Multienzyme organic fertilizer

An organic fertilizer and laccase technology, applied in fertilization methods, fertilization devices, fertilizer mixtures, etc., can solve the problems of low soil improvement efficiency and low nutrient content of organic fertilizers, so as to alleviate soil compaction, improve stress resistance, and improve The effect of internal environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

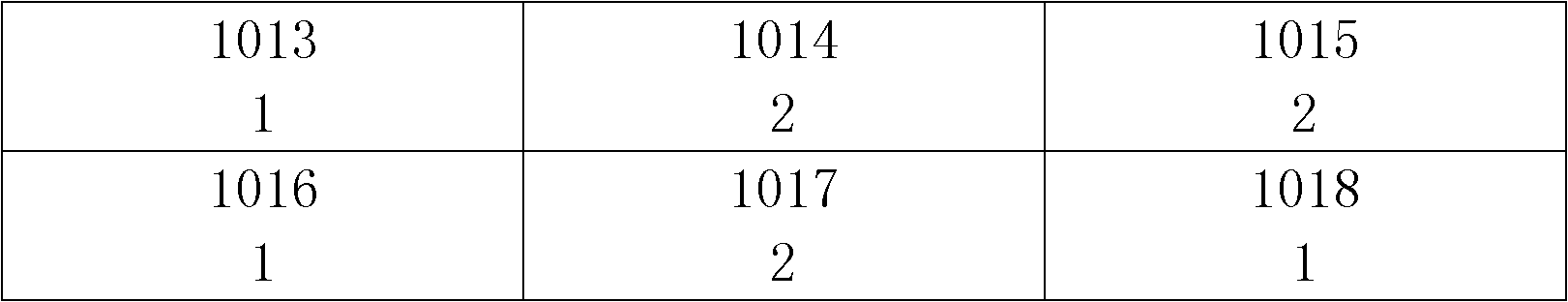

Image

Examples

Embodiment approach 1

[0034] Produce 1 ton of multi-enzyme organic fertilizer, and the qualified raw materials enter each feeding port according to the following weight: 120kg of laccase, 80kg of neutral protease, 100kg of phytase, 70kg of cellulase, 30kg of xylanase, and 20kg of pectinase , 20kg of amylase, 560kg of organic fertilizer powder, all kinds of raw materials are transported to the mixing tank with an auger and mixed evenly, packed by an automatic vacuum packaging machine, randomly sampled and tested, and packed into a warehouse.

Embodiment approach 2

[0036] For the production of multi-enzyme organic fertilizer, the qualified raw materials enter the feeding ports according to the following weight percentages: laccase 10-15%, neutral protease 5-10%, phytase 10-15%, cellulase 5-10% , xylanase 1-5%, pectinase 1-5%, amylase 1-5%, organic fertilizer powder 55-60%, use auger to transport various raw materials to the mixing tank to mix evenly, automatic vacuum Packaging machine packaging, random sampling inspection, packaging and storage.

[0037] Applying this multi-enzyme organic fertilizer as base fertilizer, applying 3 kg per mu, can achieve the following effects:

[0038] ①. Improve soil quality, alleviate soil compaction, reduce the amount of pesticide residues in the soil, long-term use can radically solve the problem of soil compaction.

[0039] ②Comprehensive nutrition, quick-acting and long-acting combination.

[0040] ③, increase yield, improve crop quality.

[0041] ④, enhance crop stress resistance and resistance t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com