Patents

Literature

869results about How to "Reduce compaction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ethanol production with dilute acid hydrolysis using partially dried lignocellulosics

InactiveUS20030199049A1Increase sugar yieldImprove digestibilityBiofuelsWaste based fuelCelluloseGrowth phase

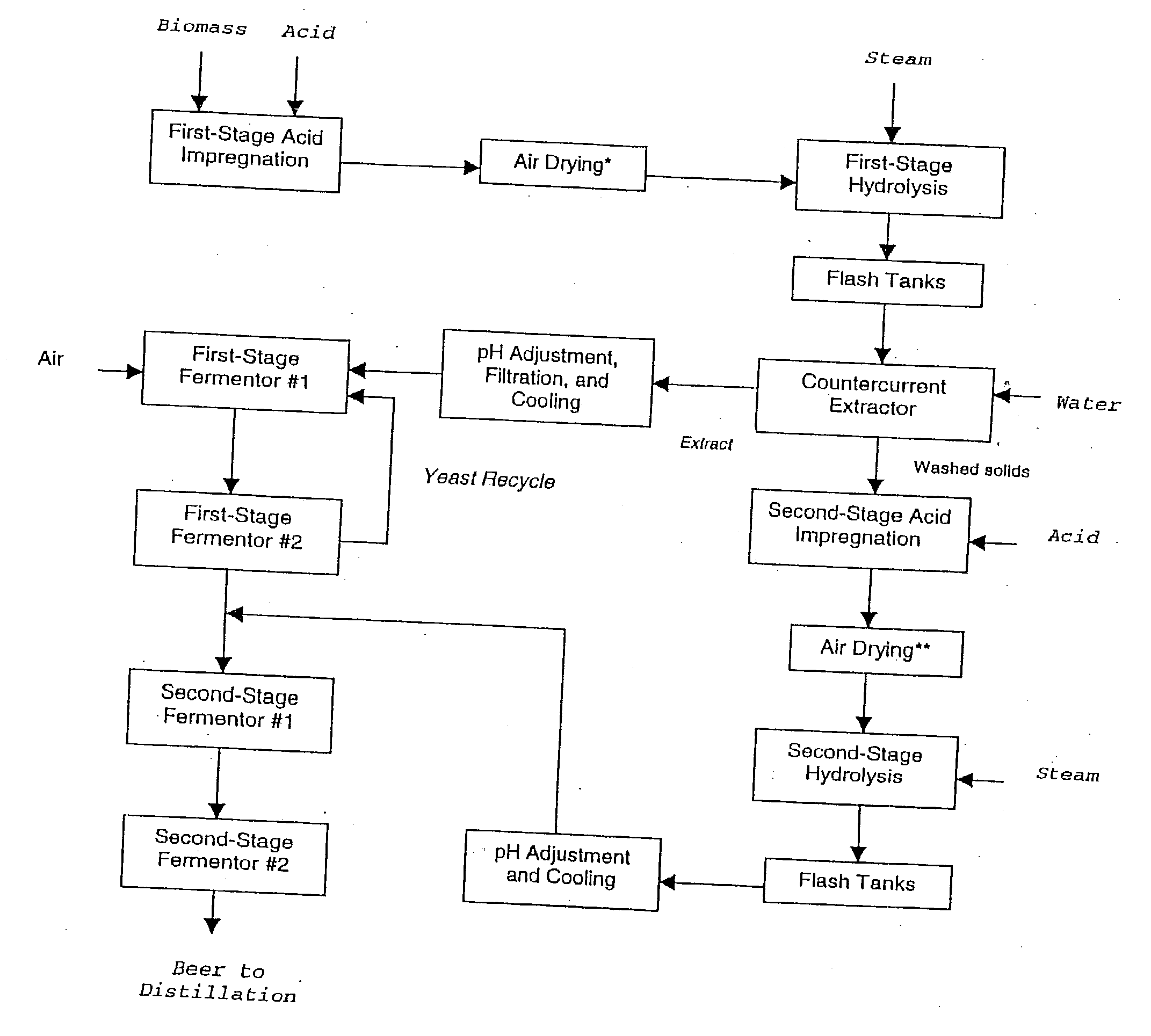

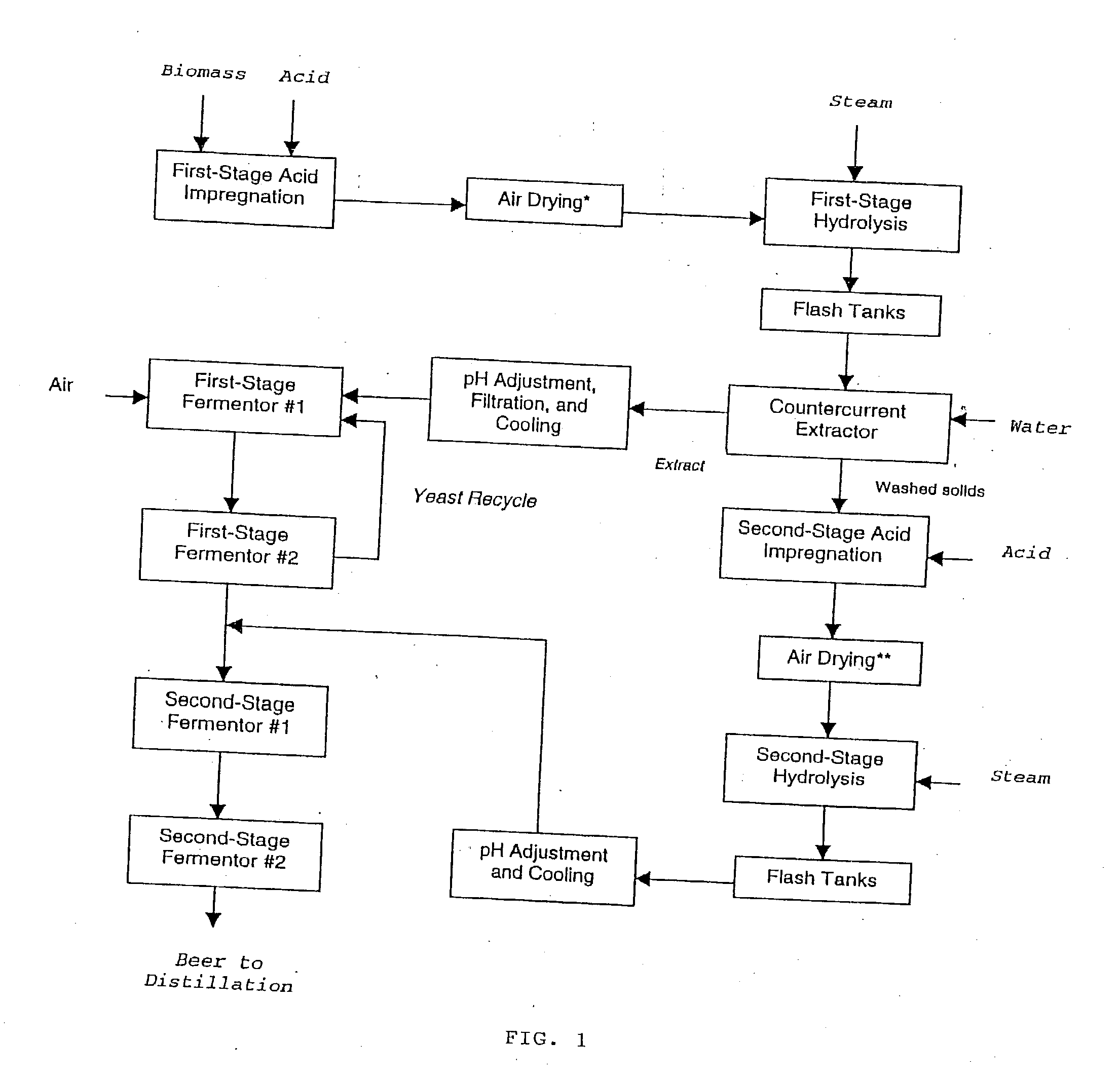

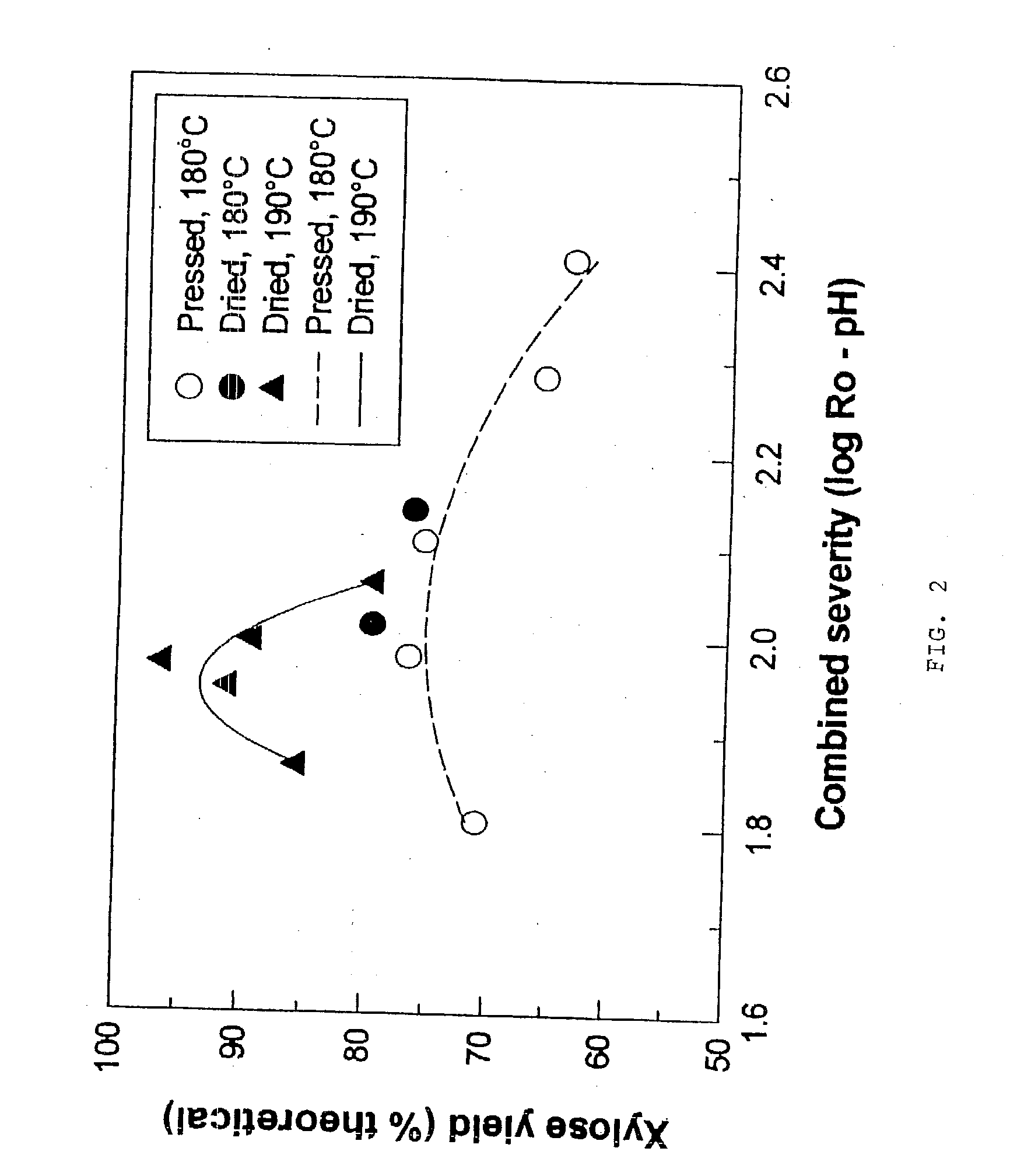

In a process for converting lingnocellulosic biomass to ethanol, the improvement of obtaining higher fermentable soluble sugar yields by drying acid impregnated biomass particles, comprising: a) feeding moist lignocellulosic biomass into an acid impregnator to render it acid-soaked and draining the acid-soaked biomass to about 30% to 35% by weight solids; b) dewatering the acid-soaked biomass by drying or centrifugation to prevent compaction of the biomass and arrive at about 40% to 60% by weight solids; c) subjecting the acid-impregnated biomass to a first-stage hydrolysis reactor at a temperature of from 130° C. to 220° C. and discharging formed hydrolysate into a flash tank at about 120° C. to 140° C. to hydrolyze most of the remaining soluble oligosaccharides to monomeric sugars, and flashing remaining hydrolysate to a second flash tank at a lower temperature than the first flash tank-the second flash tank serving as a feed surge tank for a counter-current extractor; d) washing the hydrolysate, adjusting the pH of the sugar extract to about 5, and recovering more than 95% of the soluble sugars in the first-stage hydrolysate slurry by a counter-current extractor; e) subjecting remaining washed-first stage solids of pretreated biomass to a second-stage acid and metal salt impregnator and dewatering by drying or centrifugation to prevent compaction of biomass to arrive at 40% to 60% by weight solids; f) subjecting the acid and metal salt-impregnated biomass to a second-stage hydrolysis reactor at a temperature from 190° C. to 240° C. and discharging formed hydrolysate into a flash tank, at about 120° C. to 140° C. to hydrolyze most of the remaining soluble oligosaccharides to monomeric sugars and flashing remaining hydrolysate to a second flash tank at a lower temperature than the first flash tank, the second flash tank serving as a feed surge tank for second-stage fementors; g) cooling pH-adjusted extract from the counter-current extractor, feeding the extract to a first-stage fermentor and air sparging the first-stage fermentor at a rate sufficient to promote enough yeast growth to compensate for loss through second-stage fermentors; h) pH adjusting second-stage hydrolysate slurry to 4.5, cooling the slurry and adding it into the top of the first fermentor of a two-fermentor train in the second stage fermentors, pumping broth from the bottom of the first stage fermentors to the second stage fermentors while the yeast is in the growth phase for a period sufficient to consume over 95% of fermentable sugars; and i) recovering ethanol.

Owner:MIDWEST RES INST

Alkali free glass

InactiveUS20060003884A1Reduce compactionIncreasing strain pointChemistryLinear expansion coefficient

To present an alkali free glass capable of reducing compaction caused by heat treatment, without significantly increasing the strain point. An alkali free glass characterized in that the ratio (Δan-st / α50-350) of the equilibrium density curve gradient Δan-st (ppm / ° C.) in a temperature range of from about the annealing point (Tan) to about the strain point (Tst) to the average linear expansion coefficient α50-350 (×10−6 / ° C.) in a range of from 50 to 350° C., is at least 0 and less than 3.64.

Owner:ASAHI GLASS CO LTD

Bio-organic compound fertilizer

InactiveCN101781149AImprove fat retention capacityImprove buffering effectFertilizer mixturesPotassiumOrganic compound

The invention relates to a bio-organic compound fertilizer, which comprises the following components in part by weight: 10 to 30 parts of organic matter, 2 to 10 parts of compound microbial inoculants, 5 to 20 parts of humic acid, 5 to 20 parts of amino acid, 4 to 10 parts of chitin, 1 to 5 parts of polypeptide, 530 parts of nitrogen, phosphorus and potassium, 5 to 10 parts of secondary and trace elements, 5 to 15 parts of algae fertilizer, 5 to 10 parts of zeolite powder and 1 to 5 parts of synergistic agent. Through the scientific and rational formula, the bio-organic compound fertilizer achieves nutritive equilibrium and can satisfy the need of crop growth in nutrient. The microbial inoculants are added to quickly degrade natural macromolecular organic compounds into the organic fertilizer and decompose organic pollutants, which effectively improves the capacity of crops in the absorption of nutrient components, reduces the waste of the fertilizer and reduces the damage of the chemical fertilizer to soil to further achieve the nutritive equilibrium, satisfy the need of the crop growth in the nutrient, achieve the aims of low investment and high output value, improve the quality of the crops and improve the economic benefit brought by the crops.

Owner:张钧

Inorganic-organic microbial compound fertilizer and preparation method thereof

ActiveCN102001870AAvoid competitionPromote growthOrganic fertilisersBacillus licheniformisHigh concentration

The invention relates to an inorganic-organic microbial compound fertilizer and a preparation method thereof. The inorganic-organic microbial compound fertilizer is characterized by comprising ordinary high-concentration three-element compound fertilizer, humic acid, fly ash, microbial compound bacteria powder and other elements, wherein the microbial compound bacterial powder is obtained by mixing bacterial powders which are prepared by respectively fermenting and culturing photosynthetic bacteria, yeast, lactic acid bacteria, bifidobacterium, bacillus subtilis, bacillus licheniformis, bacilluslaterosporus, bacillus megaterium, bacillus mucilaginosus, azotbacteria chroococum and actinomycetes. In the inorganic-organic microbial compound fertilizer, the microbial content of the yeast is no less than 2.0*108cfu / g, and the microbial contents of the other strains are all no less than 2.0*109cfu / g. The inorganic-organic microbial compound fertilizer can centralize the advantages of an organic fertilizer, an inorganic fertilizer and microorganisms, thereby enhancing the stress resistance and the disease resistance of crops, enhancing the fertilizer absorption ability of the crops, lowering the soil hardening degree and improving the soil ecological environment and the quality of the crops.

Owner:山西晨雨晋中肥业有限公司

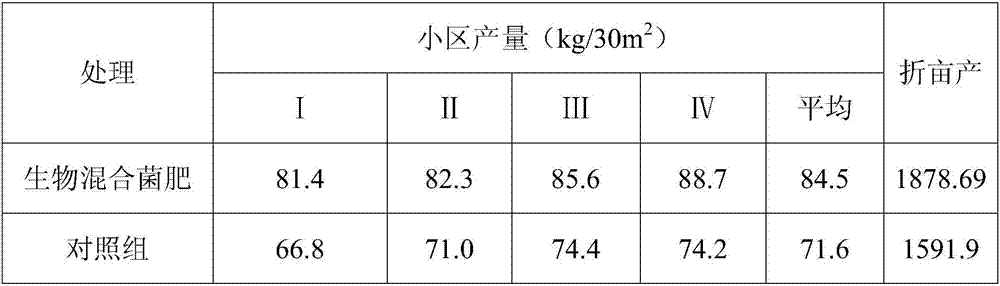

Biological mixed bacterial fertilizer and preparation method and application thereof

InactiveCN107285918AImprove the living environmentEnhanced back soil effectCalcareous fertilisersBio-organic fraction processingTrace elementInorganic materials

The invention discloses a biological mixed bacterial fertilizer and a preparation method and application thereof. The biological mixed bacterial fertilizer is prepared from, by weight, 1-20 parts of a compound bacterial agent, 300-400 parts of organic materials, 500-600 parts of inorganic materials, 800-1000 parts of chemical fertilizers, 5-10 parts of trace elements, 300-500 parts of waste liquid, 30-50 parts of amino acid salts and 50-100 parts of additives.

Owner:英丽华

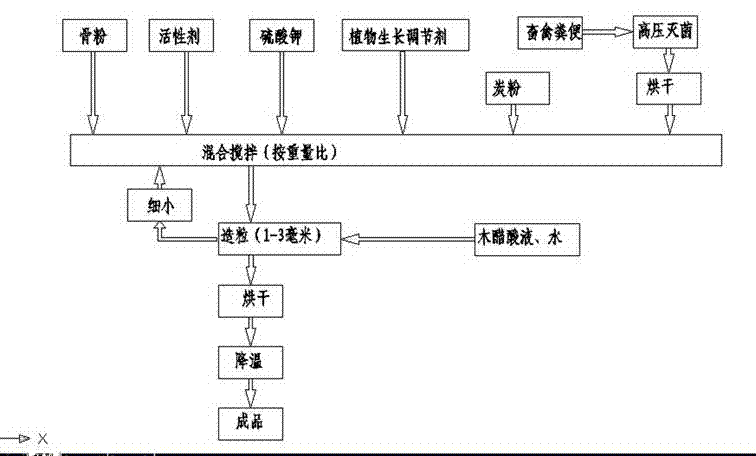

Preparation method of soil conditioner

InactiveCN102180744AHigh organic contentReduce compactionFertilizer mixturesActive agentOrganic content

The invention relates to a preparation method of a soil conditioner, belonging to the technical field of fertilizer preparation. The soil conditioner is mainly prepared from the following raw materials in parts by weight: 50-70 parts of plant straw carbon, 20-35 parts of fowl / livestock dung, 10-15 parts of bone meal, 1-8 parts of potassium sulfate, 2-8 parts of wood vinegar liquid, 3-9 parts of plant growth regulator and 0.5-1 part of active agent. The preparation method comprises the following steps: preparing carbon powder, pretreating the fowl / livestock dung, preparing a mixture, assaying and detecting, granulating and packaging. The soil conditioner is prepared by mixing the crop straw / bamboo / wood / grass carbon, which is used as the main component, with certain amounts of trace elements, plant growth regulator and bamboo / wood / grass vinegar liquid; since the soil conditioner not only is rich in the three main nutrient elements (nitrogen, phosphorus and potassium) which are essential for crops, but also contains secondary and trace elements, such as calcium, magnesium, sulfur, iron, boron, molybdenum, copper, cobalt and the like, the nutrient proportion of the soil conditioner is reasonable; and when being used as a conditioner, the soil conditioner can increase the organic content of soil and provide more comprehensive nutrients for crops, so that the crops have the advantages of good growth vigor, plump grains and much higher yield.

Owner:唐山汇力科技有限公司

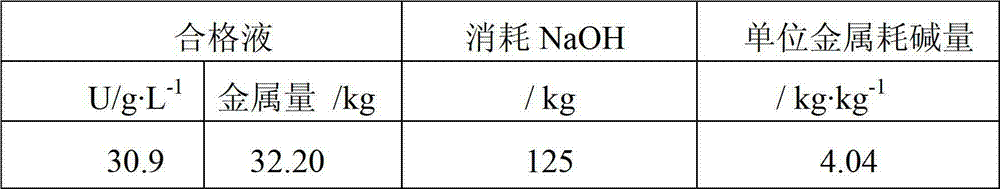

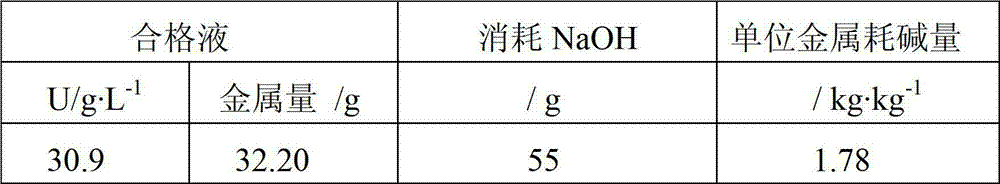

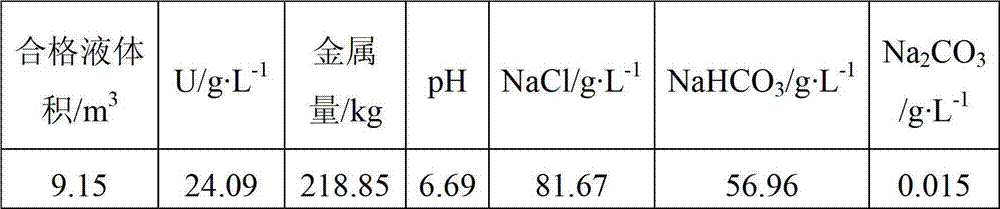

In-situ uranium leaching and mining treatment method by adding O2 into CO2

The invention provides an in-situ uranium leaching and mining treatment method by adding O2 into CO2. The invention comprises the steps of (1) adding O2 into leaching solution, then injecting an underground mine-water contained layer into a liquid injection pipeline, and preparing the leaching solution by adopting different oxygenation concentrations according to different underground leaching periods; (2) adding 100-300mg / L of CO2 into the leaching solution containing uranium; (3) conducting ion exchange adsorption on the leaching solution containing uranium, adopting macroporous styrene strong-base anion exchange resin, adsorbing to obtain saturated resin adsorption tail solution; and (4) washing saturated resin by adopting an eluting agent, and then analyzing uranyl carbonate ion solution to obtain Na2U2O7 sediment slurry and sediment mother liquor. According to the method, a high-temperature heating device is eliminated, so that the energy consumption and equipment investment are lowered greatly, the alkali consumption is lowered, control parameters are refined, the consumption of alkali is saved, and the production cost is lowered.

Owner:BEIJING RESEARCH INSTITUTE OF CHEMICAL ENGINEERING AND METALLURGY

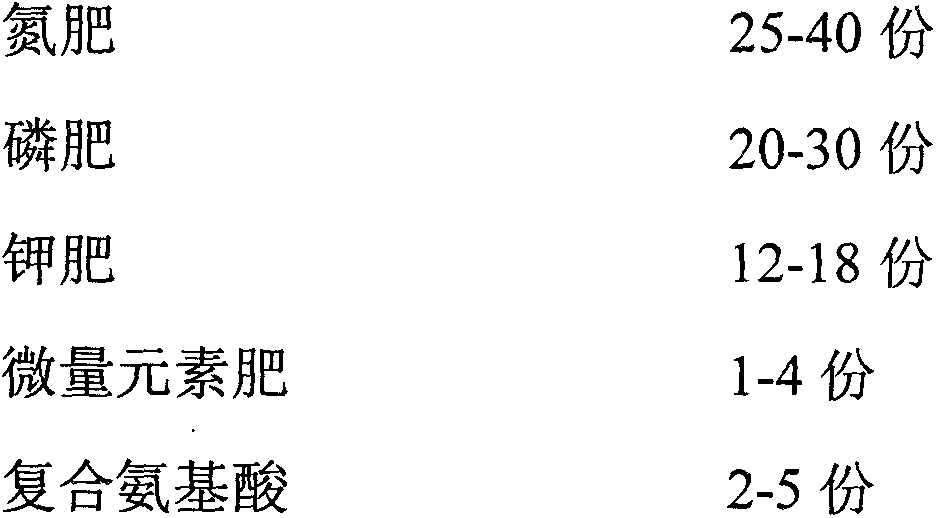

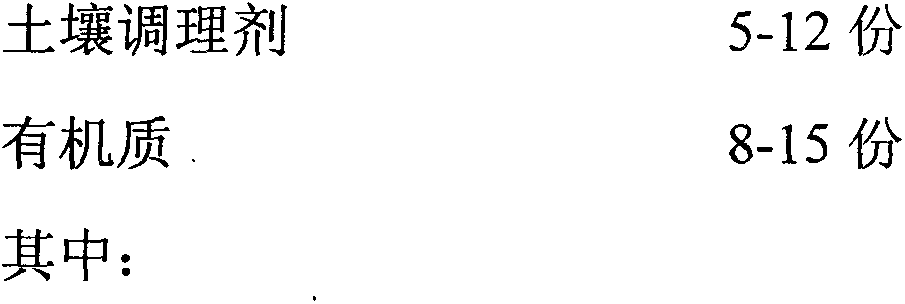

Water-holding and cultivating functional compound fertilizer and preparation method thereof

ActiveCN103896693ANutritional balanceReduce the frequency of fertilizationFertilizer mixturesTrace elementWater holding

The invention relates to a water-holding and cultivating functional compound fertilizer, comprising a nitrogen fertilizer, a phosphate fertilizer a potash fertilizer, a trace element fertilizer, a compound amino acid, a soil conditioner, an organic matter and the like. In addition, the invention relates to a preparation method of the water-holding and cultivating functional compound fertilizer. The invention also relates to use of the water-holding and cultivating functional compound fertilizer for improvement of the growth characters and / or yield of crops.

Owner:中利丰肥业有限公司

Compound microbial organic fertilizer and preparation method thereof

ActiveCN103113167AStrong stress resistancePromote growthFertilizer mixturesPotassiumOrganic fertilizer

The invention relates to a compound microbial organic fertilizer and a preparation method thereof. The compound microbial organic fertilizer is prepared from the following ingredients in parts by weight: 1-4 parts of trichoderma viride JUWEI002 fermentation liquor, 1-4 parts of bacillus subtilis JUWEI001 fermentation liquor, 20-30 parts of turfy soil, 33-38 parts of tobacco residue, 33-38 parts of silkworm faeces, 6-7 parts of calcium powder and 1-2 parts of potassium fulvate. The compound microbial organic fertilizer disclosed by the invention has the advantages that the quality of crops can be remarkably improved, the yield of the crops is increased, and the soil structure is improved.

Owner:JINAN ZEYUAN BIOTECH

Glass plate, process for producing it, and process for producing TFT panel

ActiveUS20100129944A1Little influenceLow B2O contentGlass drawing apparatusGlass forming apparatusThermal expansionGlass sheet

To provide a glass plate which has a low B2O3 content and which can be used as a glass plate for e.g. an LCD panel.A glass plate which comprises, as a glass matrix composition as represented by mass % based on oxide, from 53 to 74 mass % of SiO2, from 15 to 23 mass % of Al2O3, from 0 to 3 mass % of B2O3, from 2 to 17 mass % of MgO, from 0 to 12 mass % of CaO, from 0 to 6 mass % of SrO, from 6 to 28 mass % of MgO+CaO+SrO, from 0 to 9 mass % of Na2O, from 0 to 6 mass % of K2O and from 0.8 to 11 mass % of Na2O+K2O, contains from 100 to 500 ppm of SO3, has an average coefficient of thermal expansion from 50 to 350° C. of at most 60×10−7 / ° C., and has a strain point of at least 600° C.

Composite bacterium agent for organic material fermentation

The invention relates to an organic materials zymolysis complex bacillus agent in the field of zymolysis bacillus agent technology. It comprises: low temperature bacteria, Bacillus cereus, gliotoxin, pseudomonas, slim streptomycete, high temperature bacteria and high temperature actinomyces with the weight ration 4:2:1:1:3:2:2. The low temperature bacterium is enzyme yeast with the heat resisting temperature below 20 deg. The high temperature bacterium is enzyme yeast with the heat resisting temperature below 70 deg. The heat resisting temperature below 70 deg of the high temperature actinomyces bellows 70 deg.

Owner:青岛地恩地生物科技有限公司

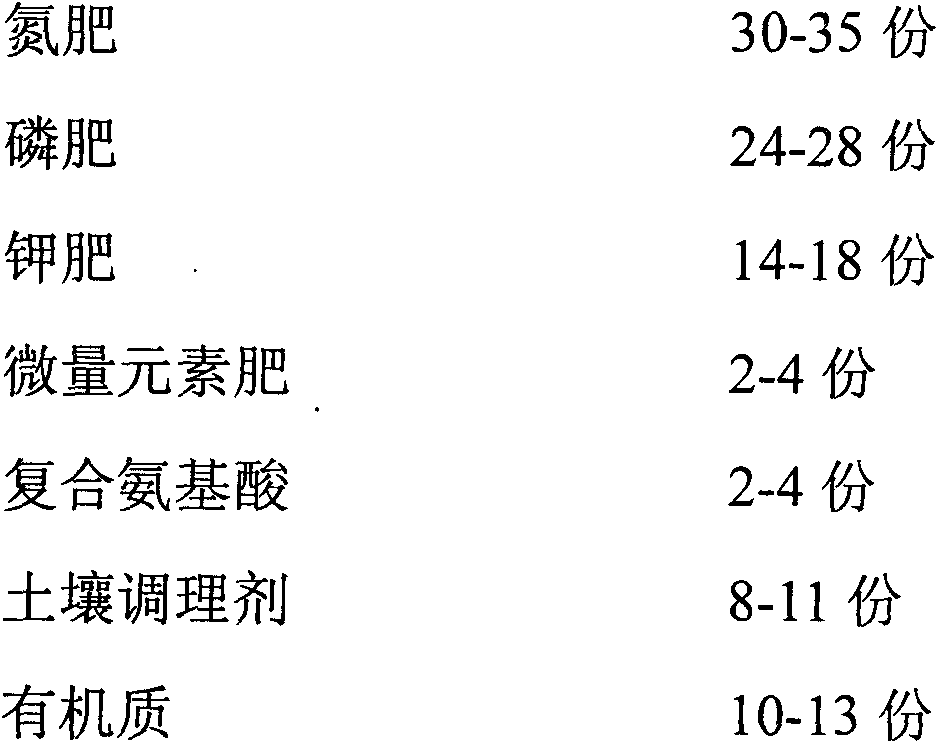

Saline-alkali land soil conditioner and preparation method thereof

ActiveCN102154013AReduce compactionImprove breathabilityOrganic fertilisersSoil conditioning compositionsAlkali soilFatty alcohol

The invention discloses a saline-alkali land soil conditioner and a preparation method thereof. The saline-alkali land soil conditioner is prepared by adding water in citric acid, polymaleic acid-acrylic acid copolymer, sodium polycrylate and fatty alcohol-polyoxyethylene ether. The preparation method comprises the following steps: weighing raw materials in weight proportioning; adding partial water in a reaction kettle for heating to 50-60 DEG C; adding the fatty alcohol-polyoxyethylene ether, the polymaleic acid-acrylic acid copolymer, the sodium polycrylate and the citric acid in the reaction kettle in turn for fully dissolving; subsequently, adding rest water in the reaction kettle and cooling to 20 DEG C; and after sampling and qualified inspection, measuring and packaging to form a finished product. By using the conditioner, the physical and chemical properties of the saline-alkali soil are obviously improved, heavy metal ions are complexed, emulsification and oil removal are achieved, salinity infiltration is accelerated, alkaline of soil is neutralized, and the pH value is regulated; and the desalination amount of the conditioner can reach above 50%, and the conditioner has the advantages of short improvement period, durable management effect and universality, saves water, increases benefits, yield and income and is environment-friendly.

Owner:新疆昆仑雷士农业科技有限公司

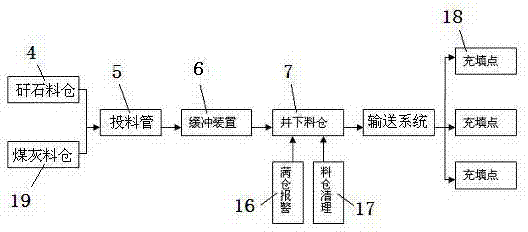

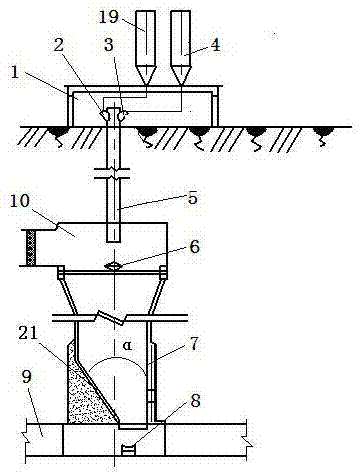

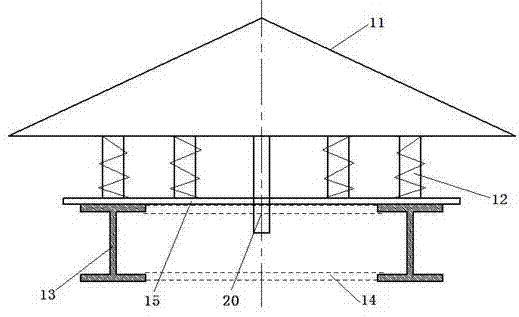

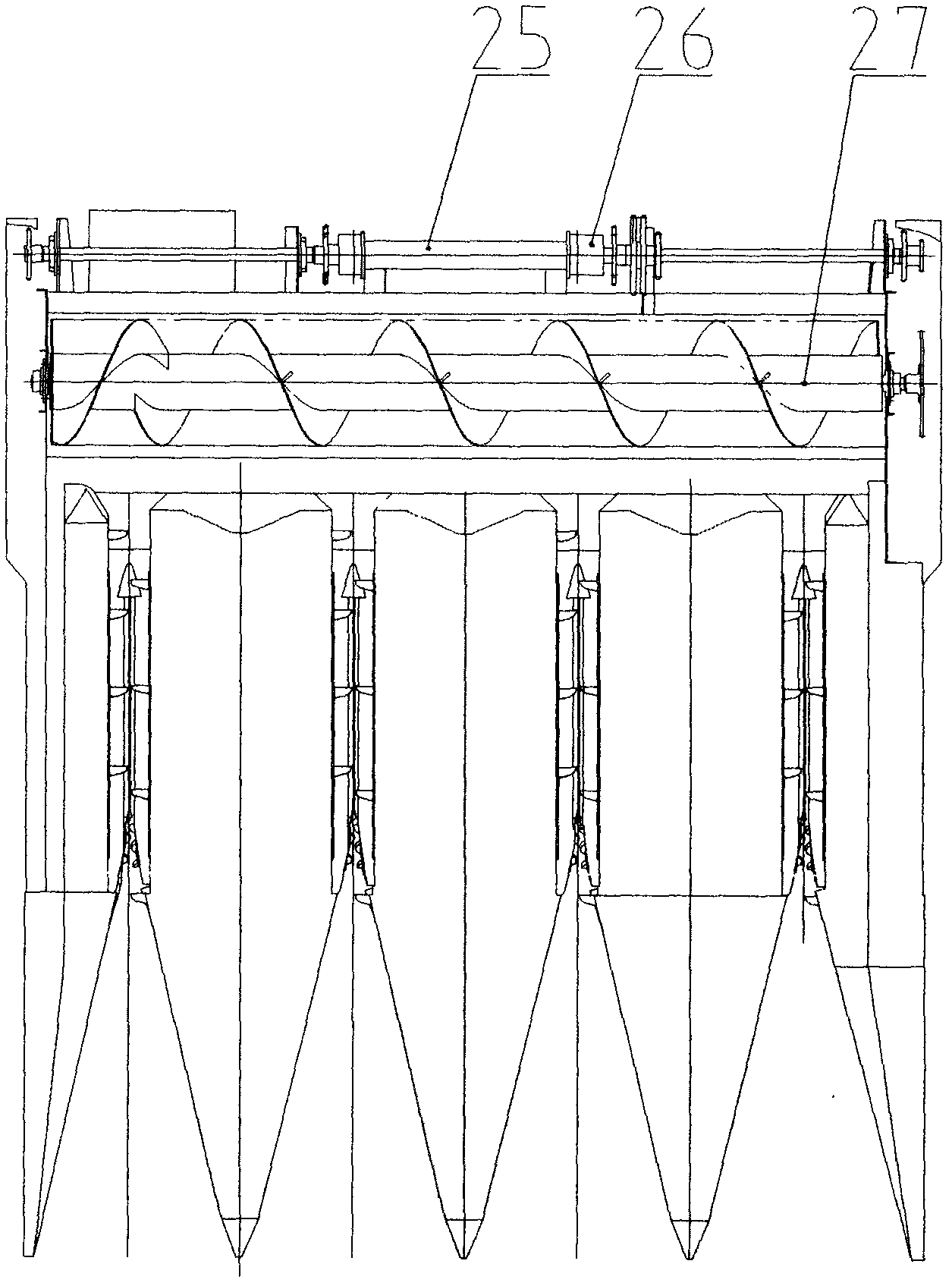

System for feeding coal mine solid filling material

InactiveCN102889097AImprove delivery capabilitiesAvoid cloggingMaterial fill-upFilling materialsClosed chamber

The invention relates to a system for feeding a coal mine solid filling material. The system comprises a filling control chamber, a gangue material bin, a coal ash material bin, a feeding pipe, an underground closed chamber, an impact resistance buffering device, an underground material bin and an underground conveying system, wherein the impact resistance buffering device is positioned at the bottom of the underground closed chamber; the feeding pipe is connected with the underground material bin through the underground closed chamber; the underground material bin is connected with the underground conveying system; the underground conveying system comprises a conveying passage and a conveyer; the conveyer is connected to a filling point; the feeding pipe consists of a protection hole wall steel pipe and a double-layer anti-abrasion pipe; a ceramic anti-abrasion pipe is sleeved on a shrinkage wall at the bottom of the underground material bin; and an outwards discharging type air guide hose is arranged at the upper opening of the underground material bin. According to the system, a large-aperture perpendicular feeding pipe is used for feeding the material, so that the feeding capacity of the filling material is improved, and a filling effect and the safety are improved; by the umbrella-shaped impact resistance buffering device, falling impact force of the filling material can be relieved; the compactness of the filling material in the bin can be reduced; and the bins can be prevented from being plugged.

Owner:HEBEI COAL SCI RES INST

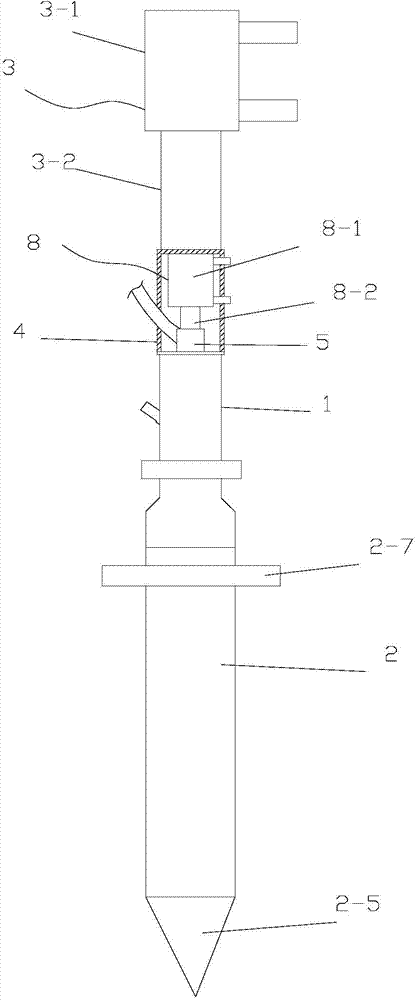

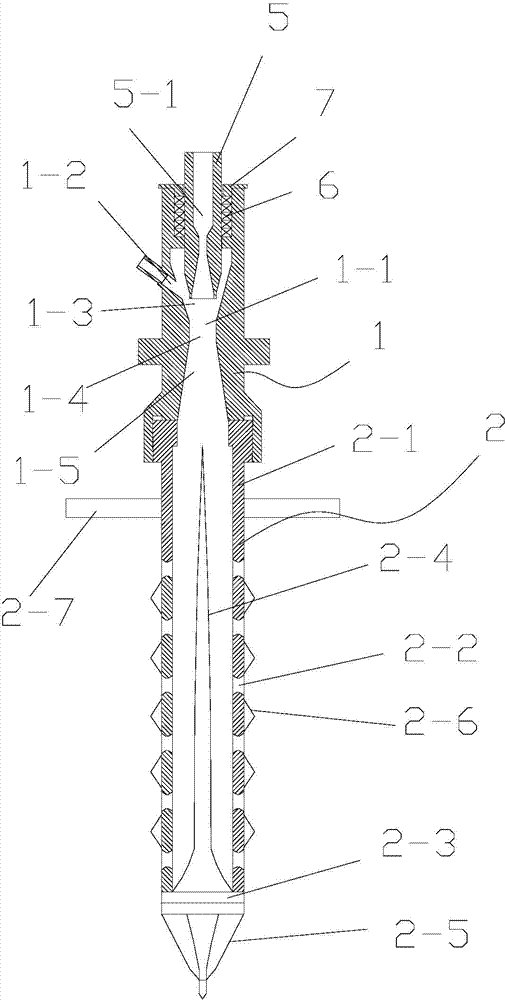

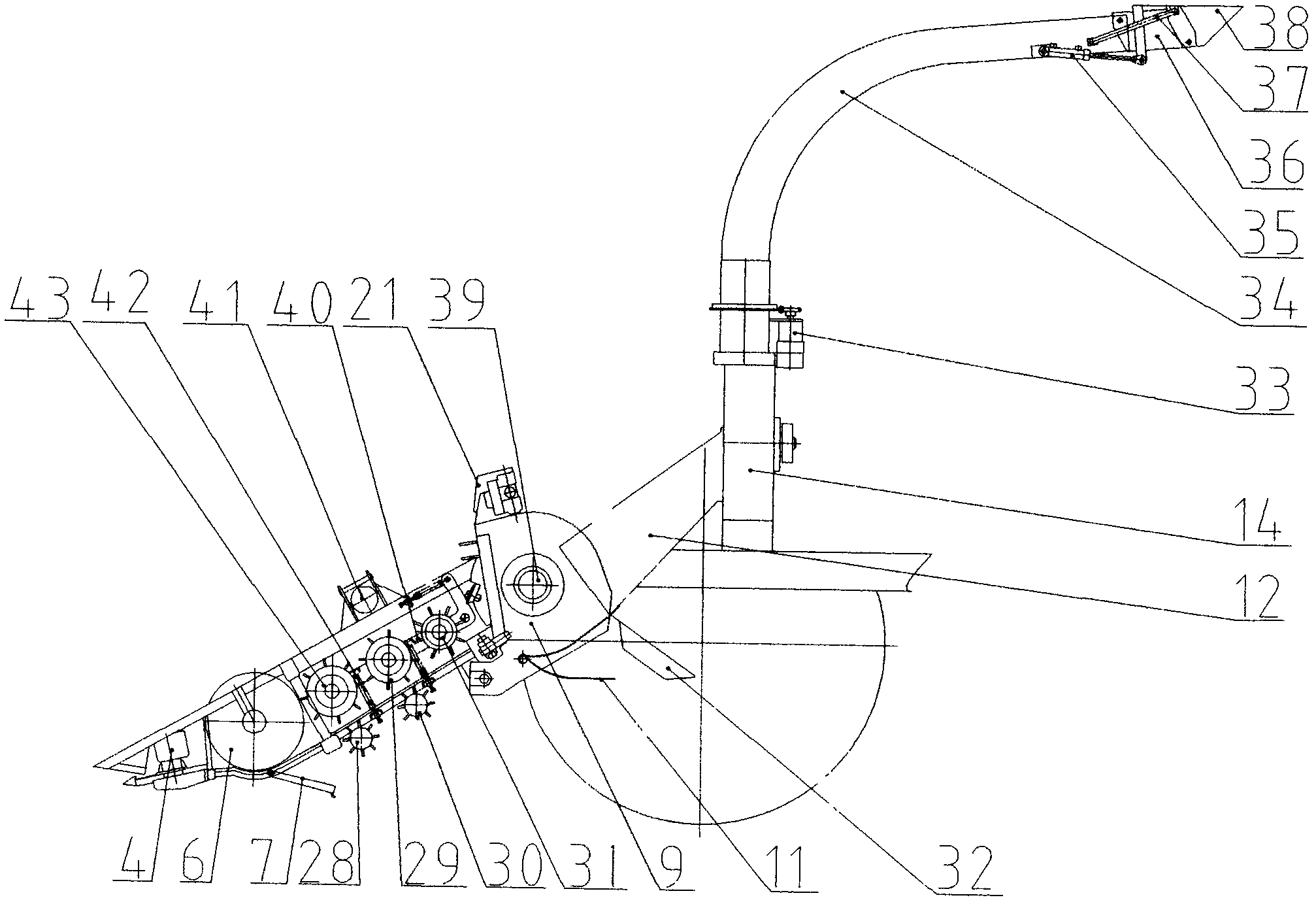

Ejector for soil deep placement

ActiveCN104704971ASolve the problem that deep loosening and deep construction cannot be carried out at the same timeSolve the distance problemFertiliser distributersAgricultural engineeringHigh pressure

The invention discloses an ejector for soil deep placement. The ejector comprises an airflow conveyer for conveying high-pressure jet airflow, wherein an airflow channel and a fertilizer channel for feeding a fertilizer are arranged in the airflow conveyer; the airflow channel is in a venturi structure; a fertilizer outlet of the fertilizer channel is communicated with a shrinkage area of the airflow channel; and the airflow conveyer is used for conveying the high-pressure jet airflow. The airflow channel is in the venturi structure, and can play an accelerating role in the flowing airflow; meanwhile, the fertilizer channel and the fertilizer outlet of the fertilizer channel are communicated with the shrinkage area of the airflow channel; and negative-pressure material suction is formed on a powder fertilizer by the high-pressure jet airflow flowing through the airflow channel, so that the powder fertilizer is mixed with the high-pressure je airflow in the airflow channel to enter soil along with the high-pressure je airflow, and thus the target of the deep placement is reached.

Owner:CHENGDU TOBEST DIYUAN TECH CO LTD

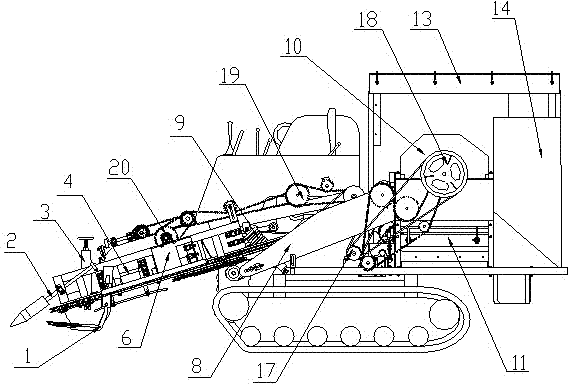

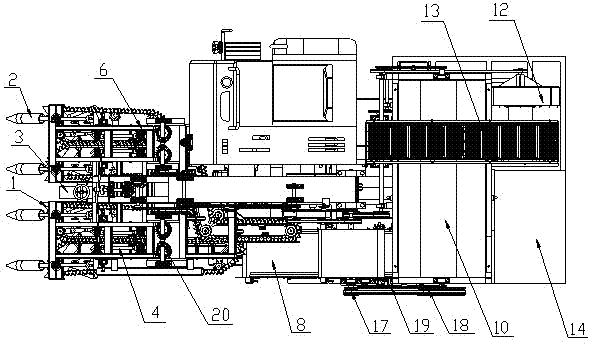

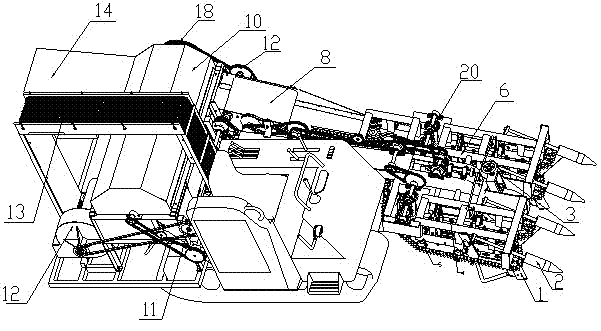

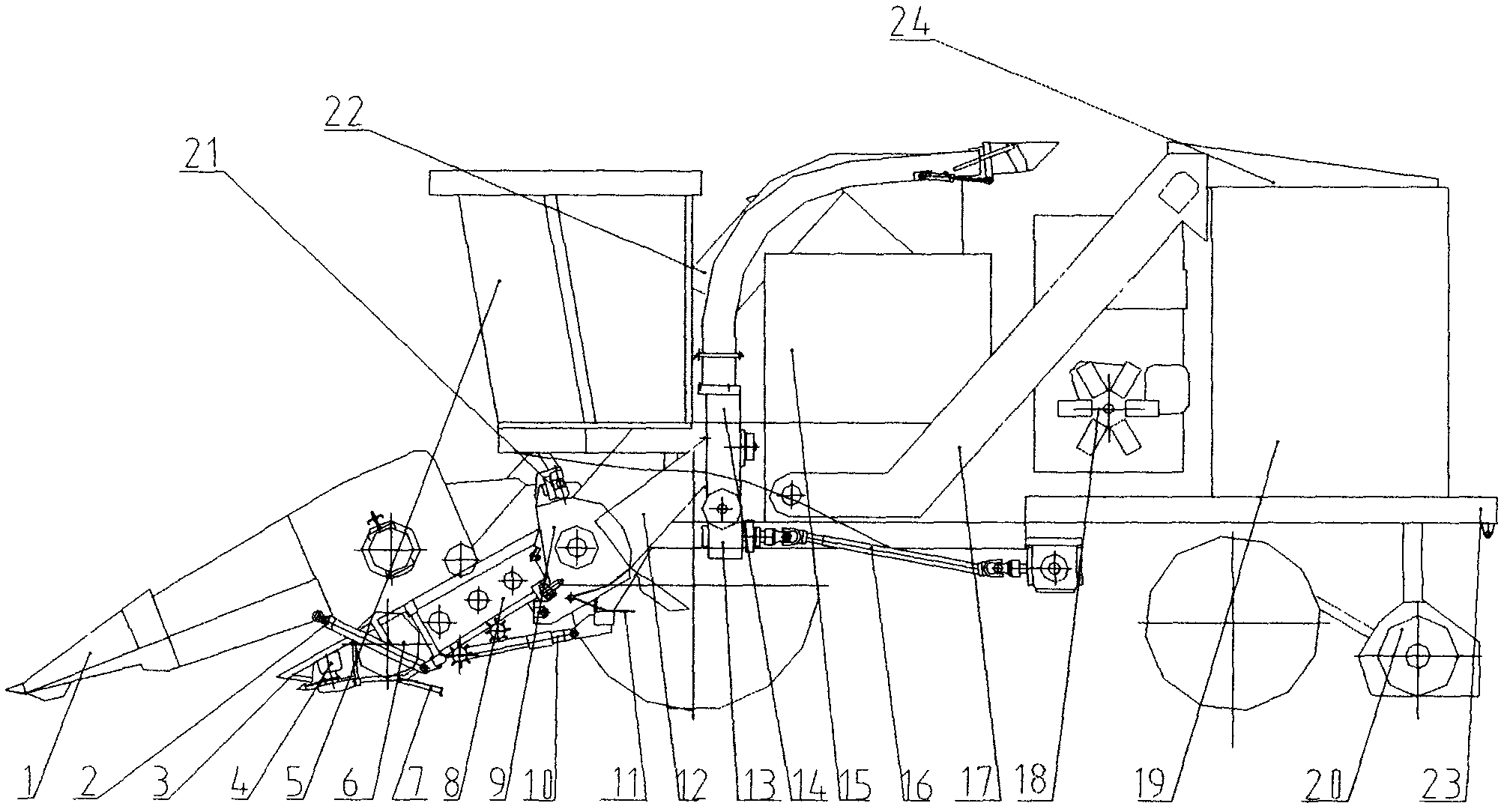

Two-ridge four-row whole-feeding peanut combine harvester

InactiveCN103039175AAchieve harvestRealize the clamping effectDigger harvestersThreshersEngineeringCombine harvester

Disclosed is a two-ridge four-row whole-feeding peanut combine harvester. The two-ridge four-row whole-feeding peanut combine harvester comprises a driving device, a clamping conveying device, a peanut picking sorting device and a peanut lifting device, the clamping conveying device comprises a two-ridge four-row clamping conveying collecting device and a conveying device, the two-ridge four-row clamping conveying collecting device comprises a clamping chain rack and clamping chains I, II, III, IV and V, a peanut vine clamping conveying path A is achieved by meshing of the clamping chain I and the clamping chain II, a peanut vine clamping conveying path B is achieved by meshing of the clamping chain III and the clamping chain IV, the clamping conveying collecting device further comprises a clamping collecting device, and the clamping conveying path A, the clamping conveying path B and conveyed peanut vines are gathered at a position of the clamping collecting device. By means of the two-ridge four-row whole-feeding peanut combine harvester, two-ridge four-row peanut vines can be harvested, clamped and conveyed, peanuts can be picked, sorted and collected, the work efficiency of the peanut combine harvester is improved, and time costs are lowered.

Owner:QINGDAO AGRI UNIV +1

Multienzyme organic fertilizer

InactiveCN102432400AImprove internal environmentIncrease productionFertilising methodsFertilizer mixturesPectinaseCellulose

The invention discloses a multienzyme organic fertilizer, wherein the fertilizer can increase soil organic matter contents and varieties of bioactivators, and improve physical, chemical and biological characteristics for soil, and improve soil fertility, and alleviate soil hardened state, and reduce pesticide residue in the soil; on the other hand, the fertilizer can provide progressive, continuous and complete nutrients for plant growth, and improve inner environment of crops at the same time such that the crops have abilities of full digestion and nutrient absorption. The invention can not only improve the yields of the crops, but also can improve qualities of agricultural products, and enhance healthcare functions for agricultural products. The fertilizer is suitable to be used by field crops and greenhouse vegetables, land vegetables, fruits, flowers, commercial crops and so on. The multienzyme organic fertilizer is composed of the following raw materials in percentages by weight: 10-15% of laccase, 5-10% of neutral protease, 10-15% of phytase, 5-10% of cellulose, 1-5% of xylanase, 1-5% of pectinase, 1-5% of amylase and 55-60% of organic fertilizer powder.

Owner:郝伟星

Preparation and application of composite bioactive material taking attapulgite to load bacillus

InactiveCN105272621APromote growthIncrease productionBiological water/sewage treatmentFertilizer mixturesSoil heavy metalsPlant disease

The invention relates to a method for preparing a composite material which takes modified or unmodified attapulgite as a carrier to immobilize bacillus, belonging to the technical fields of microbial fertilizers, biological control of plant diseases, soil remediation and pollution abatement. A microorganism-mineral immobilization technology is realized by means of preparing a proper amount of attapulgite with a proper amount of bacillus viable bacteria preparation according to a certain technology. The composite material prepared according to the method disclosed by the invention has the advantages that the plant growth can be promoted, the soil-borne diseases, such as root rot, blight, soft rot and the like, of various crops can be inhibited, and the effect of preventing threadworm from spawning is achieved; the composite material further has the capabilities of keeping the local moisture of plant root systems, and enhancing the plant resistance to drought, saline and alkaline as well as oxidization; moreover, the composite material can be further used for purifying organic pollutants in water, absorbing soil heavy metals and relieving soil hardening, so that the effects of soil moisture conservation and fertilizer conservation are achieved. The composite material prepared according to the method disclosed by the invention is an environment-friendly composite material, which has the advantages that environment harm and pollution can be prevented through correct use of the composite material, and a wide application prospect is obtained.

Owner:COLD & ARID REGIONS ENVIRONMENTAL & ENG RES INST CHINESE

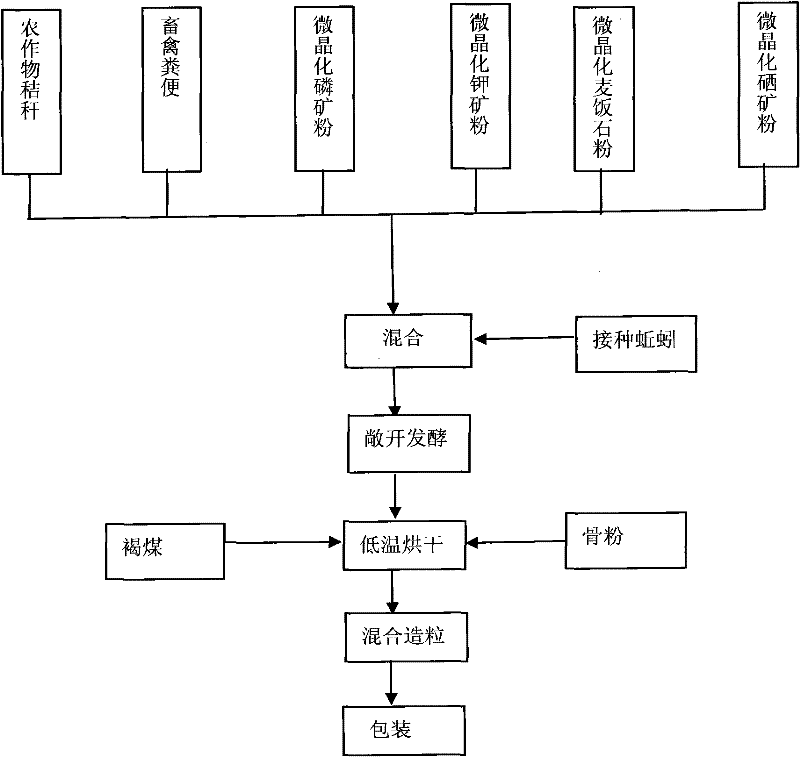

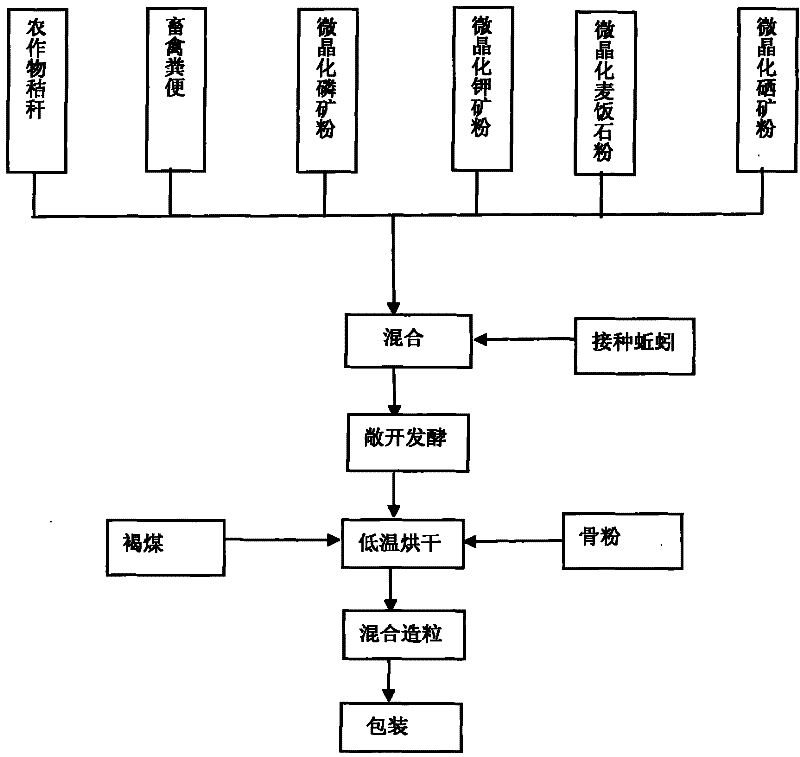

Efficient green micro-crystallized mineral-biological compound fertilizer and production method thereof

ActiveCN102408279AIncrease commodity rateNo pollution in the processFertilizer mixturesPhosphatePotassium

The invention discloses an efficient green micro-crystallized mineral-biological compound fertilizer and a production method thereof. The compound fertilizer comprises the following components in parts by mass: 7-9 parts of N, 7-9 parts of P2O5, 7-9 parts of K2O, 25-30 parts of organic matters, 8-12 parts of humic acid, 3-6 parts of amino acid and 15-20 parts of chemical elements such as calcium,silicon, magnesium, selenium, molybdenum, boron and zinc, as well as not less than 0.02 billion / kg of available active bacteria. The efficient green micro-crystallized mineral-biological compound fertilizer has the beneficial effects of being capable of adapting to acidic-alkaline soil and neutral soil in various regions, improving the soil, enhancing the adsorption ability of the soil on nutrients, preventing nitrogen and potassium from being washed away by water due to a large amount of rainfall, reducing formation of insoluble phosphate and improving fertility of the soil; and in addition,nitrogen, phosphorus and potassium in the original soil can be activated to be absorbed by crops by virtue of microelements contained in the fertilizer, and the supply capability of the deep soil nutrients can be enhanced, thus the physiochemical indexes and biological environment of the soil can be improved in case of long-term application, hardened soil can be reduced, and the quality of crops can be obviously improved.

Owner:山东清大生态科技有限公司

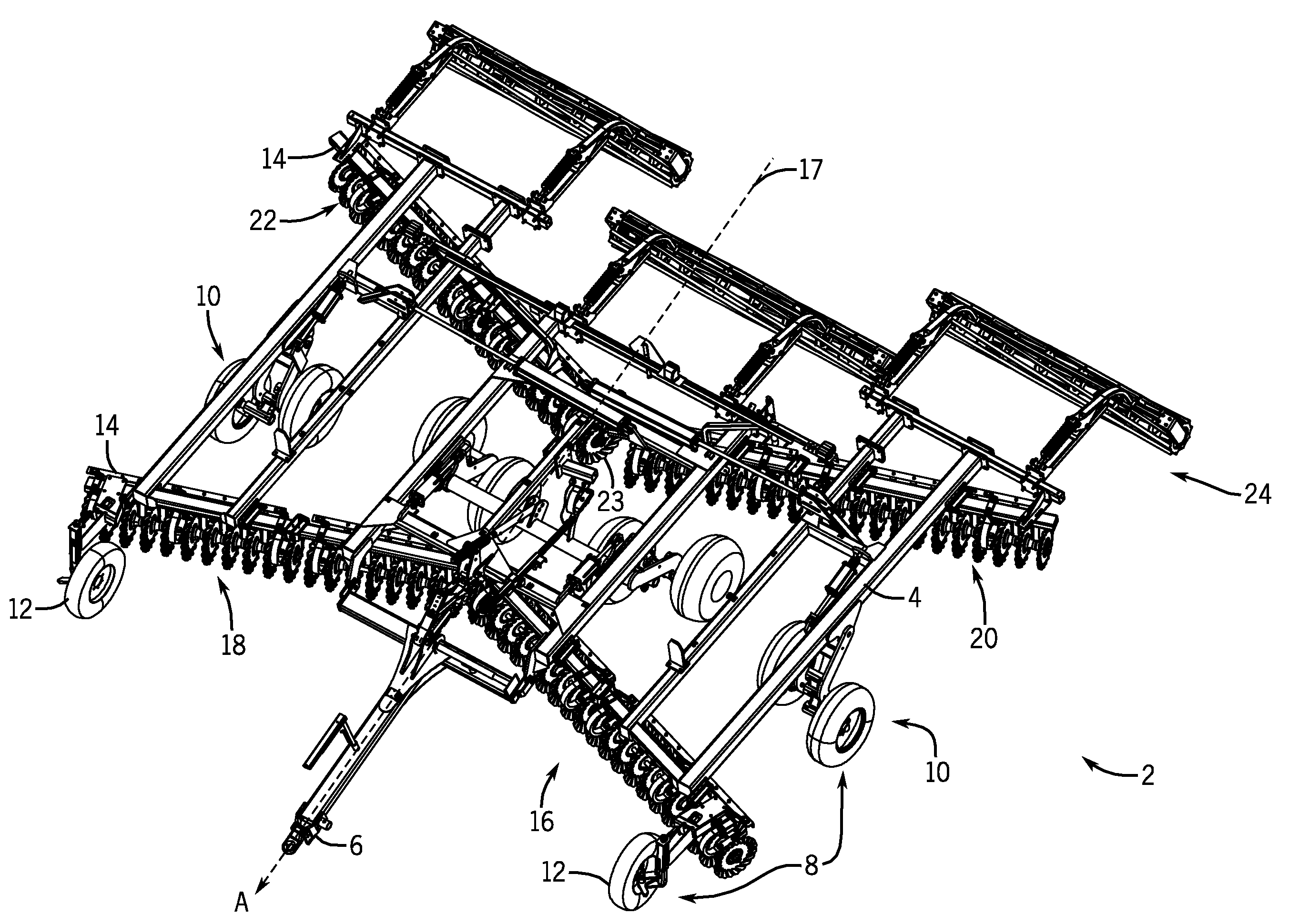

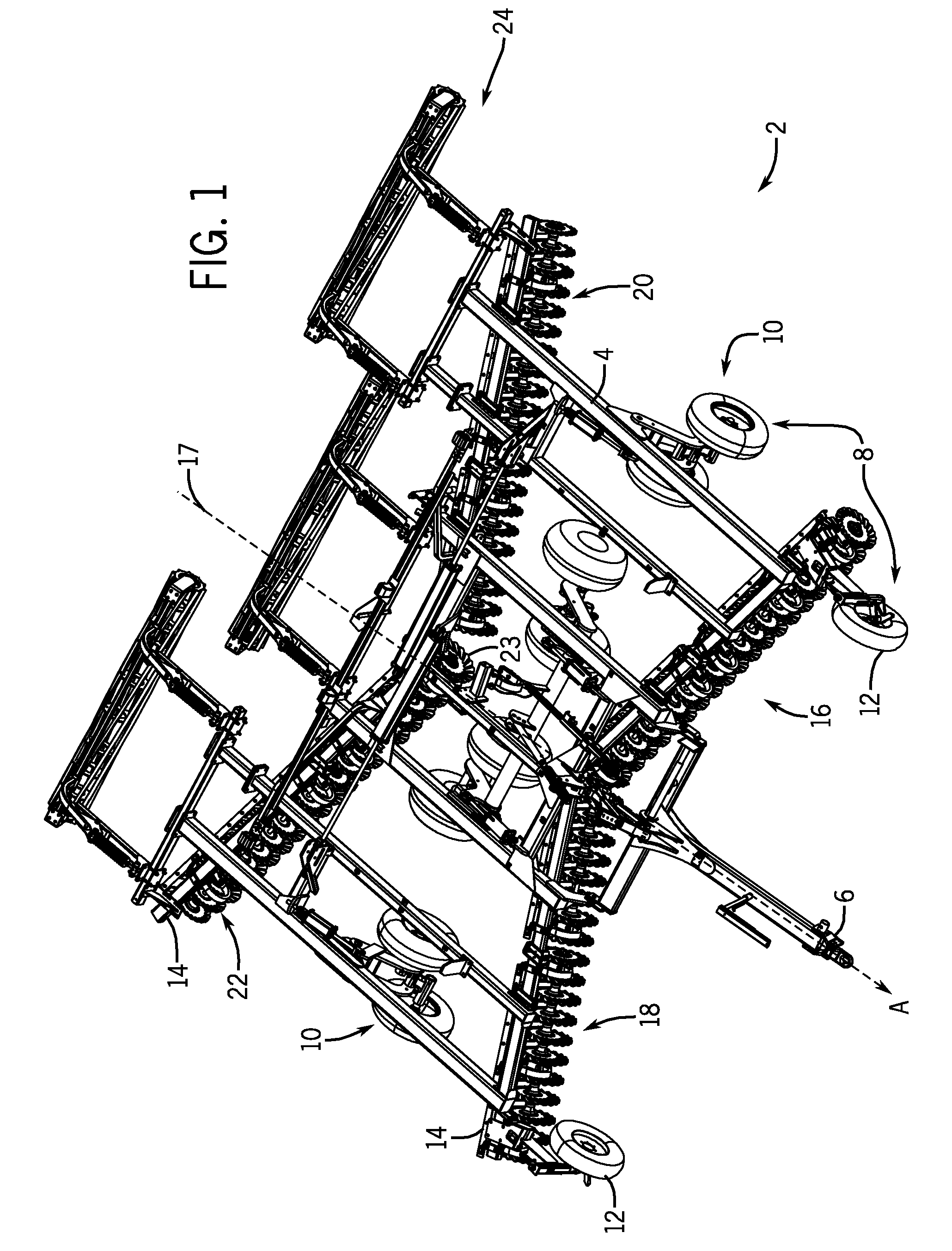

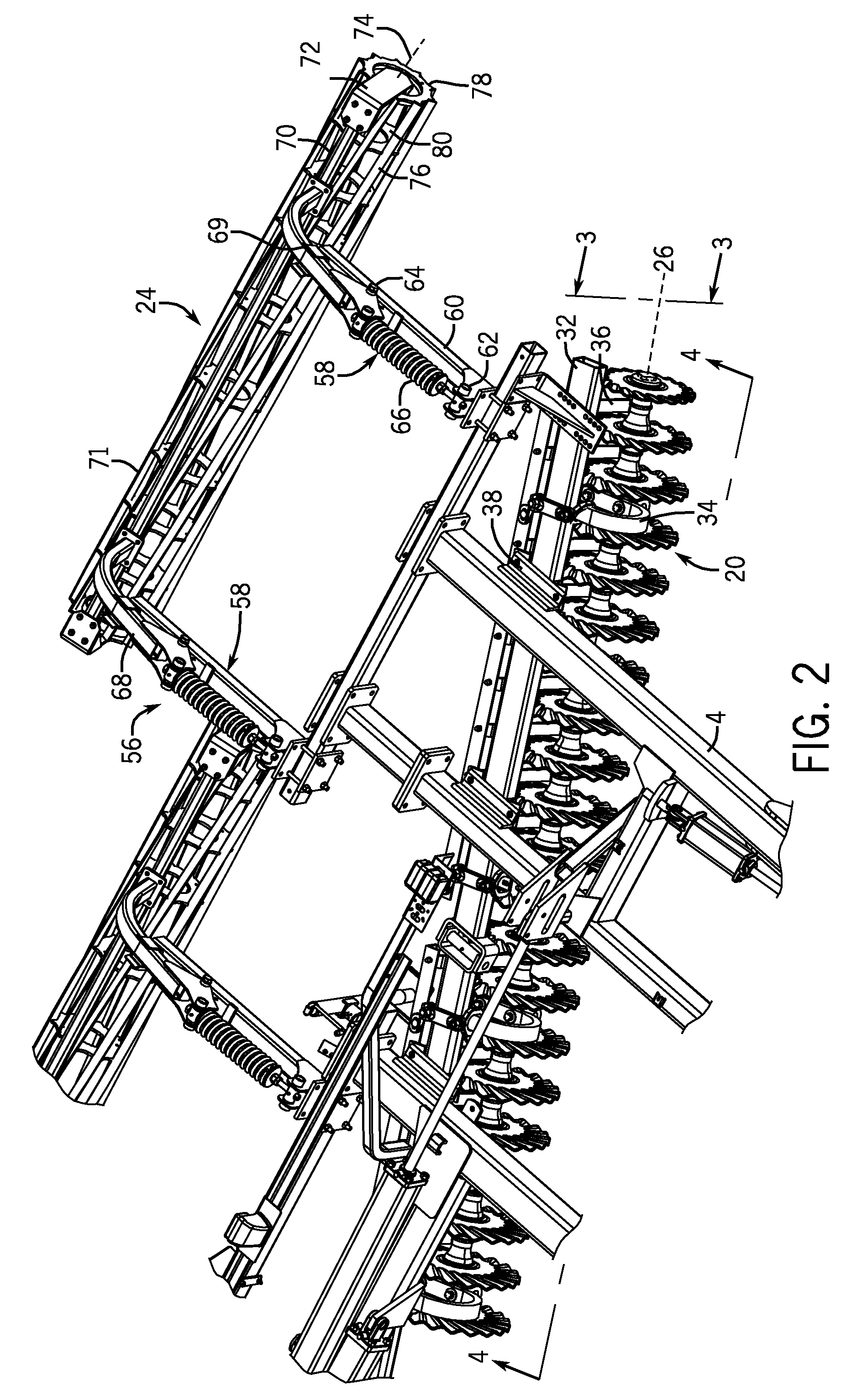

Vertical Tillage System

ActiveUS20090133888A1Reduces subsoil compactionOvercomes drawbackSpadesSoil-working equipmentsAgricultural engineeringSubsoil

A vertical tilling implement to be pulled behind and agricultural vehicle having a number of gangs of fluted-concave disc blades, rolling baskets, and wheels connected to a main frame. As the vertical tilling implement is pulled, the fluted-concave disc blades move the soil in a direction lateral to the side of the blades as well as up. Meanwhile, the rolling bars aid in leveling the seedbed and crushing the remaining large pieces of soil. The vertical tilling implement reduces the amount of subsoil compaction and cuts through heavy residue making it ideal for use in the fall or in the spring.

Owner:BLUE LEAF I P

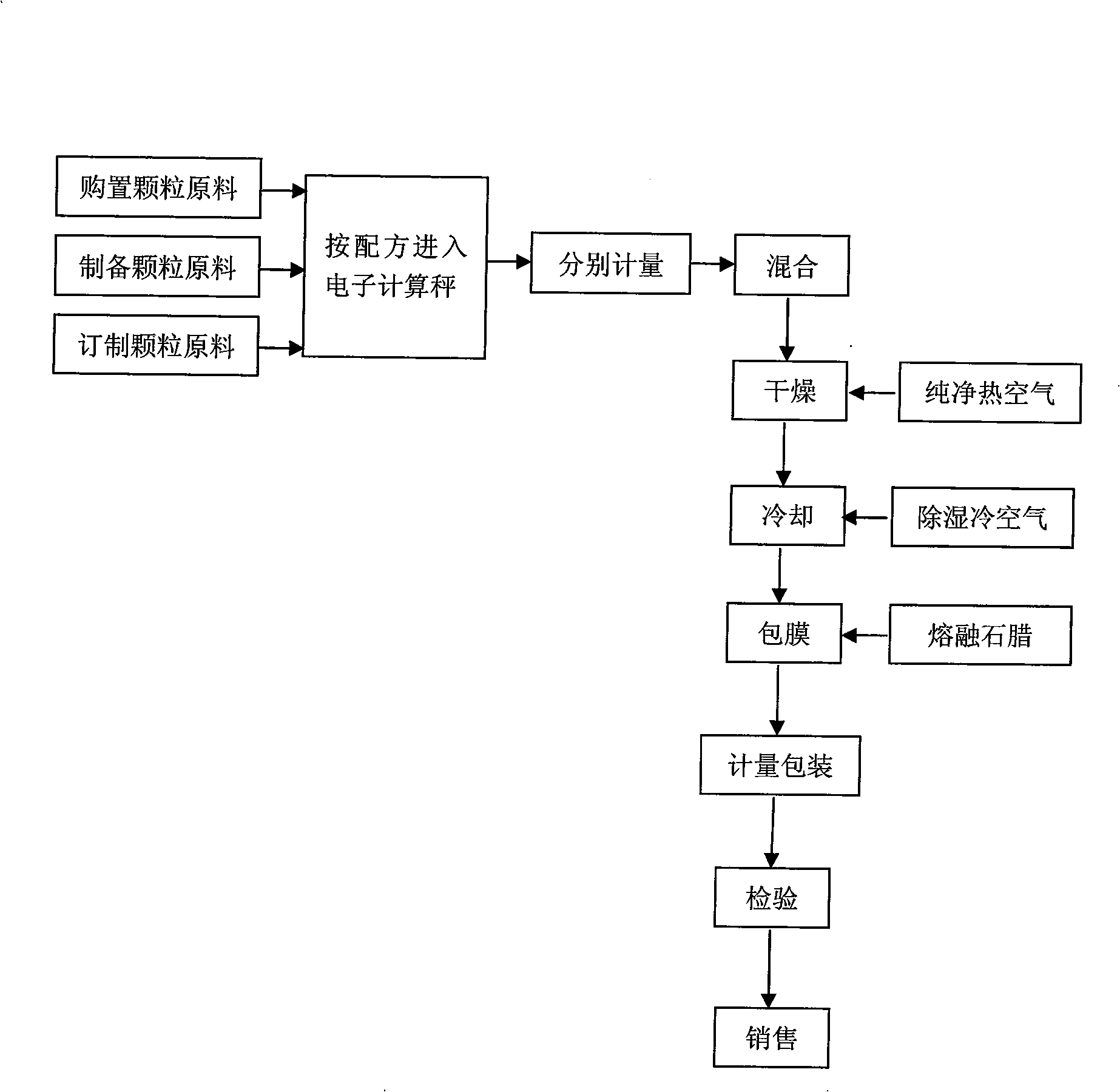

An ecological BB fertilizer

ActiveCN101514133AEfficient use ofReduce dosageAlkali orthophosphate fertiliserAmmonium orthophosphate fertilisersBiological StressEcological environment

The invention discloses an ecological BB fertilizer, relating to a mutifunctional ecological environment friendly compound fertilizer, which is formed by mixing functional urea, controllable slow release sulfurcoated urea, monoammonium phosphate, diammonium phosphate, potassium sulfate particle (or potassium chloride), agricultural magnesium sulfate particle, ammonium sulfate, bio-organic inorganic compound fertilizer, endophytic PASP fertilizer synergist DA-6, plant growth regulator and trace elements. Special ecological BB fertilizer for different plants can be prepared by soil testing formula, according to different farm crops and different soil structure. The ecological BB fertilizer can take effect for 3-120 days, the nutrition release is balanced, biological stress of the farm crop such as drought resistance, cold resistance, salt resistance, or the like can be improved. The product of the invention has great operation significance for increasing yield of grain, reducing production cost, steadily increasing grain production, keeping rural incomes growing, improving utilization rate of the fertilizer, reducing fertilizer waste, protecting ecological environment, guaranteeing farm crop quality and safety, and ensuring sustainable development of the agriculture.

Owner:苏州盛泽科技创业园发展有限公司

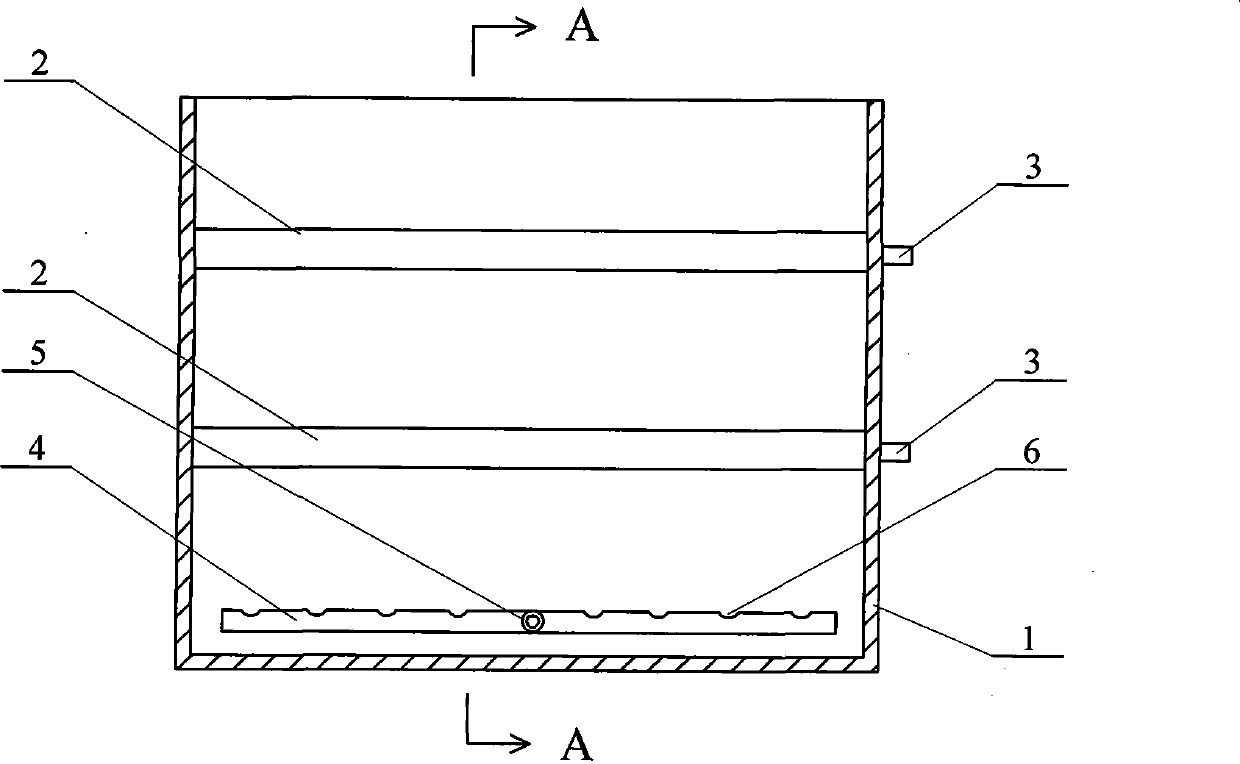

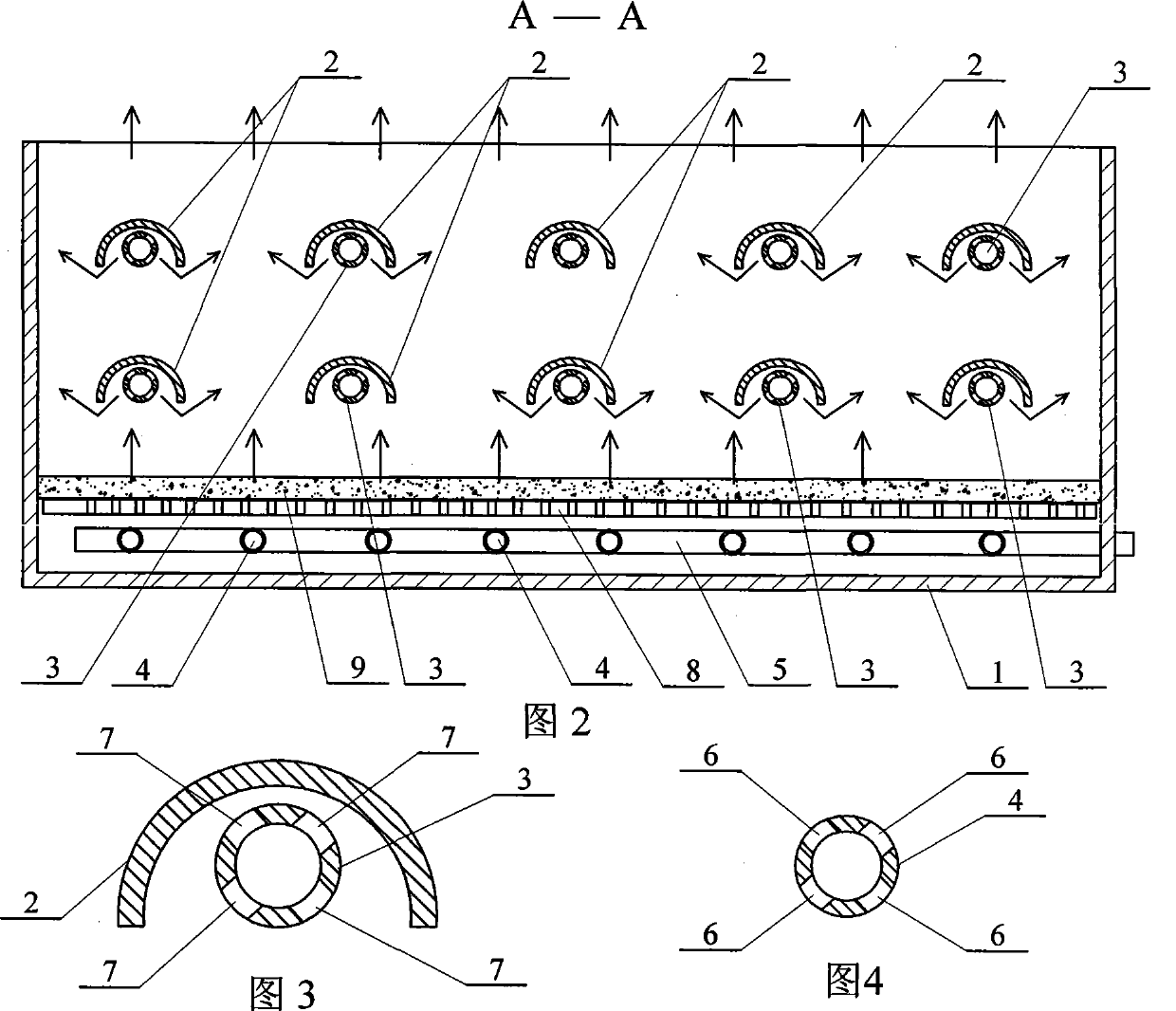

Solid waste high temperature aerobic composting method using stereoscopic ventilating apparatus

InactiveCN101372427AImprove mass transfer effectImprove uniformity and stabilityBio-organic fraction processingOrganic fertiliser preparationAgricultural engineeringCompost

A high-temperature and aerobic composting method for solid wastes which adopts a vertical ventilation device relates to a high-temperature and aerobic composting method for the solid wastes. The composting method aims at solving the problems that in the aerobic fermentation process, the conventional bottom ventilation method causes obvious uneven fermentation at the upper part and the lower part of a stacking body in a fermentation device, thus quality stability and uniformity of the fermented product are affected. In the composting method, middle air distribution pipes are fixed in a fermentation tank arranged at the lower side of an inverted ventilating slot; both the bottom part and the middle part of the fermentation tank adopt intermittent ventilation type, the ventilation time is 5-30 minutes, intermittent time is 15-120 minutes and ventilation rate is 0.03-2m<3> / (min m<3> mixing materials). The composting method increases the contact area between air and materials; air direction forms a reverse rotational flow, which increases residence time of fresh air in the fermentation device, thus improving the mass transfer efficiency, and the operational cycle of a single fermentation is shortened by over 1 / 4.

Owner:李伟光 +1

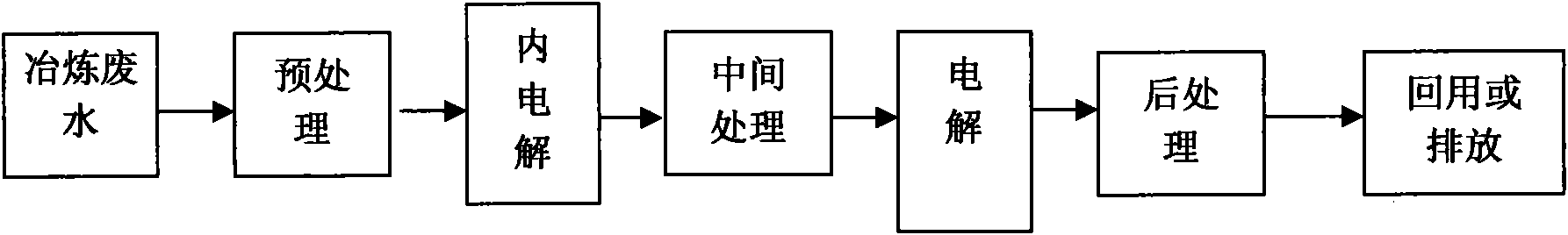

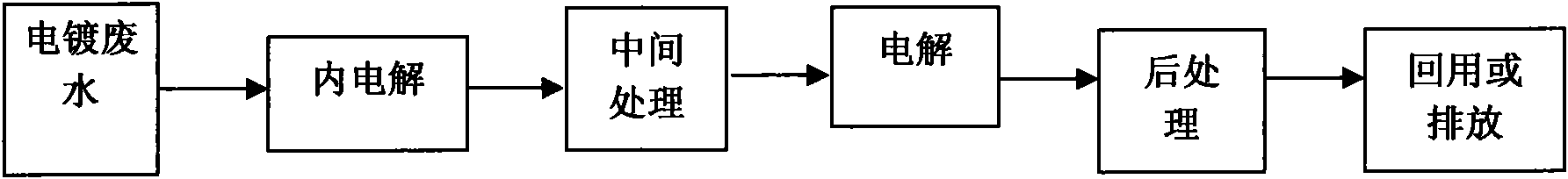

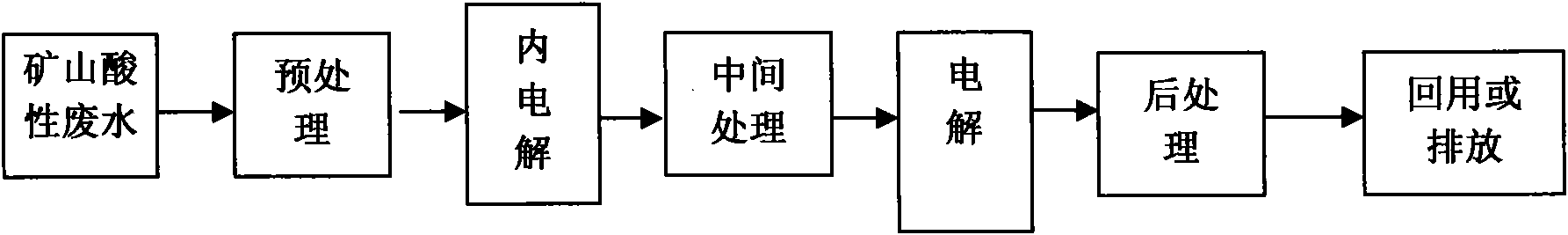

Method for processing waste water containing heavy metals by utilizing internal electrolysis-electrolysis method

InactiveCN101962240AIncrease reaction rateLower pHWater contaminantsWater/sewage treatmentElectrolysisEmission standard

The invention discloses a method for processing waste water containing heavy metals by utilizing an internal electrolysis-electrolysis method, which is characterized in that the waste water meeting the requirements of microelectrolysis processing is microelectrolyzed; the waste water is electrolyzed after the microelectrolysis reaches to the requirements thereof in a certain time so as to reach effluent standards or the requirements of recycle and the subsequent processing; the microelectrolysis bears a part of the task for processing the waste water containing the heavy metals and plays a preprocessing role of the electrolysis method; and the electrolysis method bears the remaining task for processing the rest waste water containing the heavy metals and plays the postprocessing role of the microelectrolysis. The invention organically integrates the microelectrolysis method and the electrolysis method, the two methods cooperate with each other and play roles together, and the processing method has the advantages of simple technique, processing efficiency enhancement of the waste water containing the heavy metals, and processing cost reduction.

Owner:KUNMING UNIV OF SCI & TECH

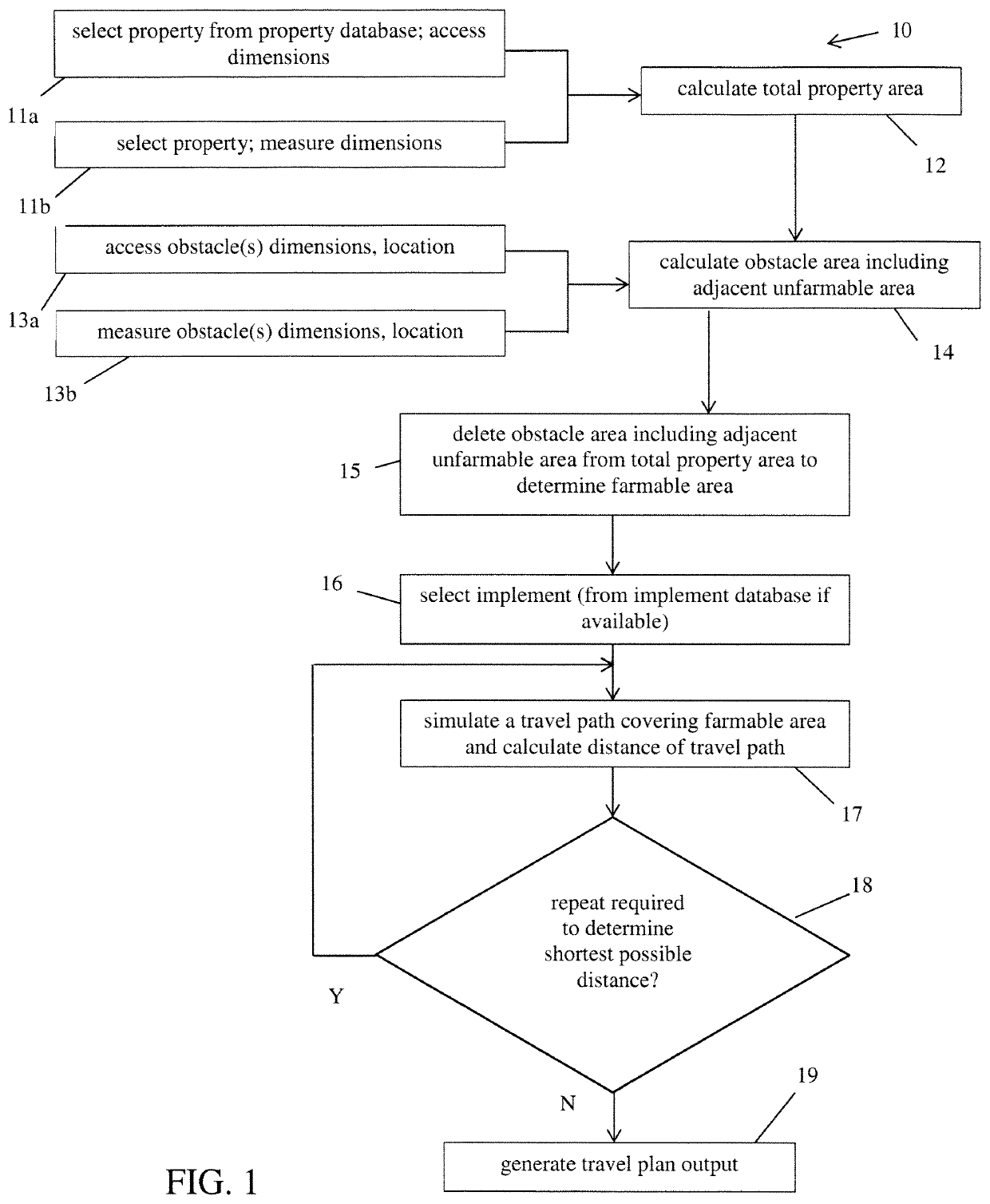

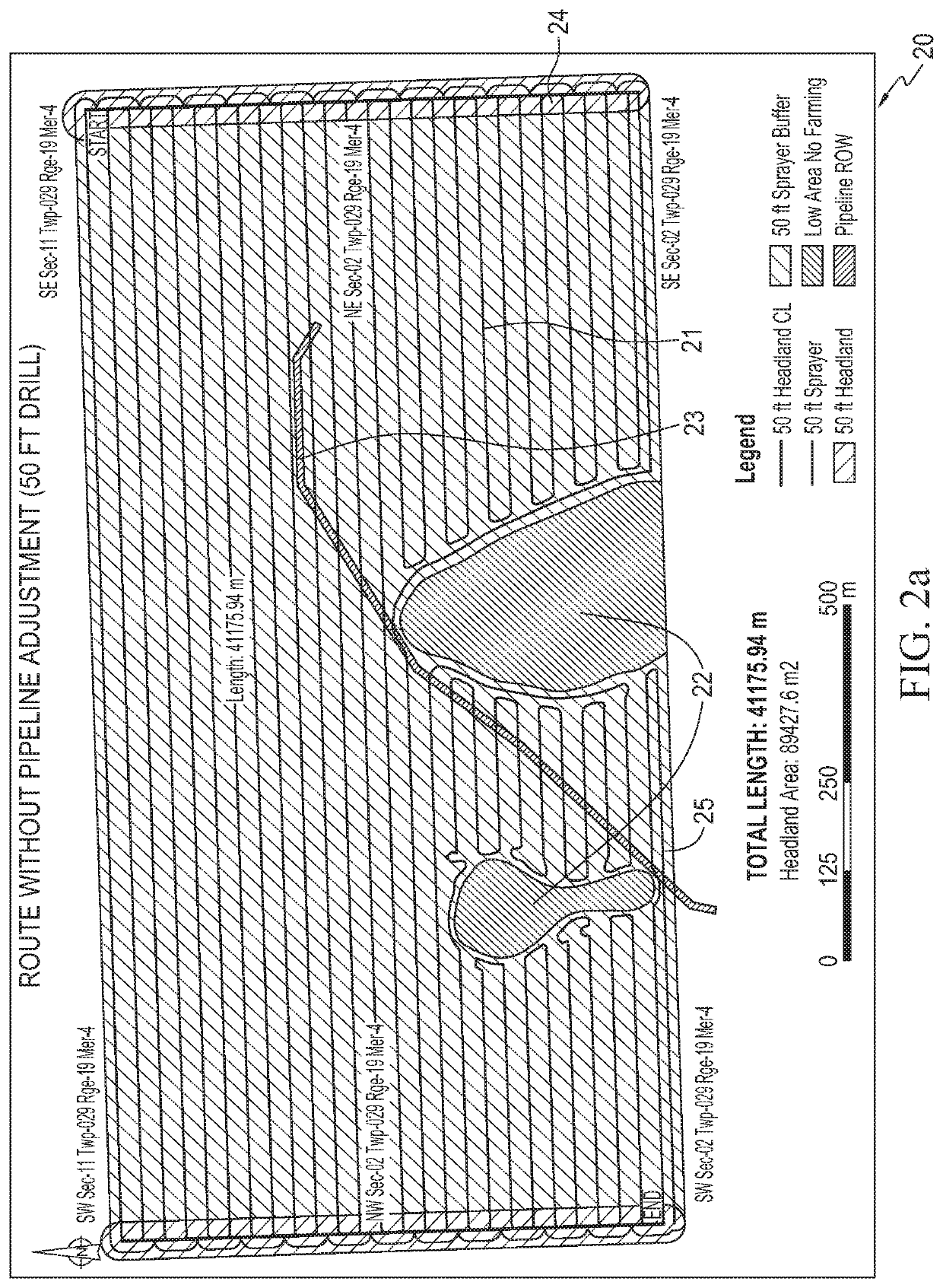

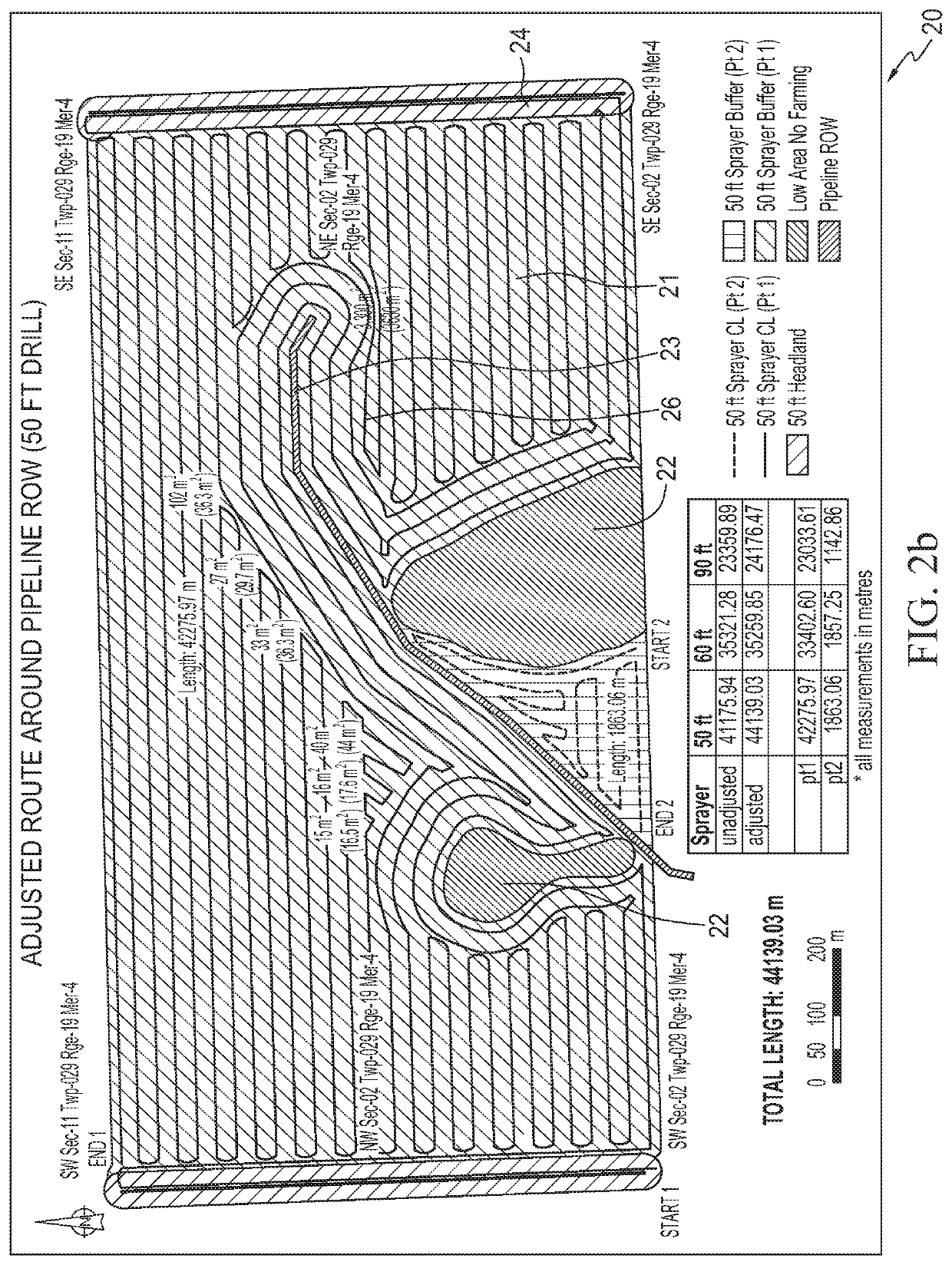

Method and system for determining optimized travel path for agricultural implement on land with obstacle

ActiveUS10740703B2Low efficiencyShorten the timeForecastingAgricultural landEnvironmental resource management

Owner:VERGE TECH INC

Organic, inorganic and microbe compound fertilizer for rice production and preparation method thereof

InactiveCN104529642AIncrease productionImprove stress resistanceAlkali orthophosphate fertiliserExcrement fertilisersEcological environmentAdditive ingredient

The invention belongs to the technical field of rice fertilizer, and particularly relates to organic, inorganic and microbe compound fertilizer for rice production and a preparation method of the organic, inorganic and microbe compound fertilizer for the rice production. The organic, inorganic and microbe compound fertilizer for the rice production mainly solves the problems that poor symbiosis environment, poor biological activity and low fertilizer efficiency exist in existing compound fertilizer. The technical scheme of the organic, inorganic and microbe compound fertilizer for the rice production is characterized in that the organic, inorganic and microbe compound fertilizer for the rice production is composed of the following ingredients, by weight, 24%-40% of inorganic fertilizer, 40%-56% of organic fertilizer and 15%-25% of biological agents. The organic, inorganic and microbe compound fertilizer for the rice production centralizes the advantages of the organic fertilizer, the inorganic fertilizer and microbes, has lower product price than chemical fertilizer, improves the yield, stress resistance, disease resistance and quality of rice, decomposes poisonous and harmful substances, reduces the degree of soil hardening, and improves the ecological environment of soil.

Owner:YANGQUAN LANDING BIOTECH

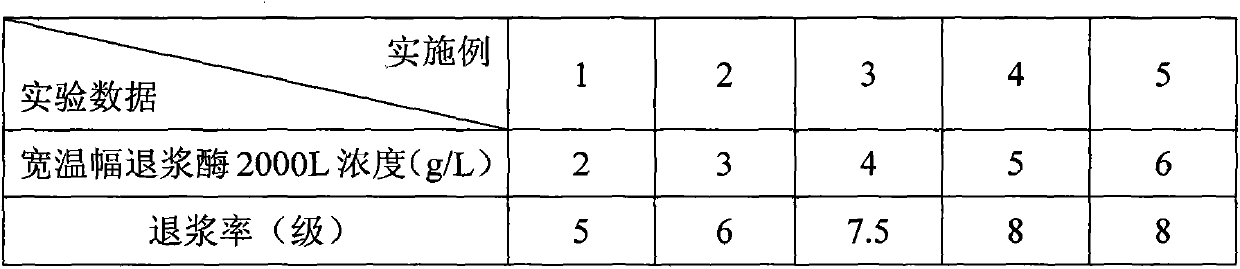

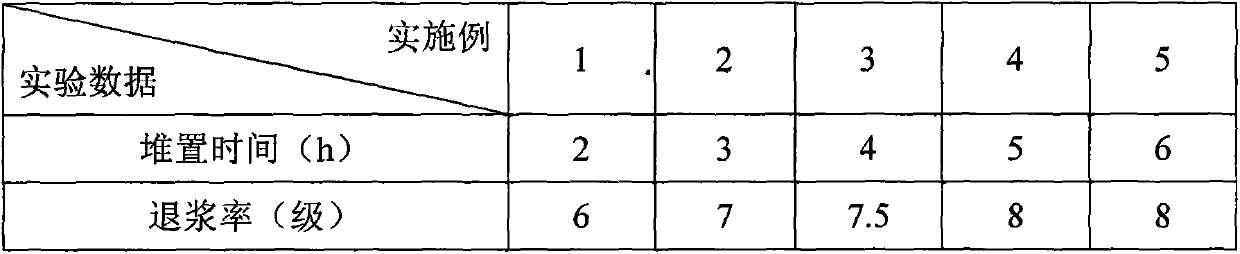

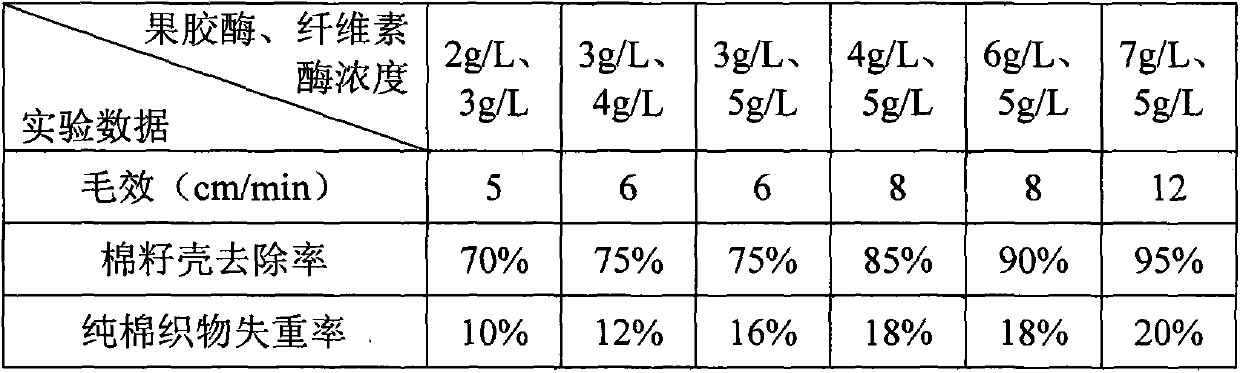

Dyeing treatment process for pure cotton fabrics based on pure natural biological preparations

ActiveCN103437141AHarm reductionEasy to operateShrinkingFabric breaking/softeningWastewaterEngineering

The invention discloses a dyeing treatment process for pure cotton fabrics based on pure natural biological preparations, which is designed for solving the technical problems that the environment is seriously harmed in an existing pure cotton fabric dyeing treatment process, and the human health is harmed in an application process. The adopted technical scheme is as follows: the dyeing treatment process comprises the steps of singeing, desizing, boiling-out, bleaching, dyeing, softening treatment and preshrinking treatment, and the key point is that biological preparations, which are respectively a desizing enzyme solution, a boiling-out enzyme solution, glucose oxidase solution and a plant dye, are respectively adopted in the steps of desizing, boiling-out, bleaching and dyeing. The dyeing treatment process has the technical effects that the operation is simple; the pure natural biological preparations almost do not contain any toxic substance, and wastewater produced in the treatment process is less and biodegradable, so that under the premise of keeping the characteristics such as softness, sweat absorption, comfortableness and naturalness and the like of pure cotton fabrics, the harm to the environment is alleviated, and the harm to human body is avoided, and therefore, the process has a zero-pollution environmental friendliness characteristic.

Owner:HEBEI NINGFANG GRP

Green environment protective biological organic compound fertilizer and production method thereof

InactiveCN101671204AEasy to handleDealing with environmental pollution is goodBacteriaClimate change adaptationGreen environmentLitter

The invention relates to a green environment protective biological organic compound fertilizer produced by adopting biological azotobacter, organic phosphorus bacteria, crop growth factor, organism, inorganic substance and microelement which are processed by a special technology, and a production method thereof. Biological bacterial fertilizer, organic fertilizer and inorganic fertilizer are interdependent and decomposed, and play mutual synergistic action to reach the special efficacy of fully utilizing the biological bacterial fertilizer to decompose the organic fertilizer and the inorganicfertilizer and reach the effect of stimulating the growth of crops, thus leading crops to absorb and utilize fertilizer well so as to achieve the purposes of crop production increasing and fertilizersaving. The invention has simple technical method and process, effectively utilizes urban garbage and subsidiary agricultural product offal as raw materials of the organic fertilizer, saves inorganicfertilizer, reduces cost, can be widely used in crops and fruit bearing forests, is especially suitable for greenhouses, base fertilizer and additional fertilizer of crops at the temperature of more than 20 DEG C, and is suitable for popularization and application across the country.

Owner:北京中国科学院老专家技术中心 +1

Multi-element and slow-released fertilizer

InactiveCN101284748AImprove physiological activityImprove physical functionSuperphosphatesAlkali orthophosphate fertiliserSodium BentoniteField experiment

The invention relates to a long-acting multi-element fertilizer which is prepared by raw materials of urea, overbearing calcium phosphate or diammonium phosphate, ammonium diacid phosphate, agricultural potassium sulphate, potassium oxide or potassium chloride and fertilizer additives. The fertilizer is based on nitrogen, phosphorus and potassium, and has humate and yellow phosphorus furnace slag silicon fertilizer or iron slag silicon fertilizer as well as blended raw ore powder containing porphyraceous feldspar granite, medical stone, bentonite clay and lanthanide rare earth added thereto, wherein, the humate and the yellow phosphorus furnace slag silicon fertilizer or iron slag silicon fertilizer contain many active materials, the blended raw ore powder contains long-acting elements such as phosphorus, potassium, middle elements, trace elements, as well as beneficial elements including silicon, sodium, cobalt, selenium, nickel, titanium and iodine, etc. According to the field experiments, the long-acting multi-element fertilizer can supply all nutrient elements required by crops, thereby promoting the crop growth.

Owner:谢浩

Multimodal polymer particles and uses thereof

A multimodal polymer particle composition containing two or more populations of polymer particles having a total rubbery weight fraction of less than 90 weight percent is provided. Also disclosed is a process for preparing multimodal polymer particle compositions that can be dried to a powder. Multimodal polymer particle dispersions are disclosed for preparing impact modifiers that can be dried to a powder. Also provided are polymeric compositions having a matrix resin component and impact modifiers prepared from multimodal polymer particles.

Owner:ROHM & HAAS CO

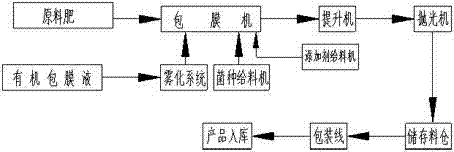

Ecological fertilizer, preparation method, and application of ecological fertilizer in agricultural or forestry production

InactiveCN102358710AIncrease potassium intakeImprove nitrogen utilizationHorticultureFertilizer mixturesNutritional deficiencyEnvironmental engineering

The present invention discloses an ecological fertilizer, a preparation method of the ecological fertilizer, and an application of the ecological fertilizer in agricultural or forestry production, and belongs to the fields of agriculture and forestry. According to the present invention, the ecological fertilizer adopts raw fertilizer as the core, an organic coating liquid, plant probiotics, medium element additives and microelement additives are coated on the outer of the core. Compared to the prior art, with the ecological fertilizer provided by the present invention, according to different nutrient requirements of crops in different growth stages, a lot of nutrients can be long-acting and balancedly provided for the crops, the sensitive medium elements and the microelements are added to the special products of different crops, and the generations of the nutritional deficiency symptoms of plants, vegetables and other crops can be controlled.

Owner:WIN WIN GROUP

Corn combine harvester for both ears and stalks

InactiveCN102523827AStrong pulling powerPull the stem quicklyMowersThreshersEngineeringCombine harvester

The invention relates to agricultural machinery, in particular to a multifunctional corn combine harvester for both ears and stalks, which comprises a header including an upper layer and a lower layer. The upper header is an ear picking table, and the lower header is a stalk header. The corn combine harvester for both ears and stalks further comprises an ear harvesting collection box device, a stalk crushing device, a stalk thrower, a stalk baler, an intermediate drive device and a stalk stubble cleaning and returning device mounted on the rear lower portion of a frame and the like. Compared with the prior art, the corn combine harvester for both ears and stalks has the advantages that the functions of corn ear picking, husking and collection, stalk laying, stalk crushing and returning, stalk crushing for feed or industrial materials, and stalk stubble cleaning and returning are achieved on the corn combine harvester, the requirements of different users in different areas can be met, operation functions and cross-area operational adaptability of the corn combine harvester are improved greatly, comprehensive usability of corn stalks is improved greatly.

Owner:SHANDONG AGRI MACHINERY RES INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com