Patents

Literature

317results about How to "Reduce decomposition rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

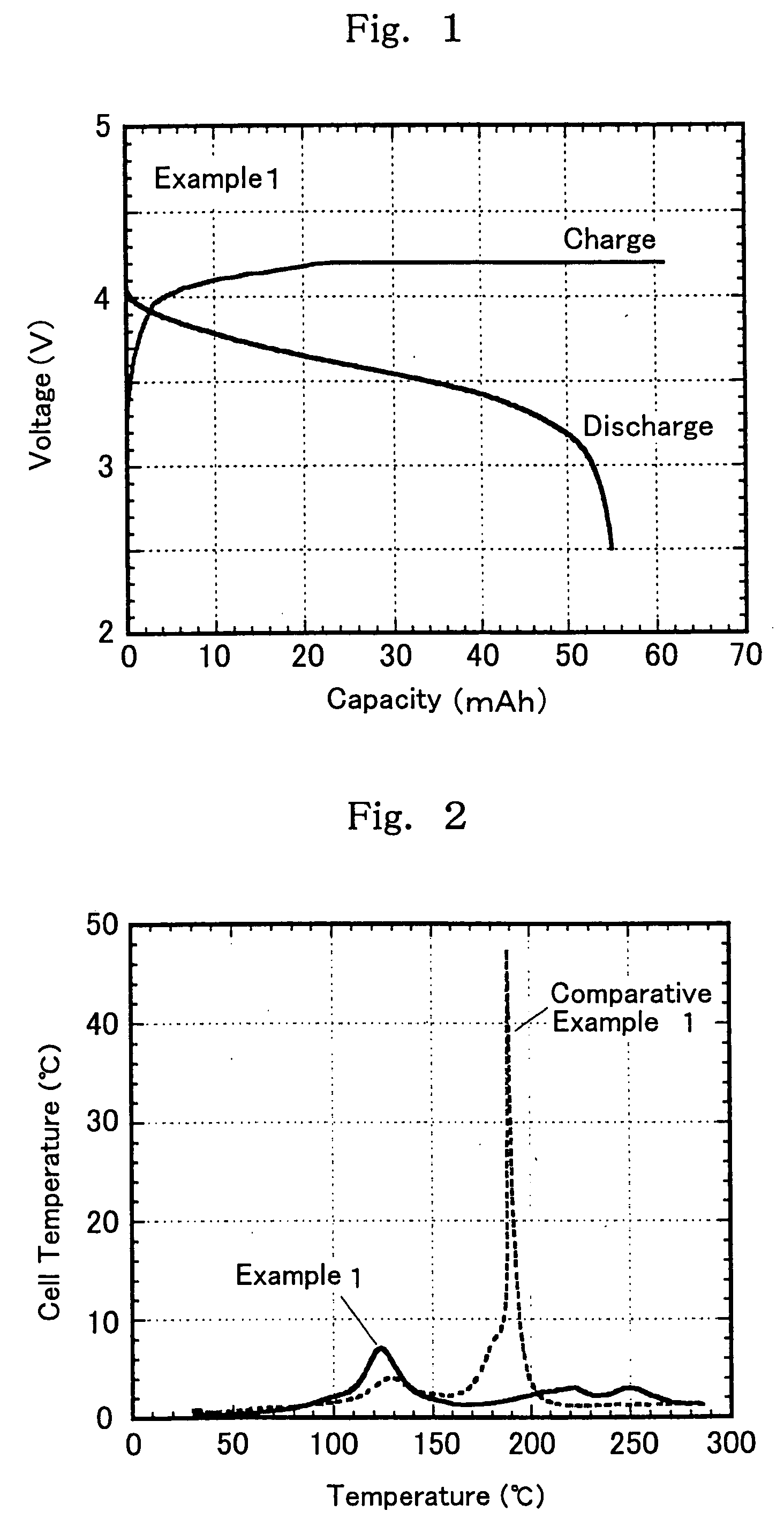

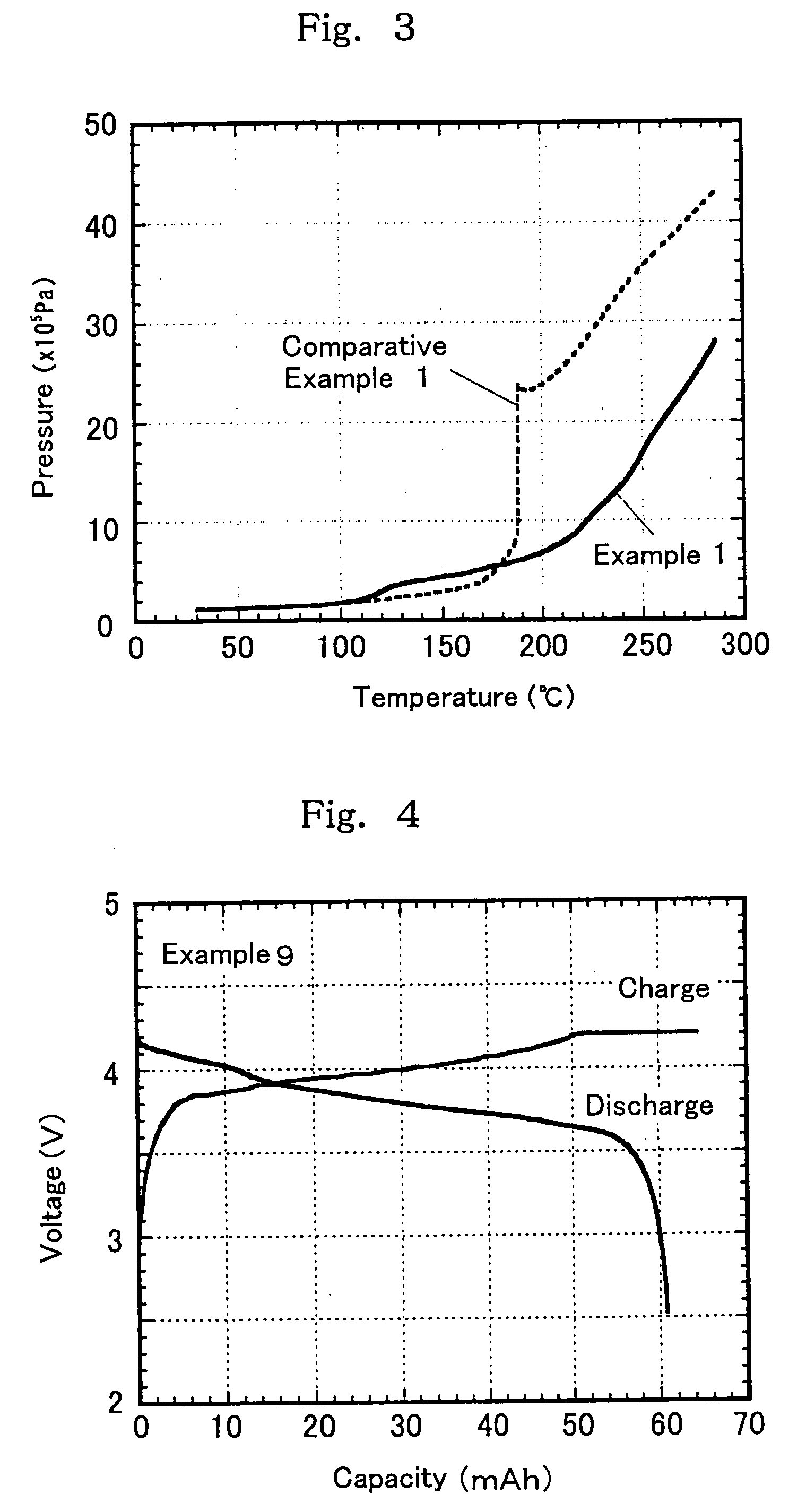

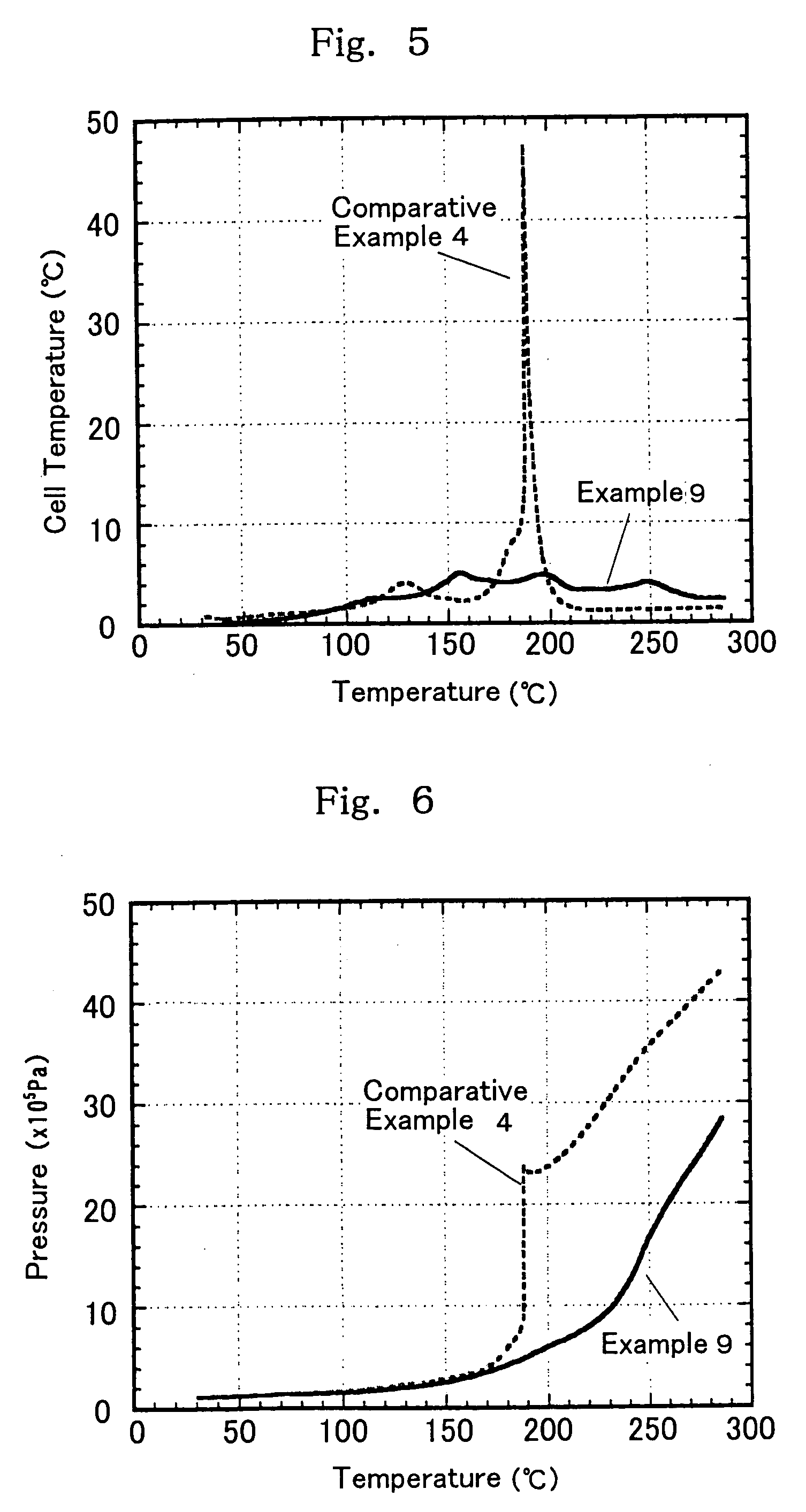

Non-aqueous electrolyte and lithium secondary battery using the same

InactiveUS20060172201A1High conductivityExcellent charge discharge characteristicOrganic electrolyte cellsNegative electrodesSolventCarboxylate

The present invention is directed to a non-aqueous electrolyte for lithium secondary battery, having both flame retardancy (self-extinguishing property) or nonflammability (having no flash point) and high conductivity and being electrochemically stable, and a lithium secondary battery using the non-aqueous electrolyte. Specifically, the non-aqueous electrolyte of the present invention comprises a non-aqueous solvent which comprises (a) at least one phosphate selected from (a1) a chain state phosphate and (a2) a cyclic phosphate as an essential component, and which may contain (b1) a cyclic carboxylate and (b2) a cyclic carbonate. Further, the non-aqueous electrolyte comprises the above non-aqueous solvent which further comprises (c1) a vinylene carbonate compound and / or (c2) a vinylethylene carbonate compound, and at least one compound selected from the group consisting of (d1) a cyclic amide compound, (d2) a cyclic carbamate compound, and (d3) a heterocyclic compound.

Owner:MITSUBISHI CHEM CORP

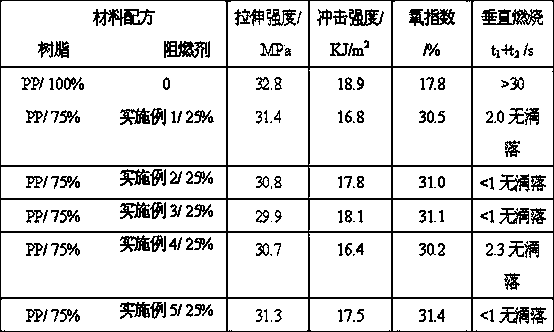

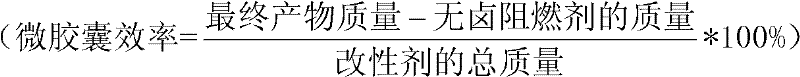

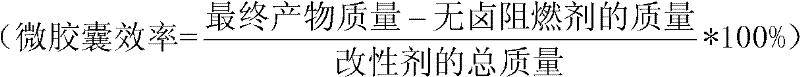

Composite flame retardant containing microcapsule-coated intumescent flame retardant and preparation method

InactiveCN103724666AHigh flame retardant efficiencyOvercome moisture absorptionPolymer scienceHindered amine light stabilizers

The invention belongs to the field of flame retardant materials, and particularly relates to a composite flame retardant containing a microcapsule-coated intumescent flame retardant and a preparation method. The composite flame retardant containing the microcapsule-coated intumescent flame retardant consists of the following components in percentage by mass: 60-94 percent of microcapsule intumescent flame retardant, 5-25 percent of flame-retardant synergist, 0.9-10 percent of smoke suppressant and 0.1-5 percent of hindered amine light stabilizer. The preparation method comprises the following steps: preparing the microcapsule-coated intumescent flame retardant; placing the microcapsule-coated intumescent flame retardant, the flame-retardant synergist, the smoke suppressant and the hindered amine light stabilizer into a high-speed mixer for mixing uniformly, and discharging to obtain the composite flame retardant containing the microcapsule-coated intumescent flame retardant. Multiple components in the composite flame retardant can play roles in retarding flame in a synergetic way, so that the flame retardance of a high polymer material is improved remarkably, the production of toxic and harmful smog in a burning process can be suppressed, and the flame retarding efficiency is increased greatly.

Owner:LIAONING TECHNICAL UNIVERSITY

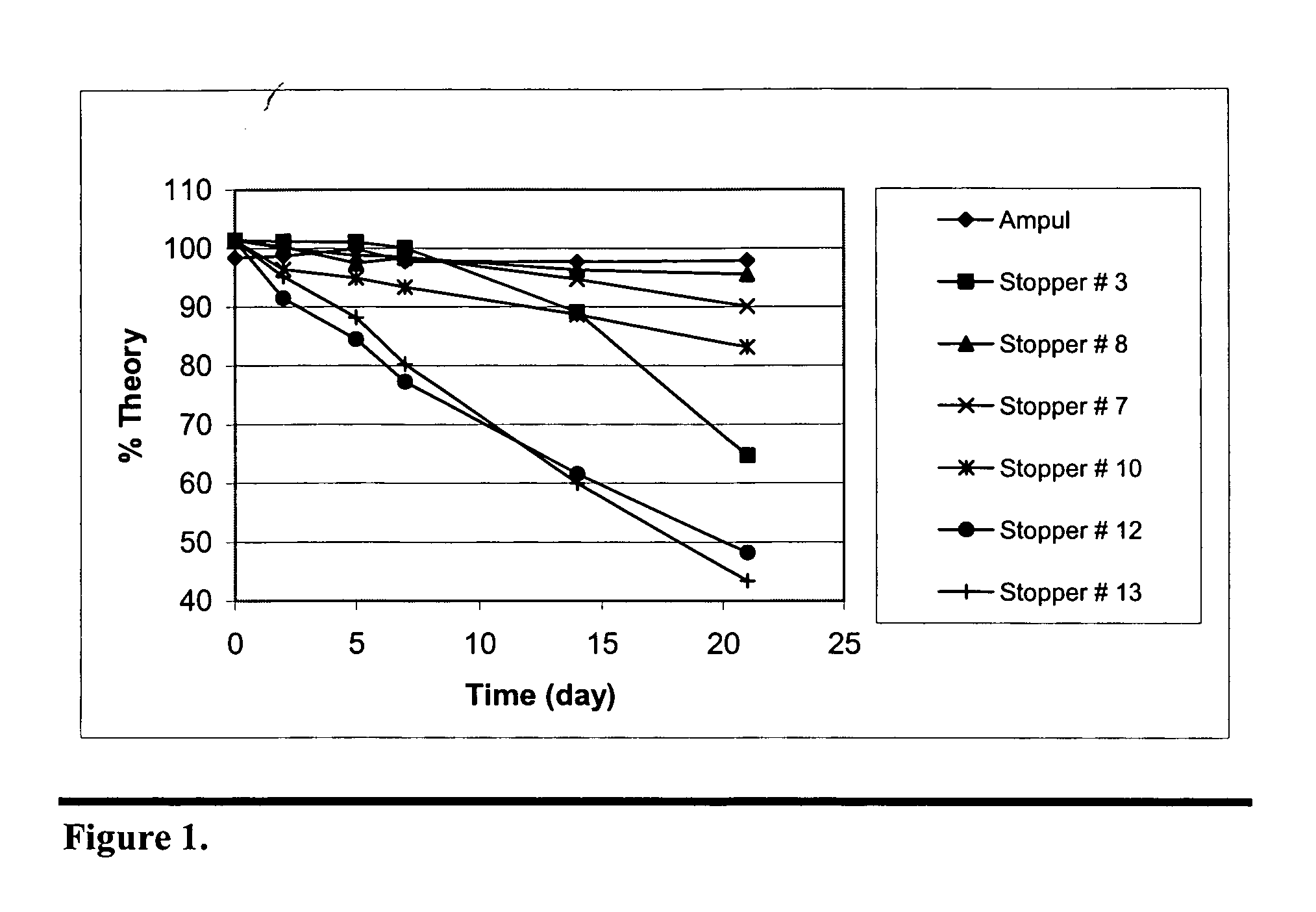

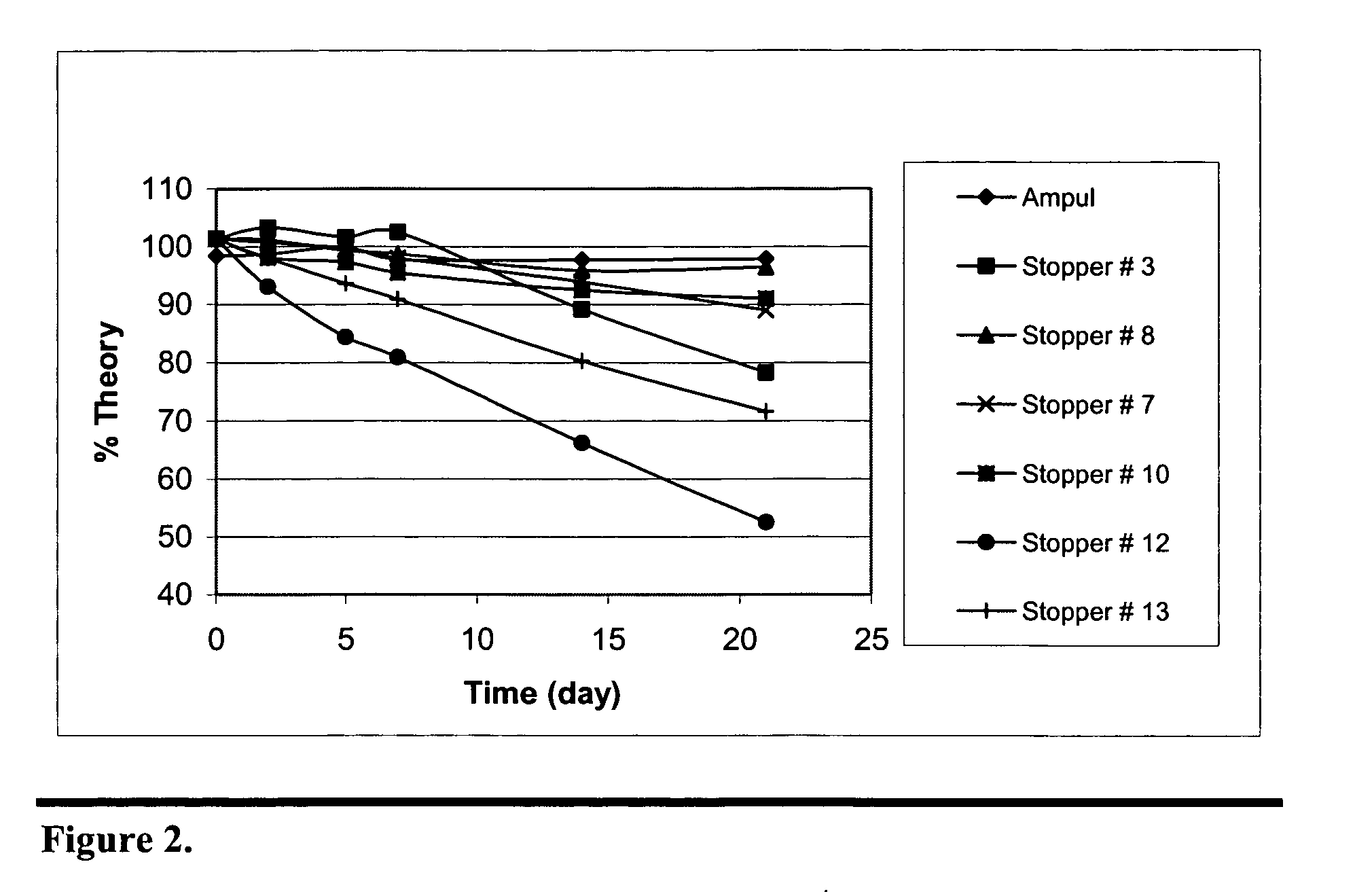

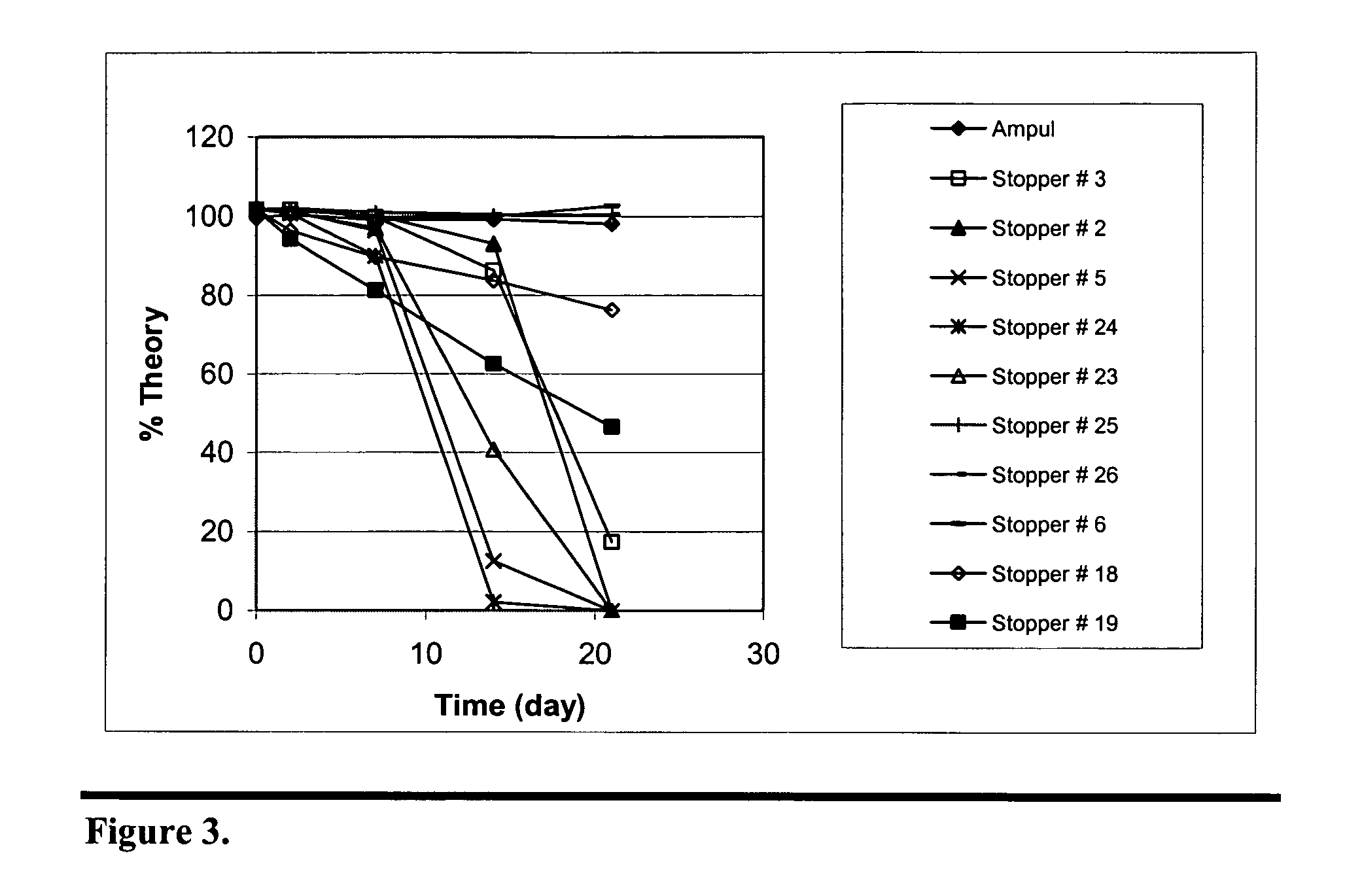

Stabilization of paricalcitol using chlorobutyl or chlorinated butyl stoppers

InactiveUS20070166187A1Extended shelf lifeImprove drug stabilityPharmaceutical containersPharmaceutical delivery mechanismParicalcitolEnvironmental chemistry

This invention relates to a method of enhancing the stability of paricalcitol solution in a container by using a chlorobutyl or chlorinated butyl stopper in the container.

Owner:ABBOTT LAB INC

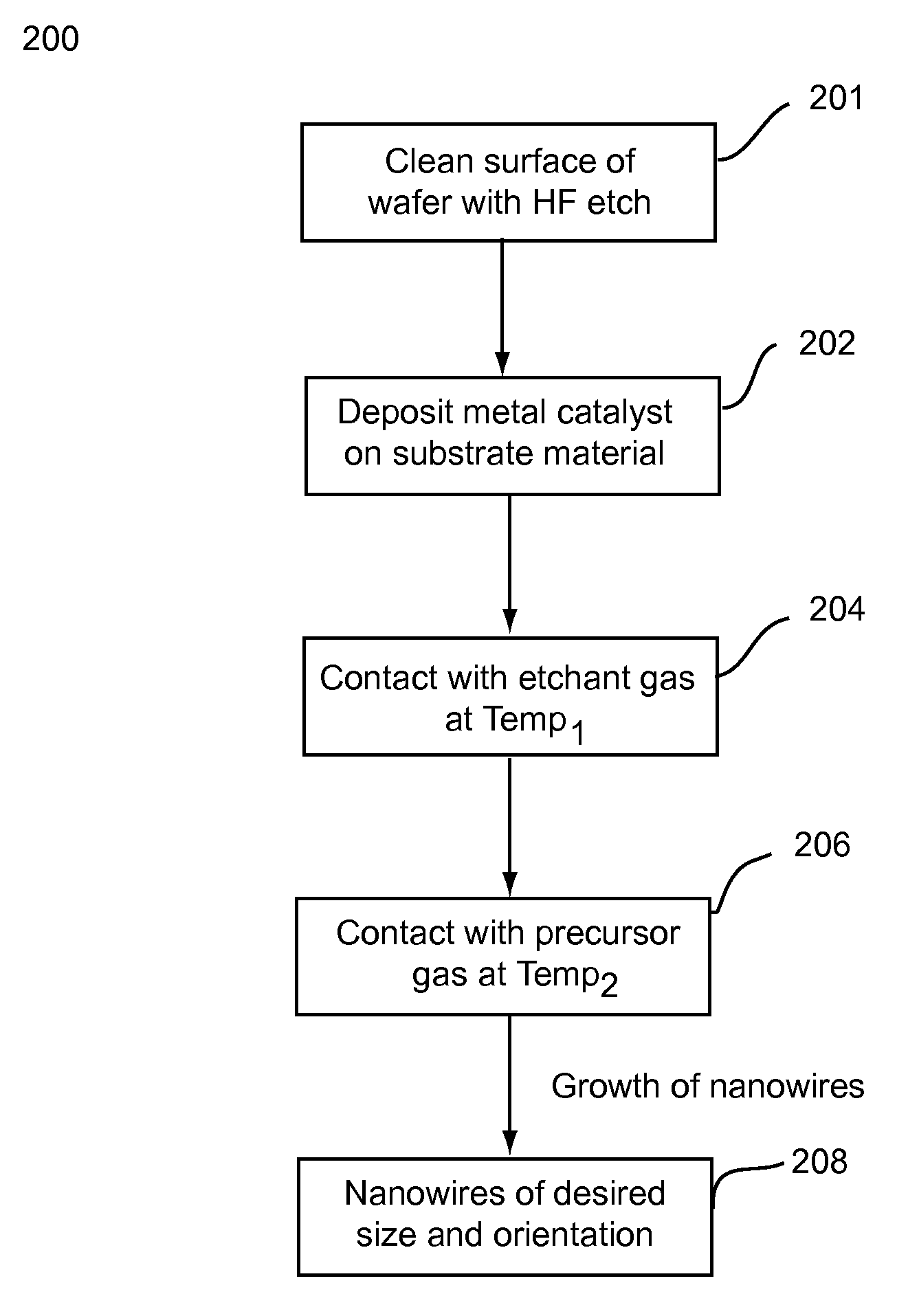

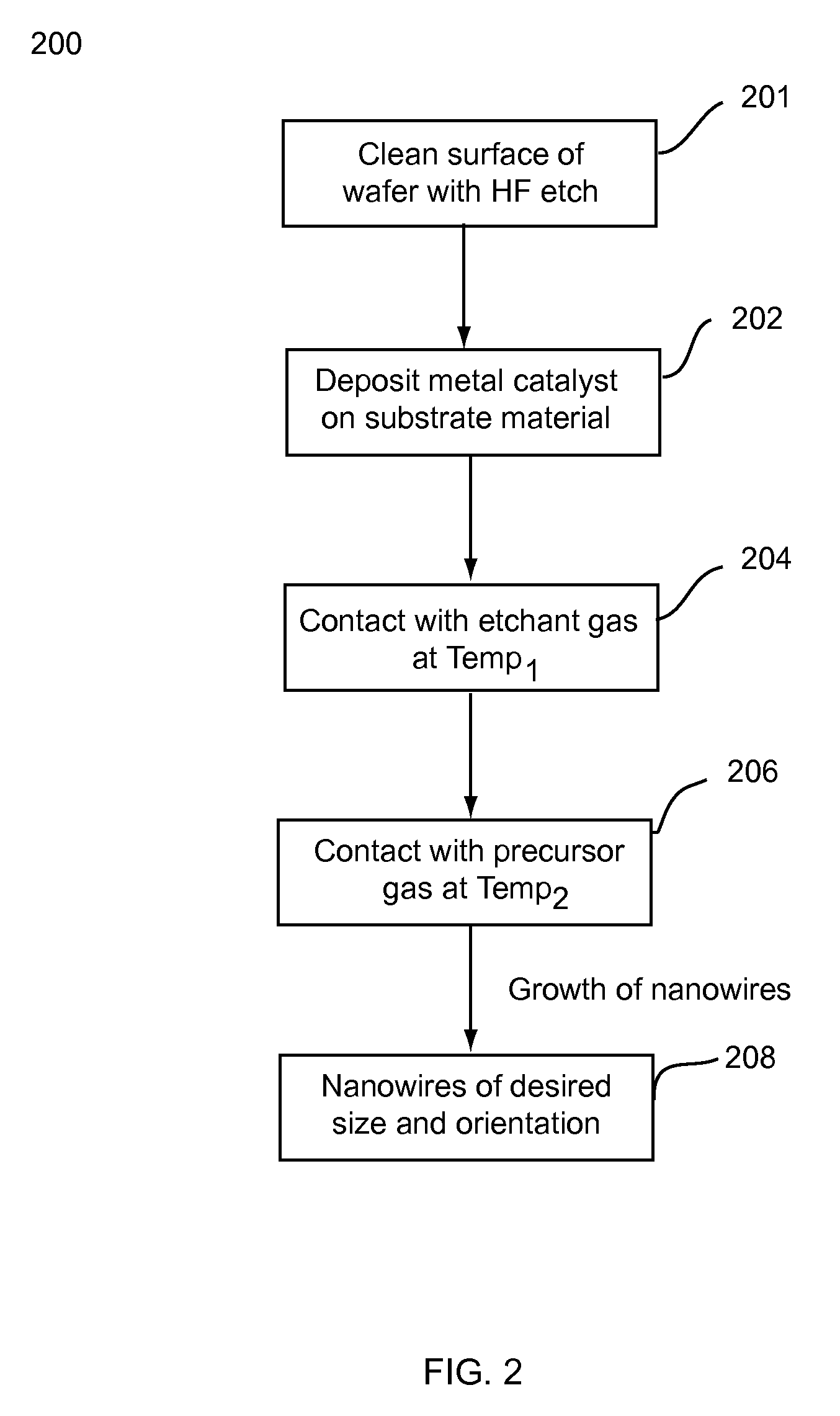

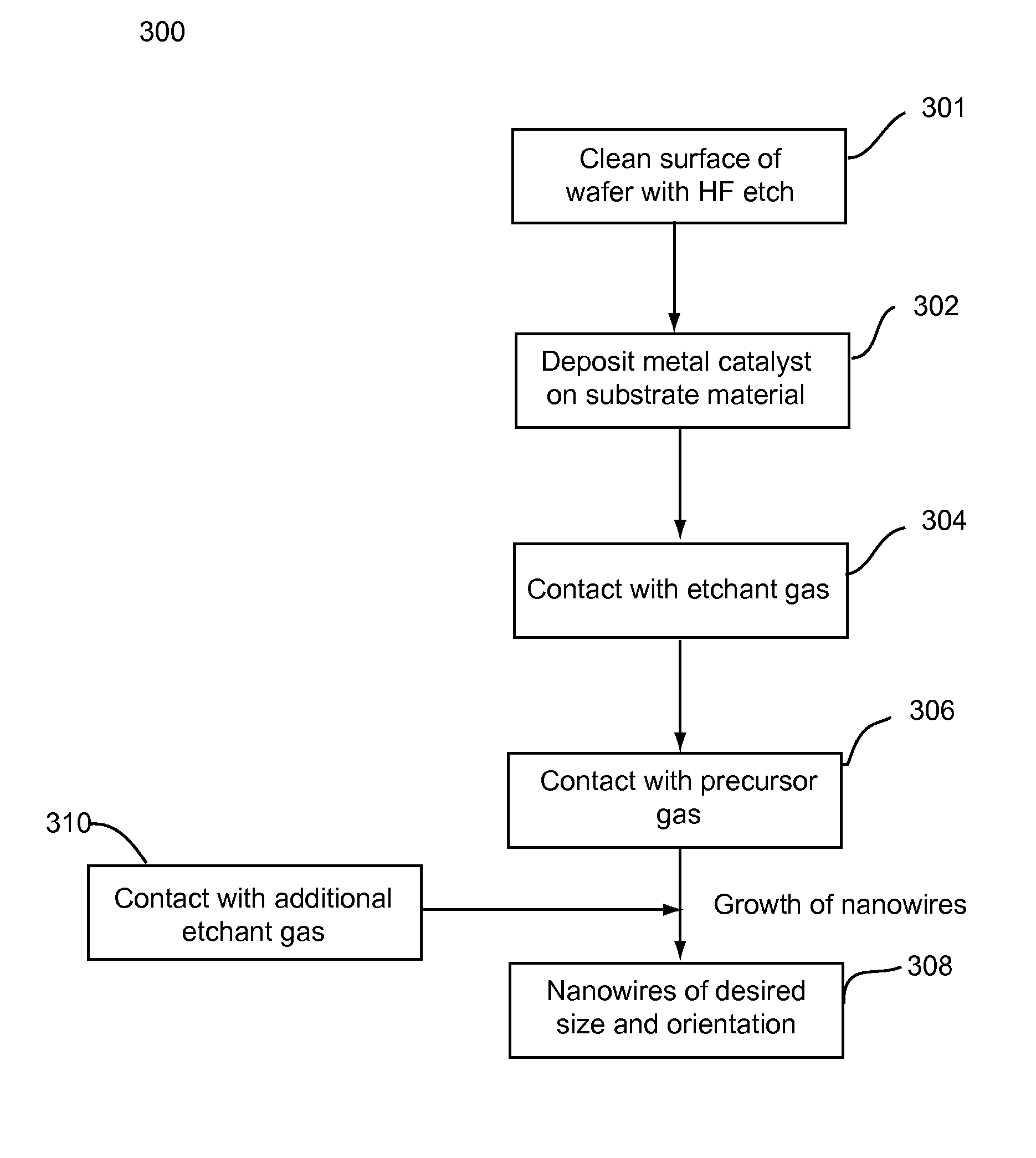

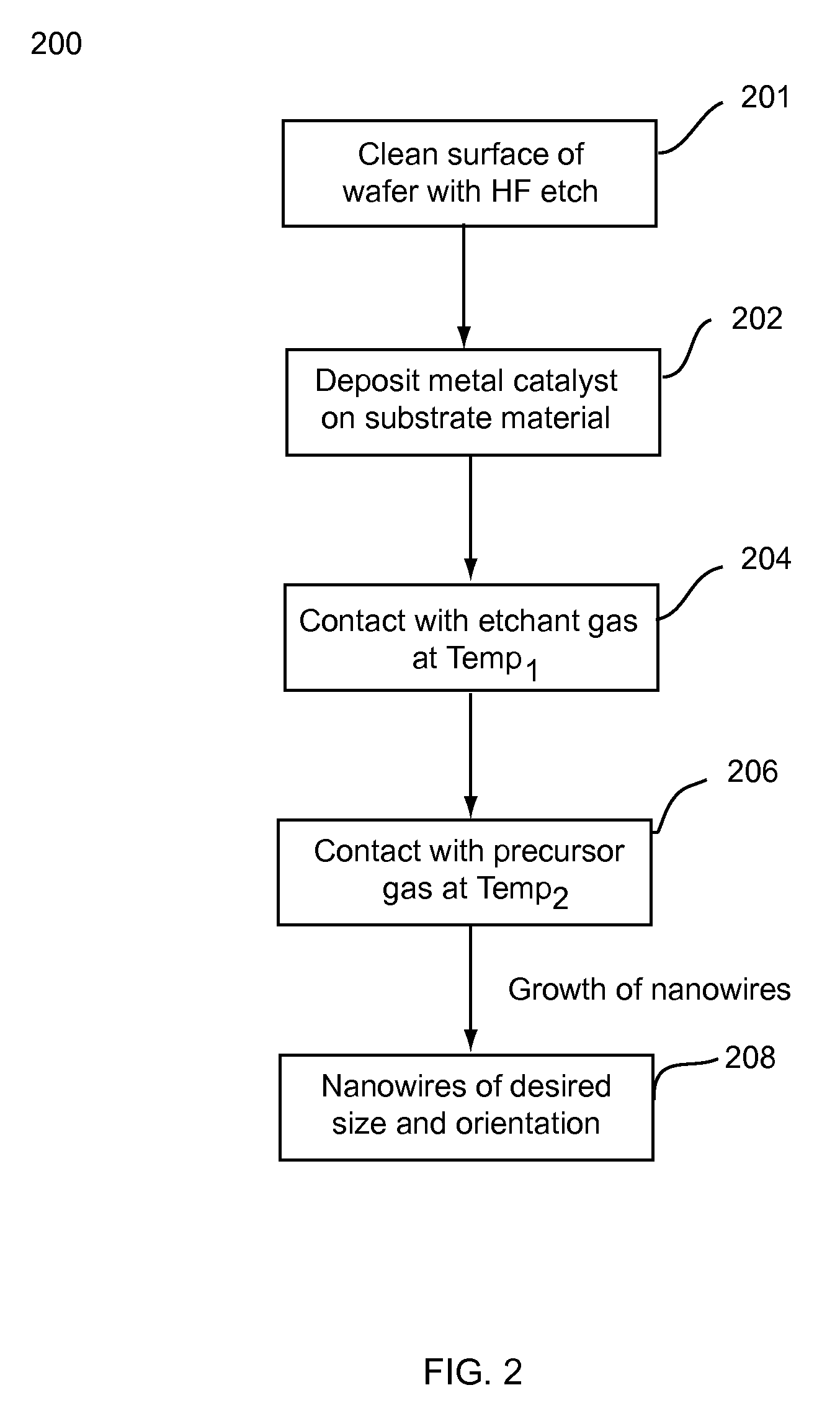

Systems and Methods for Nanowire Growth

ActiveUS20090127540A1Good ohmic contactReduce decomposition ratePolycrystalline material growthIndividual molecule manipulationReaction chamberAlloy

The present invention is directed to systems and methods for nanowire growth. In an embodiment, methods for nanowire growth and doping are provided, including methods for epitaxial vertically oriented nanowire growth including providing a substrate material having one or more nucleating particles deposited thereon in a reaction chamber, introducing an etchant gas into the reaction chamber at a first temperature which gas aids in cleaning the surface of the substrate material, contacting the nucleating particles with at least a first precursor gas to initiate nanowire growth, and heating the alloy droplet to a second temperature, whereby nanowires are grown at the site of the nucleating particles. The etchant gas may also be introduced into the reaction chamber during growth of the wires to provide nanowires with low taper.

Owner:ONED MATERIAL INC

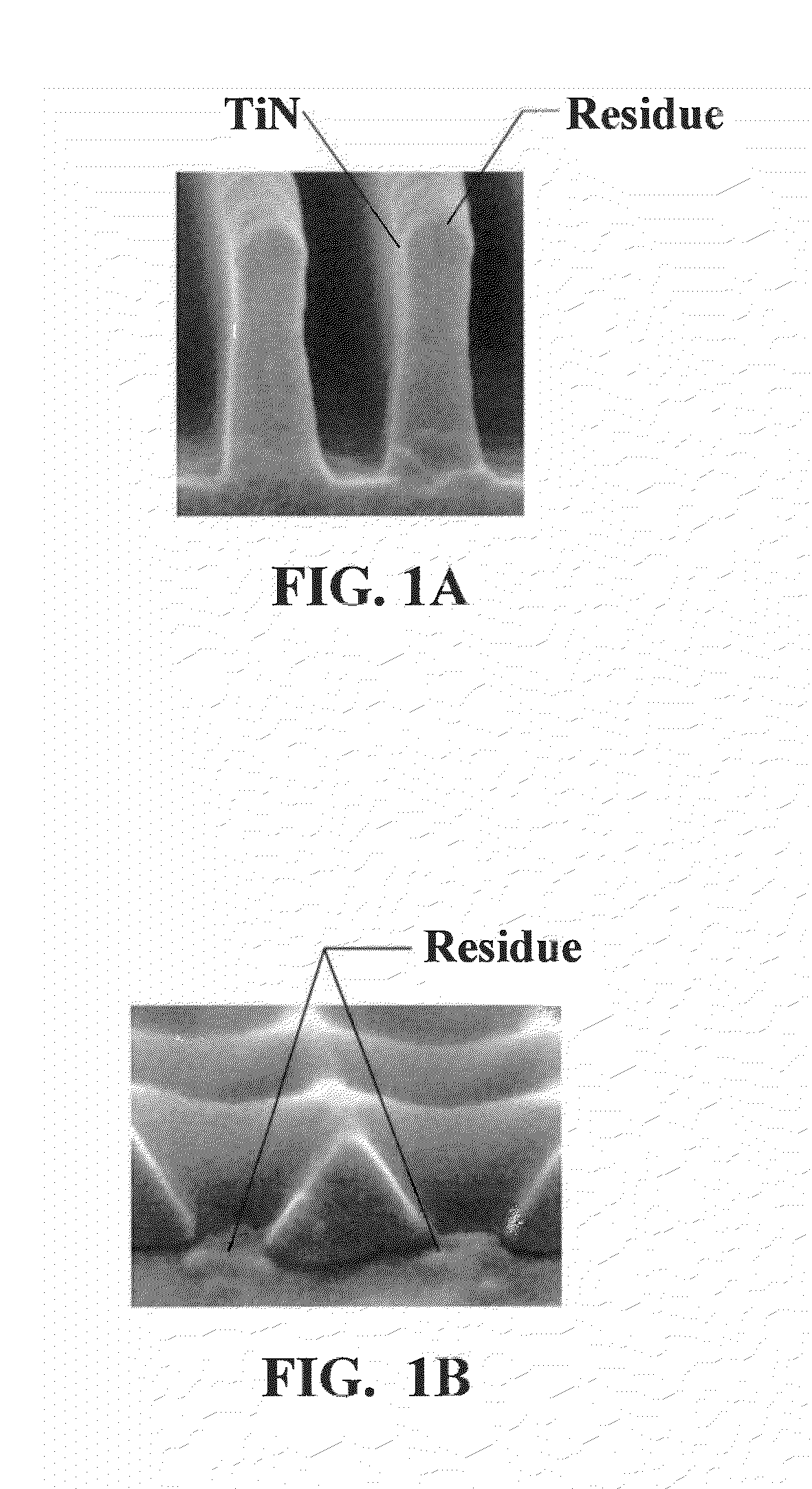

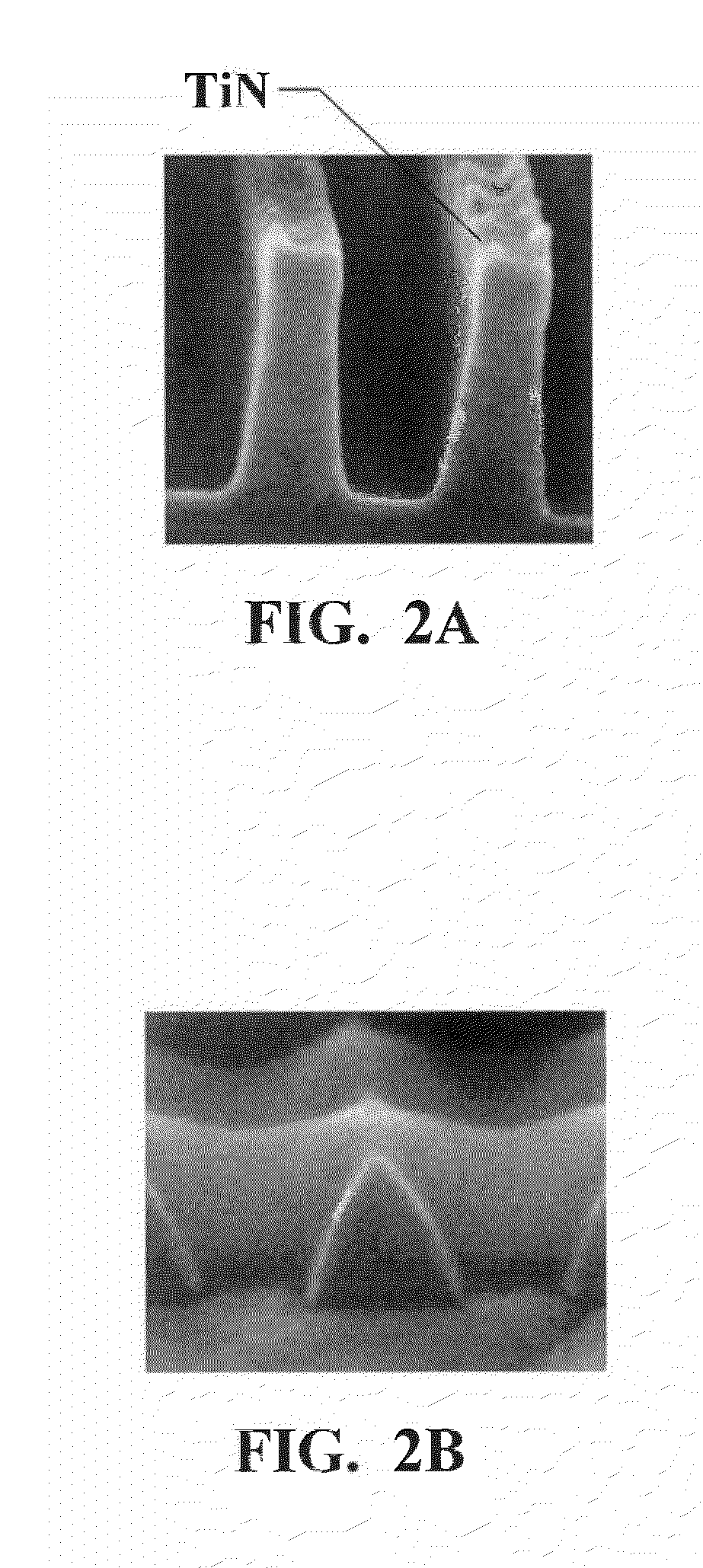

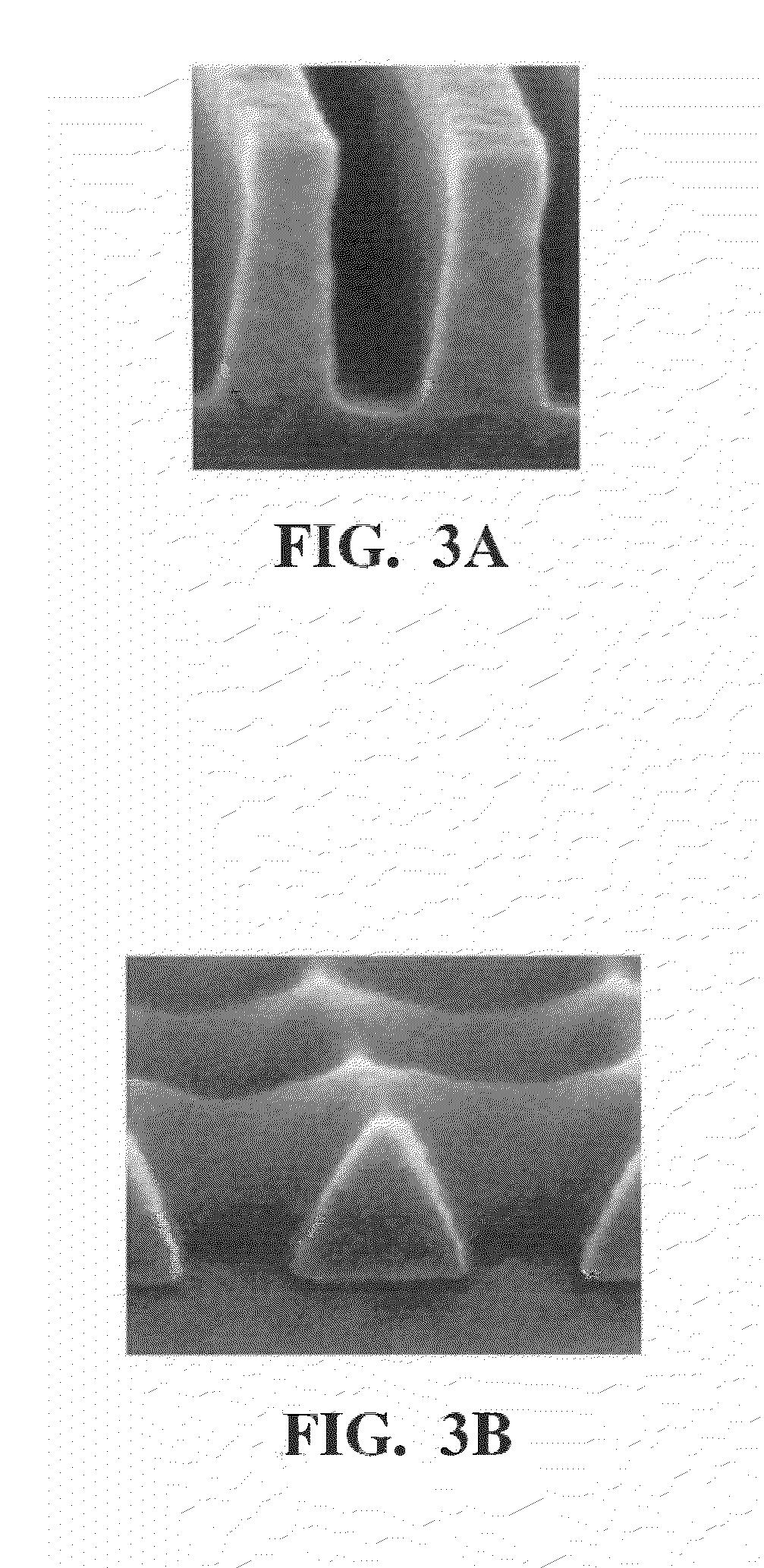

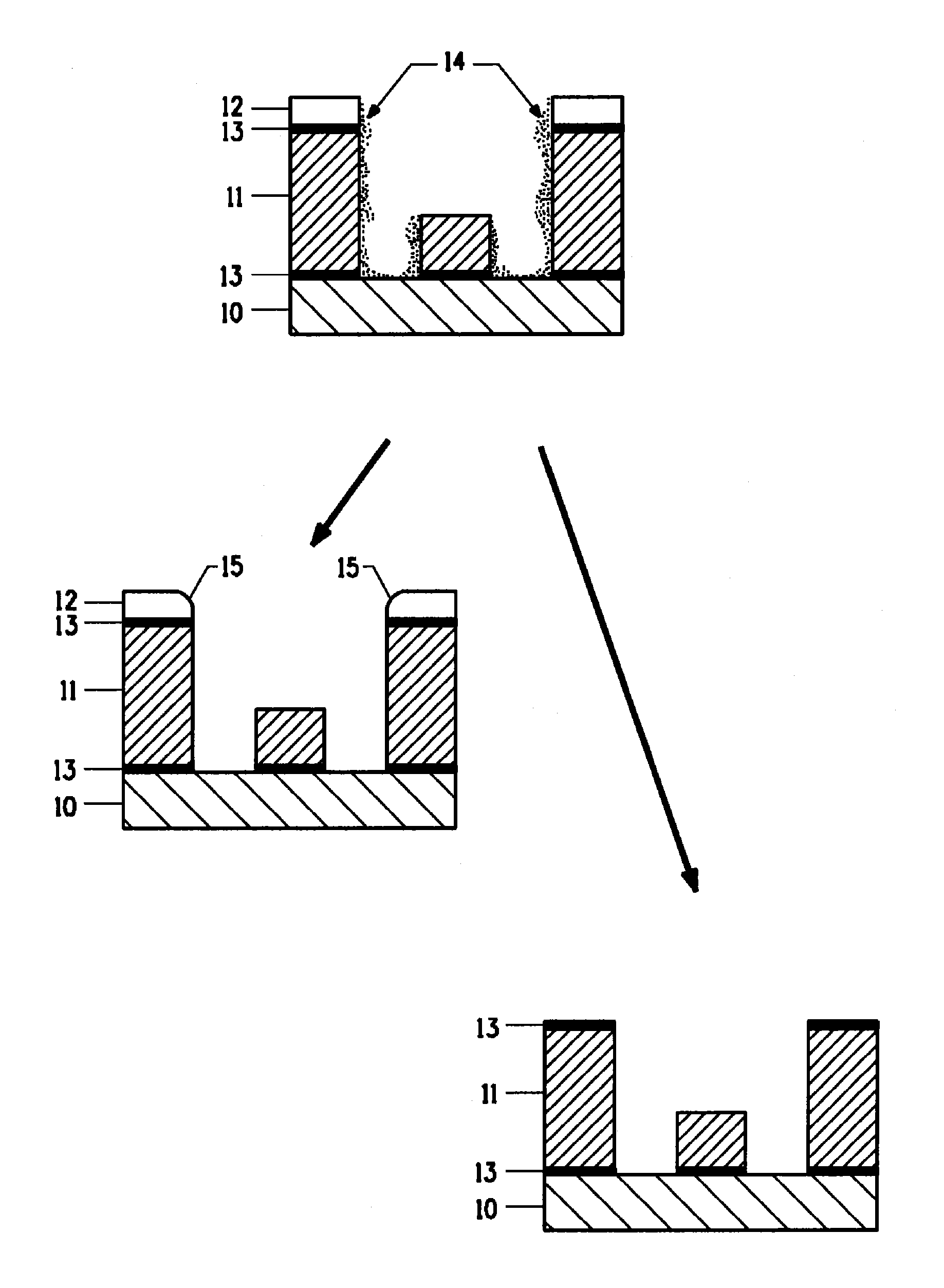

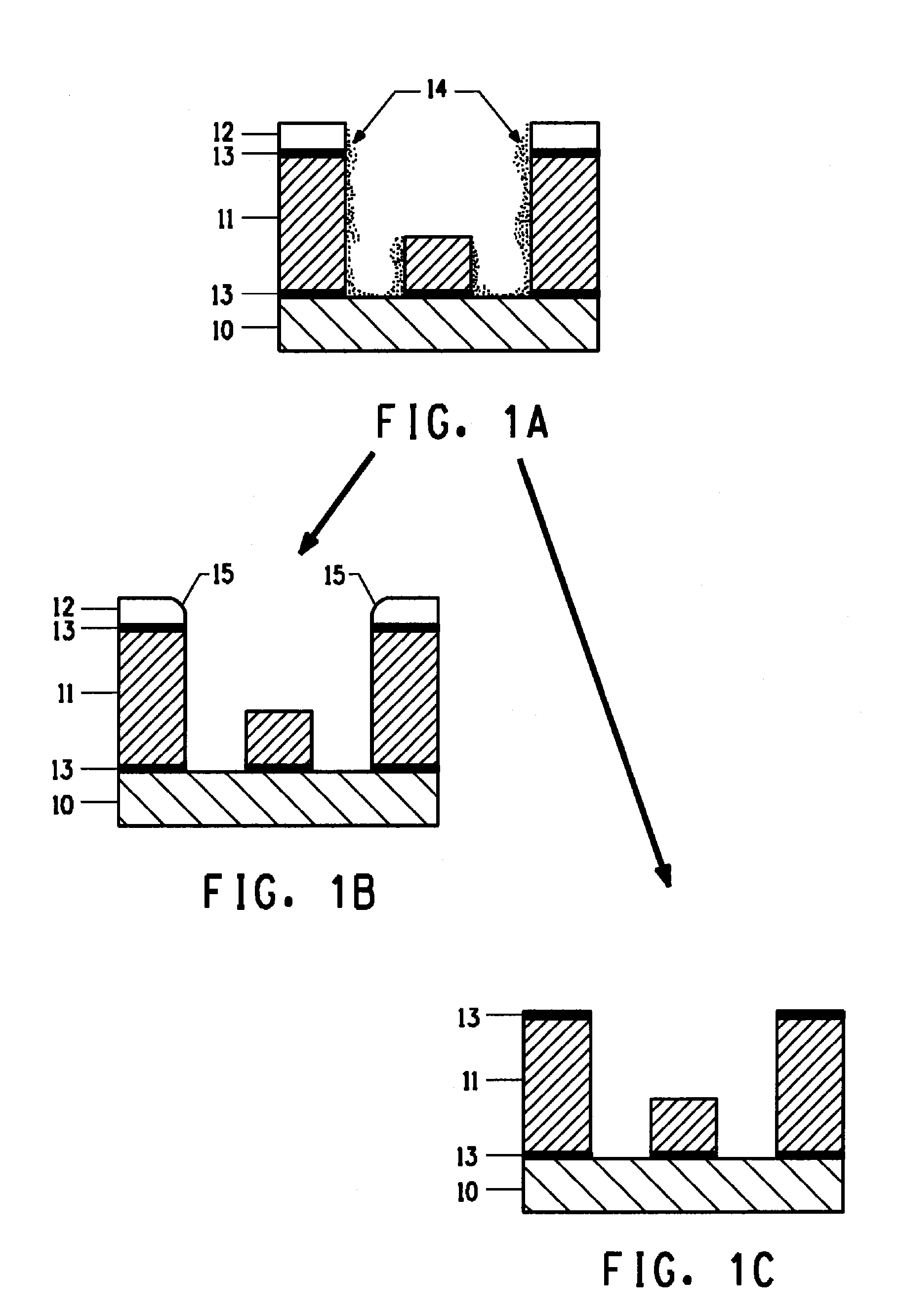

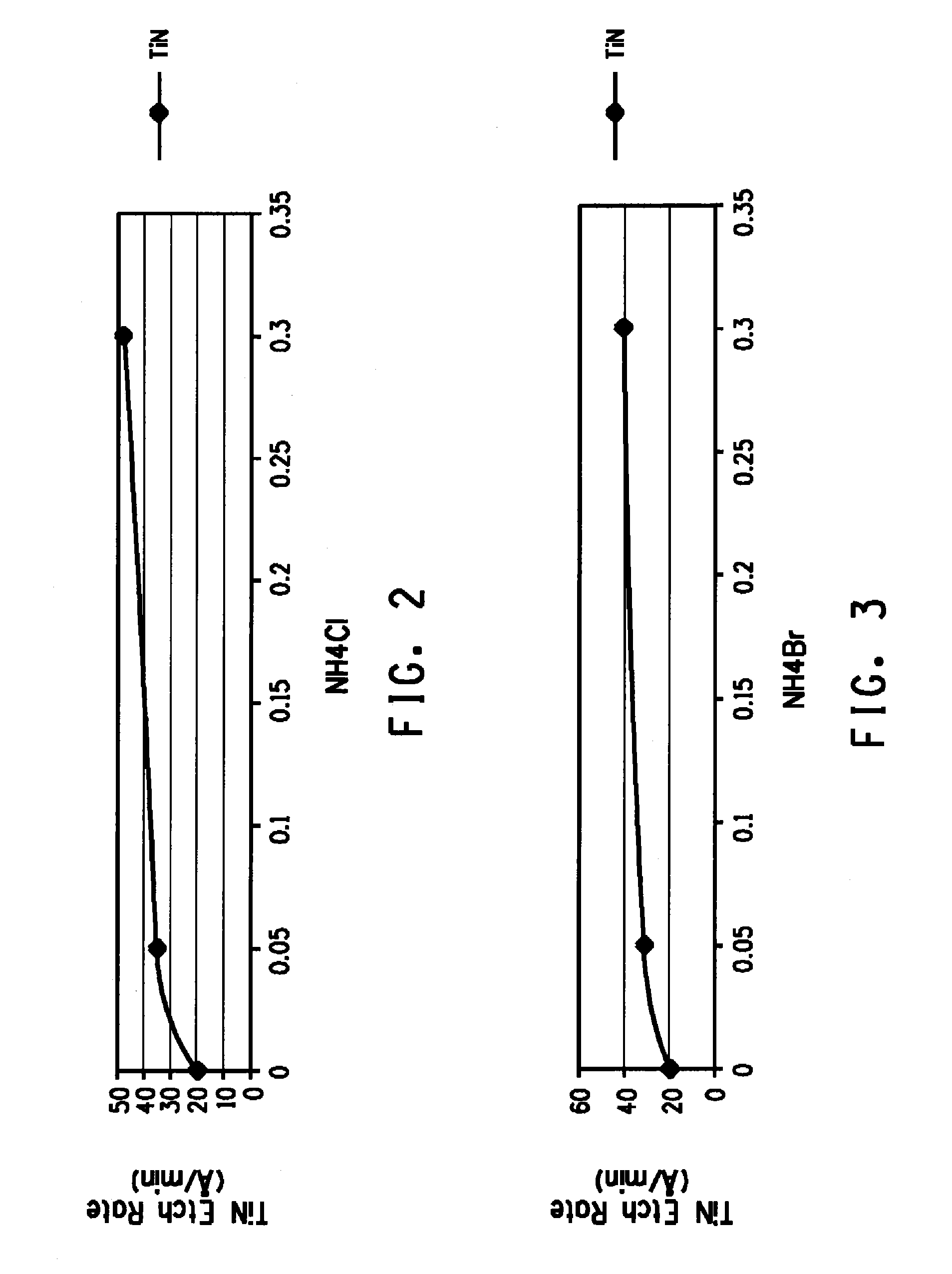

Method and composition for removing resist, etch residue, and copper oxide from substrates having copper, metal hardmask and low-k dielectric material

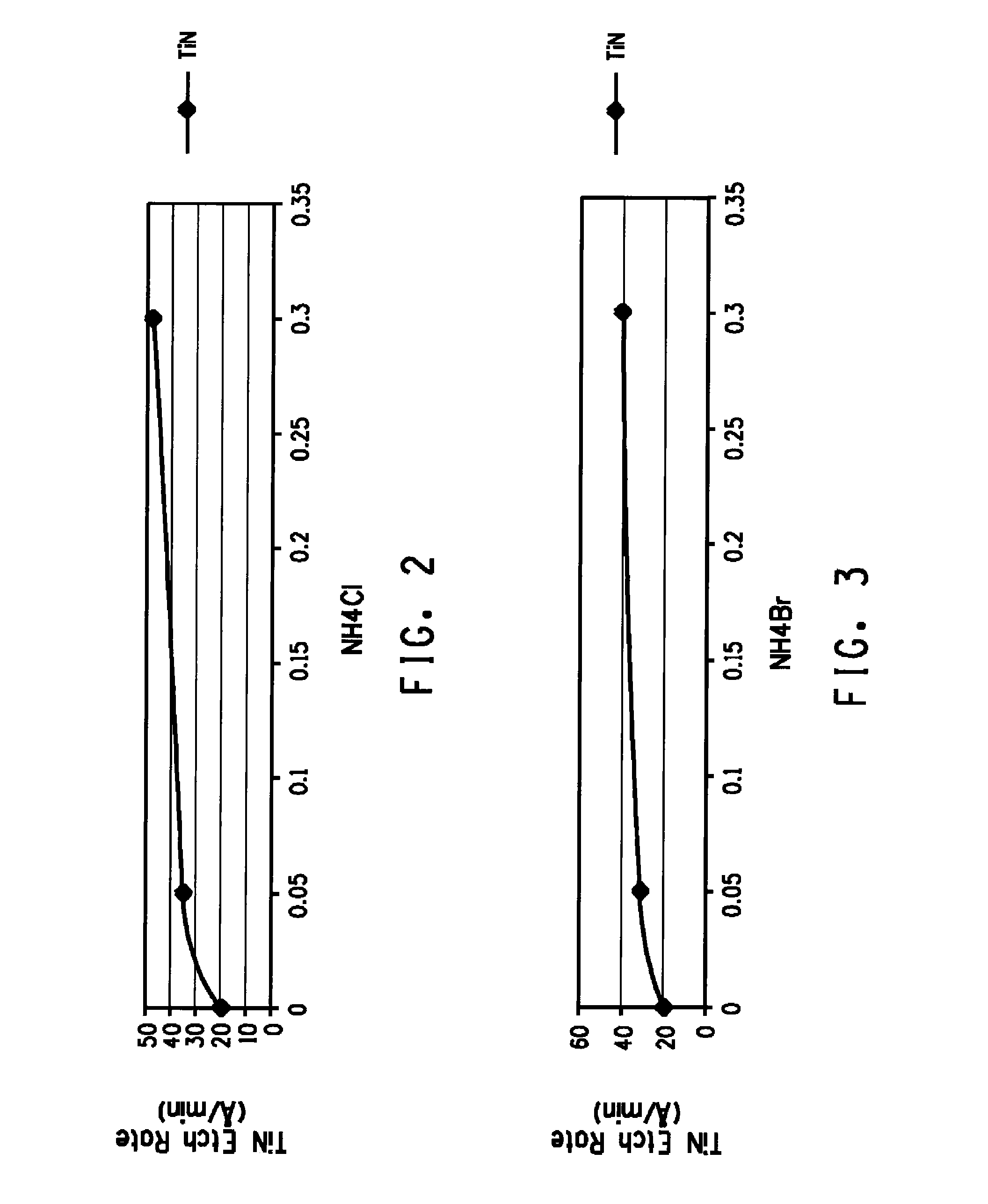

ActiveUS20130157472A1Increase etch rateReduced oxidizer decomposition rateNon-surface-active detergent compositionsDetergent mixture composition preparationResistPhotoresist

A semiconductor processing composition and method for removing photoresist, polymeric materials, etching residues and copper oxide from a substrate comprising copper, low-k dielectric material and TiN, TiNxOy or W wherein the composition includes water, at least one halide anion selected from Cl− or Br−, and, where the metal hard mask comprises only TiN or TiNxOy, optionally at least one hydroxide source.

Owner:EKC TECH

Cleaning compositions for hard to remove organic material

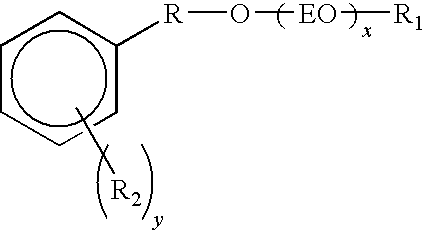

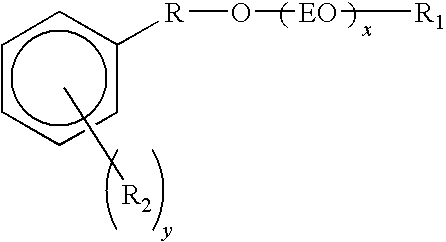

ActiveUS20100236582A1Improve stabilityLow foamingInorganic/elemental detergent compounding agentsNon-ionic surface-active compoundsCelluloseHydrotrope

An oxidizing cleaning composition comprises a low concentration of aqueous hydrogen peroxide that is environmentally friendly and has good stability in strong alkaline solutions. The aqueous hydrogen peroxide composition contains a synergistic combination of one or more hydrophilic surfactants having an HLB of 10 or greater, one or more hydrotropes, one or more UV-analyzable surfactants having an aromatic detectable functional group, and optionally a surfactant having an HLB of less than 10. The cleaning composition when mixed with an alkaline compound is very effective in removing dried or baked residues of polymers, modified or natural celluloses starches, natural gels, and the like at low concentrations and temperatures.

Owner:AMERICAN STERILIZER CO

Method and composition for selectively removing metal hardmask and other residues from semiconductor device substrates comprising low-k dielectric material and copper

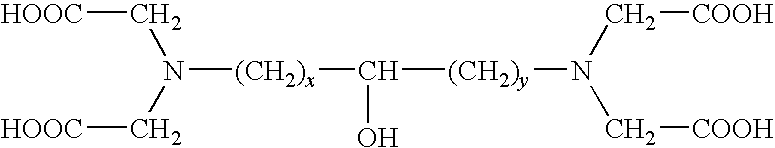

InactiveUS20150104952A1Increase etch rateReduced oxidizer decomposition rateDetergent mixture composition preparationSemiconductor/solid-state device manufacturingCarboxylic acidAlloy

An aqueous removal composition having a pH in the range of from 2 to 14 and method for selectively removing an etching mask consisting essentially of TiN, TaN, TiNxOy, TiW, W, or alloy of Ti or W relative to low-k materials from a semiconductor substrate comprising said low-k materials having a TiN, TaN, TiNxOy, TiW, W, or alloy of Ti or W etching mask thereon wherein the removal composition comprises at least one oxidizing agent and a carboxylate compound.

Owner:EKC TECH

Systems and methods for nanowire growth

ActiveUS7776760B2Good ohmic contactReduce decomposition ratePolycrystalline material growthIndividual molecule manipulationNanowireAlloy

Owner:ONED MATERIAL INC

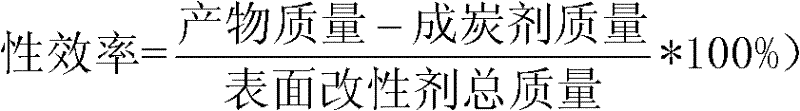

Preparation method of microencapsulated gradient halogen-free flame retardant system

InactiveCN102516603AEvenly dispersedLiquidMicroballoon preparationMicrocapsule preparationPolymer scienceMoisture

The invention relates to a preparation method of a microencapsulated gradient halogen-free flame retardant system. The preparation method comprises the steps of: mixing a phosphorus-series flame retardant with an inorganic flame retardant according to a certain ratio to obtain a microencapsulated halogen-free flame retardant, then carrying out surface modification on a charring agent, and then mixing the microencapsulated halogen-free flame retardant, a phosphorus-containing organic flame retardant and surface-modified charring agent according to a certain ratio to obtain the microencapsulated gradient halogen-free flame retardant system. By using the system, distributed gradient flame retarding is realized, the flame retardancy of a polymer material is greatly improved, the defect that compatibility between the flame retardant and the polymer is poor is solved, the migration of the halogen-free flame retardant from the polymer matrix under high-temperature and moisture conditions is significantly reduced, and the long-term storage of a flame-retardant polymer material is facilitated. The method has the characteristics of simple process, convenience for operation, environmental friendliness, and lower cost. The obtained flame retardant system has good flame retarding effect and wide application field.

Owner:JILIN UNIV

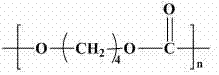

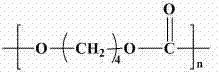

Fully biodegradable aliphatic polycarbonate mulch film and preparation method thereof

ActiveCN102311630AHigh molecular weightHigh tear strengthPlant protective coveringsPolymer sciencePolycarbonate

The invention relates to a fully biodegradable aliphatic polycarbonate mulch film and a preparation method thereof. The mulch film comprises the following raw materials by weight ratio: 30-50 parts of aliphatic polycarbonate butanediol ester, 10-50 parts of starch, 10-50 parts of polylactic acid, 1-5 parts of herbicide, 1.0-3.5 parts of antiblocking agent, 0.5-6 parts of lubricant, 4.0-15 parts of plasticizer, 1.5-4 parts of heat-resistance stabilizing agent, 0.05-1.5 parts of anti-oxidant, 0.5-2.0 parts of coupling agent, 0.05-1.5 parts of biodegradation promoter and 0.5-5.0 parts of photodegradation agent. The Fully biodegradable aliphatic polycarbonate mulch film can be prepared by mixing and stirring the raw materials and extruding to granulate by a twin-screw machine. The fully biodegradable aliphatic polycarbonate mulch film of the invention has the advantages of low cost, good temperature toleration, temperature tolerance and water resistance, and is capable of regulating the degradation rate and has the function of weeding.

Owner:JIANGSU XINGYE PLASTIC

Method for preparing brake block by calcium carbonate crystal whisker

InactiveCN101205456AImprove high temperature resistanceReduce decomposition rateOther chemical processesPorosityDecomposition

The invention relates to a method for preparing a brake sheet through adopting calcium carbonate crystal whisker, belonging to the friction material field, wherein the following raw materials of corresponding part by weight are adopted: 5 to 15 portions of adhesive which adopts phenol formaldehyde resin, 20 to 30 portions of reinforcing material which is obtained through mixing steel fiber or ceramic fiber with one or several of aramid fiber, mineral fiber and glass fiber, 1 to 15 portions of grinding agent which comprises one or combination of several of aluminum sesquioxide, ferric oxide, magnesium oxide and friction powder, 5 to 15 portions of lubricant which comprises one or combination of several of graphite, molybdenum disulfide and mica, 5 to 15 portions of stabilizer calcium carbonate crystal whisker, and 30 to 50 portions of filler which comprises one or combination of several of barium sulfate, potassium titanate and magnesium oxide. The brake sheet, which is made through the method, can effectively increase porosity and improve the high-temperature resistance of material, thereby lowering the decomposition rate of organic material at a high temperature; meanwhile, the brake sheet can slow down the gaseous escape speed on a friction surface during fading, thereby reducing fading rate and the change rate of friction coefficient at high speed to less than 10 percent.

Owner:信义集团公司

Cleaning compositions for hard to remove organic material

ActiveUS20070259802A1Improve stabilityLow foamingInorganic/elemental detergent compounding agentsNon-ionic surface-active compoundsCelluloseHydrotrope

An oxidizing cleaning composition comprises a low concentration of aqueous hydrogen peroxide that is environmentally friendly and has good stability in strong alkaline solutions. The aqueous hydrogen peroxide composition contains a synergistic combination of one or more hydrophilic surfactants having an HLB of 10 or greater, one or more hydrotropes, one or more UV-analyzable surfactants having an aromatic detectable functional group, and optionally a surfactant having an HLB of less than 10. The cleaning composition when mixed with an alkaline compound is very effective in removing dried or baked residues of polymers, modified or natural celluloses starches, natural gels, and the like at low concentrations and temperatures.

Owner:AMERICAN STERILIZER CO

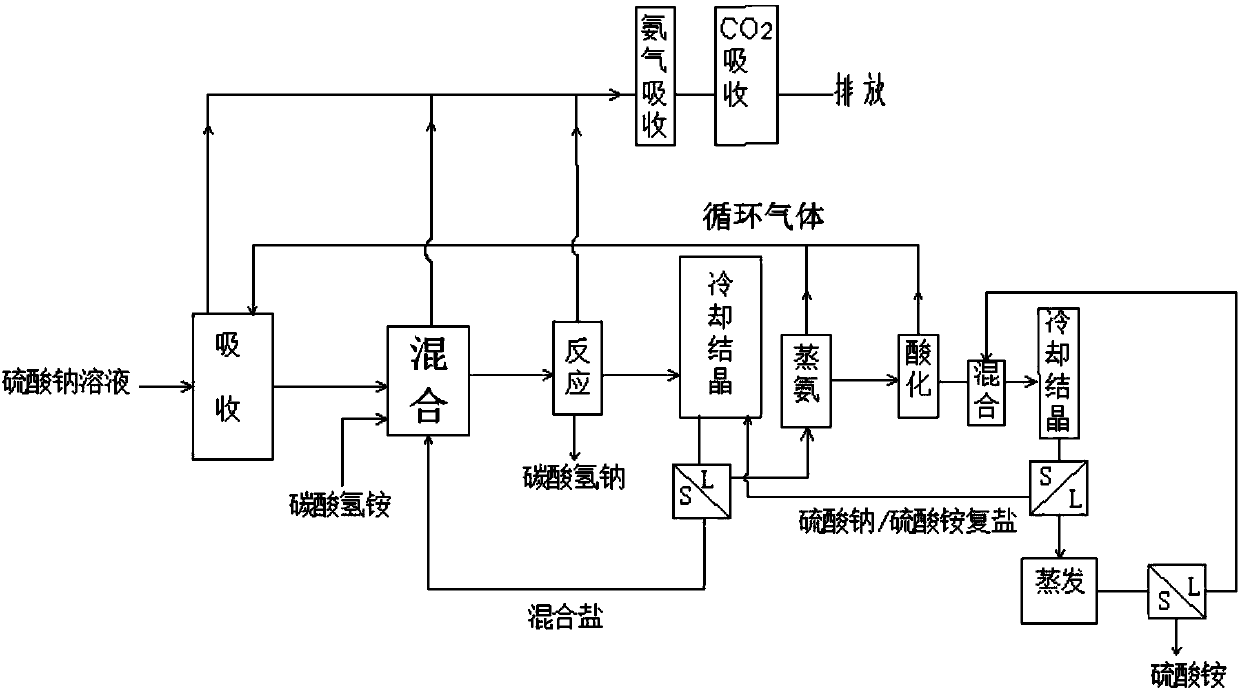

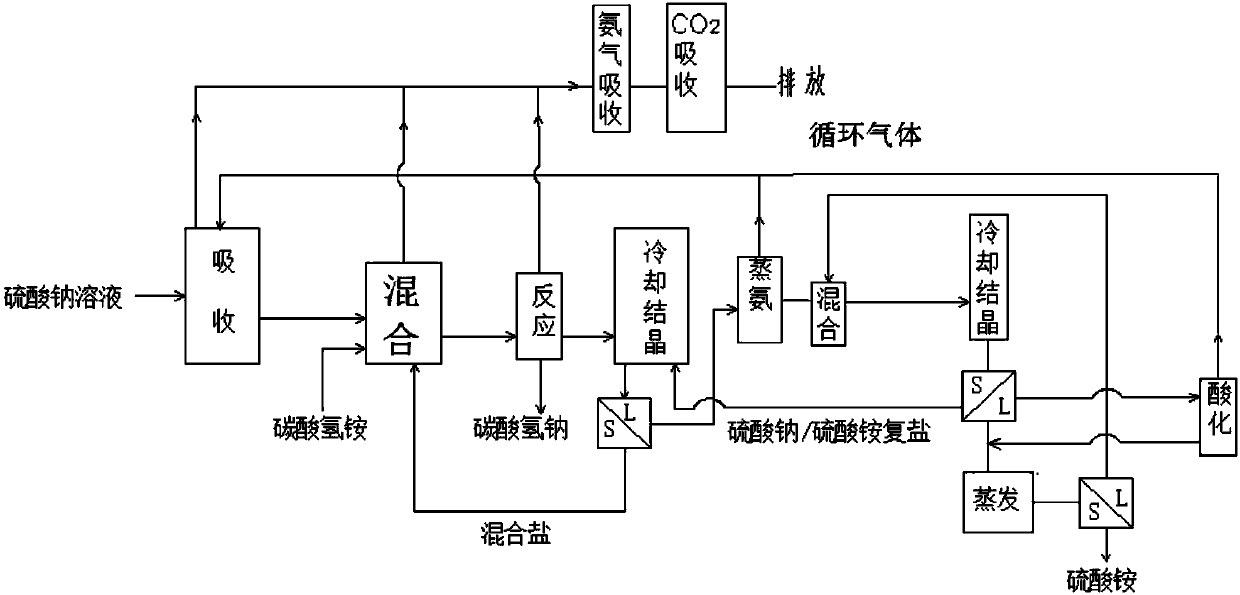

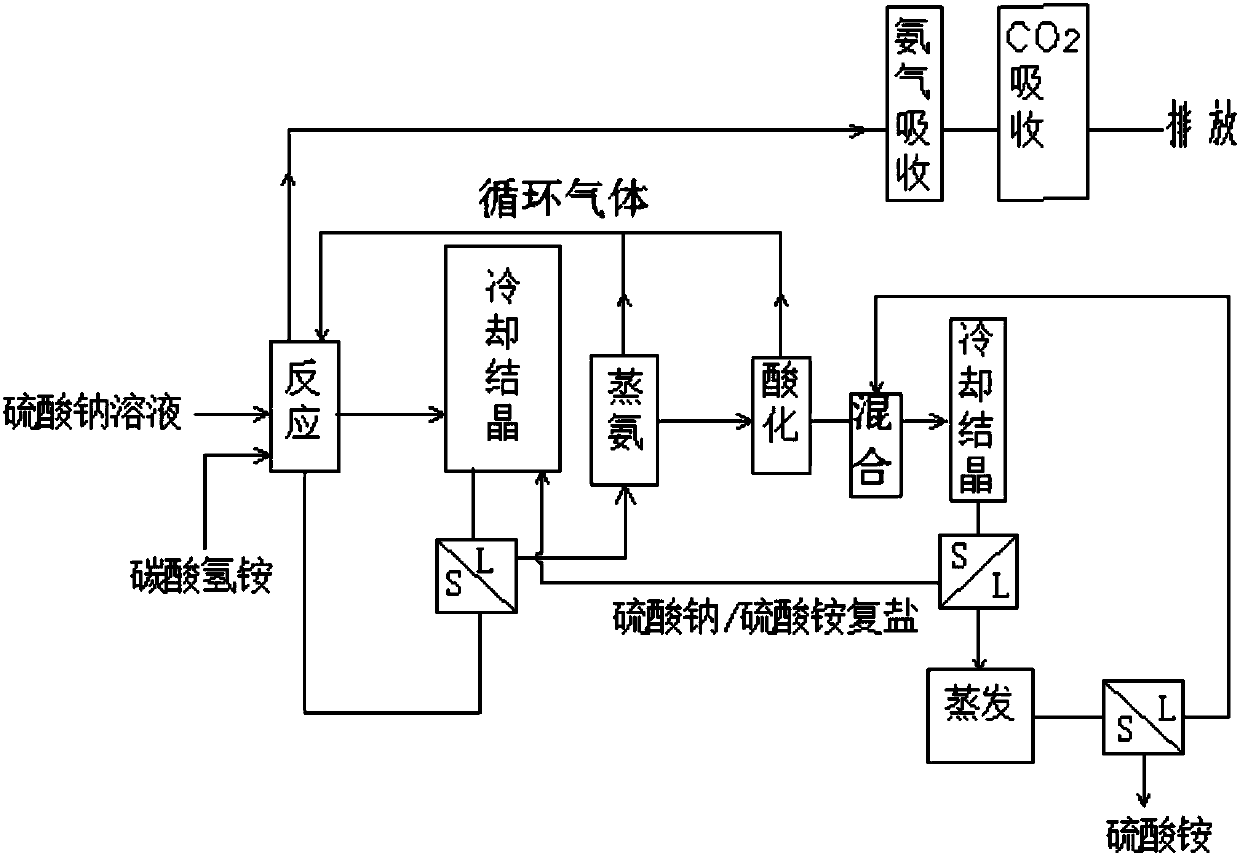

Method for producing sodium hydrogen carbonate and ammonium sulfate by using sodium sulfate solution

ActiveCN108046295ASolve pollutionImprove absorption rateCarbonate preparationAmmonia compoundsSodium bicarbonateHydrogen

The invention relates to a method for producing sodium hydrogen carbonate and ammonium sulfate by using a sodium sulfate solution, and belongs to the technical field of chemical engineering. The method comprises the following steps: a, absorbing circulating gas by using the sodium sulfate solution at -5 to 10 DEG C to obtain absorbing liquid; b, mixing the absorbing liquid, ammonium hydrogen carbonate and / or mixed salt at -5 to 20 DEG C to obtain mixed slurry; c, performing sealed reaction on the mixed slurry to obtain sodium hydrogen carbonate and reaction mother liquid; d, mixing the reaction mother liquid and complex salt to obtain salt mixture and primary frozen mother liquid after freezing; e, distilling the primary frozen mother liquid to obtain carbon dioxide, ammonium circulating gas and ammonium steaming mother liquid; f, adjusting the ammonium steaming mother liquid by acid to obtain an acidified solution and gas; g, mixing and freezing the acidified solution and crystallizedmother liquid to obtain complex salt and secondary frozen mother liquid; and h, evaporating and concentrating the secondary frozen mother liquid to separate out ammonium sulfate. The method is low inenvironmental pollution and high in raw material utilization rate.

Owner:SICHUAN UNIV

Method and composition for removing resist, etch residue, and copper oxide from substrates having copper, metal hardmask and low-k dielectric material

InactiveUS20130045908A1Increase etch rateReduced oxidizer decomposition rateNon-surface-active detergent compositionsDetergent mixture composition preparationResistCopper oxide

A semiconductor processing composition and method for removing photoresist, polymeric materials, etching residues and copper oxide from a substrate comprising copper, low-k dielectric material and TiN, TiNxOy or W wherein the composition includes water, a Cu corrosion inhibitor, at least one halide anion selected from Cl− or Br−, and, where the metal hard mask comprises TiN or TiNxOy, at least one hydroxide source.

Owner:EKC TECH

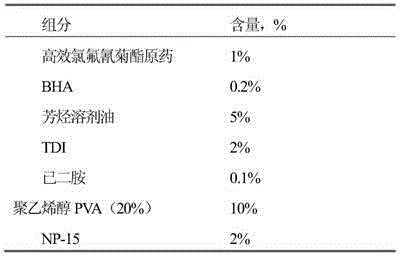

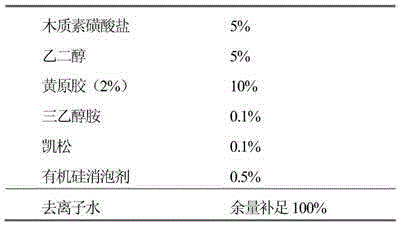

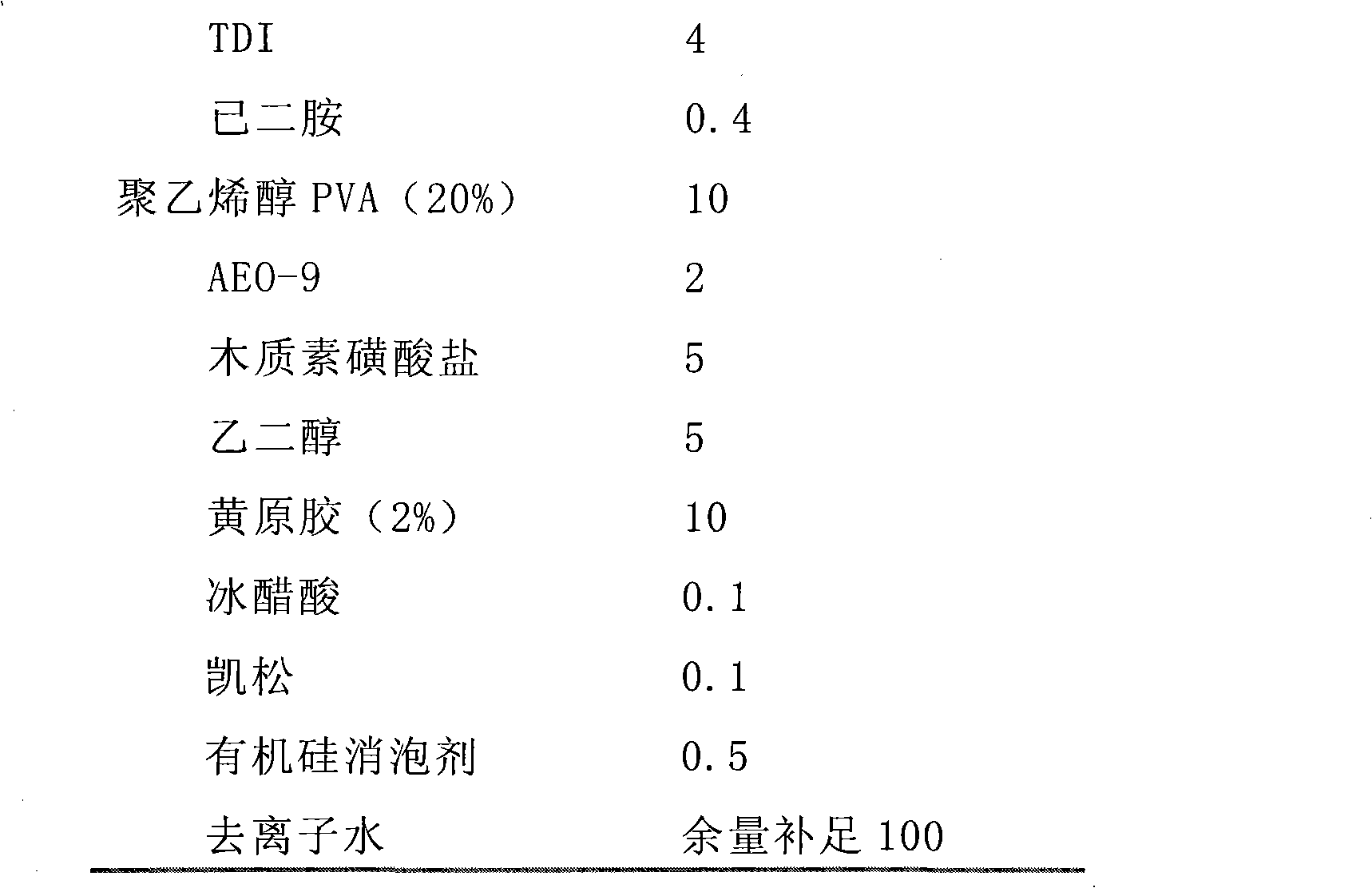

High-efficiency cyhalothrin microcapsule suspension and preparation method thereof

InactiveCN105076188AMeet the anti-efficacy requirementsReduce decompositionBiocideAnimal repellantsNon target organismControlled release

The invention relates to a microcapsule suspension, the high-efficiency cyhalothrin microcapsule suspension comprises the following components: 1-20% of high-efficiency cyhalothrin, 1-10% of a solvent, 1-8% of a capsule wall material, 0.1-3% of a protecting adhesive, 2-5% of an emulsifier, 3-5% of a dispersant, 0.01-14% of an adjuvant and 1-99% of water. The preparation method is characterized in that a high-efficiency cyhalothrin active substrate is taken as the capsule core, a polyurea resin is taken as the capsule wall material, an interfacial polymerization technology is used for preparing the high-efficiency cyhalothrin microcapsule suspension, and finally the cyhalothrin microcapsule suspension is prepared. The effective components in the cyhalothrin microcapsule suspension are concentrated in the capsule core, and other medium can be water, such that environmental pollution is reduced, and production cost is effectively reduced. The high-efficiency cyhalothrin microcapsule suspension has release controlling capability, pesticide lasting period can be prolonged by 3-10 times, acute toxicity of original medicine can be reduced, toxicity of the cyhalothrin microcapsule suspension on non-target organisms is also reduced, and the high-efficiency cyhalothrin microcapsule suspension is safe to use and transport.

Owner:南通联农佳田作物科技有限公司

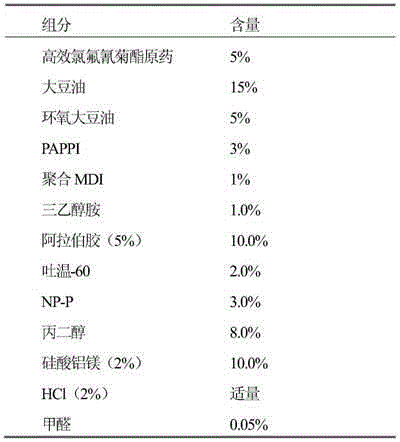

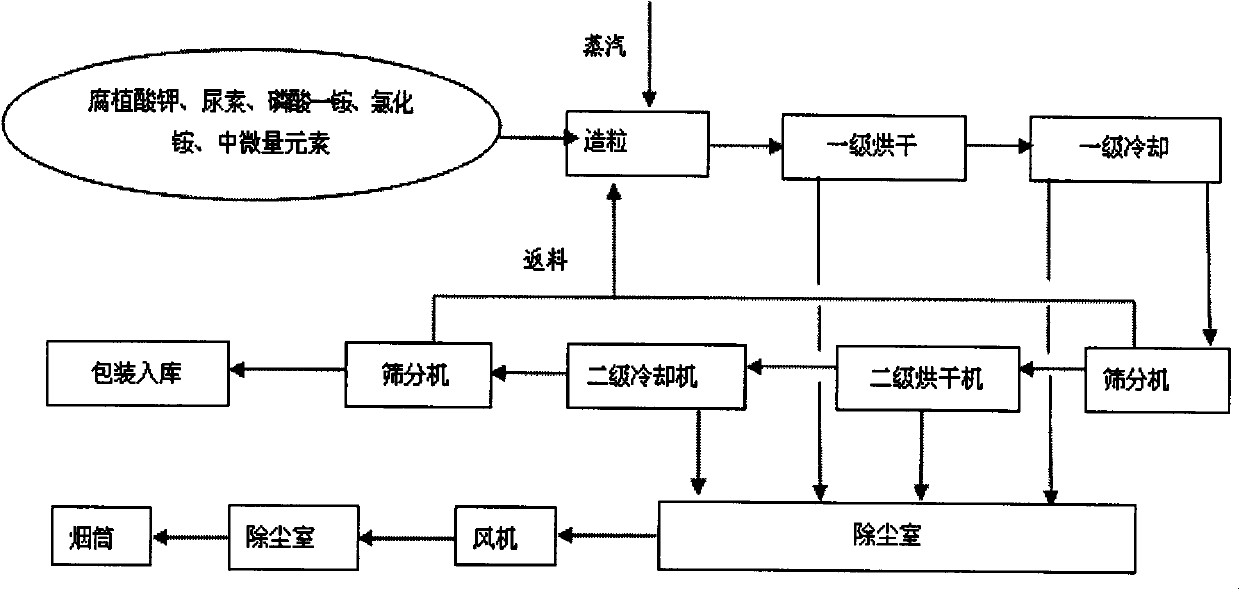

Potassium humate compound fertilizer and preparation method thereof

InactiveCN102001898AImprove aggregate structureSimple structureFertilizer mixturesSodium BentonitePhosphate

The invention belongs to the field of a fertilizer, in particular to a potassium humate compound fertilizer and a preparation method thereof. The potassium humate compound fertilizer is prepared by mixing urea, potassium humate, monoammonium phosphate, ammonium chloride, calcium powder and bentonite with magnesium sulfate, zinc sulfate and medium / trace elements. The potassium humate compound fertilizer granulated by using a steam drum physical agglomeration method and the preparation method of the compound fertilizer have the advantages that the prepared potassium humate compound fertilizer has large particle size and high strength and does not agglomerate; the capabilities of water and fertility retention, heat preservation and ventilation of the soil are enhanced; the soil structure is improved; the soil fertility is increased; the problems of reduced soil fertility, environmental pollution, soil hardening, nutrition unbalance and stress resistance of crops are solved; the utilization rate of the fertilizer is improved; the defects of low fertilizer efficiency, insufficient nutrition utilization, overproof pesticide residue, severe nitrate accumulation and heavy metal pollution are overcome; the sustained-release effect against pesticide is realized; the agroecological environment is protected; and the efficiency, yield and crop quality are improved.

Owner:李林

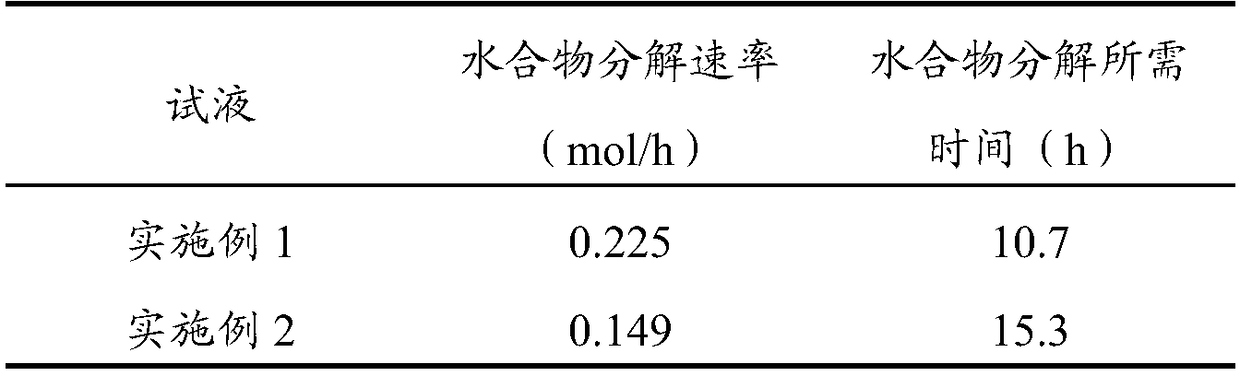

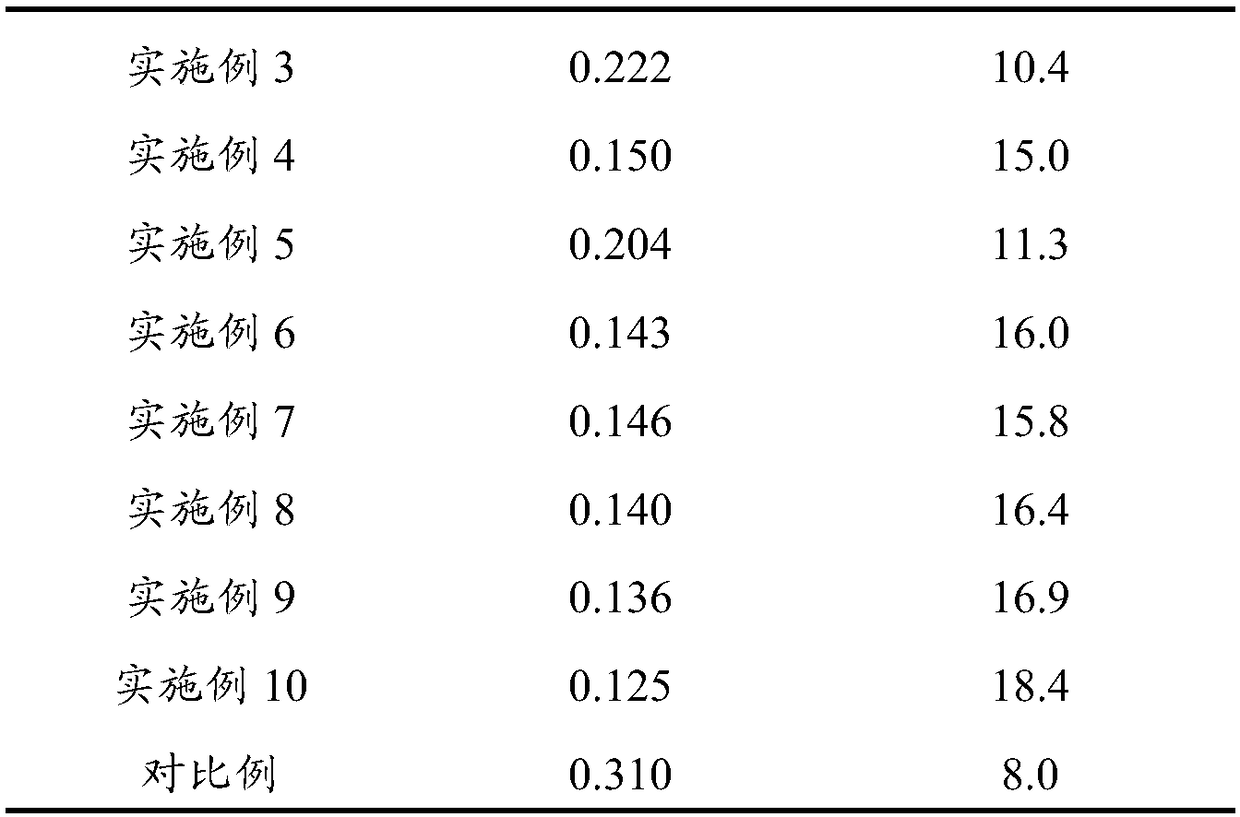

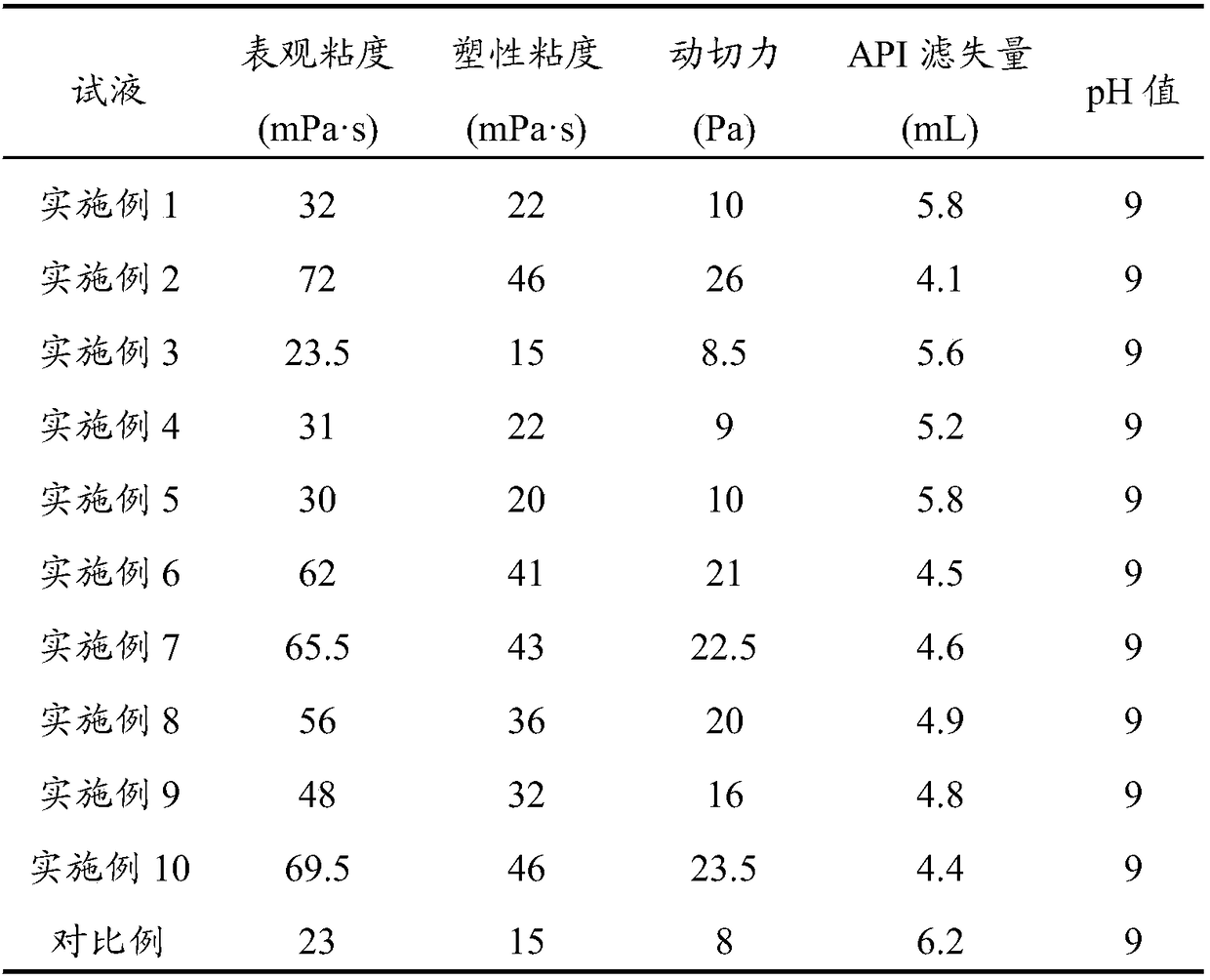

Hydrate decomposition inhibitor suitable for natural gas hydrate formation drilling

InactiveCN109321215AAvoid decompositionReduce decomposition rateDrilling compositionDecompositionHydrate decomposition

The invention discloses a hydrate decomposition inhibitor suitable for natural gas hydrate formation drilling. The hydrate decomposition inhibitor is prepared from the following raw materials by masspercent: 0 to 100 percent of poly 3-methylene2-pyrrolidone, 0 to 100 percent of lecithin, and 0 to 100 percent of poly N-vinylpyrrolidone. When the hydrate decomposition inhibitor suitable for naturalgas hydrate formation drilling, provided by the invention is used for ocean or frozen earth natural gas hydrate drilling operation, the decomposition of the hydrate can be effectively inhibited, thestability of the natural gas hydrate formation can be improved, and a series of underground accidents caused by the decomposition of the hydrate can be avoided.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

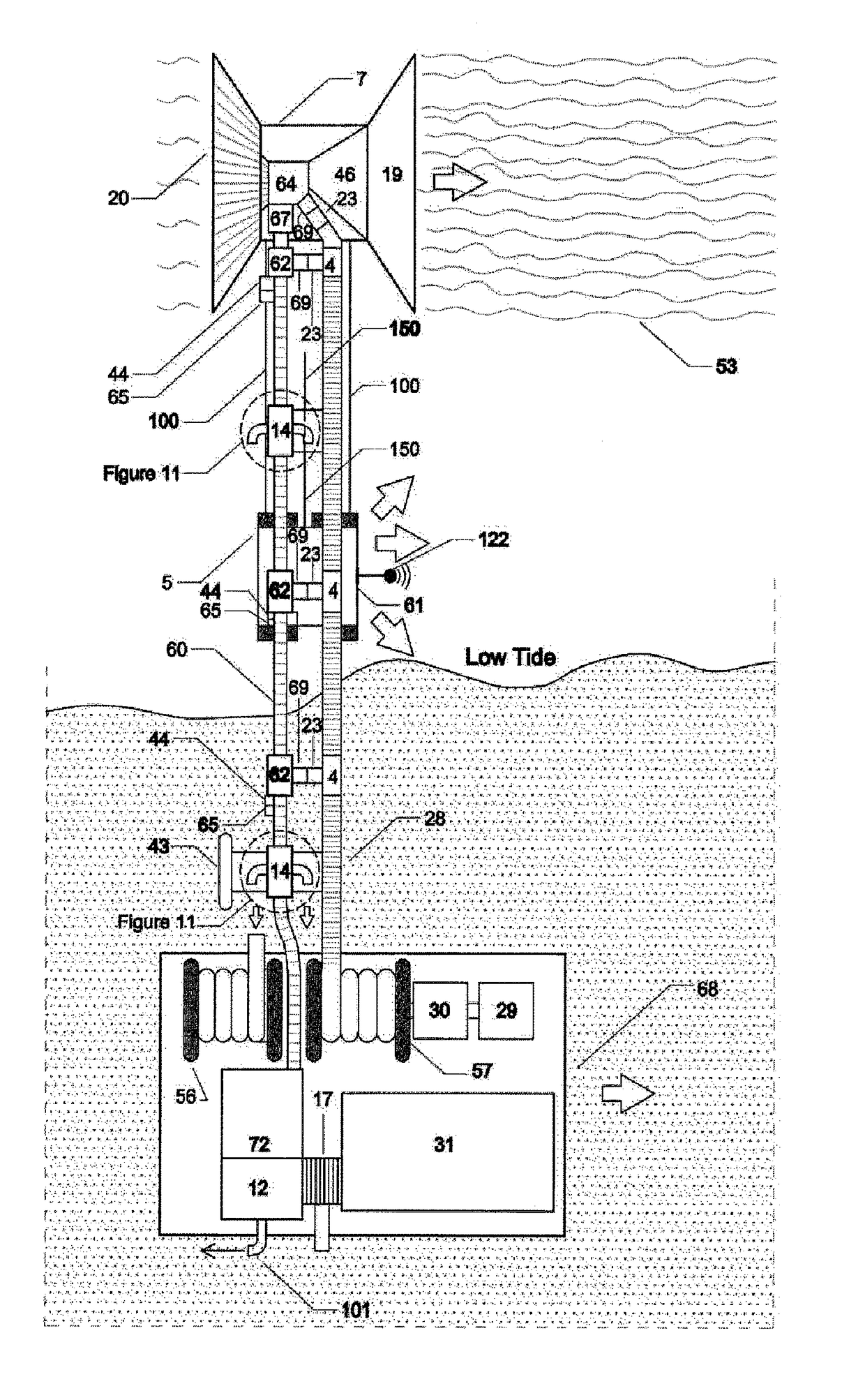

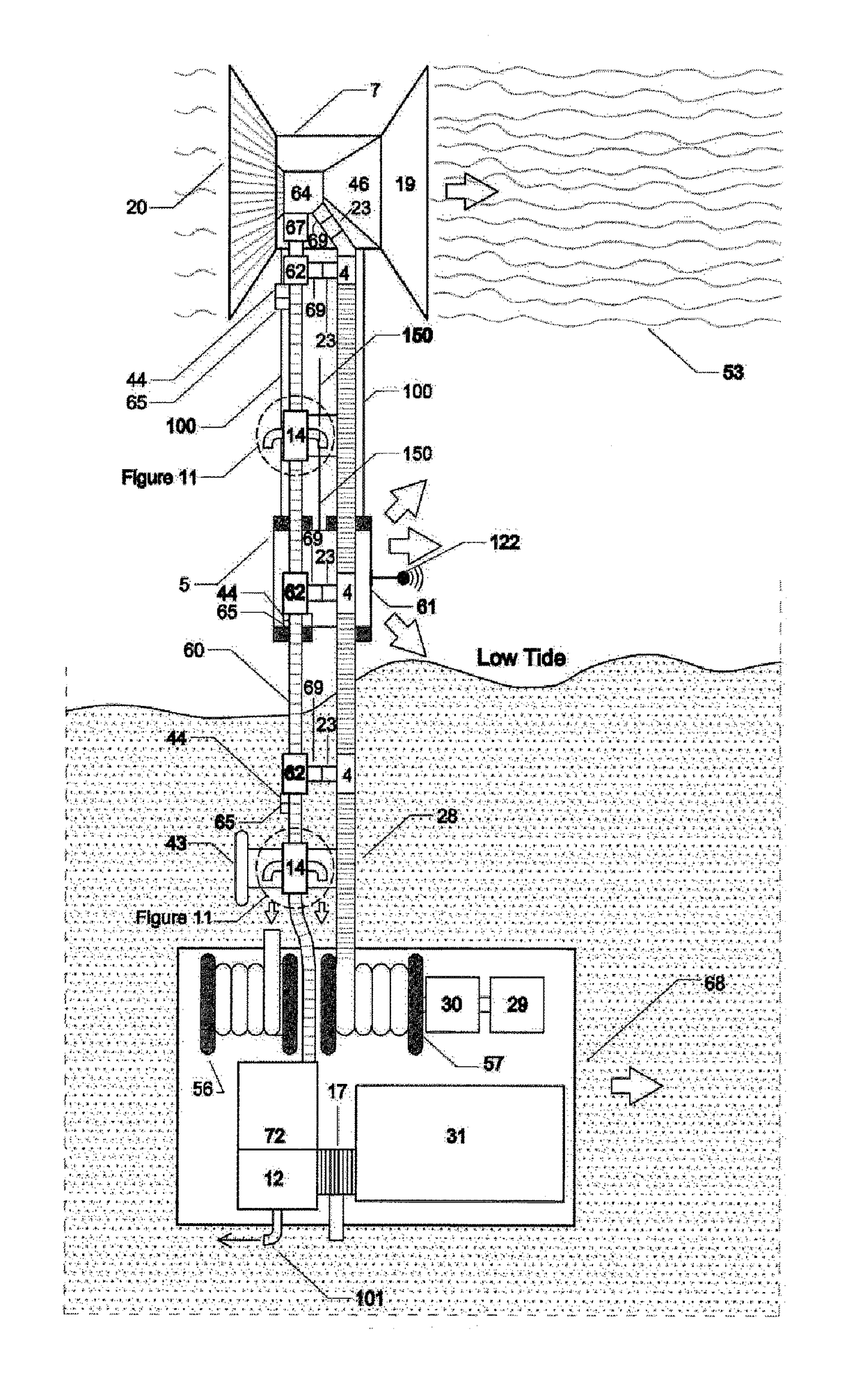

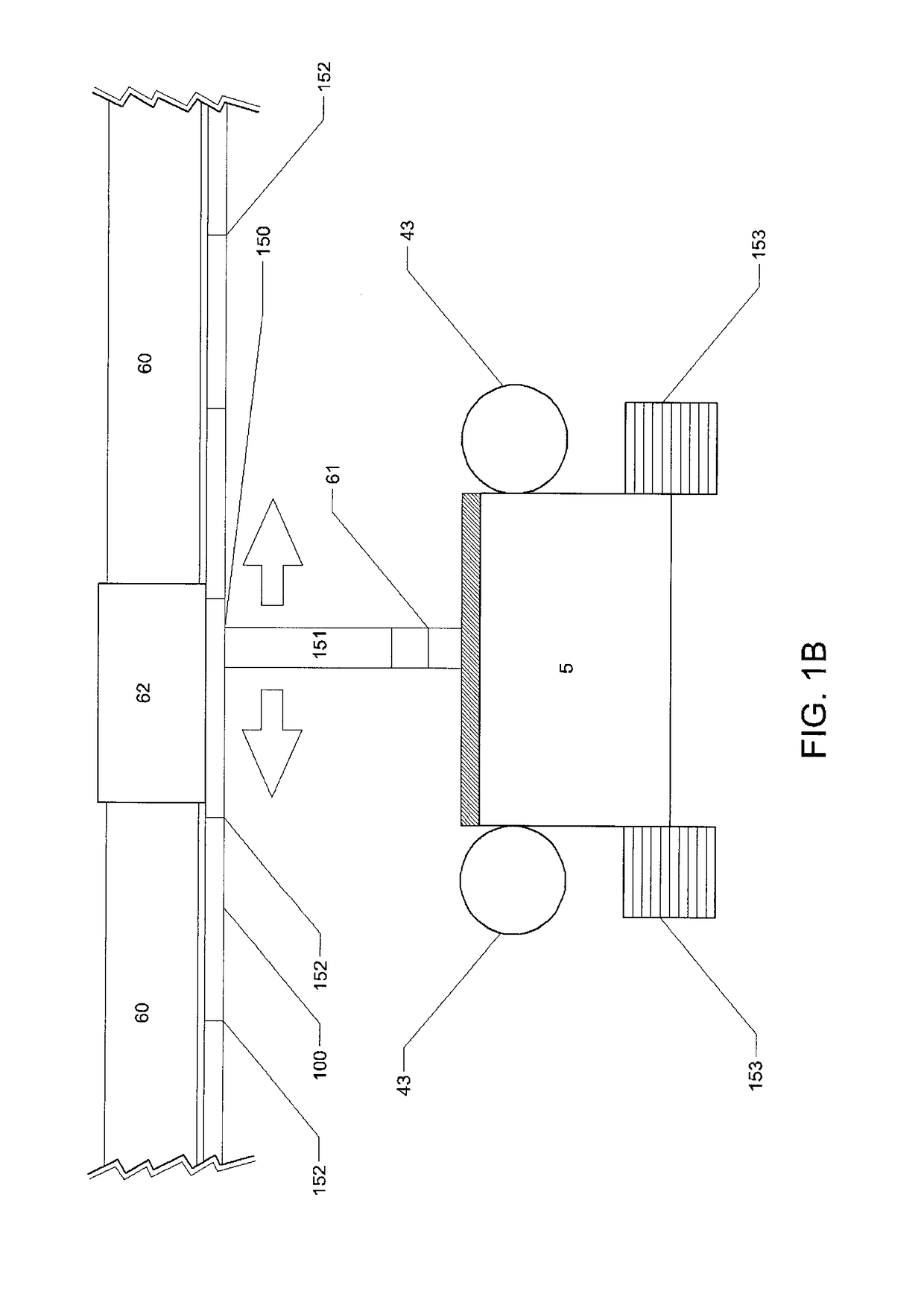

System for harvesting seaweed and generating ethanol therefrom

InactiveUS20170268192A1Reduce decomposition rateReduce the temperatureWater cleaningClimate change adaptationSolventPolypropylene mesh

A floatable-material harvester is disclosed, including vacuum source, transport hose, and a floatable-material receiver. In one embodiment, the transport hose has at least one air inductor / intake along its length, which allows air to enter the transport hose to accelerate its contents, by negative pressure air induction. In another embodiment, a transport hose has at least one floatable-material thruster along its length, comprised of at least one nozzle, which provides pressurized fluid (e.g., air or water) in the direction of the flow of the harvested floatable material by positive pressure induction. A method is disclosed whereby the floatable material harvester is used to harvest an absorbent material (e.g., wood chips, straw, perlite, zeolite, polypropylene mesh, titanate nanofibres) that has absorbed a pollutant (e.g., oil, solvent, radioactive isotopes) from a beach or in water.

Owner:DIXON SHELLEY L

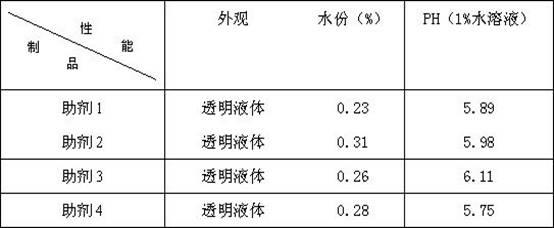

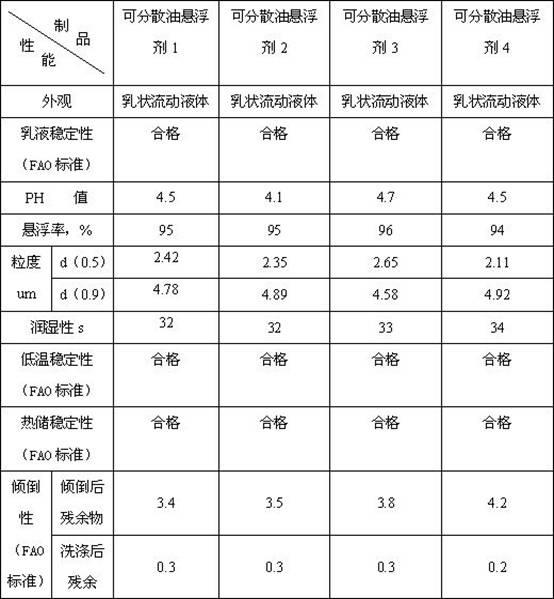

Addition agent for nicosulfuron oil-based suspension concentrate and nicosulfuron oil-based suspension concentrate

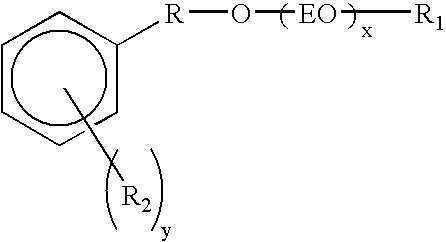

InactiveCN102657161AGood dispersionImprove performanceBiocideAnimal repellantsOrganosolvSuspending Agents

The invention relates to an addition agent for nicosulfuron oil-based suspension concentrate. The addition agent is prepared by the following materials, by weight: 10-60% of nonylphenol polyoxyethylene ether, 10-50% of castor oil polyoxy ethyl ether, 5-20% of fatty alcohol polyoxy ethyl ether, 5-25% of alkyl benzene sulfonic acid and 5-40% of solvent oil. The invention further relates to nicosulfuron oil-based suspension concentrate. The novel addition agent for the nicosulfuron oil-based suspension concentrate is good in dispersibility and stable in performance, and can not only be used for preparing the nicosulfuron oil-based suspension concentrate of 4%, but also be used for preparing the nicosulfuron oil-based suspension concentrate of 20%. Active ingredients in the preparation are improved after the nicosulfuron oil-based suspension concentrate with a high concentration is prepared, using quantities of organic solvents and the addition agent are reduced, the pollution to the environment is reduced, and the cost can be reduced. Epoxidized soybean oil is further added to serve as a stabilizing agent, reduces decomposition rate of nicosulfuron, and maintains pesticide effect.

Owner:南京太化化工有限公司

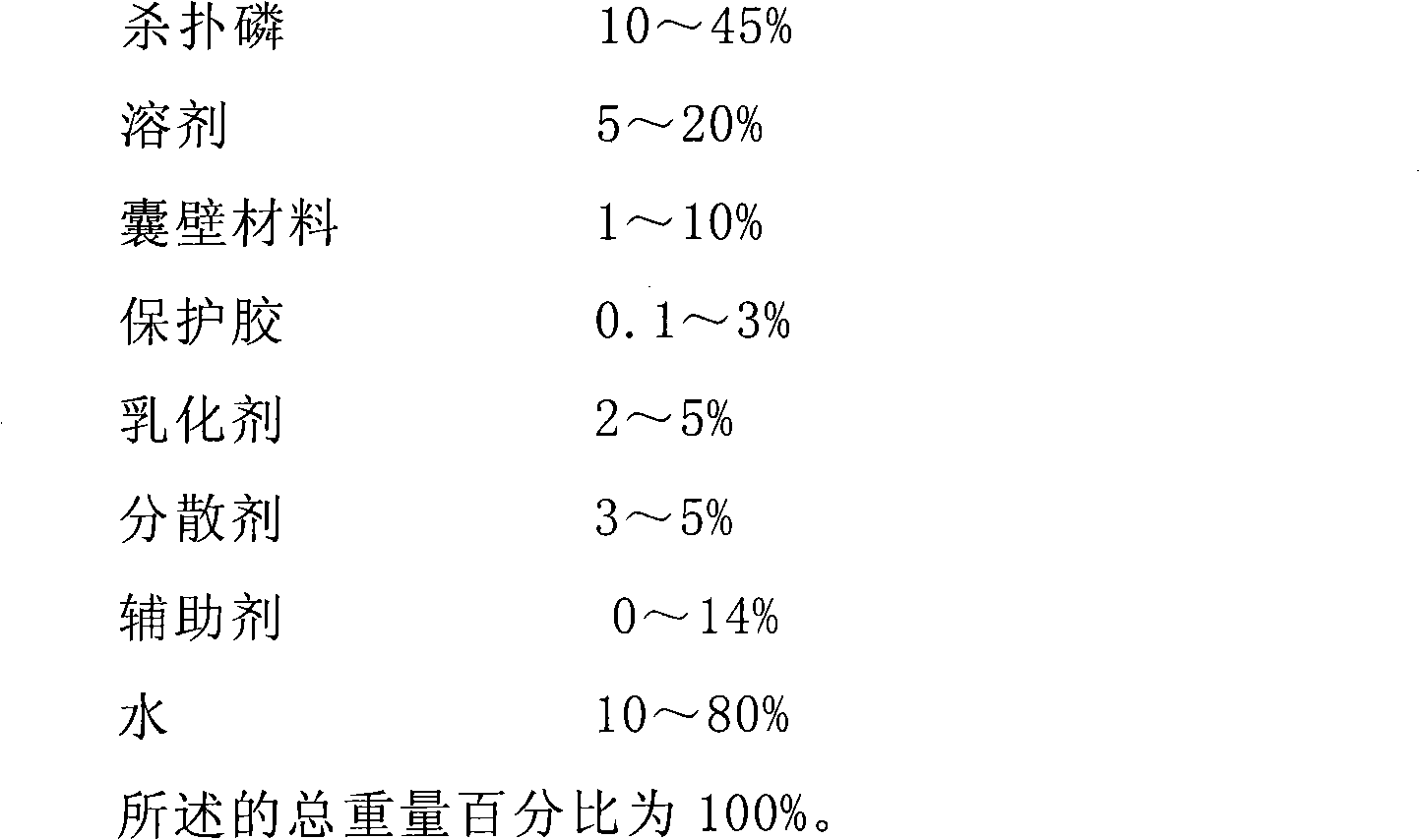

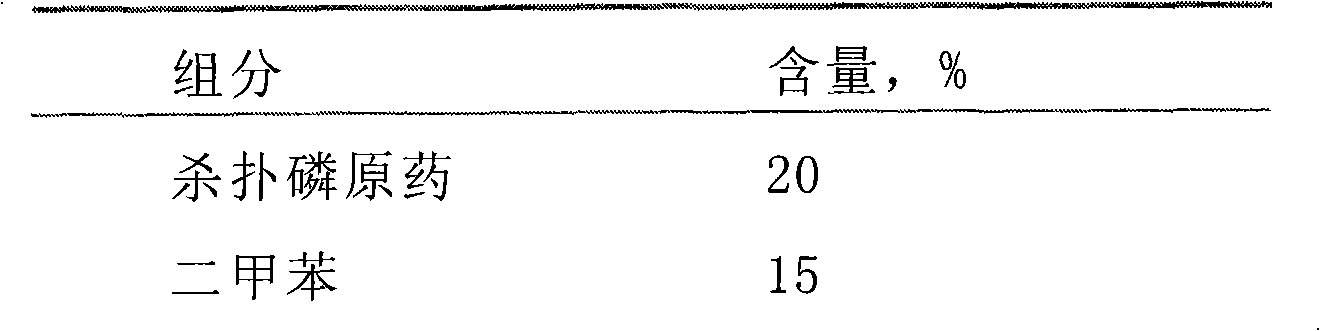

Chlorpyrifos microcapsule suspension and preparation method thereof

InactiveCN102057897ASatisfy the appropriate anti-efficacy requirementsLong durationBiocideAnimal repellantsChlorpyrifosAcute toxicity testing

The invention discloses a chlorpyrifos microcapsule suspension. The chlorpyrifos microcapsule suspension mainly comprises the following components in percentage by weight: 10 to 45 percent of chlorpyrifos, 5 to 20 percent of solvent, 1 to 10 percent of capsule wall material, 0.1 to 3 percent of lacquer, 2 to 5 percent of emulsifier, 3 to 5 percent of dispersant, 0 to 14 percent of auxiliary agentand 10 to 80 percent of water. The invention also discloses a preparation method of the chlorpyrifos microcapsule suspension. The chlorpyrifos microcapsule suspension has the advantages of reducing acute toxicity of raw medicaments, reducing environmental pollution and stimulation to people and livestock, improving prevention and control effect on insect damages such as a citrus tree scale insectand the like, greatly prolonging duration of a pesticide and reducing pesticide application frequency and agricultural cost. Since microcapsule technology is adopted and water is used as a dispersingmedium in the chlorpyrifos microcapsule suspension, the chlorpyrifos microcapsule suspension is difficult to flame and explode, and can be safely and reliably used and transported.

Owner:联合国南通农药剂型开发中心 +1

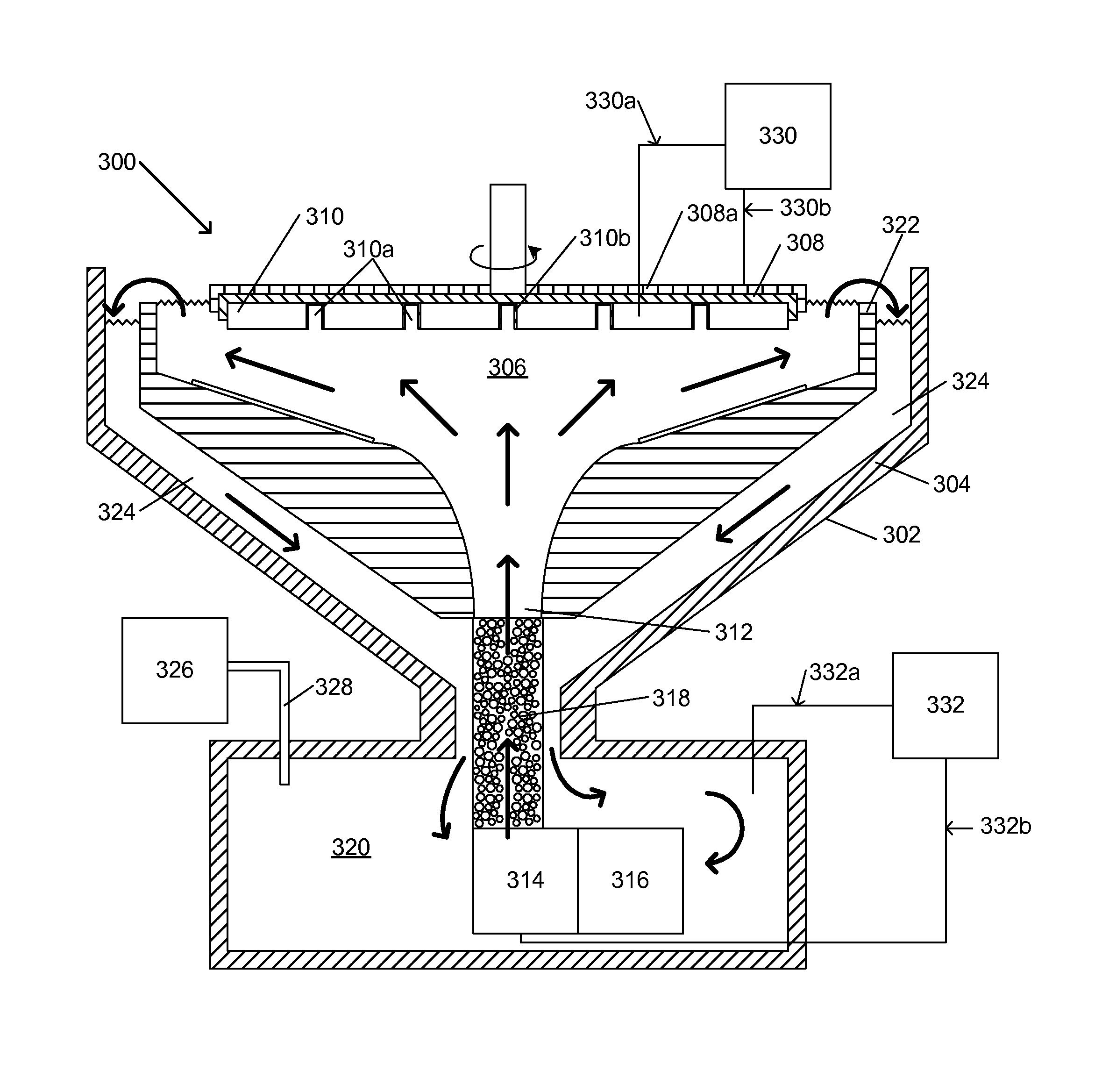

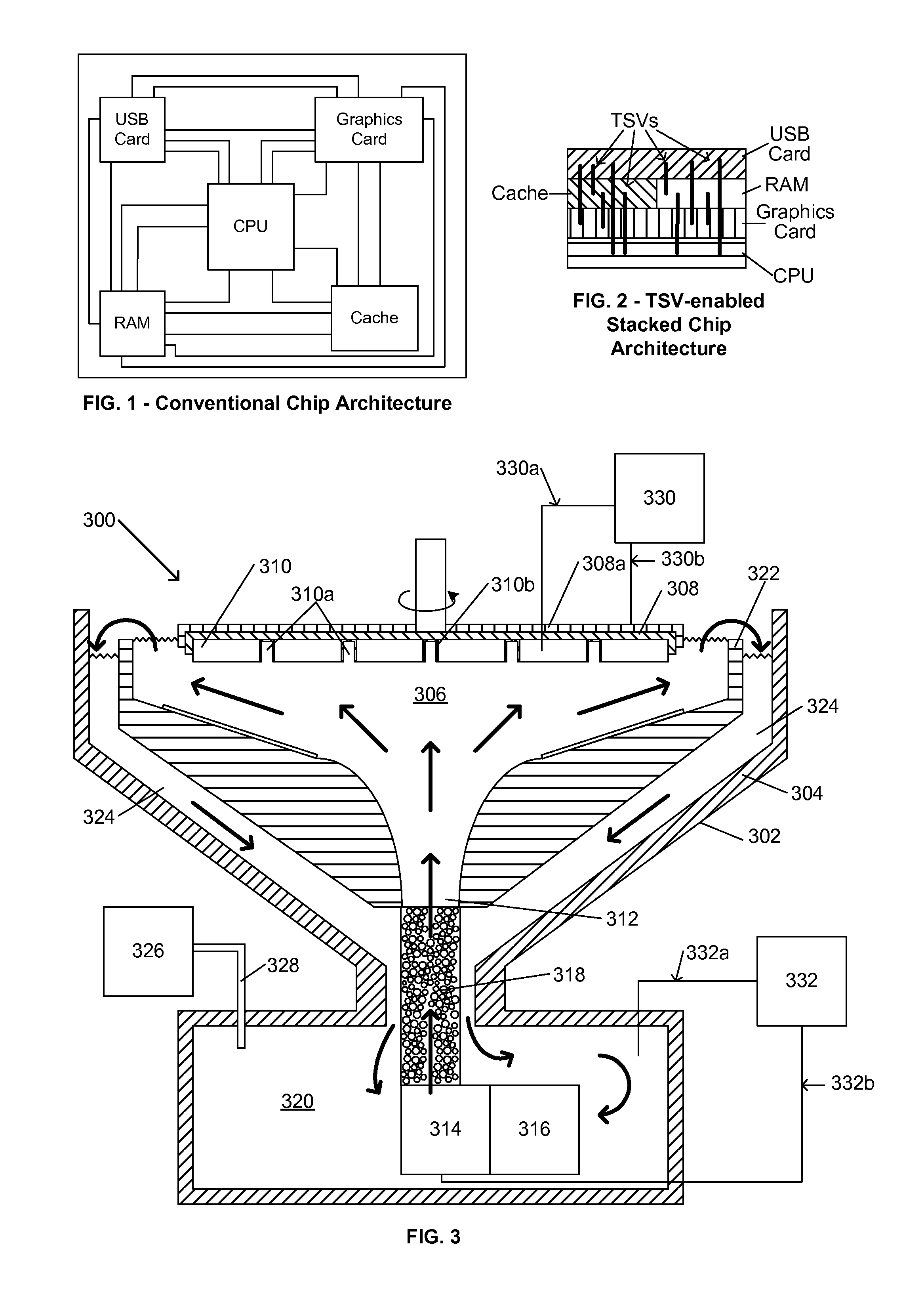

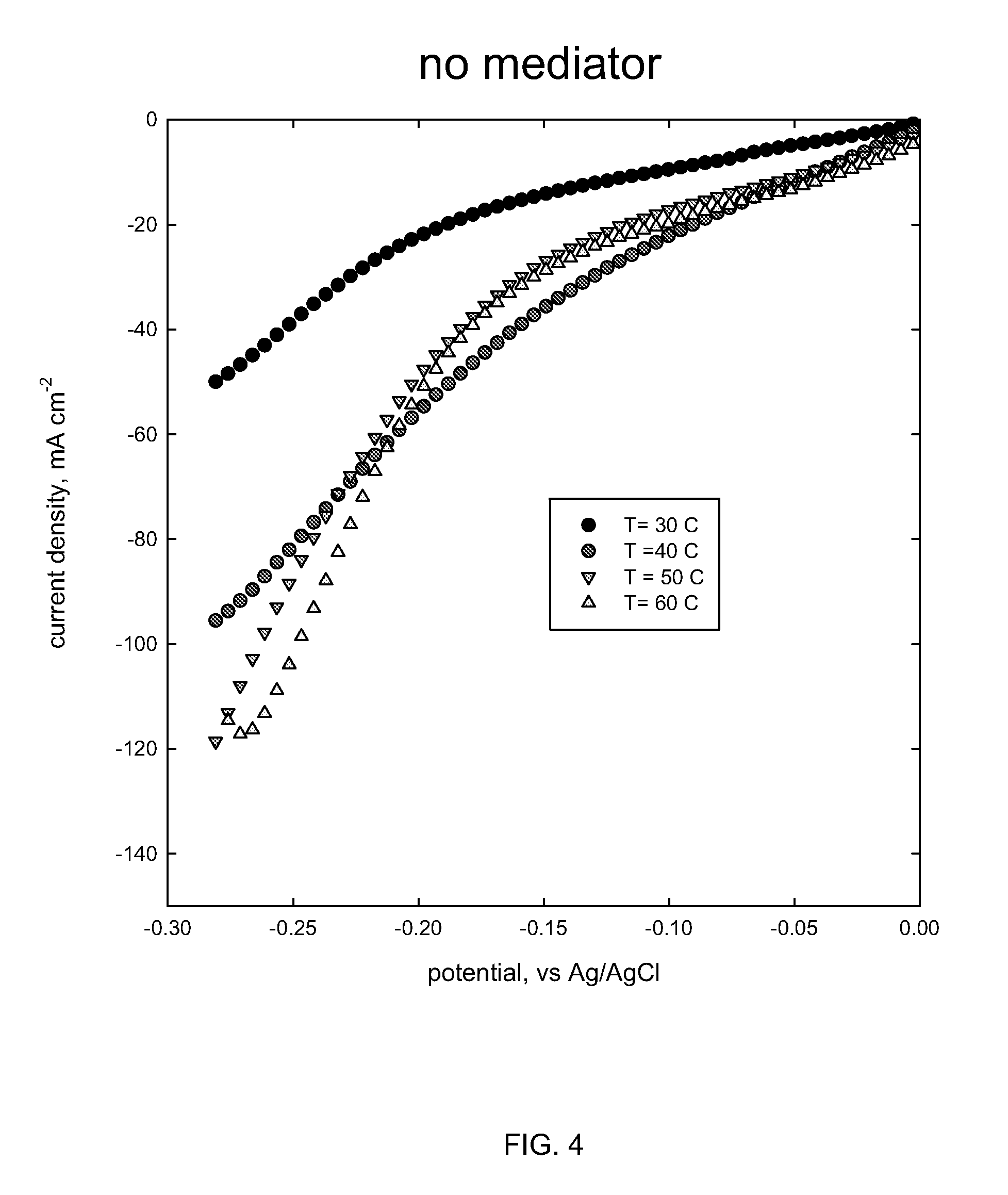

Process for electrodeposition of copper chip to chip, chip to wafer and wafer to wafer interconnects in through-silicon vias (TSV) with heated substrate and cooled electrolyte

InactiveUS20120024713A1Maximize rateMinimize stressCellsSolid-state devicesAspect ratioElectroplating

Process of electrodepositing a metal in a high aspect ratio via in a silicon substrate to form a through-silicon-via (TSV), utilizing an electrolytic bath including a redox mediator, in an electrolytic metal plating system including a chuck adapted to hold the silicon substrate and to heat the silicon substrate to a first temperature, a temperature control device to maintain temperature of the electrolytic bath at a second temperature, in which the first temperature is maintained in a range from about 30° C. to about 60° C. and the second temperature is maintained at a temperature (a) at least 5° C. lower than the first temperature and (b) in a range from about 15° C. to about 35° C.

Owner:ATOTECH DEUT GMBH

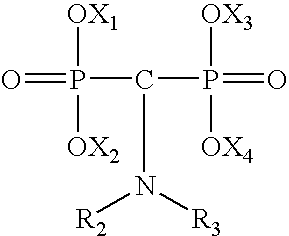

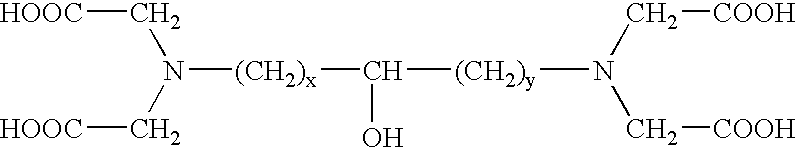

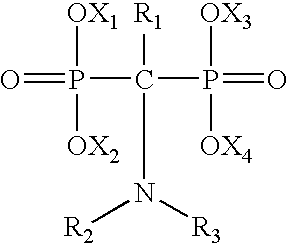

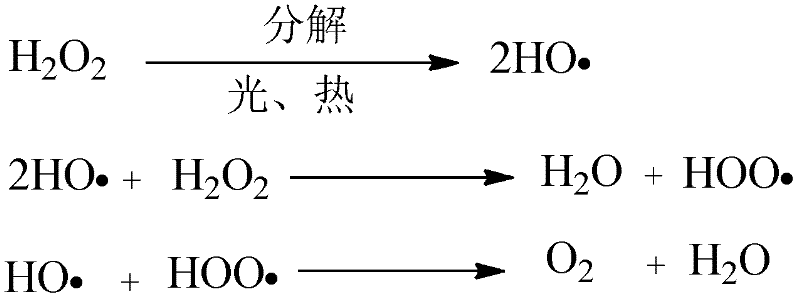

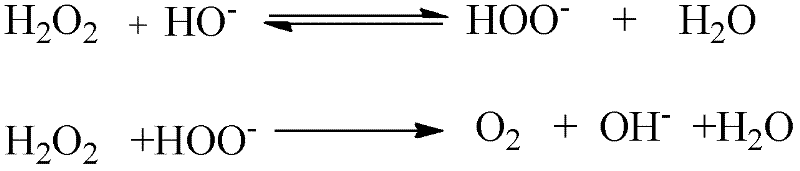

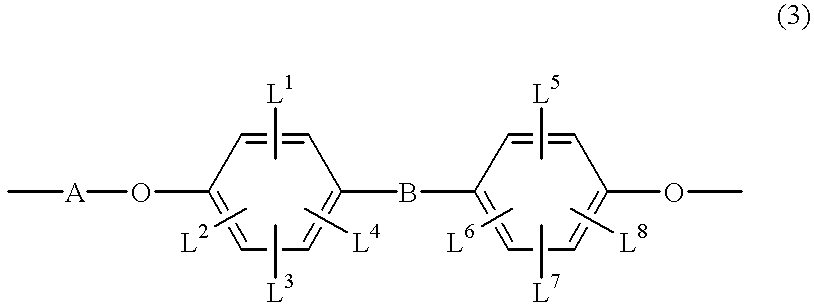

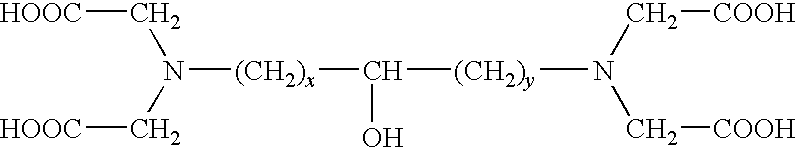

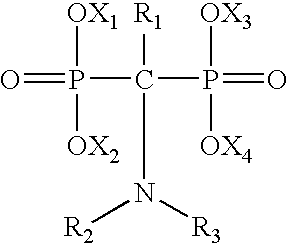

A hydrogen peroxide stabilizer

InactiveCN102295274AAchieve stabilityLow costPeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesMagnesium saltAcid group

The invention discloses a hydrogen peroxide stabilizer, the mass percentage of which is composed of: 15-30% of organic phosphonic acid; 10-15% of magnesium salt; 55-75% of distilled water; the sum of each component is 100%. Magnesium salts include magnesium chloride, magnesium sulfate, magnesium acetate, magnesium nitrate or magnesium perchlorate; the organic phosphonic acid has the structure of general formula (1), wherein R represents a substituent, which is an alkyl group or a heteroatom-substituted alkyl group ; n represents the number of phosphonic acid groups connected to the substituent R, and n=2-5. Under the synergistic action of organic phosphonic acid and magnesium salt, the stabilizer of the invention can effectively realize the stabilization of hydrogen peroxide under strong alkaline conditions.

Owner:TIANJIN YUNSHENG CHEM

Hydrogen peroxide stabilizer composition in paper pulp bleaching

InactiveCN101265678AReduce decomposition rateAvoid it happening againPulp bleachingBleaching agents additionFiberDecomposition

A hydrogen peroxide stabilizer composition in paper pulp bleaching contains the following materials by the weight percentages: ethylenediaminetetraacetic acid 8%-10%, polyacrylic acid 3%-5%, nitrilortiacetic acid 5%-10%, hydroxy ethylidene-1, 1-diphosphonic acid 5%-8%, sodium hydroxide in suitable amount and the rest of deionized water,. The preparation method includes: mixing the materials in the material ratio, adjusting the pH value to 6.8-7.1 with the sodium hydroxide and adding the deionized water to 100%. The inventive hydrogen peroxide stabilizer composition in the paper pulp bleaching can reduce the decomposition rate of the hydrogen peroxide to less than 20%, prevent the fouling from generating and dispersing pulp fibers and chelating metal ions.

Owner:JIANGXI SCI & TECH NORMAL UNIV

Ivermectin transdermal liniment for animals

InactiveCN102440944APromote percutaneous absorptionReduce decomposition rateOrganic active ingredientsPharmaceutical delivery mechanismIrritationEthyl acetate

The invention discloses an ivermectin transdermal liniment for animals, which is prepared from medicinal liquor and ivermectin, wherein the medicinal liquor is prepared from the following components in percentage by volume: 20-40% of ethyl acetate, 2-5% of azone and 55-75% of propylene glycol; and the ratio of ivermectin to medicinal liquor is (0.5-1g):100mL. The novel transdermal accelerator selected in the formula can enhance the absorption of skin for medicines, does not have toxicity or irritation on the skin and body, does not have pharmacological action, and does not react with the medicines and other additives. The invention is simple to prepare and convenient to use, has high stability, and can achieve favorable anthelminthic effect.

Owner:INNER MONGOLIA AGRICULTURAL UNIVERSITY

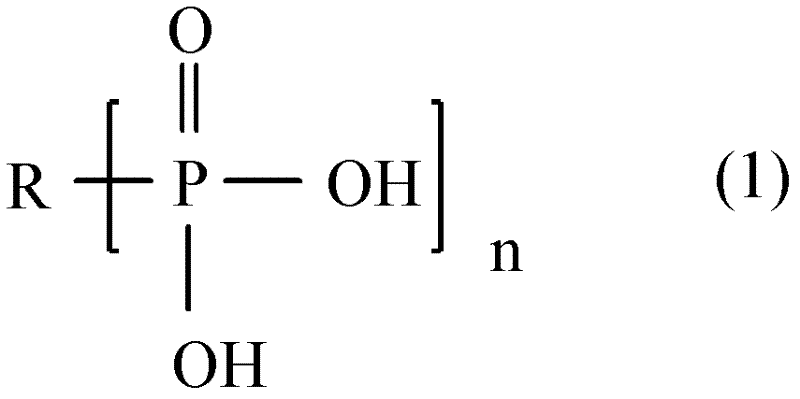

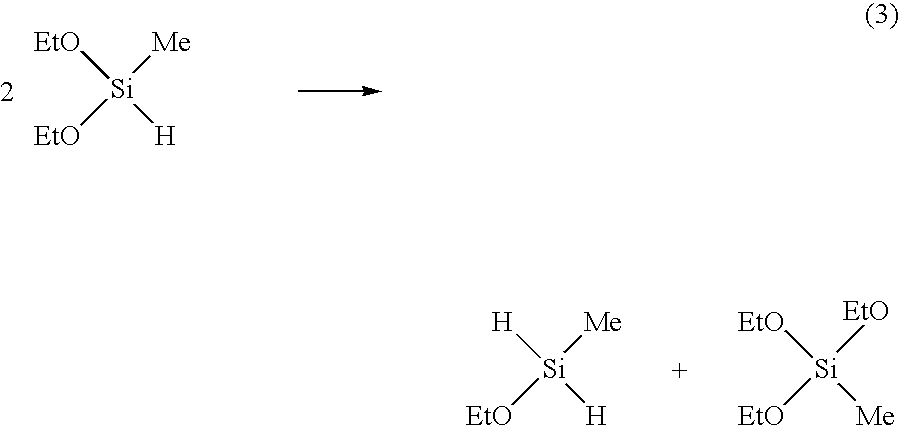

Stabilization of nitrogen-containing and oxygen-containing organosilanes using weakly basic ion-exchange resins

ActiveUS20080058541A1Reduce decomposition rateExtended shelf lifeSilicon organic compoundsSilanesDecomposition

A process to stabilize nitrogen-containing or oxygen-containing organosilane from acid catalyzed attack and retard the resulting decomposition is disclosed. Such organosilanes, and the nitrogen-containing organosilane in particular, with a least one Si—H or N—H group are susceptible to this type of product decomposition. Treatment with a weakly basic ion exchange media retards this decomposition by scavenging the anions or acids that are attacking the Si—H group. Dilute exposures to these anions can initiate significant decomposition and effect product stability and long-term shelf-life for semiconductor processing for the use of silicon oxide, silicon oxynitride and silicon nitride films.

Owner:VERSUM MATERIALS US LLC

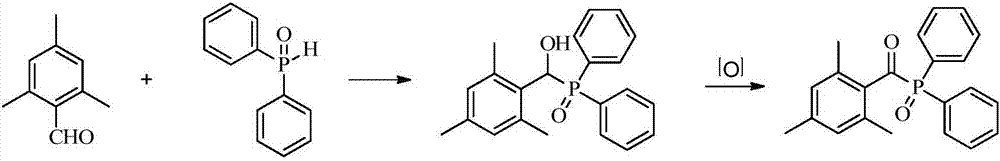

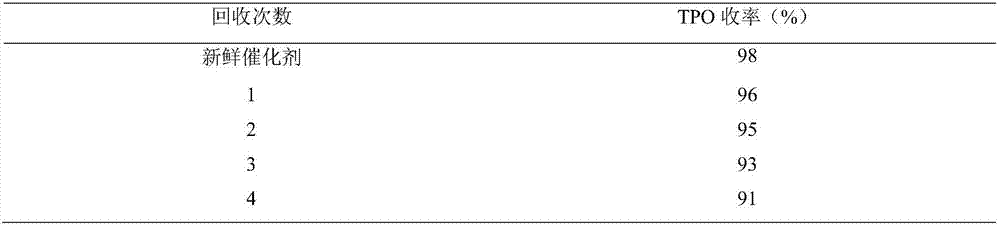

Method for efficiently and recyclably synthesizing 2,4,6-trimethylbenzoyldiphenyl phosphine oxide

ActiveCN106883265AReduce decomposition rateHigh yieldGroup 5/15 element organic compoundsChemical recyclingWater bathsOxygen

The invention discloses a method for efficiently and recyclably synthesizing 2,4,6-trimethylbenzoyldiphenyl phosphine oxide. The method comprises the following steps of a, selecting a vanadium source and a molecular sieve as reaction raw materials to prepare a vanadium molecular sieve catalyst; b, adding 2,4,6-trimethylbenzaldehyde and diphenyl phosphine oxide into a three-opening bottle in which dichloromethane is contained, and stirring at normal temperature to react for 6 hours; c, cooling the three-opening bottle in a low-temperature water bath to 8 to 10 DEG C, sequentially adding the vanadium molecular sieve catalyst and tert-butyl hydroperoxide into the three-opening bottle, stirring to react for 0.5 hour, and continuously stirring at normal temperature for 3 to 5 hours to obtain reaction liquid; and d, filtering the reaction liquid, recycling a vanadium molecular sieve, treating the obtained filtrate by aqueous solution of sodium thiosulfate to remove unreacted oxide, and performing post treatment to obtain a TPO (2,4,6-trimethylbenzoyldiphenyl phosphine oxide) product. As the vanadium molecular sieve serves as the catalyst and is matched with the tert-butyl hydroperoxide to prepare the TPO, the yield of the target product is increased, and the catalyst is environment friendly and recyclable.

Owner:SHANDONG UNIV OF SCI & TECH

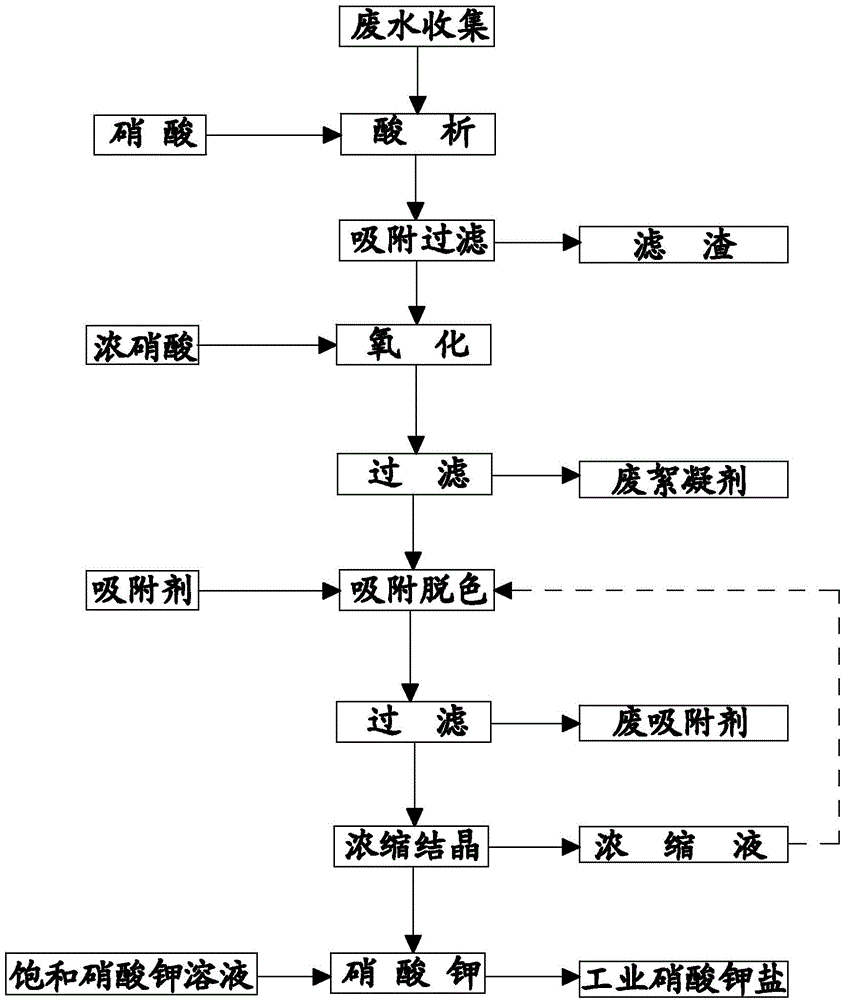

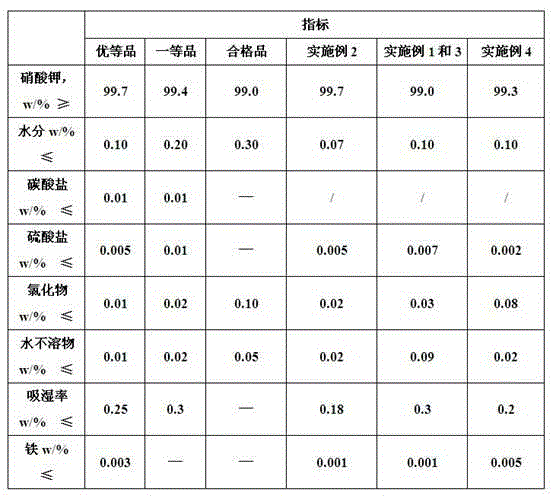

Method for recovering potassium nitrate from anthraquinone dye alkali wastewater

ActiveCN103979705AImprove recycling efficiencyHigh removal rateAlkali metal nitrate preparationMultistage water/sewage treatmentPotassium nitrateSorbent

The invention relates to a method for recovering potassium nitrate from anthraquinone dye alkali wastewater and belongs to the technical field of recovery and recycle of printing and dyeing wastewater. The method comprises the following steps of adding nitric acid into collected alkali wastewater, carrying out primary acidification with stirring for primary acidification time of 0.5-12h, when a solution pH value is in a range of 1-4, adding an adsorbent, a neutral flocculating agent or an acidic flocculating agent into the solution so that a precipitation reaction occurs, filtering the reaction product, adding nitric acid into the solution, carrying out secondary acidification with stirring for secondary acidification time of 0-8h, when a solution pH value is in a range of 3-5h, adding an adsorbent, a neutral flocculating agent or an acidic flocculating agent into the solution so that a precipitation reaction occurs, filtering the reaction product, and carrying out HNO3 oxidation, decoloring, condensation and salt-leaching so that a qualified industrial salt is obtained. The method is used for anthraquinone dye alkali wastewater, can realize recovery of a large amount of potassium nitrate, can remove organic matters in wastewater, can reduce a COD value of the wastewater, and can recover and recycle potassium nitrate.

Owner:ZHEJIANG QICAI ECO TECH CO LTD

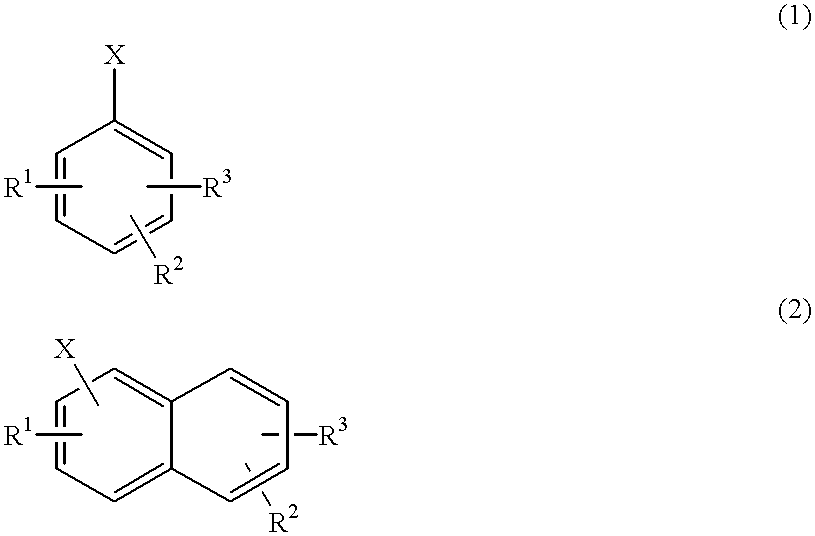

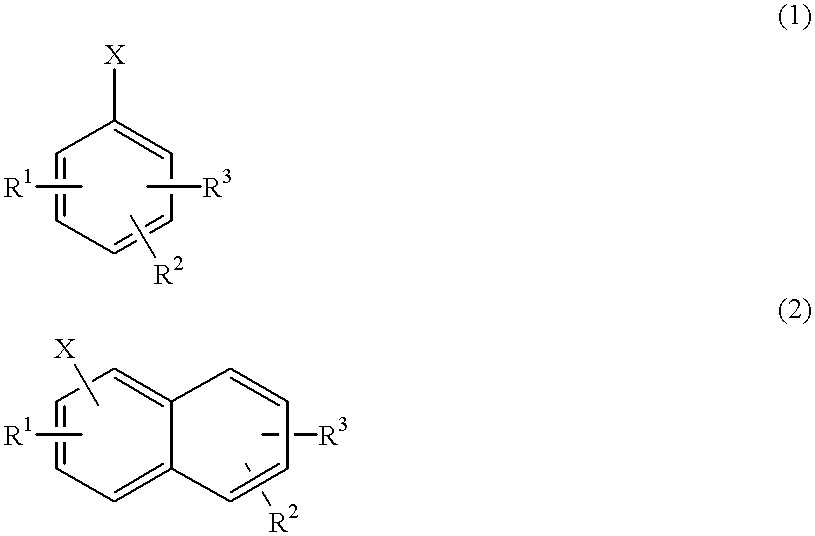

Coating solution for forming porous organic film

InactiveUS6534595B2Low dielectric constantEasy to introducePlastic/resin/waxes insulatorsPretreated surfacesOrganic filmPolymer science

A coating solution for forming porous organic film comprising the following A) to C), wherein A) and B) have respective heat decomposition initiation temperatures Ta and Tb satisfying a relation: Ta>Tb:A) a thermosetting resin having an aromatic ring in the main chain,B) a heat decomposable resin obtained by polymerization of monomers which include at least one compound represented by the following formula (1) or (2), andC) an organic solvent,wherein, X and each of R1 to R3 are defined in the specification.

Owner:SUMITOMO CHEM CO LTD

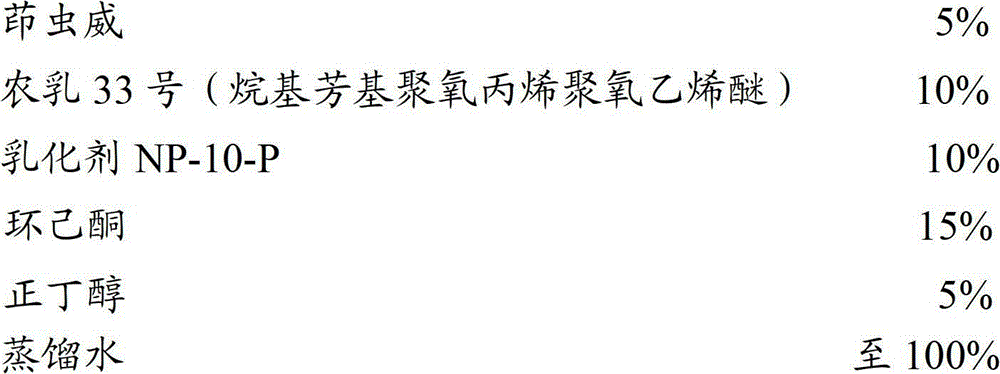

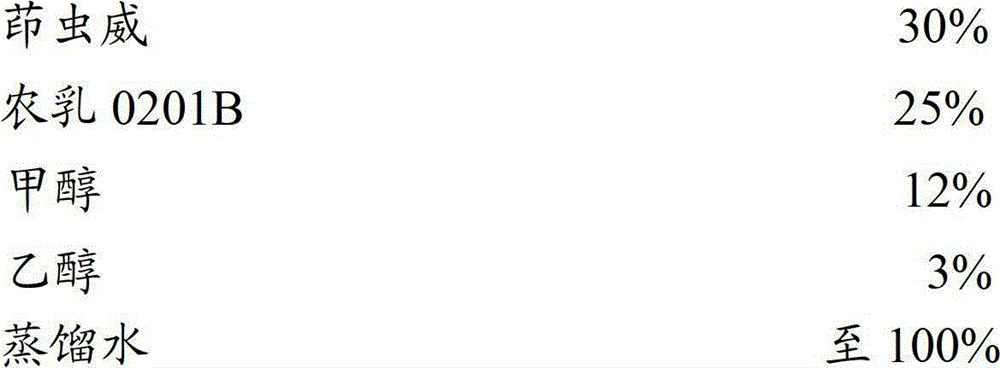

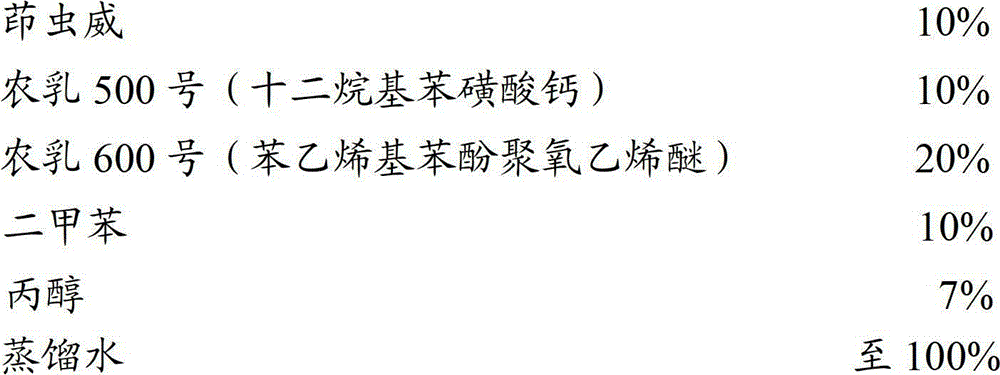

Indoxacarb microemulsion and preparation method of indoxacarb microemulsion

ActiveCN102715152AImprove performanceWide range of transparencyBiocideAnimal repellantsWater dispersibleOrganic solvent

The invention relates to the field of pesticide preparation and discloses an indoxacarb microemulsion and a preparation method of the indoxacarb microemulsion. The indoxacarb microemulsion provided by the invention comprises the following ingredients in percentage by weight (accounting for the total weight of the microemulsion): 1 to 30 percent of indoxacarb, 10 to 20 percent of solvents, 10 to 30 percent of emulsifying agents, 0.5 to 10 percent of cosolvents and the balance water. The indoxacarb microemulsion provided by the invention has the advantages that the cost is low, the preparation process is simple, the package requirement is low, meanwhile, the consumption of organic solvents is reduced, the residue is little, the environment pollution is little, in addition, the prevention effect is higher than that of indoxacarb water dispersible granules, the medication quantity can be reduced, and the indoxacarb microemulsion is suitable for large-area popularization.

Owner:LIANBAO CROP TECH

Cleaning compositions for hard to remove organic material

ActiveUS7781388B2Improve stabilityLow foamingInorganic/elemental detergent compounding agentsNon-ionic surface-active compoundsCelluloseHydrotrope

An oxidizing cleaning composition comprises a low concentration of aqueous hydrogen peroxide that is environmentally friendly and has good stability in strong alkaline solutions. The aqueous hydrogen peroxide composition contains a synergistic combination of one or more hydrophilic surfactants having an HLB of 10 or greater, one or more hydrotropes, one or more UV-analyzable surfactants having an aromatic detectable functional group, and optionally a surfactant having an HLB of less than 10. The cleaning composition when mixed with an alkaline compound is very effective in removing dried or baked residues of polymers, modified or natural celluloses starches, natural gels, and the like at low concentrations and temperatures.

Owner:AMERICAN STERILIZER CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com