Patents

Literature

1094 results about "Graphite composite" patented technology

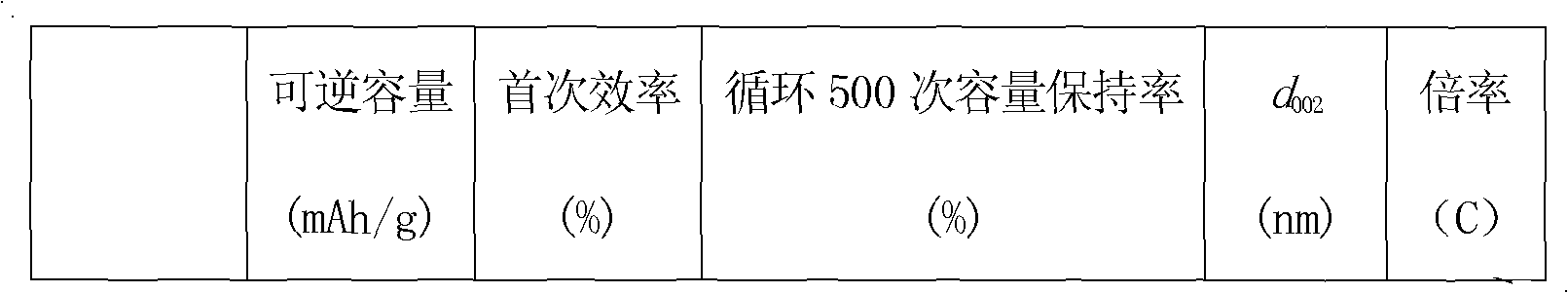

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

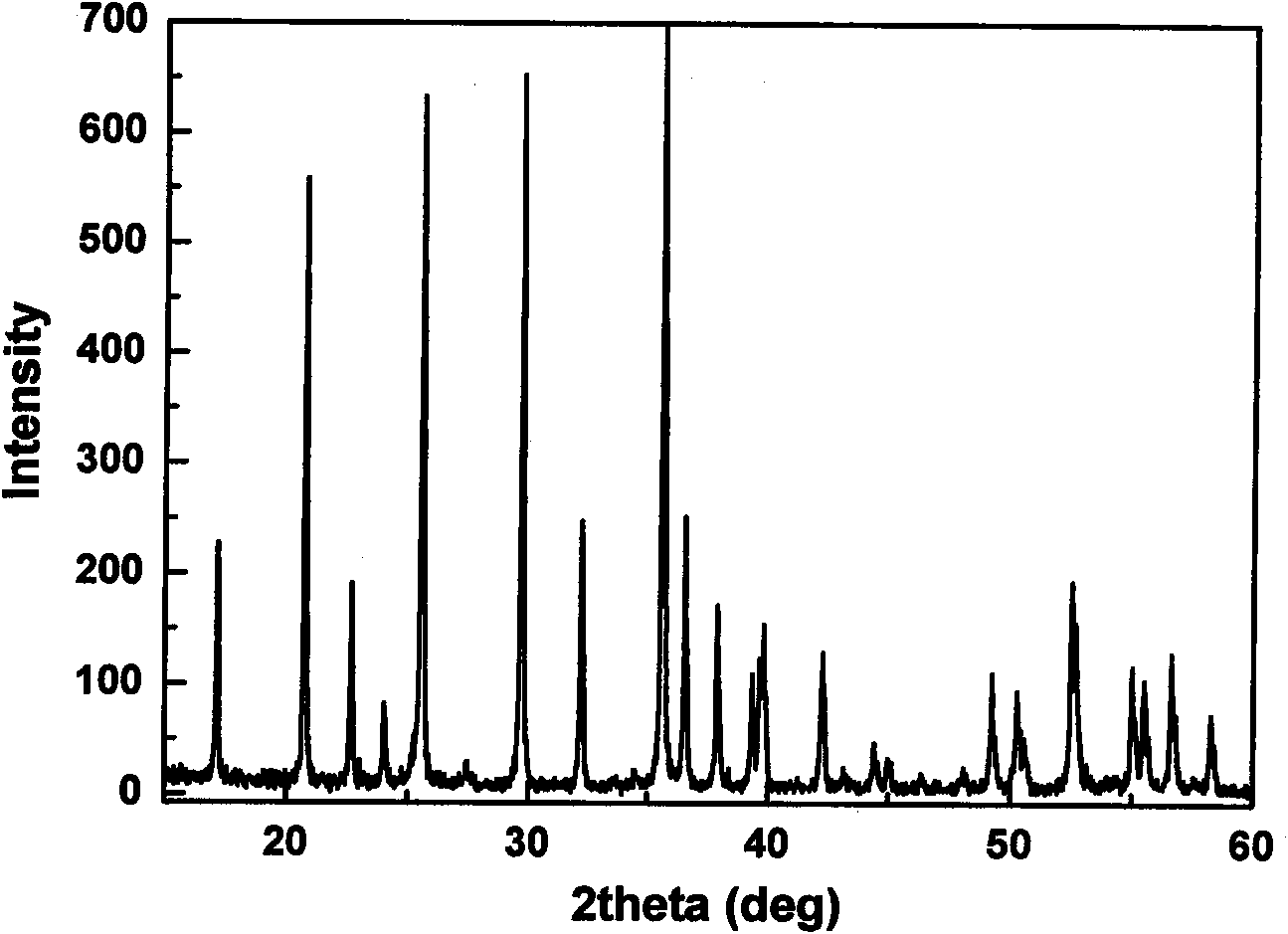

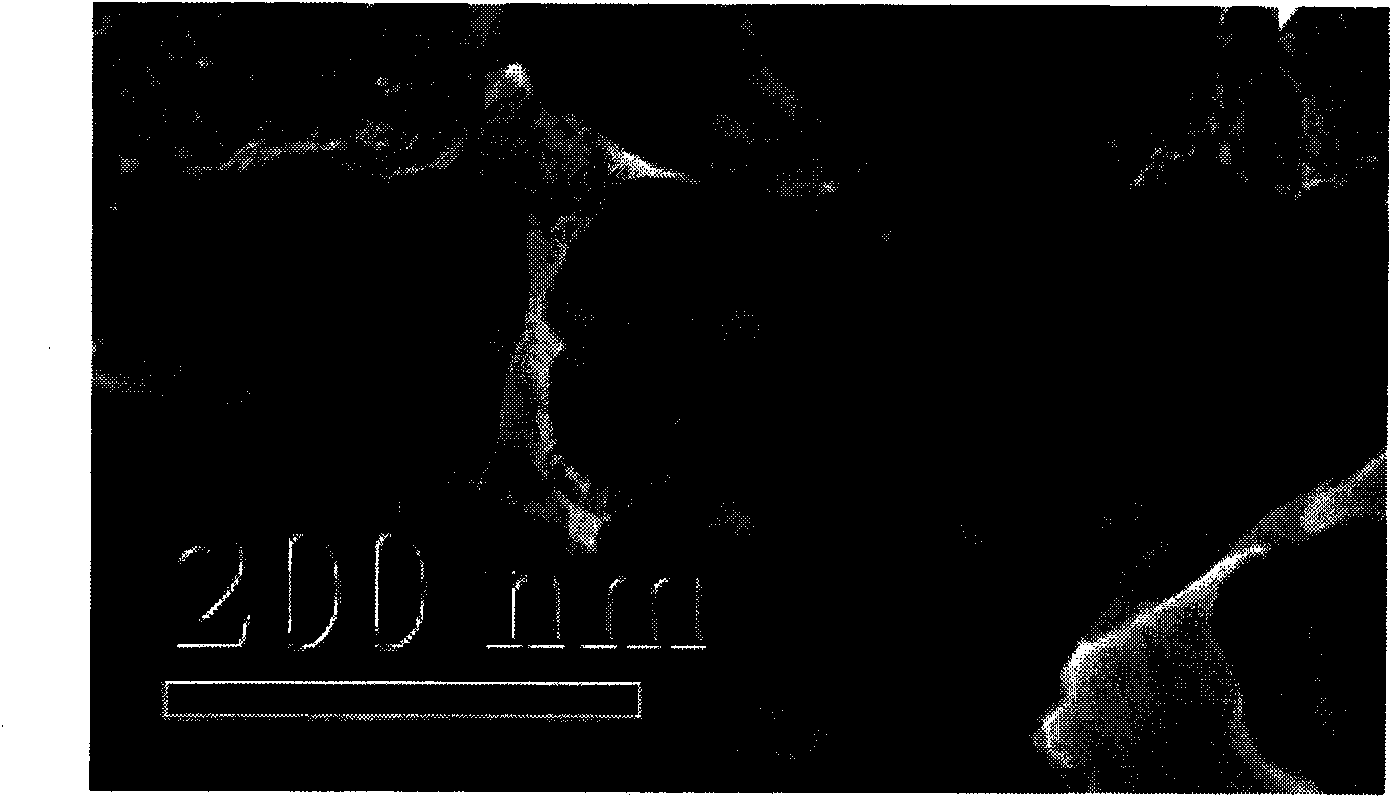

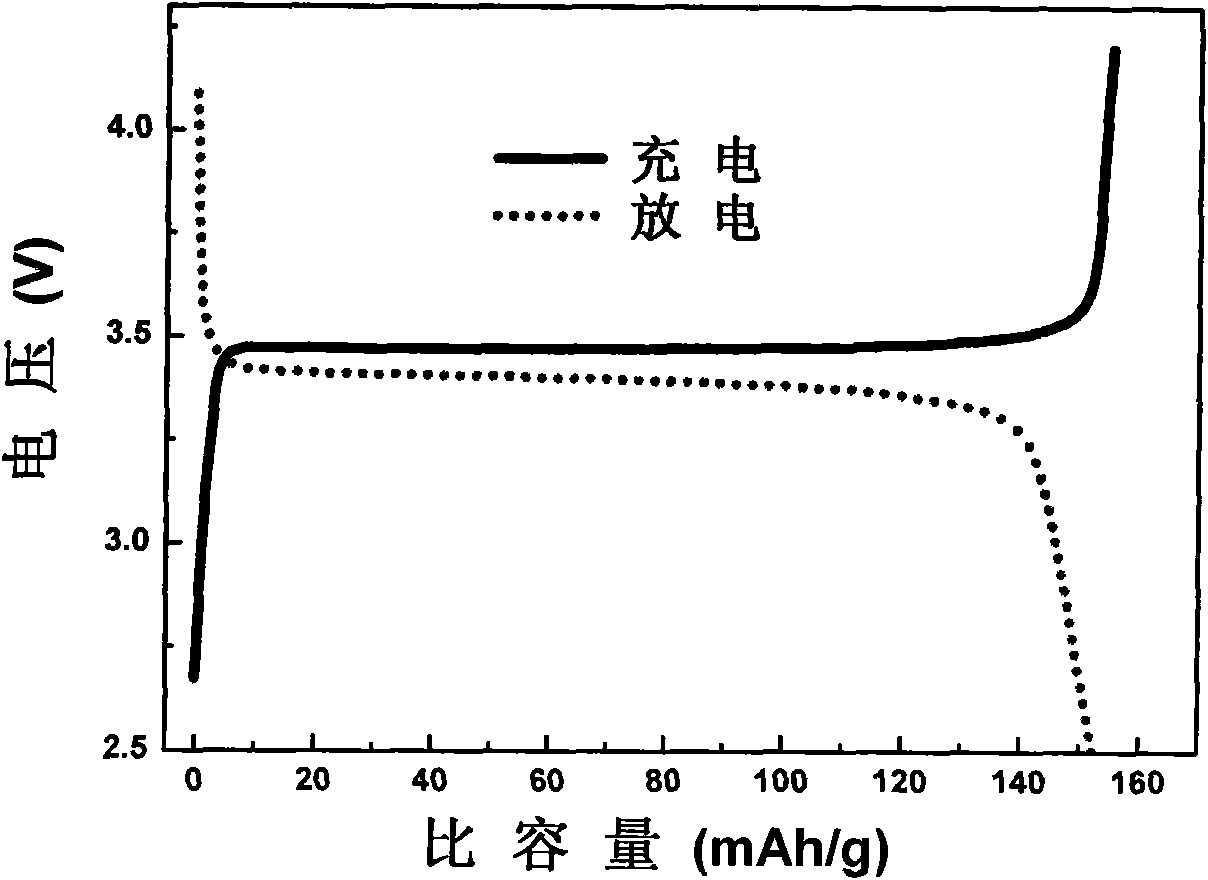

Graphite composite lithium ion battery anode material lithium iron phosphate and preparation method thereof

ActiveCN101562248AImprove electronic conductivityImprove tap densityElectrode manufacturing processesPower batteryChemical Linkage

The invention relates to a graphene composite lithium ion battery anode material lithium iron phosphate and a preparation method thereof. The composite material of lithium iron phosphate and graphene is connected by interface of chemical bonding. The invention also provides the method for preparing the graphene composite lithium ion battery anode material lithium iron phosphate in an in-situ symbiosis reaction mode, and the obtained anode material has high tap density and good magnifying performance, and is suitable to be used as a anode material of a lithium ion power battery.

Owner:龚思源

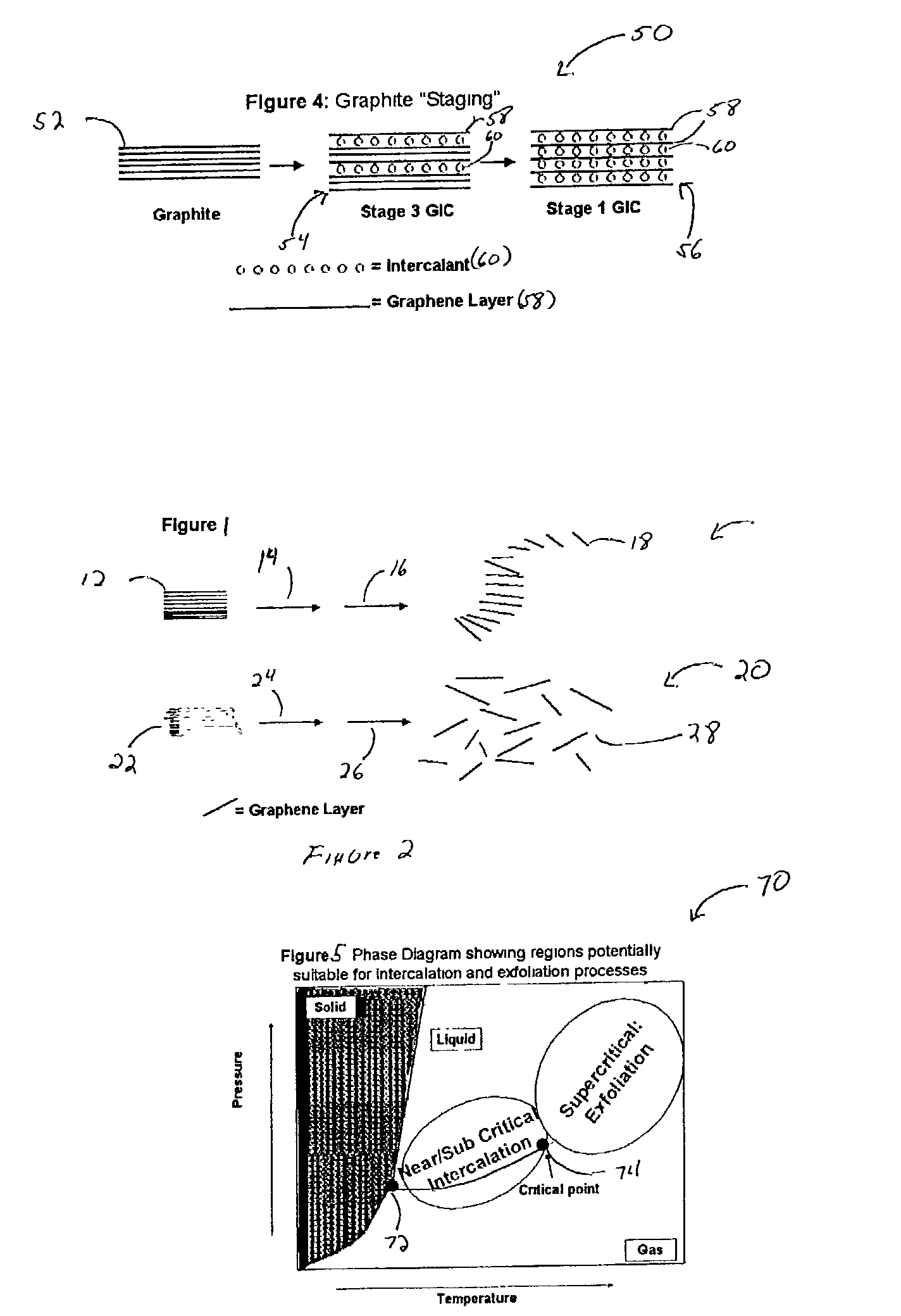

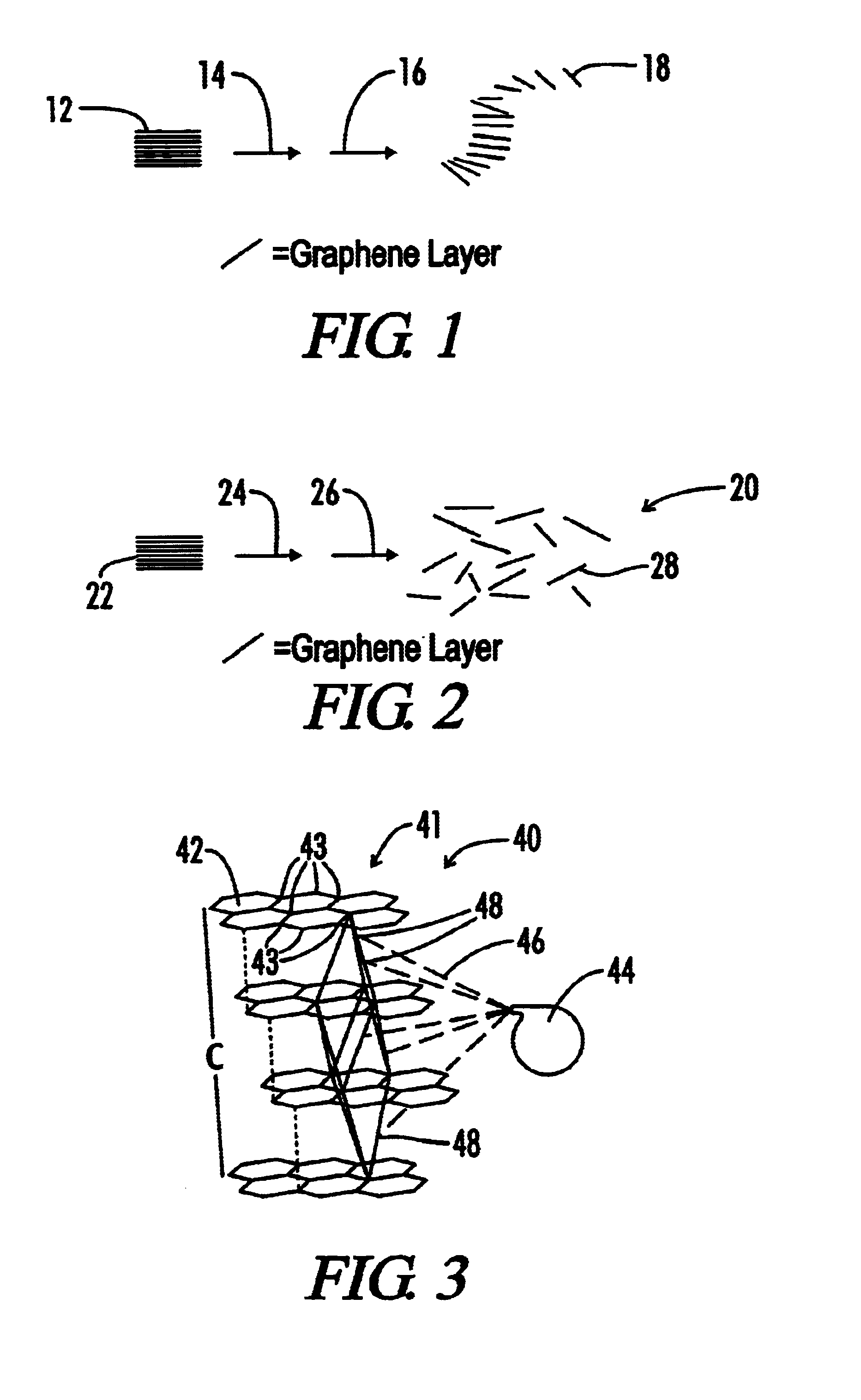

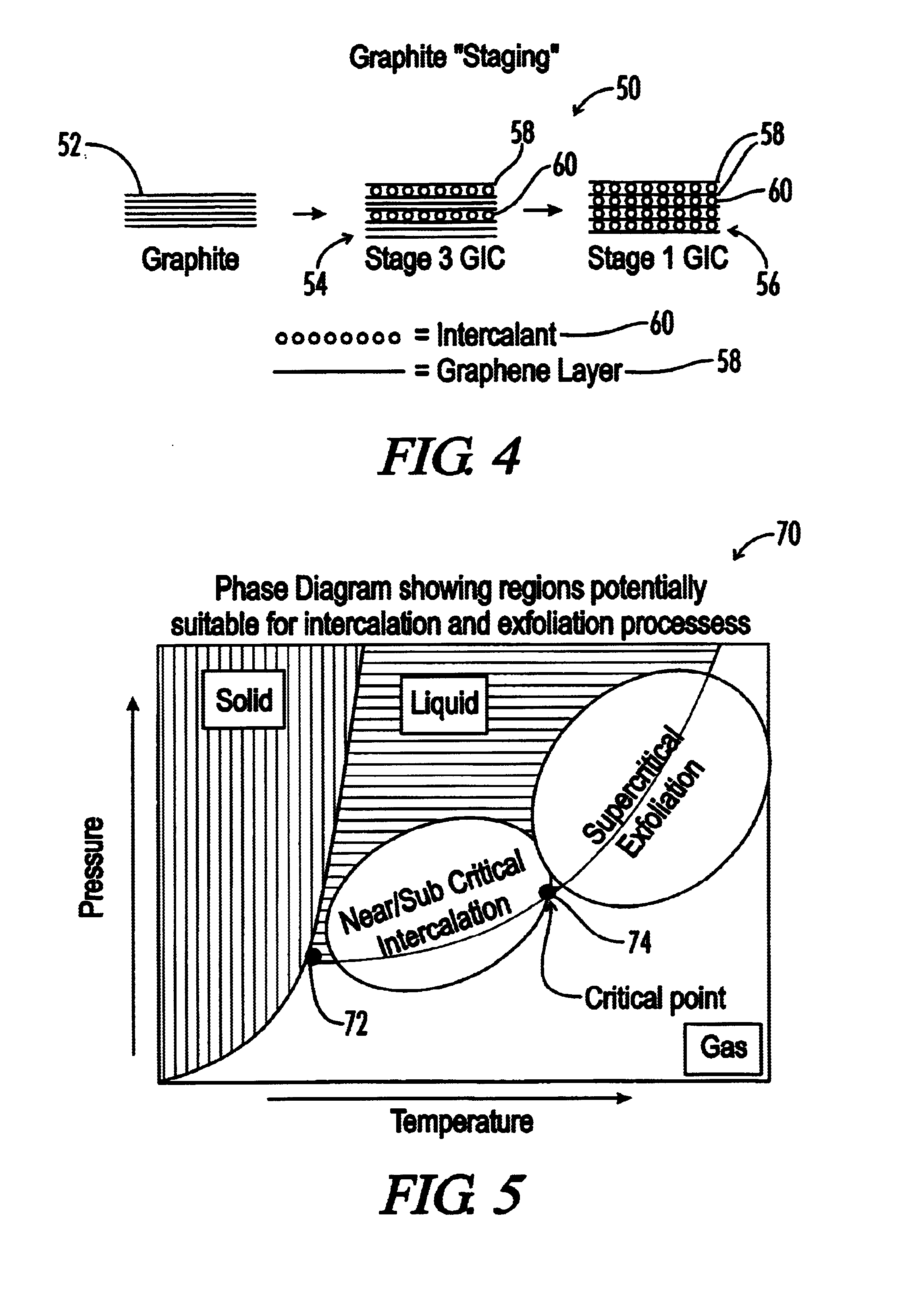

Graphite intercalation and exfoliation process

InactiveUS7105108B2Improve volume expansionReduce needMaterial nanotechnologyGraphiteConductive polymerGraphite particle

The invention relates to expanded graphite and methods of making the graphite and products that can be made from the graphite made from the inventive process. The invention includes the step of introducing a fluid into at least one of a plurality of interstices of graphite flake, wherein the fluid comprises at least one of a sub-critical point fluid, a near critical point fluid, or a supercritical fluid. The graphite flake is also intercalated with an intercalant and optionally an oxidizing agent. The invention may further include novel techniques of exfoliating the graphite. The invention may be practiced to make nano-sized graphite particles and also graphite composites. Preferred composites which may be made in accordance with the invention include conductive polymeric composites (thermally or electrically), paint composites, battery composites, capacitor composites, and pollution abatement catalyst support composites.

Owner:GRAFTECH INT HLDG INC

Inorganic hydrated salt expanded graphite composite phase-changing heat storage material and preparation method thereof

The invention relates to an inorganic hydrated salt expanded graphite composite phase-changing heat storage material. In the preparation method thereof, 85-89 mass parts of inorganic hydrated salt sodium acetate trihydrate as a heat storage matrix, 5.5-6.5 mass parts of disodium hydrogenphosphate as a nucleating agent, 2.5-3.5 mass parts of carboxymethyl cellulose as a thickening agent, and 3-4.5 mass parts of expanded graphite is blended in an inorganic hydrated salt mixture as a material with a high thermal conductivity. Due to the use of the expanded graphite, the material not only maintains excellent properties of natural flake graphite such as good thermal conductivity, no toxicity and the like, but also has adsorbability which the natural flake graphite does not have. The invention solves the problems of sub-cooling degree, phase stratification and low thermal conductivity during the heat storage process. The composite phase-changing material has a low sub-cooling degree after the phase changing performance is improved, the solution thereof is uniform without sedimentation and stratification during the solid-liquid phase change, the performance is stable, the repeatability of good, and the phase-changing heat storage can be enhanced through improving the thermal conductivity of the material.

Owner:ENG COLLEGE OF ENG CORPS PLA UNIV OF SCI & TECH

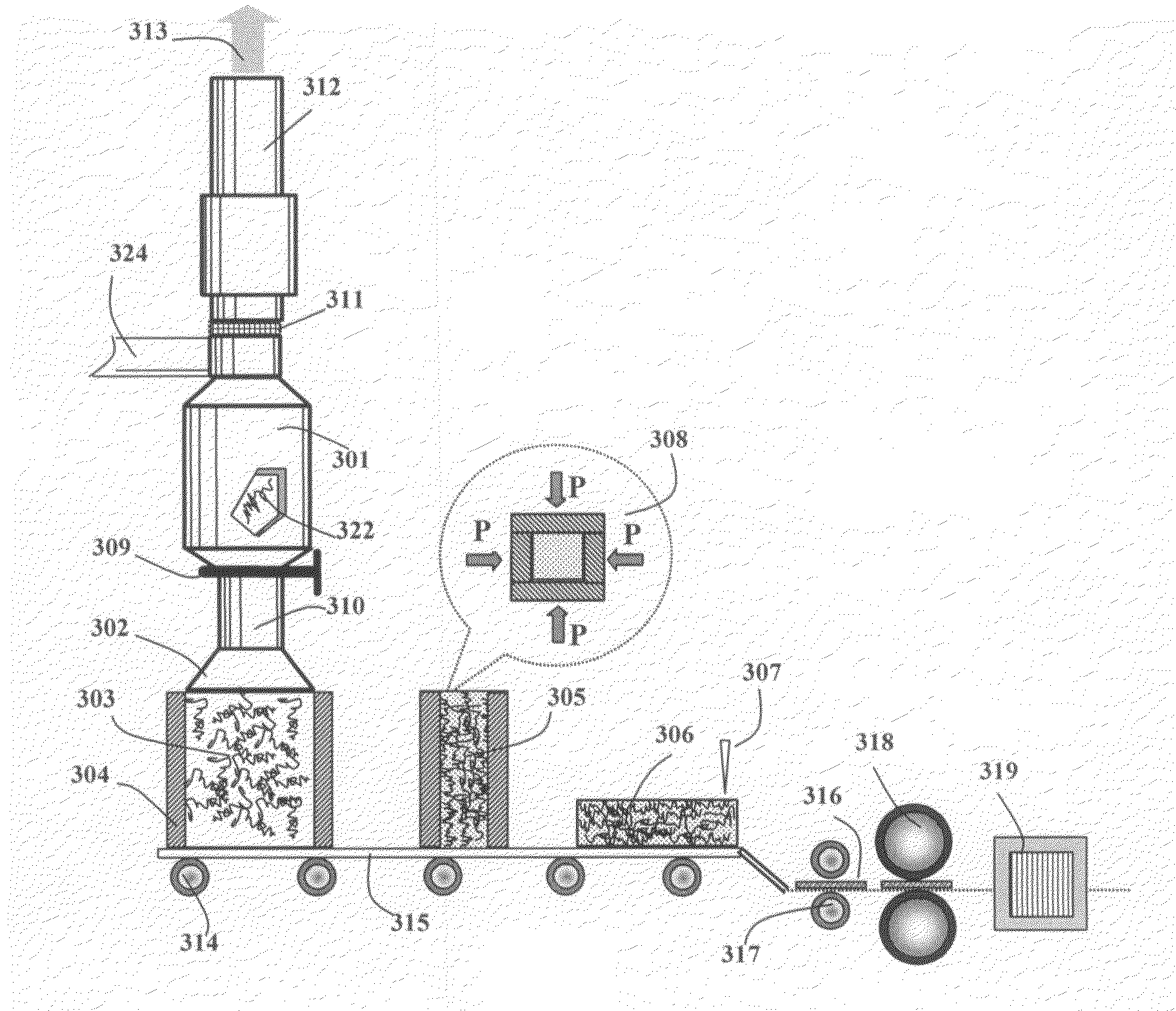

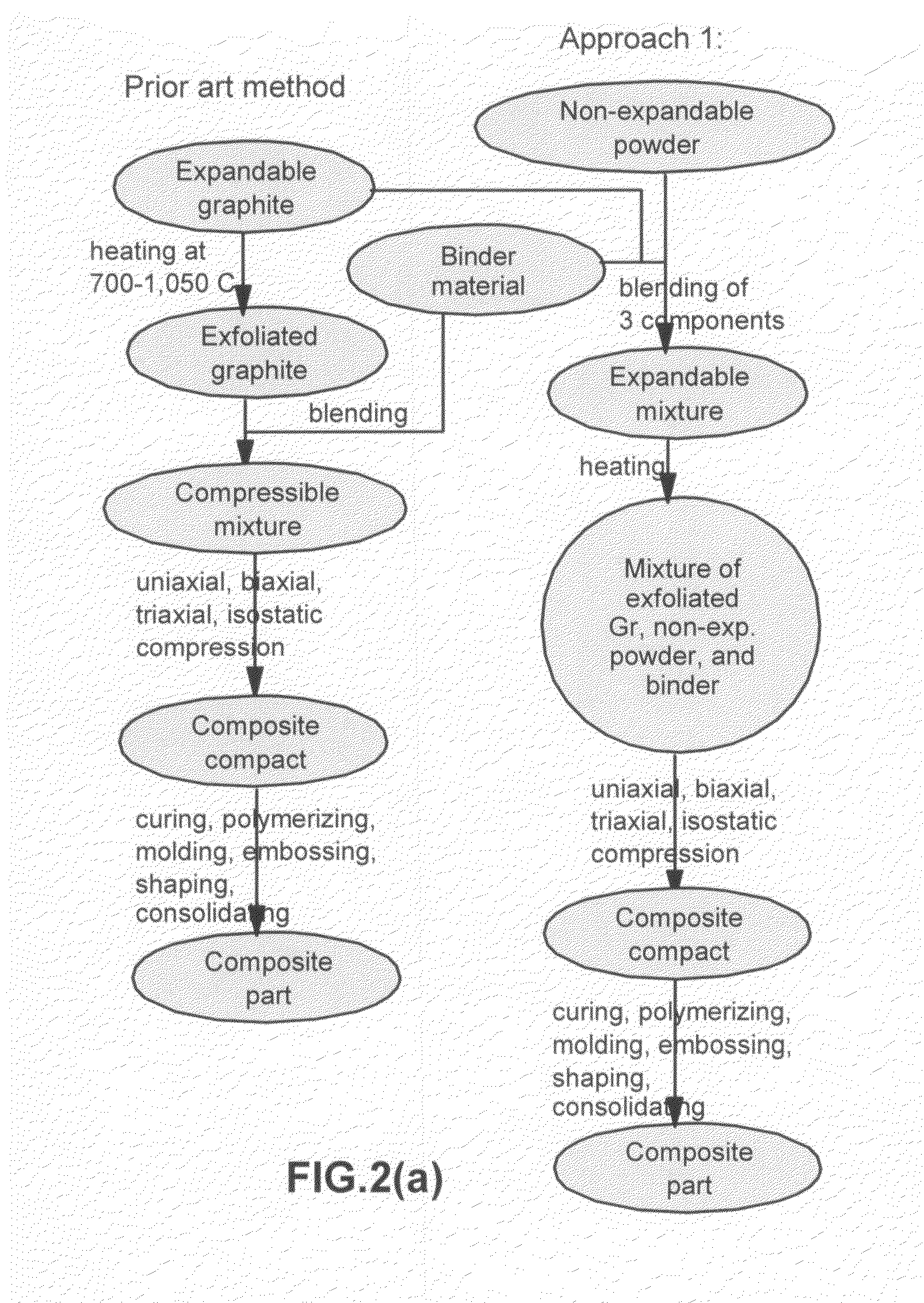

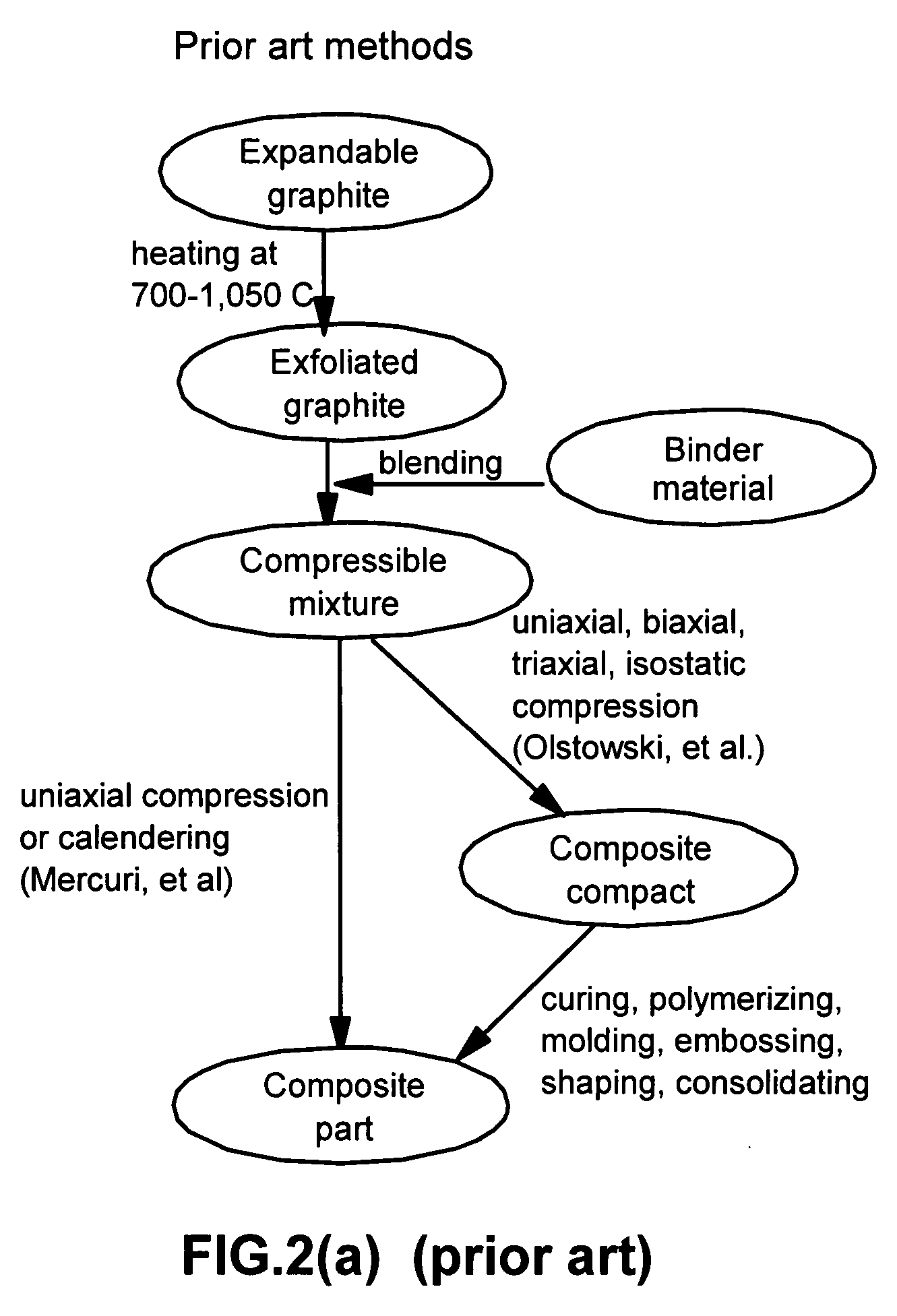

Method of producing exfoliated graphite composite compositions for fuel cell flow field plates

ActiveUS20080279710A1Improve adhesionEliminate or reduce this further anisotropyTransportation and packagingMetal-working apparatusFuel cellsPowder mixture

A method of producing an electrically conductive composite composition, which is particularly useful for fuel cell bipolar plate applications. The method comprises: (a) providing a supply of expandable graphite powder; (b) providing a supply of a non-expandable powder component comprising a binder or matrix material; (c) blending the expandable graphite with the non-expandable powder component to form a powder mixture wherein the non-expandable powder component is in the amount of between 3% and 60% by weight based on the total weight of the powder mixture; (d) exposing the powder mixture to a temperature sufficient for exfoliating the expandable graphite to obtain a compressible mixture comprising expanded graphite worms and the non-expandable component; (e) compressing the compressible mixture at a pressure within the range of from about 5 psi to about 50,000 psi in predetermined directions into predetermined forms of cohered graphite composite compact; and (f) treating the so-formed cohered graphite composite to activate the binder or matrix material thereby promoting adhesion within the compact to produce the desired composite composition. Preferably, the non-expandable powder component further comprises an isotropy-promoting agent such as non-expandable graphite particles. Further preferably, step (e) comprises compressing the mixture in at least two directions. The method leads to composite plates with exceptionally high thickness-direction electrical conductivity.

Owner:NANOTEK INSTR GRP LLC

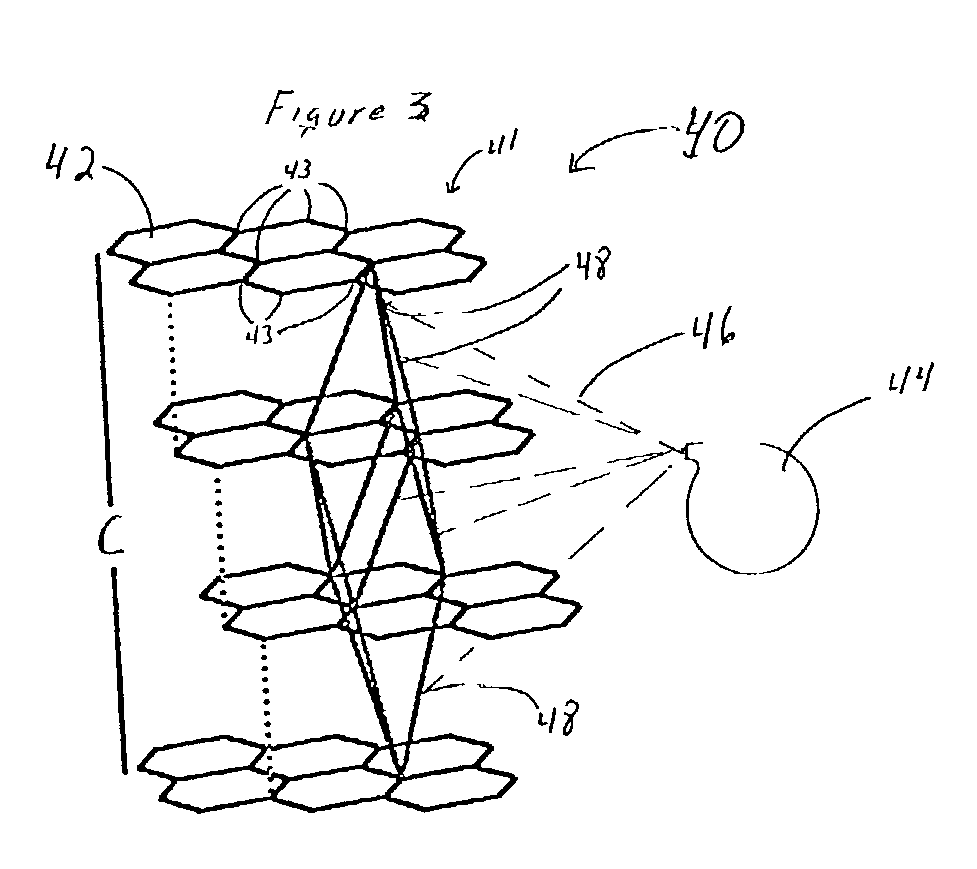

Graphite composites and methods of making such composites

InactiveUS6927250B2Improve volume expansionReduce needSpecial tyresBulk chemical productionConductive polymerPolymer composites

The invention may be practiced to make graphite composites. Preferred composites which may be made in accordance with the invention include conductive polymeric composites (thermally or electrically), paint composites, battery composites, capacitor composites, and pollution abatement catalyst support composites. One method of making the graphite aforementioned composites includes introducing an intercalant into at least one interstice of at least one flake of natural graphite. The method also includes introducing a fluid into the at least one interstices of the flake. Preferably, the fluid comprises at least one of a sub-critical fluid, near critical point fluid, or a supercritical fluid. Furthermore the method includes blending the flake with a polymer, thereby forming a graphite-polymeric composite.

Owner:GRAFTECH INT HLDG INC

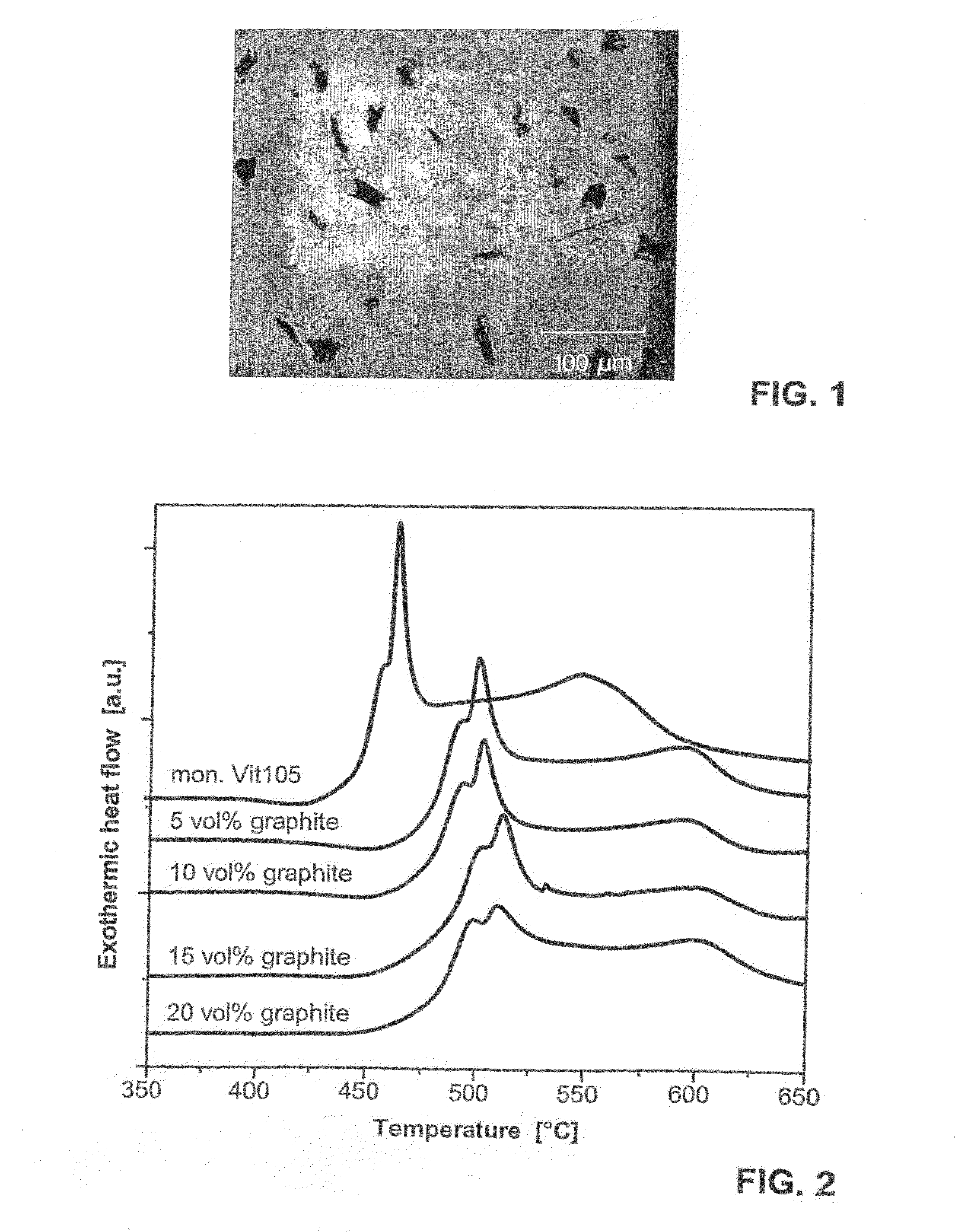

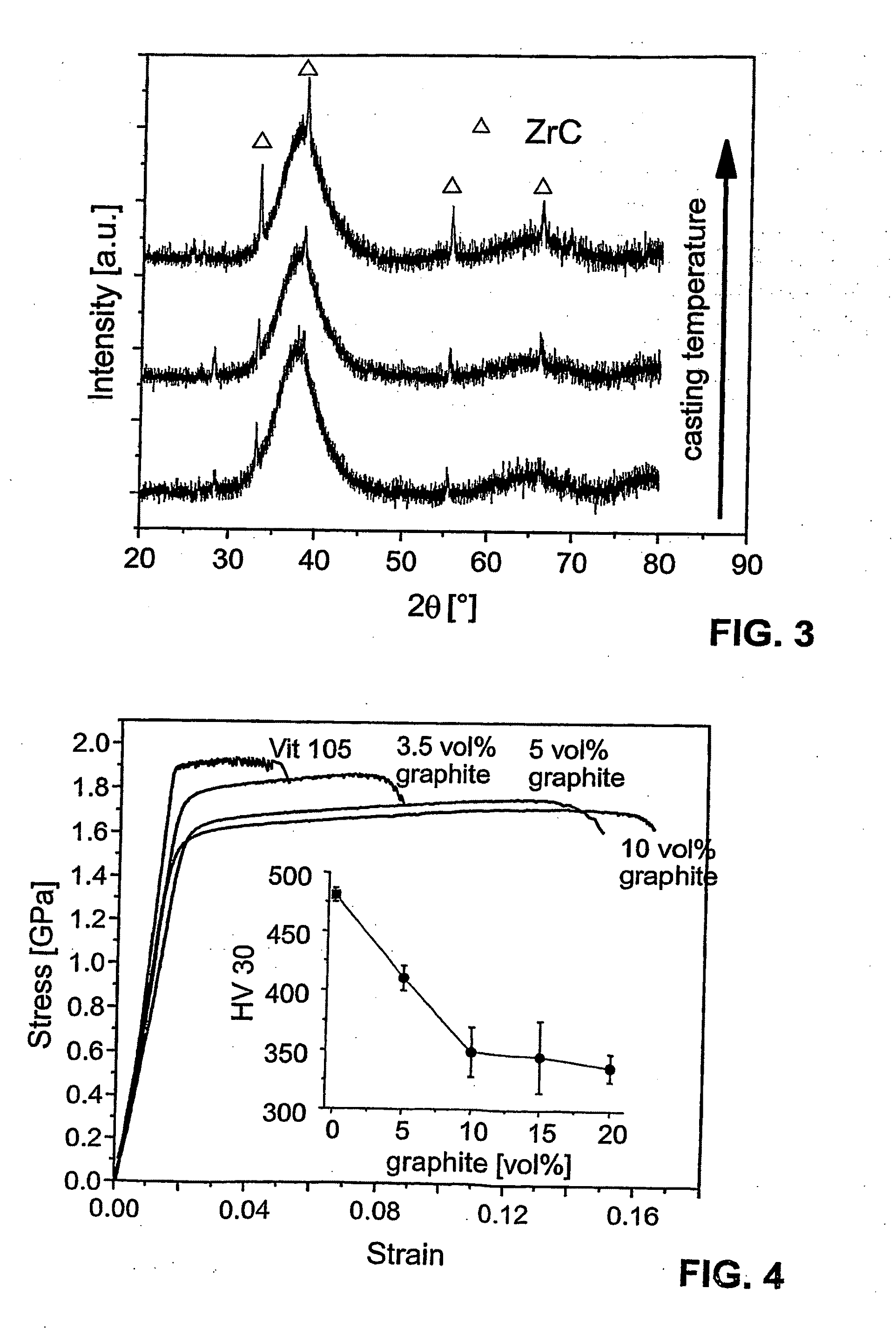

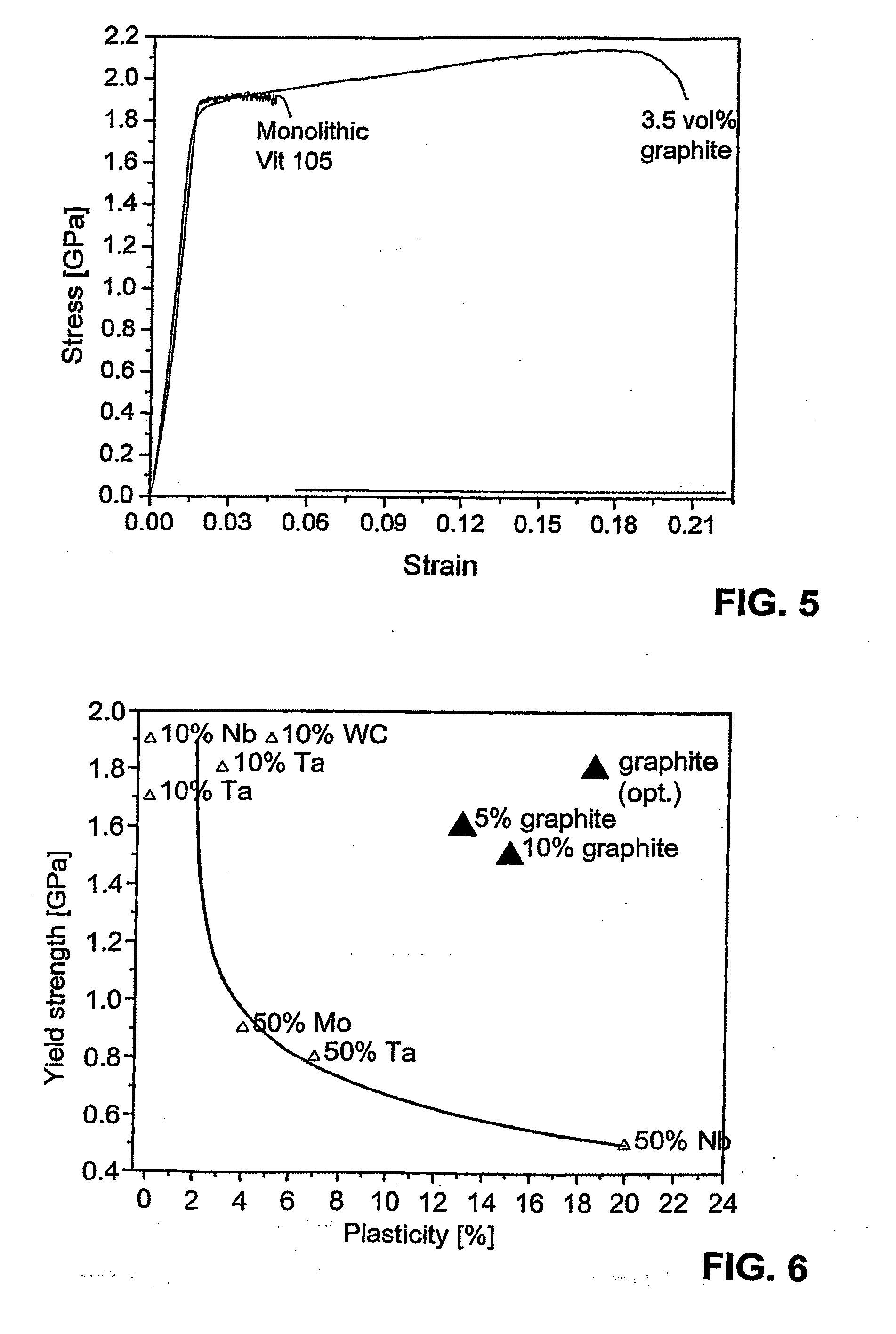

Bulk Metallic Glass/Graphite Composites

A composite material based on a bulk metallic glass is disclosed. In an amorphous alloy phase forming a substantially continuous matrix, a second phase comprising graphite particles is embedded. The alloy is preferably zirconium based. The particles may have a carbide surface layer, which may be formed phase comprising carbide particles may also be present. The composite material has high plasticity, high yield strength, good elasticity and low coefficient of friction, which renders it a good candidate for applications like joints, frictional bearings or Springs.

Owner:ETH ZZURICH

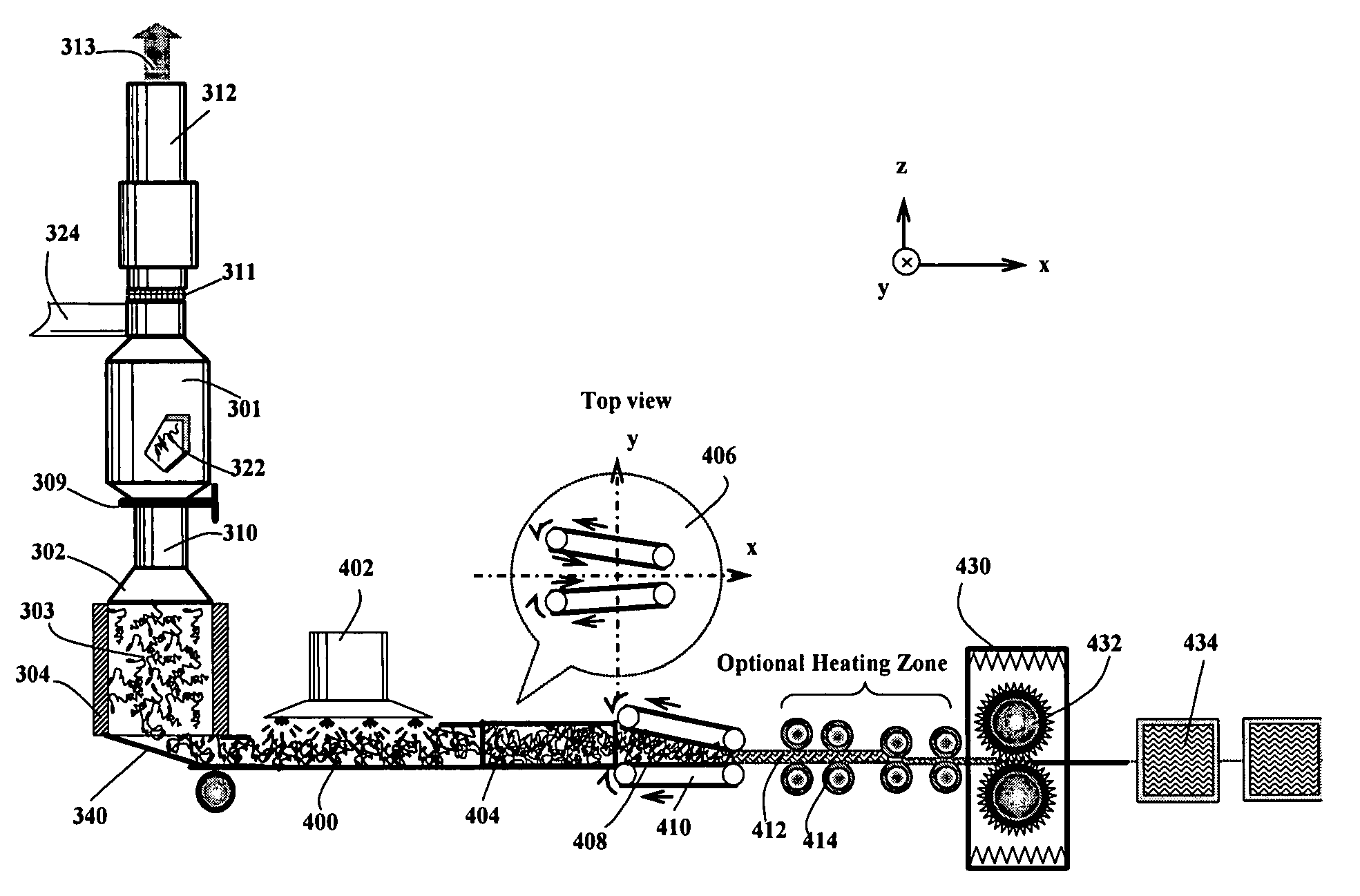

Continious production of exfoliated graphite composite compositions and flow field plates

InactiveUS20090072448A1Eliminate or reduce this further anisotropyPromote wettingTurbinesElectric discharge heatingHost materialComposite plate

A process of continuously producing a more isotropic, electrically conductive composite composition is provided. The process comprises: (a) continuously supplying a compressible mixture comprising exfoliated graphite worms and a binder or matrix material, wherein the binder or matrix material is in an amount of between 3% and 60% by weight based on the total weight of the mixture; (b) continuously compressing the compressible mixture at a pressure within the range of from about 5 psi or 0.035 MPa to about 50,000 psi or 350 MPa in at least a first direction into a cohered graphite composite compact; and (c) continuously compressing the composite compact in a second direction, different from the first direction, to form the composite composition in a sheet or plate form. The process leads to composite plates with exceptionally high thickness-direction electrical conductivity.

Owner:NANOTEK INSTR GRP LLC

Non-aqueous secondary battery-use graphite composite particle, cathode active substance material containing it, cathode and non-aqueous secondary battery

ActiveUS20090130561A1Small charge-discharge irreversible capacitySmall charge-dischargeGraphiteSecondary cellsCharge dischargePeak value

To provide a nonaqueous secondary battery ensuring that a charge-discharge irreversible capacity at an initial cycle is sufficiently small even when an active material layer comprising a negative electrode active material on a current collector is increased in a density for obtaining a high capacity.This object is attained by a graphite composite particle for a nonaqueous secondary battery, which satisfies the requirements (1) and (2):(1) DL / DS is more than 1 and 2 or less, wherein DL μm means a volume-based median size measured by a laser diffraction / scattering-type particle size distribution measuring apparatus, and DS μm means an average circle-equivalent particle size which is determined from a measured area S of particles each having a contour not overlapped with a contour of another particle in a SEM; and(2) a Raman R value is 0.04 or more and 0.14 or less, wherein the Raman R value means an intensity ratio IB / IA between an intensity IA of a maximum peak of 1580 cm−1 around and an intensity IB of a maximum peak of 1360 cm−1 around in a Raman spectrum.

Owner:TOKAI CARBON CO LTD +1

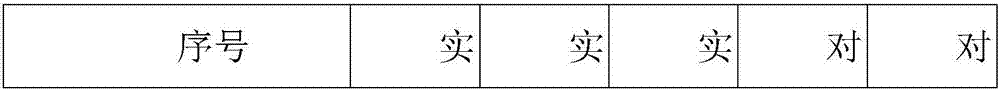

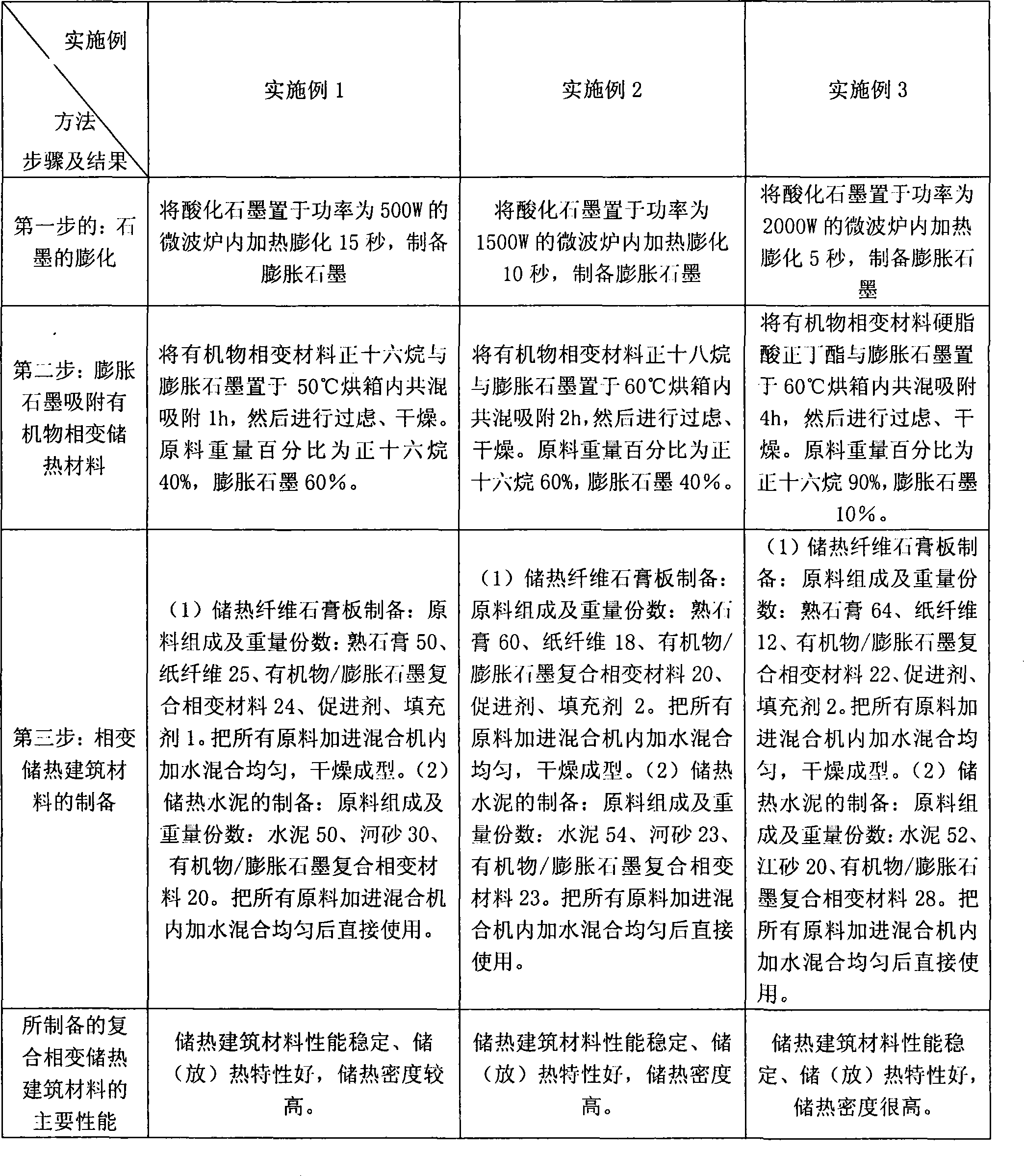

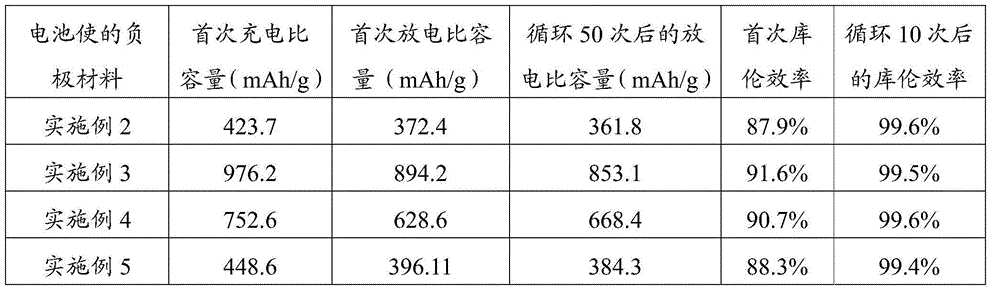

Artificial graphite composite negative electrode material for lithium ion battery and preparation method for negative electrode material

ActiveCN107369823ALarge specific surface areaLarge particles and small specific surface area of needle cokeElectrode thermal treatmentDischarge efficiencyGranularity

The invention discloses an artificial graphite composite negative electrode material for a lithium ion battery. The negative electrode material is 16-21[mu]m in average grain diameter D50, 1.1-1.2g / cm<3> in tap density, 1.0-3.0m<2> / g in surface specific area, and less than 0.05% in ash content; the preparation method comprises the steps of performing smashing and grading on needle coke to obtain powder of two kinds of granularities; performing uniform mixing on the powder of two kinds of granularities to obtain a composite precursor; performing balling and shaping treatment on the composite precursor; performing high-temperature graphitization treatment on the shaped material; performing uniform mixing on the graphitized material and an organic carbon source; and performing carbonization on the mixture and cooling to the room temperature. The obtained negative electrode material can be 1.75g / cm<3> in compaction density; the initial reversible capacity can be higher than 355mAh / g; the initial discharge efficiency can be as high as 97%; the cycling performance at middle rate (0.5C, 1C, 2C) can be greatly improved; and in addition, the preparation method is simple and low in cost and suitable for industrial production.

Owner:GUANGDONG DONGDAO NEW ENERGY

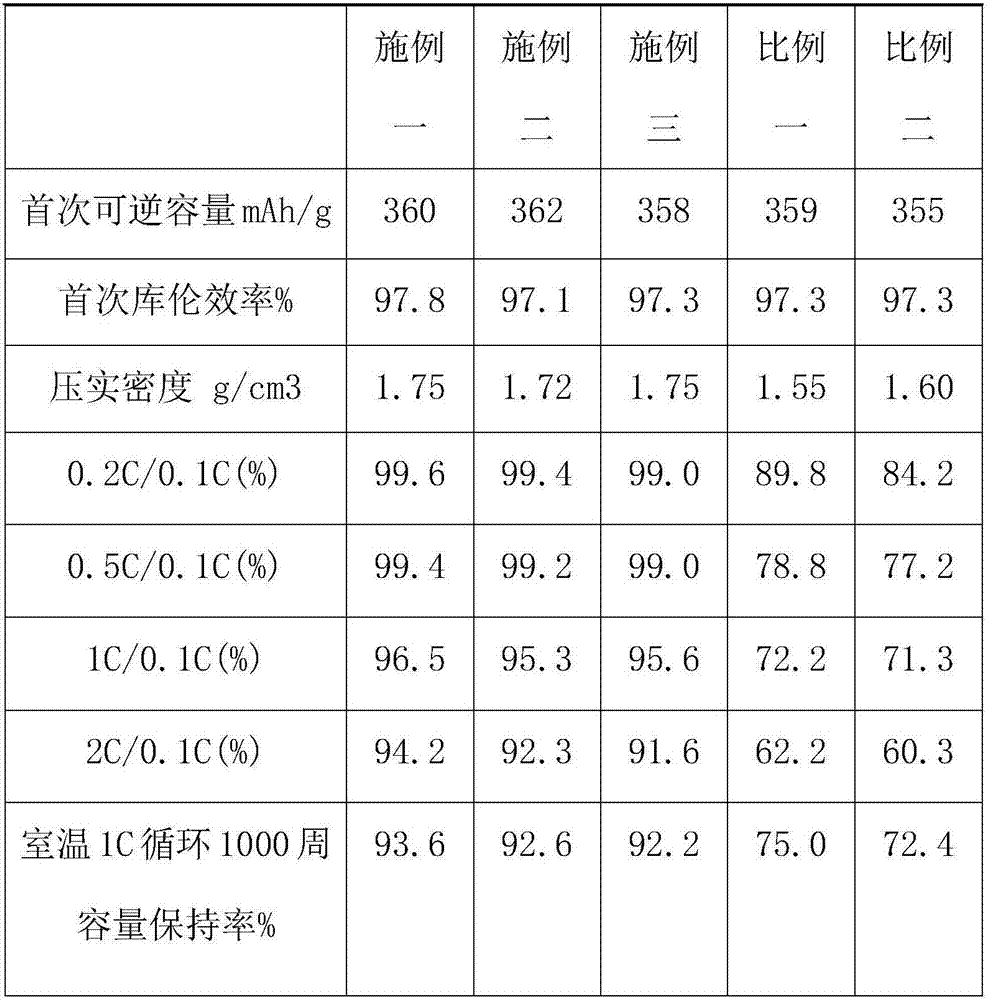

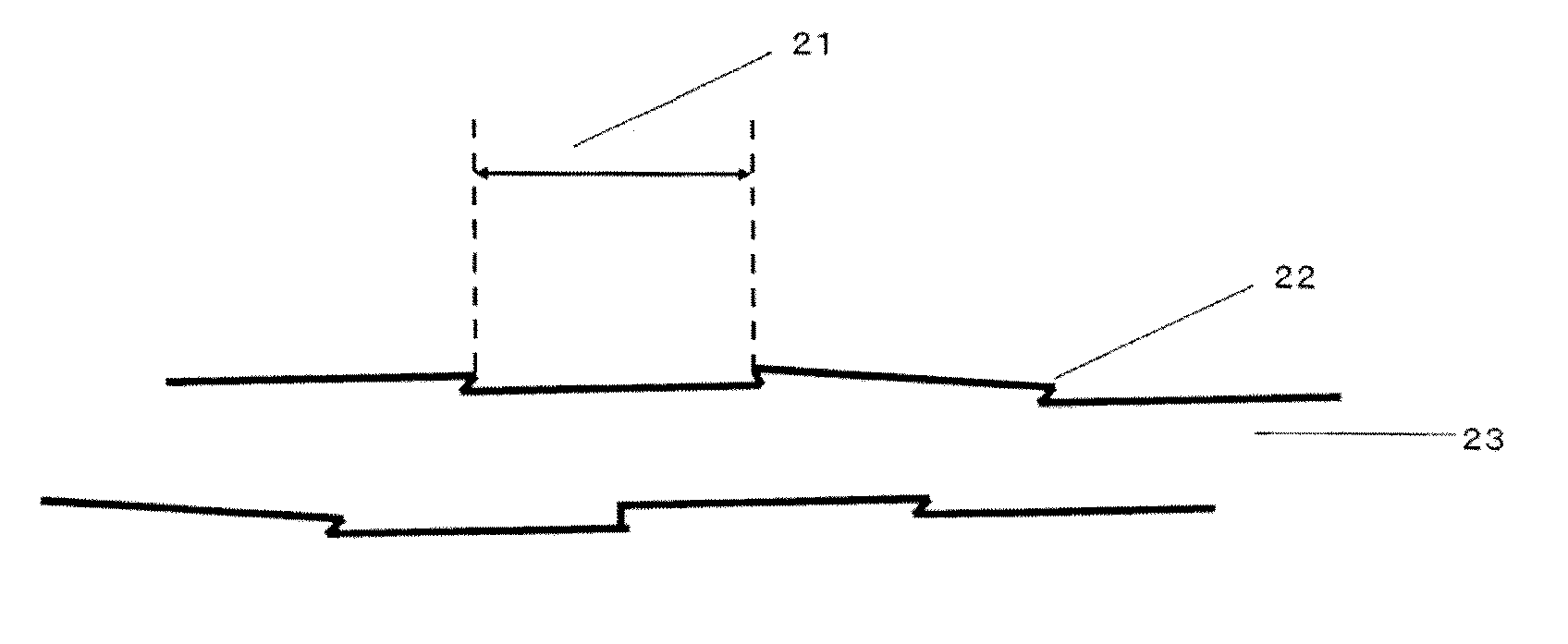

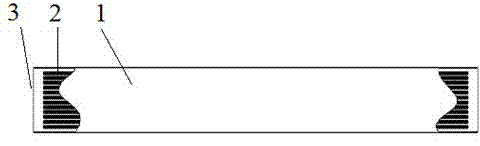

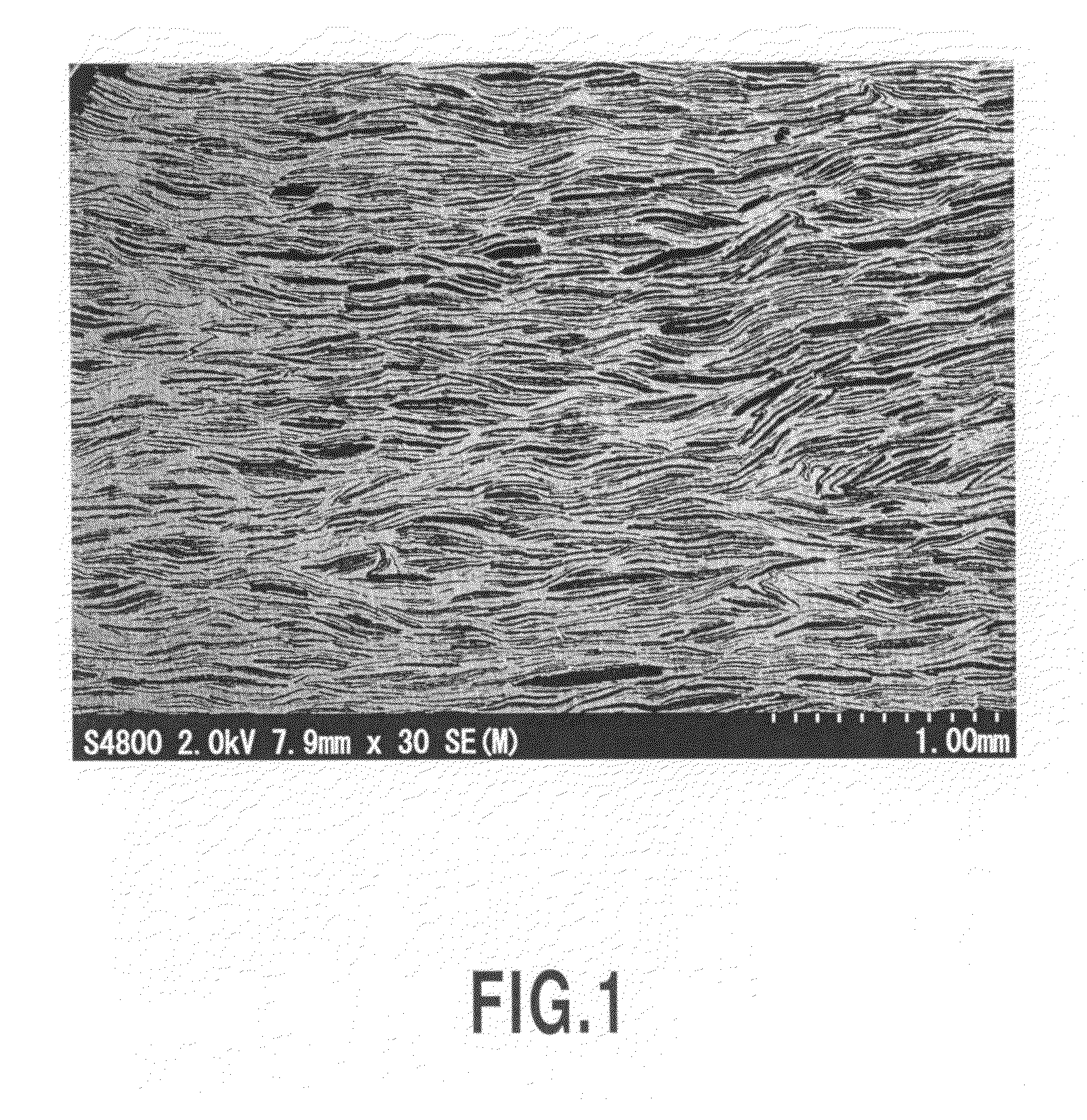

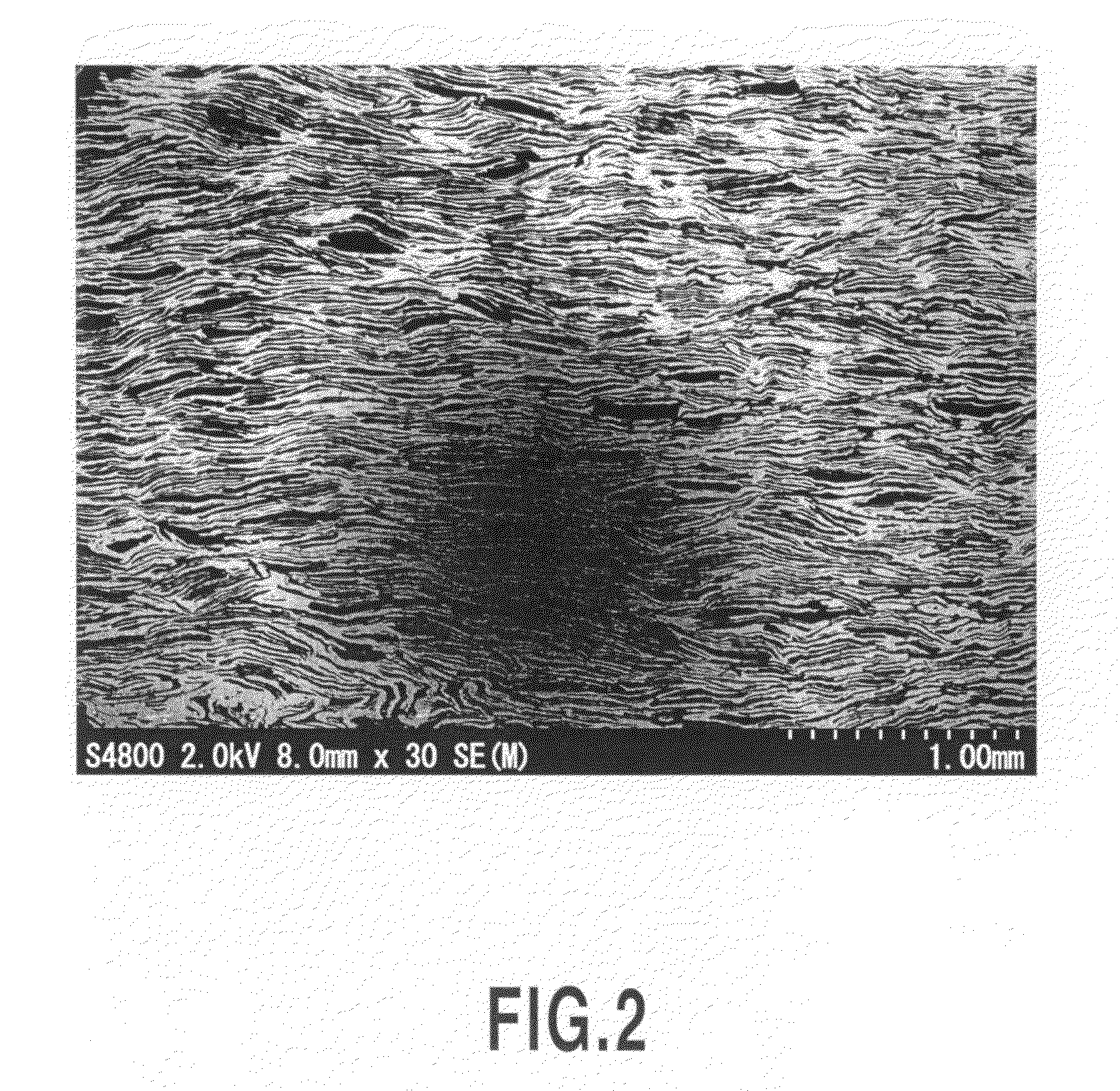

Graphite Film and Graphite Composite Film

ActiveUS20100196716A1Improve flex resistanceExcellent thermal diffusivityGraphiteSemiconductor/solid-state device detailsFolding enduranceElectronic instrument

An object of the present invention is to provide a graphite film, and a graphite composite film both having an excellent thermal diffusivity which can sufficiently manage heat dissipation of electronic instruments, precision instruments and the like, along with an excellent flex resistance which can withstand application to bent portions.Means for Resolution of the present invention is a graphite film exhibiting the number of reciprocal foldings being 10,000 times or more as measured using a rectangular strip test piece having a width of 15 mm until the test piece breaks in a MIT folding endurance test under conditions of: a curvature radius R of the bending clamp being 2 mm; a left-and-right bending angle being 135°; a bending rate being 90 times / min; and a load being 0.98 N.

Owner:KANEKA CORP

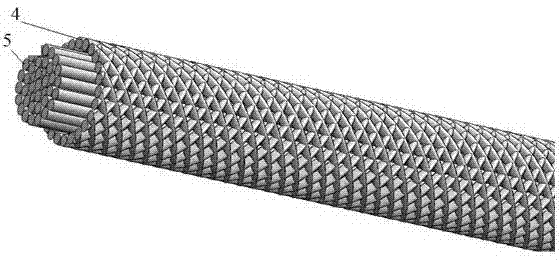

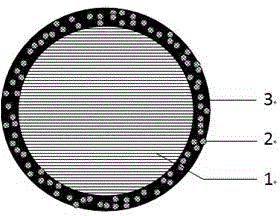

Novel graphite composite grounding material and preparation method thereof

ActiveCN103490180ASolving Corrosion ProblemsIncrease contact areaContact member manufacturingConnection contact member materialYarnCorrosion resistant

The invention discloses a novel graphite composite grounding material and a preparation method thereof. The novel graphite composite grounding material is in the shape of a rope or stranded wire, and comprises a composite graphite yarn inner core and a composite graphite yarn knitted layer wrapped outside the composite graphite yarn inner core, wherein the composite graphite yarn inner core is a composite graphite yarn bundle composed of a plurality of first composite graphite yarns or a single first composite graphite yarn; each first composite graphite yarn is prepared by twisting a first composite graphite belt; the composite graphite yarn knitted layer is prepared by knitting a second composite graphite yarn; and the second composite graphite yarn is prepared by twisting a second composite graphite belt. The graphite composite grounding material disclosed by the invention has the advantages of corrosion resistance, favorable conductivity, high flexibility, low price, precise soil association and the like, and is easy for transportation; since the price is low, artificial theft destroy can be avoided; and the graphite composite grounding material is suitable for the fields of transformer stations, overhead transmission line towers, tall buildings and all other projects in need of electric grounding.

Owner:WUHAN HONGMEN ELECTRICAL TECH CO LTD

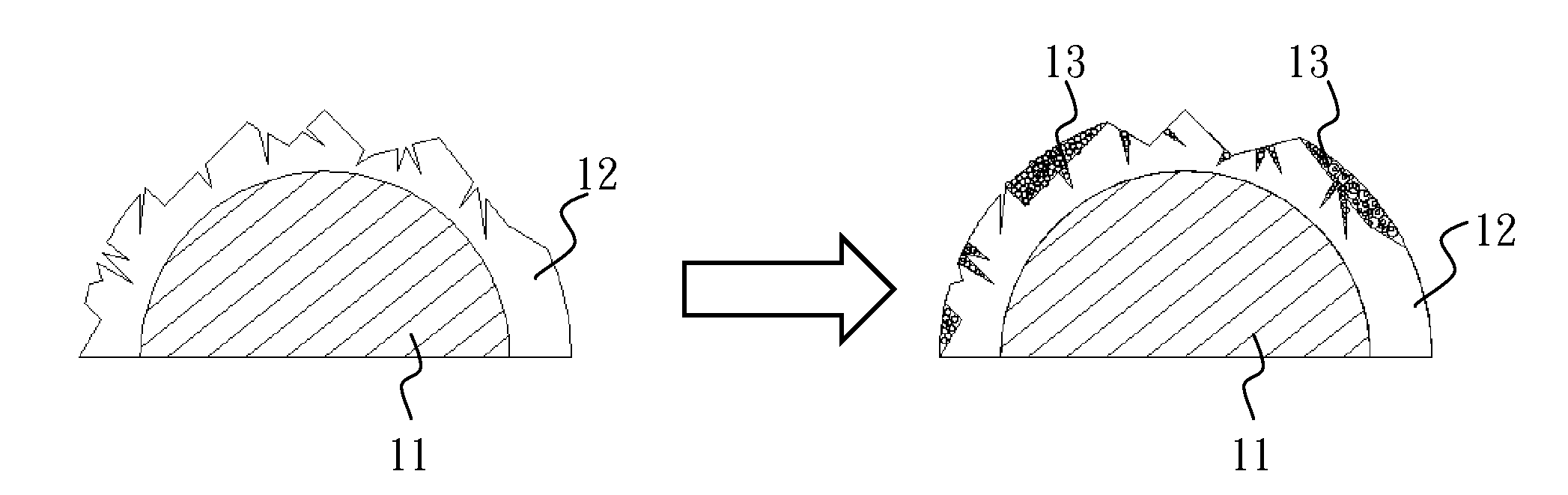

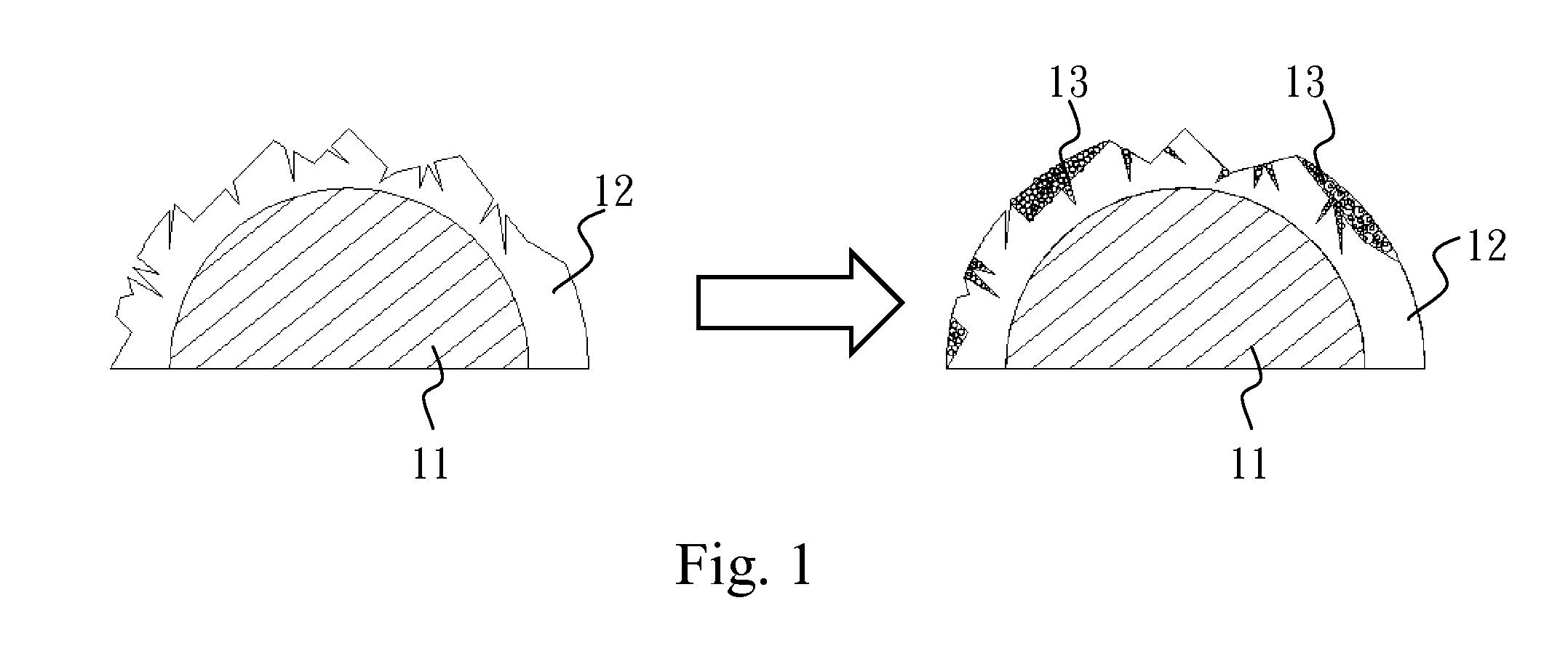

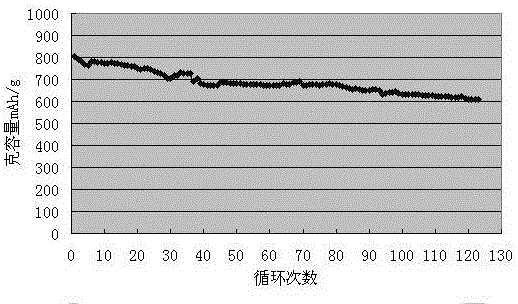

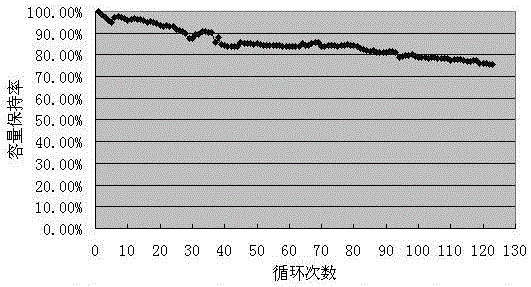

Anode material of lithium-ion secondary battery and preparation method thereof

ActiveUS20120074610A1Low costManufacturing process is complicatedConductive materialCarbon monoxideLithiumElectrical battery

In an anode material of a lithium-ion secondary battery and its preparation method, a natural graphite, an artificial graphite or both are mixed to form a graphite powder, and the graphite powder is mixed with a resin of a high hard carbon content and processed by a mist spray drying process, and finally added or coated with a special resin material after a carburizing heat treatment takes place to prepare a graphite composite of the anode material of the lithium-ion secondary battery and achieve a smaller surface area of an anode graphite composite of the battery and extended cycle life and capacity.

Owner:LONG TIME TECH

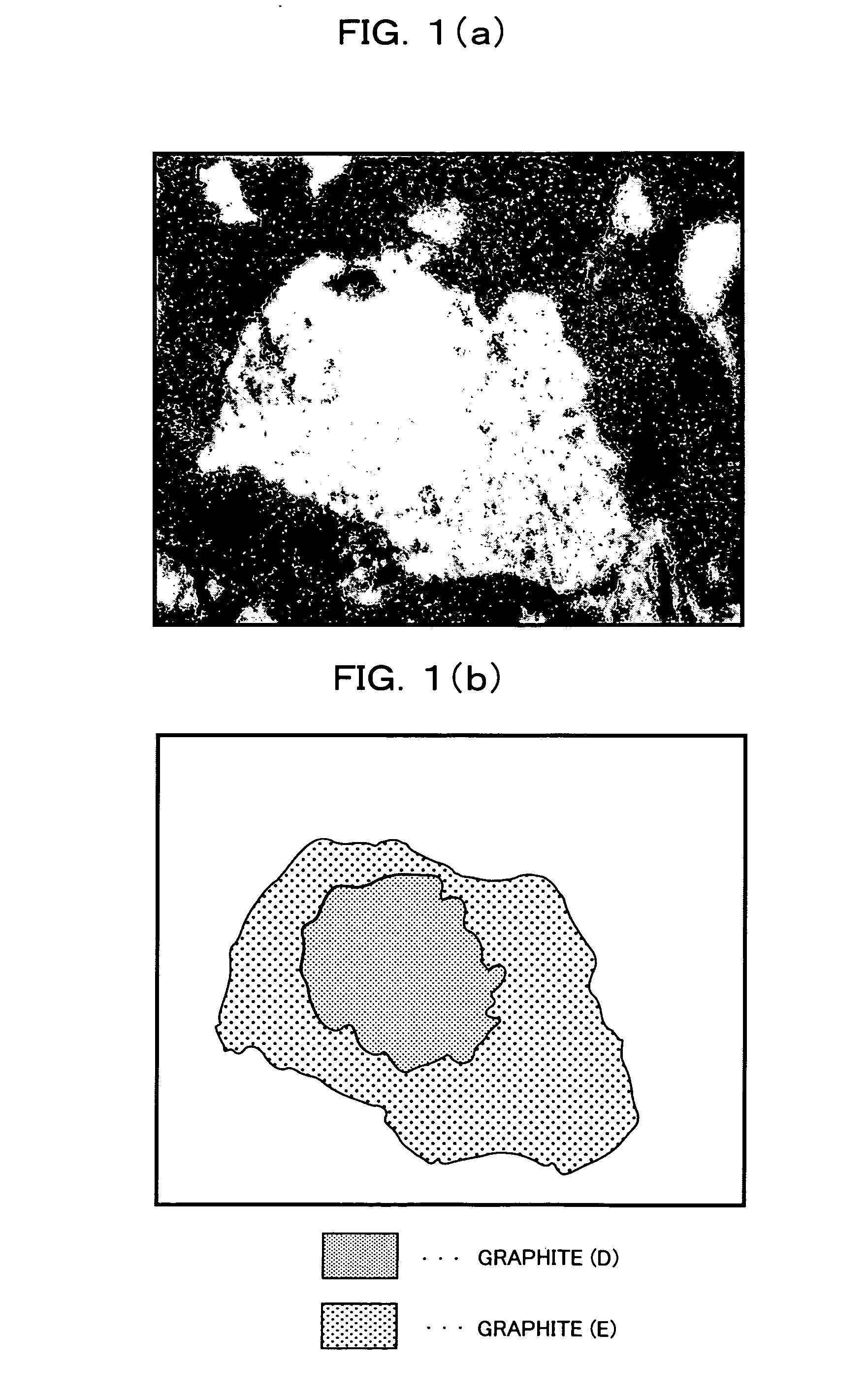

Negative electrode material for lithium secondary battery, method for producing same, negative electrode for lithium secondary battery using same, and lithium secondary battery

InactiveUS20070128518A1Easy to optimizeLarge discharge capacityPigmenting treatmentGraphiteLithiumBattery cell

There is provided an excellent negative-electrode material using graphite for lithium secondary battery that, when used in high electrode density, can yield an excellent lithium secondary battery which has large discharging capacity, achieves high efficiency during charging and discharging, exhibits superior load characteristics, and involves only a small amount of swelling of the electrode during charging. The material has a graphite-composite mixture powder (C) that comprises: a graphite composite powder (A) in which a graphite (D), whose aspect ratio is 1.2 or larger and 4.0 or smaller, is compounded with a graphite (E), which has orientation different from orientation of said graphite (D); and an artificial graphite powder (B).

Owner:MITSUBISHI CHEM CORP

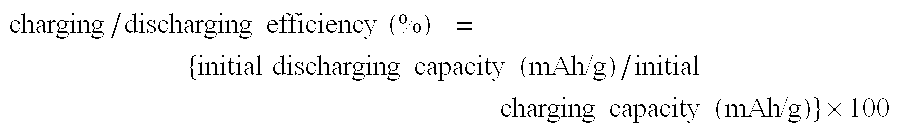

Organic matter/expandable graphite composite phase change heat-storing building material and preparation method thereof

InactiveCN101239798AGood chemical stabilityIncrease inertiaSolid waste managementHeat-exchange elementsFiberMicrowave

The present invention discloses an organic matter / expanded graphite composite phase-changing heat-storing building material and the preparation thereof, the method comprises the following procedures: (1) the swelling of the acidic graphite under the function of the microwave to form the expanded graphite with abundant micropore structure; (2) executing blending adsorption to the organic phase-changing material and the expanded graphite at the condition higher than the phase transition temperature, and the organic phase-changing material is adsorbed to the micropore structure of the expanded graphite; (3) the preparing of the organic / expanded graphite composite phase-changing heat storing building material comprising the following steps: (a) the preparing of the heat storing fiber gypsum board, (b) the preparing of the heat storing cement. The method of the invention settles the compatibility of the problem of organic phase-changing material and the building material and the stability. The organic / expanded graphite composite phase-changing heat storing building material has the advantages of low cost, large heat storing density, good heat conducting property and no inflammability.

Owner:SOUTH CHINA UNIV OF TECH

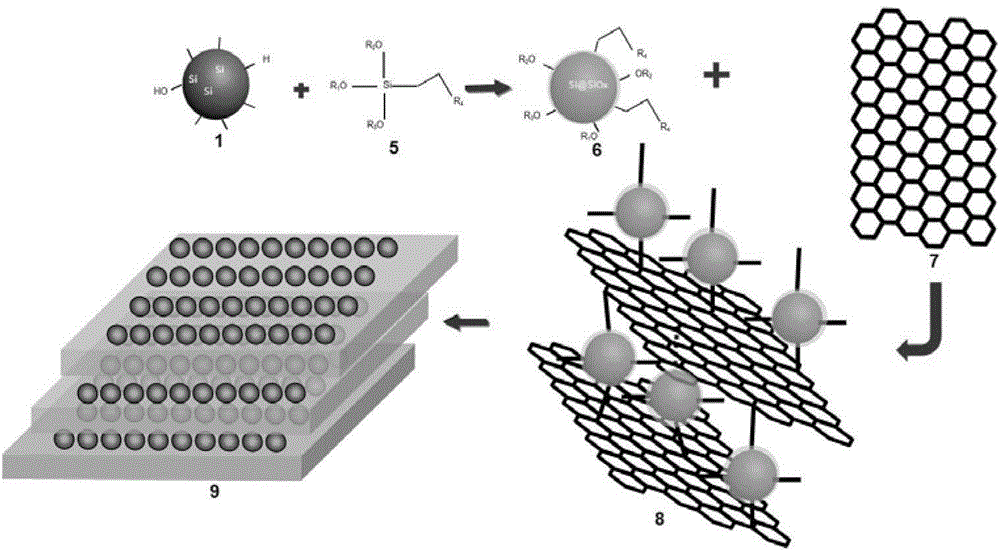

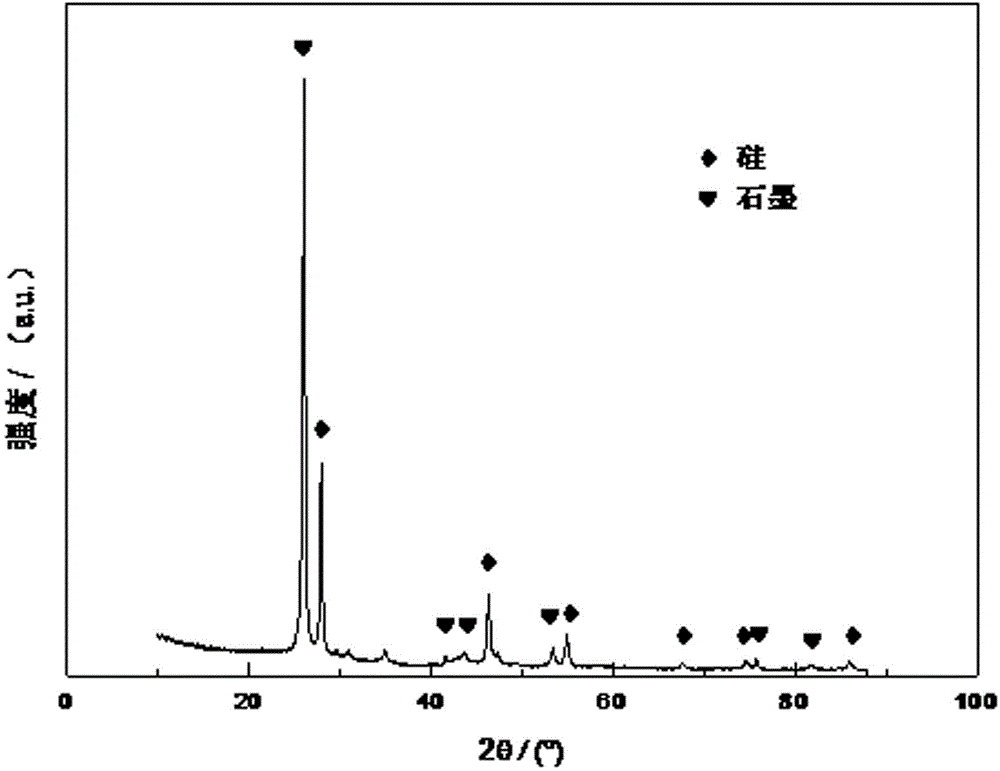

Silicon/silicon oxycarbide/graphite composite negative electrode material

ActiveCN104466142AAdjustable capacityStable structureElectrode carriers/collectorsSecondary cellsSilicon oxygenLithium-ion battery

The invention relates to a silicon / silicon oxycarbide / graphite composite negative electrode material which is a silicon-containing material which has the size being lower than 3 microns uniformly and is firmly distributed on the surface of a negative electrode of graphite. The invention further provides a preparation method of the composite negative electrode material. The preparation method comprises the steps of dispersing a silicon-containing material in a liquid organo-siloxane monomer, sequentially adding an acid liquid of alcohol and water, a curing agent and a graphite negative electrode material, then carrying out ball milling or mechanical stirring, pinching and mixing to obtain a paste-type mixture; calcining the paste-type mixture at high temperature under a protective atmosphere, crushing and sieving to obtain different-particle-size silicon / silicon oxycarbide / graphite lithium-ion battery negative electrode material. The silicon-containing materials of the silicon / silicon-oxygen carbon / graphite composite negative electrode material are firmly and uniformly distributed on the surface of a graphite material; due to the structure, the silicon-containing materials can be effectively adsorbed on the surface of the graphite, the self agglomeration of the silicon-containing material can be avoided and the silicon-containing material is prevented from peeling off from the graphite; the silicon / silicon oxycarbide / graphite composite negative electrode material has the characteristics that the charge and discharge specific capacities are adjustable, and the electrochemical cycle stability is high.

Owner:CHINA AUTOMOTIVE BATTERY RES INST CO LTD

Preparation of polystyrene/expanded graphite composite foaming material

InactiveCN101891852APhysical and mechanical properties do not deteriorateImprove physical and mechanical propertiesCompression moldingFoaming agent

Owner:SHANGHAI BOTAO ENVIRONMENT PROTECTION SCI & TECH +1

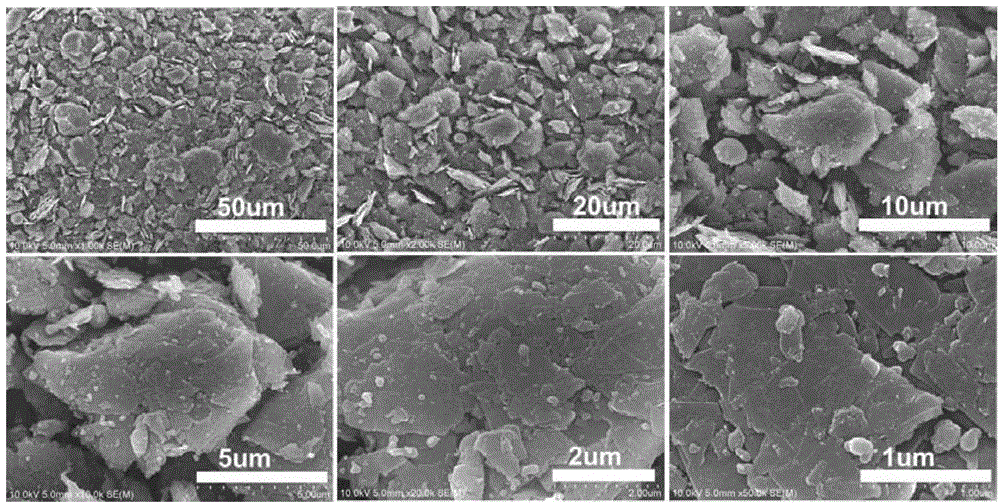

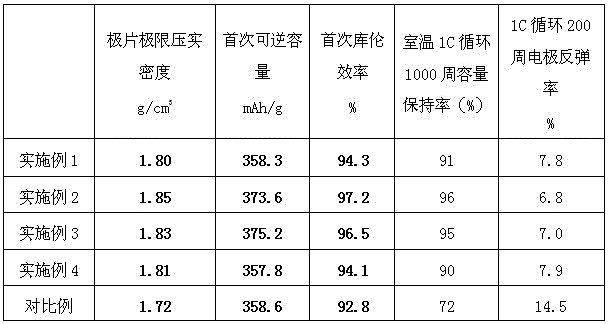

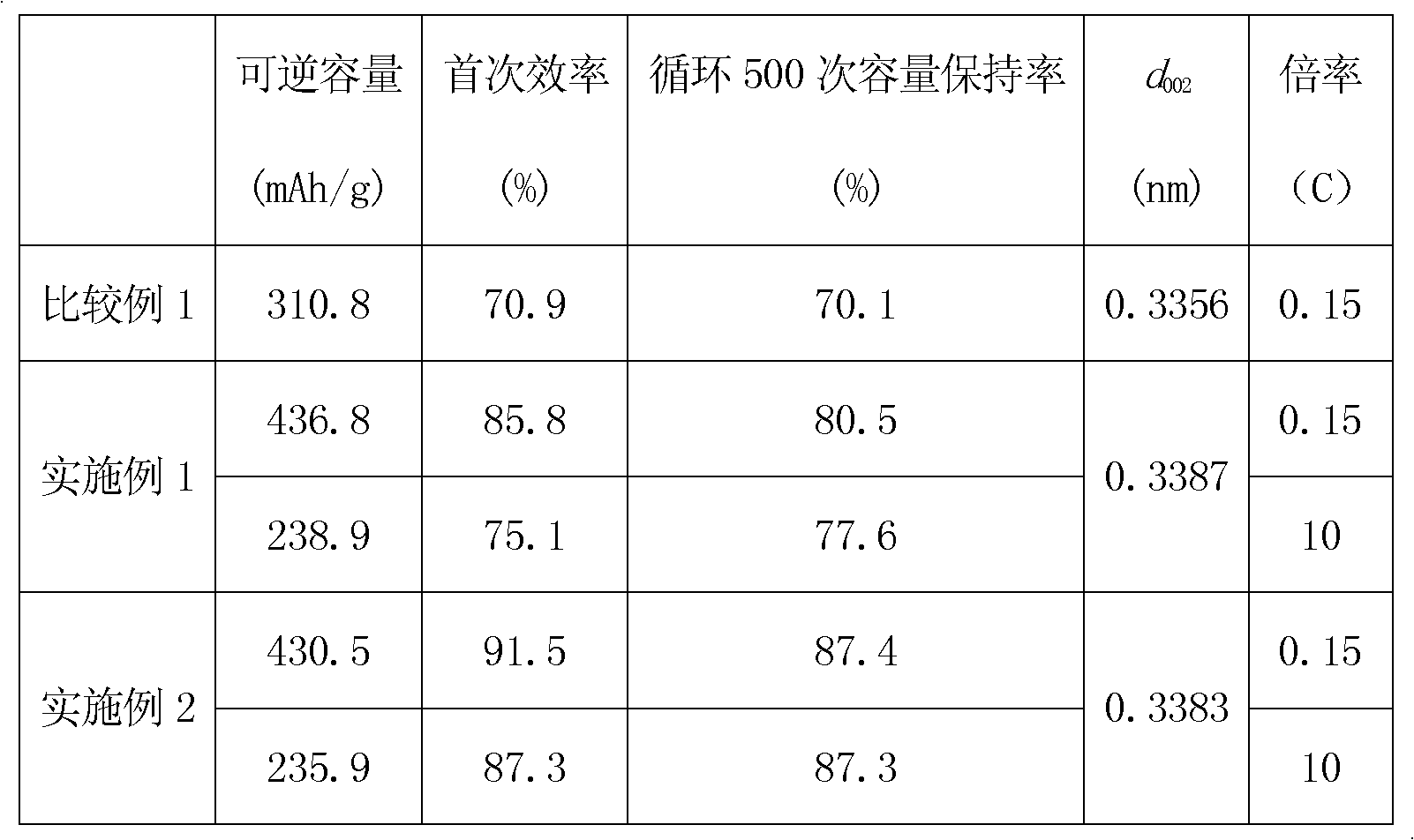

Artificial graphite composite negative electrode material for lithium-ion battery and preparation method of artificial graphite composite negative electrode material

ActiveCN105938906AAvoid easy disassemblyImprove bindingCell electrodesSecondary cellsIon beamLithium-ion battery

The invention provides an artificial graphite composite negative electrode material for a lithium-ion battery and a preparation method of the artificial graphite composite negative electrode material. The material is a secondary particle complex of pure artificial graphite, and is prepared by the technologies of crushing, grading, spheroidizing, ion beam bombardment, mixing, high-temperature compounding, grading, graphitizing, screening, demagnetizing and the like, and the needle coke is taken as a raw material and the asphalt is taken as a binder. The compaction density of the composite negative electrode material prepared by the method can reach 1.80g / cc; the reversible capacity is higher than 355mAh / g; the first efficiency is about 94%; and the electrode expansion ratio after circulating 200 cycles is lower than 8%. The adopted technologies are traditional powder processing technologies or carbon technologies; and industrialization is easy to achieve.

Owner:HUNAN SHINZOOM TECH

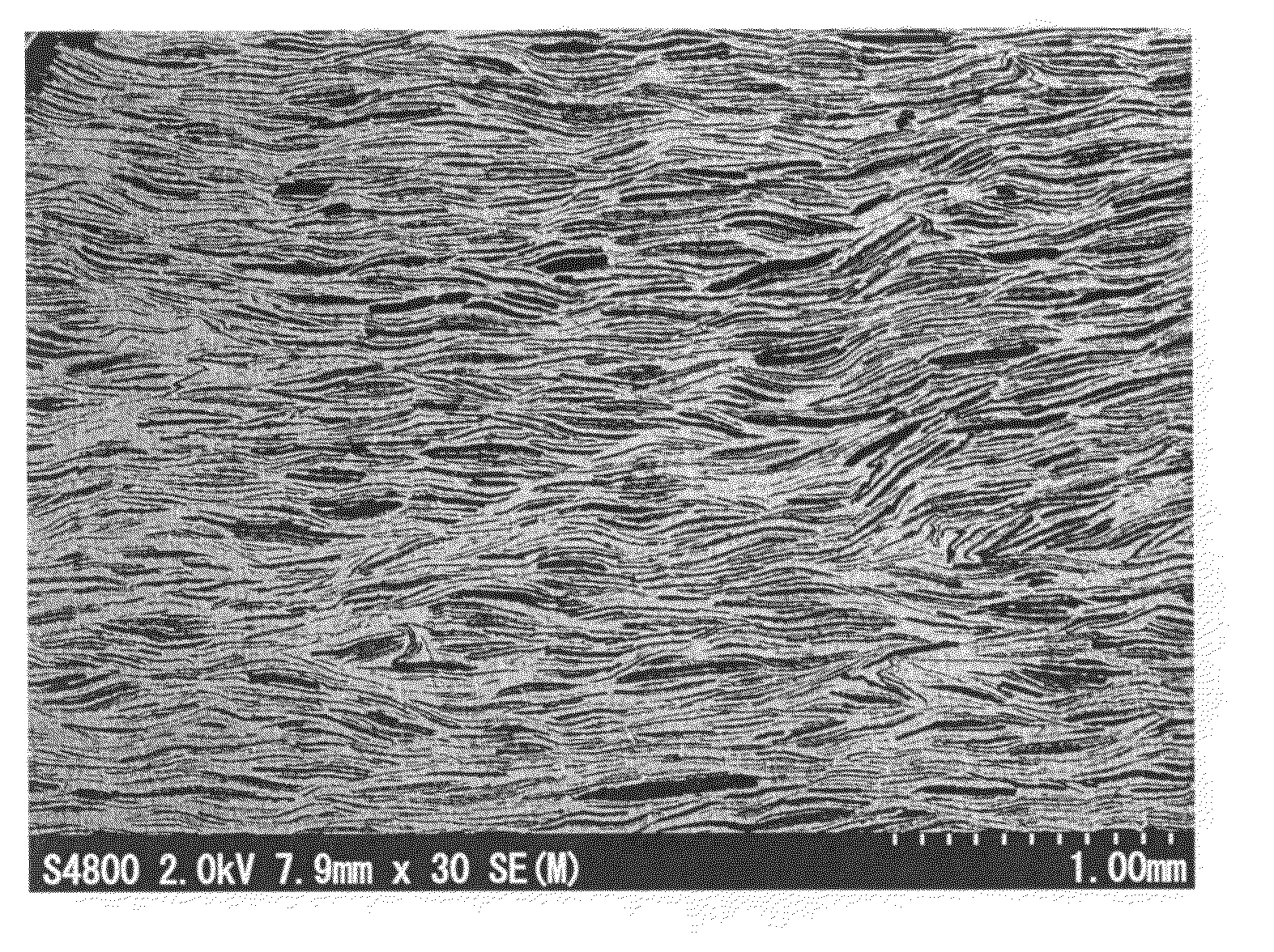

Metal-graphite composite material having high thermal conductivity and production method therefor

InactiveUS20100207055A1Improve thermal conductivityReliable bonding stateSemiconductor/solid-state device detailsConductive materialAlloyCopper

The present invention provides a metal-graphite composite material favorable to two-dimensional diffusion of heat and having a high thermal conductivity in two axial directions, and a production method therefor. The metal-graphite composite material of the present invention includes: 20 to 80% by volume of a scaly graphite powder; and a matrix selected from the group consisting of copper, aluminium and alloys thereof, wherein the scaly graphite powder in which a normal vector to a scaly surface thereof is tilted at 20° or higher with respect to a normal vector to a readily heat-conducting surface of the metal-graphite composite material is 15% or less relative to a whole amount of the scaly graphite powder, and the metal-graphite composite material has a relative density of 95% or higher.

Owner:SHIMANE PREFECTURAL GOVERNMENT MATSUE

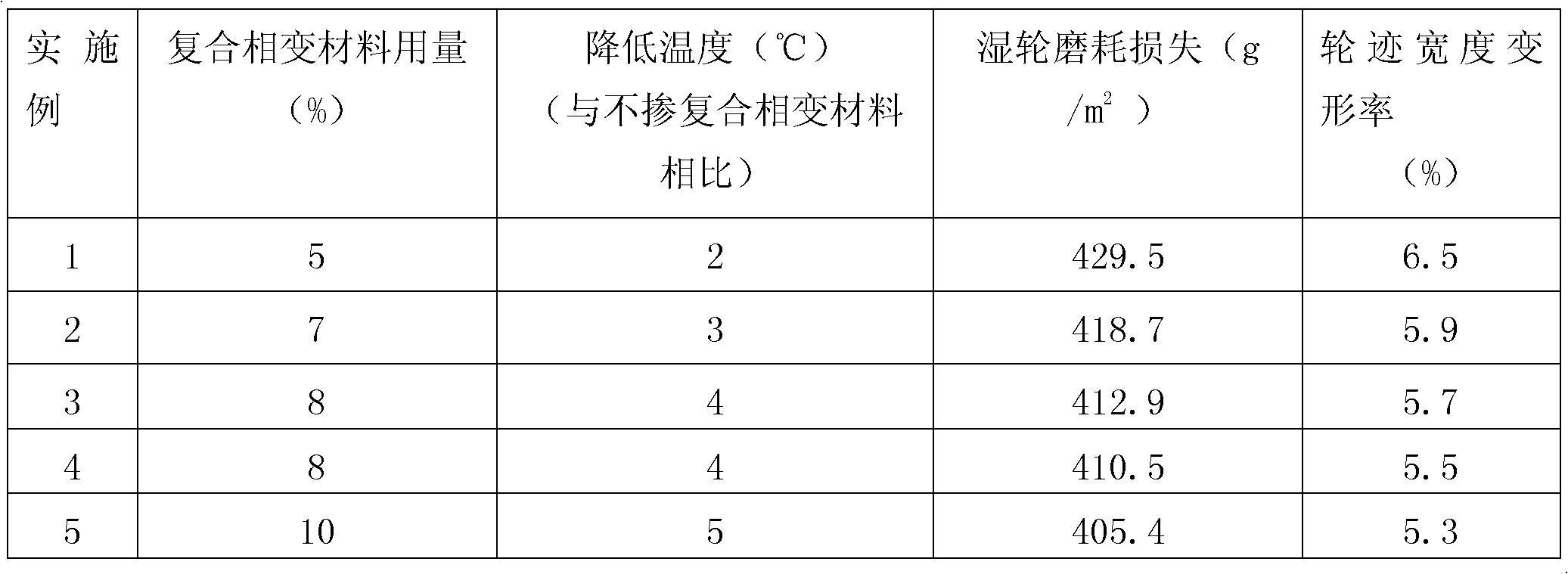

Self temperature adjustment cold mixing bituminous concrete and preparation method thereof

The invention belongs to the technical of bituminous pavement maintenance materials, and particularly relates top a cold mixing bituminous concrete and a preparation method thereof. The self temperature adjustment cold mixing bituminous concrete is characterized by being prepared from the following raw mateirals in percentage by weight: 70-80 percent for the aggregate, 1-3 percent for the filler, 5-10 percent for the composite phase change material, 8-10 percent for water and 6-8 percent for the modified emulsified asphalt. The composite phase change material is made of wax and expanded graphite composited together, the mass ratio of the expanded graphite and the wax is 1:8-9, the phase change temperature of the composite phase change material is 40-50 DEG C, and the phase change heat is 150-160kJ / kg. The process is simple, the cost is low and implementation is easy. The concrete has the function of reducing pavement temperature.

Owner:WUHAN UNIV OF TECH

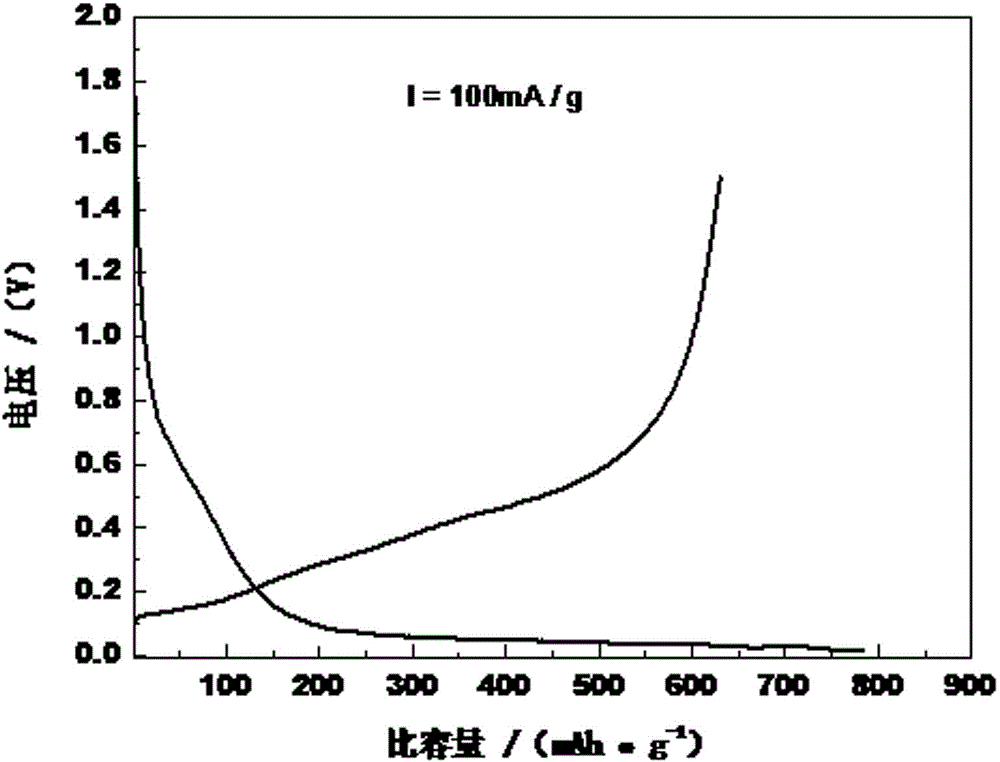

Method for preparing Si/C/graphite composite negative electrode material

InactiveCN104143629AImprove cycle stabilityInhibition of pulverization failureCell electrodesSecondary cellsRoom temperatureNitrogen

The invention discloses a method for preparing a Si / C / graphite composite negative electrode material. The method for preparing the Si / C / graphite composite negative electrode material comprises the following steps that micron silicon and an organic carbon source are evenly mixed, and deionized water or absolute ethyl alcohol is added to the mixture of the micron silicon and the organic carbon source; ball-milling is conducted on the obtained mixture, so that a nanometer silicon mixture which is evenly dispersed is obtained; a natural spherical graphite negative electrode material is obtained and is evenly mixed with the nanometer silicon mixture, deionized water or absolute ethyl alcohol is added to the mixture of the natural spherical graphite negative electrode material and the nanometer silicon mixture, and stirring is conducted; a mixture is obtained after drying, and a spherical particle precursor is obtained; under the nitrogen condition, the precursor is baked, cooled to the room temperature and then is crushed, and then the Si / C / graphite composite negative electrode material is obtained. According to the method for preparing the Si / C / graphite composite negative electrode material, the micron silicon is taken as the raw material, the Si / C / graphite composite negative electrode material high in cycle performance is prepared, the technology is simple and easy to control, and large-scale production of Si / C / graphite composite negative electrode materials can be achieved easily.

Owner:广东省工业技术研究院(广州有色金属研究院)

Graphine composite electric conduction agent for iron phosphate lithium battery and preparation method thereof

ActiveCN102244264AEvenly dispersedImprove stabilityCell electrodesInternal resistanceAlternating current

The invention discloses a graphine composite electric conduction agent for an iron phosphate lithium battery, and simultaneously discloses a preparation method of the electric conduction agent. The electric conduction agent provided by the invention consists of graphine, active carbon and a bonding agent in a weight ratio of 1:(0.001-0.1):(0.01-1). The preparation method comprises the following steps: 1) preparing a solution A; 2) preparing a solution B; and 3) preparing the electric conduction agent. According to the invention, the preparation method is simple, the prepared electric conduction agent has the advantages of uniform dispersion, good stability, high electron conduction capability and uniform heat conduction, and the electric conduction agent has higher liquid absorption and liquid protection capabilities when being doped into the iron phosphate lithium battery; and the electric chemical property of the iron phosphate lithium battery which is prepared by adopting the electric conduction agent provided by the invention is improved prominently, compared with the iron phosphate lithium anode material in which the composite electric conduction agent is not doped, when the prepared graphite composite electric conduction agent is doped into the 50AH iron phosphate lithium anode material, the alternating current internal resistance is reduced by 20%, and the circulating service life is improved by 15%.

Owner:JIANGSU LENENG BATTERY INC

Silicon carbide graphite composite material and preparation method thereof

ActiveCN103833363AHigh densityImprove high strength and high wear resistanceCeramic materialsCompositermes

The invention belongs to the technical field of material preparation, and particularly relates to a silicon carbide graphite composite material and a preparation method thereof. According to the invention, the preparation raw materials of graphite powder, silicon carbide powder, and a sintering aid are subjected to ball milling mixing, drying, crushing, sieving, and compression molding; after compression molding, degumming treatment and hot pressing sintering are carried out; the sintering process is a temperature-controlled pressure-controlled two-stage pressure-maintaining sintering process; and furnace cooling is performed to obtain the silicon carbide graphite composite material. The method greatly shortens the production period, and improves the product yield; the sintering aid of submicron silicon carbide powder, alumina and yttrium oxide is used for liquid phase sintering under pressure; the high density and low porosity of the product are ensured; the high strength and high wear resistance of the product are improved; no free silicon is contained, which improves the corrosion resistance of the product; temperature increasing and temperature maintaining control are carried out at key sections, which inhibits and eliminates defects of cracks and deformation during sintering. The preparation process is low in time consumption which is 48-72 hours, and the product has high strength, has a bending strength of up to 181 MPa, and has a relative density of up to 95%.

Owner:UNIV OF SCI & TECH BEIJING

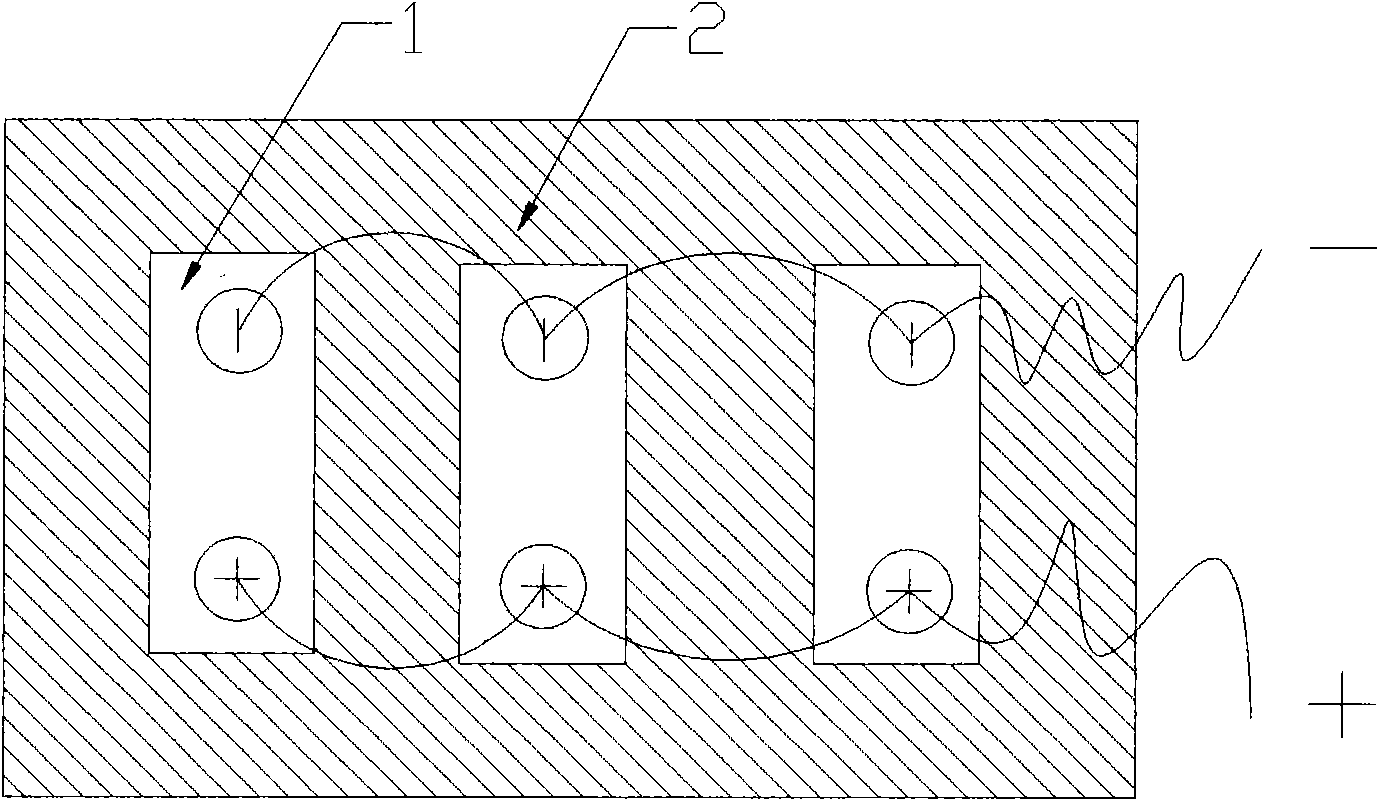

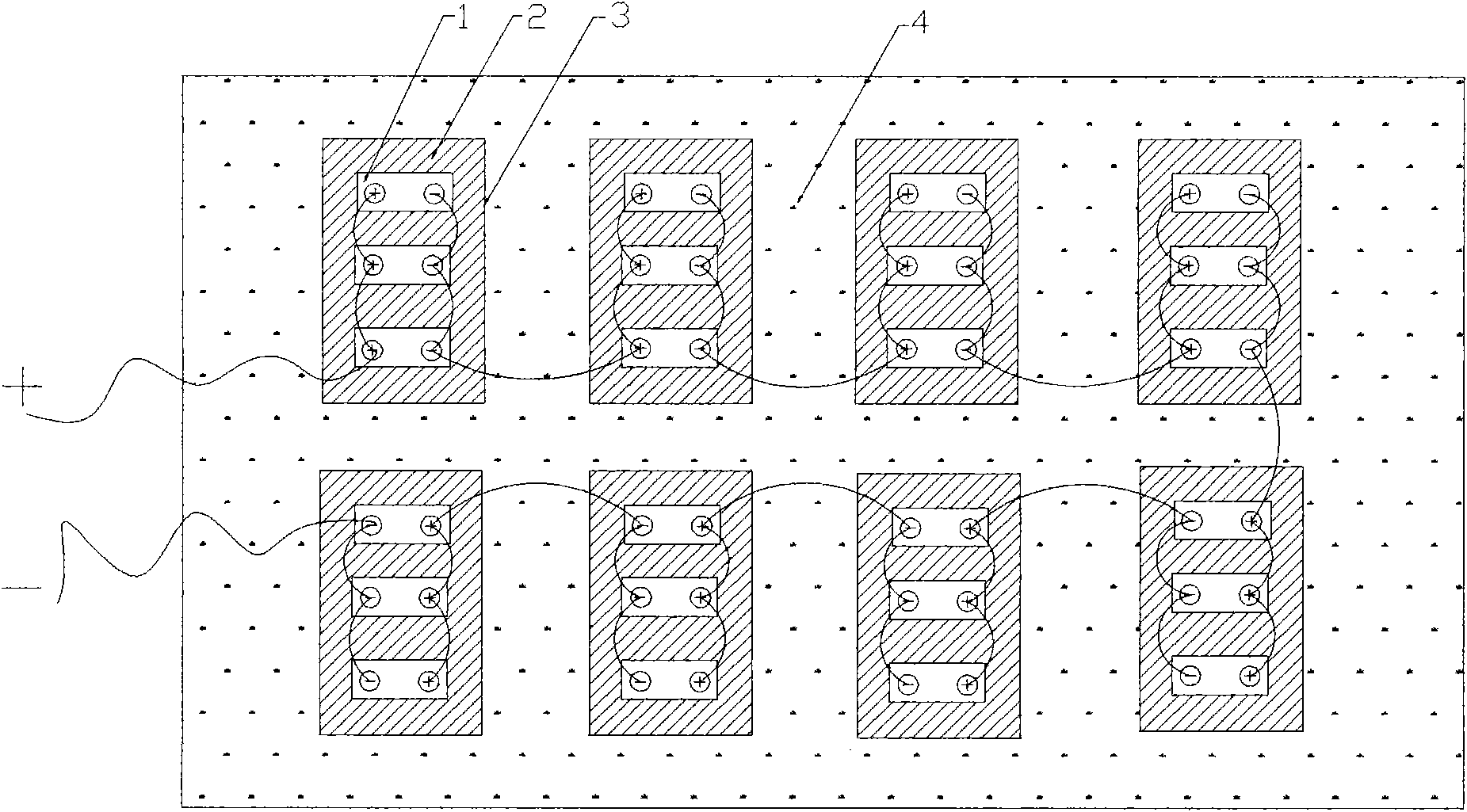

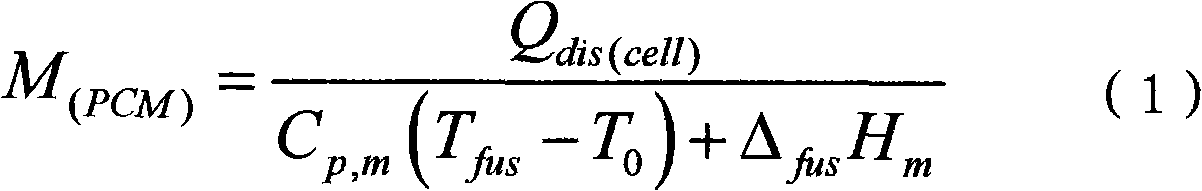

Heat-dissipating method of power lithium battery

InactiveCN101635382ASimple preparation processEasy maintenanceSecondary cellsTemperature controlWork performance

The invention discloses a heat-dissipating method of a power lithium battery, belonging to the technical field of the temperature control of lithium ion battery. In the power lithium battery heat-dissipating method, phase-change materials are filled into a gap inside the lithium ion battery, the phase-change materials are one or two of paraffin / (Al / C) compound material and GMB / graphite compound material, wherein the weight percentage of paraffin and Al / C compound material contained in the paraffin / (Al / C) compound material are respectively 75-100 percent and 0-25 percent, and phase-change points of the paraffin and the Al / C compound material are 15 DEG C-55 DEG C; the weight percentage of GMB and graphite contained in the GMB / graphite compound material are respectively 60-80 percent and 20-40 percent, and phase-change points of the GMB and the graphite are 55 DEG C-65 DEG C. The heat-dissipating method is convenient to operate and maintain, low in cost and used for the heat dissipation of the power lithium battery with high power and fast charge and discharge, has obvious effect and can enhance the working performance and the reliability of the power lithium battery. Experiments show that the heat-dissipating method reduces the temperature rise of the power lithium battery by more than 20 DEG C and has wide application prospect compared with heat-dissipating modes, i.e. the prior battery wind cooling and the like.

Owner:NANJING SHUANGDENG SCI TECH DEV RES INST

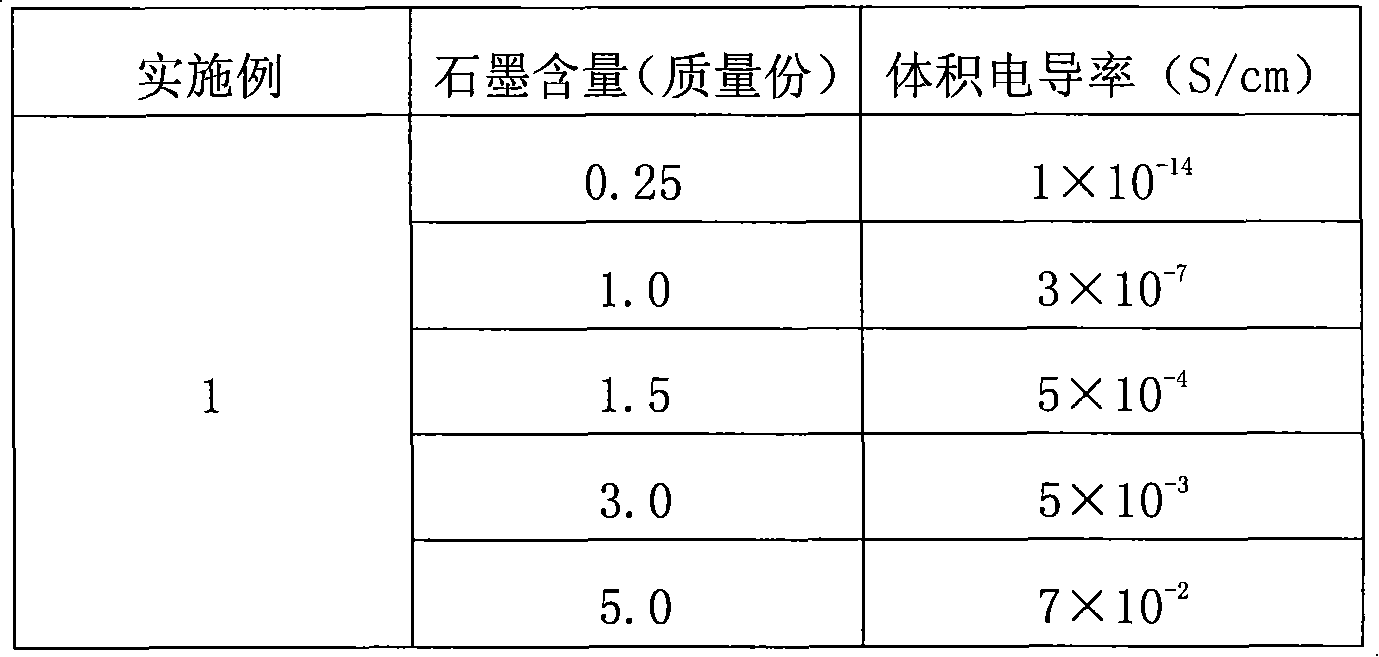

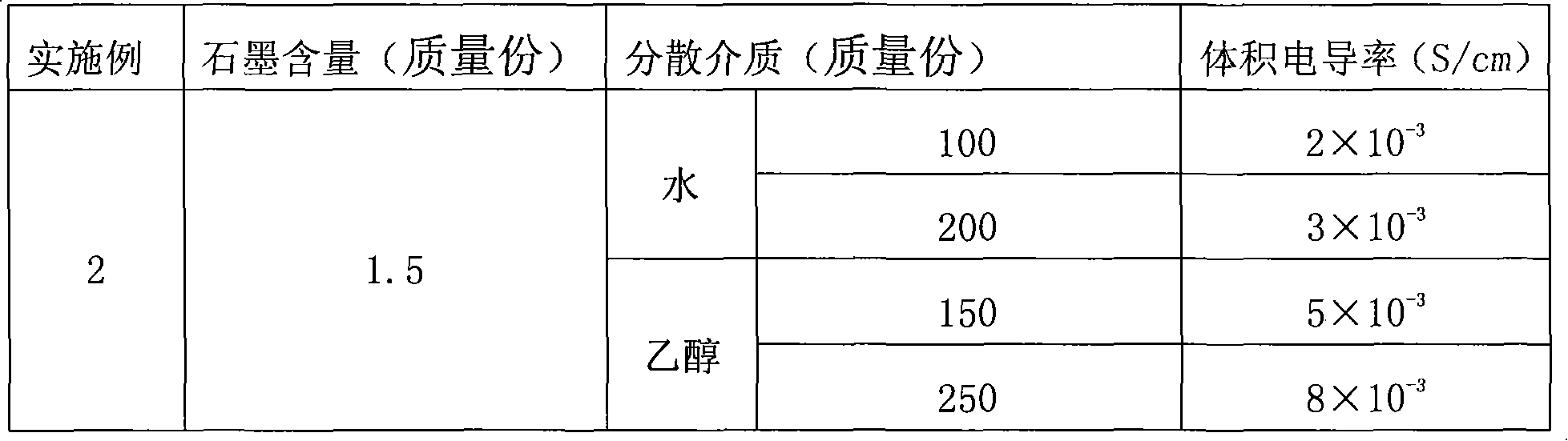

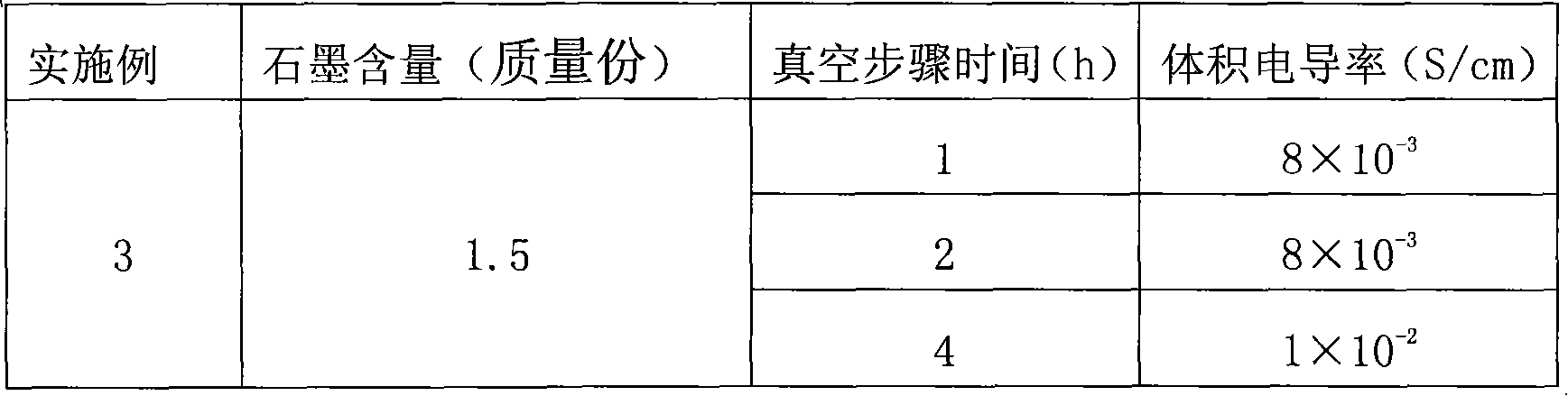

Polyamide/oxidized graphite composite material with high conduction performance and preparation method thereof

InactiveCN101608061AImprove conductivityReduce the amount of fillerIn situ polymerizationConductive polymer

The invention discloses a polyamide / graphite composite material with high conduction performance and a preparation method thereof. The composite material consists of a polyamide substrate and nanometer graphite and is prepared through in-situ polymerization. The nanometer graphite has high diameter-to-thickness ratio; and an effective conduction network can be formed in a polymer by using little nanometer graphite. With the low content of a conduction filling of the nanometer graphite, a conduction polymer material keeps original good mechanical performance. The volume conductivity of the polyamide / graphite composite material with high conduction performance can reach 8*10S / cm; and compared with a conventional natural graphite and expanded graphite conductive composite material, the polyamide / graphite composite material has excellent properties of low filling amount and high conductivity.

Owner:TORAY IND INC

Preparation method of high-capacity silicon-based negative electrode material of lithium-ion battery

InactiveCN106025211AImprove the reunion effectAvoid performance degradationCell electrodesSecondary cellsDispersitySlurry

The invention discloses a preparation method of a high-capacity silicon-based negative electrode material of a lithium-ion battery. The method comprises the preparation processes of: mixing nano silicon, graphite and a pyrolytic carbon organic matter precursor to obtain composite material precursor slurry; and carrying out spray drying to obtain precursor powder; and finally carrying out roasting treatment in an inert atmosphere and then carrying out grinding to obtain an organic matter pyrolytic carbon-coated nano silicon / graphite composite material. According to the preparation method, the dispersity of the nano silicon in the silicon-carbon negative electrode material can be improved; the structure stability of the material in a lithium intercalation and deintercalation process is improved; the condition that the material has relatively high conductivity is ensured; a pyrolytic carbon coating layer effectively coats the surfaces of material particles; the interface characteristic of the material can be effectively improved; and the electrochemical properties of the silicon-carbon negative electrode material are improved.

Owner:田东

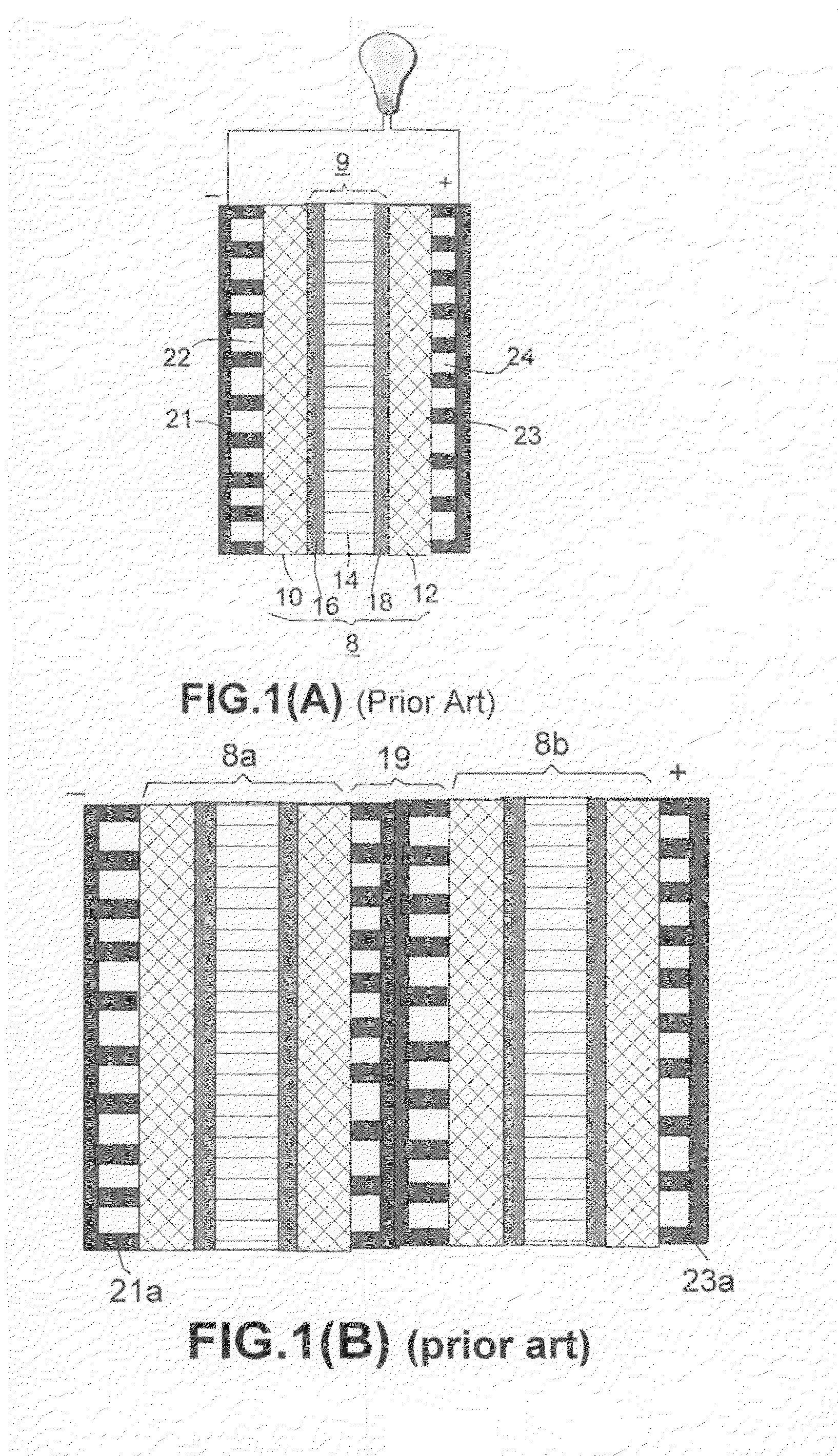

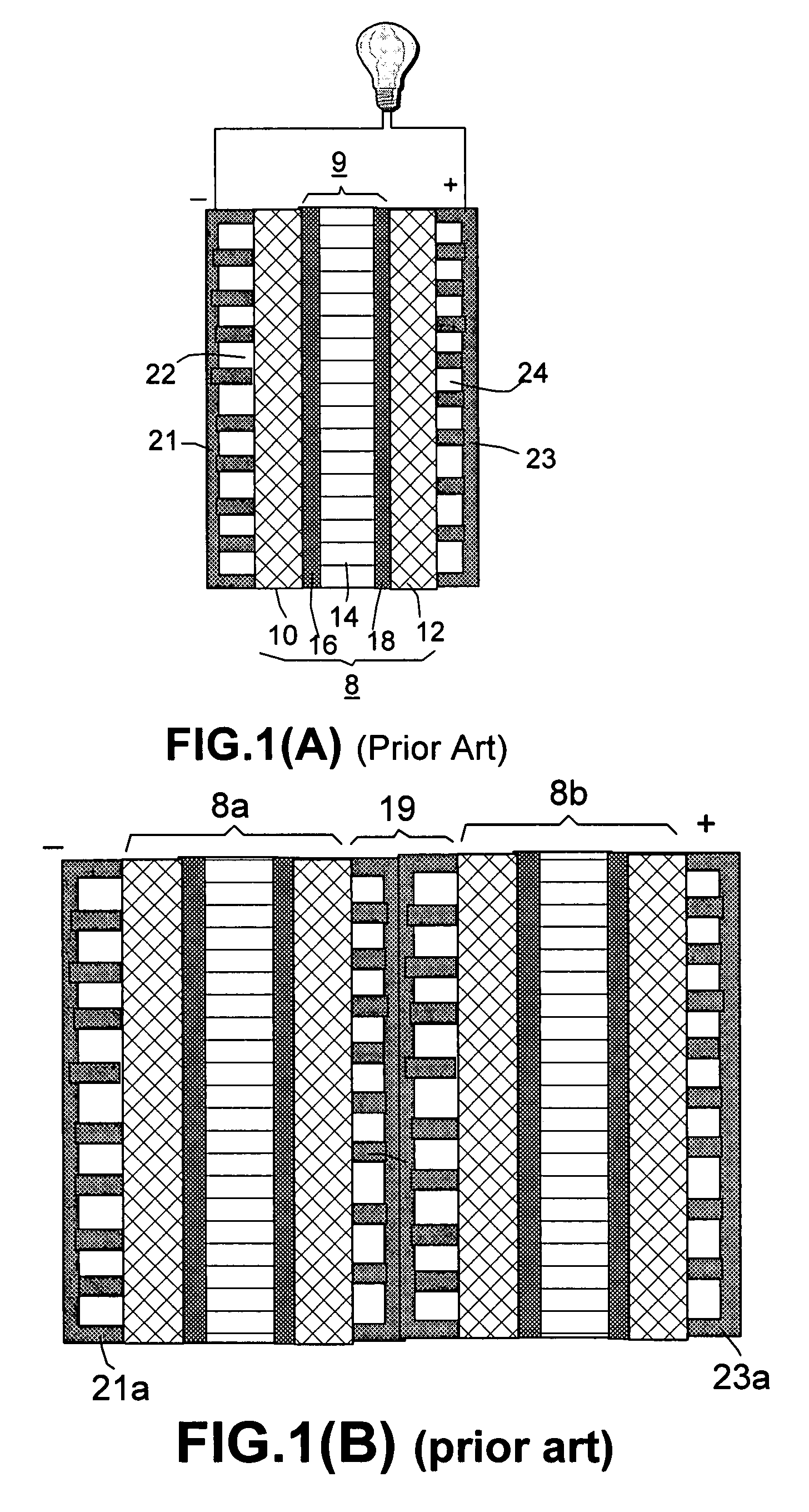

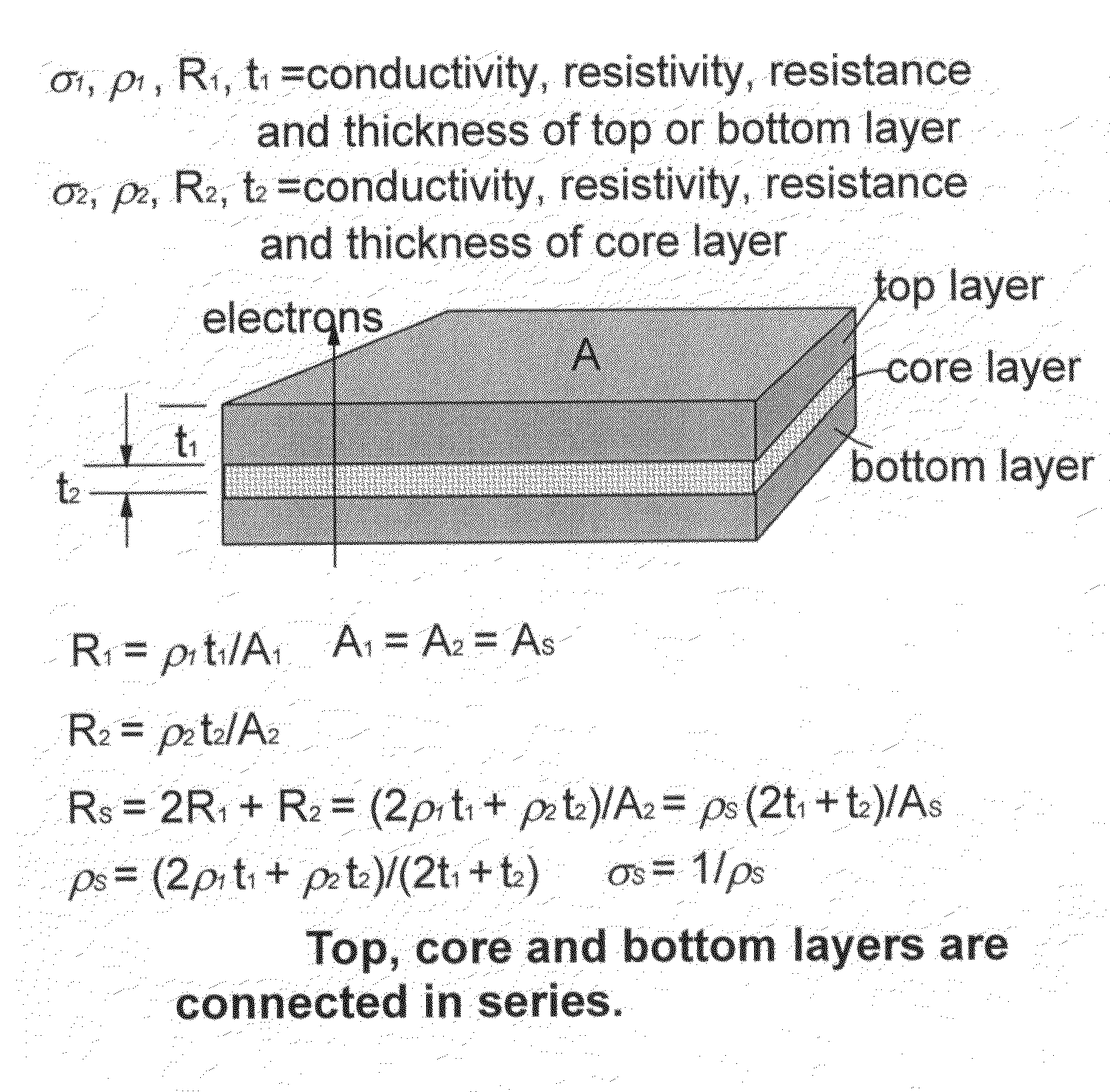

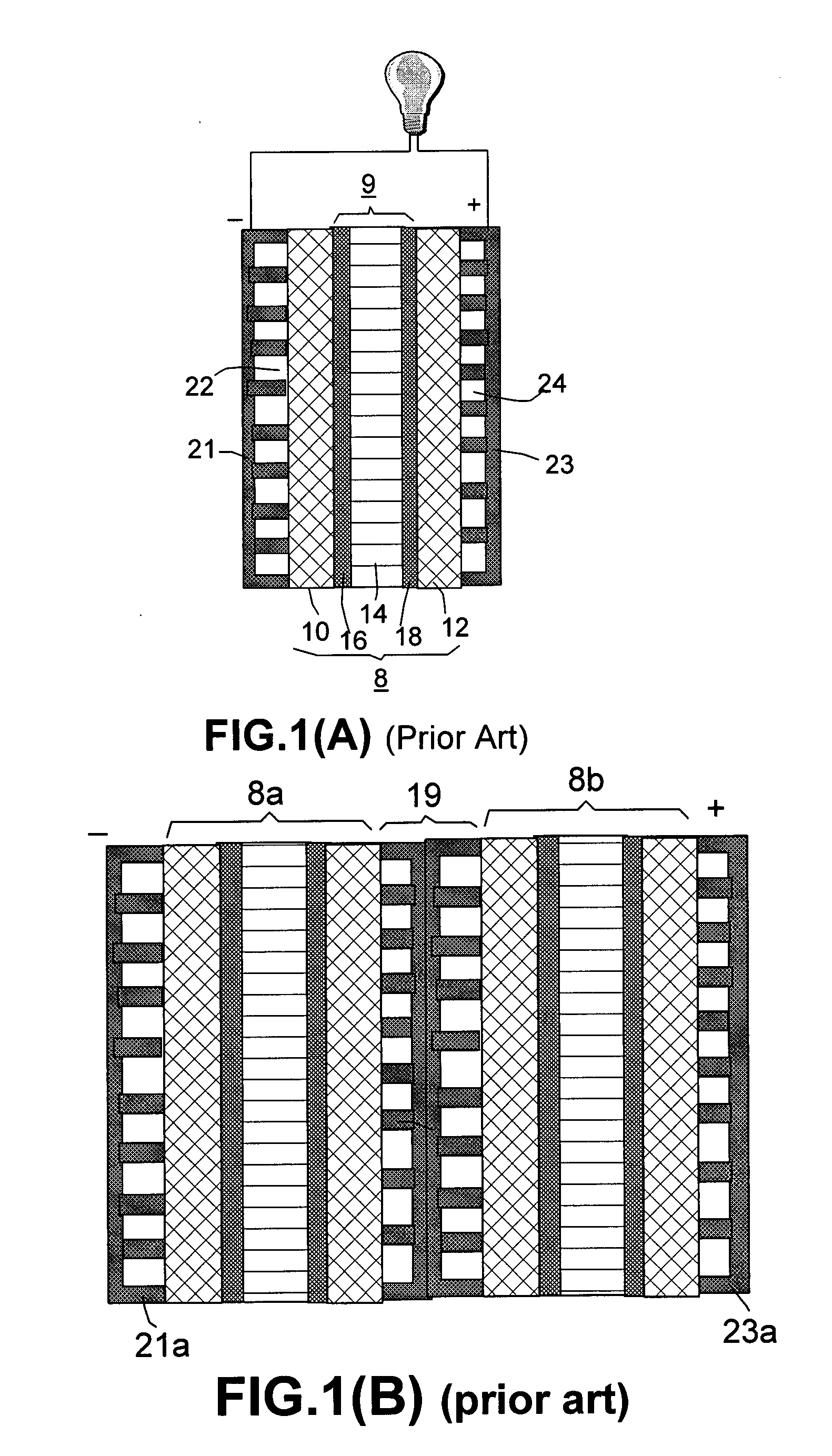

Laminated exfoliated graphite composite-metal compositions for fuel cell flow field plate or bipolar plate applications

ActiveUS20080299419A1Super high conductivityExcellent hydrogen permeation resistanceFuel cell auxillariesThin material handlingThin metalFuel cells

An electrically conductive laminate composition for fuel cell flow field plate or bipolar plate applications. The laminate composition comprises at least a thin metal sheet having two opposed exterior surfaces and a first exfoliated graphite composite sheet bonded to the first of the two exterior surfaces of the metal sheet wherein the exfoliated graphite composite sheet comprises: (a) expanded or exfoliated graphite and (b) a binder or matrix material to bond the expanded graphite for forming a cohered sheet, wherein the binder or matrix material is between 3% and 60% by weight based on the total weight of the first exfoliated graphite composite sheet. Preferably, the first exfoliated graphite composite sheet further comprises particles of non-expandable graphite or carbon in the amount of between 3% and 60% by weight based on the total weight of the non-expandable particles and the expanded graphite. Further preferably, the laminate comprises a second exfoliated graphite composite sheet bonded to the second surface of the metal sheet to form a three-layer laminate. Surface flow channels and other desired geometric features can be built onto the exterior surfaces of the laminate to form a flow field plate or bipolar plate. The resulting laminate has an exceptionally high thickness-direction conductivity and excellent resistance to gas permeation.

Owner:NANOTEK INSTR GRP LLC

Silicon/graphite composite anode material and preparation method thereof

ActiveCN104319367AImprove Coulombic efficiencyImprove cycle stabilityCell electrodesCyclic processSilicon particle

The invention discloses a silicon / graphite composite anode material and a preparation method thereof, belonging to the field of a lithium ion battery anode material. The method comprises the following steps: ball milling the mixture of monomer silicon particles and graphite by utilizing a ball mill to obtain a ball mill product; carrying out surface hydroxylation treatment on the ball mill product, so that the surface of each monomer silicon particle in the ball mill product is combined with a hydroxyl to obtain a hydroxylation product; processing the hydroxylation product by utilizing a silane coupling agent, so that organic functional groups in the silane coupling agent modify the monomer silicon particle surface in the hydroxylation product to obtain the silicon / graphite composite anode material. In the primary cycling process of the anode material, an SEI membrane formed on the surface of the silicon particle is intersected with the organic functional groups on the surface of the silicon particles, so that the stability of the SEI membrane is improved, the thickness increment of the SEI membrane is avoided, and the coulombic efficiency and cycling stability of the prepared anode material can be effectively improved.

Owner:CHERY AUTOMOBILE CO LTD

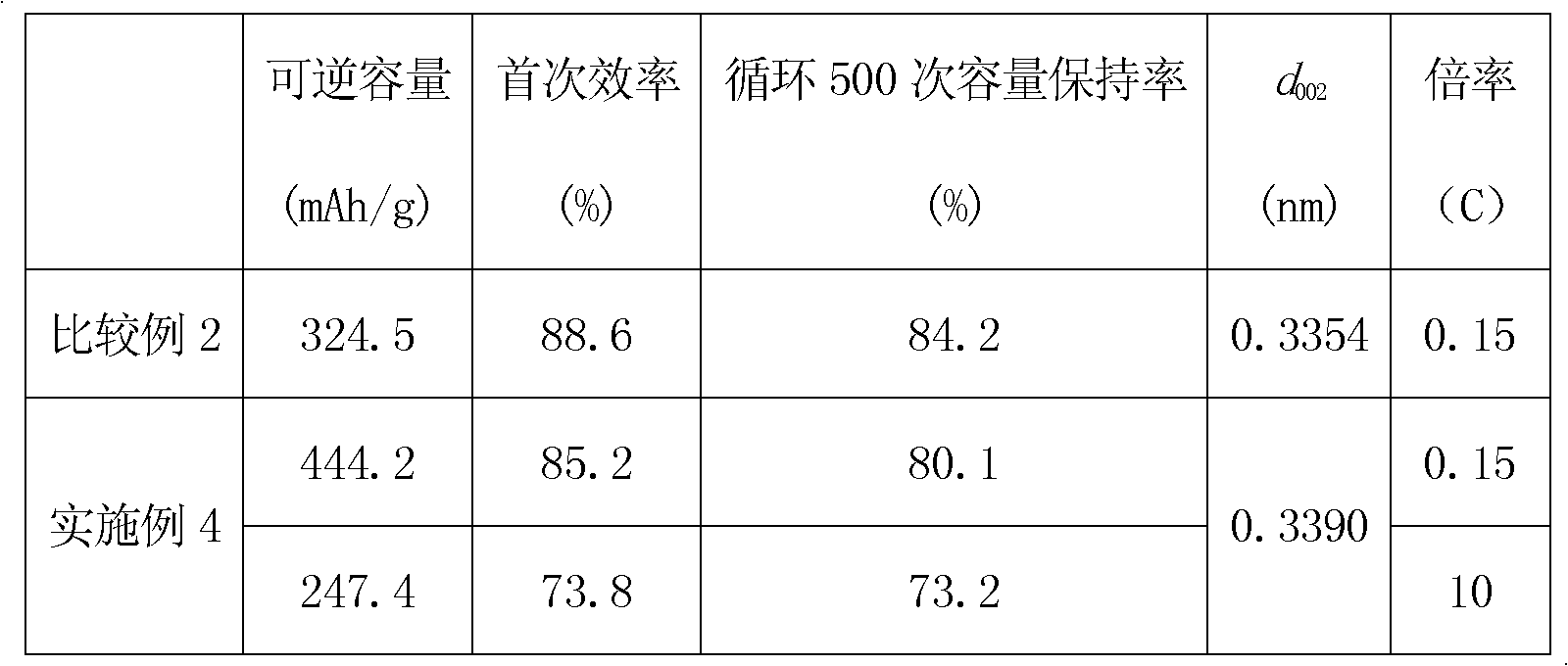

Carbon cladding layer expansion graphite composite material used for lithium ion batteries and preparation method thereof

InactiveCN101841019AImprove lithium intercalation spaceHigh reversible specific capacityCell electrodesPhosphatePhosphoric acid

The invention provides a carbon cladding layer expansion graphite composite material used for lithium ion batteries and a preparation method thereof. The carbon cladding layer expansion graphite composite material has a shell-kernel structure, wherein, the inner kernel is phosphorus-doped layer expansion graphite, and the layer spacing is 0.3360-0.3390nm; the outer shell is a pyrolysis product of phenolic resin; the carbon cladding layer expansion graphite composite material is prepared by the processes of raw material pretreatment, oxidized intercalation, cladding and layer removing; phosphoric acid dissolved with organic acid or a phosphate-nitrate system is adopted as oxidized intercalator. Lithium ion battery cathode prepared by the carbon cladding layer expansion graphite composite material of the invention has the characteristics of high capacity, high power and long service life. The preparation method of the invention has the characteristics of simple and easily operated process, and moderate and practical conditions and the like.

Owner:HUNAN UNIV

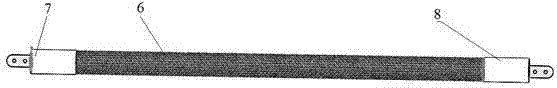

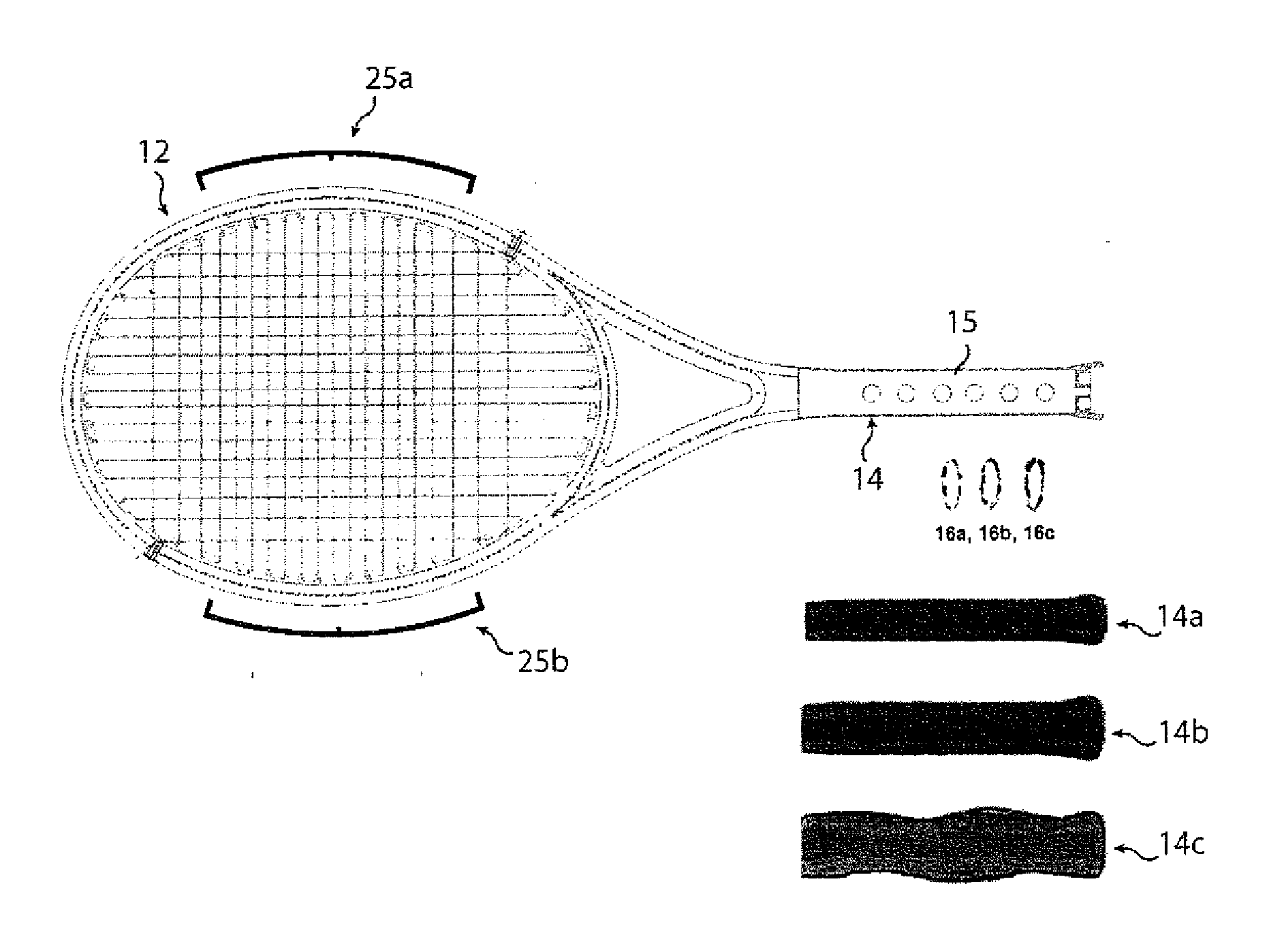

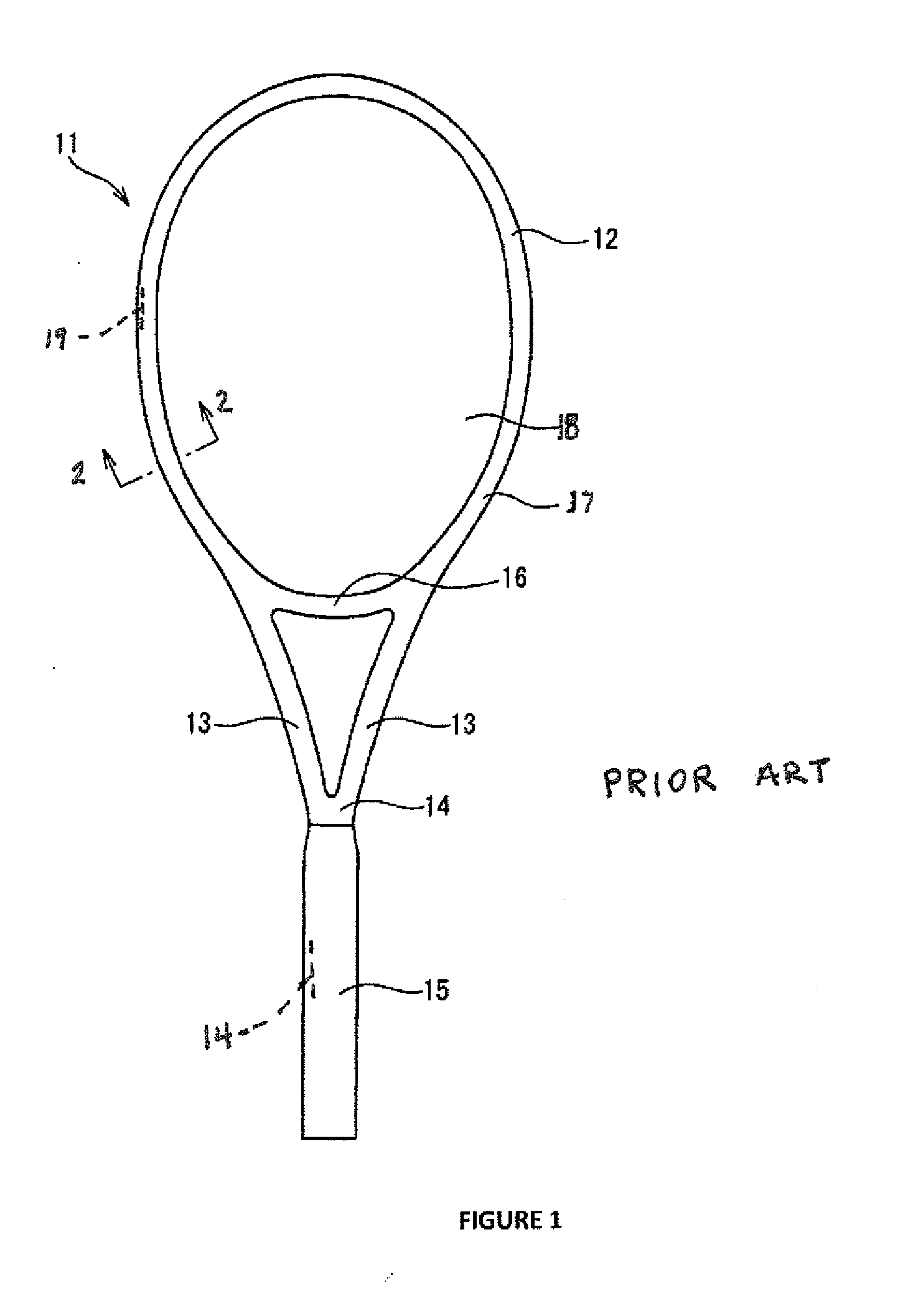

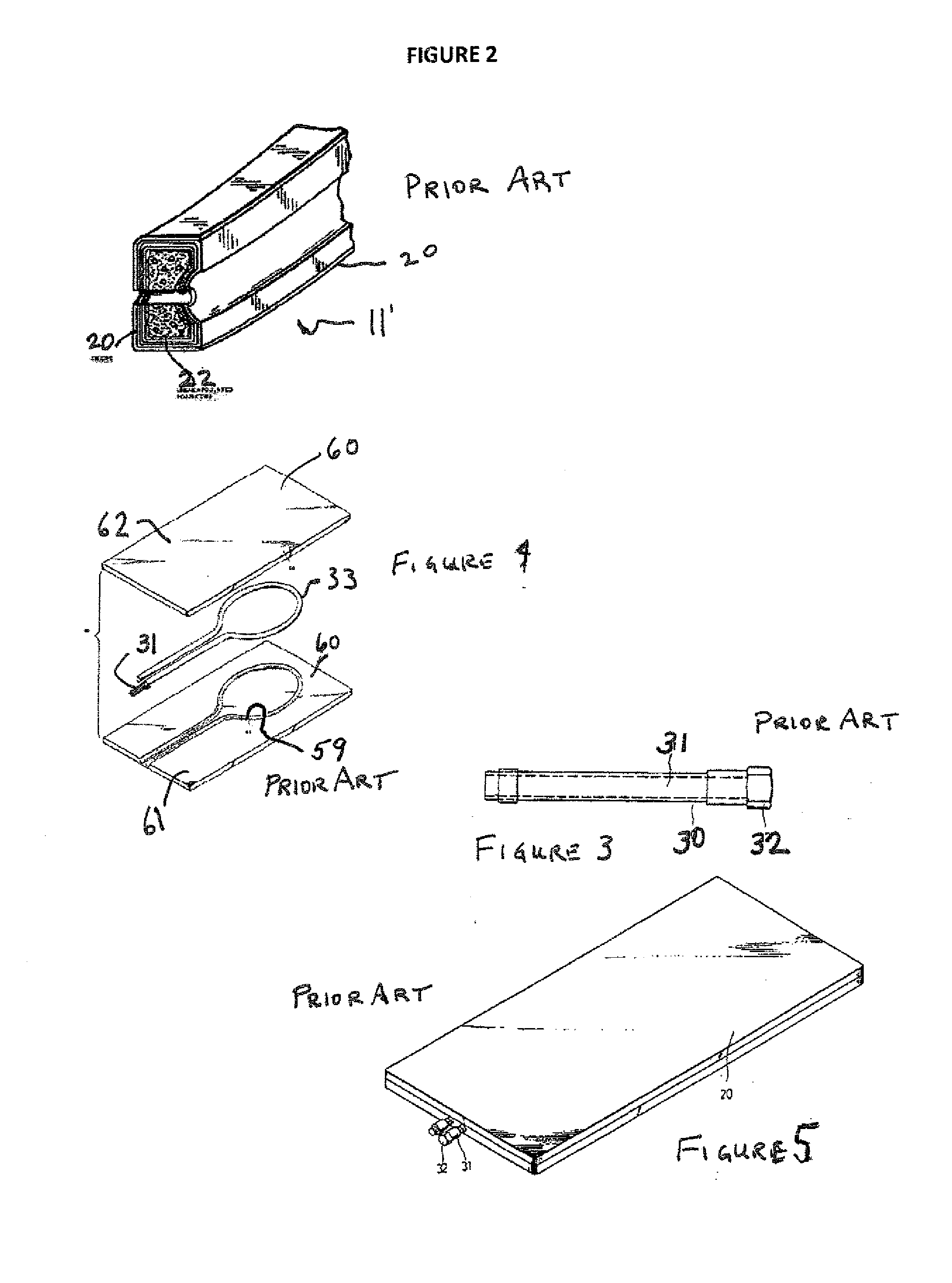

Fiber composite and process of manufacture

InactiveUS20110136602A1Additional injuryShock can worsenLayered product treatmentDomestic articlesEngineeringFibrous composites

The inventive fiber manufacturing process is particularly adapted for demanding applications such as sports racquets, including tennis racquets, badminton racquets and other sports applications. Because of the improved strength to weight ratio of components formed using the inventive method, a wide range of flexibility is achieved, allowing use of the inventive process to manufacture, for example, a fiber reinforced (for example, graphite) modular sports racquet, optionally provided with user-selectable weights and / or handle replacements. From the standpoint of the player, this allows a racquet frame featuring self customization. From the standpoint of a retailer, the benefit provided is reduction of inventory. The inventive fiber, for example graphite fiber) racquet frame is filled with a plastic foam and is formed using, for example, microencapsulation technology to time, generate and apply the pressure used to form the graphite composite material of which the racquet is comprised. Advantageously, inner and outer tubular members may be used to form the racquet frame, with the inner tubular member extending around the head of the racquet frame. This compares to the standard industry technique of air injection. The racquet is thus not hollow like conventional graphite racquets, and the walls therefore can be made thinner than those of existing graphite racquets still being of the same strength or being stronger, which gives the racquet exceptional performance. In addition, the overall dimensions of, for example the cross-section, of the racquet can also be reduced while still maintaining performance characteristics.

Owner:XENE CORP

Preparation method of graphite radical composite material

The present invention provides preparation process of graphite-base composite material. The preparation process includes the following steps: mixing expandable graphite powder and coke powder and pressing at pressure of 5-50 MPa to form base board with graphite as main component; dissolving asphalt in organic solvent, adding reinforcing material and graphitization catalyzing stuffing, mixing, and eliminating solvent to obtain adhesive mixture; smelting the adhesive mixture at 110-140 deg.c, and soaking the base board at gas pressure of 1-50MPa for 10-120 min; taking out the base board, cooling to room temperature and crushing; and molding the crushed mixture. The graphite-base composite material has excellent electric performance, excellent heat performance, excellent mechanical performance and low cost.

Owner:HARBIN ENG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com