Patents

Literature

785results about How to "Improve physics" patented technology

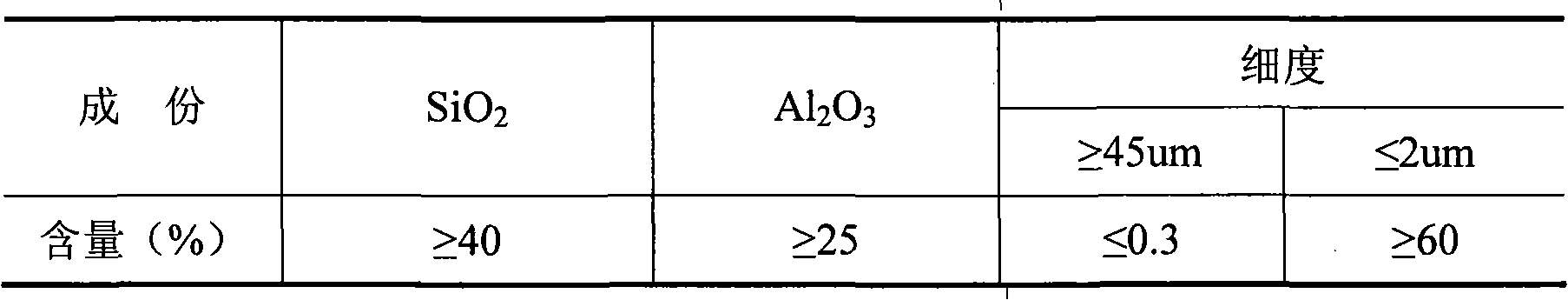

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

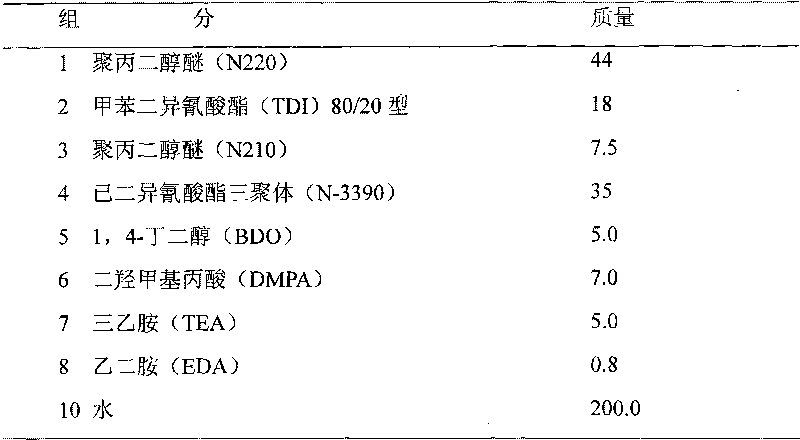

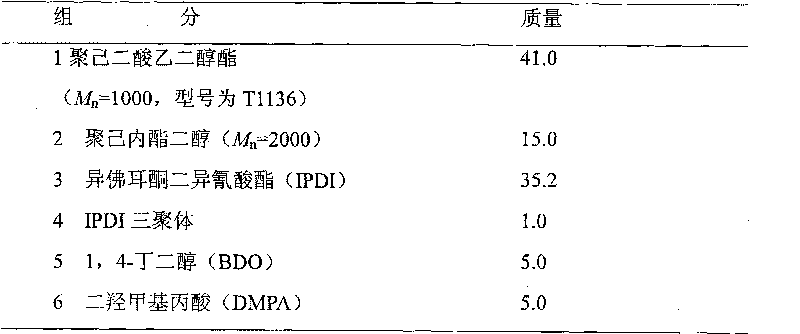

Preparation method and application of modified polyurethane aqueous dispersions of polyisocyanate curing agents

InactiveCN101696262ASimple processEasy to operatePolyurea/polyurethane coatingsLeather surface finishingPolyesterSolvent

The invention discloses a preparation method and application of modified polyurethane aqueous dispersions of polyisocyanate curing agents. The preparation method comprises the following steps of: carrying out prepolymerization reaction by using polyester polyol, vulcabond monomer and a polyisocyanate curing agent; reacting with a hydrophilic chain-extending agent and a micro-molecule chain-extending agent to obtain polyurethane prepolymer containing hydrophilic groups (carboxyl or sulfonic groups) and isocyanate(NCO)-terminated groups; neutralizing the polymer into salt, and then dispersing the salt into water; and preparing the modified polyurethane aqueous dispersions of the polyisocyanate curing agents by the chain extending of a polyamine chain-extending agent. The modified polyurethane aqueous dispersions of the polyisocyanate curing agents have self-crosslinking function at room temperature, and the self-crosslinking density is over 85%. Compared with non-modified polyurethane aqueous dispersions prepared under the same condition, the modified polyurethane aqueous dispersions have superior film forming property, water resistance, alcohol resistance, pollution resistance, cold resistance, dry / wet rubbing resistance and chemical solvent resistance; and coating films have especially high drying speed, high hardness increment speed and high final hardness.

Owner:SOUTH CHINA UNIV OF TECH

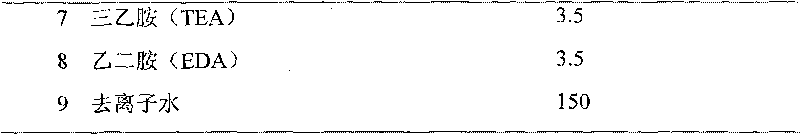

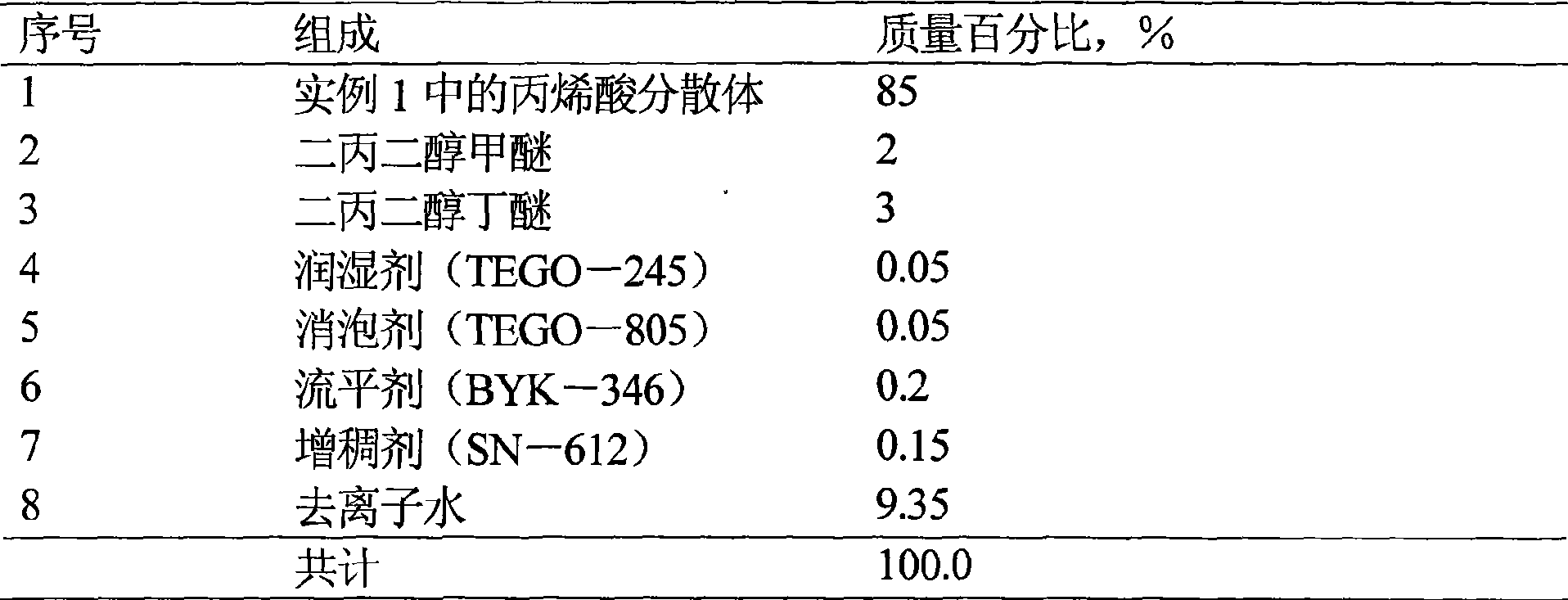

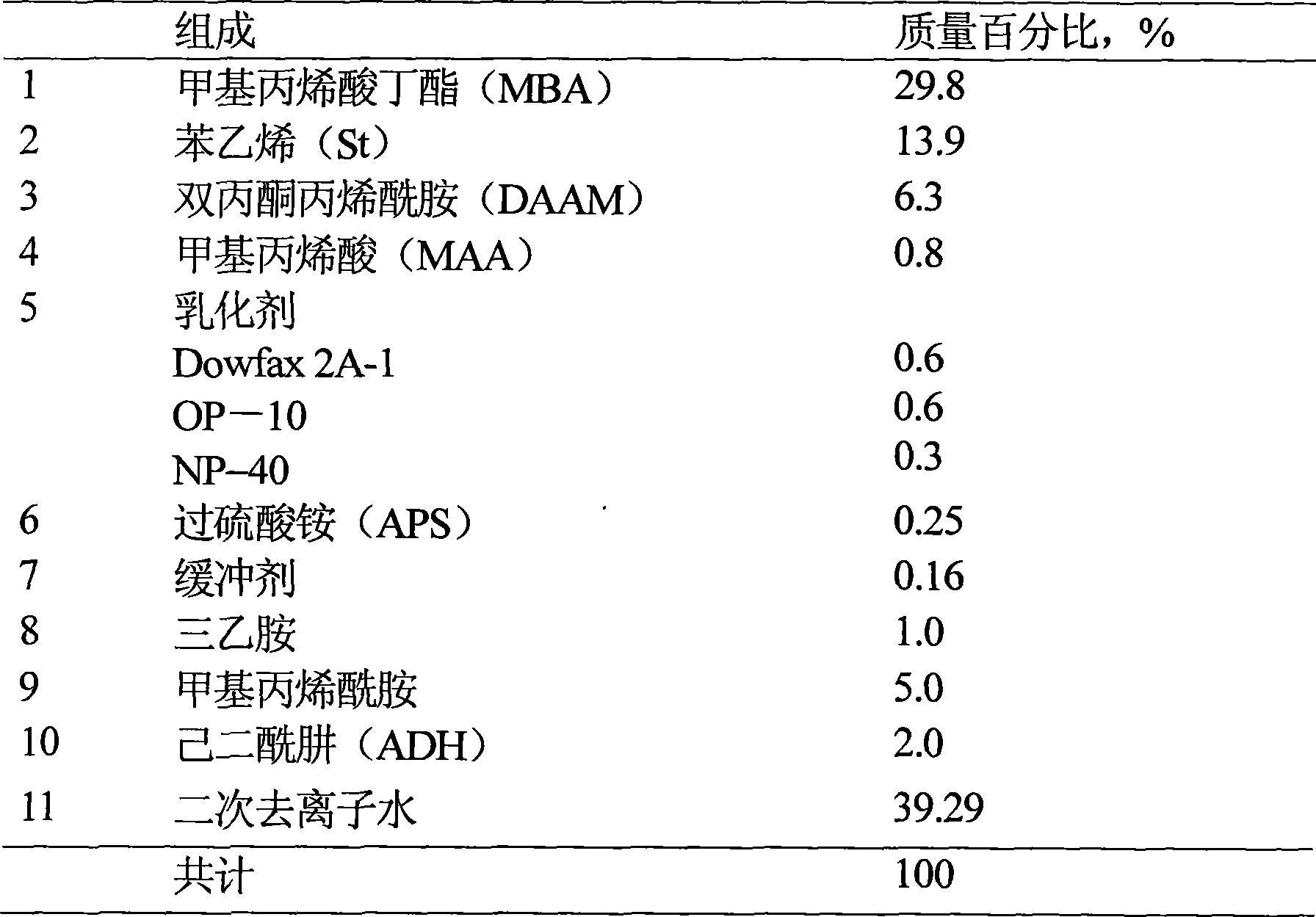

Preparation of high closeness polyacrylacid ester dispersion

The invention relates to a high-sealing polyacrylic ester dispersoid and a preparation method thereof; a multi-element emulsifier system which consists of an anionic emulsifier and a compound non-ionic emulsifier is adopted for controlling the charging process and components of the emulsifier in different polymerization periods, and the room-temperature self-crosslinking high-sealing polyacrylic ester dispersoid is prepared by a semi-continuous seeding emulsion polymerization process. The dispersoid has small particle size, good electrolyte-resistance (calcium ion) stability and high tolerance to various film forming accessory ingredients (various organic solvents with high boiling point). The dispersoid is used as seal coat of water-based wood coating and has good sealing performance to various woods; harmful volatile organic compounds (VOC) such as formaldehyde, and the like sealed against escaping from plates to pollute indoor environment, and the colored compounds such as turpentine, pine oil and tannin and the like are sealed against dissolving out of the plates to pollute pure top coating and white top coating of a water-based wooden ware; and in addition, the dispersoid can be used in water-based leather finishing agents.

Owner:SOUTH CHINA UNIV OF TECH

Composite epoxy anticorrosive paint and preparation method thereof

ActiveCN104231857AHigh glass transition temperatureGood flexibilityConjugated diene hydrocarbon coatingsAnti-corrosive paintsEpoxyPolymer science

The invention discloses composite epoxy anticorrosive paint and a preparation method thereof. The composite epoxy anticorrosive paint is composited by a component A and a component B at a ratio of 2:1, wherein the component A comprises constituents as follows: organosilicon modified epoxy resin, a pigment, filler, a plasticizer, a dispersant, a coalescing agent and a antifoaming agent; the component B comprises constituents as follows: polyphenyl ether resin powder, styrene-butadiene rubber, toluene, a plasticizer, a coupling agent, auxiliary materials and a flame retardant; and the components A and B are mixed respectively for preparation, and B is sprayed on A to form the composite epoxy anticorrosive paint. The composite epoxy anticorrosive paint is prepared by two components, has superior high-temperature resistance and abrasion resistance as well as good adhesion and low shrinkage simultaneously, has good corrosion resistance and penetration resistance to water, medium acid, alkali and other solvents and further has superior flexibility and paint application simultaneously; and the preparation method of the composite epoxy anticorrosive paint is simple and low in cost.

Owner:JIANGSU MARINE VICTORY COATING

Composite material of modified micro plant fiber powder and natural rubber and its prepn process and application

The present invention discloses one kind of composite material of modified micro plant fiber powder and natural rubber and its preparation process and application. The composite material includes natural rubber or latex 100 weight portions, modified micro plant fiber powder 1-60 weight portions, sulfur 0.5-3.3 weight portions, promoter 1.2-4.3 weight portions, antiager 1-3 weight portions and other assistant. The preparation process includes mixing, forming, vulcanizing and other steps. The composite material has high tensile strength, high tearing strength, high ageing resistance, high virus permeation resistance, etc. and may be used widely in making urinary catheter, blood transfusion tube, condom, medical gloves and other products.

Owner:JINAN UNIVERSITY

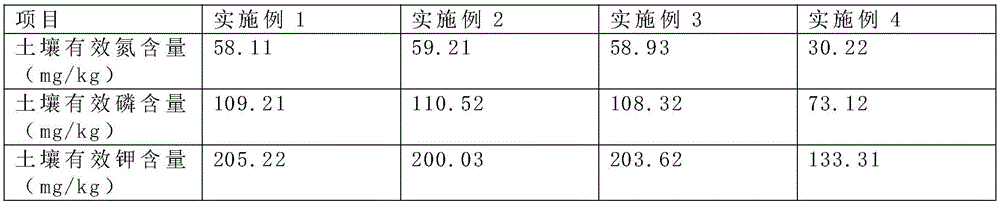

Composite microbial inoculum organic multielement compound fertilizer and production method thereof

ActiveCN102690151AImprove physicsGood biological propertiesFertilizer mixturesThiobacillus ferrooxidansBran

The invention discloses a composite microbial inoculum organic multielement compound fertilizer which is prepared from microbial inoculum, organic component and inorganic fertilizer. The microbial inoculum is a composite microbial inoculum which comprises the following three types of microbial inocula: resource type microbial inoculum, which contains Bacillus megaterium, thiobacillus thiooxidans, Bacillus mucilaginosus and Bacillus circulans; environment-friendly microbial inoculum, which contains Arthrobacter and Alcaligenes; and antibiotic microbial inoculum, which contains Streptomycs micuoflavus and Streptomyces jingyangensis. The organic component is one or more of cereal crop straw, subsidiary agricultural product dreg, sugar mill bagasse, bran coat, municipal and rural domestic waste, and livestock and poultry dung. The inorganic fertilizer is one or more of nitrogen fertilizer, phosphate fertilizer, potash fertilizer and medium / micro-nutrient element fertilizer. The weight proportion of microbial inoculum to organic constituent to inorganic fertilizer is (5-25):(18-28):(47-77).

Owner:赵大伟

High-temperature (800 DEG C) wear-resistant paint and preparation method thereof

The invention discloses high-temperature (800 DEG C) wear-resistant paint and a preparation method thereof. The high-temperature wear-resistant paint comprises a component 1 and a component 2, wherein the component 1 is prepared by mixing a component A and a component B; the component A in the component 1 comprises the following components: black silicon carbide, fine-grain aluminum oxide, dispersing agent, zinc oxide, modified epoxy resin, flatting agent and an auxiliary material; the component B in the component 1 comprises the following components: organic silicon modified epoxy resin, a filler, antimony trioxide, film-forming assistant and thickener; and the component 2 is curing agent and coupling agent. The high-temperature (800 DEG C) wear-resistant paint is prepared by the following steps: mixing the component A and the component B in the component 1, and curing the component 1 with the component 2. The high-temperature wear-resistant paint is prepared by compounding the double components, has excellent high temperature resistance and wear resistance, and also has the fine properties of favorable hardness, high heat stability, ductility, workability and the like. The invention also designs the method for preparing the high-temperature wear-resistant paint. The preparation method is simple and low in cost.

Owner:JIANGSU XIN AN NEW MATERIALS TECH

Functional nutrition fertilizer and preparation method thereof

InactiveCN106116925APromote seedling growthGood insecticidal effectBiocideCalcareous fertilisersHorticultureUrea

The invention discloses a functional nutrition fertilizer, which comprises the following raw materials in parts by weight: 200-500 parts of organic wastes, 20-60 parts of grass carbon, 60-120 parts of livestock manure, 200-600 parts of rice washing water, 50-100 parts of seaweed mud, 10-50 parts of EM bacteria agent, 1-3 parts of ferrous sulfate, 1-3 parts of copper sulfate, 1-3 parts of zinc sulfate, 0.5-2 parts of manganese sulfate, 0.5-3 parts of ammonium molybdate, 0.3-2 parts of sodium tetraborate, 0.3-3 parts of strontium nitrate, 0.5-1 parts of selenium dioxide, 2-6 parts of magnesium sulfate, 3-8 parts of potassium chloride, 2-8 parts of calcium carbonate, 3-10 parts of bentonite, 5-10 parts of urea, 10-50 parts of traditional Chinese medicine extract, and 10-30 parts of traditional Chinese medicine residue fermented product. According to the functional nutrition fertilizer, the nutrition components are complete and balanced, the disease and insect resistance capacity of soil can be enhanced, the fertilizer efficiency of soil can be increased, and the functional nutrition fertilizer has no environment pollution. The invention further discloses a preparation method of the functional nutrition fertilizer.

Owner:李怀峰

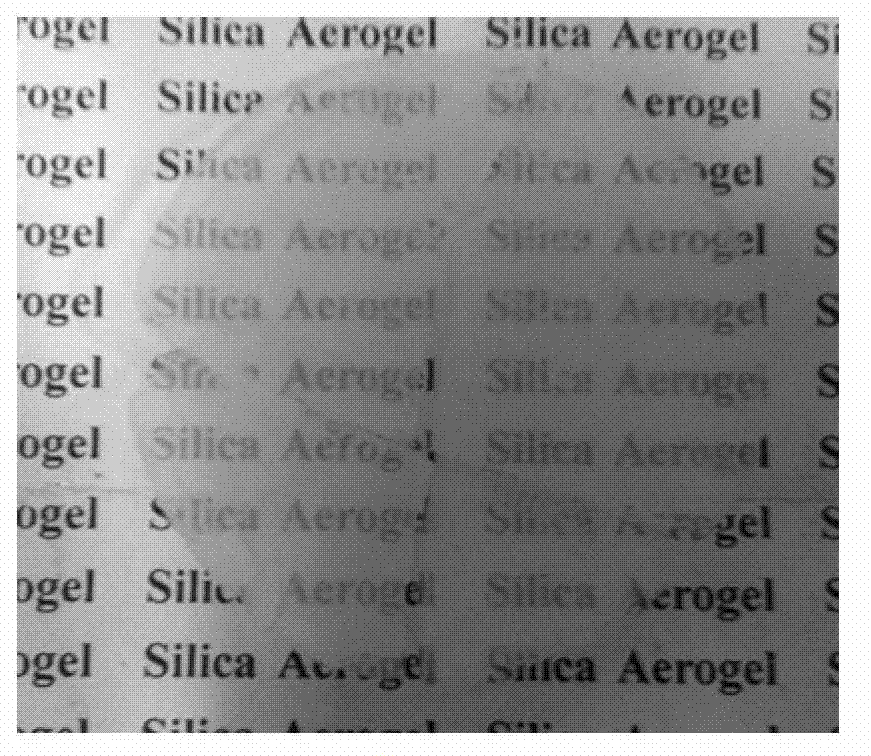

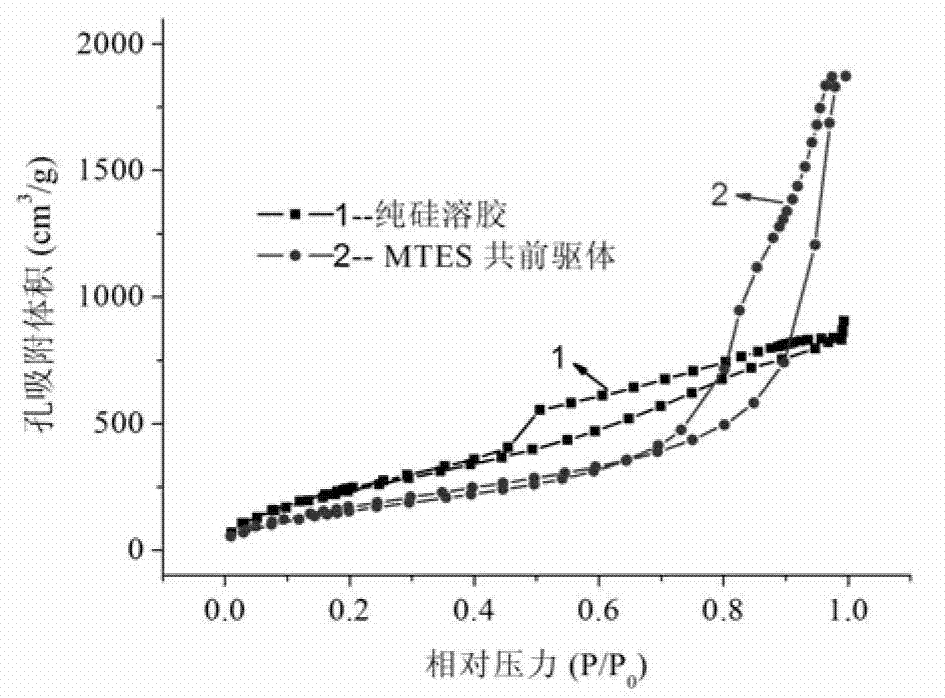

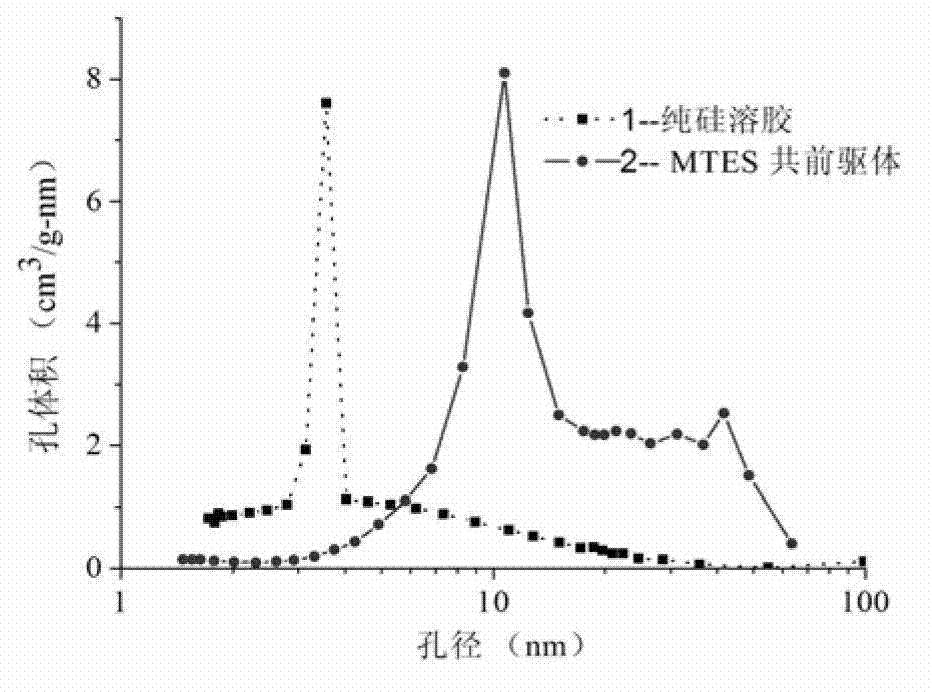

Preparation method of transparent silicon dioxide aerogel

The invention relates to aerogel and provides a preparation method of transparent silicon dioxide aerogel, which has the advantages of low cost, simple process, short production period, controllable reacting process and continuous production and adopts secondary modification process and normal-pressure drying steps. The preparation method comprises the following steps: 1) solution preparation and silicon source co-precursor hydrolysis; 2) ion exchange and silicon dioxide hydrogel preparation by using gel; and 3) aging, alcoholizing, modifying and normal-pressure drying of the silicon dioxide gel.

Owner:ZHONGKE RUNZI (CHONGQING) ENERGY SAVING TECH CO LTD

Sewing-free hot melt adhesive TPU-PU leather and preparation method thereof

ActiveCN103437195AExcellent physical and chemical propertiesHigh bonding strengthPolyureas/polyurethane adhesivesSynthetic resin layered productsPolyesterPolymer science

The invention provides a piece of novel sewing-free hot melt adhesive TPU-PU leather, and a preparation method thereof. The TPU-PU leather comprises release paper, a hot melt adhesive film, a TPU film and a dry-type PU film, wherein the release paper comprises a paper bottom layer, an adhesive layer, a plastic layer, a transition layer, and a release layer; a hot melt adhesive raw material is composed of polyester polyol, diisocyanate, polyether polyol, and a plurality of additives; a TPU raw material is composed of polymer polybasic alcohol, 1,4-cyclohexane-diisocyanate, a chain extender and a plurality of functional additives; a PU raw material is composed of polyester dibasic alcohol, straight chain diol, isocyanate, TDI trimer, dimethyl formamide, butanone, black sand, and a plurality of functional addictives. Through the adoption of the preparation method, innovations are conducted on the raw material components of the release paper, the hot melt adhesive, the TPU film and the PU film; the manufactured sewing-free TPU-PU leather has the technical advantages of firmness in adhesion, durability, environment-friendly materials, no invisible harm to a human body, and the like.

Owner:DONGGUAN XIONGLIN NEW MATERIAL TECH

High strong adhesive and method for preparing same

The powerful adhesive includes neoprene, grafting monomer, thickener, dispersant, adhesion promoter, catalyst, antioxidant, solvent, stuffing, etc. The present invention also discloses the preparation process of the adhesive, and the preparation includes introducing grafting monomer to neoprene molecule chain to raise the adhesion strength, selecting proper adhesion promoting resin to increase the initial adhesion force, and adopting mixed solvent to form high adhering performance. The adhesive has high solid content and excellent environment protecting performance, and has also excellent antiageing performance, high resistance to heat, oil, chemical and corrosion, high weather resistance, good mildew-proof performance, antibiotic performance, etc. and may be used for adhering timber, concrete, rubber, metal, gypsum board, brick and other building material.

Owner:GUANGZHOU GLORYSTAR CHEM

Biodegradable coated compound fertilizer and preparation method thereof

The invention relates to a coated compound fertilizer, in particular to a totally biodegradable coated compound fertilizer and a preparation method thereof. The coated compound fertilizer consists of a coated layer and a compound fertilizer core. The main body of the coated layer is polylactic acid and / or polybutylene succinate. The coating process adopts fluidized bed spraying-coated technology, and comprises the following steps: dissolving polylactic acid and / or polybutylene succinate in trichloromethane, adding carboxymethylcellulose, urease and / or nitrification inhibitor, organic and / or inorganic conditioner in the solution, spraying and coating the surfaces of the fluidized compound fertilizer granules after uniformly mixing the mixture under the stirring of a stirrer to form the uniform and complete organic polymeric membrane layer. The process has the advantages of easy implementation, and capacity of effectively slowing down the release of the fertilizer nutrient to the outside and the conversion rate of nitrogen in soils, effectively controlling the release and conversion of the fertilizer nutrient in soils, and reducing the pressure on environment caused by the rapid release of nutrient. The coated material can be totally biodegradable, and the degradation products have no secondary pollution to the environment.

Owner:SHENYANG INST OF APPLIED ECOLOGY - CHINESE ACAD OF SCI

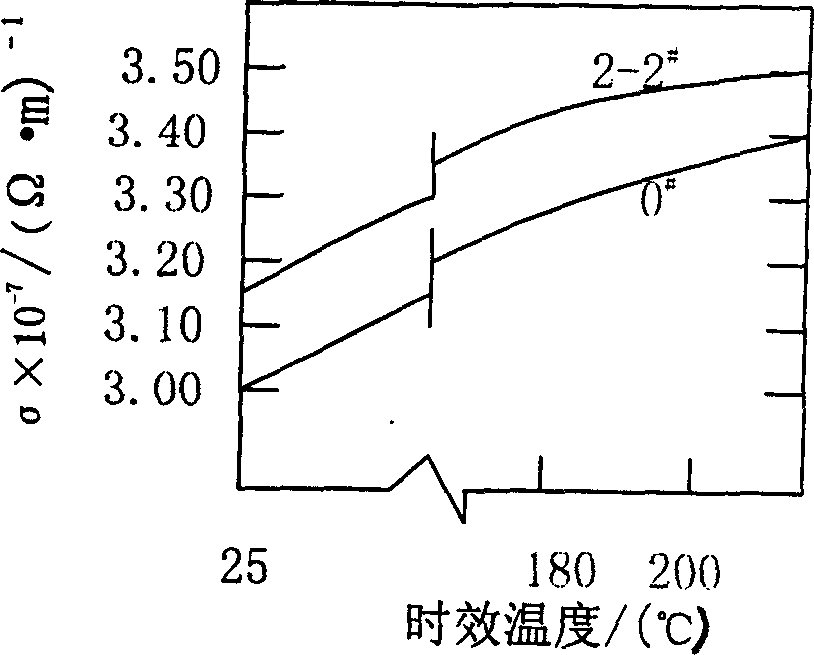

Improved 6063 aluminium alloy materials

ActiveCN1456697AImprove mechanical propertiesImprove thermal conductivityRare-earth elementAluminium alloy

Owner:广东广铝铝型材有限公司

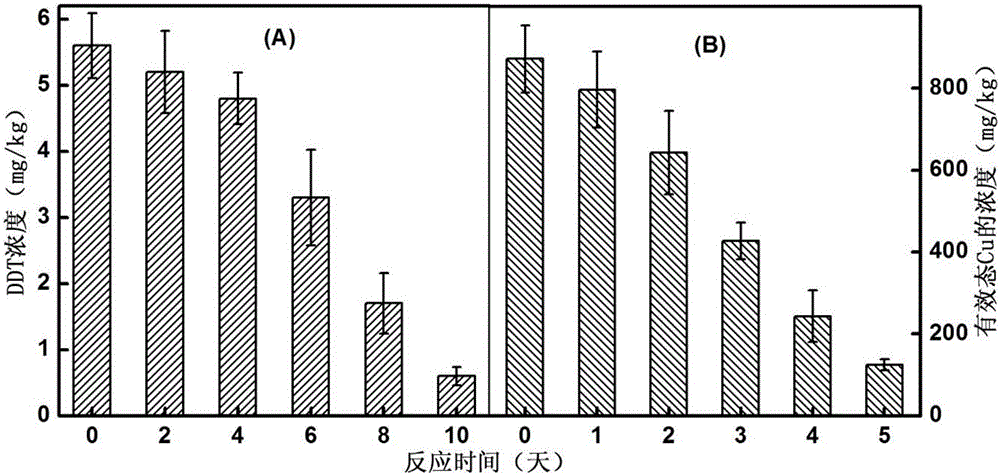

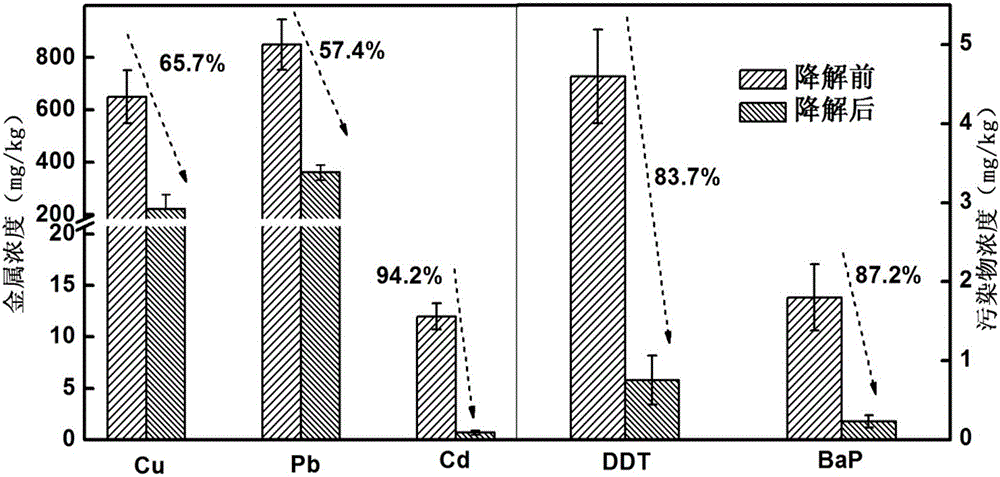

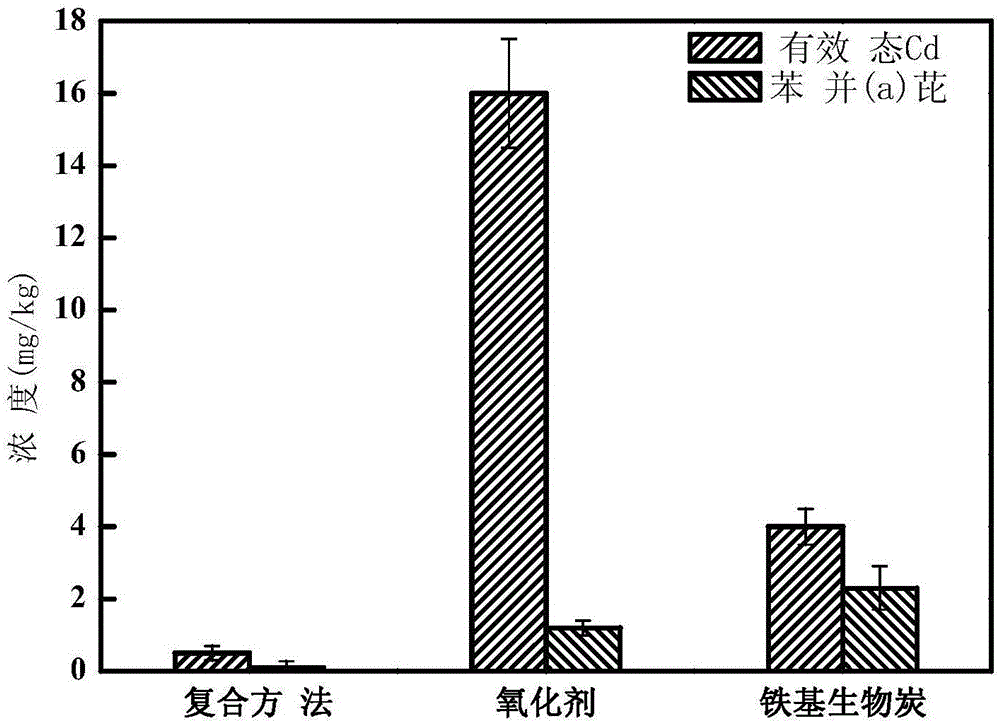

Remediation method of organic contaminant-heavy metal compound contaminated soil

ActiveCN106623380AEfficient repairReduce repair costsContaminated soil reclamationHeavy metal compoundPersulfate

The invention discloses a remediation method of organic contaminant-heavy metal compound contaminated soil. The remediation method comprises the following steps: adding persulfate into organic matter-heavy metal compound contaminated soil, and on the basis of effective oxidative degradation of organic contaminant, further using iron-based biochar for passivating heavy metals after playing an activating effect so as to achieve effective remediation of the organic matter-heavy metal compound contaminated soil. Compared with the method for remedying contaminated soil with single contamination by using the biochar or the persulfate, the remediation method provided by the invention has the advantages as follows: two methods are combined for remedying organic matter-heavy metal compound contamination, the persulfate is used for oxidizing organic matters and can fully mineralize the organic matters; for heavy metal contaminated soil, the persulfate can oxidize the heavy metals, and reduces the pH of the soil to cause an increase in the concentration of effective-state metal; the biochar fixes the heavy metals to the surface through adsorption, so that the bioavailability of the heavy metals is reduced.

Owner:GUANGDONG INST OF ECO ENVIRONMENT & SOIL SCI

Multienzyme organic fertilizer

InactiveCN102432400AImprove internal environmentIncrease productionFertilising methodsFertilizer mixturesPectinaseCellulose

The invention discloses a multienzyme organic fertilizer, wherein the fertilizer can increase soil organic matter contents and varieties of bioactivators, and improve physical, chemical and biological characteristics for soil, and improve soil fertility, and alleviate soil hardened state, and reduce pesticide residue in the soil; on the other hand, the fertilizer can provide progressive, continuous and complete nutrients for plant growth, and improve inner environment of crops at the same time such that the crops have abilities of full digestion and nutrient absorption. The invention can not only improve the yields of the crops, but also can improve qualities of agricultural products, and enhance healthcare functions for agricultural products. The fertilizer is suitable to be used by field crops and greenhouse vegetables, land vegetables, fruits, flowers, commercial crops and so on. The multienzyme organic fertilizer is composed of the following raw materials in percentages by weight: 10-15% of laccase, 5-10% of neutral protease, 10-15% of phytase, 5-10% of cellulose, 1-5% of xylanase, 1-5% of pectinase, 1-5% of amylase and 55-60% of organic fertilizer powder.

Owner:郝伟星

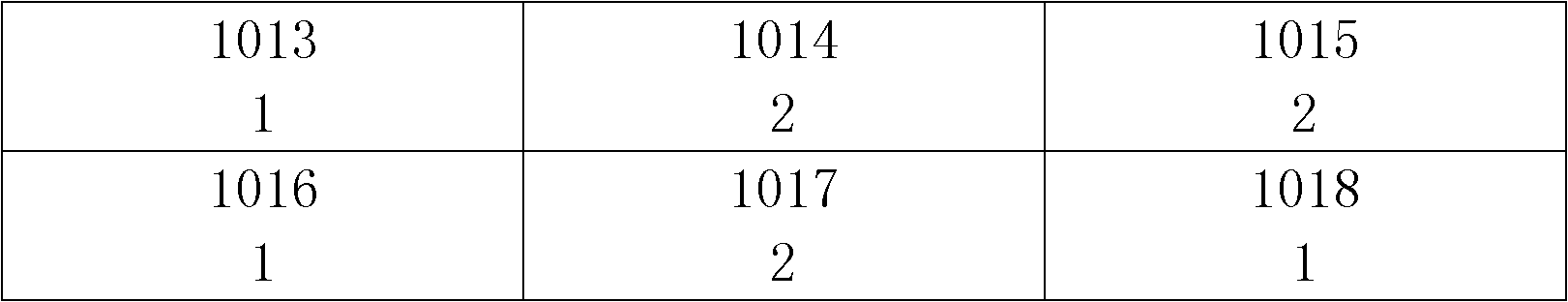

Production process of biological-organic-inorganic ternary compound fertilizer

InactiveCN101676243AShorten the decay cycleReduce nutrient lossBio-organic fraction processingOrganic fertiliser preparationChemistryOrganic component

The invention provides a production process of a biological-organic-inorganic ternary compound fertilizer which is prepared by the following steps: mixing crop stalks, such organic components as livestock manures and active biological agents, regulating the carbon nitrogen ratio from 26 to 35, PH from 5.5-8.2 and moisture from 40% to 65% according to the organic matter contents of the crop stalksand the livestock manures, fermenting the mixture at minus15-75 DEG C for 20-50 days and ensuring the living bacteria count to be 0.03-0.2 billion / g, carrying out turning and oxygenating, fermenting in deep tanks and grinding on the mixture to prepare the biological organic fertilizers, mixing the biological organic fertilizers with the inorganic fertilizers and trace elements and simultaneously adopting the low-temperature drying process after extruding granulation and the biological agent spraying and cooling technology. The method can greatly shorten the decay period, ensure little nutrientloss and little generating capacity of sour gases in the processes of fermentation and decay and complete decay and fermentation, can enhance the stress resistance of the crops, ensure obvious disease-resistant effects and high survival rates of specific functional bacteria and has wide application. Through field contrast tests, both the production and income are increased by 10-25% by applying the biological organic fertilizer.

Owner:辽宁元亨生物科技有限公司

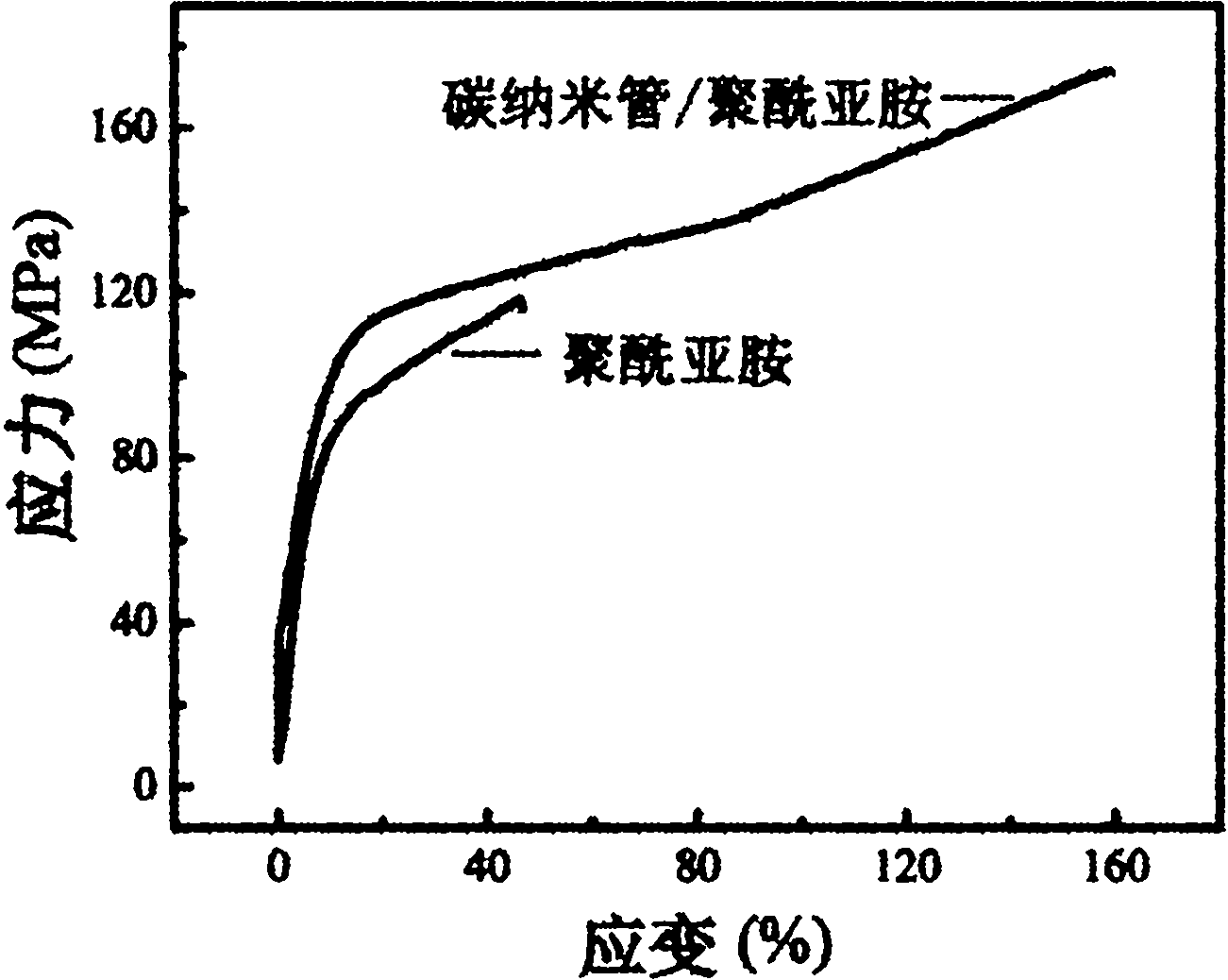

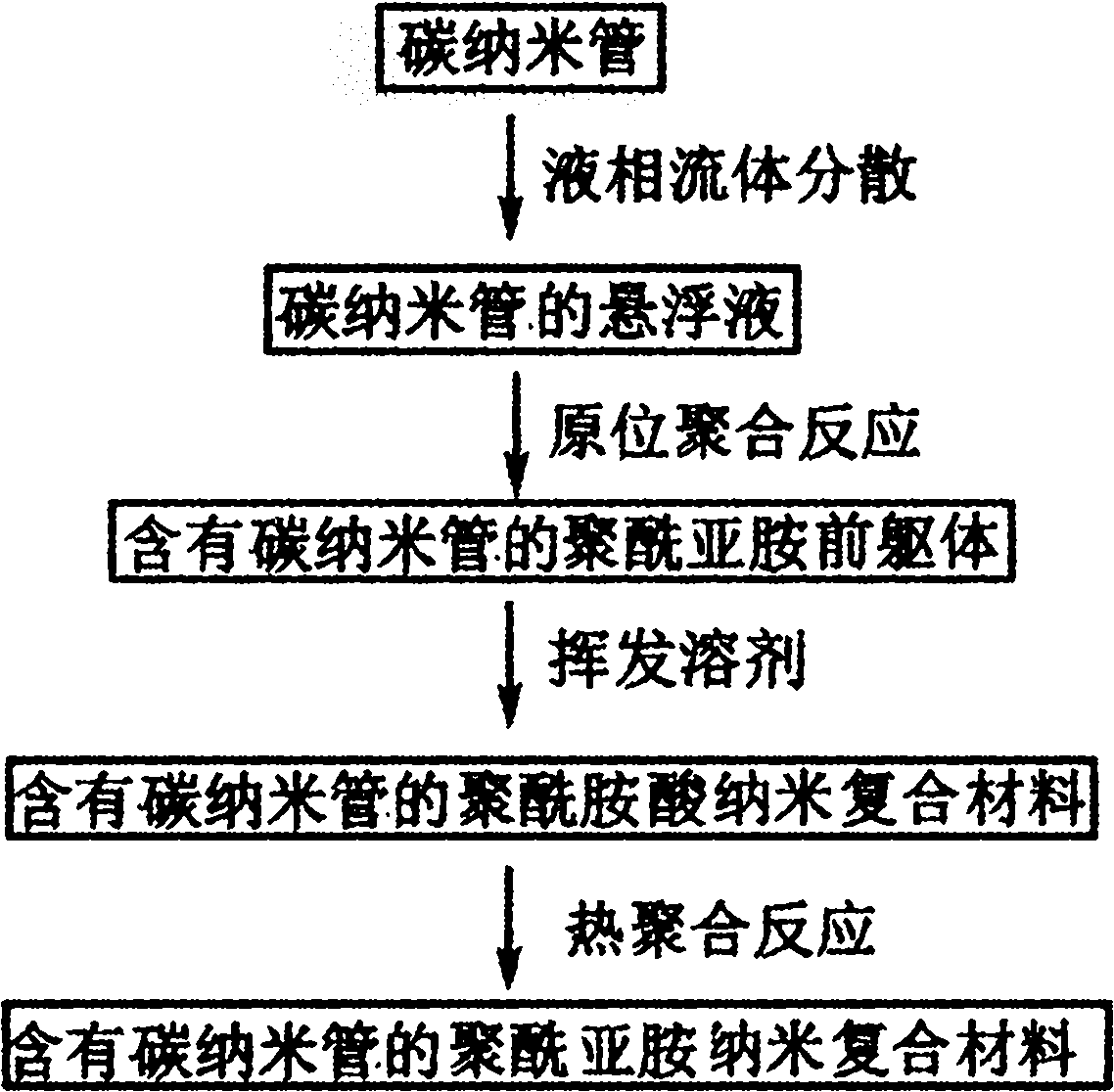

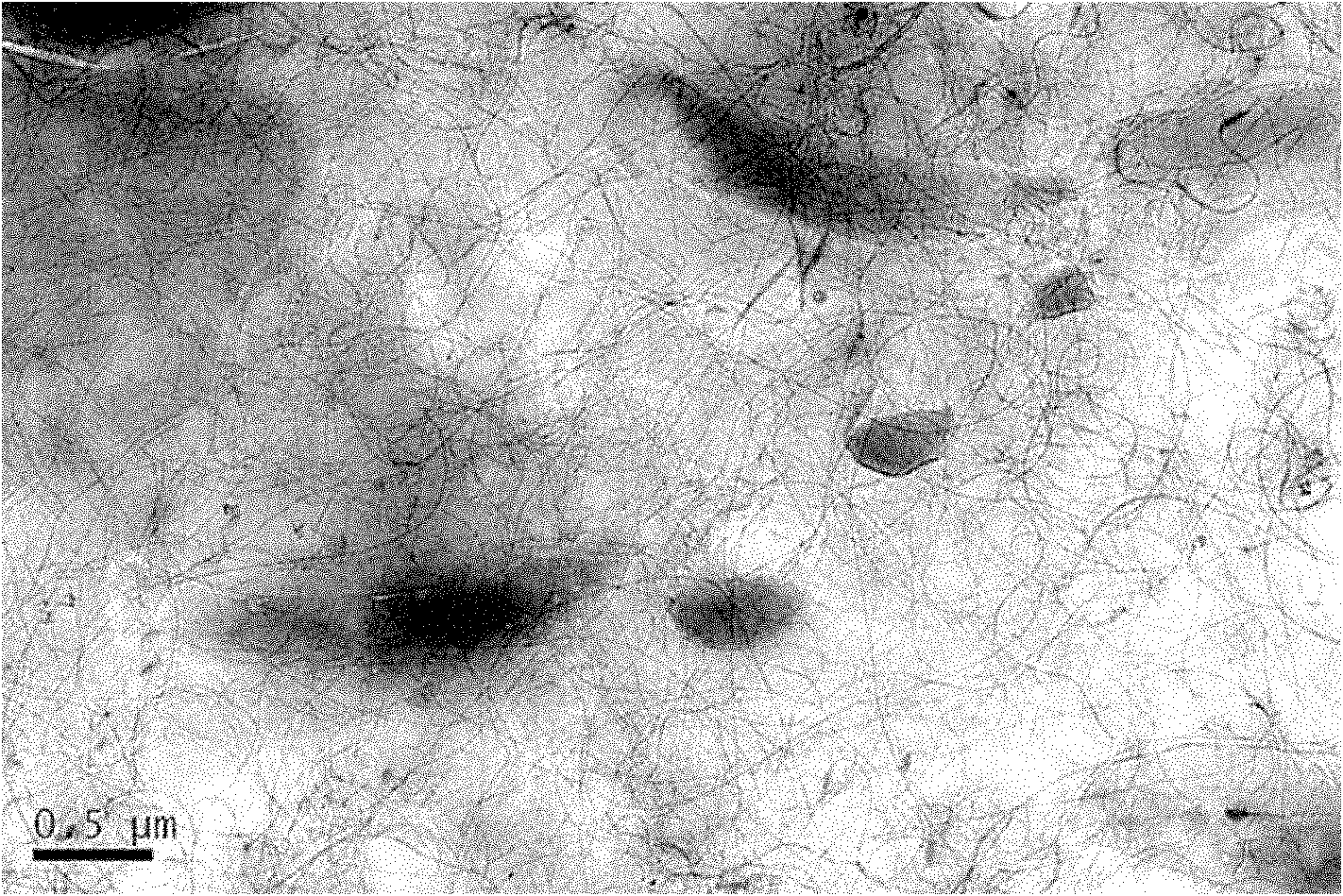

Preparation method of carbon nanotube reinforced polyimide nano composite material

ActiveCN102093715AImprove thermal stabilityIncrease contentMonocomponent synthetic polymer artificial filamentFiberImide

The invention relates to a preparation method of a carbon nanotube reinforced polyimide nano composite material, which comprises the following steps: carrying out liquid-phase shearing dispersion on 10-10000 micrometer long carbon nanotubes in an organic solvent; adding 4,4-diaminodiphenyl ether and pyromellitic dianhydride into the dispersed carbon nanotube slurry to carry out an in-situ polymerization reaction; and carrying out vacuum degasification to obtain a thin film or fibers, volatilizing the solvent, and carrying out heat treatment to obtain the carbon nanotube / polyimide nano composite material. By using the high-length-diameter ratio carbon nanotubes to provide interfaces for adequate slip of polyimide molecules and favorable interface combination, the composite material has excellent mechanical properties, thereby being hopefully applied to fields such as aerospace, automobiles, flexible substrates and the like.

Owner:TSINGHUA UNIV

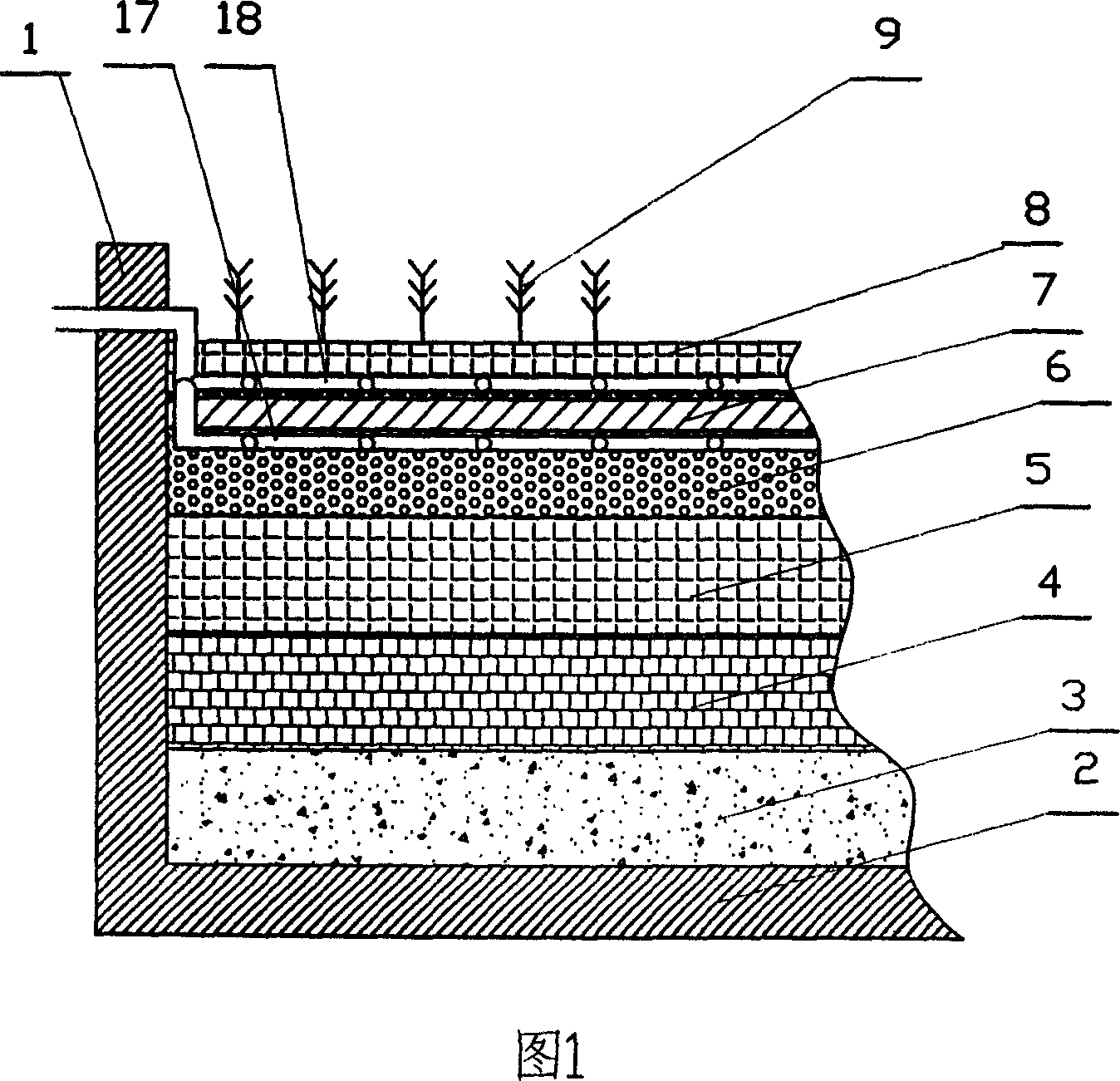

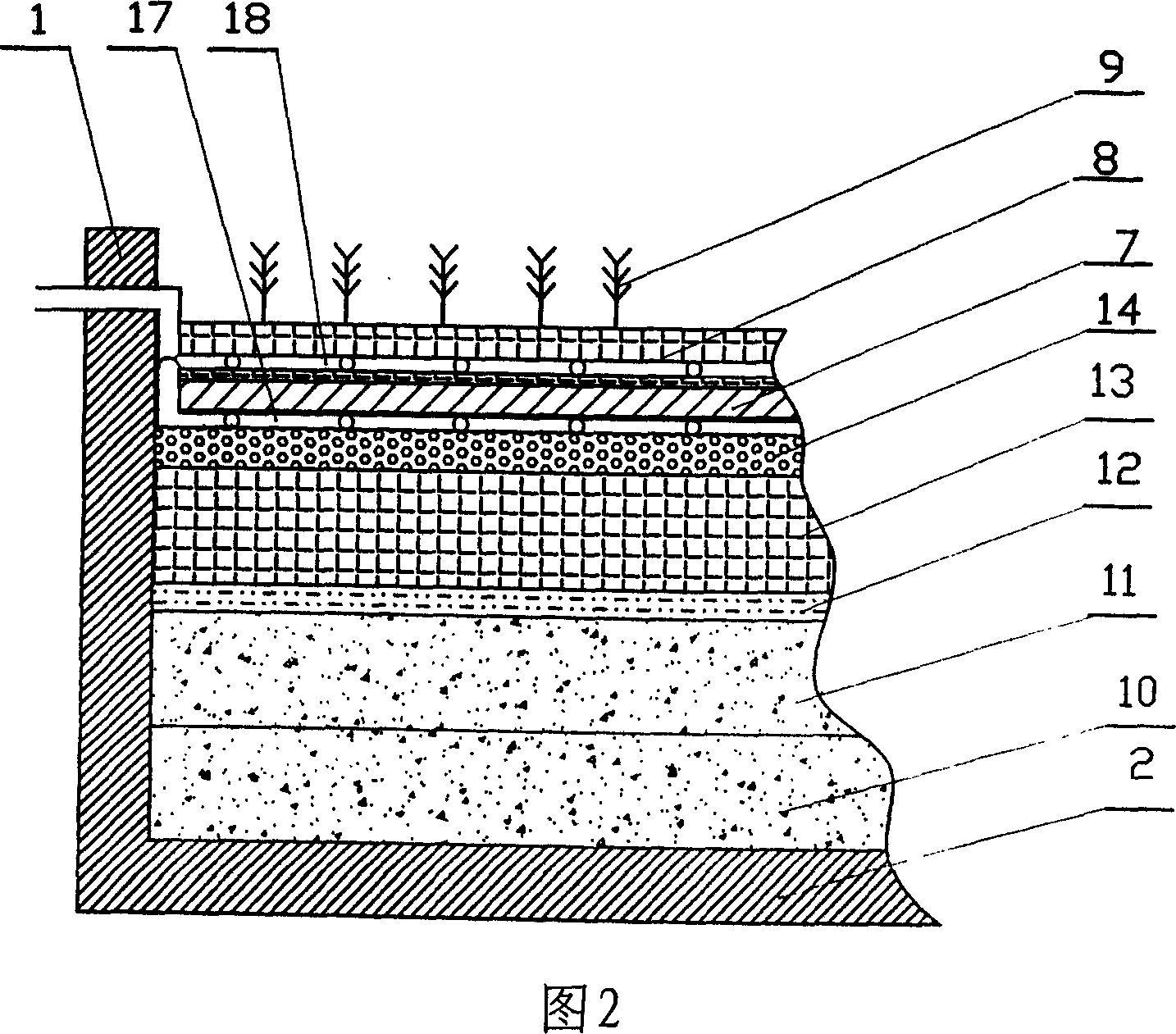

Method for purifying sewage in artificial wet land by northern vertical subcurrent method

InactiveCN101028951AImprove physicsEasy to handleSustainable biological treatmentBiological water/sewage treatmentConstructed wetlandWater quality

A method for cleaning sewage by vertical undercurrent type artificial wet land in northern area features that a scientific microbe carrier network consisting filler layers, insulating reproduction layer, etc is disclosed for fast forming a biomembrane system for playing its cleaning role without plants in the winter, a deeply buried multi-layer water tube network can prevent freeze and cracking, and more insulating techniques are used to keep the temp of sewage to be treated to 15-20 deg.C.

Owner:河南亚神环保科技有限公司

Aramid fiber surface modification processing method

InactiveCN1936167APromote infiltrationFacilitate cross-linkingPhysical treatmentFibre typesLiquid mediumIrradiation

The invention relates to process method for aramid fiber surface modification that includes the following steps: drying aramid fiber, sealing the dried aramid fiber with gas medium or liquid medium in glass reactor, using gama radial of 60Co irradiating for 12-15 hours, under normal temperature and normal pressure, irradiation dose is 0.1-3000kGy. The invention has the advantages of simple technology, environment protection, high efficiency and suitable for industrial manufacturing.

Owner:HARBIN INST OF TECH

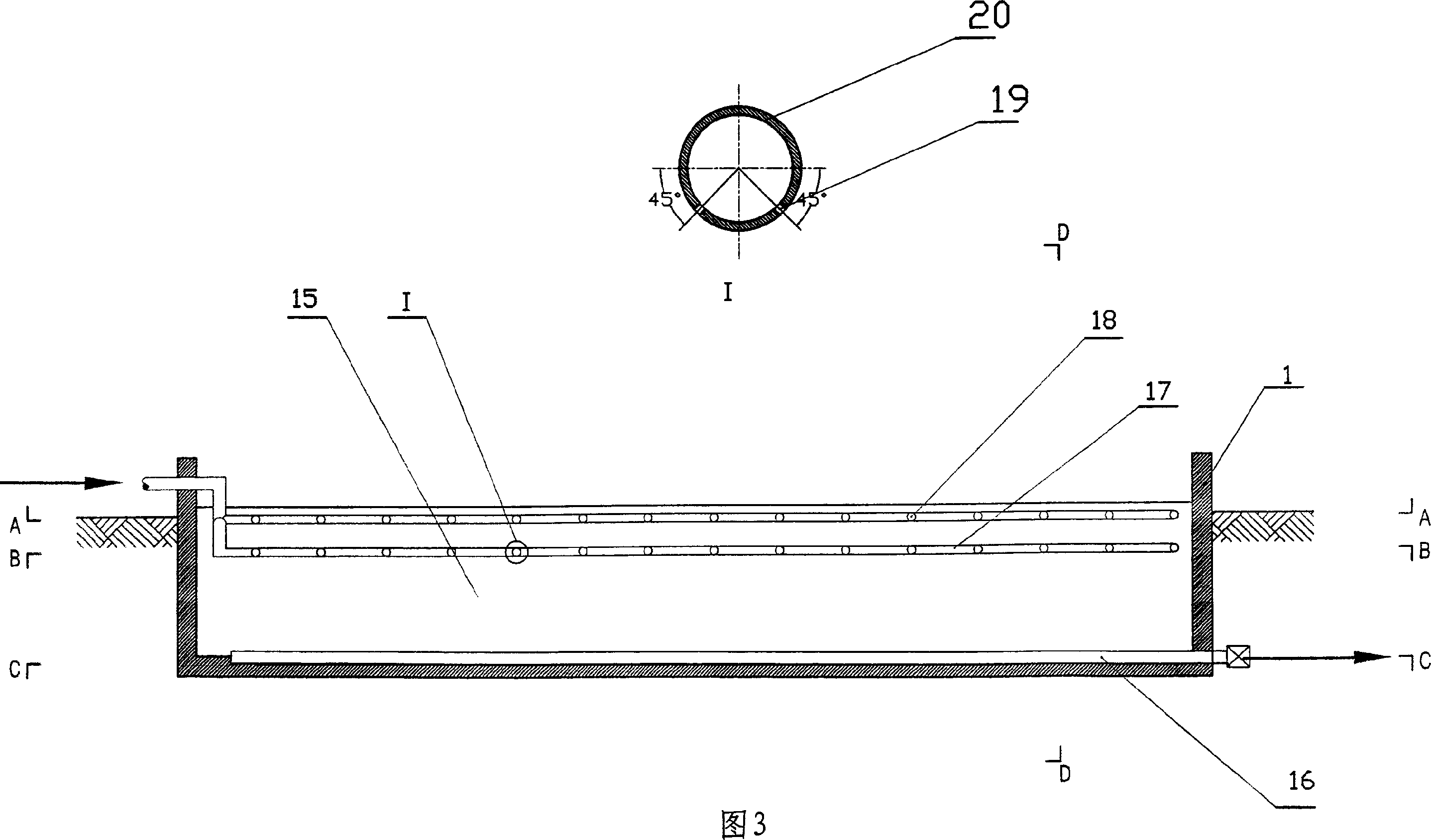

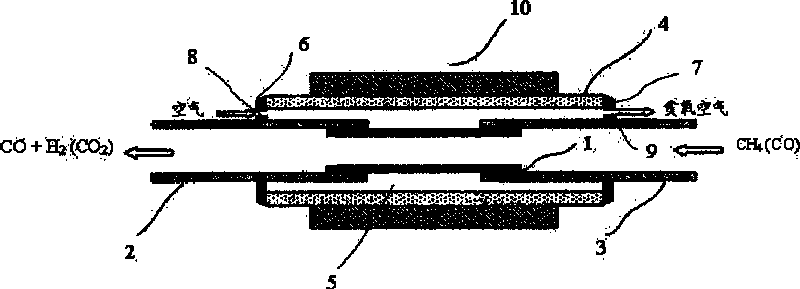

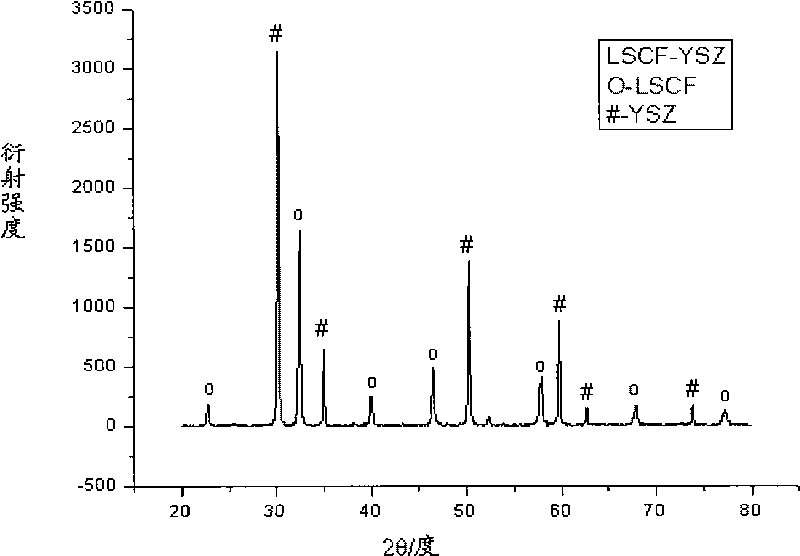

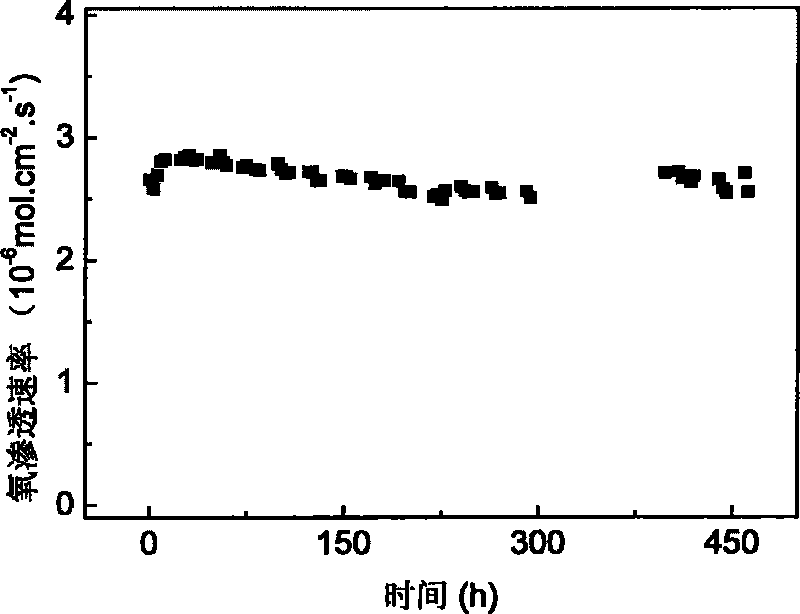

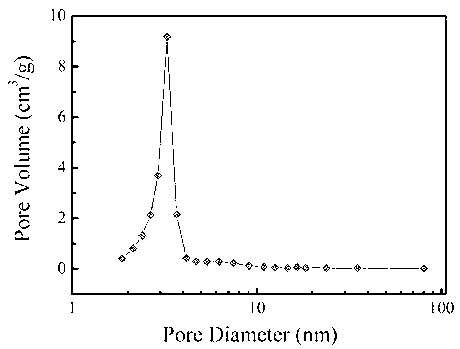

Hollow fiber membrane reactor for gaseous oxidation reaction, preparation and application thereof

InactiveCN101733048AImprove physicsImprove compatibilitySemi-permeable membranesHydrogenFiberComposite ceramic

The invention discloses a hollow fiber membrane reactor for gaseous oxidation reaction, a preparation method and application thereof. The membrane reactor is made of a compact hollow fiber oxygen permeation membrane, wherein the wall thickness of a pipe is between 0.1 and 0.3mm, and the outer pipe diameter is between 1 and 3mm; the oxygen permeation membrane is made of a dual-phase composite ceramic oxygen permeation membrane material which is prepared by mixing an electron conductive phase material and an ion conductive phase material in a volume ratio of 0.43-1.5:1; the electron conductive phase material is provskite-type chromic lanthanum composite oxide (Ln1-xAx)1-zCr1-yByO3 and / or strontium titanate-based composite oxide (LnxSr1-x)1-zTi1-yByO3; and the ion conductive phase material is stabilized fluorite type zirconium dioxide Zr1-x1Rx1O2-delta, or doped cerium dioxide R'z1Ce1-z1O2-delta. The method for preparing the membrane reactor comprises the following steps: mixing the electron conductive phase material and the ion conductive phase material in the volume ratio of 0.43-1.5:1 to prepare a hollow fiber membrane blank by adopting a wet phase inversion method; and sintering the blank at the temperature of between 1,300 and 1,600 DEG C for 10 to 18 hours. The membrane reactor has high oxygen permeation performance, excellent high temperature reduction resistance and long-term stability and low production cost.

Owner:UNIV OF SCI & TECH OF CHINA

Inorganic polymer material for sealing heavy metal castoff

InactiveCN101318788AImprove physicsImprove mechanical propertiesSolid waste managementCement productionSlagMetakaolin

The invention provides an inorganic polymeric material used to fixedly seal heavy metal wastes, which is an inorganic silicon-aluminum polymeric material used in the environmental protection field. The material comprises the following compositions in weight percentage: 9.9 to 35.1 percent of metakaolin, 3.94 to 27.6 percent of ore slag, 0.1 to 9.9 percent of active low calcium silicon-aluminum material, 9.6 to 10.6 percent of alkali excitant and 50.0 to 54.7 percent of sand. The material has the advantages of high doped quantity of the heavy metal wastes, high fixing seal efficiency, wide source of raw materials, convenient preparation and processing, high mechanical strength, excellent durability and low cost.

Owner:SOUTHEAST UNIV

Biodegradable coated carbamide and preparation method thereof

InactiveCN101723751AReduce releaseReduce rateUrea compound fertilisersFertilizer mixturesCoated ureaNitrification inhibitors

The invention relates to coated carbamide, in particular to a totally biodegradable coated carbamide and a preparation method thereof. The coated carbamide consists of a coated layer and a carbamide core. The main body of the coated layer is polylactic acid and / or polybutylene succinate. The coating process adopts fluidized bed spraying-coated technology, and comprises the following steps: dissolving polylactic acid and / or polybutylene succinate in trichloromethane, adding carboxymethylcellulose, organic and / or inorganic conditioner, urease and / or nitrification inhibitor in the solution, spraying and coating the surfaces of the fluidized carbamide after uniformly mixing the mixture under the stirring of a stirrer to form the uniform and complete organic polymeric membrane layer. The process has the advantages of easy implementation, and capacity of effectively slowing down the release of the nutrient to the outside and the conversion rate of nitrogen in soils, effectively controlling the release of the nitrogen nutrient in soils, and reducing the pressure on environment caused by the rapid release of nutrient. The coated material can be totally biodegradable, and the degradation products have no secondary pollution to the environment.

Owner:SHENYANG INST OF APPL ECOLOGY CHINESE ACAD OF SCI

Method for improving interfacial properties of aramid fiber/epoxy resin composite material

InactiveCN101205686AEnhanced interface bindingPromote infiltrationPhysical treatmentEpoxyLiquid medium

An aramid fibre / epoxy resin composite interface performance improving method relates to a macromolecule material modification processing method. The invention solves the problems that the interface between the prior Kevlar-49 fibre and the prior epoxy resin has weak combination and the fiber surface modification processing method is not suitable for industrialized production. The Kevlar-49 fibre surface modification processing method of the invention is as follows: firstly the Kevlar-49 fibre is dried, then the dried Kevlar-49 fibre and liquid medium are sealed in a glass reactor; under the condition of normal temperature, normal atmosphere and the protection of protective gas, a gamma ray with <60>Co as radiation source is adopted to radiate; the radiation dosage is between 0.1 and 1000 kGy and the radiation dosage rate is between 3 and 7 kGy / h. The invention has the advantages of simple operation, stable technique, reliable product quality, environmental protection and industrialized production. The method of the invention improves the fibre surface energy, thereby improving the combination intensity of the interface between the fibre and the epoxy resin matrix and exerting the comprehensive performance of Kevlar-49 fiber reinforced composite farthest.

Owner:HARBIN INST OF TECH

Layer-by-layer clicked, bonded and self-assembled graphene oxide polyolefin separation membrane and preparation method thereof

InactiveCN104138715AImprove hydrophilicityImprove anti-pollution performanceSemi-permeable membranesPolymer sciencePolyolefin

The invention relates to the technical field of chemical engineering and in particular relates to a layer-by-layer clicked, bonded and self-assembled graphene oxide polyolefin separation membrane and a preparation method thereof. The preparation method comprises the following steps: mixing an unmodified polyolefin separation membrane with bromine and irradiating bromine by ultraviolet light so as to prepare a bromo-membrane; performing nucleophilic substitution on the bromo-membrane and sodium azide to prepare a polymer membrane with an azide group; preparing graphene oxide with the azide group and alkynyl by using open-looping and condensation methods; performing layer-by-layer clicking, bonding and self-assembling on the graphene oxide with the azide group and alkynyl to be formed onto the surface of the polyolefin separation membrane with the azide group, thereby achieving layer-by-layer clicking and self-assembling modification on graphene oxide on the surface of the polyolefin separation membrane. The preparation method is a universal method for polyolefin separation membrane surface modification. The hydrophilia and the anti-pollution property of the polymer membrane are improved, the polyolefin separation membrane is permanently modified, and thus the polyolefin separation membrane can be widely applied to the field of chemical engineering.

Owner:ANHUI NORMAL UNIV

Heat resistant anticorrosive composite polyphenylene sulfide epoxy paint and its prepn

InactiveCN1887996AImprove physicsGood chemical propertiesInorganic pigment treatmentAnti-corrosive paintsEpoxyHigh intensity

The present invention discloses one kind of heat resistant anticorrosive composite polyphenylene sulfide epoxy paint and its preparation process. The anticorrosive paint consists of primer, finishing paint and intercoat paint. The primer consists of polyphenylene sulfide, epoxy resin, glass scale and cyanamide dimmer. The finishing paint consists of polyphenylene sulfide, epoxy resin, silicon carbide, 4, 4'-diamino diphenyl sulphone and cyanamide dimmer. The intercoat paint consists of polyphenylene sulfide, epoxy resin, silicon carbide, glass scale, dihydrazide sebacate and 4, 4'-diamino diphenyl sulphone. The anticorrosive paint produces no sag, and can form homogeneous and smooth coating with excellent physical and chemical performance, high heat resistance, high corrosion resistance, high impact strength, and high insulating performance.

Owner:NEW MATERIAL INST OF SHANDONG ACADEMY OF SCI

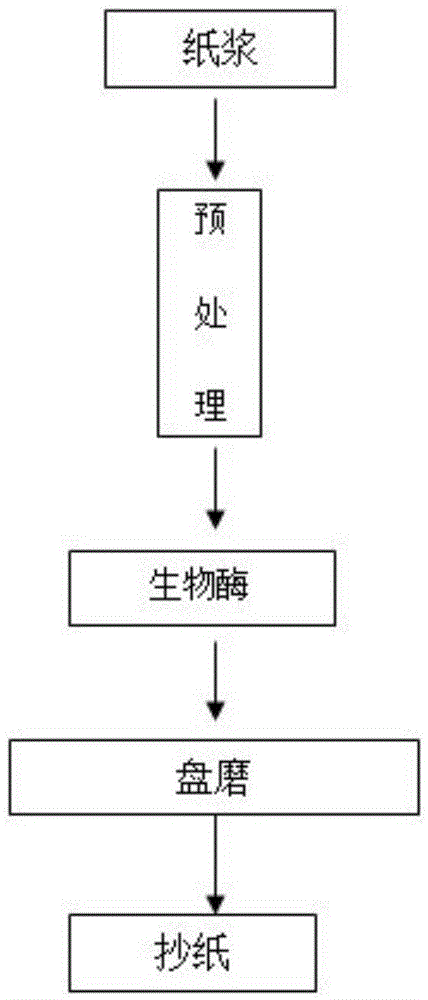

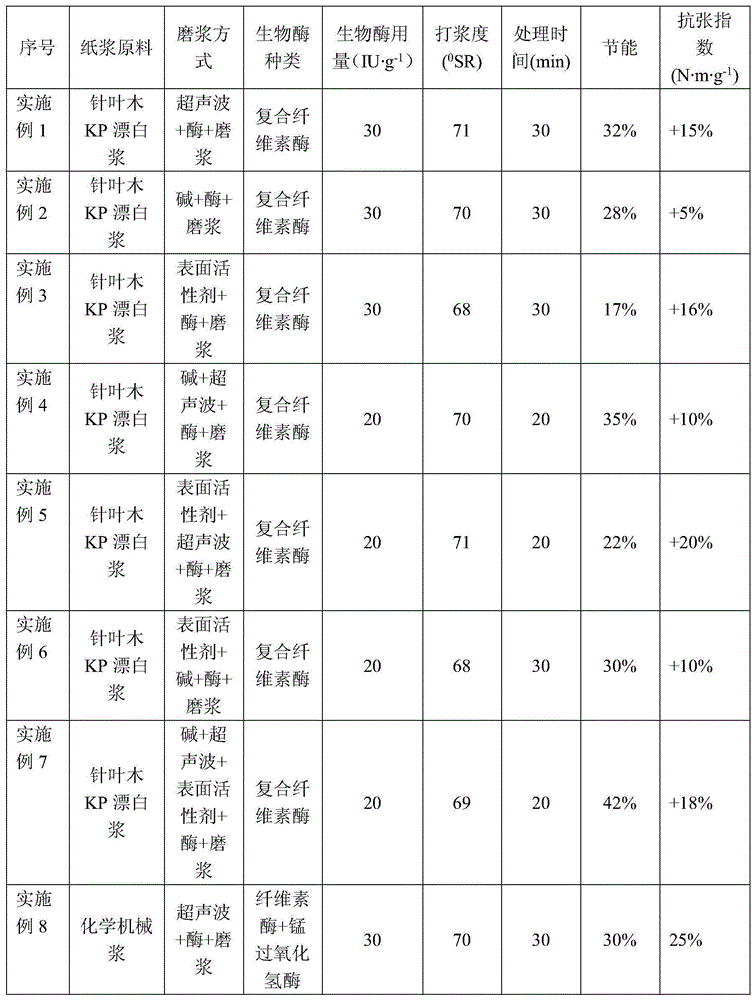

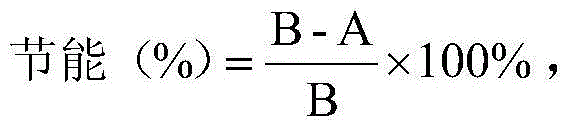

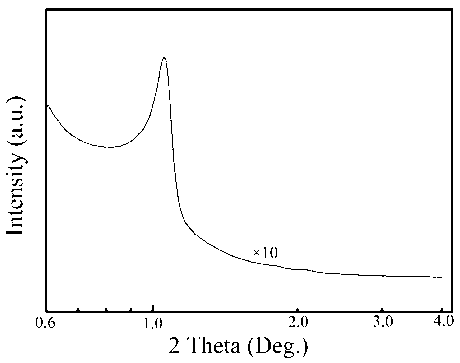

Energy-saving enhanced defibrination method for composite pretreatment and production of viscous paper pulp

ActiveCN104452398AImprove the physical properties of paperSave paper physical propertiesMicroorganism/enzyme additionPaper/cardboardPre treatmentPulp fibre

The invention discloses an energy-saving enhanced defibrination method for composite pretreatment and production of viscous paper pulp. The method comprises the following steps that (1) paper pulp fibers are dissolved in water, even defibering is carried out, and then pretreatment is carried out; (2) biological enzymes are added to the treated paper pulp for treatment, the dosage of the biological enzymes ranges from 10 IU / g to 60 IU / g, the temperature ranges from 40 degrees to 60 degrees, the pH value ranges from 6 to 9, the concentration of the paper pulp ranges from 3 wt% to 8 wt%, and treatment is carried out for 10 min to 30 min; (3) continuous millstone milling and beating are carried out on the pulp of the step (2), and the pulp is stored for standby application. The method remarkably improves the efficiency of subsequent biological enzyme treatment, and overcomes the defects that enzyme treatment time is too long in biological enzyme assistant defibrination production and energy conservation in defibrination and the physical strength of finished paper formed by fibers cannot be achieved at the same time, the defibrination energy consumption and the defibrination time for producing the viscous paper pulp are saved, the defibrination energy consumption of chemical bleached needle wood pulp and chemithermomechanical pulp of needle wood is reduced by 15%-45%, and the physical properties of finished paper formed by pulp fibers can be improved.

Owner:五洲特种纸业(龙游)有限公司

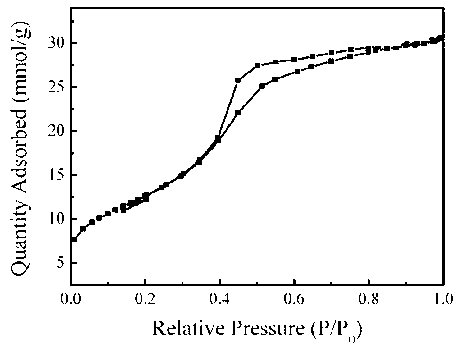

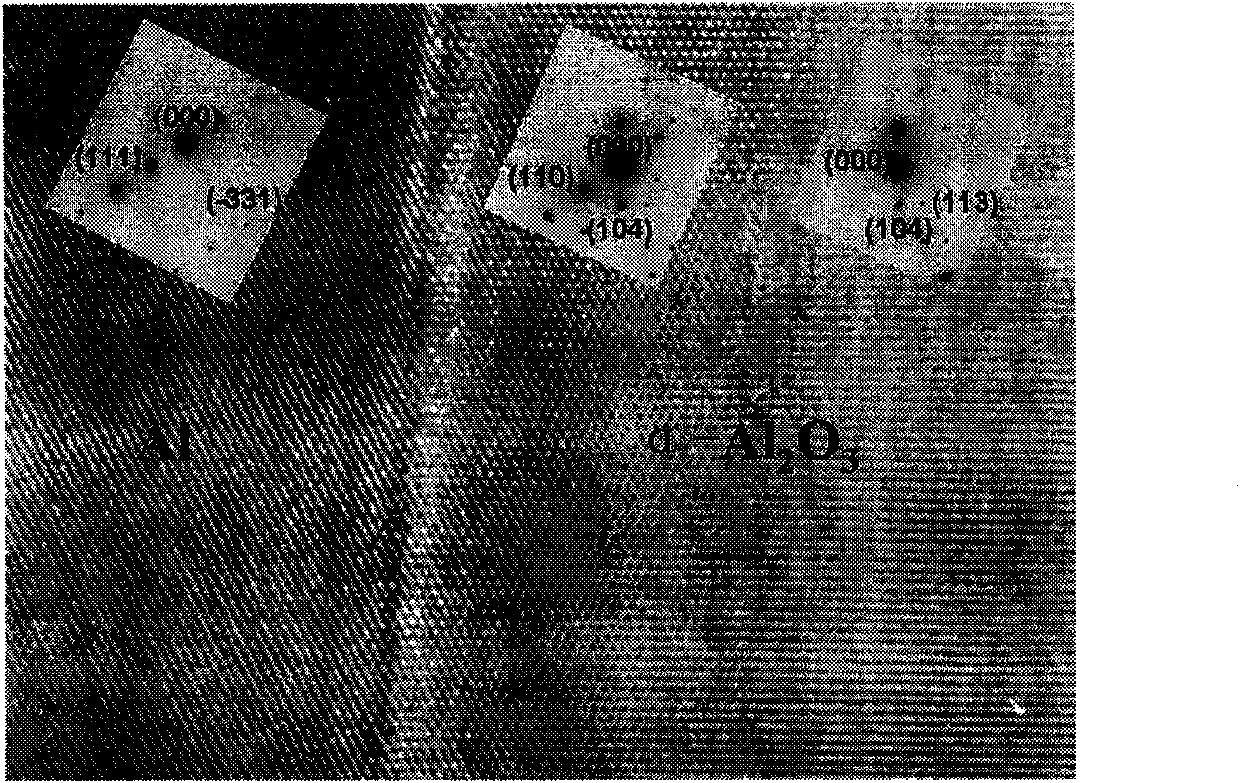

Preparation method of nitrogen and sulfur co-doping ordered mesoporous carbon materials

InactiveCN103072972AHigh dopingImprove physicsCarbon preparation/purificationPtru catalystIncipient wetness impregnation

The invention relates to a preparation method of nitrogen and sulfur co-doping ordered mesoporous carbon materials. According to the method, pyrrole is used as carbon sources and nitrogen sources, sulfuric acid is used as acid catalysts and sulfur sources, pyrrole oligomers are used as precursors, mesoporous silica molecular sieves SBA-15 (space group P6mm) and KIT-6 (space group Ia3d) are used as templates, a primary wet impregnation method is combined with the high-temperature themolysis technology for preparing the nitrogen and sulfur co-doping ordered mesoporous carbon materials in two-dimensional orthohexagonal and three-dimensional cubic ordered mesostructures.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

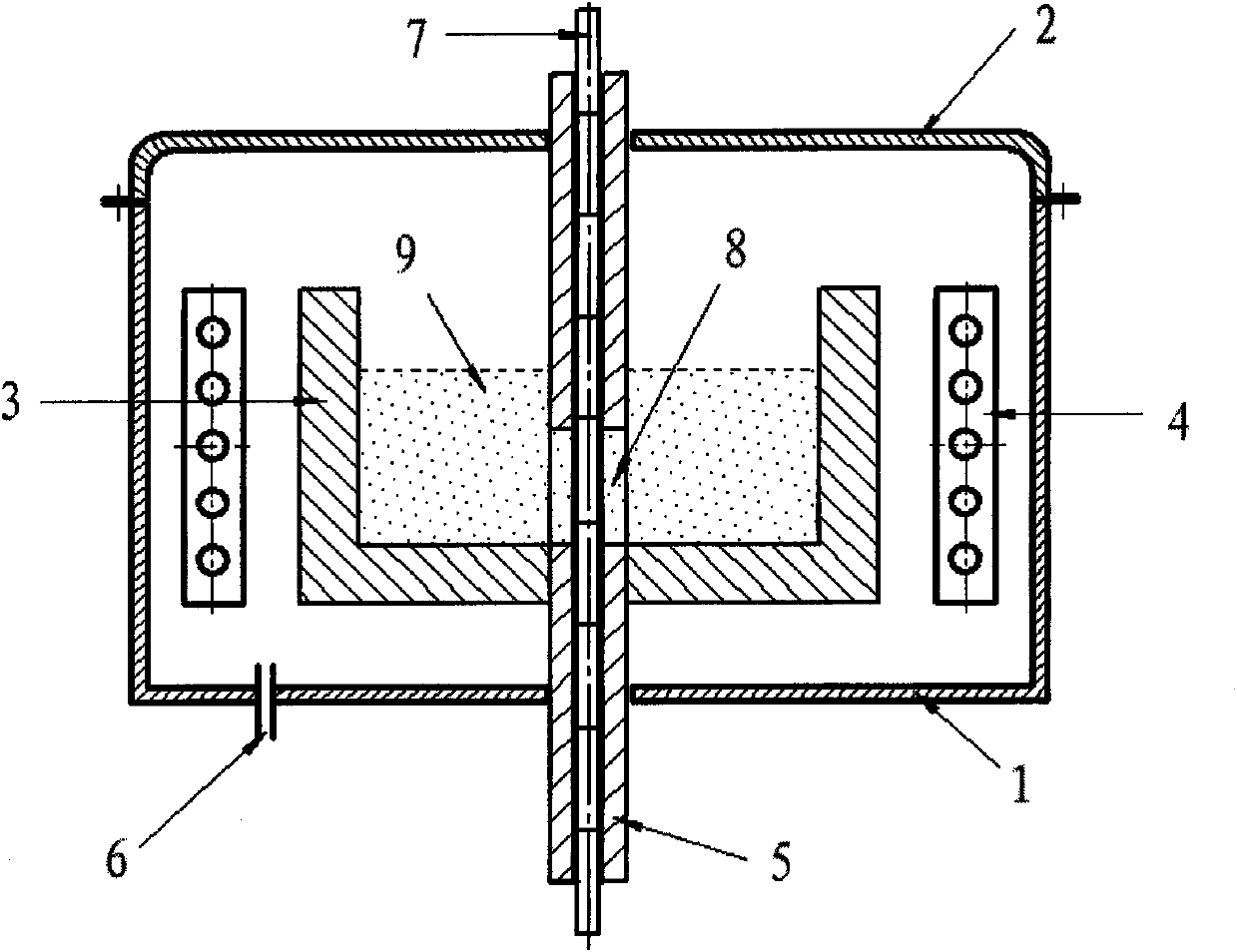

Method for connecting ceramic and metal

The invention discloses a method for connecting ceramic and ceramic, and ceramic and metal. The method comprises the following steps of: 1) forming a compact aluminum or aluminum alloy thin film with thickness of several to tens of microns on a connecting surface of the ceramic to obtain the ceramic with the connecting surface covered by the aluminum or aluminum alloy thin film; and 2) connectingthe ceramic with the connecting surface covered by the aluminum or aluminum alloy thin film and the metal by using the aluminum or aluminum alloy thin film, or connecting the ceramic with the connecting surface covered by the aluminum or aluminum alloy thin film and the ceramic with the connecting surface covered by the aluminum or aluminum alloy thin film by using the aluminum or aluminum alloy thin film. Compared with the prior art, the method has the advantages that: oxide inclusion originated from an aluminum surface oxide film is not formed on the interface between the aluminum film and the ceramic, which is formed by the method, the ceramic is firmly connected with the ceramic or the metal and the ceramic and the metal do not fall off easily, and the separating and peeling strength between the thin film and a ceramic chessboard is greater than or equal to 4.1N / cm. After an aluminum brazing process or an aluminum or aluminum alloy workpiece connection are adopted, defects of the connecting interface of the aluminum or aluminum alloy workpiece and the ceramic are avoided, the 90-degree tear strength of the connection can reach over 12kg / cm, fracture does not occur on the interface, and the ceramic and metal are connected very firmly.

Owner:TSINGHUA UNIV

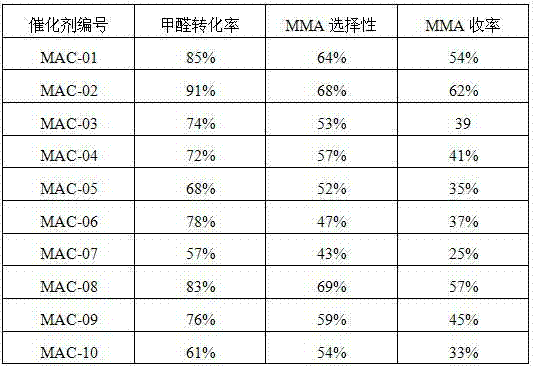

Catalyst for synthesis of methyl methacrylate by formaldehyde and methyl propionate and preparation method of catalyst

ActiveCN102962062ALarge specific surface areaImprove physicsOrganic compound preparationCarboxylic acid esters preparationPolymer sciencePtru catalyst

The invention discloses a catalyst for synthesis of methyl methacrylate by formaldehyde and methyl propionate and a preparation method of the catalyst. The catalyst mainly comprises a main active component, an activated auxiliary and a carrier, wherein the main active component is Cs, the activated auxiliary is selected from one or more of Sb, Nb and Ag, and the carrier is a nanometer SiO2 / Al2O3-ZrO2 composite carrier; and metered by oxides and according to mass percentage, the main active component Cs accounts for 5%-20%, the activated auxiliary accounts for 1%-5%, and the balance is the carrier. Simultaneously, the invention discloses a preparation method of the catalyst. The catalyst provided by the invention is good in activity, selectivity and stability, simple in manufacture technology, suitable for large-scale industrialized application and environment-friendly.

Owner:SOUTHWEST RES & DESIGN INST OF CHEM IND

Laser hard-surface coating process method of titanium alloy vane of gas turbine

InactiveCN101613860AEasy to adjustImprove physicsMetallic material coating processesLaser processingStructural geometry

The invention belongs to a laser processing technology for enhancing the surface hardness, i.e. the wearing resistance of titanium or titanium alloy, in particular to a laser hard-surface coating process method of a titanium alloy vane of a gas turbine. In the invention, corresponding mantle clamping fixture is adopted according to the geometrical shapes of structure of vane apex or damping convex shoulders of the vane, powder is placed in the mantle clamping fixture in advance, a static powder bed is formed by the mantle clamping fixture and the powder added in the mantle clamping fixture, powder is uniformly placed on the vane apex of the vane or the damping convex shoulders of the vane in advance by the static powder bed, and inert gases or N2 is adopted to protect a laser radiation area and carry out laser radiation on the vane. A hard-surface coating with the hardness of 35 to 62 HRC and the thickness of 0.05 to 2.0mm can be formed on the vane apex or the damping convex shoulder of the titanium alloy vane when the invention is adopted. The invention has the advantages that vacuum is not needed; laser cladding can be carried out only under the protection of inert gases of Ar, He, and the like in atmosphere conditions; the operation is convenient; and the formed hard-surface coating and basal body of the vane have good adapter properties in physics and chemistry.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

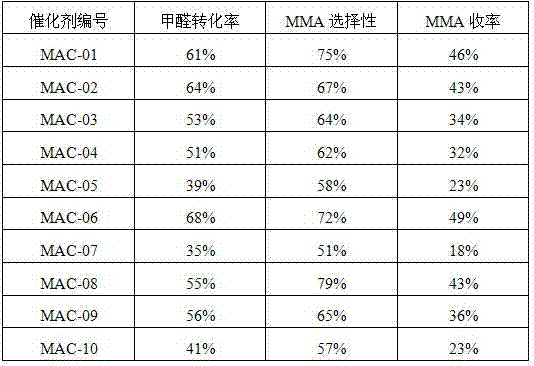

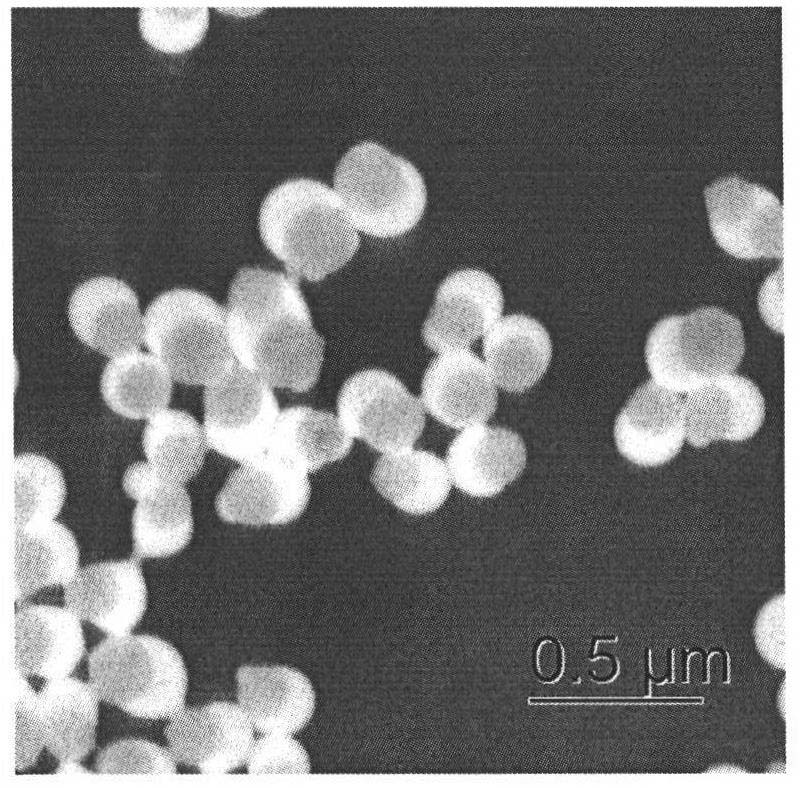

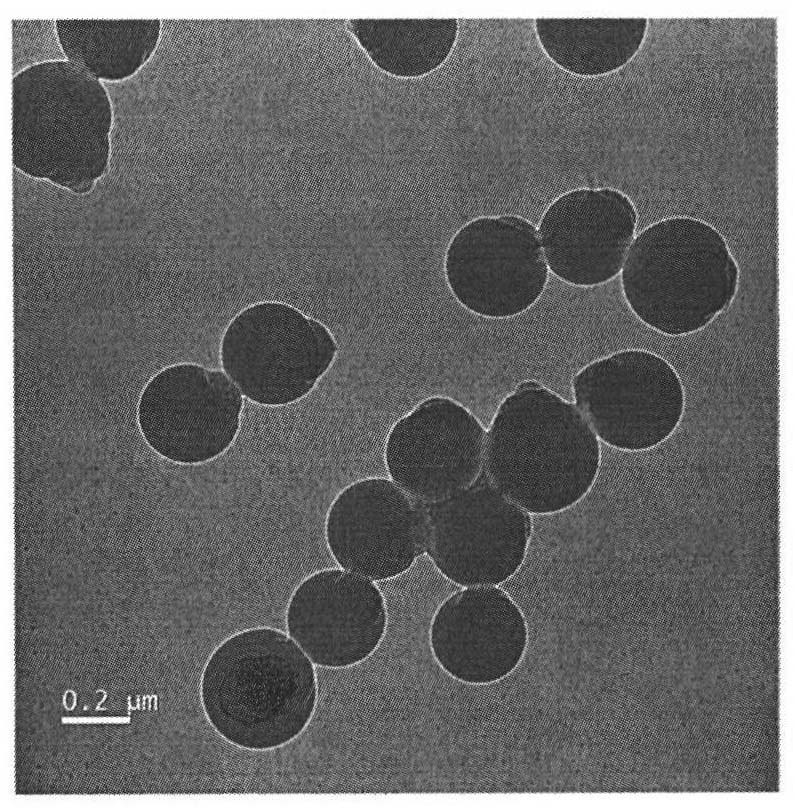

Preparation method of Janus-structure composite emulsion particle

The invention relates to a preparation method of a Janus-structure composite emulsion particle. The method comprises the following steps: adding deionized water into a PVDF seed emulsion, performing ultrasonic dispersion for 1 hour, pouring the dispersed emulsion into a reactor equipped with a reflux condensing tube, a stirring device, and a nitrogen introducing port, starting stirring and continuously introducing nitrogen, after 15 min, heating the reaction system, adding monomers, introducing cooling water into the reflux condensing tube; when the system is heated to a reaction temperature, adding an initiator, performing a polymerization reaction at a reaction temperature of 20-80 DEG C for 1-8 hours; drying the emulsion at a reduced pressure and a low temperature to obtain a constant weight so as to obtain the Janus-structure composite particle. Through the selection of PVDF seeds with different particle sizes, the seed monomer mass ratio and the polymerization time, the invention can effectively control the form and the size of the composite particle. The invention is widely applicable to various fields in polymer blending modification, such as compatilizers, self-cleaned coatings, and the like.

Owner:HEBEI UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com