Patents

Literature

2863results about "Electro-spinning" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

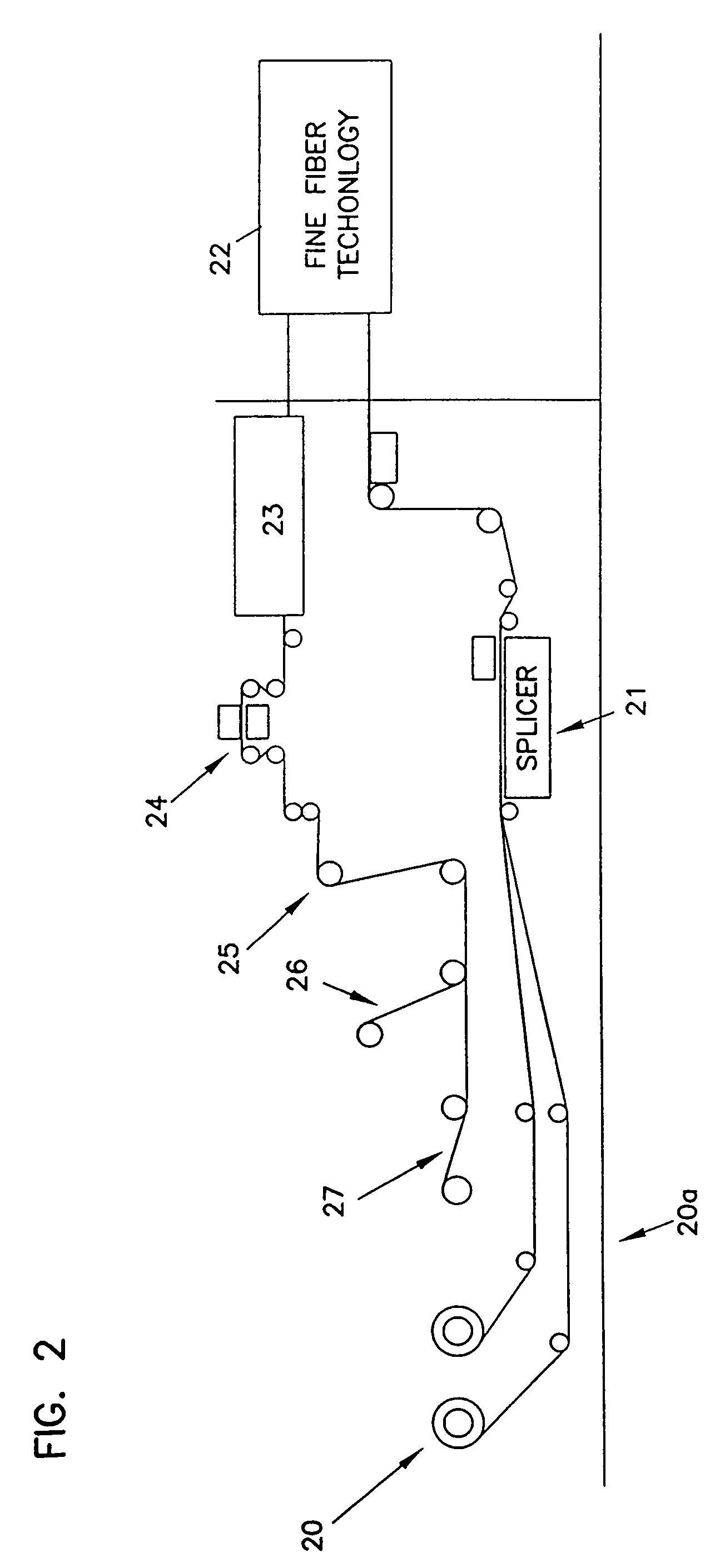

Process if making fine fiber material

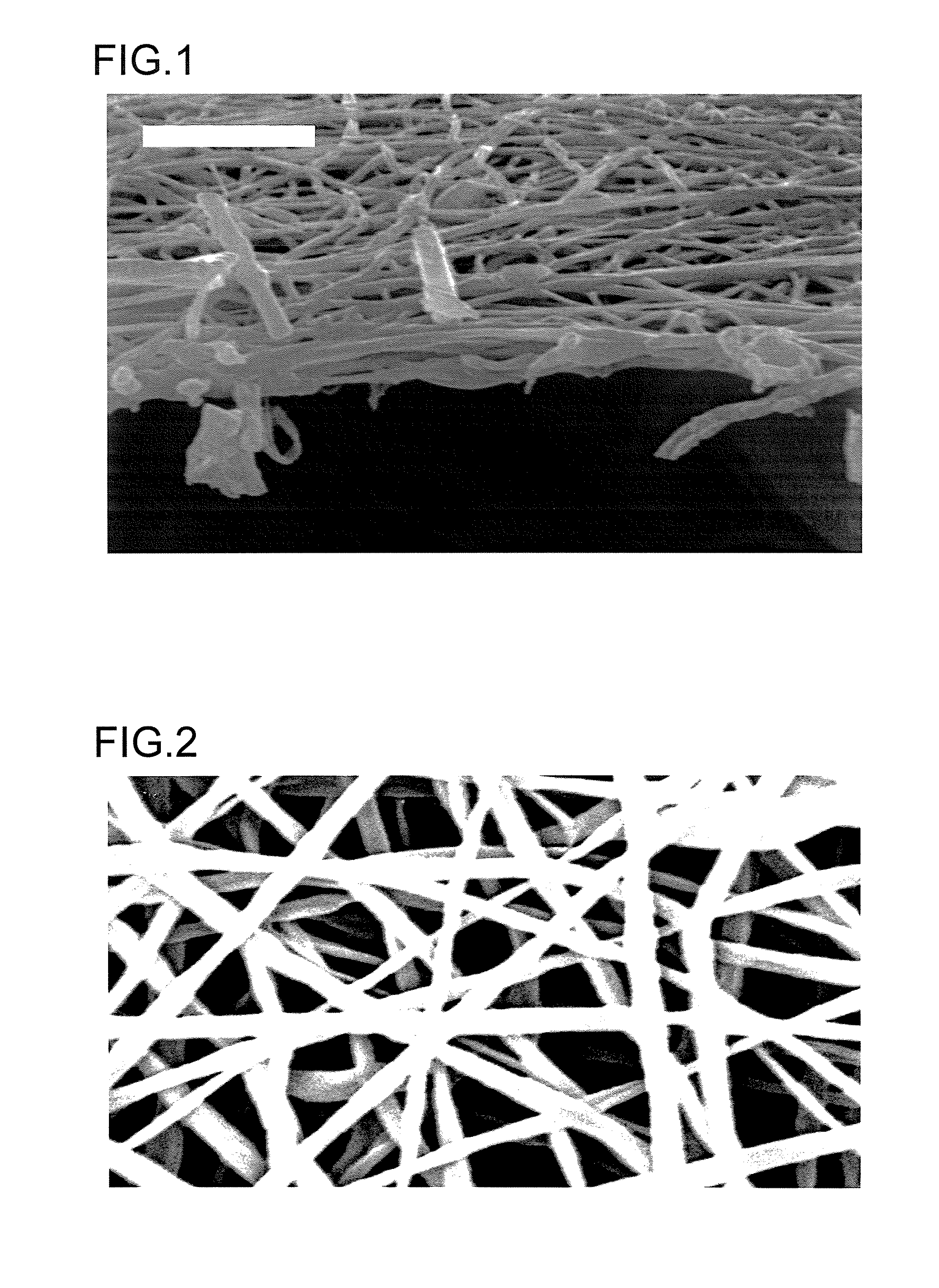

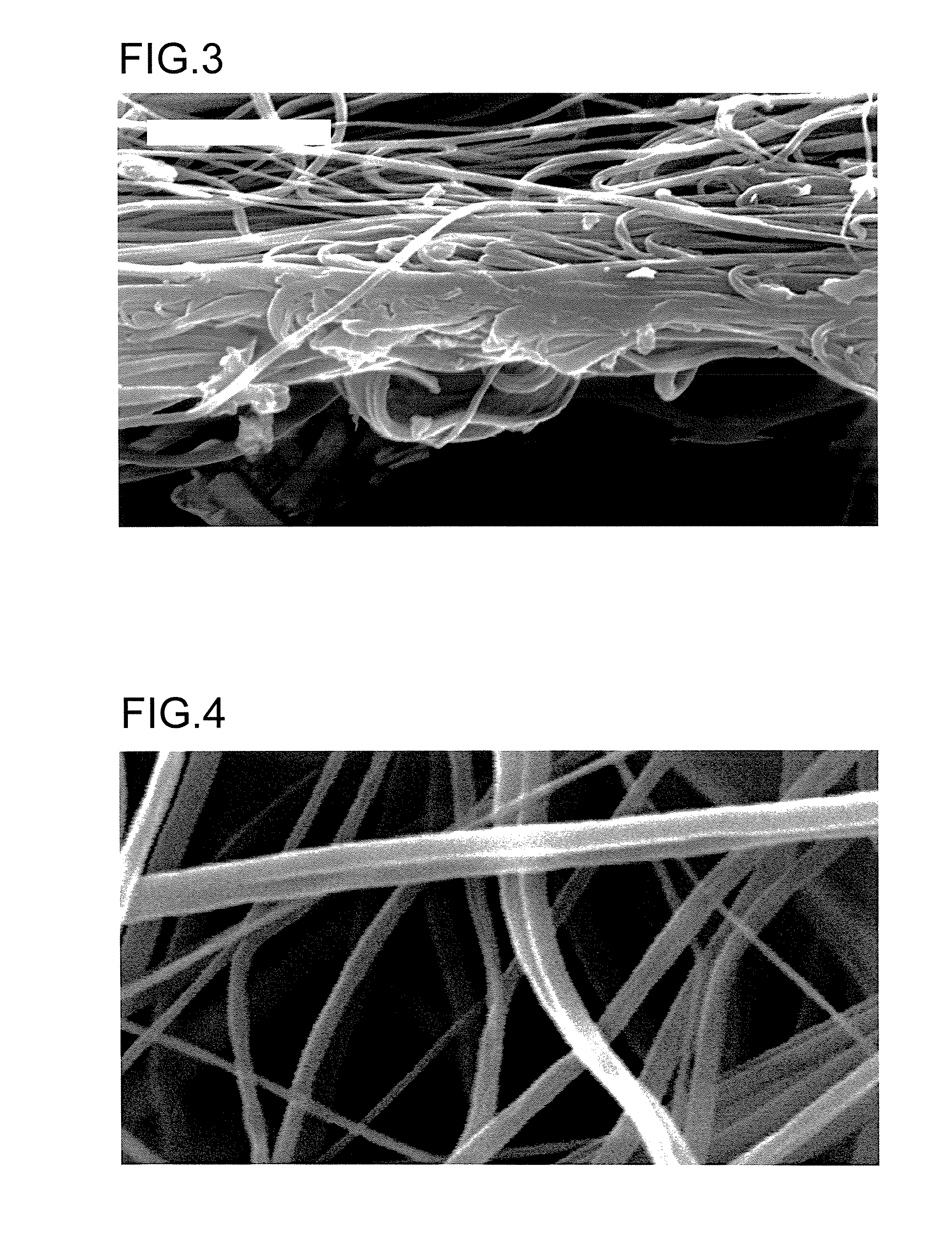

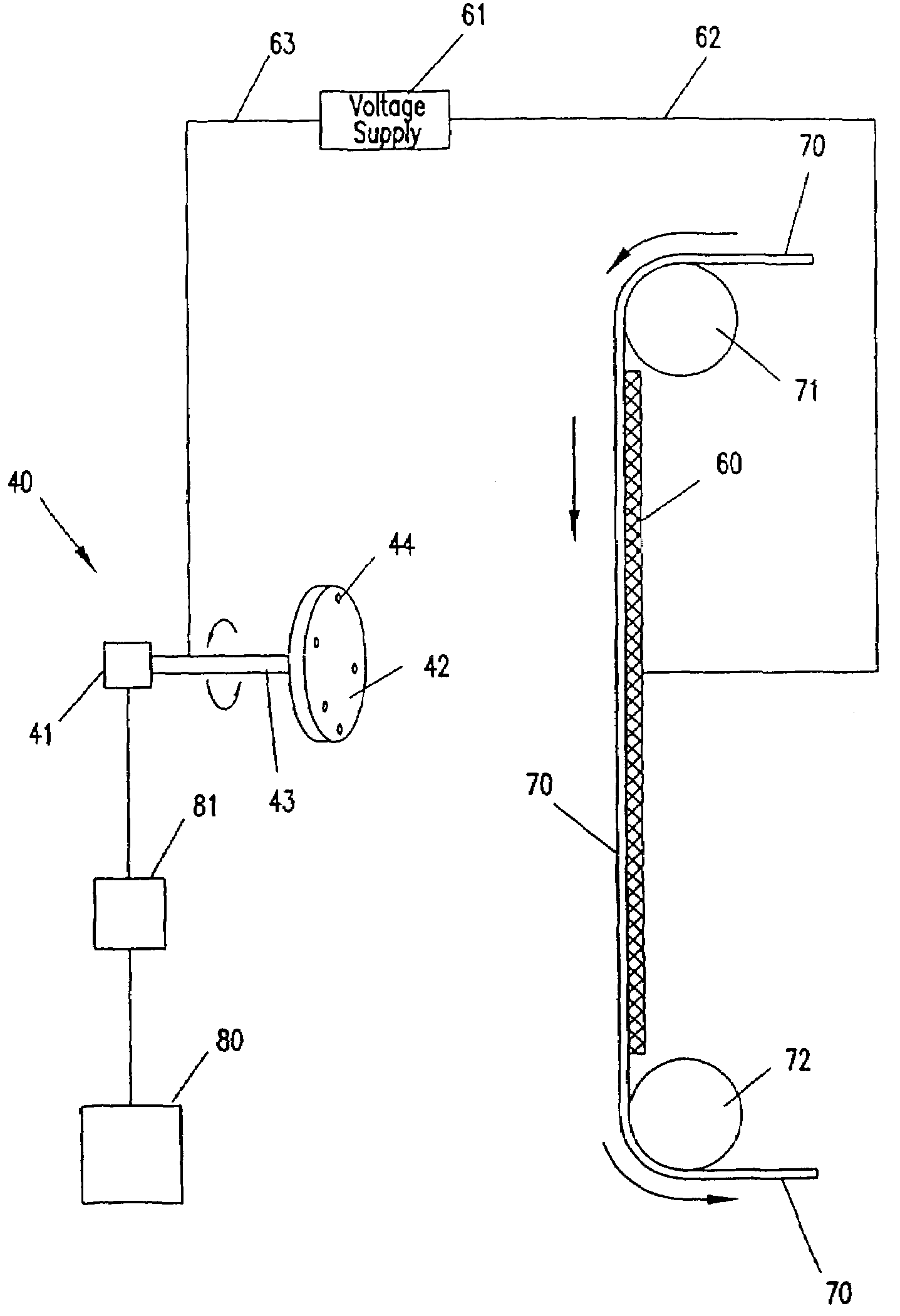

Improved polymer materials and fine fiber materials can be made from the improved polymeric materials in the form of microfiber and nanofiber structures. The microfiber and nanofiber structures can be used in a variety of useful applications including the formation of filter materials.

Owner:DONALDSON CO INC

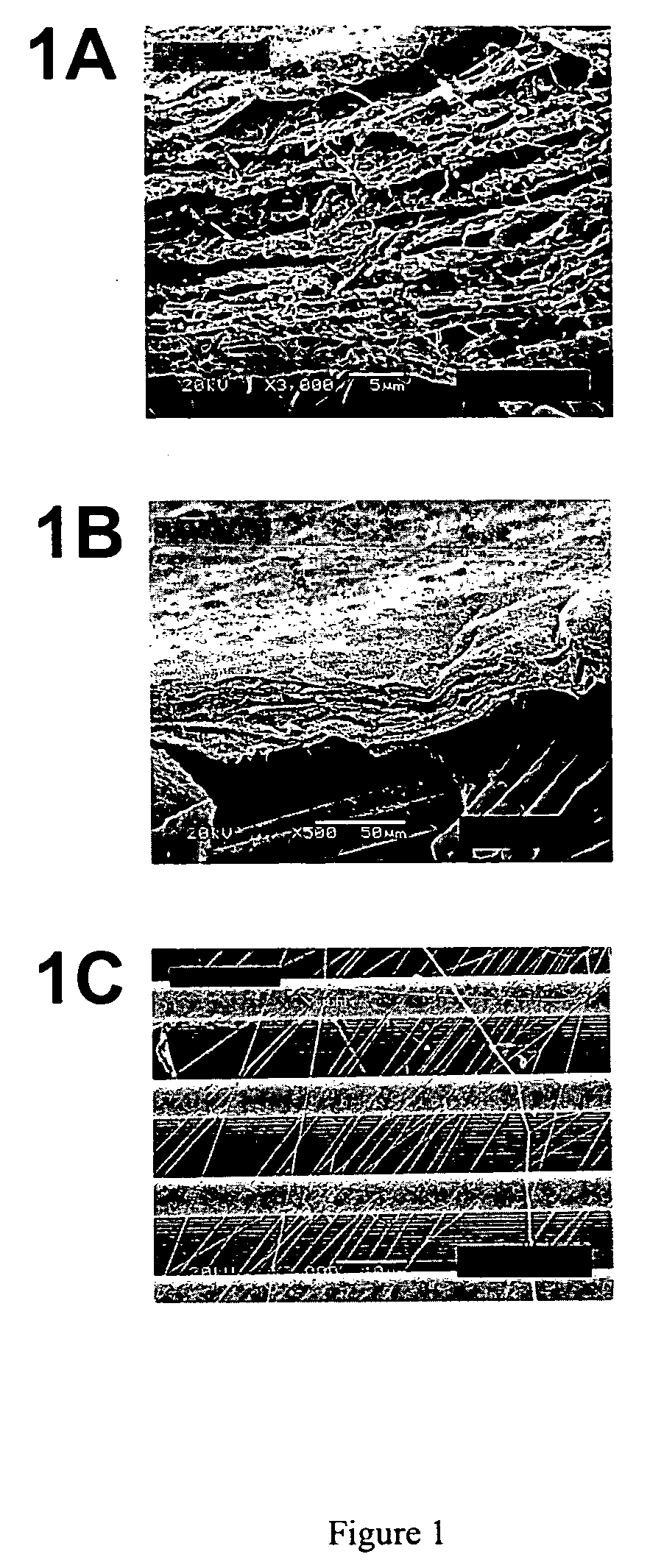

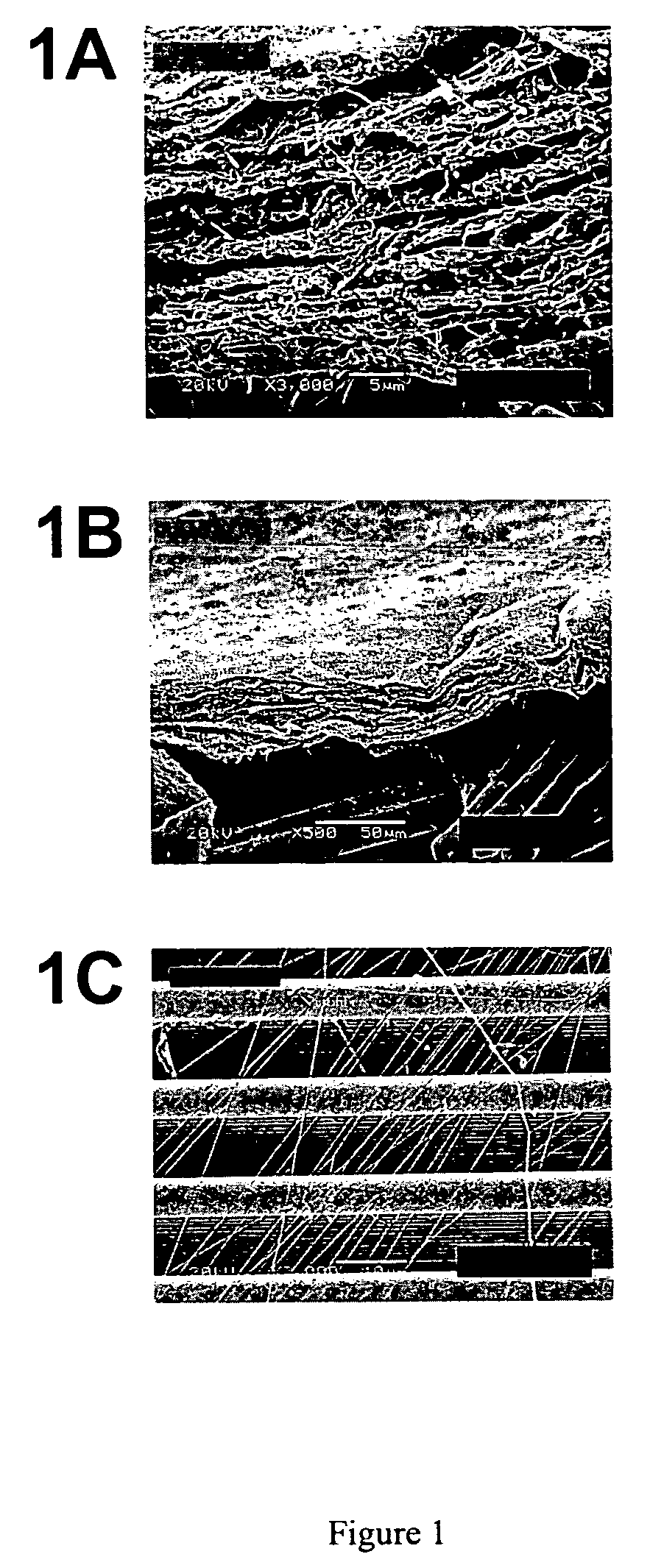

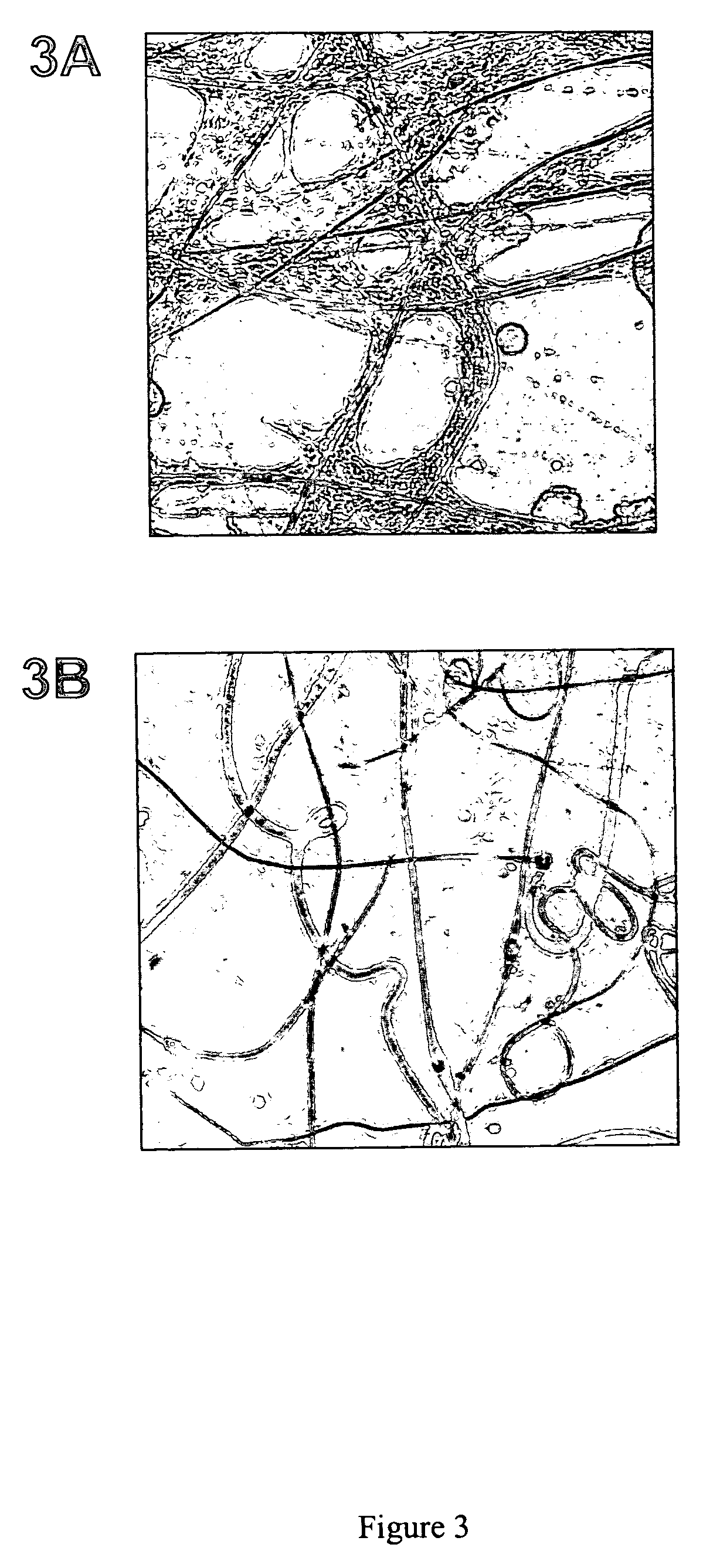

Nanofibrillar structure and applications including cell and tissue culture

ActiveUS20050095695A1Reduce usageBioreactor/fermenter combinationsNanostructure manufactureLipid formationNanofiber

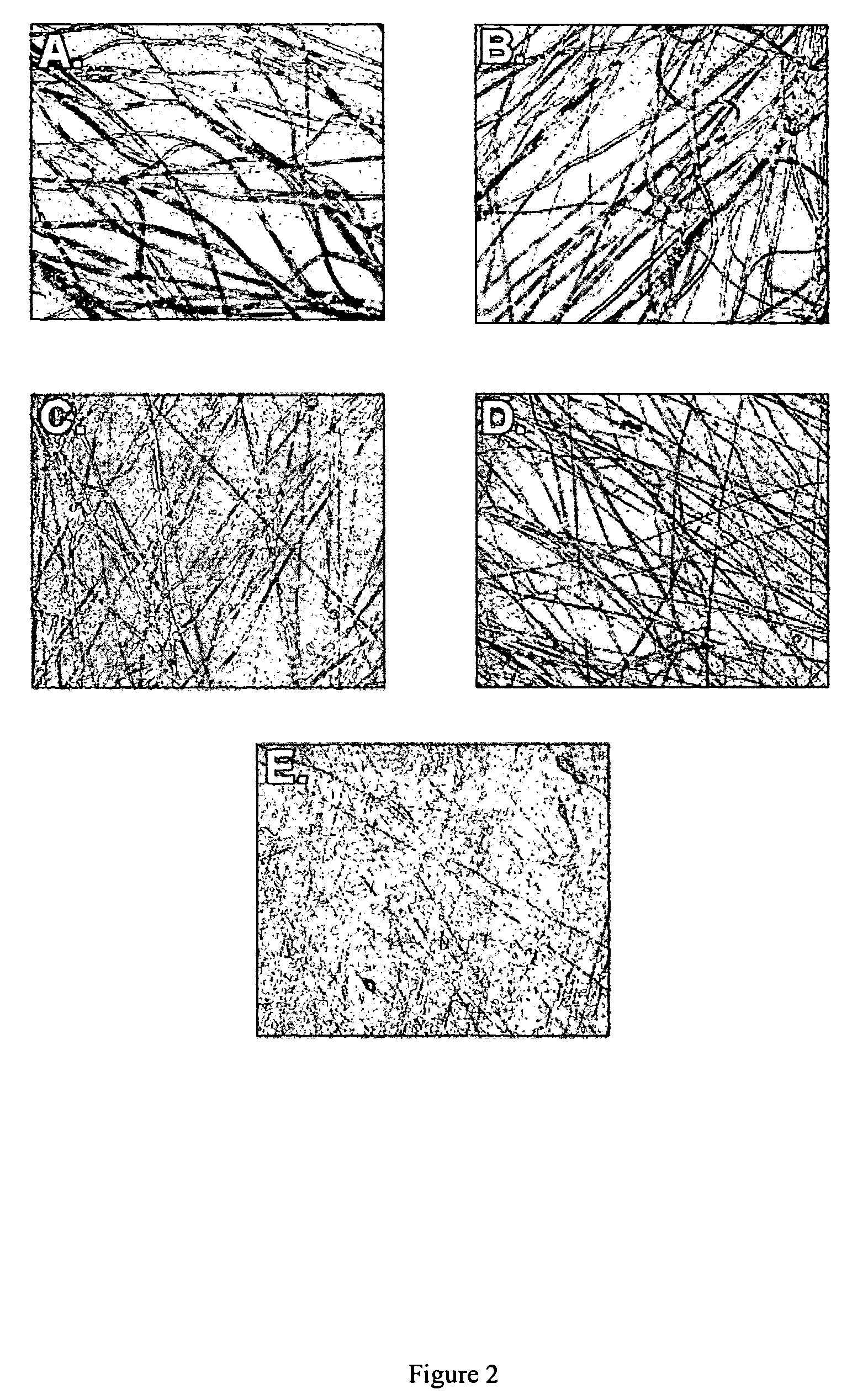

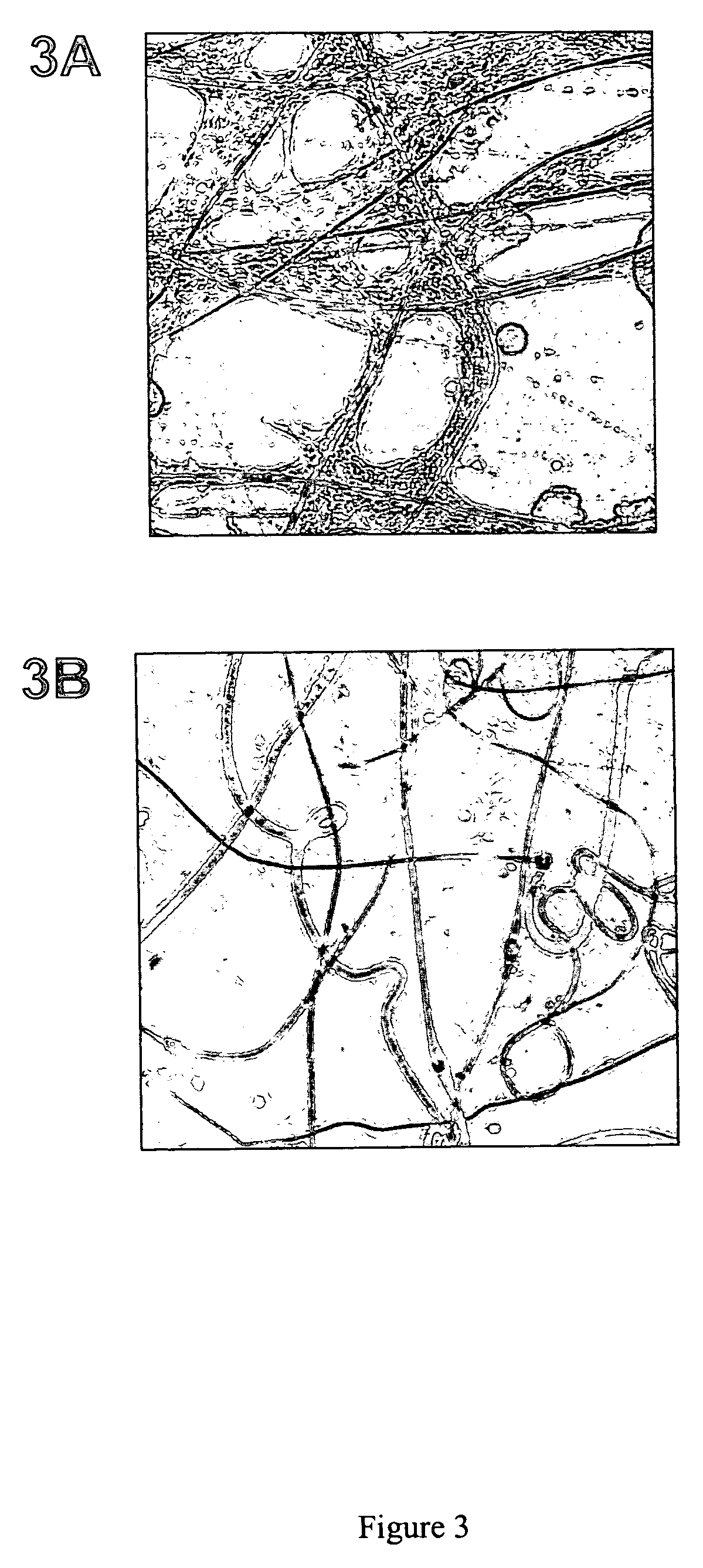

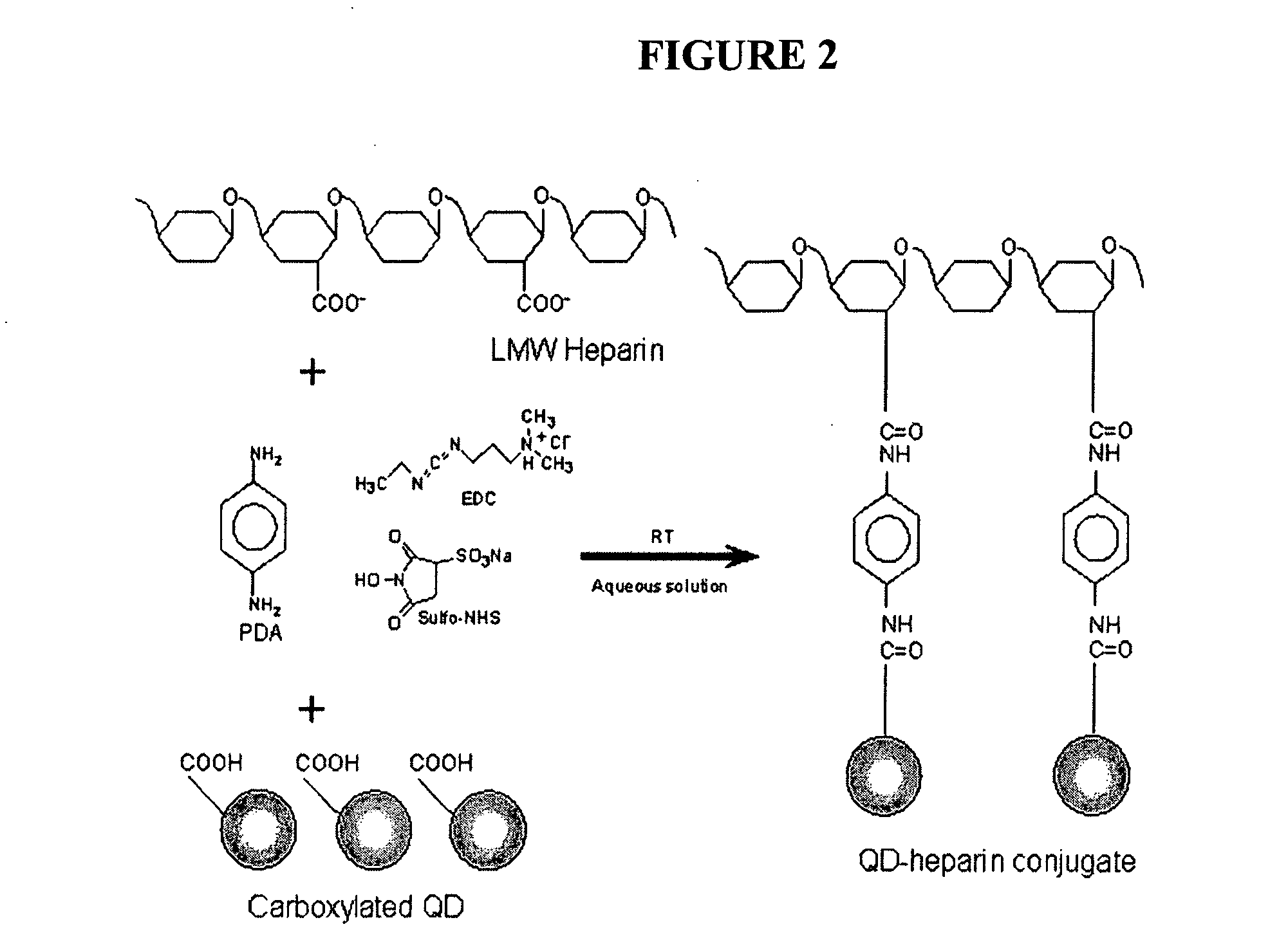

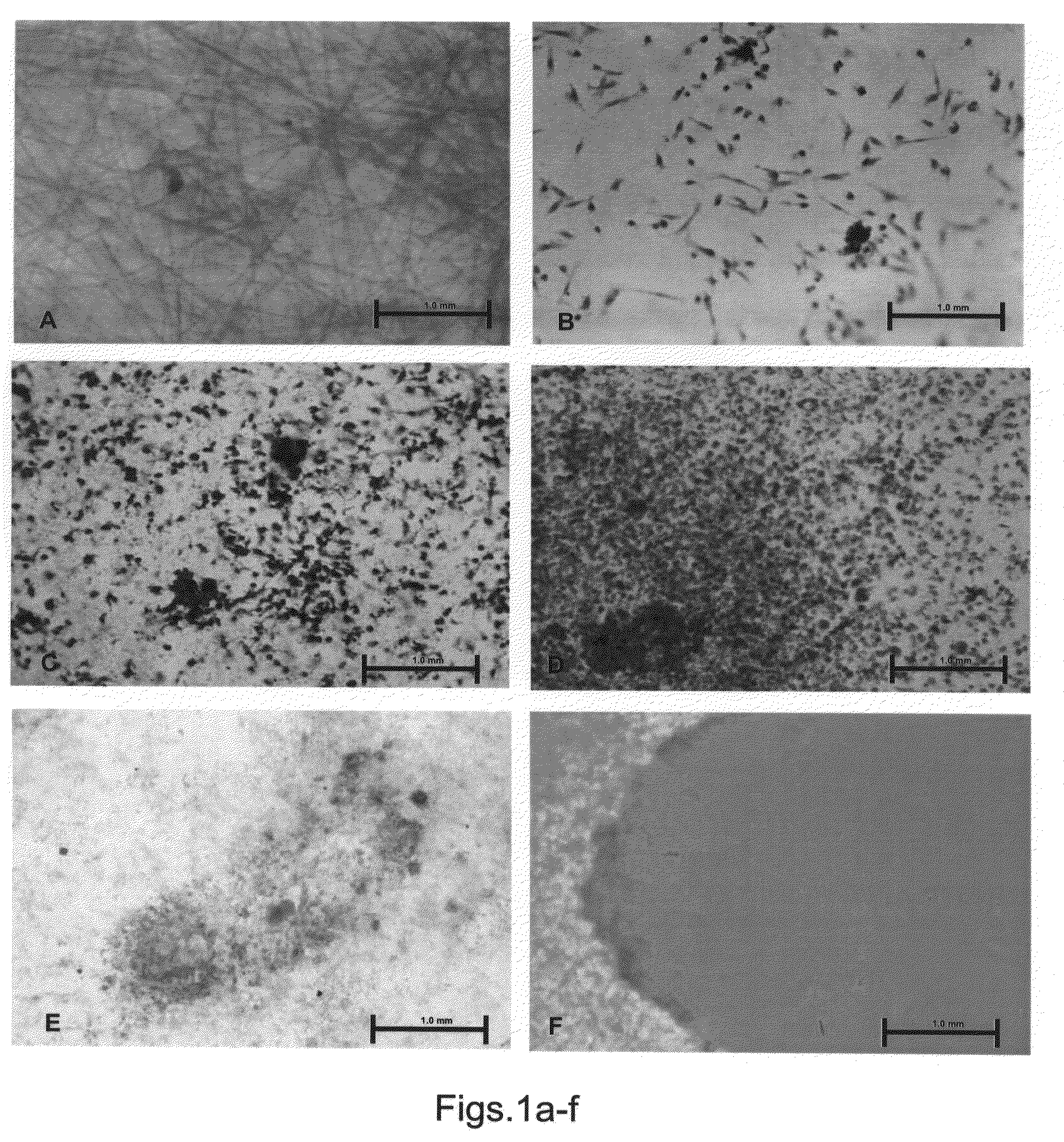

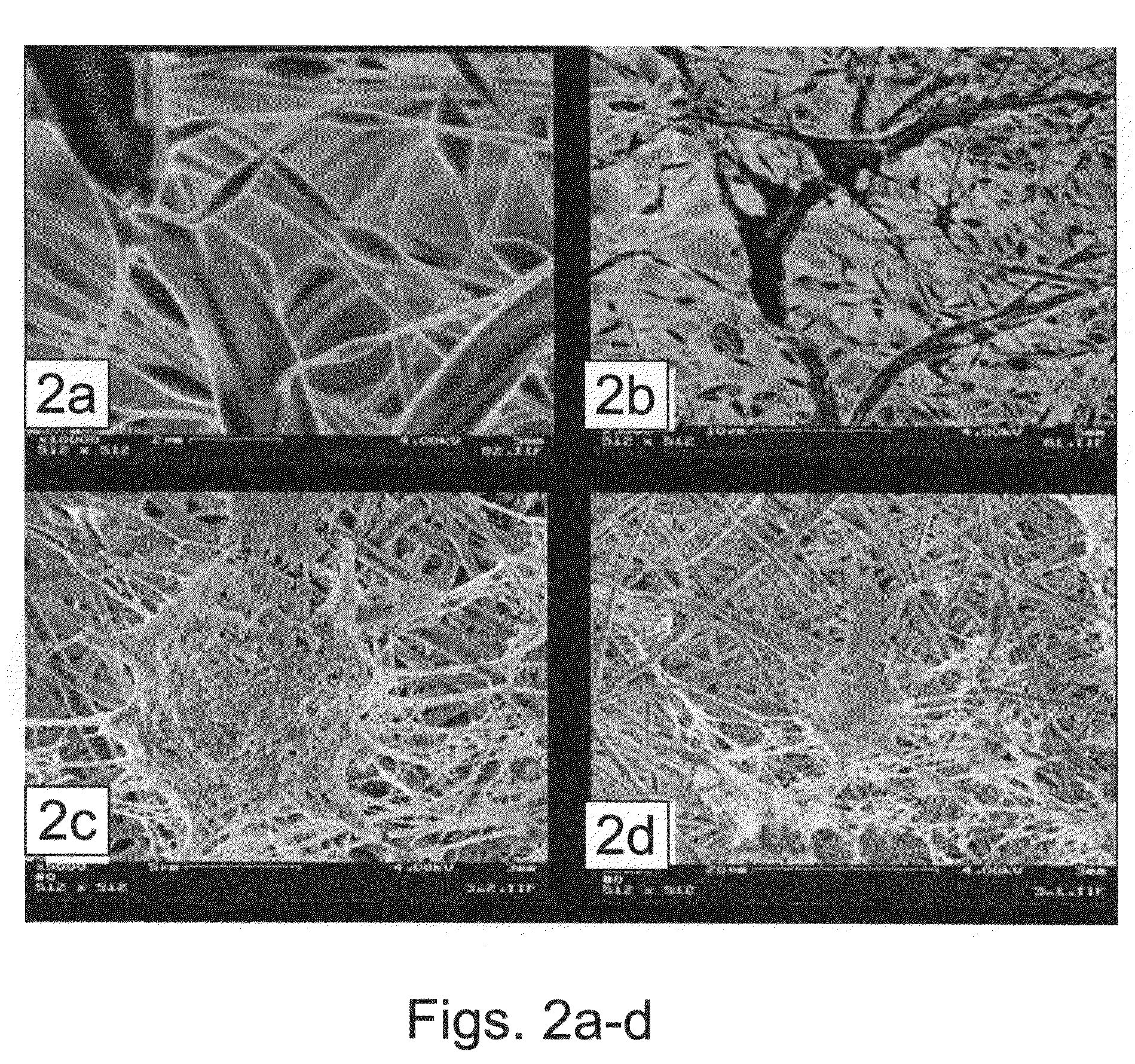

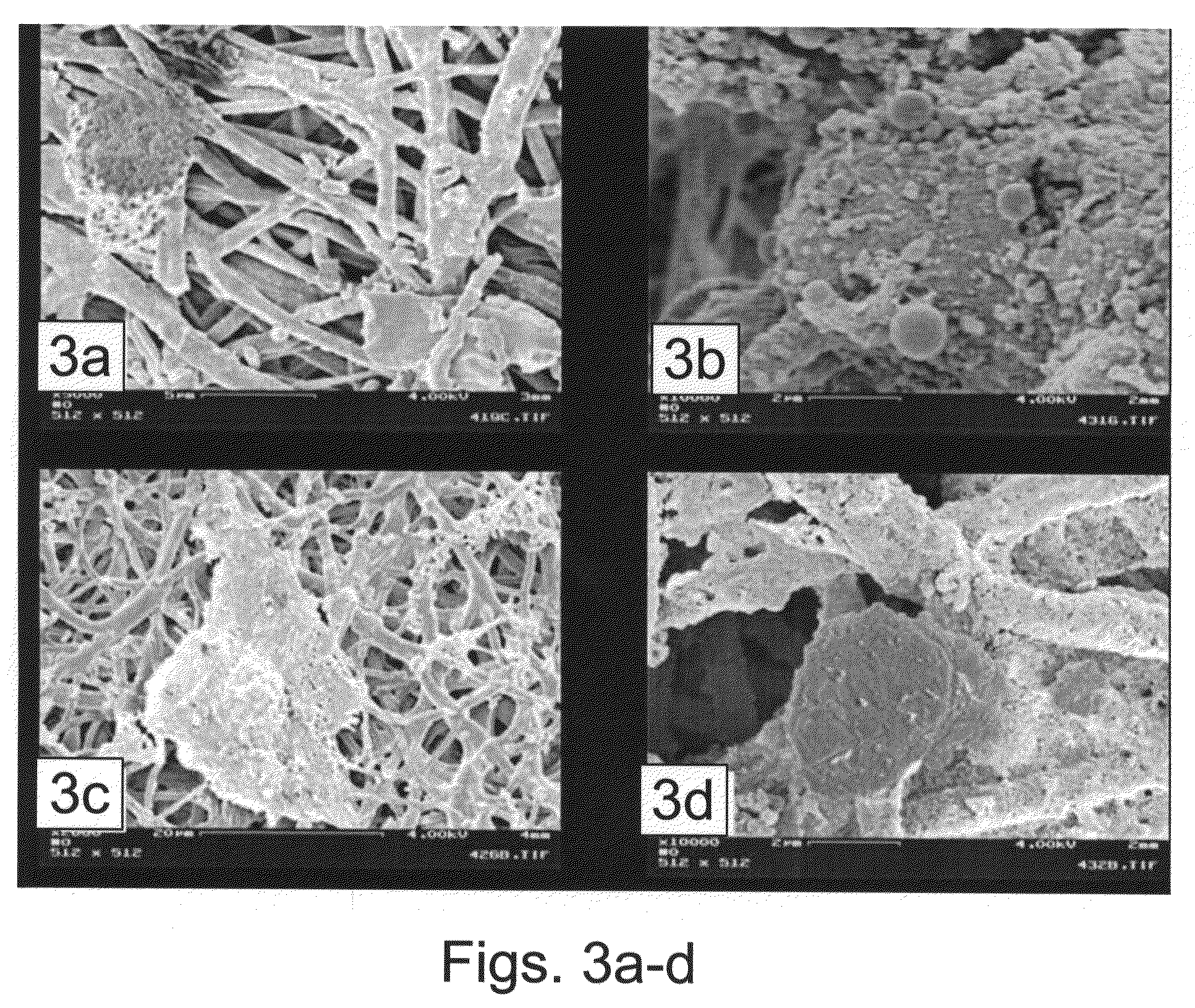

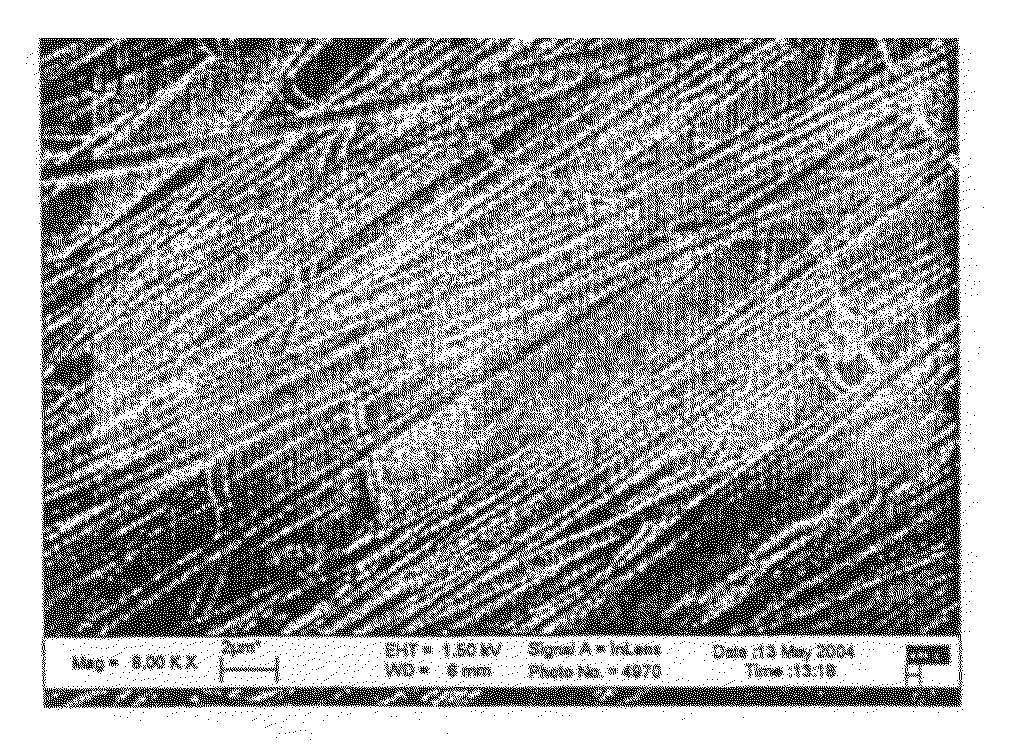

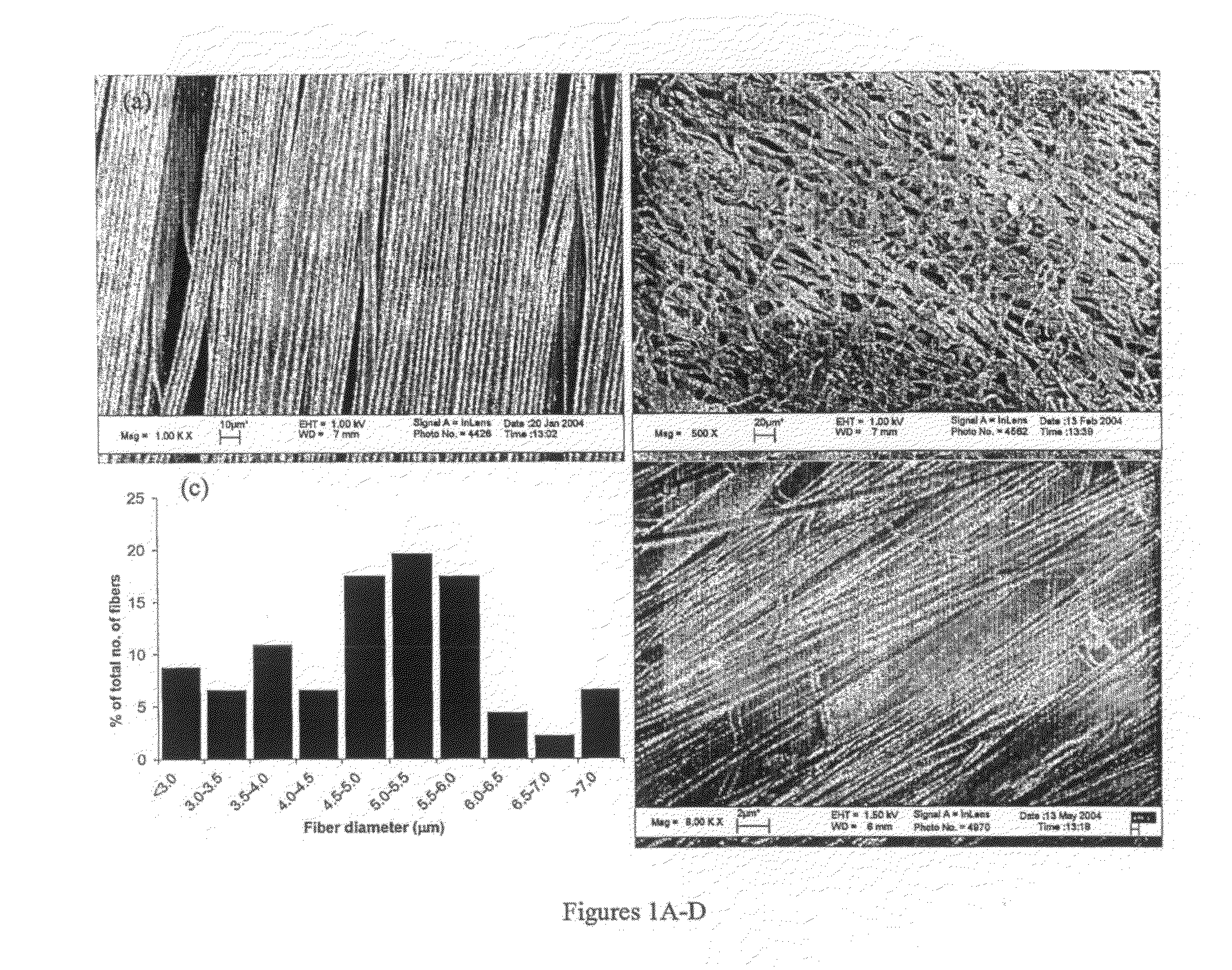

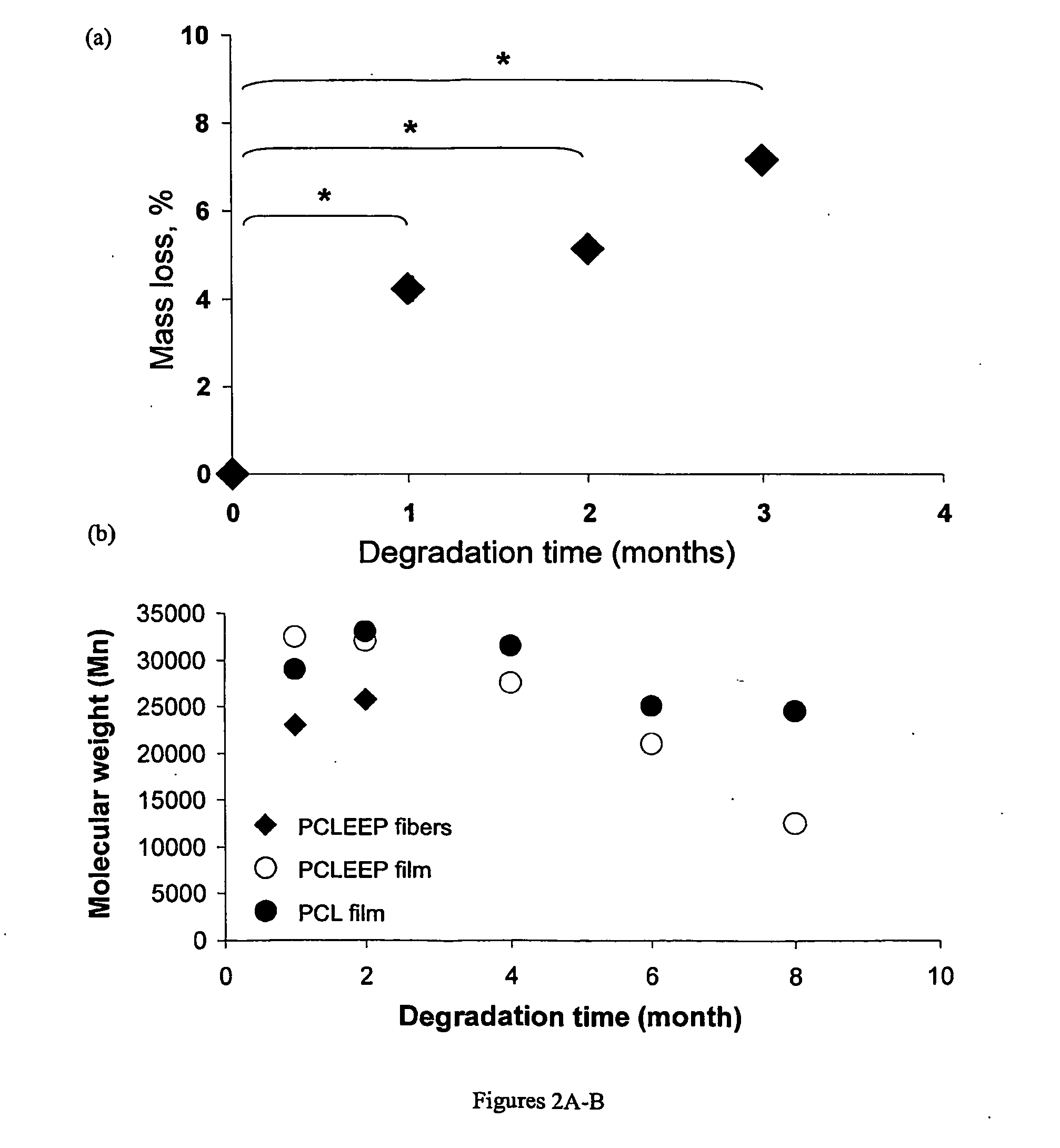

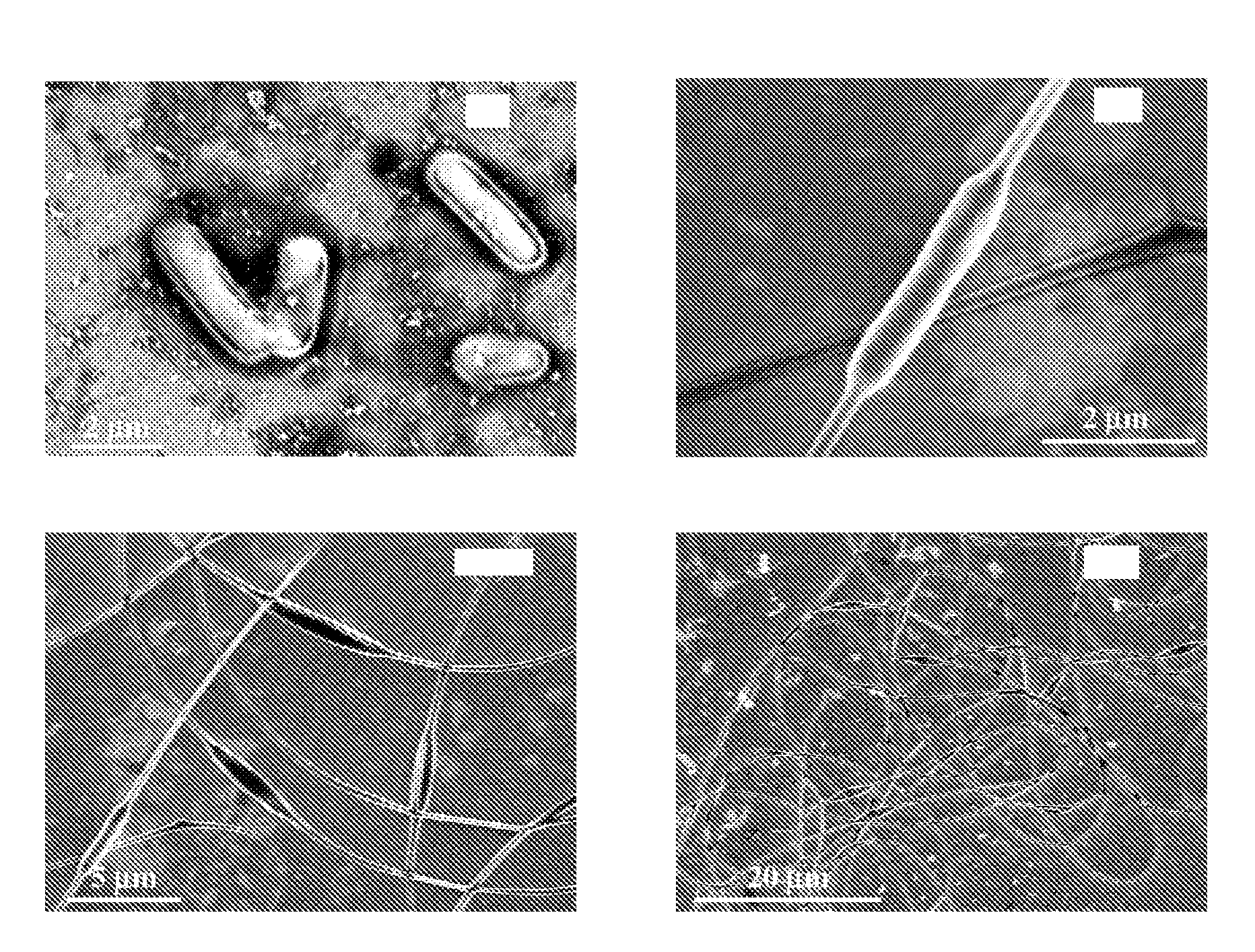

A nanofibrillar structure for cell culture and tissue engineering is disclosed. The nanofibrillar structure can be used in a variety of applications including methods for proliferating and / or differentiating cells and manufacturing a tissue. Also disclosed is an improved nanofiber comprising a lipid, lipophilic molecule, or chemically modified surface. The nanofibers can be used in a variety of applications including the formation of nanofibrillar structures for cell culture and tissue engineering.

Owner:BOARD OF TRUSTEES OPERATING MICHIGAN STATE UNIV

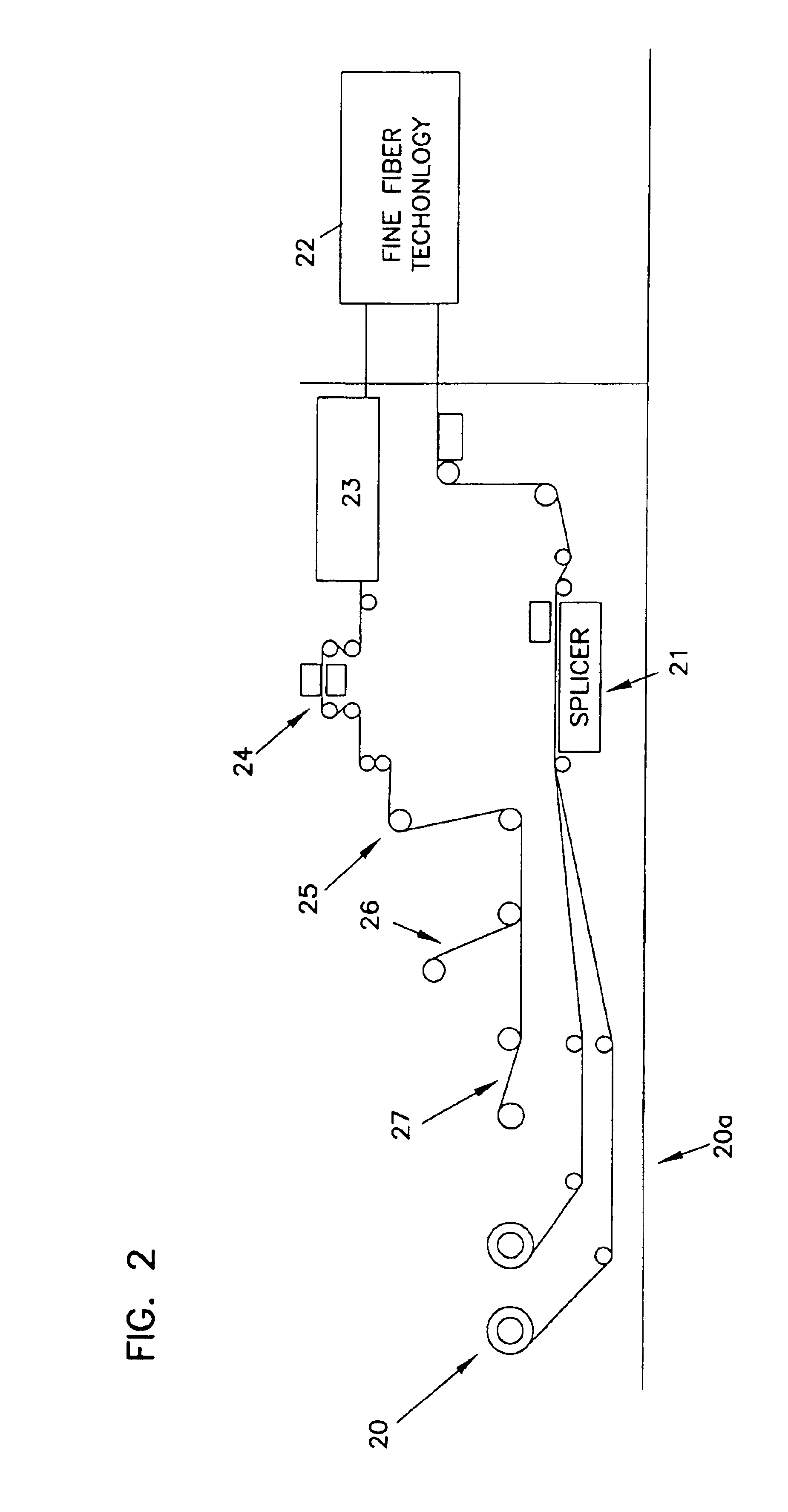

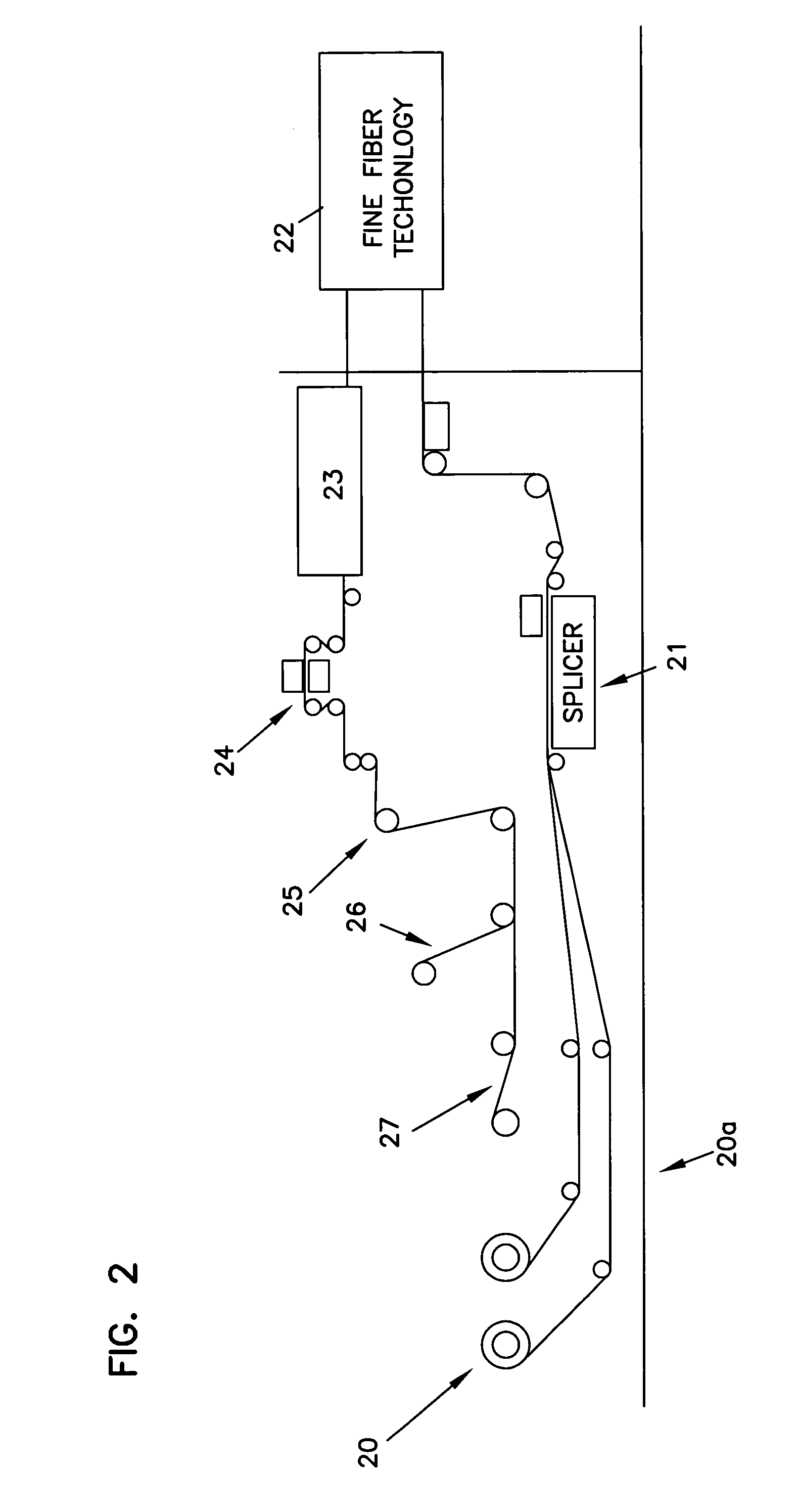

Polymer, polymer microfiber, polymer nanofiber and applications including filter structures

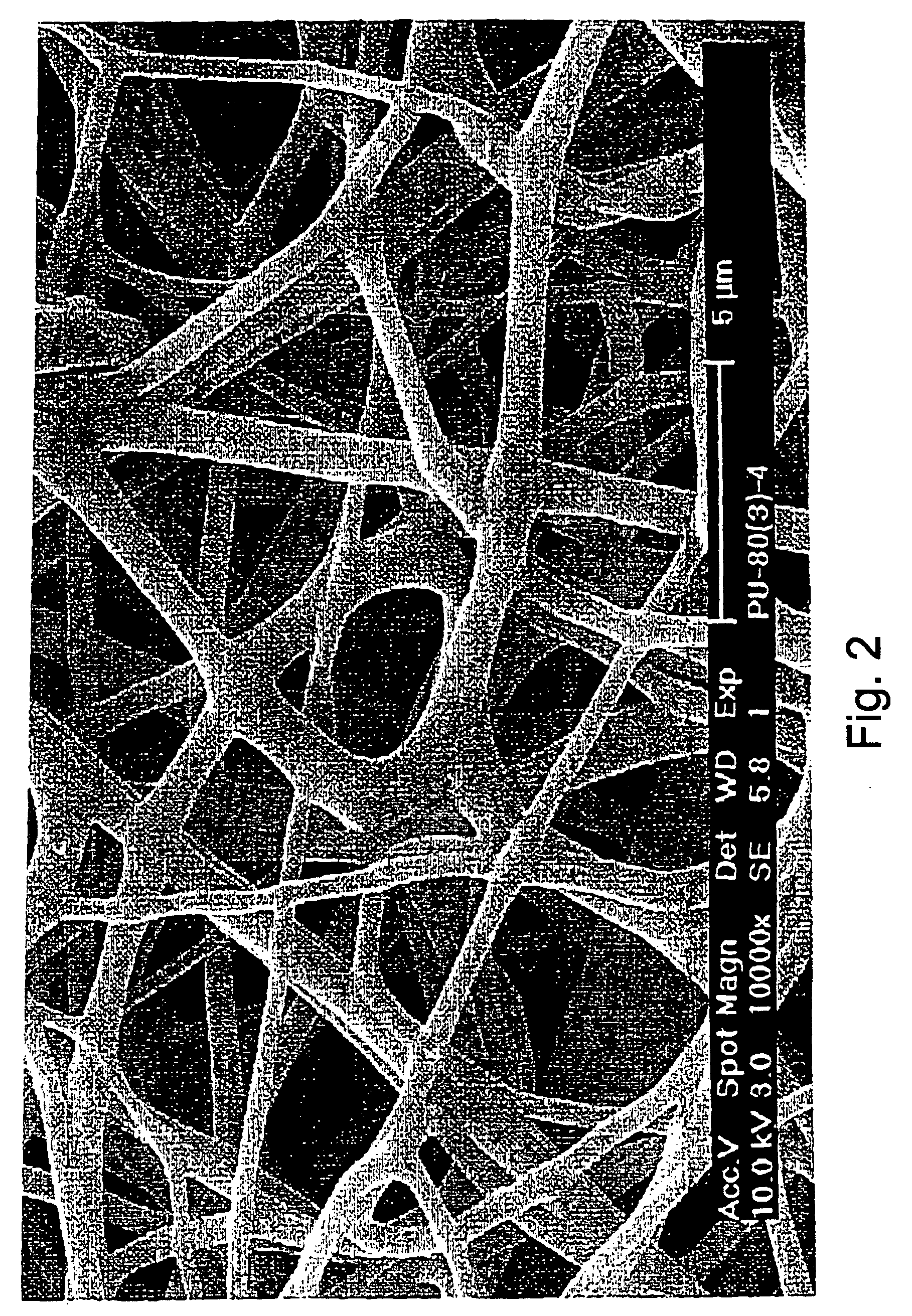

InactiveUS6924028B2Simple materialSubstantial surface loadingCombination devicesMaterial nanotechnologyPolymer scienceNanofiber

Disclosed are improved polymer materials. Also disclosed are fine fiber materials that can be made from the improved polymeric materials in the form of microfiber and nanofiber structures. The microfiber and nanofiber structures can be used in a variety of useful applications including the formation of filter materials.

Owner:DONALDSON CO INC

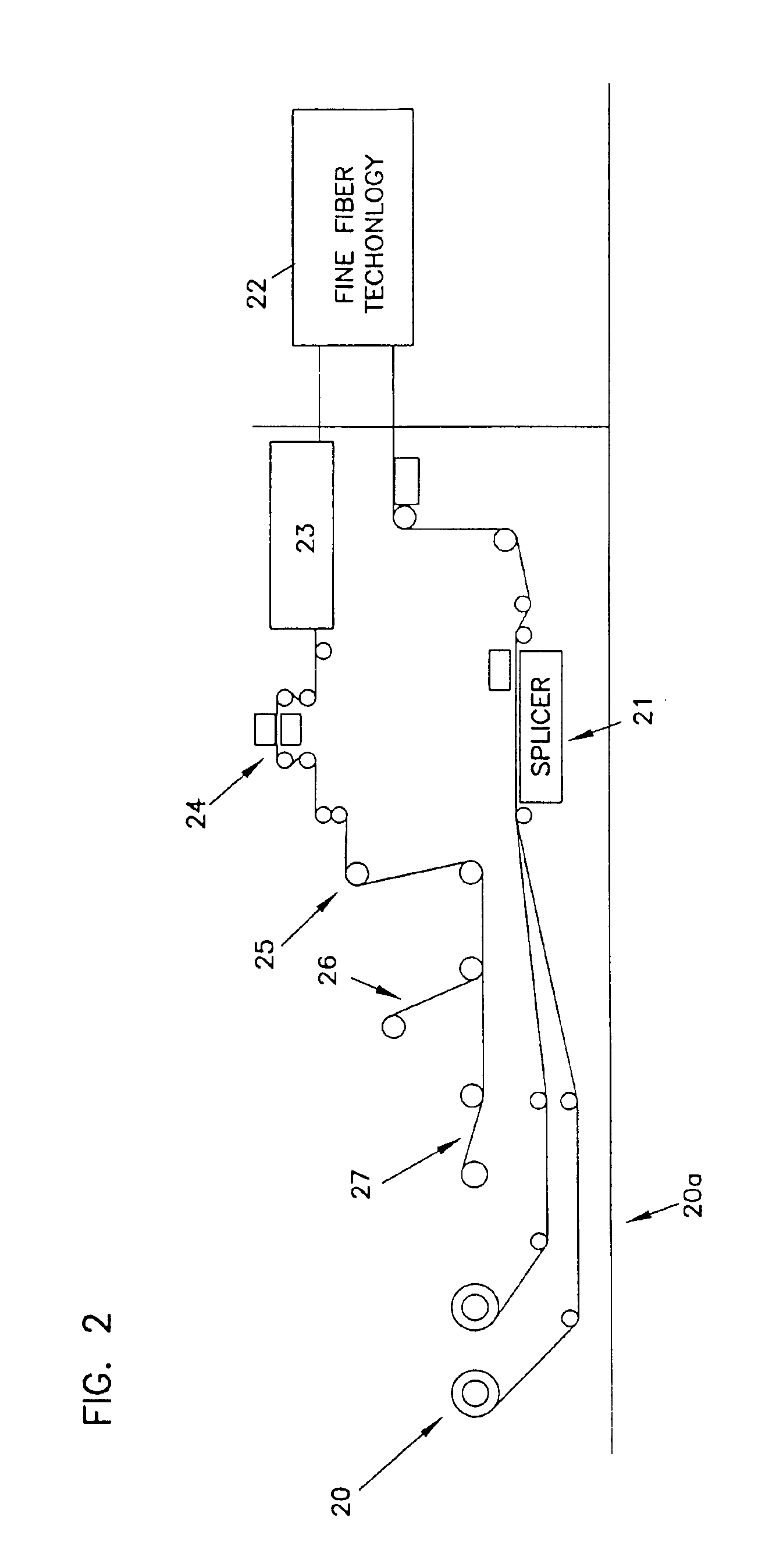

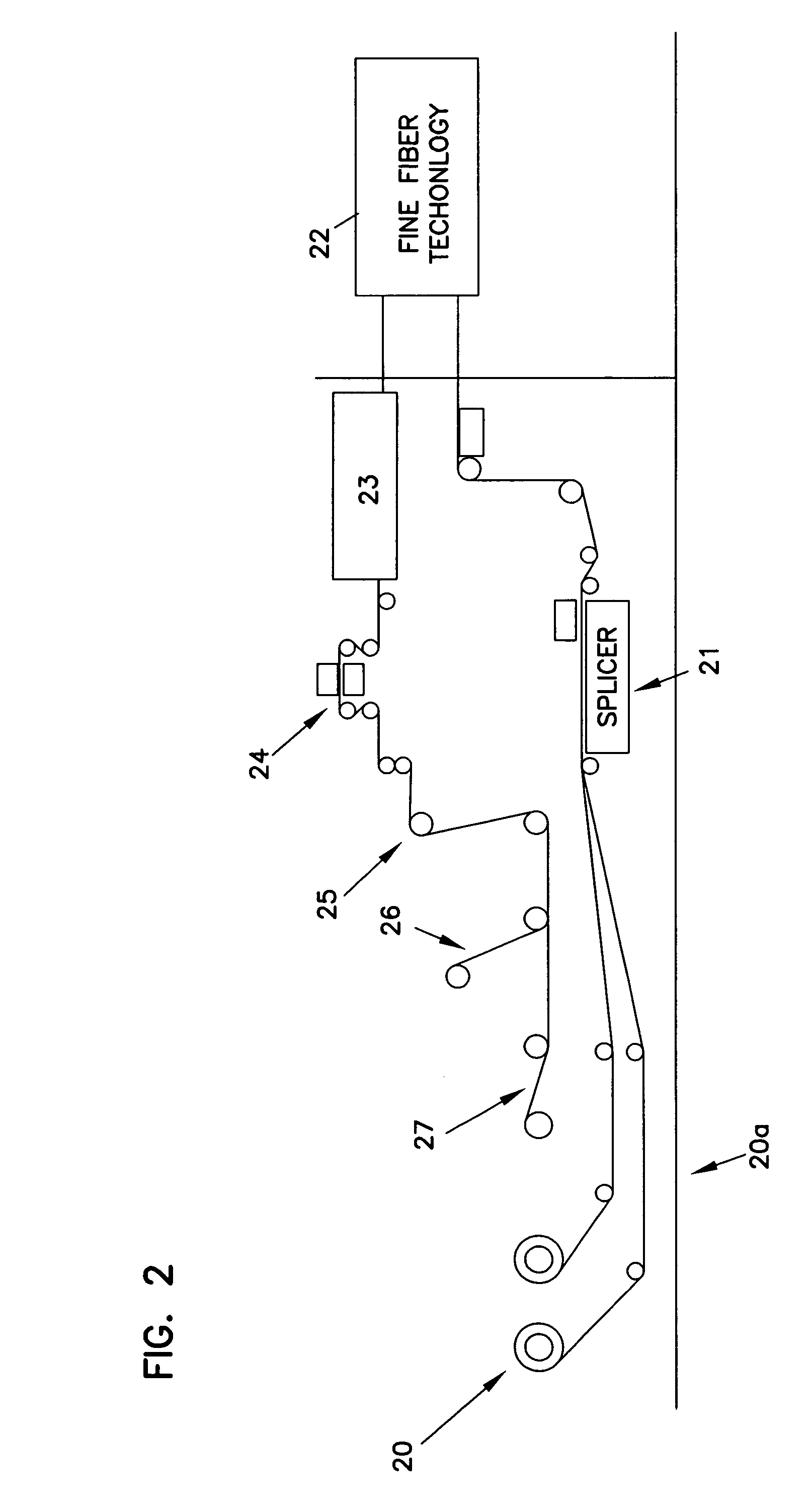

Air filter with fine fiber and spun bonded media

Disclosed are improved polymer materials. Also disclosed are fine fiber materials that can be made from the improved polymeric materials in the form of microfiber and nanofiber structures. The microfiber and nanofiber structures can be used in a variety of useful applications including the formation of filter materials.

Owner:DONALDSON CO INC

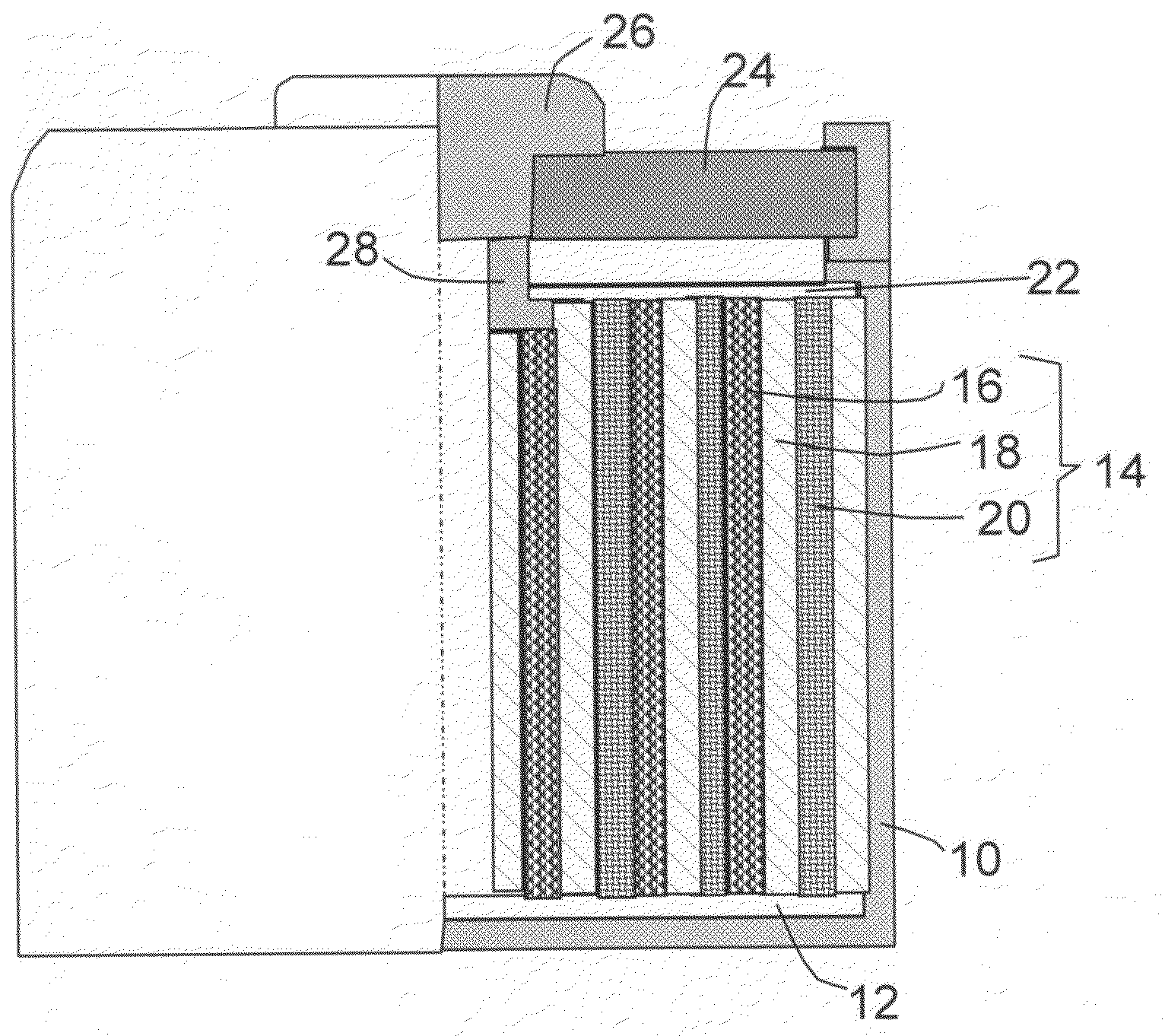

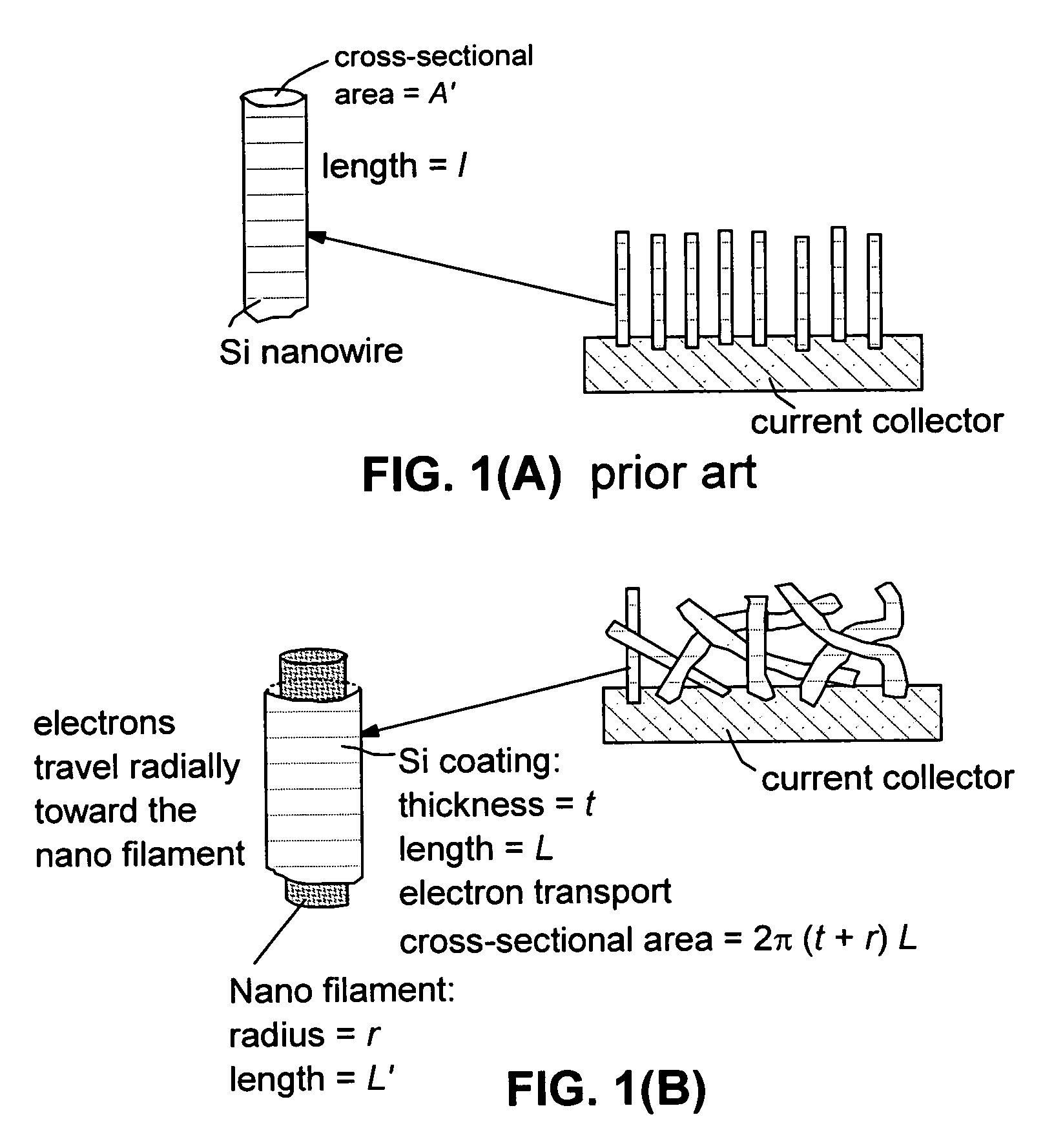

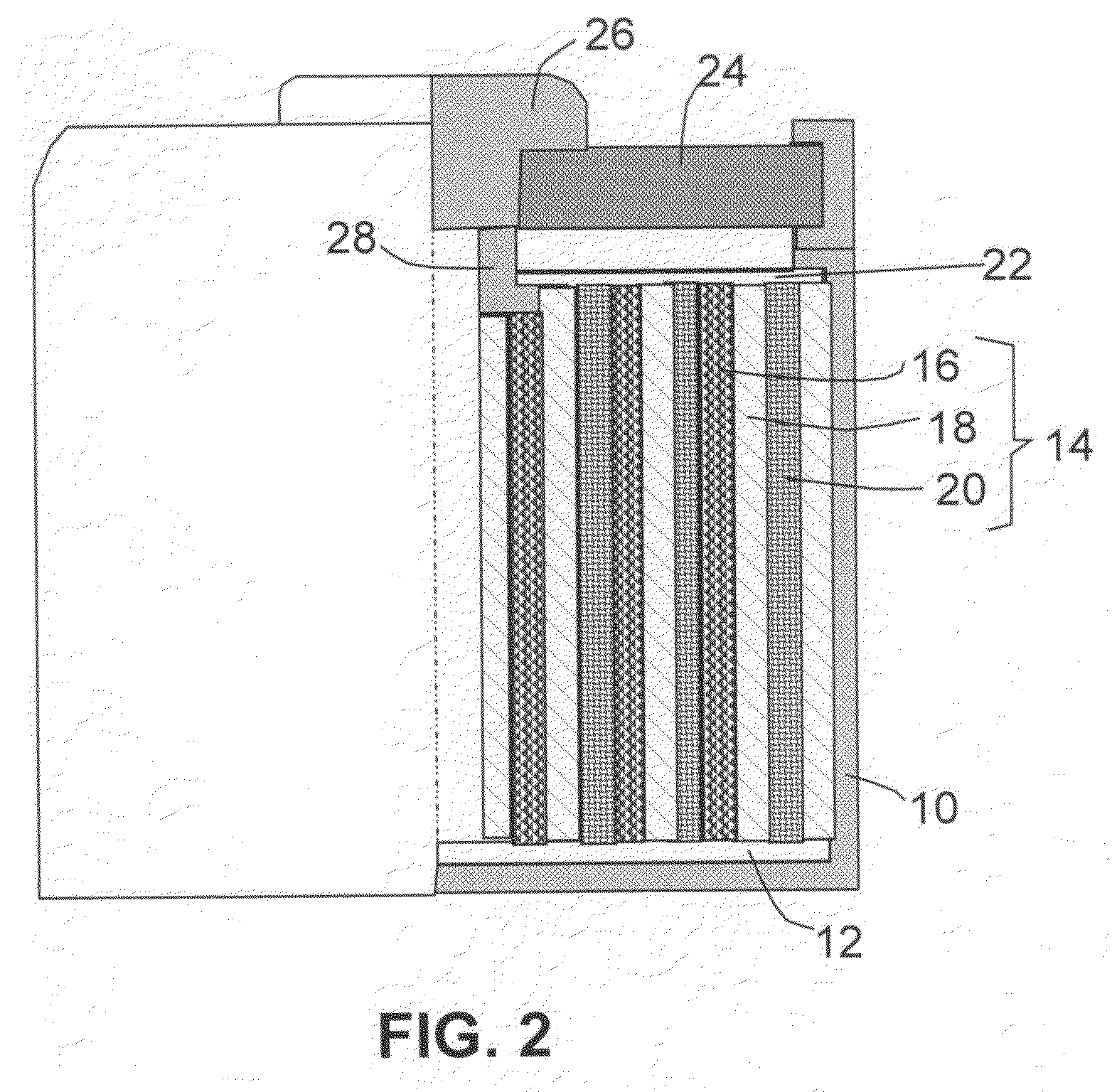

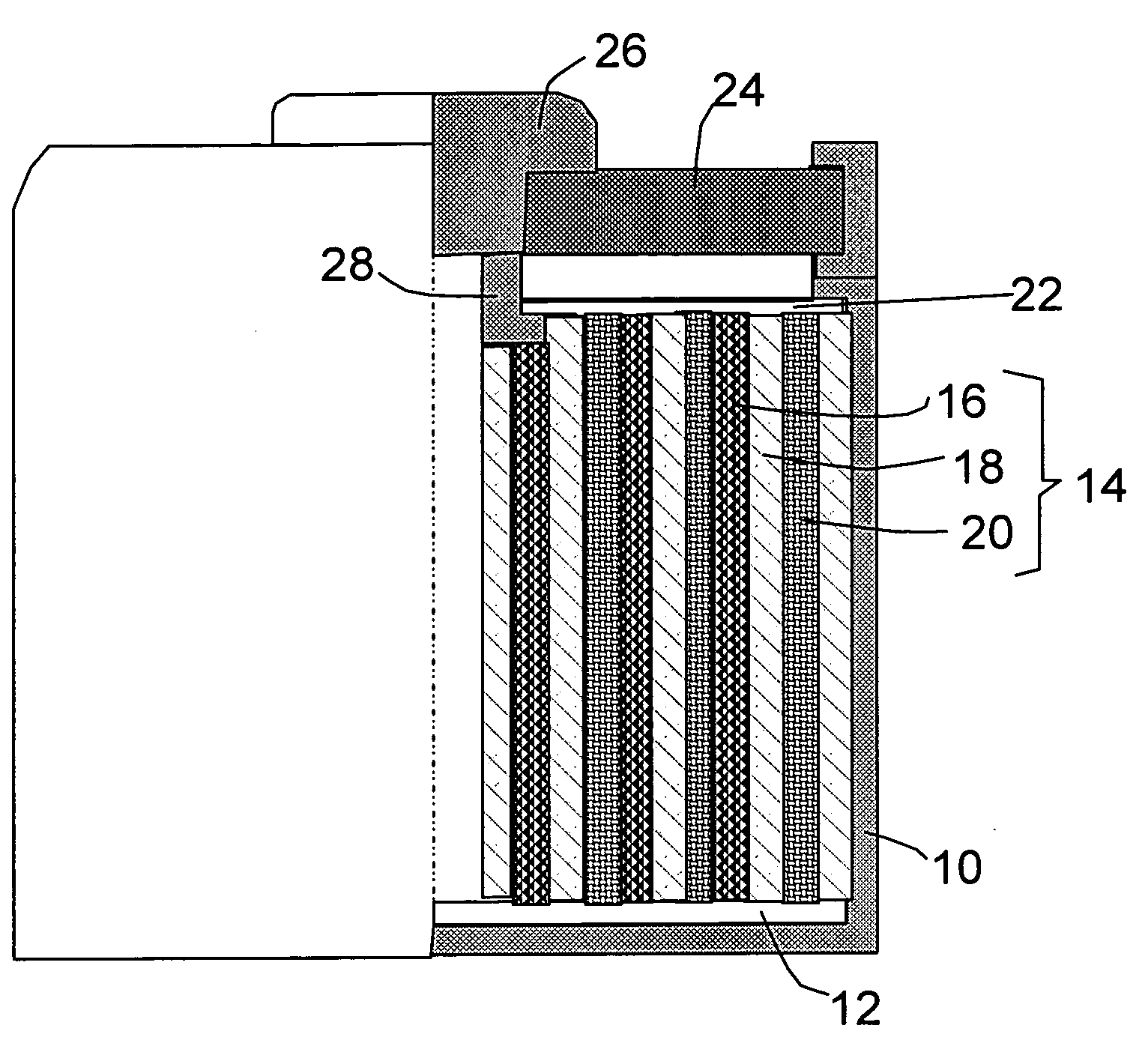

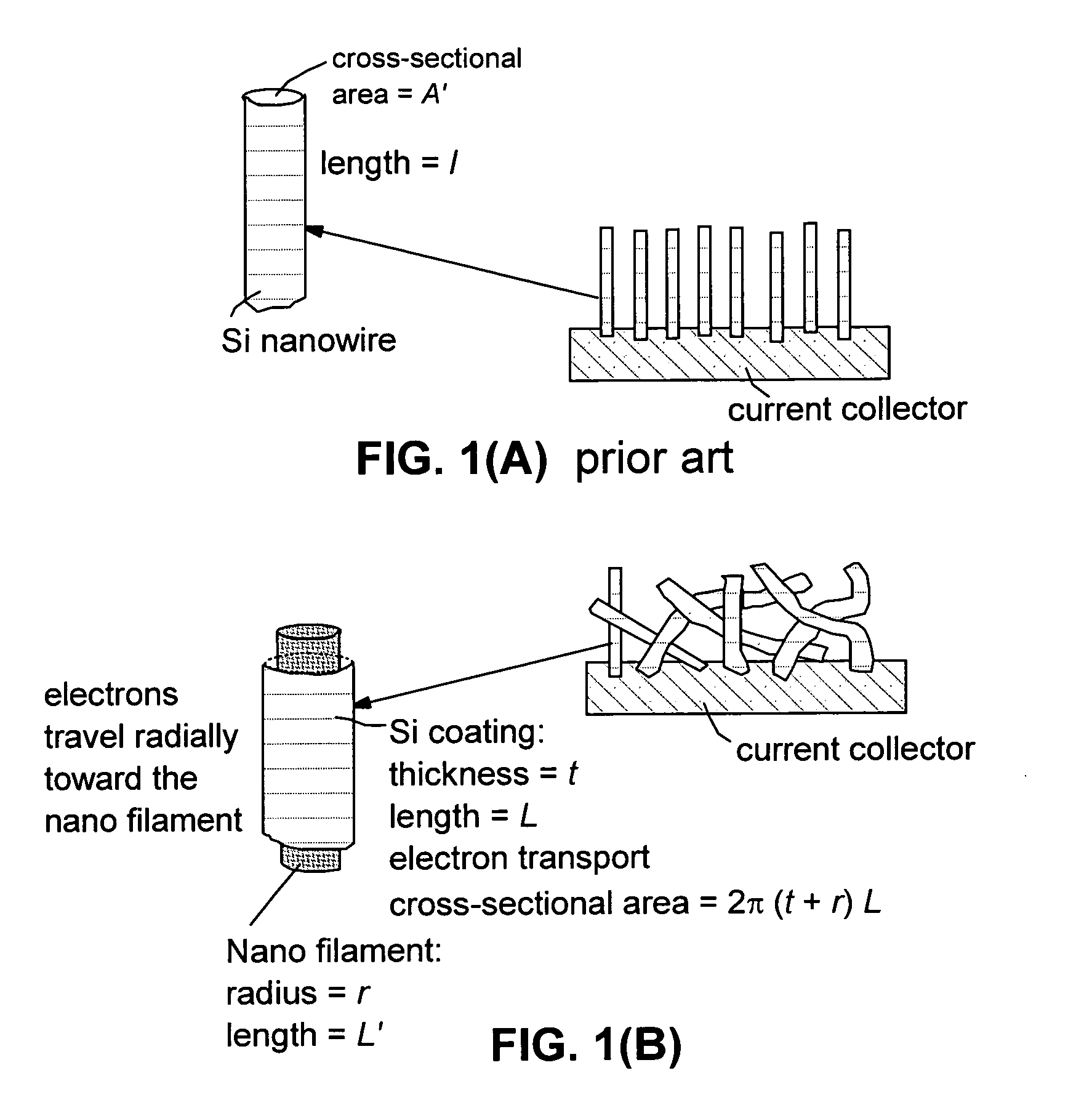

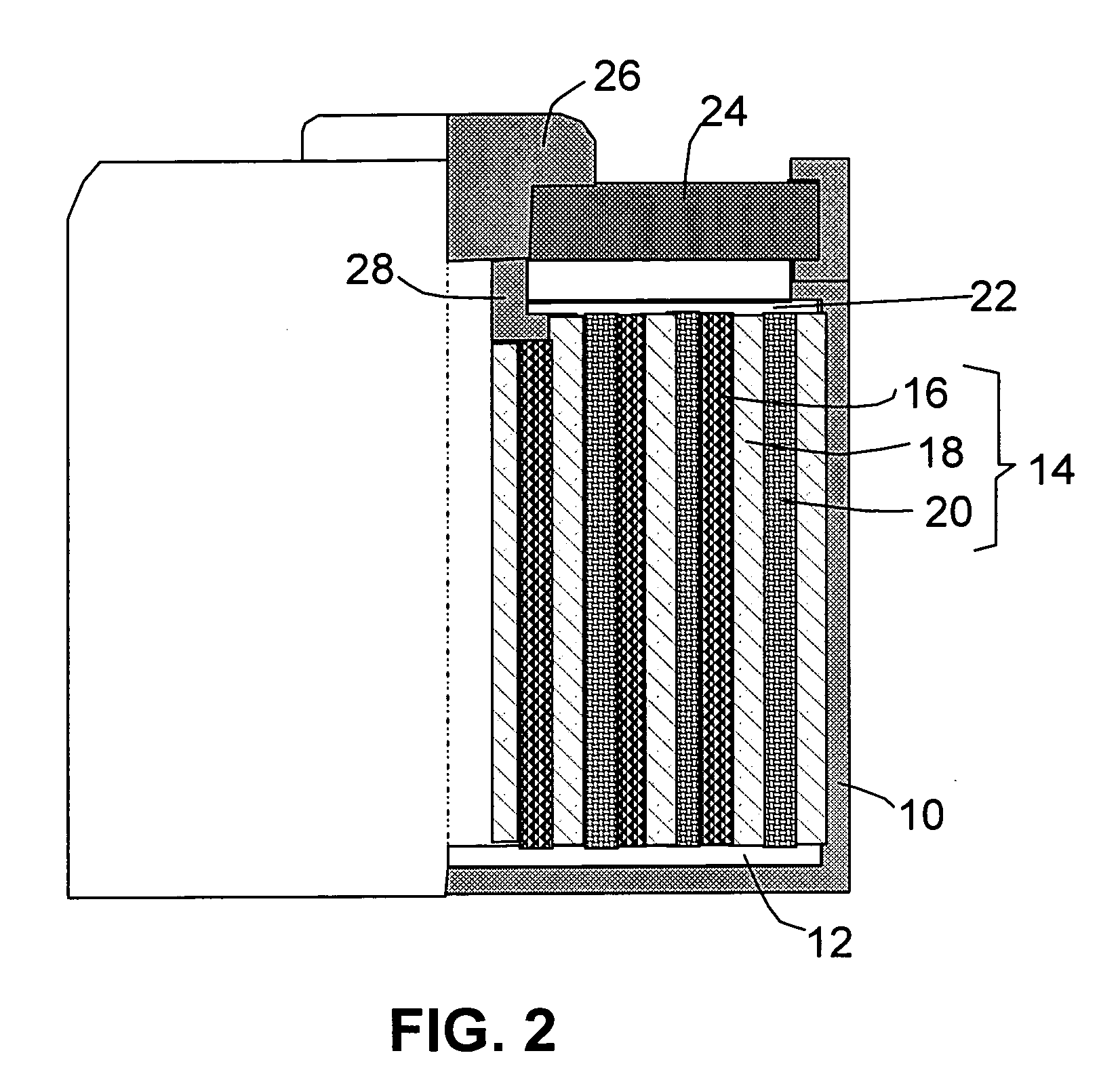

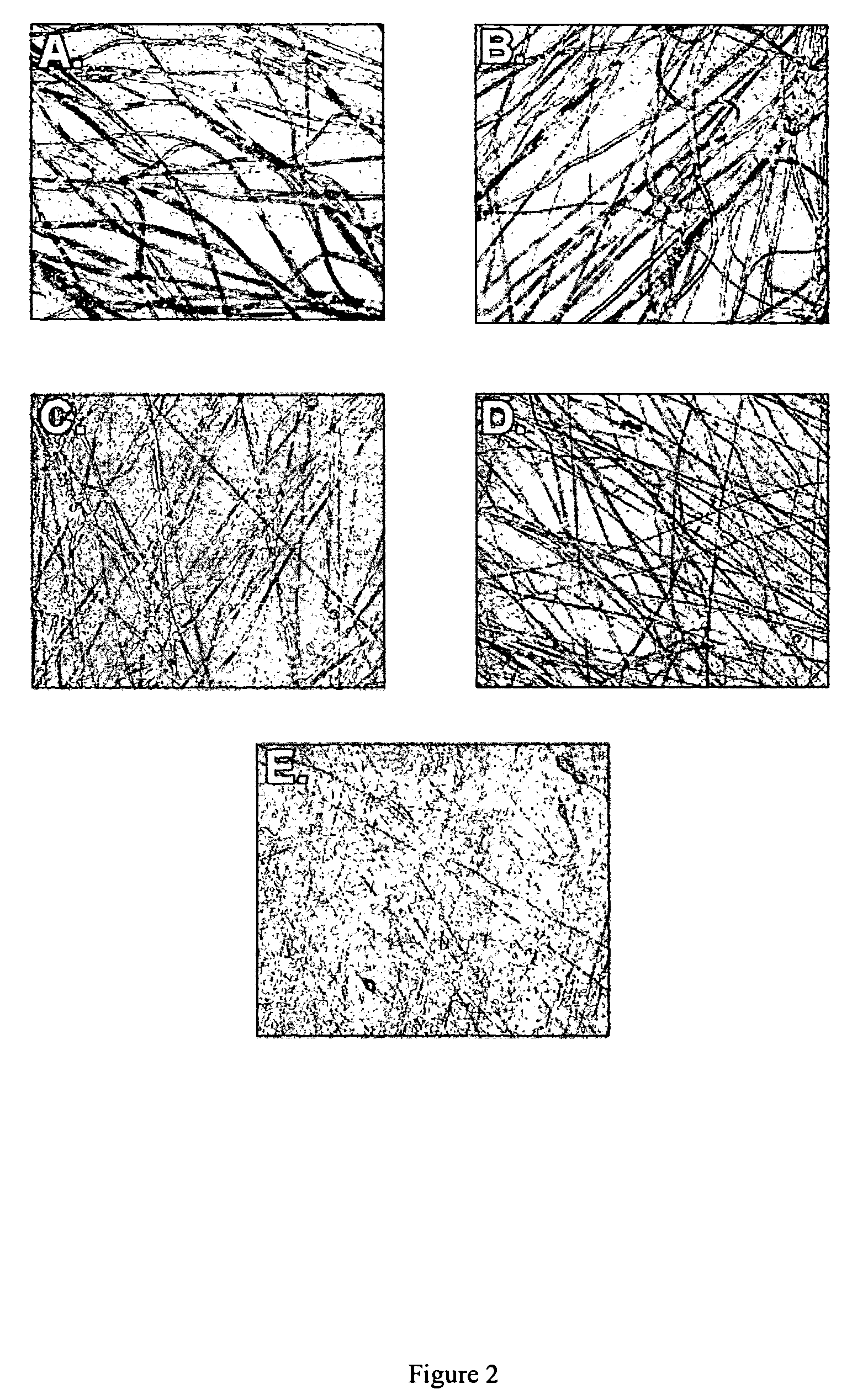

Hybrid nano-filament anode compositions for lithium ion batteries

ActiveUS20090169996A1Superior multiple-cycle behaviorImprove cycle lifeElectrochemical processing of electrodesElectrode thermal treatmentLithium-ion batteryNanometre

This invention provides a hybrid nano-filament composition for use as an electrochemical cell electrode. The composition comprises: (a) an aggregate of nanometer-scaled, electrically conductive filaments that are substantially interconnected, intersected, or percolated to form a porous, electrically conductive filament network comprising substantially interconnected pores, wherein the filaments have an elongate dimension and a first transverse dimension with the first transverse dimension being less than 500 nm (preferably less than 100 nm) and an aspect ratio of the elongate dimension to the first transverse dimension greater than 10; and (b) micron- or nanometer-scaled coating that is deposited on a surface of the filaments, wherein the coating comprises an anode active material capable of absorbing and desorbing lithium ions and the coating has a thickness less than 20 μm (preferably less than 1 μm). Also provided is a lithium ion battery comprising such an electrode as an anode. The battery exhibits an exceptionally high specific capacity, an excellent reversible capacity, and a long cycle life.

Owner:GLOBAL GRAPHENE GRP INC

Fluoropolymer fine fiber

ActiveUS20090032475A1Advantageously employedHeat stableDispersed particle filtrationLiquid suspension thickening by filtrationPolymer scienceFiltration

A layer of fluoropolymer fine fiber can be made. The fine fiber can be made by electrospinning from a solvent or a solvent blend. The layers of the invention are useful in general filtration of fluid streams including gaseous and liquid streams. The fine fiber layers are also useful as hydrophobic filtration layers that can be used to separate water from a hydrocarbon stream.

Owner:DONALDSON CO INC

Polymer, polymer microfiber, polymer nanofiber and applications including filter structures

Owner:DONALDSON CO INC

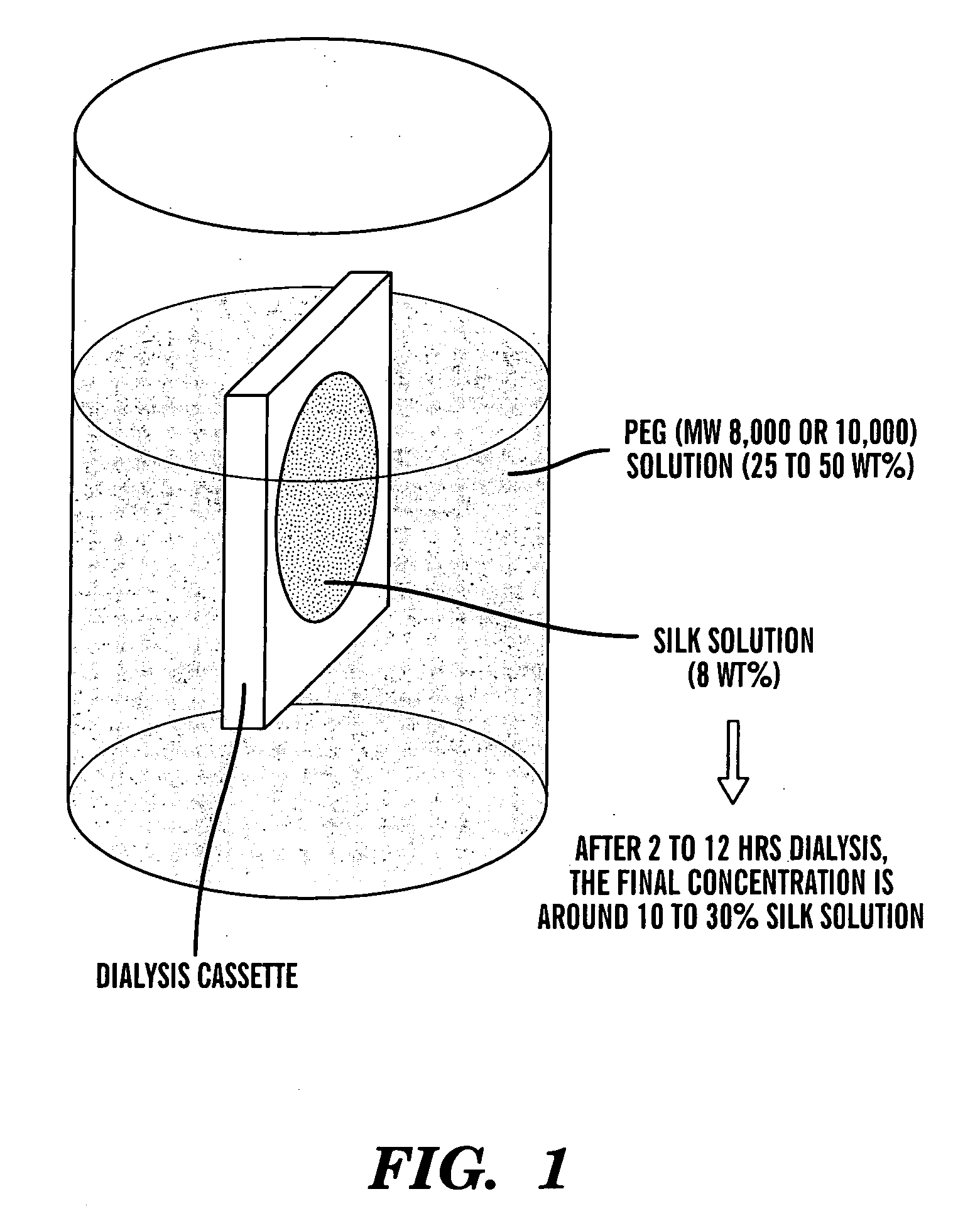

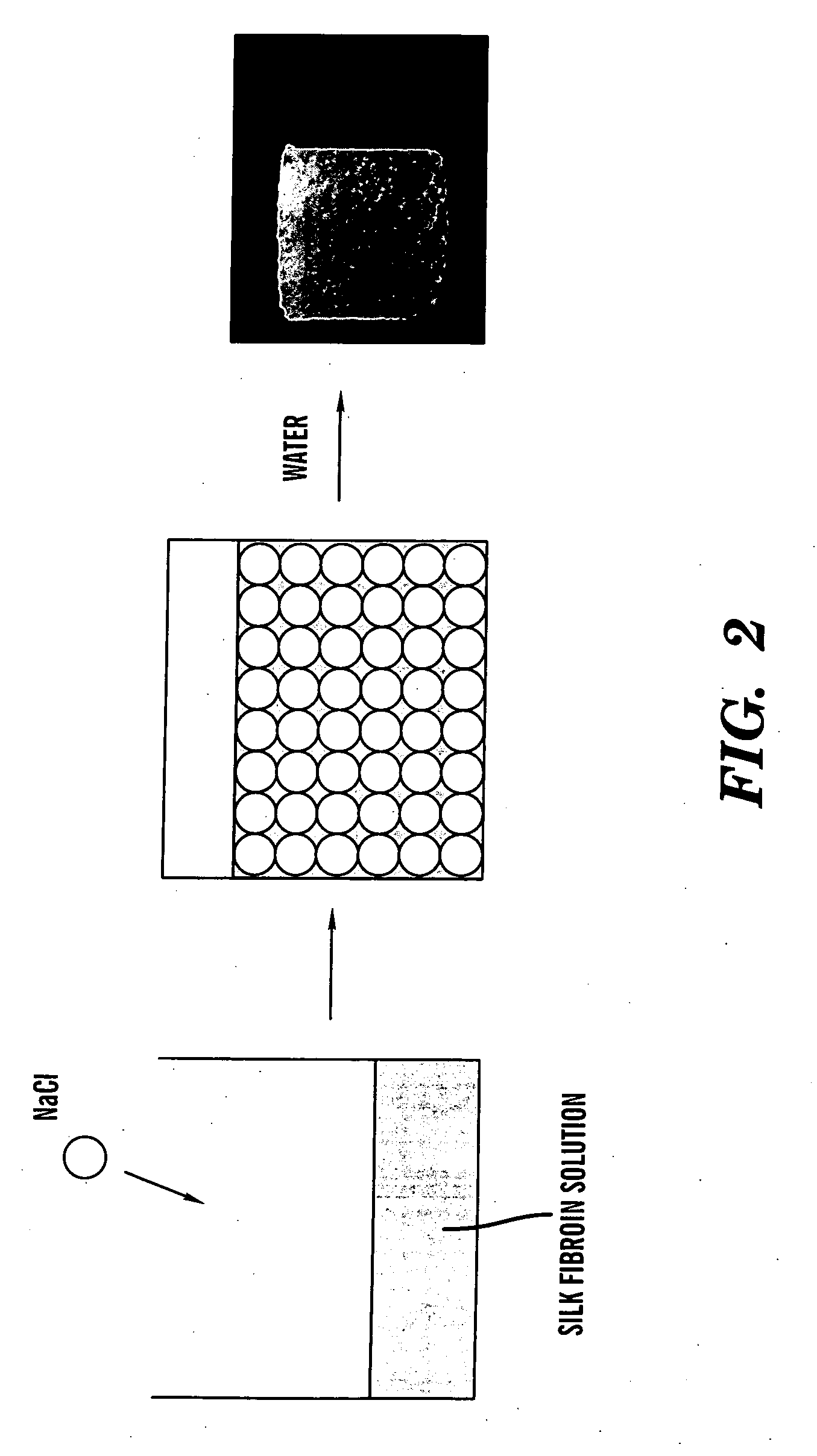

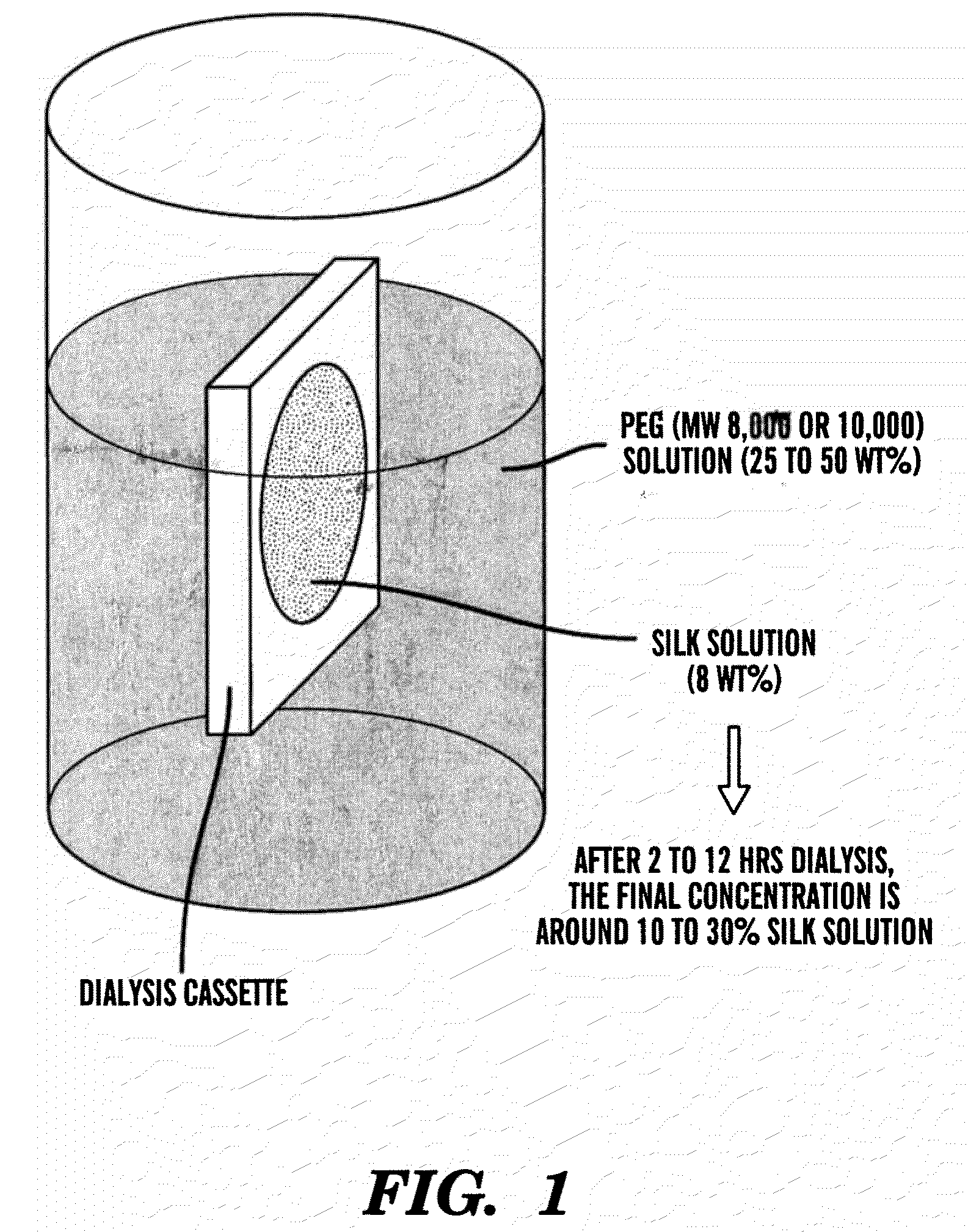

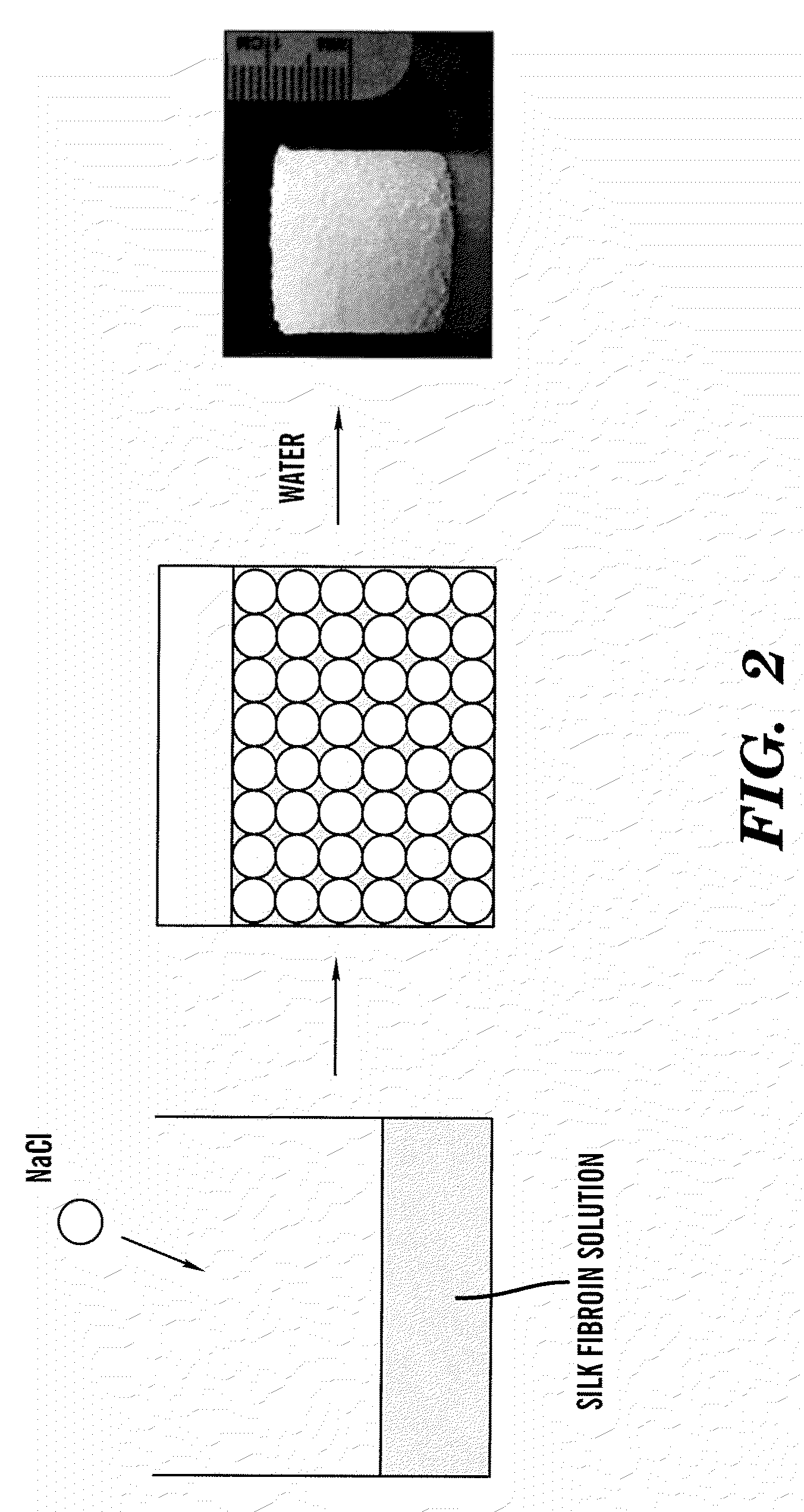

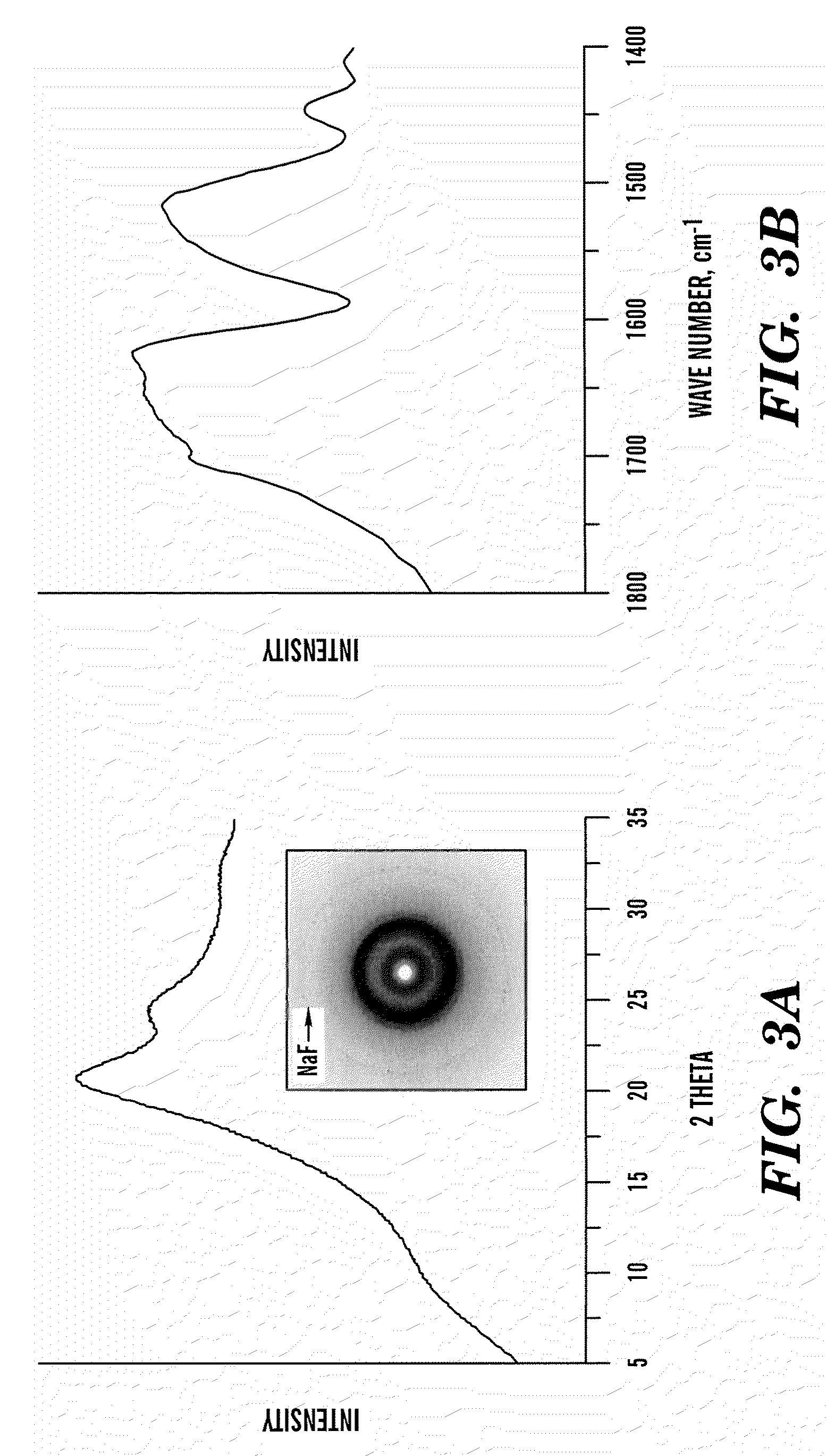

Concentrated aqueous silk fibroin solution and use thereof

ActiveUS20070187862A1Reduce usageConnective tissue peptidesPeptide/protein ingredientsFiberOrganic solvent

The present invention provides for concentrated aqueous silk fibroin solutions and an all-aqueous mode for preparation of concentrated aqueous fibroin solutions that avoids the use of organic solvents, direct additives, or harsh chemicals. The invention further provides for the use of these solutions in production of materials, e.g., fibers, films, foams, meshes, scaffolds and hydrogels.

Owner:TRUSTEES OF TUFTS COLLEGE TUFTS UNIV

Polymer, polymer microfiber, polymer nanofiber and applications including filter structures

Disclosed are improved polymer materials. Also disclosed are fine fiber materials that can be made from the improved polymeric materials in the form of microfiber and nanofiber structures. The microfiber and nanofiber structures can be used in a variety of useful applications including the formation of filter materials.

Owner:DONALDSON CO INC

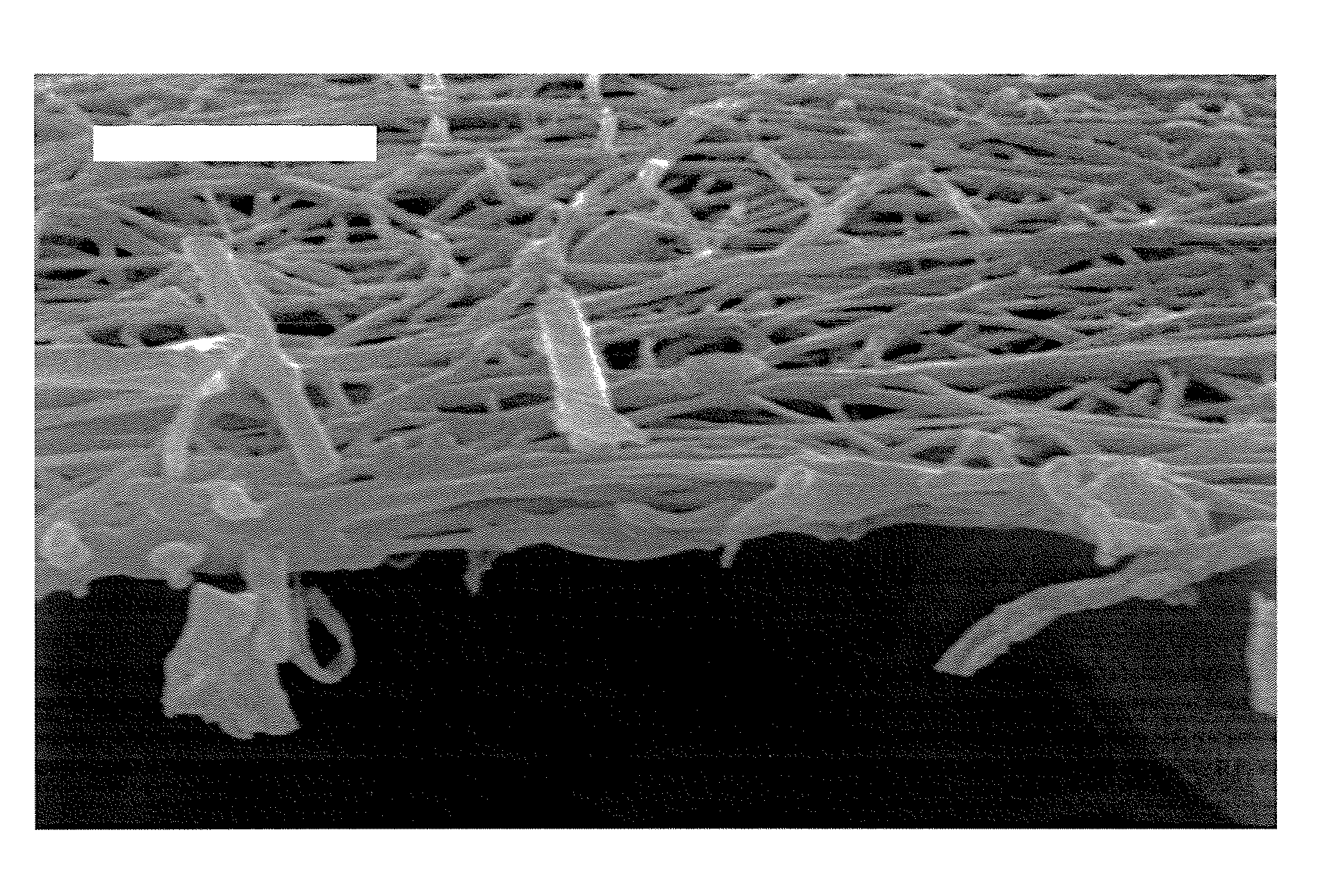

Method of producing hybrid nano-filament electrodes for lithium metal or lithium ion batteries

ActiveUS20090169725A1High reversible capacityLower internal resistanceElectrochemical processing of electrodesElectrode thermal treatmentChemical LinkageFiber

Disclosed is a method of producing a hybrid nano-filament composition for use in a lithium battery electrode. The method comprises: (a) providing an aggregate of nanometer-scaled, electrically conductive filaments that are substantially interconnected, intersected, physically contacted, or chemically bonded to form a porous network of electrically conductive filaments, wherein the filaments comprise electro-spun nano-fibers that have a diameter less than 500 nm (preferably less than 100 nm); and (b) depositing micron- or nanometer-scaled coating onto a surface of the electro-spun nano-fibers, wherein the coating comprises an electro-active material capable of absorbing and desorbing lithium ions and the coating has a thickness less than 10 μm (preferably less than 1 μm). The same method can be followed to produce an anode or a cathode. The battery featuring an anode or cathode made with this method exhibits an exceptionally high specific capacity, an excellent reversible capacity, and a long cycle life.

Owner:GLOBAL GRAPHENE GRP INC

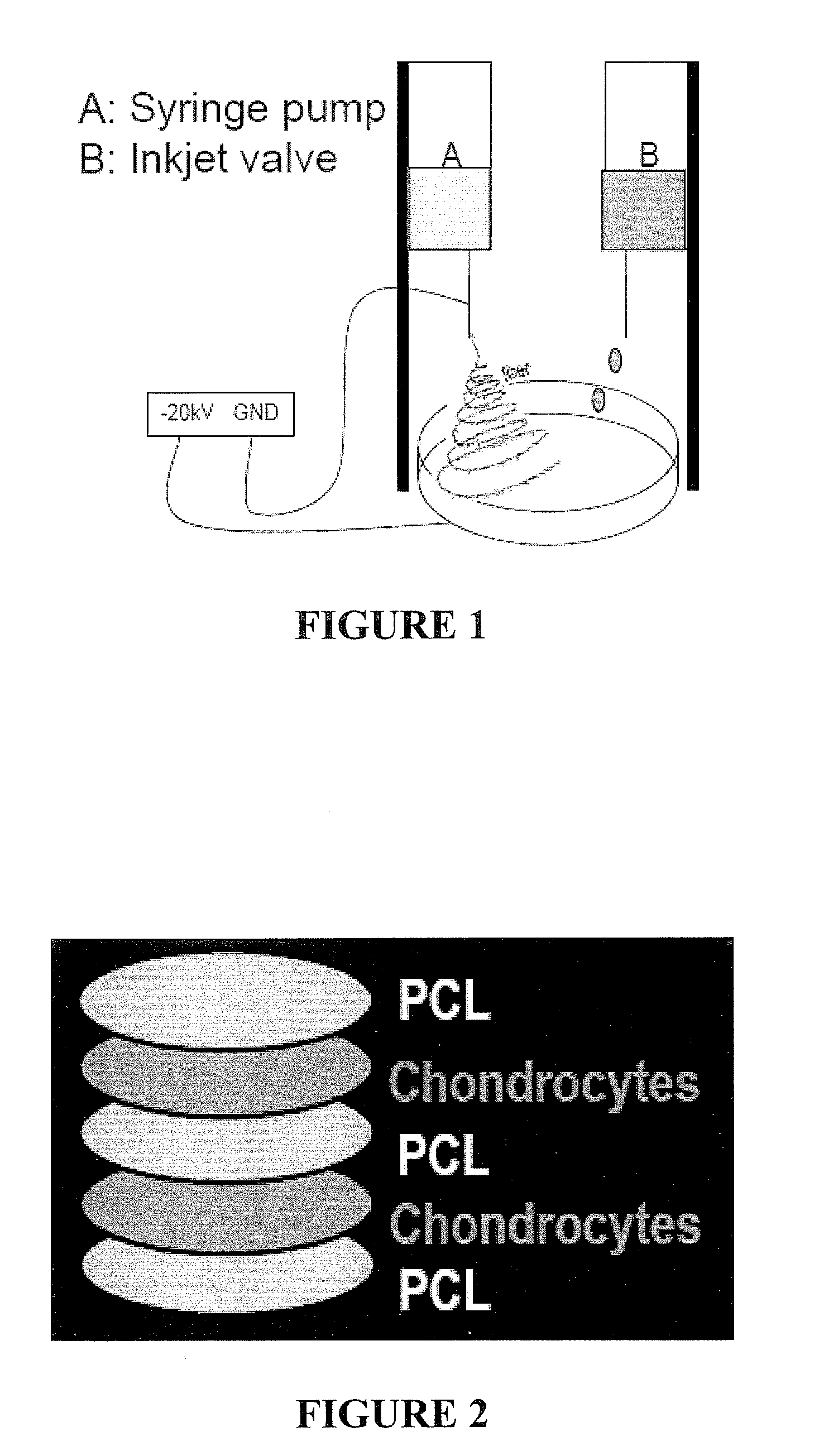

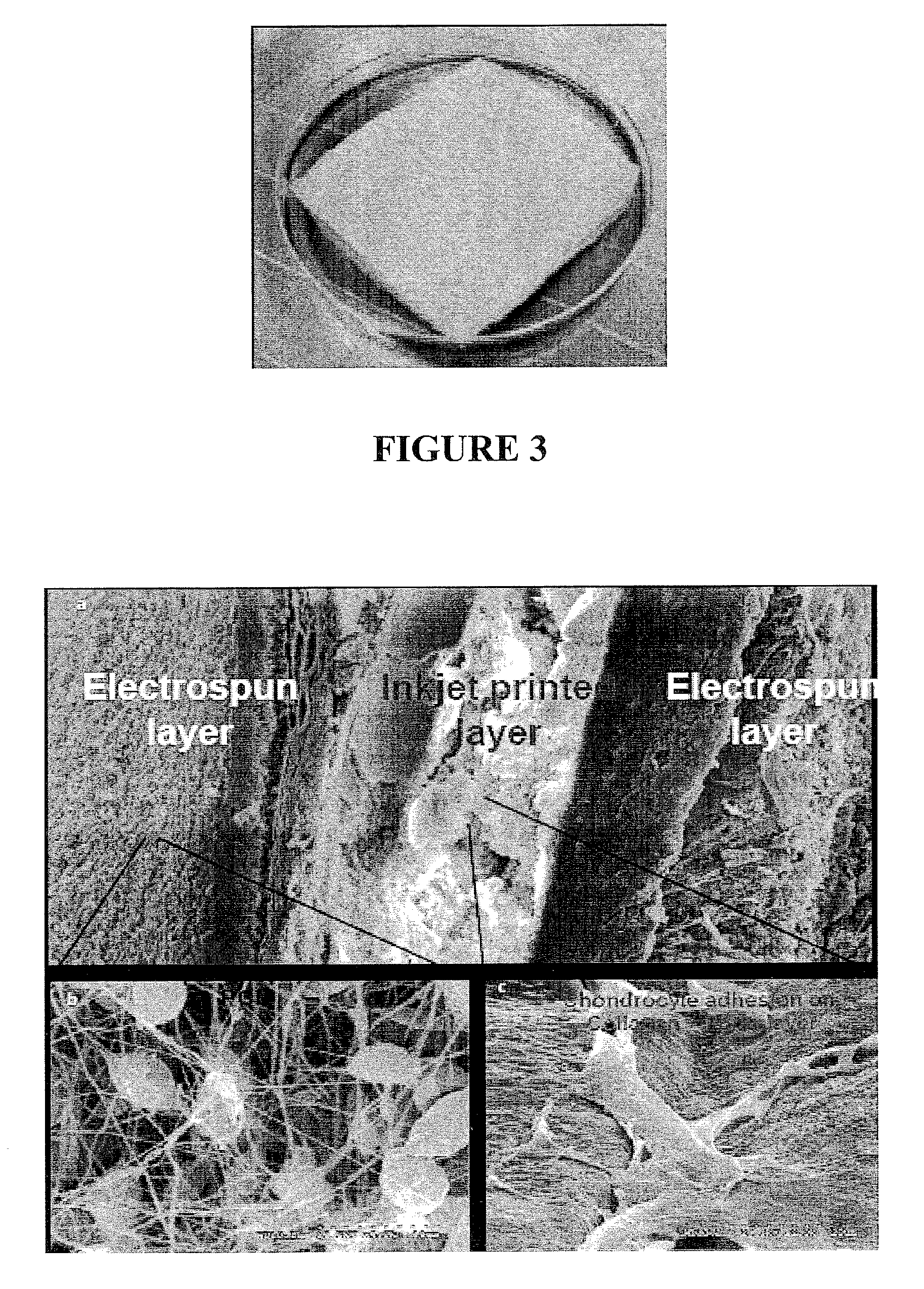

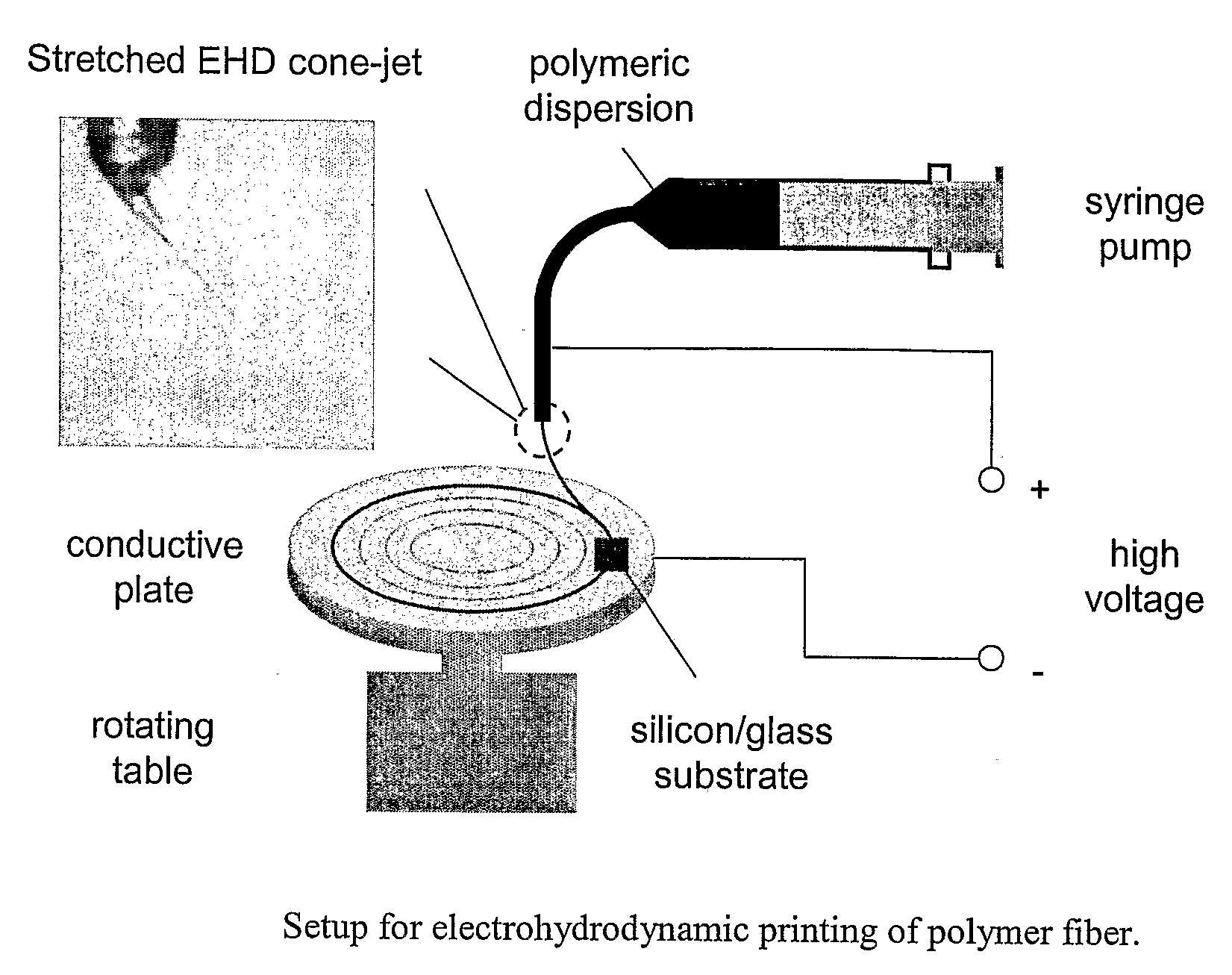

Inkjet Printing of Tissues and Cells

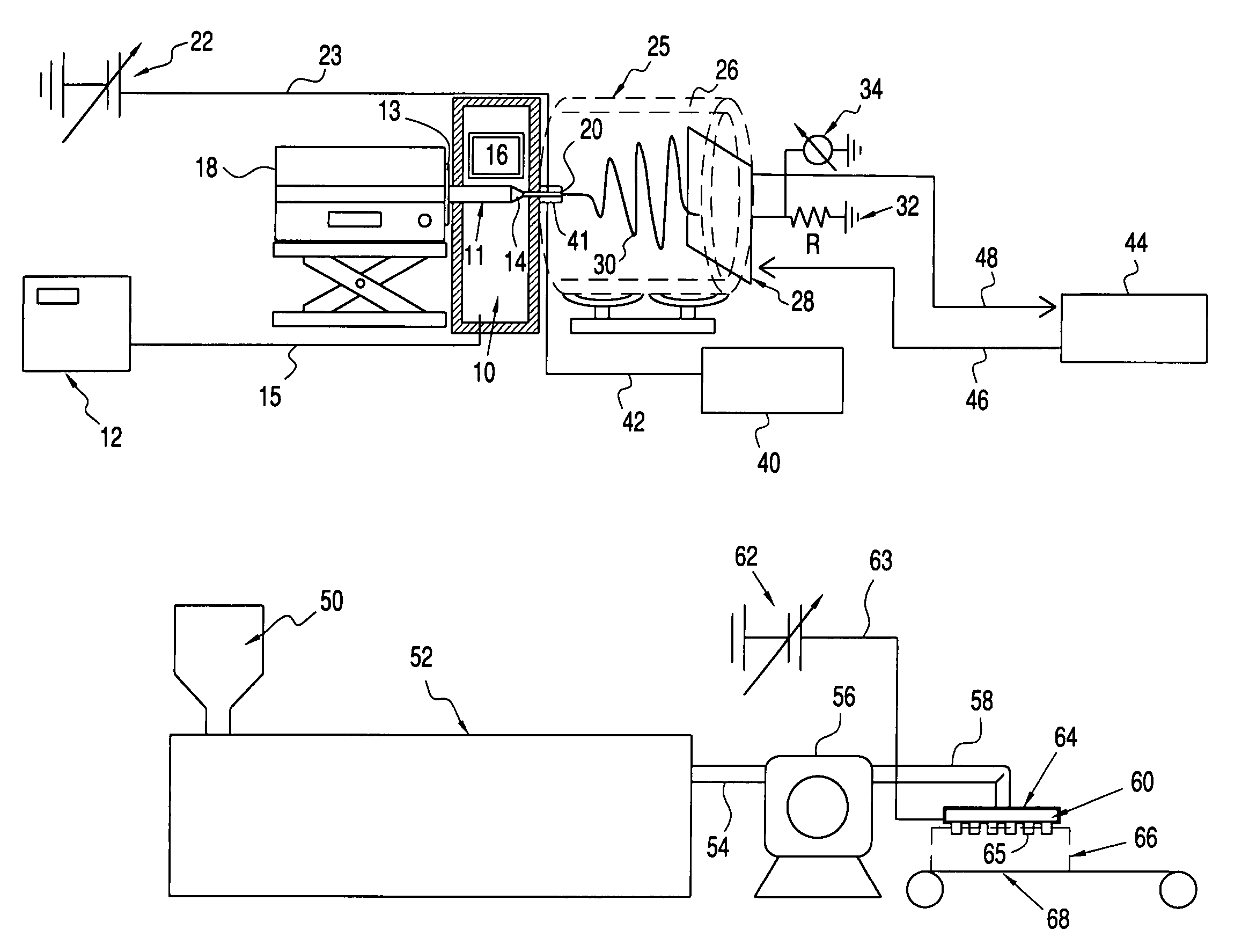

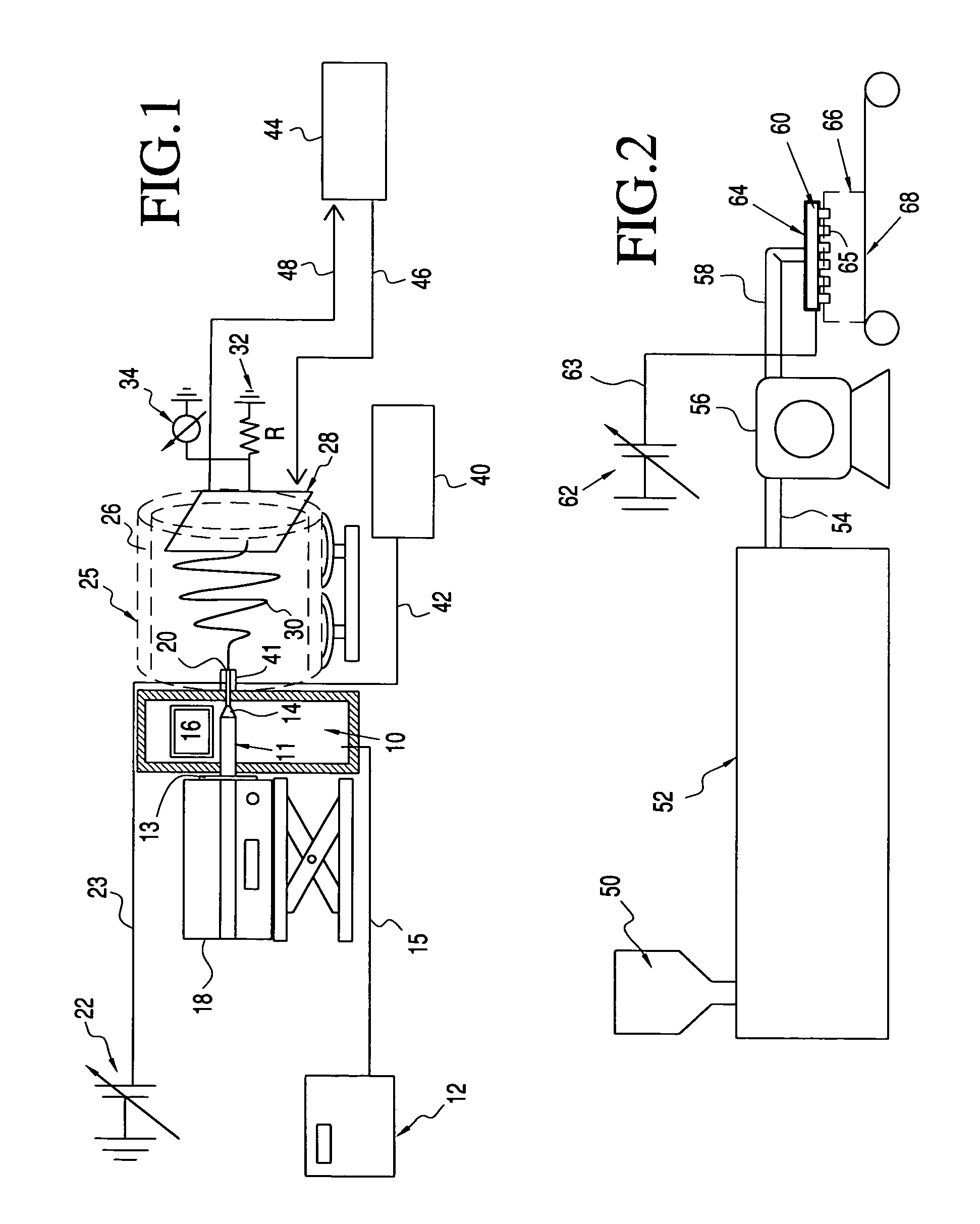

Provided herein is an apparatus for printing cells which includes an electrospinning device and an inkjet printing device operatively associated therewith. Methods of making a biodegradable scaffold having cells seeded therein are also provided. Methods of forming microparticles containing one or more cells encapsulated by a substrate are also provided, as are methods of forming an array of said microparticles.

Owner:WAKE FOREST UNIV HEALTH SCI INC

Concentrated aqueous silk fibroin solution and use thereof

ActiveUS20090234026A1Reduce usageBiocideMonocomponent fibroin artificial filamentFiberOrganic solvent

The present invention provides for concentrated aqueous silk fibroin solutions and an all-aqueous mode for preparation of concentrated aqueous fibroin solutions that avoids the use of organic solvents, direct additives, or harsh chemicals. The invention further provides for the use of these solutions in production of materials, e.g., fibers, films, foams, meshes, scaffolds and hydrogels.

Owner:TRUSTEES OF TUFTS COLLEGE

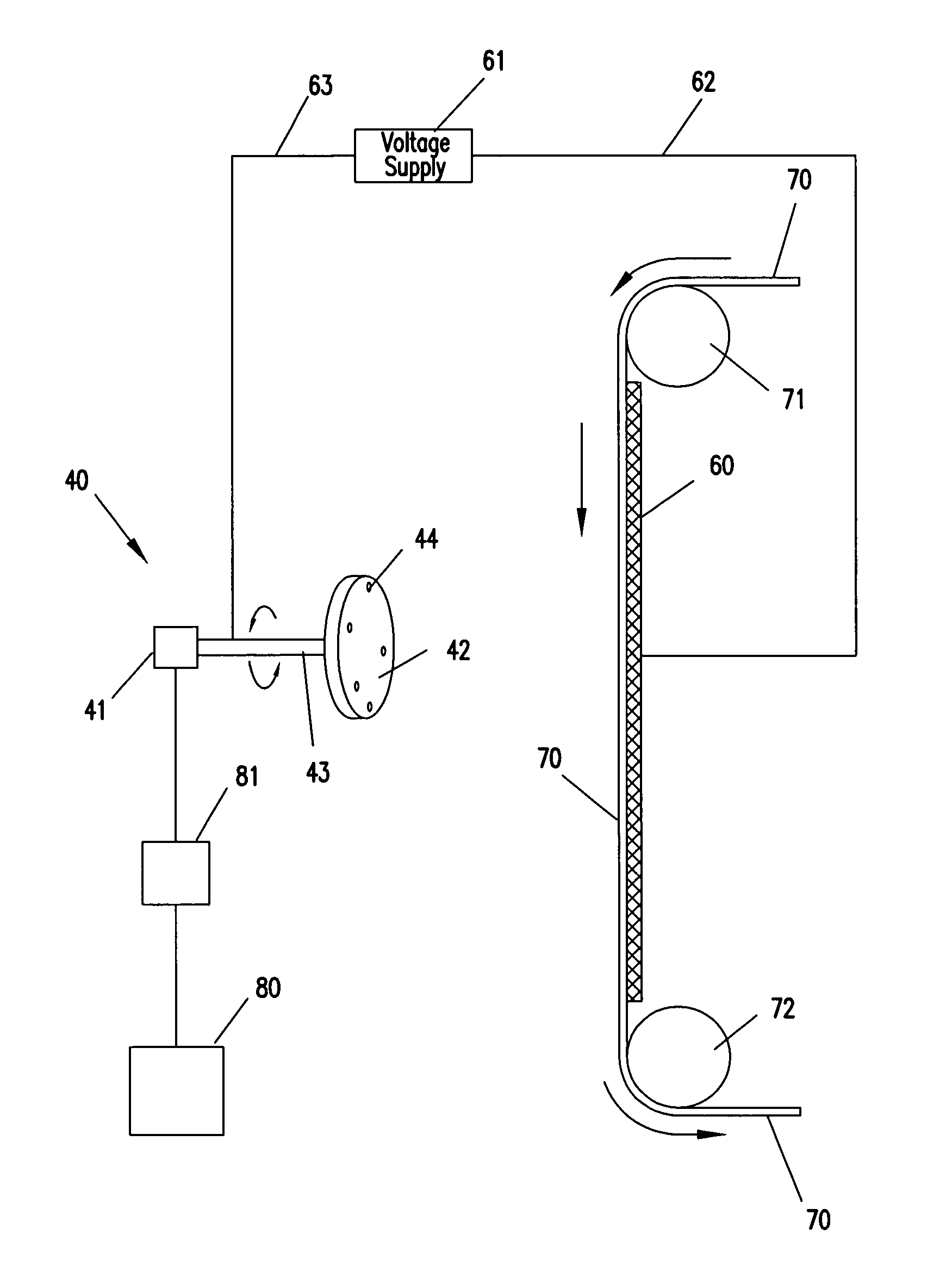

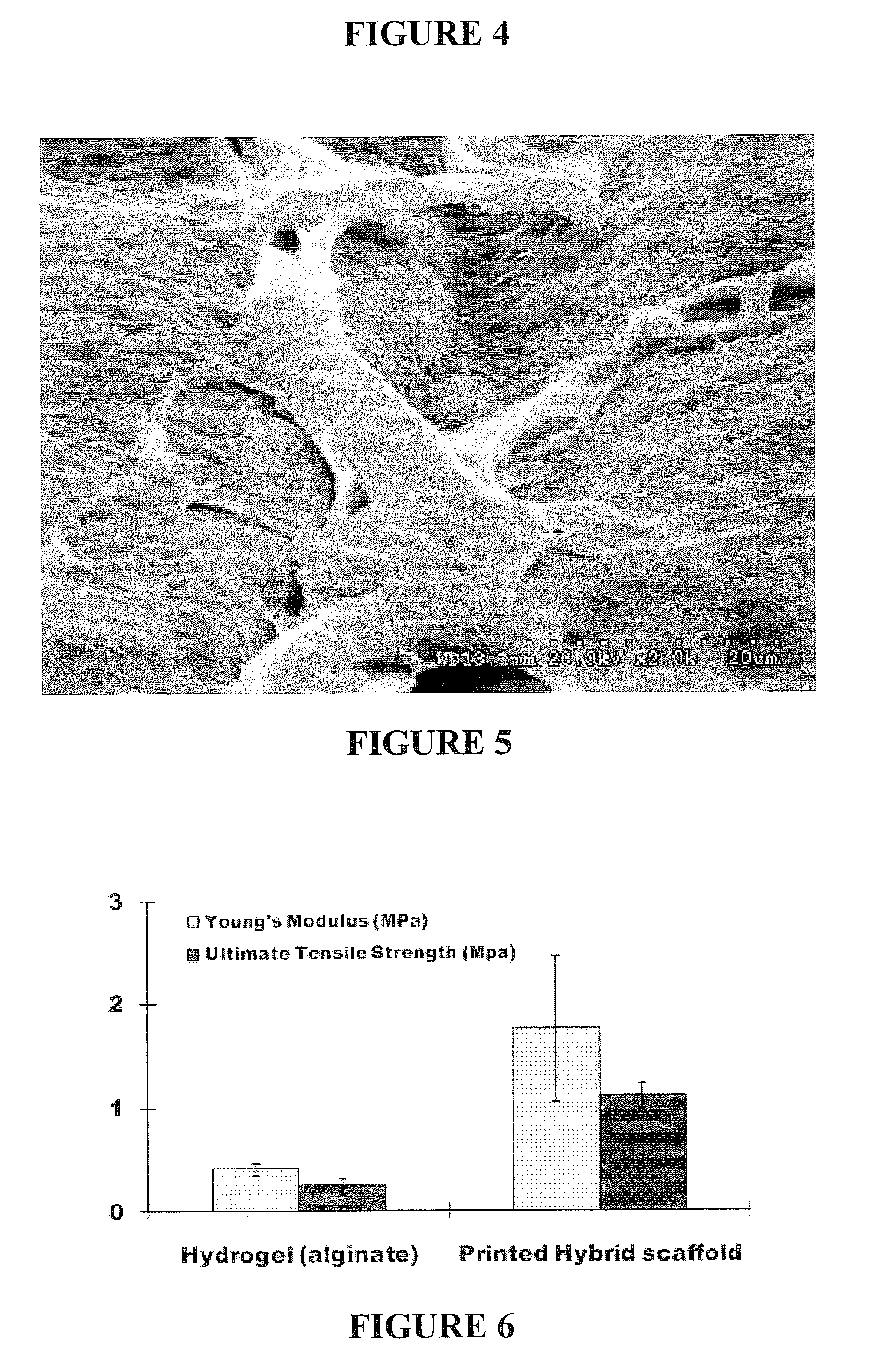

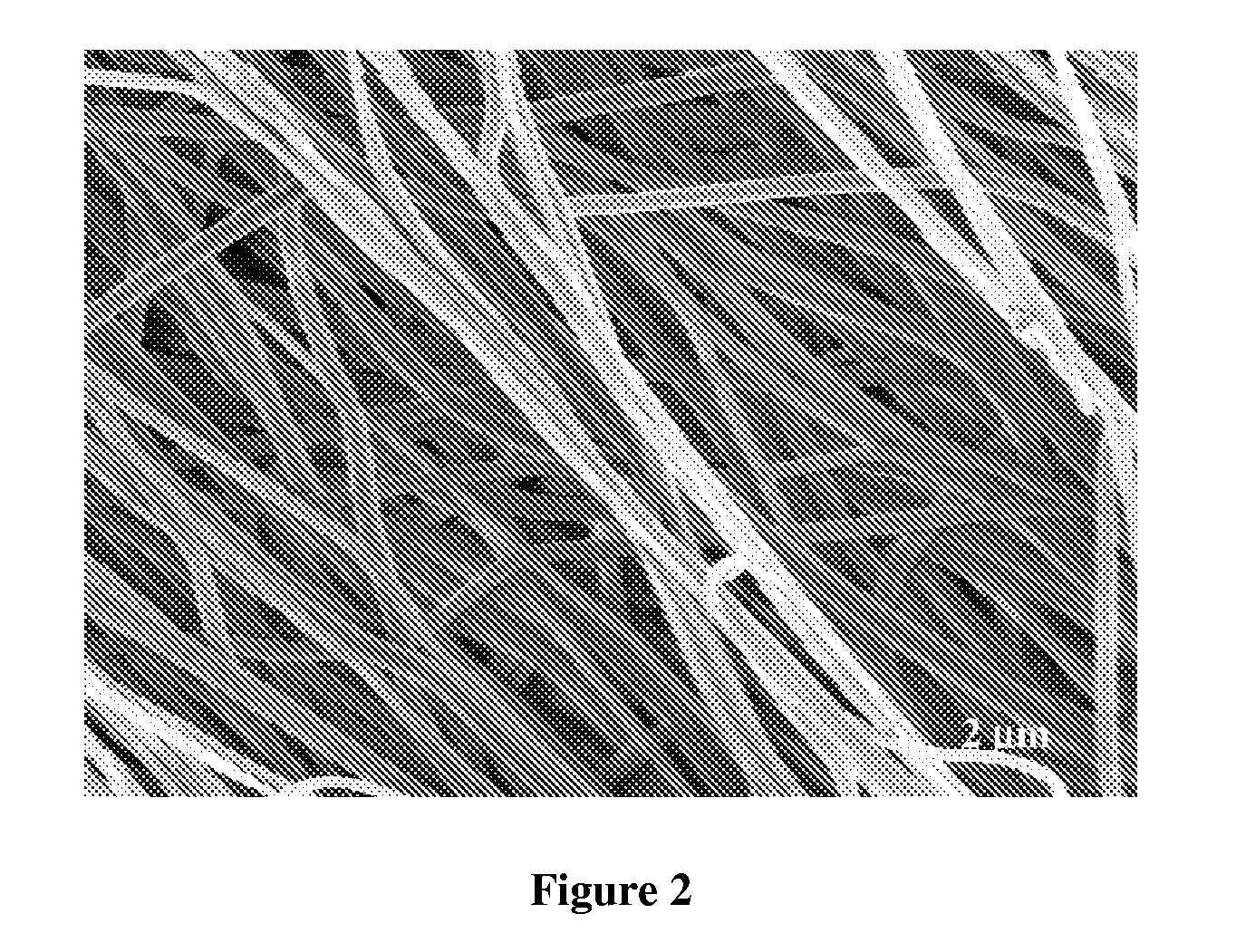

Electrospun cell matrices

InactiveUS20060204539A1Function increaseFiber sizeMonocomponent protein artificial filamentElectro-spinningElectrospinningUltimate tensile strength

The invention is directed to compositions and methods for preparing electrospun matrices comprising at least one natural biological material component and at least one synthetic polymer material. The natural component makes the matrices highly biocompatible while the molecular weight polymer component can impart additional strength mechanical strength to the scaffold and / or improve ease of manufacture by increasing viscosity and spinning characteristics of the solution during electrospining.

Owner:WAKE FOREST UNIV

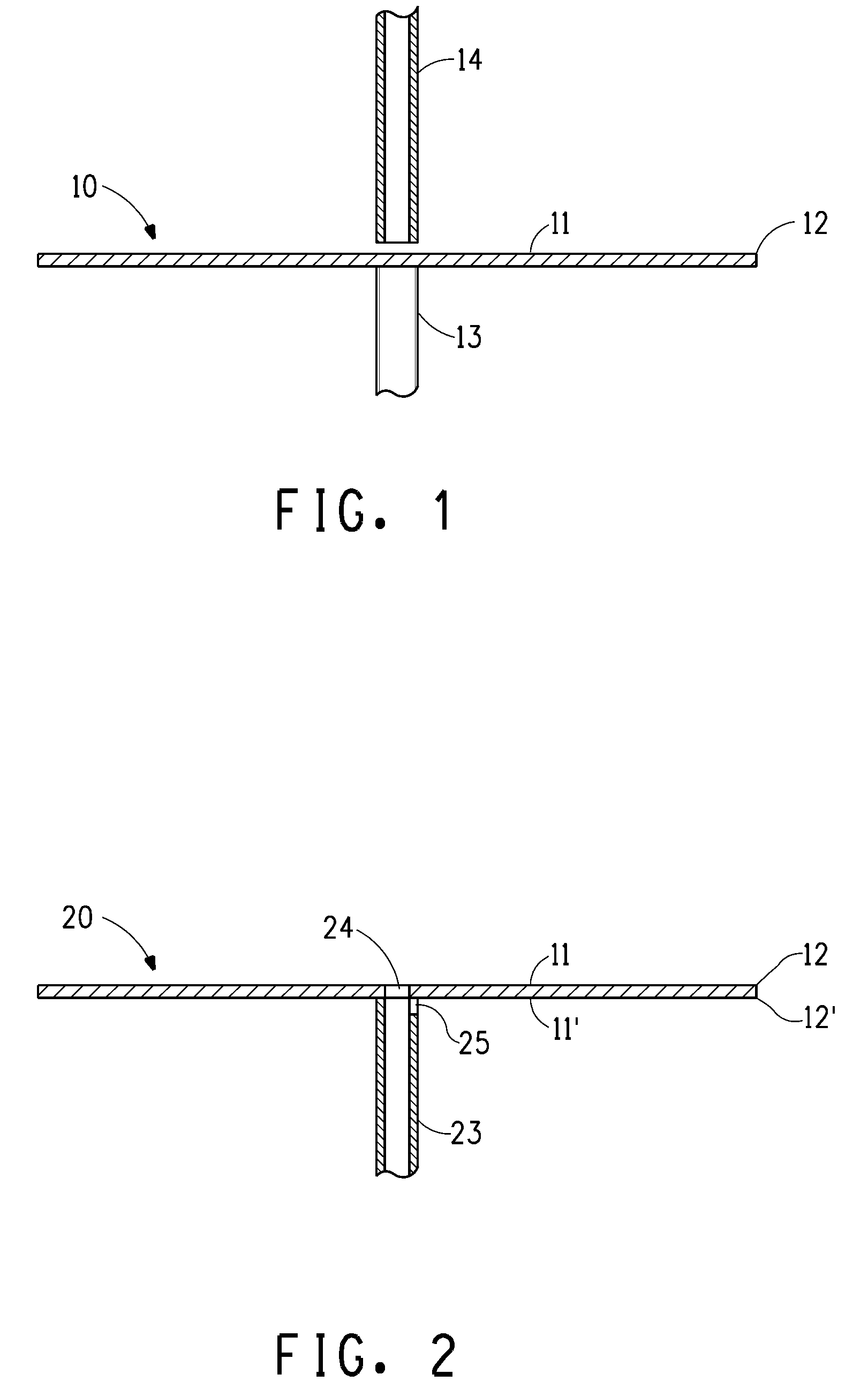

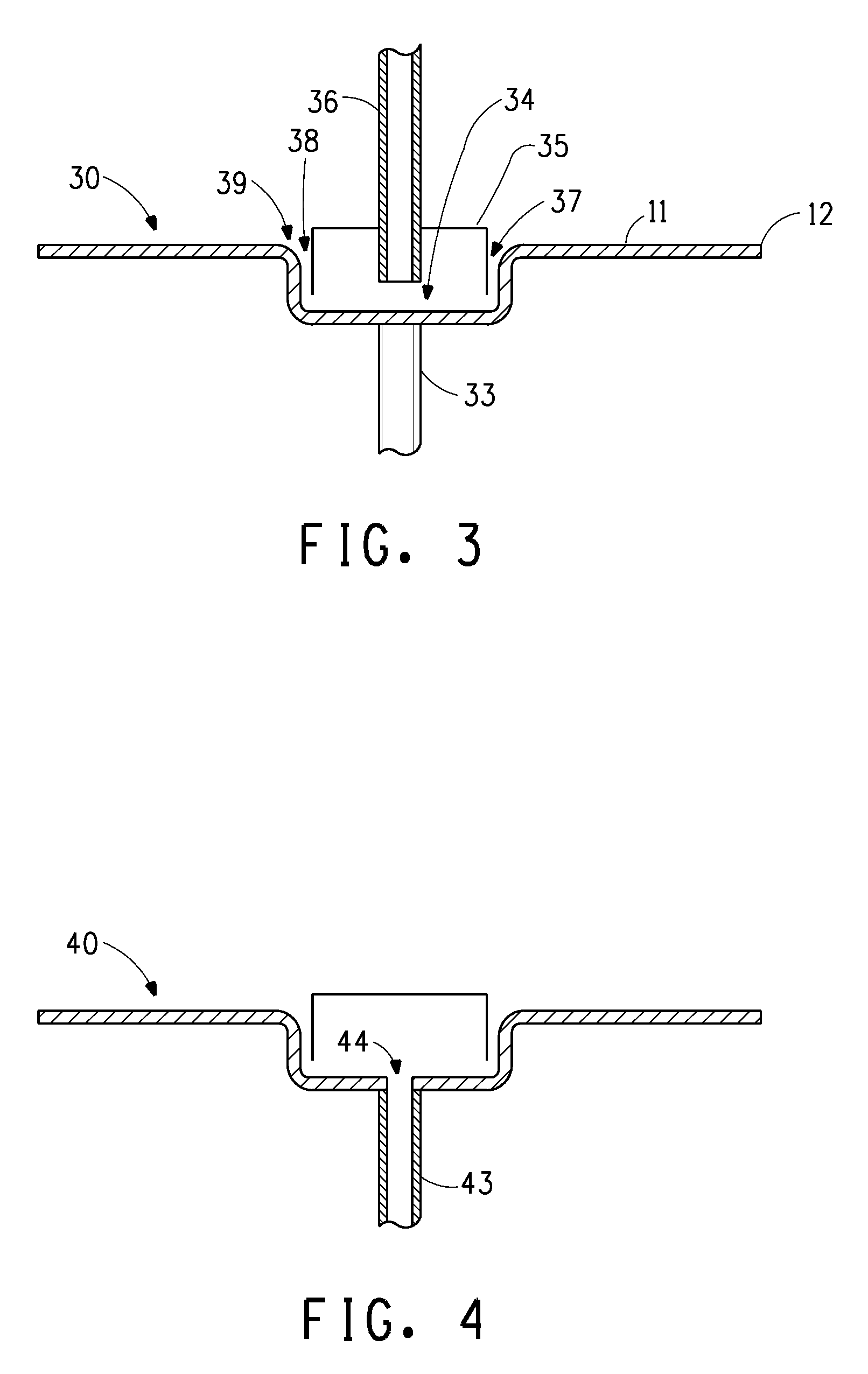

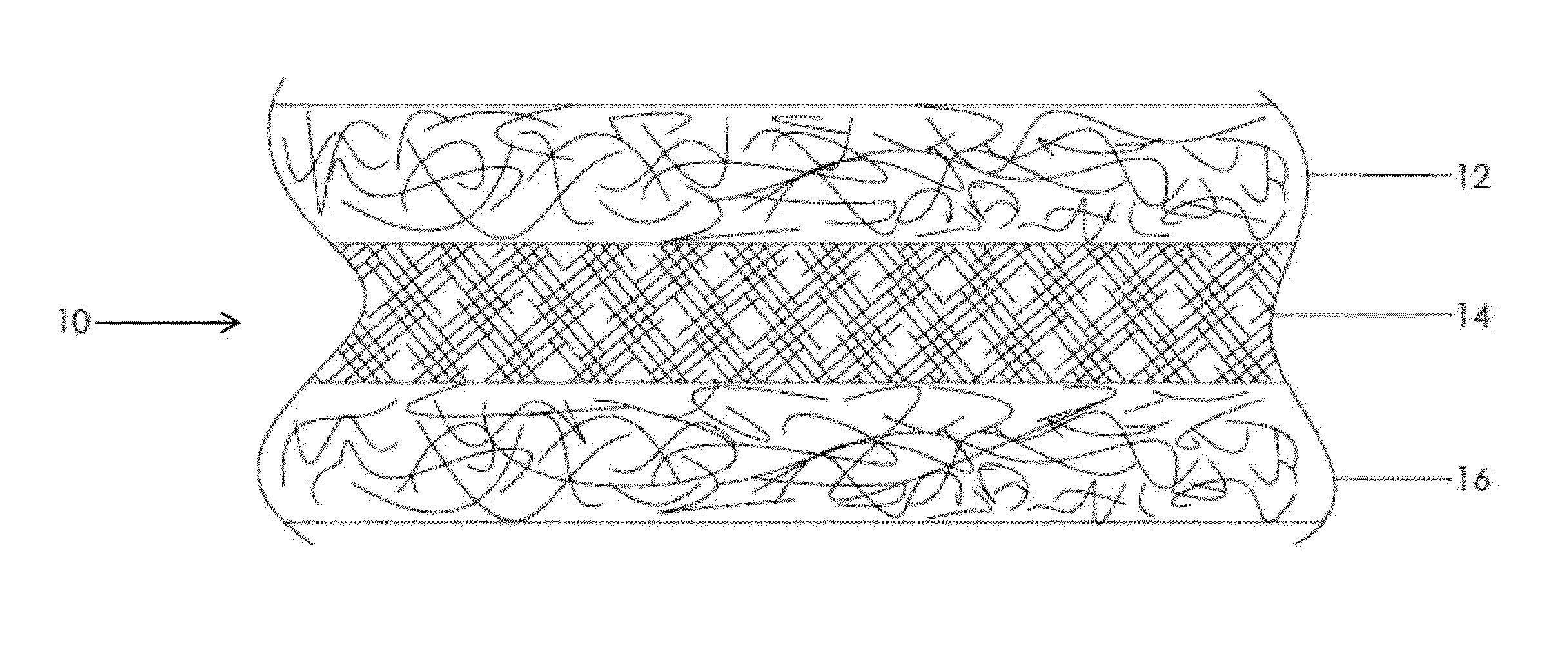

Vascular prosthesis and method for production thereof

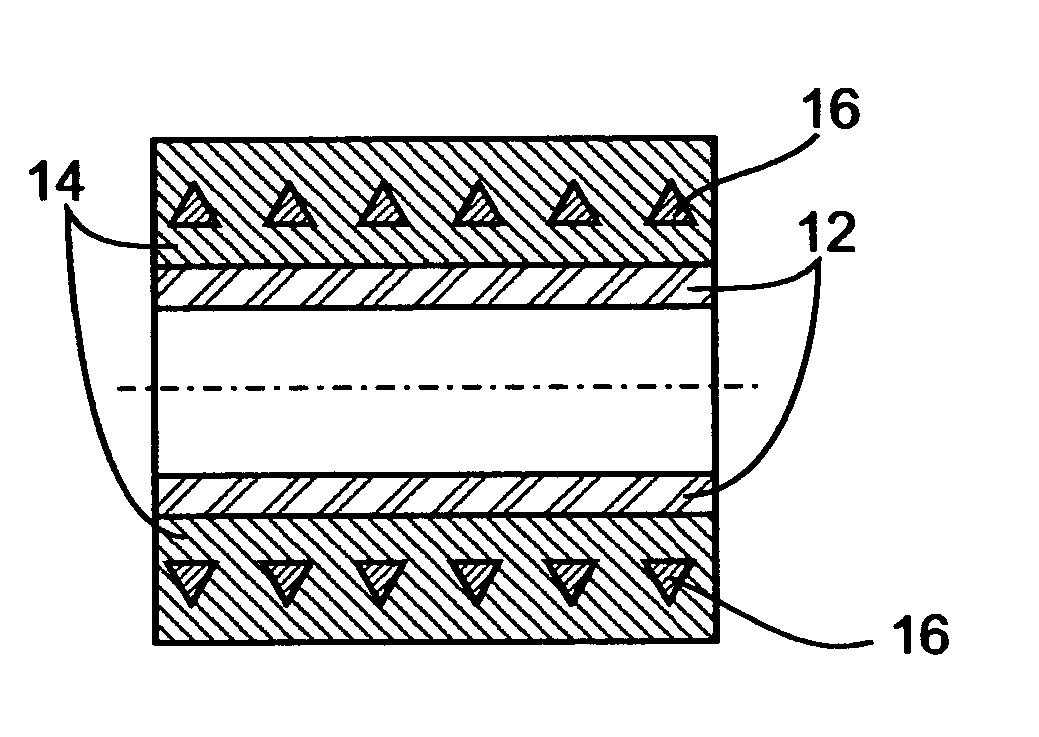

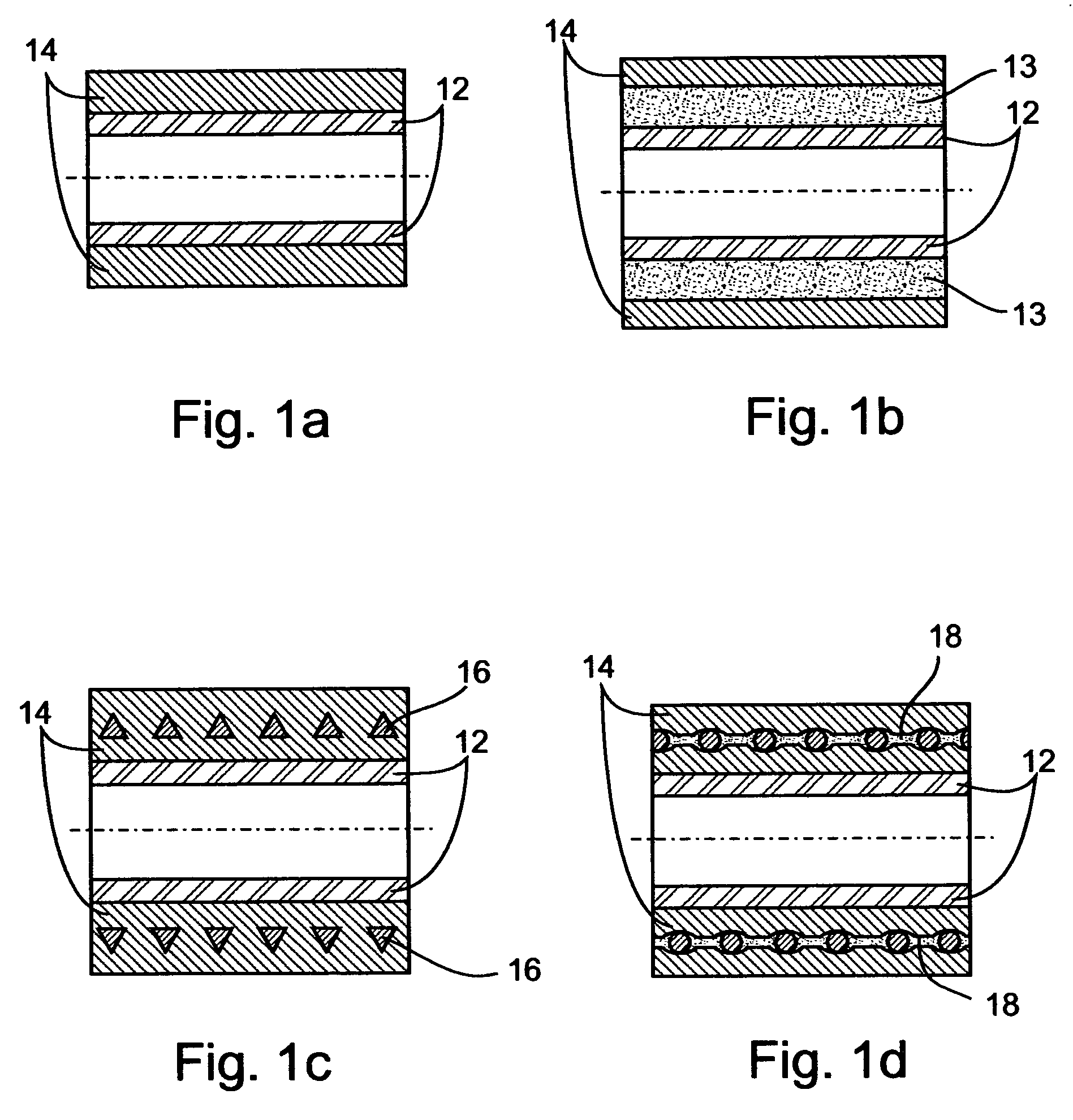

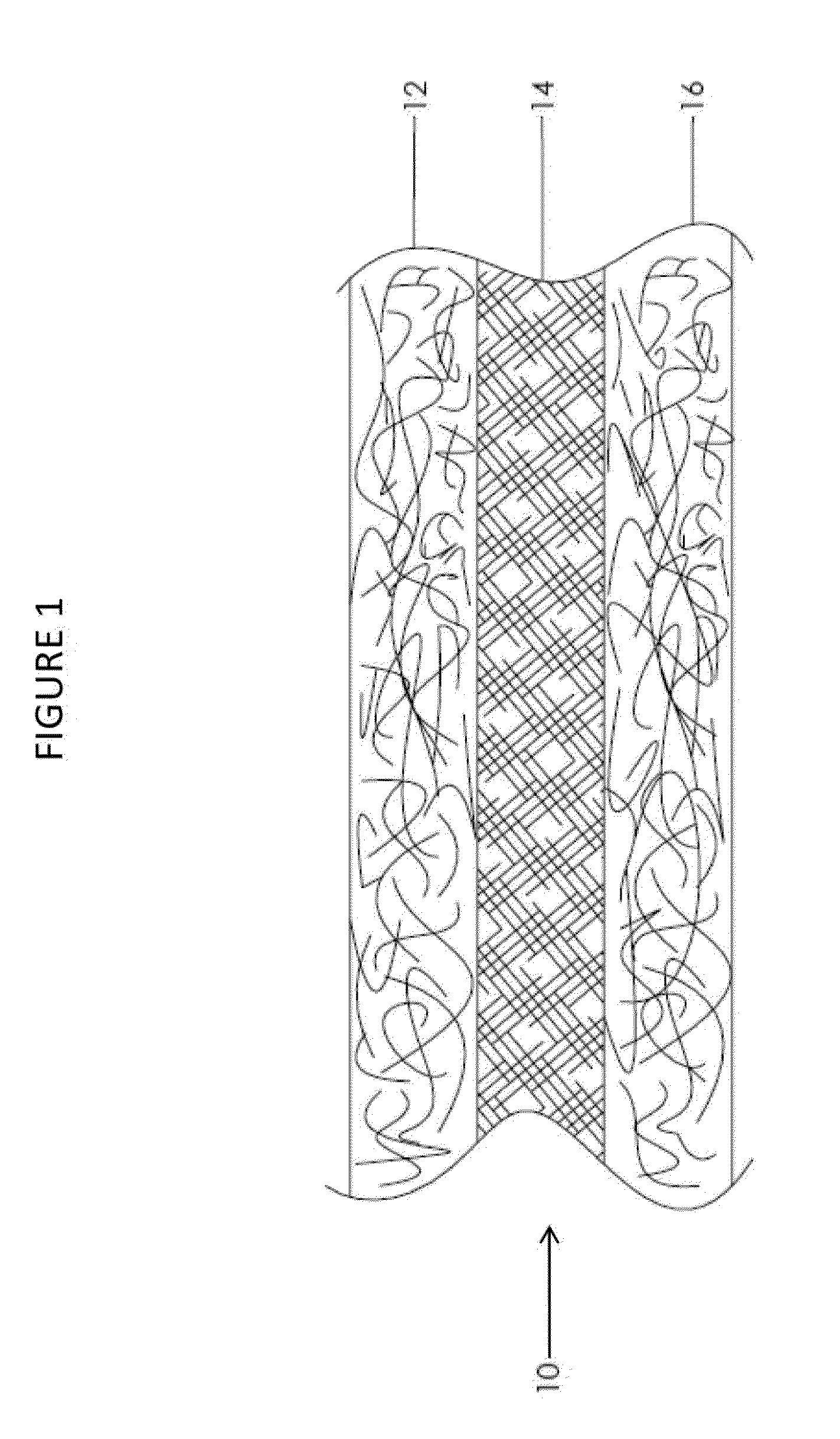

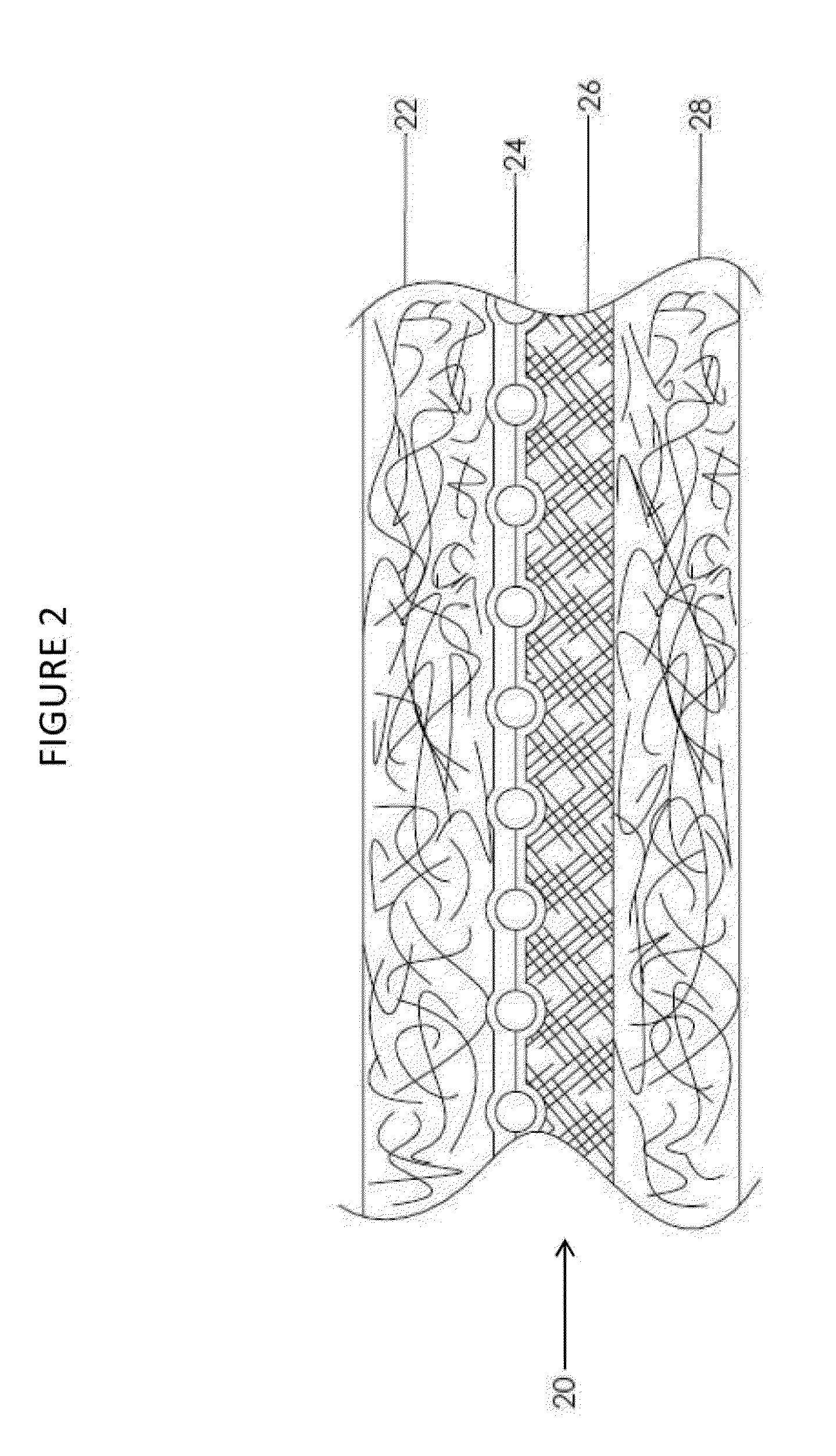

A vascular prosthesis comprising a first layer having a predetermined first porosity and a second layer having a predetermined second porosity, wherein the first layer and the second layer are each made of first and second electrospun polymer fibers.

Owner:NICAST LTD

Medical Scaffold, Methods of Fabrication and Using Thereof

Articles of manufacturing comprising electrospun elements having continuous or stepwise gradients of porosity, average pore size, weight per volume and / or of agents for promoting cell colonization, differentiation, extravasation and / or migration are provided. Also provided are methods of manufacturing and using same for guiding tissue regeneration.

Owner:TECHNION RES & DEV FOUND LTD

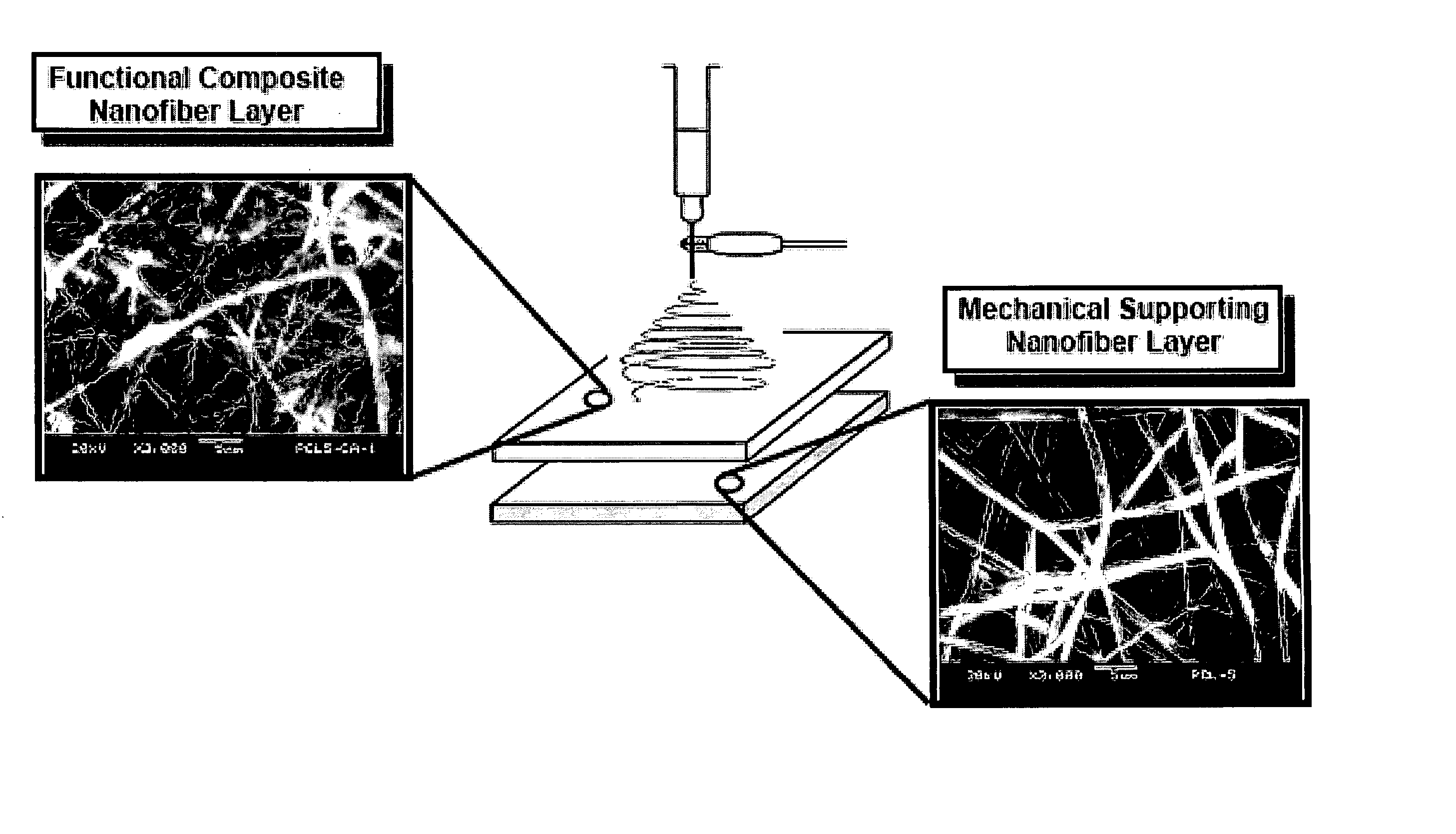

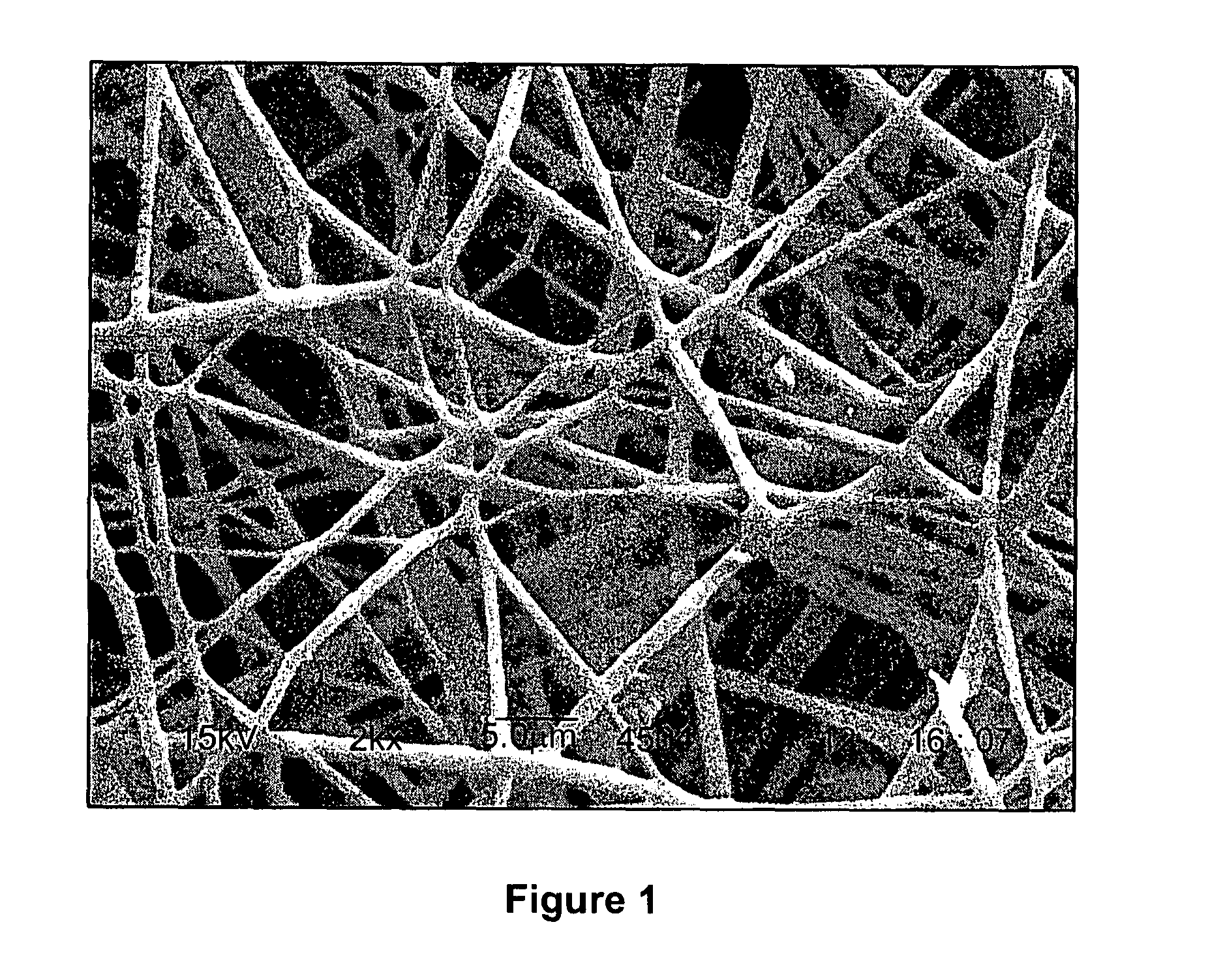

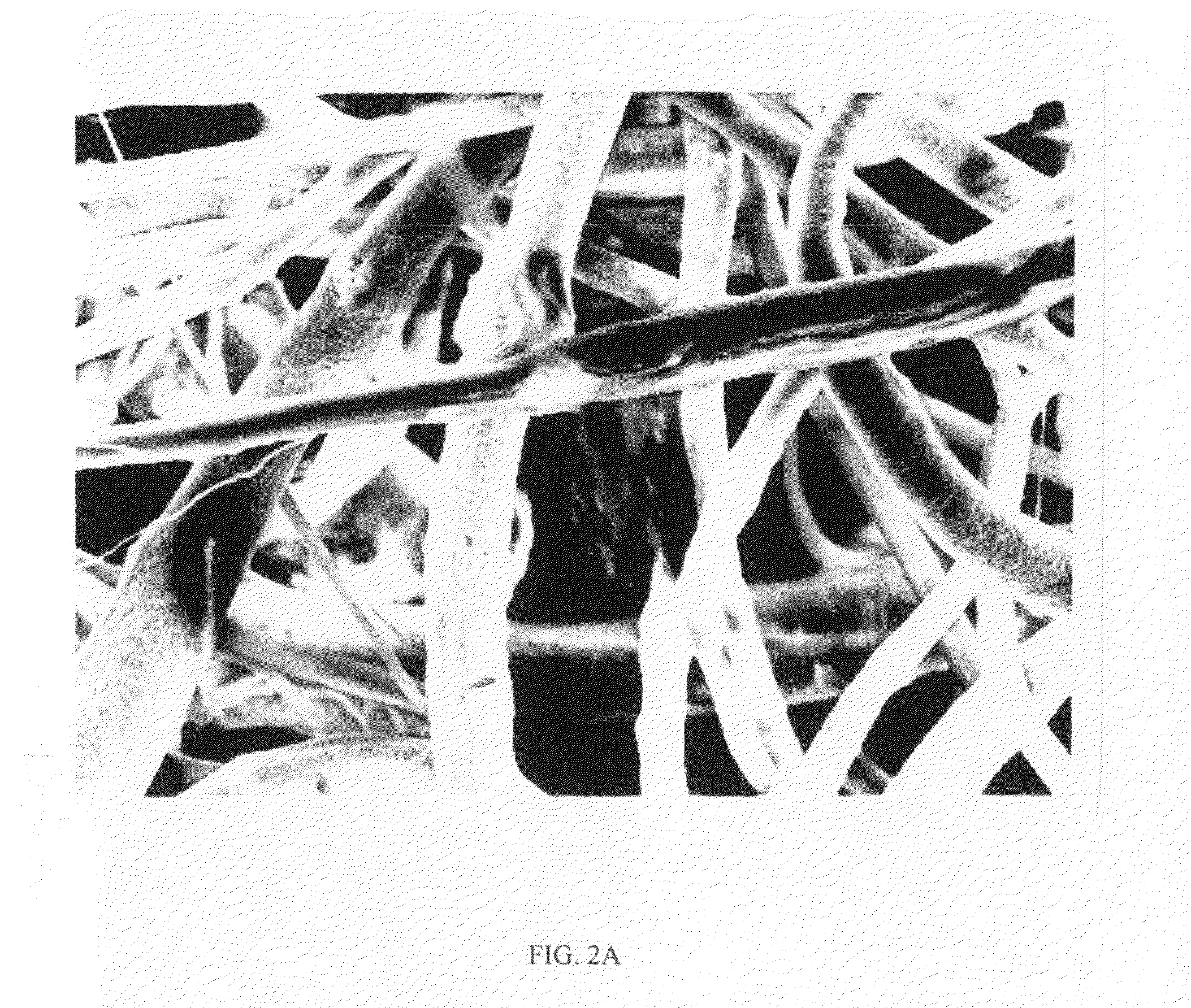

Nanofiber construct and method of preparing thereof

InactiveUS20060154063A1Improve hydrophilicityGood bone conductionPharmaceutical delivery mechanismElectro-spinningFiberComposite nanofibers

The present invention provides a composite nanofiber construct comprising: at least a first nanofiber comprising at least a polymer and at least a calcium salt nanoparticle, wherein the ratio of polymer to calcium salt nanoparticle is between the range of 99:1 and 10:90 weight percent; and at least a second nanofiber comprising at least a polymer and at least a calcium salt nanoparticle, wherein the ratio of polymer to calcium salt nanoparticle is between the range of 100:0 and 70:30 weight percent. The present invention also provides a method of preparing the composite nanofiber construct.

Owner:NAT UNIV OF SINGAPORE

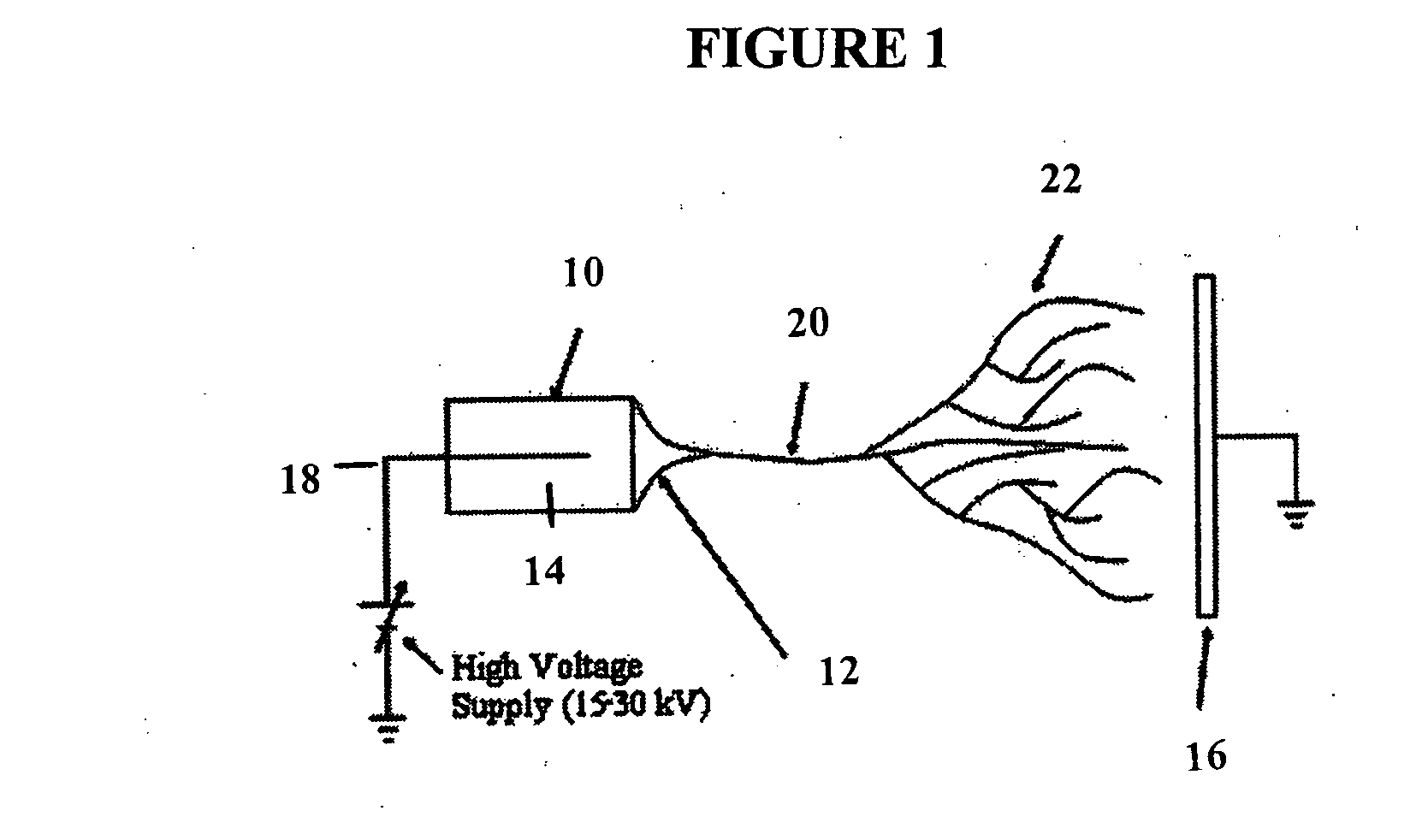

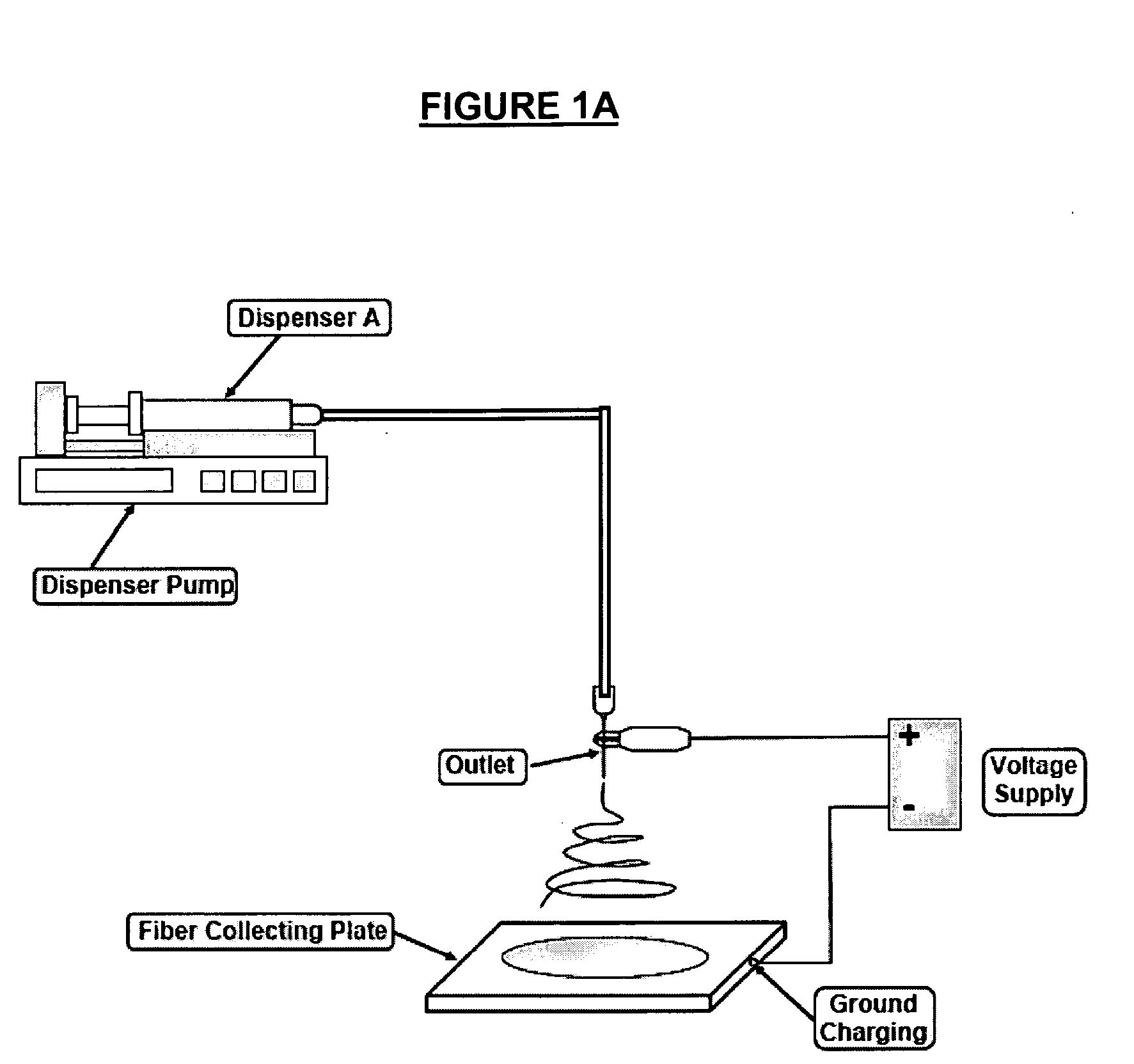

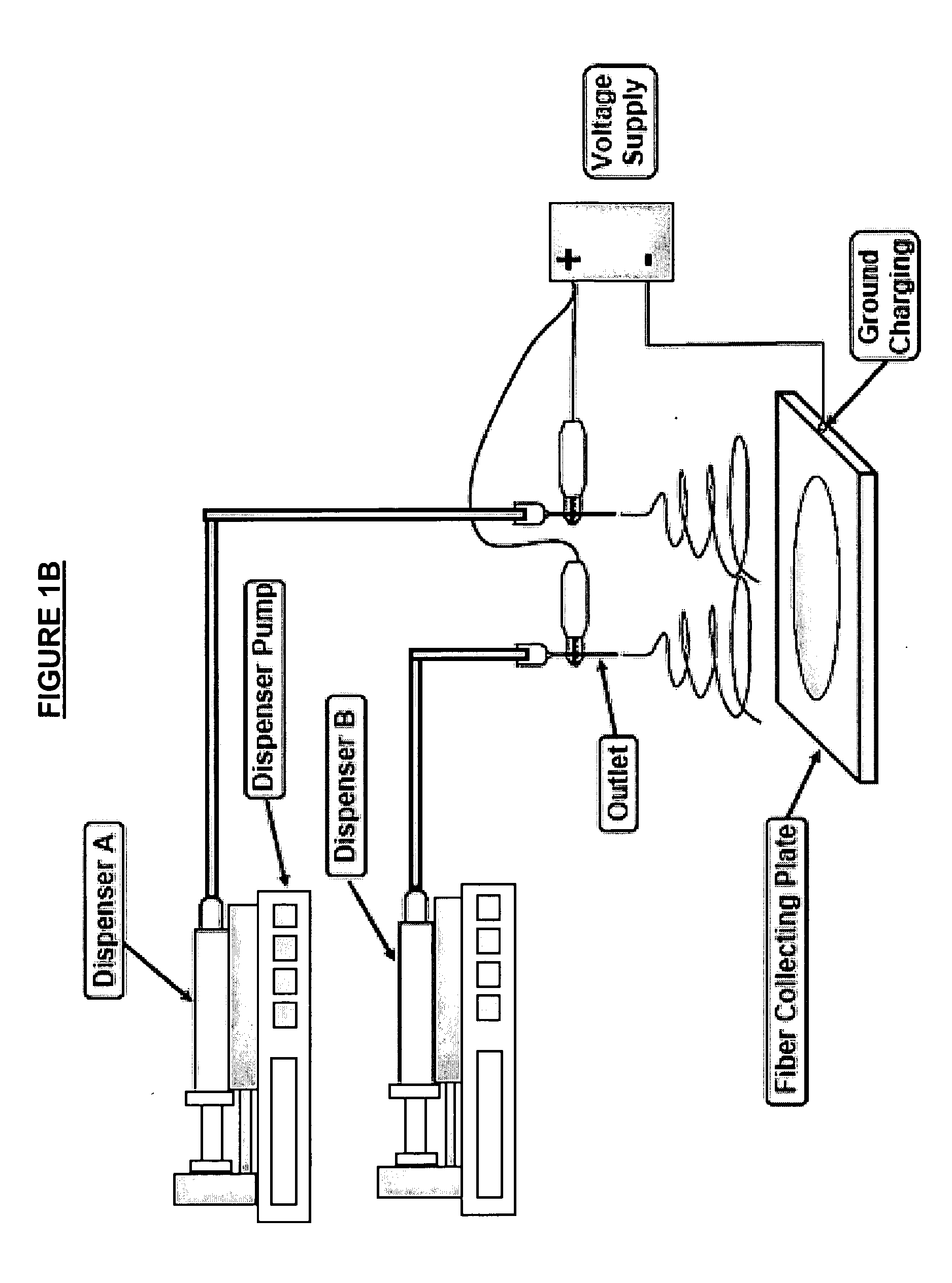

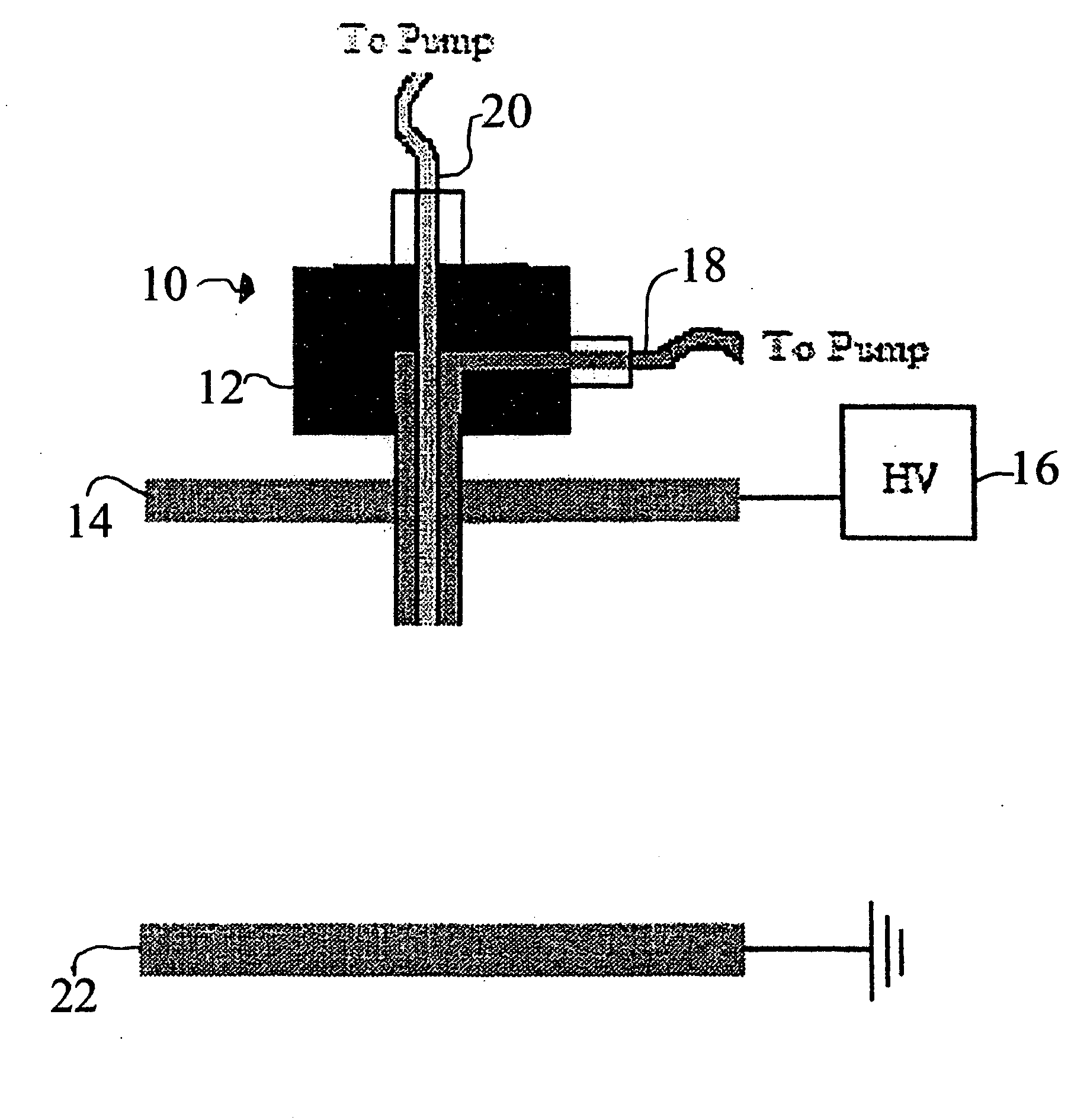

Production of submicron diameter fibers by two-fluid electrospinning process

InactiveUS20060213829A1Conjugated cellulose/protein artificial filamentsElectro-spinningHollow fibreNanowire

Electrospinning of materials that are difficult or impossible to process into nanofibers by conventional fiber-forming techniques or by electrospinning are prepared by an electrospinning procedure which uses an electrospinnable outer “shell” fluid around an inner “core” fluid, which may or may not be electrospinnable, to form nanofibers of the inner core fluid having a core / shell morphology. The resulting shell around the nanofiber can remain in place or be removed during post-processing with the core of the fiber remaining intact. The dual-fluid electrospinning process can produce core fibers having diameters less than 100 nm, insulated nanowires, as well as tough, bio-compatible silk fibers. Alternatively, the core can be removed leaving a hollow fiber of the shell fluid.

Owner:MASSACHUSETTS INST OF TECH

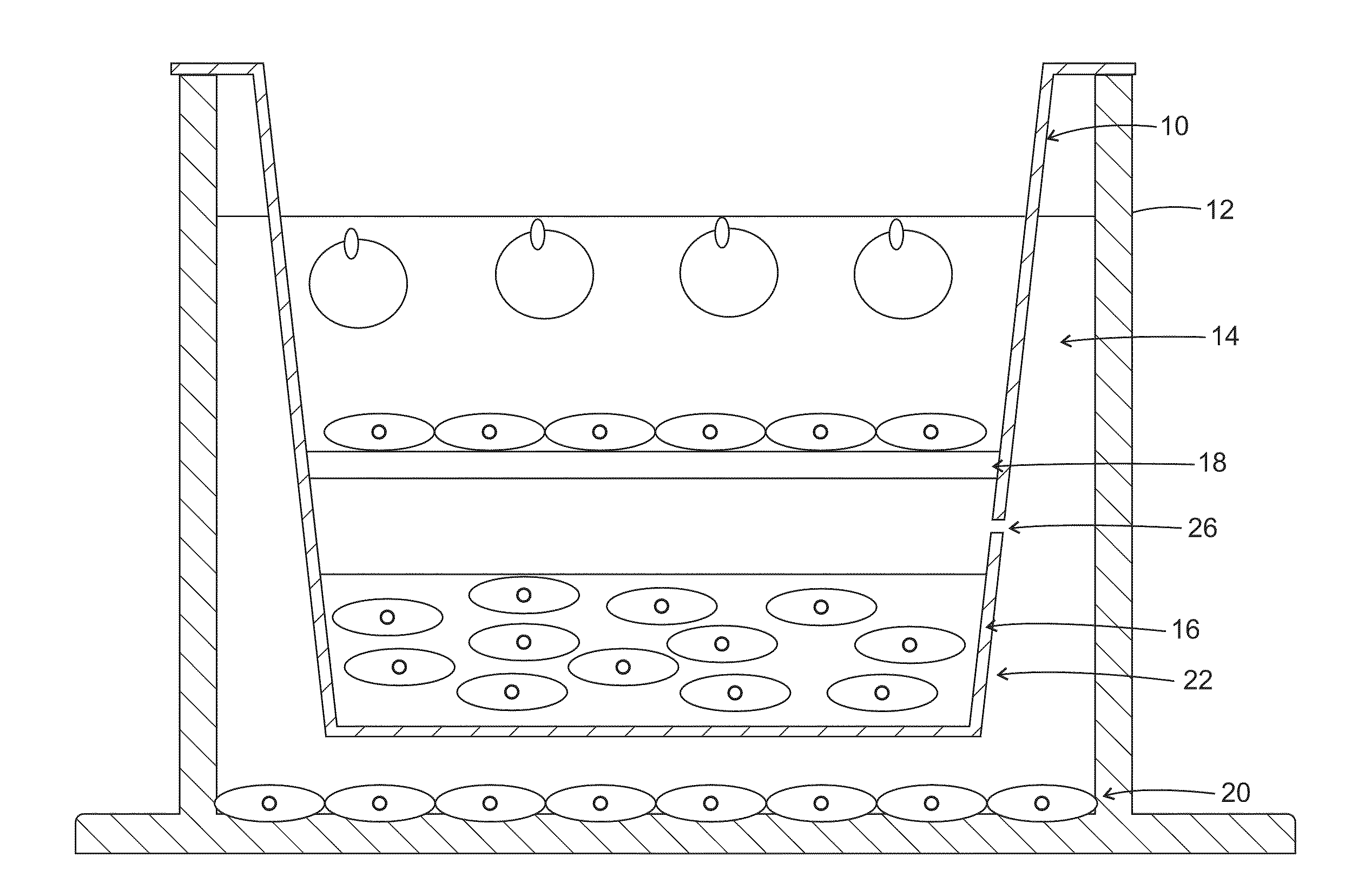

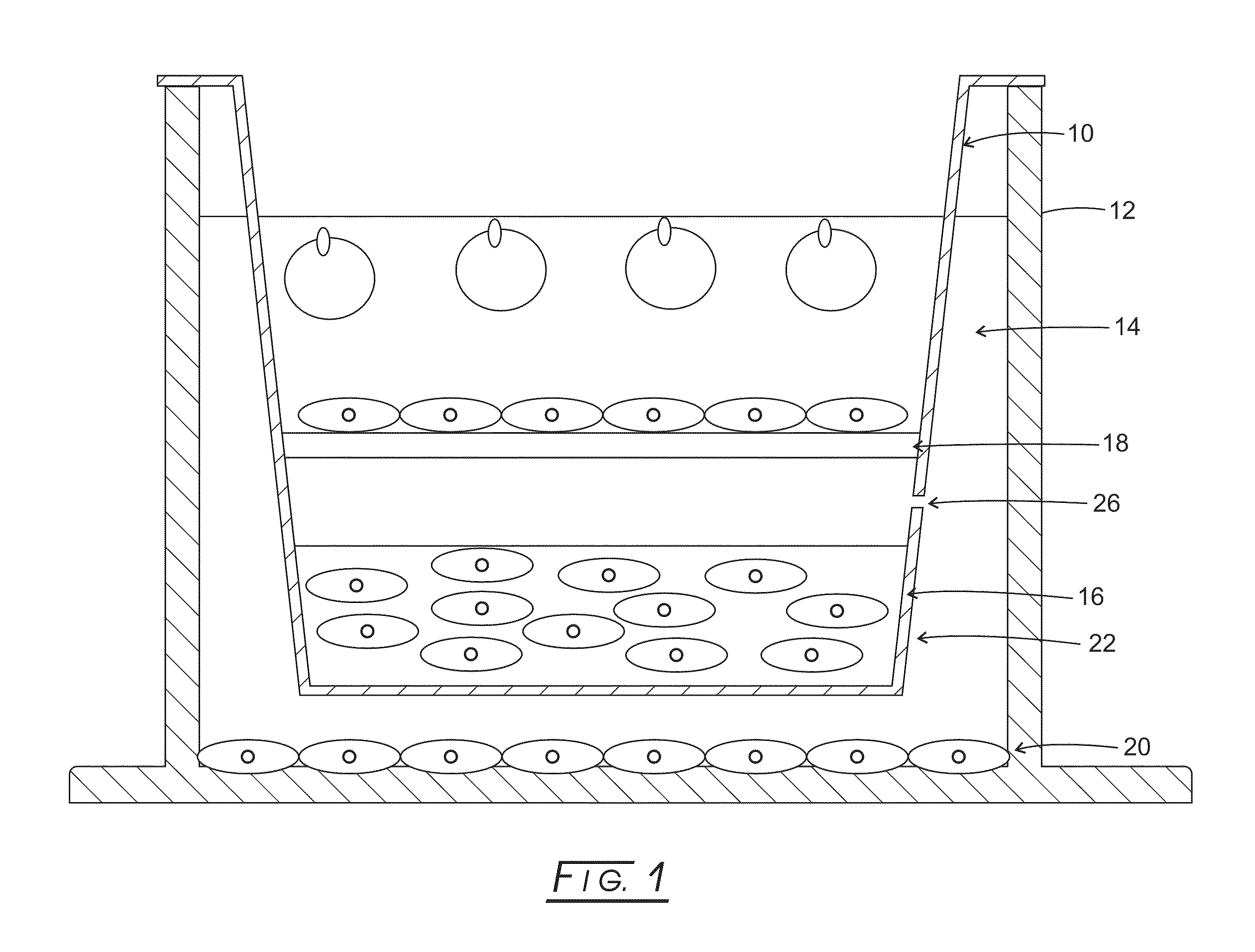

Interactive Microenvironment System

InactiveUS20100273258A1Targeted optimizationBioreactor/fermenter combinationsBiological substance pretreatmentsPorosityCulture cell

A culture cell for growing animal cells in vitro has sides and a bottom forming a volume. The volume contains a layer of nanofiber upon which animal cells can be cultured. The layer of nanofiber can be oriented or non-oriented. Multiple layers can be placed in the volume, where the layers have different composition and / or different porosity. The nanofiber can be, for example, surface treated or of a core-shell construction.

Owner:THE OHIO STATES UNIV

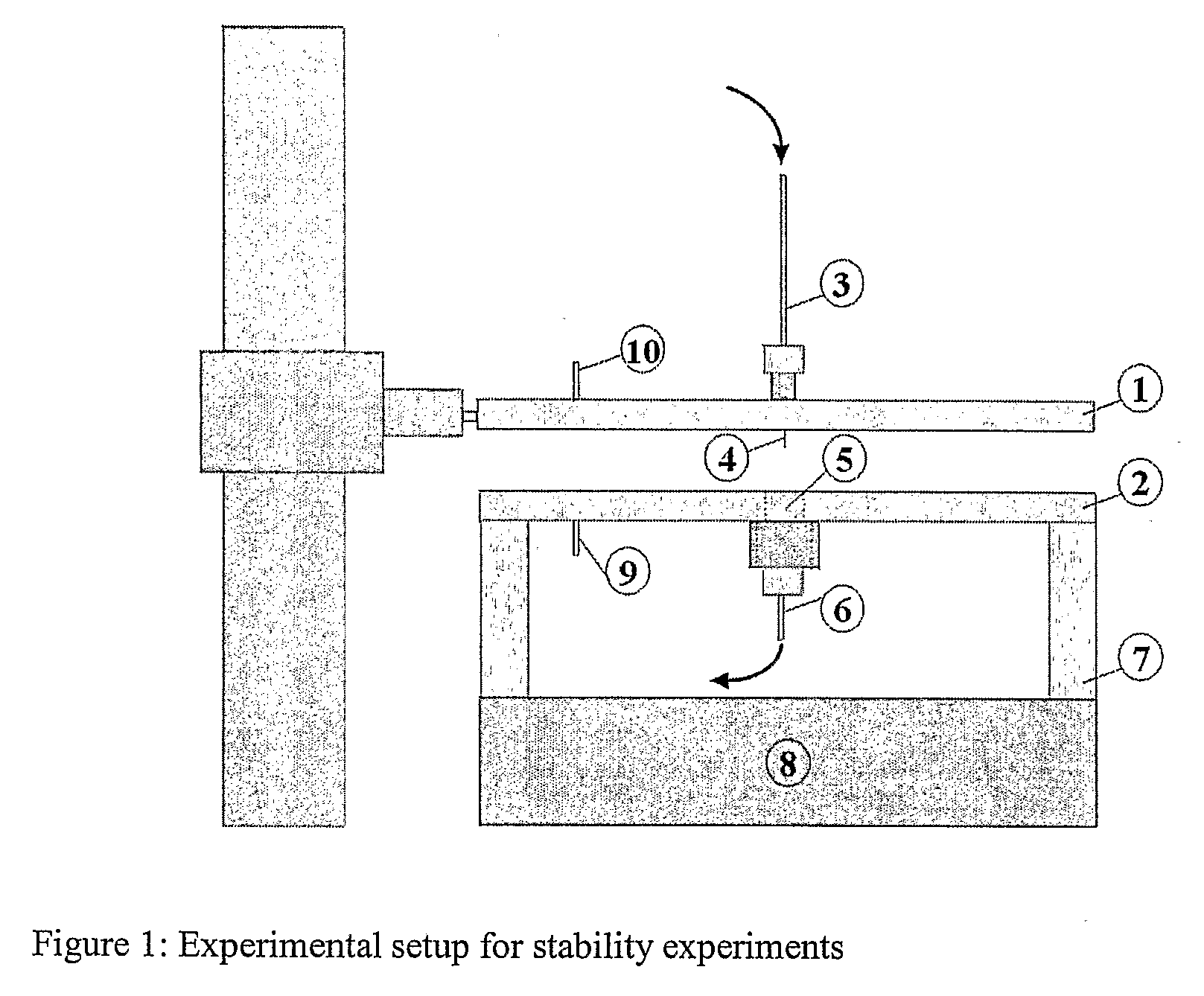

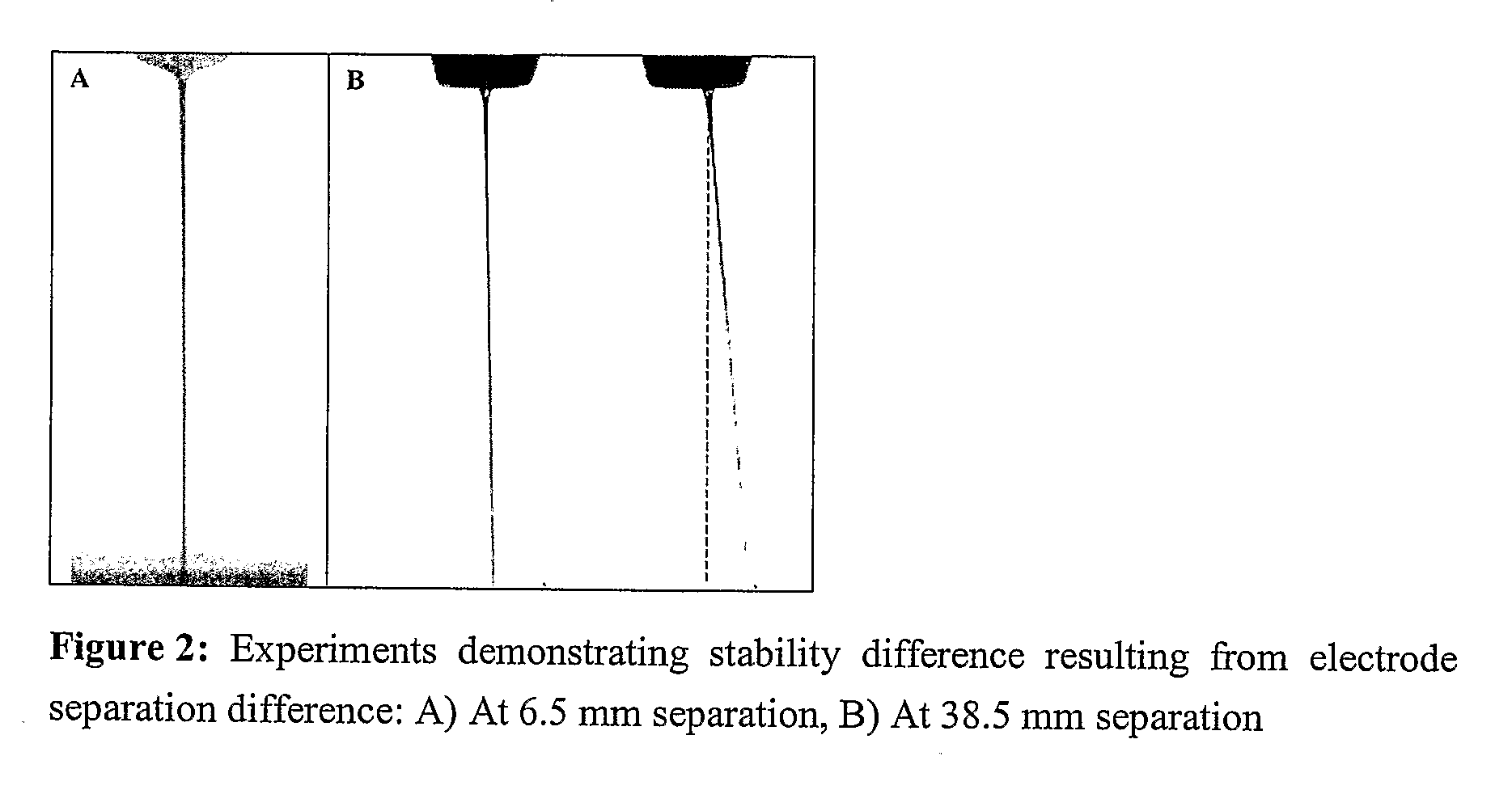

Electrohydrodynamic printing and manufacturing

ActiveUS20090233057A1Liquid surface applicatorsElectric discharge heatingFiberManufacturing technology

An stable electrohydrodynamic filament is obtained by causing a straight electrohydrodynamic filament formed from a liquid to emerge from a Taylor cone, the filament having a diameter of from 10 nm to 100 μm. Such filaments are useful in electrohydrodynamic printing and manufacturing techniques and their application in liquid drop / particle and fiber production, colloidal deployment and assembly, and composite materials processing.

Owner:THE TRUSTEES FOR PRINCETON UNIV

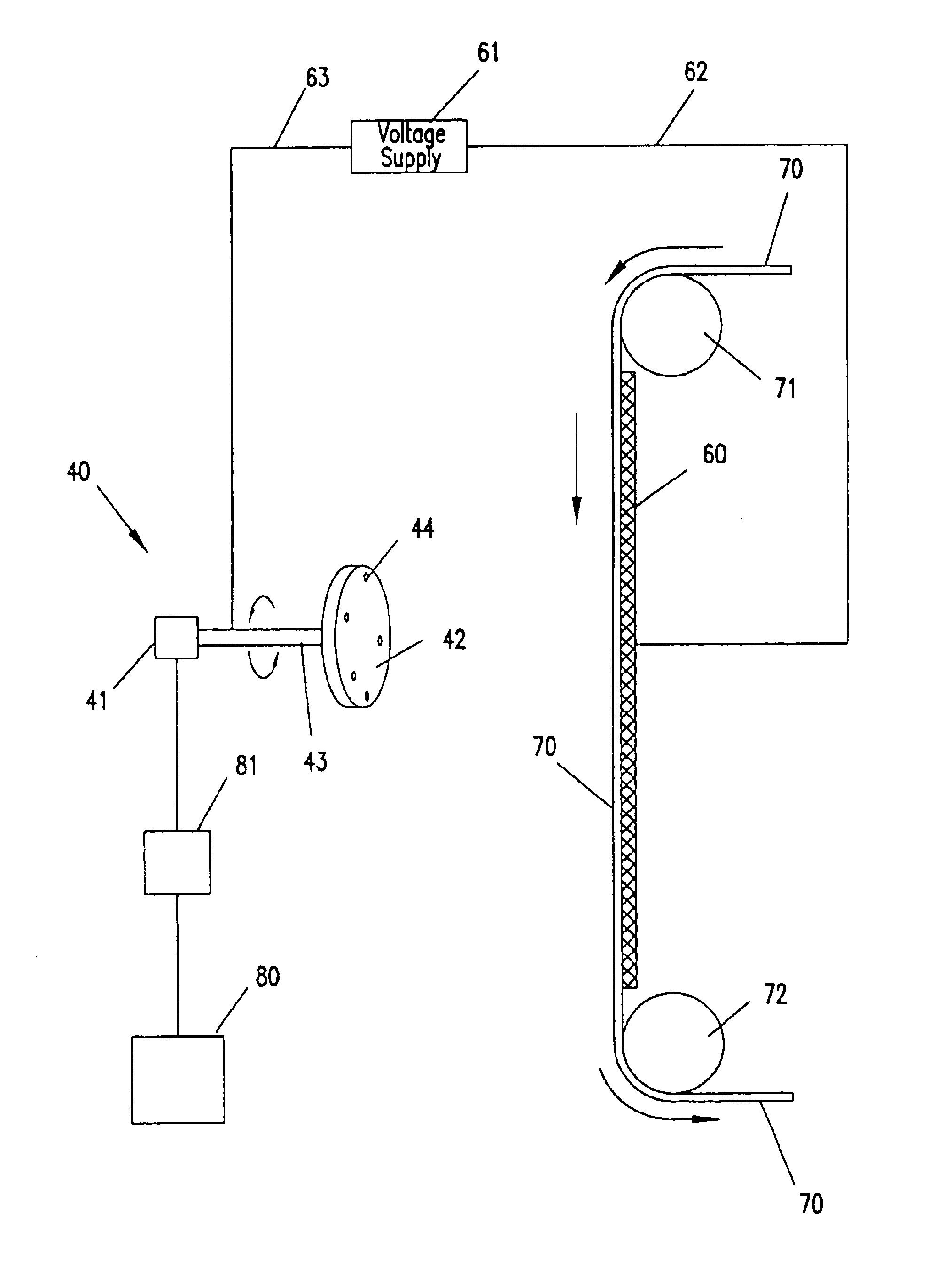

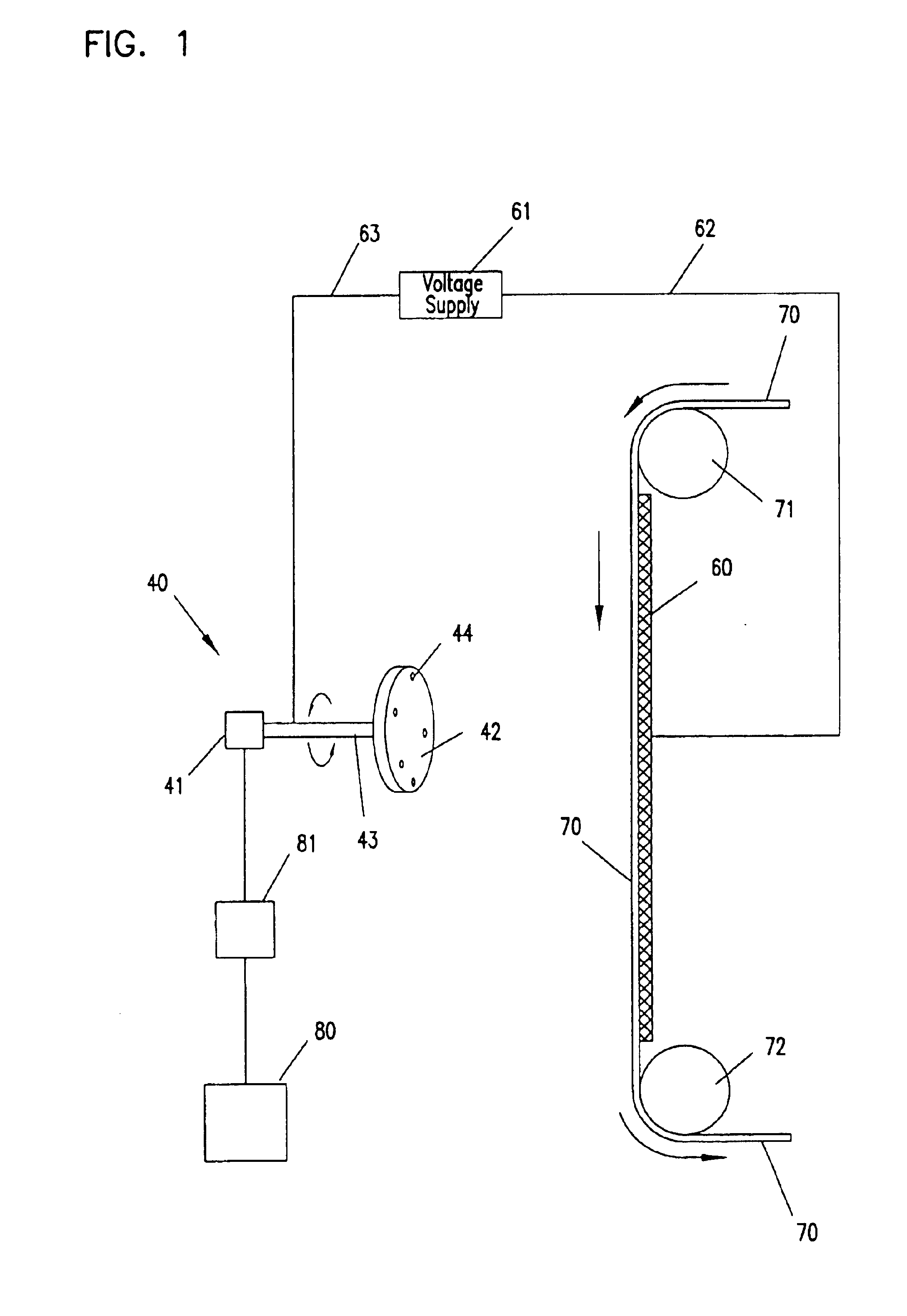

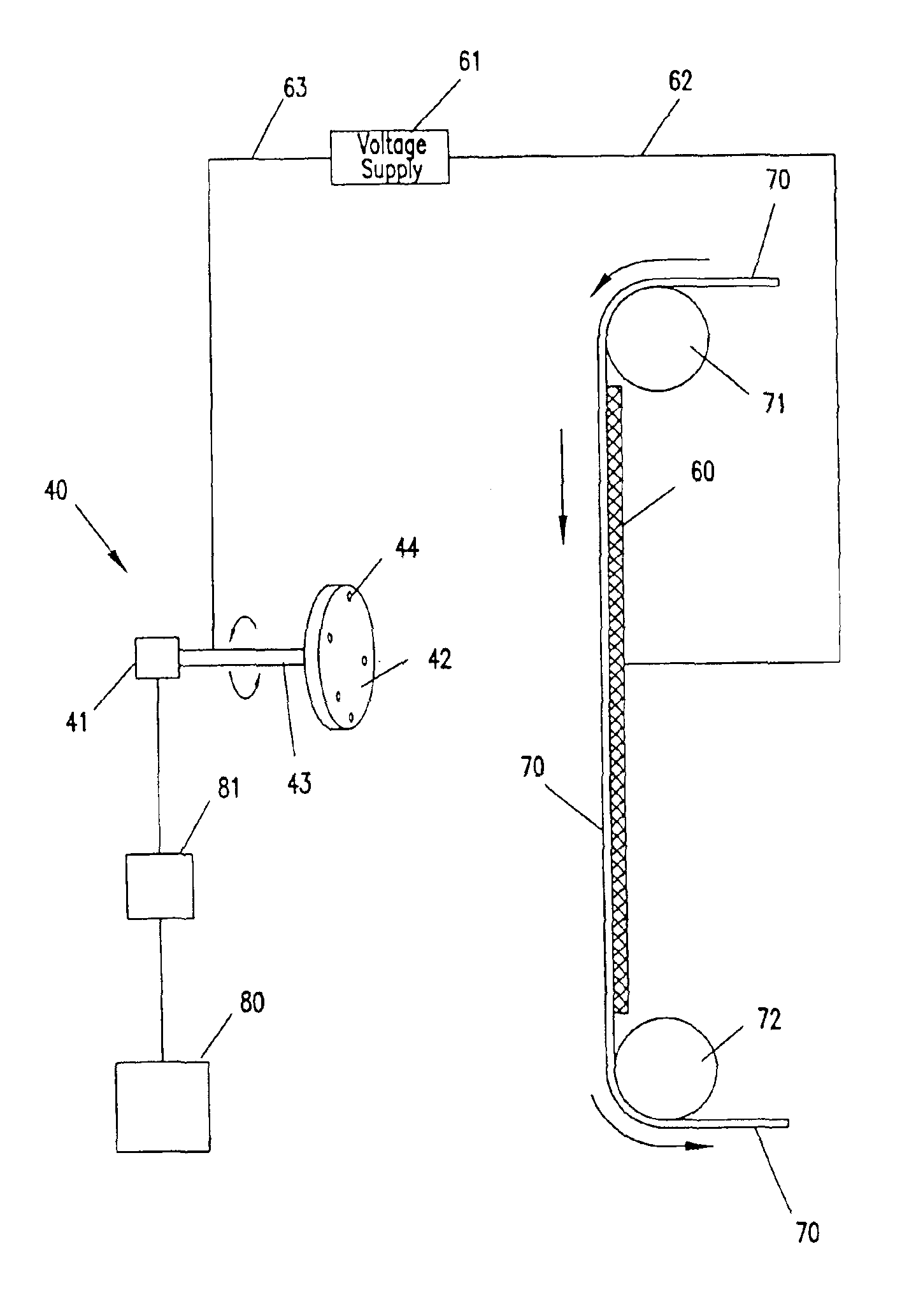

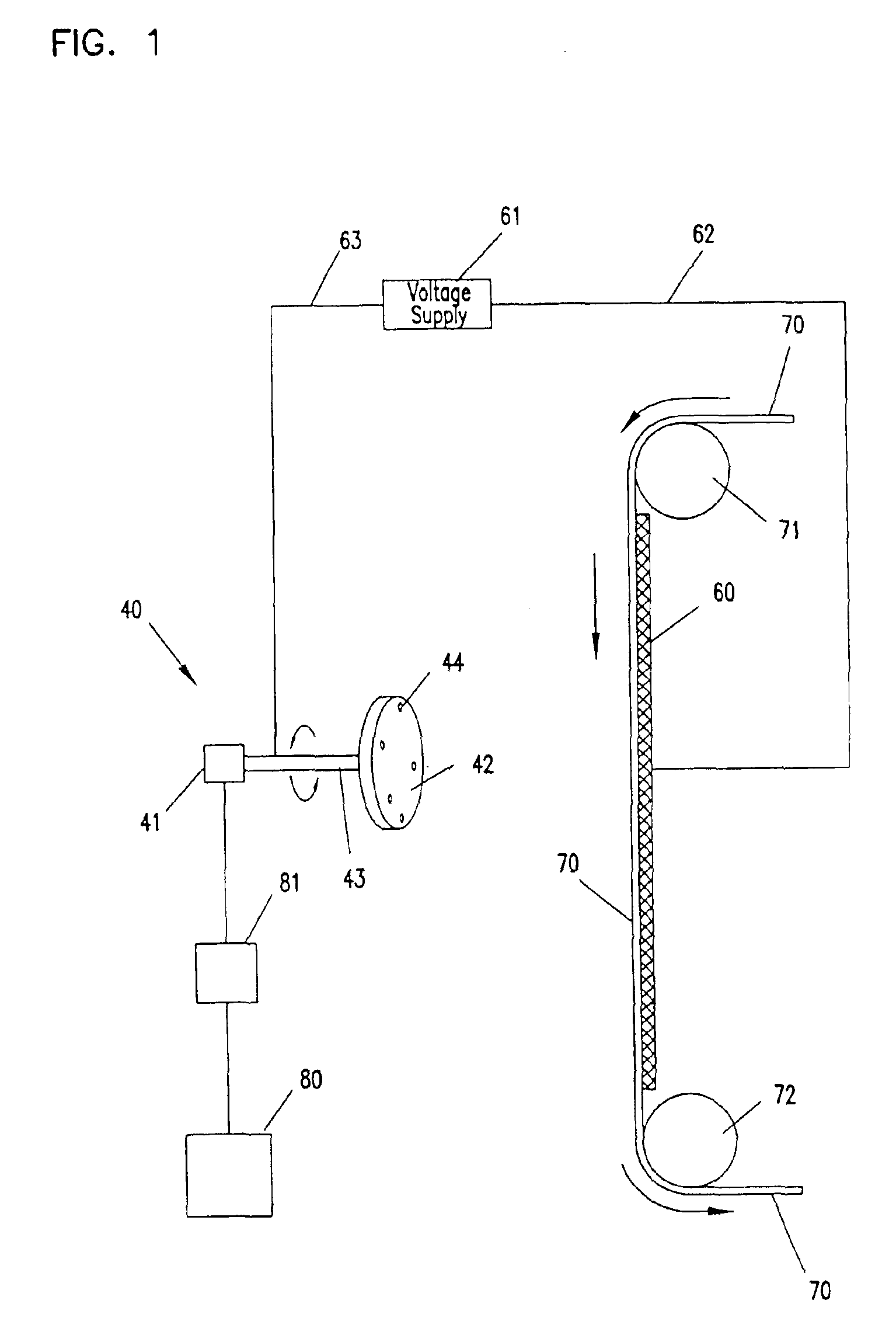

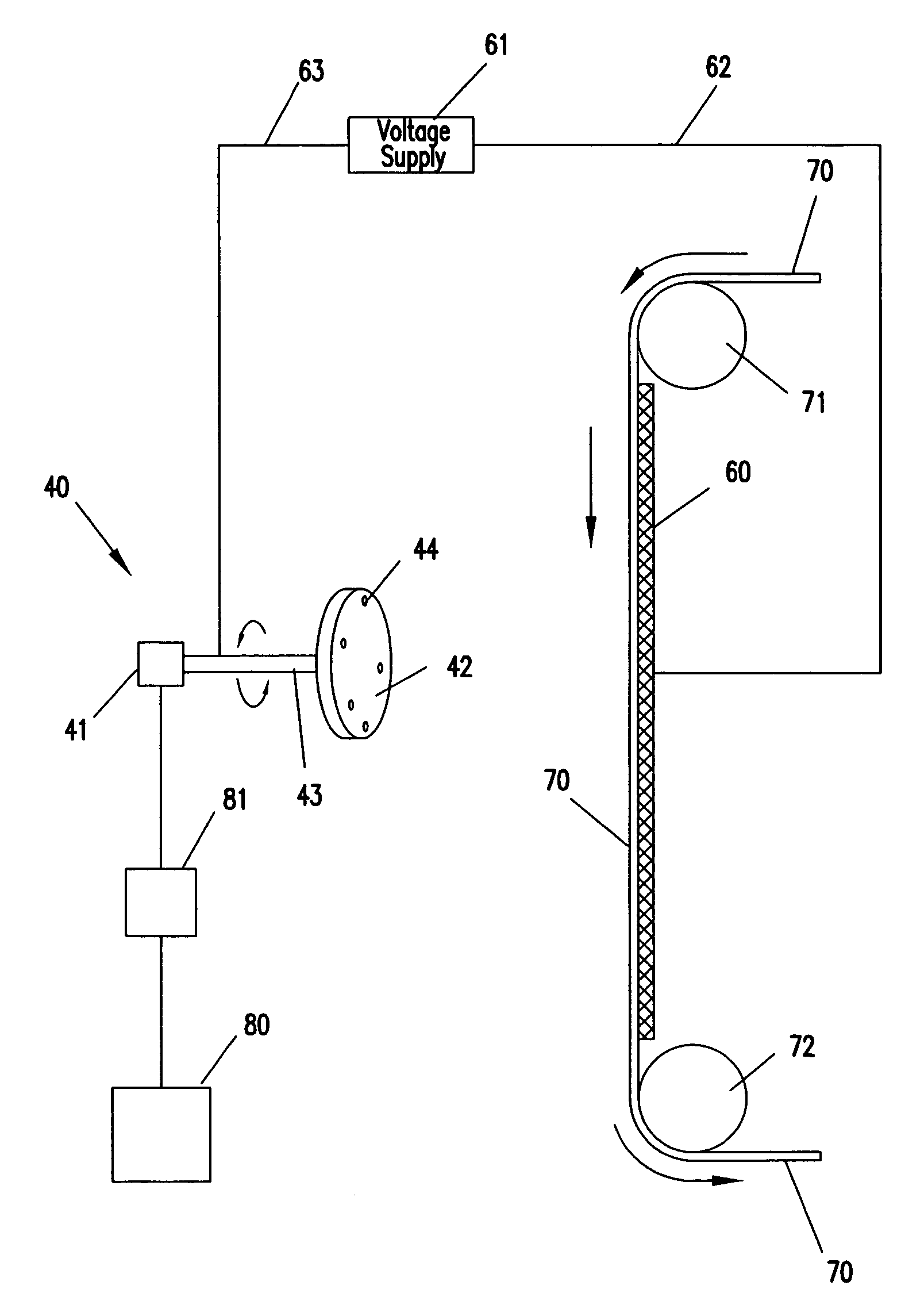

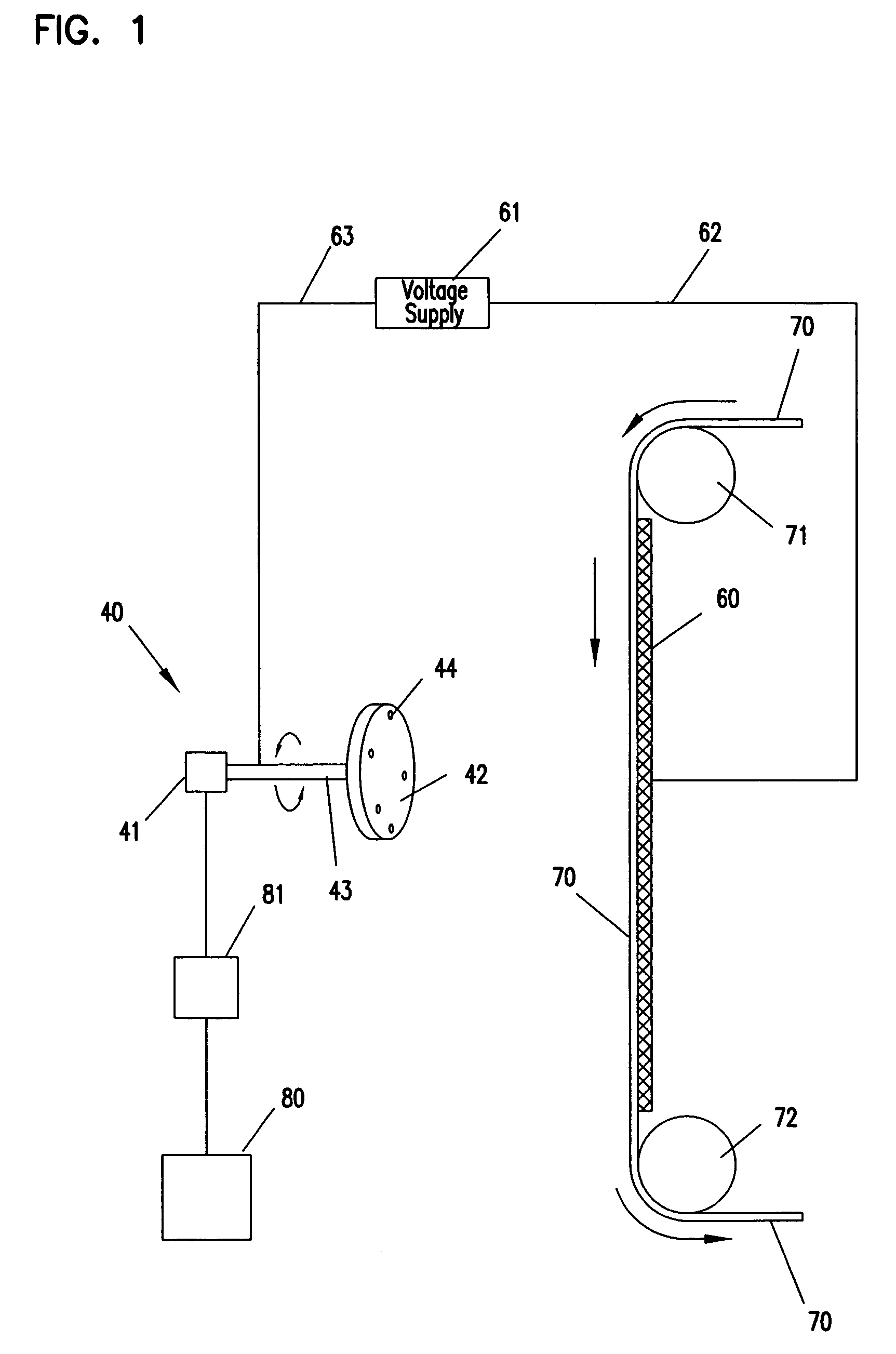

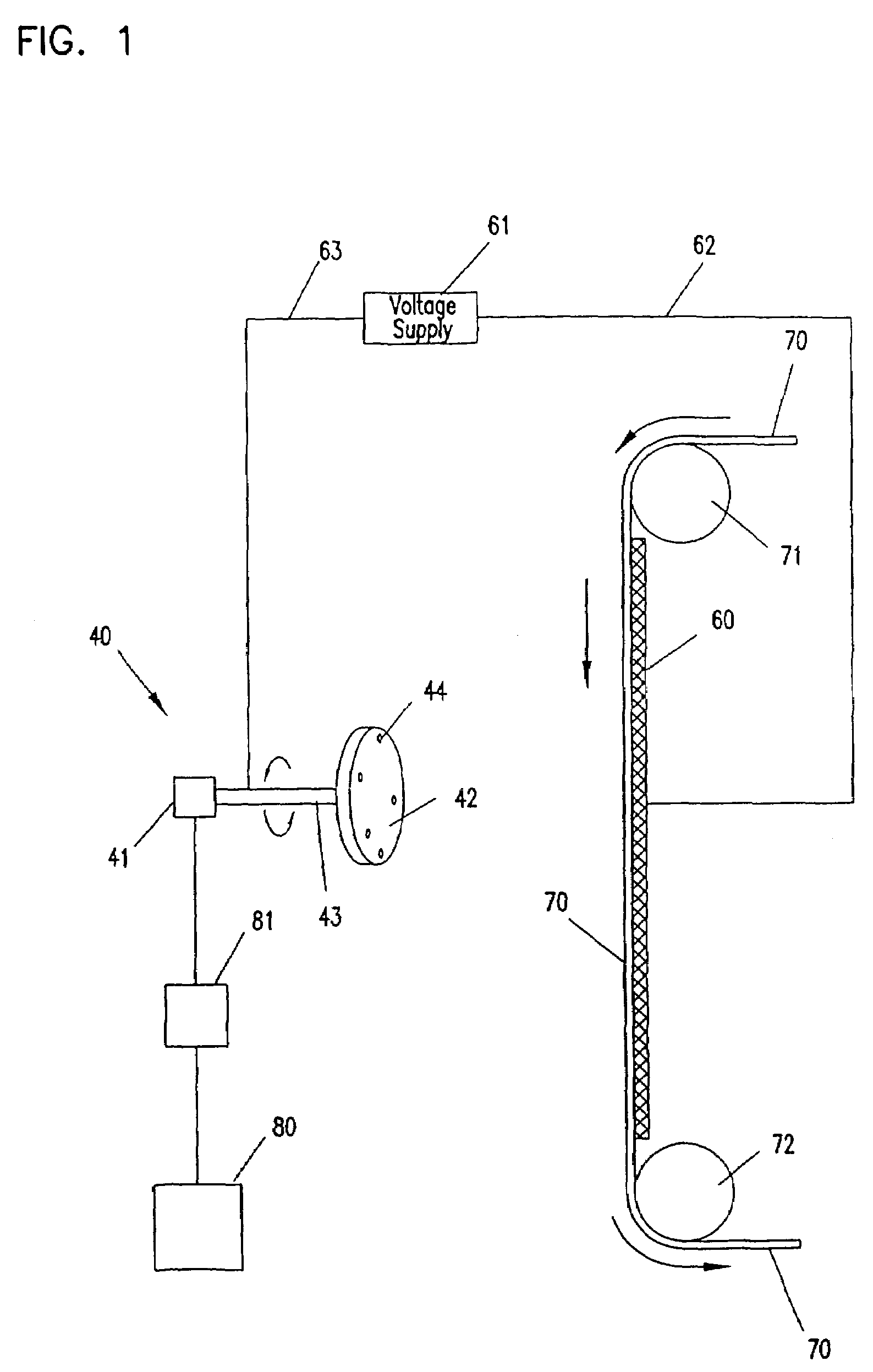

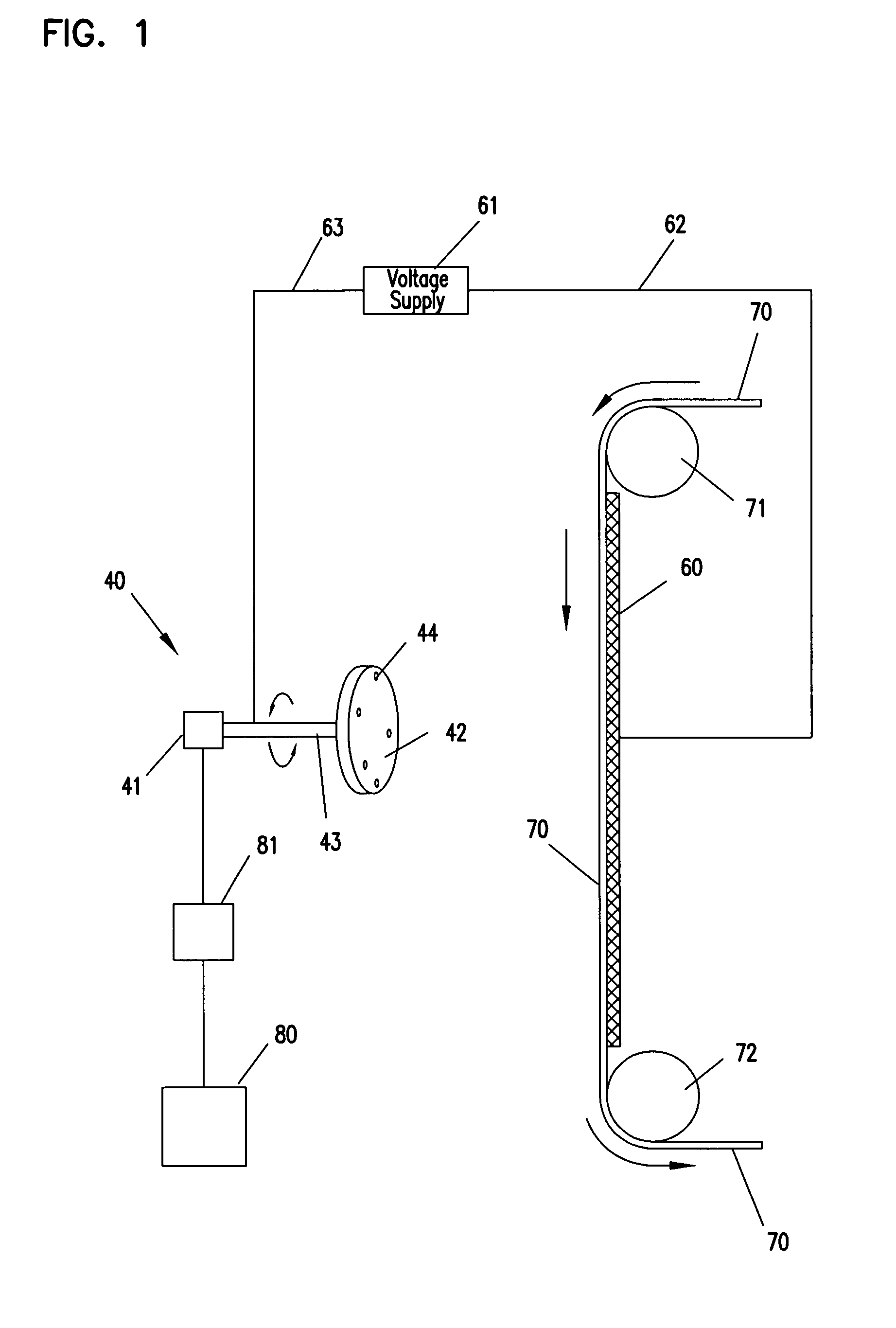

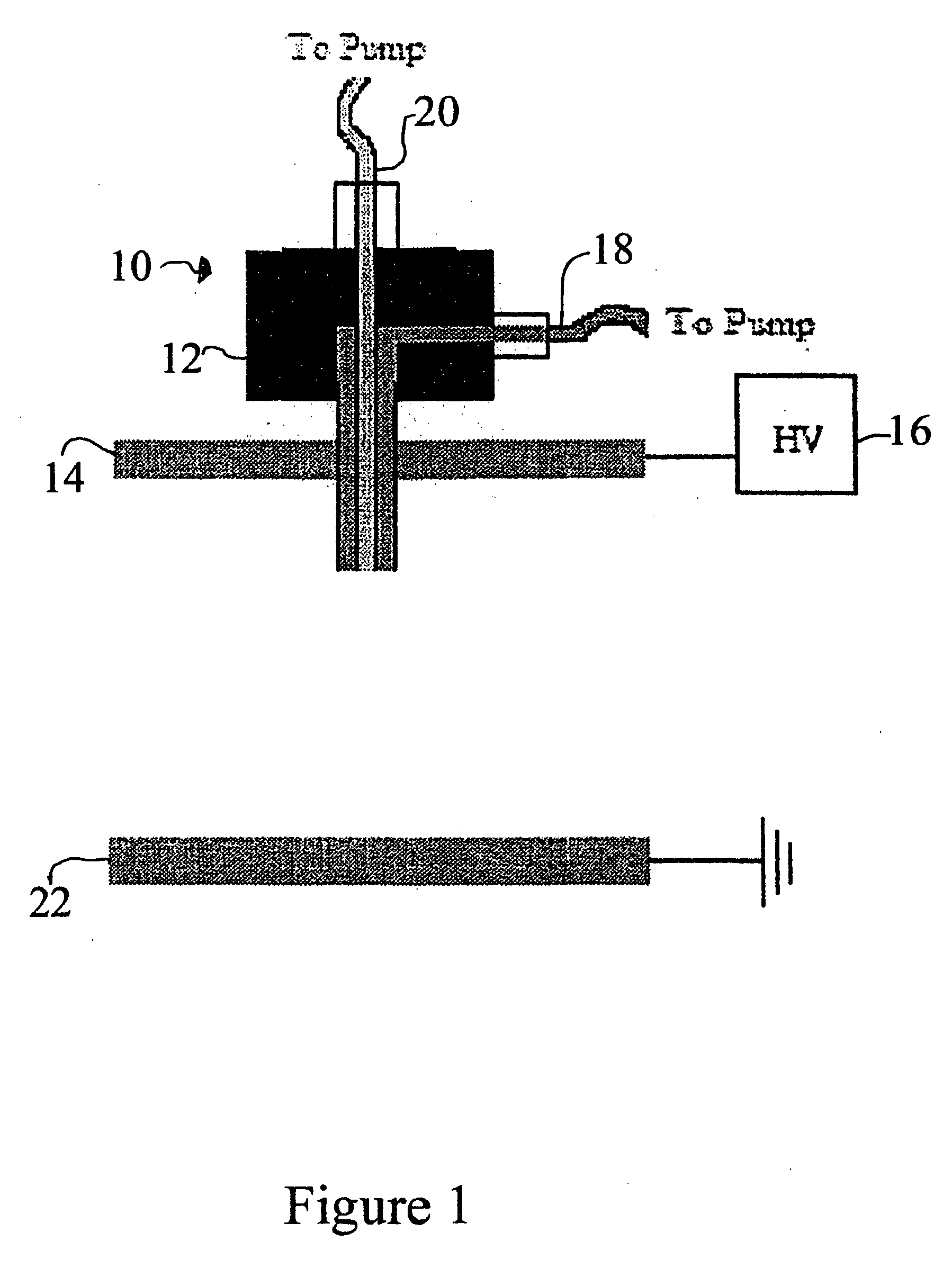

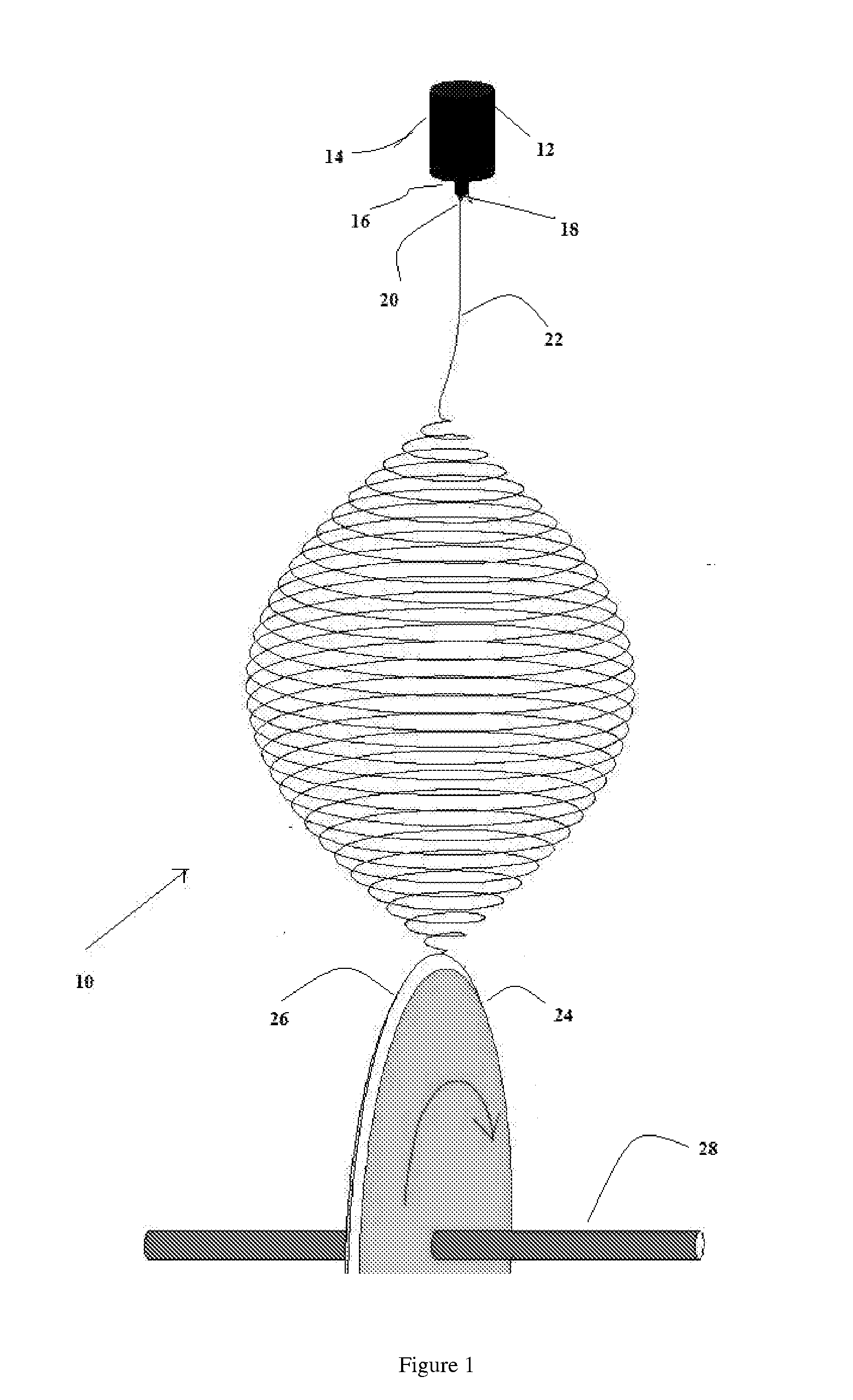

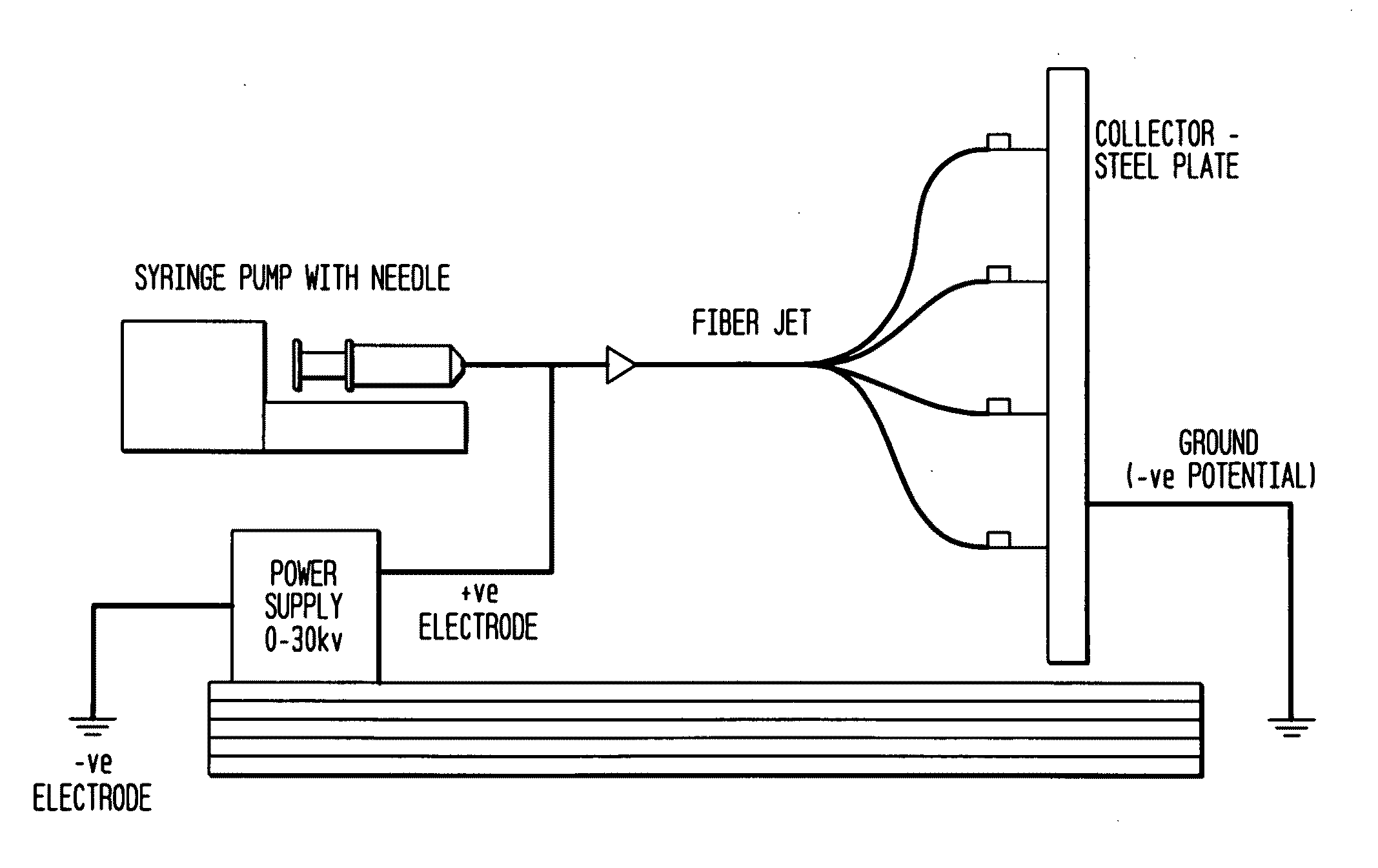

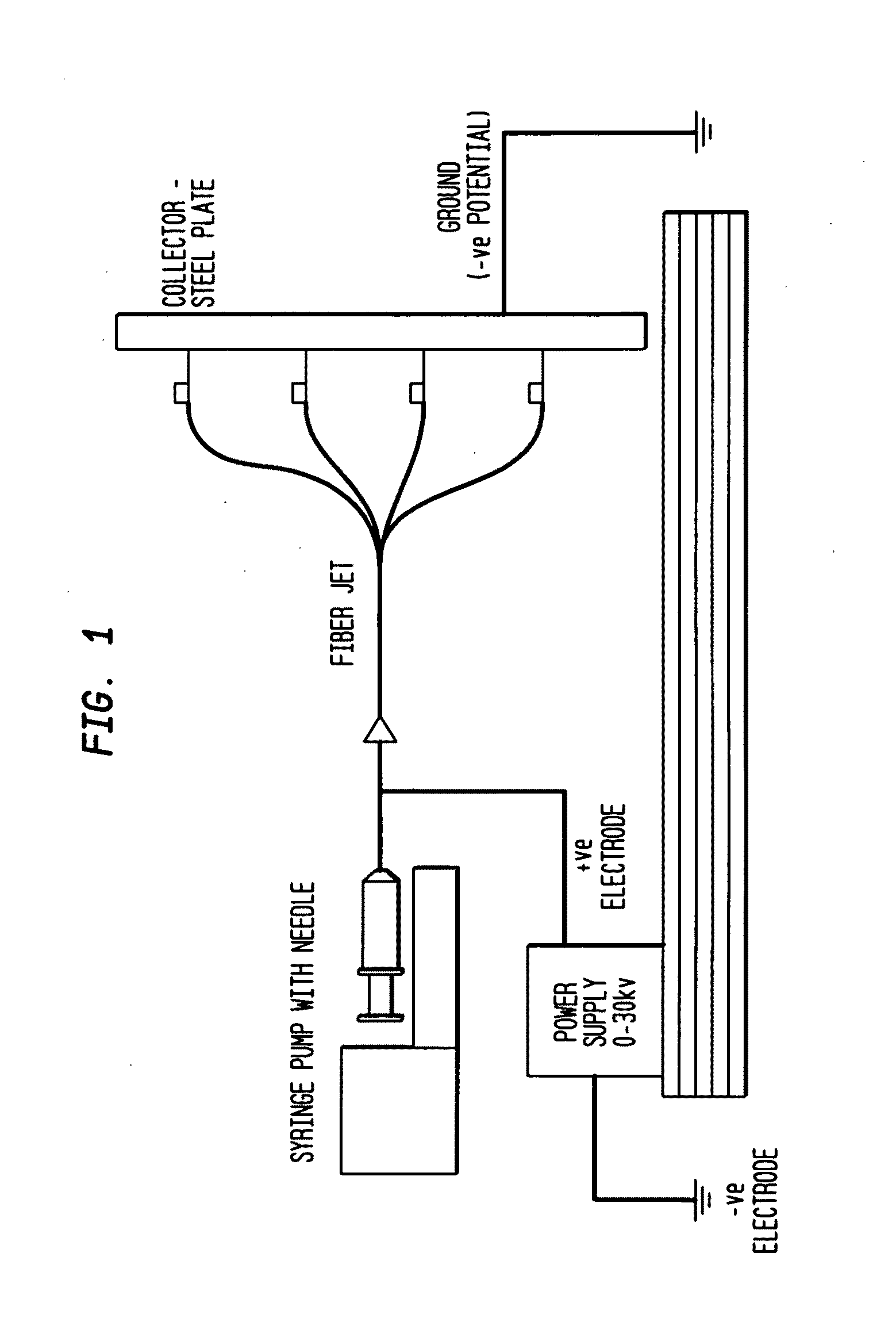

Apparatus and method for elevated temperature electrospinning

ActiveUS7326043B2Avoid disadvantagesConfectioneryWood working apparatusElectrical resistance and conductanceSpinning

Elevated temperature electrospinning apparatus comprises a pump upstream of or containing a resistance heater, means to shield applied electrostatic field from the resistance heater, and a temperature modulator for modulating temperature in the spinning region.

Owner:CORNELL RES FOUNDATION INC

Electrospinning of PTFE with high viscosity materials

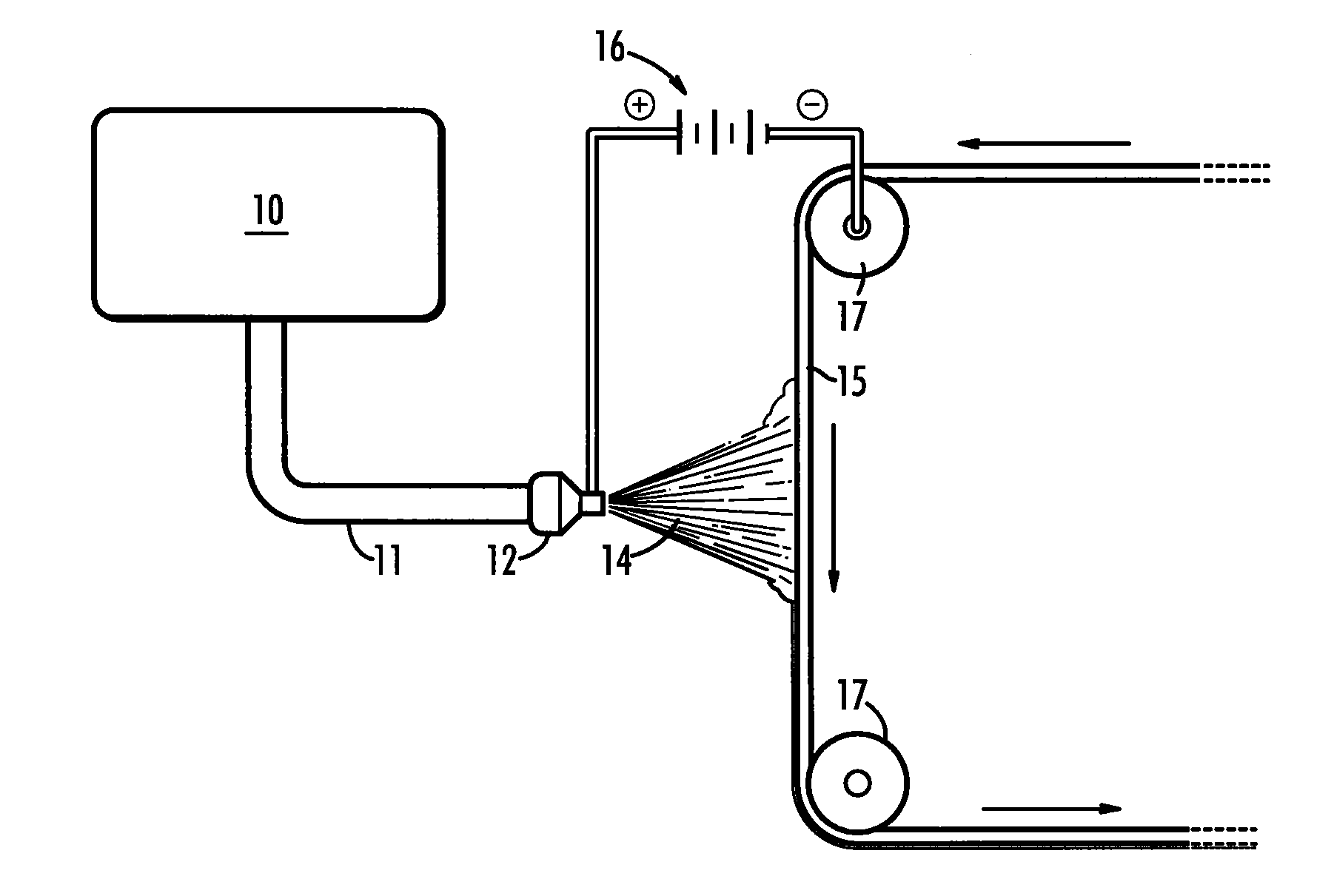

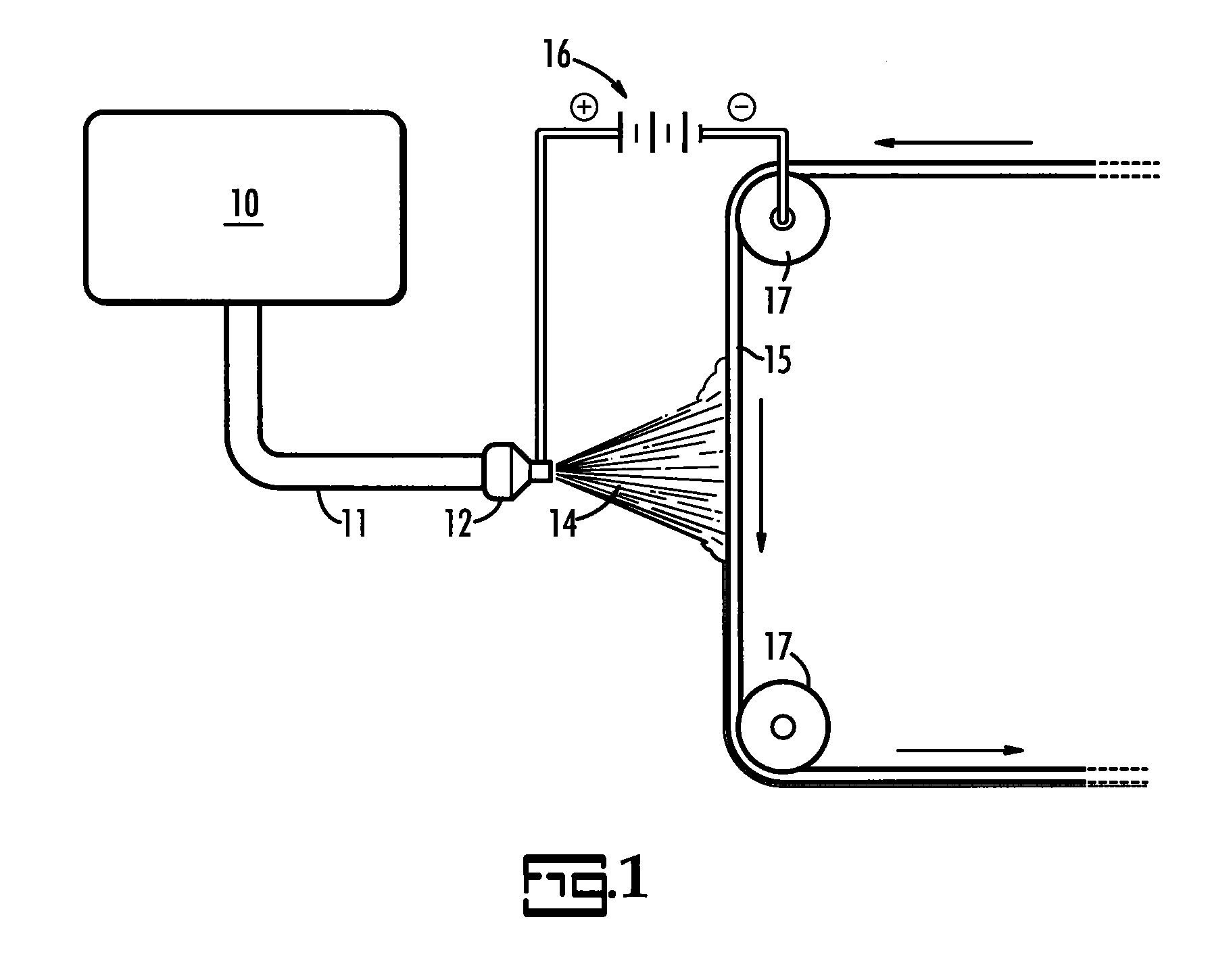

An improved process for forming a PTFE mat is described. The process includes providing a dispersion with PTFE, a fiberizing polymer and a solvent wherein said dispersion has a viscosity of at least 50,000 cP. An apparatus is provided which comprises a charge source and a target a distance from the charge source. A voltage source is provided which creates a first charge at the charge source and an opposing charge at the target. The dispersion is electrostatically charged by contact with the charge source. The electrostatically charged dispersion is collected on the target to form a mat precursor which is heated to remove the solvent and the fiberizing polymer thereby forming the PTFE mat.

Owner:ZEUS COMPANY INC

Absorbent Articles

InactiveUS20170258651A1Soft touchEasy accessElectro-spinningSanitary towelsEngineeringMechanical engineering

Owner:THE PROCTER & GAMBLE COMPANY

Therapeutic Electrospun Fiber Compositions

InactiveUS20100303881A1Promote nerve growthEfficient releaseBiocideNervous disorderFiberActive agent

The instant invention provides electrospun fiber compositions comprising one or more polymers and one or more biologically active agents. In specific embodiments, the biologically active agents are nerve growth factors. In certain embodiments, the electrospun fiber compositions comprising one or more biologically active agents are on the surface of a film, or a tube. The tubes comprising the electrospun fiber compositions of the invention can be used, for example, as nerve guide conduits.

Owner:THE JOHN HOPKINS UNIV SCHOOL OF MEDICINE

Encapsulation of bacteria and viruses in electrospun fibers

A method of preserving organisms in viable form, the method comprising: suspending organisms in a solution of electrospinnable polymer; drawing droplets of said solution through a spinneret; applying an electrostatic field to said droplets under electrospinning conditions; so as to form fibers having a diameter no greater than about 5 μm within which distinct organisms are encapsulated in viable form.

Owner:TECHNION RES & DEV FOUND LTD

Nanofibrillar structure and applications including cell and tissue culture

Owner:BOARD OF TRUSTEES OPERATING MICHIGAN STATE UNIV

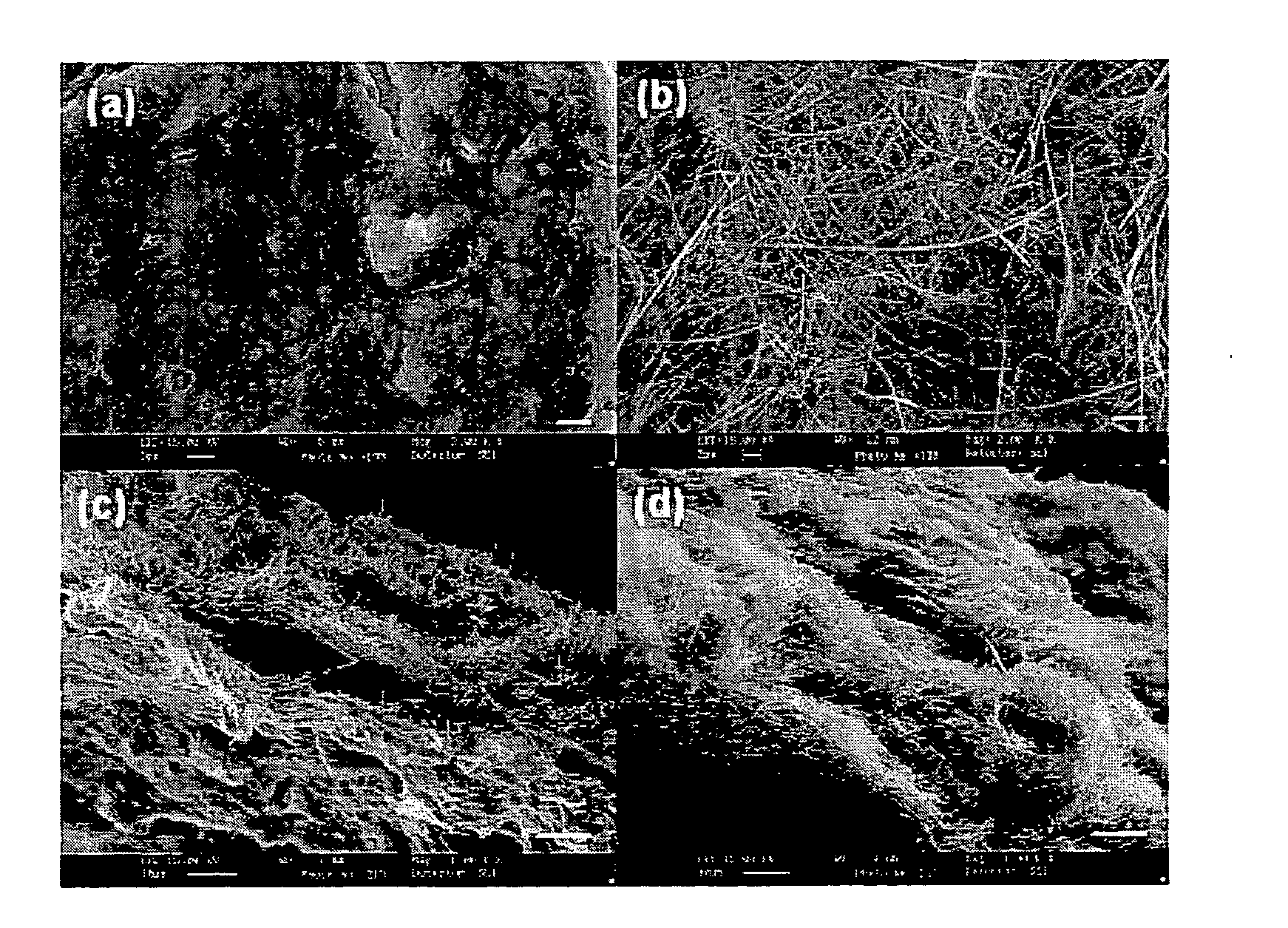

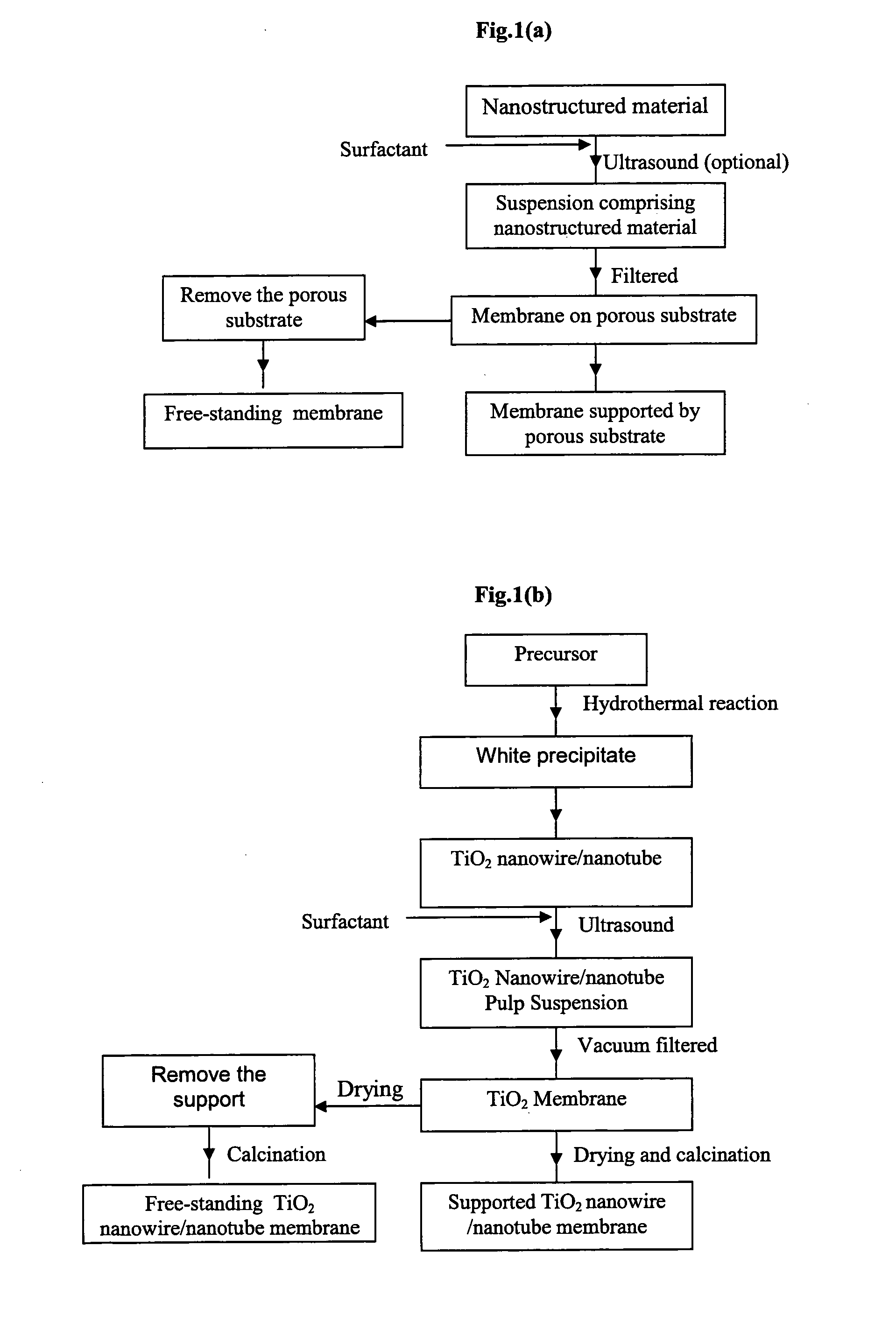

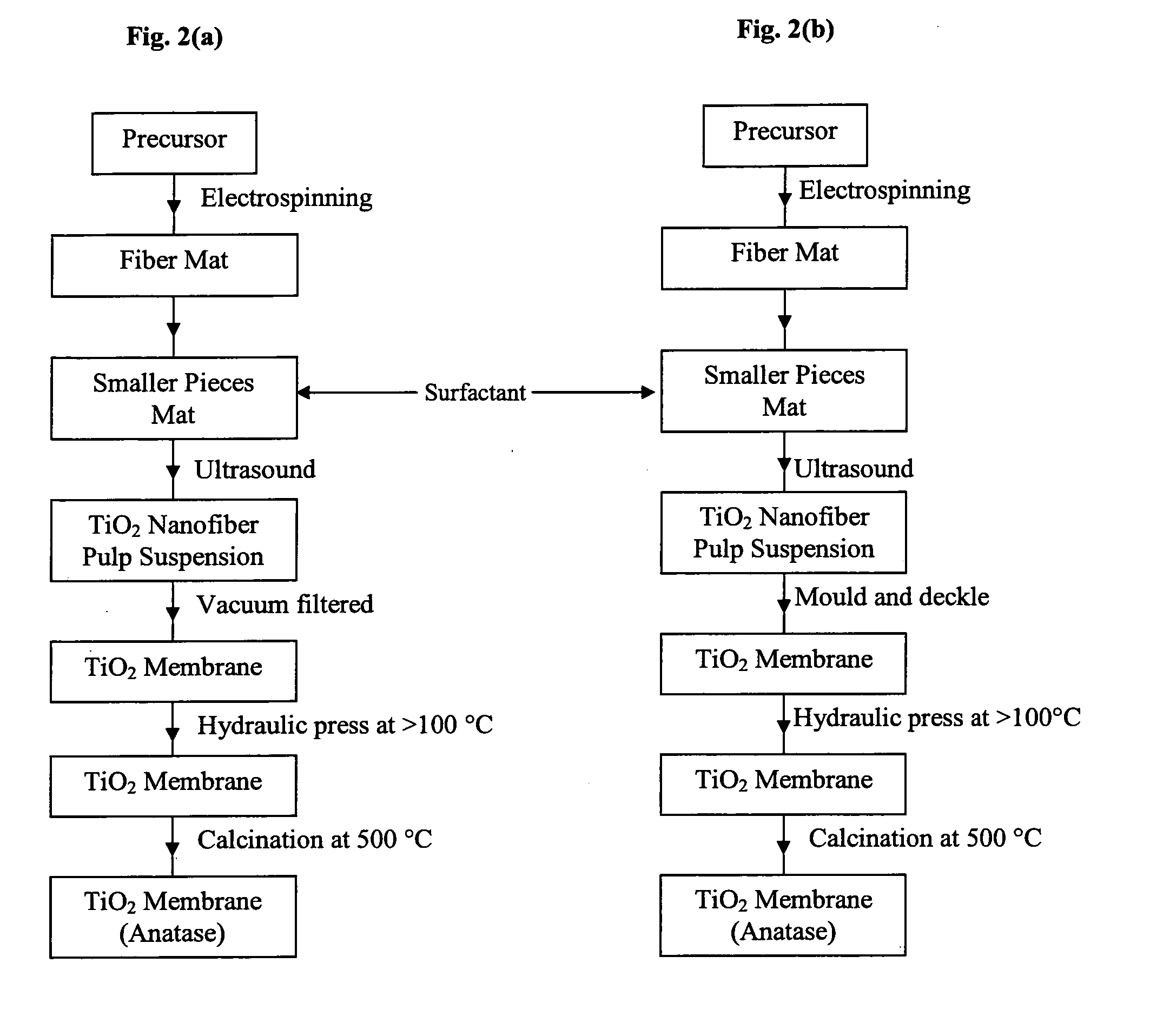

Membrane made of a nanostructured material

Owner:NANYANG TECH UNIV +1

Centrifugal solution spun nanofiber process

The invention relates to a process for forming nanofibers from a spinning solution utilizing a high speed rotating spin disk having a flat surface. The nanofibers can be collected into a uniform web for selective barrier end uses.

Owner:DUPONT SAFETY & CONSTR INC

Composite prosthetic devices

The present disclosure provides composite prosthetic devices comprising two or more layers of electrospun polymers and methods of preparation thereof. In some embodiments, the two or more layers can be porous and in other embodiments, one or more components is nonporous. The composite prosthetic devices can comprise various materials and the properties of the prosthetic devices can be tailored for use in a range of different applications.

Owner:ZEUS INDUSTRIAL PRODUCTS INC

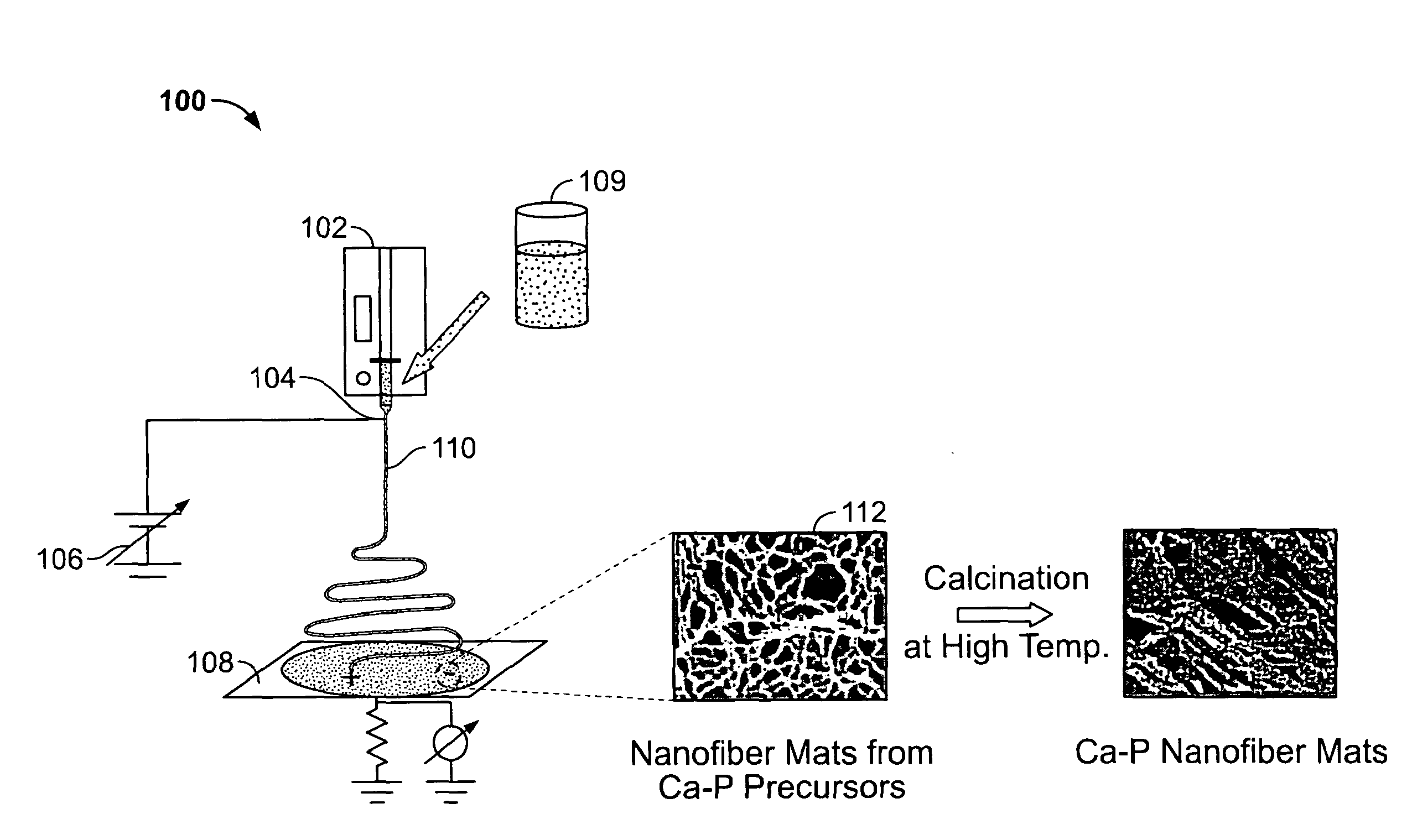

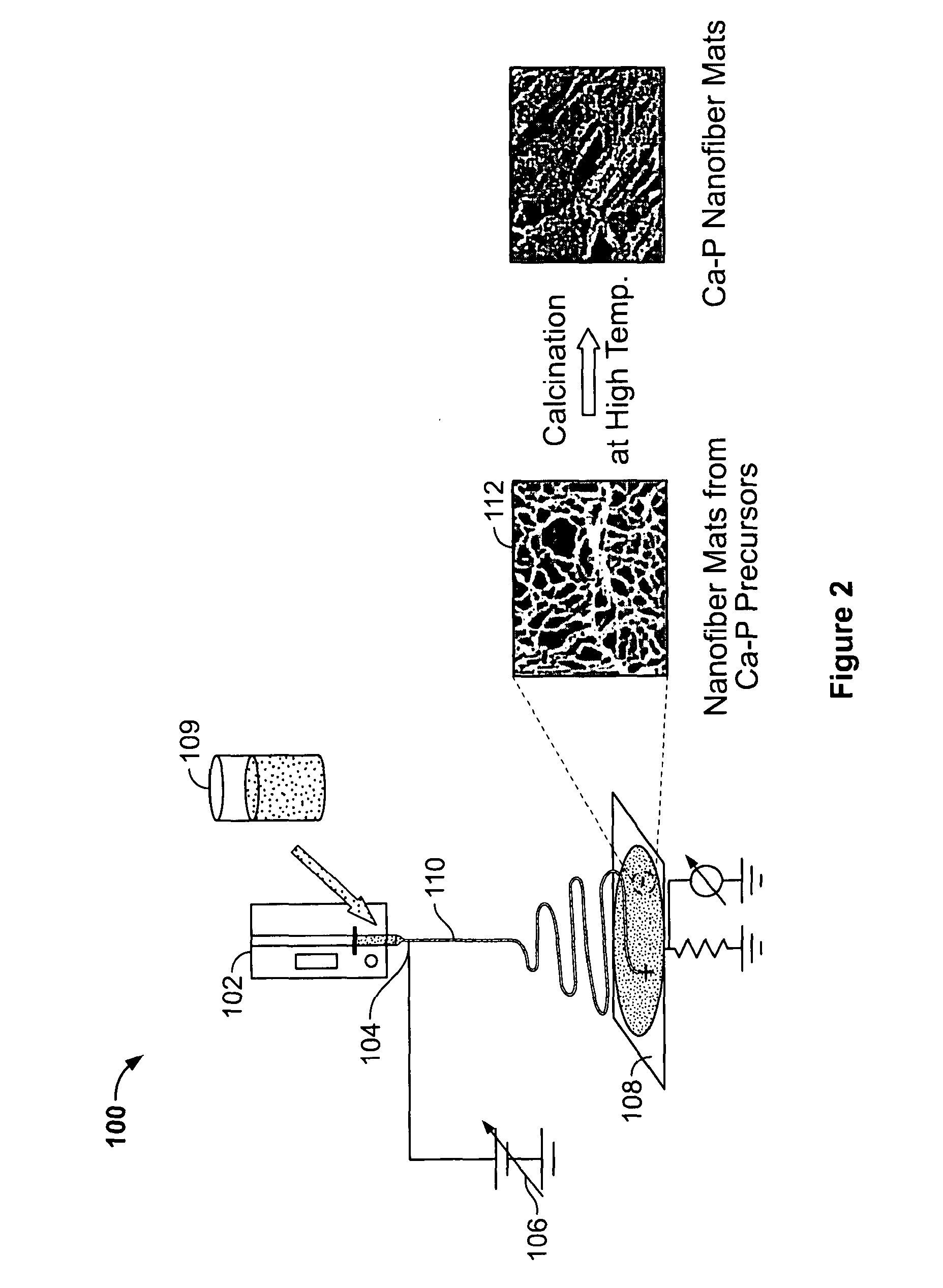

Calcium Phosphate Nanofibers

ActiveUS20090317446A1Suitable environmentMaterial nanotechnologyDental implantsCalcium biphosphateFiber

Calcium-phosphate nanofiber matrices comprising randomly dispersed crystalline calcium-phosphate nanofibers are provided. The nanofibers are synthesized using sol-gel methods combined with electrospinning. The nanofibers may be hollow, solid or may comprise a calcium-phosphate shell surrounding a polymer containing inner core to which biologically functional additives may be added. The nanofiber matrices may be used to culture bone and dental cells, and as implants to treat bone, dental or periodontal diseases and defects.

Owner:CORNELL RES FOUNDATION INC

Electrospun Ceramic-Polymer Composite As A Scaffold For Tissue Repair

The present invention relates to compositions and methods of preparing a three-dimensional matrix of micron sized electrospun fibers, wherein the electrospun fibers are formed from a electrospun composite comprising a bioactive ceramic component and a polymer component. The matrix provides an osteoconductive and osteoinductive scaffold supporting osteogenesis and thereby facilitates bone repair.

Owner:NEW JERSEY INSTITUTE OF TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com