Biopolymer nano tunica fibrosa material capable of being biological degraded and absorbed, preparing method and uses of the same

A biopolymer and nanofiber membrane technology, applied in fiber processing, textiles, papermaking, catheters, etc., can solve problems such as serious fiber adhesion and uneven fiber thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

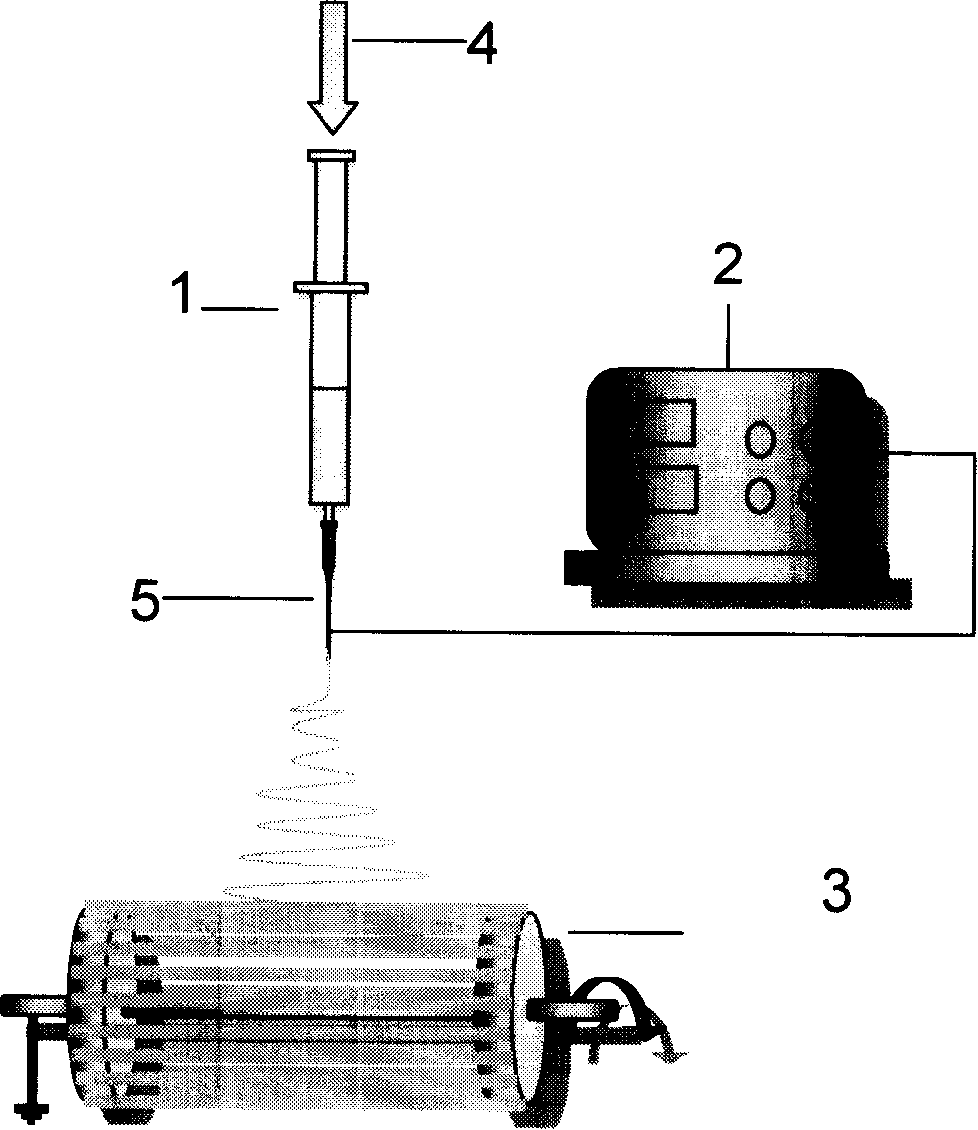

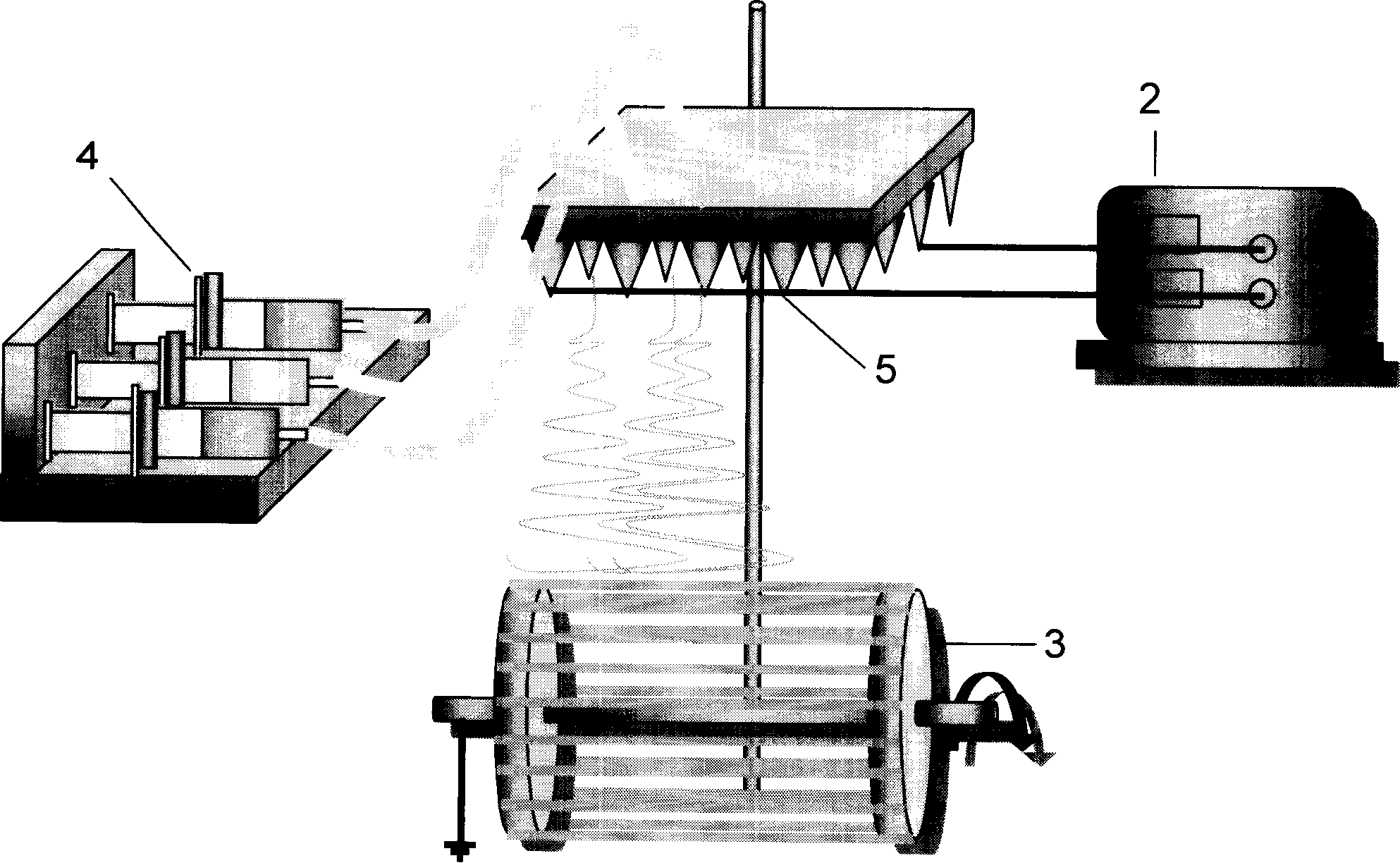

[0061] See figure 1 . The high-voltage power supply 2 adopts a negative DC high-voltage output power supply, and the maximum output voltage is 40kV. The high-voltage power supply is connected to the injection end of the spinneret 5 of the syringe 1 through wires; the output mode of the syringe pump 4 adopts output pumps with various output frequencies to drive the syringe. Feeding, the maximum output range is 300 microliters per minute, the syringe pump is connected to the feed end of the spinneret of syringe 1 through a catheter; the material of the spinneret is stainless steel, and the diameter of the spinneret is 0.8mm; the collection device is copper wire parallel Arranged rotating drums 3, the diameter of the drums 3 is 80mm, and the distance between the copper wires is 7.5mm; the electrospinning environment temperature control device adopts infrared lamp heating method, the system is PID control, and the control accuracy is within the range of ±3°C.

[0062] (1) Prepara...

Embodiment 2

[0067] The equipment is the same as in Example 1.

[0068] (1) Preparation of solution: preparation concentration is the ionic liquid 1-allyl of the cellulose of 10wt%, 3-methyl imidazolium acetate solution 10ml, wherein cellulose is the wood pulp cellulose that the degree of polymerization is 800, in above-mentioned An organic solvent dimethylformamide is added to the solution, wherein the mass ratio of dimethylformamide / cellulose solution is 2 / 1, stirred evenly, and placed in a syringe;

[0069] (2) Adjust the electrospinning device: select a single spinneret device, and the rotating drum is used as a collector; adjust the distance between the spinneret and the collecting device to be 15cm; the ambient temperature of spinning is 45 degrees, and the air velocity in the environment Controlled at 0.5~0.8m 3 / hr;

[0070] (3) Set the spinning process parameters: turn on the high-voltage power supply, adjust the voltage to 18KV, the feeding speed of the solution is 60ul / min, th...

Embodiment 3

[0073] The equipment is the same as in Example 1, and the collection device is changed to a rotating drum with copper wires arranged crosswise.

[0074] (1) Preparation of solution: preparation concentration is the ionic liquid 1-allyl of the cellulose of 10wt%, 3-methylclomidazolium salt solution 5ml, wherein cellulose is the wood pulp cellulose that the degree of polymerization is 800, in above-mentioned Add organic solvent dimethyl sulfoxide to the solution, wherein the mass ratio of dimethyl sulfoxide / cellulose solution is 2 / 1, stir evenly, and place in a syringe;

[0075] (2) Adjust the electrospinning device: select a single spinneret device, and the rotating drum is used as a collector; adjust the distance between the spinneret and the collecting device to be 15cm; the ambient temperature of spinning is 25 degrees, and the air velocity in the environment Controlled at 0.5~0.8m 3 / hr;

[0076] (3) Set the spinning process parameters: turn on the high-voltage power supp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com