Patents

Literature

938 results about "Chemical Linkage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

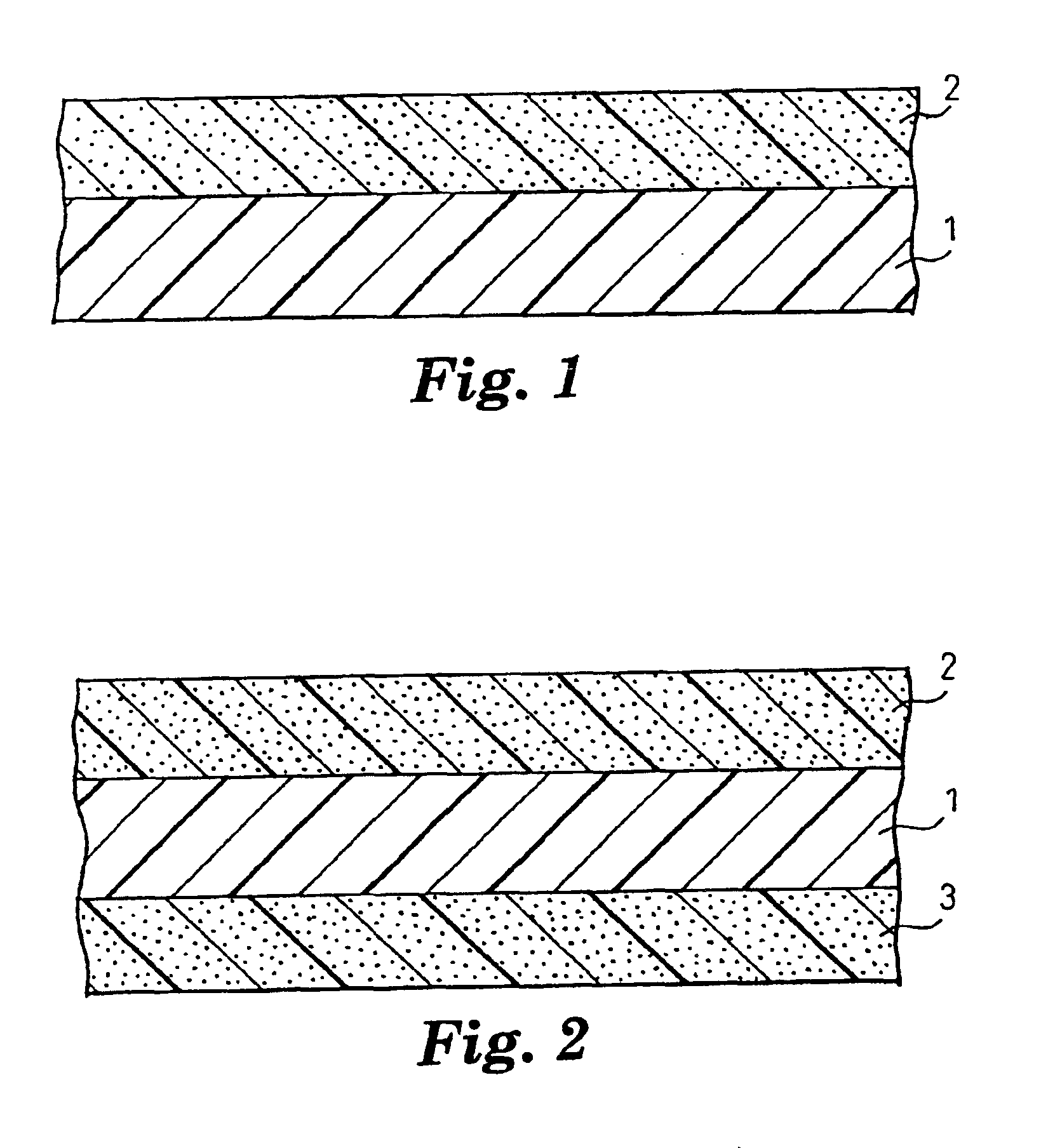

Damage resistant glass article for use as a cover plate in electronic devices

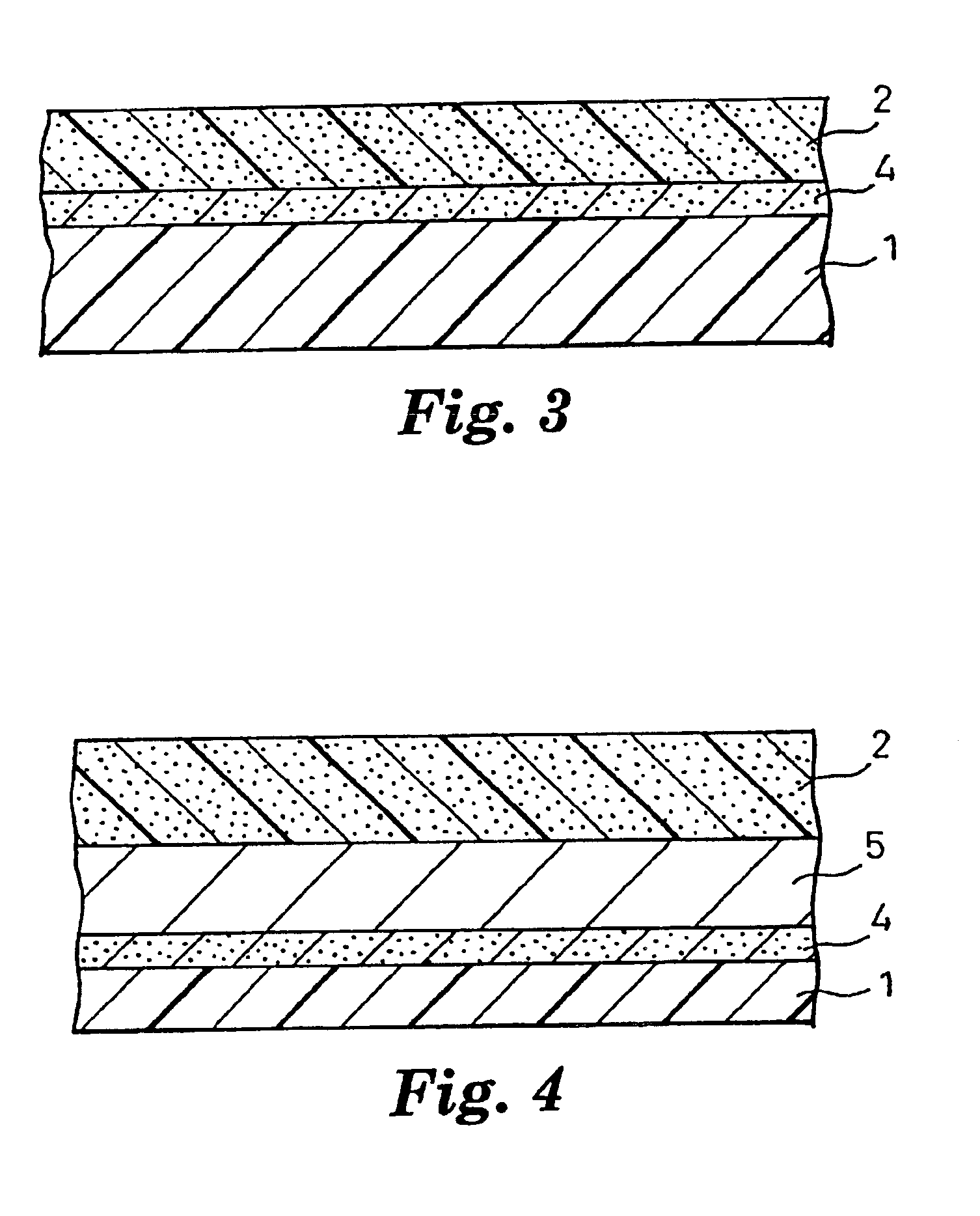

InactiveUS20090197048A1Minimizing transportEasy to disassembleFilm/foil adhesivesSynthetic resin layered productsAnti-reflective coatingChemical Linkage

An alkali aluminosilicate glass article, said alkali aluminosilicate glass having a surface compressive stress of at least about 200 MPa, a surface compressive layer having a depth of at least about 30 μm, a thickness of at least about 0.3 mm and an amphiphobic fluorine-based surface layer chemically bonded to the surface of the glass. In one embodiment the glass has an anti-reflective coating applied to one surface of the glass between the chemically strengthened surface of the glass and the amphiphobic coating. In another embodiment the surface of the chemically strengthened glass is acid treated using a selected acid (e.g., HCL, H2SO4, HClO4, acetic acid and other acids as described) prior to placement of the amphiphobic coating or the anti-reflective coating.

Owner:CORNING INC

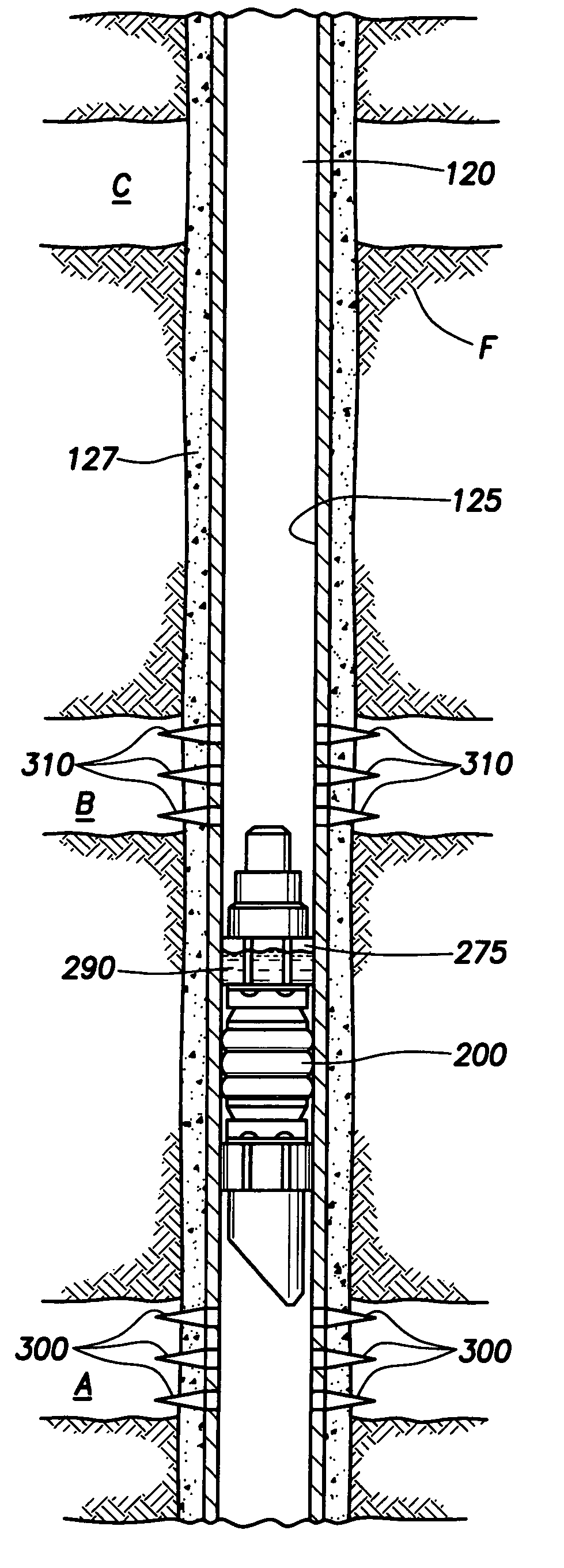

One-time use composite tool formed of fibers and a biodegradable resin

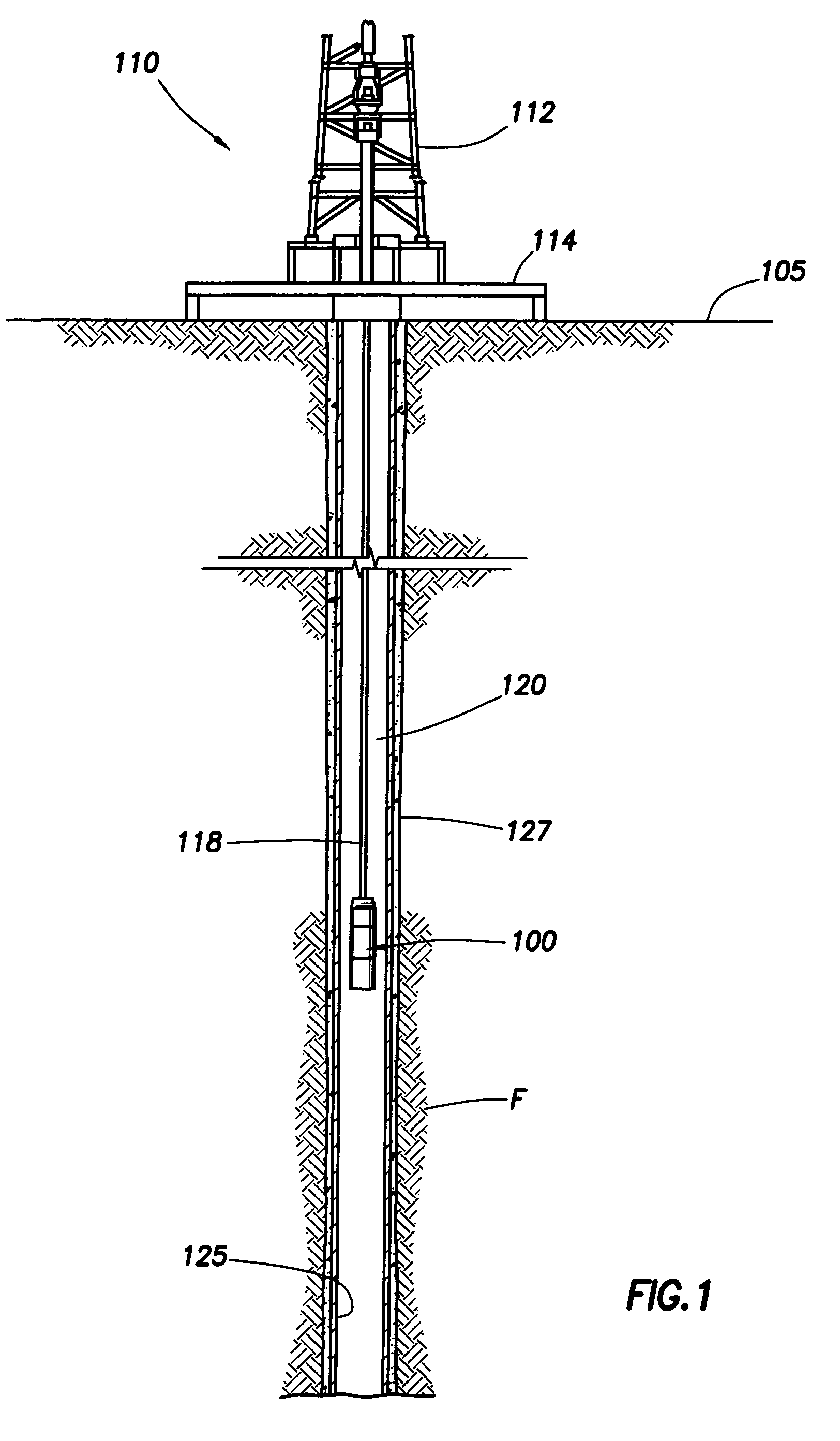

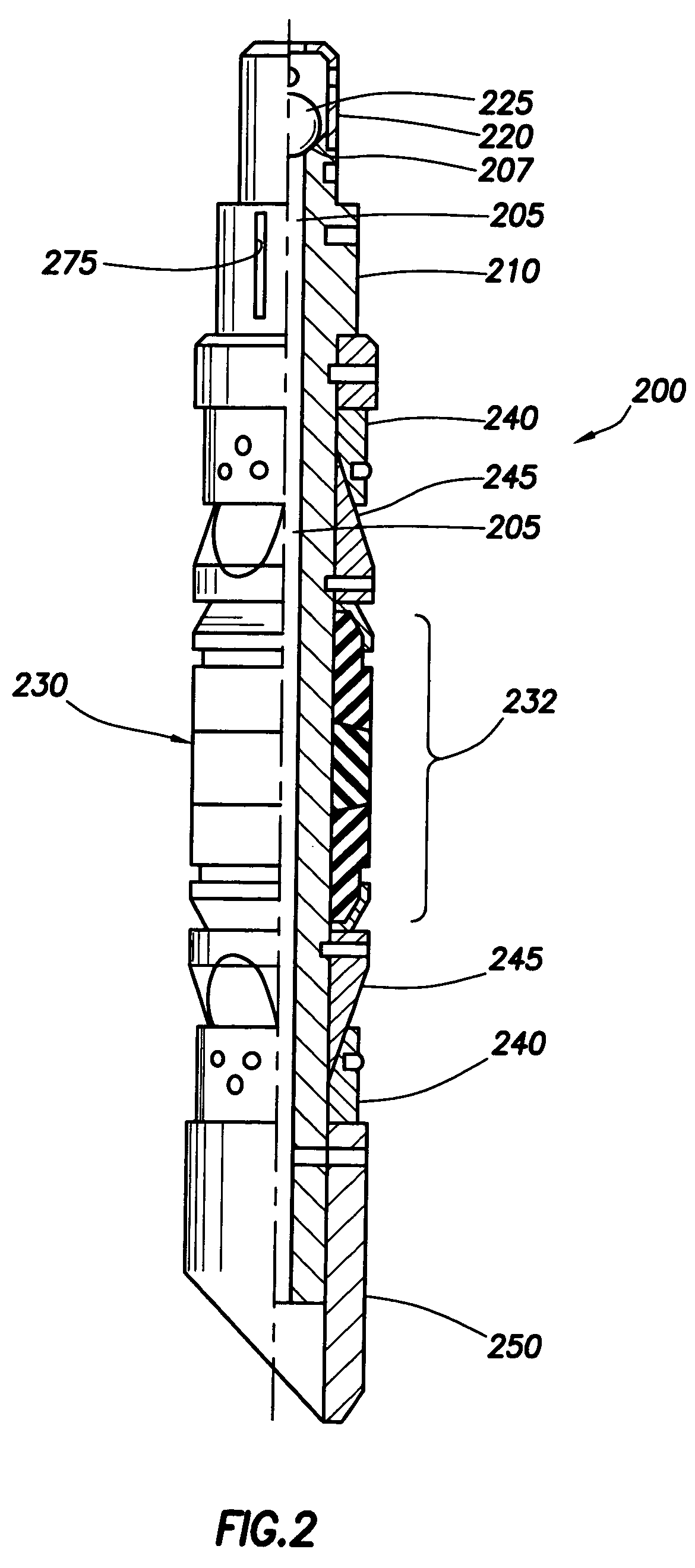

ActiveUS7093664B2Eliminates and at least minimizes drawbackFluid removalWell/borehole valve arrangementsFiberChemical Linkage

The present invention is directed to disposable composite downhole tool formed of a resin-coated fiber. The fiber is formed of a degradable polymer, such as a poly(lactide) or polyanhydride. The resin is formed of the same degradable polymer as the fiber. It chemically bonds to the fiber, thereby making a strong rigid structure once cured. The fiber may be formed into a fabric before being coated with the resin. Alternatively, the fiber is formed of a non-biodegradable material.

Owner:HALLIBURTON ENERGY SERVICES INC

Lubricious coating for a medical device

InactiveUS6866656B2Reduce frictionNot degradedFilm/foil adhesivesSynthetic resin layered productsElastomerChemical Linkage

A lubrication system is disclosed which minimizes friction and that is useful for application on the surface of a flexible portion of a medical device. Such a lubrication system includes a lubricant that is able to move when the flexible portion of the medical device flexes and is biocompatible and is not degraded by the application of alcohol or other conventional medical sterilizing and cleaning agents. The lubricant is bonded to the surface of the flexible portion of the medical device. The lubrication system may be used on an elastomeric septum, such as a silicone rubber elastomer. The lubricant coating may be any type of coating that can be chemically bonded to the elastomer, such as di-paraxylene, poly-(p-xylene), polytetrafluoroethylene, or polyvinylpyrrolidone.

Owner:BECTON DICKINSON & CO

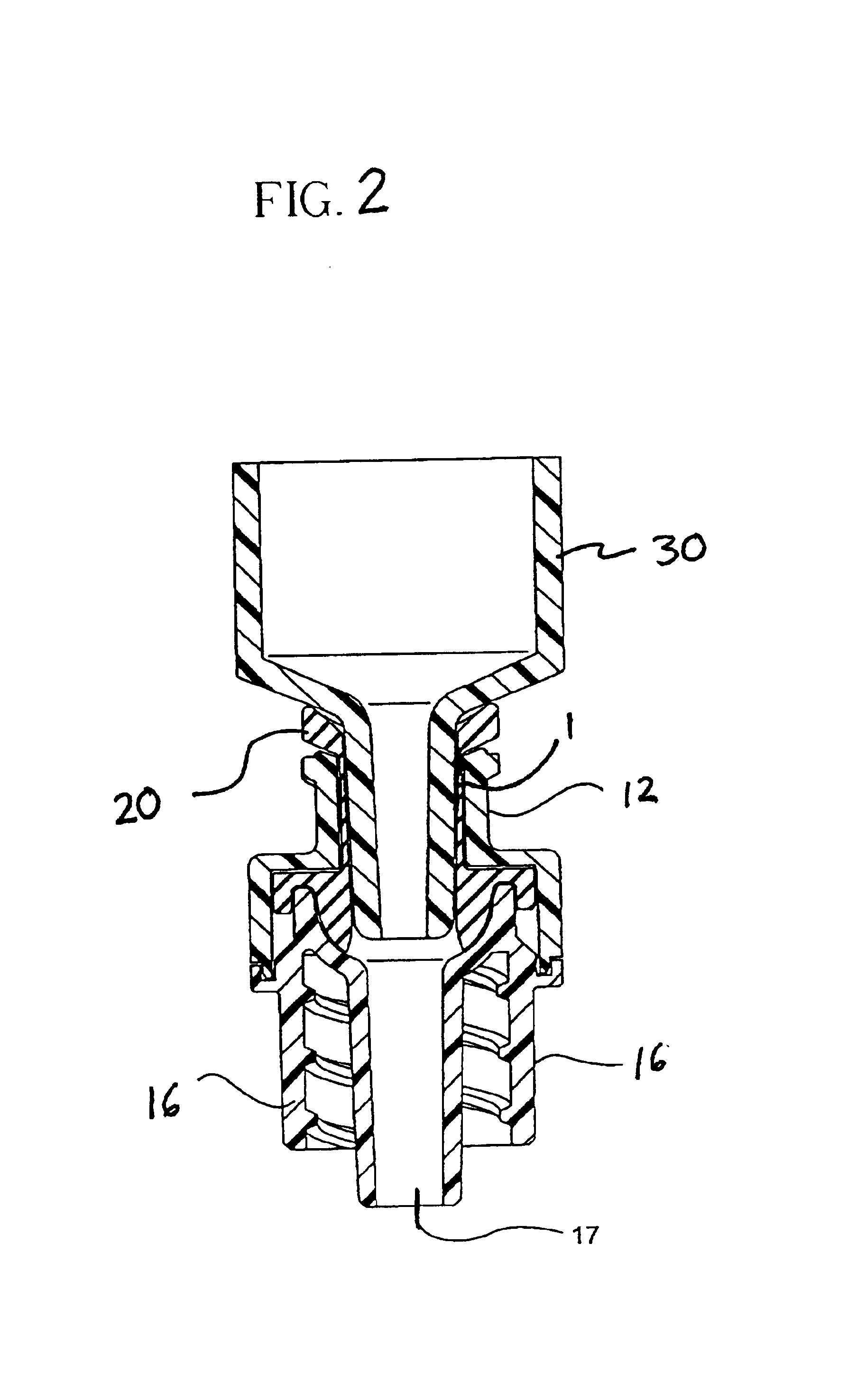

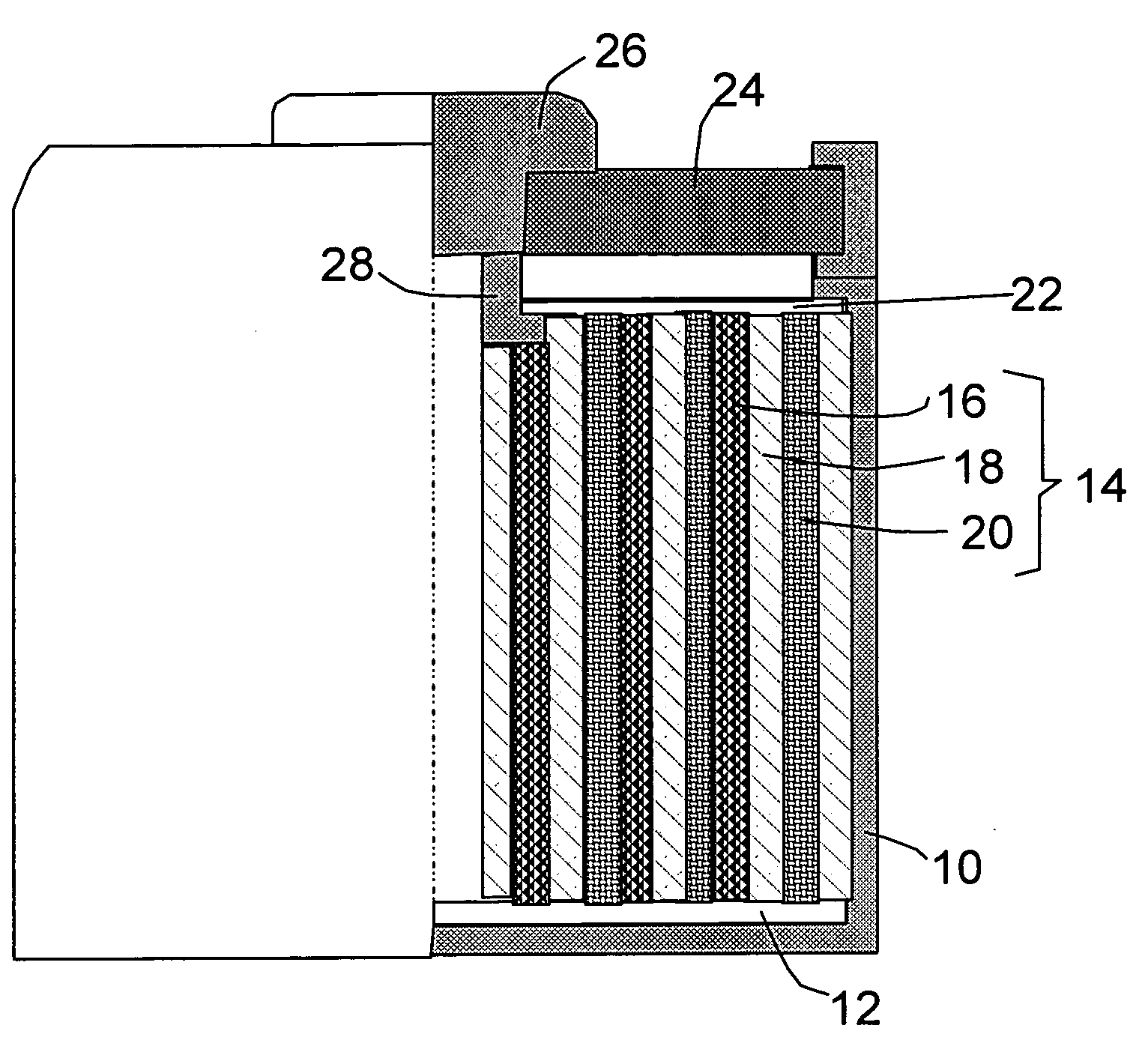

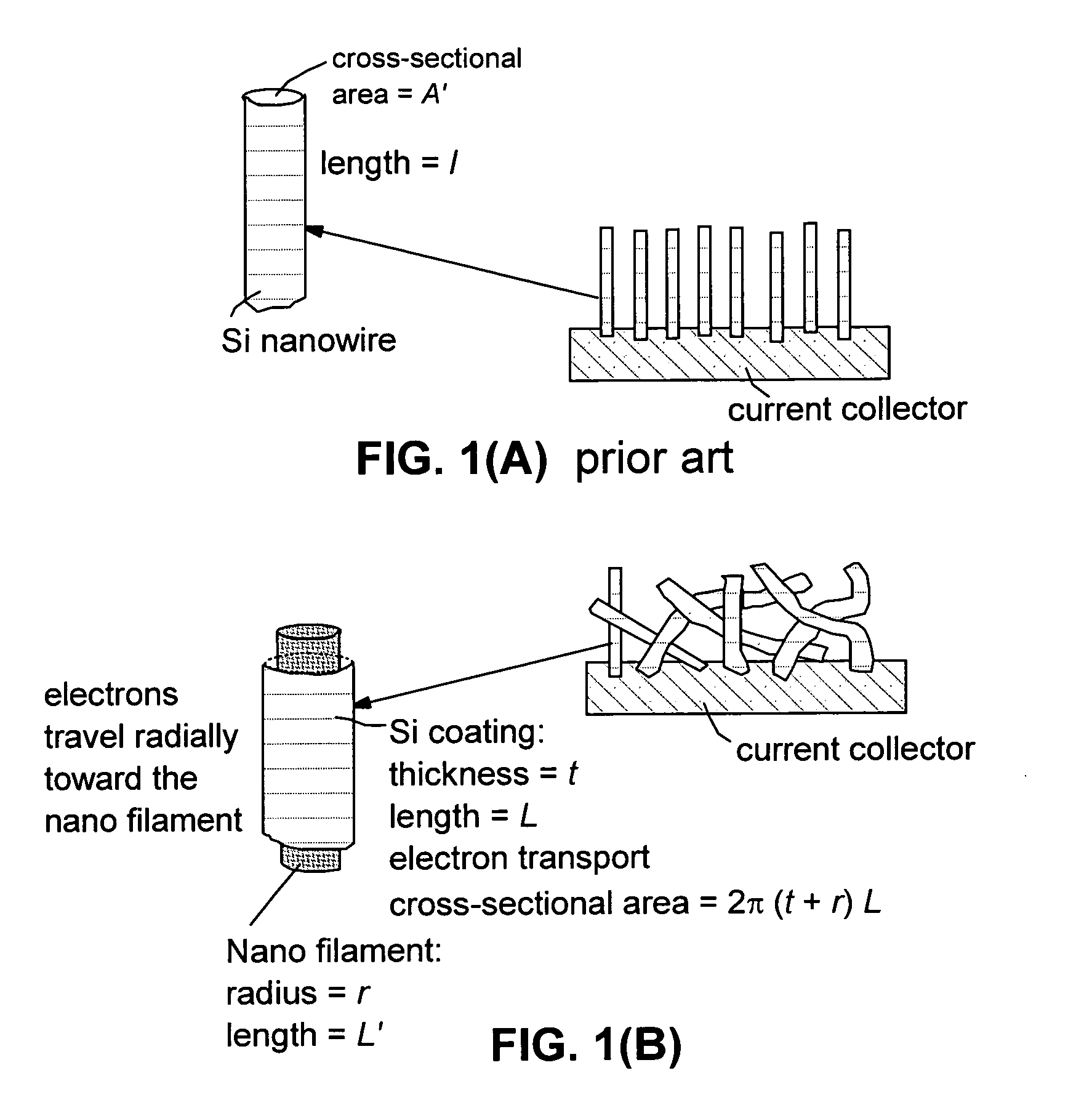

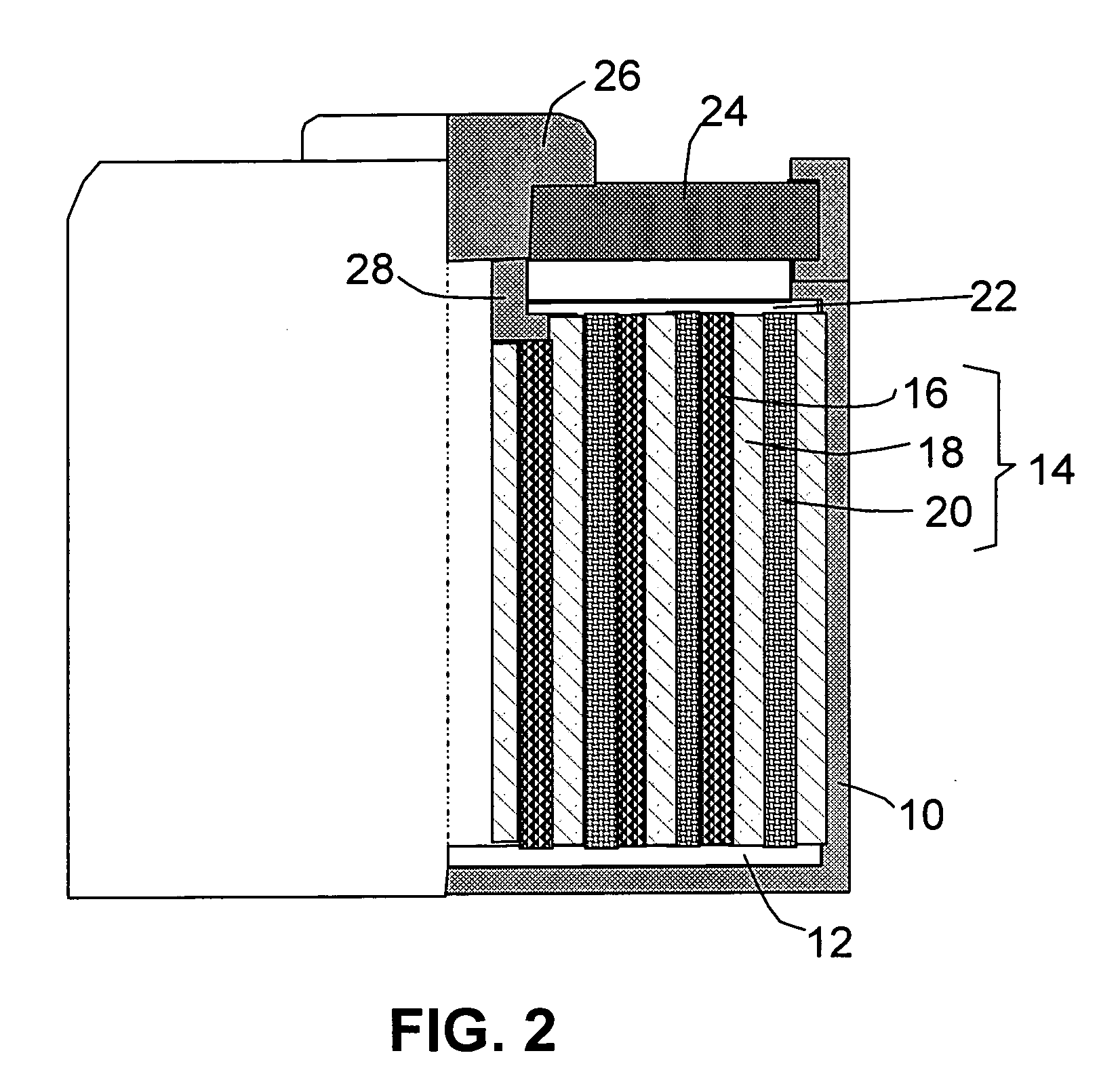

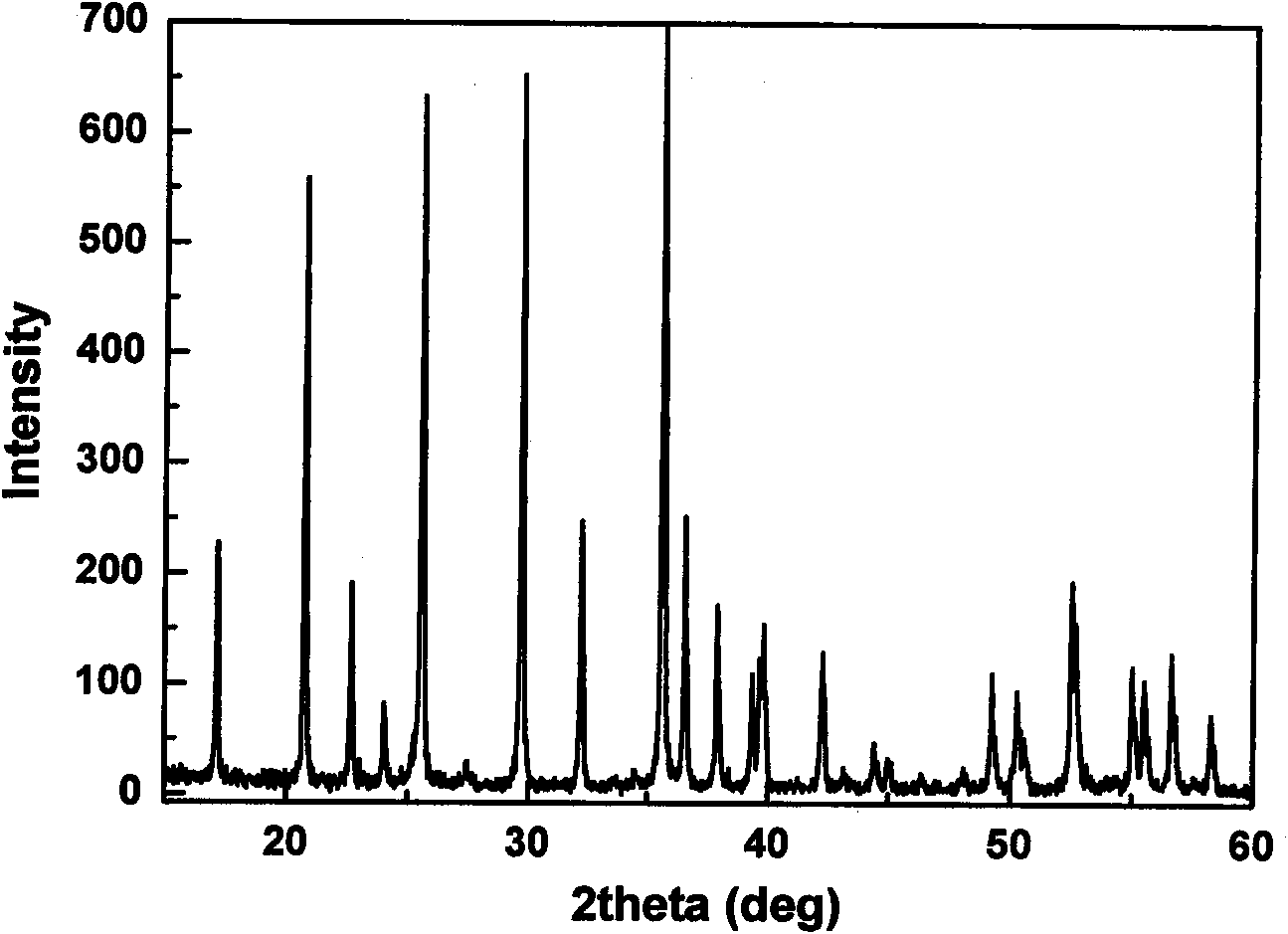

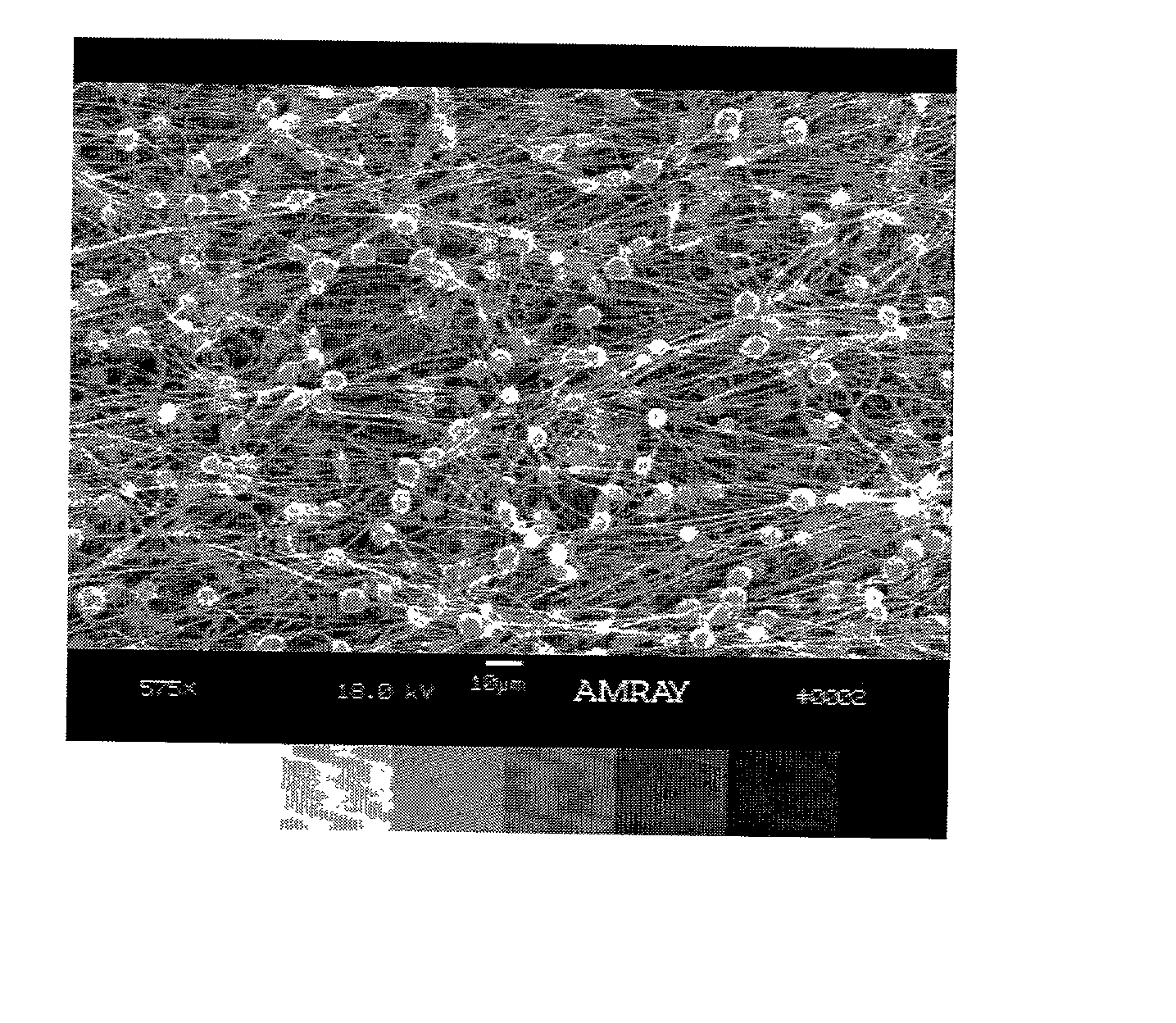

Method of producing hybrid nano-filament electrodes for lithium metal or lithium ion batteries

ActiveUS20090169725A1High reversible capacityLower internal resistanceElectrochemical processing of electrodesElectrode thermal treatmentChemical LinkageFiber

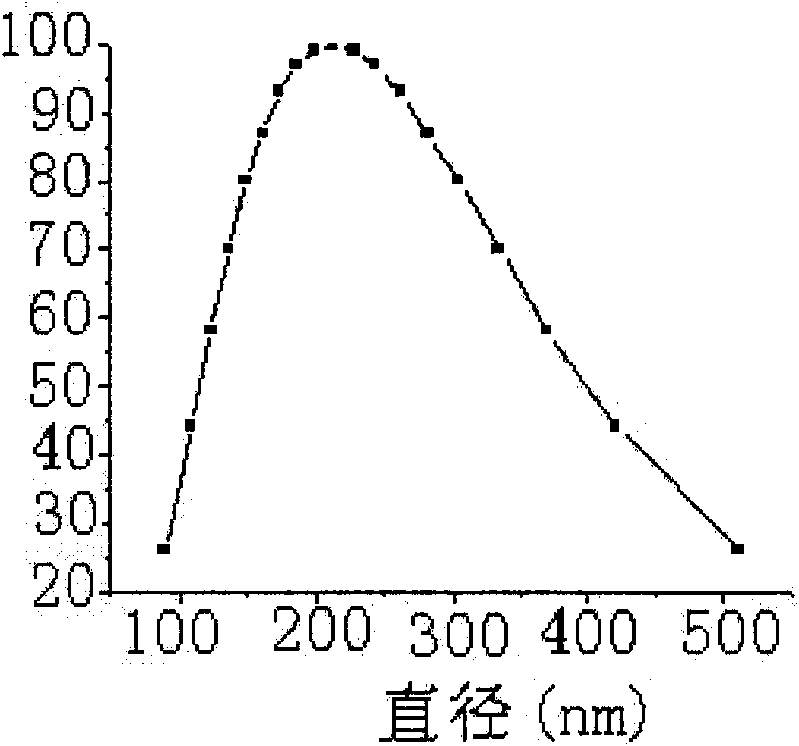

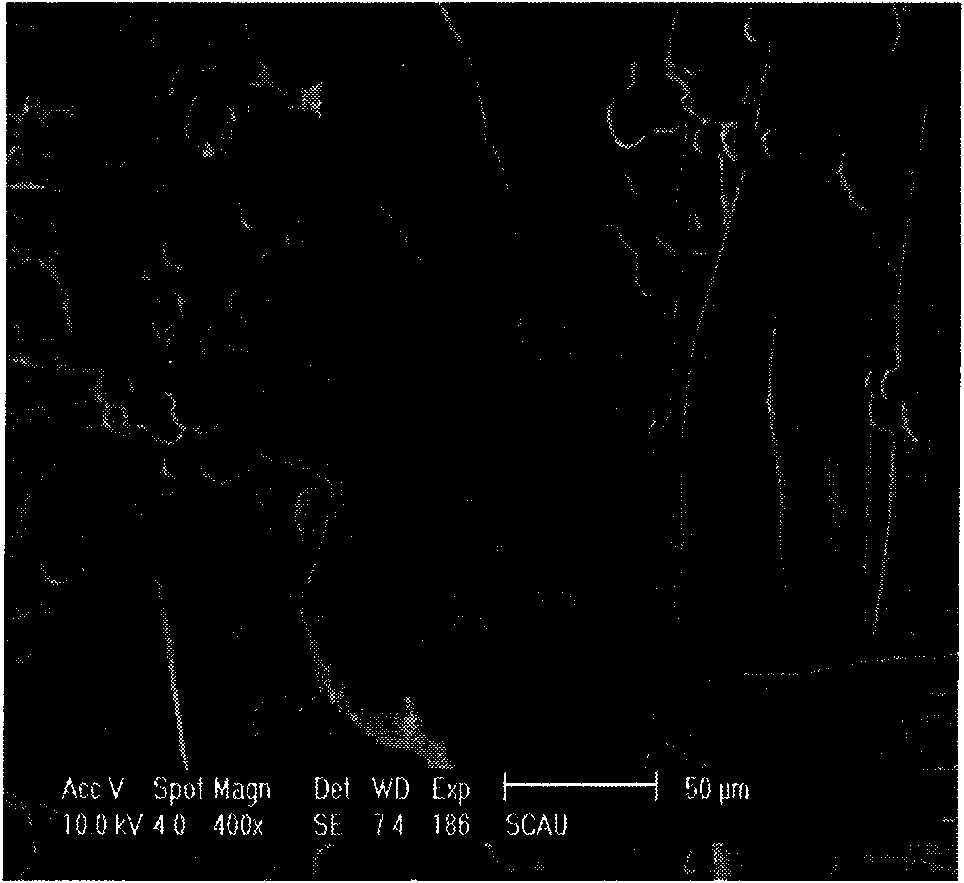

Disclosed is a method of producing a hybrid nano-filament composition for use in a lithium battery electrode. The method comprises: (a) providing an aggregate of nanometer-scaled, electrically conductive filaments that are substantially interconnected, intersected, physically contacted, or chemically bonded to form a porous network of electrically conductive filaments, wherein the filaments comprise electro-spun nano-fibers that have a diameter less than 500 nm (preferably less than 100 nm); and (b) depositing micron- or nanometer-scaled coating onto a surface of the electro-spun nano-fibers, wherein the coating comprises an electro-active material capable of absorbing and desorbing lithium ions and the coating has a thickness less than 10 μm (preferably less than 1 μm). The same method can be followed to produce an anode or a cathode. The battery featuring an anode or cathode made with this method exhibits an exceptionally high specific capacity, an excellent reversible capacity, and a long cycle life.

Owner:GLOBAL GRAPHENE GRP INC

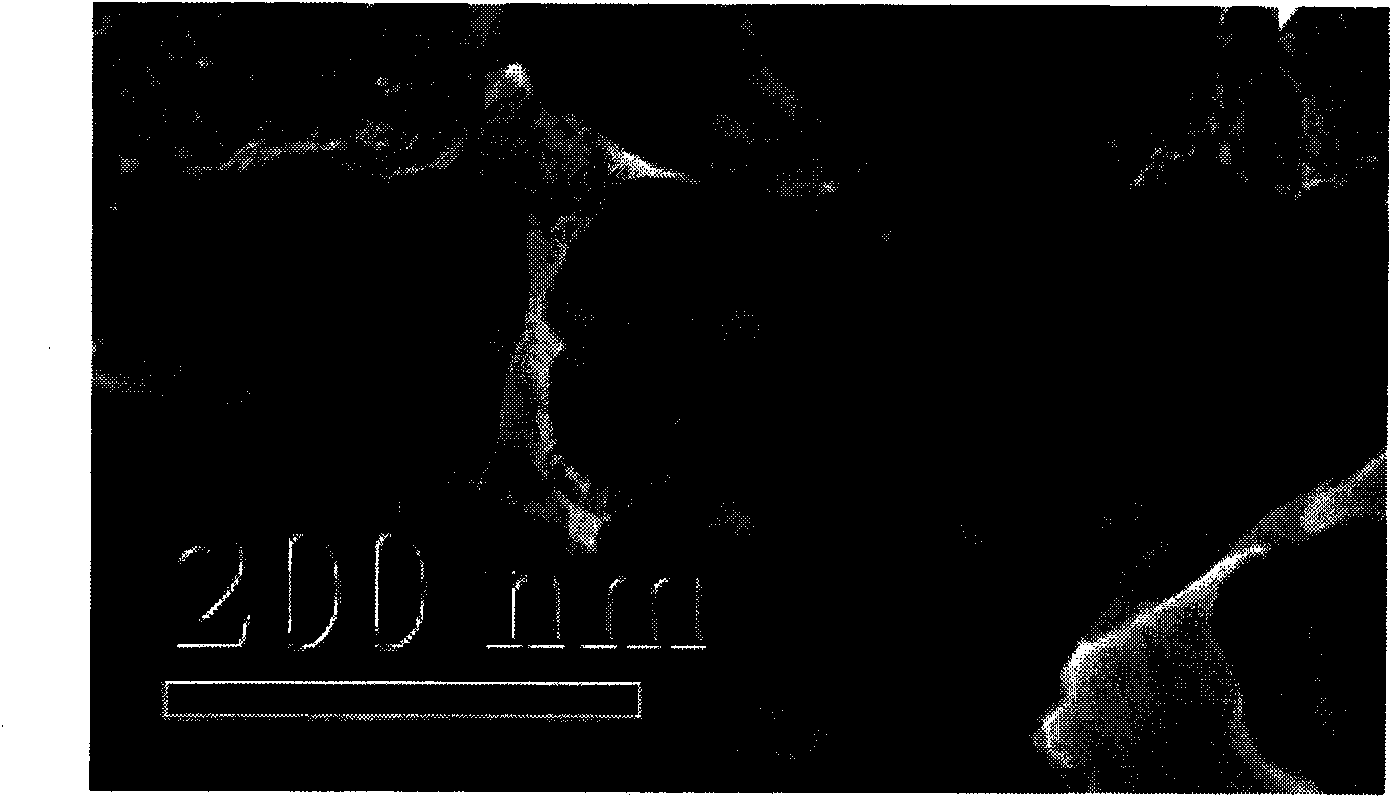

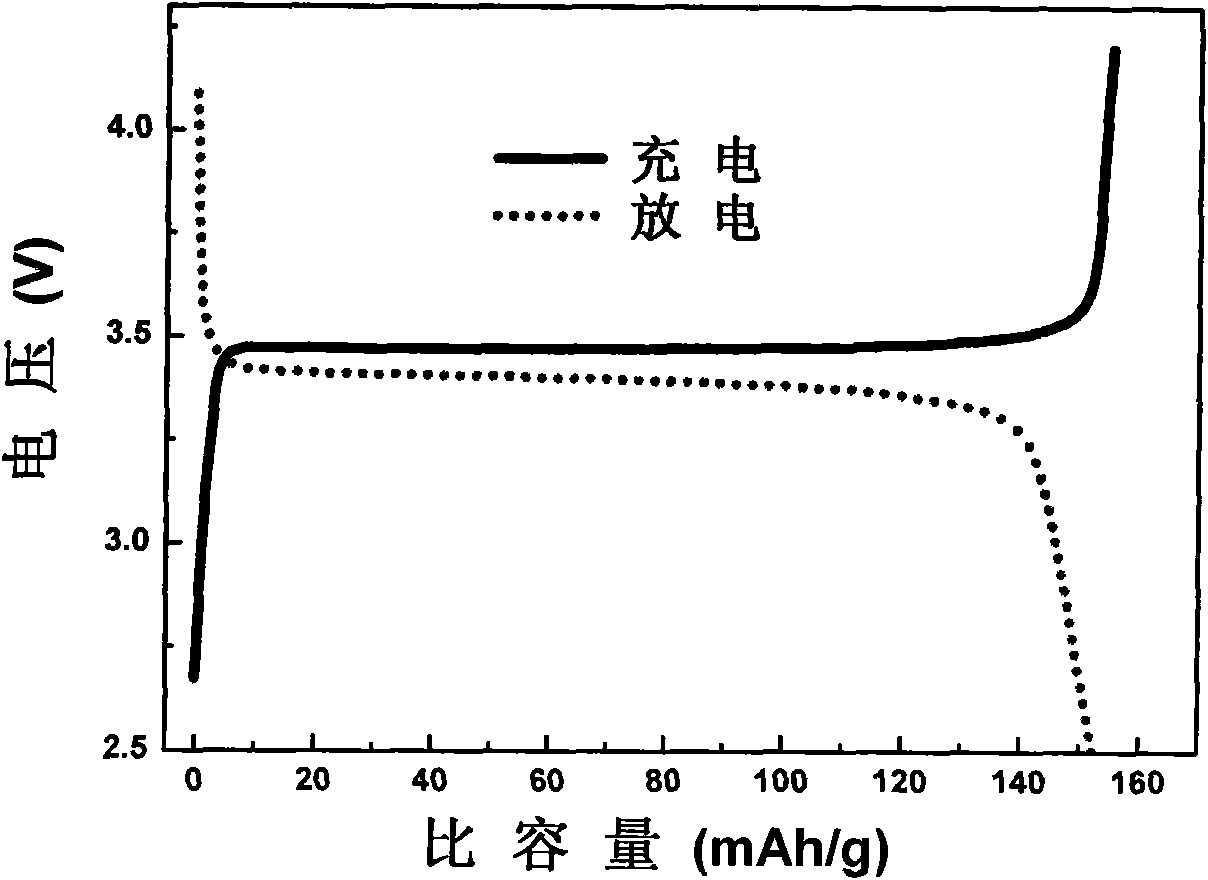

Graphite composite lithium ion battery anode material lithium iron phosphate and preparation method thereof

ActiveCN101562248AImprove electronic conductivityImprove tap densityElectrode manufacturing processesPower batteryChemical Linkage

The invention relates to a graphene composite lithium ion battery anode material lithium iron phosphate and a preparation method thereof. The composite material of lithium iron phosphate and graphene is connected by interface of chemical bonding. The invention also provides the method for preparing the graphene composite lithium ion battery anode material lithium iron phosphate in an in-situ symbiosis reaction mode, and the obtained anode material has high tap density and good magnifying performance, and is suitable to be used as a anode material of a lithium ion power battery.

Owner:龚思源

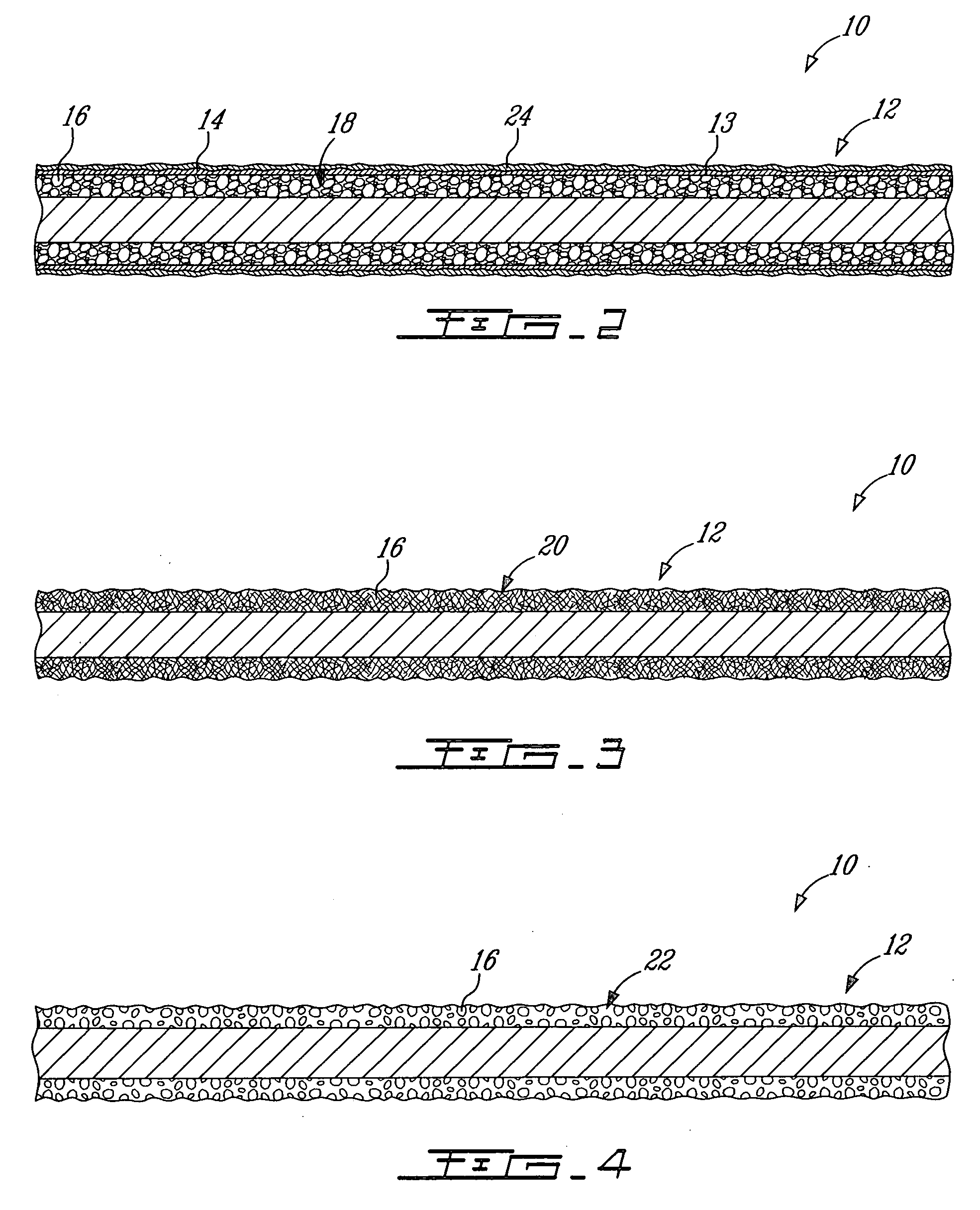

Vascular graft having a chemicaly bonded electrospun fibrous layer and method for making same

InactiveUS20030100944A1Improve surface morphologyGood tissue responseNon-woven fabricsCoatingsChemical LinkageElectrospinning

A vascular graft comprising a traditional graft material and an electrospun fibrous layer. The solvent used to reduce the material for the electrospun layer is also capable of reducing the graft material to a liquid solution. The electrospun layer is chemically bonded to the graft material, without adhesives, by either spraying the graft with the solvent prior to electrospinning or by assuring that a sufficient amount of residual solvent reaches the graft while electrospinning.

Owner:DATASCOPE INVESTMENT

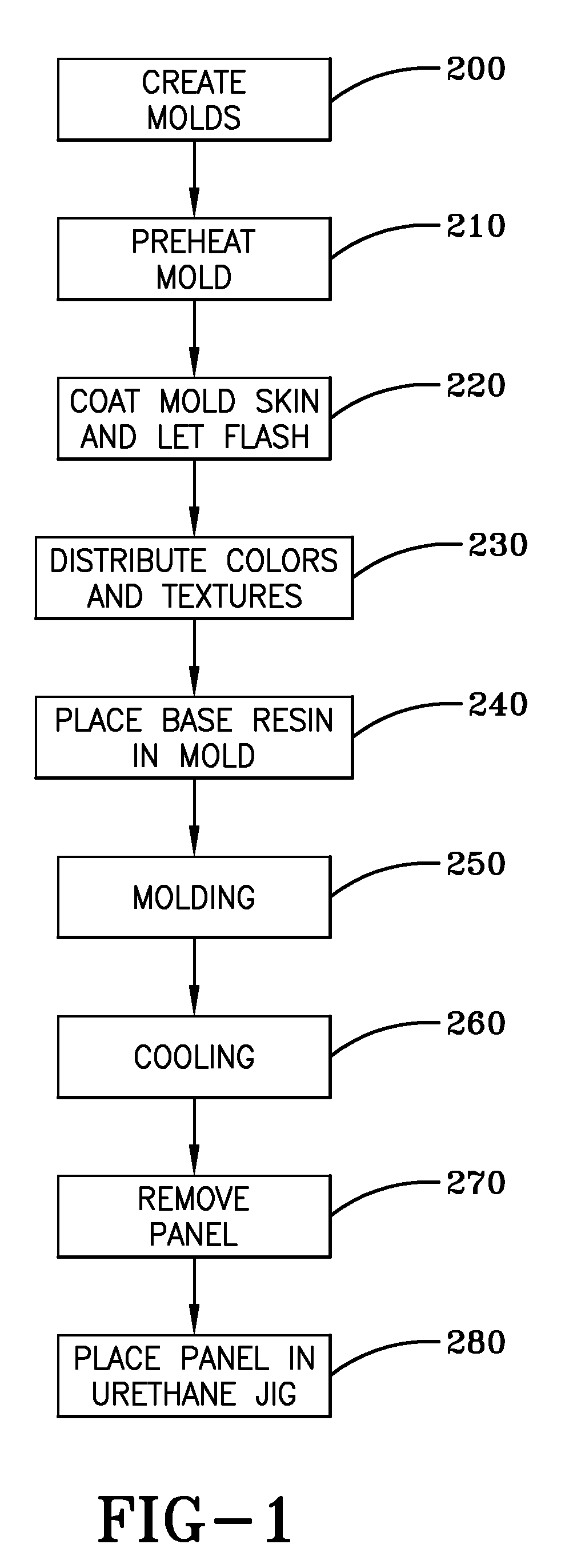

Composition of fillers with plastics for producing superior building materials

InactiveUS20090062413A1Minimize limitationEasy to assembleCovering/liningsSolid waste managementChemical LinkageBrick

The use of high aspect fillers in the production of simulated stone, masonry and brick textured products such as cladding, siding, panels, or other building and construction materials. High aspect fillers increase the dimensional stability, rigidity, thermal and sound insulation. The high aspect fillers may be included into a matrix polymer with or without chemical bonding. The disclosed invention is not limited to products in the building or construction industries and may be applied in the manufacture of a wide variety of products in other industries.

Owner:CRANE BUILDING PRODS

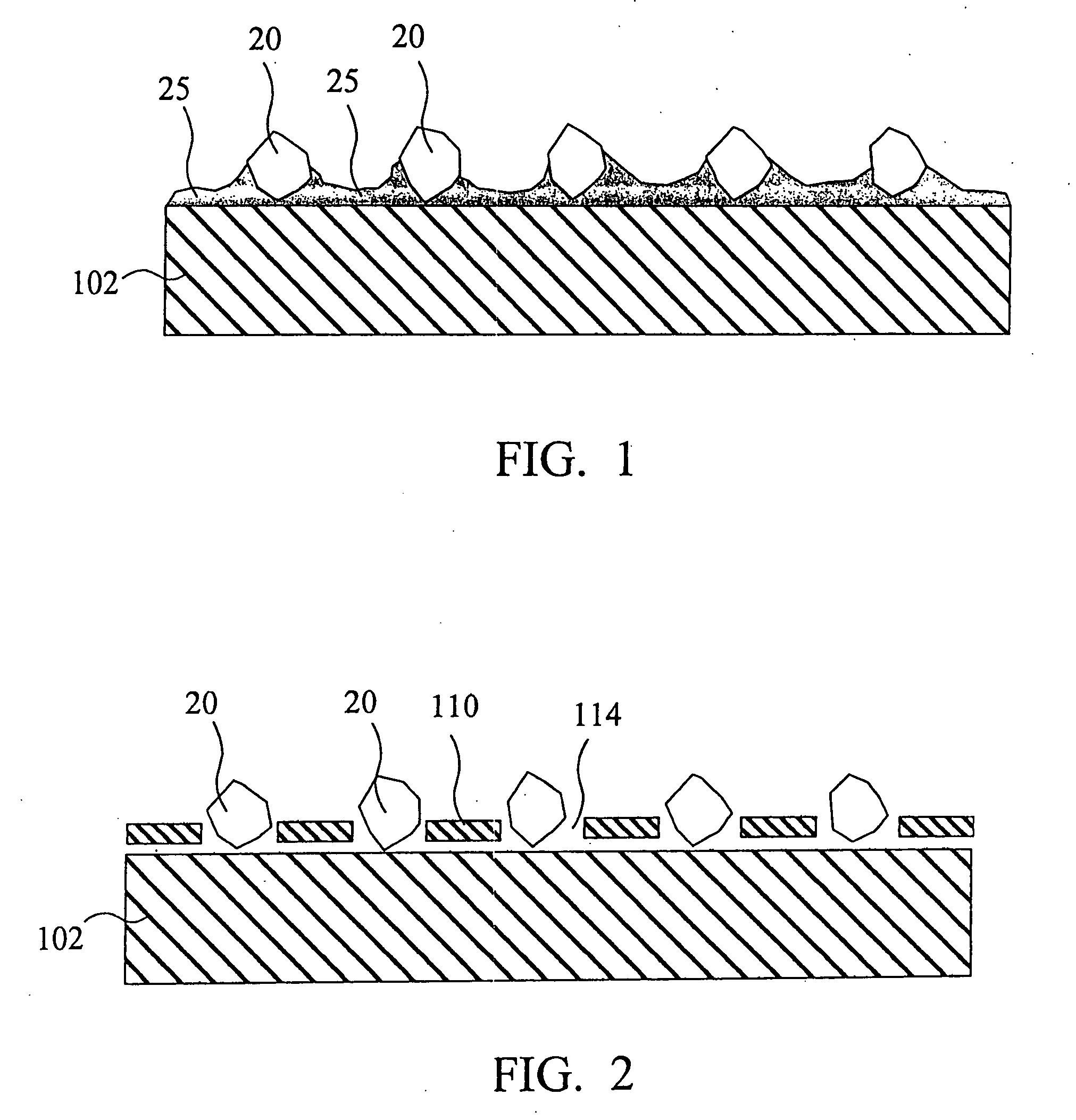

Brazed diamond tools and methods for making the same

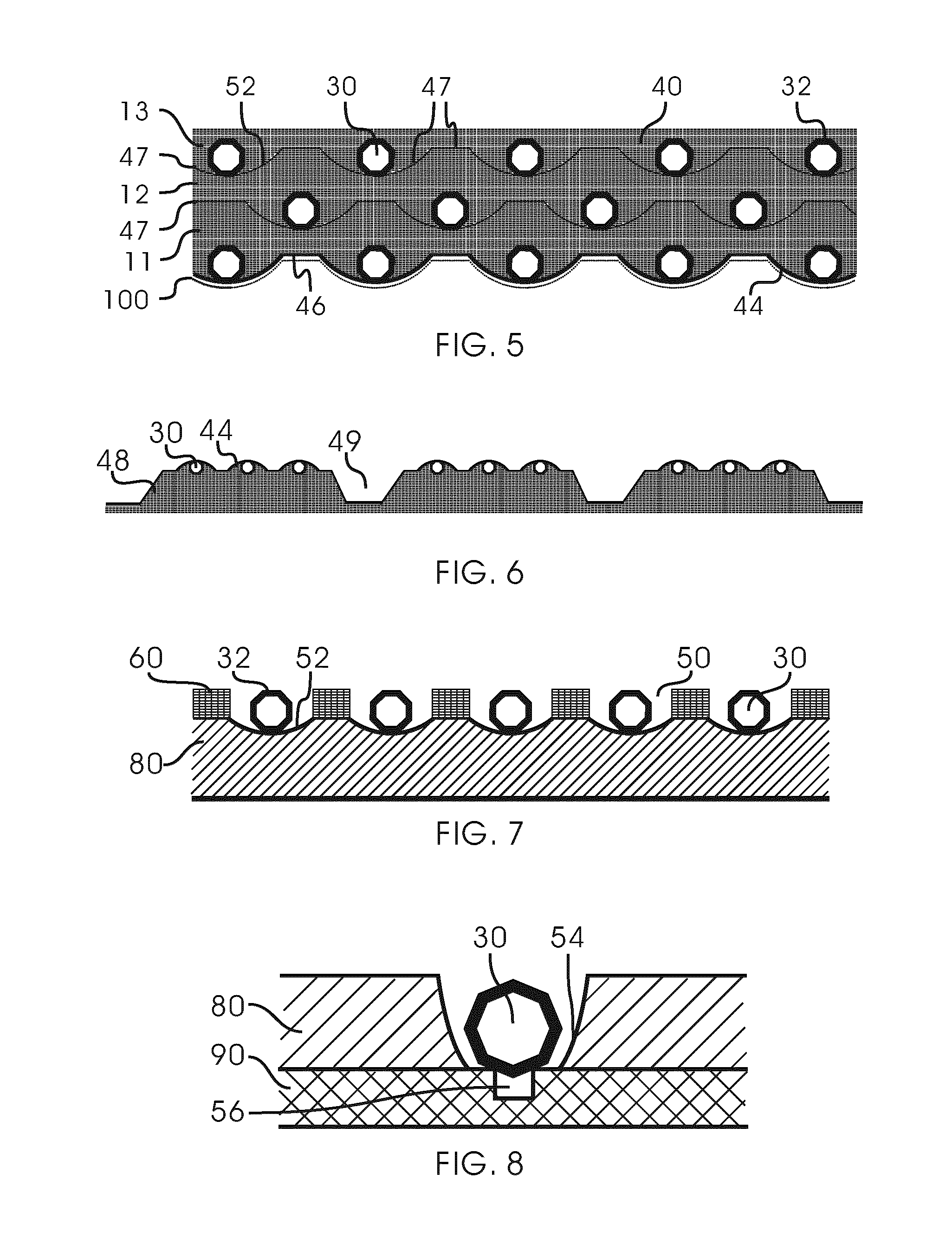

InactiveUS20040112359A1Avoid large movementsImprove cutting efficiencyDrill bitsConstructionsChemical LinkageBraze alloy

Superabrasive tools and methods for the making thereof are disclosed and described. In one aspect, superabrasive particles are chemically bonded to a matrix support material according to a predetermined pattern by a braze alloy. The brazing alloy may be provided as a powder, thin sheet, or sheet of amorphous alloy. A template having a plurality of apertures arranged in a predetermined pattern may be used to place the superabrasive particles on a given substrate or matrix support material.

Owner:SUNG CHIEN MIN

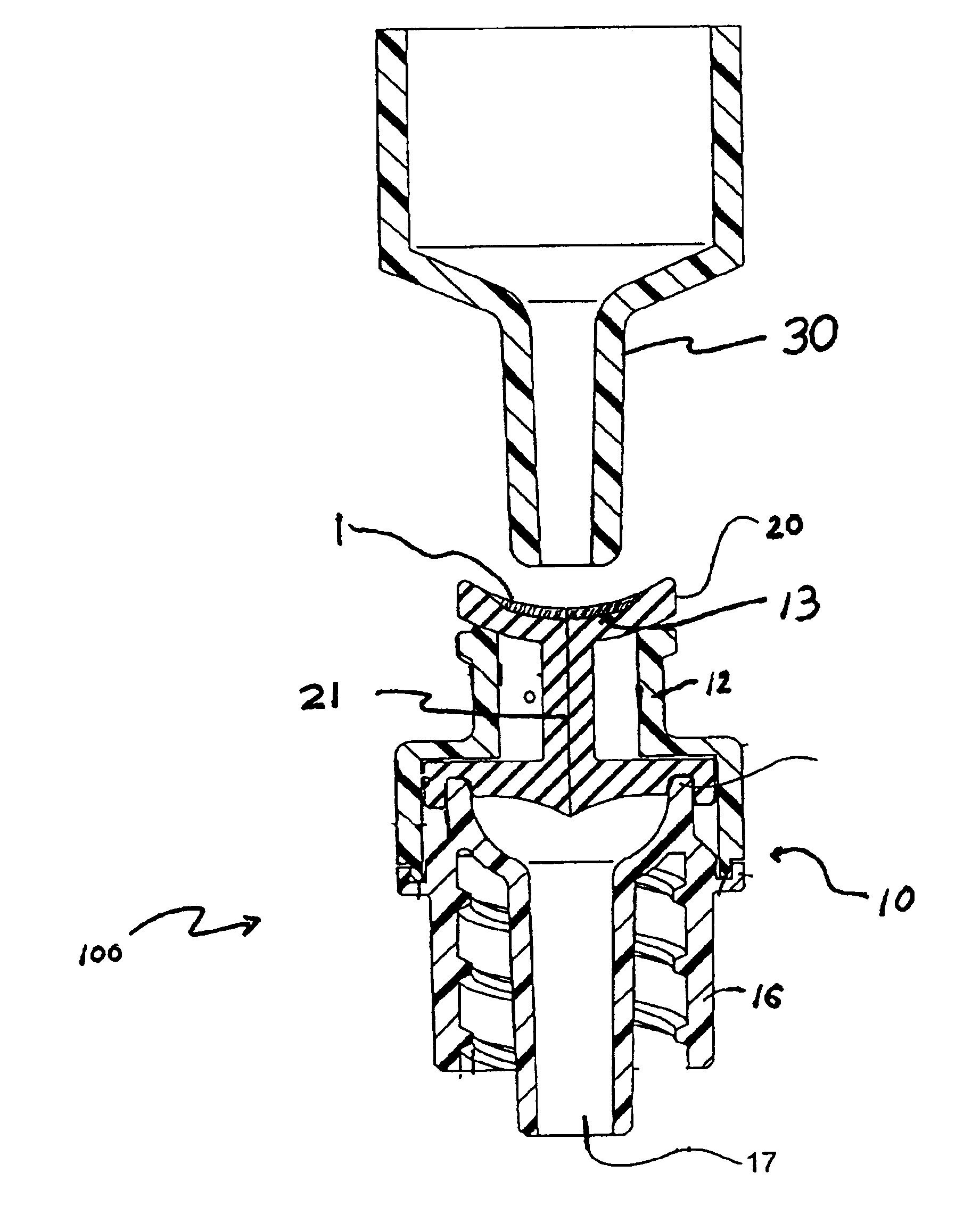

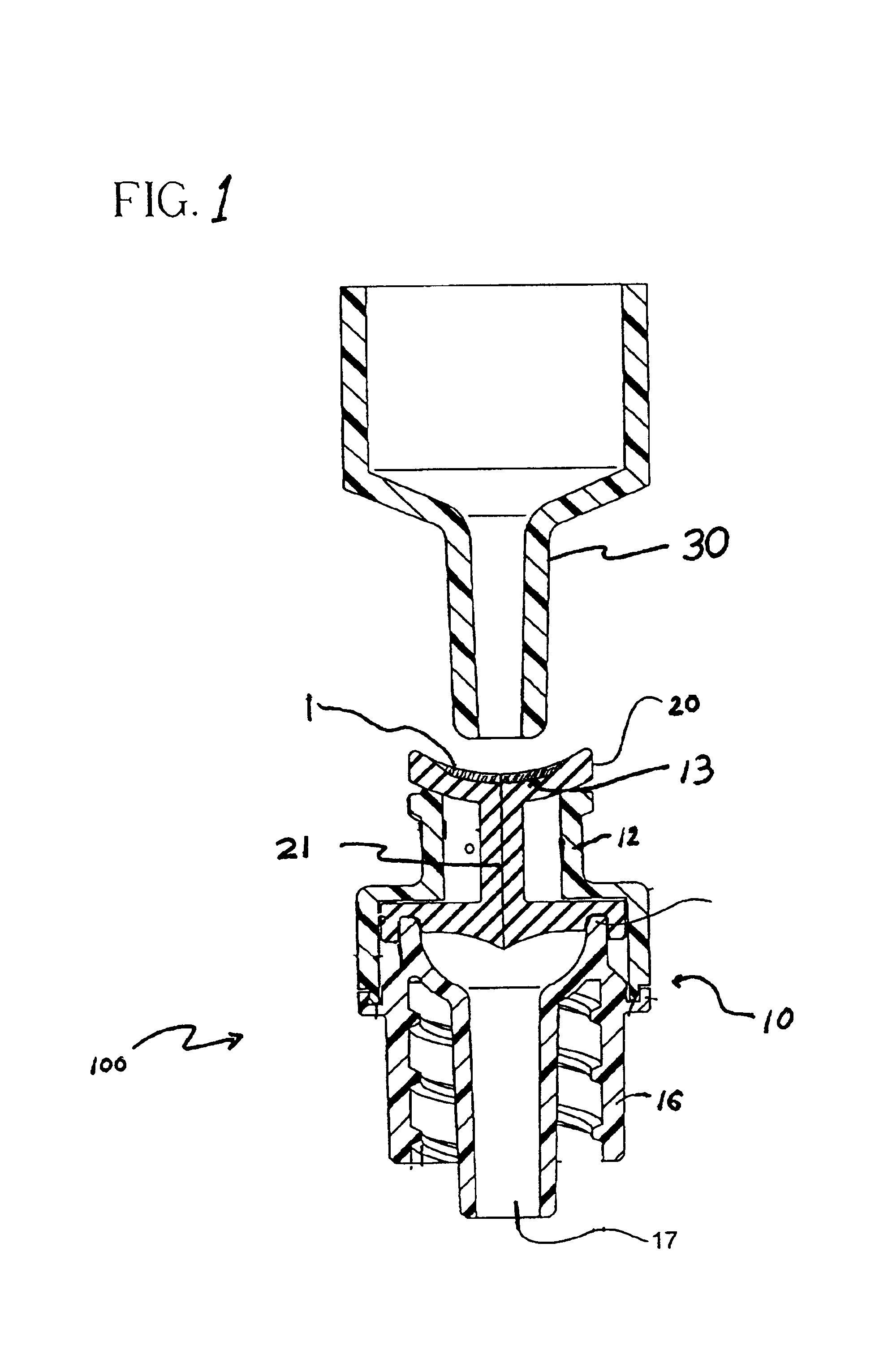

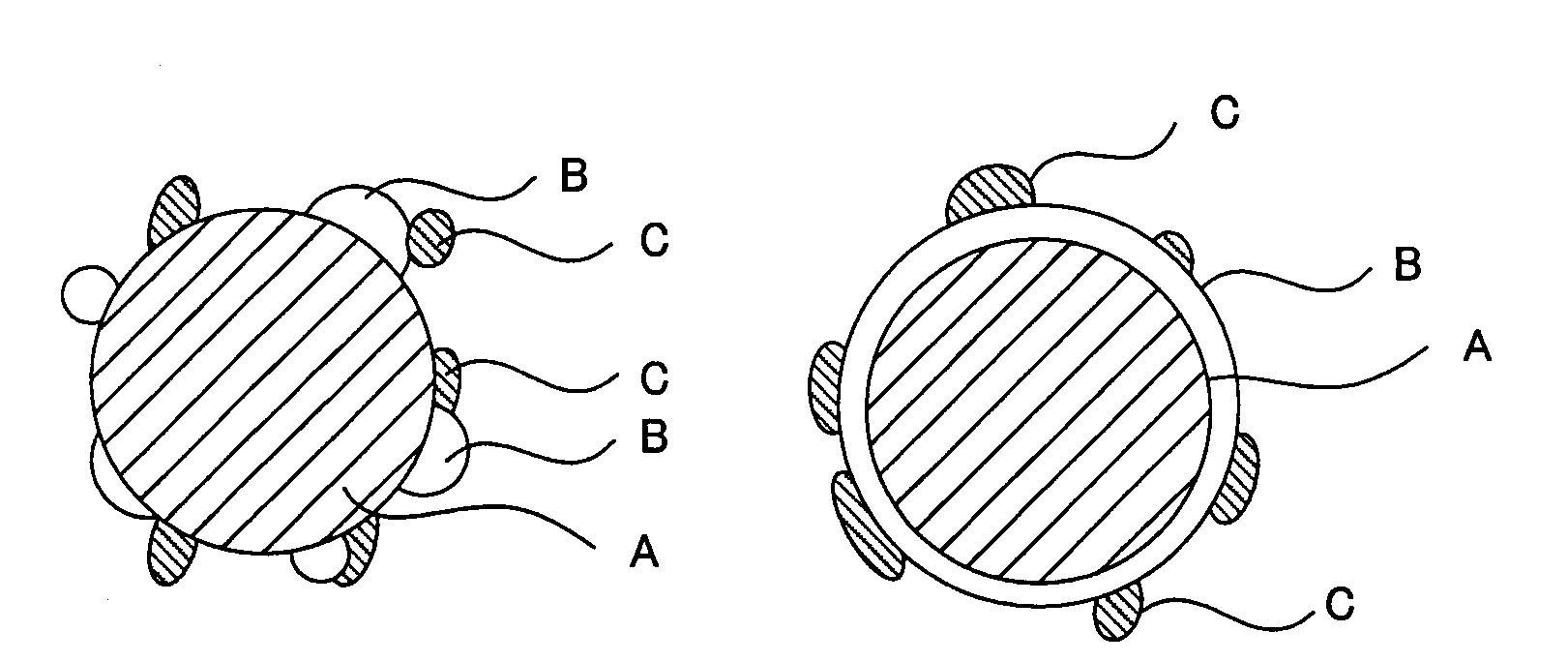

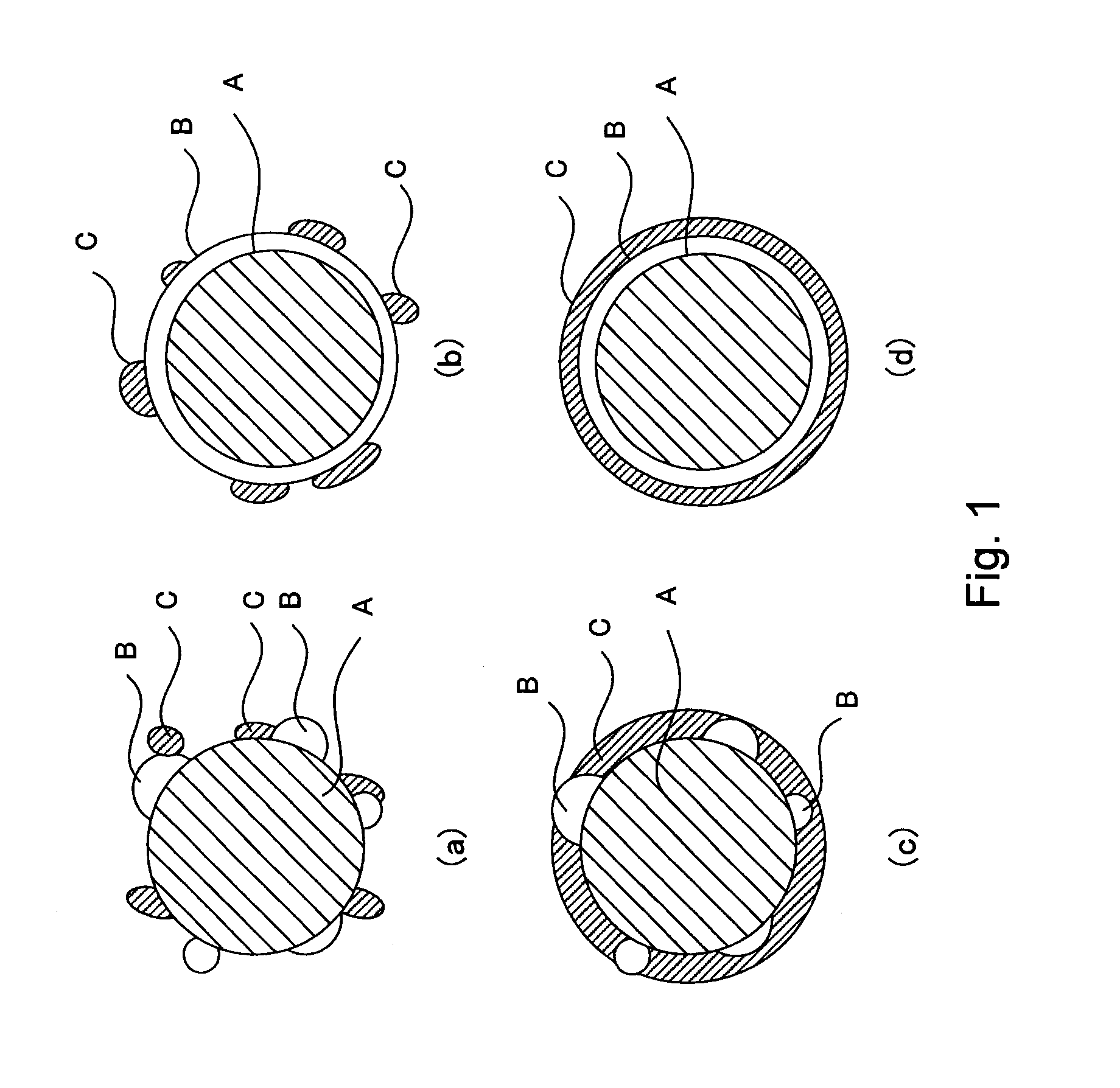

Proppant with composite coating

ActiveUS20140162911A1Improve crush resistanceEnhanced level of hardnessFluid removalFlushingParticulatesChemical Linkage

Proppants for hydraulic fracturing of oil and gas wells have a polymeric coating that is strengthened with reinforcing particulates that are reactive with, or chemically bonded to, the polymeric proppant coating. Preferably, these particulates are added into the coating during the coating process. In one embodiment, functionalized particulates are used that become grafted into the polymer of the proppant coating through the chemical functionality imparted to the particulates. If non-functionalized particulates are used, a coupling agent is preferably added to enhance the bond strength between the added particulates and the polymeric matrix of the proppant coating.

Owner:PREFERRED TECH

Reaction bonding type node sealant and preparation method thereof

ActiveCN102911638AImprove stabilityImprove bindingNon-macromolecular adhesive additivesOther chemical processesChemical LinkagePolyvinyl chloride

The invention provides a reaction bonding type node sealant and a preparation method thereof. The sealant comprises asphalt, modifiers, an emulsifier, a crosslinking agent, thickeners, a reinforcing agent and water. In the formula system, more appropriate modifiers are adopted compared with the prior art, so that a rubber asphalt mixture can achieve good emulsification effect, elasticity and strength of a sealing layer after drying are greatly improved, and the sealing effect can be good and lasting; the chemical linkage effect with concrete is formed by using the crosslinking agent, and bonding force with the concrete is improved; and a lot of thickeners are used for adjusting the stickness of the sealant system, so that the reaction bonding type node sealant can better adhere to the surface of a pentatricopeptide repeats (PPR) or polyvinyl chloride (PVC) pipe, and good sealing at positions where PPR or PVC water supply and drainage pipes are connected with base surfaces of concrete.

Owner:XI NIU PI WATERPROOFING TECH CO LTD

Blumea oil microcapsule textile composite finishing agent and use thereof

InactiveCN101591859AStir wellSmall particle sizeFibre treatmentMicroballoon preparationCross-linkChemical Linkage

The invention discloses a blumea oil microcapsule textile composite finishing agent and use thereof. Gelatin or acacia of natural polymers is used the main ingredient of a wall material, the blumea oil serving as a Chinese medicinal material is used as a core material, and complex coacervation is adopted to prepare an blumea oil microcapsule aqueous emulsion; a shrink-resistance crosslinker and a catalyst are added to be combined with the blumea oil microcapsule aqueous emulsion into a multifunctional blumea oil microcapsule textile composite finishing agent; researches on the use of blumea oil microcapsules in textile finishing are carried out; and a novel cross linked graft method is used to perform the microcapsule finishing of textiles to form chemical bonds between the microcapsules and the textiles though the shrink-resistance crosslinker and free formaldehyde molecules in 2D resin further participate in a cross-linking and curing reaction as a microcapsule curing agent, so the textiles achieve a long lasting antibacterial and health-care function, a shrink-resistance function and low formaldehyde release content performance.

Owner:SOUTH CHINA AGRI UNIV

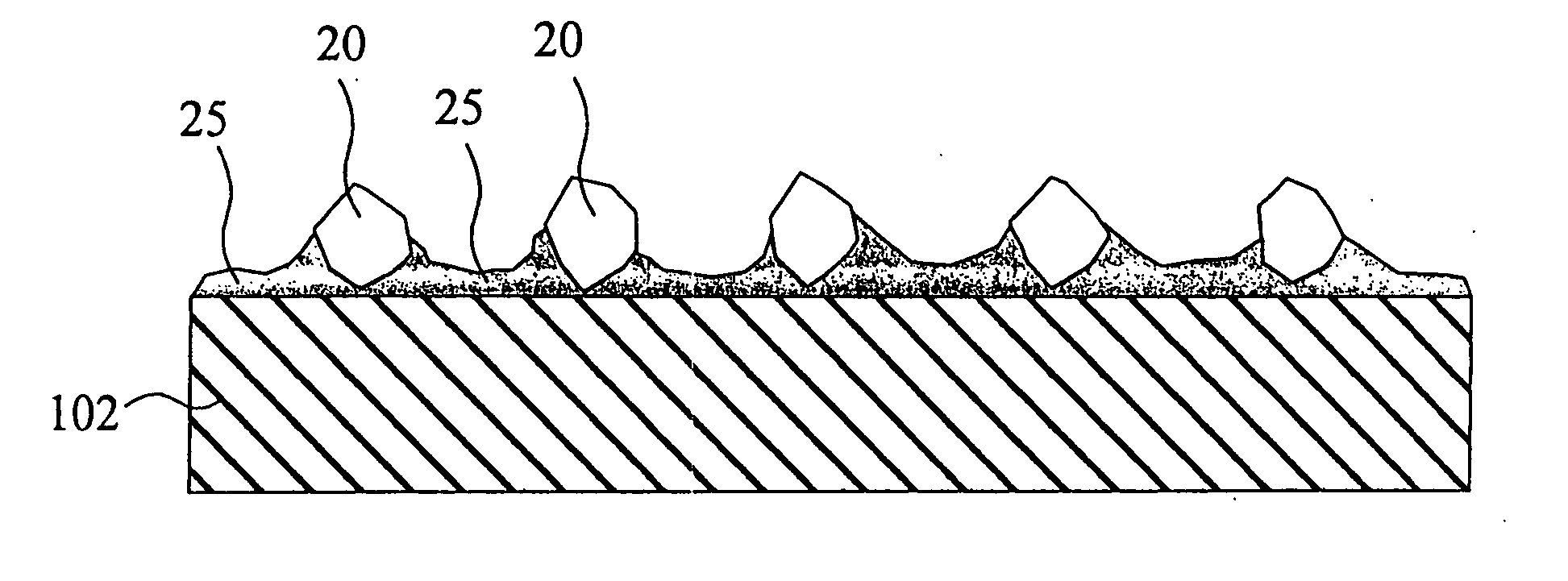

Abrasive article and method for making the same

InactiveUS20150290771A1Reduce the amount requiredMaximize efficiencyPigmenting treatmentOther chemical processesChemical LinkageWear particle

An abrasive article comprising a plurality of abrasive grains that are precisely arranged in accordance with a predetermined pattern and are chemically bonded with a matrix material, and a method for the making thereof are disclosed. A coating layer on each of the abrasive grains functions as a bridge to form chemical bonding between the abrasive grains and the matrix material. In addition to a plated material, the matrix material can include a braze, a solder, a sintered material, an infiltrant, an organic material, and a vitrified material. The method for making the abrasive article comprises the steps of: coating abrasive grains with a coating layer that chemically bonds to each of the abrasive grains; arranging the coated abrasive grains in accordance with a predetermined pattern; and chemically bonding the coated abrasive grains with a matrix material.

Owner:LI YUNDONG

Implant improving local bone formation

InactiveUS20060188542A1Improve effectivenessBiocideDental implantsChemical LinkageCalcium biphosphate

A bone implant comprises an active agent on at least a portion thereof. The active agent is locally deliverable to bone proximate the implant in at least a two-phased release scheme. A first phase rapidly releases a first quantity of the active agent, and at least a second phase gradually releases a second quantity of the active agent, whereby bone formation stimulated by the active agent is modulated. In one embodiment, a porous implant comprises a porous portion coated with a calcium phosphate compound and which is contacted with a bisphosphonate compound to form a bisphosphonate layer chemically bound to the calcium phosphate at the surface of the porous portion and to form bisphosphonate molecules being non-chemically attached inside the pores of the porous portion. The non-chemically attached bisphosphonate molecules are released in the subject at a rate greater than that of the chemically bound bisphosphonate layer.

Owner:BOBYN JOHN DENNIS +1

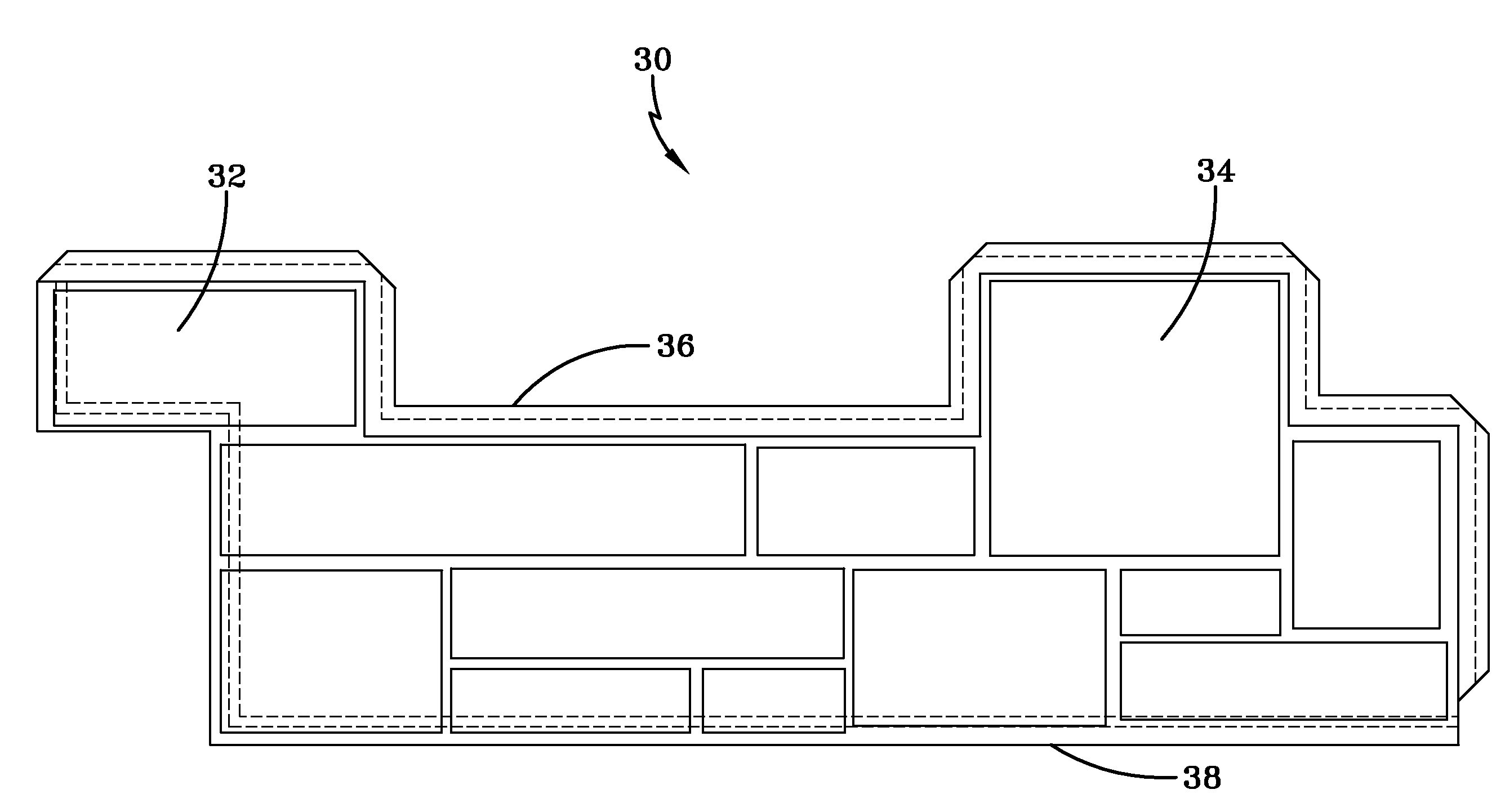

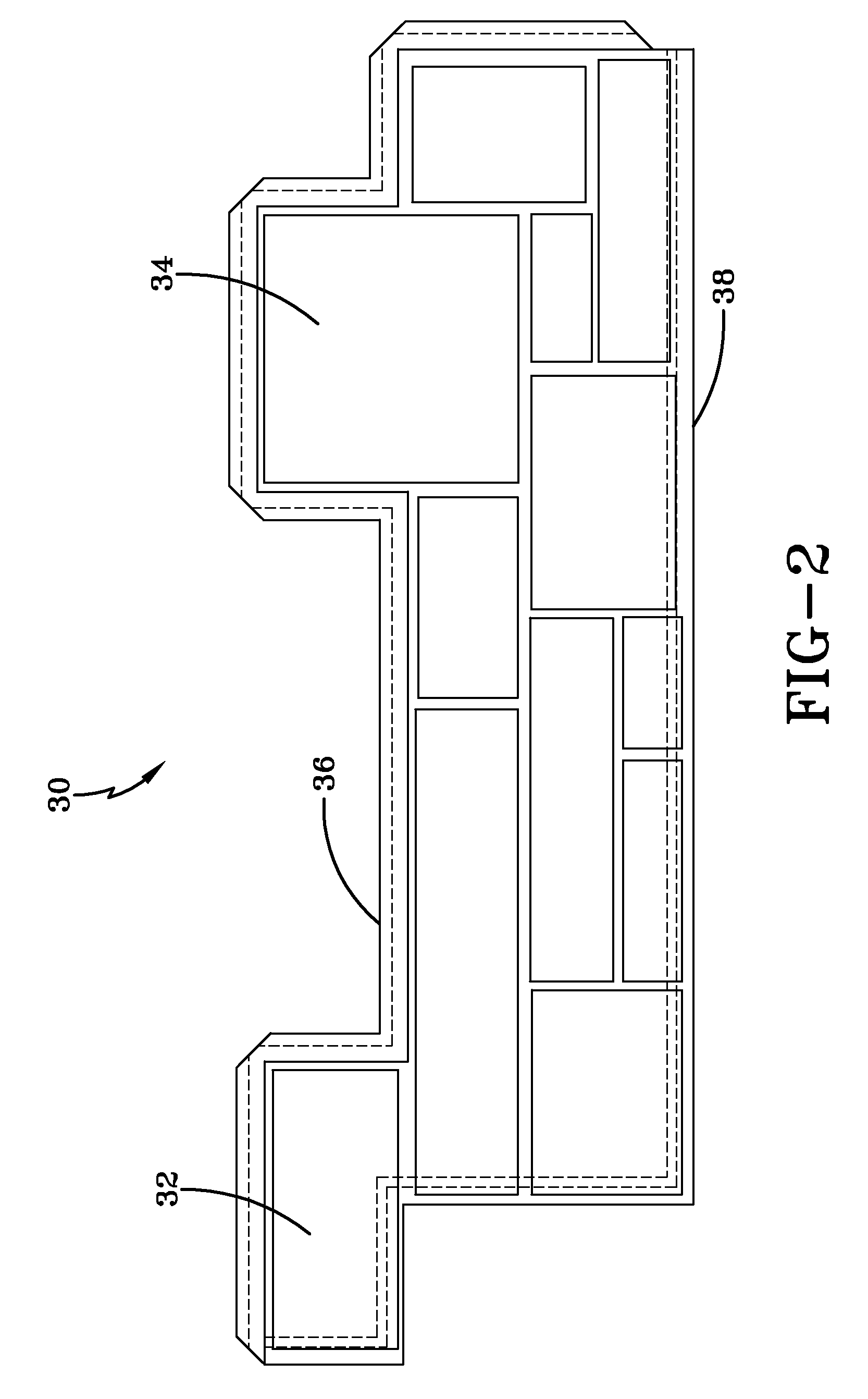

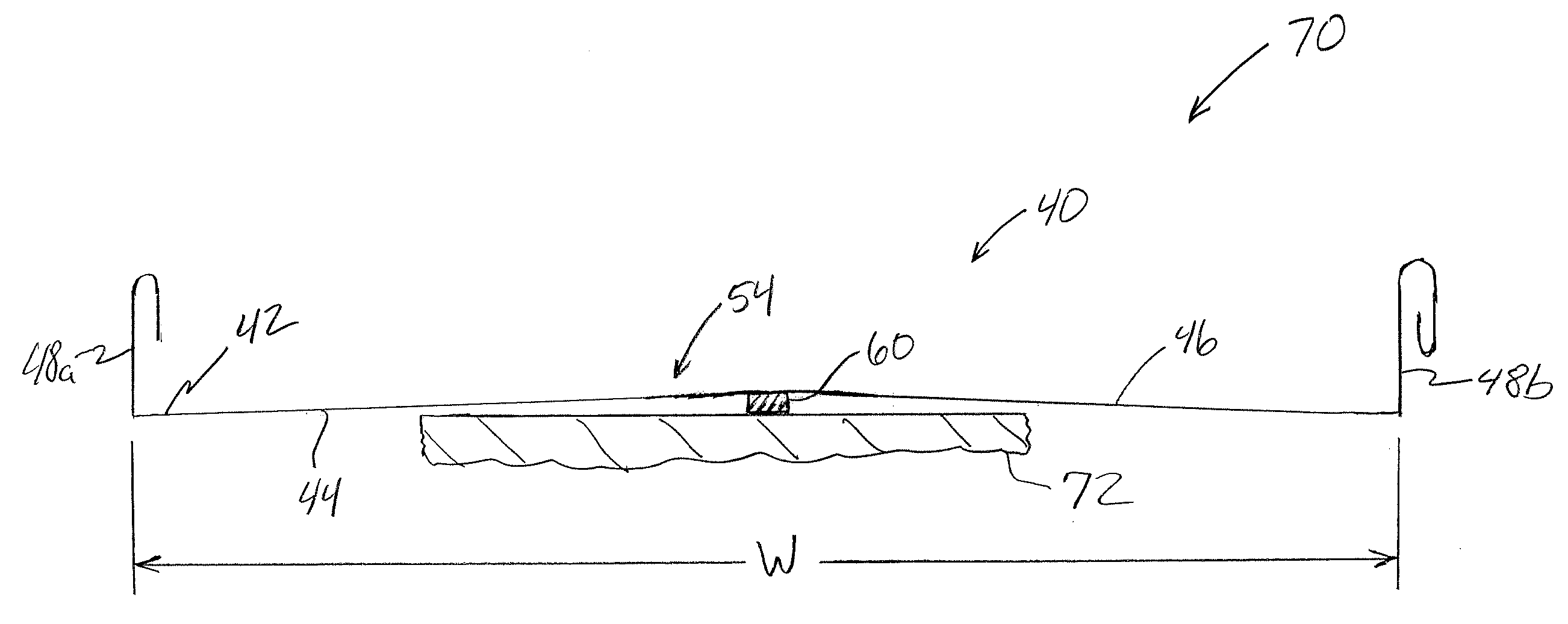

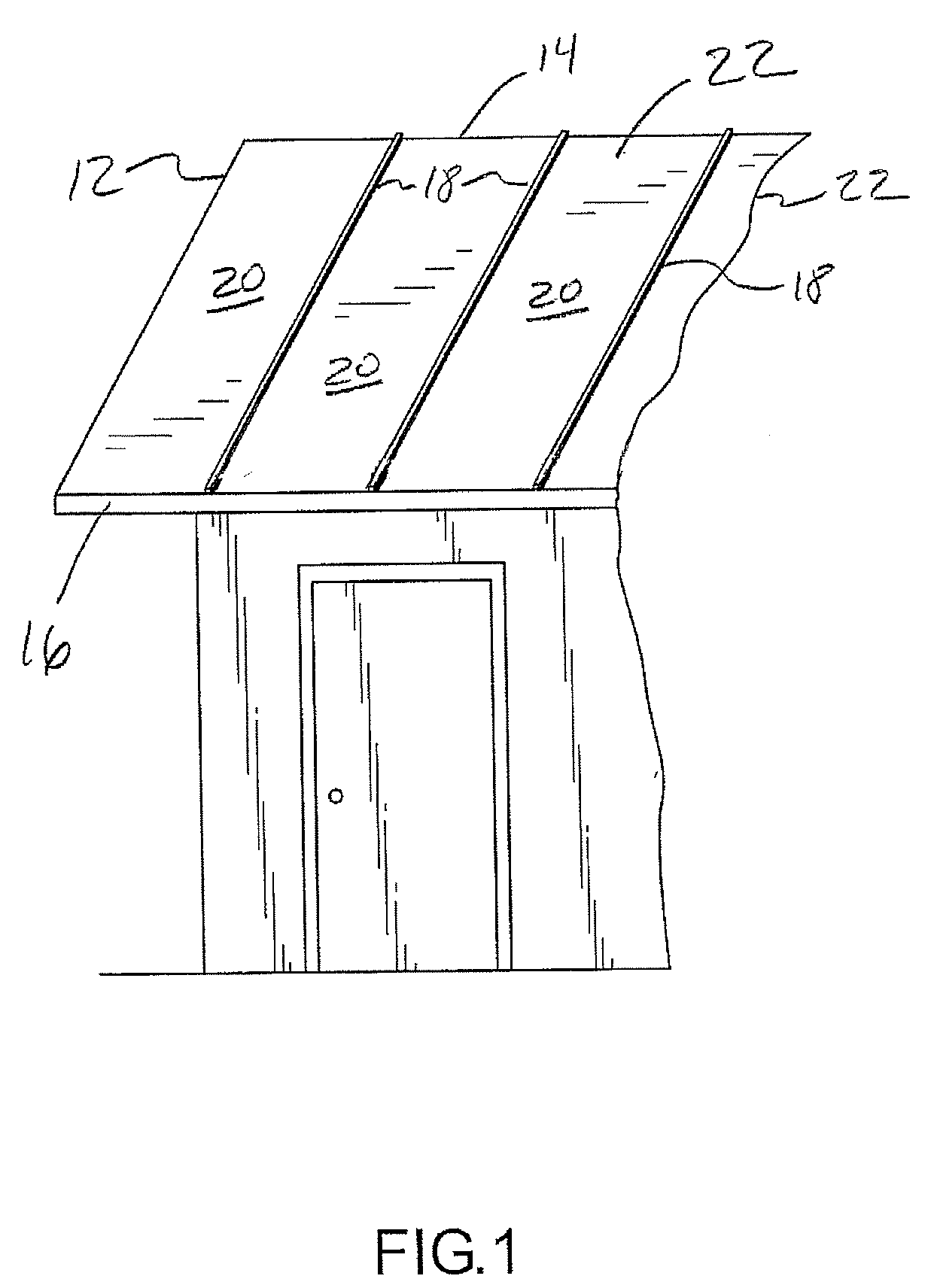

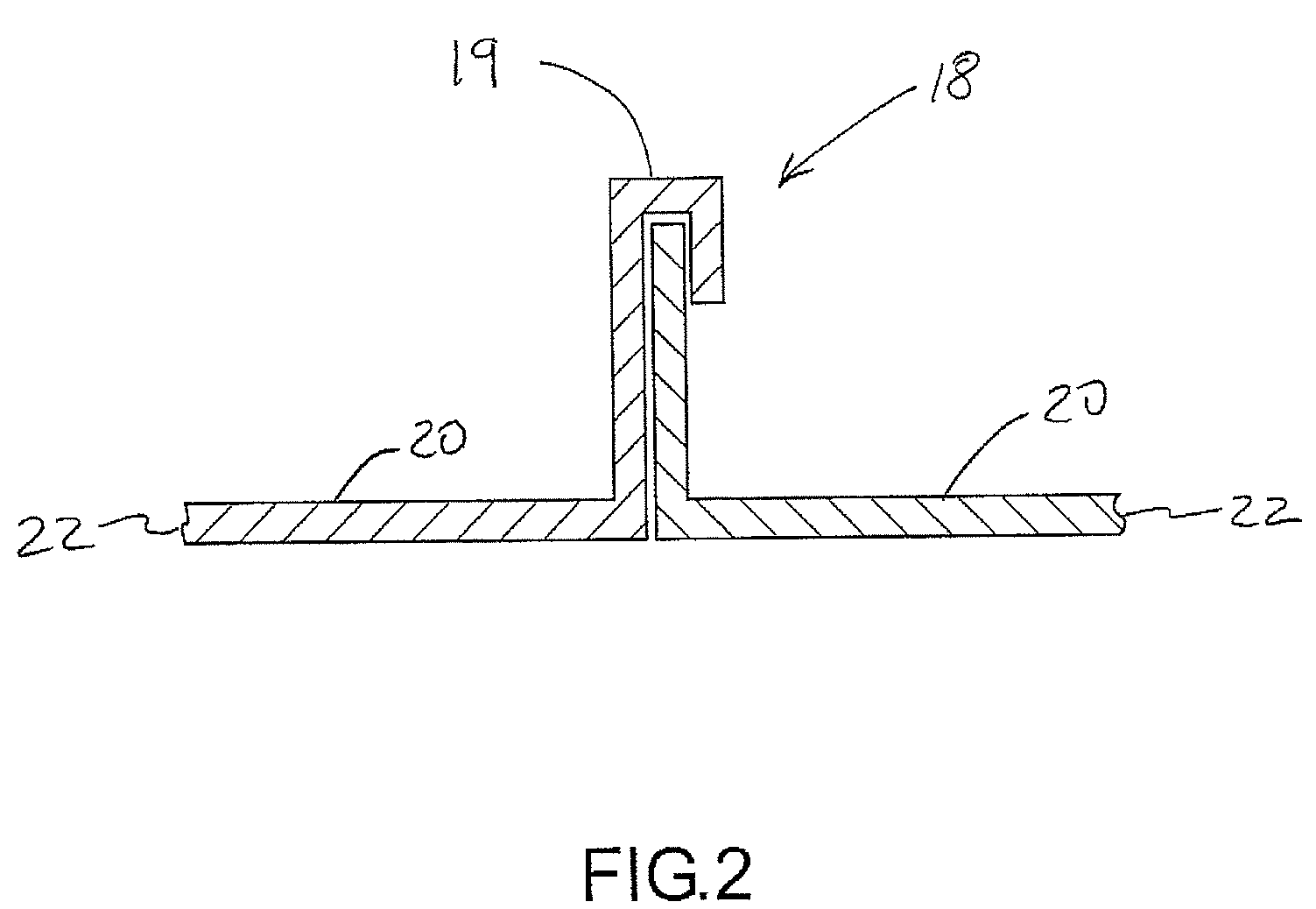

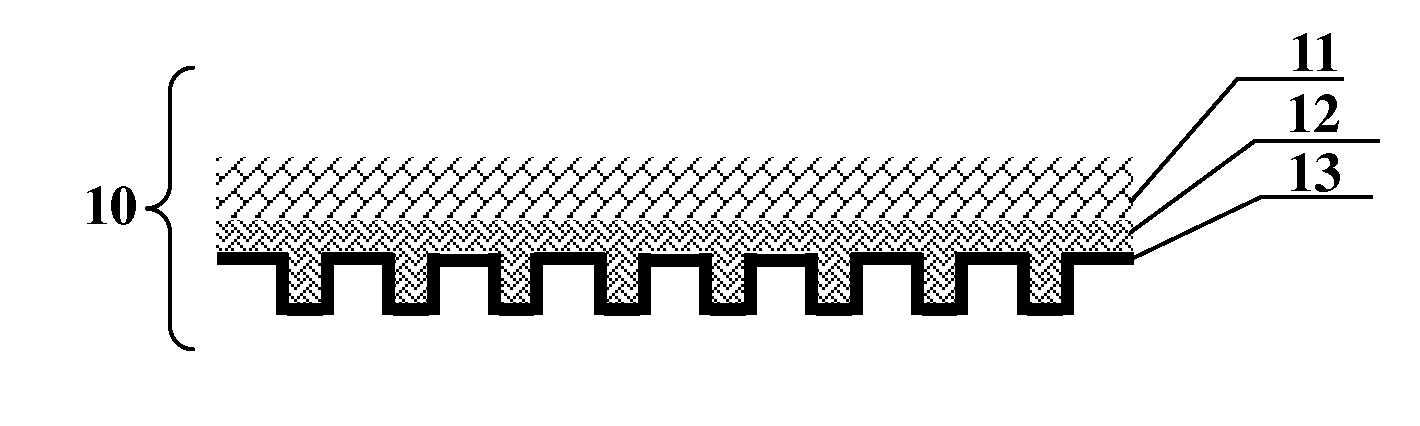

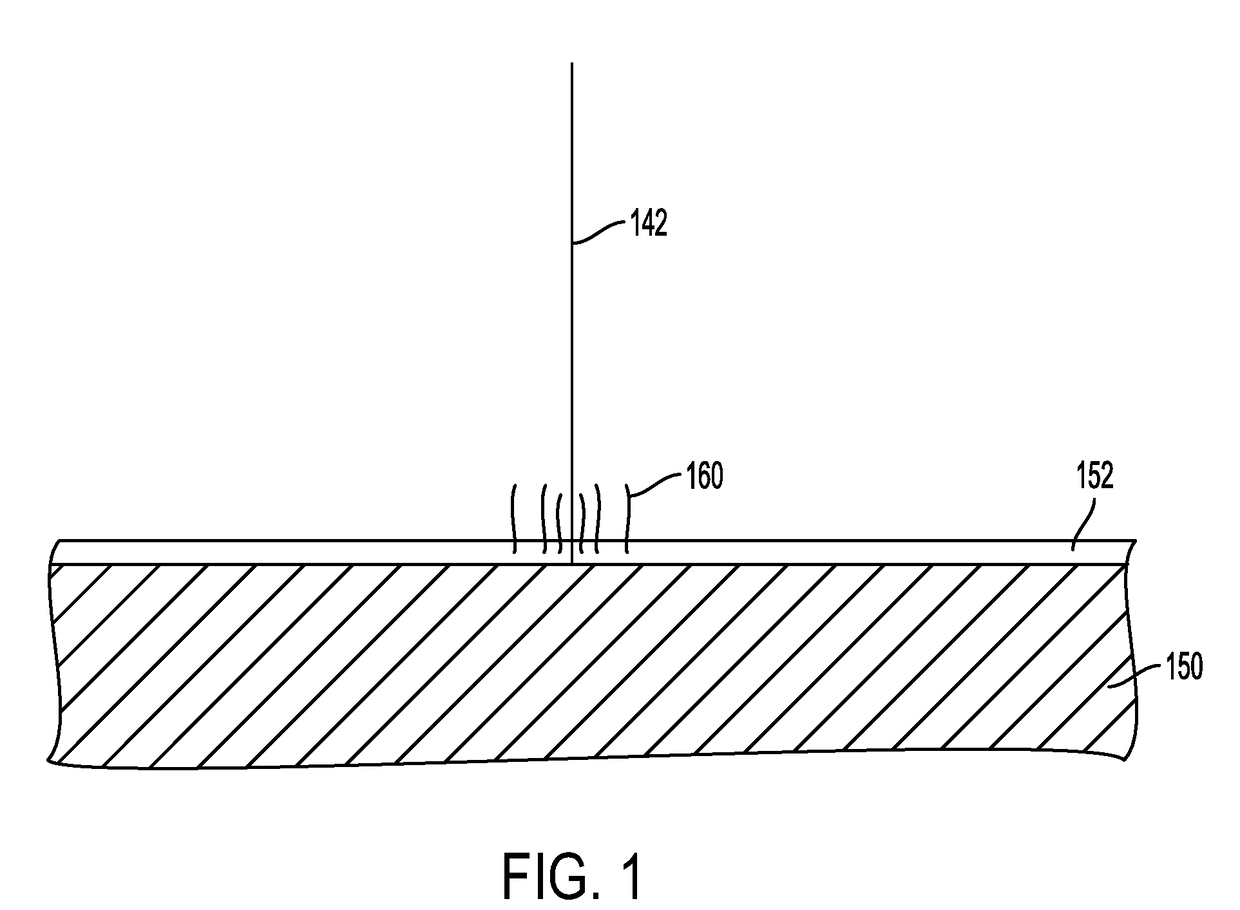

Crowning panel assembly

InactiveUS20070289233A1Reduce visual impactSolve stressRoof covering using slabs/sheetsConstruction materialChemical LinkageEngineering

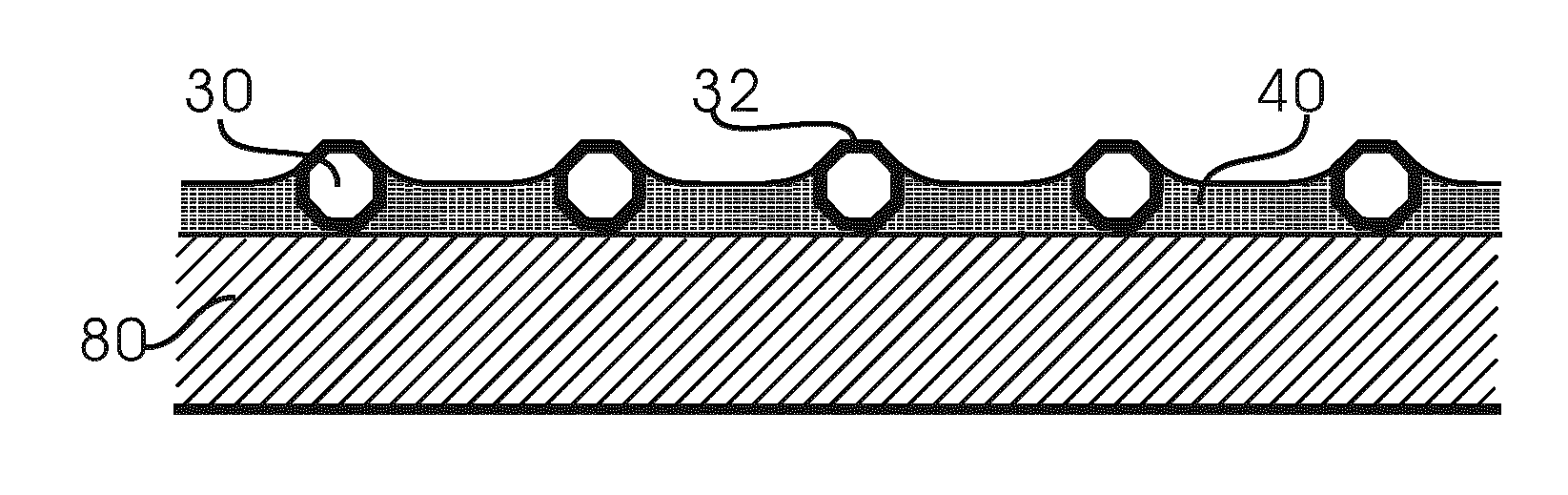

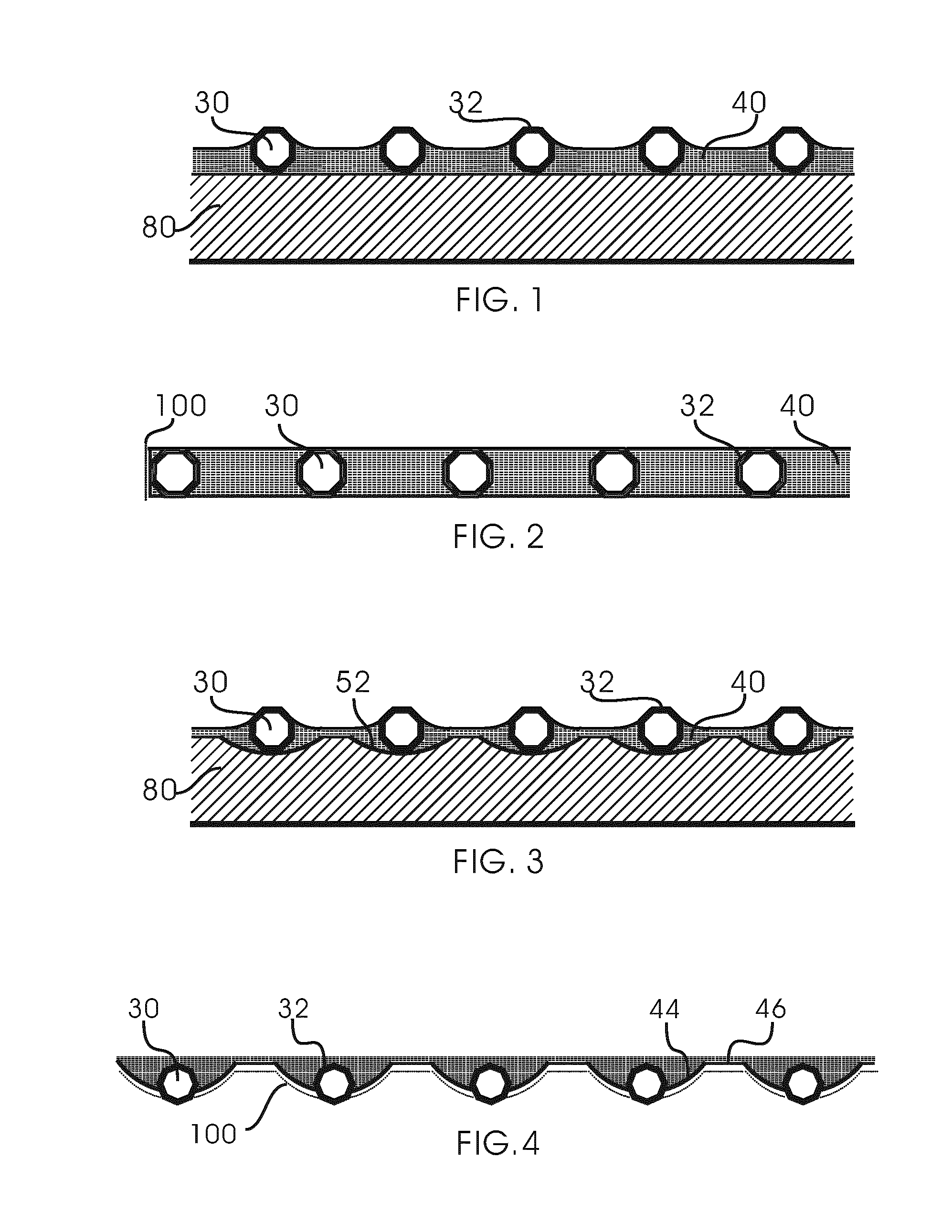

A panel assembly (40) that addresses oil canning when installed over a substrate or deck (72) is disclosed. The panel assembly (40) includes a panel (42). The panel (42) includes a first primary panel surface (44) that faces the substrate (72) in the installed configuration, as well as a second primary panel surface (46) that faces away from the substrate (72) in the installed configuration. Another component of the panel assembly (40) is a first structure (60) that is disposed between the panel (42) and the substrate (72). Typically, either a first surface (62) of the first structure (60) is chemically bonded directly to the first primary panel surface (44) such that an interface between the first surface (62) and the first primary panel surface (44) includes a chemical bond, or a second surface (64) is chemically bonded directly to the substrate (72) such that an interface between the second surface (64) and the substrate (72) includes a chemical bond. In any case, the first structure (60) produces a convexity on the second primary panel surface (46) to address oil-canning effects or stress wrinkling of the panel (42).

Owner:RMH TECH LLC

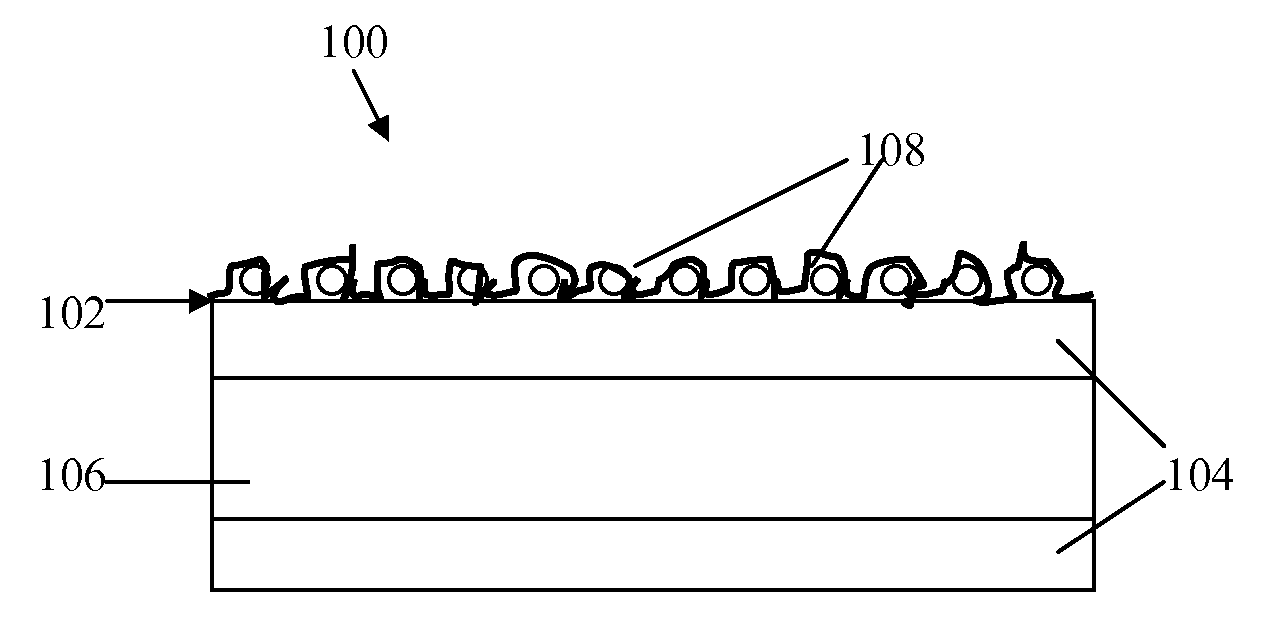

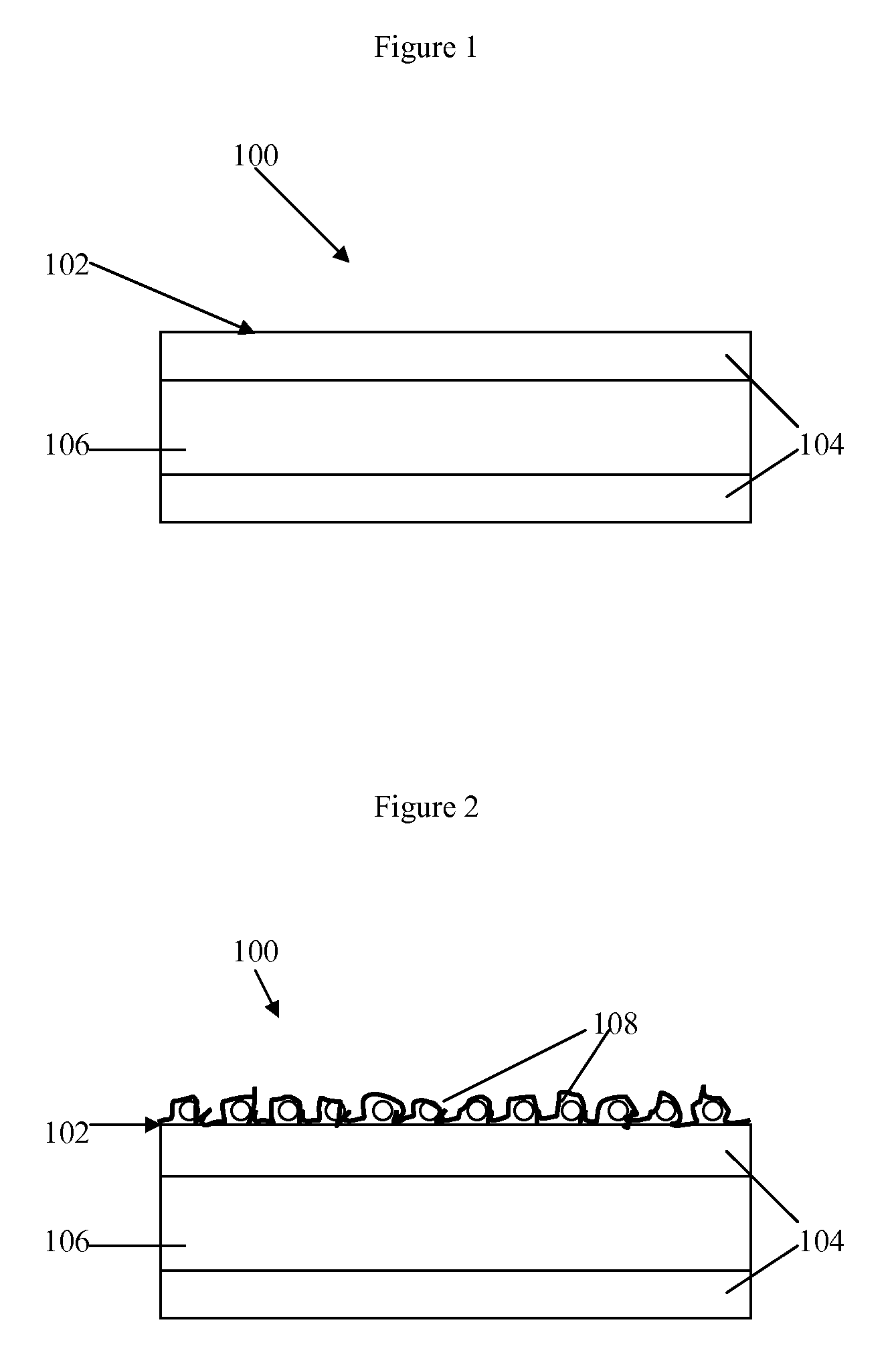

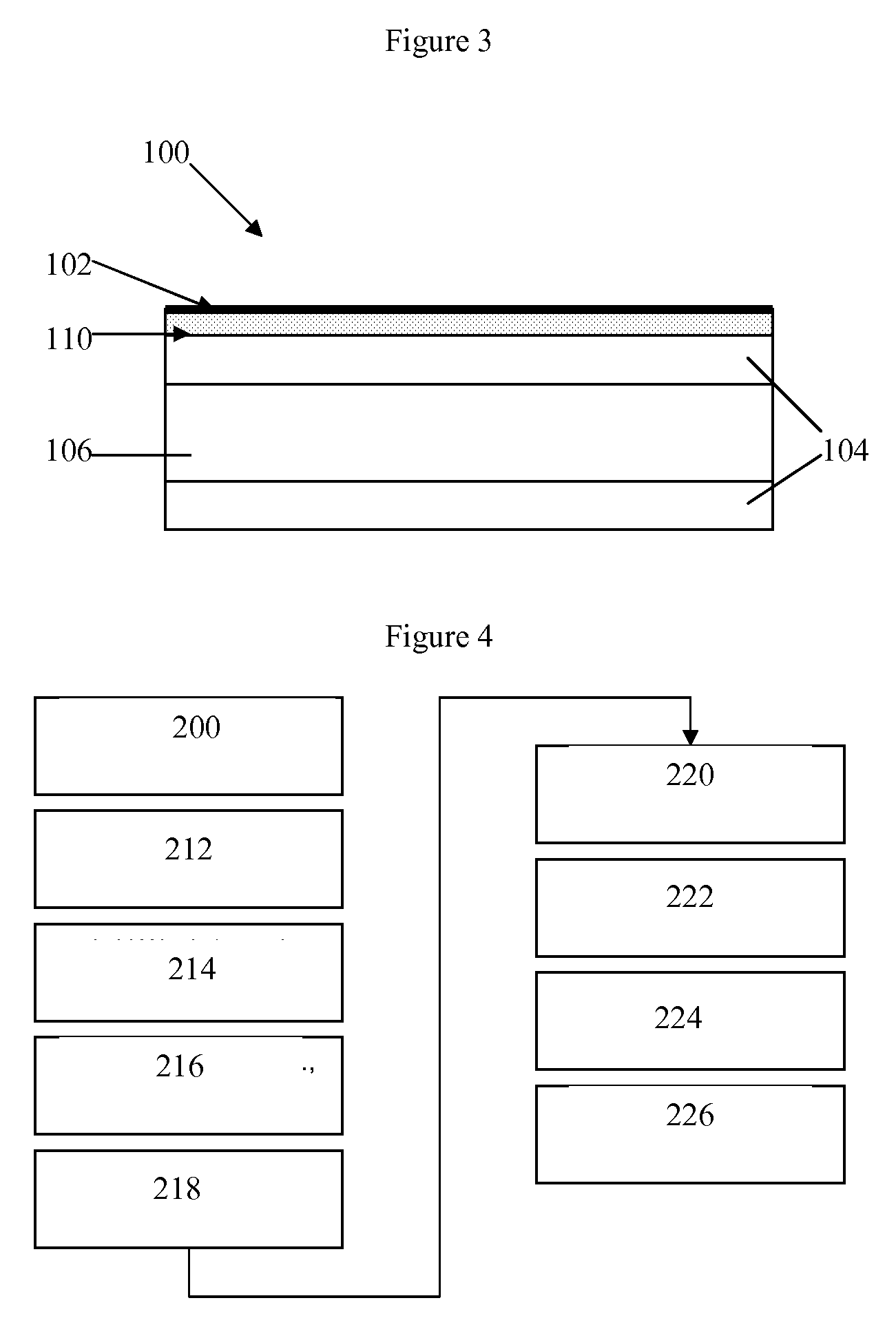

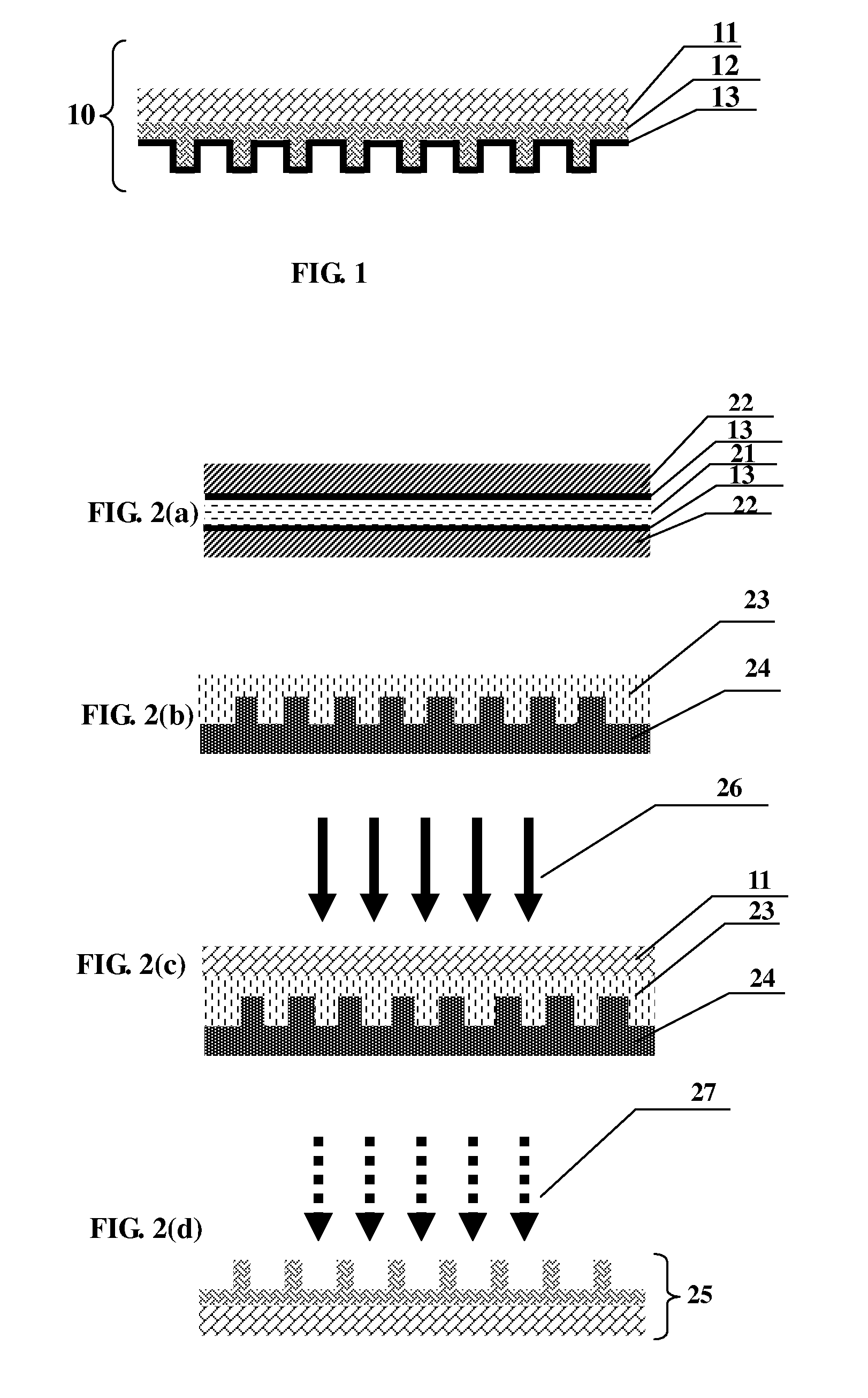

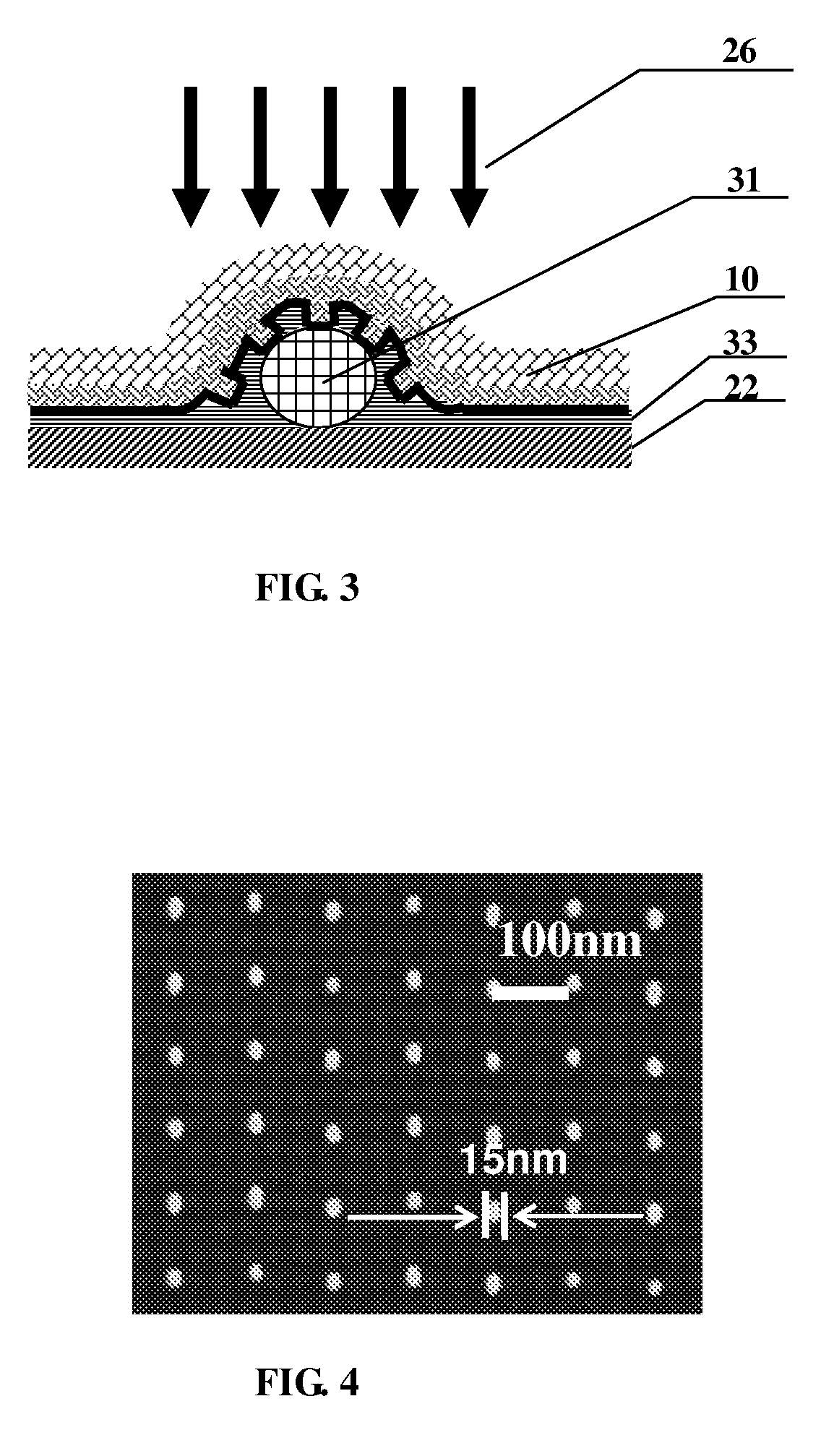

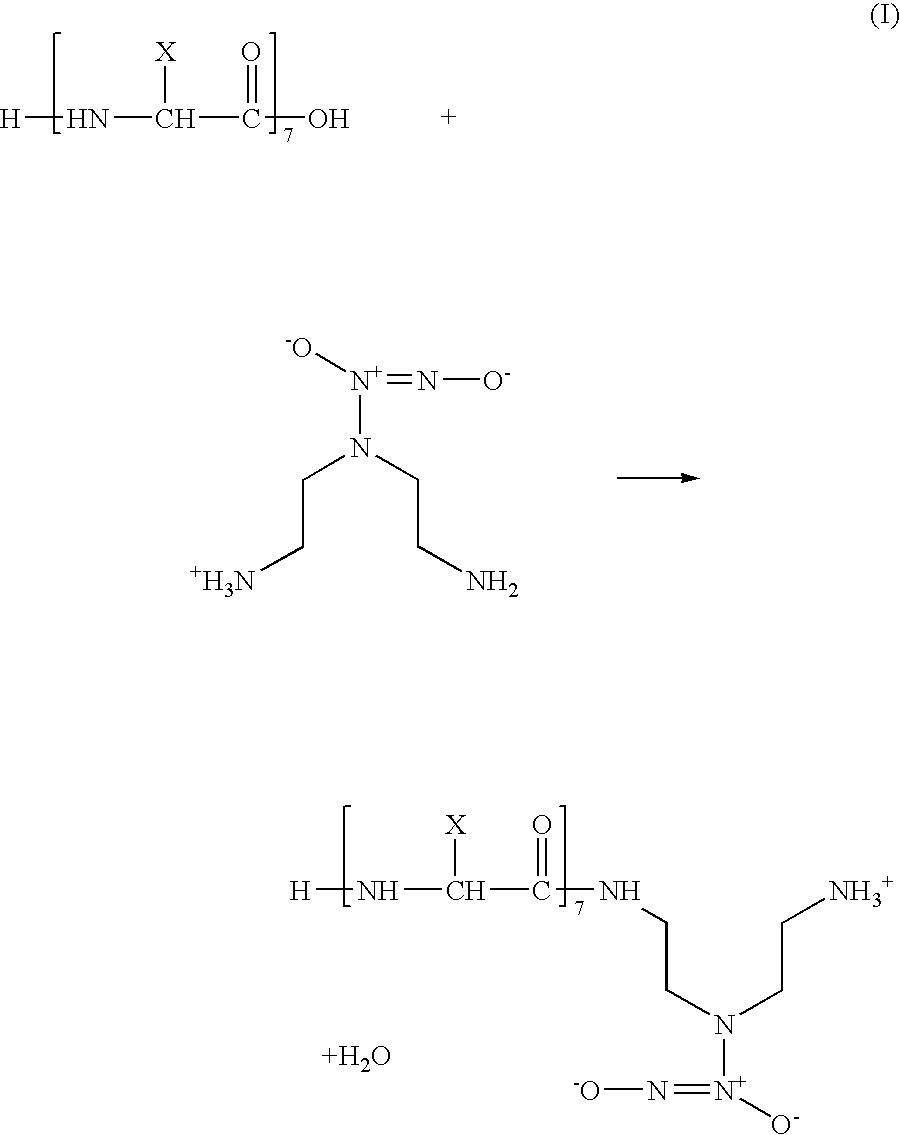

Flexible nanoimprint mold, method for fabricating the same, and mold usage on planar and curved substrate

ActiveUS20100109203A1High contactHigh resolutionLiquid surface applicatorsNanoinformaticsChemical LinkageElastomer

The present invention provides a flexible nanoimprint mold which can fabricate sub-15 nm ultra fine structures on either planar or curved substrates. The mold comprises a top ultra-thin rigid layer of imprint patterning features and a bottom thick flexible layer of polymer elastomer. The two distinct layers are preferably integrated via chemically bonding. The top layer of the mold enables a sub-15 nm resolution of pattern fabrication and the bottom layer affords a conformal contact to planar or curved surface of substrates. The methods for fabricating the same are disclosed.

Owner:NANJING UNIV

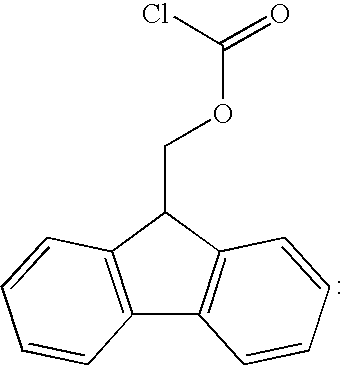

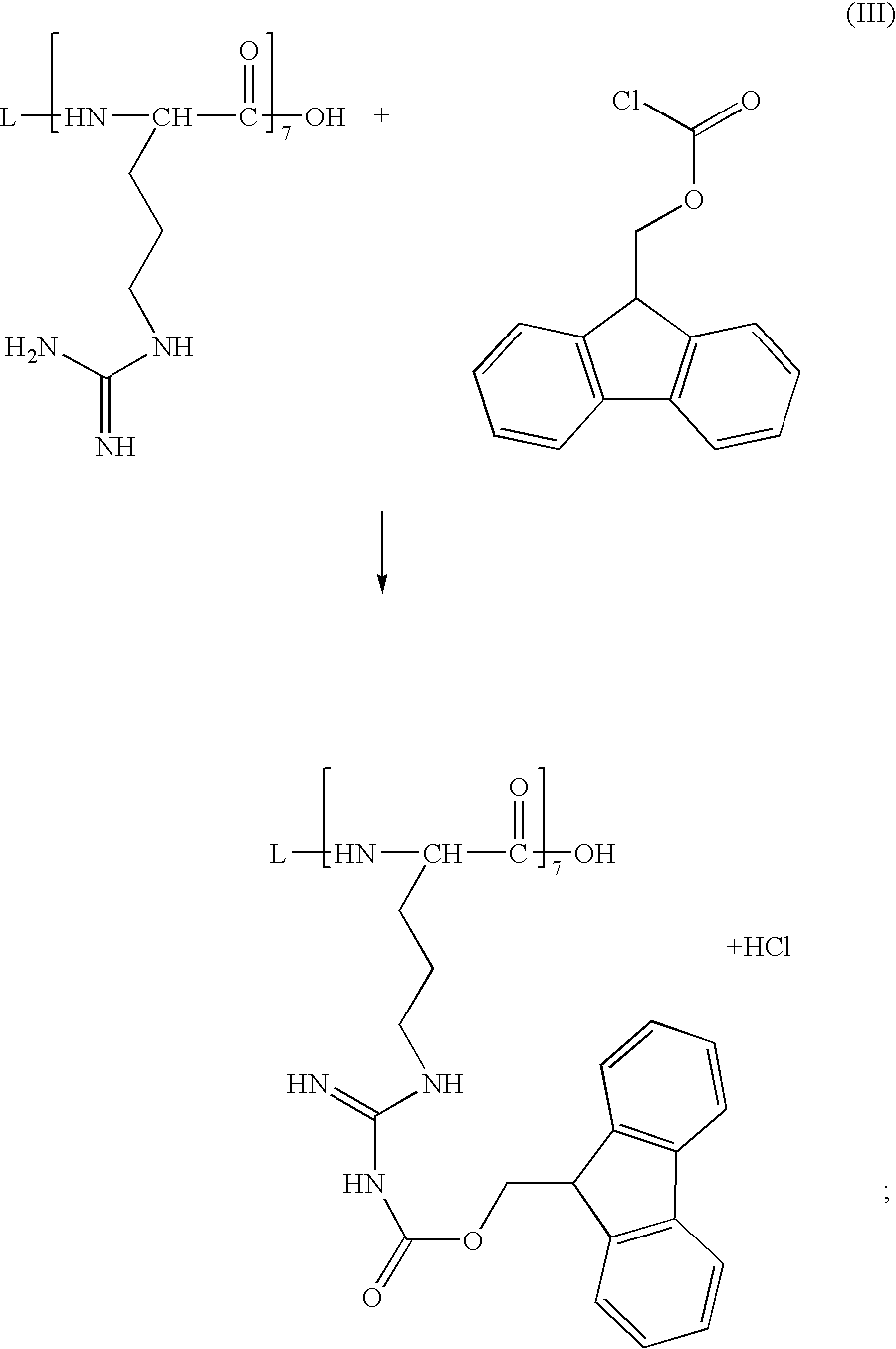

Coatings for implantable medical devices incorporating chemically-bound polymers and oligomers of L-arginine

InactiveUS7070798B1Inhibiting and eliminating restenosisPowder deliverySurgeryChemical LinkageOligomer

A coating for an implantable medical device is disclosed. The coating comprises a polymer and an amino acid chemically bonded, attached or conjugated to the polymer. In one embodiment, the coating can include a therapeutic substance. In lieu of bonding the amino acid to the polymer, the amino acid can be chemically bonded to the therapeutic substance or both the substance and the polymer. The amino acid can be polymers and / or oligomers of L-arginine, and copolymers of L-arginine with lysine. The coating can optionally include a nitric oxide donor, such as diazenium diolate type nitric oxide donors, chemically conjugated to the amino acid.

Owner:ABBOTT CARDIOVASCULAR

Method for continuously preparing liquid reclaimed rubber by aid of screw extruder

The invention relates to a method for continuously preparing liquid reclaimed rubber by the aid of a screw extruder, which belongs to the field of waste rubber recycling. The method is characterized in that a cross-linked network of pretreated waste rubber powder is crushed to obtain the liquid reclaimed rubber under the combined action of temperature, pressure, shearing and desulfurizer in the screw extruder by means of a physical and chemical linkage method and by the aid of the screw extruder. The method is simple in technical process and has the advantages of high desulfurization and depolymerization degree, energy conservation, environmental protection and continuity. The obtained liquid reclaimed rubber can be used with asphalt or replaces the asphalt for paving, and can be used with pure rubber to manufacture waterproof anticorrosion materials and the like.

Owner:宿迁绿金人橡塑机械有限公司

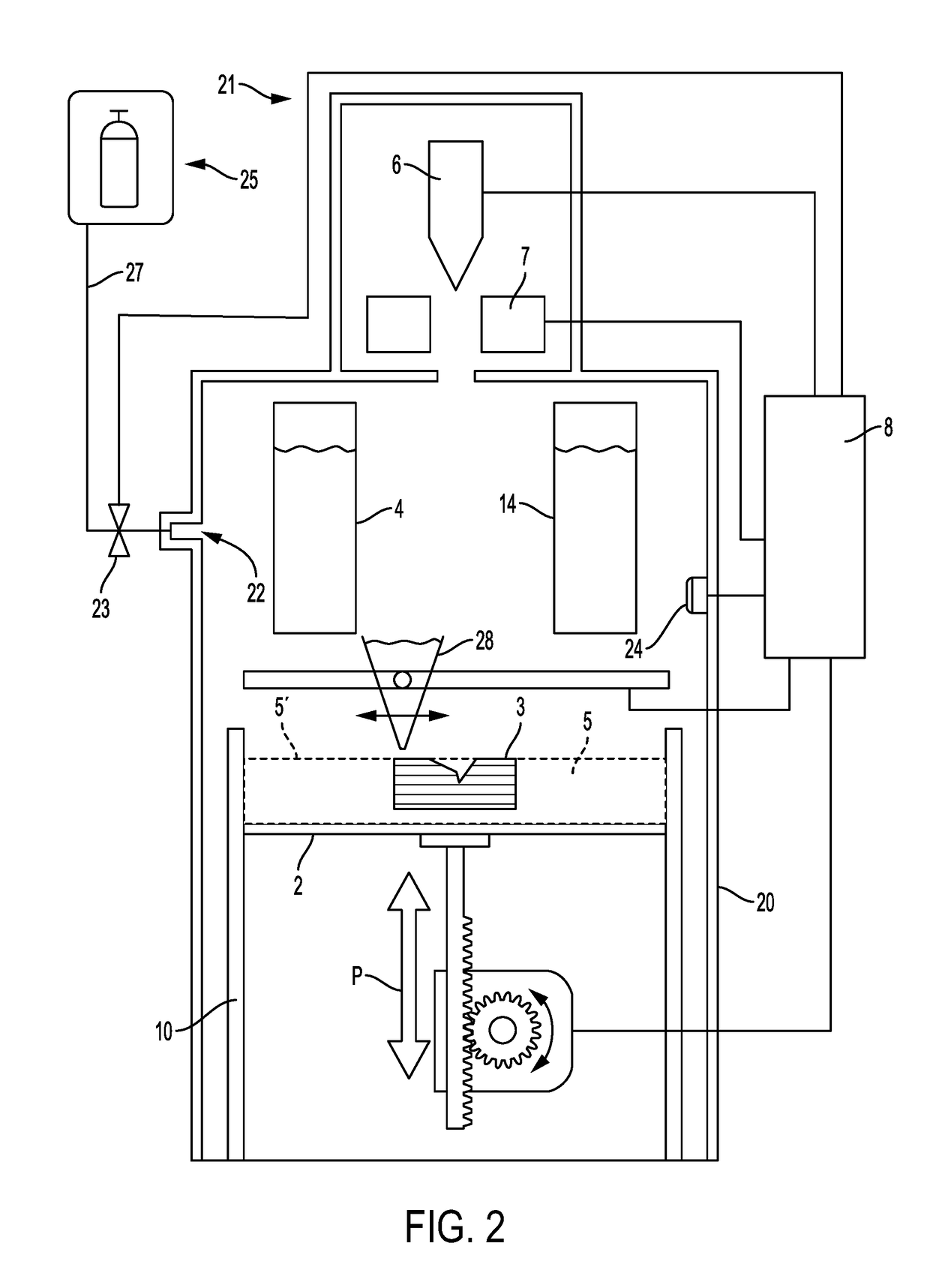

Method for additive manufacturing

ActiveUS20170341142A1Affect propertyEasily ionizedAdditive manufacturing apparatusSolid state diffusion coatingChemical LinkageHydrogen

A method comprising the steps of: distributing a titanium alloy or pure titanium powder layer on a work table inside a vacuum chamber, directing at least one electron beam from at least one electron beam source over the work table causing the powder layer to fuse in selected locations, distributing a second powder layer on the work table of a titanium alloy or pure titanium inside the build chamber, directing the at least one electron beam over the work table causing the second powder layer to fuse in selected locations, and releasing a predefined concentration of the gas from the metal powder into the vacuum chamber when at least one of heating or fusing the metal powder layer, wherein at least one gas comprising hydrogen is absorbed into or chemically bonded to the titanium or titanium alloy powder to a concentration of 0.01-0.5% by weight of the hydrogen.

Owner:ARCAM AB

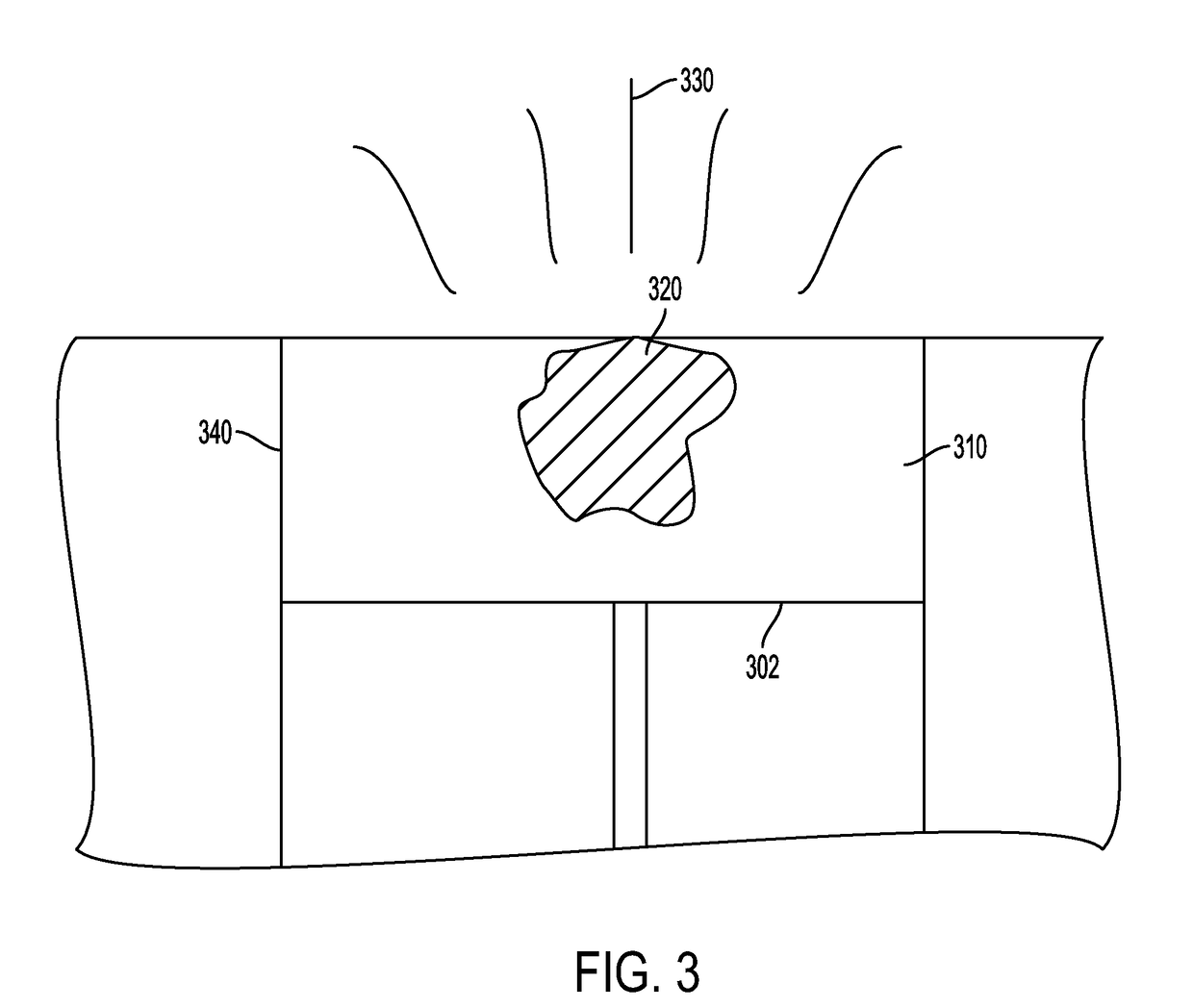

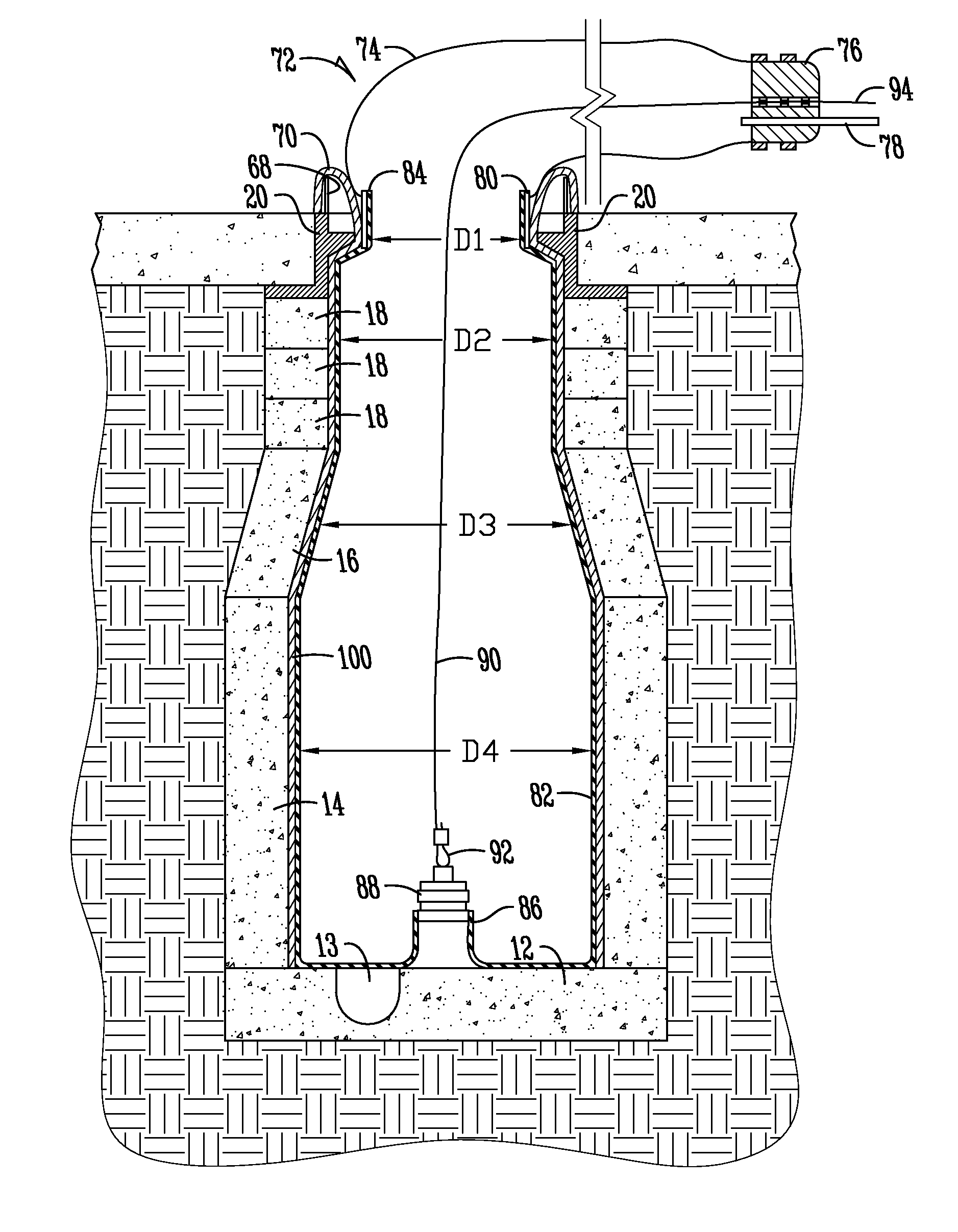

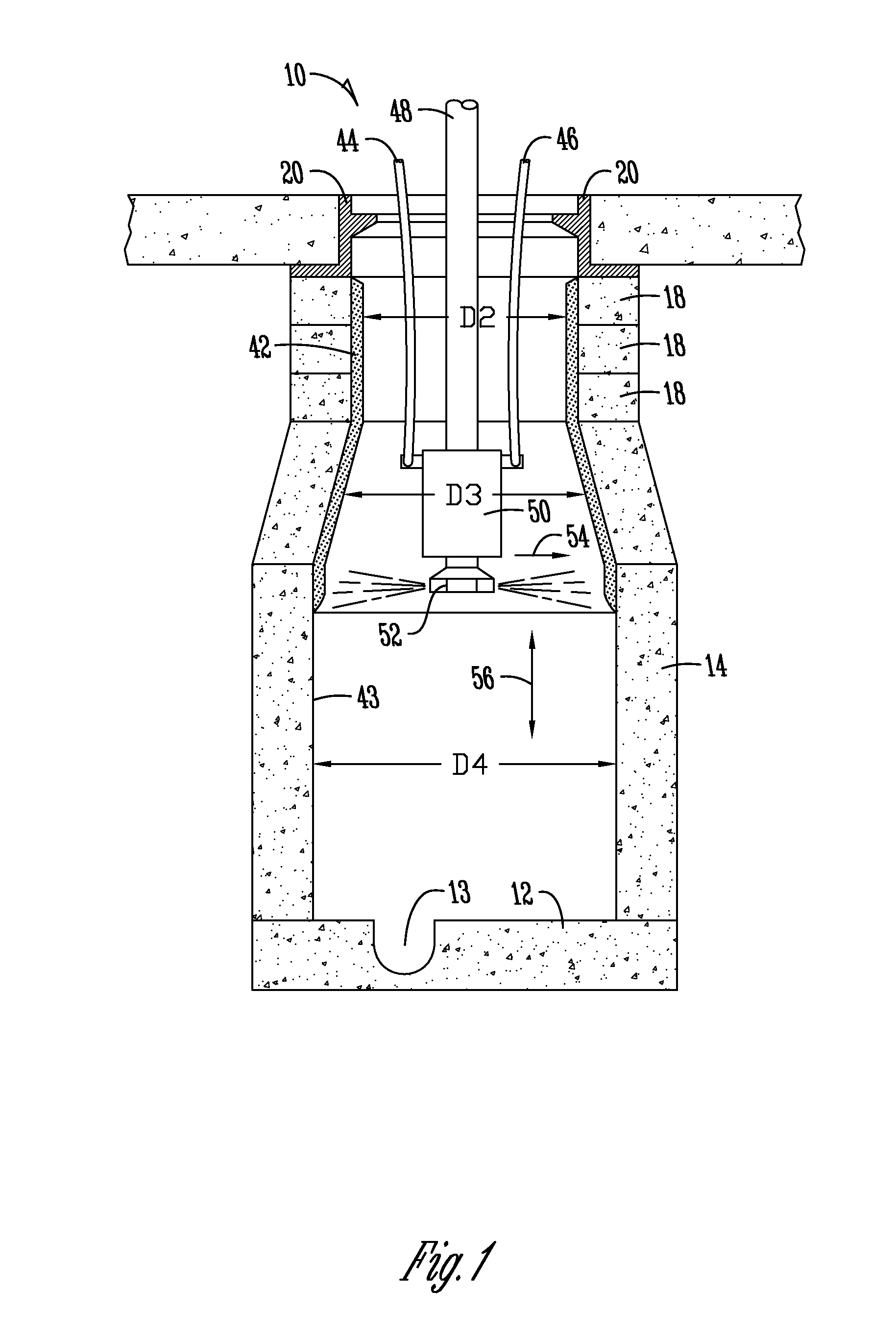

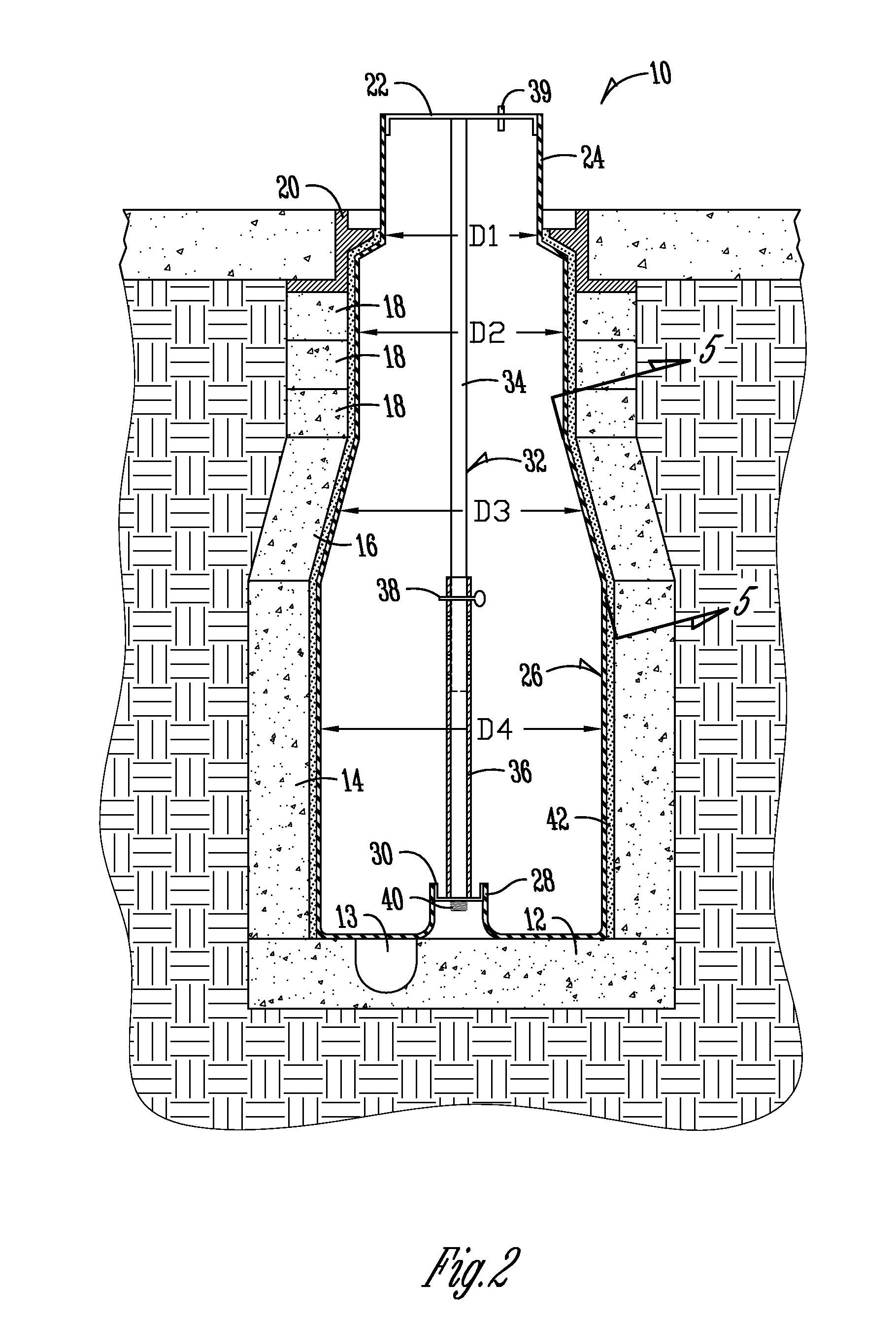

Method and apparatus for repairing the wall of a manhole

ActiveUS20120141210A1Improves over and solvesUnderground chambersUnderwater structuresChemical LinkageMaterials science

Owner:LMK TECH LLC

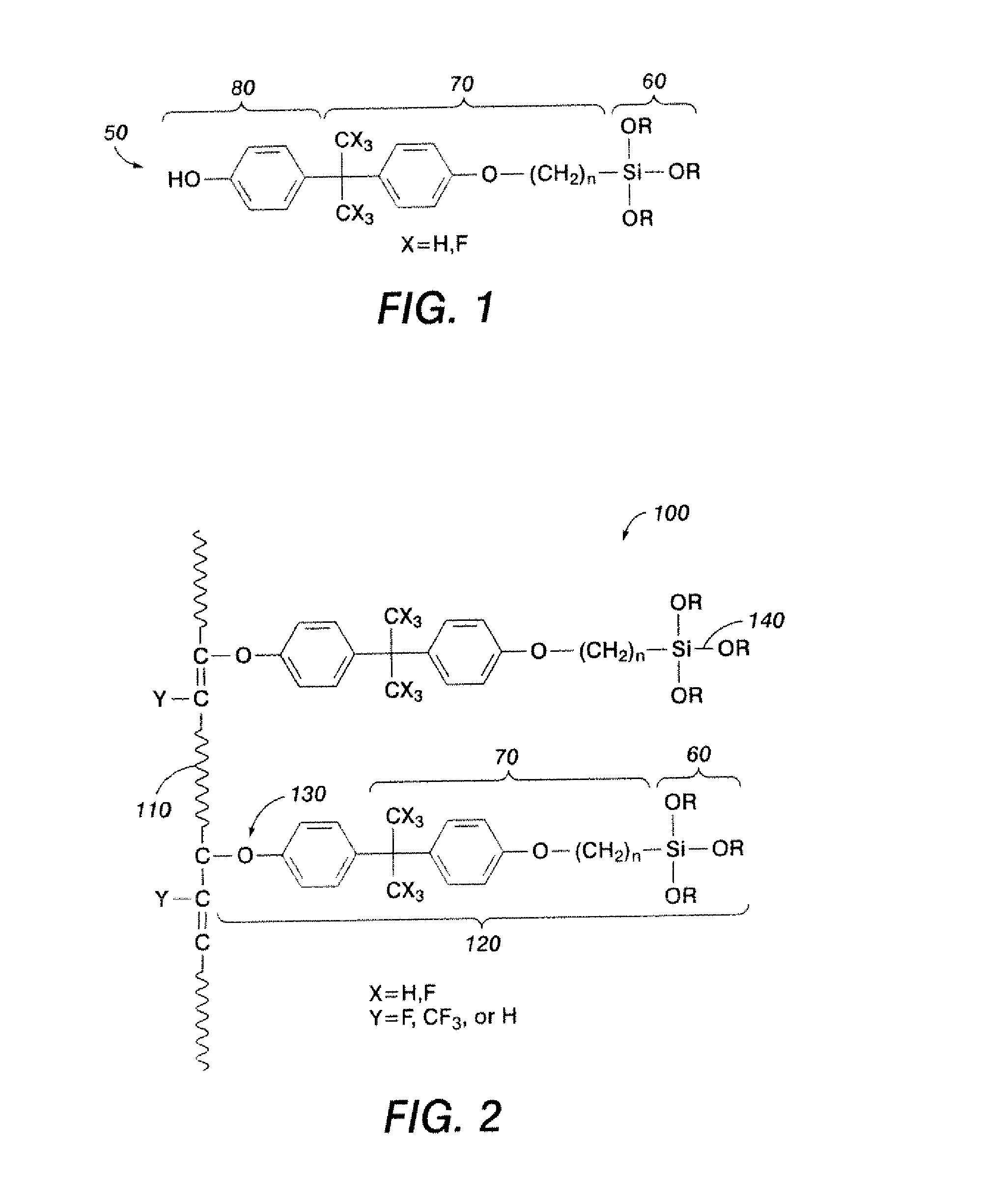

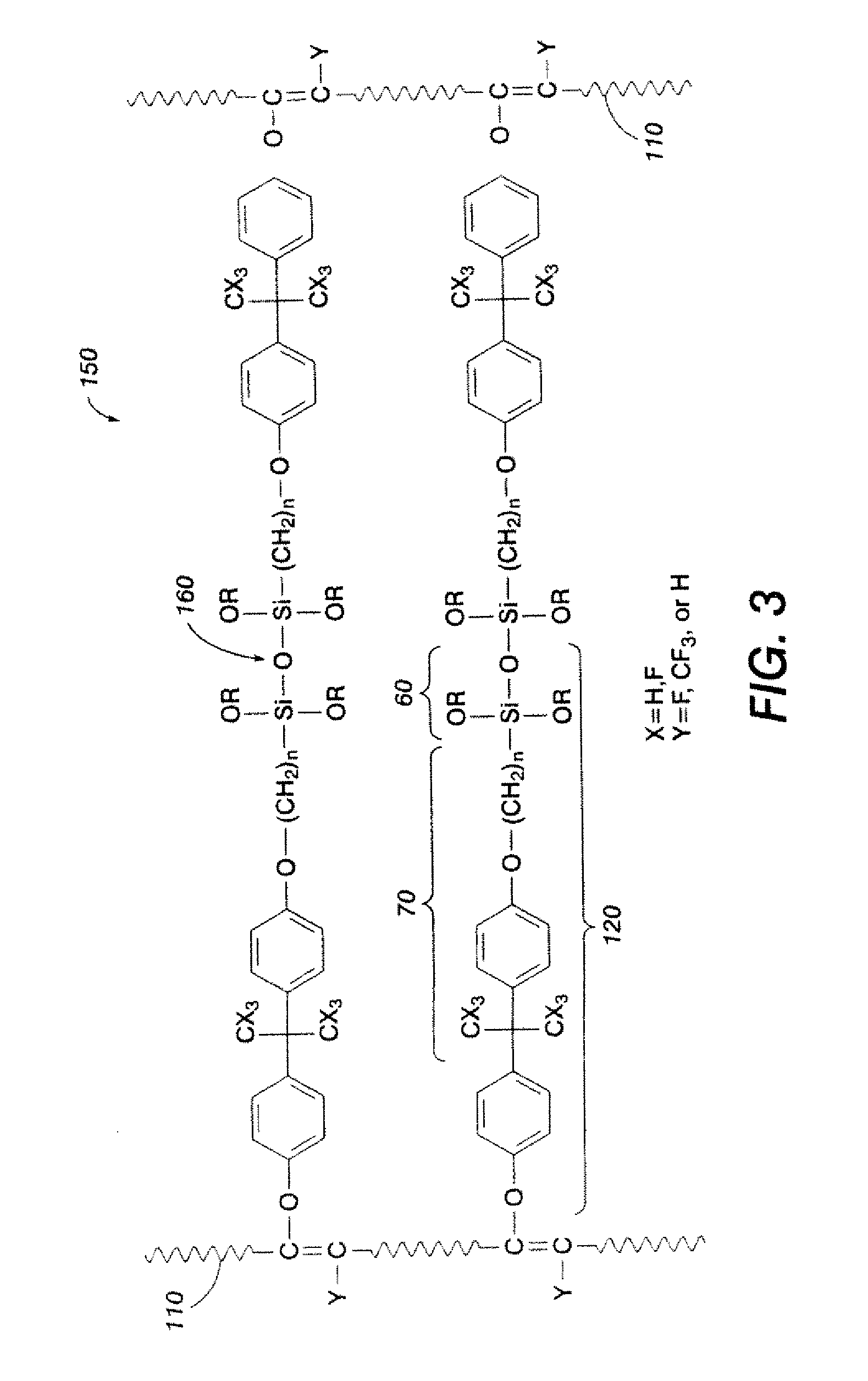

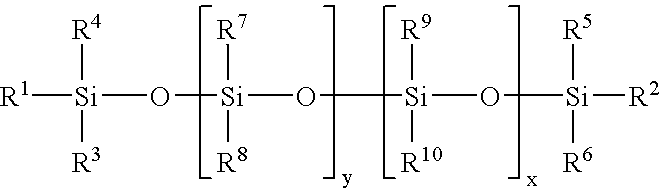

Silane Functionalized Fluoropolymers

A composition of matter includes a plurality of fluoropolymer chains. Each of the fluoropolymer chains is chemically bonded to at least one organic graft. The at least one organic graft includes a phenoxy group, a linking group, and at least one silane end group. The phenoxy group is chemically bonded to the fluoropolymer chain, and the linking group chemically bonds the phenoxy group with the at least one silane end group.

Owner:XEROX CORP

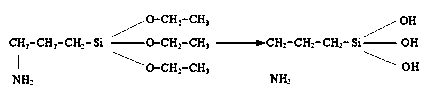

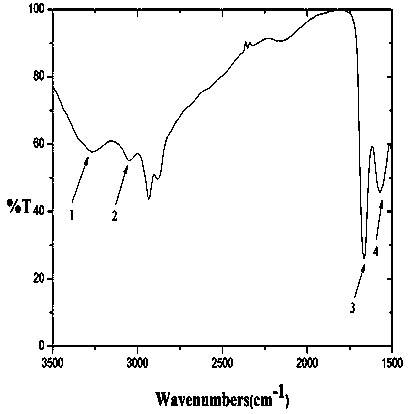

Method for preparing composite graphene/silane film on surface of metal

ActiveCN103628050AImprove corrosion resistanceHigh bonding strengthLiquid/solution decomposition chemical coatingChemical LinkageComposite film

The invention relates to metal surface protection, and in particular relates to a method for preparing a composite graphene / silane film on the surface of metal. The method overcomes the defect that the binding strength of a graphene film and the metal is weak; a silane coupling agent with two different chemical functional groups is introduced as a transition film layer to prepare a composite film, and the composite film is prepared from graphene and the silane coupling agent. The chemical bond connection between the metal and graphene is achieved through the silane coupling agent, and the binding strength of graphene and the metal is improved; the prepared composite film is long in service life, and the anti-corrosion property of the metal is effectively improved.

Owner:扬中方略科技信息有限公司

Ink composition containing a polymer complex, and an image formation method and equipment using the ink composition

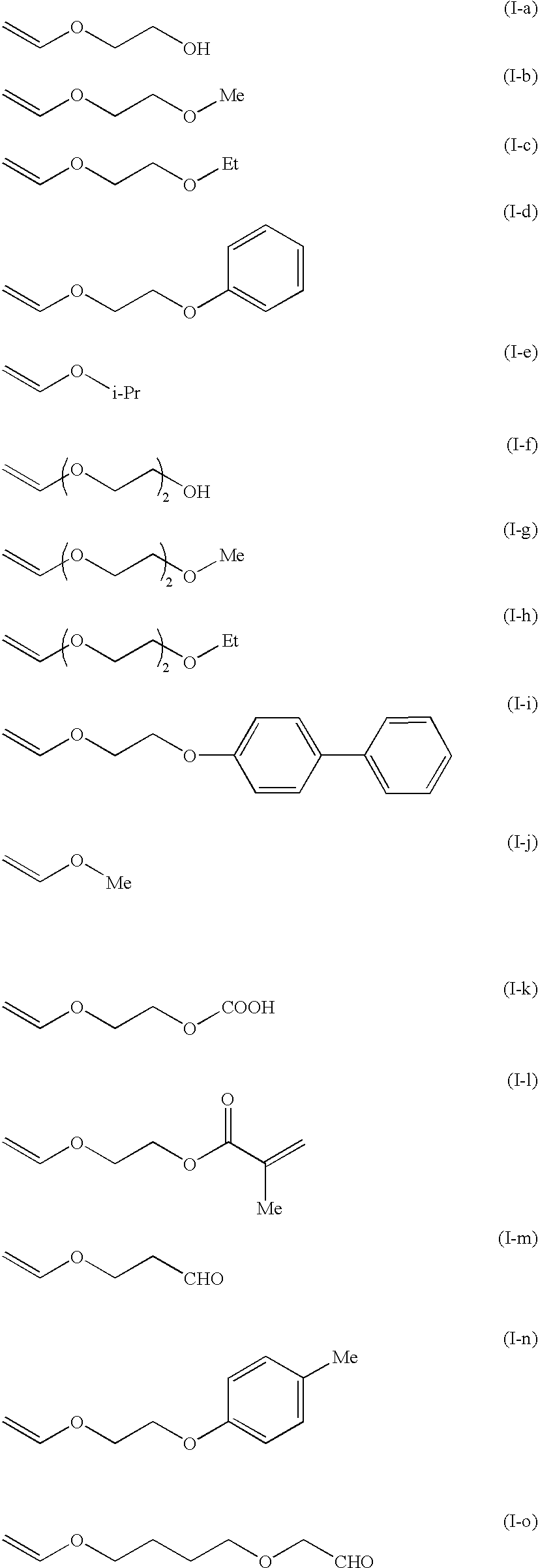

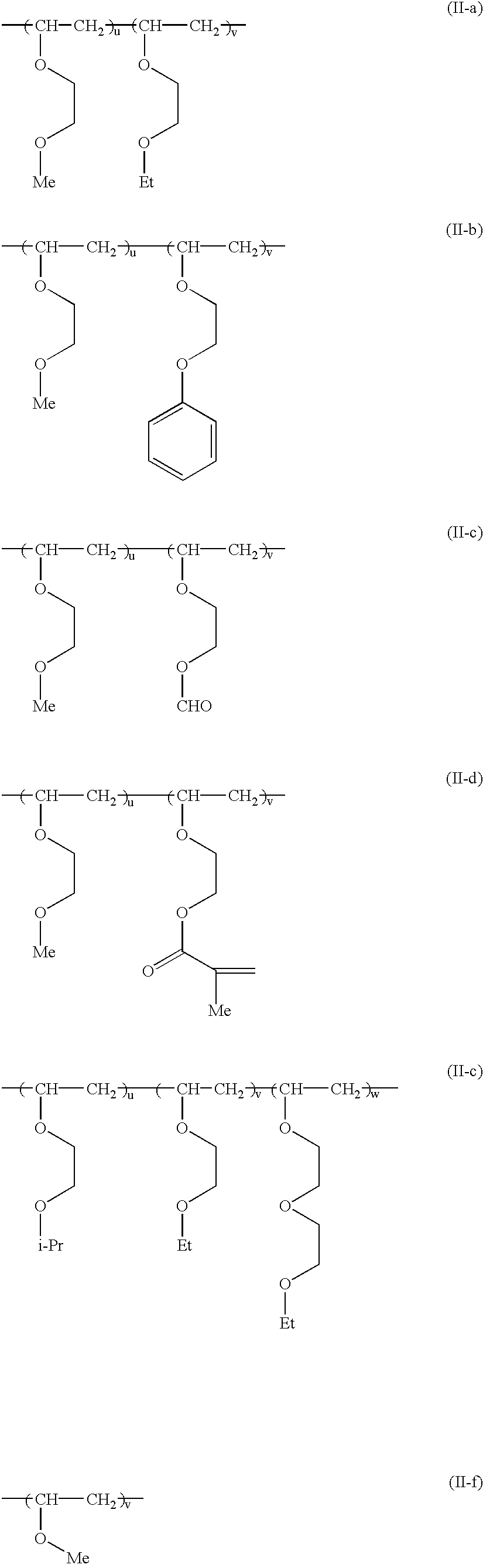

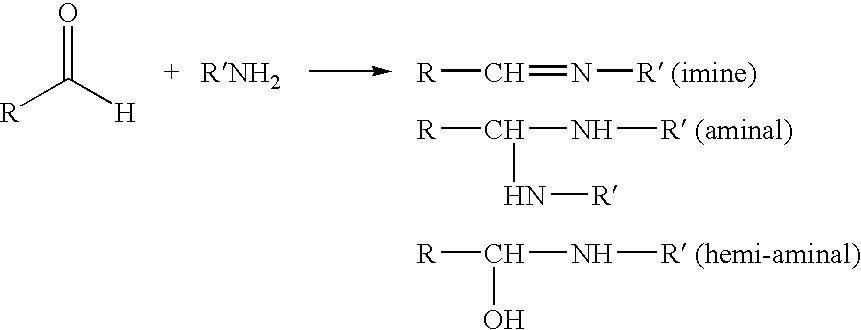

InactiveUS7004579B2Good dispersionImprovement in bleeding and featheringMeasurement apparatus componentsFilm/foil adhesivesChemical LinkageEther

The present invention relates to a stimulus responsive composition, which includes a polymer complex that a polymer including repeated units of polyvinyl ether structure is chemically bonded to a functional substance, and a solvent. It is desirable that a solvent is water and that the polymer in the composition contains a polyvinyl ether structure. The present invention also relates to an ink composition including the above composition, an image forming method and image forming device using the above composition, and recording medium contains a stimulating material or composition which stimulates the above composition.

Owner:CANON KK

Modified Polyamides, Uses Thereof and Process for Their Preparation

InactiveUS20090149590A1Conveniently addedImprove hydrolysis resistancePigmenting treatmentAlkaline-earth metal silicatesChemical LinkageAlcohol

A polymeric matrix having improved flowability and wettability is provided, as well as a process for making it. The matrix contains a polyamide and a polyhydric alcohol which is chemically bonded at least to a part of the polyamide, and it is suitable particularly for manufacturing fiber-reinforced polyamide articles exhibiting a very good surface appearance and excellent mechanical properties.

Owner:NILIT

Combined cracking and selective hydrogen combustion for catalytic cracking

A catalyst system and process for combined cracking and selective hydrogen combustion of hydrocarbons are disclosed. The catalyst comprises (1) at least one solid acid component, (2) at least one metal-based component comprised of one or more elements from Group 3 and one or more elements from Groups 4-15 of the Periodic Table of the Elements; and at least one of oxygen and sulfur, wherein the elements from Groups 3, Groups 4-15 and the at least one of oxygen and sulfur are chemically bound both within and between the groups and (3) at least one of at least one support, at least one filler and at least one binder. The process is such that the yield of hydrogen is less than the yield of hydrogen when contacting the hydrocarbons with the solid acid component alone.

Owner:EXXONMOBIL CHEM PAT INC

Process for bonding chemical additives on to substrates containing cellulosic materials and products thereof

InactiveUS6916402B2Cellulosic pulp after-treatmentNon-fibrous pulp additionChemical LinkageCellulose

Articles containing cellulose materials and treated with a chemical additive are disclosed. In accordance with the present invention, at least a portion of the cellulose containing the article is modified to include a first moiety. A chemical additive, such as softener or a humectant, is then chosen that includes a second moiety. When the chemical additive is applied to the article, the second moiety on the chemical additive forms a chemical linkage with the first moiety on the cellulose material. In this manner, the chemical additive becomes bonded to the cellulose material alleviating problems associated with retention. In one embodiment, the present invention is directed to the formation of tissue products, such as facial tissue, bath tissue and paper towels.

Owner:KIMBERLY-CLARK WORLDWIDE INC

Apoptosis inhibitor

InactiveUS6087384ALow in toxic potentialSafety managementBiocideNervous disorderChemical LinkageHydrogen

An apoptosis inhibitor which comprises a compound of the formula: wherein R represents a hydrocarbon group that may be substituted or a heterocyclic group that may be substituted; Y represents a group of the formula: -CO-, -CH(OH)- or -NR3- where R3 represents an alkyl group that may be substituted; m is 0 or 1; n is 0, 1 or 2; X represents CH or N; A represents a chemical bond or a bivalent aliphatic hydrocarbon group having 1 to 7 carbon atoms; Q represents oxygen or sulfur; R1 represents hydrogen or an alkyl group; ring E may have further 1 to 4 substituents, which may form a ring in combination with R1; L and M respectively represent hydrogen or may be combined with each other to form a chemical bond; or a salt thereof, or a compound having an insulin sensitivity enhancing activity.

Owner:TAKEDA PHARMA CO LTD

Low-melting point superabrasive tools and associated methods

InactiveUS20080096479A1Promote wettingLow melting pointAbrasion apparatusGrinding devicesChemical LinkageCopper

Superabrasive tools and their methods of manufacture are disclosed. In one aspect, a method for making a low-melting point superabrasive tool having a plurality of superabrasive particles is provided. Such a method may include coating each of the plurality of superabrasive particles with a reactive element that chemically bonds to each of the plurality of superabrasive particles and bonding together the plurality of superabrasive particles with a molten braze that wets the reactive element at a temperature of less than about 700° C. In some aspects, the method may further include arranging the plurality of superabrasive particles on a leveling surface and bonding the plurality of superabrasive particles together with the molten braze such that, upon formation of the superabrasive tool, the plurality of superabrasive particles have been leveled by the leveling surface to an RA value of less than about 40 μm.

Owner:SUNG CHIEN MIN

Method for modifying hydroophilicity of highly active separation membrane made from polymer

InactiveCN1539550AImprove hydrophilicityGood biocompatibilitySemi-permeable membranesChemical LinkagePolymer science

A process for hydrophilic modification of efficient separating polymer membrane includes coating the grafting monomer containing glycosyl compound on the surface of polymer membrane, evaporating solvent, and radiating said monomer for triggering graft reaction to modify said polymer membrane. Its advantages are high hydrophilic effect, and easy washing.

Owner:ZHEJIANG UNIV

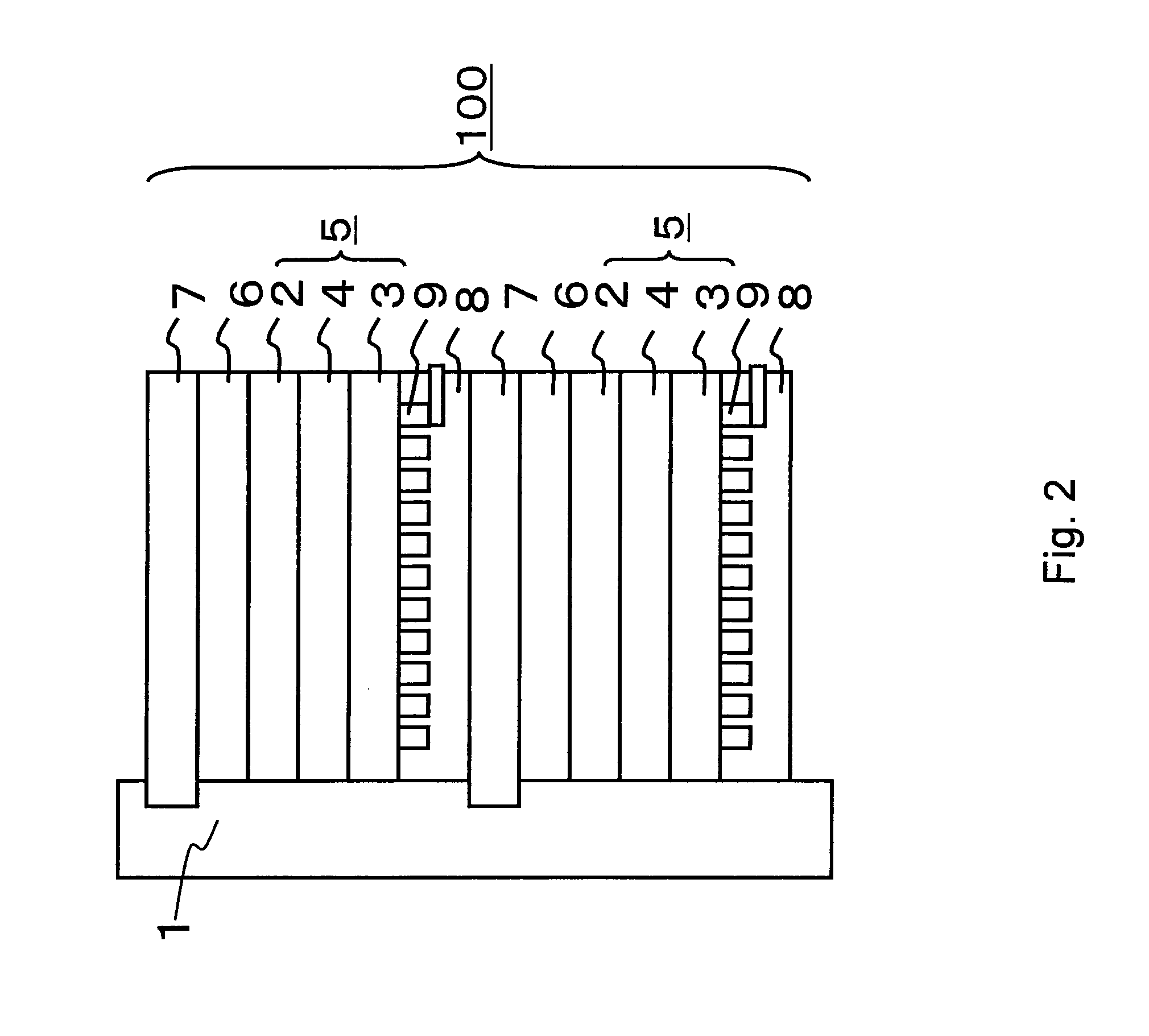

Electrode for fuel cell, membrane electrode composite and fuel cell, and method for manufacturing them

InactiveUS20080026282A1Stable outputMaintain power generation performanceActive material electrodesSolid electrolyte fuel cellsChemical LinkageInorganic oxide

A fuel cell, which can supply stable output even at elevated temperatures and can maintain its power generation performance over a long period of time, can be realized by an electrode for a fuel cell comprising a catalyst layer formed of a catalyst composite and a binder, the catalyst composite comprising a proton-conductive inorganic oxide and an oxidation-reduction catalyst phase supported on the proton-conductive inorganic oxide, the proton-conductive inorganic oxide comprising a catalyst carrier selected from tin(Sn)-doped In2O3, fluorine(F)-doped SnO2, and antimony(Sb)-doped SnO2 and an oxide particle phase chemically bonded to the surface of the catalyst carrier. The catalyst composite is manufactured by dispersing a catalyst carrier in a solution containing a material as a starting material for an oxide particle phase, heat treating the dispersion to form a proton-conductive inorganic oxide, further dispersing the proton-conductive inorganic oxide in a catalyst precursor-containing solution, and subjecting the dispersion to heat treatment or pH adjustment to deposit a catalyst phase.

Owner:KK TOSHIBA

Pressure sensitive adhesive sheet and production method thereof

Owner:3M INNOVATIVE PROPERTIES CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com