Graphite composite lithium ion battery anode material lithium iron phosphate and preparation method thereof

A lithium-ion battery and graphene composite technology, applied in electrode manufacturing, battery electrodes, circuits, etc., can solve the problems of reducing the tap density of materials and the large volume of lithium-ion power batteries, and improve the tap density and electrochemical performance. Excellent, reducing the effect of internal resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

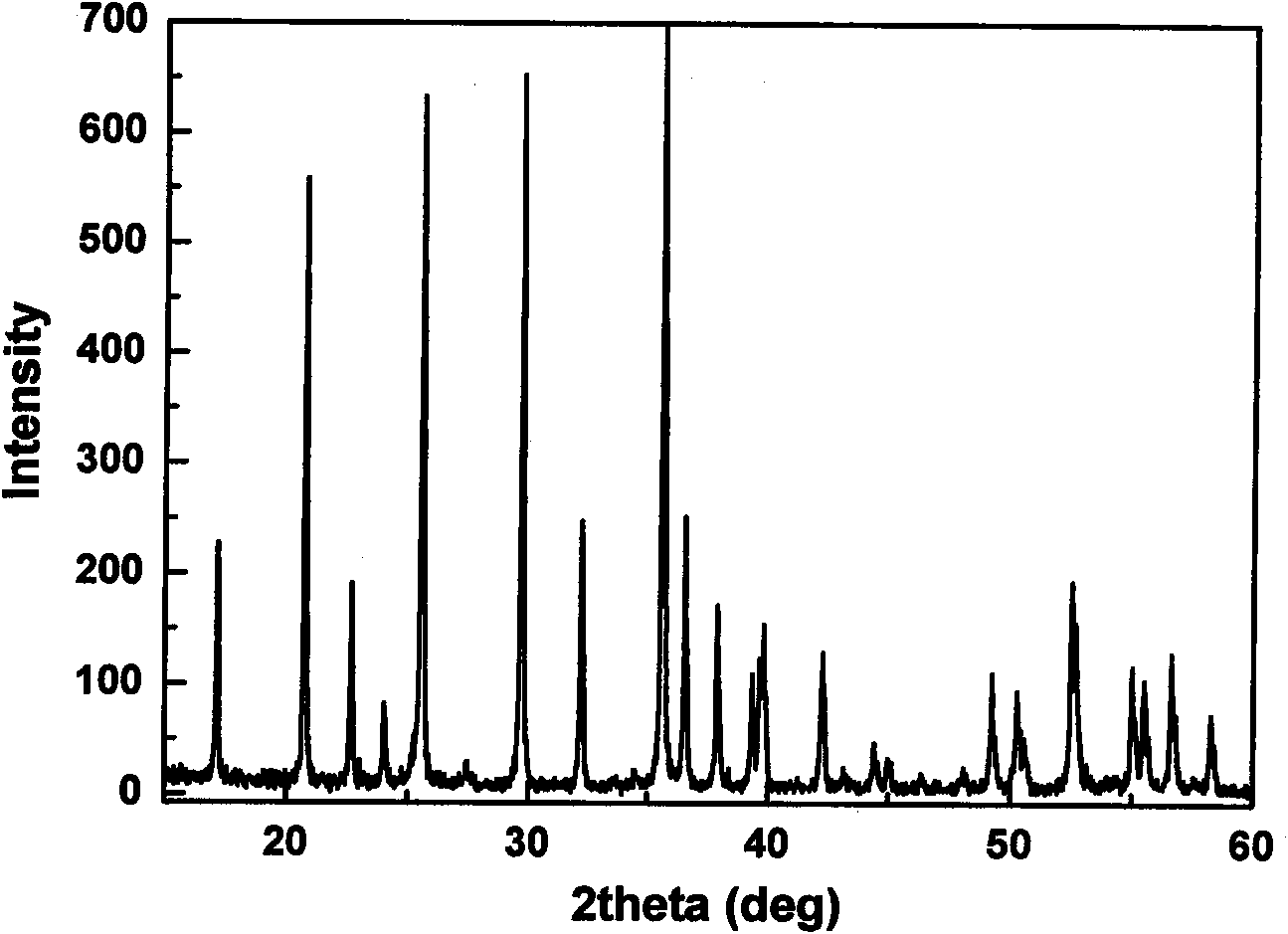

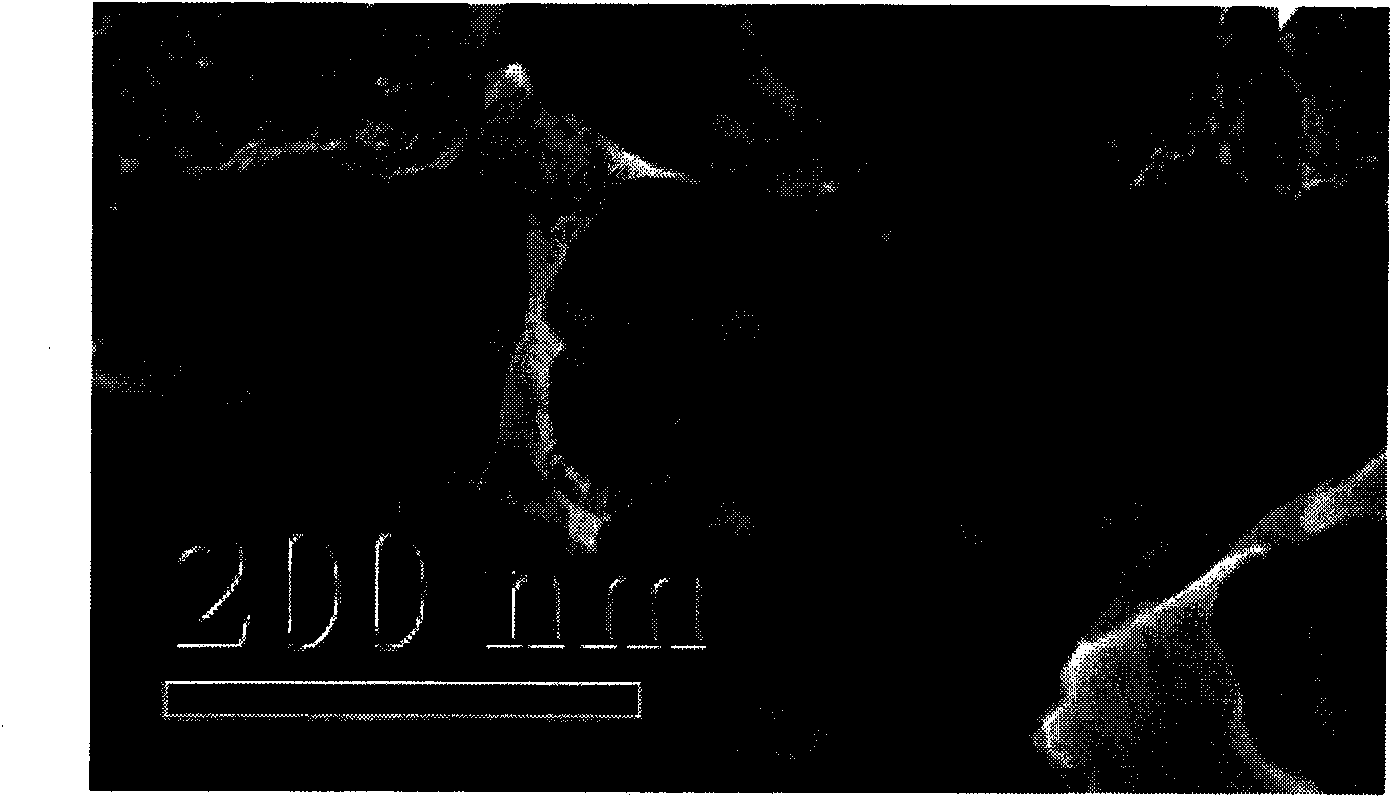

[0020] Fully mix the pure phase powder of nano-lithium iron phosphate and 1% graphene according to the weight ratio of lithium iron phosphate for 5 hours, keep it in a furnace at 550°C with a nitrogen protective atmosphere for 1.5 hours, and then cool to room temperature to obtain a graphene composite lithium iron phosphate cathode material. Conductivity of graphene-composite lithium iron phosphate from pure phase 10 -9 S / cm increased to 10 -4 S / cm order of magnitude, tap density is 1.8g / cm 3 . figure 1 It is an X-ray diffraction pattern, and the raw material lithium iron phosphate analyzed is pure lithium iron phosphate of olivine-type orthorhombic single-phase structure, figure 2 is a transmission electron microscope image of the composite material.

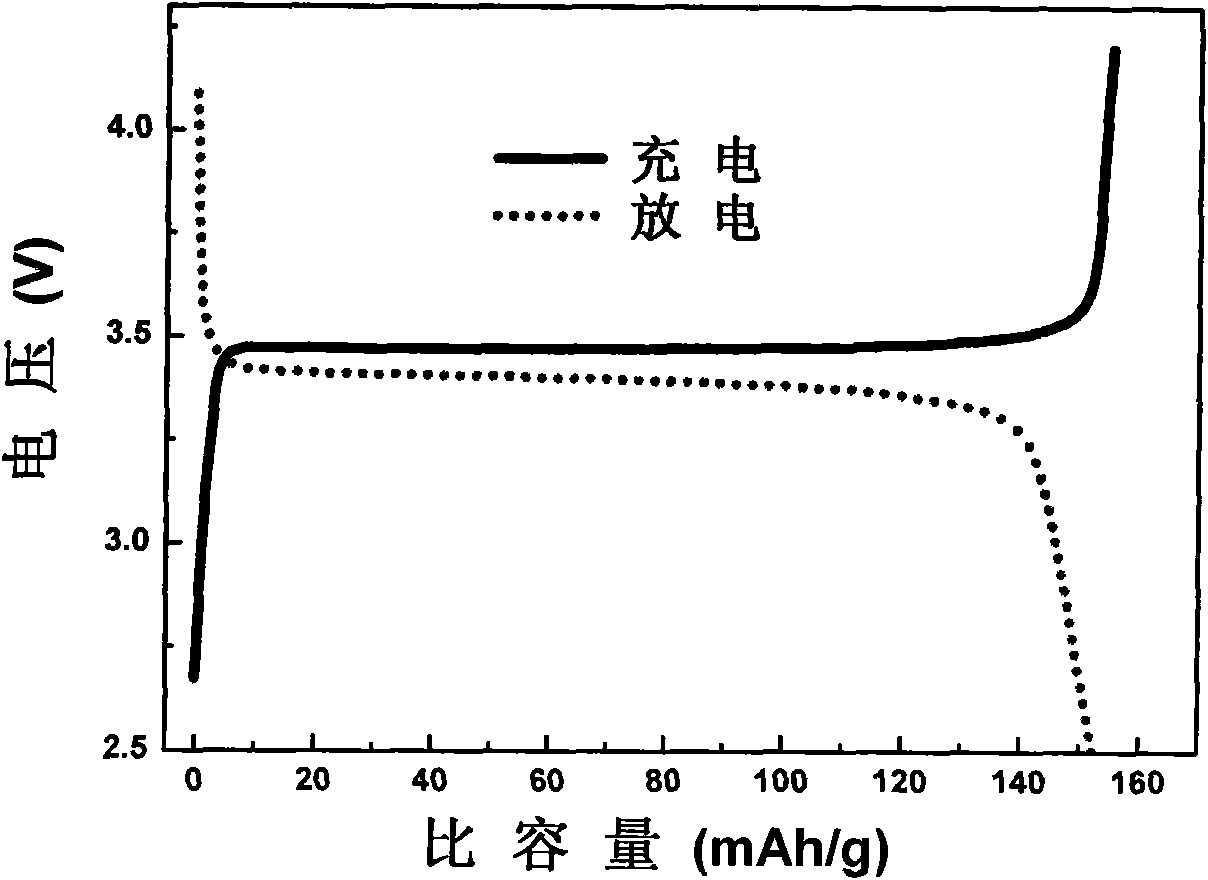

[0021] The active material lithium iron phosphate powder, the conductive agent acetylene black and the binder polyvinylidene fluoride are mixed in a mass ratio of 8.5:0.5:1 and evenly coated on the aluminum foil to form a ...

Embodiment 2

[0024] The pure phase powder of nano-lithium iron phosphate and 0.1% graphene according to the weight ratio of lithium iron phosphate are fully ball-milled for 2 hours in ethanol, which is 2 times the weight ratio of all raw materials, as a liquid medium, and then heated in a furnace at 300 ° C with an argon protective atmosphere Insulated and reacted for 5 hours, then cooled to room temperature to obtain graphene-composite lithium iron phosphate positive electrode material. Conductivity before and after compounding from 10 -9 S / cm increased to 10 -4 S / cm order of magnitude, tap density is 1.9g / cm 3 . The specific capacities of the obtained products are about 145 and 96mAh·g when discharged at 1C and 20C rates, respectively. -1 .

Embodiment 3

[0026] The pure phase powder of nano-lithium iron phosphate and 2.5% graphene oxide in the weight ratio of lithium iron phosphate were fully mixed for 30 hours, kept in a furnace at 850°C with a mixed protective atmosphere of hydrogen and argon for 2 hours, and then cooled to room temperature to obtain Graphene composite lithium iron phosphate cathode material. Conductivity before and after compounding from 10-9 S / cm increased to 10 -4 S / cm order of magnitude, tap density is 1.75g / cm 3 . The specific capacities of the obtained products are about 152 and 103 mAh·g when discharged at 1C and 20C rates, respectively. -1 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com