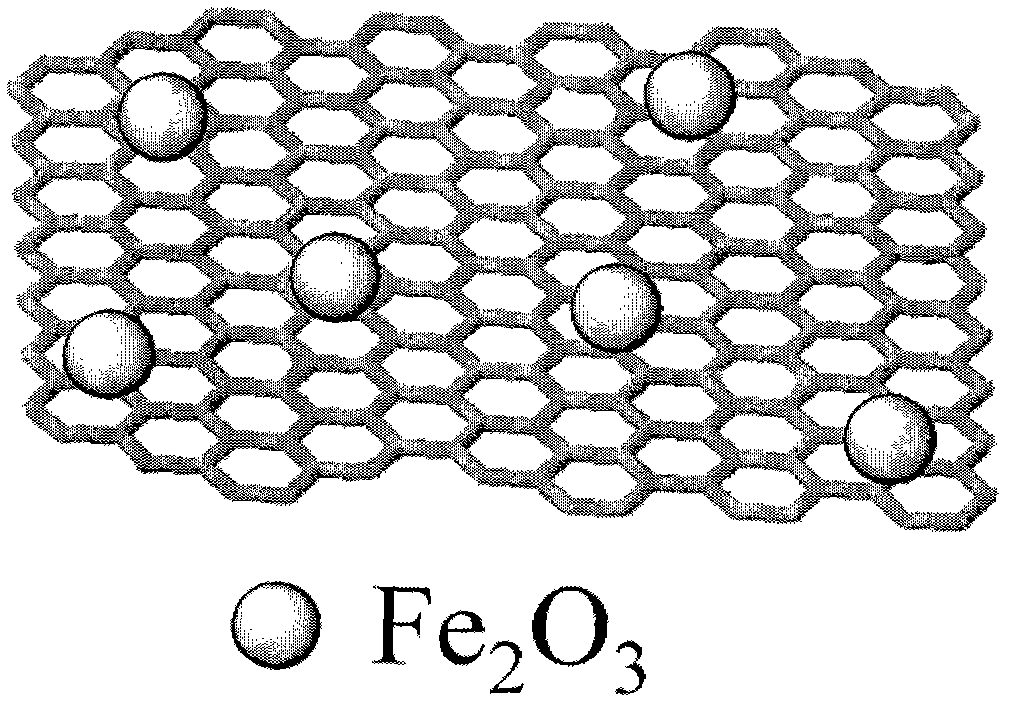

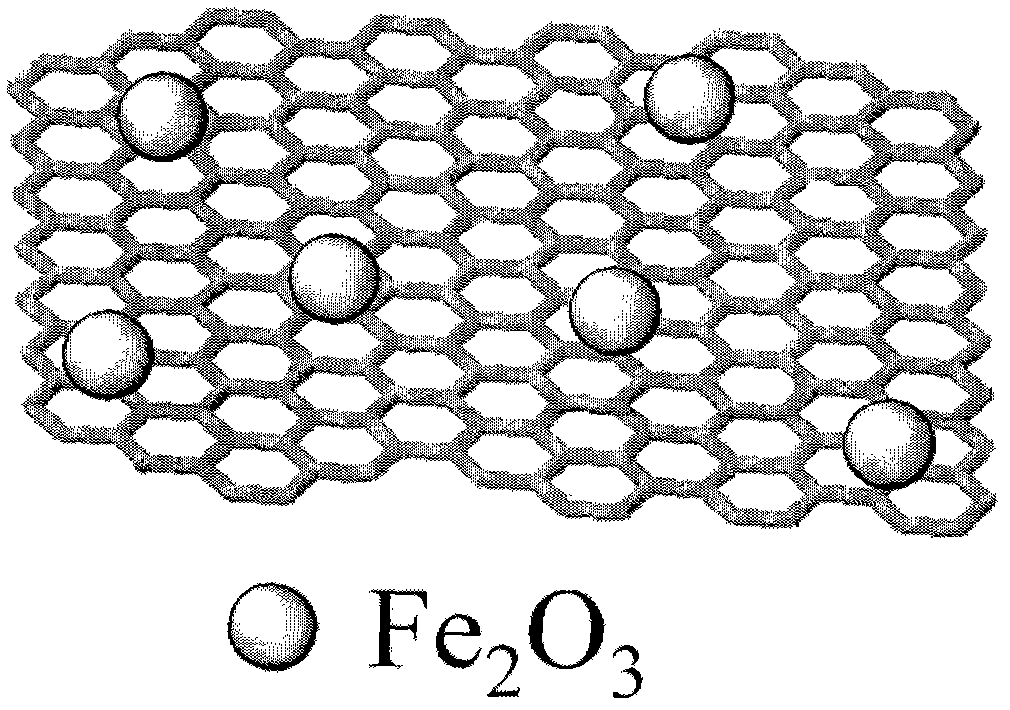

Environment-friendly and efficient method for preparing iron sesquioxide/graphene composite material

A technology of ferric oxide and composite materials, which is applied in the field of energy, can solve the problems of large discharge of industrial three wastes, huge volume effect, and obstacles to wide application, and achieve the effects of easy expansion of production, stable product performance, and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Graphene oxide prepared by the Hummers method was dispersed in deionized water at a concentration of 0.4 mg / mL, treated with ultrasonic waves for 10 min, and peeled off to obtain 100 mL of suspension. Then add 0.8mmol of ferrous chloride and 0.5g of urea therein successively, and fully stir and dissolve. The above mixed solution was placed in a three-necked flask, and after passing through pure nitrogen for 10 minutes, it was heated by microwave, condensed and refluxed for 15 minutes. Samples were separated, washed, and dried at 60°C. Treat the dried sample in argon at 300°C for 30 minutes to obtain Fe 2 o 3 / graphene composites.

Embodiment 2

[0026] A suspension of graphene oxide was prepared in the same manner as in Example 1, and then 1.2 mmol of ferrous chloride and 1.2 g of urea were sequentially added thereto, fully stirred and dissolved. The above mixed solution was placed in a three-necked flask, and after passing through pure nitrogen for 10 minutes, it was heated by microwave, condensed and refluxed for 15 minutes. Samples were separated, washed, and dried at 60°C. Treat the dried sample in argon at 340°C for 30 minutes to obtain Fe 2 o 3 / graphene composites.

Embodiment 3

[0028] According to the same method as in Example 1, a graphene oxide suspension with a concentration of 0.6 mg / mL was prepared, ultrasonically treated for 15 min, and then 2.0 mmol of ferrous chloride and 1.2 g of urea were sequentially added thereto, fully stirred and dissolved. The above mixed solution was placed in a three-necked flask, and after passing through pure nitrogen for 10 minutes, it was heated by microwave, condensed and refluxed for 15 minutes. Samples were separated, washed, and dried at 60°C. Treat the dried sample in argon at 350°C for 30 minutes to obtain Fe 2 o 3 / graphene composites.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com