Patents

Literature

32results about How to "Suitable pore structure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

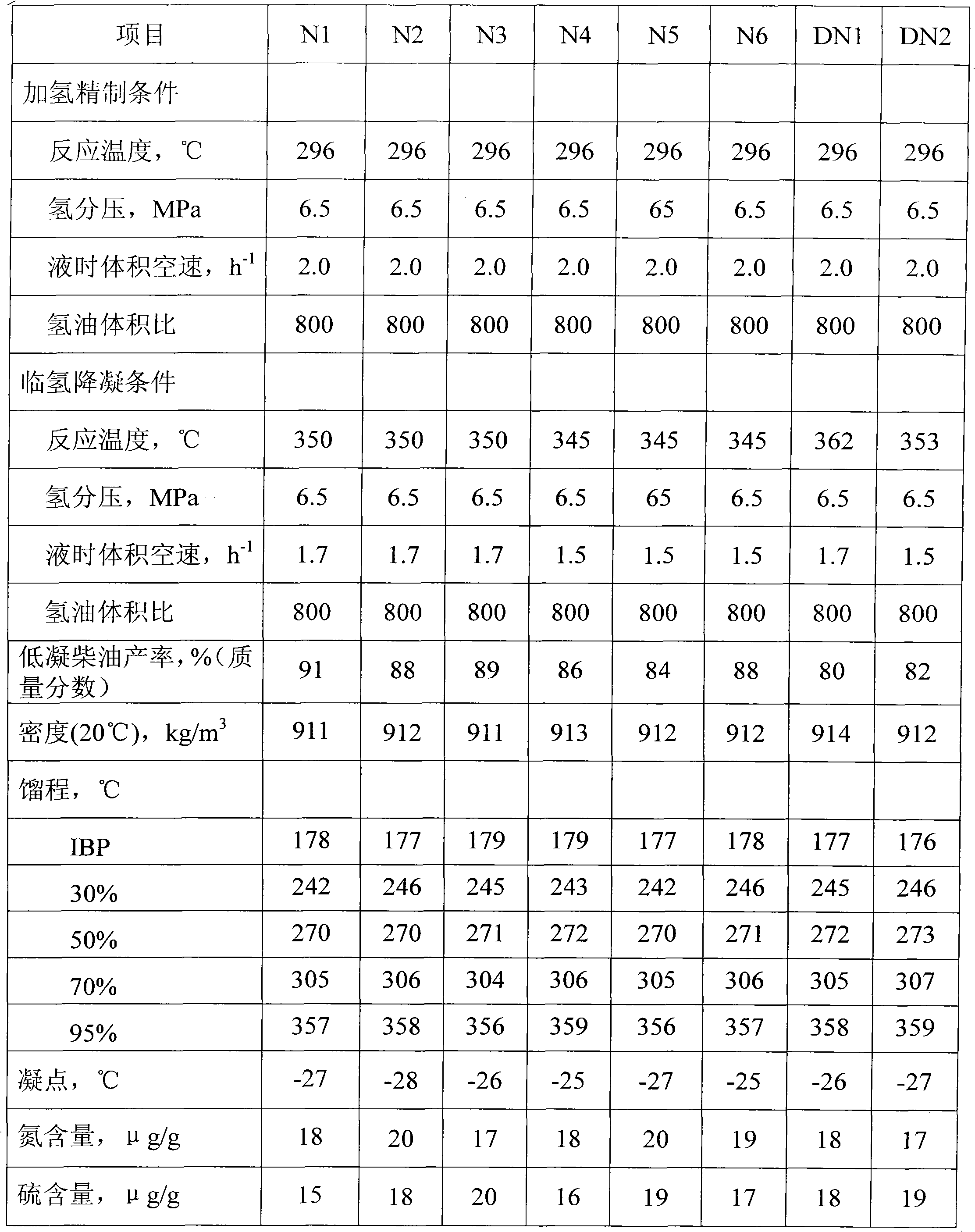

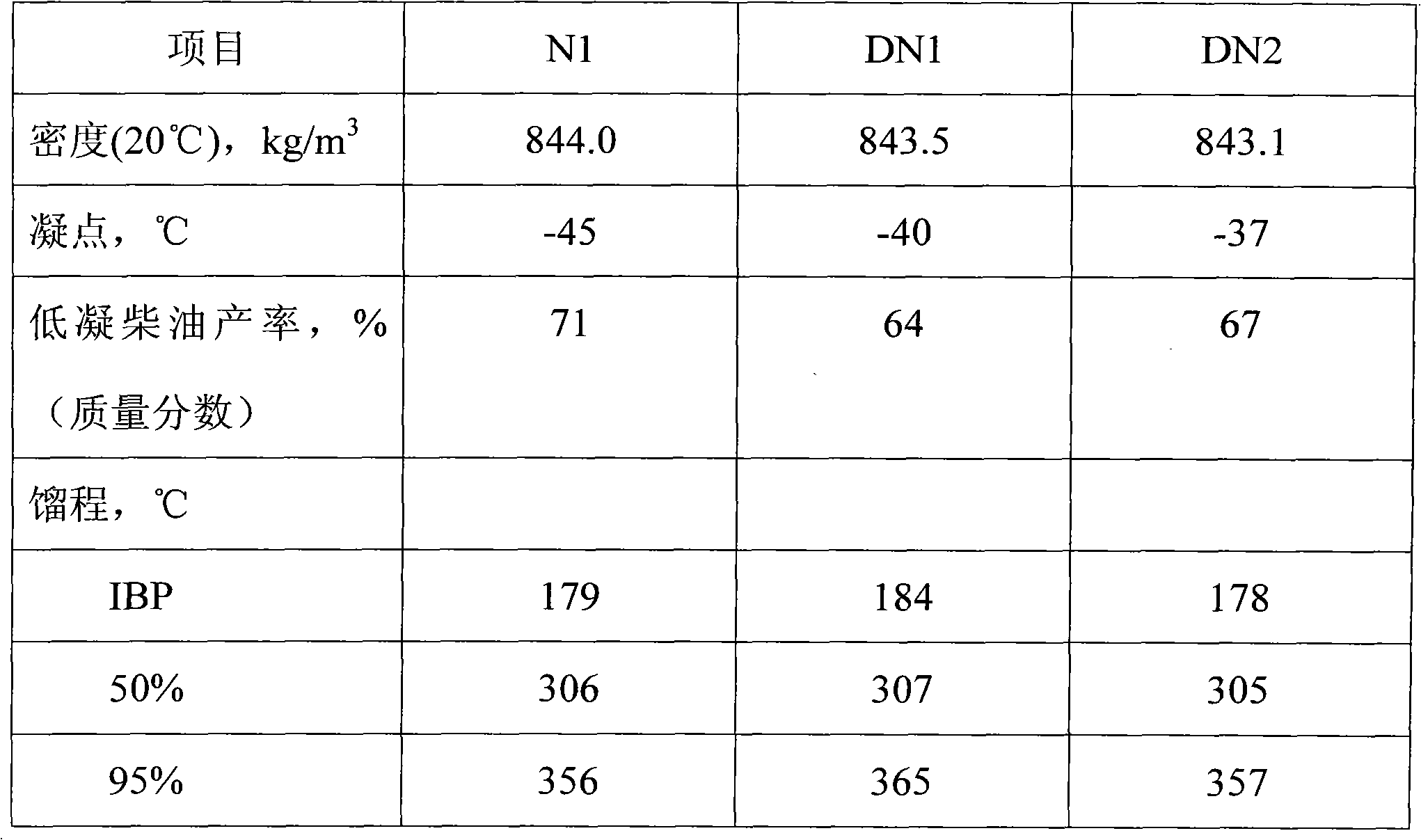

Diesel oil hydrogenation pour point depressing method

ActiveCN102051232ASuitable pore structureAppropriate pore inner surface propertiesCatalyst carriersMolecular sieve catalystsMolecular sieveWax

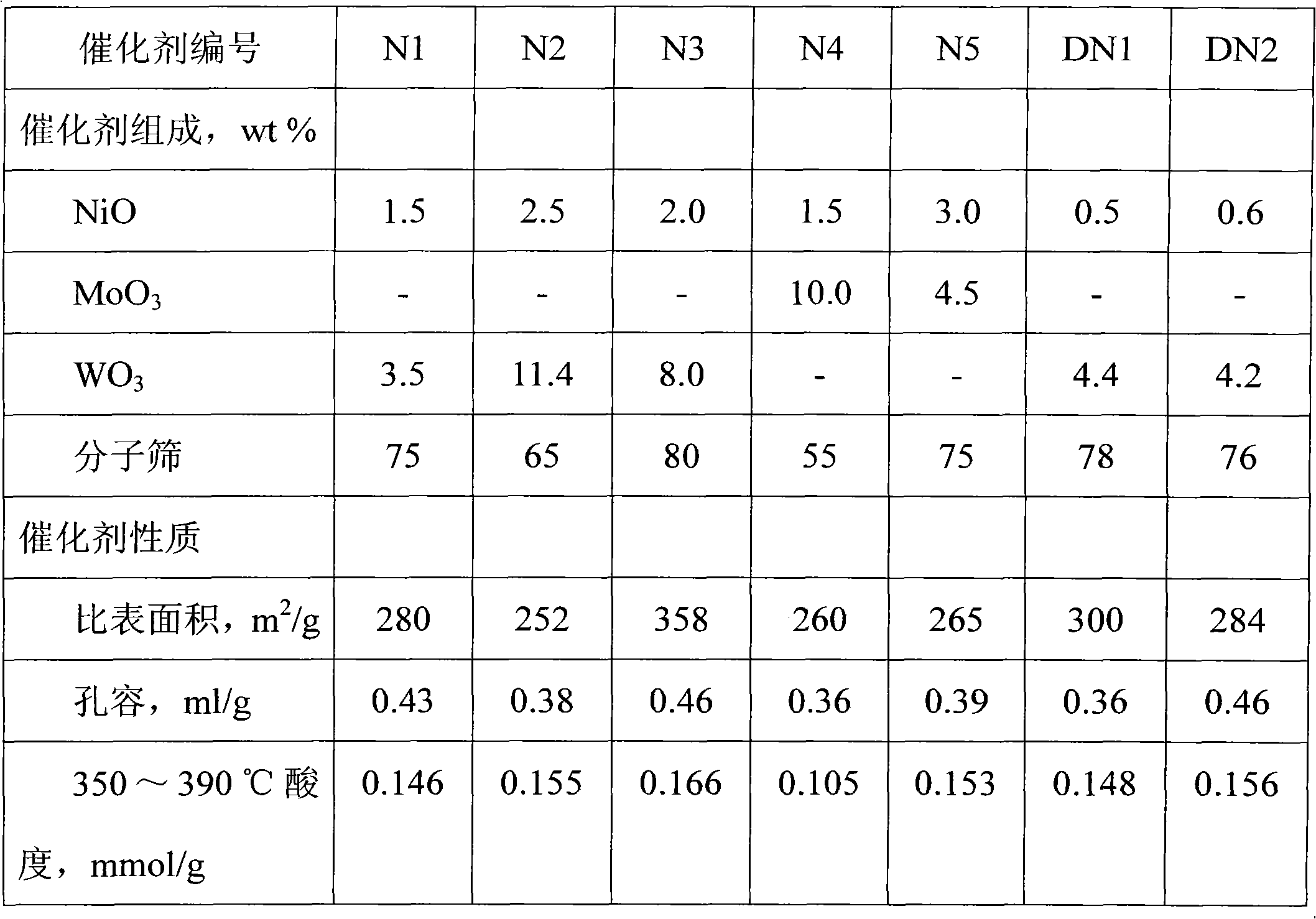

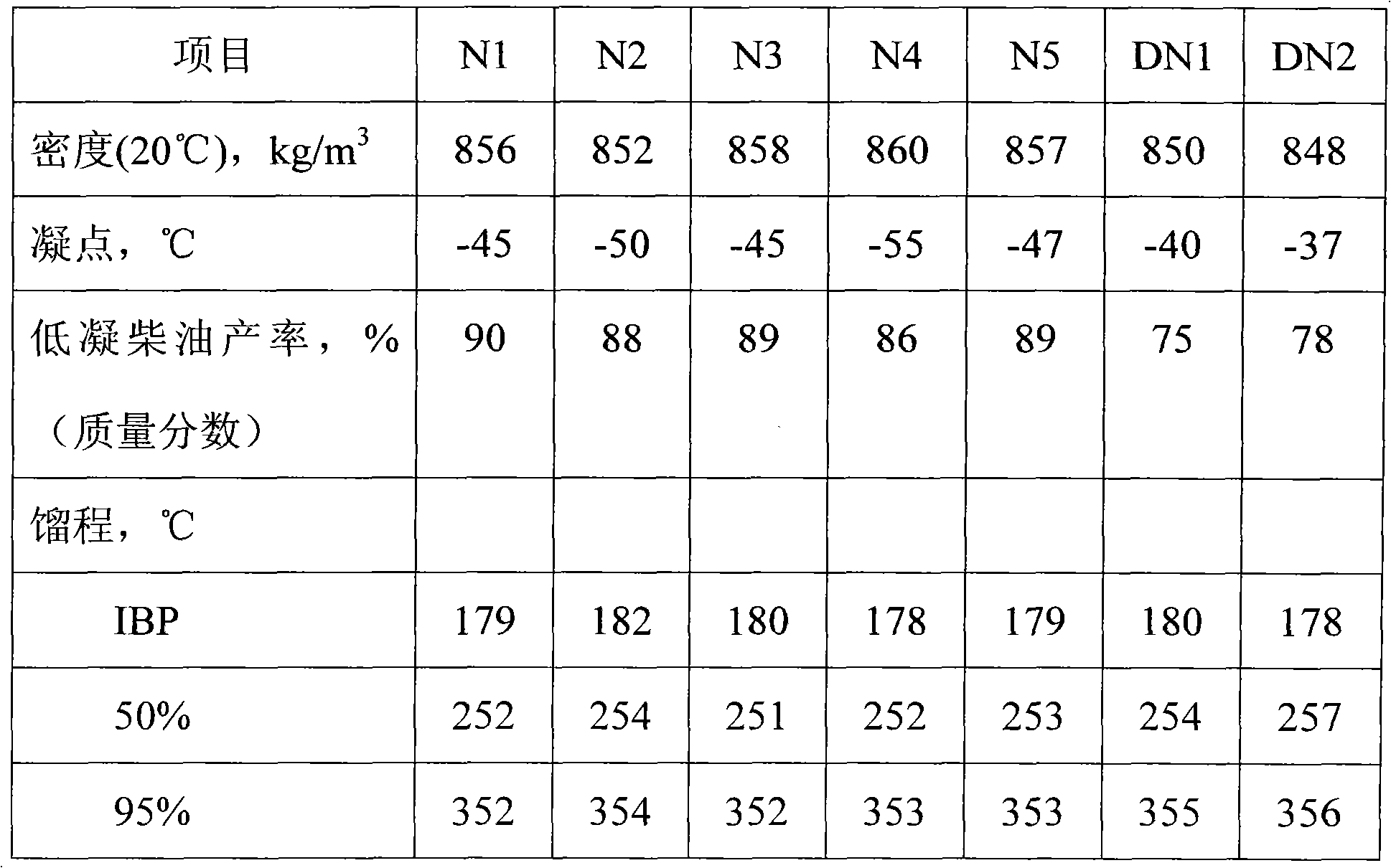

The invention discloses a diesel oil hydrogenation pour point depressing method. A series flow of hydrofining and hydrogenation pour point depressing is adopted in the method, wherein a hydrogenation pour point depressing catalyst is modified by metal auxiliary agent and silicon, effectively regulates the acidity and orifice shape of the inner surface and the outer surface of a shape-selective cracking molecular sieve, is favorable for dispersing wax molecules in a diesel oil raw material into pore canals of the molecular sieve to perform shape-selective cracking reaction, and has high catalytic activity and selectivity of a target product; and because the acidity of the outer surface of the molecular sieve is weak, side reactions such as secondary cracking and the like are reduced, the pour point depressing effect of the diesel oil is good, and the fraction yield of the diesel oil is high.

Owner:CHINA PETROLEUM & CHEM CORP +1

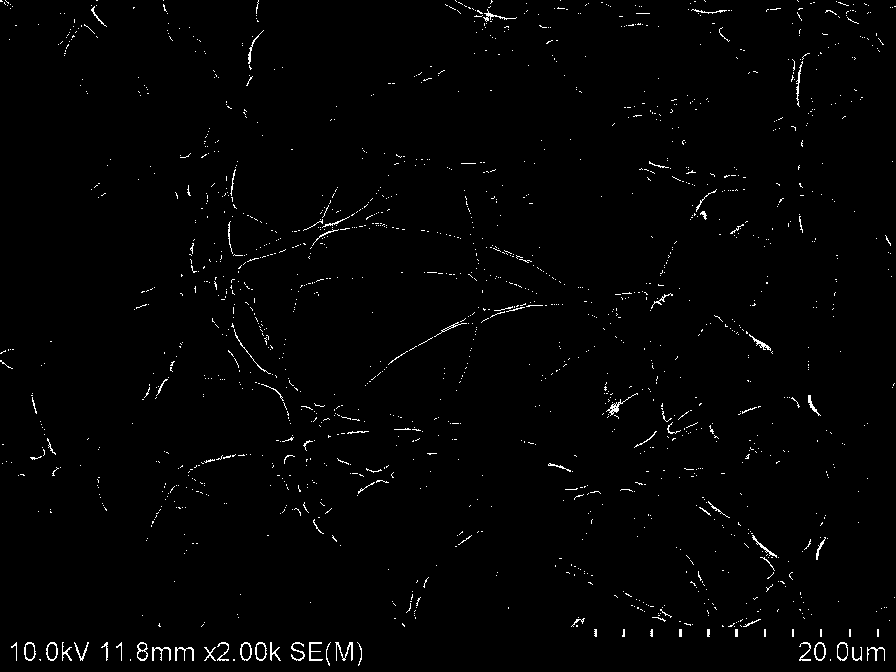

Iron group fischer-tropsch synthesis catalyst and its preparation method

ActiveCN102380390AEasy to prepareSuitable for mass productionLiquid hydrocarbon mixture productionMetal/metal-oxides/metal-hydroxide catalystsWater-gas shift reactionIron group

The invention relates to an iron group fischer-tropsch synthesis catalyst and its preparation method. The iron group fischer-tropsch synthesis catalyst comprises the components of Fe, Cu, K, Li and SiO2 with weight proportion of 100:0.1-15:0.1-10:0.05-10:2-50. On the premise of good fischer-tropsch synthesis activity and methane selectivity, the iron group fischer-tropsch synthesis catalyst is capable of reducing water gas shift reaction activity in a system and enhancing the effective utilization rate of CO reaction gas.

Owner:CHNA ENERGY INVESTMENT CORP LTD +2

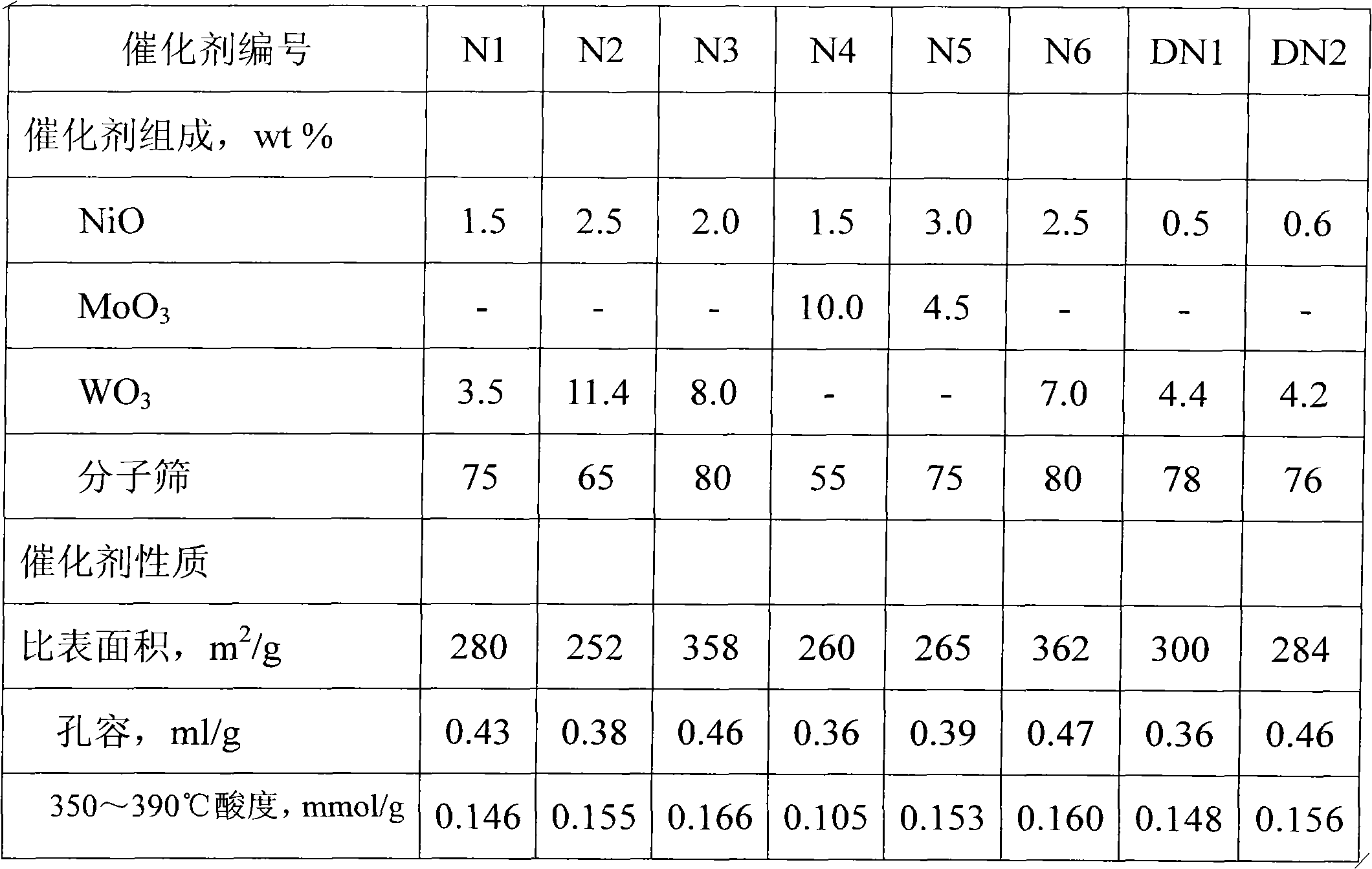

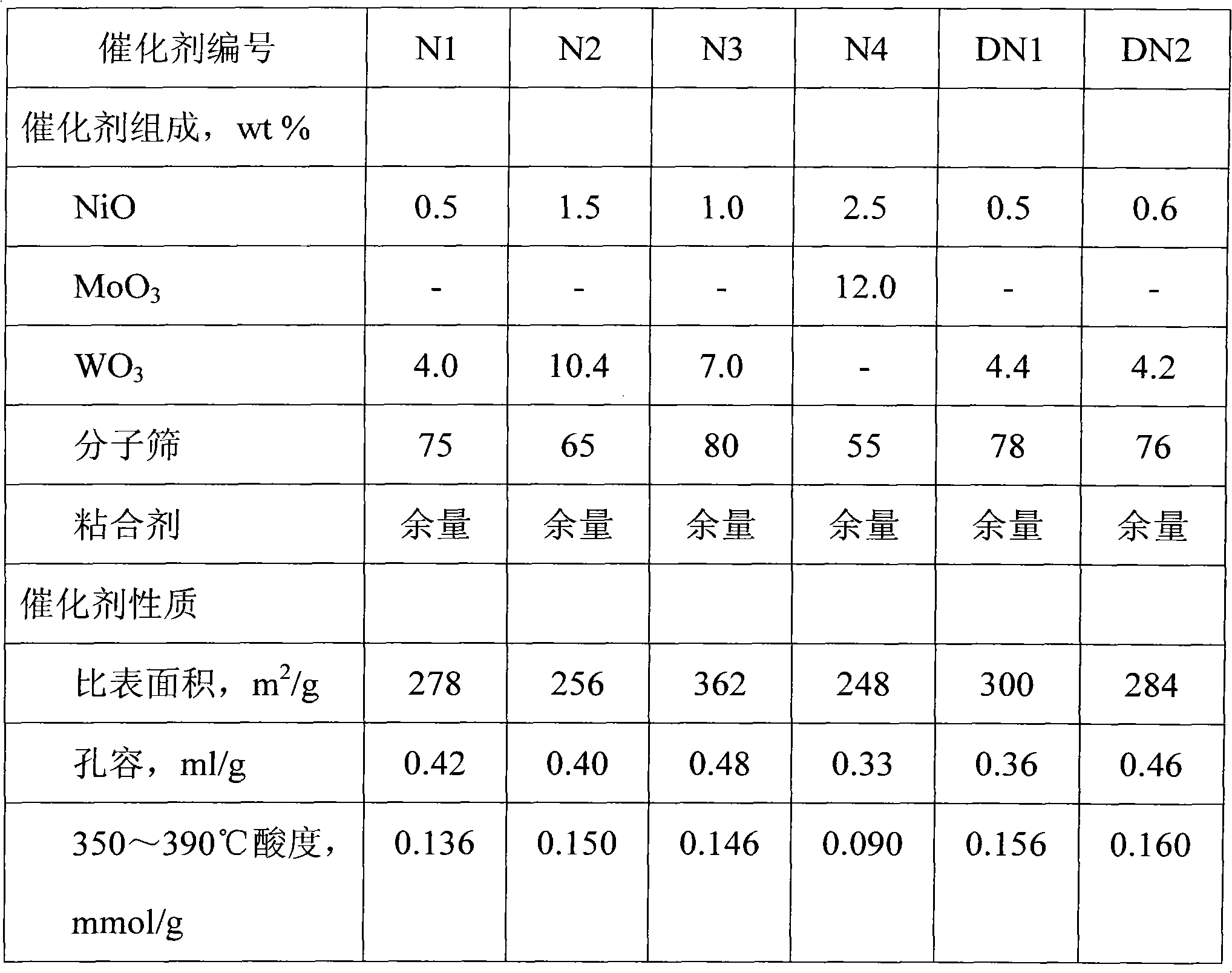

Hydro-dewaxing catalyst and preparation method and application thereof

ActiveCN102049286ASuitable pore structureAppropriate pore inner surface propertiesCatalyst carriersMolecular sieve catalystsMolecular sieveHydrogen

The invention discloses a hydro-dewaxing catalyst and a preparation method and application thereof. The hydro-dewaxing catalyst comprises a carrier modified by a metal aid and silicon, and is prepared by the following steps of: supporting the metal aid by using a conventional carrier impregnation method, modifying by using silicon oil, and forming a silica coating on the surface of the carrier. The method can effectively regulate the acidity and pore shapes of the inner surface and the outer surface of a molecular sieve to contribute to diffusing wax molecules into the pores of the molecular sieve for shape-selective cracking reaction, and ensures higher catalytic activity and higher selectivity for target products; in addition, the acidity of the outer surface of the molecular sieve is lower, the cracking capacity is low, and the side reaction of the target products is reduced. The hydro-dewaxing catalyst is suitable for the hydro-dewaxing process for wax-containing raw materials, particularly the diesel hydro-dewaxing or lubricating oil hydro-dewaxing process.

Owner:CHINA PETROLEUM & CHEM CORP +1

In situ type molecular sieve hydrogenation cracking catalyst and method for preparing same

ActiveCN101618334AGood choiceHigh activityMolecular sieve catalystsHydrocarbon oil crackingIn situ crystallizationMolecular sieve

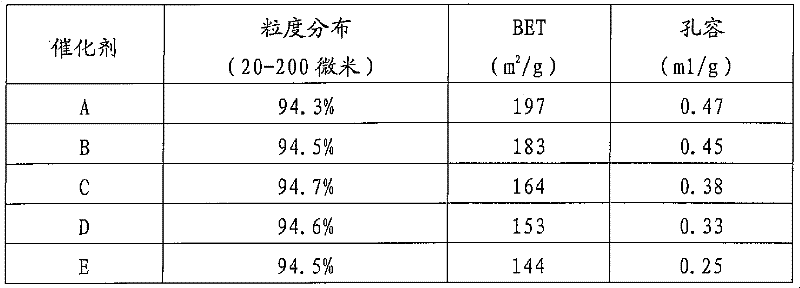

The invention relates to an in situ type molecular sieve hydrogenation cracking catalyst and a method for preparing the same. The in situ type molecular sieve hydrogenation cracking catalyst contains a hydrogenation activity metallic component and a cracking activity component, wherein the cracking activity component comprises a Y type molecular sieve obtained by in situ crystallization synthesis, the weight of the in situ type molecular sieve cracking component is 10 to 90 percent of that of the hydrogenation cracking catalyst, the specific surface of the hydrogenation cracking catalyst is between 150 and 500m<2> / g, the pore volume is between 0.2 and 0.4ml / g, and the pore volume with mesoporous structure which is between 2 and 10nm is over 40 percent of the total pore volume. The common impregnation method is adopted in the process of preparing the catalyst. When the hydrogenation cracking catalyst is used for the hydrogenation of heavy hydrocarbons, the catalyst has the characteristics of high activity, good selectivity, good product quality and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method of three-dimensional ordered macroporous carrier loaded heteropoly compound catalyst and application thereof

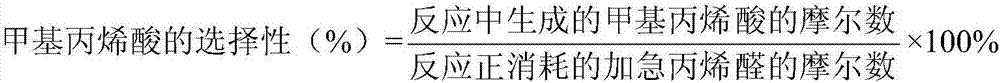

ActiveCN107042121ALarge specific surface areaSuitable pore structureOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsPolystyreneHigh activity

The invention discloses a preparation method of a three-dimensional ordered macroporous carrier loaded heteropoly compound catalyst and belongs to the technical field of preparation of catalysts. The preparation method comprises the following steps of: adding tetraethoxysilane, a vanadium-containing compound and hydrochloric acid into a polystyrene colloidal crystal template; immersing and calcining the template to obtain a VOx-SiO2 three-dimensional ordered macroporous carrier; modifying the carrier; and finally, introducing a heteropoly compound to obtain the three-dimensional ordered macroporous carrier loaded heteropoly compound catalyst. According to the preparation method of the three-dimensional ordered macroporous carrier loaded heteropoly compound catalyst, disclosed by the invention, the catalyst has a proper duct structure and a relatively large specific surface area, so that the diffusing process of reactants and products is facilitated; and the oxidation-reduction quality of the catalyst can be improved by doping vanadium in the carrier, so that the catalyst shows high activity and high selectivity in catalyzing the oxidizing reaction of methylacrolein.

Owner:QUFU NORMAL UNIV

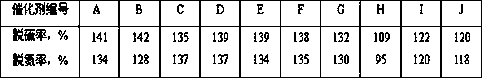

Preparation method of poisoning-resistant catalyst for unsaturated oil hydrogenation

ActiveCN102513114AHigh strengthStable physical parametersFatty acid hydrogenationMetal/metal-oxides/metal-hydroxide catalystsNickel saltHydrogen

The invention discloses a preparation method of a poisoning-resistant catalyst for unsaturated oil hydrogenation. The preparation method is characterized by comprising the following steps of 1, putting an alkaline precipitator solution into a reactor, and heating to a temperature of 60 to 70 DEG C, 2, adding a mixed solution of a soluble nickel salt, a ferric salt and a rare earth salt into the heated alkaline precipitator solution with stirring in a period of 1 to 2 hours, 3, then fast adding alumina carriers into the mixed solution obtained by the steps 2, stirring for 0.5 to 1 hour, filtering, and washing by deionized water until acid radical ions are removed completely, and 4, drying at a temperature of 110 to 120 DEG C for 4 to 5 hours, crushing, and carrying out hydrogen feeding at a temperature of 400 to 500 DEG C for 2 to 3 hours to obtain the poisoning-resistant catalyst for unsaturated oil hydrogenation, wherein an Ni / Fe atomic ratio of the soluble nickel salt to the ferric salt is in a range of 5 to 25 and the poisoning-resistant catalyst for unsaturated oil hydrogenation contains 30 to 50 wt% of nickel, 2 to 5 wt% of iron, 0.5 to 1.0 wt% of a rare earth salt of cerium and 0.5 to 1.0 wt% of a rare earth salt of lanthanum.

Owner:CHINA NAT OFFSHORE OIL CORP +1

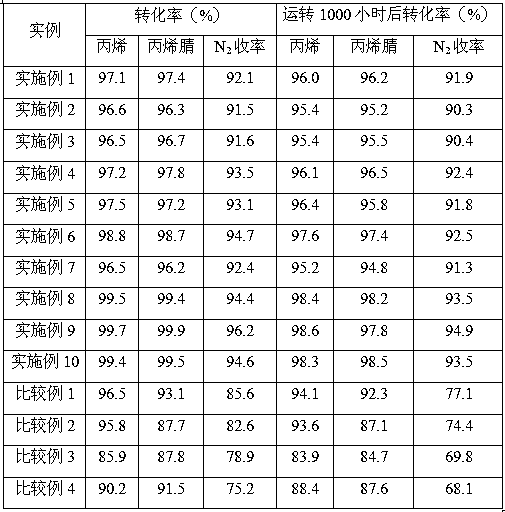

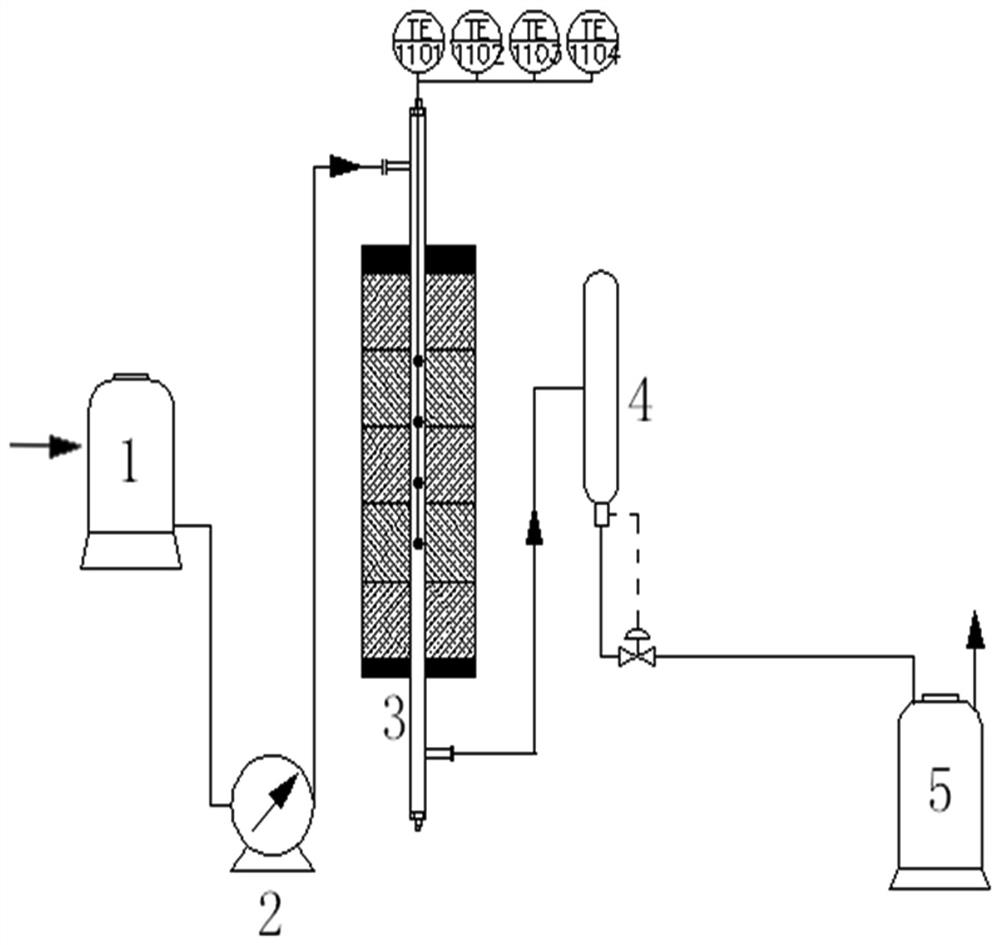

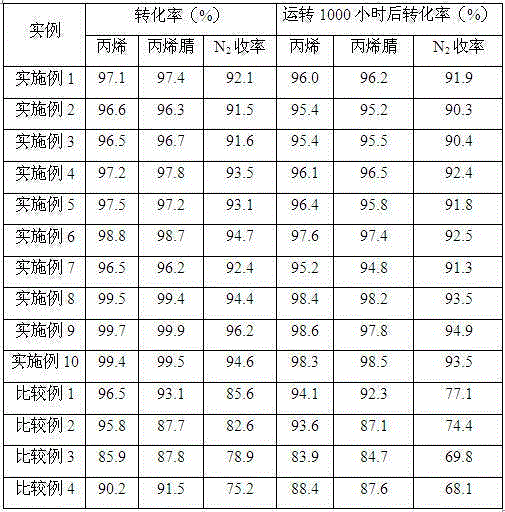

Catalytic combustion catalyst for nitrogen-containing organic compound as well as preparation method and application thereof

ActiveCN106732577AFacilitated DiffusionImprove adsorption capacityIncinerator apparatusMetal/metal-oxides/metal-hydroxide catalystsActive componentAcrylonitrile

The invention relates to a catalytic combustion catalyst for nitrogen-containing organic compound as well as a preparation method and application thereof. The catalytic combustion catalyst for the nitrogen-containing organic compound is characterized in that Al2O3 is taken as a carrier; Ir is taken as an active component; one or several of Sm, In and Sn oxides are taken as the components of an additive; on the basis of the Al2O3, the charge capacity of the active component Ir is 0.1-1wt%, and the charge capacity of the additive is 1-10wt%. The preparation method comprises the following steps: (1) dipping the carrier Al2O3 into a precursor solution of the additives, and drying and roasting to obtain an additive-carrying composite carrier Al2O3, wherein the additive is composed of one or some of Sm, In and Sn oxides; (2) dipping the composite carrier A2lO3 obtained in step (1) into a salt solution containing the active compound, and drying and roasting to obtain the catalyst, wherein the active component is Ir. The method is simple in preparation processes; the prepared catalyst is high in catalyzing combustion activity on nitrogen-containing organic waste gas, high in selectivity and high in stability, and particularly applicable to the treatment of propylene and acrylonitrile containing organic waste gas.

Owner:CHINA PETROLEUM & CHEM CORP +1

A catalyst for catalytic cracking to prepare olefins, a preparing method thereof and applications of the catalyst

ActiveCN106552665AHigh pore volumeIncrease the areaMolecular sieve catalystsHydrocarbon by hydrocarbon crackingMolecular sieveAlkaline earth metal

A catalyst for catalytic cracking to prepare olefins, a preparing method thereof and applications of the catalyst are disclosed. The catalyst includes, by weight, 5-30% of an alkaline earth metal-modified MFI molecular sieve and 0.1-3% of heteropoly acid, with the balance being SiO2, wherein the weight of the alkaline earth metal is 0.5-2% of the weight of the MFI molecular sieve. The preparing method includes (1) weighing a proper amount of the heteropoly acid, dissolving the heteropoly acid into water and fully stirring the solution, (2) adding a proper amount of an ethanol solvent and a proper amount of a silicon-containing precursor into the solution obtained in the step (1), fully stirring the solution, and adjusting the pH value of the solution to be 1-7, (3) adding the alkaline earth metal-modified MFI molecular sieve into the solution in the step (2), fully stirring the solution at a constant temperature, then adding an ionic liquid, and continuously stirring the solution until the solution is converted into sol, and then performing room-temperature ageing to obtain gel, and (4) drying the gel in the step (3) until the weight is constant and grinding the dried gel to obtain the catalyst for catalytic cracking. The catalyst has advantages of a high olefin yield, low reaction temperatures, good catalyst stability, and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

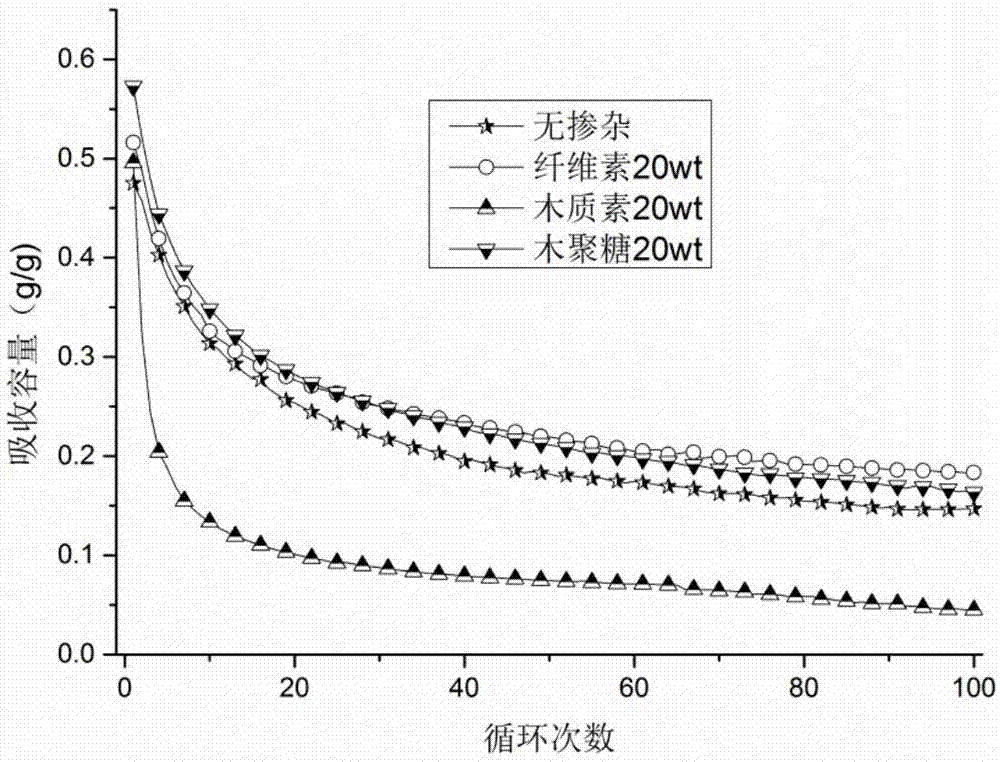

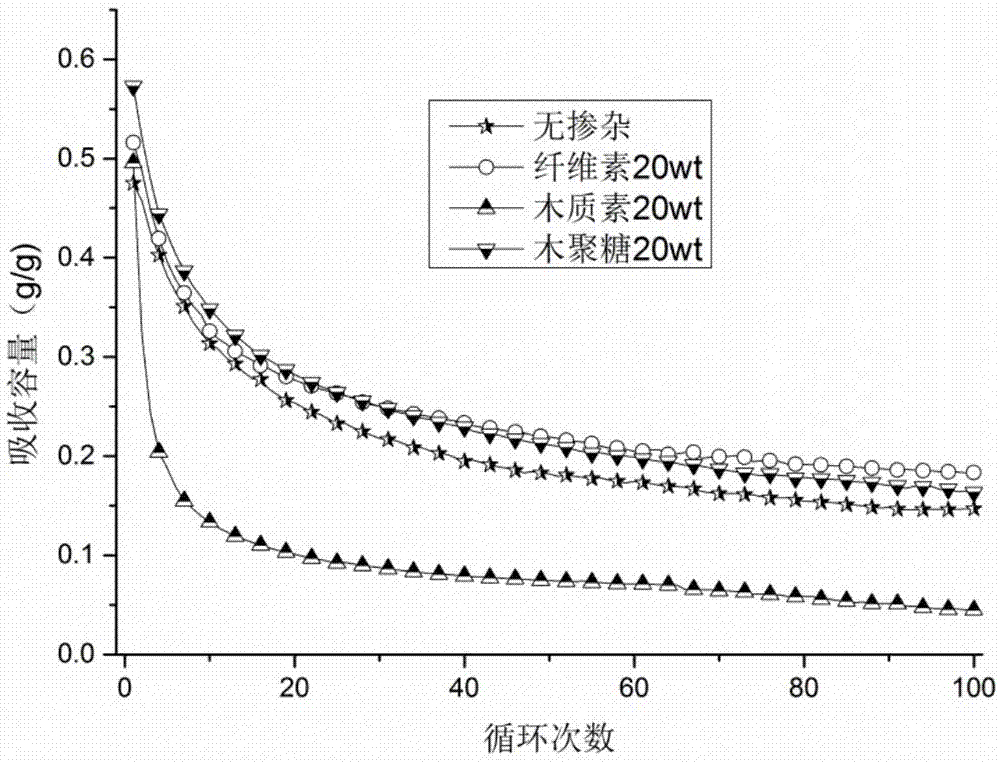

High-performance porous calcium-based absorbent and preparation method thereof

ActiveCN107262018AHigh adsorption capacityGood bonding performanceGas treatmentOther chemical processesBiomassBatch production

The invention belongs to the technical fields of environmental pollution control and clean coal combustion, and concretely relates to a high-performance porous calcium-based absorbent. The high-performance porous calcium-based absorbent comprises calcium source powder and biomass powder, and the biomass powder is pyrolyzed and volatilies when the calcium-based absorbent is calcined at a high temperature in order to form a porous structure in the biomass powder. The invention also discloses a preparation method of the calcium-based absorbent. Pores formed by the pyrolysis and volatilization of the cellulose-rich biomass powder are used to improve the adsorption capacity and the cycle stability of the calcium-based absorbent, so the prepared spherical calcium-based absorbent is suitable for capturing CO2 in a fluidized bed system; the characteristic of low cost of biomass is fully used in the whole preparation process, and the preparation method also has the advantages of high efficiency, high quality, low cost and convenience in control, so the method is especially suitable for being used in large-scale batch production.

Owner:HUAZHONG UNIV OF SCI & TECH

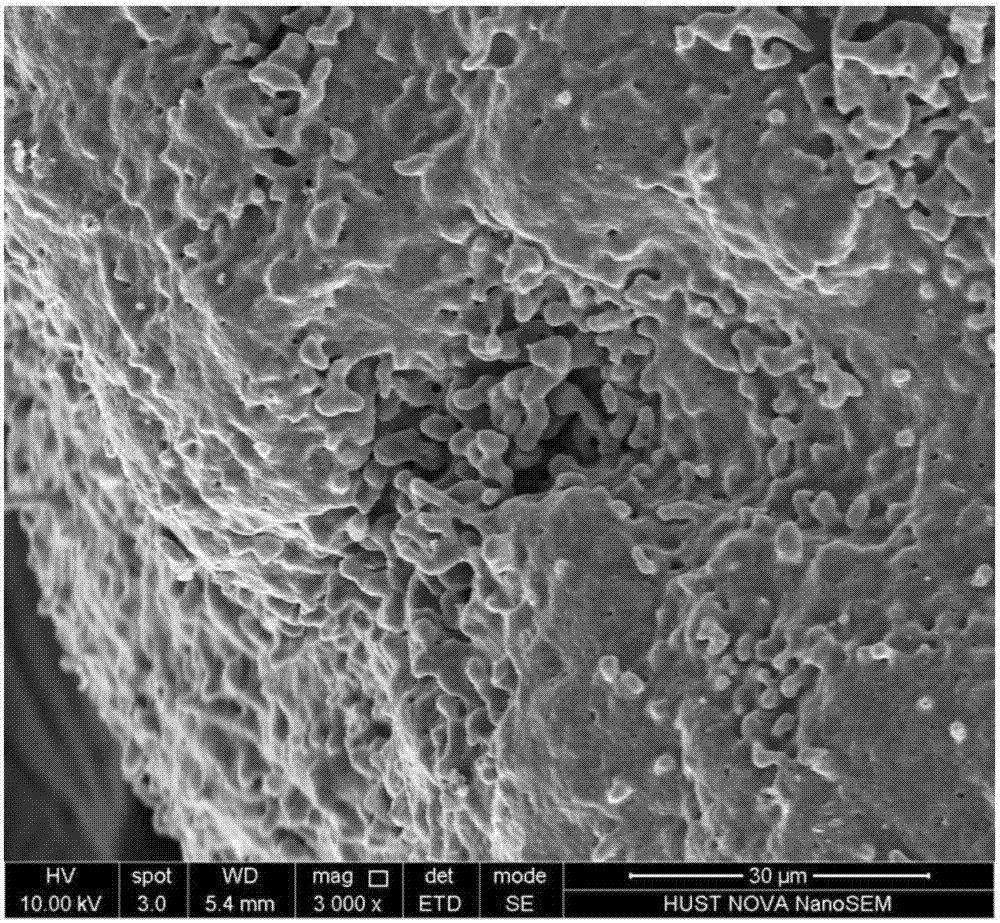

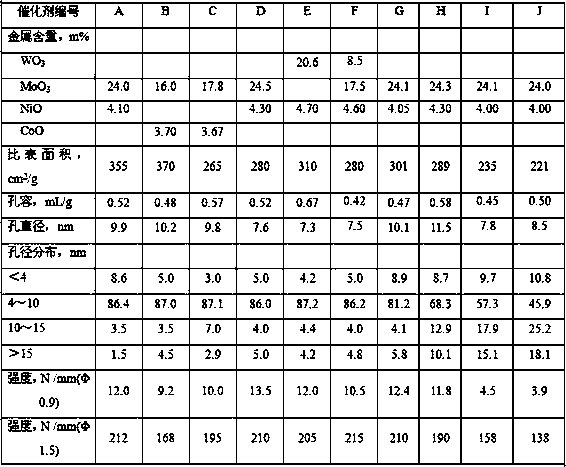

Preparation method of vulcanized hydrogenation catalyst

ActiveCN108067271AHigh catalytic activityReduce manufacturing costPhysical/chemical process catalystsHydrocarbon oils treatmentPore diameterSlurry

The invention discloses a preparation method of a vulcanized hydrogenation catalyst. The method comprises the steps as follows: (1) a vulcanizing agent, a vulcanizing aid, an emulsifier and additive particles are uniformly mixed, the mixture is subjected to a constant-temperature reaction, then, an aqueous solution containing hydrogenation active metal is added, the mixture reacts for 5-60 min, the additive particles are removed by separation, and a liquid mixture I is obtained; (2) a peptizing agent, water and urea are uniformly mixed and a liquid mixture II is obtained; (3) an aluminum source is added to an acidic aqueous solution for slurry making, the liquid mixtures I and II are added, and the slurry is mixed uniformly; (4) the slurry in the step (3) is subjected to quick evaporativeconcentration to form concentrated slurry, slow drying treatment is performed, and a semi-dried material is obtained; (5) the semi-dried material obtained in the step (3) is ground, subjected to extrusion molding and roasting, and the vulcanized hydrogenation catalyst is obtained. The catalyst preparation and vulcanizing processes are completed simultaneously, and the catalyst has uniform pore diameter distribution, is simple to prepare and has wider market application prospects.

Owner:CHINA PETROLEUM & CHEM CORP +1

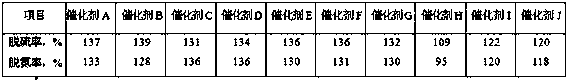

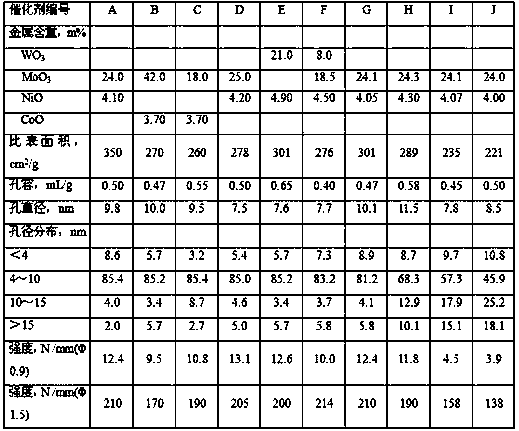

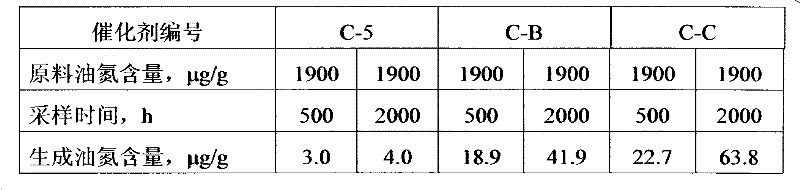

Method for preparing catalyst by hydrotreatment

ActiveCN102451699ACentralized distributionRegular hole structureMetal/metal-oxides/metal-hydroxide catalystsRefining to eliminate hetero atomsSimple Organic CompoundsAluminium hydroxide

The invention discloses a method for preparing a catalyst by hydrotreatment. The method comprises the following steps: gelatinizing aluminum hydroxide and adding a stable boron-containing organic compound solution, introducing a boron auxiliary agent to obtain the boron-containing aluminum hydroxide, mixing active metal ingredients with boron-containing aluminum hydroxide by a wet-mixing-kneadingmethod, three-segment roasting to obtain a catalyst intermediate, dipping the residual partial active metal and loading on the catalyst intermediate, drying to obtain the hydrotreatment catalyst. According to the invention, the boron auxiliary agent and the active metal ingredients are uniformly distributed on the surface of the catalyst, active metal ingredients introduced by two modes has different forms in the catalyst, mutual cooperation enables reduction of activity loss rate of the catalyst, and the running period of the apparatus can be prolonged. The catalyst has the characteristics of large pore volume and large specific surface area, and possesses proper pore structure and acidity, is especially suitable for hydrodenitrogenation process of heavy hydrocarbon.

Owner:CHINA PETROLEUM & CHEM CORP +1

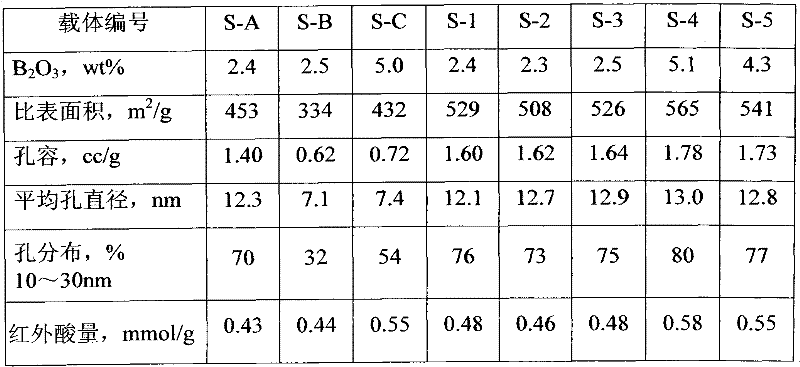

Boron-containing alumina carrier and preparation method thereof

ActiveCN102451771AEffectively regulates acidityImprove anti-cokingCatalyst carriersAdhesiveAluminium hydroxide

The invention discloses a preparation method of a boron-containing alumina carrier. The method comprises the following steps of: gelling the conventional aluminum hydroxide; adding into a stable boron-containing organic compound solution; aging, filtering, washing and drying to obtain dry boron-containing aluminum hydroxide gel; mixing and molding with an adhesive; and heating and performing gradual programmed heating and baking to obtain the boron-containing alumina carrier. Boron-containing alumina is a high-performance carrier component, which can be used for providing a large pore volume and a large specific surface area, has an appropriate pore structure and acidity, and is particularly suitable for a catalyst material needed by a heavy hydrocarbon catalytic processing process.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for preparing high acid value oil hydrogenation catalyst

InactiveCN102895975AHigh strengthStable physical parametersFatty acid hydrogenationMetal/metal-oxides/metal-hydroxide catalystsPtru catalystHigh activity

The invention relates to a method for preparing high acid value oil hydrogenation catalyst. The method comprises the following steps: making macro-pore-volume aluminum oxide as a carrier; making nickel and iron as active components; and making magnesium as auxiliary agent so as to prepare catalyst. A catalyst preparation method is characterized by simple operation, easy filter, high activity and good selectivity; compared with other kindred catalyst, the use quantity of the catalyst is reduced by 15-20%.

Owner:CHINA NAT OFFSHORE OIL CORP +1

Hydrodewaxing catalyst as well as preparation method and application thereof

ActiveCN102049287ASuitable pore structureAppropriate pore inner surface propertiesCatalyst carriersMolecular sieve catalystsAlkaline earth metalSilica coating

The invention discloses a hydrodewaxing catalyst as well as a preparation method and application thereof. The hydrodewaxing catalyst is prepared by using a carrier modified with alkaline-earth metals and silicon. The carrier is modified through the following steps: firstly loading the alkaline-earth metals onto the carrier by a traditional carrier immersion method; and then modifying the carrier with silicon oil to form a silica coating on the surface of the carrier. By utilizing the method, the acidity of internal and external surfaces of a molecule sieve and the shape of holes can be effectively adjusted, thereby being beneficial for wax molecules to diffuse into the hole paths of the molecule sieve and be subjected to a shape-selective cracking reaction. Thus the catalyst provided by the invention has the advantages of higher catalyst activity and better target product selectivity. Moreover, due to the weak acidity of the external surface of the molecule sieve and low cracking capacity, the side reaction in the preparation of the target products are reduced. The catalyst is suitable for the hydrodewaxing process of wax-containing raw materials, especially for a hydrodewaxing process of diesel oil or lubricating oil.

Owner:CHINA PETROLEUM & CHEM CORP +1

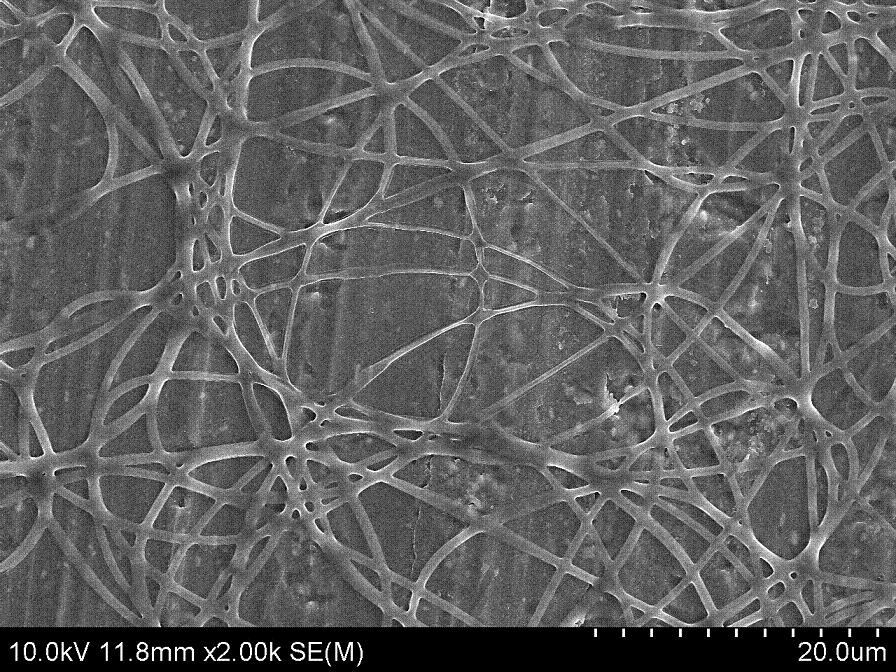

Periosteum material with tissue oxygenation function as well as preparation method and application of periosteum material

ActiveCN107812234AImprove securityWith oxygen functionElectro-spinningTissue regenerationOxygenTissue oxygenation

The invention relates to a periosteum material with a tissue oxygenation function as well as a preparation method and an application of the periosteum material. The preparation method comprises the following steps: preparing PLGA (Poly(Lactic-Co-Glycolic Acid)) wrapped PFOB (Perfluorooctyl Bromide) granules, preparing an electrostatic spinning liquid, and preparing a periosteum material. All raw materials used in the periosteum material are approved medical materials in service, and through specific process steps, the periosteum material has a specific functional and is high in security; the periosteum material provided by the invention has an oxygenation function, the problem that an artificial periosteum is insufficient in blood supply in a primary transplanting period relative to a selfperiosteum is solved, essential oxygen is supplied to cell proliferation, and the speed of tissue healing is increased; and the periosteum prepared by using an electrostatic spinning method is of anappropriate pore structure, is beneficial to bone cell growth and bone tissue repairing and is simple in process and easy to transfer.

Owner:SHANGHAI NAT ENG RES CENT FORNANOTECH

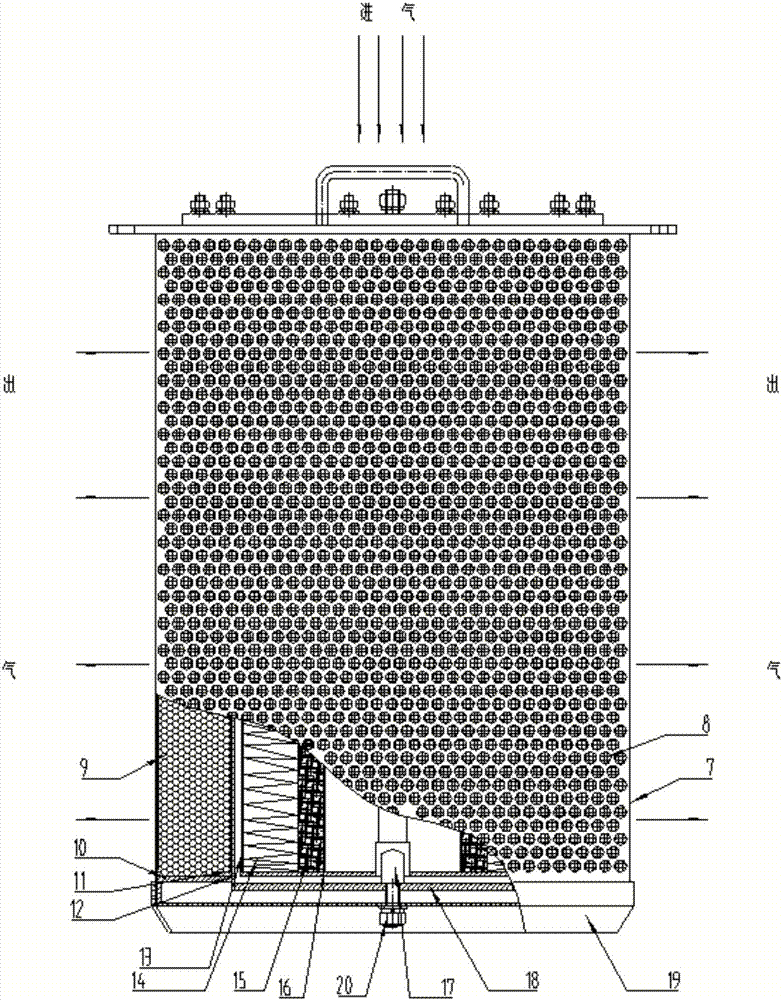

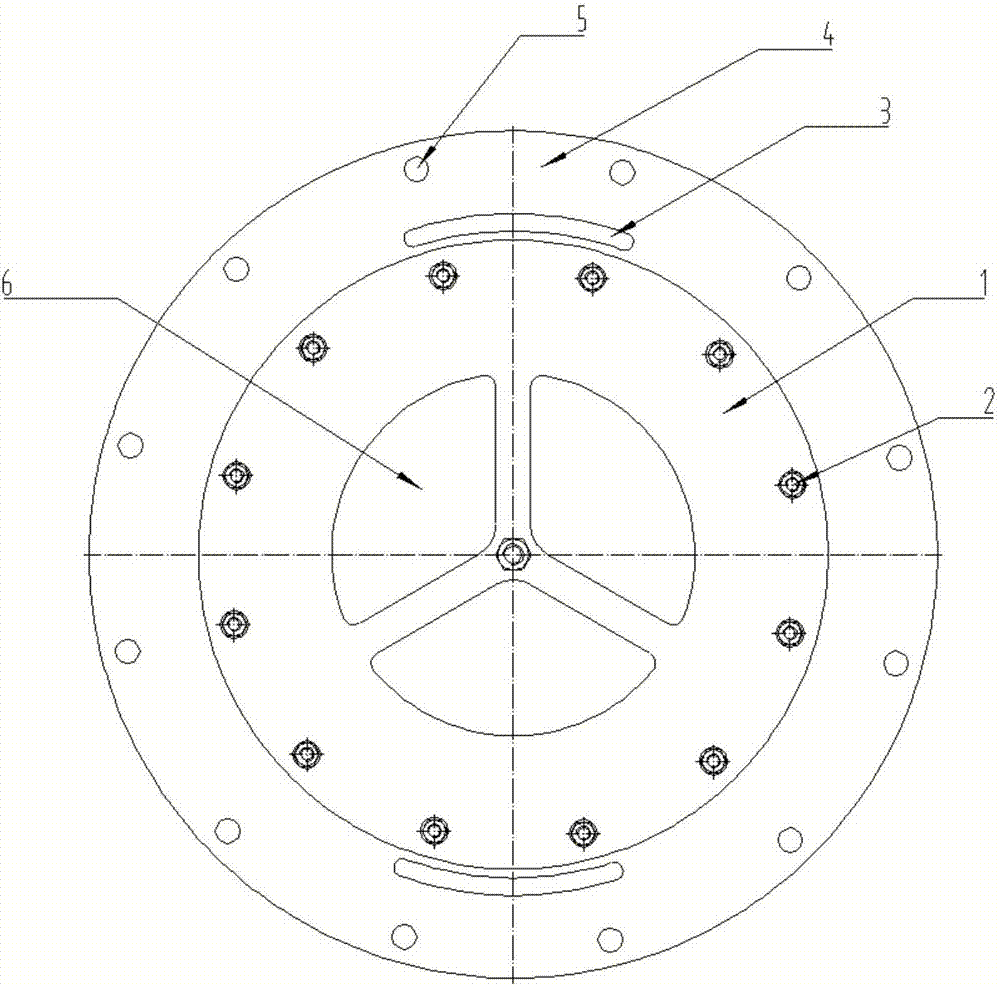

Air filtering absorber

PendingCN107469487AReduce resistanceIncrease the adsorption areaDispersed particle filtrationTransportation and packagingActivated carbonAir filtration

The invention relates to an air filtering absorber. The air filtering absorber is of a cylindrical combined type structure, and is mainly composed of a filtering absorber housing, a paper filer, and an active carbon adsorption layer; the filtering absorber housing is composed of an internal pore plate, an external pore plate, an internal screen net, an external screen net, a pressing pad, and a sealing plate; the paper filter is composed of a primary efficiency filtering layer, a high efficiency filtering layer, and a paper filter internal pore plate. The air filtering absorber adopts the cylindrical combined type structure, resistance is low, adsorption area is large, multi-stage adsorption is realized, purifying capturing efficiency is high, high efficiency filtering material impregnated activated carbon is adopted, the air filtering absorber is invented based on pure physical principles, no energy consumption is caused, maintenance is simple and convenient. The air filtering absorber is suitable to be used in sealed spaces such as sealed defense works, vehicles, ships, and shelters, can be used for filtering radioactive ash, chemical toxins, and biological toxins, and purifying rate is increased to be 99.999% at a nominal air delivery.

Owner:718TH RES INST OF CHINA SHIPBUILDING INDAL CORP

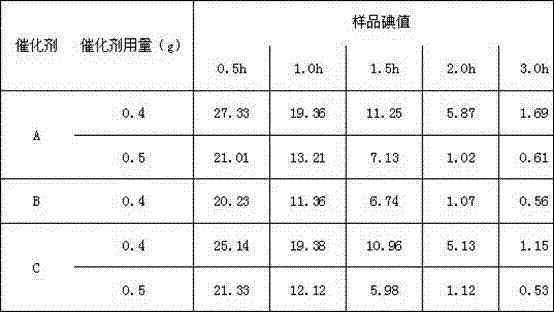

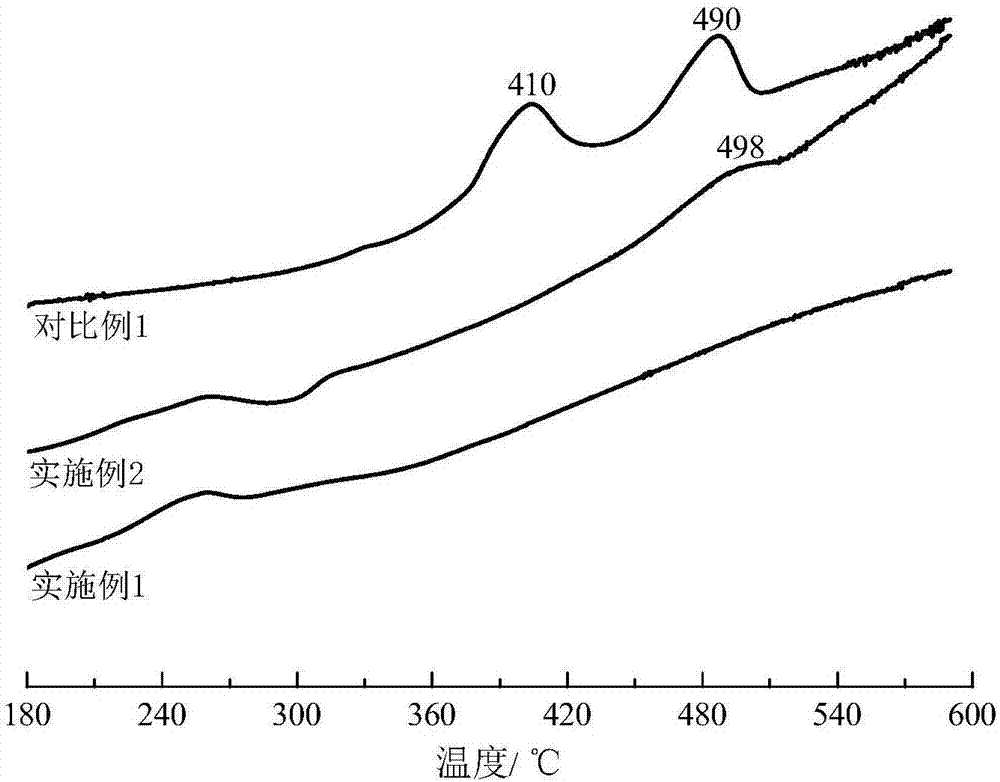

Amorphous catalyst for one-step preparation of cyclohexanone through aqueous phase phenol hydrogenation

ActiveCN106966876ALarge specific surface areaSuitable pore structurePreparation by hydroxy compound hydrogenationOrganic compound preparationCyclohexanoneActivated carbon

The invention discloses an amorphous catalyst for one-step preparation of cyclohexanone through aqueous phase phenol hydrogenation. The catalyst takes gamma-Al2O3 or activated carbon as a carrier, takes Ni and B as active ingredients and takes transition metal and / or Ce as auxiliaries. By carrier mass, the total capacity of the active ingredients and the auxiliaries is 15-35%. When the auxiliaries are the transition metal and Ce, the transition metal is any one of Cu, Fe and Co. When the auxiliaries are the transition metal or Ce, the transition metal is Cu. The amorphous catalyst is cheap and easy to obtain and has high specific surface area and suitable duct structure, the active ingredients and the auxiliaries are small in particle size and are evenly dispersed on the carrier, and the amorphous catalyst has good heat stability and good chemical stability. When the amorphous catalyst is used for phenol hydrogenation, cyclohexanone can be prepared highly selectively while the conversion rate of phenol is high, in a clean water phase at a low pressure and a low temperature.

Owner:XI'AN PETROLEUM UNIVERSITY

Preparation method of sulfurized type hydrogenation catalyst

ActiveCN108067256AHigh catalytic activityReduce manufacturing costPhysical/chemical process catalystsHydrocarbon oils treatmentEvaporationSlurry

The invention discloses a preparation method of a sulfurized type hydrogenation catalyst. The method comprises the following steps: (1) preparing a solution containing a reactive metal complex, performing drying dehydration to obtain a reactive metal precursor, and preparing a semi-sulfurized material from the reactive metal precursor, a sulfurizing reagent and a sulfurizing aid by a mixed reaction; (2) uniformly mixing a peptizer, water and urea to obtain a liquid mixture; (3) adding an aluminum source to an acid aqueous solution, performing pulping, and then adding the semi-sulfurized material and the liquid mixture to the slurry; (4) performing rapid evaporation and concentration on the slurry to obtain concentrated slurry, and then performing slow drying treatment to obtain a semi-dried material; (5) performing rolling and extruding forming on the semi-dried material obtained in step (4), and performing roasting to obtain the sulfurized type hydrogenation catalyst. Catalyst preparation and sulfurization are finished simultaneously, pore size distribution of the catalyst is centralized, the preparation process is simple, and broader market application prospect is provided.

Owner:CHINA PETROLEUM & CHEM CORP +1

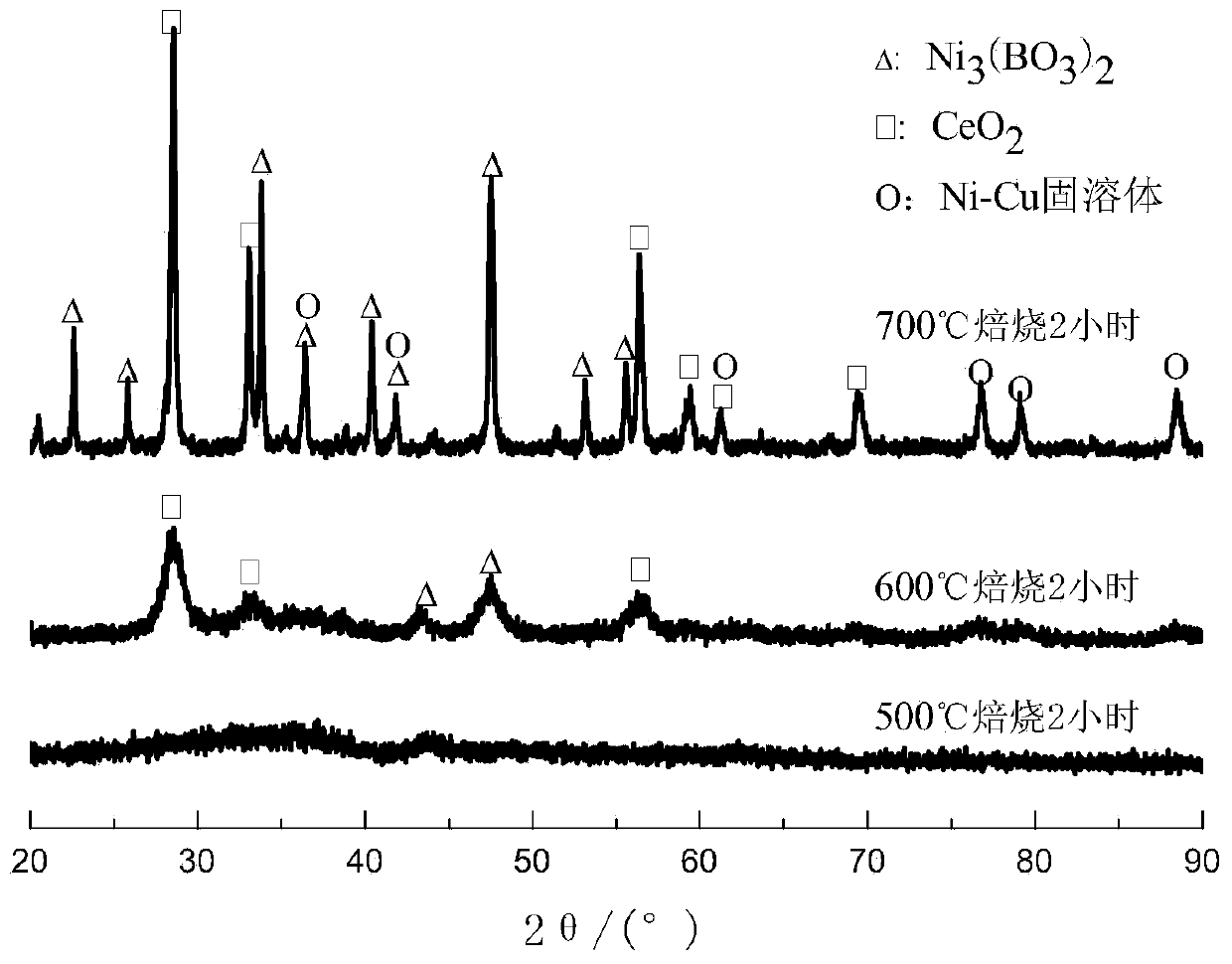

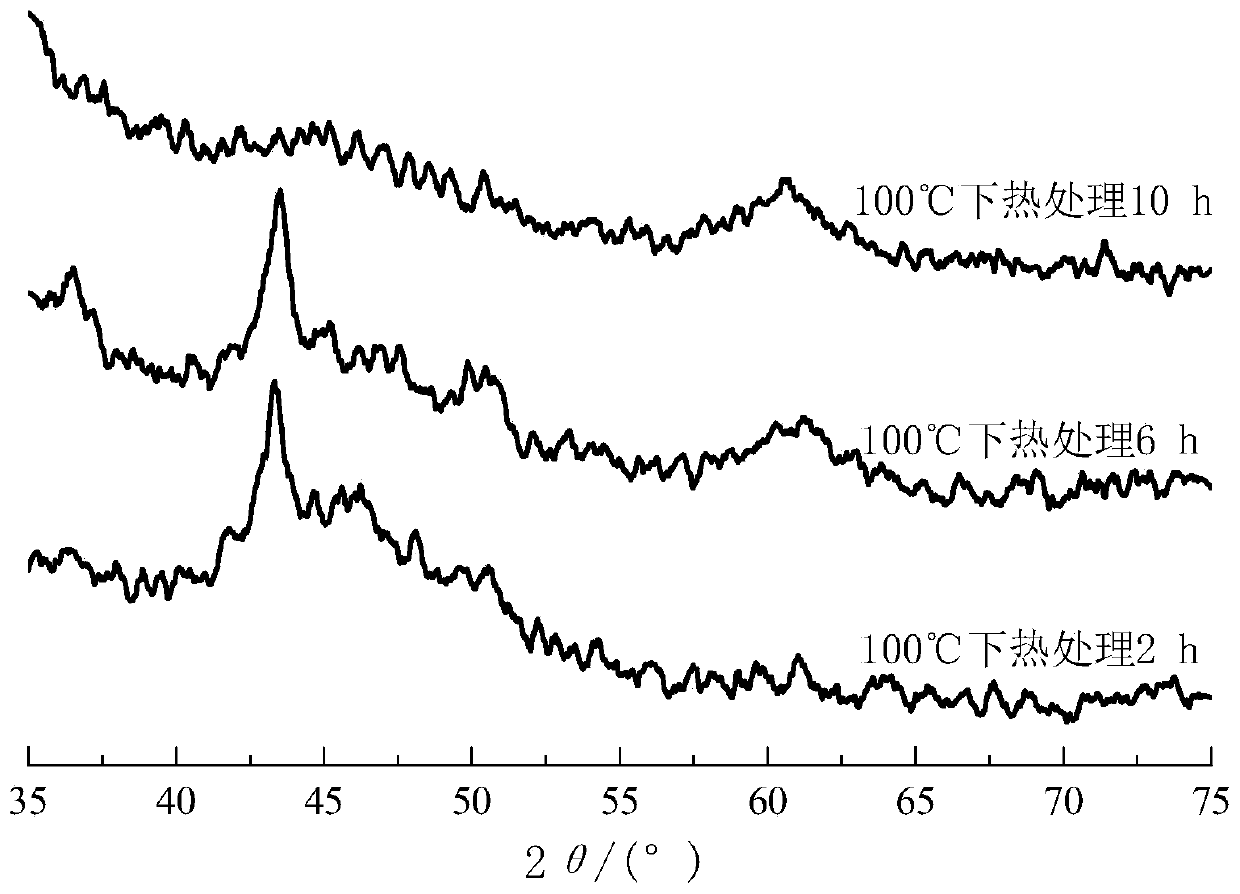

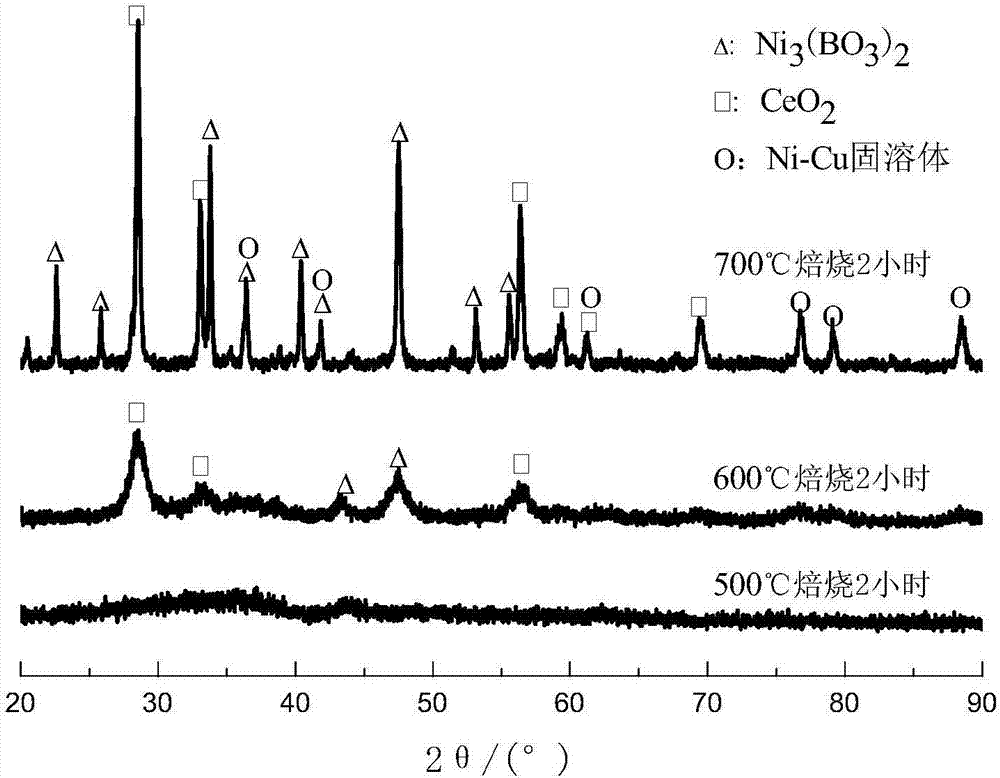

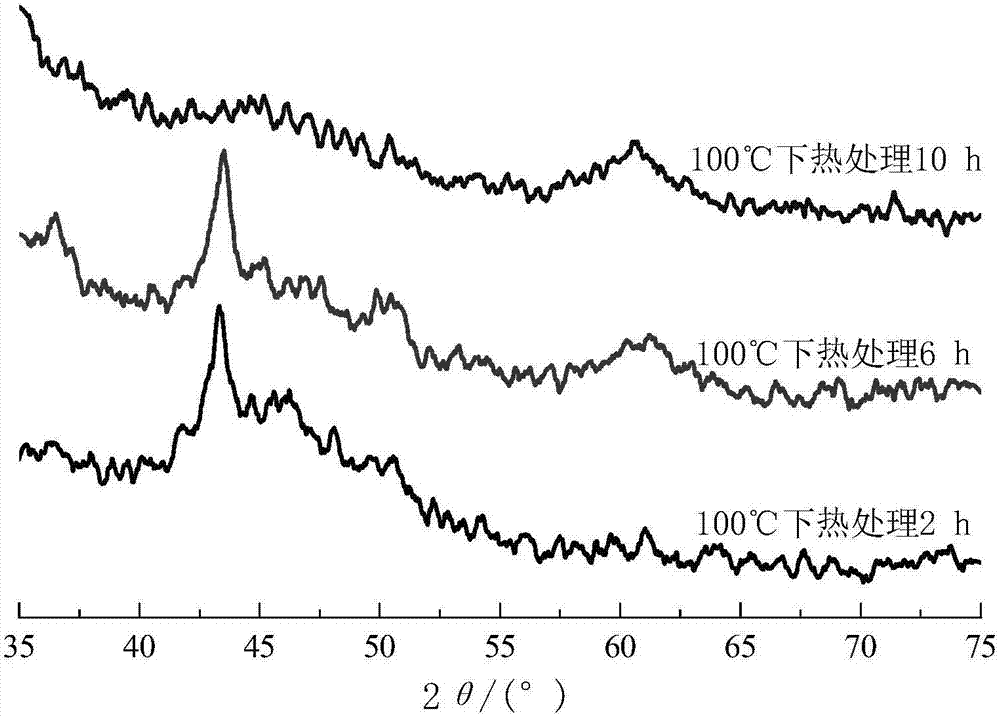

A method for n-hexadecane hydroisomerization reaction on a supported crystalline nickel phosphide catalyst

ActiveCN106748613BLow costImprove toleranceMolecular sieve catalystsHydrocarbon by hydrogenationAlkaneIsomerization

The invention relates to an n-hexadecane hydroisomerization reaction method on a loaded crystalline state nickel phosphide catalyst, belongs to the field of heavy alkane isomerization, and particularly relates to the n-hexadecane hydroisomerization reaction method on the loaded crystalline state nickel phosphide catalyst. The invention aims at solving the problems of a precious-metal-containing catalyst used for long-carbon-chain heavy alkane isomerization in the prior art of high cost and poor sulfide poisonousness resistant performance and the problem of a precious-metal-free isomerization catalyst of low selectivity. According to the method, Ni(NO3)2 6H2O and (NH4)2HPO4 are dissolved into water; SAPO-31 molecular sieves are added; drying is performed at the temperature being 100 DEG C; then, the materials are put into a muffle furnace to be roasted; then, temperature-programmed reduction is performed in hydrogen gas atmosphere to obtain the catalyst; the catalyst is filled into a reactor; the n-hexadecane hydroisomerization reaction is performed.

Owner:HEILONGJIANG UNIV

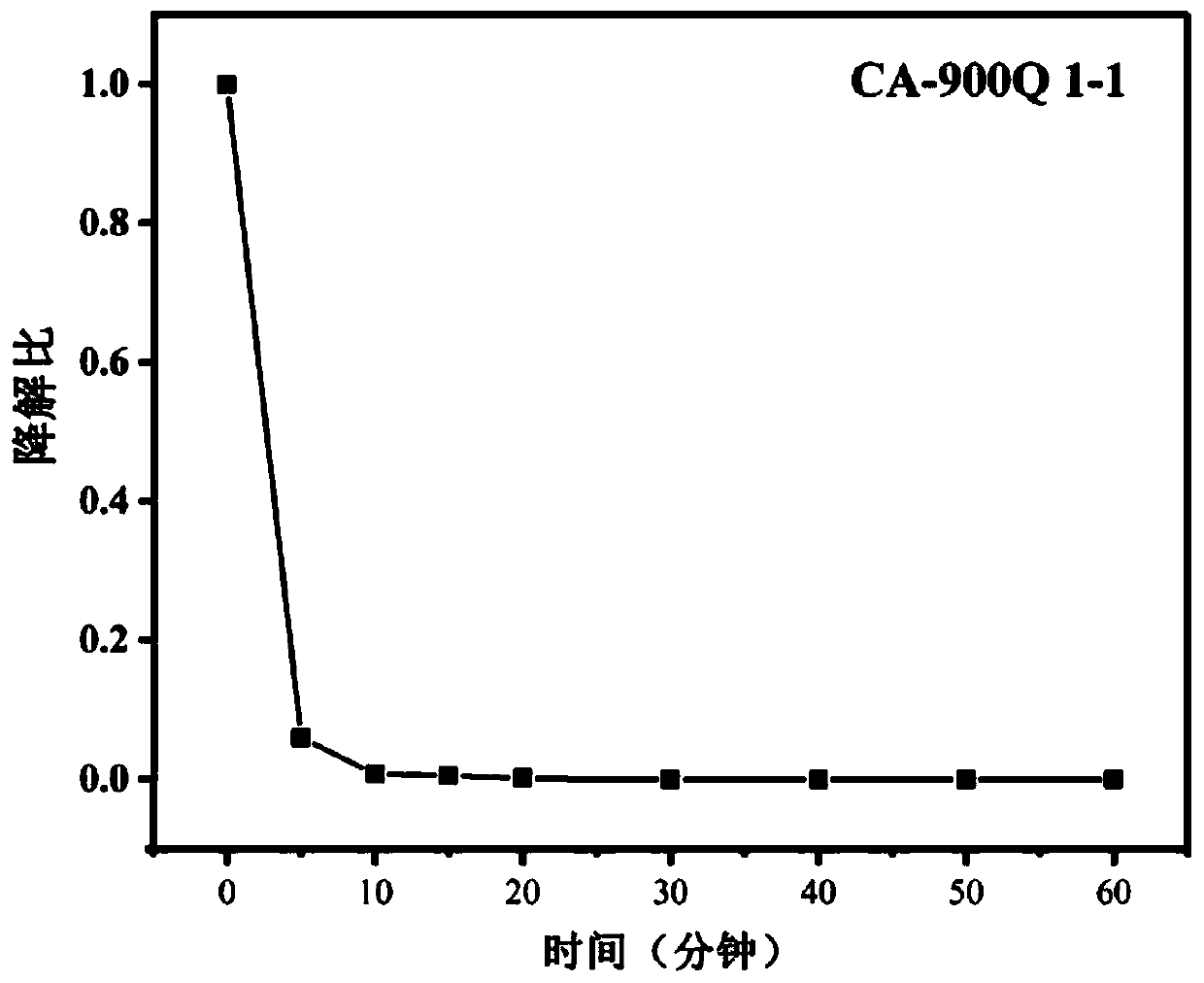

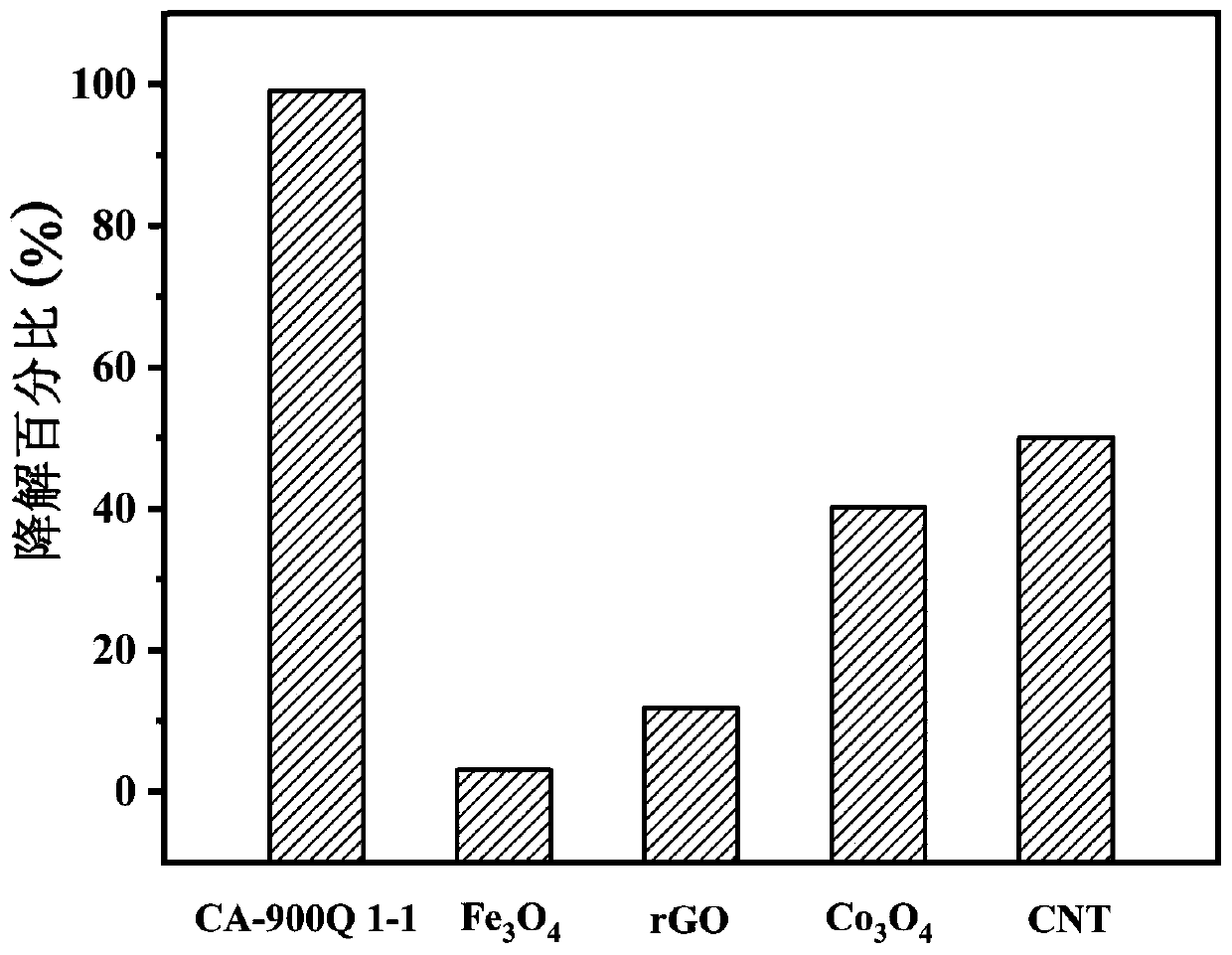

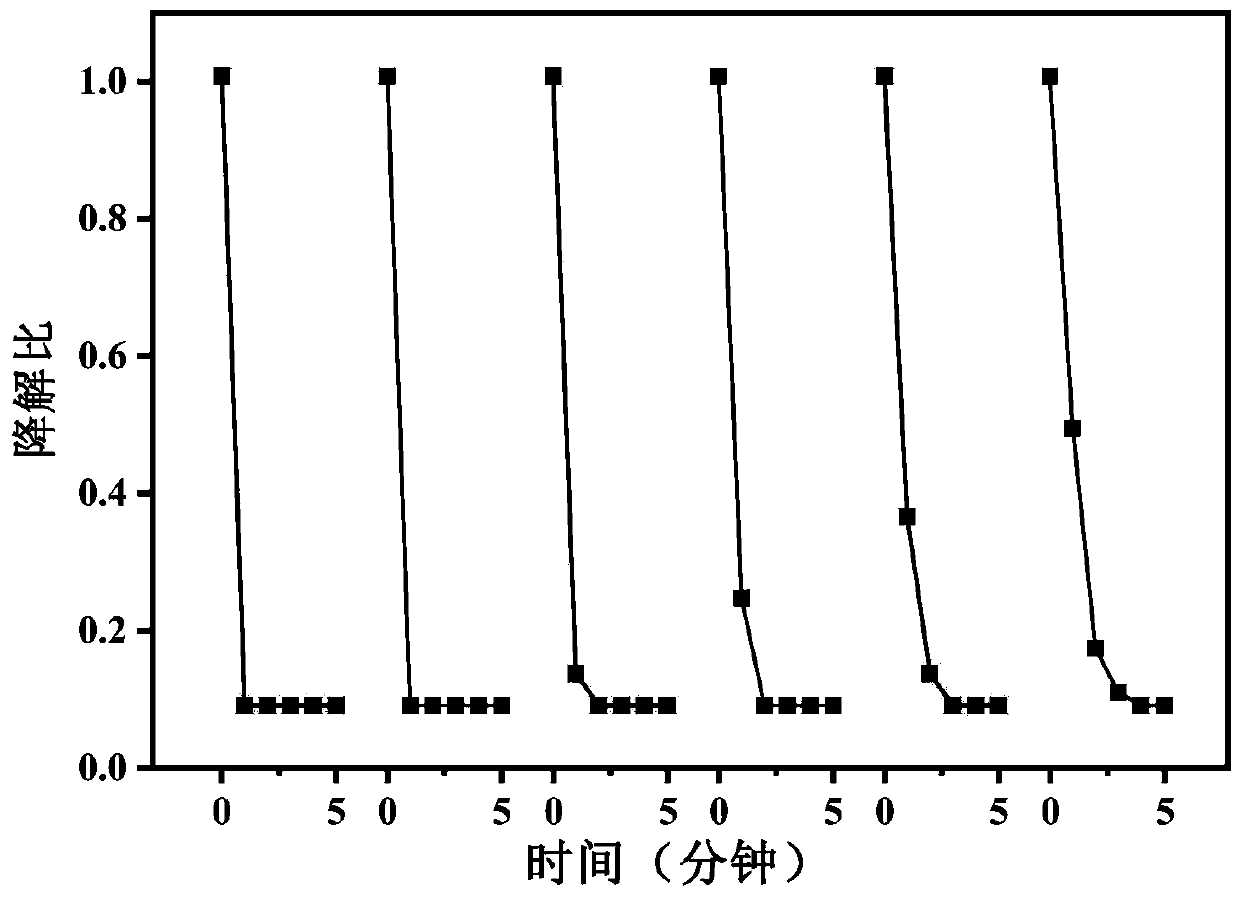

Preparation method and application of adsorption and degradation material

PendingCN111282549ALarge specific surface areaWill not cause secondary pollutionOther chemical processesWater contaminantsAcetic acidPtru catalyst

The invention belongs to the field of preparation of environmental materials, and provides a preparation method and application of an adsorption and degradation material. The preparation method comprises the step: taking chitosan as a raw material; adding glacial acetic acid into a chitosan solution to obtain hydrogel; slowly dropwise adding the hydrogel into liquid nitrogen and carrying out rapidfreezing; freezing and drying to obtain aerogel; calcining the obtained aerogel at a high temperature in a nitrogen or argon atmosphere to obtain a first calcined product; and adding the primary calcined product and KOH into water according to a mass ratio of 1:1-1:3 to obtain a uniformly mixed suspension, drying to obtain a dried product, carrying out secondary high-temperature calcination on the dried product in a nitrogen or argon atmosphere, washing with diluted hydrochloric acid, deionized water and absolute ethyl alcohol, and drying to obtain the adsorption and degradation material. Theobtained material has a relatively high specific surface area, can be used for catalytic degradation of rhodamine B without depending on a heavy metal catalyst, does not cause secondary pollution tothe environment, and has a relatively good catalytic degradation effect and good cyclicity.

Owner:SHANGHAI UNIVERSITY OF ELECTRIC POWER

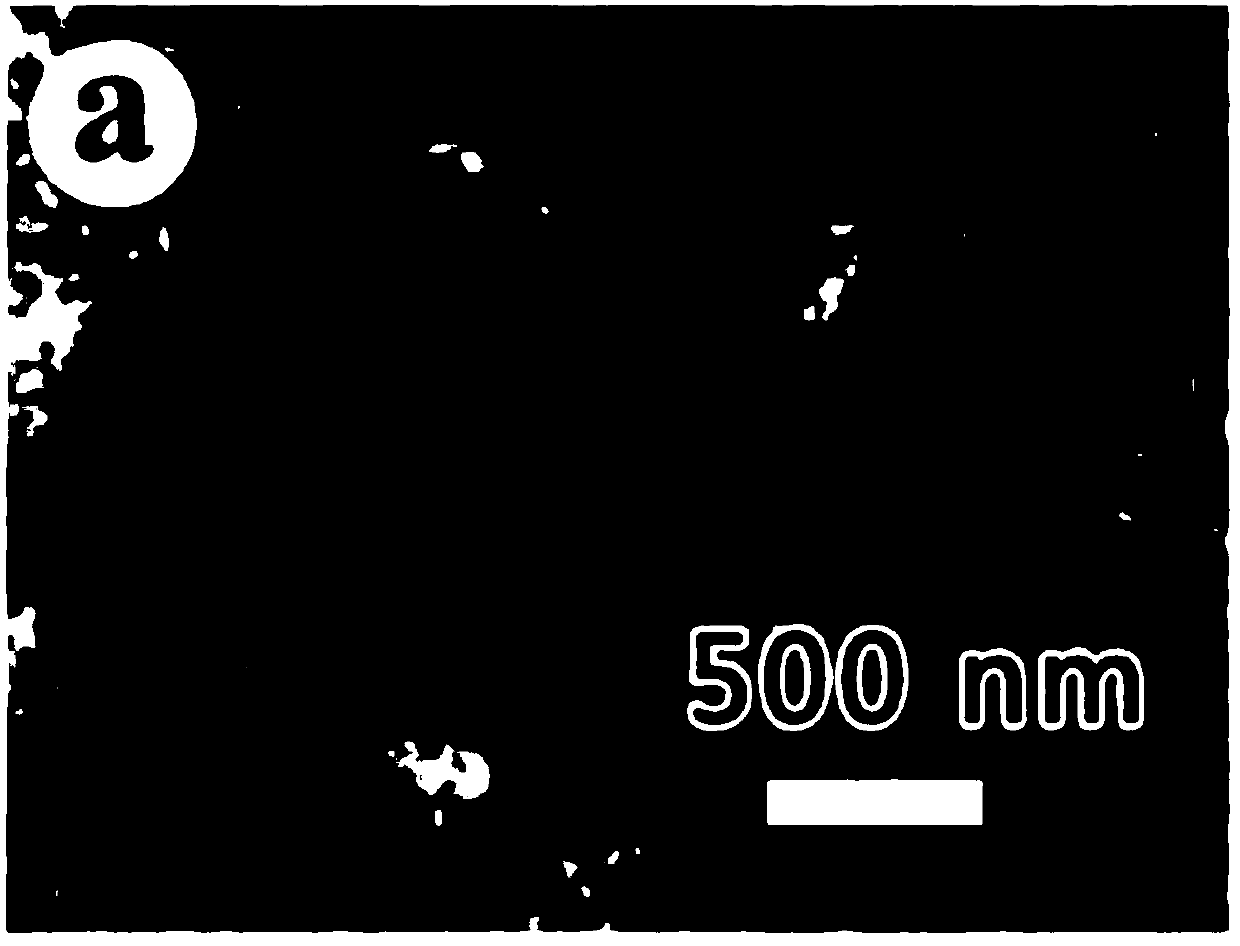

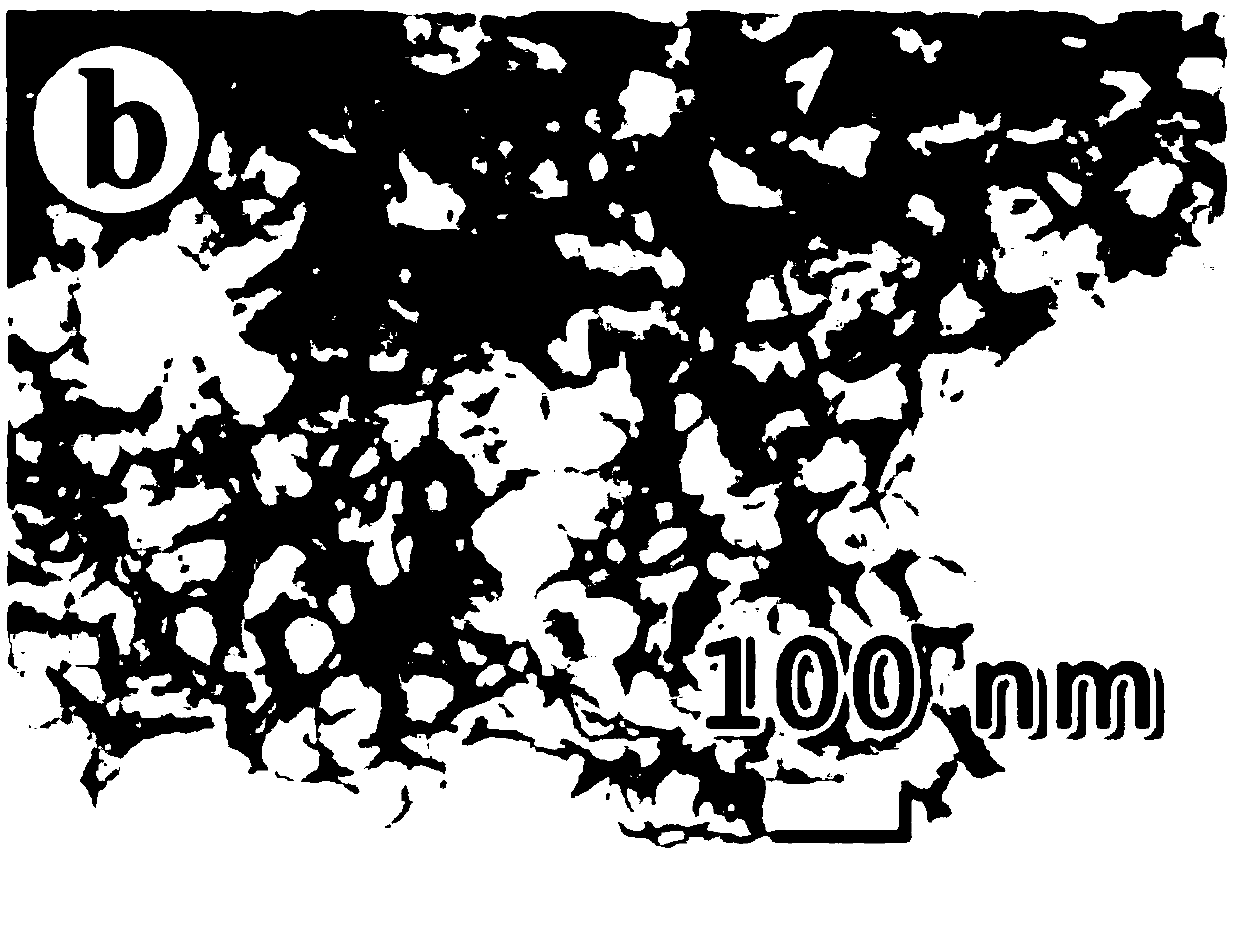

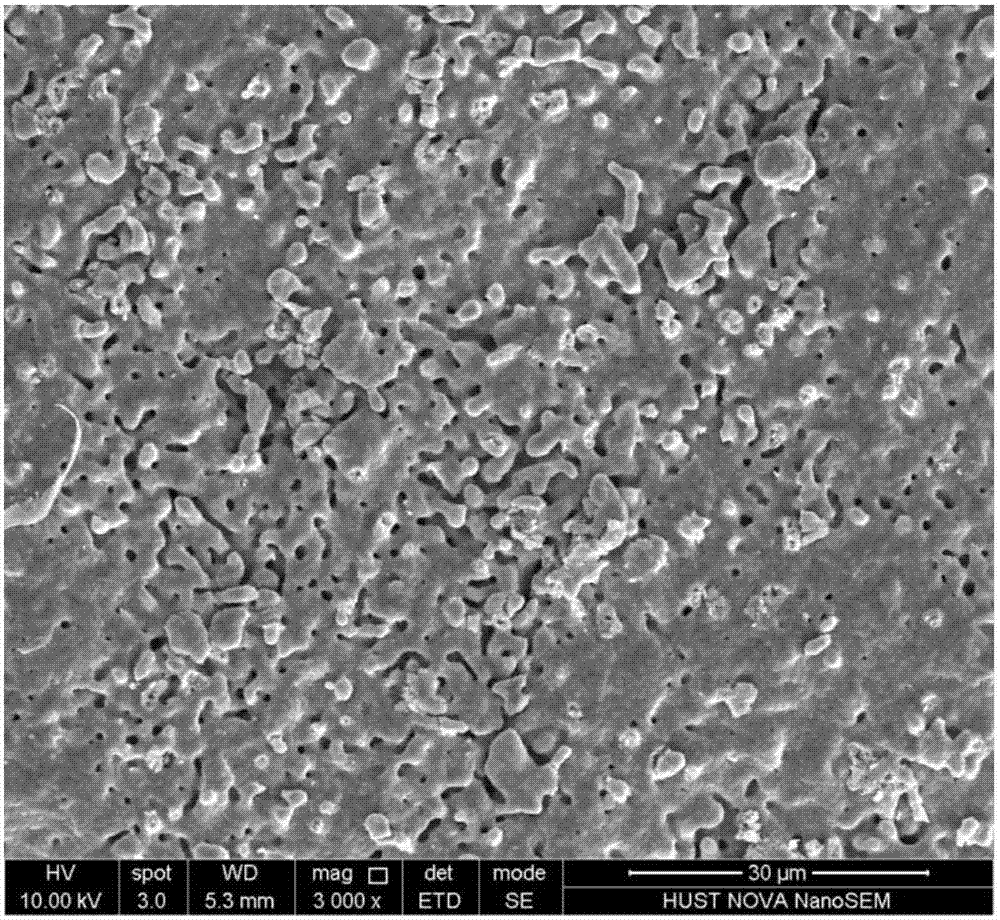

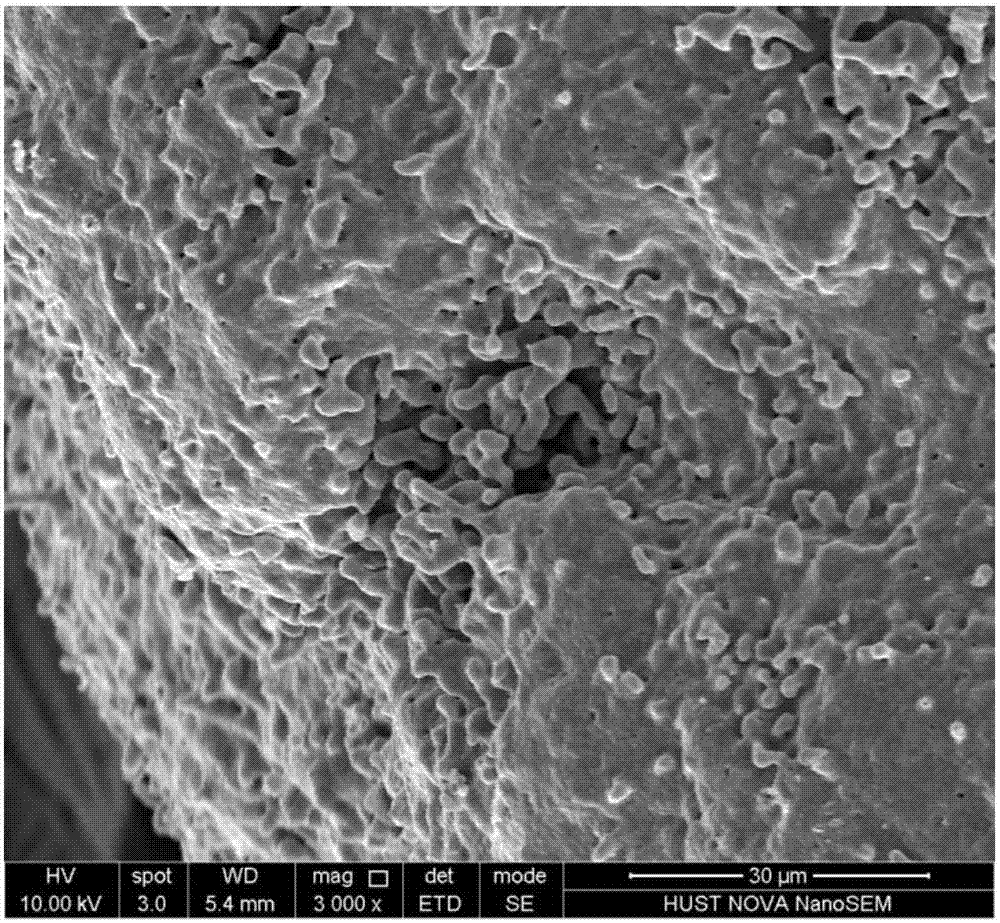

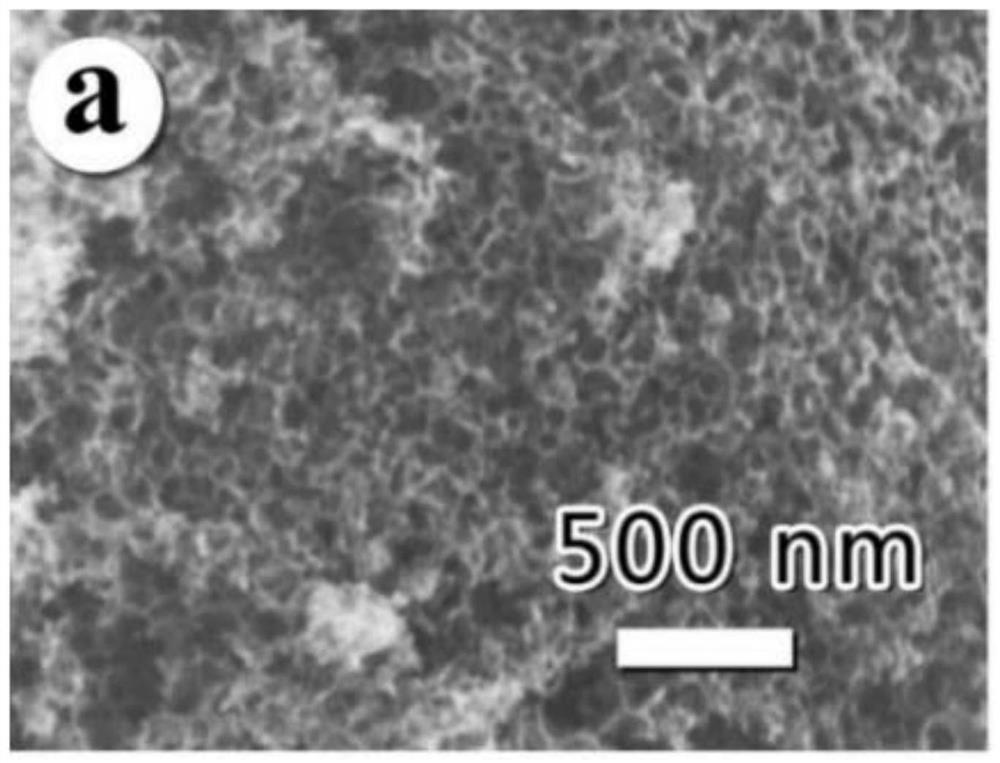

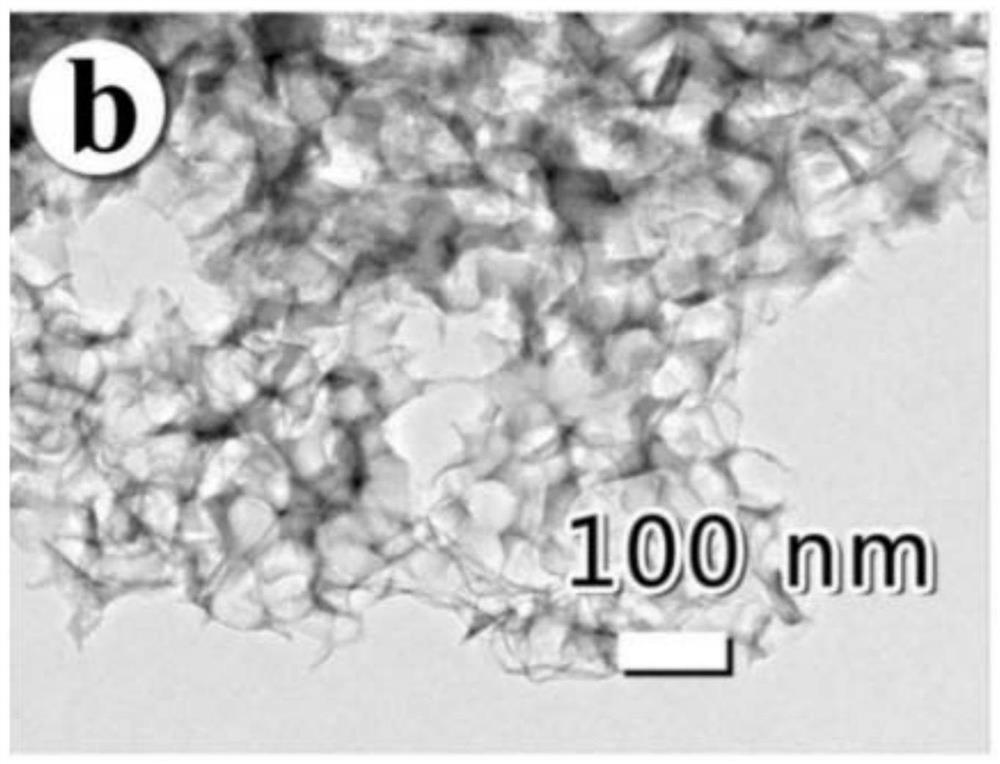

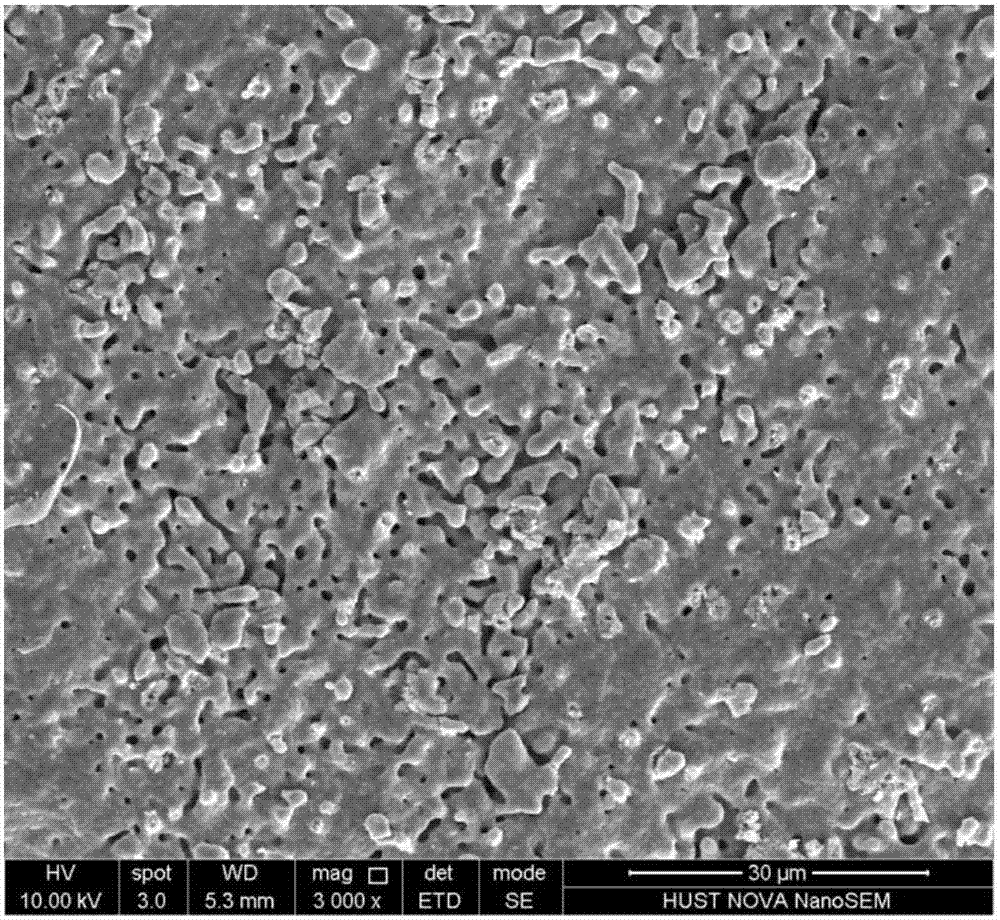

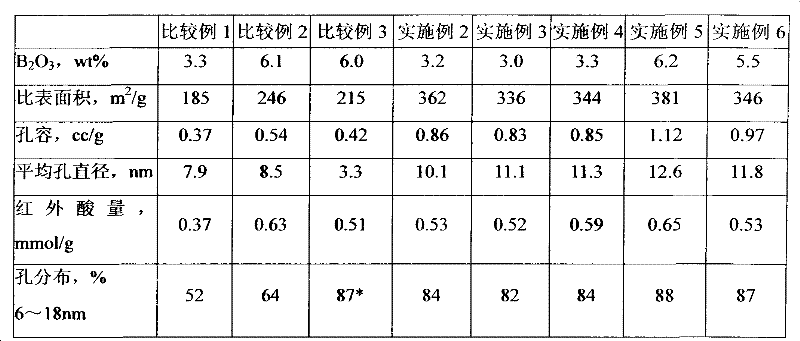

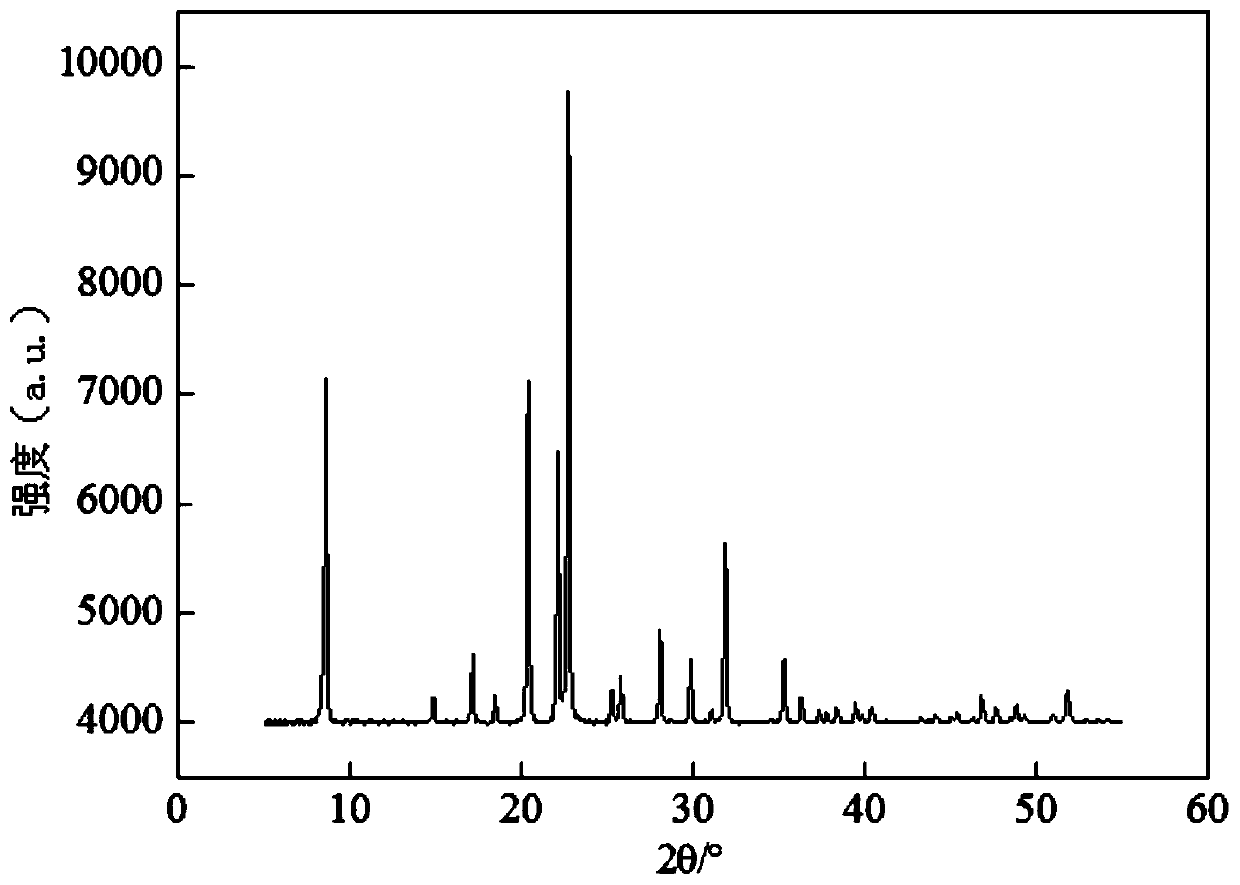

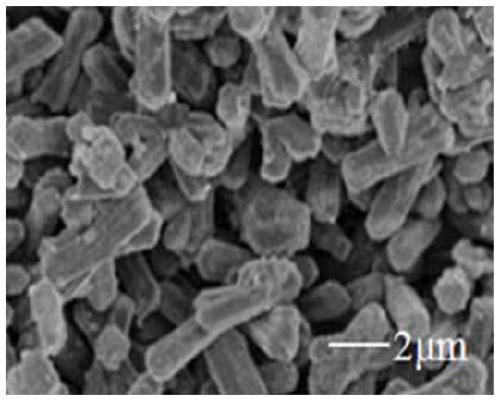

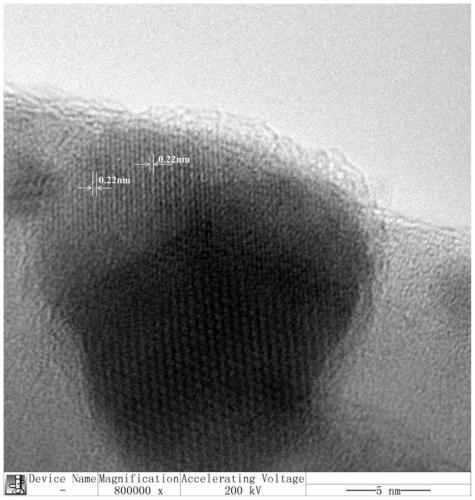

Sulfonyl bridged calix[4]arene iron-based porous complex for extracting uranium from seawater and preparation method of complex

InactiveCN113307981AHighly selective adsorptionGood choiceOther chemical processesSeawater treatmentTetrazoleAcyl group

The invention discloses a preparation method of a sulfonyl bridged calix[4]arene iron-based porous complex for extracting uranium from seawater, which comprises the following steps: adding sulfonyl bridged calix[4]arene, ferric trichloride and isophthalonitrile tetrazole into a composite solvent containing ethanol and N,N-dimethylformamide, and uniformly conducting mixing; and then rapidly conducting heating in a reaction kettle, conducting reacting under a constant temperature condition, slowly conducting cooling to obtain a brown yellow blocky transparent crystal, and conducting cleaning and drying to obtain a product, wherein the molar ratio of the sulfonyl bridged calix[4]arene to the ferric trichloride to the isophthalonitrile tetrazole is 1:4:1, and the volume ratio of the ethanol to the N,N-dimethylformamide is 1:1. The porous complex material prepared by the method is a monoclinic crystal, has a cuboid structure with a cavity, and has a molecular formula of Fe4(H2O)(TC4A-SO2)]4(H2L)8. The material has a proper pore structure, unsaturated coordination sites in the bridged ligand isophthalonitrile tetrazole and uranyl ions have a complexing effect, the uranium extraction performance of the material is enhanced through mutual synergism of the unsaturated coordination sites and the uranyl ions, and the material has the advantages of being high in adsorption rate, excellent in selectivity and stability and the like.

Owner:HAINAN UNIVERSITY

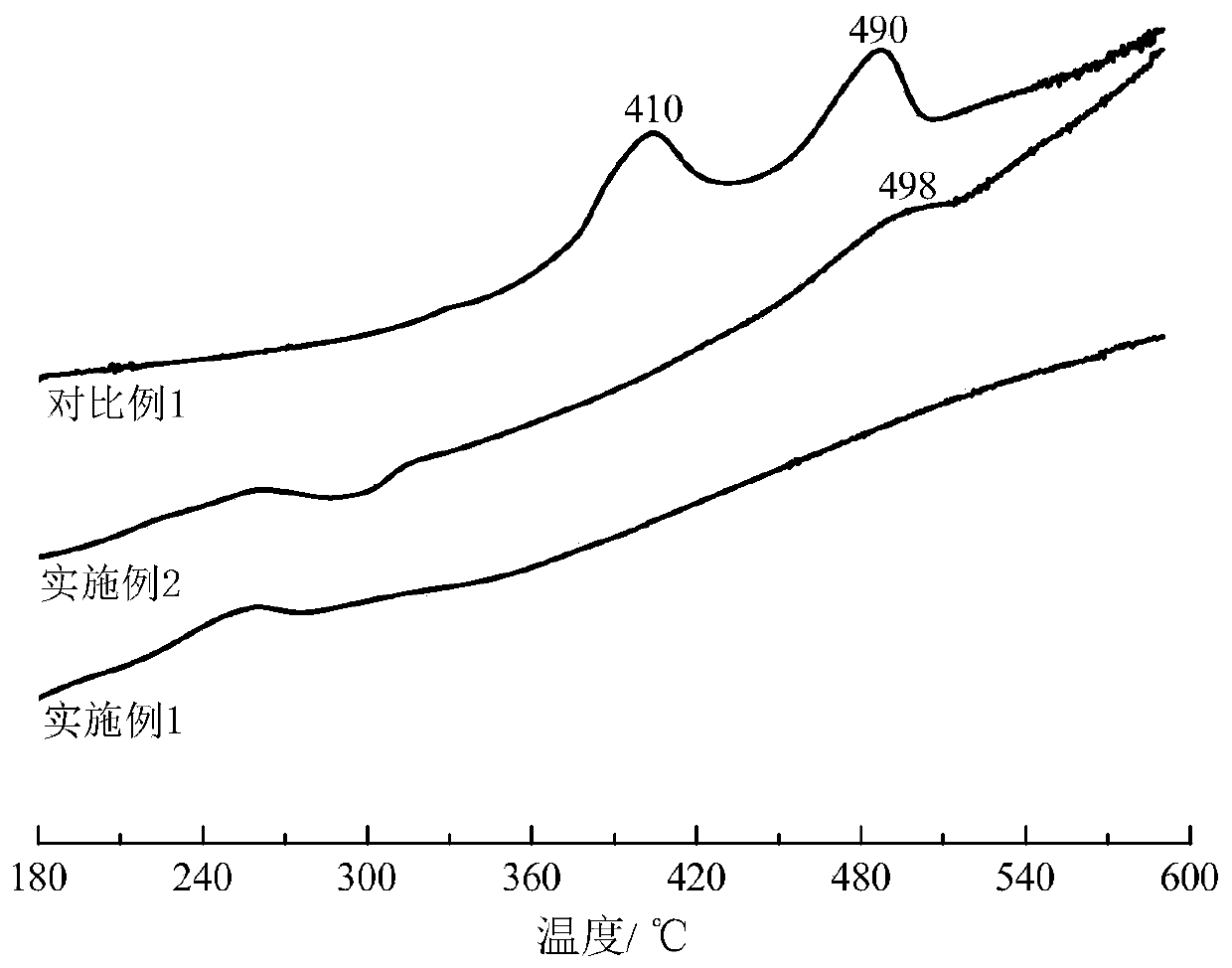

Sulfur-doped catalytic slurry oil-based porous carbon material and preparation method thereof

ActiveCN109560275AAlleviate volume effectImprove cycle stabilityMaterial nanotechnologyCell electrodesPorous carbonSlurry

A sulfur-doped catalytic slurry oil-based porous carbon material and a preparation method thereof are provided, belonging to the field of comprehensive utilization of catalytic cracking slurry oil andfunctional carbon materials. The technical problem to be solved by the invention is the current problem of deep processing and utilization of catalytic slurry oil. The method comprises the steps of adding a certain volume of cyclohexane to catalytic slurry oil under the heating condition, stirring until the catalytic slurry oil is uniform, filtering under vacuum, distilling the filtrate under reduced pressure, adding a certain amount of pore-forming agent to the clarified oil, stirring uniformly under the ultrasonic heating condition, heating a heating furnace to a certain temperature under the protection of inert gas, injecting the prepared mixture into the heating furnace through an injector for pyrolysis reaction to obtain pyrolysis products, elemental sulfur and carbon disulfide, stirring for a certain time under the ultrasonic condition, filtering under vacuum, collecting insoluble matters, and drying to obtain a sulfur-doped catalytic slurry oil-based porous carbon material. Thematerial is used to alleviate the volume effect of a sulfur positive electrode.

Owner:ENERGY & ENVIRONMENT RES INST OF HEILONGJIANG PROVINCE

Catalyst for catalytic combustion of nitrogen-containing organic matter and its preparation method and application

ActiveCN106732577BFacilitated DiffusionImprove adsorption capacityIncinerator apparatusMetal/metal-oxides/metal-hydroxide catalystsSimple Organic CompoundsActive component

Owner:CHINA PETROLEUM & CHEM CORP +1

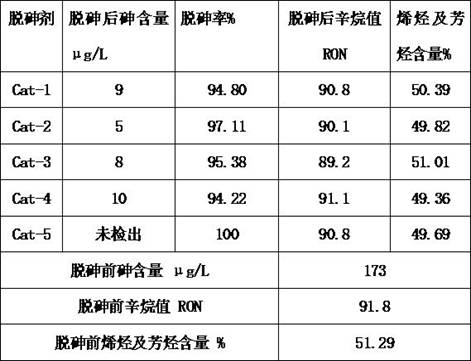

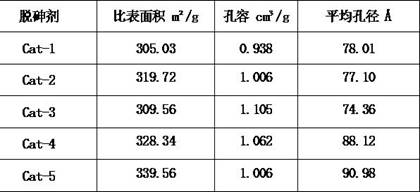

Preparation method of low-temperature FCC gasoline dearsenification agent

ActiveCN111849581AEasy to makeEasy to operateLiquid carbonaceous fuelsFuel additivesPtru catalystSilicic acid

The invention belongs to the field of gasoline dearsenification agents, and particularly relates to a preparation method of a low-temperature FCC (fluid catalytic cracking) gasoline dearsenification agent. The preparation method comprises the following steps of: (1) dropwisely adding completely dissolved sodium silicate and manganese salt, mixing, and uniformly stirring; (2) stirring and aging themixed solution for 2-12 hours, washing, filtering, and calcining in a muffle furnace at 350-400 DEG C for 2-12 hours to obtain a manganese silicate catalyst precursor; and (3) adding an adhesive, kneading, extruding and molding to obtain the target product, namely the low-temperature FCC gasoline dearsenification agent. The target product provided by the invention has large specific surface areaand arsenic capacity and high arsenic removal selectivity, and does not cause side reaction of unsaturated hydrocarbon in gasoline or gasoline octane number loss in the arsenic removal process.

Owner:LIAONING UNIVERSITY OF PETROLEUM AND CHEMICAL TECHNOLOGY

Catalytic cracking olefin catalyst and its preparation method and application

ActiveCN106552665BHigh pore volumeIncrease the areaMolecular sieve catalystsHydrocarbon by hydrocarbon crackingAlkaline earth metalHeteropoly acid

A catalyst for catalytic cracking to prepare olefins, a preparing method thereof and applications of the catalyst are disclosed. The catalyst includes, by weight, 5-30% of an alkaline earth metal-modified MFI molecular sieve and 0.1-3% of heteropoly acid, with the balance being SiO2, wherein the weight of the alkaline earth metal is 0.5-2% of the weight of the MFI molecular sieve. The preparing method includes (1) weighing a proper amount of the heteropoly acid, dissolving the heteropoly acid into water and fully stirring the solution, (2) adding a proper amount of an ethanol solvent and a proper amount of a silicon-containing precursor into the solution obtained in the step (1), fully stirring the solution, and adjusting the pH value of the solution to be 1-7, (3) adding the alkaline earth metal-modified MFI molecular sieve into the solution in the step (2), fully stirring the solution at a constant temperature, then adding an ionic liquid, and continuously stirring the solution until the solution is converted into sol, and then performing room-temperature ageing to obtain gel, and (4) drying the gel in the step (3) until the weight is constant and grinding the dried gel to obtain the catalyst for catalytic cracking. The catalyst has advantages of a high olefin yield, low reaction temperatures, good catalyst stability, and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

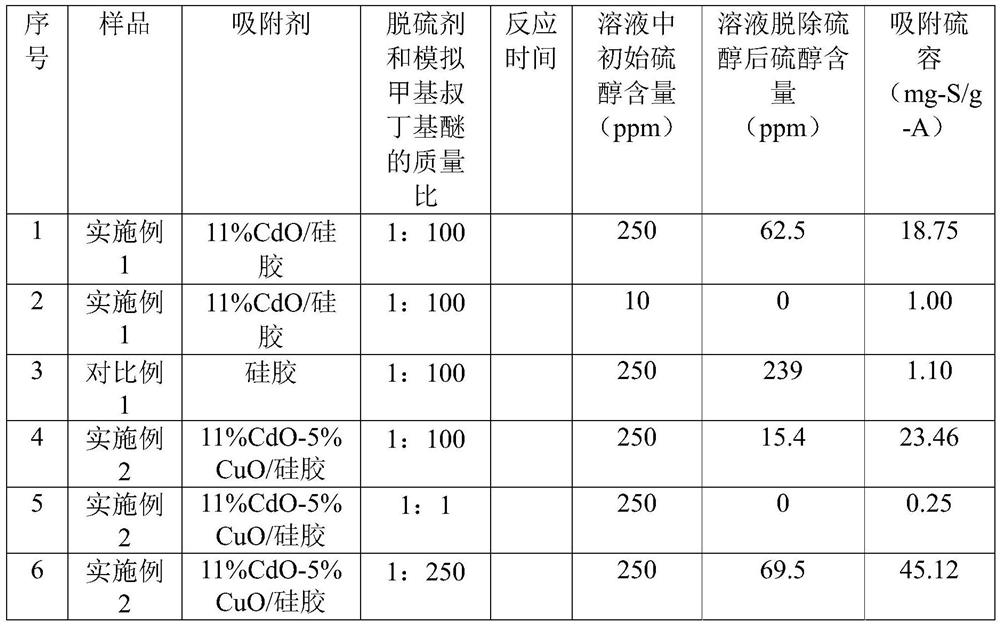

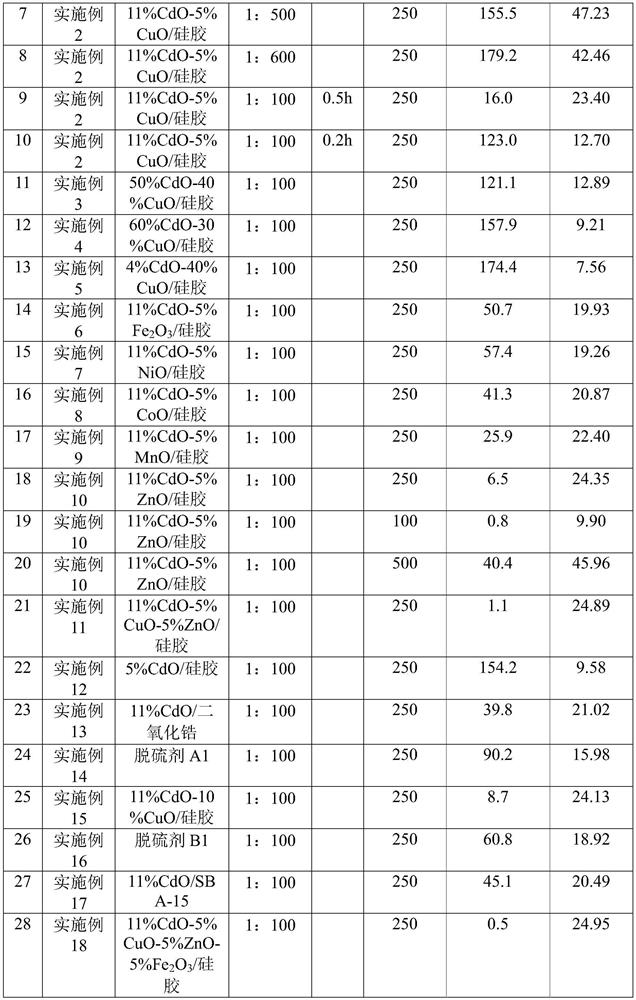

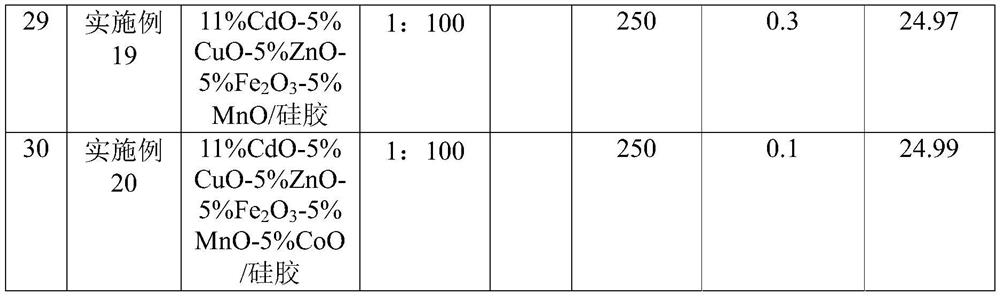

Desulfurization adsorbent as well as preparation method and application thereof

PendingCN114082394AReduce sulfur contentAchieve deep deodorizationEther separation/purificationOther chemical processesMethyl t-butyl etherSulfide compound

The invention discloses a desulfurization adsorbent as well as a preparation method and an application thereof, and belongs to the technical field of methyl tert-butyl ether desulfurization. The desulfurization adsorbent comprises a supported cadmium-based compound, the supported cadmium-based compound comprises an active component and a carrier, and the active component is supported on the carrier; the active component comprises an active component I, and the active component I is cadmium oxide. The supported cadmium-based composite metal oxide can be used as an adsorbent for methyl tert-butyl ether mercaptan removal to overcome the technical defects of low mercaptan removal efficiency, high cost, difficulty in reduction of total sulfide content and the like in the existing methyl tert-butyl ether mercaptan removal.

Owner:DALIAN JIACHUN GAS PURIFICATION TECH DEV +1

A kind of high-performance porous calcium-based absorbent and its preparation method

ActiveCN107262018BImprove efficiencyQuality improvementGas treatmentOther chemical processesCelluloseFluidized bed

The invention belongs to the technical fields of environmental pollution control and clean coal combustion, and concretely relates to a high-performance porous calcium-based absorbent. The high-performance porous calcium-based absorbent comprises calcium source powder and biomass powder, and the biomass powder is pyrolyzed and volatilies when the calcium-based absorbent is calcined at a high temperature in order to form a porous structure in the biomass powder. The invention also discloses a preparation method of the calcium-based absorbent. Pores formed by the pyrolysis and volatilization of the cellulose-rich biomass powder are used to improve the adsorption capacity and the cycle stability of the calcium-based absorbent, so the prepared spherical calcium-based absorbent is suitable for capturing CO2 in a fluidized bed system; the characteristic of low cost of biomass is fully used in the whole preparation process, and the preparation method also has the advantages of high efficiency, high quality, low cost and convenience in control, so the method is especially suitable for being used in large-scale batch production.

Owner:HUAZHONG UNIV OF SCI & TECH

A sulfur-doped catalytic oil slurry-based porous carbon material and its preparation method

ActiveCN109560275BAlleviate volume effectImprove cycle stabilityMaterial nanotechnologyCell electrodesPorous carbonPhysical chemistry

A sulfur-doped catalytic slurry oil-based porous carbon material and a preparation method thereof are provided, belonging to the field of comprehensive utilization of catalytic cracking slurry oil andfunctional carbon materials. The technical problem to be solved by the invention is the current problem of deep processing and utilization of catalytic slurry oil. The method comprises the steps of adding a certain volume of cyclohexane to catalytic slurry oil under the heating condition, stirring until the catalytic slurry oil is uniform, filtering under vacuum, distilling the filtrate under reduced pressure, adding a certain amount of pore-forming agent to the clarified oil, stirring uniformly under the ultrasonic heating condition, heating a heating furnace to a certain temperature under the protection of inert gas, injecting the prepared mixture into the heating furnace through an injector for pyrolysis reaction to obtain pyrolysis products, elemental sulfur and carbon disulfide, stirring for a certain time under the ultrasonic condition, filtering under vacuum, collecting insoluble matters, and drying to obtain a sulfur-doped catalytic slurry oil-based porous carbon material. Thematerial is used to alleviate the volume effect of a sulfur positive electrode.

Owner:ENERGY & ENVIRONMENT RES INST OF HEILONGJIANG PROVINCE

Periosteum material with tissue oxygenation function and its preparation method and application

ActiveCN107812234BImprove securityWith oxygen functionElectro-spinningTissue regenerationBone tissueElectrospinning

The invention relates to a periosteum material with tissue oxygenation function and its preparation method and application, including the preparation of PLGA-wrapped PFOB particles (PLGA-PFOB), the preparation of electrospinning solution and the preparation of periosteum material. All the raw materials used in the present invention are medical materials that have been approved for use, and have specific functions and high safety through special process steps; In the early stage of transplantation, the problem of lack of blood supply provides necessary oxygen for cell proliferation and accelerates the speed of tissue healing; the periosteum prepared by electrospinning method in the present invention has a suitable pore structure, which is beneficial to bone cell growth and bone tissue repair, and the process is simple , easy to transform.

Owner:SHANGHAI NAT ENG RES CENT FORNANOTECH

Amorphous Catalyst for One-step Hydrogenation of Aqueous Phenol to Cyclohexanone

ActiveCN106966876BLarge specific surface areaSuitable pore structurePreparation by hydroxy compound hydrogenationOrganic compound preparationCyclohexanoneActivated carbon

The invention discloses an amorphous catalyst for one-step preparation of cyclohexanone through aqueous phase phenol hydrogenation. The catalyst takes gamma-Al2O3 or activated carbon as a carrier, takes Ni and B as active ingredients and takes transition metal and / or Ce as auxiliaries. By carrier mass, the total capacity of the active ingredients and the auxiliaries is 15-35%. When the auxiliaries are the transition metal and Ce, the transition metal is any one of Cu, Fe and Co. When the auxiliaries are the transition metal or Ce, the transition metal is Cu. The amorphous catalyst is cheap and easy to obtain and has high specific surface area and suitable duct structure, the active ingredients and the auxiliaries are small in particle size and are evenly dispersed on the carrier, and the amorphous catalyst has good heat stability and good chemical stability. When the amorphous catalyst is used for phenol hydrogenation, cyclohexanone can be prepared highly selectively while the conversion rate of phenol is high, in a clean water phase at a low pressure and a low temperature.

Owner:XI'AN PETROLEUM UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![Sulfonyl bridged calix[4]arene iron-based porous complex for extracting uranium from seawater and preparation method of complex Sulfonyl bridged calix[4]arene iron-based porous complex for extracting uranium from seawater and preparation method of complex](https://images-eureka.patsnap.com/patent_img/06fbe299-4ed0-42d6-9df2-9cb31fe026af/HDA0003111647660000011.png)

![Sulfonyl bridged calix[4]arene iron-based porous complex for extracting uranium from seawater and preparation method of complex Sulfonyl bridged calix[4]arene iron-based porous complex for extracting uranium from seawater and preparation method of complex](https://images-eureka.patsnap.com/patent_img/06fbe299-4ed0-42d6-9df2-9cb31fe026af/HDA0003111647660000012.png)

![Sulfonyl bridged calix[4]arene iron-based porous complex for extracting uranium from seawater and preparation method of complex Sulfonyl bridged calix[4]arene iron-based porous complex for extracting uranium from seawater and preparation method of complex](https://images-eureka.patsnap.com/patent_img/06fbe299-4ed0-42d6-9df2-9cb31fe026af/HDA0003111647660000021.png)