Patents

Literature

13606 results about "Salt solution" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

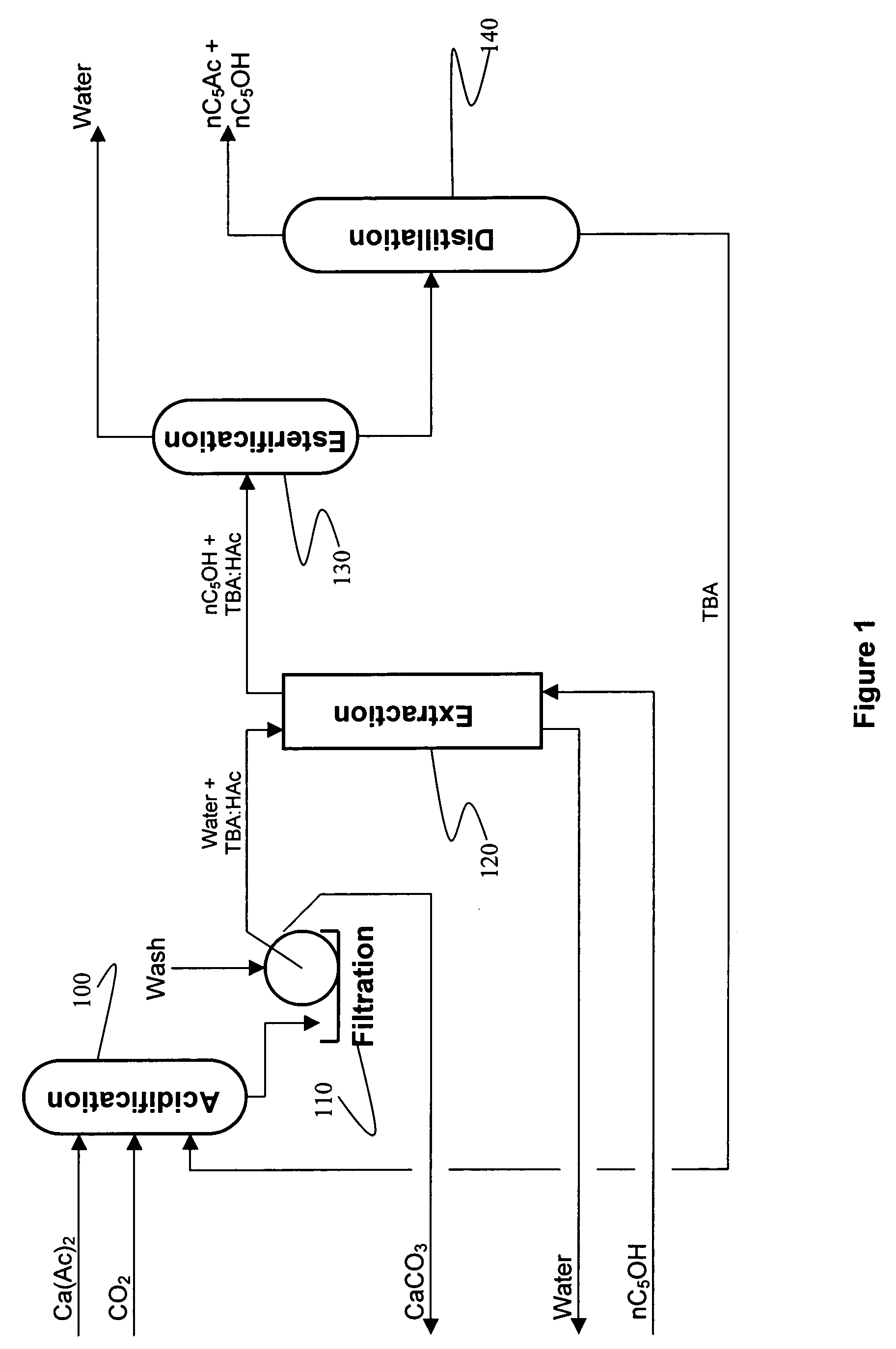

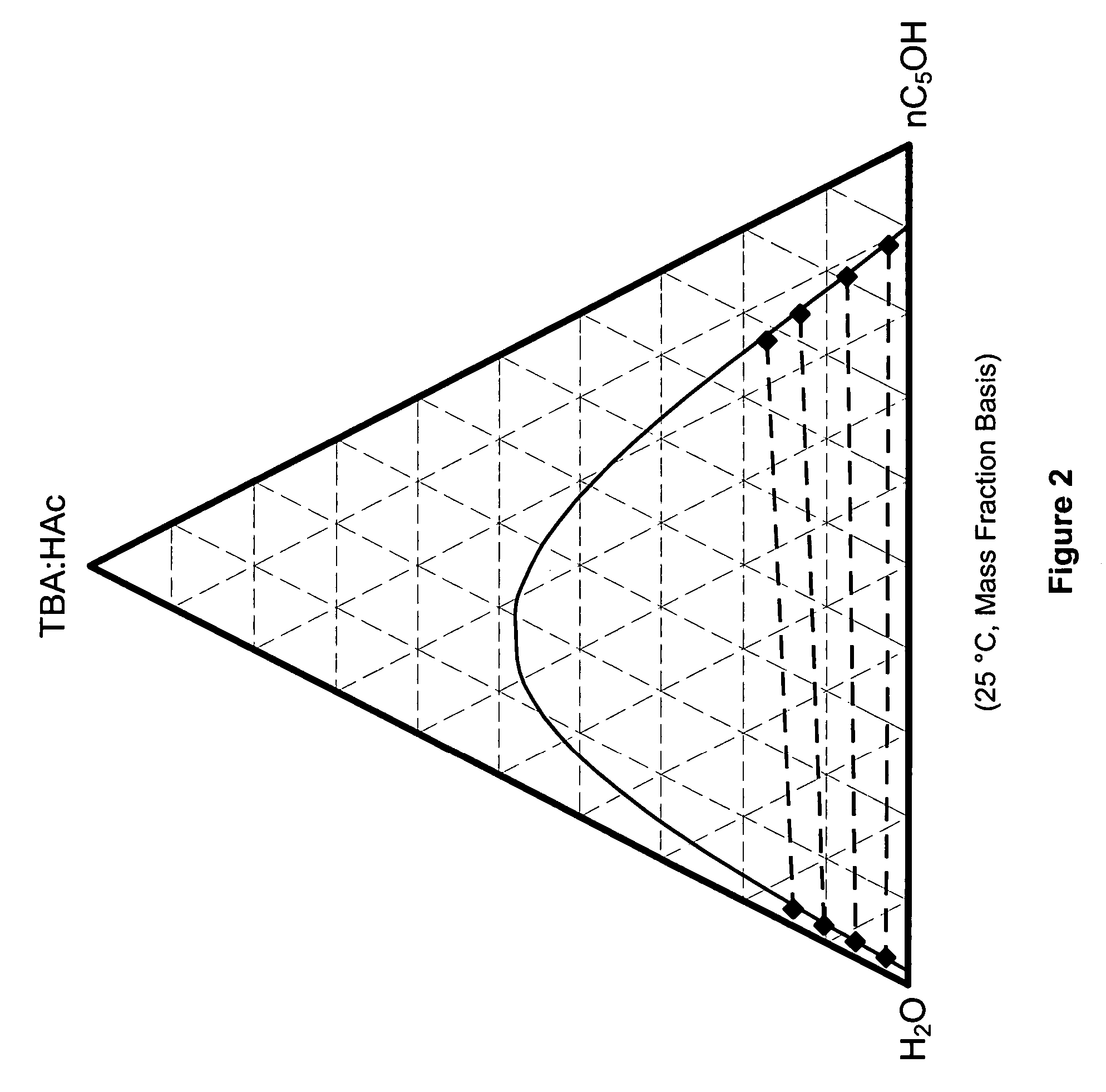

Recovery of organic acids

InactiveUS20090281354A1Promote recoveryOvercome consumptionPreparation from carboxylic acid saltsOrganic compound preparationOrganic acidReactive distillation

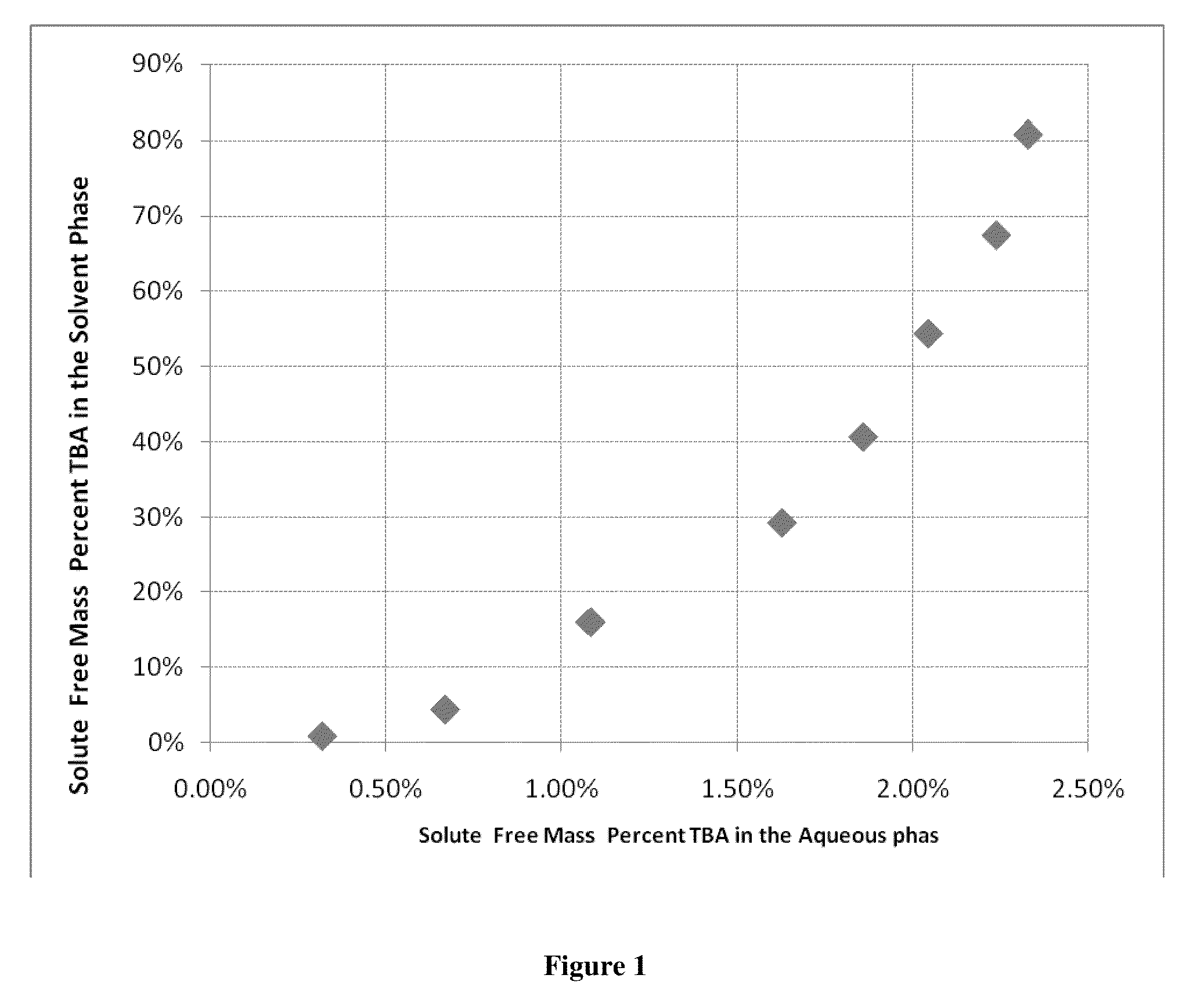

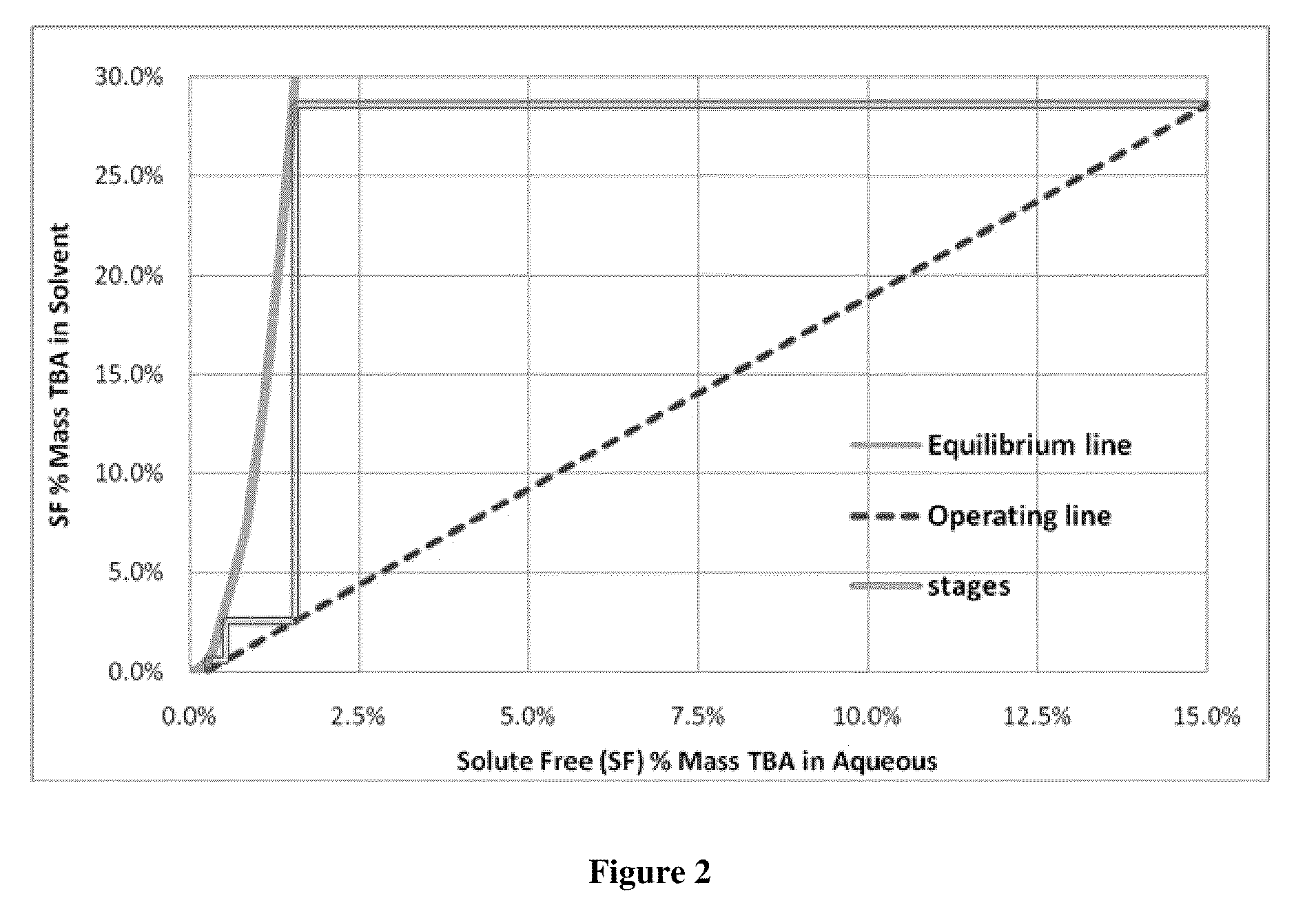

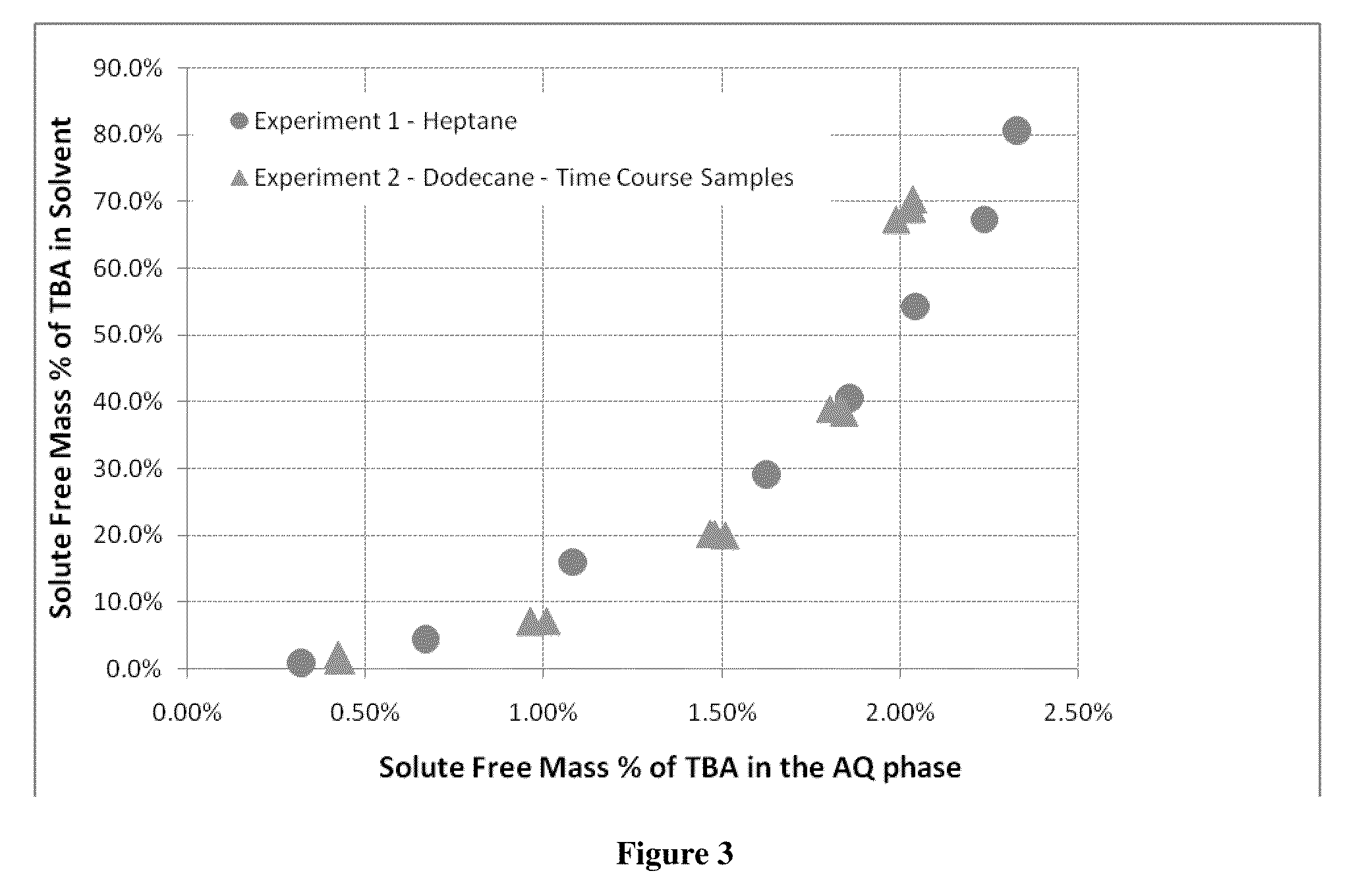

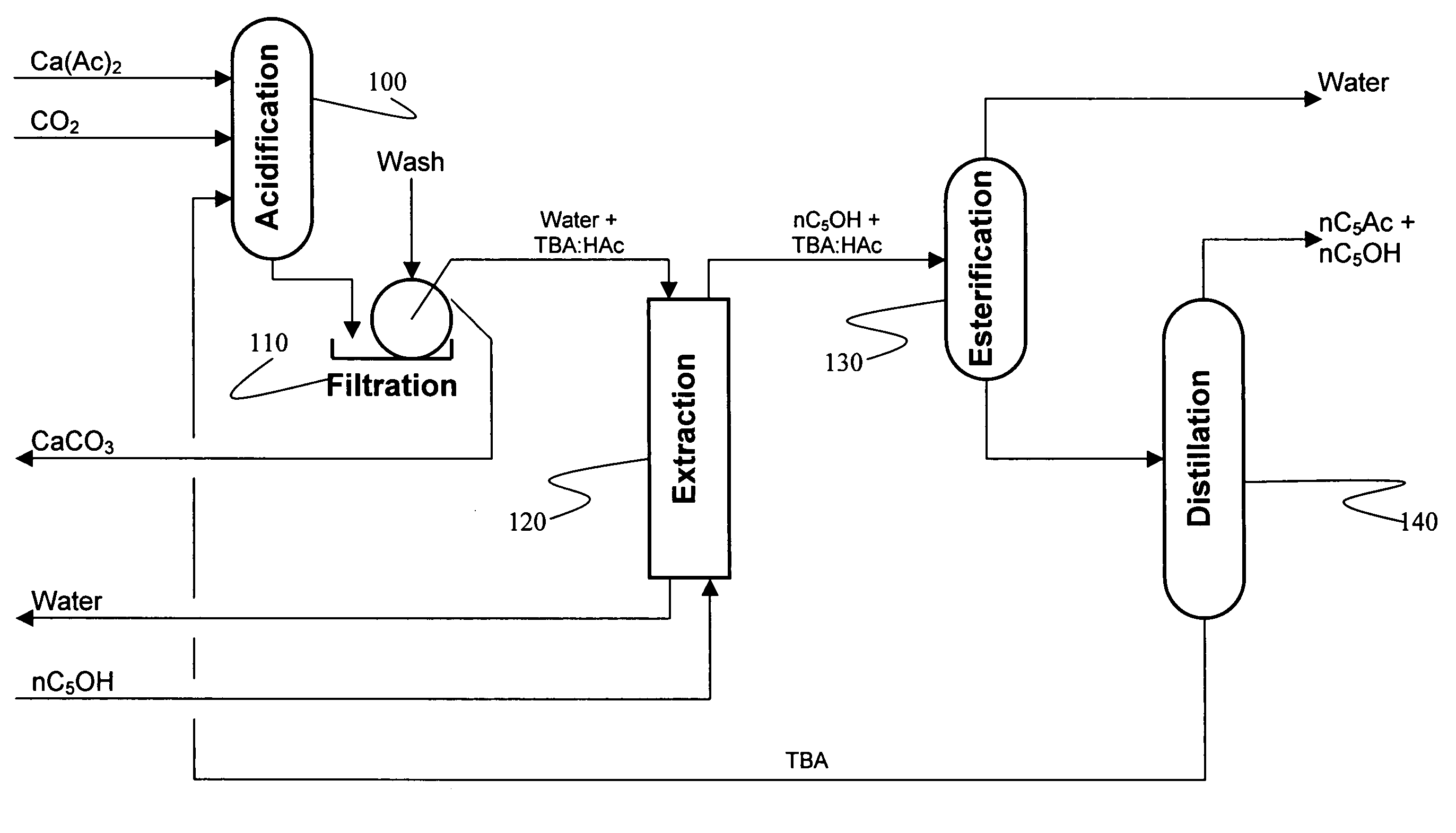

A method is disclosed for the recovery of an organic acid from a dilute salt solution in which the cation of the salt forms an insoluble carbonate salt. An amine and CO2 are introduced to the solution to form the insoluble carbonate salt and a complex between the acid and the amine. The acid / amine complex is thermally dissociated, or “cracked”, in the presence of a water immiscible solvent in which the amine is selectively soluble and in which the acid is not appreciably soluble. The organic acid may then be recovered from the water by any suitable means such as distillation, reactive distillation, extraction, or reactive extraction.

Owner:ZEACHEM

Recovery of organic acids

InactiveUS7601865B2Promote recoveryOvercome consumptionPreparation from carboxylic acid saltsOrganic compound preparationOrganic acidAlcohol

Owner:ZEACHEM

Methods of sealing compositions and methods

InactiveUS6187839B1Shorten the timeShorten the overall cycleDrilling compositionSealing/packingHigh densitySalt solution

The present invention provides methods of sealing subterranean zones using high density sealing compositions. The methods are basically comprised of introducing a sealing composition into the subterranean zone comprised of a high density aqueous salt solution, a polymerizable monomer and a polymerizable initiator and allowing said sealing composition to form a sealing gel in said zone.

Owner:HALLIBURTON ENERGY SERVICES INC

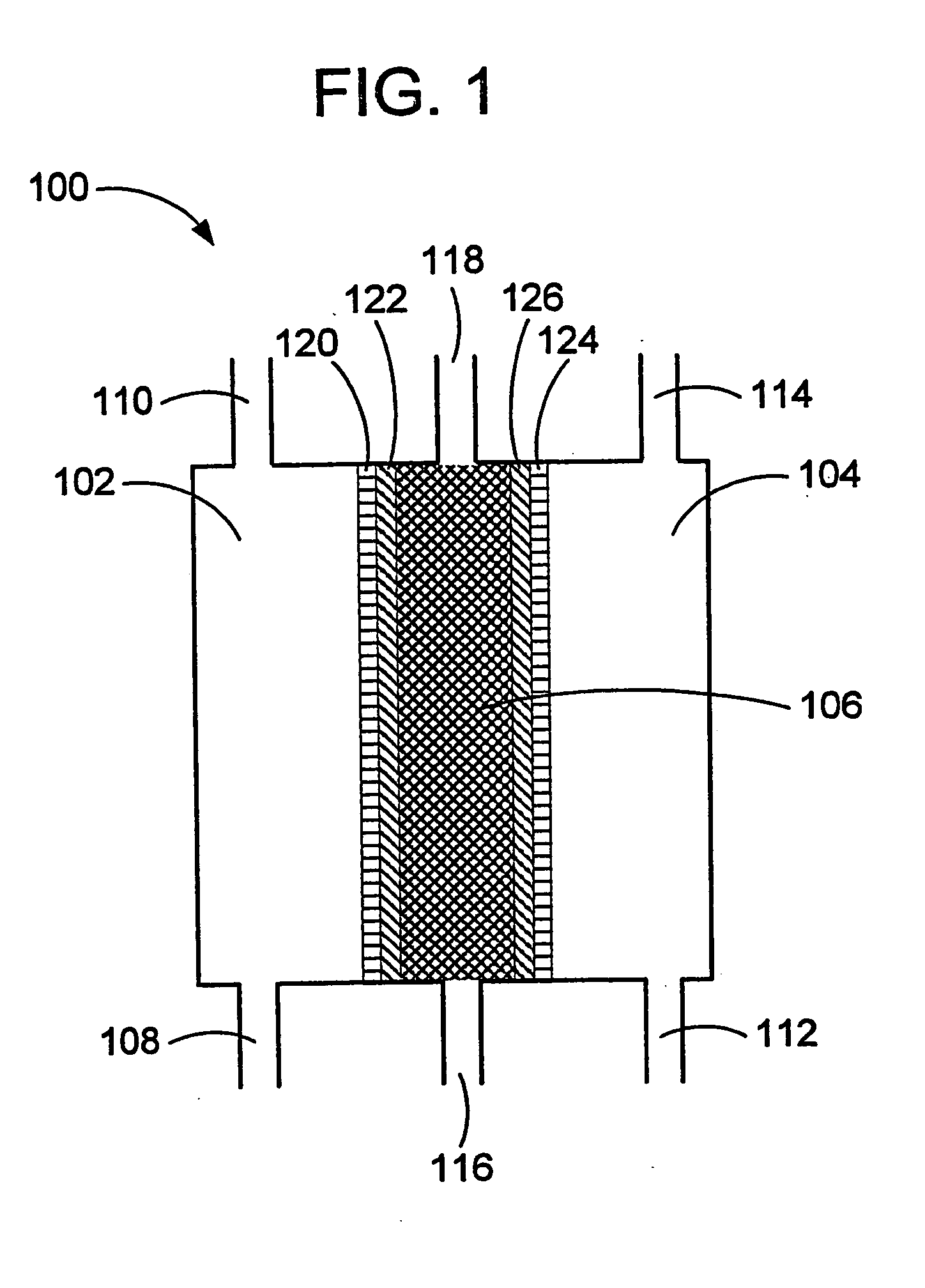

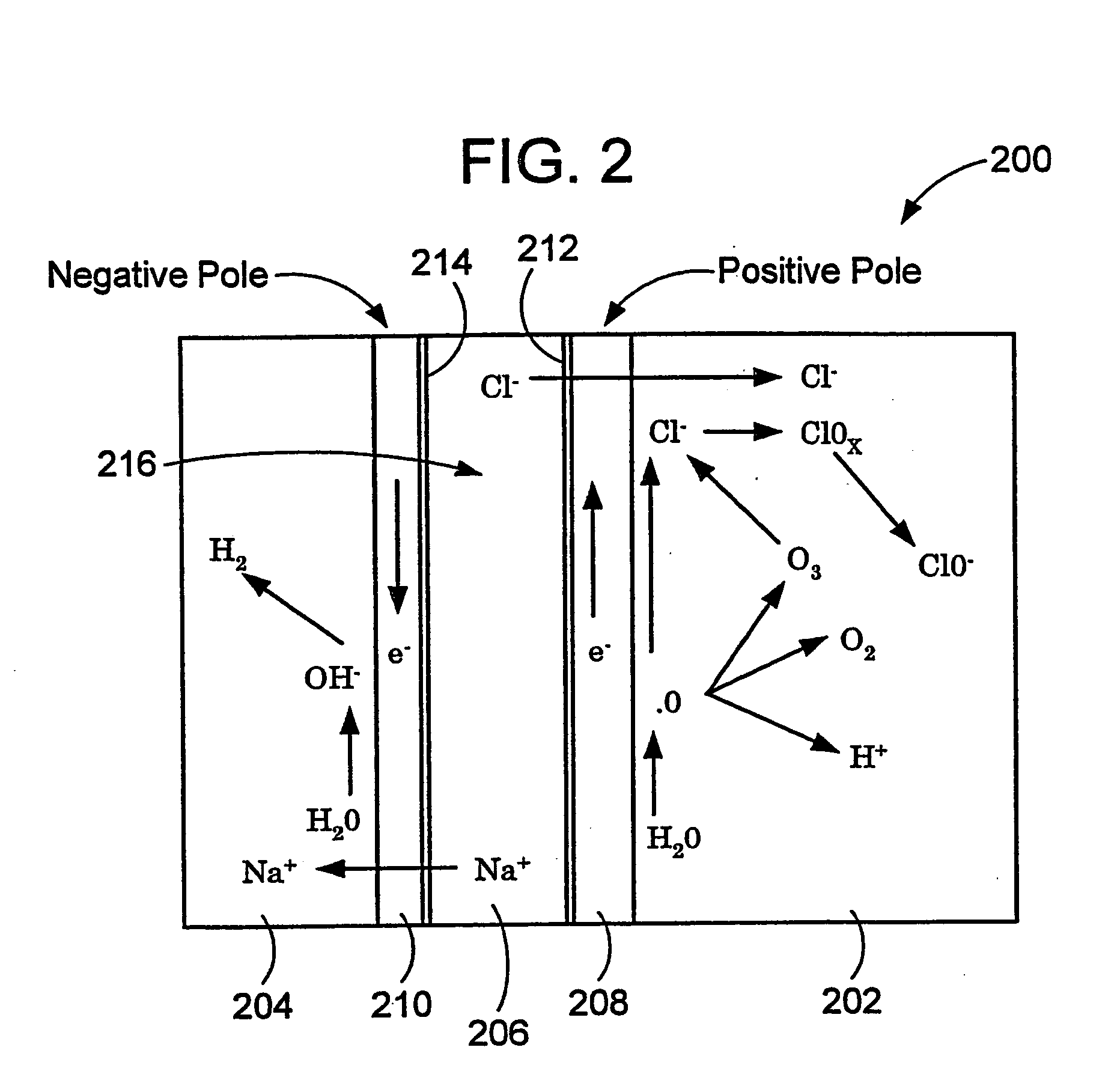

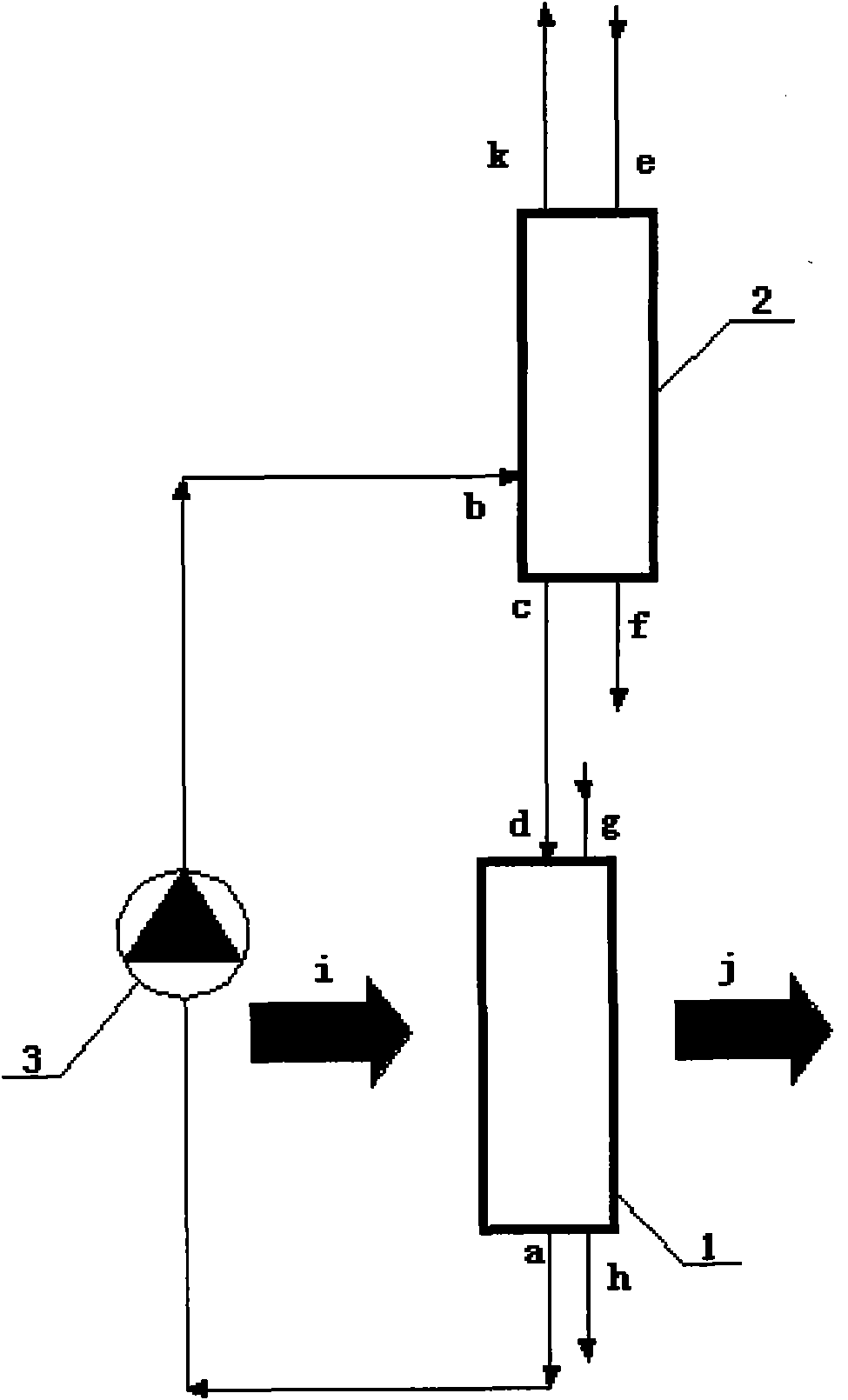

Oxidative reductive potential water solution and process for producing same

An oxidative reduction potential water solution that is stable for at least twenty-four hours. The invention also relates to an ORP water solution comprising anode water and cathode water. Another aspect of the invention is an apparatus for producing an ORP water solution comprising at least two electrolysis cells, wherein each cell comprises an anode chamber, cathode chamber and salt solution chamber located between the anode and cathode chambers, wherein the anode chamber is separated from the salt solution chamber by an anode electrode and a first membrane, and the cathode chamber is separated from the salt solution chamber by a cathode electrode and a second membrane.

Owner:SONOMA PHARMA INC

Production of Soluble Protein Solutions from Soy ("S701")

ActiveUS20100098818A1Prevent oxidationMilk preparationProtein composition from vegetable seedsProtein solutionSports drink

A soy protein product, which may be an isolate, produces transparent heat-stable solutions at low pH values and is useful for the fortification of soft drinks and sports drinks without precipitation of protein. The soy protein product is obtained by extracting a soy protein source material with an aqueous calcium salt solution to form an aqueous soy protein solution, separating the aqueous soy protein solution from residual soy protein source, adjusting the pH of the aqueous soy protein solution to a pH of about 1.5 to about 4.4 to produce an acidified clear soy protein solution, which may be dried, following optional concentration and diafiltration, to provide the soy protein product.

Owner:BURCON NUTRASCI MB

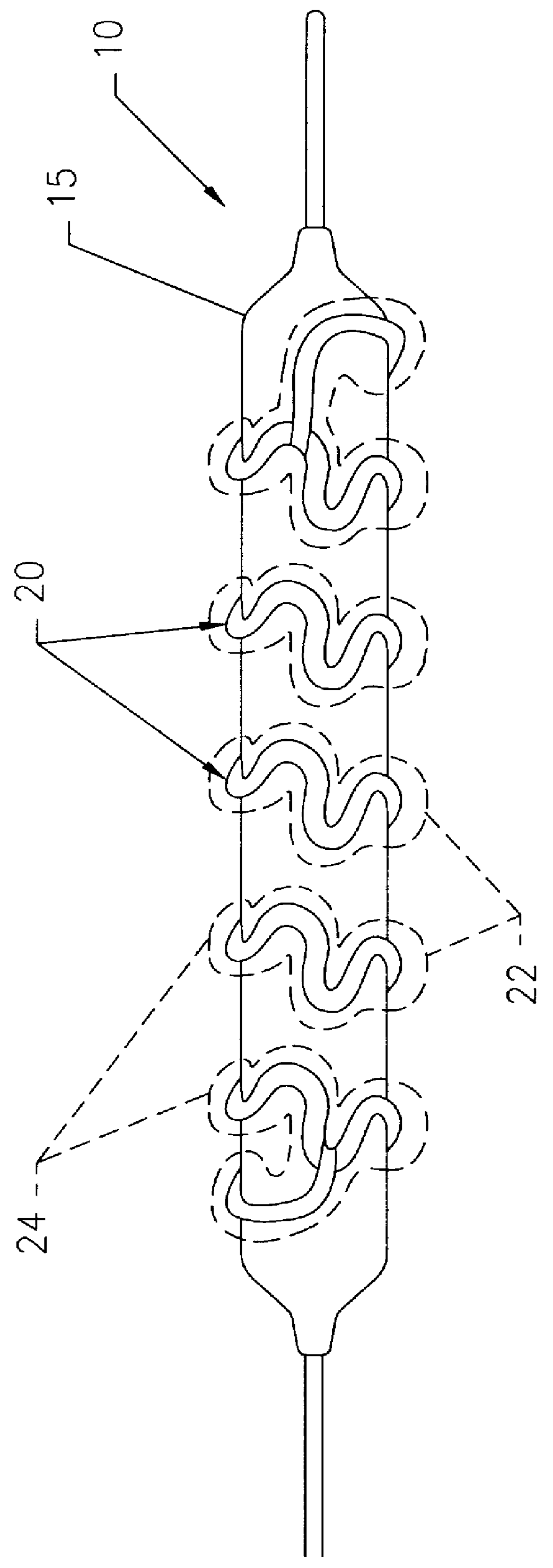

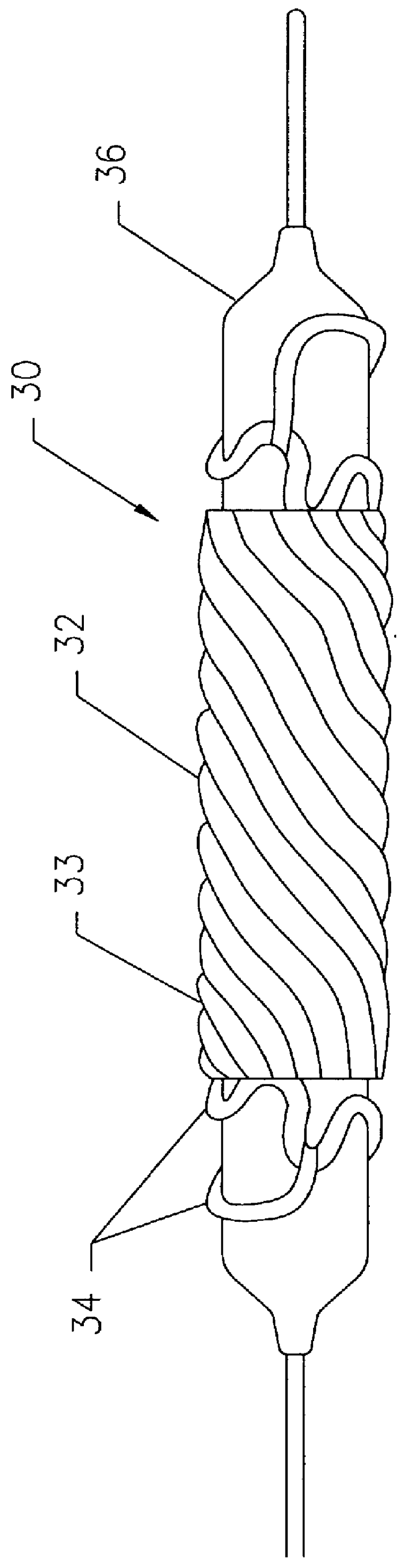

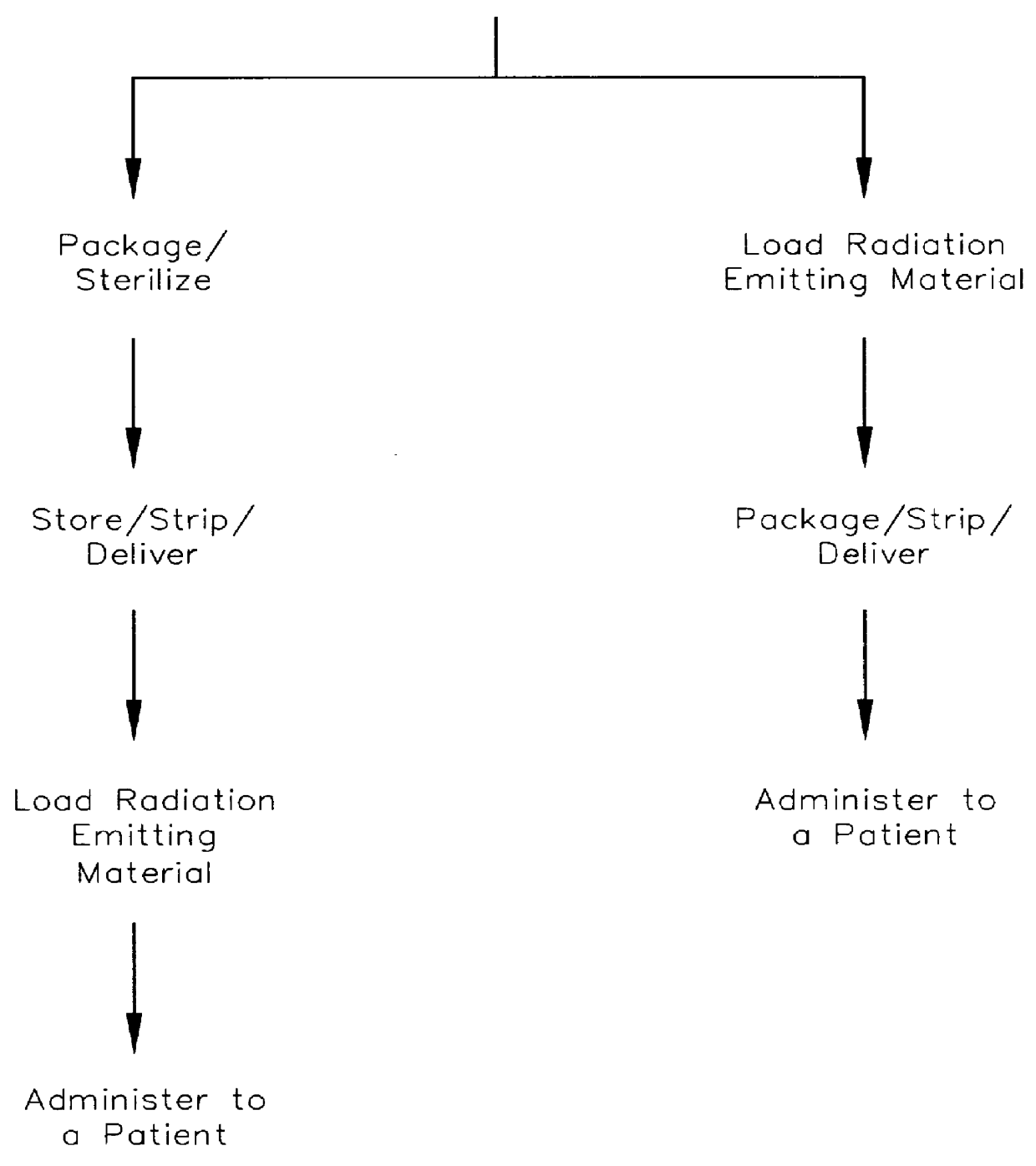

Medical device for delivering localized radiation

InactiveUS6106454AShort half-lifeUniform deliverySurgeryDiagnostic recording/measuringWater insolubleMedicine

A medical device useful for localized delivery of radiation in vivo is provided. The medical device includes a structure including a porous material; and a plurality of discrete particles including a water-insoluble radioactive salt dispersed throughout a substantial portion of the porous material. The water-insoluble radioactive salt is formed by contacting an aqueous radioactive salt solution with a heavy metal water-soluble salt dispersed throughout a substantial portion of the porous material. The heavy metal water-soluble salt can be dispersed in the porous material so that the device can be sterilized and the radioactive material can be loaded in the device in situ, for example, just prior to implantation.

Owner:MEDTRONIC INC

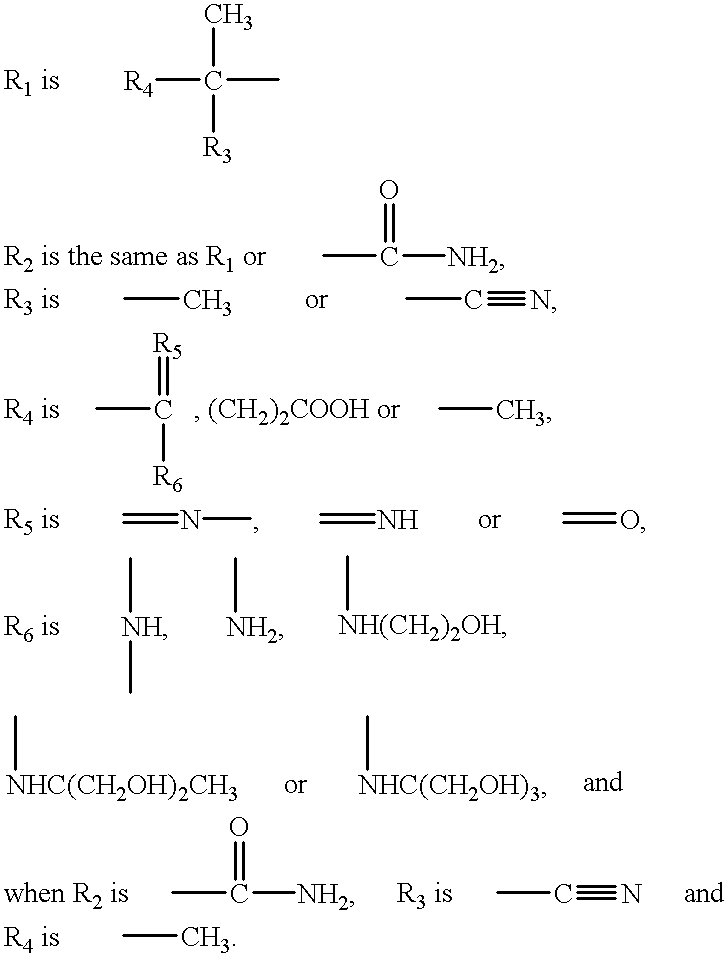

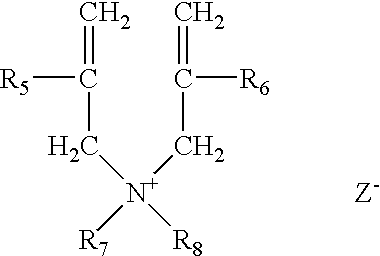

Method for making hydrophobically associative polymers, methods of use and compositions

InactiveUS6417268B1Cosmetic preparationsSludge treatment by de-watering/drying/thickeningHydrophilic monomerSludge

Method for producing an hydrophobically associative polymer is provided which is characterized by forming a monomer solution comprising a surfactant, at least one hydrophobic ethylenically unsaturated monomer, at least one hydrophilic monomer selected from nonionic ethylenically monomers, cationic ethylenically unsaturated monomers, anionic ethylenically unsaturated monomers or mixtures thereof, and water; forming a salt solution comprising a multivalent salt and water; mixing the monomer solution and salt solution to form a mixed solution; and charging the mixed solution with an initiator, thereby polymerizing the monomers to form the hydrophobically associative polymer in a dispersion. Aqueous dispersion containing the hydrophobically associative polymer formed by the method. The aqueous dispersion containing the hydrophobically associative polymer may be used in a paint formulation, in a mobility control fluid useful in enhanced oil recovery, in a secondary or tertiary oil recovery system, in an enhanced oil recovery method, in a cementious composition, in an oil well drilling mud formulation, in a fracturing fluid formulation, in a wastewater treatment system, or in a dewatering sludge system.

Owner:SOLENIS TECH CAYMAN

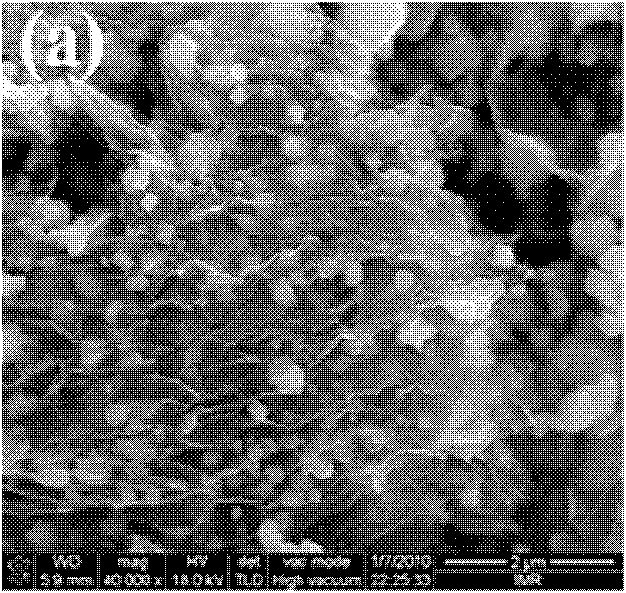

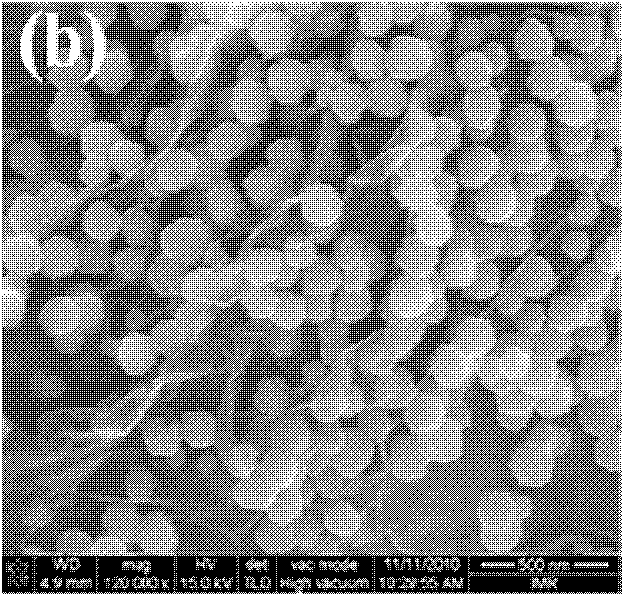

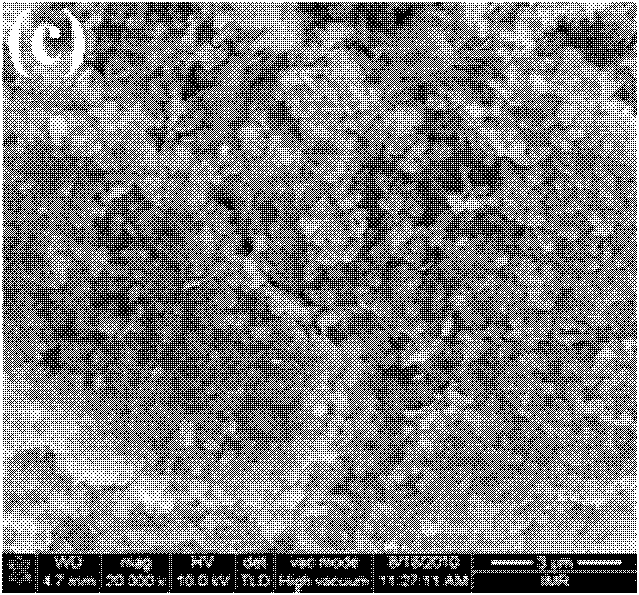

Graphene/metal oxide composite cathode material for lithium ion battery and preparation

InactiveCN102646817APromote circulationExcellent rate performanceCell electrodesHigh energyIn situ polymerization

The invention belongs to the fields of material synthesis and energy technology, and especially relates to a graphene / metal oxide composite cathode material for lithium ion batteries and a preparation method thereof. Grapheme is dispersed into various metal oxide precursor salt solutions; a graphene / metal oxide compound is obtained directly by a hydrothermal method, or an graphene / metal oxide compound is obtained by a liquid in-situ polymerization method or a coprecipitation process; and the graphene / metal oxide compound is obtained by heat treatment or hydrothermal treatment. In the invention, the novel three-dimensional composite cathode material of graphene-coated metal oxide or graphene-anchored metal oxide is prepared by carrying metal oxide particles with graphene as a carrier. The obtained composite material can be used as a lithium ion battery cathode, which has a high specific capacity, excellent cycle stability and rate capability, and is expected to be used as a lithium ion battery cathode material with a high energy density and a high power density.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

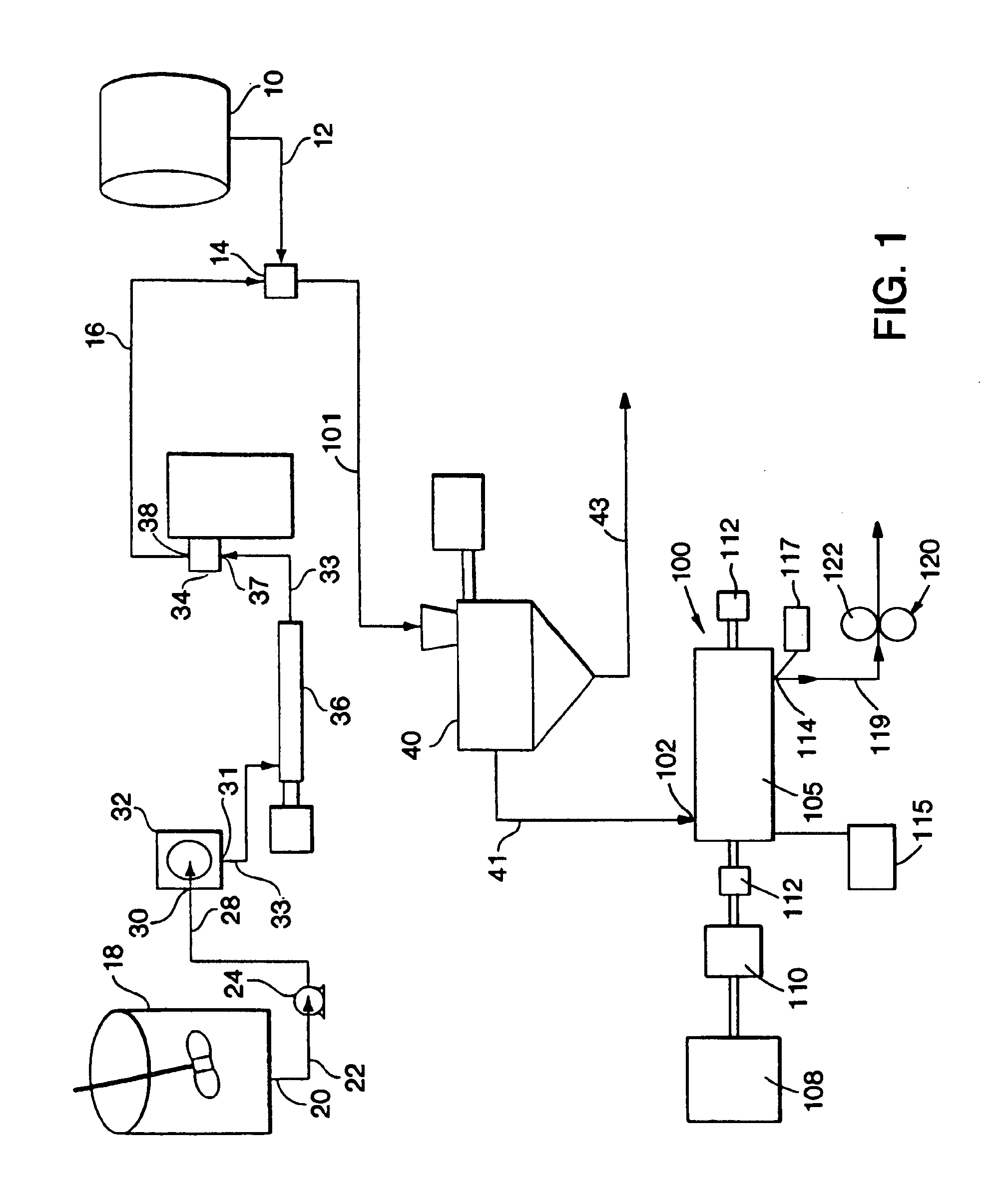

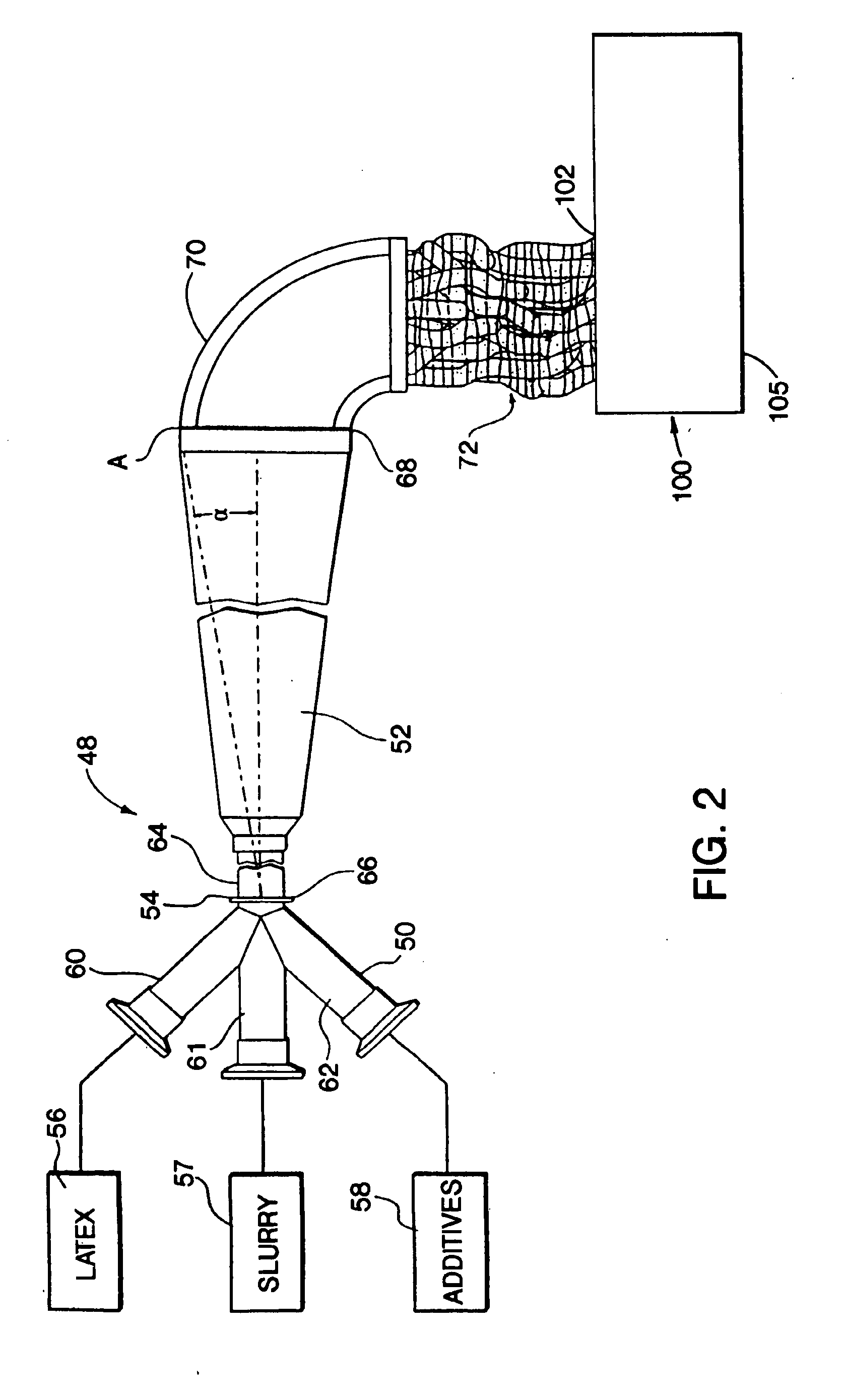

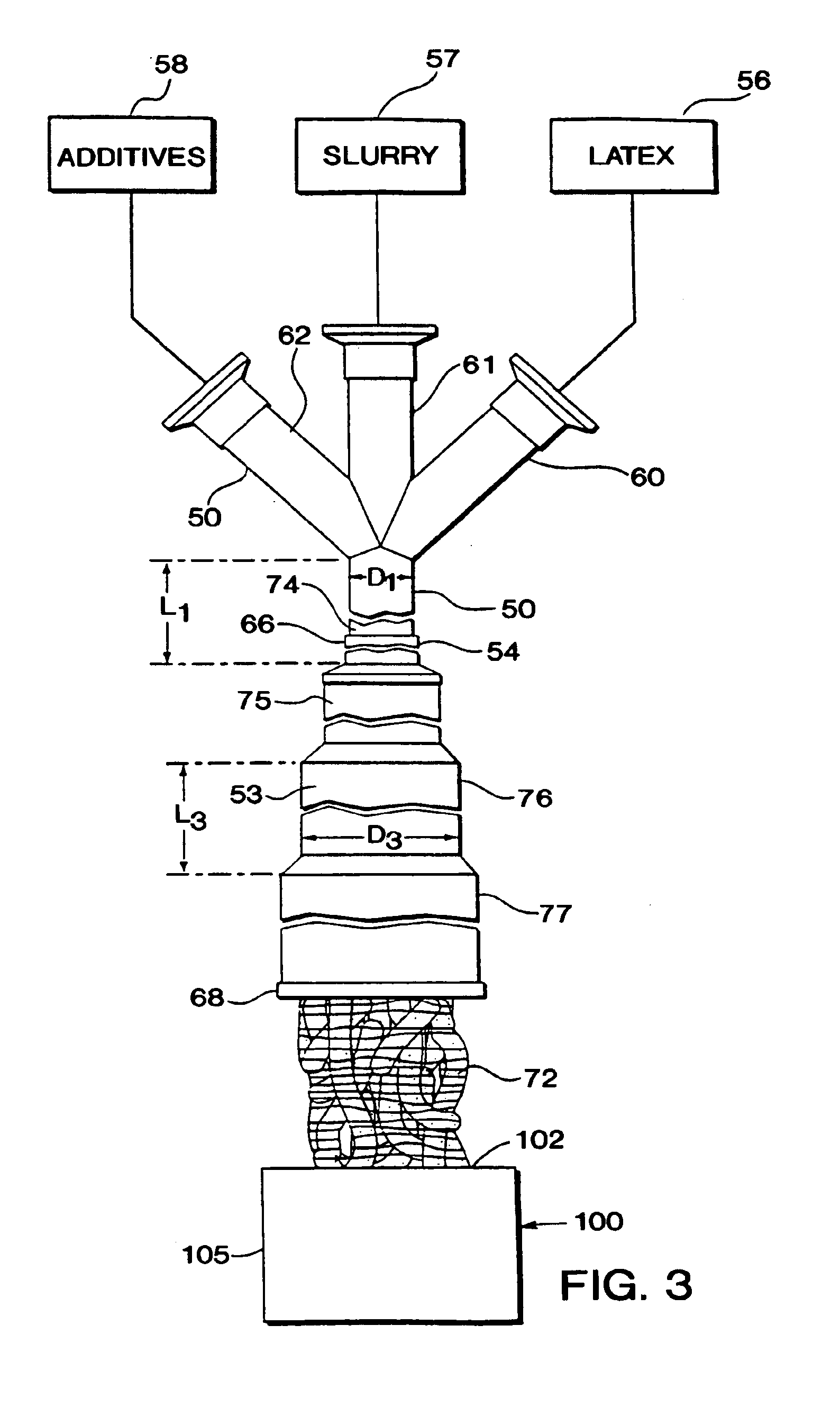

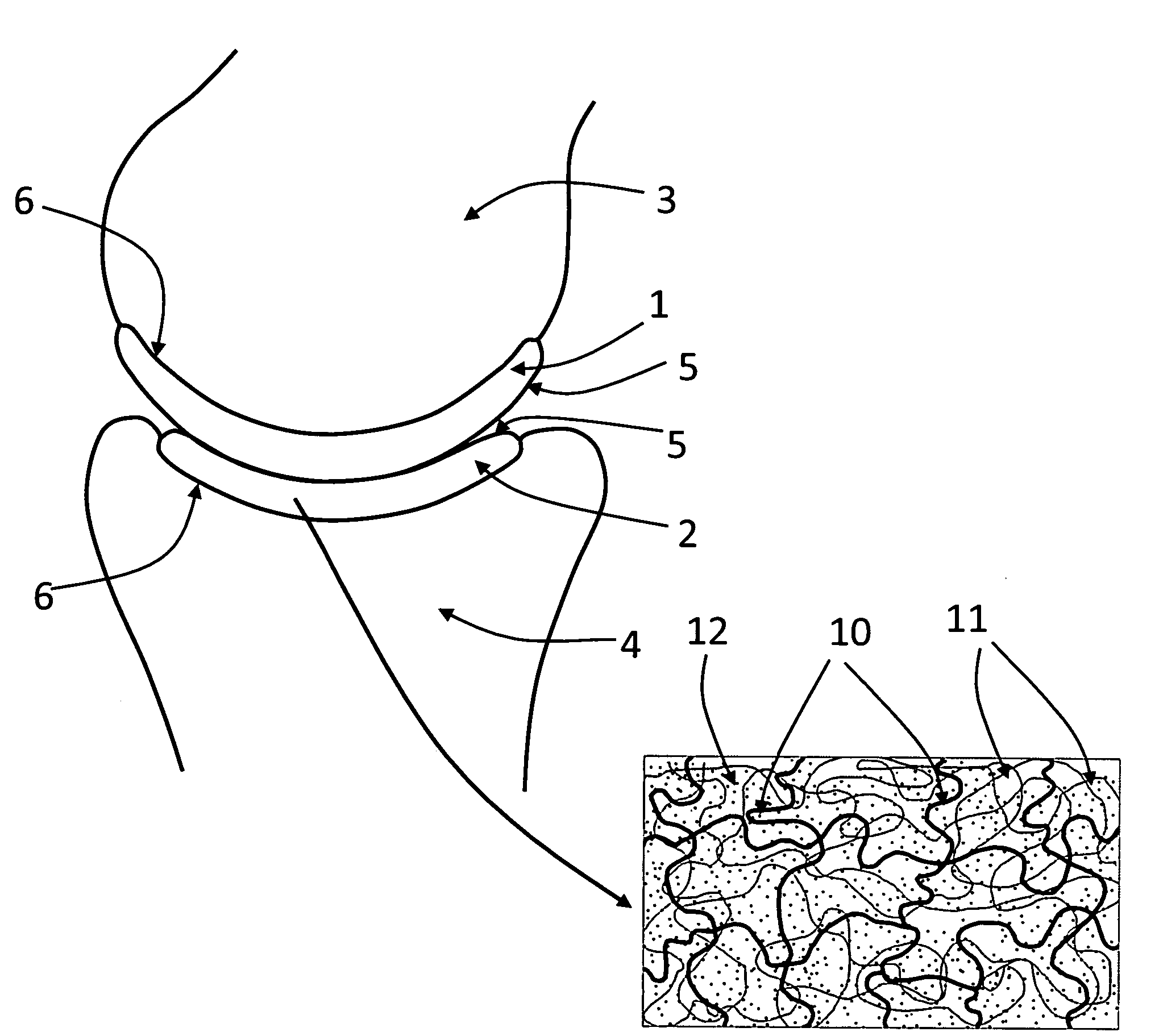

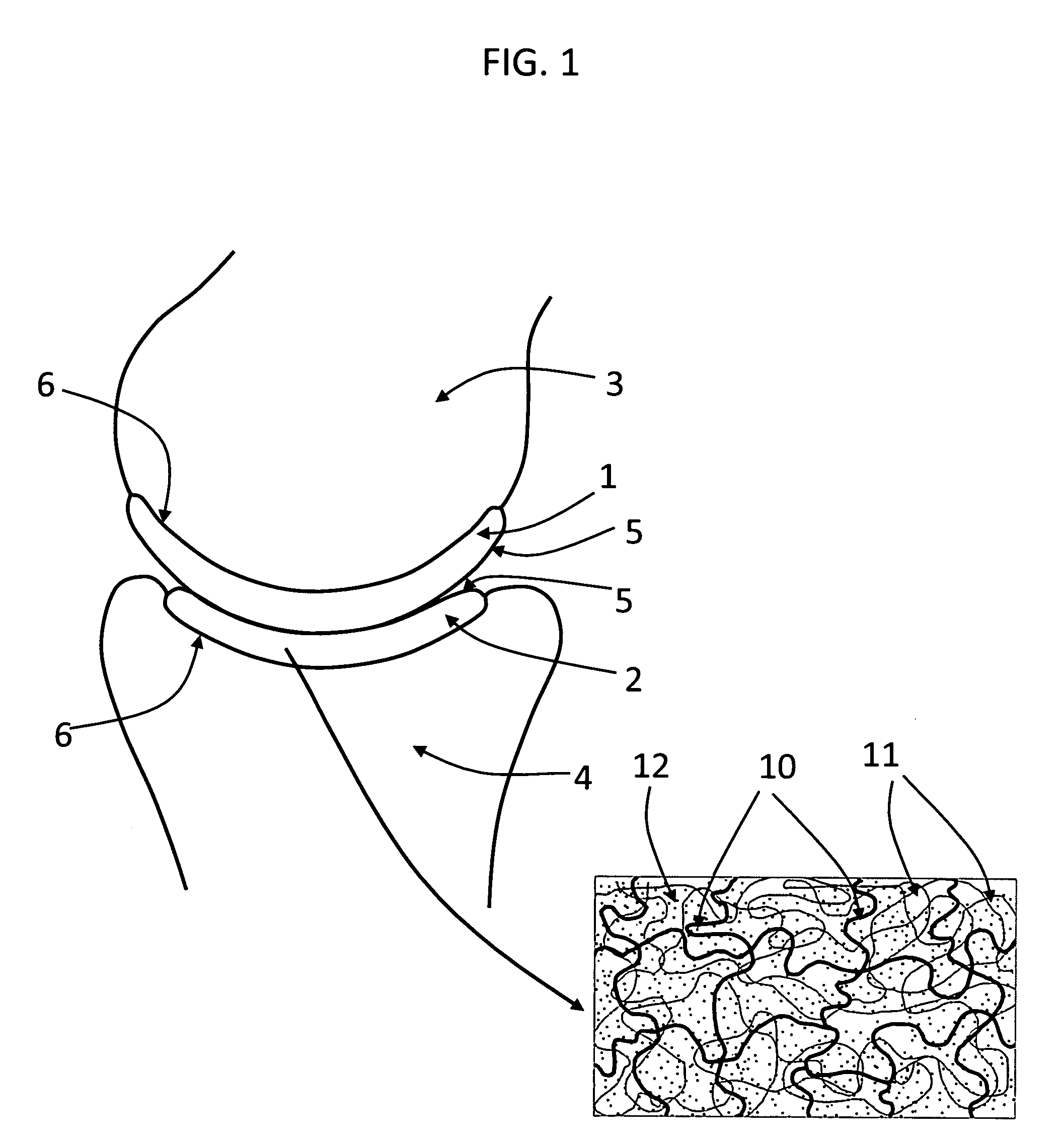

Method and apparatus for producing and treating novel elastomer composites

InactiveUS6929783B2Facilitate controlling and changing operating parameterImprove economyLiquid degasificationSpecial tyresParticulatesMasterbatch

Elastomer masterbatch is processed in a continuous compounder having multiple parallel elongate rotors axially oriented in an elongate processing chamber. Optionally, additional materials are compounded into the masterbatch, e.g., additives, other elastomeric compositions, etc. Preferably, the masterbatch then is further processed in an open mill. Excellent control of Mooney Viscosity is achieved.In certain preferred embodiments, elastomer composites are produced by novel continuous flow methods and apparatus in which fluid streams of particulate filler and elastomer latex are fed to the mixing zone of a coagulum reactor to form a coagulated mixture in semi-confined flow continuously from the mixing zone through a coagulum zone to a discharge end of the reactor. The particulate filler fluid is fed under high pressure to the mixing zone, such as to form a jet stream to entrain elastomer latex fluid sufficiently energetically to substantially completely coagulate the elastomer with the particulate filler prior to the discharge end without need of adding acid or salt solution or other coagulation step. The coagulated elastomer and particulate filler composite is fed into the aforesaid continuous compounder for processing and control of its moisture level and Mooney Viscosity. Novel elastomer composites are produced. Such novel elastomer composites combine material properties and characteristics, such as choice of filler, elastomer, level of filler loading, moisture level, Mooney Viscosity, balance between molecular weight and amount of bound rubber, and macro-dispersion not previously achieved.

Owner:CABOT CORP

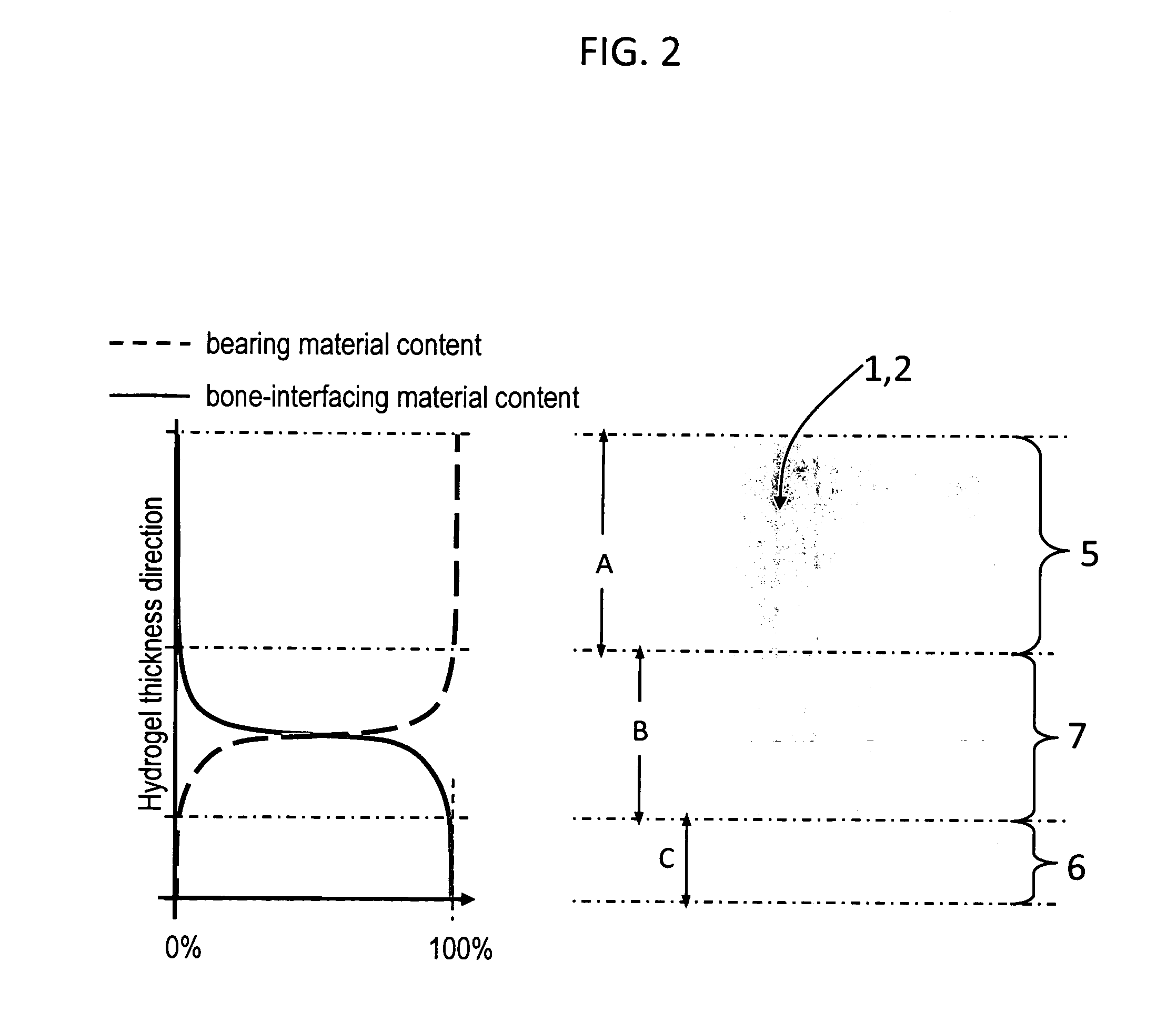

Hydrogel arthroplasty device

InactiveUS20090088846A1Stimulate bone cell growthEasy adhesionFinger jointsPowder deliveryCross-linkNeutral ph

An arthroplasty device is provided having an interpenetrating polymer network (IPN) hydrogel that is strain-hardened by swelling and adapted to be held in place in a joint by conforming to a bone geometry. The strain-hardened IPN hydrogel is based on two different networks: (1) a non-silicone network of preformed hydrophilic non-ionic telechelic macromonomers chemically cross-linked by polymerization of its end-groups, and (2) a non-silicone network of ionizable monomers. The second network was polymerized and chemically cross-linked in the presence of the first network and has formed physical cross-links with the first network. Within the IPN, the degree of chemical cross-linking in the second network is less than in the first network. An aqueous salt solution (neutral pH) is used to ionize and swell the second network. The swelling of the second network is constrained by the first network resulting in an increase in effective physical cross-links within the IPN.

Owner:THE GOVERNMENT OF THE UNITED STATES OF AMERICA AS REPRESENTED BY THE DEPT OF VETERANS AFFAIRS +1

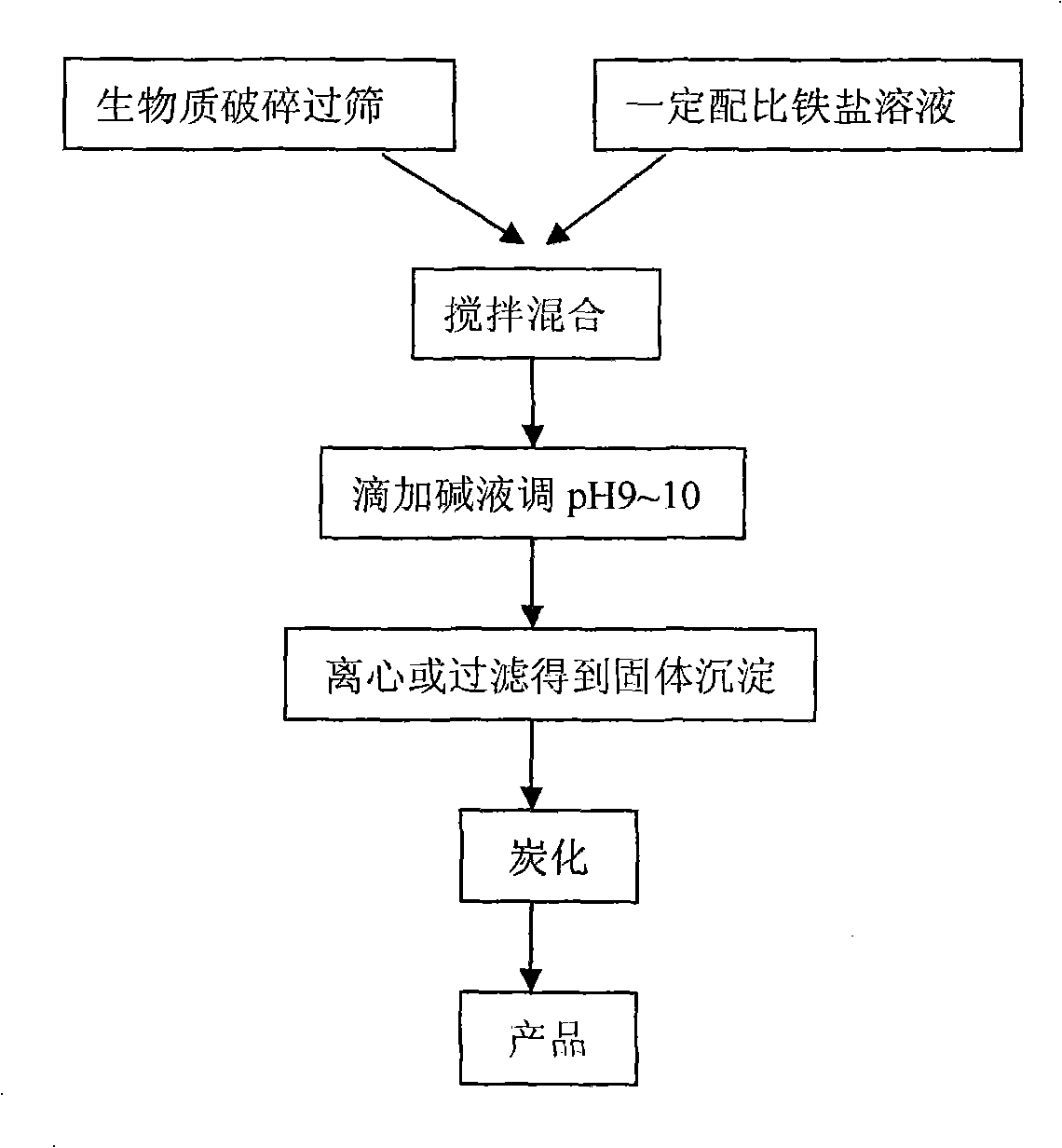

Method for preparing magnetic biological carbon adsorbing material and usage thereof

The invention discloses a method for preparing magnetic biological carbon adsorbing material and the usage thereof. The method comprises the steps: 1) drying and crushing waste biomass, and sieving by20-100 meshes; 2) putting the sieved biomass into 0.1-0.5mol / L of iron salt solution with the weight percent of the biomass being 1-10% of the total quantity; under stirring, dripping 3-6mol / L of NaOH solution until the pH value of the solution is 9-10; 3) filtering, drying and compacting the solid precipitate, and then limiting oxygen carbonizing for 1-5h at the temperature of 100-700 DEG C, thus obtaining the magnetic biological carbon adsorbing material; 4) putting the magnetic biological carbon adsorbing material into waste water, and simultaneously removing organic pollutant and phosphate radical in the waste water. The method realizes synchronization of preparation of the adsorbing material and the process of magnetization, and is simple in preparation process, rich in the source ofthe biomass material and low in cost; furthermore, the prepared magnetic adsorbent is covered by biological carbon or embedded with magnetic nano Fe3O4 granules, has special structure and stable existence, can effectively remove the organic pollutant and phosphate in the waste water, and is easy for magnetic separation.

Owner:ZHEJIANG UNIV

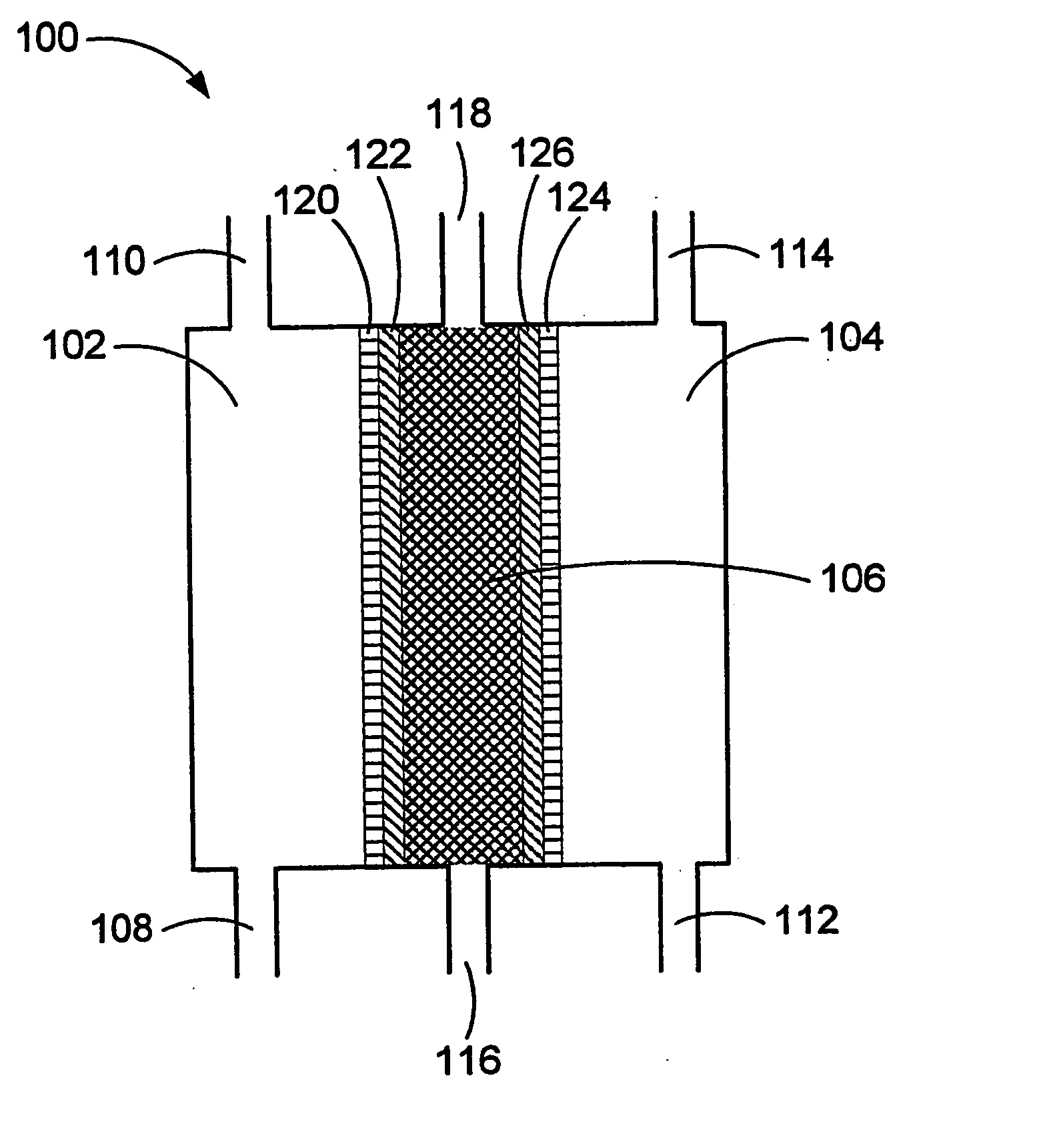

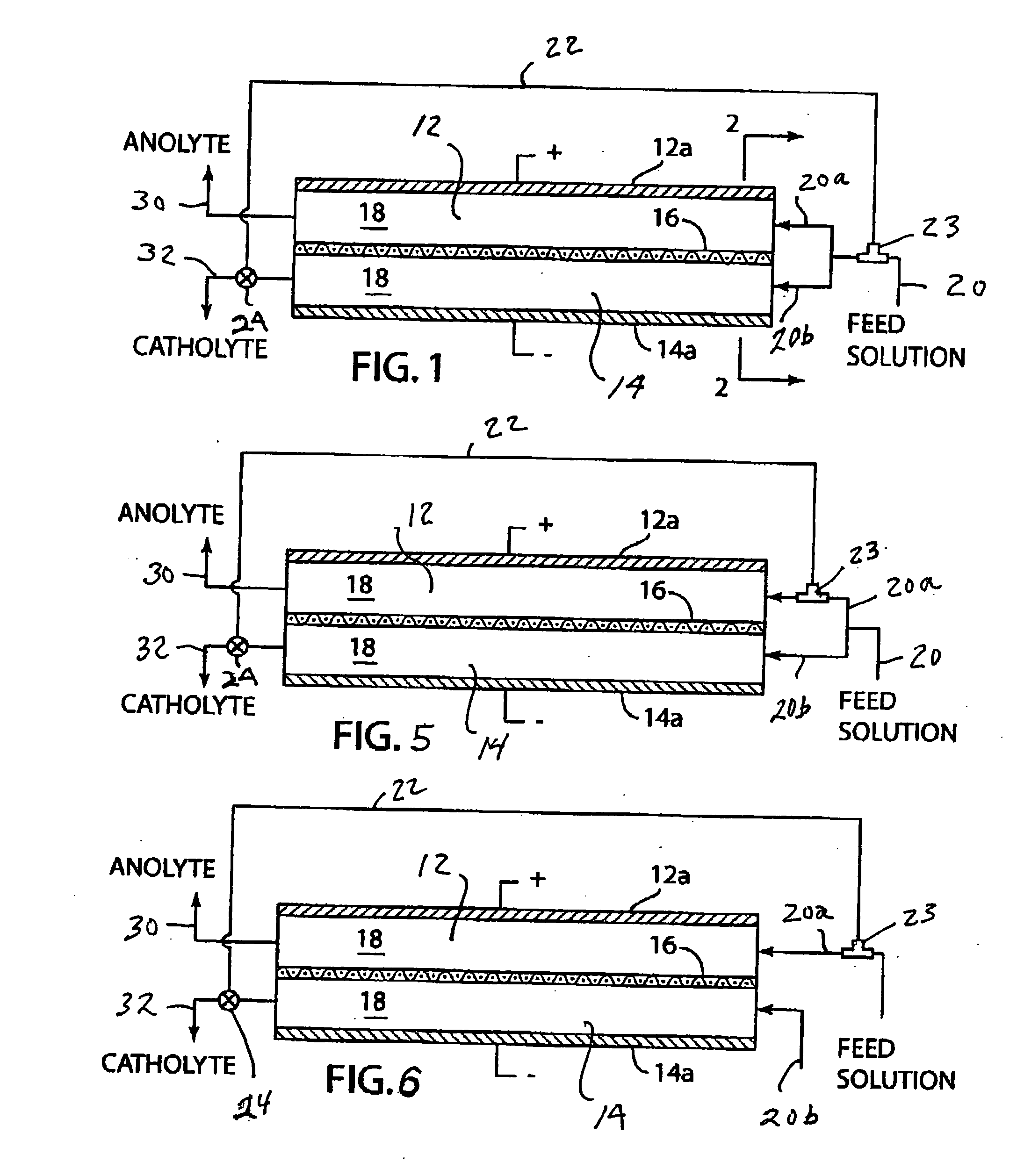

Method and apparatus for electrolyzing water

InactiveUS20050126928A1Increase chanceCellsWater treatment parameter controlElectrolysed waterSalt solution

Feed water comprising an aqueous salt solution is supplied to an anode chamber and to a cathode chamber. The feed water is cathodically electrolyzed in the cathode chamber to produce alkaline electrolyzed water (catholyte) and is anodically electrolyzed in the anode chamber to produce electrolyzed water (anolyte) whose pH is modified. A portion of alkaline catholyte from the cathode chamber is recycled back to the feed water during continuous electrolysis to provide a blend of feed water and alkaline catholyte to the anode chamber to control pH of the anodically electrolyzed water therein to provide more stable bactericidal activity thereof over time.

Owner:UNIV OF GEORGIA RES FOUND INC

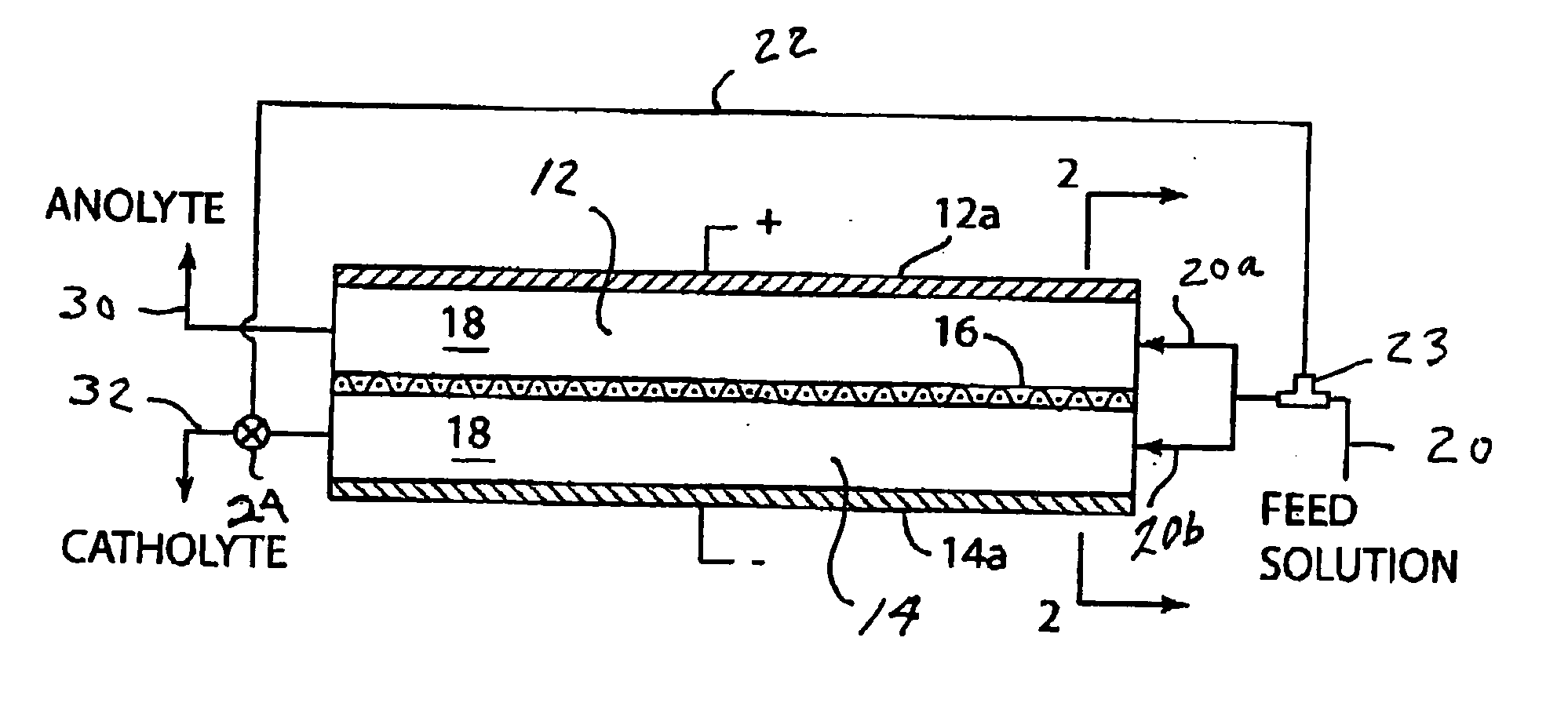

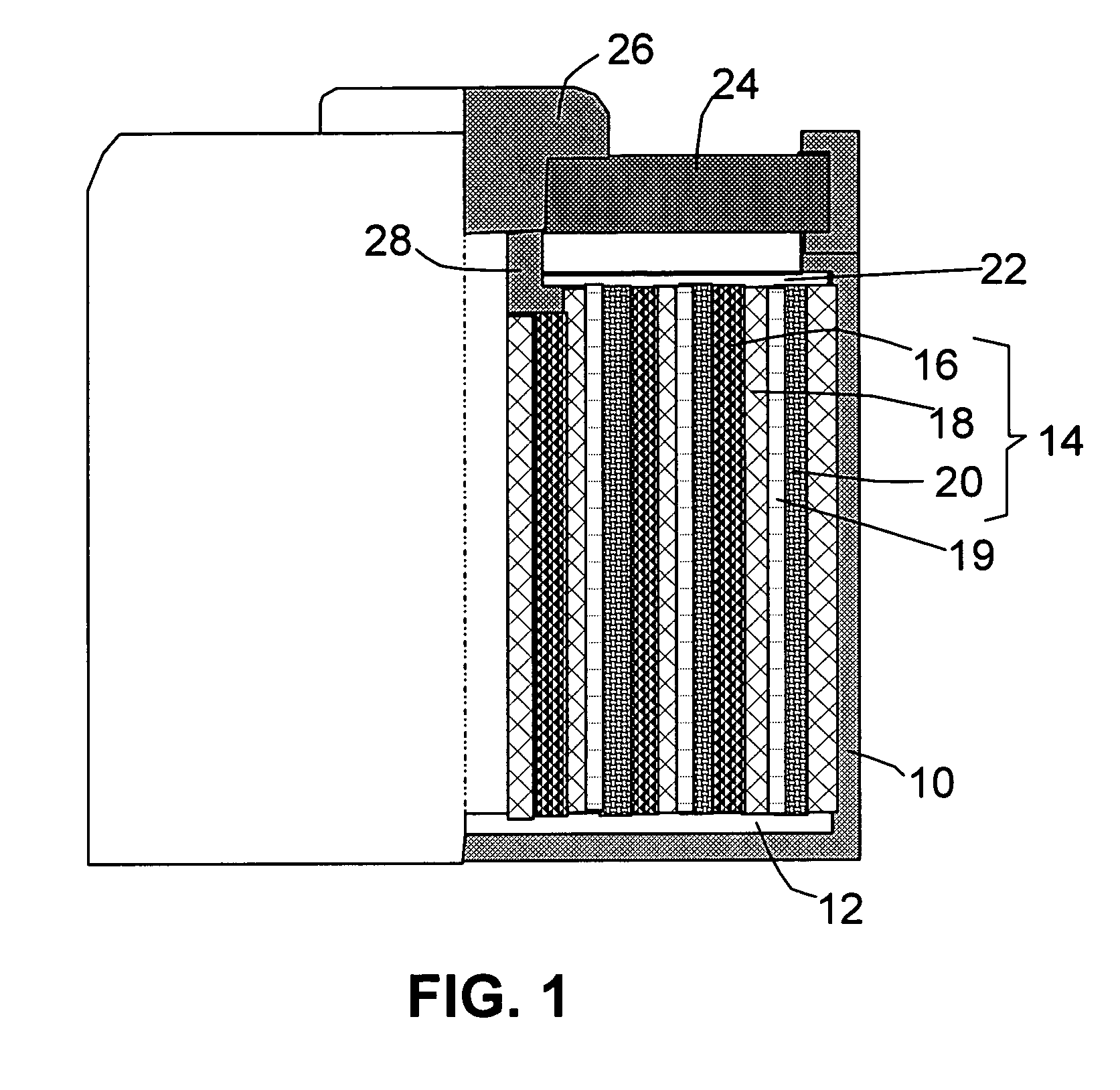

Method and apparatus for producting negative and positive oxidative reductive potential (orp) water

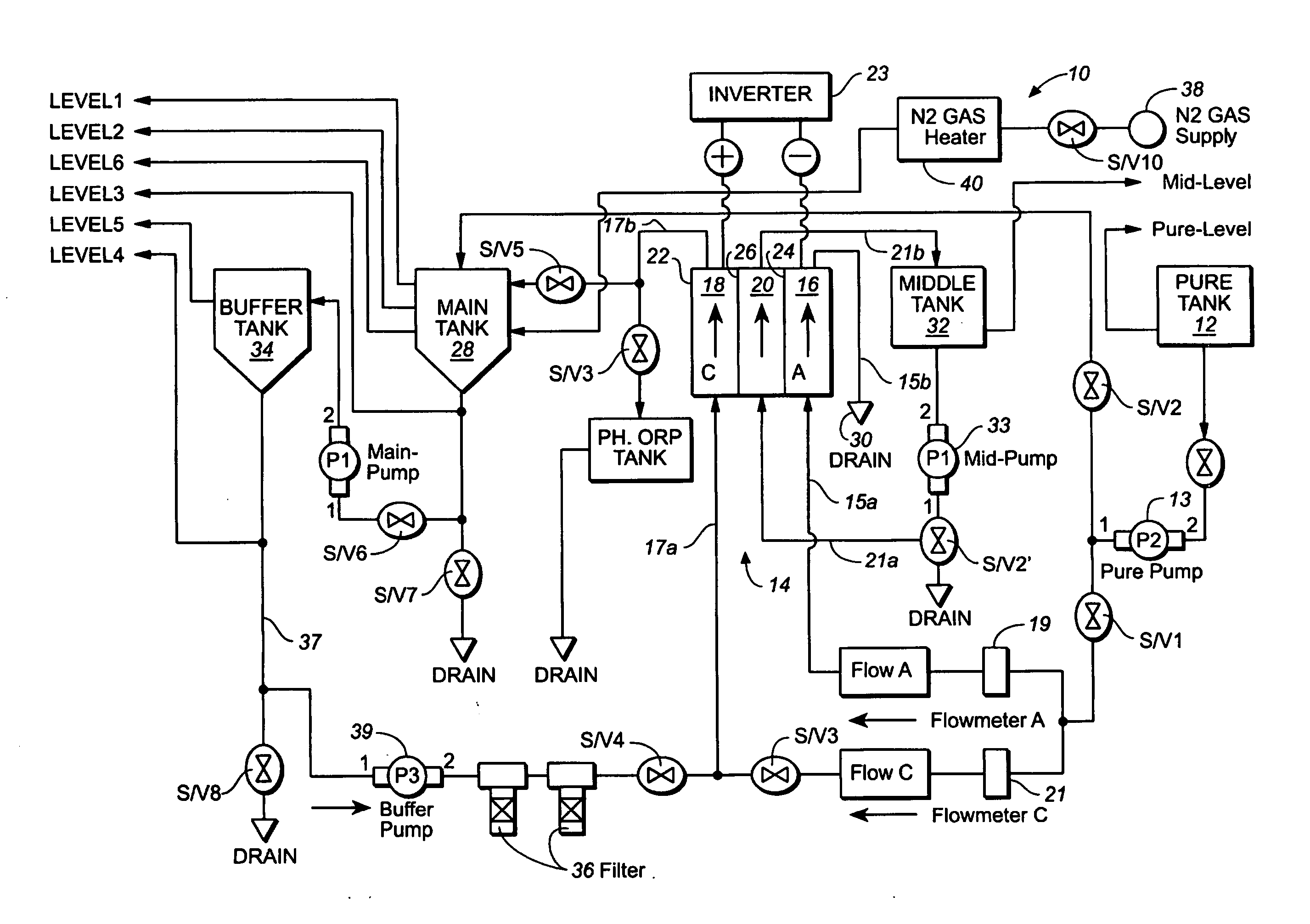

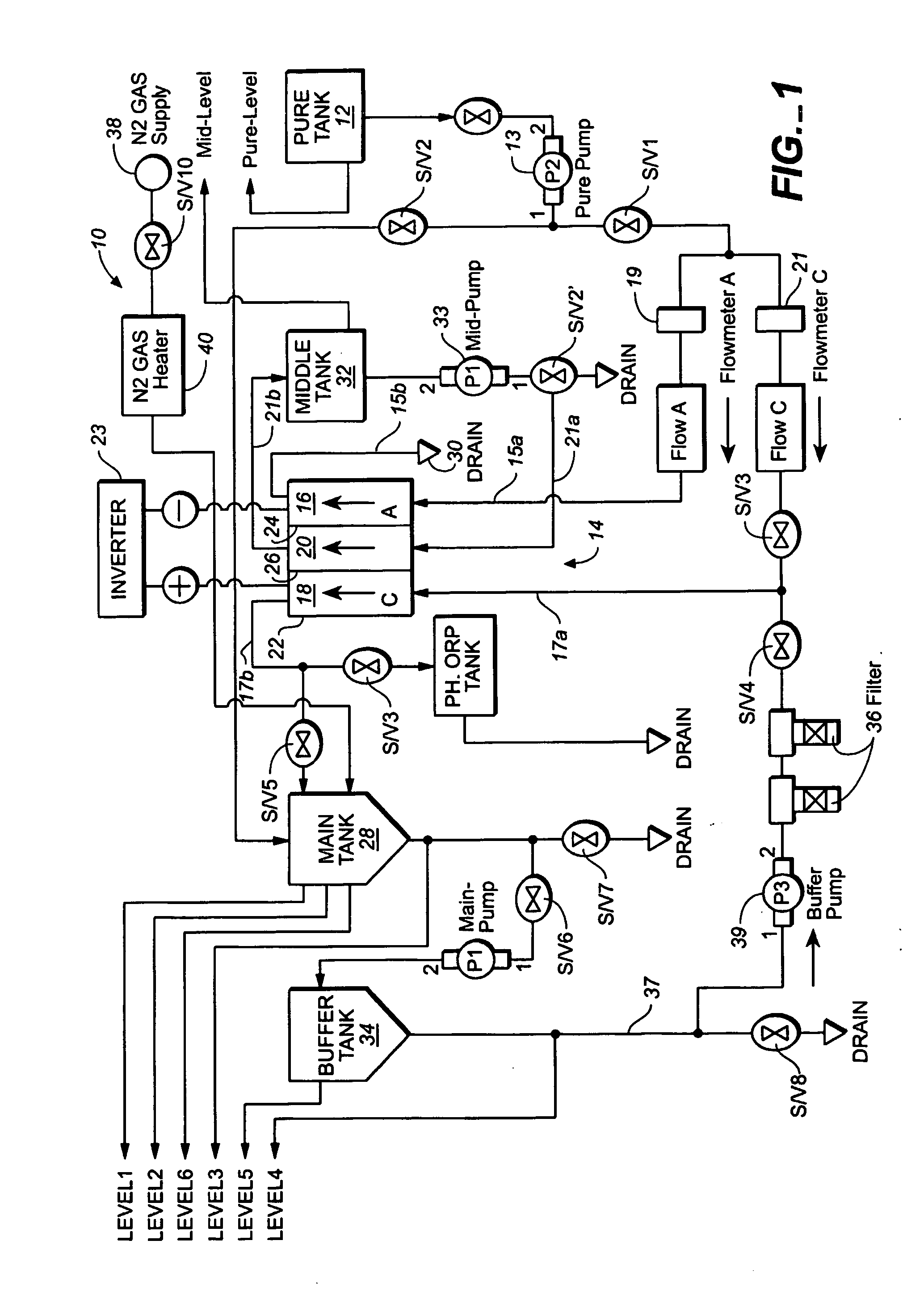

ActiveUS20050121334A1Effective and efficient and economicalCellsWater treatment parameter controlParticulatesElectrolysis

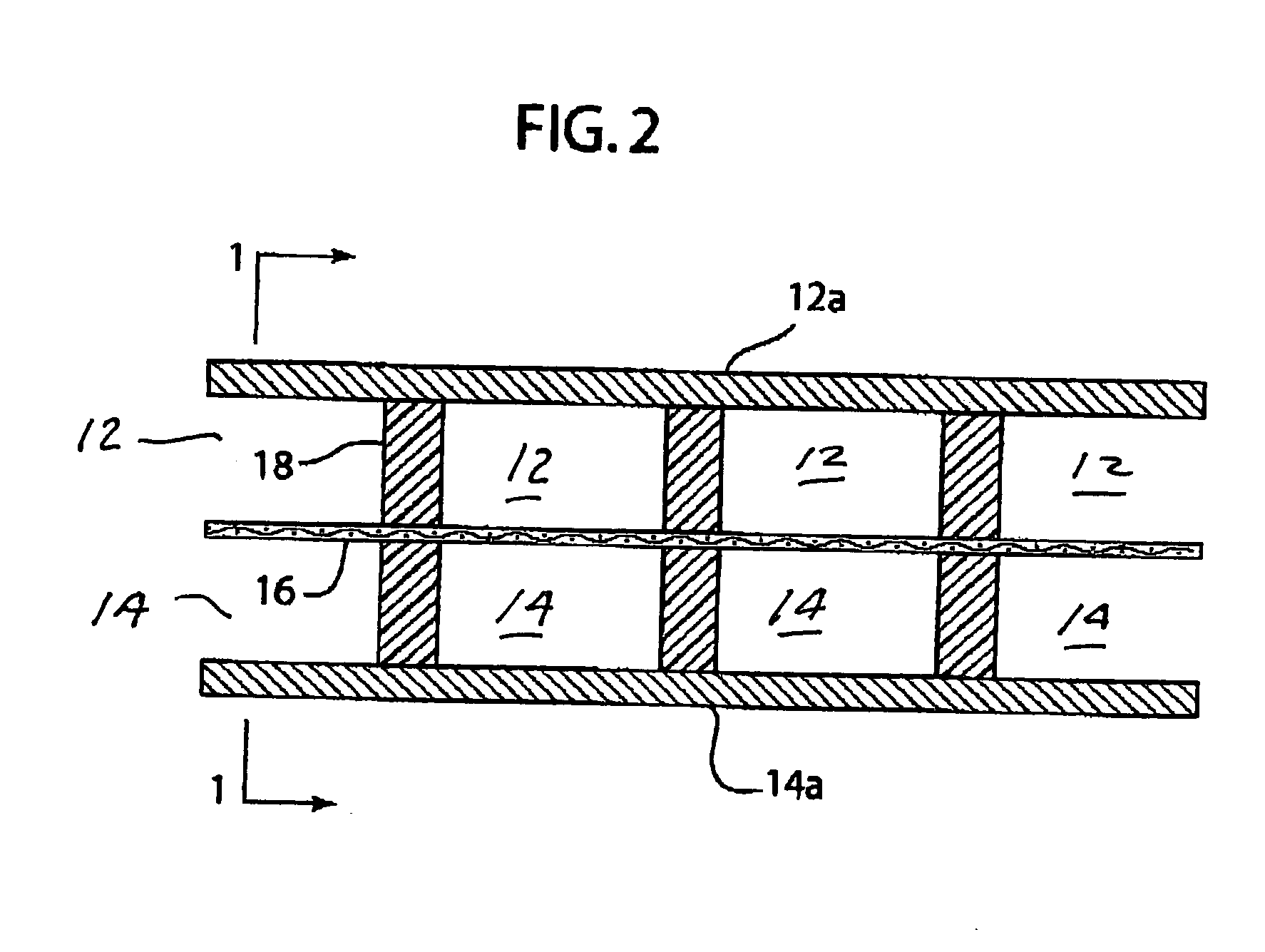

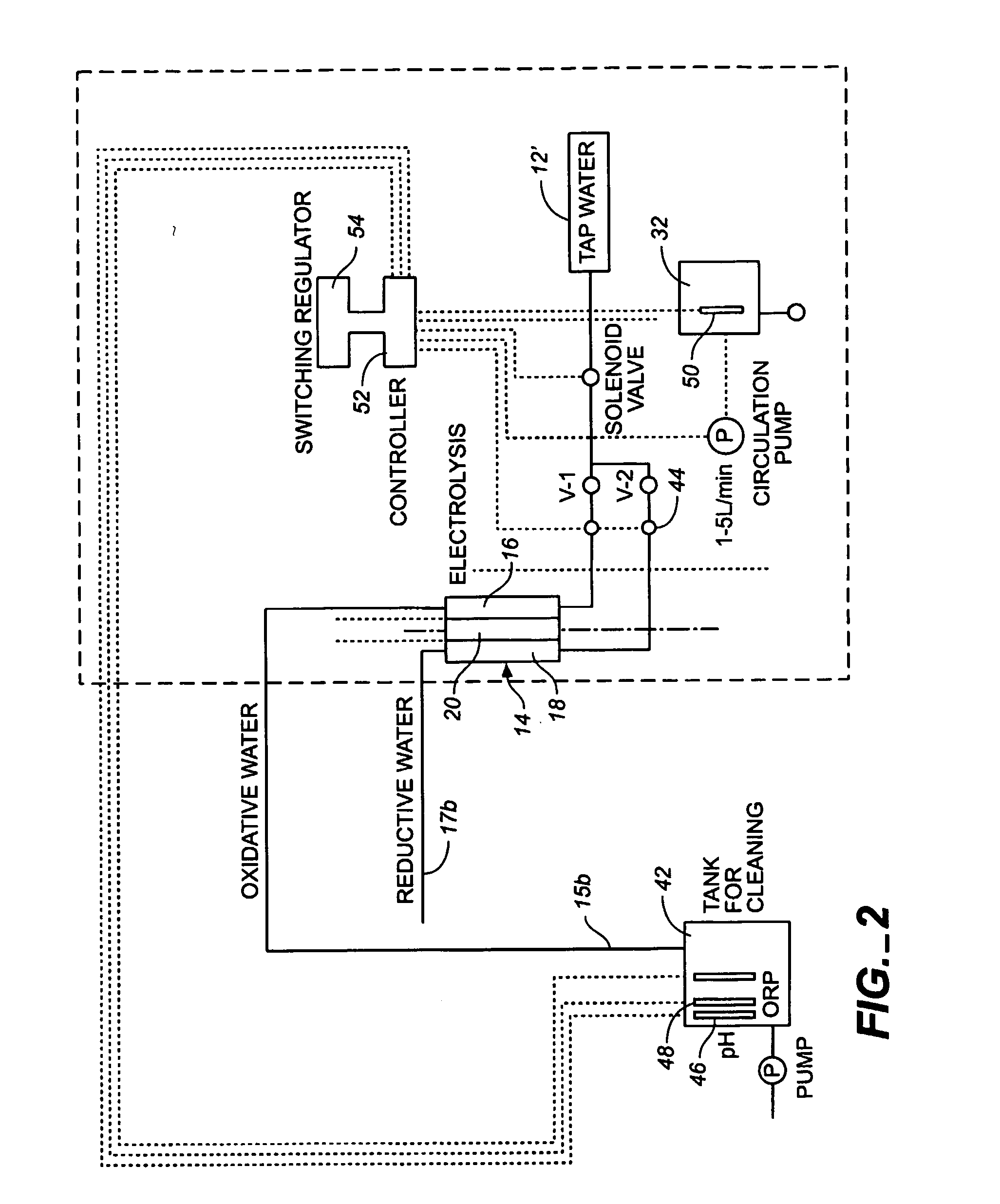

A method and apparatus for electrolytically producing oxidation reduction potential water from aqueous salt solutions for use in disinfection, sterilization, decontamination, wound cleansing. The apparatus includes an electrolysis unit having a three-compartment cell (22) comprising a cathode chamber (18), an anode chamber (16), and a saline solution chamber (20) interposed between the anode and cathod chambers. Two communicating (24, 26) membranes separate the three chambers. The center chamber includes a fluid flow inlet (21a) and outlet (21b) and contains insulative material that ensures direct voltage potential does not travel through the chamber. A supply of water flows through the cathode and anode chambers at the respective sides of the saline chamber. Saline solution flows through the center chamber, either by circulating a pre-prepared aqueous solution containing ionic species, or, alternatively, by circulating pure water or an aqueous solution of, e.g., aqueous hydrogen chloride and ammonium hydroxide, over particulate insulative material coated with a solid electrolyte. Electrical current is provided to the communicating membranes separating the chambers, thus causing an electrolytic reaction that produces both oxidative (positive) and reductive (negative) ORP water.

Owner:SONOMA PHARMA INC

Methods to improve heteroatom lattice substitution in large and extra-large pore borosilicate zeolites

InactiveUS6790433B2Controlled catalytic propertyAluminium compoundsMolecular sieve catalystsIron saltsAluminosilicate

The invention, in one embodiment, is a method for preparing crystalline zeolites by (a) contacting a calcined essentially aluminum free borosilicate zeolite with an aqueous acid solution, thereby producing an at least partially deboronated zeolite; (b) contacting said at least partially deboronated zeolite with a solution selected from the group consisting of an aqueous aluminum salt solution, thereby producing an aluminosilicate zeolite; an aqueous gallium salt solution, thereby producing a gallosilicate zeolite; an aqueous iron salt solution, thereby producing a ferrosilicate zeolite; and mixtures thereof; and (c) where the contacting in step (b) occurs at a pH of not greater than about 3.5. In another embodiment, the present invention provides a method for preparing crystalline zeolites by contacting a calcined essentially aluminum free large or extra-large pore borosilicate zeolite with a solution selected from the group consisting of an aqueous aluminum salt solution, thereby producing an aluminosilicate zeolite; an aqueous gallium salt solution, thereby producing a gallosilicate zeolite; an aqueous iron salt solution, thereby producing a ferrosilicate zeolite; and mixtures thereof; and where the contacting occurs at a pH of not greater than about 3.5.

Owner:CHEVROU USA INC

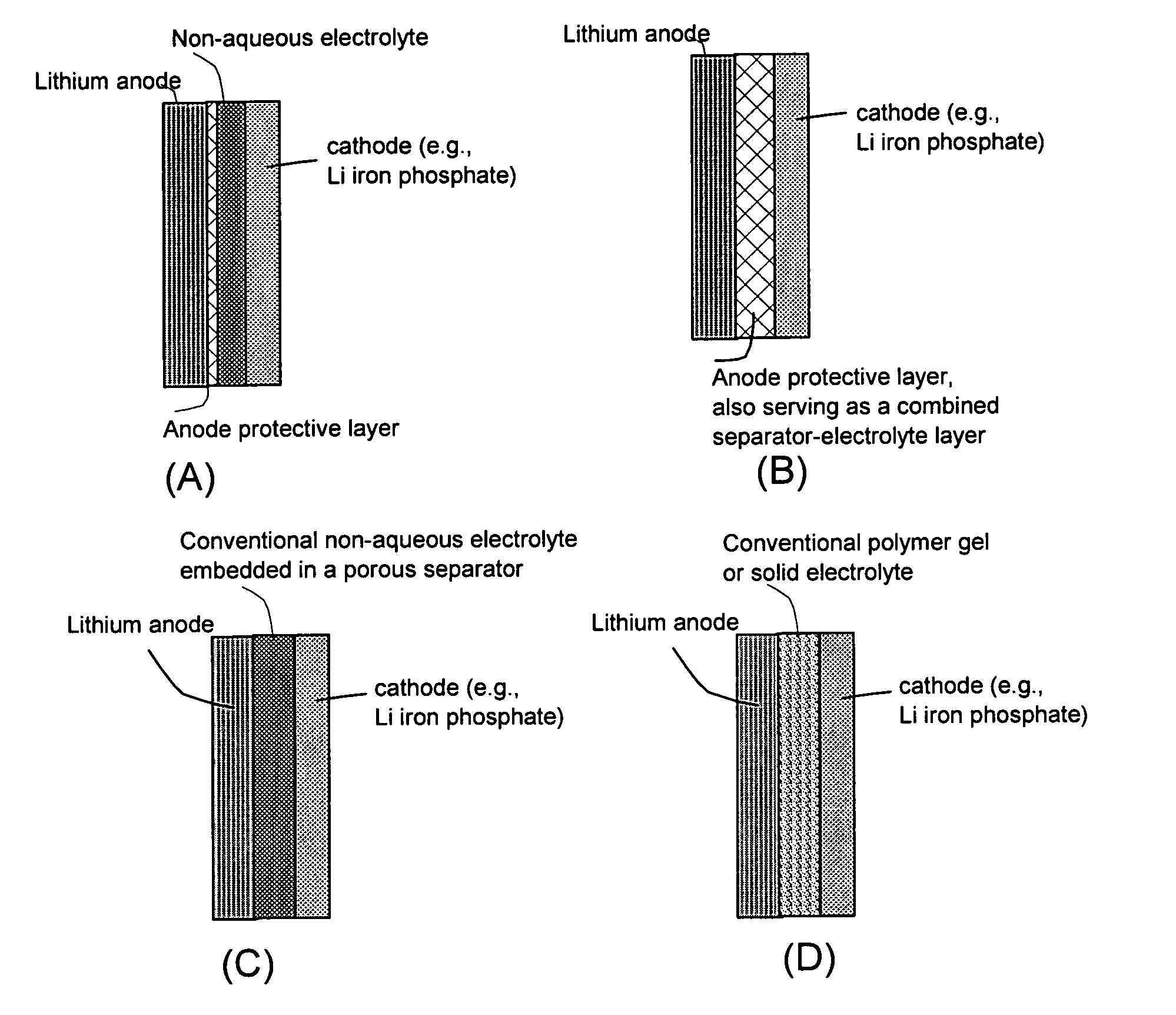

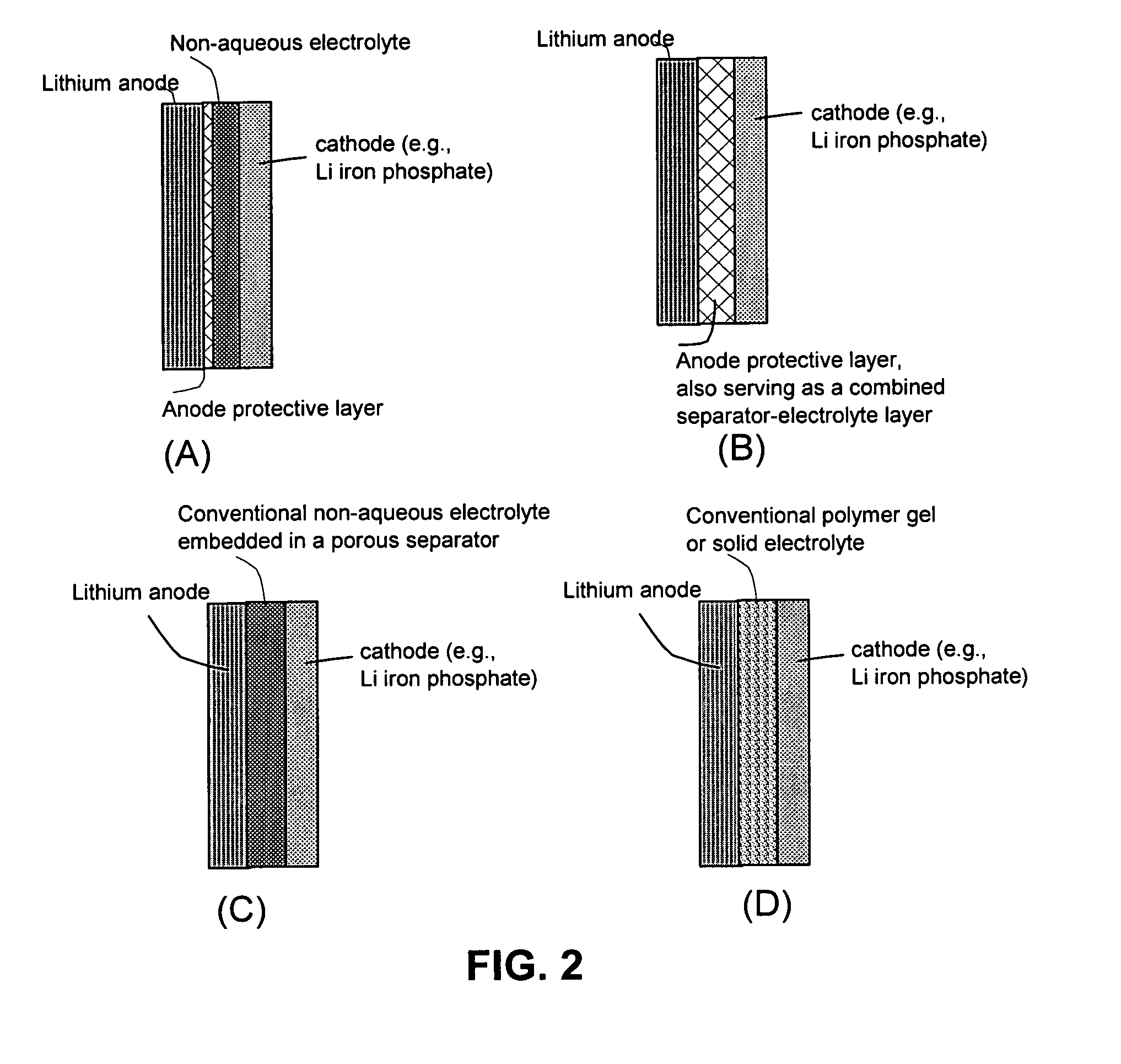

Anode protective layer compositions for lithium metal batteries

ActiveUS20090155676A1Safe and long and stable cycle lifeLi-accumulatorsCell component detailsLithium metalElectric vehicle

The present invention provides a battery cell, comprising: (a) an anode comprising an active metal or a metal ion storage material (e.g., an intercalation compound that accommodates lithium ion); (b) a cathode structure; and (c) an ionically conductive protective layer on a surface of the anode and interposed between the anode and the cathode structure. This protective layer comprises a porous membrane having pores therein and a soft matter phase disposed in at least one of the pores, wherein the soft matter phase comprises oxide particles dispersed in a non-aqueous alkali, alkaline, or transition metal salt solution. Most preferably, this battery cell is a lithium metal secondary cell that is essentially free from dendrite and exhibits a safer and more stable cycling behavior. Such a high-capacity rechargeable battery is particularly useful for powering portable electronic devices and electric vehicles.

Owner:GLOBAL GRAPHENE GRP INC

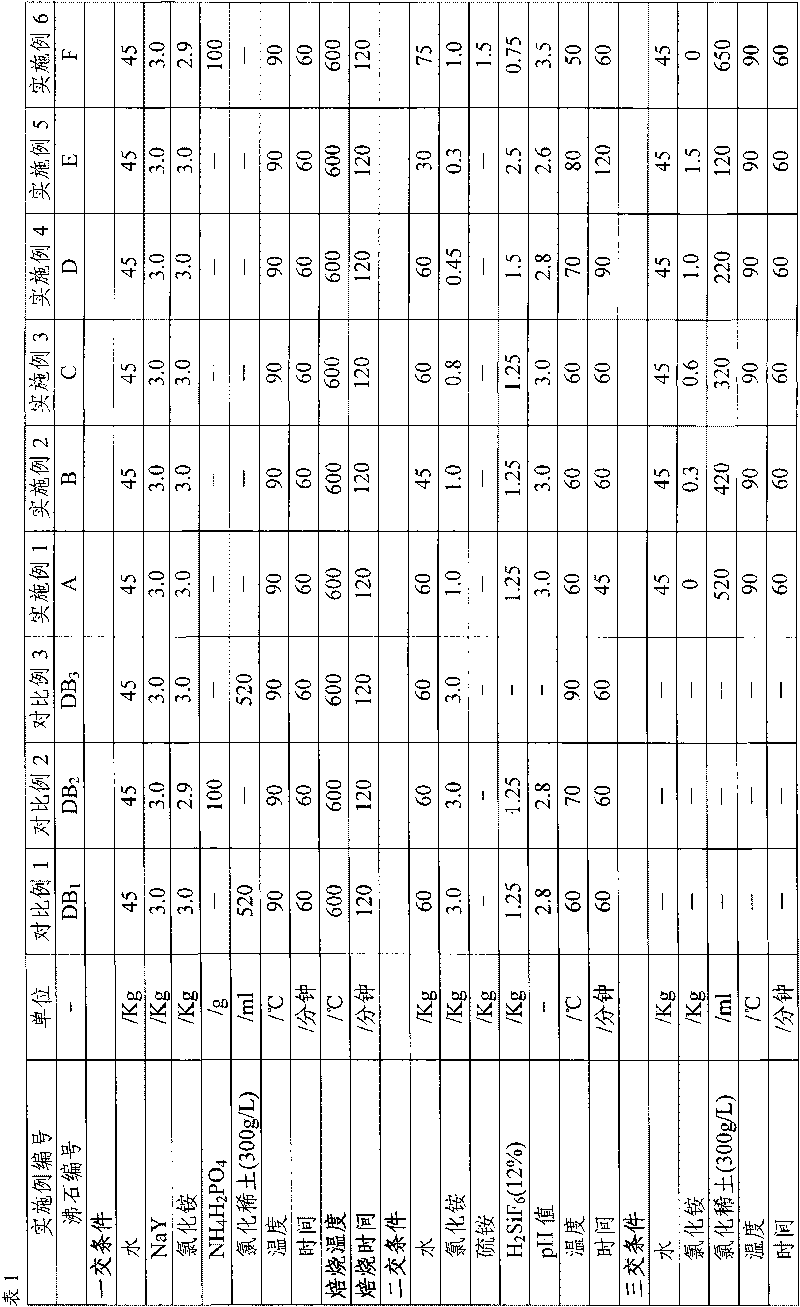

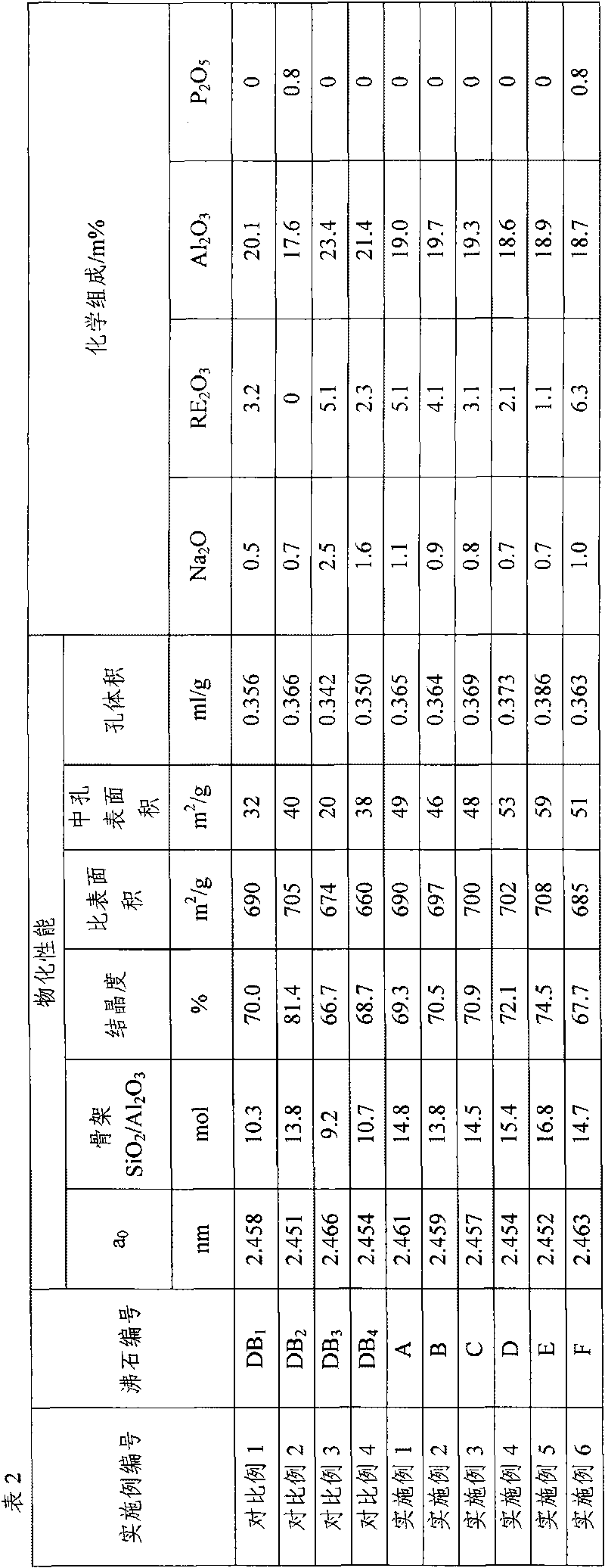

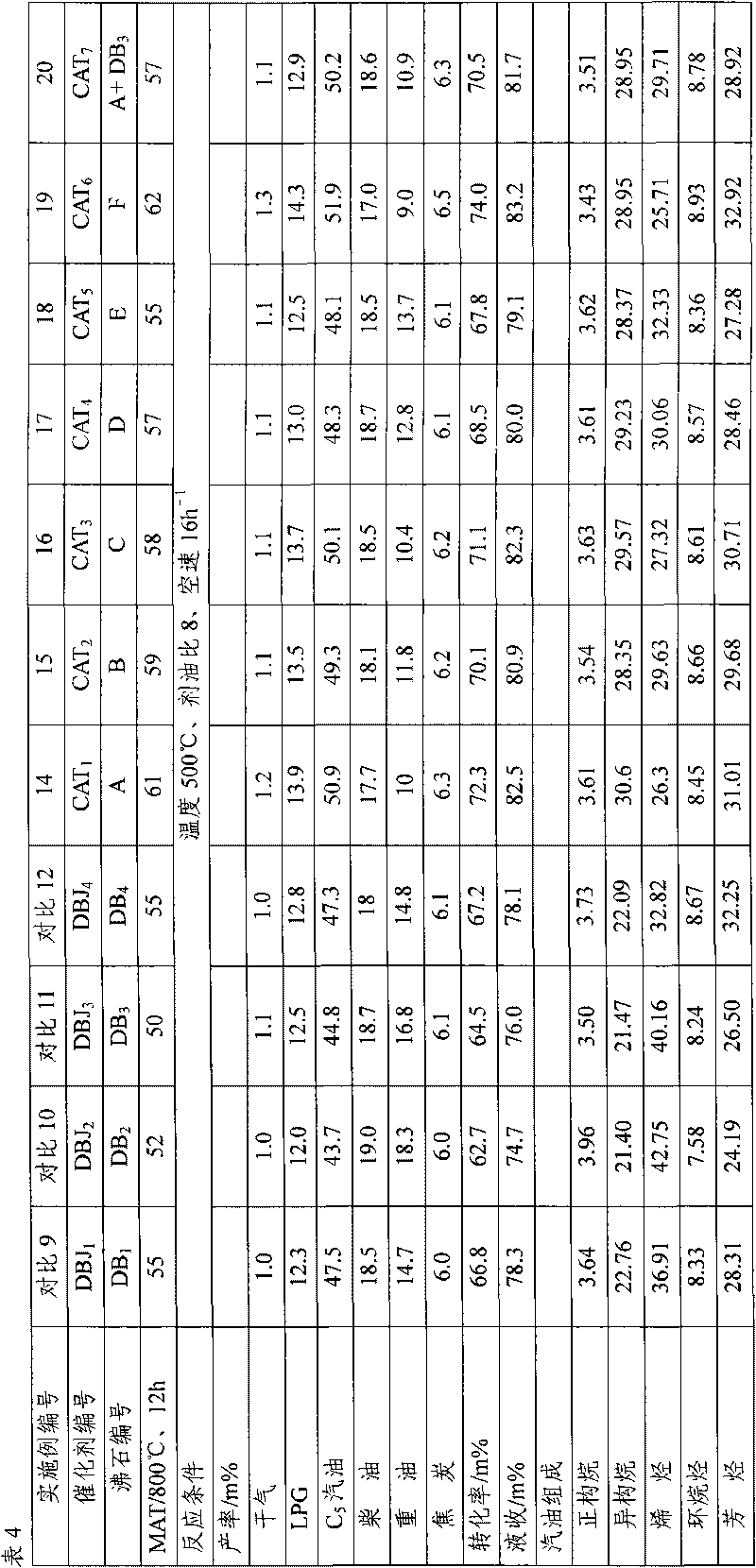

Catalytic cracking catalyst, preparation and application thereof

ActiveCN101745418AHigh yieldReduce olefin contentCatalytic crackingMolecular sieve catalystsAlkaneWater vapor

The invention provides a catalytic cracking catalyst, a preparation method and an application method thereof. The catalyst contains high silica-alumina ratio REUSY zeolite prepared by a liquid-phase villiaumite method. The method for preparing the zeolite comprises: allowing NaY zeolite and inorganic ammonium salt solution to be in contact for ion exchange and washing; ensuring that the Na2O content of zeolite is lower than 6 weight percent; roasting the obtained product in a 100 percent steam atmosphere; allowing the obtained product to be in contact with fluosilicic acid solution for liquid-phase aluminum-pumping silicon-replenishing reaction; allowing the obtained product filtered and washed to be in contact with rare earth salt solution for ion exchange. The catalyst is used for heavy oil catalytic cracking, and has good capability of cracking heavy oil macromolecules, performance of reducing the olefin content of gasoline and performance of increasing the isoparaffin content of gasoline.

Owner:CHINA PETROLEUM & CHEM CORP +1

Hybrid Conductors and Method of Making Same

ActiveUS20110005808A1Improve conductivityLow resistivityNon-insulated conductorsConductive materialElectrical conductorCarbon nanotube

Hybrid conductors capable of achieving enhanced conductivity and current capacity over a wide range of frequencies are disclosed. The hybrid conductors may be used in electrical or thermal applications, or combinations of both. One method of fabricating such hybrid conductors includes complexing conductive metal elements (e.g., silver, gold, copper), transition metal elements, alloys, wires, or combinations thereof, with carbon nanotube materials. In the alternative, the hybrid conductors may be formed by doping the carbon nanotube materials in salt solutions.

Owner:NANCOMP TECHNOLOGIES INC

Method for preparing metal mesh for oil-water separation

InactiveCN101708384AAchieve the purpose of separationAcid resistantFiltration separationLiquid separationChemical industryNanoscopic scale

The invention belongs to the technical field of chemistry and chemical industry and functional materials, and relates to a method for preparing a metal mesh which has special wetting properties and is used for oil-water separation. The method adopts simple wet-method chemical etching technology, nano-scale microscopic bulges are prepared on the surface of a metal mesh with micron-grade pore diameters, and then a compound which does not contain fluorine and has low surface energy is modified on the surfaces of the microscopic bulges. For the surface of the prepared material, a contact angle of a water drop is more than 150 degrees, and a contact angle of oil is close to 0 degree. Due to the specific wetting properties, the material can allow the oil to pass through the metal mesh smoothly, but the water cannot permeate through the metal mesh completely, so that the property of effectively separating oil-water mixtures is realized. Particularly, the specific wetting properties of the surface of the material can keep stable in acid solution, alkali solution and salt solution, and thus the functional metal mesh can be excellently applied in aspects of metal corrosion prevention and the like. A mesh membrane does not contain the fluorine, and has the advantages of simple preparation method, high permeability of pore space and good oil-water separation effect, and corrosion resistance.

Owner:JILIN UNIV

Method of soft tissue augmentation

InactiveUS20050226936A1Prevents and diminishes migrationPrevents and diminishes migration and displacementPowder deliveryDrug compositionsSalt solutionBiomedical engineering

Particles according to the invention are made of a viscoelastic medium, are injectable gel particles, and have a size, when subjected to a physiological salt solution, in the range of from 1 to 5 mm. The particles are useful in a soft tissue augmentation implant. The implant comprises particles of a viscoelastic medium, wherein a major volume of the particles are injectable gel particles according to the invention. The implant is useful in a method of soft tissue augmentation in a mammal, including man, comprising subepidermal administration at a site in said mammal where soft tissue augmentation is desirable, of an implant according to the invention.

Owner:Q MED AB

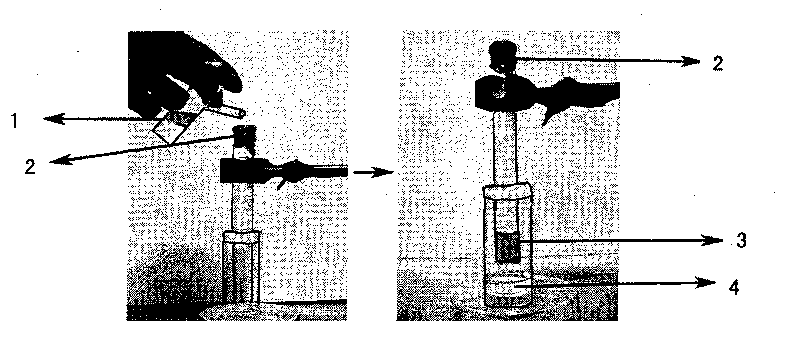

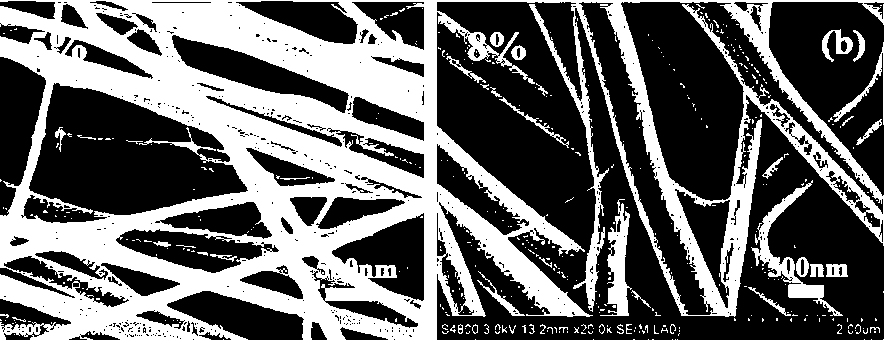

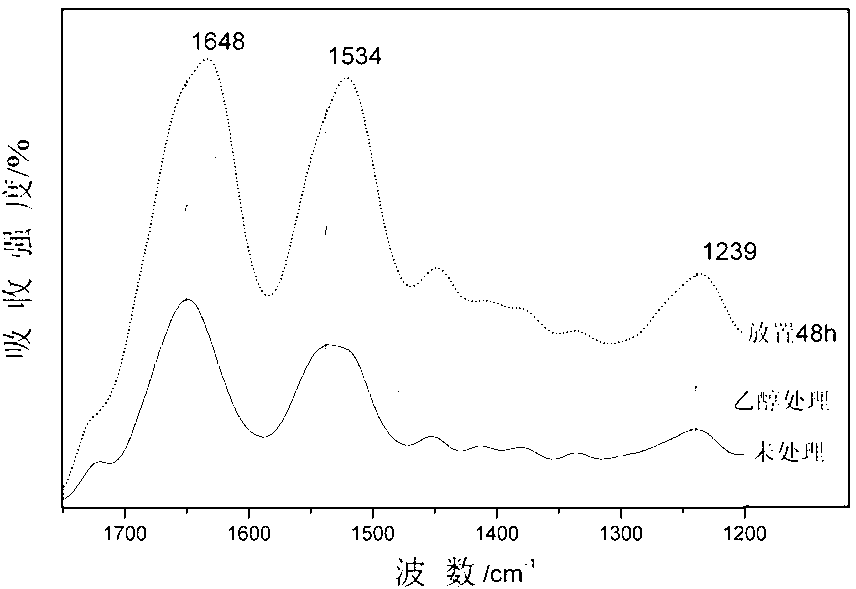

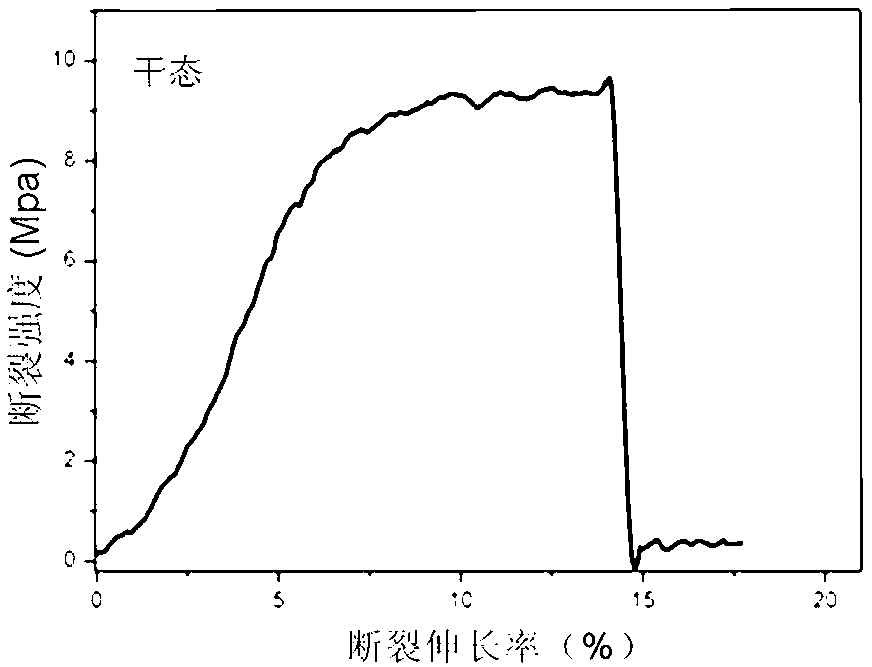

Silk fibroin nanofiber membrane and preparation method thereof

The invention discloses a silk fibroin nanofiber membrane and a preparation method of the silk fibroin nanofiber membrane. The preparation method comprises the following specific steps of: dissolving natural silk taken as a main raw material by an acid salt solution, forming a membrane, desalting the membrane, dissolving the membrane by methanoic acid and hexafluoroisopropanol to prepare a spinning solution, and carrying out electrostatic spinning to prepare the silk fibroin nanofiber membrane. The silk fibroin nanofiber membrane comprises fibers with the diameter of 10nm-10 microns and has the excellent mechanical property, the breaking strength of greater than 8Mpa at dry state, the breaking elongation of greater than 15% at dry state, the breaking strength of greater than 1Mpa at wet state and the breaking elongation of greater than 100% at wet state. In addition, the silk fibroin nanofiber membrane prepared by the method is stable and controllable in structure, has good biocompatibility and can serve as a medicinal biological material. The preparation method disclosed by the invention is simple and short in flow path, has high film formation and spinning efficiency and is suitable for industrialization large-scale production.

Owner:上海丝波敦生物科技有限公司

Method of in-situ generation of nano particle on separating membrane surface

The invention relates to the technical field of separating membranes, and in particular to a method of in-situ generation of a nano particle on a separating membrane surface. The method comprises the following steps: conducting surface modification on a basic separating membrane surface for more than once, and conducting in-situ generation of the nano particle for more than once on the separating membrane surface subjected to the surface modification, wherein the special points are that the surface modification refers to the following steps: soaking the basic separating membrane in dopamine buffer salt solution with the concentration of 0.001 mg / mL-100 mg / mL and the PH value of 7-12, modifying for 1 min-7 d under the condition that oxygen or oxidant is participated to form a poly-dopamine layer on the basic separating membrane surface; the in-situ generation of the nano particle refers to the following steps: soaking the separating membrane with the poly-dopamine layer generated on the surface in metal salt solution with the concentration of 0,001-10,000 mM / L for 1 min-300 d to generate the nano particle in situ, or accelerating the in-situ generation of the nano particle under the action of reducer. Compared with the prior art, the preparation method is simple and easy to be operated, economic, efficient and environmental-friendly, and facilitates industrialisation.

Owner:山东净泽膜科技有限公司

Antimicrobial salt solutions for food safety applications

ActiveUS7090882B2Reduce in quantityInhibit microorganismsMilk preservationDough treatmentBiologyFood processing

Owner:CARGILL INC

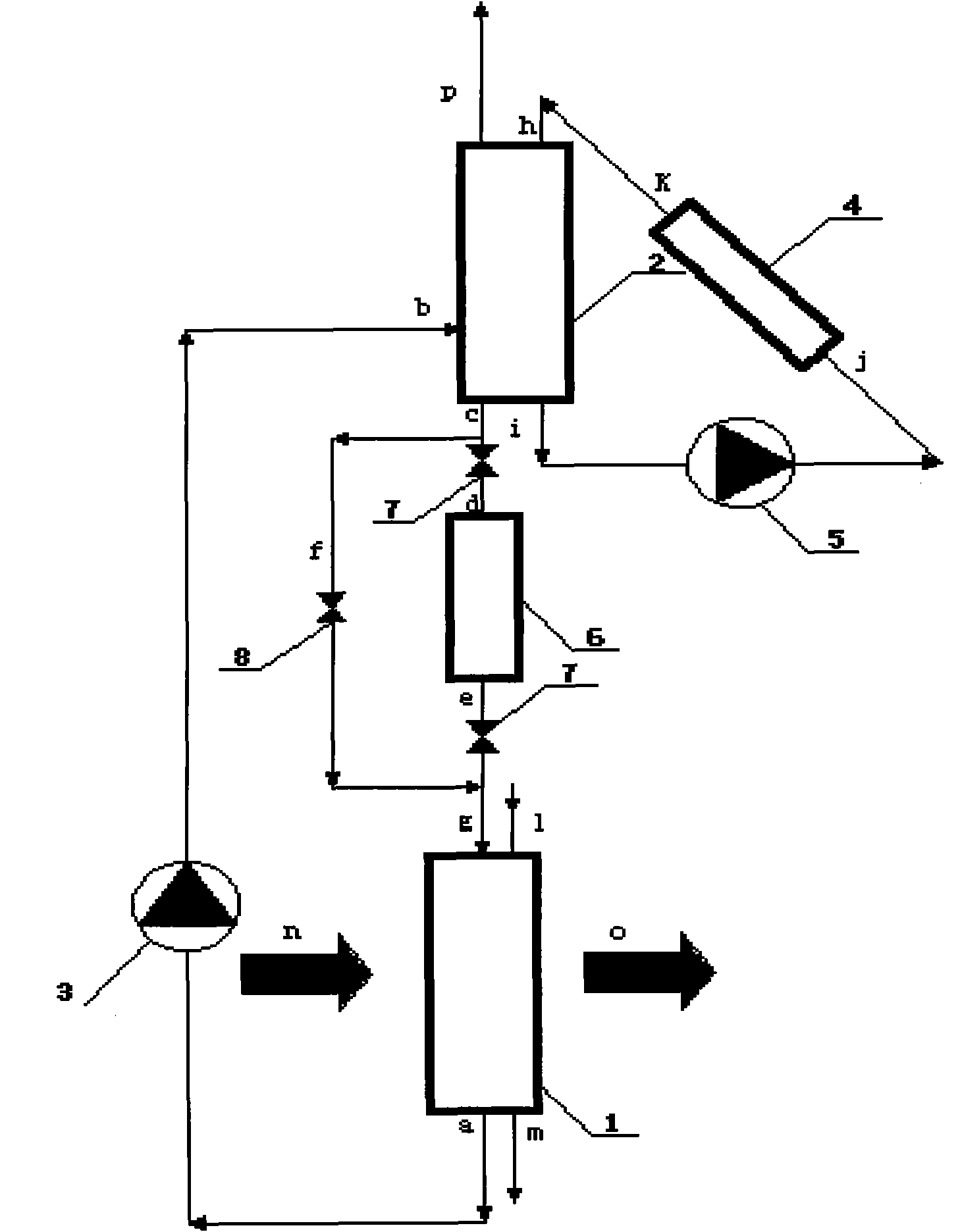

Dehumidizer for air dehumidification, air dehumidification method and device

InactiveCN102335545AEfficient removalQuick removalLighting and heating apparatusDispersed particle separationLithium chlorideWater vapor

The invention discloses a dehumidizer for air dehumidification. The dehumidizer provided by the invention is an ionic liquid solution formed by dissolving an ionic liquid in water, wherein the ionic liquid is formed by organic positive ions and inorganic negative ions, and the melting point of the ionic liquid is close to or is lower than room temperature. In addition, the invention further discloses a method and a device for air dehumidification by the adoption of the above dehumidizer. In comparison with traditional salting liquids (lithium bromide, lithium chloride and calcium chloride aqueous solutions and the like), the dehumidizer provided by the invention has the following advantages: 1) the applied ionic liquid solution is in the liquid state at normal temperature, is intermiscible with water, and will not be crystallized during operation, so as to guarantee the reliable operation of a system; 2) the applied ionic liquid solution has similar or lower water vapor pressure than a traditional dehumidifying salting liquid so as to raise the dehumidifying efficiency; 3) the applied ionic liquid solution will not corrode metal equipment such as steel equipment such that the equipment has low cost and long service life; 4) the dehumidizer has nonvolatility so as to reduce the environmental pollution.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

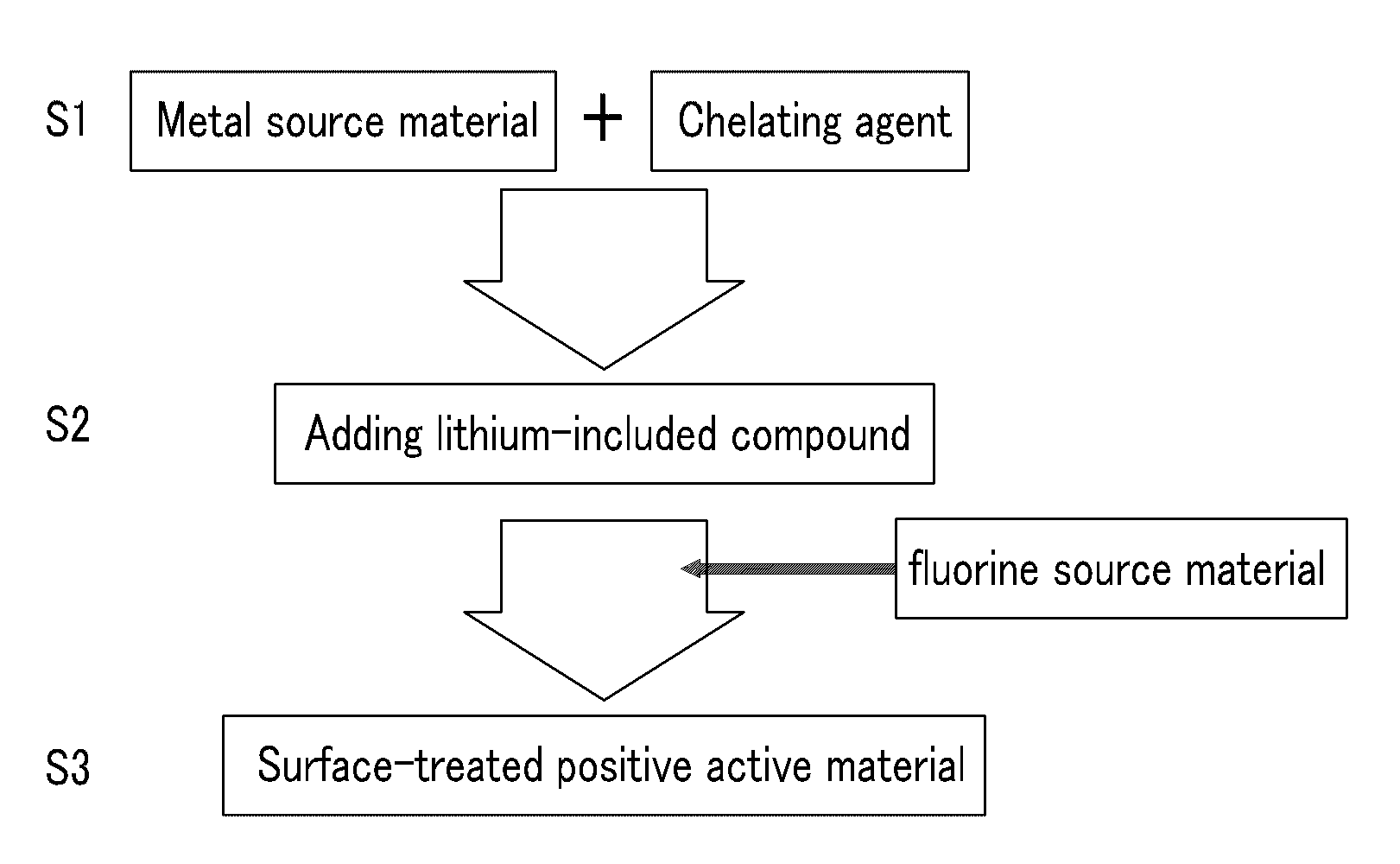

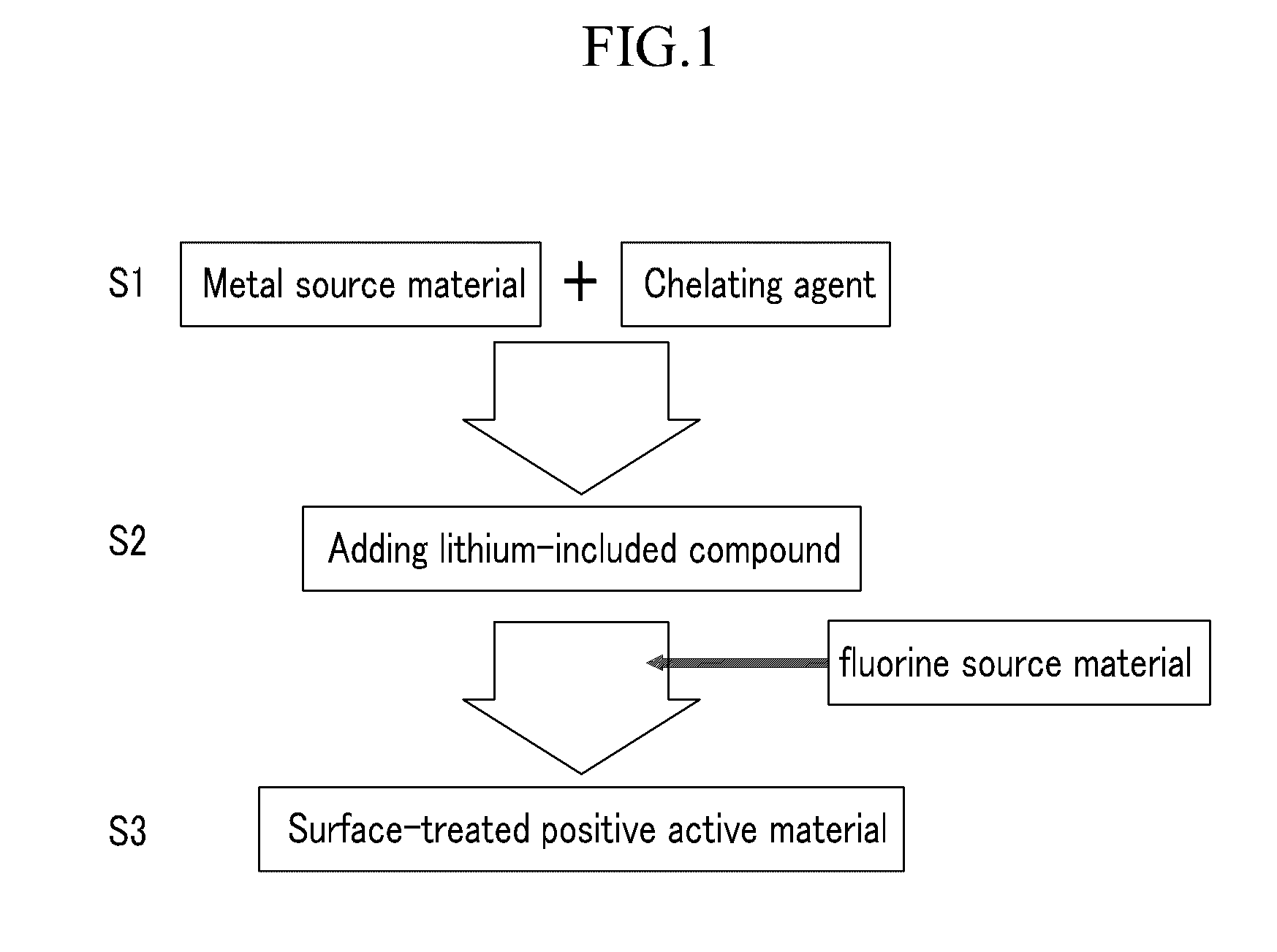

Method of preparing positive active material for rechargeable lithium battery, positive active material for rechargeable lithium battery prepared by same, and rechargeable lithium battery including positive active material

InactiveUS20090253042A1Improve mobilityHigh characteristicsNon-aqueous electrolyte accumulator electrodesLi-accumulatorsSource materialConductive materials

The present invention relates to a method of preparing a positive active material for a rechargeable lithium battery, a positive active material prepared according to the method, and a rechargeable lithium battery including the same. This manufacturing method includes preparing a complex salt solution by mixing a solution including a metal source material and a chelating agent, disposing the complex salt on the surface of a lithium-included compound by adding a lithium-included compound to the complex salt solution, adding a solution including a fluorine source material to the solution including a lithium-included compound with the complex salt on the surface, and heat-treating the mixture. The present invention provides a simple method of economically preparing a positive active material in which structural transition on the surface is prevented and securing a uniform coating layer. In addition, the positive active material can have improved charge and discharge characteristics, cycle life characteristic, and rate characteristic. It also has improved ion conductivity, and accordingly can improve mobility of lithium ions in an electrolyte and thereby improve discharge potential of a battery. Furthermore, the positive active material can decrease the amount of a conductive material and increase density of a substrate.

Owner:ENERCERAMIC

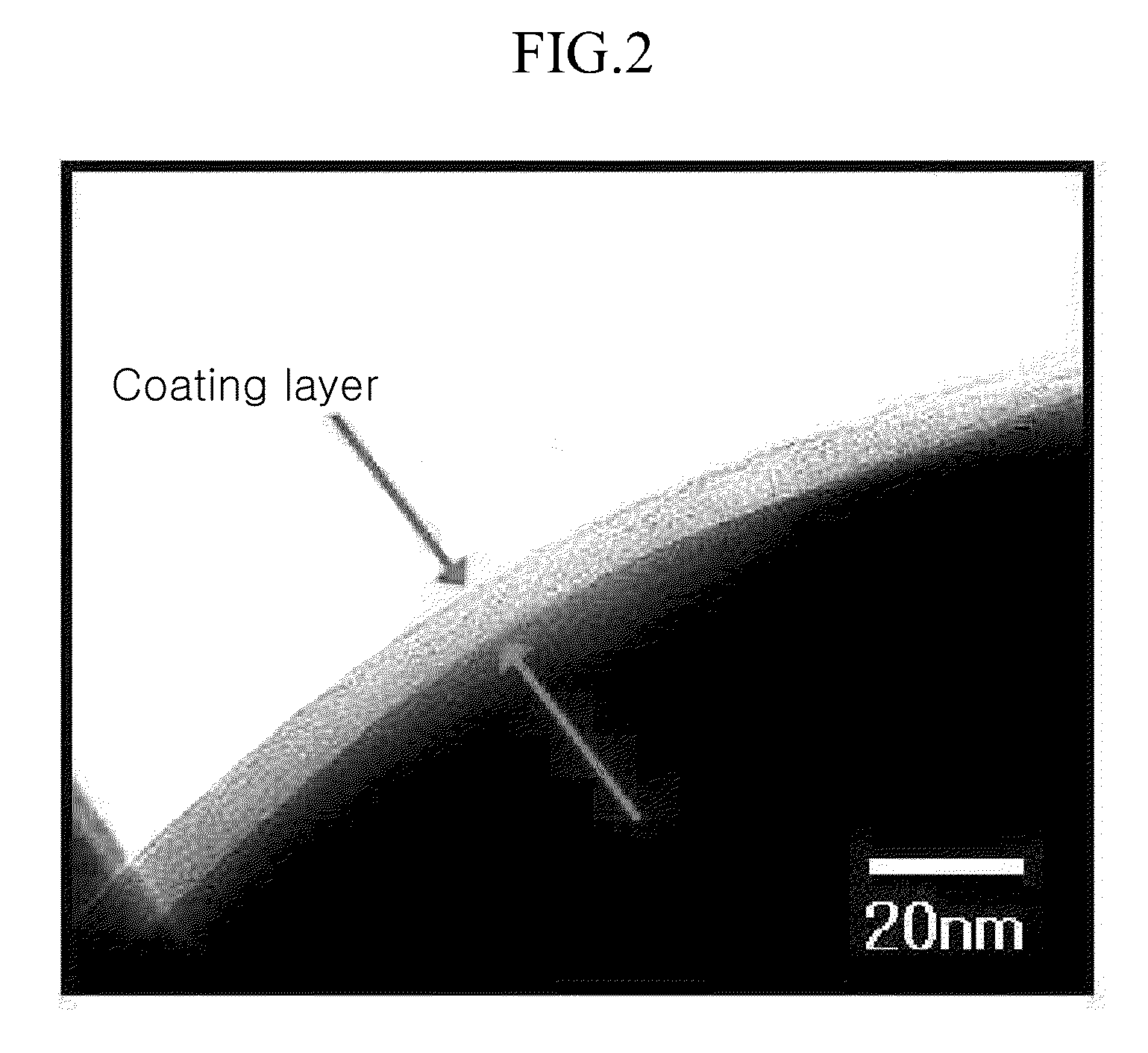

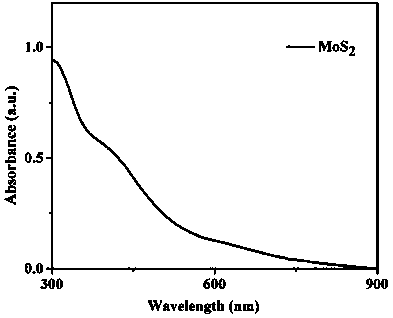

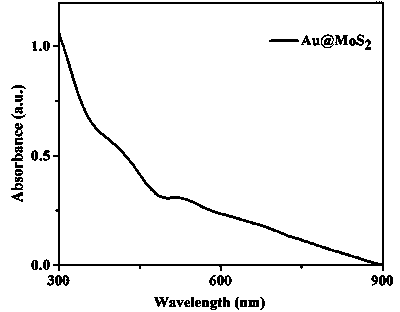

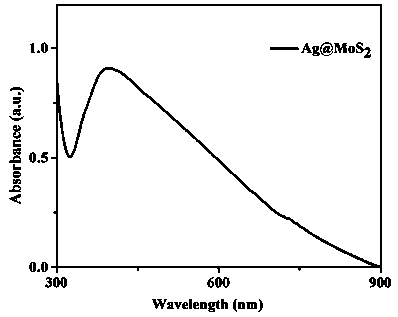

Method for preparing nanocomposite by using two-dimensional transition metal chalcogenide nanosheets and metal

InactiveCN103480856AOvercome limitationsEasy to operateMaterial nanotechnologySulfide/polysulfide preparationNanocompositeReducing agent

The invention relates to a method for preparing a nanocomposite by using two-dimensional transition metal chalcogenide nanosheets and metal, and belongs to the field of nanomaterial synthesis. The method mainly includes adding a reducing agent and a stabilizing agent into monolayer or multi-layer two-dimensional transition metal chalcogenide nanosheet aqueous dispersion obtained after chemical intercalation, then injecting a certain amount of metal salt solution, and preparing the metal nanocomposite based on monolayer or few-layer two-dimensional transition metal chalcogenide nanosheets on the conditions of ice bath, hydrothermal method, microwaves, ultrasound and the like. In the composite, metal nanoparticles can be evenly distributed on the surfaces of the nanosheets, and the obtained composite can be evenly dispersed in water, and can be used in the solution phase and further processed. Through compositing of the metal nanoparticles, photoelectric property of two-dimensional transition metal chalcogenide can be improved, and the nanocomposite has good application prospects in the fields of supercapacitors, fuel cells and biosensors based on surface enhanced Raman detection, and the like.

Owner:NANJING UNIV OF POSTS & TELECOMM

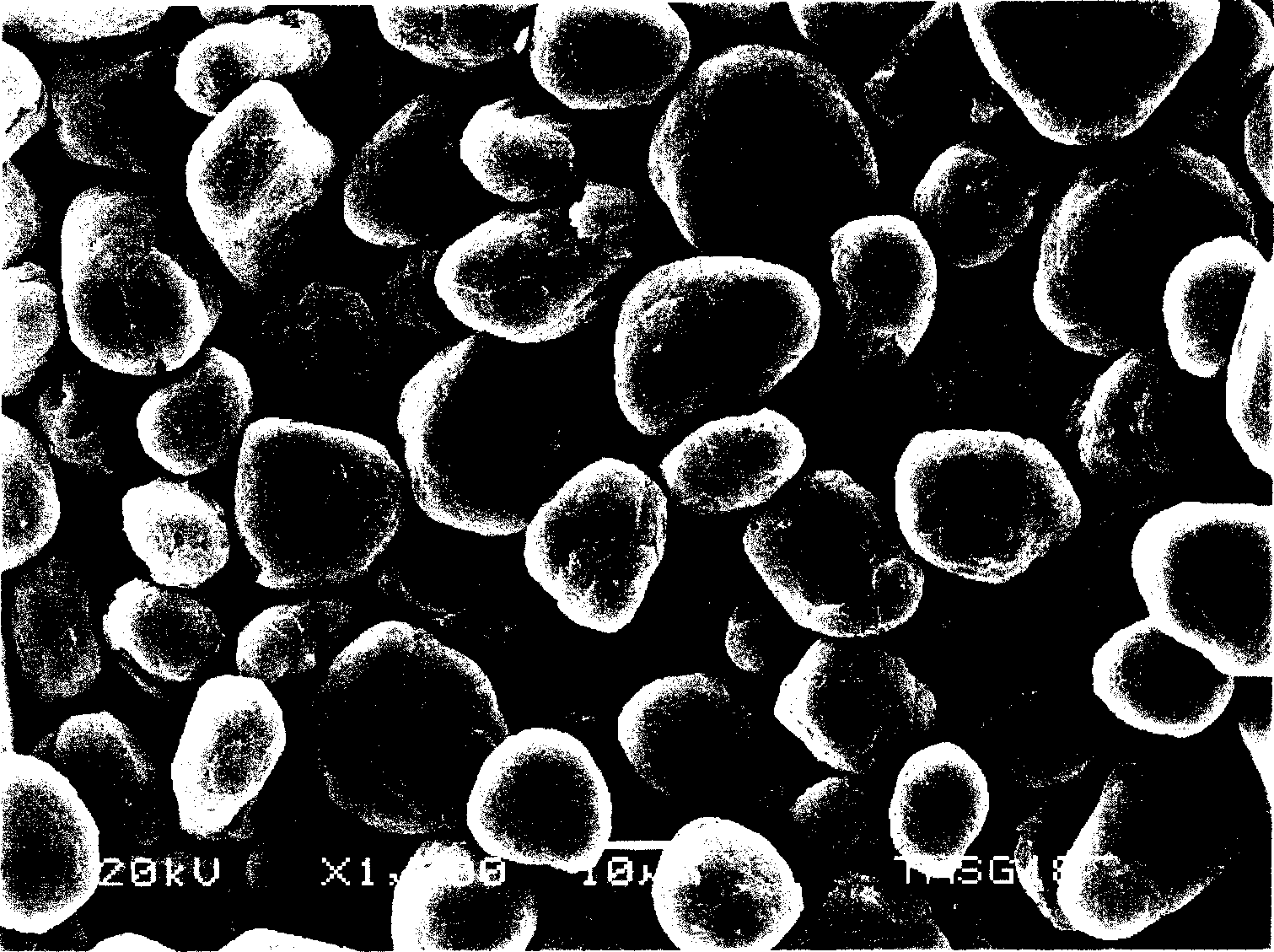

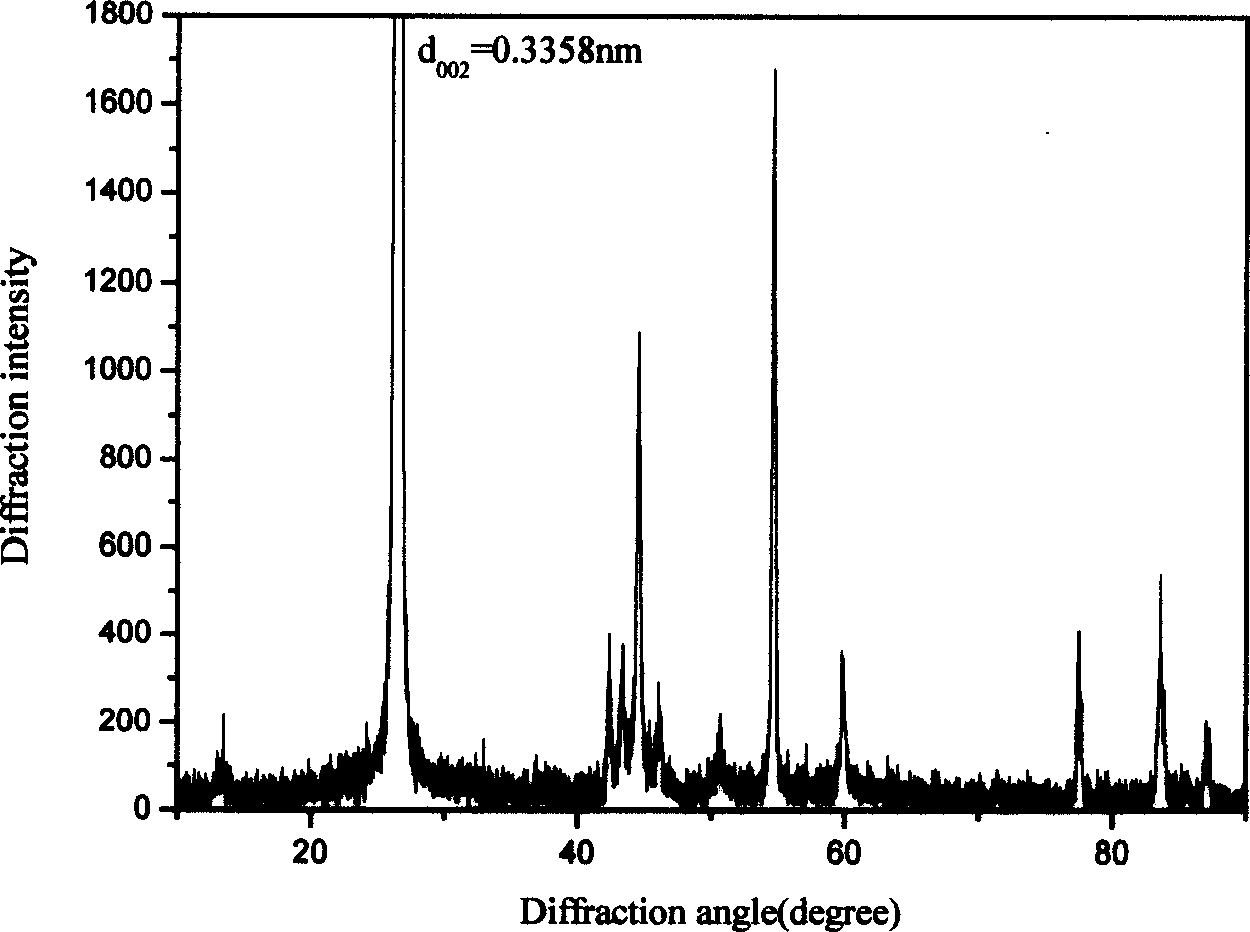

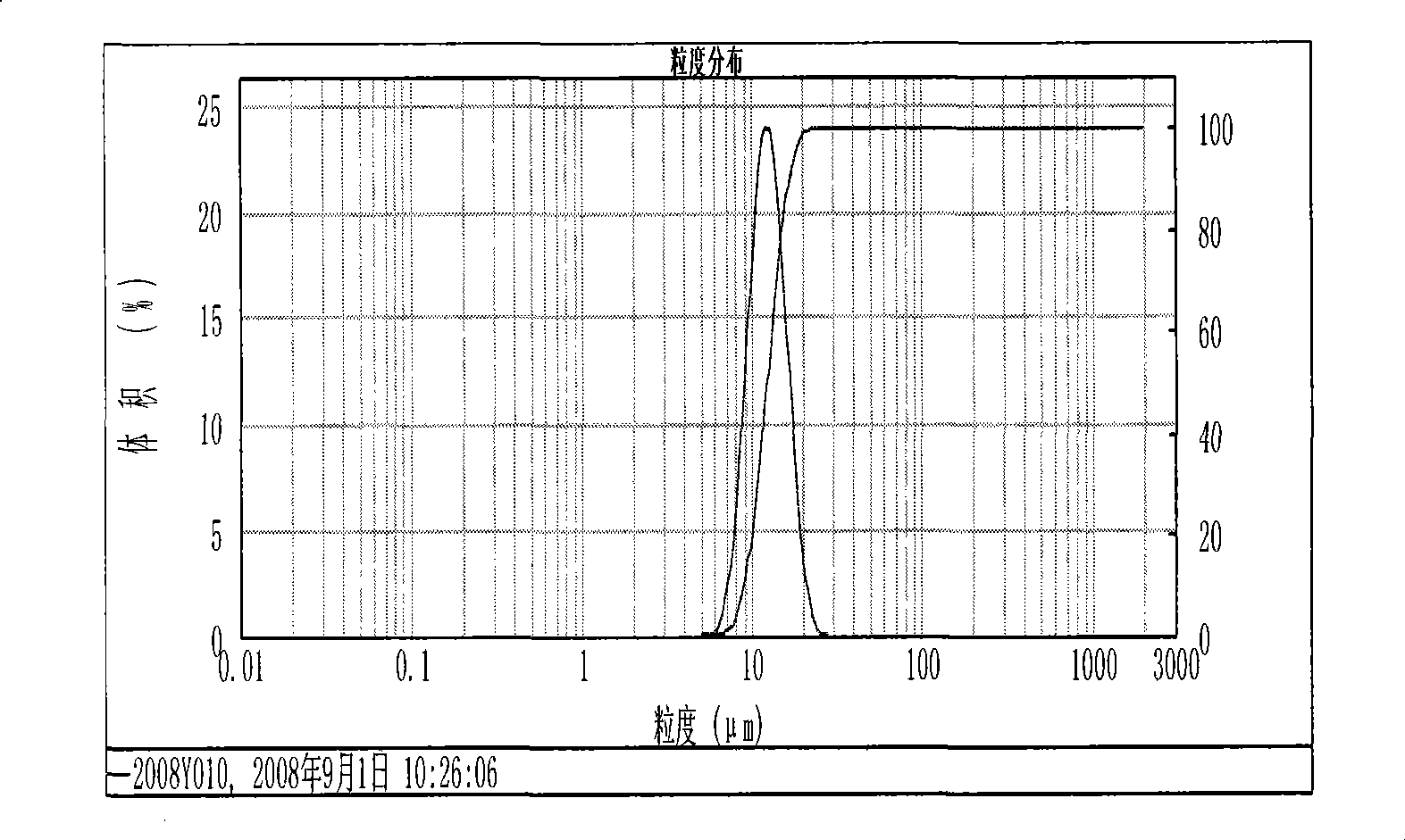

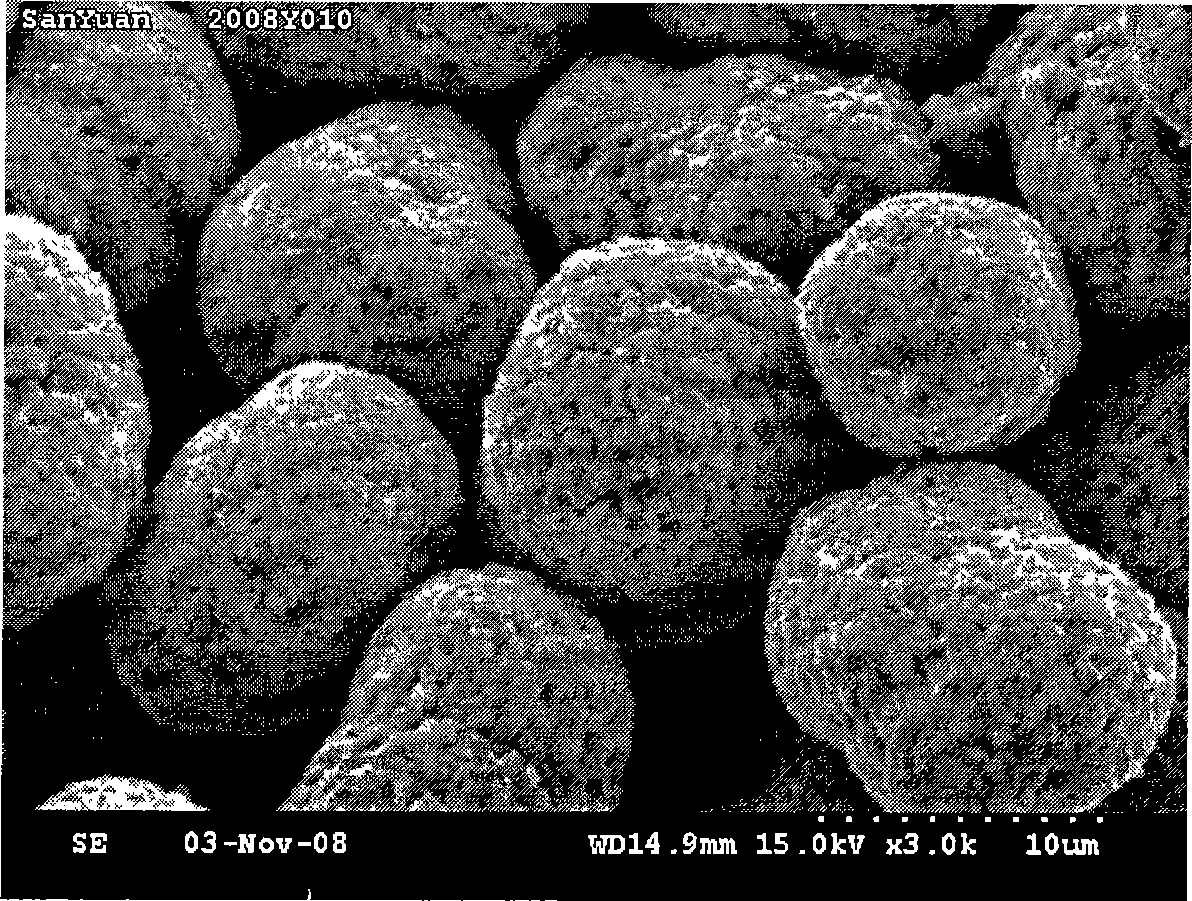

Cathode material of composite carbon in use for lithium ion battery and preparation method

ActiveCN1697215ASimple preparation processEasy to operateElectrode manufacturing processesActive material electrodesLithium-ion batteryMaterials science

The disclosed composite carbon material of negative pole in lithium ion cell is composite graphite including spherical graphite and covering layer, which is pyrolytic carbon of organic matter. Inserted transition metal elements are contained between layers of graphite crystal. Preparation method is as following: crushing graphite, shaping and sphericized, purifying treatment, washing, dewatering and drying, dipped in salt solution doped by transition metal in multivalence, mixed with organic matter, covering treatment, and carbonizing treatment or graphitization treatment. Comparing with prior art, the disclosed material of negative pole possesses advantages of fine capability of embedding lithium and taking off lithium, high cyclical stability, reversible specific capacity larger than 350mAh / g, coulomb efficiency higher than 94% at first cycle, conservation rate for capacity larger than 80% in 500 times of circulation.

Owner:BTR NEW MATERIAL GRP CO LTD

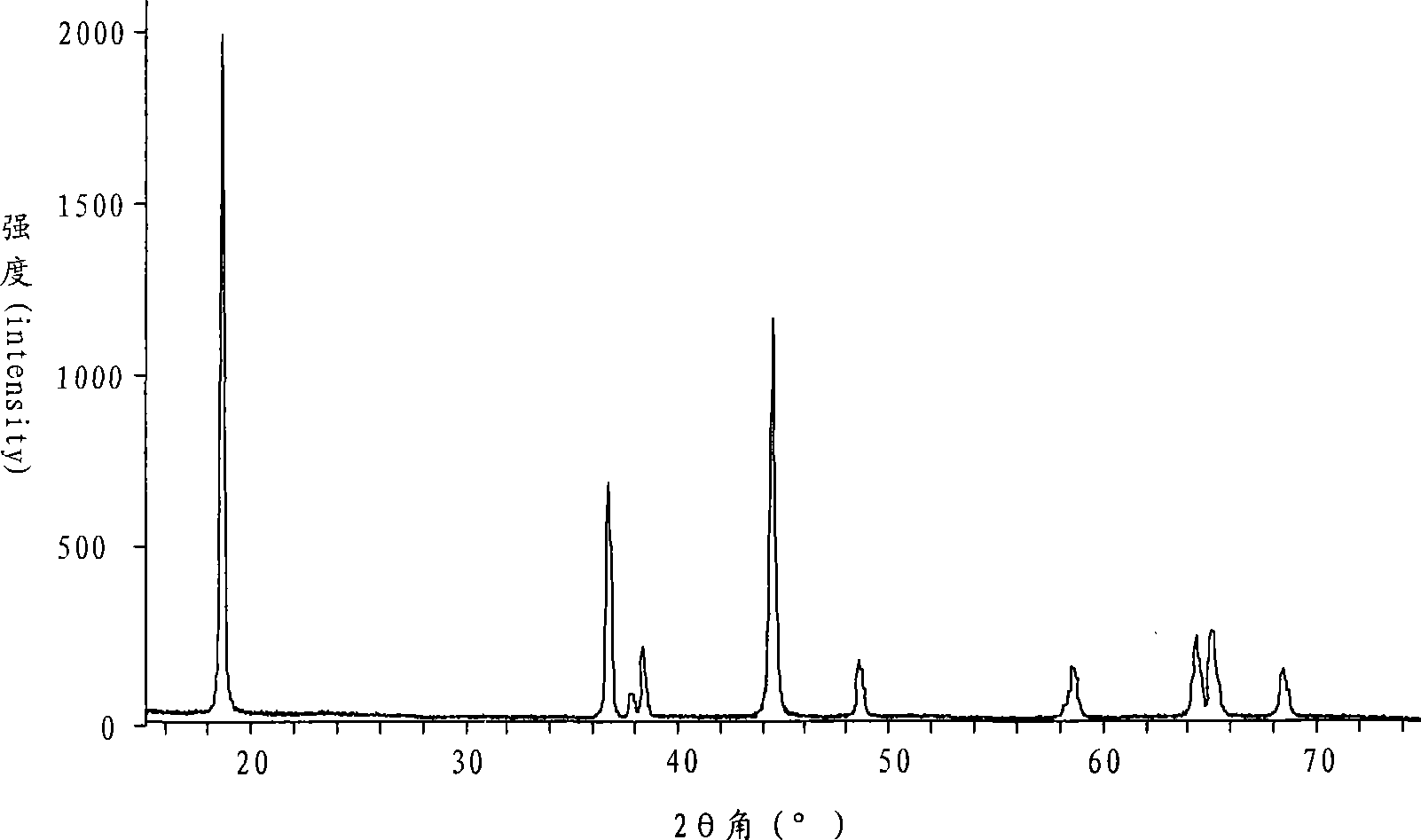

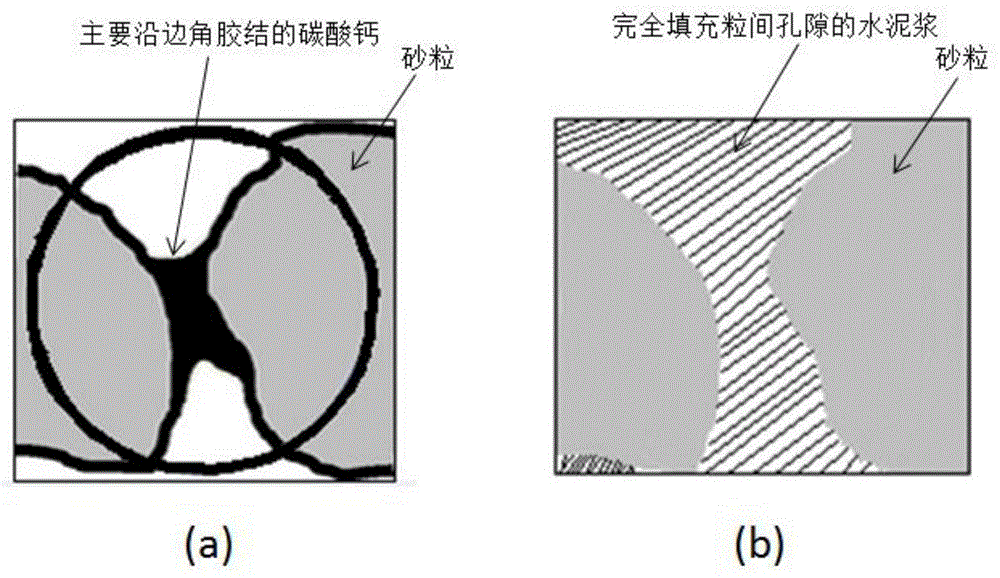

Multi-element composite positive pole material for lithium secondary battery and preparation thereof

ActiveCN101478044AEnsure mixing uniformityAvoid destructionElectrode manufacturing processesSecondary cellsManganeseSpherical shaped

Owner:XTC NEW ENERGY MATERIALS(XIAMEN) LTD

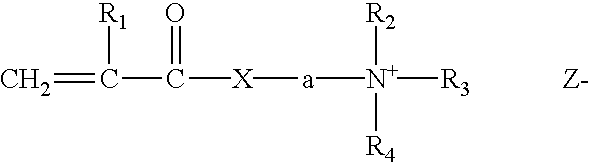

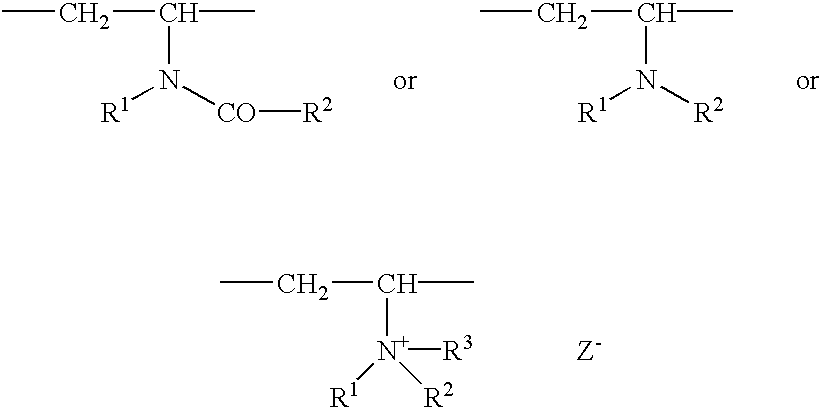

Aqueous dispersion polymers

InactiveUS6020422AOrganic-compounds/hydrides/coordination-complexes catalystsInorganic compound additionEmulsionWater soluble

Water soluable, aqueous salt solution dispersible polymers and aqueous salt solutions containing dispersed polymers are produced by polymerization of ethylenically unsaturated soluble monomers in an aqueous salt solution in the presence of at least one carbohydrate. The polymers and aqueous salt solutions containing the dispersed polymers are useful for paper making, water clarification and emulsion breaking.

Owner:BETZEARBORN INC

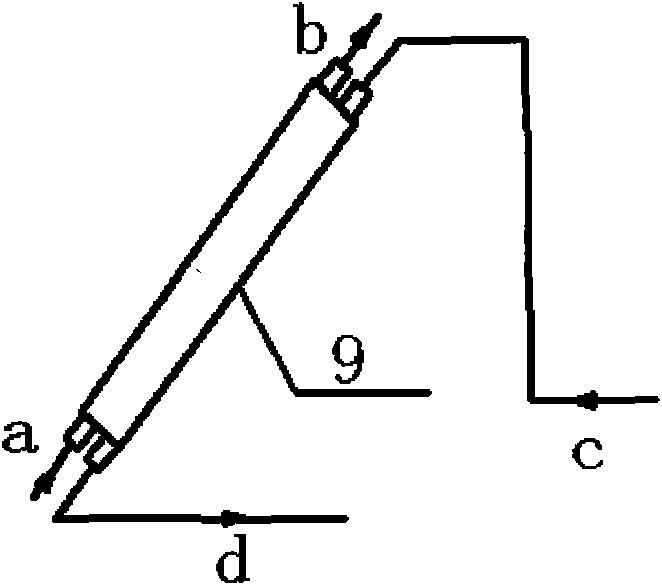

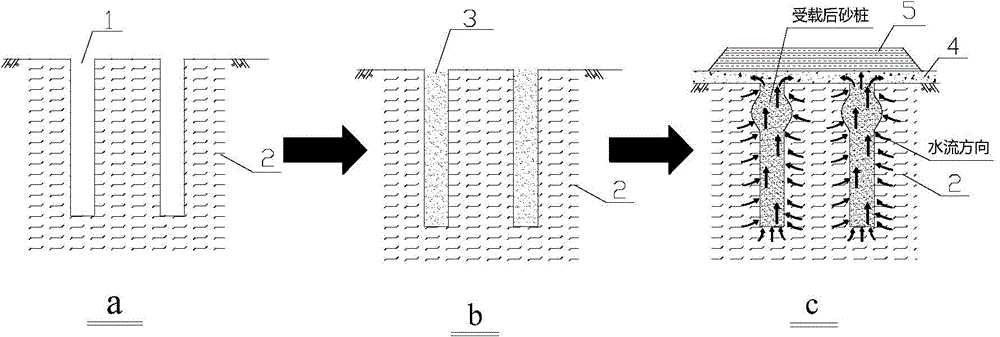

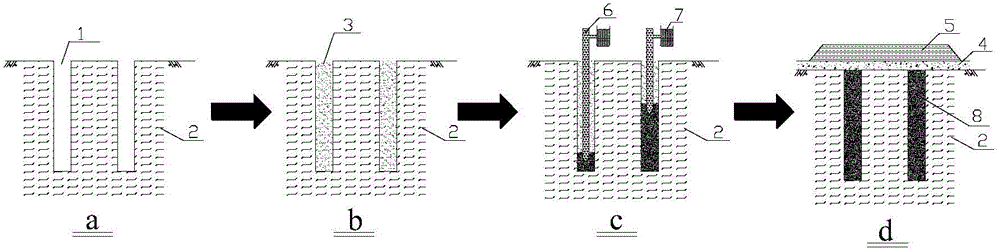

Method for soft soil foundation treatment through microorganism grouting sand drain

InactiveCN104631430AImprove vertical load carrying capacityPermeability changeOrganic fertilisersSoil conditioning compositionsSoil scienceSalt solution

Disclosed is a method for soft soil foundation treatment through microorganism grouting sand drain. The method comprises the steps that a, a pile hole 1 is formed in a soft soil foundation to be treated, and sand is poured into the pile hole 1 to form a sand pile; b, a urease-producing microorganism solution 9 and a nutritive salt solution 10 are sequentially and evenly injected into the sand pile through a grouting tube 6, sand cementation is achieved through the microorganism induction calcium carbonate crystal technology, the concentration of the urease-producing microorganism solution 9 and the concentration of the nutritive salt solution 10 are controlled, sand in the pile body forms a specific cementation mode, and the good water permeable characteristic is ensured; c, after the microorganism grouting solidification sand pile is formed, a flexible water permeable sand cushion 4 is laid on the top of the foundation jointly formed by the sand oil and pile space soil 2, prepressing loads 5 are exerted on the top of the flexible water permeable sand cushion 4, pore water in the pile space soil 2 is made to be drained along a drainage channel formed by the sand pile and the sand cushion, the pile space soil is solidified, and the composite foundation with the high bearing capacity is formed jointly through the soft soil obtained after drainage and solidification are carried out on the microorganism grouting sand pile and the flexible water permeable sand cushion covering the soft soil.

Owner:NANJING FORESTRY UNIV

Method for preparing high purity vanadium pentoxide through using ammonium metavanadate

The invention which relates to a method for preparing high purity vanadium pentoxide through using ammonium metavanadate belongs to the wet metallurgy field. The method comprises the following steps: heating and dissolving crude ammonium metavanadate in water, adjusting the pH value to 8-10 with an alkali after dissolving, adding an impurity removing agent to remove impurities, filtering to obtain a sodium metavanadate solution, adding ammonia water or an ammonium salt to the sodium metavanadate solution to precipitate to obtain an ammonium metavanadate precipitate, dehydrating the ammonium metavanadate precipitate, carrying out water washing on the precipitate through using a dilute ammonium salt solution, dehydrating after the wash washing, and roasting to obtain the high purity vanadium pentoxide. Vanadium pentoxide produced through adopting the method of the invention has the advantages of high purity and less impurities, and completely satisfies production requirements of high-end products; and the method of the invention has the advantages of short process flow, simple equipment, low cost and high benefit, and is suitable for the large-scale industrial production.

Owner:崇阳县恒通工贸有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com