Patents

Literature

209results about How to "High reversible specific capacity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

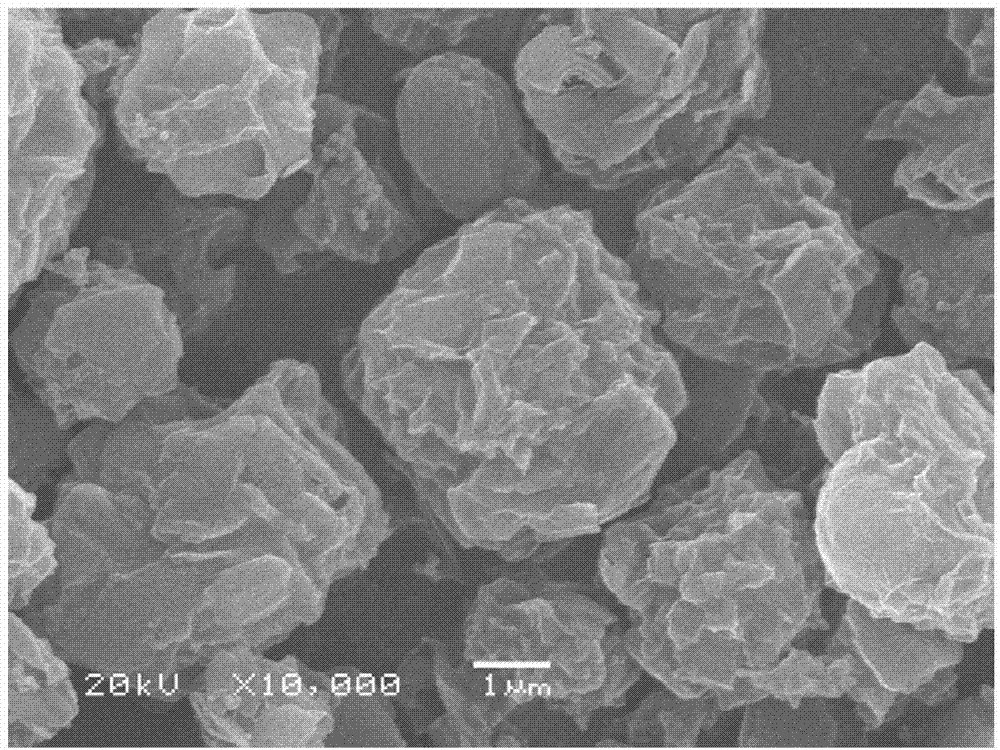

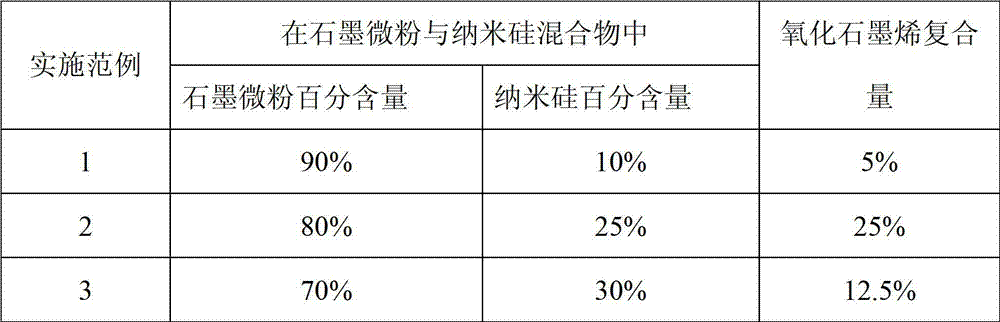

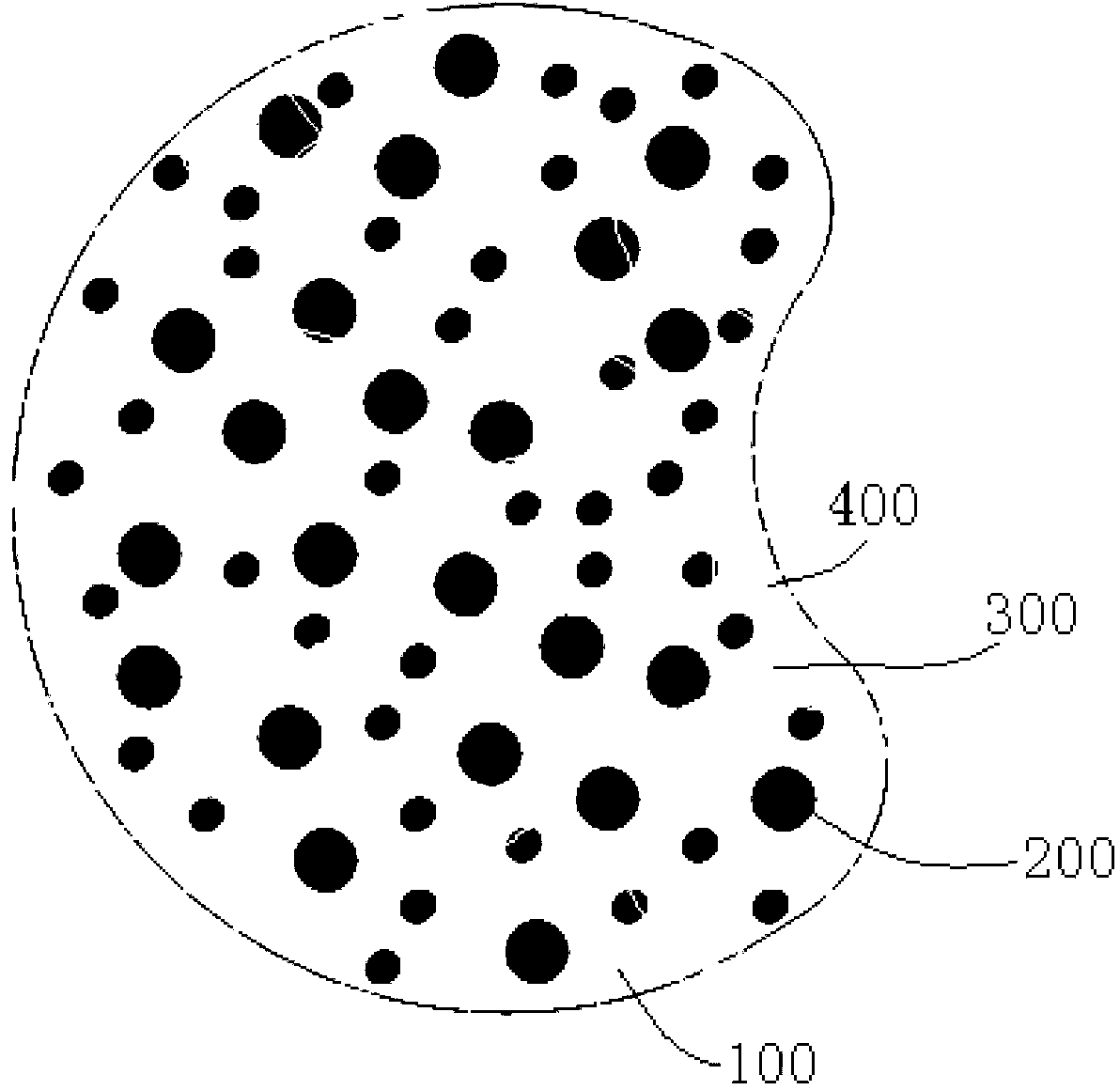

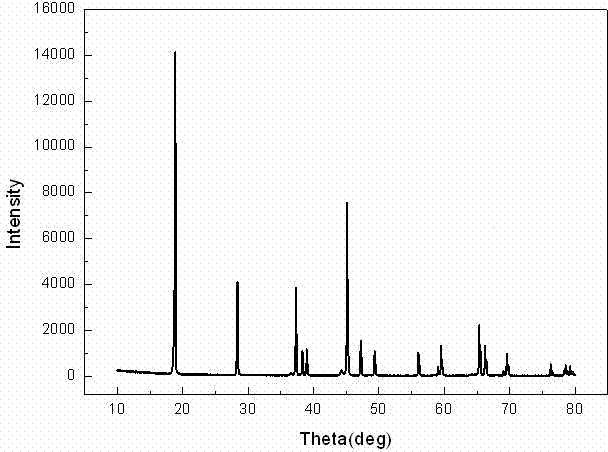

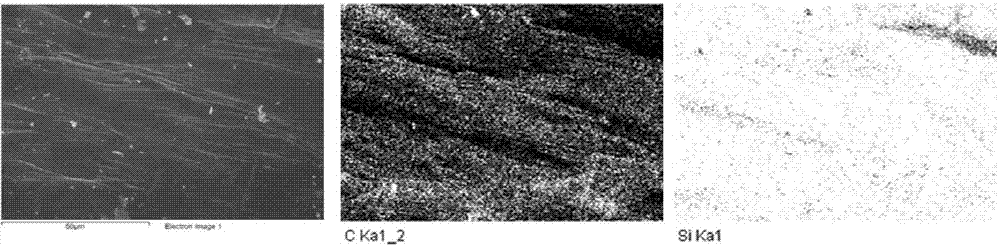

Preparation method of silicon and carbon-coated graphene composite cathode material

ActiveCN103050666ARealize in situ restorationThe preparation process is simple, convenient and practicalMaterial nanotechnologyCell electrodesCarbon coatedStructural stability

The invention discloses a preparation method of a silicon and carbon-coated graphene composite cathode material. The technical problem to be solved is to enhance the electronic conductivity of the silicon-based cathode material, buffer the volume effect produced in the process of deintercalation of the lithium in the silicon-based cathode material and enhance the structure stability in the circulation process of the material at the same time. The material is prepared by using a spray drying-thermally decomposing treatment process in the invention. The preparation method comprises the following steps of: evenly dispersing nano silicon and graphite micro powder in a dispersion solution of oxidized graphene, carrying out thermal treatment under an inert protection atmosphere after spray drying, subsequently cooling along a furnace to obtain the silicon and carbon-coated graphene composite cathode material. The extra binder does not need to add in the process of manufacturing balls in the invention and the outer oxidized graphene is thermally reduced in situ to graphene in the thermal treatment process of the composite precursor, so that the process is simple and easy to operate; and the practical degree is high. The prepared composite material has the advantages of great reversible capacity, designable capacity, good cycling performance and high-current discharging performance, high tap density and the like.

Owner:CENT SOUTH UNIV

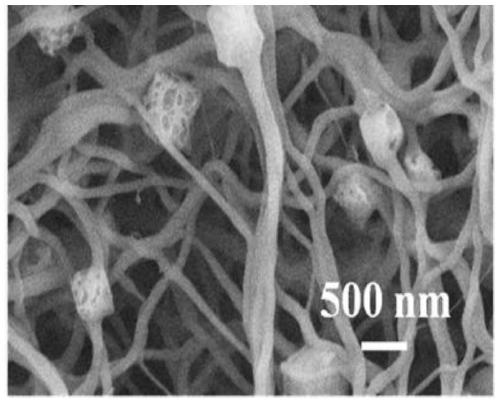

Silicon-carbon composite material with nano micropores and preparation method as well as application thereof

ActiveCN103305965AImprove lithium storage performanceImprove electrochemical performanceCell electrodesFilament/thread formingCarbon compositesCarbon fibers

The invention discloses a silicon-carbon composite material with nano micropores and a preparation method as well as application thereof. The material comprises nano-silicon (Si) particles and a carbon nanofiber matrix, wherein the nano-silicon particles are dispersed in the carbon nanofiber matrix; and nano pores and micropores communicated with the nano pores are distributed in the carbon nanofiber matrix. The method comprises the steps of dissolving the nano-Si particles and polyacrylonitrile (PAN) in a solvent to prepare a mixed spinning solution, then carrying out electrostatic spinning on the mixed spinning solution, and curing spinning trickles in a coagulating bath to obtain a porous PAN-Si composite nanofiber; and then carrying out oxidation and carbonization treatment in sequence to obtain the silicon-carbon composite material with a nano micropore structure. The silicon-carbon composite material is applied to preparation of lithium ion battery cathode materials. Compared with the prior art, the silicon-carbon composite material ensures the overall electron transport capacity of the material while reserving buffer space for expansion of the nano-Si particles.

Owner:深圳石墨烯创新中心有限公司

High-voltage high-capacity anode material for lithium ion battery and preparation method of anode material

InactiveCN103618081AGuaranteed stabilityImprove electrochemical performanceCell electrodesSecondary cellsDopantElectrical battery

The invention discloses a high-voltage high-capacity anode material for a lithium ion battery. The anode material contains a cobalt source substance, a lithium source substance, a dopant M and a coating material, wherein the molar ratio of Li to Co is 0.95-1.2, the doping amount of the dopant M is 0.01-10wt%, and the total doping amount of the coating material is 0.01-20wt%. The structural stability of lithium cobalt oxide is enhanced by means of doping, the advantages of the lithium cobalt oxide in a base layer and the active material in a coating layer are complemented mutually by means of coating with an active substance, so that the electrochemical performance of the anode material is enhanced; stable cycling can be achieved under the condition of high voltage of 3.0-4.5V and the anode material has excellent electrochemical performance. In a word, the anode material has the advantages of high voltage platform, high reversible specific capacity, excellent thermal cycling performance, stable structure, good safety and the like; the problem that the calcination temperature of the base layer and the coating layer cannot be unified is solved and the anode material has excellent uniformity.

Owner:NANTONG RESHINE NEW MATERIAL

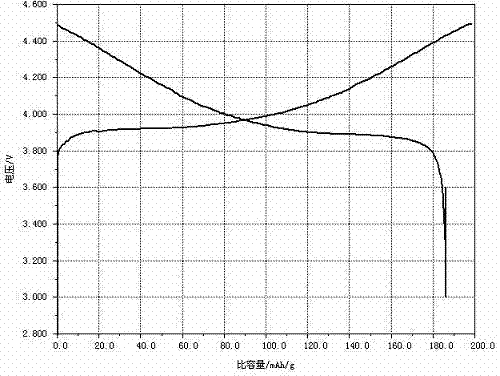

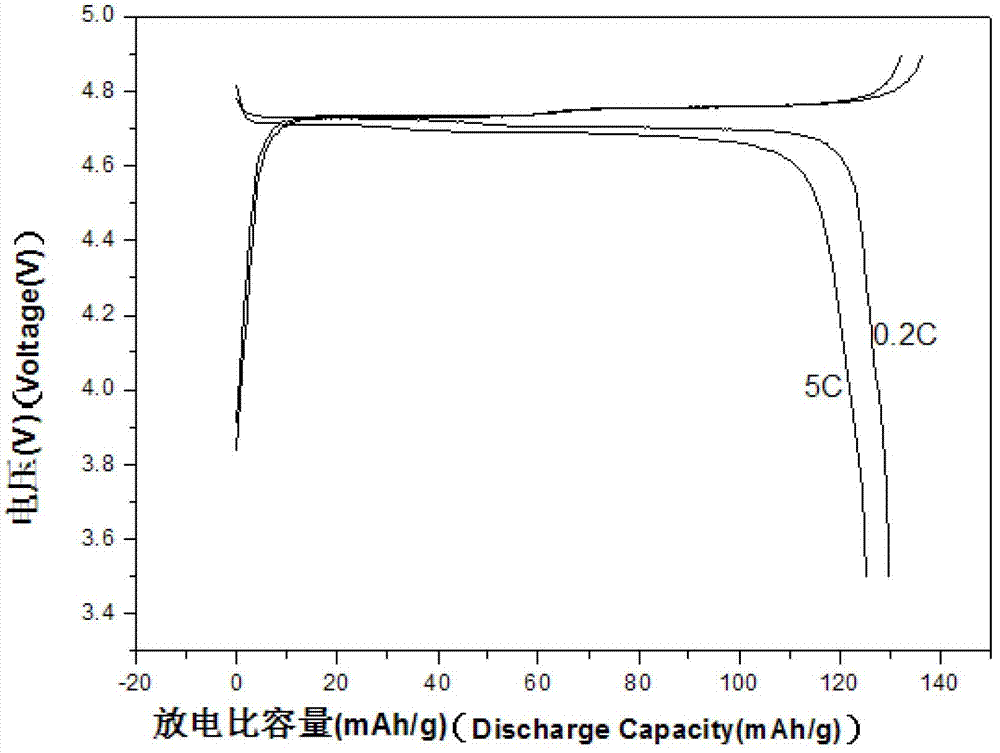

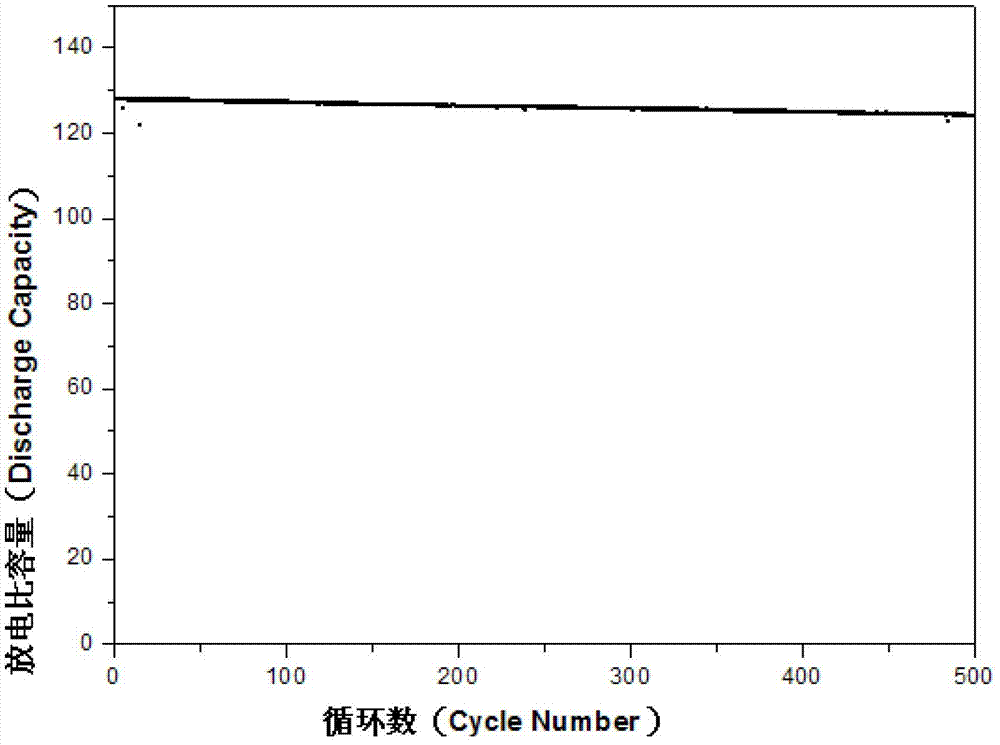

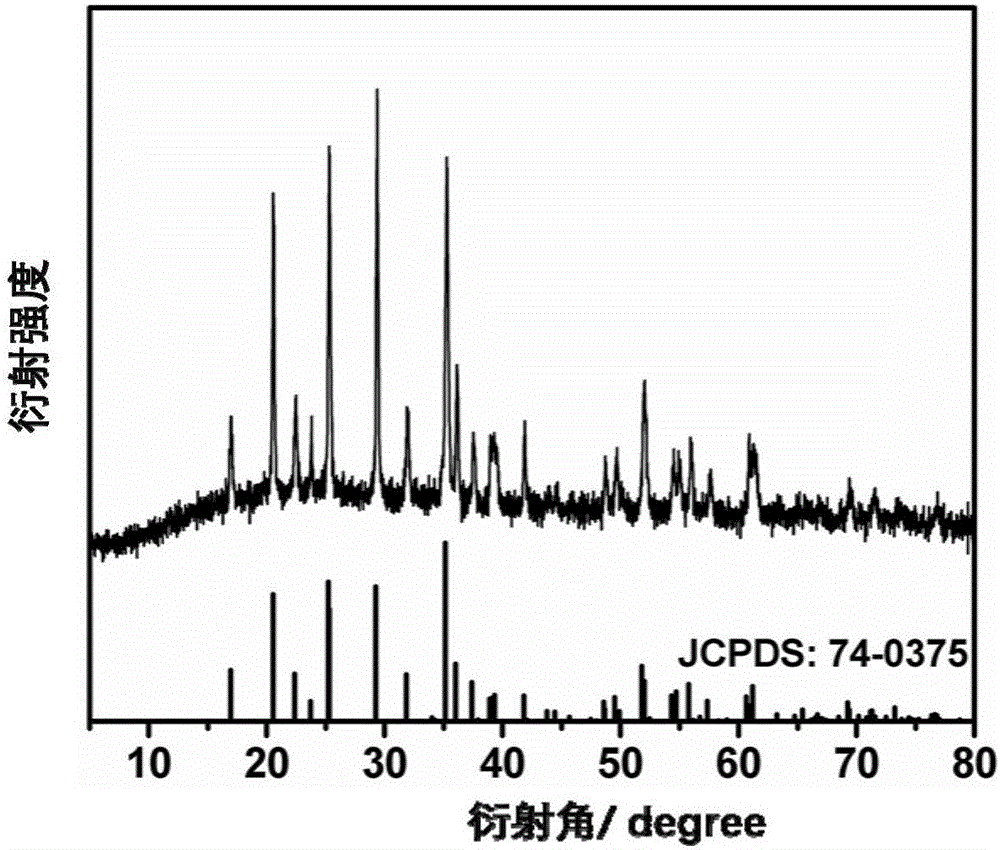

Surface coating method of 5V lithium ion battery positive pole material LiNi0.5-xMn1.5MxO4

ActiveCN103094552AImprove surface chemistryImprove conductivityElectrode thermal treatmentTube furnacePhysical chemistry

The invention discloses a surface coating method of a 5V lithium ion battery positive pole material LiNi0.5-xMn1.5MxO4, which comprises the following steps: (1) grinding and mixing a coating material or precursor thereof and a positive pole active material in a mass ratio of (1-50):100; (2) dispersing the mixture in a certain liquid-phase medium, and carrying out ultrasonic pulverization; (3) mixing the mixture and the medium by ball milling; (4) filtering and drying; and (5) putting the dried mixture in the step (4) into a pipe furnace, heating in inert gas at the heating speed of 1-30 DEG C / minute, calcining at the constant temperature of 200-500 DEG C for 1-5 hours, carrying out quick cooling or furnace cooling to room temperature, and grinding the coated high-voltage lithium ion battery positive pole material LiNi0.5-xMn1.5MxO4. The product obtained by the method disclosed by the invention has high reversible specific capacity: the capacity retentivity after 500 2C charging / discharging cycles is higher than 95%, and the specific capacity of 5C discharge is more than 96% of 0.2C. The method has the advantages of simple and controllable synthesis technique and uniform coating, and is suitable for industrial production.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

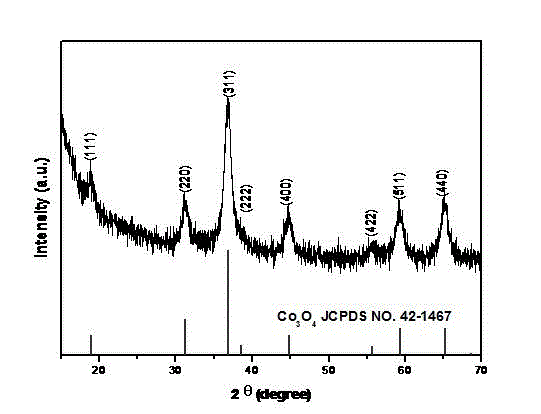

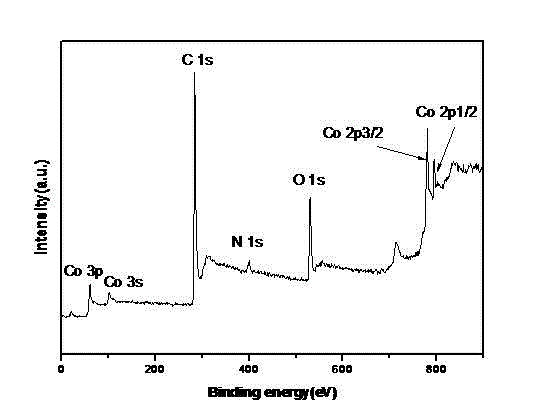

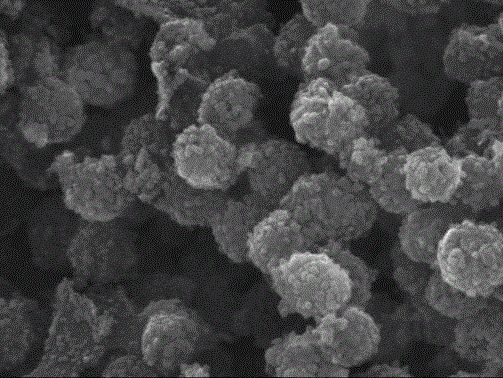

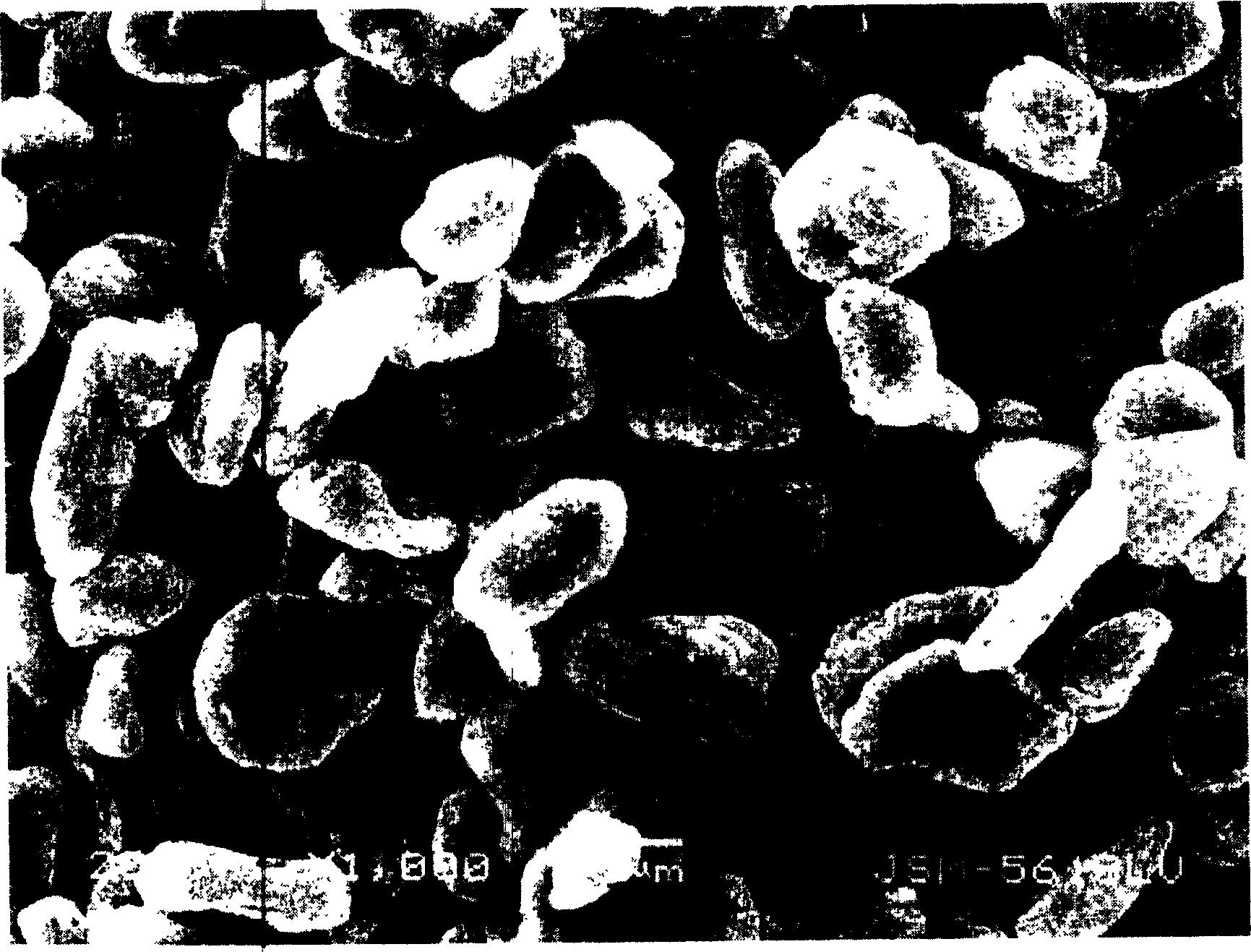

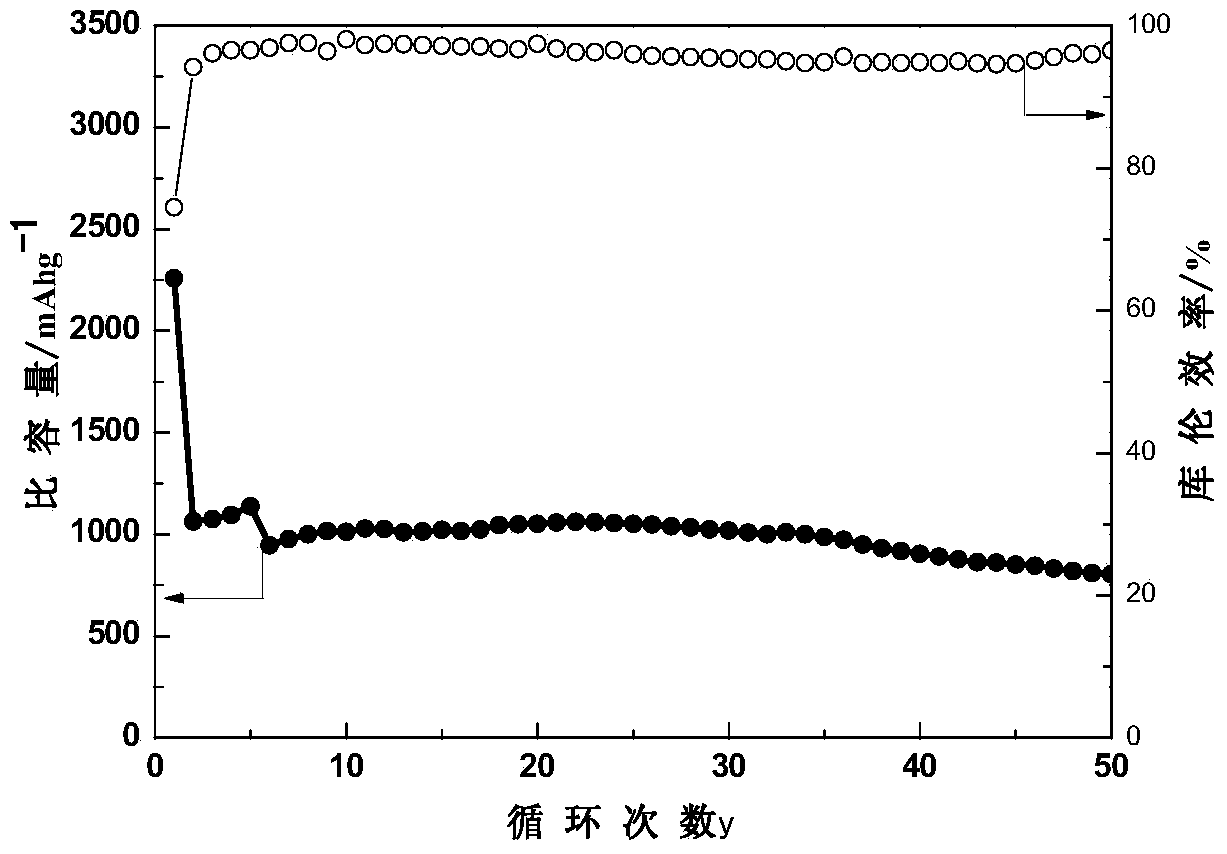

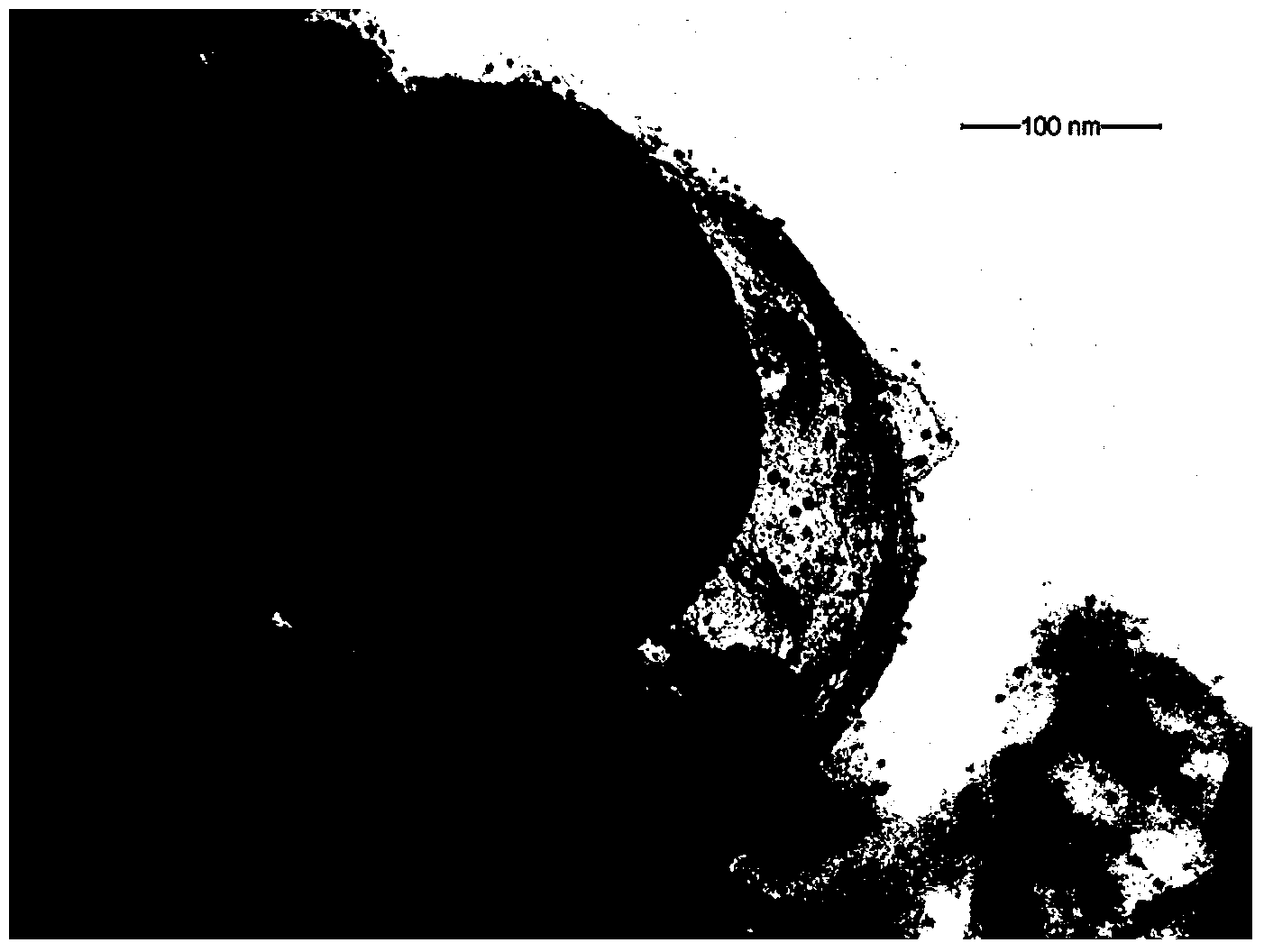

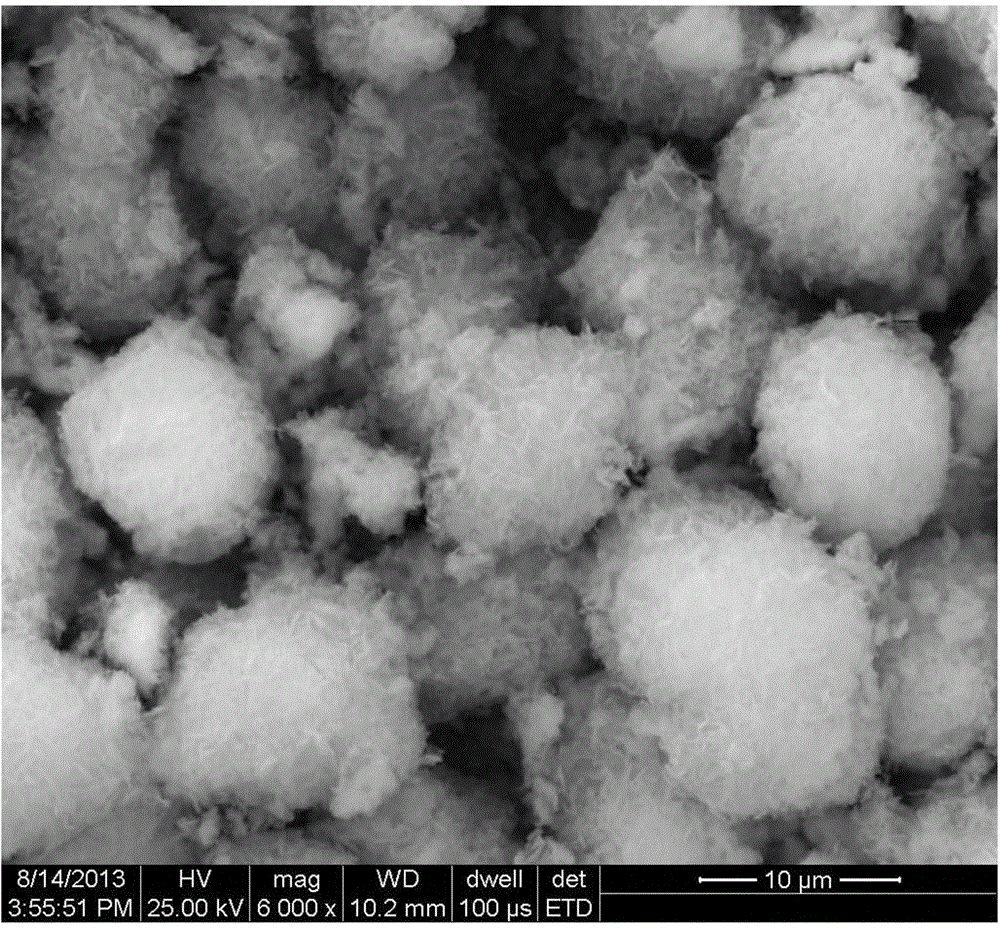

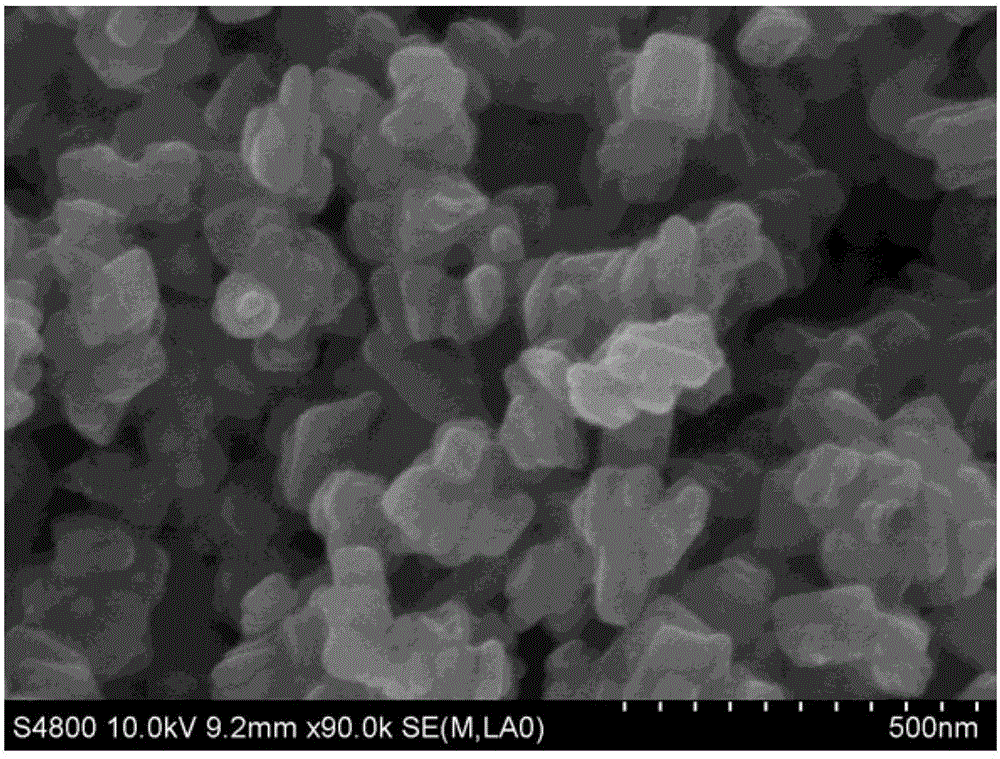

Nitrogen-doped porous carbon sphere and cobaltous oxide nano-composite anode material based on chitosan and derivatives thereof and preparation method thereof

InactiveCN104966824AShorten the diffusion distanceImprove mobilityCell electrodesSecondary cellsPorous carbonElectrical battery

The invention discloses a nitrogen-doped porous carbon sphere and cobaltous oxide nano-composite anode material based on chitosan and derivatives thereof and a preparation method thereof and belongs to the fields of electrochemistry and new energy resource materials. According to the nitrogen-doped porous carbon sphere and cobaltous oxide nano-composite anode material based on the chitosan and the derivatives thereof and the preparation method thereof, firstly the chitosan and the derivatives thereof are taken as carbon source and nitrogen source precursors, a hard template carbonization method is adopted to prepare nitrogen-doped porous carbon spheres; then a mild hydrothermal method is adopted to load cobaltous oxide nano particles to the nitrogen-doped porous carbon spheres, and then the nitrogen-doped porous carbon sphere and cobaltous oxide nano-composite material is obtained. The material synthesizes the structural features of the nitrogen-doped porous carbon spheres and the small-size effect advantages of the cobaltous oxide nano particles, and due to the expression of the synergistic effect of the nitrogen-doped porous carbon spheres and the cobaltous oxide nano particles, the prepared material shows higher reversible specific capacity, better cycling stability and more excellent large rate discharge performance than a commercial graphite material when used as a lithium ion battery anode material. The method is strong in operability, preparation conditions are mild, the requirement for equipment is not rigorous, and the preparation method is suitable for industrial production; the nitrogen-doped porous carbon sphere and cobaltous oxide nano-composite material prepared by the method has potential application value in electrochemistry fields including lithium ion batteries, supercapacitors and the like.

Owner:HUBEI ENG UNIV

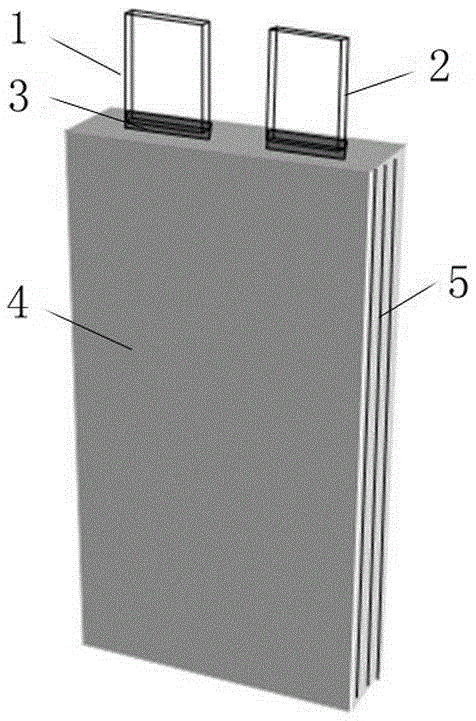

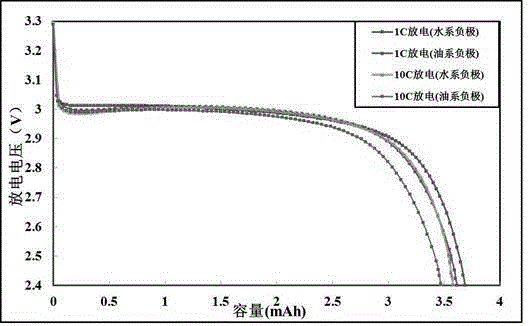

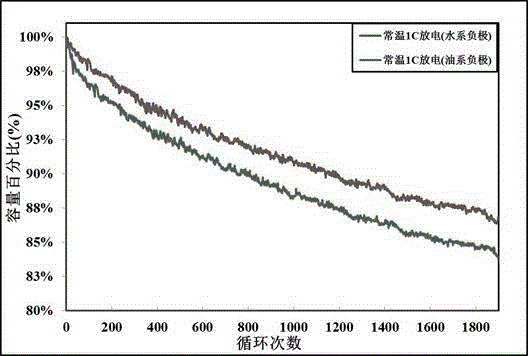

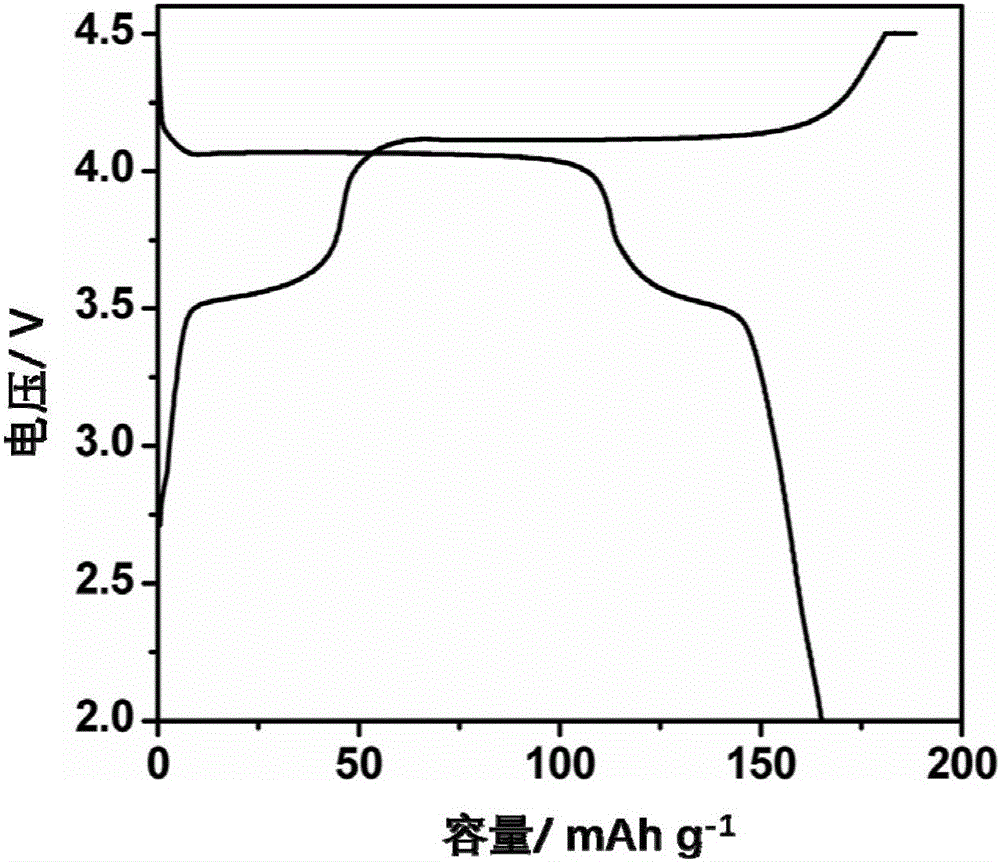

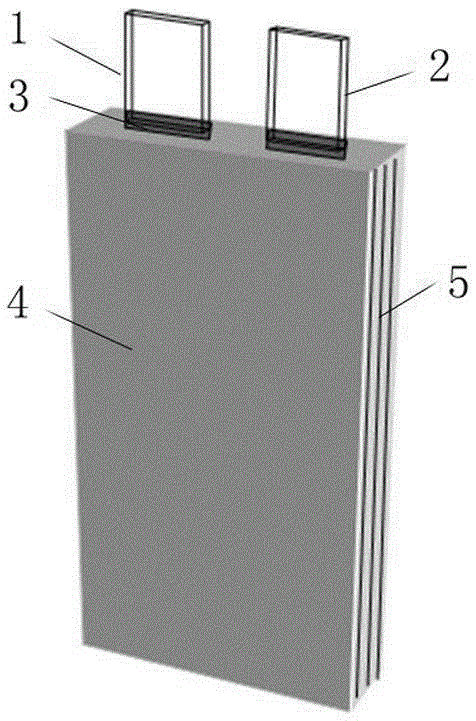

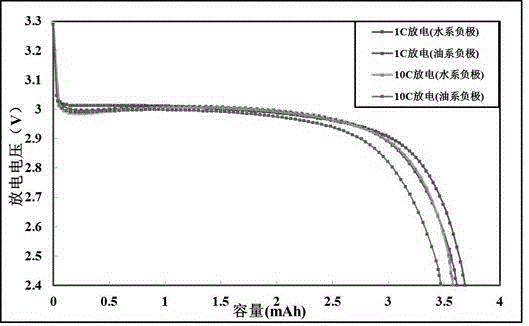

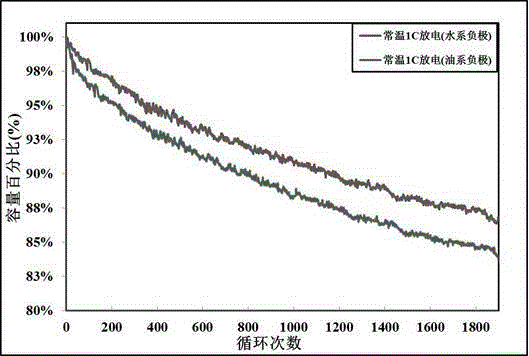

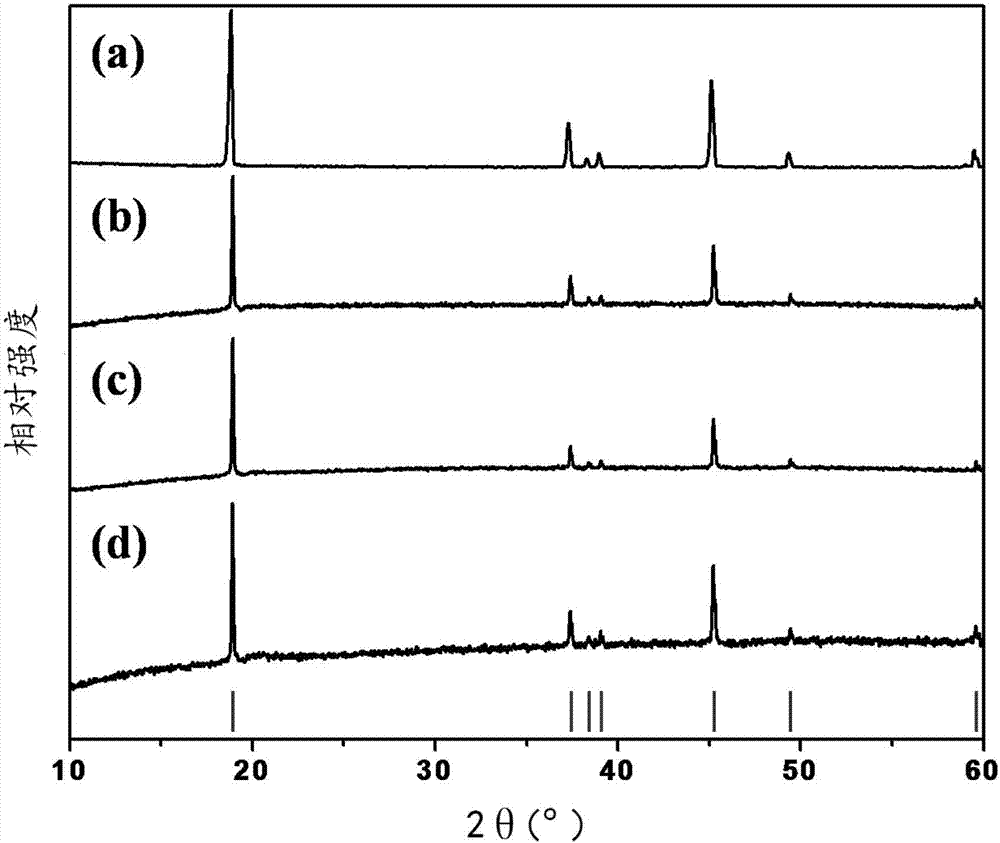

Lithium battery formed on basis of lithium nickel manganese oxide and lithium titanate and preparation method of lithium battery

InactiveCN105336943ALong cycle lifeFast cycle lifeFinal product manufactureCell electrodesElectrolytic agentElectrical battery

The invention discloses a lithium battery formed on the basis of lithium nickel manganese oxide and lithium titanate and a preparation method of the lithium battery. The lithium battery comprises an aluminum-plastic film casing, an anode lug, a cathode lug and a tab film, wherein the aluminum-plastic film casing contains a battery cell and electrolyte; the battery cell comprises an anode piece, a diaphragm and a cathode piece; materials of the anode piece comprise an anode slurry coating consisting of a positive active material, a binding agent, a conductive agent and a solvent and an anode current collector; the positive active material adopts an Al2O3 coating of lithium nickel manganese oxide; the binding agent adopts one or two of polyvinylidene fluoride and polytetrafluoroethylene; the conductive agent adopts one or more of conductive carbon black, conductive graphite and carbon nanotubes; the solvent adopts N-methyl-2-pyrrolidinone; the anode current collector adopts an aluminum foil; the cathode piece adopts an aqueous cathode or an oil-based cathode. According to the designed lithium battery, the purposes of improvement of the reversible specific capacity, the energy density and the rapid charge-discharge capability, the cycle performance and the safety performance of the battery are achieved while the production cost is reduced.

Owner:四川省有色冶金研究院有限公司

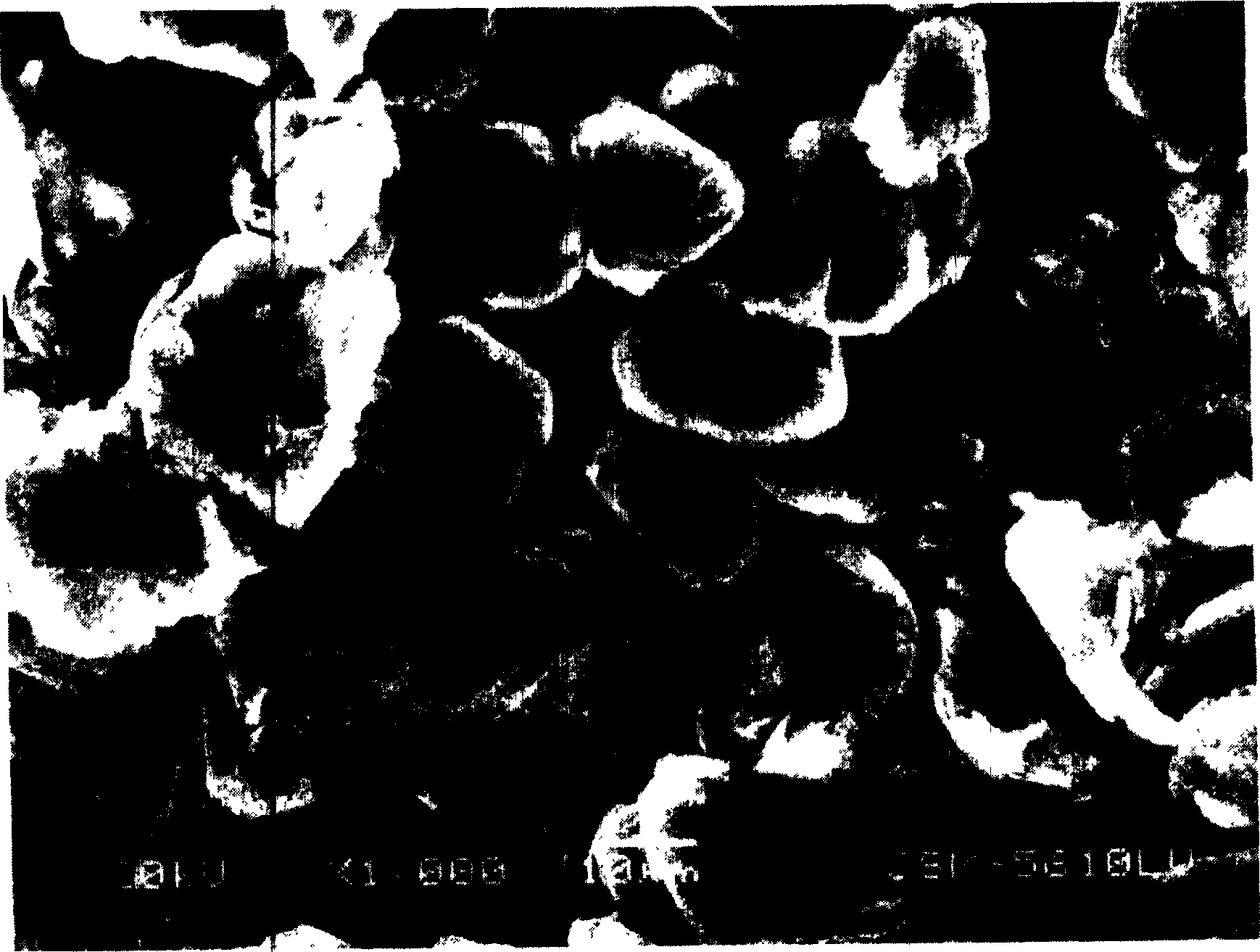

Modified graphite and its preparing method

InactiveCN1581544AGood high current performanceHigh reversible specific capacityCell electrodesPolymeric surfaceGraphite

Modified graphite includes granules of graphite core material and amorphous carbon membrane layer. Distance of between micro crystal layers d002 as 0.335-0.340 nm. Specific surface area of modified graphite is 1.3-4.2m2 / g and average particle diameter is 8-35 micro. The preparing method includes following steps: dipping granules of graphite core material in solution of polymer coating materials; then through mixing, separating, sieving, solidifying and carbonizing steps. Advantages are: large current, higher reversible specific capacity, longer cycle life. Features are simple, low cost and easy for industrialization production.

Owner:BYD CO LTD

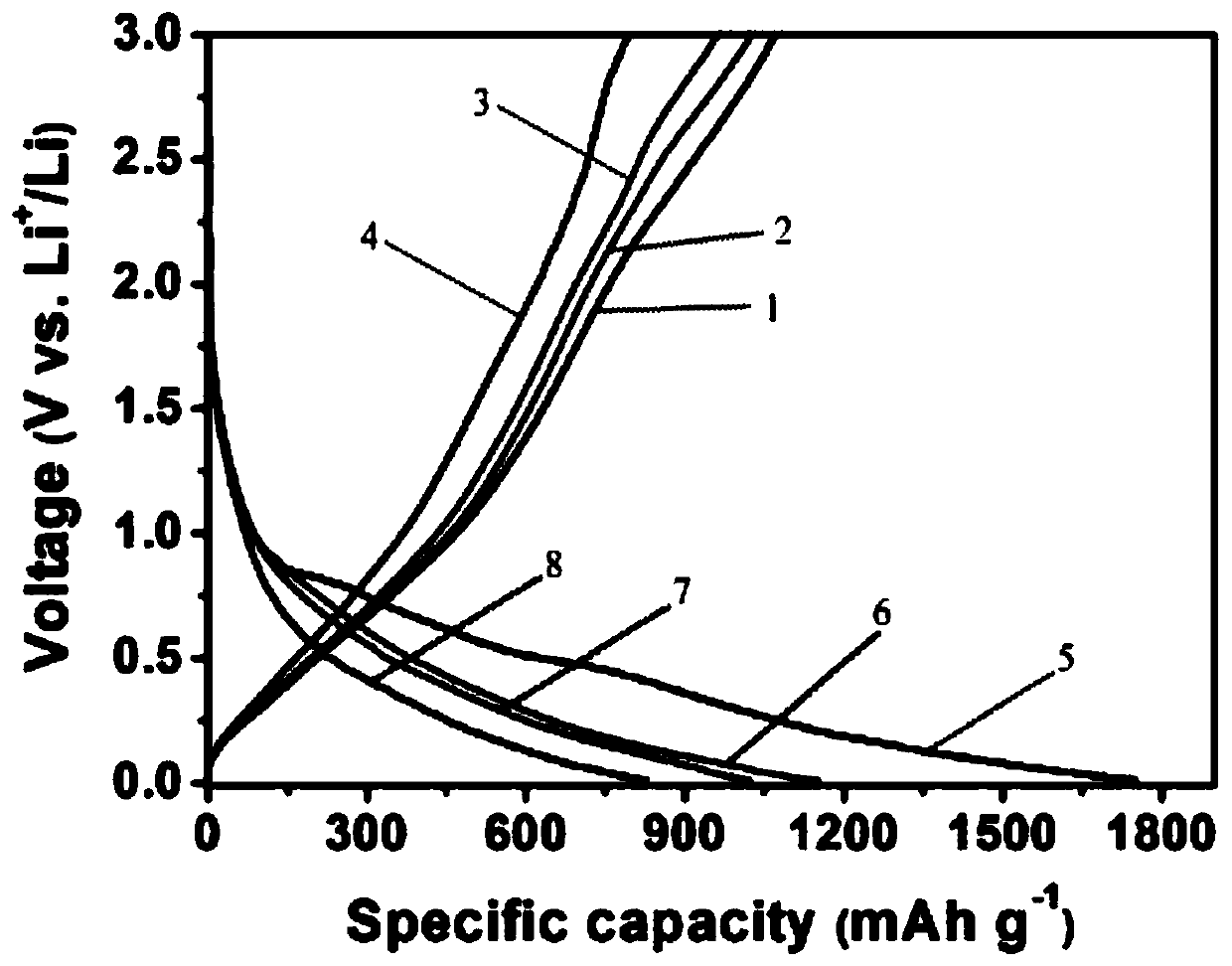

Phosphorus/carbon composite negative electrode material of lithium ion battery and preparation method thereof

InactiveCN101604752AHigh reversible specific capacityGood electrochemical cycle stabilityElectrode manufacturing processesSource materialCarbon source

The invention discloses a phosphorus / carbon composite negative electrode material of a lithium ion battery and a preparation method thereof, which belong to the technical field of electrode materials of the lithium ion batteries and preparation thereof. In the composite material, the mass ratio of P to C is 8 / 2-4 / 6, and the composite material has an amorphous structure containing P-C chemical bonds. A phosphorus source material and a carbon source material are mixed according to the mass ratio of the P to the C of 8 / 2-4 / 6; then the mixed material is added into a stainless steel tank; stainless steel balls are added into the mixed material according to the mass ratio of the mixed material and the stainless steel balls of 1:20-1:80; and the ball milling is performed for 5 to 30 hours under the protection of nitrogen to obtain the phosphorus / carbon composite material. The phosphorus / carbon composite material has higher reversible specific capacity and good electrochemical cycle stability; and the material has simple process and convenient operation, and is easy to realize mass industrial production.

Owner:BEIJING UNIV OF CHEM TECH

Lithium ion battery and anode active material thereof

ActiveCN102368547AImprove power densityExtended service lifeCell electrodesSecondary cellsHigh energyHeat stability

The invention relates to the technical field of lithium ion batteries, and in particular relates to an anode active material of the lithium ion battery. The molecular formula of the material is shown as Li(1-alpha)A(alpha)[Li(1 / 3-beta)MI(beta)Mn(2 / 3-gamma)MII(gamma)]O2-deltaXz. The lithium ion battery manufactured by the anode material has the reversible specific capacity which is higher than 200mAh / g, good circulation and heat stability performances and perfect multiplying power performance. The anode materials can meet requirements of the lithium ion battery effectively, such as the high energy density, the high-power density and the long service life and high safety.

Owner:DONGGUAN AMPEREX TECH +1

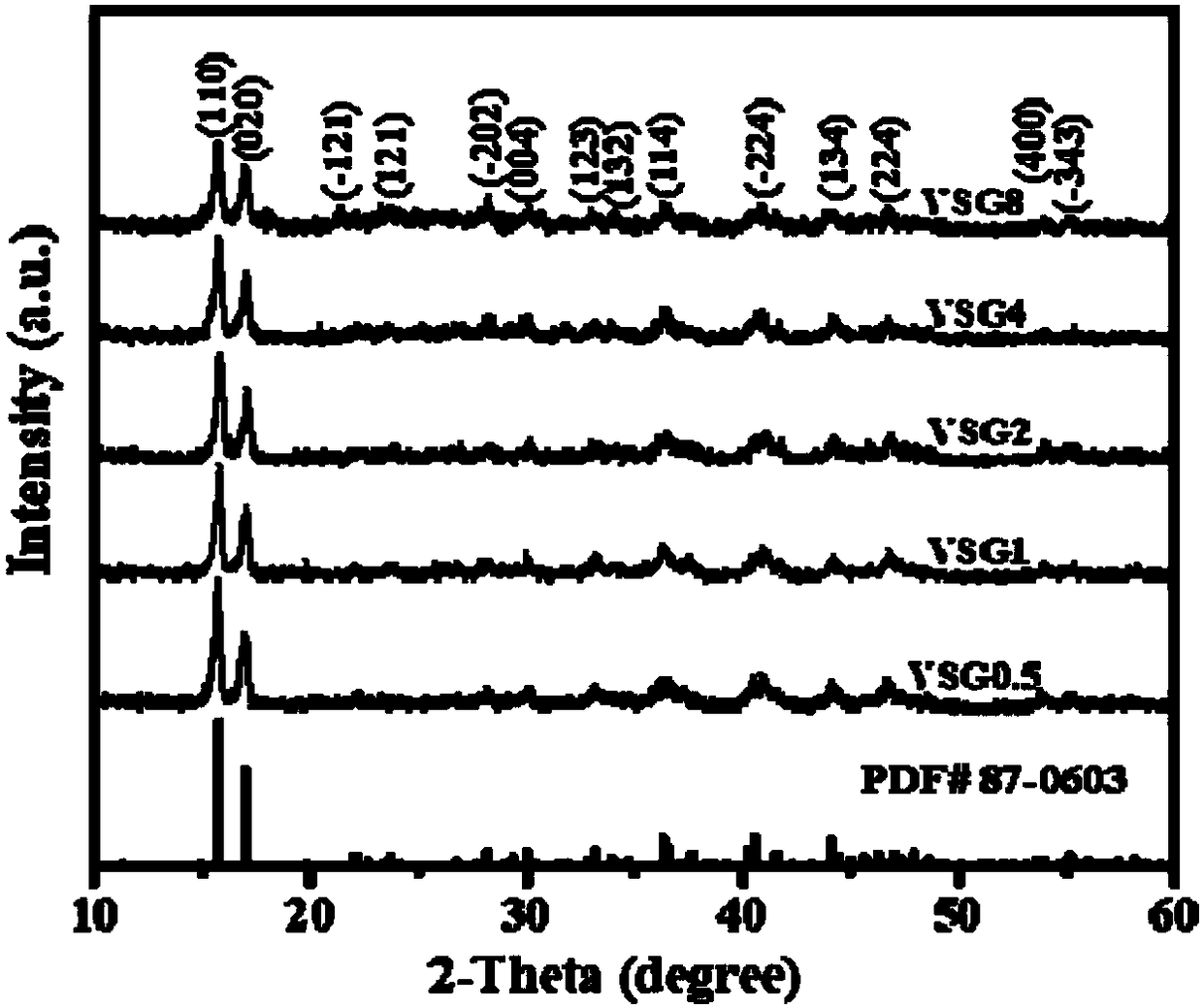

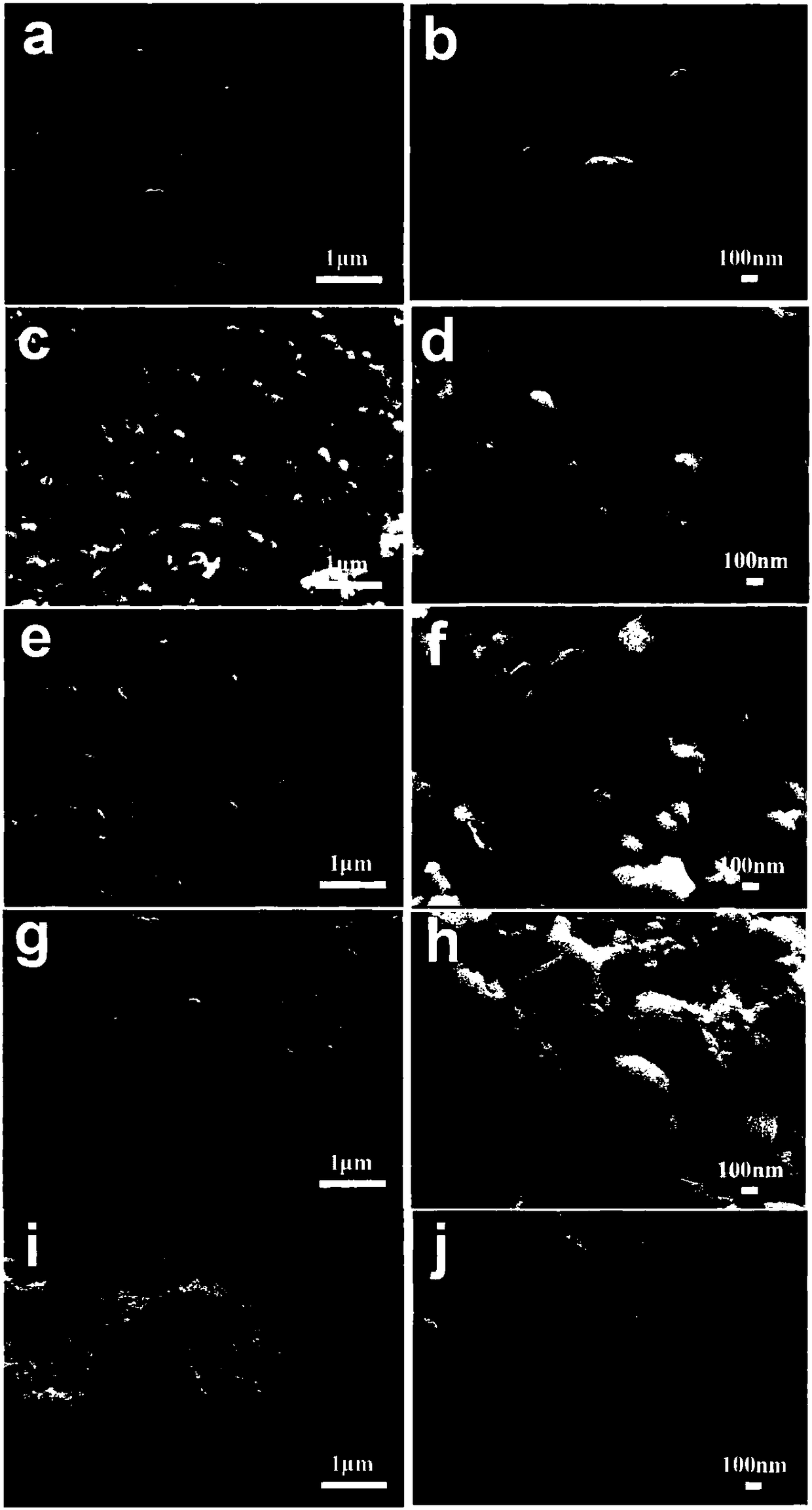

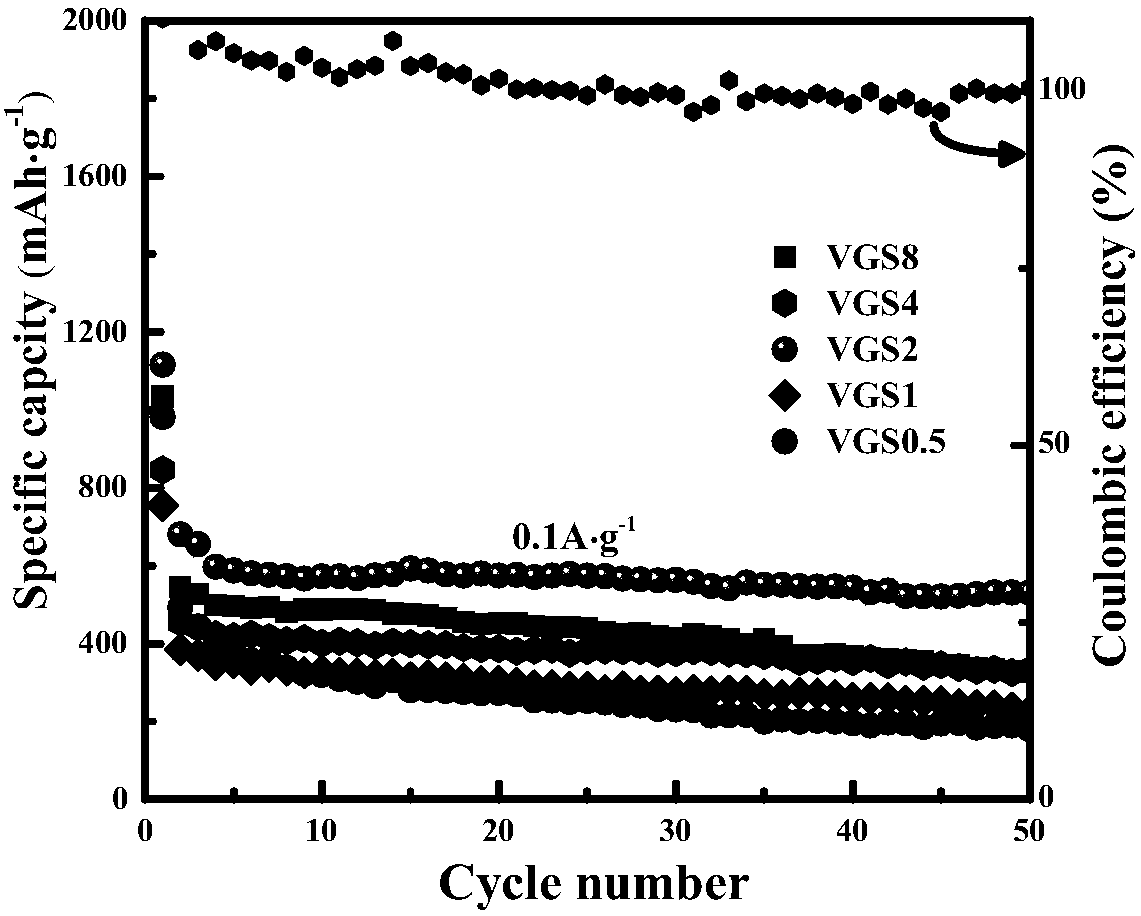

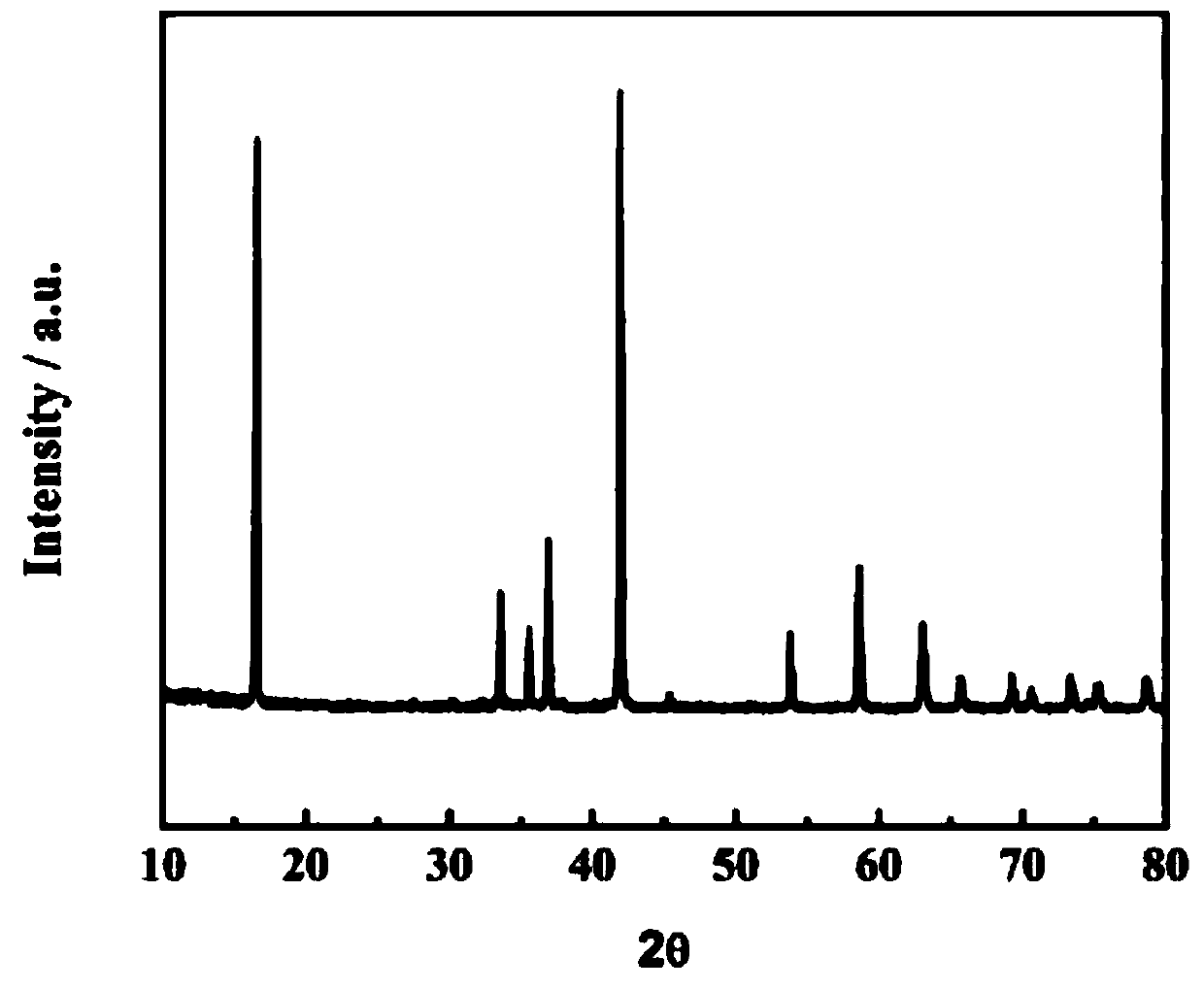

Preparation method of vanadium tetrasulfide/graphene composite material used for electrode of sodium ion battery

InactiveCN108598432AImprove conductivitySimple processMaterial nanotechnologyCell electrodesHigh rateNew energy

The invention belongs to the technical field of a new energy material, specifically a preparation method of a vanadium tetrasulfide / graphene composite material used for an electrode of a sodium ion battery. By adopting a hydrothermal synthesis method and by adopting layered graphene as a template, vanadium tetrasulfide is grown on the layered graphene template (or vanadium tetrasulfide particles are coated with graphene) so as to form the vanadium tetrasulfide / graphene composite material; the method is simple in process, low in cost, high in repeatability, and suitable for a commercial application of the electrode material of the sodium ion battery; according to the preparation method, by virtue of a graphene thin film sheet layers, the nanometer vanadium tetrasulfide particles are connected between the sheet layers to form a stable solid electrolyte interface film, thereby effectively improving conductivity of the composite electrode material, and showing high rate capability and cycle stability; and the reversible specific capacity in charging and discharging cycles at the current of 0.2A.g<-1> can reach 580mAh.g<-1>, and high-current charging and discharging capability of as high as 20A.g<-1> can be realized, so that the commercial electrode application of the sodium ion battery can be satisfied.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Lithium ion battery cathode material and non-aqueous electrolyte batterie

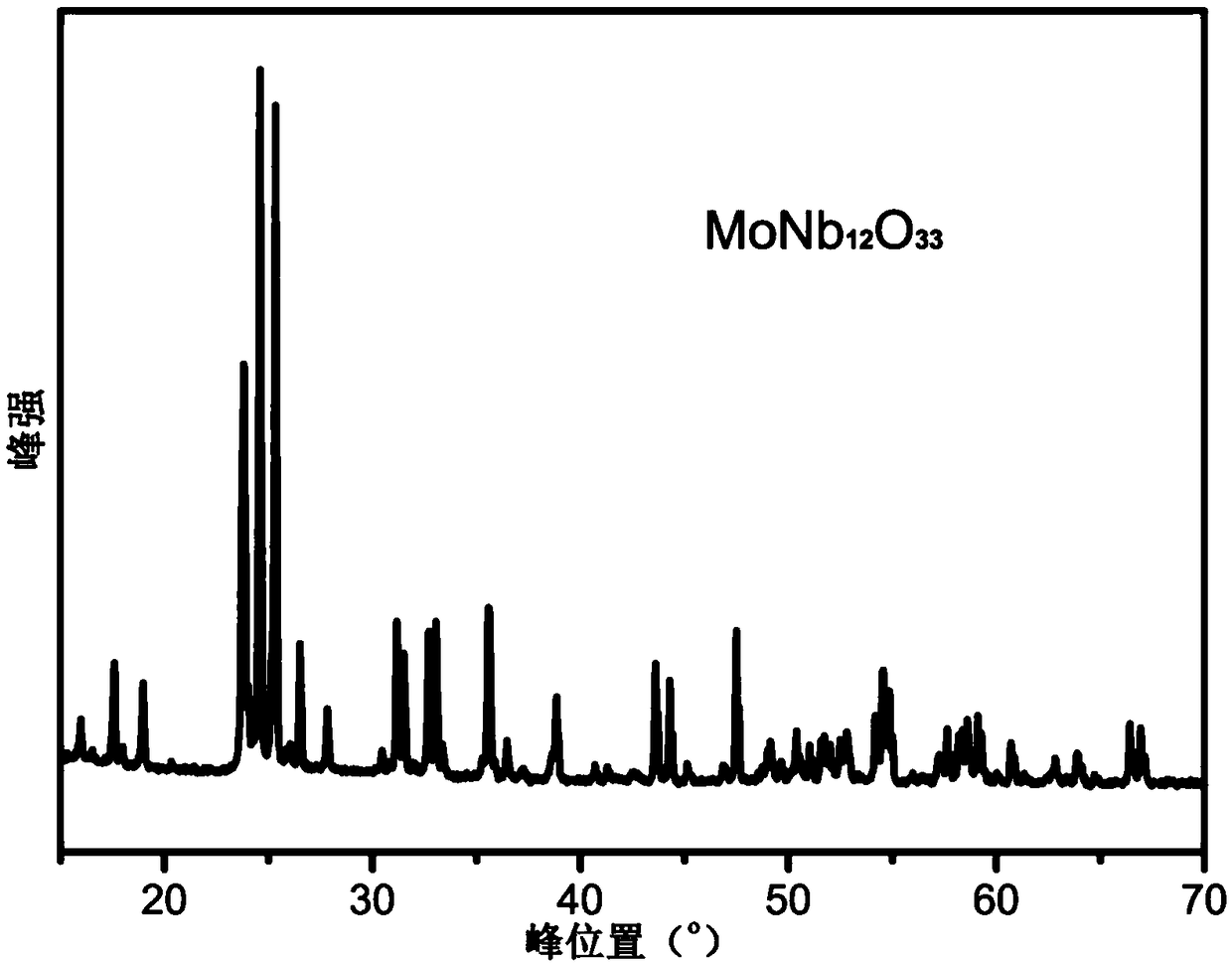

InactiveCN109244443AHigh theoretical specific capacityImprove securityNegative electrodesElectrode collector coatingNiobiumPhysical chemistry

Owner:AAC TECH NANJING

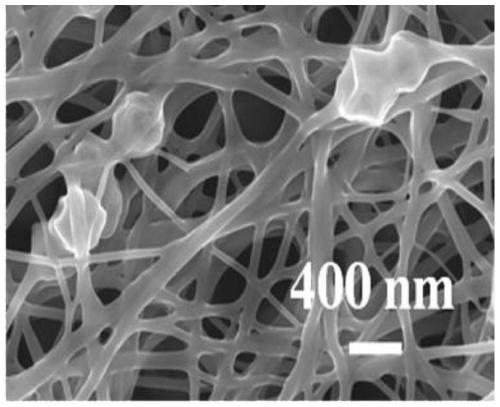

Preparation method of carbon nanofiber electrode material based on MOFs derived metal oxide

PendingCN111081995AHigh reversible specific capacityImprove electrical conductivitySecondary cellsNegative electrodesElectro conductivityLithium electrode

The invention discloses a preparation method of a carbon nanofiber electrode material based on an MOFs derived metal oxide, and belongs to the technical field of lithium ion battery negative electrodematerials. According to the preparation method, an N-N dimethylformamide solution formed by mixing MOFs particles and polyacrylonitrile fibers is adopted as a spinning precursor. The MOFs are connected to the polyacrylonitrile fibers in series through electrostatic spinning, so that a precursor film can be obtained; the MOFs derived metal oxide and carbon nanofiber composite material is preparedthrough subsequent pre-oxidation and carbonization treatment. The MOFs-derived metal oxide can maintain the unique frame structure of the precursor MOF material to be used as a lithium ion memory; thecarbon nanofibers can promote the rapid transfer of electrons so as to improve the conductivity of the electrode material; the metal organic framework (MOFs) derived material (metal oxide) with a unique structure is embedded into the carbon nanofibers, so that a three-dimensional conductive network structure can be formed; and used as a lithium ion battery negative electrode material, the three-dimensional conductive network structure shows relatively high reversible specific capacity and excellent cycle performance.

Owner:NORTHEASTERN UNIV

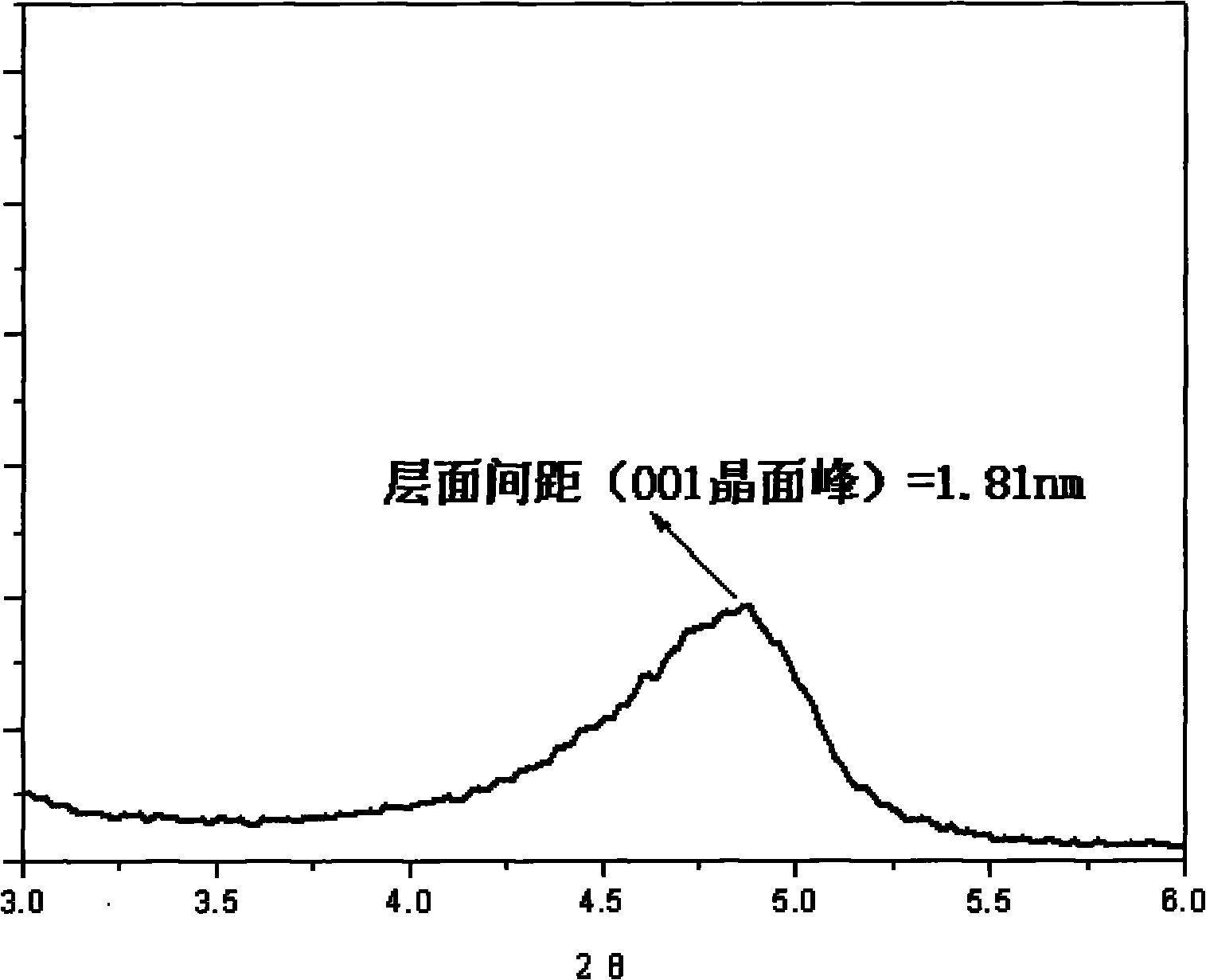

Lithium secondary battery cathode material and preparation method thereof

InactiveCN101777642AHigh reversible specific capacityGood dimensional stabilityCell electrodesMass ratioVacuum drying

The invention relates to a lithium secondary battery cathode material and a preparation method thereof, and belongs to the technology of the lithium secondary battery cathode material. The cathode material is prepared from montmorillonite or organic modified montmorillonite, acetylene black and polyvinylidene fluoride. The preparation process of the cathode material comprises the following steps of: mixing the montmorillonite or the organic modified montmorillonite, the acetylene black and the polyvinylidene fluoride in mass ratio; putting the mixture into a mortar for grinding; adding N-methyl pyrrolidone in the mass ratio of the mixture; continuously grinding the mixture, and coating the mixture onto an aluminum foil; and drying the mixture in a blower drying oven and a vacuum drying oven in sequence to obtain the lithium secondary battery cathode material. The prepared lithium secondary battery cathode material has the advantages of high reversible specific capacity, good dimensional stability in the process of charging and discharging, low price, availability, large scale production and wide application prospect.

Owner:TIANJIN UNIV

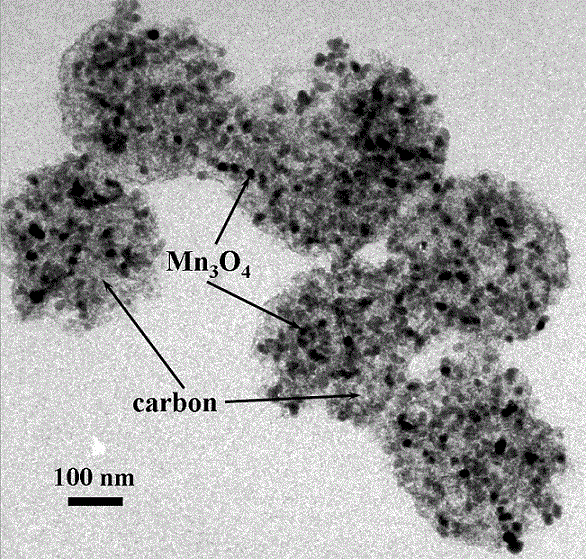

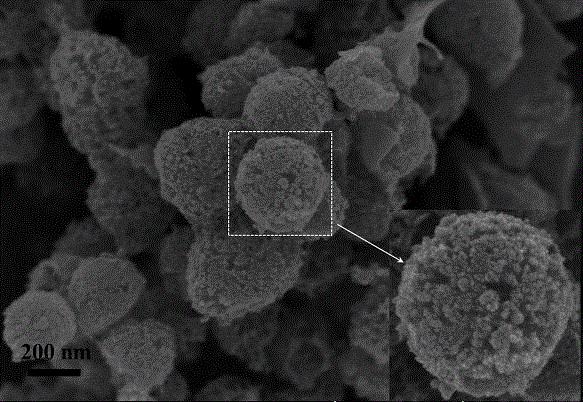

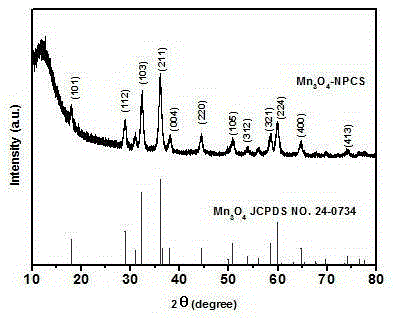

Nitrogen-doped porous carbon ball/manganic manganous oxide nanometer composite electrode material and preparation method thereof

InactiveCN105355874AAbundant and easy to get resourcesLow costMaterial nanotechnologyCell electrodesPorous carbonElectrical battery

The invention discloses a nitrogen-doped porous carbon ball / manganic manganous oxide nanometer composite electrode material and a preparation method thereof. The preparation method comprises that chitosan and its derivative as carbon source and nitrogen source predecessors and porous silica as a hard template are carbonized, then silica is removed so that nitrogen-doped porous carbon balls are obtained, manganic manganous oxide nanometer particles grow on the nitrogen-doped porous carbon balls by a mild solvothermal method, and the nitrogen-doped porous carbon balls with the manganic manganous oxide nanometer particles are subjected to centrifugation washing and drying so that the nitrogen-doped porous carbon ball / manganic manganous oxide nanometer composite electrode material is obtained. The prepared material as a lithium ion battery negative electrode material has a high reversible specific capacity, good cycling stability and excellent multiplying power discharge performances. The preparation method can be operated easily, has mild preparation conditions and no harsh requirement on equipment and is suitable for industrial production. The nitrogen-doped porous carbon ball / manganic manganous oxide nanometer composite electrode material has a wide application prospect in the electrochemistry fields of high performance lithium ion batteries and super capacitors.

Owner:HUBEI ENG UNIV

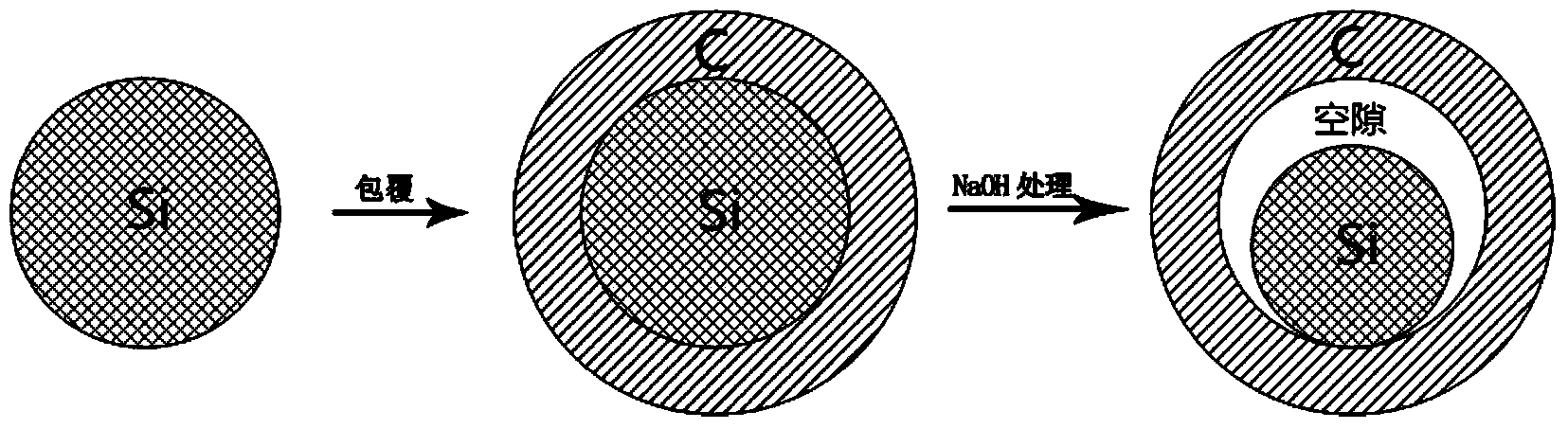

Lithium ion battery negative electrode material and preparation method thereof

InactiveCN103872330AEasy to prepareThe preparation process is simple and controllableSecondary cellsNegative electrodesElectrochemical responseCyclic process

The invention discloses a lithium ion battery negative electrode material and a preparation method thereof. The material has a core-shell structure; a core material is silicon grains and a shell material is carbon; a gap etched by an alkaline solution is formed between the core material and the shell material, so that the volume effect of the silicon grains can be inhibited to a certain extent, the diffusion distance of lithium ions can also be reduced and the electrochemical reaction speed is enhanced; therefore, the cycle performance of the silicon-based negative electrode material is improved, the structural stability of the material in a cyclic process is improved and the aims of high capacity and high cycle are realized.

Owner:SHANGHAI JIAO TONG UNIV

Cathode material for lithium-ion battery, preparation method of cathode material and battery

ActiveCN104577096AHigh reversible specific capacityImprove cycle performanceCell electrodesSecondary cells servicing/maintenanceElectrical batteryPhysical chemistry

The invention discloses a cathode material for a lithium-ion battery, a preparation method of the cathode material and the battery. The material adopts the structure that a lithium-nickel-cobalt-manganese material used as the core is coated with an aluminum-doped lithium-nickel-cobalt-manganese material, the molecular formula of the lithium-nickel-cobalt-manganese material used as the core is Lim(Ni1-x-yCoxMny)O2, the molecular formula of the aluminum-doped lithium-nickel-cobalt-manganese material for coating is Lim(Ni1-x-y-zCoxMnyAlz)O2, m is larger than or equal to 1 and smaller than or equal to 1.4, x is larger than or equal to 0.05 and smaller than or equal to 0.35, y is larger than or equal to 0.1 and smaller than or equal to 0.4, and z is larger than 0 and smaller than or equal to 0.08. A shell layer of the cathode material is doped with aluminum, so that on one hand, the usage amount of cobalt in the whole cathode material adopting the core-shell structure is reduced, and the cost is reduced; on the other hand, corrosion caused by an electrolyte to the lithium-nickel-cobalt-manganese material used as the core can be reduced due to the aluminum in the shell layer, so that the reversible specific capacity of the lithium-ion battery made of the cathode material can be improved, and the cycle performance of the battery can be improved.

Owner:CHERY AUTOMOBILE CO LTD

Fluorine-doped carbon-coated positive electrode composite material and preparation method and application thereof

ActiveCN105895879AImprove conductivityAvoid erosionCell electrodesSecondary cellsHigh energyCarbonization

The invention belongs to the technical field of lithium-ion batteries, and particularly relates to a fluorine-doped carbon-coated positive electrode composite material and a preparation method and an application thereof. The method comprises the following steps: with a lithium source, a manganese source and / or an iron source and a phosphorus source as materials, obtaining a positive electrode material LiMn<1-x>Fe<x>PO<4> (x=0-1) by a solvothermal method or a solid phase method; and mixing the obtained positive electrode material with a fluorine-containing material and carrying out high-temperature carbonization under inert gas protection to obtain the fluorine-doped carbon-coated positive electrode composite material. According to the fluorine-doped carbon-coated positive electrode composite material, the electron conduction velocity can be accelerated by fluorine-doped carbon; corrosion of an electrolyte to the material LiMn<1-x>Fe<x>PO<4> (x=0-1) is reduced; and the prepared positive electrode material has high reversible specific capacity, good rate capability, excellent cycle performance and high energy density. The technology is simple; the repeatability is good; and the prepared high-performance positive electrode material is suitable for the field of application of lithium-ion power batteries.

Owner:QINGDAO INST OF BIOENERGY & BIOPROCESS TECH CHINESE ACADEMY OF SCI

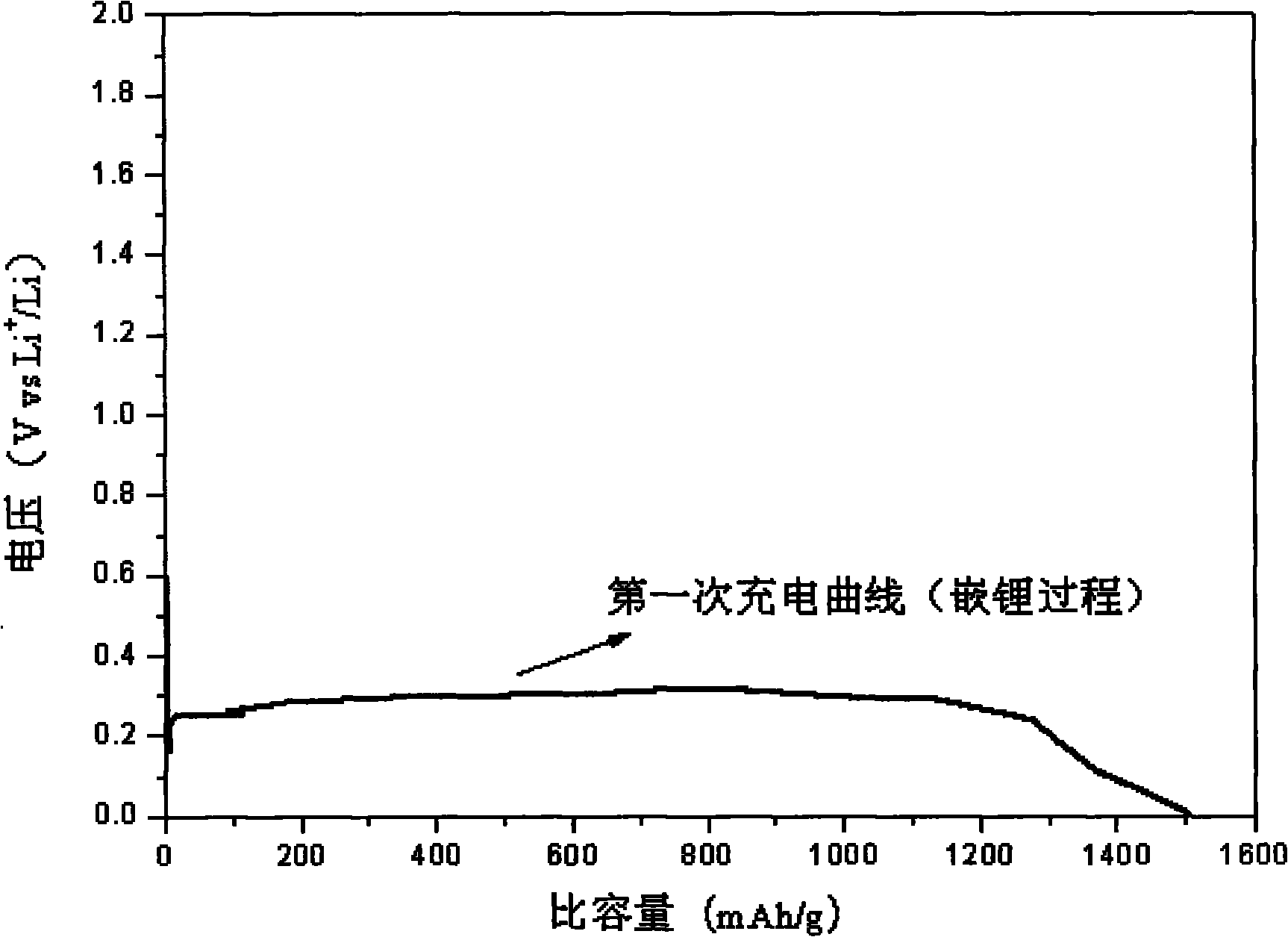

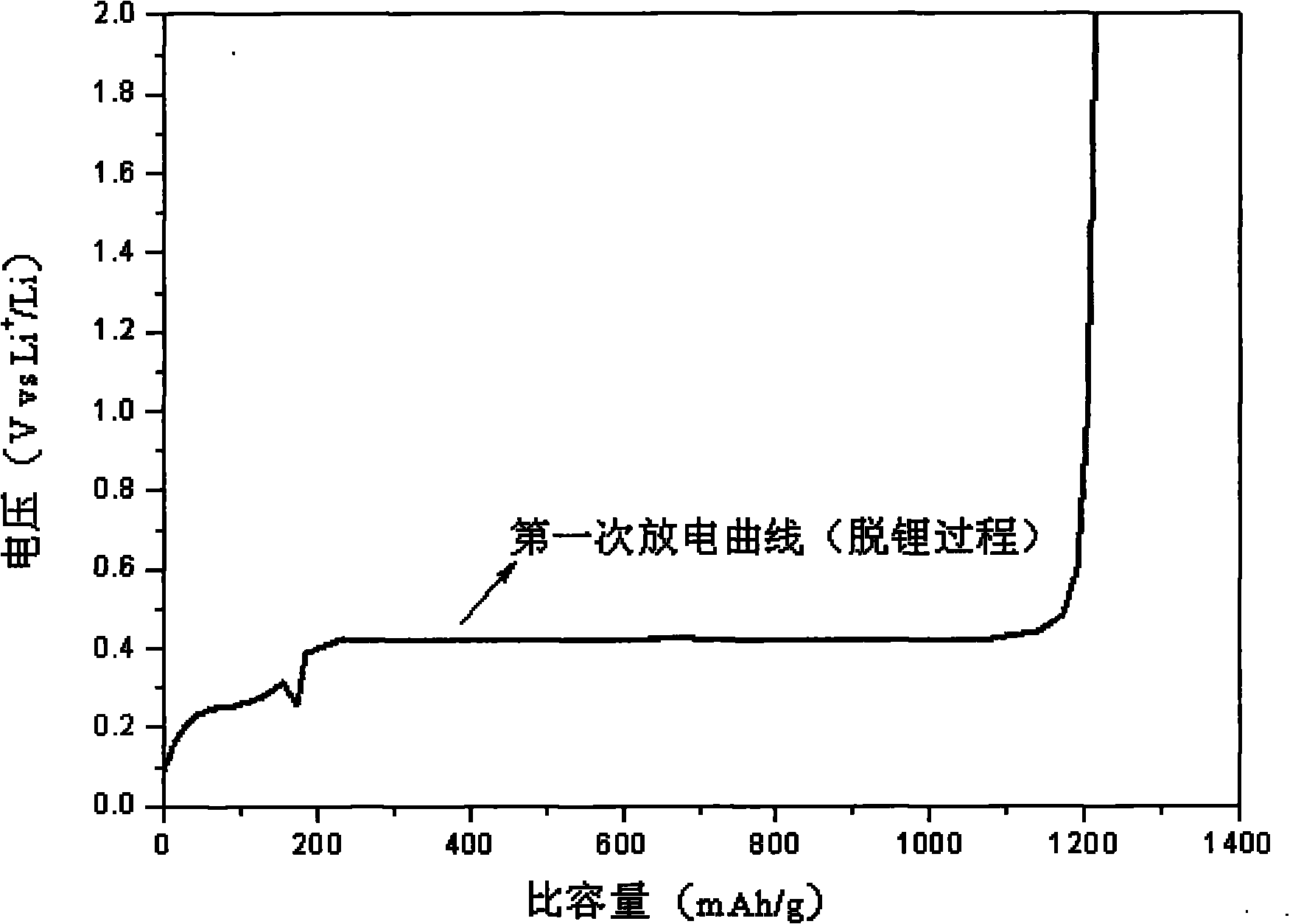

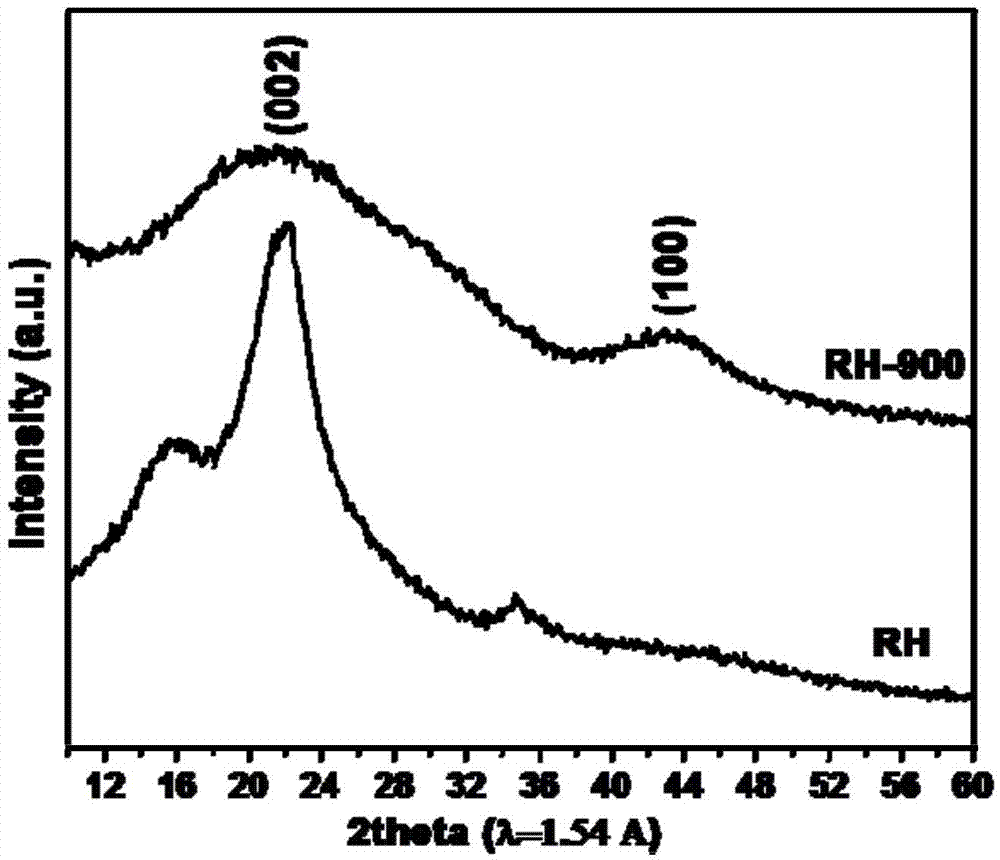

Preparation method for silicon dioxide/carbon compound and application to lithium/sodium ion batteries

ActiveCN104300124AWide variety of sourcesLow costCell electrodesSecondary cellsFurnace temperatureWater vapor

The invention provides a preparation method for a silicon dioxide / carbon compound and application to lithium / sodium ion batteries, and belongs to the technical field of composite materials. The technical scheme is shown as follows: firstly, crushing biomass ash into particles with the size less than centimeter level; then performing heat processing at 800-1500 DEG C in an argon, nitrogen, carbon monoxide, hydrogen or water vapor atmosphere for 4-20 h, and cooling to room temperature along with the furnace temperature; and finally cleaning the obtained product in water or a diluted acid, separating, and drying the solid obtained after separation in a vacuum drying box at 80 DEG C, so as to obtain the silicon dioxide / carbon compound. The silicon dioxide / carbon compound is wide in raw material resource, low in cost and free of pollution to environment, and is suitable for industrialized large-scale production, and the obtained silicon dioxide / carbon compound is a lithium / sodium ion battery anode material with excellent performances.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

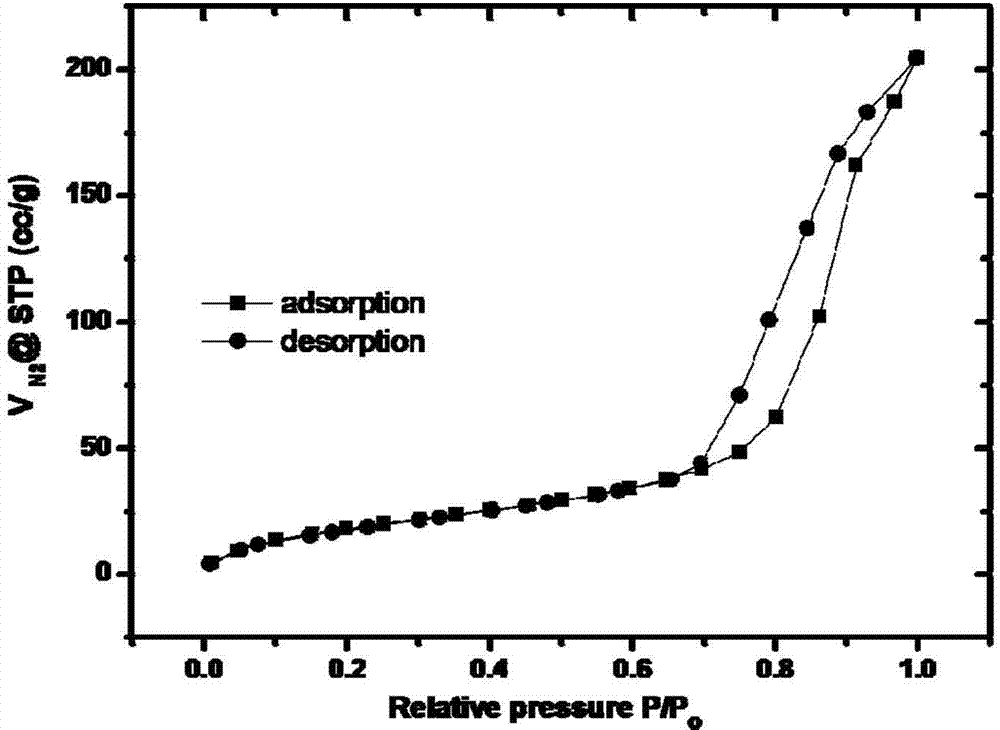

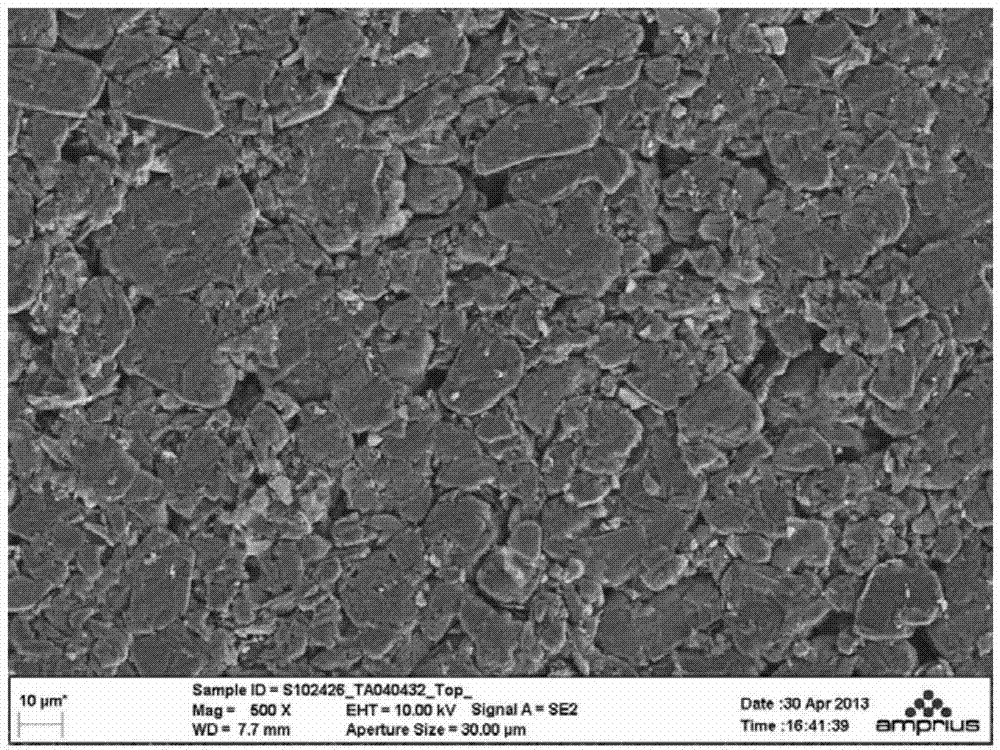

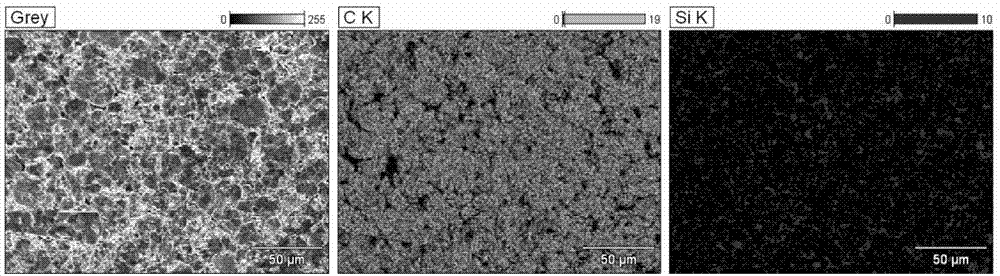

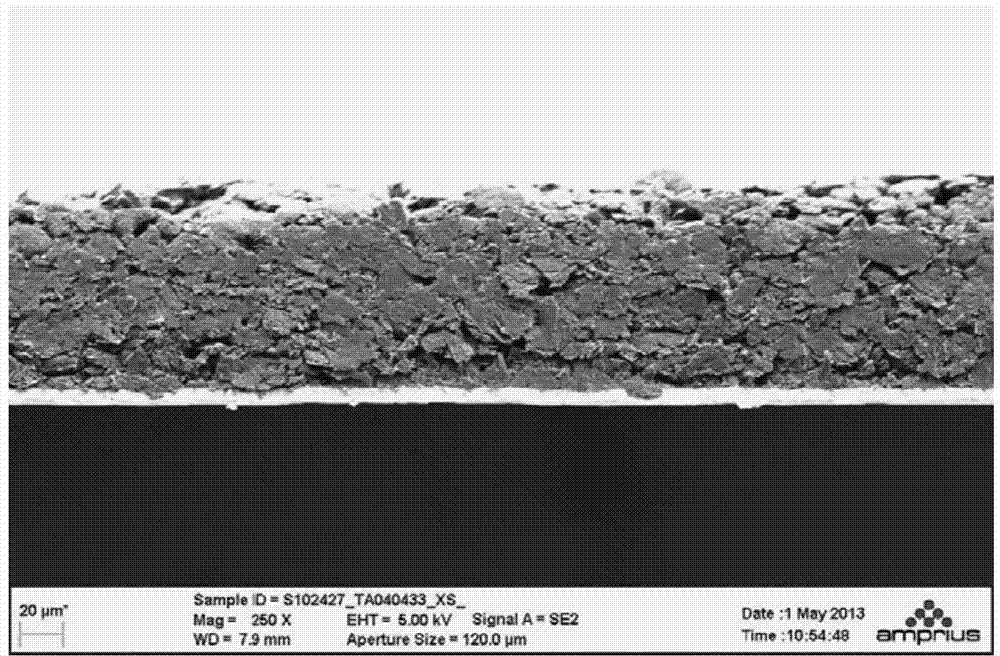

Silicon-containing negative electrode of lithium ion battery and preparation method of silicon-containing negative electrode

ActiveCN103779536AHigh reversible specific capacityIncrease energy densityCell electrodesSodium-ion batteryLithium-ion battery

The invention discloses a silicon-containing negative electrode of a lithium ion battery. The negative electrode contains an active material, a thickening agent and a binder, wherein the active material is a mixture formed by carbon-based powder and silicon-containing powder, the carbon-based powder accounts for 93wt%-98wt% of the total weight of the silicon-containing negative electrode, the silicon-containing powder accounts for 0wt%-5wt% (except 0%) of the total weight of the silicon-containing negative electrode; the ratio of the average particle size D50 of the carbon-containing powder to the average particle size D50 of the silicon-containing powder is within 3.0-96.9. Meanwhile, the invention discloses a preparation method of the silicon-containing negative electrode, the negative electrode has the characteristics of high volume, high efficiency, small expansion rate and good cycle performance, low material cost, simple steps and good repeatability, and scale production of the silicon-containing negative electrode in the lithium ion battery field is realized.

Owner:安普瑞斯(无锡)有限公司

Preparation method of nano-composite membrane electrode material

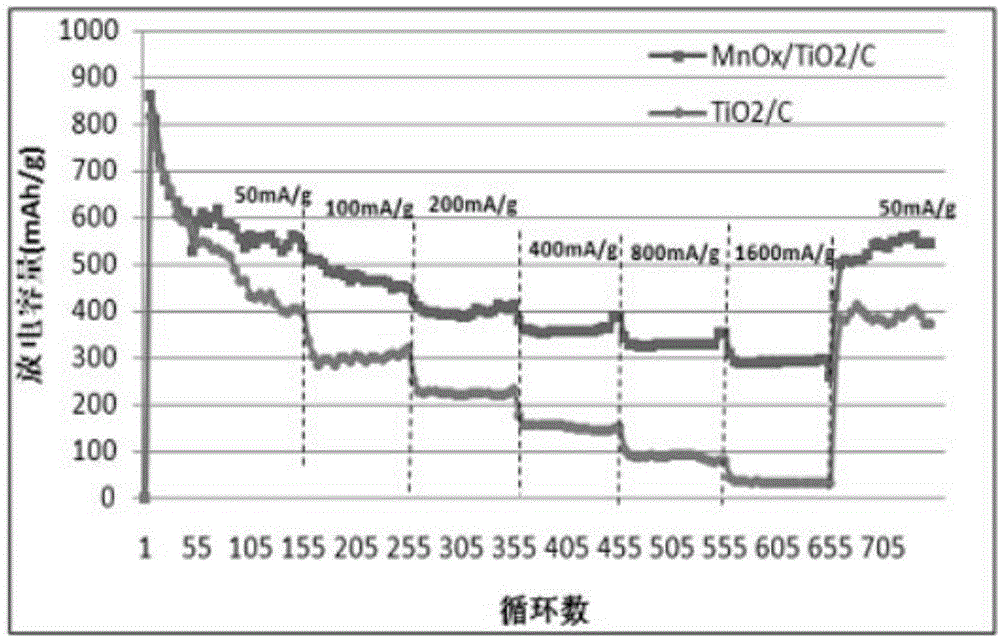

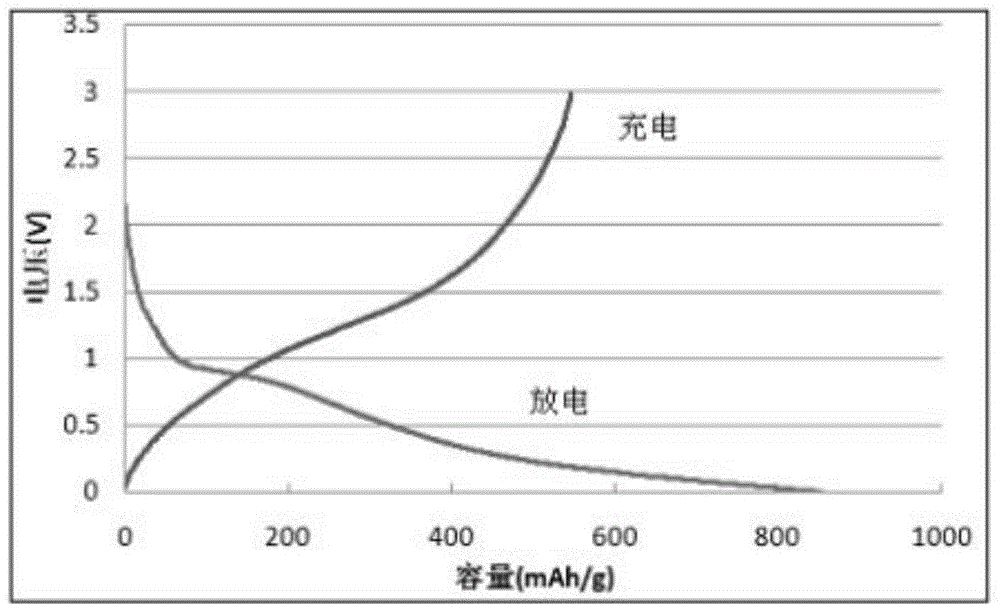

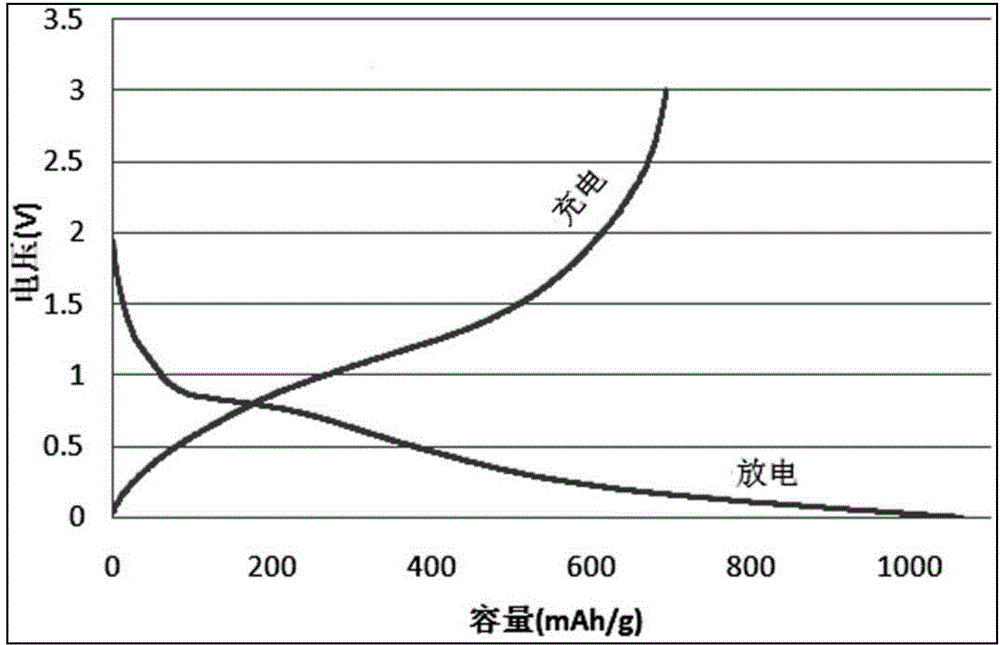

InactiveCN104868100AIncrease electrochemical potentialImprove cycle performanceMaterial nanotechnologyCell electrodesFiberManganese

The invention discloses a preparation method of a nano-composite membrane electrode material. The preparation method comprises the following steps: (1) dissolving a precursor of manganese, a precursor of titanium and a precursor of carbon in an organic solvent to prepare a spinning solution; (2) performing electrostatic spinning on the spinning solution to obtain a nano-fiber material; and (3) after performing pre-oxidation treatment on the nano-fiber material, performing carbonization treatment in an inert atmosphere to obtain the required nano-composite membrane electrode material. The MnOx / TiO2 / C nano-fiber composite membrane electrode material prepared by the preparation method is excellent in performance, nano particles of MnO2 and TiO2 are distributed on carbon nanofibers with good electric conductivity and porous structure in a mutually interlaced manner, and crystal structures of MnO2 and TiO2 nano particles affect each other and the MnO2 and TiO2 nano particles coordinately distribute on the carbon nanofiber membrane , so that the intercalation and deintercalation efficiency of lithium is improved, and the cycle performance and rate performance of the electrode material are improved; and moreover, the porous structure of the carbon nano-fibers provides a passage for the intercalation and deintercalation of lithium ions, and the electric conductivity is improved.

Owner:BEIJING BORGWARD AUTOMOBILE CO LTD

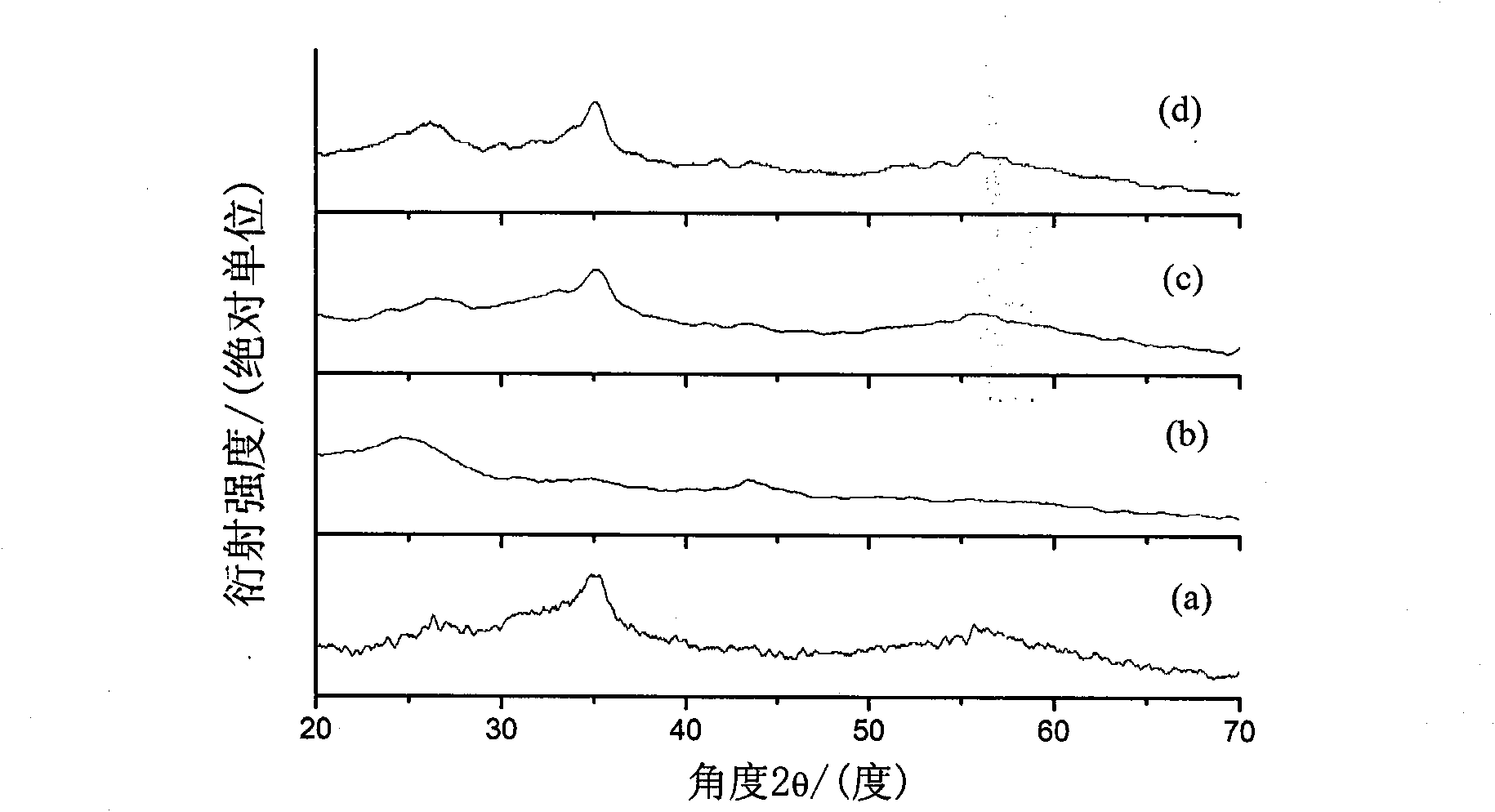

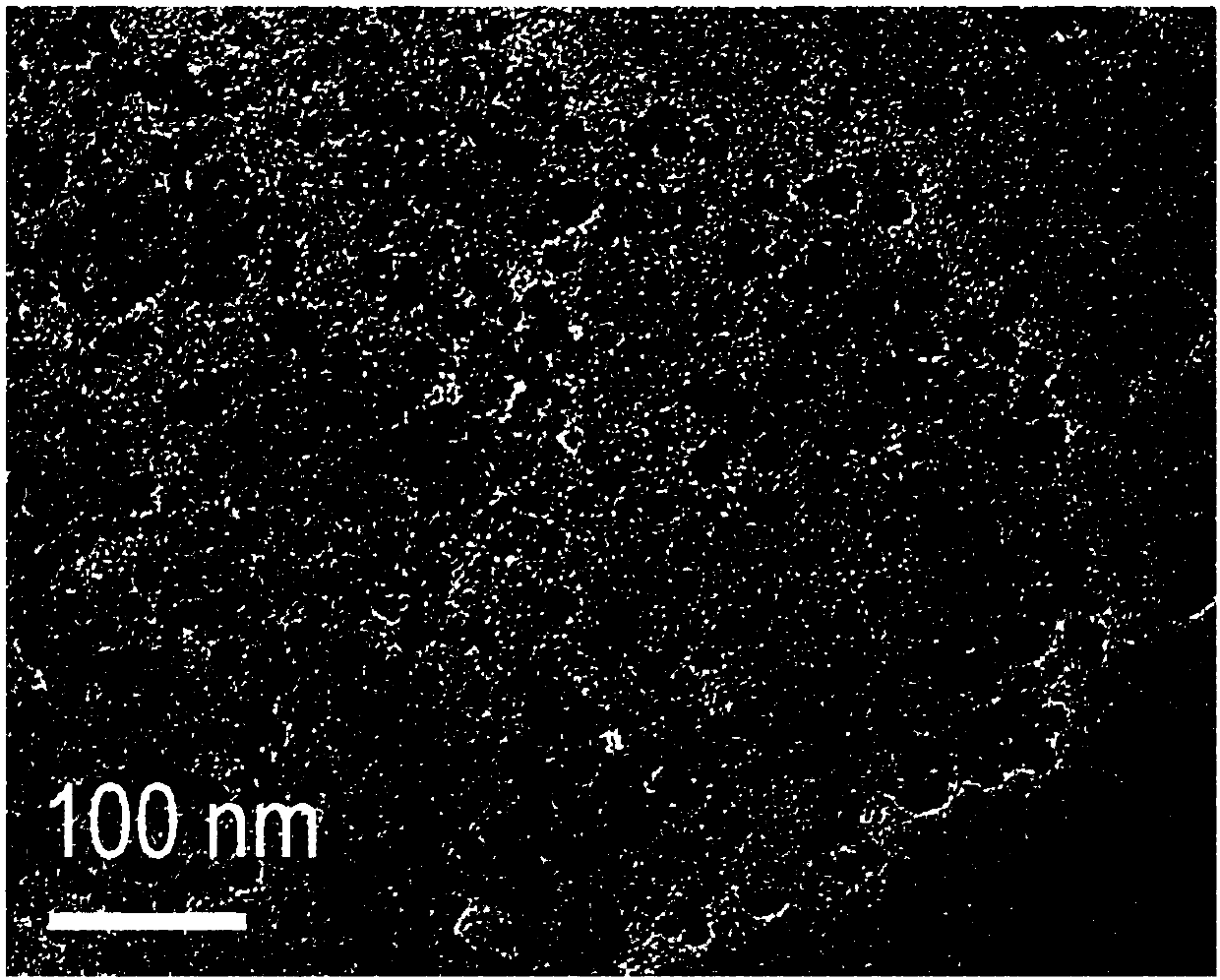

V2O5 nanoparticle/graphene lithium ion battery positive pole material and preparation method thereof

InactiveCN103746100AImprove electrochemical performanceImprove stabilityMaterial nanotechnologyCell electrodesHigh rateLithium-ion battery

The invention relates to a V2O5 nanoparticle / graphene (V2O5-GE) lithium ion battery positive pole material and a preparation method thereof, belonging to the field of lithium ion battery positive pole materials. The V2O5-GE positive pole material is synthesized by simple hydrothermal reaction, and is a nano composite positive pole material formed by distributing 20-40nm V2O5 nanoparticles on the surface of two-dimensional transparent graphene sheets. Compared with the V2O5 nanoparticles, due to the introduction of the graphene, the V2O5-GE nano composite material has the advantages of excellent electrochemical properties, higher reversible specific capacity, high loop stability and higher rate capability. The graphene nanosheets perform the function of the conductive reticular structure, and improve the conductivity of the composite material electrode; the flexible reticular structure maintains the stability of the electrode material structure and inhibits the particle agglomeration and volume expansion, thereby improving the electrochemical properties of the V2O5 nanoparticles; and the positive pole material is hopeful to be used as a high-performance lithium ion battery positive pole material.

Owner:CHINA JILIANG UNIV

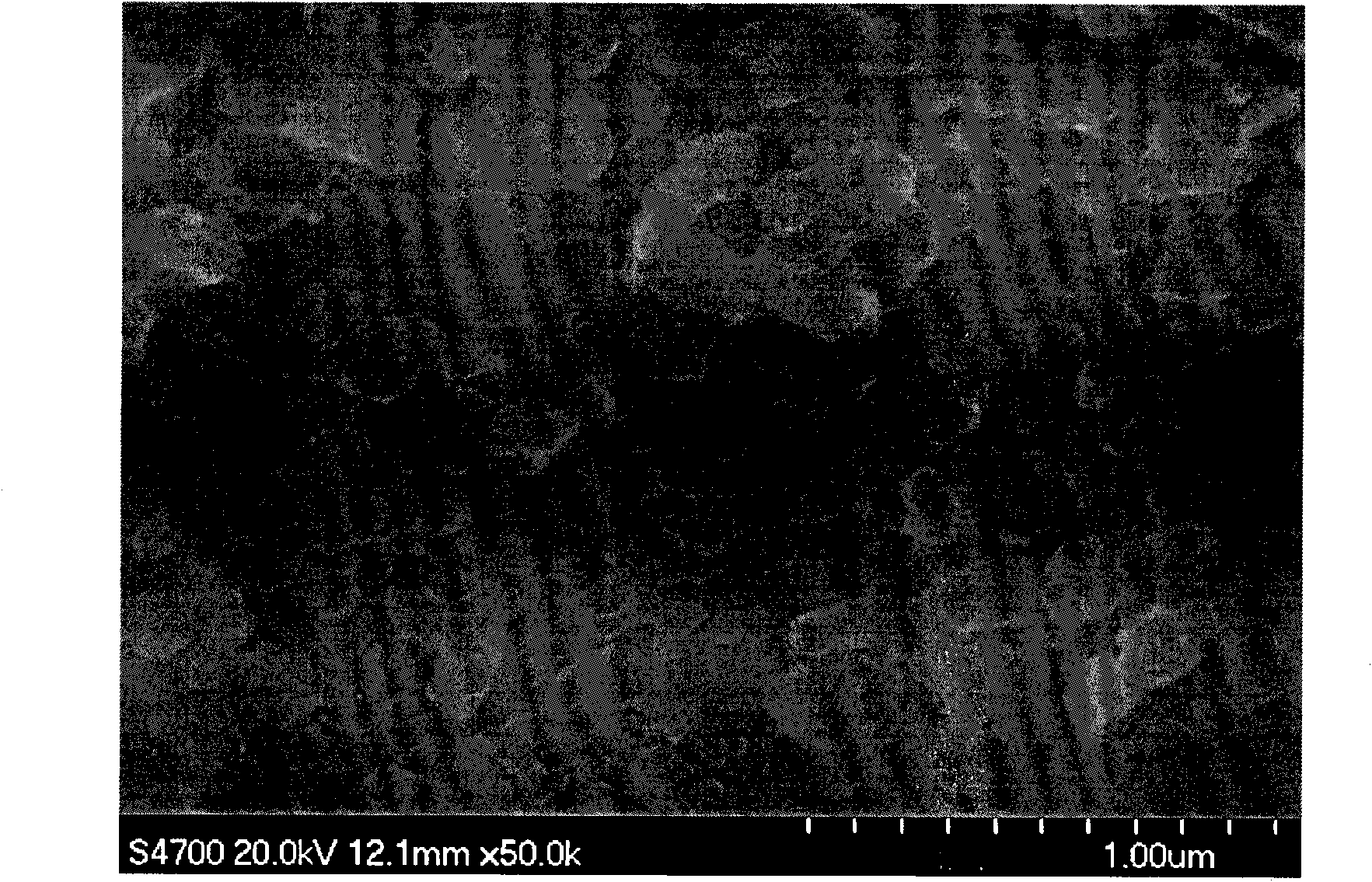

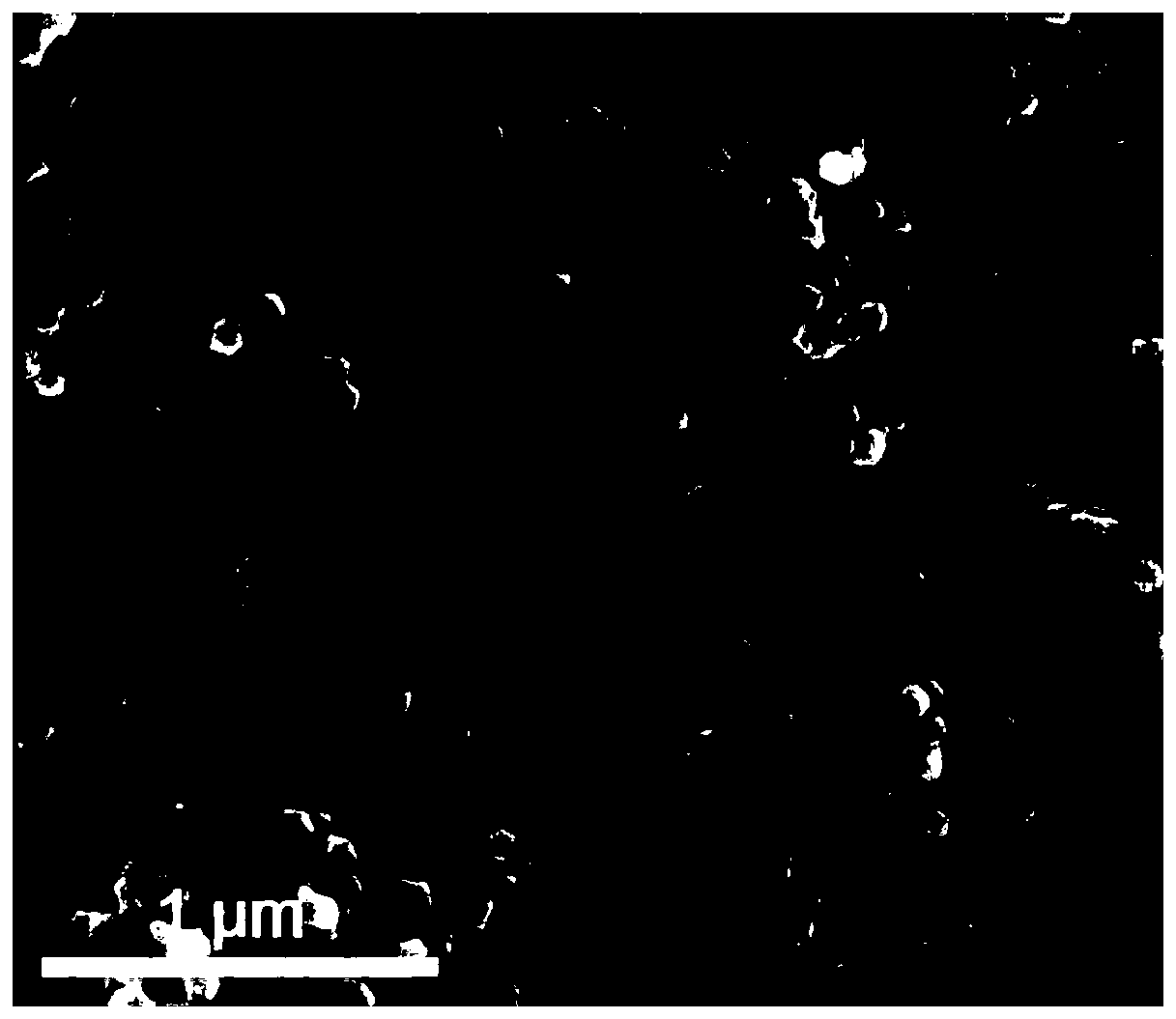

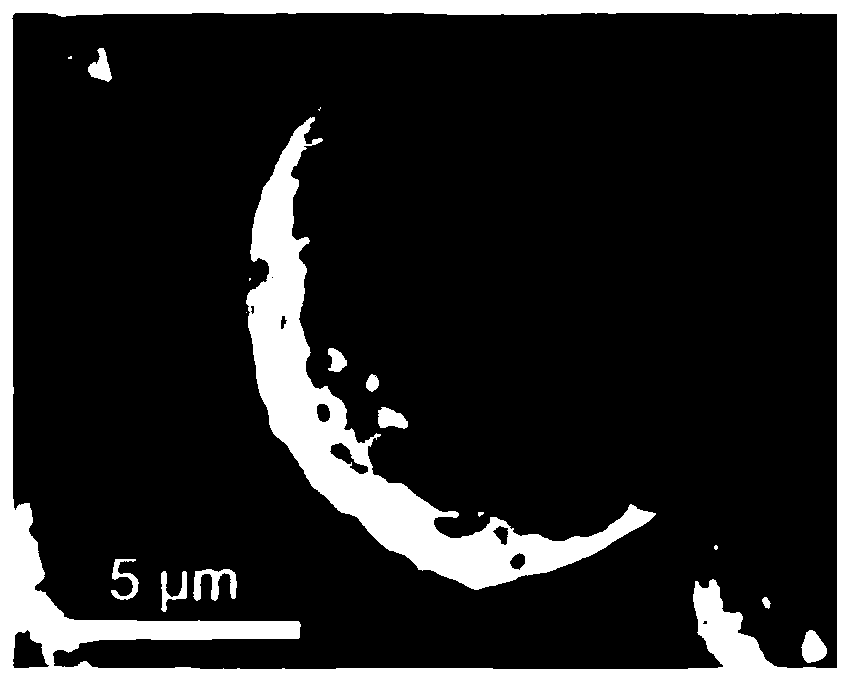

Membrane electrode based on spiral carbon nanofiber bundle and preparation method thereof

InactiveCN102306749AHigh reversible specific capacityImproved magnification performanceCell electrodesFiberGas phase

The invention discloses a membrane electrode based on a spiral carbon nanofiber bundle and a preparation method thereof, belonging to the technical field of lithium ion batteries. The membrane electrode comprises a copper coil current collector and the spiral carbon nanofiber bundle growing on the surface of the copper coil current collector, wherein the spiral carbon nanofiber bundle is formed by spirally winding a plurality of carbon nanofibers, and a graphite layer of the carbon nanofibers is vertical to the axial direction of the carbon nanofibers. The preparation method of the membrane electrode comprises the following steps: loading a nickel-based catalyst on the surface of a copper coil; and then growing the spiral carbon nanofiber bundle on the surface of the copper coil by adopting a chemical vapor deposition method. The membrane electrode and the preparation method provided by the invention have the advantages that the unique structure of the membrane electrode enables the membrane electrode to have higher reversible specific capacity, good electrochemical cycle stability and higher multiplying power performance; and the preparation technology is simple, convenient to operate, and easy to implement large-scale industrial production.

Owner:BEIJING UNIV OF CHEM TECH

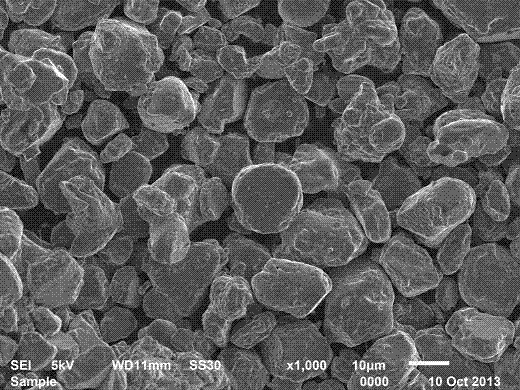

Nickel lithium manganate-based positive electrode material of lithium ion battery and preparation method thereof

InactiveCN105355903AHigh reversible specific capacityFast charge and dischargeCell electrodesSecondary cellsSlurry coatingCarbon nanotube

The invention discloses a nickel lithium manganate-based positive electrode material of a lithium ion battery and a preparation method thereof. A material used for a positive plate comprises a positive electrode current collector and a positive electrode slurry coating which is composed of a positive electrode active substance, a binder, a conductive agent and a solvent, wherein the positive electrode active substance is an Al2O3 coating of nickel lithium manganate, the binder is one or more selected from the group consisting of polyvinylidene fluoride and polytetrafluoroethylene, the conductive agent is one or more selected from the group consisting of conductive carbon black, conductive graphite and a carbon nanotube, the solvent is N-methylpyrrolidone, and the positive electrode current collector employs an aluminum foil. The lithium ion battery designed in the invention has reduced cost, and the purposes of improving reversible specific capacity, energy density, rapid charging and discharging capability, cycle performance and safety performance are achieved.

Owner:四川省有色冶金研究院有限公司

Anode material for lithium ion battery and preparation method thereof

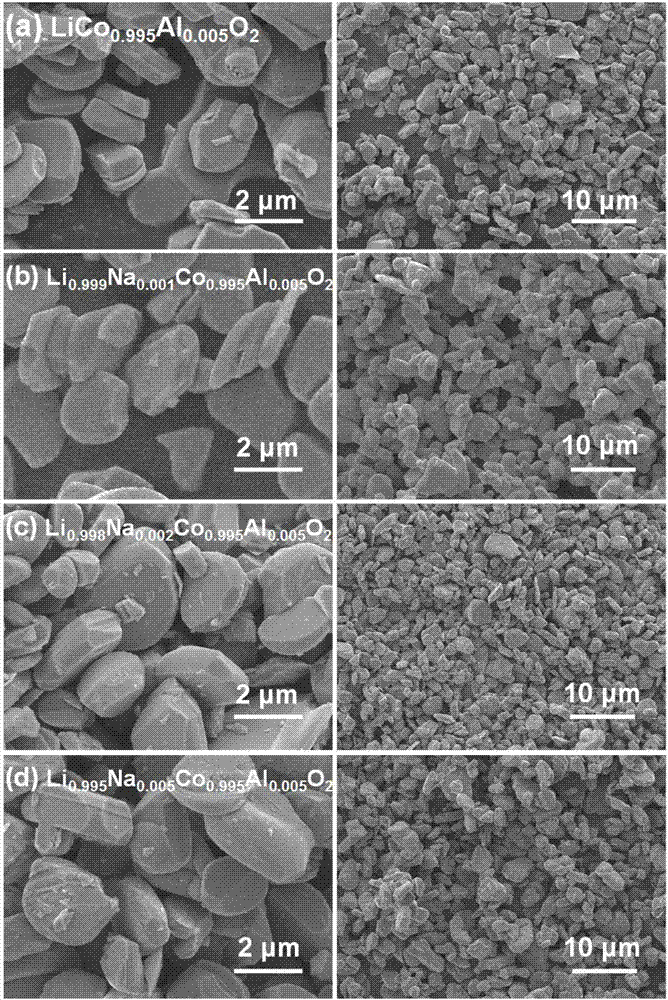

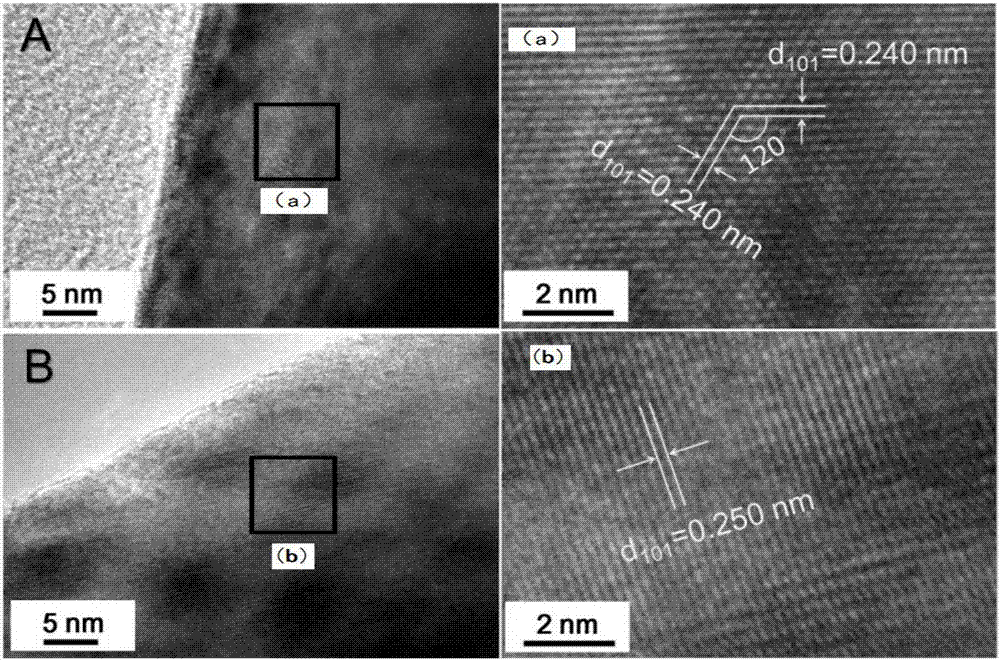

InactiveCN107017405AImprove uniformityImprove cycle stabilityCell electrodesSecondary cellsPhysical chemistryHigh pressure

The invention relates to an anode material for a lithium ion battery and a preparation method thereof, and in particular to a preparation method of micro-sodium ion doped high voltage lithium cobalt oxide, and belongs to the field of anode material for the lithium ion battery. The anode material for the lithium ion battery is lithium cobalt oxide doped by more than two metal elements. The chemical general formula of the anode material is Li(1-y)NayCo(1-x)MxO2, wherein y is greater than or equal to 0.0001 but less than or equal to 0.01, x is greater than 0 but less than or equal to 0.5, and M represents one or more of Al, Mg, Zr, Mn, Ni, Ti, Cr, Nb, Y, Cu, Sn, Sc, Ga, In, Ce and La. By doping the metal M, the cyclic stability of the lithium cobalt oxide material is improved; by doping the micro-sodium ions, the specific capacity of the material is improved on the basis of improvement of the cyclic stability of the lithium cobalt oxide material.

Owner:HUNAN NORMAL UNIVERSITY

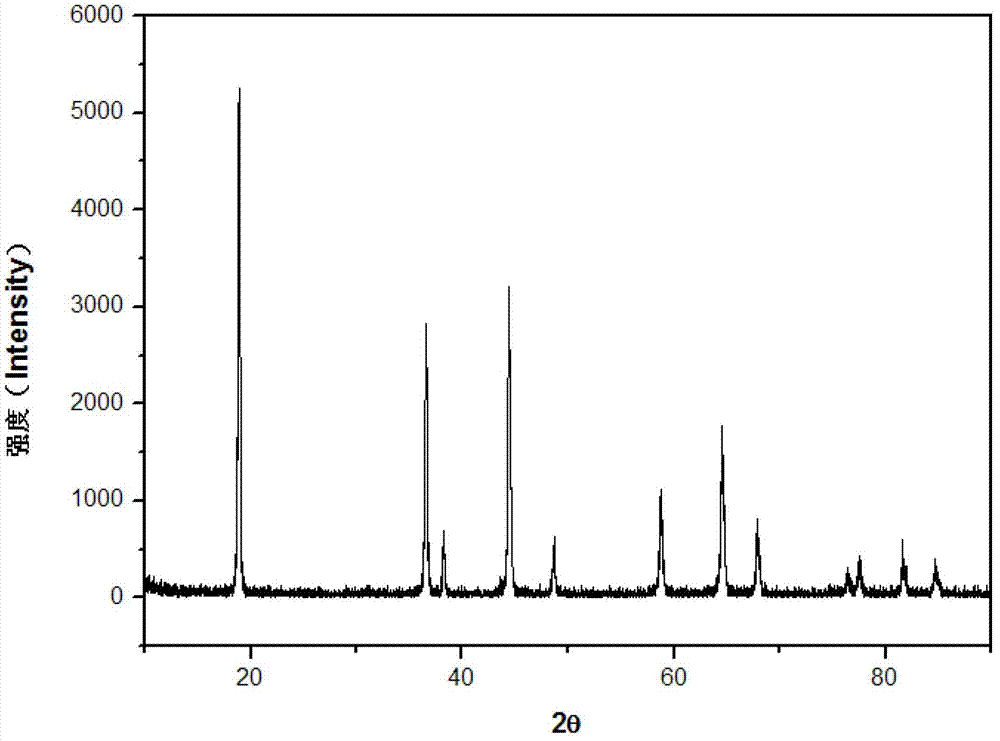

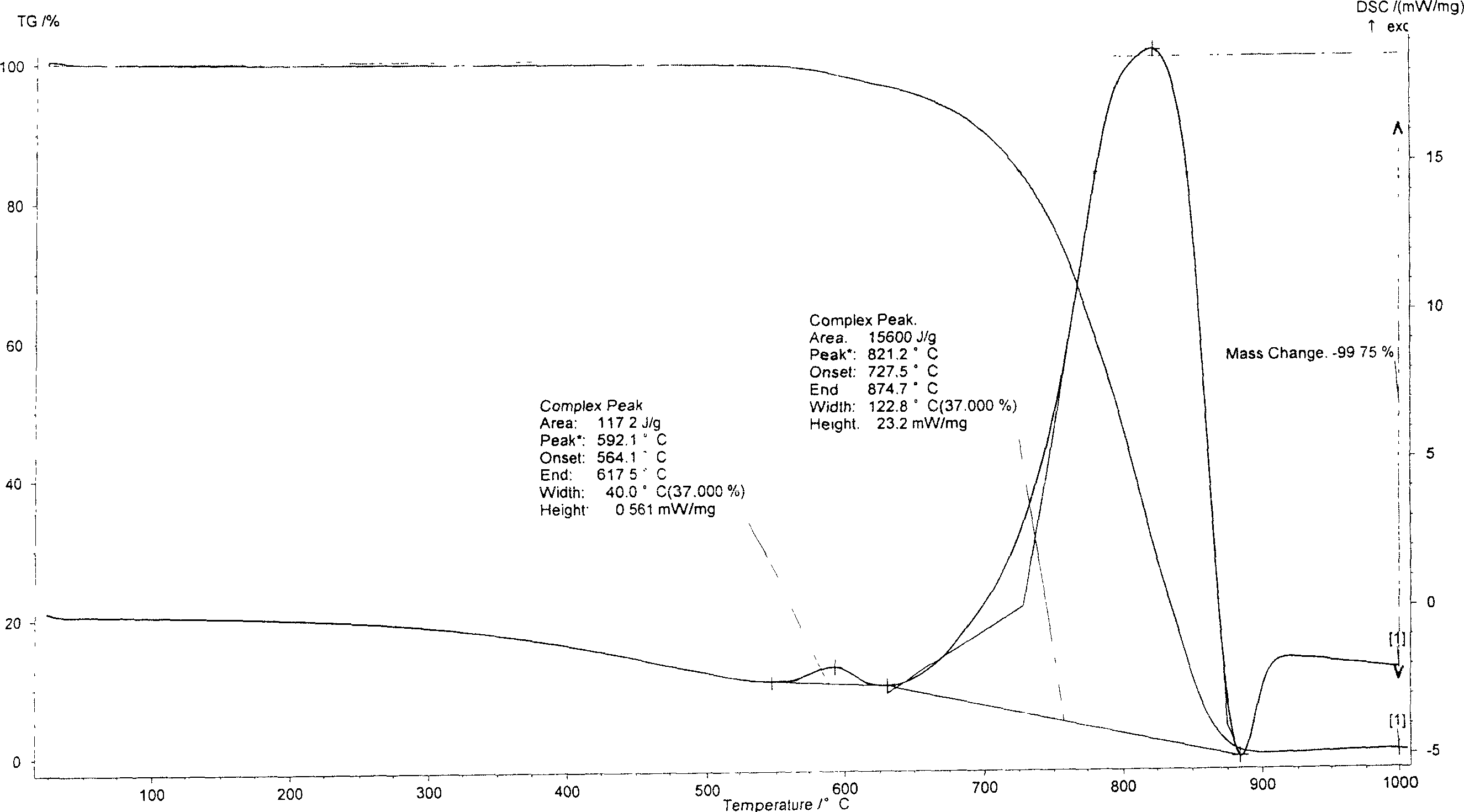

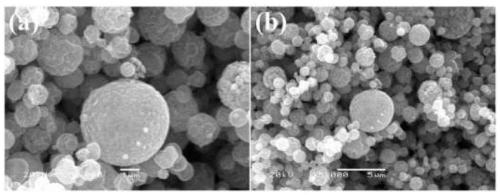

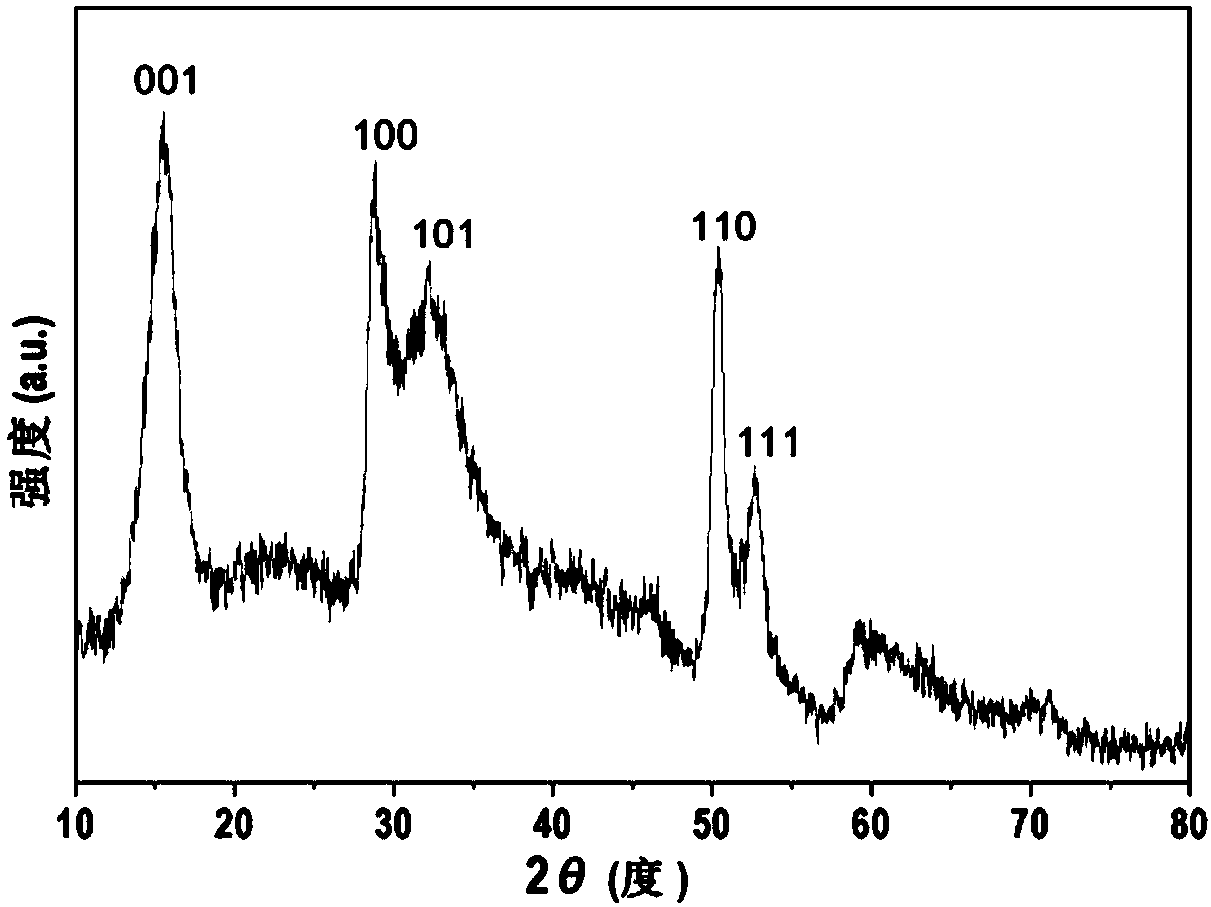

O3 type sodium ion battery cathode material and preparation method thereof

InactiveCN109873153AUniform particle sizeHigh reversible specific capacityCell electrodesSecondary cellsManganeseSodium-ion battery

The invention provides an O3 type sodium ion battery cathode material and a preparation method thereof. The preparation method comprises the following steps: firstly preparing metal salt of nickel, manganese, iron, and aluminum into a precursor solution; performing spraying pyrolysis on the precursor solution to obtain powder product; and finally uniformly mixing the powder material and the sodiumsalt to perform tabletting and high-temperature sintering to obtain the O3 type sodium ion battery cathode material. The preparation method is simple in operation, high in production efficiency, large in capacity, and strong in adaptability. The manufactured cathode material is a sheet structure, the sheet diameter is 1-5 microns, the thickness is 0.5-0.1 micron, the morphology and particle sizeis uniform, the reversible specific capacity under high voltage is high, the cycling stability is good; the charging / discharging specific capacity is measured in the 2.0-4.2V voltage interval, the first discharging specific capacity is more than 148mAh.g-1, and the coulombic efficiency is more than 92%.

Owner:CENT SOUTH UNIV

High-capacity potassium ion battery negative electrode material and preparation method and application thereof

ActiveCN107895779AOvercoming Particle Swelling ProblemsMild responseMaterial nanotechnologySecondary cellsComposite electrodePotassium

The invention provides a high-capacity potassium ion battery negative electrode material and a preparation method and application thereof. A potassium ion battery prepared from a nano SnS2 / graphene composite electrode material can obtain the high reversible specific capacity of 714 mAh / g, and has excellent rate capability and cycle performance. Under the condition that the current density is 500 mA / g, the battery can still give play to the reversible capacity of 483 mA / g; under the condition of 50 circles of circulation at the current density of 250 mA / g, the reversible capacity of 464 mAh / g can still be kept, and the bottleneck problem of low capacity of a conventional potassium ion battery is effectively solved.

Owner:INST OF CHEM CHINESE ACAD OF SCI

Preparation method of silicon-carbon negative electrode material of lithium ion battery

InactiveCN109713268AInhibit side effectsImprove cycle efficiencyCell electrodesSecondary cellsCarbon compositesCarbonization

The invention discloses a preparation method of a silicon-carbon negative electrode of a lithium ion battery. The preparation method comprises the following steps: weighing a proper amount of nano silicon powder, a dispersing agent and an organic carbon source, and dispersing the nano silicon powder, the dispersing agent and the organic carbon source in absolute ethyl alcohol to obtain mixed solution; adding graphene and Ketjen black into absolute ethyl alcohol to obtain mixed solution after dispersing; dispersing the two types of mixed solution to obtain precursor mixed solution; fully dryingthe obtained precursor solution to obtain powder particles, and carrying out high-temperature carbonization on the powder particles to obtain a silicon-carbon composite material; and uniformly mixingthe obtained silicon-carbon composite material with other carbon materials according to a certain ratio to obtain the silicon-carbon negative electrode material of the lithium ion battery. Accordingto the invention, the nano silicon particles are uniformly coated by graphene and Ketjen black, thereby avoiding the side reaction between the silicon negative electrode and the electrolyte, improvingthe cycle efficiency of the lithium battery, and solving the problem that the discharge capacity and the cycle capacity of the battery are reduced due to the side reaction between nano silicon particles and the electrolyte caused by direct mixing of graphene by the negative electrode material of the existing lithium battery.

Owner:江西中汽瑞华新能源科技有限公司

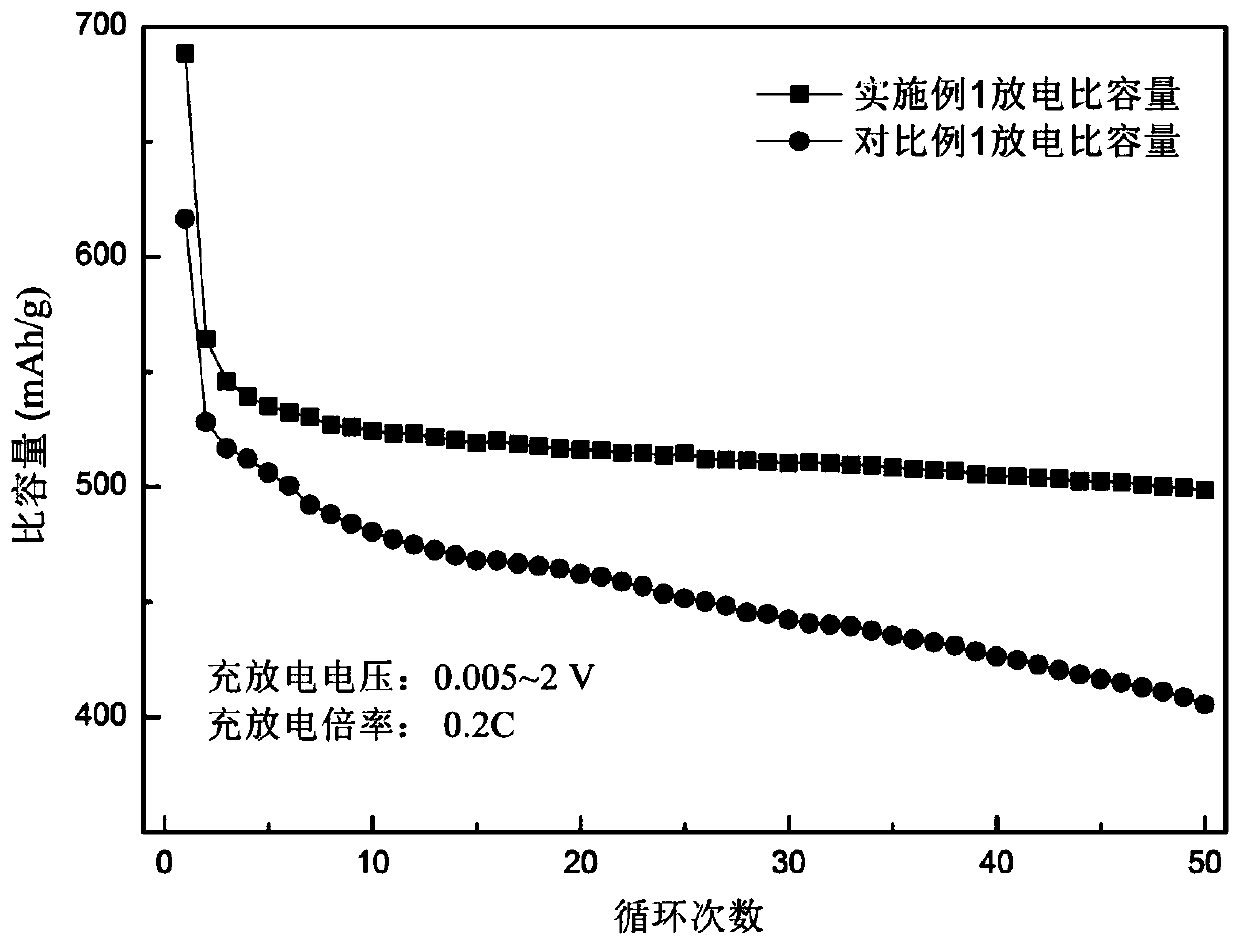

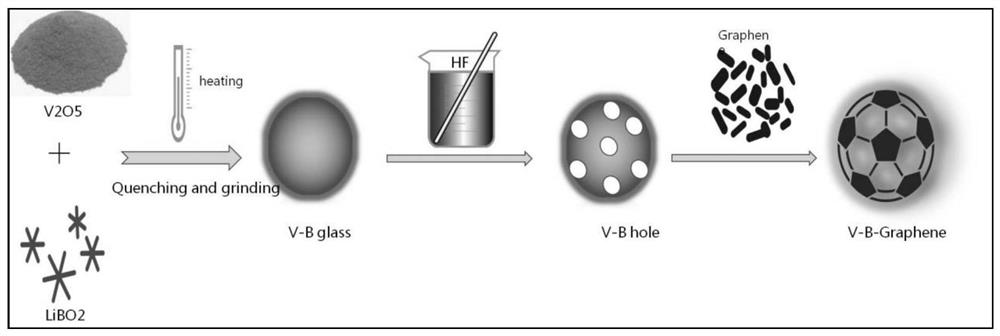

Vanadium pentoxide-lithium borate-graphene glass positive electrode material and preparation method and application thereof

ActiveCN111668468AImprove conductivityHigh reversible specific capacityCell electrodesSecondary cellsElectrical batteryGlass particle

The invention provides a V2O5-LiBO2-graphene glass positive electrode material and a preparation method and application thereof. The method comprises the following steps: a) uniformly mixing V2O5 andLiBO2, heating, keeping the temperature, and quenching; carrying out heat preservation again, cooling, and carrying out ball milling to obtain powder with the particle size D50 of less than 10mu m; b)mixing the powder with corrosion, forming pores, and ultrasonically mixing with the flake graphene dispersion liquid to obtain a precursor; and c) in an Ar atmosphere, annealing the precursor, and carrying out heat preservation to obtain the glass positive electrode material. According to the preparation method, through introducing flaky graphene into V2O5-LiBO2, using the flaky graphene as a strong conductive agent, using a corrosive agent for corrosion pore forming, and then performing heat treatment and ultrasonic treatment, the V2O5-LiBO2 glass particles are assembled, embedded and filledwith flaky graphene, the defects of vanadium-boron glass used as an electrode of the lithium ion battery are overcome, and the lithium ion battery has the performance advantages of high conductivity,high reversible specific capacity and high battery cycling stability.

Owner:HAINAN UNIVERSITY

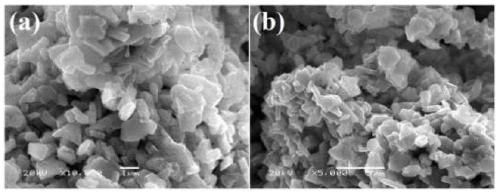

Preparation method of high capacity lithium ion battery lithium cobalt manganese nickel oxide positive electrode material

InactiveCN1514502AHigh reversible specific capacityPromote circulationElectrode thermal treatmentActive material electrodesManganeseLithium-ion battery

The method consists of procedures of solid phase synthesis and burning in high temperature including following steps. (1) According to lithium: cobalt, manganese, nickel=1-1.1 : 1 (atomic ratio), and cobalt : manganese : nickel=1:1:1, polyacrylamide and neodymia are added into even mixed sources of cobalt, manganese, nickel. The above admixture is mixed round evenly till it becoming colloid. (2) Baking drys the said colloid for 30 hr. under 150 deg.C, and ball milling is carried out till powder is passed through sieve. (3) With being preburned for 10 hr. at 300-450 deg.C, the said powder is cooled to room temperature. (4) Product is obtained after fine ball milling the preburned powder, passing through sieve, burning and sifting the powder by 300 screen mesh again. Comparing with prior art, the invented method adds polyacrylamide and neodymia as well as preburning step so as to possess features of high specific capacity, good cycle performance and pollution-free.

Owner:XINXIANG ZHONGKE SCI&TECH

Lithium ion battery cathode material and preparation method thereof

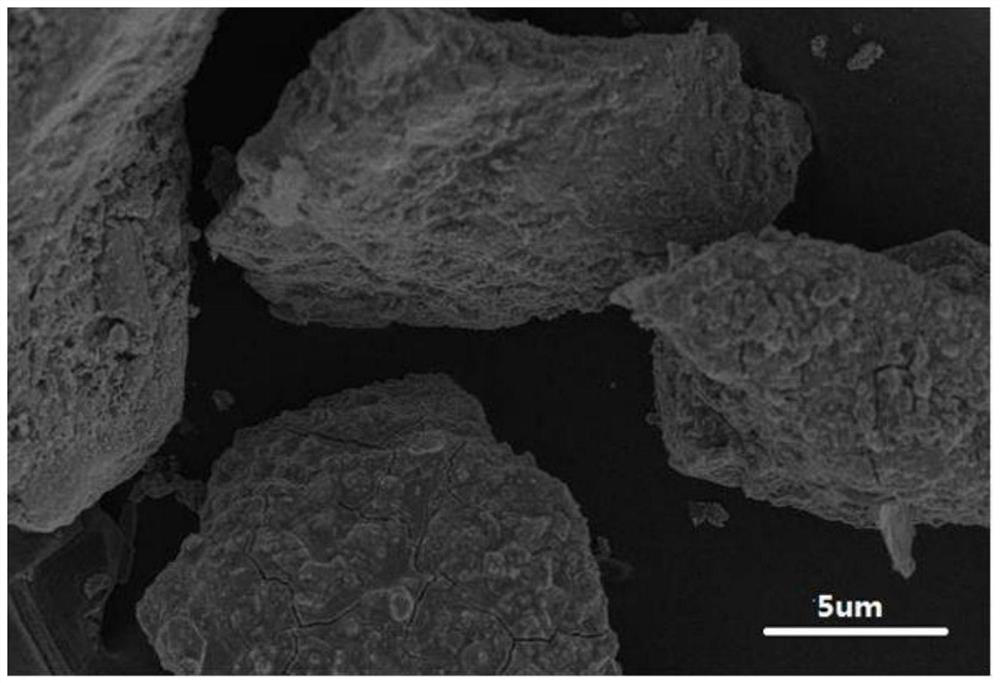

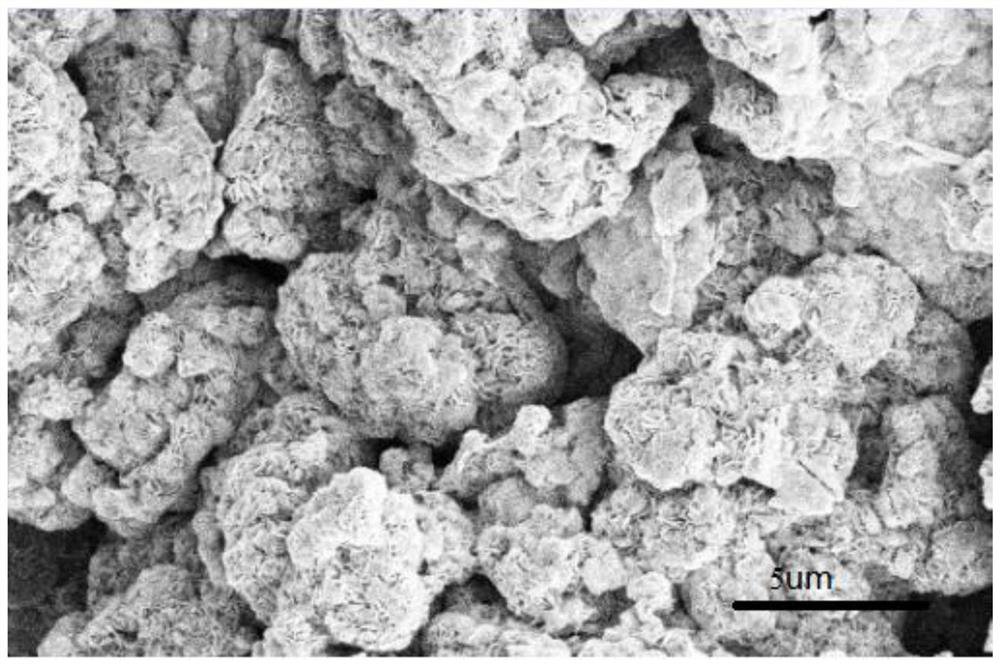

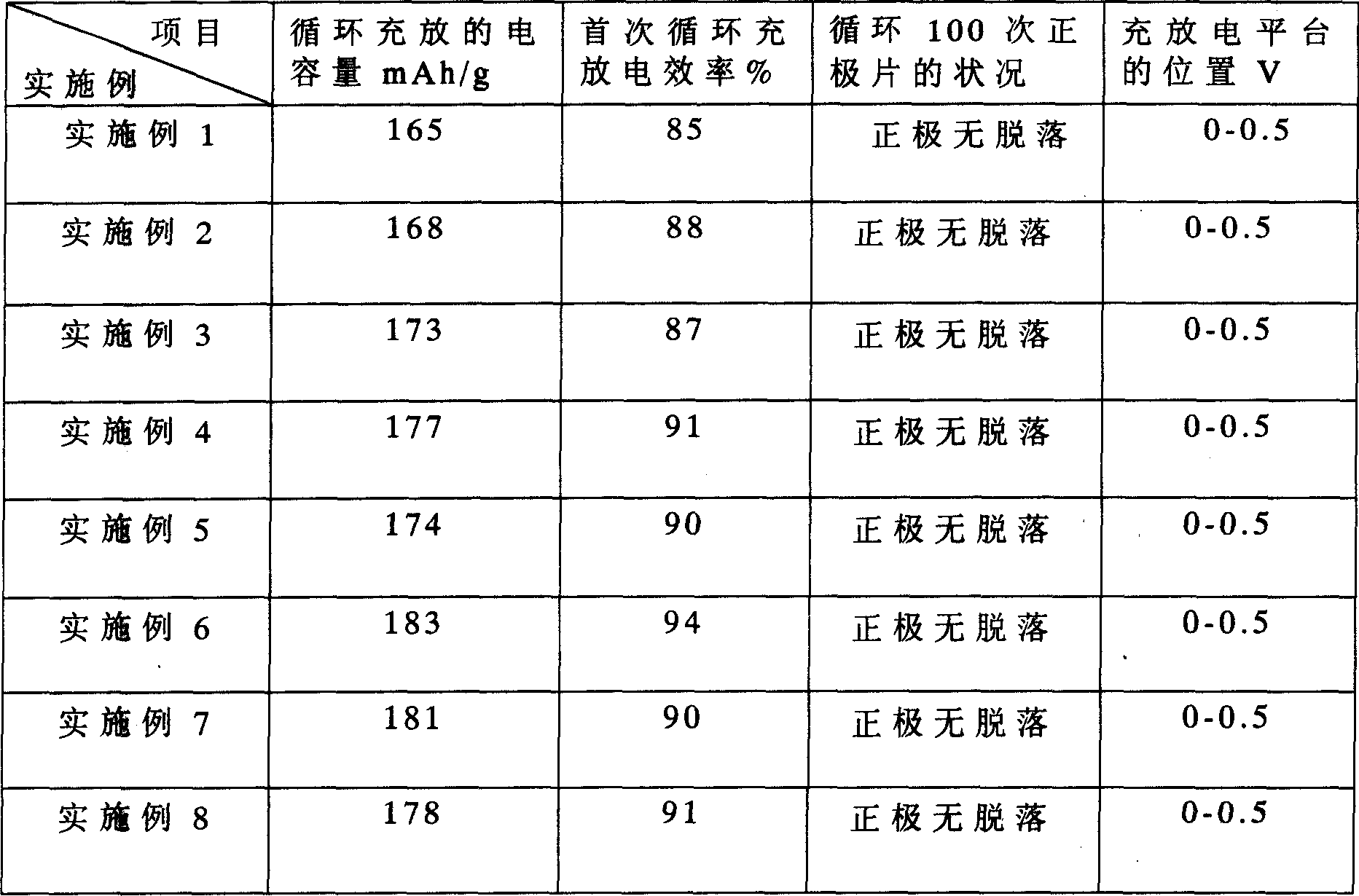

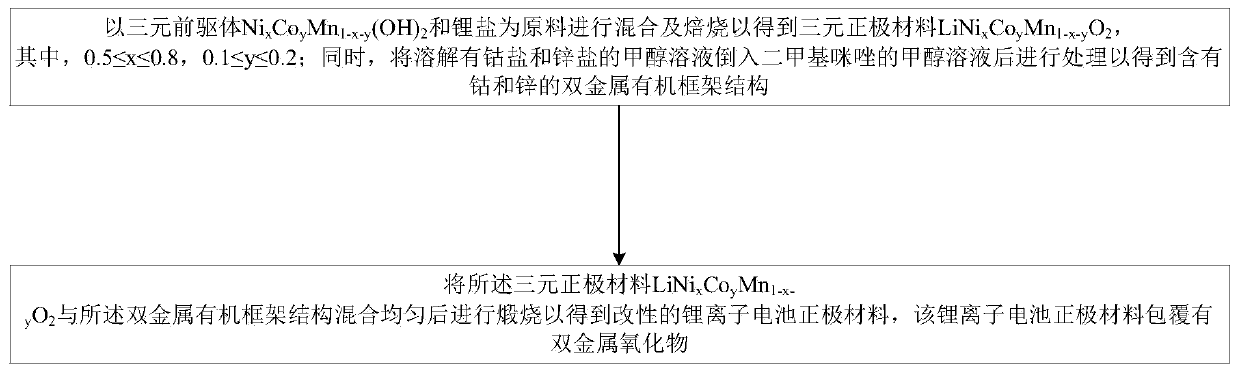

InactiveCN110085828AHigh porosityLow densitySecondary cellsPositive electrodesCobalt saltLithium-ion battery

The invention discloses a lithium ion battery cathode material and a preparation method thereof, and belongs to the technical field of lithium ion battery cathode materials. The method comprises the following steps that (1) raw materials of a ternary precursor NixCoyMn1-x-y(OH)2 and lithium salt are mixed and roasted to obtain a ternary cathode material LiNixCoyMn1-x-yO2, 0.5<=x<=0.8, 0.1<=y<=0.2,and a methanol solution dissolved with cobalt salt and zinc salt are poured into a methanol solution with dimethyl imidazole, and processed to obtain a bimetallic organic frame structure with cobaltand zinc; and (3) the ternary cathode material LiNixCoyMn1-x-yO2 and the bimetallic organic frame structure are mixed uniformly and then burned to obtain the lithium ion battery cathode material wrapped in a bimetallic oxide. The lithium ion battery cathode material is stable in structure, and high in conductivity, and the power multiplying and circulation performances of the material are improved.

Owner:HUAZHONG UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com