Method for preparing polymethoxy dimethyl ether through reaction and rectification of fixed bed

A polymethoxydimethyl ether, fixed bed reaction technology, applied in catalytic reaction, chemical instruments and methods, preparation of organic compounds, etc., can solve the problems affecting the reaction conversion rate and product yield, reaction conversion rate and The product yield is low, the reaction product and the catalyst are not easily separated, etc., to achieve the effect of uniform distribution of the reaction product, improving the purity and yield, and saving equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

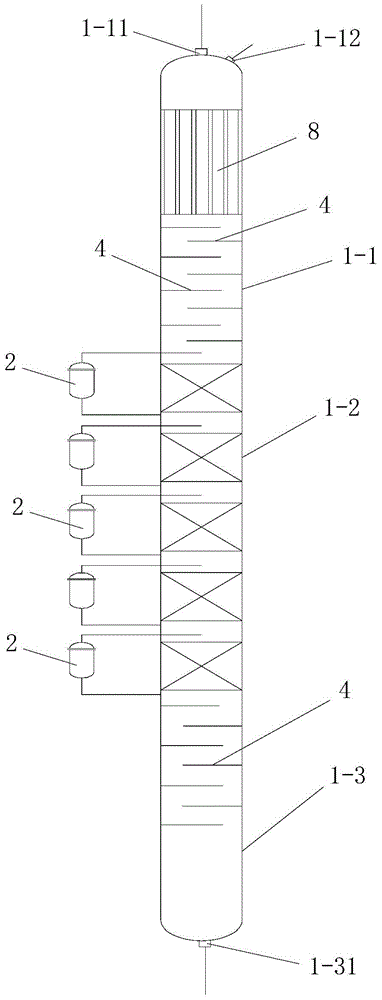

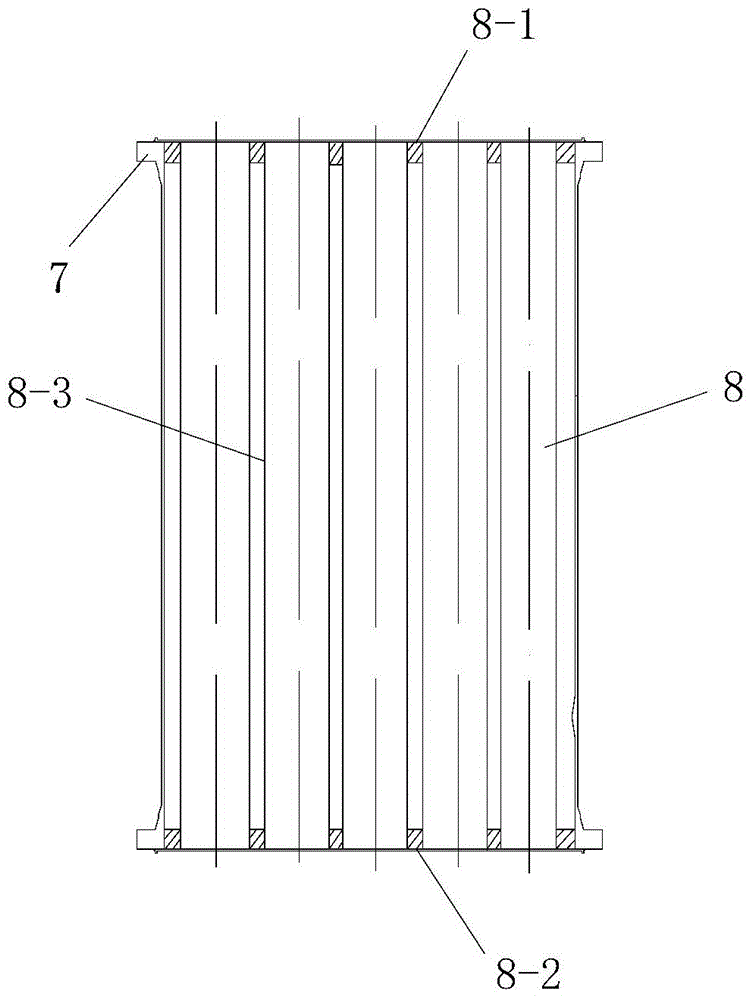

[0072] Such as figure 2 As shown, the reactive distillation tower of the present invention comprises a rectification tower body arranged vertically and a plurality of side line reactors 2 arranged outside the rectification tower body, and a plurality of side line reactors 2 are composed of Arranged from top to bottom; the rectification tower body includes an upper tower body 1-1, a lower tower body 1-3 located directly below the upper tower body 1-1, and a lower tower body 1-3 connected to the upper tower body 1-1 and the lower tower body 1 The middle tower body 1-2 between -3; the upper part of the upper tower body 1-1 is a cluster rectification section and its lower part is an upper tray layout section, and the cluster rectification section is divided into a plurality of vertical The cluster rectification zone 8 arranged vertically, the upper tray layout section and the top of the upper tower body 1-1 are connected through a plurality of cluster rectification zones 8, and e...

Embodiment 2

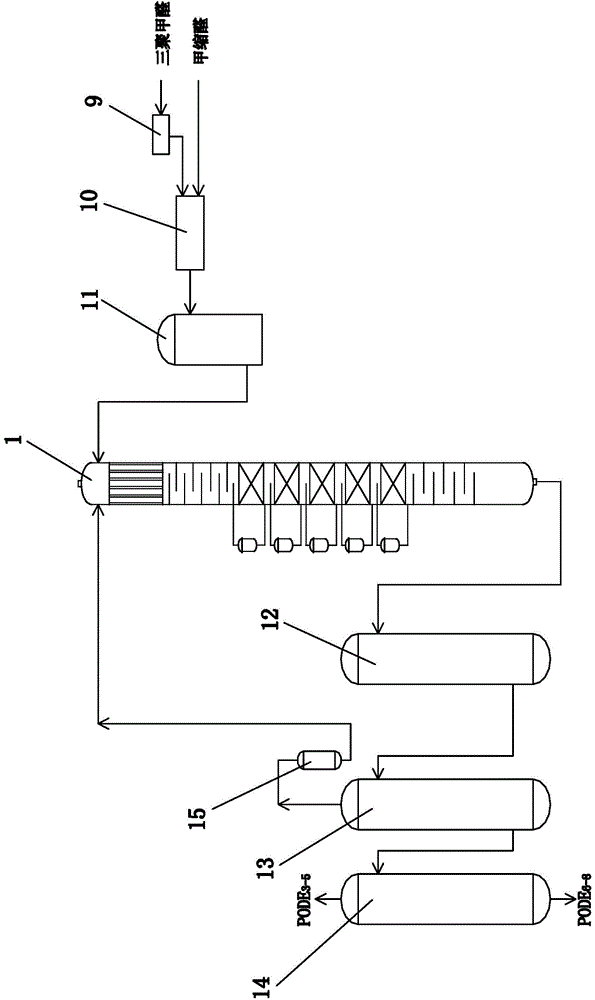

[0099] Step one, such as figure 1 As shown, pass the paraformaldehyde into the preheater 9 to preheat to 65°C, then mix the methylal and the preheated paraformaldehyde in the mixer 10 according to the molar ratio of 1.0:1 and send them into The etherification reaction is carried out in a fixed-bed reactor 11 filled with a catalyst; the temperature of the etherification reaction is 50° C., and the reaction pressure is 0.10 MPa; the catalyst is a strongly acidic styrene-based cation exchange resin modified with rare earth elements, The preparation method of the catalyst is as follows: a lanthanum nitrate aqueous solution with a mass concentration of 1% and a basic cerium nitrate aqueous solution with a mass concentration of 1% are uniformly mixed according to the mass ratio of lanthanum nitrate and basic cerium nitrate at a ratio of 1:1, and then Strongly acidic styrene-based cation-exchange resin (purchased from Jiangsu Sekesaisi Resin Co., Ltd.) was placed in the mixed solutio...

Embodiment 3

[0104] Step one, such as figure 1 As shown, the paraformaldehyde is passed into the preheater 9 to preheat to 80°C, and then the methylal and the preheated paraformaldehyde are mixed uniformly in the mixer 10 according to the molar ratio of 2.0:1 and then sent into The etherification reaction is carried out in a fixed-bed reactor 11 filled with a catalyst; the temperature of the etherification reaction is 120° C., and the reaction pressure is 0.55 MPa; the catalyst is a strongly acidic styrene-based cation exchange resin modified with rare earth elements, The preparation method of the catalyst is as follows: a lanthanum nitrate aqueous solution with a mass concentration of 3% and a basic cerium nitrate aqueous solution with a mass concentration of 2% are uniformly mixed according to the mass ratio of lanthanum nitrate and basic cerium nitrate at a ratio of 1.5:1, and then Strongly acidic styrene-based cation-exchange resin (purchased from Jiangsu Sekesaisi Resin Co., Ltd.) was...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com