Patents

Literature

1459results about How to "Improve mass transfer effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Surface-functionalized mesoporous carbon materials

ActiveUS20140294701A1Effectively and efficiently functionalizedPractical and cost-effective for large scale productionTransuranic element compoundsProcess efficiency improvementSolventIon

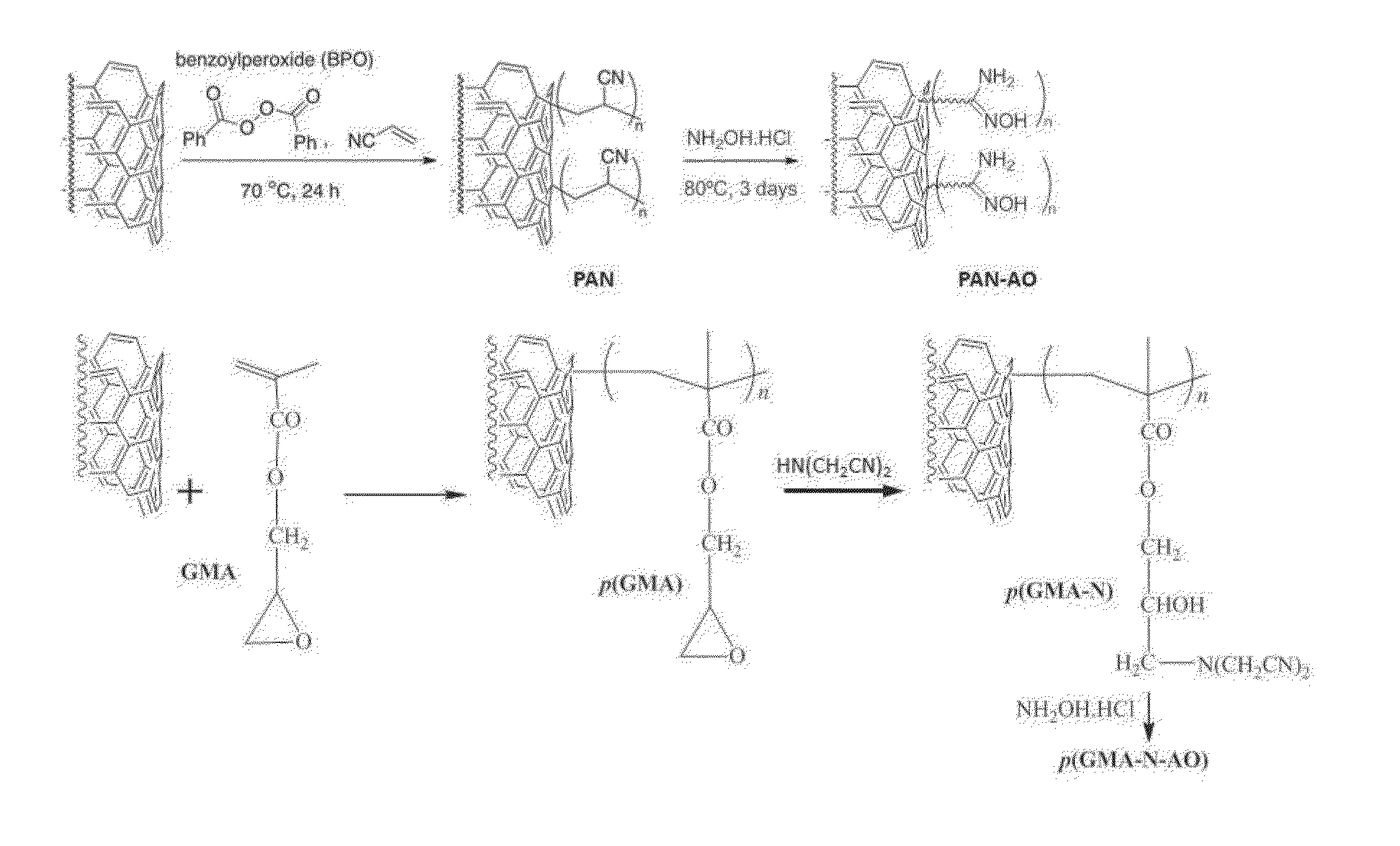

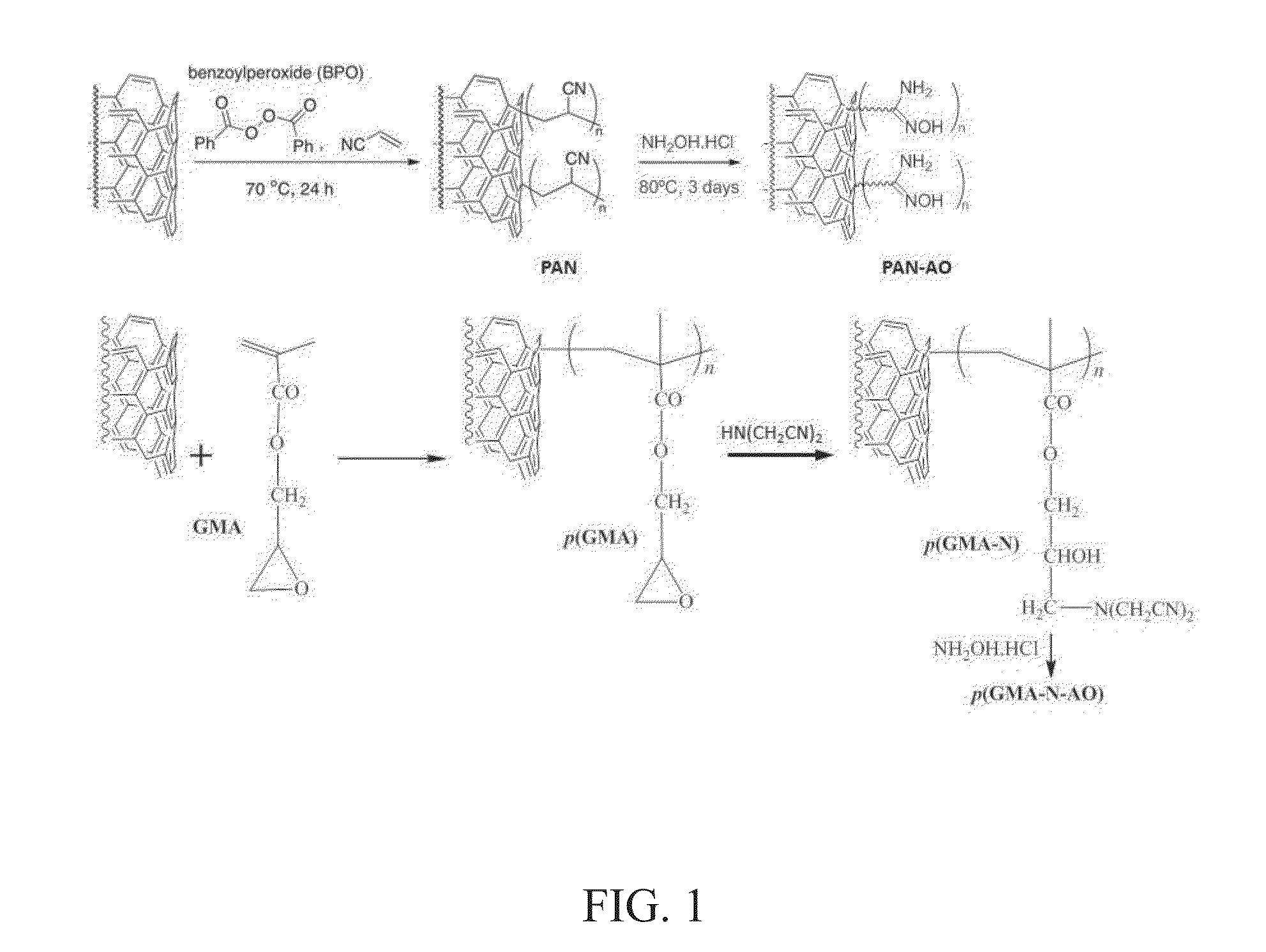

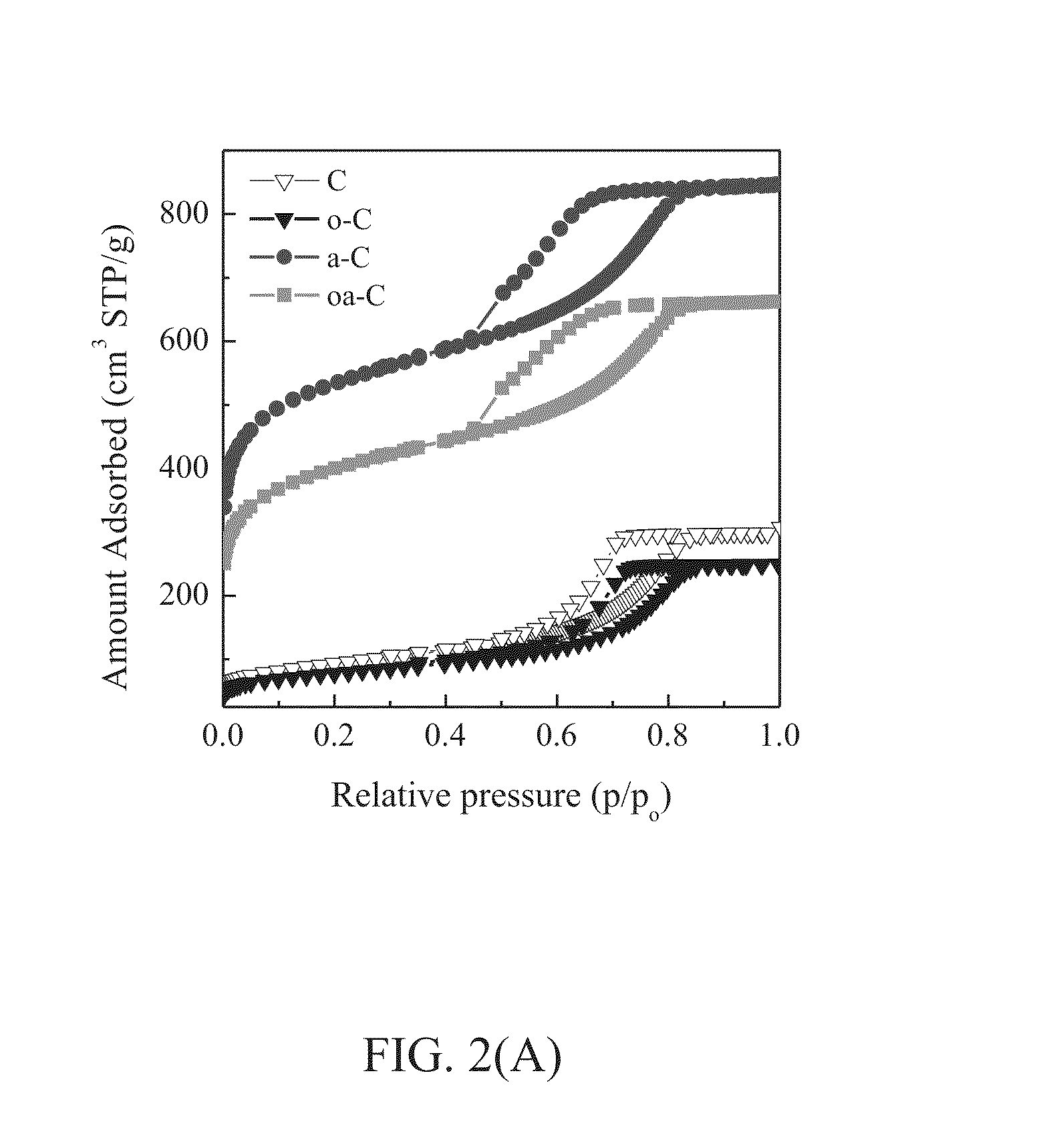

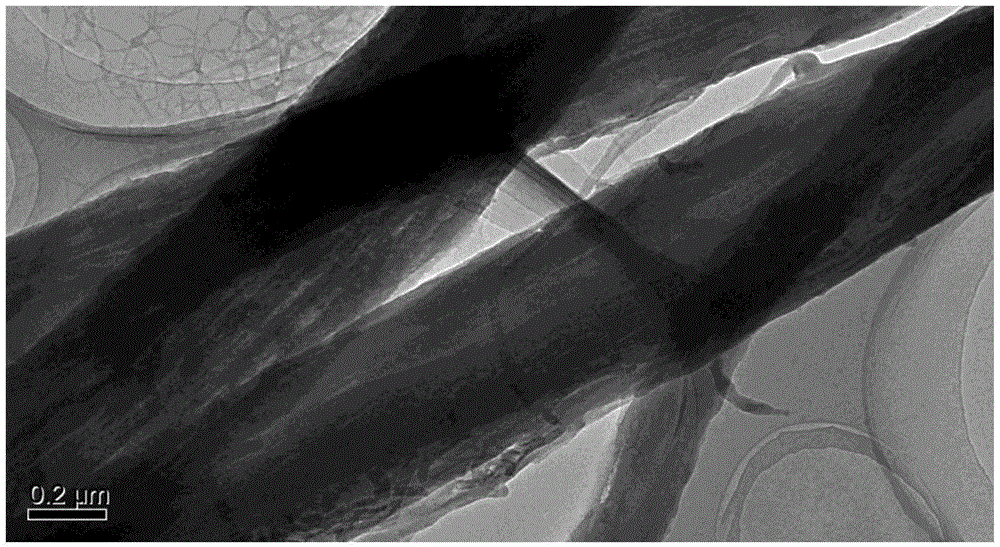

A functionalized mesoporous carbon composition comprising a mesoporous carbon scaffold having mesopores in which polyvinyl polymer grafts are covalently attached, wherein said mesopores have a size of at least 2 nm and up to 50 nm. Also described is a method for producing the functionalized mesoporous composition, wherein a reaction medium comprising a precursor mesoporous carbon, vinyl monomer, initiator, and solvent is subjected to sonication of sufficient power to result in grafting and polymerization of the vinyl monomer into mesopores of the precursor mesoporous carbon. Also described are methods for using the functionalized mesoporous carbon, particularly in extracting metal ions from metal-containing solutions.

Owner:UT BATTELLE LLC

Surface-functionalized mesoporous carbon materials

ActiveUS9249241B2Effectively and efficiently functionalizedPractical and cost-effective for large scale productionProcess efficiency improvementPolyvinyl polymerSolvent

A functionalized mesoporous carbon composition comprising a mesoporous carbon scaffold having mesopores in which polyvinyl polymer grafts are covalently attached, wherein said mesopores have a size of at least 2 nm and up to 50 nm. Also described is a method for producing the functionalized mesoporous composition, wherein a reaction medium comprising a precursor mesoporous carbon, vinyl monomer, initiator, and solvent is subjected to sonication of sufficient power to result in grafting and polymerization of the vinyl monomer into mesopores of the precursor mesoporous carbon. Also described are methods for using the functionalized mesoporous carbon, particularly in extracting metal ions from metal-containing solutions.

Owner:UT BATTELLE LLC

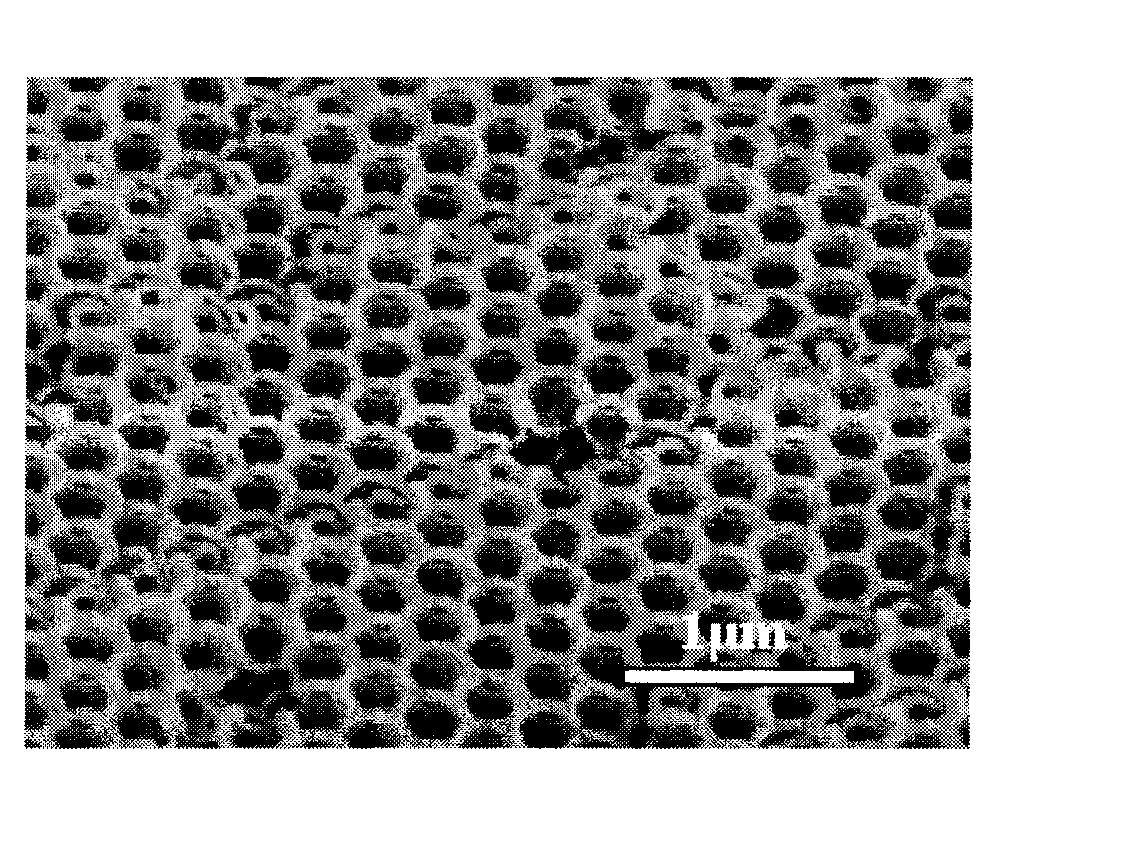

Three-dimensional ordered macroporous alumina and preparation method thereof

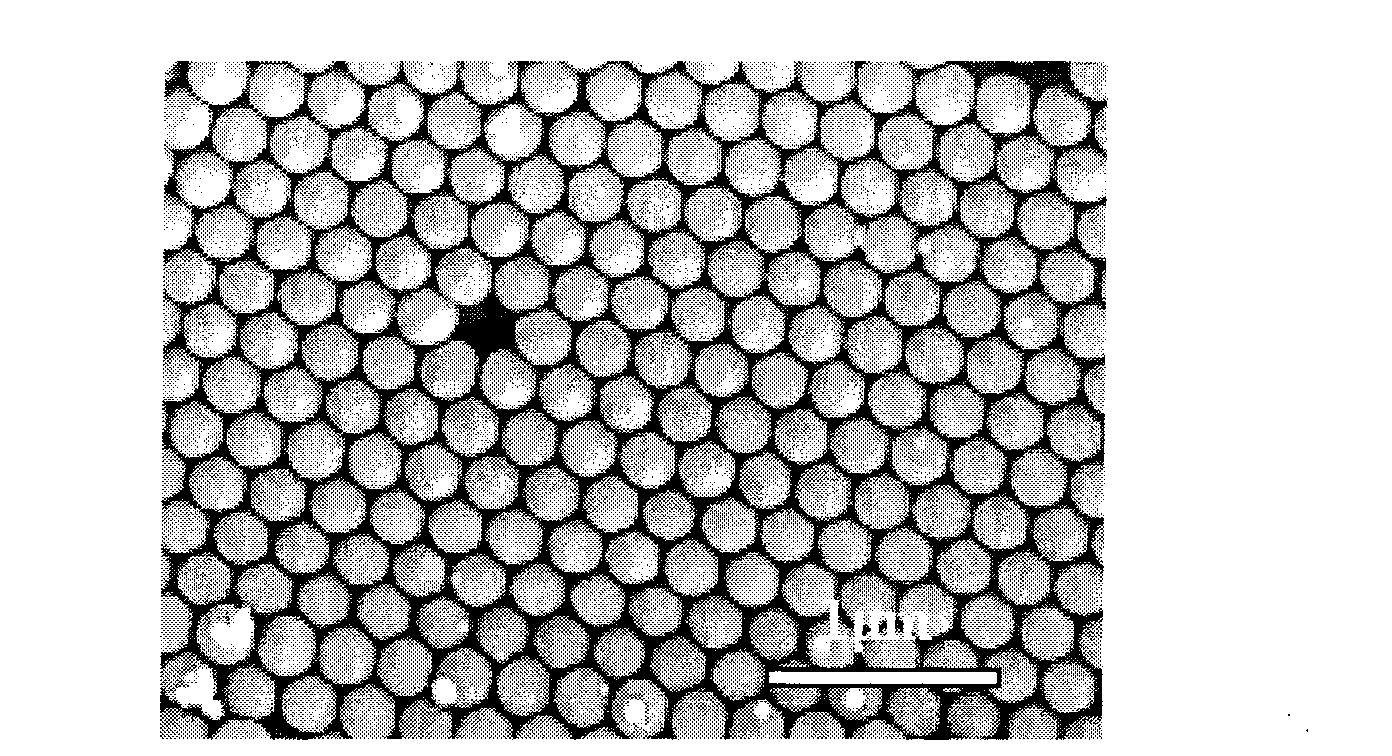

ActiveCN102040235AHigh activityGood choiceOther chemical processesAluminium oxides/hydroxidesMicrosphereNetwork structure

The invention provides a three-dimensional ordered macroporous alumina and a preparation method thereof, wherein the method comprises the following steps of: assembling polymer microspheres which are singly dispersed to form a colloidal crystal template, filling the alumina sol which is prepared by means of a special method into the template, and drying and roasting to obtain macroporous alumina. The method provided by the invention has the advantages that the alumina sol and the compounding process of the alumina sol and the polymer microspheres can be controlled well, the network structure of the alumina sol is protected possibly, the alumina which is prepared by means of the method not only has three-dimensional ordered macroporous channels but also has a high specific surface area. Furthermore, the macropores within the material are communicated to the surrounding macropores by means of 12 small window holes, and the window holes are formed by sintering the template properly. The alumina prepared by means of the method provided by the invention is suitable for being used as a catalyst carrier of heavy oil and an adsorption and separation material of organic macromolecule. The alumina prepared by means of the method which is provided by the invention is suitable for improving the mass transfer capability of the material within the catalyst and is suitable for improving the activity and the selectivity of the catalyst during the application process as a catalyst carrier.

Owner:CHINA PETROLEUM & CHEM CORP +1

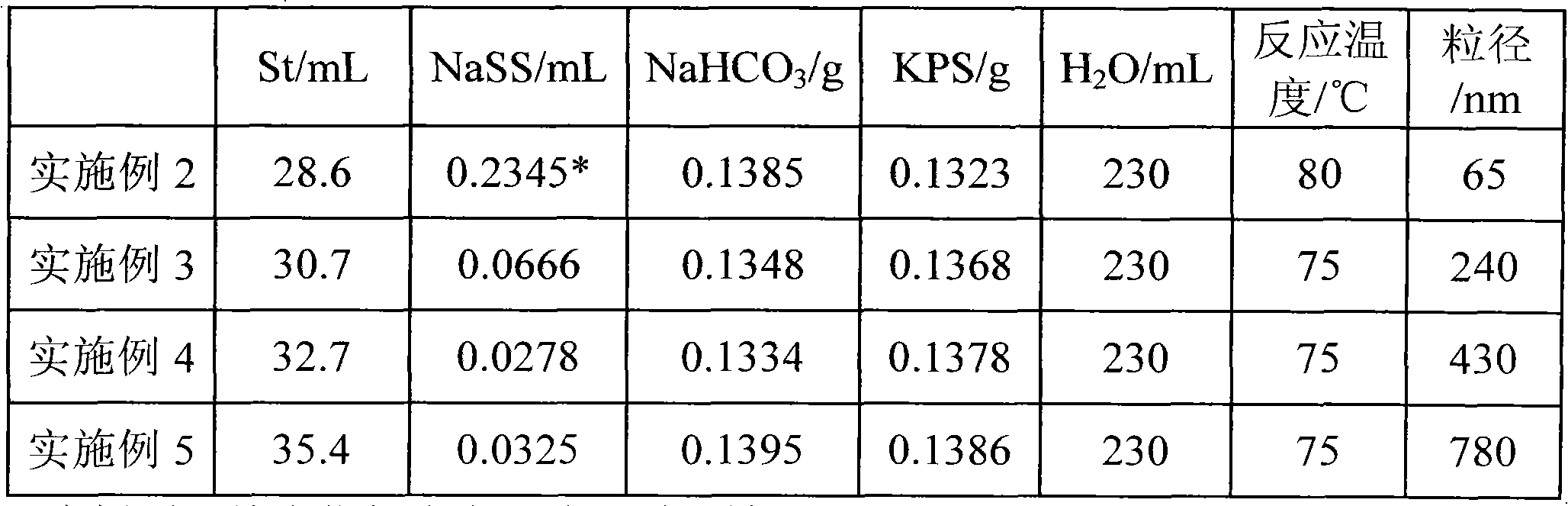

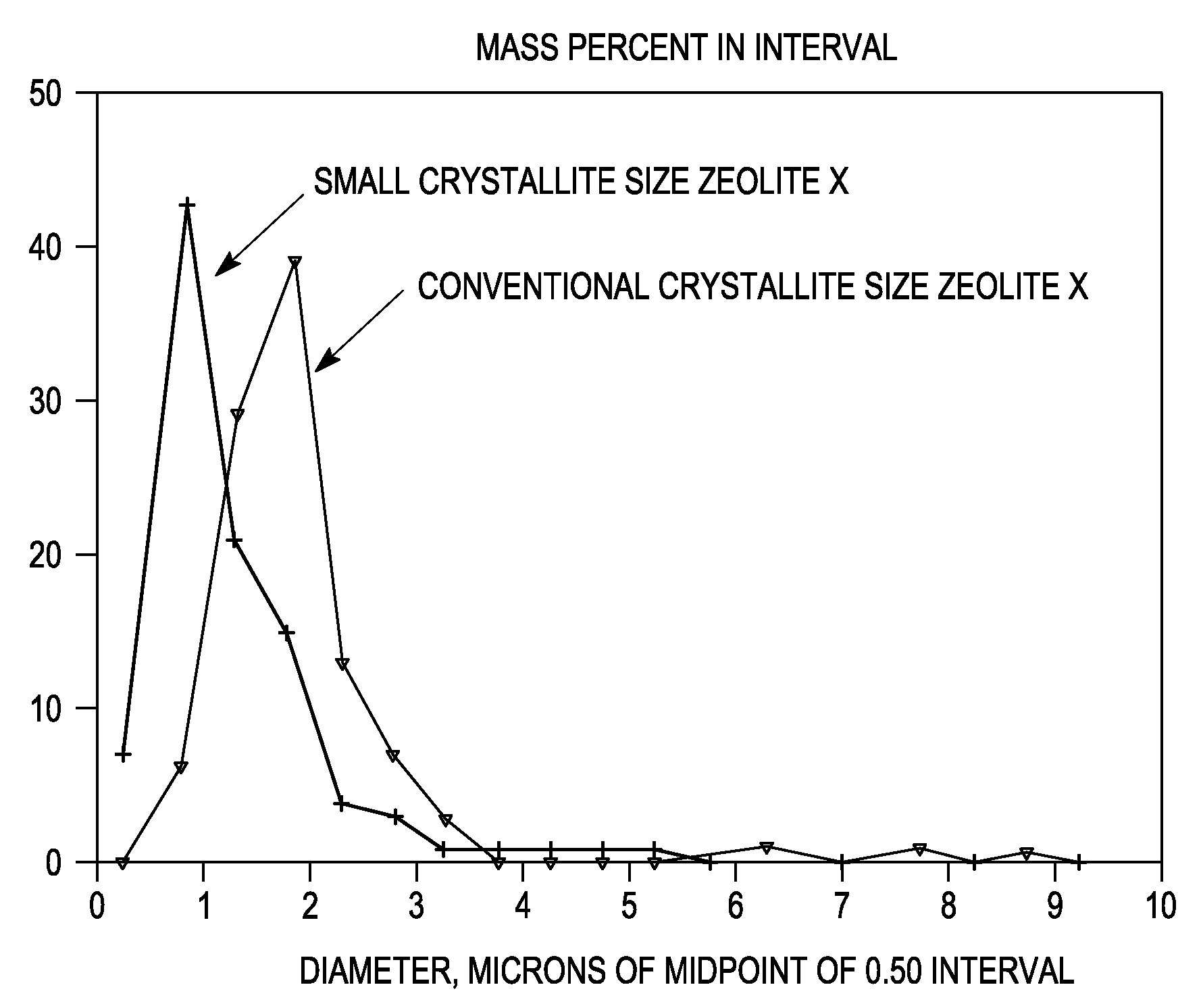

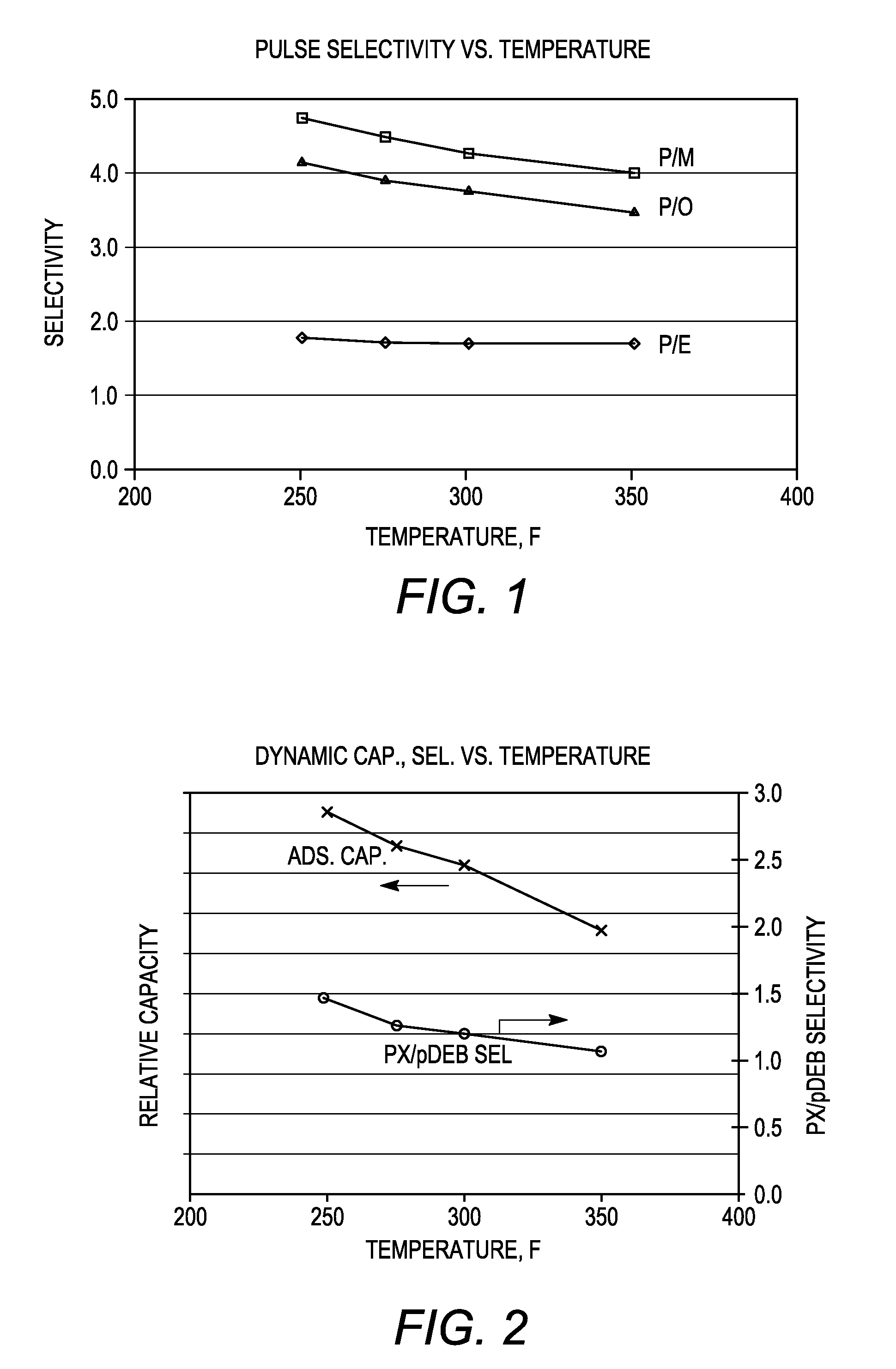

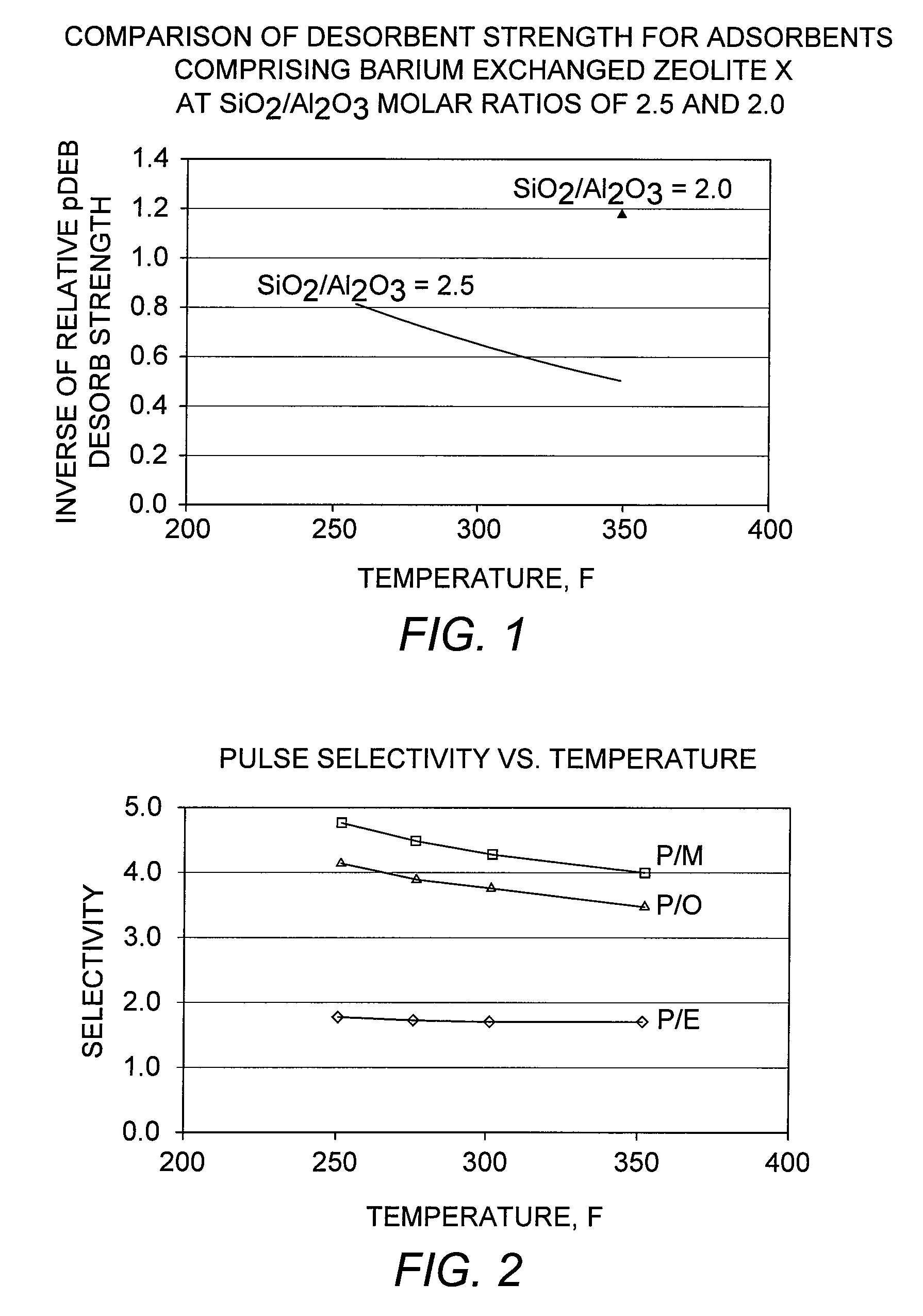

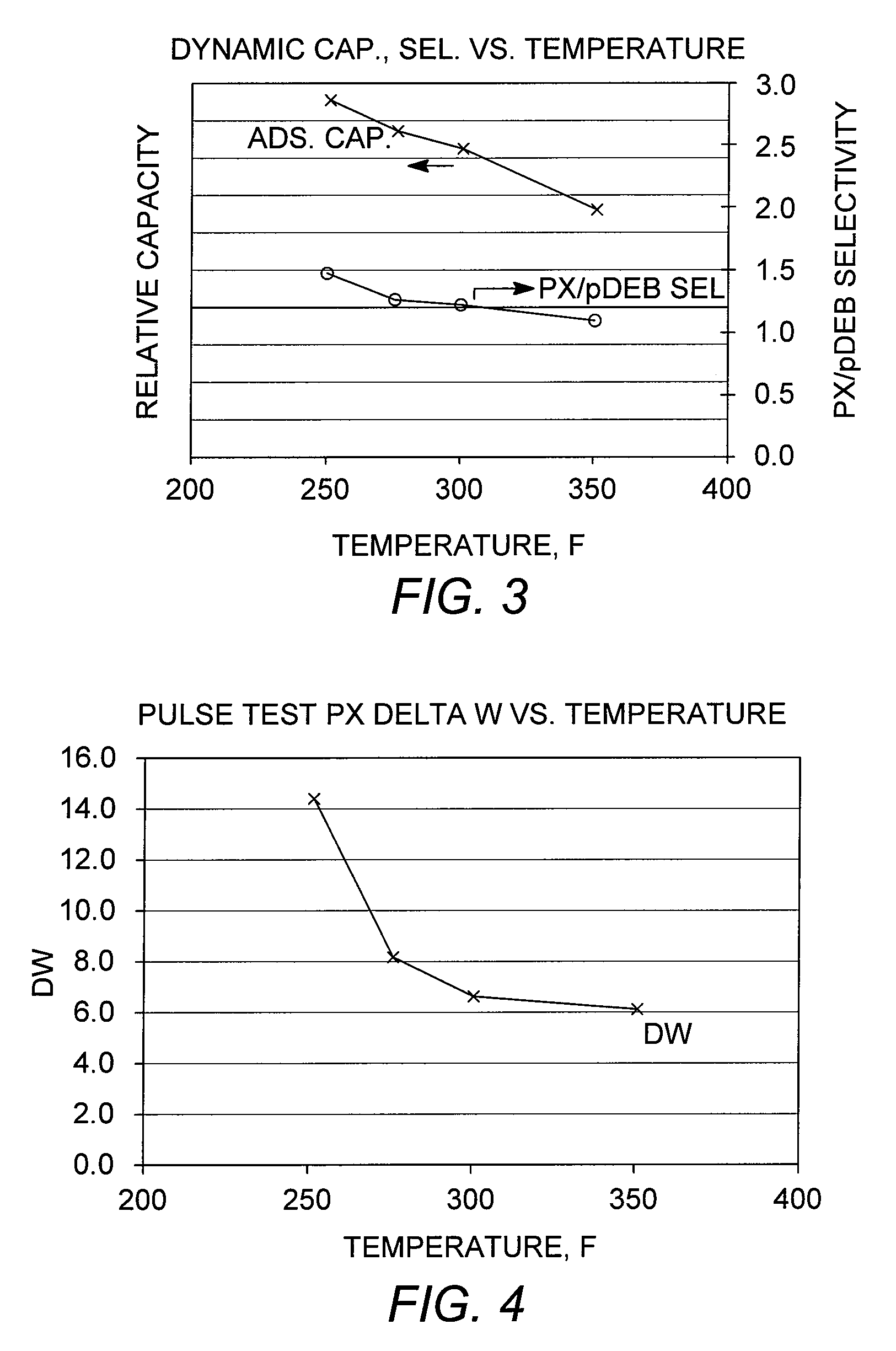

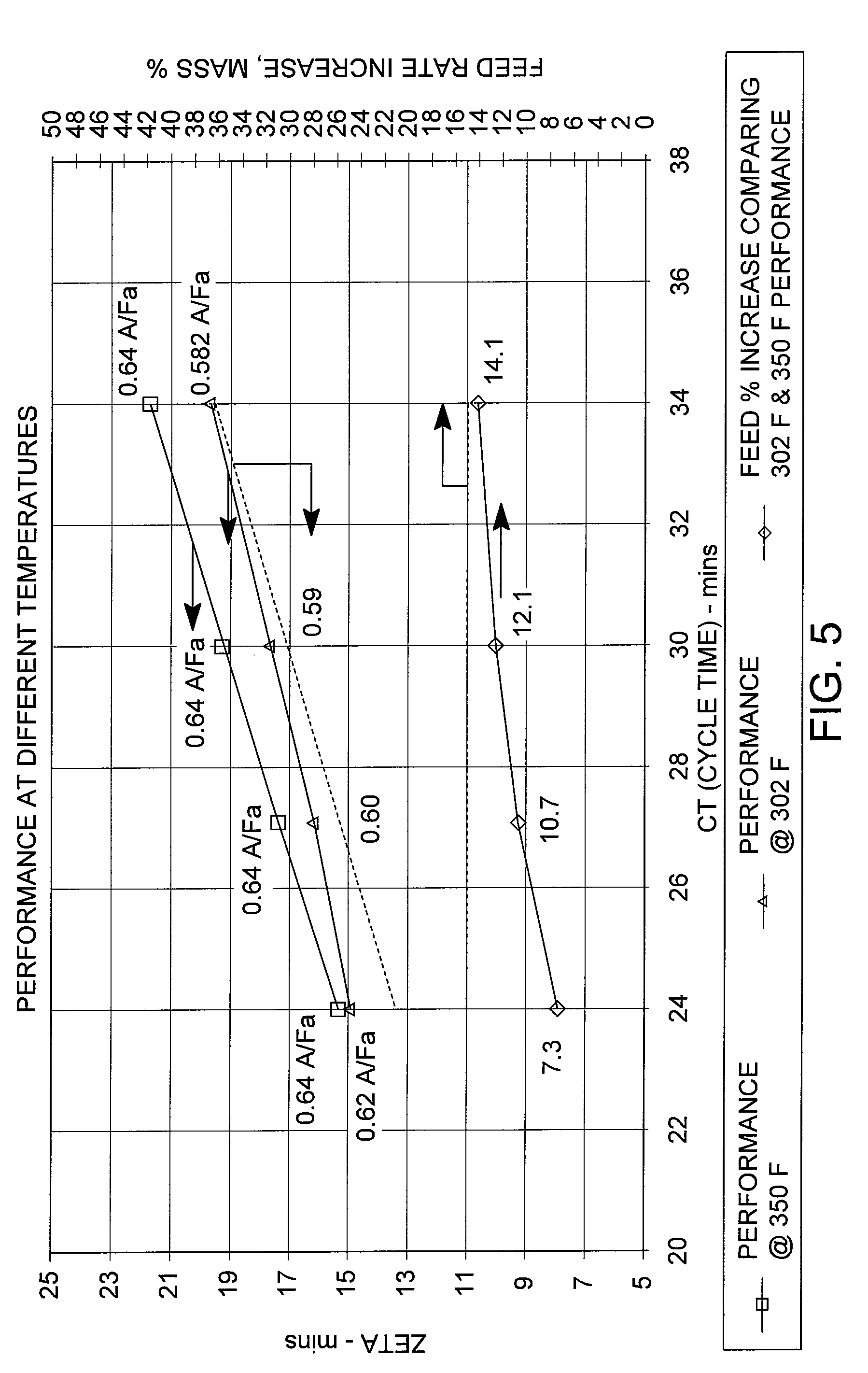

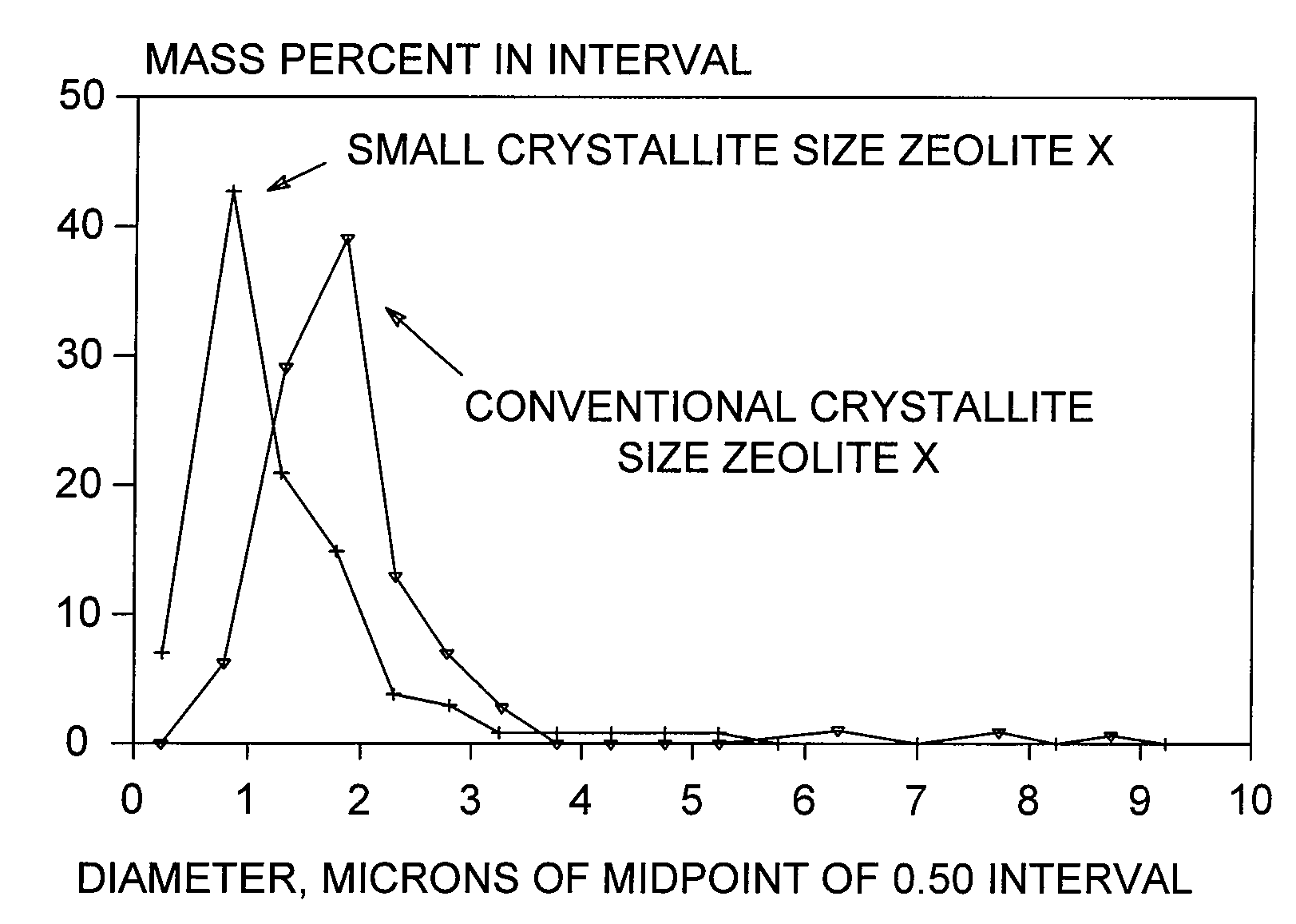

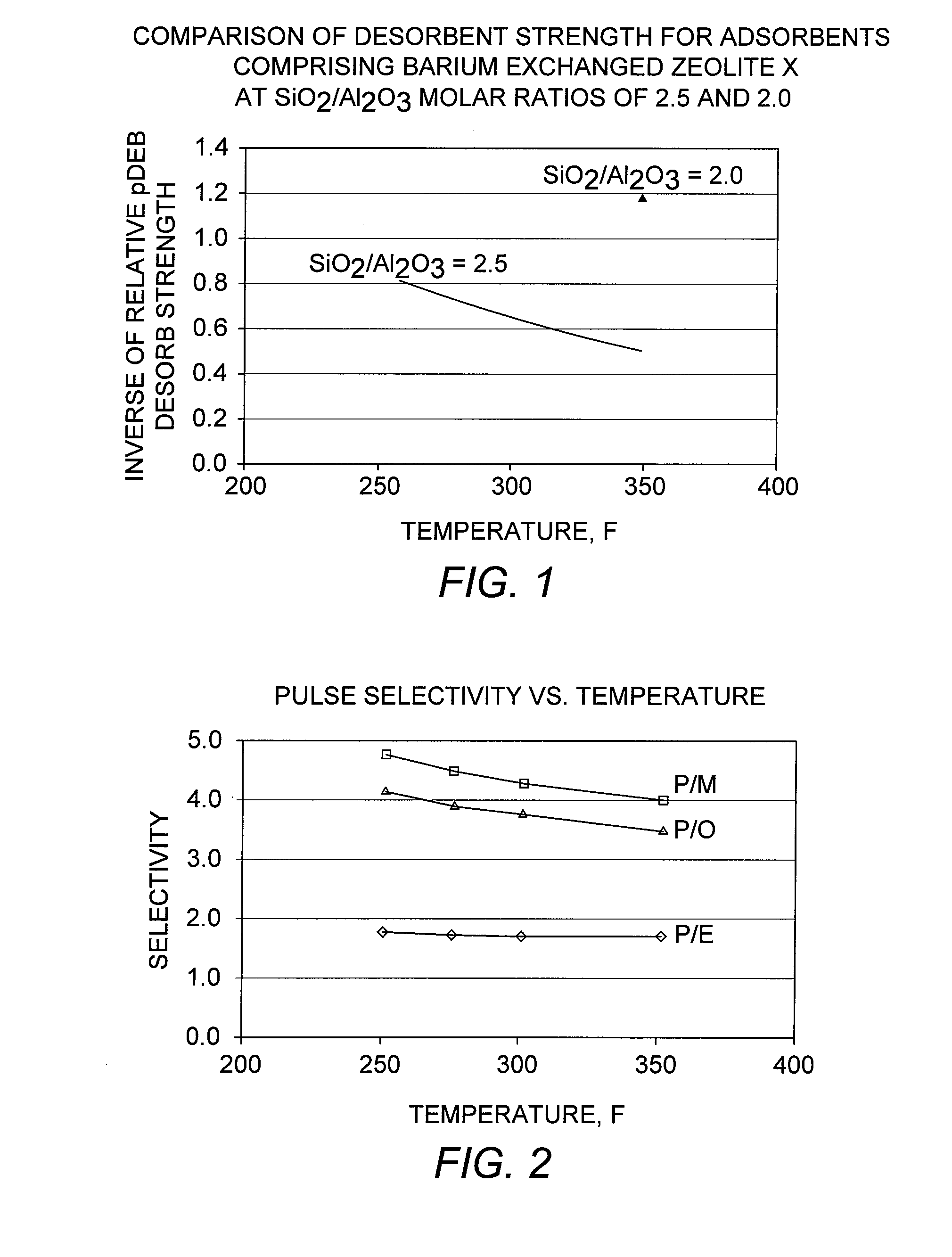

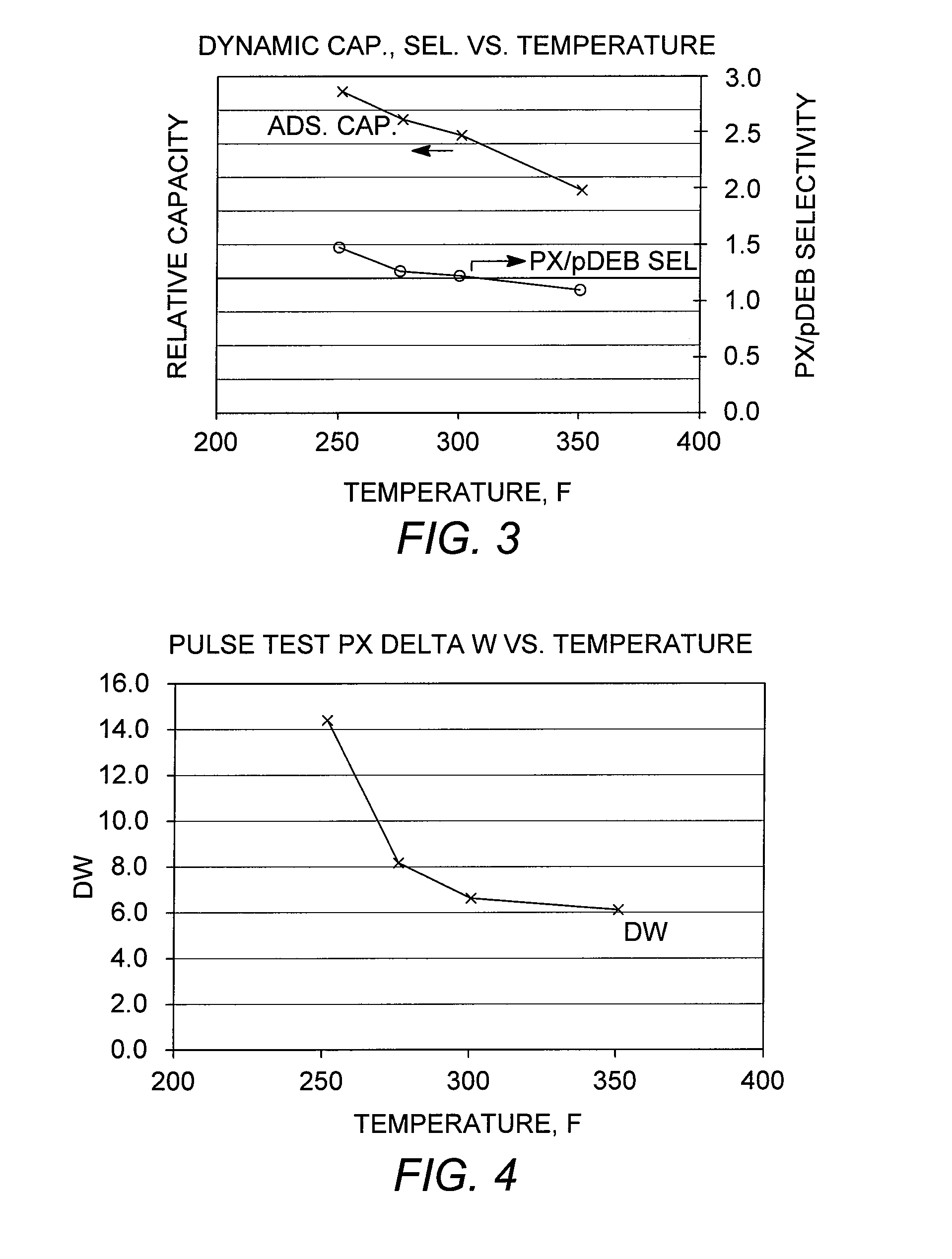

Binderless adsorbents comprising nano-size zeolite x and their use in the adsorptive separation of para-xylene

InactiveUS20090326308A1High adsorbent capacity/mass transfer propertyIncreased para-xylene productivityMaterial nanotechnologyOther chemical processesSimulated moving bedSorbent

Adsorbents and methods for the adsorptive separation of para-xylene from a mixture containing at least one other C8 aromatic hydrocarbon (e.g., a mixture of ortho-xylene, meta-xylene, para-xylene, and ethylbenzene) are described. Suitable adsorbents comprise nano-size zeolite X having an average crystallite size of less than about 500 nanometers. The adsorbents provide both improved capacity and mass transfer, which is especially advantageous for improving productivity in low temperature, low cycle time adsorptive separation operations in a simulated moving bed mode.

Owner:UOP LLC

Electrochemical cell electrodes comprising coal-based carbon foam

InactiveUS6899970B1Improve mass transfer effectHighly inertElectrode thermal treatmentGraphiteParticulatesElectrical battery

Coal based carbon foams that are produced by the controlled beating of coal particulate in a mold and under a non-oxidizing atmosphere and subsequently graphitized have been found to provide excellent electrode materials for electrochemical cell applications.

Owner:CFOAM LLC

Binderless adsorbents with improved mass transfer properties and their use in the adsorptive separation of para-xylene

ActiveUS7812208B2Improve performanceImprove mass transfer effectOther chemical processesMolecular-sieve and base-exchange compoundsProduction rateSorbent

Owner:UOP LLC

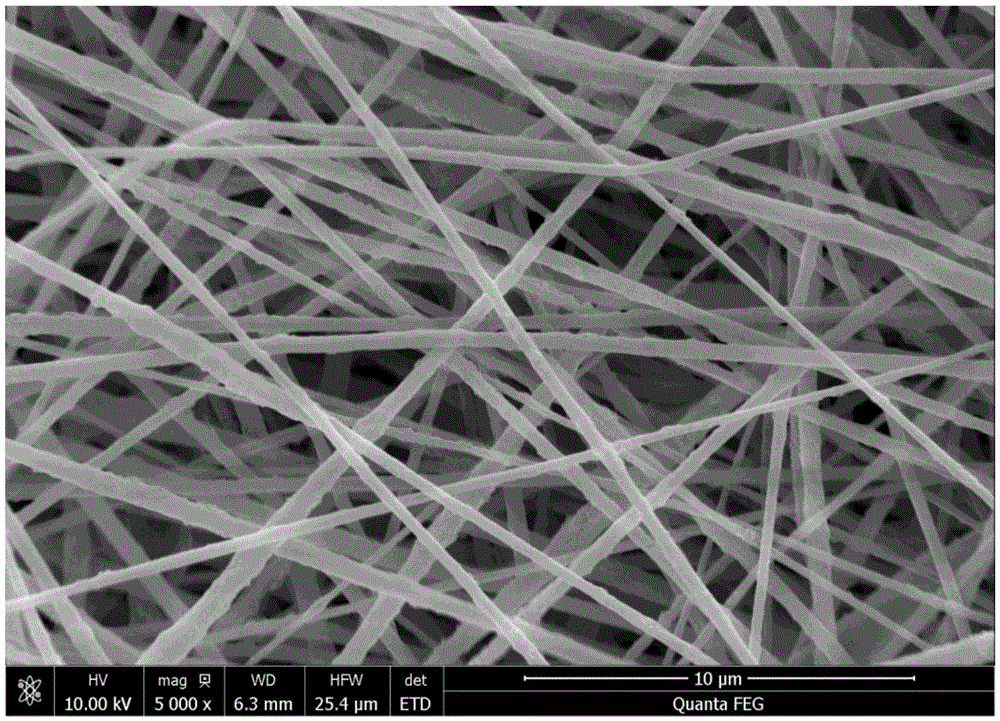

Three-dimensional fiber-based aerogel catalyst carrier and preparation method thereof

ActiveCN103285920AGood flexibilitySufficient reactive sitesCatalyst carriersOrganic-compounds/hydrides/coordination-complexes catalystsFiberPliability

The invention relates to a preparation method of a three-dimensional fiber-based aerogel catalyst carrier and a product thereof. The preparation method comprises the following steps of: firstly dispersing fibers in solvents to form turbid liquid; secondly curing the turbid liquid to form cured pieces; thirdly removing cured solvents to form non-crosslinked fiber-based aerogel; finally carrying out crosslinking stabilization treatment and then carrying out activation treatment, thus obtaining the three-dimensional fiber-based aerogel catalyst carrier. The product is a three-dimensional network-shaped material formed through mutual penetration and stagger of fibers. The fiber crossing points are effectively interconnected through non-hydrogen-bond bonding. The three-dimensional fiber-based aerogel catalyst carrier has volume density of 0.1-500mg / cm<3>, average pore size of 0.01-2000mu m and specific surface area of 0.2-2000m<2> / g. The preparation method and the product have the advantages that the preparation process is simple; the raw material limitations are less; and the aerogel catalyst carrier product has good flexibility, connectivity and catalyst supporting capacity and has broad application prospects in the catalytic application field.

Owner:DONGHUA UNIV

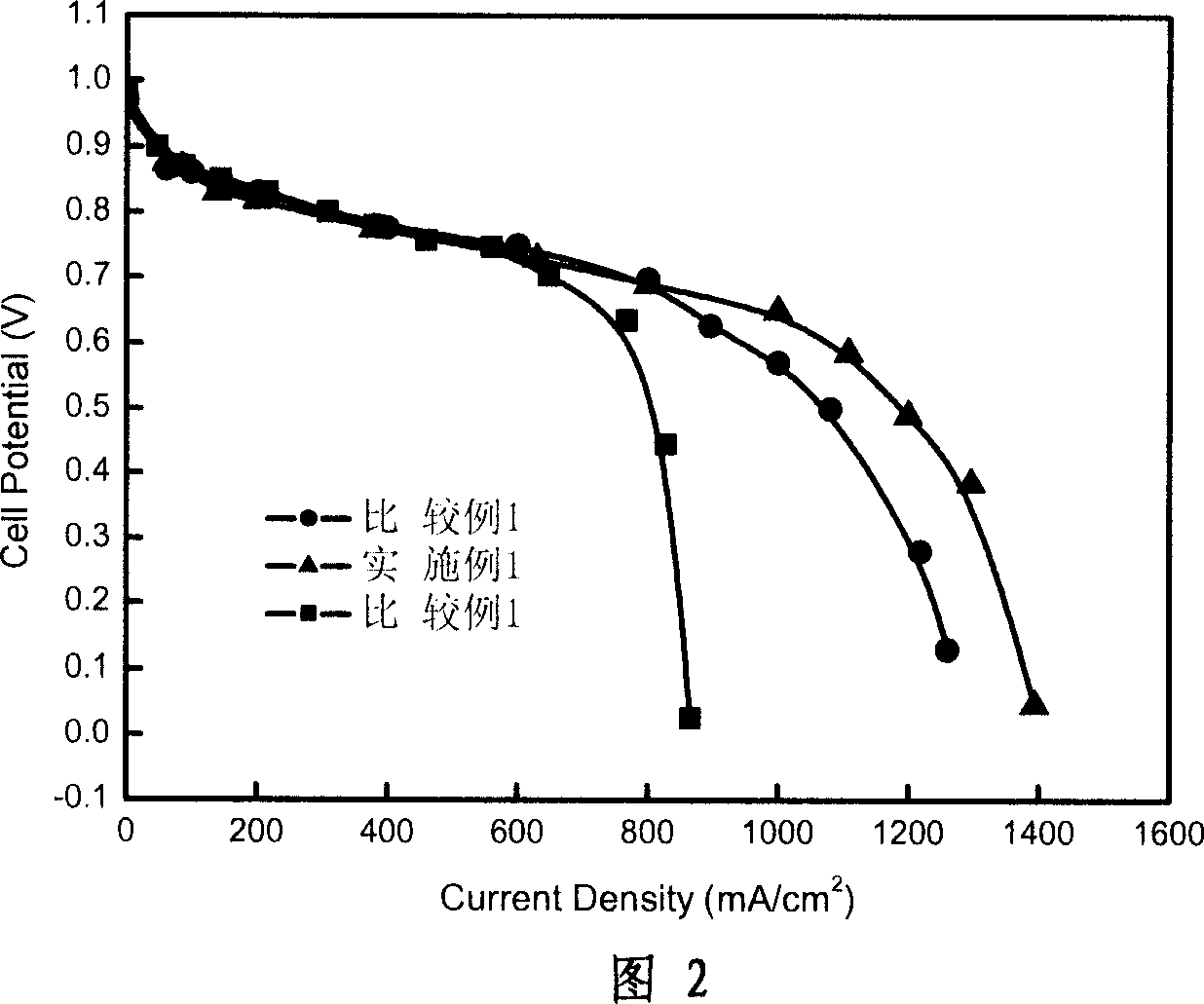

Gas diffusion layer for low temp fuel cell and preparing process thereof

ActiveCN1949570AImprove mass transfer effectNot easy to coagulateCell electrodesFuel cell detailsFuel cellsLiquid water

The invention relates to a low-temperature fuel cell, concretely a gas diffusion layer for low-temperature fuel cell and the preparing method thereof, where the gas diffusion layer is composed of substrate layer and microporous laye, and the microporous layer is mixed of two or more conductive carbon materials. And the preparing method: taking and mixing two or more conductive carbon materials in proportion into composite conductive material, uniformly diffusing the composite condutive material and hydrophobic agent in solvent to form plup; uniformly arranging the pulp on one or two sides of a hydrophobic processed porous conductive substrate; finally forming the gas diffusion layer by thermal treatment. Because of preparing microporous layer by compositive conductive material, it forms a double-function hole structure beneficial to reacting gas transmission and liquid water transmission, improving battery performances.

Owner:SUNRISE POWER CO LTD

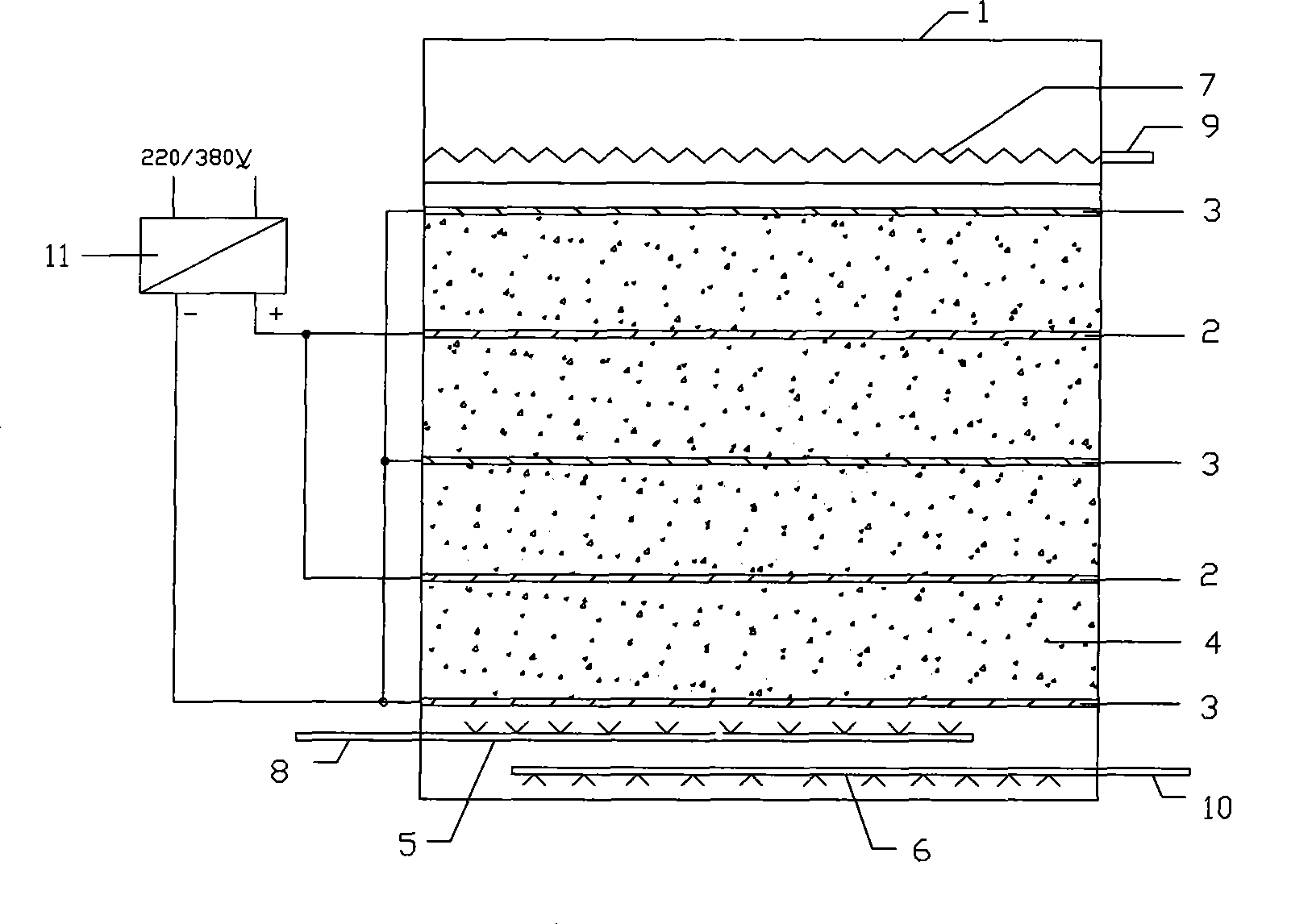

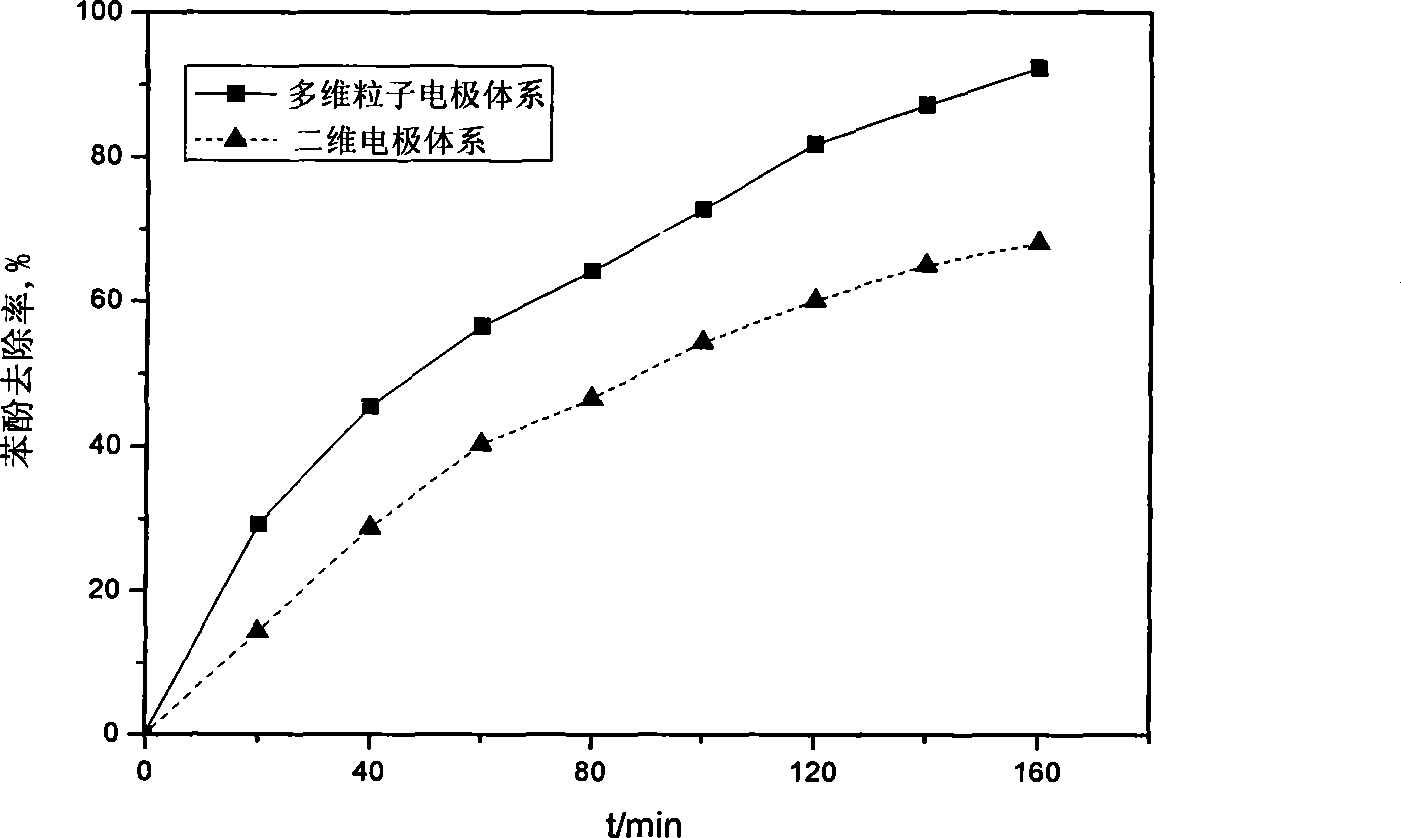

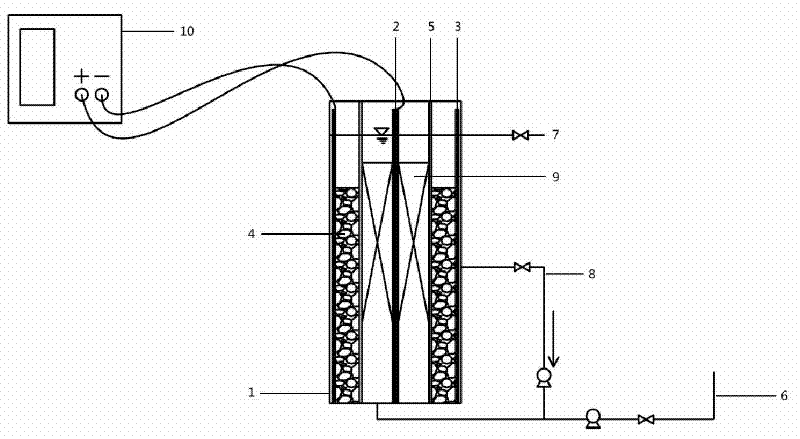

Wastewater treatment device of horizontal polar plate multi-electrodes electrocatalysis reactor

ActiveCN101423266AGuaranteed to alternateAvoid short circuitWater/sewage treatment by electrochemical methodsElectricityWater flow

Horizontal polar plate multi-dimensional electrode electrocatalysis reactor wastewater treatment equipment comprises a shell, a cathode plate and an anode plate which are relatively parallel, a particle electrode filled between the cathode plate and the anode plate, a water distributor, a water inlet pipe, an aerator, an air inlet pipe, an effluent weir trough, a water outlet pipe and a power supply; the cathode plate and the anode plate are respectively connected with the cathode and the anode of the power supply; a plurality of through holes are distributed on the cathode plate and the anode plate which are horizontally positioned in the shell of the equipment; the water distributor, the water inlet pipe, the aerator and the air inlet pipe are positioned at the lower part of the shell of the equipment; and the effluent weir trough and the water outlet pipe are arranged at the upper part of the shell of the equipment. After being evenly distributed by the water distributor, the wastewater flows across a reactor from bottom to top; the horizontal polar plate structure design not only avoids the short circuit of water flow and improves the mass transfer effect, but also ensures that the wastewater can alternatively flow across the cathode plate and the anode plate and the oxidation reaction of the anode plate and the reduction reaction of the cathode plate coexist in a system, and causes different organic pollutants in wastewater which can be degraded by the oxidation reaction and the reduction reaction to be degraded and treated.

Owner:南京赛佳环保实业有限公司

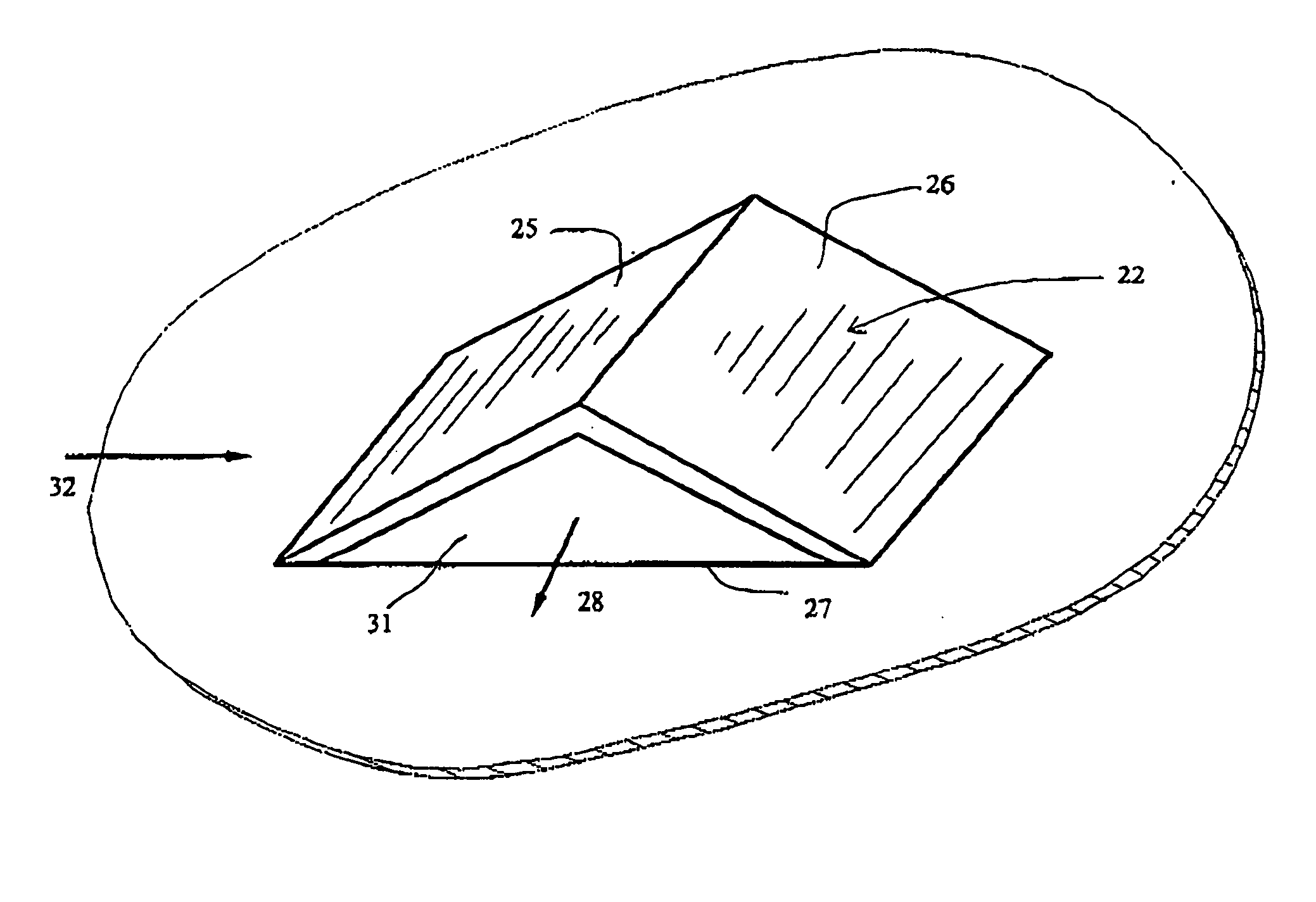

Gas-liquid contact tray with fixed valves for mass transfer

InactiveUS20050280169A1Low liquid entrainmentLow liquid weepingMixing methodsFuel re-atomisation/homogenisationMaterial PerforationVALVE PORT

A gas-liquid contact tray with fixed valves for mass transfer, in which the fixed valve comprising an upstream portion, a midportion and a downstream portion is made by punch from the tray deck so as to form as a deflector, and the upstream portion and the downstream portion are integrated with the tray deck, characterized in that said midportion has a central plane portion and downward inclined margins, and the tray deck is further provided with perforations which are arranged between the fixed valves adjacent in the liquid flow direction. The gas-liquid contact tray with fixed valves for mass transfer according to the present invention has a low liquid entrainment, low liquid weeping, a high mass transfer capacity and good turn-down characteristics.

Owner:CHINA PETROCHEMICAL CORP +1

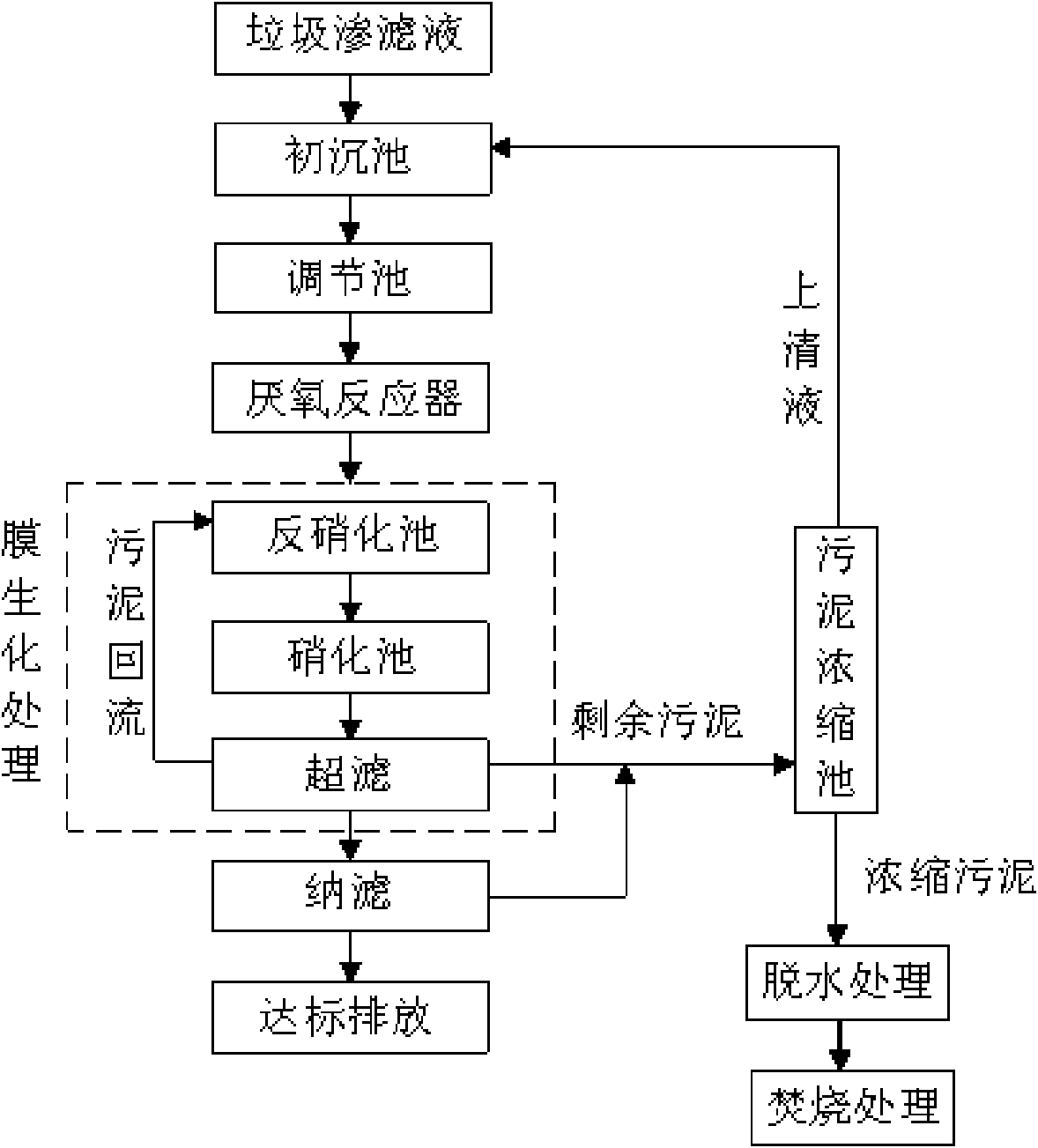

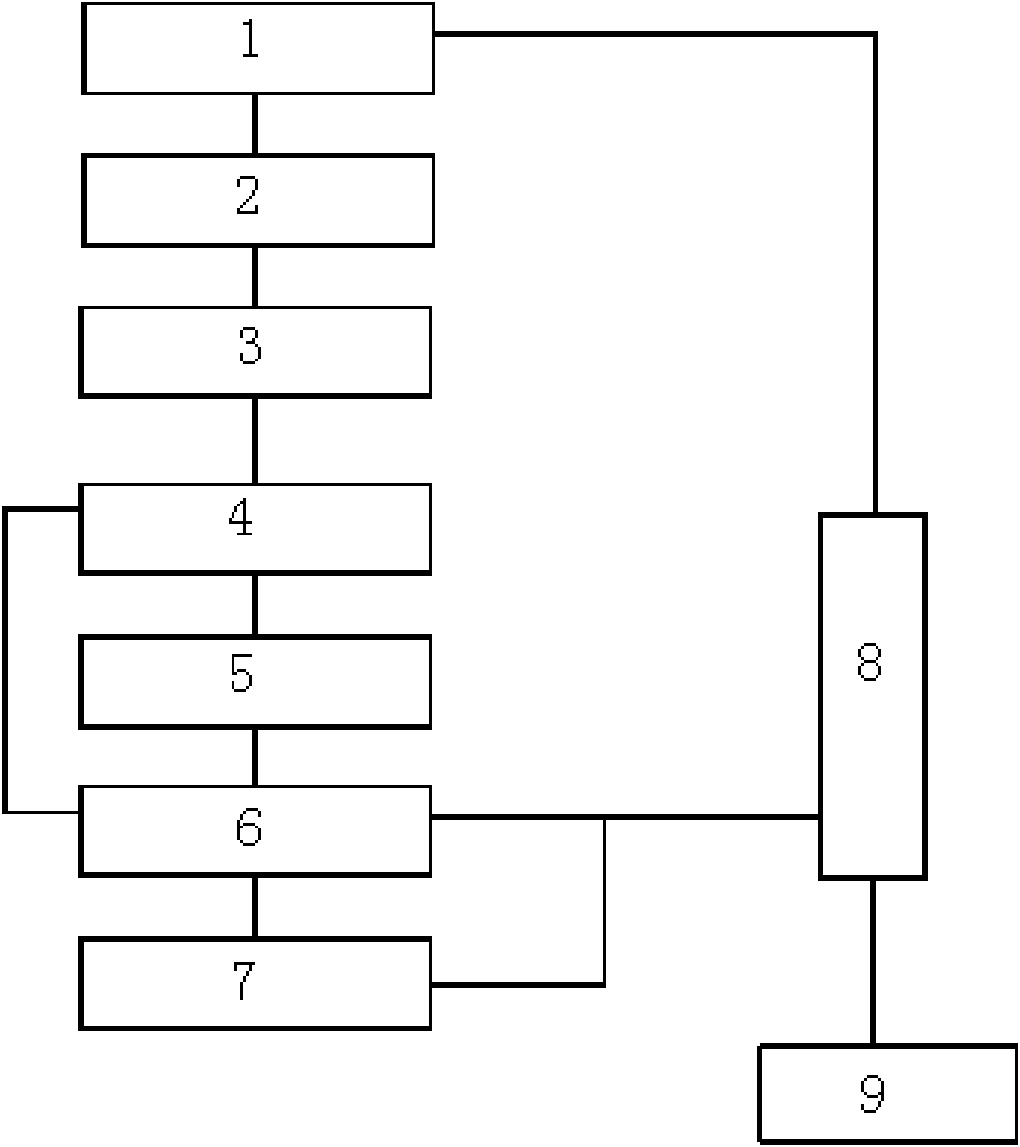

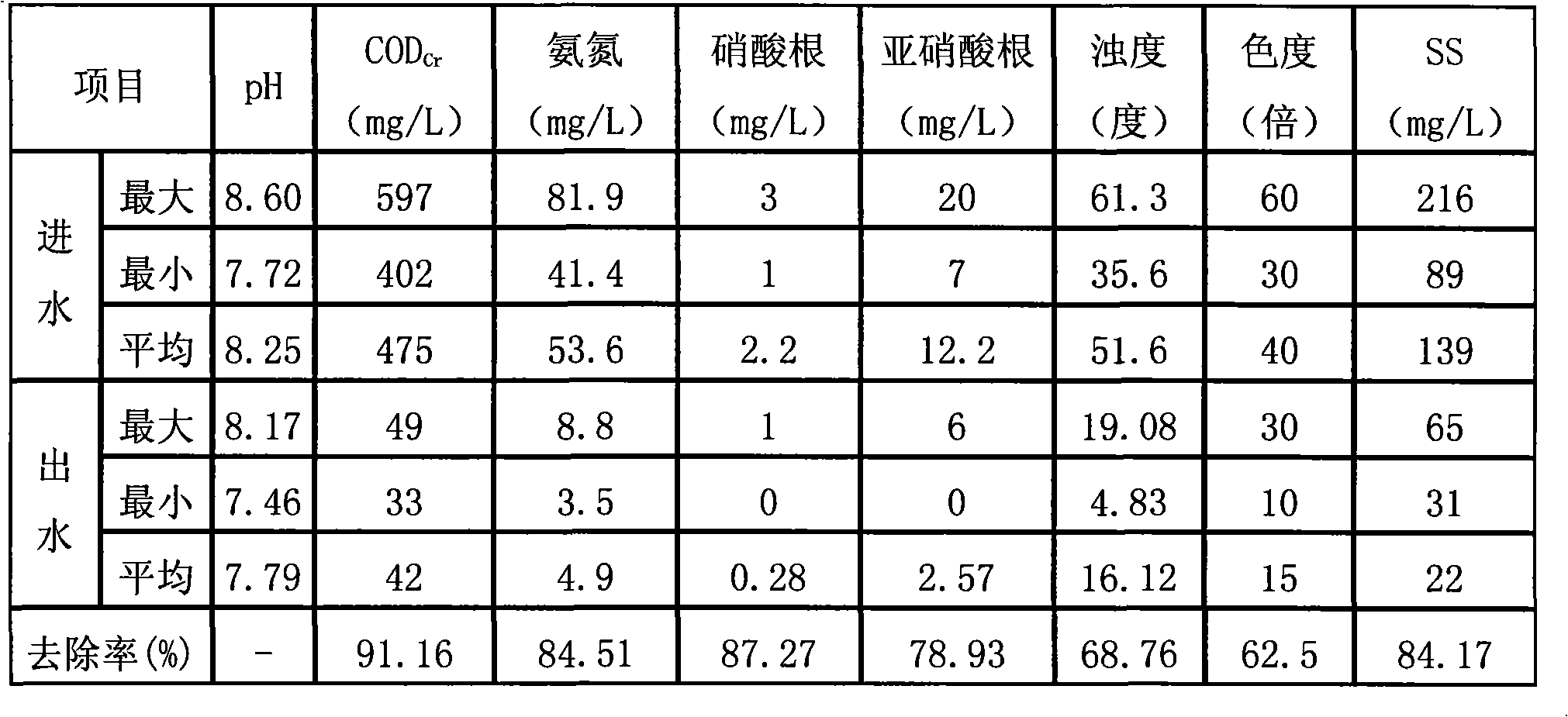

Method and device for treating garbage percolate

ActiveCN101597131AAchieving zero emissionsRelieve stressSludge treatment by de-watering/drying/thickeningTreatment with aerobic and anaerobic processesHigh concentrationAfter treatment

The invention discloses a method and a device for treating garbage percolate, wherein the method comprises the steps of pretreatment, anaerobic treatment, membrane biochemical treatment, nanofiltration treatment, sludge treatment and the like; the device comprises a primary sedimentation tank (1) and an adjusting tank (2), the adjusting tank (2) is connected with an anaerobic reactor (3), the anaerobic reactor (3) is connected with a denitrification tank (4), and the denitrification tank (4) is communicated with a nitrification tank (5); and the nitrification tank (5) is connected with an ultrafiltration apparatus (6), and the ultrafiltration apparatus (6) is connected with a nanofiltration device (7). The method and the device achieve COD degradation of high-concentration wastewater so that the COD of high-concentration COD of 50,000 reaches about 50 after treatment and reaches the standard of industrial reuse water, thus the method and the device achieve zero discharge of the percolate, initiate a new attempt to treat high-concentration percolate, and fill up the domestic blank.

Owner:汕头市澄海洁源垃圾发电厂有限公司

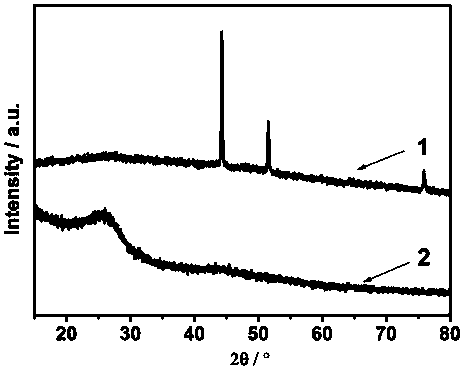

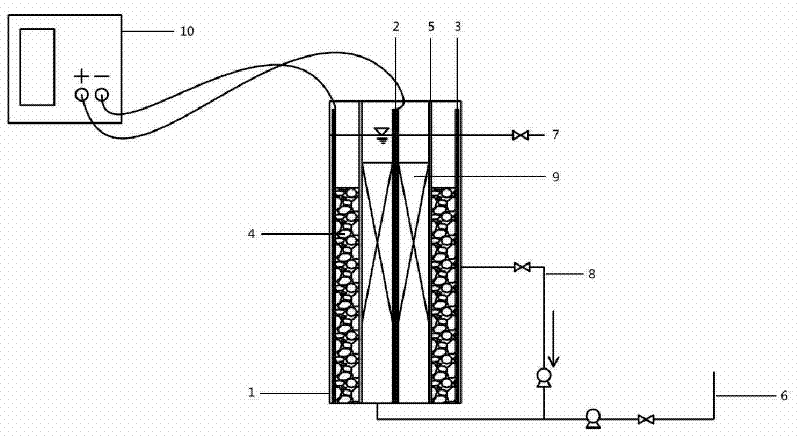

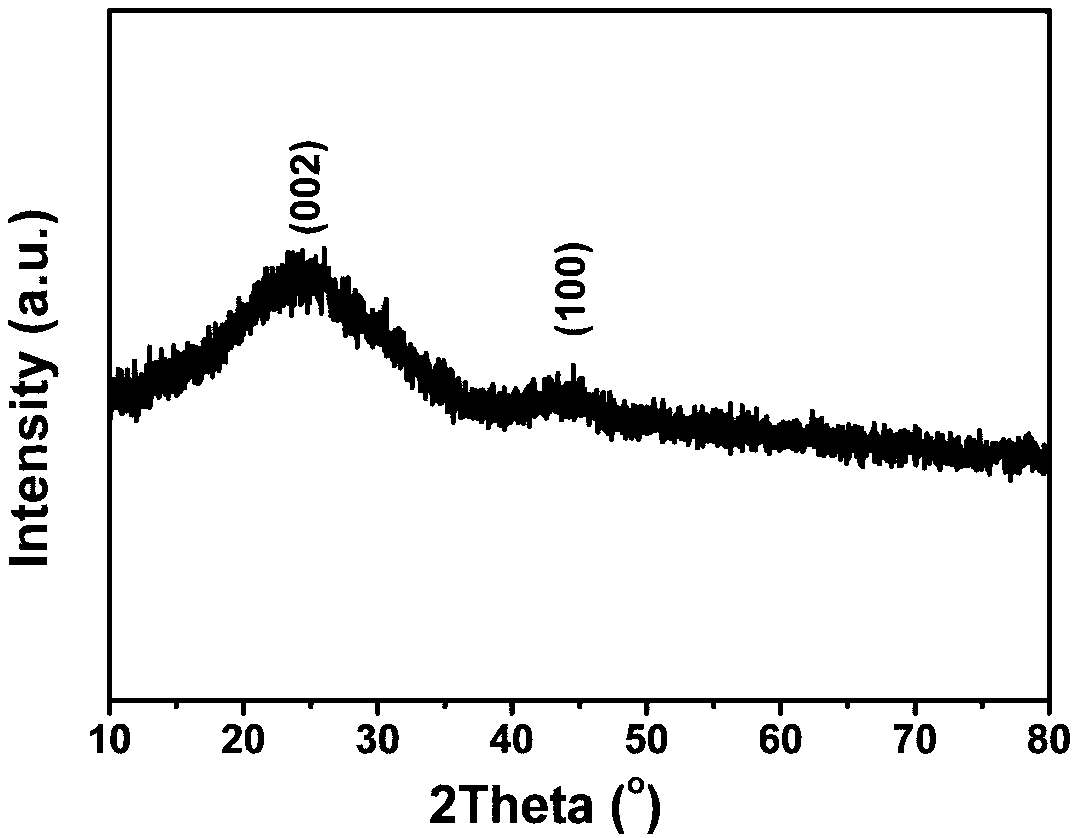

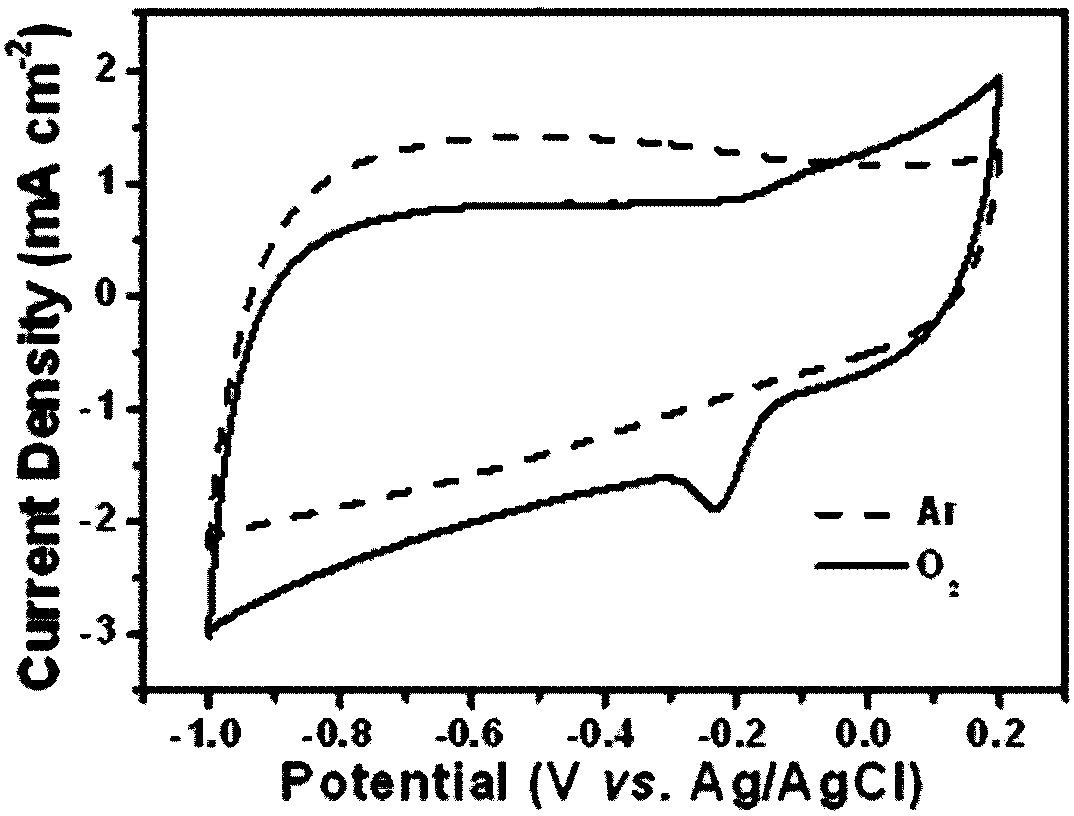

Preparation method of mono-atomic cobalt based nitrogen-sulfur dually-doped carbon material catalyst

InactiveCN108686693AImprove mass transfer effectImprove conductivityPhysical/chemical process catalystsCarbon layerCarbonization

A metal ligand is changed, and through precisely controlled carbonization and metal high temperature reduction, a metal mono-atomic nitrogen-sulfur dually-doped carbon material is obtained. An S-containing ligand is added to prevent the generation of metal carbides during the pyrolysis process; the temperature and time of pyrolysis are controlled to avoid the precipitation of a carbon layer; metalions are anchored in a carbon skeleton of graphene; exposed metal nitrides and metal sulfides on the surface can be easily removed by acids; mono-atom level dispersion of metals in a graphene structure is realized, and at the same time, more active sites are exposed. The adjusting function of S during the pyrolysis process is smartly utilized to synthesize a metal mono-atomic catalyst, all metalatoms (100%) are utilized, and the dispersion, stability, and characteristic activity of the catalyst are all improved. Furthermore, the synergistic effect is generated by co-doping of nitrogen and sulfur and the catalytic activity is further enhanced. The prepared mono-atomic catalyst has excellent hydrogen evolution / oxygen reduction catalytic activity, the operation is simple, the industrial production is easy, and the catalyst can be widely applied to fuel cells that take a proton exchange membrane as the electrolyte.

Owner:CHONGQING UNIV

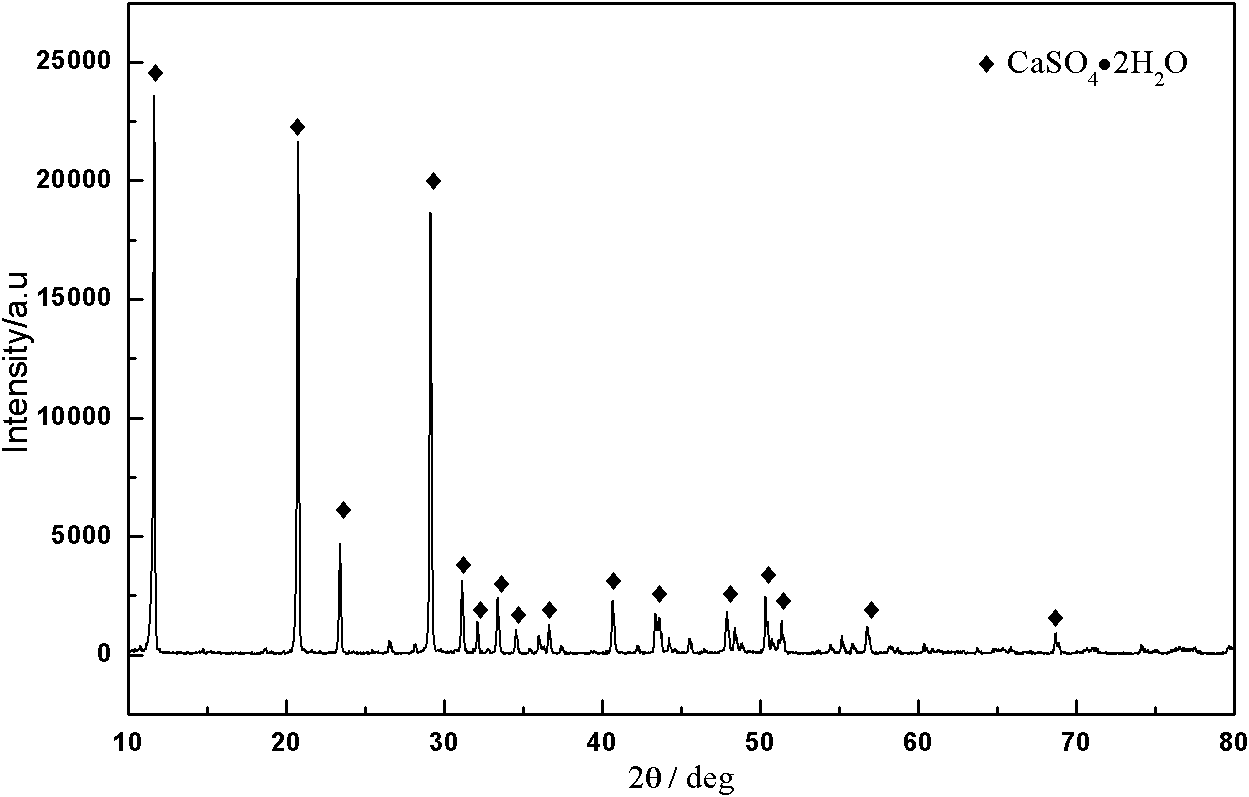

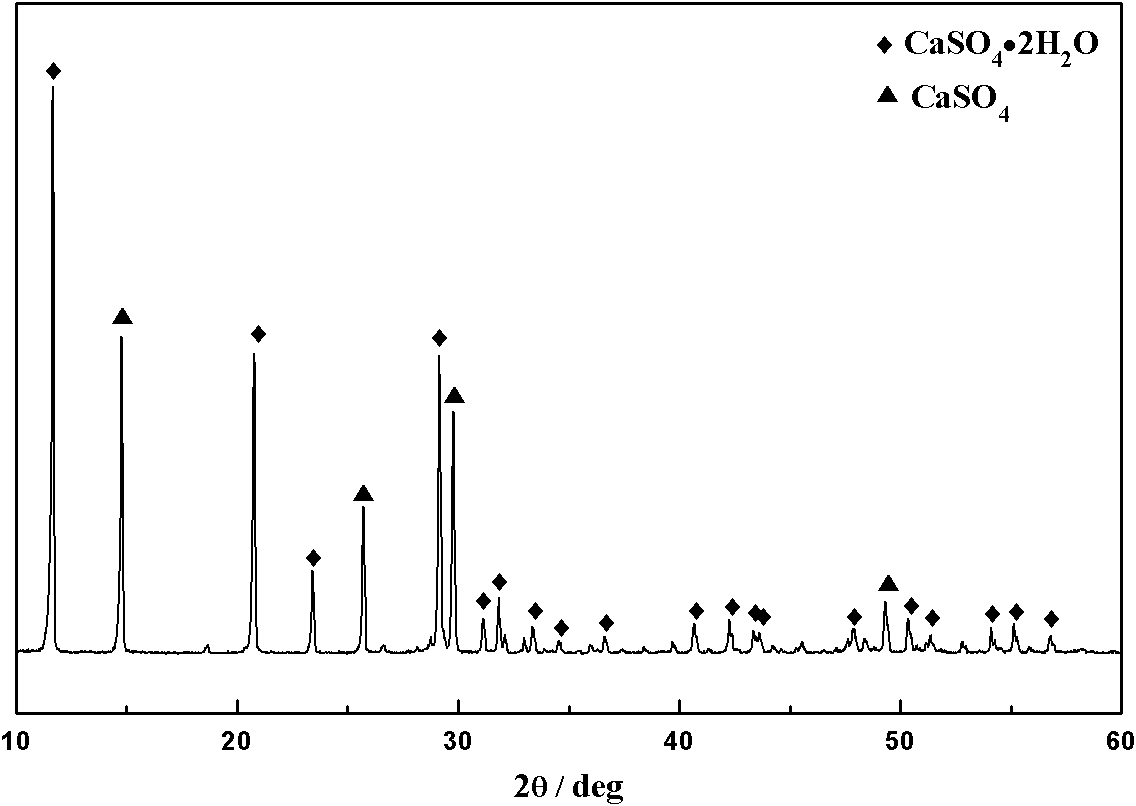

Method for extracting tungsten from scheelite

ActiveCN102021328AReduce lossesLow costProcess efficiency improvementWater dischargeReaction temperature

The invention discloses a method for extracting tungsten from scheelite, comprising the following steps of: mixing the scheelite with a mixed solution of phosphoric acid and sulfuric acid for reaction, adding dihydrate gypsum as seed crystals, and controlling the concentration of SO4<2->, the content of P2O5 and the reaction temperature to obtain the dihydrate gypsum with good filtering and washing properties. The invention has the advantages that one-step efficient normal pressure leaching of the scheelite is achieved, thus resources and energy consumption are saved, and the resolution ratio of the scheelite is up to above 98%; the problems of Cl<-> corrosion and serious HCl volatilization are overcome; the cyclic utilization of phosphoric acid is basically achieved, and the leaching cost and waste water discharge are greatly reduced; leaching equipment is simple, is convenient for operation and is easy to realize industrialization; the single and stable dihydrate gypsum is obtained, the filter efficiency of the dihydrate gypsum is high, the washing property of the dihydrate gypsum is good, and the P2O5 content in the washed dihydrate gypsum is reduced to be below 2%, thereby reducing the loss of phosphoric acid; and the passivation phenomenon of calcium sulfate solid film when the tungsten ore is leached is avoided.

Owner:CENT SOUTH UNIV

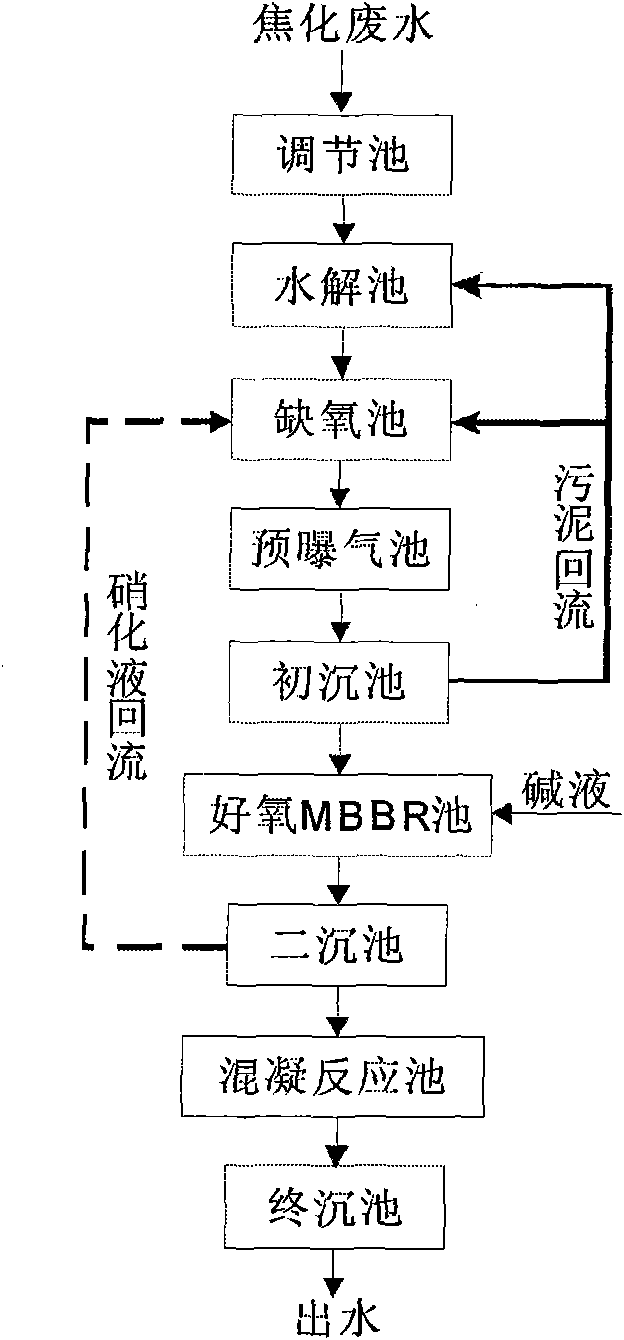

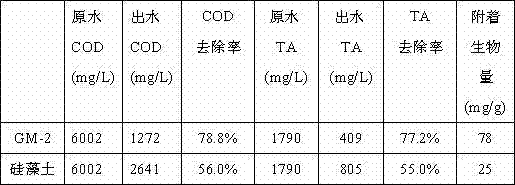

Method for treating coking wastewater

InactiveCN101602564AHigh activityNo reflow requiredTreatment with aerobic and anaerobic processesMultistage water/sewage treatmentHigh concentrationSludge

The invention discloses a method for treating coking wastewater, which belongs to the field of wastewater treatment. The method comprises the following steps that: wastewater of a coking plant enters a regulating reservoir for the adjustment of water quality and water amount, and orderly enters a hydrolytic tank, an anaerobic tank, a preaeration tank, a preliminary sedimentation tank, an aerobic tank, a secondary sedimentation tank and a coagulation reaction tank for treatment, wherein the hydrolytic tank and the preaeration tank are filled with a bio-cord filler; the sludge of the preliminary sedimentation tank refluxes into the hydrolytic tank and the anaerobic tank respectively; a clarifying solution of the secondary sedimentation tank refluxes into the anaerobic tank; and the aerobic tank adopts a moving bed bio-film reactor. The bio-cord filler adopted in the invention has short film formation time and high biomass, does not need repeated washing, and has strong shock resistance; and the moving bed bio-film reactor can fix a large amount of nitrobacteria with long generation time, and has no the problem of blocking. The method can remove high-concentration ammonia nitrogen and organic substances in the coking wastewater, and the COD and the ammonia nitrogen of treated effluent can synchronously achieve the primary standard of the national integrated wastewater discharge standard (GB9878-1996).

Owner:NANJING UNIV

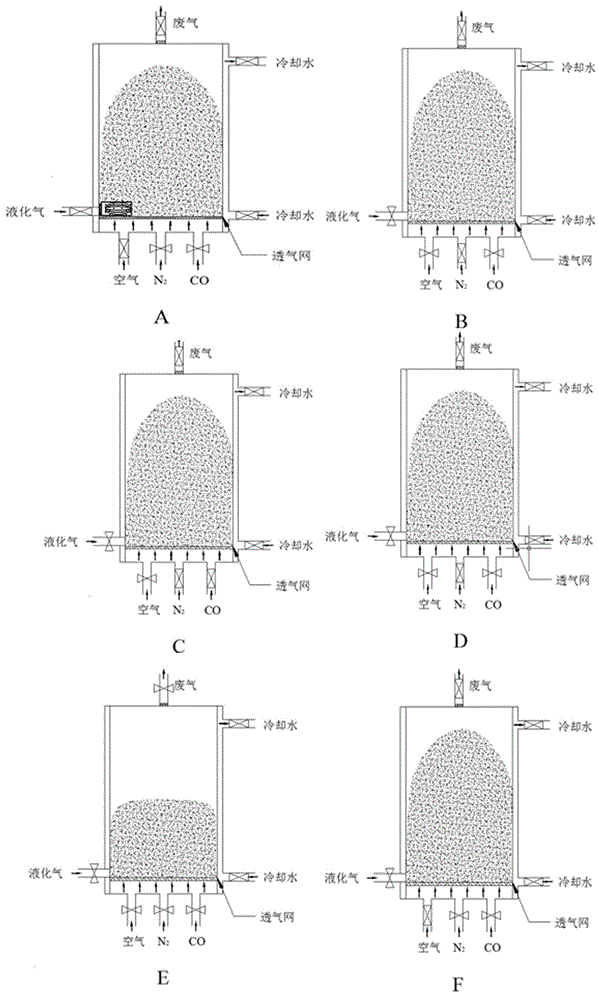

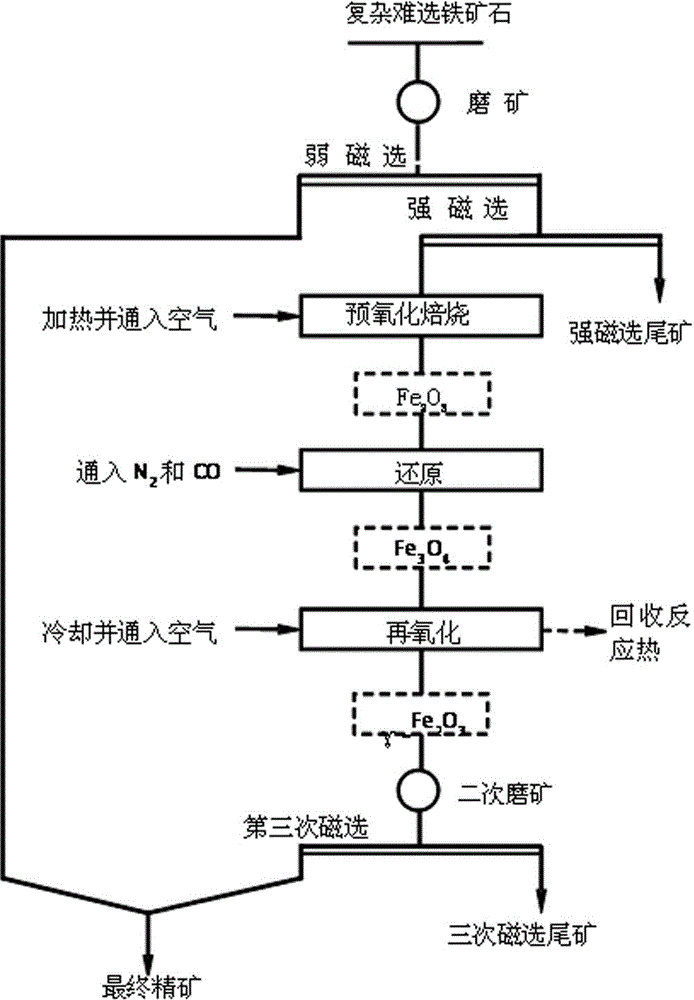

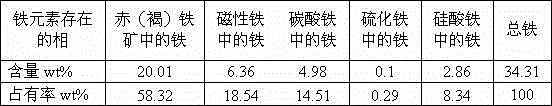

Preenrichment-three segment suspension roasting-magnetic separation treatment method of complex refractory iron ores

The invention discloses a preenrichment-three segment suspension roasting-magnetic separation treatment method of complex refractory iron ores, and belongs to the technical field of mineral processing. The method comprises the following steps: 1, levigating the complex refractory iron ores, carrying out weak magnetic separation, and carrying out strong magnetic separation on mine tailings; 2, putting concentrate obtained after strong magnetic separation in a suspension roasting furnace, and heating to 450-800DEG C in a suspension state in order to carry out pre-oxidation roasting; 3, introducing nitrogen to displace air, and introducing a reducing gas to carry out reduction in a suspension loose state; 4, introducing air when the temperature decreases to 250-400DEG C in order to oxidize, taking out the obtained material when the temperature decreases to below 100DEG C, and carrying out ore milling; and 5, carrying out third segment magnetic separation, and mixing concentrate obtained after three segment magnetic separation with concrete obtained after the weak magnetic separation to obtain finial concentrate. The method has the advantages of simple process, improvement of the recovery rate of the complex refractory iron ores, strong adaptability, safe and reliable process, uniform and stable product quality, energy saving and consumption reduction.

Owner:上海逢石科技有限公司

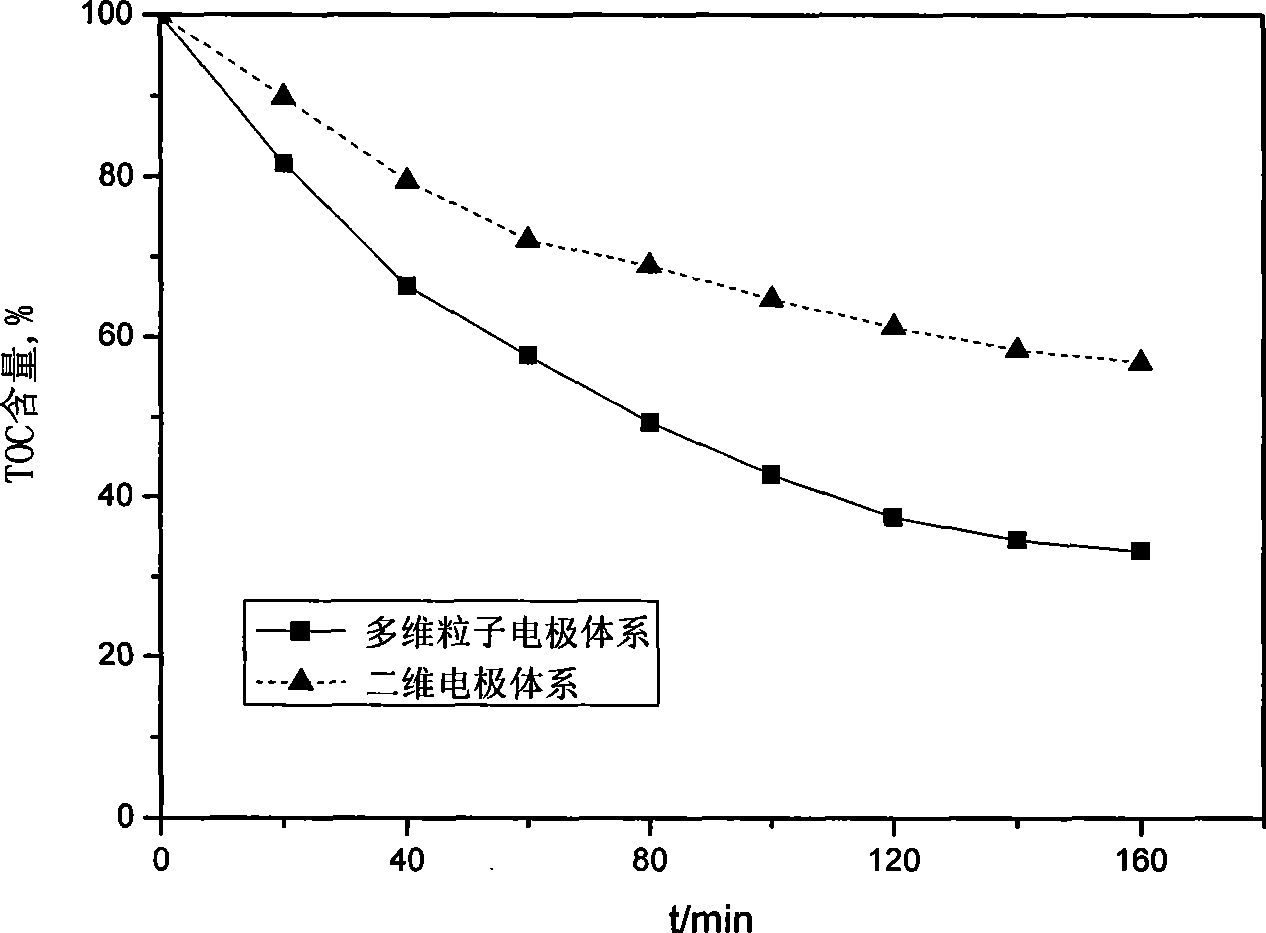

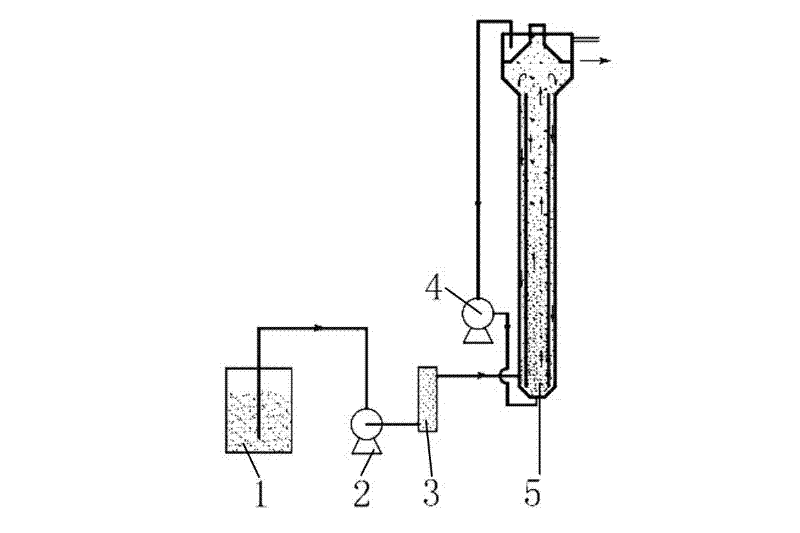

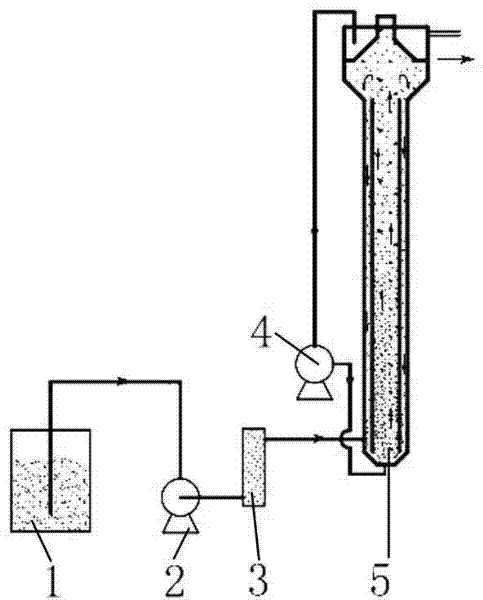

Three-dimensional electrode bio-membrane system used for processing high-ammonium-nitrogen wastewater with low carbon-nitrogen ratio

InactiveCN102491515AGood synergySave energyTreatment with aerobic and anaerobic processesElectron donorMembrane reactor

The invention discloses a three-dimensional electrode bio-membrane system used for processing high-ammonium-nitrogen wastewater with a low carbon-nitrogen ratio. According to the invention, a barrier membrane concentric with a reactor body is arranged in the reactor body; with the barrier membrane, the reactor body is separated into a round anode zone and an annular cathode zone; a microbe carrier filling material is filled in the anode zone, and a positive electrode is arranged at the center of the anode zone; a negative electrode is arranged in the cathode zone, and conductive particles arefilled in the cathode zone, wherein the conductive particles serve as a third electrode; the negative electrode and the conductive particles both serve as microbe carriers; a water inlet pipe is arranged on the bottom of the anode zone, and a water outlet pipe is arranged in the cathode zone; the water outlet pipe is arranged on an outer wall on the upper end of the reactor body. According to theinvention, in a same electrode bio-membrane reactor, an eligible environment for the microbes is created with an electrochemical effect; an electron acceptor and an electron donor are respectively provided, such that nitrification and denitrification actions are respectively carried out, and ammonium-nitrogen wastewater can be effectively treated. The system is advantaged in low energy consumption, high efficiency, simple structure, and easy operation.

Owner:CHONGQING UNIV

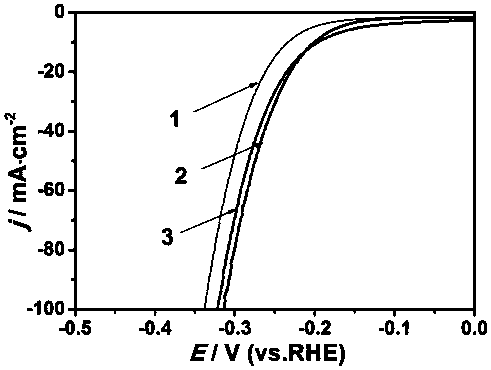

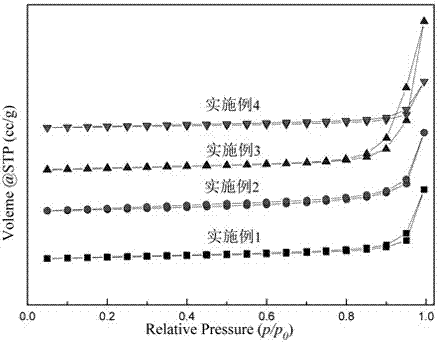

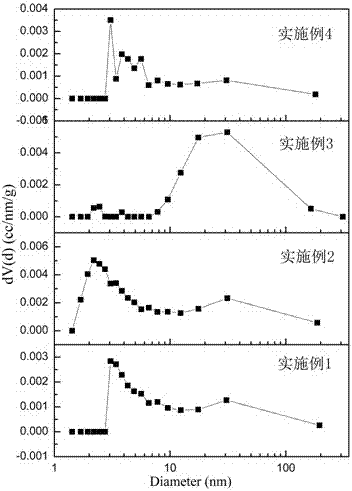

Nitrogen-doped carbon-supported monoatomic oxygen reduction catalyst and preparation method thereof

ActiveCN109841854ALarge specific surface areaHigh porosityCell electrodesBiological activationNitrogen doped

The invention relates to a nitrogen-doped carbon-supported monoatomic oxygen reduction catalyst and a preparation method thereof, and belongs to the technical field of electrocatalytic materials. Themethod is characterized in that a composite of a Zn-based bimetallic MOF and glucose is used as a precursor, the catalyst is obtained by high-temperature heat treatment and post-activation in ammoniagas, the monoatomic content is 2wt% to 4wt%, and the nitrogen doping amount is 4wt% to 15wt%. The addition of volatile Zn can increase the spatial distance of metal atomic nodes, the glucose can makea three-dimensional ZIF form a cross-linked structure, the structure and composition of a modulating material can improve the electrocatalytic activity, the nitrogen content can be further increased by post-activation treatment in the ammonia gas, and therefore, the electrochemical activity is improved. At the same time, the preparation method has the advantages of low cost, simple steps, mild conditions, good repeatability and easy mass production. The monoatomic catalyst exhibits good performance in an electrocatalytic oxygen reduction reaction (ORR) under an alkaline condition and has certain market application prospects.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Multi-hole foam glass carrier for fast mass transfer biological fluidized bed and preparation method and application thereof

InactiveCN102515551AEvenly distributedImprove chances of interphase contactTreatment with anaerobic digestion processesBiocompatibilityFoam glass

The invention relates to a multi-hole foam glass carrier for a fast mass transfer biological fluidized bed and a preparation method and application thereof, which belong to sewage disposal technology. The multi-hole foam glass carrier is prepared by using waste glass as a raw material to be composited with volcanic rocks, coal ash, coal gangue, furnace clinker, iron powder, aluminum powder, binding agents, foaming agents, foam stabilizer and fluxing agents by weight, and multi-hole foam glass is obtained by stages of preheating, fast sintering, foaming, fast cooling and annealing. The preparation process of the multi-hole foam glass carrier is simple in route, easy to control and low in cost, and the prepared carrier is stable in performance, high in porosity, large in specific surface area, resisting in impact, good in mechanical performance, high in biocompatibility, favorable to efficient fixing of the microorganism, and suitable to the fast mass transfer biological fluidized bed. The multi-hole foam glass carrier solves the problem that biological immobilization carriers in the prior art are easy to abrade, small in bio-film formation amount, low in mass transfer effects and the like in the fast mass transfer biological fluidized bed. The preparation method opens up new approaches for preparing the biological carriers, and fills blank spaces in using of foam glass materials in sewage disposal.

Owner:NANJING UNIV OF TECH

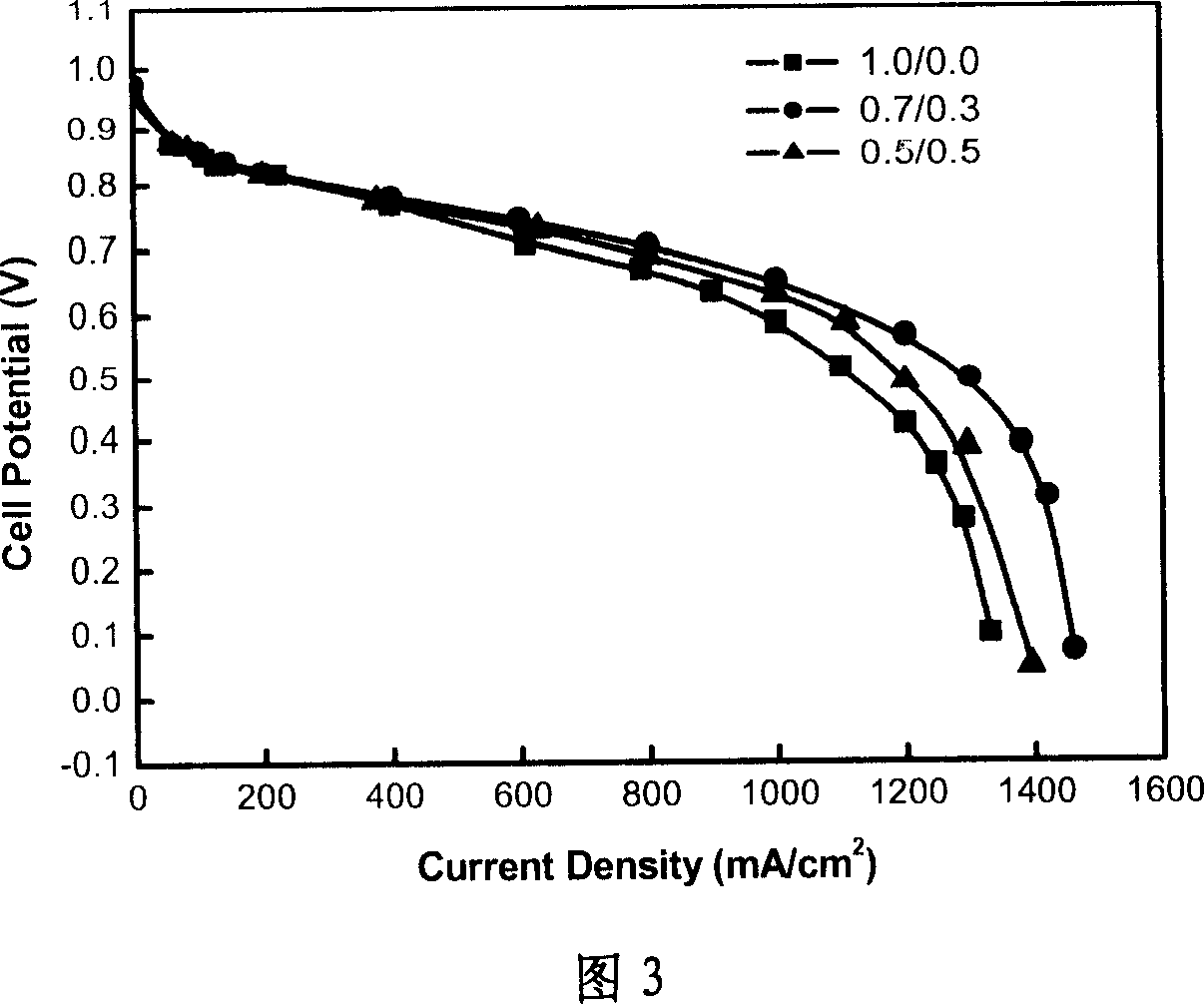

Gas diffusion layer for proton exchange membrane fuel cells and preparation method thereof

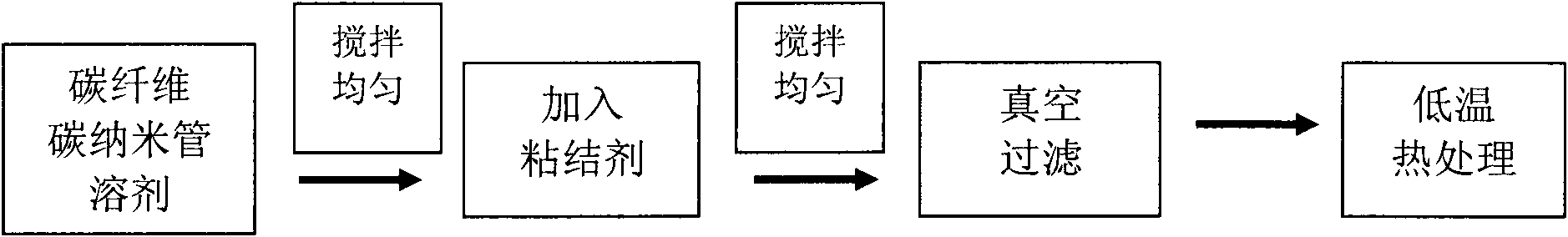

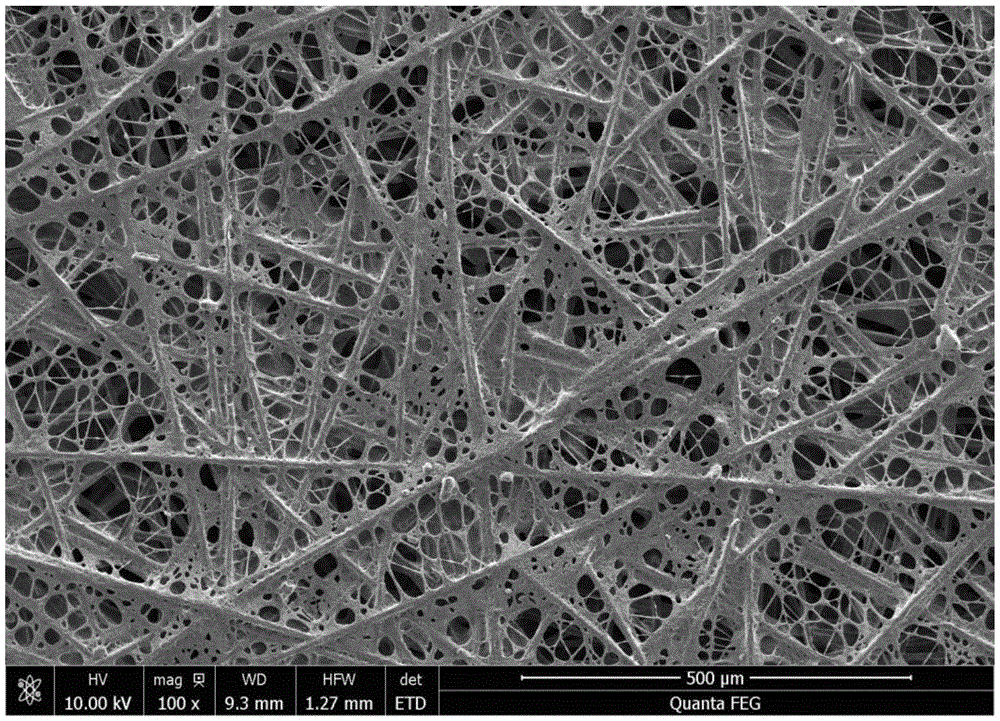

ActiveCN101771155ALow electrical resistanceImprove electronic conductivityCell electrodesFinal product manufactureFiberCarbon fibers

The invention relates to a gas diffusion layer for proton exchange membrane fuel cells; the gas diffusion layer is composed of a carbon nano tube, a carbon fiber and a binder and can be directly used as the gas diffusion layer for the proton exchange membrane fuel cells; the preparation process is as follows: a certain amount of the carbon fiber and the carbon nano tube are weighted according to the proportion and are dispersed uniformly in the solvent; and then a certain amount of the binder is added in the mixture and is mixed uniformly to form slurry; and then the slurry is poured into a filter to carry out vacuumizing filtration, so as to obtain a wet type gas diffusion layer; finally, the prepared wet type gas diffusion layer is placed in a calcining furnace for carrying out heat treatment. The gas diffusion layer in the invention has good electrical conductivity and mass transfer property, can be directly used as the gas diffusion layer for the proton exchange membrane fuel cells, so as to avoid complex treatment process when commodity carbon paper is used; the gas diffusion layer prepared by the method has the advantages of low raw material price, easily-obtaining raw material, simple technology process and controllable thickness / shape, thereby being suitable for mass production.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

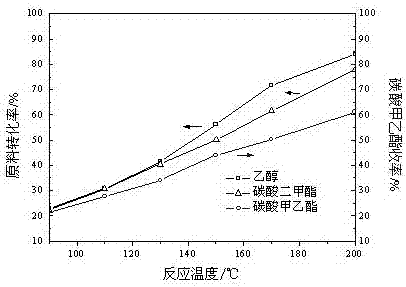

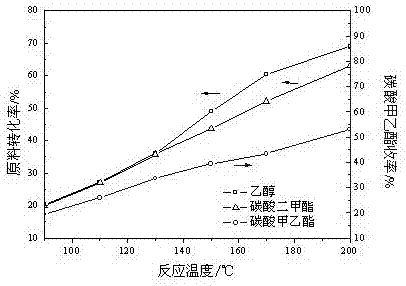

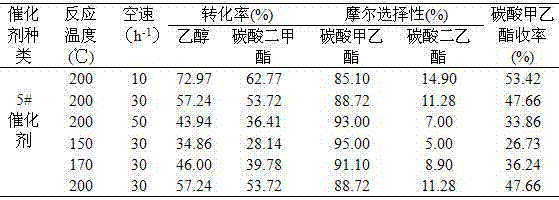

Method for preparing ethyl methyl carbonate through ester exchange method

InactiveCN107473968AGood dispersionImprove mass transfer effectPhysical/chemical process catalystsPreparation from organic carbonatesDispersityMethyl carbonate

The invention provides a method for preparing ethyl methyl carbonate through an ester exchange method, and relates to a method for preparing a chemical raw material. A first catalyst prepared by the method simultaneously has macropore and micropore structures, wherein the macropores can obviously improve the mass transfer effect; and the micropores can obviously improve the specific surface area of a carrier and simultaneously improve the dispersity of active centers. Meanwhile, the prepared first catalyst simultaneously has an alkali active center and a Lewis acid catalytic active center. The prepared 15%MgO-5%MgCl2-2%La2O3 / Al2O3-SiO2 is used in a dimethyl carbonate and ethanol ester exchange fixed bed continuous reaction; when the reaction temperature is 200 DEG C and the space velocity is 30h<-1>, the catalyst is not inactivated after 5000h of continuous reaction, the dimethyl carbonate conversion rate can be kept at 70%, the ethanol conversion rate can be kept at 80%, and the yield of the product ethyl methyl carbonate is 56%; and after the reaction, the catalyst can be reused through simple filtration treatment, and the activity of the catalyst can still be kept unchanged after the catalyst is reused for multiple times.

Owner:SHENYANG INSTITUTE OF CHEMICAL TECHNOLOGY

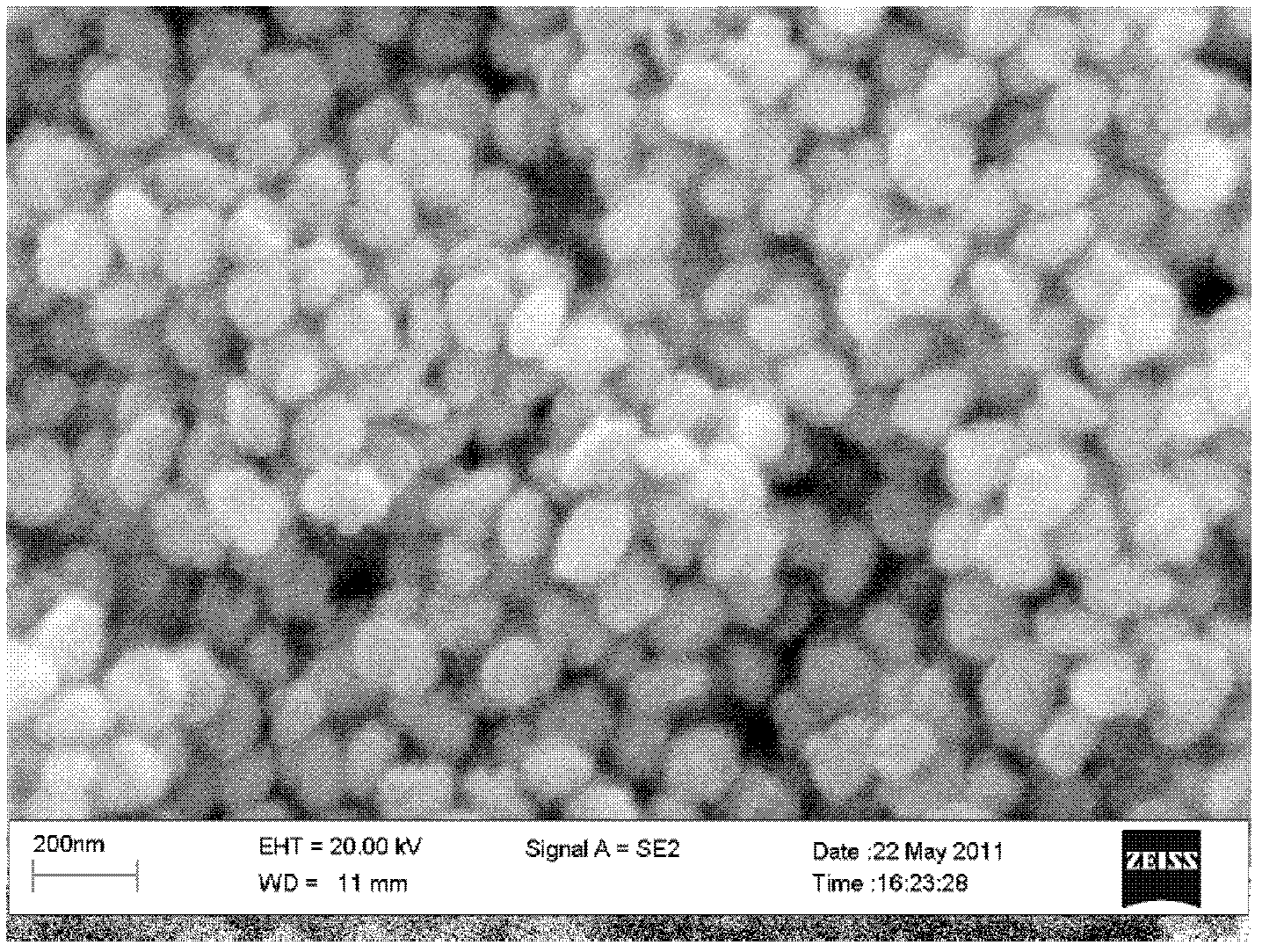

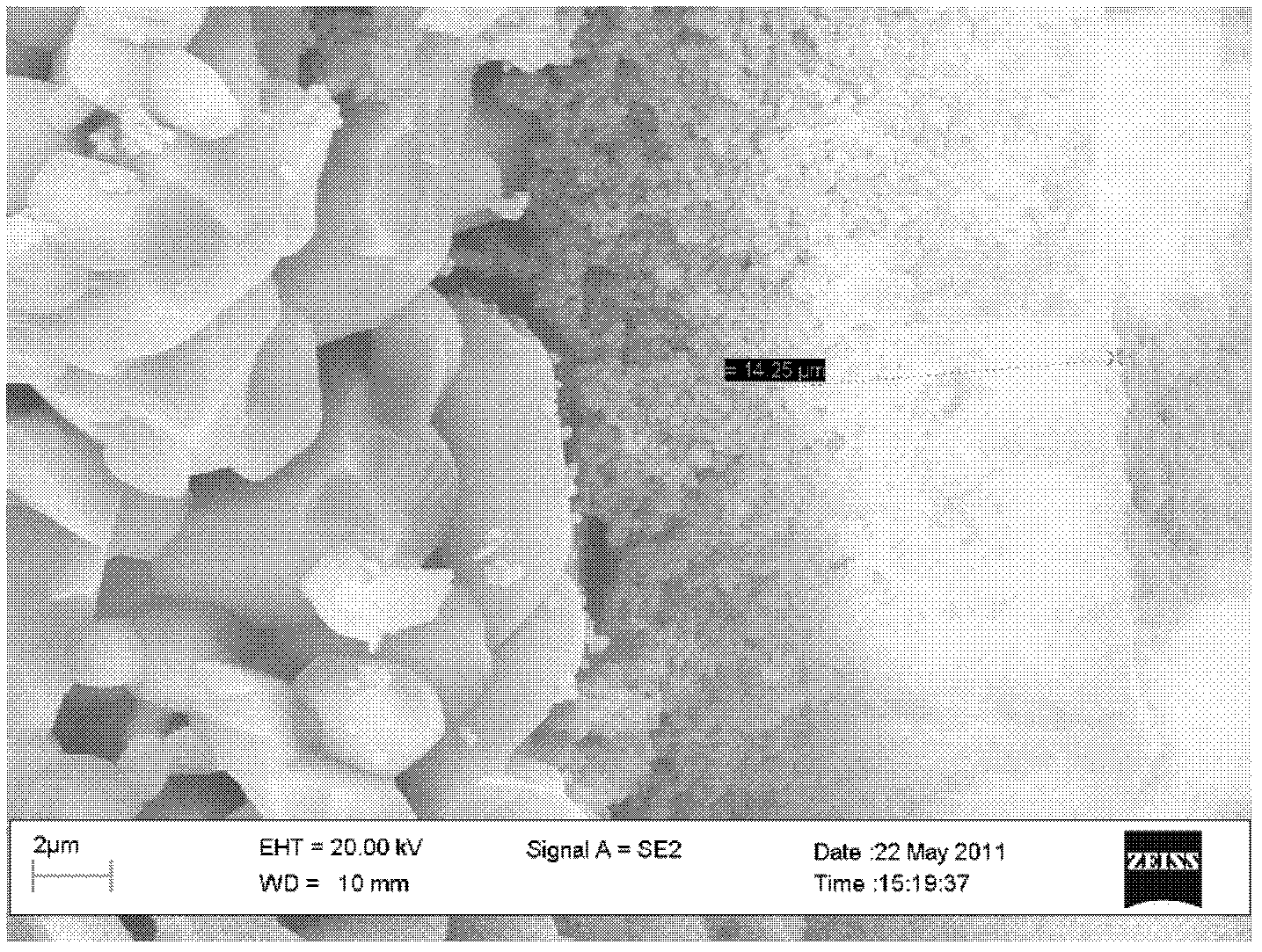

Binderless adsorbents with improved mass transfer properties and their use in the adsorptive separation of para-xylene

ActiveUS20100076243A1Improve performanceImprove mass transfer effectOther chemical processesMolecular-sieve and base-exchange compoundsProduction rateSorbent

Adsorbents and methods for the adsorptive separation of para-xylene from a mixture containing at least one other C8 aromatic hydrocarbon (e.g., a mixture of ortho-xylene, meta-xylene, para-xylene, and ethylbenzene) are described. Suitable adsorbents comprise small-crystallite-size zeolite X having an average crystallite size of less than 1.8 microns. The adsorbents may be binderless (e.g., formulated with the substantial absence of an amorphous material that normally reduces selective pore volume) to further improve capacity and mass transfer. These properties are especially advantageous for improving productivity in low temperature, low cycle time adsorptive separation operations in a simulated moving bed mode.

Owner:UOP LLC

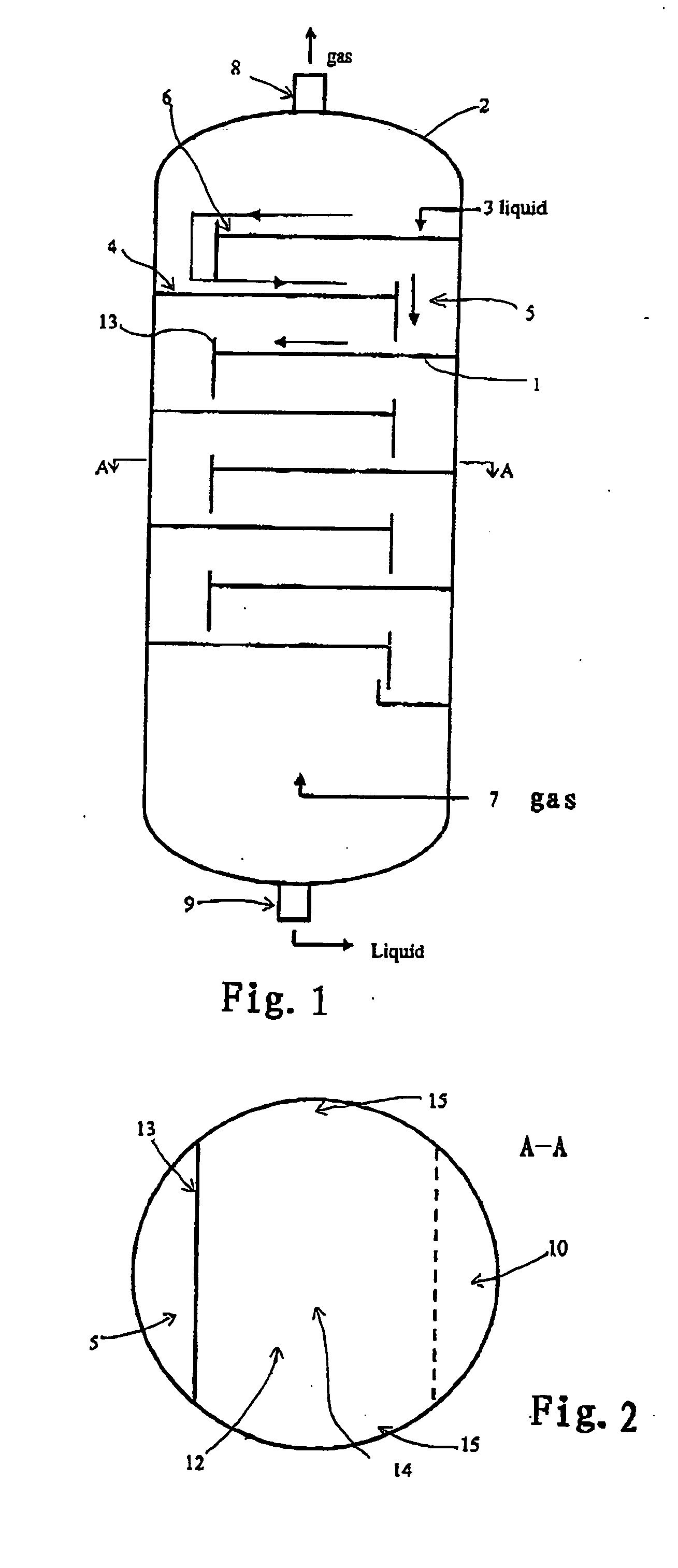

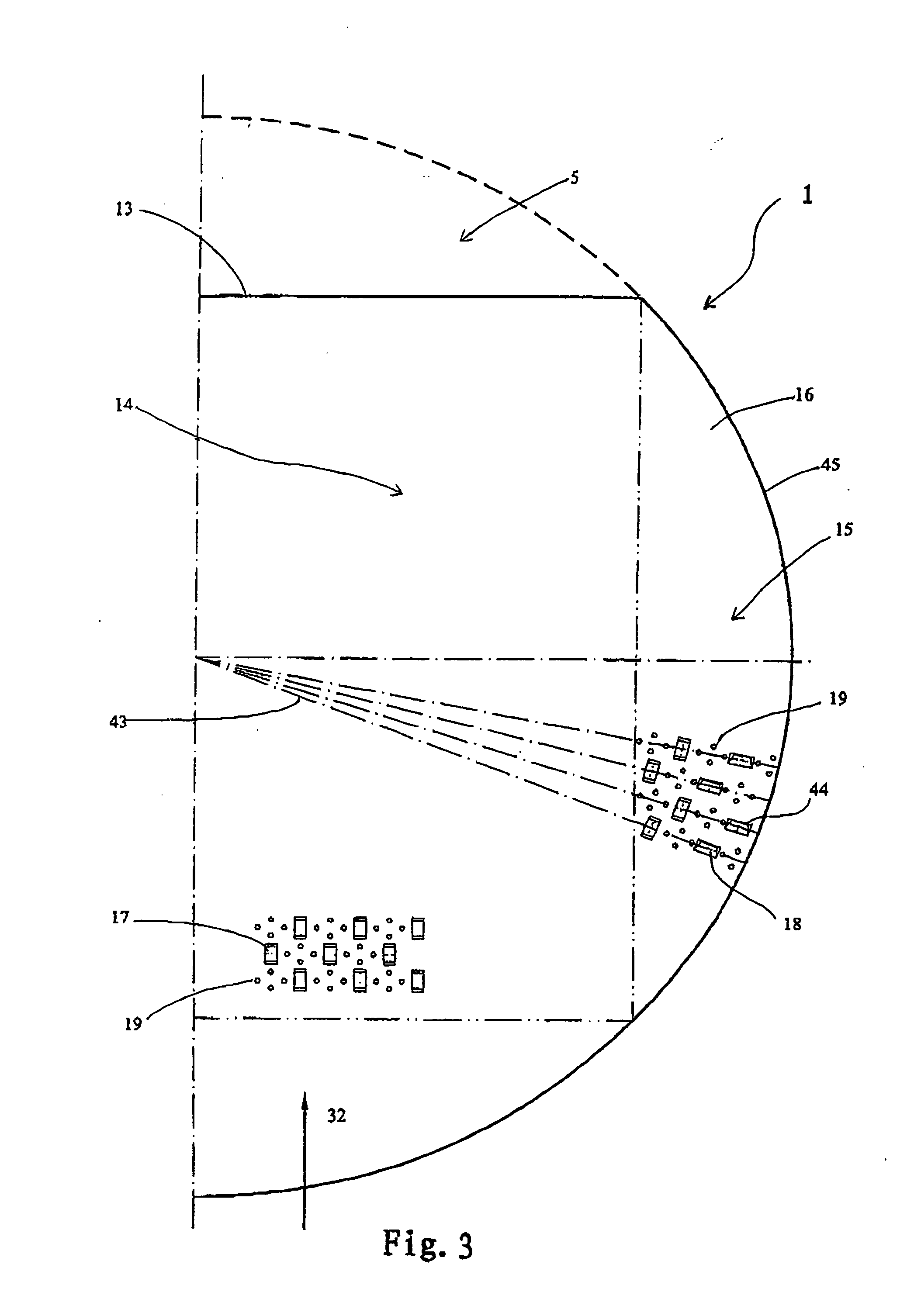

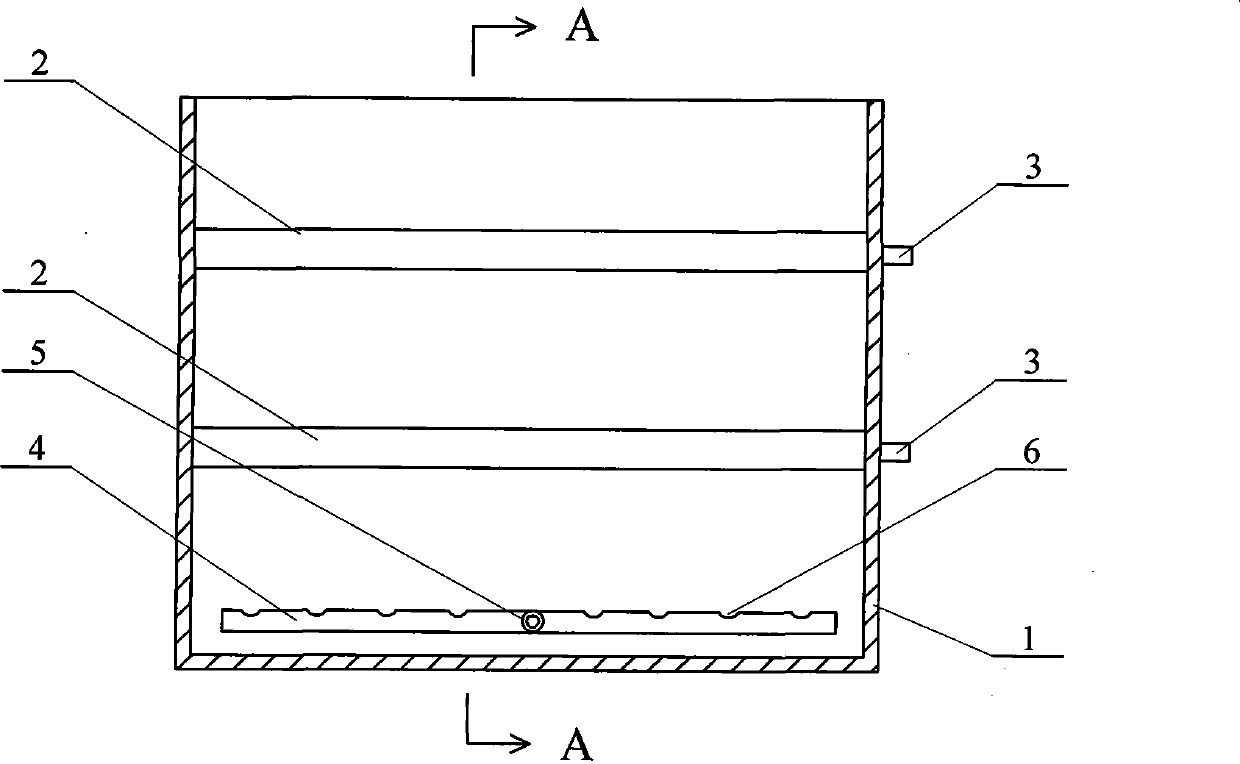

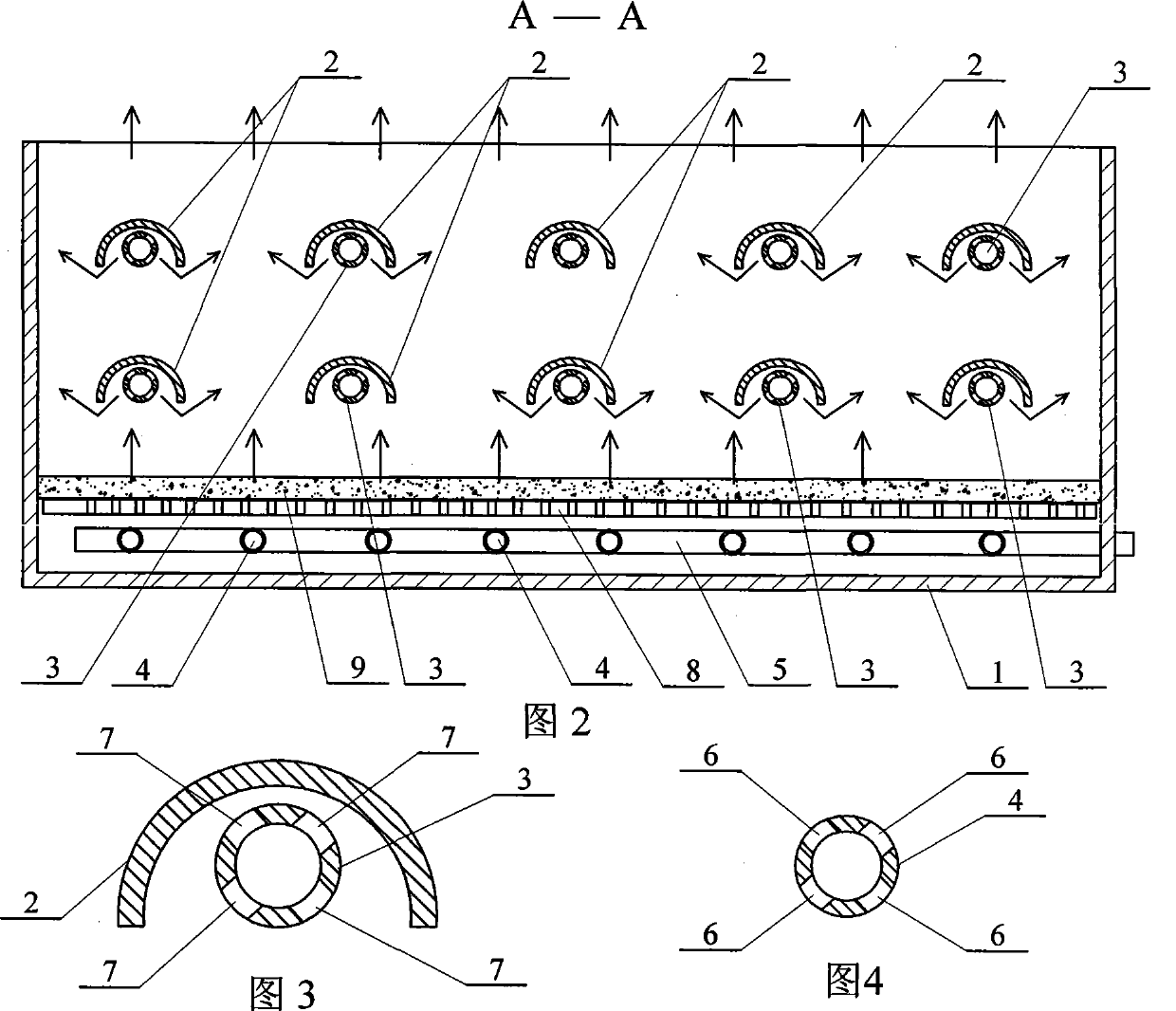

Solid waste high temperature aerobic composting method using stereoscopic ventilating apparatus

InactiveCN101372427AImprove mass transfer effectImprove uniformity and stabilityBio-organic fraction processingOrganic fertiliser preparationAgricultural engineeringCompost

A high-temperature and aerobic composting method for solid wastes which adopts a vertical ventilation device relates to a high-temperature and aerobic composting method for the solid wastes. The composting method aims at solving the problems that in the aerobic fermentation process, the conventional bottom ventilation method causes obvious uneven fermentation at the upper part and the lower part of a stacking body in a fermentation device, thus quality stability and uniformity of the fermented product are affected. In the composting method, middle air distribution pipes are fixed in a fermentation tank arranged at the lower side of an inverted ventilating slot; both the bottom part and the middle part of the fermentation tank adopt intermittent ventilation type, the ventilation time is 5-30 minutes, intermittent time is 15-120 minutes and ventilation rate is 0.03-2m<3> / (min m<3> mixing materials). The composting method increases the contact area between air and materials; air direction forms a reverse rotational flow, which increases residence time of fresh air in the fermentation device, thus improving the mass transfer efficiency, and the operational cycle of a single fermentation is shortened by over 1 / 4.

Owner:李伟光 +1

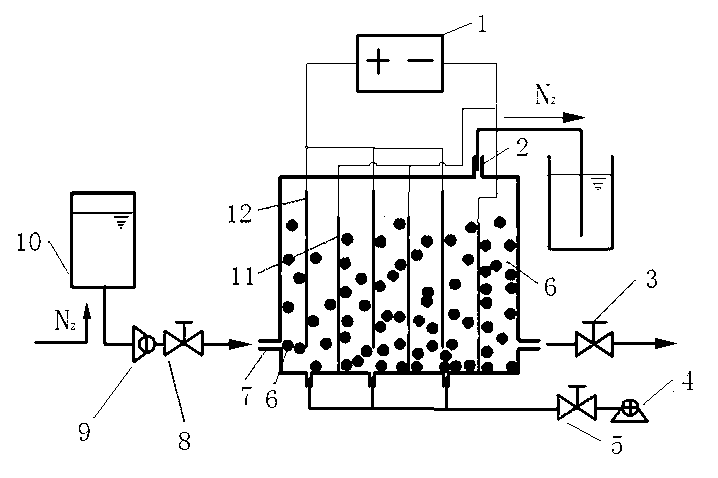

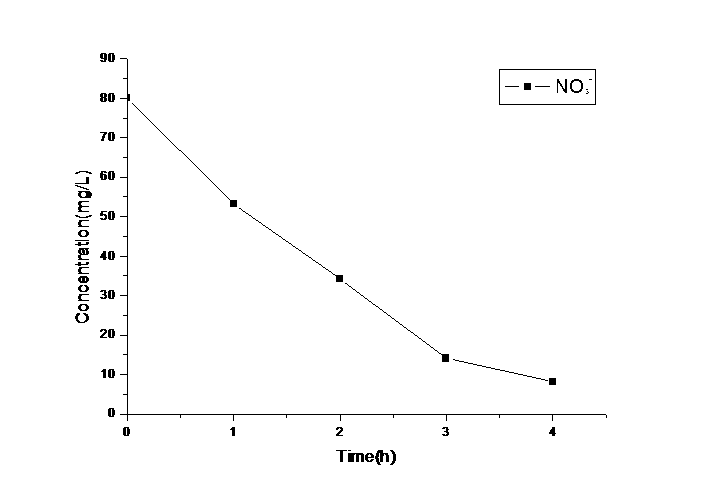

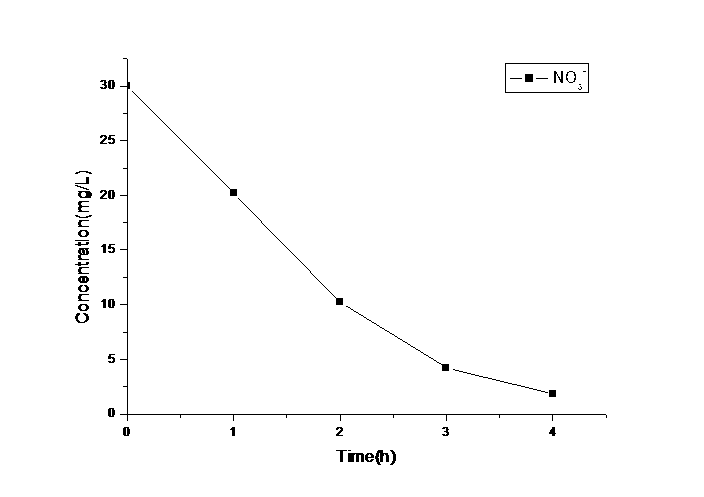

Electrochemical reactor for processing nitrogenous organic wastewater, and application and processing method thereof

InactiveCN103193301AEfficient removalAmmonium Oxide StrongWater contaminantsWater/sewage treatment by magnetic/electric fieldsElectrochemical responseChemical oxygen demand

The invention discloses an electrochemical reactor for processing nitrogenous organic wastewater, and an application and a processing method thereof, and belongs to the field of processing nitrogenous organic wastewater. The device comprises a reaction container, a power supply, a gas outlet pipe, a water outlet pipe, a water outlet pipe valve and a water inlet system, and further comprises a packing material, a negative plate and a positive plate, wherein the packing material is formed by mixing active carbon and magnet particles; the negative plate is connected with the negative electrode of the power supply; the negative plate is a silicon dioxide plate loaded copper-palladium coating electrode, and the coating material consists of Pd and Cu at a mass ratio of 6: 1; and the positive plate is a digital subtraction angiography (DSA) oxide coating electrode Ti / IrO2-PtO2. The reactor is a batch-type operation three-dimensional electrode reactor which adopts a mixture of active carbon particles and magnet particles with similar diameter as the packing material, and has the functions of efficiently removing nitrate nitrogen, ammonia nitrogen and COD (chemical oxygen demand), and is low in energy consumption; and the reactor is capable of achieving a purpose of removing nitrogen and COD in the nitrogenous organic wastewater.

Owner:GUODIAN ENVIRONMENTAL PROTECTION RES INST CO LTD +1

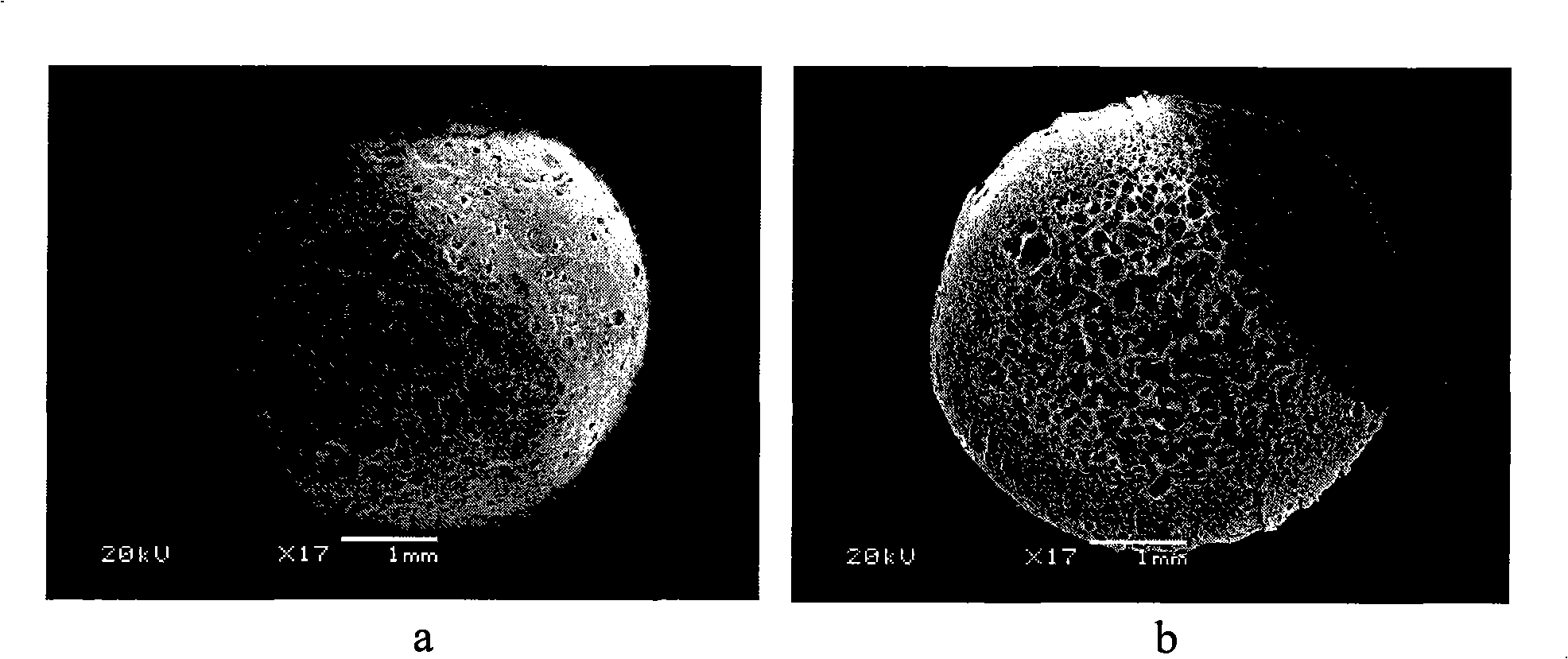

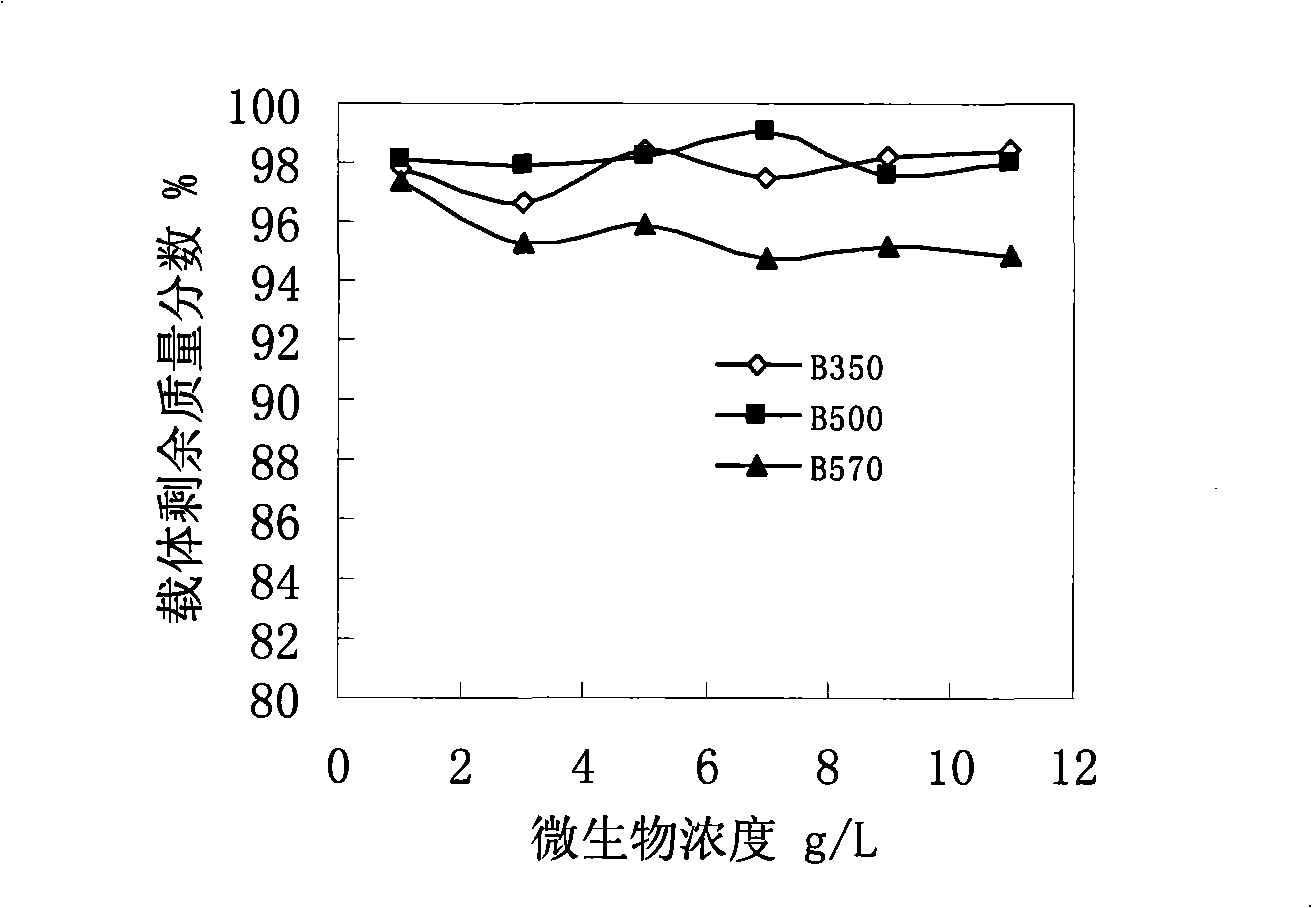

Macroreticular polyvinyl alcohol bead carrier and preparation thereof

InactiveCN101348782AIncrease the specific surface area of contactIncrease chance of contactOn/in organic carrierPeristaltic pumpDissolution

The invention provides a method for preparing a macroporous reticulated polyvinyl alcohol spherical vector. The method comprises the following steps: firstly, polyvinyl alcohol, calcium carbonate, sodium alginate and water are mixed in a certain mass proportion, and stirring is performed for full dissolution of the polyvinyl alcohol and uniform mixture, and then white PVA sol is obtained; secondly, the sol obtained is added into saturated boric acid solution containing 3 percent of calcium chloride by a peristaltic pump, and PVA gel beads are formed, cleaned by water and then placed into diluted hydrochloric acid solution for dipping until no air bubble is generated; thirdly, a spherical vector is thrown into glutaral pentanedial water solution and adjusted into acidity so as to generate crosslinking reaction to form a more stable crosslinking structure; and fourthly, the spherical vector is dipped into water and cleaned into neutrality, and then the white macroporous reticulated PVA spherical vector with elasticity is obtained. The macroporous reticulated polyvinyl alcohol vector prepared by the method has stable macroporous reticulated structure and good hydrophilicity, physical and chemical stability and anti-biological degradability, is suitable for immobilized enzymes and microorganisms so as to form a plurality of bed-shaped bioreactors, and is used in the modern bioengineering field such as sewage treatment and so on.

Owner:LANZHOU UNIVERSITY

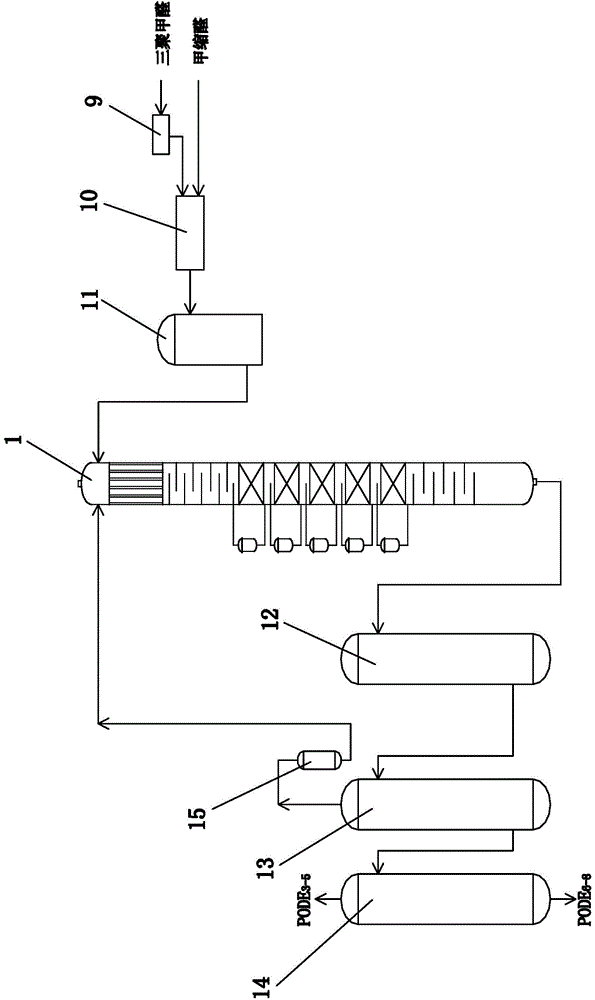

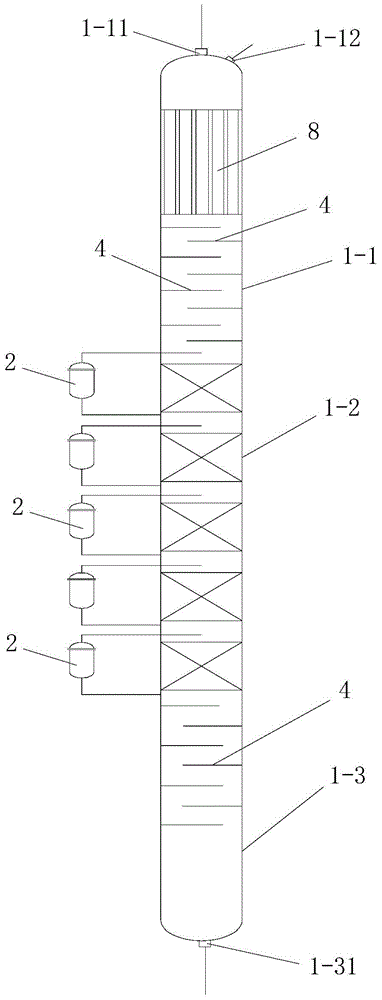

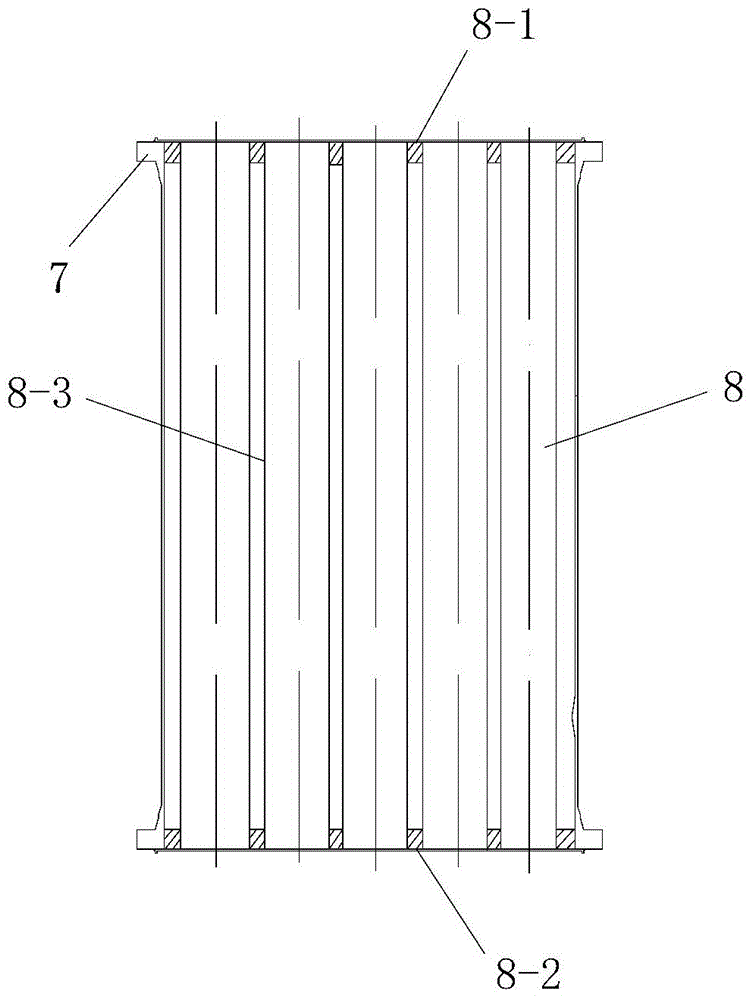

Method for preparing polymethoxy dimethyl ether through reaction and rectification of fixed bed

ActiveCN104355973AHigh catalytic activityEasy to separateOrganic chemistryOrganic compound preparationMolecular sieveTower

The invention discloses a method for preparing polymethoxy dimethyl ether through reaction and rectification of a fixed bed. The method comprises the following steps: (1) preheating trioxymethylene, uniformly mixing the preheated trioxymethylene and methylal, and feeding the trioxymethylene and the methylal which are uniformly mixed into a fixed bed reactor for an etherification reaction; (2) feeding materials after the etherification reaction into a reaction rectifying tower for the reaction and the rectification, and discharging PODE2-8 from the tower bottom of the reaction rectifying tower; (3) transporting the PODE2-8 to a dewatering tower loaded with a 3A molecular sieve for dehydration, then transporting the dehydrated PODE2-8 into a first refining tower, transporting materials which are discharged from the tower bottom of the first refining tower into a second refining tower, discharging PODE3-5 from the tower top of the second refining tower, and discharging PODE6-8 from the tower bottom of the second refining tower. When the method disclosed by the invention is used for preparing the PODE3-8, the yield of the polymethoxy dimethyl ether can reach 95%, wherein the products of the PODE3-8 can reach 80%-95%, and after refinement, the PODE3-5 of which the quality purity reaches 99.9% can be obtained.

Owner:XIAN SHANGHUA TECH DEV CO LTD

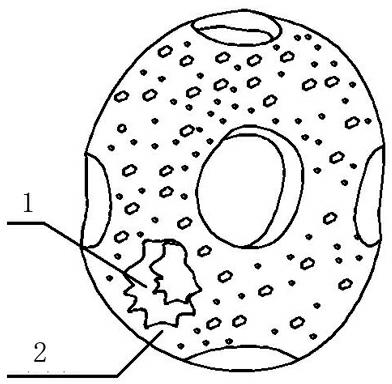

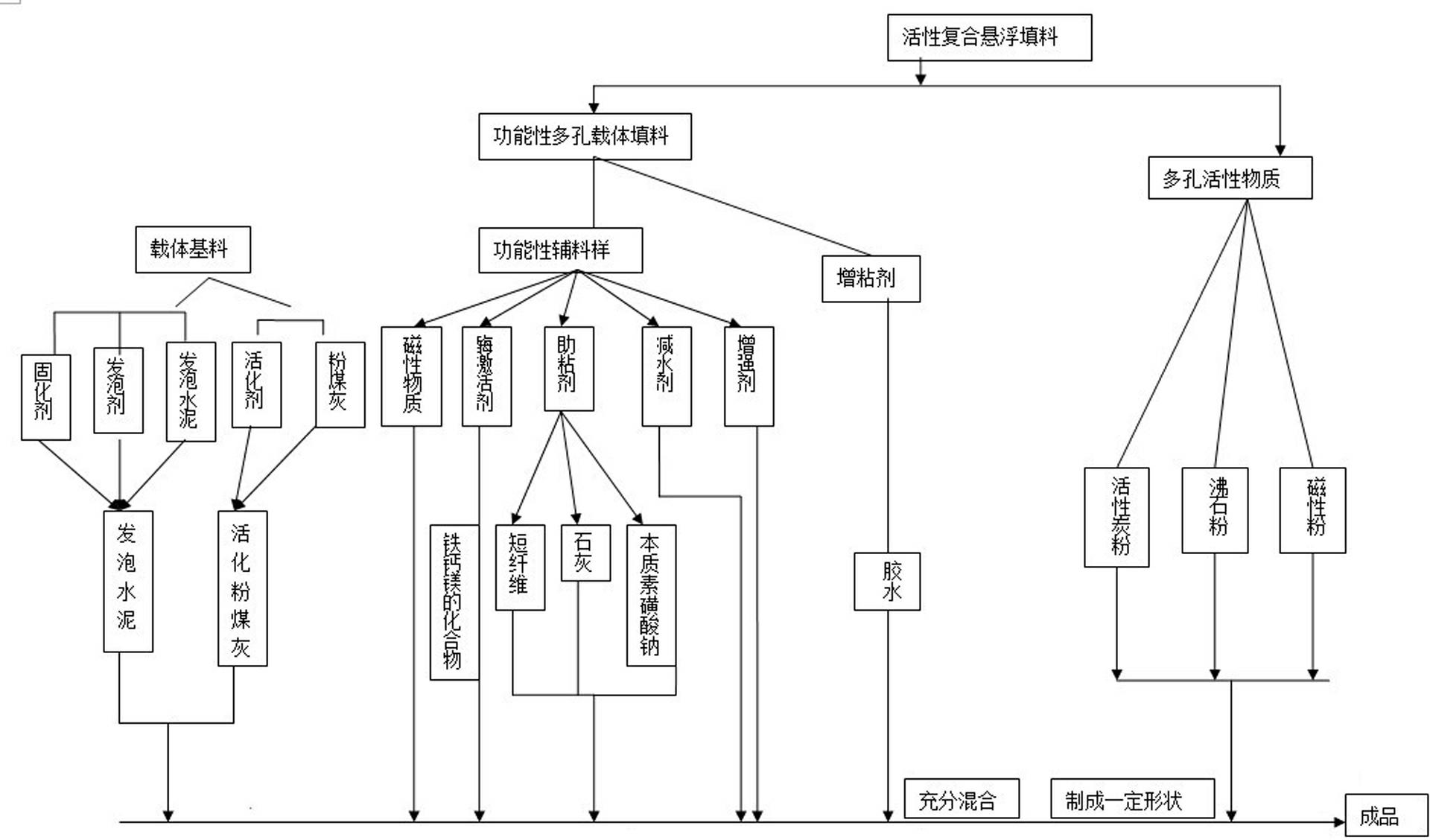

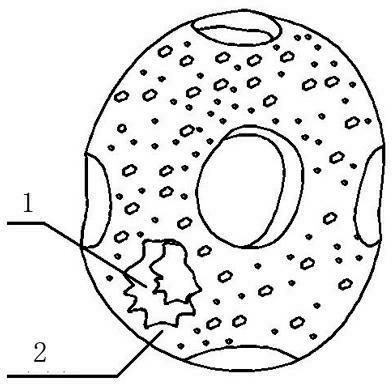

Active composite suspended filler

ActiveCN102583719AHigh activityKeep aliveTreatment with aerobic and anaerobic processesSustainable biological treatmentChemical oxygen demandHoneycomb

The invention relates to an active composite suspended filler, which is applied to the technology of biochemical treatment of organic wastewater, and discloses a porous support filler formed by a carrier basic materials and functional assistant materials. The porous support filler is in a through-hole spheroidal body or a through-hole cylindrical body, and one layer of porous active powder material layer is bonded on an outer surface of the through-hole spheroidal body or the through-hole cylindrical body. The active composite suspended filler is an inorganic suspended filler, has an uneven surface and roughness height; and pores with different sizes are distributed on the filler and are shaped like a honeycomb. The filler not only has high adsorption performance on harmful substances and dissolved oxygen, but also can form different dissolving intensity, is beneficial to improving processing efficiency for removing COD (Chemical Oxygen Demand) and ammonia nitrogen, and will be a novel high-efficient filler.

Owner:GUANGDONG LVYUAN ENVIRONMENTAL TECH CO LTD

Nano carbon-doped porous fiber single electrode, membrane electrode and preparation method

InactiveCN105261767AQuality improvementLight in massMaterial nanotechnologyCell electrodesElectrospinningNanofiber

The invention relates to a nano carbon-doped porous fiber single electrode, a membrane electrode and a preparation method. According to the nano carbon-doped porous fiber single electrode, a semi-ordered porous nano fiber thin film is deposited at one side of a gas diffusion layer material; and a layer of metal nanoparticles with catalytic activity is evenly deposited on the nanofiber surface of the semi-ordered porous nano fiber thin film to form the nano carbon-doped porous fiber single electrode, wherein the semi-ordered porous nano fiber thin film is formed by a co-spun high-molecular polymer nano charged superfine fiber attached with a nano carbon material on the surface, and comprises a co-spun high-molecular polymer doped with the nano carbon material as the component. According to the nano carbon-doped porous fiber single electrode, the semi-ordered porous nano fiber layer is formed by the nano carbon material and a high-molecular polymer solution through electrostatic spinning and cospinning for the first time; a catalyst is sprayed on the porous nano fiber layer; and a mico-pore layer and a catalyst layer are combined into one, so that the properties of a prepared single battery are greatly improved; and the lifetime is greatly prolonged.

Owner:WUHAN UNIV OF TECH

Ultrafine molecular sieve structured catalytic material based on porous silicon carbide carrier and preparation thereof

ActiveCN102716762ACrystal size can be controlledImprove bindingMolecular sieve catalystsMolecular sieveHigh activity

The invention, belonging to the technical field of catalyst and its application, particularly relates to an ultrafine molecular sieve structured catalytic material based on a porous silicon carbide carrier and a preparation method thereof. The material comprises ultrafine molecular sieve crystals as active elements and has a hierarchically porous structure, and the whole ultrafine molecular sieve coating has catalytic activity. The method is characterized by coating a colloidal molecular sieve precursor on the surface of a modified foam silicon carbide carrier, converting the molecular sieve precursor into ultrafine molecular sieve crystals by vapor phase treatment to realize the firm combination between the coating and the carrier. According to the invention, by controlling the synthesis conditions of the colloidal molecular sieve precursor and the method of adding a pore forming agent, the size of the molecular sieve crystals, silica-alumina ratio and intercrystalline porosity can be controlled; a pore structure and the type of the molecular sieve can be designed according to the geometrical structure of a target product; and the capacity of accommodating carbon is raised, the mass transfer capability of the catalyst is reinforced, and the life of catalyst is prolonged while keeping the high activity of the ultrafine molecular sieve and high target product selectivity.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

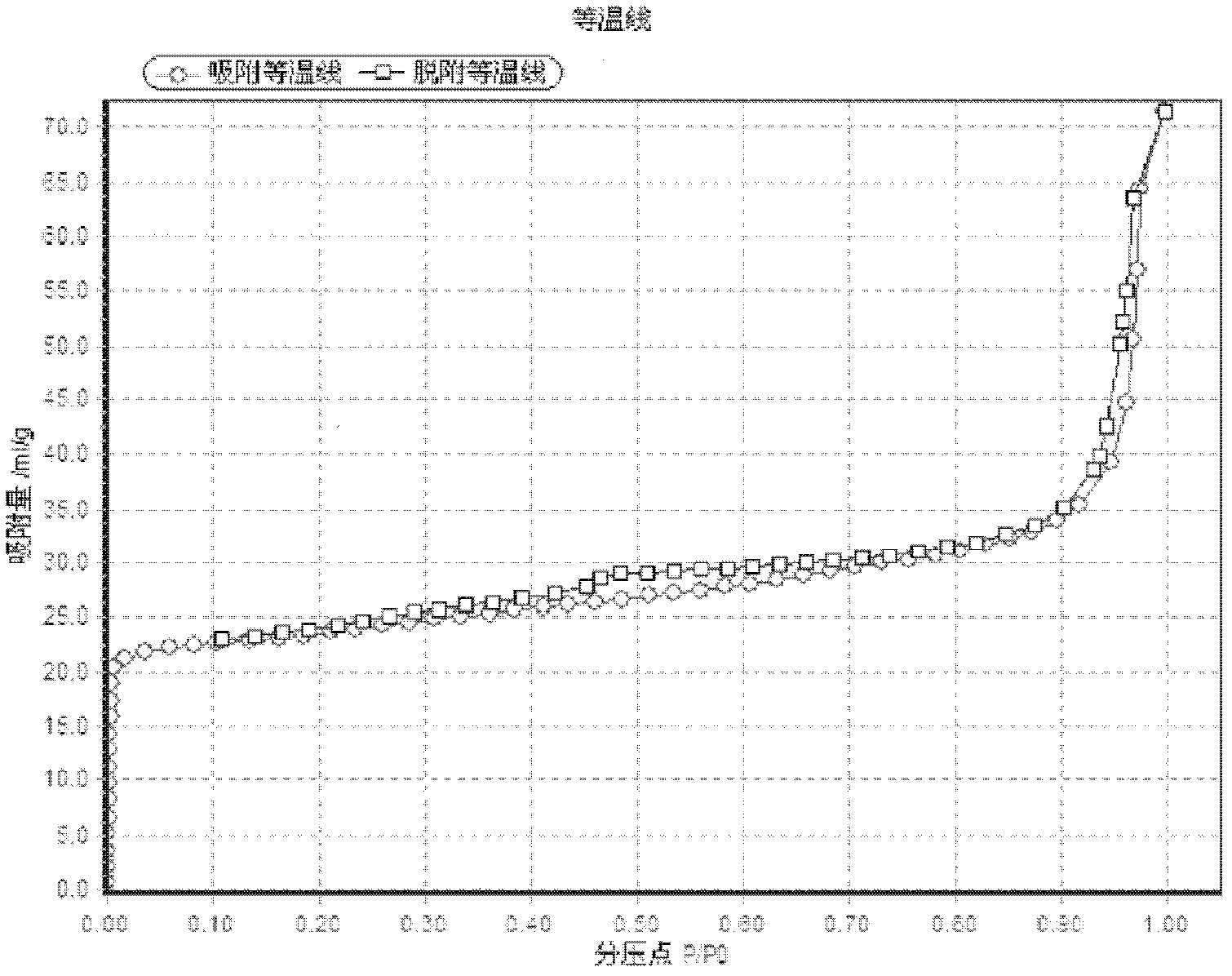

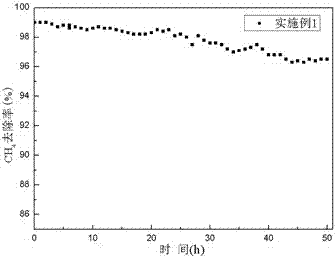

Preparation method for hierarchical pore perovskite catalyst

ActiveCN107376924AImprove adsorption capacityLarge specific surface areaGas treatmentMethane captureMetal nitrateNitrate

The invention relates to a preparation method for a hierarchical pore perovskite catalyst. The method comprises the following steps: 1) weighting metal nitrate mixture and complexing agent and mixing, wherein the mole number of the complexing agent is 1-2 times of the sum of the mole number of all the nitrate in the metal nitrate mixture; 2) adding the metal nitrate mixture and the complexing agent into deionized water and stirring under room temperature; 3) heating and stirring the acquired product at 60 DEG C-90 DEG C till forming a wet gel; 4) leaving the wet gel in a standby state, ageing, drying and grinding; 5) sintering for 5h at 800 DEG C; 6) reacting for 2-36h in a reaction kettle at 150-200 DEG C; 7) naturally cooling, filtering and drying; 8) sintering for 1-12h at 600 DEG C. The prepared catalyst has the advantages of excellent absorption property and large specific surface area.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY +1

Three-dimensional proton conductor based ordered single electrode and membrane electrode as well as preparation methods

InactiveCN102738477AReduce dosageIncrease contact areaMaterial nanotechnologyCell electrodesPtru catalystElectrical conductor

The invention relates to a three-dimensional proton conductor based single electrode and a membrane electrode as well as preparation methods. According to the invention, firstly a three-dimensional proton conductor with a nanofiber array structure is prepared, then the proton conductor of the structure is prepared into an ordered single electrode, and two single electrodes are then combined into an ordered fucel cell membrane electrode. The single electrode is characterized in that a three-dimensional proton conductor is adopted as the basis, and a magnetron sputtering technology is employed for uniform vapor deposition of a layer of a nano-active metal catalyst on a nanofiber surface. The membrane electrode is characterized in that nanofiber arrays grow on two sides of the membrane electrode, and a layer of a nano-active metal catalyst is formed on surfaces of the nanofiber arrays through vapor deposition. The nanofiber arrays grow on two sides of the membrane electrode, so that the area of a catalytic layer is substantially increased while the proton conduction efficiency is ensured simultaneously, thus being in favor of mass transfer and reduction of proton conductor dosage. Meanwhile, the vapor deposition technology is adopted, the nano-active metal membrane has controllable thickness and is uniform, and while improving the catalytic performance of a noble metal or its alloy, consumption of the active metal catalyst can be reduced substantially.

Owner:WUHAN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com