Patents

Literature

928 results about "Sesquioxide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A sesquioxide is an oxide containing three atoms of oxygen with two atoms (or radicals) of another element. For example, aluminium oxide (Al₂O₃) is a sesquioxide. Many sesquioxides contain the metal in the +3 oxidation state and the oxide ion, e.g., Al₂O₃, La₂O₃. The alkali metal sesquioxides are exceptions and contain both peroxide, (O²⁻₂) and superoxide, (O⁻₂) ions, e.g., Rb₂O₃ is formulated [(Rb⁺)₄(O²⁻₂)(O⁻₂)₂]. Sesquioxides of iron and aluminium are found in soil.

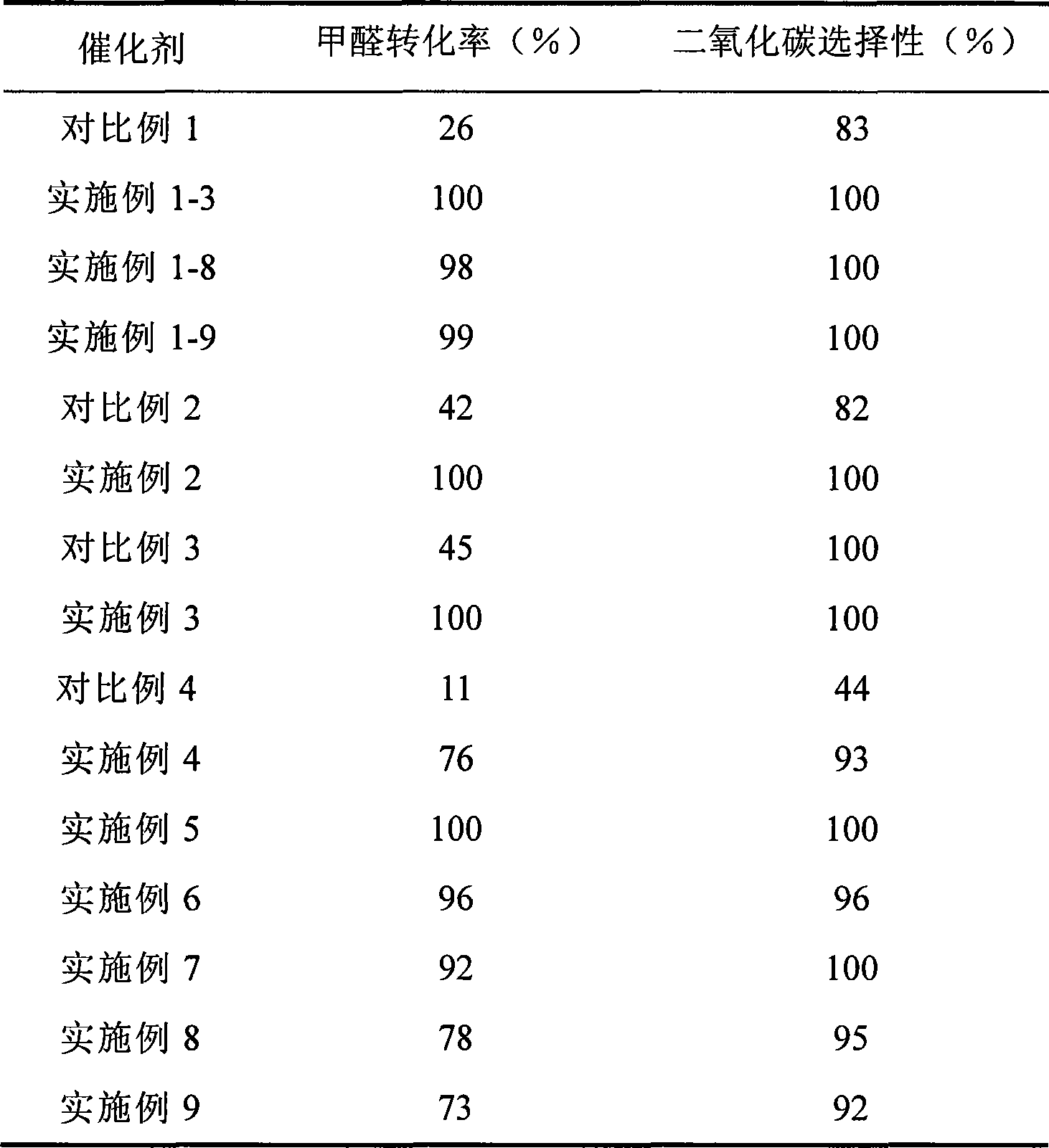

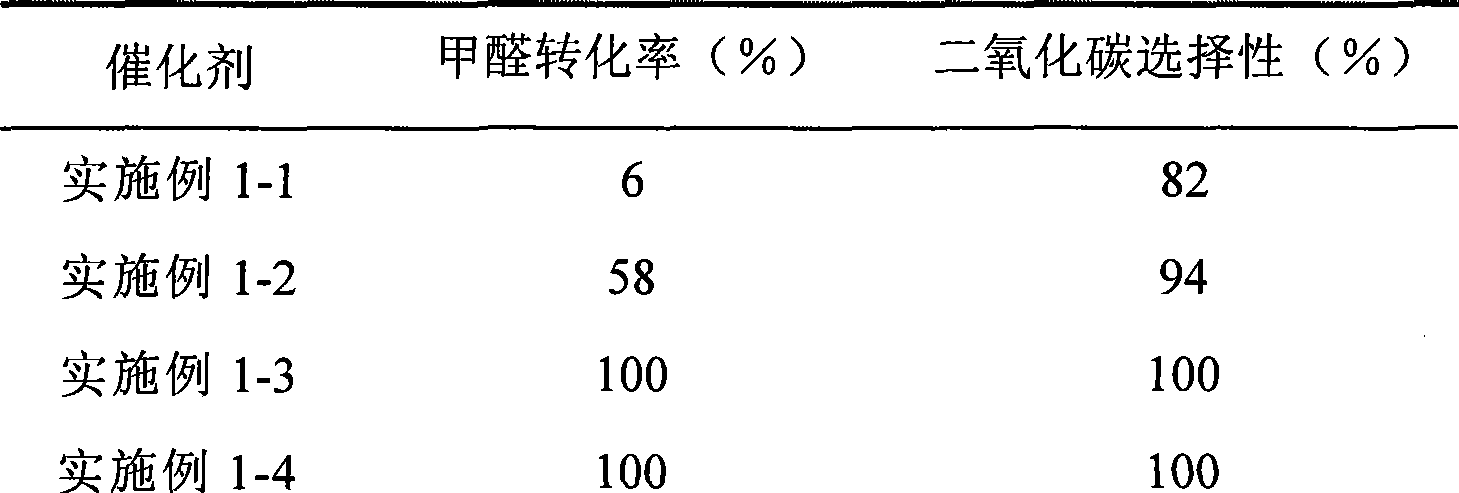

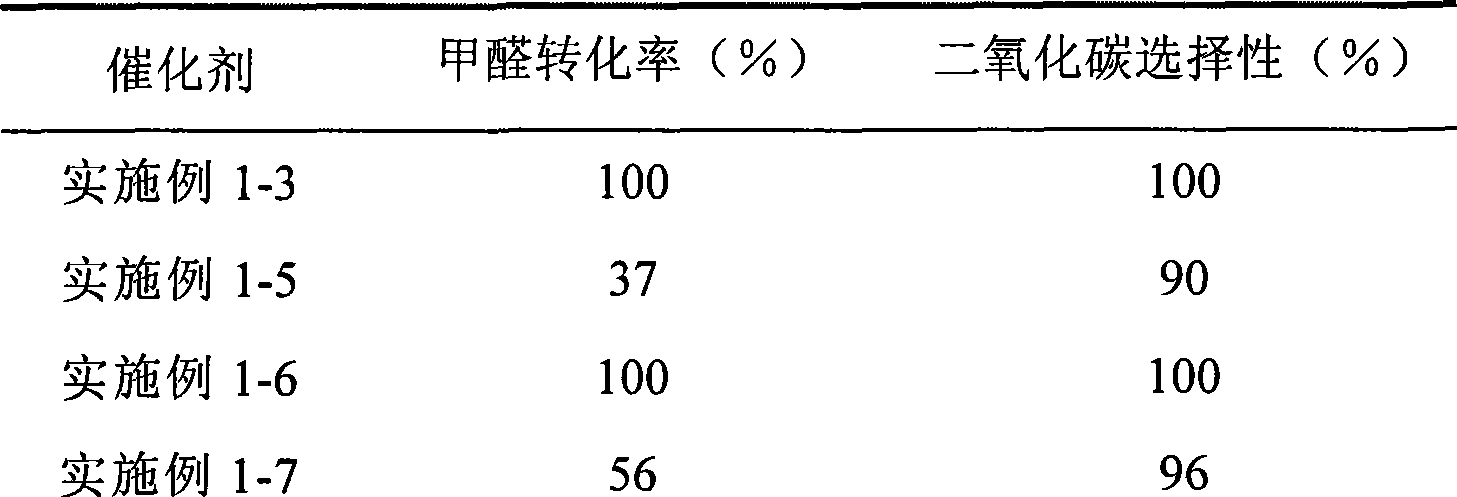

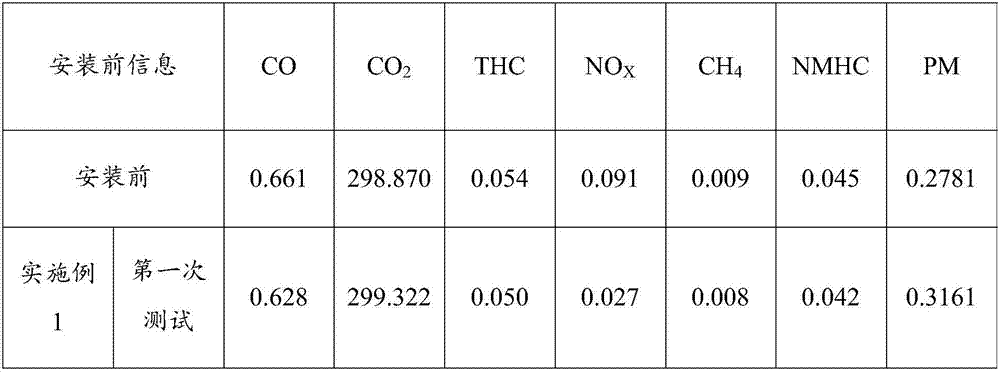

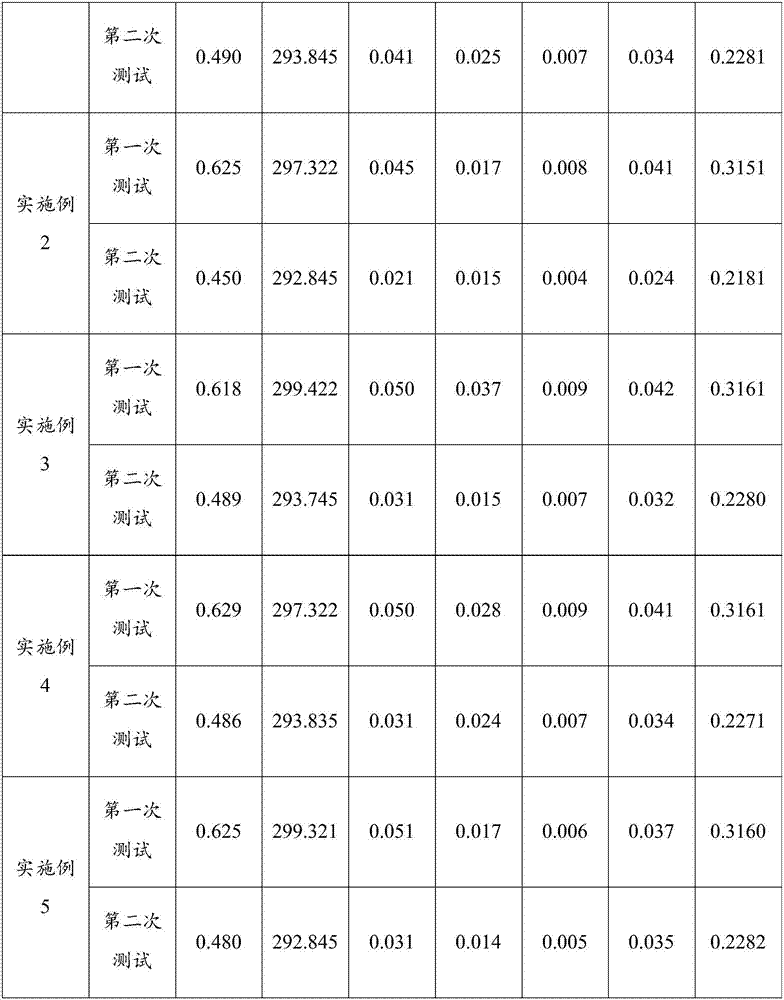

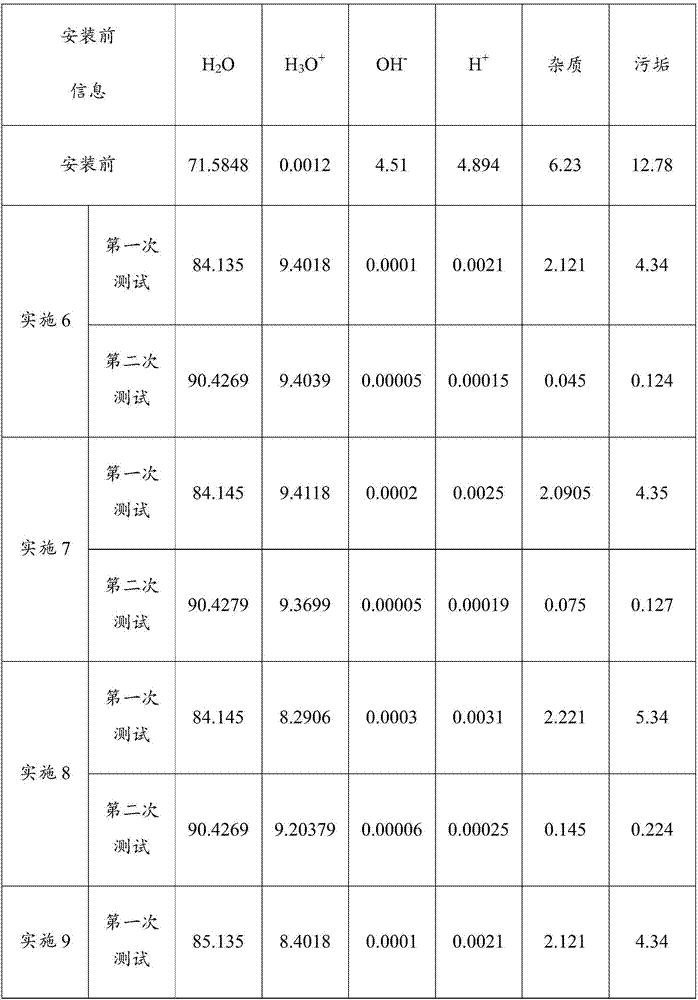

Catalyst for complete oxidation of formaldehyde at room temperature

ActiveCN101380574AEasy to makeEasy to operateDeodrantsMetal/metal-oxides/metal-hydroxide catalystsPorous carbonPt element

The invention provides a high selectivity catalyst used for catalyzing and completely oxidizing formaldehyde with low concentration at room temperature. The catalyst can catalyze formaldehyde completely so as to lead the formaldehyde to be converted into carbon dioxide and water at room temperature. In addition, the conversion rate of formaldehyde remains 100% within a long period of time, without complex auxiliary facilities such as light source, a heating oven and the like, and external conditions. The catalyst comprises three parts which are inorganic oxide carrier, noble metal component and auxiliary ingredient. Porous inorganic oxide carrier is one of cerium dioxide, zirconium dioxide, titanium dioxide, aluminium sesquioxide, tin dioxide, silicon dioxide, lanthanum sesquioxide, magnesium oxide and zinc oxide or the mixture thereof or composite oxide thereof, zeolite, sepiolite and porous carbon materials. The noble metal component of the catalyst is at least one of platinum, rhodium, palladium, gold and silver. The auxiliary ingredient is at least one of the alkali metals of lithium, sodium, kalium, rubidium and cesium. The loading of the noble metal component used in the catalyst of the invention is 0.1 to 10% according to weight converter of metal elements and the selective preference is 0.3 to 2%. The loading of the auxiliary ingredient is 0.2 to 30% according to weight converter of metal elements and the selective preference is 1 to 10%. When the loading of the auxiliary ingredient is lower than 0.2% or higher than 30%, the activity of the catalyst for catalyzing and oxidizing formaldehyde at room temperature is decreased remarkably.

Owner:广东顺德中科鸿图环境材料有限公司

Anion powder

InactiveCN102702833APurify waterPurifying airAntibacterial agentsCosmetic preparationsSolubilitySesquioxide

The invention discloses anion powder which includes the following components: by weight, 10-15 parts of coral fossil, 10-15 parts of tourmaline, 30-50 parts of opal, 5-10 parts of serpentine, 2-4 parts of medical stone, 2-4 parts of odd ice stone, 2-4 parts of radiobarite, 2-4 parts of king stone, 3-6 parts of shell, 15-25 parts of diatomite, 2-4 parts of iron sesquioxide, 2-4 parts of aluminium sesquioxide, 2-4 parts of zirconium oxide and 2-4 parts of zirconium phosphate. Air ions generated by the anion powder prepared is high in solubility and is not easy to modify at high temperature and long in effects, and original characters of products cannot be modified when used with other functional materials.

Owner:山东天宇圣邦涂料有限公司

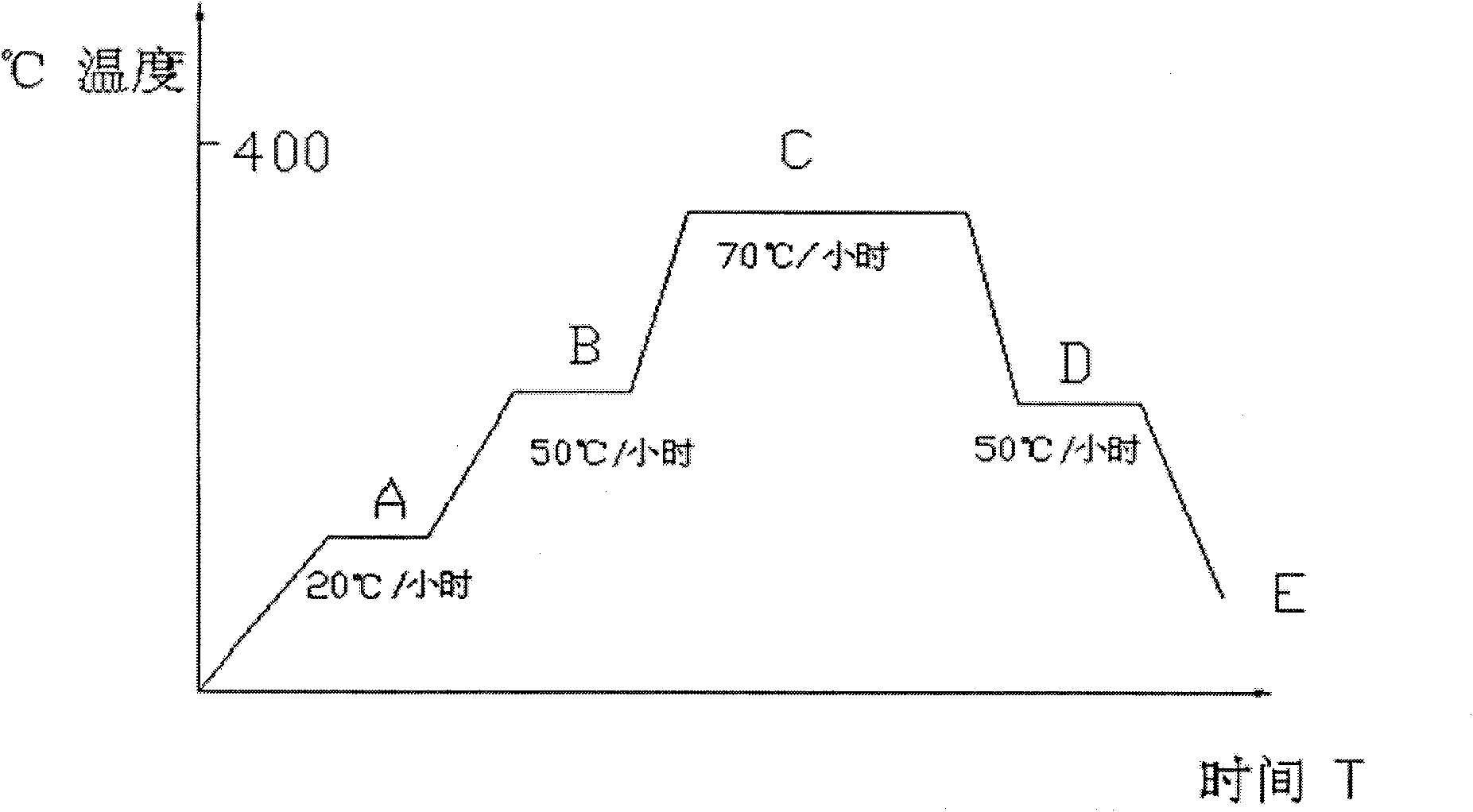

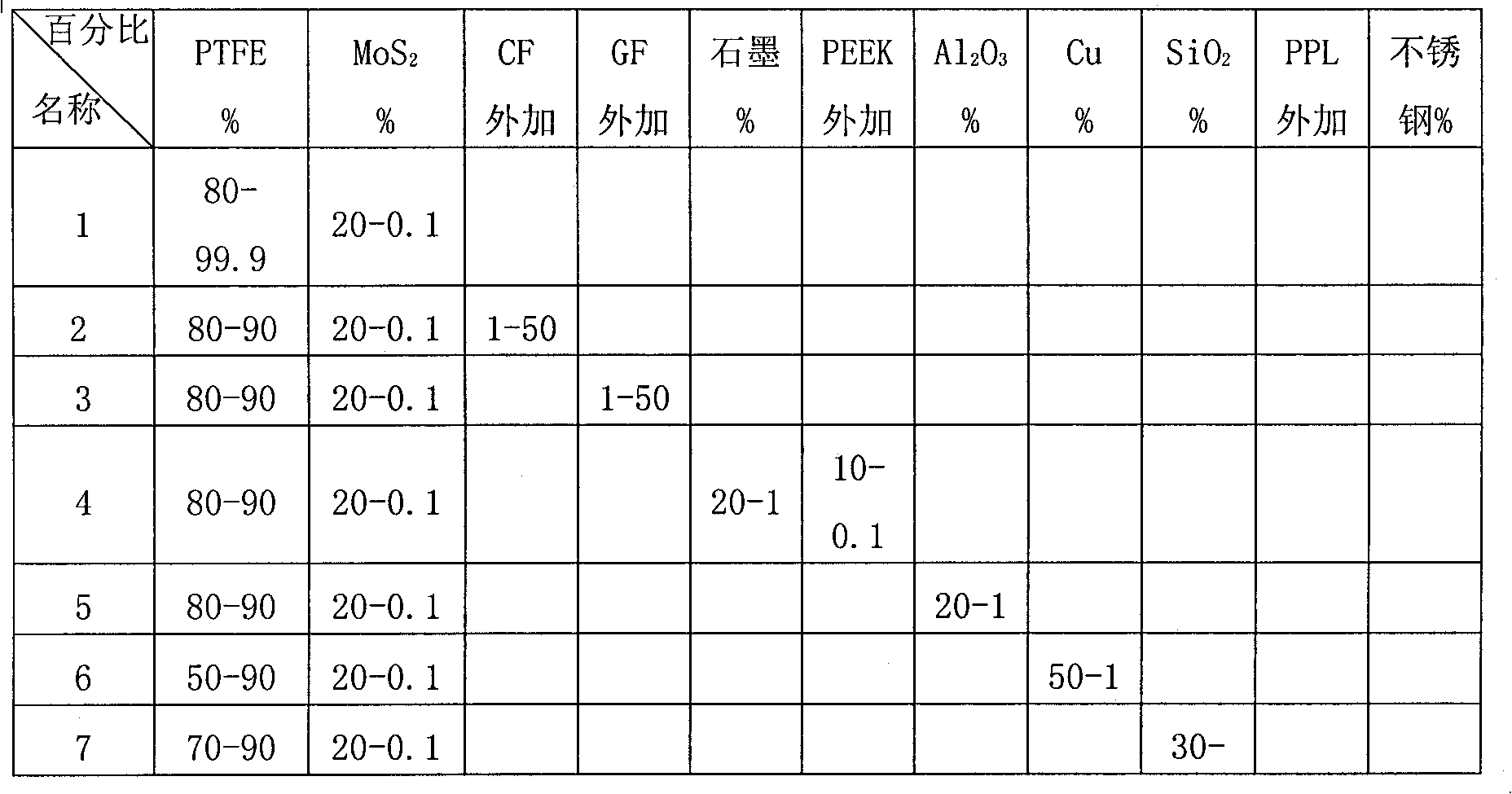

Polytetrafluoroethylene composite material and product preparation method thereof

ActiveCN101775186AImprove thermal conductivityImproved ball compressive strengthFiberTetrafluoroethylene

The invention discloses a polytetrafluoroethylene composite material, which comprises one or more of molybdenum disulfide, aluminum sesquioxide, copper powder, graphite, silicon dioxide and stainless steel powder and polytetrafluoroethylene, wherein the polytetrafluoroethylene composite material is a binary polytetrafluoroethylene composite material, which comprises 80 to 99.9 weight percent of the polytetrafluoroethylene, and the balance of other components. A product preparation method for the material comprises the following steps: compounding the materials of polytetrafluoroethylene (PTFE), molybdenum disulfide (MoS2), aluminium oxide (Al2O3), Cu powder, silicon dioxide (SiO2), polyphenylester (PPL), stainless steel powder, carbon fiber (CF), glass fiber (GF) and the like, molding the materials by a mold pressing sintering method, and then mechanically machining the materials to form an L-shaped sealing element.

Owner:NANJING COMPTECH MATERIALS

Supported noble metal catalyst for low-temperature catalytic oxidation benzene series and preparation method thereof

The invention discloses a supported noble metal catalyst for low-temperature catalytically oxidizing benzene series (benzene, methylbenzene and dimethylbenzene) gas to CO2 and H2O. Active components of the noble metal catalyst are: at least one of Pd, Pt, Ag, Au and Rh; carrier is at least one of active carbon, red mud, molecular sieve, aluminum sesquioxide, titanium dioxide, manganese dioxide, zirconium dioxide, silicon dioxide, cerium dioxide, lanthanum sesquioxide, cobalt oxide, magnesium oxide, zinc oxide, calcium oxide and cupric oxide. Under general pressure, in atmosphere ambient, in fixed bed reactor, with a space velocity range from 10,000 to 100,000h<-1> and at a temperature range from 110 to 210 DEG C, the catalyst can be used for directly oxidizing 100 to 800ppm benzene series gas to CO2 and H2O without byproduct, which shows good low-temperature catalytic activity. The catalyst of the invention has the advantages of simple preparation, lower complete oxidation temperature, immunity to H2O, good stability and high practical value.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

Extinguishing agent

InactiveCN102058951AReduce pollutionRestricted free movementFire extinguisherSesquioxideAluminium hydroxide

The invention discloses an extinguishing agent. The extinguishing agent is formed by mixing and stirring strong hydrophobic solid particles and aqueous solution at high speed, wherein the strong hydrophobic solid particles are one type or more of magnesium hydroxide particles, silicon dioxide particles, calcium carbonate particles, talcum particles, aluminium oxide particles, aluminium hydroxide particles, zinc borate particles, zinc oxide particles, iron sesquioxide particles, titanium dioxide particles, montmorillonite particles, hydrotalcite particles, coal ash particles, diatomite particles, mica particle, attapulgite particles and zeolite particles after hydrophobic modification. The extinguishing agent disclosed by the invention is nontoxic, environmental pollution is less, and secondary loss caused by strong flowability of water can be avoided while playing the advantages of the water as the extinguishing agent and reducing the using amount.

Owner:XIAN UNIV OF SCI & TECH

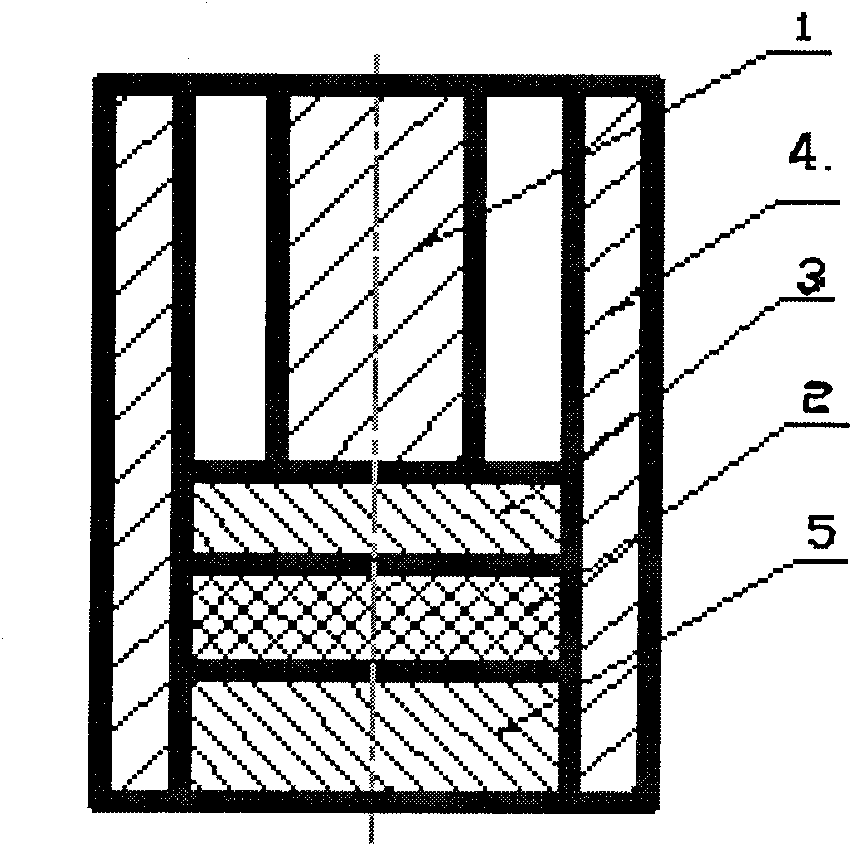

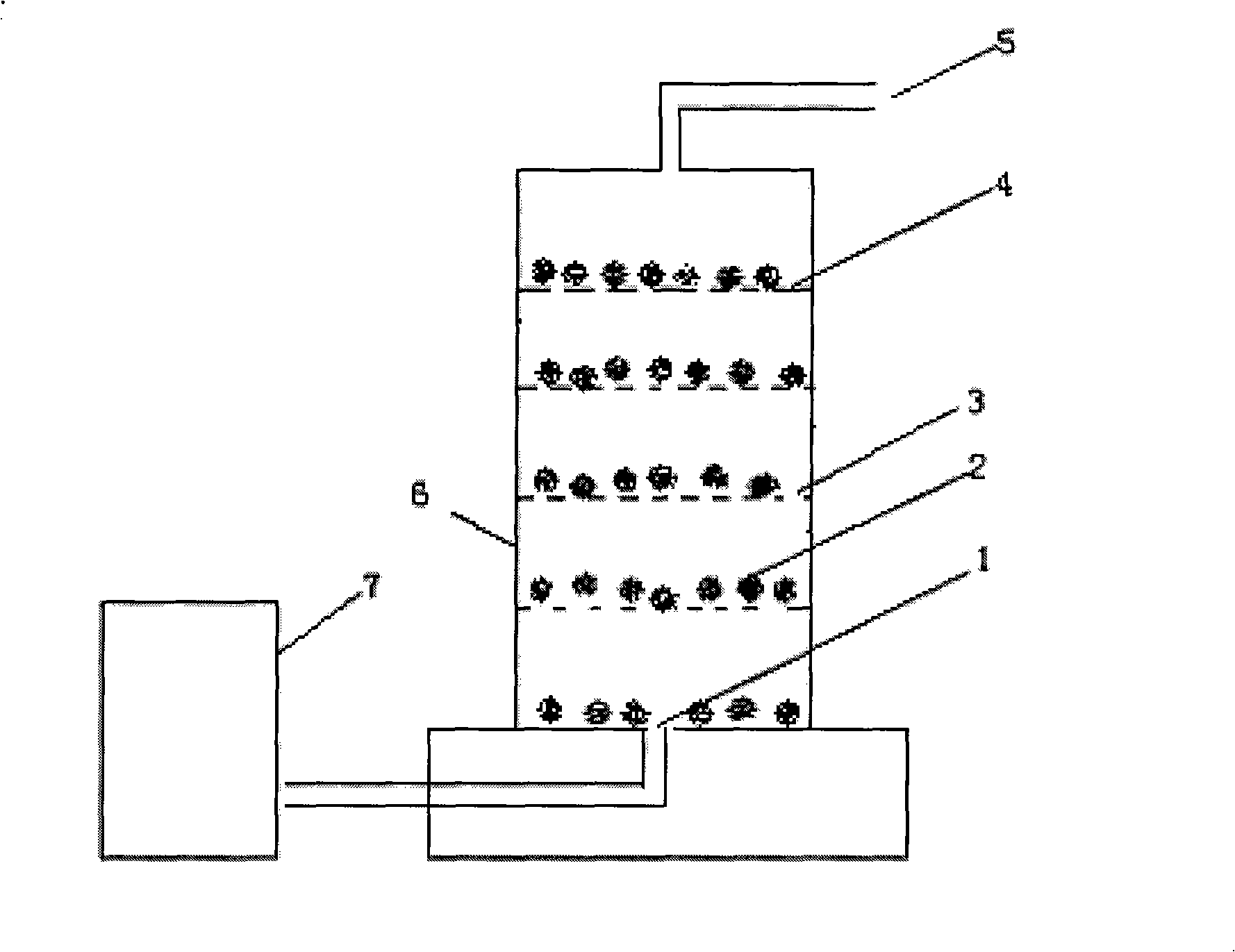

Method for producing MnO2 supported catalyst as well as method of using the same and apparatus for treating waste water

InactiveCN101406831AGood granularityEasy to recycleMolecular sieve catalystsMetal/metal-oxides/metal-hydroxide catalystsMANGANESE ACETATESesquioxide

The invention discloses a method for preparing MnO2 supported catalysts, an application method thereof and a wastewater treatment device. The preparation method comprises the following steps: manganese acetate is prepared into a solution; one of activated carbon, active aluminium sesquioxide, white silica gel, a molecular sieve, zeolite or diatomite is taken as a carrier and dipped in the solution; and supported solid catalysts are prepared through dipping, evaporation, concentration, drying and roasting. A reactor of the wastewater treatment device is divided into a plurality of reaction spaces by baffles, and the catalysts exist as fluidized beds on every baffle. When the MnO2 supported catalysts prepared by the method are used in the reaction of degrading refractory organic matter through ozone catalytic oxidation, the contact time among the MnO2 supported catalysts, wastewater and ozone is between10 and 120 minutes, and the mass ratio of the adding amount of the catalysts to the wastewater in the reaction is between 1 to 200 and 1 to 20. The MnO2 supported catalysts prepared by the method have the characteristics of easy recovery, high repeat utilization property and high efficiency of catalyzing and degrading refractory organic matters.

Owner:GUANGDONG UNIV OF TECH

Biomass curing-forming fuel and preparation method thereof

The invention discloses a biomass curing-forming fuel. The biomass curing-forming fuel consists of straws, saw dust, coal dust, a combustion improver, a sulfur-fixing agent and a dust-falling agent according to parts by weight, wherein the straw is one or combination of the straw of crops such as rice, wheat, soybean, corn, sorghum, cotton, rape and tobacco, a branch and a bark of trees and shrubs, rice hull, chaff and peanut coat; the combustion improver is one or more of table salt, sodium nitrate, potassium permanganate, potassium oxide, sodium nitrite and sodium hypochlorite and capable of realizing decomposition and combustion supporting at different temperatures; the sulfur-fixing agent is in a manner that sodium carbonate, calcium hydroxide and alkyl alcohol amine compounds are synergistically used and is capable of reducing discharging of sulfur dioxide; and the dust-falling agent is selected from iron sesquioxide and capable of lowering a melting point of ash and reducing dust volume. The biomass curing-forming fuel has the advantages that the combustion efficiency is high, the slag bonding and the soot formation are not generated, the black smoke is little, the fire power strong, the combustion is sufficient, the ash does not fly, the biomass curing-forming fuel is clean and sanitary and the like. The invention further discloses a preparation method of the biomass curing-forming fuel.

Owner:JINAN SANNONG ENERGY TECH

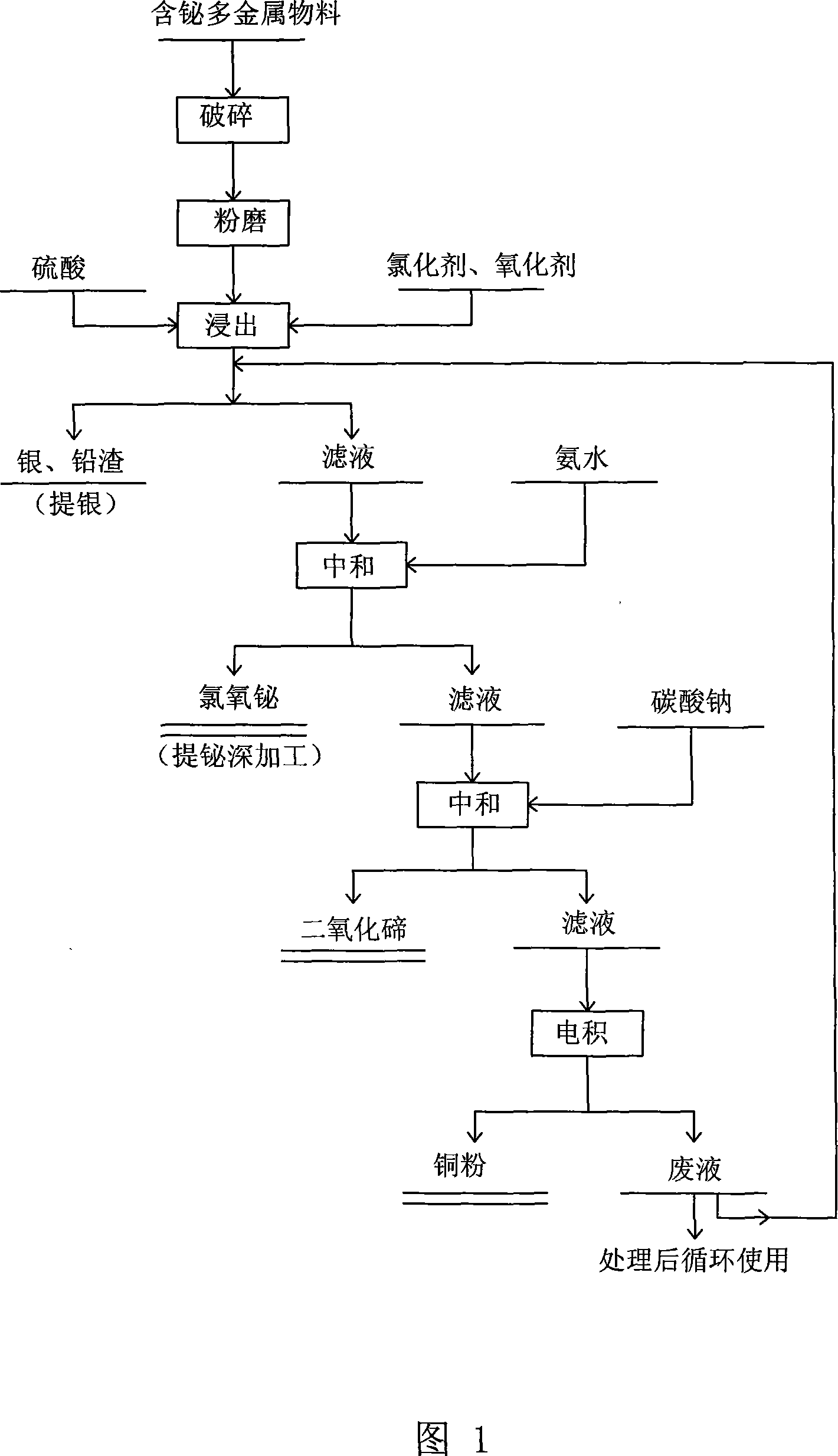

Comprehensive extraction of valent metal from bismuth-containing polymetallic material

InactiveCN101029353AHigh recovery rateImprove product added valuePhotography auxillary processesProcess efficiency improvementSesquioxideTe element

A method for extracting metal from bismuth-contained multi-metal material is carried out by leaching out copper and tellurium from bismuth-contained multi-metal by sulfuric acid, adding into chlorinating agent and oxidant to leach out metal bismuth, extracting silver from leaching-out slag with AgCl, PbSO4 and PbC12, adding ammonia water into leaching-out liquid, adjusting pH value to 1.5 to obtain bismuth oxychloride slag with 70% bismuth content, smelting into coarse bismuth by firing method or machining to obtain high-purity bismuth sesquioxide, adjusting pH value to 4.5 by Na2CO3, depositing tellurium to obtain tellurium dioxide and copper-contained solution, and electrically depositing to obtain copper powder with copper-contained content90%. It adopts wetting and firing metallurgical technology, has higher metal recovery rate and excellent leaching-out separation effect and effluent circulating utilization and no environmental pollution.

Owner:HUNAN JINWANG BISMUTH

High-manganese high-nitrogen low-nickel stainless steel plate blank continuous casting crystallizer covering slag and preparation method thereof

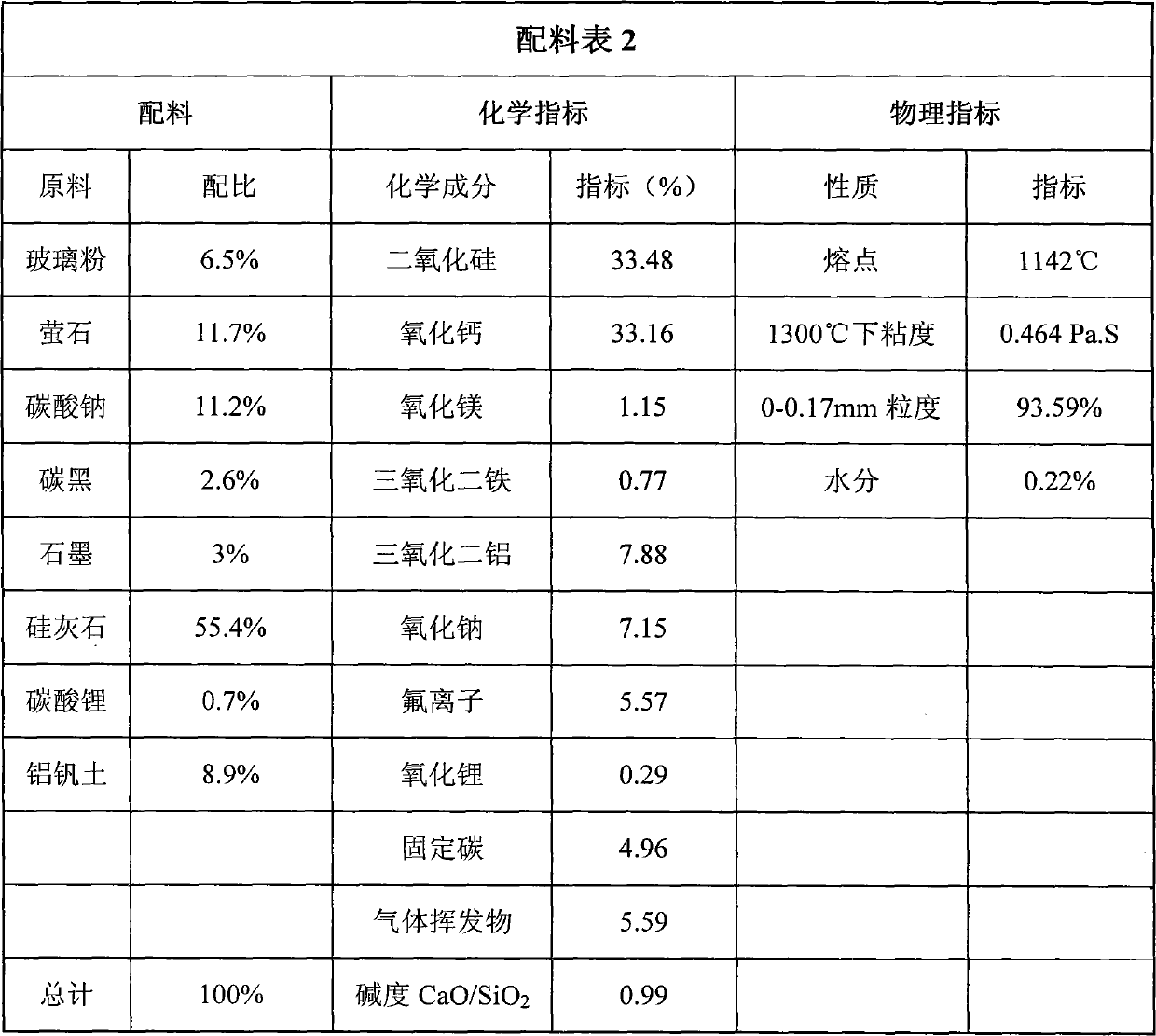

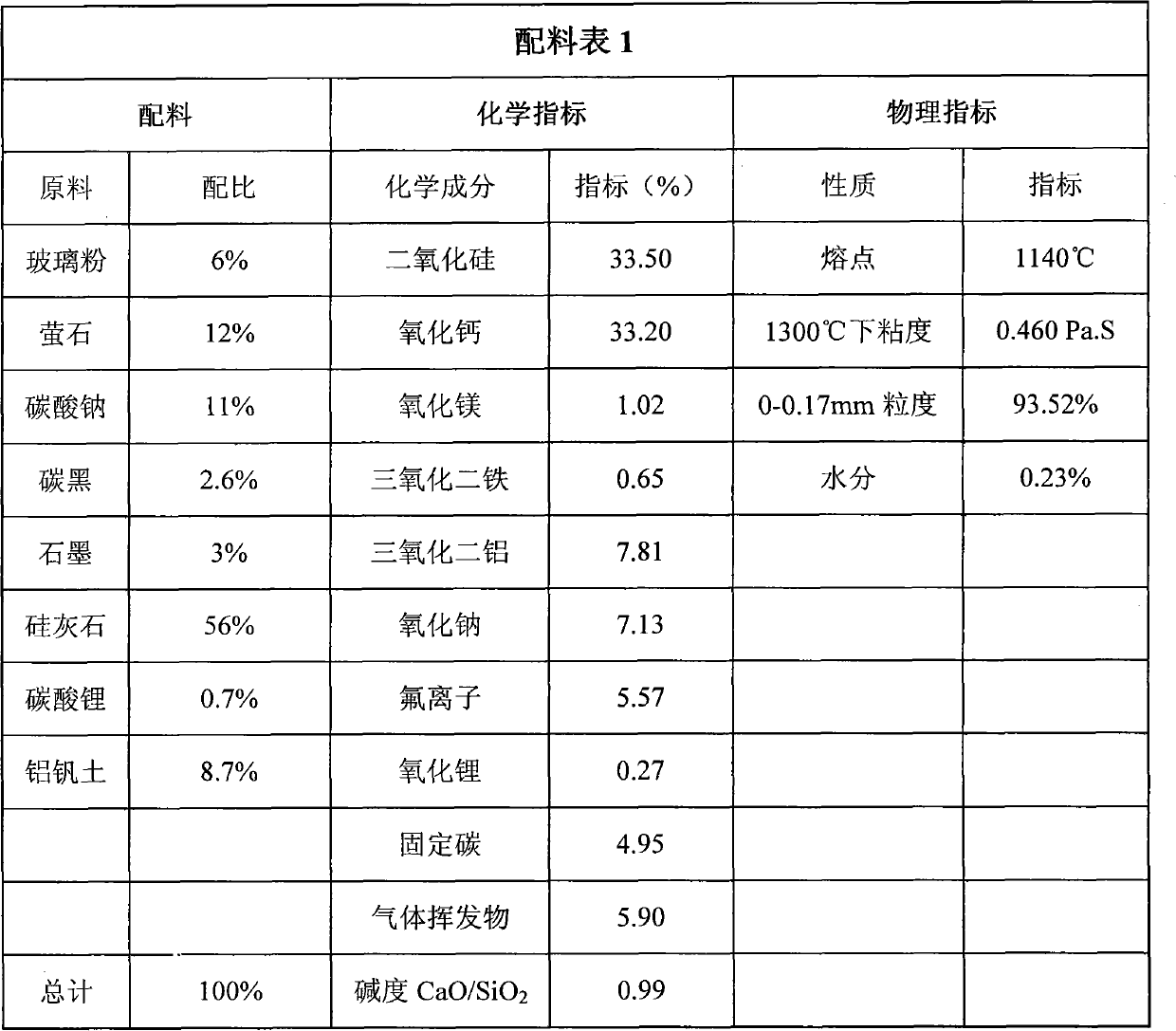

The invention discloses high-manganese high-nitrogen low-nickel stainless steel plate blank continuous casting crystallizer covering slag which comprises the following components in percentage by weight: 54-57% of wollastonite, 9-13% of fluorite, 9-13% of sodium carbonate, 0-1% of lithium carbonate, 5-7% of glass dust, 8-12% of vanadine soil, 2.5-2.7% of soot carbon and 3-3.5% of graphite, and comprises the chemical components in percentage by weight: 31.9-34.9% of calcium oxide, 32.1-35.1% of silicon dioxide, 7.3-8.3% of aluminium oxide, 0.5-1.5% of magnesium oxide, 0.5-1.4% of iron sesquioxide, 4.4-6.4% of fluorion, 6.5-7.5% of sodium oxide, 0-0.39% of lithium oxide, 4.5-6.0% of fixed carbon and 4-7% of gas volatile matters. The alkalinity of the covering slag, namely the ratio of CaO to SiO2, is 0.91 to 1.00, the melting point of the covering slag is 1100 DEG C to 1160 DEG C, and the viscosity of the covering slag is 0.3 to 0.6 Pa.s at 1300 DEG C. The invention can solve the problems of easy crusting, slag entrainment, slag inclusion, slag sticking on casting blank surfaces, bubbles under skins, cracks, deep chatter mark, felting, bleed-out, and the like of the covering slag in the crystallizer during high-manganese high-nitrogen low-nickel stainless steel plate blank continuous casting, and has the advantages of uniform and stable slagging in the crystallizer, good casting blank quality, difficult felting and bleed-out, and the like.

Owner:XIXIA LONGCHENG METALLURGICAL MATERIALS CO LTD

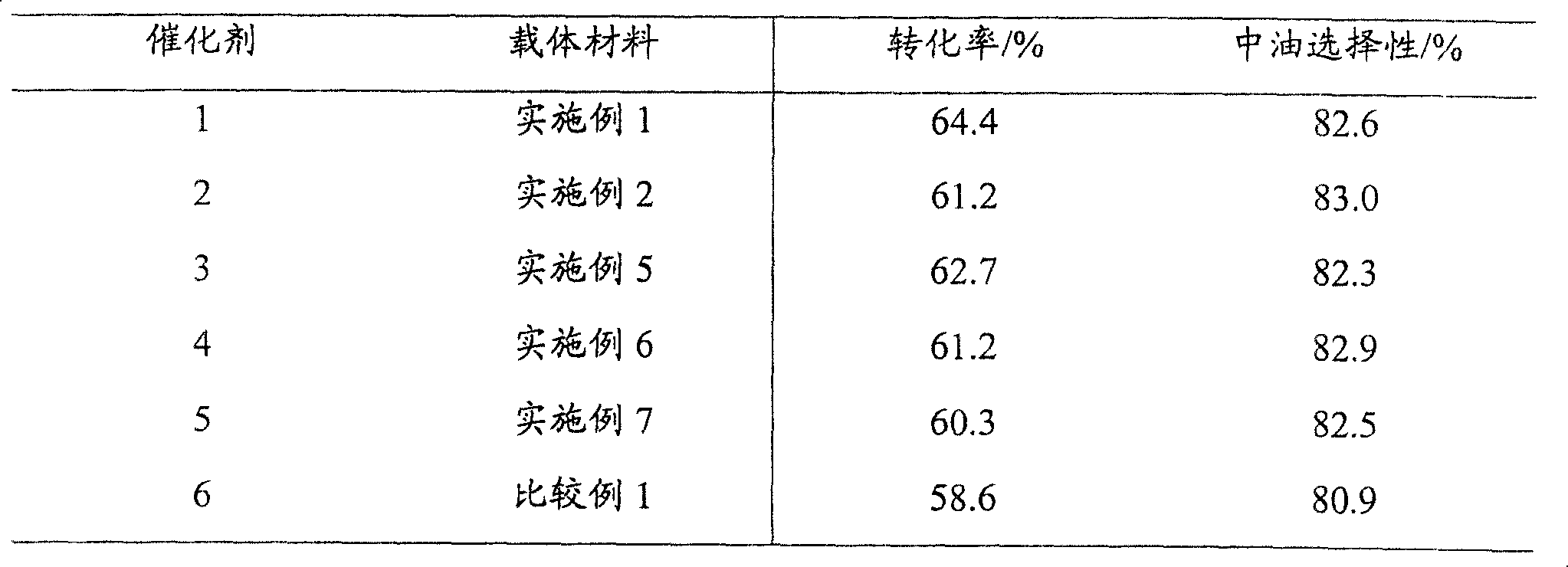

Process for preparing compound catalytic material of nanometer molecular sieve and silica-sesquioxide

InactiveCN101204663ANot easy to gatherConducive to oil conversionNanostructure manufactureMolecular sieve catalystsAluminium sulfateMolecular sieve

The invention provides a preparation method of a composite catalytic material for nanometer molecular sieve or silicon and aluminum oxides, which is characterized in that the method comprises the steps that: firstly, the nanometer molecular sieve is synthesized with directing agent, of which the depositing and dissolving process is treated with microwave and / or ultrasonic, then the serum containing the nanometer molecular sieve is added with a mixed aqueous solution of water glass and aluminum sources and then PH is adjusted to 7 to 9.5 by adding acid to form a gel. The composite catalyst material is obtained after dying and baking the gel. The aluminum source is selected from sodium metaaluminate or aluminium sulphate. The method keeps granule of the molecular sieve product smaller than 100nm and the nanometer molecular sieve thereof is resistant to aggregation. The method is free from acid sol process so that the molecular sieve is not destroyed by acid. The composite material is suitable for catalytic cracking and hydrocracking reactions of large molecules of heavy oils.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Refractory far infrared radiation ceramics coating

The invention provides a high temperature resistance infrared radiation pottery dope, which belongs to the thermal engineering field. The dope is a mixture of the following materials in mass share: 200 mesh zirconium dioxide 10, 200 mesh zircon quartz sand 20, 300 mesh feldspar 10, 300 mesh cerium oxide 7, 300 mesh manganese sesquioxide 15, 300 mesh manganic oxide 3, 600 mesh titanium dioxide 2, 200 mesh alumina 10, 400 mesh graphite 10, 400 mesh boron nitride 3 and 200 mesh carborundum 10. The graphite and boron nitride in the dope are of lubricating and anti-bonding functions, the carborundum is of wear resistance function, the manganic oxide, titanium dioxide and alumina are of strong infrared ray emission and the dope mad of zirconium dioxide, zircon quartz, feldspar and cerium oxide has good compact structure and strong fire-proof and the manganese sesquioxide can catalyze C, S and N for conversion. Therefore, the invention is applicable for use in dynamic furnaces such as coal dust furnace, boiling furnace and fluidized bed furnace.

Owner:颐珑达绝热材料技术(北京)有限公司

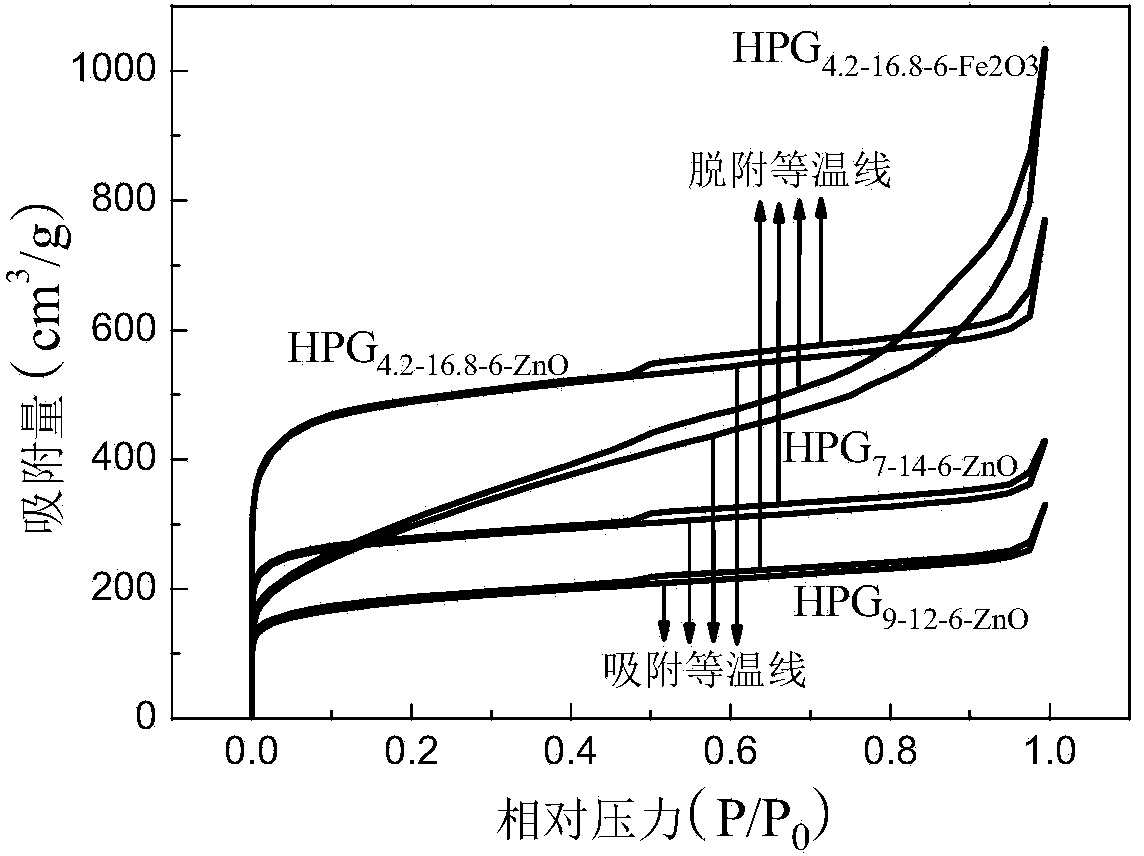

Preparation method of graded porous graphene material for super-capacitor

The invention discloses a preparation method of a graded porous graphene material for a super-capacitor, belonging to the technical field of preparation of carbon materials. The graded porous graphene material for the super-capacitor is prepared by taking coal asphalt as a carbon source, taking nano zinc oxide or nano iron sesquioxide formed by a transitional metal as a template, taking potassium hydroxide as an activator, transferring a grinded mixture of the three into a porcelain boat, placing the porcelain boat in a tubular furnace for heating under a negative-pressure condition through a one-step process. A specific surface area of the graded porous graphene material is between 664m<2> / g and 1862 m<2> / g, total pore volume is between 0.51 cm<3> / g and 1.60 cm<3> / g, average pore size is between 2.53 nm and 5.91 nm, and yield of the graded porous graphene is between 16.9% and 62.8%. According to the preparation method disclosed by the invention, the cheap coal asphalt is taken as the material, preparation process is greatly simplified and operation safety is increased. The preparation method disclosed by the invention has the advantages of being simple in process, low in cost, suitable for industrial production, and the like.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

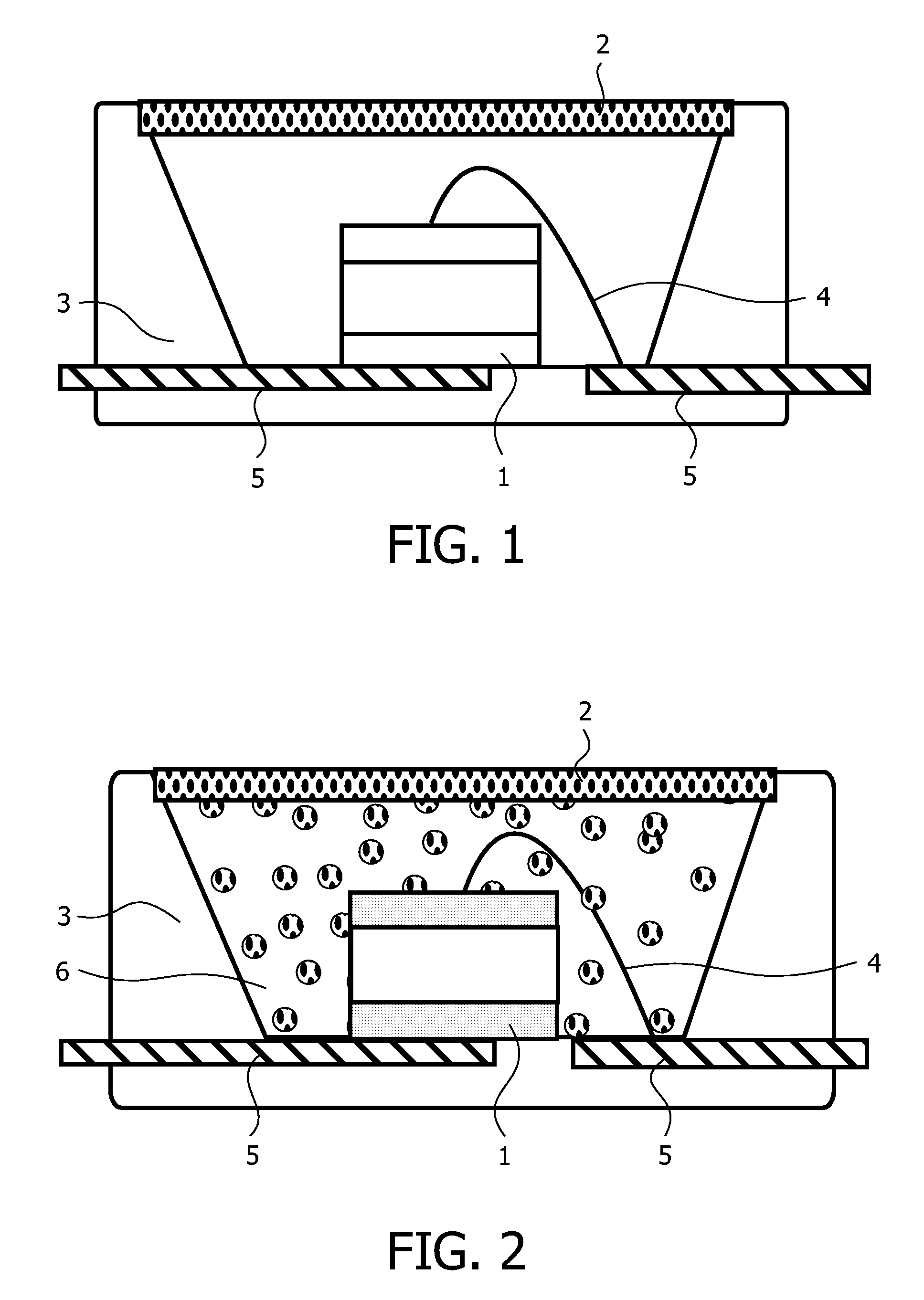

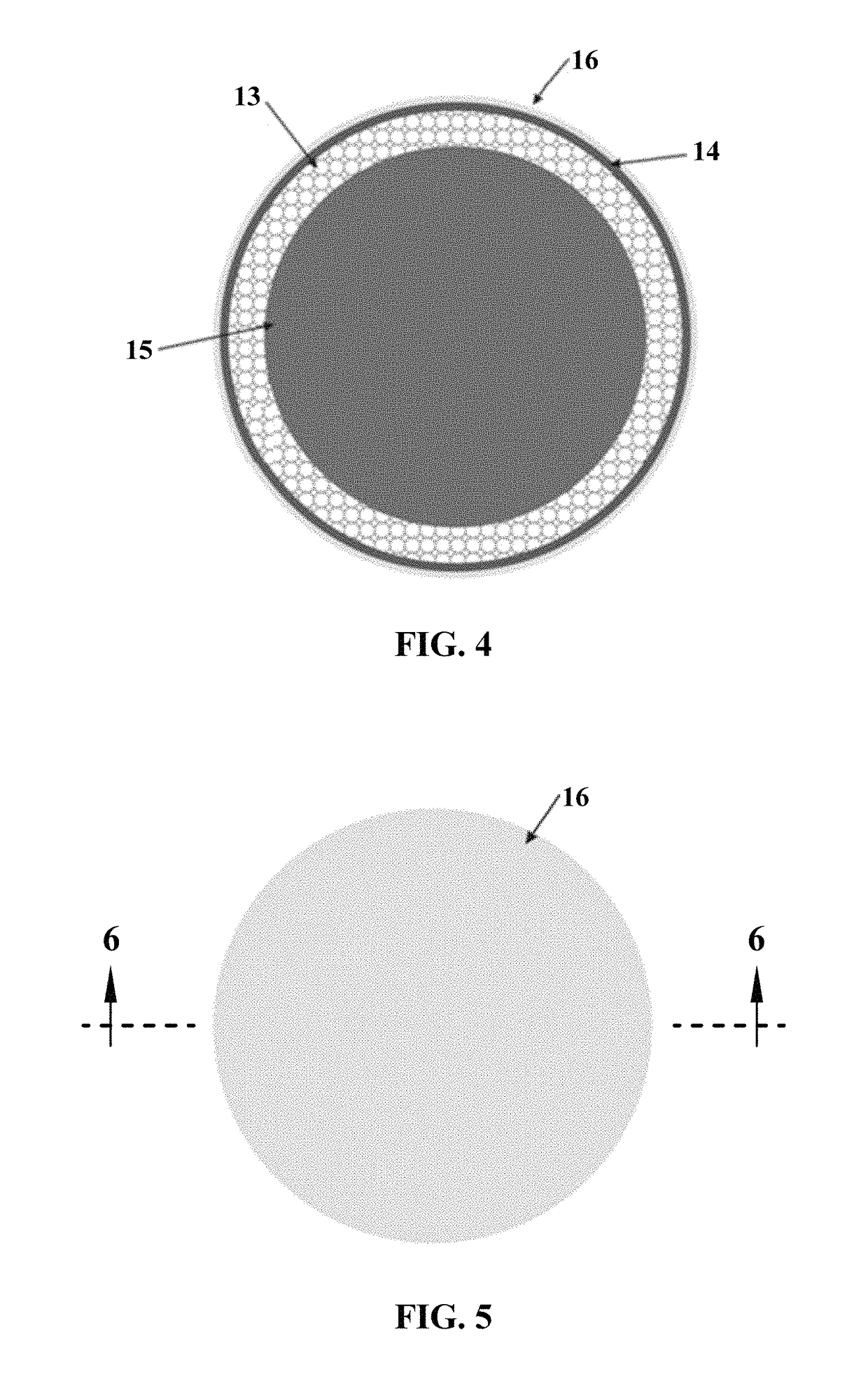

Illumination System Comprising a Red-Emitting Ceramic Luminescence Converter

InactiveUS20080191609A1Suitable light extraction efficiencySuitable transparencyDischarge tube luminescnet screensLamp detailsScandiumAntimony

An illumination system, comprising a radiation source and a monolithic ceramic luminescence converter comprising at least one phosphor capable of absorbing a part of light emitted by the radiation source and emitting light of wavelength different from that of the absorbed light; wherein said at least one phosphor is an europium(III)-activated rare earth metal sesquioxide of general formula (YY-x-XEx)2-z(EU1-a-3Aa)z, wherein RE is selected from the group of gadolinium, scandium, and lutetium, A is selected from the group of bismuth, antimony, dysprosium, samarium, thulium, and erbium, 0≦x<1, 0.001≦z≦0.2; and 0≦a<1 can provide light sources having high luminosity and color-rendering index, especially in conjunction with a light emitting diode as a radiation source. The invention is also concerned with an amber to red-emitting a monolithic ceramic luminescence converter comprising an europium(III)-activated rare earth metal sesquioxide of general formula (Y1-x-REx)2-zO3:(Eu1-aAa)Z, wherein RE is selected from the group of gadolinium, scandium, and lutetium, A is selected from the group of dysprosium, samarium, thulium, and erbium, 0≦x<1, 0.001≦z≦; and 0≦a<1.

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

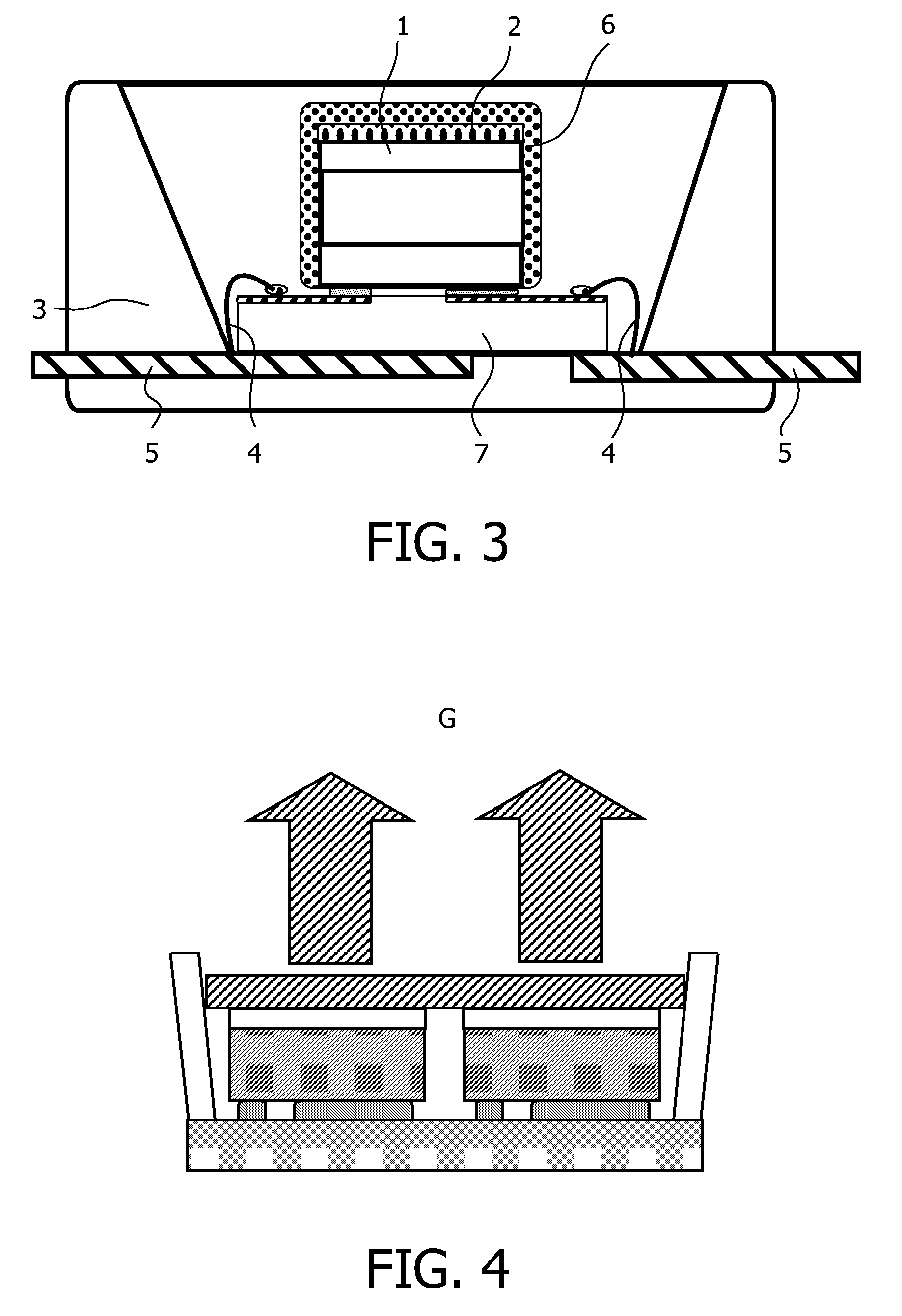

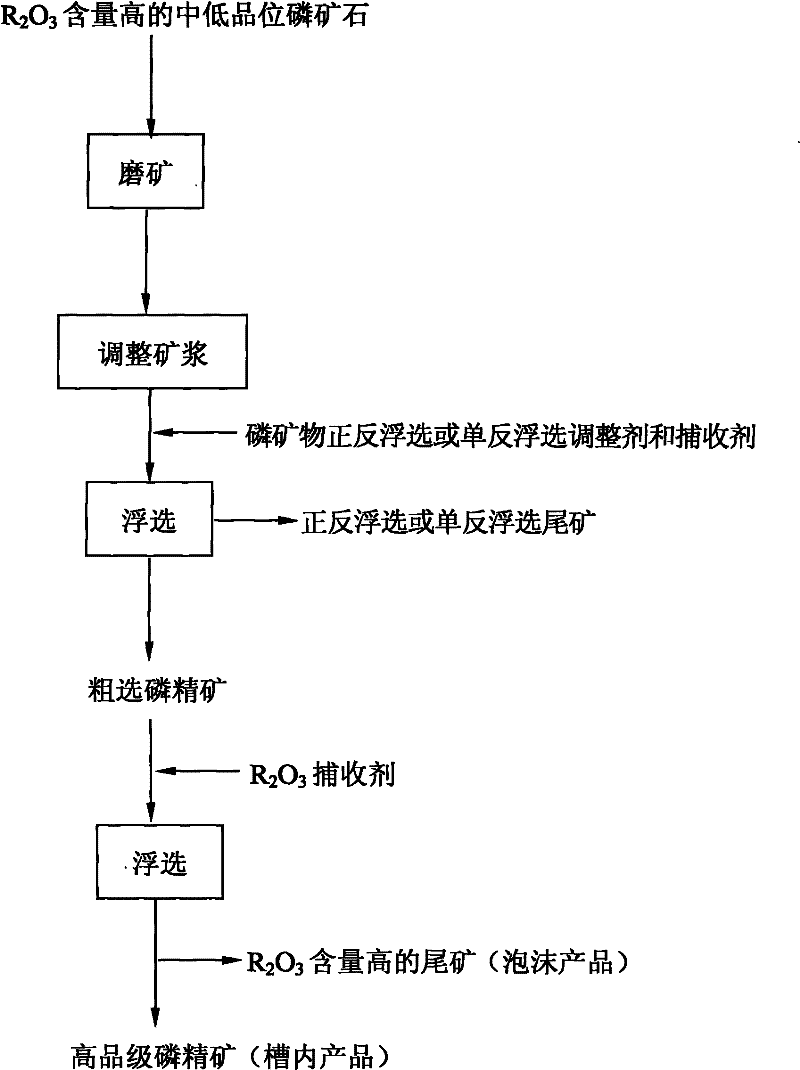

Oredressing method for removing sesquioxide of iron and aluminum

The invention relates to an oredressing method for pertinently reducing content of sesquioxide of iron and aluminum (R2O3) in the collophanite floatation process in advance. The process comprises the following steps of: (1) levigating raw collophanite until grains with the grain size of 0.038mm are more than or equal to 76 weight percent, and controlling the pulp mixing concentration to be 25-40 weight percent; (2) introducing ore pulp into a mineralizing agitation tank of a floatation machine, adding an agent for floating conventional mid-low grade collophanite for pneumatic flotation, ensuring that a spindle speed of the floatation machine is 1,800-2,100r / min, the floating aeration quantity is 0.05-0.10m<3> / h and the floating scraper speed is 20-30r / min, and obtaining phosphate concentrate subjected to rough concentration; and (3) controlling the pH of the phosphate concentrate subjected to rough concentration to be 4.5-5.5, adding a collector for removing R2O3, performing pneumatic flotation for 4 to 8 minutes, removing an impurity of R2O3 from foam, and obtaining base flow, namely a high grade phosphate concentrate product. By the method, the R2O3 content in the concentrate can be obviously reduced, the quality of the phosphate concentrate is improved, and production processes, flows and cost during purification in the subsequent acid making process can be reduced.

Owner:YUNNAN PHOSPHATE CHEM GROUP CORP

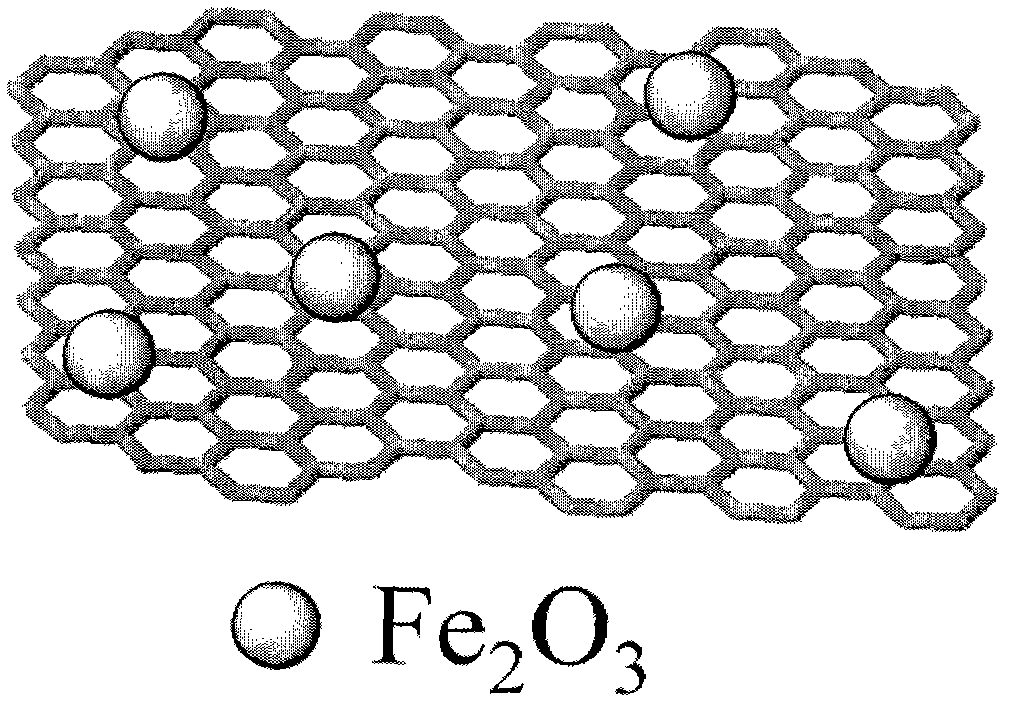

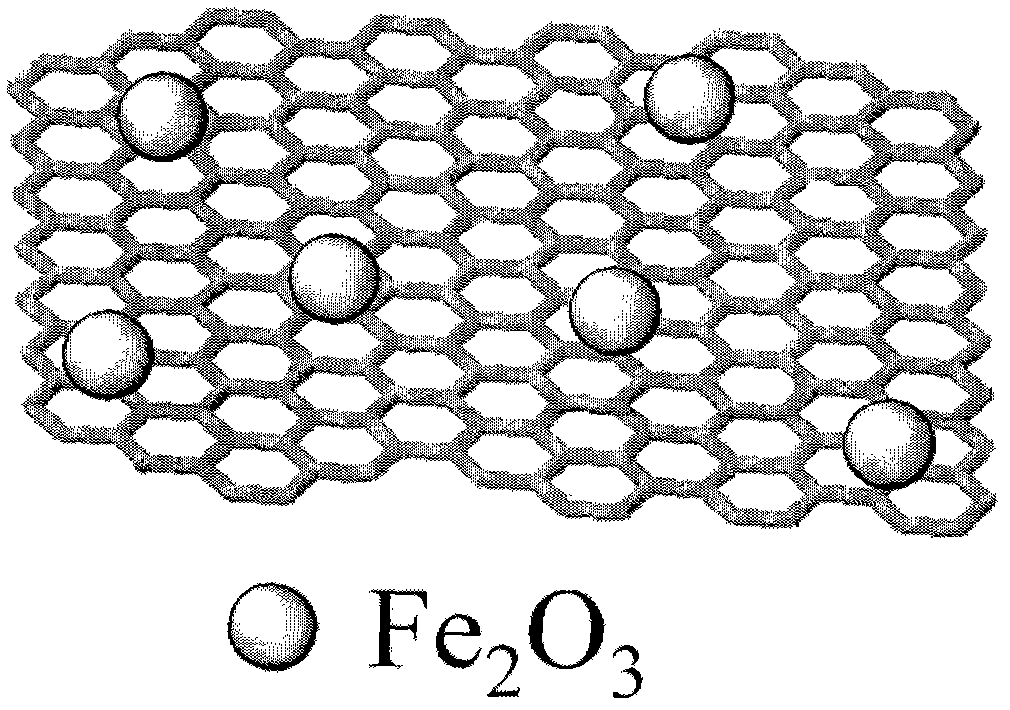

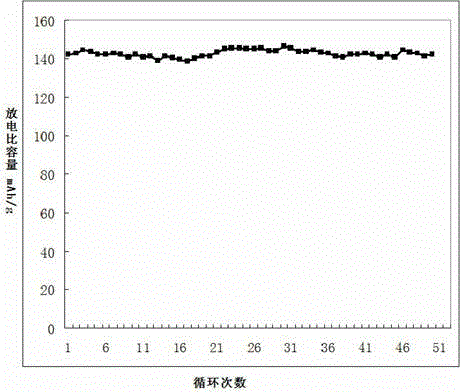

Environment-friendly and efficient method for preparing iron sesquioxide/graphene composite material

The invention relates to an environment-friendly and efficient method for preparing an iron sesquioxide / graphene composite material. In the method, cheap and abundant soluble ferrous salt serves as an iron source and reducing agent, graphene oxide is quickly reduced into the graphene by the characteristics of microwave heating, and ferrous is oxidized and converted into iron sesquioxide so as to obtain a sesquioxide / graphene composite material. The environment-friendly and efficient method fully utilizes the characteristics of ferrite, has the advantages of simple and efficient preparation technology, no industrial three-waste pollution and stable product performance and is favorable for producing on a large scale, and a product has a wide application prospect in the cathode material of a lithium-ion secondary battery.

Owner:BEIJING ZHONGKE MICRO NANO NETWORKING SCI TECH

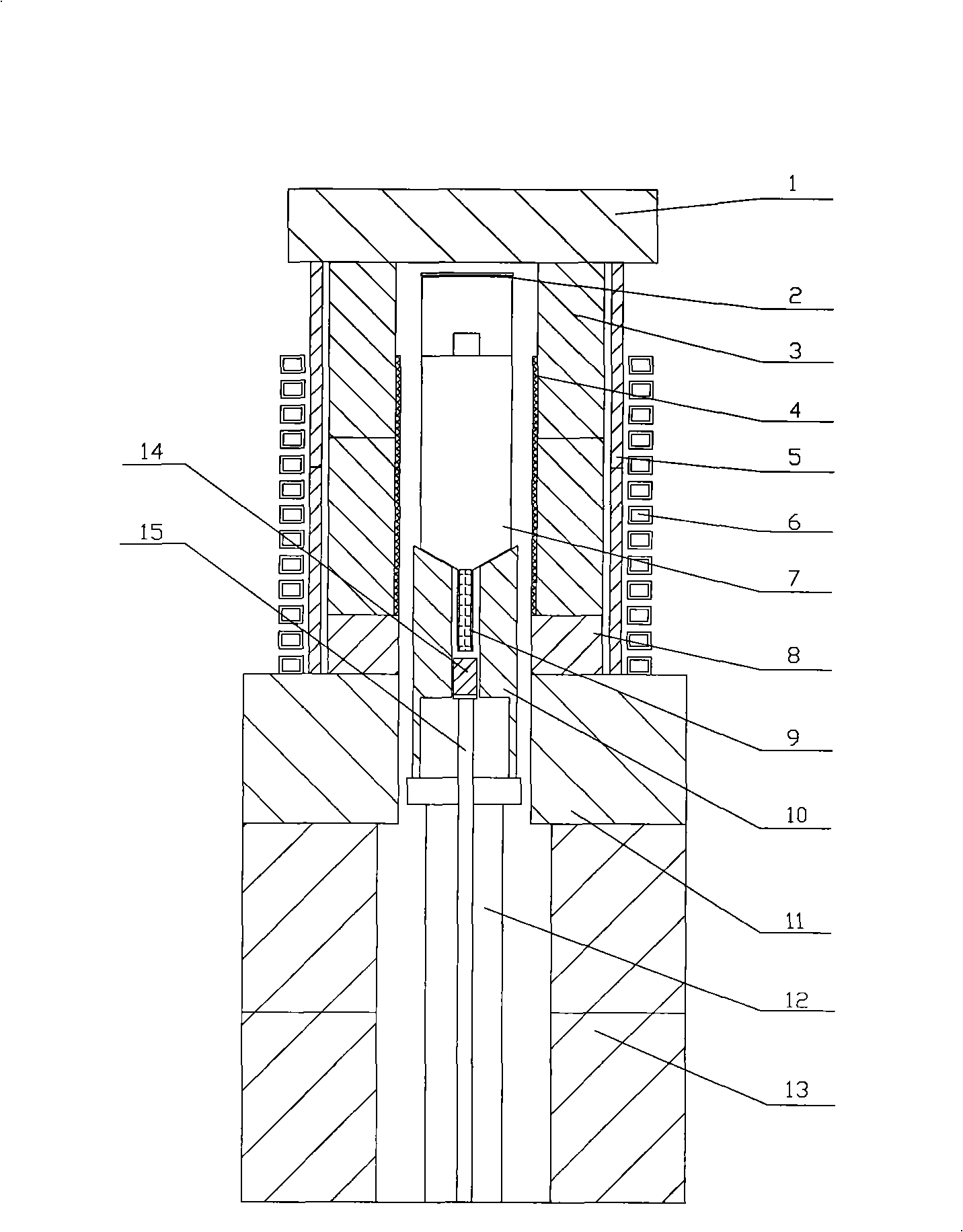

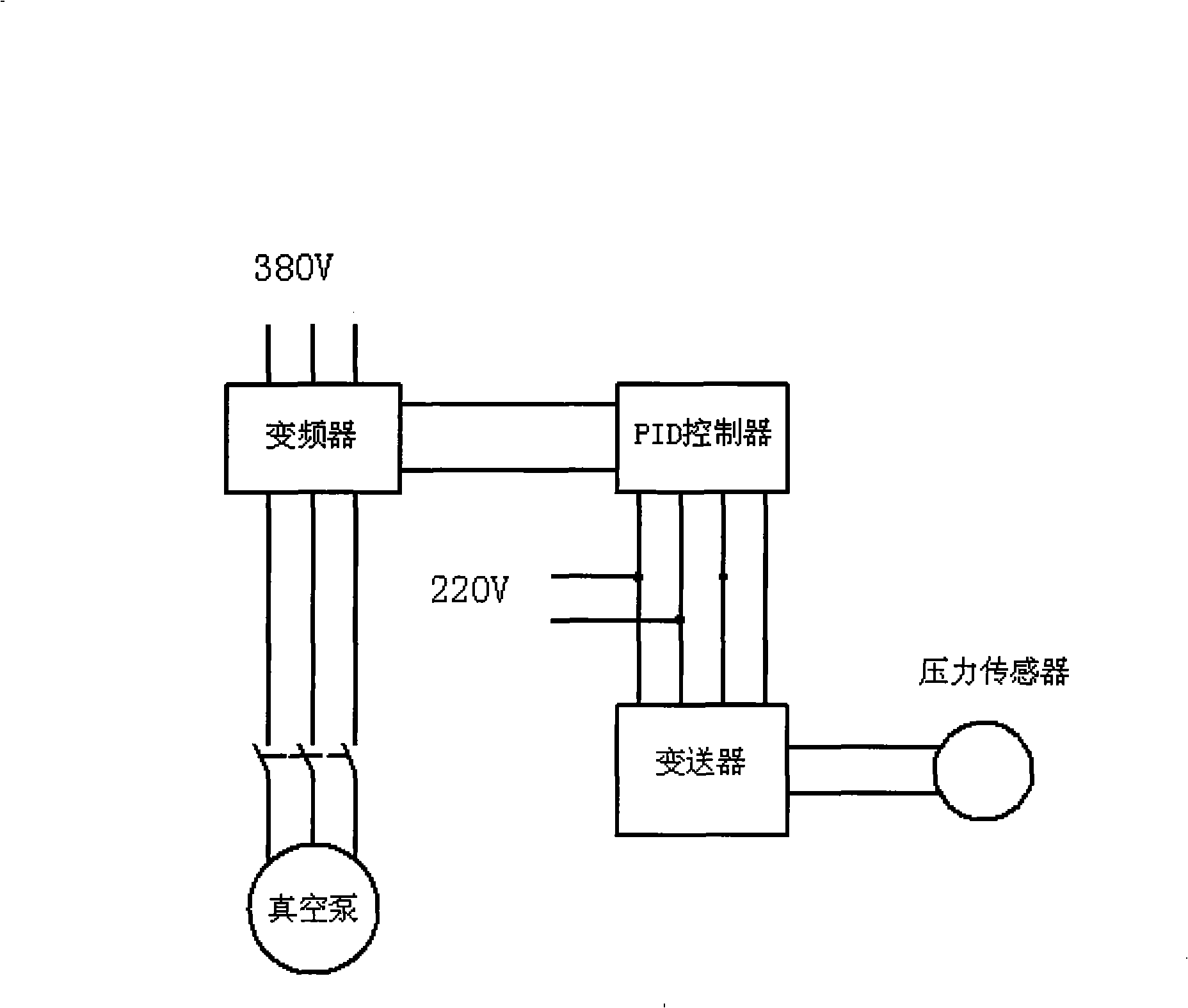

Large size sapphire crystal preparing technology and growing apparatus thereof

ActiveCN101323978AAvoid crackingImprove cleanlinessPolycrystalline material growthFrom frozen solutionsCrucibleSesquioxide

The invention relates to a preparing technique and a growth device of a large-size sapphire crystal, and the preparing technique of the large-size sapphire crystal comprises the following steps: (1) aluminum sesquioxide with high purity that is weighted is filled into a molybdenum crucible pot, a stove is vacuumized until the atmospheric pressure inside the stove is less than 10<-3> Pa, and then protective gases are filled into the stove, and the stove pressure achieves minus 90 to plus 20 KPa; (2) raw materials are heated until complete melting is achieved, and heat is preserved for 3 to 5 hours; (3) seed crystals are lowered by 15 to 120mm under heat preservation, and then the molybdenum crucible pot is lowered by the height of the molybdenum crucible pot; (4) the temperature in the stove is decreased until 1600 to 1750 DEG C; (5) the molybdenum crucible pot is re-raised to a heating region, and heat is preserved for 100 to 150 hours and then the temperature is decreased slowly until room temperature. The preparing technique of the large-size sapphire crystal of the invention is characterized by simple device structure, low production cost, good preparing technique stability, reliable process, easier bubble elimination and high yield, and can cultivate the single sapphire crystal with large size, small dislocation density and high quality.

Owner:成都东骏激光股份有限公司

Promoter for generation of gas hydrate, and preparation method and application thereof

InactiveCN102784604APromote generationAchieve a high degree of dispersionPressurized chemical processGaseous fuelsGeneration rateSesquioxide

The invention discloses a promoter for generation of gas hydrates, and a preparation method and application thereof. The promoter for generation of gas hydrates is a dry powdery solution formed after high speed shearing and dispersion of a surfactant solution and strong hydrophobic solid particles in a high intensity stirrer, wherein the surfactant solution is an aqueous solution of one or more anionic surfactants, cationic surfactants or nonionic surfactants, and the strong hydrophobic solid particles are one or more selected from the hydrophobically modified particles consisting of silica, titanium dioxide, titanium sesquioxide, alumina, zinc oxide, calcium carbonate, montmorillonite, diatomite, fly ash, zeolite, talcum and mica particles, etc. The promoter provided by the invention is highly dispersed solution microdroplets and has a great gas-liquid contact area, the dispersed microdroplets contain surfactants, which enables gas-liquid contact during growth process of hydrates to be further reinforced, and therefore, a generation rate of gas hydrates and gas storage amount in a static system are substantially improved; meanwhile, the promoter has the advantages of low cost, no pollution and convenient preparation and usage.

Owner:SOUTH CHINA UNIV OF TECH

Infrared energy-saving coating of high-temperature kiln and preparation method thereof

Owner:CHINA SILICON ZIBOCERAMIC TECH

Preparation method for manganese oxide nano rods

InactiveCN104211123ASmall diameterUniform size distributionMaterial nanotechnologyManganese oxides/hydroxidesSesquioxideReaction temperature

The invention relates to a preparation method for manganese oxide nano rods, belonging to the field of nano function materials. According to the preparation method, rod-shaped alkaline manganese oxide can be prepared by using hypermanganate and ethylene glycol under a hydrothermal condition, wherein the longest length of the alkaline manganese oxide can be up to six microns and the diameter size is 10nm-130nm; alkaline manganese oxide precursors are calcined under different calcining conditions to obtain the manganese oxide nano rods with different valence states and different sizes, namely manganese dioxide nano rods, manganese sesquioxide nano rods and trimanganese tetraoxide nano rods. By adopting the preparation method, the problems of an existing solvothermal method that the reaction time is long and the reaction temperature is high when the alkaline manganese oxide nano rods are synthesized and the diameters of the products are great and the products are not uniformly distributed are solved; and the preparation method has the advantages of simplicity in operation and many product varieties.

Owner:JILIN UNIV

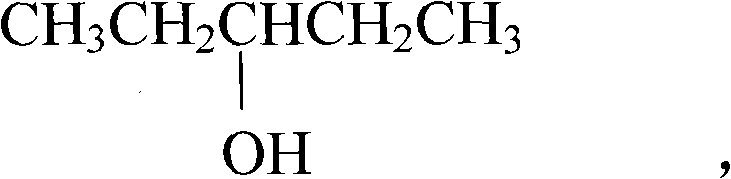

Phosphorite low-temperature foam flotation collector and preparation method thereof

ActiveCN101791591AStrong harvesting abilityHigh selectivityFlotationSesquioxideTemperature resistance

The invention relates to a phosphorite low-temperature foam flotation collector and a preparation method thereof. The collector consists of the following substances in part by weight: 0.7 to 0.9 part of cottonseed acidic oil, 0.1 to 0.3 part of fatty acid methyl ester, 0.01 to 0.05 part of sodium dodecyl benzene sulfonate, and 0.01 to 0.05 part of foaming agent. The preparation method comprises the following steps: mixing the 0.7 to 0.9 part of cottonseed acidic oil and the 0.1 to 0.3 part of fatty acid methyl ester; heating the mixture to the temperature of between 100 and 120 DEG C; adding alkali liquor into the mixture, stirring the mixture for saponification; controlling pH to be between 8 and 10; and adding the 0.01 to 0.05 part of sodium dodecyl benzene sulfonate and the 0.01 to 0.05 part of foaming agent into the mixture by using the saponified semi-finished product as a reference part to prepare the phosphorite low-temperature foam flotation collector. When the collector can be used in 'Haizhou type' phosphorite low-temperature direct flotation, the produced product still can achieve low sesquioxide concentrate and has higher recovery rate. Compared with the conventional 'Haizhou type' phsophorite low-temperature direct flotation collector, the collector has the characteristics of high collection capability, high selectivity, small using amount, low-temperature resistance, low mineral separation cost and the like.

Owner:HUBEI FORBON NEW MATERIAL CO LTD

Far infrared magnetic fiber and application and manufacturing method thereof

InactiveCN101445969AGood for healthGood far infrared effectMelt spinning methodsMonocomponent polyesters artificial filamentFiberState of art

The invention relates to a far infrared magnetic fiber and the application and a manufacturing method thereof; base material of the magnetic fiber contains superfine micro powder which is mixed by multiple elements and has the weight percentage of 2-8%; the superfine micro powder is prepared by the materials based on the weight percent: 20-50% of ferroferric oxide, 5-15% of gamma-aluminium sesquioxide, 15-30% of silicon dioxide and 25-40% of rutile titanium dioxide; the mean particle size of the superfine micro powder mixed by multiple elements is less than or equal to 0.5 micron. Compared with the prior art, the far infrared magnetic fiber has remarkable health care effect, stable magnetism, good far infrared effect and excellent dispersion effect of superfine micro powder granules; at the same time, the manufacturing method of the far infrared magnetic fiber has the advantages of simple technique and stable performance of the products.

Owner:上海阳山材料科技有限公司

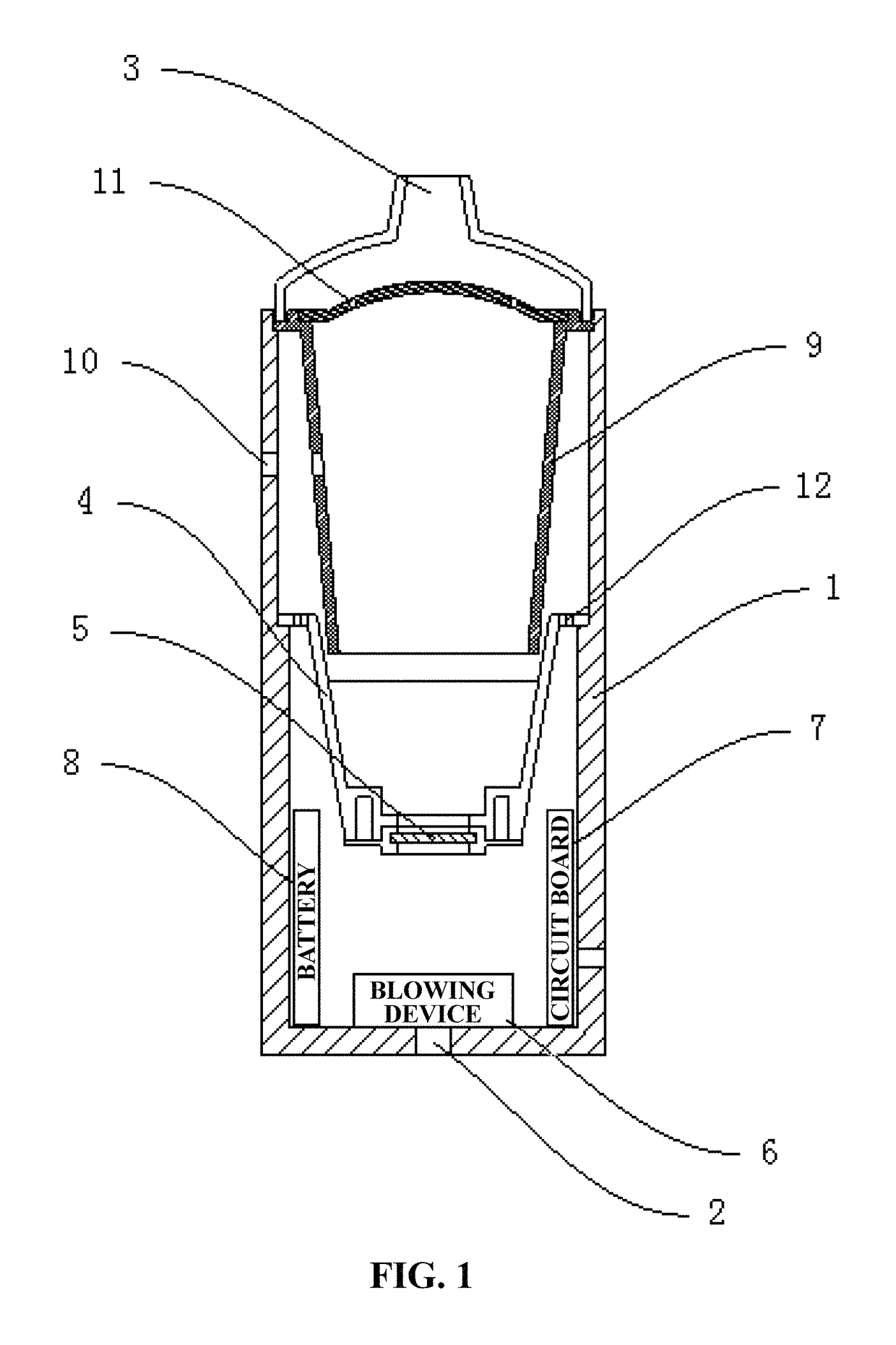

Terahertz radiating material and preparation method and application thereof

InactiveCN106883896ALower activation energyLow viscosityLiquid carbonaceous fuelsCombustionSesquioxide

The invention relates to the field of energy source and environment and particularly discloses a terahertz radiating material and a preparation method and application thereof. The terahertz radiating material is prepared from various raw materials which comprise the following components in parts by weight: 30-85 parts of silicon dioxide powder, 5-30 parts of aluminum oxide aluminum powder, 1-20 parts of iron sesquioxide powder, 1-15 parts of zirconium compound powder, 1-10 parts of potassium oxide powder and 0.01-0.1 part of a rare earth oxide. The preparation method comprises the specific steps of: mixing the various raw materials; and sintering the raw materials at 500-1800 DEG C. The radiating material has high terahertz radiating property, can emit terahertz waves to induce molecular resonance of oil molecules or water molecules, reduce the activating energy and promote reaction. The terahertz radiating material is applied to fuel oil to improve the combustion efficiency, and is applied to tape water to purity the water.

Owner:SICHUAN FULI ENVIRONMENTAL PROTECTION TECH CO LTD

Handheld high frequency ultrasonic nebulizer for whole respiratory tract drug delivery

Owner:CHANGZHOU ZHENGYUAN MEDICAL TECH +1

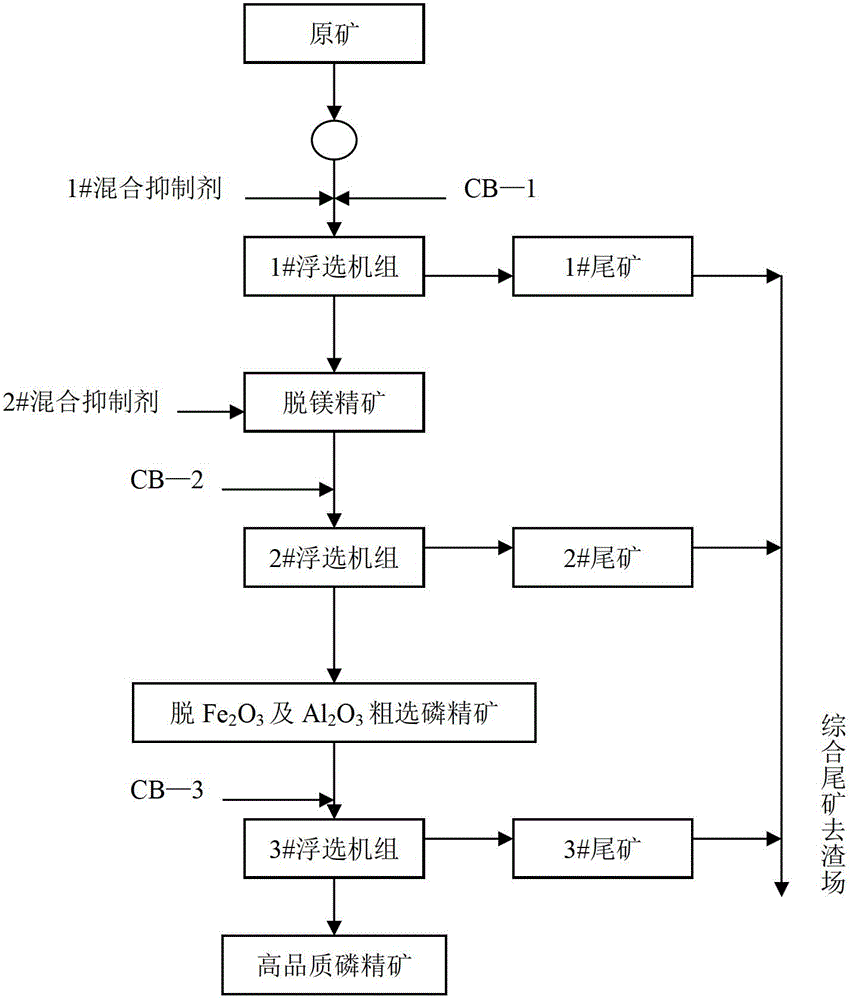

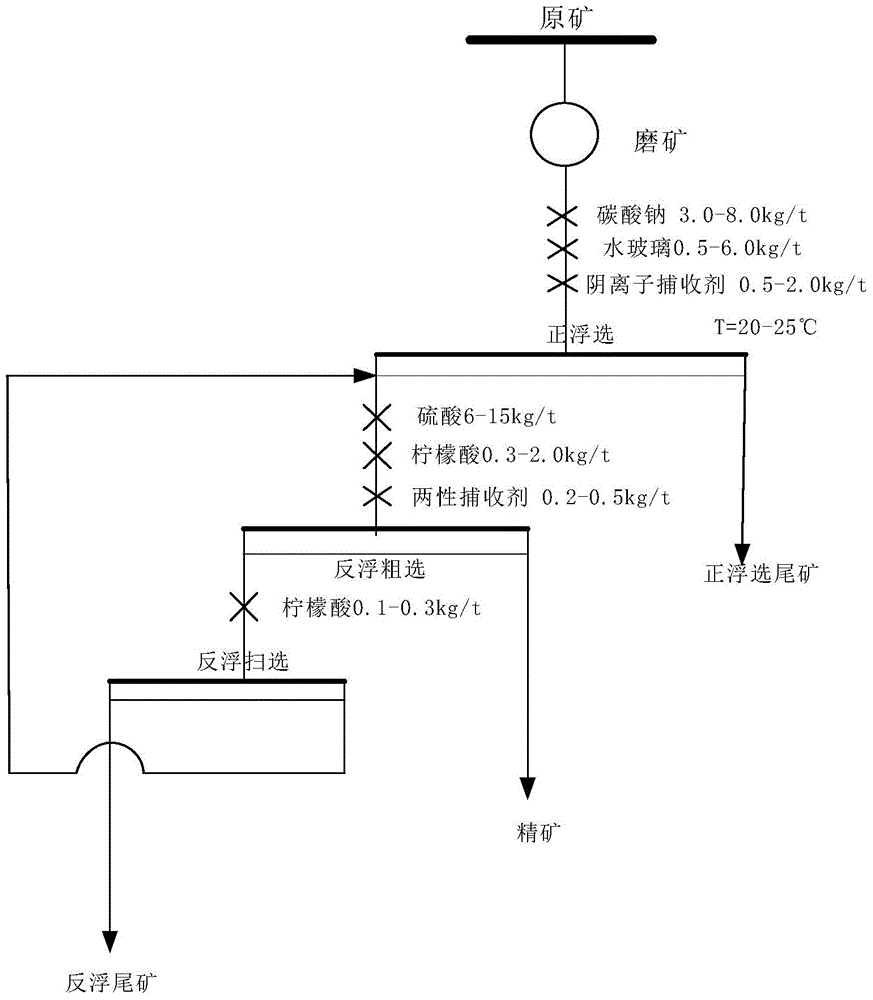

Method for simultaneously removing magnesium oxide, ferric oxide and aluminum oxide sesquioxide in middle-grade and low-grade phosphate ores by adopting double-reverse floatation process

The invention relates to a method for simultaneously removing magnesium oxide, ferric oxide and aluminum oxide sesquioxide in middle-grade and low-grade phosphate ores by adopting a double-reverse floatation process. The method adopts the double-reverse floatation process to remove MgO, Fe2O3 and Al2O3 so as to realize continuous production of an industrialization device. The method comprises the following process steps of: levigating raw phosphate ore, wherein more than or equal to 85 percent of raw phosphate ore is minus 200 messes in size, and the solid content of ore pulp is 20-45 percent; adding a No.1 mixed inhibitor in the ore pulp, introducing the regulated ore pulp into a floatation machine, adding a collecting agent CB-1, aerating, and collating, so as to obtain magnesium removal phosphate concentrate; adding a No.2 mixed inhibitor in the magnesium-removal phosphate concentrate, adding a collecting agent CB-2, aerating, and collating, so as to obtain crude phosphate concentrate without ferric oxide and aluminum oxide; and adding a collecting agent CB-3 into the crude phosphate concentrate without ferric oxide and aluminum oxide, aerating, and collating, so as to obtain high-grade phosphate concentrate. The method can simultaneously remove the content of magnesium oxide, ferric oxide and aluminum oxide from the concentrate, thus obviously improving the quality of the phosphate concentrate and lowering the production cost in follow-up acid making process.

Owner:KUNMING CHUAN JINNUO CHEM IND

Exothermic insulating riser sleeve and preparation method thereof

InactiveCN103551512ALong holding timeFast feverFoundry mouldsFoundry coresSesquioxideThermal insulation

The invention discloses an exothermic insulating riser sleeve and a preparation method thereof and aims to solve the problems of bad heat insulation, insufficient heating and single effect in a conventional exothermic insulating riser sleeve. According to the formula, the exothermic insulating riser sleeve is prepared from quartz sand, vermiculite, potassium nitrate, calcium chloride, iron sesquioxide powder, graphite powder, aluminum powder, magnesium powder and modified sodium silicate. The method comprises the following steps: (1) weighing raw materials; (2) preparing a mixed wet material; and (3) filling the mixed wet material into a mold, pre-tightening while filling the wet material, performing compression molding, and demolding, thus finishing the operations. According to the formula of the exothermic insulating riser sleeve, the content of an exothermic agent is increased, the exothermic agent has the advantages of rapid heating, and a heating effect is improved. Moreover, the vermiculite serves as a thermal insulation material, is long in thermal insulation time and has a good thermal insulation effect, so that the molten iron feeding ratio in a riser is improved under the combined action of rapid heating and long thermal insulation.

Owner:HARBIN UNIV OF SCI & TECH

Method for preparing aluminum oxide from low aluminum-silicon ratio aluminum-containing mineral

InactiveCN101100304ANo emissionsRealize refined utilizationSulfur compoundsAluminates/aluminium-oxide/aluminium-hydroxide purificationDecompositionSesquioxide

This invention discloses a method for producing aluminium oxide by using aluminium-containg are with low aluminium / silicon ratio. The method comprises procedures of: (1), atomizing raw material ore; (2), dressing by magnetic separation; (3), acid treatment; (4), filtering and separation; (5), heating for dehydration decomposition; (6), recovering sulfur trioxide. After that, produced is the inventive product aluminium sesquioxide with high pureness upto 99.5%, meeting the standard of Non-Ferrous Metals Industries SY / T274-1998. The advantages of this invention are; full reutilization of materials, simple process, simple equipment, no discharge of wastes of solid, liquid and gas, no secondary pollution.

Owner:NORTHEASTERN UNIV

Method for preparing brake block by calcium carbonate crystal whisker

InactiveCN101205456AImprove high temperature resistanceReduce decomposition rateOther chemical processesPorosityDecomposition

The invention relates to a method for preparing a brake sheet through adopting calcium carbonate crystal whisker, belonging to the friction material field, wherein the following raw materials of corresponding part by weight are adopted: 5 to 15 portions of adhesive which adopts phenol formaldehyde resin, 20 to 30 portions of reinforcing material which is obtained through mixing steel fiber or ceramic fiber with one or several of aramid fiber, mineral fiber and glass fiber, 1 to 15 portions of grinding agent which comprises one or combination of several of aluminum sesquioxide, ferric oxide, magnesium oxide and friction powder, 5 to 15 portions of lubricant which comprises one or combination of several of graphite, molybdenum disulfide and mica, 5 to 15 portions of stabilizer calcium carbonate crystal whisker, and 30 to 50 portions of filler which comprises one or combination of several of barium sulfate, potassium titanate and magnesium oxide. The brake sheet, which is made through the method, can effectively increase porosity and improve the high-temperature resistance of material, thereby lowering the decomposition rate of organic material at a high temperature; meanwhile, the brake sheet can slow down the gaseous escape speed on a friction surface during fading, thereby reducing fading rate and the change rate of friction coefficient at high speed to less than 10 percent.

Owner:信义集团公司

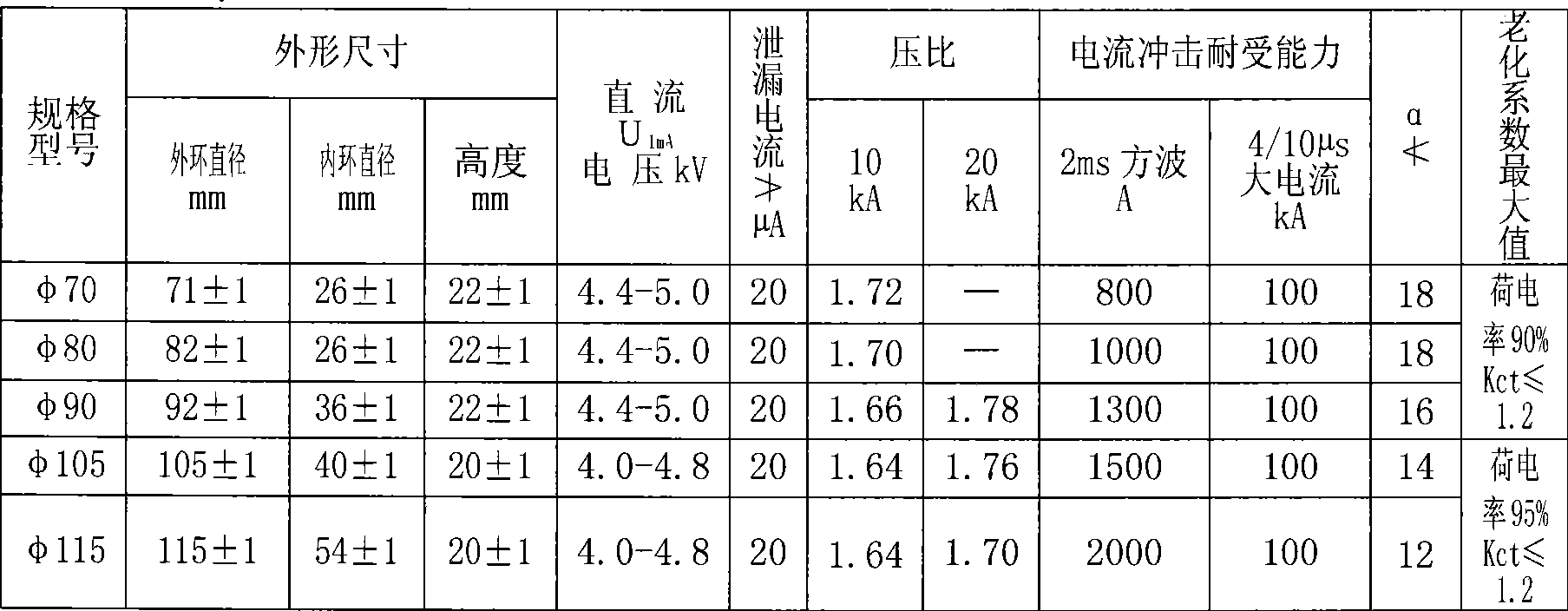

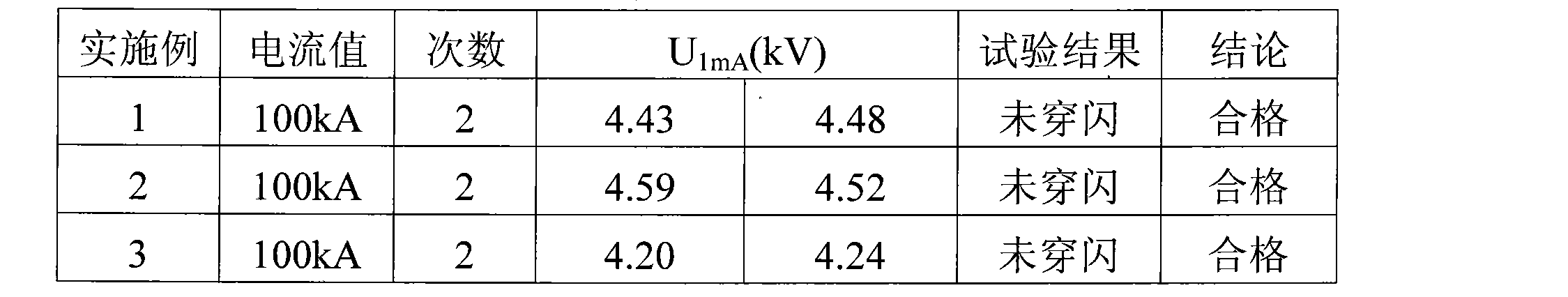

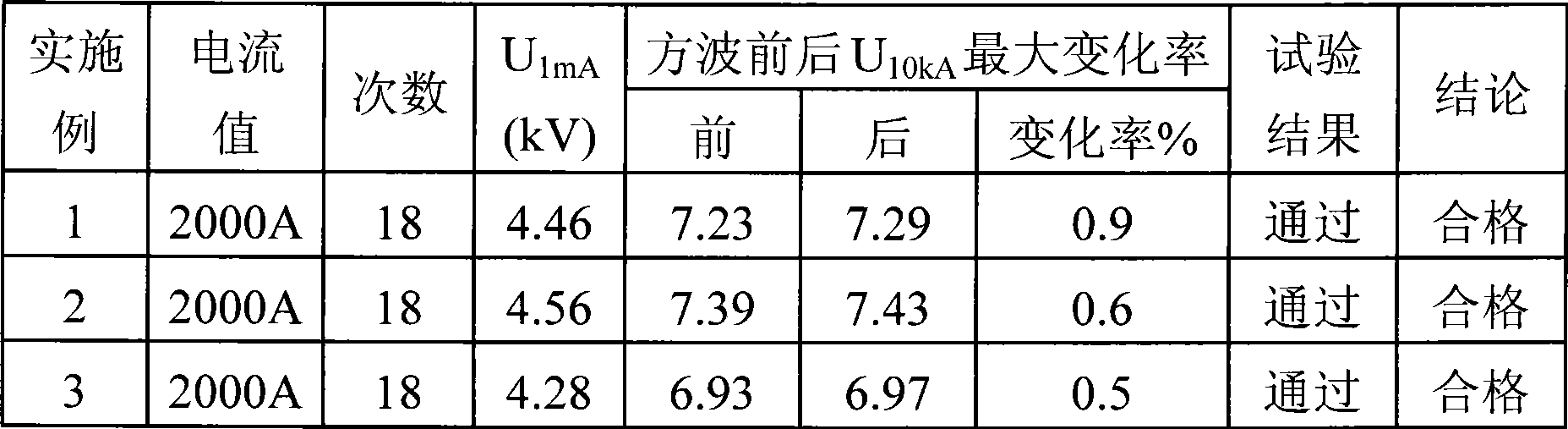

Formula of direct current zinc oxide resistance chip

ActiveCN101503292AUniform and stable structureReduce defect concentrationVaristor coresSesquioxideAntimony trioxide

The invention discloses a formulation of an AC zinc oxide resistance chip. The formulation is characterized by comprising the following additives and a main material ZnO by weight percentage: 4.0 to 4.9 percent of Bi2O3, 3.0 to 4.0 percent of Sb2O3, 0.5 to 1.0 percent of SiO2, 2.0 to 3.0 percent of Co2O3, 0.50 to 0.80 percent of Cr2O3, 0.50 to 0.80 percent of MnCO3, 0.70 to 0.90 percent of NiO, 0.03 to 0.05 percent of aluminum nitrate, 0.10 to 0.20 percent of glass dust, 0.07 to 0.10 percent of B2O3 and 85.0 to 88.0 percent of ZnO. The formulation of the resistance chip has the following characteristics and advantages: the nickel protoxide and the glass dust are introduced into the formulation, so that the stability and the aging performance of the internal structure of the resistance chip is more excellent; and 2, dosage of cobalt sesquioxide, dibismuth trioxide and diantimony trioxide are added in the formulation, the mixture ratio of each composition is more reasonable, and the non-linearity coefficient of the resistance chip can be improved, the pressure ratio is reduced, the circulation capability is improved, and the comprehensive performance is excellent.

Owner:FUSHUN ELECTRIC PORCELAIN MFG CO LTD

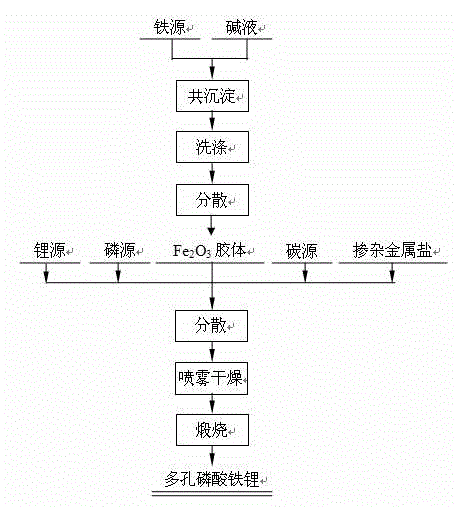

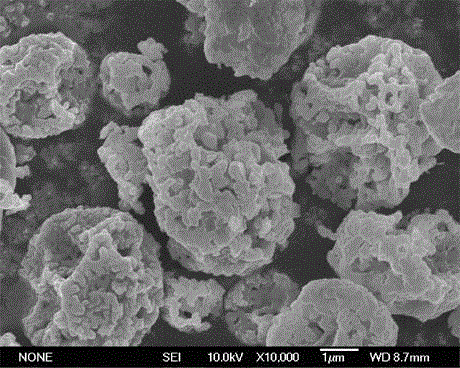

Preparation method of porous lithium iron phosphate powder

Disclosed is a preparation method of porous lithium iron phosphate powder. The preparation method includes dissolving trivalent iron salt into water and preparing solution; adding alkali liquor in the boiling state to obtain Fe(OH)3 nano particles, dispersing the Fe(OH)3 nano particles in the water after washing, forming iron sesquioxide colloid with stirring intensively; adding a water-soluble lithium source, a phosphorus source, a carbon source and doped ion compound into the iron sesquioxide colloid, intensively stirring to form colloid-shaped mixed pulp uniformly molecularly mixed; drying the pulp by mist and obtaining spherical lithium iron phosphate precursor with average grain diameter ranging from D50=2-3 micrometers; sintering the precursor in the inertia atmosphere at the temperature of 300-500 DEG C for 2-10 hours, and sintering the precursor again at the temperature of 500-800 DEG C for 2-12 hours and obtaining carbon-coated spherical porous lithium iron phosphate powder with average grain diameter of D50=2-3 micrometers.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

Silica-calcia low-grade collophanite positive and inverse floatation process

ActiveCN104907183AReduce contentRealize beneficiation and enrichmentFlotationCalcium in biologySesquioxide

The invention relates to a silica-calcia low-grade collophanite positive and inverse floatation process, which comprises the steps: 1 silica-calcia low-grade collophanite ores are broken up and grinded to enable phosphate minerals and gangue mineral monomers to dissociate, then are added with water to mix size, enter positive and inverse floatation, get rid of impurities in ores, and improve grade of phosphorite. Compared with the prior art, the silica-calcia low-grade collophanite positive and inverse floatation process has the advantages that the content of only one kind of gangue minerals can be reduced by adopting direct floatation and single inverse floatation, can reduce the contents of silicate minerals, carbonate minerals and iron and aluminum silicate minerals, can obtain low magnesium low power half oxide low silicon phosphate concentrate by adopting the silica-calcia low-grade collophanite positive and inverse floatation process, successfully achieves mineral processing enrichment of collophane calcium collophanite, and can improve use rate of phosphorus resource. The silica-calcia low-grade collophanite positive and inverse floatation process overcomes the defects that an existing floatation process can not be applied for mineral processing of silica-calcia collophanite which is high in content of high power half oxides.

Owner:WUHAN INSTITUTE OF TECHNOLOGY +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com