Patents

Literature

257results about How to "Improve lithium storage performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

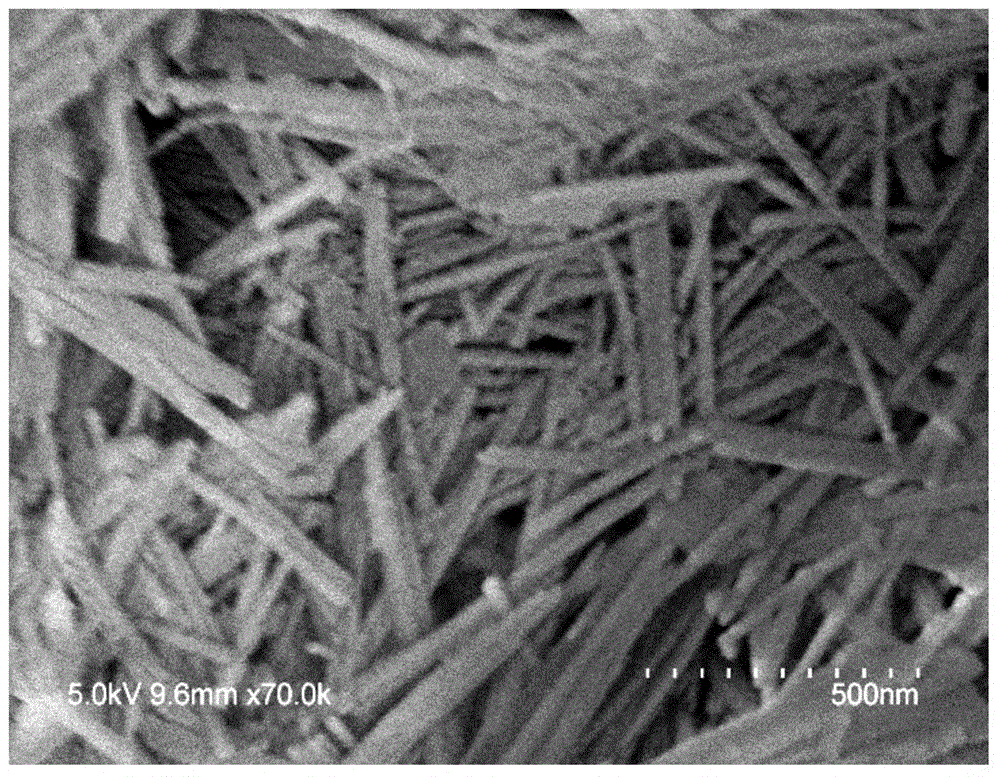

Silicon-carbon composite material with nano micropores and preparation method as well as application thereof

ActiveCN103305965AImprove lithium storage performanceImprove electrochemical performanceCell electrodesFilament/thread formingCarbon compositesCarbon fibers

The invention discloses a silicon-carbon composite material with nano micropores and a preparation method as well as application thereof. The material comprises nano-silicon (Si) particles and a carbon nanofiber matrix, wherein the nano-silicon particles are dispersed in the carbon nanofiber matrix; and nano pores and micropores communicated with the nano pores are distributed in the carbon nanofiber matrix. The method comprises the steps of dissolving the nano-Si particles and polyacrylonitrile (PAN) in a solvent to prepare a mixed spinning solution, then carrying out electrostatic spinning on the mixed spinning solution, and curing spinning trickles in a coagulating bath to obtain a porous PAN-Si composite nanofiber; and then carrying out oxidation and carbonization treatment in sequence to obtain the silicon-carbon composite material with a nano micropore structure. The silicon-carbon composite material is applied to preparation of lithium ion battery cathode materials. Compared with the prior art, the silicon-carbon composite material ensures the overall electron transport capacity of the material while reserving buffer space for expansion of the nano-Si particles.

Owner:深圳石墨烯创新中心有限公司

Silicon-carbon composite material with nano micropores and preparation method as well as application thereof

ActiveCN103311523AImprove lithium storage capacitySuppression of shortcomingsMaterial nanotechnologyCell electrodesCarbon compositesLithium electrode

The invention discloses a silicon-carbon composite material with nano micropores and a preparation method as well as application thereof. The composite material comprises nano-silicon (Si) particles and a carbon nanofiber matrix, wherein nano pores and micropore channels communicated with each other are distributed in the carbon nanofiber matrix; the nano-Si particles are distributed in the carbon nanofiber matrix; one part of the nano-Si particles are embedded in the carbon nanofiber matrix; and the other part of the nano-Si particles are positioned in the nano pores. The method comprises the steps of carrying out electrostatic spinning on a polyacrylonitrile (PAN) spinning solution doped with the nano-Si particles and a polymer pore former (PPM) to obtain a PAN-Si-PPM composite nanofiber, and then carrying out oxidation and carbonization to obtain the silicon-carbon composite material. The silicon-carbon composite material is applied to preparation of lithium ion battery cathode materials. Compared with the prior art, the silicon-carbon composite material ensures the overall electron transport capacity of the material while reserving buffer space for expansion of the nano-Si particles.

Owner:深圳石墨烯创新中心有限公司

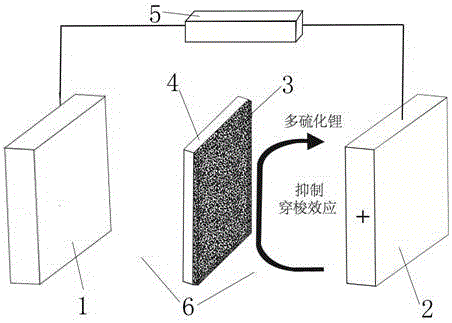

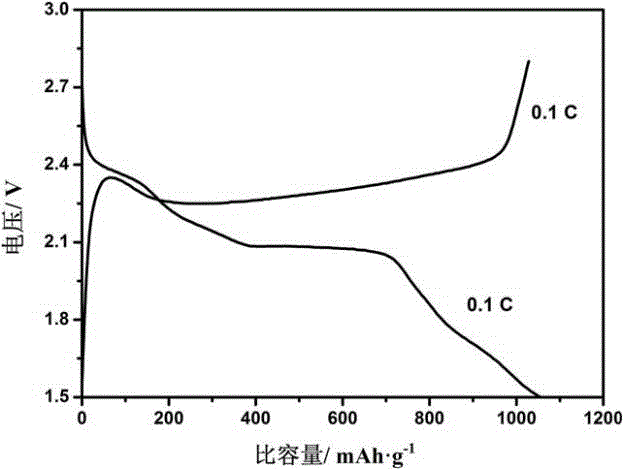

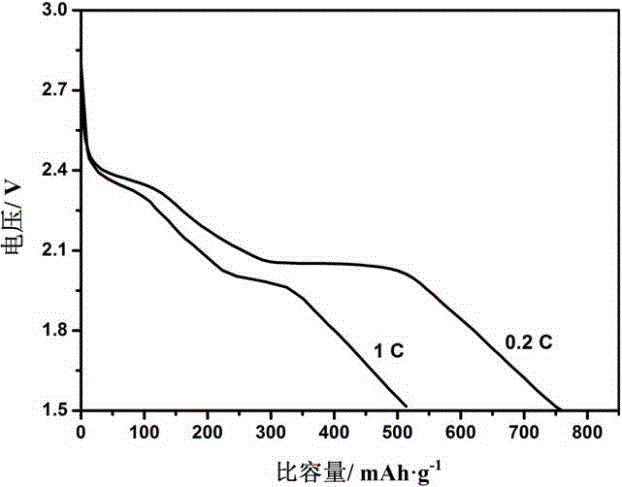

Lithium-sulfur battery

InactiveCN106129455AImprove conductivityCan improve charge transfer kineticsCell seperators/membranes/diaphragms/spacersCell electrodesPorous graphenePolyolefin

The invention discloses a lithium-sulfur battery. The lithium-sulfur battery comprises three-dimensional porous graphene covalence fixing nanometer lithium sulfide as a composite positive electrode, a polyolefin membrane coated with graphene oxide as a modified membrane, and a lithium sheet negative electrode and an electrolyte which are generally adopted. The particle size of lithium sulfide in the composite positive electrode is between 1 nm and 100 nm, and the lithium sulfide is combined with oxygen-containing functional groups on the surface of three-dimensional porous graphene in the form of a C-O-S covalent bond. The modified membrane is prepared from graphene oxide with the thickness of 0.1 to 10 microns uniformly deposited on the surface of a traditional polyolefin membrane; and the graphene oxide can be coated on both sides of the polyolefin membrane, and can also be coated on the side facing the lithium sulfide positive electrode when the battery is assembled. According to the lithium-sulfur battery disclosed by the invention, the dissolution of the sulfur positive electrode can be effectively prevented, the shuttle effect is inhibited, the overpotential of the battery is reduced, the structural damage generated by positive electrode volume expansion is avoided, and the rate characteristic and cycle performance of the lithium-sulfur battery are substantially improved.

Owner:SHANGHAI UNIV

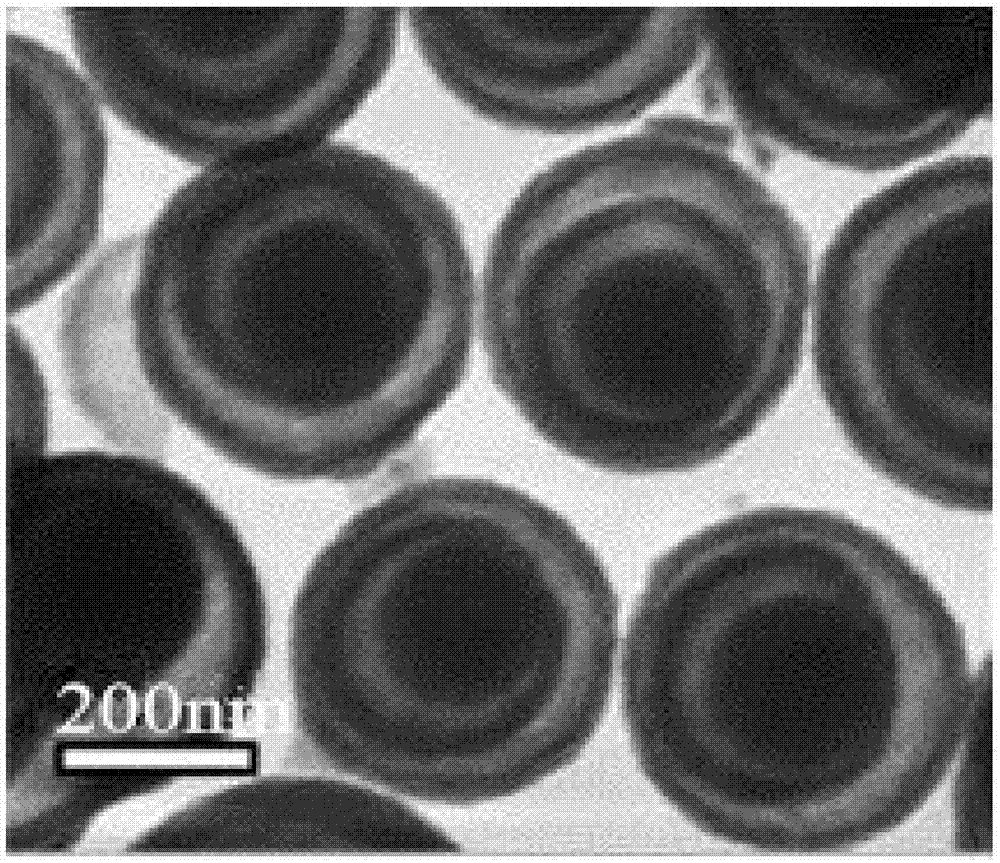

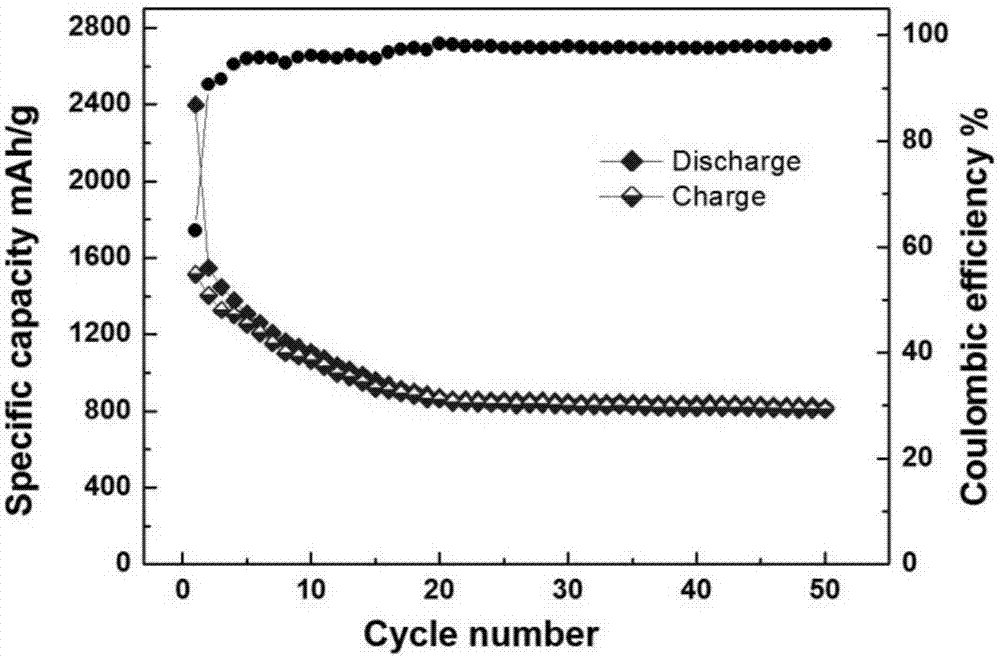

Anode material for double-shell capsule-shaped silicon-based lithium-ion battery and preparation method of anode material

InactiveCN104319401AHigh specific capacityImprove conductivityMaterial nanotechnologyCell electrodesNano siliconCarbonization

The invention discloses an anode material for a double-shell capsule-shaped silicon-based lithium-ion battery and a preparation method of the anode material. In the material, a nano-silicon nuclear is coated by a double-layer carbon shell; a certain space exists between the silicon nuclear and an inner-layer carbon shell. According to the preparation method, the material disclosed by the invention can be obtained by taking a capsule-shaped structural silicon dioxide-coated silicon nano-composite material as a template, performing pyrolysis on an organic carbon source to coat the inner surface and the outer surface of the template silicon dioxide, performing high-temperature carbonization under an inert atmosphere, and finally, etching the silicon dioxide template. According to the material, the first lithium embedding capacity is 3,125 mAh / g; the specific capacity can still be kept at 1,161mAh / g after 30-time repeated charge-discharge cycles. The preparation method provided by the invention is simple in process and environmentally friendly; industrial production is easy to realize.

Owner:SHANGHAI JIAO TONG UNIV

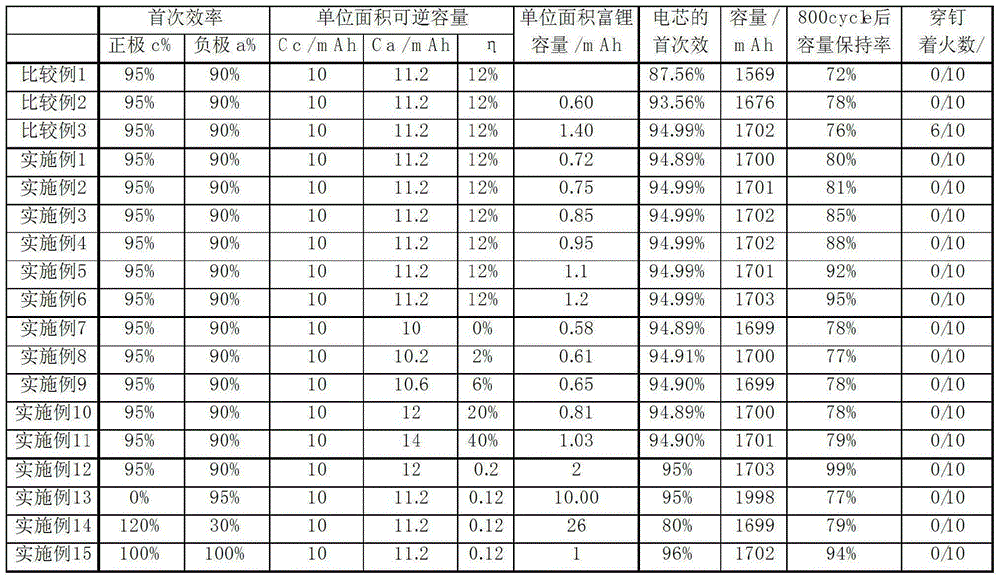

Electrochemical energy storage device and preparation method hereof

ActiveCN105047986AImprove first-time efficiencyIncrease energy densityCell electrodesFinal product manufactureLithiumElectrical battery

The invention belongs to the technical field of electrochemical energy storage, and particularly relates to an electrochemical energy storage device. The electrochemical energy storage device comprises a cathode plate, an anode plate, an isolating membrane, electrolyte and an outer package, wherein the initial coulomb efficiency of a cathode active substance on the cathode plate is c%; the reversible capacity of the cathode plate in unit area is Cc mAh; the initial coulomb efficiency of an anode active substance on the anode plate is a%; the reversible capacity of the anode plate in unit area is Ca mAh; the anode capacity excess rate eta in unit area is (Ca-Cc) / Cc*100%; electrode plates are subjected to lithium-rich treatment; and the lithium-rich capacity m in unit area is that: Ca*(1-a%) / a%-Cc*(1-c%) / c% is smaller than or equal to m. When lithium-rich treatment is carried out, the lithium-rich capacity m in unit area is that Ca*(1-a%) / a%-Cc*(1-c%) / c% is smaller than or equal to m; the first lithium loss of the anode can be supplemented; and excessive lithium can be used for supplementing lithium consumption in the cycling process, so that the cycle performance of the battery is improved.

Owner:GUANGDONG ZHUGUANG NEW ENERGY TECH

Environment-friendly and efficient method for preparing iron sesquioxide/graphene composite material

The invention relates to an environment-friendly and efficient method for preparing an iron sesquioxide / graphene composite material. In the method, cheap and abundant soluble ferrous salt serves as an iron source and reducing agent, graphene oxide is quickly reduced into the graphene by the characteristics of microwave heating, and ferrous is oxidized and converted into iron sesquioxide so as to obtain a sesquioxide / graphene composite material. The environment-friendly and efficient method fully utilizes the characteristics of ferrite, has the advantages of simple and efficient preparation technology, no industrial three-waste pollution and stable product performance and is favorable for producing on a large scale, and a product has a wide application prospect in the cathode material of a lithium-ion secondary battery.

Owner:BEIJING ZHONGKE MICRO NANO NETWORKING SCI TECH

Lithium ion battery anode material and preparation method thereof

The invention discloses a lithium ion battery anode material which comprises graphite and a shell layer arranged outside the graphite, wherein the shell layer is an asphalt-based carbon material cladding layer with a porous structure. A preparation method of the lithium ion battery anode material comprises the steps of: 1, in the terms of the weight, uniformly mixing 100 parts of graphite particles with particle diameter of 5-50mum with 1-25 parts of asphalt monomers; 2, carrying out Friedel-Crafts cross-linking reaction; and 3, in an inert gas, thermally treating at 800-1500 DEG C for 1-12h,then cooling to be below 100 DEG C, taking out, crushing and sieving to prepare a composite asphalt material with the porous structure carbon material cladding layer. Due to the adoption of the invention, gram volume of the graphite material is greatly increased, reversible volume and coulomb efficiency are increased, and circulating stability of the anode material is greatly enhanced. Meanwhile,production cost is low.

Owner:FUJIAN XFH NEW ENERGY MATERIALS CO LTD

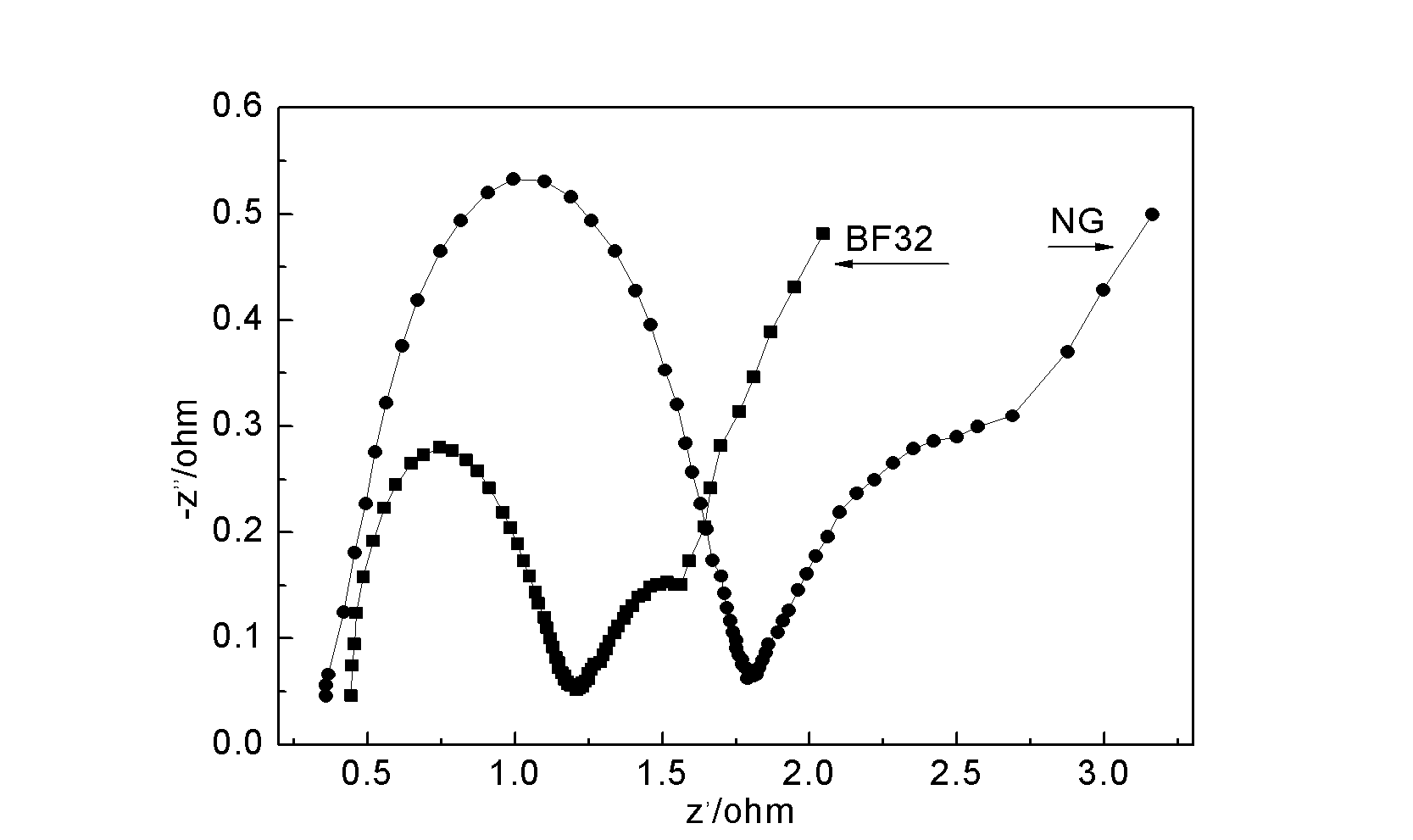

Method for preparing three-dimensional nitrogen-doped graphene/CoOx composite material

InactiveCN104319395AEasy to prepareEvenly dispersedMaterial nanotechnologyCell electrodesDoped grapheneActive agent

The invention relates to a method for preparing a three-dimensional nitrogen-doped graphene / CoOx composite material, and belongs to the technical field of functional materials. The method comprises the main processes of: by taking phthalonitrile as a nitrogen-containing precursor, cobalt acetate as a transition metal precursor, and graphene oxide prepared by the Hummers method as a carbon carrier, adding a surface active agent and carrying out solvent-thermal-technology one-step in-situ coordination, assembling, freeze drying and calcination treatment to obtain the three-dimensional structured nitrogen-doped graphene / CoOx composite nano material. In comparison with the prior art, the three-dimensional nitrogen-doped graphene / CoOx composite material prepared by the invention has the advantages that particles are homogeneous and do not agglomerate; in addition, more electron transmission channels exit because of mesopores left after the surface active agent is removed, the impedance is reduced, and the electrochemical property of the material is improved.

Owner:SHANGHAI UNIV

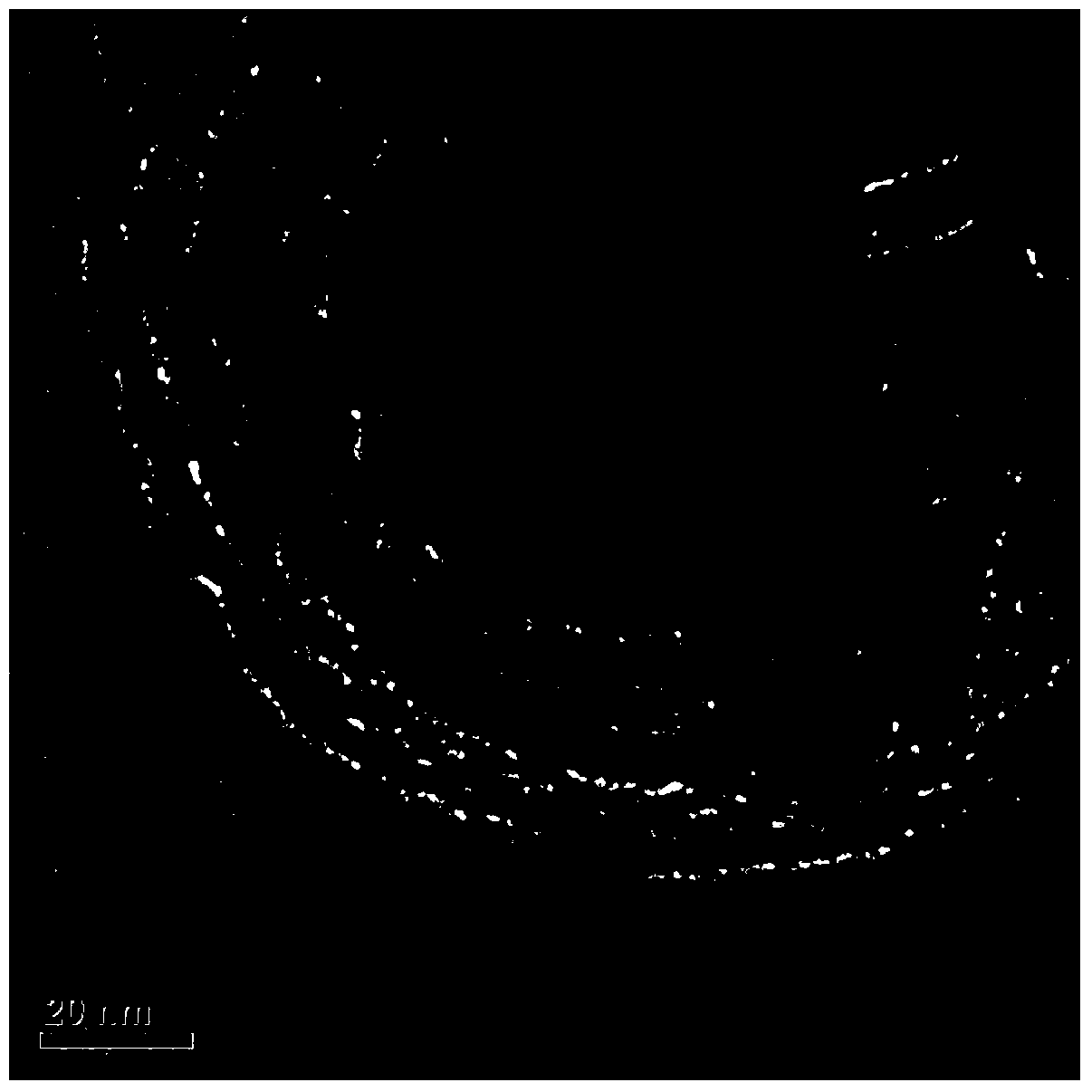

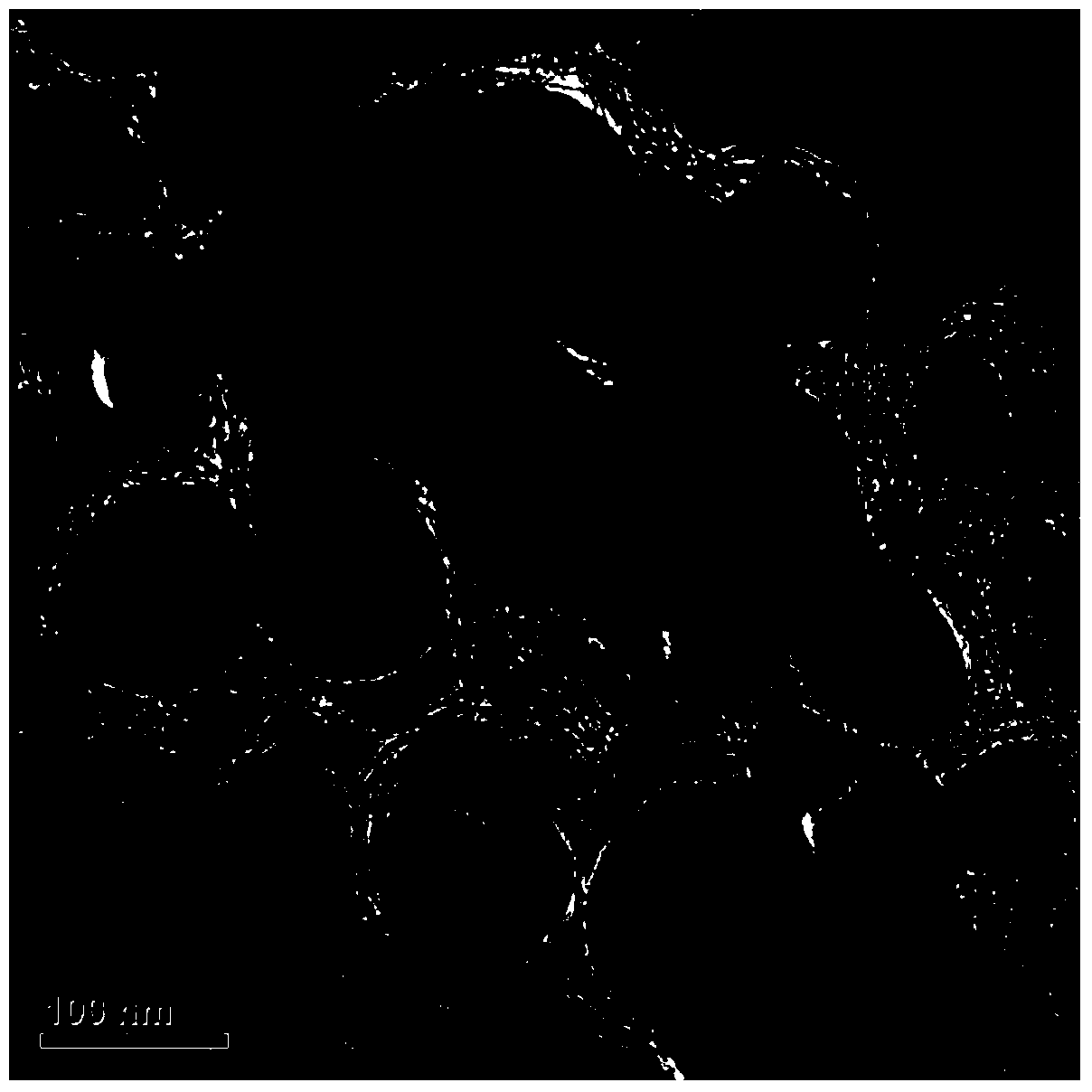

Nano-silicon material and application thereof

ActiveCN104577082AEasy to scale up and synthesizeLow costMaterial nanotechnologyCell electrodesCarbon coatingGram

The invention discloses a nano-silicon material which is prepared by the following steps: using a rod-shaped nano SiO2 material with the length of 300-800nm and the width of 20-40nm, and preparing the nano-silicon material by virtue of a magnesiothermic reduction method, wherein the rod-shaped nano SiO2 material is prepared by the steps of taking attapulgite as a raw material, screening, pickling and performing high-temperature heat treatment. According to the nano-silicon material disclosed by the invention, cheap and natural attapulgite serves as a precursor, the rod-shaped nano SiO2 is purified from the attapulgite, an elemental silicon material with uniform particle size distribution is prepared in one step, amplified synthesis is easily realized in the method, gram-grade reaction can be achieved in a lab, and the cost is low; and moreover, the obtained elemental silicon material is high in yield, the elemental silicon material subjected to carbon coating treatment serves as a negative electrode material of a lithium ion battery, and excellent lithium storage performance is achieved.

Owner:NANJING UNIV

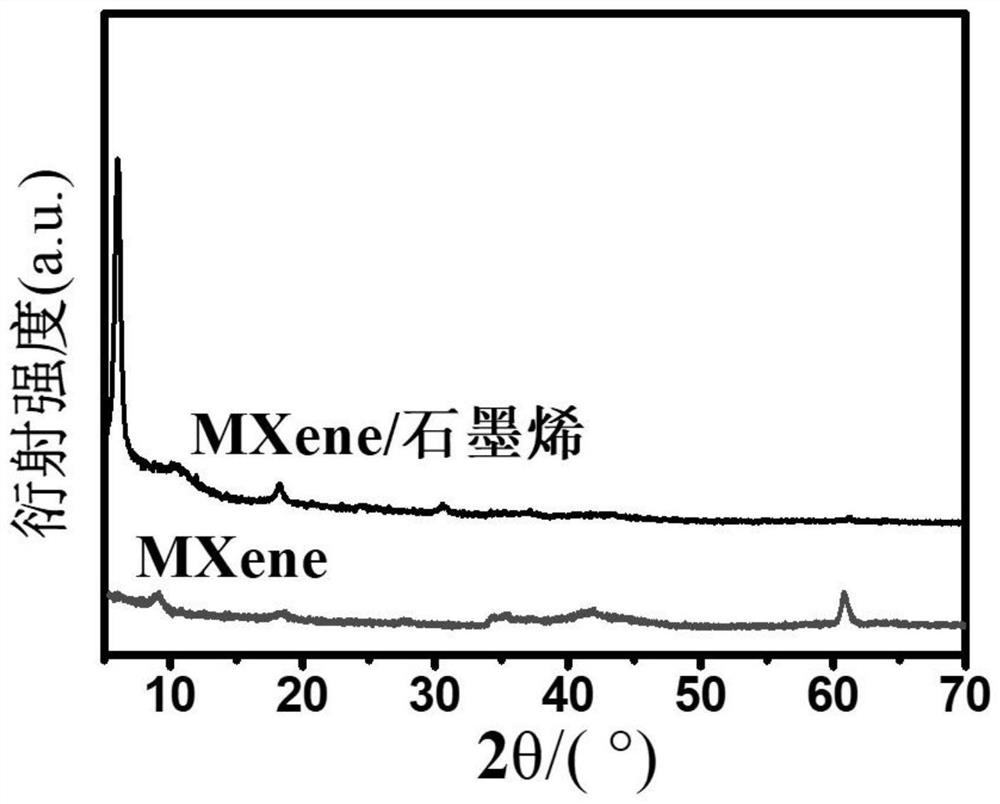

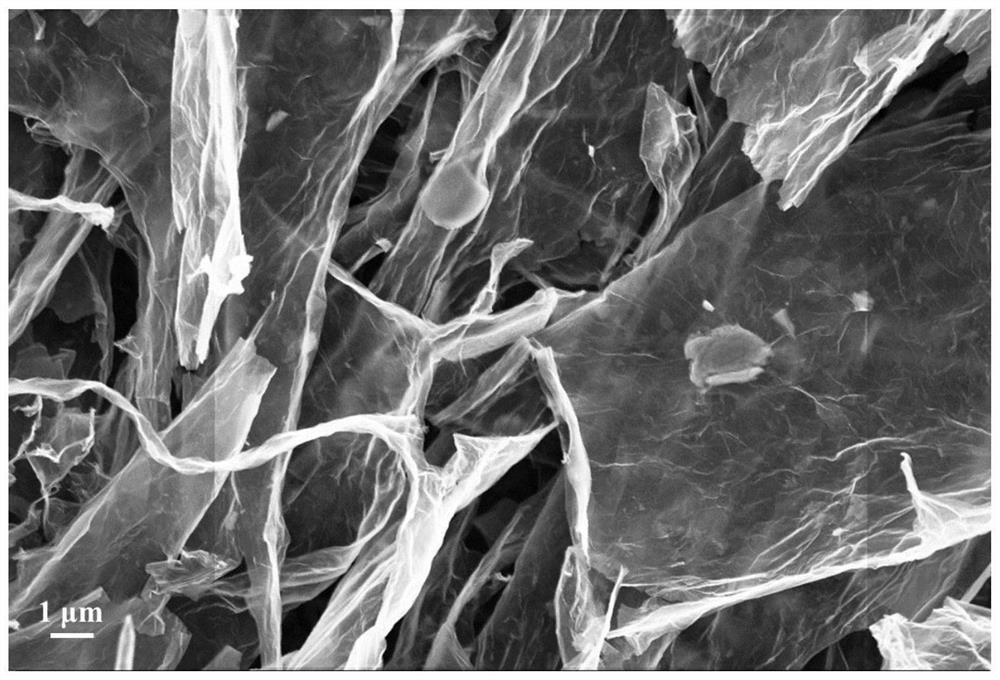

MXene/graphene composite nanosheet, preparation method and application thereof, electrode plate and application thereof

ActiveCN111799464AWon't restackMaintain a unique two-dimensional structurePhysical/chemical process catalystsHybrid capacitor electrodesHydrofluoric acidTetrabutylammonium hydroxide

The invention provides an MXene / graphene composite nanosheet, a preparation method and application thereof, an electrode plate and application thereof, and belongs to the technical field of two-dimensional materials. The invention provides the preparation method of the MXene / graphene composite nanosheet, the method comprises the following steps: mixing MAX and a hydrofluoric acid solution, and etching to obtain MXene; mixing the MXene with a tetrabutylammonium hydroxide solution, carrying out electrostatic adsorption, and then carrying out ultrasonic treatment so as to obtain a stripped MXenenanosheet; mixing the stripped MXene nanosheet with a graphene oxide suspension, and carrying out a self-assembly reaction to obtain an MXene nanosheet / graphene oxide nanosheet; and under a protectiveatmosphere, carrying out a reduction reaction on the MXene nanosheet / graphene oxide nanosheet to obtain the MXene / graphene composite nanosheet. The graphene in the MXene / graphene composite nanosheetprepared by the preparation method provided by the invention cannot be stacked again, the MXene / graphene composite nanosheet has excellent lithium storage performance, and the unique two-dimensional structure of the MXene and the graphene can be maintained.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

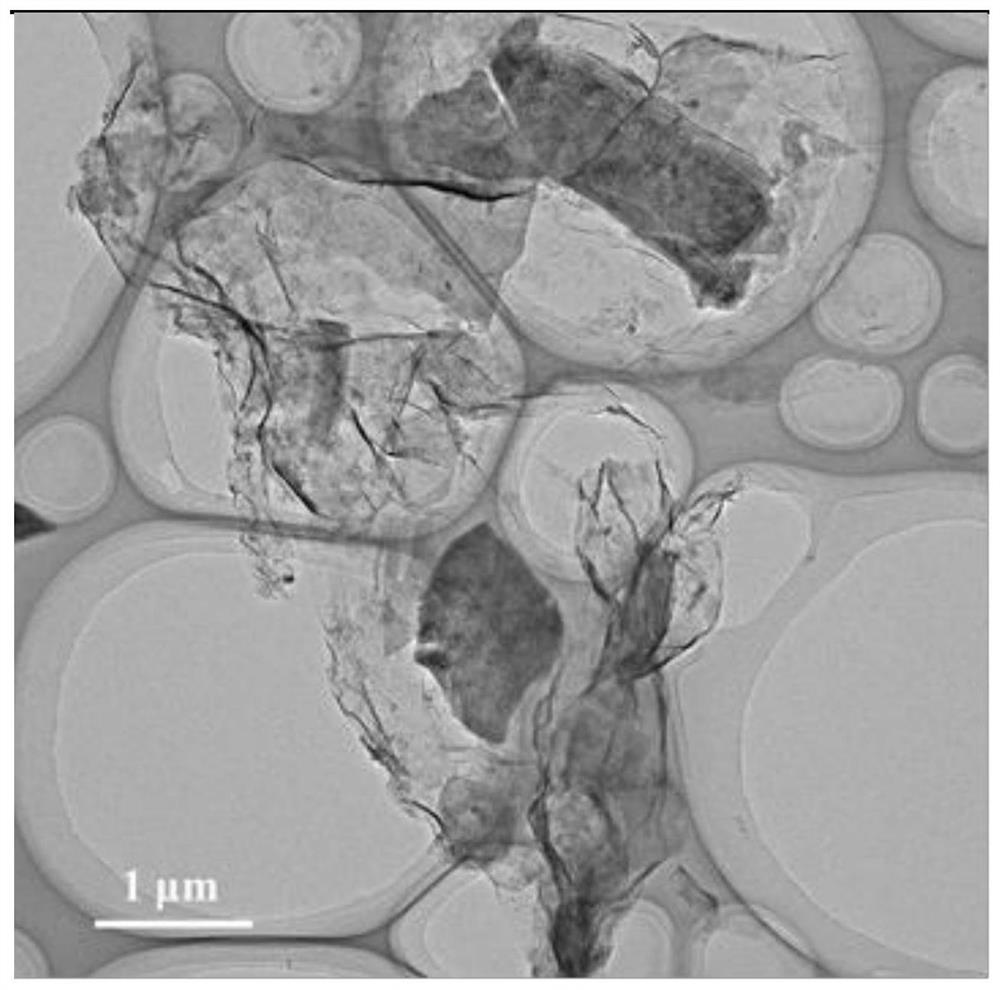

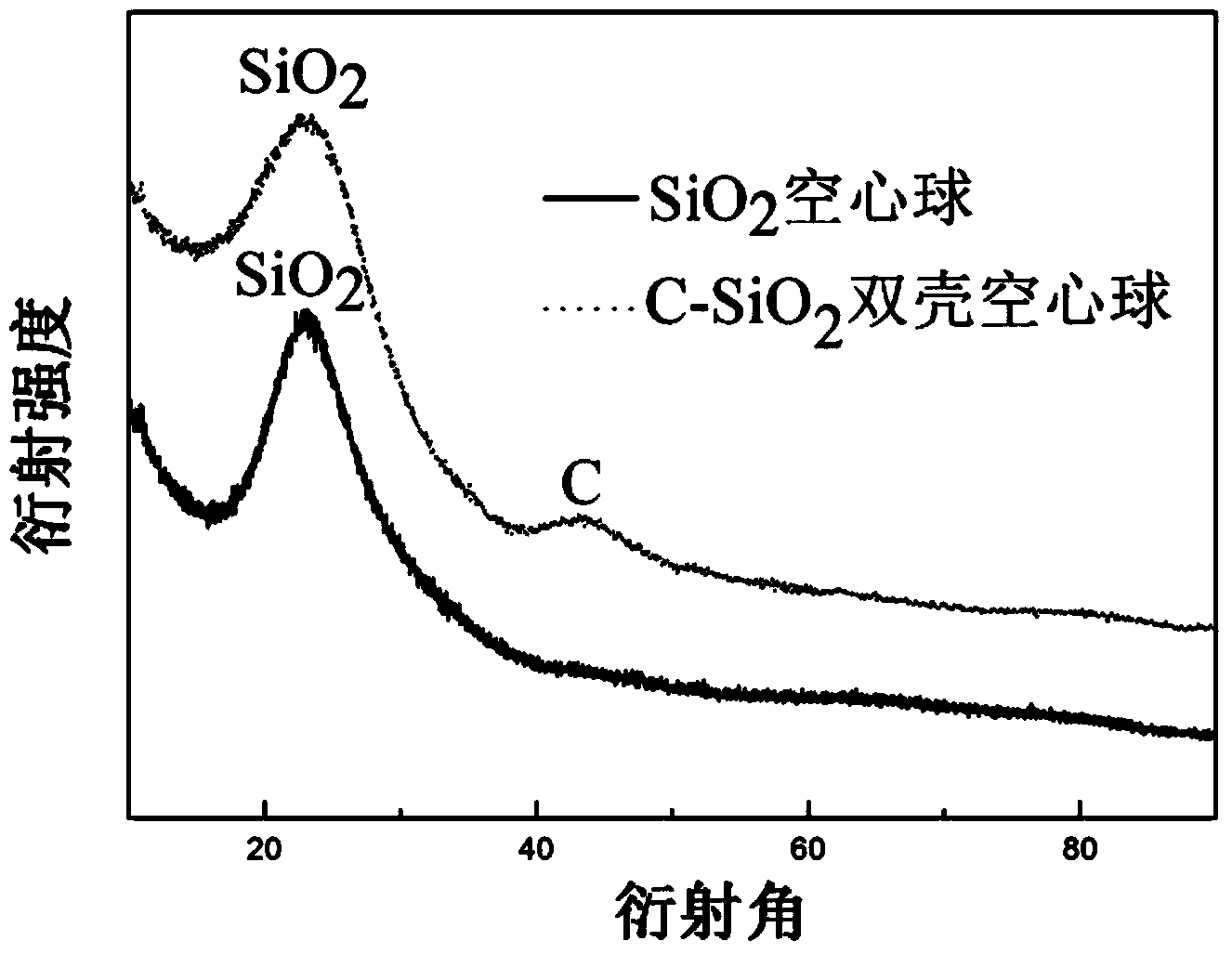

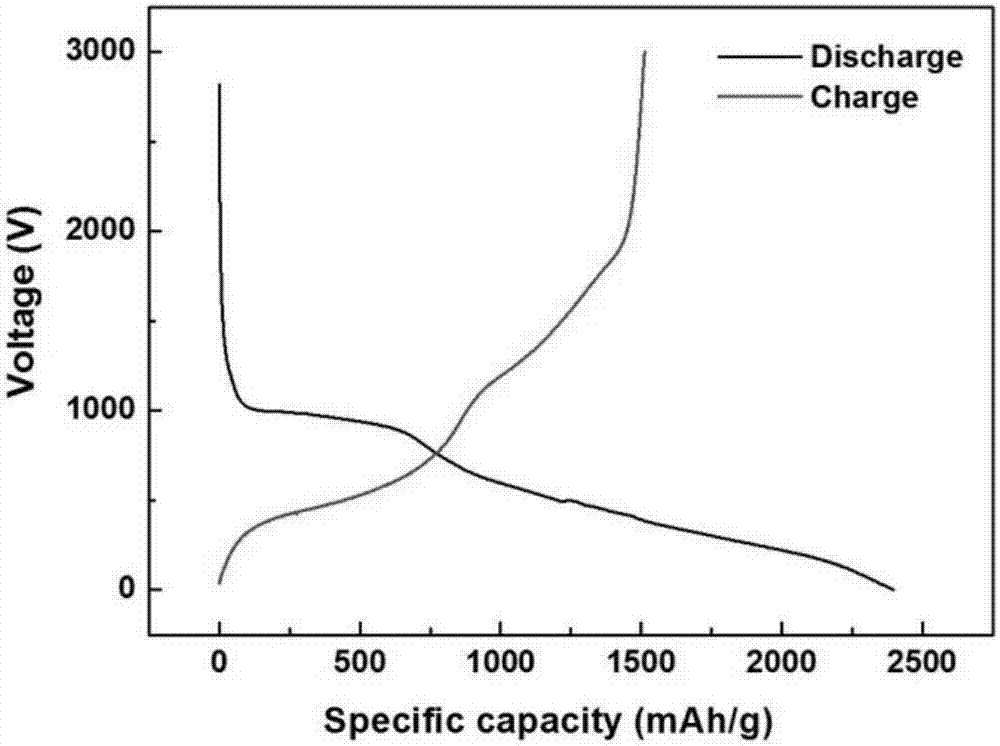

Lithium ion battery cathode material and preparation method thereof

InactiveCN103682272AImprove conductivityImprove stabilityMaterial nanotechnologyCell electrodesSurface-active agentsSilicon dioxide

The invention discloses a lithium ion battery cathode material and a preparation method of the lithium ion battery cathode material. In the lithium ion battery cathode material, silicon dioxide is in a spherical hollow structure, and the surface of the silicon dioxide is uniformly coated with carbon to form a carbon-silicon dioxide double-shell hollow sphere. The preparation method is characterized in that 3-aminopropyl triethoxysilane and tetraethoxysilane are adopted as silicon sources, and the hollow silicon dioxide is prepared by adopting a surface active agent soft template method; then the silicon dioxide hollow sphere is coated with organic carbon source through a pyrolysis way, and the silicon dioxide hollow sphere is carbonized at a high temperature under the inert atmosphere to obtain the lithium ion battery cathode material. The primary lithium embedding capacity of the material is 1394mAh / g, and the specific capacity can still be maintained at 498mAh / g after the material is repeatedly charged and discharged for 20 times. The preparation method is simple in process, environmentally friendly and easy for realizing the industrialized production.

Owner:SHANGHAI JIAO TONG UNIV

Porous carbon microsphere, preparation method and lithium ion battery negative electrode material

The invention relates to a porous carbon microsphere prepared by utilizing an emulsion aggregation method. The porous carbon microsphere is simultaneously provided with a microporous structure, a mesoporous structure and a macroporous structure. When the porous carbon microsphere is applied to the lithium ion battery negative electrode material, the macroporous structure is used for providing a fast migration passage for electrolyte, the mesoporous structure is identical to size of ion in the organic electrolyte, so that the rapid adsorption and desorption of the ion can be favored; the microporous structure favors the insertion of lithium ions, so that a lithium ion secondary battery has high specific capacitance and good high-power charging-discharging performance.

Owner:BEIJING UNIV OF CHEM TECH +1

Egg-shaped dual-carbon shell layer tin-based negative electrode material of lithium ion battery and preparation method for negative electrode material

InactiveCN107369819AHigh specific capacityImprove conductivityMaterial nanotechnologyCell electrodesTin dioxideCarbonization

The invention provides an egg-shaped dual-carbon shell layer tin-based negative electrode material of a lithium ion battery and a preparation method for the negative electrode material. The egg-shell-shaped dual-layer carbon-coated stannic oxide nanocomposite comprises a porous stannic oxide sphere kernel and a dual-layer carbon shell for coating the surface of the porous stannic oxide sphere kernel, and a hollow layer exists between the two parts; the preparation method comprises the steps of preparing the egg-shell-shaped silicon dioxide-coated porous stannic oxide sphere nanocomposite by adopting a surfactant soft template method, and then attaching an organic pyrolytic carbon raw material on the surface of the nanocomposite, and performing a hydrothermal reaction and then carrying out condensation polymerization and carbonization to obtain the egg-shell-shaped carbon-silicon dioxide-carbon-coated stannic oxide sphere nanocomposite, and finally, performing etching by adopting a sodium hydroxide alkali solution to obtain the egg-shell-shaped dual-layer carbon-coated stannic oxide nanocomposite. Finally, the invention provides the tin-based negative electrode material of the lithium ion battery with nanometer scale, high conductivity and capability of effectively suppressing the volume effect of stannic oxide, and a preparation method for the negative electrode material.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

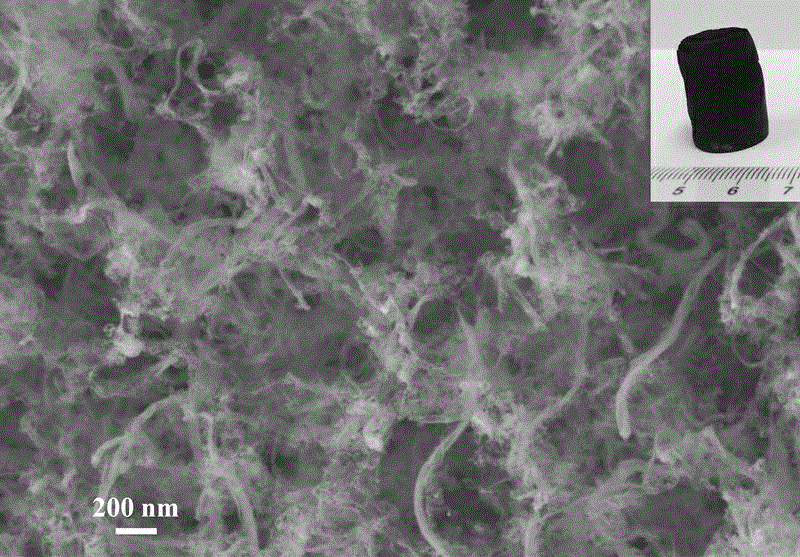

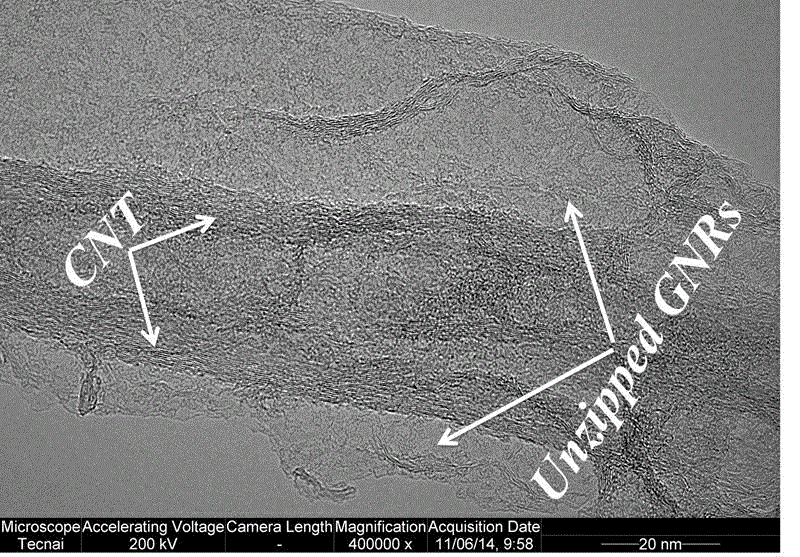

Three-dimensional graphene nanoribbon/carbon nanoribbon bridged structural material, and preparation method and application thereof

InactiveCN104860294ALarge specific surface areaGood mechanical propertiesMaterial nanotechnologyCvd grapheneCarbon nanotube

The invention belongs to the technical field of nanometer materials, and specifically relates to a three-dimensional graphene nanoribbon / carbon nanoribbon bridged aerogel material, a preparation method and application thereof. According to the invention, aerogel is prepared by assembling basic structural units formed by bridging the graphene nanoribbon stripped from the carbon nanoribbon with unstripped carbon nanoribbon and doping the basic structural units with heteroatom as needed. The preparation of the aerogel comprises the following steps: preparing a carboxylic carbon nanotube solution, wherein a proper amount of a soluble dopant is added or not added into the solution; then carrying out hydrothermal treatment so as to obtain uniform hydrogel, placing the hydrogel in an ionic impregnation agent for complete replacement, then carrying out secondary hydrothermal treatment so as to finish a stripping process; and finally, carrying out drying and carbonizing so as to obtain the graphene nanoribbon / carbon nanoribbon bridged structural aerogel. The aerogel can be used as an anode material of lithium ion battery, shows high specific capacity and excellent stability and rate performance, and has important research significance and good application prospects.

Owner:FUDAN UNIV

Lithium ion battery cathode material as well as preparation method and applications thereof

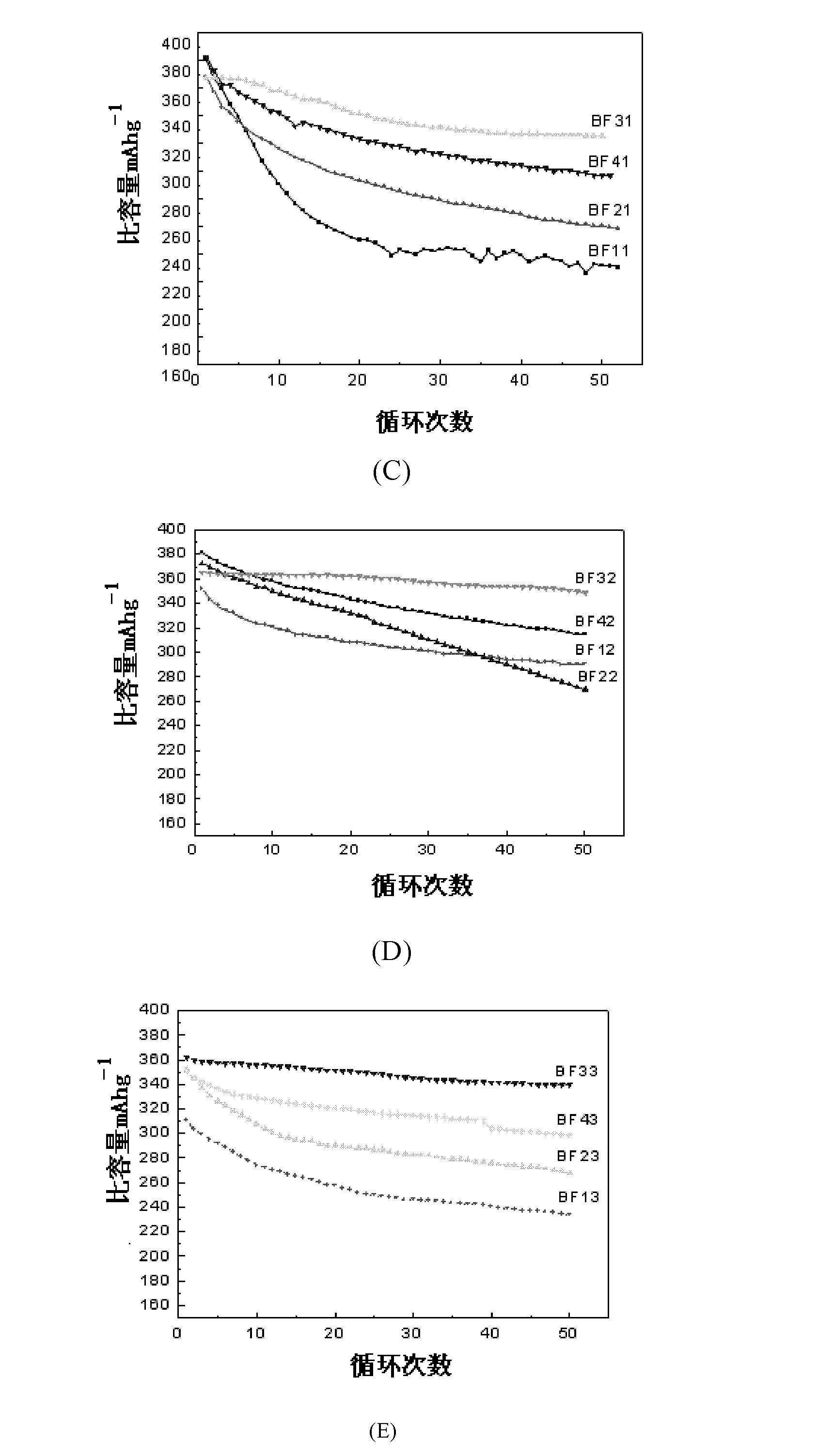

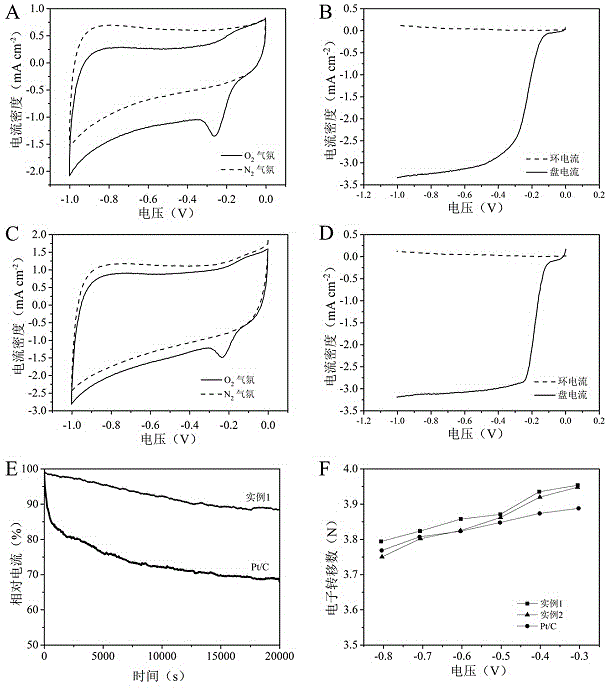

ActiveCN103050663AImprove lithium storage performanceImproved magnification performanceCell electrodesCarbon preparation/purificationPower batteryChemical physics

The invention relates to a lithium ion battery cathode material as well as a preparation method and applications of the lithium ion battery cathode material. The cathode material is an intermediate-phase carbon microsphere after low-temperature carbonization treatment, impregnation doping treatment and low-temperature sintering treatment, and are spherical or similar spherical with the ratio of long diameter to short diameter less than 2; and micro crystal structures in the cathode material are in unordered arrangement. The battery cathode material provided by the method provided by the invention has the advantages of rapid electric charge and discharge with large current, high lithium storage capability, high capacity, excellent high-rate performance and low-temperature performance and the like; and the discharge capacity under 25 DEG C can reach 412mAh / g, the discharge capacity under -20 DEG C can reach 328mAh / g, the rate performance is favorable, and the specific capacity under 20C current test in circulation for 100 times is not less than 340mAh / g, thus the high requirements on rate performance and circulation performance by a power battery can be met well.

Owner:天津市贝特瑞新能源科技有限公司

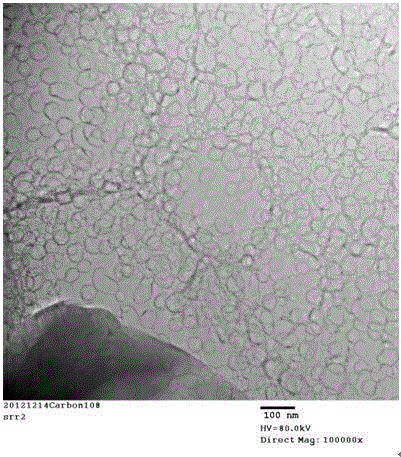

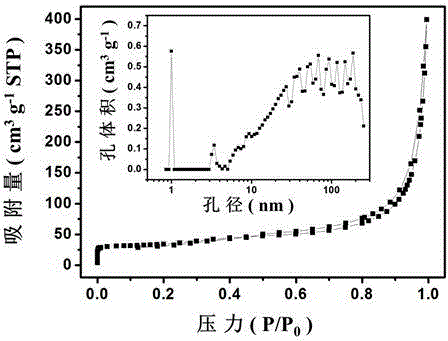

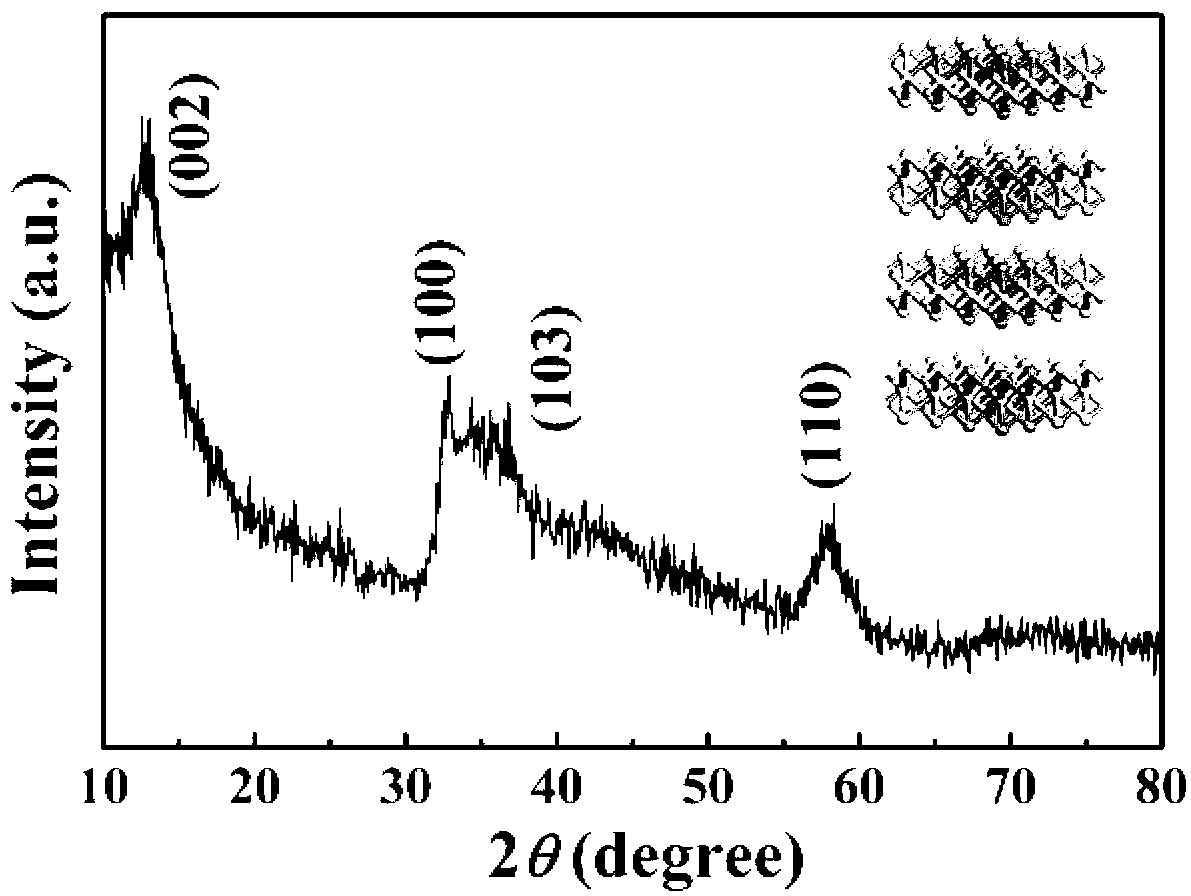

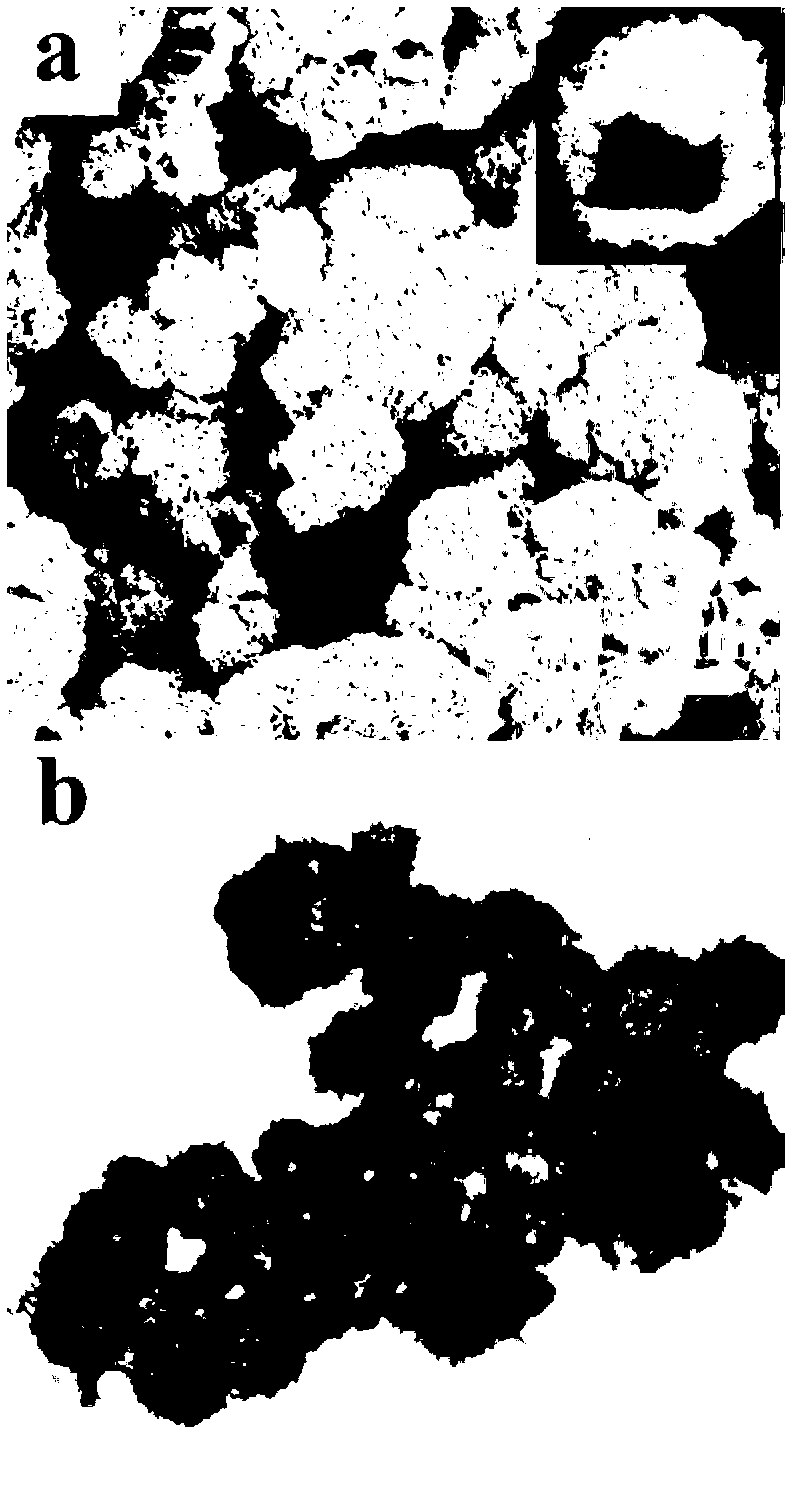

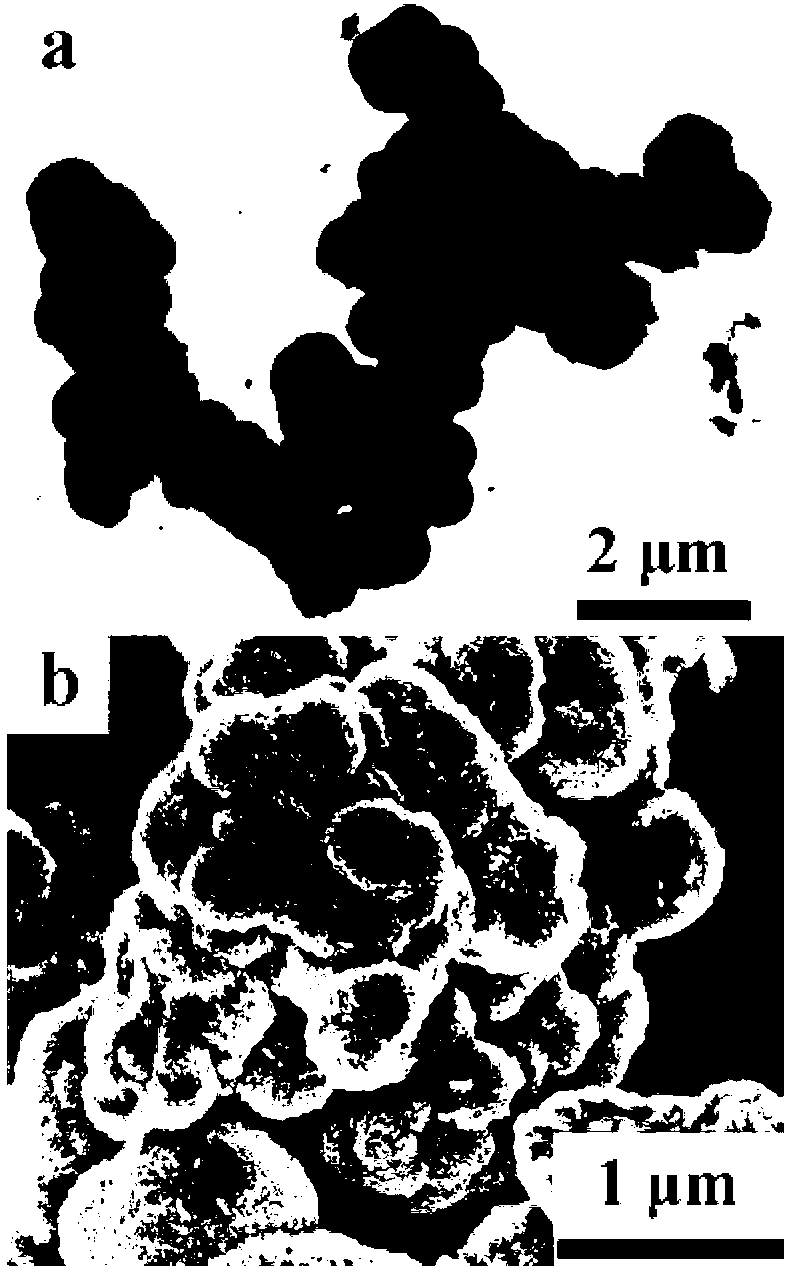

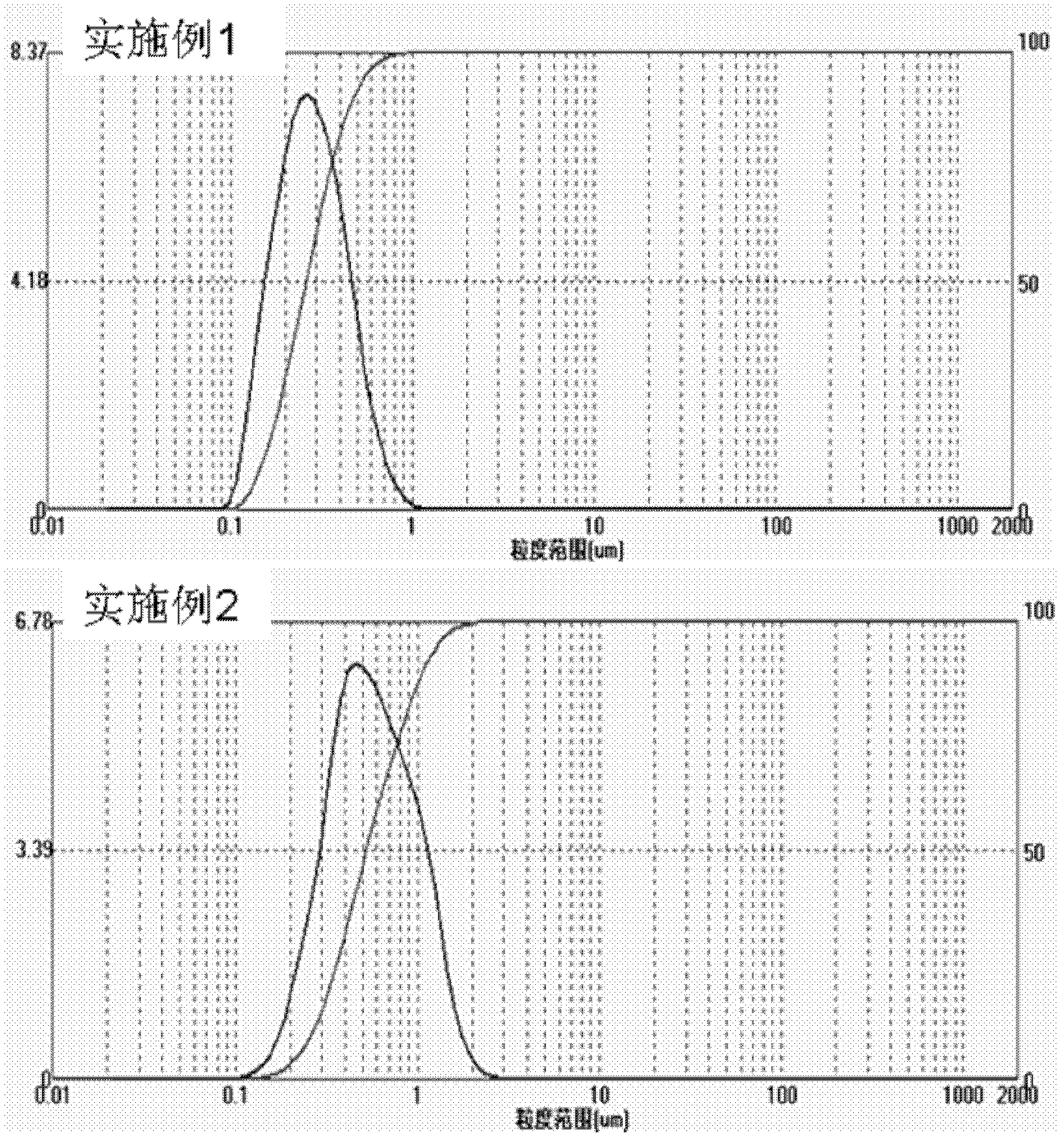

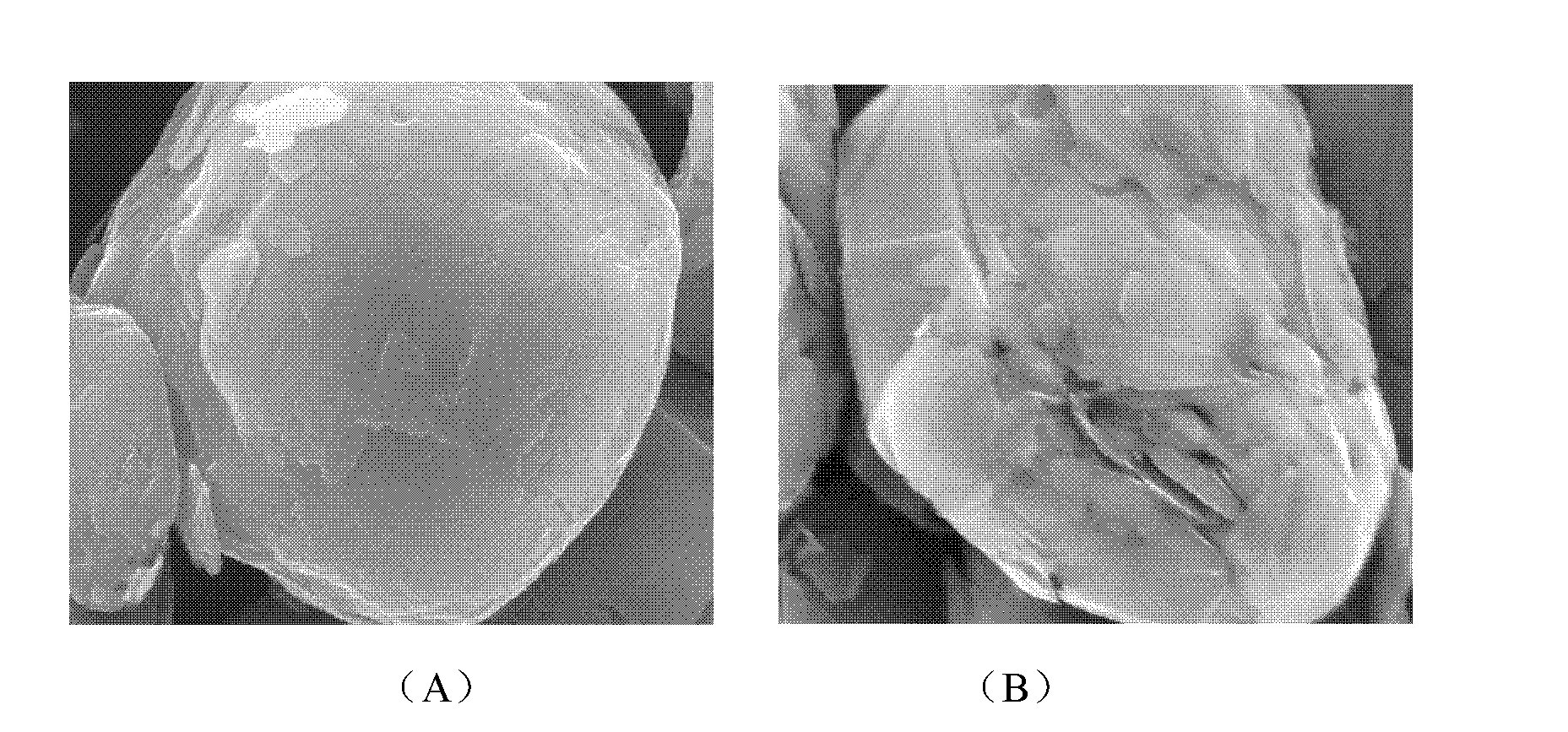

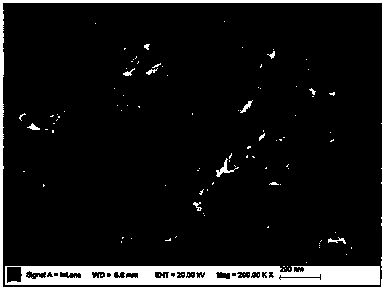

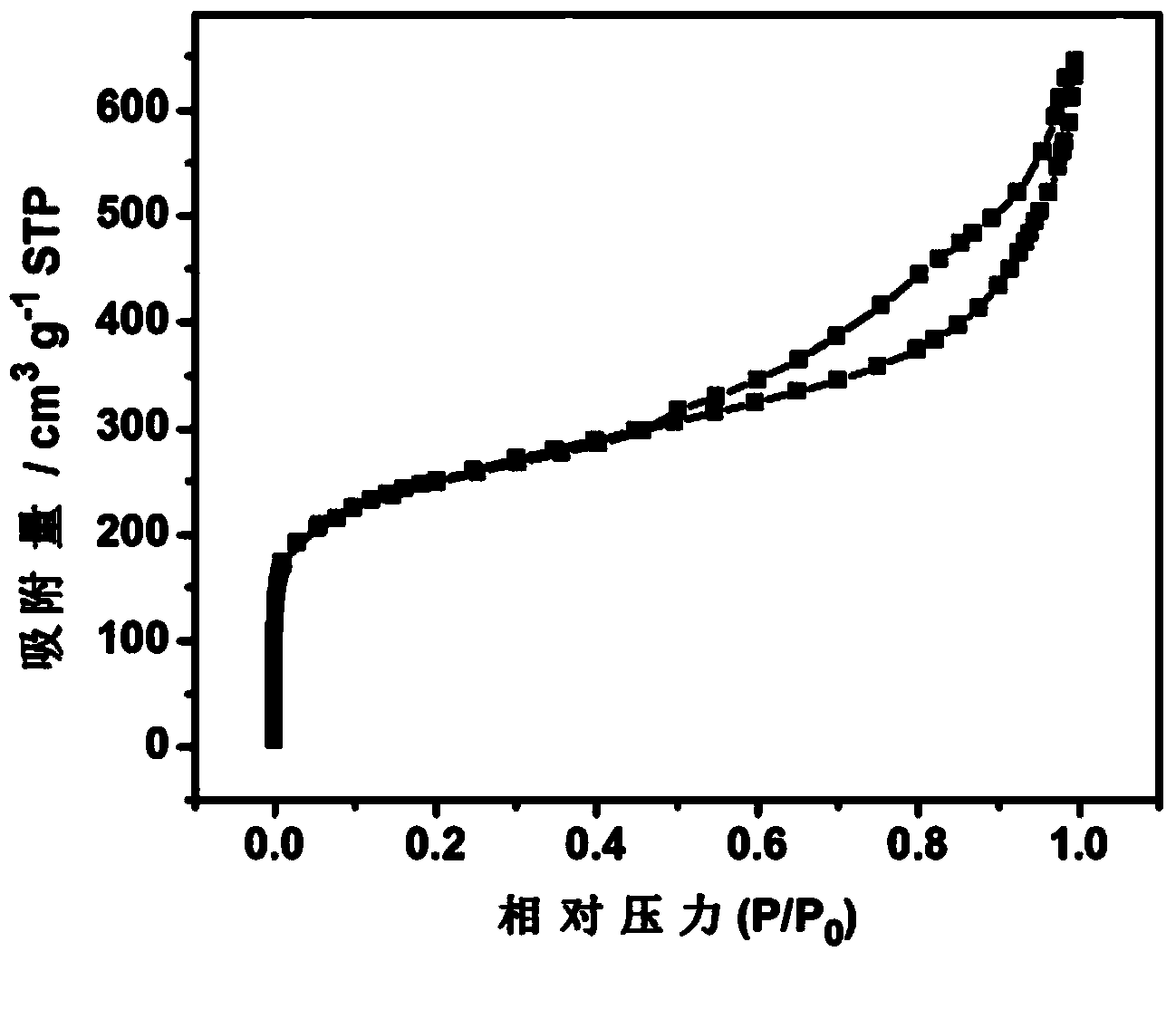

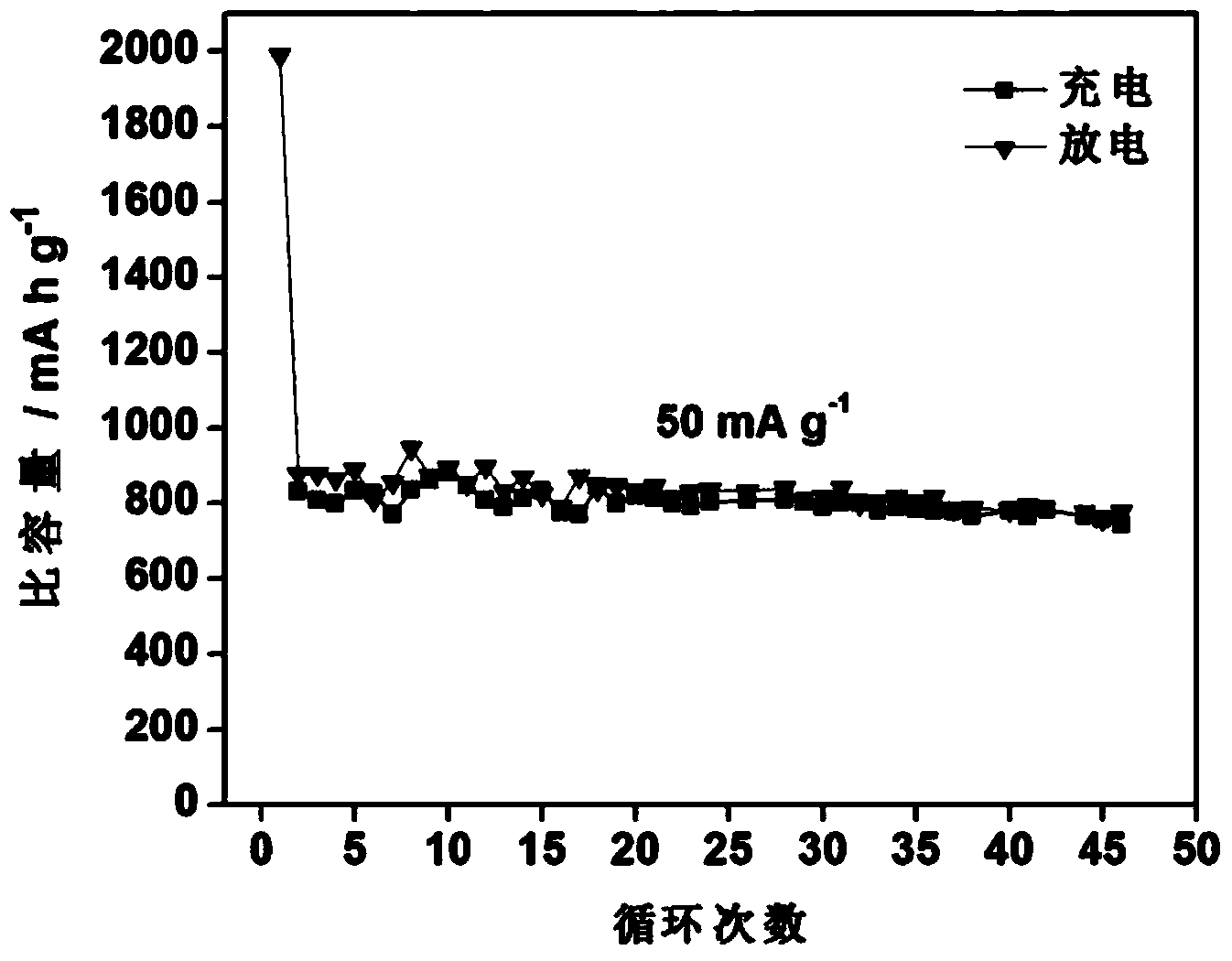

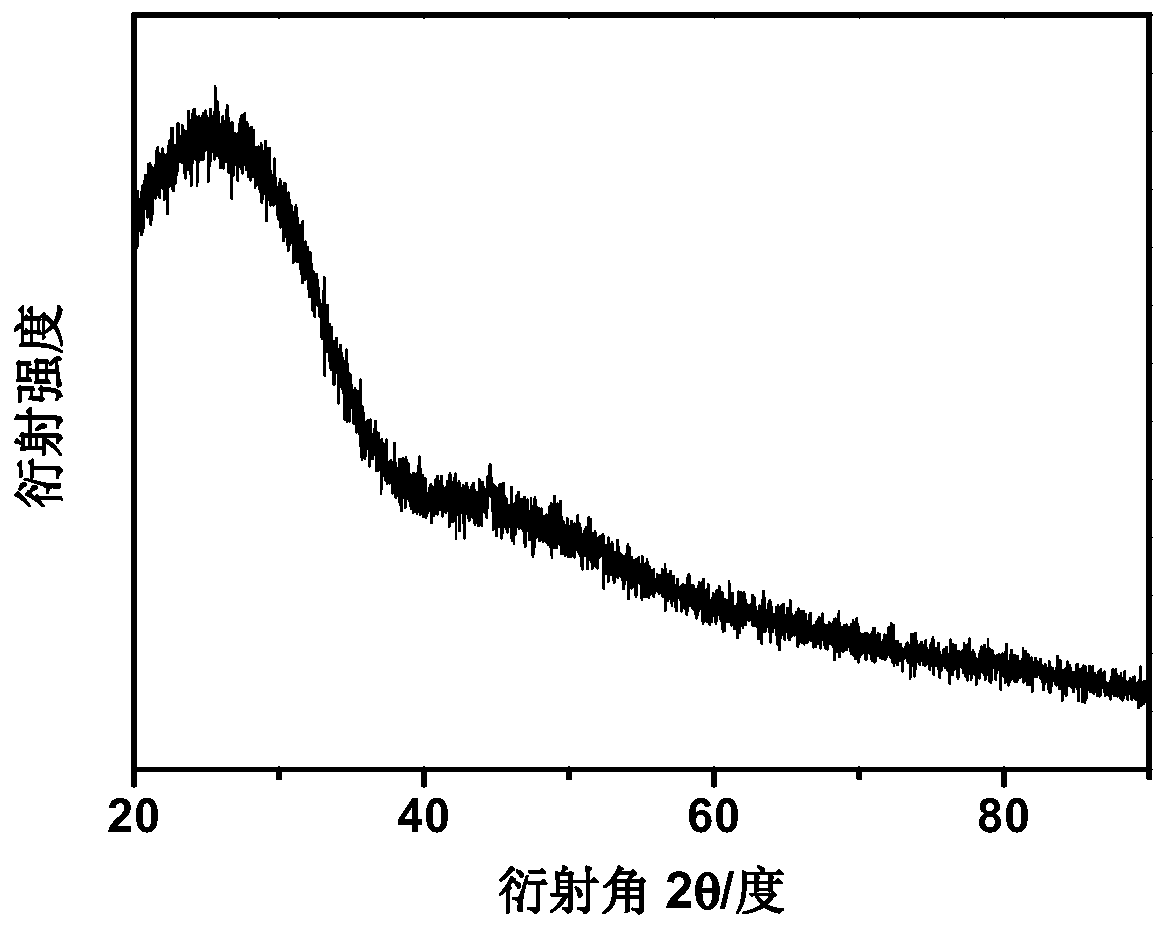

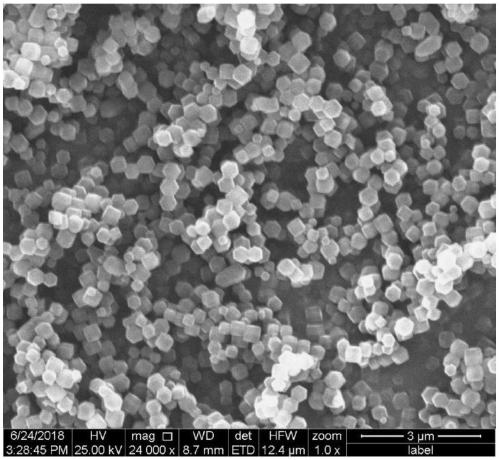

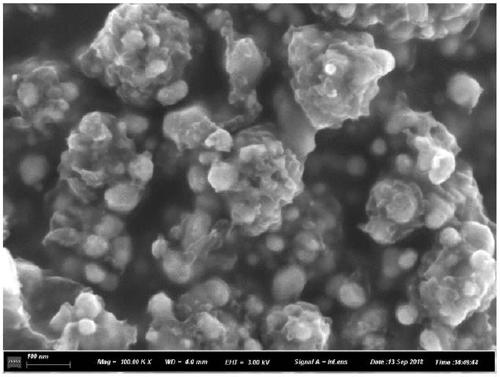

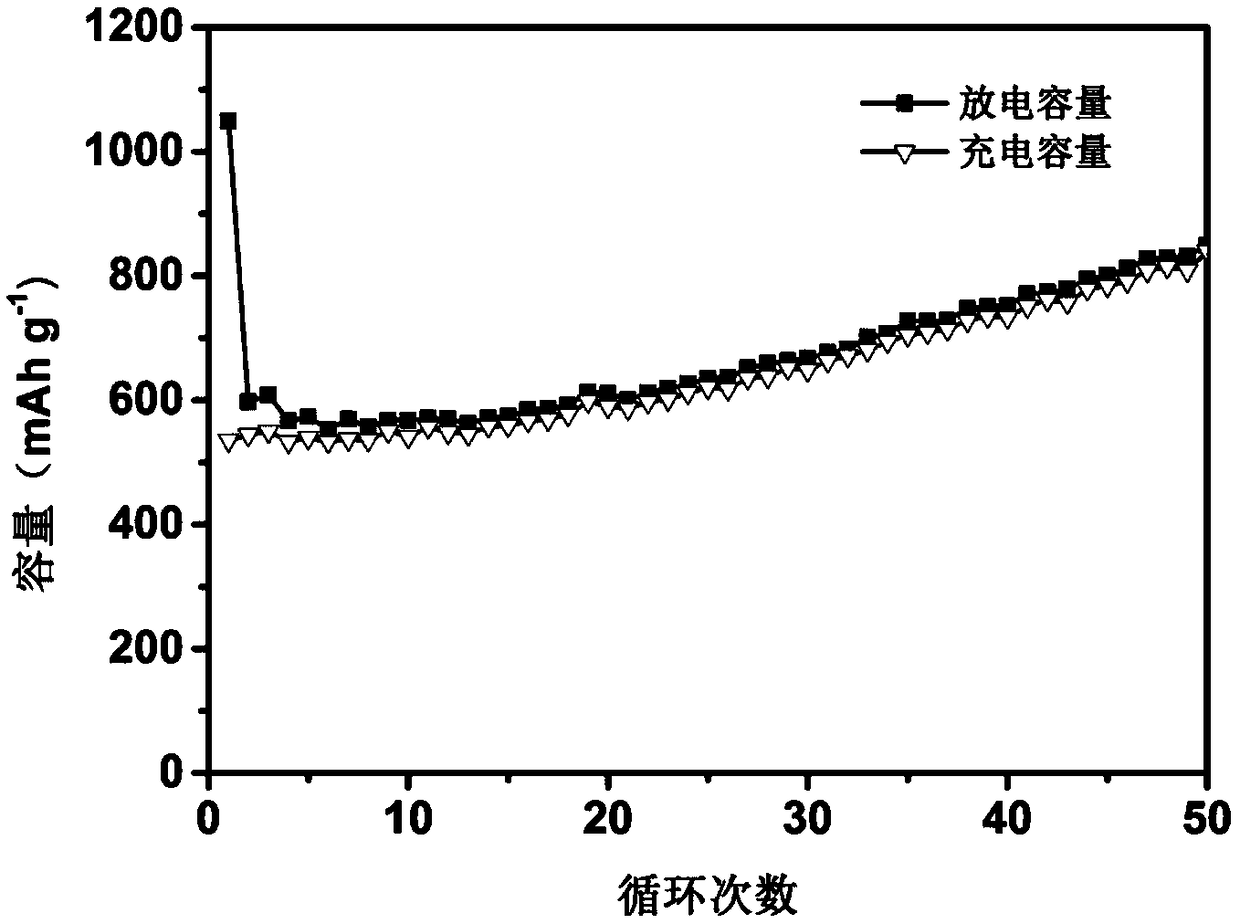

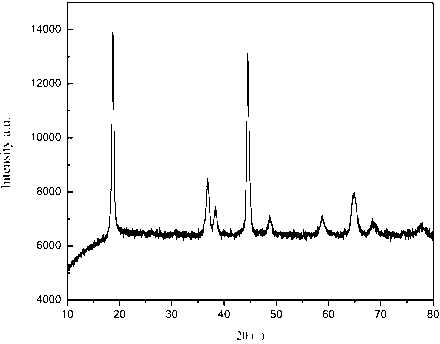

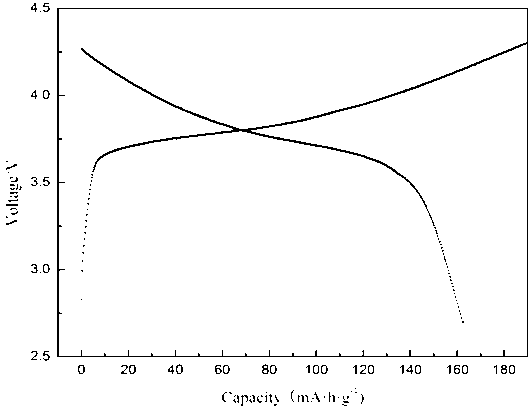

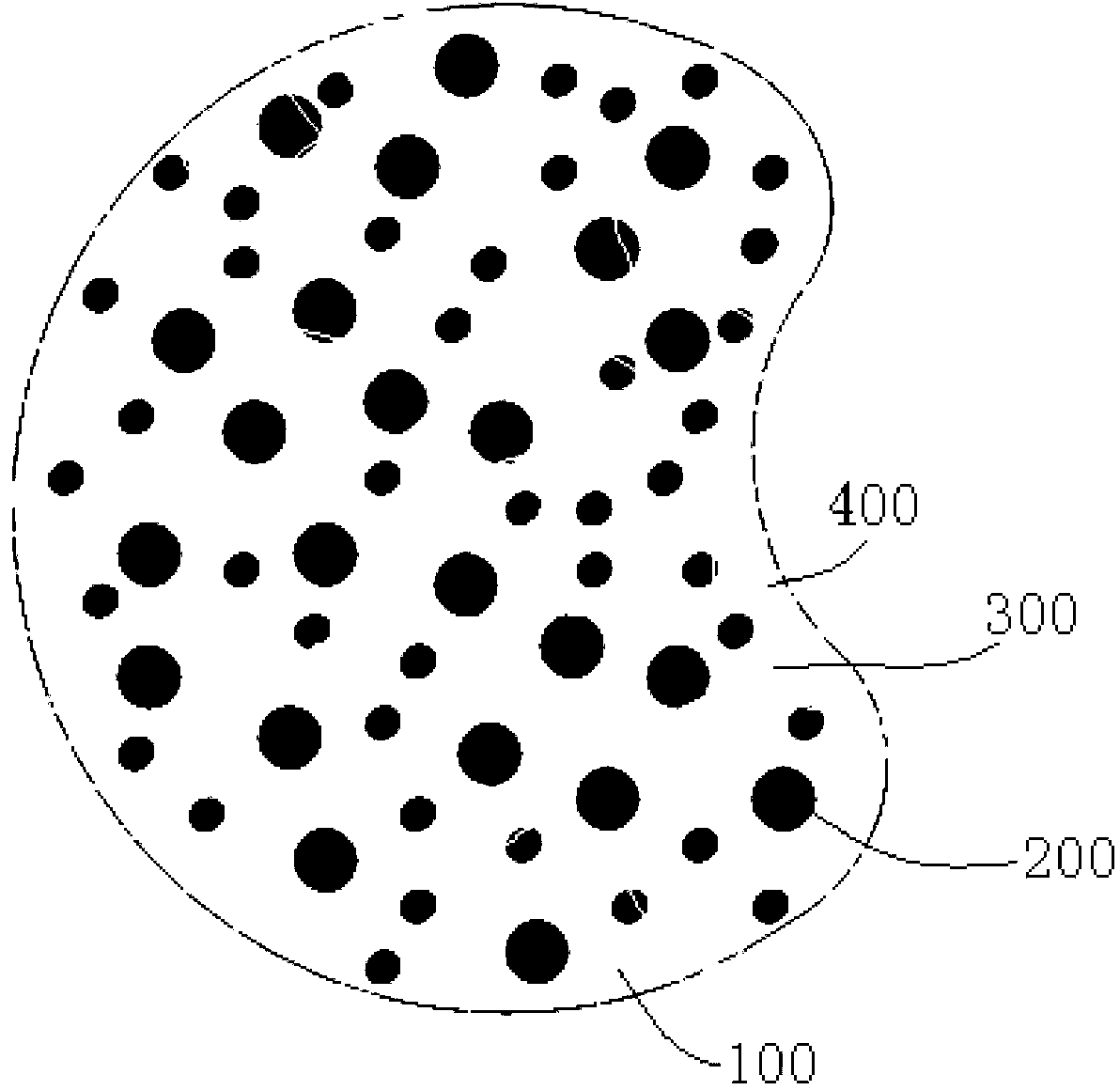

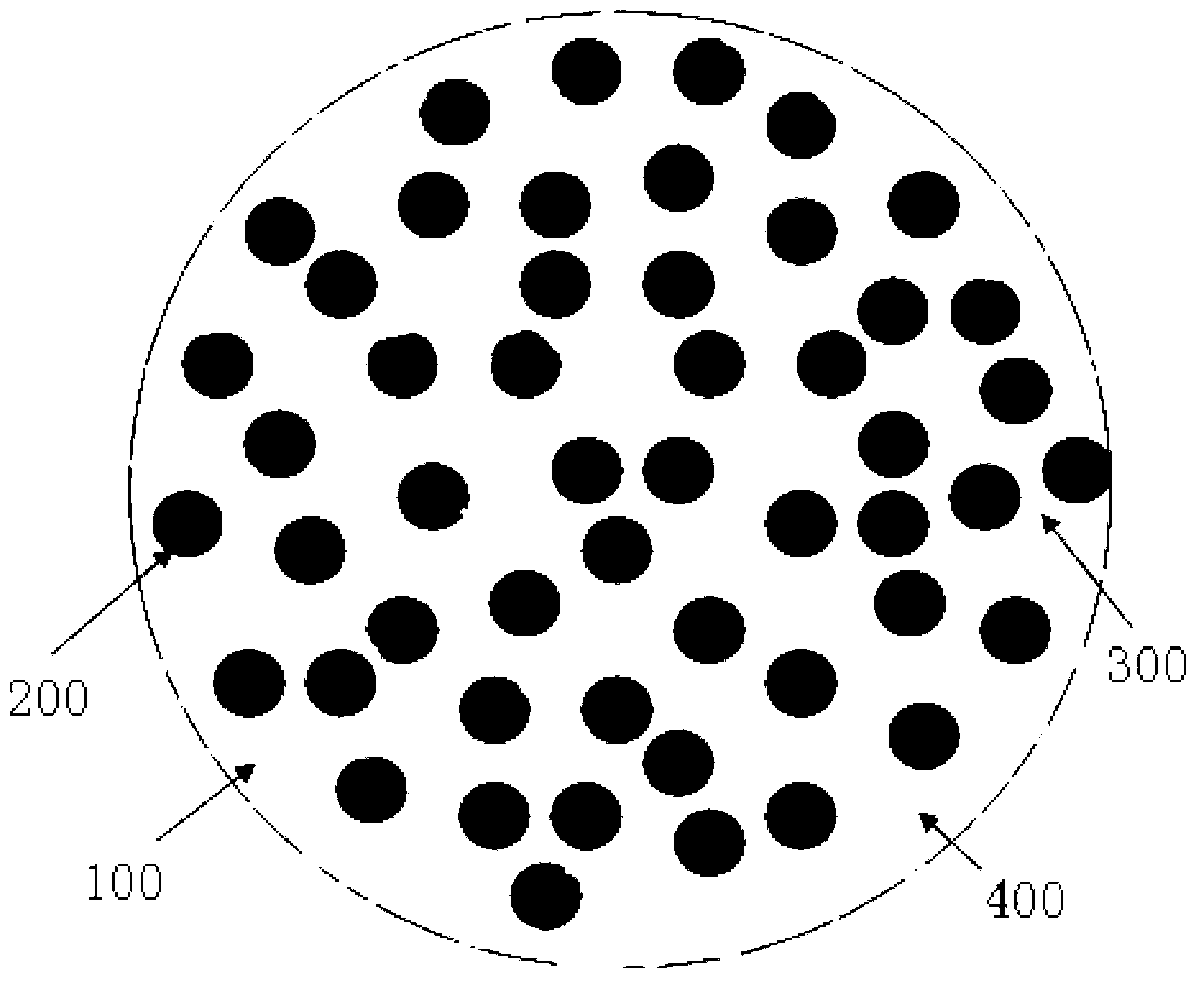

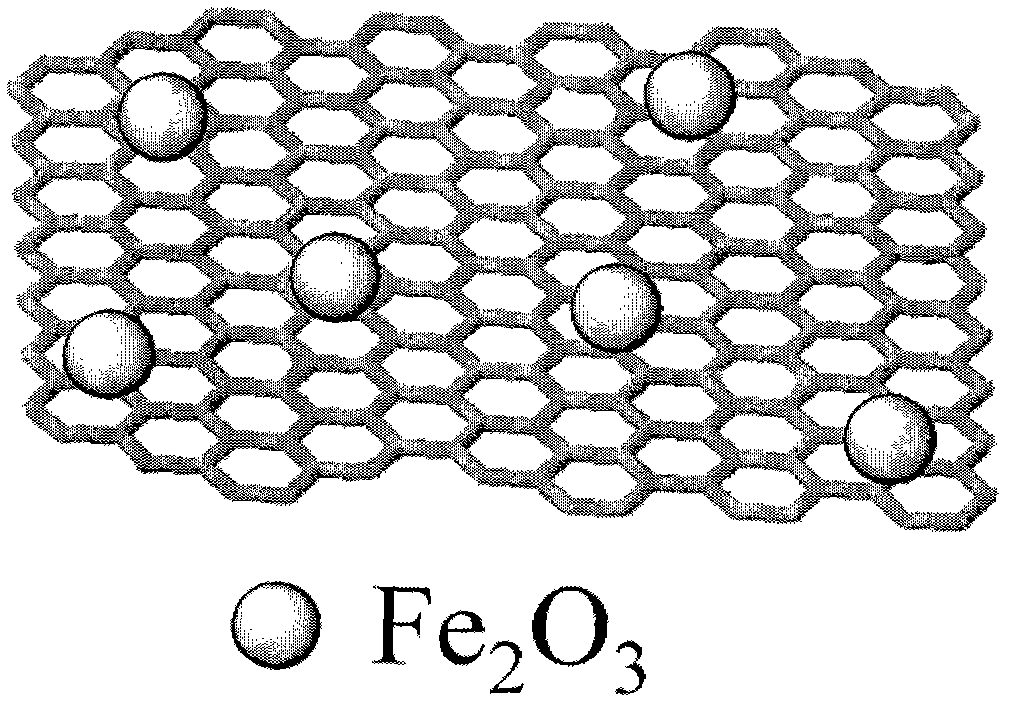

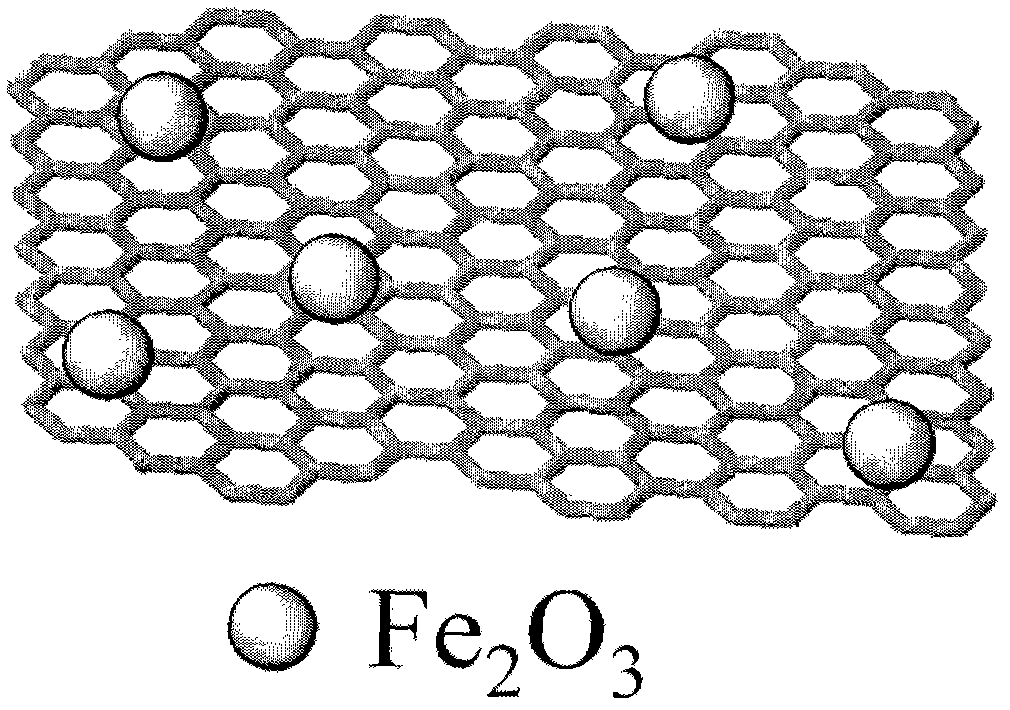

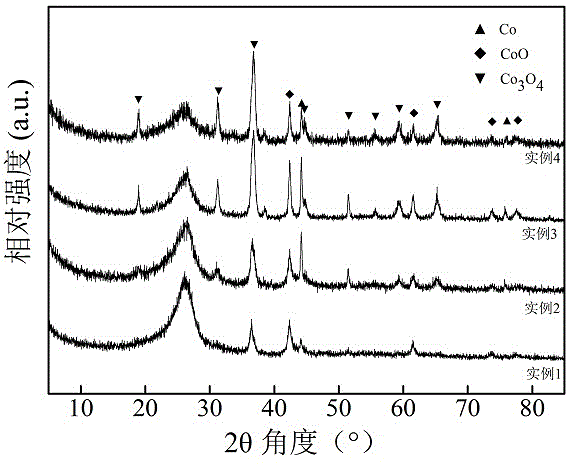

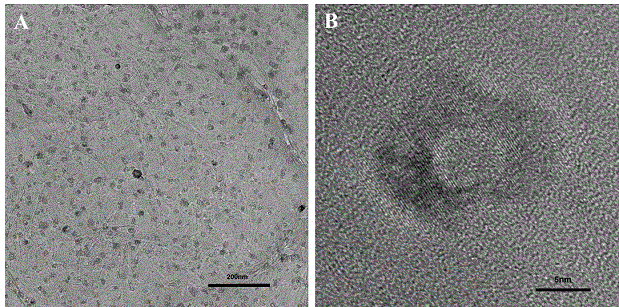

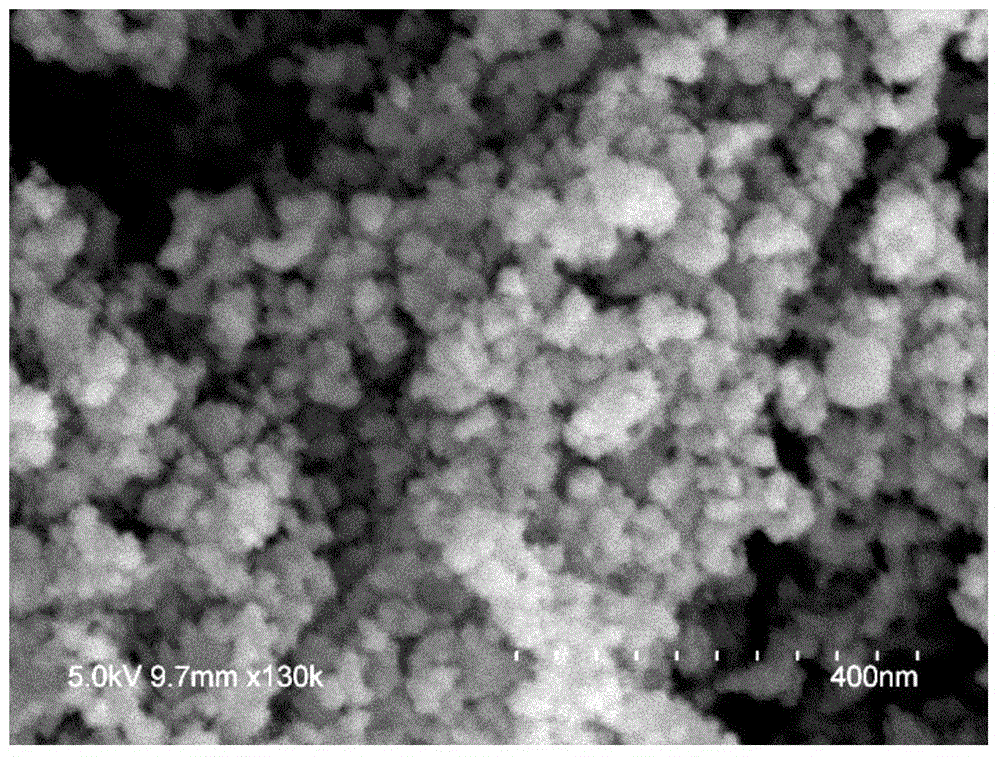

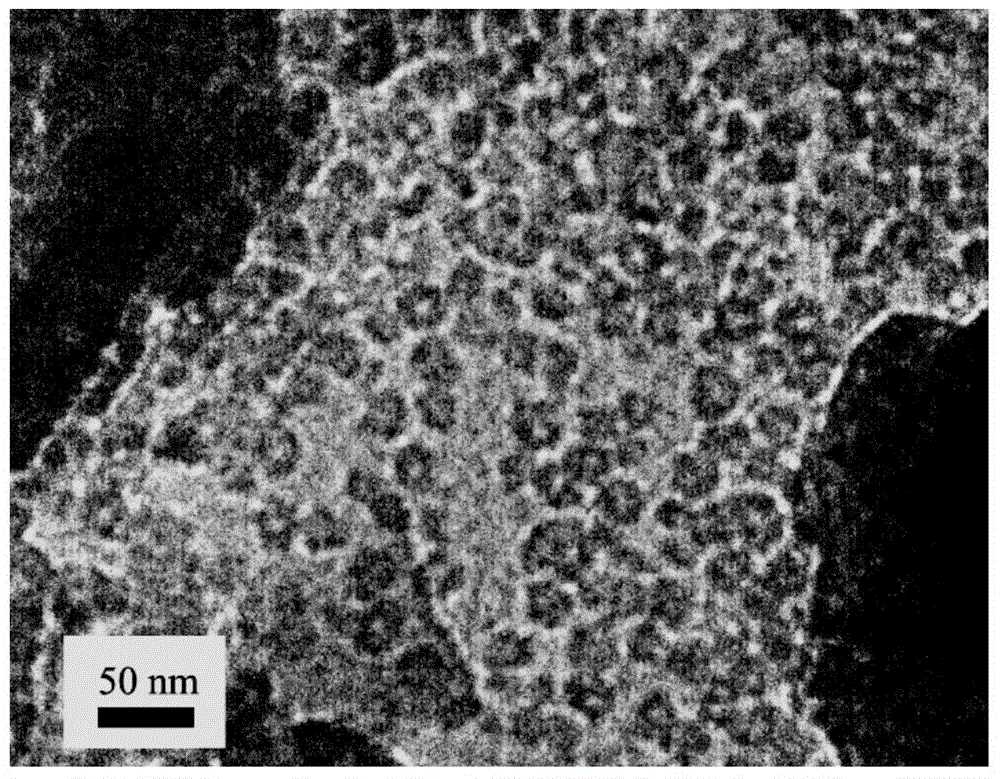

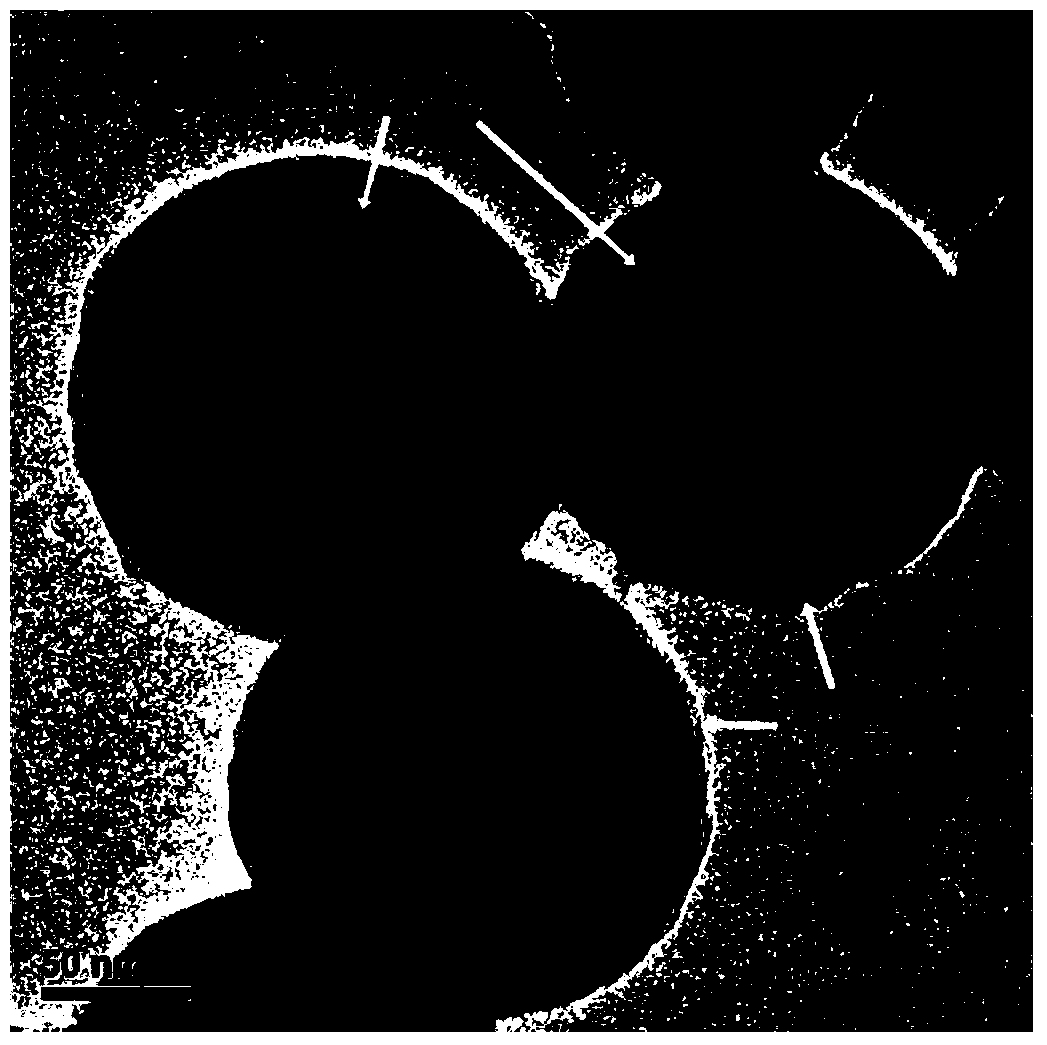

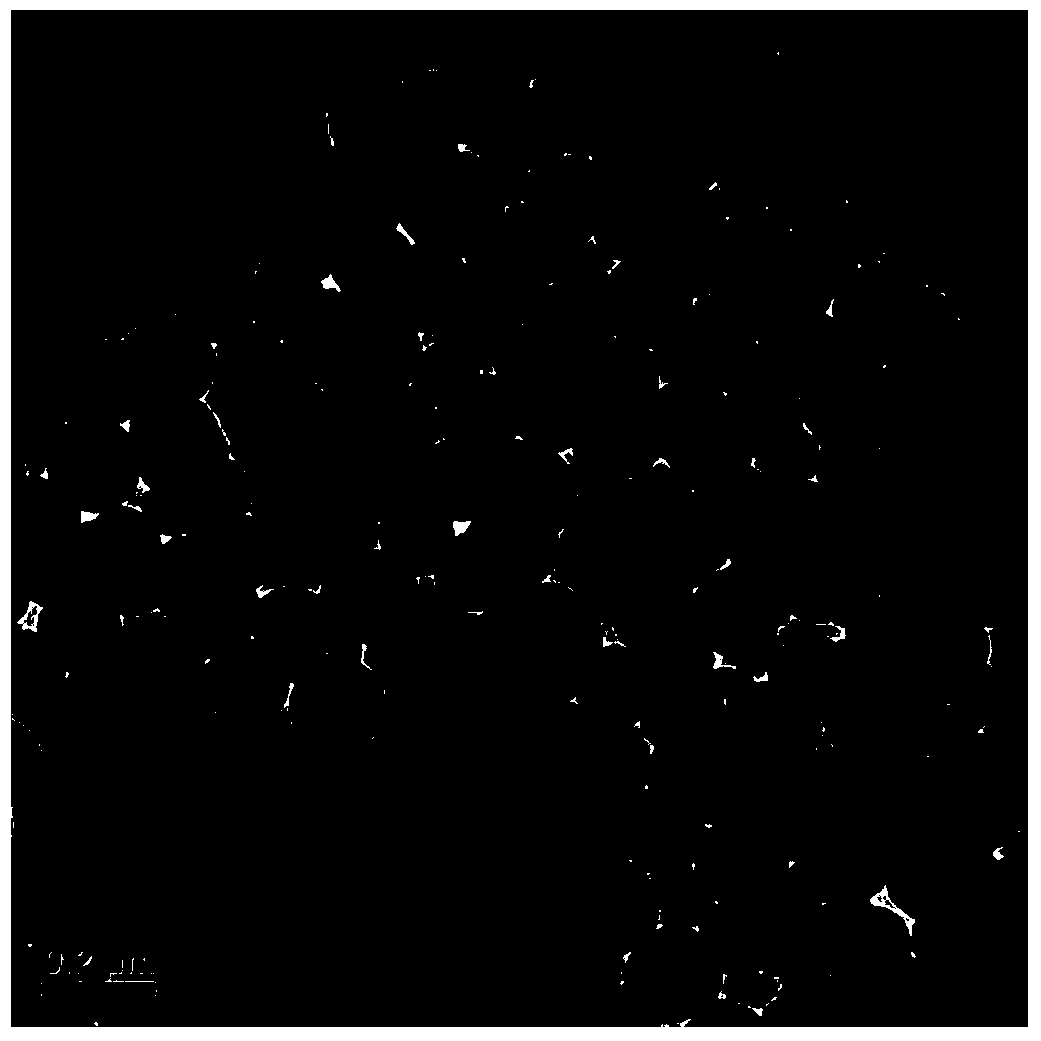

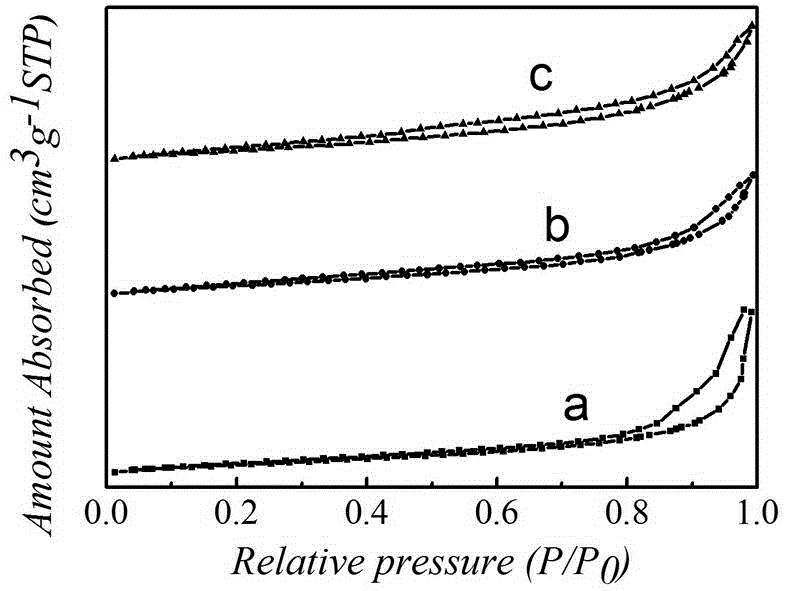

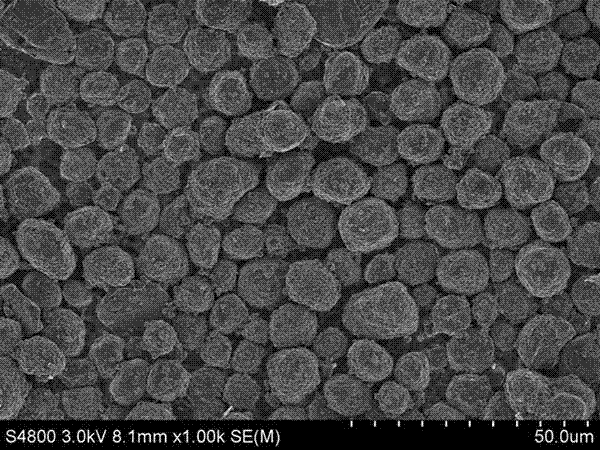

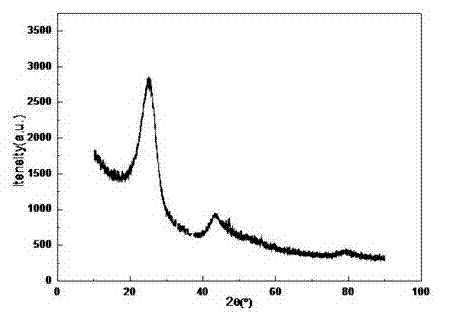

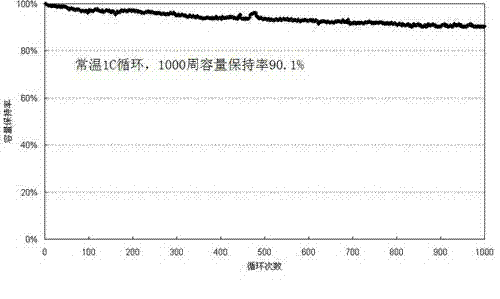

[Alpha]-phase ferric oxide porous core-shell microspheres and controllable synthetic preparation method thereof

InactiveCN104003448AIncreased sensitivityExcellent lithium batteryMaterial nanotechnologyCell electrodesMicrosphereActive agent

The invention discloses [alpha]-phase ferric oxide porous core-shell microspheres and a controllable synthetic preparation method thereof. The [Alpha]-phase ferric oxide microspheres having porous core-shell structures can be prepared through a hydrothermal method with an inorganic soluble ferric salt being a raw material, deionized water and anhydrous alcohol being solvents and at a certain temperature for a certain time. The microspheres are 3 [mu]m in the average diameter. Cores and shells are composed of nano particles, wherein the average diameter of the nano particles is 200 nm and the average thickness of the shells is 100nm. A plurality of pores with pore diameters being 40nm are uniformly distributed on the surface of each shell with of a plurality of pores with pore diameters being 40nm. The preparation method is free of any dispersing agent and surfactant, and subsequent processes are convenient since a template is not needed. The preparation method is simple in technology, short in reaction time, large in output, is environmental-friendly and cheap in raw materials, is beneficial to large scale industrial production and the porous core-shell microspheres can be used for a lithium ion battery electrode material and a gas-sensitive material.

Owner:JIANGSU UNIV

Porous graphene nanosheet, preparation method and application of porous graphene nanosheet as electrode material

ActiveCN104701546AImprove lithium storage performanceImproved magnification performanceCell electrodesPorous grapheneGraphite

The invention relates to a porous graphene nanosheet preparation method, which takes resin as a carbon source, resin and a metal source are solidified and charred to obtain carbon plate with a hierarchical pore structure, and the carbon plate is graphitized to obtain the porous graphene nanosheet. The preparation method of the porous graphene nanosheet has the advantages of simple process, low cost, little pollution and easy realization of large scale production; and the porous graphene nanosheet presents high capacity and excellent multiplying power performance when being as a cathode material of a lithium ion battery.

Owner:BEIJING UNIV OF CHEM TECH

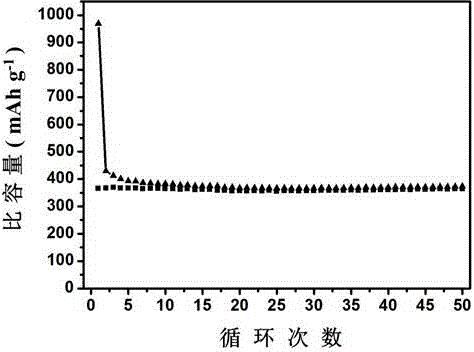

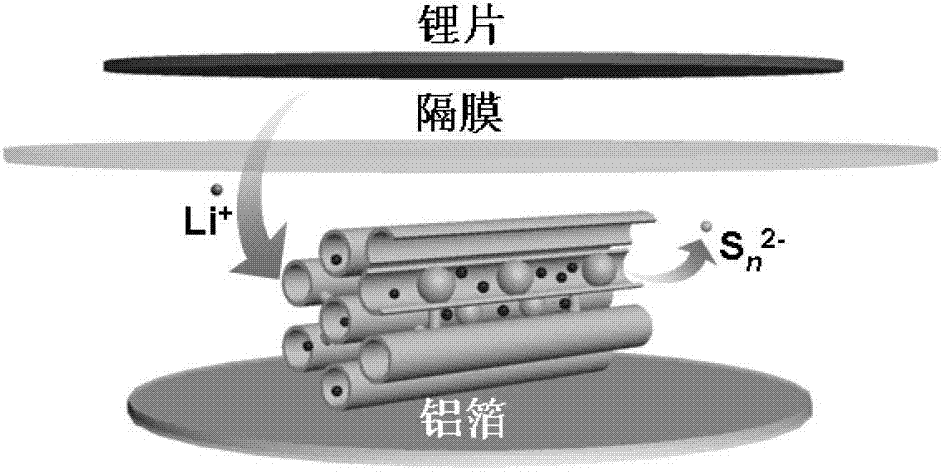

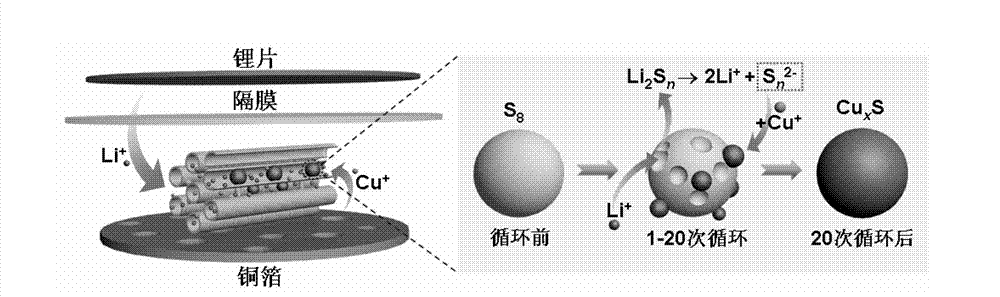

Lithium sulfur battery

InactiveCN103050729AImprove lithium storage performanceSlow corrosionElectrode carriers/collectorsLi-accumulatorsLithium–sulfur batterySulfide

The invention provides a lithium sulfur battery taking a transition metal material as a current collector, which comprises a positive electrode, a negative electrode, an electrolyte, a diaphragm and a battery case, wherein the positive electrode is composed of the transition metal material current collector, a sulfur-based composite applied onto the current collector, a conductive agent and a bonding agent. The transition metal current collector adopted in the battery can be corroded by the electrolyte or oxidized during the charging / discharging process, so as to release transition metal ions, which can rapidly react with an intermediate product Sn2- of the lithium sulfur battery to generate a transition metal sulfide precipitate and further prevent the Sn2- from escaping. Meanwhile, the transition metal sulfide has outstanding electrochemical activity, can improve utilization rate of active sulfur, and further improves reversible capacity. Therefore, due to use of the transition metal current collector, the performance of the lithium sulfur battery is significantly improved.

Owner:DALIAN UNIV OF TECH

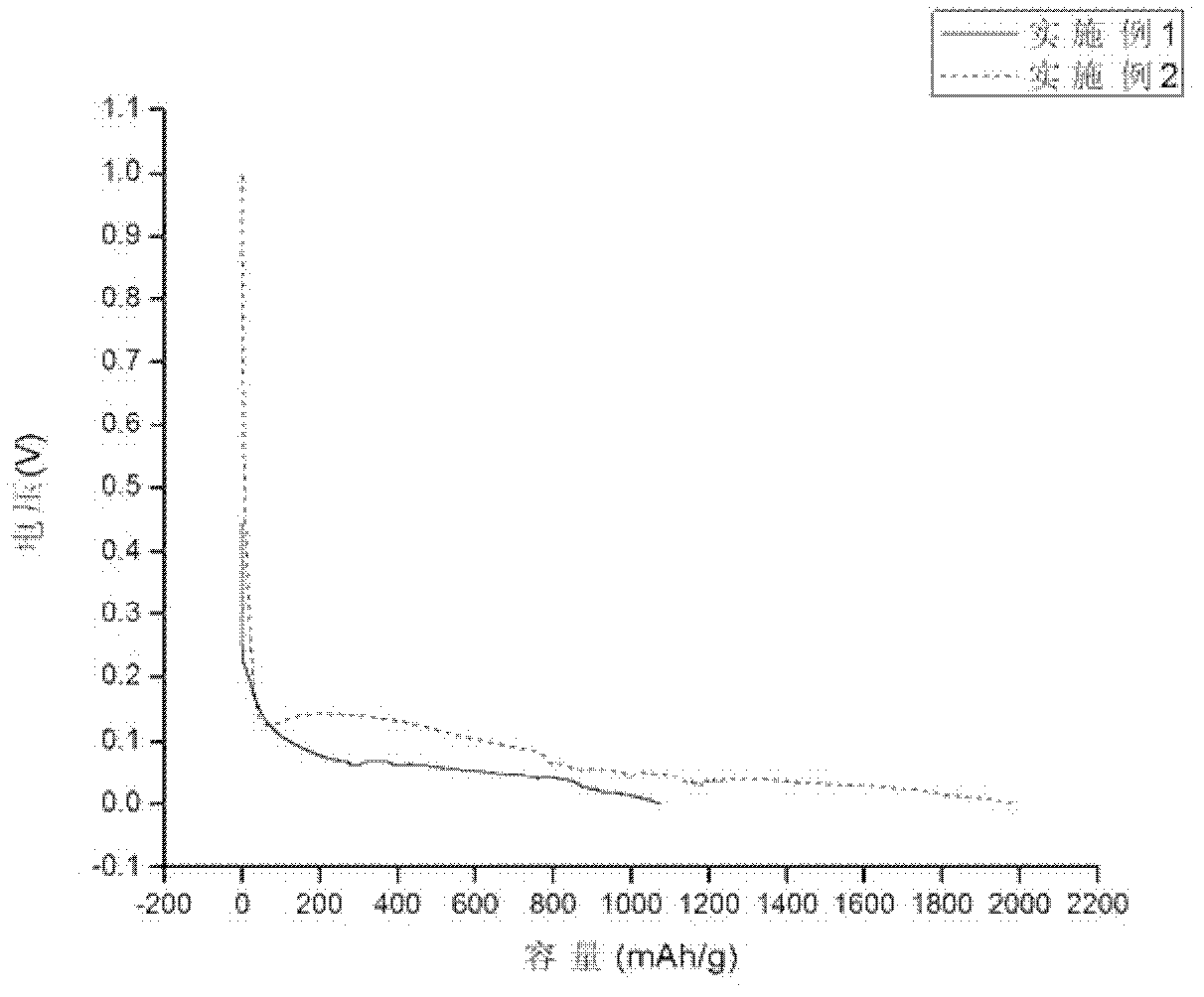

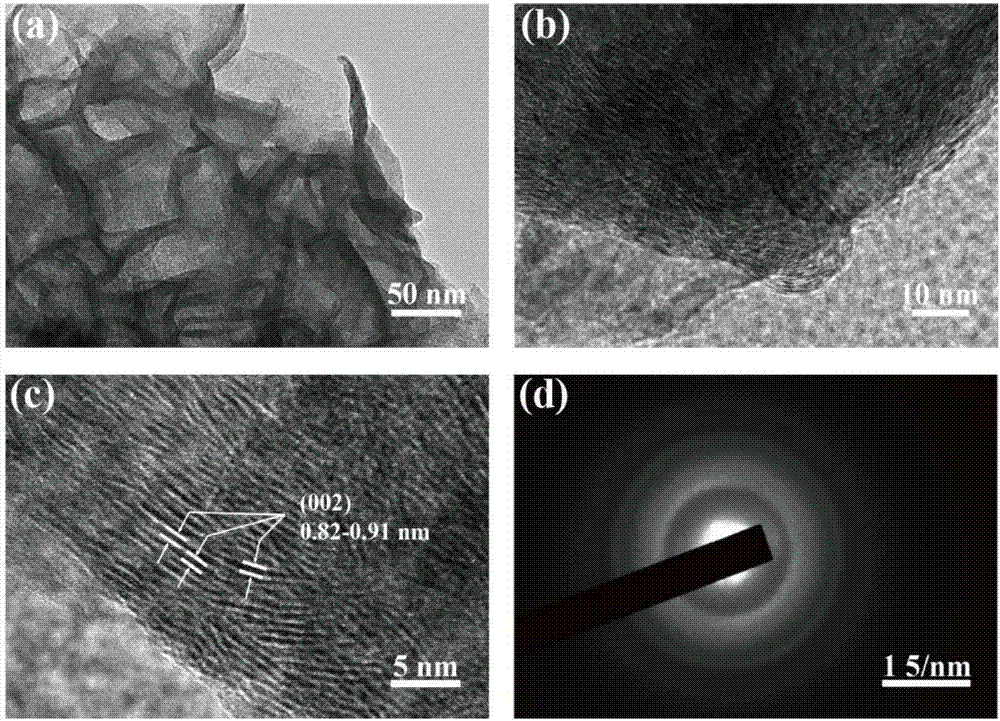

Nano sheet self-assembled MoS2 nano hollow material and preparation and application of MoS2 nano hollow material serving as lithium storage electrode material

InactiveCN102938461AImprove lithium storage performanceGood lookingCell electrodesLithiumPotassium thiocyanate

The invention discloses a nano sheet self-assembled MoS2 nano hollow material and preparation and application of the MoS2 nano hollow material serving as a lithium storage electrode material. The nano sheet self-assembled MoS2 nano hollow material is obtained by mixing raw materials including molybdenum oxide, sodium fluoride and potassium thiocyanate according to the mass ratio of 0.8-0.9:0.5-0.6:1.5-2.9; adding into water-ethanol mixed solvent; placing into a reaction kettle to be sealed; reacting at 140-220 DEG C for 12-30h; and performing washing, separating and drying to obtain products. The method is simple and easy in required condition, cheap and facile in raw materials and controllable in shape and height and easily achieves industrial production. Lithium storage electrodes prepared by adopting the prepared nano sheet self-assembled MoS2 nano hollow material not only have high electro-chemical lithium storage reversible capacity and excellent cycling performance, but also have good rate capability.

Owner:SHANDONG UNIV

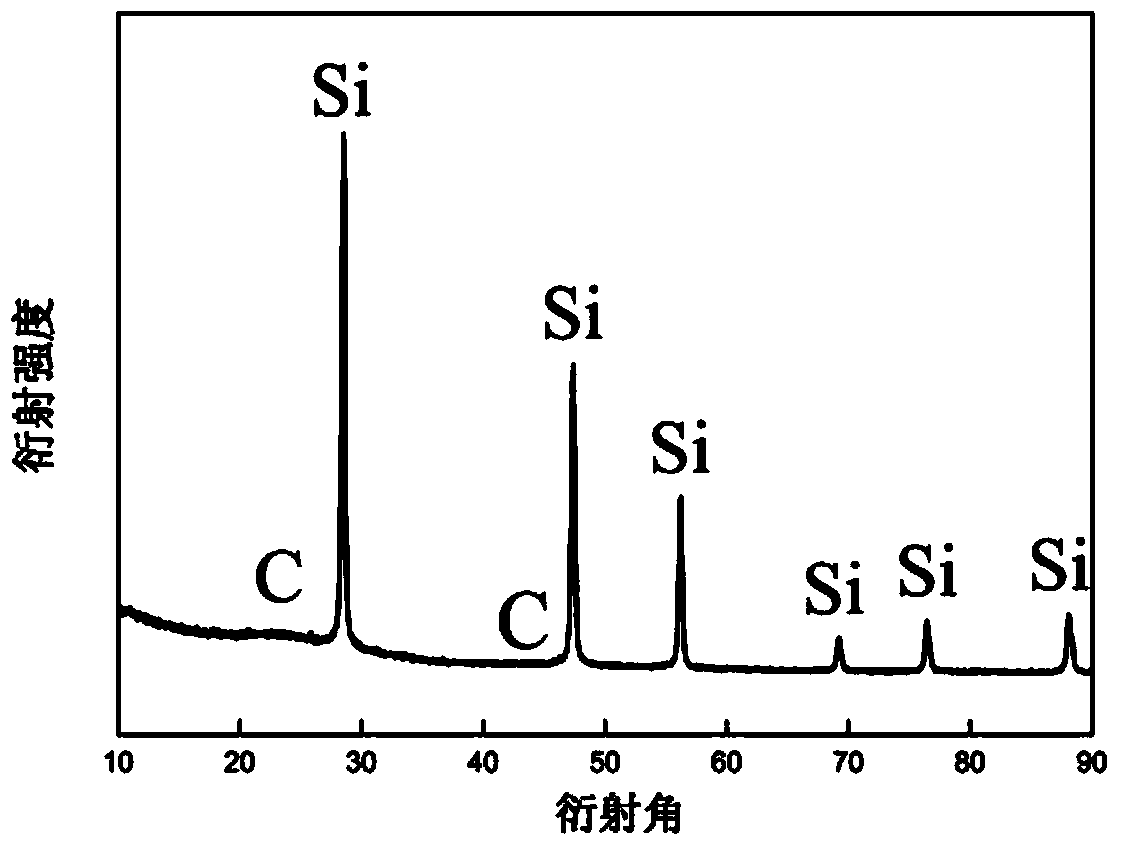

Process for producing silicon-based carbon composite material for lithium ion battery cathode

InactiveCN102623682AImprove lithium storage performanceImprove conductivityElectrode manufacturing processesSilicon matrixCarbon composites

Disclosed is a process for producing a silicon-based composite material for a lithium ion battery cathode. The process comprises that silicon powder serves as a main material, graphite powder or flocculent carbon black serves as an auxiliary material, the main material and the auxiliary material are mixed and placed in a ball-grinding steel tank, argon serves as a shielding gas, the ball-grinding steel tank inflated with the shielding gas is placed in a planetary ball mill, and powder with granularity of less than 20 mum, which is the silicon-based composite material for the lithium ion battery cathode, is obtained after the mixture is subjected to ball milling at 500 revolutions / minute for 80 hours. The process has the advantages that the silicon material having the good lithium-storing capacity is mixed with the carbon material having the good electrical conductivity, atomic-grade mixing of the silicon material and the carbon material is achieved in a mechanical alloying mode, the electrical conductively of the silicon matrix is fully improved, and the inert carbon material can reduce volume expansion caused by the processes of lithium intercalation and lithium deintercalation of the silicon material in the processes of charging and discharging of the inert carbon material, so that the cycle performance of the silicon material is improved, the electrical conductivity and the cycle performance of the carbon-doped material are better than those of the pure silicon material.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

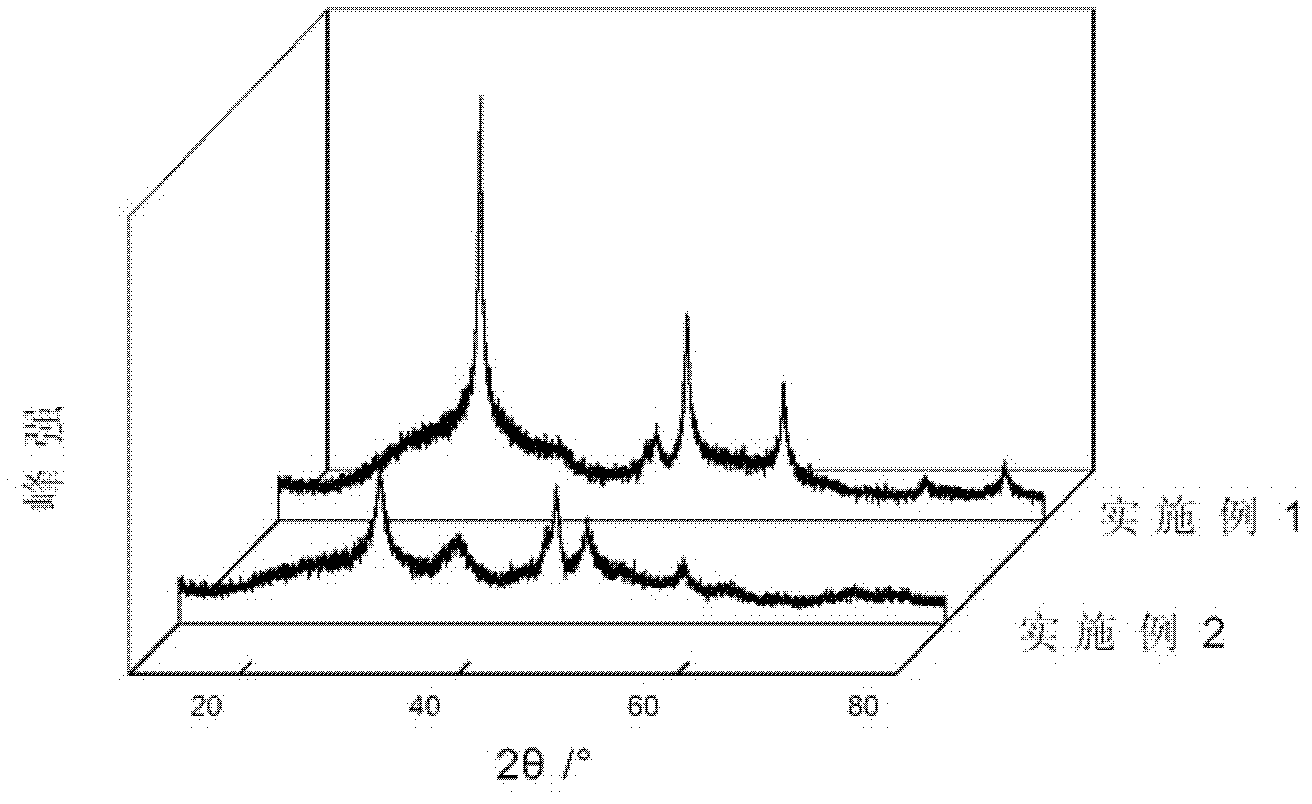

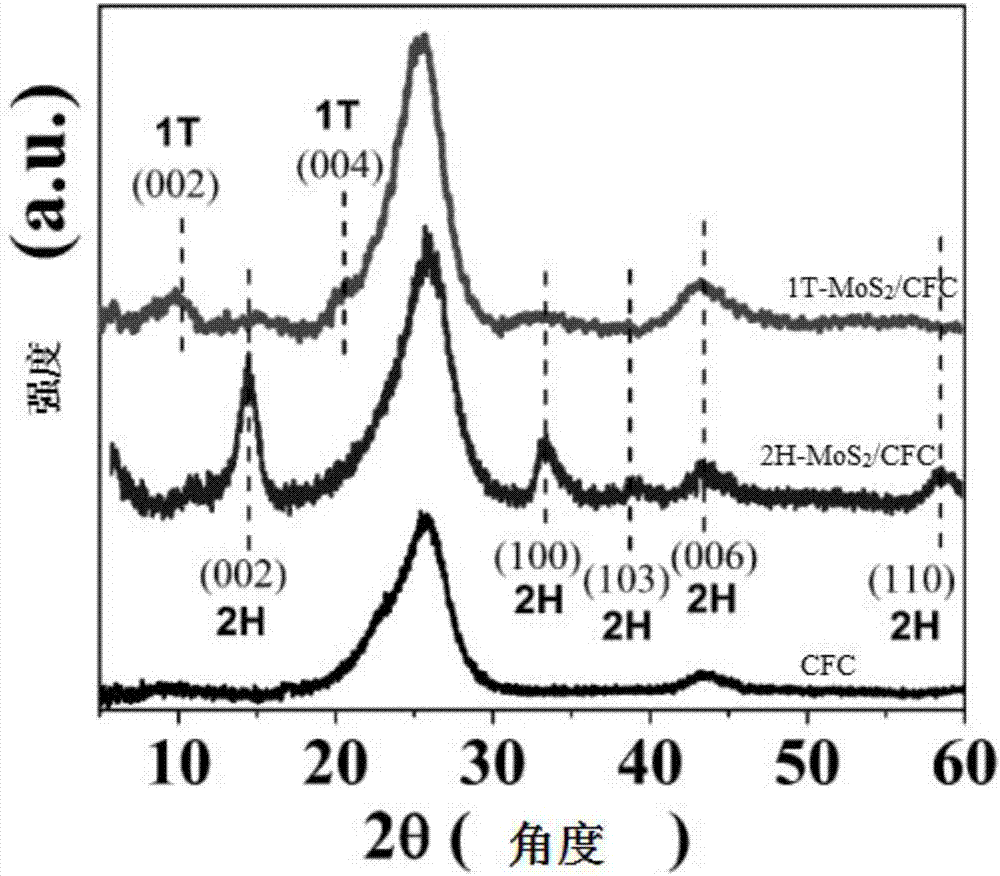

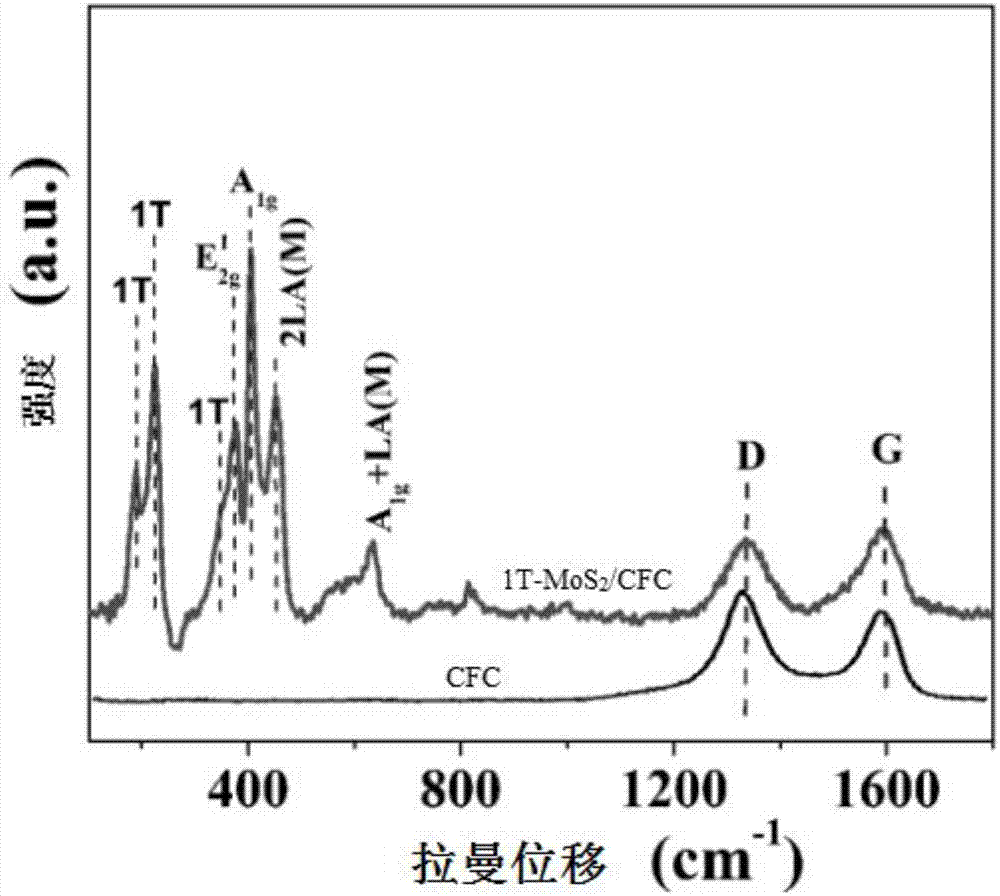

Metallic 1T molybdenum disulfide nano-sheet array as well as preparation method and application thereof

InactiveCN107285385AImprove wettabilityHigh yieldMaterial nanotechnologyCarbon fibresMolybdateSulfur

The invention provides a metallic 1T molybdenum disulfide nano-sheet array as well as a preparation method and application thereof. The method comprises the following steps: carrying out thermal treatment on a substrate to obtain a functionalized substrate; carrying out solvothermal reaction on the functionalized substrate, molybdate and a sulfur compound in a solvent to obtain the metallic 1T molybdenum disulfide nano-sheet array. According to the method disclosed by the invnetion, the thermal treatment on the substrate is carried out firstly, so that the wettability of the surface of the substrate is improved; then through the one-step solvothermal reaction, the metallic 1T molybdenum disulfide nano-sheet array can be obtained on the surface of the substrate. The preparation method disclosed by the invention has simple steps, is low-cost, is high in yield and meets a requirement on environment protection; the prepared metallic 1T molybdenum disulfide nano-sheet array has excellent lithium storage performance, and has wide application prospect in lithium ion batteries.

Owner:SHANGHAI UNIV

Graphite compound modification method and lithium ion battery anode material preparation method

InactiveCN102544510AImprove lithium storage performanceReduce reactive groupsCell electrodesSolventGram

The invention relates to a graphite compound modification method, which mainly comprises the graphite oxidative modification technology and the graphite coating modification technology. The graphite oxidative modification technology further comprises the following steps: graphite is smashed and subject to ball milling and oxidation reaction together with concentrated nitric acid in a certain temperature. The graphite coating modification technology further comprises the following steps: a surface finishing solvent containing asphalt is prepared; graphite is coated in the surface finishing solvent; and the graphite and asphalt mixture is subject to heat treatment. The prepared compound modified graphite serves as an active material to further prepare an electrode material for a lithium ion battery. According to the method provided by the invention, the capacity per gram and cycle life of natural graphite are effectively improved and prolonged respectively.

Owner:河源市天恒金科技有限公司

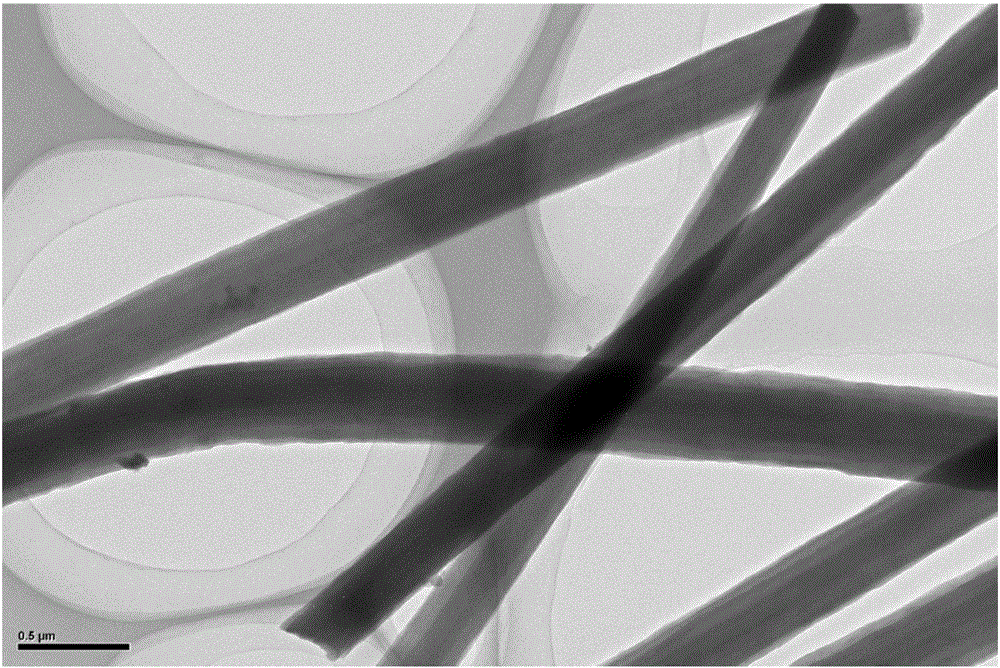

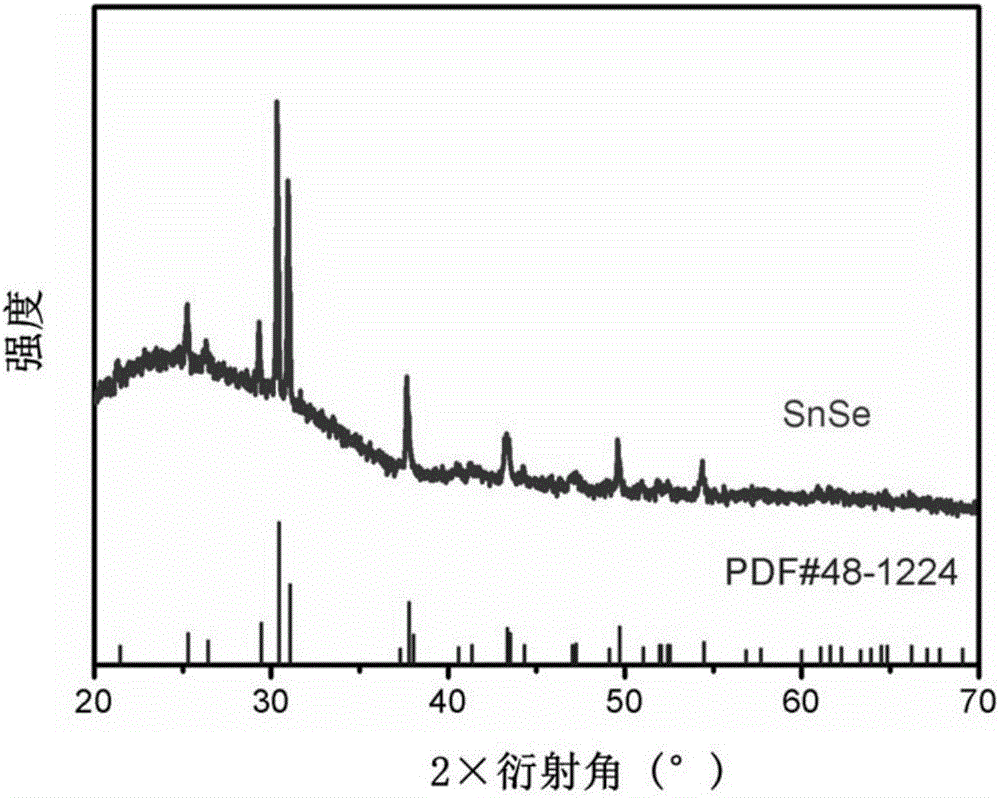

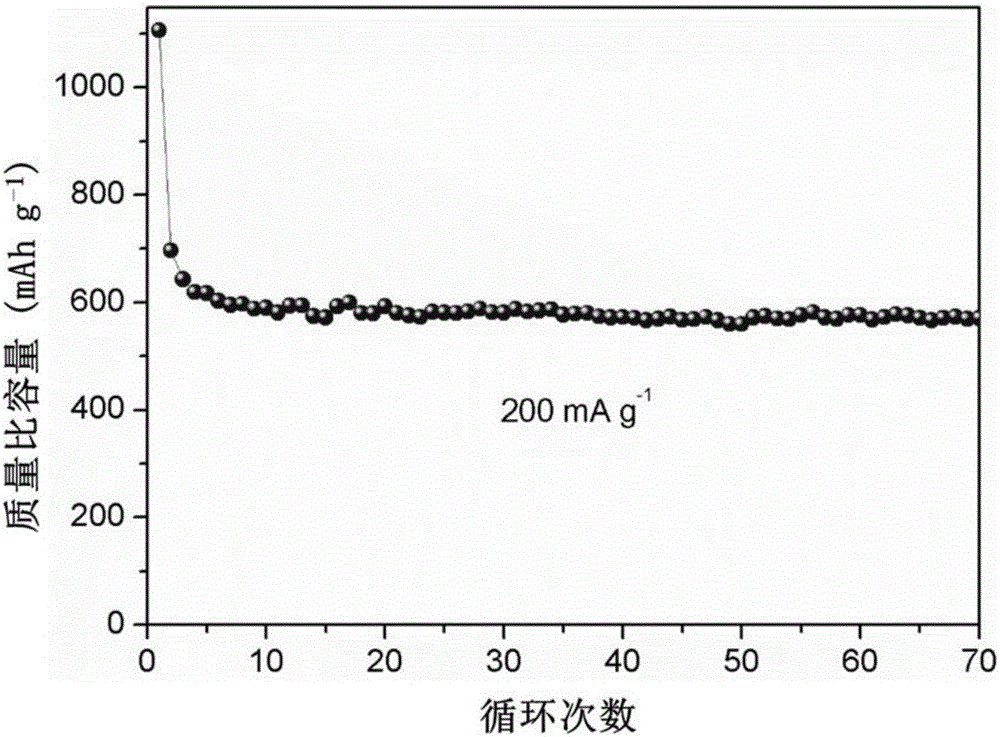

Tin selenide @ carbon nano fiber composite material, and preparation method and application thereof

InactiveCN106784834APromote infiltrationImprove cycle performanceCell electrodesMaterials preparationFiber

The invention relates to a tin selenide @ carbon nano fiber composite material, and a preparation method and application thereof, and solves the technical problems that the existing material preparation method is complex and the cost is high. In-situ generated tin selenide is uniformly dispersed in carbon nano fiber, and the diameter of the carbon nano fiber is 300-400 nanometers. The invention also provides the preparation method and application of the tin selenide @ carbon nano fiber composite material. The tin selenide @ carbon nano fiber can be widely used in the field of preparation of electrode materials.

Owner:BEIJING UNIV OF CHEM TECH

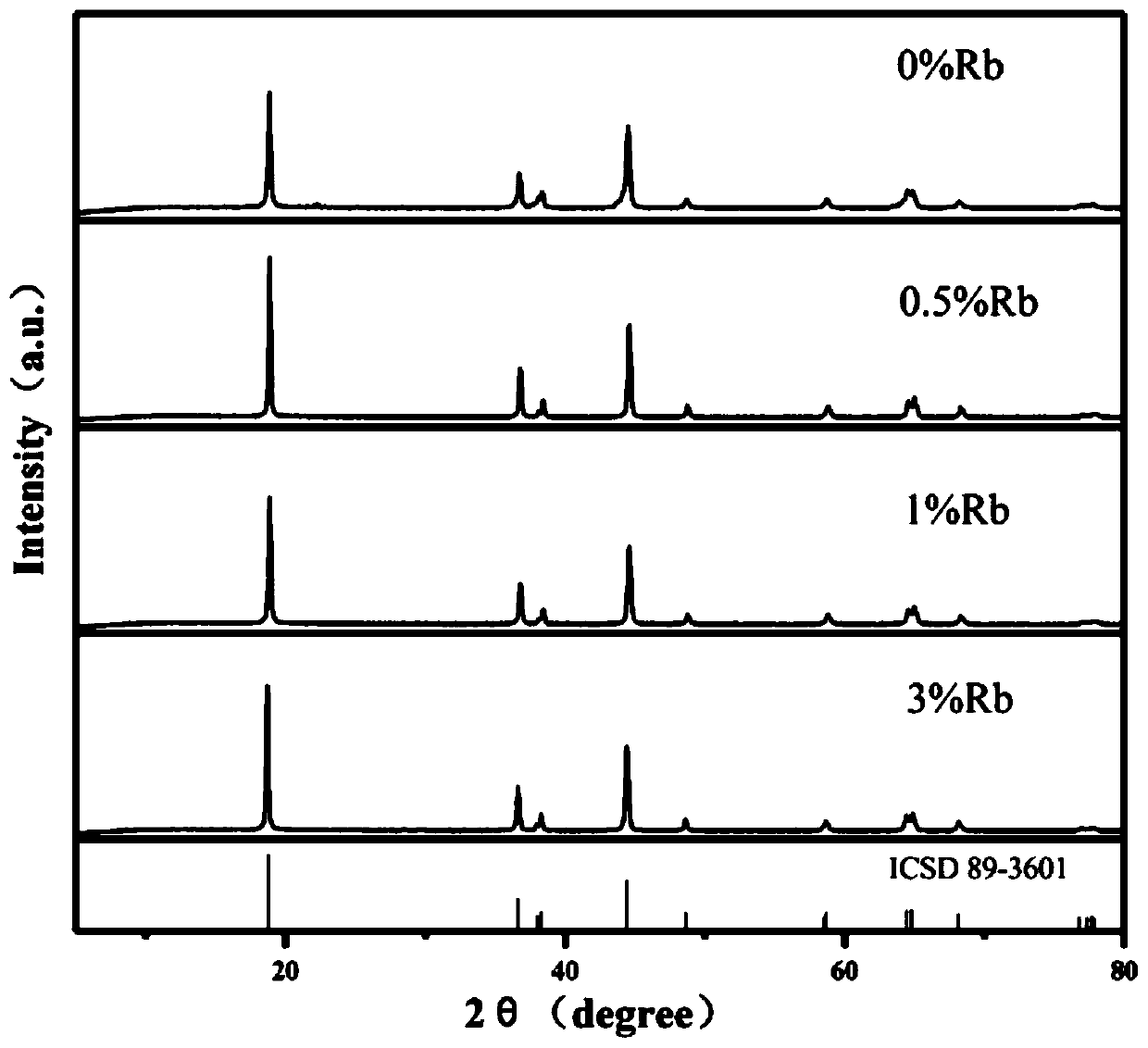

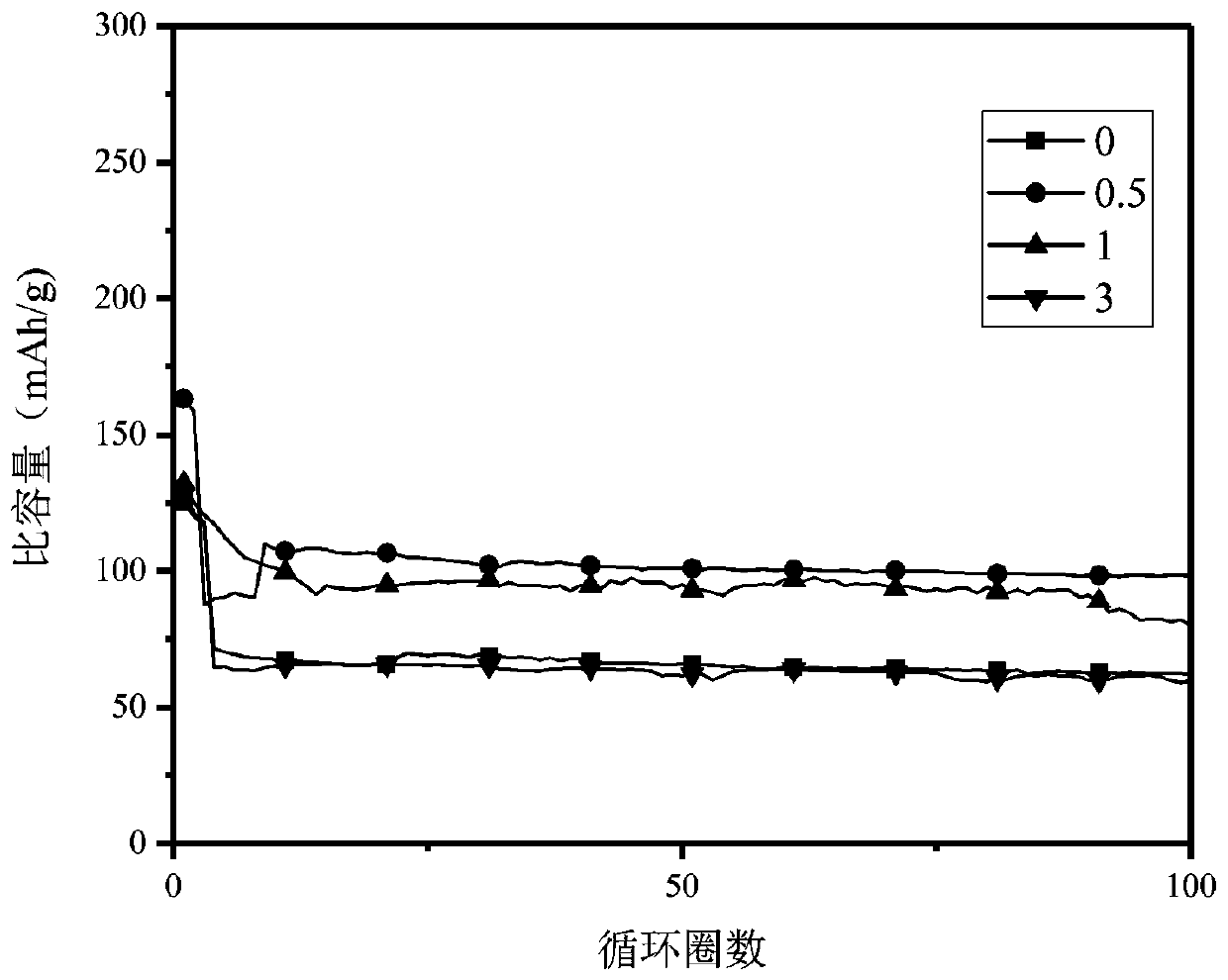

Preparation method and application of rubidium lithium nickel-cobalt manganate

InactiveCN109786736AUniform particlesControl micro-nano sizeCell electrodesSecondary cellsMicro nanoRubidium

The invention discloses a preparation method and application of a rubidium lithium nickel-cobalt manganate material. The chemical formula of a rubidium-doped high-nickel ternary positive pole materialis Li1-xRbxNiyCozMn1-y-zO2, wherein y is not less than 0.6, x is more than 0 and not more than 0.1, and z is more than 0 and less than 0.4. The preparation method of the rubidium-doped high-nickel ternary positive pole material comprises the following steps of mixing nickel-cobalt-manganese ternary material precursor, a Li source and a Rb source to acquire a mixture; pre-sintering under the an oxygen atmosphere after grinding, and then sintering at high temperature, thus acquiring the rubidium lithium nickel-cobalt manganate material. The rubidium lithium nickel-cobalt manganate material provided by the invention is uniform in particle, has the micro-nano size and is low in positive ion mixing degree; when the rubidium lithium nickel-cobalt manganate material is applied to the lithium ionbattery, the acquired lithium ion battery is high in specific discharge capacity, high in rate capability, good in cycle performance and long in service life.

Owner:CENT SOUTH UNIV

Preparation method of porous carbon material and application of porous carbon material as electrode material

InactiveCN103979529AGood practical application valueImprove lithium storage performanceCell electrodesCarbon preparation/purificationComposite materialElectrical battery

The invention relates to a porous carbon material used in a cathode of a lithium ion battery, and a preparation method of the porous carbon material. The slit-type porous carbon material which mainly comprises micropores and mesopores is prepared by mixing layered plate-shaped magnesium-aluminum hydrotalcite used as a template with a carbon source, curing, carbonizing and performing acidification treatment. The preparation process is simple, the cost is low, and the specific surface area is adjustable. The slit-type porous carbon provided by the invention has good electrochemical properties when being used as a lithium ion electrode material.

Owner:BEIJING UNIV OF CHEM TECH

Amorphous tetratin triphosphate/phosphorus/few-layer graphene negative material for lithium ion batteries and preparation method and application thereof

InactiveCN109841820AImprove efficiencyAlleviate volume changesCell electrodesSecondary cellsLithium iron phosphatePhosphate

The invention discloses an amorphous tetratin triphosphate / phosphorus / few-layer graphene negative material for lithium ion batteries and a preparation method and an application thereof. The negative material is formed by coating amorphous tetratin triphosphate and phosphorus with a few layers of graphene carbon. The preparation method includes the following steps: mixing and ball-milling tin powder and phosphorus powder to obtain tin triphosphate; and mixing the obtained tin triphosphate with expanded graphite and carrying out ball-milling to obtain the amorphous tetratin triphosphate / phosphorus / few-layer graphene negative material. The negative material prepared in the invention is matched with a lithium iron phosphate positive material, and a lithium ion battery assembled by using the negative material and the lithium ferrous phosphate positive material has the advantages of high capacity and stable cycle and has application potential. The preparation method of the invention has theadvantages of simple process, good repeatability, less time consumption and environment friendliness, and is conducive to actual industrial production.

Owner:SOUTH CHINA UNIV OF TECH

Preparation method of metal-organic framework compound and application thereof

InactiveCN109485867ASkeletal particle size is smallUniform sizePhysical/chemical process catalystsCell electrodesMetal-organic frameworkLithium

The invention discloses a preparation method of a polyhedral metal-organic framework compound ZIF-67. The preparation method comprises the following steps: preparing a solution from Co(NO3)2.6H2O, 2-methylimidazole and methanol, mixing and stirring, reacting at a normal temperature, performing centrifugal washing, drying and the like. The ZIF-67 presents bluish violet, is in the shape of rhombic dodecahedron, and has the particle size of 300-920nm. The prepared ZIF-67 is in the shape of rhombic dodecahedron, the particle size of the framework is small and uniform and can be controlled to be about 300nm, the specific surface area is large, and the overall distribution is uniform. The material disclosed by the invention is high in degree of crystallinity, has high specific surface area and porosity, homogeneous distribution can be formed, the prepared framework is small in particle size, and the overall distribution is uniform. Meanwhile, the compound is high in electric shock capacity and long in service life, has excellent lithium storage property, and can avoid attenuation after 200 charge-discharge cycles at most. The stability in the application is excellent, the condition thatthe current is unstable is avoided, and the product purity is high. The yield of the preparation method is high and can reach 70% or higher, and the preparation process is simple and feasible and worthy of market popularization.

Owner:CHONGQING UNIV OF ARTS & SCI

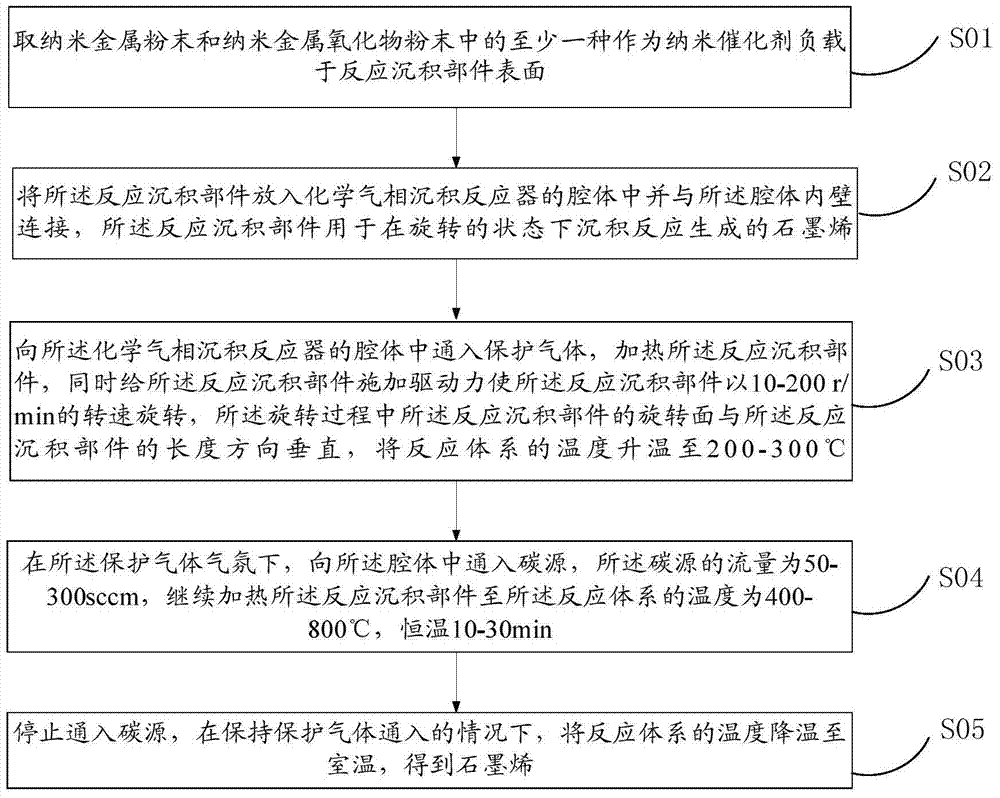

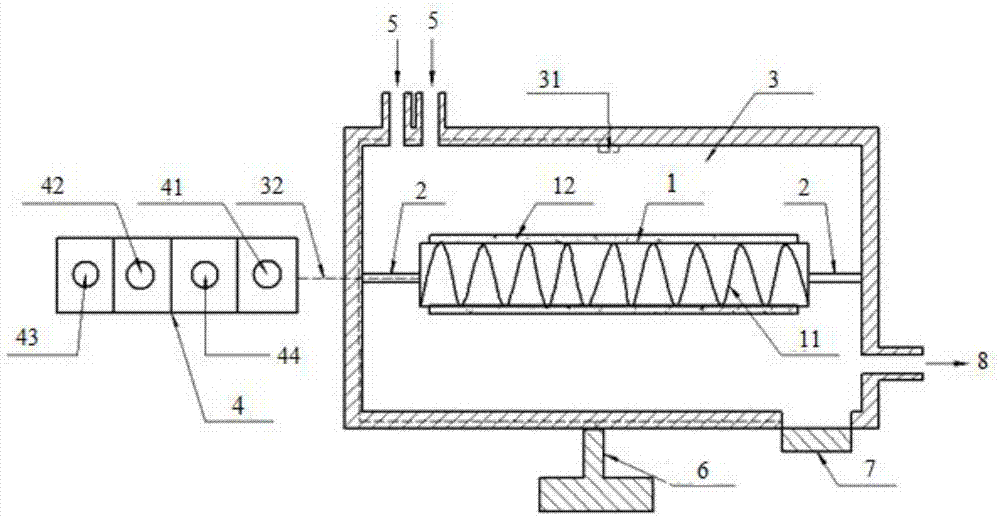

Graphene and preparation method thereof

The invention provides a preparation method of graphene. According to the method, a nano-scale metal and / or metal oxide catalyst is attached on a rotatable reaction deposition part, a carbon source which can be decomposed into carbon and hydrogen is introduced, and the carbon source is cracked into the graphene under the action of the nano-scale catalyst; as the reaction deposition part is rotatable, the carbon source is in three-dimensional and dynamic contact with the catalyst, and more graphene can be deposited; in addition, the catalytic efficiency of the nano-scale catalyst to the carbon source is higher, and the preparation of the high-quality graphene even in thickness and controllable in number of layers can be effectively realized. The method is simple in process; the problems of less deposited graphene, large catalyst scale and low catalytic efficiency due to the static placement of the catalyst in the existing chemical vapor deposition technology are solved. The invention also provides a graphene; the layers of the graphene are bent to form a hollow cloth bag shape; the graphene of the structure has excellent hydrogen storage and lithium storage functions.

Owner:SHENZHEN DYNANONIC +1

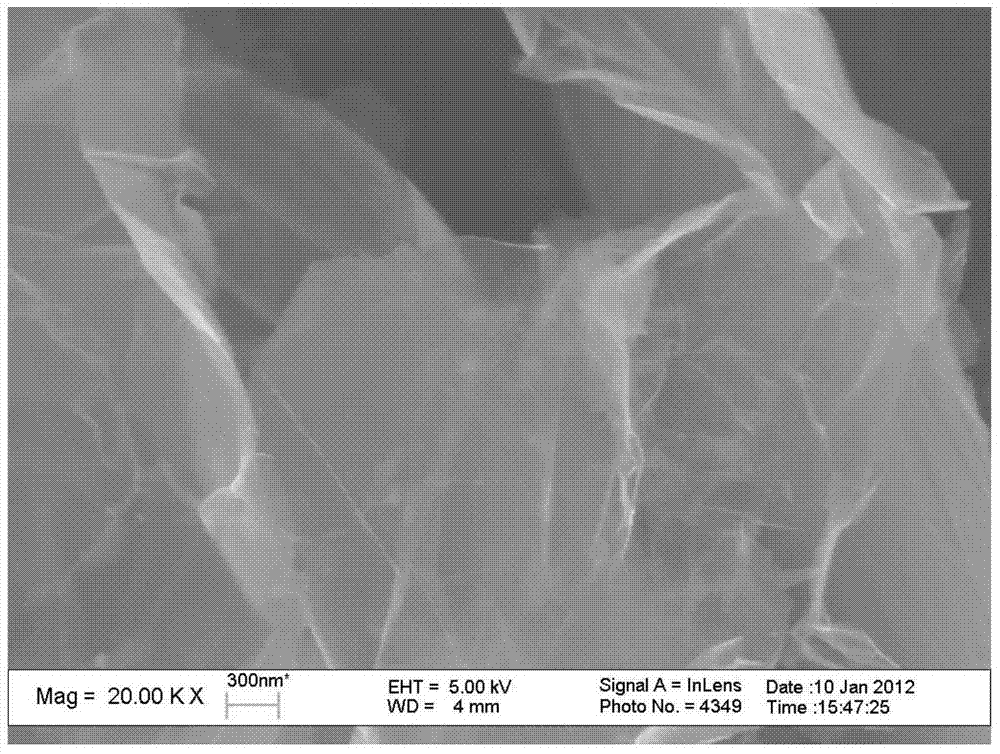

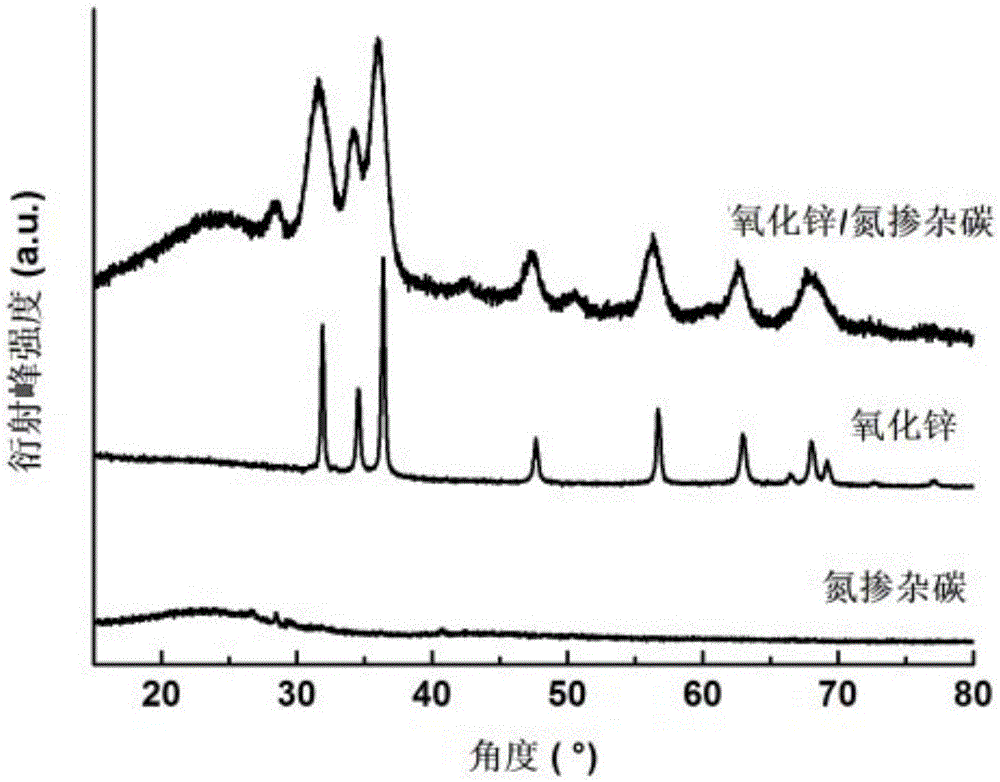

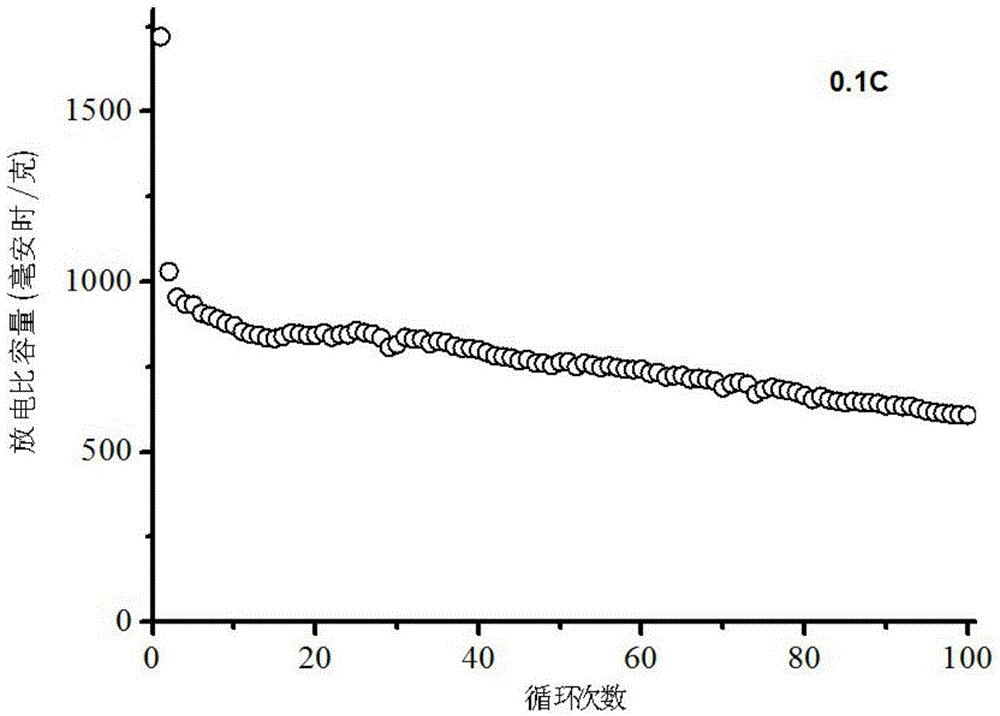

Preparation method of zinc oxide/nitrogen-doped carbon composite material capable of being used for lithium ion battery negative electrode

ActiveCN105591090AImprove conductivityImprove electrochemical performanceCell electrodesSecondary cellsCarbon compositesPolypyrrole

The invention provides a preparation method of a zinc oxide / nitrogen-doped carbon composite material capable of being used for a lithium ion battery negative cathode. The method is applied to low-temperature polymerization reaction to prepare polypyrrole, then polypyrrole is prepared into nitrogen-doped carbon, and then the zinc oxide / nitrogen-doped carbon composite material is prepared through a sol-gel method. Compared with other carbon materials, nitrogen elements in nitrogen-doped carbon can change distribution of electron cloud around carbon atoms, agglomeration of the carbon atoms is effectively prevented, and compared with other common carbon materials, the nitrogen-doped carbon composite material has more excellent electrical conductivity and chemical stability.

Owner:SYNERGY INNOVATION INST OF GDUT HEYUAN

Method for preparing LiNi1/3Co1/3Mn1/3O2 fibrous material by electrostatic spinning

ActiveCN104178929ASmall diameterUniform and continuousCell electrodesFilament/thread formingFiberManganate

The invention discloses a method for preparing a LiNi1 / 3Co1 / 3Mn1 / 3O2 fibrous material by electrostatic spinning and belongs to the technical field of lithium ion battery electrode materials and preparation thereof. The method includes: taking deionized water as a dissolvent, regulating solution viscosity through polyvinylpyrrolidone, then adding a lithium source, a nickel source, a cobalt source and a manganese source to prepare a spinning solution, preparing a nanofiber film by a electrostatic spinning technique, and then sintering the nanofiber film to obtain the LiNi1 / 3Co1 / 3Mn1 / 3O2 fibrous material. The fibrous material prepared by the method is smooth in surface, small in fibre diameter and large in specific surface area and has good charge and discharge performance and large storage capacity, the preparation method is simple in technology, reaction condition parameters are easy to control, sintering temperature is low, and large-scale industrialization of cathode materials of lithium nickelate, lithium cobaltate and lithium manganate are benefited.

Owner:DAXIN MANGANESE MINE BRANCH OF CITIC DAMENG MINING IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![[Alpha]-phase ferric oxide porous core-shell microspheres and controllable synthetic preparation method thereof [Alpha]-phase ferric oxide porous core-shell microspheres and controllable synthetic preparation method thereof](https://images-eureka.patsnap.com/patent_img/5f2b24c9-dd25-4aa1-a644-769905492dab/140520101516.PNG)

![[Alpha]-phase ferric oxide porous core-shell microspheres and controllable synthetic preparation method thereof [Alpha]-phase ferric oxide porous core-shell microspheres and controllable synthetic preparation method thereof](https://images-eureka.patsnap.com/patent_img/5f2b24c9-dd25-4aa1-a644-769905492dab/140520101520.PNG)

![[Alpha]-phase ferric oxide porous core-shell microspheres and controllable synthetic preparation method thereof [Alpha]-phase ferric oxide porous core-shell microspheres and controllable synthetic preparation method thereof](https://images-eureka.patsnap.com/patent_img/5f2b24c9-dd25-4aa1-a644-769905492dab/140520101523.PNG)