thermopoint bonding. This invention also concerns a process for manufacturing an elastic multilayer composite, comprising: bonding under neutral tension or substantially neutral tension at least one elastic film layer to at least one elastic nonwoven layer. This invention also concerns a process for manufacturing an elastic multilayer composite, comprising: bonding under differential tension or stretch at least one elastic film layer to at least one elastic nonwoven layer, where either the film or the nonwoven or both are stretched Further the invention relates to a process whereby the elastic nonwoven(s), the film, the composite or any combination is activated, especially stretch activated, to create or enhance elasticity or the touch of the nonwoven, to create pores in the elastic film, or to soften the composite.

Owner:ADVANCED DESIGN CONCEPTS GMBH

Water-dispersible and multicomponent fibers from sulfopolyesters

Owner:EASTMAN CHEM CO

Nanofibrous nonwoven membrane of silk fibroin for guided bone tissue regeneration and manufacturing method thereof

InactiveUS20060095137A1Easy to controlSimple processMaterial nanotechnologyElectric discharge heatingBone tissueBiocompatibility Testing

The present invention relates to a membrane for guided bone tissue regeneration and, more particularly, to a membrane for guided bone tissue regeneration having a structure that silk fibroin nanofibers obtained by removing sericin from silk fibers are formed as a nonwoven, and a manufacturing method thereof. A membrane for guided bone tissue regeneration according to the present invention has a predetermined strength, biocompatibility, and biodegradability, and may maintain a sustained drug release system, when drugs are added in the manufacturing process. Additionally, a membrane for guided bone tissue regeneration according to the present invention may be modified corresponding to the condition of usage, because a thickness of the membrane may be adjusted by controlling fineness of nanofibers, compactness of nanofibers, and pore size of a multiporous structure may be adjusted, in a nonwoven manufacturing process. A nanofibrous membrane for guided bone tissue regeneration according to the present invention is manufactured by freezing rapidly, drying a silk fibroin solution obtained by removing sericin from silk fibers, and by electrospinning after dissolving the dried silk fibroin in an electrospinning solvent. The membrane according to the present invention has excellent adhesion and air permeability, and is thereby effective in regeneration of damaged periodontal tissues.

Owner:SEOUL NAT UNIV R&DB FOUND

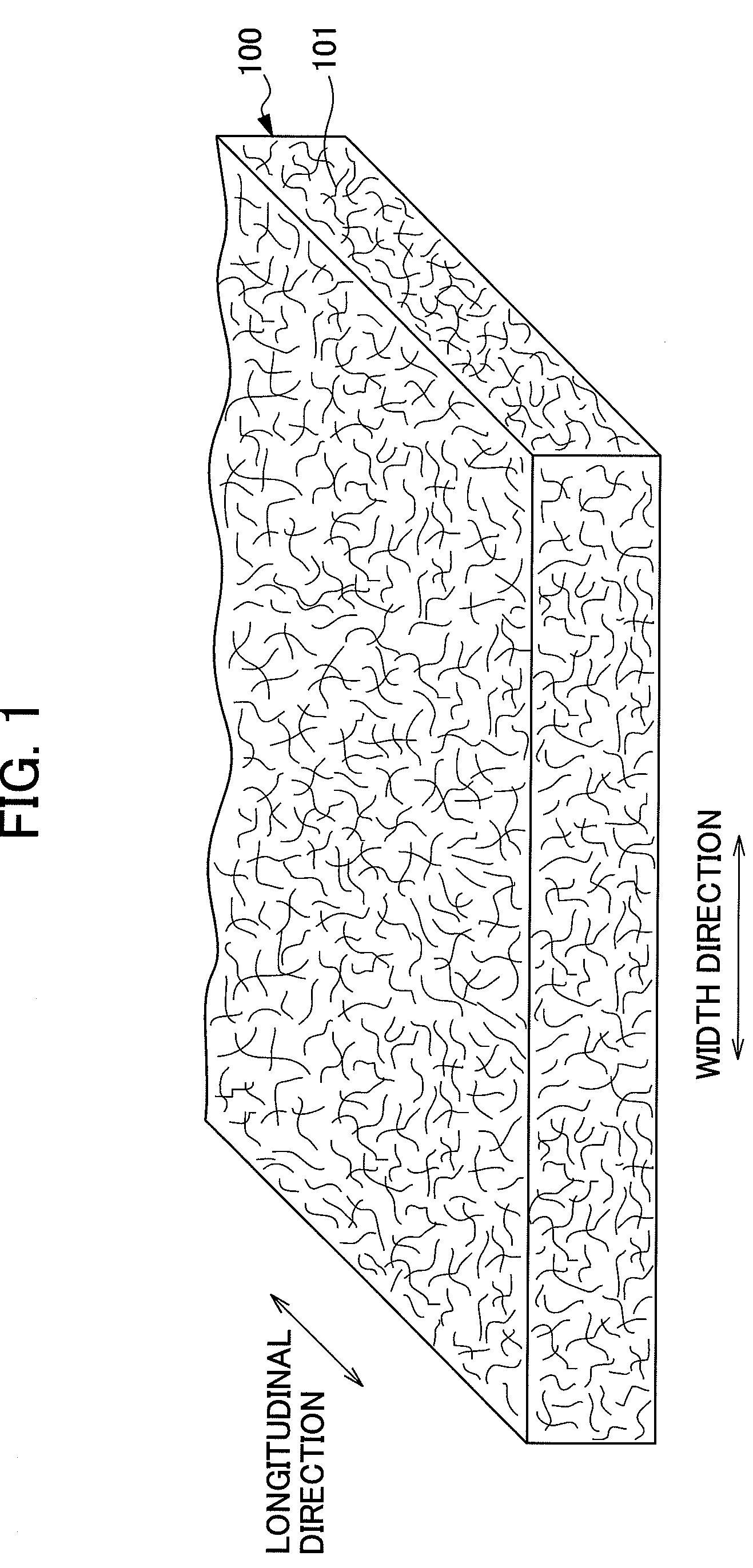

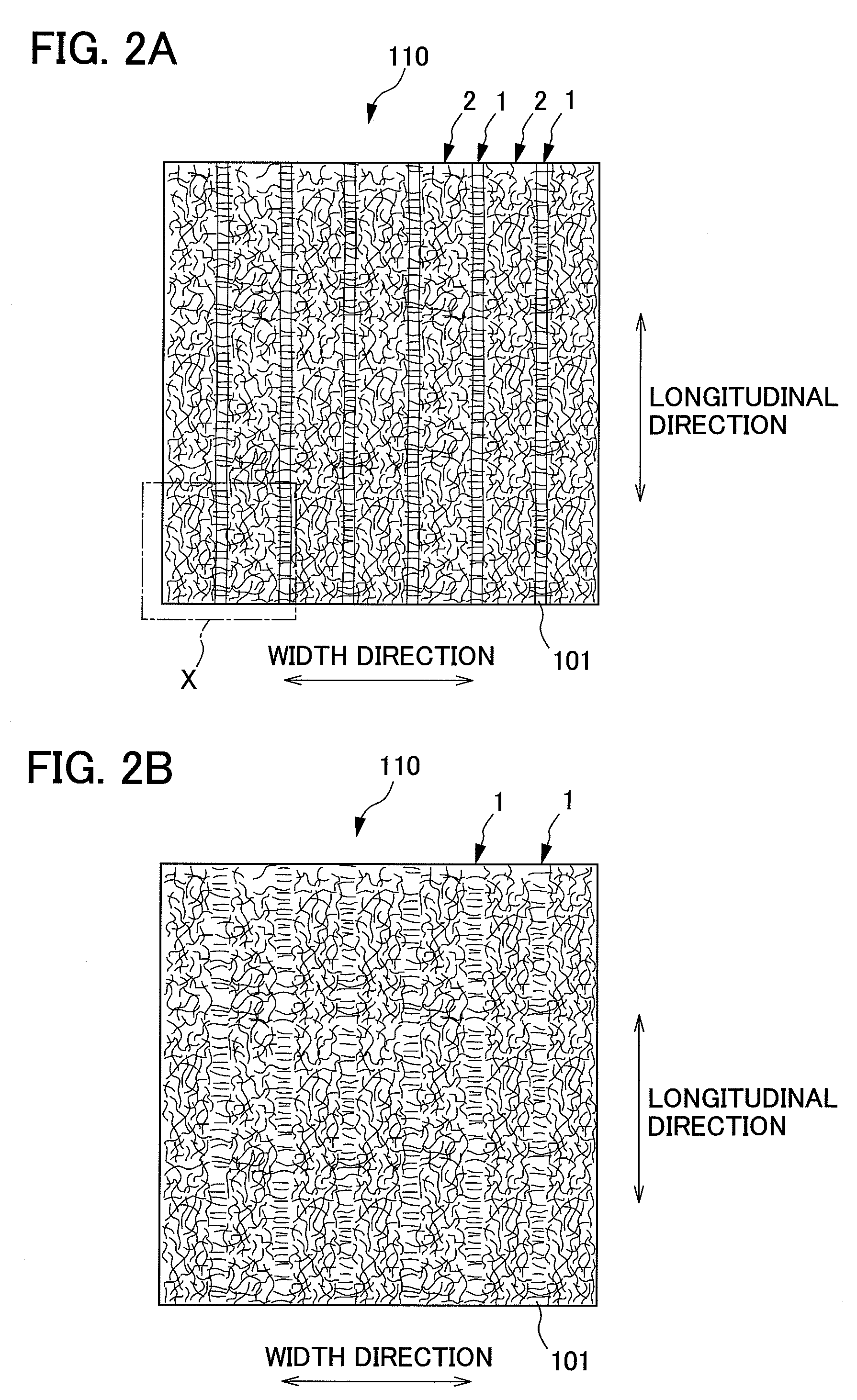

Nonwoven fabric

Owner:UNI CHARM CORP

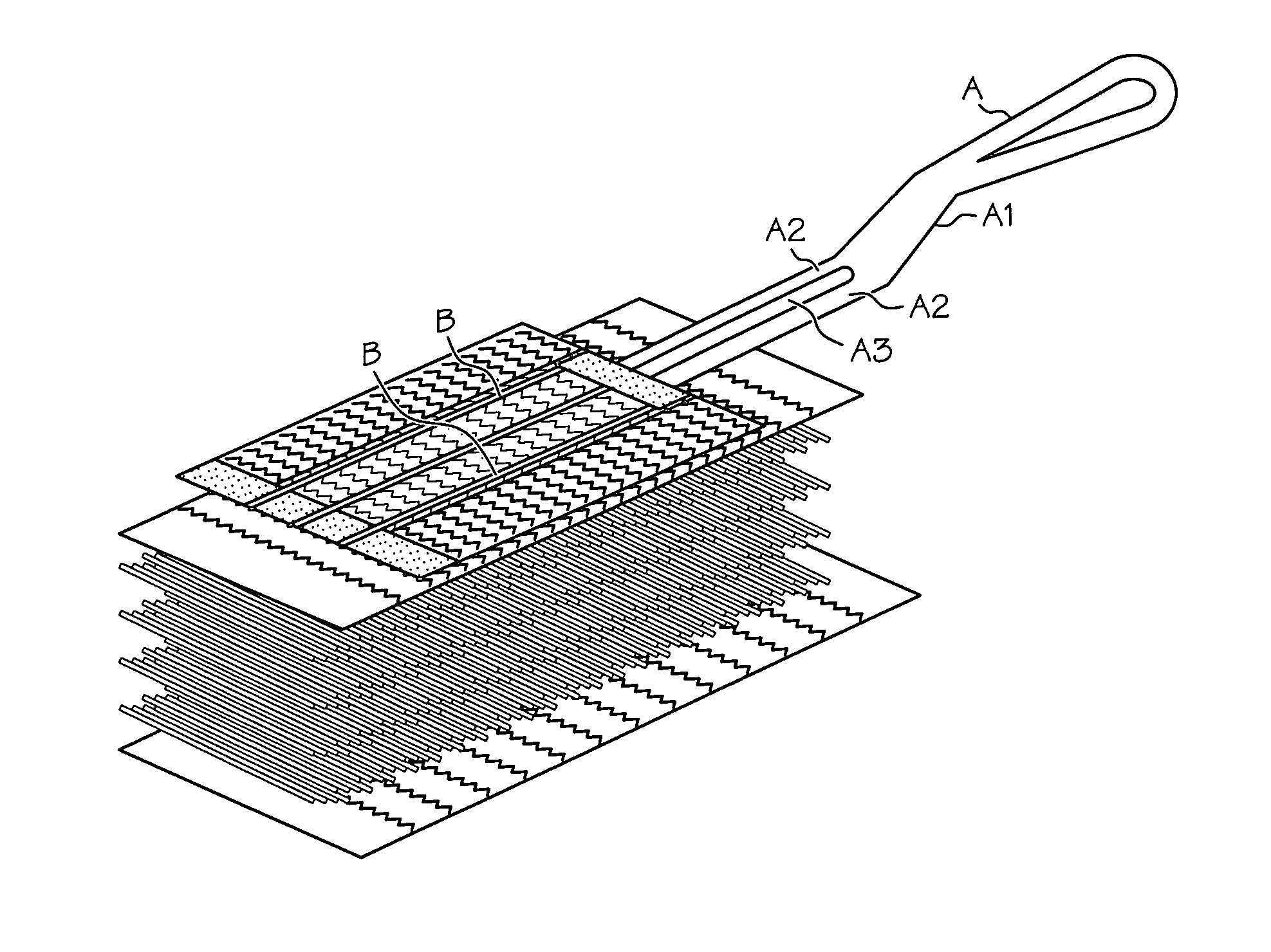

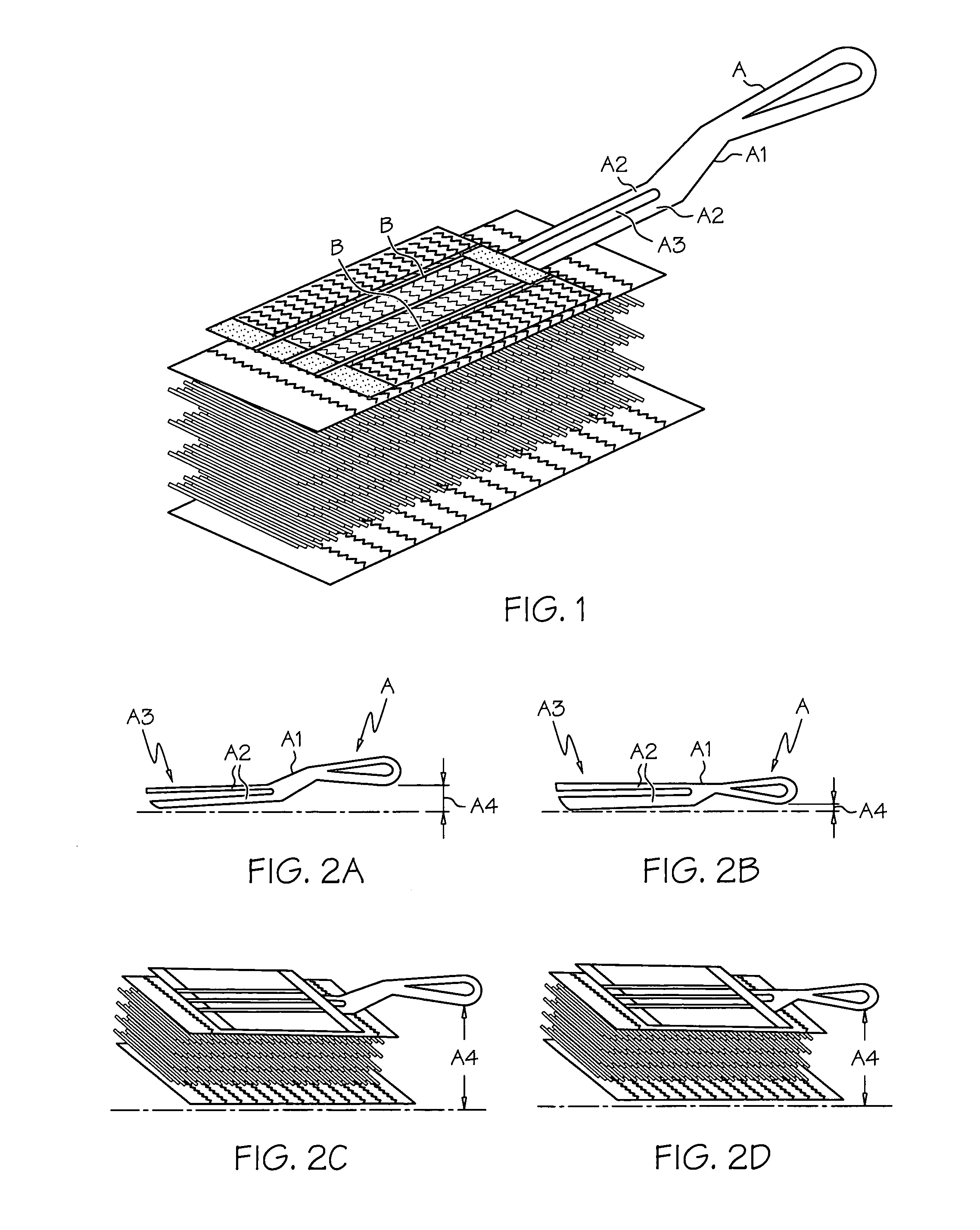

Duster system for damp and dry dusting

A kit duster pad and a cleaning composition said duster pad comprising at least one layer comprising hydrophilic non-woven fibers capable of contacting a surface to be cleaned; and at least one non-woven layer capable of being attached to a handle, wherein the at least one layer comprises at least one free end; and wherein said cleaning composition comprises a solids content at least about 0.5% by weight of the cleaning composition.

Owner:THE PROCTER & GAMBLE COMPANY

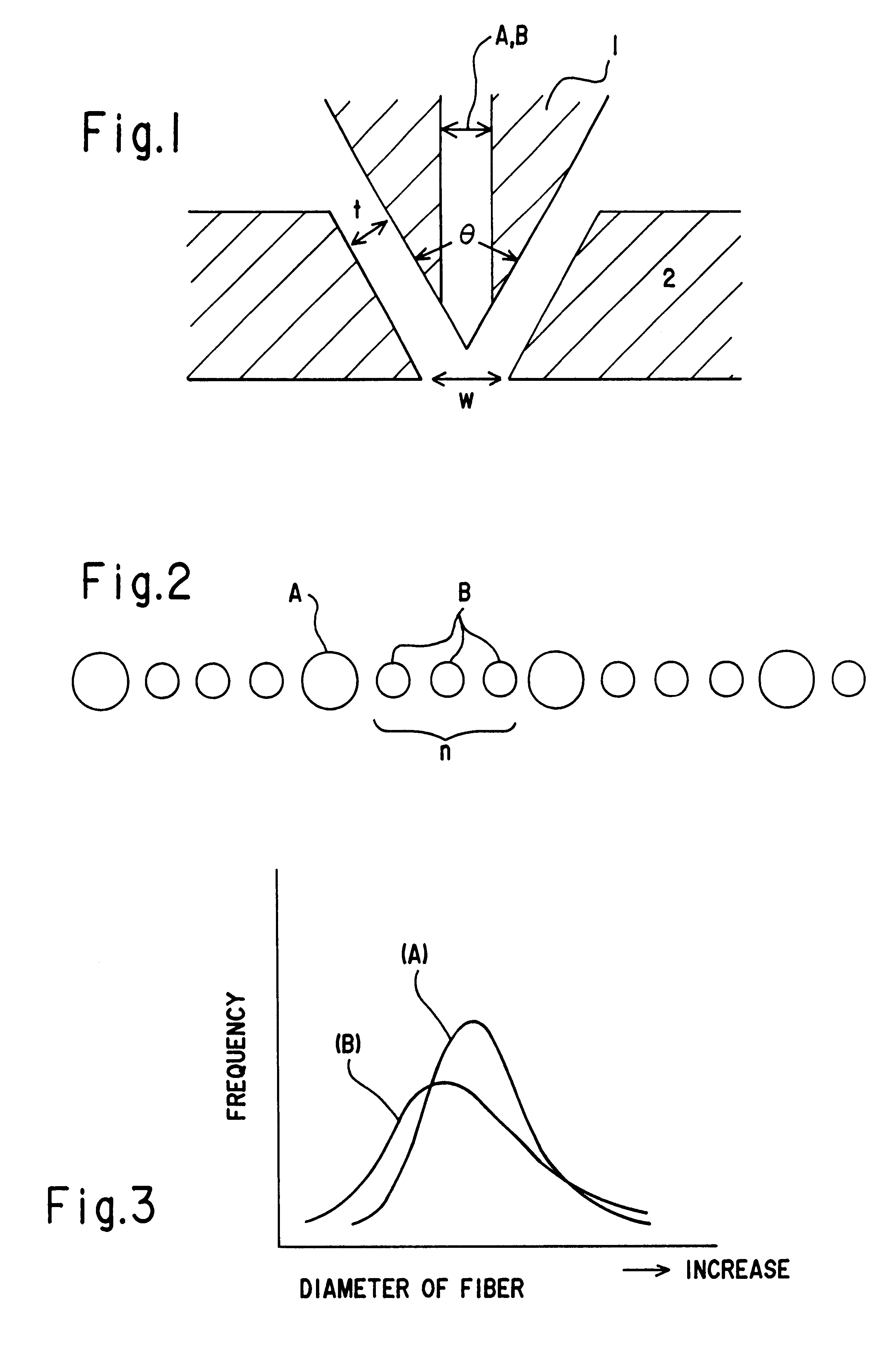

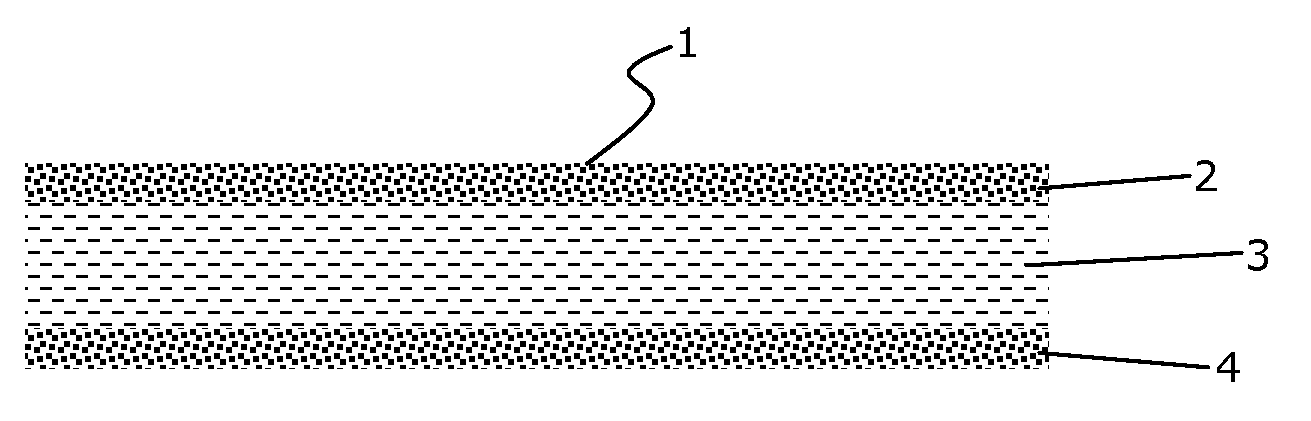

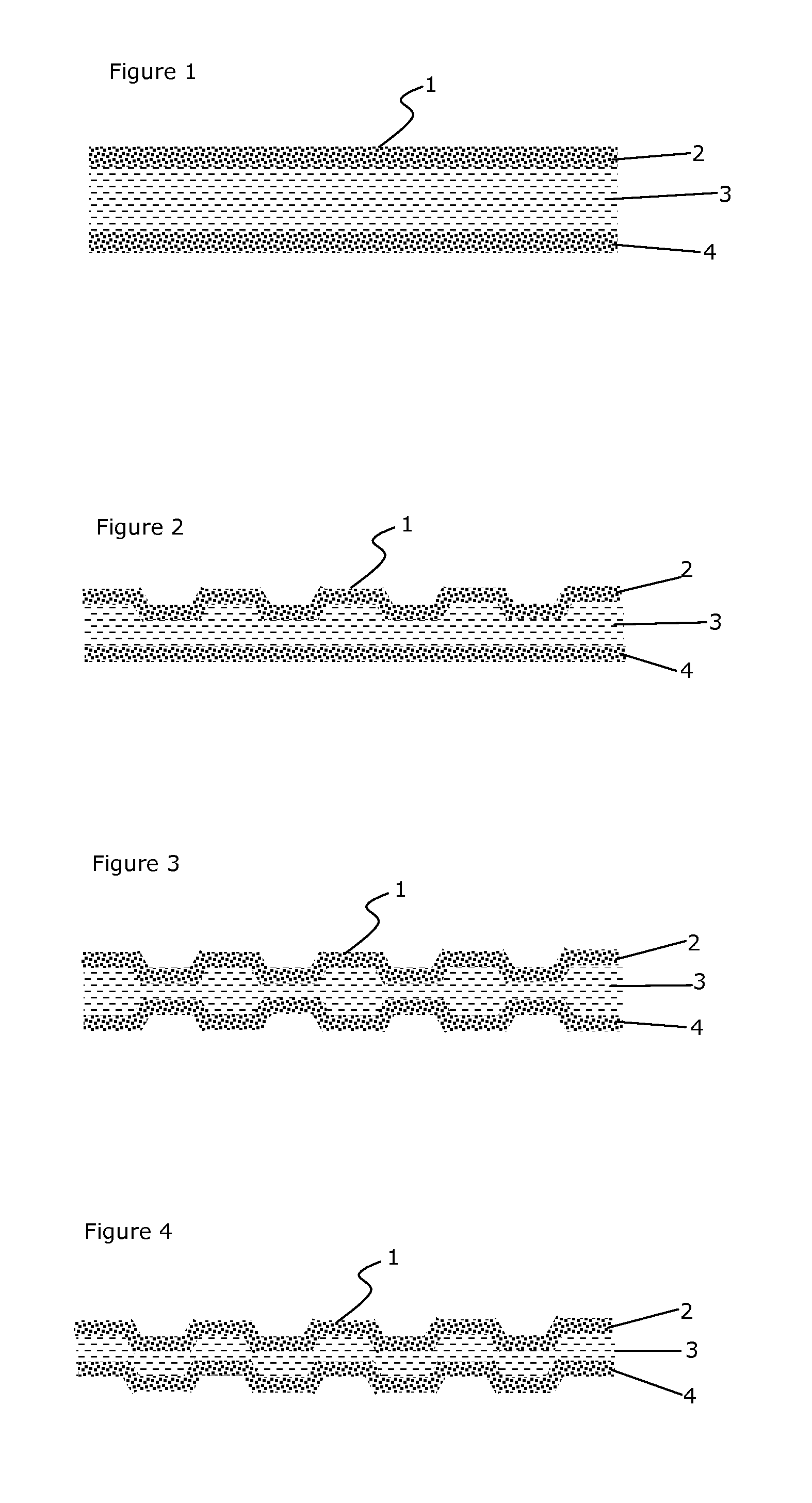

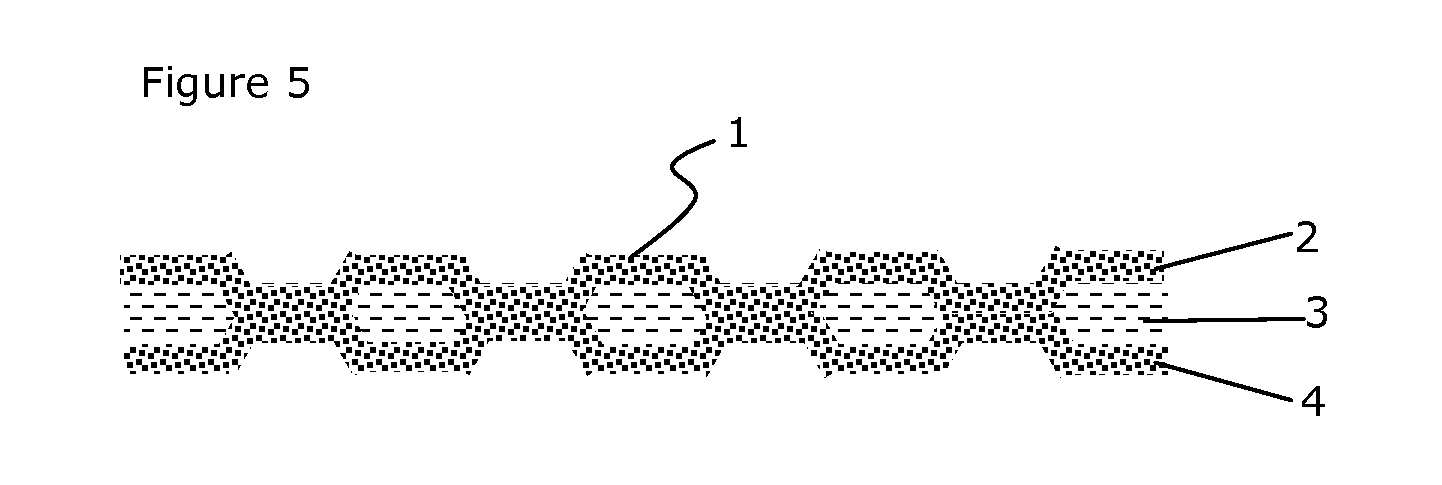

High cellulose content, laminiferous nonwoven fabric

ActiveUS20120177888A1AdvantageousDry and wet softnessLamination ancillary operationsPersonal careCelluloseWet wipe

The present invention provides a laminiferous nonwoven fabric with a high woodpulp content suitable for use in wipes, absorbent articles and other applications, and a method of making the same. The laminiferous nonwoven comprises 3 layers bonded together, where the outer layers are lightweight meltspun webs and the middle layer comprises mainly woodpulp fibres. Each of the first (3), second (2) and third (4) nonwoven layer are preferably first formed separately and individually to be self-supported webs, whereafter the three self-supported webs are brought together essentially immediately before bonding them together. When used as a substrate for wet wipes, the inventive fabric exhibits a combination of several useful properties; good wet and dry softness and bulk, good wet abrasion resistance and low wet linting propensity, and where the majority raw material is woodpulp.

Owner:SUOMINEN CORP

Nonwoven fabric for separator of non-aqueous electrolyte battery and non-aqueous electrolyte battery using the same

InactiveUS6200706B1Uniform and efficient productionImprove various performanceOrganic electrolyte cellsPaper/cardboardSurface roughnessEngineering

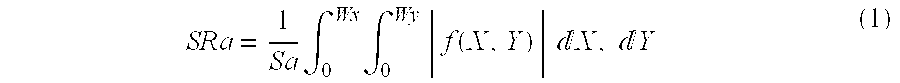

The object of the present invention is to provide a nonwoven fabric for separators of non-aqueous electrolyte batteries which is superior in adhesion to electrodes, causes no breakage of the separator and neither slippage nor space between electrode and the separator at the time of fabrication of battery, provides superior battery processability such as rollability with electrodes, causes no internal short-circuit due to contact between electrodes caused by shrinking or burning of the nonwoven fabric even when electrodes generate heat owing to external short-circuit, whereby ignition of the battery can be inhibited, has no pin holes and is superior in retention of electrolyte and penetration of electrolyte, and which can give non-aqueous electrolyte batteries superior in capacity, battery characteristics and battery storage characteristics. Specifically, the nonwoven fabric for separators of non-aqueous electrolyte batteries according to the present invention has a thickness non-uniformity index (Rpy) of 1000 mV or less or a center surface average roughness SRa of 6 mum or less in whole wavelength region as measured using a tracer method three-dimensional surface roughness meter.

Owner:MITSUBISHI PAPER MILLS LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com