Multi-element composite positive pole material for lithium secondary battery and preparation thereof

A secondary battery and multi-component composite technology, which is applied in secondary batteries, electrode manufacturing, battery electrodes, etc., can solve the problems of affecting material cycle performance, material instability, and no advantage in gram specific capacity, etc., and achieve excellent physical and electrochemical performance, improved uniformity, and improved unit cell development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

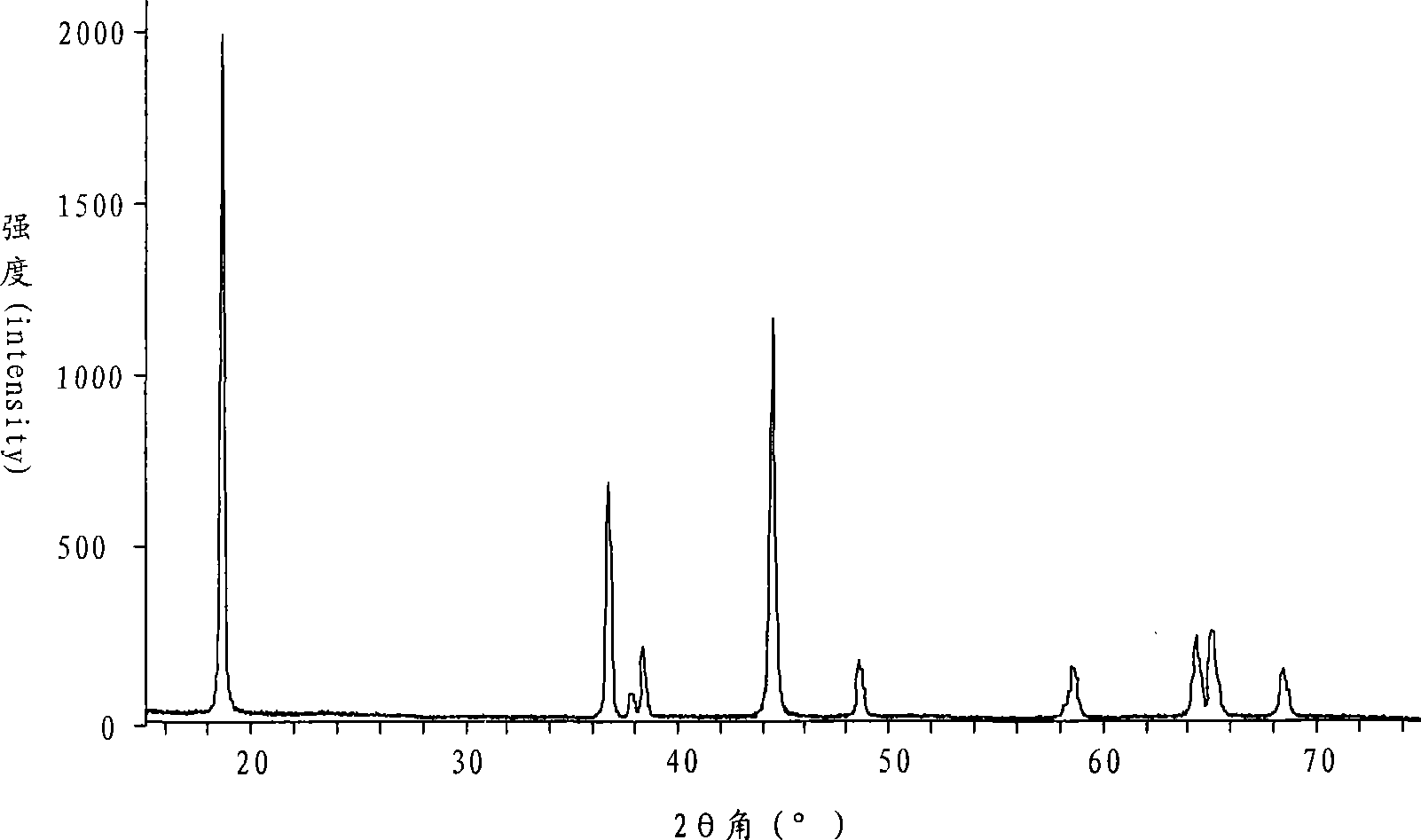

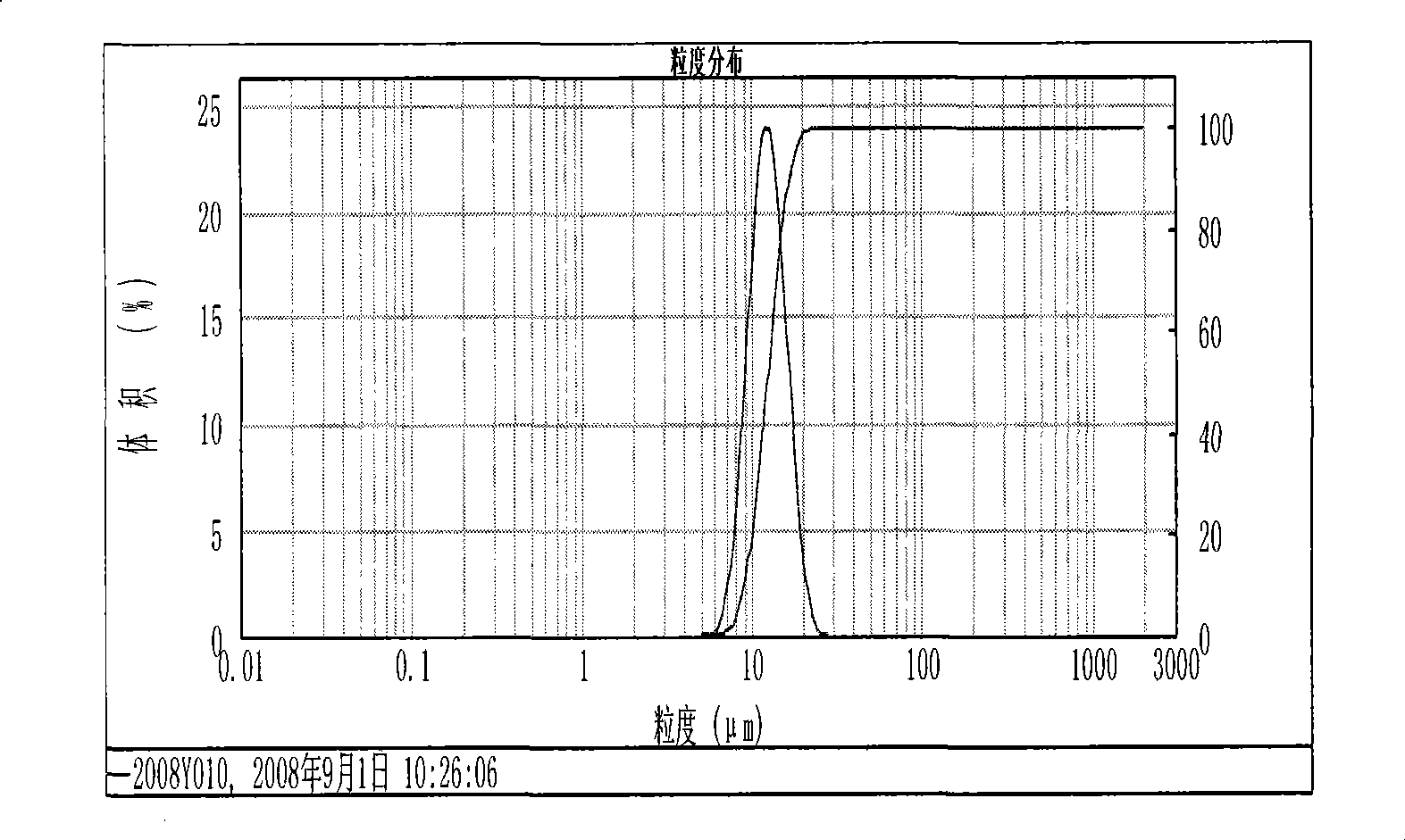

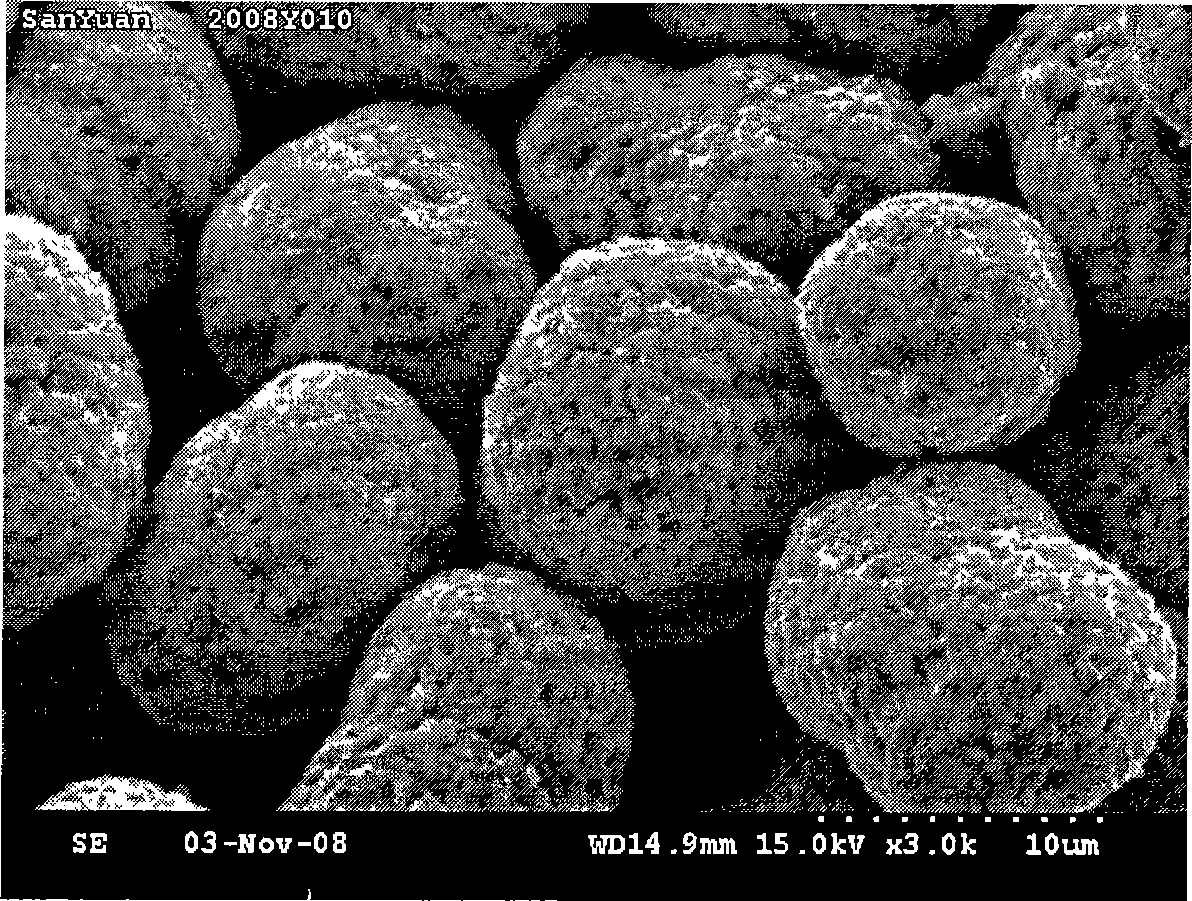

Embodiment 1

[0027] Mn(NO 3 ) 2 , Co(NO 3 ) 2 , Ni(NO 3 ) 2 Mn in molar ratio 2+ / Co 2+ / Ni + =Mix in the ratio of 3:2:5 and dissolve in deionized water to form 【Mn 2+ +Co 2+ +Ni + 】A mixed salt solution with a total metal ion concentration of 2.0 mol / L, a NaOH solution with a concentration of 4 mol / L, and an ammonia solution with a concentration of 6.0 mol / L. The mixed three kinds of solutions (salt solution, NaOH solution and ammonia solution) are slowly and dropwise added to the ternary reactor with liquid flow turbine circulation, under the protection of nitrogen or other inert gases, the precipitation of the sediment is controlled in a batch operation. For crystallization and growth, the reaction temperature is controlled to 50°C, the stirring speed is 600r / min, the pH value is 11, and the reaction time is 48 hours. After the reaction is completed, the reaction product is washed with deionized water several times until the pH of the filtrate is neutral, and then dried at 100°C for 12 hour...

Embodiment 2

[0033] Mn(NO 3 ) 2 , Co(NO 3 ) 2 , Ni(NO 3 ) 2 Mn in molar ratio 2+ / Co 2+ / Ni + =Mix in the ratio of 2:2:6, dissolve in deionized water, and mix into 【Mn 2+ +Co 2+ +Ni + 】A mixed salt solution with a total metal ion concentration of 1.5 mol / L, a NaOH solution with a concentration of 3 mol / L, and an ammonia solution with a concentration of 5 mol / L. The three solutions are slowly added dropwise to a three-element reactor with liquid flow turbine circulation, under the protection of nitrogen or other inert gases, and the crystallization and growth of the precipitate are controlled in a batch operation mode, and the reaction temperature is controlled to 60°C. The stirring speed is 400r / min, the pH value is 11.5, and the reaction time is 36 hours. After the completion of the reaction, the reaction product was washed with deionized water several times until the pH of the filtrate was neutral, and then dried at 100°C for 12 hours to obtain a precursor with dense crystals, spherical morp...

Embodiment 3

[0038] Mn(NO 3 ) 2 , Co(NO 3 ) 2 , Ni(NO 3 ) 2 Mn in molar ratio 2+ / Co 2+ / Ni + =Mix in the ratio of 2:1:7, dissolve in deionized water, and mix into 【Mn 2+ +Co 2+ +Ni + 】A mixed salt solution with a total metal ion concentration of 1.8mol / L, a NaOH solution with a concentration of 2.5mol / L, and an ammonia solution with a concentration of 5mol / L. The three solutions are slowly added dropwise to a three-element reactor with liquid flow turbine circulation, under the protection of nitrogen or other inert gases, and the crystallization and growth of the precipitate are controlled in a batch operation mode, and the reaction temperature is controlled to 60°C. The stirring speed is 300r / min, the pH value is 11, and the reaction time is 36 hours. After the completion of the reaction, the reaction product was washed with deionized water several times until the pH of the filtrate was neutral, and then dried at 100°C for 12 hours to obtain a precursor with dense crystals, spherical morphol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tap density | aaaaa | aaaaa |

| Current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com